A method for low-temperature production of defatted insect pupae protein powder

A protein powder and insect technology, which is used in the production of fat, fat oil/fat production, grain processing, etc., can solve the problems of difficulty in grinding fineness to meet the requirements of food and medical protein powder raw materials, residual oil in raw materials, and low economic benefits. , to achieve the effect of long retention period, guaranteed quality and low oil residue rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

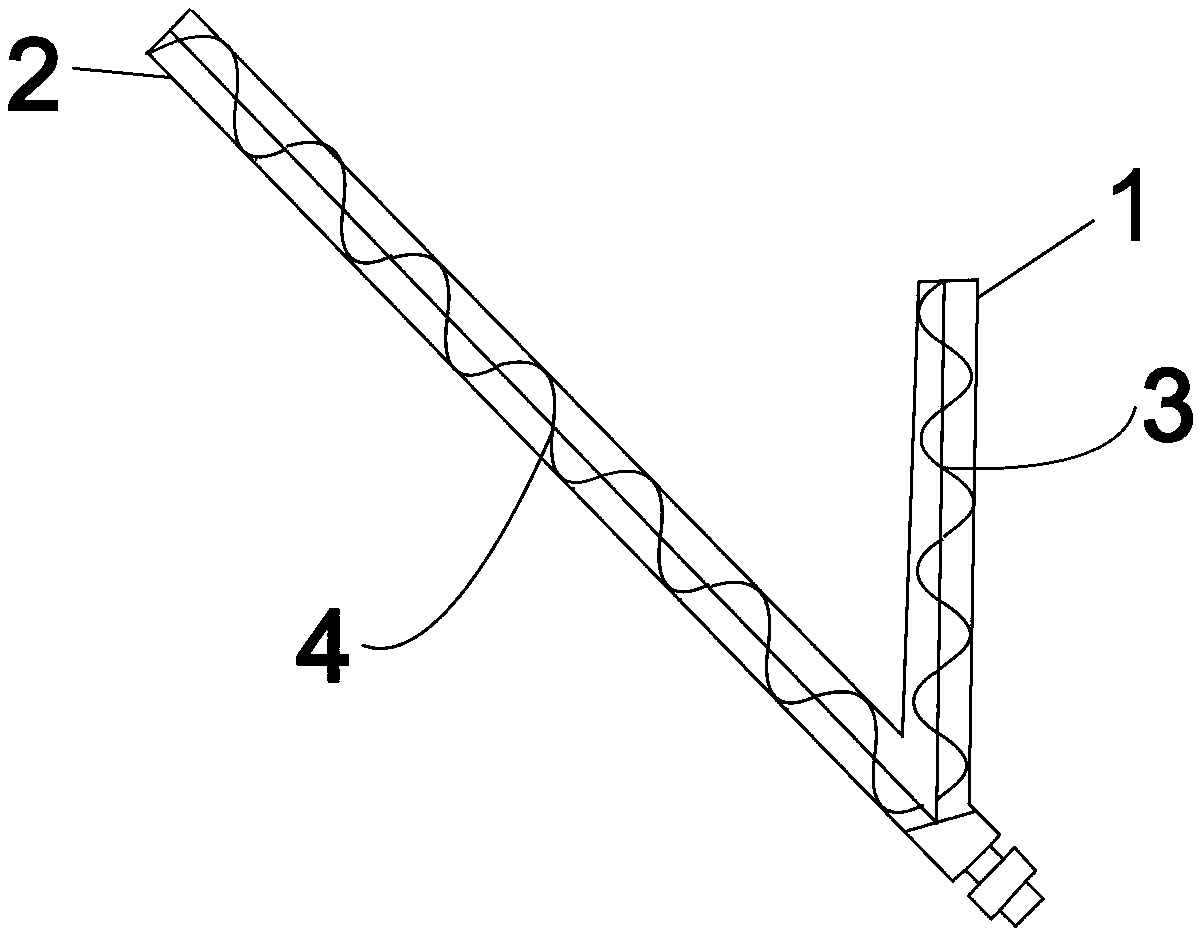

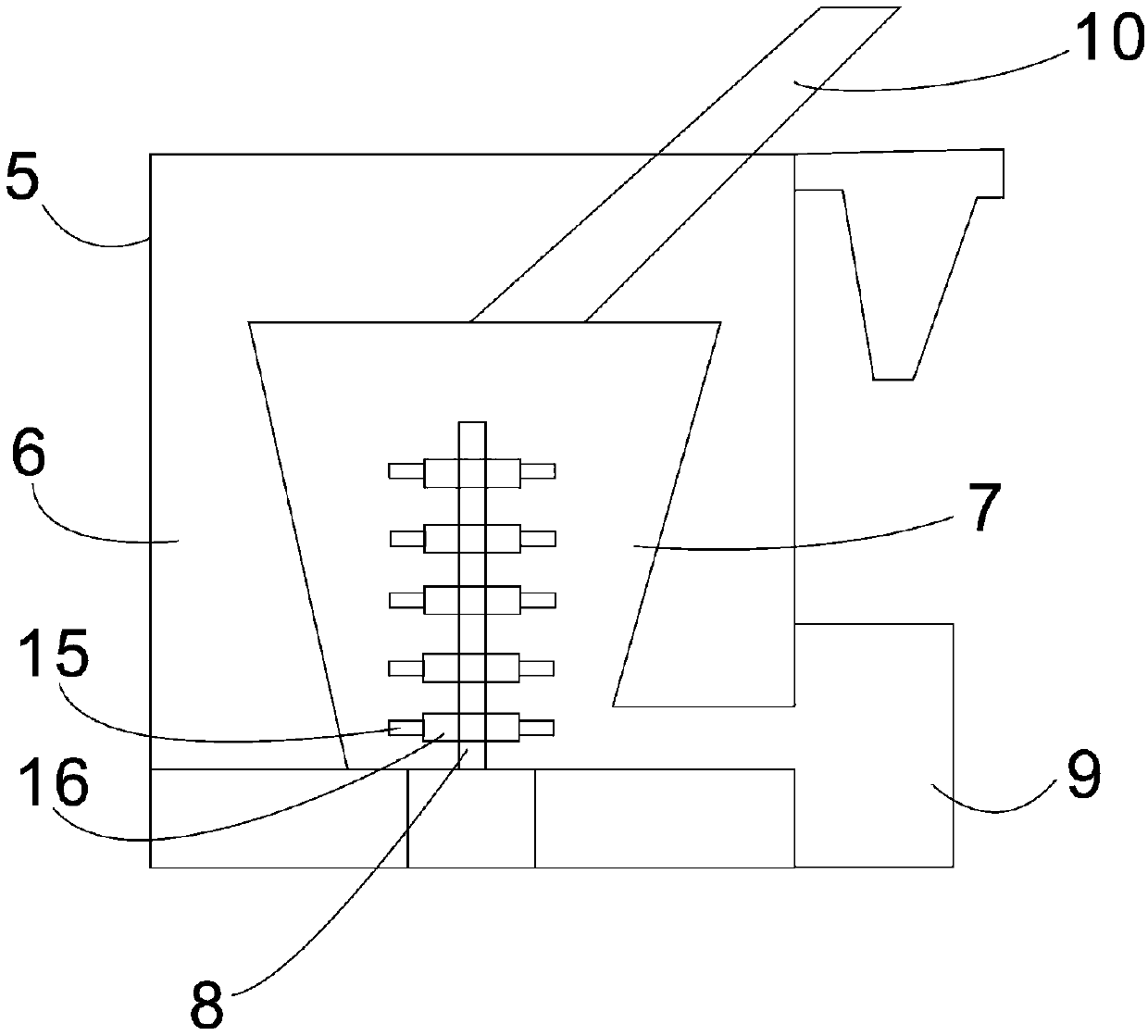

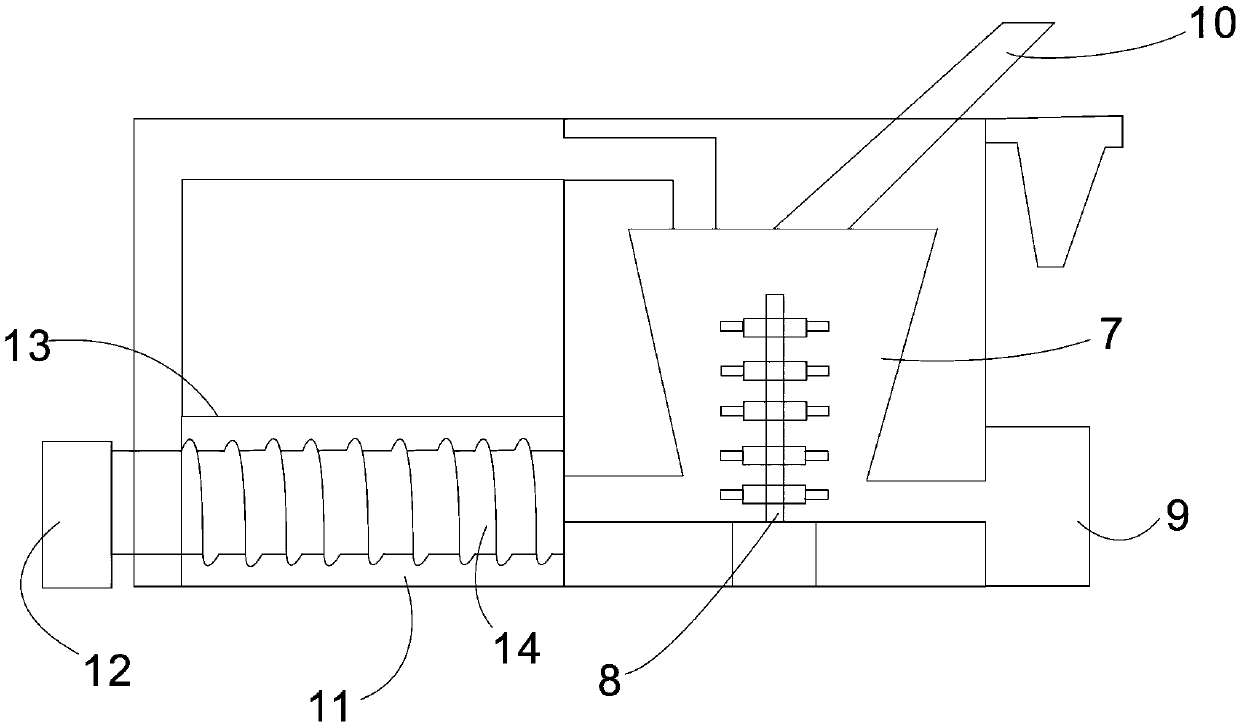

[0024] see Figure 1-Figure 3 Shown, a kind of method for low-temperature production defatted insect dry pupa protein powder, comprises the steps:

[0025] (1) Clean the fresh and live Tenebrio molitor pupae, and then dry them, wherein the microwave rate is 10kg / KW·h, the temperature is 40°C, and dry until the water content is 9%; then the dried Tenebrio molitor pupae are crushed, and the crushed The dried Tenebrio molitor pupae are put into the rotary conveying extractor, the extraction temperature is 10°C, and liquefied butane is used as the solvent, and the amount added is 6 times of the weight of the Tenebrio molitor dry pupae, and continuous countercurrent extraction is carried out on the dried Tenebrio molitor; wherein, for the rotary conveying extractor, see figure 1 As shown, the rotary conveying extractor includes a vertical rotary conveyor 1 and an oblique rotary conveyor 2, the bottom of the oblique rotary conveyor 2 communicates with the bottom end of the vertical ...

Embodiment 2

[0031] Implementation with reference to embodiment 1, different from embodiment 1 is:

[0032] In step (1), the microwave rate is 12kg / KW·h, the temperature is 45°C, and the drying is performed until the water content is 7%; the extraction temperature is 12°C, and the amount of butane added is 8 times the weight of the dried Tenebrio molitor pupae.

[0033] In step (2), the water content of dried Tenebrio molitor pupae is 7%.

Embodiment 3

[0035] Implementation with reference to embodiment 1, different from embodiment 1 is:

[0036] In step (1), the microwave rate is 15kg / KW·h, the temperature is 50°C, and the drying is performed until the water content is 5%; the extraction temperature is 15°C, and the amount of butane added is 10 times the weight of the dried Tenebrio molitor pupae.

[0037] In step (2), the water content of dried Tenebrio molitor pupae is 5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com