Patents

Literature

97results about How to "Improve the crushing fineness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of soybean milk

ActiveCN104798890AIncrease concentrationNot easy to agglomerateBeverage vesselsMilk substitutesWater vaporDry bean

The invention relates to a preparation method of soybean milk. The preparation method at least comprises the following stages: (a), flour preparation stage: providing a crushing container, a heating element for heating the crushing container and a crushing device, directly heating the crushing container through the heating element, so as to ensure that the temperature of the crushing container is increased to 70-90 DEG C, adding dried beans into the crushing container, crushing the dried beans into bean flour through the crushing device, and ensuring that lipase and beany flavor of the bean flour are removed in the crushing container at ambient temperature; (b), preparation and boiling stage: adding water to the bean flour, so as to prepare the bean flour into pulp, and heating and boiling the pulp till the pulp is well cooked. By adopting the air temperature inside the crushing device, crushing, lipase removal and beany flavor removal are performed at the same time, protein can keep invariant, beany flavor can be effectively removed, and crushing the beans into bean flour firstly can greatly enhance the crushing fineness, so that the soybean milk concentration can be effectively enhanced. In addition, water vapor can be evaporated during crushing of the beans in the high-temperature environment, the bean flour is not easy to agglomerate, and the crushing effect is good.

Owner:JOYOUNG CO LTD

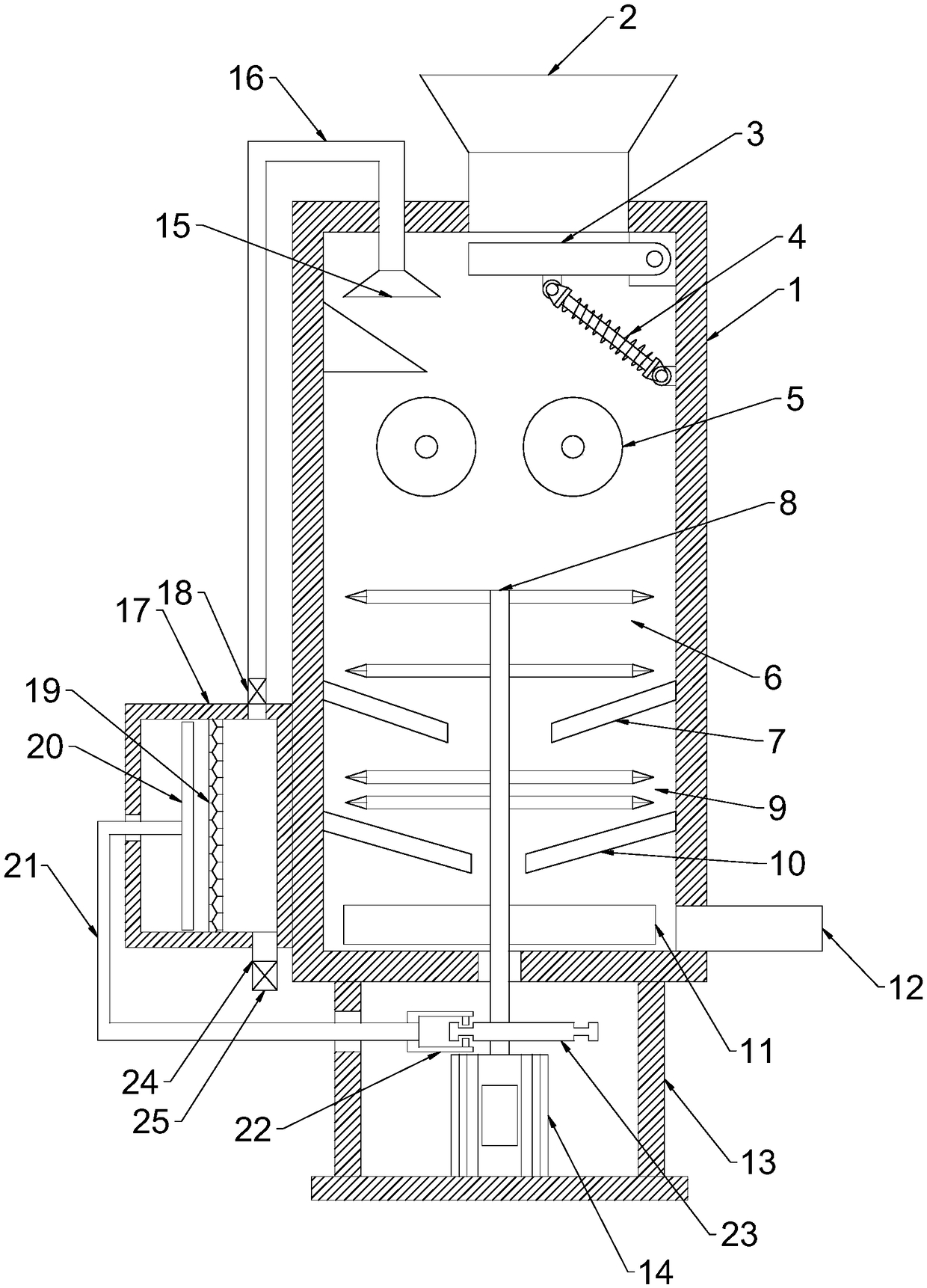

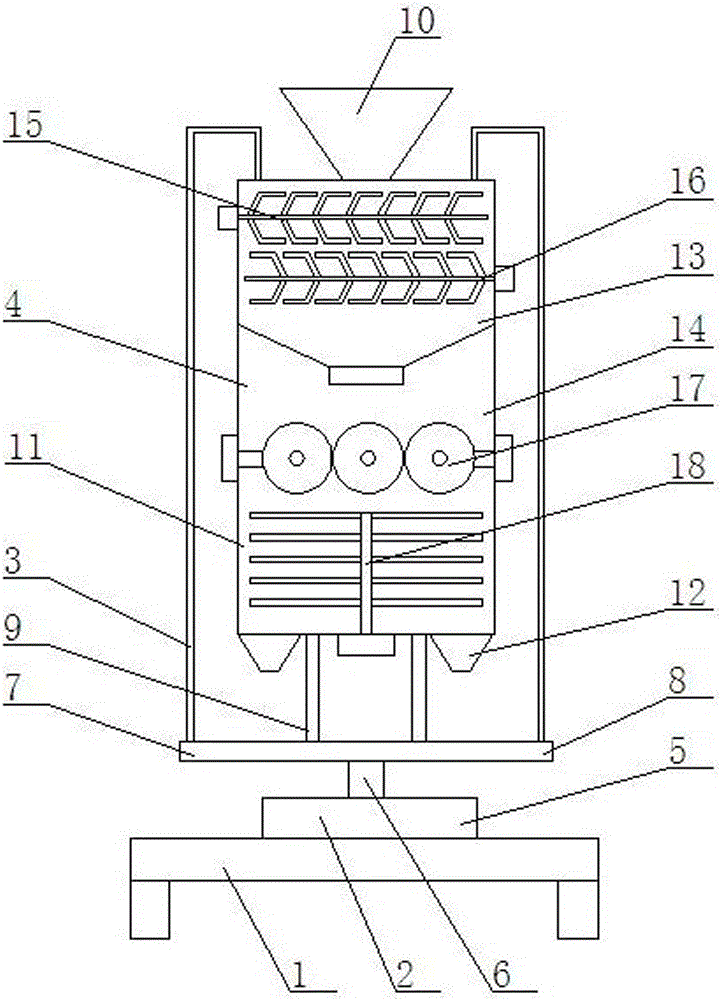

Construction waste crushing and reusing device with iron recovery function

InactiveCN107737631AImprove crushing efficiencyImprove the fineness of crushingMagnetic separationGrain treatmentsMotor shaftScrap

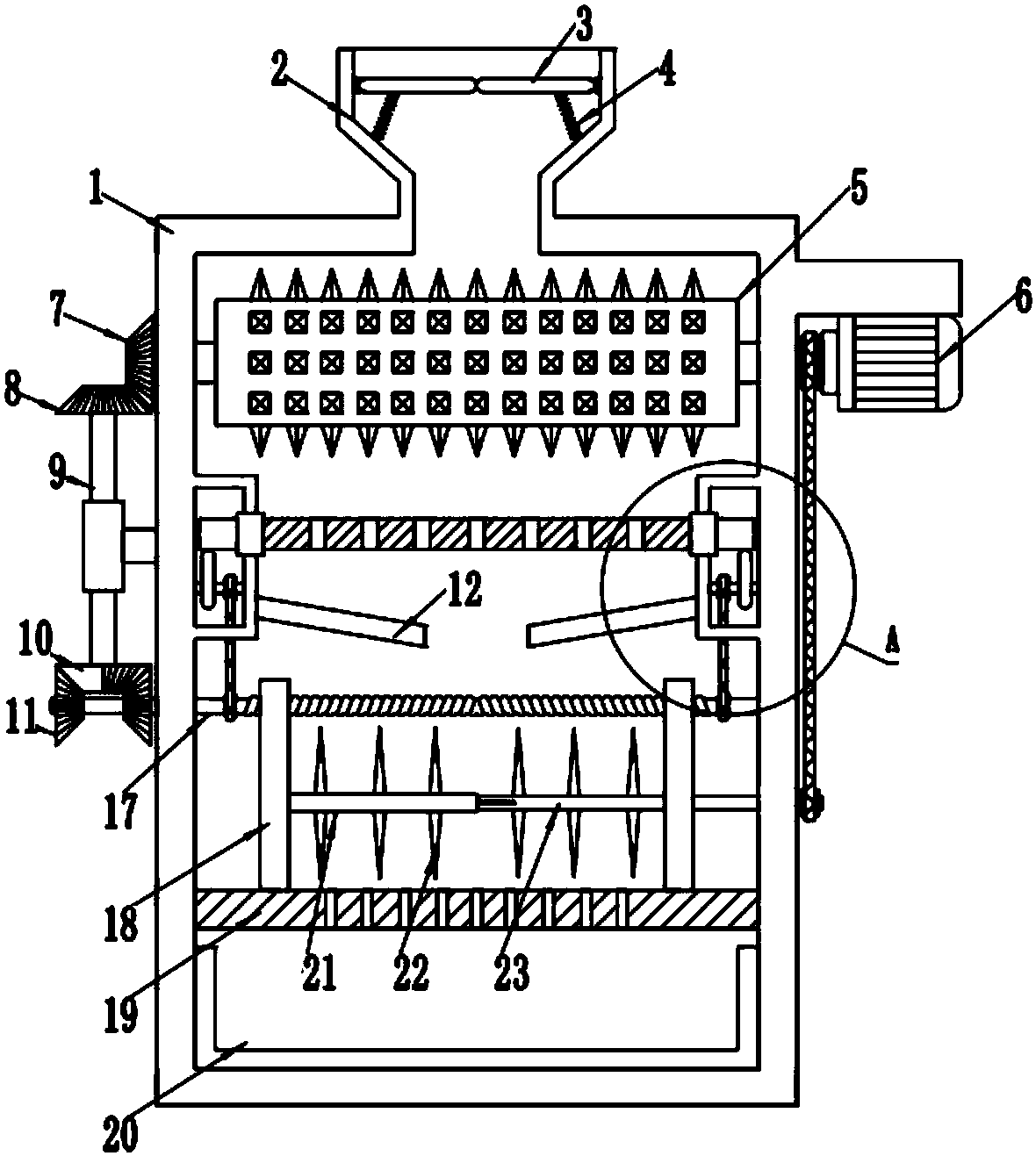

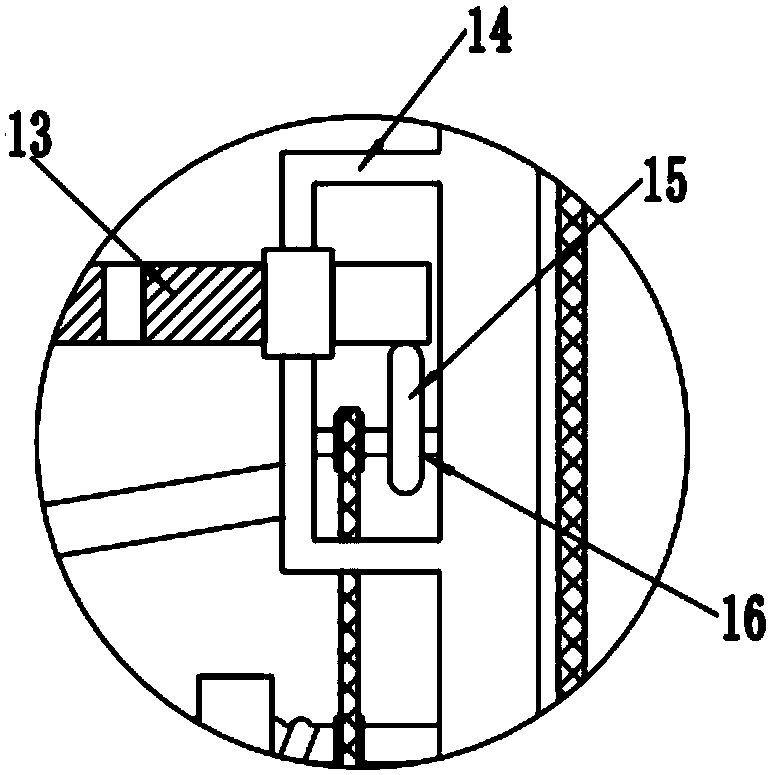

The invention discloses a construction waste crushing and reusing device with an iron recovery function. The construction waste crushing and reusing device comprises a base. A working box is fixedly arranged on the top of the base through a bracket. A left second rotary shaft and a right second rotary shaft are arranged on the top in the working box. Second crushing rollers which are matched witheach other are correspondingly and fixedly mounted in the middle parts of the left second rotary shaft and the right second rotary shaft. Gears which are engaged with each other are correspondingly mounted on the left second rotary shaft and the right second rotary shaft. A gear motor is fixedly arranged on the rear side wall of the working box. A motor shaft at the front end of the gear motor isconnected with the rear end of the second rotary shaft on the right side. An opening is formed in the right side wall of the working box. A receiving tank is hinged to the opening position through a hinge. The receiving tank is located below a first crushing roller. The receiving tank is inclined to the lower left corner. An electromagnet is fixedly arranged at the bottom of the receiving tank andlocated in the working box. According to the construction waste crushing and reusing device with the iron recovery function, iron is attracted by the electromagnet at the bottom of the receiving tankand accordingly recovered; and when the receiving tank is inclined to the lower right corner, the electromagnet is de-energized, and the iron can slide into the iron recovery box.

Owner:徐得强

Wood crushing device for papermaking

InactiveCN108525752AAvoid environmental impactImprove screening efficiencySievingScreeningPapermakingEngineering

The invention discloses a wood crushing device for papermaking. The wood crushing device comprises a shell, a feeding hopper, a dustproof mechanism, a primary crushing mechanism, an extruding and crushing mechanism and a collection groove, wherein the primary crushing mechanism is arranged at the upper end of the inner side of the shell; the primary crushing mechanism comprises a crushing roller,a motor, a first sieving plate, a sliding rail, an eccentric wheel and a second rotating rod; the extruding and crushing mechanism is arranged below the primary crushing mechanism; the extruding and crushing mechanism comprises a bidirectional thread rod, side plates, a second sieving plate, a sleeve, a crushing blade and a rotating shaft. The wood crushing device disclosed by the invention is novel in design; the dustproof mechanism can be used for effectively preventing wood dust generated in a wood crushing process from flying out to lead the environment influence; when the bidirectional thread rod rotates, the two side plates are driven to do face-to-face movement or opposite-direction movement; when the side plates do face-to-face movement, wood blocks at the inner sides of the side plates can be pressurized and gathered toward the middle, so that the crushing effect of the wood blocks is improved.

Owner:苏加强

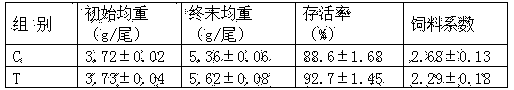

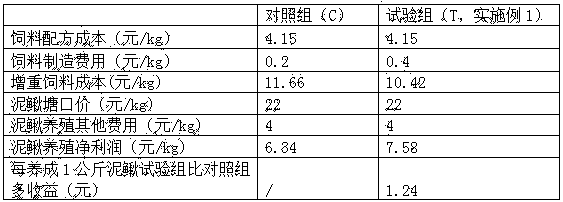

Loach settling-type puffing mixed feed and preparing method thereof

ActiveCN104000050AMaintain Gut HealthImprove Nutrient Utilization EfficiencyFood processingClimate change adaptationSOYBEAN SEED OILNutrition

The invention relates to loach settling-type puffing mixed feed and a preparing method thereof, and belongs to the technical field of puffing feed production used for aquatic products. The feed comprises the following raw materials, that is, fish meal, meat meal, corn gluten meal, spray-dried animal blood cells, fermented soybean meal, soybeans, bean pulp, rapeseed dregs, DDGS, flour, soybean oil, monocalcium phosphate, bentonite, 98.5% lysine hydrochloride, 99% DL methionine, choline chloride, decavitamin premix compound, 35% vitamin C phosphate, composite mineral substance premix compound and sodium butyrate. The loach settling-type puffing mixed feed can well maintain intestinal health of loaches, further improves the nutrition utilization rate, invigorates health and improves anti-stress capacity of the loaches. The prepared loach settling-type puffing mixed feed is used in breeding stage of the loaches, the ingestion characteristics of the loaches are combined, the ingestion and growth states of the loaches are good, the physique of the loaches is strong, the feed coefficient is obviously reduced than that of an existing popular hard particle feed product, the survival rate is obviously improved and culture benefits are substantially improved.

Owner:TONGWEI

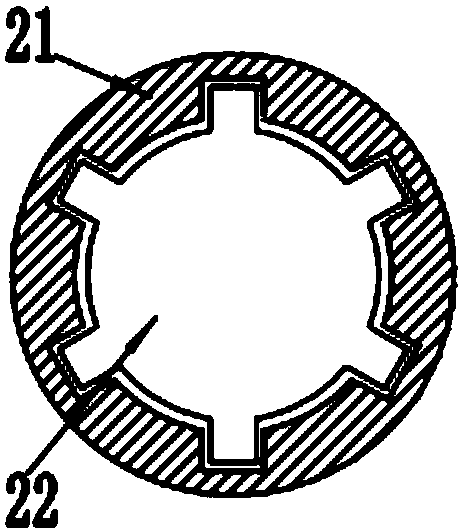

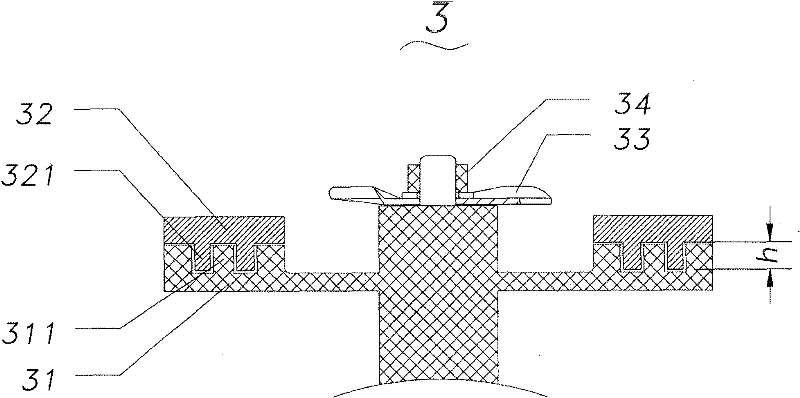

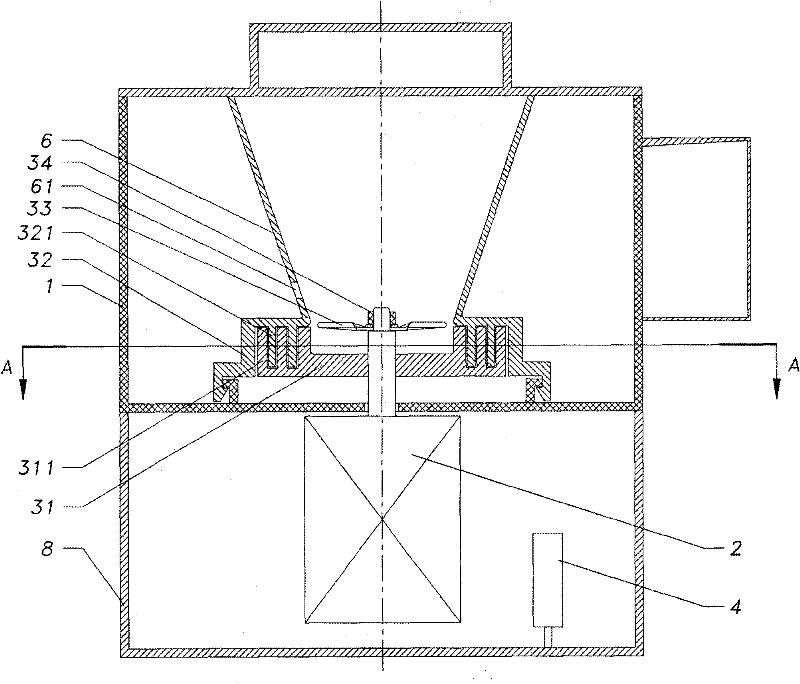

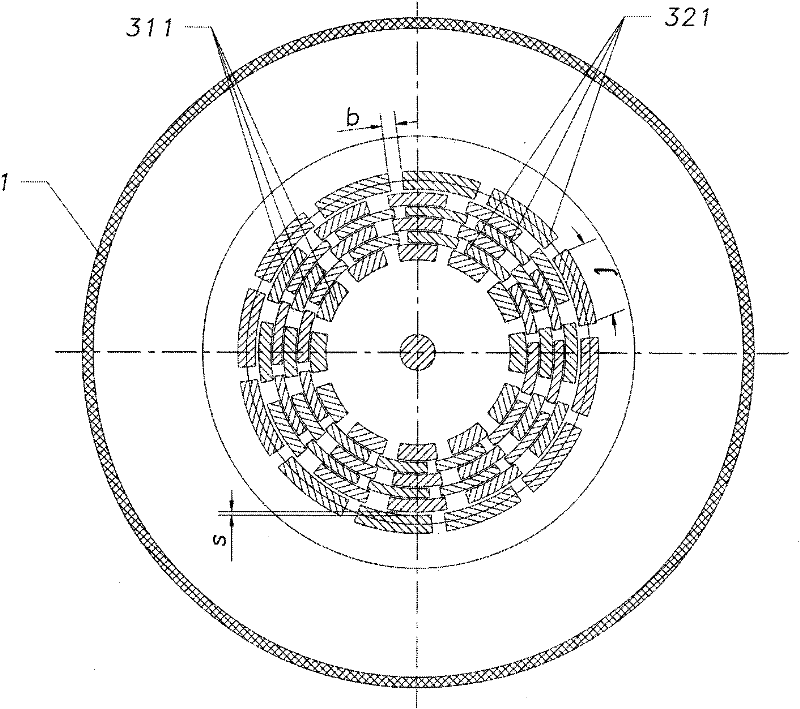

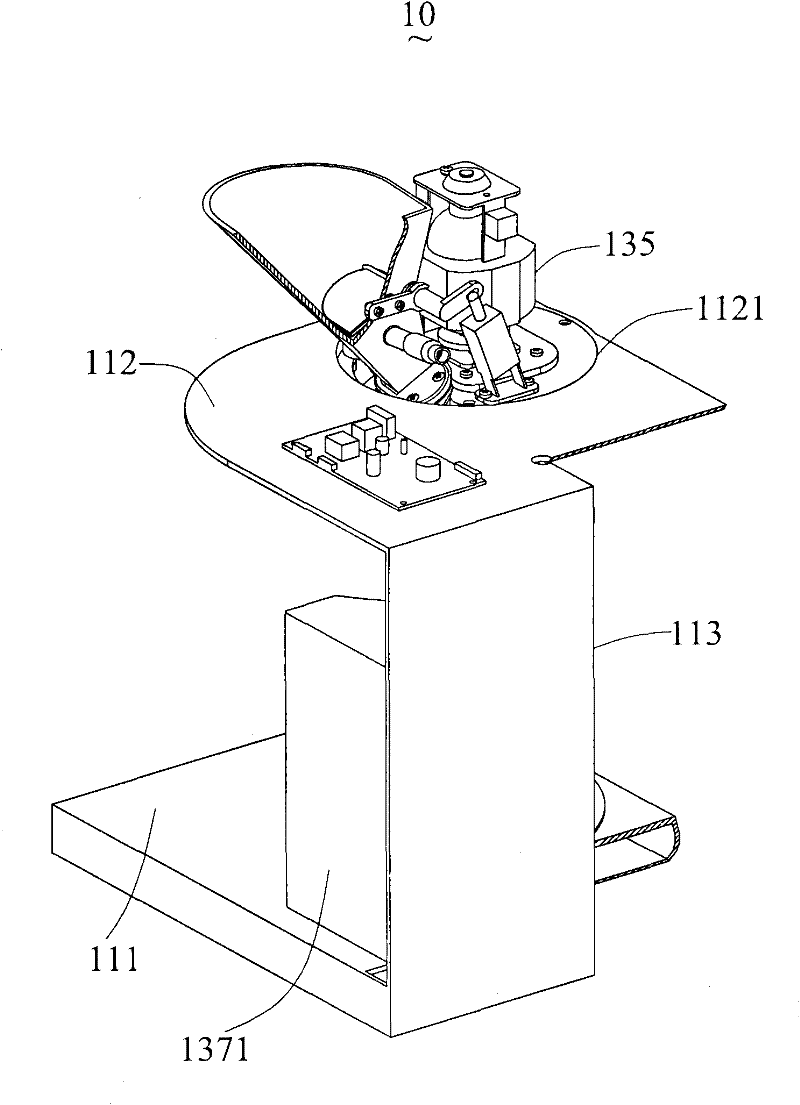

Micro-grinding soymilk maker

ActiveCN102210347AImprove crushing efficiencyIncrease profitCocoaGrain treatmentsEngineeringMechanical engineering

The invention relates to a kitchen appliance, in particular to a micro-grinding soymilk maker. The soymilk maker comprises a motor, a grinding device and a control device, wherein the grinding device comprises a movable grinding disc and a fixed grinding disc, the motor is used for driving the movable grinding disc to operate, and the soymilk maker is characterized in that shearing parts which are mutually staggered and matched are arranged on the movable grinding disc and the fixed grinding disc, and the linear velocity of the shearing parts is 7m / s-60m / s. The invention provides the soymilk maker which can thoroughly grind soybeans and make soymilk capable of being directly drunk without filtering, and the soymilk maker is simple in structure, stable in performances, safe and reliable.

Owner:JOYOUNG CO LTD

Puffed demersal crucian carp mixed feed and preparation method thereof

InactiveCN104431636AReduce dosageReduce the cost of farmingAnimal feeding stuffBiotechnologySodium Bentonite

The invention discloses a puffed demersal crucian carp mixed feed. The puffed demersal crucian carp mixed feed comprises, by weight, raw materials including fish meal 3-10 parts, pig meat powder 4-8 parts, corn protein powder 5-8 parts, insect protein powder 2-5 parts, fermented soybean meal 3-6 parts, soybean meal 15-20 parts, rapeseed meal 15-25 parts, cottonseed meal 5-15 parts, DDGS 6-15 parts, flour 15-20 parts, soybean oil 1.5-3 parts, monocalcium phosphate 2-3 parts, bentonite 1-3 parts, lysine hydrochloride 0.2-0.4 part, DL-methionine 0.05-0.2 part, choline chloride 0.05-0.1 part, decavitamin premix 0.3-0.6 part, vitamin C phosphate-35% 0.02-0.04 part, composite mineral substance premix 1.0-2.0 parts, taurine 0.01-0.03 part and inositol 0.01-0.03 part. The cost and coefficient of the feed are remarkably reduced, and pollution is reduced.

Owner:常州海大生物饲料有限公司

Ultrafine grinder liquid nitrogen cooling device

InactiveCN103913027AReduce the temperatureImprove the crushing finenessDomestic cooling apparatusLighting and heating apparatusLiquid nitrogen coolingNitrogen

The invention belongs to the technical field of cooling equipment structures, and relates to an ultrafine grinder liquid nitrogen cooling device comprising a liquid nitrogen tank carrying liquid nitrogen and a vaporizer communicated with the liquid nitrogen tank. The vaporizer is arranged in a cooling liquid tank and is provided with a nitrogen outlet communicated with outside of the cooling liquid tank, and the cooling liquid tank is filled with cooling liquid and is provided with a temperature sensor; the output end of the cooling liquid tank is communicated with a cooling liquid circulating outlet pipeline, part of the cooling liquid circulating pipeline wraps an ultrafine grinder cooling disc, and the output end of the cooling liquid circulating pipeline is communicated to the inside of the cooling liquid tank; a liquid nitrogen pump is mounted between the liquid nitrogen tank and the vaporizer; the cooling liquid circulating outlet pipeline is provided with a cooling liquid pump, and the liquid nitrogen pump, the cooling liquid pump and the temperature sensor are controlled by an electric control system. The ultrafine grinder liquid nitrogen cooling device is reasonable in structural design, high in safety and reliability, small in occupation, and capable of decreasing the temperature of the material smashed by an ultrafine grinder greatly.

Owner:LAIYANG GUIHE MACHINERY

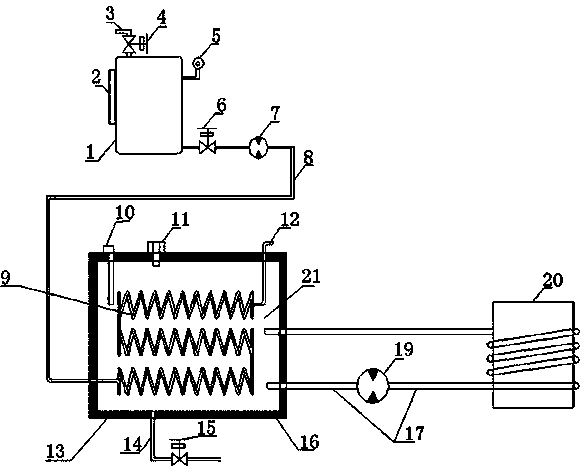

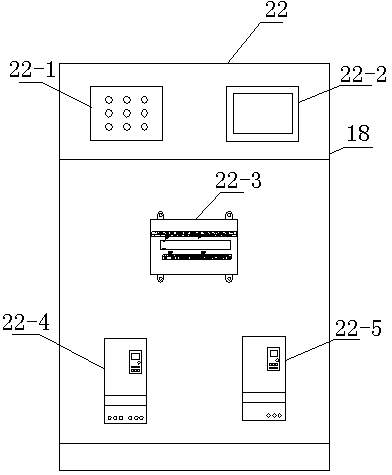

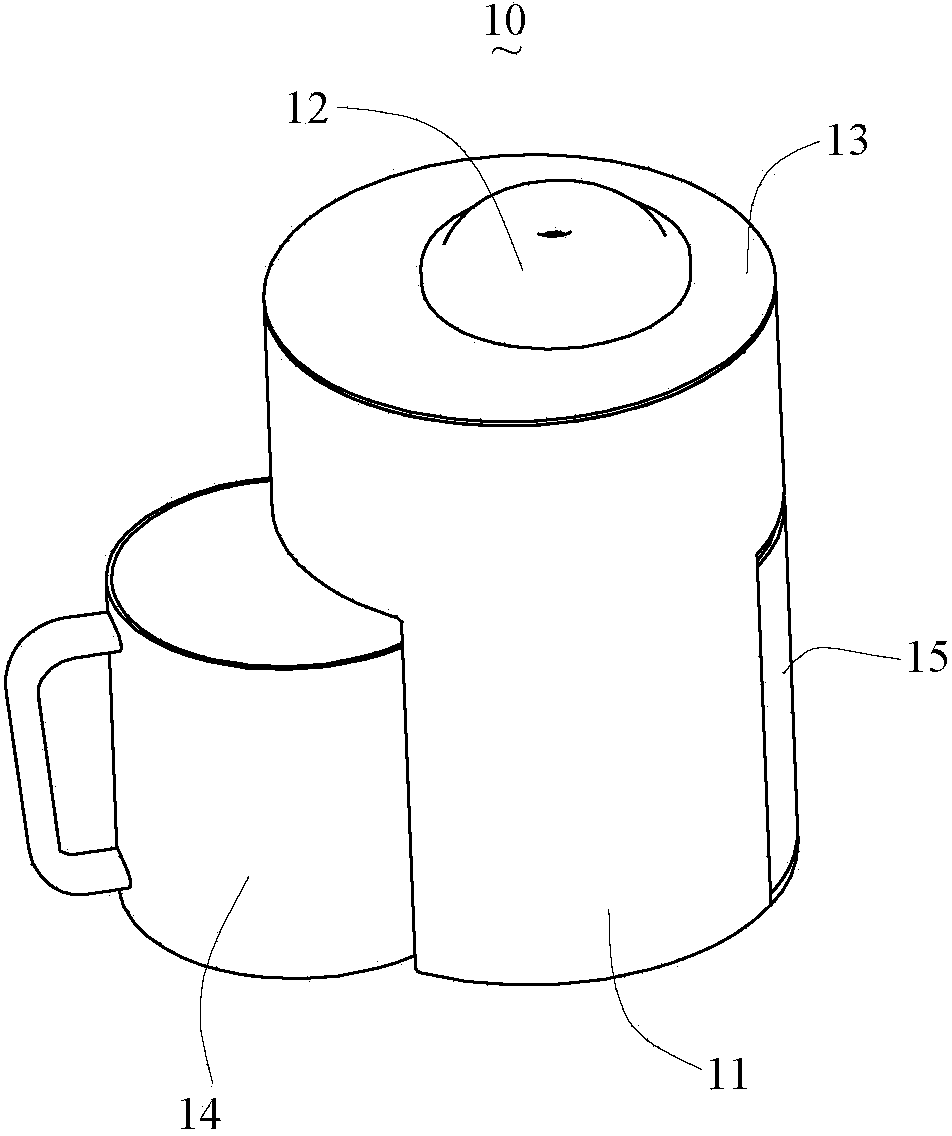

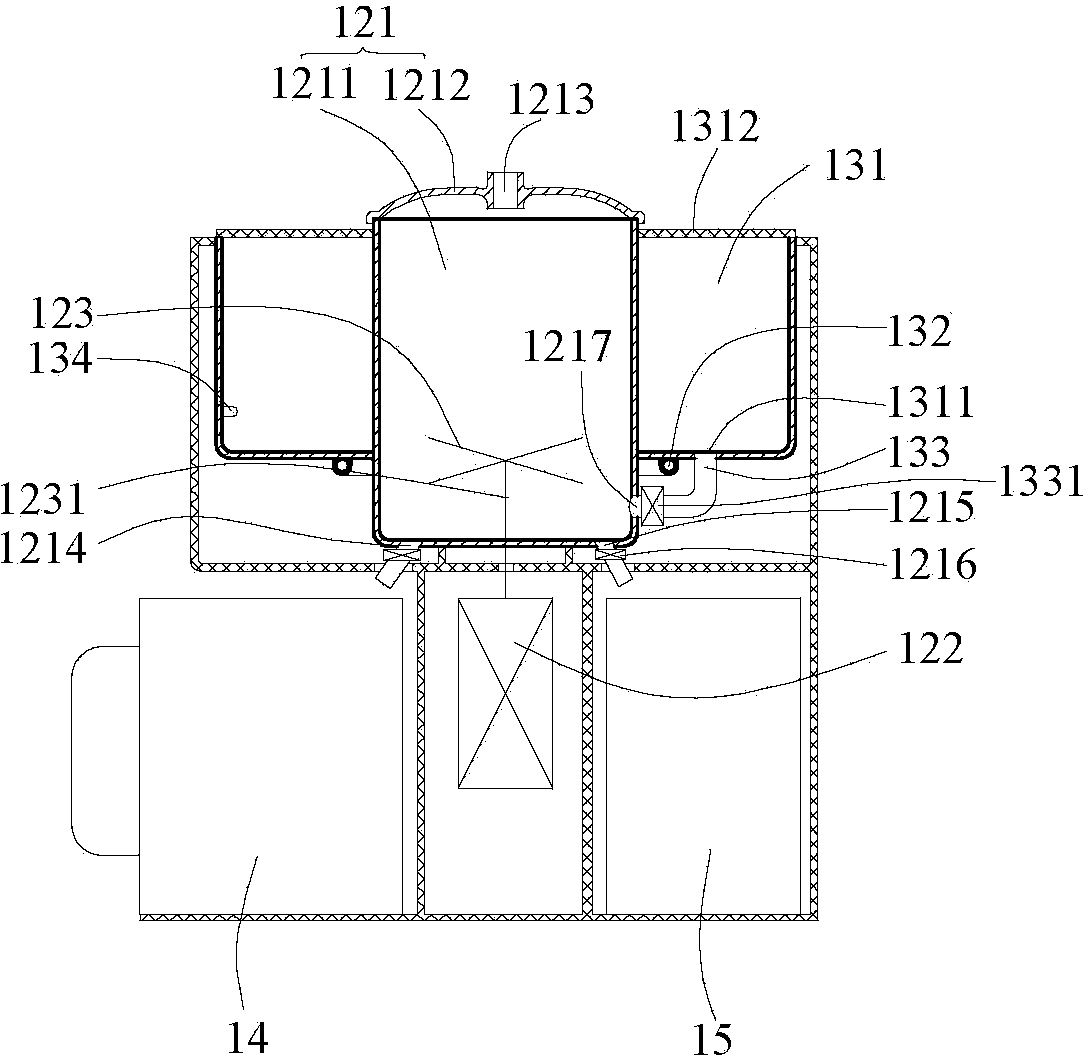

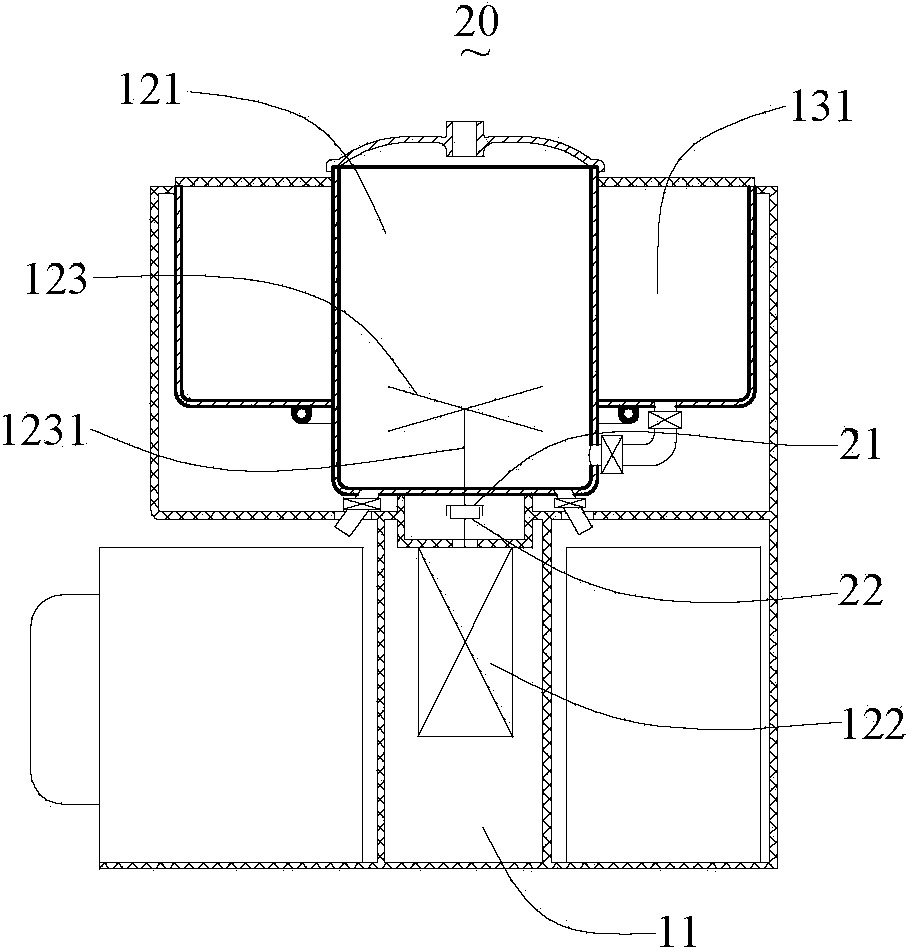

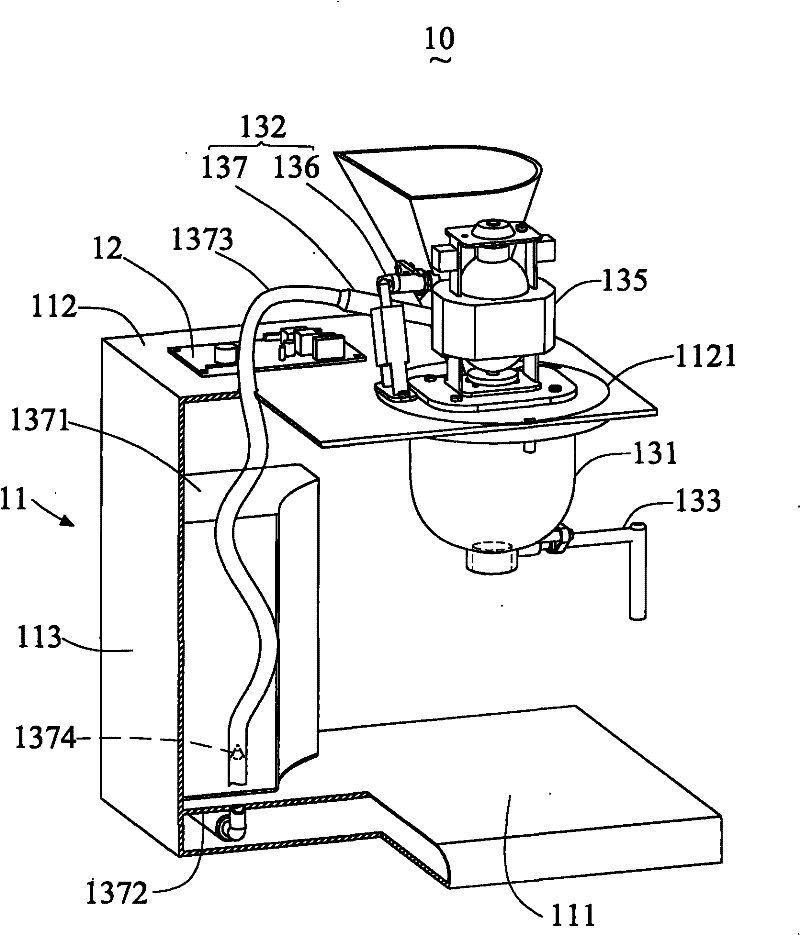

Soybean milk making method of energy-saving soybean milk machine

The invention relates to a soybean milk making method of an energy-saving soybean milk machine. The method comprises the following steps that a, water with the set amount is injected in a small-space pulverizator from a water tank; b, a motor is then started to drive a pulverization knife to rotate to pulverize materials in the small-space pulverizator, the water tank is heated through a heating element, and the heat of water is transferred to the interior of the small-space pulverizator to cook milk / a paste; c, the cooked milk / the cooked paste is discharged to a milk collection cup; d, water with the set amount is injected to the small-space pulverizator again from the water tank, and the milk / the paste in the small-space pulverizator is then discharged to the milk collection cup again. When the soybean milk making method of the energy-saving soybean milk machine is compared with the prior art, water in the water tank is heated through the heating element, the heat of the water is transferred to the small-space pulverizator, and accordingly the materials in the small-space pulverizator are preheated and cooked, the heat of the water in the water tank is reasonably and effectively utilized, energy is saved, the water tank can be continuously heated and kept warm and the soybean milk making period can also be effectively shortened.

Owner:JOYOUNG CO LTD

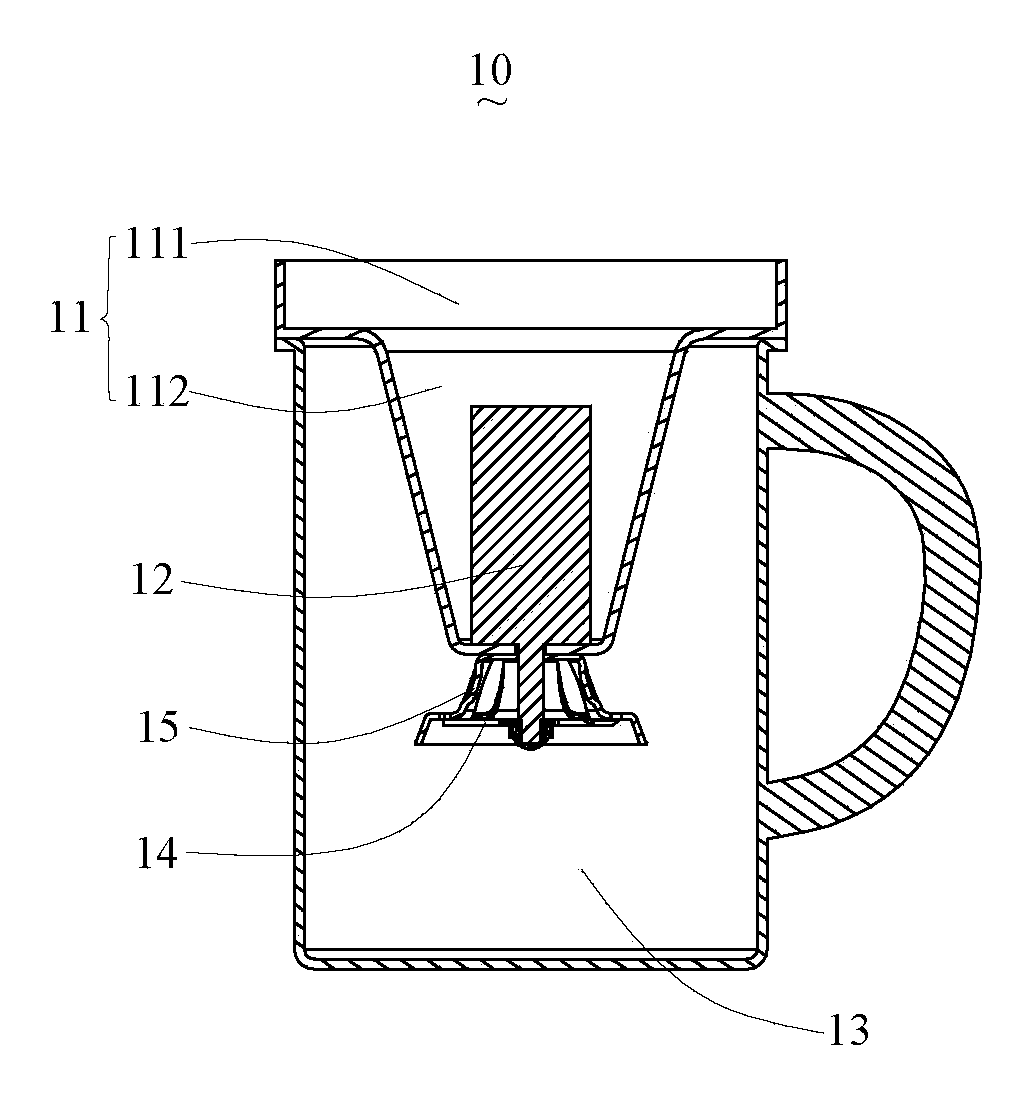

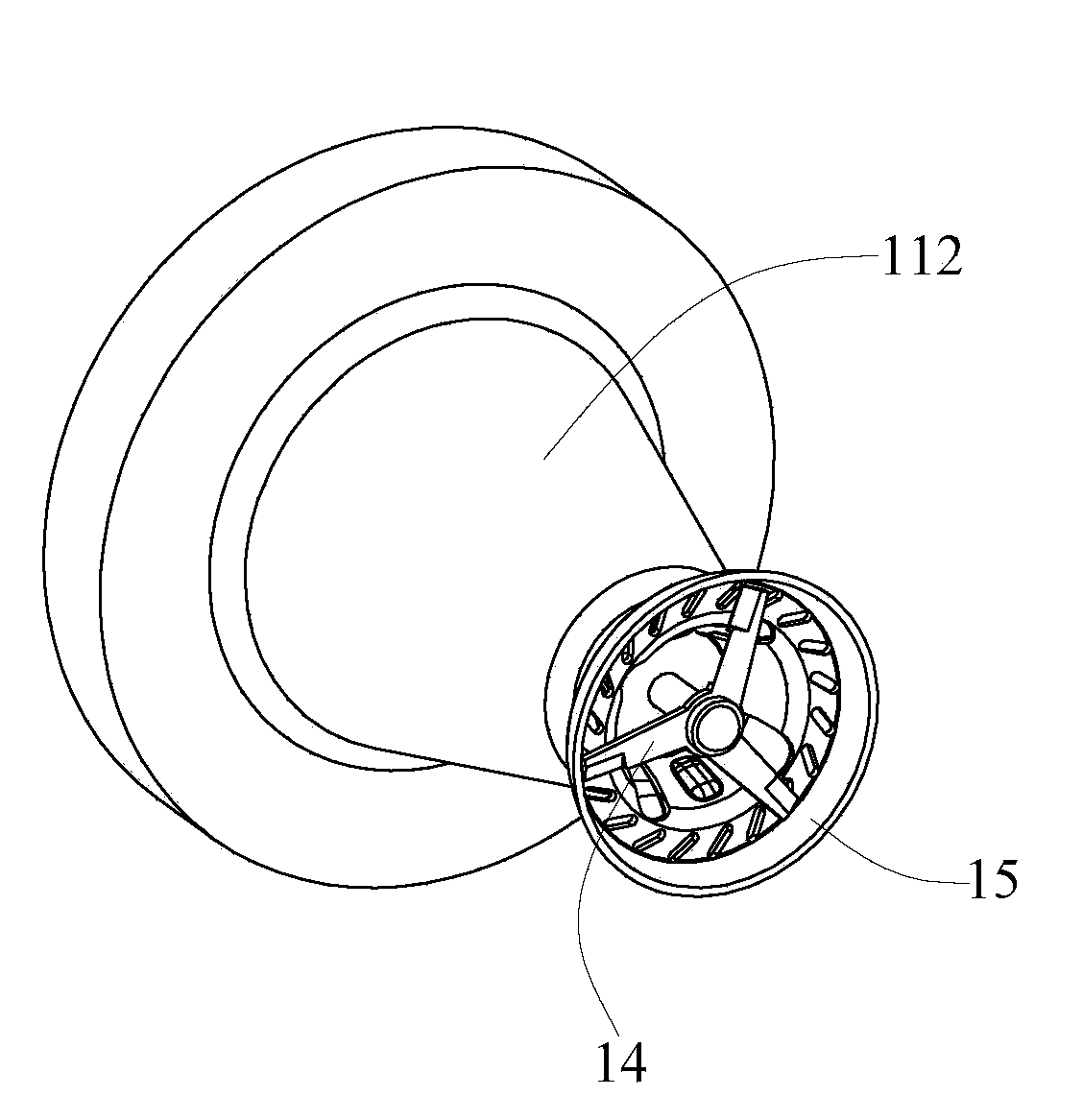

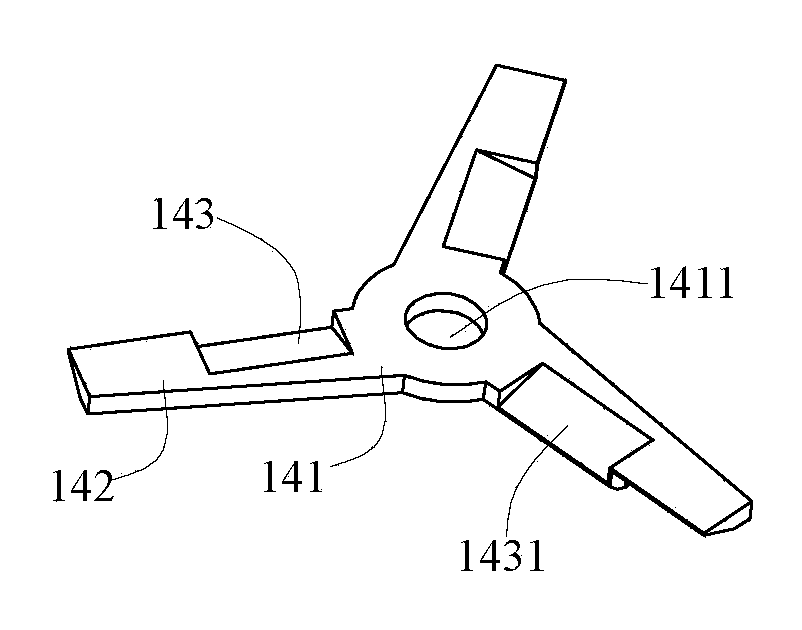

Fine-crushing soybean milk machine

ActiveCN103654397AReach the tasteRealize ultrafine pulverizationBeverage vesselsMilk substitutesAerospace engineering

The invention relates to a fine-crushing soybean milk machine which comprises a machine head, a motor, a cup and a crushing cutter, wherein the machine head is arranged on the cup in a buckled mode, and the motor is installed in the machine head and drives the crushing cutter to rotate; the crushing cutter comprises a wing root and a knife wing connected with the wing root; the machine head is further fixedly provided with a crushing cover; the knife wing includes a shearing portion; the crushing cover is provided with a shearing surface parallel to the plane where the shearing portion is located, wherein the shearing surface is provided with shearing grooves / holes, the shearing portion acts in cooperation with the shearing grooves / holes to achieve opposite-shearing crushing, and the ratio of the mutual opposite-shearing length between the shearing portion and the shearing grooves / holes to the length of the knife wing is 1:5-3:4. Compared with the prior art, materials can be sheared by the shearing portion when flowing through the shearing grooves / holes; because the shearing grooves / holes are formed in the shearing surface and can shear the materials many times like a plurality of shears, superfine crushing is achieved, crushing fineness is improved, and the mouth feel of residue-free soybean milk can be achieved.

Owner:JOYOUNG CO LTD

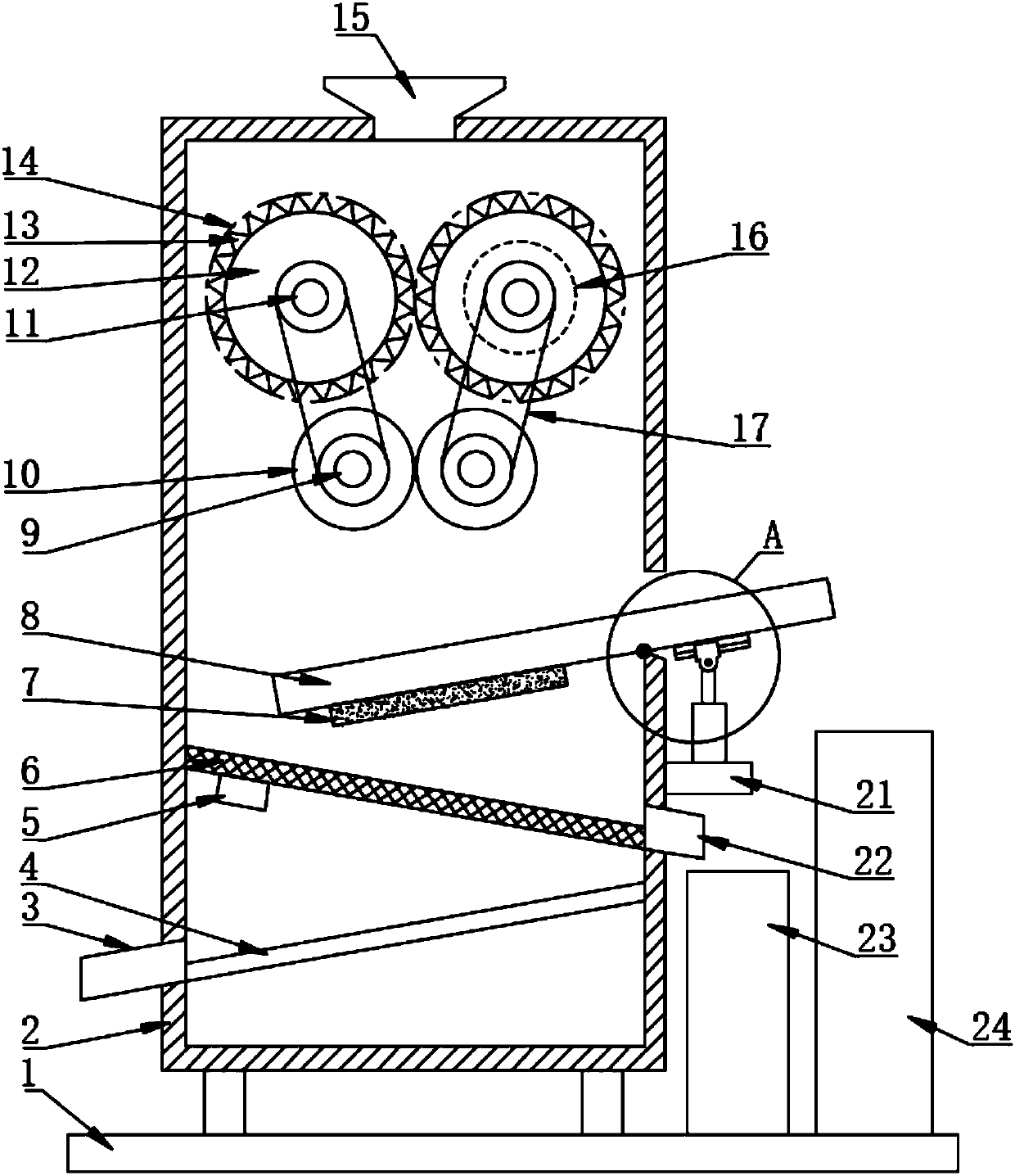

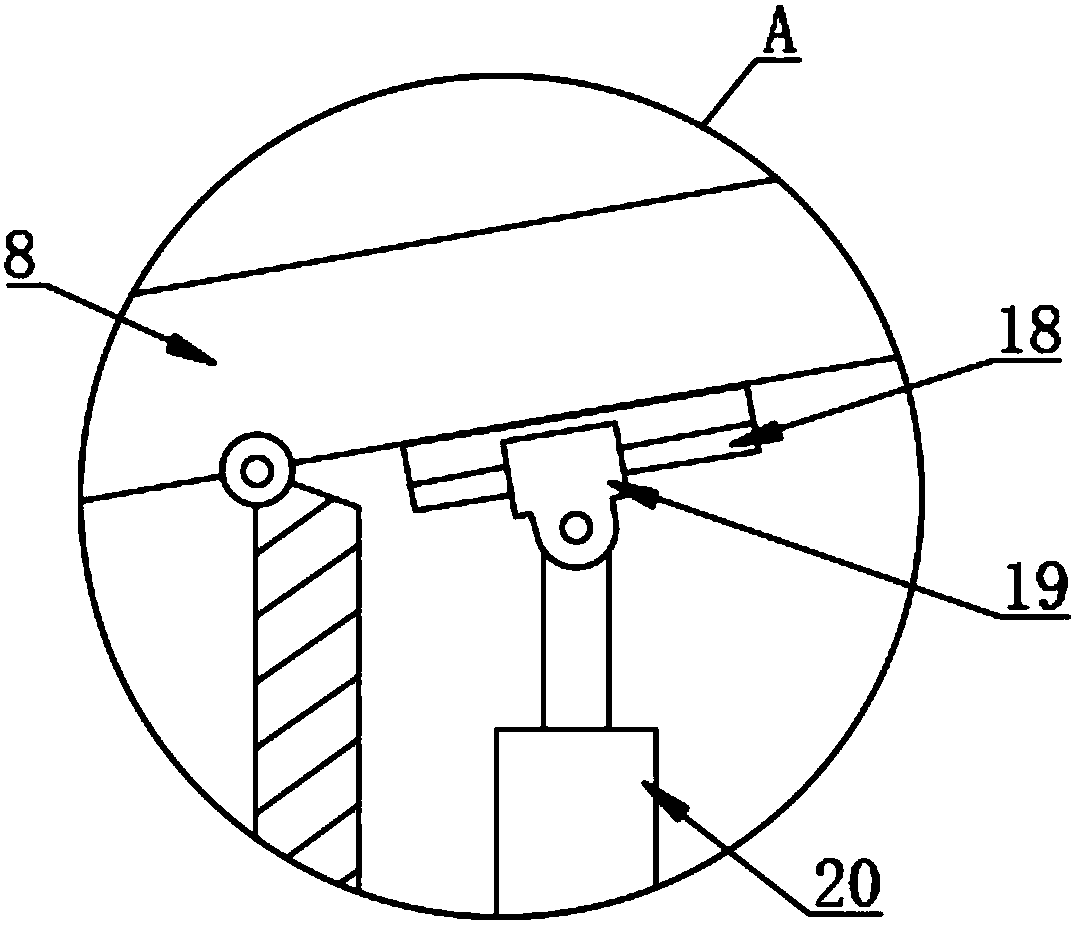

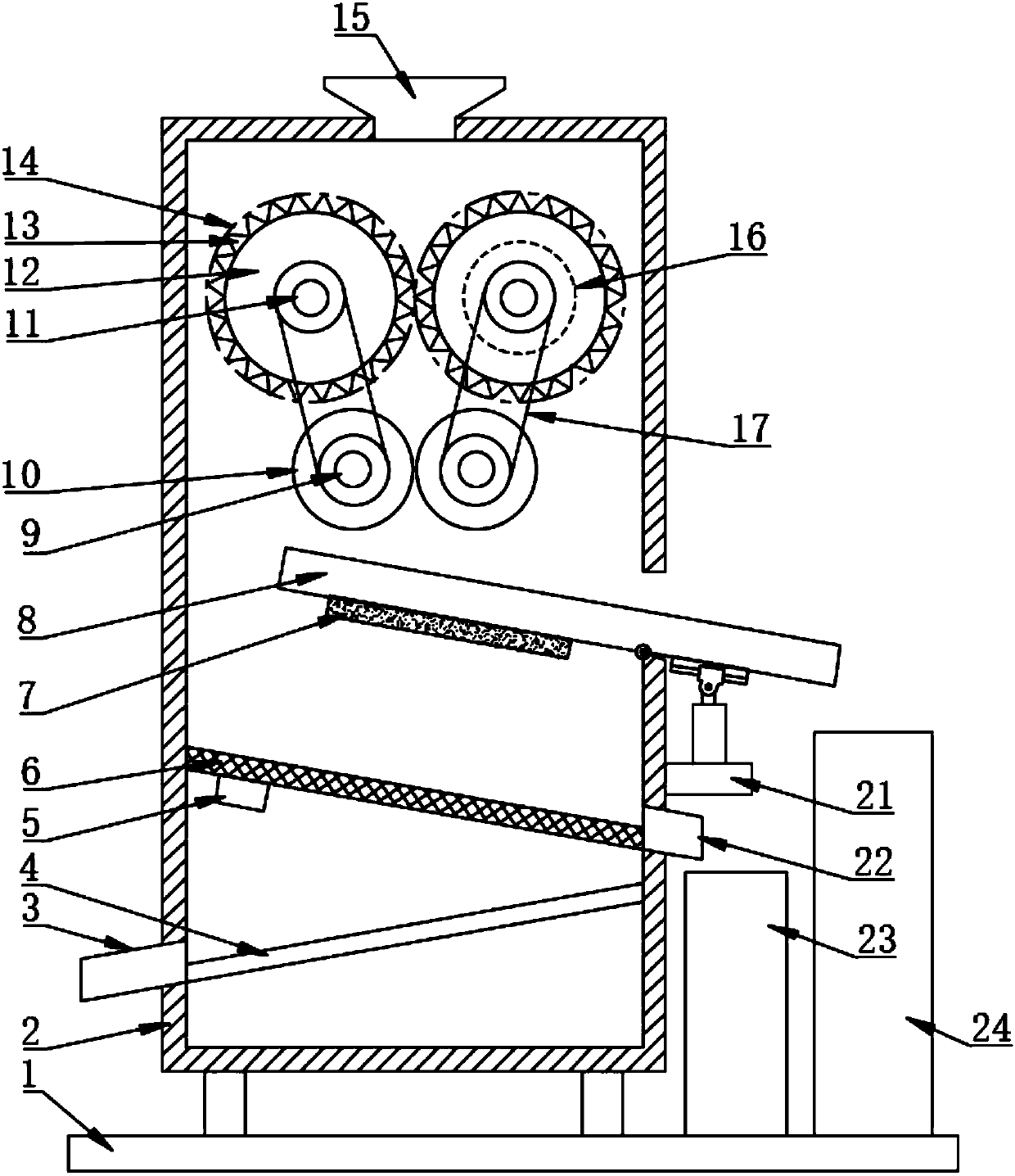

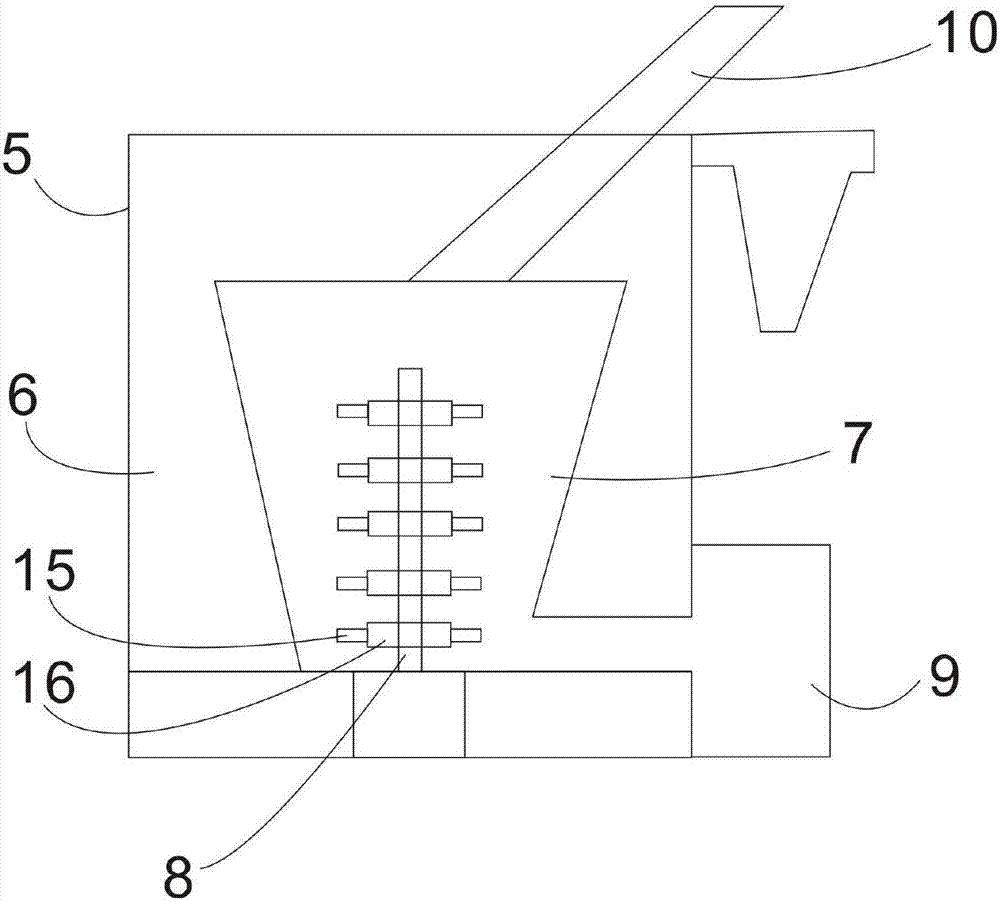

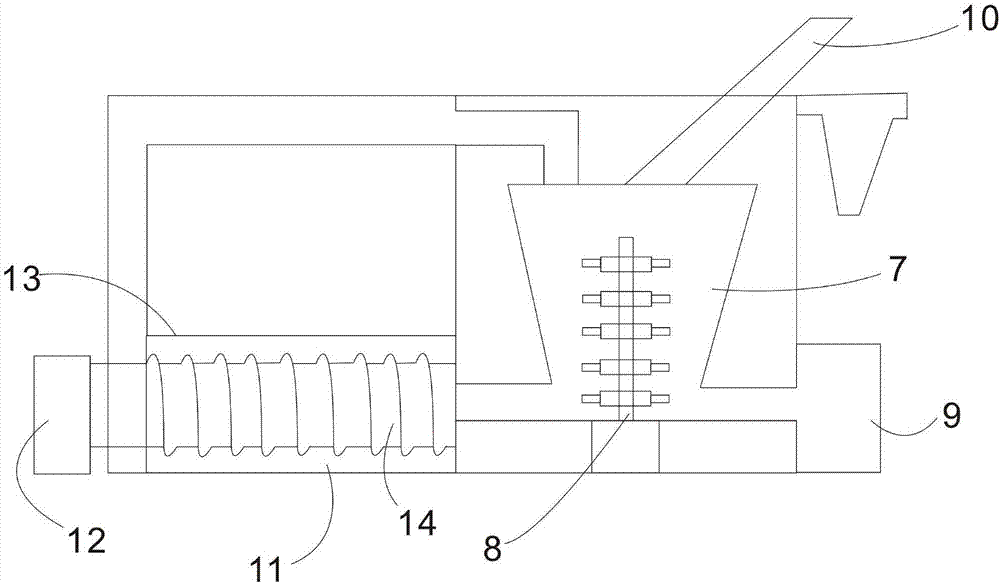

Multistage ore crushing device with dust prevention function

ActiveCN108176442AImprove crushing efficiencyImprove the crushing finenessDirt cleaningGrain treatmentsWorking environmentDrive motor

The invention discloses a multistage ore crushing device with a dust prevention function. The multistage ore crushing device comprises a barrel, crushing rollers and a drive motor. The right side of the upper portion of the barrel communicates with a feeding hopper, and the lower portion of the feeding hopper props against a baffle. The symmetrical crushing rollers are arranged below the baffle, and a first crushing blade set is arranged below the crushing rollers. A first material guide hood is arranged below the first crushing blade set. The lower end of the first material guide hood is provided with a second crushing blade set. A second material guide hood is arranged below the second crushing blade set. Through the arrangement of the crushing rollers, the crushing blade sets differentin cutter interval and the material guide hoods with discharging holes different in diameter, ores are subjected to multistage crushing, and the crushing efficiency and crushing fineness of the ores are improved. The multistage ore crushing device is provided with a suction hood, a dust collection box and the baffle, flying dust is blocked, sucked and collected, diffusion of the dust is avoided, and pollution of the work environment and the surrounding environment is avoided.

Owner:ANHUI FENGYANG HUAIHE GLASS

Feed for tiger frog tadpoles and bullfrog tadpoles and preparation method of feed

ActiveCN103535555ASimple production processStable sourceAnimal feeding stuffBiotechnologyAnimal science

The invention relates to a feed for tiger frog tadpoles and bullfrog tadpoles and a preparation method of the feed. The feed comprises the following components in parts by weight: 26-45 parts of white fish meal, 6-15 parts of oyster shell powder, 5-12 parts of krill powder, 8-22 parts of alpha-starch, 5-15 parts of soybean protein concentrate, 5-30 parts of fermented bean pulp, 3-8 parts of beer yeast powder, 10-30 parts of high-protein flour, 2-5 parts of soybean lecithin, 1-3 parts of fish oil, 0.5-1 part of vitamin premix, 1.5-2 parts of mineral premix, 0.1-0.2 part of lactic acid bacteria, 0.1-0.3 part of bacillus subtilis, 0.1-0.3 part of 50% choline chloride, 0.1-0.2 part of beta-1,3 glucan and 0.03-0.05 part of antimicrobial peptide with the content of 20,000 U / g. The raw materials of the feed disclosed by the invention are readily available, and the formula is reasonable; a production technology is simple and feasible; full-nutrition demands of the tiger frog tadpoles and the bullfrog tadpoles for high-density cultivation can be met.

Owner:珠海海为饲料有限公司

Granular feed for laying chicks

InactiveCN102210419ADoes not destroy nutritional valueReduce respiratory diseaseFood processingAnimal feeding stuffRapeseedCopper sulfate pentahydrate

The invention discloses a granular feed for laying chicks, and relates to a chicken feed. The granular feed comprises corn, wheat middling, bean pulp, cottonseed meal, rapeseed meal, corn albumen powder, fish meal, calcium hydrogen phosphate, fine rock powder, table salt, choline chloride, ferrous sulfate monohydrate, blue copperas, manganese sulfate monohydrate, zinc sulfate monohydrate, 1 percent sodium selenite, 98 percent lysine, 98 percent methionine, multiple chicken vitamins, 10 percent colistin, salinomycin, 1 percent calcium iodate and kitasamycin. The granular feed is prepared at a low temperature, so that the nutritional value of the feed is not destroyed, the crushing fineness of the feed is improved, and the feed has good palatability, is easily digested and can effectively reduce the respiratory diseases of chicks; and after the chicks are raised for 42 days by using 1Kg of the granular feed, the chick flock individuals are uniform, and the average weight can reach 480g and totally reaches the weight standard of medium laying chicks.

Owner:山西宏福农牧科技有限公司

Soya-bean milk machine capable of quickly making milk

ActiveCN102204789AReduce cooking timeImprove the crushing finenessBeverage vesselsMilk substitutesEngineeringSlurry

The invention relates to a soya-bean milk machine capable of quickly making milk. The soya-bean milk machine comprises a machine seat, a control unit, a smashing cutter, a motor for driving the smashing cutter to rotate, a smashing ager and a pre-heating device; the motor or the shaming ager is installed on the machine seat; the motor is electrically connected with the control unit; the smashing cutter is positioned in the smashing ager; materials and water are mixed in the smashing ager and are smashed by the smashing cutter into pulp / paste, heat is generated by mutual friction among the pulp / paste, the smashing cutter and the smashing ager to raise the temperature of the pulp / paste until curing; and the pre-heating device is used for heating the water and / or the materials before smashing and curing. By adopting a smashing and curing unit with higher smashing efficiency in the soya-bean milk machine, the time of comprehensively making the milk is greatly shortened, and the milk can be made only within 10 minutes.

Owner:JOYOUNG CO LTD

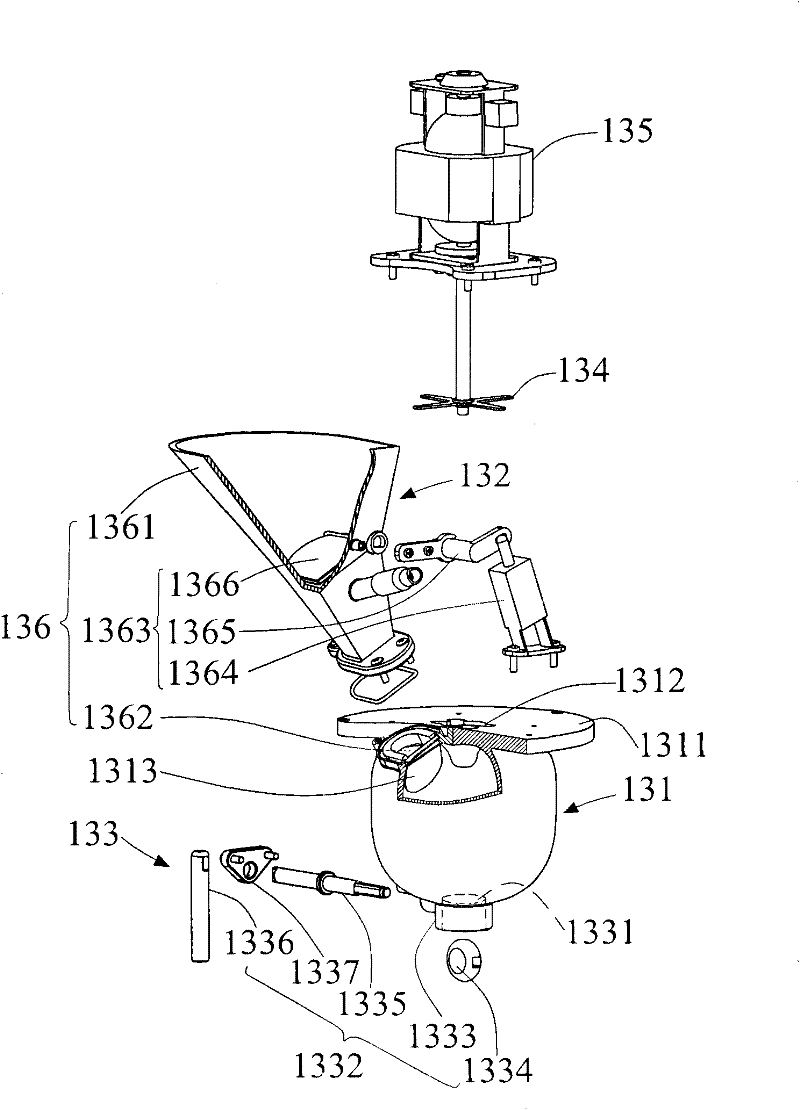

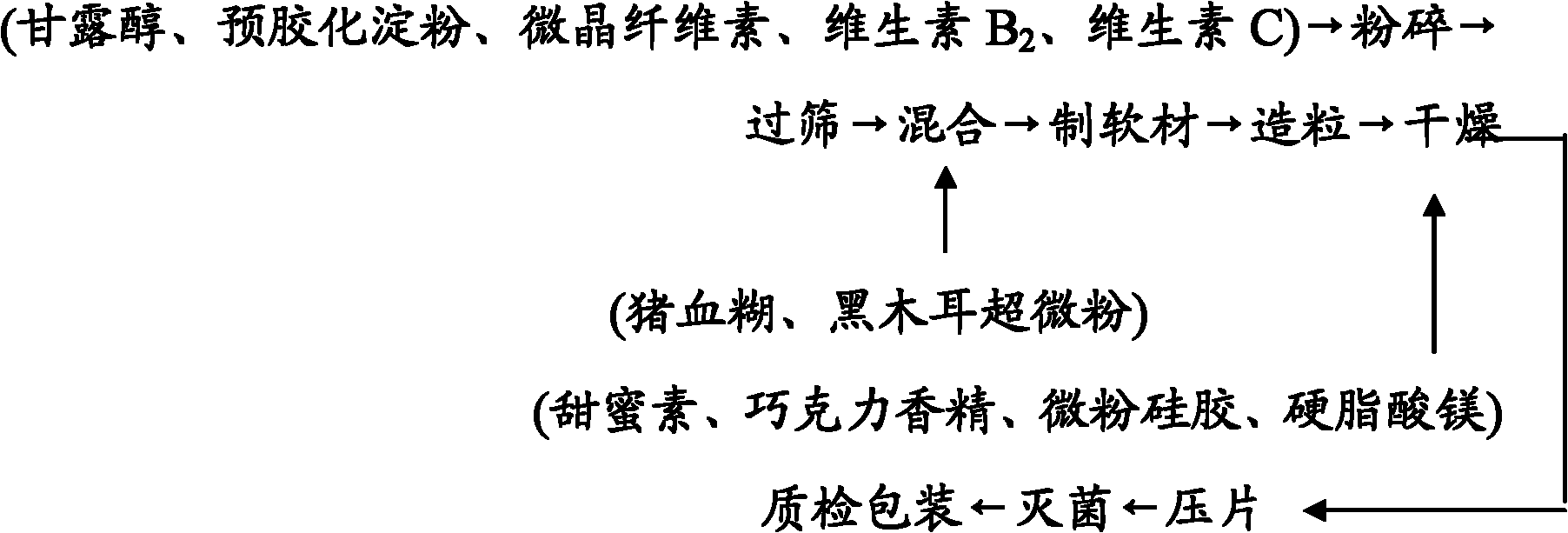

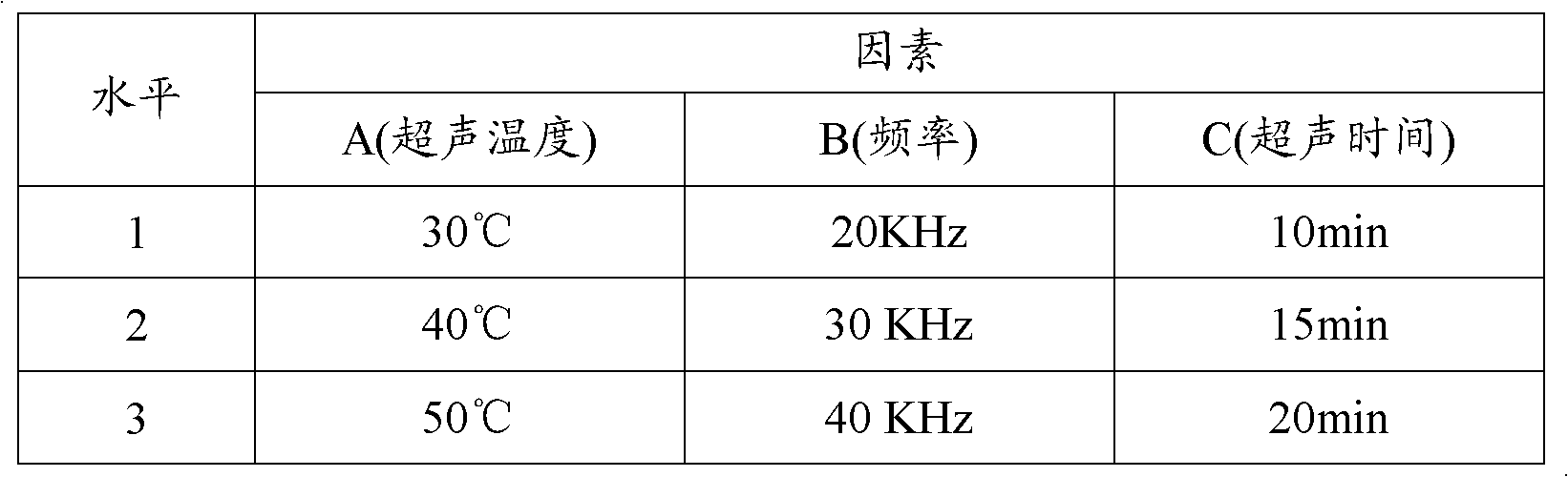

Pig blood composition and pig blood chewable tablet made therefrom

InactiveCN101829158AEasy dischargePromote peristalsisOrganic active ingredientsMetabolism disorderWater bathsVitamin C

The invention discloses a pig blood composition, mainly comprising the following components: 20-40 parts of pig blood, 10-20 parts of ultrafine black fungus powder, 0.5-2 parts of vitamin B2 and 3-12 parts of vitamin C. The pig blood is made into pig blood paste by embedding pig blood solution added with sodium citrate b for anticoagulation using hydroxypropyl beta-cyclodextrin, ; or boiling the pig blood solution added with sodium citrate for anticoagulation in a boiling water bath into a coagulated block and then filtering, taking the coagulated block and crushing into paste, then adding hydroxypropyl beta-cyclodextrin into the coagulated block (the mass of the added hydroxypropyl beta-cyclodextrin is 1 / 2 the mass of the coagulated block), and processing by ultrasonic of 20-40KHz for 10-20min. The ultrafine black fungus powder has a fineness higher than 300 meshes. The invention also discloses a pig blood chewable tablet made from the pig blood composition. The hydroxypropyl beta-cyclodextrin is taken as the wall material, and an embedding technique is combined with an ultrasonics technique so that an offensive smell of pig blood can be effectively hidden.

Owner:CHINA JILIANG UNIV

Preparation method of ecological ginseng oral freeze-dried powder

InactiveCN106942743AImprove biological activityRetain biological activityFood ingredientsCell disrupterAdditive ingredient

The invention discloses a preparation method of an ecological ginseng oral freeze-dried powder. The preparation method comprises the following steps: at first, preparing a fresh ginseng fleshy root, cutting off rootlets and fibrous roots, removing soil, washing, saving the ginseng root for later use; slicing the processed fresh ginseng root, adding pure water, squeezing the ginseng root slices to obtain pulp, filtering the pulp by a filtering device to remove residues, adding pure water into the residues, squeezing the residues to obtain pulp, filtering the pulp, mixing two processed pulps, grinding the mixed ginseng pulp by an ultrasonic cell disrupter, and finally carrying out high pressure sterilization, low temperature freezing, and vacuum drying. The prepared ginseng oral freeze-dried powder has good physiological activity, the loss of effective components is little, and the nutrient content is high.

Owner:泸州德高生物科技有限公司

High-efficiency full-automatic fertilizing device

ActiveCN107511209AImprove work efficiencyImprove automation control rateSievingScreeningBilateral symmetryThreaded rod

The invention discloses a high-efficiency full-automatic fertilizing device. The high-efficiency full-automatic fertilizing device comprises a fertilizing vehicle body and a fertilizing mechanism mounted in the fertilizing vehicle body. A storage cavity and a funnel cylinder communicating with the storage cavity are formed in the end face of the top of the fertilizing mechanism. The bottom of the funnel cavity communicates with a crushing cavity. A discharge port is formed in the bottom end face of the fertilizing mechanism in a through mode and located below the crushing cavity. The top of the discharge port communicates with the bottom of the crushing cavity. The internal bottom wall of the crushing cavity is connected with a screen plate in a sliding fit mode. The edges of the tops of the left and right sides of the screen plate are each provided with a baffle extending upwards. Guide grooves formed in bilateral symmetry are formed in the portion, between the baffles on the left and right sides, of the inner wall of the rear side of the crushing cavity. A first motor is fixedly arranged in the position, between the guide grooves on the left and right sides, of the inner wall of the fertilizing mechanism. The left and right sides of the first motor are connected with threaded rods extending to the two sides in a matched mode. The high-efficiency full-automatic fertilizing device is simple in structure, convenient to operate, capable of reducing the operation procedures and improving the working efficiency and high in automation control rate and improves the fertilizing progress.

Owner:CHANGSHU CITY YUSHAN GREEN TEA

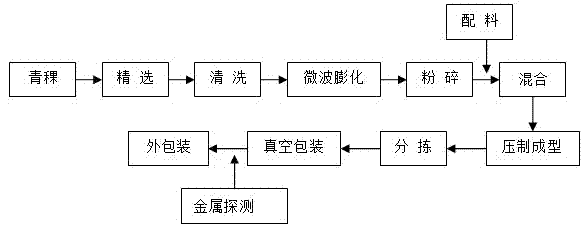

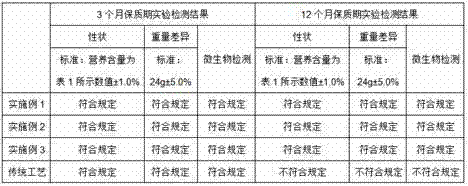

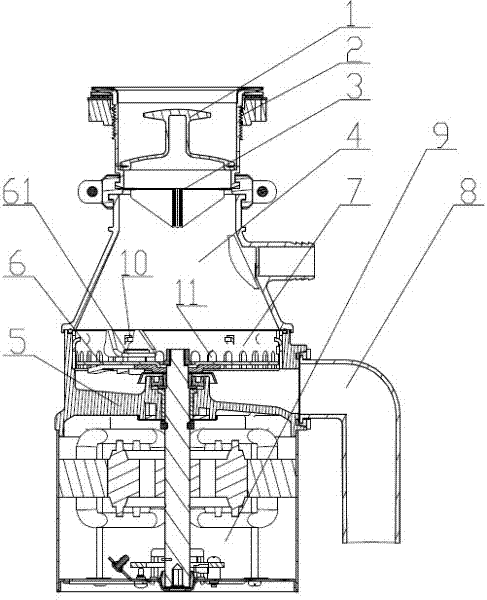

Full-highland-barley compressed biscuit and processing technology thereof

InactiveCN104719408AShort heating timeHeating evenlyDough treatmentBakery productsRipeningProcess engineering

The invention relates to a full-highland-barley compressed biscuit and a processing technology thereof and belongs to the technical field of foods. The processing technology comprises the step of raw material storing, fine selecting, washing, microwave ripening, smashing, material distributing, forming, sorting, vacuum packaging and external packaging. According to the full-highland-barley compressed biscuit and the processing technology thereof, firstly, the microwave technology is adopted to large-scale production of highland barley foods, and highland barley is directly processed into zanba after being subjected to microwave ripening; secondly, the zanba is compressed and shaped through material distributing; the traditional compressed biscuit production technology that main raw materials must be processed into biscuits firstly, then the biscuits are smashed, other ingredients are added into the smashed biscuits to be mixed, and then compressing and shaping are conducted is changed. Meanwhile, the processing technology has the advantages that the material heating time is short, and the temperature control is accurate; the quality of the produced biscuits is high, the loss of effective constituents is small, the guarantee period is long, and the processing technology is easy to apply and popularize.

Owner:迪庆香格里拉青稞资源开发有限公司

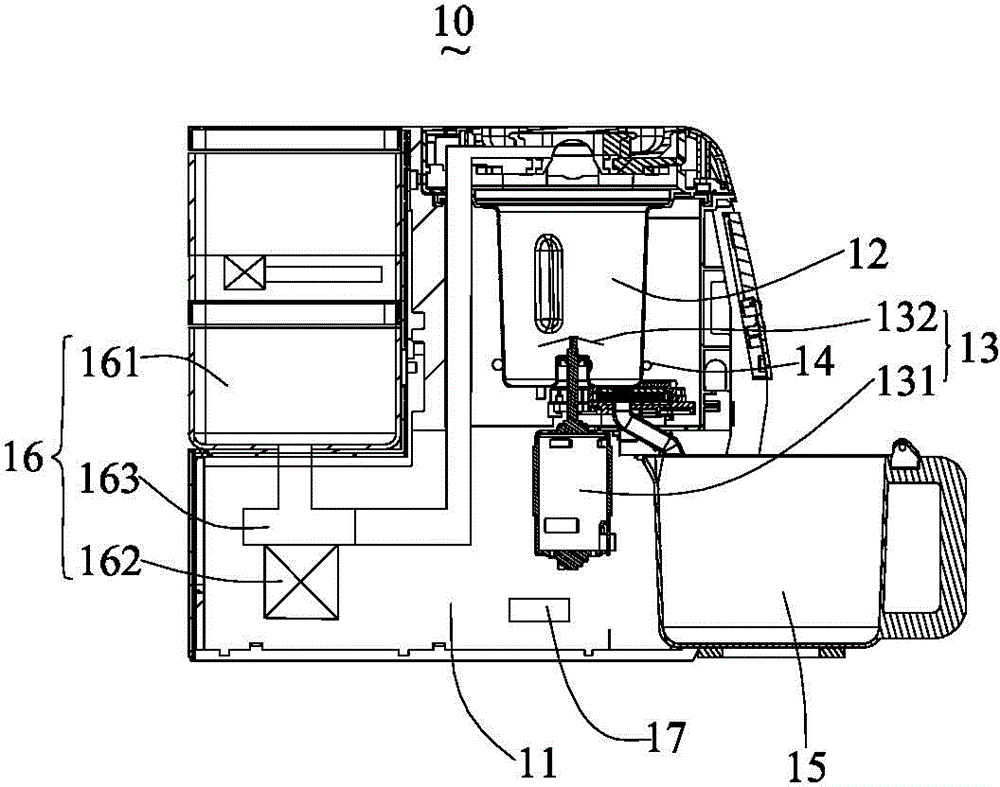

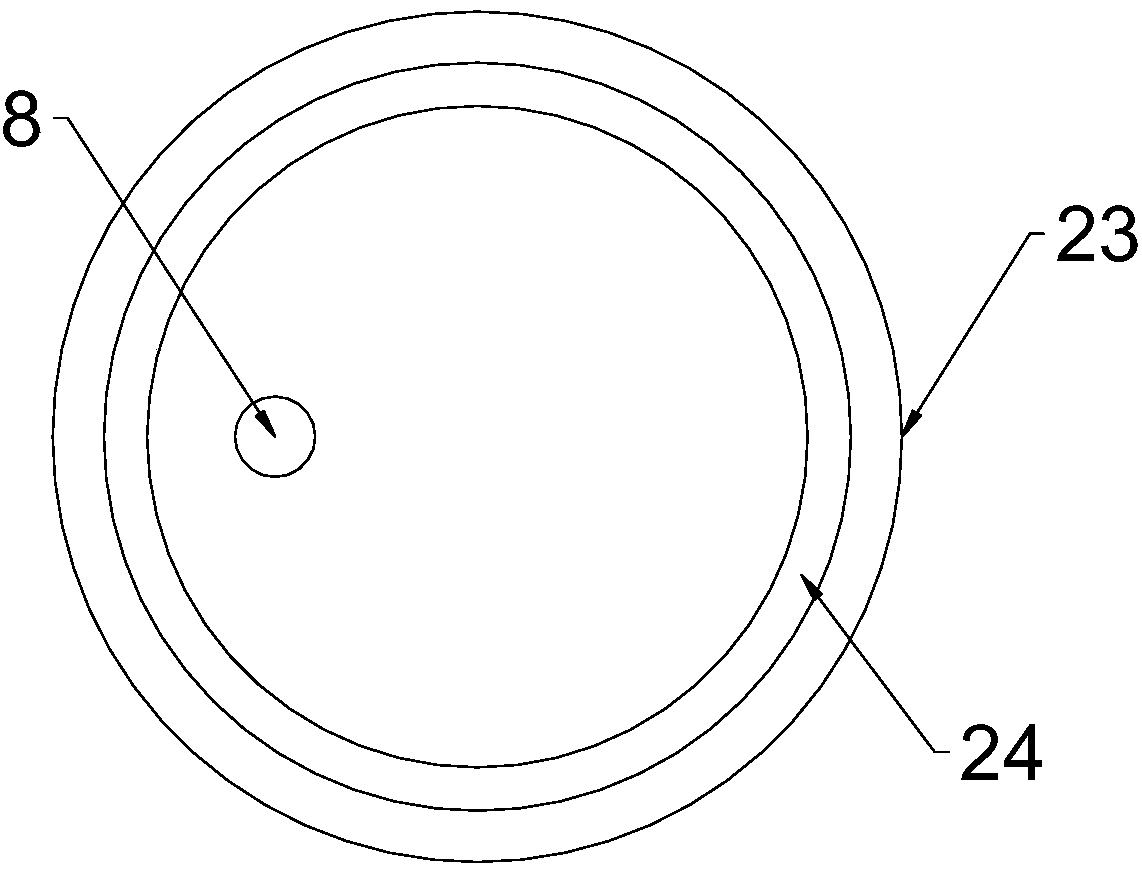

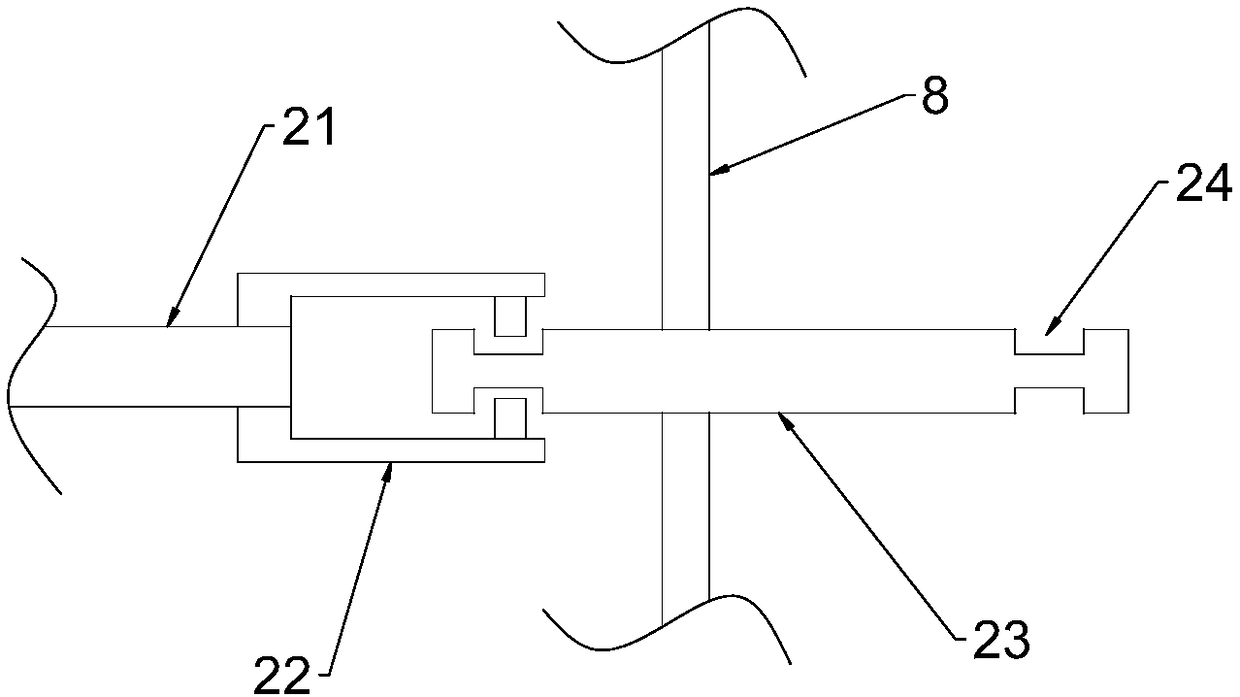

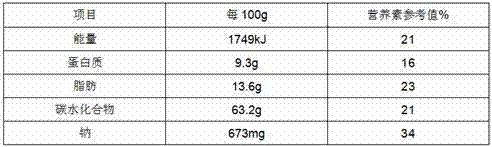

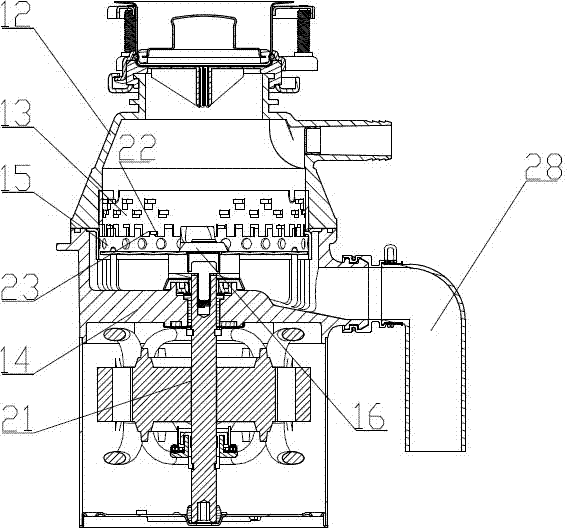

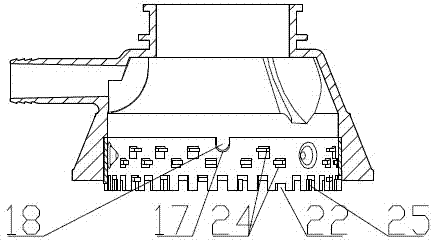

A food waste disposer

The invention is a food waste disposer. It includes a casing, an upper crushing chamber, a lower crushing chamber, a cutter head assembly, and a motor assembly, wherein the upper crushing chamber for holding food waste is arranged on the upper part of the casing, and the lower crushing chamber is arranged under the bottom of the upper crushing chamber. The upper grinding ring is installed in the upper crushing chamber, the cutter head assembly is placed in the lower crushing chamber, the motor assembly that drives the cutter head assembly to rotate is installed in the lower part of the housing, and the lower grinding ring is installed in the lower crushing chamber. In the present invention, a coaxial connecting ring is formed between the upper grinding ring and the lower grinding ring, and this structure can gather a certain amount of food waste, especially fibrous food waste. In addition, since the upper grinding ring is provided with staggered grinding grooves and transverse protrusions, the grinding fineness and grinding speed of food can be effectively improved, the impact of bone food waste on the upper grinding chamber can be avoided, and the upper grinding chamber can be extended. The service life of the crushing chamber; the invention is easy to assemble and has excellent performance.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD

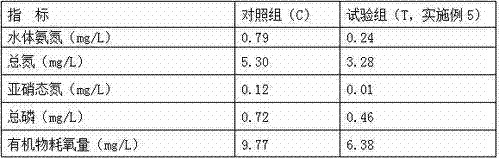

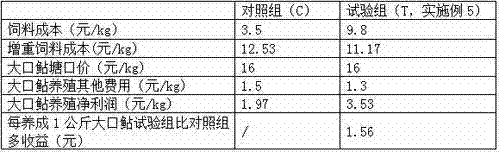

Efficient environment-friendly silurus meridionalis growing period flotation puffing mixed feed and manufacturing method thereof

InactiveCN104757335AEasy to storePromote healthy developmentAnimal feeding stuffBiotechnologyAnimal science

The invention relates to efficient environment-friendly silurus meridionalis growing period flotation puffing mixed feed and a manufacturing method thereof, and belongs to the technical field of aquaculture feed. The feed comprises fish meal, meat meal, fermented soybean meal, soybean meal, corn gluten meal, flour, soybean oil, monocalcium phosphate, 98.5-percent lysine hydrochloride, mannan oligosaccharide, sodium butyrate, 35-percent vitamin C acetate, antioxidants, vitamin premix and mineral substance premix. Silurus meridionalis is bred through the silurus meridionalis growing period flotation puffing mixed feed, compared with frozen fresh fishes and animal giblets, the nutrition is balancer, the feed is easier to store, use is convenient, and sound development of the silurus meridionalis culture industry can be promoted.

Owner:TONGWEI

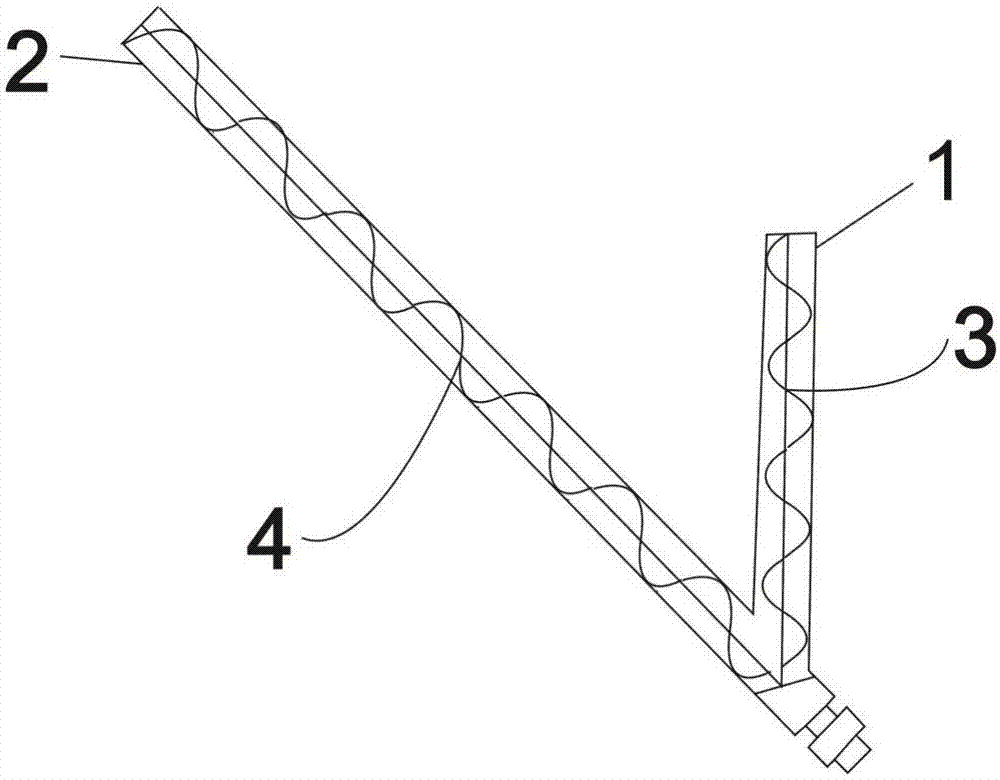

Efficient mixing and smashing device

InactiveCN106000601AImprove crushing efficiencyImprove the crushing finenessRotating receptacle mixersTransportation and packagingRotational axisElectric machine

Owner:HARBIN HUAZAO BIOTECH DEV

Method for preparing particle-shaped bag tea

InactiveCN101273742AGood net weight controllabilityNot susceptible to moisturePre-extraction tea treatmentCooking & bakingAdditive ingredient

The invention provides a preparation method of particle shape teabag, which is characterized in that the raw materials of fresh tea leaves are bagged to become finished products after being treated in sequence by spreading, deactivation of enzymes, matching ingredients, crushing, pelleting, sieving, basic baking and full drying, moreover, the sweet atmosphere abstraction can also be proceeded after full drying. The preparation method of particle shape tea bag of the invention has good controllability, high automation degree, and is suitable for convenient and quick tea bag form packaging; the produced particle shape tea bag is not added with any additives and has good tea quality, even extraction, and no deterioration.

Owner:CHONGQING YUNLING TEA IND TECH

Pearl beverage raw material and preparation method thereof

InactiveCN1666673AImprove the crushing finenessIncrease iodic acidFermentationAnimal proteins working-upInorganic saltsAquatic animal

The invention discloses a pearl beverage raw material and preparation process which comprises, disintegrating pearl raw material, charging iodic acid and edible acid to steep 24-72 hours, adjusting pH to neutral, charging minced aquatic animal meat, mixing and placing in reaction still, adjusting pH to neutral, charging 0.1-0.25% papain and 0.1-0.25% trypsin, carrying out catalytic reaction for 1.5-4 hours at 40-65 deg. C, finally filtering and removing the filtering deposit to obtain filter liquor.

Owner:DAHU AQUACULTURE +1

Method for producing nonfat dried insect pupa protein powder at low temperature

ActiveCN107469939AMix thoroughlyComplete extraction and separationFatty-oils/fats productionGrain treatmentsInsect pupaEconomic benefits

The invention discloses a method for producing nonfat dried insect pupa protein powder at a low temperature. The method comprises the following steps that (1) fresh and alive insect pupas are thoroughly cleaned and then dried, then the dried insect pupas are subjected to coarse crushing, the dried insect pupas subjected to coarse crushing are fed into a rotary delivery extractor and subjected to continuous counter-current extraction at the temperature of 10-15 DEG C with liquefied butane as solvent, and afterwards filter residues obtained through extraction of the rotary delivery extractor are nonfat dried insect pupas; and (2) the nonfat dried insect pupas which are dried are delivered into a special pulverizer to be pulverized into the nonfat dried insect pupa protein powder. By means of the method, the residue amount of raw oil is small, the smashing fineness meets the requirement of food-grade protein powder raw materials and medical protein powder raw materials, the quality guarantee period is long, and the economic benefits are high.

Owner:青岛新农康源生物工程有限公司

Process for preparing ecological cornua cervi pantotrichum oral lyophilized powder

InactiveCN107007628AImprove biological activityRetain biological activityPowder deliveryDigestive systemAdditive ingredientMedicine

The invention discloses a process for preparing ecological cornua cervi pantotrichum oral lyophilized powder. The process comprises the following steps: firstly, dehairing fresh cornua cervi pantotrichum, softening, removing stains on the surface, and slicing for later use; putting the sliced cornua cervi pantotrichum into a colloid mill, and milling to obtain cornua cervi pantotrichum slurry; then, crushing the cornua cervi pantotrichum slurry with a nano-homogenizer, and sterilizing at high pressure; and performing low-temperature freezing, vacuum drying and grinding on the prepared cornua cervi pantotrichum slurry, and sterilizing at high temperature. The cornua cervi pantotrichum oral lyophilized powder prepared by adopting the preparation method has excellent physiological activity and small loss of effective ingredients, and can be easily digested and absorbed by human bodies.

Owner:泸州德高生物科技有限公司

Preparation method of Xiaojin pills

ActiveCN105168407AImprove the crushing finenessGood sustained release effectMammal material medical ingredientsPill deliveryMyrrhFineness

The invention discloses a preparation method of Xiaojin pills, wherein the preparation method comprises steps of material preparing, moist heat sterilizing, crushing and sieving, total-mixing, medicine refining and drying. According to the preparation method disclosed by the invention, momordica cochinchinensis, pine-soot ink, processed frankincense, processed myrrh and resina liquidamberis are crushed by virtue of a jet mill with a high crushing fineness; by constantly conducing the crushing process at low temperature, a cohesion phenomenon in the resina liquidamberis, frankincense and like medicinal materials is avoided and the medicinal materials are easy to sieve; in combination with viscosities of the resina liquidamberis, the frankincense, the myrrh and the like in a prescription, the dosage of starch is reduced; by adding proper amount of a disintegrating agent to a pelleting process, the pills, before being taken, are unnecessary to be broken and are ready to be taken directly anytime and anywhere, and the pills are disintegrated into blocks in water in gastrointestinal tract, so that burden on the gastrointestinal tract is not increased and a good slow-release effect is achieved; and the method disclosed by the invention is simple to operate, convenient in preparation, low in cost and applicable to industrial large-scale production.

Owner:CHENGDU JIUZHITANG JINDING PHARMA

Preparation method for PE regenerated plastic particles

PendingCN111303522AWide range of crushingImprove the fineness of crushingUv absorbanceCorrosion resistant

The invention discloses a preparation method for PE regenerated plastic particles. The PE regenerated plastic particles comprise the following raw materials in parts by weight: 60-70 parts of regenerated plastic, 3-5 parts of a compatilizer, 10-15 parts of wood flour, 3-5 parts of an ultraviolet absorbent UV-3, 2-3 parts of a flame retardant, 3-5 parts of a dispersing agent, 6-8 parts of a plasticizer, 3-5 parts of an antibacterial agent, 3-5 parts of a wear-resistant agent, 1-2 parts of an interface modifier and 3-5 parts of nanometer silicon dioxide. According to the invention, the strengthof a polymer material can be effectively improved; the heat stability, the wear resistance and the corrosion resistance of a material are enhanced; the acceleration effect on the PE regenerated plastic particles is obvious; the PE regenerated plastic particle finished product has tensile strength of no less than 35 MPa, elastoplasticity of no less than 300 MPa and bending strength of no less than37 MPa; and the antibacterial property and the wear resistance of the material are improved.

Owner:界首市通达塑业有限公司

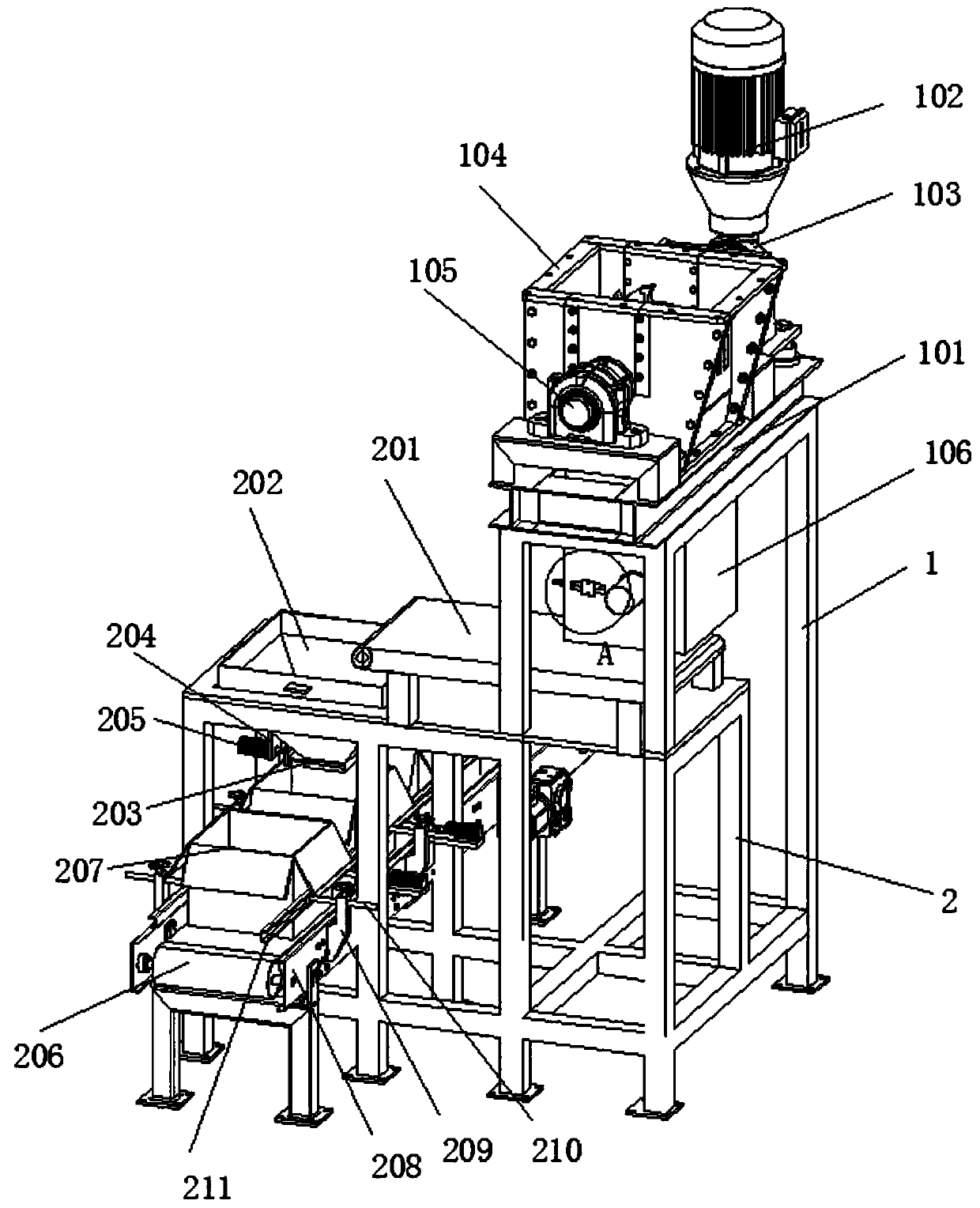

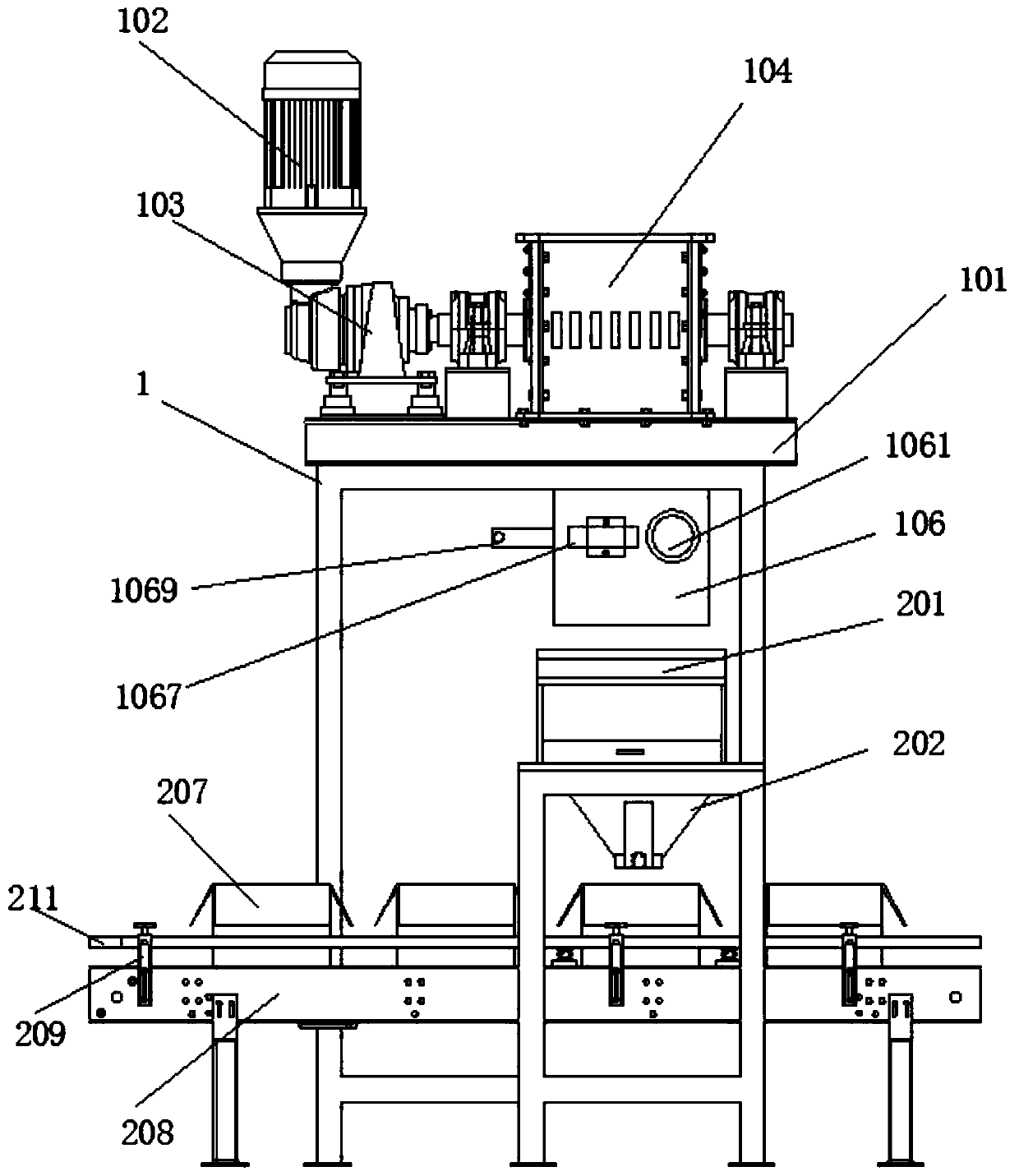

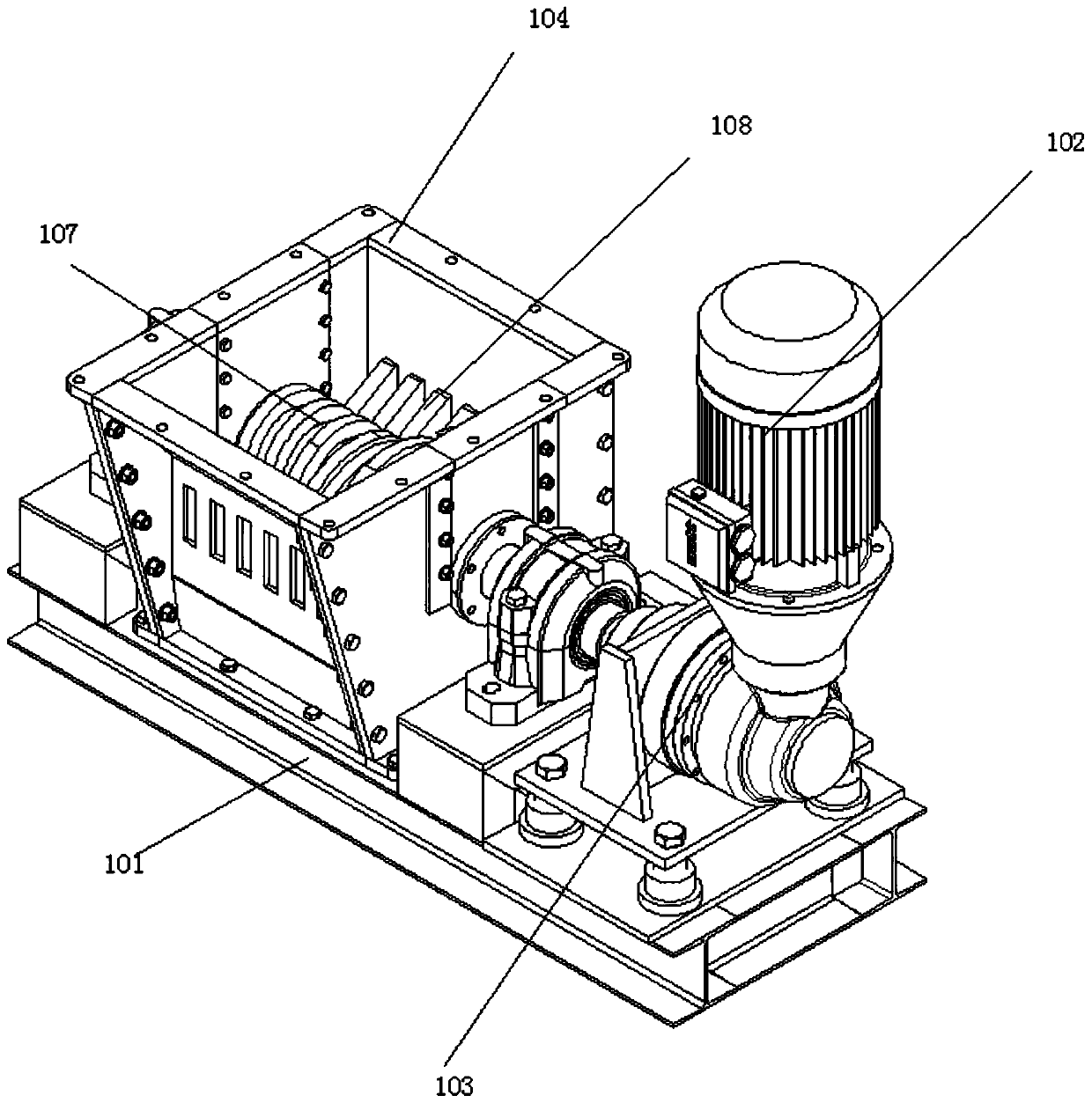

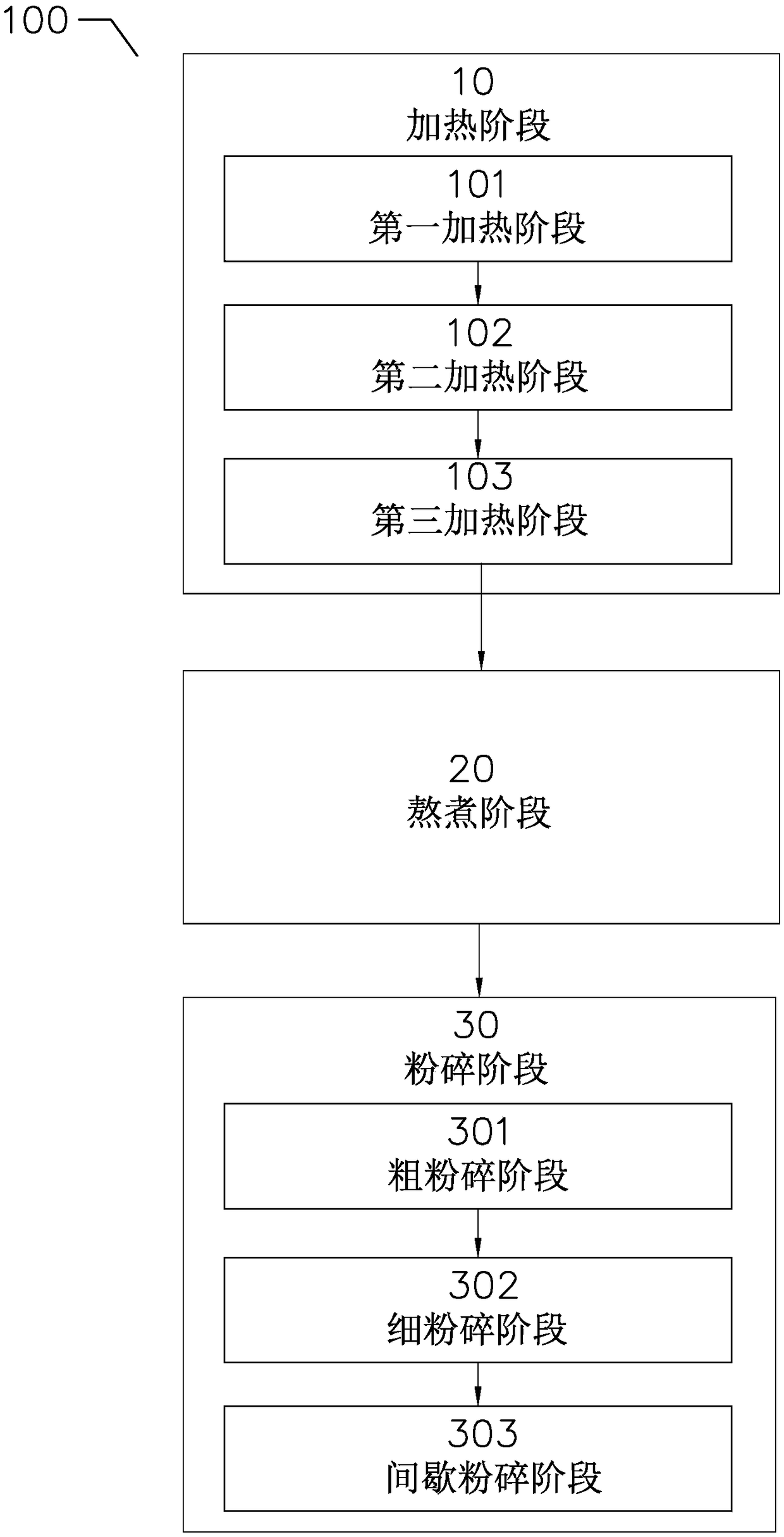

Pulping method of food processor

Owner:JOYOUNG CO LTD

Processing technology of ecological bletilla striata oral freeze-dried powder

InactiveCN106938008ARetain biological activityImprove biological activityPowder deliveryLyophilised deliveryBletilla striataFreeze-drying

The invention discloses a processing technology of an ecological bletilla striata oral freeze-dried powder, wherein the processing technology comprises the following steps: firstly, taking fresh bletilla striata root tubers, removing mud, peeling, and then washing cleanly for standby application; then slicing the treated bletilla striata root tubers, adding pure water, squeezing into a homogenate, filtering, adding pure water to the filter residue again, squeezing into a homogenate, filtering, repeating the operations for three times, and taking the final filtrate; carrying out further crushing treatment of the prepared bletilla striata homogenate through a nano homogenizer; and finally, carrying out low temperature freezing and vacuum drying of the obtained bletilla striata homogenate, carrying out high-pressure sterilization, and thus obtaining the bletilla striata oral freeze-dried powder. The bletilla striata oral freeze-dried powder prepared by the preparation method has excellent physiological activity, has less loss of effective components, and is easy to digest and absorb.

Owner:泸州德高生物科技有限公司

Making method of soybean milk being stable and free from layering

The invention relates to a making method of soybean milk being stable and free from layering. The making method is characterized by at least comprising the following stages of (a) crushing stage: crushing water and materials into slurry; and (b) boiling stage which comprises the steps of heating the slurry to first temperature T1, and maintaining the first temperature for 2-10 minutes, and the step of continuing performing warming to second temperature T2, and maintaining the second temperature for 2-10 minutes, wherein the T1 is 65-75 DEG C, the T2 is 75-95 DEG C, and the T2 is greater than the T1. Compared with the prior art, the soybean milk is stable and free from layering, and good in mouth feel.

Owner:HONGYANG HOME APPLIANCES

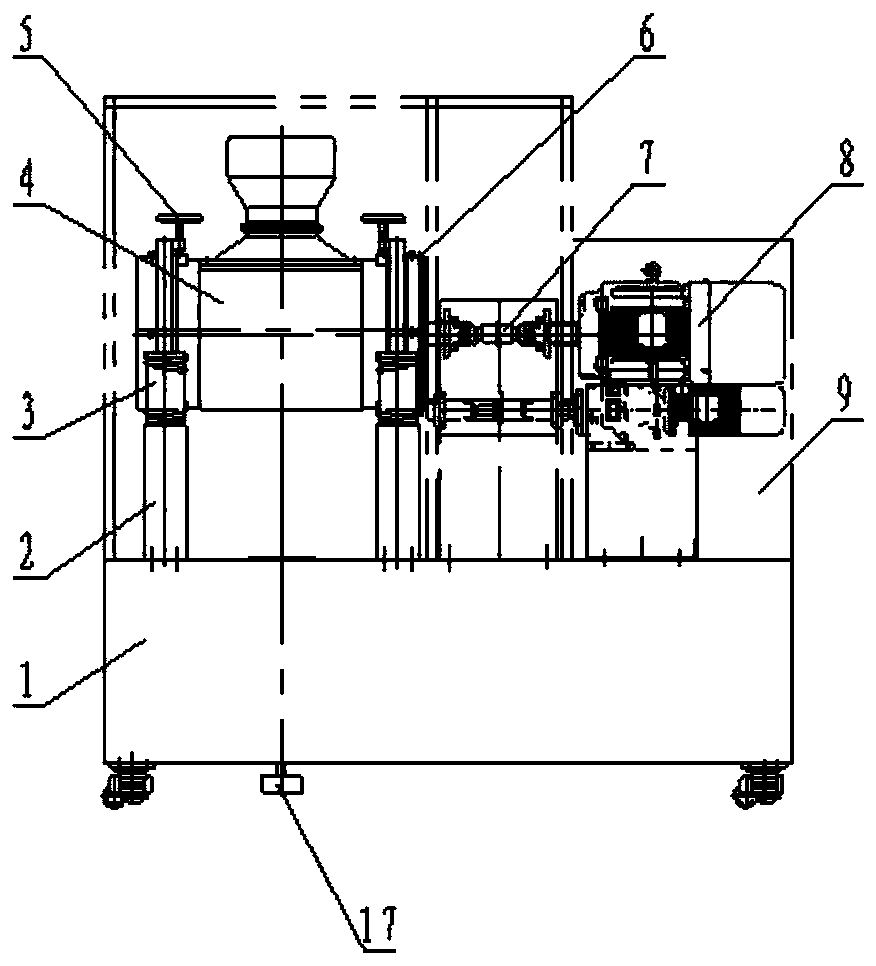

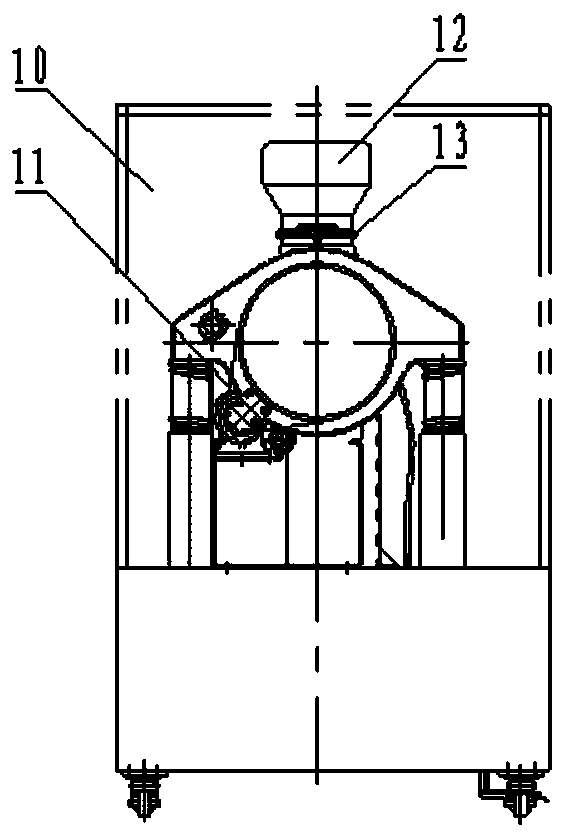

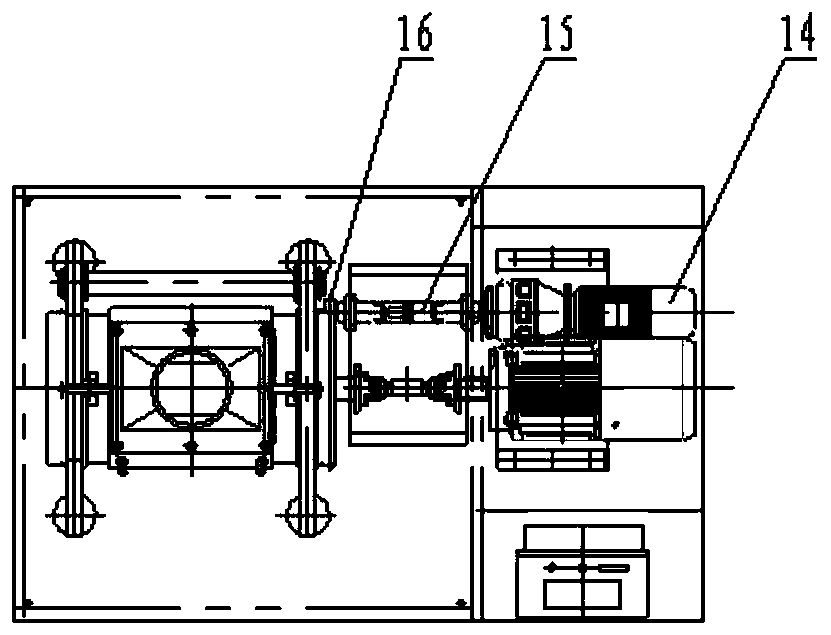

40-type whole-water-jacket automatic turning ultrafine pulverizer

PendingCN111013743ASuitable for small-scale production requirementsLower working temperatureGrain treatmentsDrive shaftElectric machinery

The invention relates to a 40-type whole-water-jacket automatic turning ultrafine pulverizer which comprises a whole-water-jacket grinding cylinder device, a grinding cylinder turning device and a lifting device. The whole-water-jacket grinding cylinder device comprises whole-water-jacket grinding cylinders, a main motor, a transmission shaft, isolation springs, stand columns, a table, a sound insulation cover and a motor cover. The grinding cylinder turning device comprises a turning speed reducer, a transmission shaft, a small chain wheel and a turning large chain wheel. The lifting device is installed at the bottom of the table, and comprises a pressing rod, a pin shaft, a lifting ejector rod, a spring, a spring check ring, a pressing plate, a shaft sleeve and a top plate. Lifting and falling are realized through foot stepping. The 40-type whole-water-jacket automatic turning ultrafine pulverizer is convenient to use, saves time and labor, is wide in material pulverizing range, improves the pulverizing fineness, prolongs the service life of bearings and prolongs the service life of the grinding cylinder, thereby improving production efficiency and saving labor cost.

Owner:济南达微机械有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com