Micro-grinding soymilk maker

A soymilk maker and micro-grinding technology, which is applied in the field of kitchen utensils, can solve the problems of not reaching the degree of fiber crushing and the impact on taste, and achieve the effects of ensuring smooth flow, improving the fineness of crushing, and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

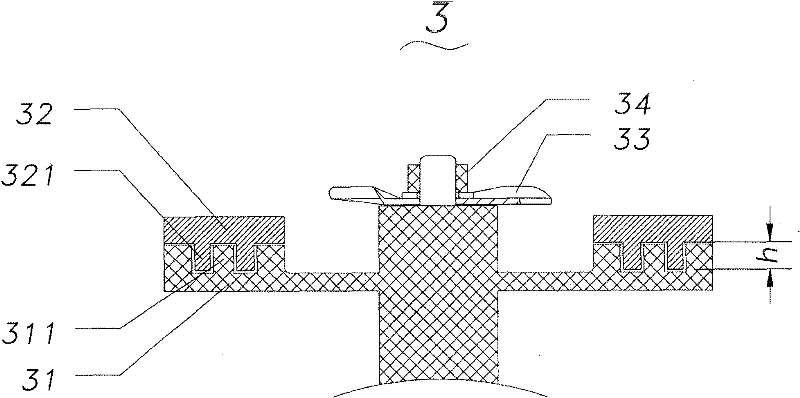

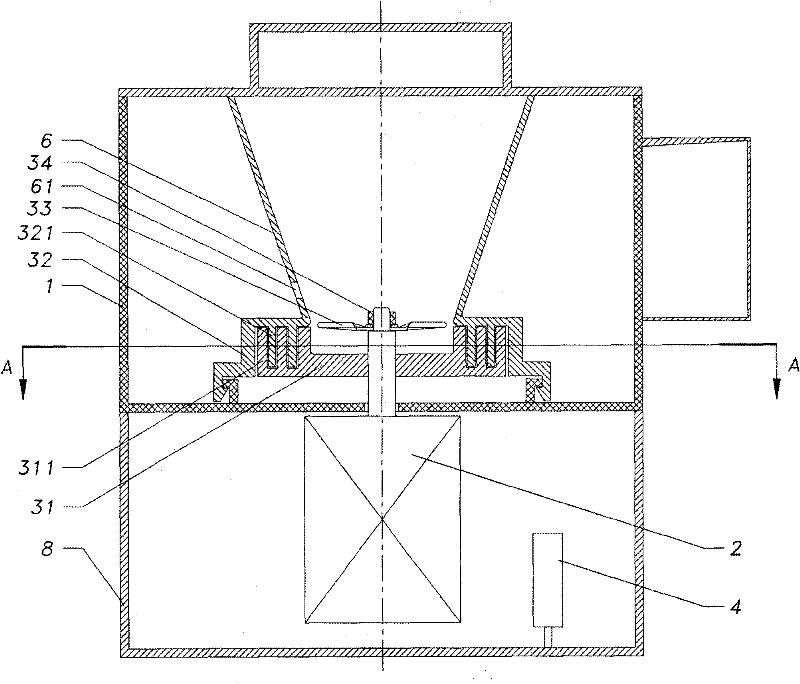

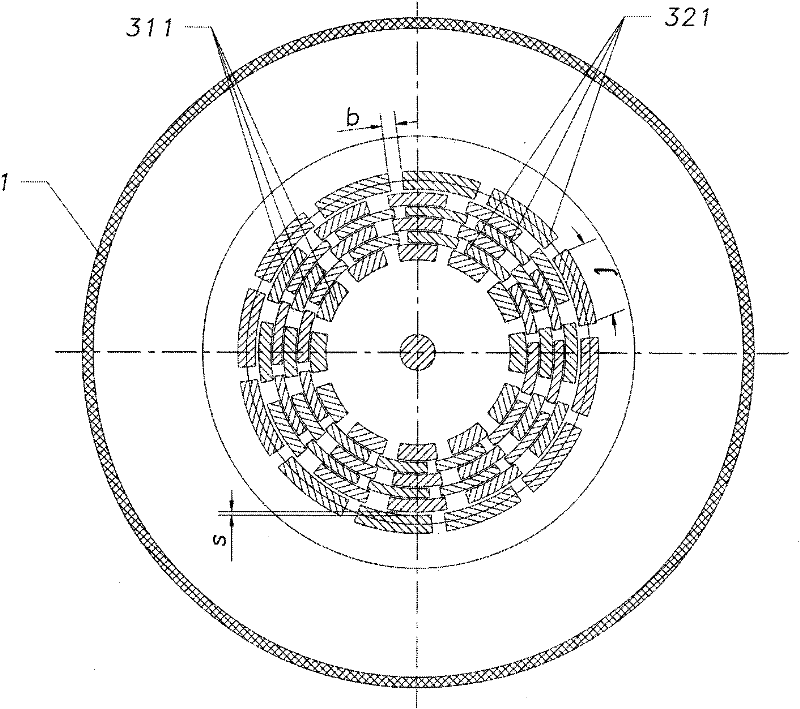

[0026] As an embodiment of the finely pulverized soybean milk machine of the present invention, such as figure 1 , figure 2 and image 3 As shown, it includes motor 2, pulverizing device 3 and control device 4. Said pulverizing device 3 includes a movable millstone 31 and a static millstone 32. The motor 2 drives the movable millstone 31 to run. The shearing part is staggered for shearing, and the linear speed of the knife teeth is between 7m / s-60m / s.

[0027] In this example, if figure 2 As shown, the soybean milk machine also includes a slurry storage container 1 and a base 8, the motor 2 is installed on the base 8, and is a type with the motor 2 under the motor, the slurry storage container 1 is arranged above the base 8, and the motor shaft extends toward the storage The slurry container 1, the static grinding disc 32 is fixed on the slurry storage container 1 through buckles, the static grinding disc 32 is provided with a hopper 6, and the side wall of the hopper 6 i...

Embodiment 2

[0035] As an embodiment of the finely pulverized soybean milk machine of the present invention, such as Figure 4 As shown, the difference from Embodiment 1 is that the soymilk machine is provided with a machine head 7, the motor 2 is fixed inside the machine head 7, and the motor 2 is mounted on top, and the static grinding disc 32 is fixed on the machine head 7 through buckles. Above; the movable grinding disc cutter teeth 311 and the static grinding disc cutter teeth 321 are detachable, and the cutter teeth can be disassembled one by one, so that the cutter teeth can be replaced after passivation or damage, without the need to replace the grinding disc as a whole, which saves costs; Said soya-bean milk machine is also provided with a centrifugal device, which is an impeller 5, located below the crushing tool 33, and fixed on the motor shaft, immersed in the liquid, when the motor shaft rotates, the impeller 5 drives the surrounding liquid to rotate at a high speed, Under th...

Embodiment 3

[0039] As an embodiment of the finely pulverized soybean milk machine of the present invention, such as Figure 5 As shown, the difference from Embodiment 1 is that the motor 2 is horizontal and fixed on the base 8, the static grinding disc 32 is fixed on the base 8, and the static grinding disc 32 is provided with a slurry discharge port 322, Connected with the slurry storage container 1 through the conduit, the crushed soybean milk can be sent into the slurry storage container 1 for boiling. The setting of the slurry outlet 322 separates the crushing process from the process of heating the soybean milk, which optimizes the structure of the soybean milk machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com