Quick crushing device for building ceramic chips

A crushing device and ceramic chip technology, which is applied in the direction of using liquid separating agent, grain processing, and separation of dispersed particles, can solve the problems of low crushing efficiency, large dust, and affecting the surrounding environment, and achieve high crushing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

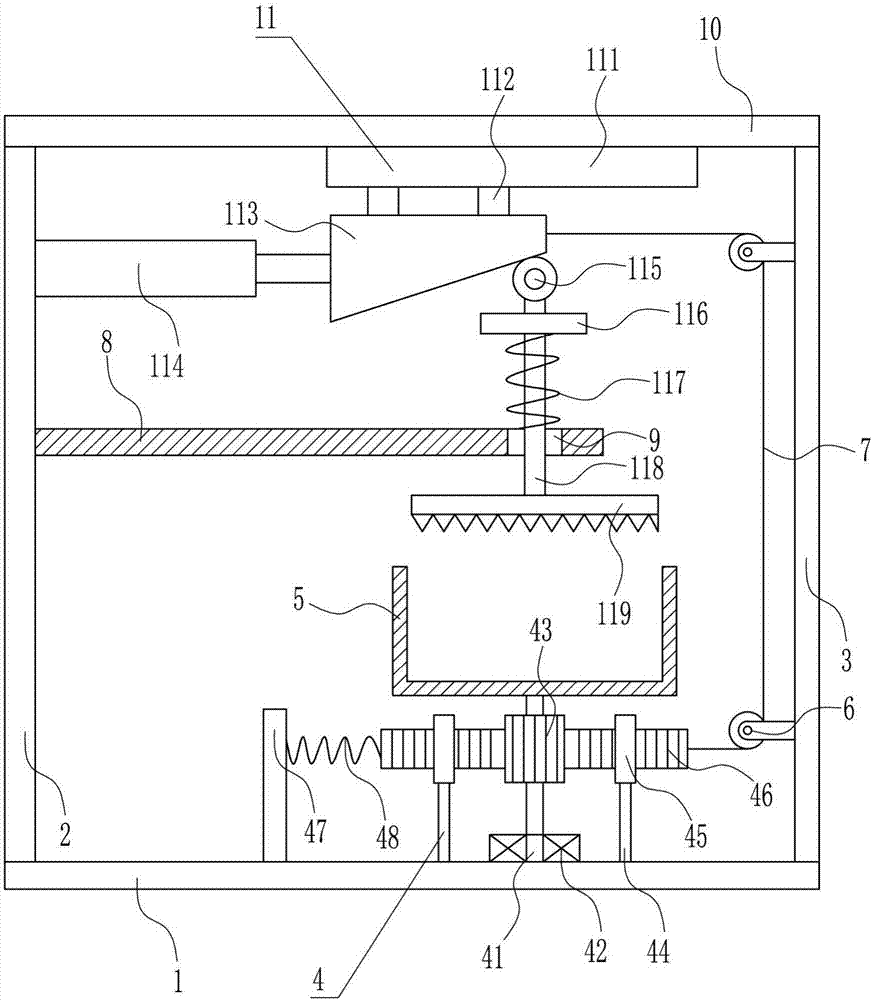

[0021] A kind of rapid crushing device for building ceramic sheets, such as Figure 1-3 As shown, it includes a bottom plate 1, a left side plate 2, a right side plate 3, a rotating device 4, a crushing frame 5, a pulley 6, a pull wire 7, a guide plate 8, a top plate 10 and an up and down moving device 11. The top of the bottom plate 1 is equipped with a rotating Device 4, the rotating device 4 includes a rotating shaft 41, a bearing seat 42, a gear 43, a vertical rod 44, a sliding sleeve 45, a rack 46, a fixing plate 47 and a first spring 48, and the right side of the top of the bottom plate 1 is installed by bolts There is a bearing seat 42, the bearing in the bearing seat 42 is provided with a rotating shaft 41, the bottom end of the rotating shaft 41 is connected with the bearing in the bearing seat 42 through an interference connection, and a gear 43 is installed on the upper part of the rotating shaft 41 through a key connection, and the bottom plate 1 Two vertical rods ...

Embodiment 2

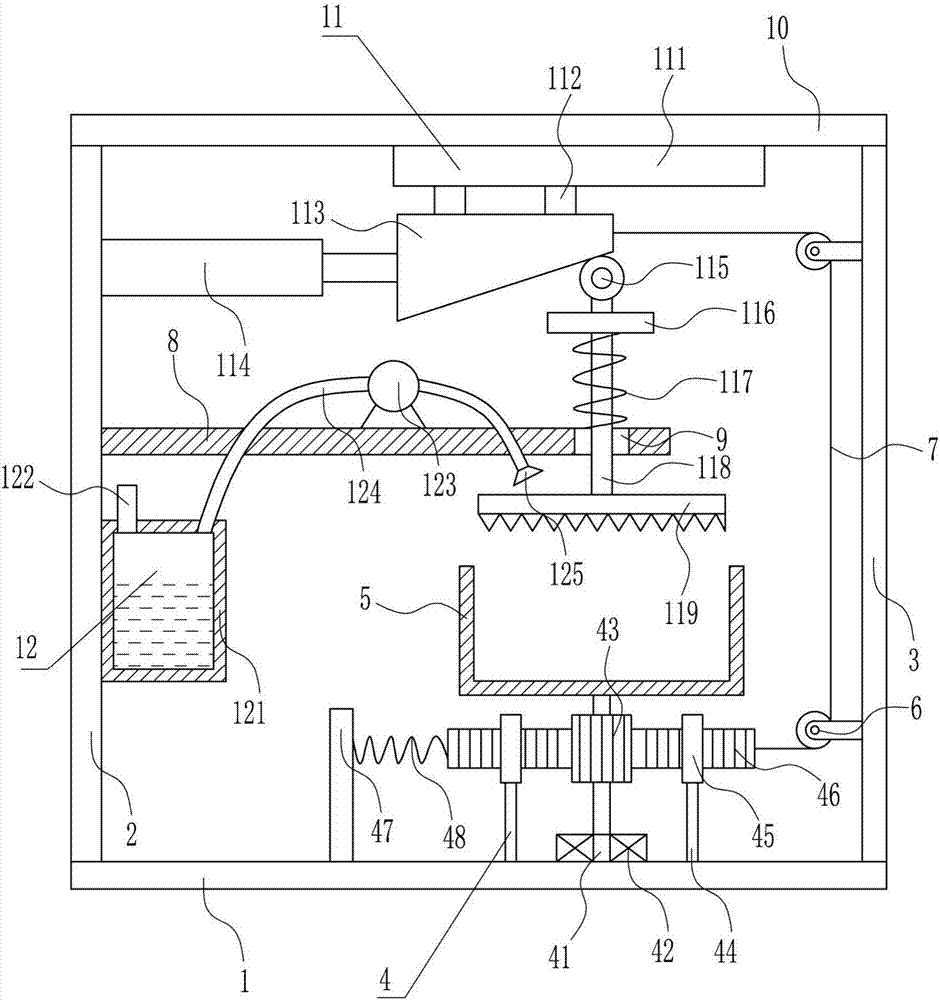

[0023] A kind of rapid crushing device for building ceramic sheets, such as Figure 1-3As shown, it includes a bottom plate 1, a left side plate 2, a right side plate 3, a rotating device 4, a crushing frame 5, a pulley 6, a pull wire 7, a guide plate 8, a top plate 10 and an up and down moving device 11. The top of the bottom plate 1 is equipped with a rotating Device 4, the rotating device 4 includes a rotating shaft 41, a bearing seat 42, a gear 43, a vertical rod 44, a sliding sleeve 45, a rack 46, a fixing plate 47 and a first spring 48, and the right side of the top of the bottom plate 1 is installed by bolts There is a bearing seat 42, the bearing in the bearing seat 42 is provided with a rotating shaft 41, the bottom end of the rotating shaft 41 is connected with the bearing in the bearing seat 42 through an interference connection, and a gear 43 is installed on the upper part of the rotating shaft 41 through a key connection, and the bottom plate 1 Two vertical rods 4...

Embodiment 3

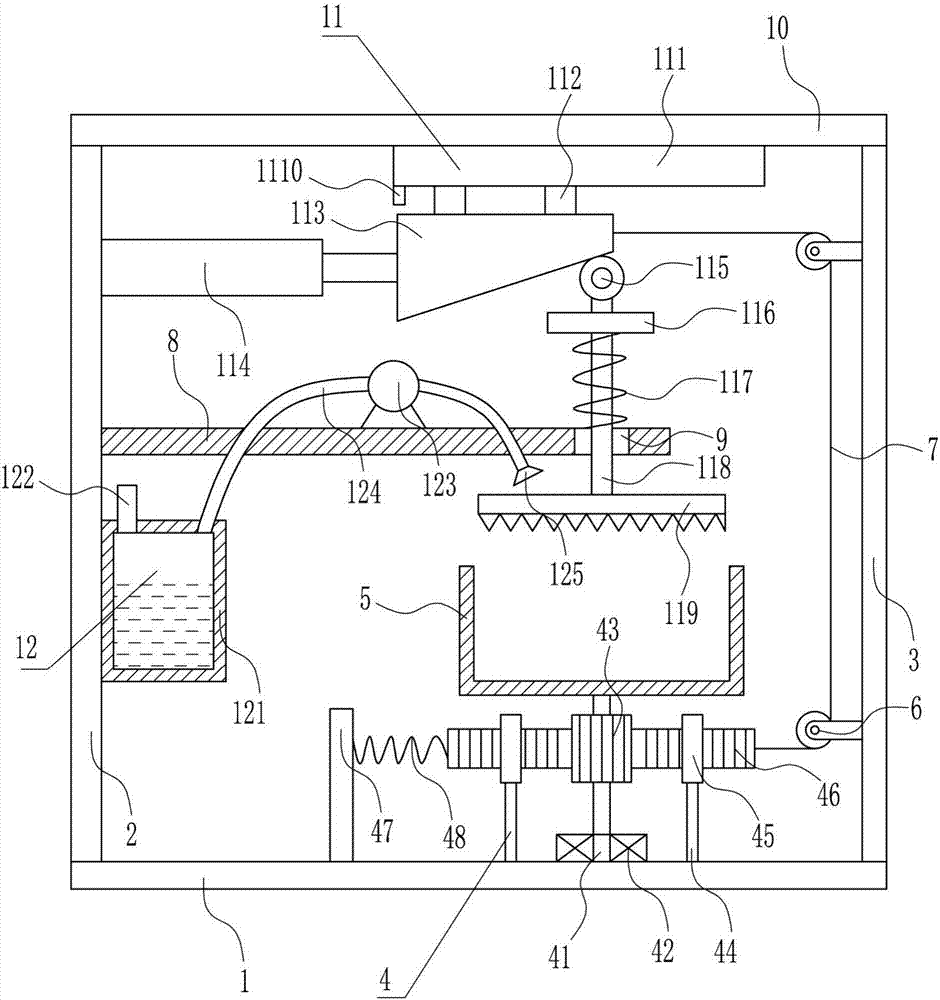

[0026] A kind of rapid crushing device for building ceramic sheets, such as Figure 1-3 As shown, it includes a bottom plate 1, a left side plate 2, a right side plate 3, a rotating device 4, a crushing frame 5, a pulley 6, a pull wire 7, a guide plate 8, a top plate 10 and an up and down moving device 11. The top of the bottom plate 1 is equipped with a rotating Device 4, the rotating device 4 includes a rotating shaft 41, a bearing seat 42, a gear 43, a vertical rod 44, a sliding sleeve 45, a rack 46, a fixing plate 47 and a first spring 48, and the right side of the top of the bottom plate 1 is installed by bolts There is a bearing seat 42, the bearing in the bearing seat 42 is provided with a rotating shaft 41, the bottom end of the rotating shaft 41 is connected with the bearing in the bearing seat 42 through an interference connection, and a gear 43 is installed on the upper part of the rotating shaft 41 through a key connection, and the bottom plate 1 Two vertical rods ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com