Patents

Literature

1154results about How to "Not easy to agglomerate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Humic acid composite material and preparation method thereof

InactiveCN101041600APromote absorptionGood water solubilityAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersPhosphorNitrogen

The invention discloses a particle-typed composite fertilizer of humic acid and manufacturing method, which consists of dressing and karyosome, wherein the dressing contains nitrogen, phosphor and potassium. The manufacturing method comprises the following steps: graining humic acid; cladding; graining; solidifying fused fertilizer on the particle of humic acid; making the composite fertilizer dissolved into water without falling; fitting for large scale of agricultural product.

Owner:阴高鹏

Water soluble humic acid multi-element solid fertilizer and production method thereof

InactiveCN101570456ADissolve fastNot easy to agglomerateAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersSoil scienceWater soluble

The invention discloses a water soluble fertilizer and a production method thereof, in particular to a water soluble humic acid multi-element solid fertilizer and a production method thereof. The water soluble humic acid multi-element solid fertilizer is made by mixing water soluble humic acid, water soluble nitrogenous fertilizer, water soluble phosphorous fertilizer, water soluble potassic fertilizer and water soluble complex trace elements. Compared with the prior art, the water soluble humic acid multi-element solid fertilizer can reduce the transporting and packing cost, can be rapidly dissolved without agglomeration when in use, is applied along with water, and has the advantages of strong points, high nutrient content, complete nutrition, good water-solubility, combination of organic and inorganic matters as well as high effect of fertilizer and utilization rate. The utilization rate of product nitrogen reaches 60%, the utilization rate of phosphorus is 30-35%, and the utilization rate of potassium is 60-70%, so that the fertilizer application utilization rate is increased by more than 10% compared with the conventional fertilizer.

Owner:新疆三赢农业科技发展有限公司

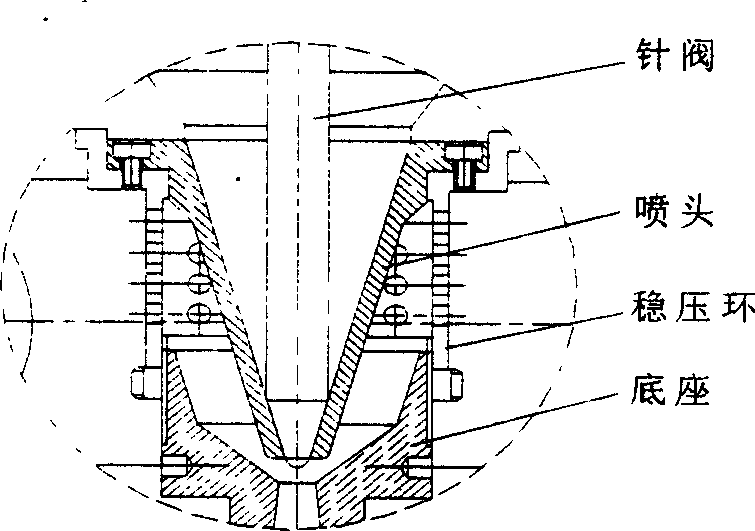

Color drought-resistance water-retention sustained-release compound fertilizer and method for producing same

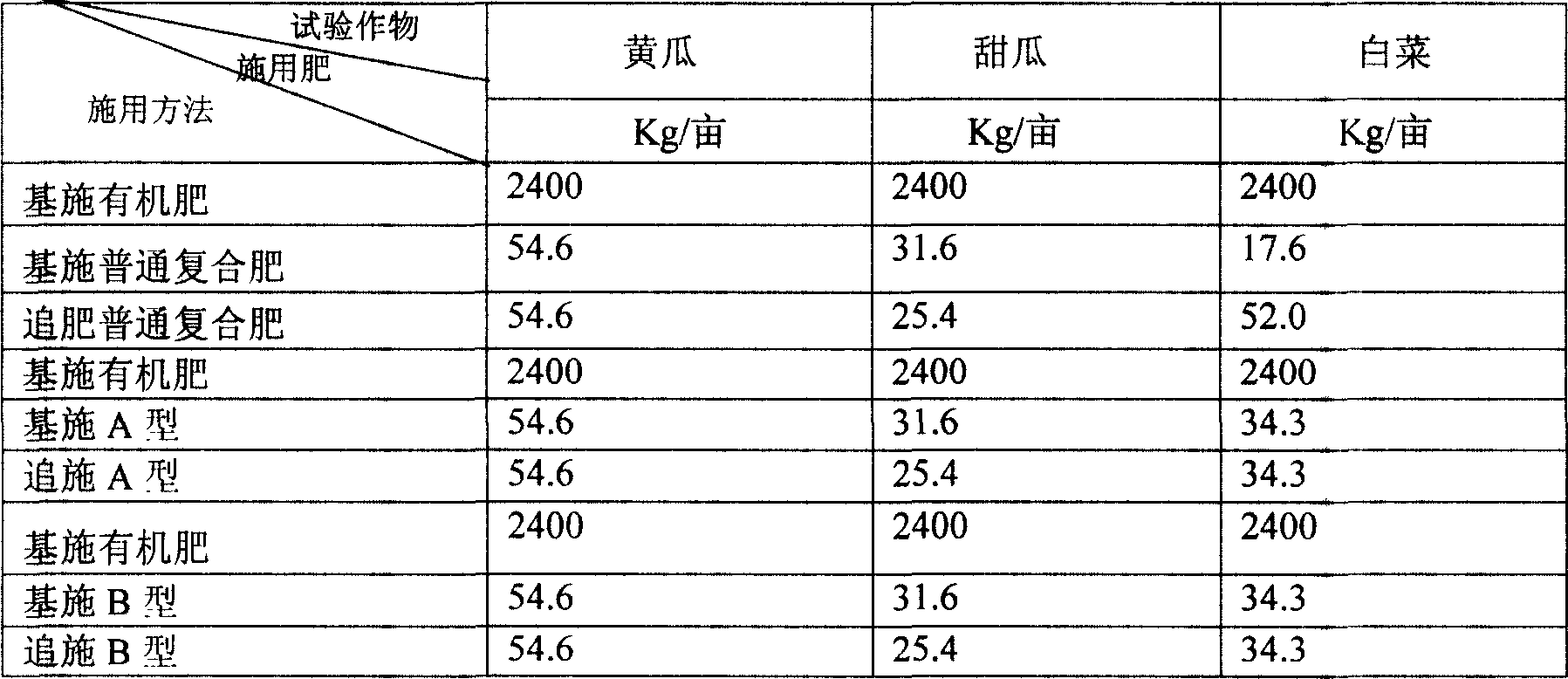

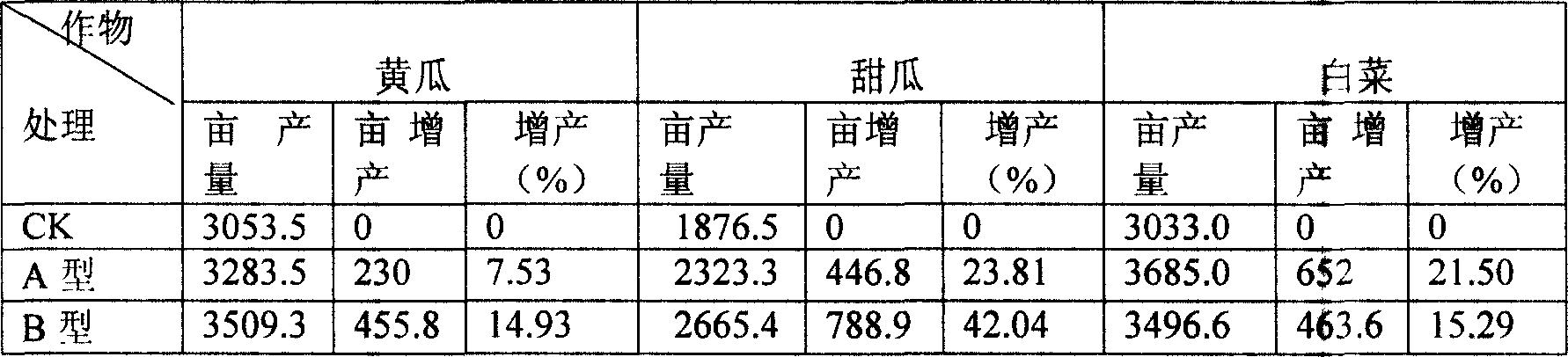

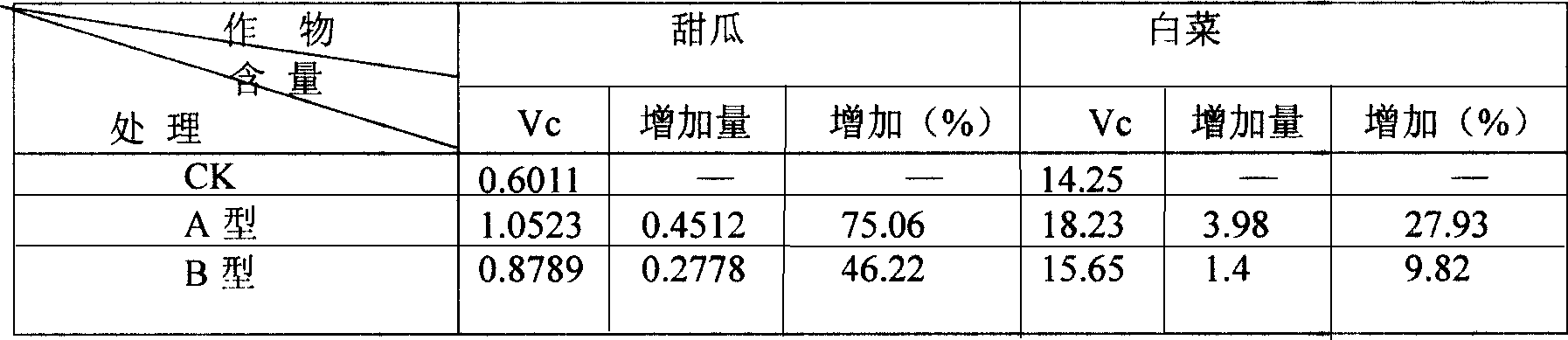

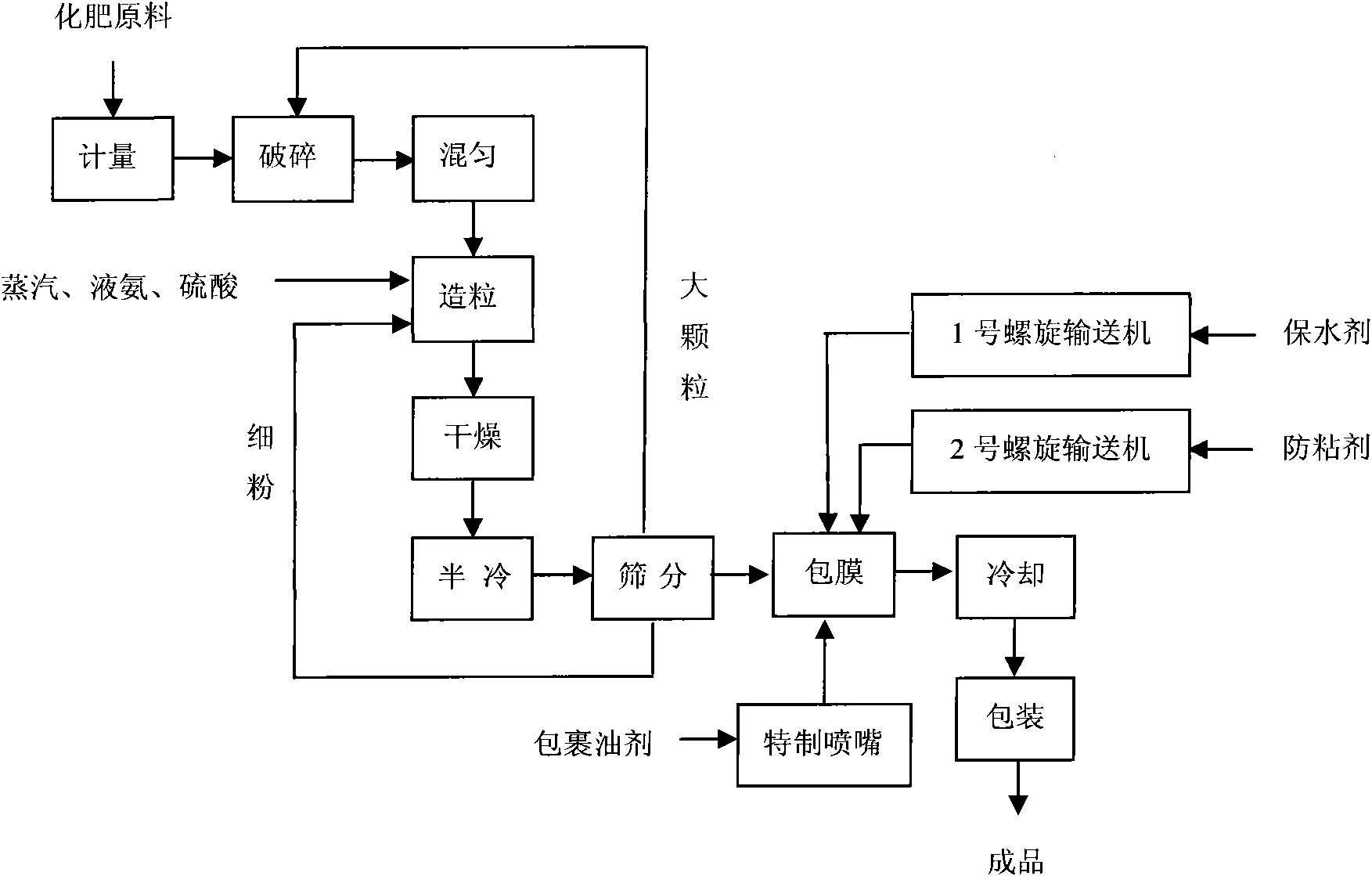

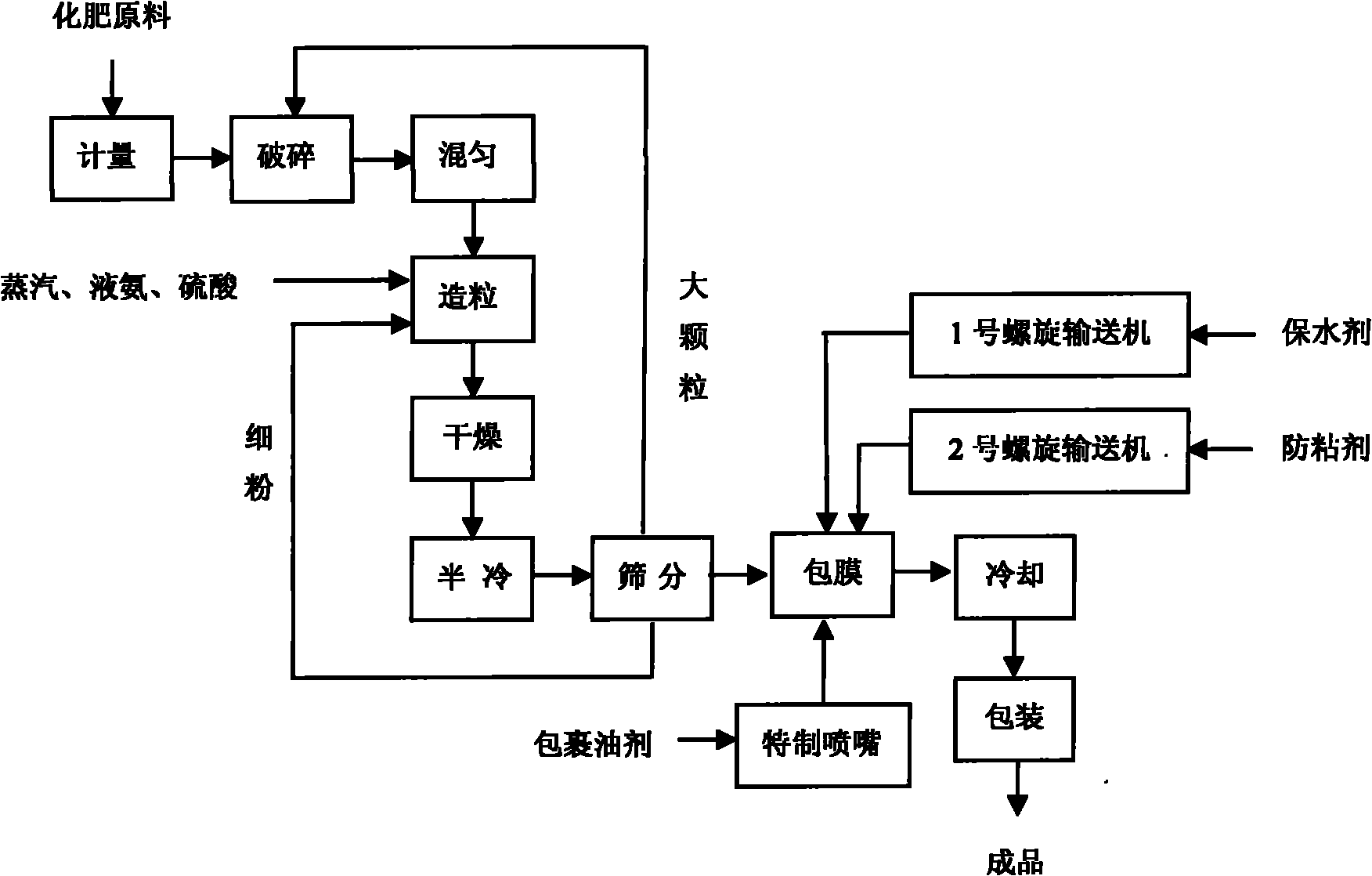

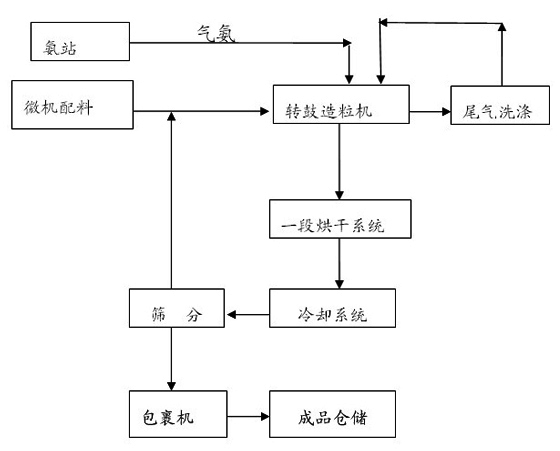

ActiveCN101792354ASimple production methodHigh ball rateFertiliser formsFertilizer mixturesFilm coatingNutrient

The invention discloses a color drought-resistance water-retention sustained-release compound fertilizer and a method for producing the same, wherein the method comprises the followings steps of: measuring, crushing and uniformly mixing fertilizer raw materials, granulating by adopting an ammonia-acid method rotary drum granulating process, performing one-stage drying, semi-cooling and screening of grains, and sending the mixture to a coating machine; adopting a continuous melting rotary drum film-coating method coating process to perform compressed air atomization and uniform coating of color coating oil sprayed by a special nozzle; and adding a water-retaining agent and an anti-adhesive agent by a screw conveyor, and performing full stirring, cooling and packaging to obtain the finishedproducts. The color drought-resistance water-retention sustained-release compound fertilizer has the effects of drought resistance, water retention, nutrient preservation, soil condition improvement and environmental protection, and the appearance of the fertilizer has color marks; and when the fertilizer is applied to crops, the fertilizer has the advantages of increasing yield and incoming, along with simple production method, convenient operation, low cost and high benefits.

Owner:CNSG ANHUI HONG SIFANG FERTILIZER IND CO LTD

Efficient sound insulation material and manufacturing method thereof

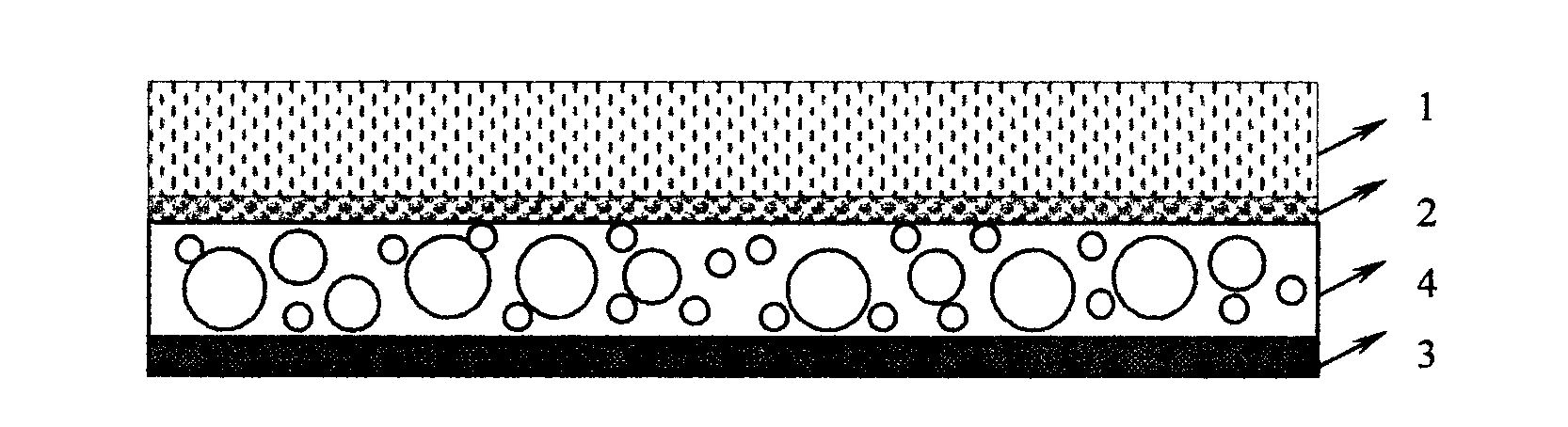

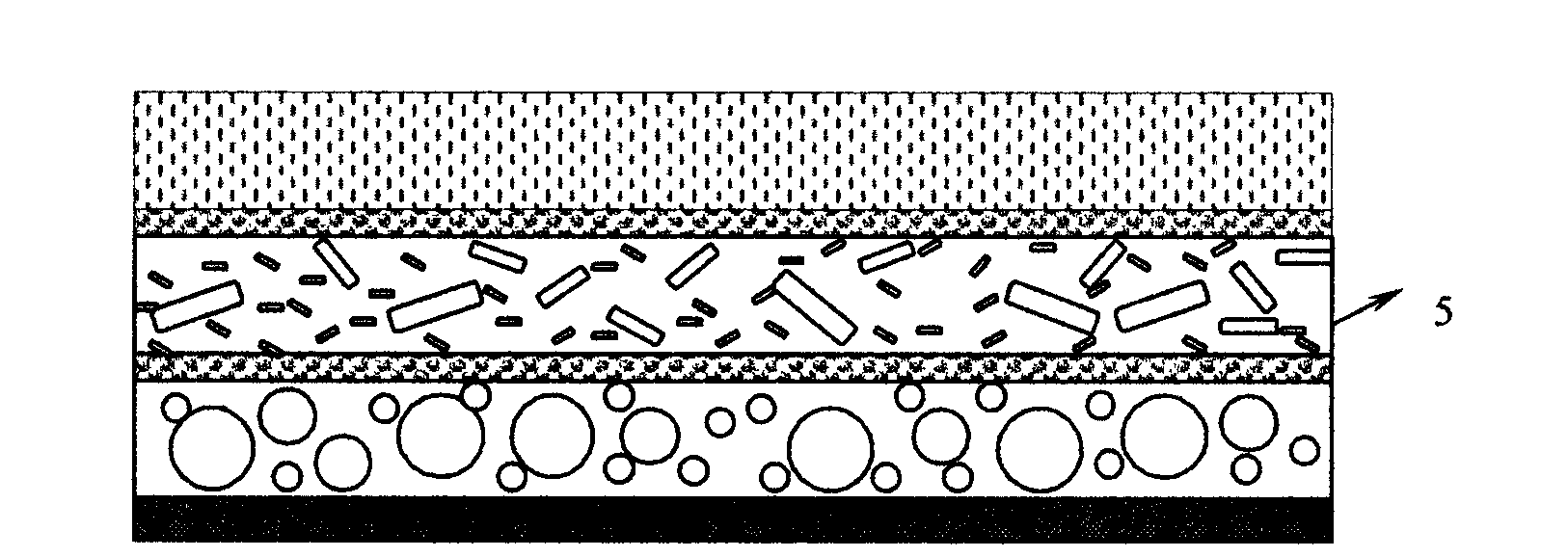

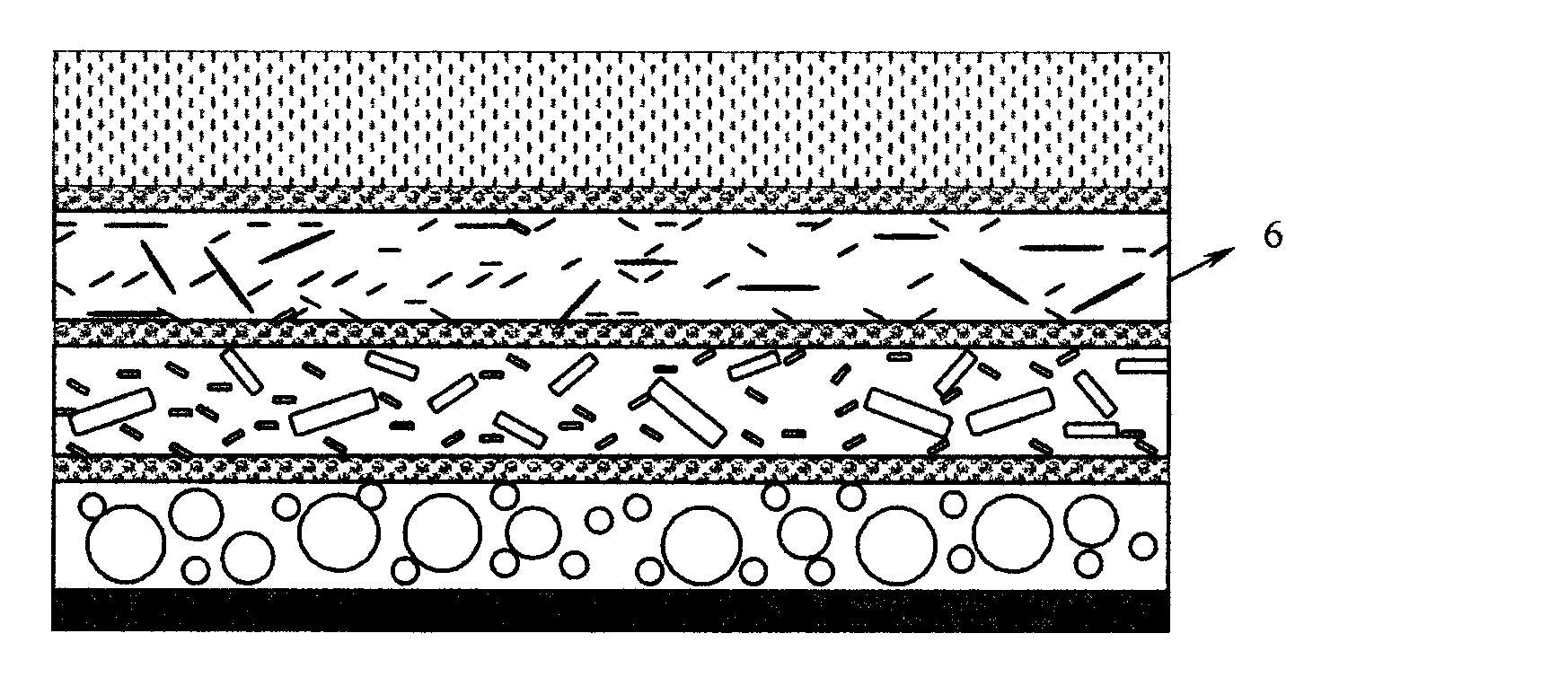

InactiveCN103903608AImprove heat and aging resistanceExcellent ozone resistanceSynthetic resin layered productsSound producing devicesInsulation layerFoaming agent

The invention relates to the field of products of sound insulation material, solves the problems in the prior art that the sound insulation material is poor in sound insulation effect, is incomprehensive in high and low frequency sound insulation, causes pollution and is easy to age, and provides an efficient sound insulation material and a manufacturing method thereof. The efficient sound insulation material includes a sound insulation layer, a sound absorption layer, and a bubble layer, wherein the bubble layer is located between the sound insulation layer and the sound absorption layer. The sound absorption layer is made of a sound insulation compound, and the sound insulation compound is prepared by raw materials of the following substances: a thermoplastic resin, inorganic fillers, and a foaming agent, wherein the inorganic fillers account for 15-80wt%, the foaming agent accounts for 5-15wt%, and the rest is the thermoplastic resin. In the efficient sound insulation material, the fillers with different particle diameters correspond to sound waves of different wave bands or frequencies, and thus consumption of sound energy of different frequencies is relatively comprehensive, and the sound insulation effect is good, so the sound insulation material is suitable for popularization and application.

Owner:浙江艾迪雅汽车部件新材料有限公司

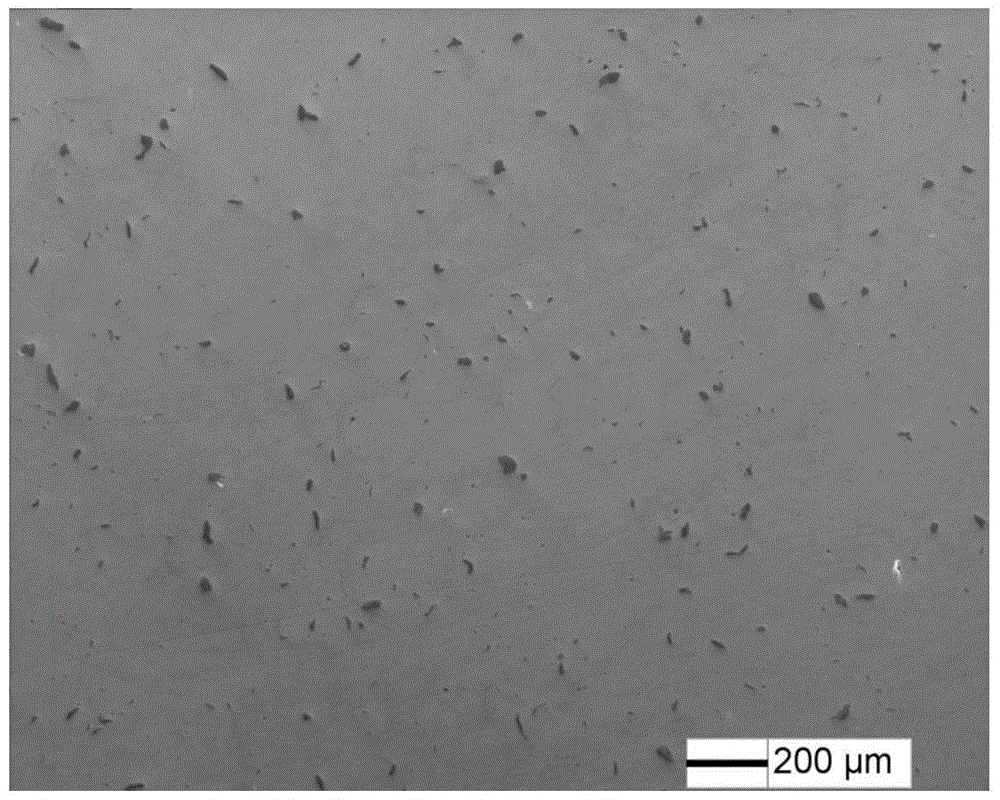

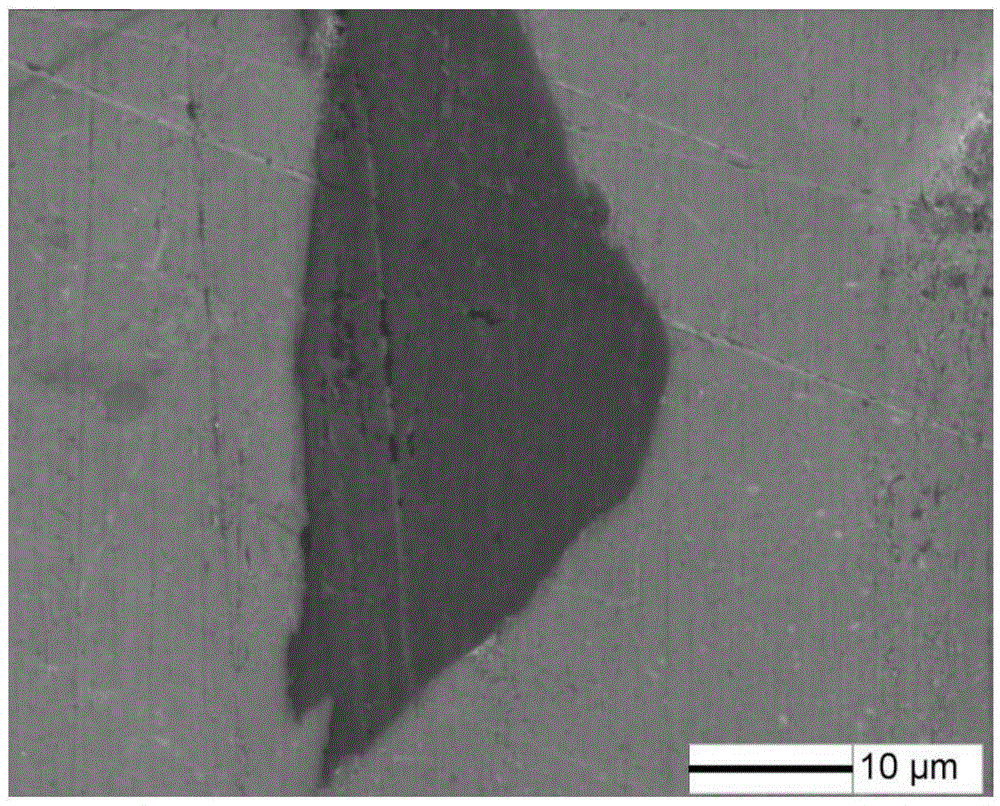

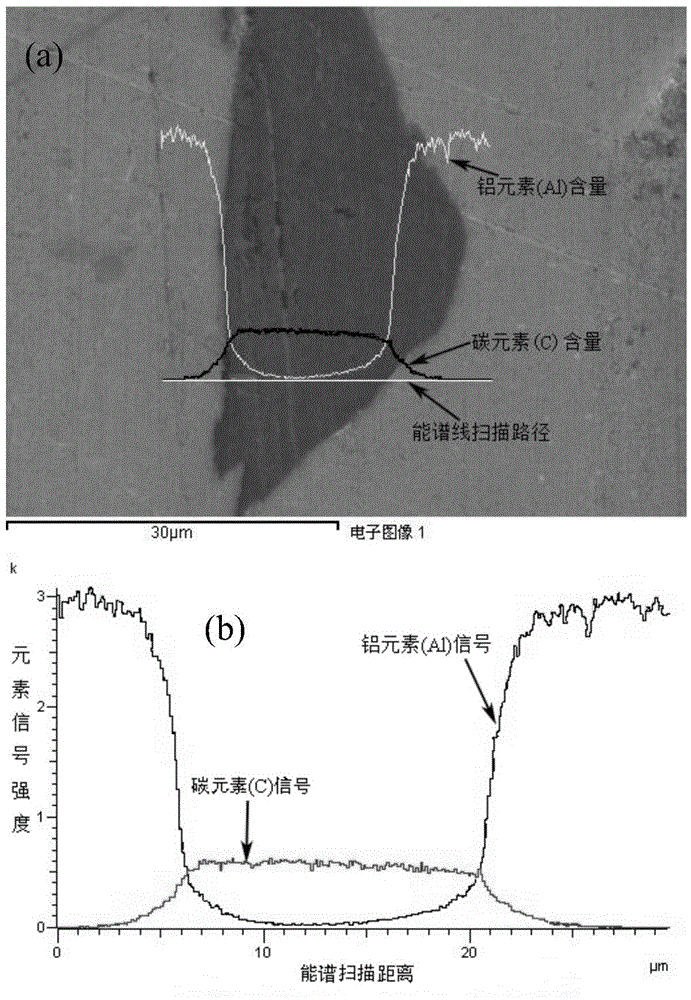

Method for preparing graphene reinforced metal-based composite material through discharge plasma (SPS) sintering

The present invention relates to a method for preparing a graphene reinforced metal-based composite material through discharge plasma (SPS) sintering. The method is characterized in that the graphene reinforced metal-based block material is prepared through SPS sintering and has the following advantages that: the preparation method is simple, the material is compact and does not have pores, the graphene mass fraction can be arbitrarily regulated, the distribution is uniform, no aggregation is generated, the material mechanical property isotropy is provided, and the wettability of the metal and the graphene interface is good. The method comprises: (1) reducing graphene oxide through a chemical method or a hydrothermal method to obtain graphene sheets with a sheet layer thickness of not more than 4 nm and sheet layer diameter of not more than 50 [mu]m; and (2) preparing metal powder with a particle size of not more than 200 [mu]m through a rotating electrode atomization method, mechanical crushing or a high-speed ball milling method; (3) carrying out mechanical or ball milling mixing on the graphene powder and the metal powder according to the required mass ratio; and (4) carrying out SPS sintering forming on the mixed powder, wherein the obtained material has characteristics of improved mechanical property, decreased density, good heat conduction capability, and good electric conduction capability, and the performance customizing can be achieved by adjusting the preparation parameters.

Owner:BEIHANG UNIV

Preparation method of soybean milk

ActiveCN104798890AIncrease concentrationNot easy to agglomerateBeverage vesselsMilk substitutesWater vaporDry bean

The invention relates to a preparation method of soybean milk. The preparation method at least comprises the following stages: (a), flour preparation stage: providing a crushing container, a heating element for heating the crushing container and a crushing device, directly heating the crushing container through the heating element, so as to ensure that the temperature of the crushing container is increased to 70-90 DEG C, adding dried beans into the crushing container, crushing the dried beans into bean flour through the crushing device, and ensuring that lipase and beany flavor of the bean flour are removed in the crushing container at ambient temperature; (b), preparation and boiling stage: adding water to the bean flour, so as to prepare the bean flour into pulp, and heating and boiling the pulp till the pulp is well cooked. By adopting the air temperature inside the crushing device, crushing, lipase removal and beany flavor removal are performed at the same time, protein can keep invariant, beany flavor can be effectively removed, and crushing the beans into bean flour firstly can greatly enhance the crushing fineness, so that the soybean milk concentration can be effectively enhanced. In addition, water vapor can be evaporated during crushing of the beans in the high-temperature environment, the bean flour is not easy to agglomerate, and the crushing effect is good.

Owner:JOYOUNG CO LTD

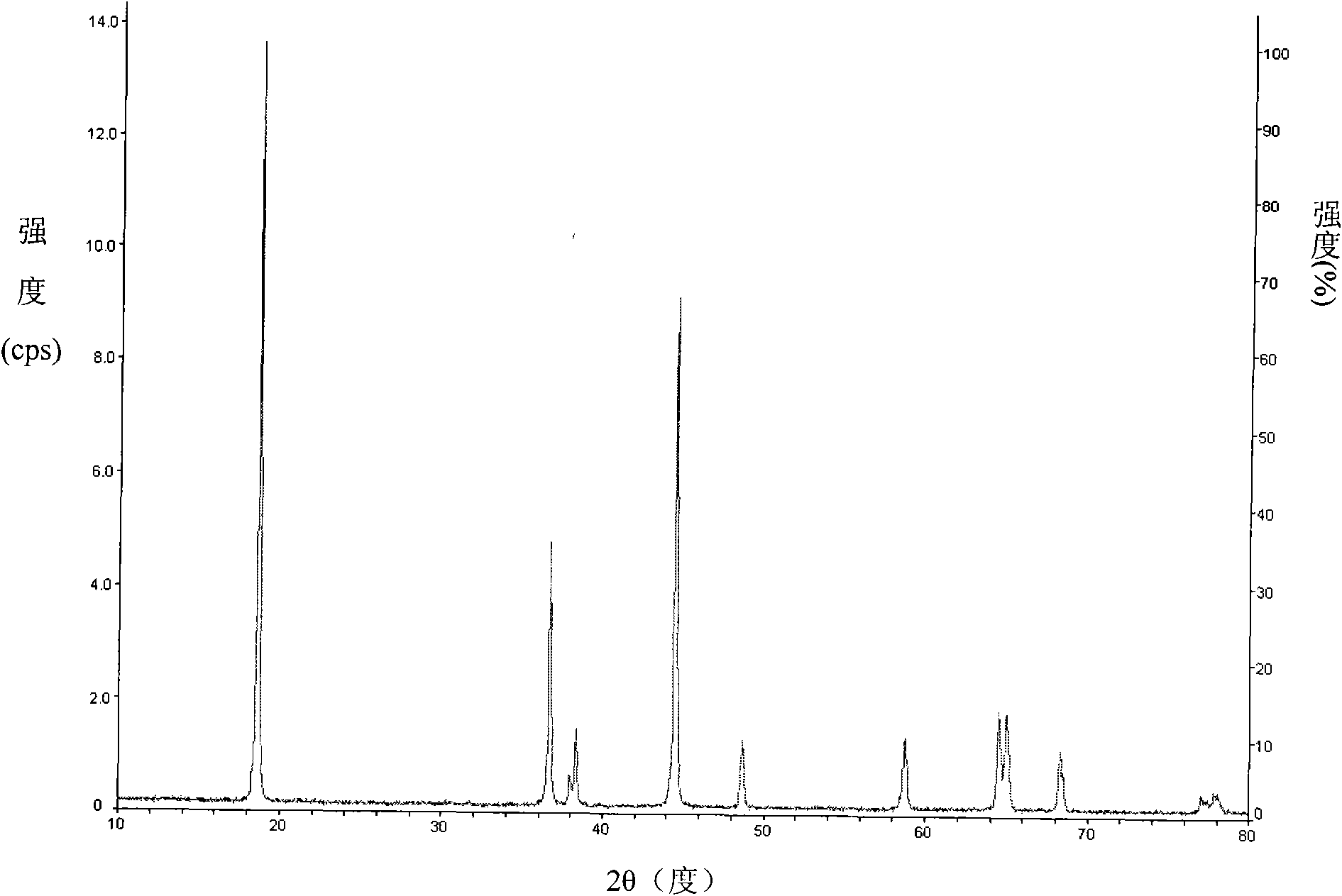

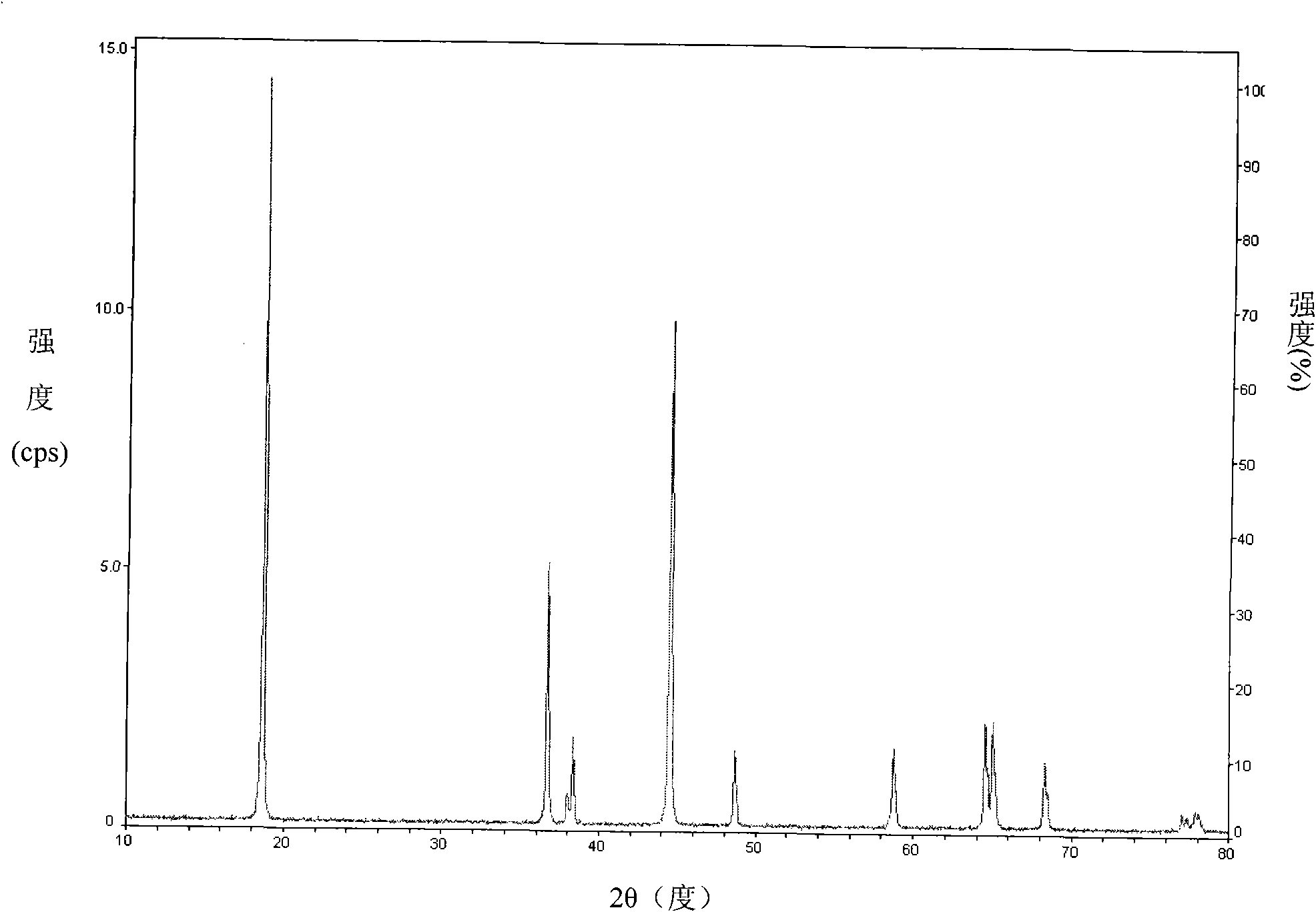

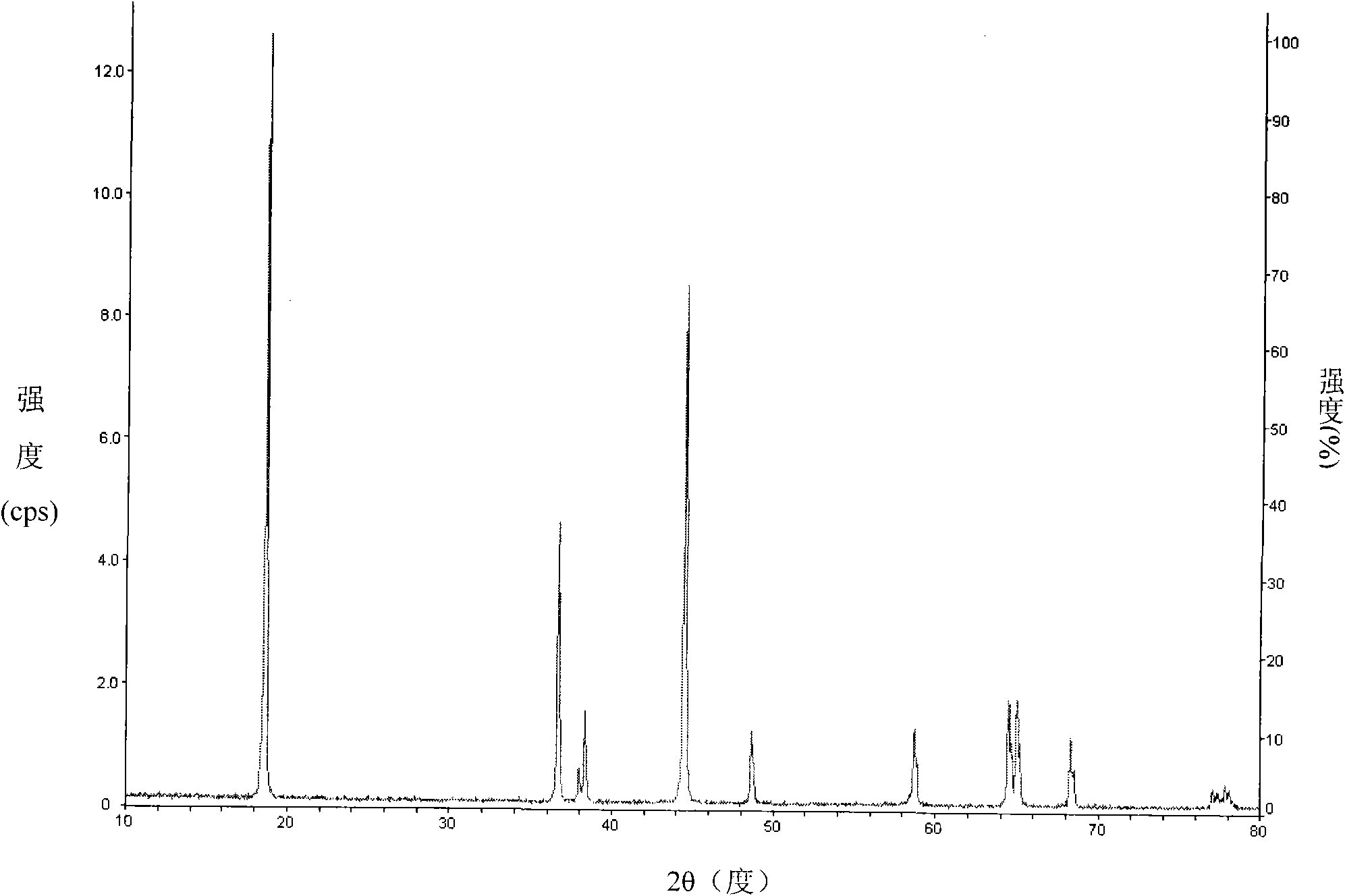

Lithium ion battery anode material as well as preparation method and battery thereof

ActiveCN101585560AIncrease production capacityHigh specific capacityCell electrodesFinal product manufacturePrepared MaterialMaterials science

The invention relates to a lithium ion battery anode material LiNi 1-x-y Cox My O2 as well as a preparation method and a battery thereof. In the formula of the material, x is not less than 0.01 and not more than 0.20, y is not less than 0 and not more than 0.10, and M is one or the composite of Mn, Al, Ti, Cr, Mg, Ca, V, Fe and Zr. The lithium ion battery anode material is characterized in that the ratio of the intensity I 003 of the (003) crystal face diffraction peak and the intensity I 104 of the (104) crystal face diffraction peak of LiNi 1-x-y Cox My O2, namely I003 / I104, is 1.21 to 1.26, and the difference value delta 2 theta of (108) crystal face diffraction peak and (110) crystal face diffraction peak is 0.520 to 0525. The prepared material has the advantages of high output, difficult agglomeration and higher discharge specific capacity.

Owner:BYD CO LTD

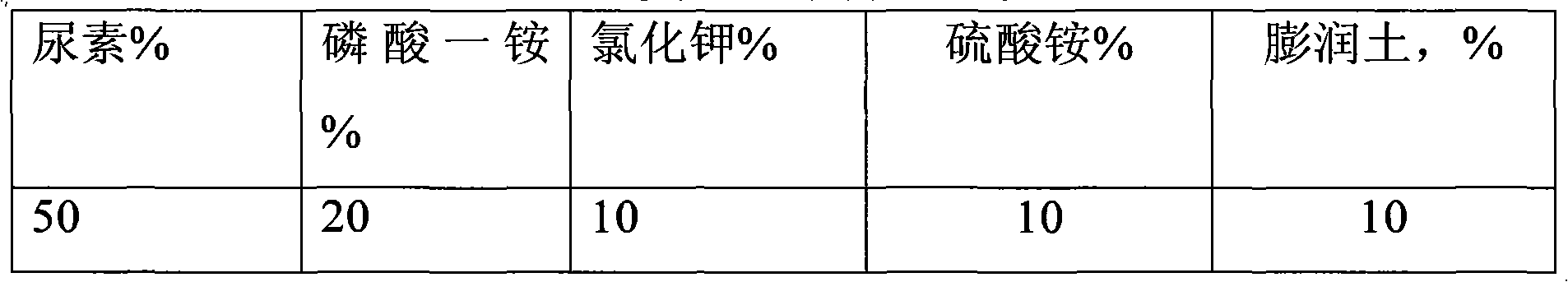

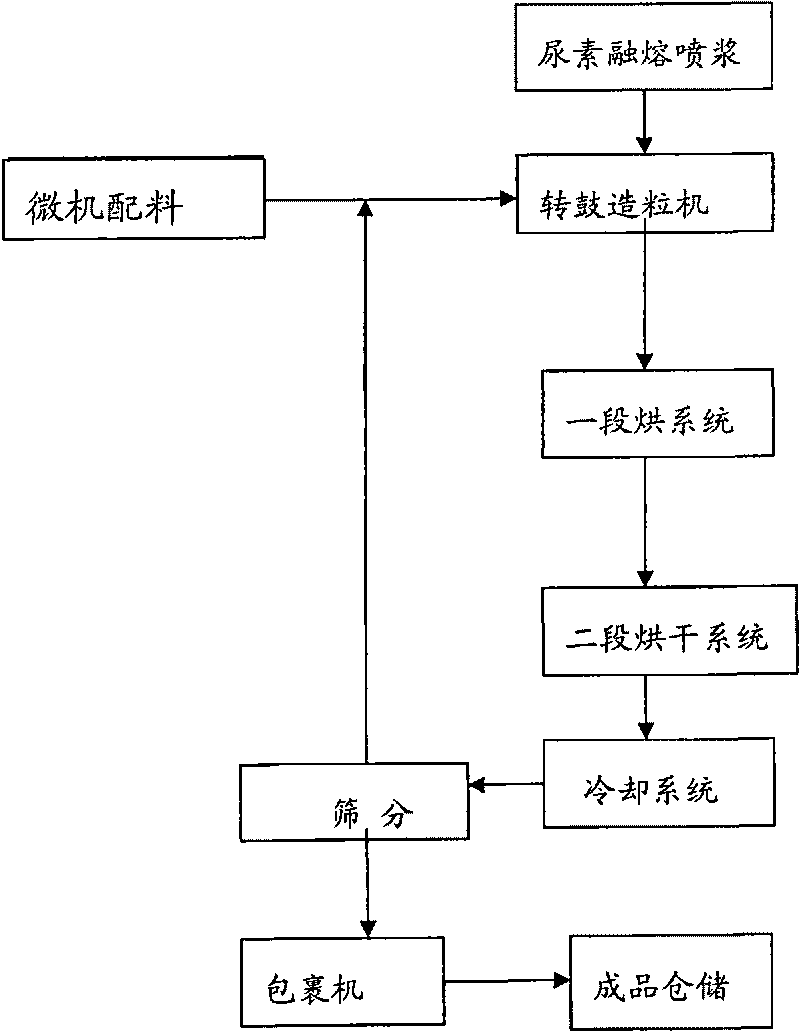

Manufacturingmethod of active humic acid controlled-release fertilizer

ActiveCN102070375AImprove physical and chemical propertiesImprove biological activityFertilizer mixturesPhosphatePotassium

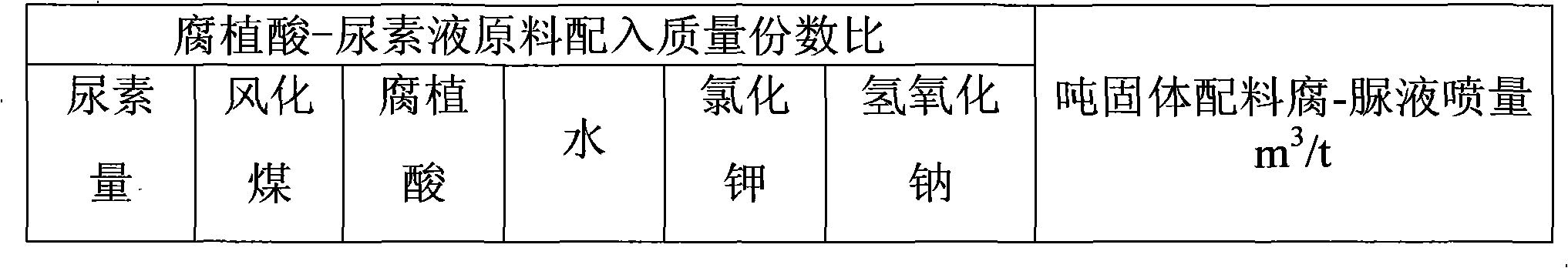

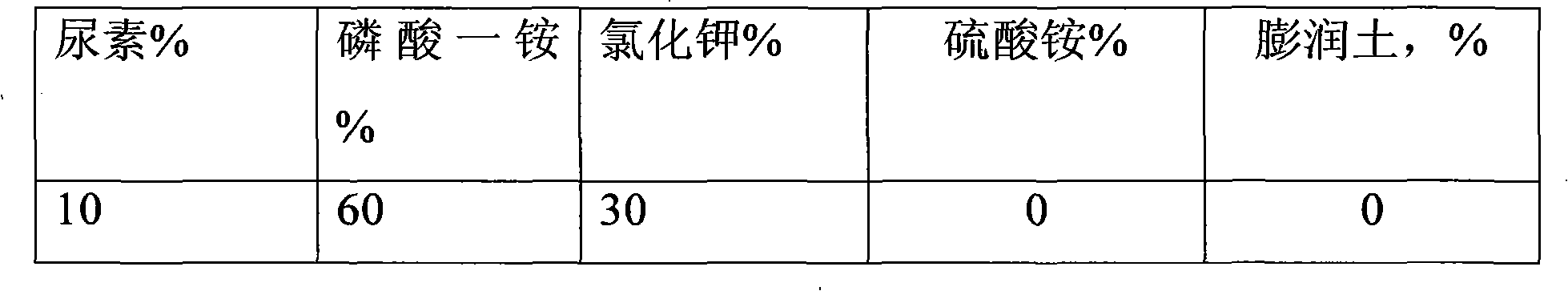

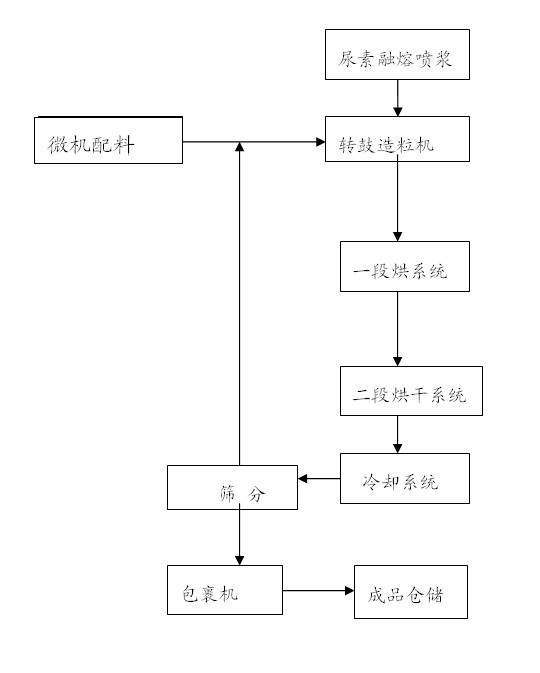

The invention discloses a manufacturing method of active humic acid controlled-release fertilizer, comprising the following steps: taking weathered coal or lignite as raw materials; adopting the production equipment of compound fertilizer; taking sodium hydroxide and urea as an activator; in an activating reaction jar, activating and converting humic acid in the weathered coal or lignite by fusedurea liquid and sodium hydroxide to form the urea liquid containing the active humic acid; producing by combing with the compound fertilizer; injecting the urea liquid containing the active humic acid onto the compound fertilizer material in a granulation barrel to round and granulate; and drying, and screening to obtain the black, light and round humic acid controlled-release fertilizer product of different content proportions. In the manufacture scheme, the humic acid urea activating liquid has the following raw materials at the ratio of urea to humic acid to potassium chloride to water tosodium hydroxide of 100:100:(15-200):(5-15):(7-12), and other solid granulation raw materials (comprising urea, monoammonium phosphate, potassium chloride, ammonium sulphate, bentonite and the like) are designed according to nutrient content proportions of different fertilizers. In the manufacture method, humic acid activation and compound fertilizer production are organically combined and are carried out simultaneously, and thus the manufacture method has the characteristics of simple operation process, low cost, large production capability, black, light and round product particle, efficient controlled release of the nutrient, high utilization ratio, wide market prospect and the like, can greatly improve the yield and the quality of crop and improves fertilization soil.

Owner:SHANDONG AGRI UNIV FERTILIZER TECH CO LTD

Soluble granule of glyhosate ammonium and preparation method

ActiveCN101564044ANot easy to agglomerateNot easy to thinBiocideAnimal repellantsPhosphatePolluted environment

The invention provides a formula of soluble granule (WSG) of glyhosate ammonium and a preparation method. The formula includes 50-95 percent of glyhosate ammonium, 0.5-25 percent of glyphosate synergistic agent, 0.27-40 percent of phosphate, 0-10 percent of filler, 0.1-0.5 percent of xanthan gum and water. The product is stable in property and not prone to absorb moisture, and the production process is simple and smooth, does not pollute the environment and meets environment-protective requirements.

Owner:SHANGHAI XIANGLIN AGRI TECH CO LTD

Charcoal fertilizer as well as preparation method and application thereof

InactiveCN105753546AImprove carbonization rateImprove the carbonization effectAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAdjuvantCarbonization

The invention discloses a charcoal fertilizer, prepared from the following raw materials in percentage by weight: 10-50% of charcoal powder, 20-70% of compound fertilizer and 5-30% of adjuvant, wherein the charcoal powder is obtained by putting straws in a carbonization furnace for dehydration and deoxygenation treatment and smashing the straws to a particle size of not more than 0.5mm after high-temperature carbonization. A preparation method of the charcoal fertilizer comprises the following steps: feeding the straws into the carbonization furnace; performing the dehydration and deoxygenation treatment for 1-2 hours at a temperature of 100-250 DEG C; carbonizing the straws at a high temperature of 600-700 DEG C for 30-240min; cooling the carbonized product and then smashing the carbonized product to form the charcoal powder with the particle size of not more than 0.5mm; uniformly mixing the charcoal powder, the compound fertilizer and the adjuvant in proportion to obtain a mixture and then pelleting the mixture to obtain pellets; cooling and screening the pellets to a particle size of 1.5-4.75mm; packing the screened pellets. The charcoal fertilizer disclosed by the invention has the advantages of an extensive source of the raw material straws, a good carbonization effect, high carbon content, conformity with the concept of environmental protection, simplicity in preparation technique, low energy consumption, high product strength and capability of processing the raw materials in a centralized manner and obviously increasing the utilization rate and quality stability of the fertilizer. The invention further discloses an application of the charcoal fertilizer in crop growth.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

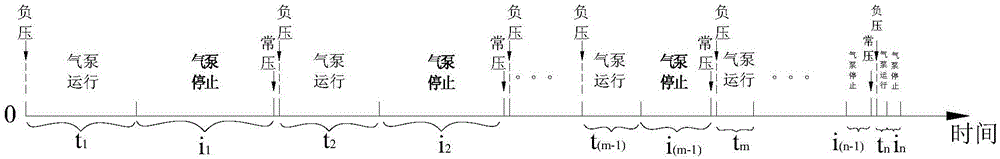

Control method for cooking utensil

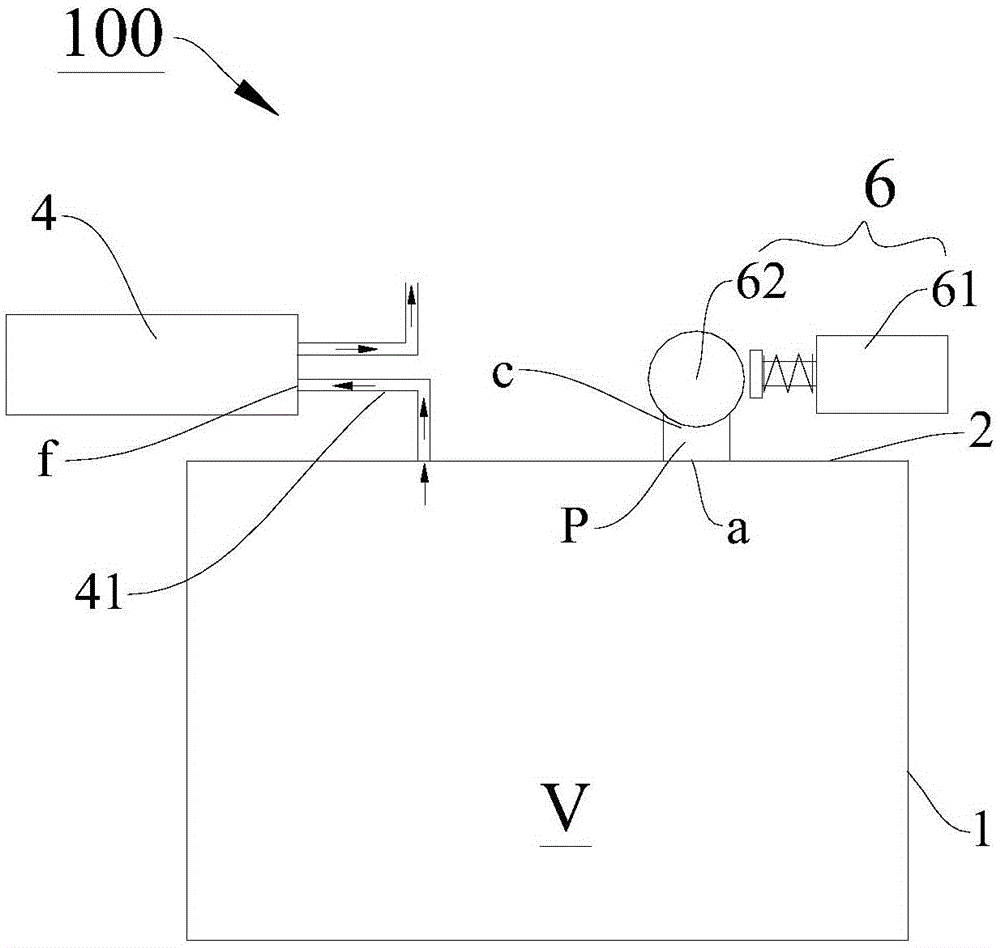

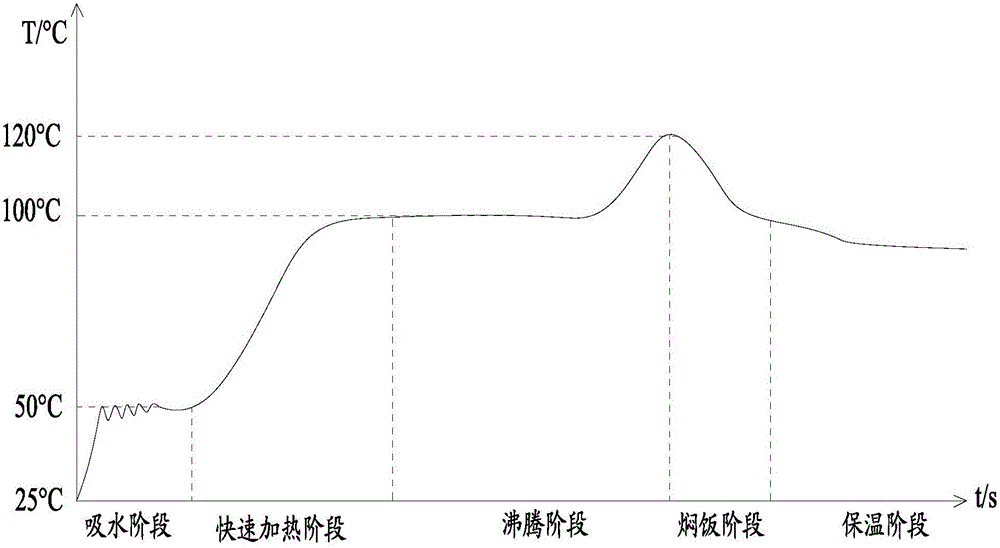

ActiveCN106551609AImprove water absorptionFast water absorptionCooking-vessel lids/coversEngineeringAir pump

The invention discloses a control method for a cooking utensil. The cooking utensil comprises a pot body, an upper cover assembly provided with a steam channel, a switch assembly and a gas pump. The switch assembly is used for connecting or stopping the steam channel. The gas pump is used for pumping gas in a containing cavity outwards. The control method includes the following steps that after the cooling utensil enters the water absorbing stage, the switch assembly stops the steam channel, the gas pump is started to pump gas of the containing cavity, the gas pump stops running after running for the first time, the steam channel is connected through the switch assembly after the gas pump stops running for the second time, then the steam channel is stopped again through the switch assembly, the gas pump is started again for gas pumping, and circulation is repeated in this way till the water absorbing stage ends. According to the control method, the water absorbing rate of food can be increased, the water absorbing speed is increased, the water absorbing time is shortened, caking can be prevented, and it is guaranteed that the food is heated uniformly.

Owner:FOSHAN SHUNDE MIDEA ELECTRICAL HEATING APPLIANCES MFG CO LTD +1

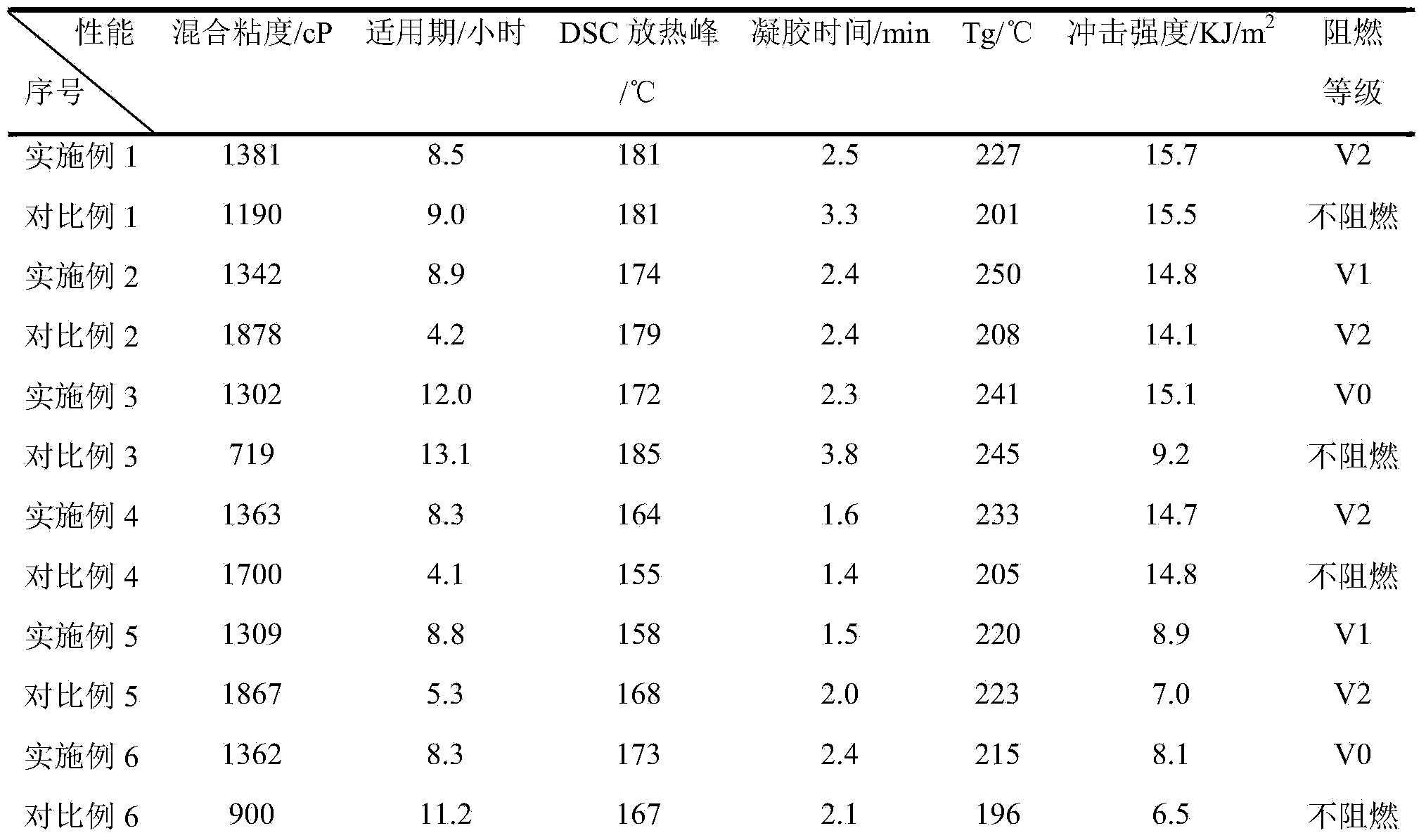

Flame-retardant high temperature-resistant epoxy resin composition capable of being used for pultrusion and preparation method thereof

The invention discloses a flame-retardant high temperature-resistant epoxy resin composition capable of being used for pultrusion and a preparation method thereof. The flame-retardant high temperature-resistant epoxy resin composition capable of being used for pultrusion comprises three components of A, B, and C, and is characterized in that the A component comprises diglycidyl ether epoxy resin, cycloaliphatic epoxy resin and an epoxy resin active diluents; the B component comprises cycloaliphatic acid anhydride, arene poly(acid anhydride), a thermoplastic phenolic resin curing agent, a maleic anhydride-grafted rubber flexibilizer, a polysiloxane toughening modifier, and an epoxy resin curing accelerator; the C component comprises an inorganic fire retardant which has an ultrafine particle size and is subjected to surface modification by a silane coupling agent and a hydrophobic modifier; the weight ratio of the A, B, and C components is that A:B:C=100:50-250:20-150.

Owner:江苏绿材谷新材料科技发展有限公司

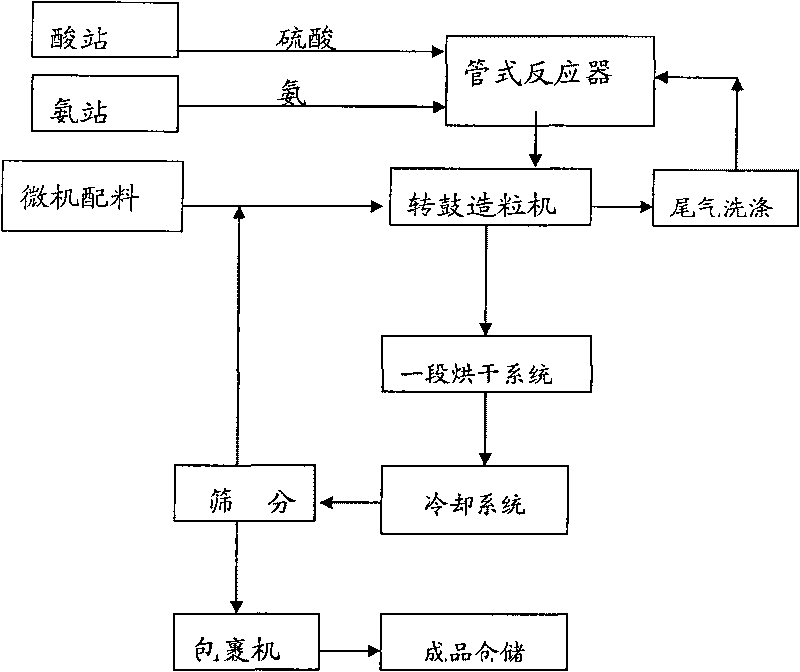

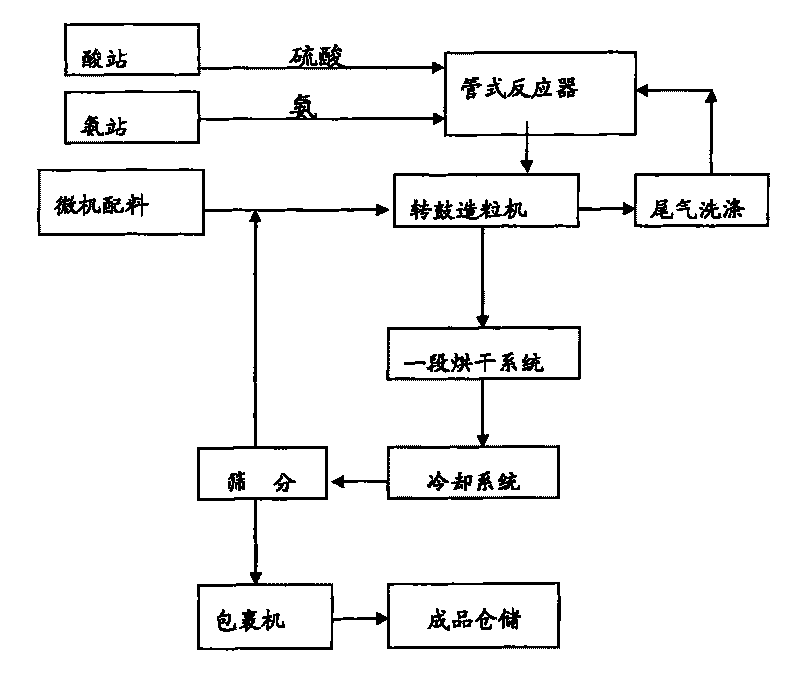

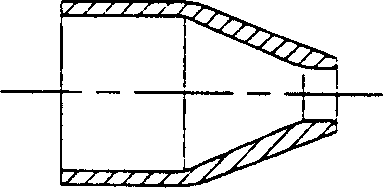

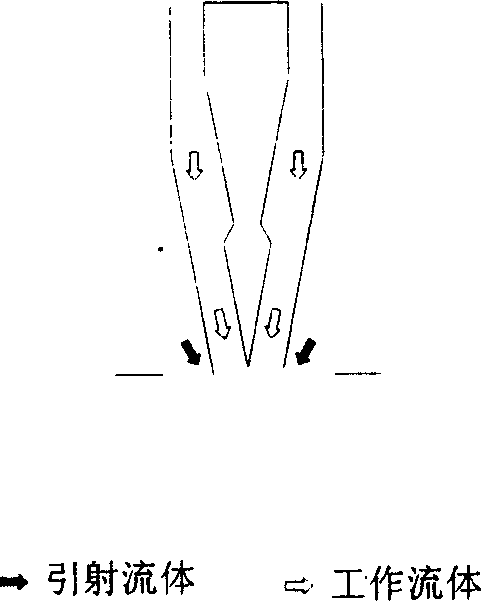

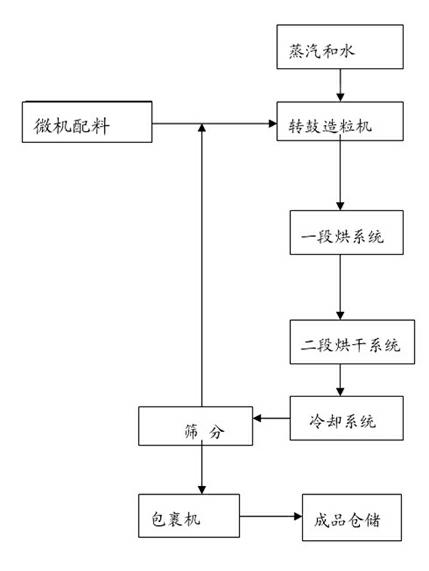

Method for producing Nitrogen-Phosphorus-Potassium compound fertilizer by ammonia and acid tubular reactor

The invention discloses a method for producing a Nitrogen-Phosphorus-Potassium compound fertilizer by using an ammonia and acid tubular reactor. The method comprises the following steps of: preparing an ammonium sulfate solution at 180-220 DEG C by concentrated sulfuric acid, ammonia and water; controlling the reaction heat of ammonia and acid by the addition amount of the water; spraying in a granulator to granulate with other base fertilizers containing nitrogen, phosphorus and potassium; drying; cooling; screening; and filming to obtain a nitrogen-phosphorus-potassium compound fertilizer. The reaction heat of the ammonia and the acid is fully utilized, the ammonium sulfate solution generated by the reaction is in liquid phase and viscosity, the balling rate is high, the moisture of granulation materials is obviously reduced, the drying load is lowered, the production need can be satisfied by changing two-section drying into one-section drying, and the equipment investment and great energy consumption are saved.

Owner:天津达汇丰生物科技有限公司

Biological phosphatic fertilizer as well as preparation method thereof

ActiveCN104016795AAvoid fixationImprove phosphorus dissolution rateFertilizer mixturesSoil sciencePhosphate solubilizing bacteria

The invention discloses a biological phosphatic fertilizer. The preparation method of the phosphatic fertilizer comprises the following steps: culturing AM mycorrhiza, phosphate solubilizing bacteria and rhizobium respectively, mixing with a phosphatic fertilizer to react, then adding various nutritional elements required for plants, and mixing and granulating to obtain porous fertilizer particles, so that the contact area between the fertilizer and water is increased, and the dissolving velocity of the fertilizer in water is accelerated. The biological phosphatic fertilizer can activate the phosphatic fertilizer, and can improve the absorption of the phosphatic fertilizer by plants, increase the utilization ratio of the phosphatic fertilizer, reduce the using quantity of the fertilizer and reduce the pollution to the environment; the fertilizer can be rapidly dissolved in water for irrigation and fertilization together with water, and is suitable for modern agricultural water and fertilization integration.

Owner:内蒙古和盛生态科技研究院有限公司

Anhydrous stemming for blast furnace tapping hole

The invention discloses anhydrous stemming for a blast furnace tapping hole, belonging to the technical field of refractory material for blast furnaces. The anhydrous stemming for a blast furnace tapping hole disclosed by the invention is composed of refractory aggregate and bonding agent, wherein the refractory aggregate comprises the following components in parts by mass: 12-14 parts of titanium dioxide, 3-5 parts of titanium carbide, 20-25 parts of corundum, 15-18 parts of silicon carbide, 30-38 parts of mullite, 5-7 parts of calcium-free chromium slag, 6-8 parts of blast furnace gas ash, and 9-11 parts of coke; and the bonding agent comprises the following components in parts by mass: 40-50 parts of asphalt, 4-6 parts of hydrogenated terphenyl, 10-12 parts of organic silicon resin, 8-11 parts of furan resin, and 11-15 parts of melamine-formaldehyde resin, wherein the mass ratio of the refractory aggregate to the bonding agent is 100:13-15. The anhydrous stemming disclosed by the invention has good opening performance, moderate plasticity, can resist scouring and erosion of high-temperature iron slag, does not pollute the environment, and is low in production cost.

Owner:ANHUI SAFE ELECTRONICS

Preparation of low DE value malt amylin by spraying alpha-amylase process

InactiveCN1528910AEasy to operateSmall fluctuations in voltage regulationFermentationFood preparationChrysanthemum FlowerAlpha-amylase

The invention uses liquefying enzyme ejecting method to produce low DE value malt dextrin, the invention refers to a kind of enzyme project manufacturing method of low DE value malt dextrin and the application. The invention uses core starch or indica rice powder as materials, uses the special device steam ejecting liquefying device and laminar current device, the product whose DE value is 2-6 is obtained through ejecting, thermal retardation and liquefying, enzyme eliminating process. The product with 5-6 DE value can be used in solid chrysanthemum flower essence beverage to replace 66% sugar powder and decrease 60% chrysanthemum extracting solution; the product with 2-3 DE value can be used in the production of gammon and icecream, the 50% aft in gammon and icecream can be replaced by malt dextrin, 30 g fat in gammon can be replaced with 6-7.5 g malt dextrin, 4 g fat in icecream can be replaced with 1 g malt dextrin. The invention fills the blank of low DE value malt dextrin in our country.

Owner:JIANGNAN UNIV

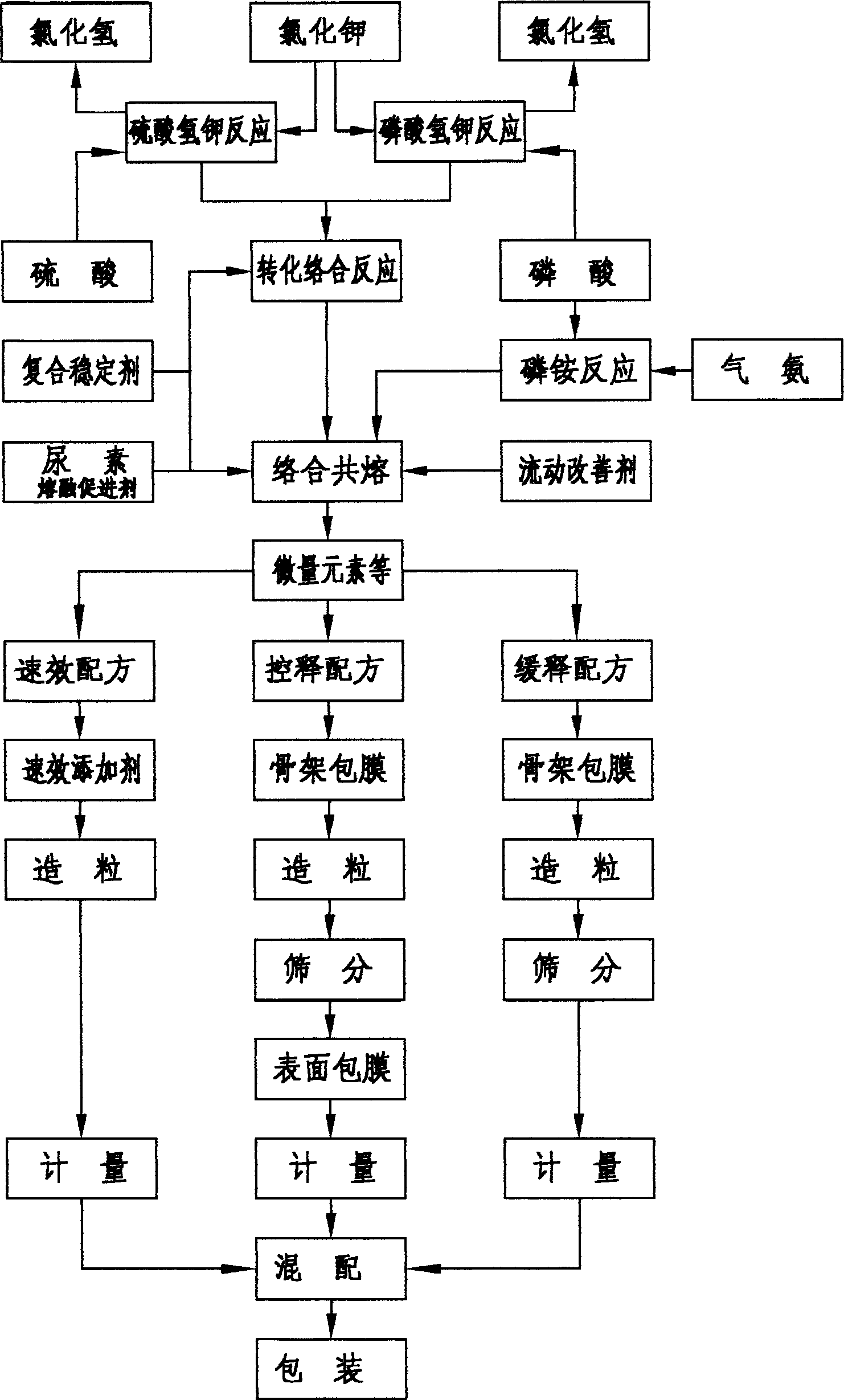

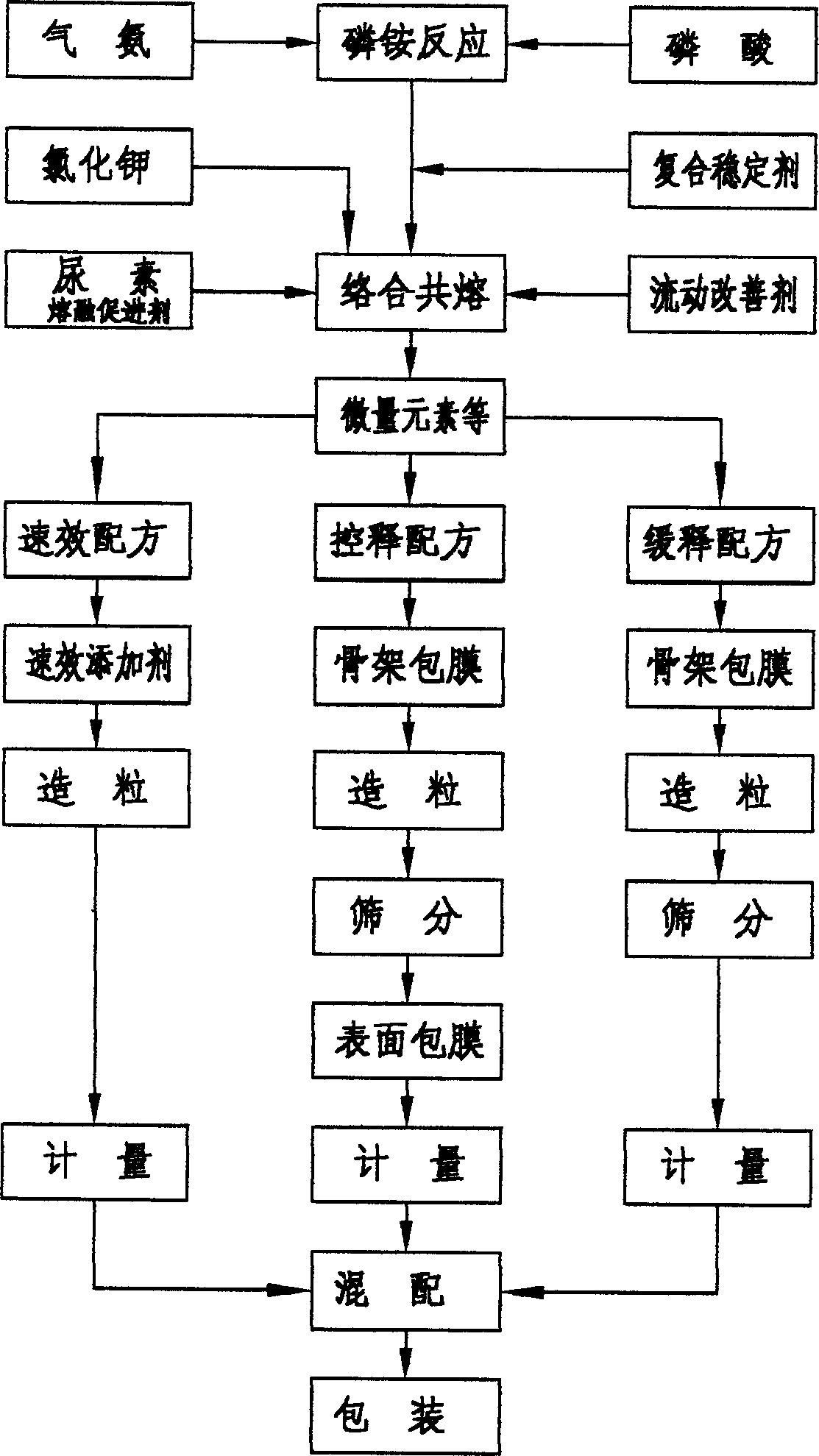

Nutrient released modle of compound controlled releasing and production thereof

InactiveCN1644568AWide range of choicesAdjustable release rateFertilizer mixturesPhosphoric acidSlurry

A controlling and releasing composite fertilizer nutrient releasing model and production are disclosed. The production is carried out by potassium chloride reacting with phosphoric acid and concentrated sulfuric acid, recovering hydrogen chloride, two products reacting, adding urine to obtain mixed slurry of potassium sulfate and urea phosphate, adding stabilizer and flowing-performance improver, reacting with urea to obtain ammonium phosphate mixing melt in melting boiler, regulating NPK proportion, adding functional additive, combing releasing mechanism with instant releasing, frame slow releasing and surface controllable releasing, granulating, coating, computing fertilizer proportion, and obtaining controllable releasing composite fertilizer. Its advantages include low cost, regulating releasing period and no environmental pollution.

Owner:周端午

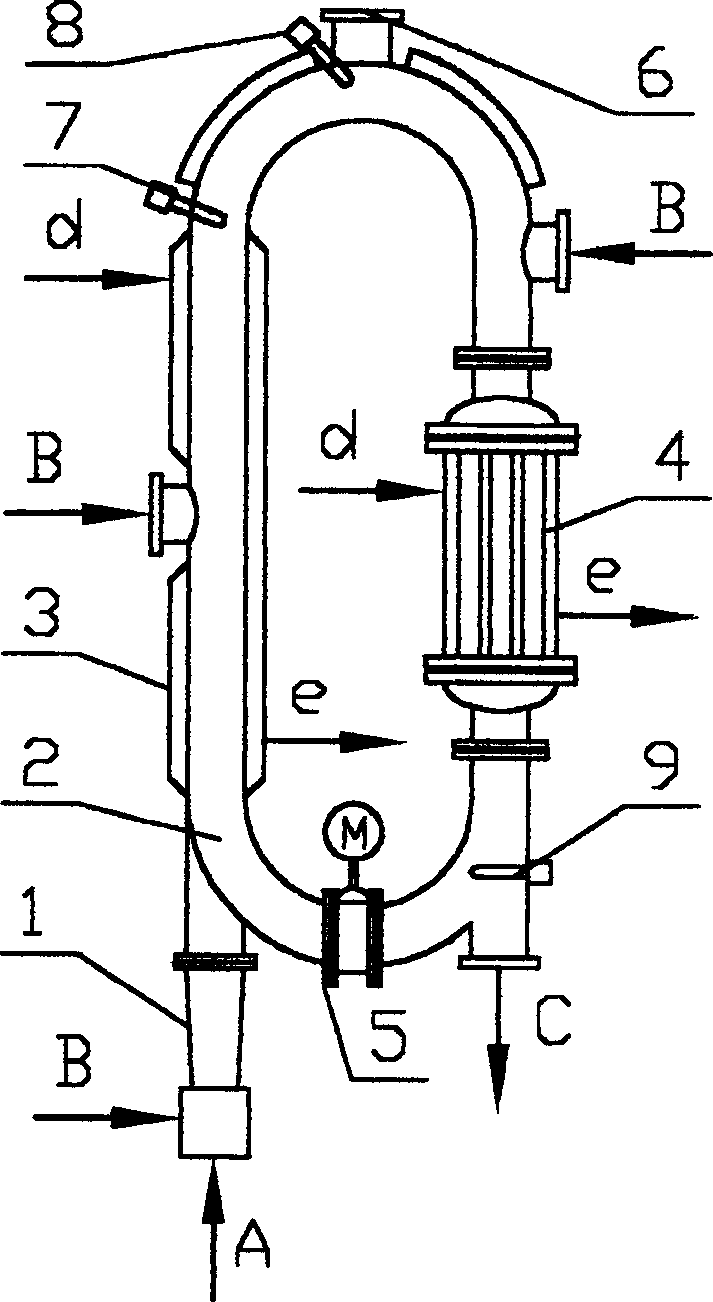

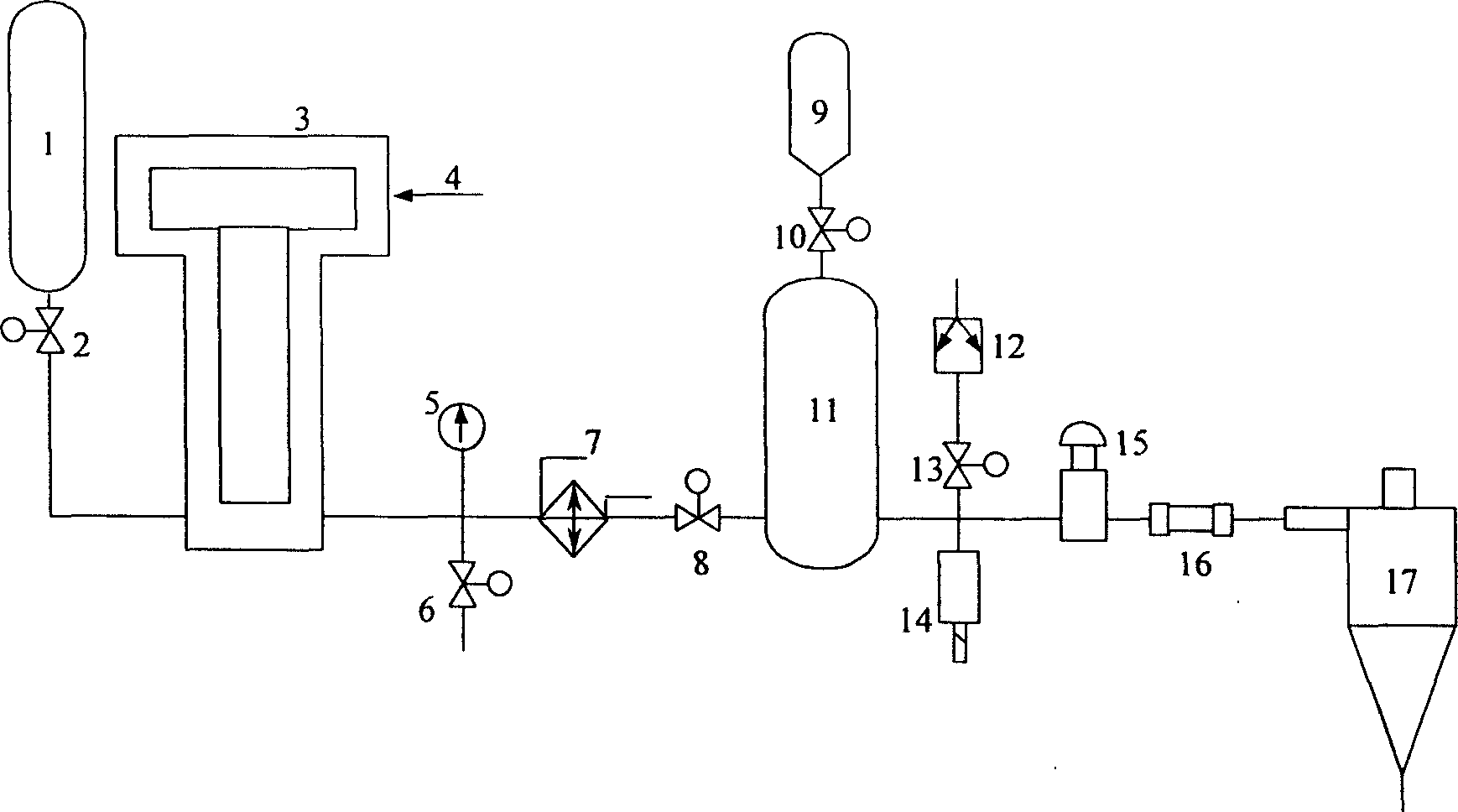

Method and apparatus for preparing superfine powder by super high pressure supercritical fluid micro jetting technology

The present invention belongs to the field of superfine powder preparing technology and proposes one new kind of superfine powder preparing method and apparatus. Super high pressure technology, supercritical fluid technology and micro jet crushing technology are combined and used in preparing submicron level superfine powder. The new method needs no grinding medium and solvent, and has high energy utilization and easy separation between the product and the work medium.

Owner:EAST CHINA UNIV OF SCI & TECH

Method for preparing TiO2/SiO2 composite microspheres

InactiveCN101890326AHigh purityGood dispersionPhysical/chemical process catalystsMicroballoon preparationSolventSal ammoniac

The invention discloses a method for preparing TiO2 / SiO2 composite microspheres. In the method, tetraethoxysilane and tetrabutyl titanate are used as raw materials, ammonia water and absolute ethyl alcohol are used as solvents, citric acid is used as a complexing agent and polyethylene glycol is used as a dispersing agent. The method comprises the following steps of: adding Si-containing sol into Ti-containing wet gel with constantly stirring; evaporating in a water bath, drying and foaming to compound the Si-containing sol and the Ti-containing wet gel constantly; and calcining to obtain the TiO2 / SiO2 composite microspheres. The method of the invention has short preparation period; and the prepared TiO2 / SiO2 composite microspheres are complete spheres of which the particle size is 100 to 900nm and have high purity and yield.

Owner:SHAANXI UNIV OF SCI & TECH

Method for producing chlorine-based high phosphorus compound fertilizer by ammoniation method

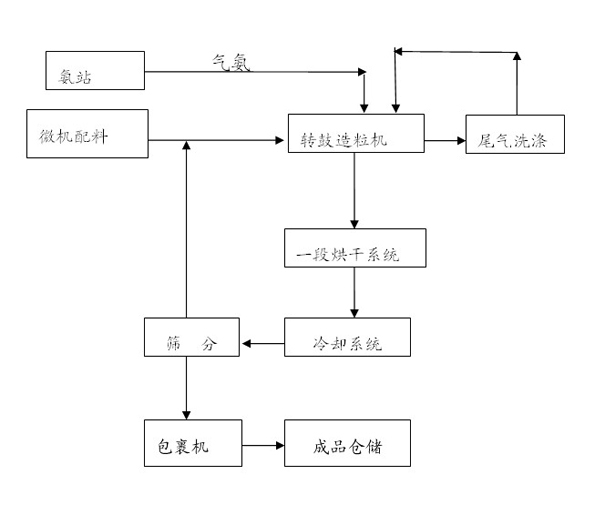

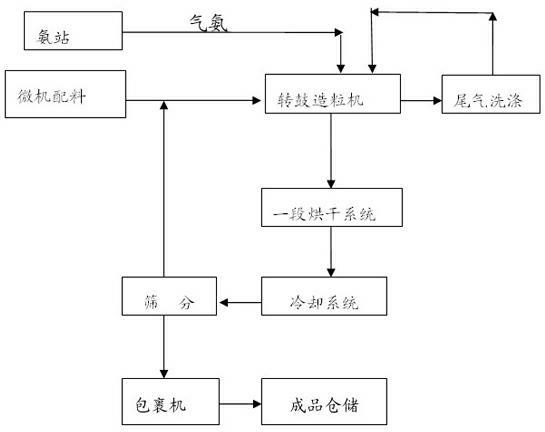

The invention discloses a method for producing a chlorine-based high phosphorus compound fertilizer by an ammoniation method. The method is characterized by directly introducing gas ammonia to a material layer of a rotary drum granulator to increase the neutralization degree of monoammonium phosphate, granulating gas ammonia with other powdered fundamental fertilizers containing nitrogen, phosphorus and potassium and obtaining the compound fertilizer containing nitrogen, phosphorus and potassium through drying, cooling, screening and enveloping after granulation. The method has the following advantages: the heat producing reaction between the gas ammonia and double superphosphate and heat of neutralization generated by the reaction between the gas ammonia and the monoammonium phosphate are fully used of to maintain the temperature of the materials, and the solubility of ammonium phosphate salt is improved to satisfy the liquid phase quantity needed by granulation; the higher granulation rate can be ensured without adding other adhesives, thus lowering the input cost of the materials; and the moisture of the materials to be granulated is obviously reduced, thus reducing the drying load and saving plenty of energy.

Owner:天津芦阳肥业股份有限公司

Crystallization method of abamectin Bla

The present invention relates to a crystallization method of abamectin B 1a. Said method includes the following steps: using crystallization solvent n-butanol to stir and dissolve primary crude powder of abamectin B 1a at 75-100deg.C to saturation, filtering while the saturated solution is hot to obtain clear hot-saturated solution; slowly cooling said solution to that when the supersaturation degree is 1-3, adding crystal seeds, constant stirring for 20-60min, its stirring speed is 120-300rpm, and cooling to make crystallization, fitering crystal slurry or centrifugally-separating said crystal slurry, washing crystal and drying so as to obtain the invented abamectin B 1a.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

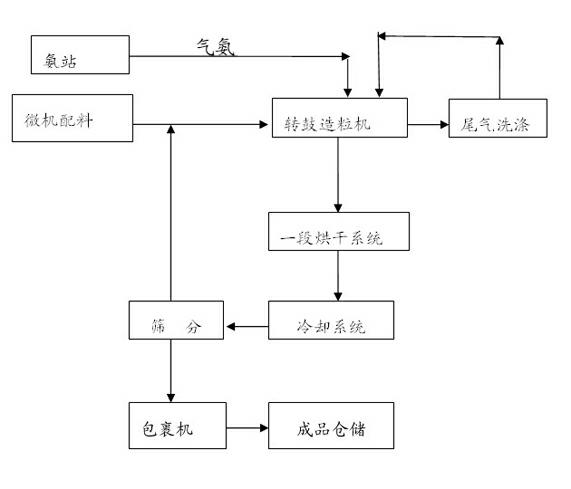

Production method of readily available and controlled release composite fertilizer containing three nitrogen elements

The invention discloses a production method of a readily available and controlled release composite fertilizer containing three nitrogen elements. The production method is as follows: raw materials containing nitric nitrogen, ammonium nitrogen and amido nitrogen are added in materials; in order to prevent that urea reacts with nitro phosphate fertilizer to generate too much urea nitrate and the production can not performed, ammonia gas is introduced in the granulation process according to different proportions to ammonify nitro phosphate fertilizer, reduce the generation of urea nitrate and increase the neutralization degree of monoammonium phosphate; and powdery fundamental fertilizers containing nitrogen, phosphorous and potassium are added to granulate, and then the composite fertilizer can be obtained through drying, cooling, screening and coating. In the production method of the invention, a lot of heat generated in the thermolysis of the nitro phosphate fertilizer and the neutralization heat of the reaction of ammonia gas and monoammonium phosphate are fully utilized to heat materials and increase the granulation temperature; and the viscosity of urea nitrate is utilized, the solubility of ammonium phosphate salt is increased, the quantity of the liquid phase for granulation can be satisfied, higher granulation rate can be realized without using other adhesive, the cost is reduced, the water content of the granulation material is significantly reduced, the drying energy consumption can be reduced and a large amount of energy consumption can be saved.

Owner:天津芦阳肥业股份有限公司

Mycotoxin toxin adsorbent of livestock and poultry feed and preparation process

InactiveCN105309777APromote digestion and absorptionImprove immunityAnimal feeding stuffAccessory food factorsMycotoxinVitamin C

The invention discloses a mycotoxin toxin adsorbent of a livestock and poultry feed and a preparation process. The mycotoxin toxin adsorbent is prepared from modified montmorillonite, yeast extract, lactobacillus acidophilus, lactobacillus amylovorus, sialic acid lactobacillus, streptococcus thermophilus, bacillus subtilis, honeysuckle extract, camellia oil extract, glycyrrhizic acid, echinacea extract, eugenol, cinnamic aldehyde, baicalin, vitamin C, vitamin E and zinc methionine. The mycotoxin toxin adsorbent provided by the invention can realize efficient adsorption on a plurality of types of common mycotoxin and the conversion rate of the feed is improved; meanwhile, the balance of intestinal flora of livestock and poultry can be promoted, and the added zinc methionine in the formula also has the effect of protecting livers; and the selected raw materials are natural and pollution-free and have a very good application value in feed and cultivation industries.

Owner:SHANDONG RUNMU BIOLOGICAL TECH CO LTD

Method for producing high-performance rubber type chlorinated polyethylene by water-phase method

The invention discloses a manufacturing method for high-performance rubber-type chlorinated polyethylene with the water-phase method. The manufacturing method comprises the following steps of: softening hot water, dispersing agent, emulsifying agent and polyethylene powder are added in a proportioning tank in turn and are stirred to form suspension feed liquid, then completing discharging; the suspension feed liquid in the proportioning tank is fed in a chlorination reaction kettle, and then initiator is added; when the mixture is heated to 75 DEG C under a sealed condition, chlorine gas is pumped into the reaction kettle, thereby obtaining the mother liquor of rubber-type chlorinated polyethylene after 2 to 3 hour reaction under 75 to 140 DEG C and pressure less than or equal to 0.45MPa; and the mother liquor is fed to a rinsing kettle to be filtered and then is neutralized through a neutralization kettle, and is made into a high-performance rubber-type chlorinated polyethylene finished product after washing, dehydration and drying. The manufacturing method has high production efficiency and stable product quality and can realize the recycling of waste water after treatment.

Owner:江苏天腾化工有限公司

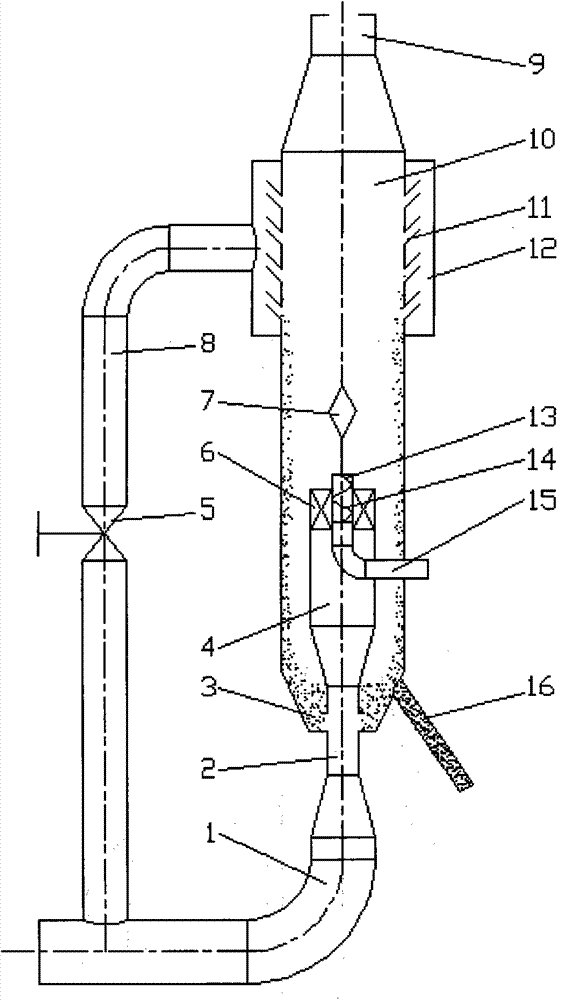

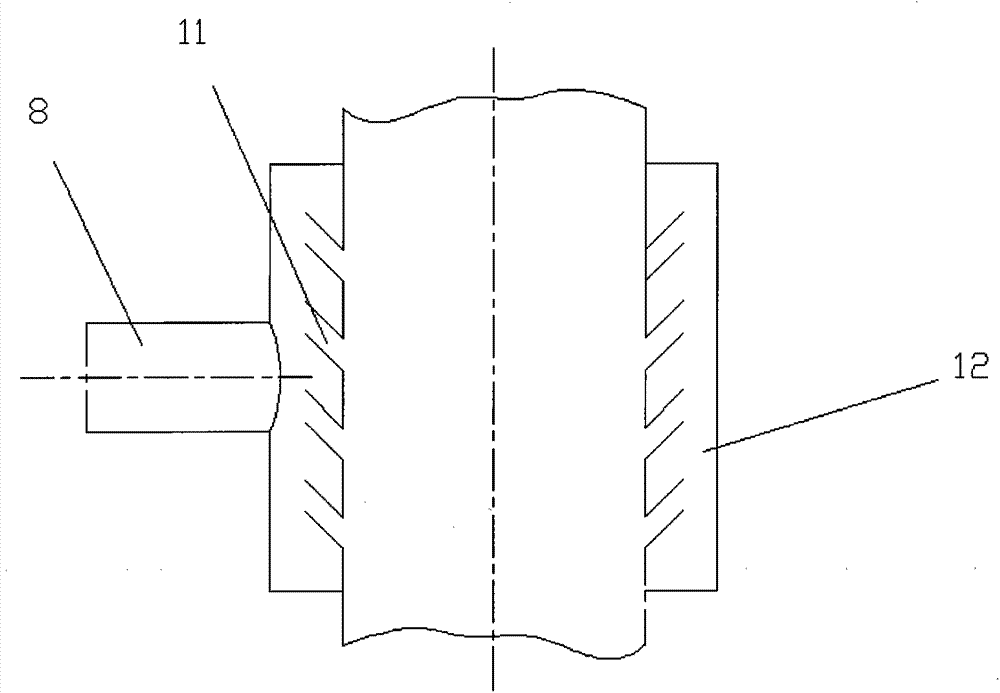

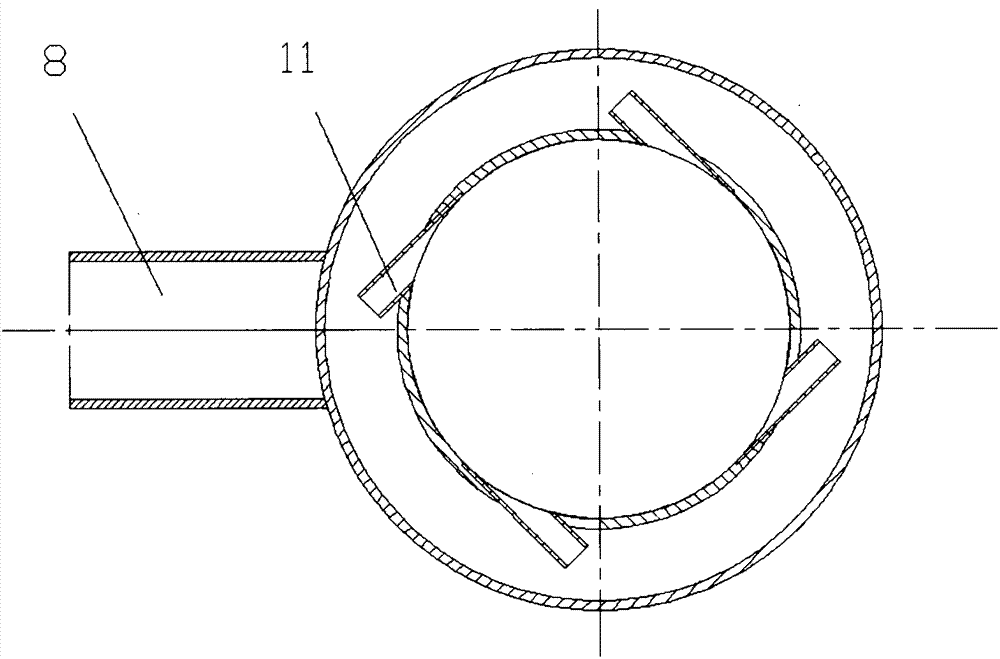

Semi-dry circulating cyclone bed desulfurizing tower

InactiveCN103480268AIncrease shear forceIncrease profitDispersed particle separationCycloneFluidized bed

The invention discloses a semi-dry circulating cyclone bed desulfurizing tower. By providing a tangential exhaust gas inlet structure of the desulfurizing tower, a rotating flow field is established inside the desulfurizing tower so as to sufficient mixing and contact of exhaust gas, so that the desulfurizing reaction process inside the desulfurizing tower is intensified, a desulfurizing agent is sufficiently utilized, the desulfurizing efficiency is improved; and secondary air is arranged to intensify the intensity of a rotating flow, so that separation of gas from solid is achieved inside the desulfurizing tower. By adopting the structure, an external cyclone separator in a conventional circulating fluidized bed desulfurizing process is omitted, so that the semi-dry circulating cyclone bed desulfurizing tower is compact in structure and easy to install and maintain.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

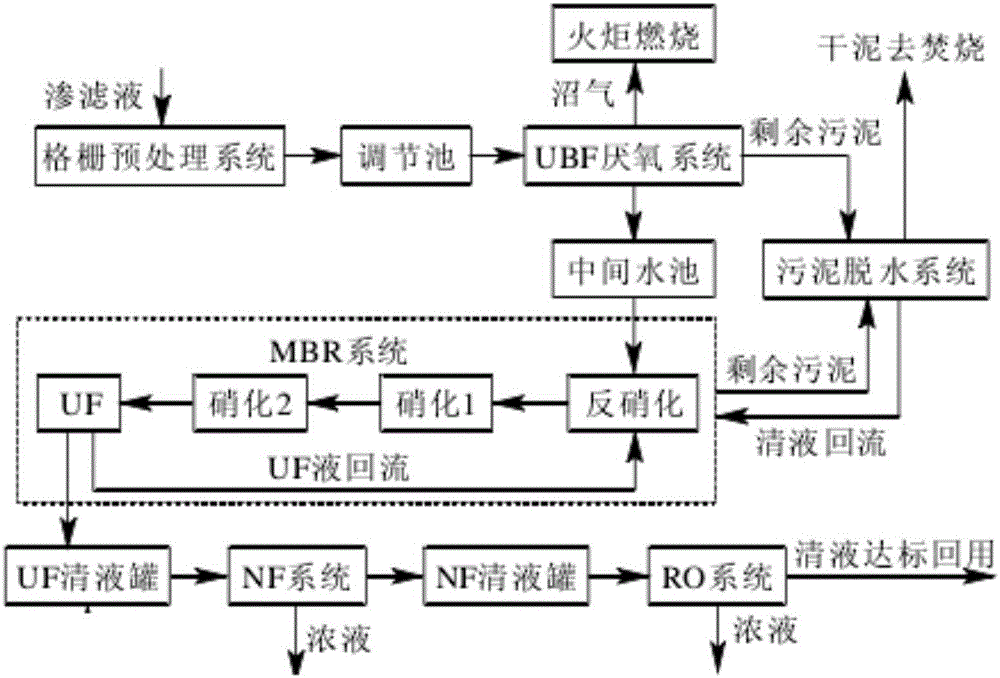

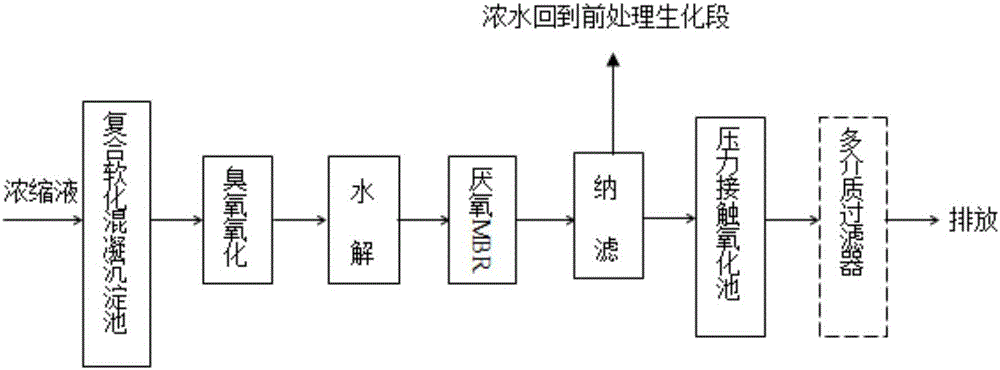

Treatment method of concentrated solution produced from landfill leachate by membrane method

ActiveCN106242163AImprove biodegradabilityReduce processing costsTreatment with anaerobic digestion processesMultistage water/sewage treatmentHigh concentrationFiltration

The invention discloses a treatment method of a concentrated solution produced from landfill leachate by a membrane method. The treatment method comprises the following steps of enabling the concentrated solution produced from the landfill leachate by the membrane method to sequentially pass through a composite softening coagulation and sedimentation pond, an ozone oxidation reactor, a hydrolyzing pond and an anaerobic MBR pond, and enabling effluent water from the anaerobic MBR pond to enter a nanofiltratoin system; enabling a permeation solution obtained through treatment of the effluent water in the nanofiltratoin system to be treated by a pressure contact oxidation reactor, and directly discharging the treated permeation solution, or after filtering the treated permeation solution by a multi-medium filter, discharging the filtered permeation solution; mixing a concentrated solution obtained after treatment by the nanofiltratoin system with the landfill leachate so as to obtain a mixed solution; and performing concentration treatment on the mixed solution by a biochemical method, an MBR method and the membrane method so as to obtain a concentrated solution, enabling the concentrated solution to enter the composite softening coagulation and sedimentation pond, and performing subsequent operations. The treatment method disclosed by the invention not only is suitable for treatment of the concentrated solution produced from the landfill leachate by membrane filtration, but also is suitable for treatment of other membrane concentrated solutions containing high concentration of organic compounds which are difficult to degrade.

Owner:江苏环保产业技术研究院股份公司

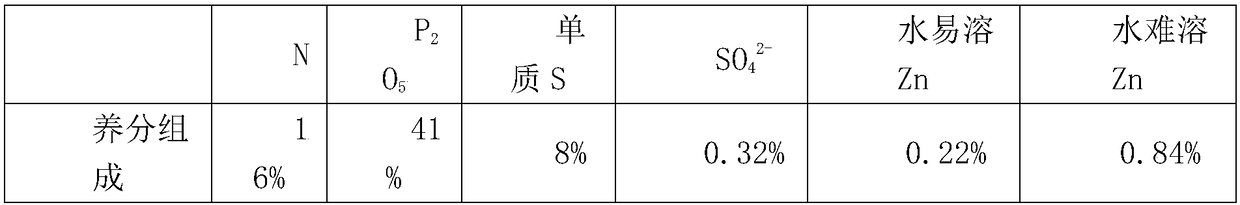

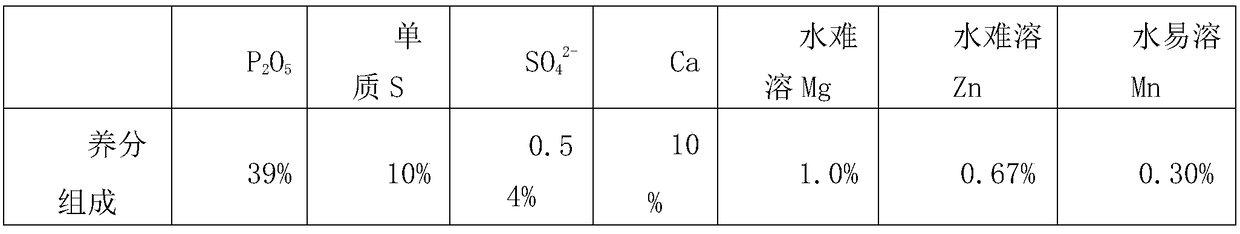

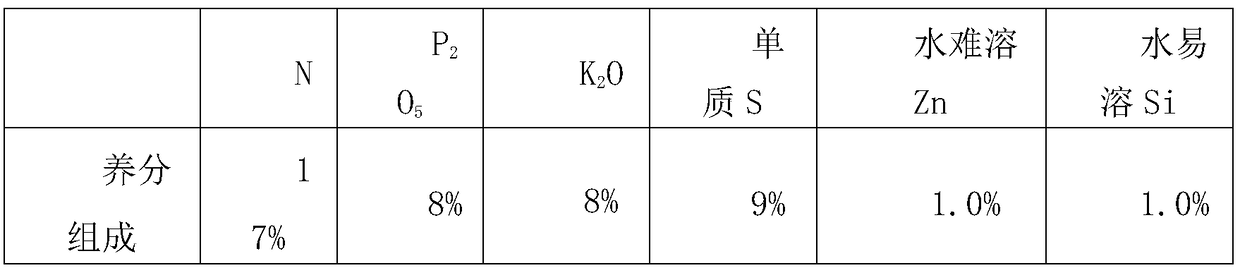

Medium trace element mixture and preparation method of medium trace element-wrapped fertilizer

InactiveCN108976018AEasy to accumulateImprove securityMagnesium fertilisersAlkali orthophosphate fertiliserLiquid stateSulfur

The invention relates to a medium trace element mixture and a preparation method of a medium trace element-wrapped fertilizer. The medium trace element mixture is prepared from the following components: 50% to 90% of sulfur, 5% to 20% of swelling material, and 5% to 45% of medium trace element other than sulfur. The preparation method comprises the following steps: adding the medium trace elementand the swelling material into liquid sulfur and evenly mixing. The preparation method of the medium trace element-wrapped fertilizer comprises the following steps: placing the conventional granular fertilizer in a wrapping device with a heating function, after heating the medium trace element mixture to a certain temperature, spraying on the surface of the granular fertilizer, and forming a medium trace element film on the surface of the fertilizer by cooling and curing. The medium trace element mixture and the preparation method of the medium trace element-wrapped fertilizer provided by theinvention have the advantages that the medium trace elements are quickly and flexibly added; the problem of uniform dispersion of the medium trace elements in soil is solved, and the local poisoning is avoided; the film formed by wrapping the medium trace element material is firmly combined with fertilizer particles, and is not easy to fall off; fast-acting and long-acting combined medium trace element materials can be wrapped, which is beneficial to the nutritional needs of crops in the whole growth cycle.

Owner:HUBEI FORBON TECH

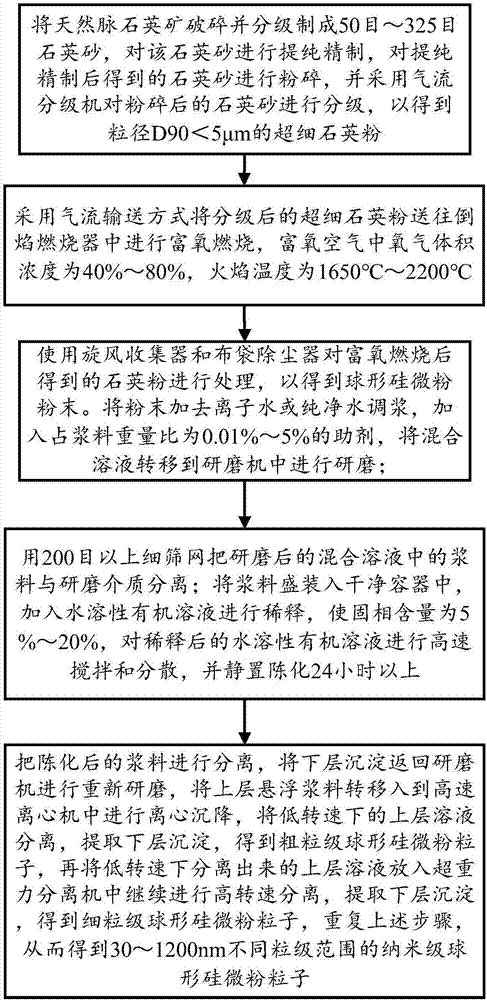

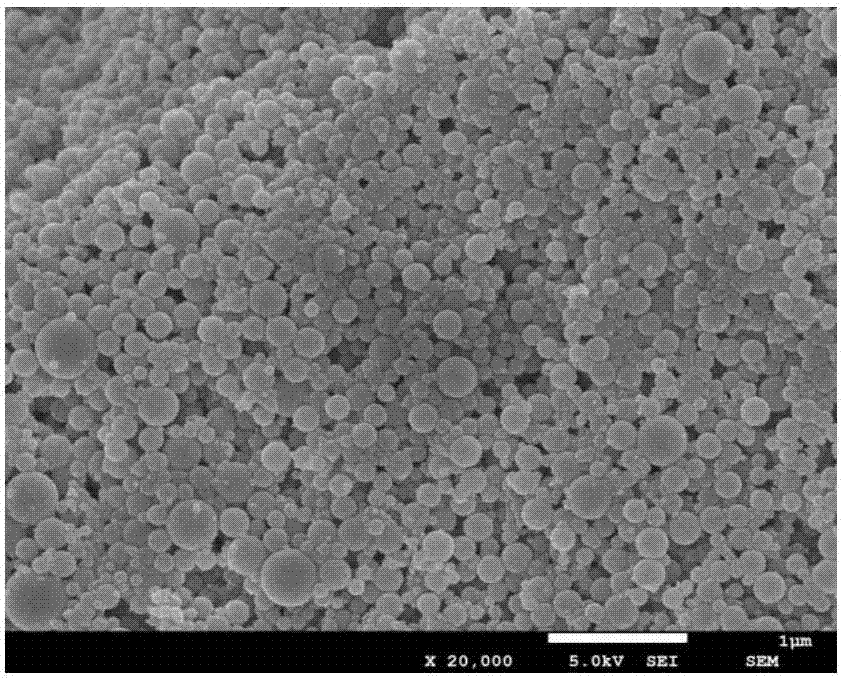

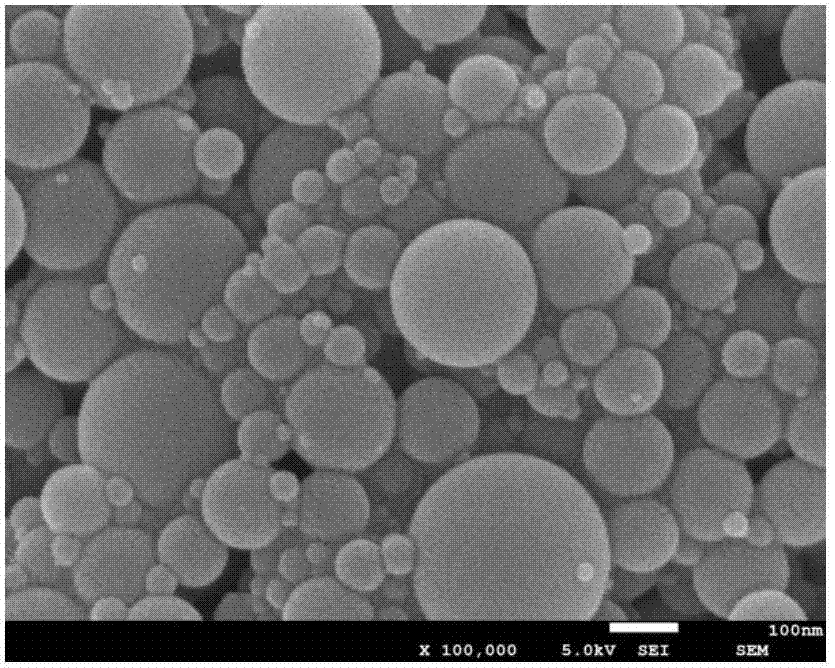

Method for preparing nano-sized spherical silicon micropowder by flame method

ActiveCN107055554AHigh bulk densityReduce surface activityMaterial nanotechnologySilicaSlurrySolvent

The invention discloses a method for preparing a nano-sized spherical silicon micropowder by a flame method. The method comprises the following steps: with natural vein quartz as a raw material, purifying, making sand, performing ultrafine grinding, grading, and then spheroidizing the graded ultrafine quartz powder through combustion in a down-draft combustion device; under the action of water and other dispersing agents, grinding the spheroidized powder by using a stirring mill, a planetary mill, or a sand mill or other machinery, and then aging; separating an aged and layered slurry to obtain a lower concentrated slurry and an upper suspended slurry respectively; diluting the suspended slurry by using a water-soluble solvent, putting into a supergravity separation device, performing supergravity precipitation separation for a fixed time of 3-60min at a fixed speed of 3000-13000r / min, extracting precipitate to obtain nano-sized spherical silicon micropowder particles with different particle sizes. By the method, submicron-sized and nano-sized spherical silicon micropowder particles with different particle size distribution ranges of 30-1200nm and smooth surfaces can be obtained respectively, the spherical degree thereof is 99% or above, and the spheroidizing rate is 100%.

Owner:中南冶金地质研究所

Net cage type biological carrier, immobilized microbiological treatment sewage device and application of immobilized microbiological treatment sewage device

ActiveCN104724817AAvoid short flowPrevent floatingTreatment using aerobic processesTreatment with anaerobic digestion processesHigh concentrationWater flow

The invention discloses a net cage type biological carrier, an immobilized microbiological treatment sewage device and application of the immobilized microbiological treatment sewage device. The net cage type biological carrier comprises a net cage and biological stuffing filled in the net cage, wherein the net cage is in the shape of a rectangle without a top cover, and a hollow-out mesh holes are formed in the side surface and bottom surface of the net cage. The immobilized microbiological treatment sewage device comprises a sewage treatment tank, a perforated mud discharge tube, a perforated aeration tube, a plurality of lower supporting beams and a sealing net, wherein a plurality of the net cage type biological carriers are stacked in the sewage treatment tank and arranged above the lower supporting beams. The net cage type biological carrier disclosed by the invention is large in specific surface area, low in accumulation, caking and blockage possibility, good in gas-water permeability, and convenient to mount and maintain. The immobilized microbiological treatment sewage device is good in gas-water flow state, conductive to bringing mass transfer effect into play, large in biological load amount, good in treatment effect and suitable for high-concentration degradation-resistant sewage treatment and advanced sewage treatment.

Owner:北京三泰正方生物环境科技发展有限公司

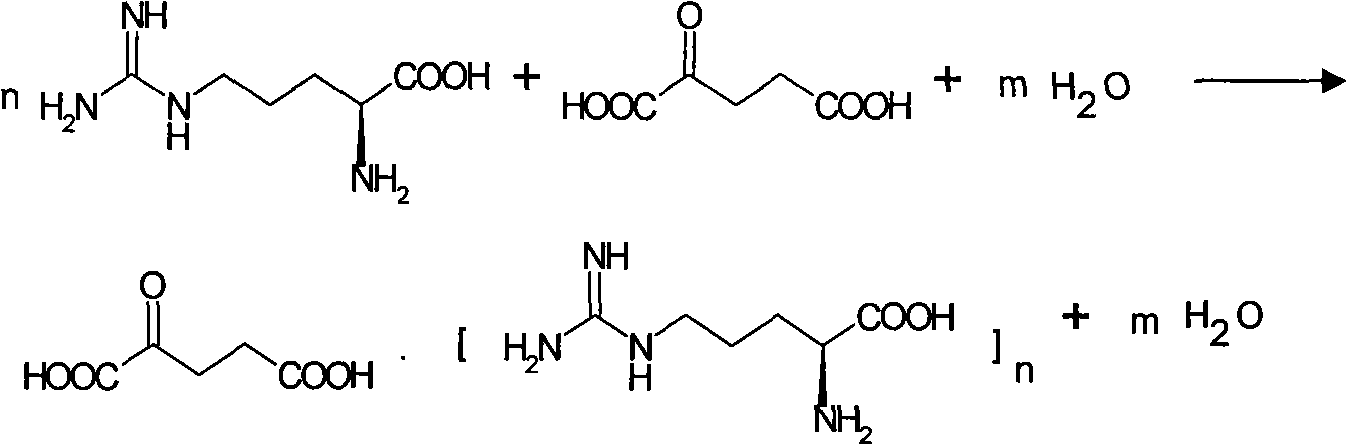

Preparation method of crystal L-arginine alpha-ketoglutarate

InactiveCN101591271AReasonable workmanshipSimple stepsOrganic chemistryFood preparationArginineL-arginine alpha-ketoglutarate

The invention relates to a preparation method of crystal L-arginine alpha-ketoglutarate, comprising the following steps: preparing water solution of L-arginine, and slowly adding alpha-ketoglutaric acid into the water solution, wherein the mol ratio of L-arginine and alpha-ketoglutaric acid is 1:1 or 2:1; reducing pressure and concentrating the alpha-ketoglutaric acid at 50-80 DEG C after complete dissolution, removing water accounting for 20-60 percent of the total volume and cooling to 20-30 DEG C; slowly adding an organic hydrophilic solvent or a mixed solvent of a polar hydrophilic solvent and a non-polar hydrophilic solvent; and carrying out temperature reduction, crystallization, filtering, washing and vacuum drying to obtain the crystal L-arginine alpha-ketoglutarate. Compared with the prior art, the invention has the advantages of reasonable process, simple steps, easy operation, good crystal form of the obtained product, difficult caking, convenient transportation and use, high purity (more than or equal to 98 percent) and high yield (80-86 percent) of the product, and the like, and is suitable for industrialization production.

Owner:上海汉飞生化科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com