Manufacturingmethod of active humic acid controlled-release fertilizer

The technology of active humic acid and production method is applied in the production field of active humic acid slow-release fertilizer, which can solve the problems of high cost and large pollution, and achieve the effects of low production cost, good effect and large space for total nutrient change.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

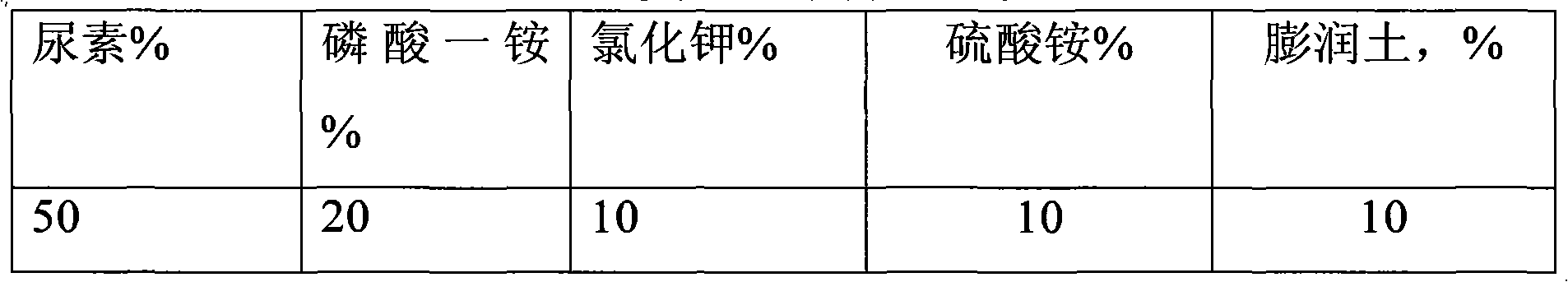

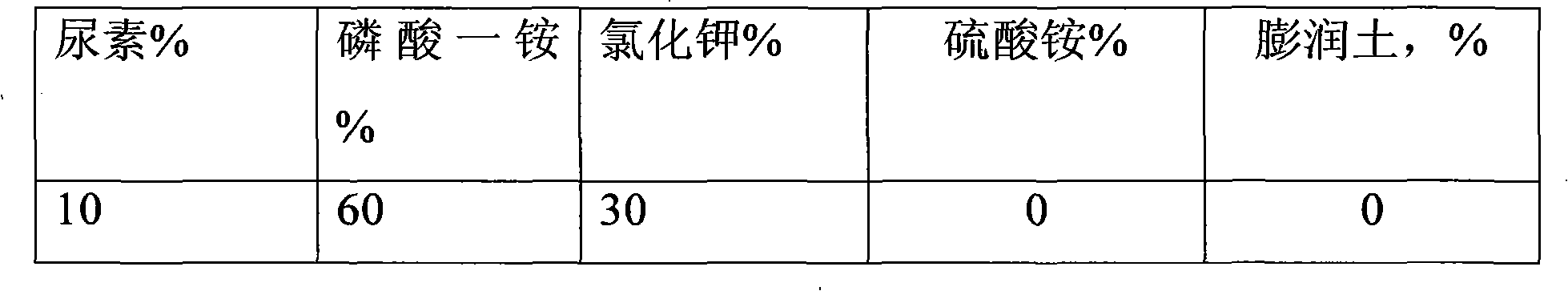

[0027] A preparation method of active humic acid slow-release fertilizer (26-6-6), comprising the following steps:

[0028] a, pulverization of weathered coal raw materials: input weathered coal raw materials (total humic acid content 50%) into the ball mill, and pulverize the raw materials to a particle size of 80 mesh;

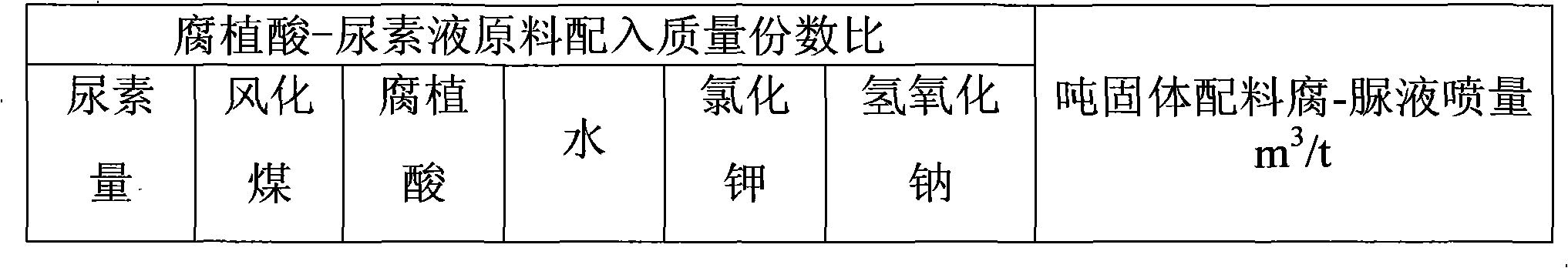

[0029] b, urea melting: powdery or small granular urea is input into the urea-based melting tank, as shown in Table 2: 100 parts by mass of urea is added to 15 parts by mass of water, and 20 parts by mass of powdered potassium chloride is added, and the steam pan is used to Heat the tube to 110°C and stir to make urea-potassium chloride eutectic to form urea liquid;

[0030] c. Humic acid activation: Add the weathered coal raw material prepared in a into another reaction tank, and add a certain amount of sodium hydroxide according to the total humic acid content in the weathered coal, the mass parts of humic acid and sodium hydroxide The ratio is 100:17, th...

specific Embodiment approach 2

[0038] A preparation method of active humic acid slow-release fertilizer (15-17-13), comprising the following steps:

[0039] a, pulverization of lignite raw material: input lignite raw material (total humic acid content 55%) in ball mill, raw material is pulverized to particle size 100 orders;

[0040] b, urea melting: powdery or small granular urea is input into the urea-based melting tank, as shown in Table 2: 100 parts by mass of urea is added to 5 parts by mass of water, and 15 parts by mass of powdered potassium chloride is added, and the steam pan is used to Heat the tube to 130°C and stir to make urea-potassium chloride eutectic to form urea liquid;

[0041] C, humic acid activation: the lignite raw material prepared in a is added in another reaction tank, and a certain amount of sodium hydroxide is added according to its total humic acid content in the lignite, and the mass and number ratio of humic acid and sodium hydroxide is 100:17, detect the urea content in the ...

specific Embodiment approach 3

[0048] A preparation method of active humic acid slow-release fertilizer (14-0-18), comprising the following steps:

[0049] a, pulverization of the mixed coal raw material of weathered coal and lignite: input the mixed raw material of weathered coal and lignite (60% of total humic acid content) into the ball mill, and pulverize the raw material to a particle size of 150 mesh;

[0050] b, urea melting: powdery or small granular urea is input into the urea-based melting tank, as shown in Table 2: 100 parts by mass of urea is added to 10 parts by mass of water, and 18 parts by mass of powdered potassium chloride is added, and the Heat the tube to 120°C and stir to make urea-potassium chloride eutectic to form urea liquid;

[0051]c, humic acid activation: put the coal raw material prepared in a into another reaction tank, and add a certain amount of sodium hydroxide according to its total humic acid content in the coal, and the mass-number ratio of humic acid and sodium hydroxid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com