Patents

Literature

32results about How to "Improve carbonization rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Charcoal fertilizer as well as preparation method and application thereof

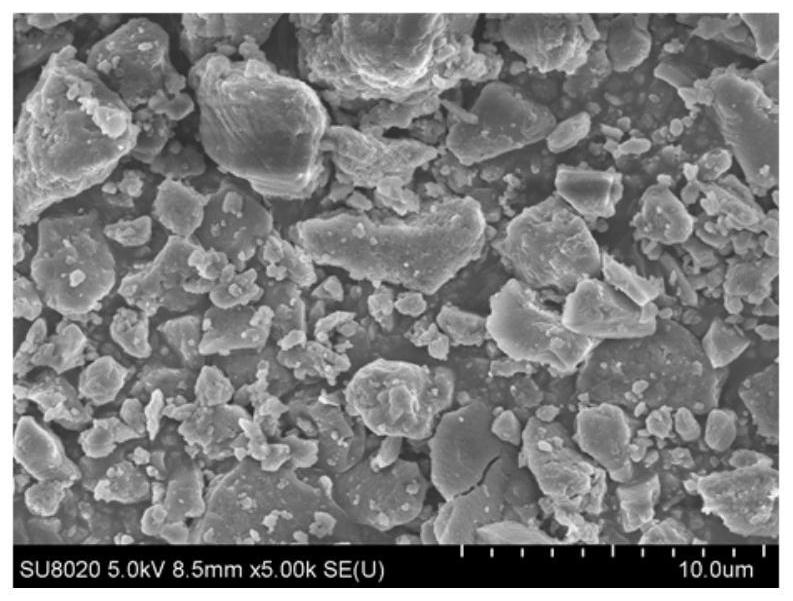

InactiveCN105753546AImprove carbonization rateImprove the carbonization effectAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersAdjuvantCarbonization

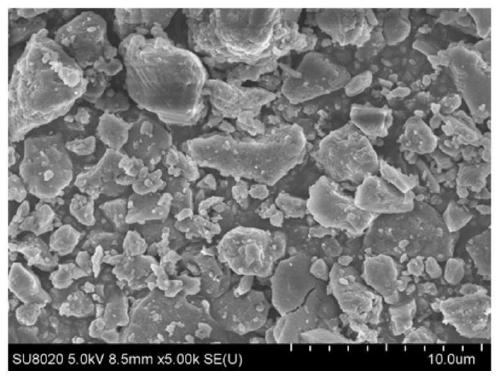

The invention discloses a charcoal fertilizer, prepared from the following raw materials in percentage by weight: 10-50% of charcoal powder, 20-70% of compound fertilizer and 5-30% of adjuvant, wherein the charcoal powder is obtained by putting straws in a carbonization furnace for dehydration and deoxygenation treatment and smashing the straws to a particle size of not more than 0.5mm after high-temperature carbonization. A preparation method of the charcoal fertilizer comprises the following steps: feeding the straws into the carbonization furnace; performing the dehydration and deoxygenation treatment for 1-2 hours at a temperature of 100-250 DEG C; carbonizing the straws at a high temperature of 600-700 DEG C for 30-240min; cooling the carbonized product and then smashing the carbonized product to form the charcoal powder with the particle size of not more than 0.5mm; uniformly mixing the charcoal powder, the compound fertilizer and the adjuvant in proportion to obtain a mixture and then pelleting the mixture to obtain pellets; cooling and screening the pellets to a particle size of 1.5-4.75mm; packing the screened pellets. The charcoal fertilizer disclosed by the invention has the advantages of an extensive source of the raw material straws, a good carbonization effect, high carbon content, conformity with the concept of environmental protection, simplicity in preparation technique, low energy consumption, high product strength and capability of processing the raw materials in a centralized manner and obviously increasing the utilization rate and quality stability of the fertilizer. The invention further discloses an application of the charcoal fertilizer in crop growth.

Owner:SHENZHEN BATIAN ECOTYPIC ENG

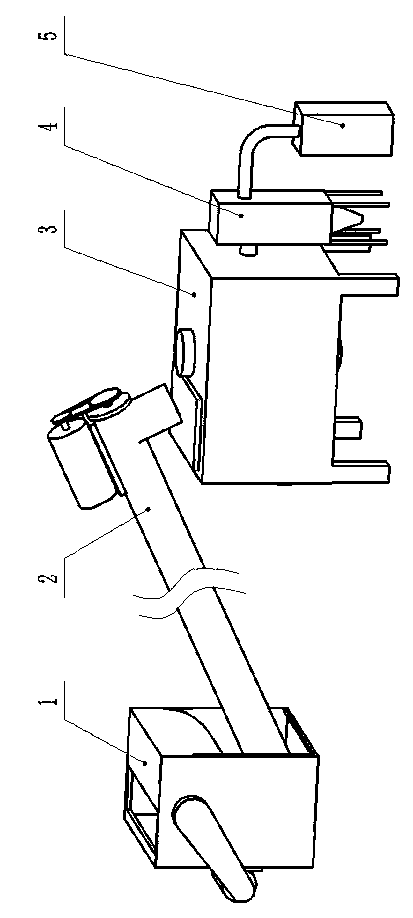

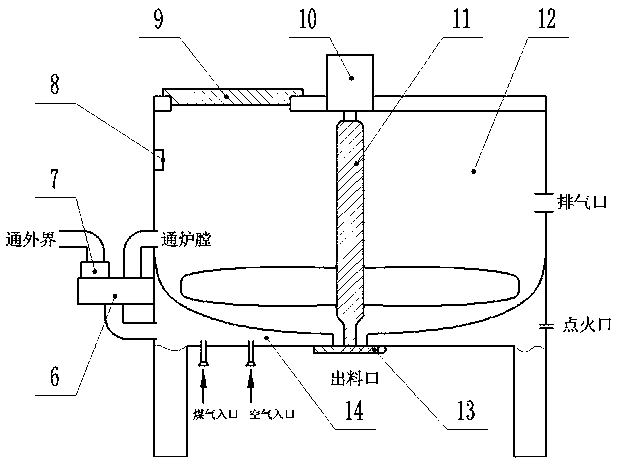

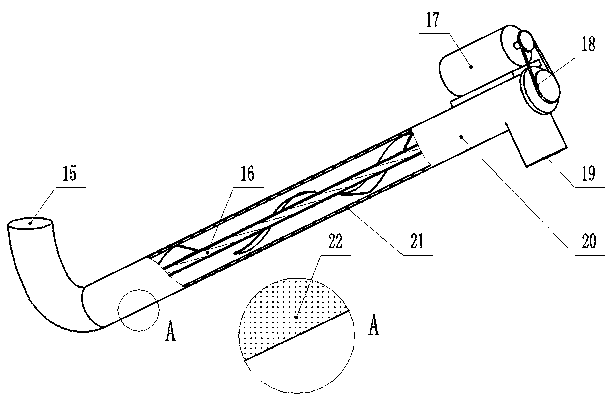

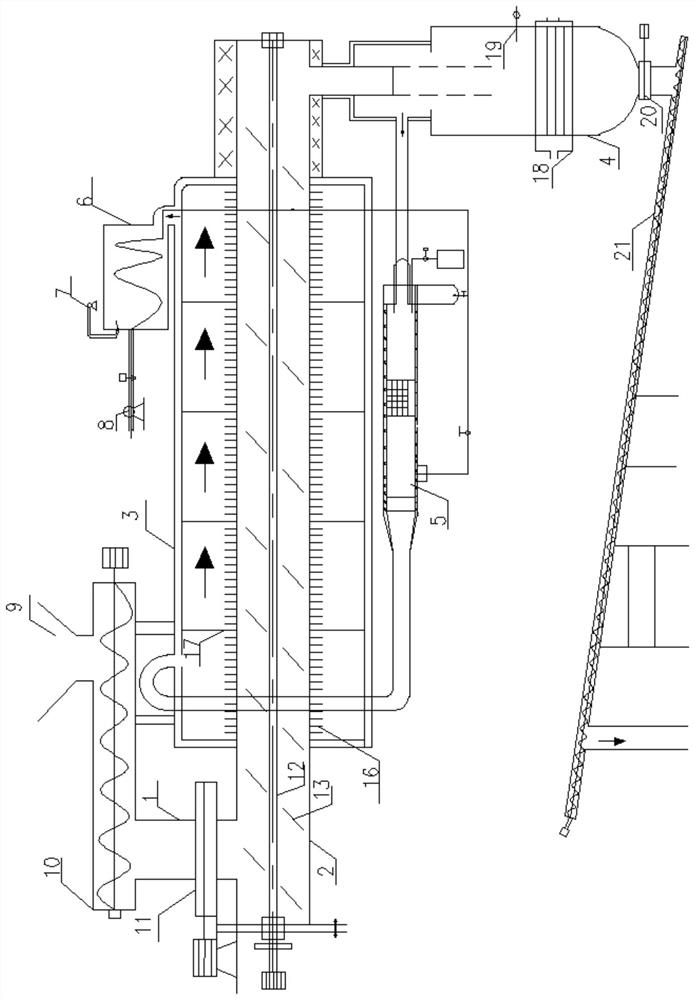

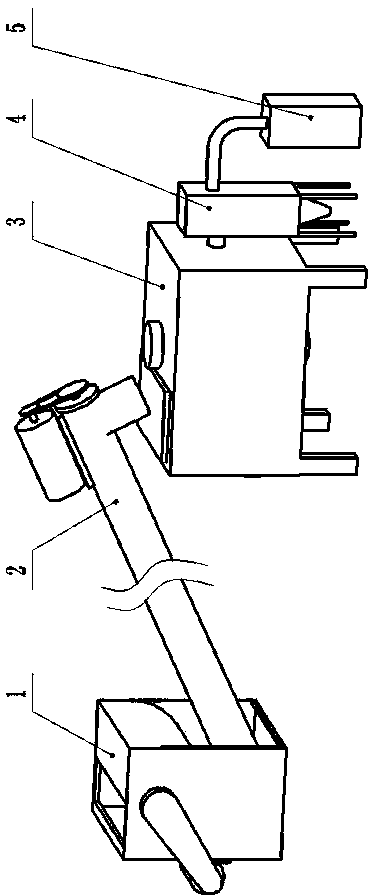

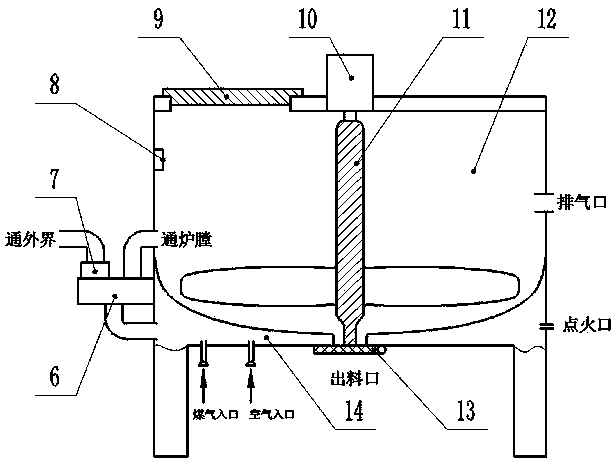

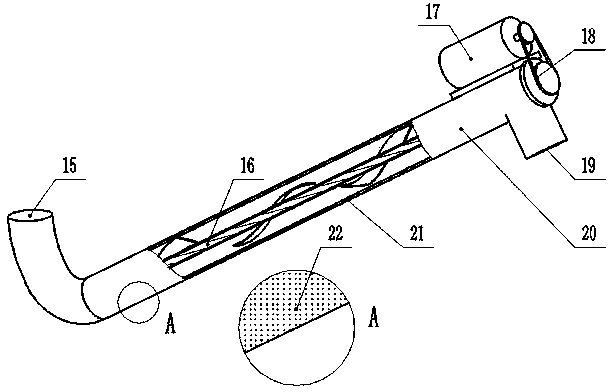

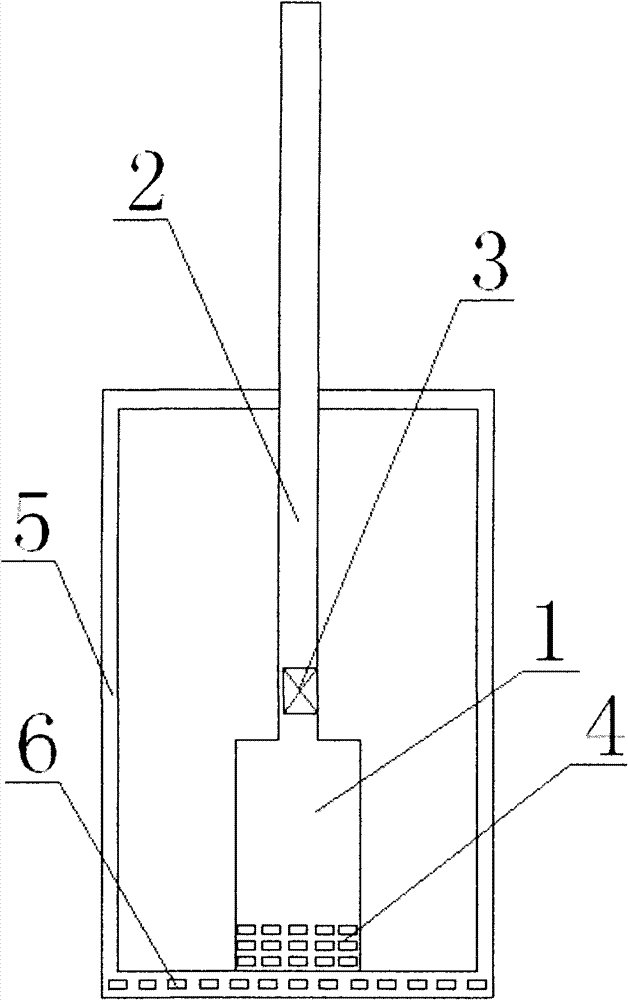

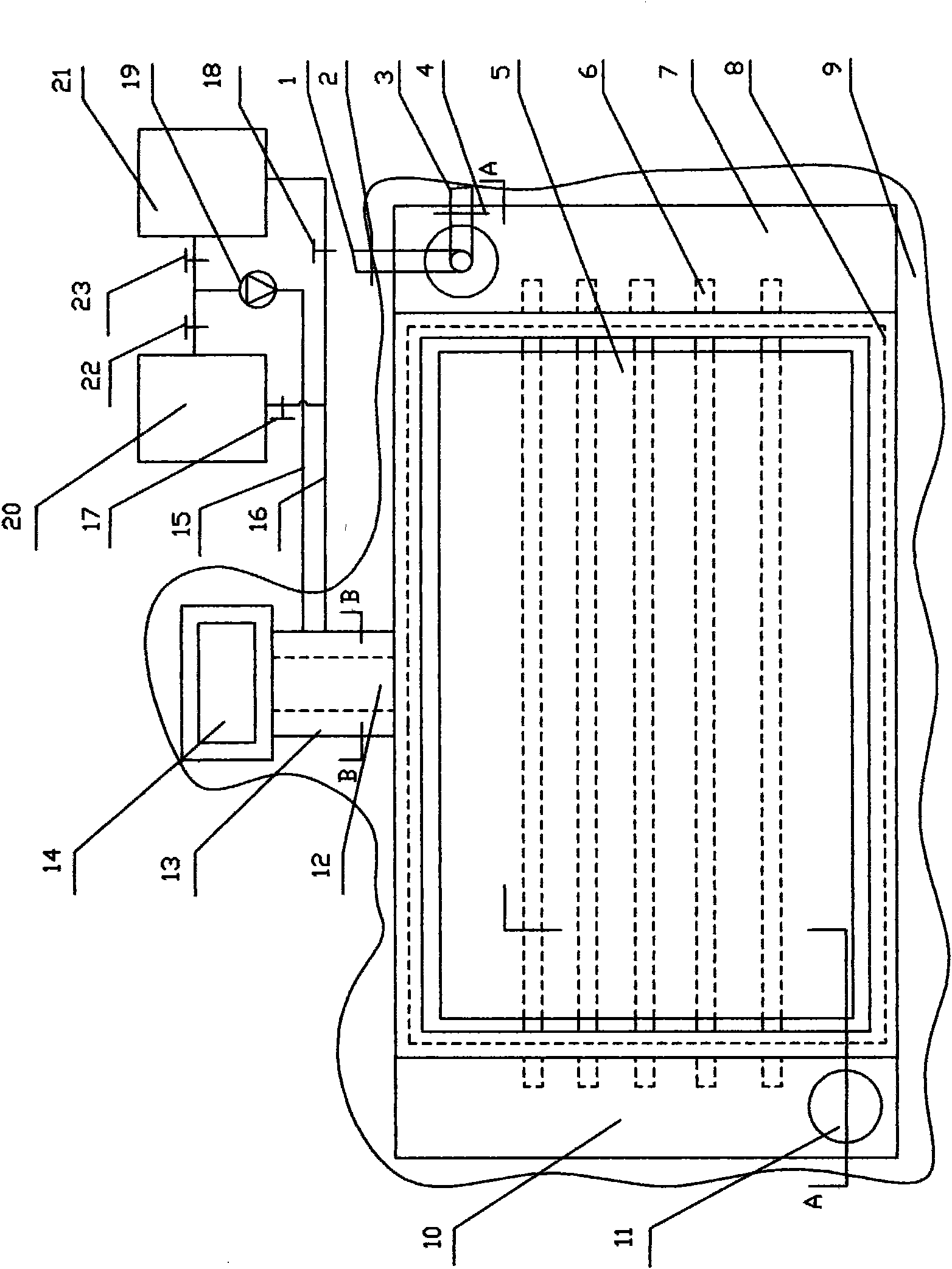

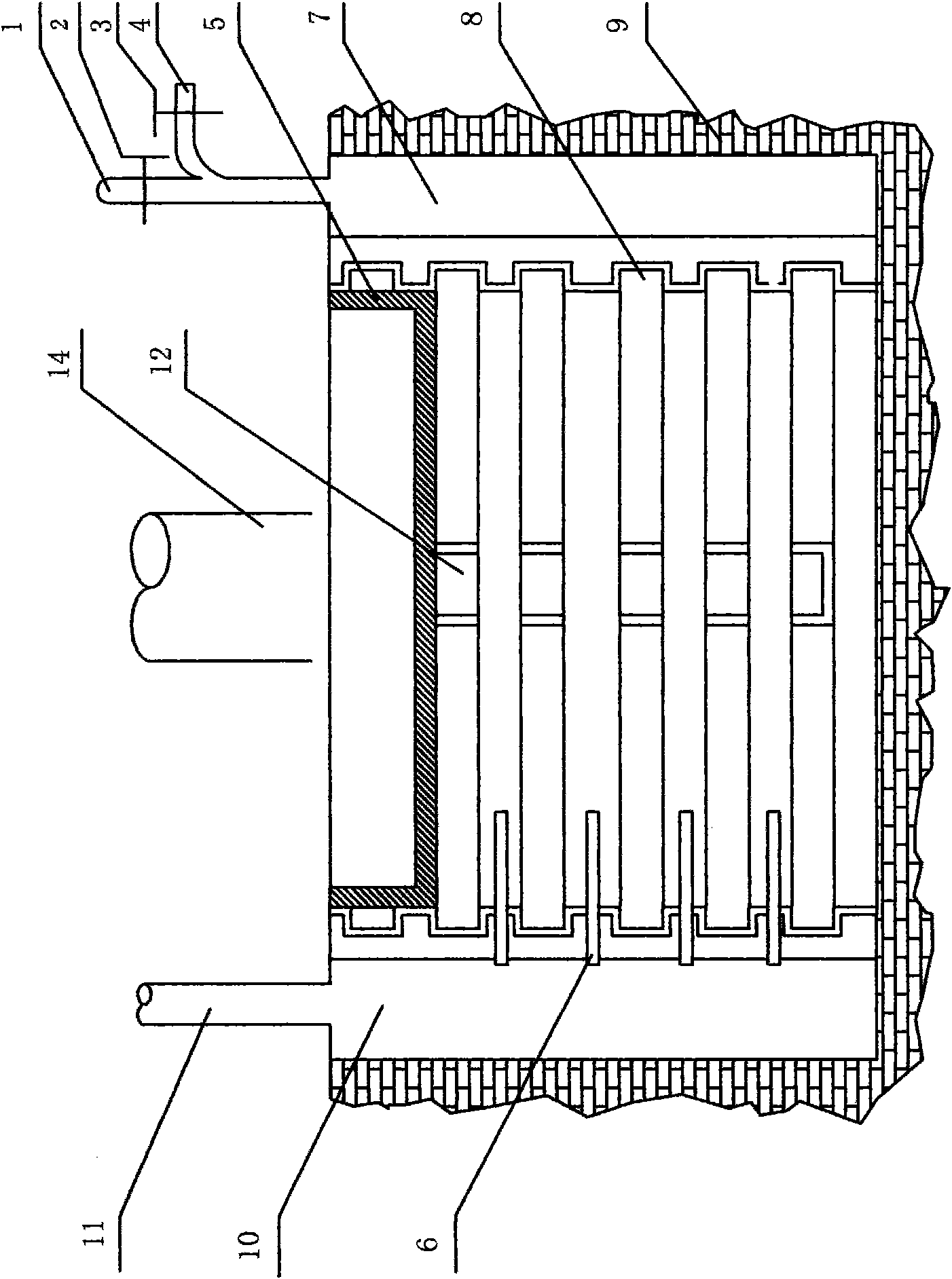

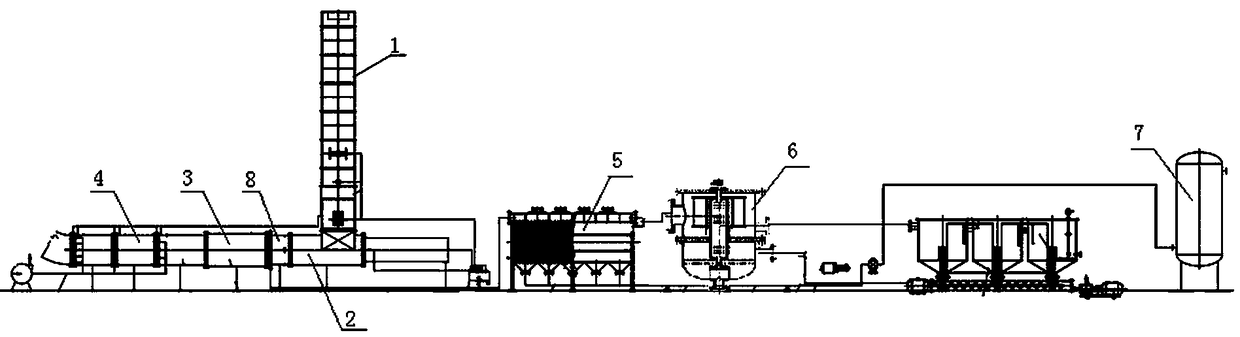

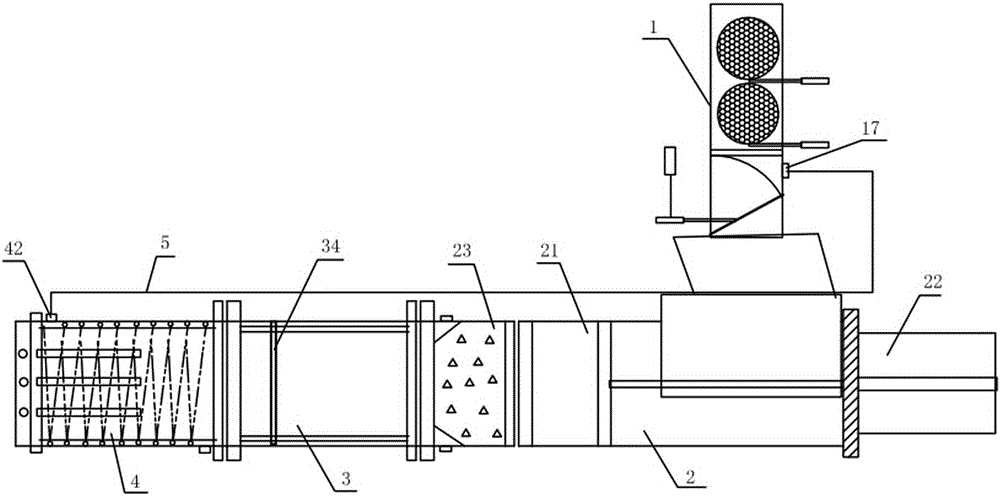

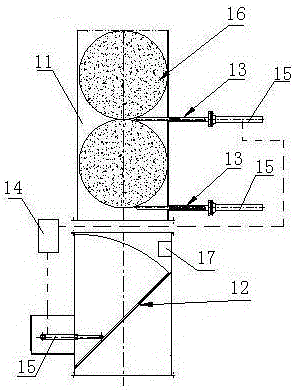

High-efficiency straw carbonization device

InactiveCN103275739AShort carbonization timeImprove efficiencyBiofuelsSpecial form destructive distillationCarbonizationCoke

The invention relates to a high-efficiency straw carbonization device. The high-efficiency straw carbonization device is characterized by comprising a crushing machine (1), an auger drying and conveying mechanism (2), a carbonization furnace (3), coke and dust removal equipment (4) and a gas collecting device (5), wherein straws are firstly crushed by the crushing machine (1) and then fed into the auger drying and conveying mechanism (2); during the conveying process, the crushed straws are quickly dried and then fed into the carbonization furnace (3) for carbonization so as to improve the carbonization efficiency; and dust and gas generated during the carbonization process are respectively collected and processed by the coke and dust removal equipment (4) and the gas collecting device (5) so as to realize zero-pollution emission. The high-efficiency straw carbonization device overcomes the disadvantages that the dehydration and carbonization of raw materials in a traditional carbonization furnace are long in time period and low in efficiency, has the advantages that the structure is reasonable, energy is saved, the environment is protected, the labor force can be reduced and the production efficiency of straw carbonization is improved, and is multipurpose, thus being easy for popularization and use.

Owner:JIANGSU ANXIN BOILER

Biochar fertilizer and preparation method thereof

InactiveCN106316673AImprove yieldImprove carbonization rateAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersOrganic farmingCarbonization

The invention discloses a biochar fertilizer which is prepared from the following raw materials in parts by weight: 60-80 parts of biochar, 20-50 parts of compound fertilizers and 15-25 parts of additives. According to the biochar fertilizer disclosed by the invention, crop straws serve as raw material components, the adopted raw straws are low in cost and highly available in source, are subjected to dehydration and deoxygenation treatment and ground into biochar powder in a high temperature carbonization manner, the carbonization effect is good, the char content is 25% or higher, the carbonization rate of the straws is effectively improved, and the char fertilizer is high in yield, good in fertilization effect and capable of passivating heavy metals in soil and improving the activity of microbes in the soil. Moreover, the fertilizer has large specific surface area, and the content of organic matters in the soil is improved. As a low-cost non-chemical fertilizer, the product disclosed by the invention can provide a yield guarantee for organic agriculture and green agriculture, and the preparation method is simple, controllable and easy to implement.

Owner:刘建伟

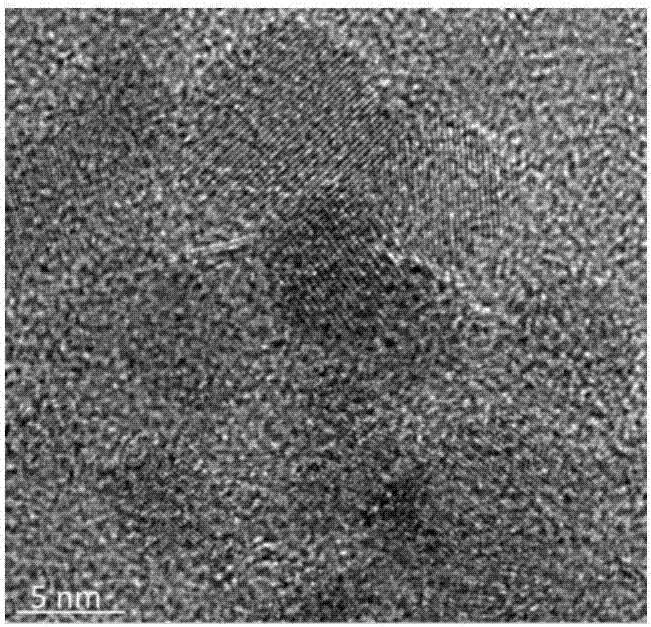

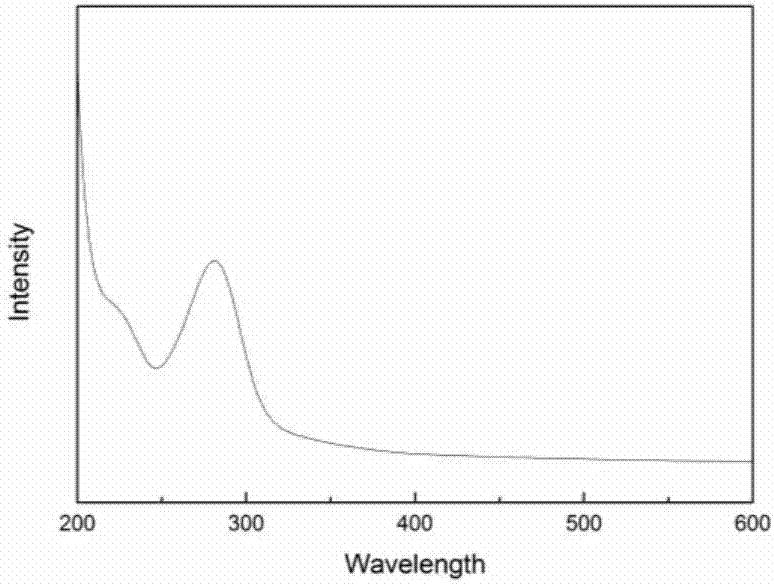

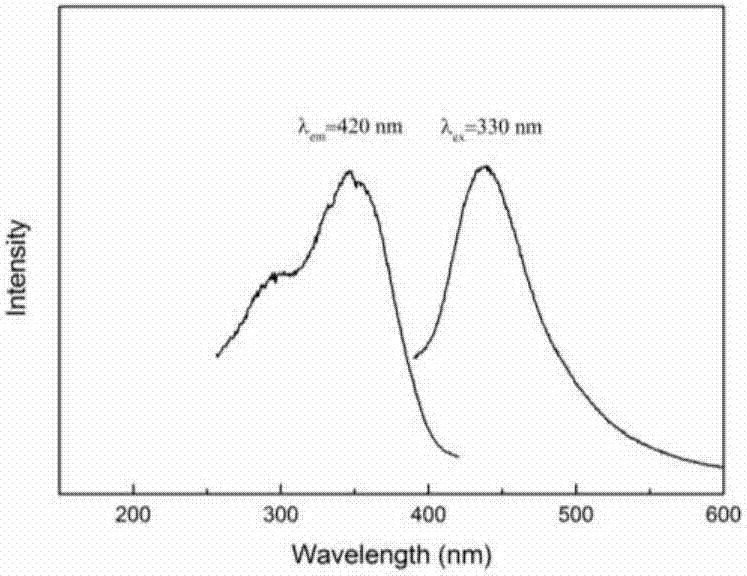

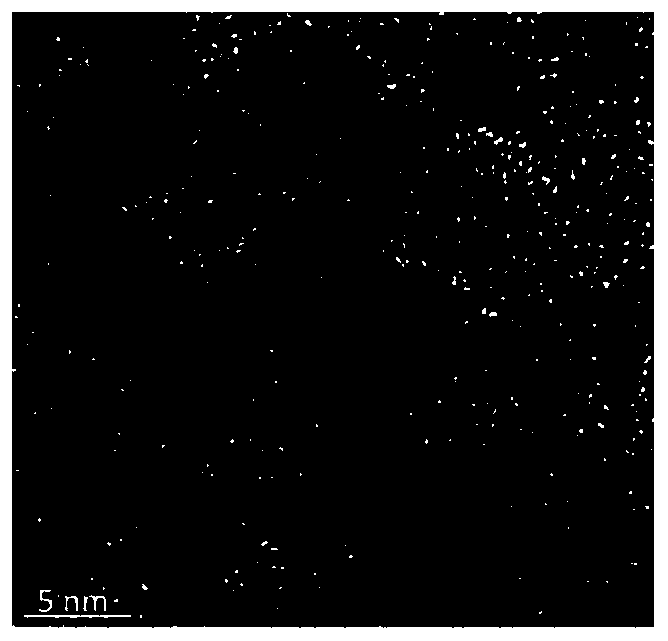

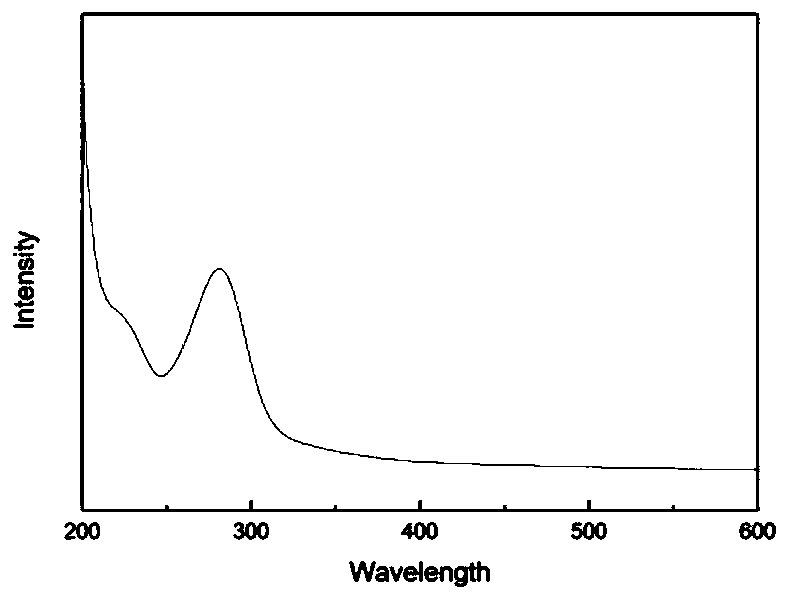

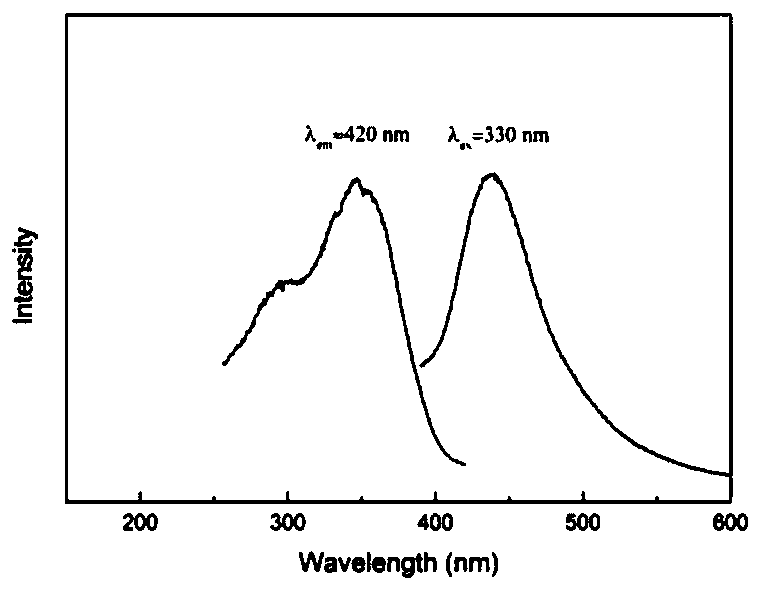

Hydrothermal preparation method of carbon quantum dot used as visible light catalytic photosensitizer

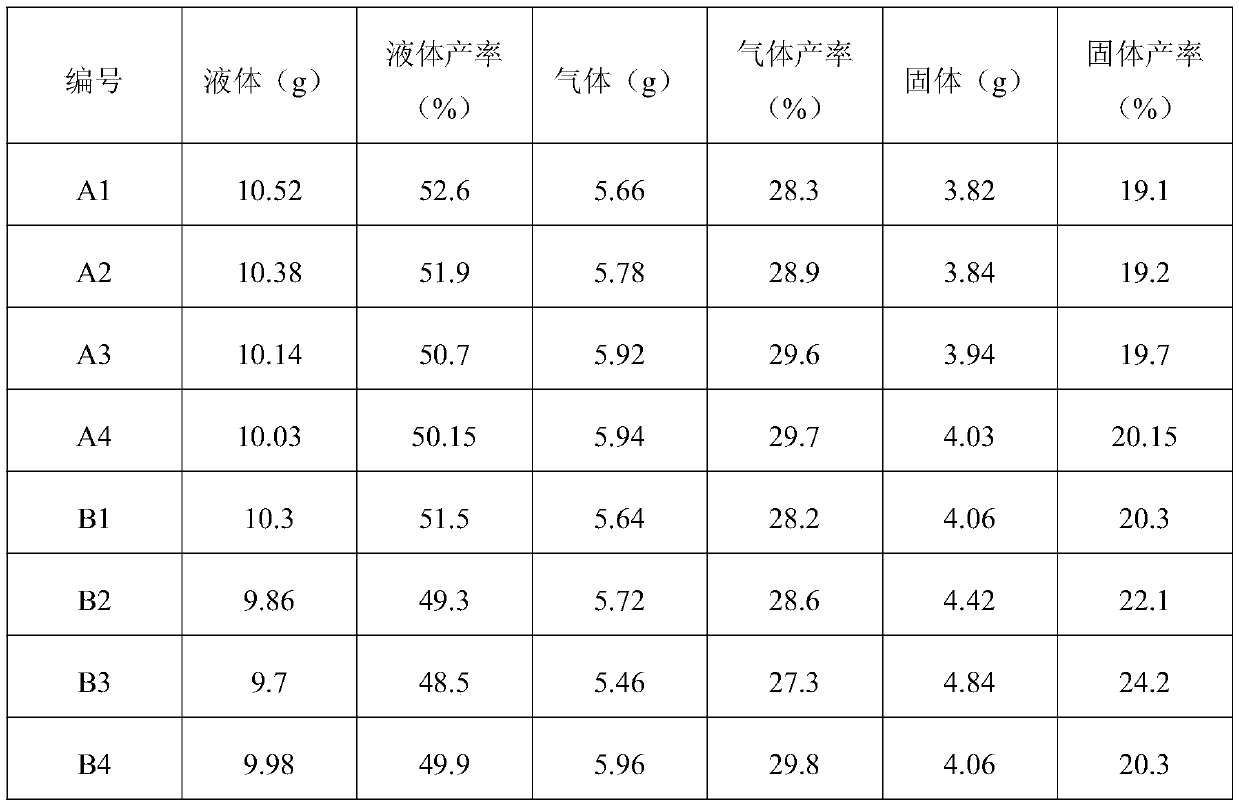

InactiveCN107099287ARich in hemicelluloseRich ligninPhysical/chemical process catalystsNanotechnologyEnvironmental resistanceLiquid product

A hydrothermal preparation method of a carbon quantum dot used as a visible light catalytic photosensitizer is characterized by comprising the following steps: taking larches as raw materials; carrying out high-temperature high-pressure hydrothermal process treatment on the raw materials; centrifugally filtering and removing a dark brown solid product to obtain a light yellow liquid product; centrifuging the liquid product at high speed; controlling centrifugal rotation speed and centrifugal time; removing insoluble small particle impurities; carrying out dialysis by using a certain molecular weight of dialysis bag to remove unreacted sugars, salt contents and the like; then carrying out concentration to obtain a target product, namely a water-soluble fluorescent carbon quantum dot. The water-soluble fluorescent carbon quantum dot is compounded with TiO2 to prepare a photocatalytic composite system; by taking antibiotics as models, photocatalytic degradation performance of the composite system on the model and interaction efficiency of the carbon dot used as the photosensitizer are inspected. The operation process has the main characteristics that larches with rich resources in Heilongjiang province are used as raw materials; the raw materials are environment-friendly, are low in cost and are easy to get; hydrothermal reaction is low in temperature and low in pressure, addition of passivating agents such as acid, alkali and salt is not needed, the product is water-soluble and has a certain fluorescent effect, the reaction process is simple to operate, and the cost is low.

Owner:QINGDAO UNIV OF SCI & TECH

Charcoal fertilizer capable of reducing heavy metal pollution

InactiveCN106278733AImprove yieldImprove carbonization rateOrganic fertilisersUrea compound fertilisersOrganic farmingCarbonization

The invention discloses a charcoal fertilizer capable of reducing heavy metal pollution. The charcoal fertilizer is prepared from the following raw materials in parts by weight: 60-80 parts of charcoal, 10-12 parts of a composite fertilizer, 10-12 parts of fermentation broth and 6-10 parts of additives. The charcoal fertilizer disclosed by the invention adopts crop straw as a raw material component, and the raw material straw is low in cost and easy to obtain, is subjected to dehydration deoxygenation treatment, and is crushed into charcoal powder in a high-temperature carbonization mode, so that a good carbonization effect can be achieved, the carbon content is greater than 25%, the carbonization rate of the straw is effectively increased, the charcoal fertilizer is high in finished product rate and good in application effect, heavy metals in soil can be passivated, and the activity of microorganisms of the soil can be improved. In addition, the charcoal fertilizer is relatively large in specific surface area, and the content of organic matters in the soil can be increased; as a low-cost non-chemical fertilizer, the charcoal fertilizer disclosed by the invention is capable of ensuring the yield of organic agriculture and green agriculture, and is simple in preparation method, good in controllability and easy to apply.

Owner:刘建伟

Method for producing biomass forming carbon

The invention discloses a method for producing biomass forming carbon, and belongs to the technical field of renewable energy. The method comprises the following steps: A, preparing 160-240 parts of an agricultural waste by-product, 96-145 parts by weight of an adhesive, 6-24 parts by weight of a combustion improver, 4-15 parts by weight of a smoke suppressor, and 130-190 parts by weight of water; at first, stoving the agricultural waste by-product for 2-4 hours, and then placing the stoved agricultural waste by-product in a carbonization furnace for carbonizing for 6-9 hours to obtain a carbonized material; B, grinding the carbonized material obtained in the step A, sieving the carbonized material to be 50 meshes, and obtaining biomass carbonize powder, and uniformly mixing the biomass carbonize powder, the adhesive, the combustion improver, the smoke suppressor and the water to obtain a mixed material; C, placing the mixed material, obtained in the step B, in the carbonization furnace and igniting, standing for 3-5 hours, curing and conducting compression moulding, and obtaining forming carbon. Compared with the prior art, the biomass forming carbon, produced according to the method, is short in carbonization furnace time, has no pollution to the environment, and is high in carton content, and high in heating value.

Owner:钟诚

Biological carbon fertilizer

InactiveCN106116980AImprove yieldImprove carbonization rateExcrement fertilisersBioloigcal waste fertilisersBiotechnologyOrganic farming

The invention discloses biological carbon fertilizer, prepared form the following raw materials in parts by weight: 30-60 parts of biological carbon powder, 20-30 parts of human and animal excreta, 4-8 parts of waste molasses and 15-25 parts of additive. The biological carbon fertilizer disclosed by the invention takes crop straw as a feed composition; the straw adopted as a raw material by the biological carbon fertilizer has low cost and easily available source and is pulverized to form the biological carbon powder through dehydration and deaeration treatment and high temperature carbonization; the carbonization effect is good, the carbon content is greater than 25%, the carbonization rate of the straw is effectively improved; and the carbon fertilizer has high yield and good application effect, and can passivate heavy metal in soil and improve the activity of soil microbes. Meanwhile, the carbon fertilizer has a greater specific area and improves the organic content of soil; as low-cost non-chemical fertilizer, the product disclosed by the invention can provide a guarantee for organic agriculture and green agriculture; and the preparation method is simple, controllable and easy to implement.

Owner:刘建伟

Biochar fertilizer with effect of balancing fertilizer-water distribution

InactiveCN106365713AImprove yieldImprove carbonization rateBio-organic fraction processingAnimal corpse fertilisersOrganic farmingSoil heavy metals

The invention discloses biochar fertilizer with the effect of balancing fertilizer-water distribution. The biochar fertilizer is prepared from 60-80 parts by weight of biochar, 20-40 parts by weight of composite fertilizer, 10-20 parts by weight of a broth and 15-25 parts by weight of additives. The biochar fertilizer utilizes crop straws as raw material components. The straw raw materials have a low cost and are easily available. Through dehydration and deoxygenation treatment and high temperature charring crushing, biochar powder is obtained. The biochar fertilizer has good charring effects and char content of 25% or more. A straw charring rate is high, a char fertilizer yield is high, use effects are good, and the biochar fertilizer can passivate soil heavy metals and improve soil microbe vitality. The biochar fertilizer has a large specific surface area, improves soil organic matter content, can be used as low cost non-chemical fertilizer and guarantees yields in organic agriculture and green agriculture. The preparation method of the biochar fertilizer has simple processes, is controllable and can be implemented easily.

Owner:刘建伟

Biological activated carbon fertilizer for reducing nutrient loss

InactiveCN106316675AImprove yieldImprove carbonization rateMagnesium fertilisersAlkali orthophosphate fertiliserOrganic farmingCarbonization

The invention discloses a biological activated carbon fertilizer for reducing nutrient loss. The biological activated carbon fertilizer is prepared from the following materials in parts by weight: 60-80 parts of biological activated carbon, 20-40 parts of a compound fertilizer, 10-20 parts of fermentation liquor, and 15-25 parts of an additive. The biological activated carbon fertilizer takes a crop straw as a material component, the used crop straw is low in cost and easy to get, is subjected to dehydration and deoxygenation, and is crushed into a biological activated carbon powder through a high temperature carbonization method, the carbonization effect is good, the carbon content is more than 25%, the carbonization rate of the straw is effectively improved, the rate of a finished product of the carbon fertilizer is high, the application effect is good, a heavy metal in the soil is passivated, and the activity of microorganisms in the soil is improved. The biological activated carbon fertilizer has a larger specific surface area, and the content of organic matters in the soil is increased; as a low-cost non-chemical fertilizer, the product guarantees the yield in organic agriculture and green agriculture, and a preparation method is simple, controllable and easy to implement.

Owner:刘建伟

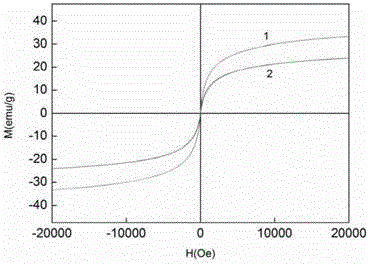

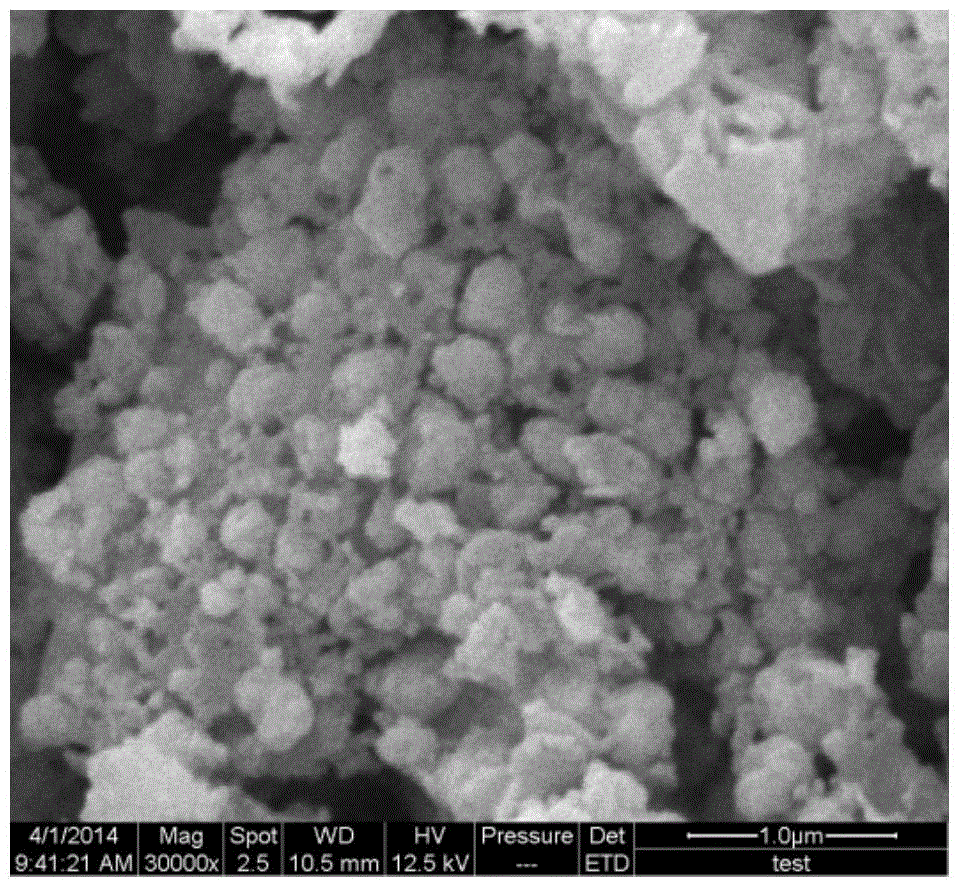

Hydrothermal preparation method of magnetic carbon micro-spheres

InactiveCN104437362AAbundant and cheap raw materialsNo pollution in the processOther chemical processesWater contaminantsMicrosphereCarbonization

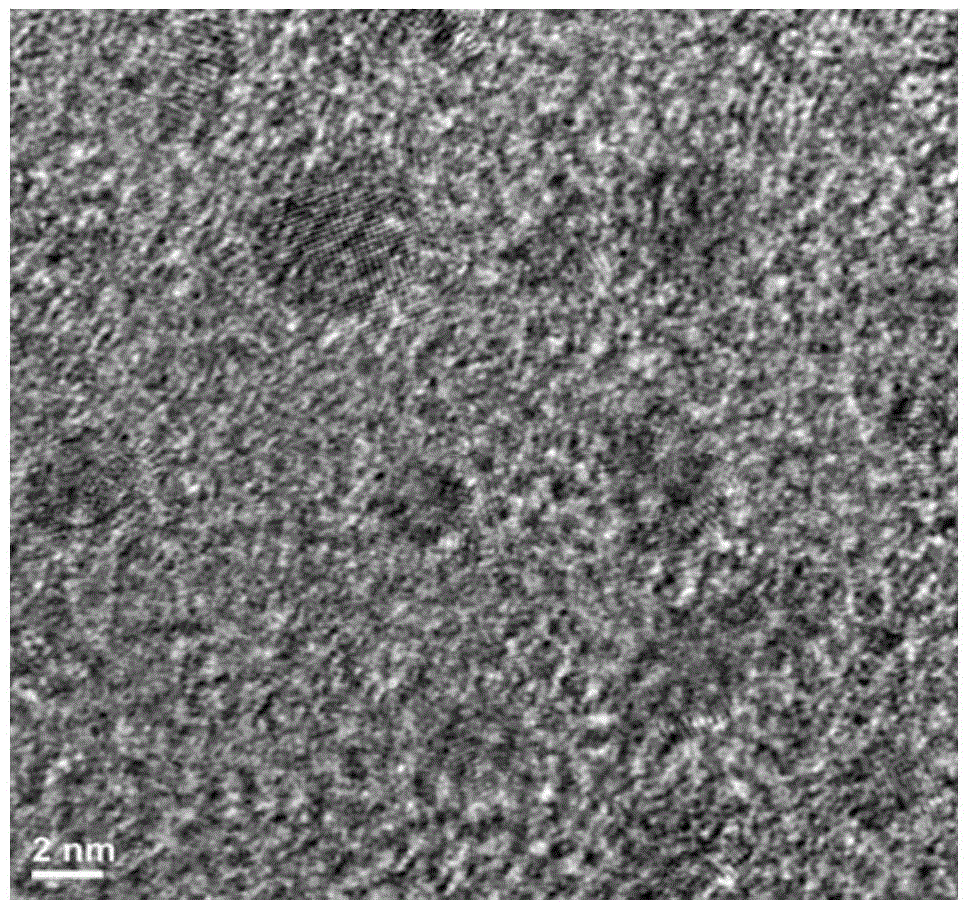

The invention provides a hydrothermal preparation method of magnetic carbon micro-spheres. The hydrothermal preparation method is characterized by comprising the following steps: with microcrystalline cellulose as a raw material, distilled water as a solvent and nickel acetate tetrahydrate as a nickel source, carrying out high-temperature and high-pressure hydrothermal treatment; then centrifugally separating to obtain a dark brown solid product; and drying the dark brown solid product at a constant temperature and carrying out high-temperature activation and carbonization on the obtained product under the protection of nitrogen gas to obtain the magnetic micro-spheres which are doped with metal nickel and have an ordered developed pore structure and a good paramagnetic property. The operation process has the main characteristics that the cheap microcrystalline cellulose is used as the raw material; and after high-temperature activation treatment, nickel exists in a stable form of coexistence of metal nickel and nickel oxide, and the paramagnetic carbon micro-spheres with high specific surface area and the developed pore structure are generated. A prepared sample has a relatively high adsorption capability on Cd<2+> in wastewater, and the carbon micro-spheres can be recycled from a solution by a magnet, so that the carbon micro-spheres are suitable for a solution system; and meanwhile, the preparation method is simple and the performance of the carbon micro-spheres is excellent.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

Organic fertilizer for camellia oleifera planting and preparation method thereof

InactiveCN109232116AIncrease productionPromote growth and developmentCalcareous fertilisersAnimal corpse fertilisersBiotechnologyCamellia oleifera

The invention discloses organic fertilizer for camellia oleifera planting. The organic fertilizer is prepared from the following raw materials in parts by weight: 30-40 parts of peanut cake, 20-25 parts of fermented soybean curb residue, 15-20 parts of vegetable waste, 10-20 parts of sweet potato vine ash, 5-15 parts of mushroom residue, 15-20 parts of biocarbon, 13-18 parts of white fungus leftover, 6-10 parts of carbonized bark, 20-30 parts of cow dung, 10-15 parts of grass ash, 5-13 parts of nano zeolite, 3-7 parts of nano bentonite, 10-15 parts of egg shell powder, 5-10 parts of vinegar residue, 11-16 parts of herba menthae extract liquid, 6-10 parts of fructus forsythiae extract liquid, 5-10 parts of cortex cinnamomi oil, 3-7 parts of a fermenting agent, 3-8 parts of a compound biological bacterial preparation, 5-10 parts of silkworm excrement, 3-6 parts of amino acid chelated microelement and 1-2 parts of borax. The organic fertilizer provides a great amount of nutrient elementsneed by growth of camellia oleifera, not only can improve the yield of camellia oleifera seeds, but also can improve a soil structure.

Owner:桐城市宜春油茶种植专业合作社

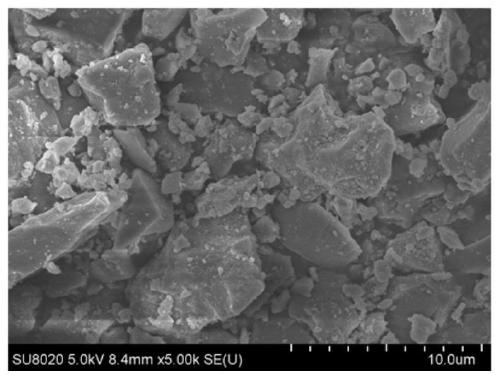

Plant type biochar adsorbing heavy metal Cd in water body and preparation method and application of biochar

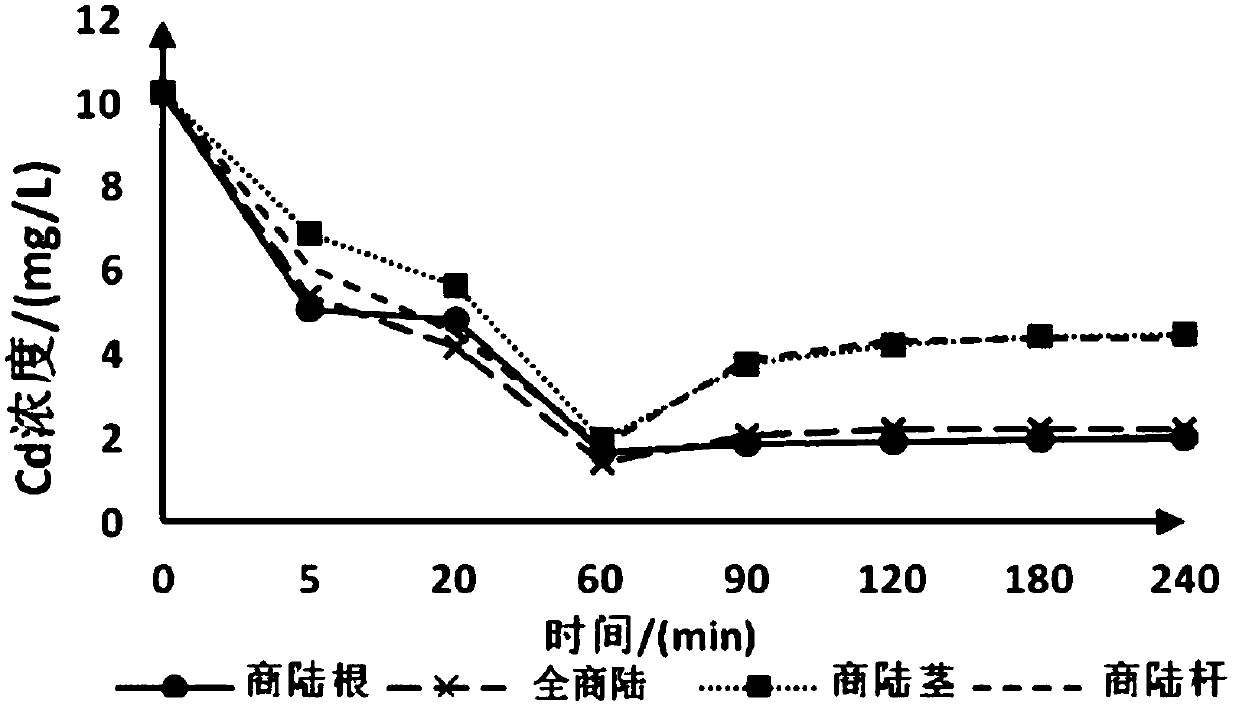

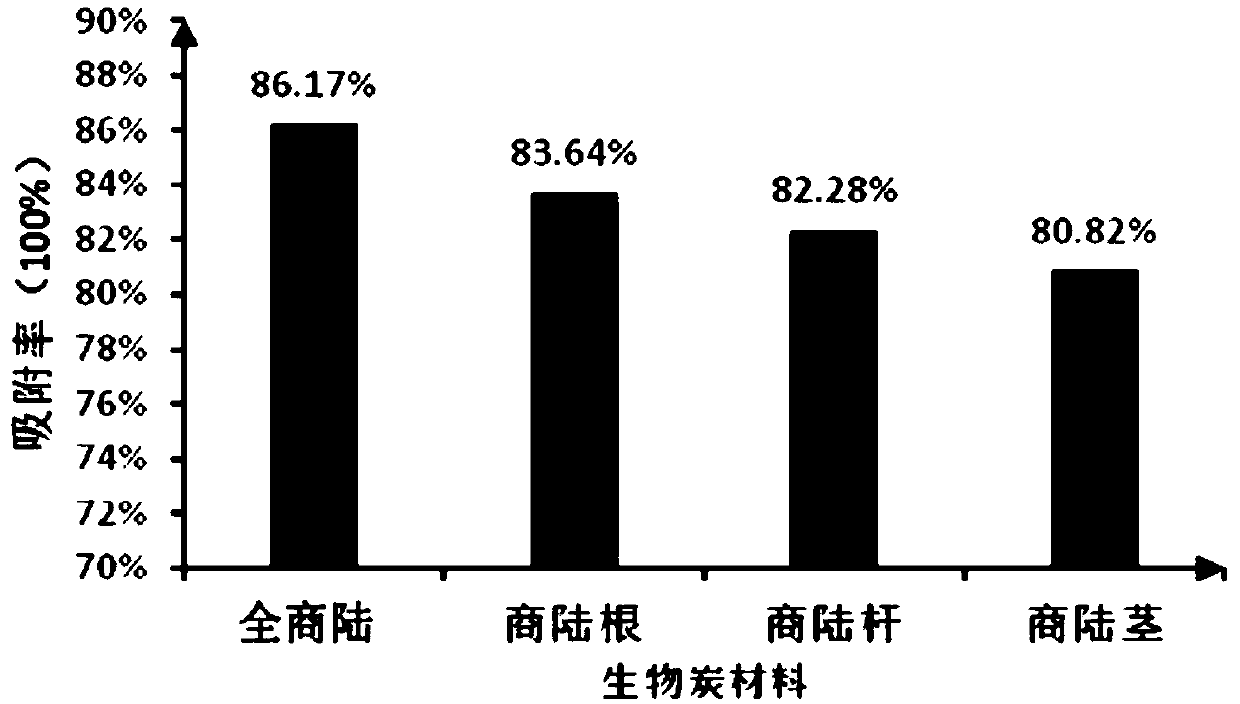

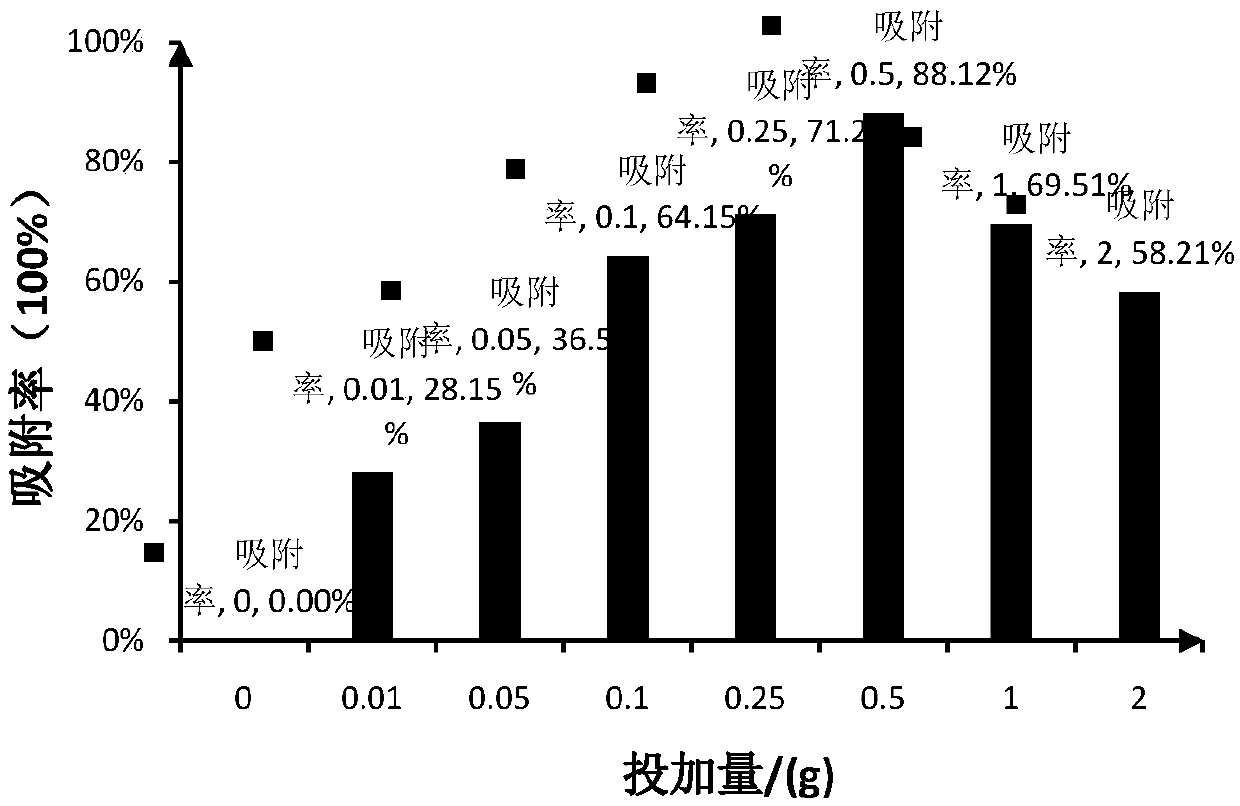

InactiveCN109621900AGood removal effectRealize resource utilizationOther chemical processesWater contaminantsCarbonizationAdsorption effect

The invention discloses a plant type biochar adsorbing heavy metal Cd in a water body and a preparation method and application of the biochar, and belongs to the field of plant type biochar preparation. The method comprises the steps that weed plant-radix phytolaccae serves as a raw material, fresh plants are subjected to crushing, drying, soil burying and compacting, high-temperature carbonizing,cooling and drying, impurity removing, grinding and sieving, and the plant type biochar is obtained. The biochar carbonization rate is high and can reach 36.70%. It has good adsorption effect on heavy metal Cd, and the adsorption rate can reach 90.16%. In addition, solid-liquid separation is conducted with waste water obtained after treatment. Raw materials are low in price and easy to obtain, and the weed plants without economic value are recycled, and an efficient, clean and inexpensive method is provided for removing heavy metal Cd-contaminated water body.

Owner:LIAONING UNIVERSITY

Method for preparing water-soluble fluorescent carbon nanoparticle dots

InactiveCN103833004AAbundant and cheap raw materialsNo pollution in the processOther chemical processesNanoopticsLiquid productSorbent

The invention provides a method for preparing water-soluble fluorescent carbon nanoparticle dots. The method is characterized by comprising the following steps: using a high temperature and high pressure hydrothermal method for treating pentosan which is obtained by using an alkaline process for extracting bleached broad leaf pulp and serves as a raw material, filtering so as to obtain a pale yellow liquid product and a dark brown solid product, wherein the solid product is used as a high-performance adsorbent for adsorption of heavy metal ions Pb (II) and Cd (II), centrifuging the pale yellow liquid product at a high speed, controlling centrifugal rotating speed and time, removing insoluble solids, removing components such as unreacted sugar and salts by using a dialysis bag, and concentrating so as to obtain the water-soluble fluorescent carbon nanoparticle dots. The operation technology has the main characteristics that the pentosan obtained by extracting pulping and papermaking byproducts is used as the raw material and is environmentally friendly, low in cost and easy to obtain, acid-base salts such as passivator do not need to be added during reaction, the product has good water solubility and fluorescent effect, the hydrothermal reaction process is simple to operate, and the cost is low.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

Insect preventing and bacteria inhibiting dedicated organic fertilizer for camellia oleifera planting and preparation method thereof

InactiveCN109232115AIncrease productionPromote growth and developmentBio-organic fraction processingAnimal corpse fertilisersCamellia oleiferaRapeseed

The invention discloses insect preventing and bacteria inhibiting dedicated organic fertilizer for camellia oleifera planting. The fertilizer is prepared from the following raw materials in parts by weight: 30 to 40 parts of tea dregs, 20 to 25 pars of fermented soybean, 15 to 20 parts of pomace, 10 to 20 parts of sweet potato vine ash, 5 to 15 parts of mushroom dregs, 15 to 20 parts of charcoal,13 to 18 parts of kelp leftovers, 6 to 10 parts of carbonized fruit tree branches, 20 to 30 parts of chicken manure, 10 to 15 parts of plant ash, 5 to 13 parts of vermiculite, 3 to 7 parts of nano medical stone, 10 to 15 parts of clam shell powder, 5 to 10 parts of distillers' grains, 11 to 16 parts of herba violae extracting solution, 6 to 10 parts of pyrethrum extracting solution, 5 to 10 partsof lime, 1 to 2 parts of wormwood powder, 3 to 7 parts of a fermenting agent, 3 to 8 parts of a compound biological bacteria preparation, 5 to 10 parts of rapeseed cake, 3 to 6 parts of powdered rockphosphate and 1 to 2 parts of microelements. The organic fertilizer disclosed by the invention can provide a lot of nutrients for camellia oleifera growth, can improve camellia seed yield and can improve soil structure.

Owner:桐城市宜春油茶种植专业合作社

Biological carbon fertilizer capable of promoting fertilizer efficiency

InactiveCN106316513AImprove yieldImprove carbonization rateAlkali orthophosphate fertiliserAmmonium orthophosphate fertilisersMicroorganismOrganic farming

The invention discloses a biological carbon fertilizer capable of promoting fertilizer efficiency. The biological carbon fertilizer is characterized by being prepared from the following raw materials in parts by weight: 60 to 80kg of biological carbon, 10 to 12kg of urea, 10 to 12kg of diammonium phosphate, 10 to 12kg of potassium sulphate and 6 to 10kg of additives. According to the invention, the biological carbon fertilizer takes crop straw as raw material components, and the straws used as the raw materials are low in cost and readily available in sources, and crushed into biological carbon powder through dehydration and deoxygenation and a way of high-temperature carbonization, the carbonization effect is good, and the carbon content is more than 25%, so that the straw carbonization rate is effectively improved, the carbon fertilizer is high in yield, the application effect is good, and heavy metals in soil can be passivated to improve the activity of soil microorganisms. The biological carbon fertilizer has a larger specific surface area and improves the organic matter content in the soil; as the low-cost non-chemical fertilizer, the product of the invention can provide a guarantee on yields of organic agriculture and green agriculture, and is further simple in preparation method, controllable and easy in implementation.

Owner:刘建伟

Separation method of oily sludge and application of sludge impurities to preparation of active carbon

ActiveCN109761469AAggregation increasedHigh degree of separationWaste water treatment from quariesCarbon compoundsGas phaseSludge

The invention provides a separation method of oily sludge and application of sludge impurities to preparation of active carbon. The separation method comprises the following steps of (1) pretreating the oily sludge: putting the oily sludge under microwave conditions for microwave treatment; performing demulsification treatment and dewatering on the oily sludge subjected to microwave treatment to obtain pretreated oily sludge; (2) separating the oily sludge: in a nitrogen environment, putting the pretreated oily sludge under heating conditions; performing dry distillation; respectively collecting gas phase and impurities after dry distillation. The application concretely comprises the steps of under the existence condition of activating agents, under the inert gas protection conditions, putting the impurities after the dry distillation under the temperature condition of 280 to 350 DEG C; performing pre-activation for 20 to 30 min; then, performing activation for 1 to 2 h under the temperature condition of 700 to 850 DEG C to obtain the high specific area active carbon. The separation method achieves the effects that the separation effect is good; the separated impurities can be effectively utilized.

Owner:东营市康杰化工科技发展有限责任公司

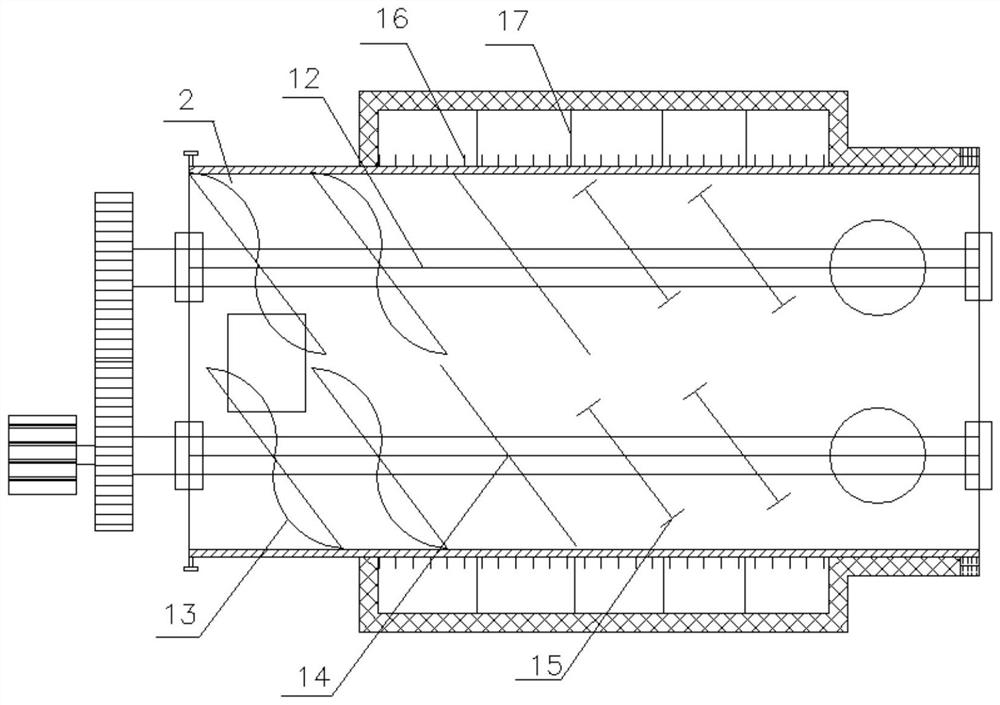

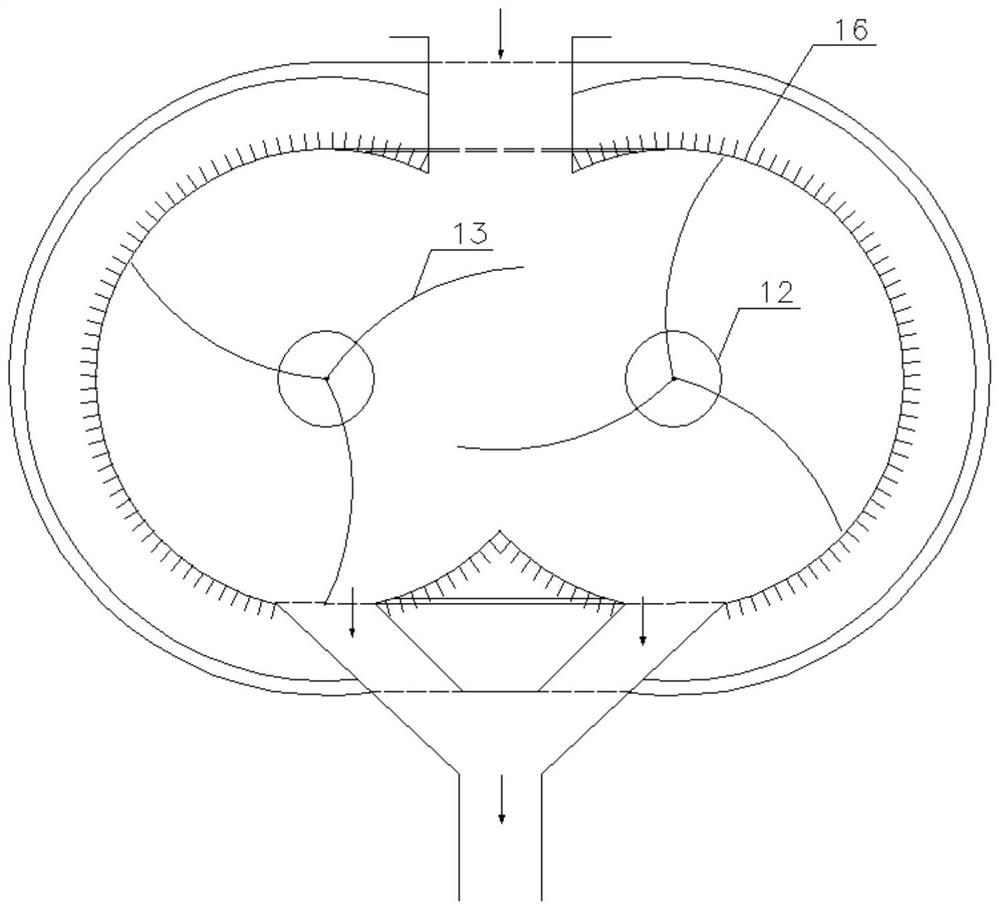

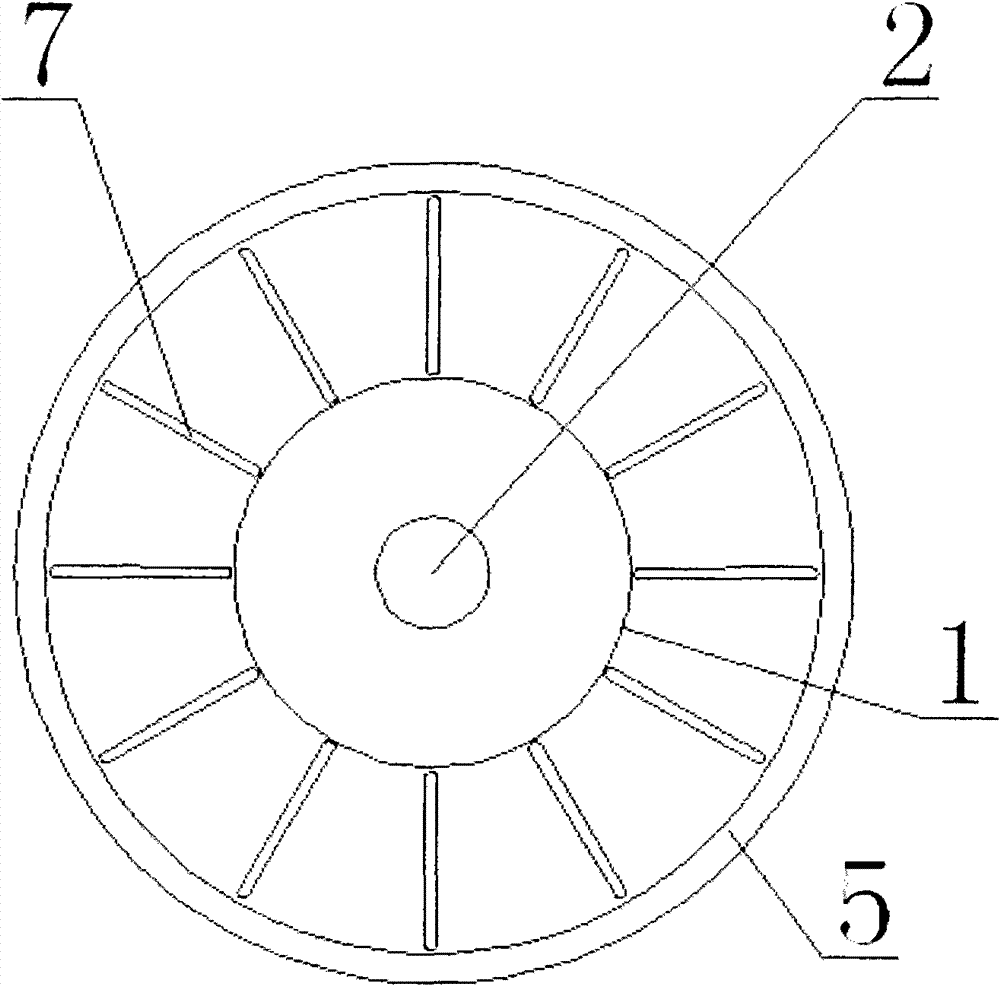

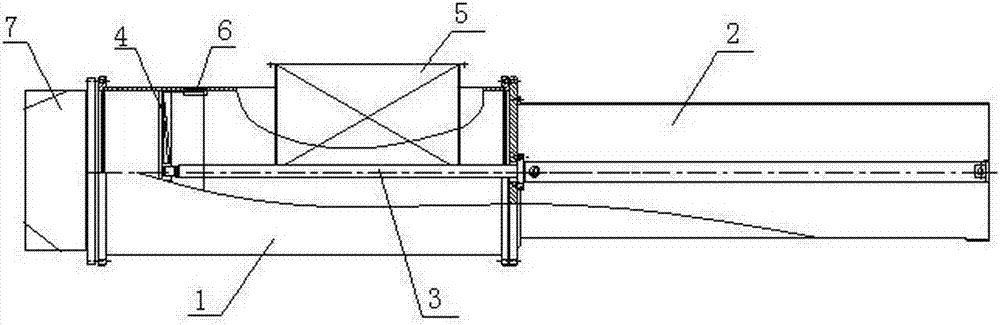

Biomass continuous pyrolysis carbonization device and biomass continuous pyrolysis carbonization method

InactiveCN112266797AIncrease the heating areaImprove heating efficiencyBiofuelsSpecial form destructive distillationCarbonizationProcess engineering

The invention relates to a biomass continuous pyrolysis carbonization device and a biomass continuous pyrolysis carbonization method, and belongs to the field of environmental protection and resourceutilization. The device comprises a pyrolysis carbonization chamber, wherein the cross section of the pyrolysis carbonization chamber is in a shape similar to a horizontal 8 shape formed by butting two C-shaped cylinders, the two C-shaped cylinders communicate with each other, a respective rotating shaft is arranged in each C-shaped cylinder, and a pushing blade, a stirring blade and a wall scraping blade are arranged on each rotating shaft. The device is compact, short in technological process, small in occupied area, high in production efficiency and free of emission of three wastes, and heat energy can be effectively utilized.

Owner:DALIAN MARITIME UNIVERSITY

High-efficiency straw carbonization device

InactiveCN103275739BShort carbonization timeImprove efficiencyBiofuelsSpecial form destructive distillationThermodynamicsCarbonization

A high-efficiency straw carbonization device, characterized in that it includes a pulverizer (1), an auger drying and conveying mechanism (2), a carbonization furnace (3), decoking and dust removal equipment (4) and a gas collection device (5), the straw After being pulverized by the pulverizer (1), it is sent to the auger drying and conveying mechanism (2). During the transportation process, the crushed straw is quickly dried and then sent to the carbonization furnace (3) for carbonization to improve the carbonization efficiency. The dust and gas generated during the carbonization process are collected and processed by the decoking and Xu dust equipment (4) and the gas collection device (5) respectively to achieve zero pollution discharge. The invention overcomes the long time cycle and low efficiency of raw material dehydration and carbonization in traditional carbonization furnaces, has the advantages of reasonable structure, energy saving and environmental protection, can reduce labor force, and improves straw carbonization production efficiency, realizes multiple purposes, and is easy to popularize and use.

Owner:JIANGSU ANXIN BOILER

Microwave-enhanced biomass carbonization treatment method

ActiveCN111484863ARich sourcesImprove thermal stabilityBiofuelsSpecial form destructive distillationPtru catalystCarbonization

The invention relates to a microwave-enhanced biomass carbonization treatment method which comprises the following steps: (1) mixing biomass, an acid and a catalyst to obtain a mixture; and (2) carrying out microwave treatment on the mixture obtained in the step (1) to obtain the carbon material. According to the method, the reaction process of the biomass and sulfuric acid is enhanced by utilizing microwaves, meanwhile, rapid separation of biomass charcoal and the sulfuric acid is realized, the reaction steps are reduced, the energy consumption is reduced, and low-cost carbonization treatmentof the biomass is realized. The biomass charcoal obtained by the reaction has the advantages of rich raw material sources, low price, large specific surface area, developed pore structure, good thermal stability and chemical stability and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

Process utilizing agroforestrial waste to produce biomass molding charcoal

InactiveCN101812344BHigh carbon contentImprove carbonization rateBiofuelsSolid fuelsAdhesiveEnvironmental engineering

The invention relates to a process utilizing agroforestrial waste to produce biomass molding charcoal, wherein the raw material utilized by the production process comprises the following components in parts by weight: 80-120 parts of biomass waste, 48-72 parts of adhesive, 64-96 parts of water, 8-12 parts of combustion improver and 2-6 parts of antismoke agent. The invention has the advantages that an internal thermal type charring mode is adopted, no waste gas is discharged basically during the charring procedure, atomized water is adopted to terminate the charring procedure without environmental pollution; the charring time is short without requiring to ignite open fire; and machinery is not in need to carry out high-temperature and high-pressure charring, biomass charring can be realized under natural condition, and the charcoal content and the charring rate are high. The generated biomass molding charcoal is combustible, smokeless, nontoxic and odorless, and has sufficient combustion, strong heat power and large heat productivity.

Owner:吴汉民

A kind of hydrothermal preparation method of carbon quantum dots used as visible light catalytic photosensitizer

InactiveCN107099287BAbundant and cheap raw materialsRaw materials are natural and environmentally friendlyPhysical/chemical process catalystsNanotechnologyLiquid productPhotosensitizer

A hydrothermal preparation method for carbon quantum dots used as visible light catalytic photosensitizers, which is characterized by: using larch as raw material, after high temperature and high pressure hydrothermal treatment, the dark brown solid product is removed by centrifugal filtration to obtain a light yellow liquid product, Centrifuge the liquid product at high speed, control the centrifugal speed and time to remove insoluble small particle impurities, dialyze with a dialysis bag of a certain molecular weight to remove unreacted sugar, salt, etc., and then concentrate to obtain the target product - water-soluble fluorescent carbon quantum dots. Combine it with TiO 2 A photocatalytic composite system was prepared by combining antibiotics as a model substance to examine the photocatalytic degradation performance of the composite system on the model substance and the efficiency of carbon dots as photosensitizers. The main features of this operation process are that it uses larch, which is rich in resources in Heilongjiang Province, as raw material. It is environmentally friendly, cheap and easy to obtain. The hydrothermal reaction is at low temperature and low pressure. There is no need to add passivating agents such as acid, alkali and salts. The product is water-soluble and has a certain fluorescence effect. The reaction process is simple to operate and low in cost.

Owner:QINGDAO UNIV OF SCI & TECH

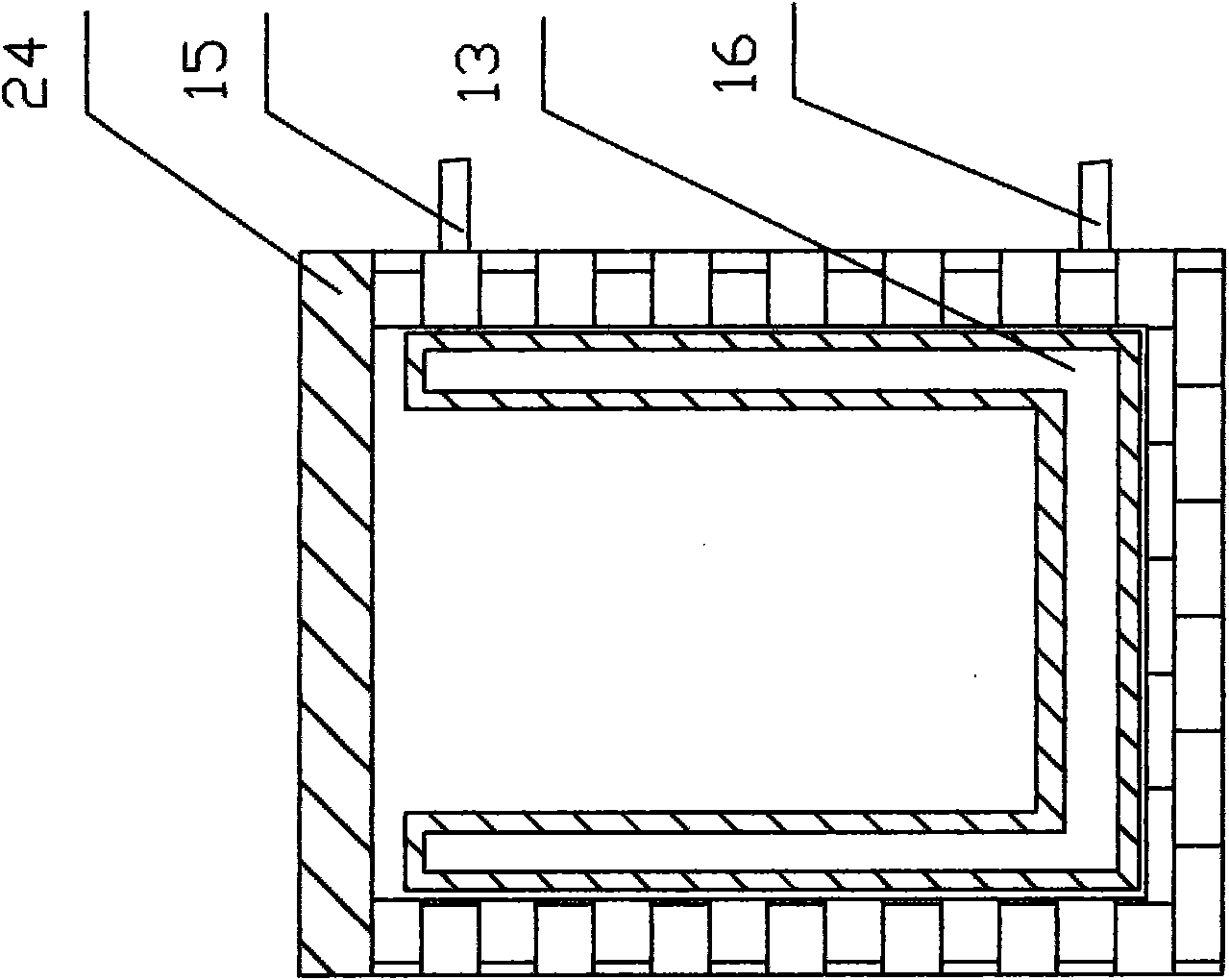

High-efficiency carbonization furnace

The invention discloses a high-efficiency carbonization furnace, which comprises a furnace body, a main fire pipe, a cold air pipe, a fire accessible duct, fire tubes, a flame inlet passage, an fume outlet duct, a fume outlet pipe, U-shaped grooves, a wood gas flue, a water jacket (or snaking hollow section), wood gas chimney and the like. The periphery of the carbonization furnace is provided with a plurality of the U-shaped grooves, and the inside of the carbonization furnace is provided with a plurality of the fire tubes of which two ends are connected with the fire accessible duct and the fume outlet duct respectively. Biomass fuels are placed in the carbonization furnace, the cover board of the furnace body is covered, flue gas passes through the small fire tube to heat the biomass fuels, and the carbonization is started and speeds up with the continuous rise of the temperature. When the carbonization of wood charcoals is finished, an air blower is started; and cool air enters the cold air pipe and the small fire tube 6 to absorb heat of the wood charcoals and flows out from the fume outlet duct to enter a heat drying chamber for drying the raw materials of the biomass fuels. Wood tar and the wood gas generated during the carbonization flow into the wood gas fuel along the U-shaped grooves, and the wood tar is cooled by the water jacket (or snaking hollow section) and changed into solid.

Owner:肖国雄 +1

Environment-friendly coal tar for producing waterless mud-gunstemming and application of environment-friendly coal tar

The invention discloses environment-friendly coal tar for producing waterless mud-gunstemming and application of the environment-friendly coal tar. Effective raw materials for preparing the environment-friendly coal tar for producing the waterless mud-gunstemming comprise the following components in parts by weight: 50 to 80 parts of coal tar, 10 to 25 parts of high adsorption active carbon micropowder, 5 to 15 parts of cross-linking agent and 3 to 12 parts of coupling agent. The environment-friendly coal tar for producing the waterless mud-gunstemming, disclosed by the invention, enables theproduced waterless mud-gunstemming to obtain the advantages of better environment friendliness, better mechanical strength, short splash time, low reaming speed and long tapping time.

Owner:河北丰能耐火材料股份有限公司

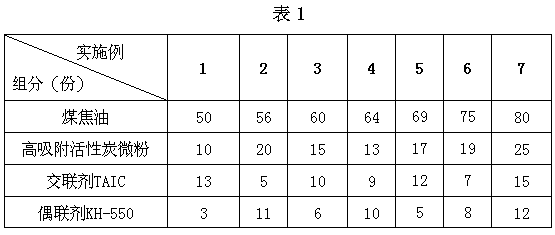

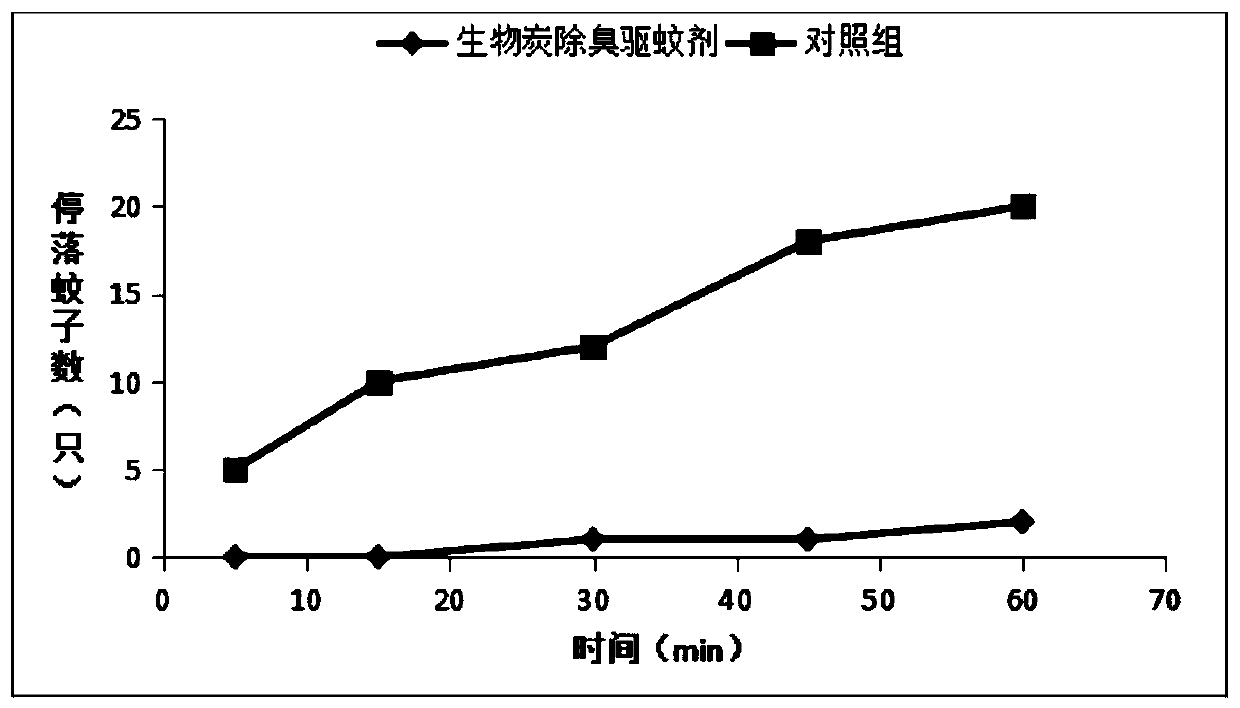

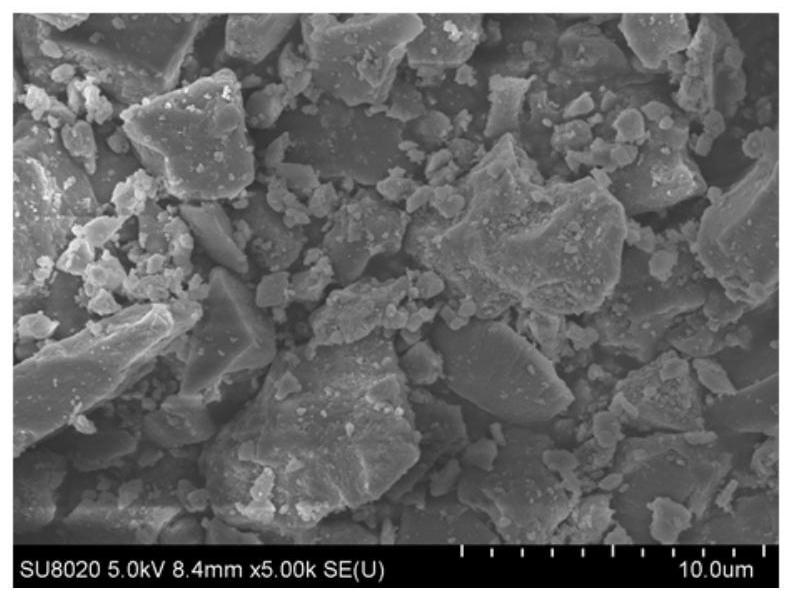

Celery-biochar deodorizing mosquito repellent and preparation method therefor

InactiveCN109845729AImprove carbonization rateLarge specific surface areaBiocidePest repellentsPollutantDeodorant

The invention relates to a celery-biochar deodorizing mosquito repellent and a preparation method therefor and belongs to the technical field of deodorization and mosquito repelling. In order to solvethe problem that the existing deodorants cannot simultaneously repel mosquitoes, the invention provides the celery-biochar deodorizing mosquito repellent. The celery-biochar deodorizing mosquito repellent is prepared from the following ingredients in parts by weight: 45-55 parts of celery biochar, 10-15 parts of alum, 20-30 parts of zeolite, 4-6 parts of crude extract of celeries, 6-10 parts of herba menthae volatile oil, 6-10 parts of folium artemisiae argyi volatile oil, 3-4 parts of radix angelicae extract and 8-10 parts of water. According to the celery-biochar deodorizing mosquito repellent and the preparation method therefor, the celery biochar, which is prepared through high-temperature carbonization under anoxybiotic conditions, has a rich micropore structure and has a relativelyhigh adsorptive action on contaminants in air. The ethanol crude extract of the celeries is added into the celery biochar, and thus, a mosquito-repelling effect is increased on the basis of deodorization; and effective ingredients of folium artemisiae argyi, herba menthae and radix angelicae are added in an assisting manner, so that the mosquito-repelling effect can be enhanced. By applying the celery-biochar deodorizing mosquito repellent to the field of deodorization and mosquito repelling, the cost can be reduced, and the effects of simultaneously deodorizing and repelling the mosquitoes are achieved.

Owner:哈工大机器人(山东)智能装备研究院

A treatment method for microwave-enhanced biomass carbonization

ActiveCN111484863BEasy to separateLow costBiofuelsSpecial form destructive distillationBiomass carbonPtru catalyst

The invention relates to a treatment method for microwave-enhanced biomass carbonization. The method comprises the following steps: (1) mixing biomass, an acid and a catalyst to obtain a mixture; (2) subjecting the mixture obtained in step (1) to microwave treatment, Obtain carbon material. The invention strengthens the reaction process of biomass and sulfuric acid by using microwaves, realizes rapid separation of biomass charcoal and sulfuric acid at the same time, reduces reaction steps and energy consumption, and realizes low-cost biomass carbonization treatment. The biochar obtained by the reaction has the advantages of abundant raw material sources, low price, large specific surface area, developed pore structure, good thermal and chemical stability, and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +2

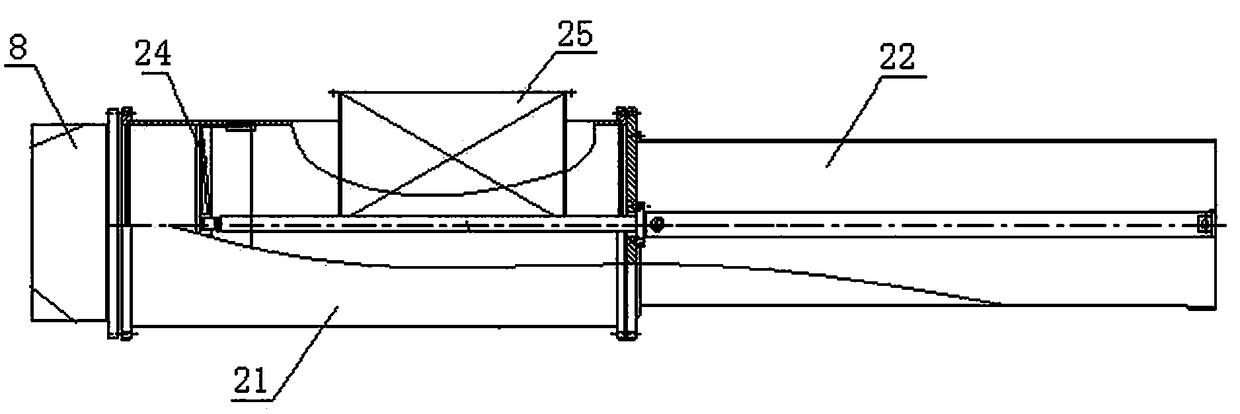

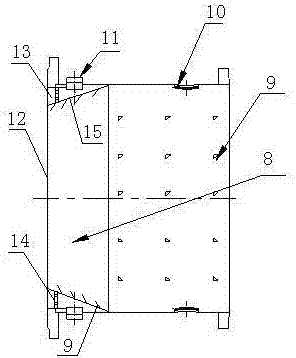

A continuous biomass decomposition process and device

ActiveCN106085475BEfficient separationEfficient use ofBiofuelsSpecial form destructive distillationDecompositionCarbonization

The invention discloses a biomass continuous decomposition process and device. The biomass continuous decomposition process comprises the following steps: compressing a dried biomass raw material in the push process; igniting and decomposing the compressed biomass raw material in a carbonization furnace, filtering a gas collected after decomposition, cooling, decoking, and compressing into a storage tank for later use; feeding the biomass carbon into a cooling device, introducing cold air into the cooling device for heat exchange, and introducing hot air after heat exchange into a drying device in step (1) to dry the biomass raw material. By adopting the biomass continuous decomposition process, a combustible gas, tar and carbon powder generated when biomass is continuously decomposed can be effectively separated and utilized, the heat generated from biomass decomposition can be effectively recycled, the energy can be saved, and the environment can be protected.

Owner:四川大宇中和生物质能源科技有限公司

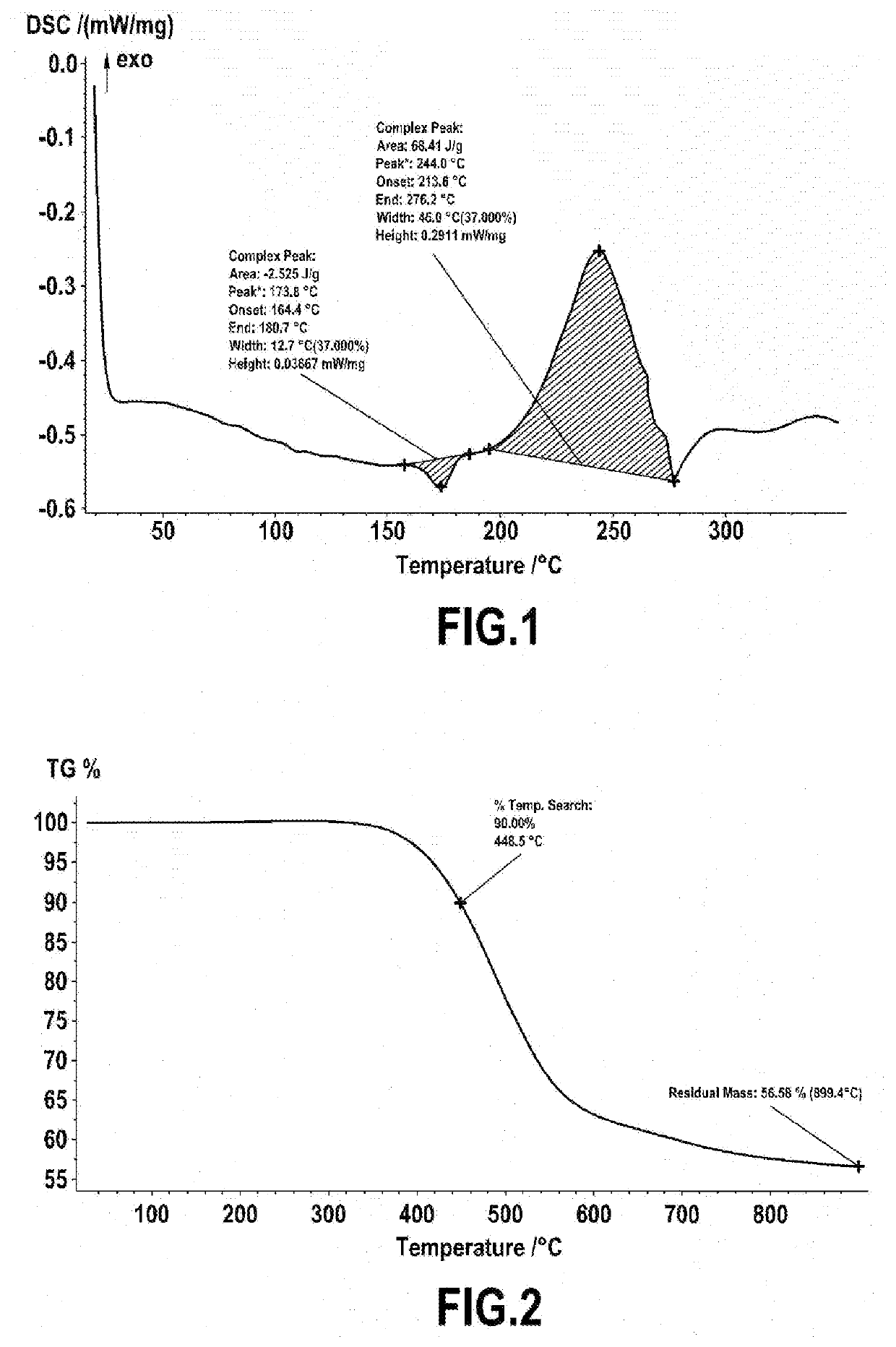

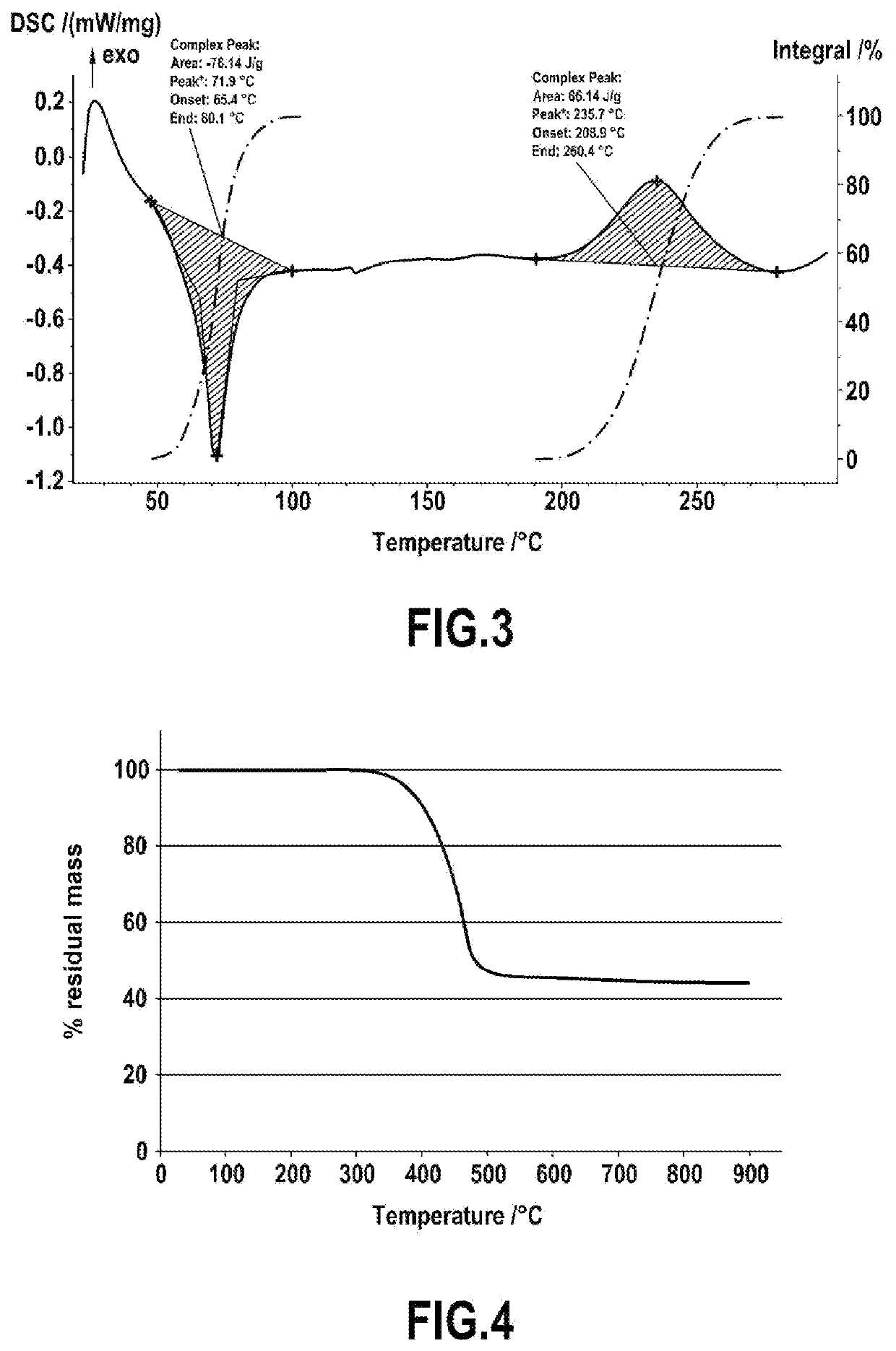

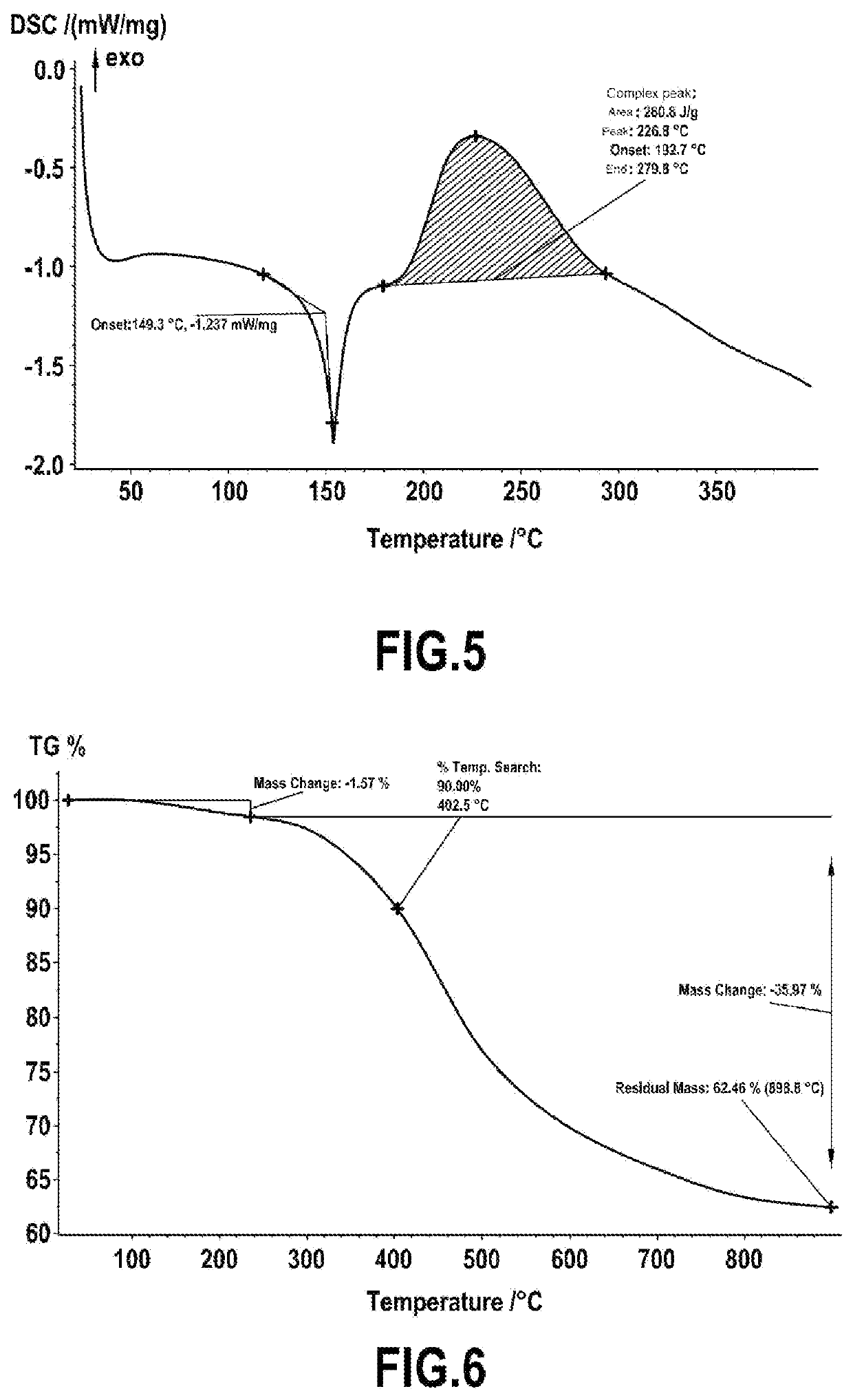

Process for producing a polybenzoxazine monomer

PendingUS20220153712A1Improve carbonization rateEasy to useOrganic chemistryChemistryComposite material

A process for manufacturing a polybenzoxazine monomer, crosslinking the latter, and using the crosslinked product to form an ablative thermal protection system for a thruster nozzle or atmospheric reentry body.

Owner:ARIANEGRP SAS +1

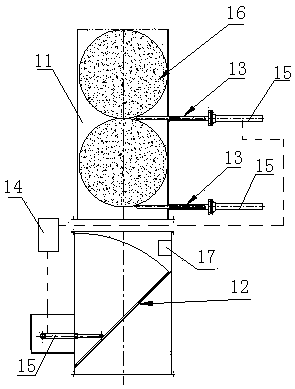

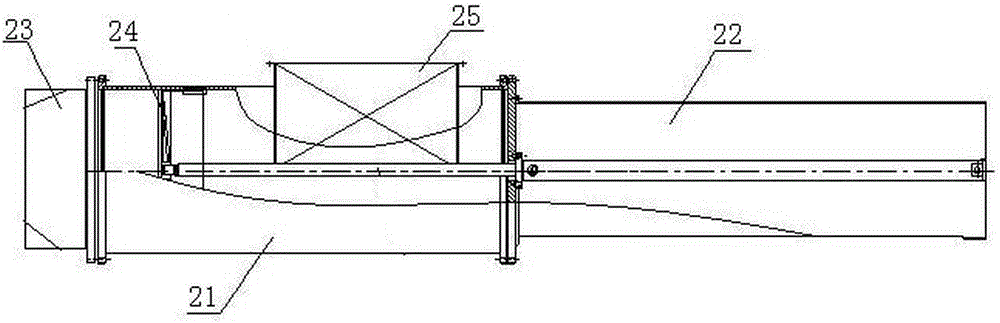

Straw continuous decomposition equipment

ActiveCN105969414BImprove carbonization rateEnable recyclingDirect heating destructive distillationBiofuelsCold airHydraulic cylinder

Owner:四川大宇中和生物质能源科技有限公司

straw propulsion device

ActiveCN106085474BImprove carbonization rateReturn reductionProductsReagentsHydraulic cylinderCarbonization

The invention discloses a straw pushing device which comprises a cylinder body, a hydraulic cylinder and a compression device. One end of the cylinder body is connected with the hydraulic cylinder, the other end of the cylinder body is connected with the compression device, a feeding port is formed in the side wall of the cylinder body, a discharging port is formed in the other end of the compression device, a piston for pushing straw bundles is arranged in the cylinder body, and the piston is connected with the hydraulic cylinder through a connecting rod. The compression device is a barrel, a conical barrel is arranged in the barrel, a compression cavity is formed inside the conical barrel, a discharging port is formed in the small-diameter end of the conical barrel, the large-diameter end of the conical barrel is connected with the inner wall of the barrel, an air channel is formed between the conical barrel and the barrel, an air taking interface is formed in the barrel and is communicated with the air channel, and the straw pushing device can discharge out air in air-dried straw bundles and improve the carbonization rate.

Owner:四川大宇中和生物质能源科技有限公司

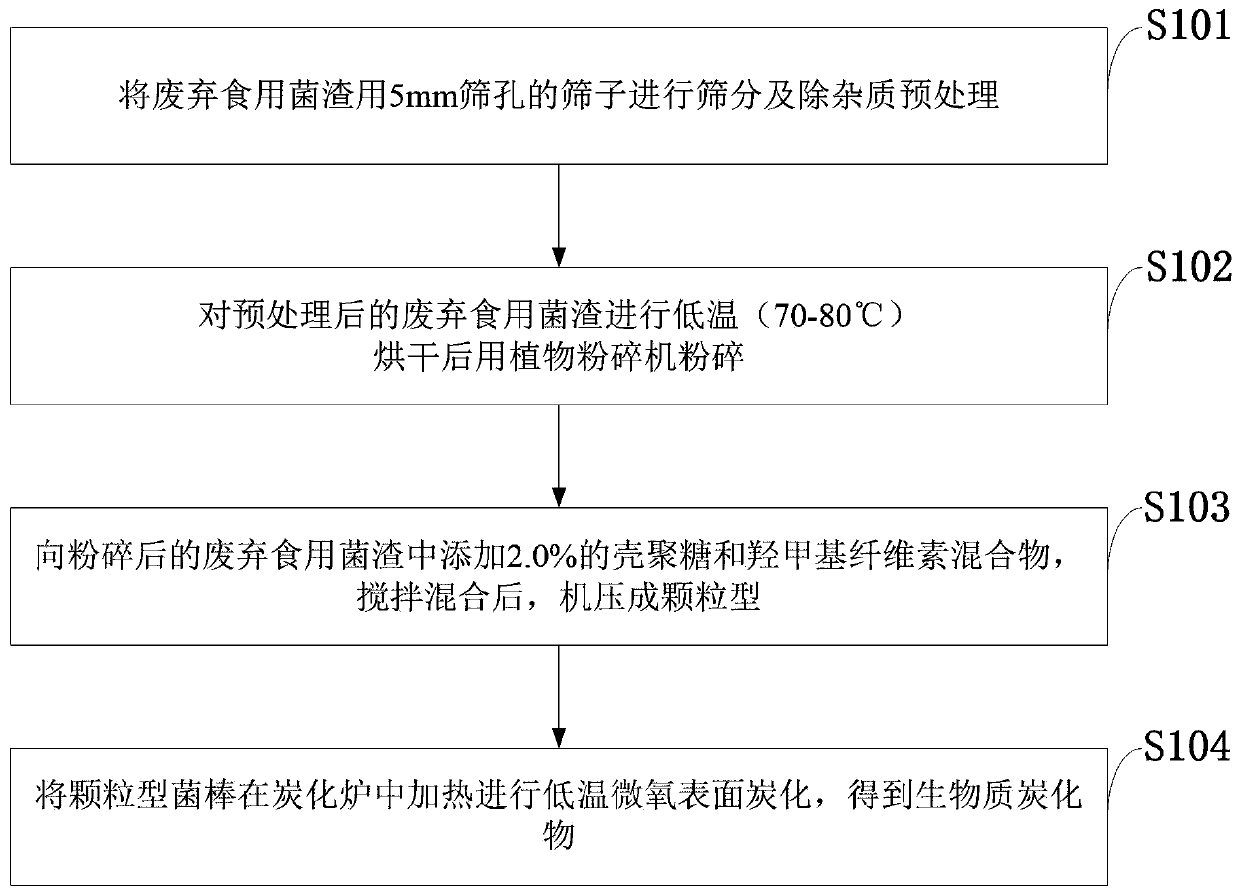

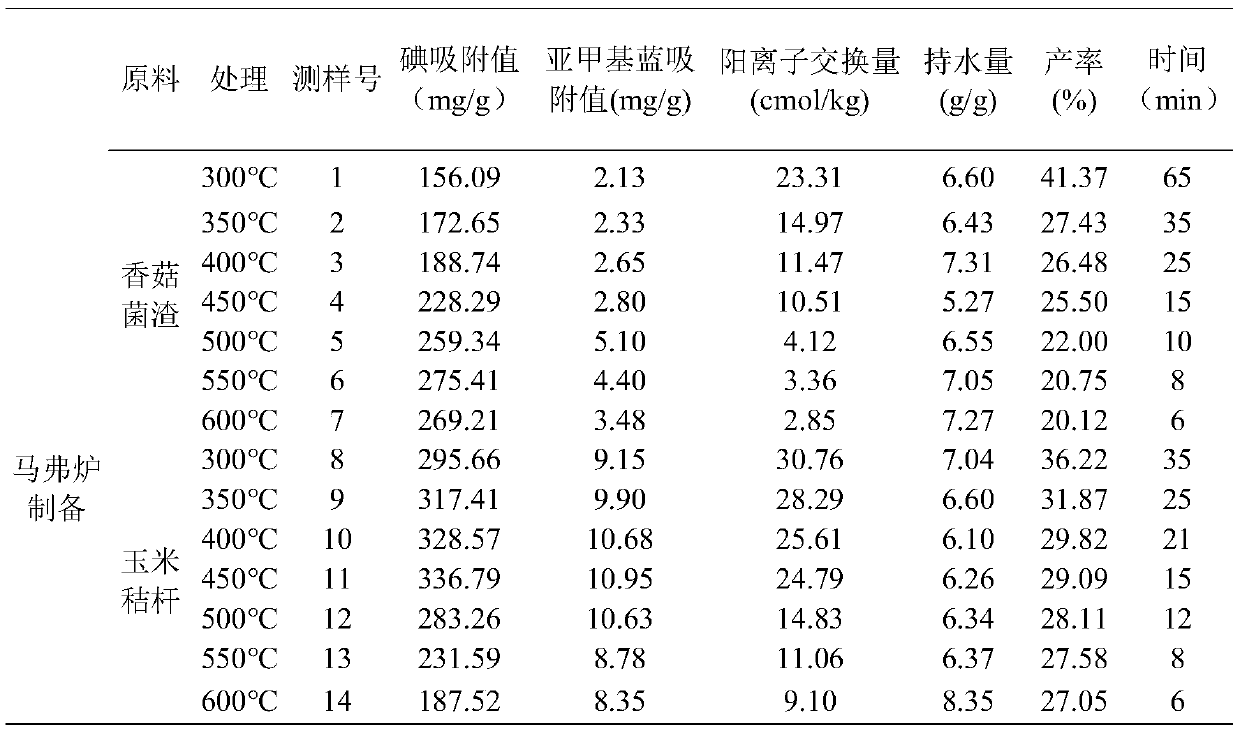

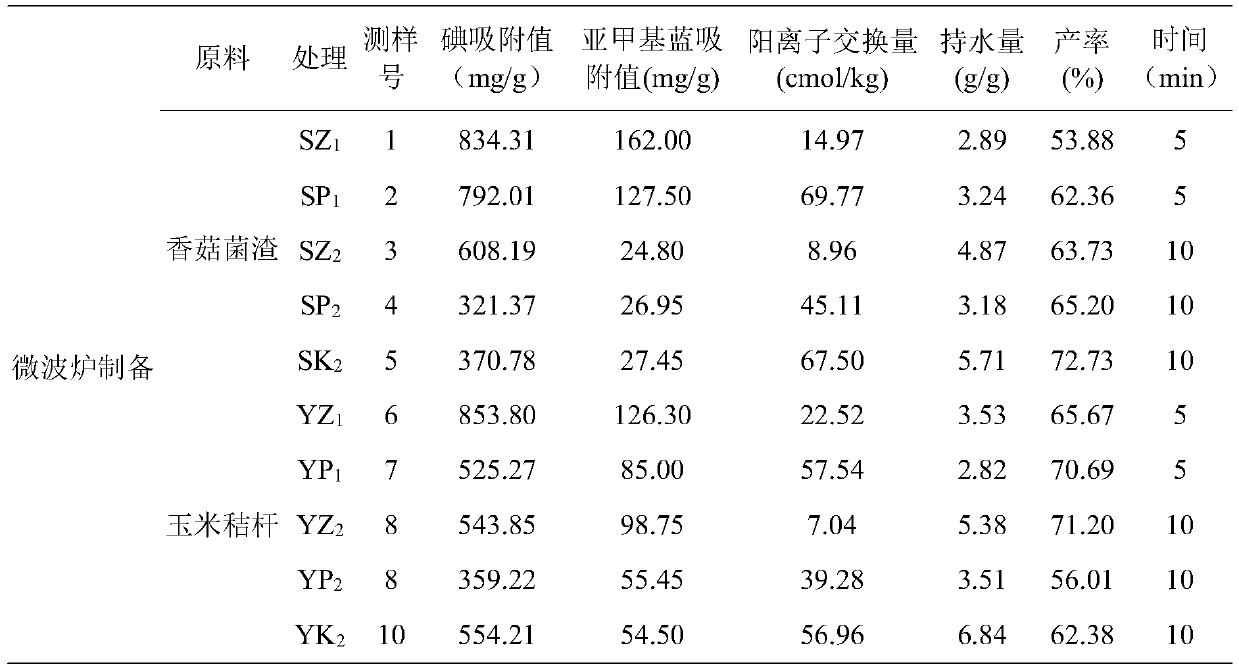

Method for quickly carbonizing edible fungus sticks and application

PendingCN111530429AFast carbonizationImprove carbonization yieldOther chemical processesWater contaminantsCarbonizationEnvironmental engineering

The invention belongs to the technical field of edible fungus carbonization, and discloses a method for quickly carbonizing edible fungus sticks and an application of the method. The method comprises:screening and pretreating waste edible fungus residues, drying and crushing the pretreated waste edible fungus residues, adding a conditioner or a cementing agent into the crushed waste edible fungusresidues, fully mixing, mechanically pressing into particles, and carrying out low-temperature surface carbonization to obtain the biomass carbide. The method provided by the invention has the advantages of high carbonization rate, low energy consumption, functional diversity of carbide and less emission of atmospheric pollutants. According to the invention, through the carbonization process of the waste mushroom stick, such as optimized material ratio, optimal carbonization temperature and time, optimal carbonization yield and the like, rapid carbonization of the surface of the waste mushroom stick of the wood-rotting edible mushroom can be realized, and the carbonization yield of the waste mushroom stick material and the nutrient characteristics of the carbide are obviously improved. The raw materials are rich in source, resource recycling of agricultural solid waste can be achieved, and the problem of environmental pollution caused by unreasonable utilization of waste edible fungusdregs can be solved.

Owner:陈祖拥

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com