Process utilizing agroforestrial waste to produce biomass molding charcoal

A technology for agricultural and forestry waste and biomass, which is applied in the fields of biofuel, waste fuel, petroleum industry, etc., can solve the problems of biomass energy waste, low production efficiency, environmental pollution, etc., and achieve full combustion, high calorific value, and carbon content high volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, utilize agricultural and forestry waste to produce the technology of biomass briquette, wherein: the composition of the raw material that this production technology adopts is made up of following weight ratio:

[0026] 80-120 parts of biomass waste, 48-72 parts of adhesive, 64-96 parts of water, 8-12 parts of combustion enhancer, 2-6 parts of smoke suppressant;

[0027] The process steps are as follows: firstly dry the biomass waste at 105°C for 2-4 hours, then carbonize at 500-600°C for 6-9 hours to obtain the carbonized material of biomass waste, crush and sieve for 50 The purpose is to obtain the carbonized powder of biomass waste, and then mix the carbonized powder of biomass waste with adhesive, combustion enhancer, smoke suppressant and water to obtain a mixed material, put it into a carbonization furnace, ignite it, After standing for 3-5 hours for aging, then press and shape;

[0028] The binder is formed by uniformly mixing clay with a weight rat...

Embodiment 2

[0031] Embodiment 2, the structure of the charring furnace that adopts is as follows:

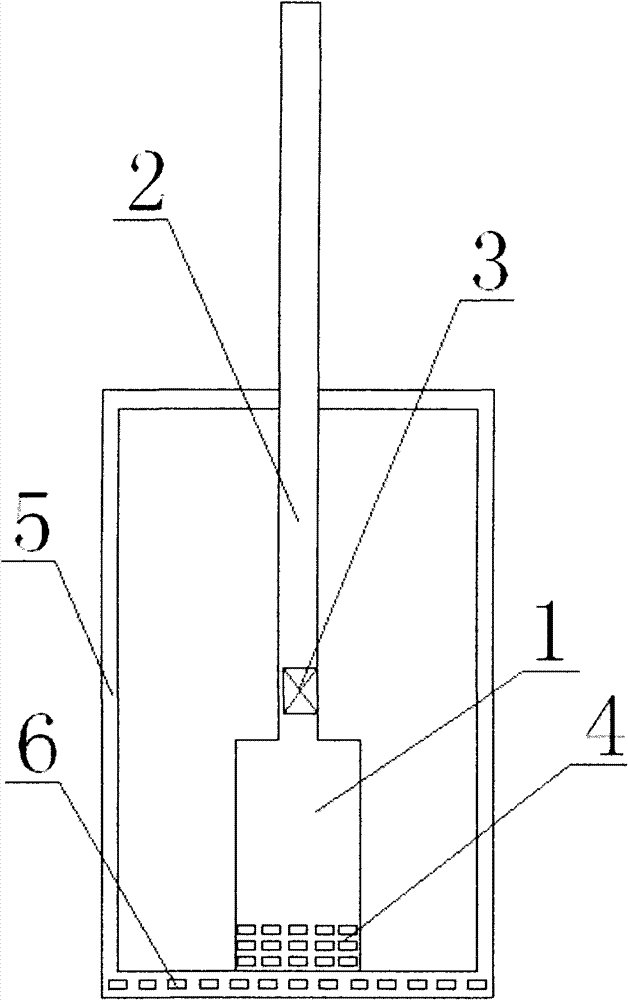

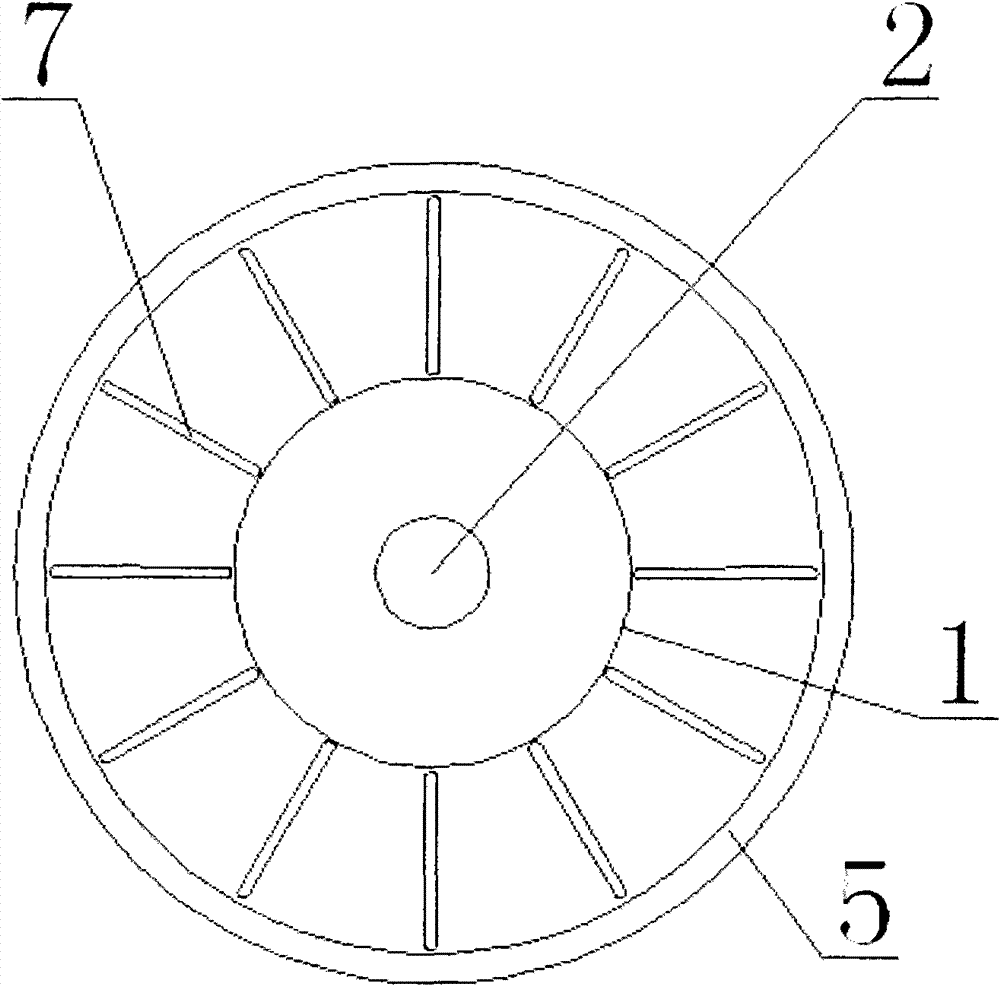

[0032] Including the inner furnace 1 and the outer furnace 5, the outer furnace 5 is covered outside the inner furnace 1, wherein: the inner furnace 1 is provided with multiple rows of vents 4 through the furnace wall near the bottom, and the lowermost part of the outer furnace 5 is provided with a through furnace A row of ignition ports 6 on the wall, the upper end of the inner furnace 1 communicates with the outside world through the flue 2, and the lower end of the flue 2 is provided with a damper 3;

[0033] A plurality of steel pipes 7 are arranged at the bottom of the cavity between the outer furnace 5 and the inner furnace 1, and the plurality of steel pipes 7 are evenly arranged toward the center of the inner furnace 1, and a plurality of small holes are distributed on the steel pipes 7;

[0034] The agricultural and forestry wastes are placed on the perforated steel pipe 7 for comb...

Embodiment 3

[0038] Embodiment 3, the technique of utilizing agricultural and forestry waste to produce biomass shaped charcoal, wherein: the composition of this production technique is proportioned according to the following proportions:

[0039] 80 parts of biomass waste, 48 parts of adhesive, 64 parts of water, 8 parts of combustion accelerant, 2 parts of smoke suppressant;

[0040] The process steps are as follows: First, dry the biomass waste at 105°C for 2 hours, then carbonize it at 500°C for 6 hours to obtain the carbonized material of biomass waste, crush and sieve 50 meshes, and obtain the biomass The carbonized powder of the waste, and then the carbonized powder of the biomass waste is mixed with the binder, the combustion enhancer, the smoke suppressant and water to obtain the mixed material, put it into the carbonization furnace, ignite it, and let it stand for 5 hours to mature After that, press molding again.

[0041] All the other are the same as embodiment 1 and embodimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com