Patents

Literature

594results about "Stationary retorts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

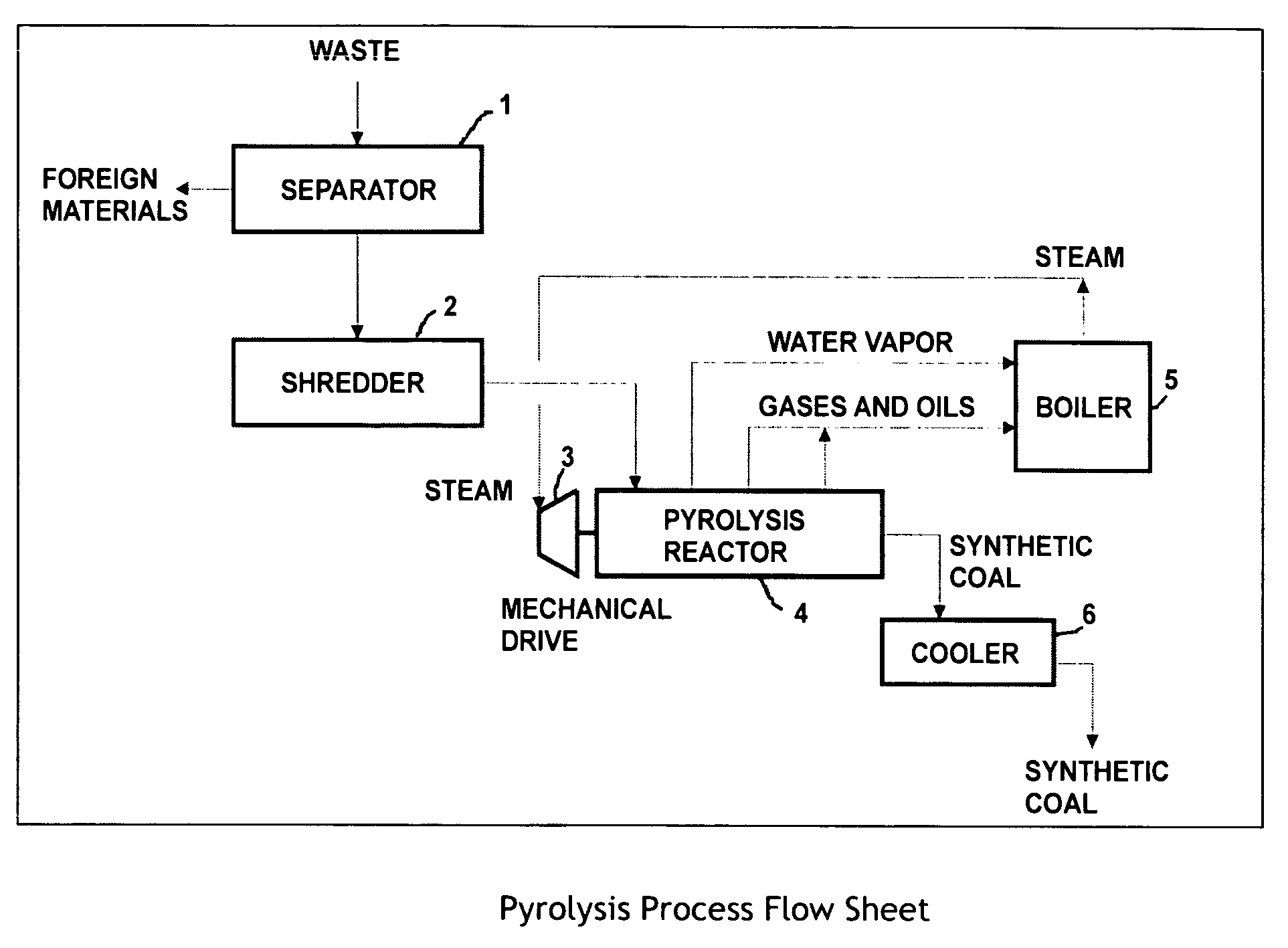

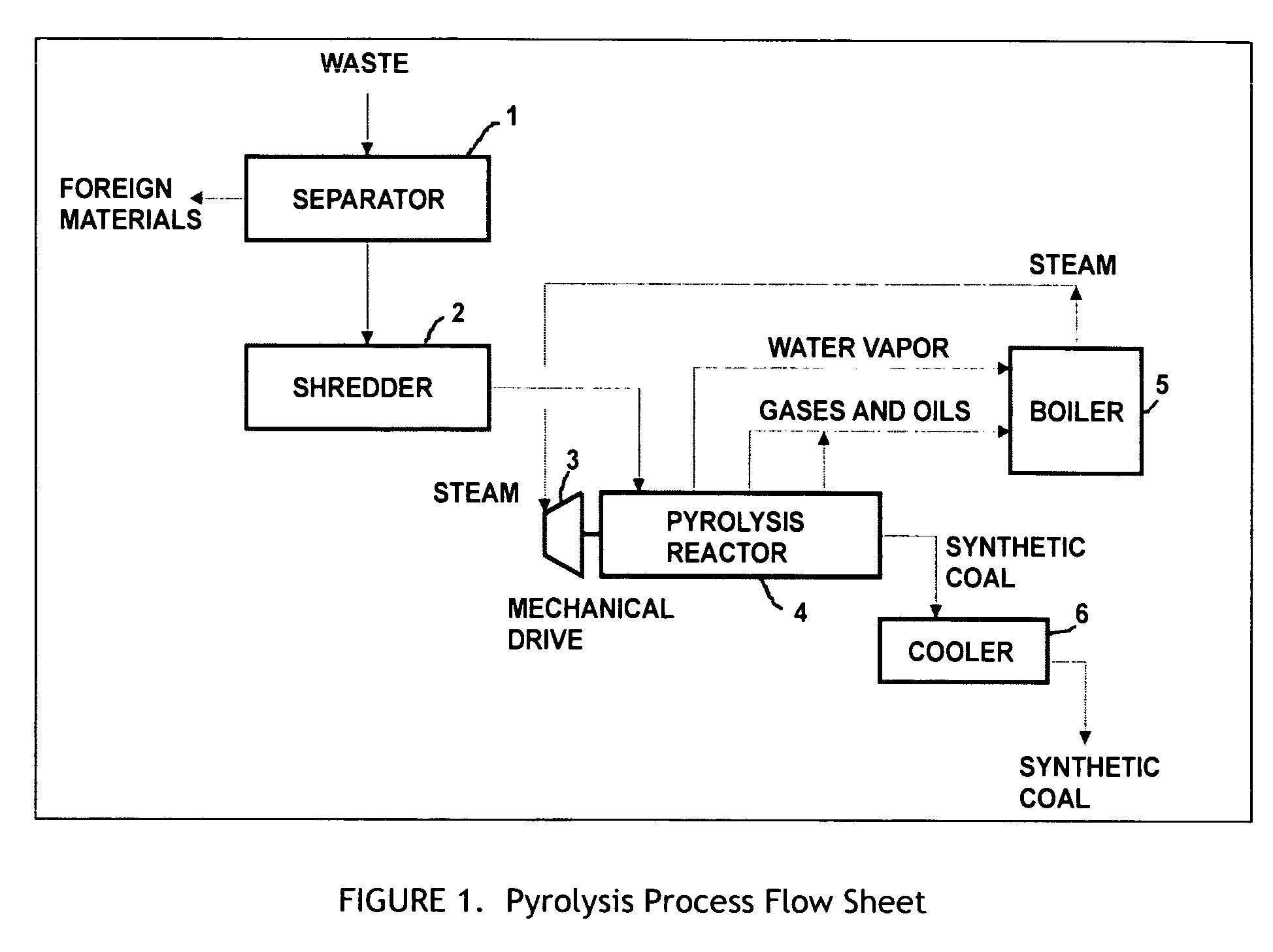

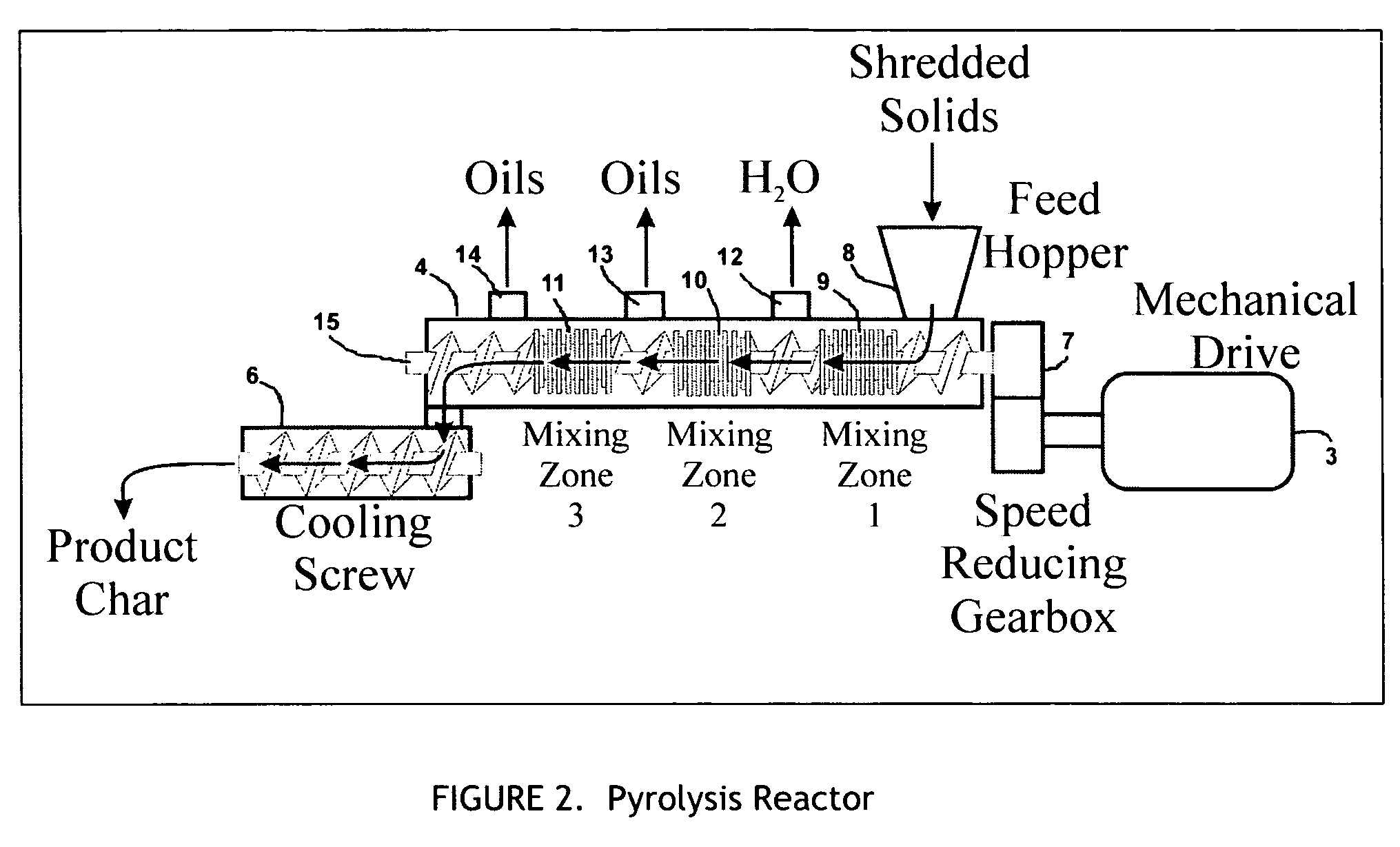

Waste conversion process

InactiveUS20060280669A1Good yieldMinimization requirementsBiofuelsIndirect and direct heating destructive distillationEnvironmental engineeringSand granules

A process for the preparation of high quality char from organic waste materials. The waste is first sorted to remove recyclable inorganic materials of economic value (metals, glass) and other foreign materials that would be detrimental to the quality of the final product (stone, sand, construction debris, etc.). After size reduction, the waste is pyrolyzed at a temperature range of 250 to 600° F., in a high capacity, continuous mixer reactor, using in-situ viscous heating of the waste materials, to produce a highly uniform, granular synthetic product similar in energy content and handling characteristics to, but much cleaner burning than, natural coal.

Owner:ENTROPIC TECH CORP

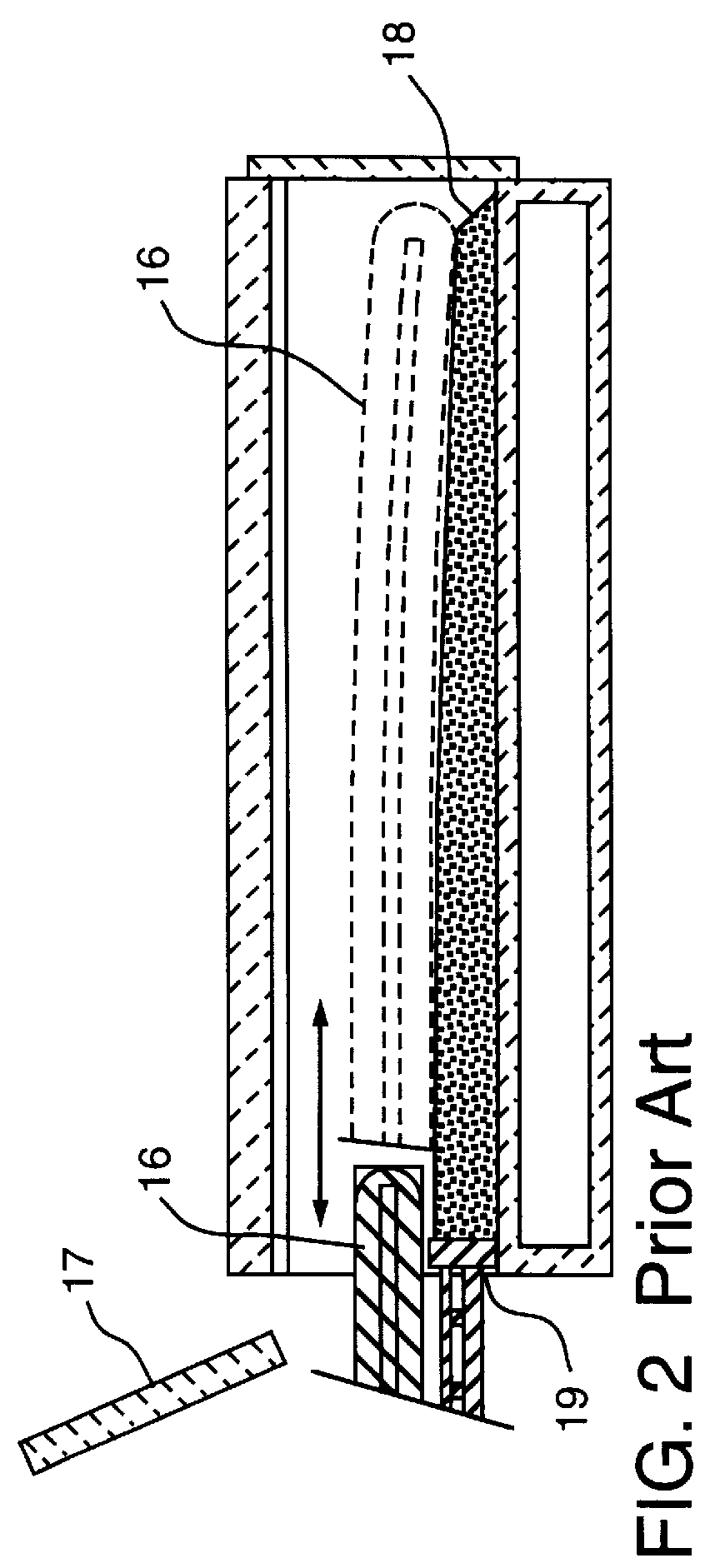

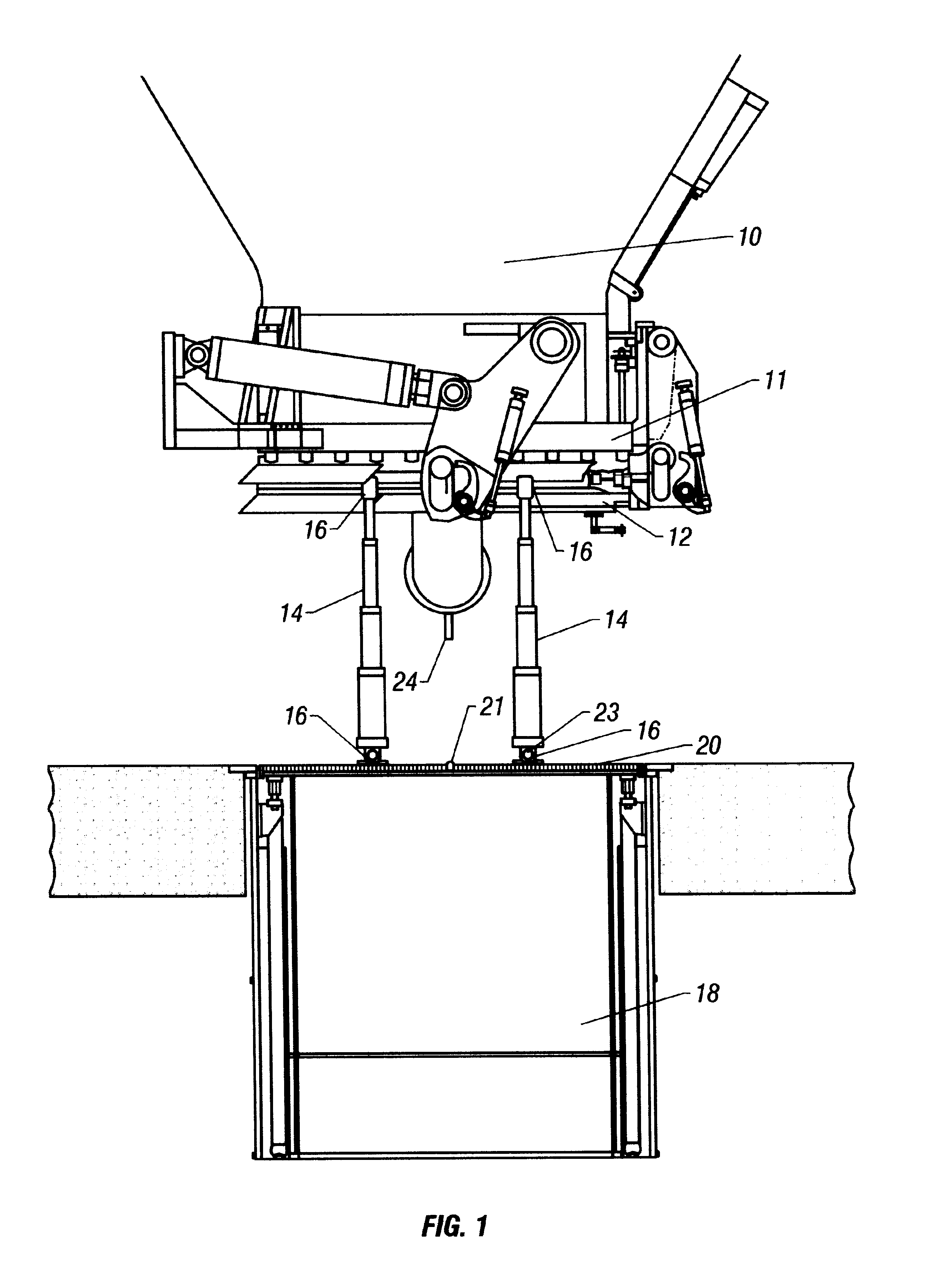

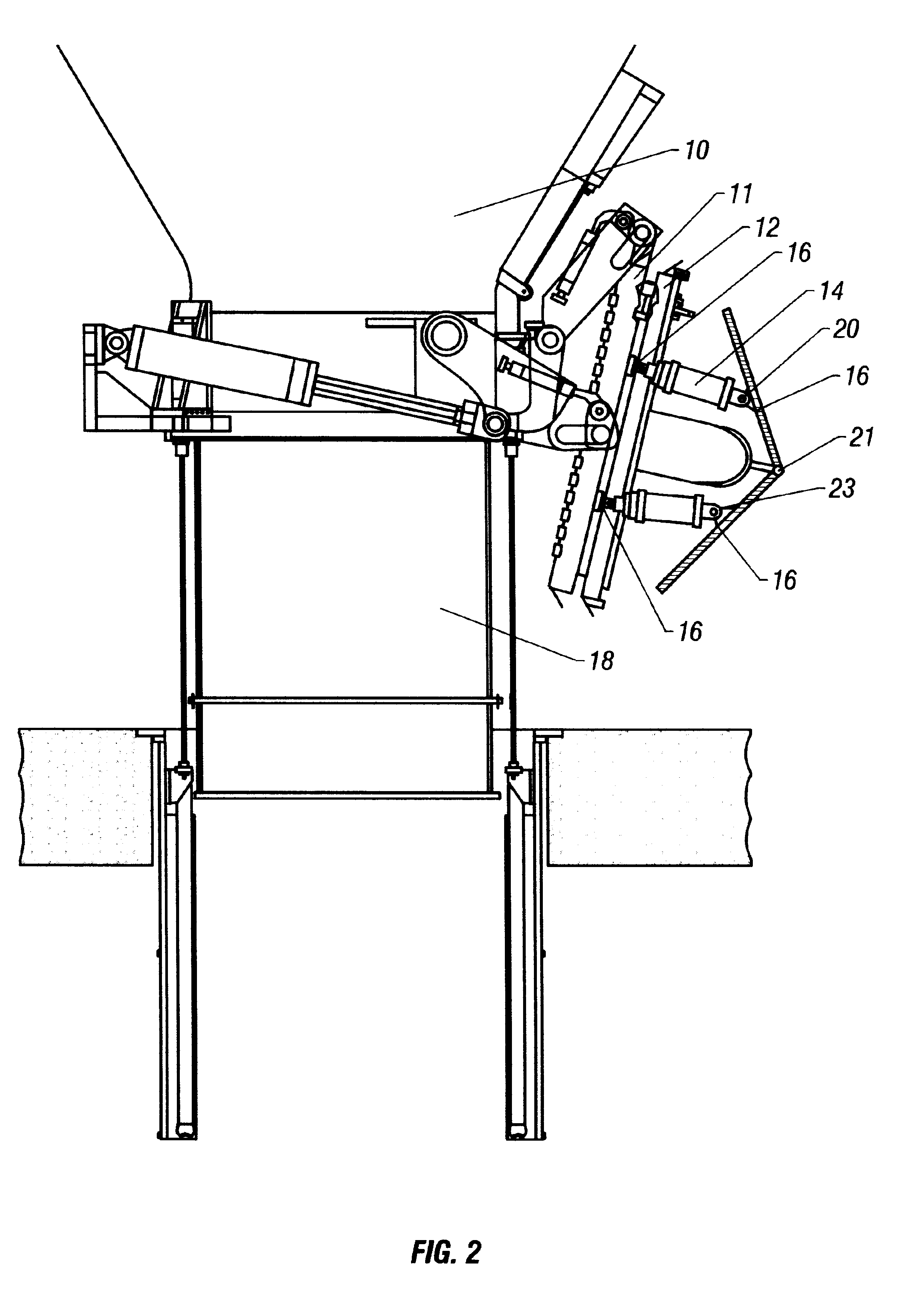

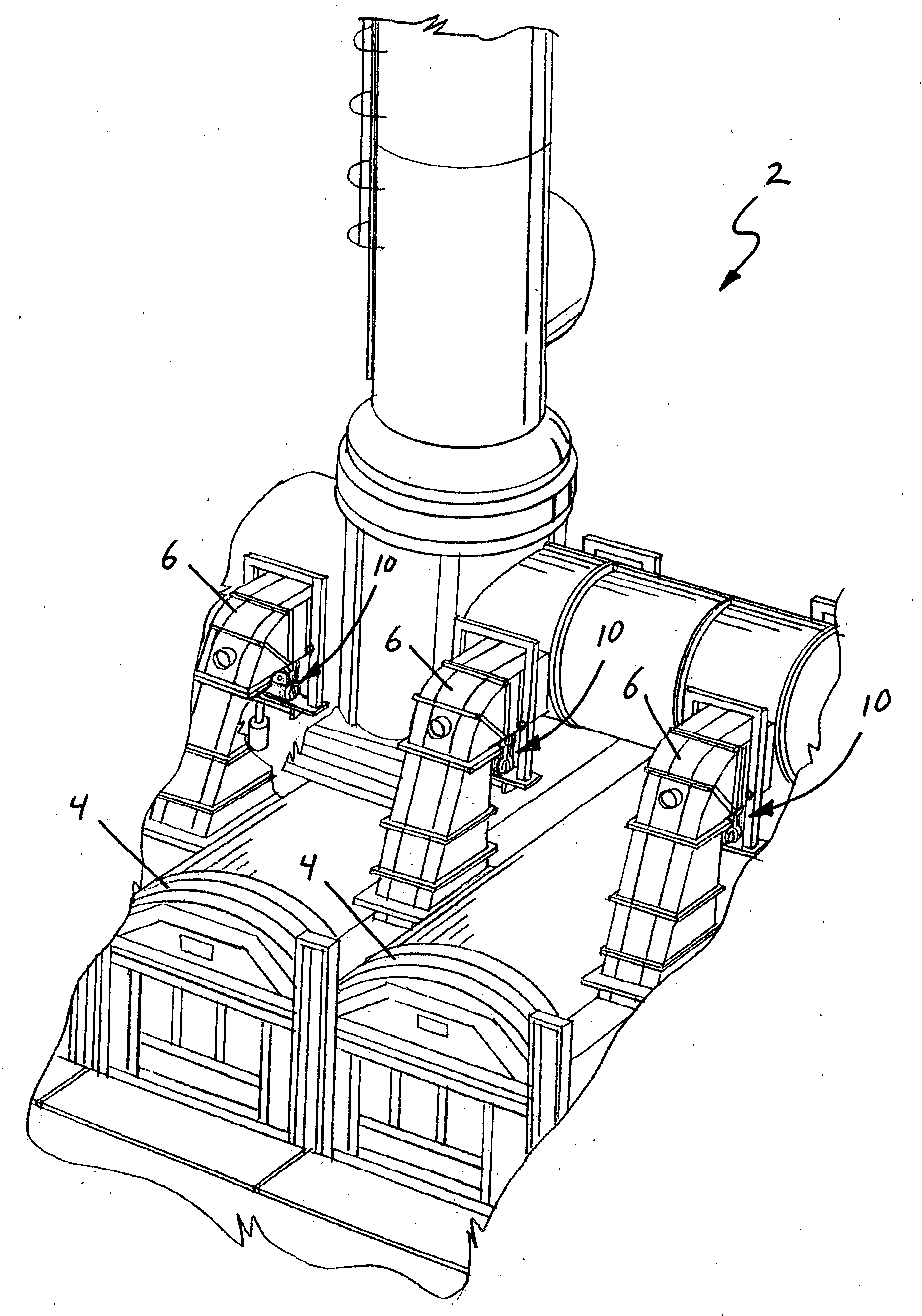

Coal bed vibration compactor for non-recovery coke oven

InactiveUS6059932AMechanical conveying coke ovensCharging-discharging device combinationsEngineeringCoke oven

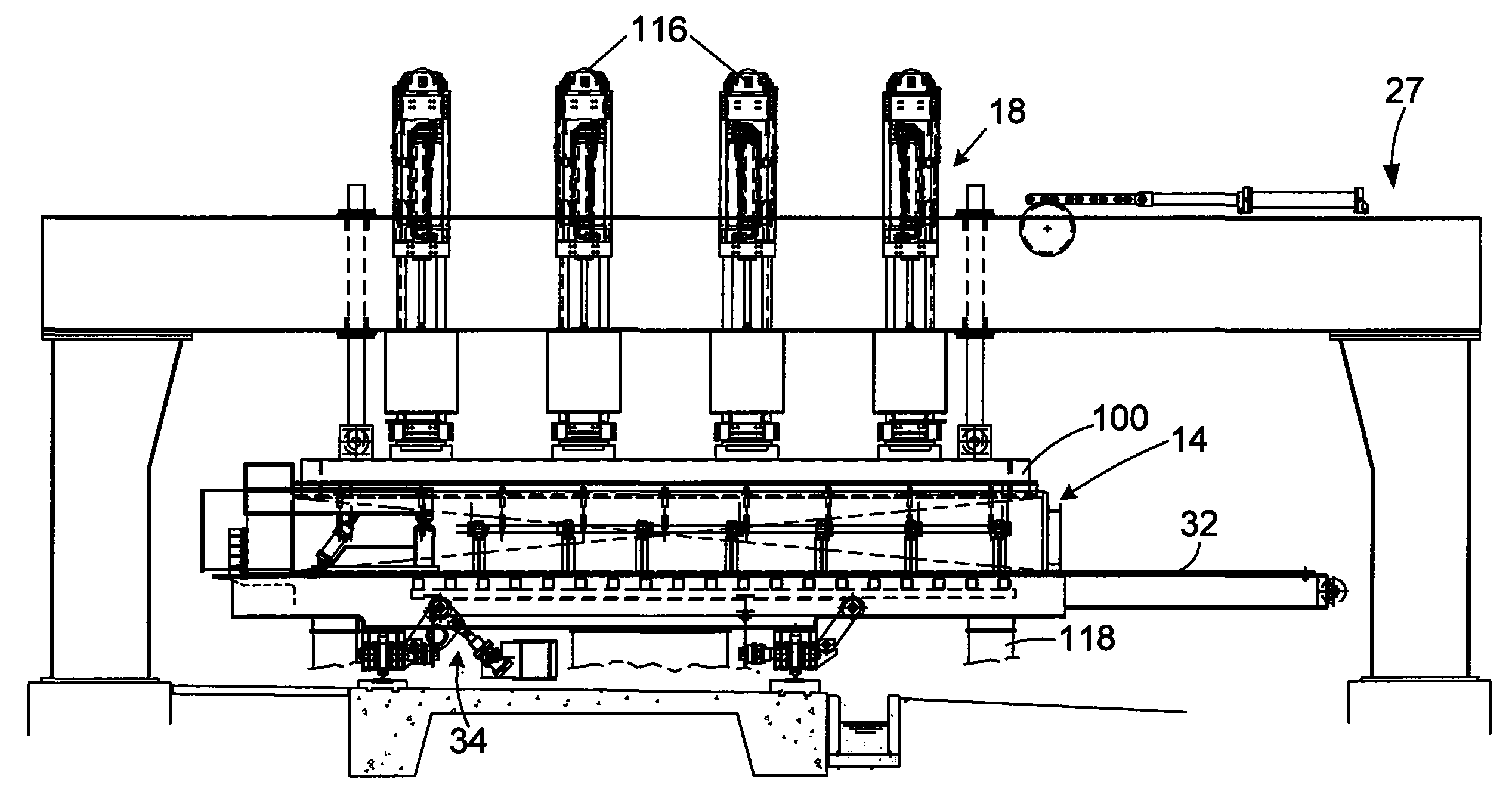

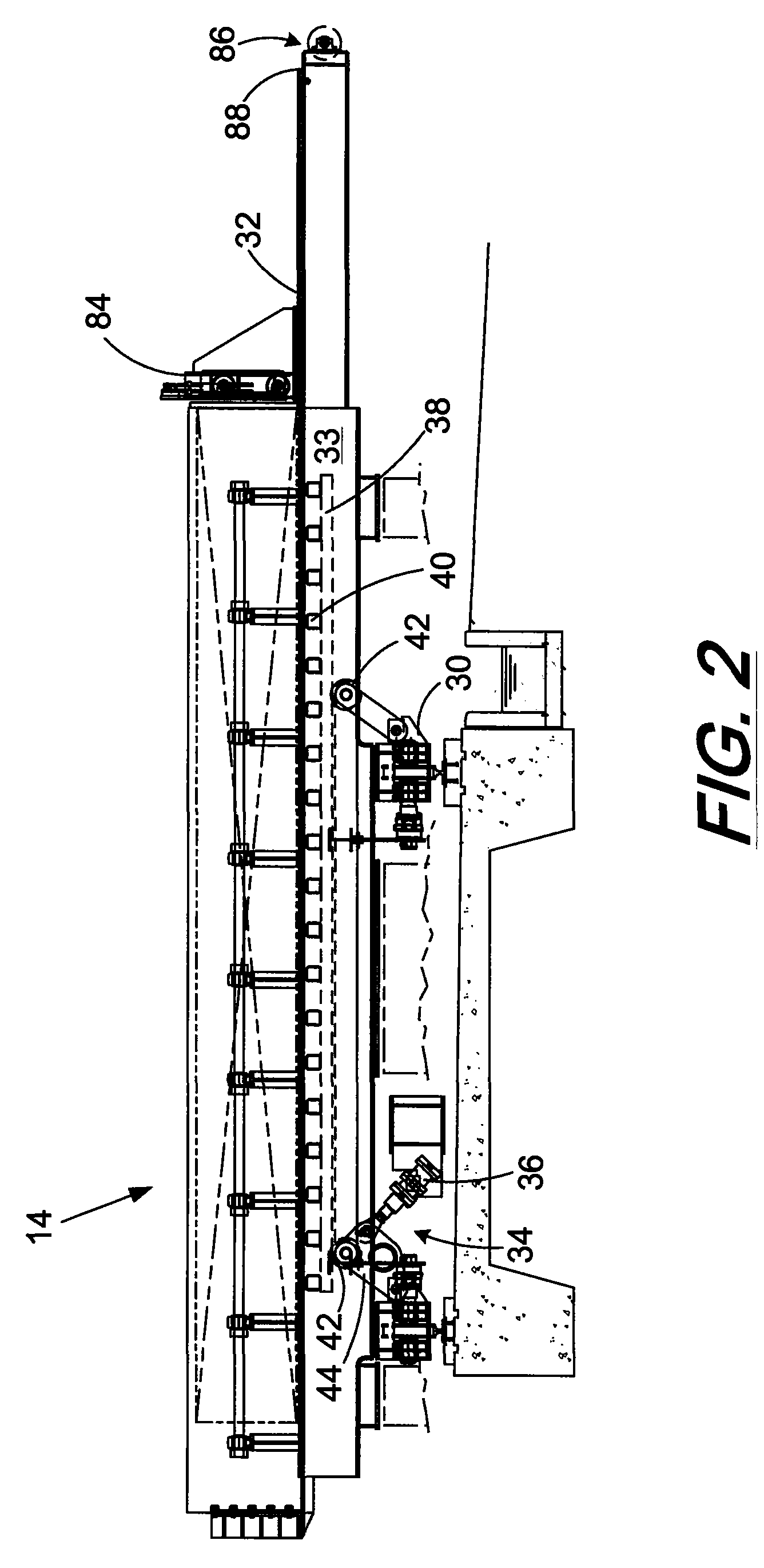

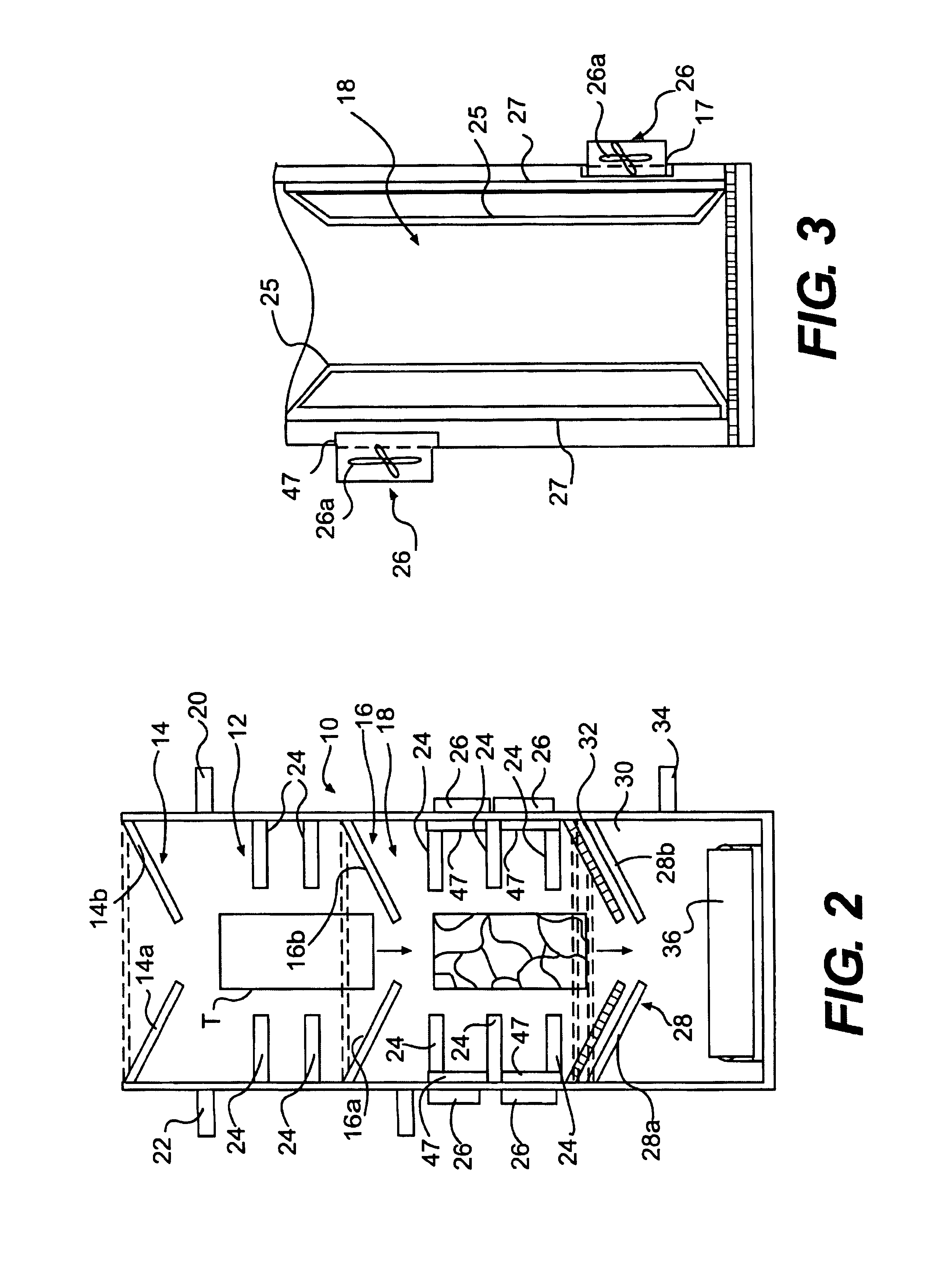

A coal compaction system and method for a non-recovery coke oven having refractory roof, floor, side walls and end doors for coal charging and coke discharge provides an improved coal charging machine carrying a coal conveyor supported intermediate the ends of the conveyor to avoid conveyor sagging and non-uniform depth of a deposited coal bed, a number of pressurized fluid-driven vibratory compactors mounted on an end of the charging machine and spaced-apart across the width of the coal bed and serving to compact the coal bed on a retraction stroke of the charging machine, a pivoted lifting frame mounted on the charging machine above the compactors and from which the compactors individually are suspended and are provided with individual supply of pressurized fluid, and a coke pusher head mounted on the charging machine behind the compactors and serving, when the lifting frame and associated compactors are raised, to push finished coke from the coke oven.

Owner:PENNSYLVANIA COKE TECH

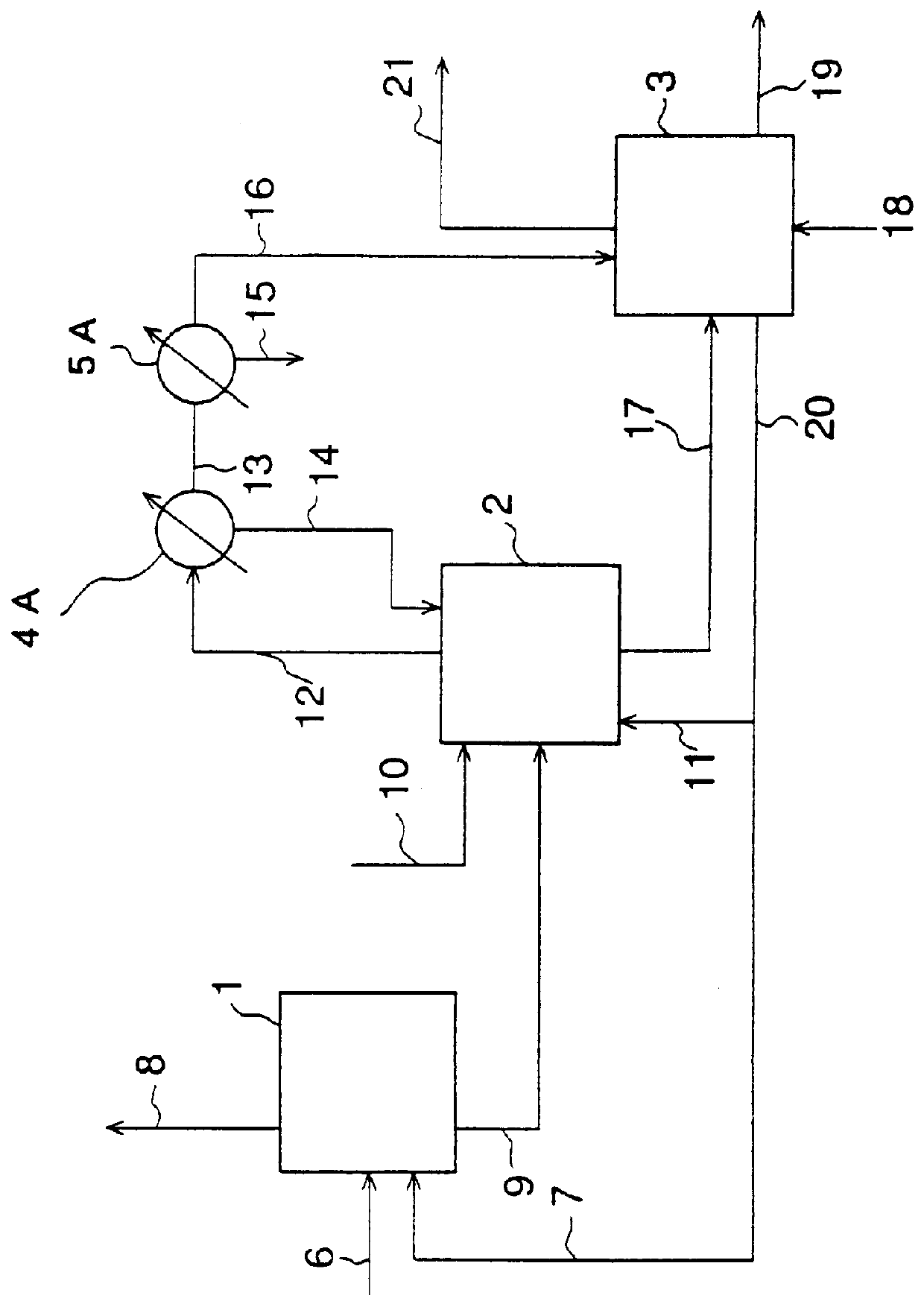

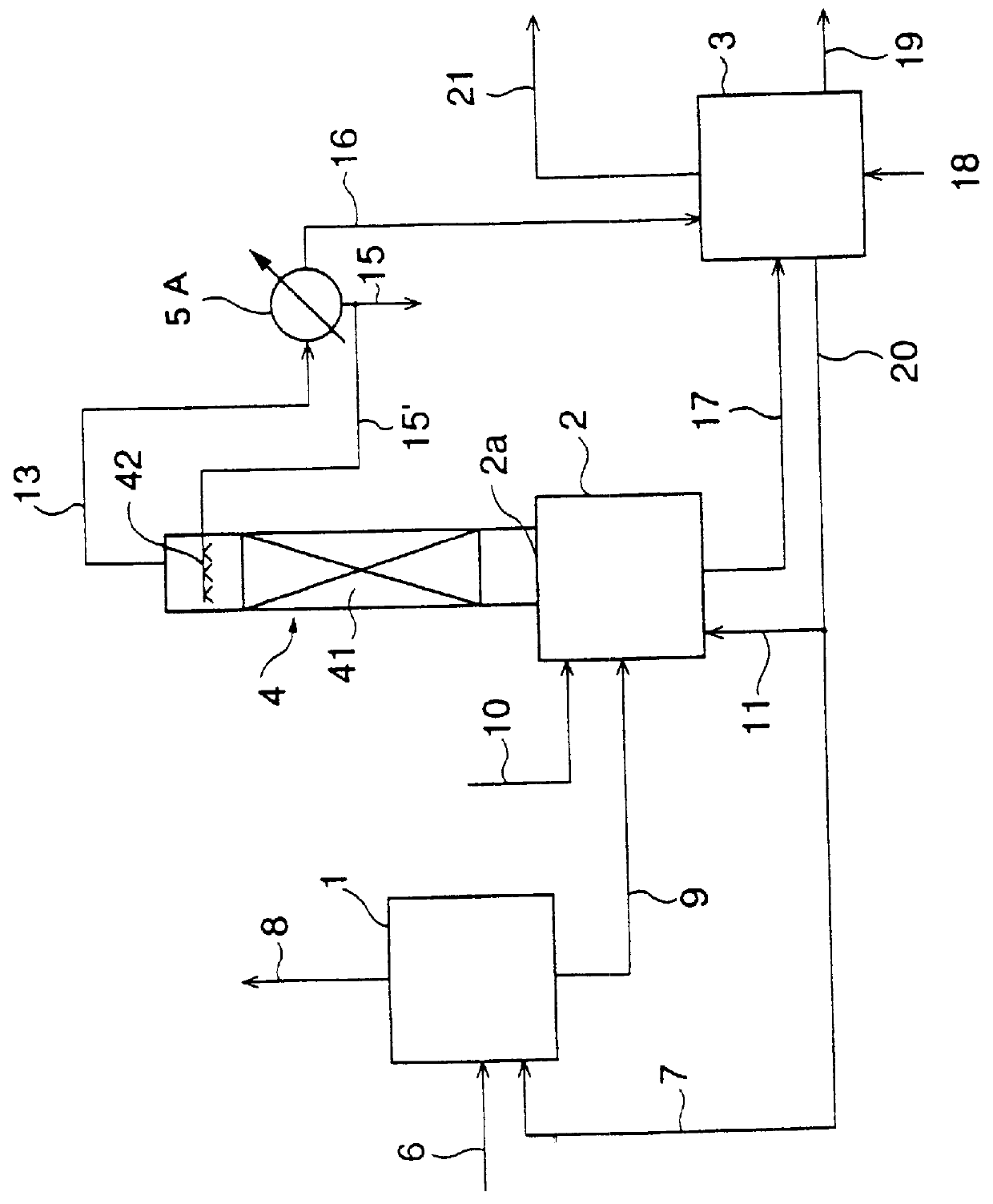

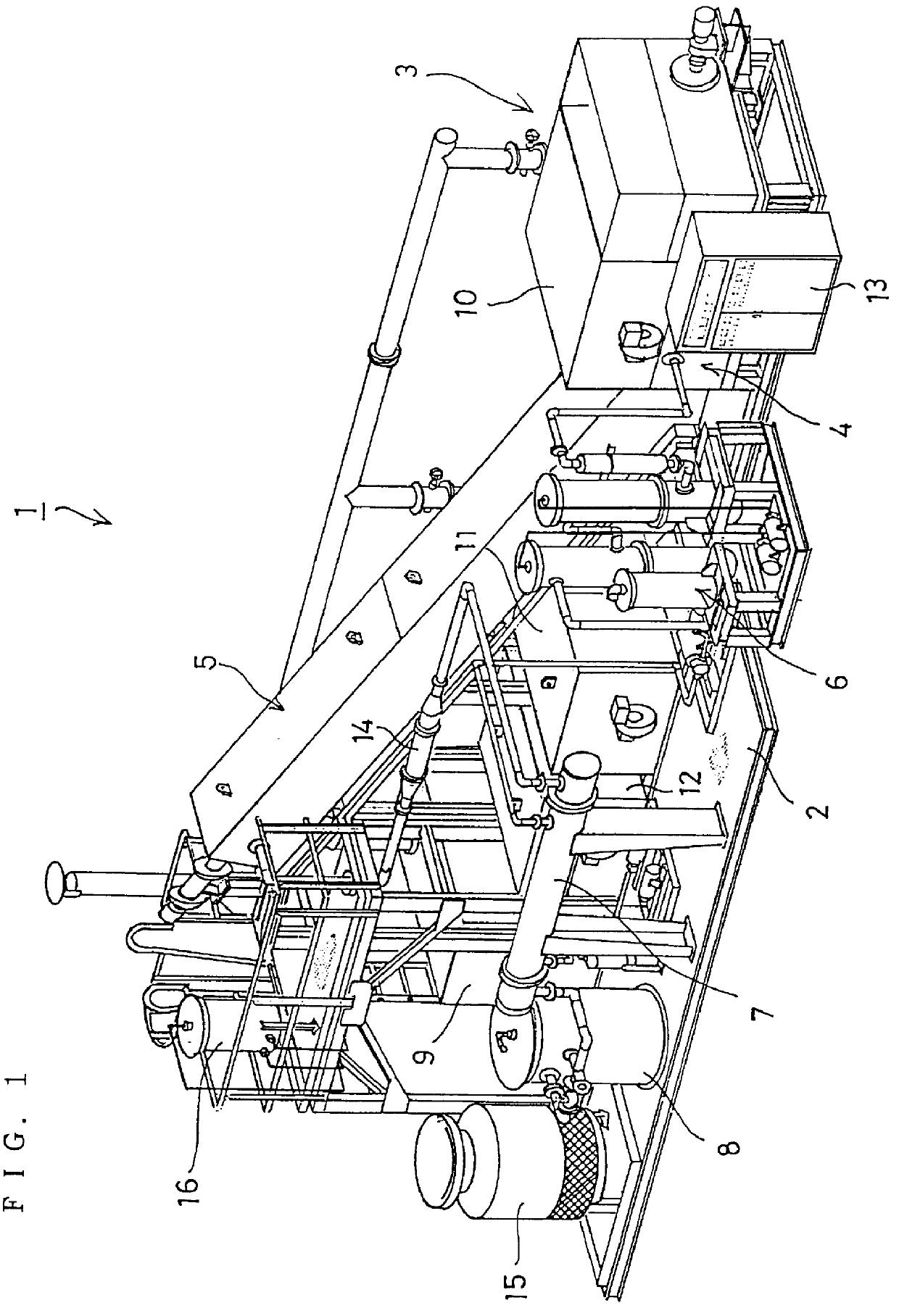

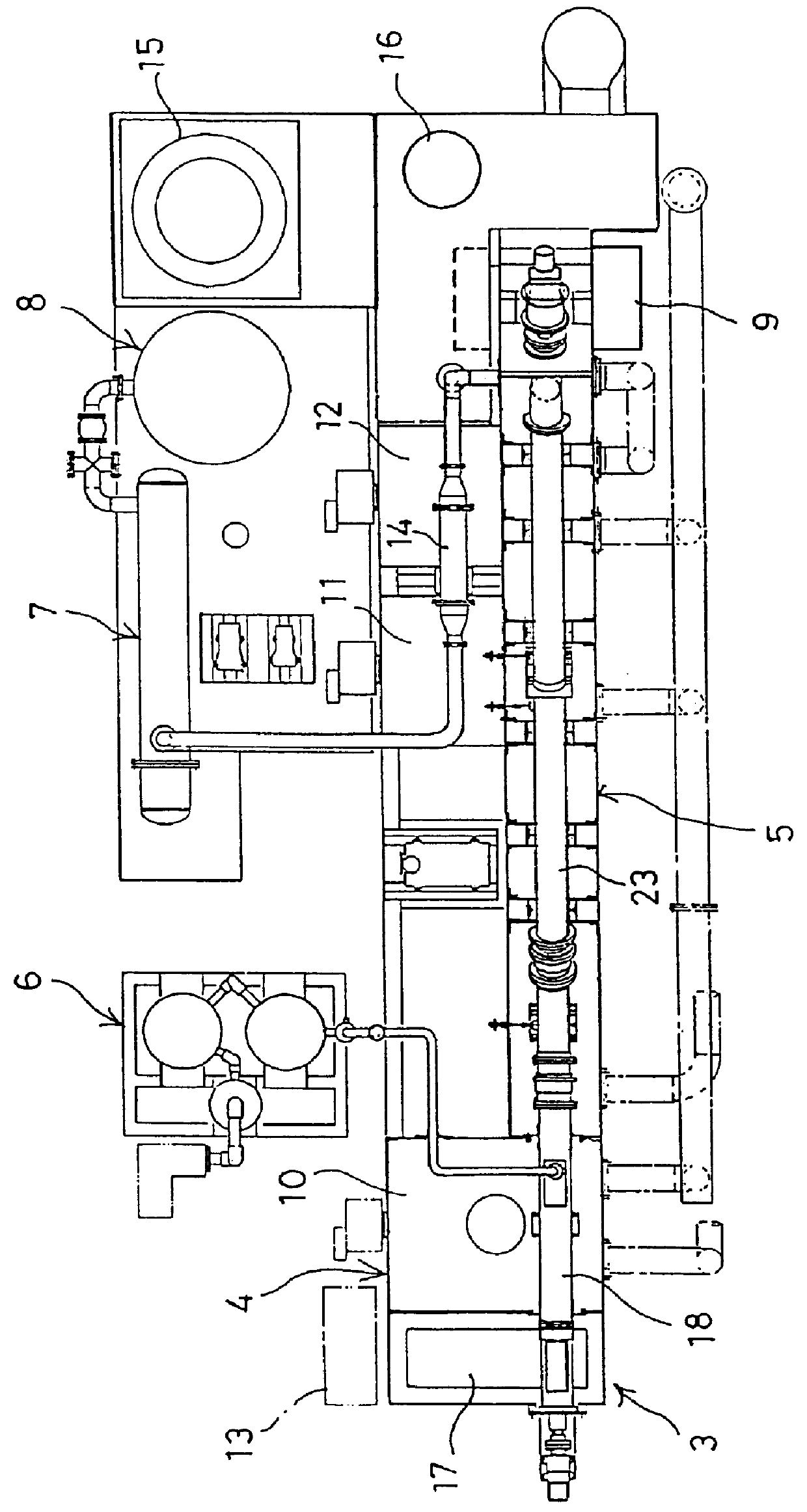

Method and apparatus for reclaiming oil from waste plastic

InactiveUS6011187AIncrease productionContinuous operationPlastic recyclingIndirect and direct heating destructive distillationForeign matterBoiling point

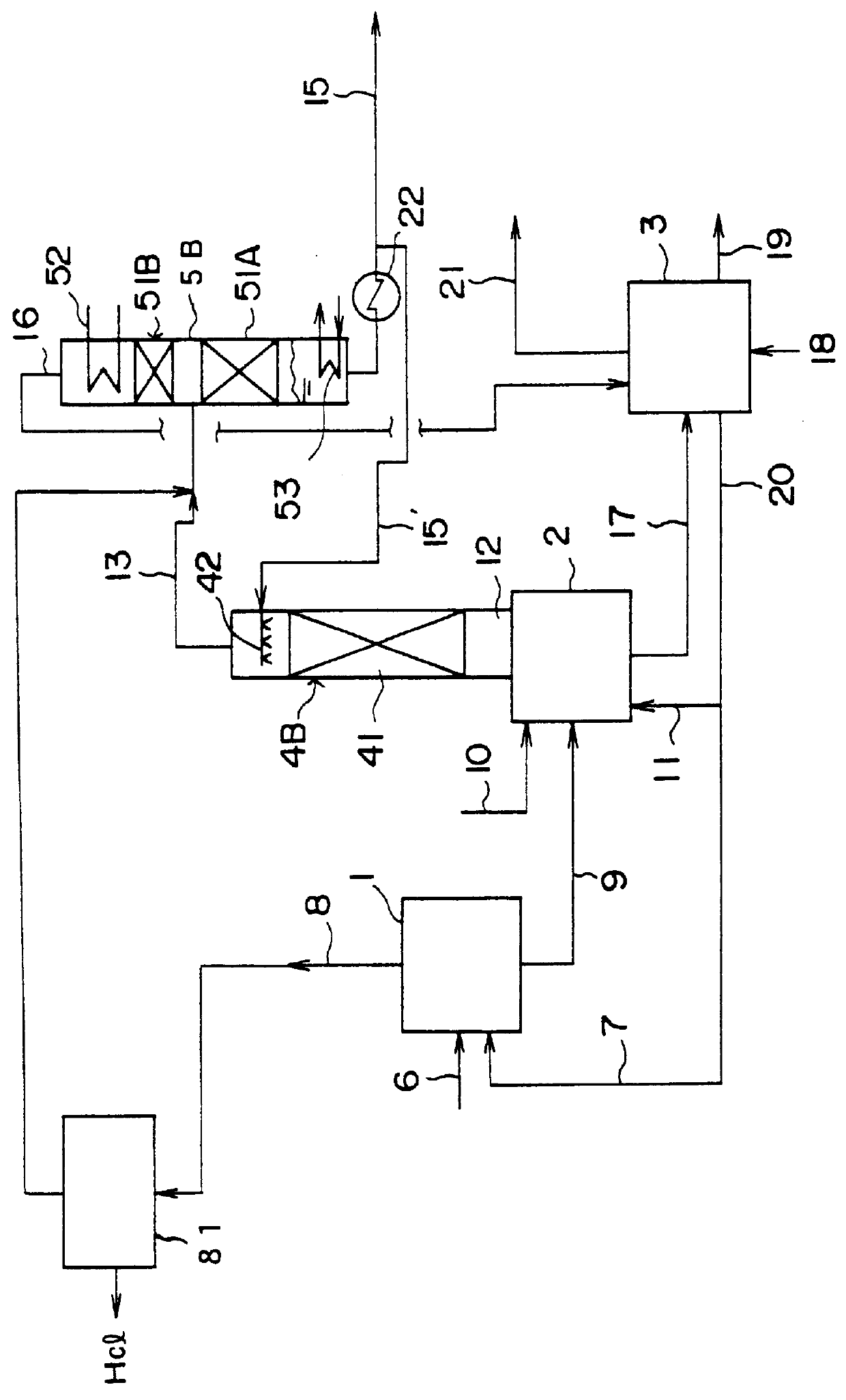

PCT No. PCT / JP97 / 00572 Sec. 371 Date Jan. 8, 1998 Sec. 102(e) Date Jan. 8, 1998 PCT Filed Feb. 27, 1997 PCT Pub. No. WO97 / 31990 PCT Pub. Date Sep. 4, 1997This invention provides a method for reclaiming oil from waste plastic in such a way that thermosetting resins and solid foreign matter in the plastic will not pose a problem. This method greatly reduces the burden of presorting the garbage or industrial waste. To achieve this objective when oil is to be reclaimed from a waste plastic containing chlorine compounds, such as vinyl chloride, the plastic must first be stripped of chlorine. Prior to pyrolysis, while being conveyed forward in a continuous stream, the plastic is mixed with heated sand and / or an additive agent to raise its temperature to 250-350 DEG C. This creates a product which is comprised of a mixture of sand and substantially dechlorinated plastic. The product is mixed with heated sand to heat it directly to a temperature of 350-500 DEG C. It is maintained at this temperature until pyrolysis occurs. In order to obtain high-quality oil with a low boiling point, a first gas / liquid separation process separates the product obtained from the aforesaid pyrolysis into liquid high-boiling point oil, gaseous low-boiling point oil and low molecular-weight gases, and recirculates the liquid high-boiling point oil to the pyrolysis process, and a second gas / liquid separation process separates the gaseous low-boiling point oil and low molecular-weight gases into liquid low-boiling point oil and low molecular-weight gases. The first and second gas / liquid separation process are connected in sequence.

Owner:MITSUBISHI HEAVY IND LTD

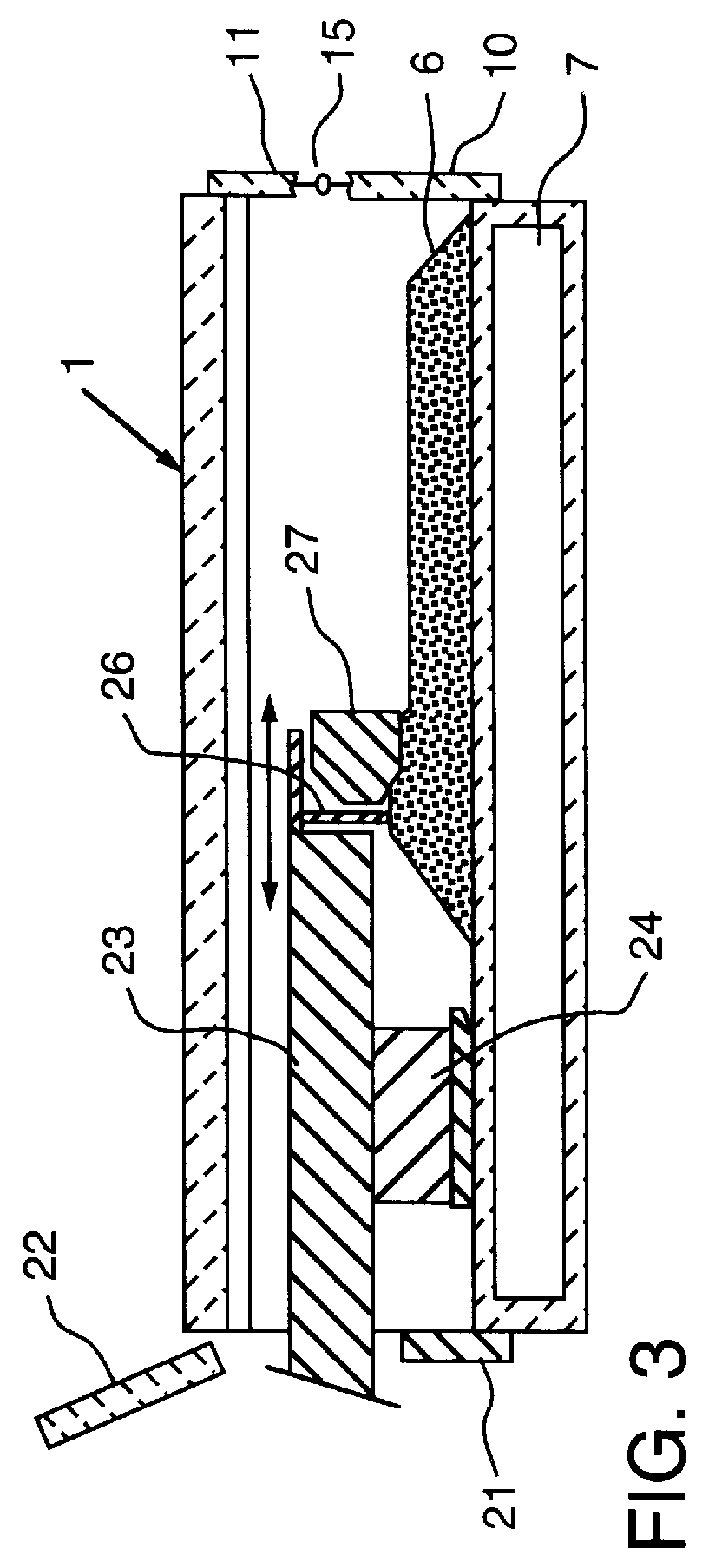

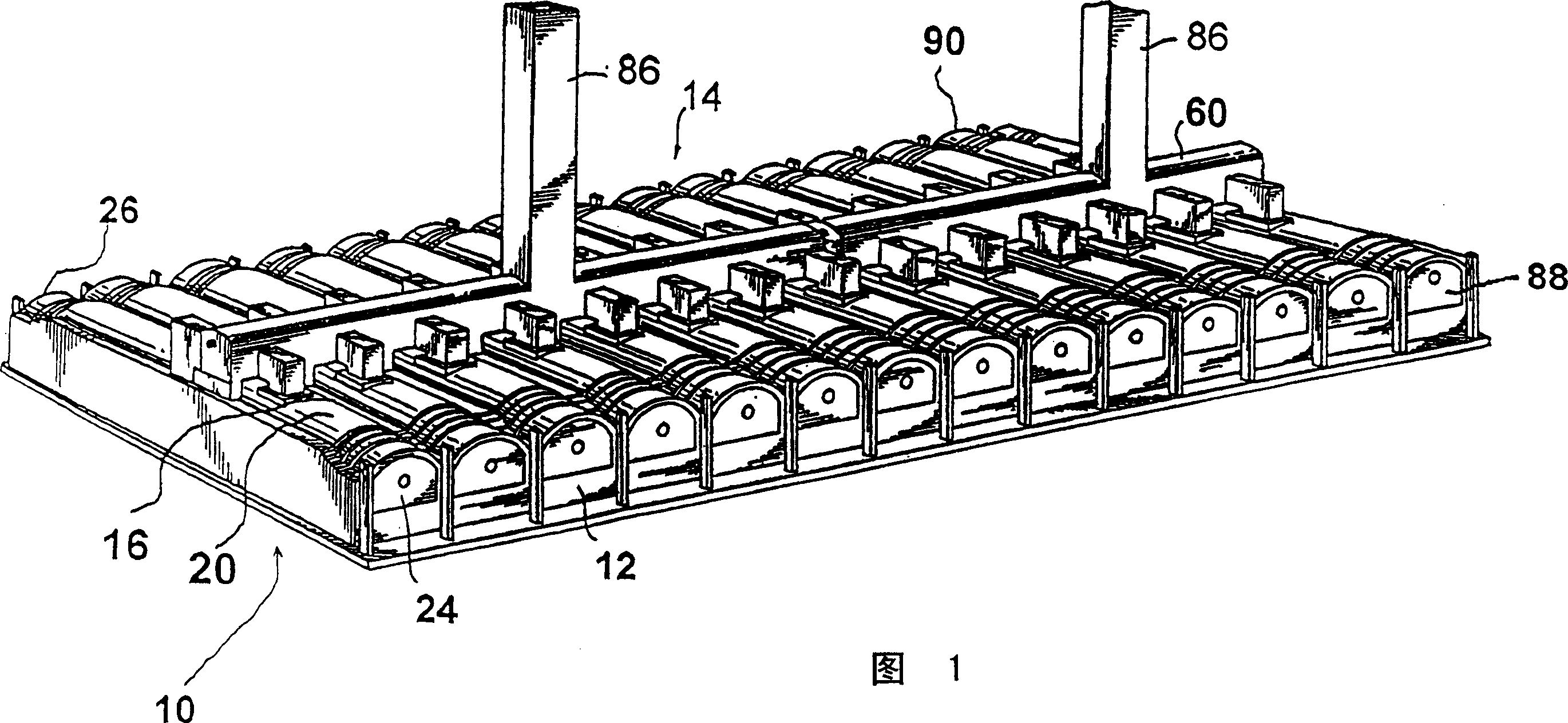

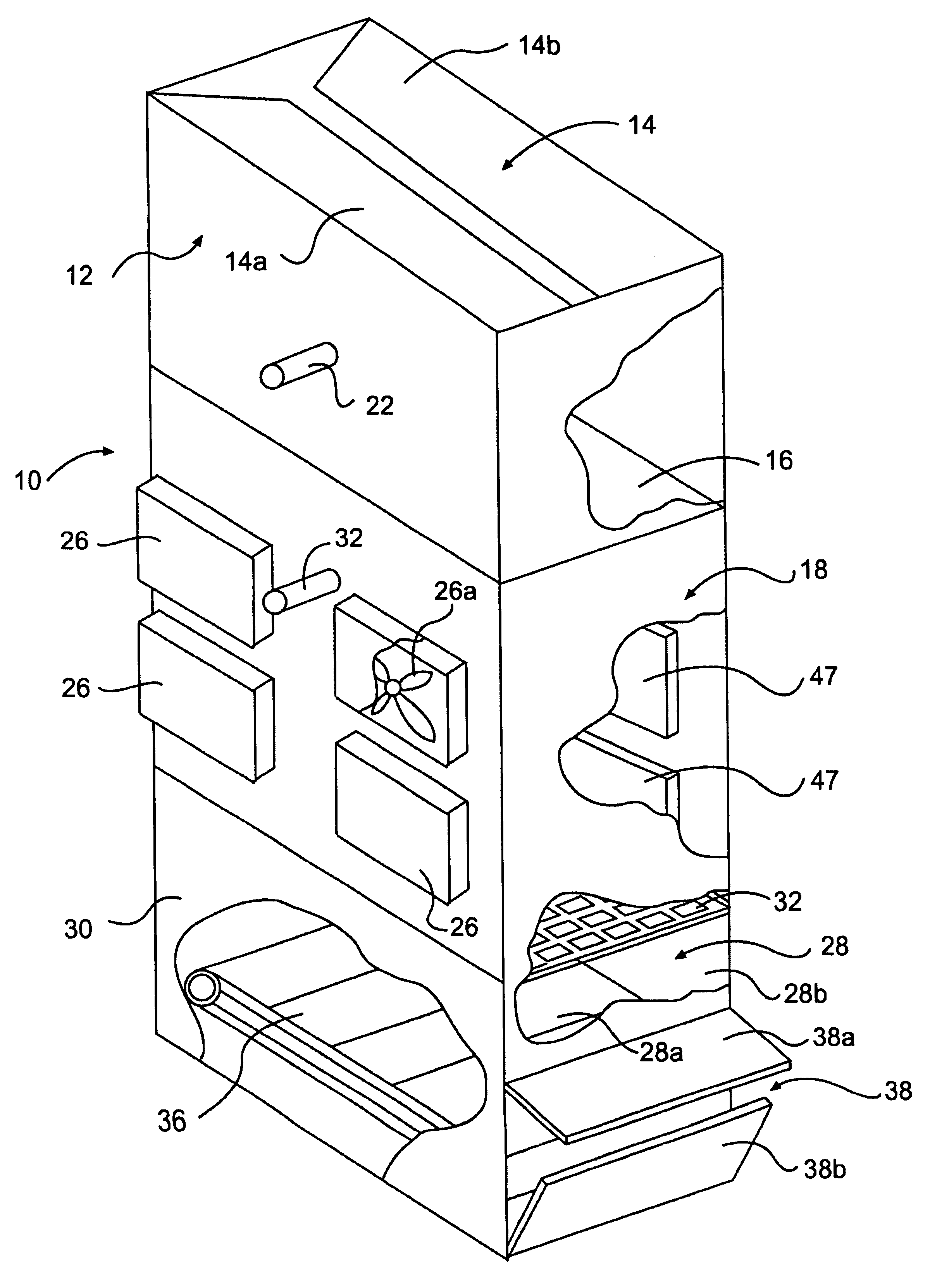

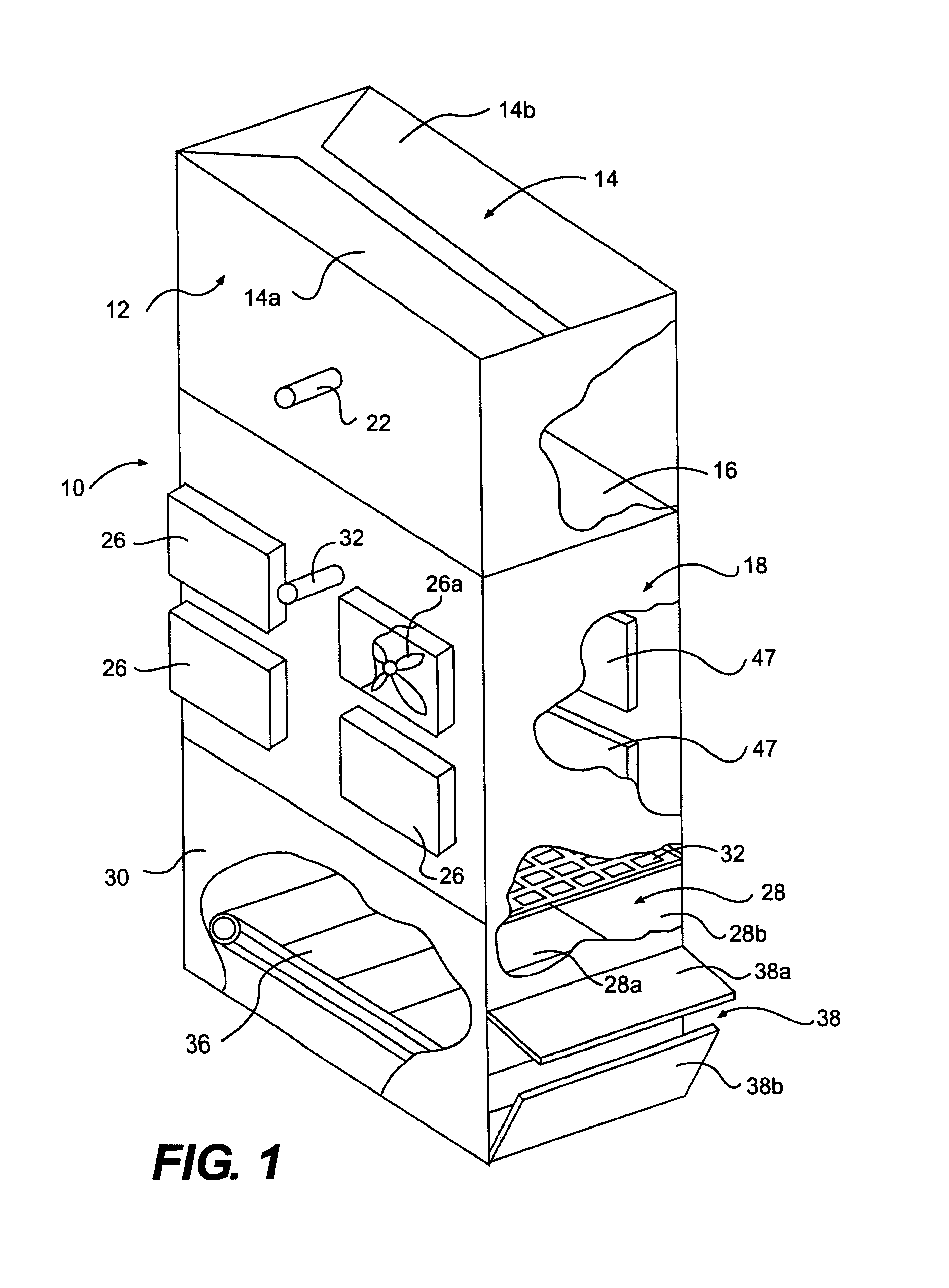

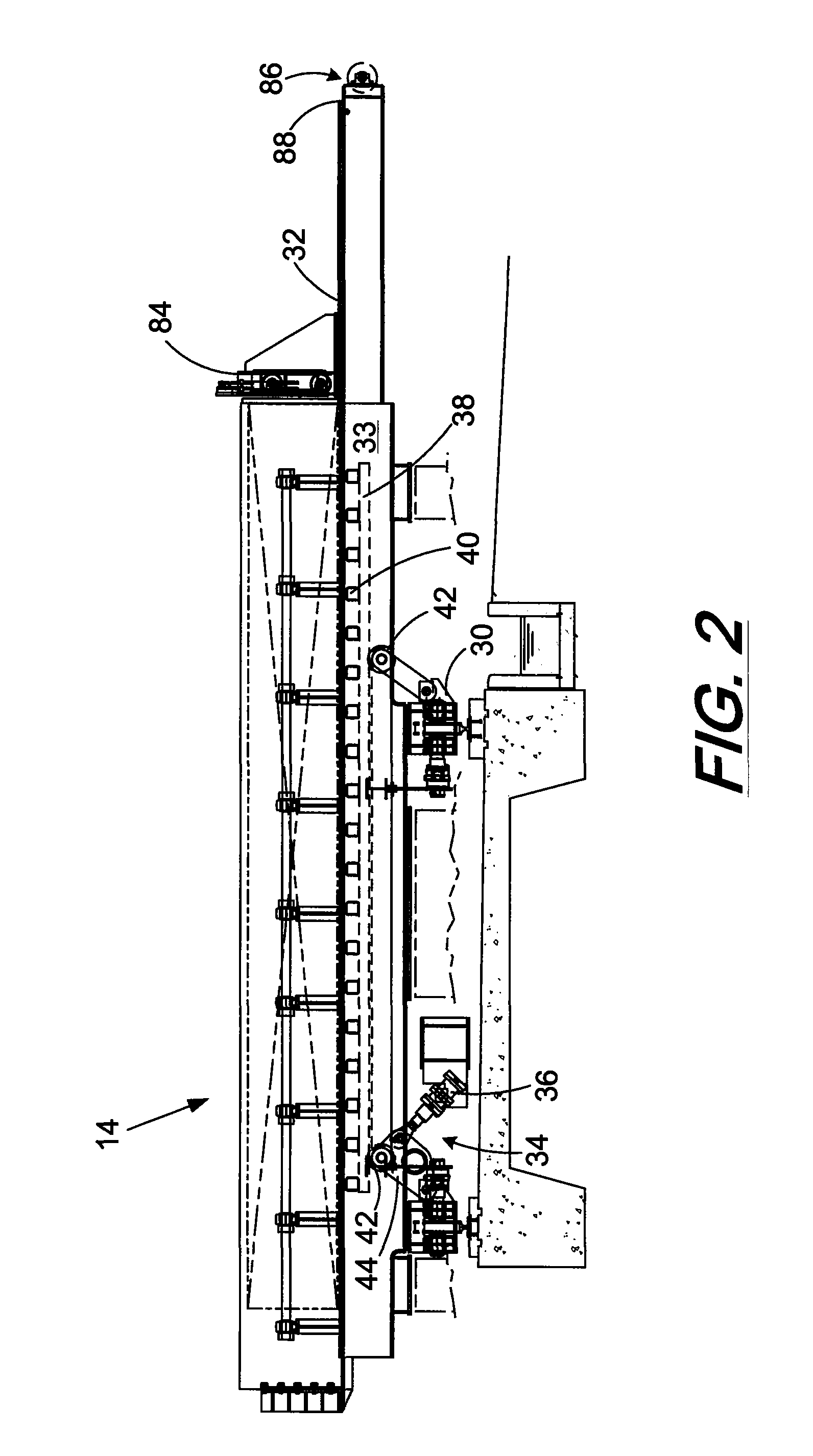

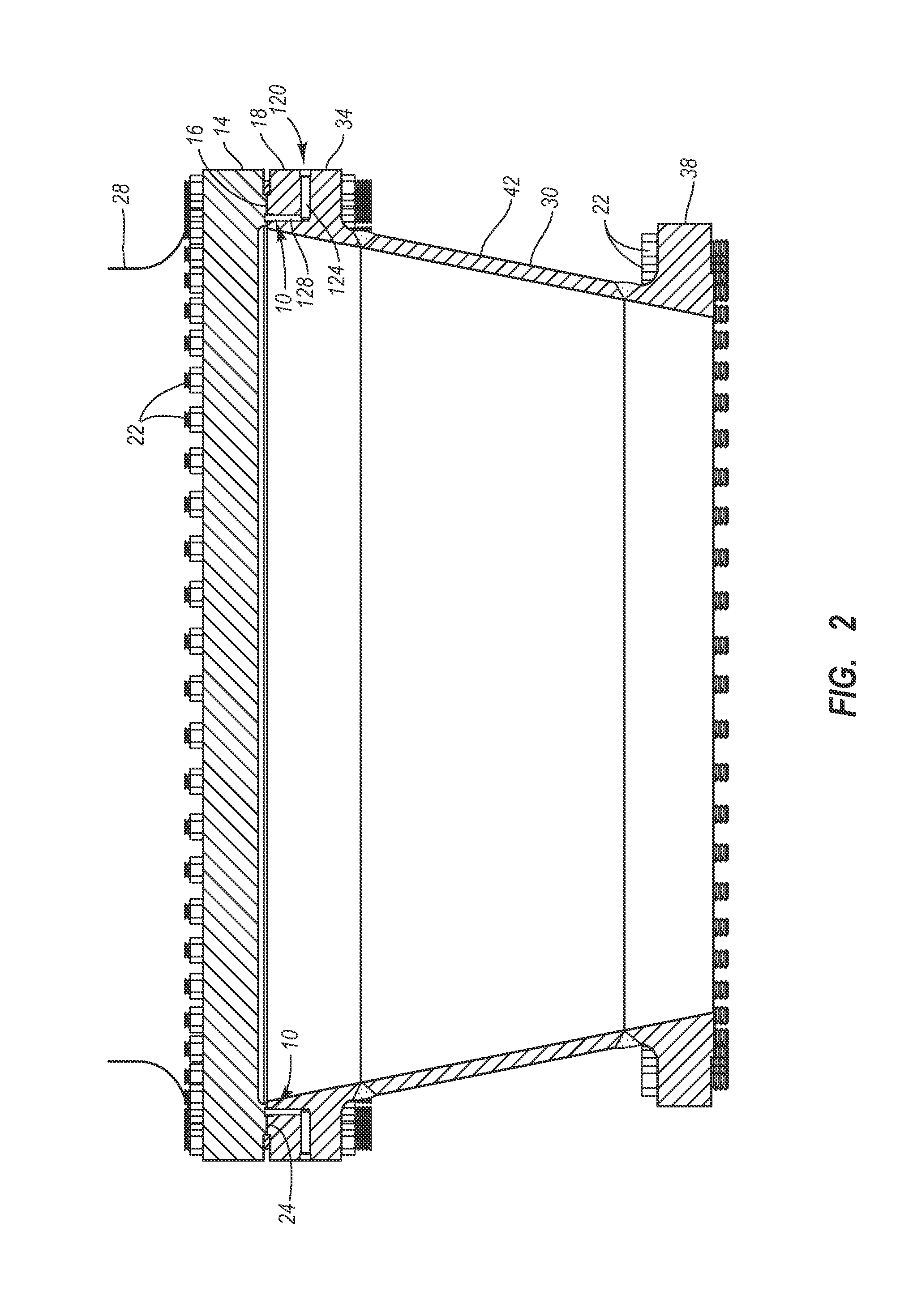

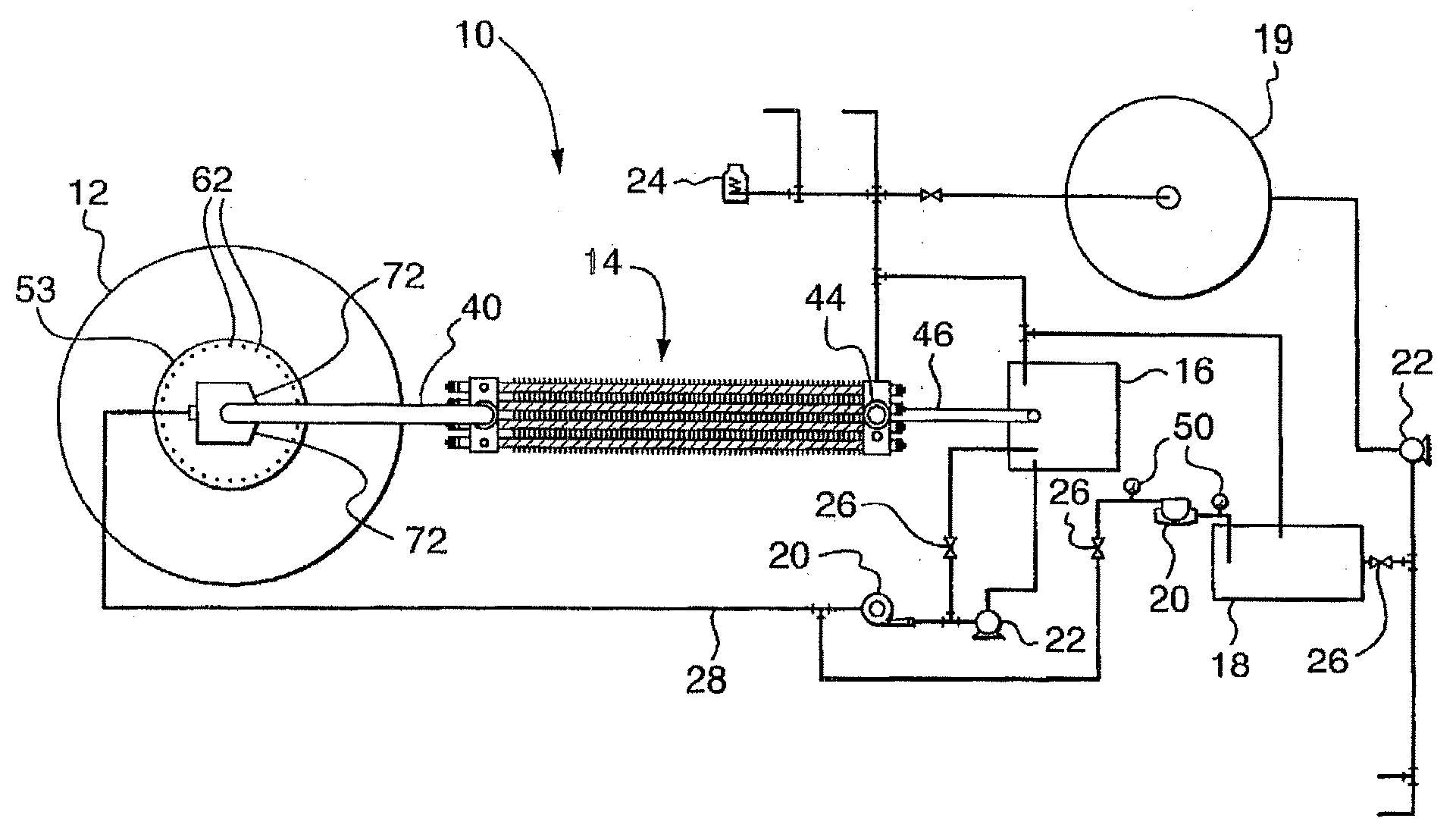

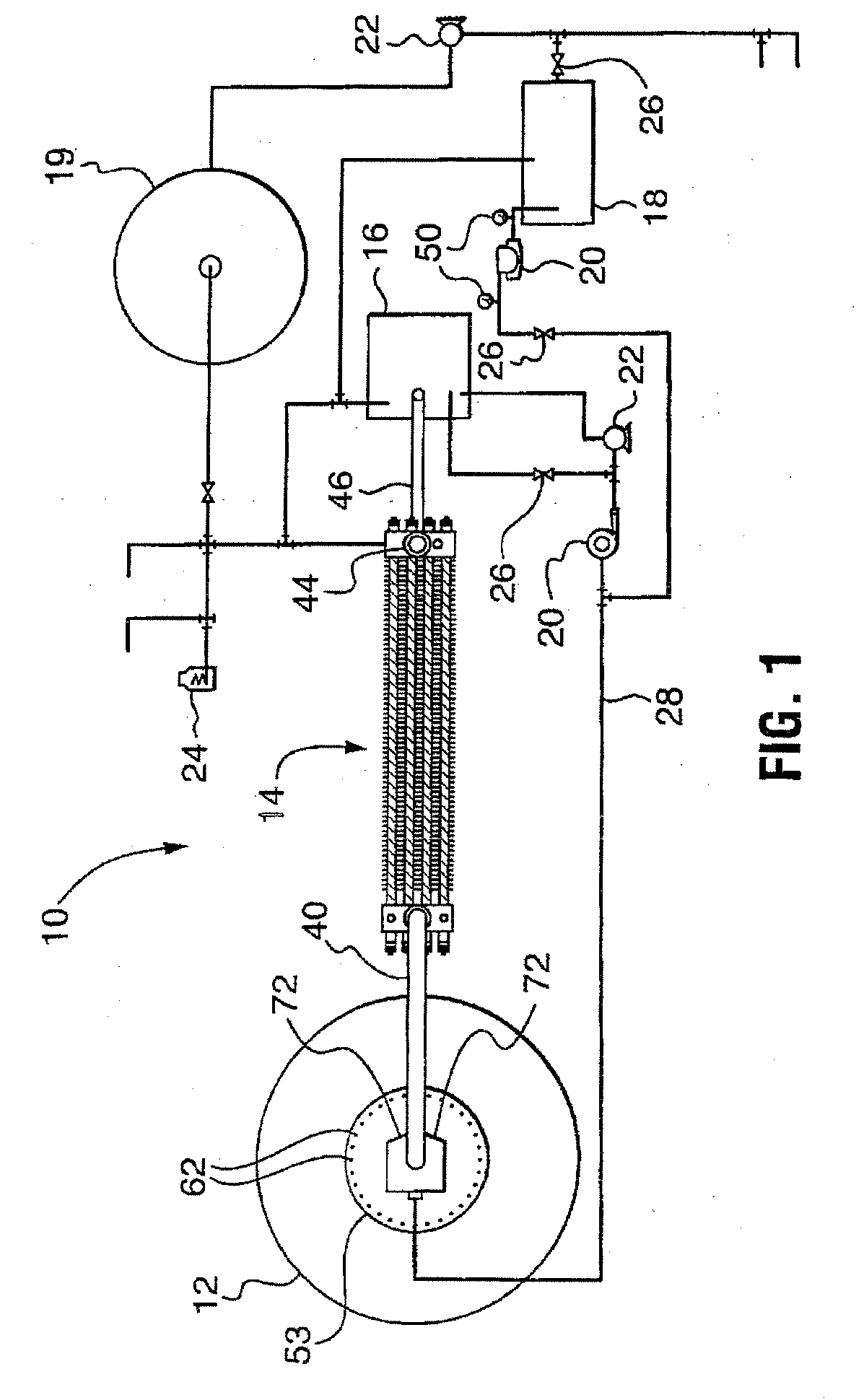

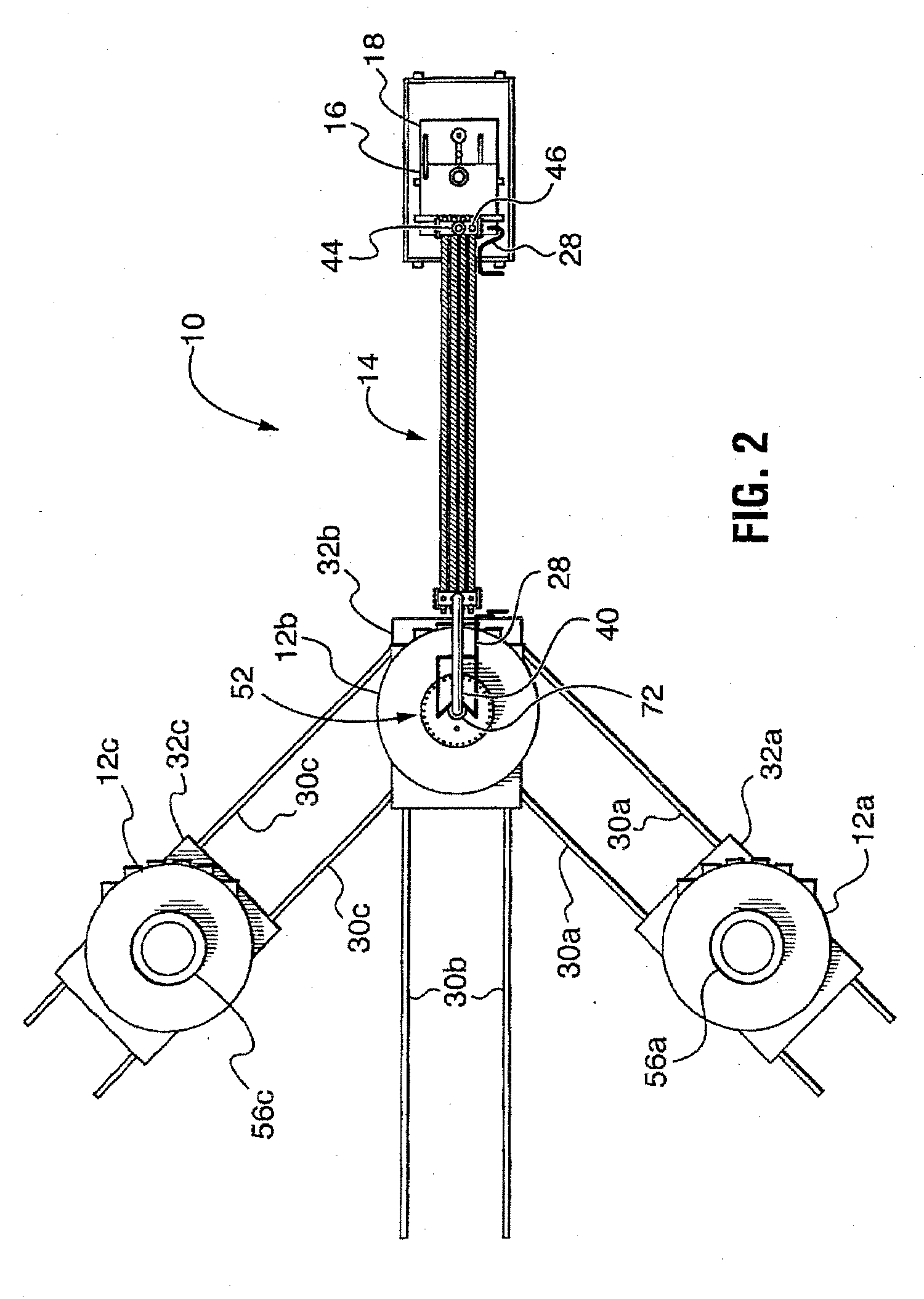

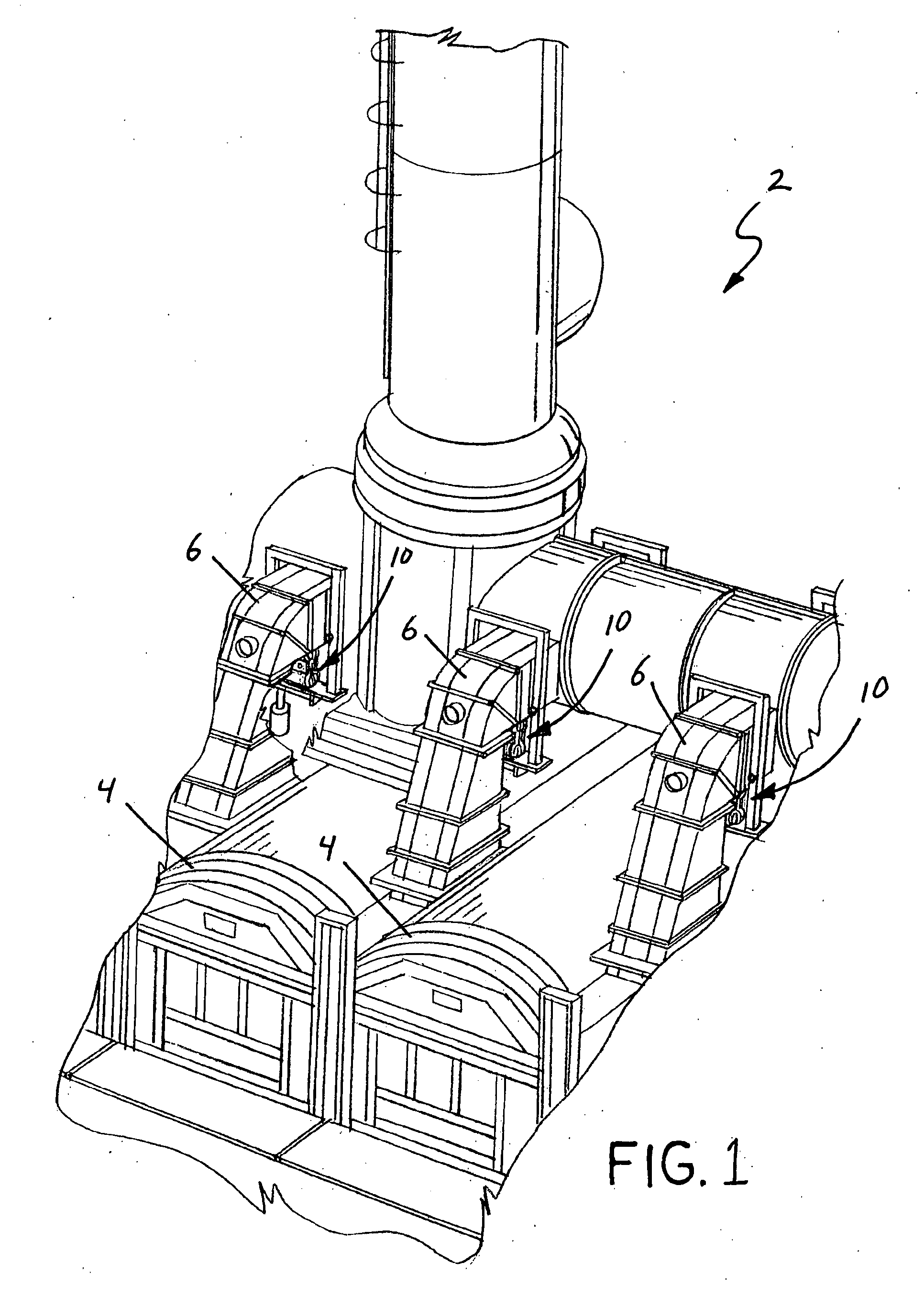

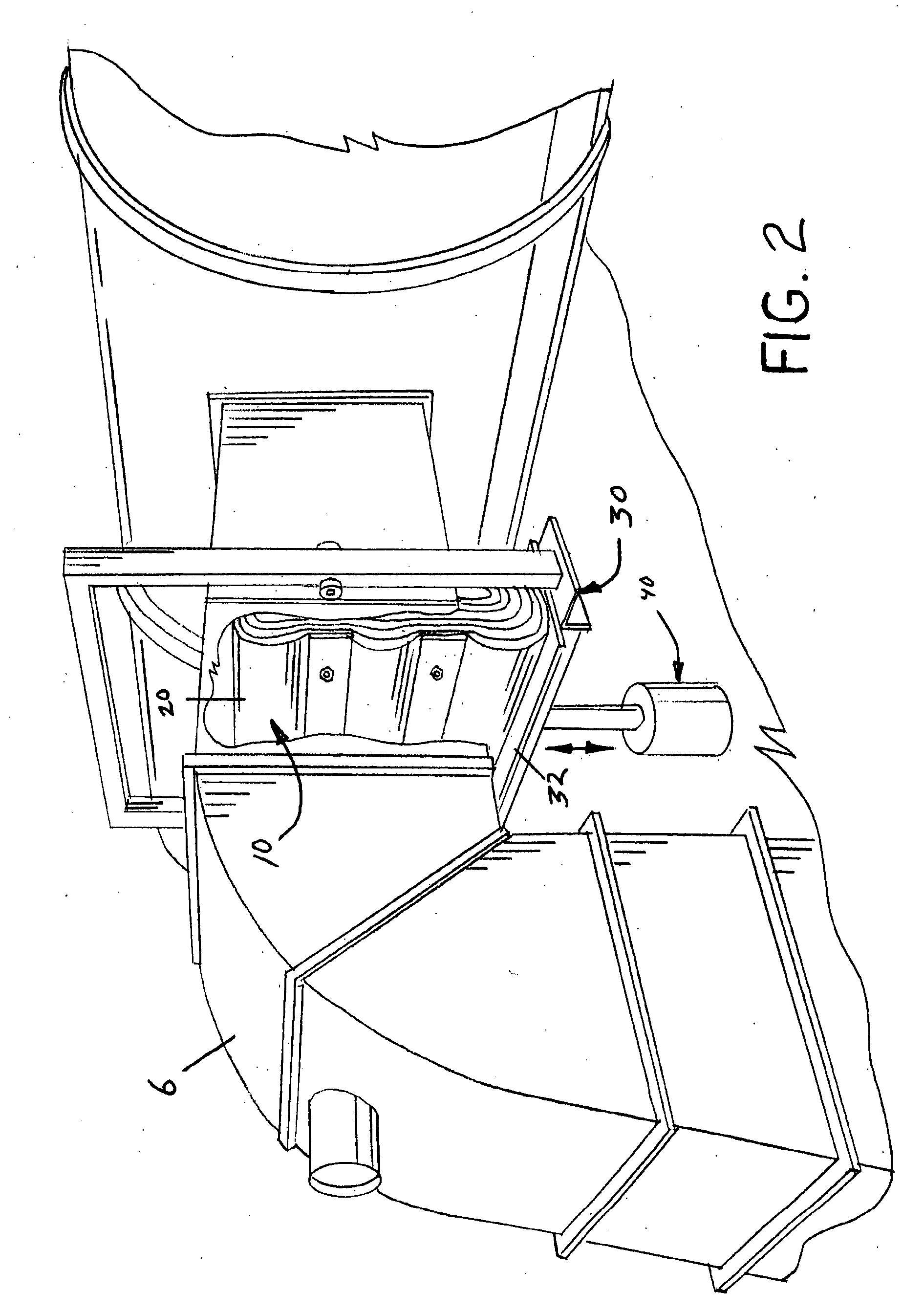

Method and apparatus for compacting coal for a coal coking process

InactiveUS7497930B2Minimize amount of timeUniform bulk densityCoke quenchingCharging-discharging device combinationsEngineeringCoke oven

Relatively high speed methods for increasing the bulk density of coal particles, apparatus for increasing the bulk density of coal particles and methods for making metallurgical coke. Once such method includes depositing coal particles onto a charging plate external to a coking oven to provide an elongate bed of dry, uncompacted coal having an upper surface of the charging plate. The charging plate has side walls, and at least one movable end wall An impact pressure is applied to the upper surface of the bed of dry, uncompacted coal while degassing the coal to provide a dry, compacted coal bed having a bulk density ranging from about 960 to about 1200 kilograms per cubic meter.

Owner:SUNCOKE TECH & DEV LLC

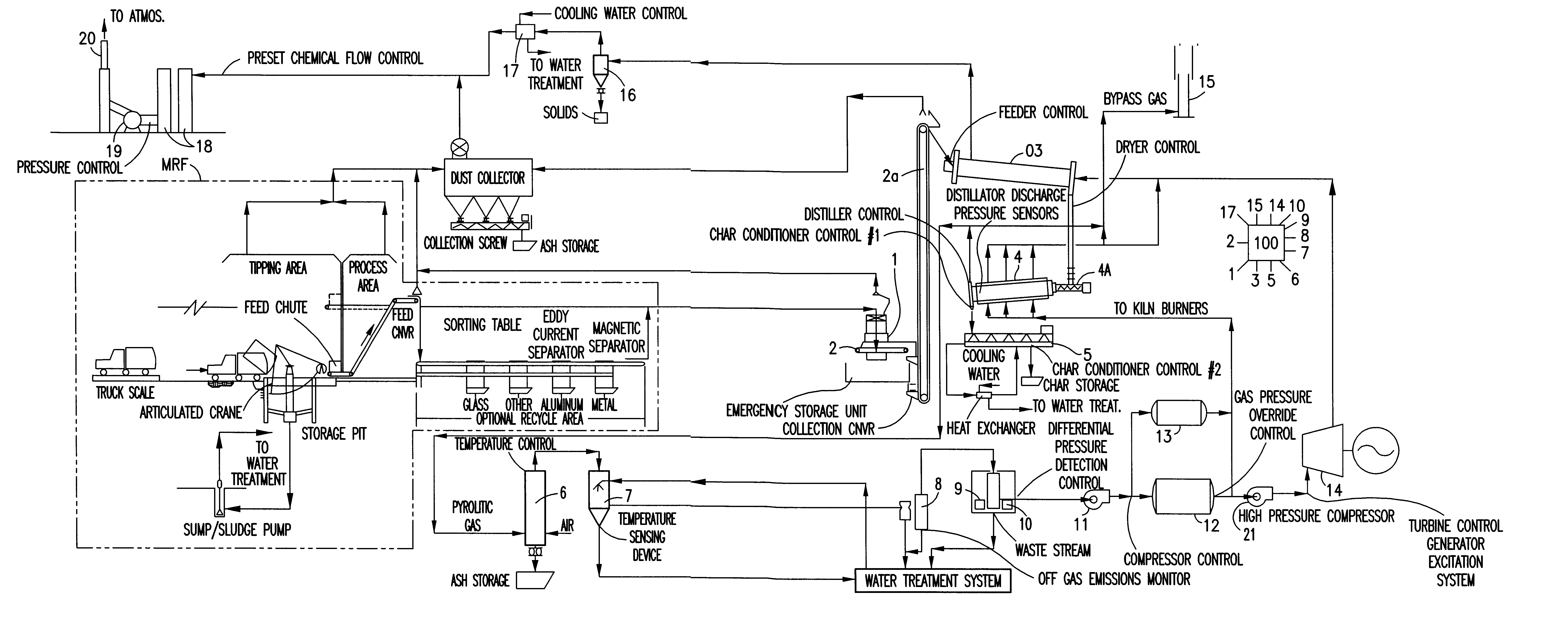

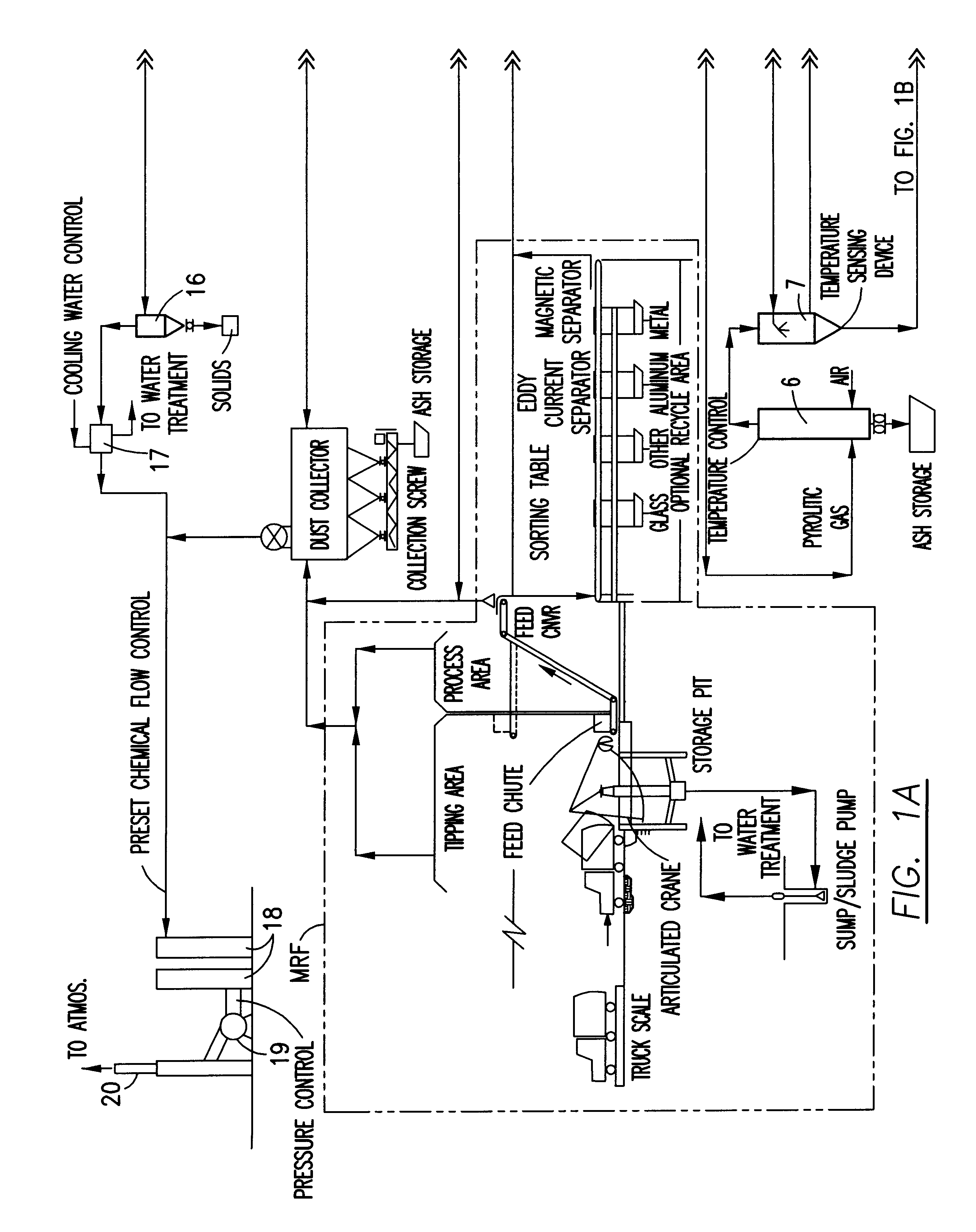

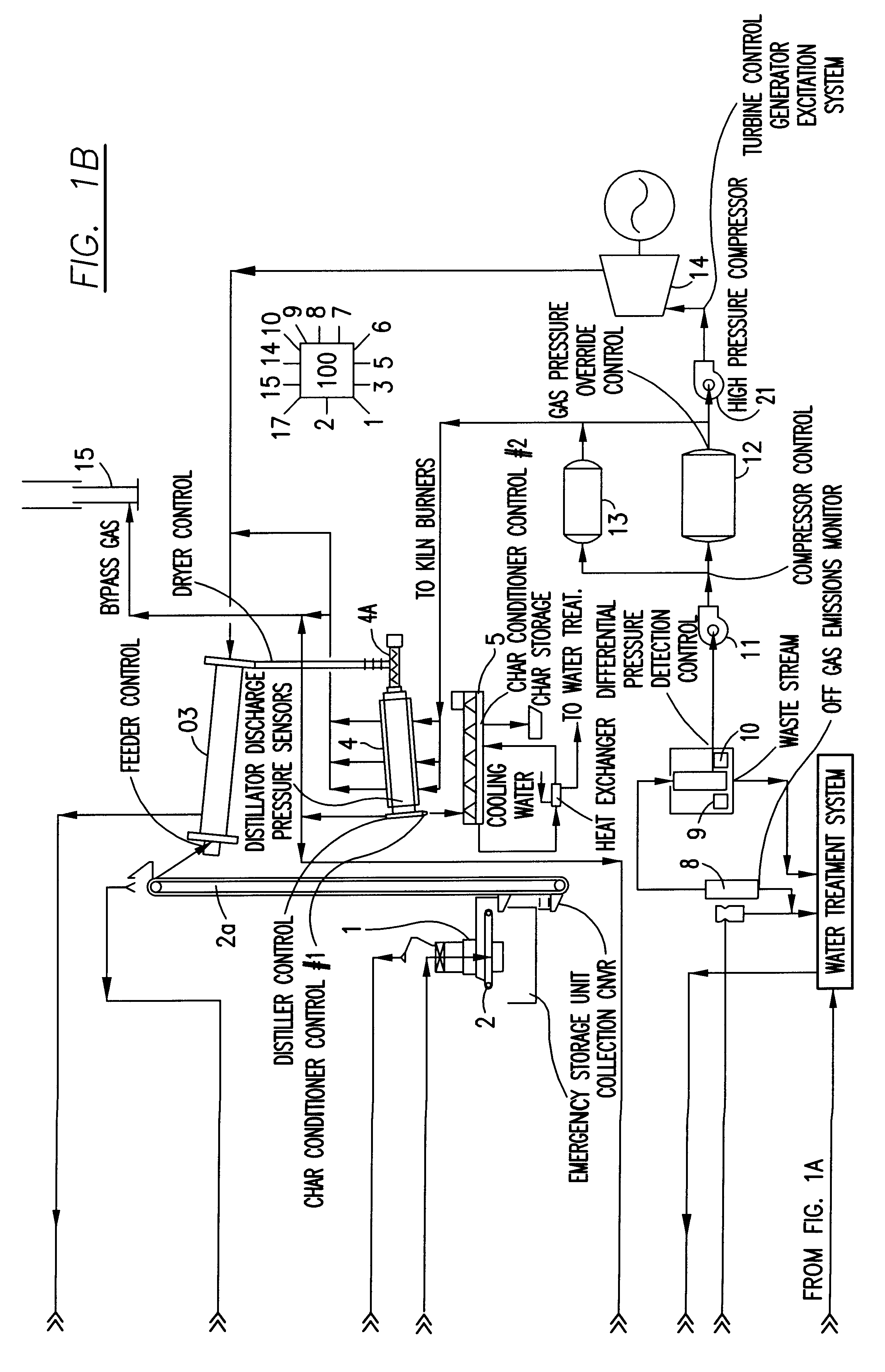

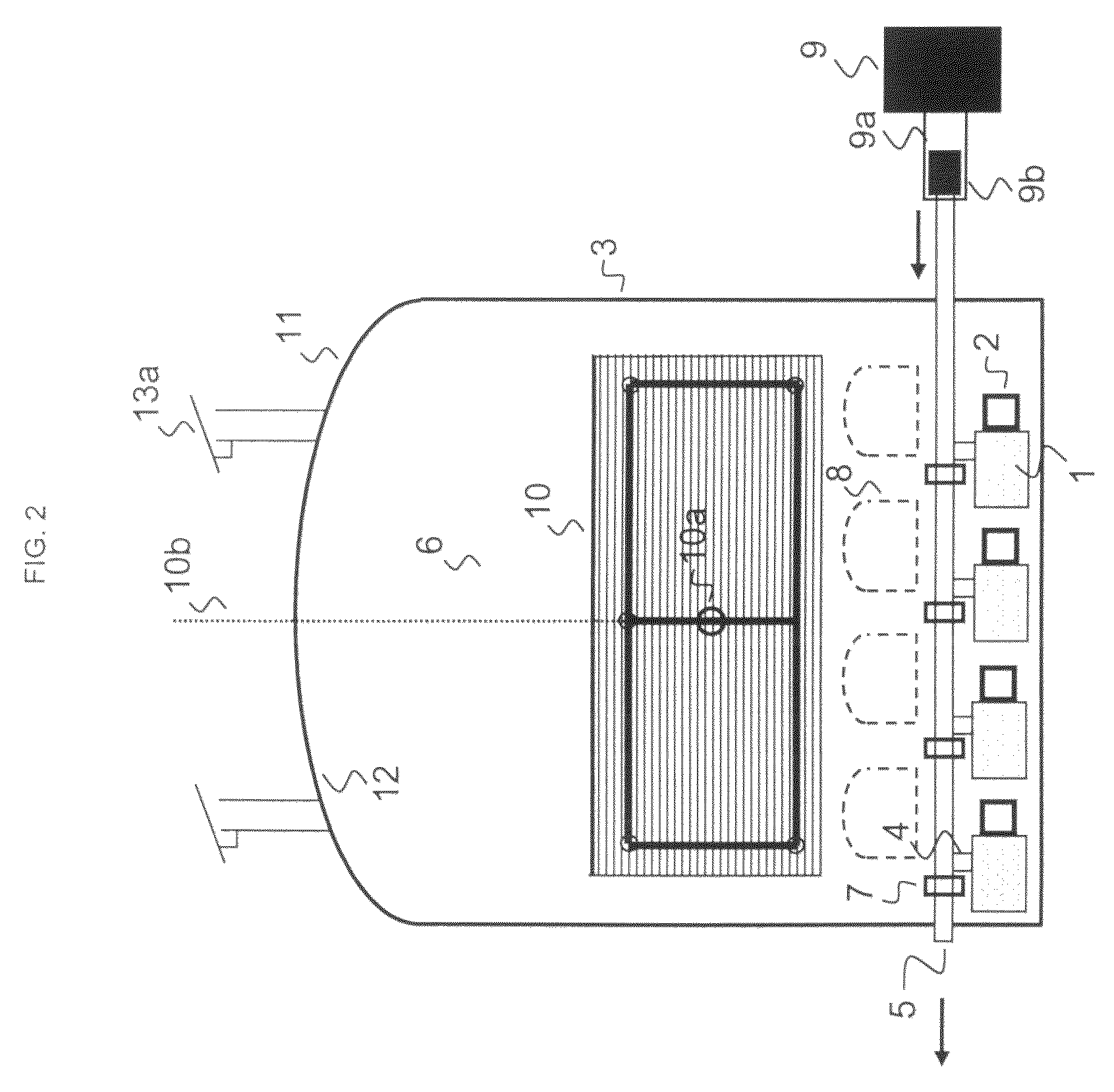

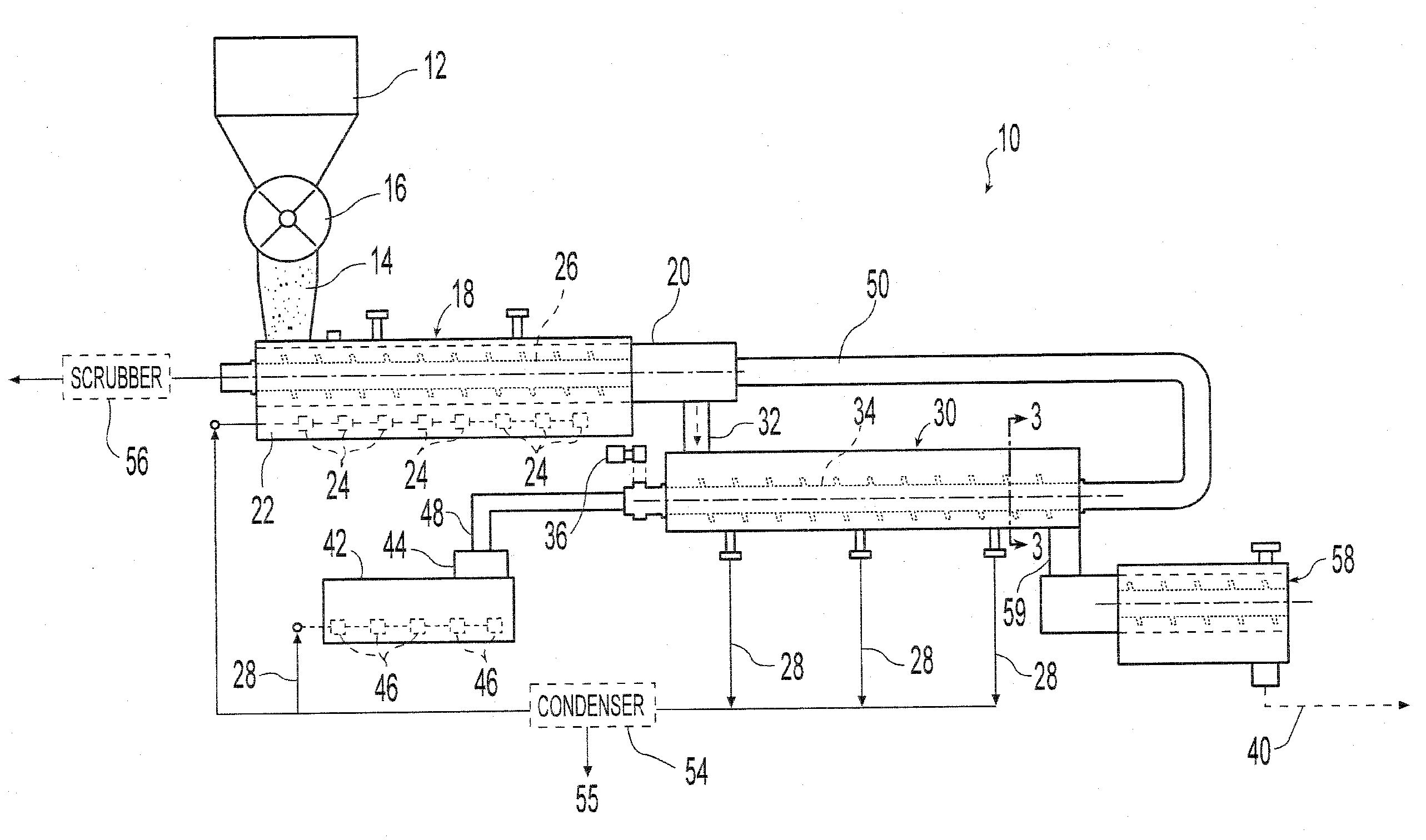

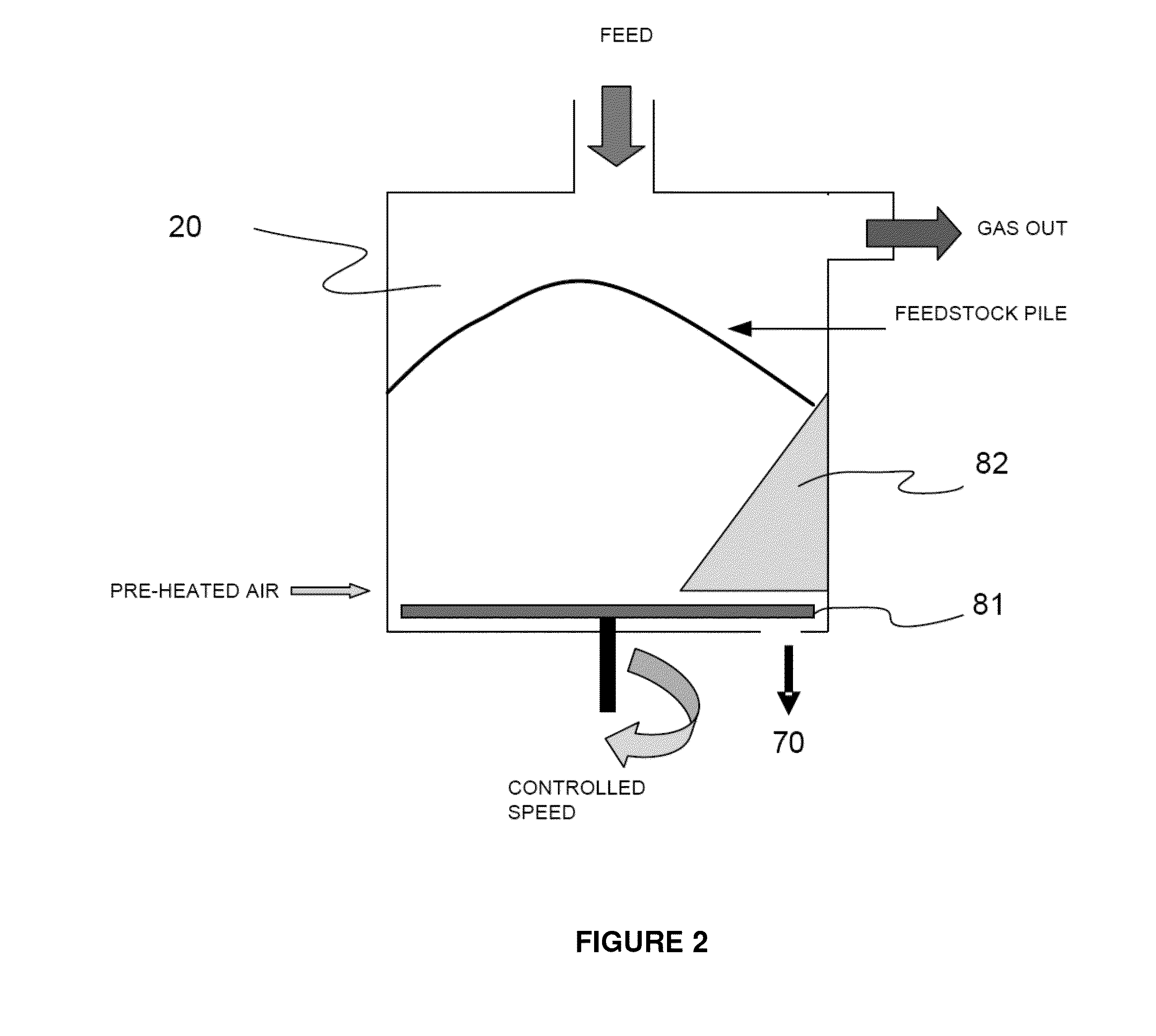

Integrated control and destructive distillation of carbonaceous waste

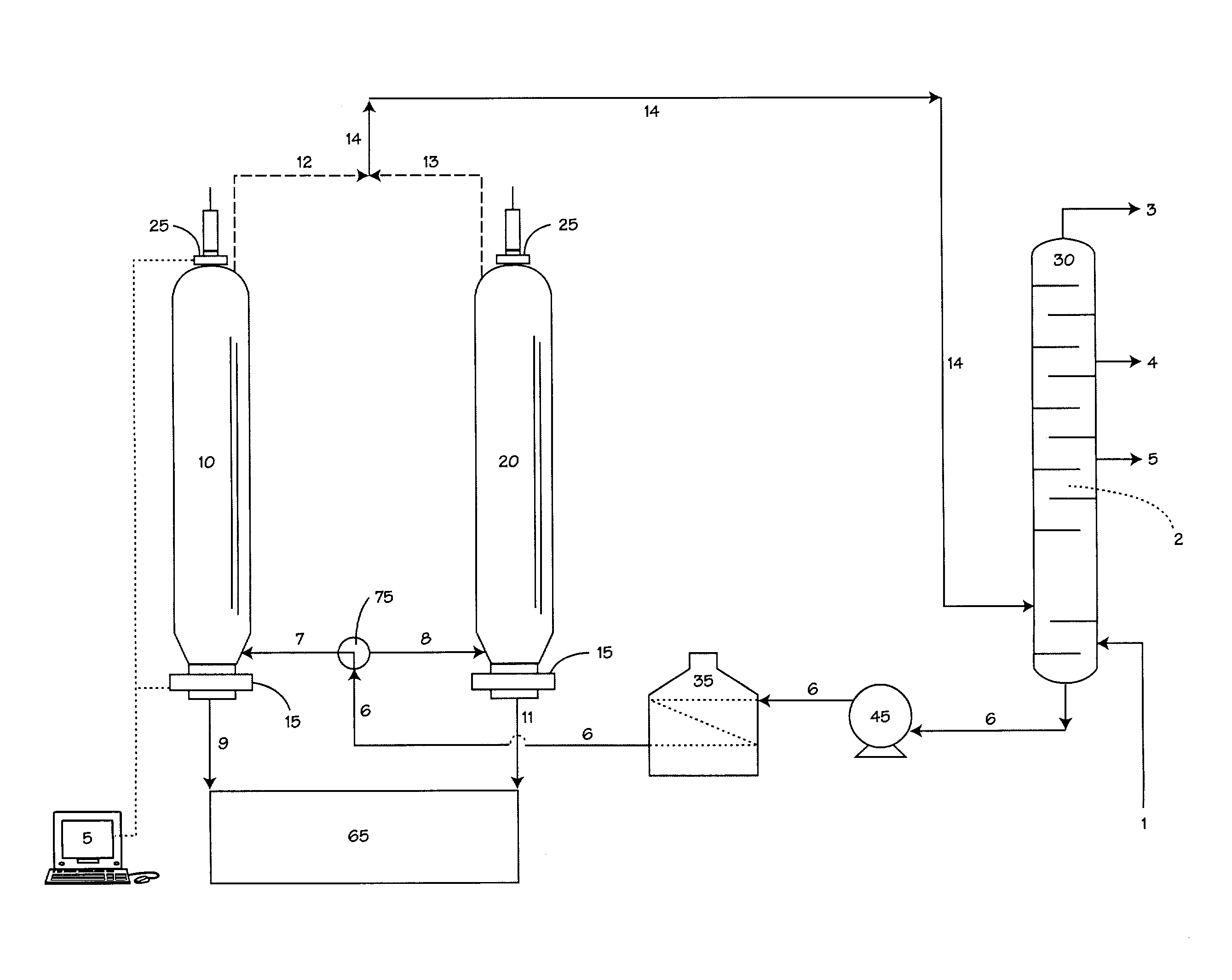

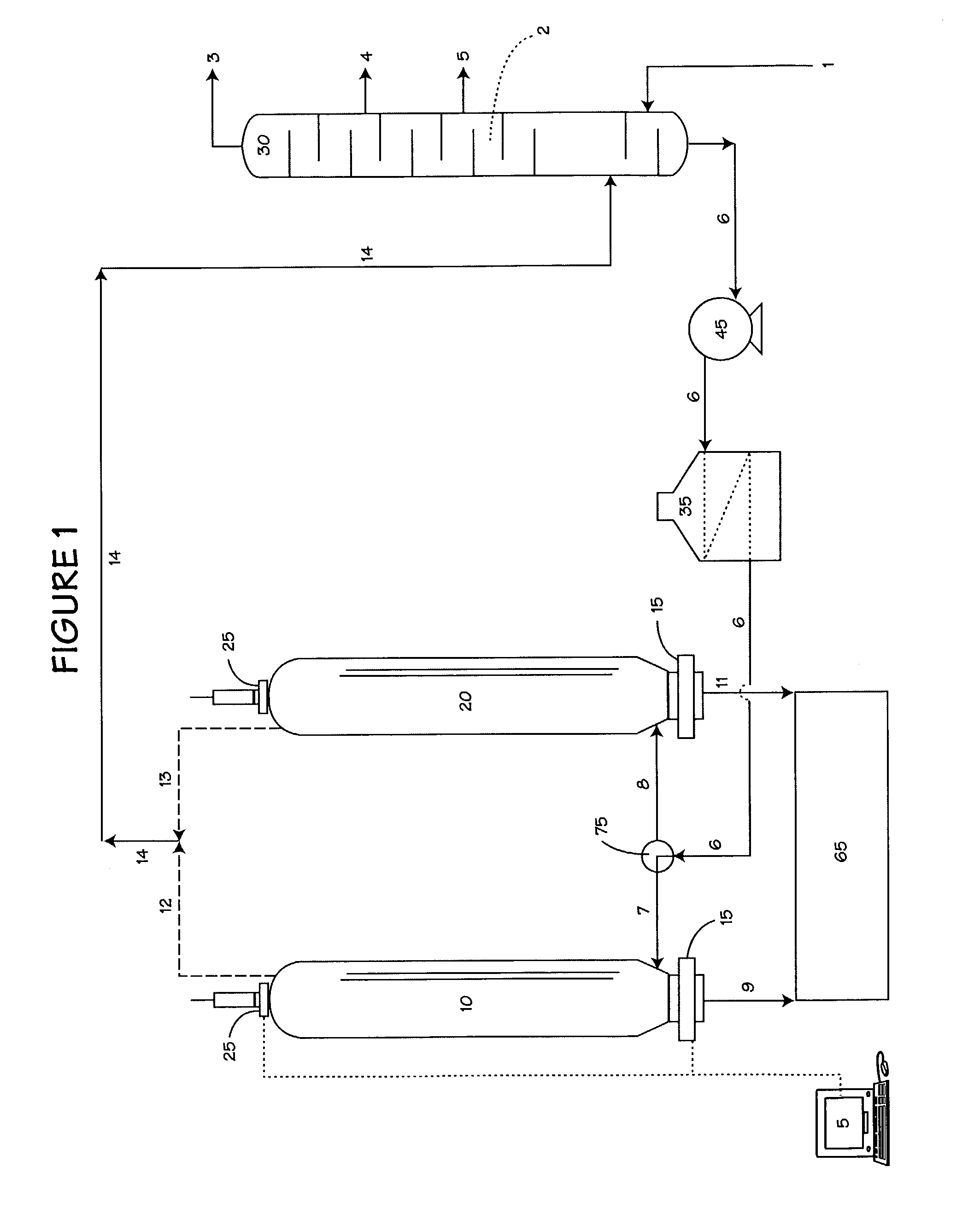

InactiveUS6182584B1High quantity and qualityEnhanced yield quantity and qualityHorizontal chamber coke ovensEmission preventionComputer control systemWaste stream

A system and process to provide integrated control for the pyrolytic composition of organic (biomass) waste products especially for municipal solid waste systems. The system includes integrated control that monitors biomass waste stream throughout the entire system and the products produced therefrom and includes presorting, controlling the amount of material processed in a continuous manner, shredding, removing moisture in a continuous process that is controlled and providing the waste stream to the distillation unit for pyrolytic action where it is converted into gaseous fuel and a char residue. The gaseous fuel is scrubbed clean and monitored and stored and reused to provide heat to the system. The entire system may be self-sustaining and continuous with very little or no human intervention. An integrated real time computer control system includes sensors and measuring devices with all the major components to ensure integrated efficiency.

Owner:ENVIRONMENTAL SOLUTIONS & TECH

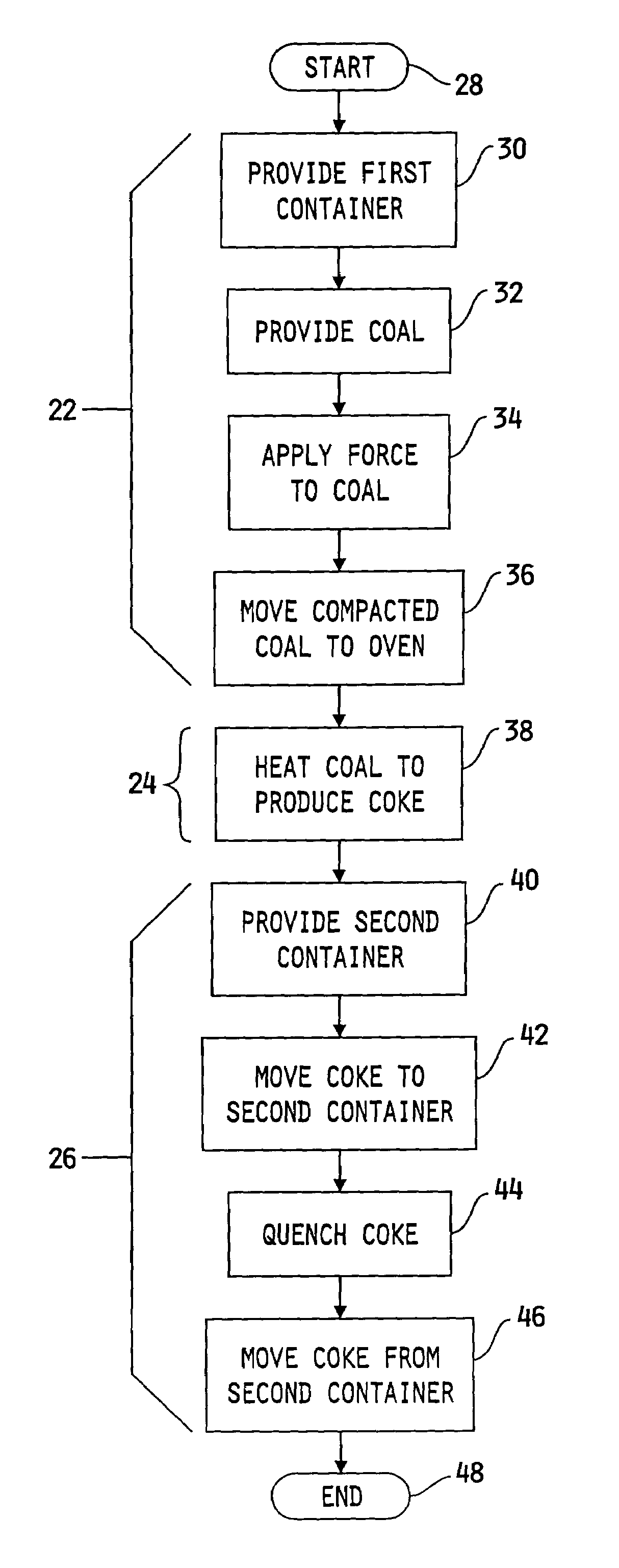

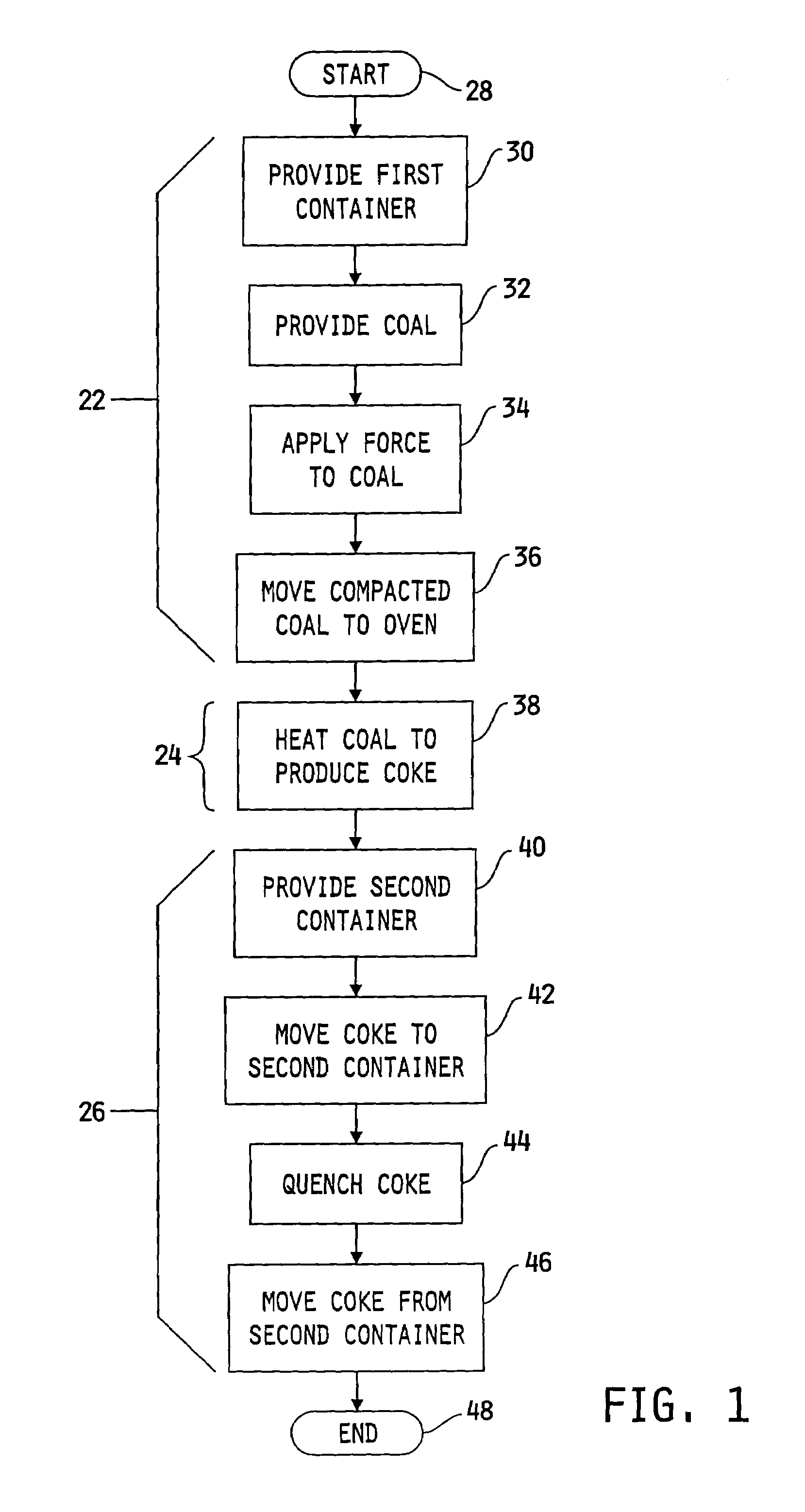

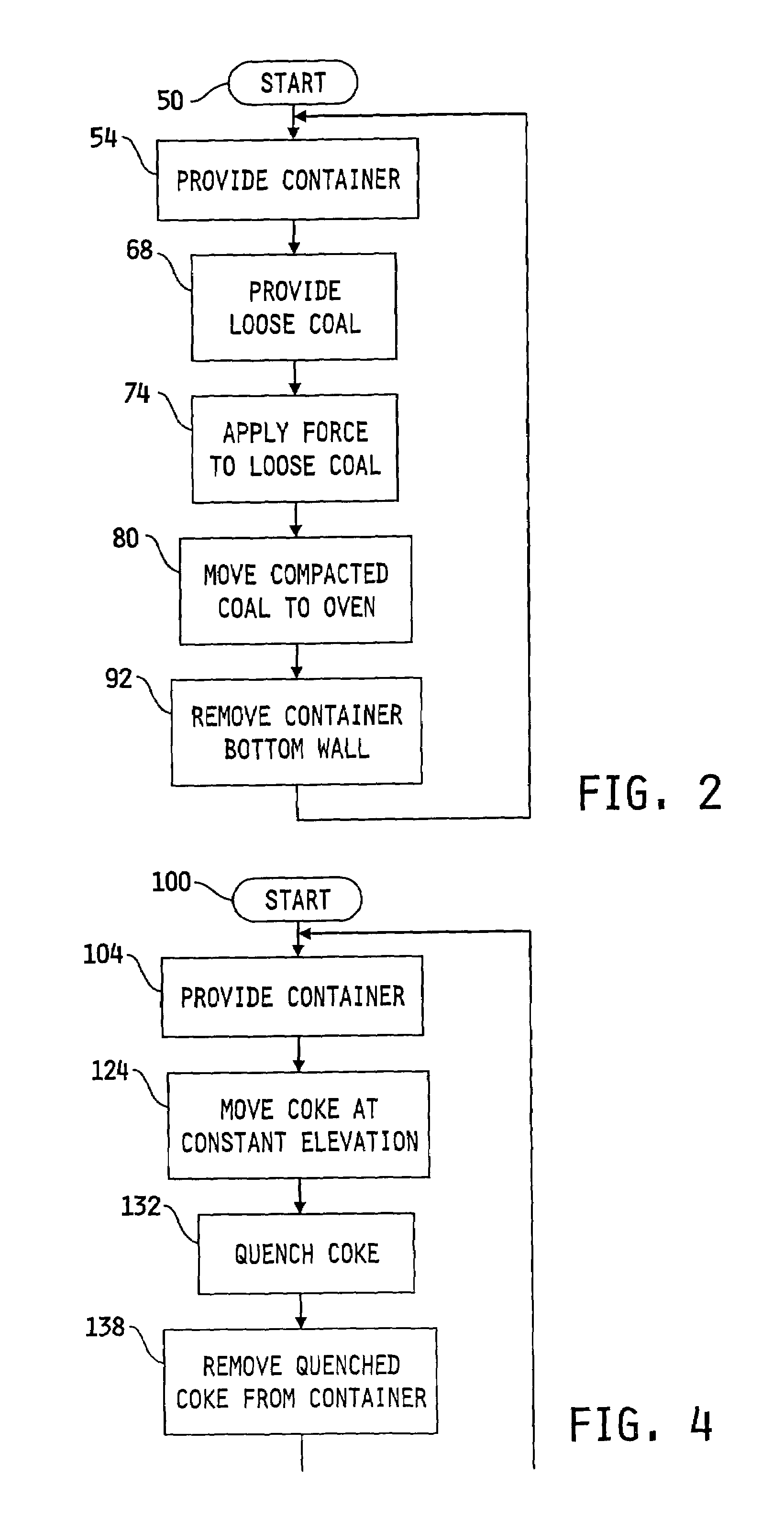

Method for producing blast furnace coke through coal compaction in a non-recovery or heat recovery type oven

A method for producing non-recovery / heat recovery coke may include the steps of providing a container, disposing a volume of loose coal into the container such that a vertical dimension of the volume of loose coal in the container is smaller than a horizontal dimension of the volume of loose coal, applying a force to the coal in the container to produce a volume of compacted coal having a substantially uniform density which is larger than that of the loose coal, disposing the compacted coal into a non-recovery / heat recovery type oven, and heating the compacted coal to produce coke. The method may also include the steps of providing a container, and moving the non-recovery / heat recovery coke mass from the oven at a substantially constant elevation to the container, quenching the coke mass in the container to produce a quenched coke mass, and removing the quenched coke mass from the container.

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

Coker feed method and apparatus

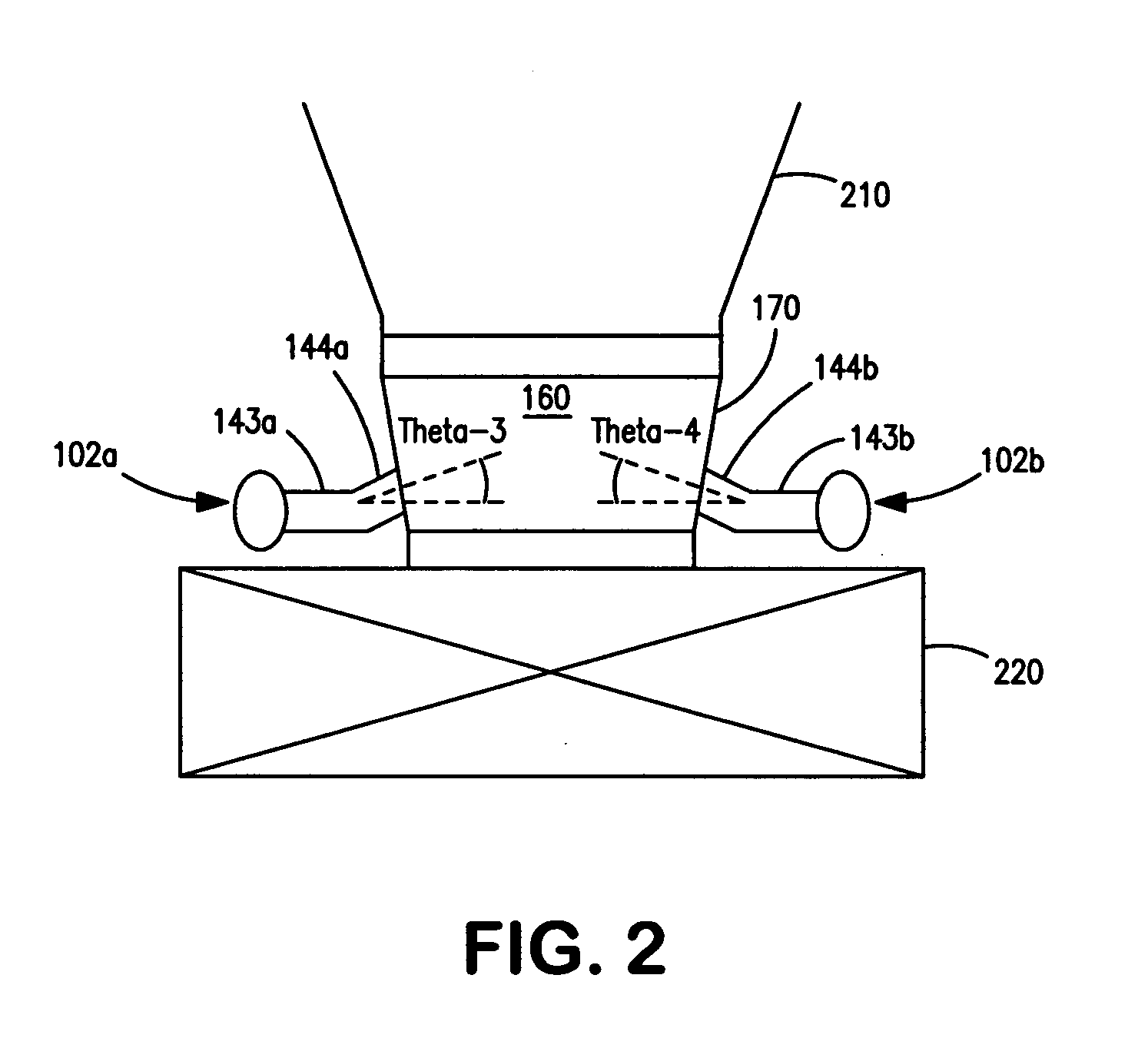

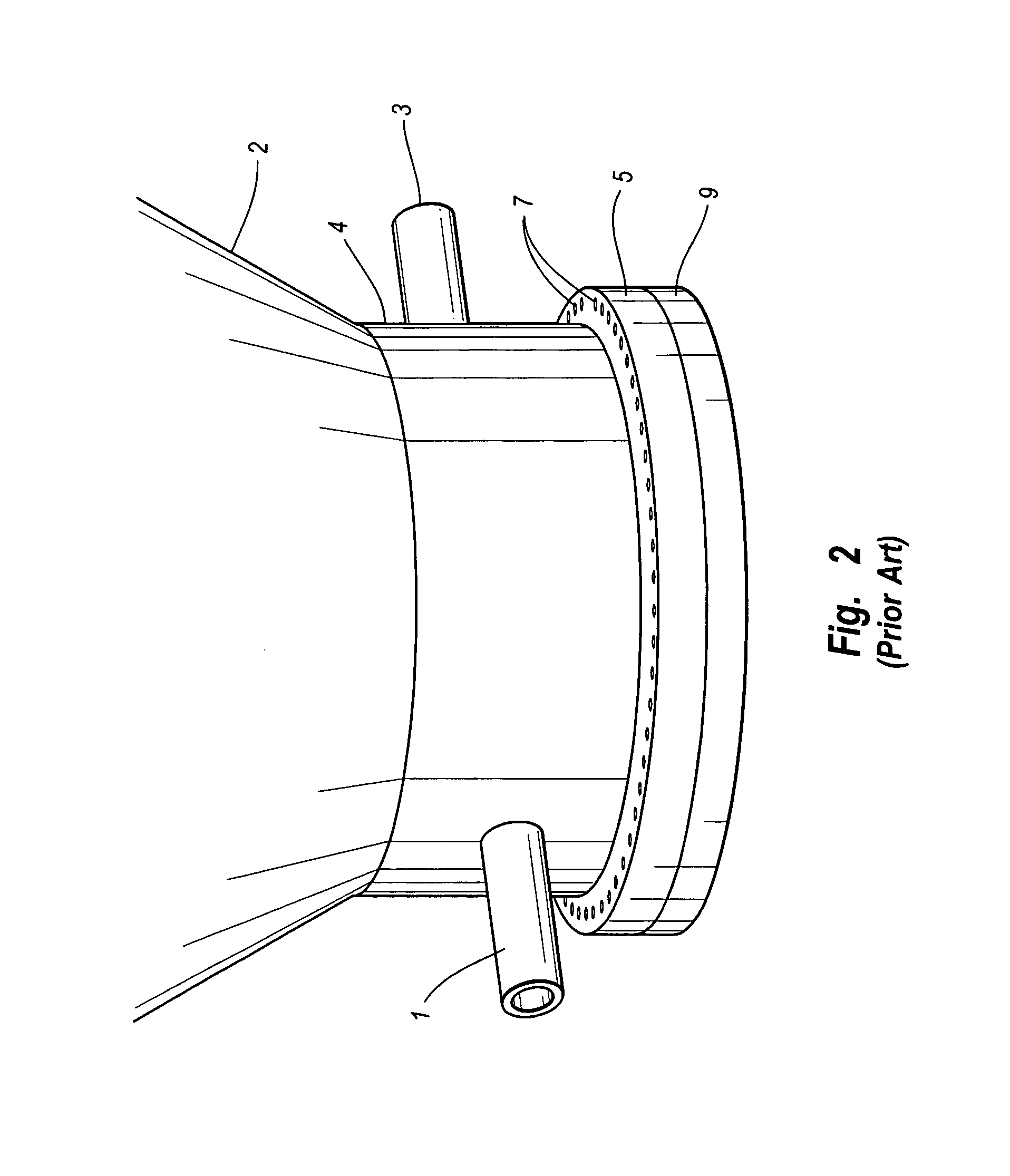

InactiveUS20080179165A1Reduces drum/vessel thermal stressReduce thermal stressThermal non-catalytic crackingCombustible gas coke oven heatingEngineeringVertical axis

Described herein are methods and mechanisms for laterally dispensing fluid to a coke drum in a predictable and maintainable manner that alleviates thermal stress. In one embodiment, the methods and mechanisms utilize a split piping system to dispense fluid through two or more inlets into a spool that is connected to a coke drum and a coke drum bottom deheader valve. A combination of block valves and clean out ports provides a more effective means to clean the lines and allows fluid to be laterally dispensed in a controllable and predictable manner. The fluid is preferably introduced to the spool in opposing directions toward a central vertical axis of the spool at equal but opposing angles ranging from minus thirty (−30) to thirty (30) degrees relative to a horizontal line laterally bisecting the spool. Alternatively, however, fluid can be introduced to the spool tangentially.

Owner:EXXON RES & ENG CO

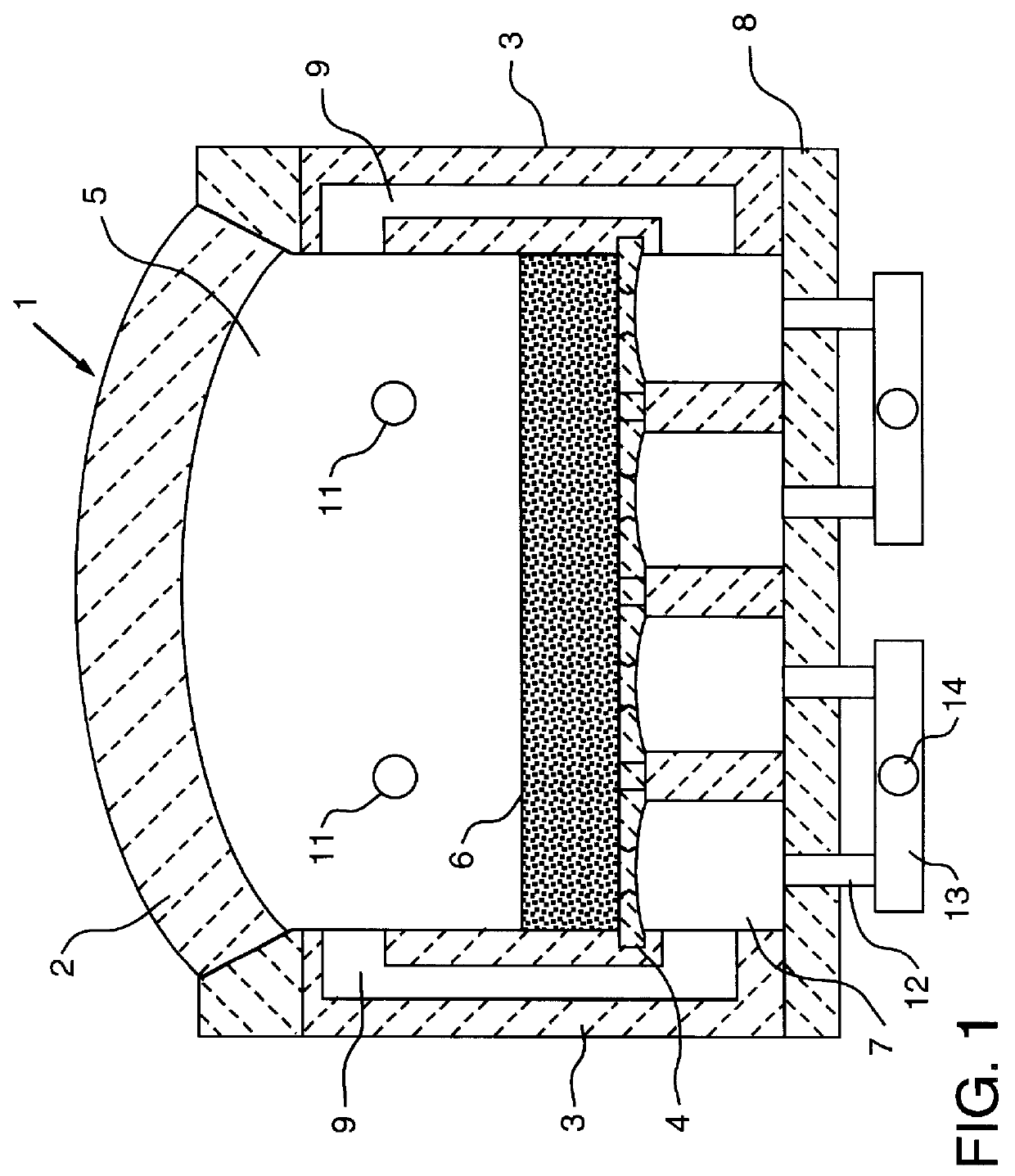

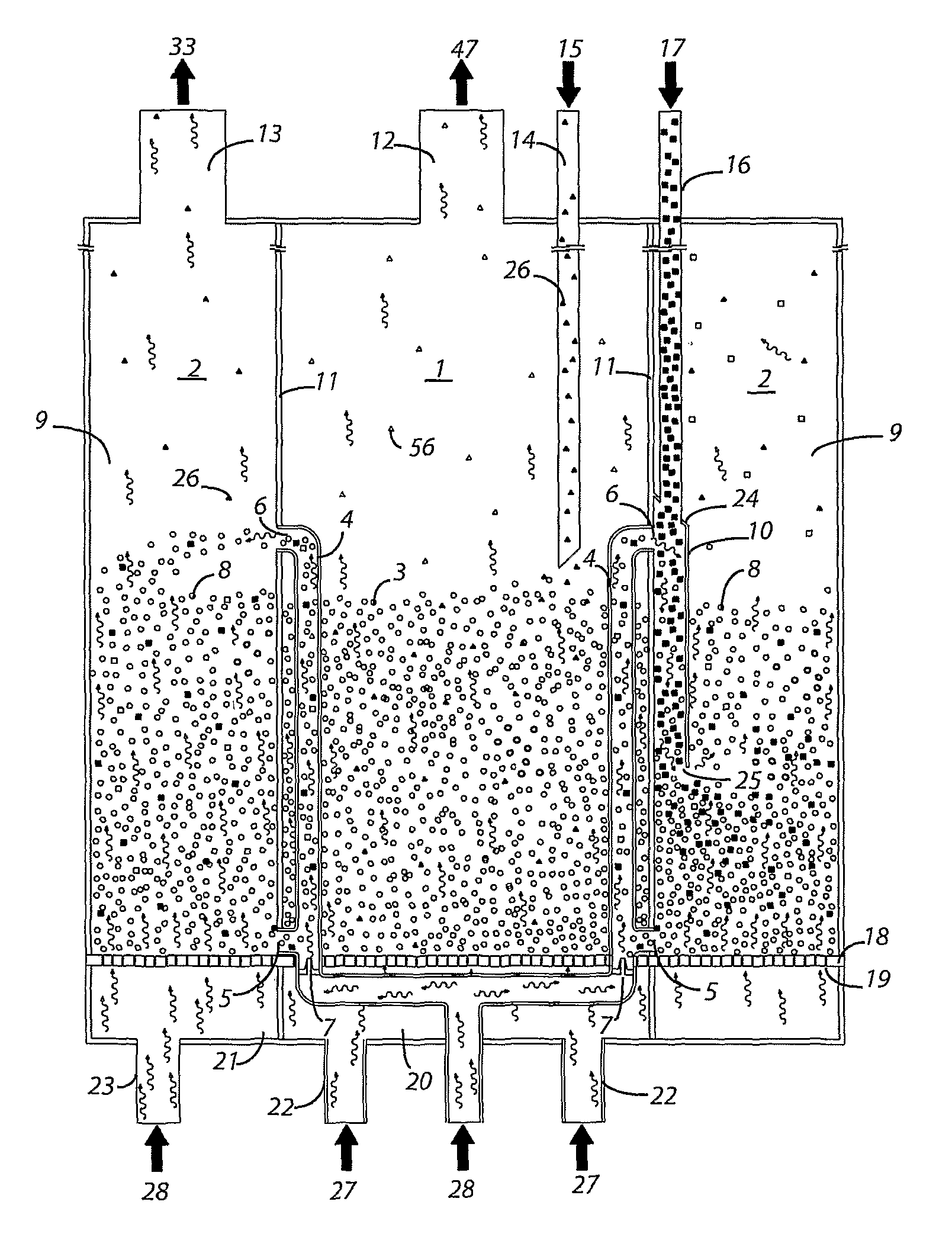

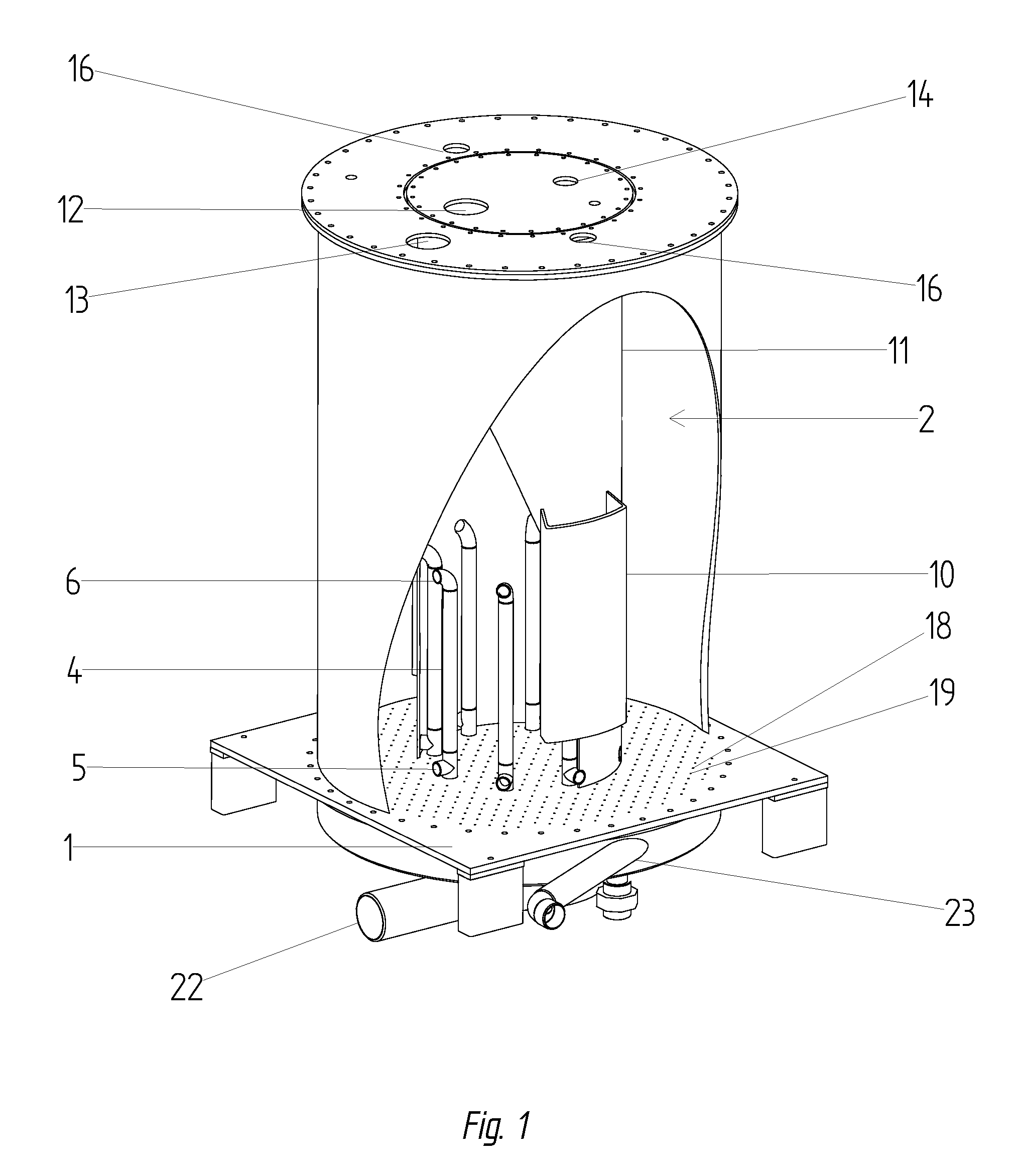

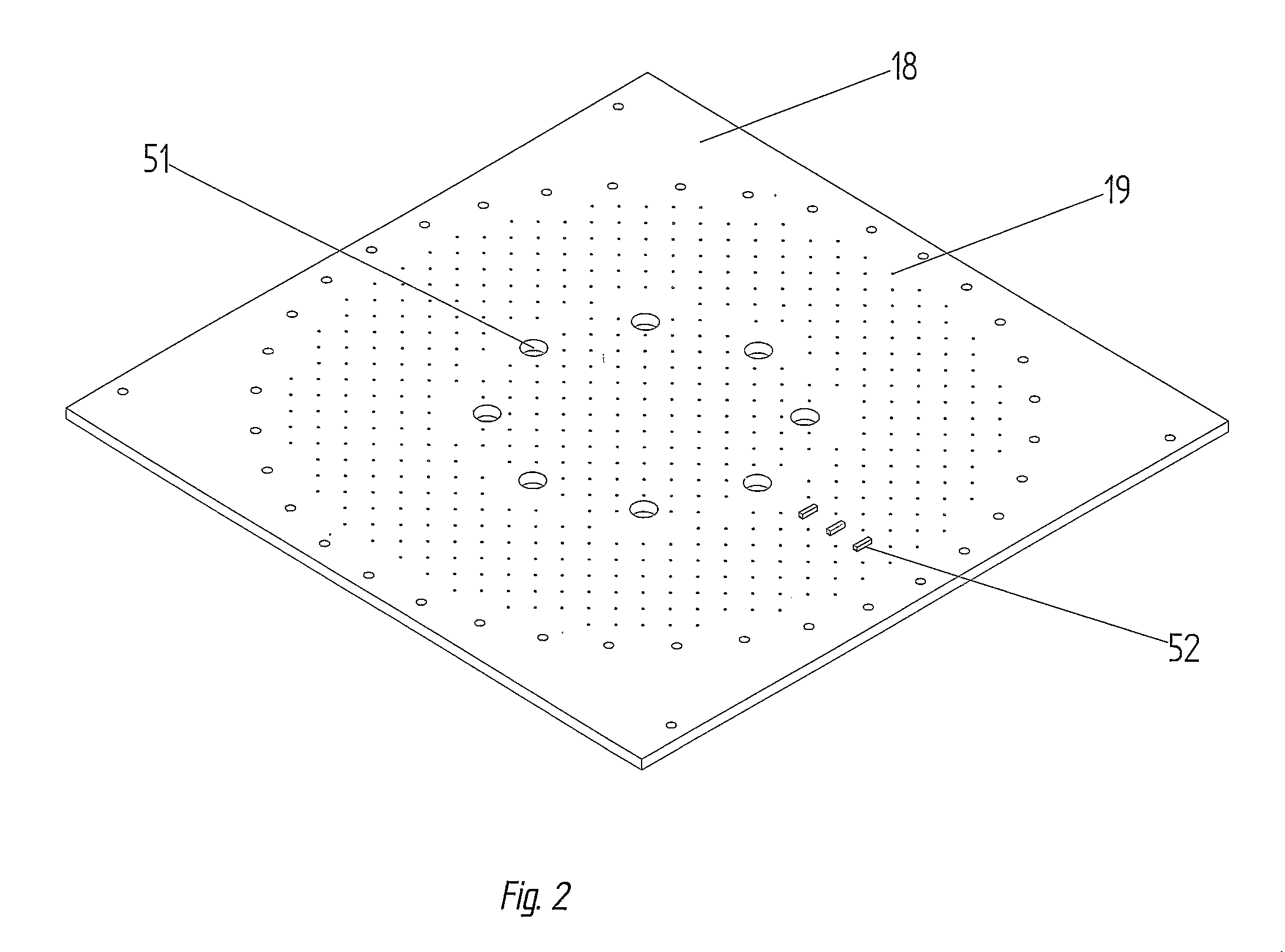

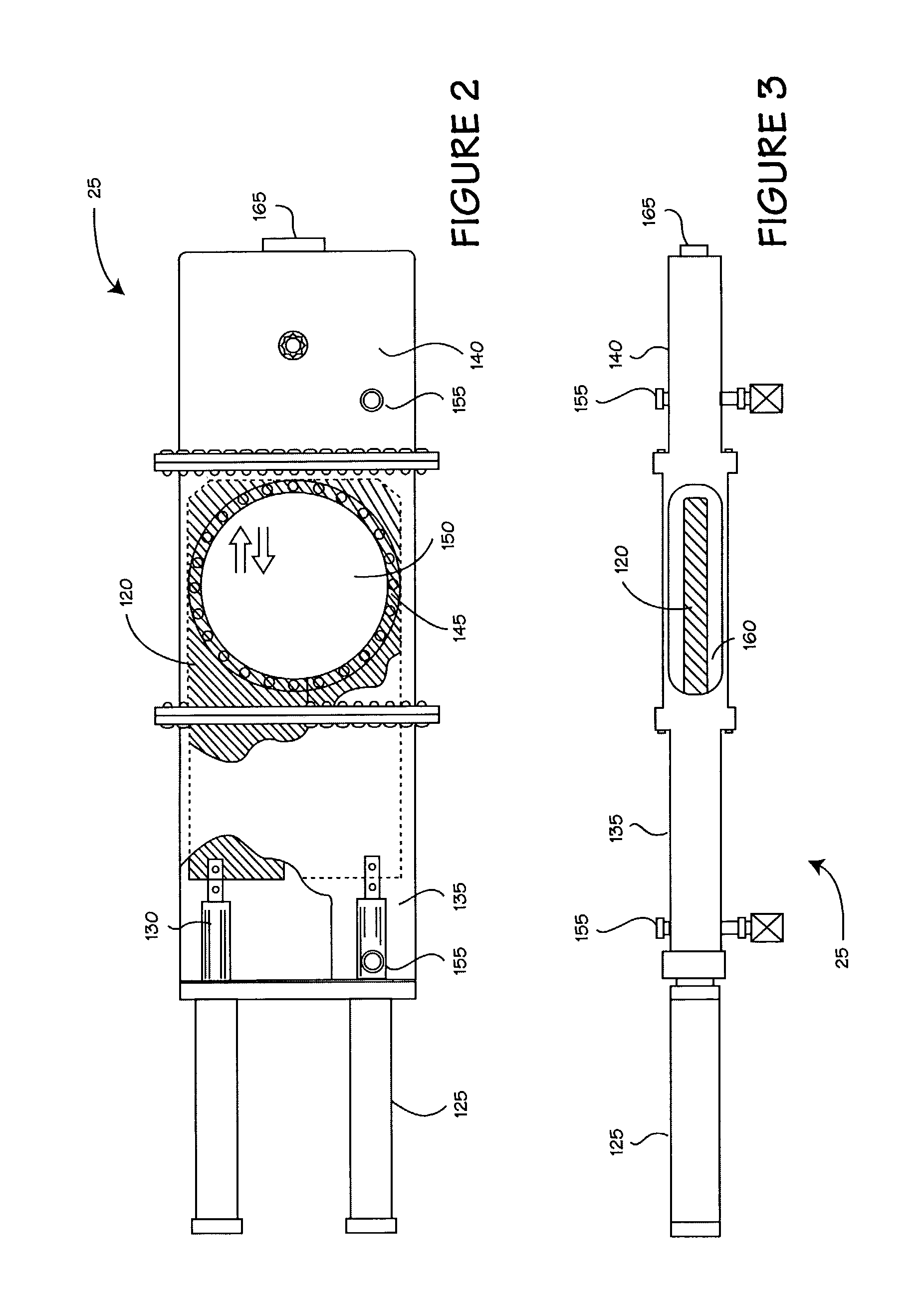

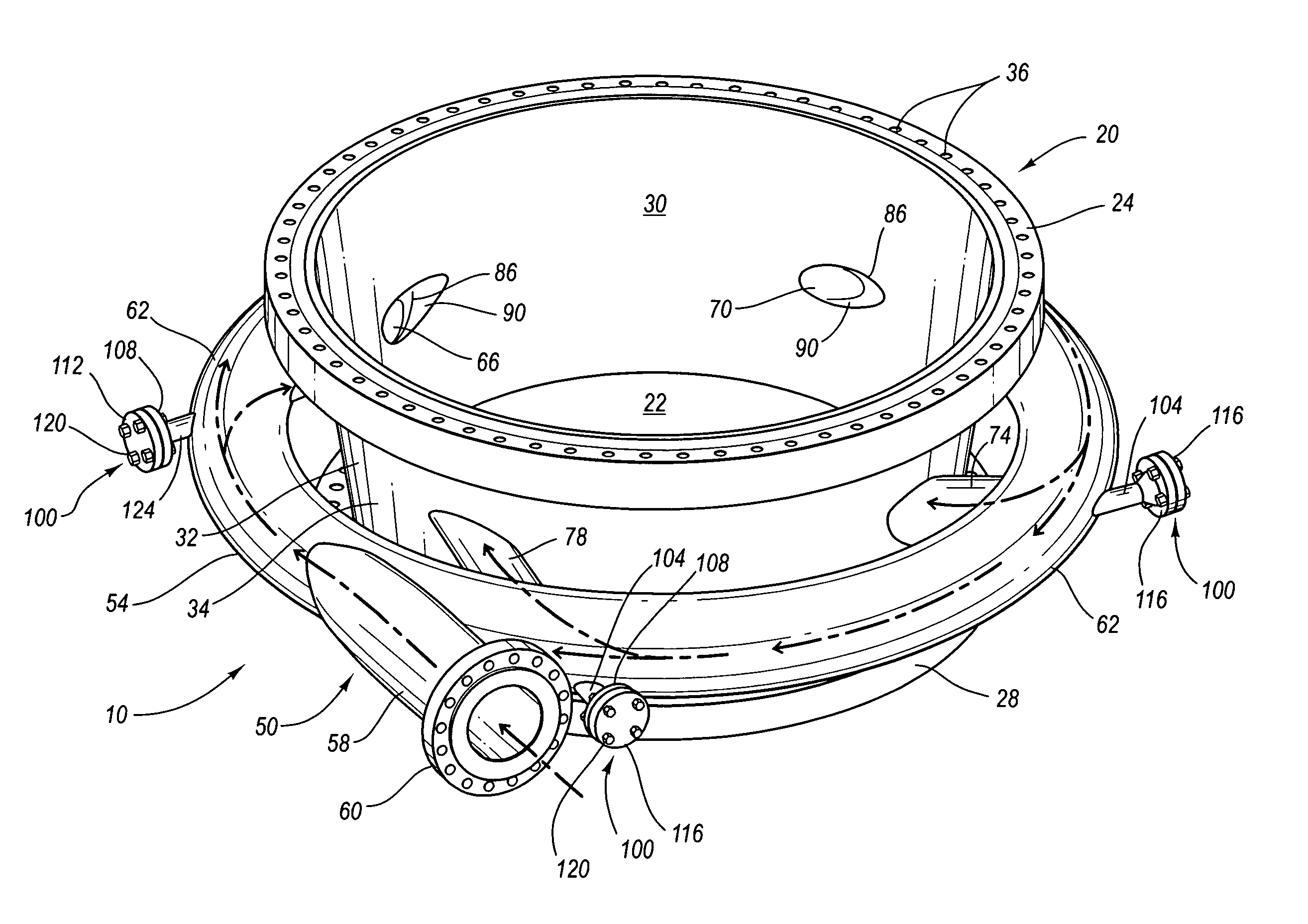

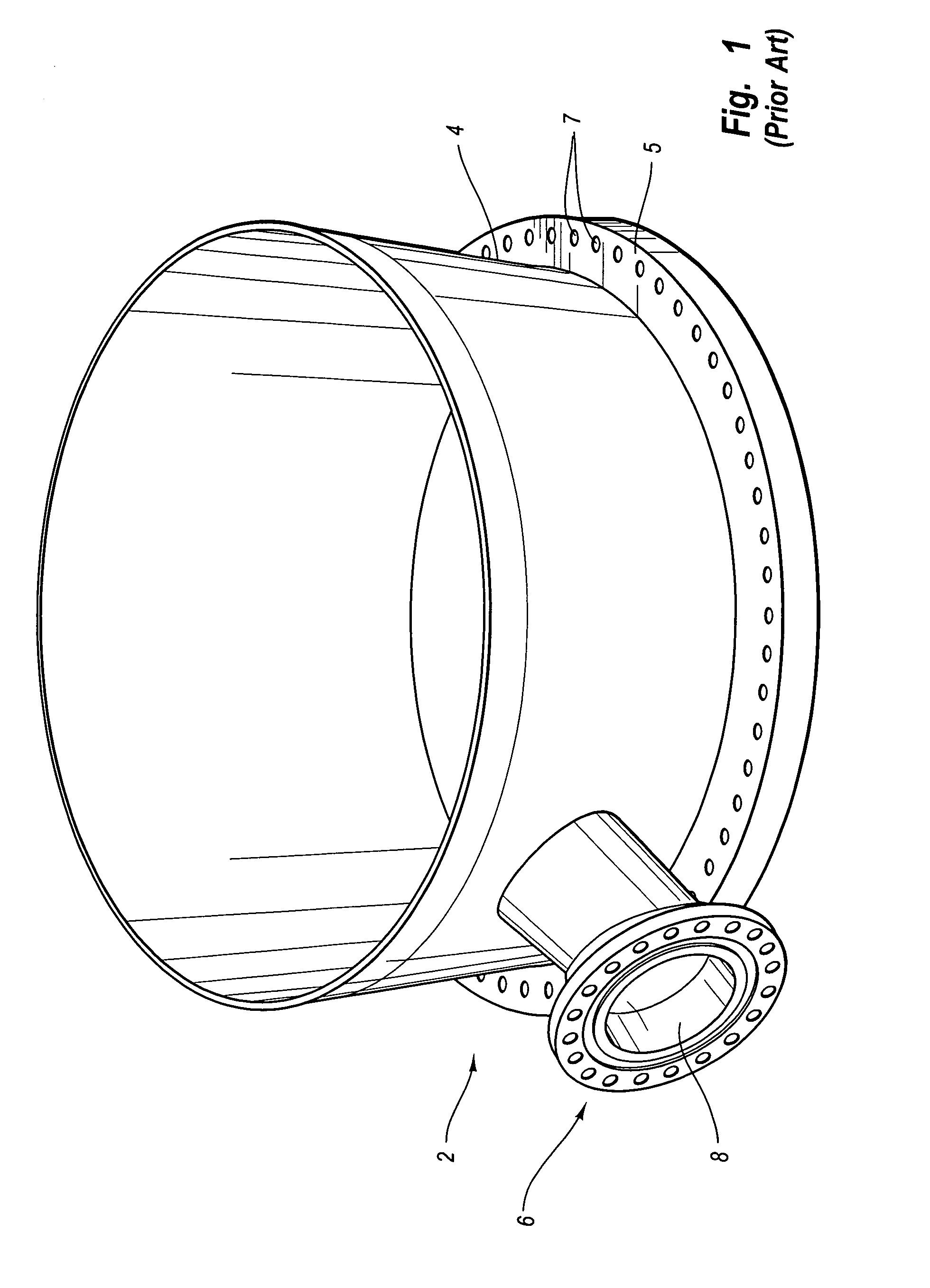

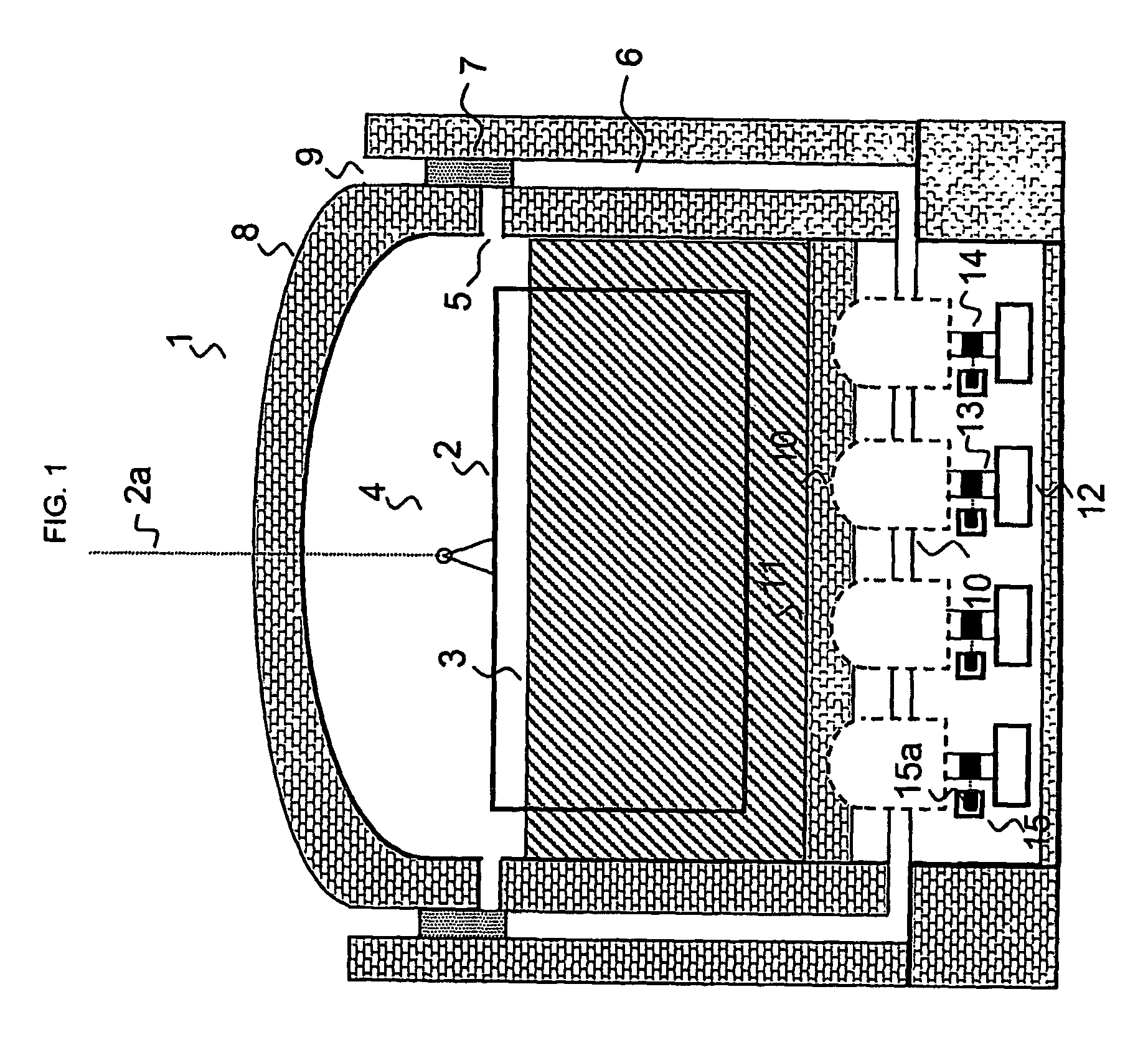

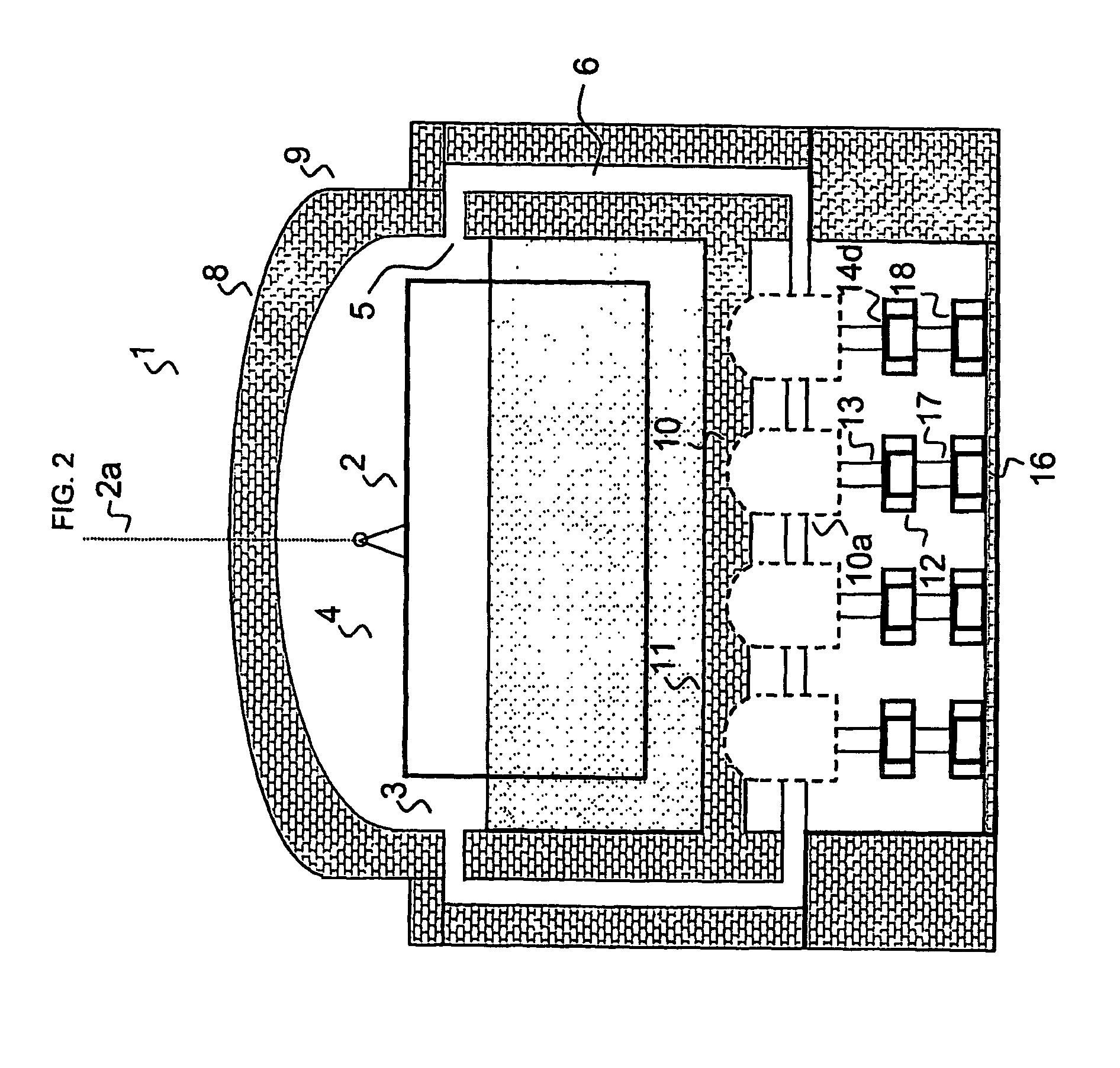

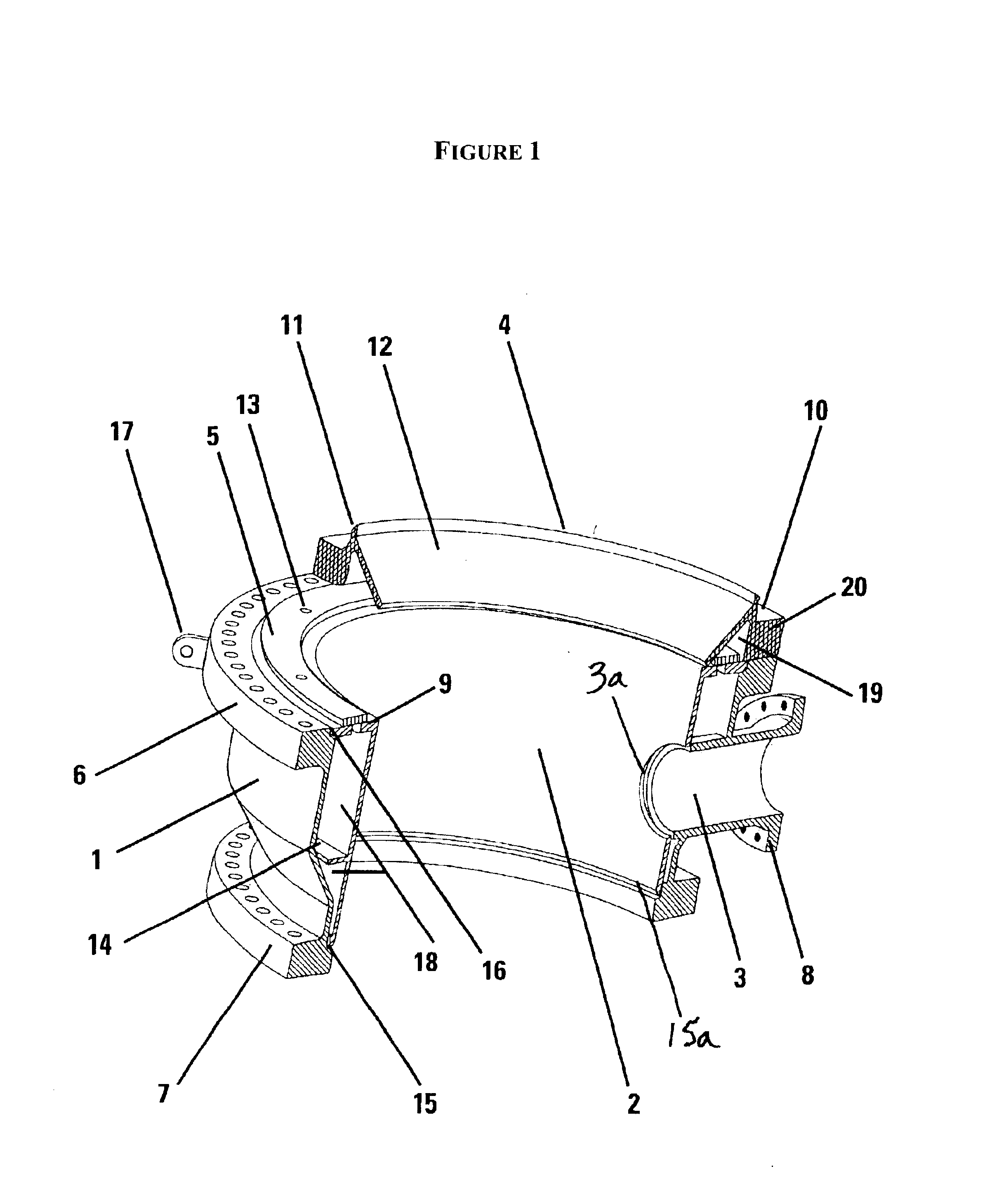

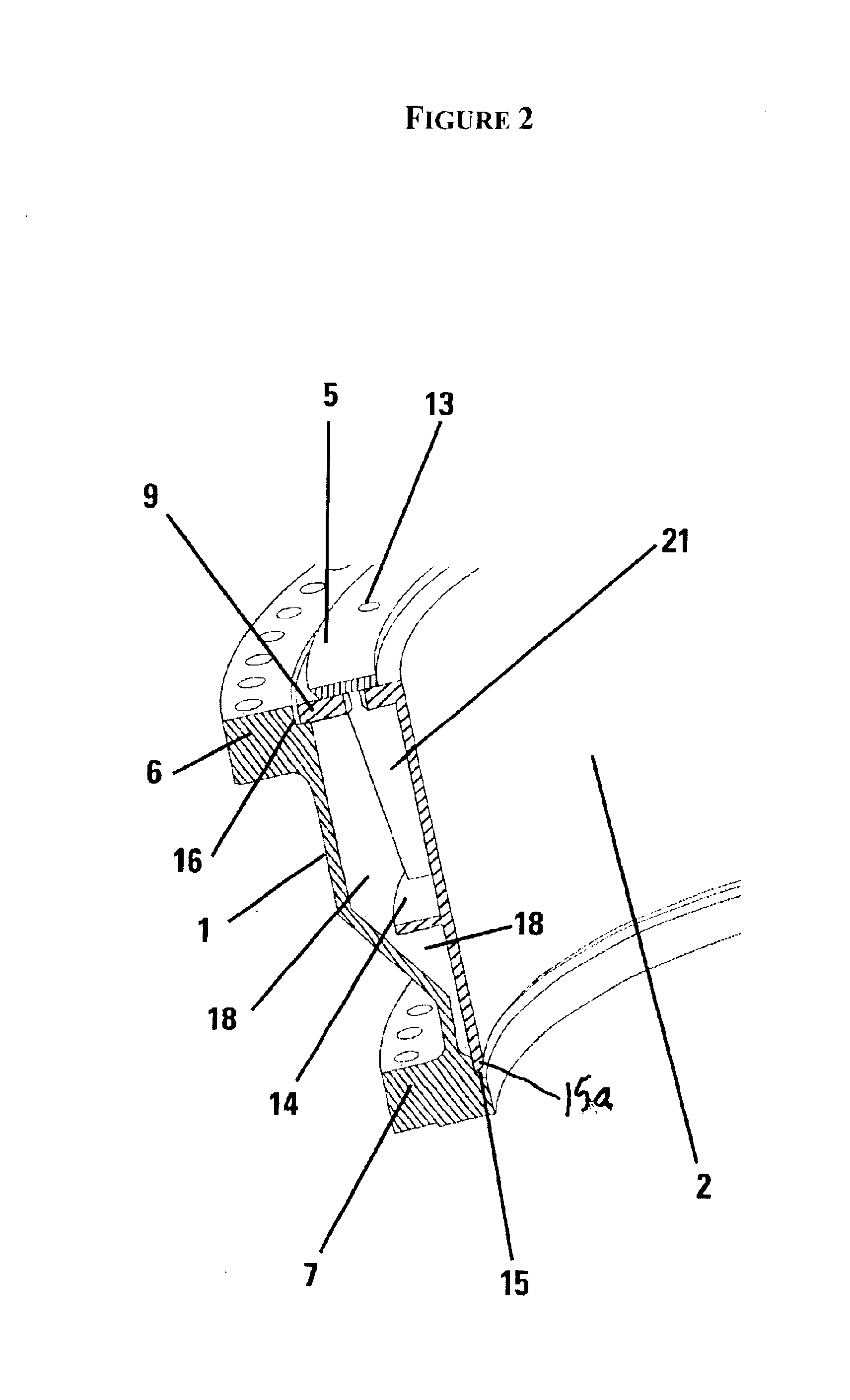

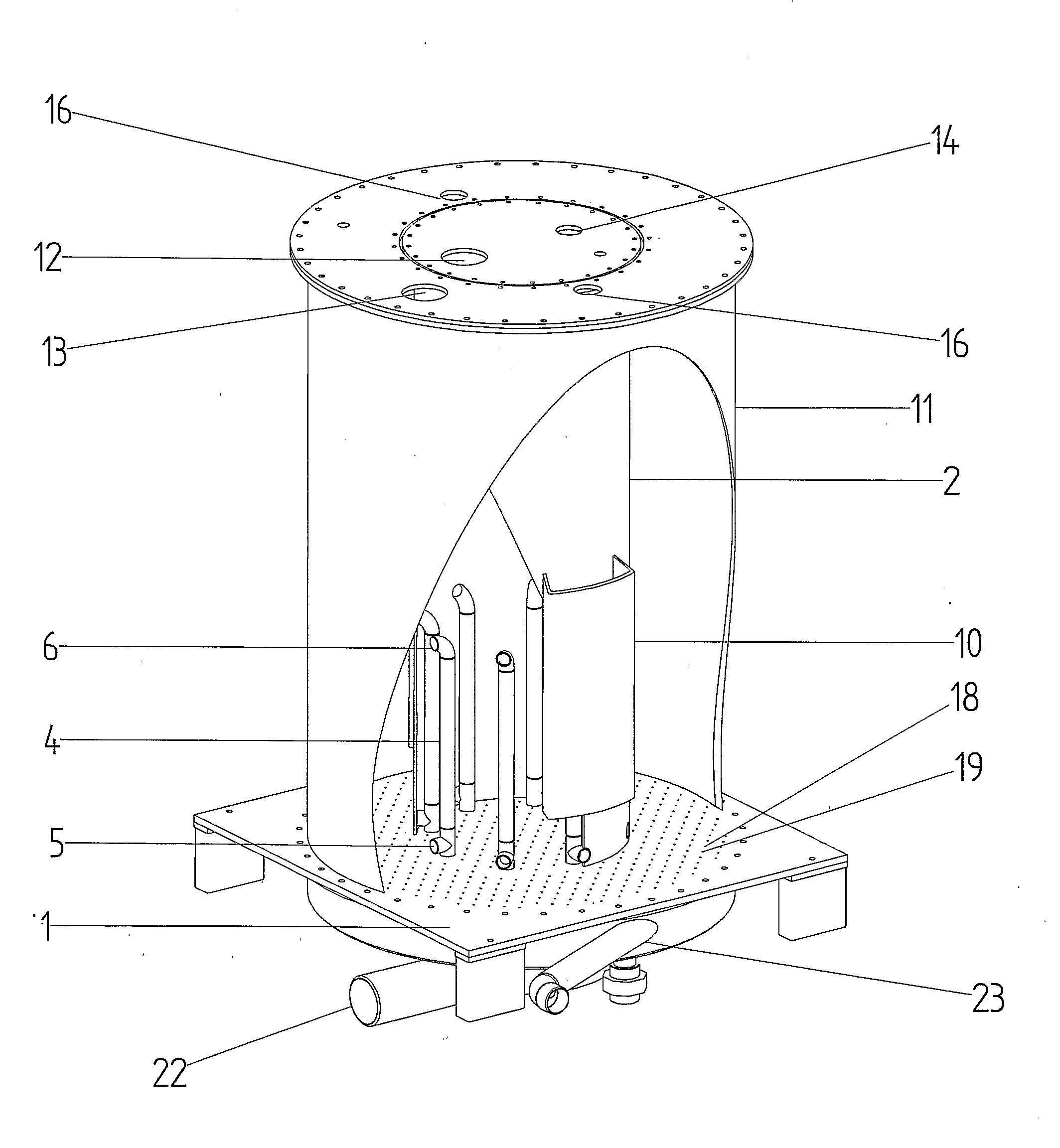

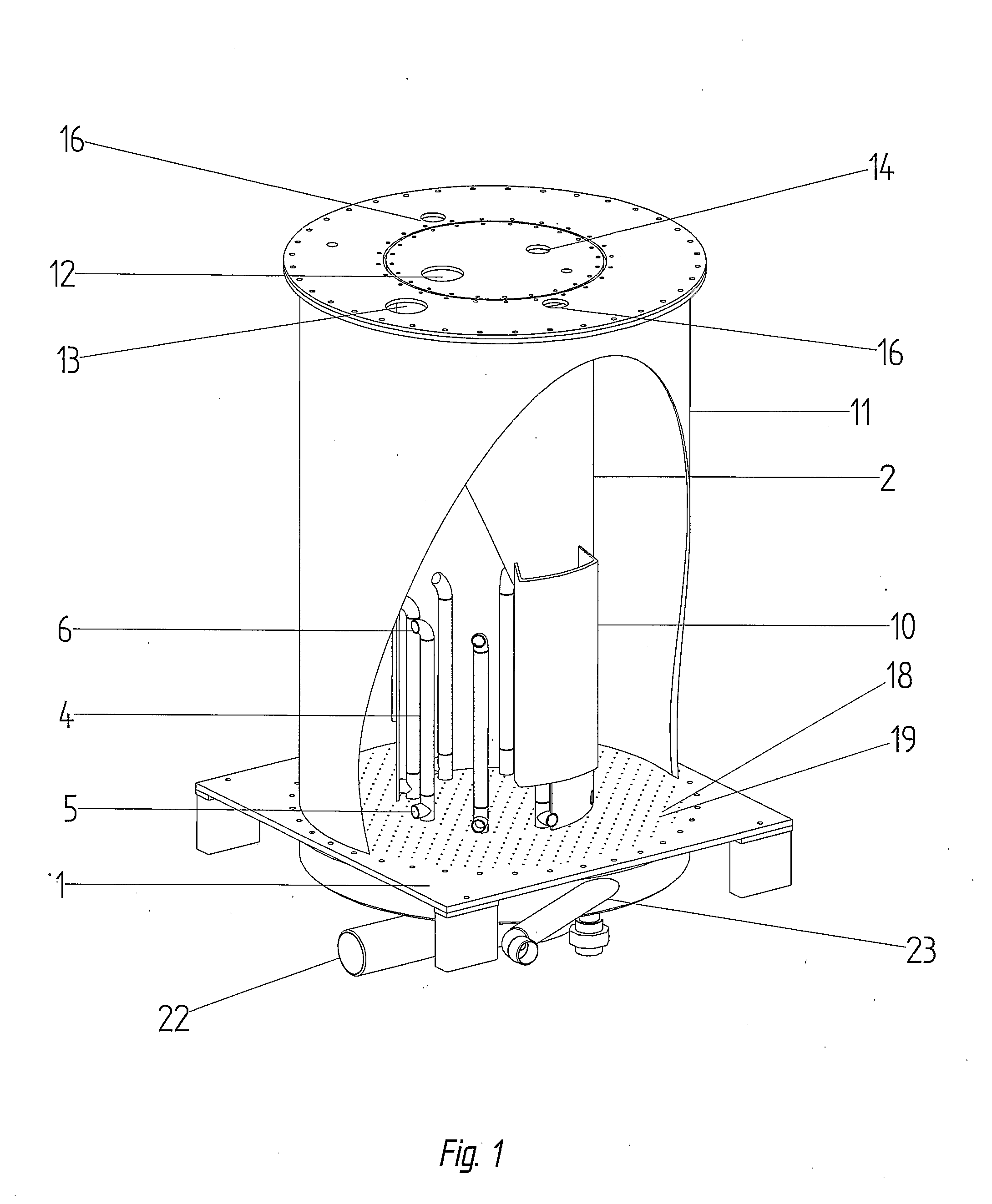

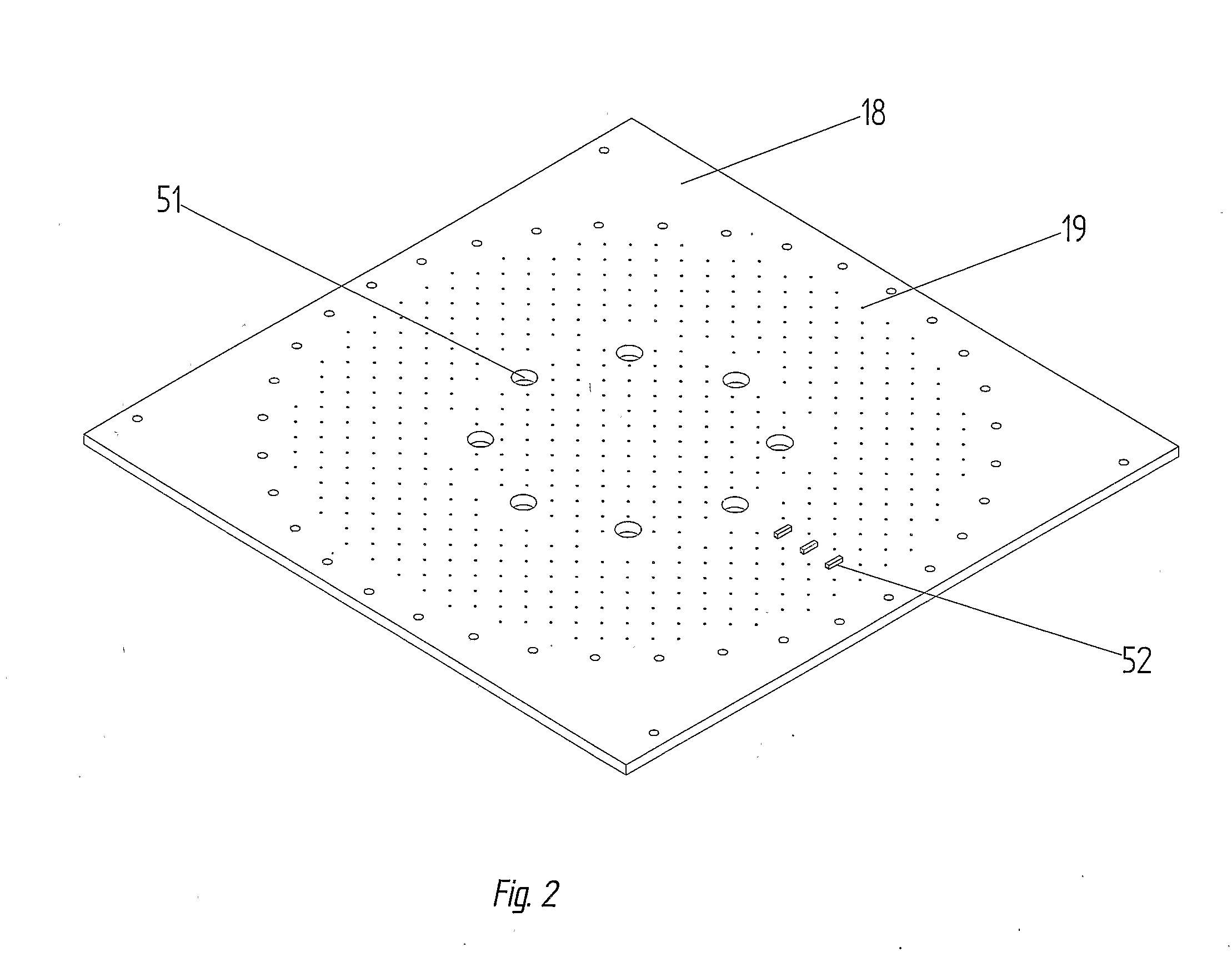

Apparatus and process for the pyrolysis of agricultural biomass

InactiveUS7943014B2Avoid cloggingPrevent escapeFluidized bed combustionCombustible gas coke oven heatingCombustion chamberFluidized bed

An integrated combustion chamber and fluidized bed pyrolysis reactor. In one embodiment, the combustion chamber is cylindrical and the pyrolysis reactor is provided annularly about the combustion chamber with an annular wall that provides a common surface for heat transfer. A lift tube in fluid communication with the pyrolysis reactor is provided within the combustion chamber for circulating biomass and an inert fluidizable media upwardly through the lift tube; this advantageously increases heat transfer and leads to more rapid pyrolysis. The media and biomass exit the lift tube into either a freeboard area of the pyrolysis reactor or into a low density region of the fluidized bed. A condensable gaseous product is produced during pyrolysis that has economic value. The apparatus and process are especially well suited to the pyrolysis of low density agricultural biomass. The apparatus is compact and particularly well suited to mobile operation.

Owner:AGRI THERM

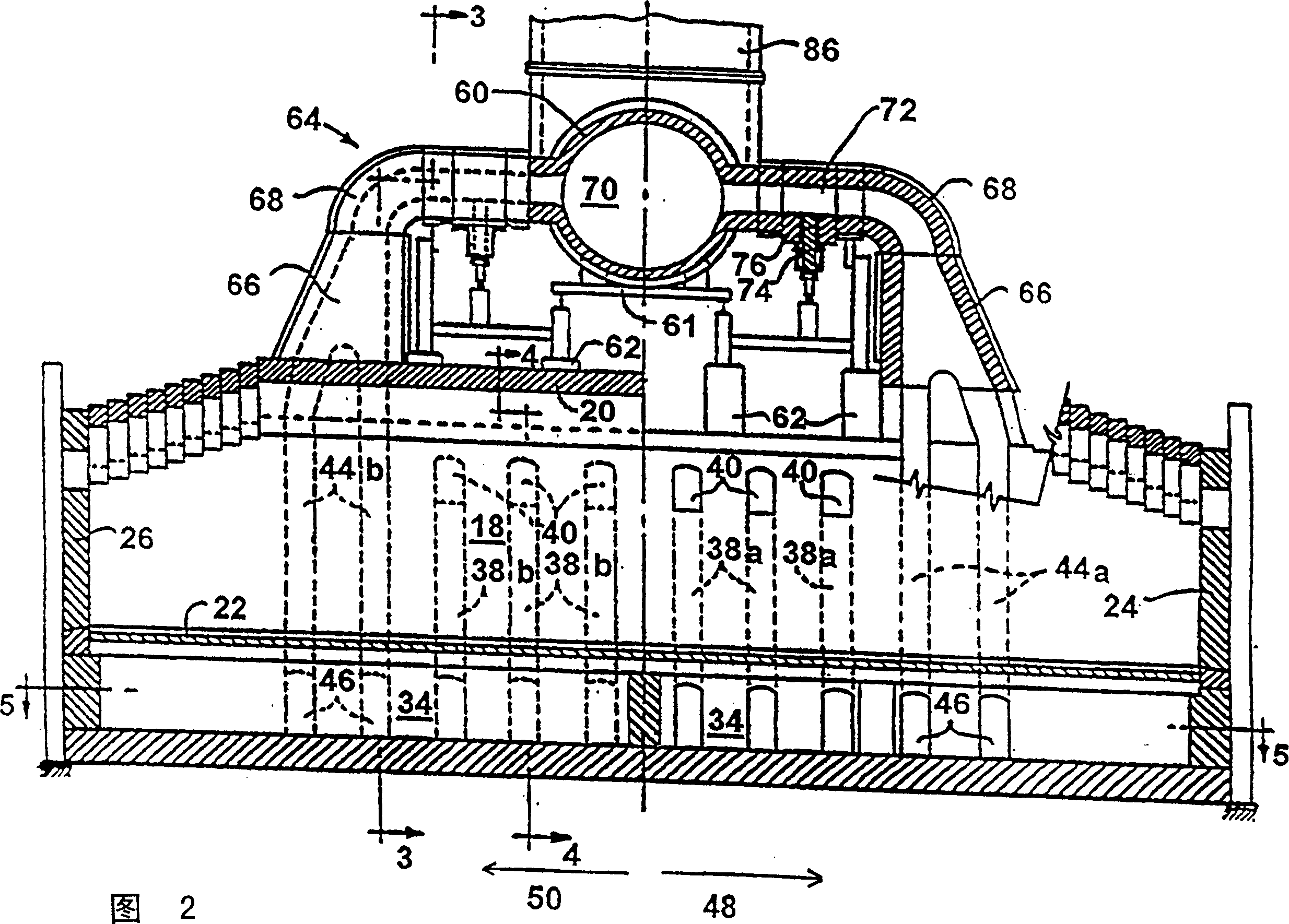

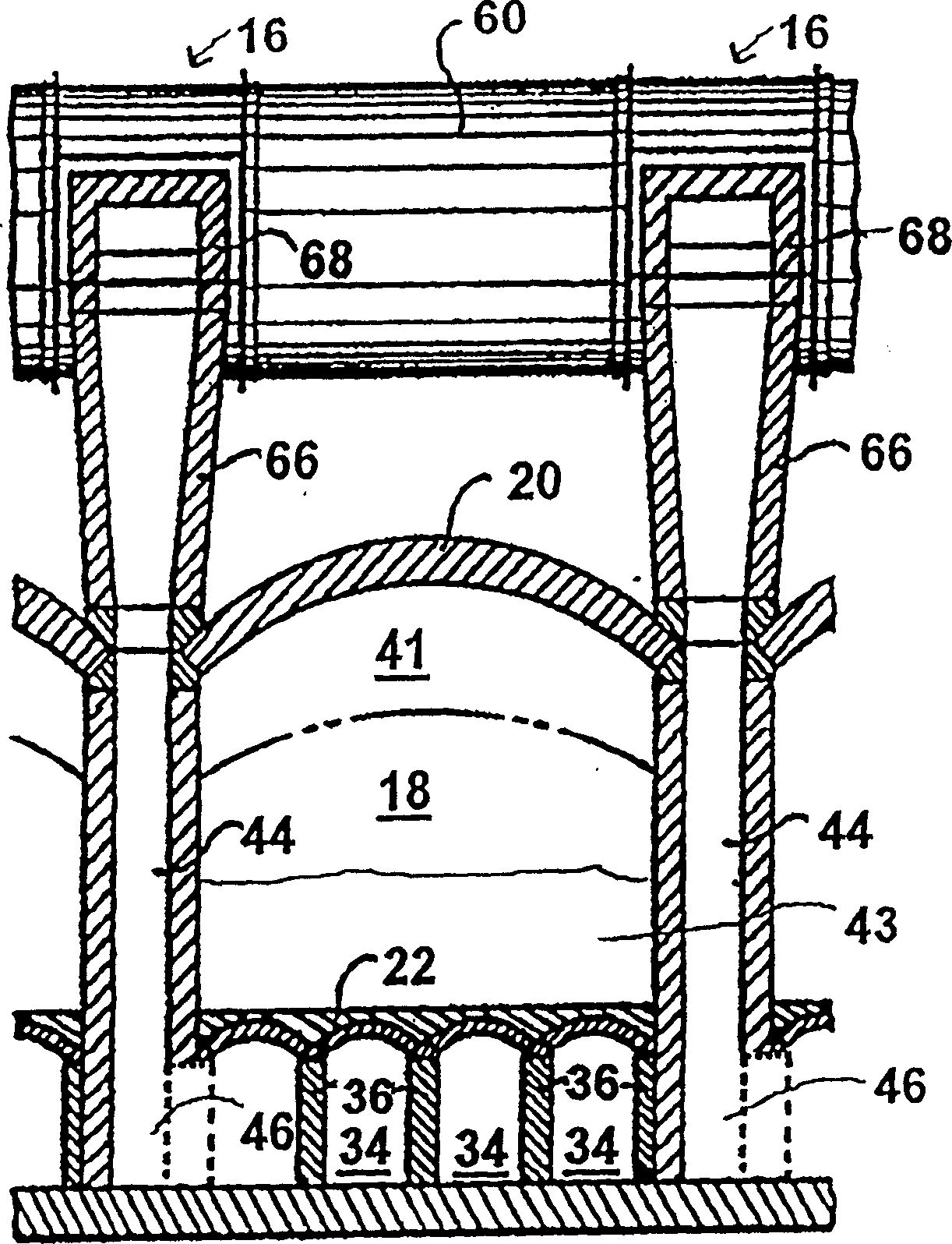

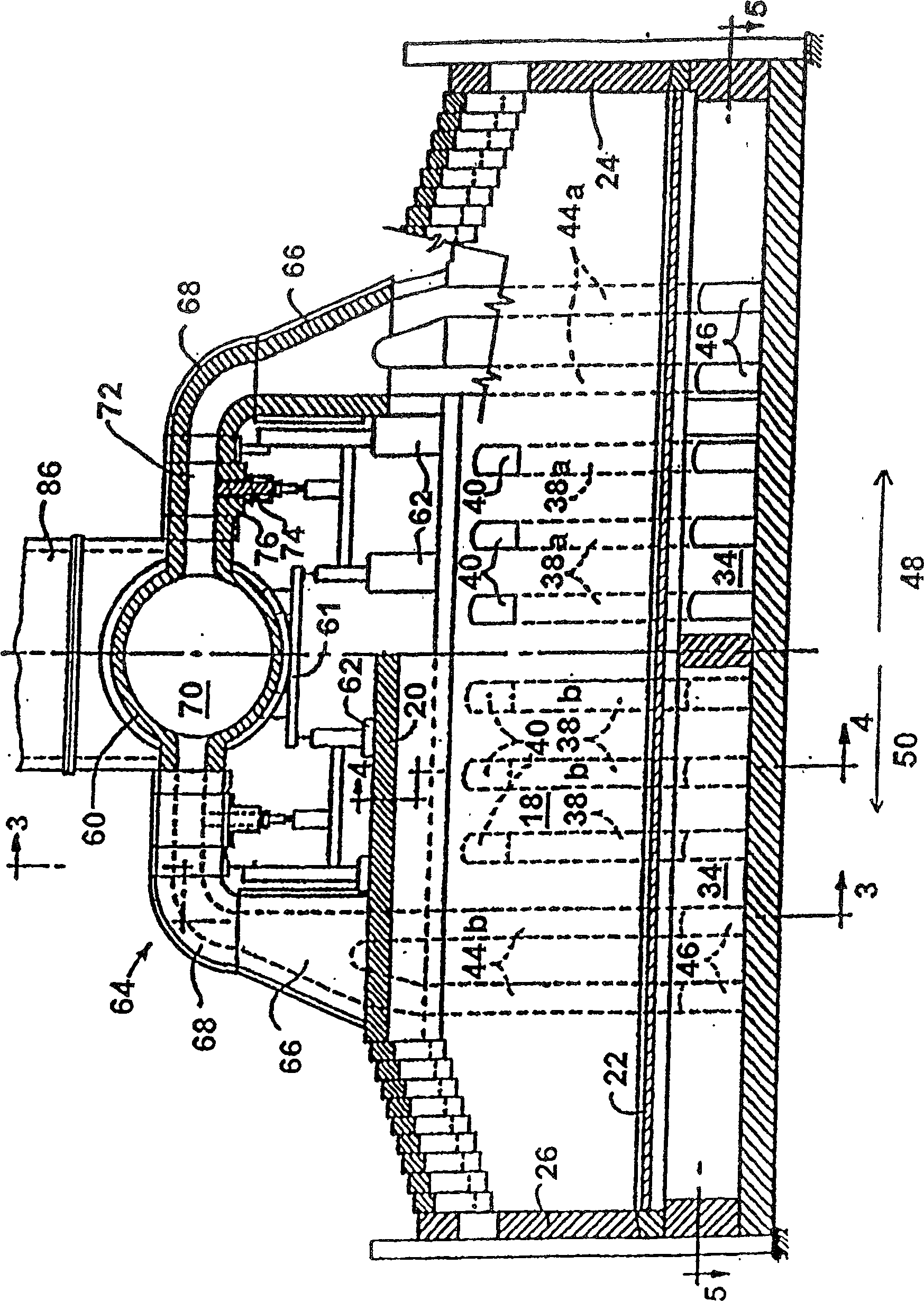

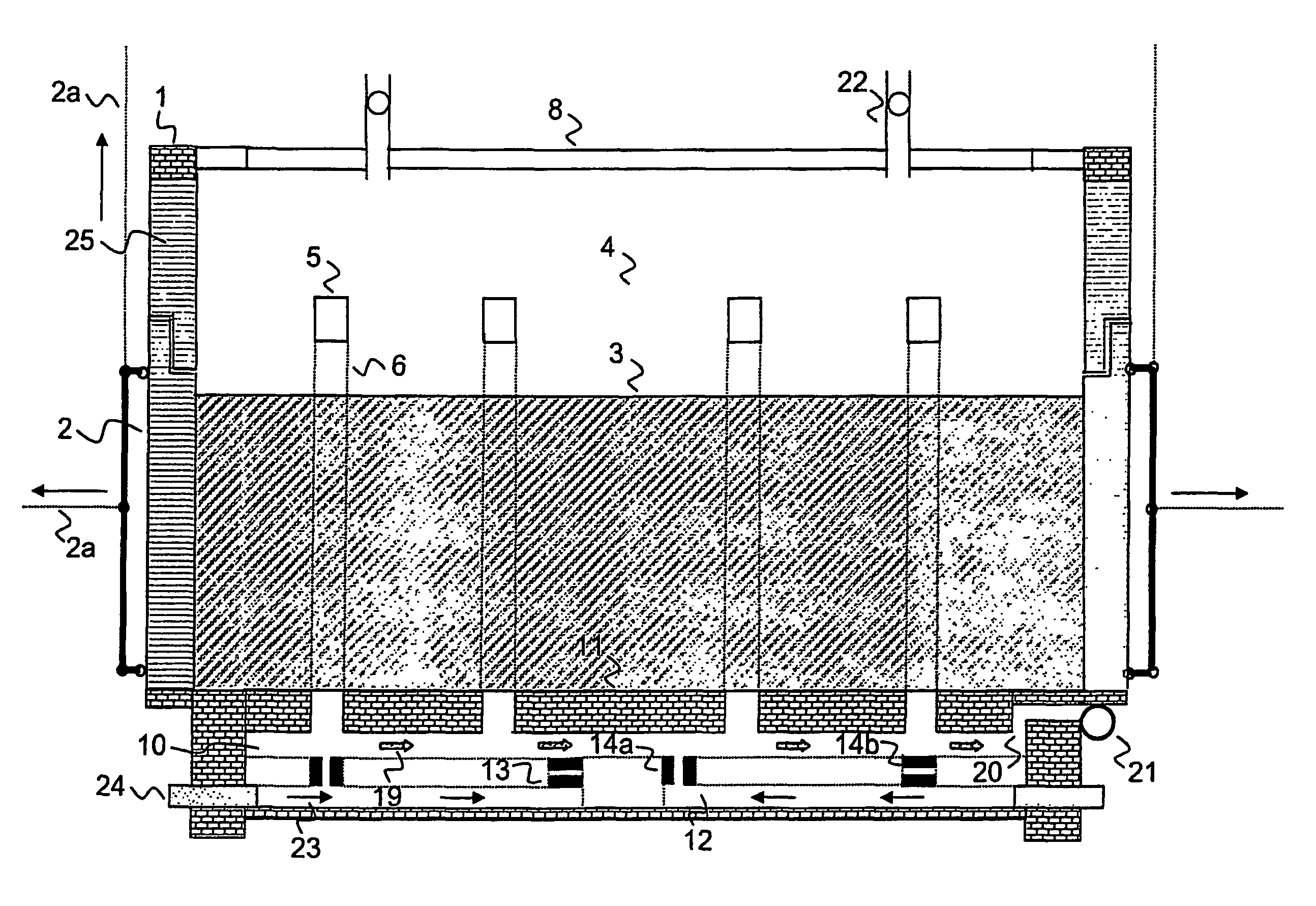

Coke oven flue gas sharing

InactiveCN1527872AExtend your lifeReduce the gas flow rateCombustible gas coke oven heatingBeehive ovensFlue gasProduct gas

The invention provide a method and apparatus for decreasing gas flow rates in a sole flue gas system for a coke oven during at least an initial coking operation after charging a coking oven with coal (43). The method includes providing a duct system (96, 98) between a first coke oven having a first coking chamber (18) and a second coke oven having a second coking chamber (18) to direct at least a portion of gas from a gas space (41) in first coking chamber (18) to the second coke oven thereby reducing a gas flow rate in the first sole flue gas system of the first coke oven. Reduction in sole flue gas flow rates has a beneficial effect on product throughput, the life of the coke oven and environmental control of volatile emissions from coke ovens.

Owner:SUNCOKE TECH & DEV LLC

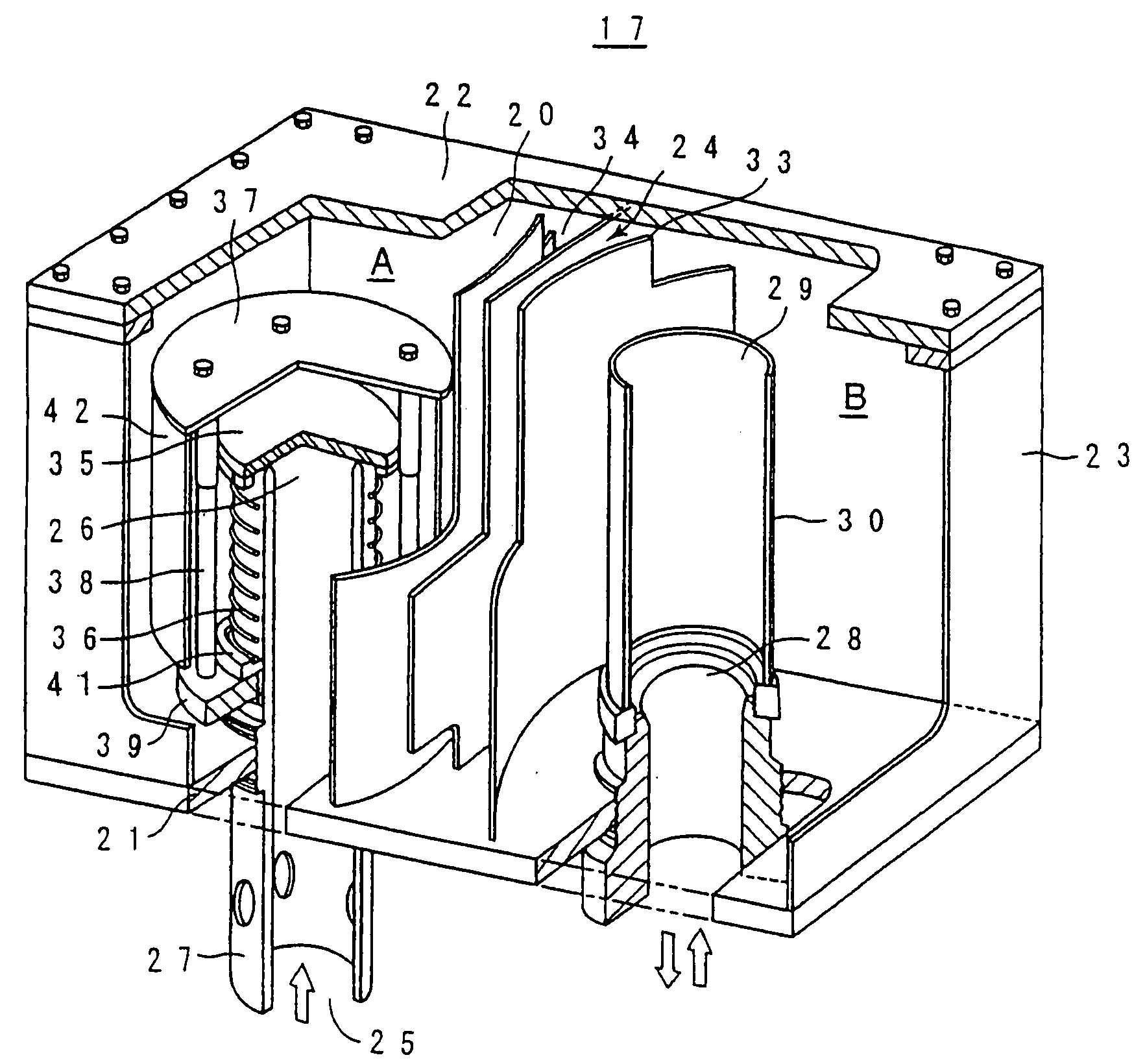

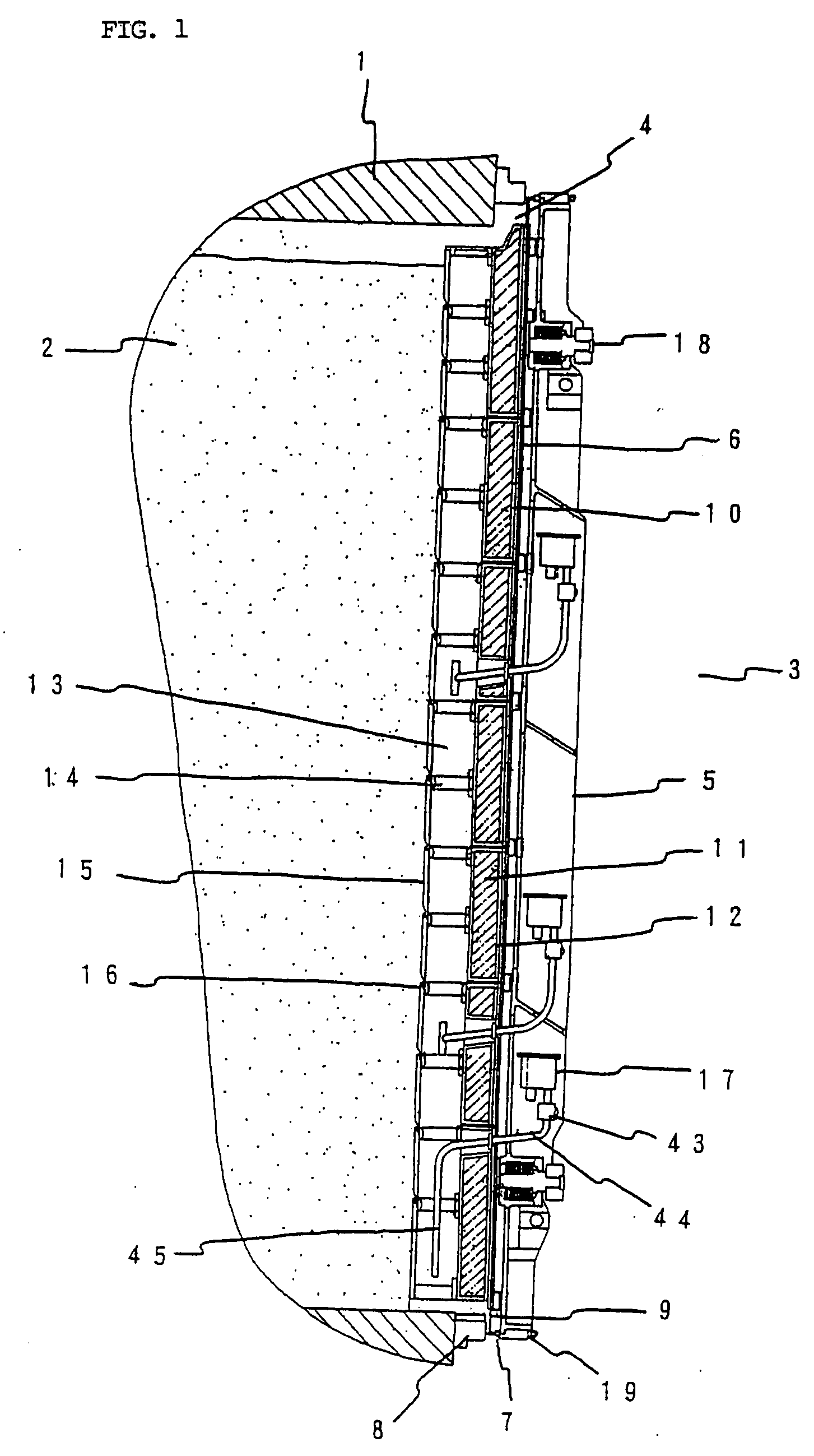

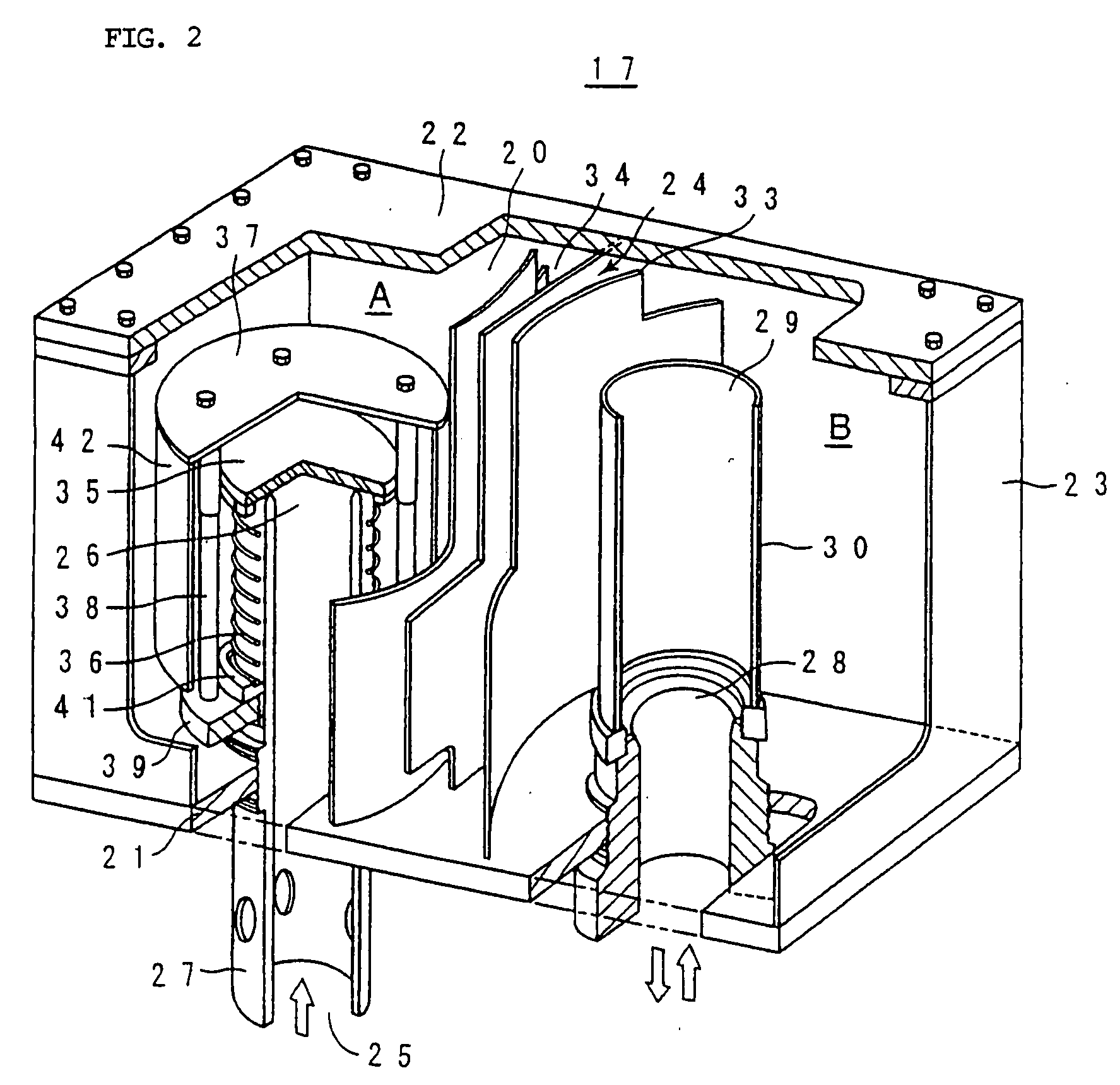

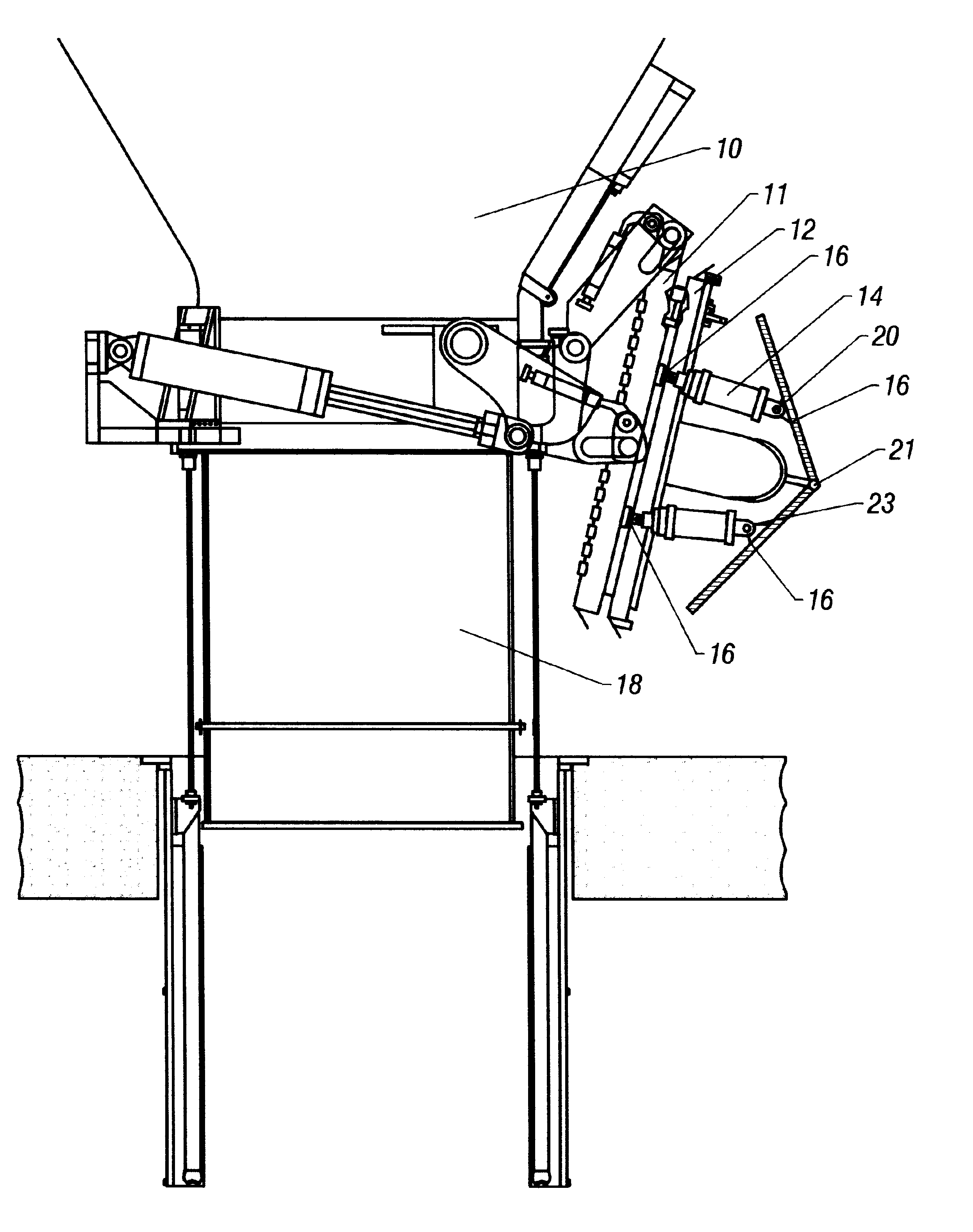

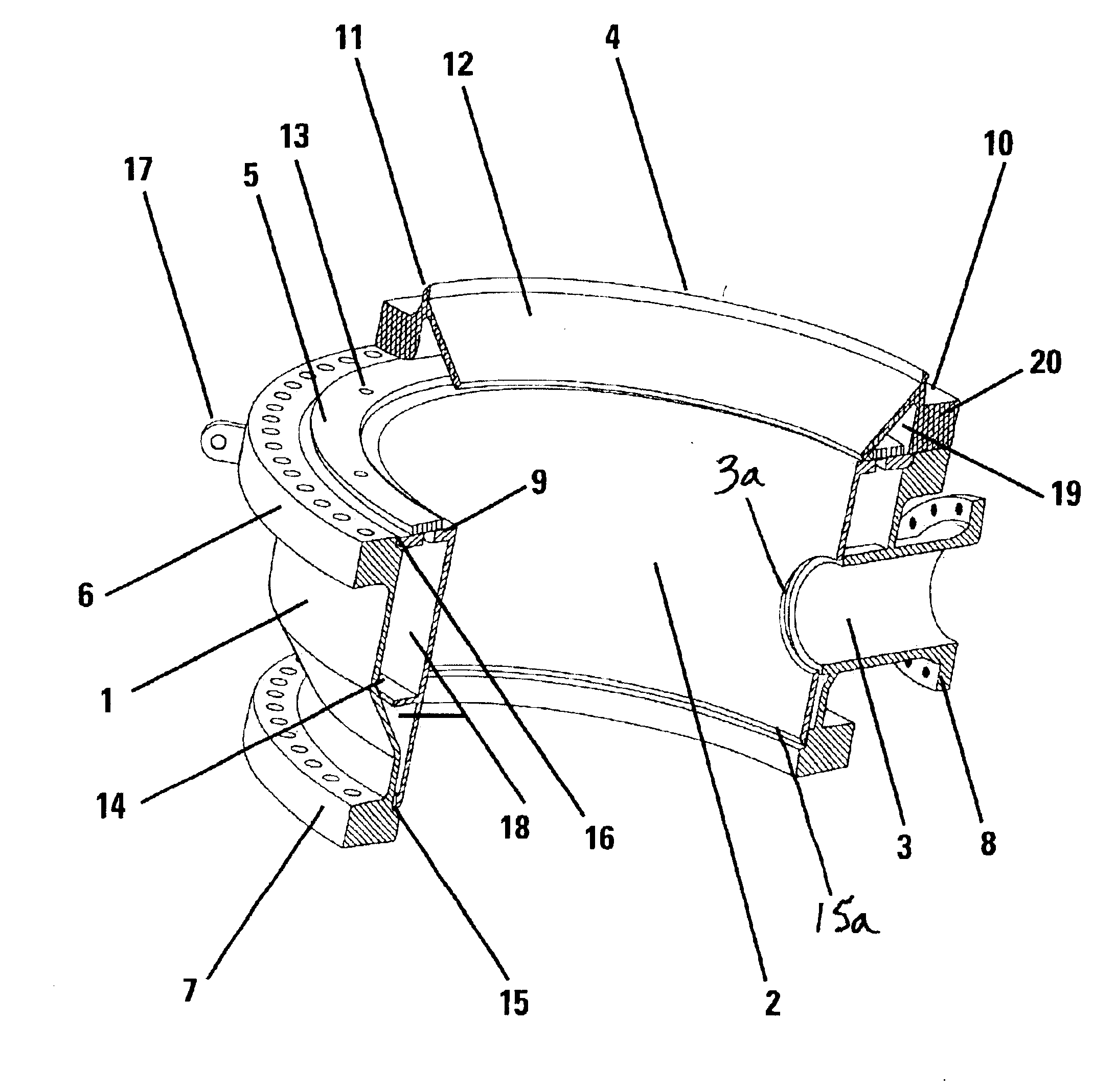

Coke Oven Doors Having Heating Function

InactiveUS20080271985A1Easy maintenance controlSupply will become excessiveCombustible gas coke oven heatingStationary retortsCombustionTar

An air chamber unit provided for a coke oven door enabling to suppress the generation of poor quality coke and reduce tar adhesion to coke oven door by accelerating coking reaction in the vicinity of coke oven door plug. An air chamber unit (17) is installed to control air supply to the bottom-less combustion space provided in hollow metallic coke oven door plug. For the purpose of long lasting stable air supply for said combustion space, air space (20) in the air chamber unit (17) is divided into two sections (A) and (B) by labyrinth partition to give different function for each of those section. Air intake pipe (27) is fitted in section (A) through bottom plate (21) of air chamber unit (17), wherein check valve plate (35) and other related components are provided as air supply control segments. Air supply pipe (30) or air delivery cup having one or more air inlet holes in upper portion is fitted in section (B) through bottom plate (21) of air chamber unit (17), wherein roles to remove contaminant particles suspended in backward flow gas are provided.

Owner:YAMASAKI IND CO LTD

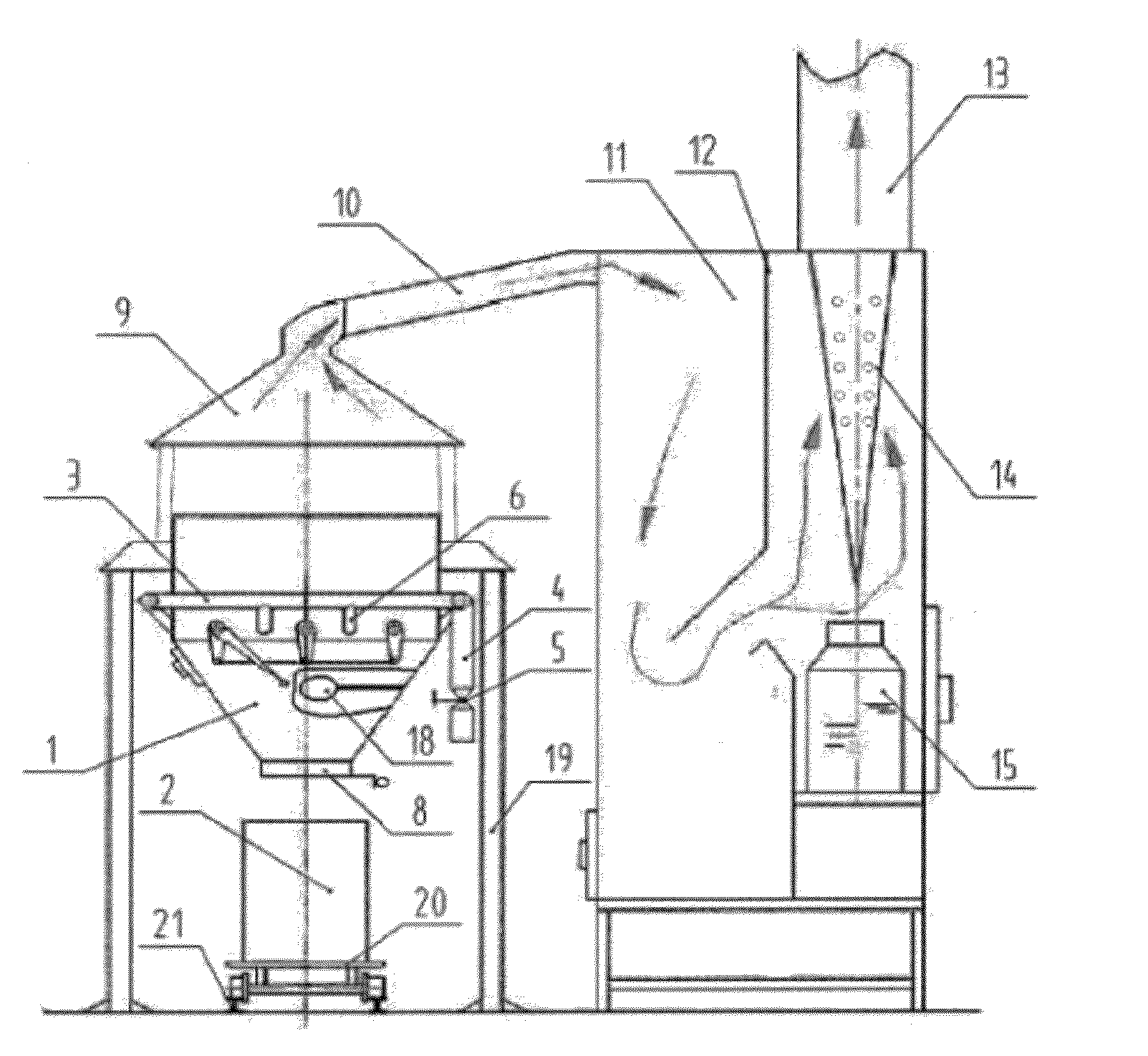

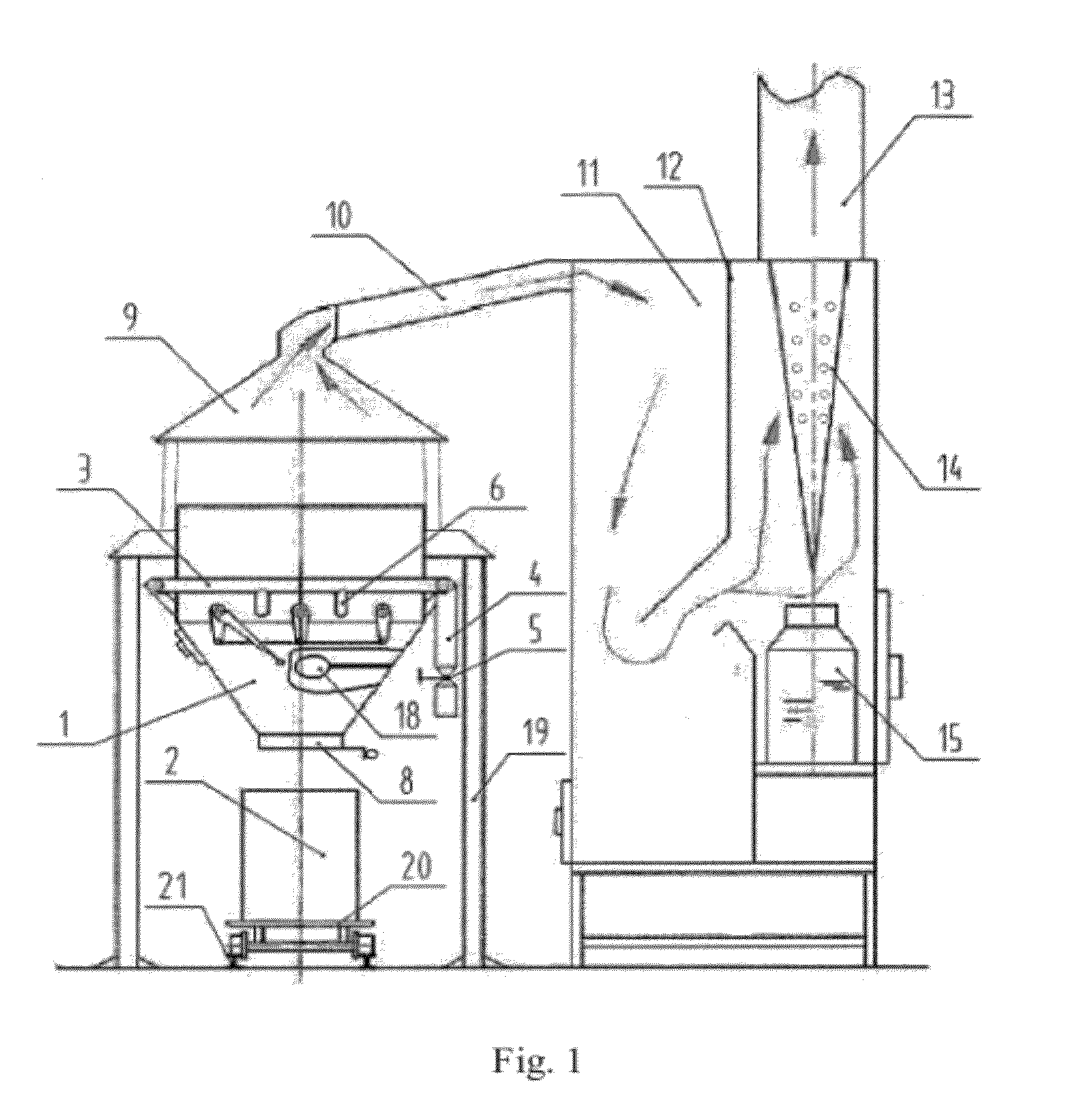

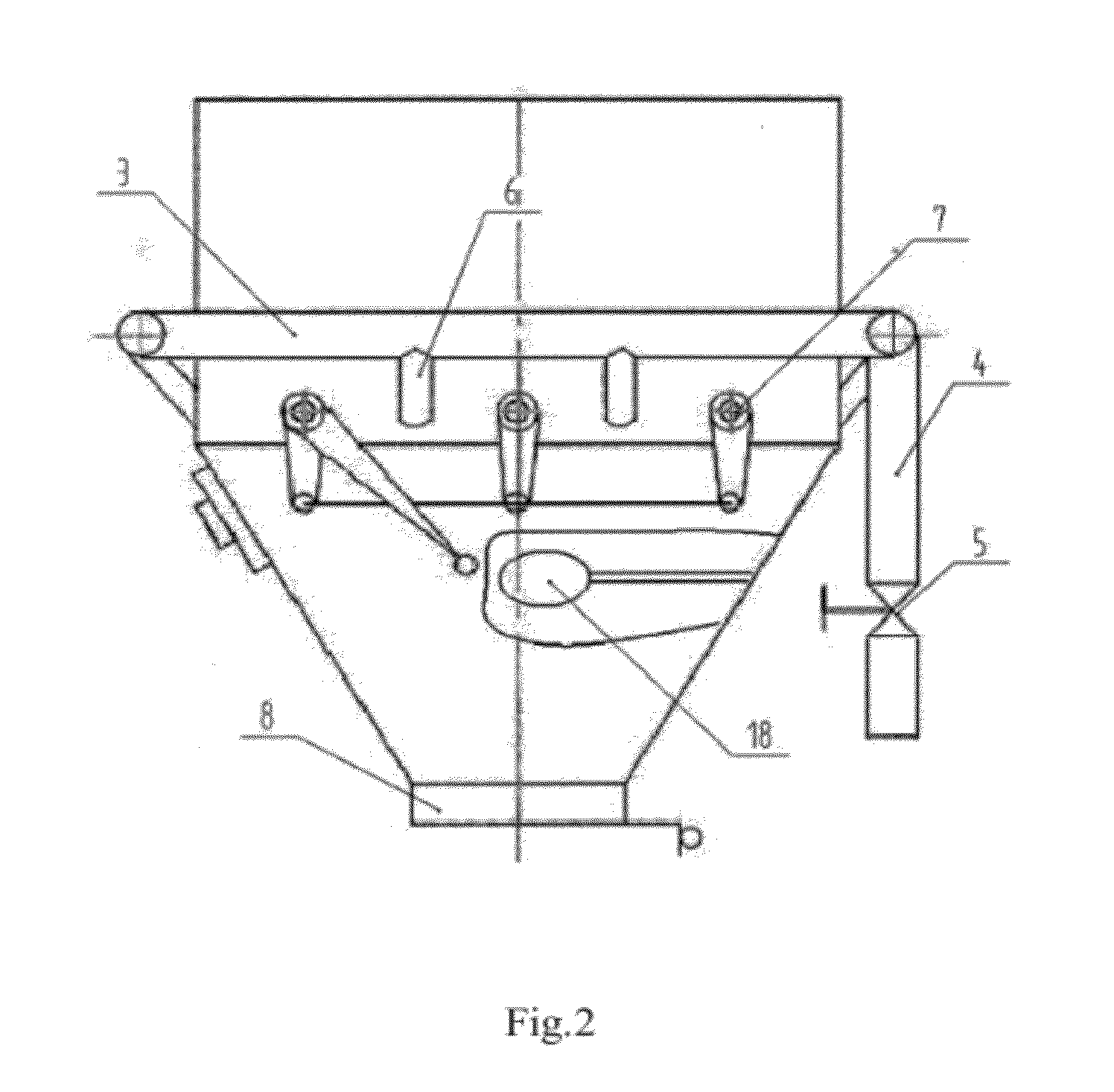

Method and device for carbonification of crop straws

ActiveUS20120305380A1SpeedReduce the temperatureCombustible gas coke oven heatingDirect heating destructive distillationEngineeringOxygen

The present invention is to provide a method for carbonification of crop straws and a device thereof. Pyrolysis process is controlled by regulating the feeding of oxygen during said pyrolysis process, and pyrolysis and carbonification are respectively conducted in separate pyrolysis and carbonification pools, wherein the straws are pyrolyzed in said pyrolysis pool and entered into said carbonification pool to be carbonified. The present invention can quickly raise the temperature of the pyrolysis process, shorten the time of the pyrolysis process, and improve the pyrolysis carbonification efficiency.

Owner:SHANXI SUPPLY & MARKETING COOP

Coke oven flue gas sharing

InactiveCN100510004CExtend your lifeReduce the gas flow rateCombustible gas coke oven heatingBeehive ovensCoke Oven EmissionFlue gas

The invention provides a method and apparatus for reducing the gas flow velocity in the bottom flue gas system of a coke oven during at least one initial coking operation after the coke oven has been charged with coal (43). The method includes providing a ductwork (96, 98) between a first coke oven having a first coking chamber (18) and a second coke oven having a second coking chamber (18) for transferring at least a portion of the gas from The gas space (41) in the first coking chamber (18) is led into the second coking oven, thereby reducing the gas flow velocity in the first bottom flue gas system of the first coking oven. Reducing the gas flow velocity in the bottom flue has beneficial effects on product yield, coke oven life and environmental control of coke oven volatile emissions.

Owner:SUNCOKE TECH & DEV LLC

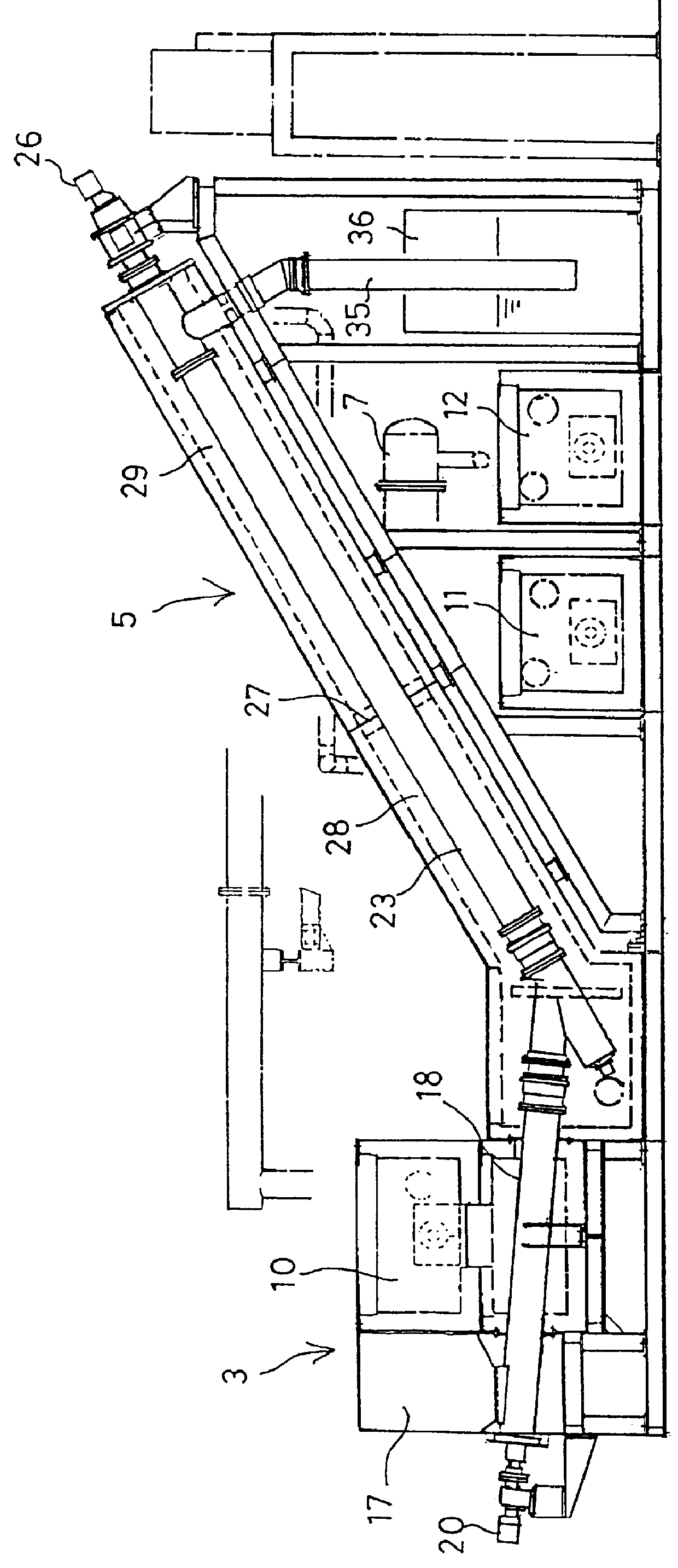

Thermal decomposition apparatus of reversed temperature gradient type for polymer waste

InactiveUS6126907ASimple structureSmall sizeSolid waste disposalDirect heating destructive distillationDecompositionSludge

A thermal decomposition apparatus for decomposing polymer waste is provided which is simple in structure, small in size and inexpensive, and also the operating cost thereof is low. A feed pipe 18 and an inclined pipe 23 are connected in the form of the letter V at a large angle therebetween, and a feed screw 19 and an feed-up screw 25 are arranged inside the respective pipes. Polymer waste introduced into a hopper 17 is melted in the interior of the feed pipe 18 by heat from a first hot air furnace 10 and accumulated in the V-shaped portion. The polymer melt is then conveyed upward by the feed-up screw 25. In the process of conveyance, the polymer melt undergoes primary decomposition by means of heat from a second hot air furnace 11 and the cracked gas thus generated undergoes secondary decomposition by the heat from a third hot air furnace 12, the resultant gas being guided to a condenser 7. Sludge drops down through a chute pipe 35 into a water tank 36.

Owner:WADA YOUICHI

Automatic cover removal system

A system is disclosed for automatically removing the cover of a chute beneath a coke drum. The system operates in conjunction with a remotely operable coke deheading device so that the chute cover is removed when the coke drum is deheaded. Also disclosed is a method for facilitating coke removal from a coke drum into a coke chute where the chute cover is automatically removed upon activation of the coke drum deheading device.

Owner:HAHN & CLAY A CORP OF TX

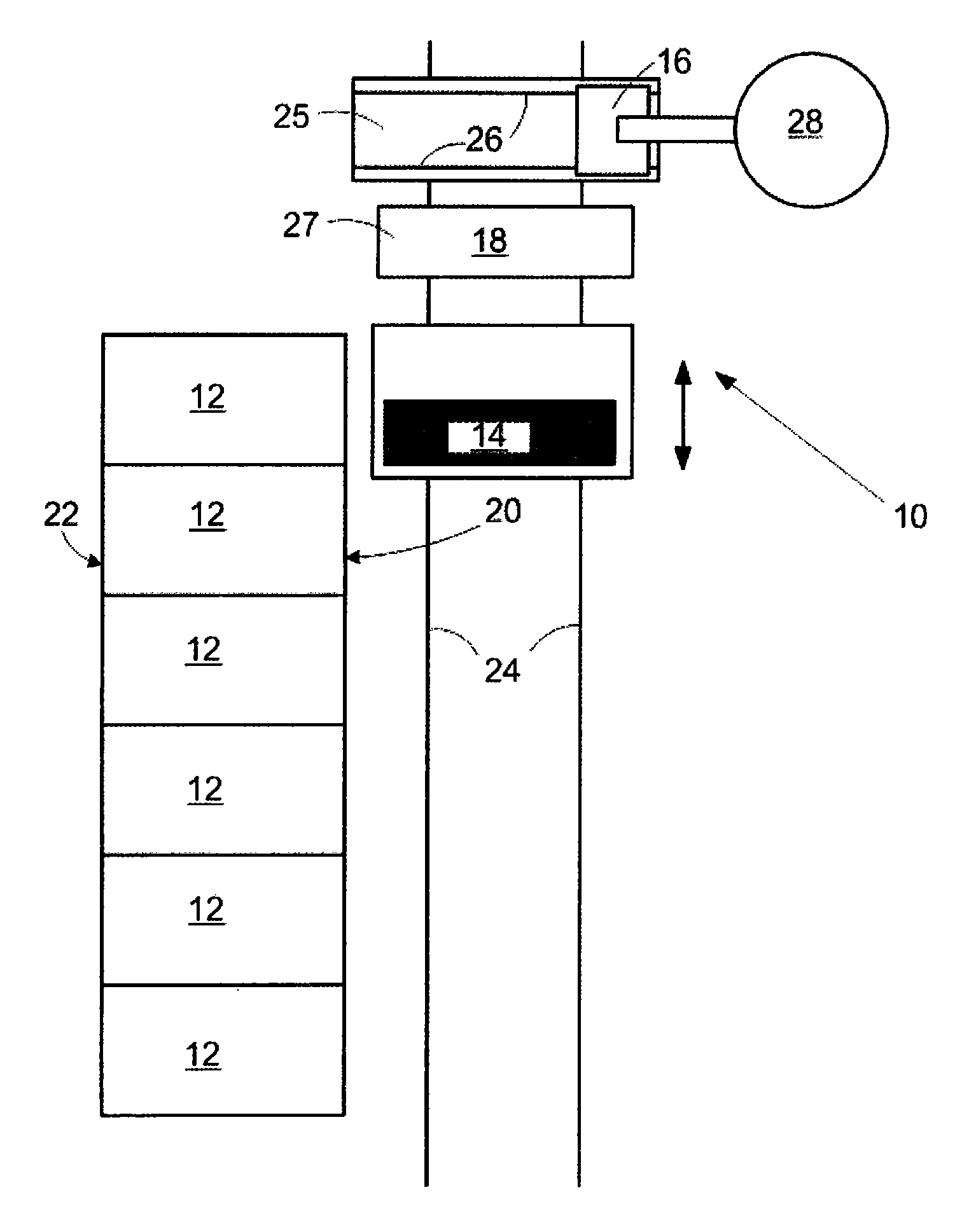

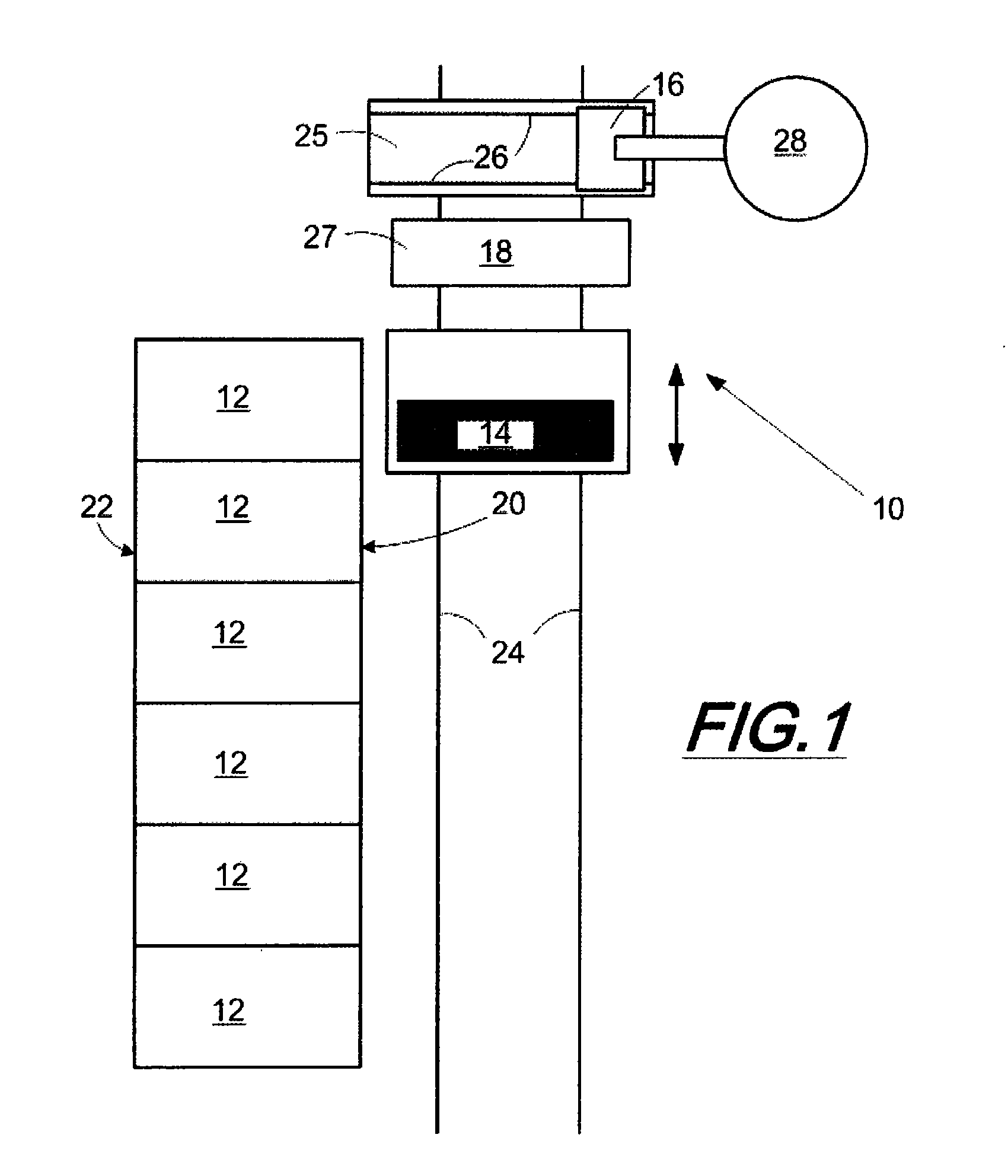

Microwave pyrolysis apparatus for waste tires

InactiveUS7101464B1Electrical coke oven heatingCombustible gas coke oven heatingMicrowave pyrolysisDistillation

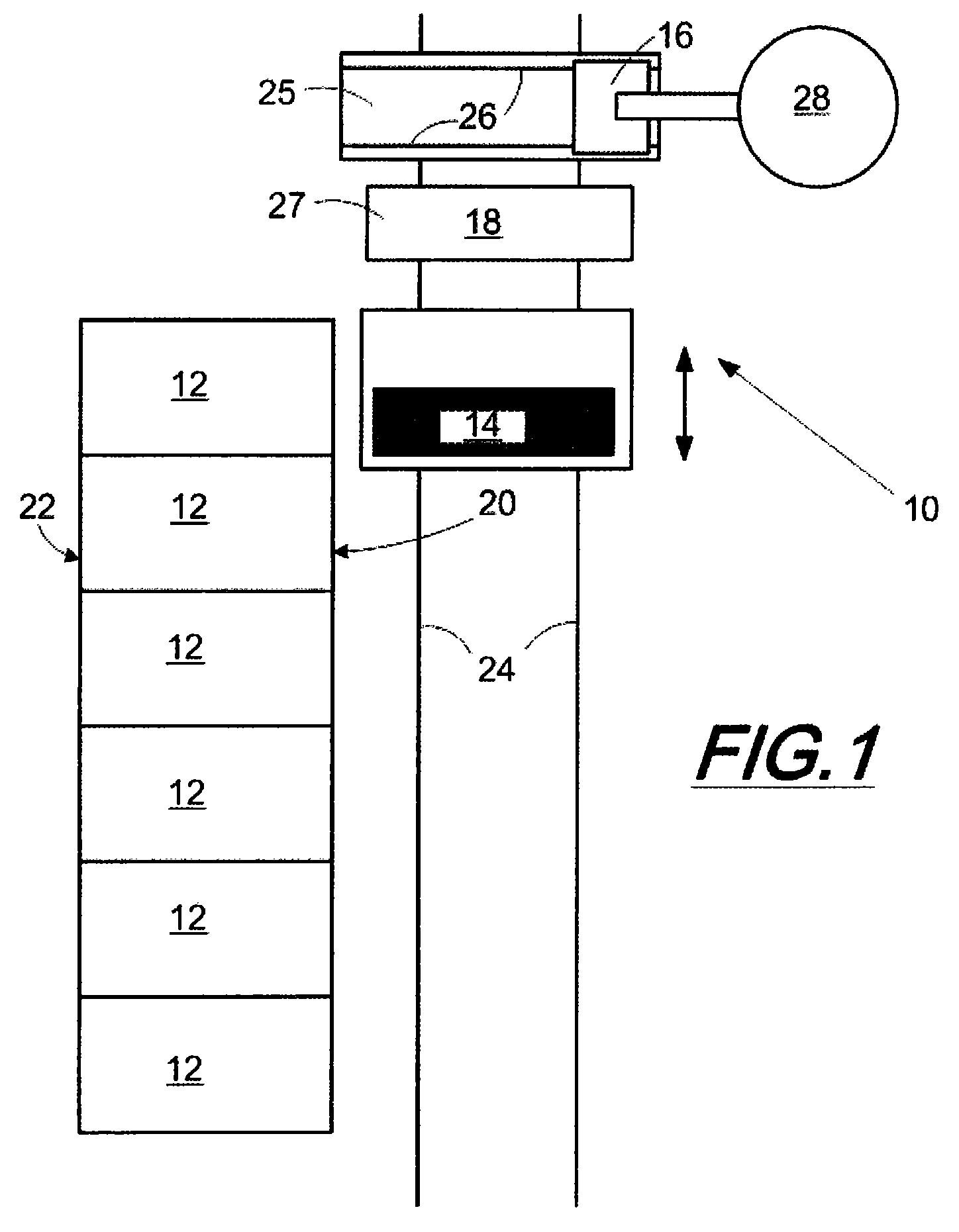

A microwave distillation apparatus provides destructive distillation of whole waste tires. The apparatus includes a housing including a plurality of vertically arranged chambers. A preheat chamber provides preheating of a whole waste tire received therein. An irradiation chamber, located below the preheat chamber and thermally coupled to the preheat chamber such that heat generated in the irradiation chamber creates heat convection currents in the preheat chamber, receives a preheated whole waste tire from the preheat chamber. A microwave energy supply supplies microwave energy to the irradiation chamber to provide destructive distillation of a tire received in that chamber. A cooling chamber, located below the irradiation chamber, receives by-products of the destructive distillation therefrom and provides delivery of the by-products from the housing.

Owner:PRINGLE JOE A MR +1

Safe and automatic method for preparation of coke for removal from a coke vessel

InactiveUS7037408B2Prevent leakageReduces and eliminates dangerousThermal non-catalytic crackingDirect heating destructive distillationSteam pressureDrill

A safe, efficient and repetitively operable coke vessel decoking system is disclosed. In a preferred embodiment the closed system comprises a coker vessel pressure-tightly sealed to a top head system, which includes a closure housing with a laterally moveable horizontal closure member therein and a cutting head enclosure, which further comprises a drill stem guide, an access door, and a cutting assembly mounted therein. A novel feature of the invention is a steam purge / blocking system whereby steam pressure is maintained in the closure housing during the coking cycle to maintain seal integrity. Personnel safety during decoking operations is greatly enhanced by eliminating dangerous manual tasks associated with the prior art such as unbolting and removing top head devices. The system can be remotely and repetitively operated through numerous coking / decoking cycles without removal of any system element.

Owner:CHEVROU USA INC

Continuous coking process

InactiveUS20070108036A1Thermal non-catalytic crackingCombustible gas coke oven heatingThermodynamicsCoke

The invention relates to a thermal conversion process for continuously producing hydrocarbon vapor and continuously removing a free-flowing coke. The coke, such as a shot coke, can be withdrawn continuously via, e.g., a staged lock hopper system.

Owner:EXXON RES & ENG CO

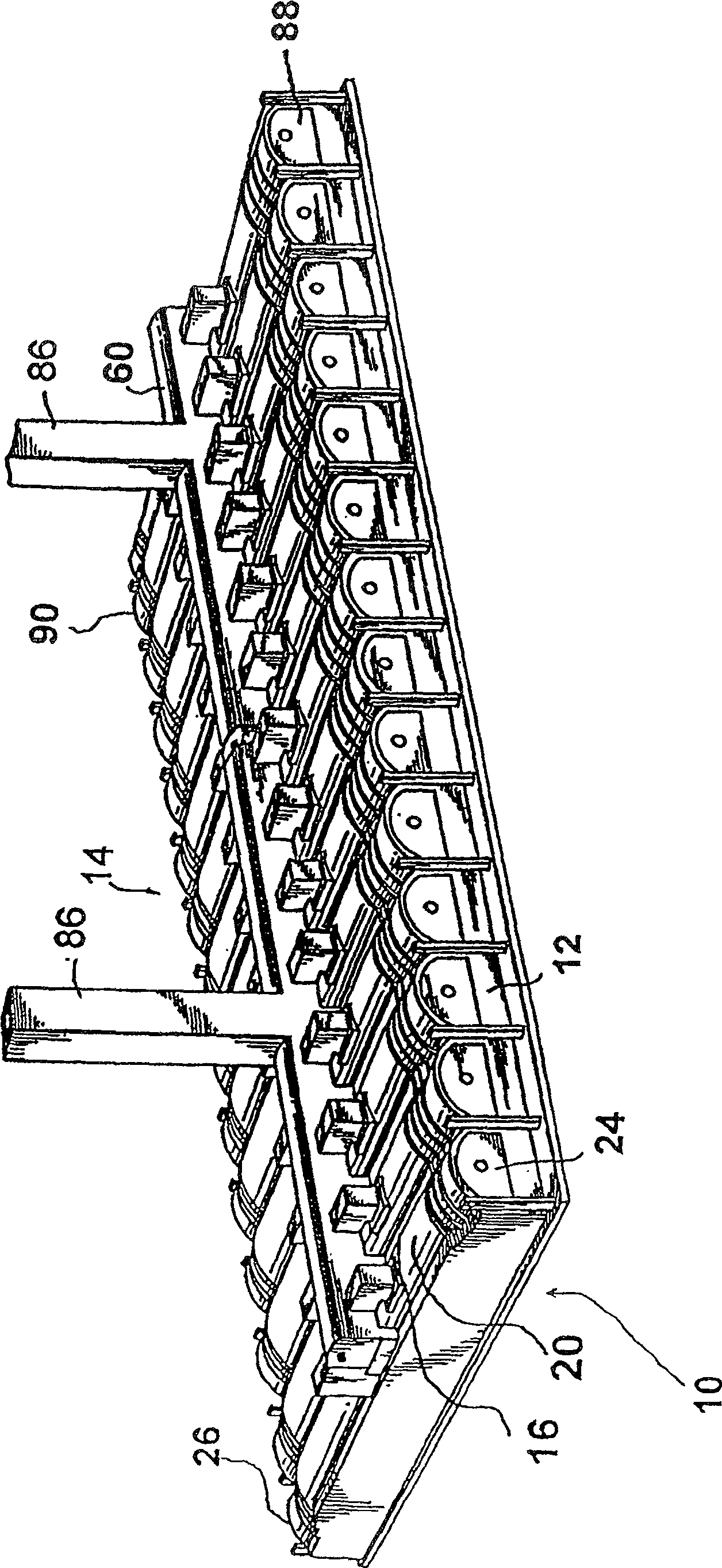

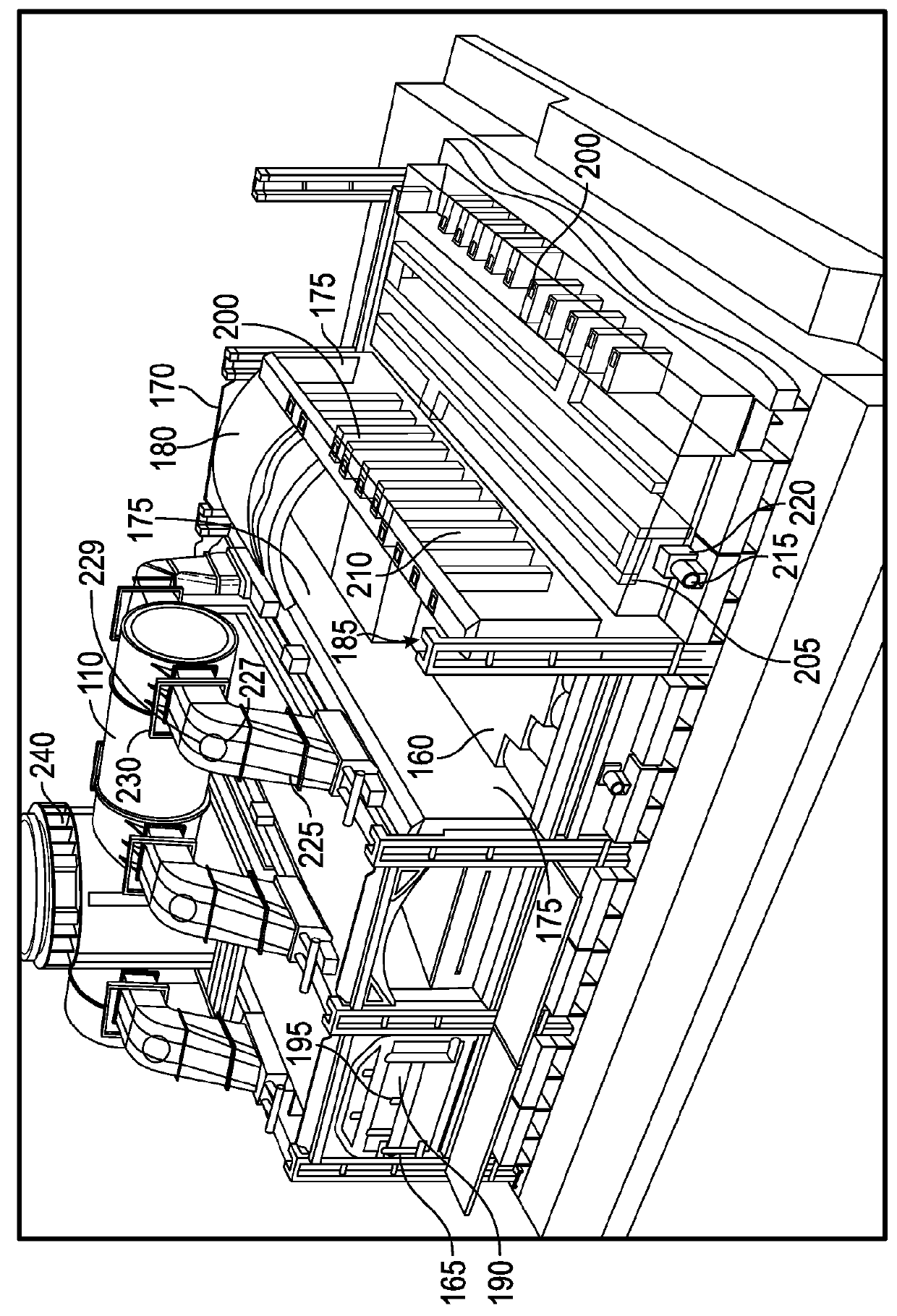

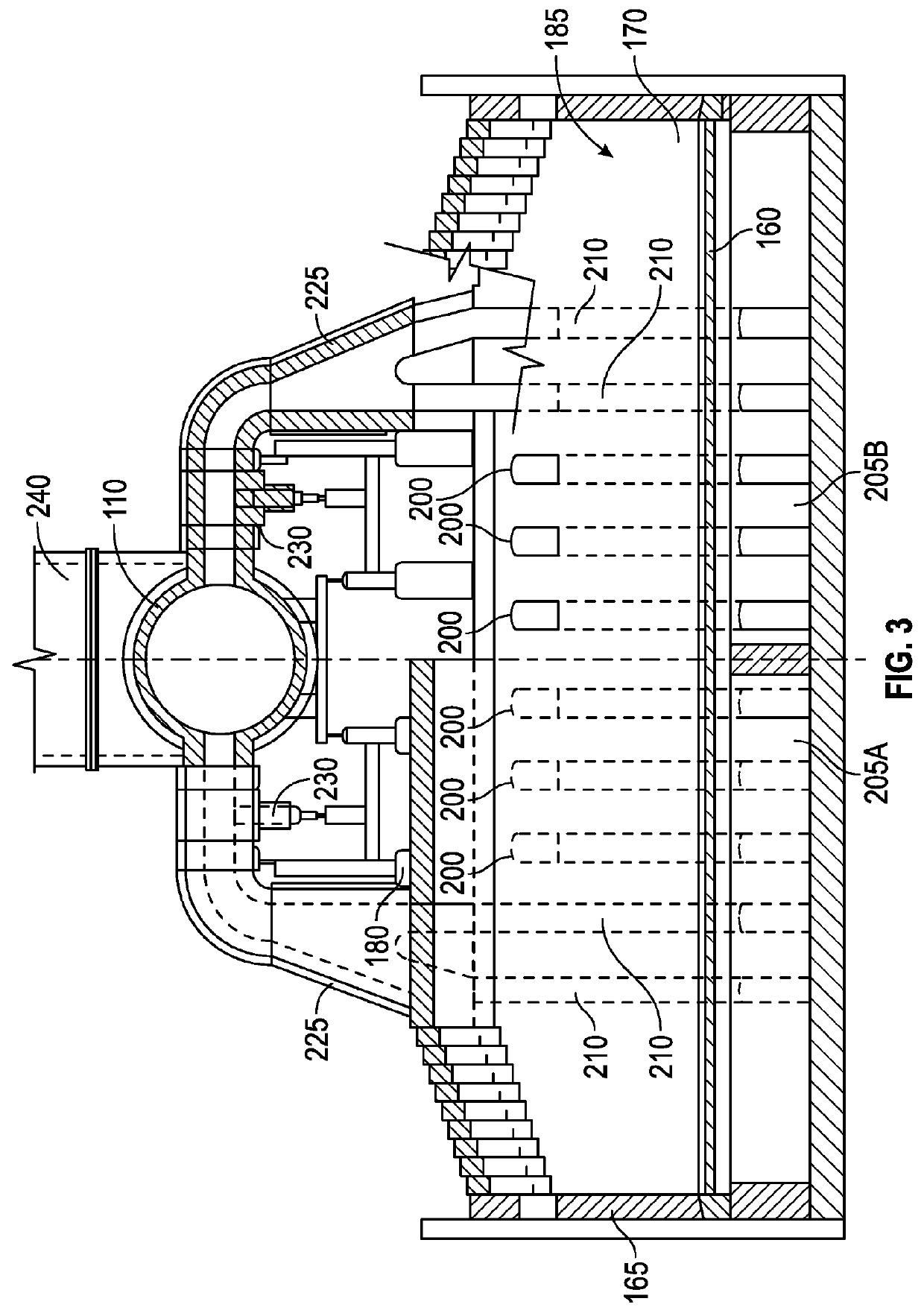

Method and apparatus for volatile matter sharing in stamp-charged coke ovens

A volatile matter sharing system includes a first stamp-charged coke oven, a second stamp-charged coke oven, a tunnel fluidly connecting the first stamp-charged coke oven to the second stamp-charged coke oven, and a control valve positioned in the tunnel for controlling fluid flow between the first stamp-charged coke oven and the second stamp-charged coke oven.

Owner:SUNCOKE TECH & DEV LLC

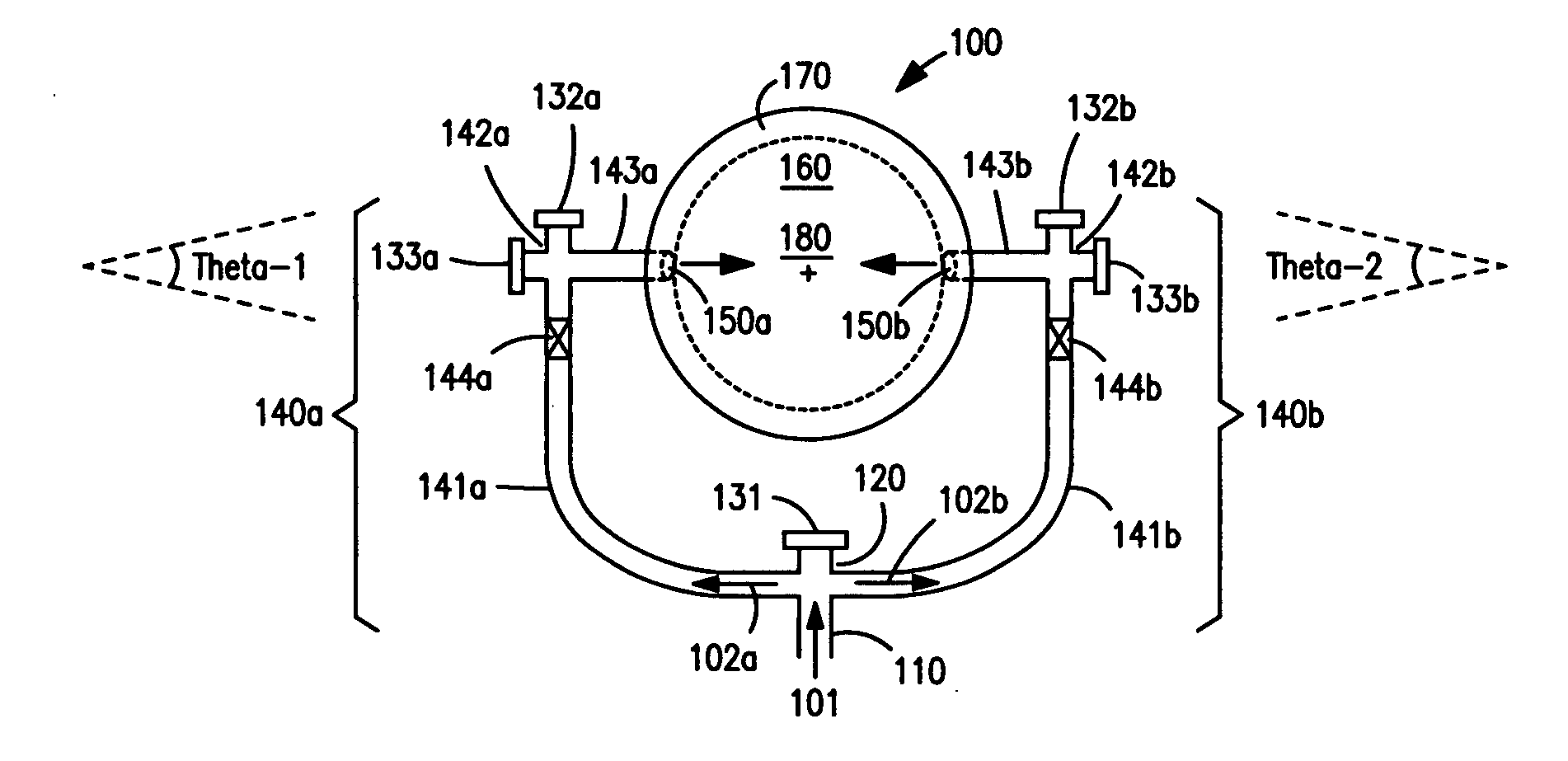

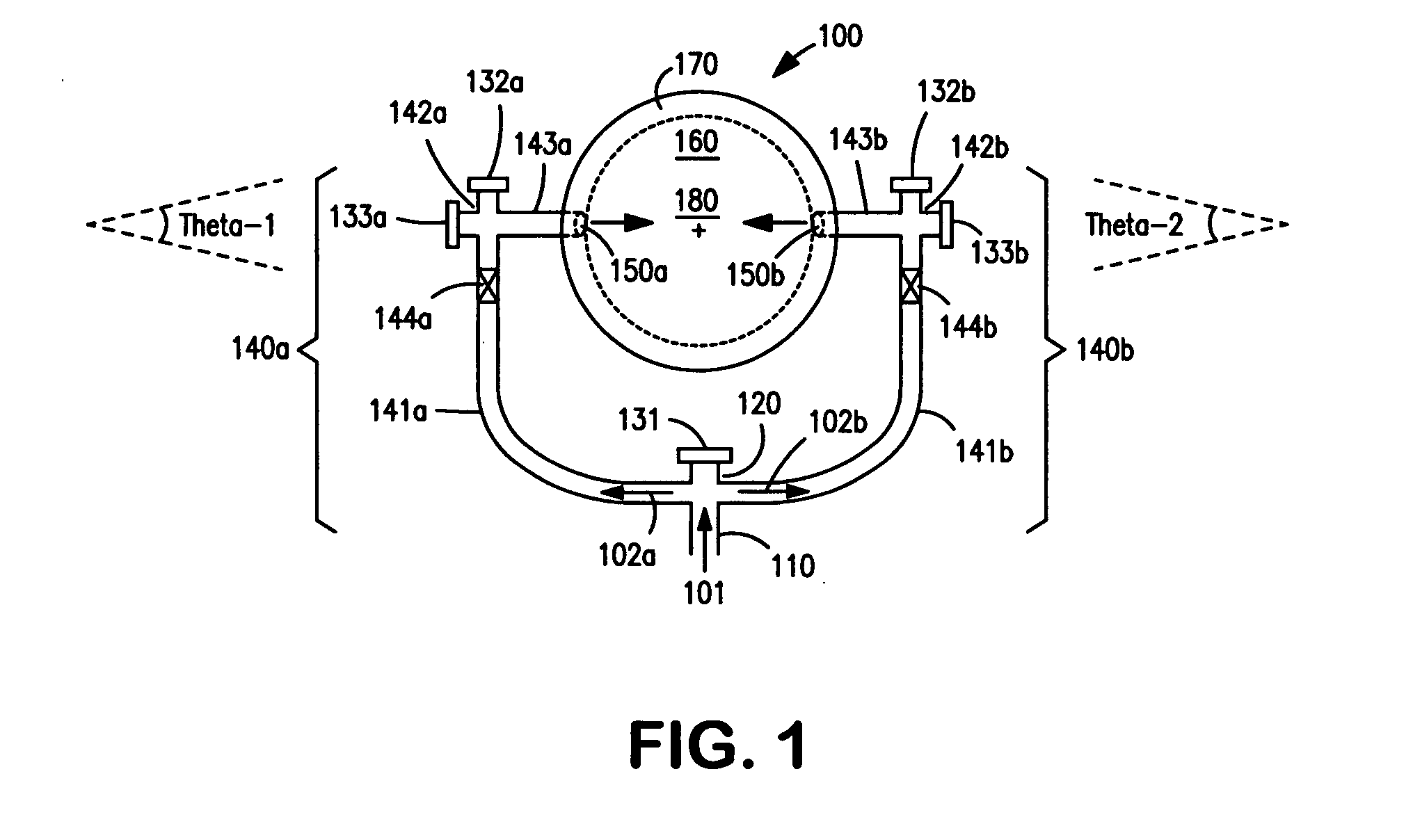

Tangential dispenser and system for use within a delayed coking system

ActiveUS7115190B2Hydrocarbon distillationLiquid hydrocarbon mixture recoveryEngineeringHeat distribution

The present invention features a tangential injection system for use within a delayed coking system, or any other similar system. The tangential injection system comprises a spool, a tangential dispenser, and a hydro blasting system, wherein the tangential dispenser comprises a delivery main surrounding the perimeter of the spool and that functions to deliver a residual byproduct or other material to a plurality of feed lines positioned at a position or at distances around the delivery main for the purpose of providing tangential dispensing of the residual byproduct into the vessel, thus effectuating or inducing even thermal distribution throughout the vessel.

Owner:DELTAVALVE

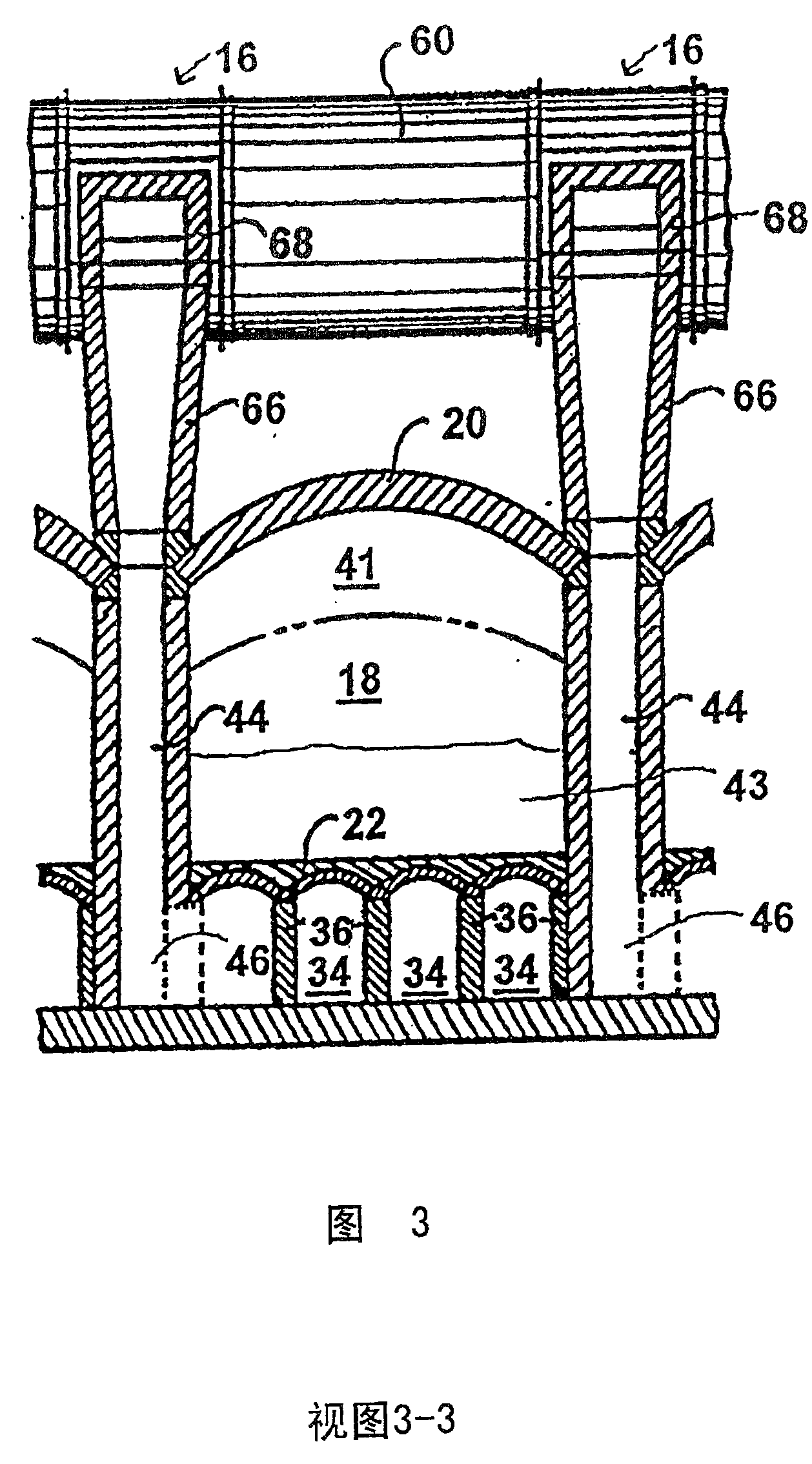

Controllable air ducts for feeding of additional combustion air into the area of flue gas channels of coke oven chambers

ActiveUS9039869B2Reduce carbonizationGood heat distributionCombustible gas coke oven heatingCoke oven safety devicesBrickCombustion

A device for feeding and controlling secondary air from secondary air ducts into flue gas channels of horizontal coke oven chambers is shown. The flue gas channels are located underneath the coke oven chamber floor on which coal carbonization is realized. The flue gas channels serve for combustion of partly burnt coking gases from the coke oven chamber. The partly burnt gases are burnt with secondary air, thus heating the coke cake also from below to ensure even coal carbonization. Secondary air comes from the secondary air ducts connected to atmospheric air and to the flue gas channels. Controlling elements are mounted in the connecting channels between the flue gas channels and secondary air ducts which can precisely control the air flow into the flue gas channels. Thereby, it is possible to achieve a much more regular heating and heat distribution in coke oven chambers. The actual controlling devices in the connecting channels can be formed by turnable pipe sections, wall bricks, or metal flaps. It is particularly advantageous to utilize a hump-like facility (tabouret) which sits in the secondary air ducts and which is comprised of a tabouret plate with a central opening that is slid under the corresponding embranchment to regulate the gas stream. The controlling mechanism can be actuated manually, electrically, or pneumatically. Thereby, the controlling device can also be automated.

Owner:UHDE GMBH

Method and apparatus for compacting coal for a coal coking process

InactiveUS20070289861A1Minimize amount of timeUniform bulk densityCoke quenchingCharging-discharging device combinationsCoke ovenEngineering

Relatively high speed methods for increasing the bulk density of coal particles, apparatus for increasing the bulk density of coal particles and methods for making metallurgical coke. Once such method includes depositing coal particles onto a charging plate external to a coking oven to provide an elongate bed of dry, uncompacted coal having an upper surface of the charging plate. The charging plate has side walls, and at least one movable end wall An impact pressure is applied to the upper surface of the bed of dry, uncompacted coal while degassing the coal to provide a dry, compacted coal bed having a bulk density ranging from about 960 to about 1200 kilograms per cubic meter.

Owner:SUNCOKE TECH & DEV LLC

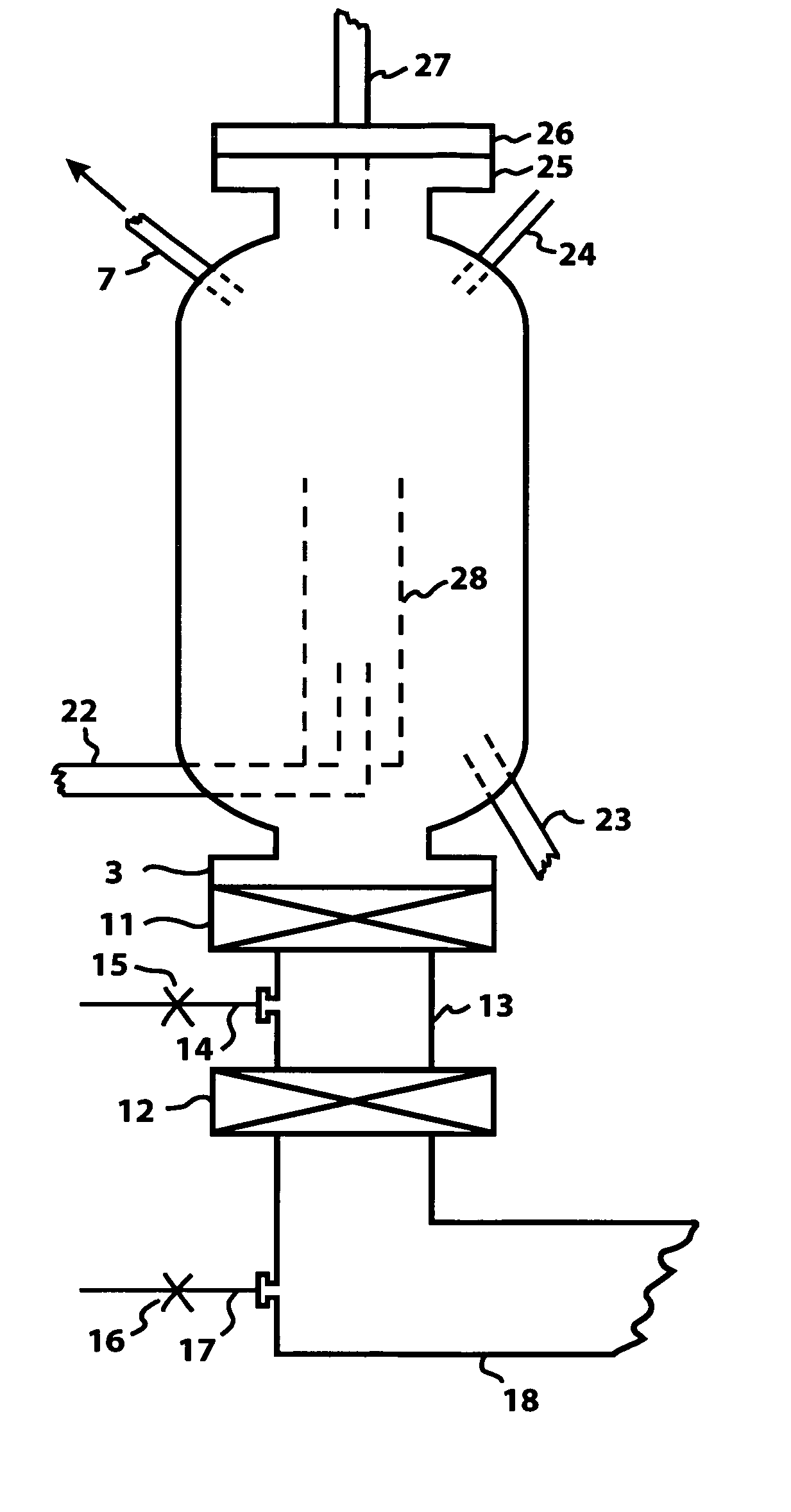

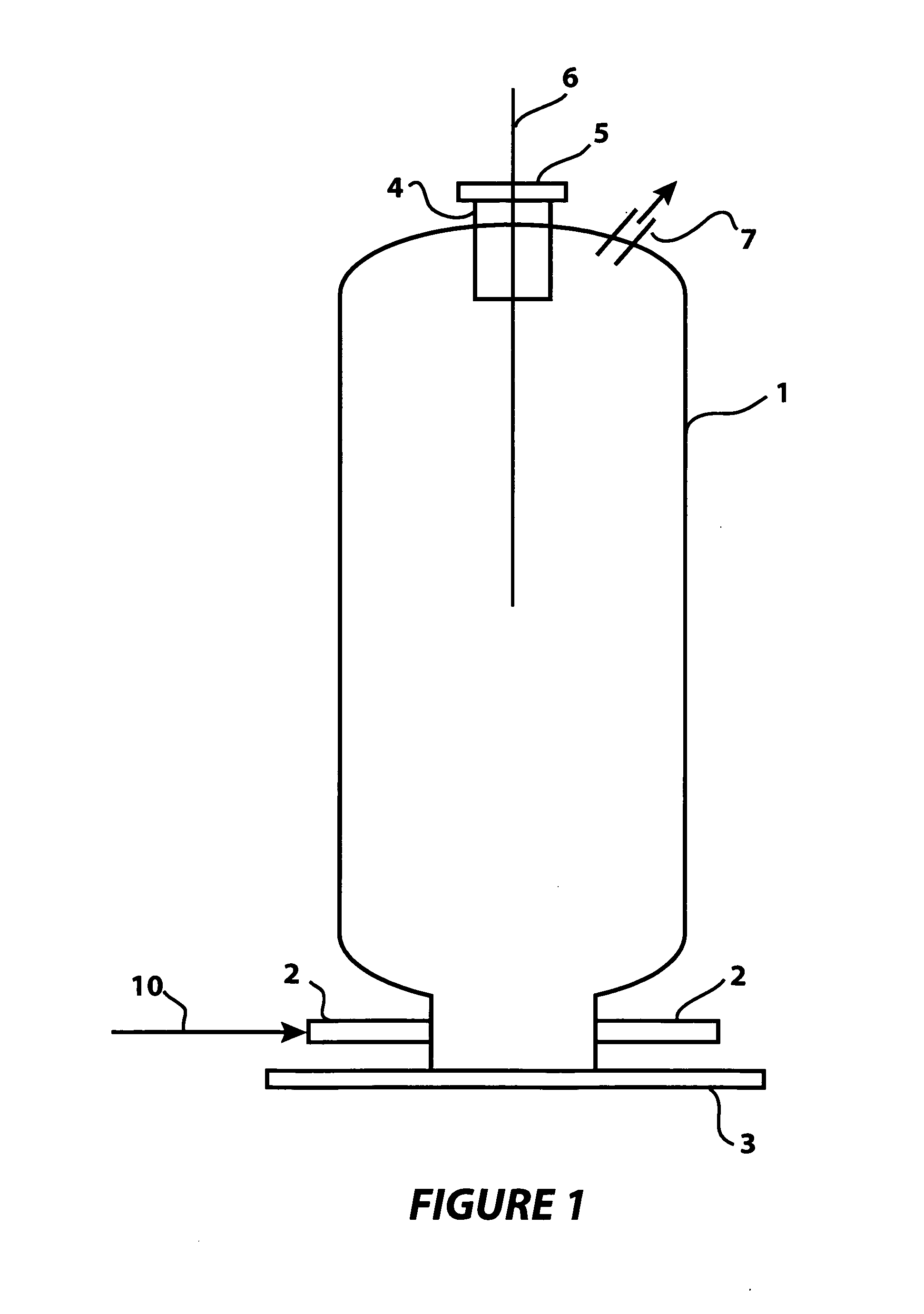

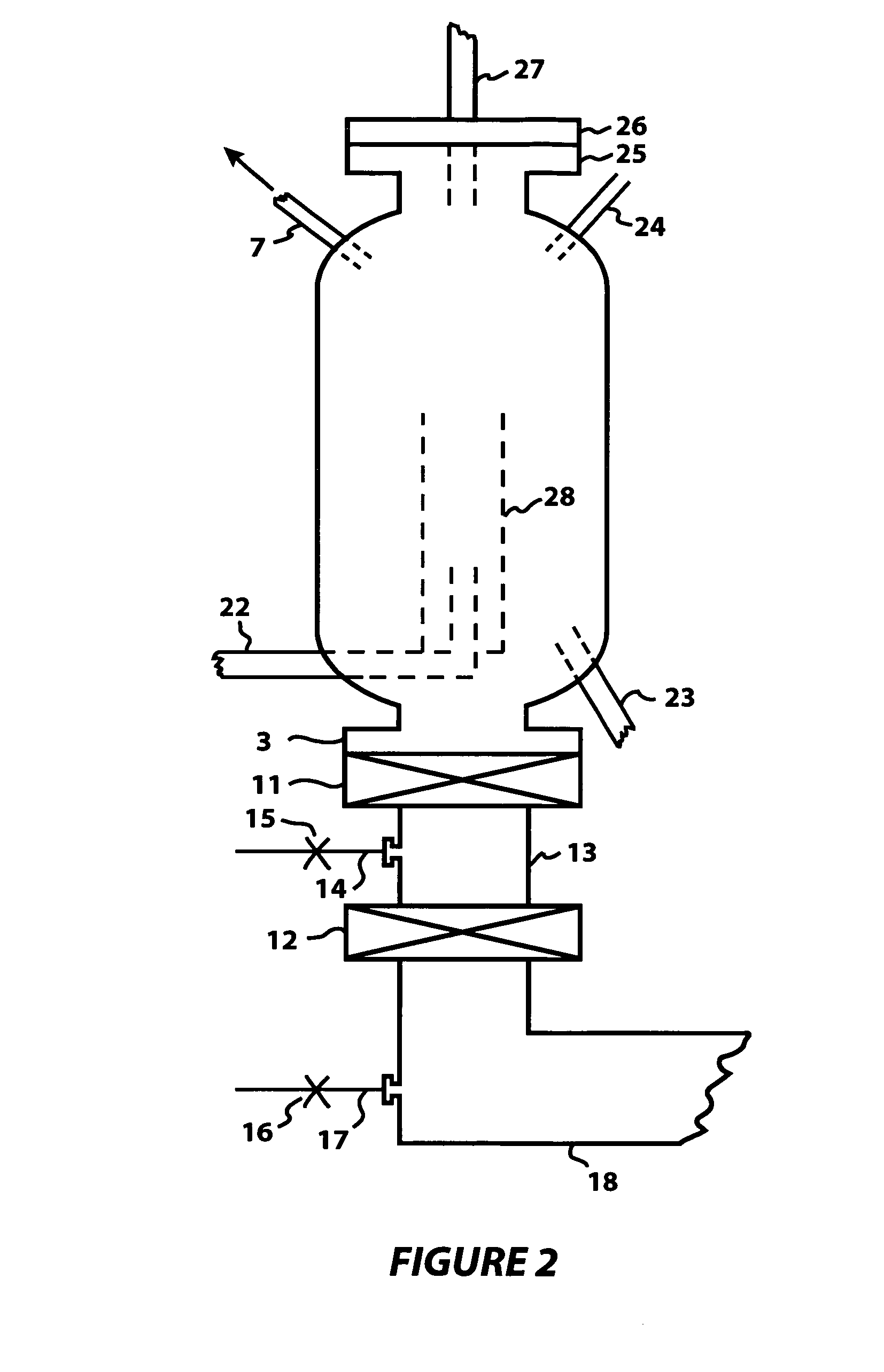

Insulated transition spool apparatus

ActiveUS6926807B2Pipe protection by thermal insulationPipe units with cleaning aperturesEngineeringPressure vessel

An insulated transition spool apparatus for mounting unheading devices to pressure vessels, such as coker vessels, and enabling repetitive operation thereof is disclosed. The apparatus comprises an outer housing, an inner housing that encloses an insulating space between the inner and outer housing, a side feed entry aperture in each housing and a spool adapter flange to facilitate attachment of the spool to the vessel.

Owner:CHEVROU USA INC

Air proportioning system for secondary air in coke ovens depending on the vault vs. sole temperature ratio

ActiveUS8980063B2Easy to useCombustible gas coke oven heatingCoke oven safety devicesCombustionCoke oven

A device for proportioning of secondary combustion air into the secondary air soles of coke oven chamber ovens is shown. The device is formed by a slide gate or a parallelepiped device or by plates moved by means of a thrust bar, the thrust bar being moved longitudinally in parallel to the coke oven chamber wall so that the plates move away from the secondary air apertures and open or close these. The thrust bar is moved by means of a positioning motor, with the power transmission being effected hydraulically or pneumatically. Via suitable measuring parameters, it is thus possible to optimize secondary heating so that heating is provided evenly from all sides, thus achieving an improvement in coke quality.

Owner:THYSSENKRUPP IND SOLUTIONS AG

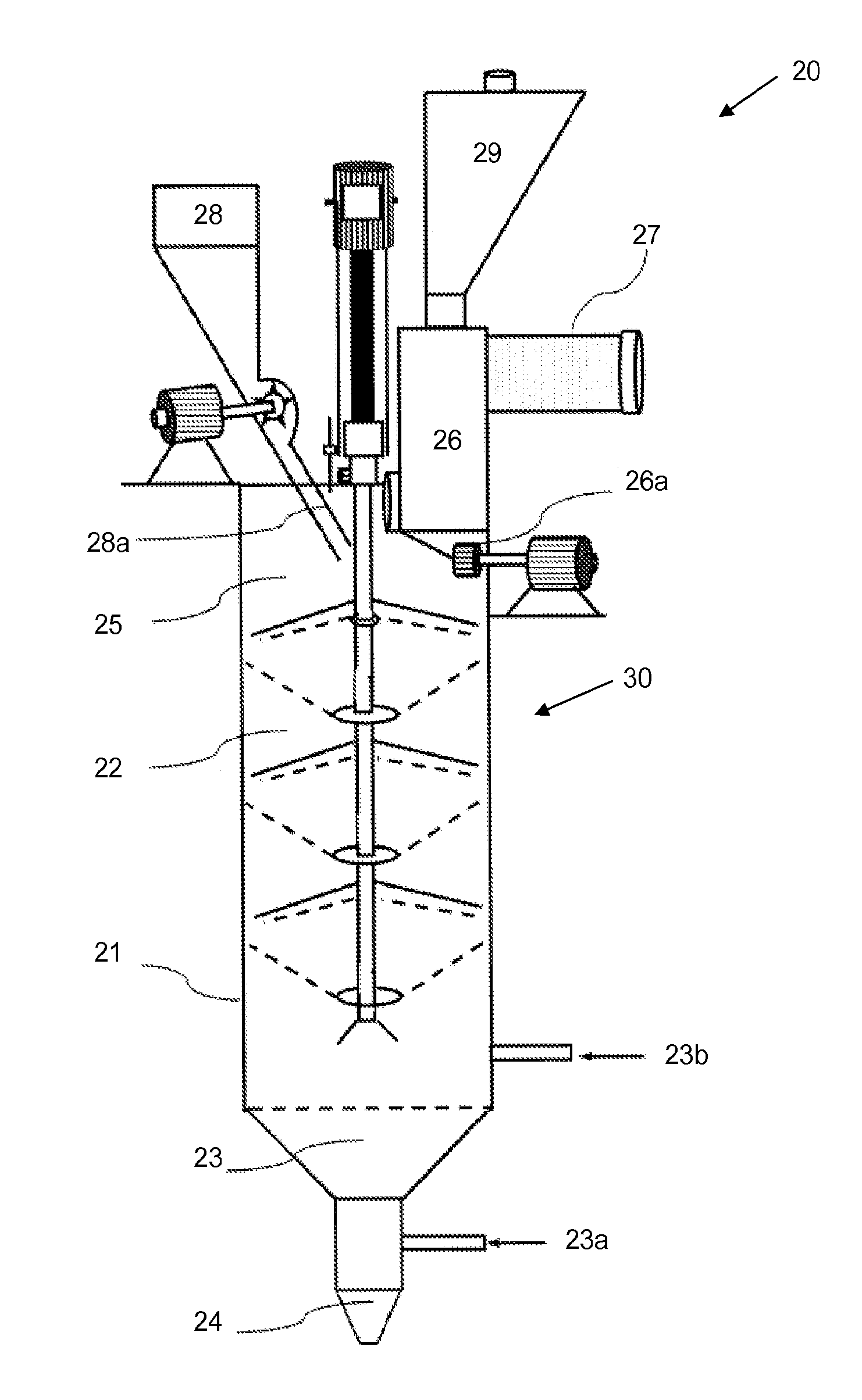

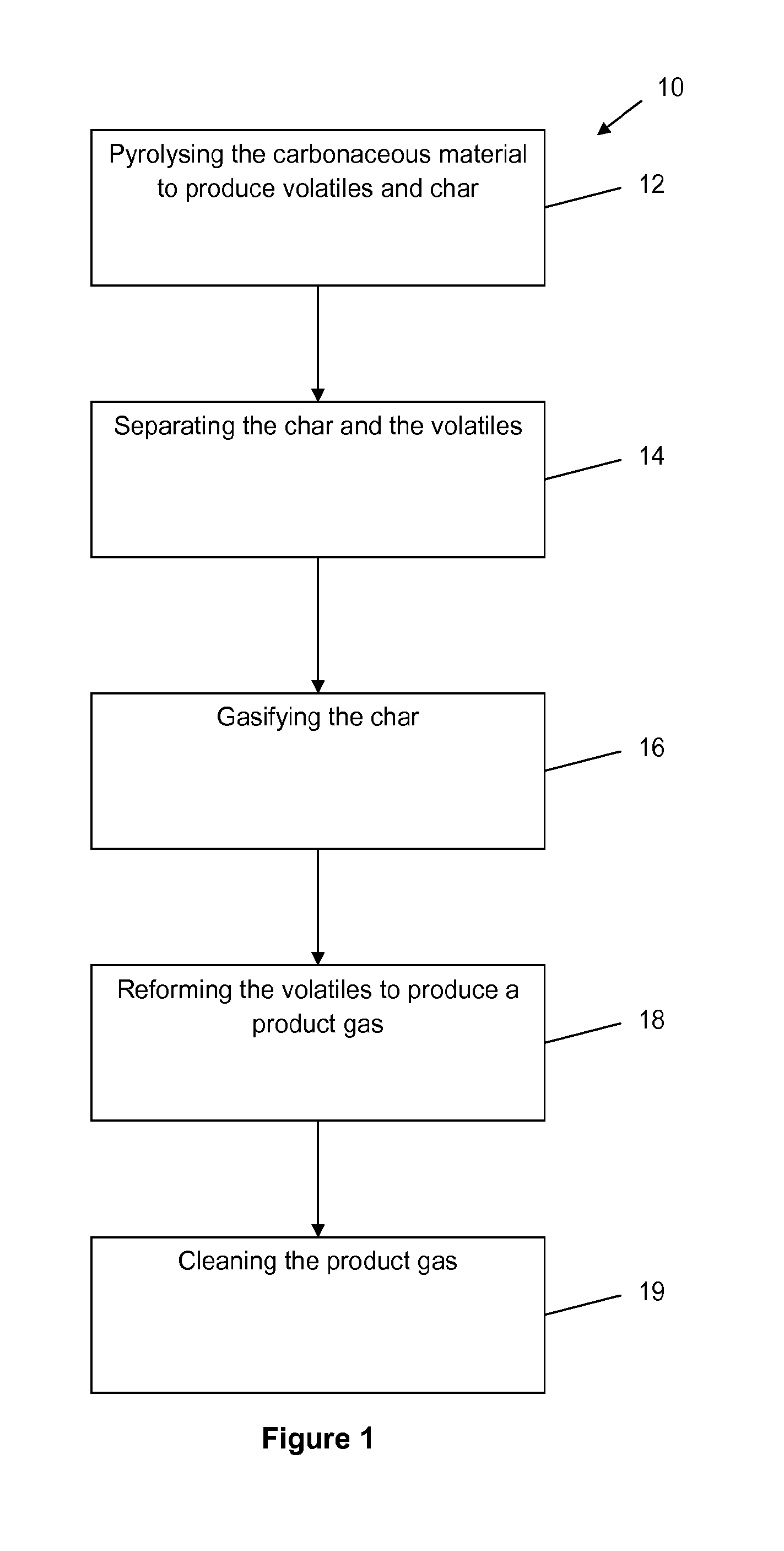

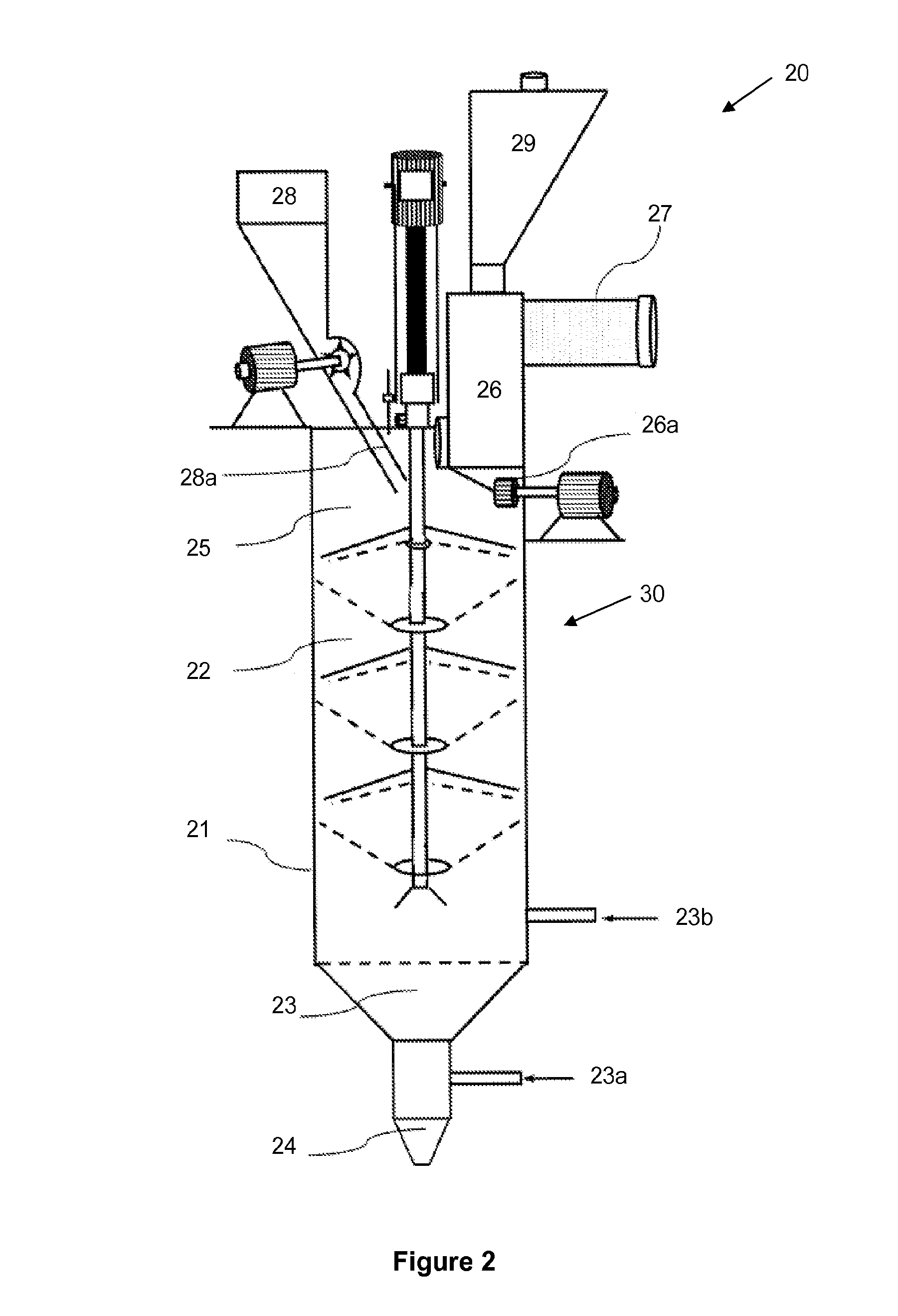

Method of gasifying carbonaceous material and a gasification system

InactiveUS20130306913A1Minimize interactionHigh hydrogen contentCombustible gas coke oven heatingGasifier mechanical detailsProduct gasOrganic chemistry

A method of gasifying carbonaceous material is described. The method comprises a first step of pyrolysing and partially gasifying the carbonaceous material to produce volatiles and char. The volatiles and the char are then separated and, subsequently, the char is gasified and the volatiles are reformed. The raw product gas is then finally cleaned with char or char-supported catalysts or other catalysts.

Owner:CURTAIN UNIV OF TECH

Dynamic flange seal and sealing system

InactiveUS7316762B2Smooth connectionImprove sealingEngine sealsFlanged jointsEngineeringHigh pressure

The present invention features a flange to flange dynamic seal and sealing system, particularly suited for use within high temperature, high pressure environments, such as a delayed coking process. The dynamic flange seal and sealing system comprises two primary elements or seals, each of which are capable of independently forming a flange seal between two flanged components or combining to create a flange seal. Specifically, these primary seals are an iconel bellows seal and a bi-material gasket, each of which surround a flange opening along a sealing surface. The flange seal created by the dynamic flange seal and sealing system is capable of being maintained in light of, or rather the sealing system adapts to, any structural or environmental changes within the connected flanges. As such, the flange seal may be a dynamic flange seal or a static flange seal or both.

Owner:CURTISS WRIGHT FLOW CONTROL CORP

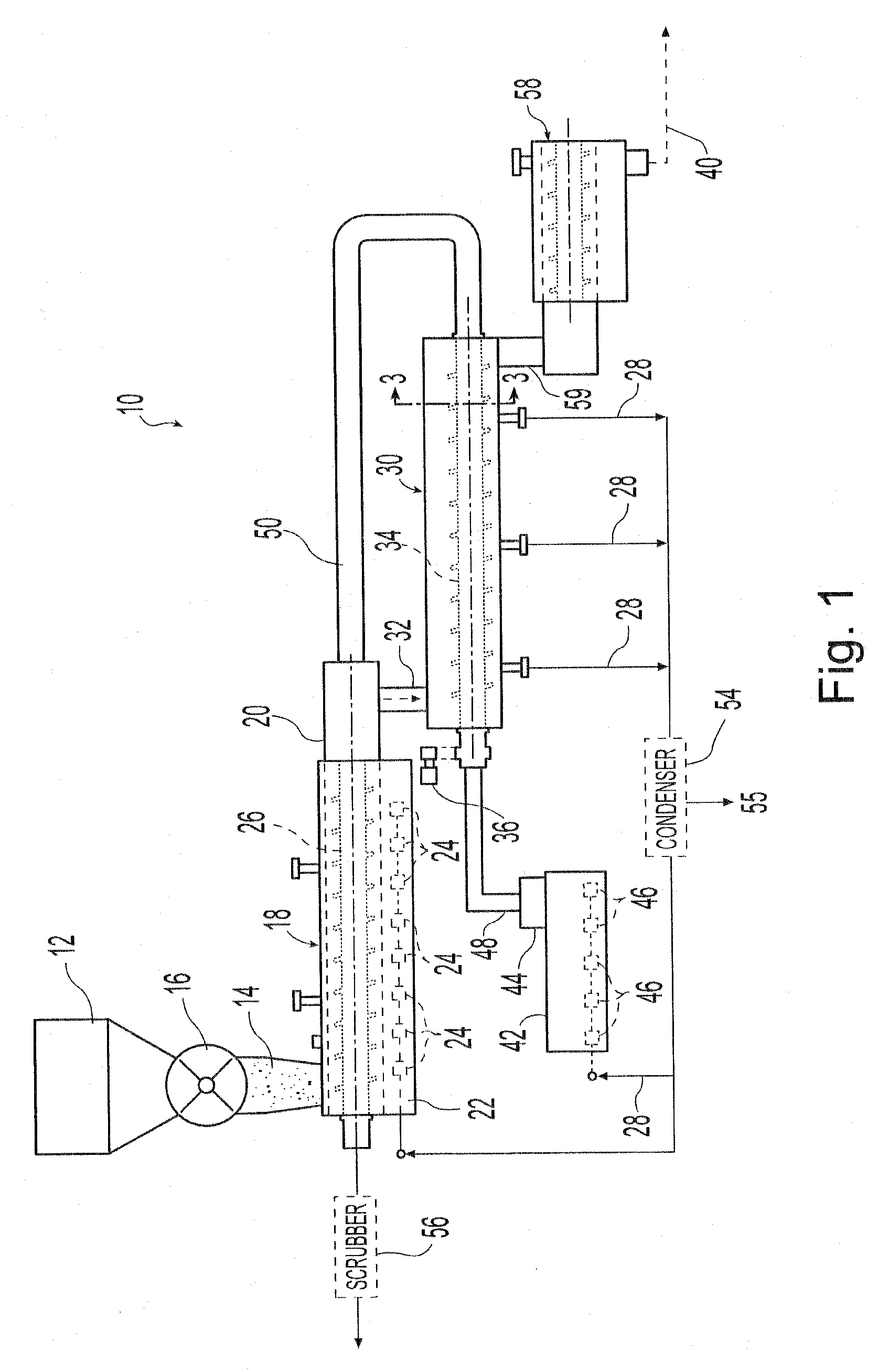

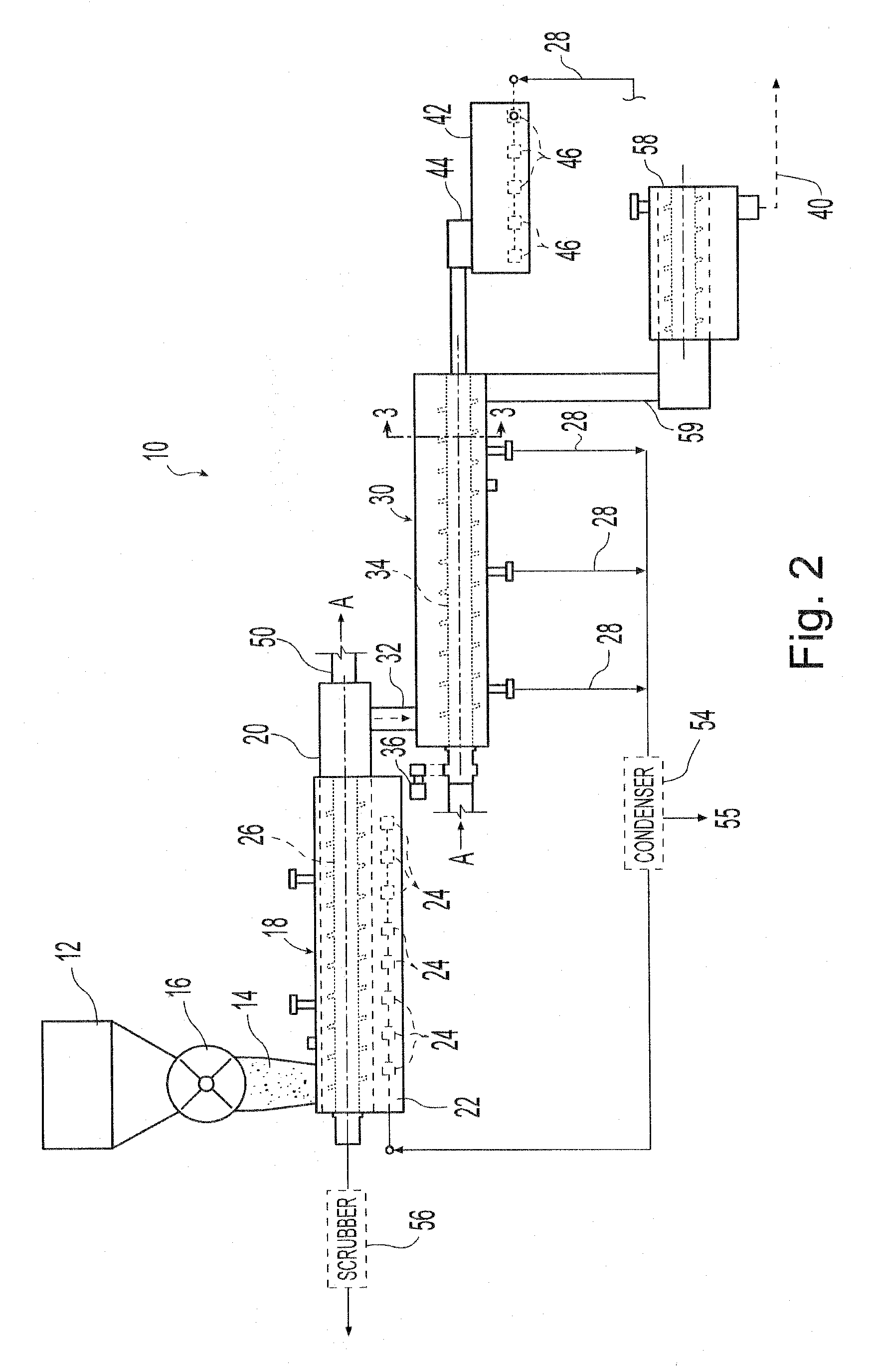

Pyrolyzer furnace apparatus and method for operation thereof

InactiveUS20130240343A1Reduce the cross-sectional areaWeaken energyCombustible gas coke oven heatingCoal charges mechanical treatmentCombustion chamberMechanical engineering

A char making apparatus comprises a longitudinal pyrolyzer furnace housing wherein coal-bearing material may be heated to a temperature to fluidize volatile materials therein and plasticize coal in the coal-bearing material. At least two rotatable drive screws are laterally positioned and interleaved within the longitudinal furnace housing and capable of conveying coal-bearing materials through the pyrolyzer furnace housing, each drive screw having a hollow drive shaft and a diverter positioned within the drive shaft to provide heating to the coal-bearing material. A heating jacket about the longitudinal furnace housing provides additional heating to the coal-bearing material. Multiple combustion chambers adjacent the heating jacket and hollow drive shaft burn fluidized volatile materials and exhaust combustion fluids through the jacket and shaft.

Owner:NUCOR CORP

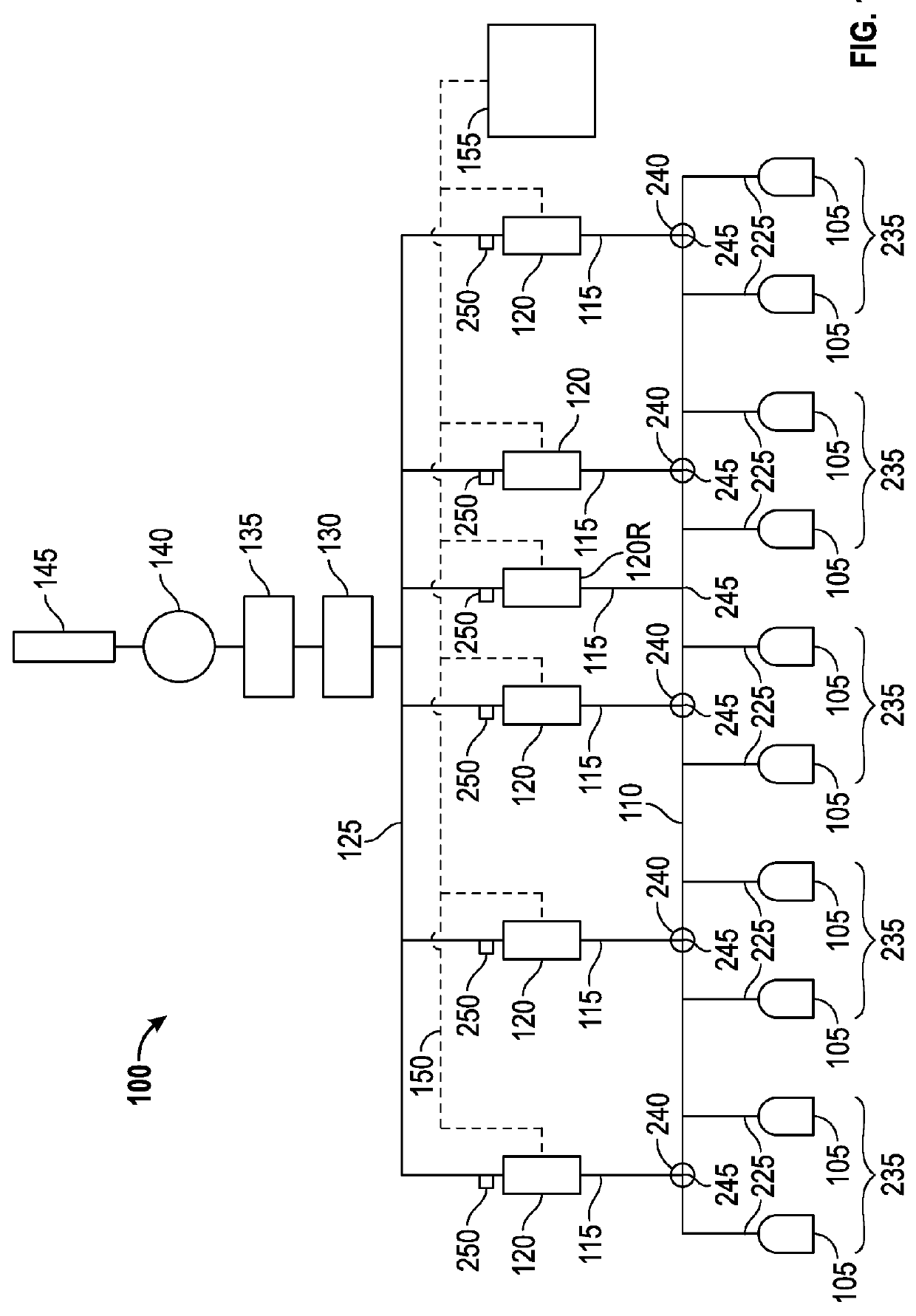

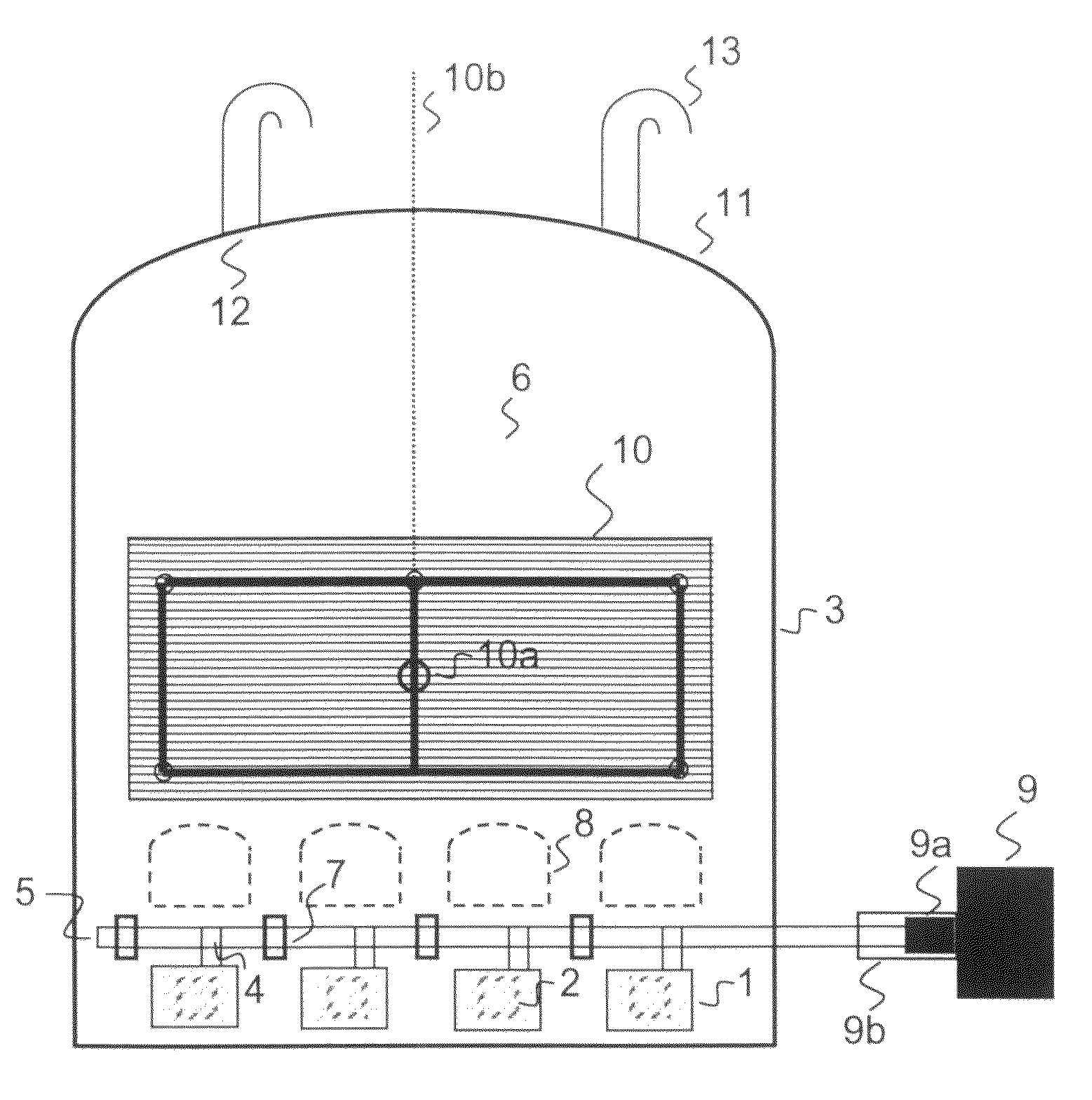

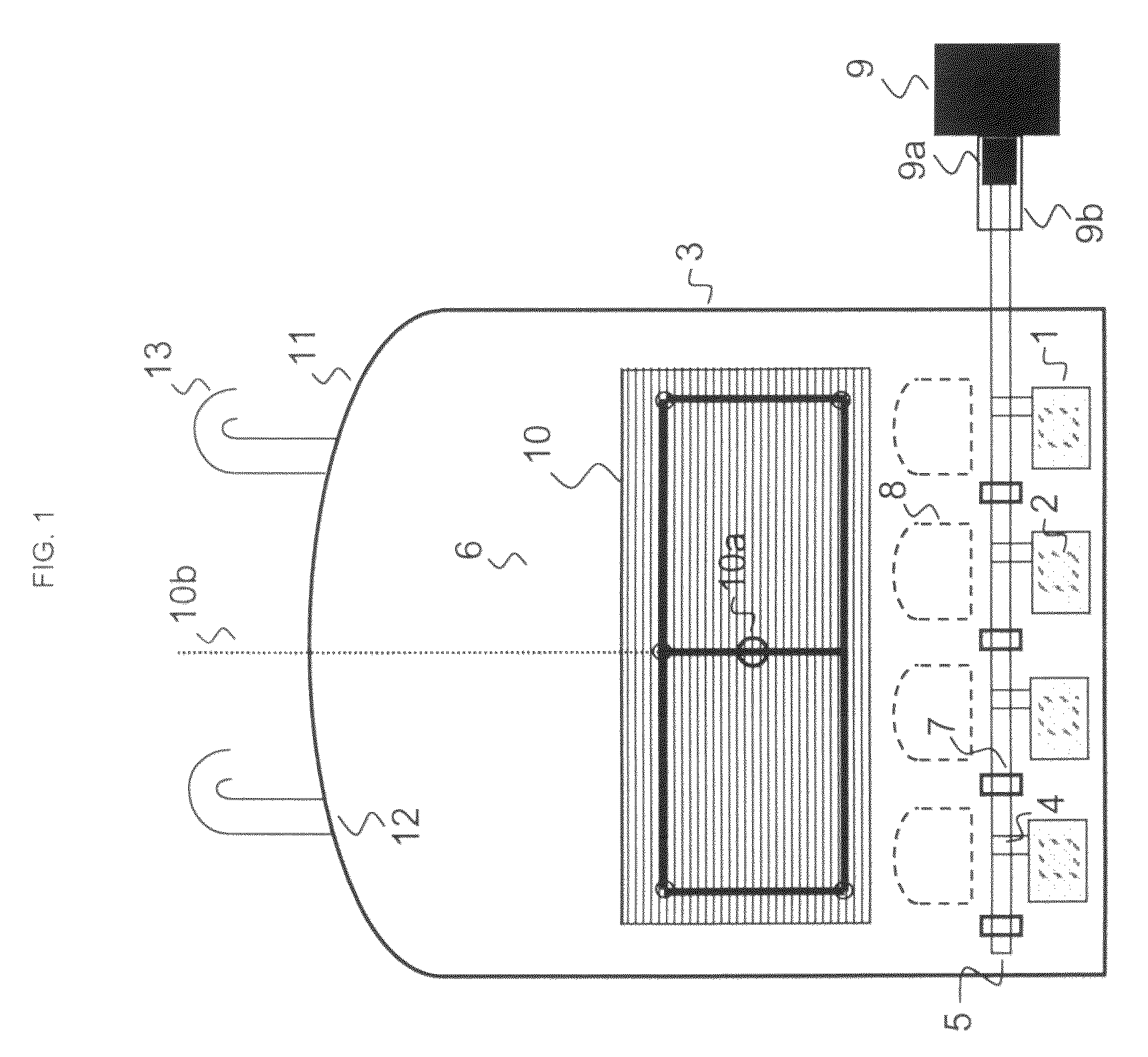

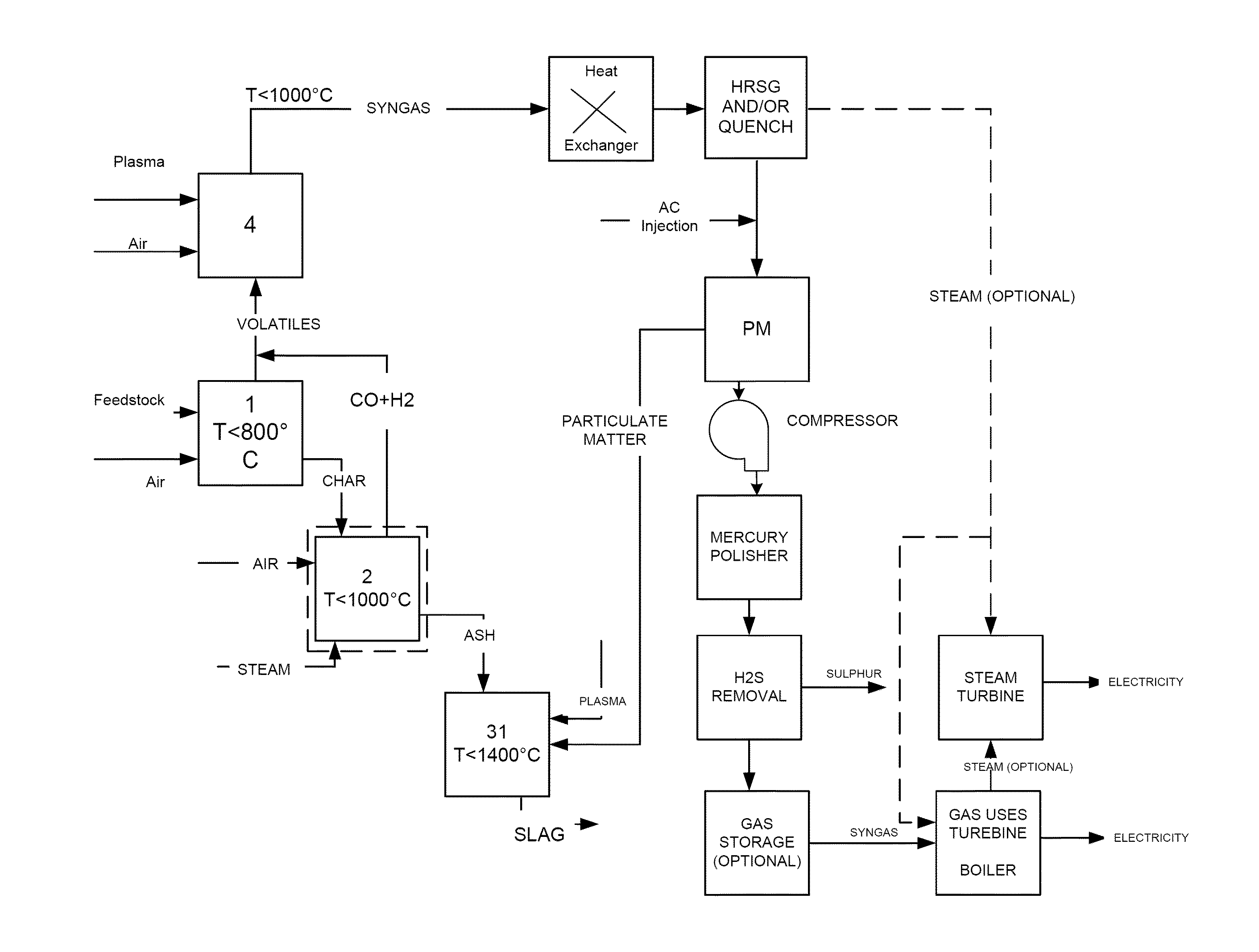

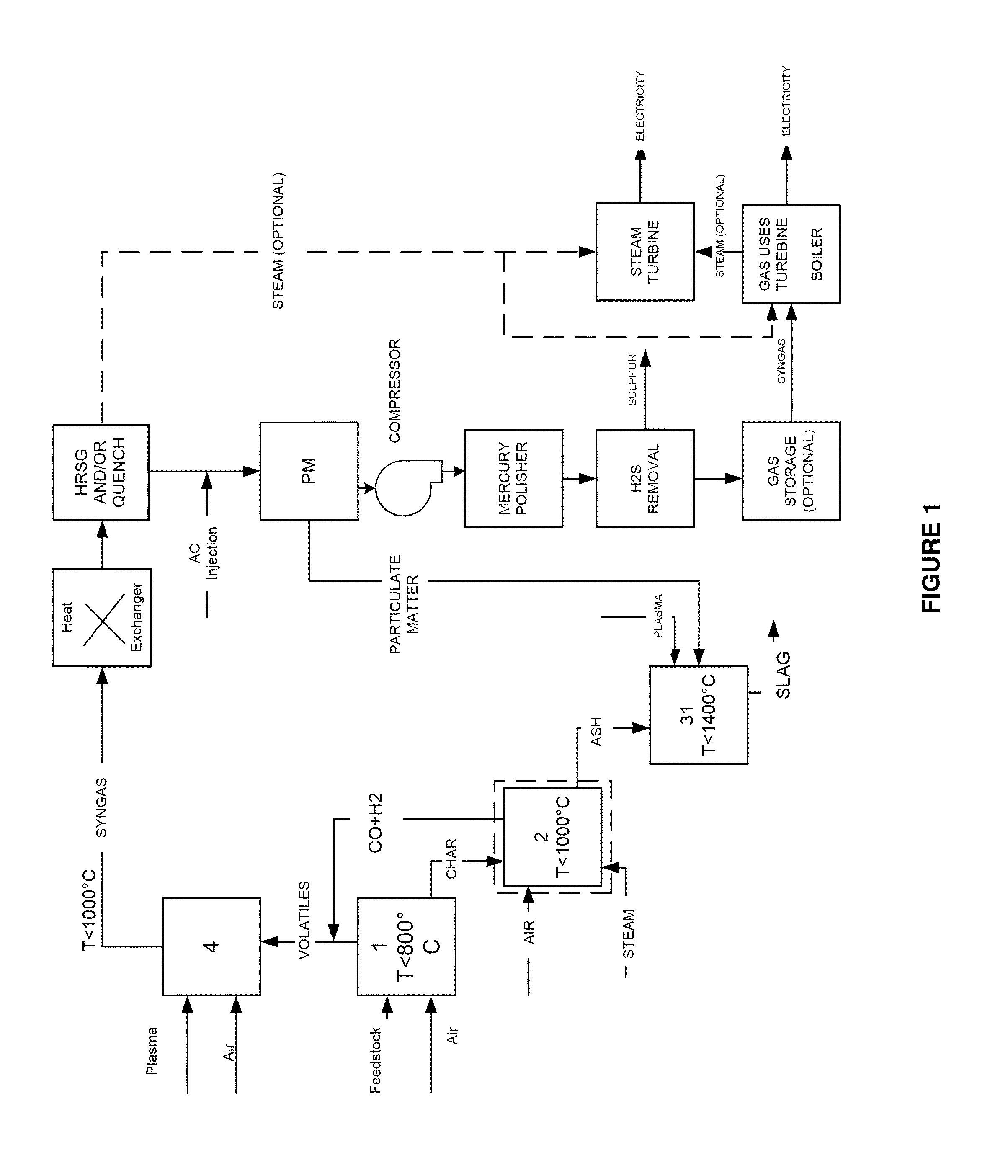

Gasification system with processed feedstock/char conversion and gas reformulation

ActiveUS20140332724A1Gasifier mechanical detailsCombustible gas thermal treatmentSyngasVitrification

The invention provides a system designed for the complete conversion of carbonaceous feedstock into syngas and slag. The system comprises a primary chamber for the volatilization of feedstock generating a primary chamber gas (an offgas); a secondary chamber for the further conversion of processed feedstock to a secondary chamber gas (a syngas) and a residue; a gas-reformulating zone for processing gas generated within one or more of the chambers; and a melting chamber for vitrifying residue. The primary chamber comprises direct or indirect feedstock additive capabilities in order to adjust the carbon content of the feedstock.The system also comprises a control system for use with the gasification system to monitor and regulate the different stages of the process to ensure the efficient and complete conversion of the carbonaceous feedstock into a syngas product.

Owner:PLASCO CONVERSION TECH INC

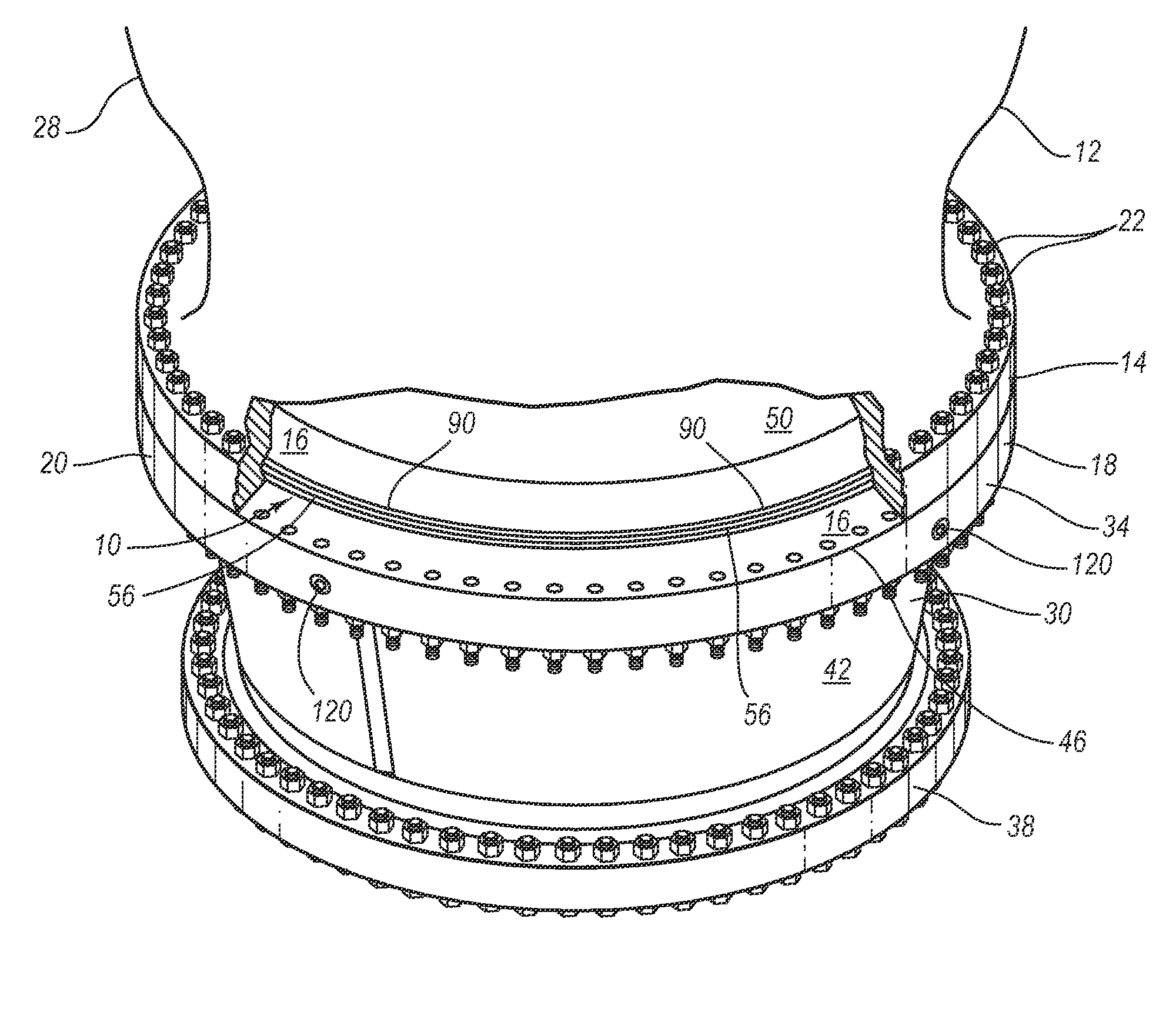

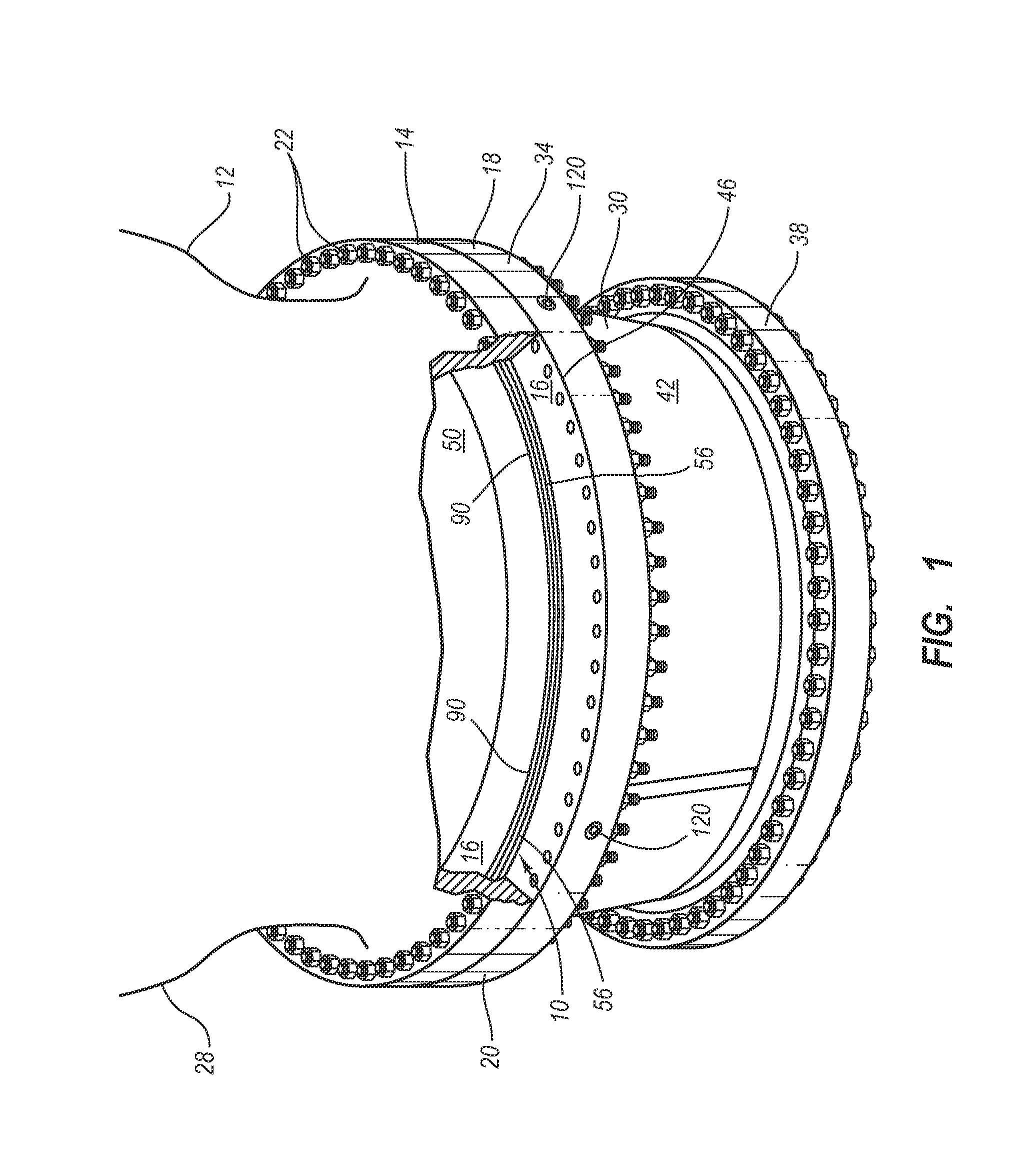

Apparatus and Process for the Pyrolysis of Agricultural Biomass

InactiveUS20080197012A1Prevent escapeFast heat transferFluidized bed combustionCombustible gas coke oven heatingCombustion chamberFluidized bed

An integrated combustion chamber and fluidized bed pyrolysis reactor. In one embodiment, the combustion chamber is cylindrical and the pyrolysis reactor is provided annularly about the combustion chamber with an annular wall that provides a common surface for heat transfer. A lift tube in fluid communication with the pyrolysis reactor is provided within the combustion chamber for circulating biomass and an inert fluidizable media upwardly through the lift tube; this advantageously increases heat transfer and leads to more rapid pyrolysis. The media and biomass exit the lift tube into either a freeboard area of the pyrolysis reactor or into a low density region of the fluidized bed. A condensable gaseous product is produced during pyrolysis that has economic value. The apparatus and process are especially well suited to the pyrolysis of low density agricultural biomass. The apparatus is compact and particularly well suited to mobile operation.

Owner:AGRI THERM

Pyrolysis system for waste rubber

InactiveUS20090211892A1Indirect and direct heating destructive distillationHeat recoveryWaste rubberProduct gas

An apparatus for separating components of batches of waste rubber by pyrolysis comprises at least one heating chamber interconnected with a condenser by a conduit. The heating oven is provided with a plurality of cooperating heating elements, an inlet for receiving waster rubber, and an outlet for egress of pyrolyzed gaseous components. The condenser condenses and separates cooled liquid components from the gaseous components. Separated gaseous components are exhausted from the condenser. Cooled liquid components are conveyed from the condenser to a re-circulation tank. The conduit is provided with a pair of opposed injectors adjacent the outlet of the heating oven. A re-circulation line interconnects the re-circulation tank with the injectors and is provided with a pressurizing device for injecting cooled liquid components through the injectors into the conduit in the form of intersecting liquid laminar sheets thereby applying a vacuum draw on the egressing pyrolyzed gaseous components.

Owner:ANDERSEN DAN

Damper baffle for a coke oven ventilation system

InactiveUS20090032385A1Fuel supply regulationCombustible gas coke oven heatingVehicle frameCoke oven

The damper baffle includes a U-shaped sub-frame and a temperature resistant insulation damper mat draped over and secured upright to the sub-frame for use in the ventilation system of a coke oven. The damper mat is a thick sheet of silica needle mat, which provides the thermal barrier of the damper baffle. The sub-frame is a bent high temperature steel rod which is bolted directly to the base plate of a conventional lift frame and lift mechanism. Two pairs of support plates secure and support the mat over the sub-frame in an upright orientation. The damper baffle seeks to provide a light-weight damper baffle for use in coke ovens, which eliminates the need for the heavy and cumbersome refractory baffle blocks.

Owner:ENGLE BRADLEY G

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com