Patents

Literature

400results about "Coke oven details" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

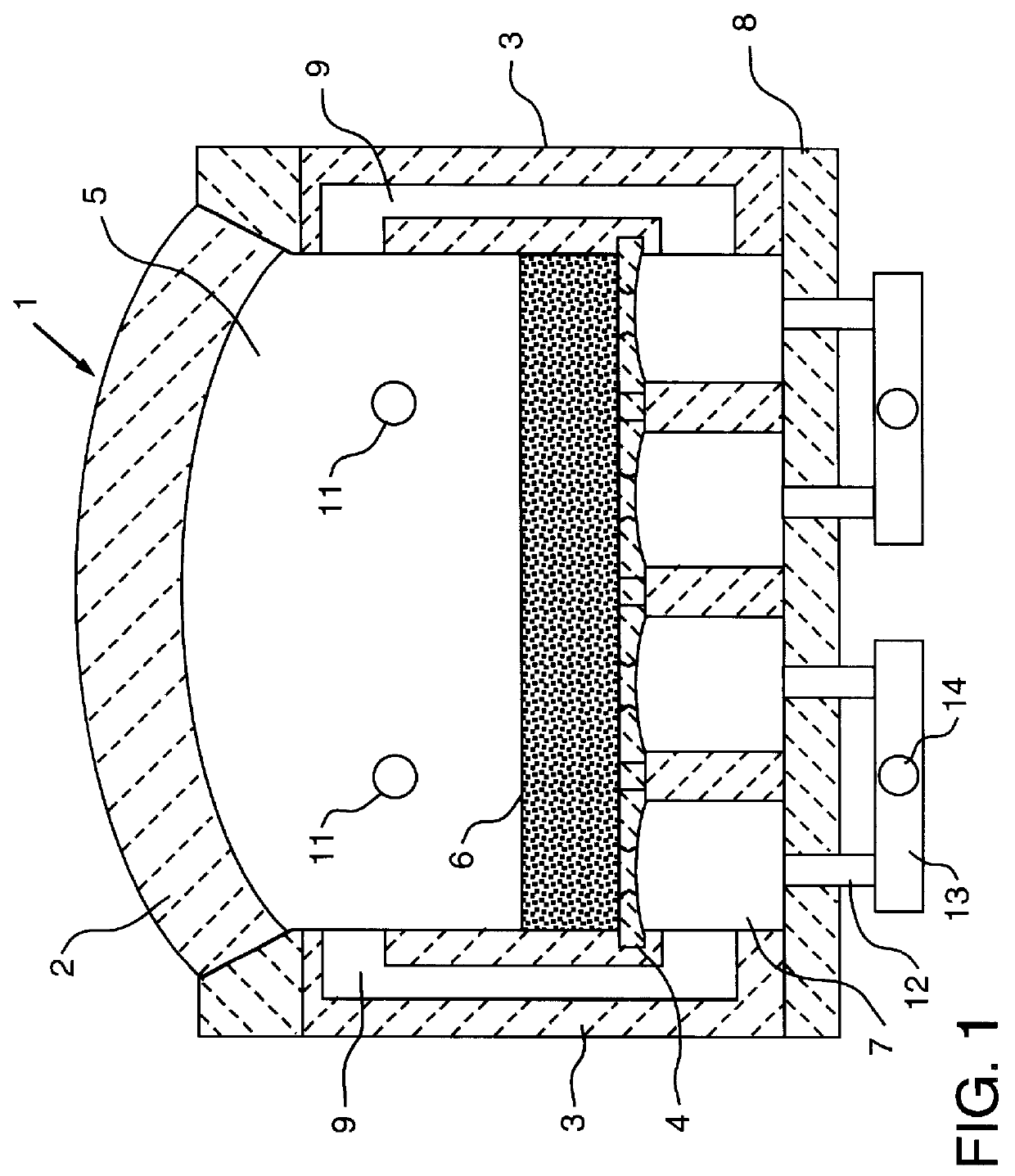

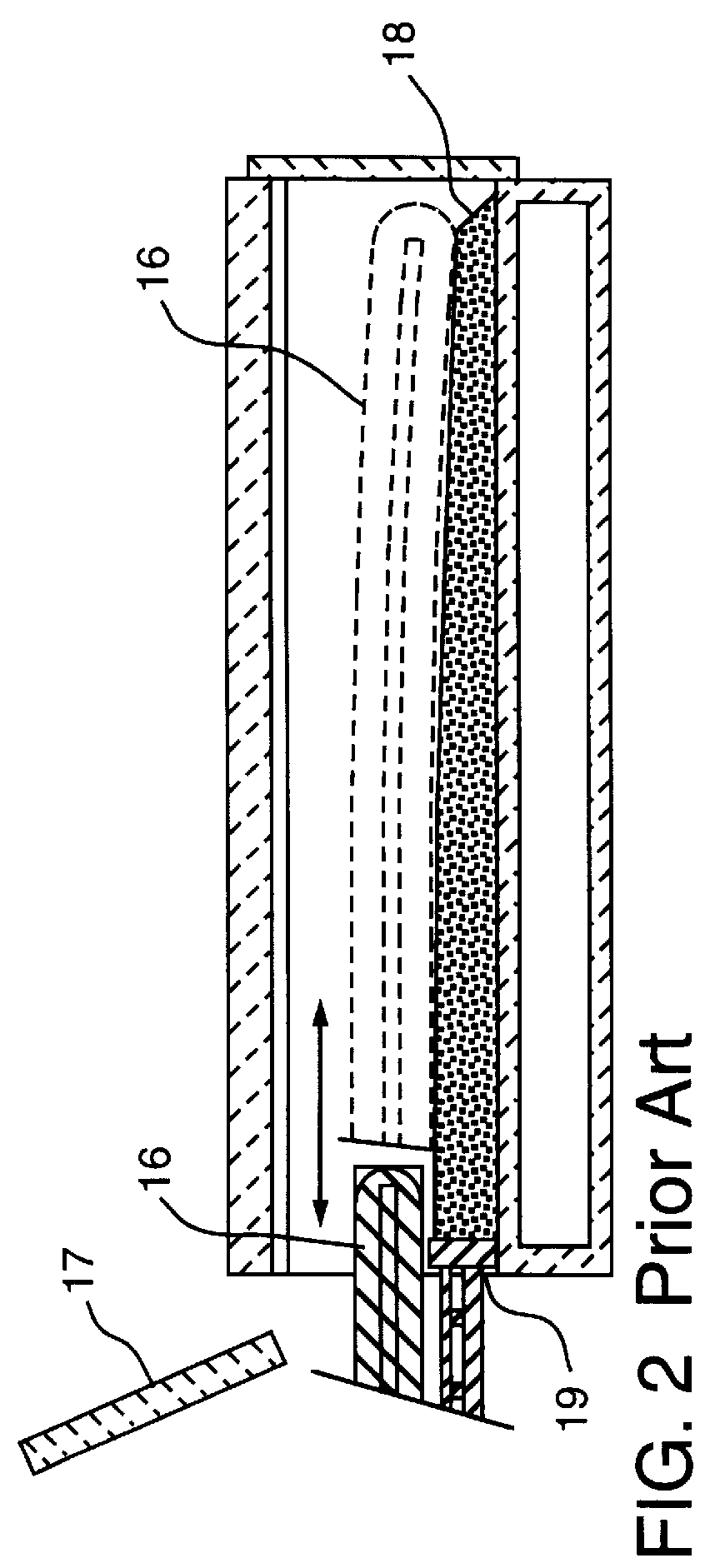

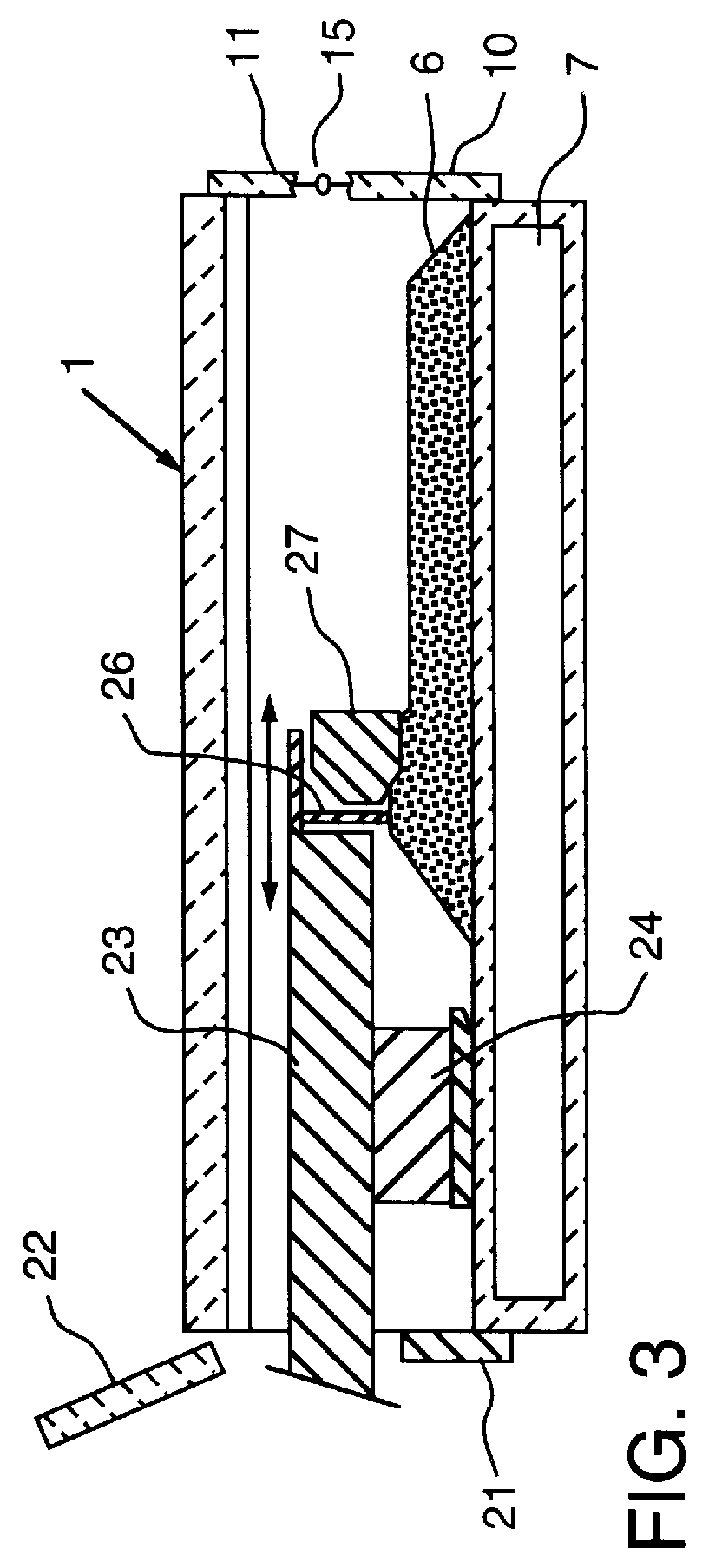

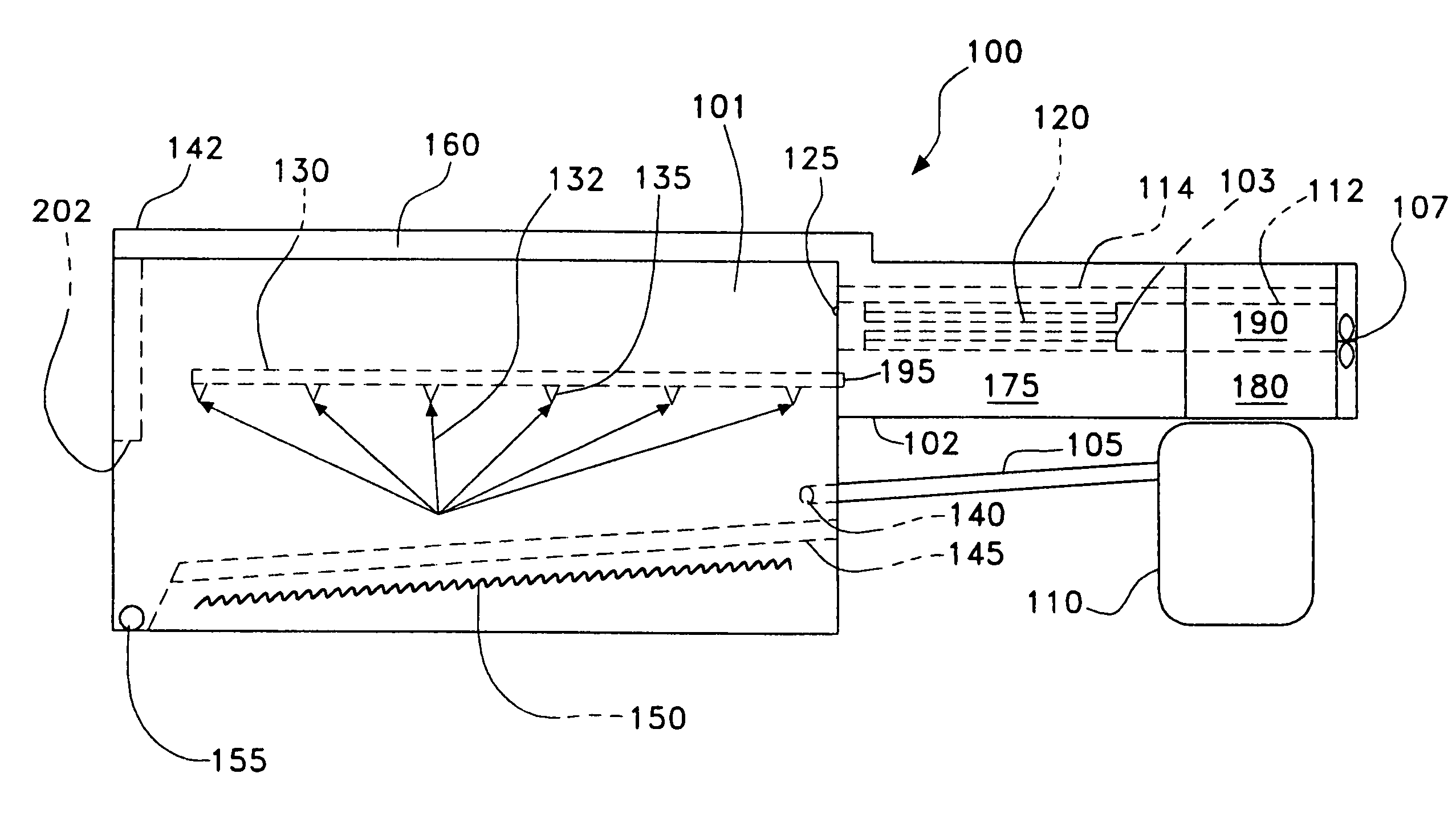

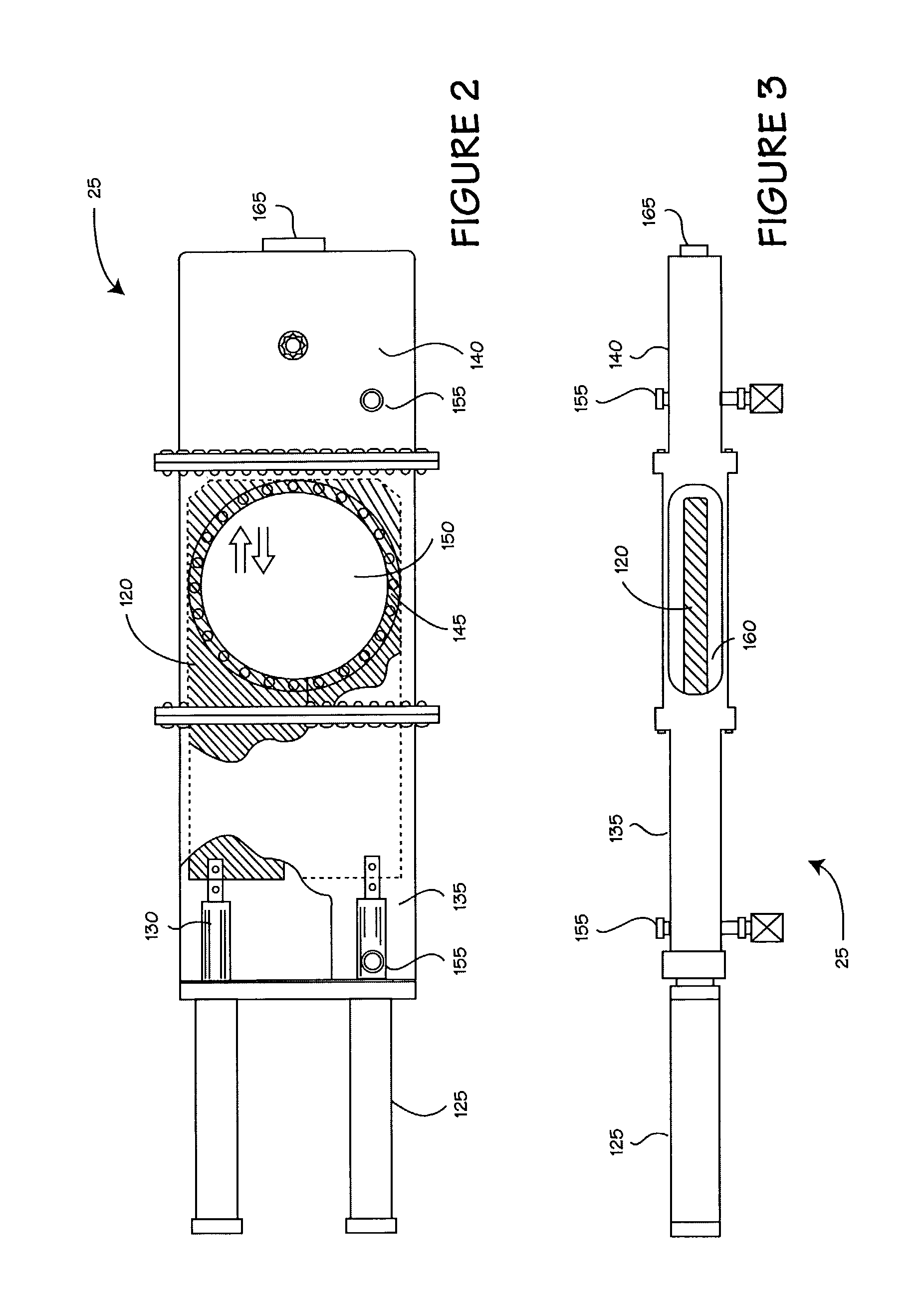

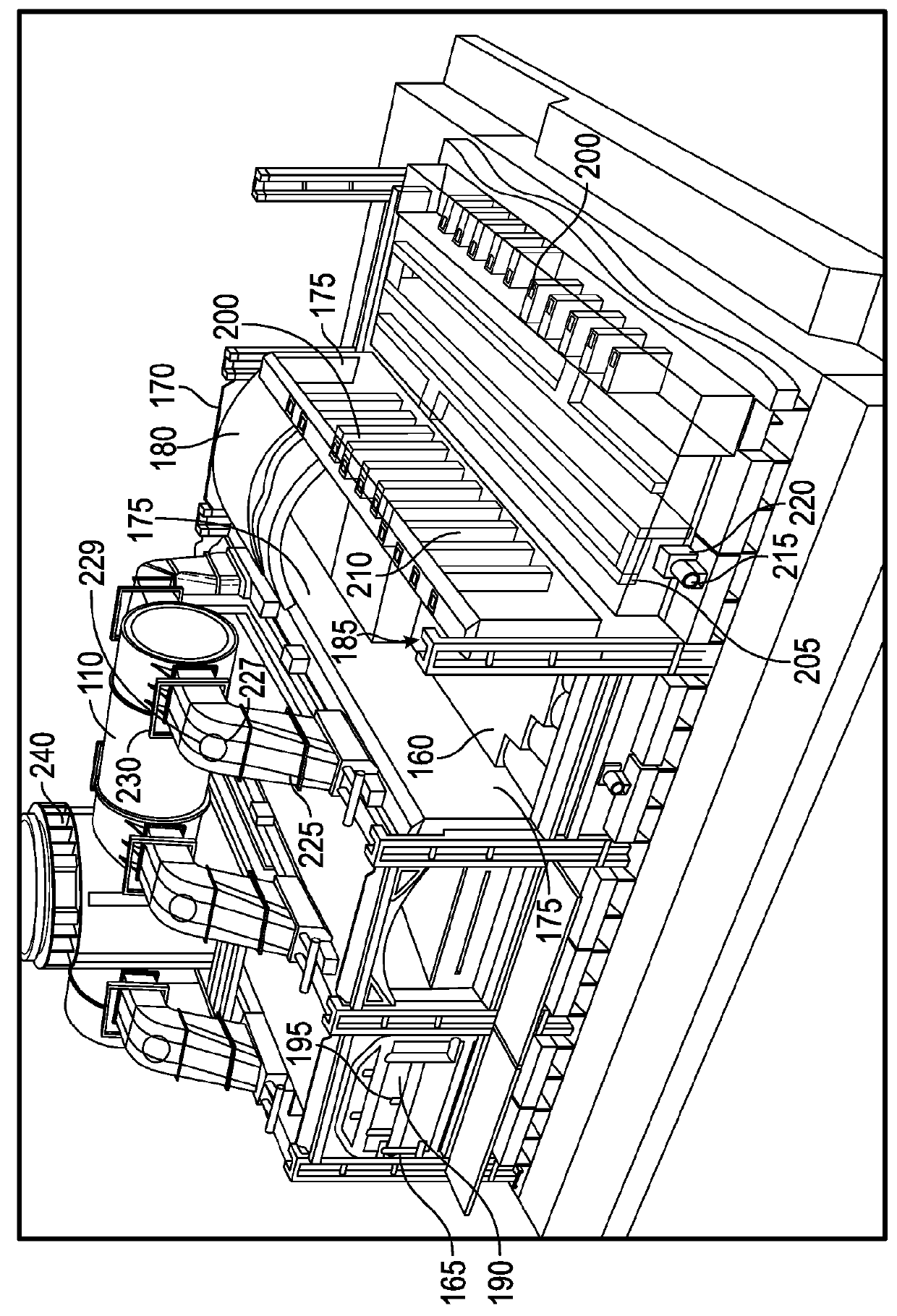

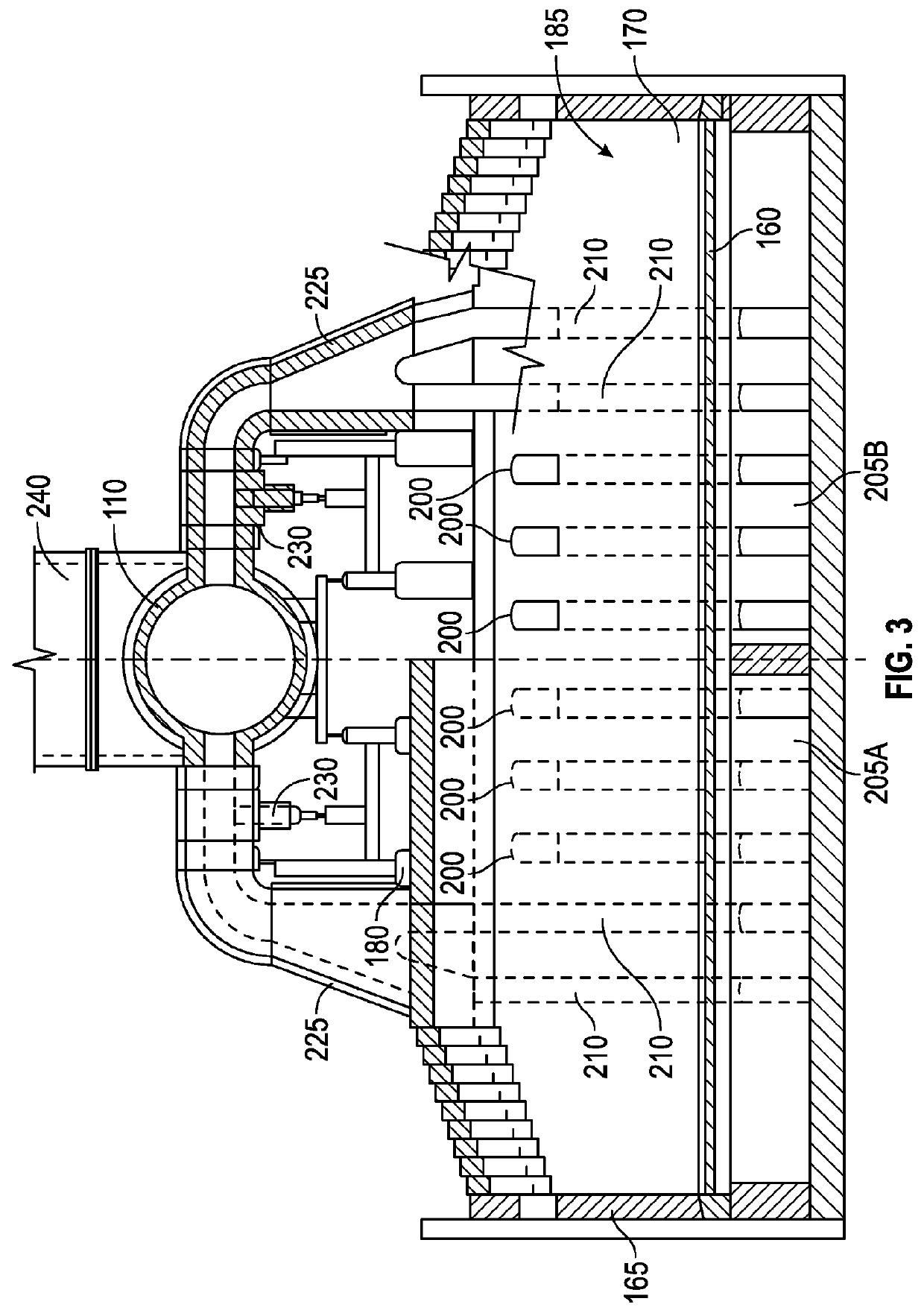

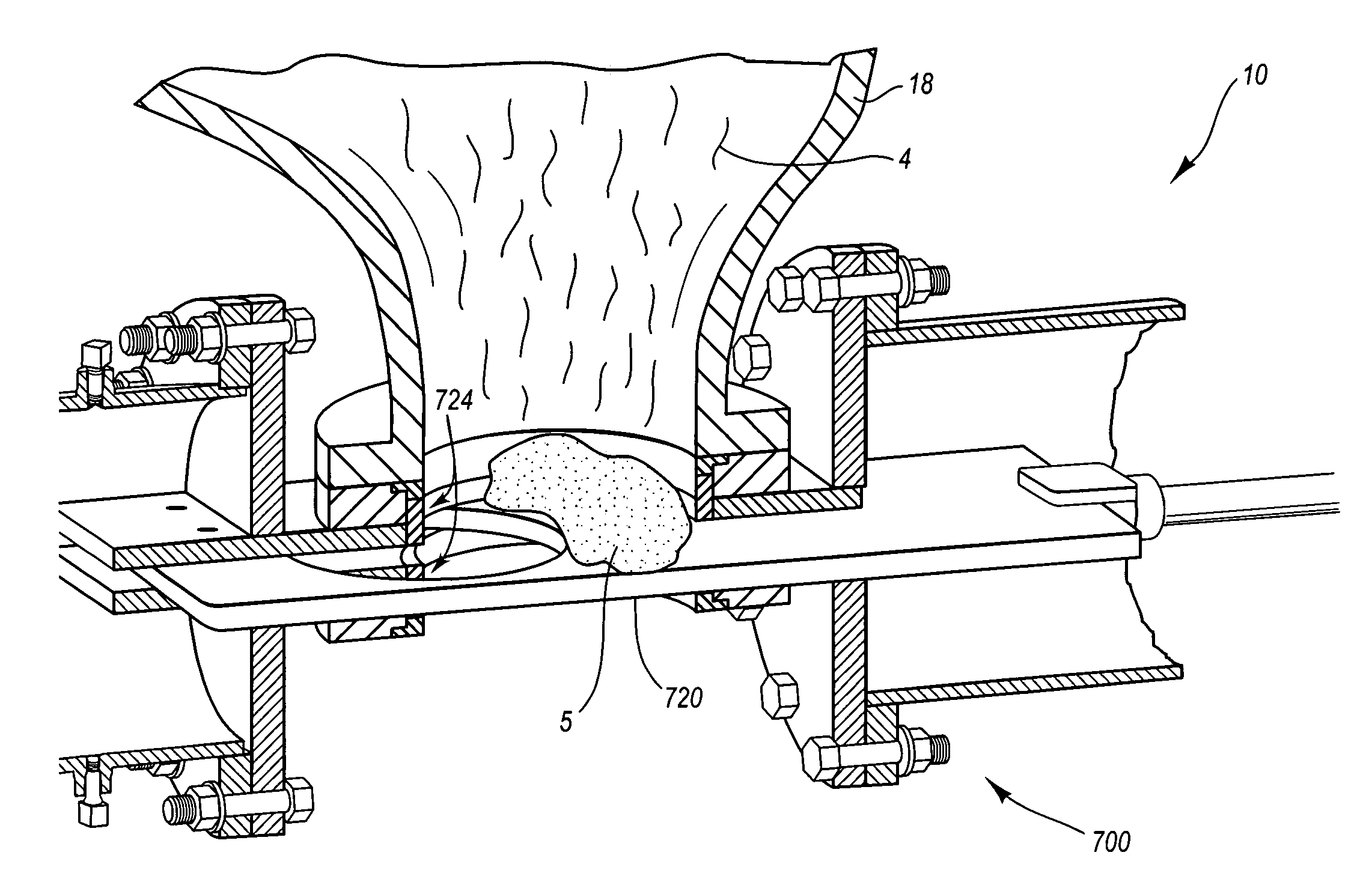

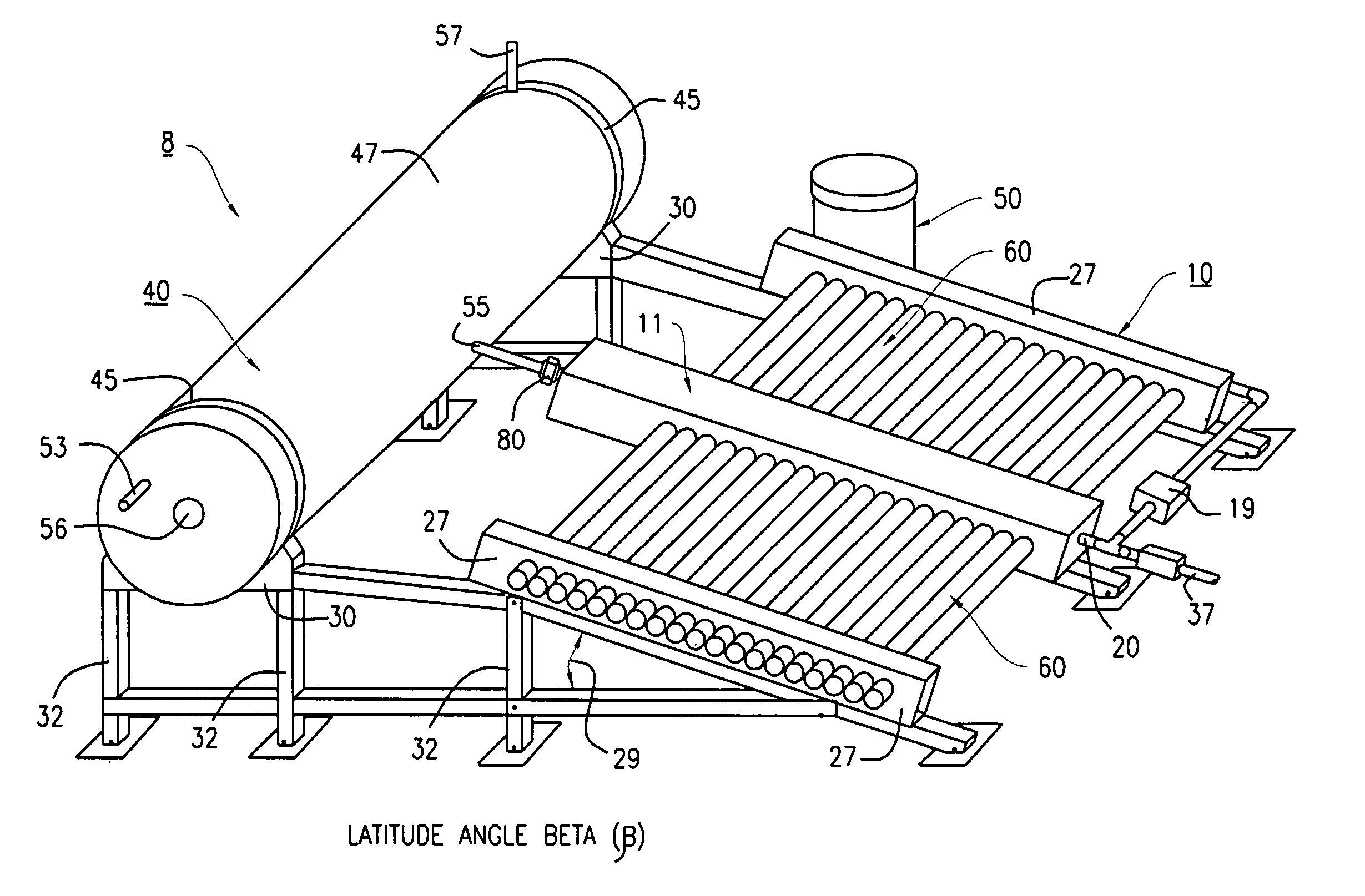

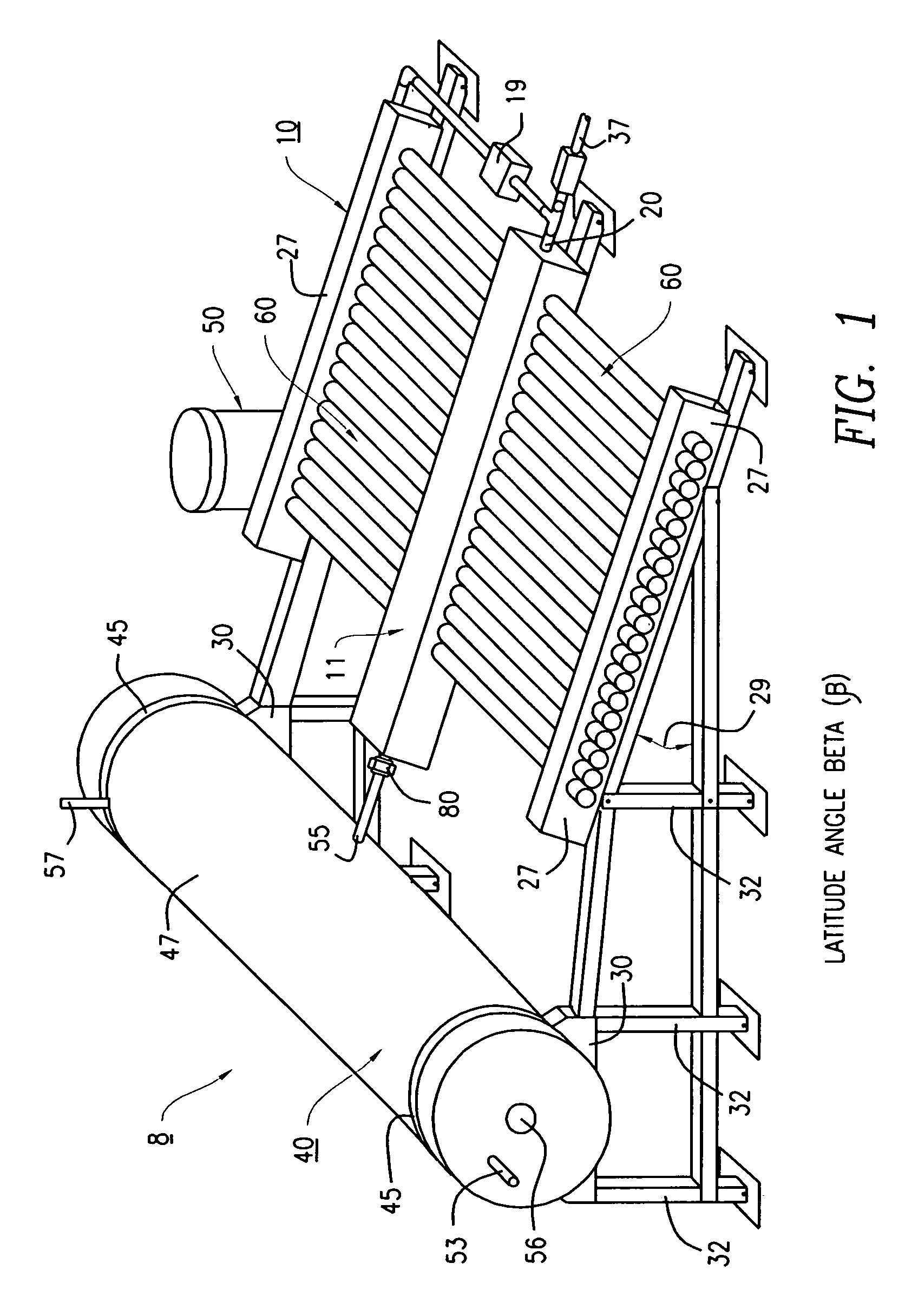

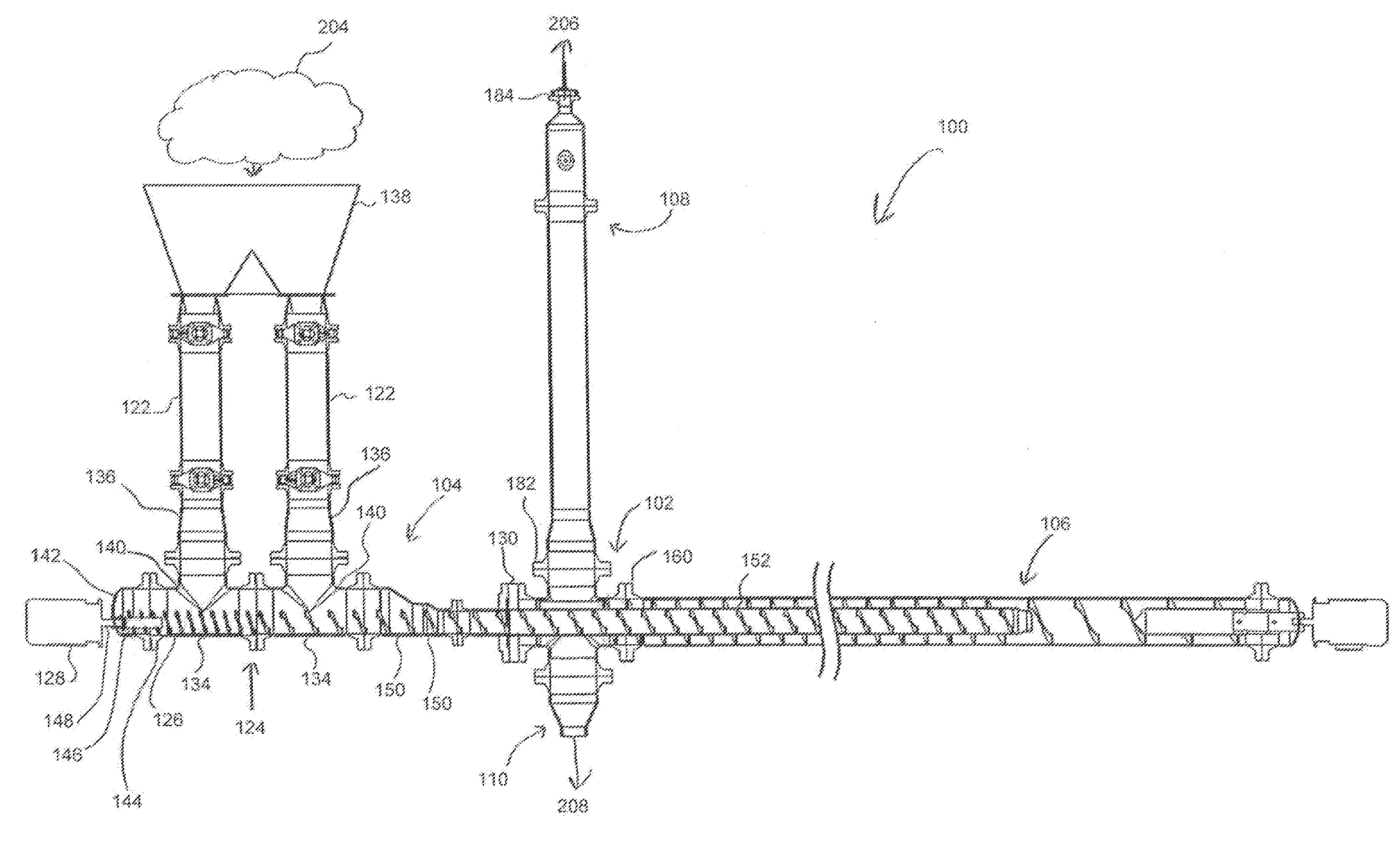

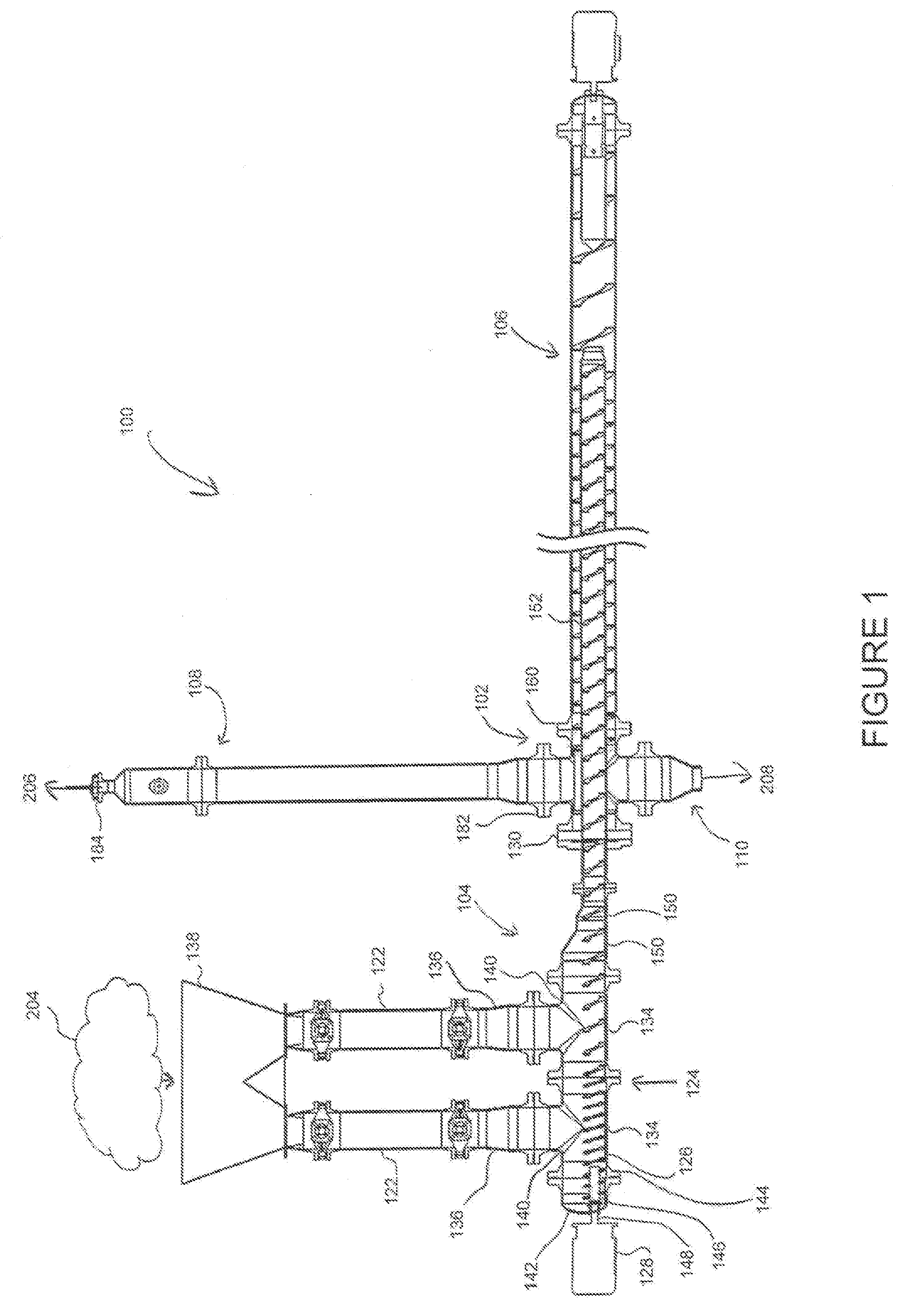

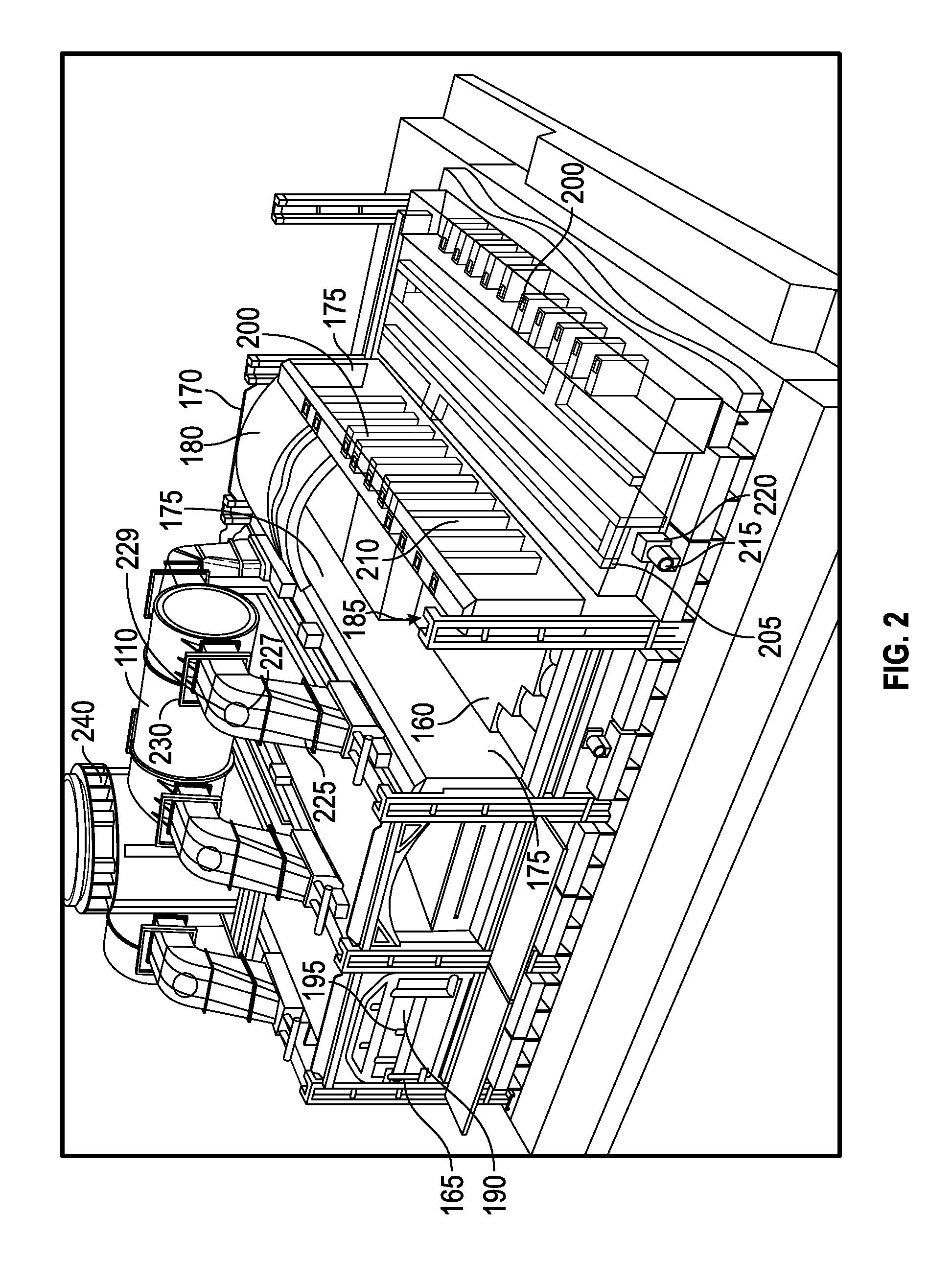

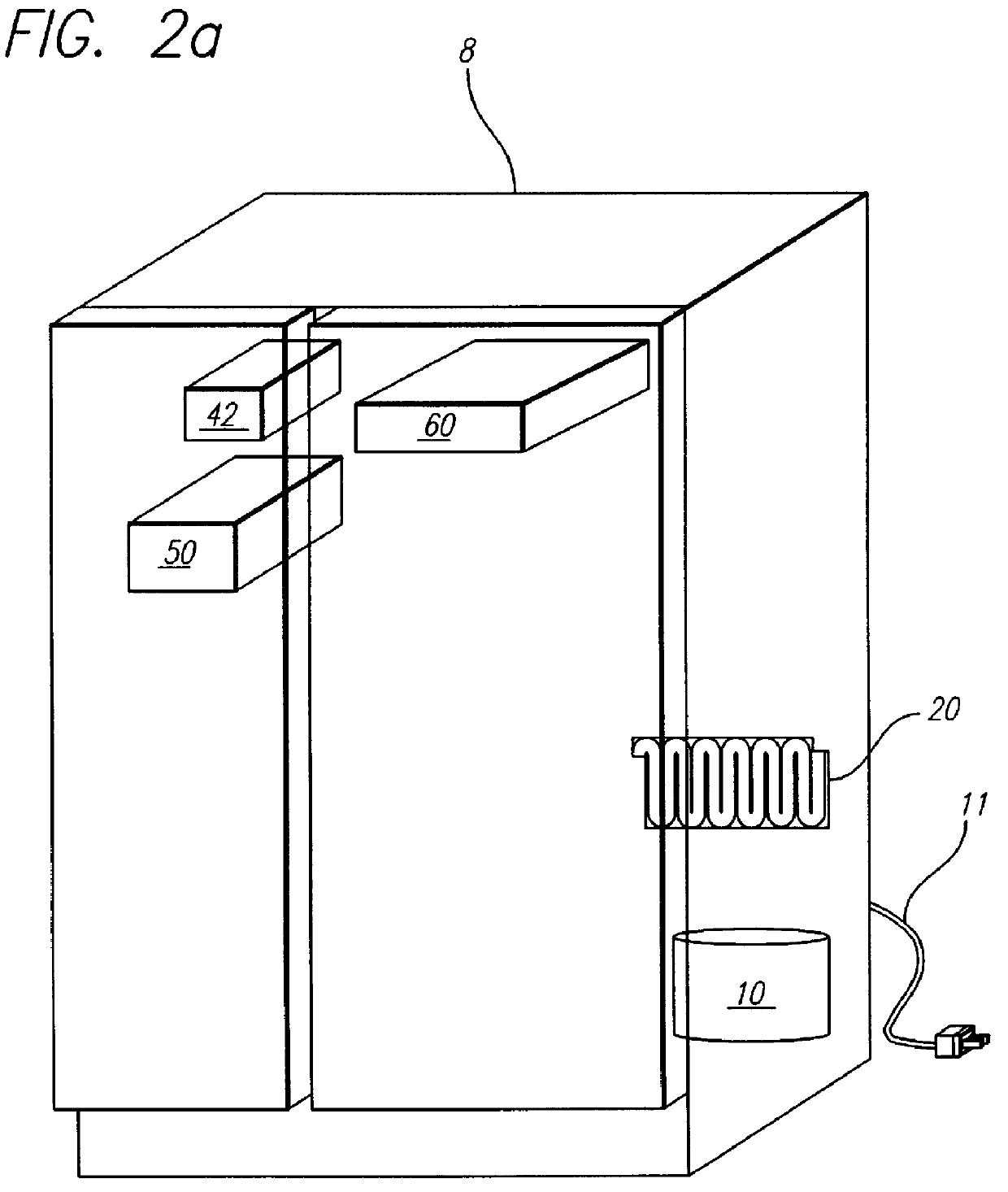

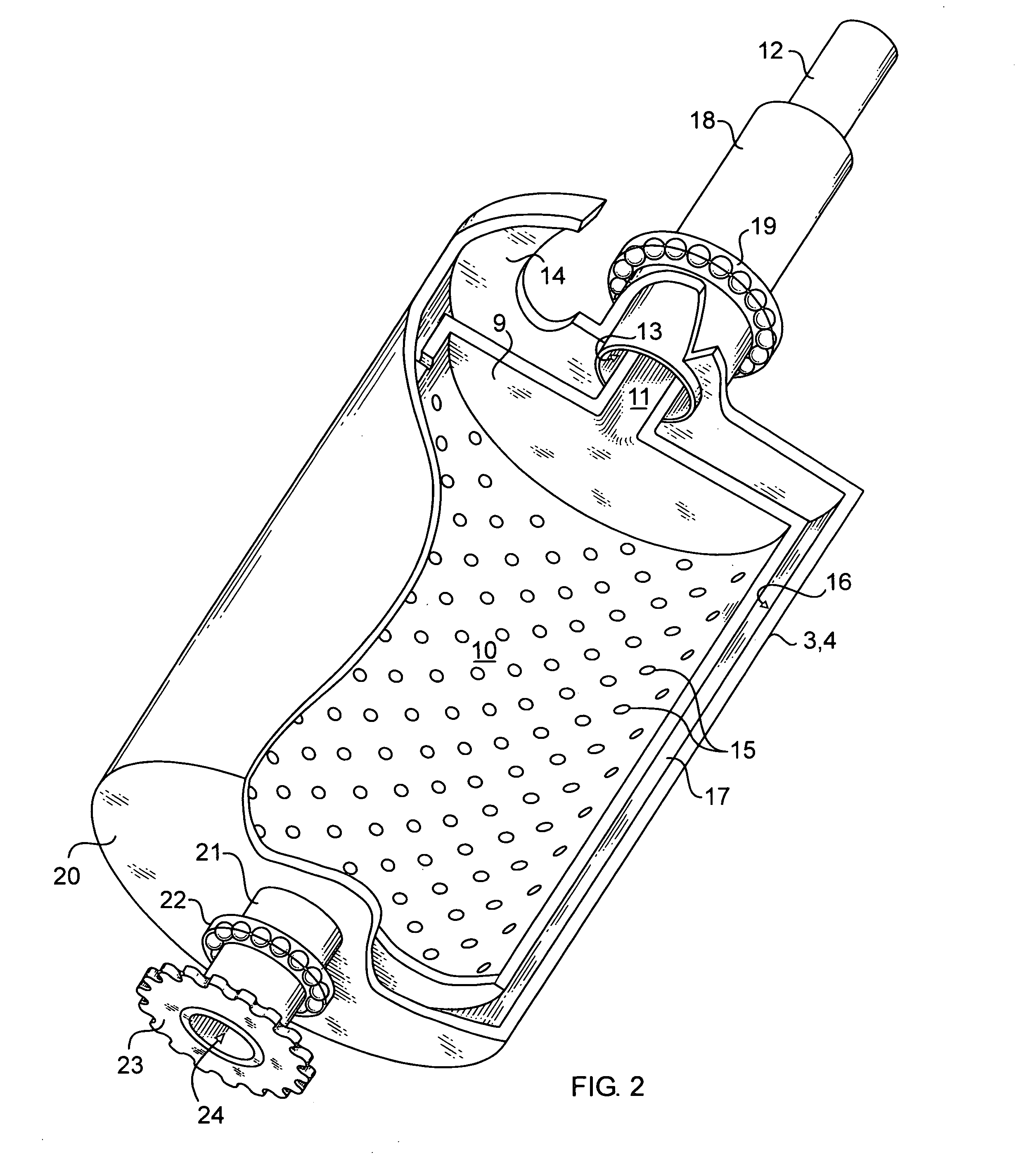

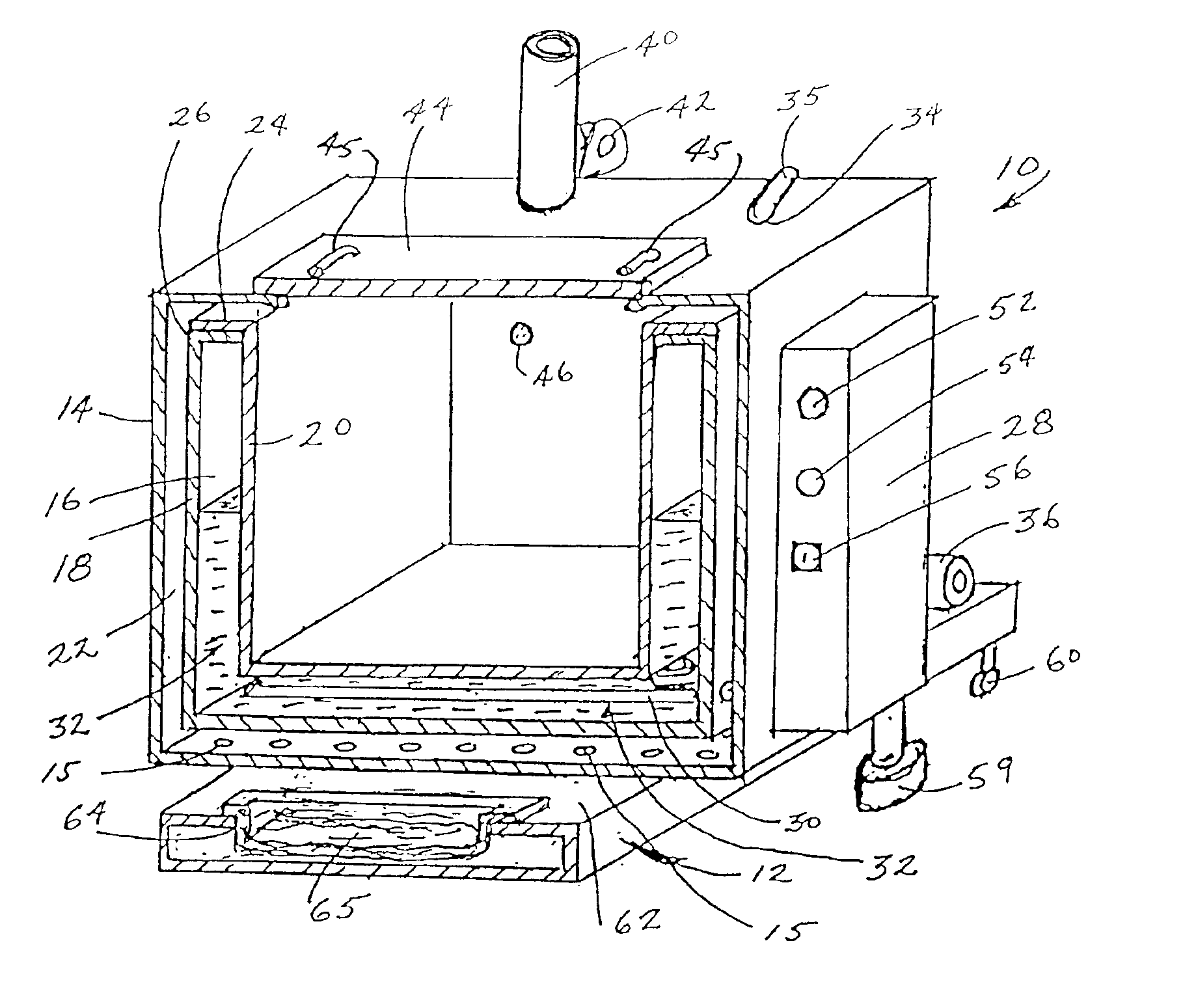

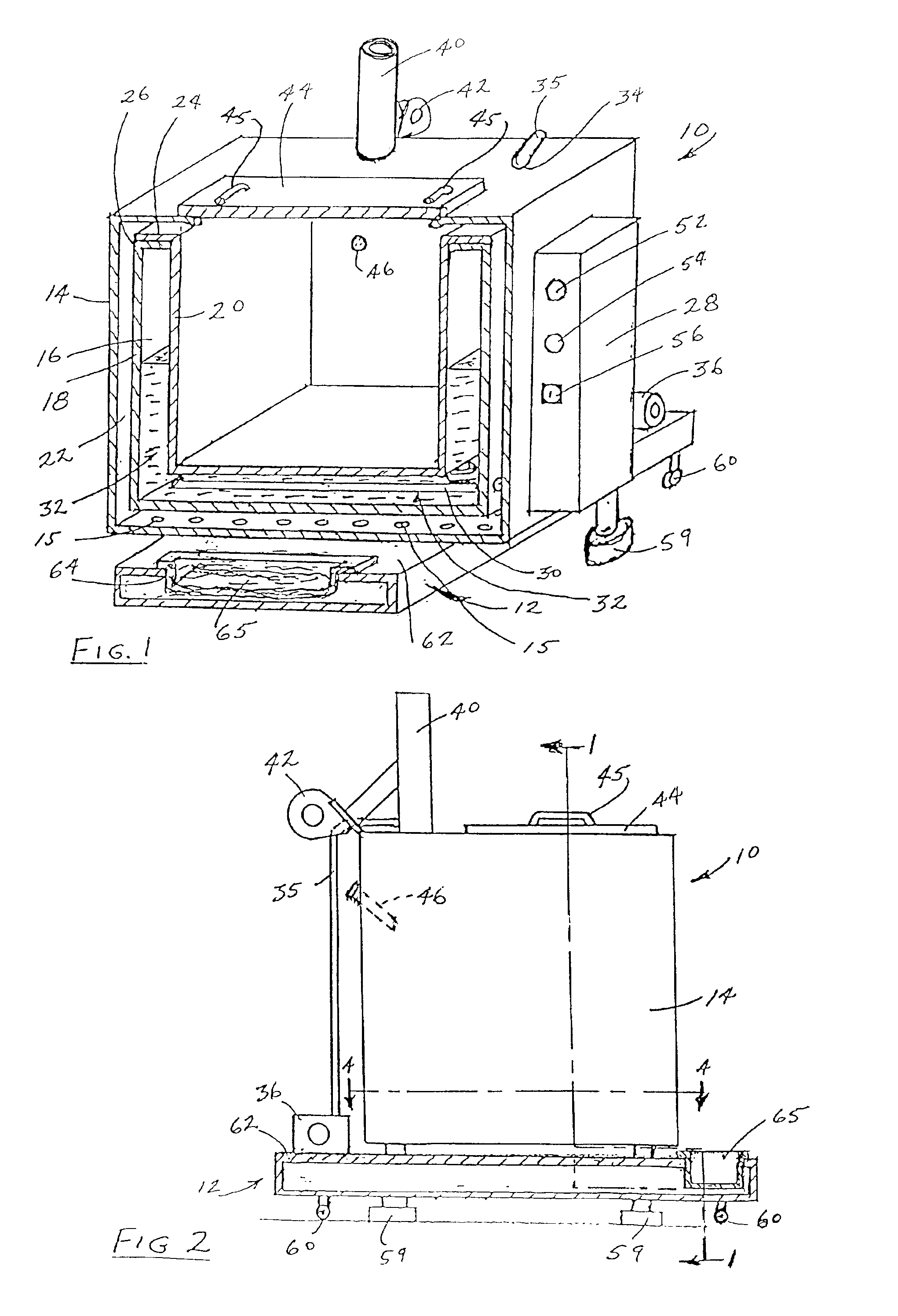

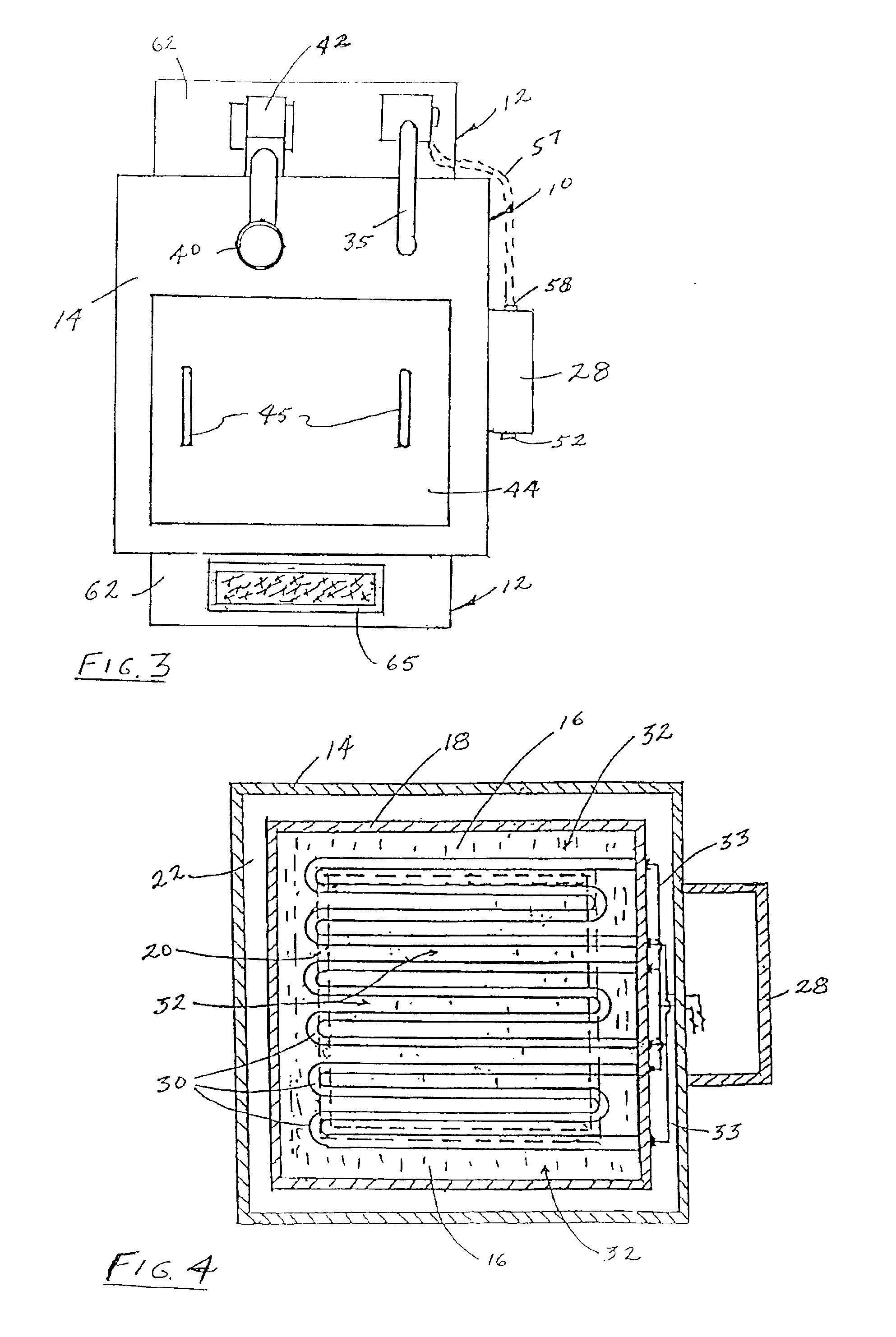

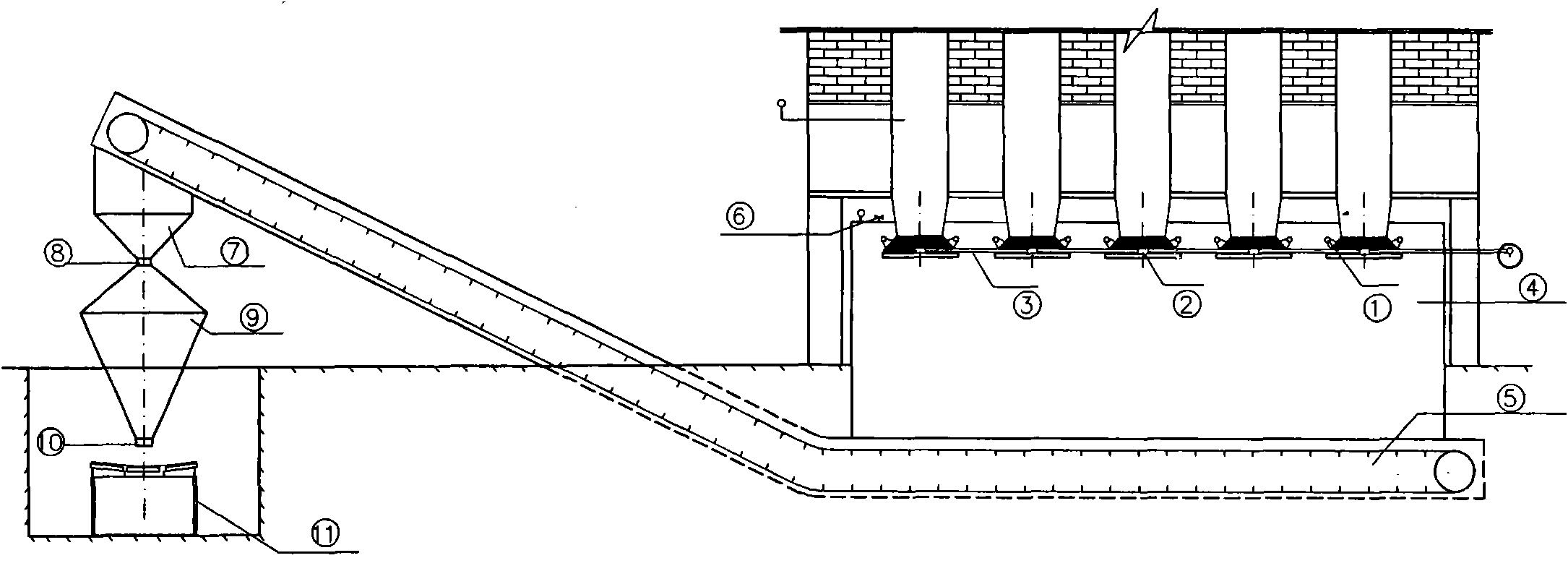

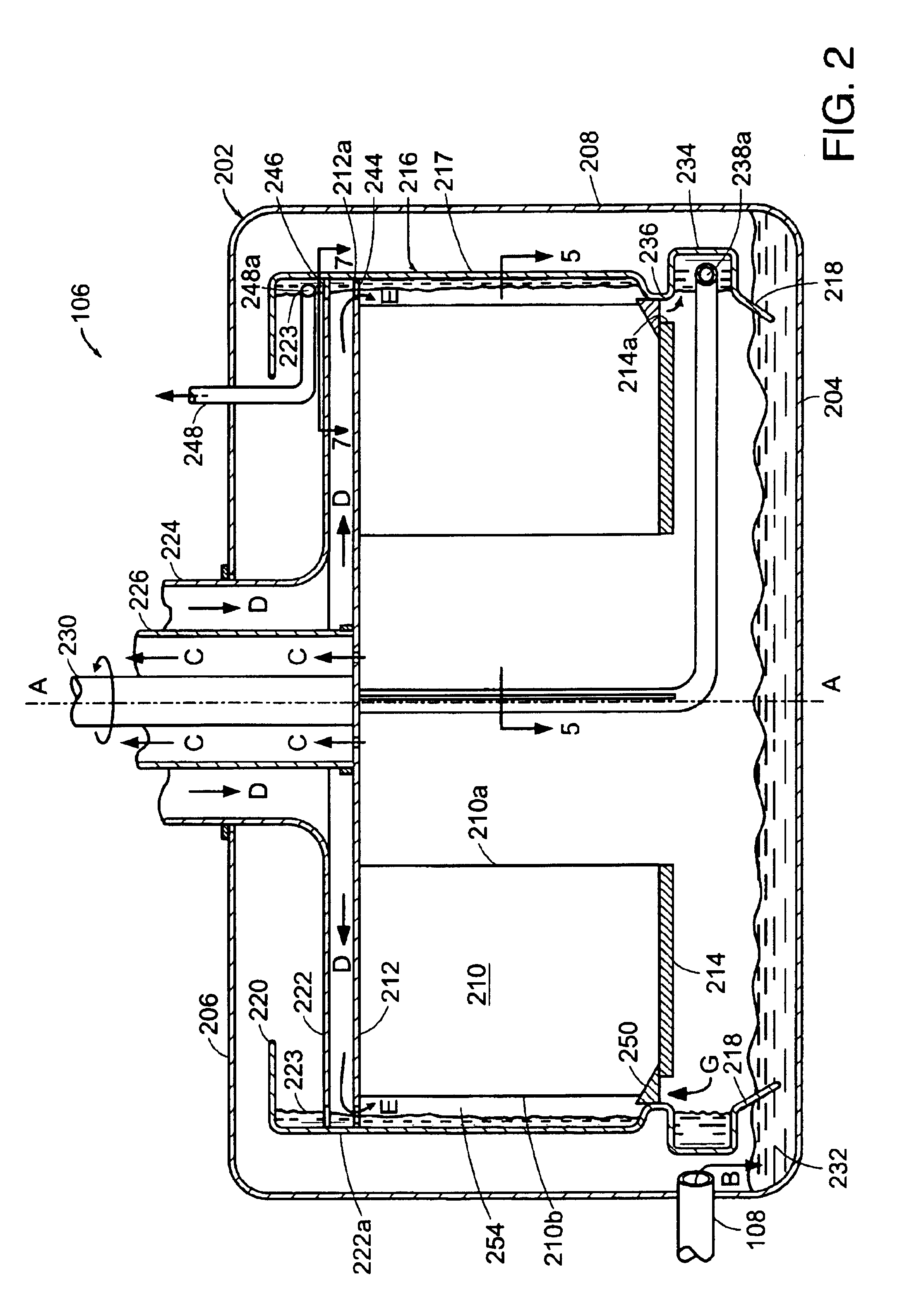

Coal bed vibration compactor for non-recovery coke oven

InactiveUS6059932AMechanical conveying coke ovensCharging-discharging device combinationsEngineeringCoke oven

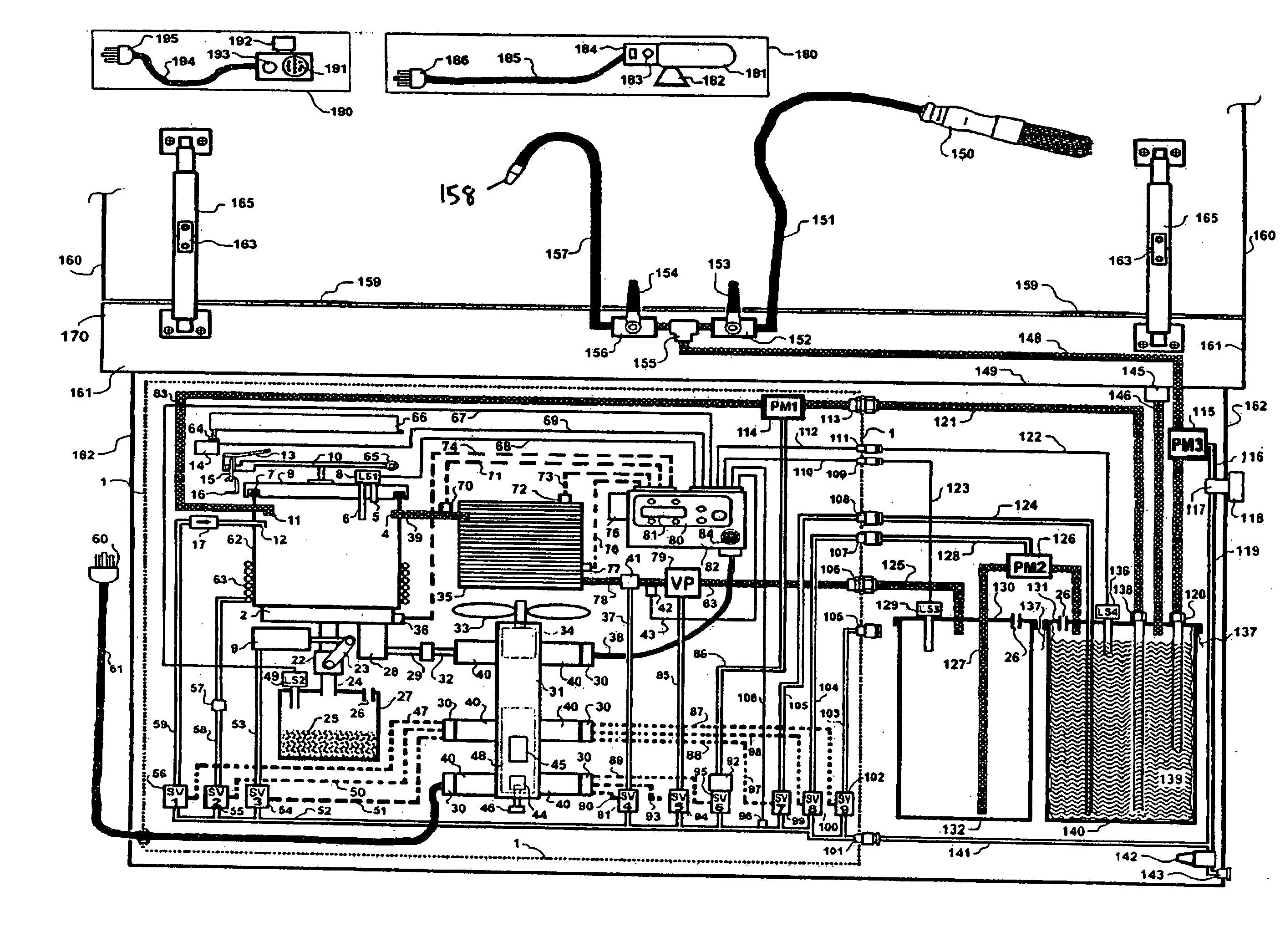

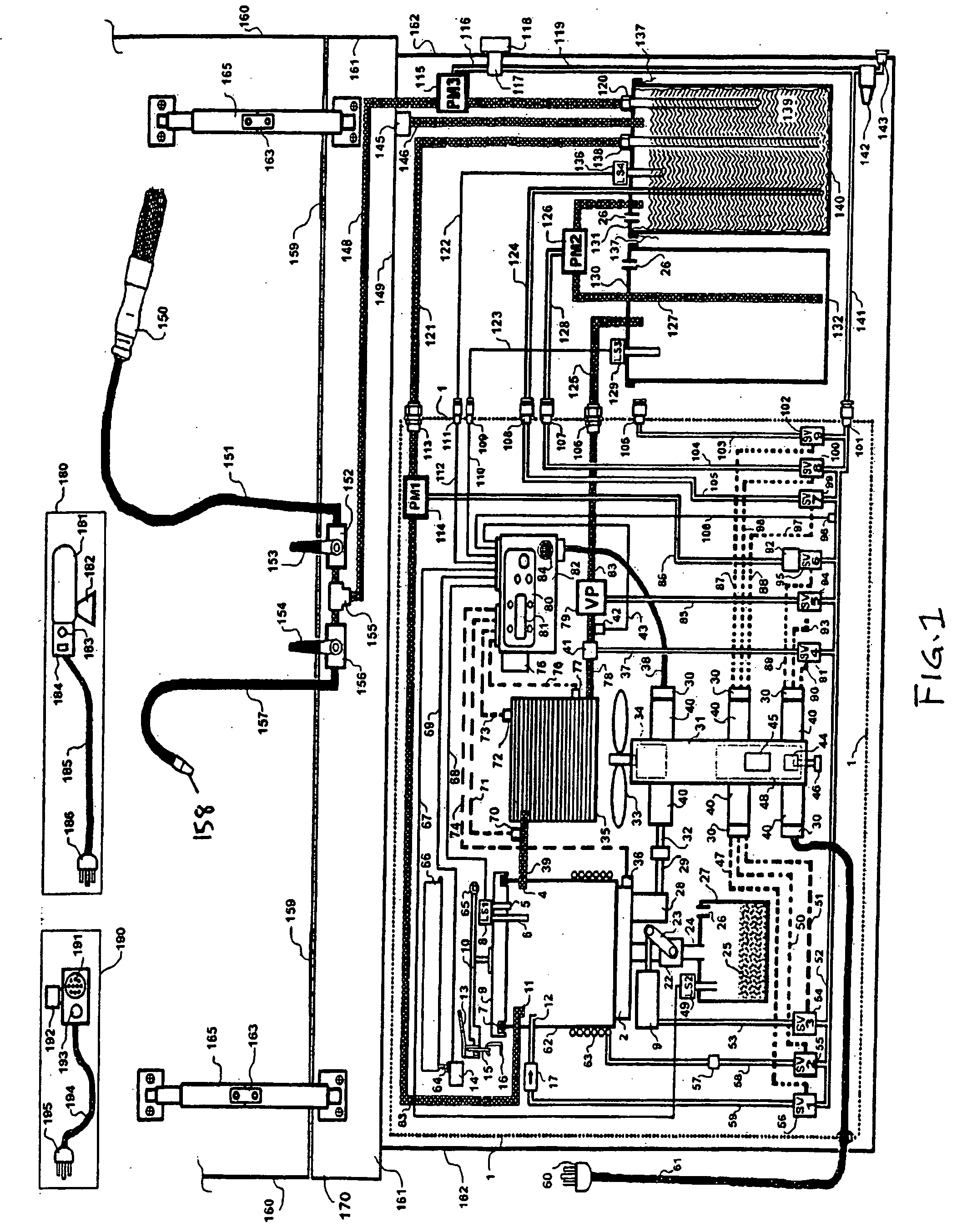

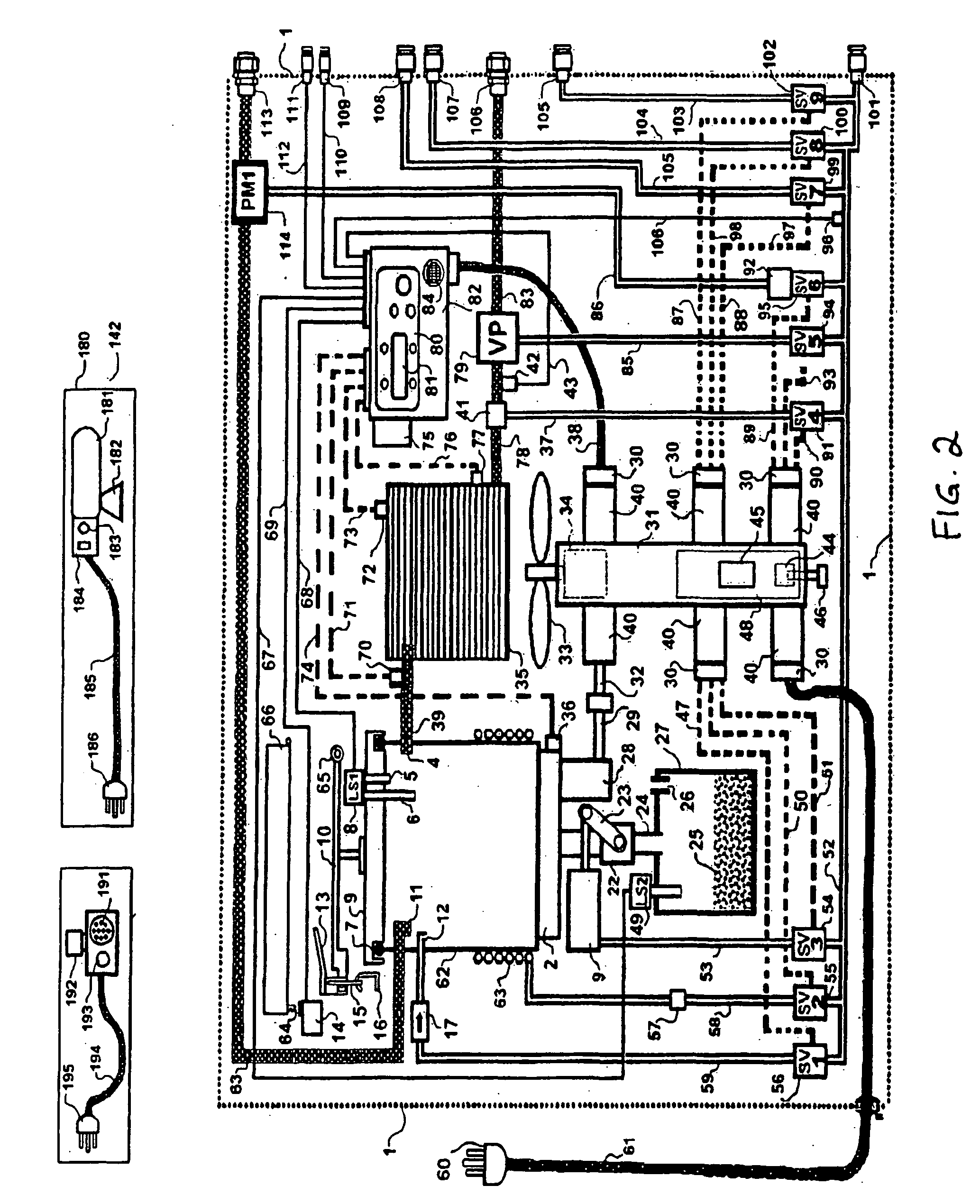

A coal compaction system and method for a non-recovery coke oven having refractory roof, floor, side walls and end doors for coal charging and coke discharge provides an improved coal charging machine carrying a coal conveyor supported intermediate the ends of the conveyor to avoid conveyor sagging and non-uniform depth of a deposited coal bed, a number of pressurized fluid-driven vibratory compactors mounted on an end of the charging machine and spaced-apart across the width of the coal bed and serving to compact the coal bed on a retraction stroke of the charging machine, a pivoted lifting frame mounted on the charging machine above the compactors and from which the compactors individually are suspended and are provided with individual supply of pressurized fluid, and a coke pusher head mounted on the charging machine behind the compactors and serving, when the lifting frame and associated compactors are raised, to push finished coke from the coke oven.

Owner:PENNSYLVANIA COKE TECH

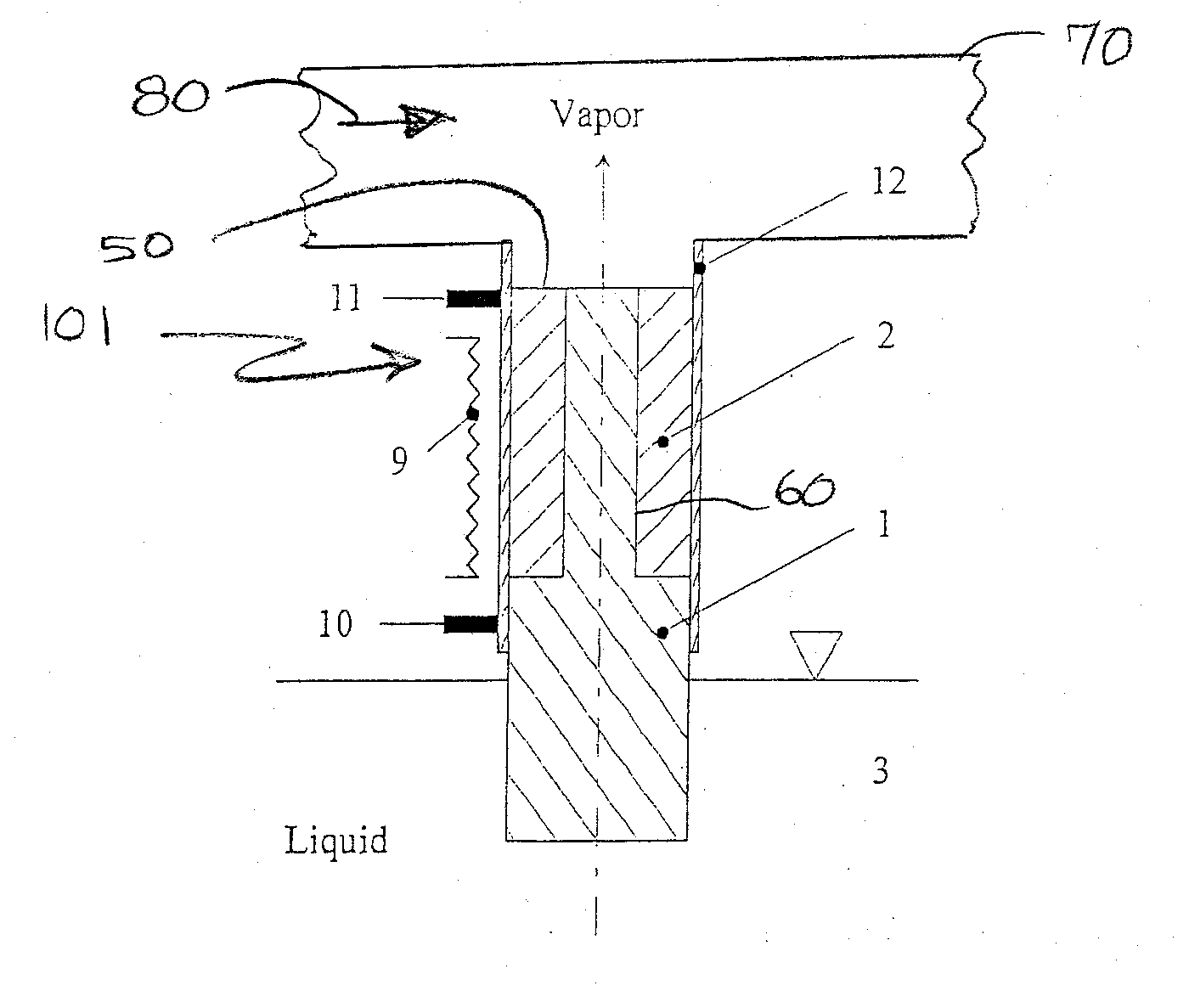

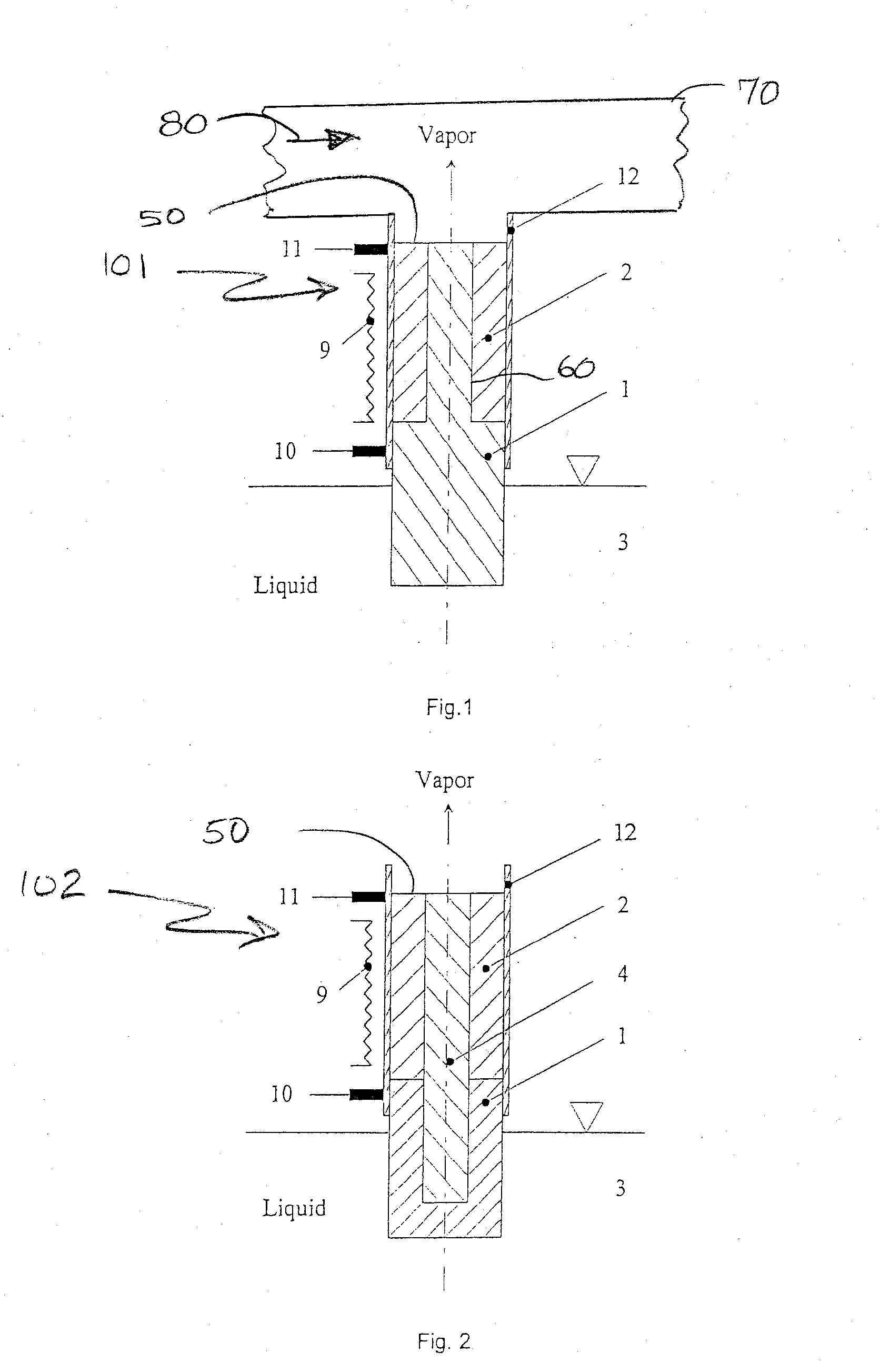

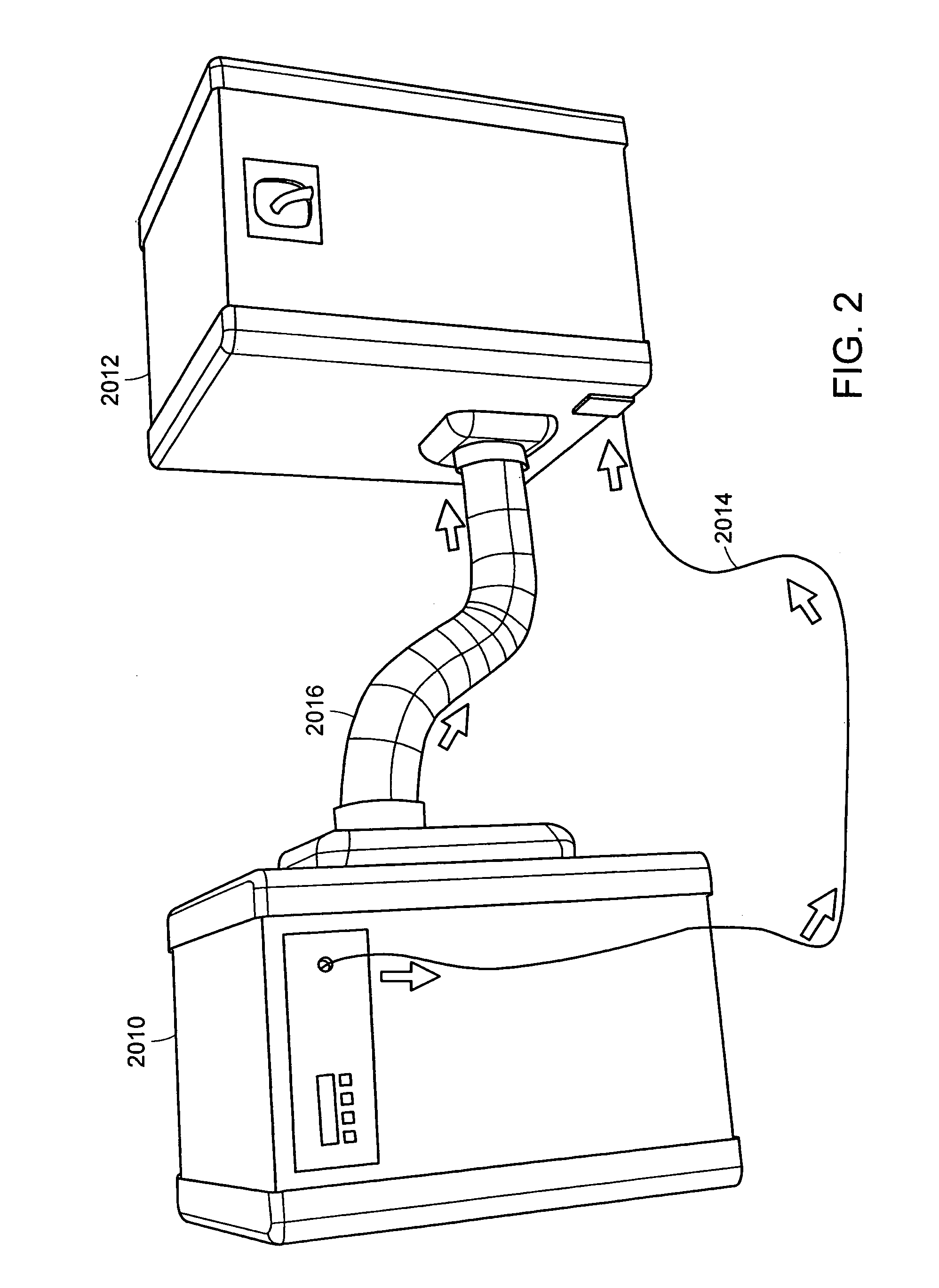

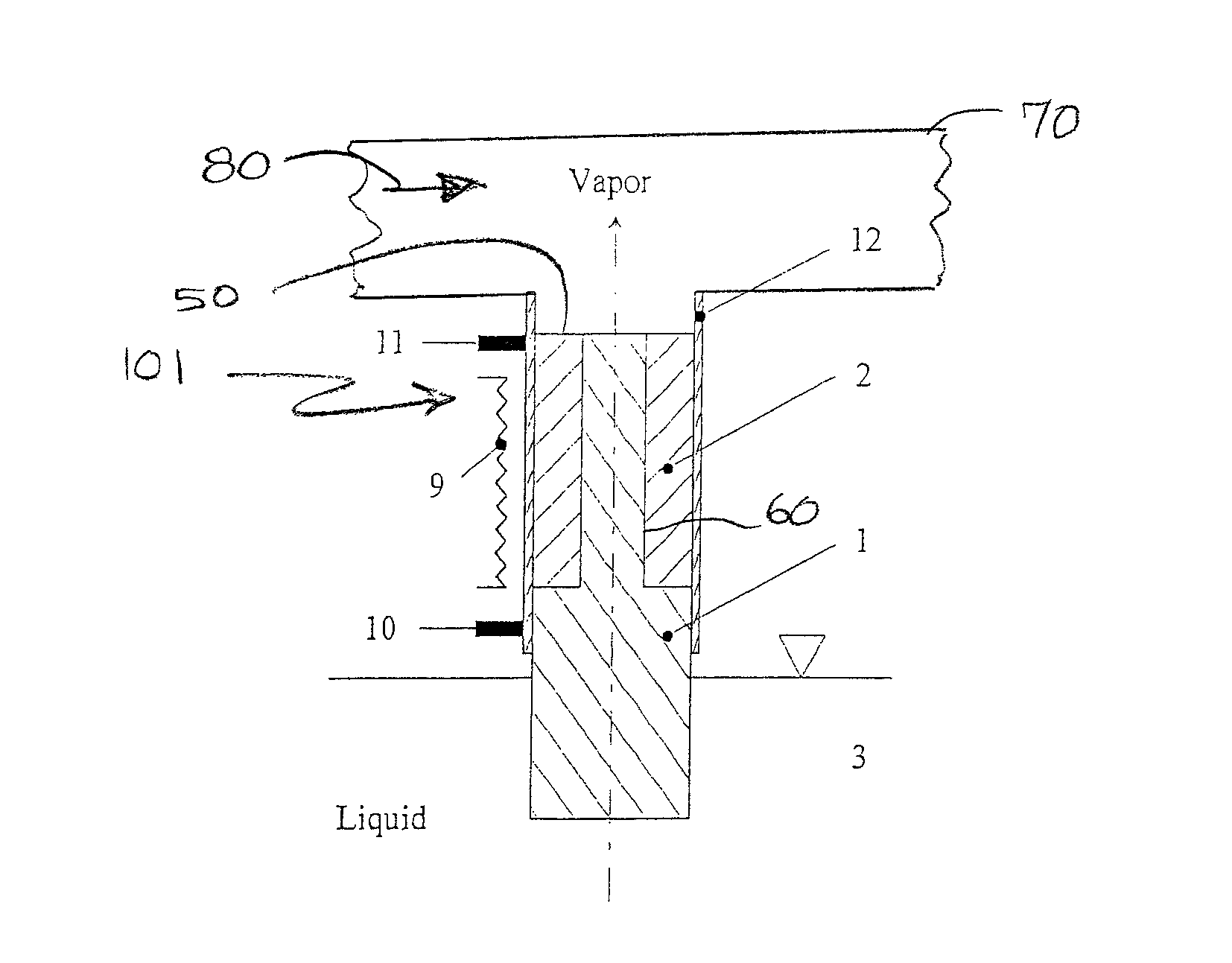

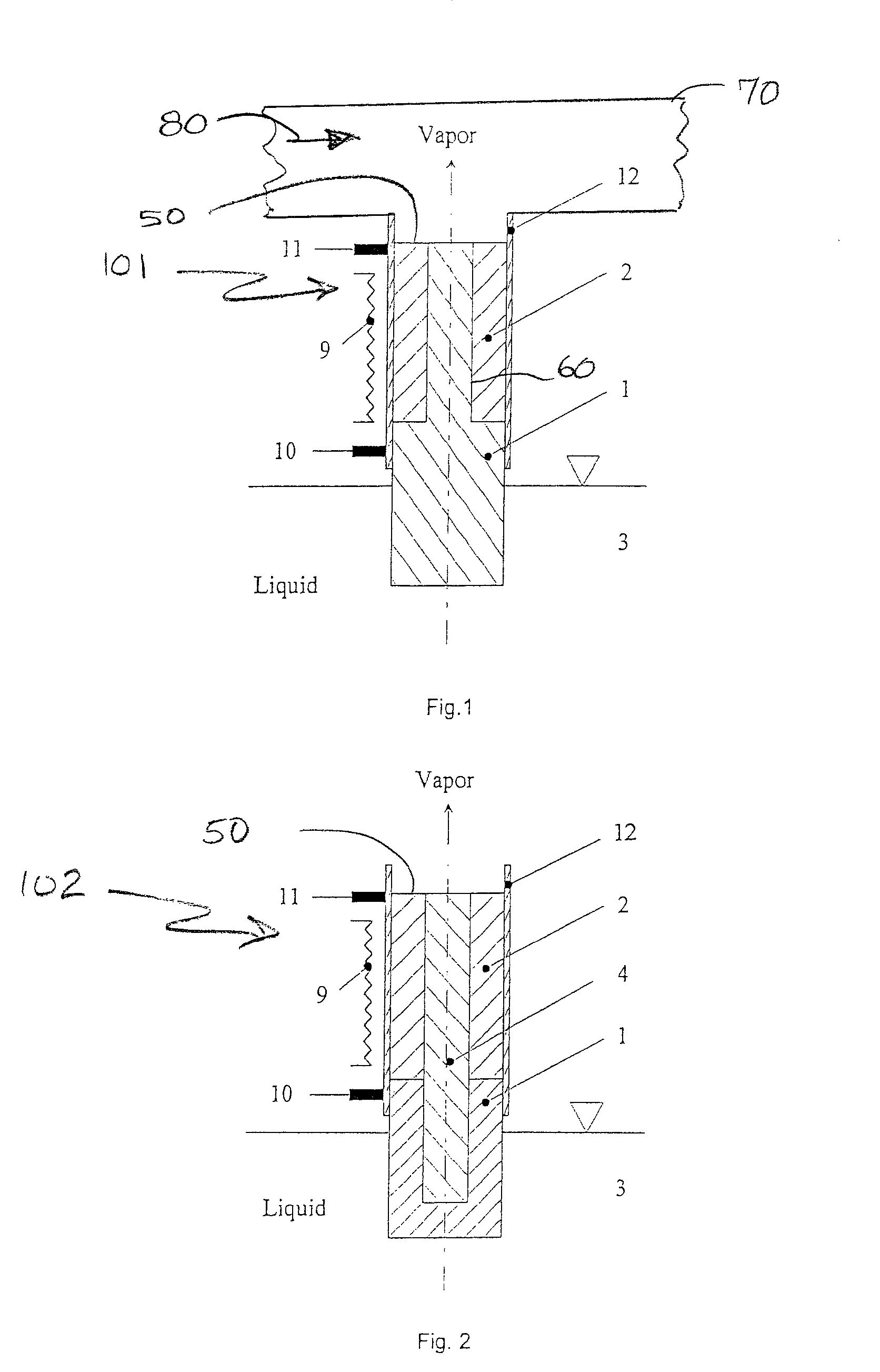

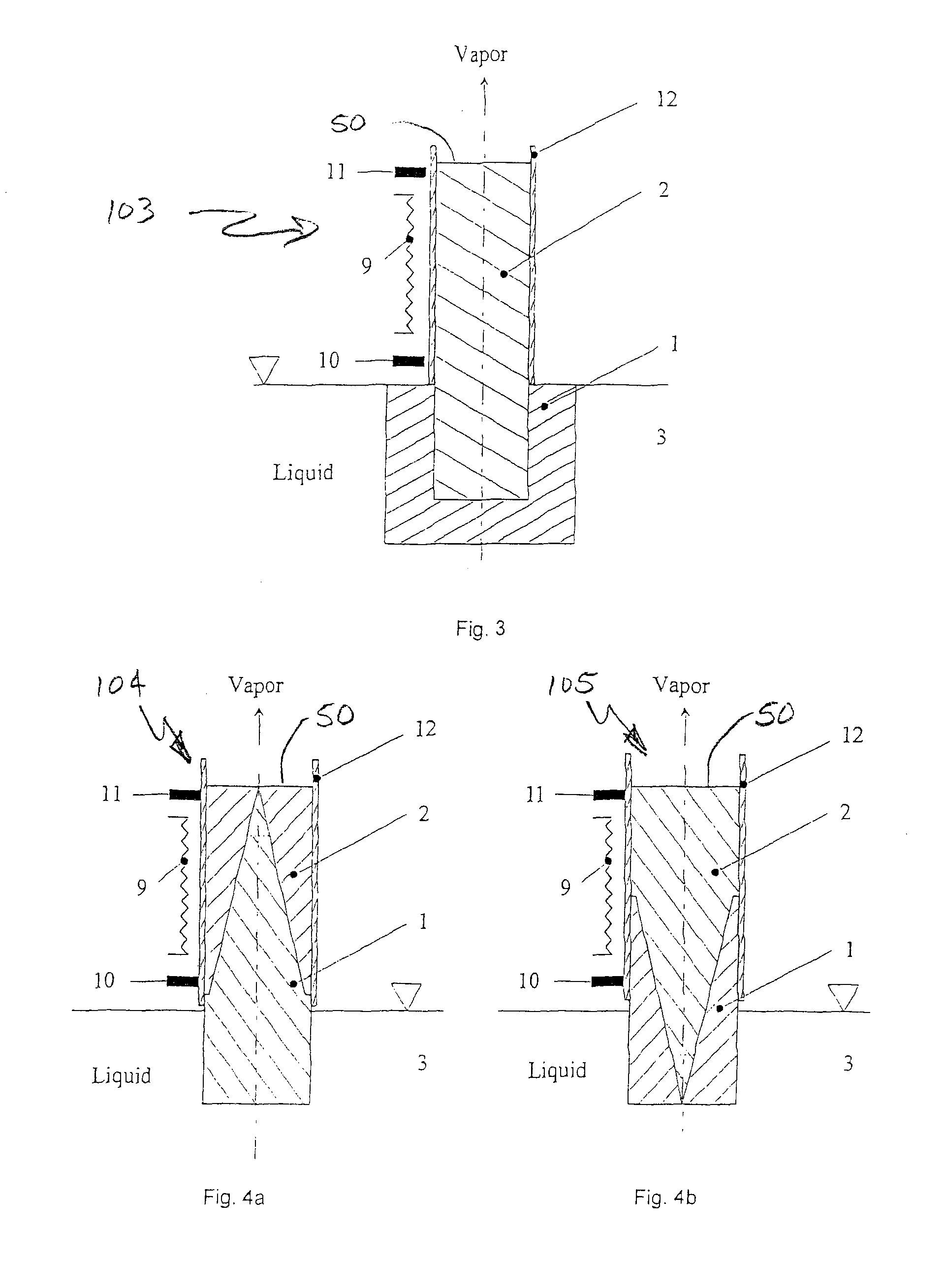

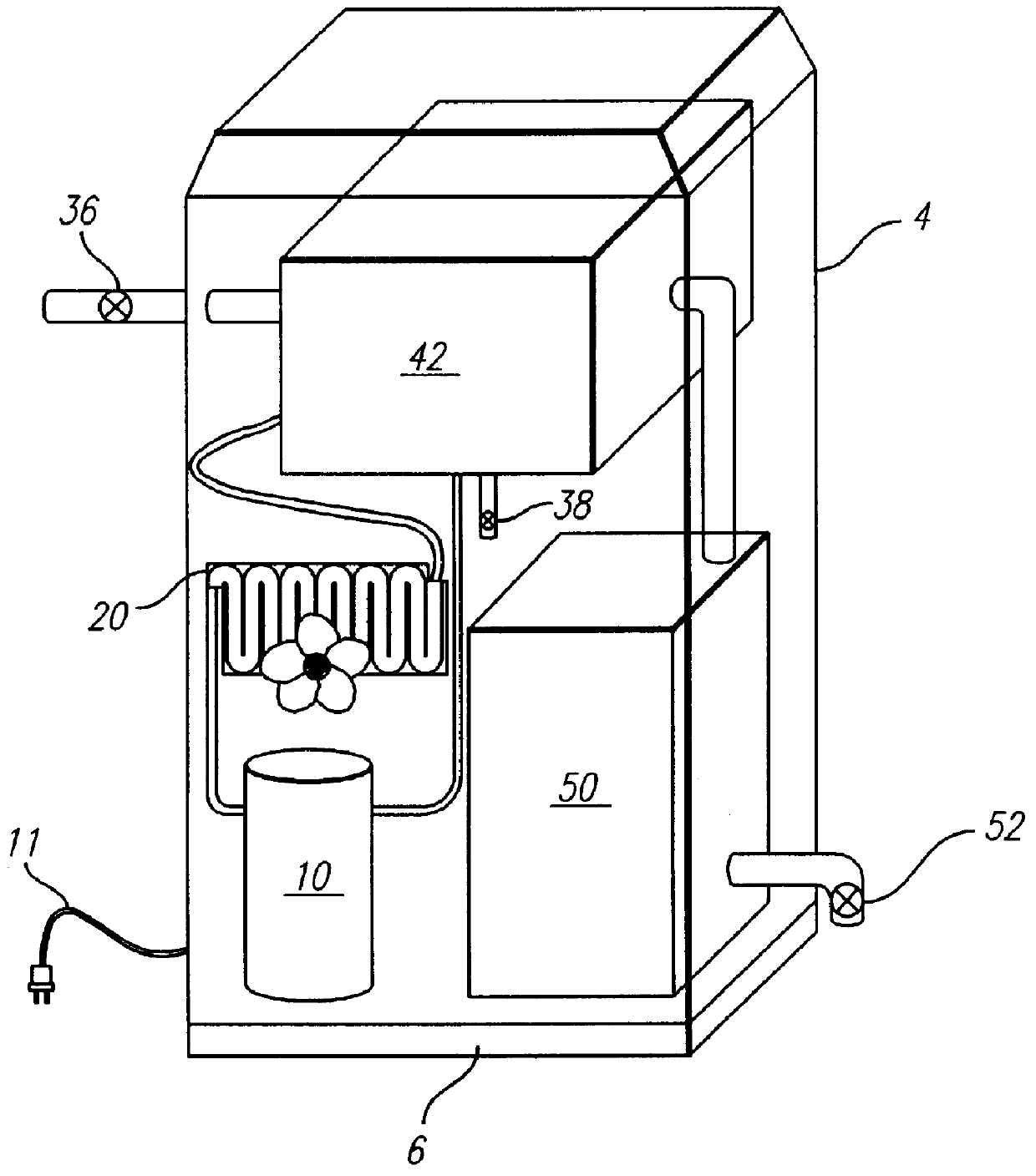

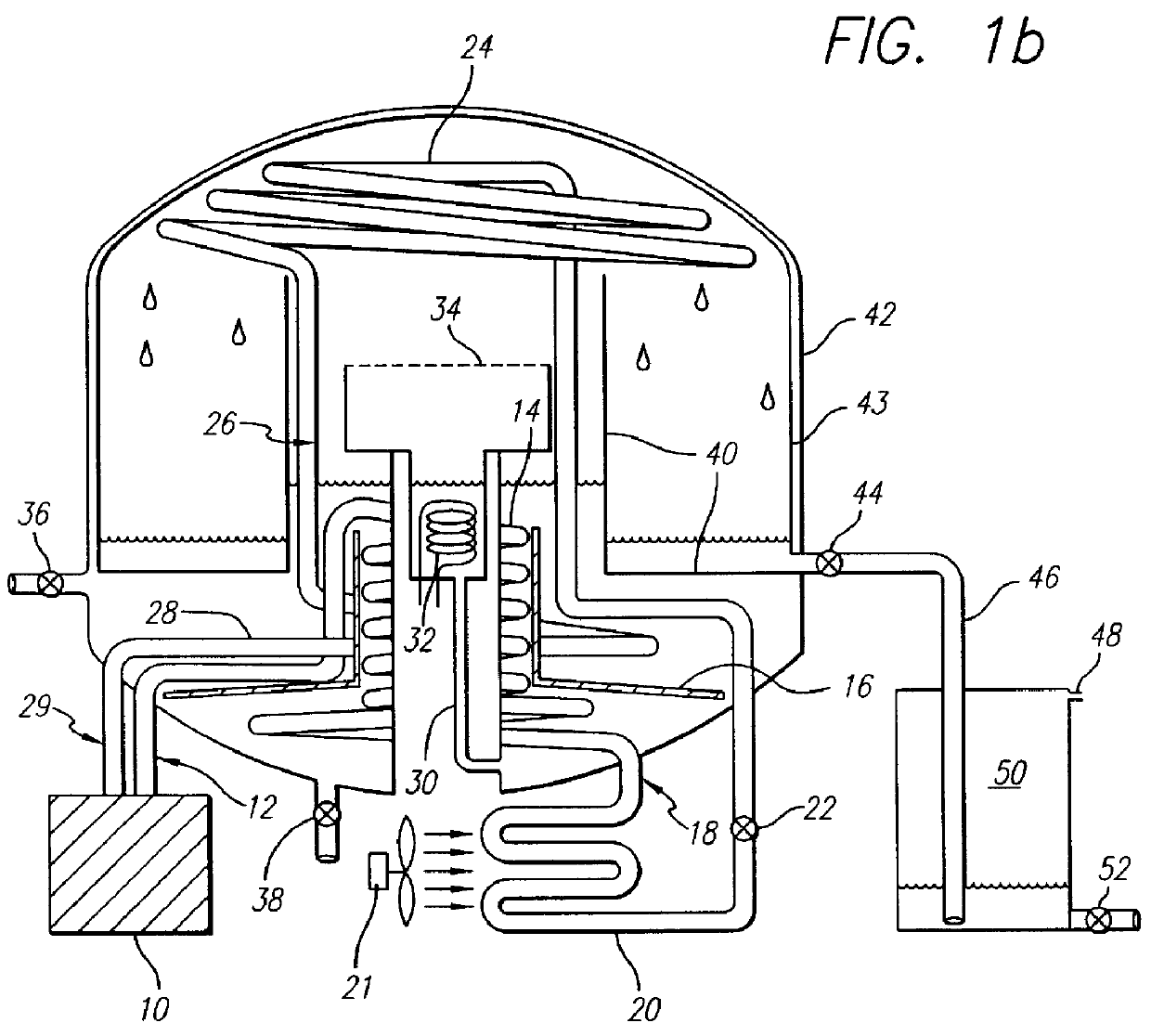

Liquid evaporator

ActiveUS20070107879A1Simple designImprove evaporation effectBurnersSpace heating and ventilationPorosityEngineering

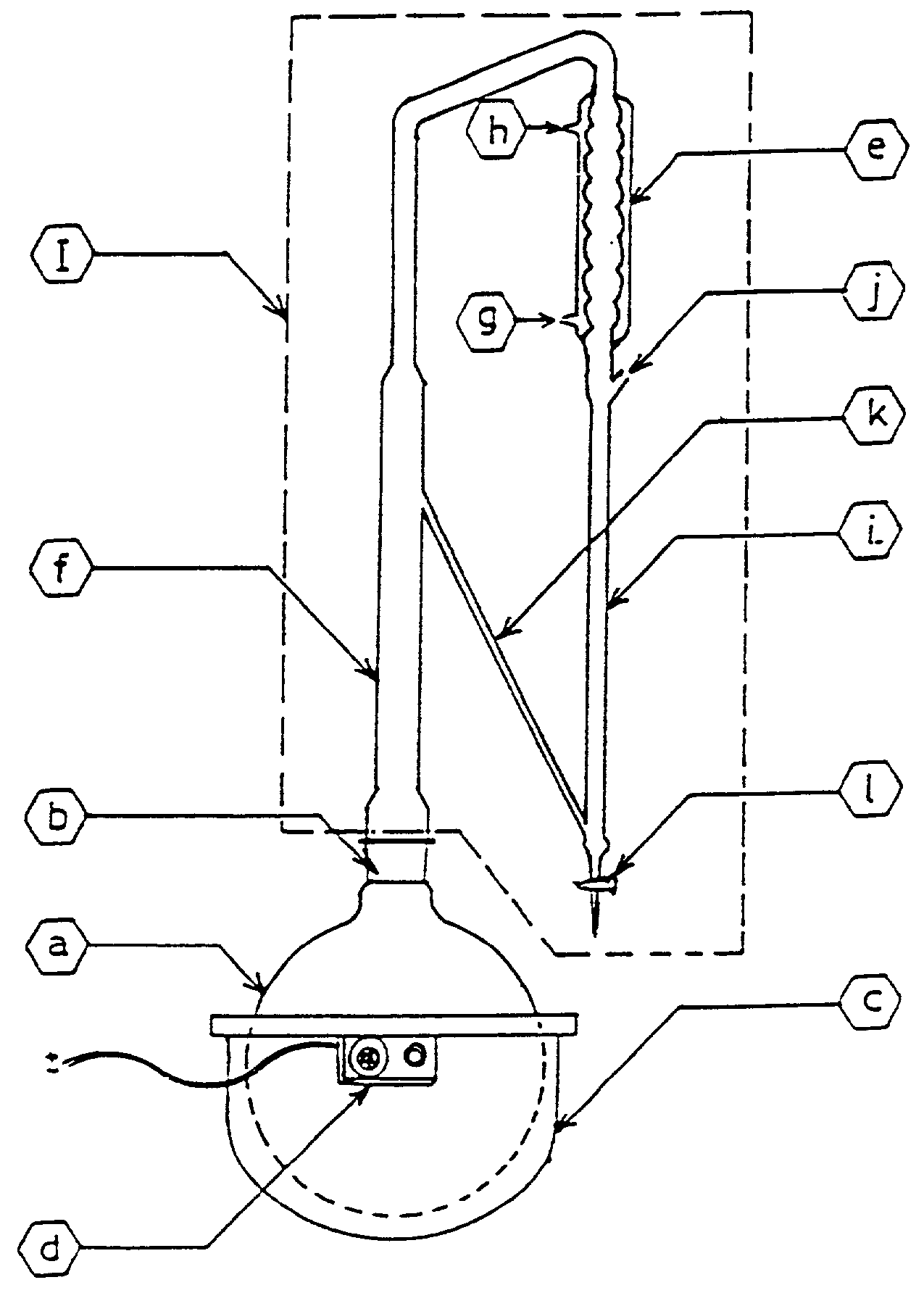

A liquid evaporator includes a liquid reservoir (3) with a liquid to be evaporated, a heater (9) and an evaporator tube (12). The evaporator tube (12) has a first porous element (1) having a first porosity and with an area in contact with the liquid in the liquid reservoir (3) and a second porous element (2) with a second porosity and with an area present on an evaporator side (50) used to dispense the evaporated liquid, and an area outside the liquid reservoir heated by the heater (9) which is not directly in connection with the liquid. The first porous element and the second porous element are in contact in contact areas with the first porous element forming a wick delivering liquid from the reservoir to the contact area.

Owner:DRAGERWERK AG

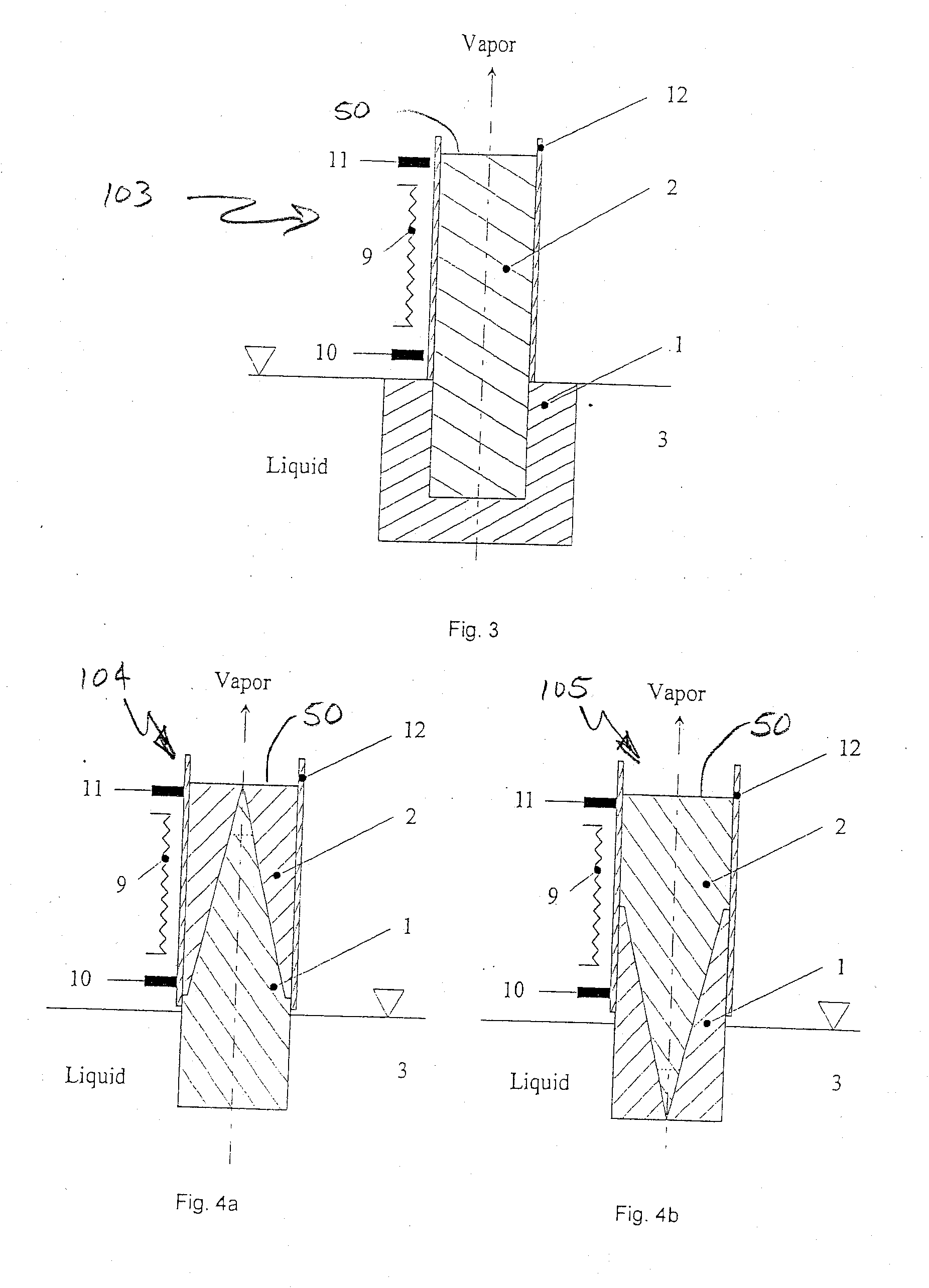

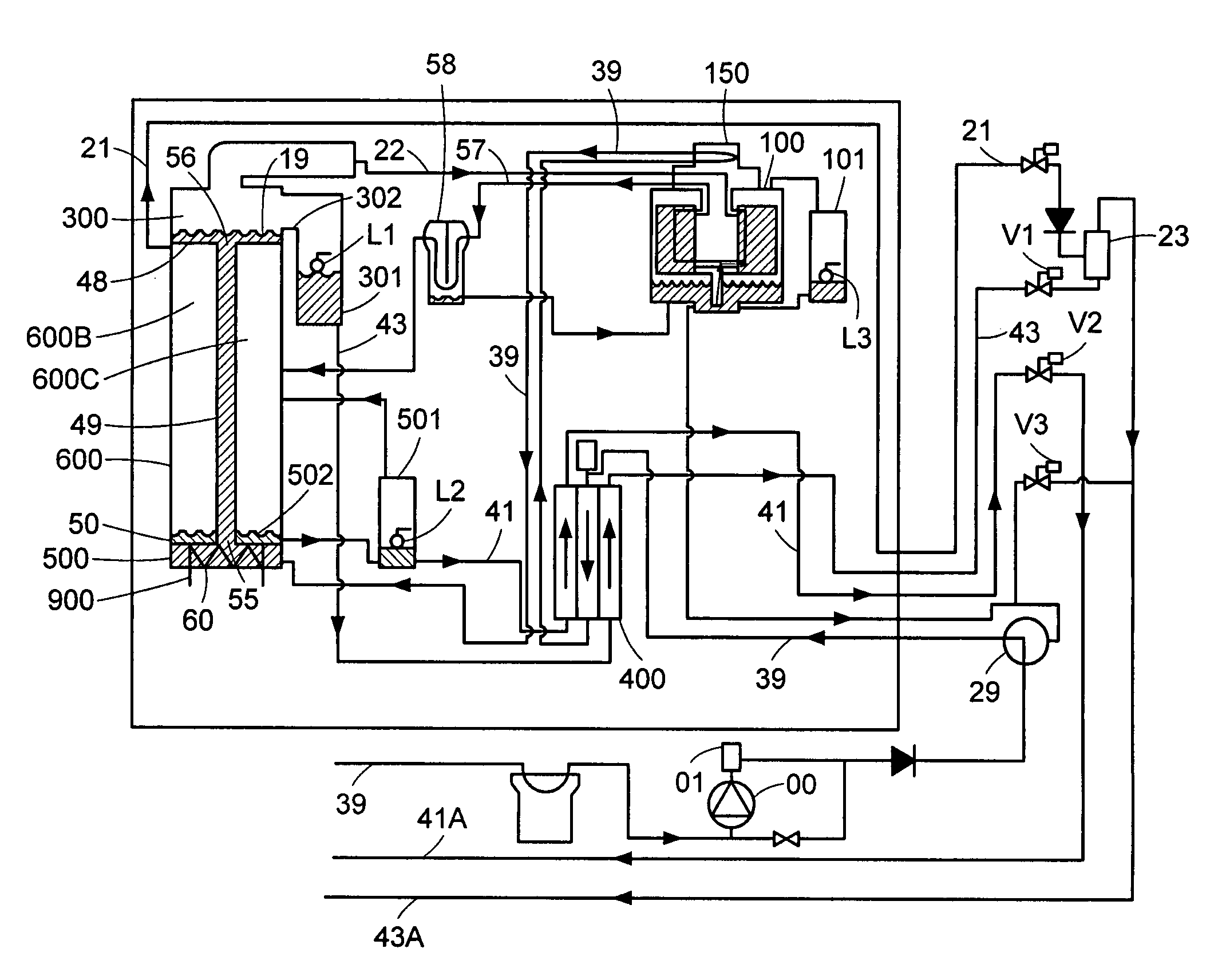

Liquid ring pumps with hermetically sealed motor rotors

ActiveUS7465375B2Easy maintenanceMaximize energy efficiencyGeneral water supply conservationDistillation regulation/controlDrive shaftDistillation

Owner:DEKA PROD LLP

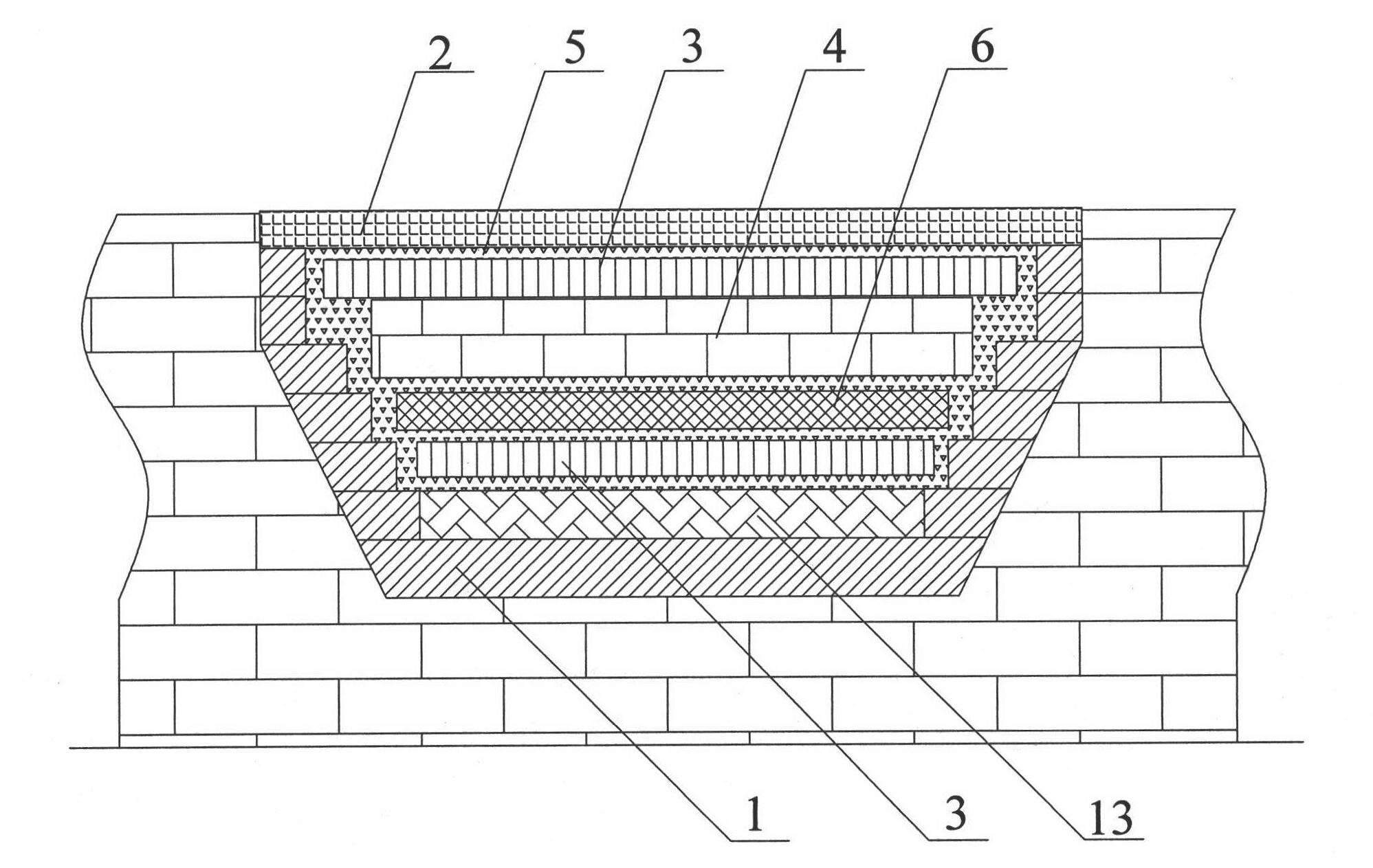

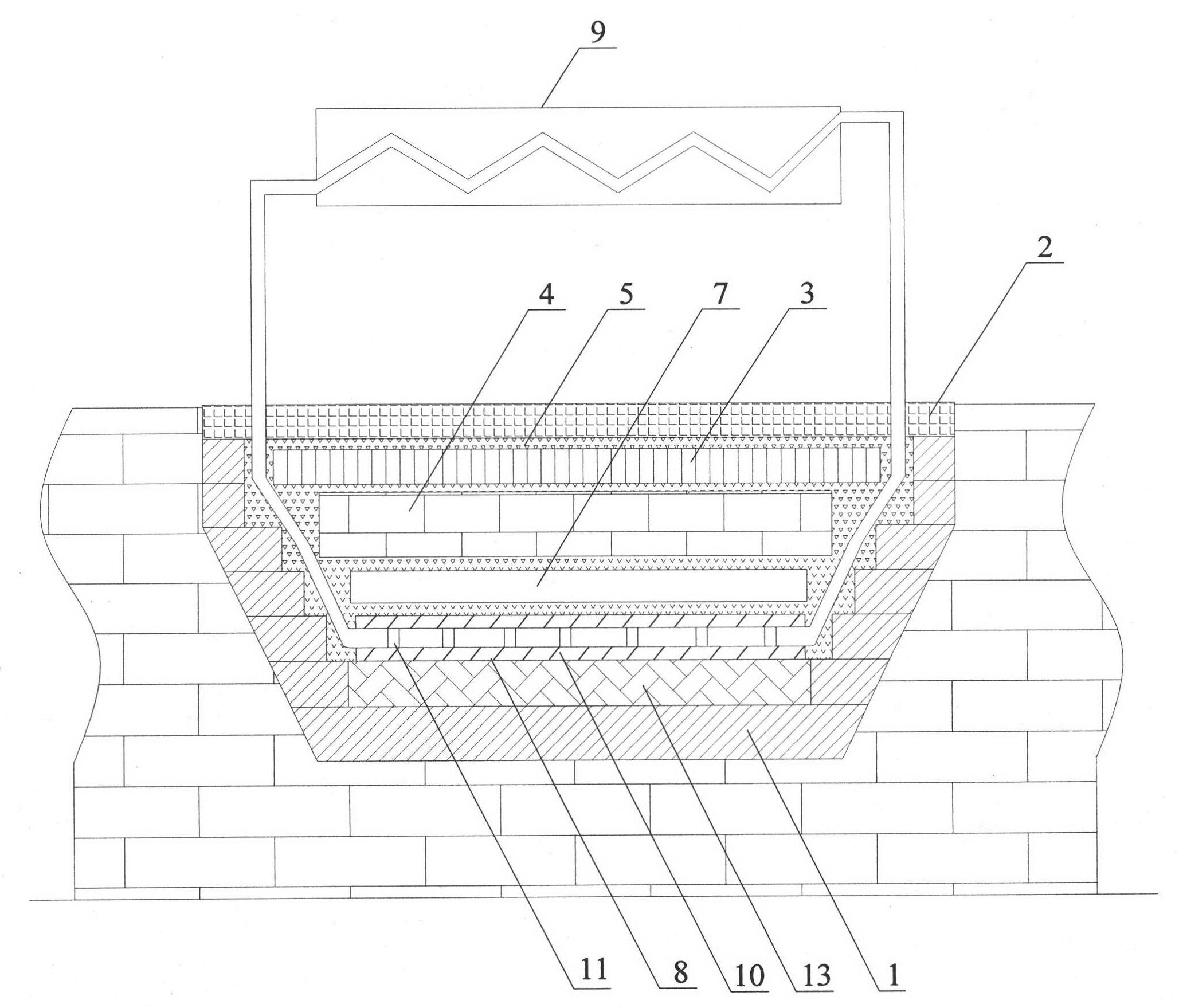

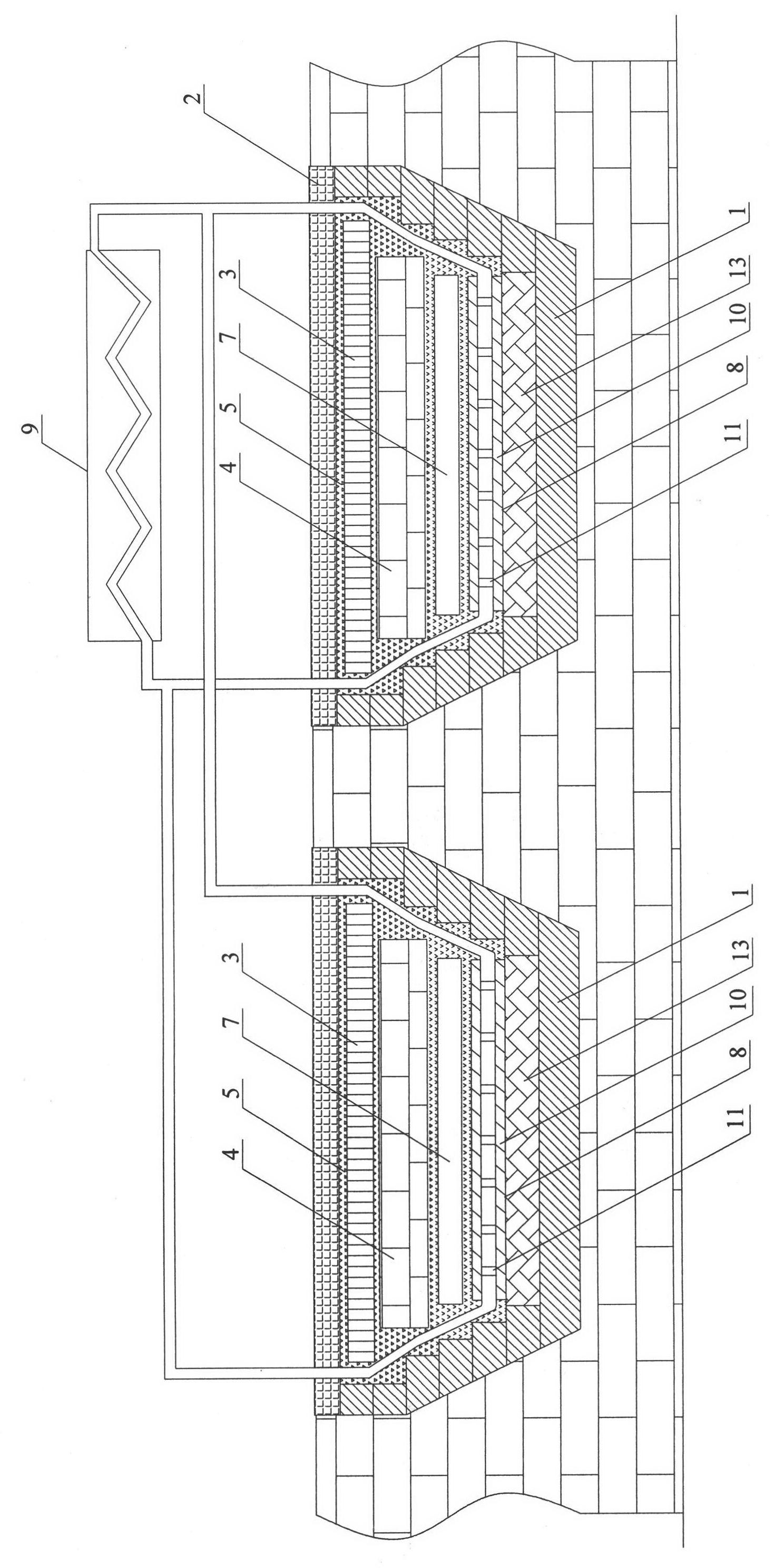

Coke oven top waste heat reclaiming system

InactiveCN102322623AReduce the temperatureImprove insulation effectSteam generation heating methodsCoke oven safety devicesEngineeringCoke oven

The invention discloses a coke oven top waste heat reclaiming system, which mainly consists of a coke oven top large pit (1) and an oven top quarry tile (2) covering the surface of the top of the large pit. The system is characterized in that a poriferous steel plate (3), a thermal baffle layer (4) and a poriferous steel plate (3) are sequentially arranged from bottom to top in the coke oven top large pit (1), and inner gaps of the coke oven top large pit (1) are filled with heat-resisting sealing slurry (5). According to the invention, through the measures that poriferous steel plates and the thermal baffle layer are arranged in the coke oven top large pit (1), the gaps are filled with the heat-resisting sealing slurry and the like, the temperature of the coke oven top surface can be effectively reduced, the heat preservation effect is very obvious, the energy-saving effect is very ideal, and the energy-saving rate can reach 0.4KW / m2.

Owner:重庆双腾化工有限公司

Salt water distillation system

The salt water distillation system includes a sprinkler to form a mist of salt water over a distillation plate. The distillation plate is heated by applying electrical current to a heating coil. The steam is transferred to a condensation chamber and condensed fresh water is collected. During the desalination process, salt impurities are deposited on the hot distillation plate. A sludge remover, i.e., a steam head and movable ram, is provided to clean the distillation plate of the salt impurities. An exhaust fan is provided to cool fresh water condensate and lower air pressure in the system. Heat transferred from the steam during condensation is used to pre-heat the salt water to increase efficiency of the system.

Owner:RIVES MICHAEL L +1

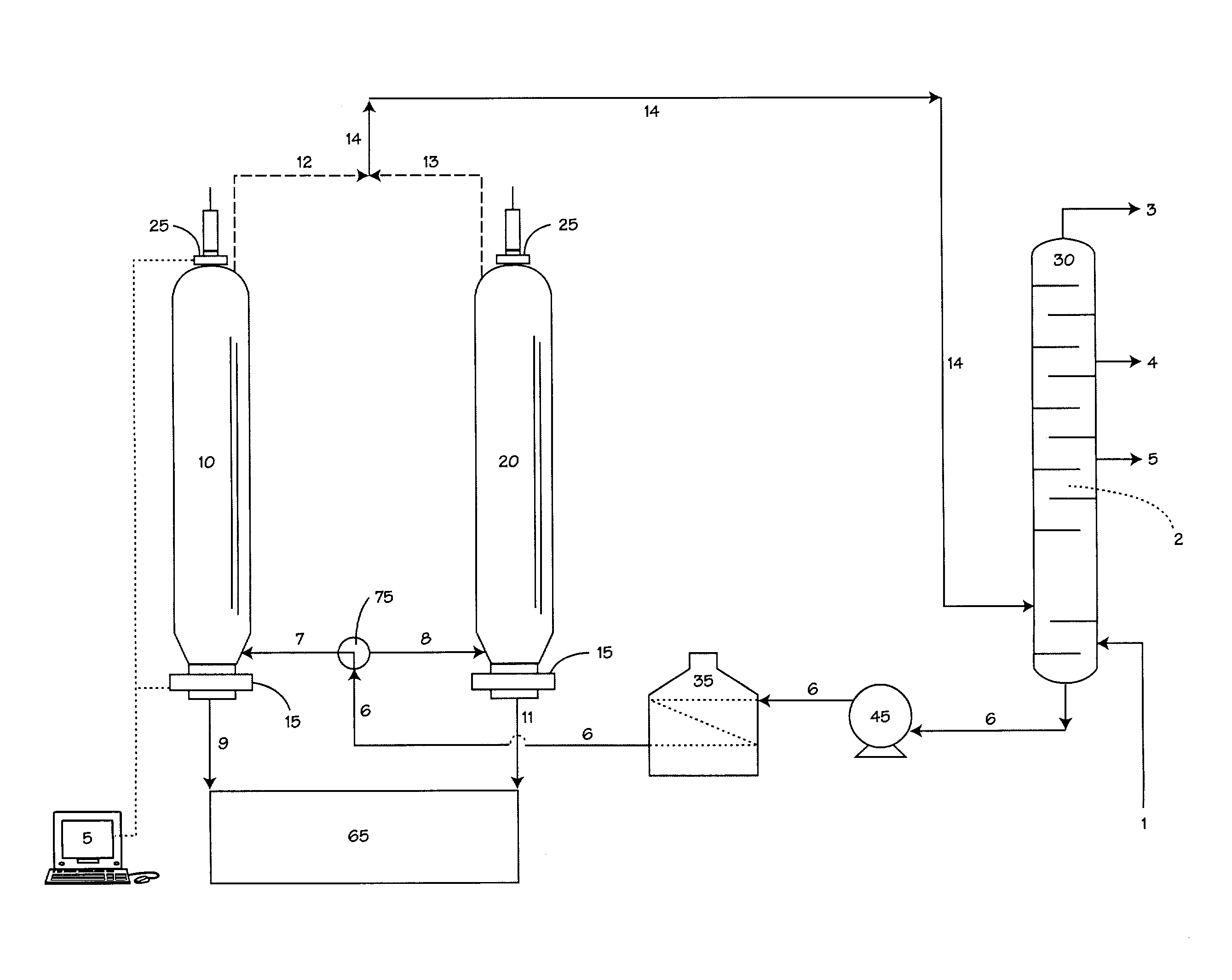

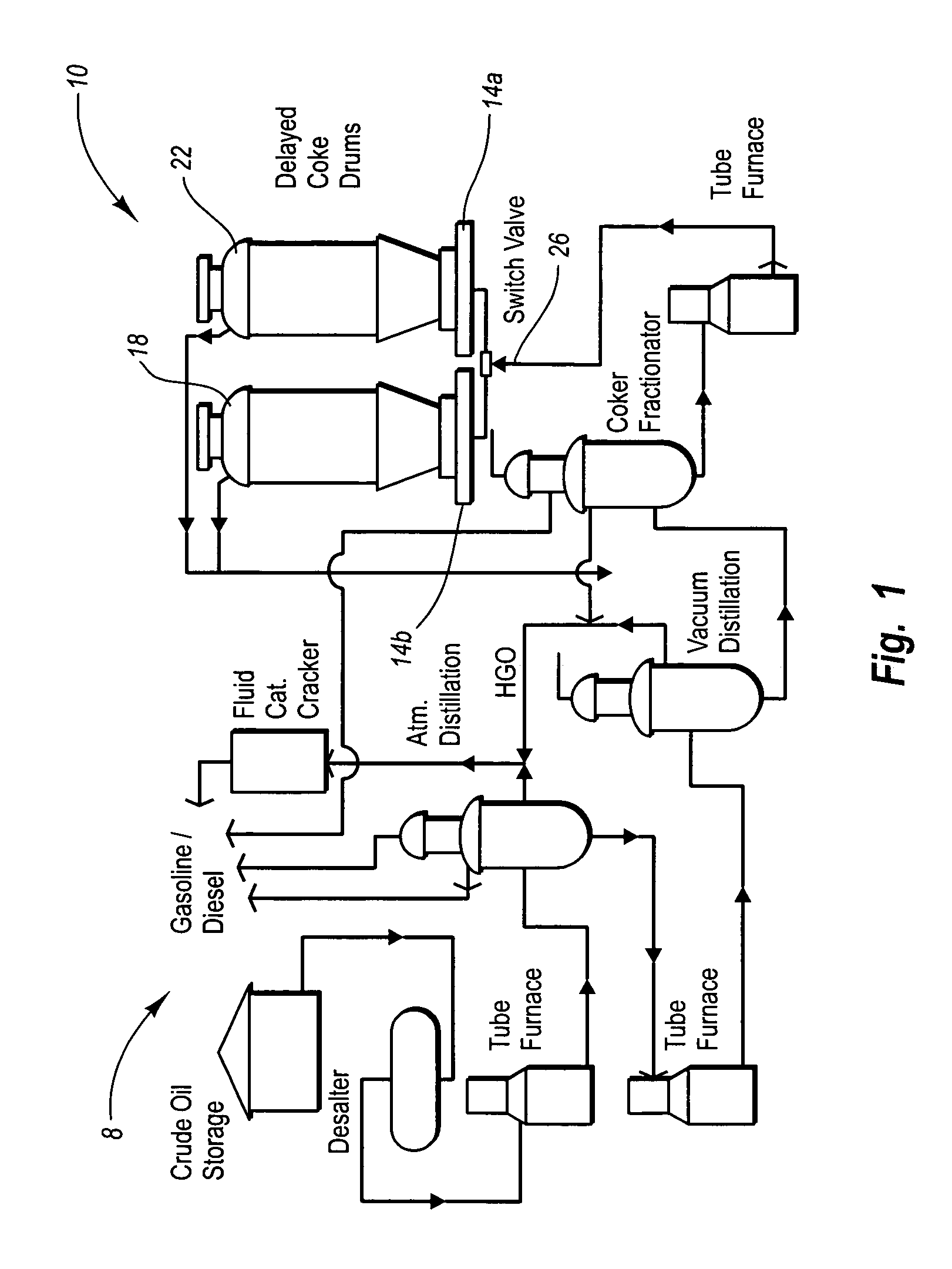

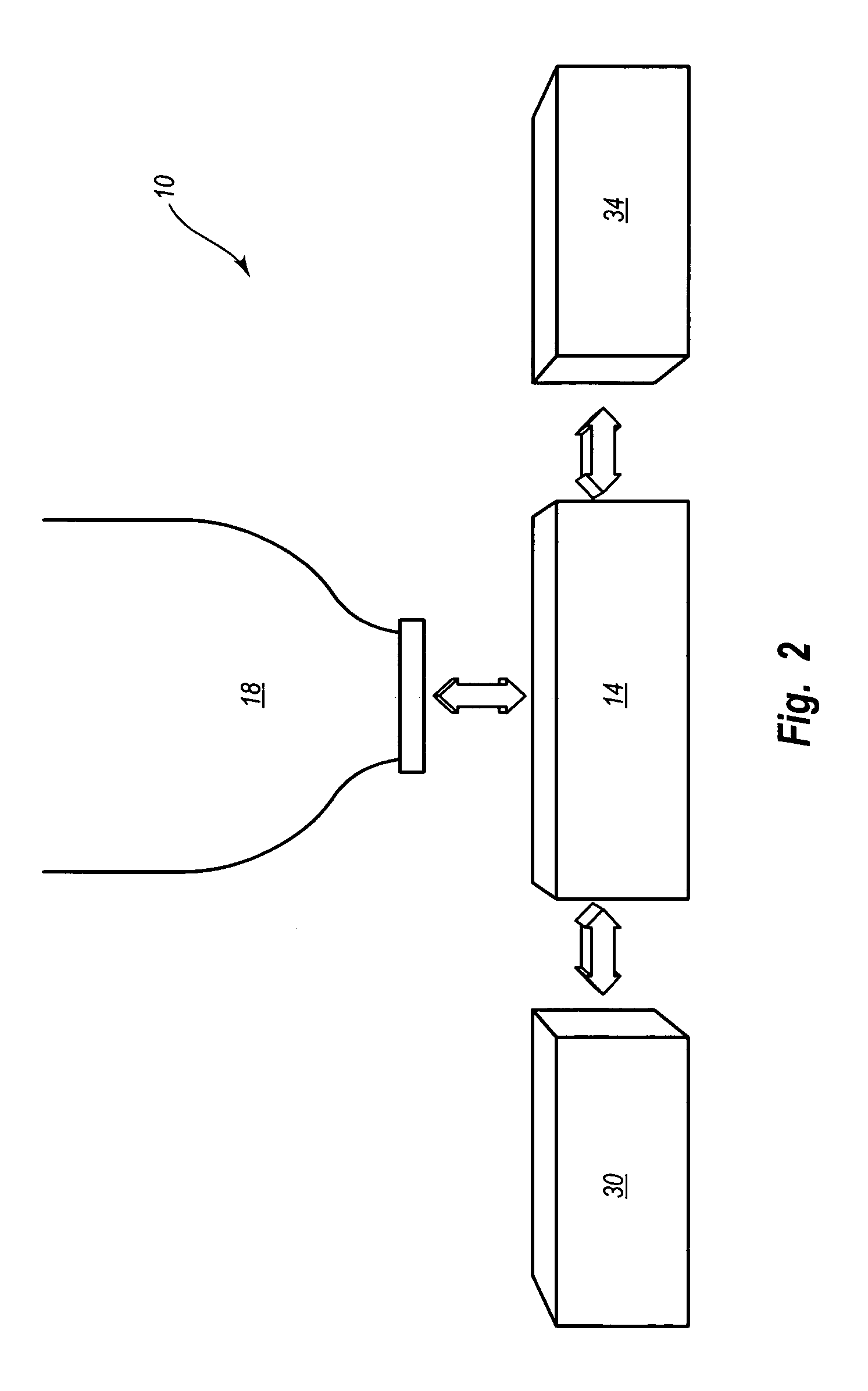

Safe and automatic method for preparation of coke for removal from a coke vessel

InactiveUS7037408B2Prevent leakageReduces and eliminates dangerousThermal non-catalytic crackingDirect heating destructive distillationSteam pressureDrill

A safe, efficient and repetitively operable coke vessel decoking system is disclosed. In a preferred embodiment the closed system comprises a coker vessel pressure-tightly sealed to a top head system, which includes a closure housing with a laterally moveable horizontal closure member therein and a cutting head enclosure, which further comprises a drill stem guide, an access door, and a cutting assembly mounted therein. A novel feature of the invention is a steam purge / blocking system whereby steam pressure is maintained in the closure housing during the coking cycle to maintain seal integrity. Personnel safety during decoking operations is greatly enhanced by eliminating dangerous manual tasks associated with the prior art such as unbolting and removing top head devices. The system can be remotely and repetitively operated through numerous coking / decoking cycles without removal of any system element.

Owner:CHEVROU USA INC

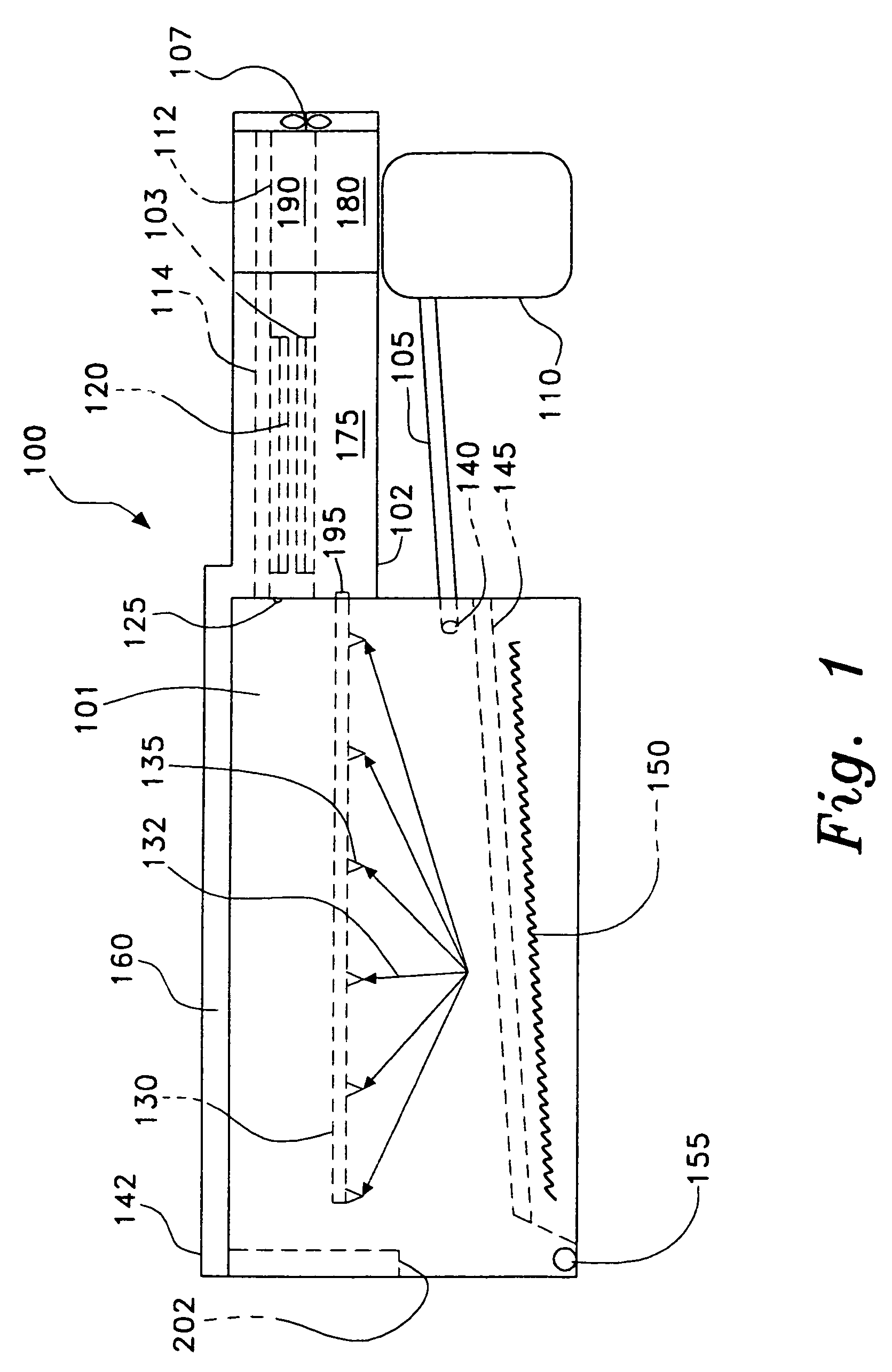

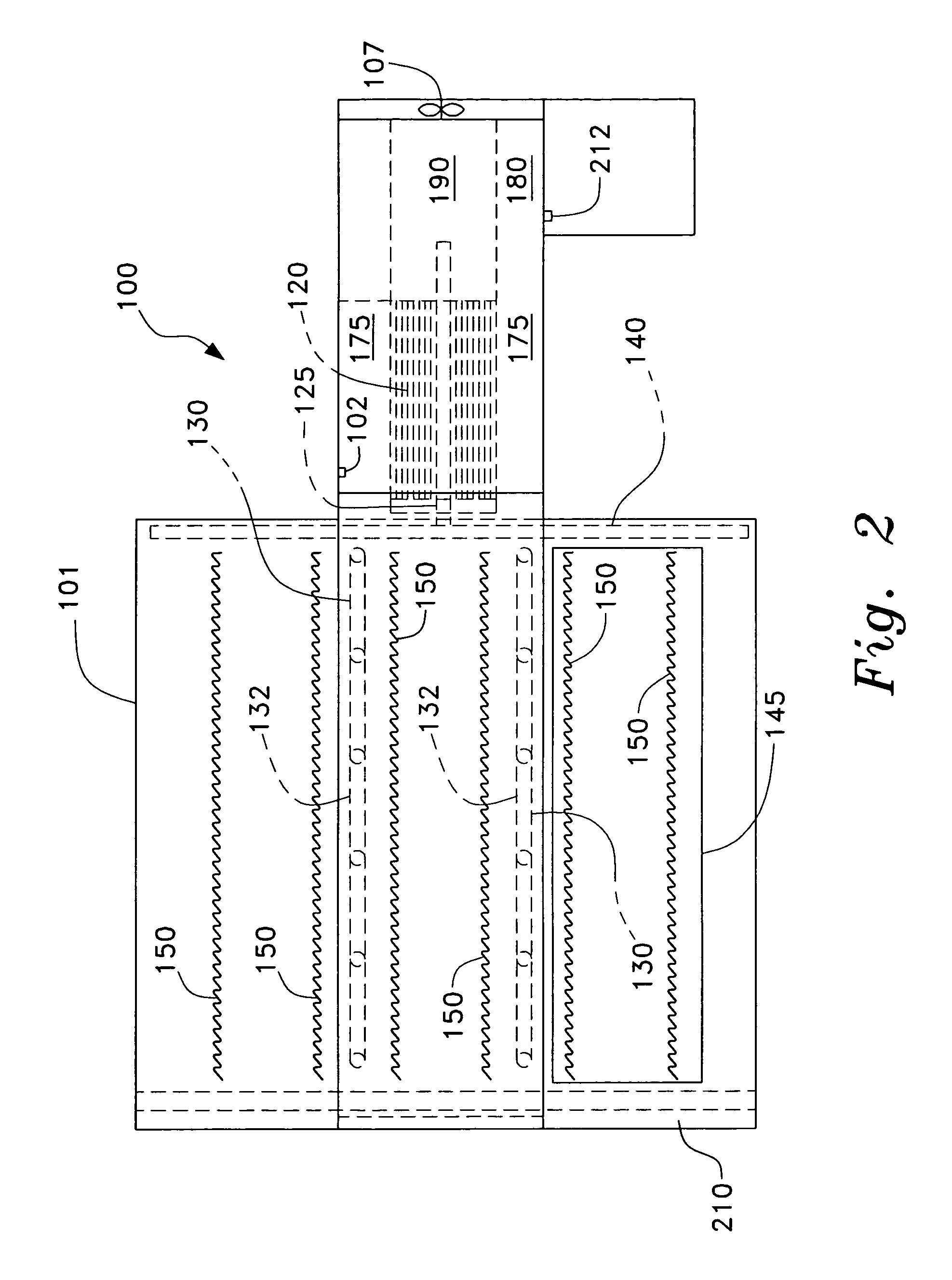

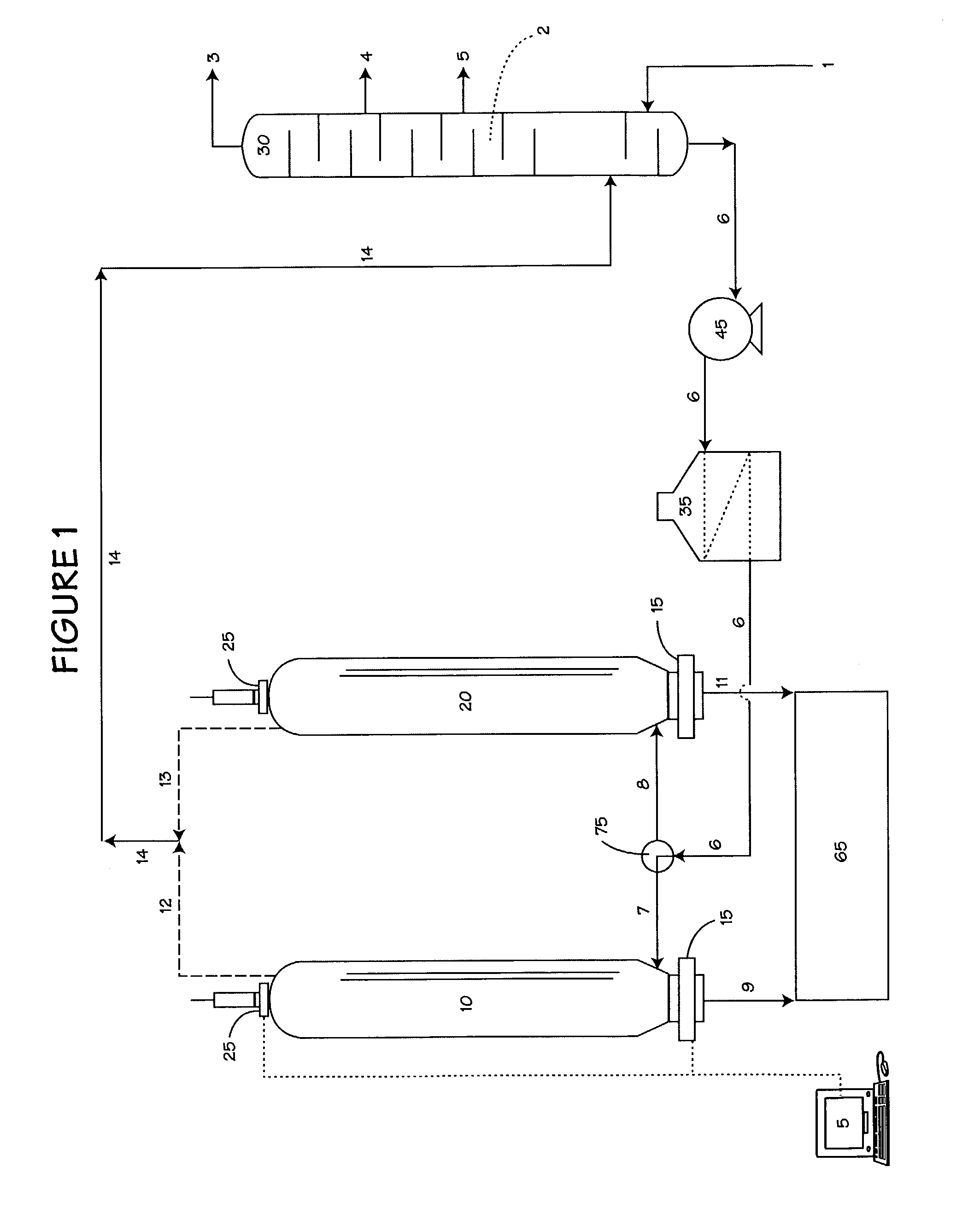

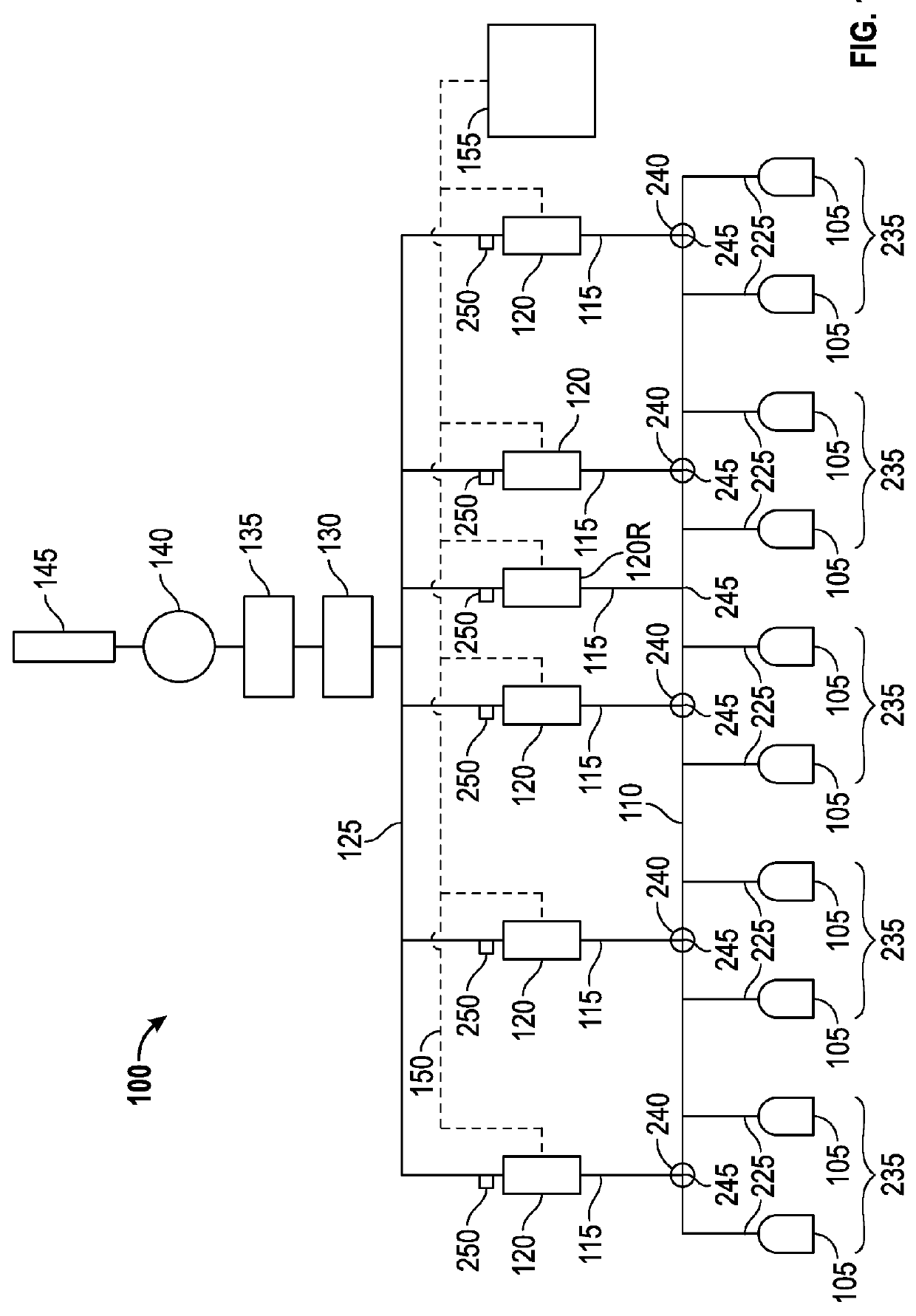

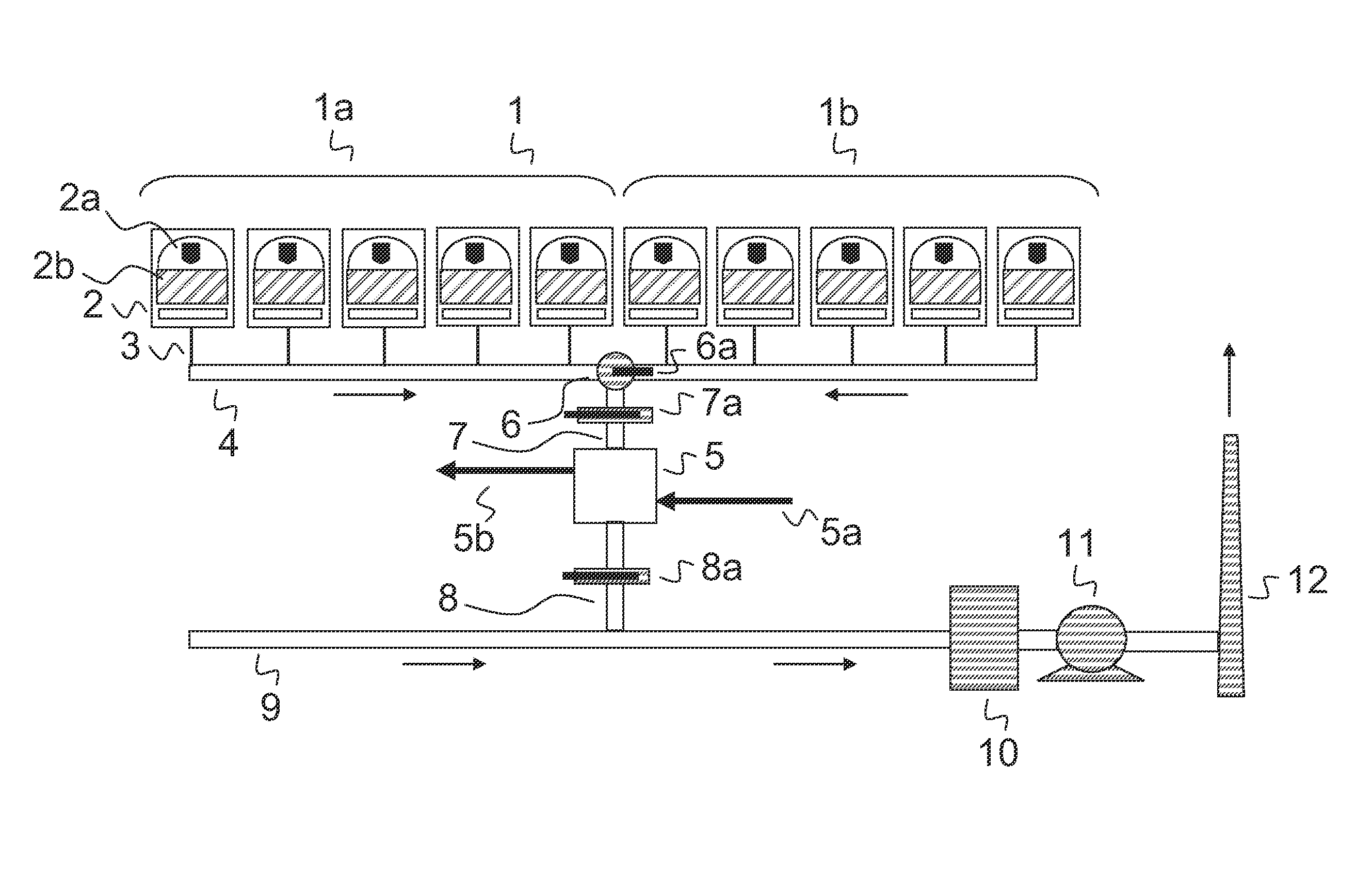

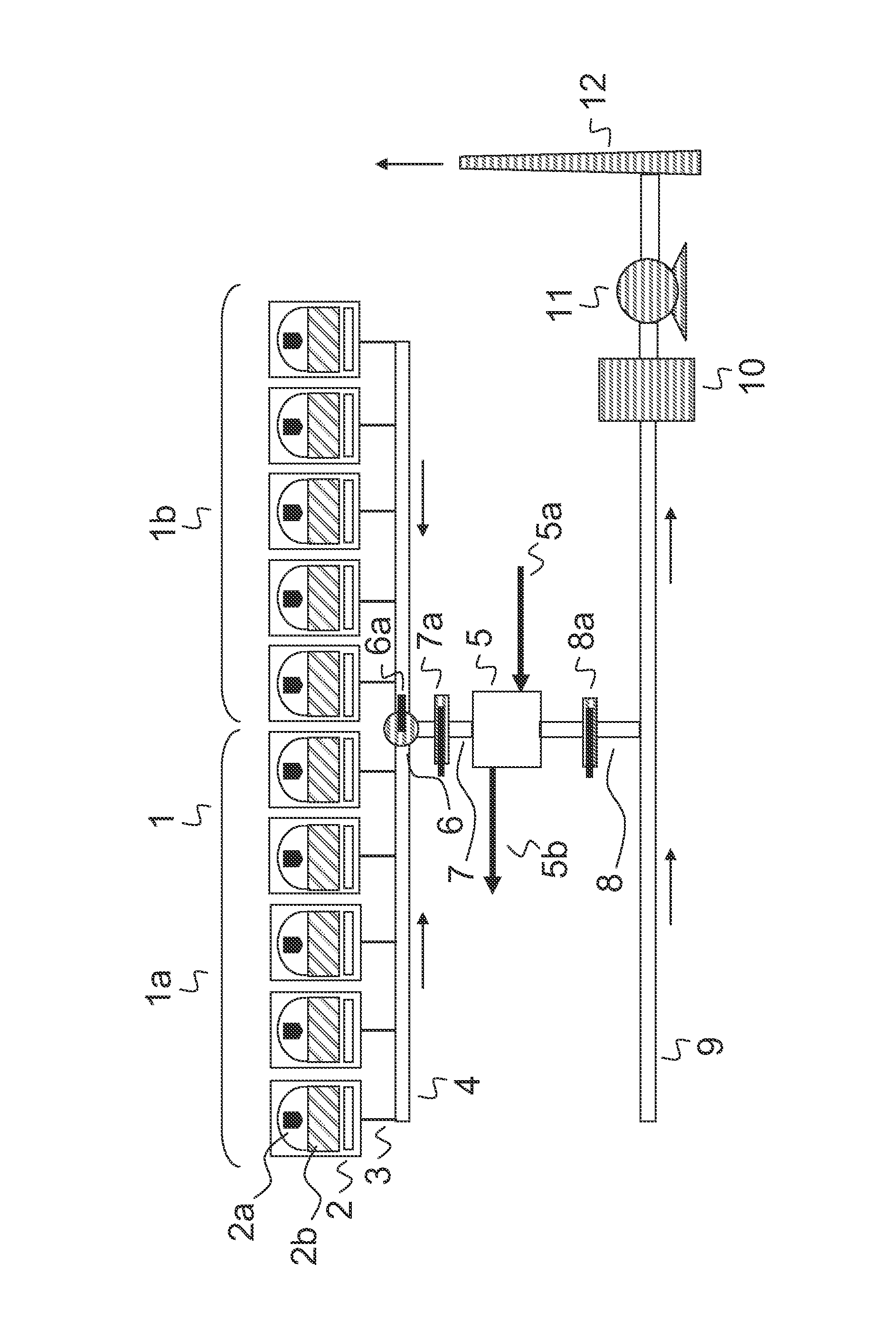

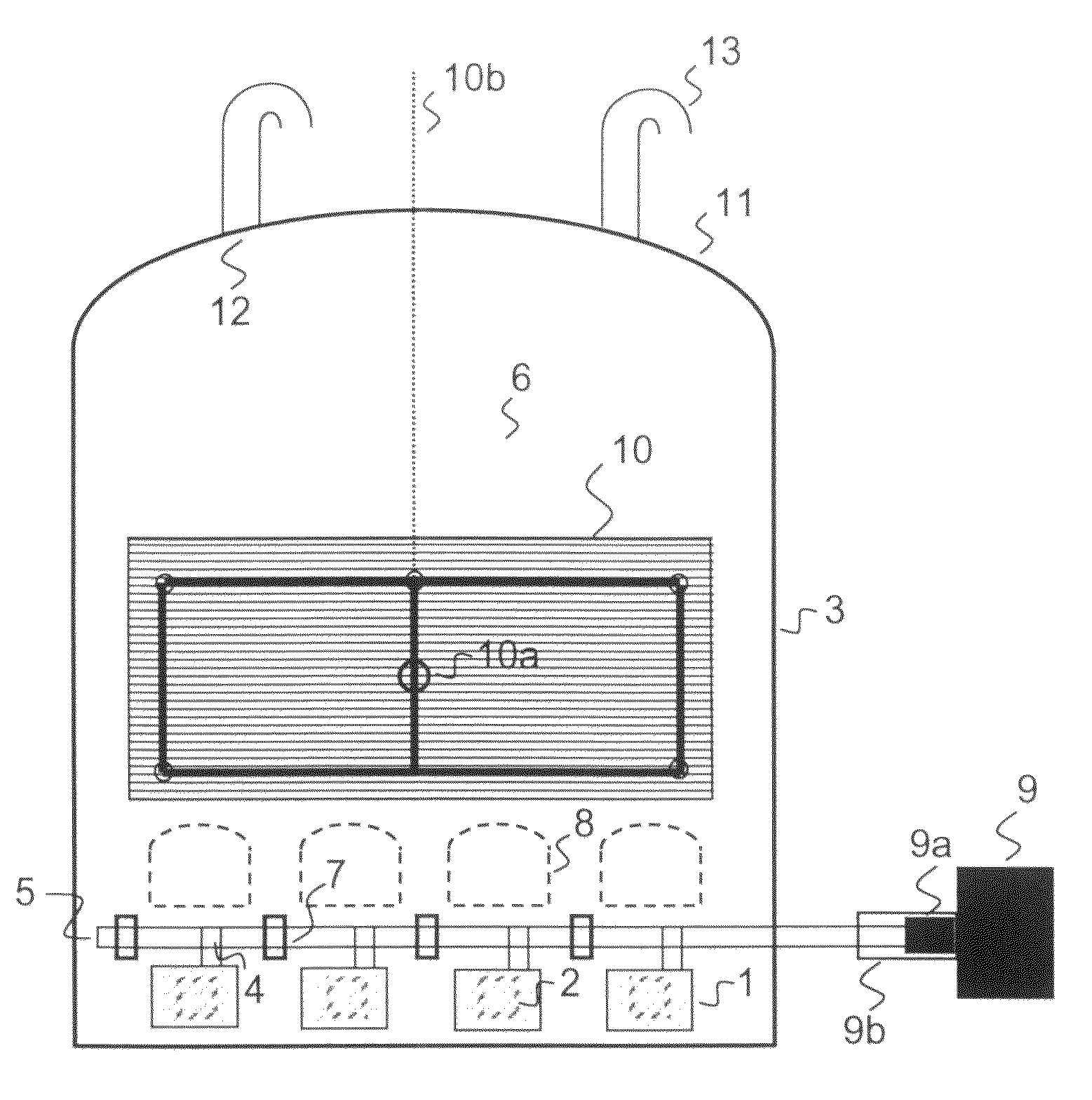

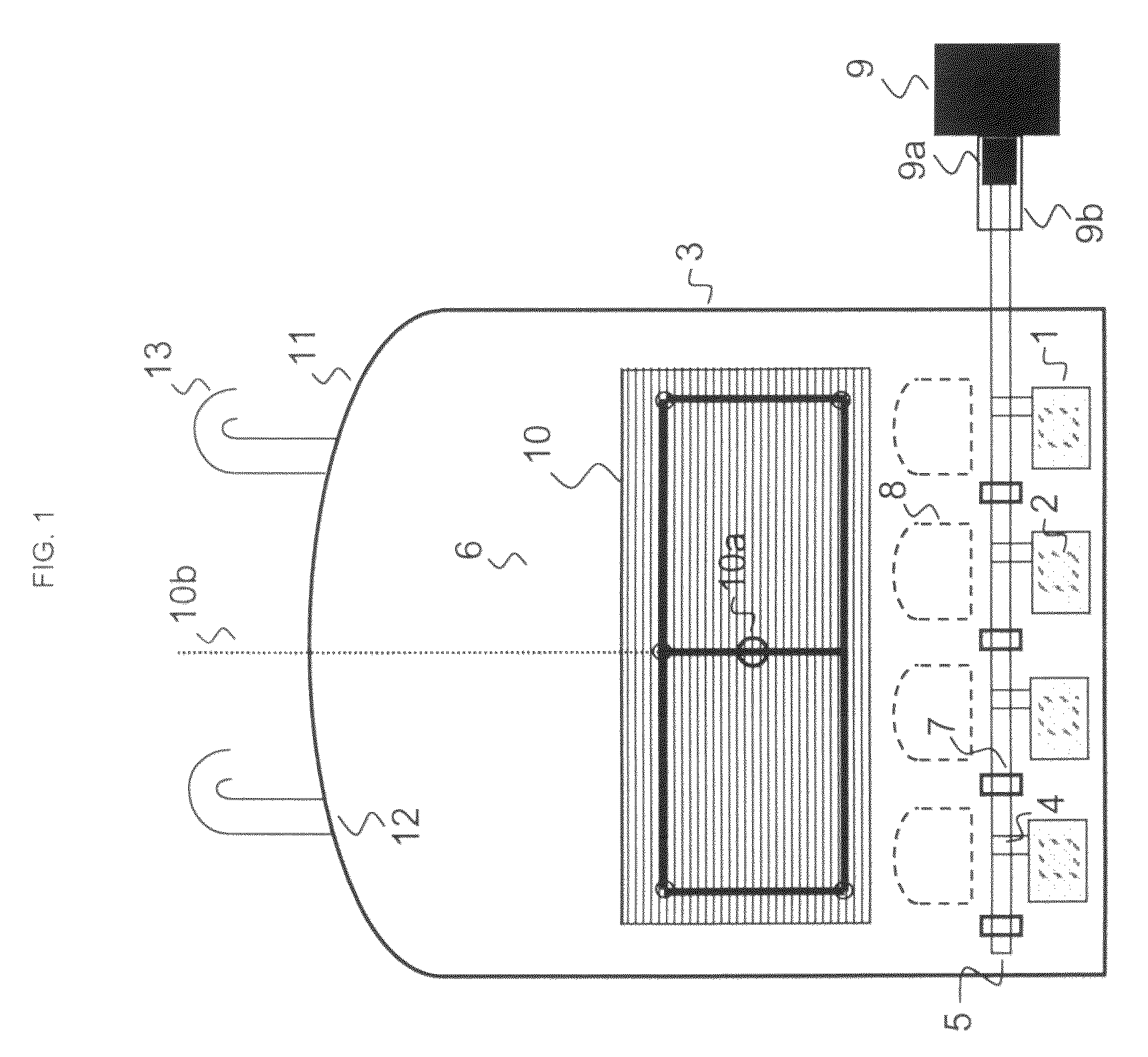

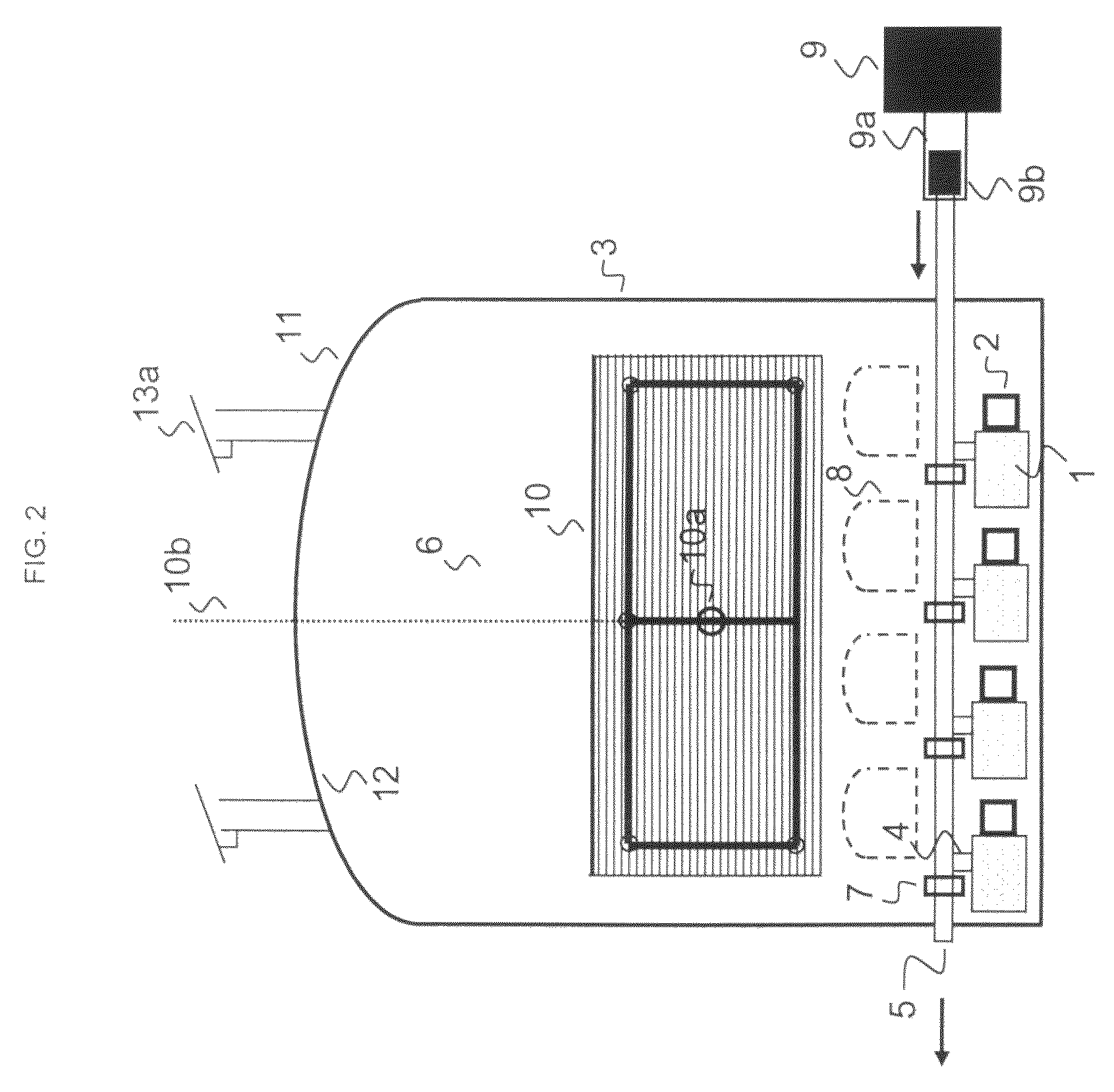

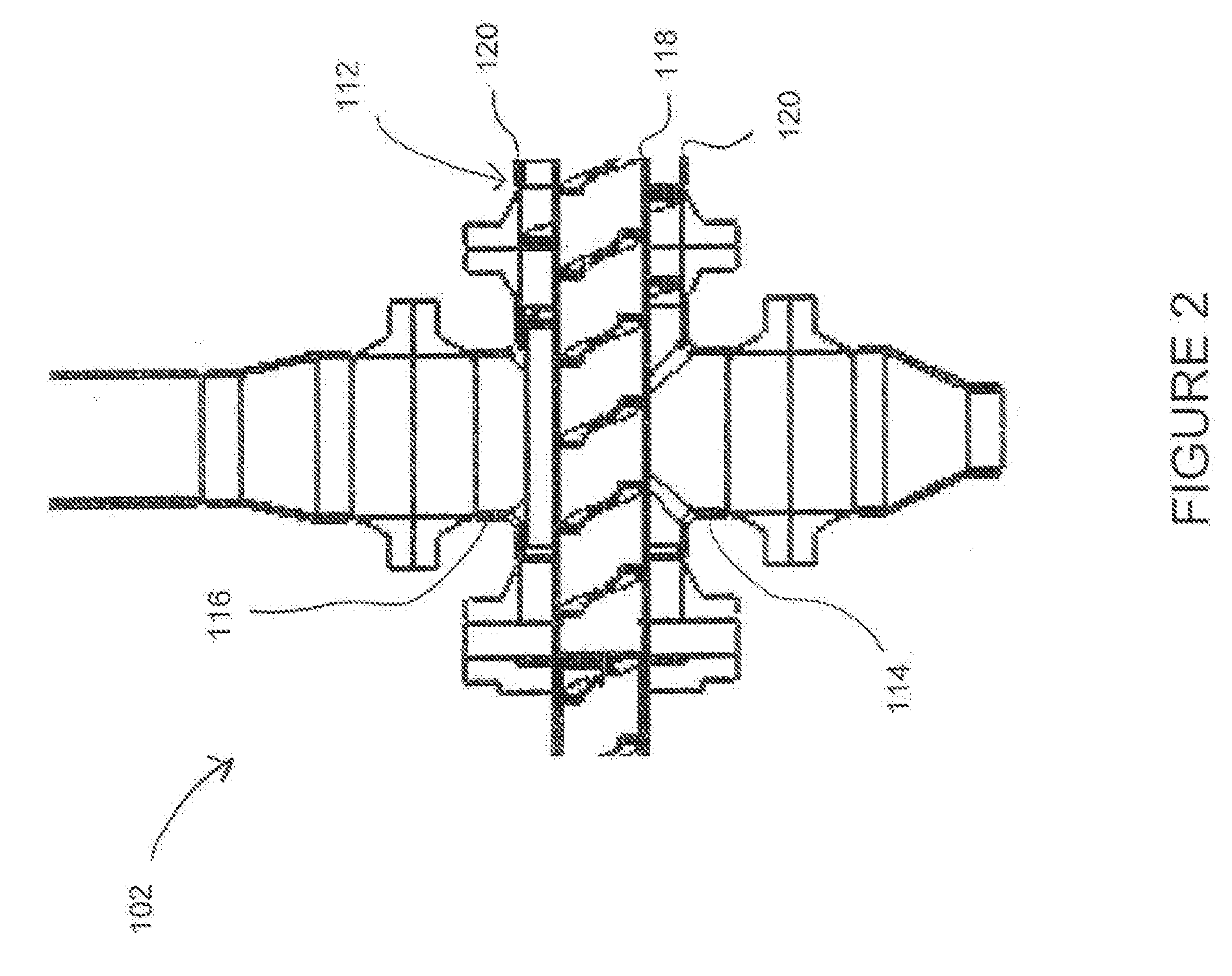

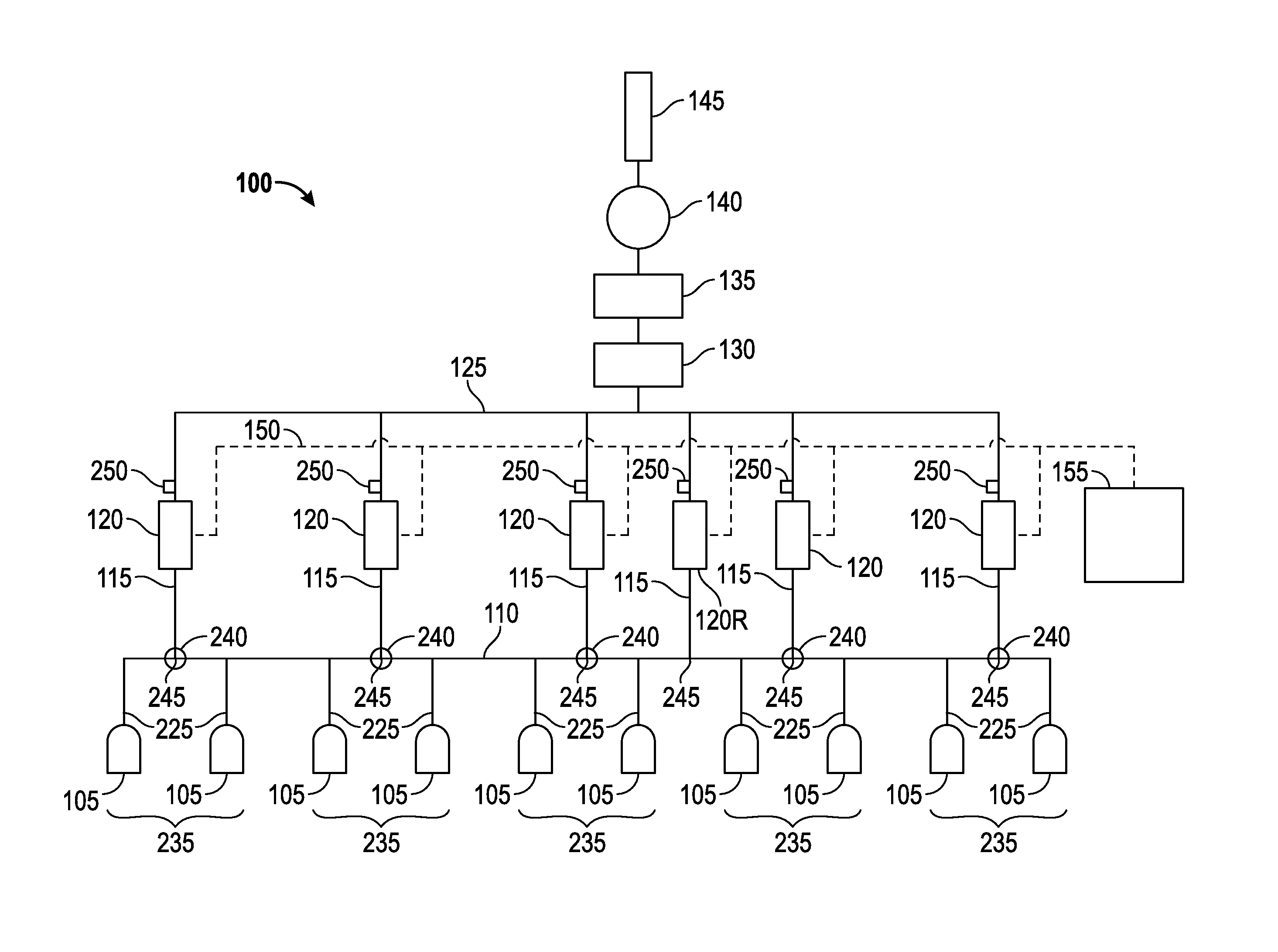

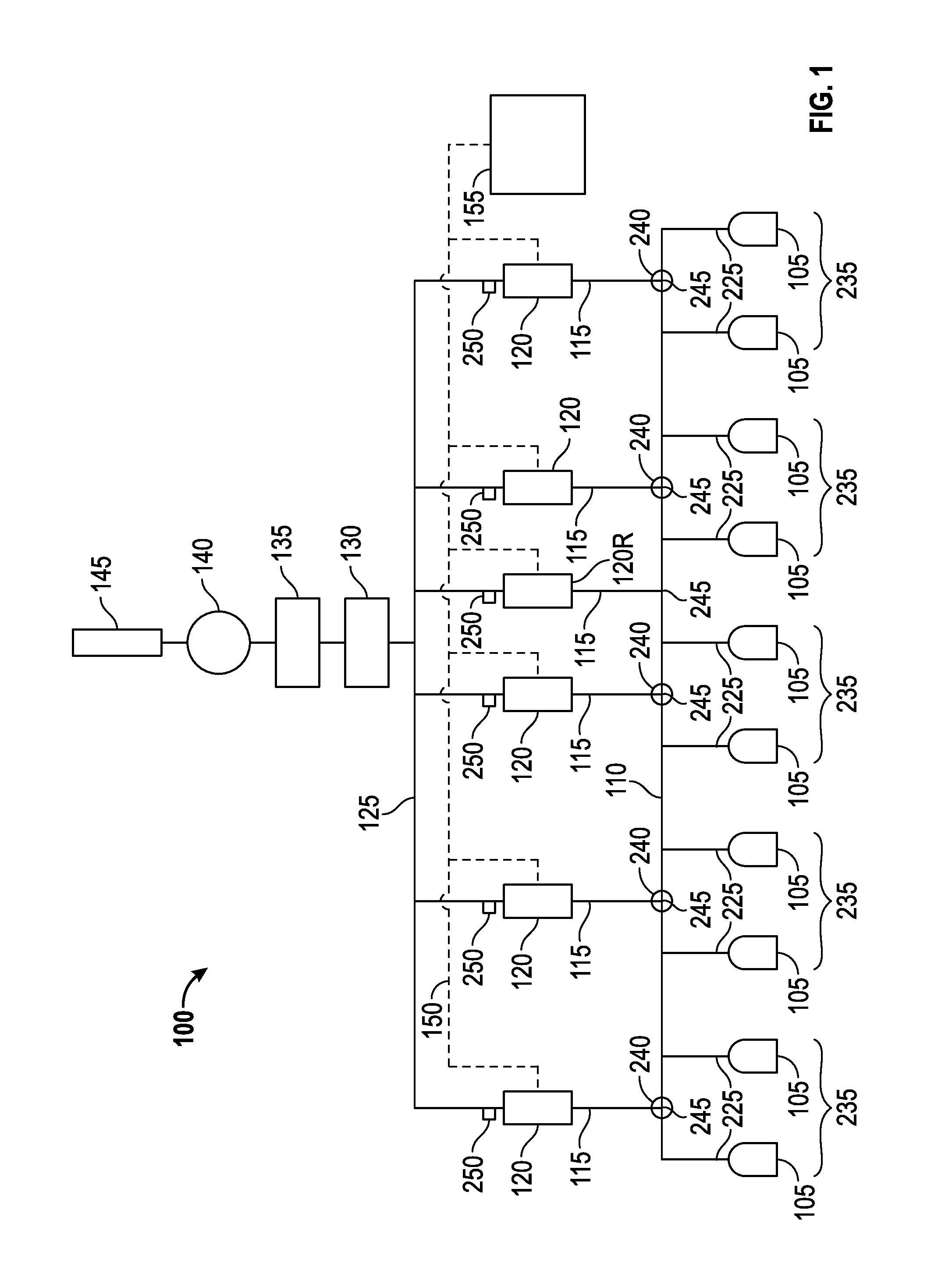

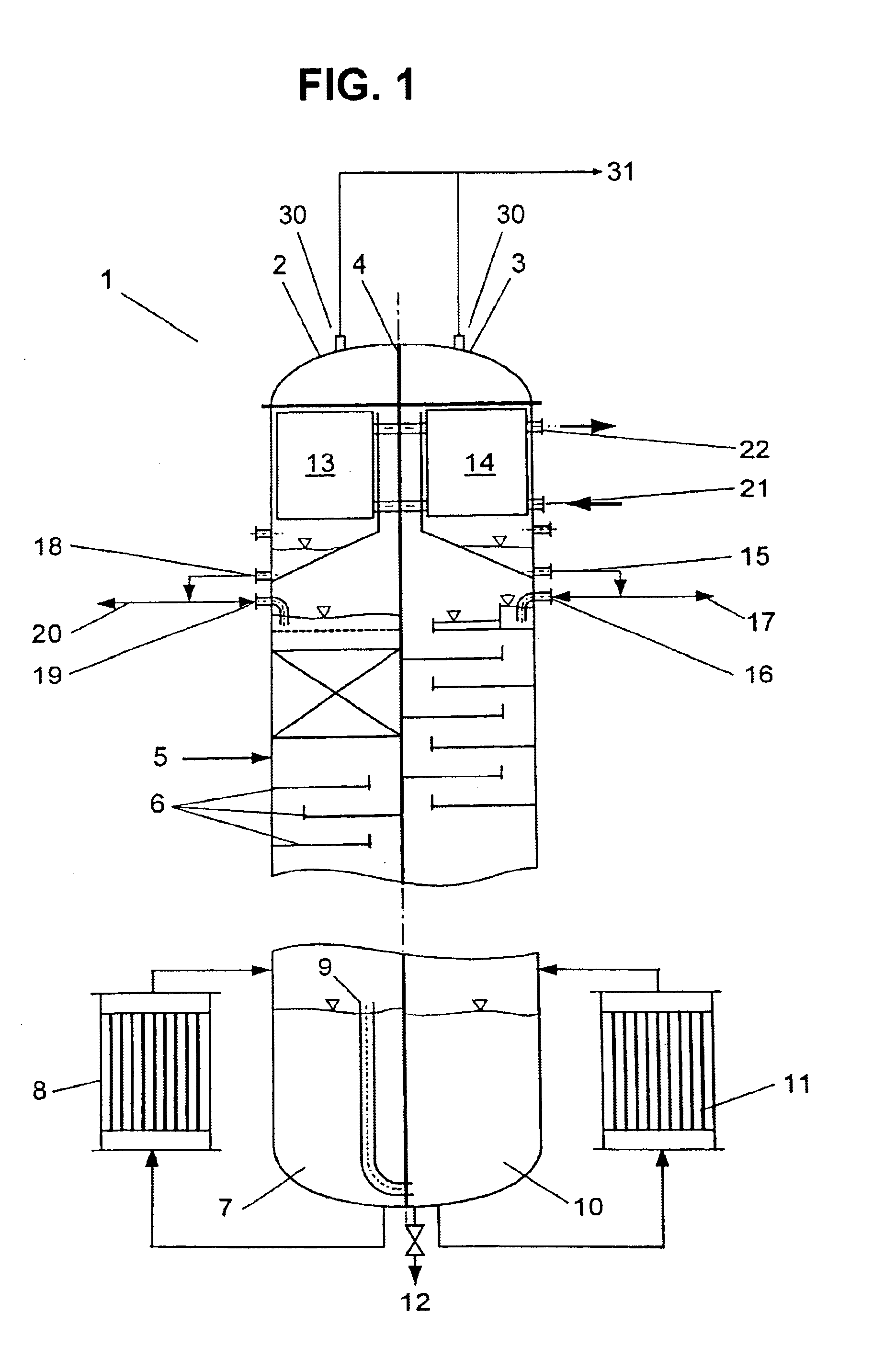

Method and apparatus for volatile matter sharing in stamp-charged coke ovens

A volatile matter sharing system includes a first stamp-charged coke oven, a second stamp-charged coke oven, a tunnel fluidly connecting the first stamp-charged coke oven to the second stamp-charged coke oven, and a control valve positioned in the tunnel for controlling fluid flow between the first stamp-charged coke oven and the second stamp-charged coke oven.

Owner:SUNCOKE TECH & DEV LLC

Liquid evaporator

InactiveUS7992554B2Simple designImprove evaporation effectBurnersSpace heating and ventilationPorosityEngineering

A liquid evaporator includes a liquid reservoir (3) with a liquid to be evaporated, a heater (9) and an evaporator tube (12). The evaporator tube (12) has a first porous element (1) having a first porosity and with an area in contact with the liquid in the liquid reservoir (3) and a second porous element (2) with a second porosity and with an area present on an evaporator side (50) used to dispense the evaporated liquid, and an area outside the liquid reservoir heated by the heater (9) which is not directly in connection with the liquid. The first porous element and the second porous element are in contact in contact areas with the first porous element forming a wick delivering liquid from the reservoir to the contact area.

Owner:DRAGERWERK AG

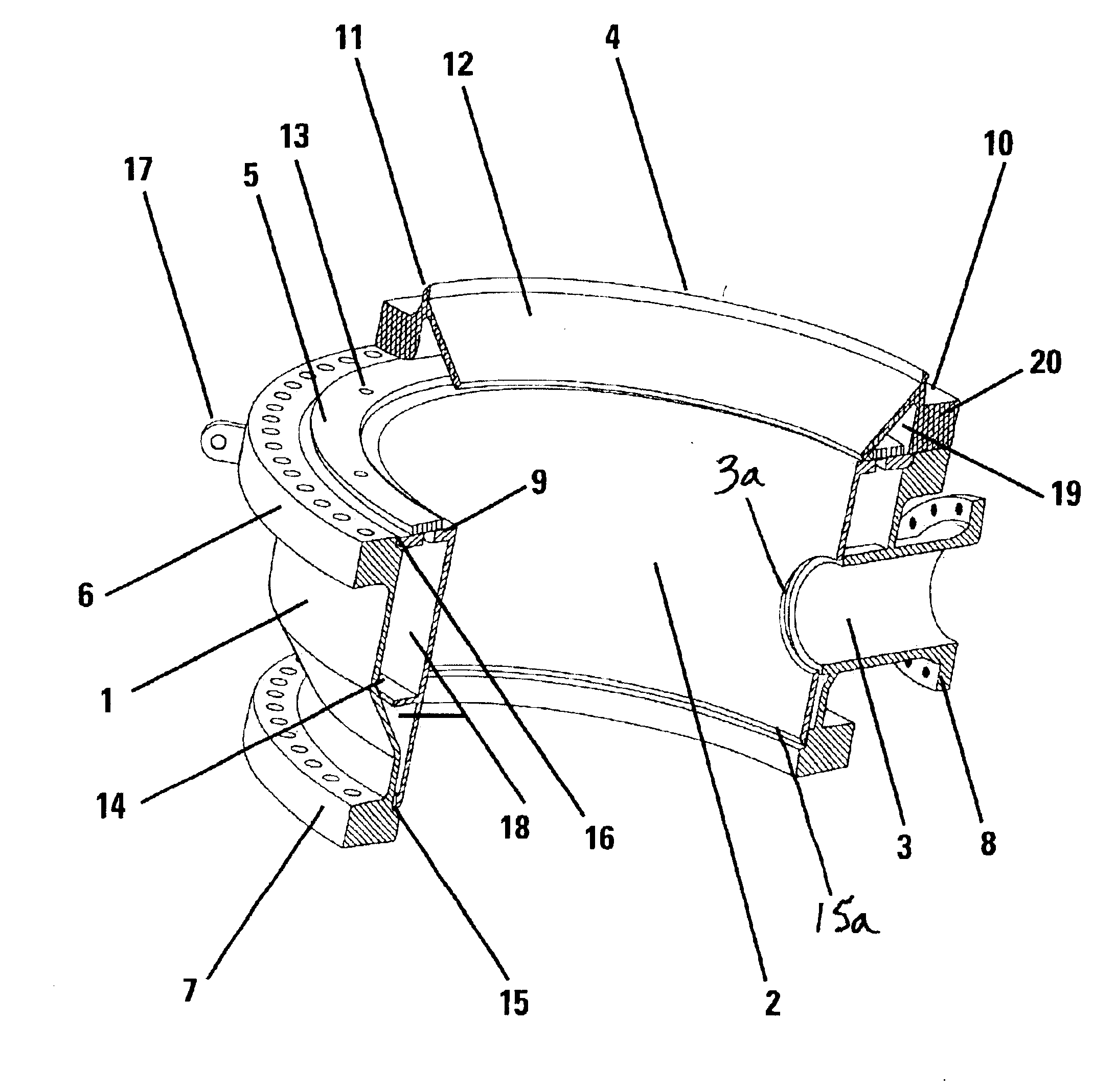

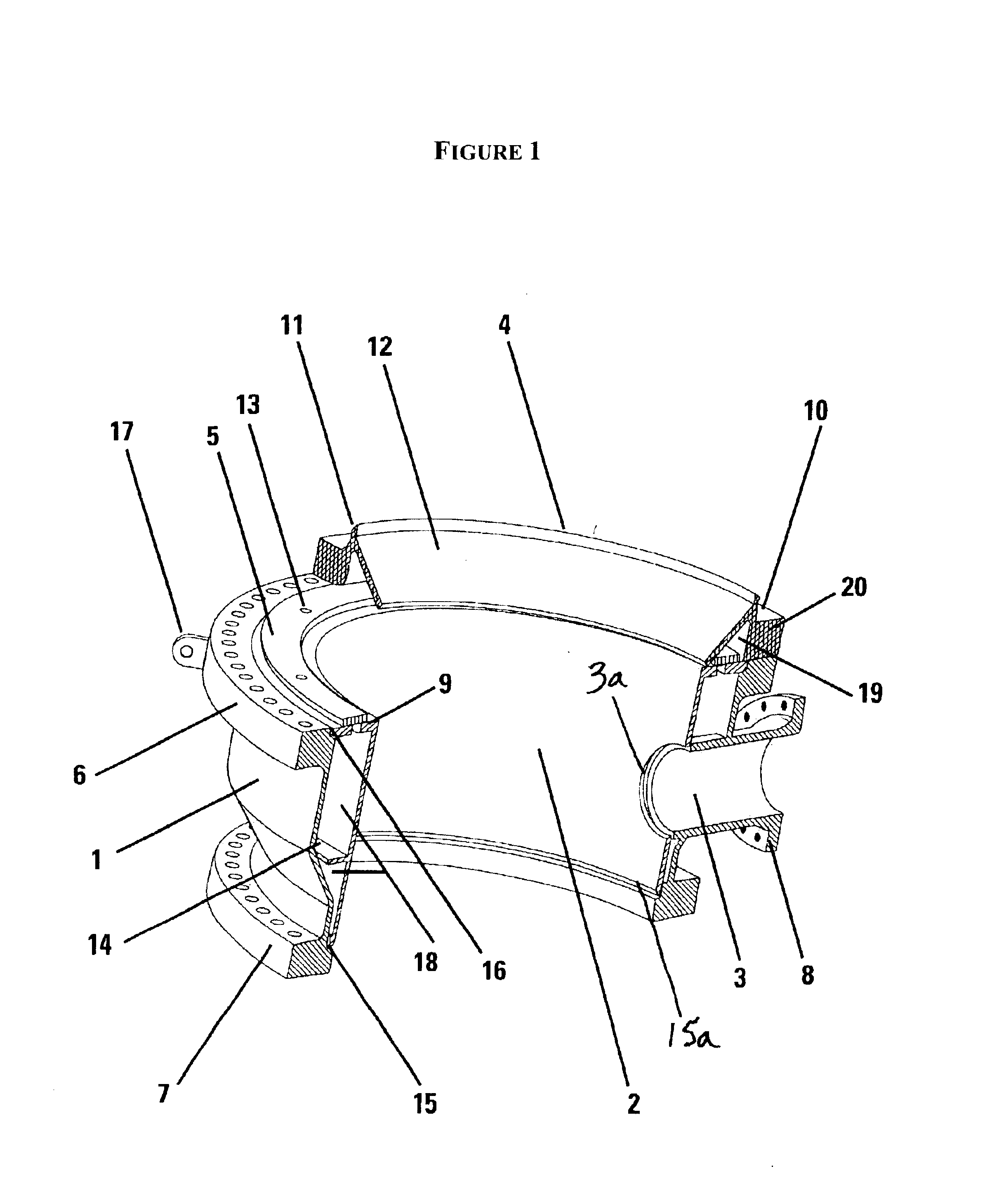

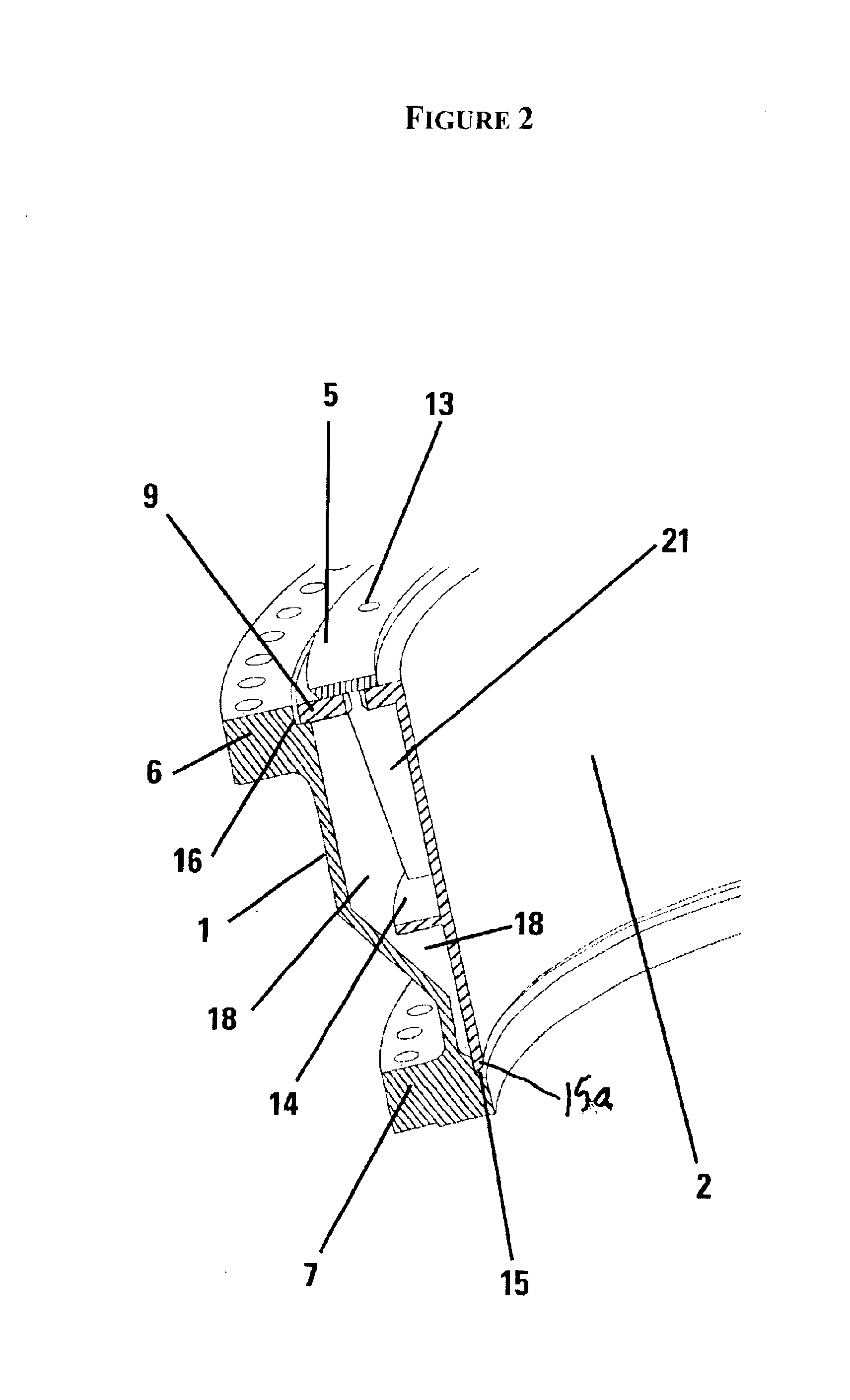

Valve system and method for unheading a coke drum

InactiveUS6989081B2Simple processProvide goodCharging-discharging device combinationsRetortsSupporting systemWindow shutter

The present invention features systems and methods for de-heading a coke drum without having to physically remove the head units. This is accomplished using a de-header valves that may be removably coupled to a coke drum. The de-header valve is equipped with, a valve closure and a seat support system capable of forming a continuous contact seal during the coke manufacturing process. Actuation of the valve closure functions to open and close the de-header valve. Once the drum is full, the de-header valve may be actuated (opened), wherein the coke that has accumulated on the blind is sheared by the seat support system, thus effectively de-heading the coke drum and facilitating the decoking process.

Owner:DELTAVALVE

Method and device for keeping coke furnace chambers hot when a waste heat boiler is stopped

InactiveUS9057023B2Avoid emissionsReduce processing stepsCombustible gas coke oven heatingVertical chamber coke ovensCombustorFlue gas

A process for keeping coke oven chambers hot during the stoppage of a waste heat boiler. The coke oven chambers are kept hot after emptying using externally heated burners, in which a flue gas low in pollutants is obtained from the burners. The waste heat boilers which, during normal operation, cool the flue gases can be shut off and overhauled, and a flue gas low in pollutants which can be dissipated directly into the atmosphere is obtained by the burner operation. Also disclosed is an apparatus for keeping coke oven chambers hot, the apparatus has a coke oven chamber bench, a flue gas collection line, a flue gas chimney, a waste heat boiler, a waste gas collection line and a waste gas purification system, wherein the flue gas chimney and the waste heat boiler can be shut off on the flue gas side and on the waste gas side.

Owner:THYSSENKRUPP IND SOLUTIONS AG

Insulated transition spool apparatus

ActiveUS6926807B2Pipe protection by thermal insulationPipe units with cleaning aperturesEngineeringPressure vessel

An insulated transition spool apparatus for mounting unheading devices to pressure vessels, such as coker vessels, and enabling repetitive operation thereof is disclosed. The apparatus comprises an outer housing, an inner housing that encloses an insulating space between the inner and outer housing, a side feed entry aperture in each housing and a spool adapter flange to facilitate attachment of the spool to the vessel.

Owner:CHEVROU USA INC

Air proportioning system for secondary air in coke ovens depending on the vault vs. sole temperature ratio

ActiveUS8980063B2Easy to useCombustible gas coke oven heatingCoke oven safety devicesCombustionCoke oven

A device for proportioning of secondary combustion air into the secondary air soles of coke oven chamber ovens is shown. The device is formed by a slide gate or a parallelepiped device or by plates moved by means of a thrust bar, the thrust bar being moved longitudinally in parallel to the coke oven chamber wall so that the plates move away from the secondary air apertures and open or close these. The thrust bar is moved by means of a positioning motor, with the power transmission being effected hydraulically or pneumatically. Via suitable measuring parameters, it is thus possible to optimize secondary heating so that heating is provided evenly from all sides, thus achieving an improvement in coke quality.

Owner:THYSSENKRUPP IND SOLUTIONS AG

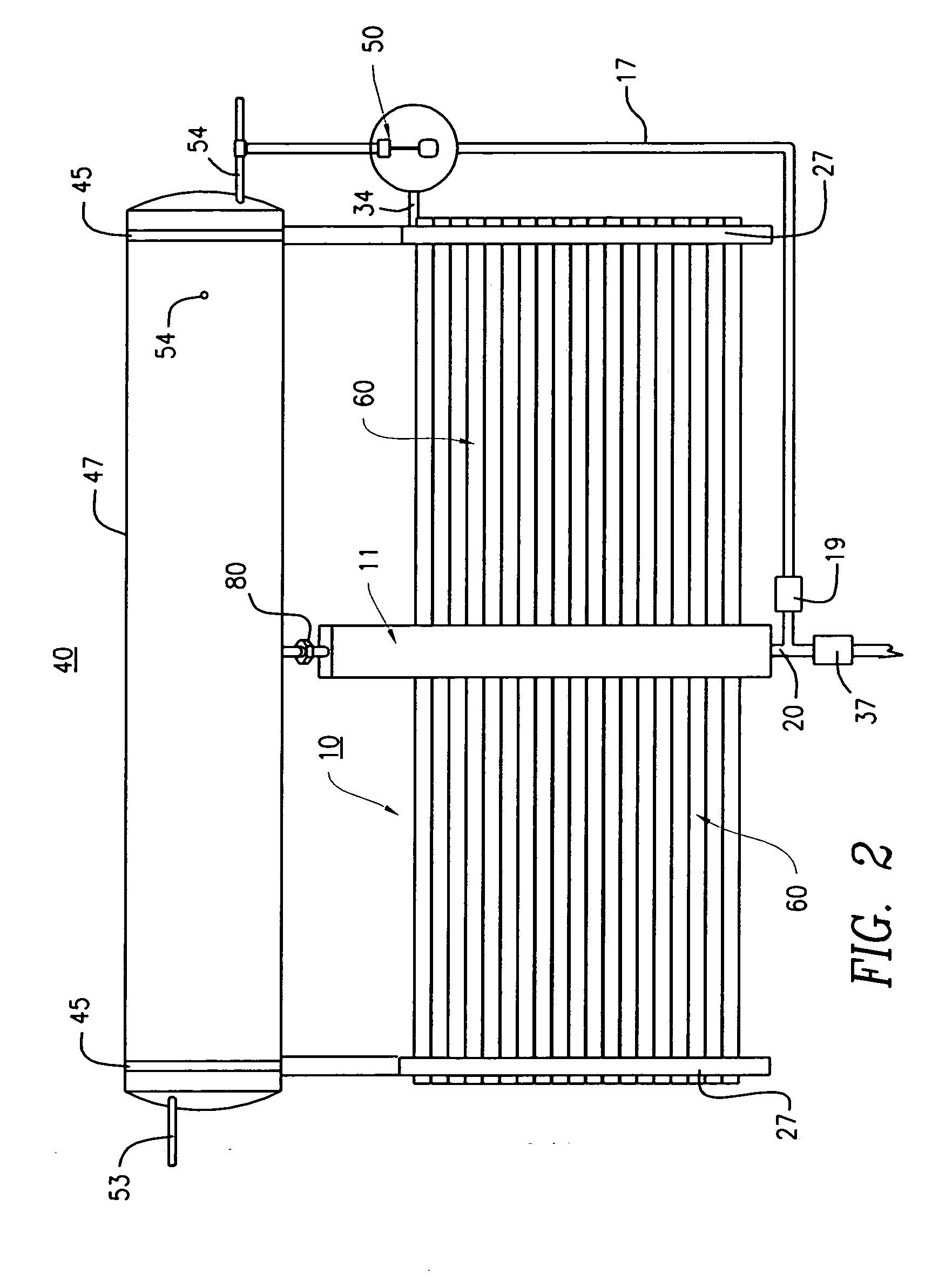

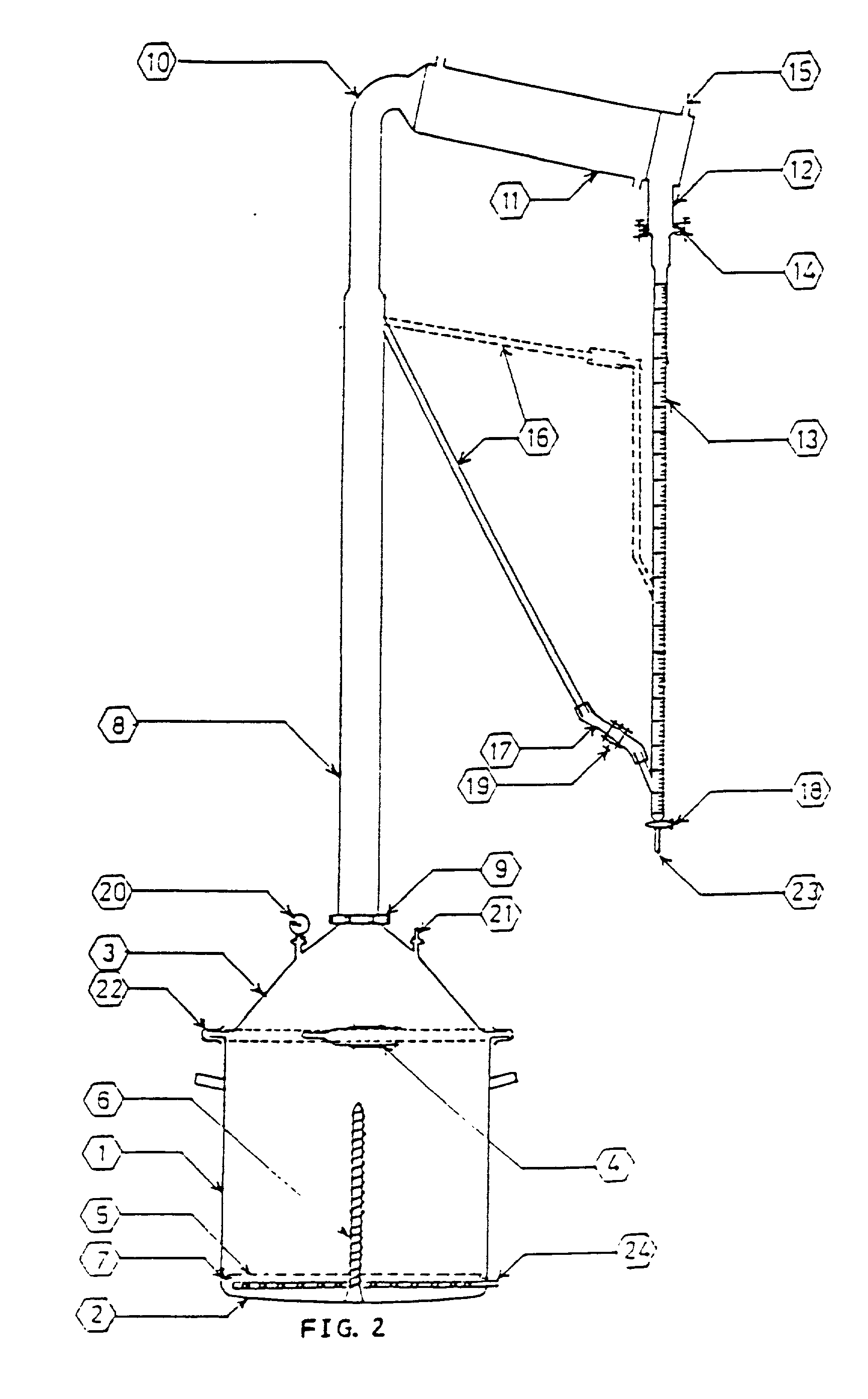

Integrated solar liquid heater, distiller and pasteurizer system

InactiveUS20070193872A1Improve storage densityImprove abilitiesSolar heating energyGeneral water supply conservationComposite constructionLiquid medium

The solar heating, distilling, and pasteurizing system of this invention comprises an integrated distillation column-reflector-bracket assembly, a heat storage system of composite construction, and at least one evacuated glass solar collector having selective absorption. The distillation column subassembly is filled with the fluid medium to be boiled which flows into the solar vacuum tube collectors where an evaporation process takes place. A float valve mechanism mounted to the frame automatically maintains the correct liquid level inside the distillation column. The height of float valve mechanism is adjustable by means of an adjustable float bracket. The distillation column subassembly collects and concentrates the steam or vapor generated inside the attached evacuated glass solar collector tubes. The column also separates the vapor from the boiling liquid medium and conducts the vapor into a heat and distilled fluid storage system. The reflector-bracket subassembly has a reflecting panel made from at least one sheet of reflective material typically flat or formed into a plurality of substantially parallel linear troughs shaped to concentrate solar radiation ideally. This reflector also acts as a means of further stress and strain distribution and dissipation into the structural elements of the bracket subassembly.

Owner:TECHNOSON PUERTO RICO

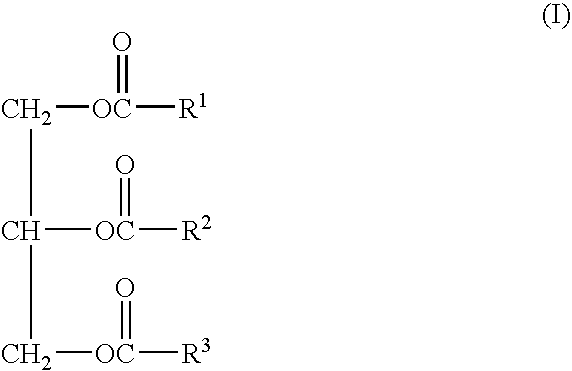

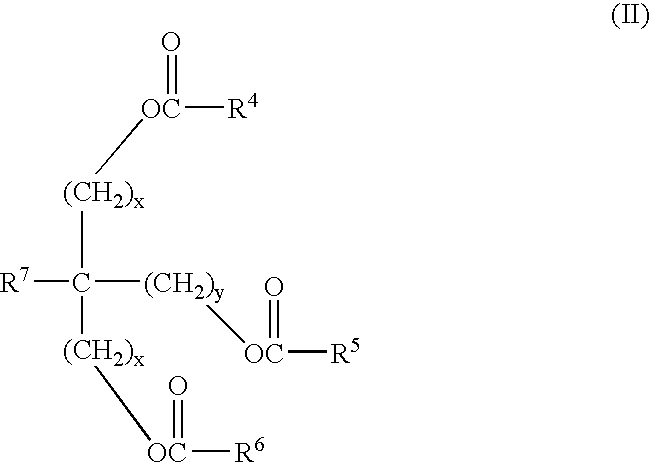

Lubricating base oil compositions and methods for improving fuel economy in an internal combustion engine using same

ActiveUS20060172898A1Improve stabilityImprove the lubrication effectElectrical coke oven heatingDirect heating destructive distillationPolyolInternal combustion engine

A lubricating base oil composition is provided comprising (a) at least one Fischer-Tropsch derived lubricating base oil characterized as having a kinematic viscosity of about 2 to about 5 centistoke (cSt) at 100° C.; and (b) at least one polyol ester. Methods for improving the fuel economy of an internal combustion engine are also provided.

Owner:CHEVRON ORONITE CO LLC

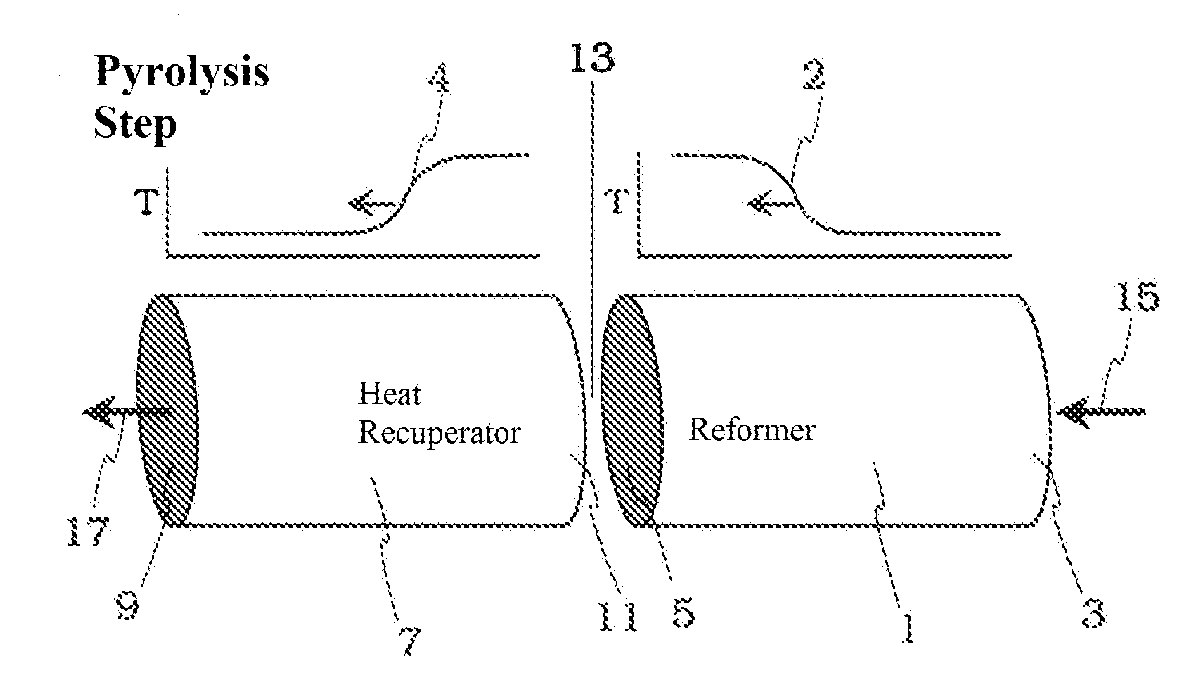

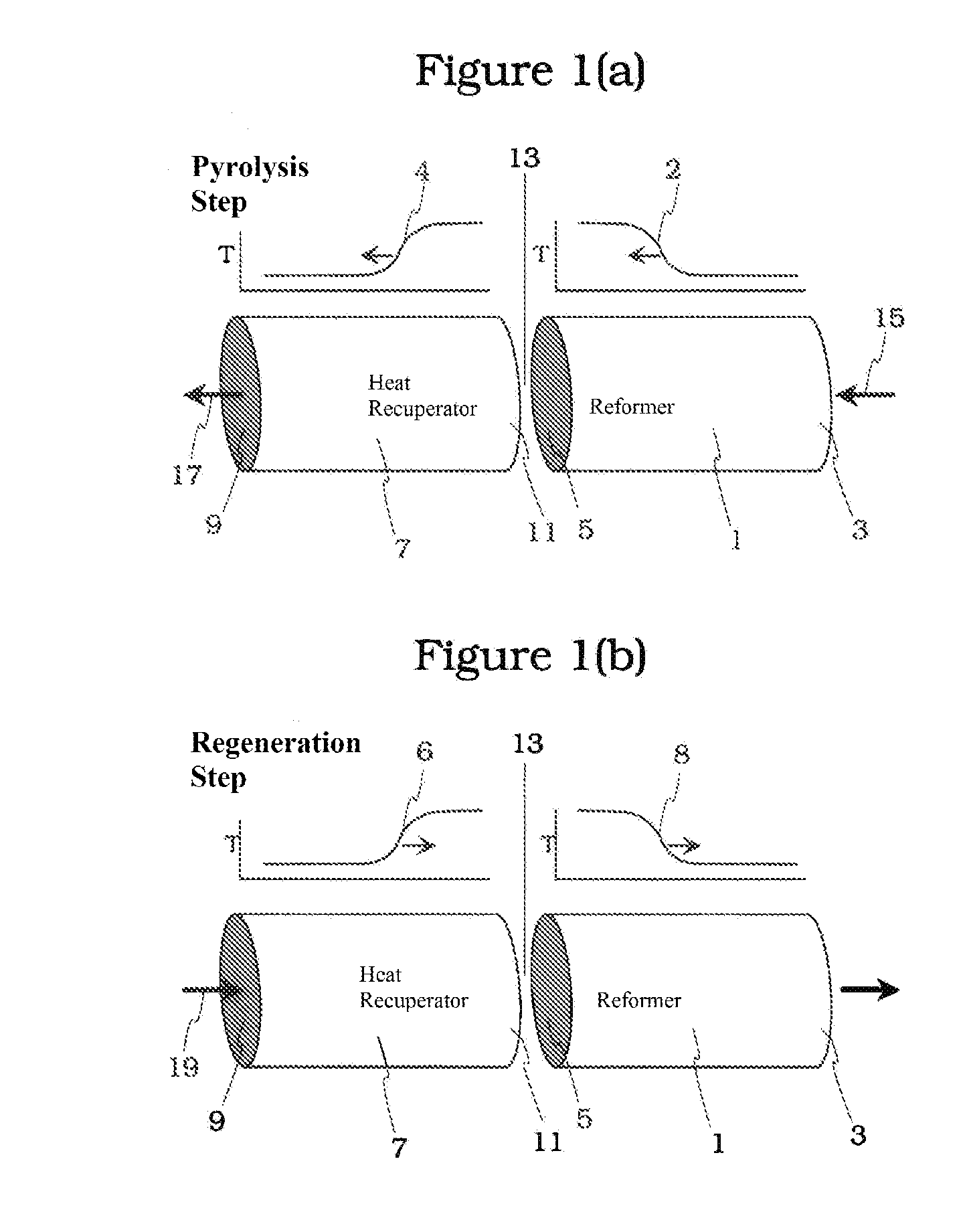

Reciprocating reactor and methods for thermal decomposition of carbonaceous feedstock

InactiveUS20120285814A1Mechanical conveying coke ovensDirect heating destructive distillationProduct gasProcess engineering

The present technology discloses apparatus, systems, and methods for the thermal decomposition of carbonaceous feedstocks through continuous pyrolysis. A reciprocating reactor is disclosed that includes an inner reactor pipe and an outer reactor pipe. The outer reactor pipe has a first portion that surrounds the inner reactor pipe forming an annulus space, and a second portion that extends beyond the inner reactor pipe and forms a turnaround zone. The inner reactor pipe defines an inner reactor zone that produces partially reacted carbonaceous feedstock, and the annulus space defines an outer reactor zone that produces product gases and solids.

Owner:INTERRA ENERGY

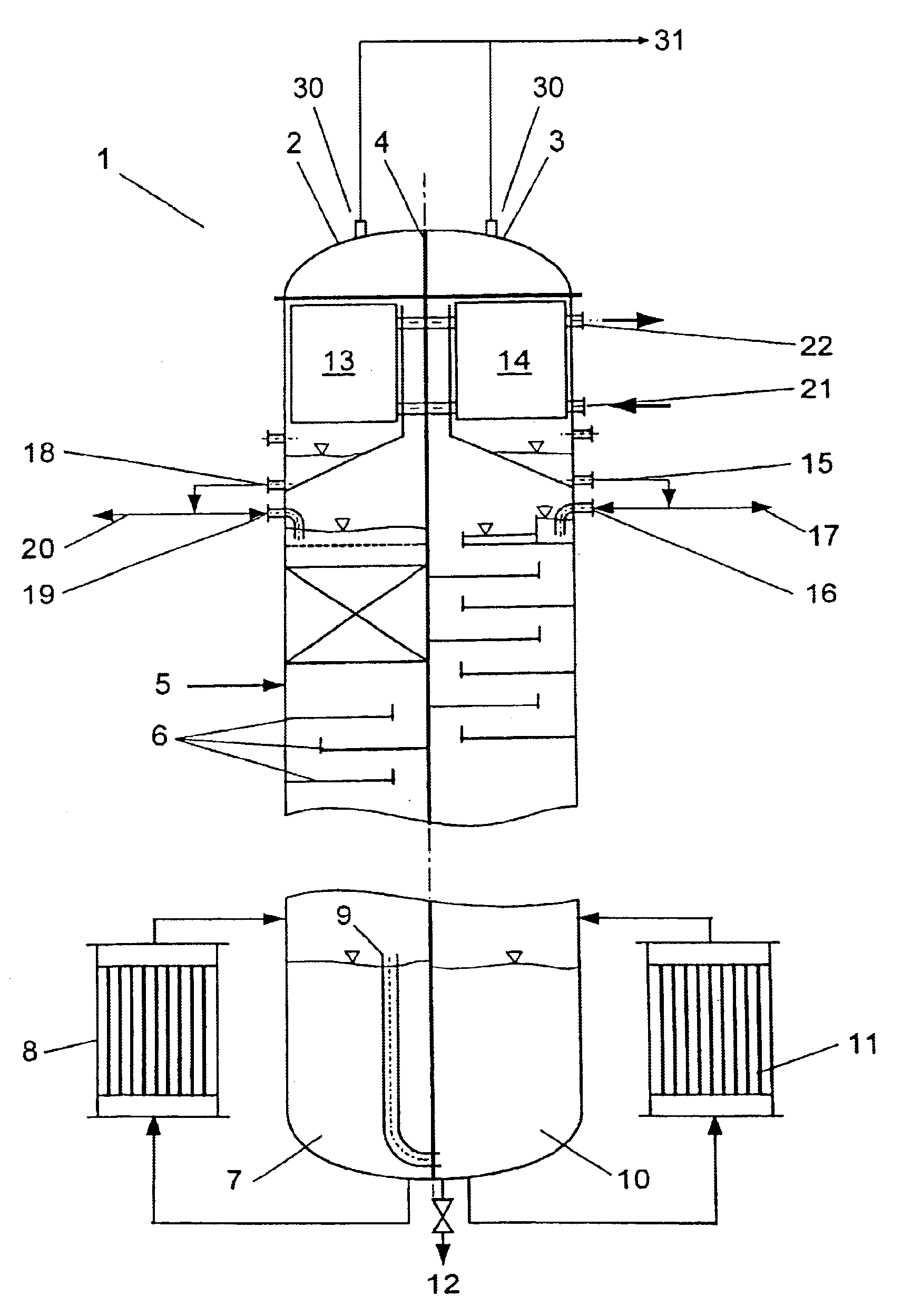

Method and apparatus for volatile matter sharing in stamp-charged coke ovens

ActiveUS20140048404A1Temperature detectionMechanical conveying coke ovensCombustible gas coke oven heatingCoke ovenProcess engineering

A volatile matter sharing system includes a first stamp-charged coke oven, a second stamp-charged coke oven, a tunnel fluidly connecting the first stamp-charged coke oven to the second stamp-charged coke oven, and a control valve positioned in the tunnel for controlling fluid flow between the first stamp-charged coke oven and the second stamp-charged coke oven.

Owner:SUNCOKE TECH & DEV LLC

Compact vacuum distillation device

InactiveUS6010599AReduce problem sizeBoiling pointUsing liquid separation agentDistillation in boilers/stillsAtmospheric airEngineering

An apparatus for batch distilling a liquid at sub-atmospheric pressure, without the aid of a vacuum pump. The apparatus includes an evaporator section having a valved entry port through which a batch of liquid in a first atmospheric condition is added to the evaporator section. A condenser section receives distillate and is in communication with the evaporator section. A valved vent is provided for sealing said apparatus from the outside atmosphere to form a second atmospheric condition which is sealed from the atmosphere after a heating element vaporizes said liquid into an initial sufficient amount of a first vapor to purge the first atmospheric condition from the apparatus through the valved vent. A condenser is disposed for condensing a sufficient amount of the first vapor to form a third atmospheric condition at a pressure below the first atmospheric condition, and for condensing a second vapor to produce distillate.

Owner:AMERICAN TECH GROUP

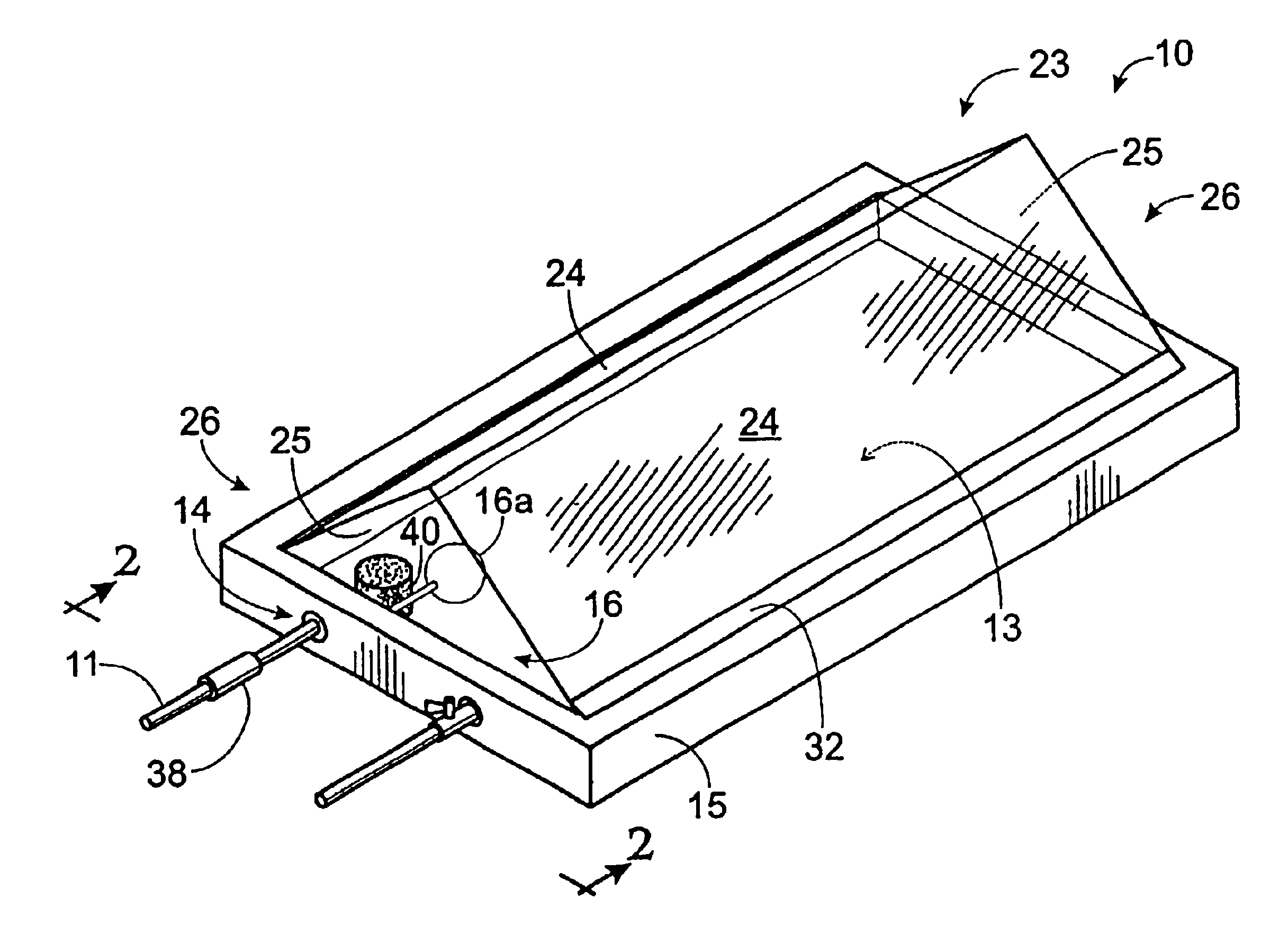

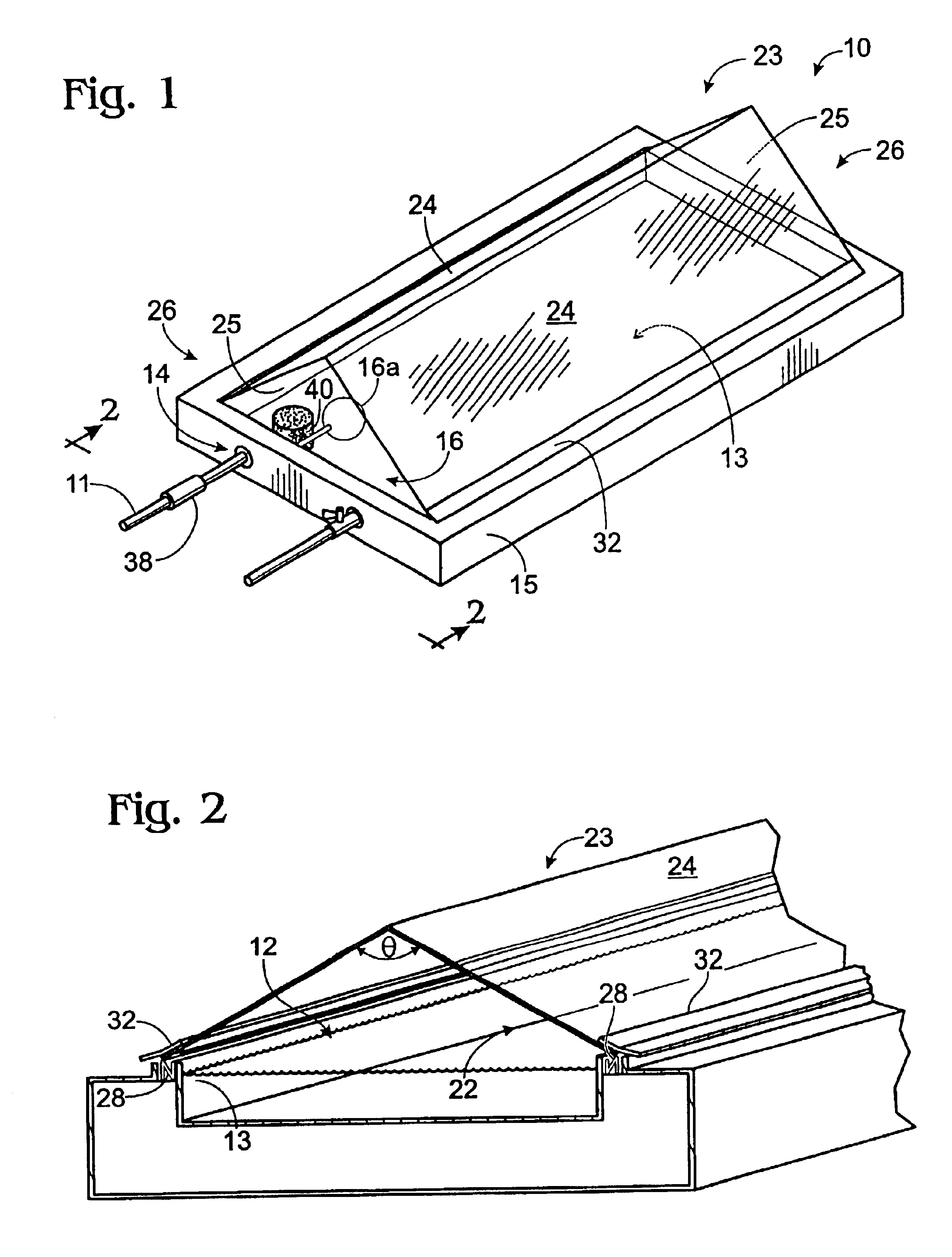

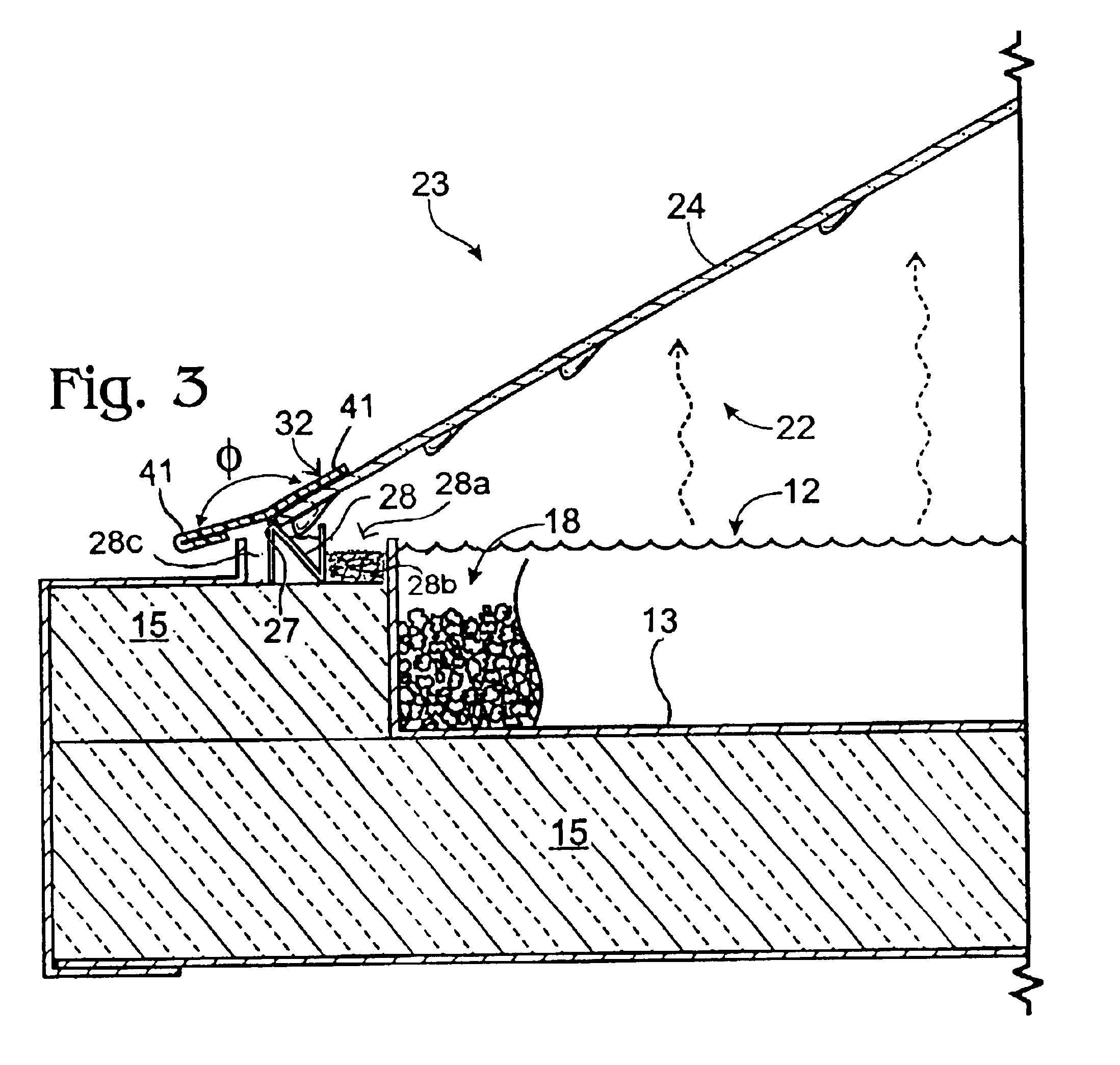

Solar distillation unit

InactiveUS6797124B2Expedited distillationHigh energyWater treatment parameter controlAuxillariesDistillationEvaporation

A solar distilling apparatus employs anthracite coal as a heat-absorbing medium. Greenhouse roof elements rest over a gutter that is isolated from the water-holding container to prevent deposit formation and algae growth from reaching the gutter. Bacterial growth is inhibited by ventilation and the use of titanium-laden magnetite mixed with the anthracite particles. The gutter is also isolated from the exterior of the unit, which prevents contamination from outside sources. The exterior side of the roof elements resting on the gutter are fitted with a metal skirt that provides a heat sink preventing the re-evaporation of condensation flowing toward the gutter.

Owner:LUDWIG DAVID M

Distillation apparatus

InactiveUS20050011742A1Improve thermal conductivityEasy to drainMechanical conveying coke ovensAuxillariesWorking fluidDistillation

A fluid distillation apparatus is removably built into a object cleaning apparatus which comprises a duty tank for retaining contaminated fluid, a receiving tank for receiving the distilled fluid from the distillation apparatus and a sink means in which the objects are cleaned. The fluid distillation apparatus comprises at least one each of a fluid inlet port through which the fluid to be distilled is transferred from a container containing the fluid to be distilled to distillation chamber, a fluid outlet port through which the distilled fluid is transferred to a container to hold the distilled fluid, an air supply port to which compressed air supply is to be connected, a power cord through which the electric power is supplied, preferably an outlet through which air pressure for fluid agitation is supplied to the said container containing the fluid to be distilled, and preferably an outlet through which air pressure is supplied to a pump means for transferring the distilled fluid from the receiving container to the duty fluid container. The fluid distillation apparatus, duty tank, and the receiving tank are built into the object cleaning apparatus in such way that any one of these components can be easily removed from and re-installed to the object cleaning apparatus.

Owner:UNI RAM CORP

Light porous heat-insulating refractory material and preparation method and applications thereof

InactiveCN101638324ARealize comprehensive utilizationSave resourcesFluid heatersFurnace componentsFiberBrick

The invention discloses a light porous heat-insulating refractory material which comprises the following component by weight percent: 15-30% of binding clay, 3-10% of mullite fiber, 15-35% of expandedperlite powder, 15-25% of inorganic bonding agent, 1.5-3.5% of waste polystyrene foam balls and the balance of water. In the invention, the light porous heat-insulating material with small density, low heat conductivity and high compressive strength is prepared by adopting the waste polystyrene foam balls as pore-forming material, taking the mullite fiber as reinforcing material, taking the binding clay and the expanded perlite heat-insulating material, adding a certain amount of bonding agent and the like through extrusion forming. The invention overcomes the technical problems that the existing green bricks of refractory material after being dehydrated, dried and sintered have large shrinkage, high scrap rate due to deformation and cracking, and complex subsequent processing, the heat-insulating bricks have lower strength, and the like; and the light porous heat-insulating refractory material has wide application.

Owner:SOUTH CHINA AGRI UNIV

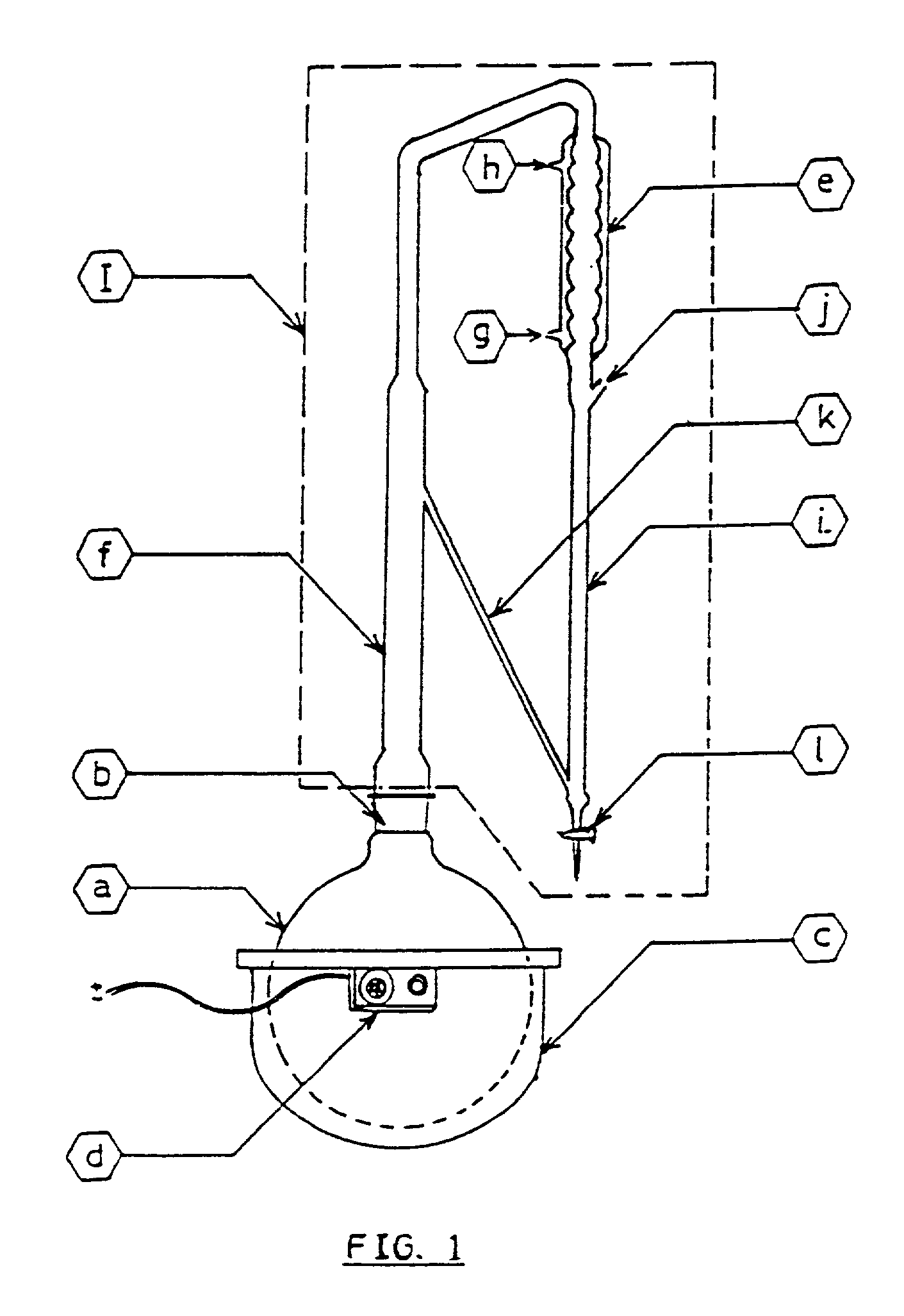

Simple portable mini distillation apparatus for the production of essential oils and hydrosols

This invention relates to a simple, convenient, portable mini-distillation apparatus for the production of essential oils and hydrosols, said apparatus is useful to distill essential oils and hydrosols such as rose water, ajowain water from fresh and dried plant material like leaves, flowers, roots and rhizomes by water distillation, water and steam distillations and as an optional, steam distillation can also be performed at atmospheric pressure as well as slightly higher and lower than atmospheric pressure, said apparatus can be heated on brick-clay furnace with small agro-waste, LPG cooking gas, electrically heated stove or kerosene / diesel burner etc. and requires minimum attention during handling; since the apparatus is made of stainless steel and glass, the essential oil distilled is of better quality.

Owner:COUNCIL OF SCI & IND RES

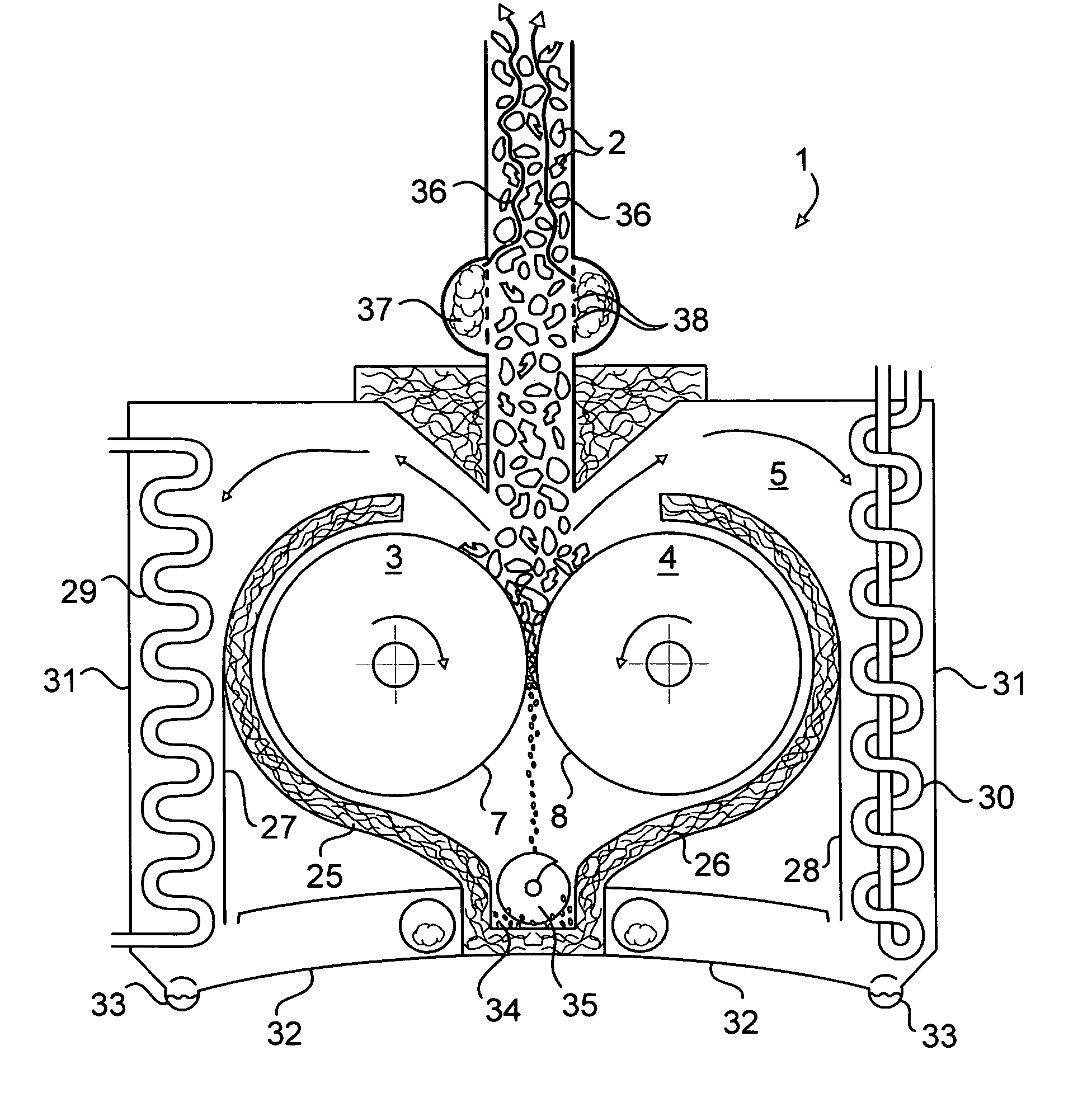

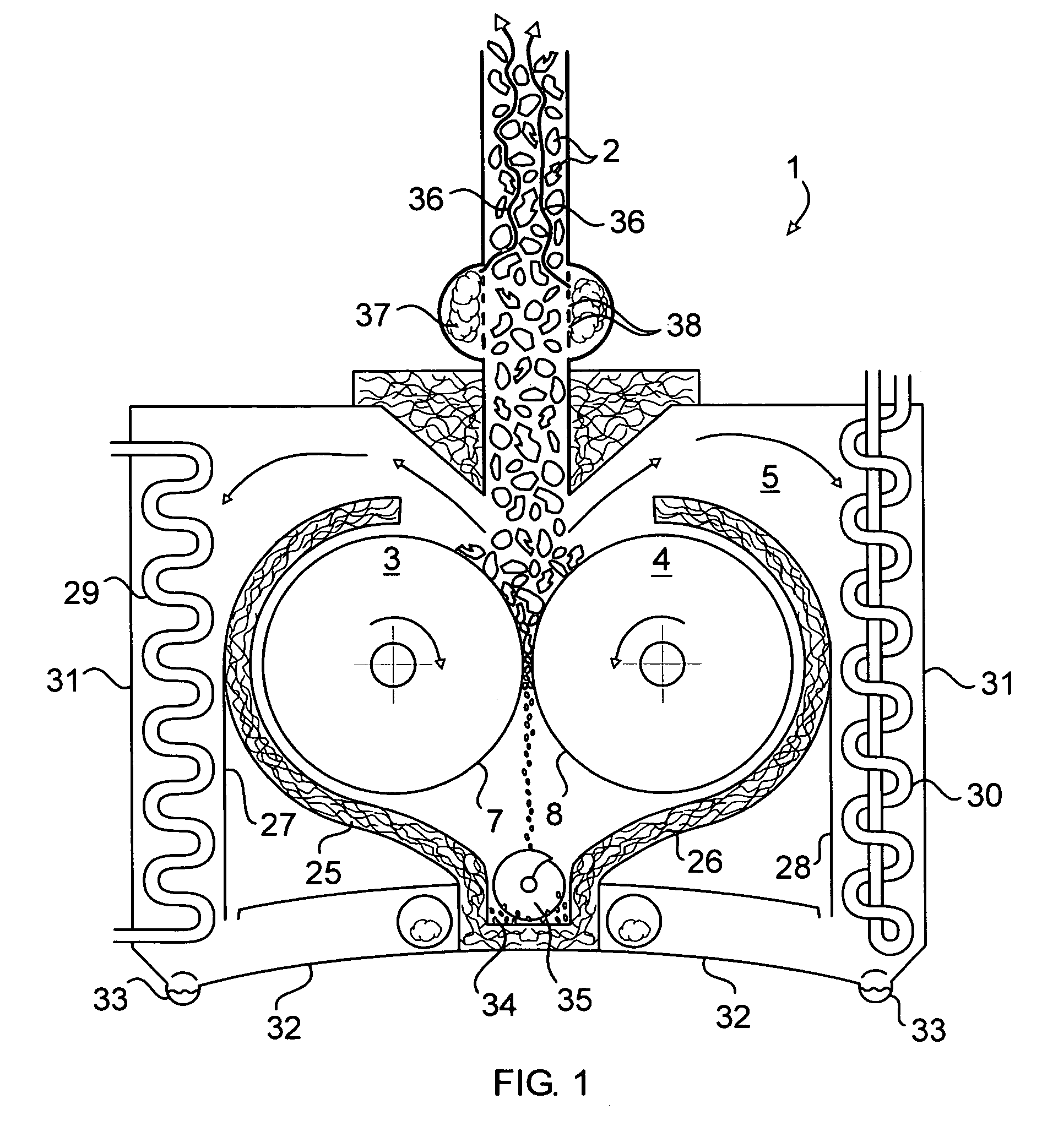

Pyrolysis machine

InactiveUS7108767B2Easily controlled and self-regulatingEconomy of energyCombustible gas coke oven heatingSolid waste disposalCombustionPulp and paper industry

Useful byproducts are recovered through the pyrolytic processing of biomass material such as vegetation, paper, or worn tires. The process is conducted in a sealed enclosure under vacuum or other controlled atmosphere. The biomass material is ablated and burned by crunching between counter-rotating rollers whose inner walls have been exposed to a highly heated fluid. The biomass material is preheated by injecting into the feeding duct super-heated: dry steam. A condenser within the enclosure reduces resulting vapors into oils that can be drained from the enclosure pan. Solid combustion residue is abstracted from the enclosure by an Archimedes screw.

Owner:NOTO VINCENT H

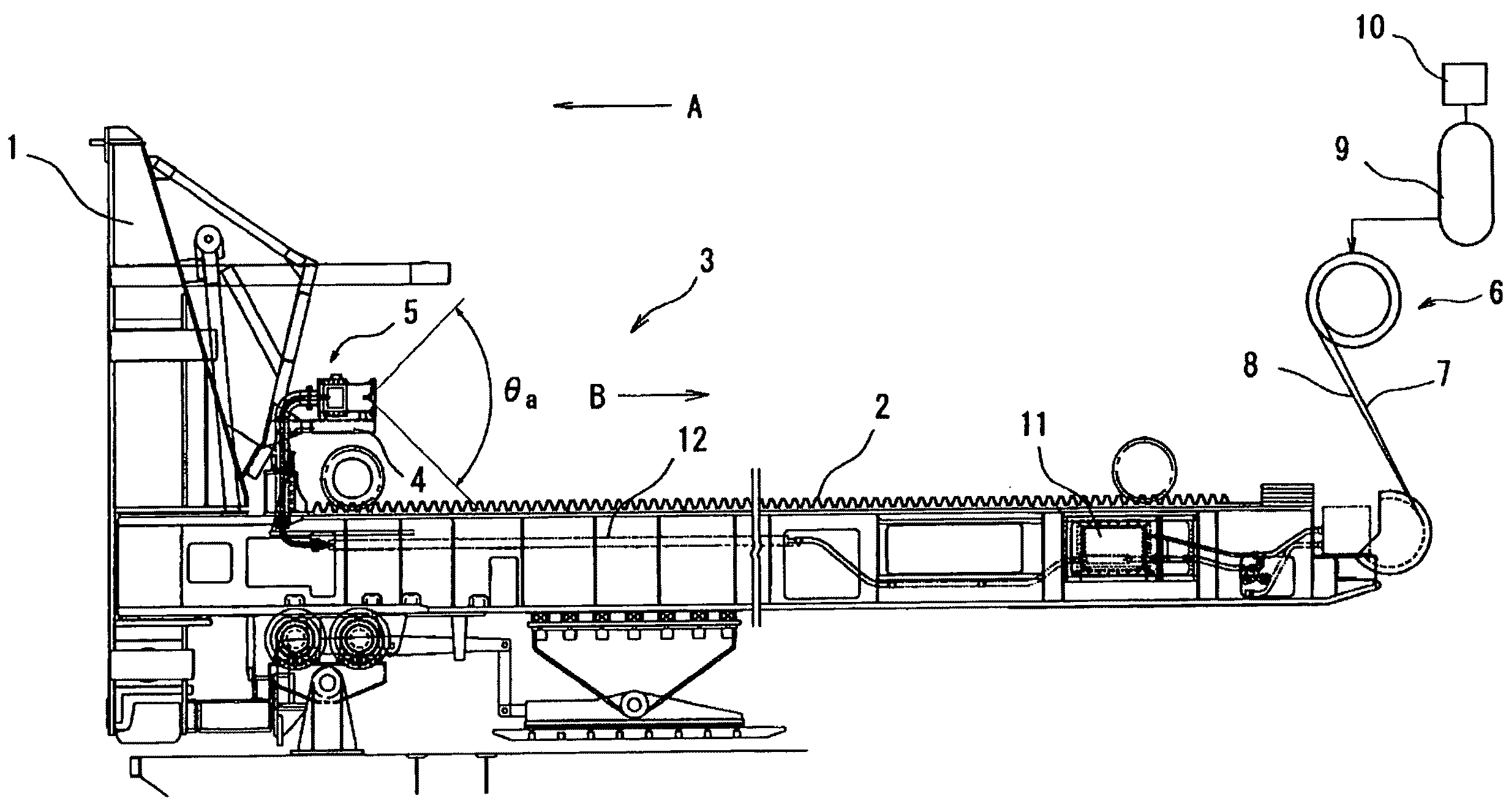

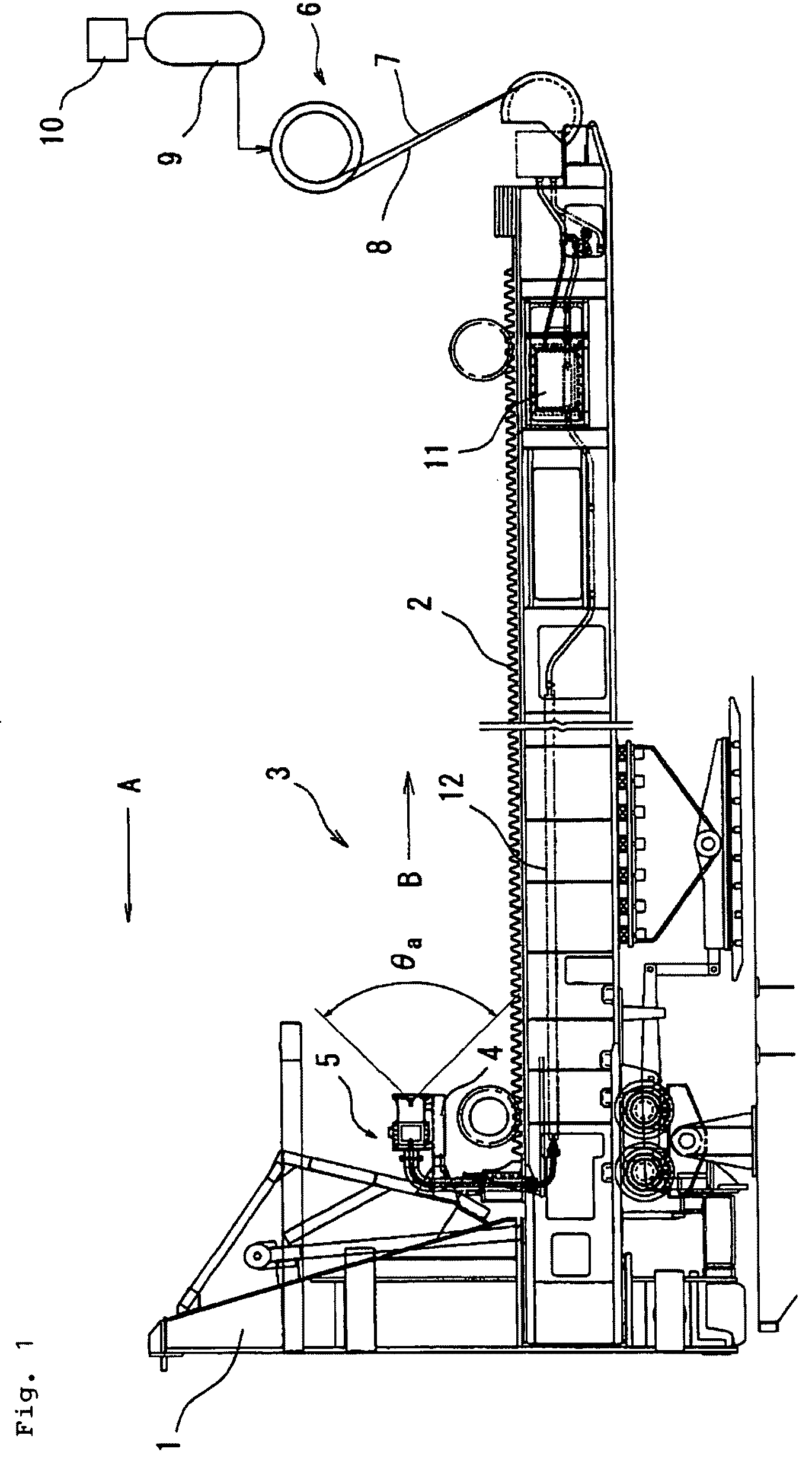

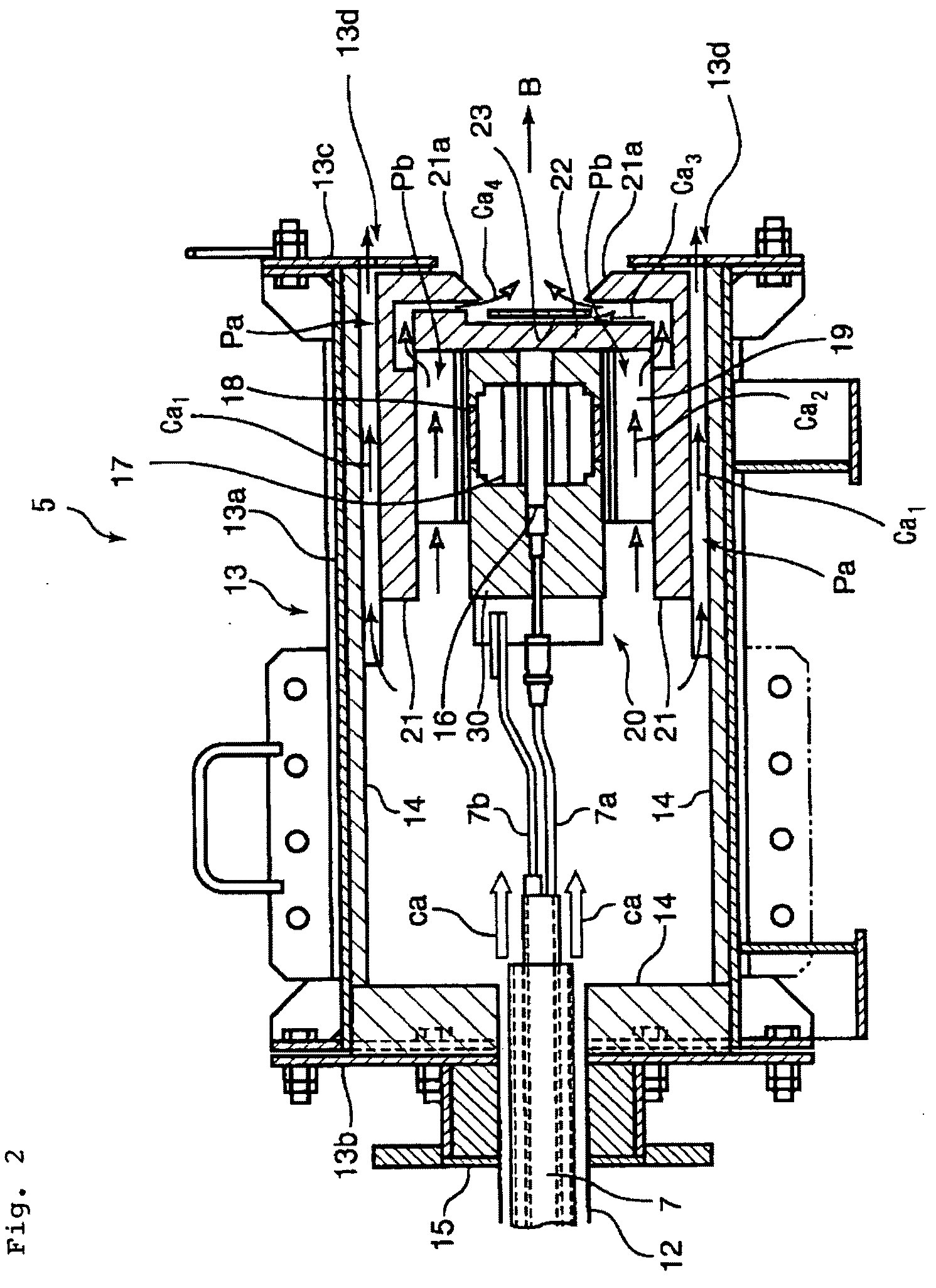

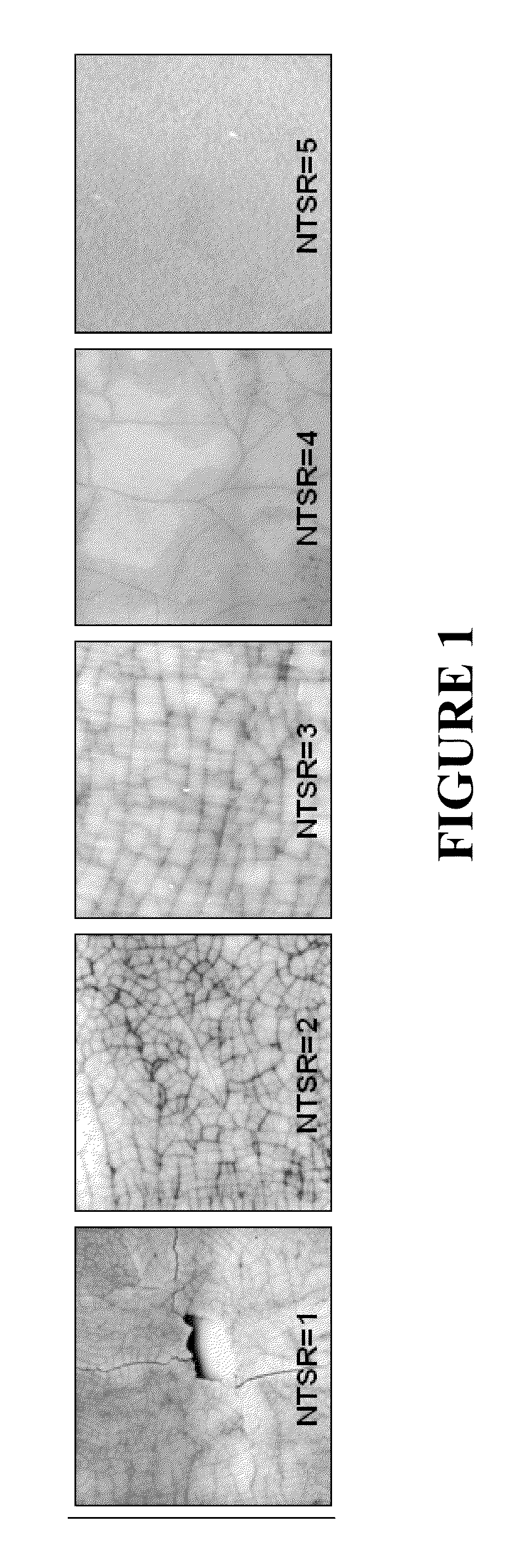

Oven Observing Equipment and Push-Out Ram Having the Same

ActiveUS20090134005A1Improve cooling efficiencyGuaranteed uptimeTelevision system detailsFurnace componentsHeat sinkPush out

An oven observing equipment capable of observing the inside of an oven turned to a high temperature precisely includes: a housing 13 having an intake part for cooling air, and a discharging part for discharging the cooling air after being used for cooling; and an imaging device 20 contained in this housing 13 near the discharge part. This imaging device 20 is composed of integrated combination of an image sensor 16; plate-like thermoelectric cooling elements 18a to 18d arranged in a state that their heat-absorbing faces surround the periphery of a body of the image sensor; thermoconductive blocks 17a to 17d embedded in the gaps between the image sensor body and the thermoelectric cooling elements 18a to 18d; and cooling fins 19a to 19d formed on the heat-radiating faces of the thermoelectric cooling elements 18a to 18d are integrated with each other.

Owner:KANSAI COKE & CHEM

Compact wastewater cleaning apparatus

InactiveUS6887344B1Facilitate rapidFacilitate clean removalAuxillariesDistillation regulation/controlOil and greaseBoiling point

A compact, self-contained apparatus for treating wastewater containing as impurities and pollutants various non-volatile (at water boiling points) fluids such as greases, oils and soaps, a vessel for collecting the wastewater, a heating chamber including electric heating elements and a heat transfer liquid such as mineral oil to heat the wastewater admixture to boil off the water and to reduce the volume of liquid for disposal, and a wastewater supply tank positioned under the apparatus. The apparatus may further include a disposable liner to isolate the wastewater from the vessel itself and facilitate rapid and clean removal and disposal of waste material after evaporation of the water, and thermally-activated sensors to maintain a desired temperature differential between the heating elements and the heat transfer liquid contained in the apparatus.

Owner:RAVAN HLDG LLC

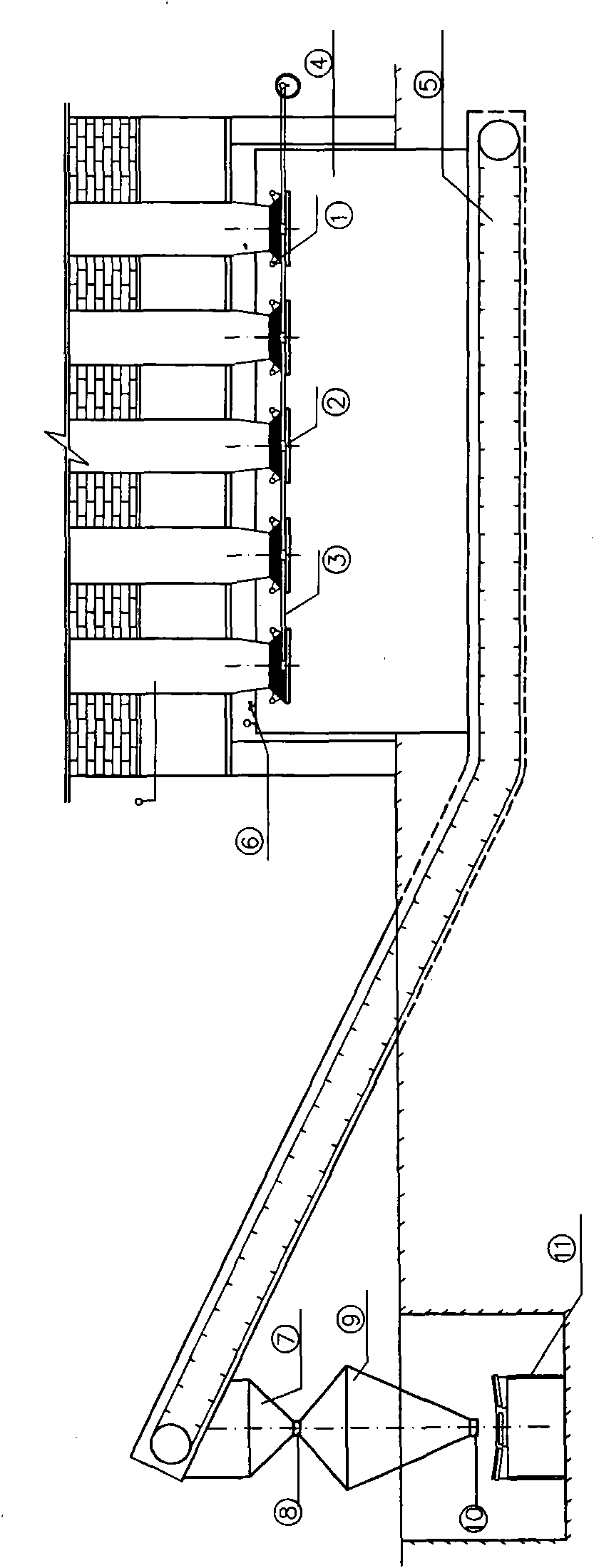

Semi-coke dry-quenching equipment of vertical internally-heated hollow carbonization furnace

ActiveCN101851517AReduce pollutionSave gasCoke quenchingVertical chamber coke ovensProduction lineAutomatic control

The invention relates to the semi-coke dry-quenching equipment of a vertical internally-heated hollow carbonization furnace, which consists of coke supporting plates, spray pipes / coke push rods, a large quenching groove, a buried scraper conveyor, a pressure adjustment valve, a first semi-coke cabin, a first switch, a second coke cabin, a second switch and a belt conveyor, wherein the porous spray pipes are arranged on the two sides of each semi-coke pile between each coke discharge opening and the corresponding coke supporting plates respectively, and each spray pipe is provided with an automatic control device; the coke push rods are arranged above the corresponding coke supporting plates; the large quenching groove is arranged below the coke supporting plates, and is provided with the pressure adjustment valve; the buried scraper conveyor is arranged at the bottom of the large quenching groove, and is connected with the first semi-coke cabin; the bottom end of the first semi-coke cabin is connected with the second semi-coke cabin; the bottom end of the first semi-coke cabin is separated from the second semi-coke cabin by the first switch; and the bottom end of the second semi-coke cabin is provided with the second switch, while a lower part is provided with the belt conveyor. The equipment simultaneously sprays water to red-hot carbonized semi-coke with the two spay pipes on the two sides of the coke supporting plate, generates steam after the water spray to quench the semi-coke and scrapes the quenched semi-coke out of the sealed large quenching groove with the buried scraper conveyor and the semi-coke has a water content about 8 percent, which saves a conventional drying procedure. For example, on a 75,000-ton semi-coke production line, about 44 m<3> water is saved every day, coal gases are saved and air pollution is reduced.

Owner:神木市经纬创科煤化工技术研究有限责任公司

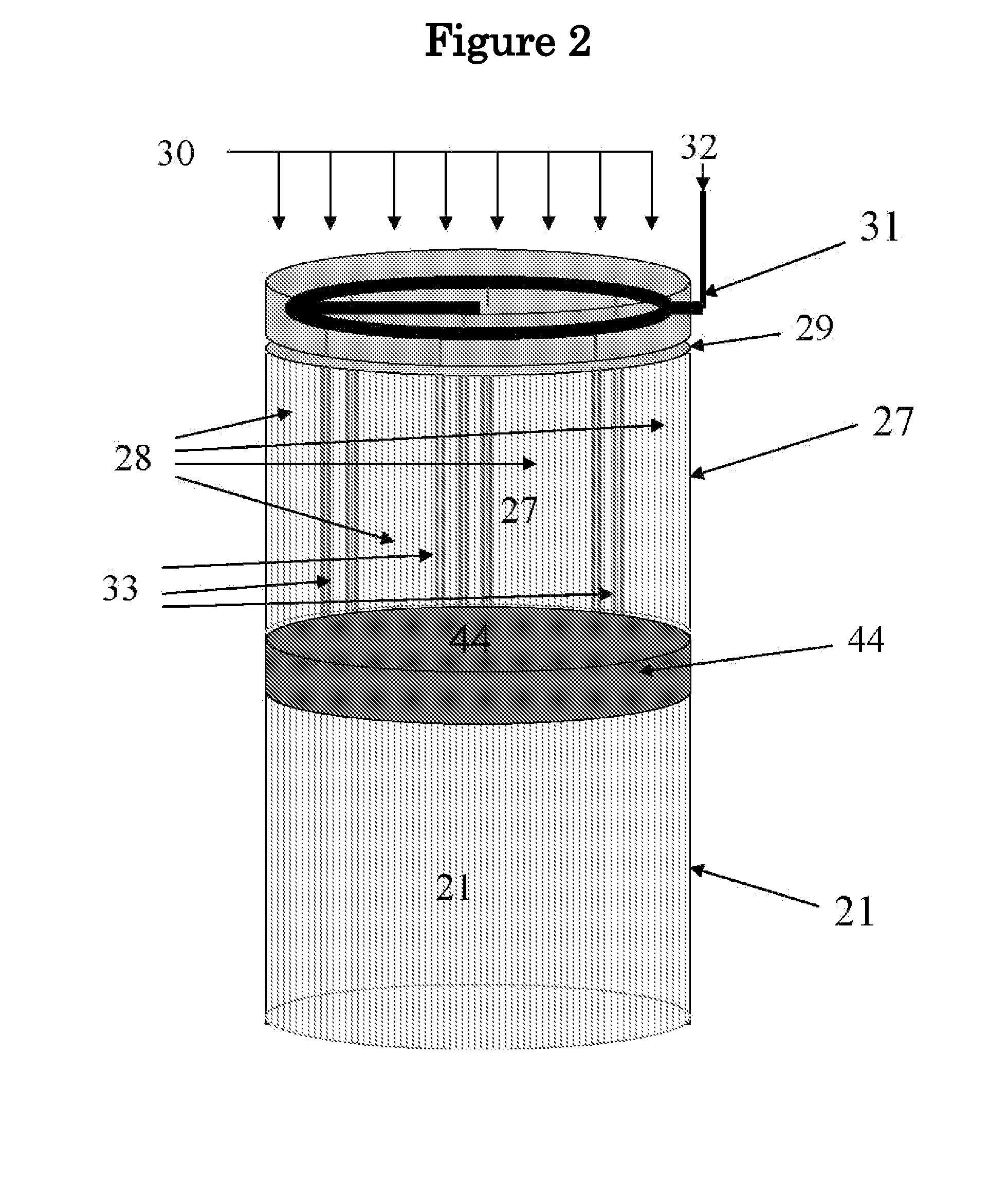

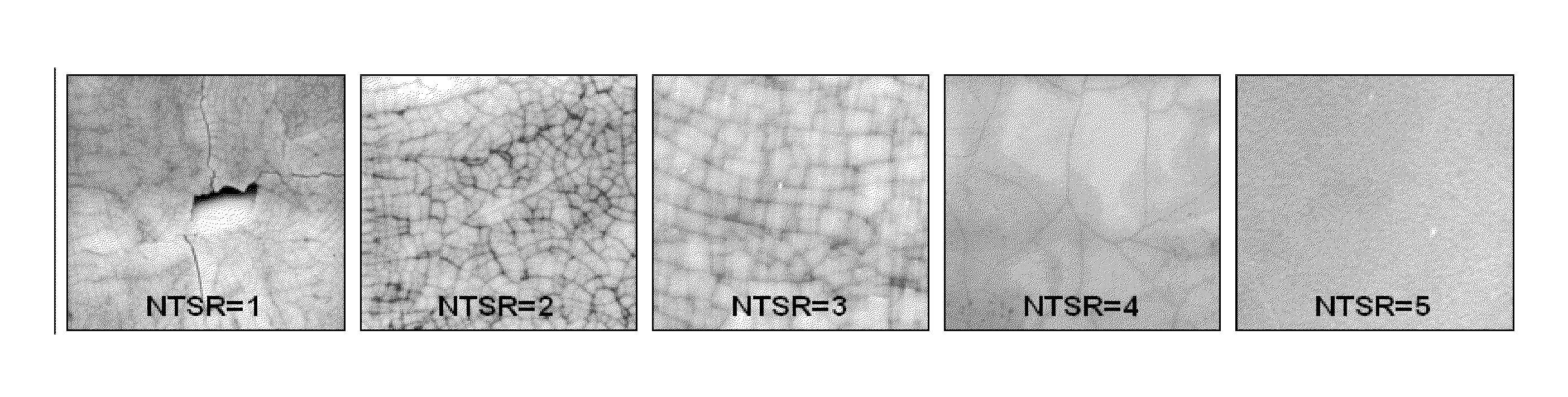

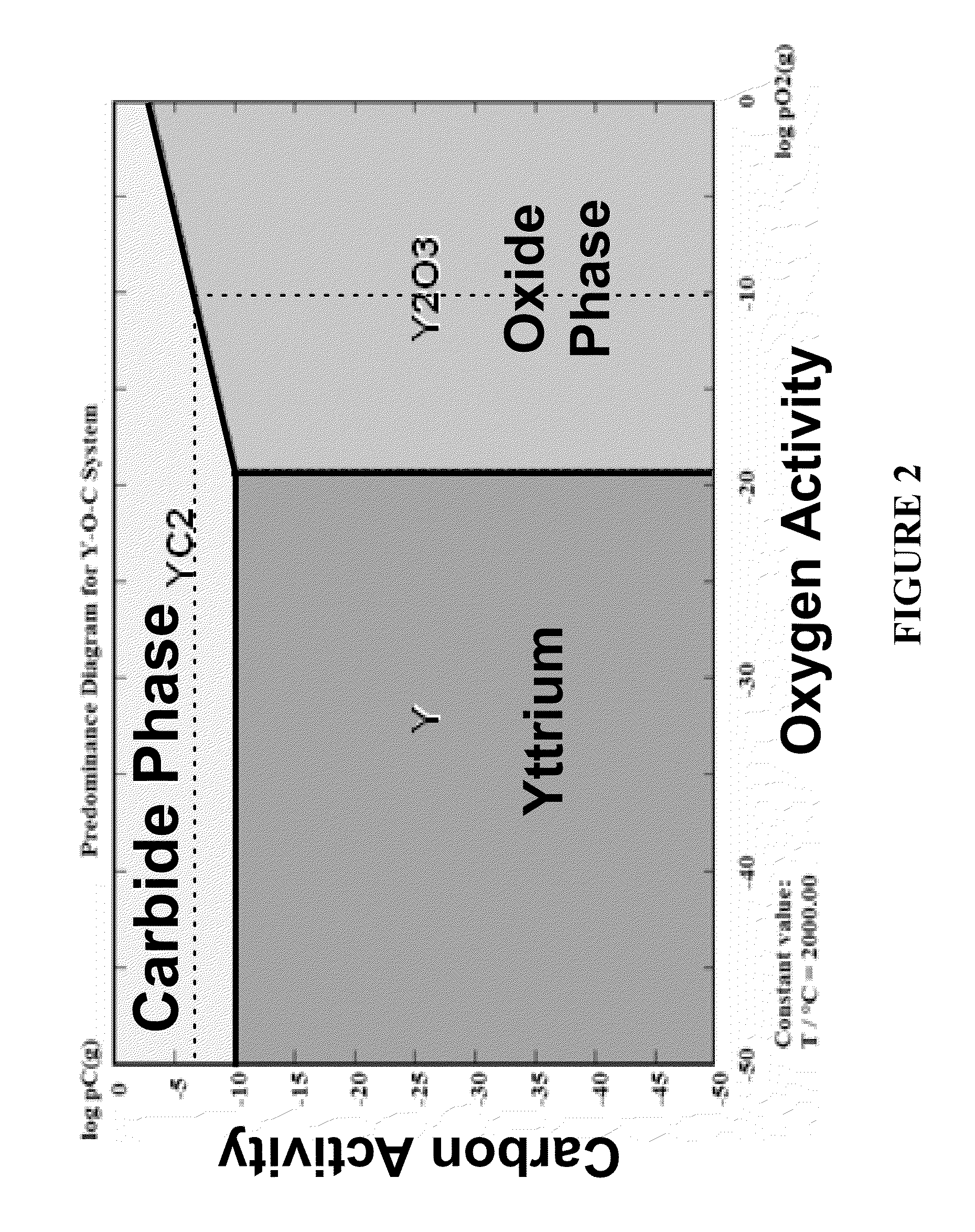

Pyrolysis Reactor Materials and Methods

ActiveUS20100288617A1Thermal non-catalytic crackingHydrocarbon by dehydrogenationReactor systemRefractory

In one aspect, the invention includes a reactor apparatus for pyrolyzing a hydrocarbon feedstock, the apparatus including: a reactor component comprising a refractory material in oxide form, the refractory material having a melting point of at least 2060° C. and which remains in oxide form when exposed to a gas having carbon partial pressure of 10−22 bar, an oxygen partial pressure of 10−10 bar, at a temperature of 1200° C. In some embodiments, the reactor comprises a regenerative pyrolysis reactor apparatus and in other embodiments it includes a reverse flow regenerative reactor apparatus. In other aspects, this invention includes a method for pyrolyzing a hydrocarbon feedstock using a pyrolysis reactor system comprising the step of providing in a heated region of a pyrolysis reactor system for pyrolyzing a hydrocarbon feedstock, apparatus comprising a refractory material in oxide form, the refractory material having a melting point of at least 2060° C. and that remains in oxide form when exposed to a gas having a carbon partial pressure of 10−22 bar, an oxygen partial pressure of 10−10 bar, at a temperature of 1200° C.

Owner:EXXONMOBIL CHEM PAT INC

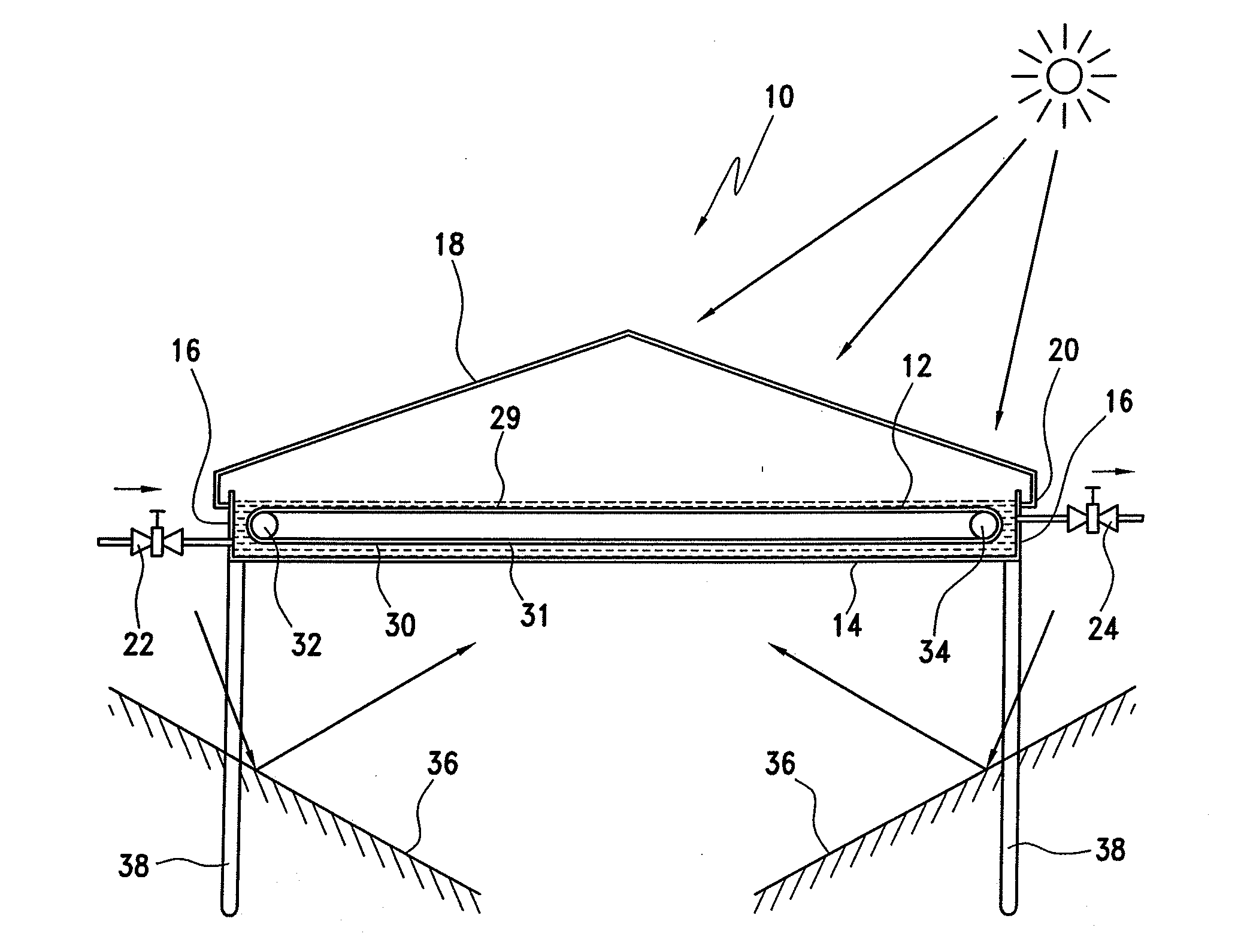

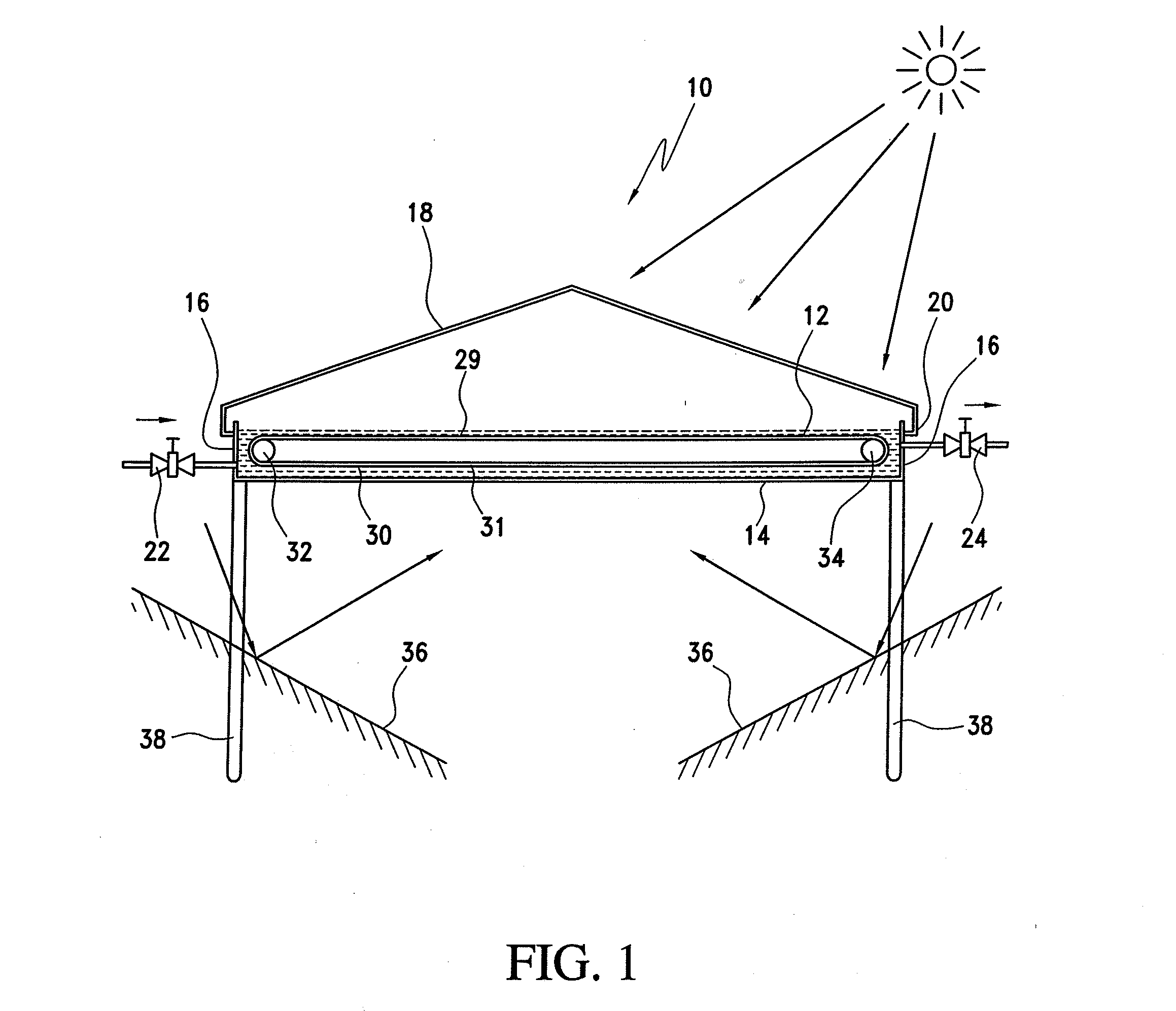

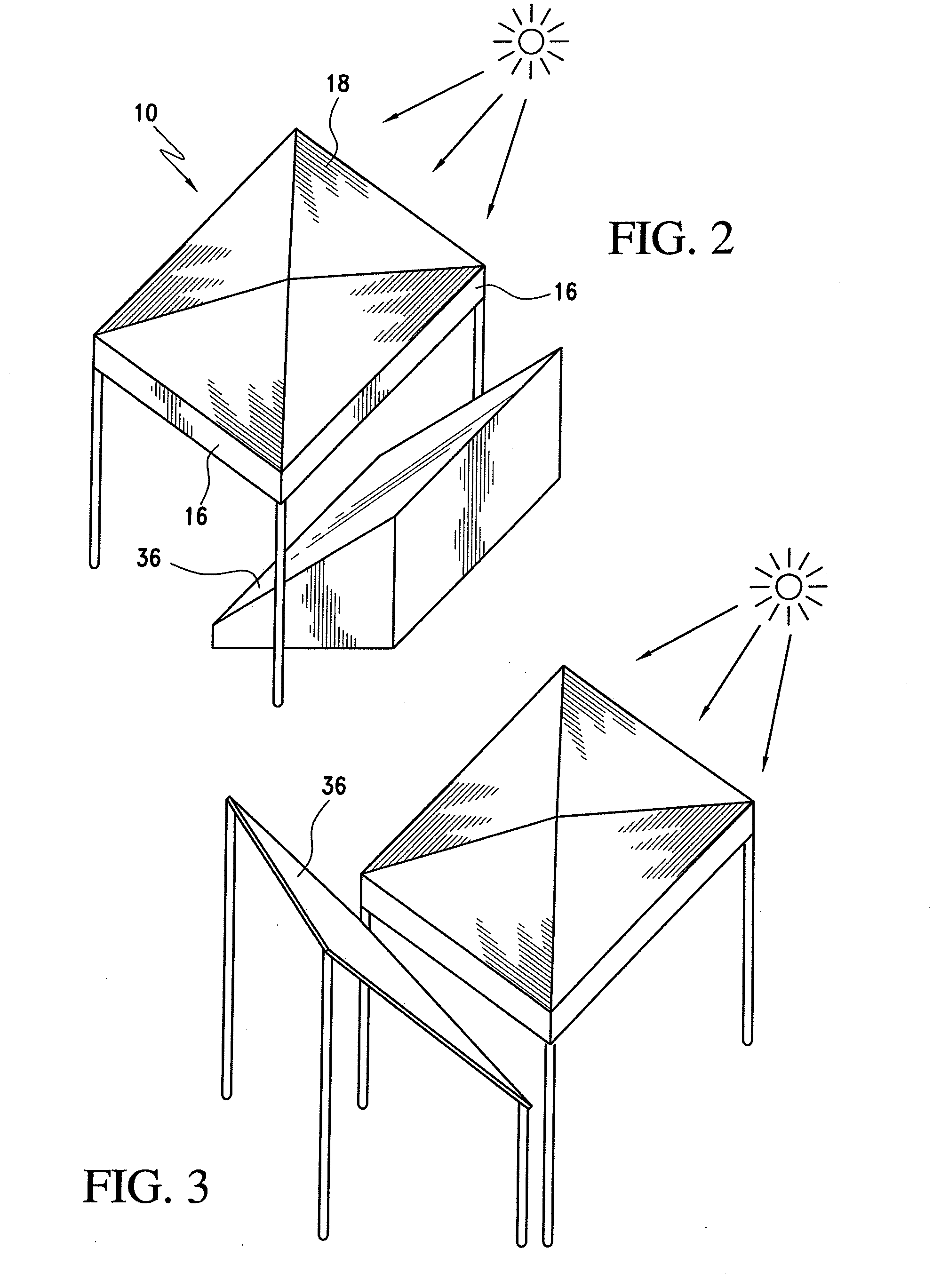

Double action solar distiller

A solar still includes a relatively shallow chamber with a pyramid shaped transparent cover and a transparent base. The still also includes a pair of rollers and an endless heat absorbing belt rotatable about the rollers. The still is positioned to receive solar energy passing through the transparent cover and impinging on an upper surface of the heat absorbing belt in order to vaporize seawater within the chamber. The efficiency of the still is increased by one or more mirrors disposed below the still for reflecting sun light up through the transparent base to impinge on a lower outer surface of the belt to enhance the vaporization of the seawater. One or more fans are also provided for cooling the cover to enhance the condensation of water that will then run down the cover and into a pure water receptacle.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Porous Pyrolysis Reactor Materials And Methods

ActiveUS20110120853A1Prevent further spreadThermal non-catalytic crackingPhysical/chemical process catalystsPorosityPartial pressure

In one aspect, the invention includes a reactor apparatus for pyrolyzing a hydrocarbon feedstock, said apparatus including: a reactor component comprising a refractory material in oxide form, the refractory material having a melting point of no less than 2060° C. and which remains in oxide form when exposed to a gas having carbon partial pressure of 10−22 bar and oxygen partial pressure of 10−10 bar, at a temperature of 1200° C.; wherein said refractory material has no less than 4 vol % formed porosity, measured at 20° C., based upon the bulk volume of said refractory material. In another embodiment, the refractory material has total porosity in the range of from 4 to 60 vol %.

Owner:EXXONMOBIL CHEM PAT INC

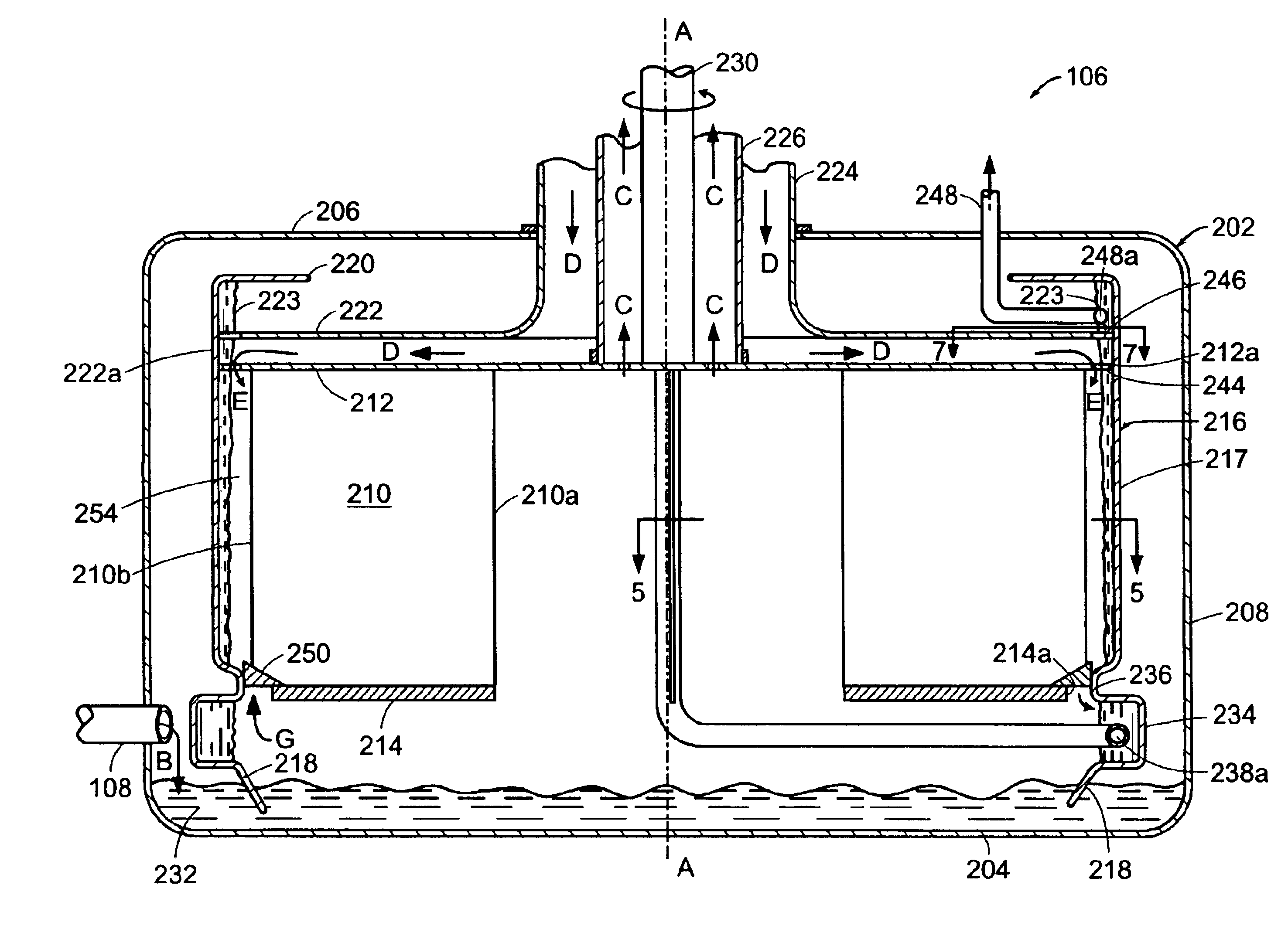

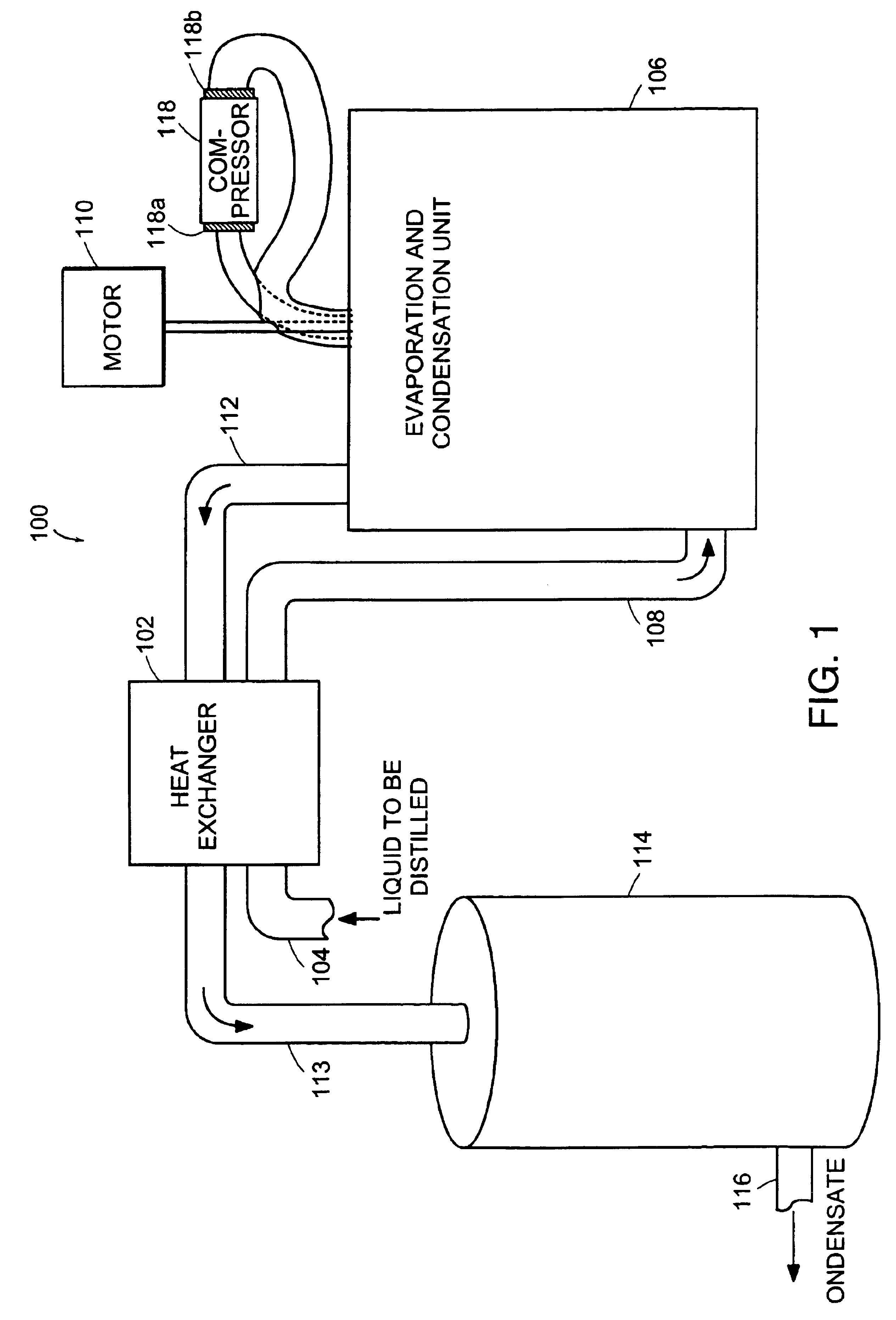

Rotating heat exchanger

An evaporator and condenser unit for use in distilling a liquid, such as water, includes a rotary heat exchanger plate having a plurality of folds or pleats. Adjacent panels of the folded plate define spaces between their oppositely facing surfaces, and these spaces are alternatingly configured as evaporating and condensing chambers. The evaporating chambers, moreover, are defined between adjacent panels that are joined at an outer diameter fold, while the condensing chambers are defined between adjacent panels that are joined at an inner diameter fold. The evaporating chambers are thus closed at their outer diameter ends and open at their inner diameter ends, while the condensing chambers are closed at their inner diameter ends and open at their outer diameter ends.

Owner:ZANAQUA TECH

Column for concentrating phthalic anhydride

InactiveUS6884324B2Organic compound preparationDistillation in boilers/stillsDistillationBoiling point

To improve the columns used so far for producing phthalic anhydride, and to make them less expensive and easier to install, it is proposed that in the column for concentrating phthalic anhydride two distillation stages are arranged, wherein the removal of the low-boiling components of the crude phthalic anhydride by distillation is effected in the first distillation stage (2) and the separation of the high-boiling components from the pure phthalic anhydride is effected in the second distillation stage (3), both distillation stages being arranged side by side and being separated from each other by a vertical wall (4), and that the bottom (7) of the first distillation stage (2) is connected with the bottom (10) of the second distillation stage (3).

Owner:LURGI

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com