Semi-coke dry-quenching equipment of vertical internally-heated hollow carbonization furnace

A technology of dry quenching charcoal and carbonization furnace, applied in coke oven with vertical carbonization chamber, coke cooling, coke oven heating, etc., can solve the problems of environmental pollution, large water consumption, large energy consumption, etc. The effect of reducing air pollution and saving gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

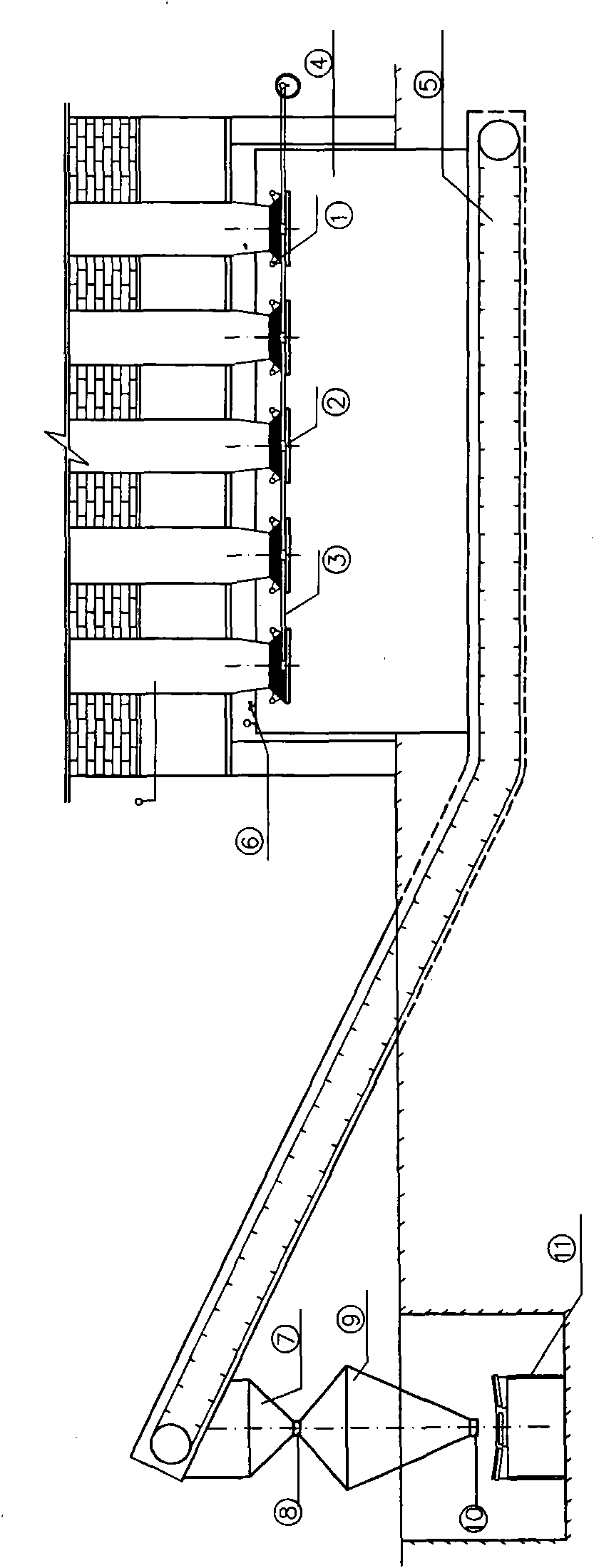

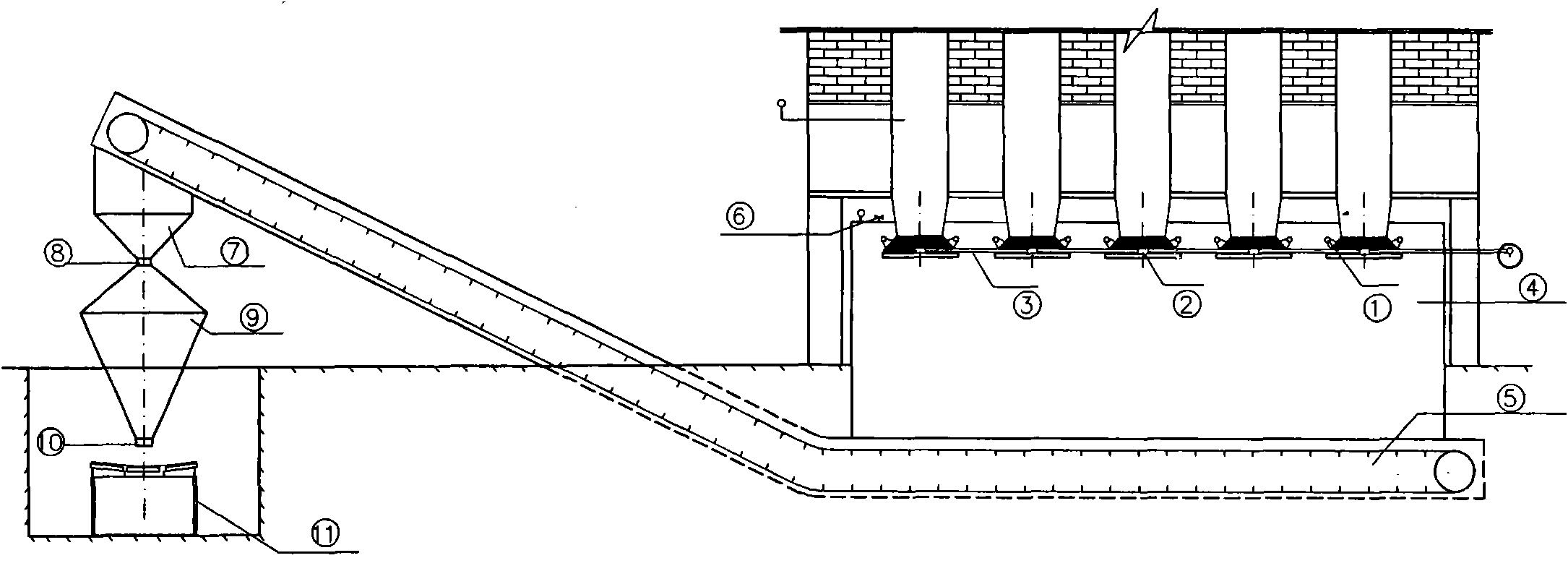

[0014] Describe an embodiment below in conjunction with accompanying drawing, the present invention is described further.

[0015] The CDQ semi-coke equipment of this embodiment is a part of the vertical internal heat fasting carbonization furnace. As shown in Figure 1, the CDQ semi-coke equipment has a coke support plate 2 outside the coke discharge port, and the coke discharge port and the coke support plate 2 The blue charcoal heap both sides between, respectively establishes a porous water spray pipe 1, and the water spray pipe adopts the mode of spraying water at intervals (by automatic control device to control the water spraying time). After spraying water on the hot semi-coke (about 350°C), steam will be generated to extinguish the semi-coke. The coke pushing rod 3 on the top of the coke holding plate 2 moves left and right in the horizontal direction—driven by an eccentric wheel, the distance of the horizontal movement is about 140mm, and the extinguished semi-coke is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com