Patents

Literature

1080 results about "Internal heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Internal heat is the heat source from the interior of celestial objects, such as stars, brown dwarfs, planets, moons, dwarf planets, and (in the early history of the Solar System) even asteroids such as Vesta, resulting from contraction caused by gravity (the Kelvin–Helmholtz mechanism), nuclear fusion, tidal heating, core solidification (heat of fusion released as molten core material solidifies), and radioactive decay. The amount of internal heating depends on mass; the more massive the object, the more internal heat it has; also, for a given density, the more massive the object, the greater the ratio of mass to surface area, and thus the greater the retention of internal heat. The internal heating keeps celestial objects warm and active.

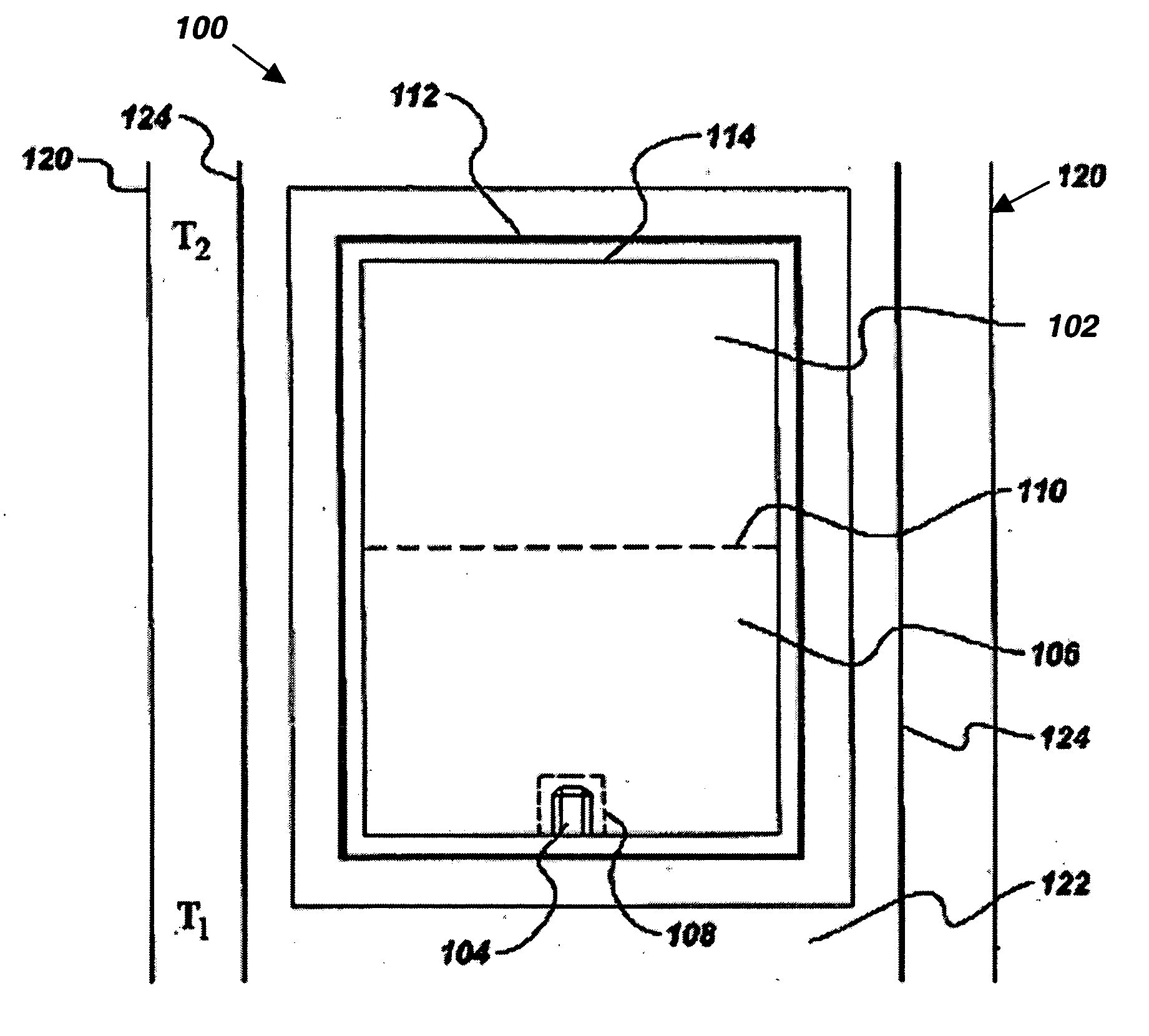

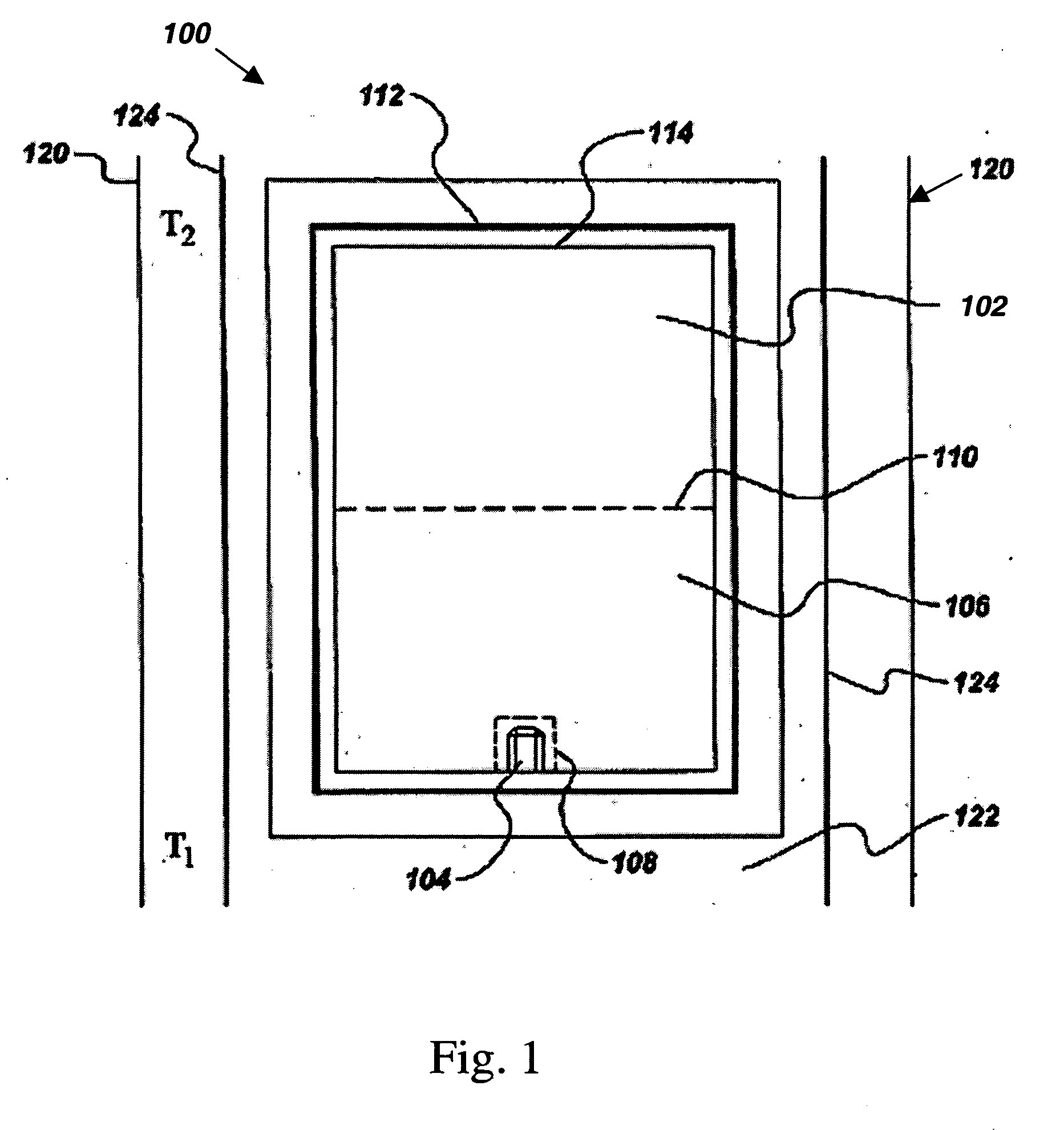

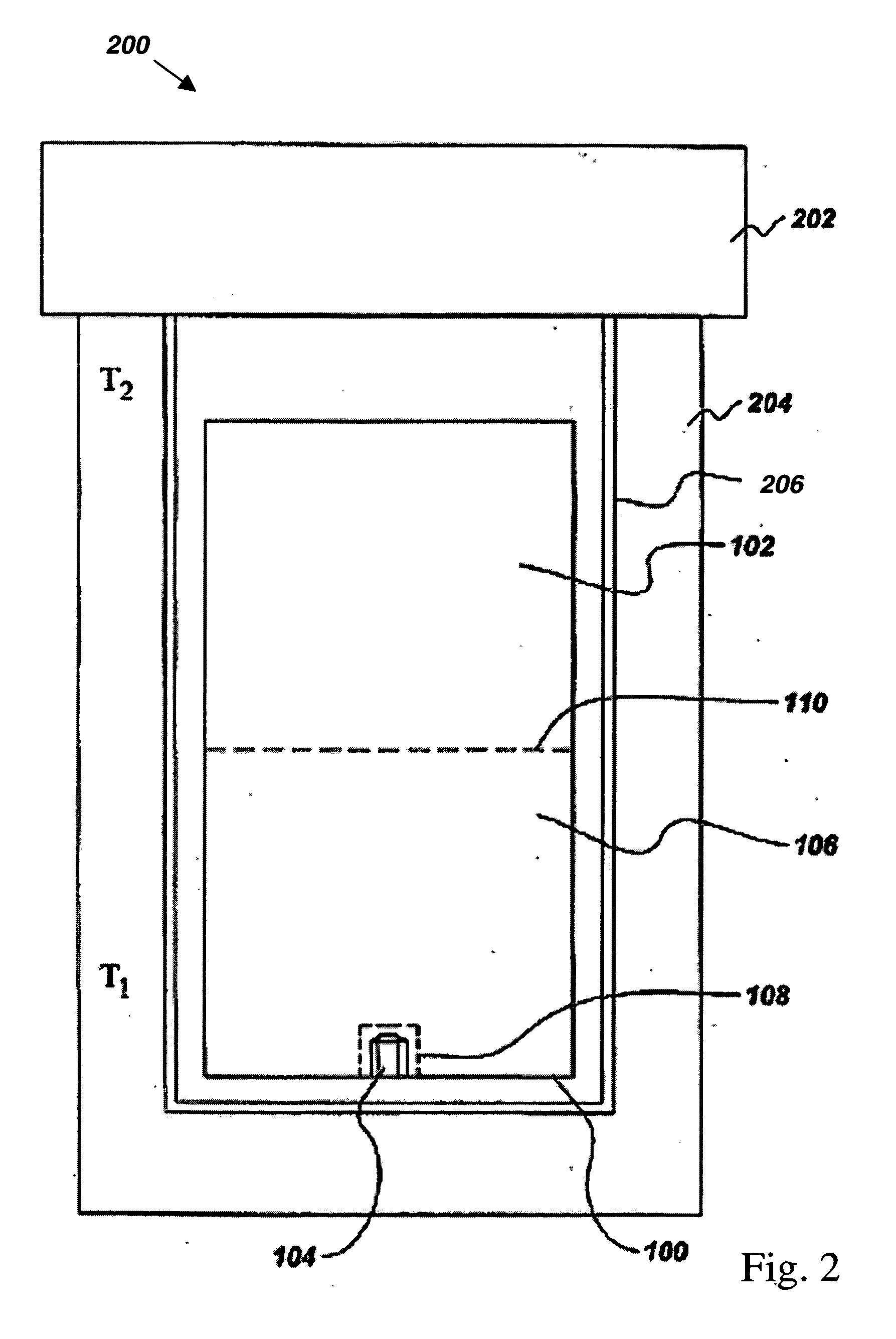

Apparatus for producing single crystal and quasi-single crystal, and associated method

An apparatus including a crucible, an energy source, and a controller is provided. The crucible may be sealed to a nitrogen-containing gas, and may be chemically inert to at least ammonia at a temperature in a range of about 400 degrees Celsius to about 2500 degrees Celsius. The energy source may supply thermal energy to the crucible. The controller may control the energy source to selectively direct sufficient thermal energy to a predefined first volume within the crucible to attain and maintain a temperature in the first volume to be in a range of from about 400 degrees Celsius to about 2500 degrees Celsius. The thermal energy may be sufficient to initiate, sustain, or both initiate and sustain growth of a crystal in the first volume. The first temperature in the first volume may be controllable separately from a second temperature in another volume within the crucible. The first temperature and the second temperature differ from each other. Associated methods are provided.

Owner:SLT TECH

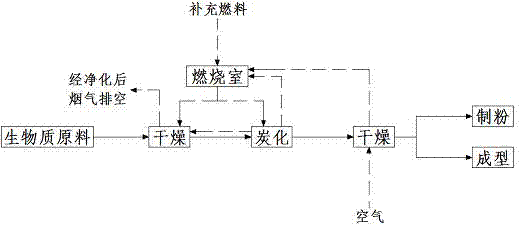

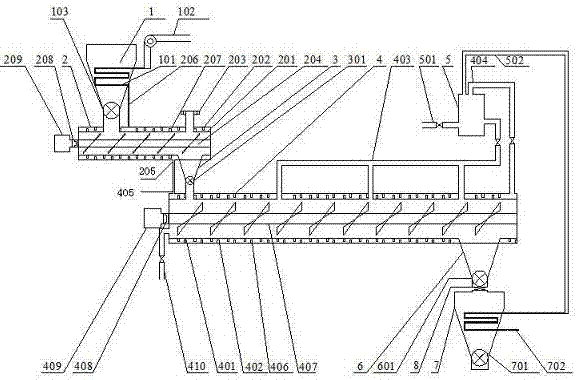

Continuous biomass low-temperature pyrolytic charring method and charring furnace thereof

InactiveCN102226092ARealize continuous carbonization productionImprove raw material adaptabilityDirect heating destructive distillationBiofuelsCombustion chamberRetention time

The invention discloses a continuous biomass low-temperature pyrolytic charring method and a charring furnace thereof, belonging to the fields of biomass charring and biomass energy source utilization. The furnace body of the charring furnace adopts a screw propelling feed mode, and the power is derived from the drive of a motor; an external heating cylinder is sheathed outside an internal heating cylinder of the furnace body, the internal cylinder and the external cylinder are spaced, and the internal flue inside the sleeve has a labyrinth path to ensure heat supply from hot flue gas to pyrolytic reaction to uniformly heat a biomass raw material; and during charring, the generated flue gas supplies heat to a reaction cylinder after combustion in a combustion chamber, and the hot flue gas enters a heat exchanger device to dry the raw material after flowing through the sleeve. Through screw propelling, the method disclosed by the invention realizes continuous low-temperature pyrolytic charring reaction, and realizes accuracy control of the retention time of the biomass inside the charring furnace; and the furnace body adopts a sleeve structure, which fully utilizes the afterheat of the charring flue gas, and the reaction cylinder adopts interior heating and outer wall heating together, which enhances the uniformity characteristic of the temperature inside the reaction cylinder and prolongs the service life of an auger shaft.

Owner:NANJING NORMAL UNIVERSITY

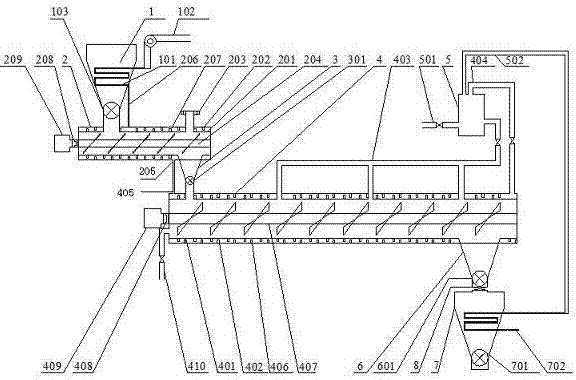

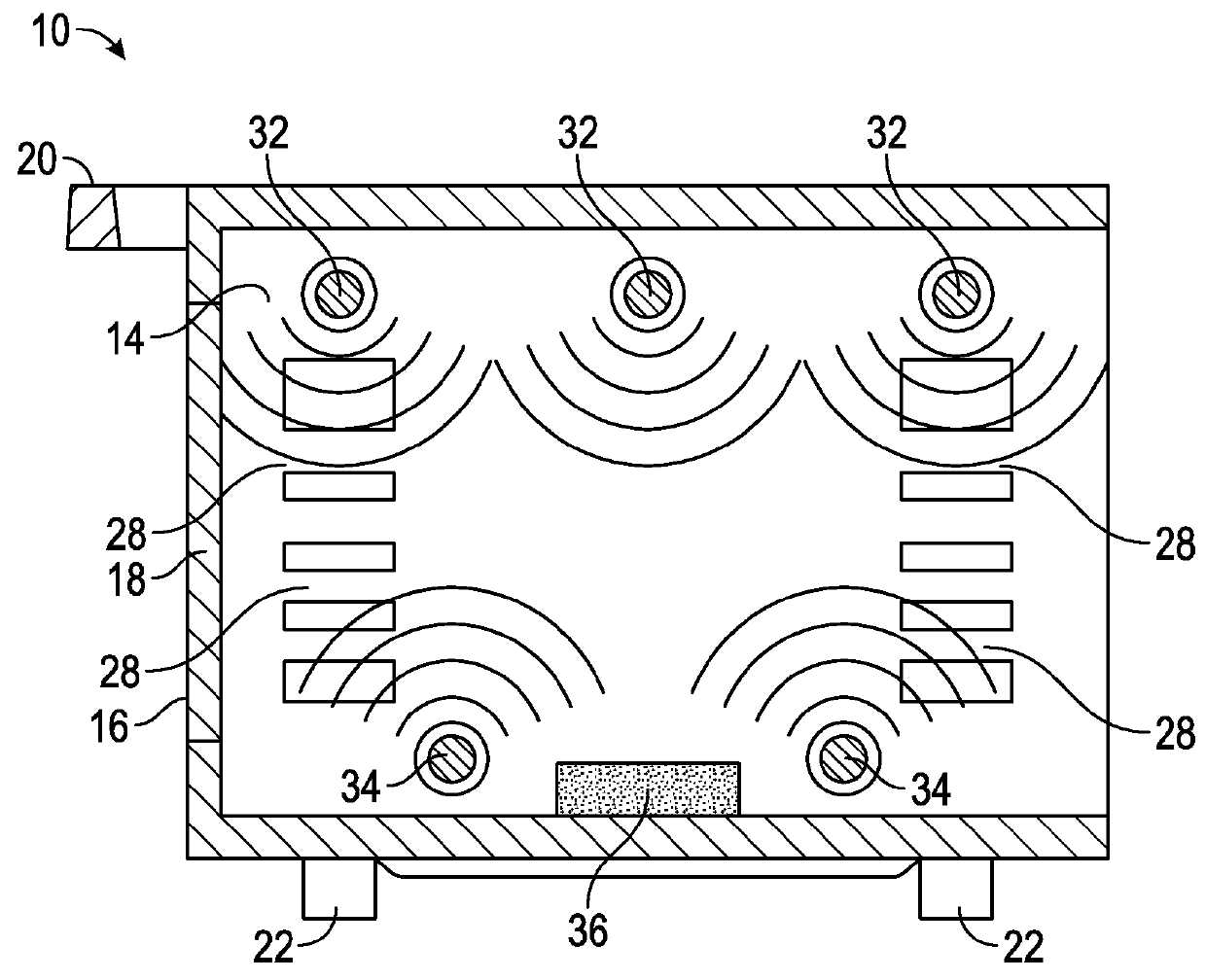

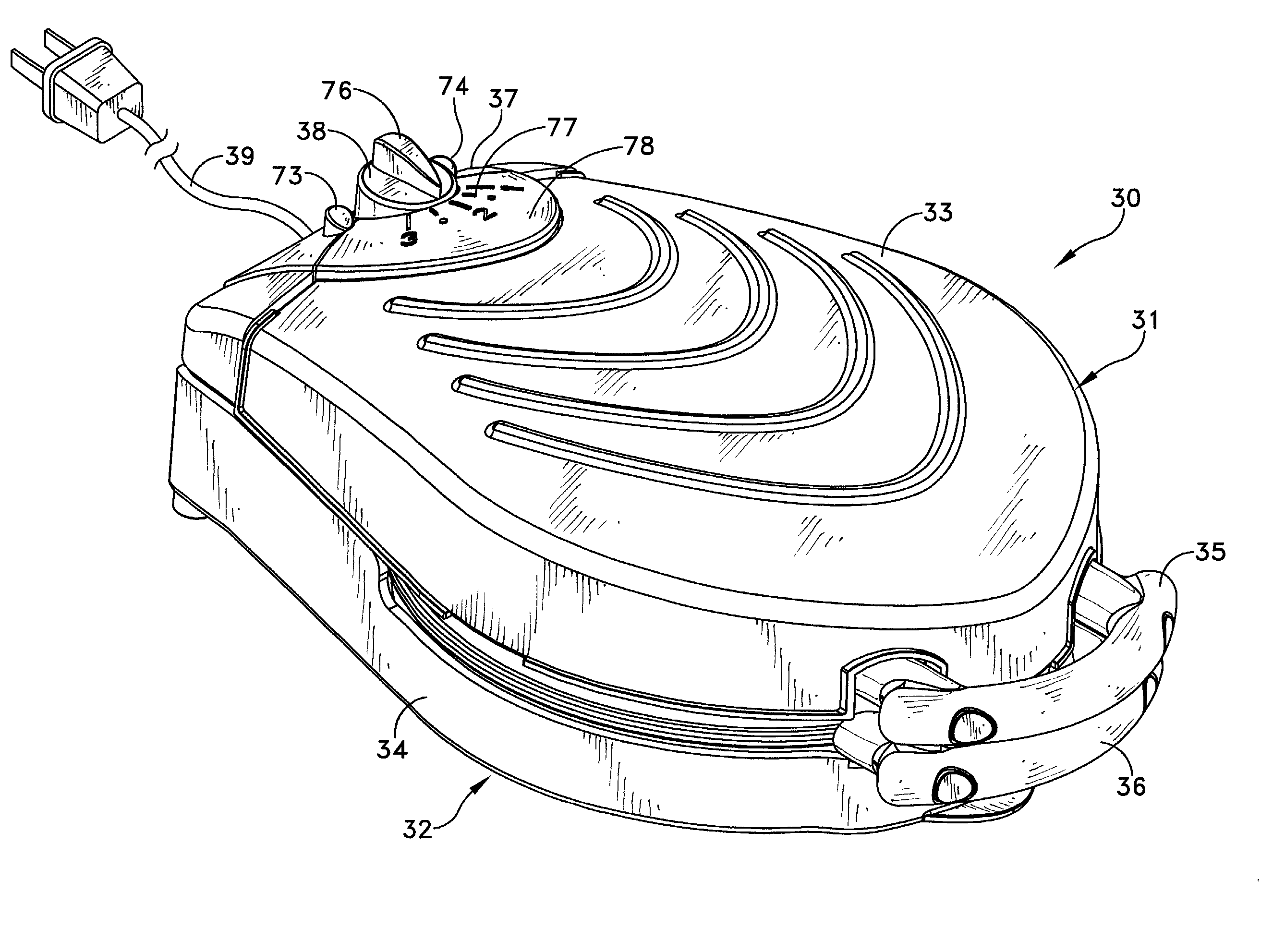

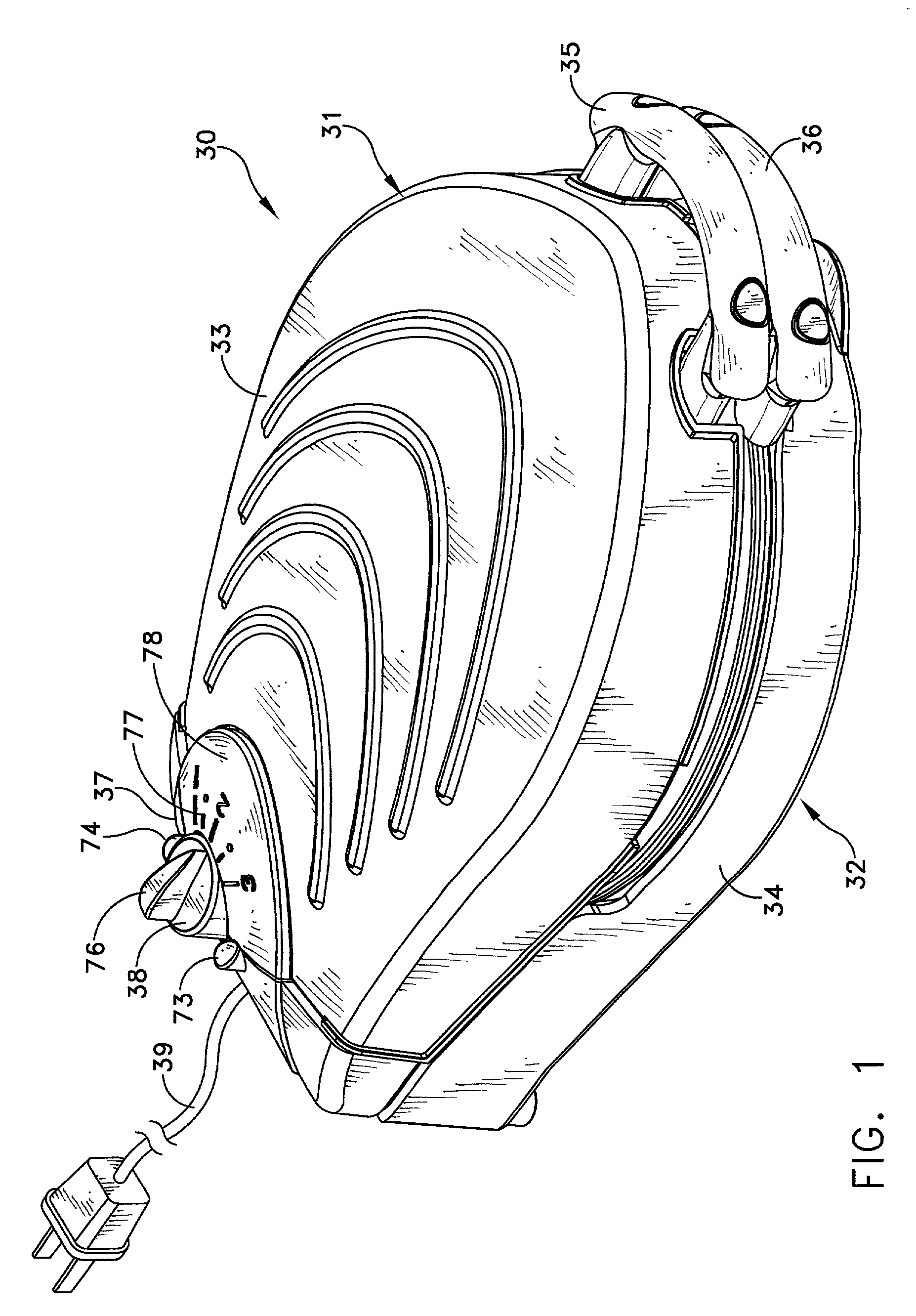

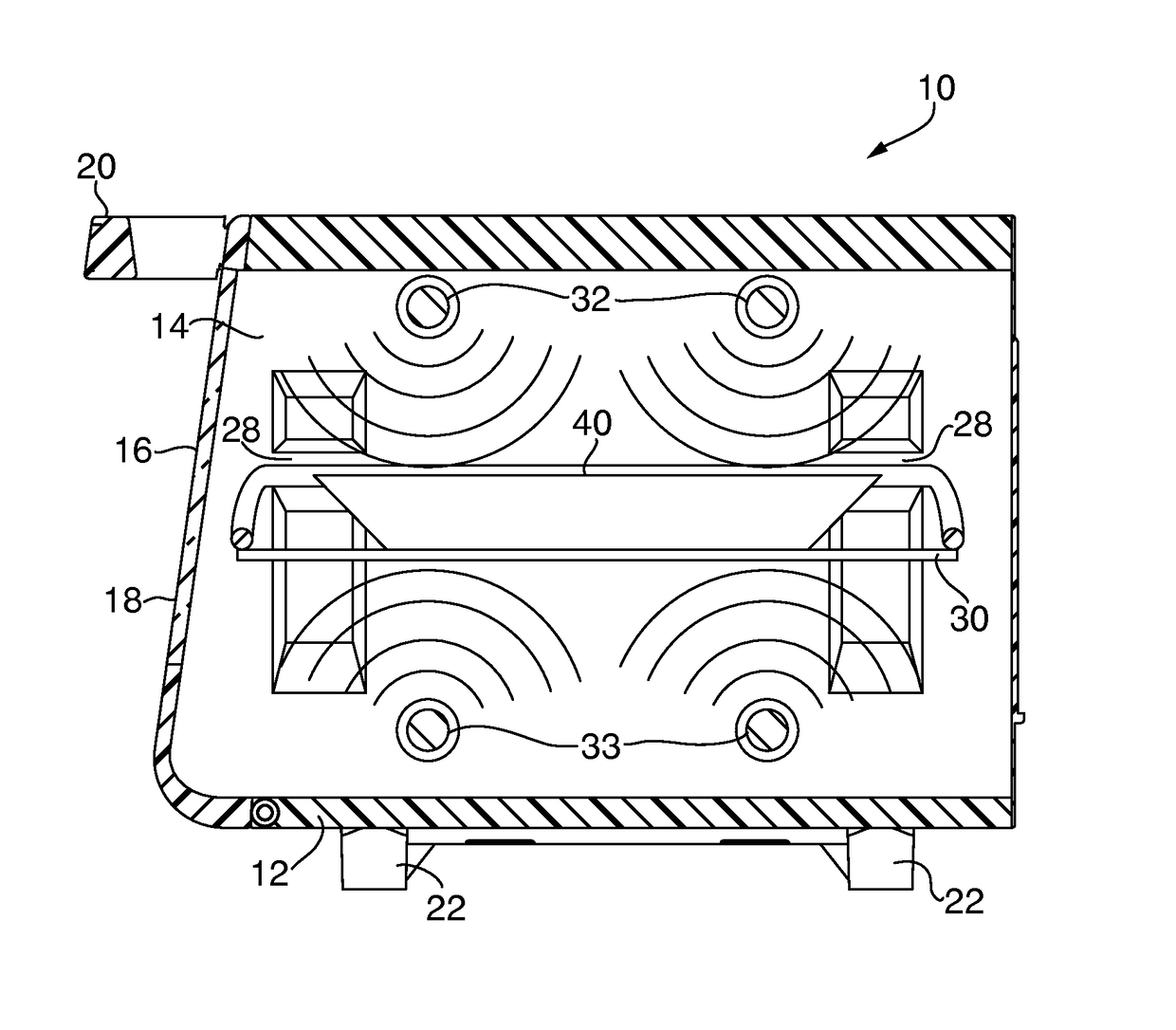

Griddle

ActiveUS20080105136A1Reduce cooking timeAir-treating devicesMilk preservationProcess engineeringInternal heating

A high-speed griddle for cooking food products has a griddle platen having a cook surface for receiving food products thereon, and heating means are provided for heating the platen. A clamshell cover is configured for sealing contact with the cook surface of the platen, the cook surface and cover cooperating to enclose a cook volume. An electromagnetic energy source is configured for emitting energy into the cook volume, the energy source emitting energy of a frequency selected to cause internal heating of food products within the cook volume. In addition, a convection air system is configured to provide a flow of heated air into the cook volume. The heated platen, electromagnetic energy source, and convection air system cooperate to rapidly cook food products within the cook volume.

Owner:TURBOCHEF TECH INC

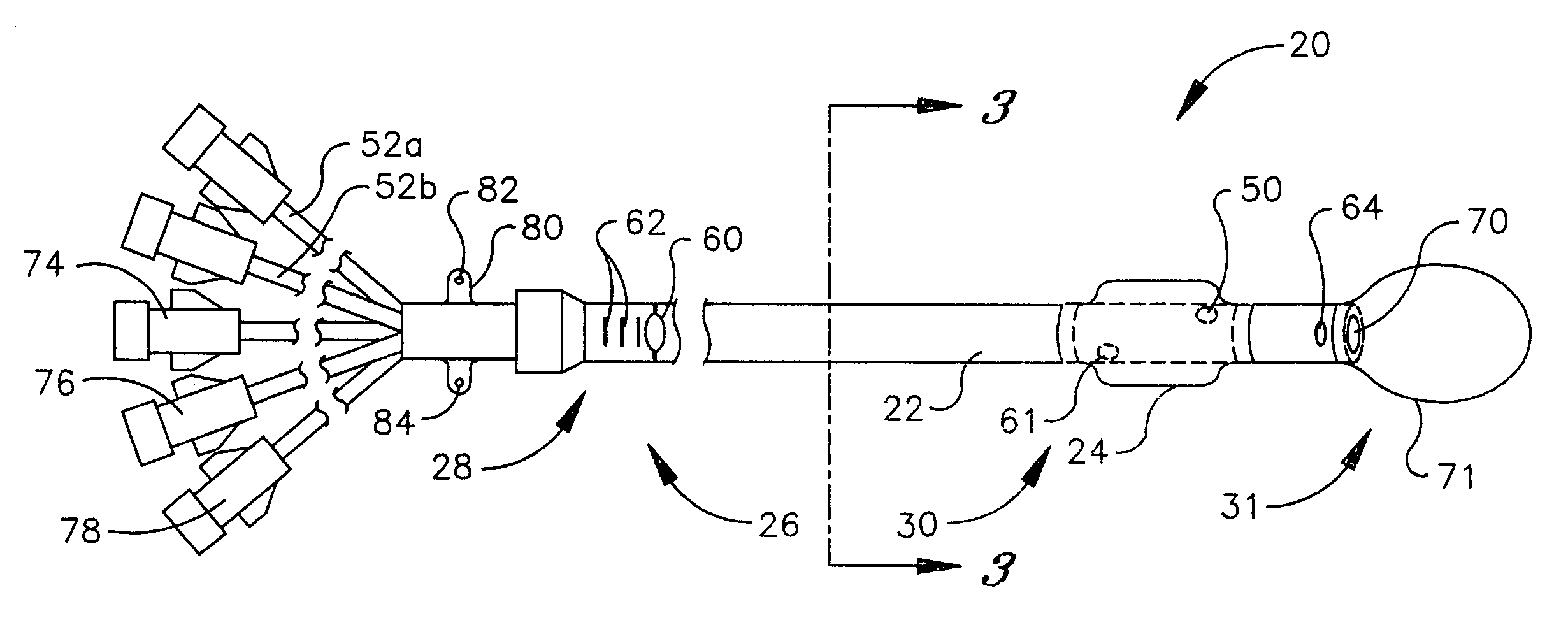

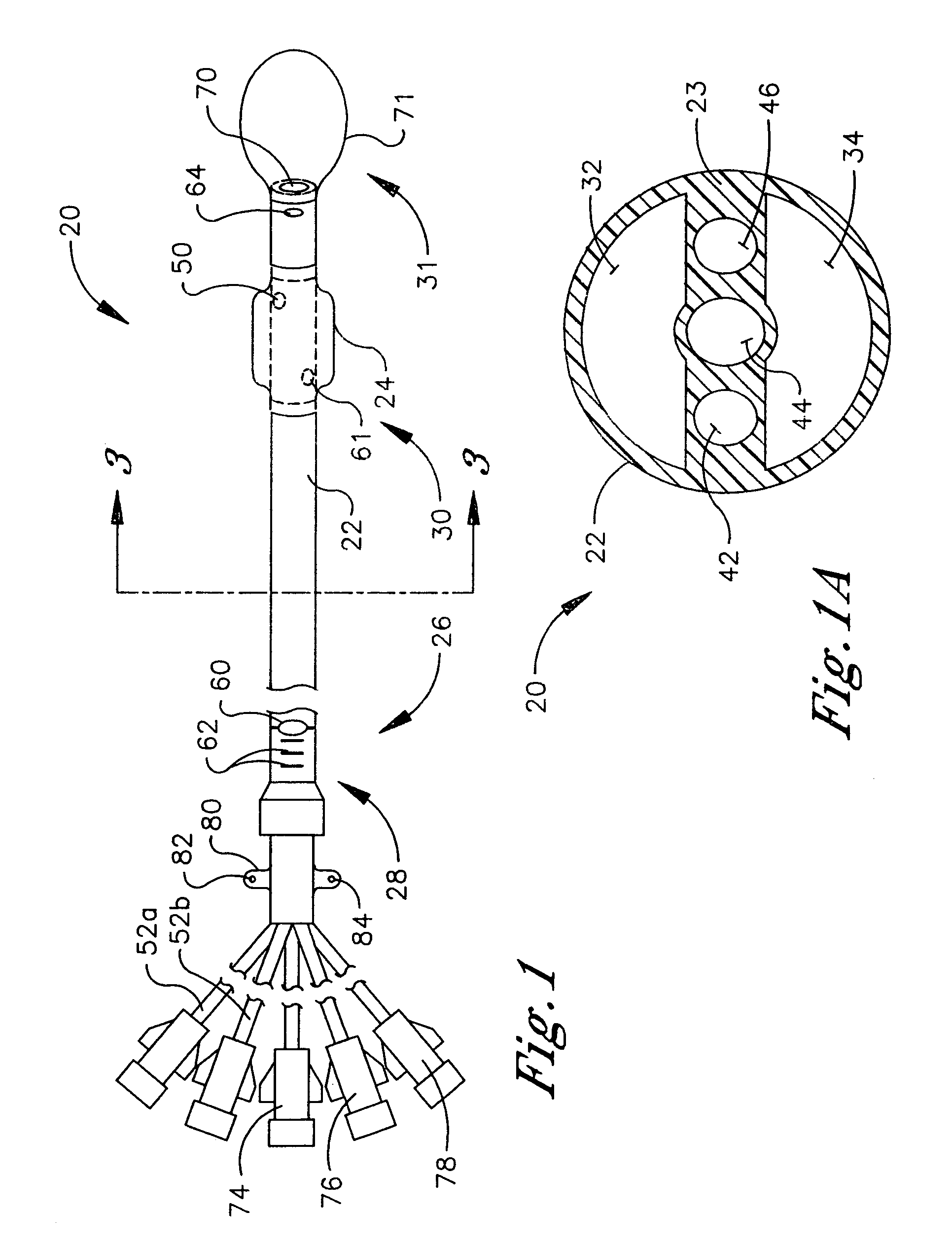

Cardiovascular intra aortic balloon pump catheter with heat exchange function and methods of use

ActiveUS7144407B1Reduce complexityEffective temperature controlSurgeryDilatorsTemperature controlVein

An intra-aortic balloon pump catheter system (apparatus and method) includes a pumping element for pumping a patient's blood and one or more heat exchange for exchanging heat with the patient's blood to provide efficient temperature control of the patient. The catheter may also provide access to the patient's central venous system through one or more infusion lumens and infusion ducts. An elongate body defines an inflation lumen that conveys an inflation fluid to and from the pumping element, and an inflow lumen and an outflow lumen that supply heat exchange fluid to and from each heat exchange element. The pumping element may include an everting pumping balloon that expands out of a cavity in the elongate body after insertion of the catheter. The catheter may have an internal heating element that heats or cools the heat exchange fluid.

Owner:ZOLL CIRCULATION

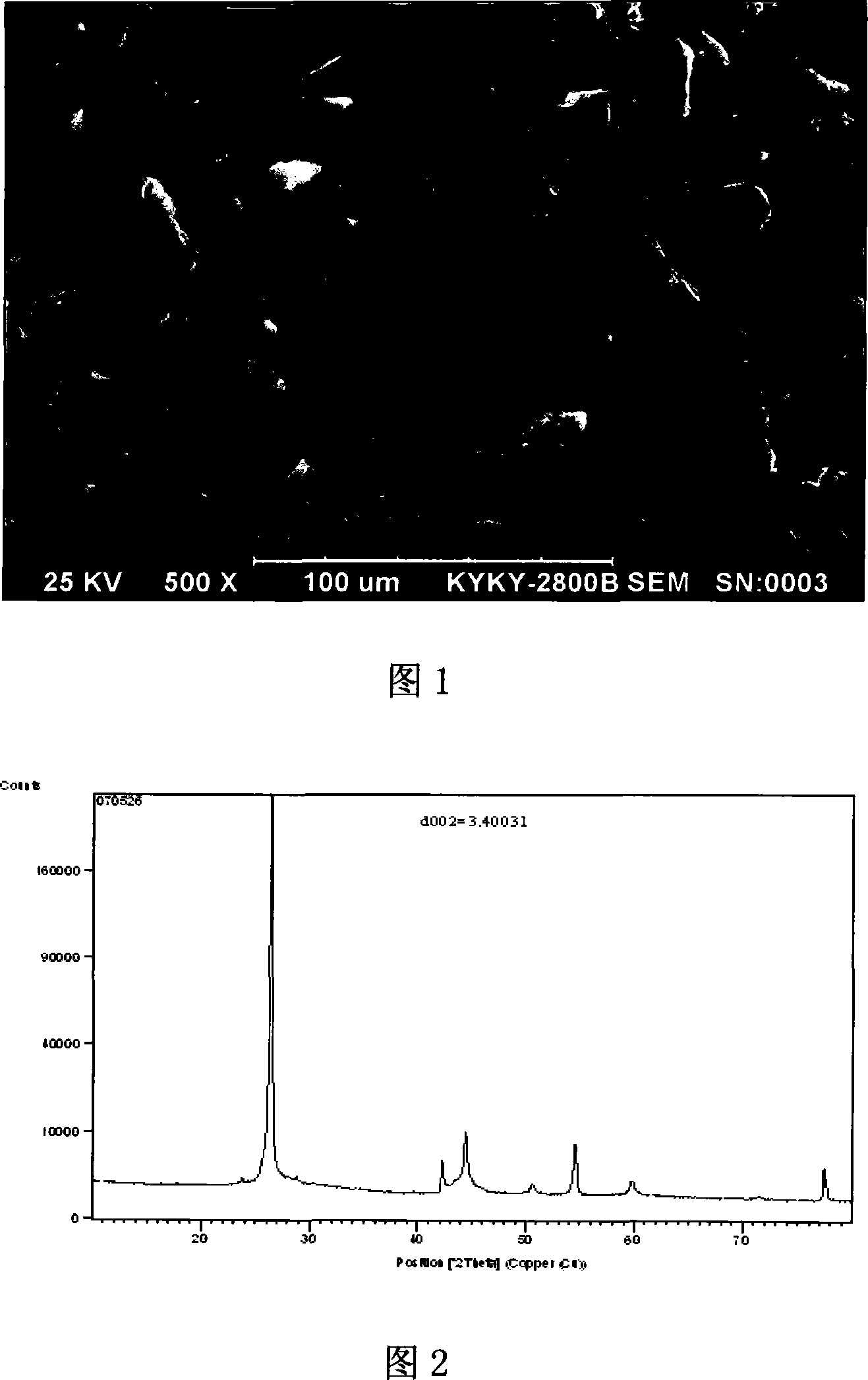

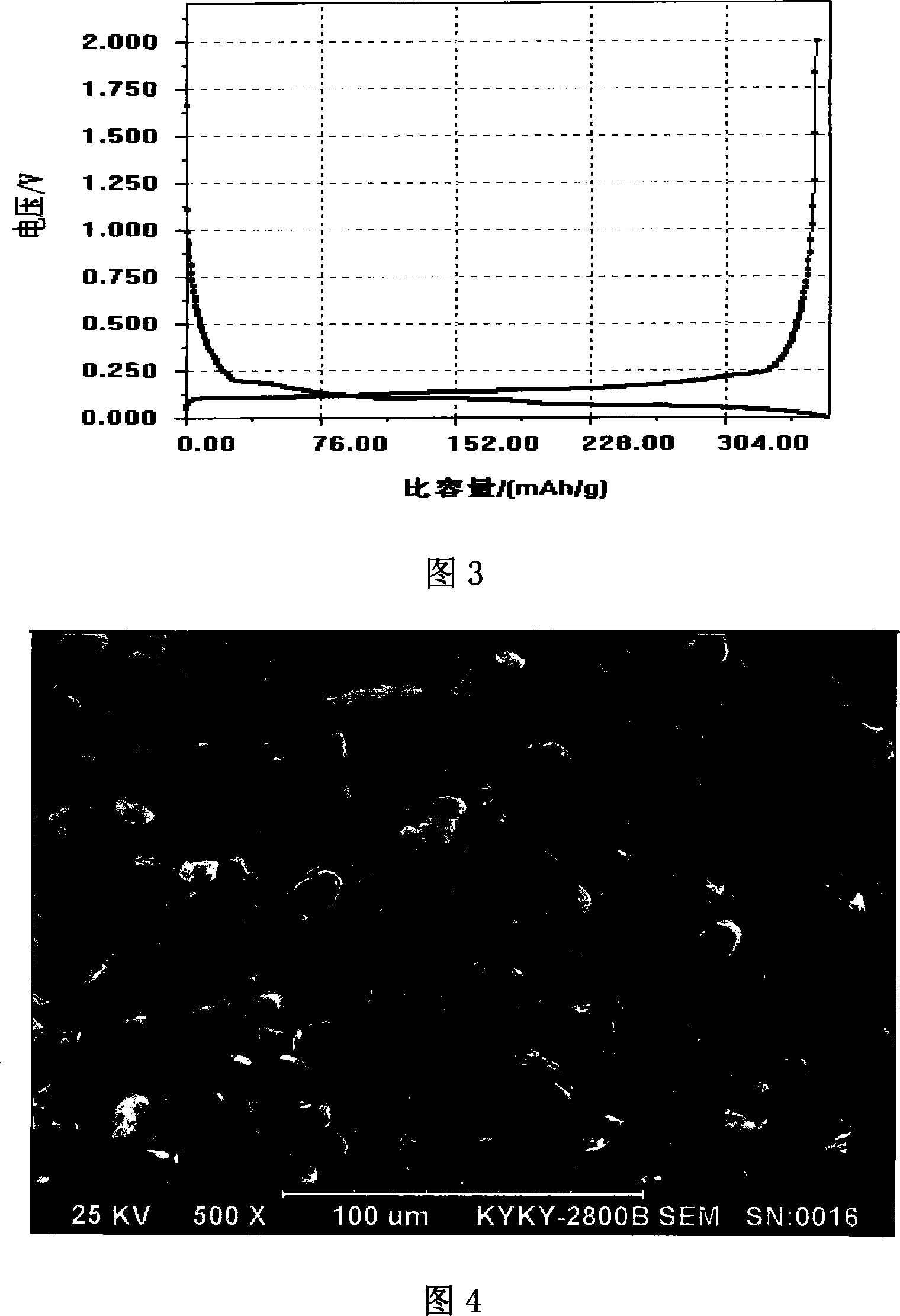

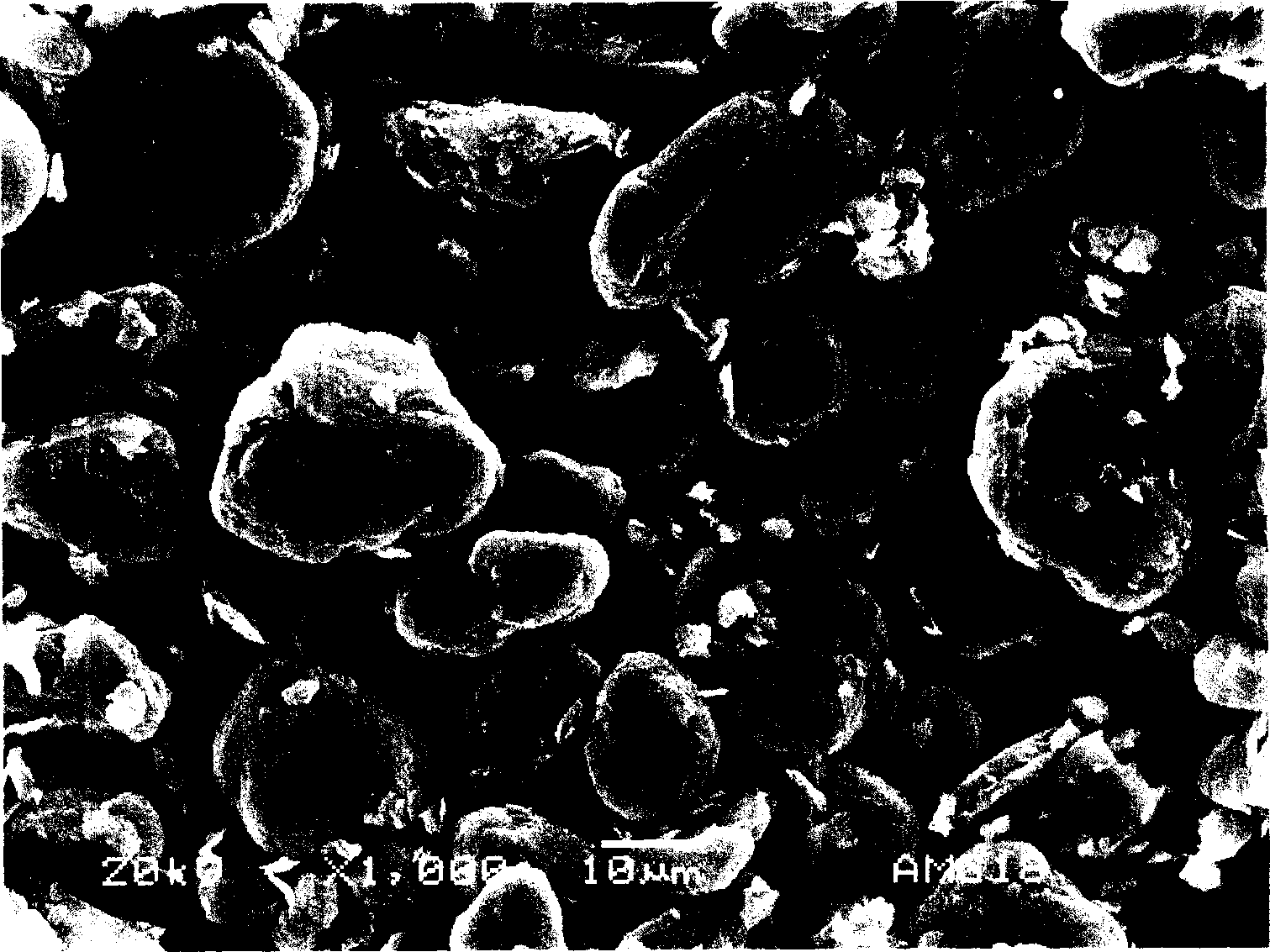

Man-made graphite cathode material for lithium ion battery and its making method

ActiveCN101087021AImprove discharge capacityPromote circulationCell electrodesAluminium-ion batteryElectrical battery

The invention discloses a preparing method of an artificial graphite cathode material used in lithium ion battery; it aims at resolving problems that cathode material possesses higher discharging capacity, coulomb efficiency and long circle life. The preparing method includes following steps: coal or petroleum needle-type coke is comminuted, and hot processed for 1-48 hours at 800deg.C-3000deg.C, comparing with current technique, the cathode material adopts needle-type coke to be comminuted, and hot process, defect that high crystallinity graphite material can not be circled in electrolyte system of PC solvent stably, and it can discharge in big times, it can be used in lithium ion drive battery, and craft is easy, and it fits for industrialization production.

Owner:BTR NEW MATERIAL GRP CO LTD

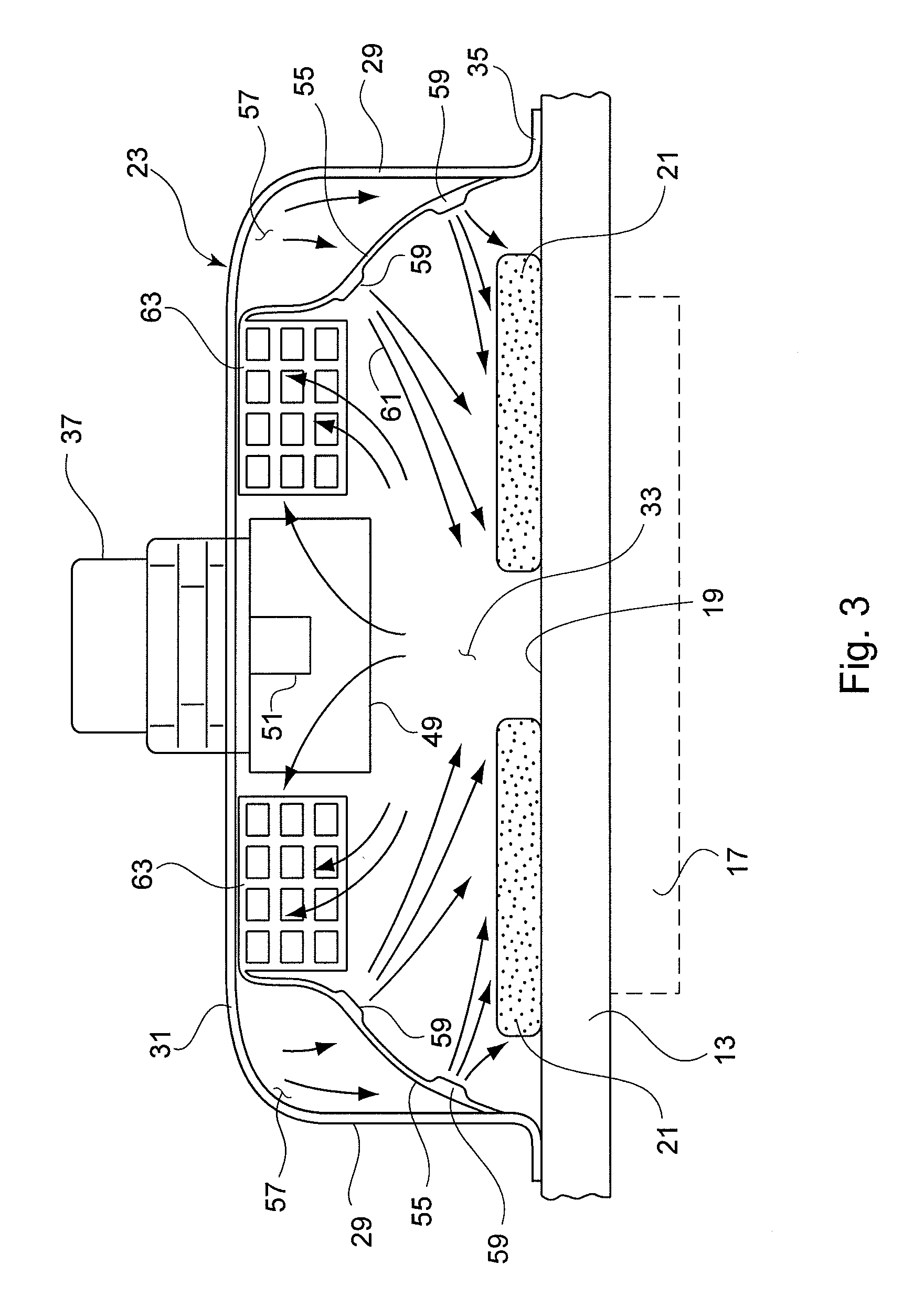

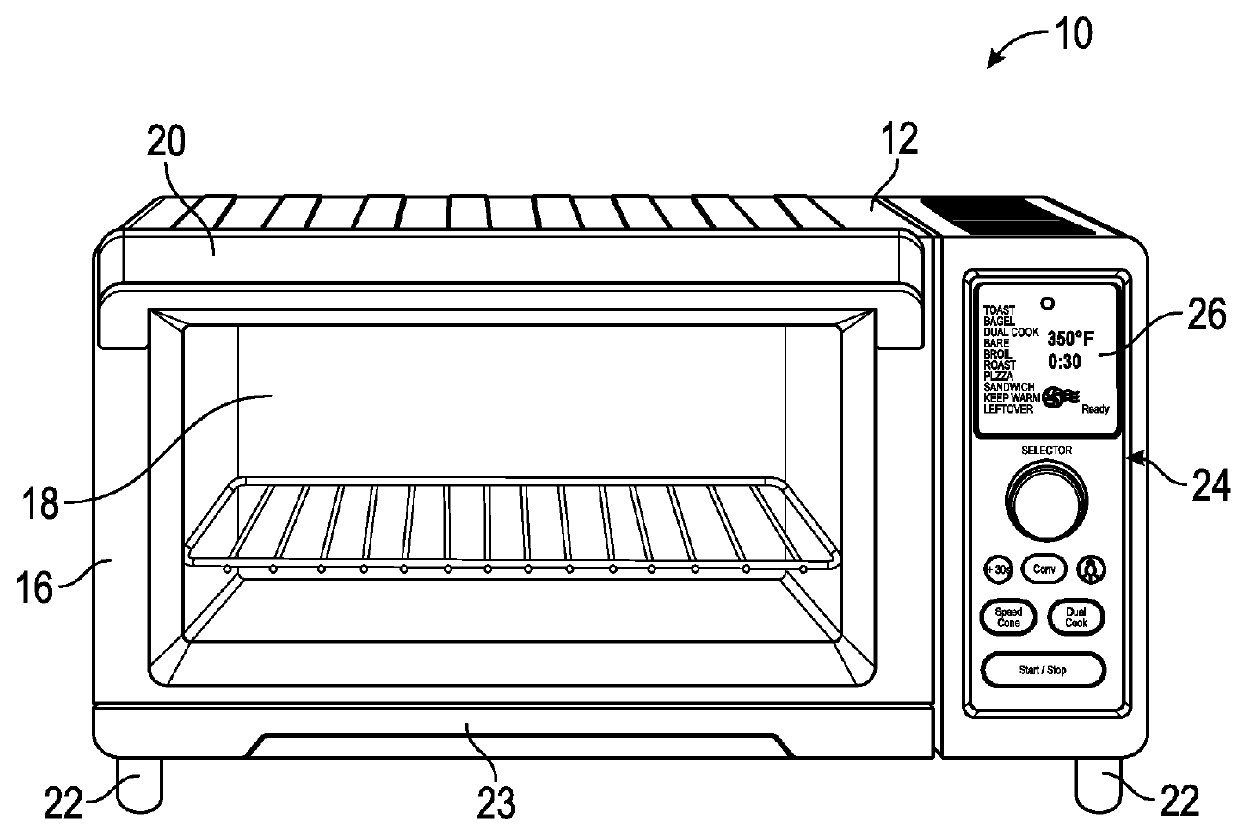

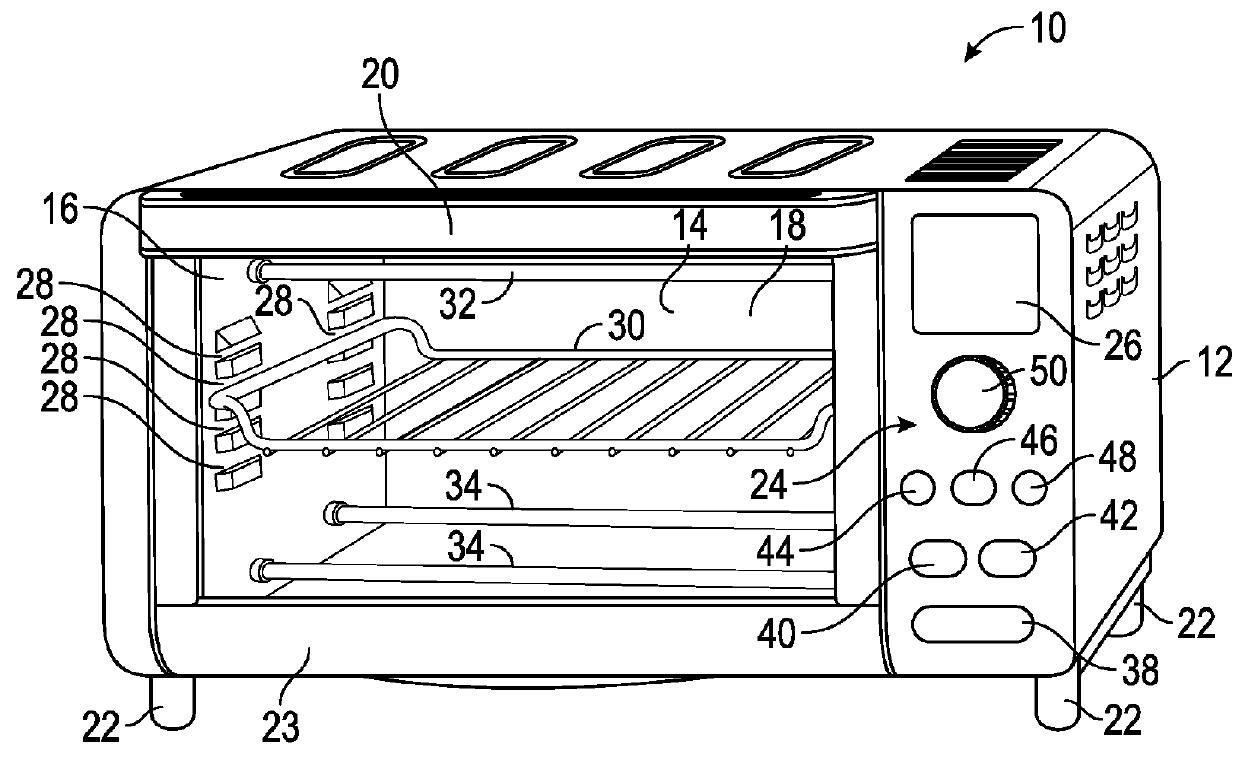

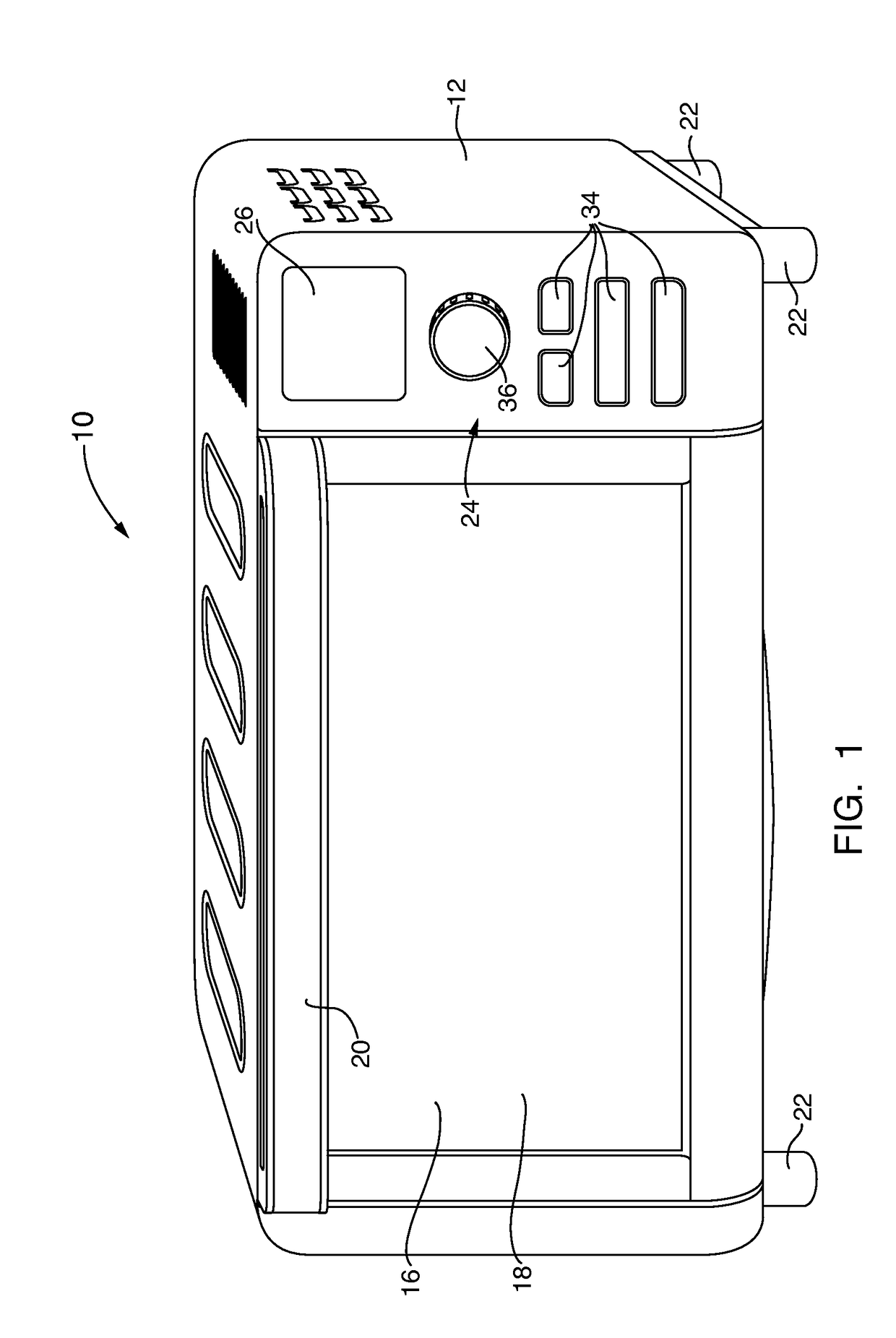

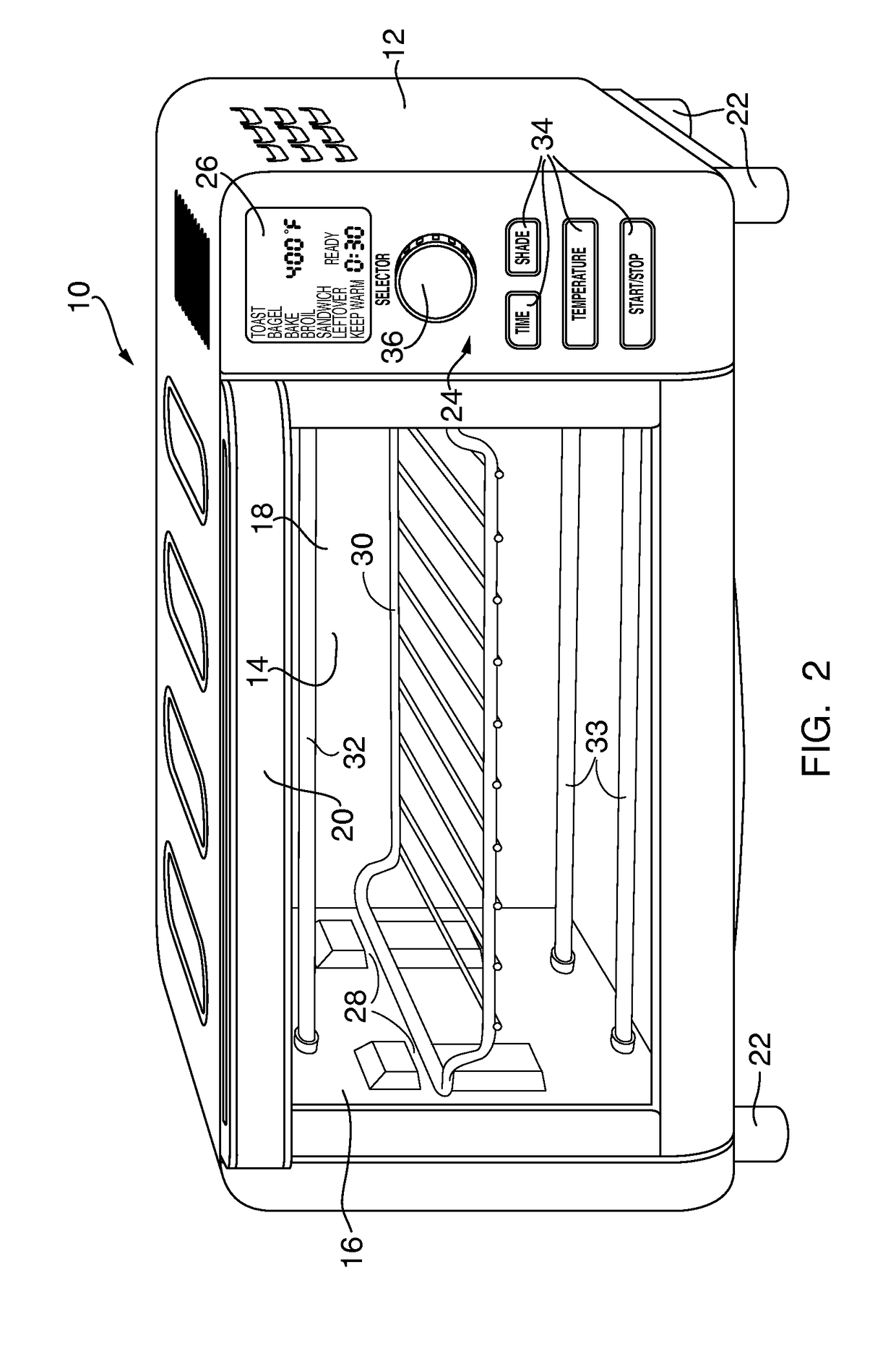

Toaster and convection oven with variable controls

A toaster and convection oven includes a housing having an internal heating compartment, a heating mechanism in thermal communication with the heating compartment and configured to heat the heating compartment, a user interface including a plurality of user controls to be manipulated by a user, the user controls allowing the user to program a dual cook mode including a first cooking mode and a second cooking mode, and a control unit operatively connected to the user interface and to the heating mechanism. The control unit is configured to receive a signal from the user interface and to control operation of the heating mechanism in dependence upon the signal to run the first cooking mode and the second cooking mode sequentially without further input from the user.

Owner:CONAIR CORP

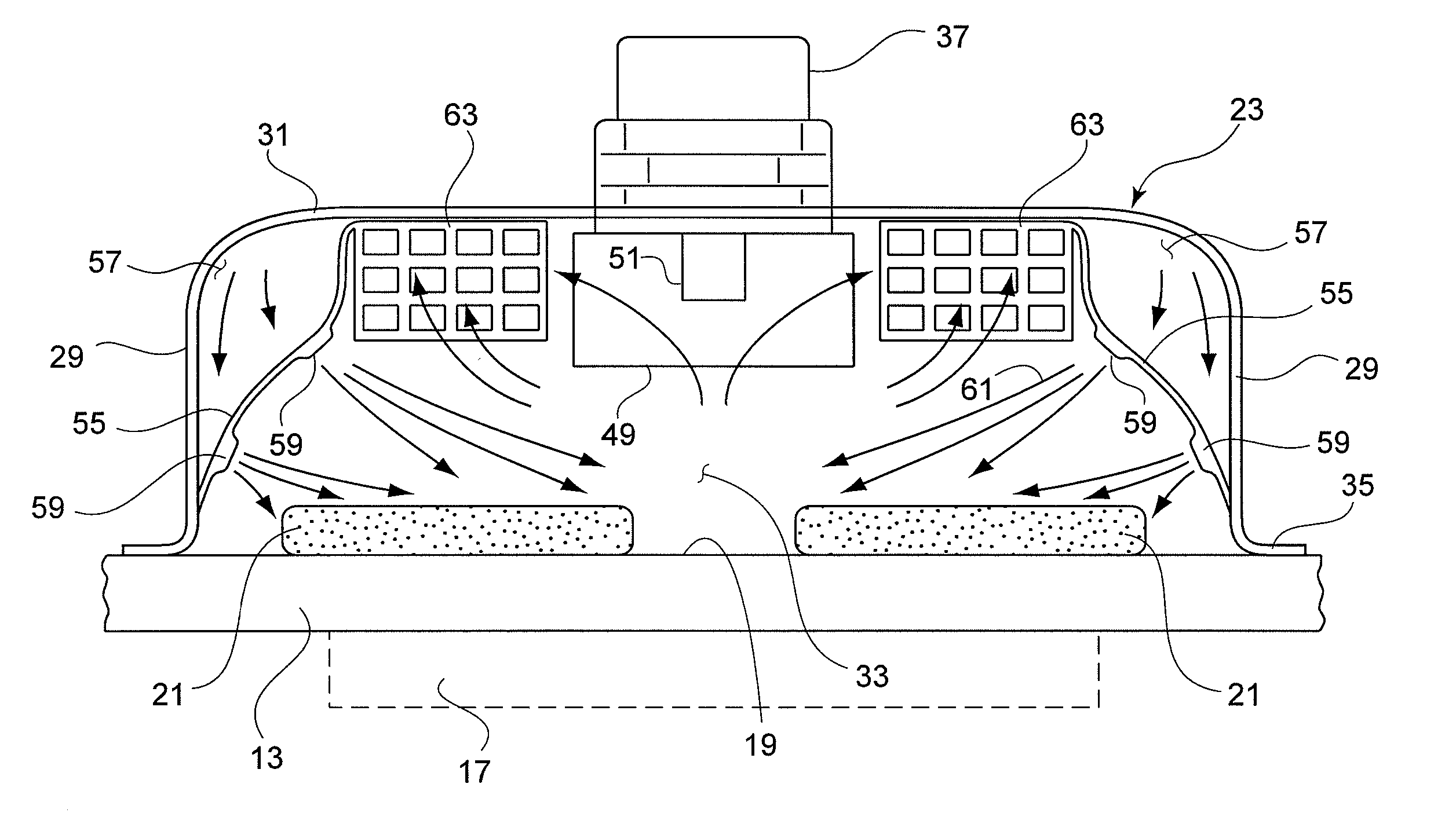

Portable information appliance

InactiveUS6859364B2Inhibit temperature riseNot to give uncomfortable feelingBiocideDomestic cooling apparatusFiberInformation device

A portable information device such as a notebook type computer is provided with a highly efficient thermal insulator capable of blocking transfer of heat between an internal heating component and a device enclosure, so as to reduce temperature rise on a surface of the device. The portable information device is also provided with a highly efficient thermal insulator to block transfer of heat between the heating component and an expansion unit mounting case, thereby reducing temperature rise and preventing malfunction of an external expansion unit. The information device includes the thermal insulator to separate between the internal heating component and the device enclosure, another thermal insulator to separate between the heating component and the expansion unit mounting case, and a heat sink. The thermal insulator is a vacuum thermal insulator including inorganic fiber as a core member.

Owner:PANASONIC CORP

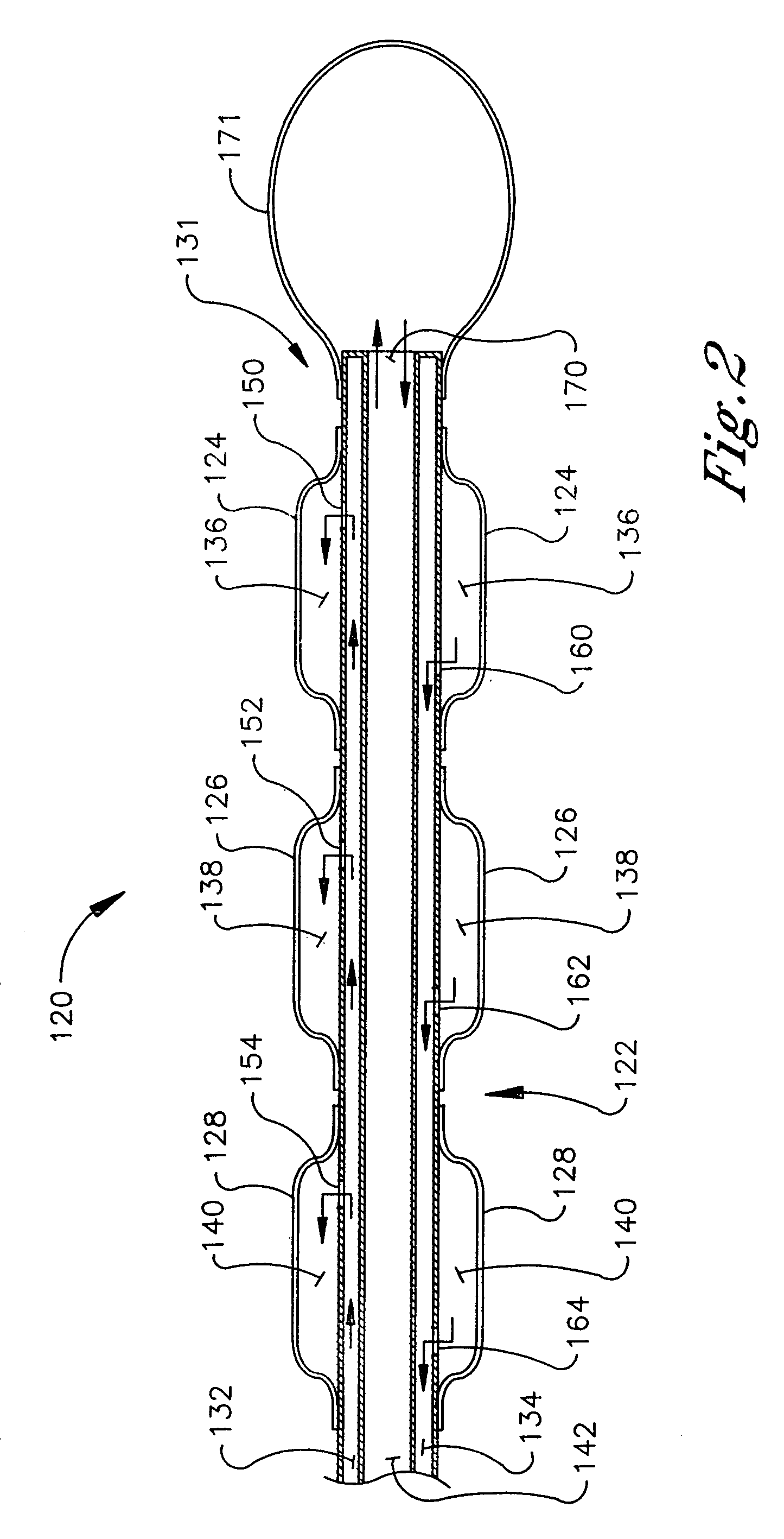

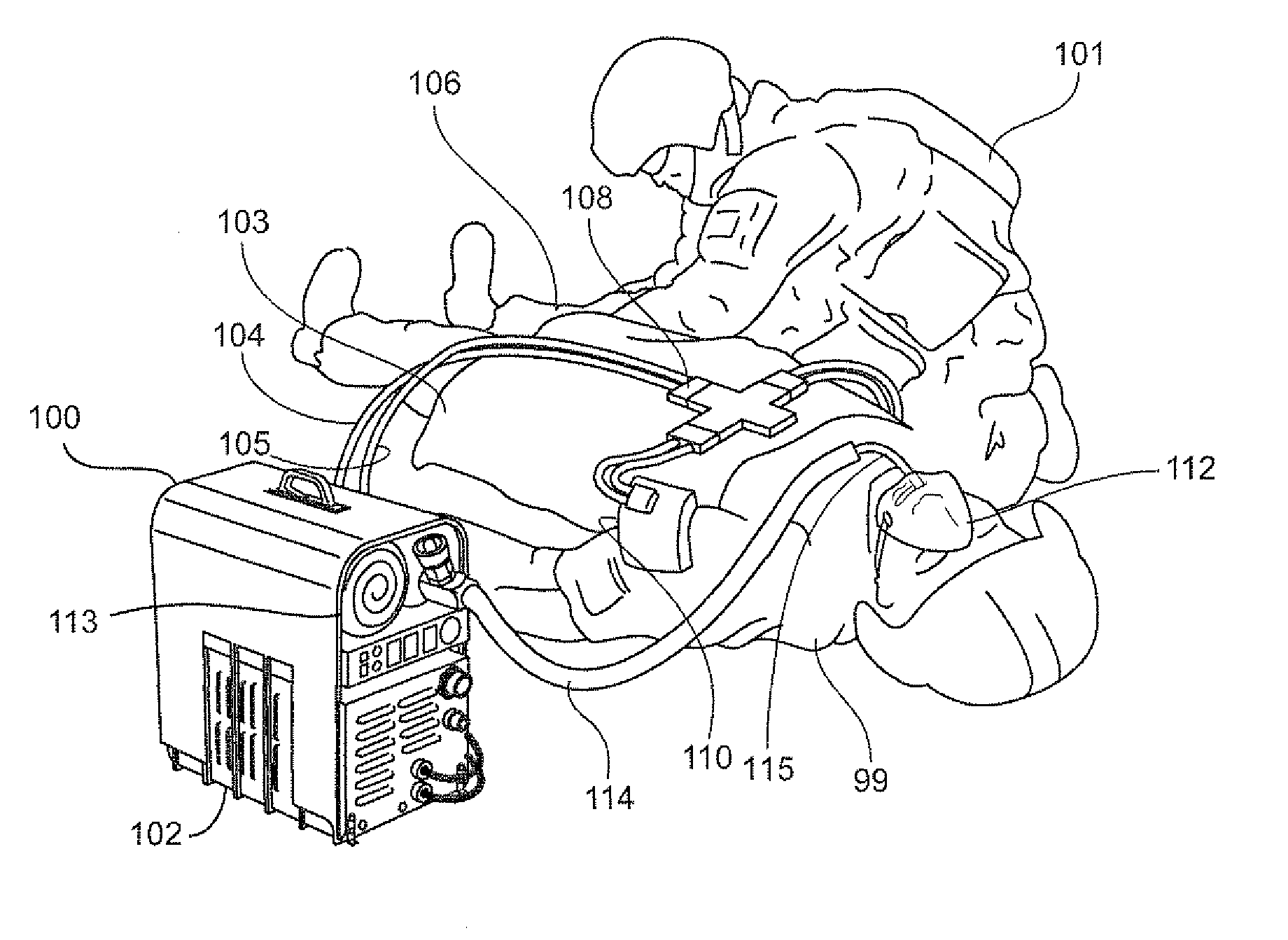

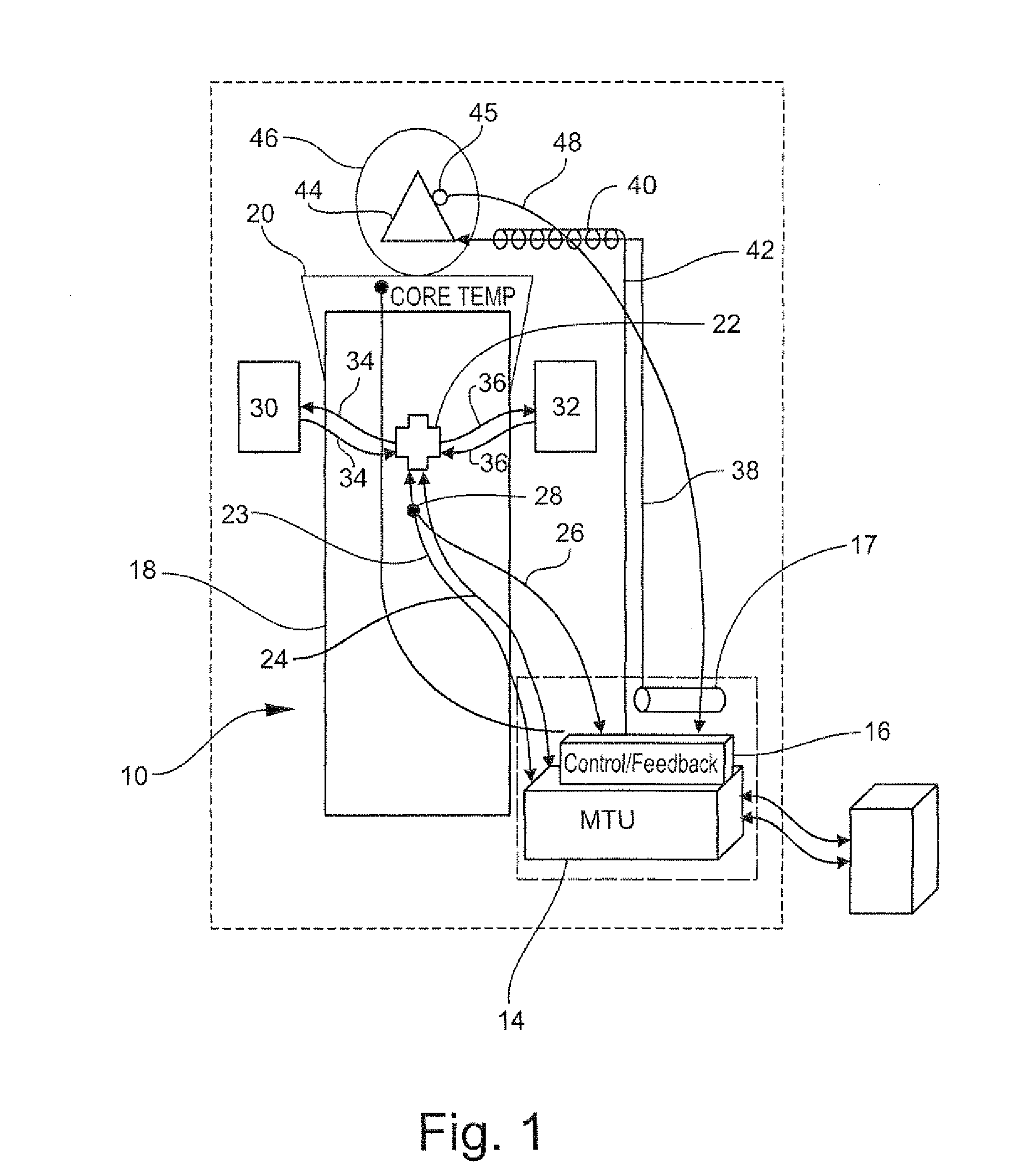

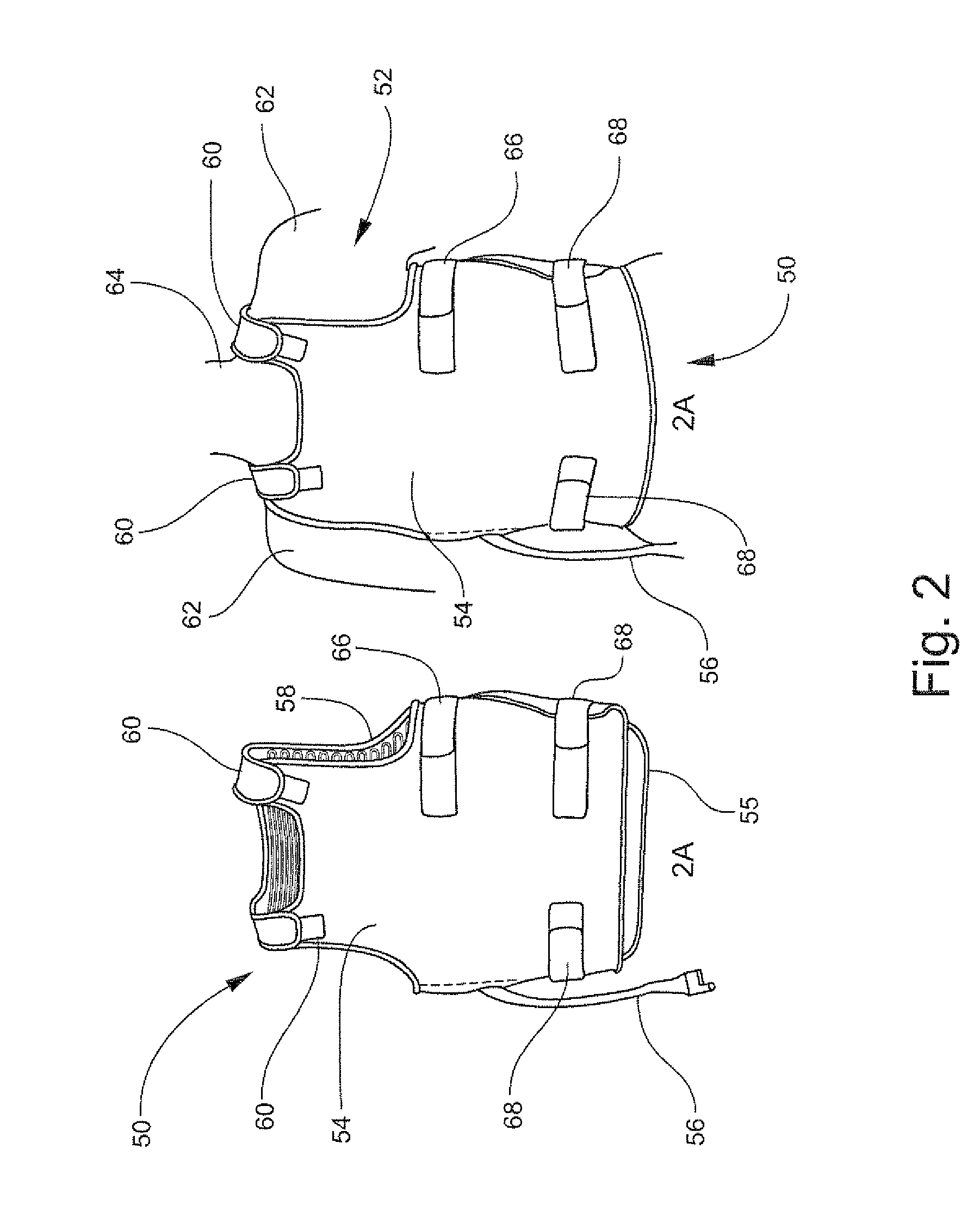

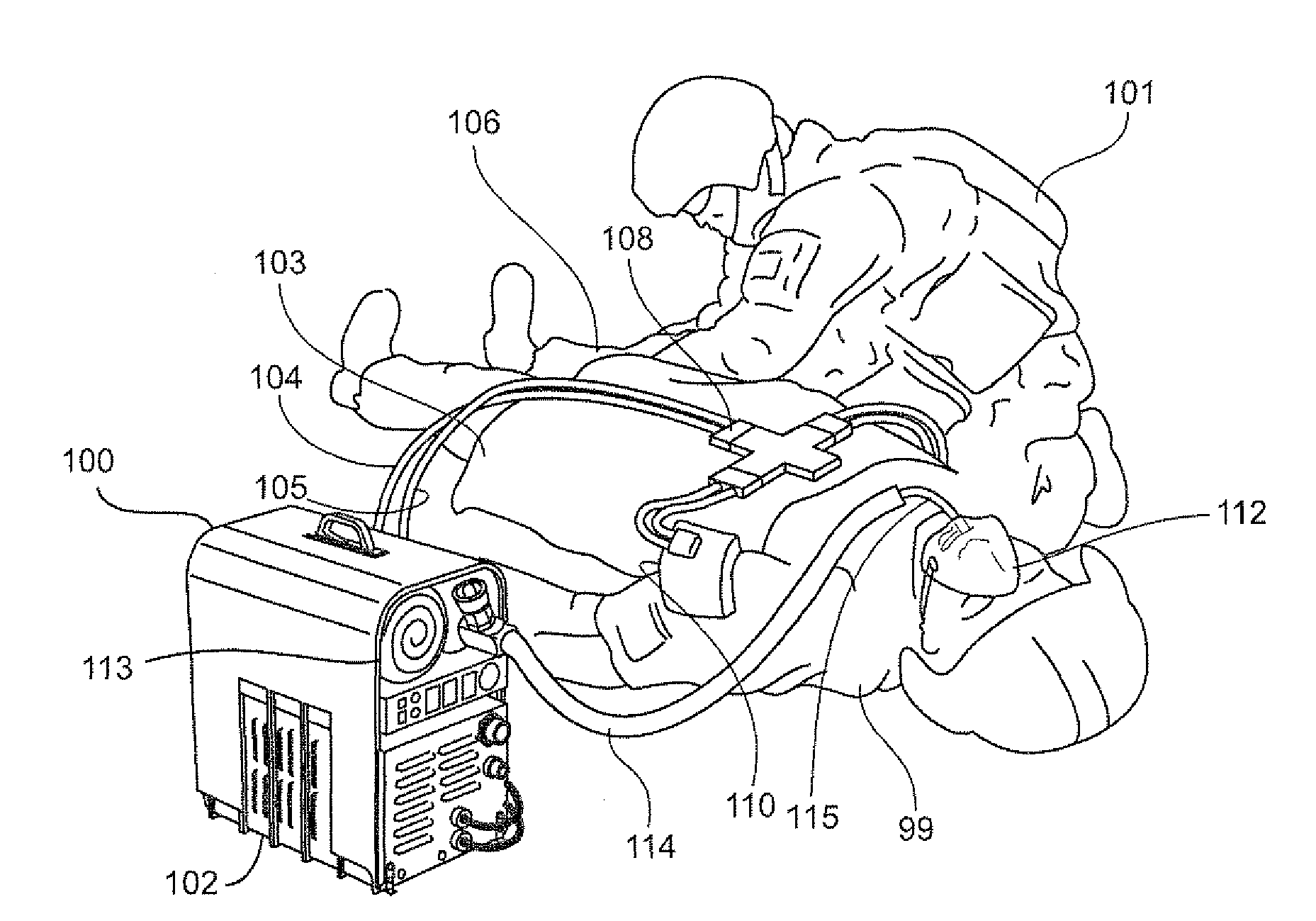

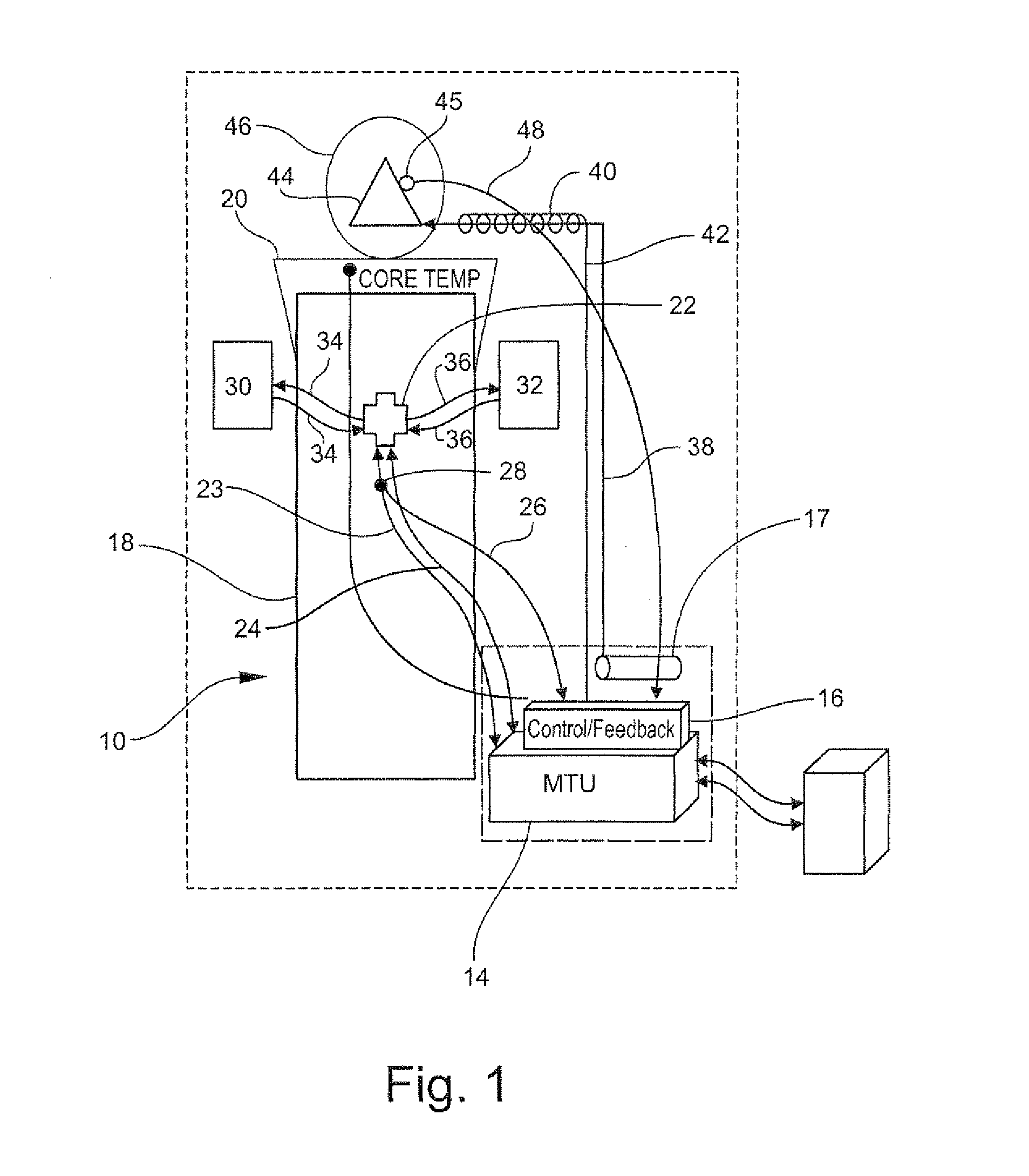

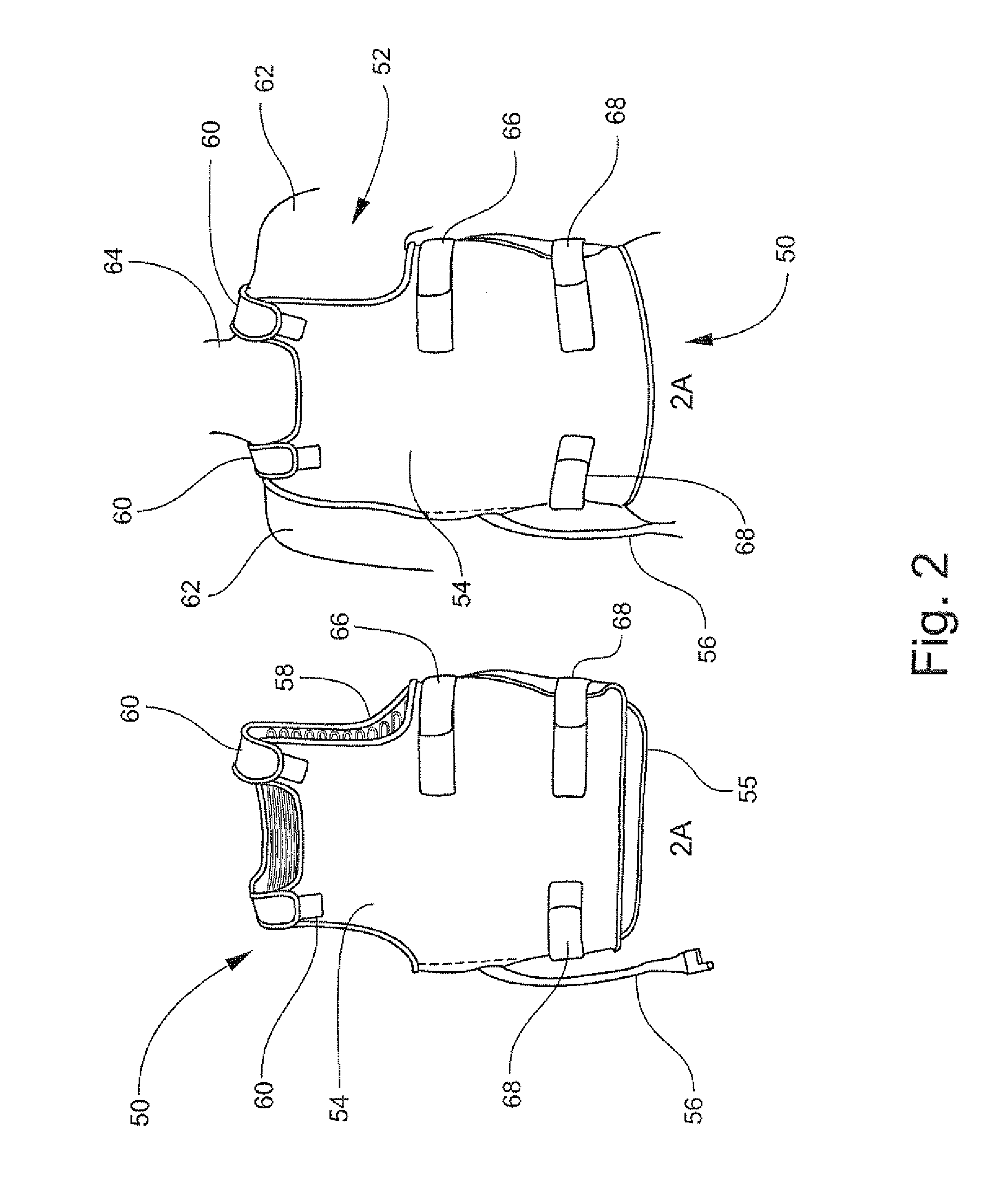

Life support and microclimate integrated system and process with internal and external active heating

InactiveUS20110184253A1Faster and improved recoveryPromote recoveryMedical devicesCatheterLife care supportEngineering

The present invention of one embodiment includes a combined microclimate, thermal management, life-support system for care of patient and system for measurement of vital signs. The system of one embodiment, provides active external heating and simultaneously provides active internal heating.

Owner:CARLETON TECH

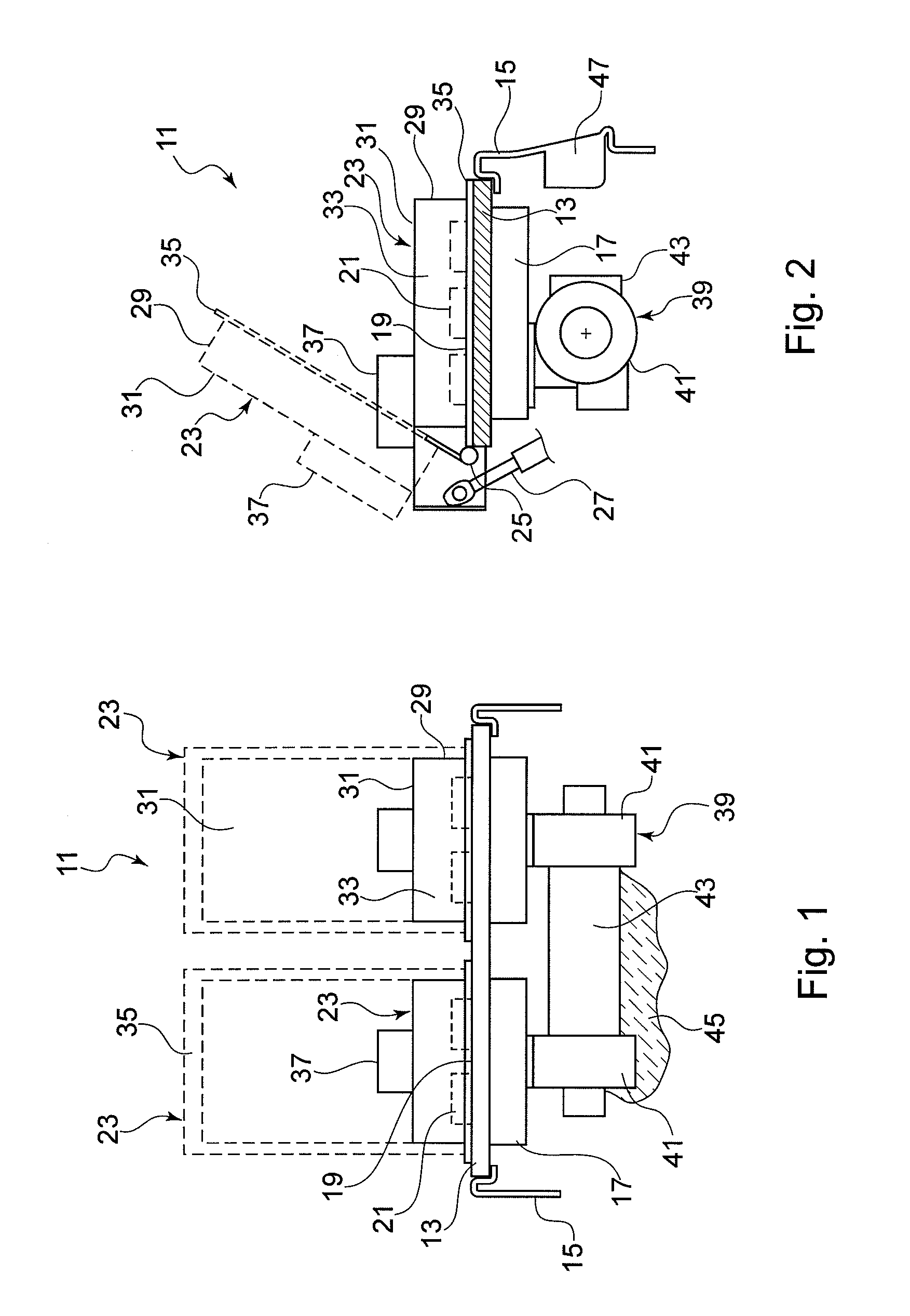

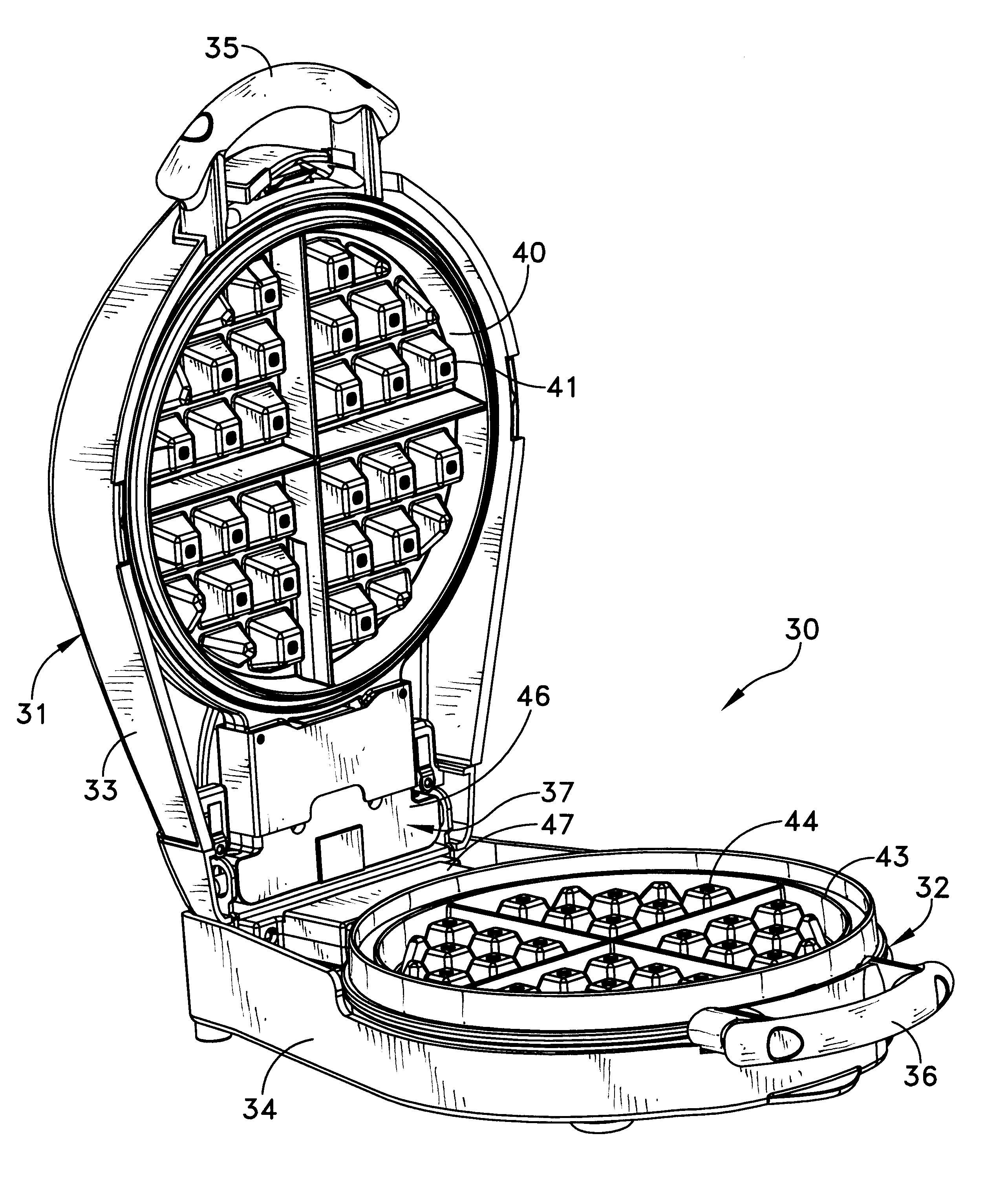

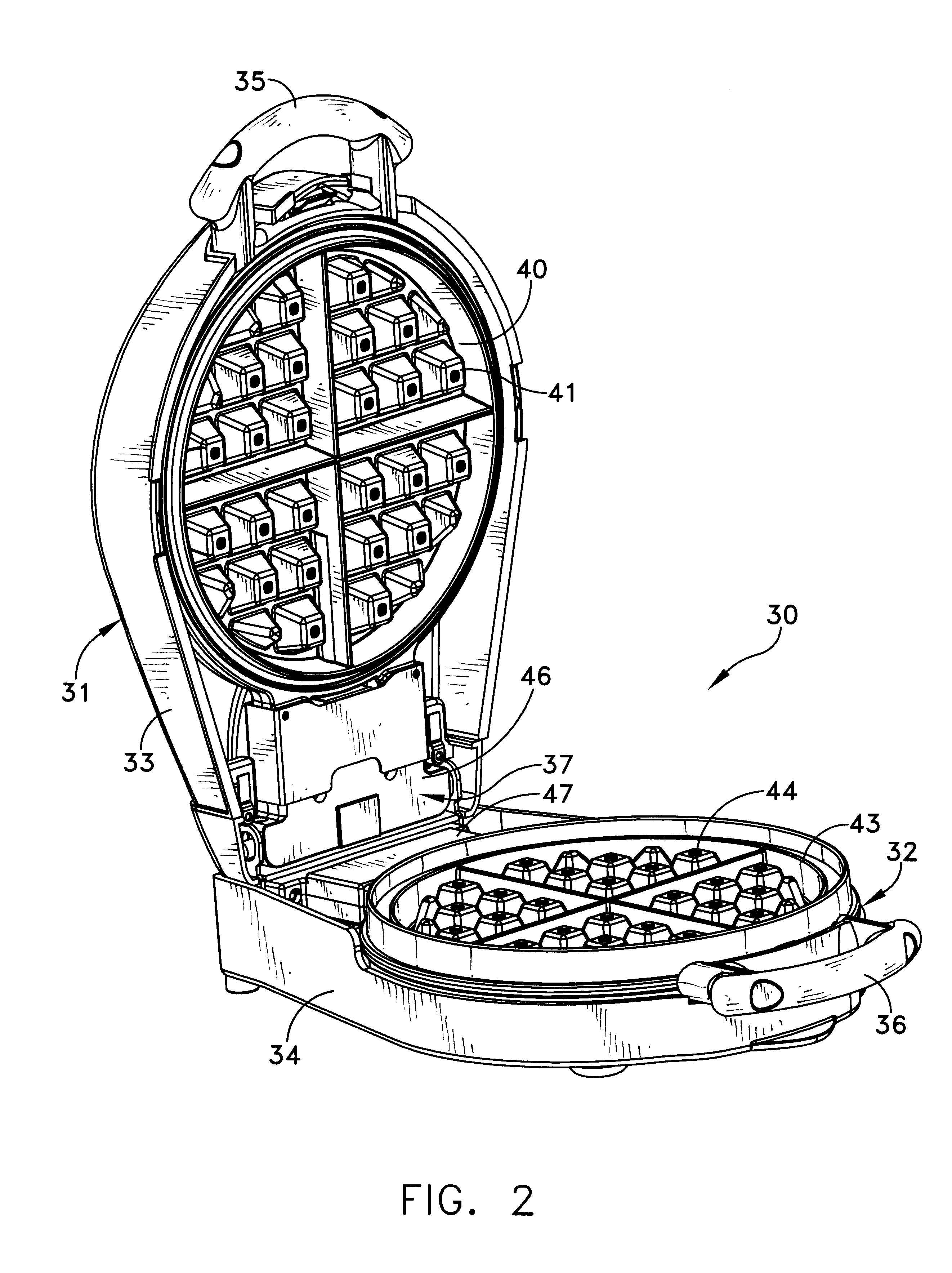

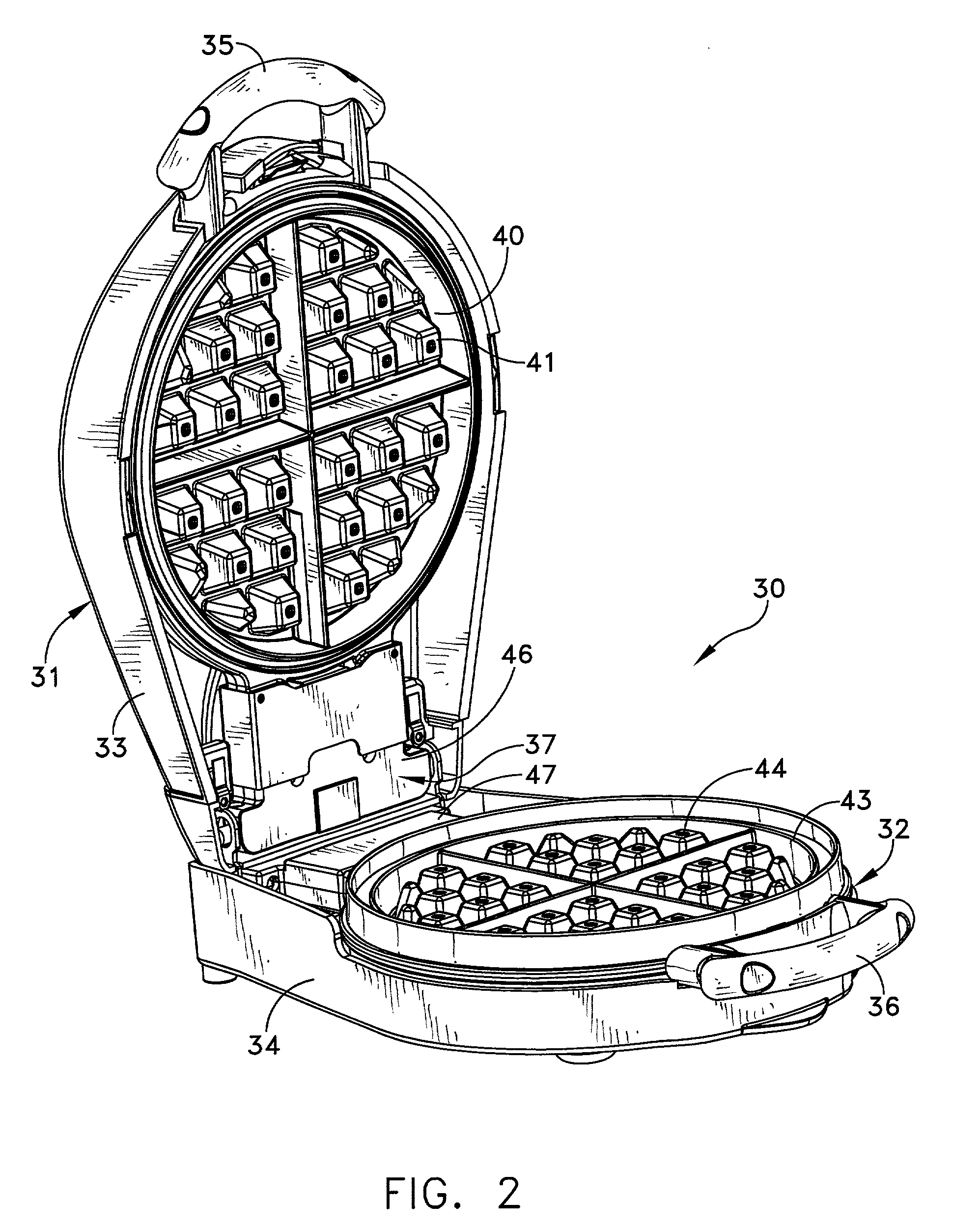

Electric cooking appliance with reversible cooking elements

InactiveUS6555795B2Easy to cleanHeater elementsHot plates heating arrangementsEngineeringInternal heating

An electric cooking appliance with reversible cooking elements. A base carries two pivoted contact boxes. Each contact box includes a support surface for receiving a cooking element including a sleeve for supporting the cooking element on the contact box. Each cooking element is molded with an integral, internal heating element and desired cooking surfaces. Reversal of cooking surfaces is accomplished by removing, flipping and reversing the cooking element with its internal heating element on its contact box.

Owner:APPLIANCE DEVMENT

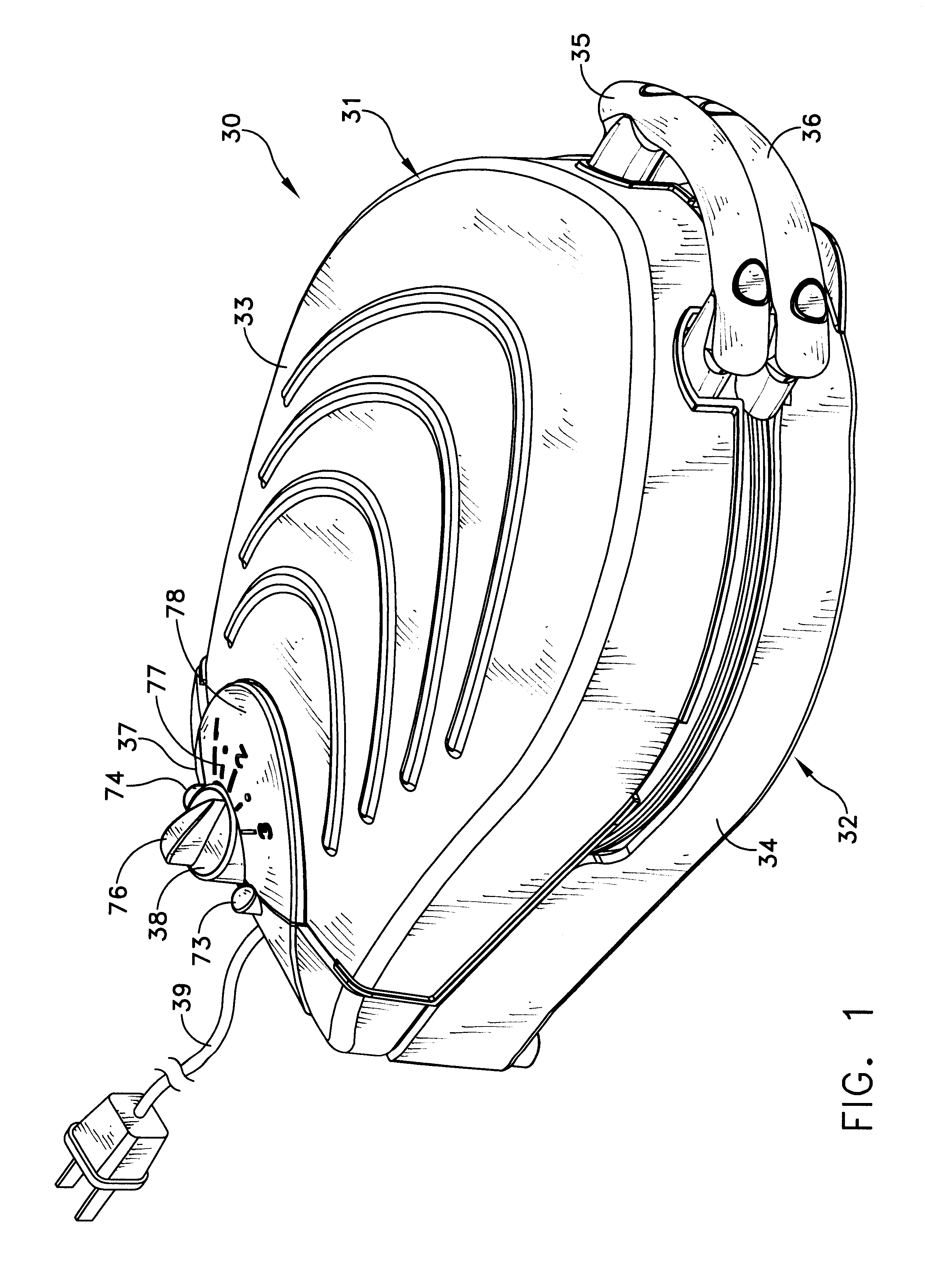

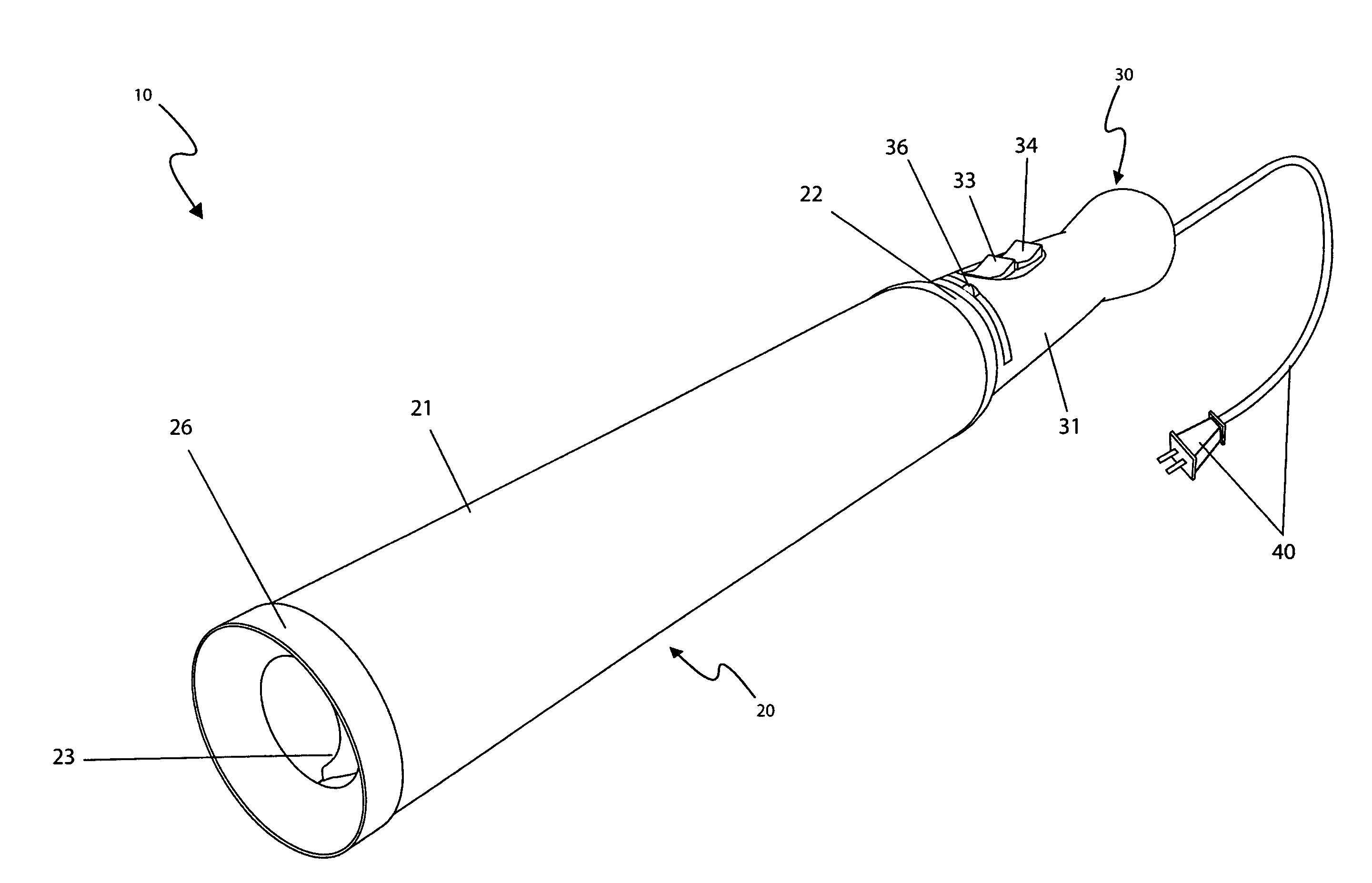

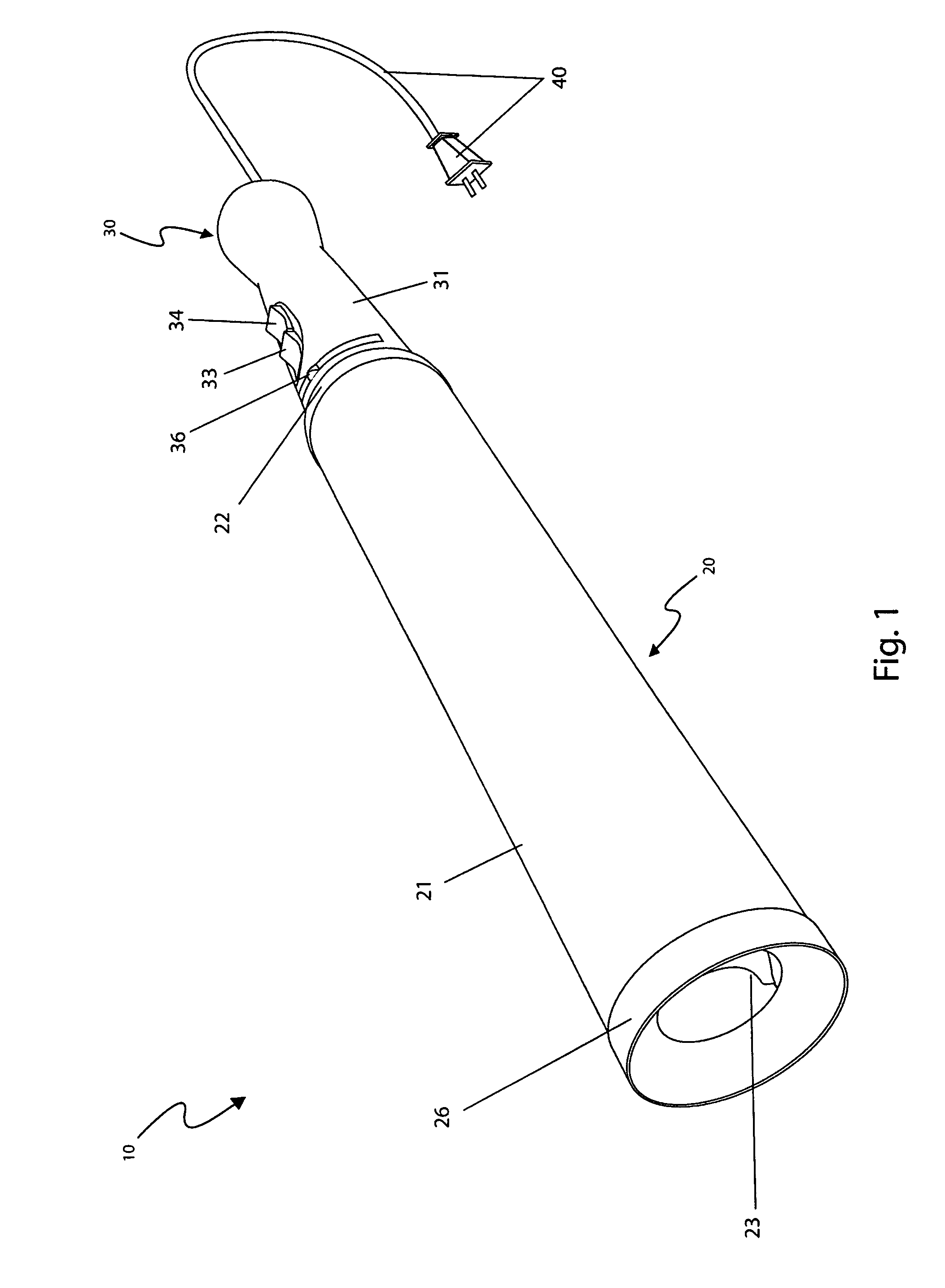

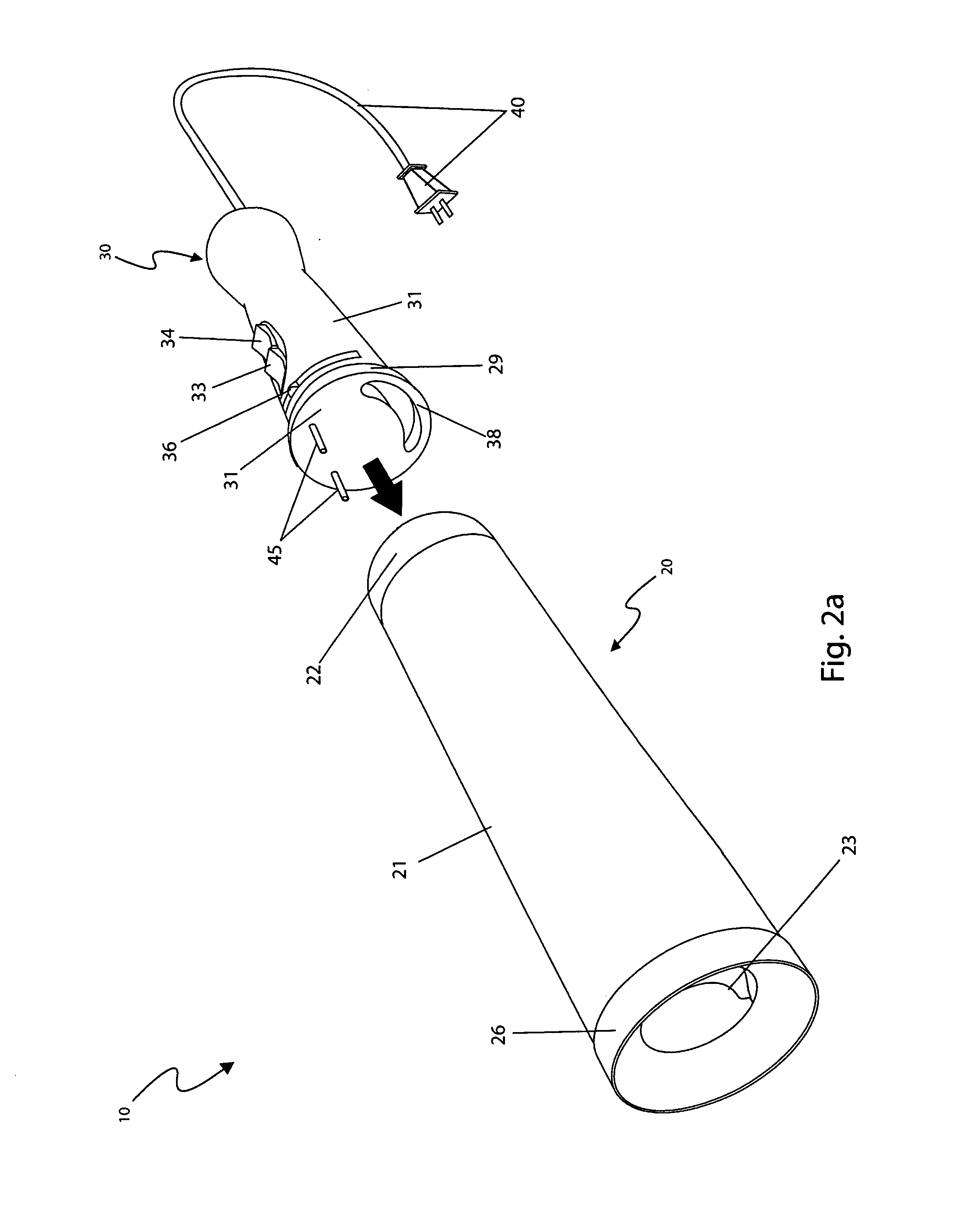

Spiral hair curling iron

InactiveUS8132571B1Reduce tanglingAvoid accumulationCurling-ironsCurling-tongsEngineeringInternal heating

A hair curling iron that forms spiral curls having an integral vacuum system and an internal heating tube is designed to eliminate the need for manual rotation of the entire curling iron when forming spiral hair curls. The curling iron provides a slot into which the hair is pulled by an integral vacuum fan mounted within the handle and controlled by an on / off pushbutton. When activated, the vacuum fan pulls the hair into the curling iron and around an interior heating tube. After several seconds, the pushbutton is released and a spiral curl is pulled out of the curling iron. A separate illuminating switch provides control of the heating portion of the curling iron. The danger of accidental burns is greatly reduced due to the interior location of the hot surfaces.

Owner:JACKSON MICHELE M

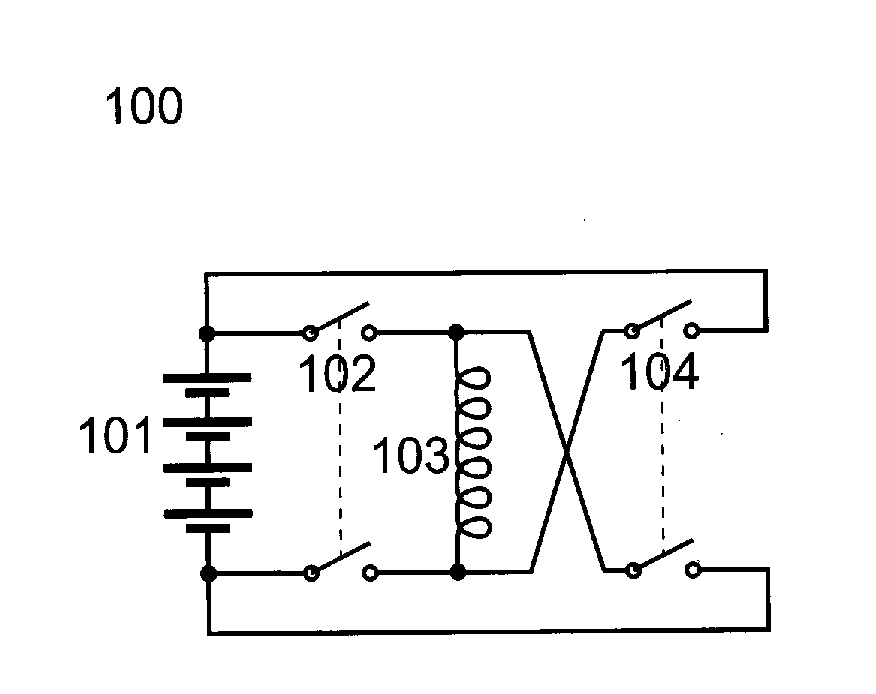

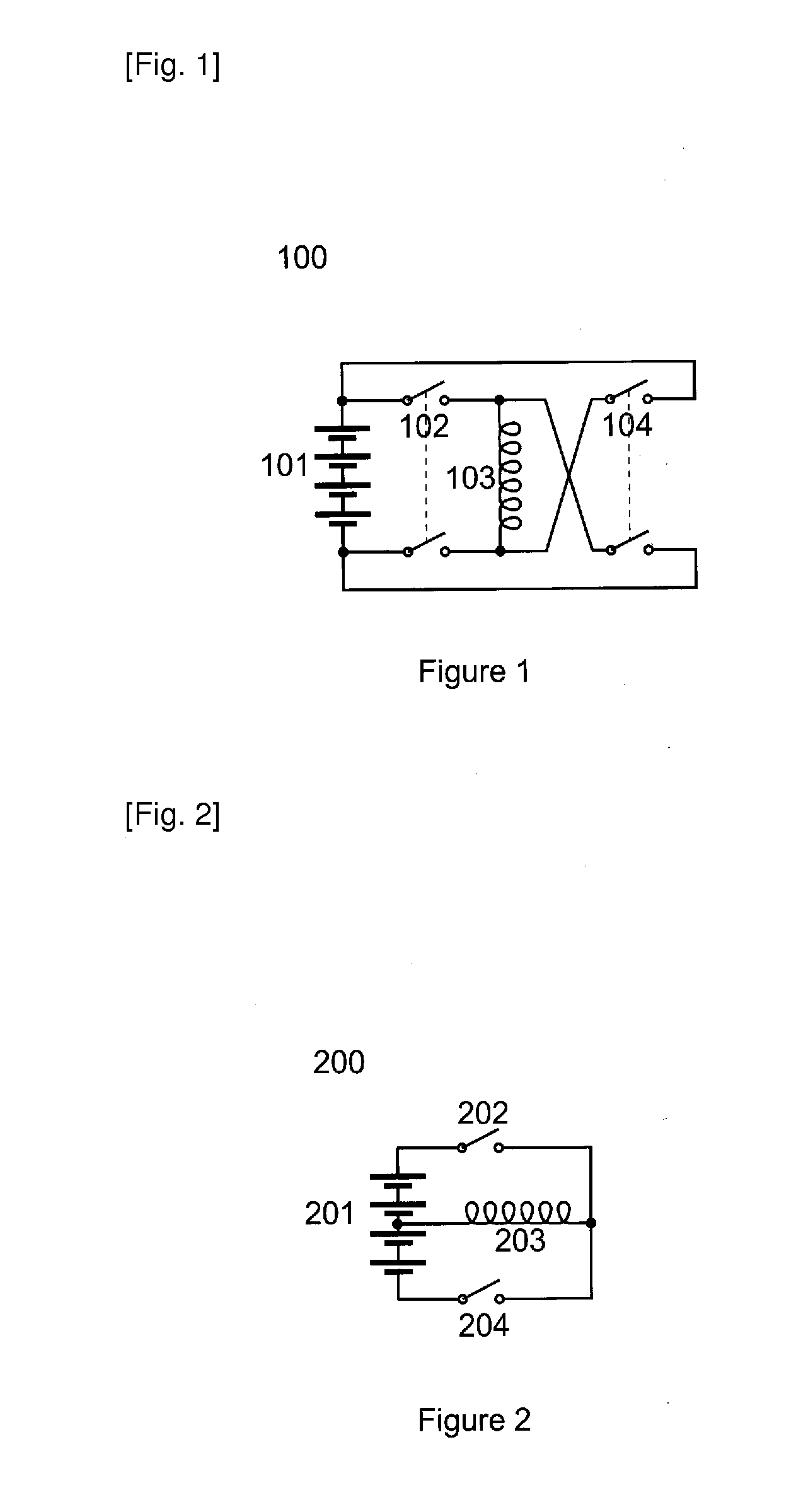

Self Heating Battery System

ActiveUS20120126753A1Supply will become excessiveHigh switching rateBatteries circuit arrangementsSecondary cellsCapacitanceCapacitive storage

A battery self heating system for batteries that experience battery impedance or internal battery resistance when temperature drops. The system comprises an energy storage element applied to the battery terminals to draw energy from the battery. The energy is stored in a magnetic or capacitive storage device. The system is self-resonant so that energy transfer from the storage device to the battery will occur at a frequency and load level that is compatible with the current state of the battery. Internal heating of the battery is accomplished by a cycle comprising the out flux and influx of energy through the impedance of the battery. Energy losses due to battery impedance are converted to heat thereby heating the battery internally.

Owner:STRYTEN ENERGY LLC

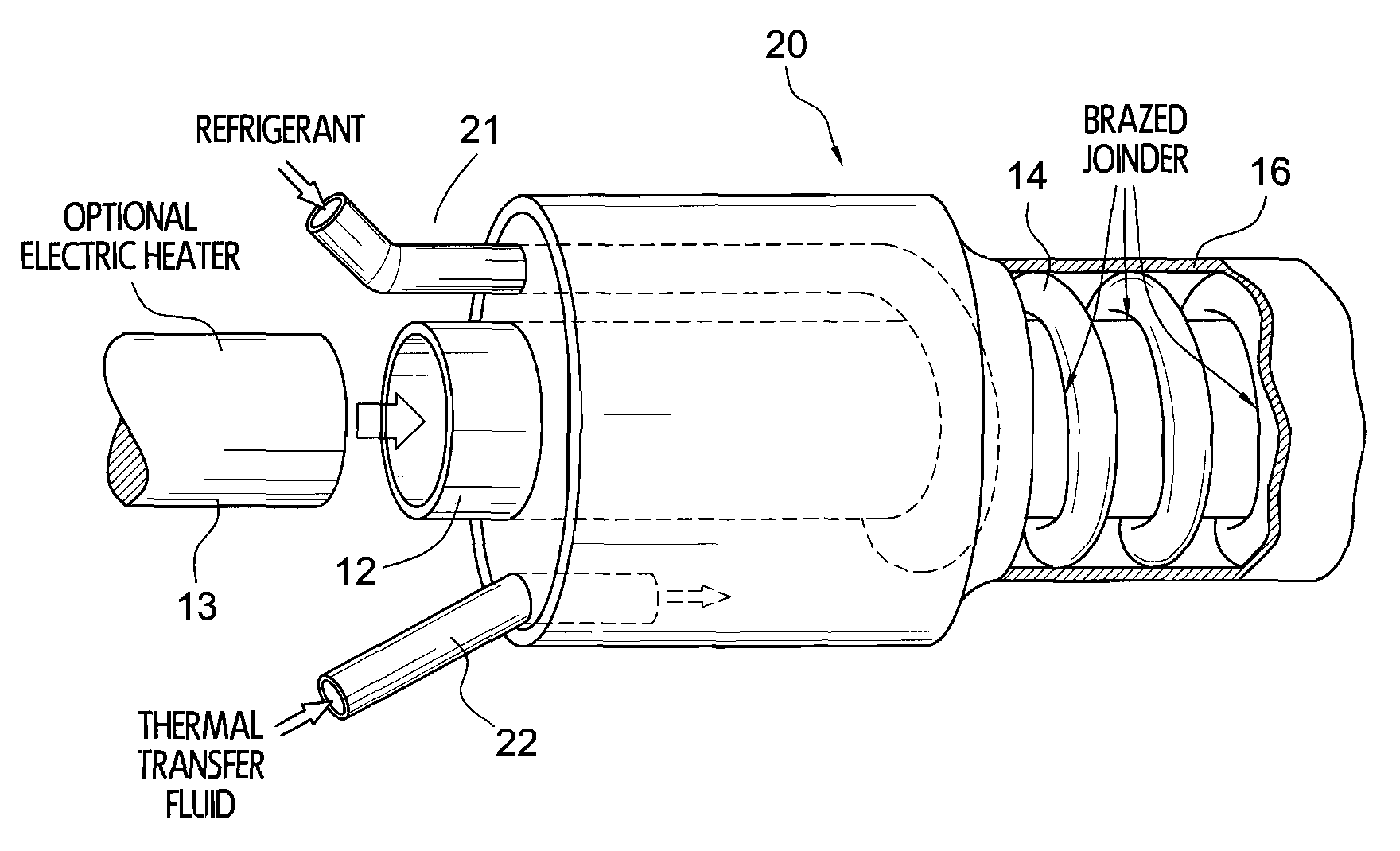

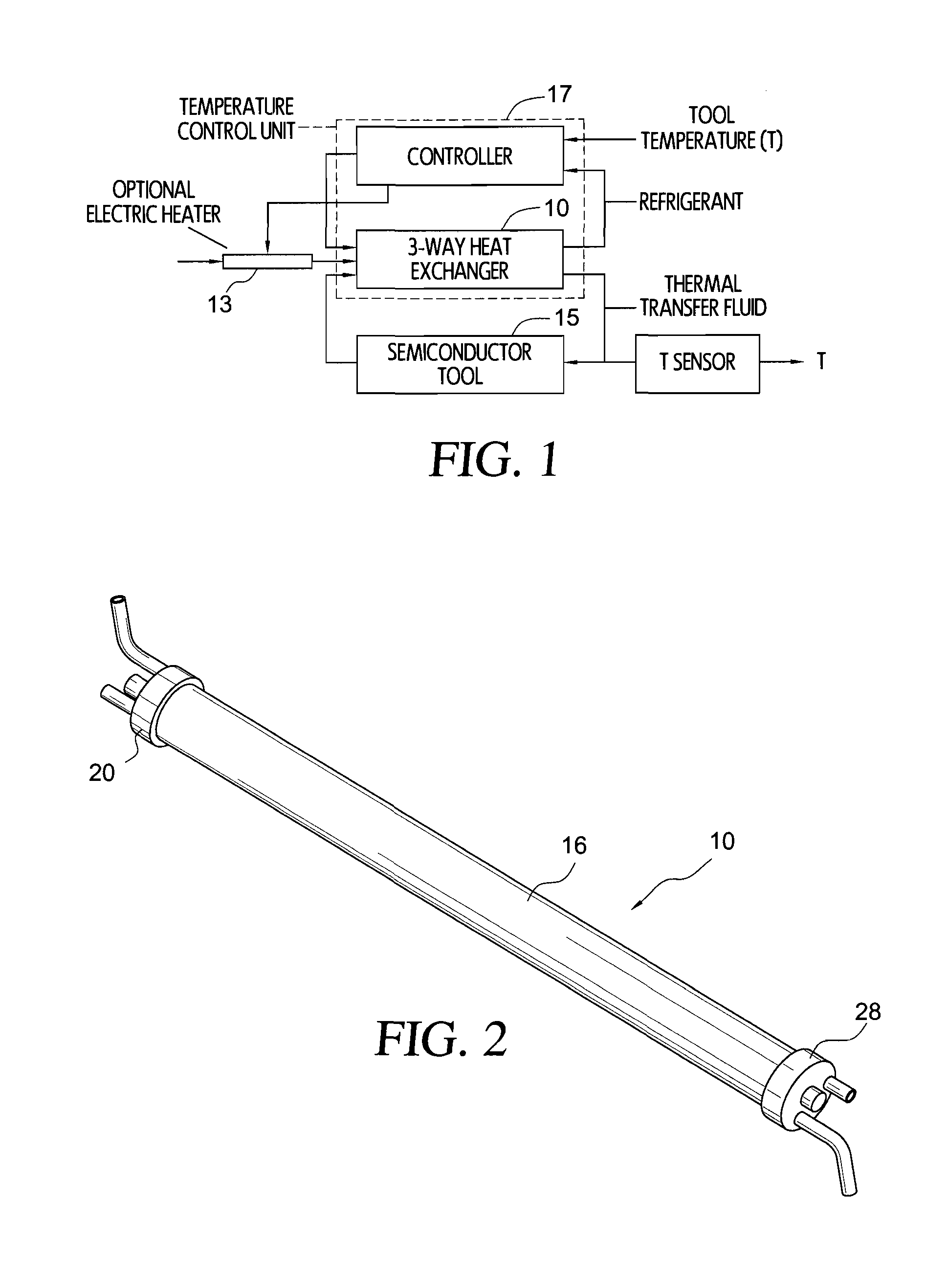

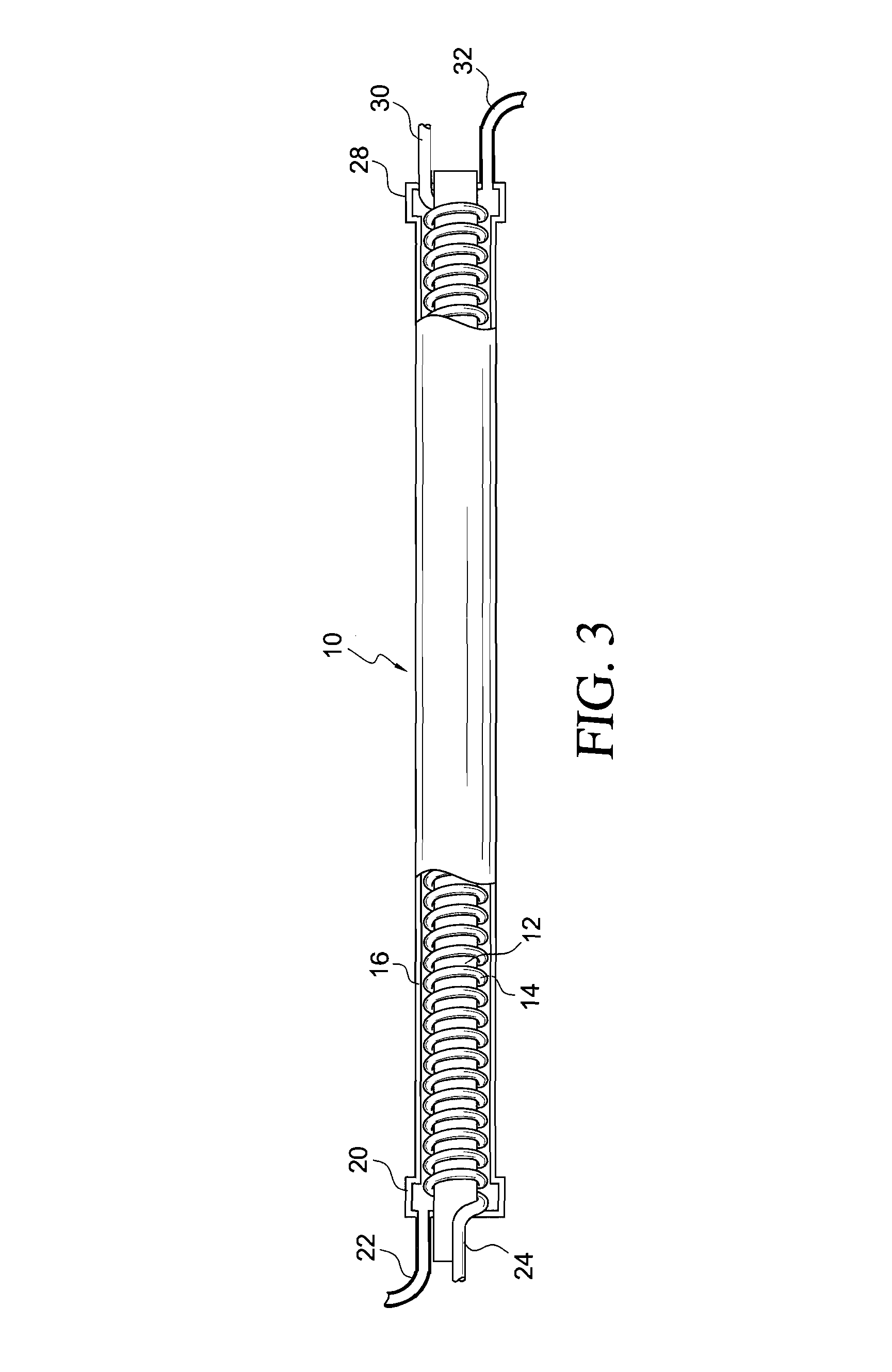

Heat exchangers for fluid media

ActiveUS7661460B1Increase temperatureReduce system costSemiconductor/solid-state device manufacturingCompression machines with several evaporatorsThermal energyCold formed

A compact heat exchanger for interchanging thermal energy between at least two fluids, one of which fluids may be a refrigerant in hot or cold form or in a liquid / vapor phase, and another of which fluids is a thermal transfer fluid. The heat exchanger may incorporate an internal heating element. The thermal transfer fluid is transported between two concentric metal tubes, while the refrigerant moves along a tubing helically wrapped about or between the tubes and is in thermal contact therewith.

Owner:BE AEROSPACE INCORPORATED

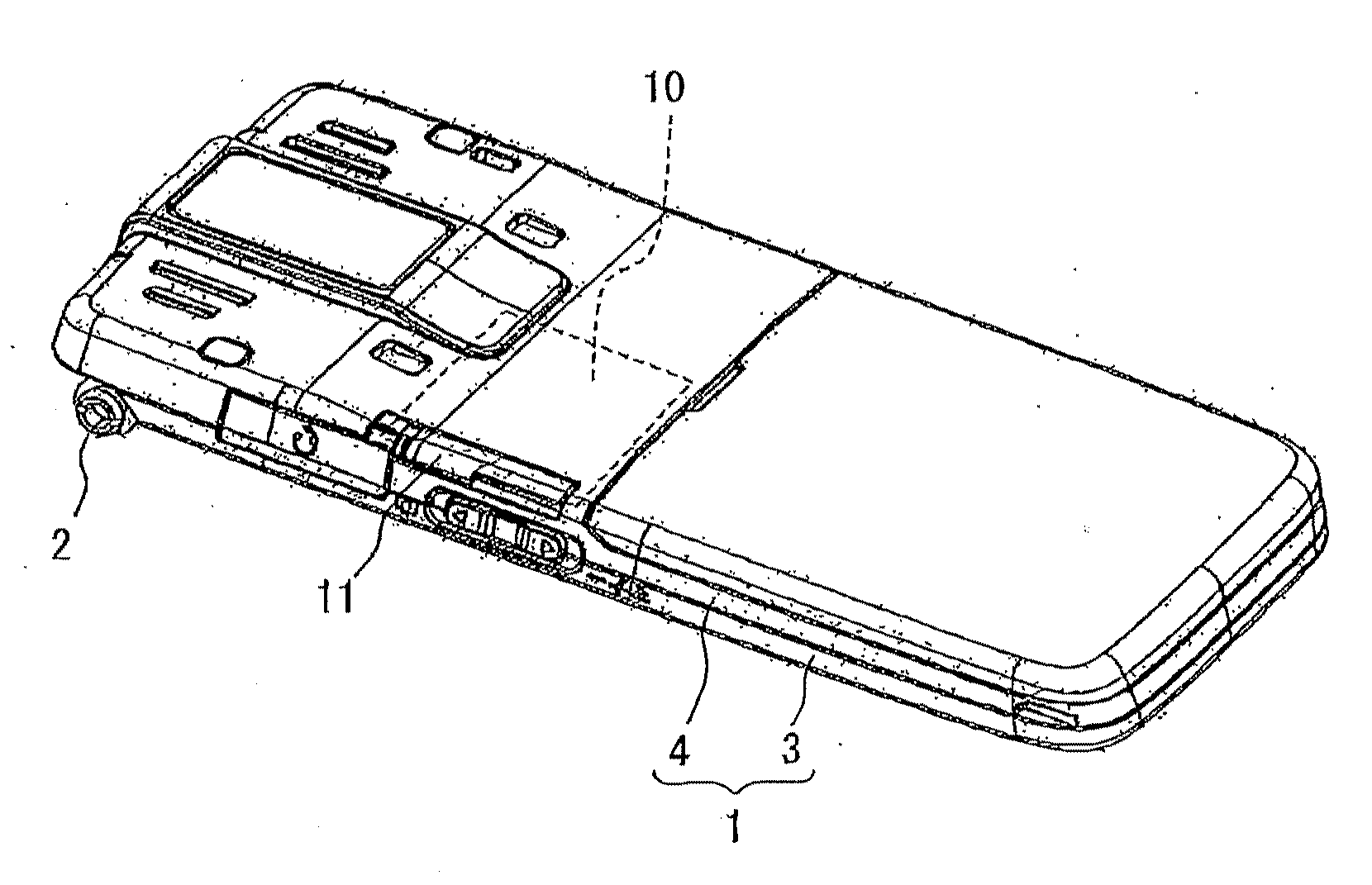

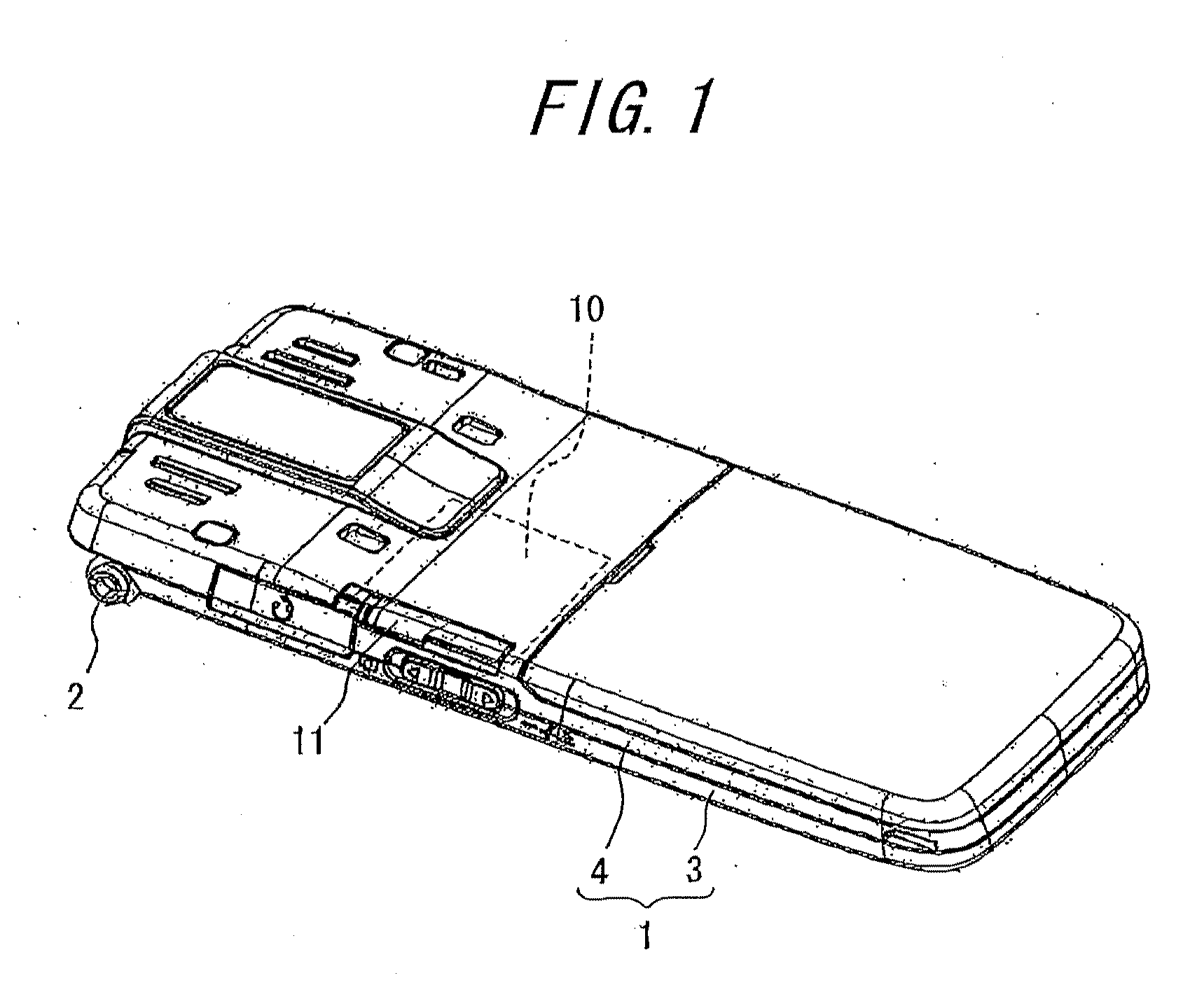

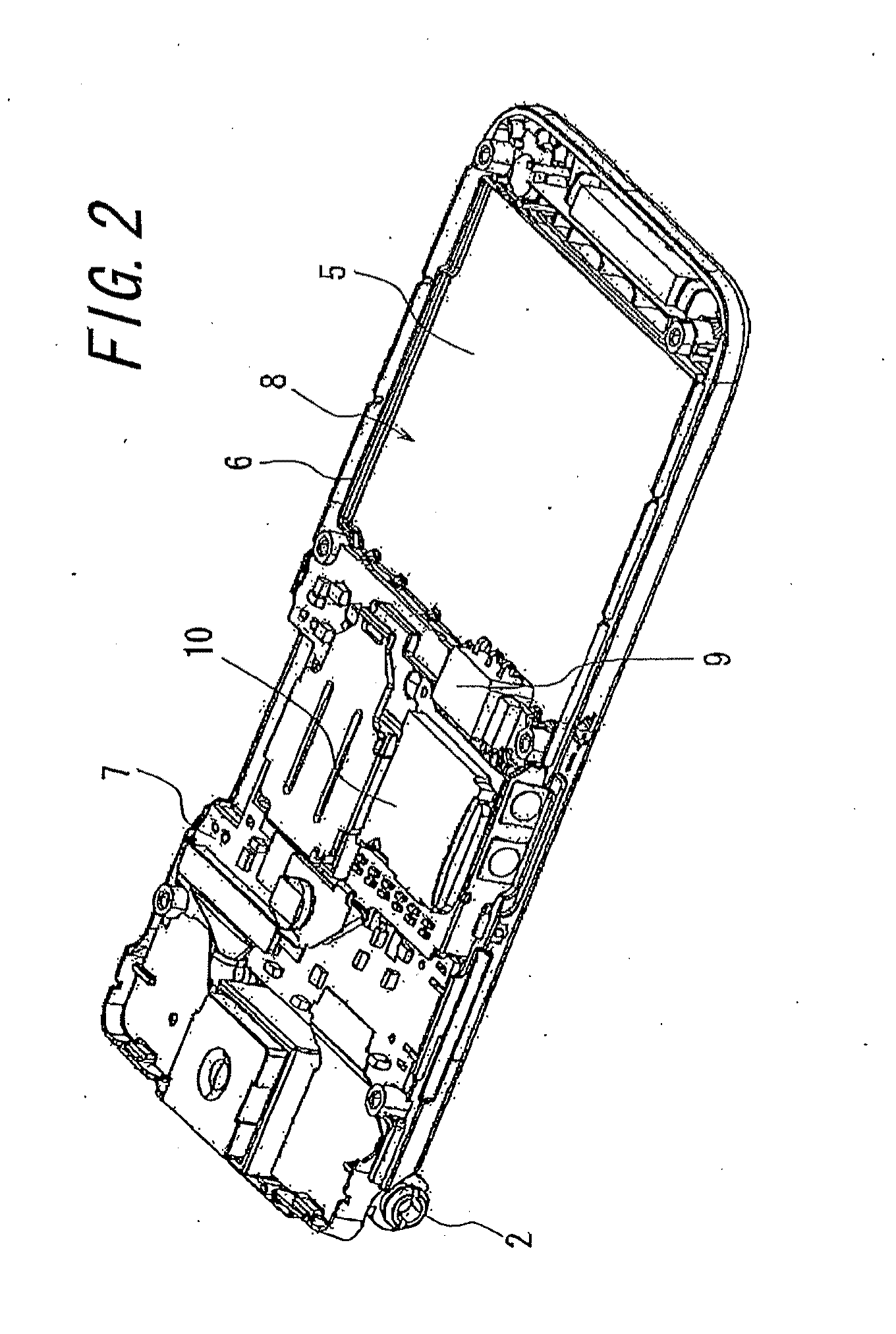

Portable electronic apparatus

ActiveUS20100072952A1Heat dissipation from the heating component can be ensuredEfficient transferBatteries circuit arrangementsSubstation equipmentMiniaturizationElectronic component

To provide a structure to dissipate heat from an internal heating component efficiently for a miniaturized, thin portable electronic apparatus. The portable electronic apparatus comprises a housing 1, a circuit board 7 accommodated in the housing and mounted with an electronic component on a surface on one side of the circuit board, a thermally conductive member 6 arranged opposite to the surface on one side of the circuit board and having thermal conductive property, and a battery accommodated in a battery chamber 8 formed in the housing. The thermally conductive member 6 forms at least a part of the battery chamber 8.

Owner:KYOCERA CORP

Electric cooking appliance with reversible cooking elements

InactiveUS20020153366A1Easy to cleanHeater elementsHot plates heating arrangementsEngineeringInternal heating

An electric cooking appliance with reversible cooking elements. A base carries two pivoted contact boxes. Each contact box includes a support surface for receiving a cooking element including a sleeve for supporting the cooking element on the contact box. Each cooking element is molded with an integral, internal heating element and desired cooking surfaces. Reversal of cooking surfaces is accomplished by removing, flipping and reversing the cooking element with its internal heating element on its contact box.

Owner:APPLIANCE DEVMENT

Life support and microclimate integrated system and process

InactiveUS20110184252A1Faster and improved recoveryPromote recoveryMedical devicesCatheterEngineeringLife support

The present invention of one embodiment includes a combined microclimate, thermal management, life-support system for care of patient and system for measurement of vital signs. The system of one embodiment, provides active external heating and simultaneously provides active internal heating.

Owner:CARLETON TECH

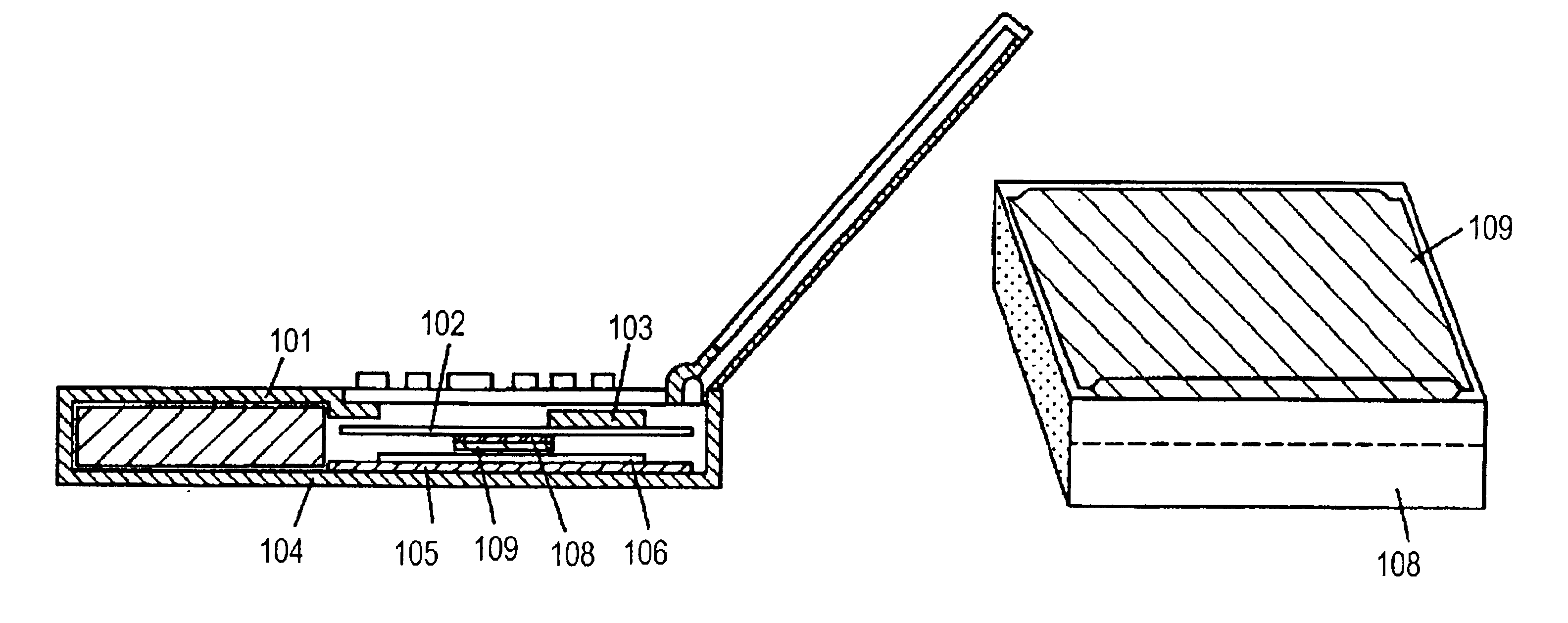

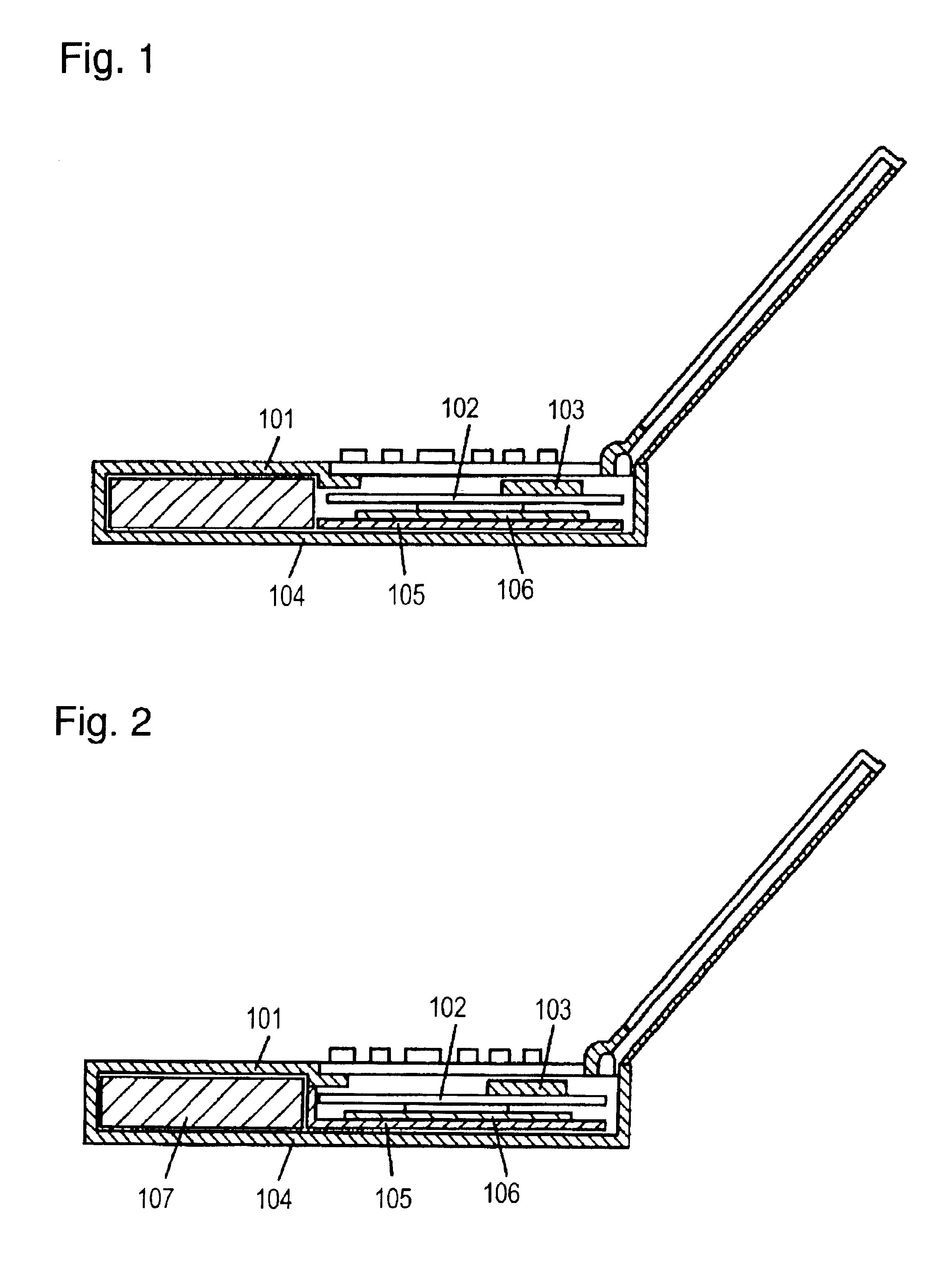

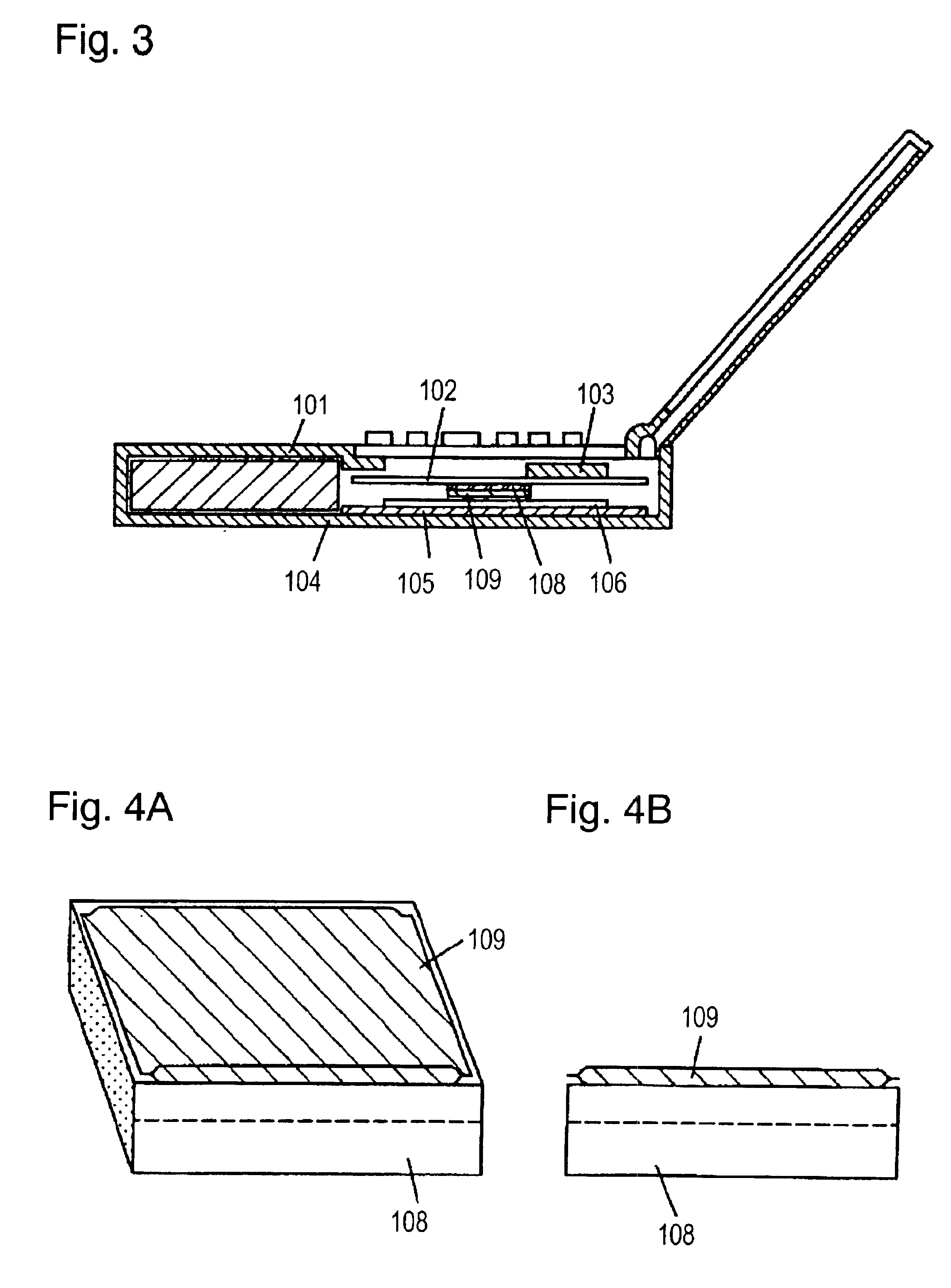

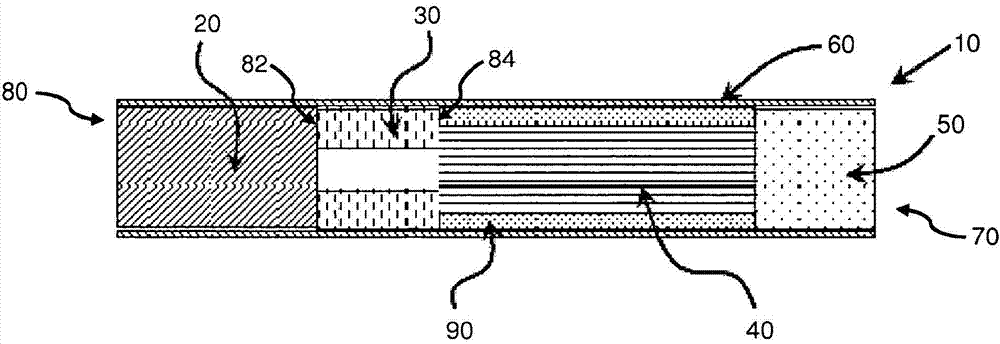

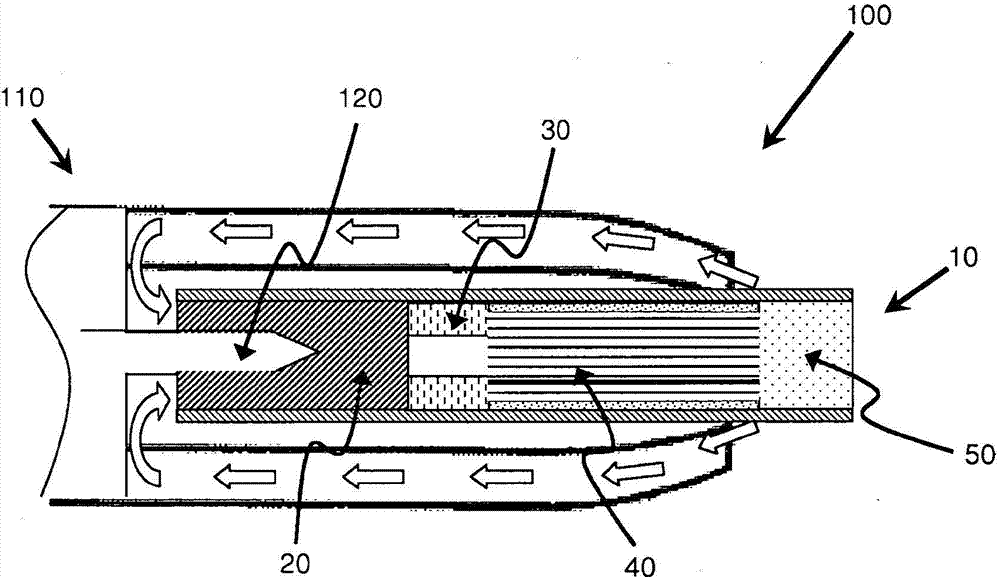

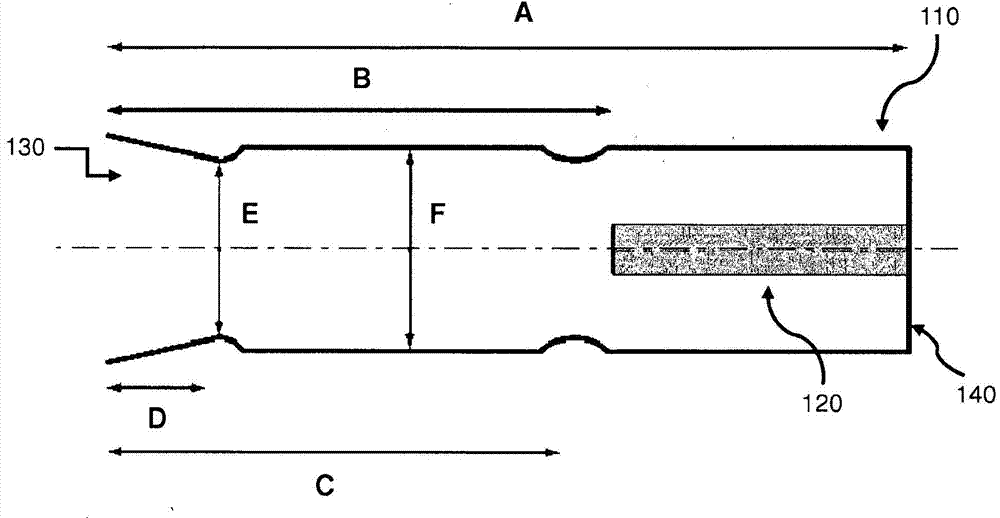

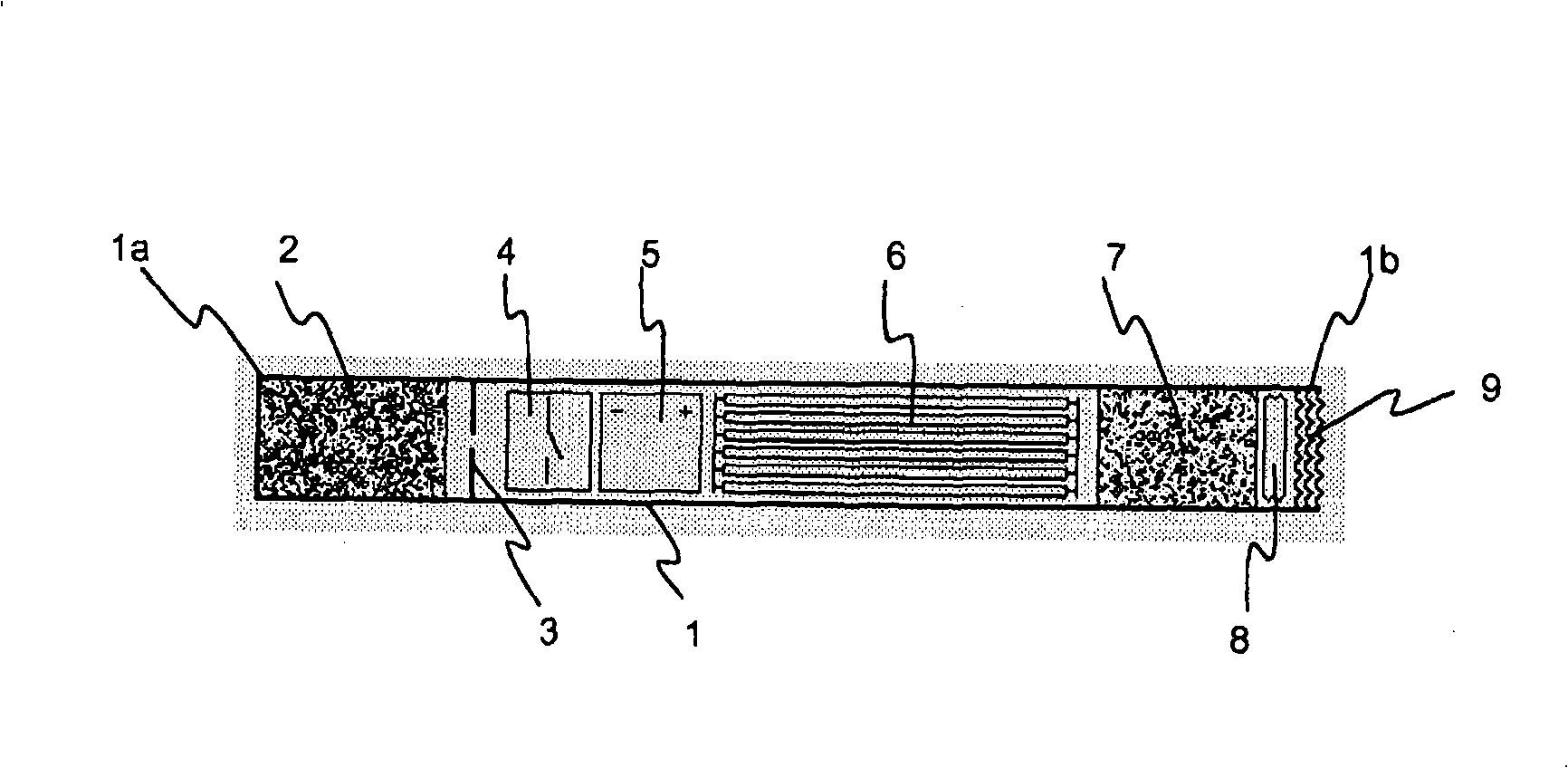

Smoking article for use with an internal heating element

A smoking article for use in an aerosol-generating device includes an aerosol-forming substrate located at an extreme upstream end of the smoking article; and a support element located immediately downstream of the aerosol-forming substrate. The support element abuts the aerosol-forming substrate and the aerosol-forming substrate is configured to be penetrable by a heating element of an aerosol-generating device having a diameter of between about 40 percent and about 70 percent of the diameter of the aerosol-forming substrate without substantial deformation of the smoking article. The support element is configured to resist downstream movement of the aerosol-forming substrate during insertion of the heating element of the aerosol-generating device into the aerosol-forming substrate.

Owner:PHILIP MORRIS PROD SA

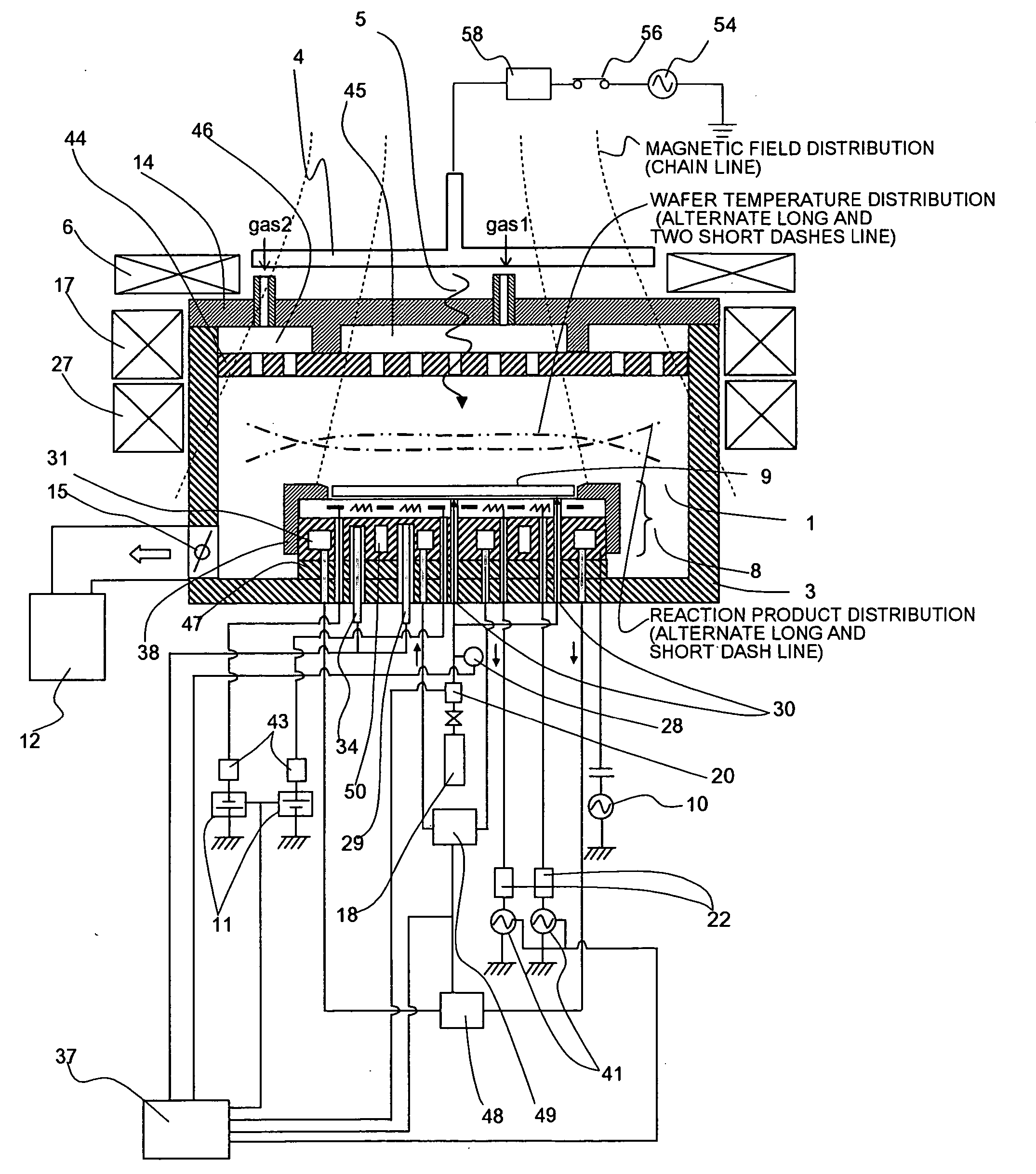

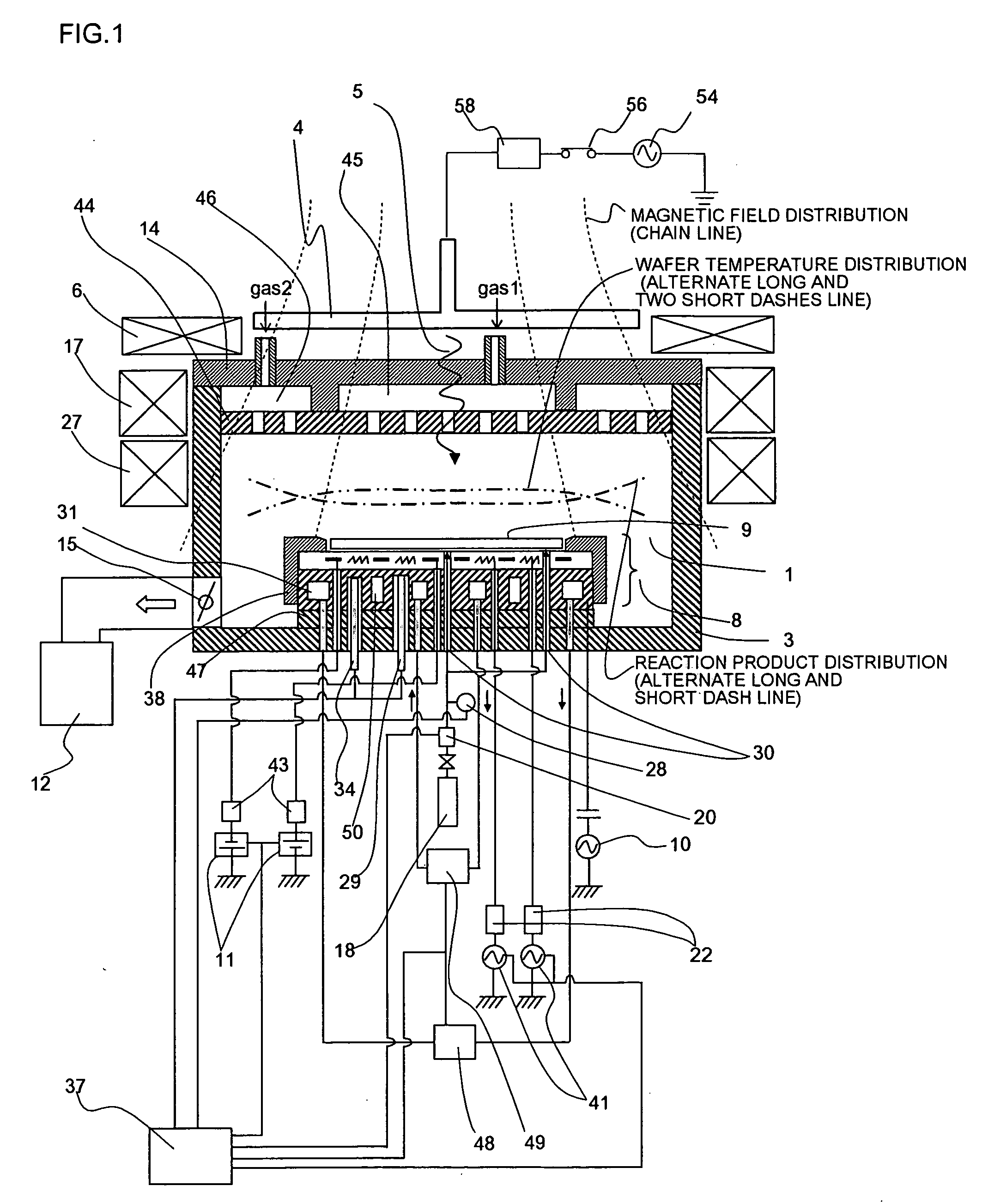

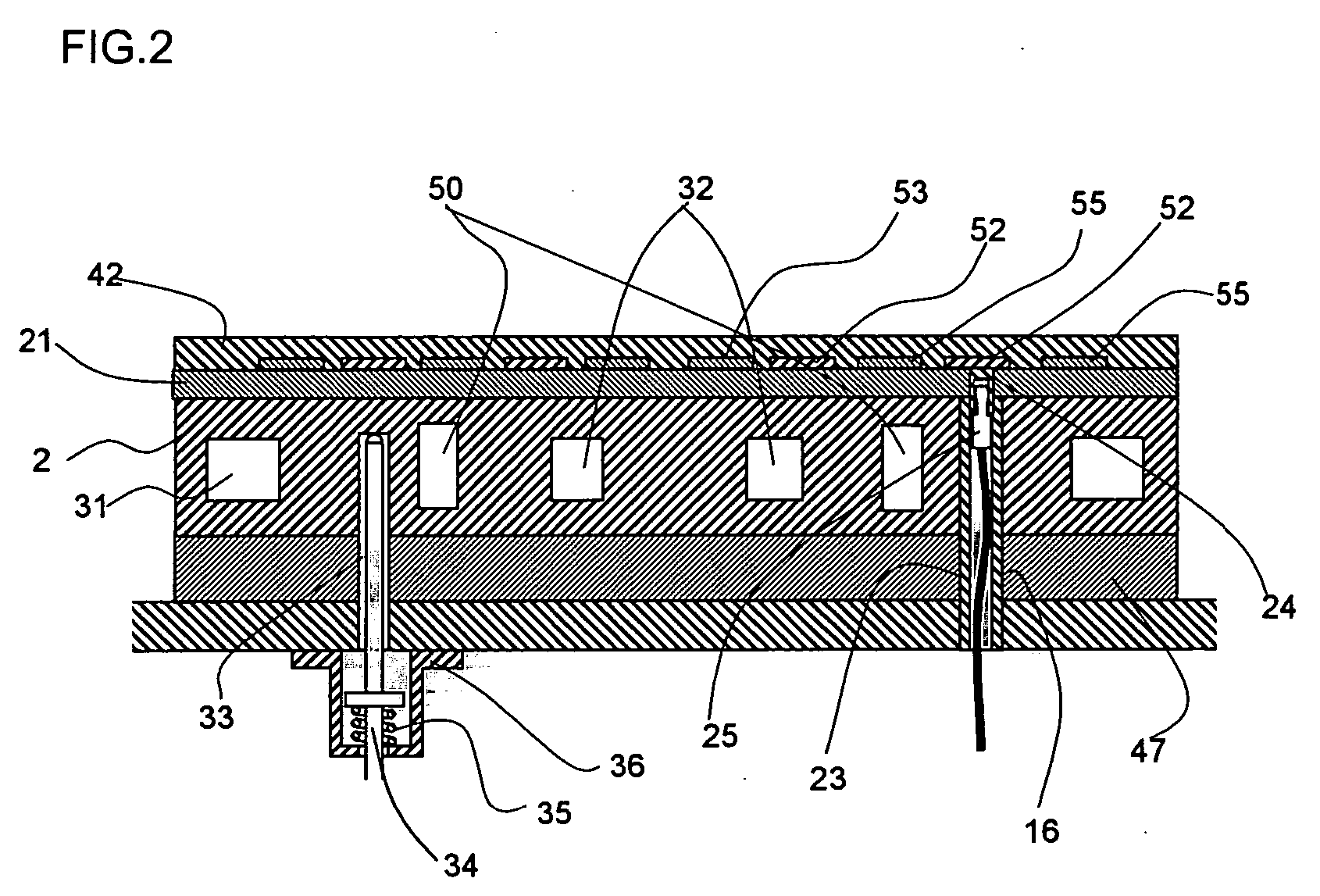

Electrostatic chuck, wafer processing apparatus and plasma processing method

InactiveUS20060291132A1Rapid responseLow costSemiconductor/solid-state device manufacturingHigh resistanceElectrical resistance and conductance

An electrostatic chuck which is built in a heater and can change, at a high speed, the temperature distribution of a wafer being processed by a plasma is provided at low cost. Also, there is provided a processing method which realizes uniform etching by suppressing CD variations in the plane of the wafer even when etching conditions change. The electrostatic chuck includes a base material in which multiple coolant grooves are formed, a high resistance layer which is formed on the base material, multiple heaters which are formed by thermally spraying conductors within the high resistance layer, multiple electrostatic chuck electrodes which are formed similarly by thermally spraying conductors within the high resistance layer, and temperature measuring means, and adjusts outputs of the heaters on the basis of temperature information of the temperature measuring means.

Owner:HITACHI HIGH-TECH CORP

Regulating method of center heating system in urban area

ActiveCN103363585AGuarantee "Dynamic Balance"Ensure dynamic balanceLighting and heating apparatusSpace heating and ventilation detailsThermal energyUrban area

The invention relates to a regulating method of a center heating system in an urban area. The method includes the steps: (1) fitting an outdoor temperature with a regression curve of a heating index, and correcting the regression curve according to practical heating situations, (2) by predicting and calculating heat load needed by a whole heat-supply network, providing guidance for a heat source, (3) calculating and setting a secondary water supply / return temperature according to a primary water supply / return temperature of heat supply output, heat-supply network averaging control is carried out on heat exchange stations according to different distances between the heat exchange stations and the heat source, and avoiding the phenomenon that users at the near end are warm and users at the far end are cold, and (4) regulating the secondary water supply / return temperature in real time by controlling the regulating range of a valve. Therefore, heat supply quality is improved, energy consumption is saved, heat energy waste is reduced, the whole system can achieve the aim of supplying heat according to needs, and the fact that the heat supply effect of users is uniform is guaranteed.

Owner:TIANJIN HAITIAN FANGYUAN ENERGY SAVING TECHCO

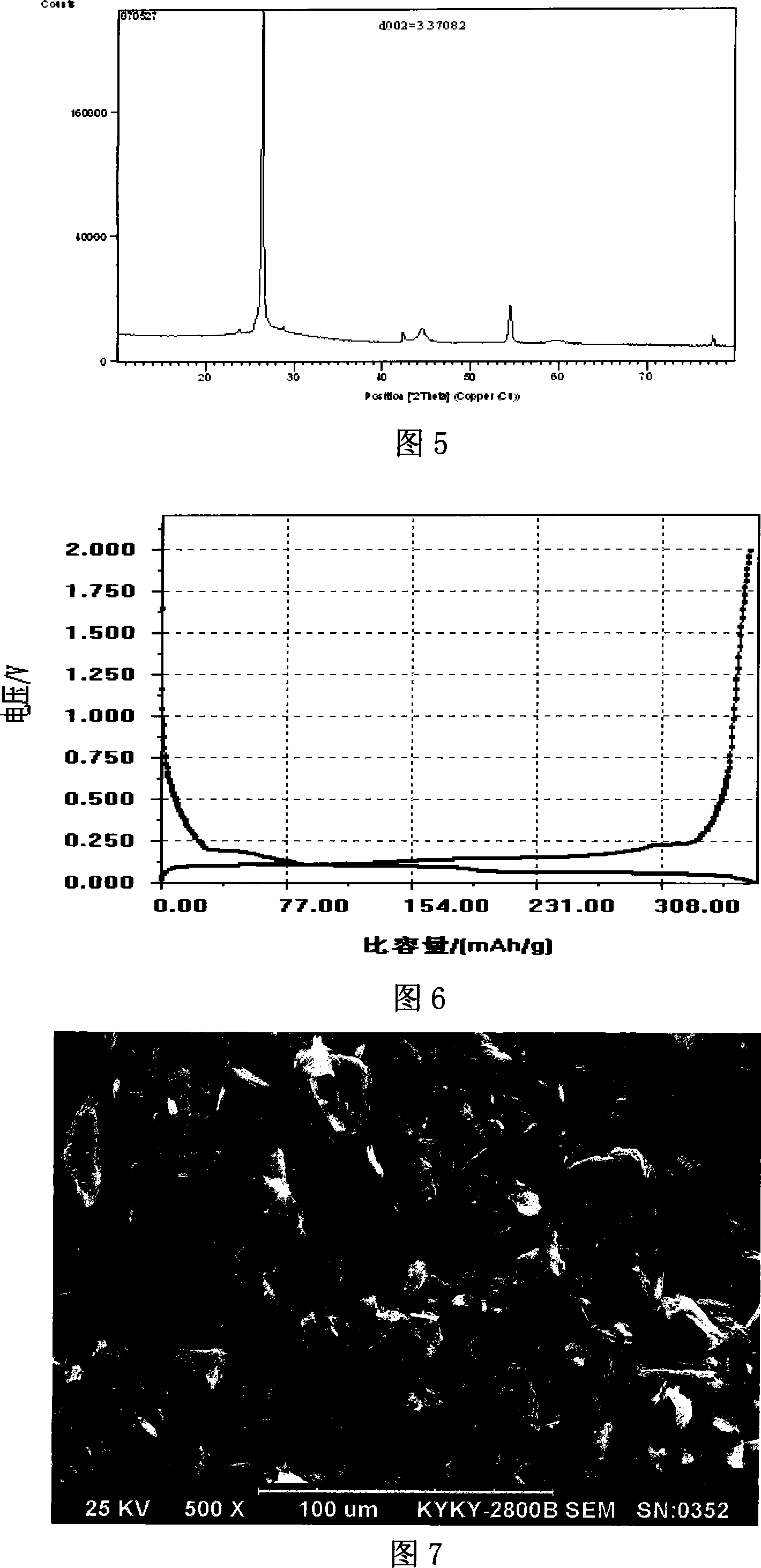

Composite graphite negative electrode material for lithium ion secondary cell and its preparation method

ActiveCN1702892AImprove discharge capacityPromote circulationElectrode manufacturing processesSecondary cellsState of artLithium

This invention discloses one lithium ion second battery compound negative materials and its process method, wherein, the materials comprise modified natural graphite and artificial graphite with quality proportion of 30í†70í½80í†20 and the process method comprises the following steps: a, the natural graphite surface is covered with organism; b, making the thermal process in temperature range of 800íµí½1500íµ for one to six hours; c, mixing the natural graphite with the artificial graphite as proportion of 30í†70í½80í†20.

Owner:BTR NEW MATERIAL GRP CO LTD

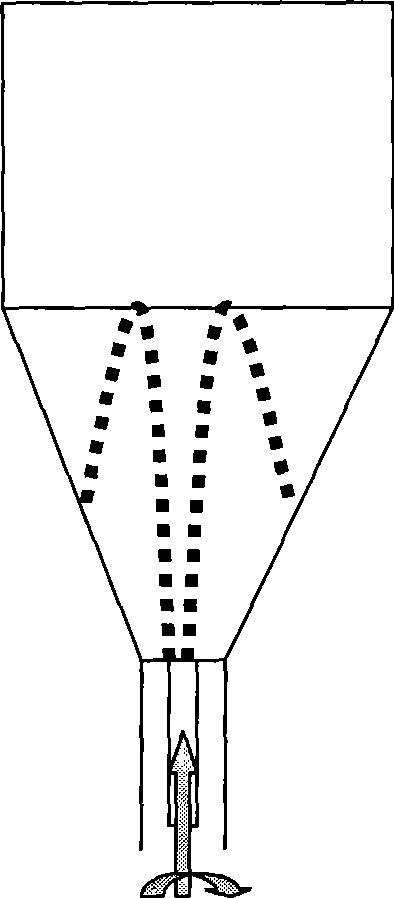

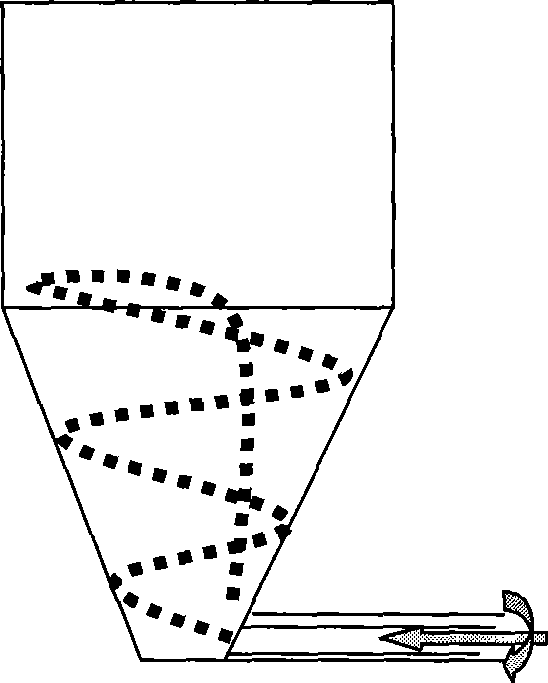

Sprouted auxiliary means for improving microwave desiccation homogeneity of granular garden stuff

InactiveCN101433233ASpray evenlyImprove uniformityFruits/vegetable preservation by dehydrationFood treatmentAir volumeAgricultural engineering

The invention discloses an auxiliary spouting method for improving the uniformity of microwave drying of granular fruits and vegetables, which belongs to the technical field of the processing of fruit and vegetable food. Pretreated fruits and vegetables are placed into a microwave spouting drying bed, the microwave power and the air intake heating temperature are preset, then the central air intake volume and the air intake angle of the spouting bed are adjusted to ensure that a dried material spouts in the spouting bed in different forms, the air intake pressure and the air intake angle are adjusted according to different drying stages of the material at the same time, and the microwave energy received by the material is more uniform than that of the prior fixation or fluidization mode; and the microwave adopts internal heating, so the moisture of the dried fruits and vegetables is effectively and quickly evaporated to achieve the aim of uniform drying. Through the auxiliary spouting method, the material is uniformly heated in a microwave field, the moisture is evaporated quickly, the drying time is greatly shortened, the prior color and luster, shape and nutrient substances of the dried fruits and vegetables can be furthest retained, and the dried fruits and vegetables have porous structures and good rehydration property, thereby obtaining a high-quality dehydrated fruit and vegetable product.

Owner:JIANGNAN UNIV +1

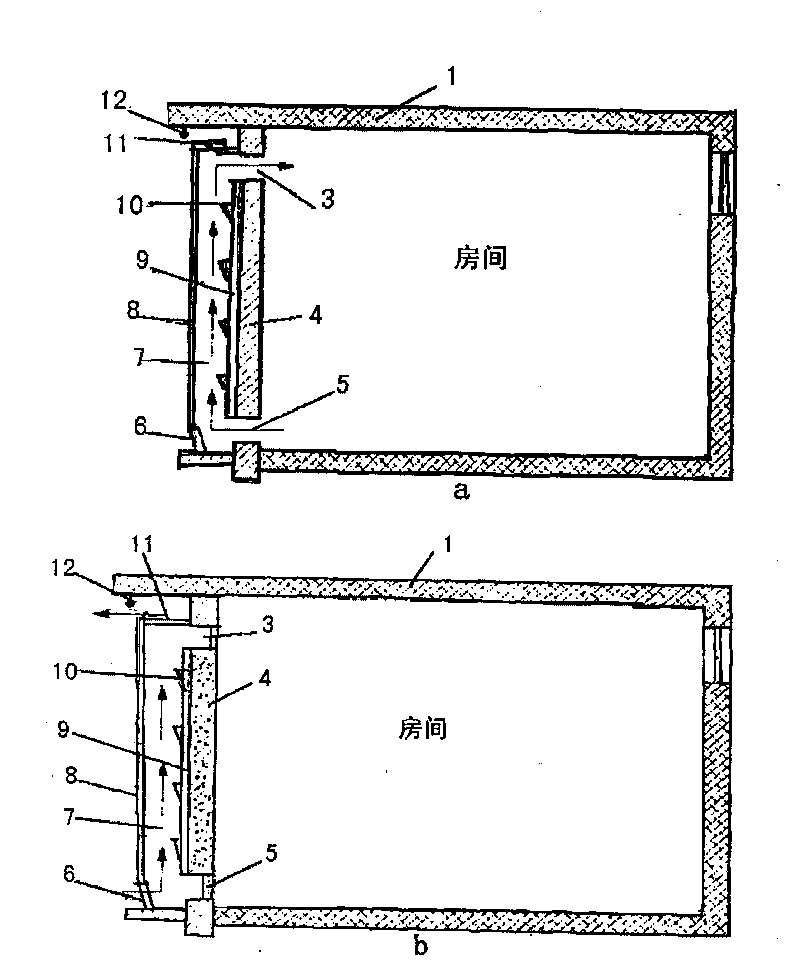

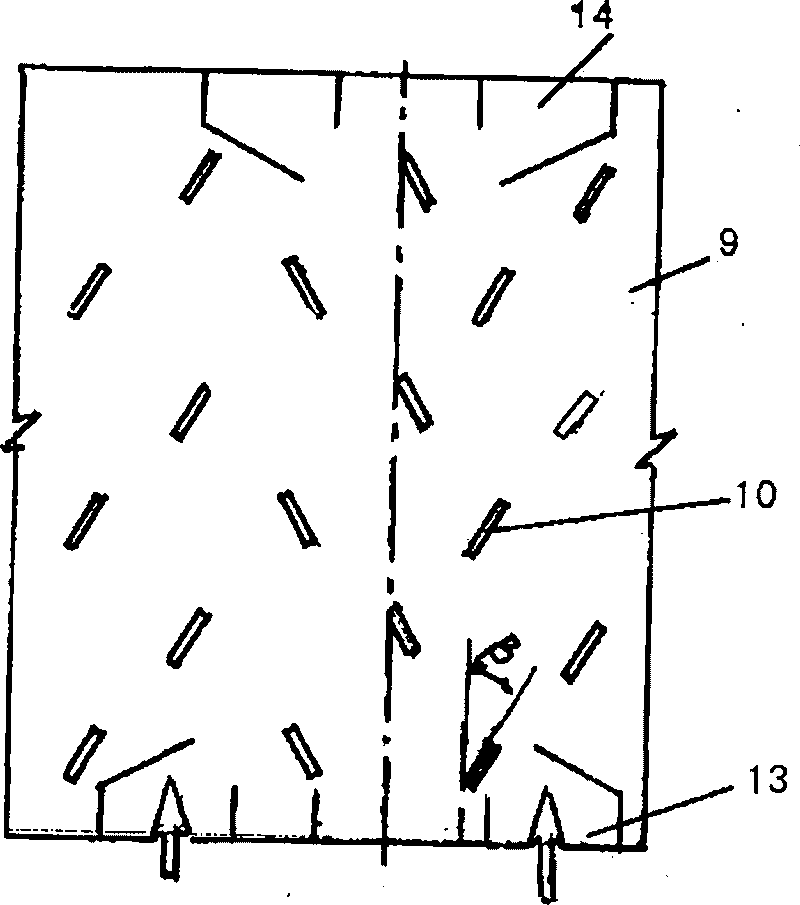

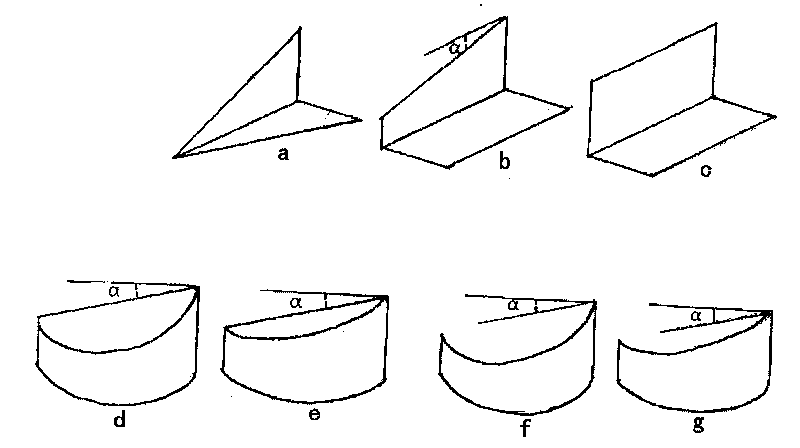

High-efficiency solar phase-change heat-accumulation heat-collection wall system

InactiveCN101761150AImprove performanceIncrease profitSolar heating energyWallsEngineeringPhase change

The invention discloses a high-efficiency solar phase-change heat-accumulation heat-collection wall system, which belongs to the technical field of a heat-accumulation heat-collection building utilizing solar energy. A phase-change material plate is attached to the surface of the wall body of a building in a passage of the solar heat-collection heat-accumulation wall, various vortex generators are arranged at the surface of the phase-change material plate at a certain attack angle of incident flow by an array mode, and vortex is induced to thin and destroy a boundary layer clinging to the wall surface or increase the turbulence intensity so as to reinforce the heat exchange of air at the surface and the phase-change material plate and enhance the heat-accumulation / heat-release rate of the phase-change material, thereby enhancing the efficacy of the solar phase-change heat-accumulation heat-collection wall system. Openings at the top end and the bottom of the passage are respectively communicated with a room of the building and an outdoor space, different operation strategies are respectively adopted in winter and summer, and heat is supplied to an indoor space in winter; and hot air in the passage is exhausted in summer, and the comfort level of the indoor space is enhanced. The solar heat-collection heat-accumulation wall has the characteristics of simple manufacture and convenient installation and has extensive application prospect and popularization value in a solar building.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

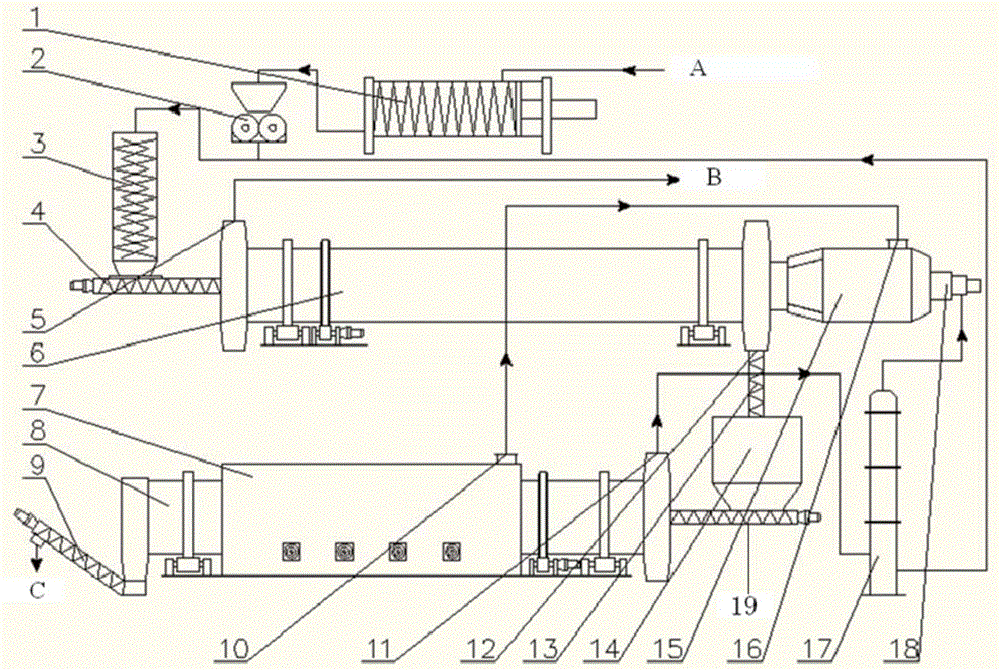

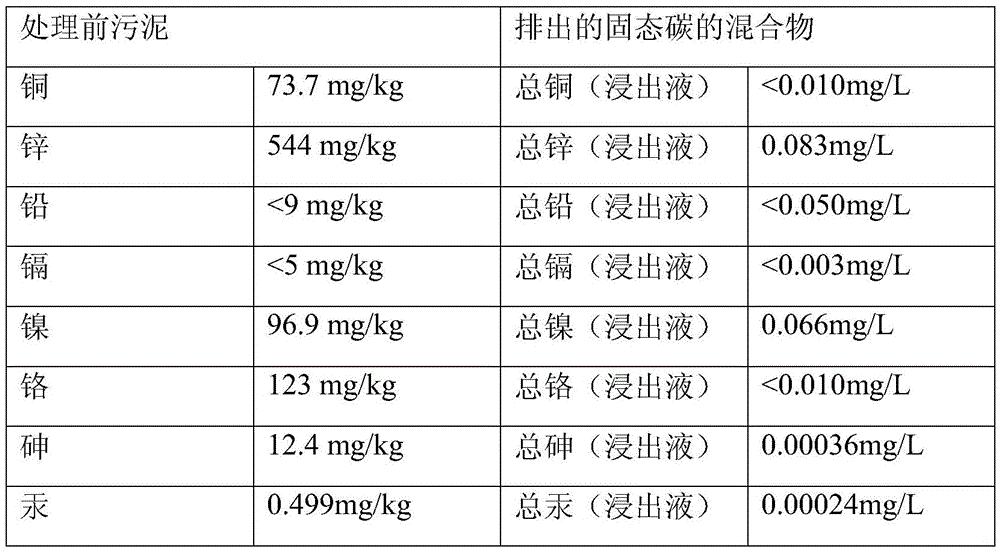

Sludge pyrolysis carbonization technique and device

ActiveCN105601075AStable stateSimple production processSludge treatment by de-watering/drying/thickeningSpecific water treatment objectivesSolid carbonWater vapor

The invention discloses a sludge pyrolysis carbonization technique and device. The technique comprises the following steps: sludge is pressed by a press, pulverized by a pulverizer, mixed by a mixer, dried in an internal heating rotary kiln drying machine, sent into a storage bin, and sent into a pyrolysis carbonization furnace; the sludge is subjected to pyrolysis carbonization in the pyrolysis carbonization furnace; the product solid carbon mixture is sent out of the system, and the products vapor and pyrolytic gas enter a separation purification tower to be separated and purified; the purified combustible gas is sent into a combustor and combusted into an internal heating rotary kiln drying machine delivery heat source, and the purified heavy components are sent into the mixture and mixed with the sludge to perform secondary pyrolysis; the flue gas generated by the heating furnace is discharged into a hot-blast furnace to perform secondary ablation; and the exhaust generated by the whole device is discharged by an outlet I of the internal heating rotary kiln drying machine, and is treated and discharged after reaching the standard. The device has the advantages of simple production technique, stable product state and no secondary pollution, and implements the reduction, harmless treatment and recycling of sludge treatment.

Owner:刘晓静

Toaster oven

Owner:CONAIR CORP

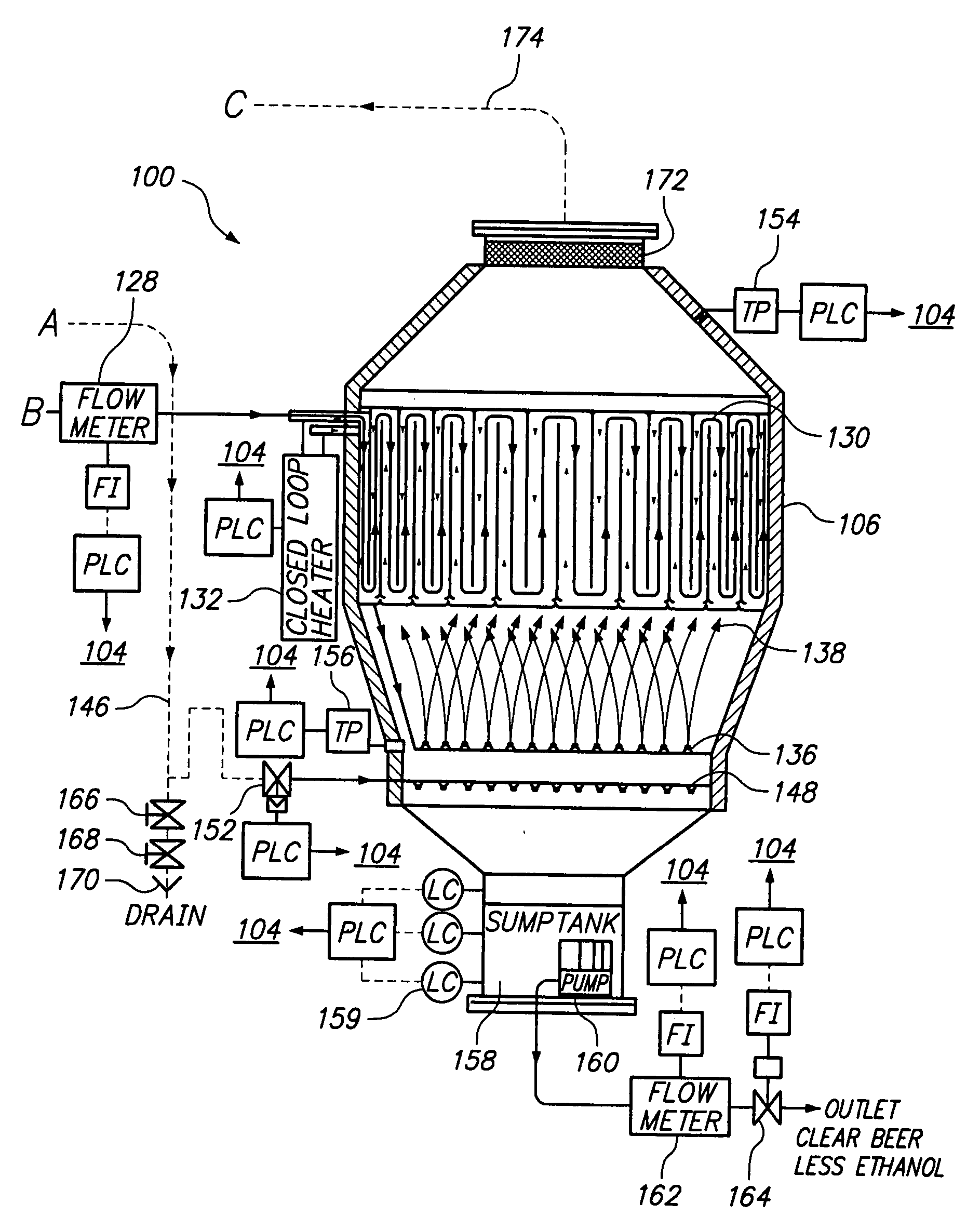

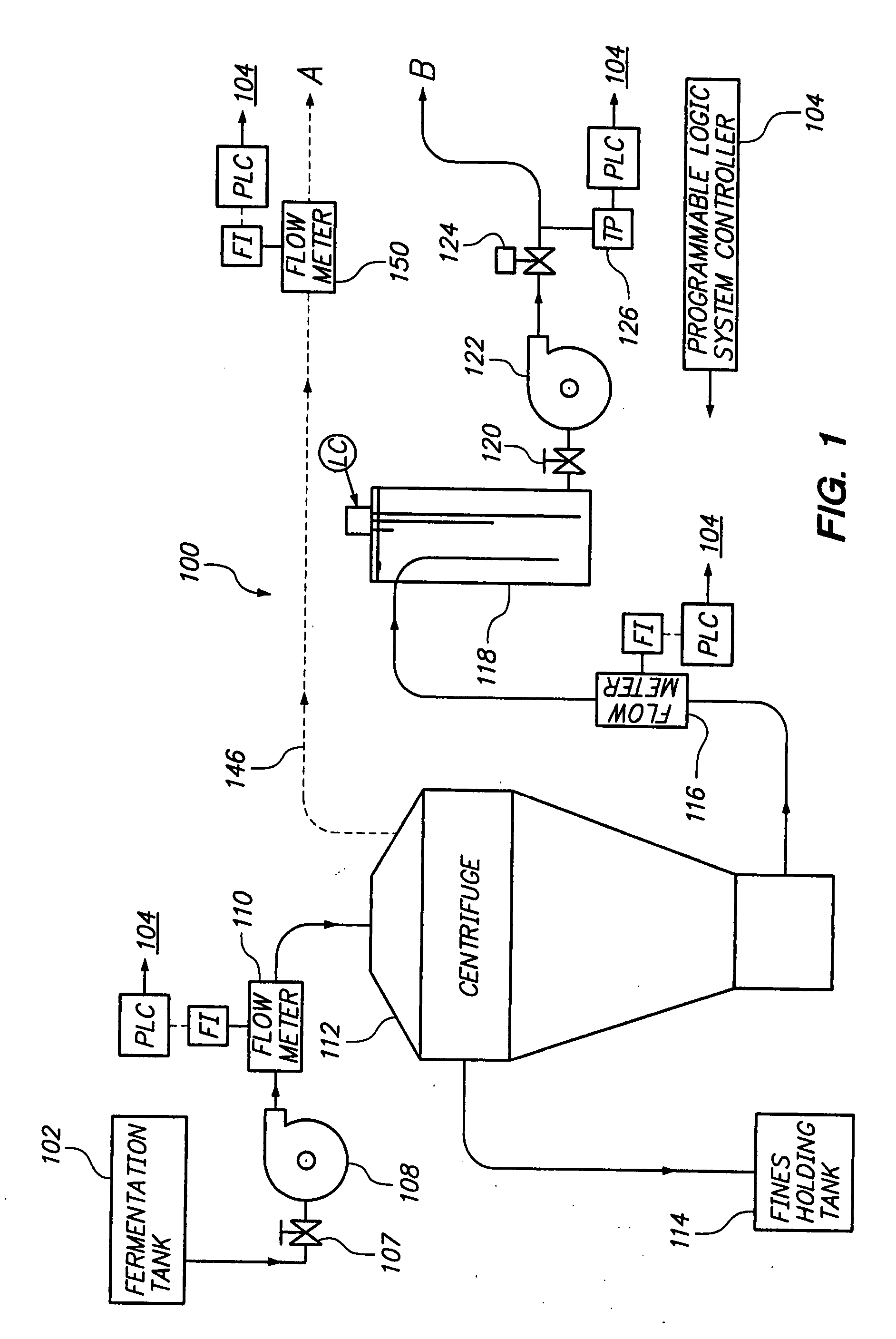

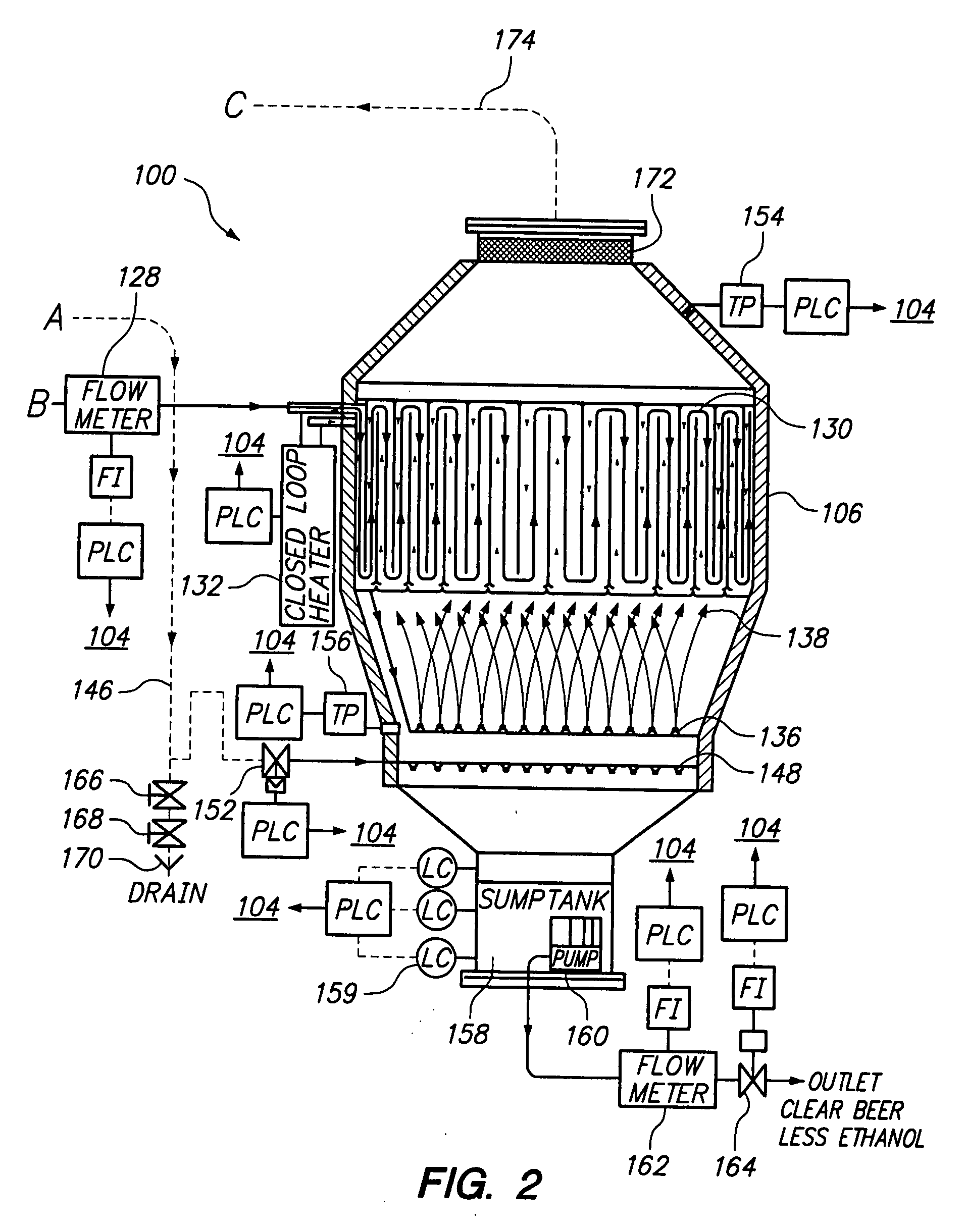

Closed system for continuous removal of ethanol and other compounds

InactiveUS20080011597A1Equally distributedPrevent channelingFermented solutions distillation/rectificationRetortsSteam condensationClosed loop

A closed system for continuous removal of ethanol and other compounds in an aqueous solution includes a centrifuge for removing debris for providing a filtered aqueous solution. A transfer pump and flow control valve control the flow and pressure of the filtered solution. A vacuum pump provides a negative pressure within a boil chamber. An internal heating element within the boil chamber receives the filtered solution preheated by a closed loop heater for maintaining the internal boil chamber temperature. An internal up-spray header sprays droplets of the filtered solution in the boil chamber for controlling the surface area and contact time of the droplets within the boil chamber. The heated vacuum environment within the boil chamber results in the ethanol within the sprayed droplets and a stream of centrifuge off-gas, to be extracted as a vapor and prevent recombination with the filtered solution. A condenser condenses the vapor to liquid ethanol.

Owner:SPANI WAYNE W

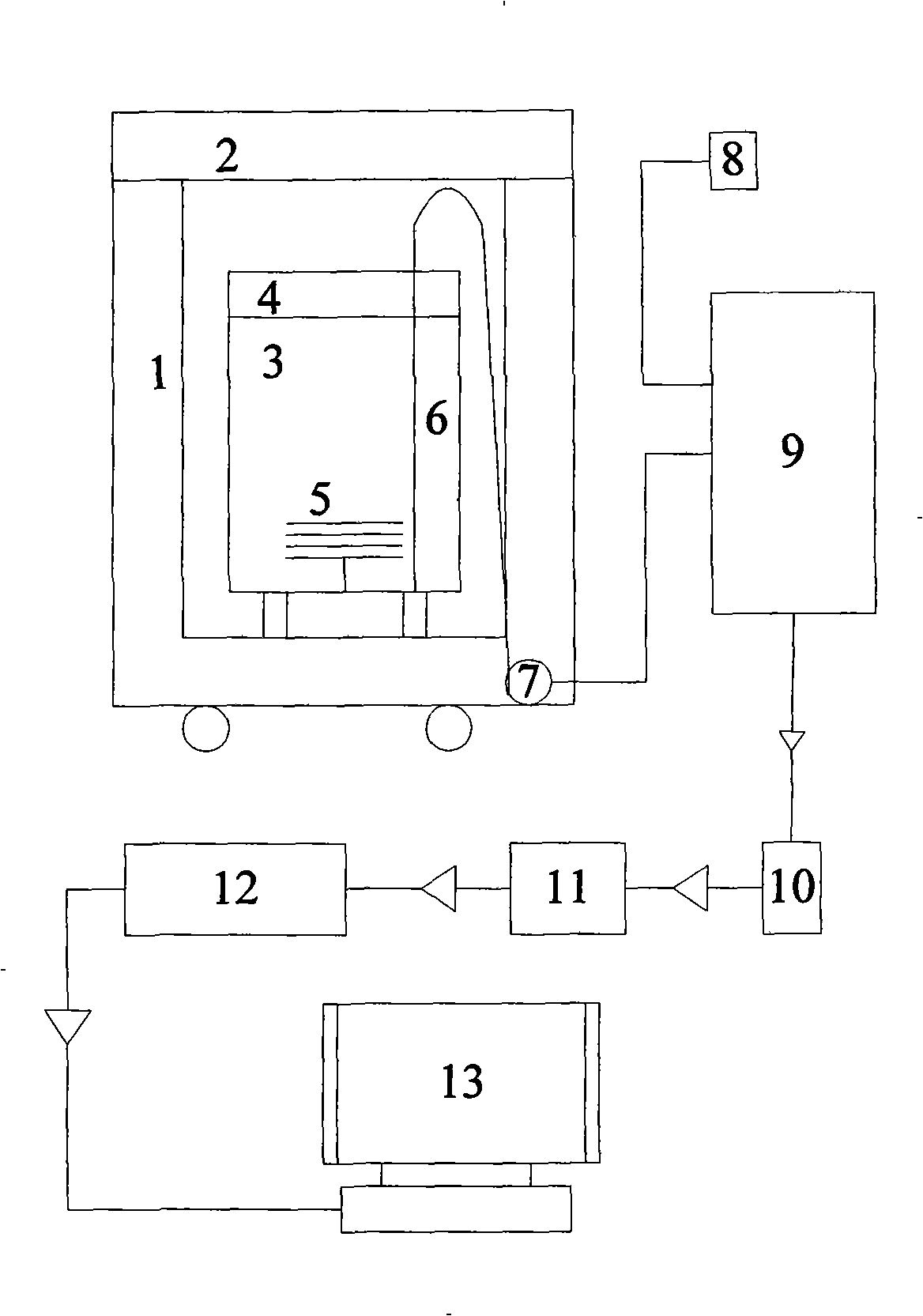

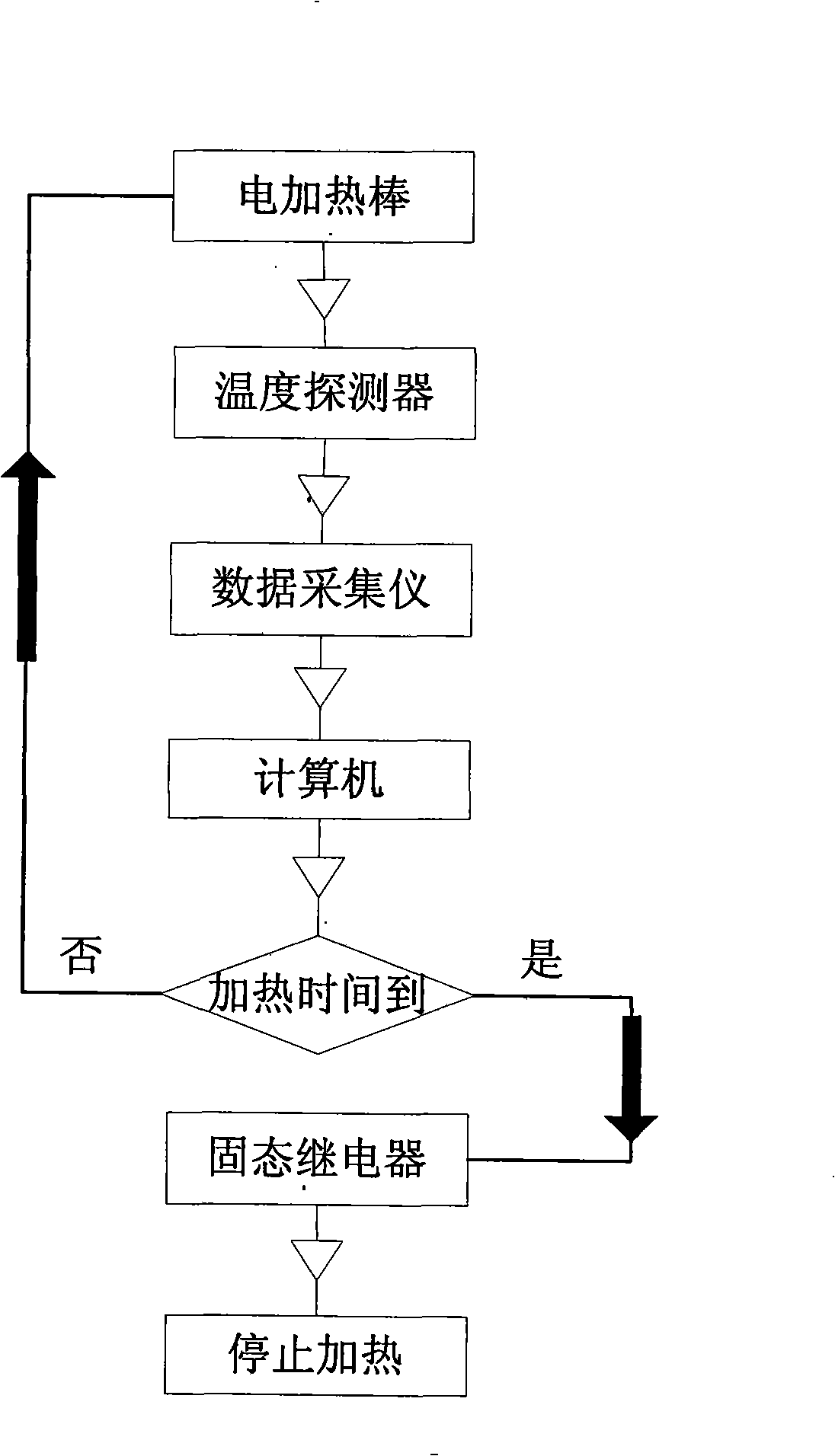

Phase change thermal storage tester

The present invention relates to a phase change thermal storage tester, and consists of a water bath, a voltage stabilizer, a solid state relay, a power converter, a temperature detector, a data acquisition instrument and a computer. The water bath consists of an internal heating barrel, an electric heating rod and an external insulating barrel. One end of the voltage stabilizer is connected with a power supply, and the other end is connected with the electric heating rod and used for providing electricity for the electric heating rod. The solid state relay, the data acquisition instrument and the computer together form the monitoring and controlling part of the whole testing process. The data collected by the data acquisition instrument is used for judging whether the heating needs stopping or starting. The computer transmits commands to connect or disconnect the solid state relay. Aiming at the defect in the existing experimental method of researching or testing phase change materials for construction, the device can heat the water bath with the phase change materials for construction, measure the temperature by the temperature sensor, map the real-time temperature curve, control the starting and stopping of the heating device, and calculate the stored heat of the phase change materials for construction according to the test data.

Owner:CHINA ACAD OF BUILDING RES

Cigarette substitute

The invention relates to a cigarette substitute, comprising a hollow tubular element (1) provided with a generator of products to be inhaled (7, 8), with internal heating means (6) for heating the inspired air or at least part of the generator of products to be inhaled, and with a device (8) for triggering the generator of products to be inhaled. It is characterized in that the triggering device comprises an element (8) sensitive to the heat produced by heating means that are situated outside the substitute (1) and are independent of the latter, said heat-sensitive element (8) being made of a material that cannot ignite or burn under the conditions of normal use of the substitute (1). It is thus possible to activate the cigarette substitute with the aid of a flame, without thereby causing combustion of the generator of products to be inhaled.

Owner:迪迪埃·热拉尔·马茨尔

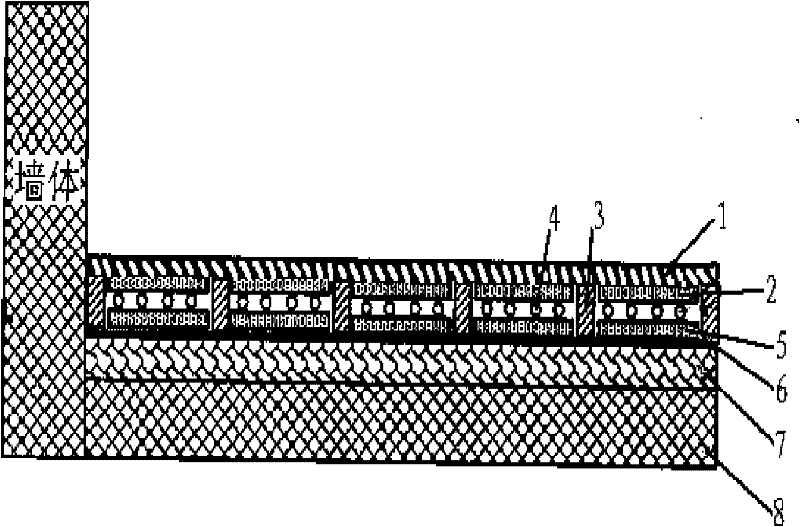

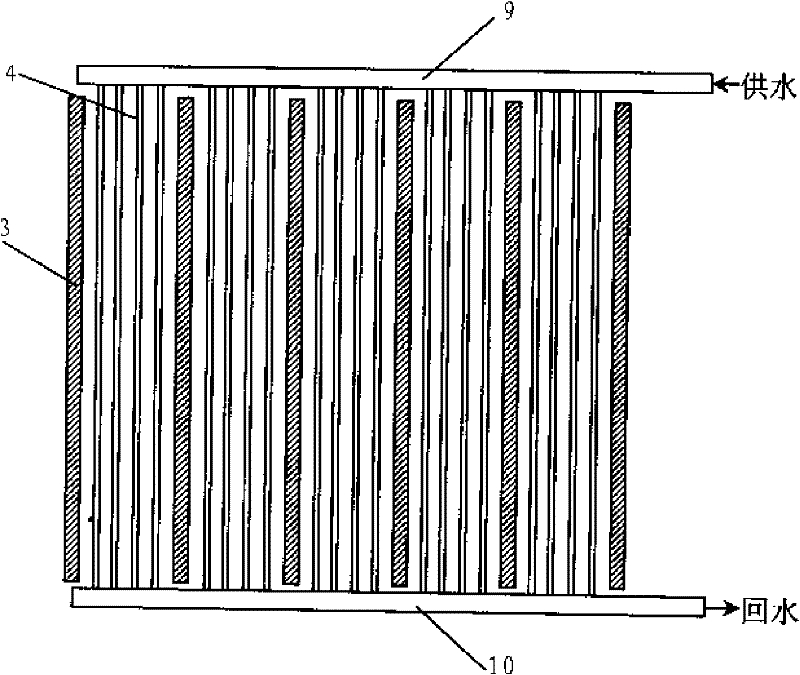

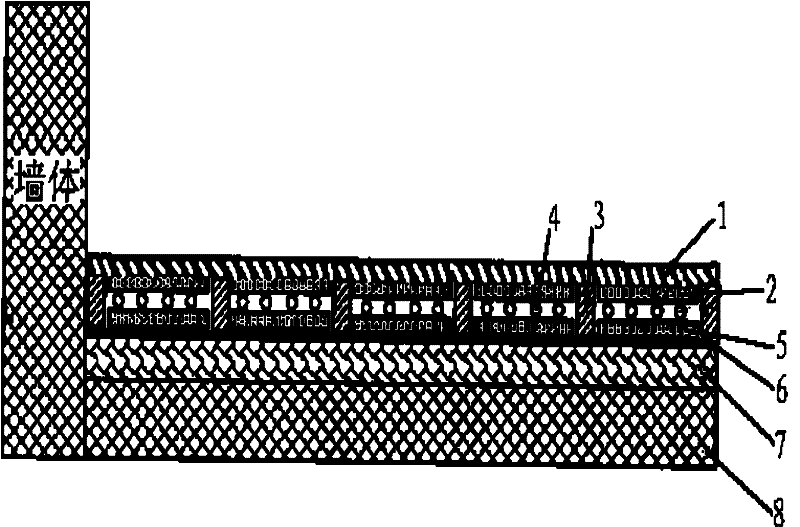

Indoor geothermal heating structure using capillary network and phase change heat storage material

InactiveCN102269443AImprove heat storage capacitySolve the problem of slow heatingLighting and heating apparatusEnergy efficient heating/coolingCapillary networkInsulation layer

The invention discloses an indoor geothermal heating structure utilizing a capillary network and a phase-change thermal storage material, which belongs to the technical field of solar building heating. The structure includes a floor decoration layer, an upper phase change material, a capillary grid, a lower phase change material, a reflection film, an insulation layer and a floor base layer from top to bottom. The floor decoration layer is supported by dragon frames laid on the insulation layer, the dragon frames pass through the tube gaps of capillary grids, and the phase change material layers are arranged between adjacent dragon frames. The hot water from the low-temperature heat source exchanges heat with the upper and lower phase-change materials in the capillary, and supplies heat to the room through the floor decoration layer; at night, the phase-change material solidifies and releases heat to supply heat to the room through the floor decoration layer. The indoor geothermal heating structure of this capillary network and phase change heat storage material has the characteristics of large heat exchange area, uniform temperature, fast start-up, less space occupation, more flexible layout, and convenient installation. The indoor temperature is uniform, and the indoor thermal comfort is good. Wide application prospects and promotion value.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

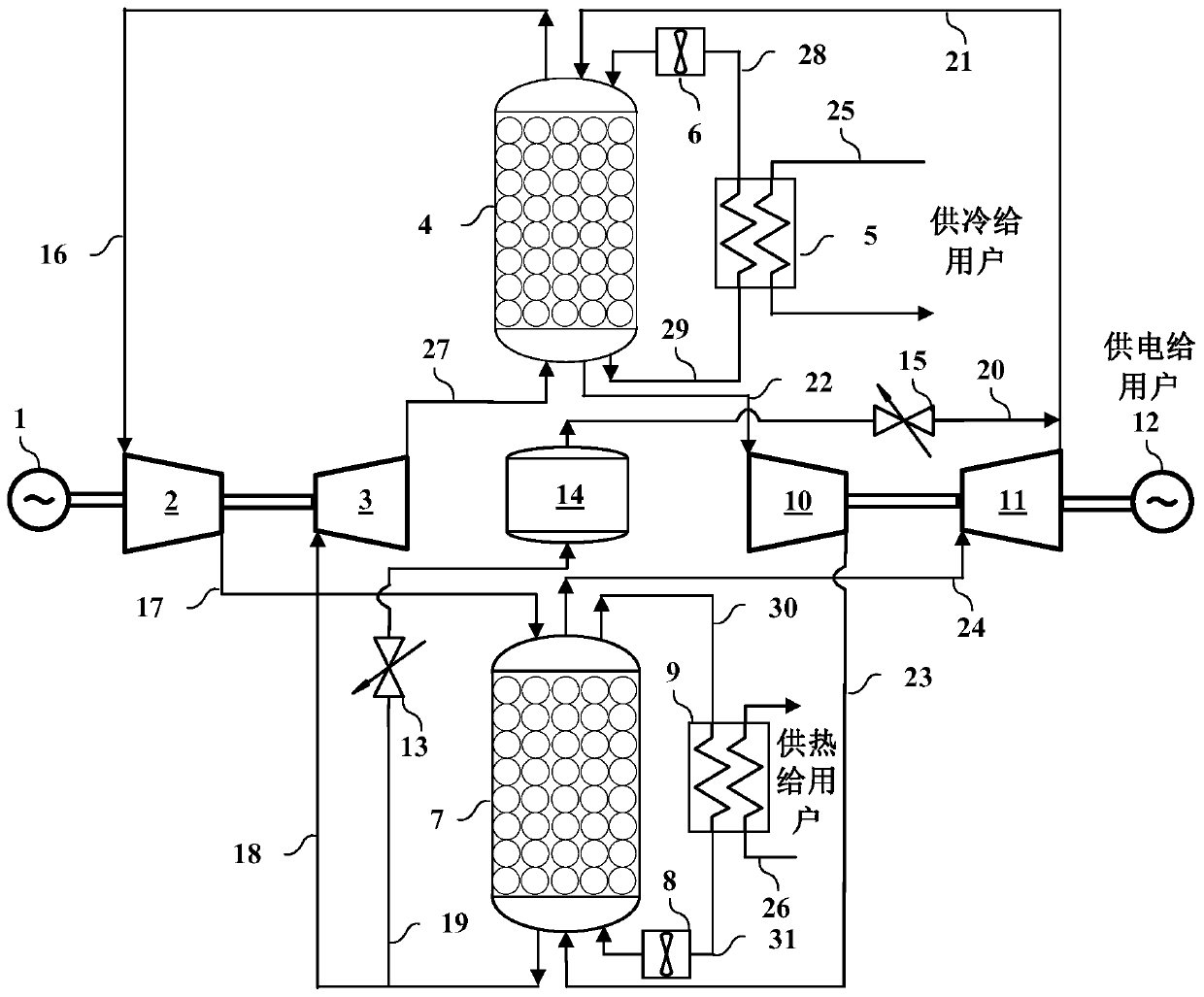

Cold, heat and electricity combined storage and combined supply system

The invention discloses a cold, heat and electricity combined storage and combined supply system. The system comprises a heat pump heating and cooling energy storage loop, a cold and heat energy heatengine power generation loop, a heat supply loop and a cold supply loop; power station off-peak (cheap) electricity is used for driving a heat pump heating and cooling circular loop to make high-temperature heat energy and low-temperature cold energy, the heat energy and the cold energy are stored in a heat storage device and a cold storage device, at the power utilization moment, gas in the loopsabsorbs the stored high-temperature heat energy and the stored low-temperature cold energy, through heat engine circulation, an electric generator is driven to generate electricity, and the electricity is supplied to a user. On the heat using time interval, the heat supply loop supplies the heat energy in the heat storage device to the user through the heat exchanger, and on the cold using time interval, the cold supply loop supplies the heat energy in the cold storage device to the user through the heat exchanger. Through the cold, heat and electricity combined storage and combined supply system, simultaneous storage and supply of cold, heat and electricity can be achieved, various needs of the user can be met, and the system has the advantages of being high in energy storage density, low in cost, high in efficiency, suitable for power grid peak shaving and various renewable power stations, free of generating room temperature gas and the like.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

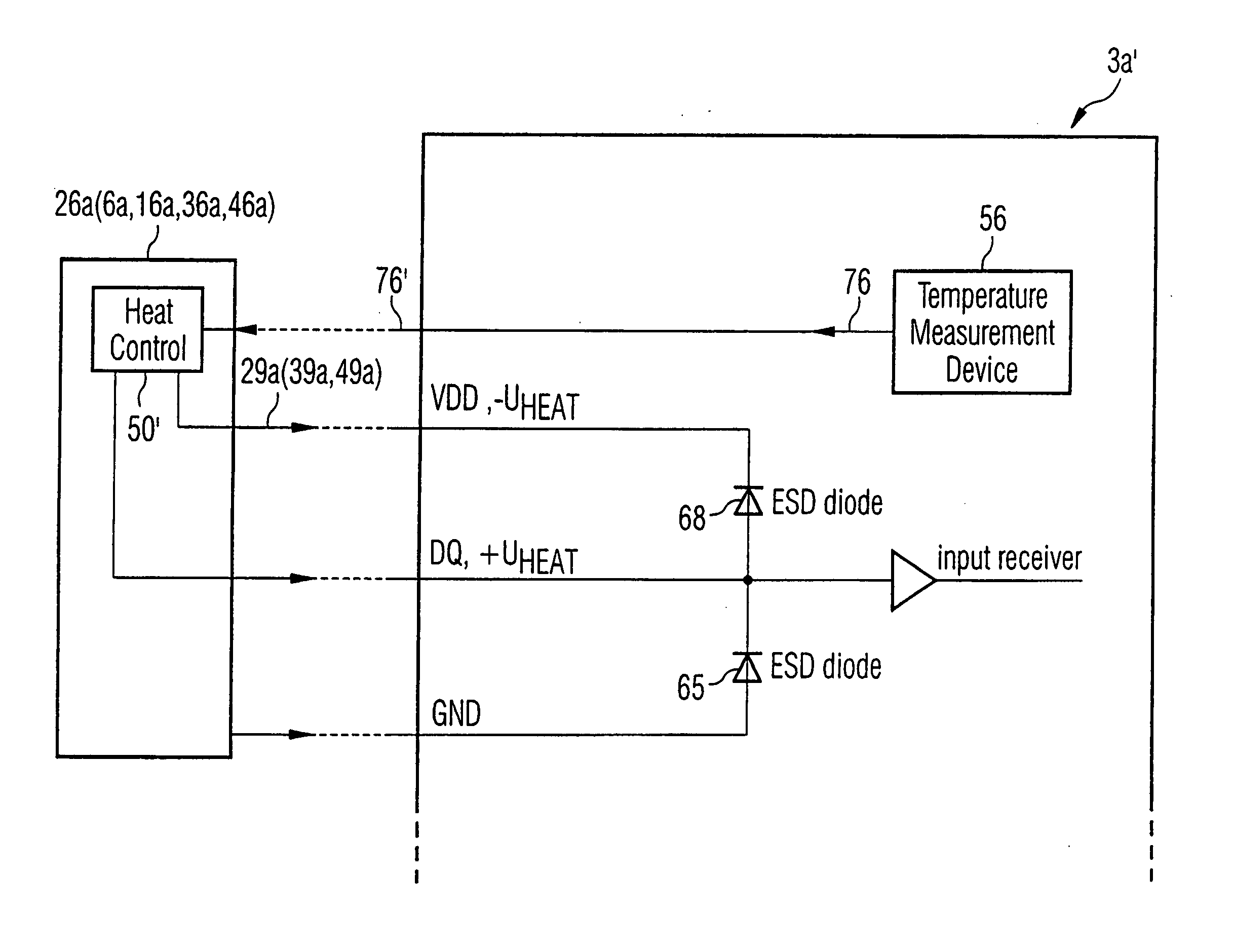

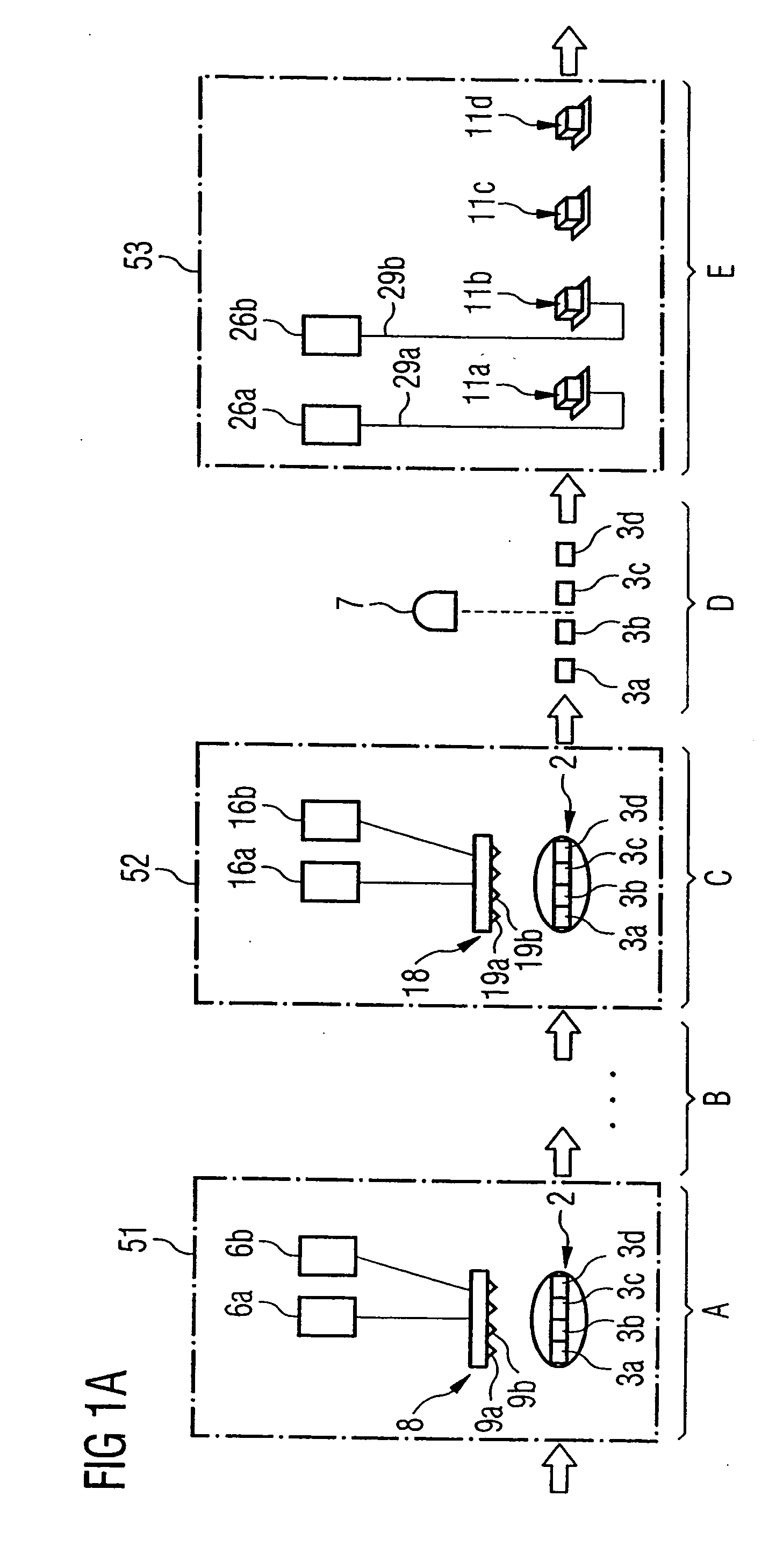

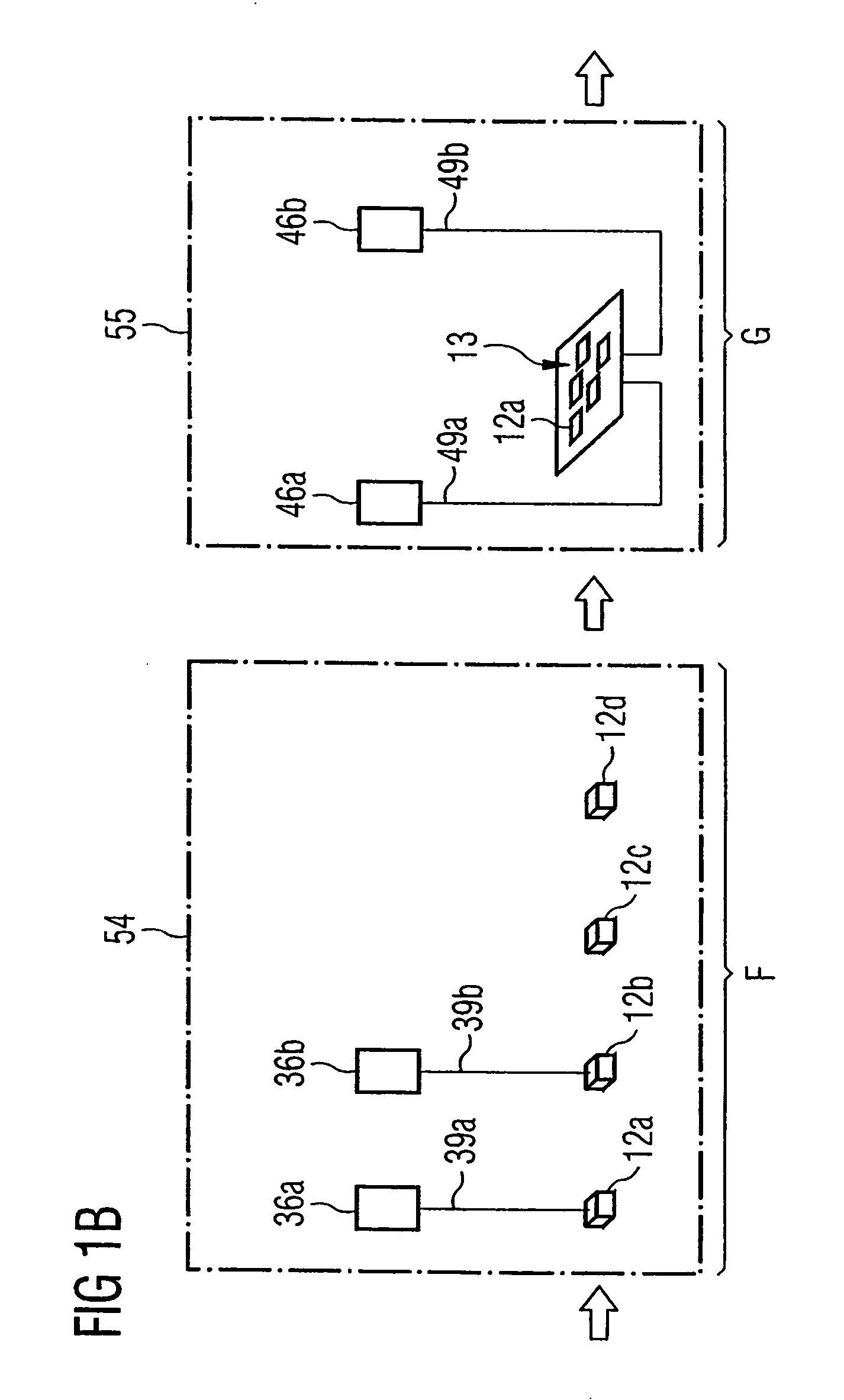

Semiconductor component with internal heating

InactiveUS20050218917A1Semiconductor/solid-state device testing/measurementElectronic circuit testingEngineeringInternal heating

Owner:POLARIS INNOVATIONS

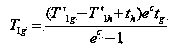

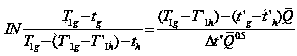

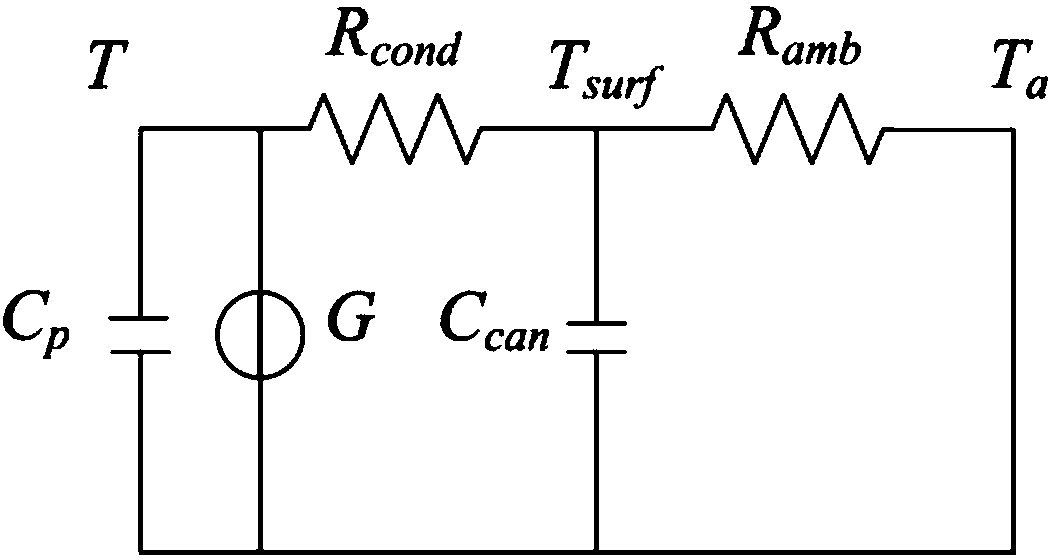

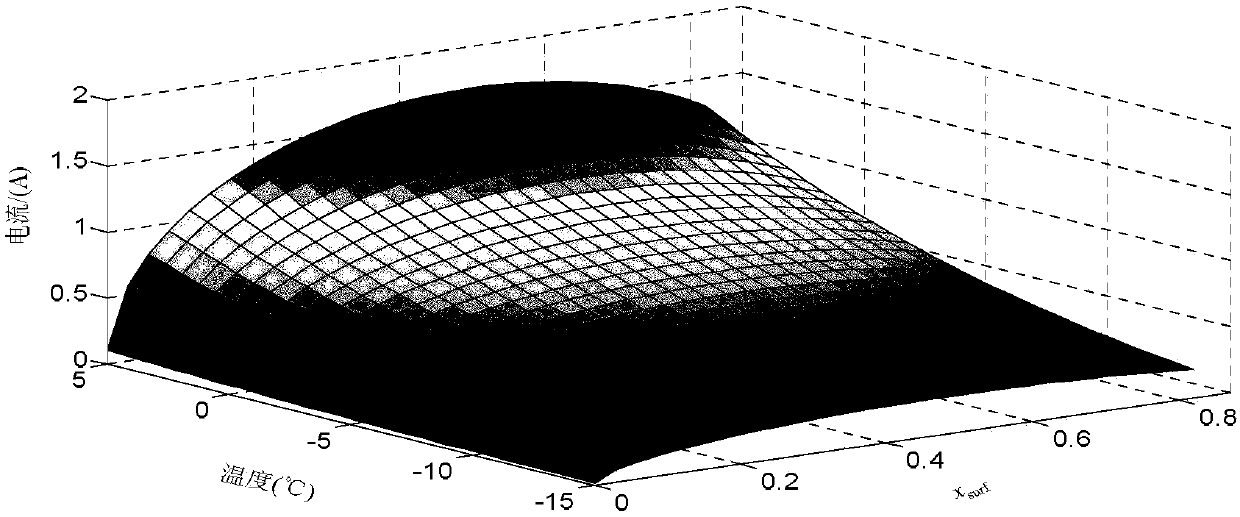

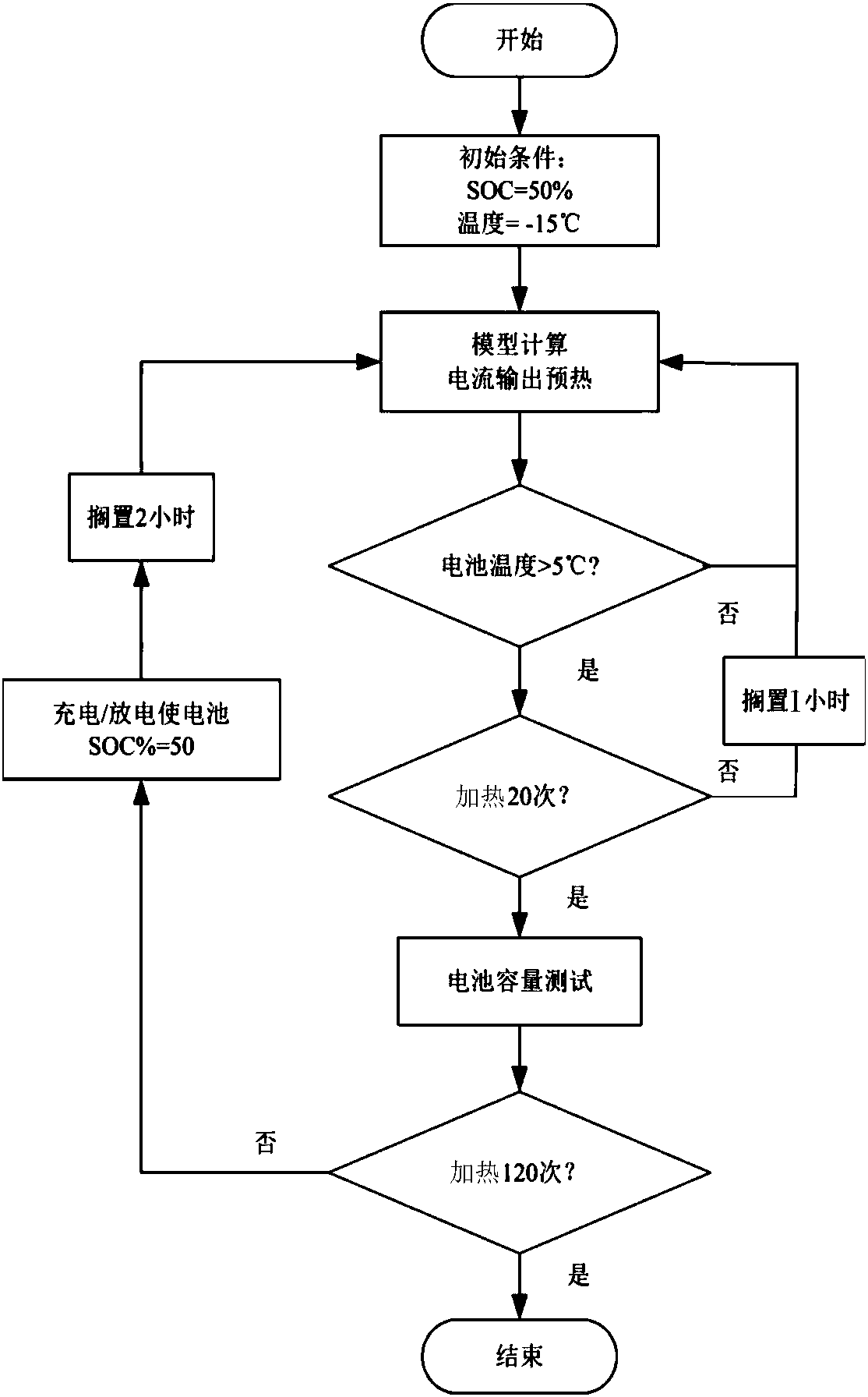

Electrochemical-thermal coupling model-based low-temperature heating method without lithium precipitation for lithium ion battery

ActiveCN108199122AAvoid damageExtended service lifeCell temperature controlAutomotive batteryLithium metal

In order to solve the problem of lithium precipitation damage to capacity of a battery due to improper selected current amplitude during low-temperature heating of an existing battery, the invention provides an electrochemical-thermal coupling model-based low-temperature heating method without lithium precipitation for a lithium ion battery, and belongs to the field of application of an electric vehicle battery management system. The method comprises the following steps of 1, acquitting a pre-heating current limitation condition according to an electrochemical-thermal coupling model on the premise that metal lithium of the lithium ion battery is not precipitated, wherein the limitation condition conforms to a formula I: -1<={3*Q<n>*c<0.5><0>*(1-x<surf>)<0.5>(x<surf>)<0.5>*[(e<(F*U<n>) / (2*R*T)-(e<(-F)*U<n> / (2*R*T))]} / P<act>, formula II: U<min><=V<=U<max>, and V=E<ocv>-Eta<act-n>-Eta<con>-Eta<ohm>; and 2, performing low-temperature heating on the lithium ion battery according to the acquired pre-heating current limitation condition. By the method, damage to the battery during the internal heating process of the battery is prevented, the service lifetime of the battery is prolonged, and the safety of the battery system is improved.

Owner:哈尔滨和睿科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com