Man-made graphite cathode material for lithium ion battery and its making method

A technology of artificial graphite negative electrode and lithium-ion battery, which is applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problems of unusable graphite, poor high-rate discharge performance, and low capacity, and achieve high discharge capacity, simple process, Ease of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] Its preparation method comprises the following steps:

[0026] 1. Coal-based or petroleum-based needle coke is pulverized mechanically and the particle size is in the range of 5-18 μm.

[0027] 2. Preheat the crushed needle coke at 50-160°C for 1-5h, and fill it with nitrogen, argon, helium, neon or carbon dioxide during the preheating process.

[0028] 3. Adding a modifying agent accounting for more than 0-10wt.% of the needle coke, or / and a catalyst accounting for more than 0-10wt.% of the needle coke; the modifying agent is one or more than one type of organic matter that can be carbonized: Furan resin, urea-formaldehyde resin, pyrimidine resin, phenolic resin, epoxy resin, polyvinyl alcohol, polystyrene, polymethyl methacrylate, polytetrafluoroethylene, polyvinylidene fluoride, polyacrylonitrile (PAN), butyl Styrene rubber (SBR), cellulose (CMC), coke, coal tar pitch or petroleum pitch; compounds with phosphorus catalyst: phosphoric acid, P 2 o 5 , boron, boron c...

Embodiment 1

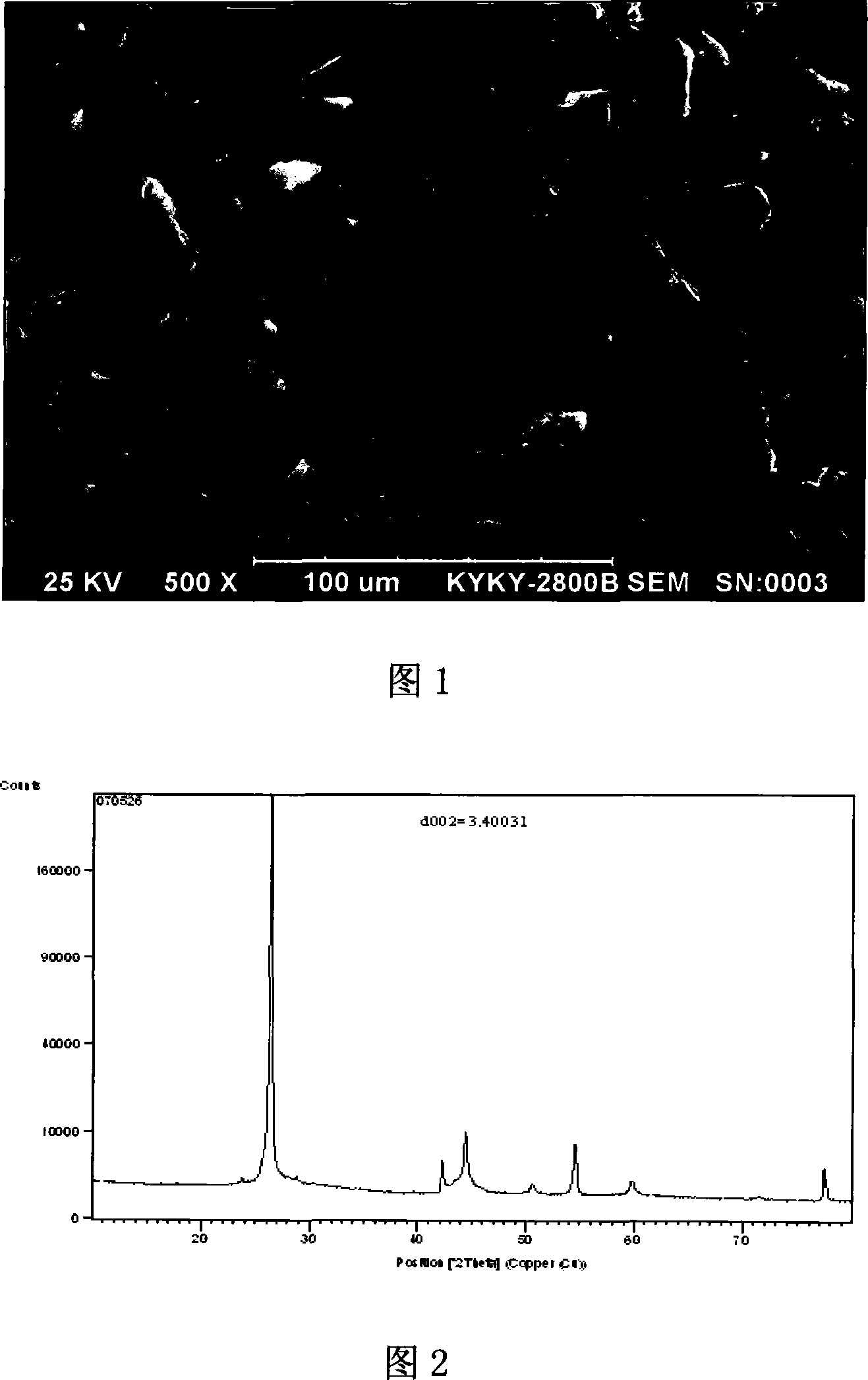

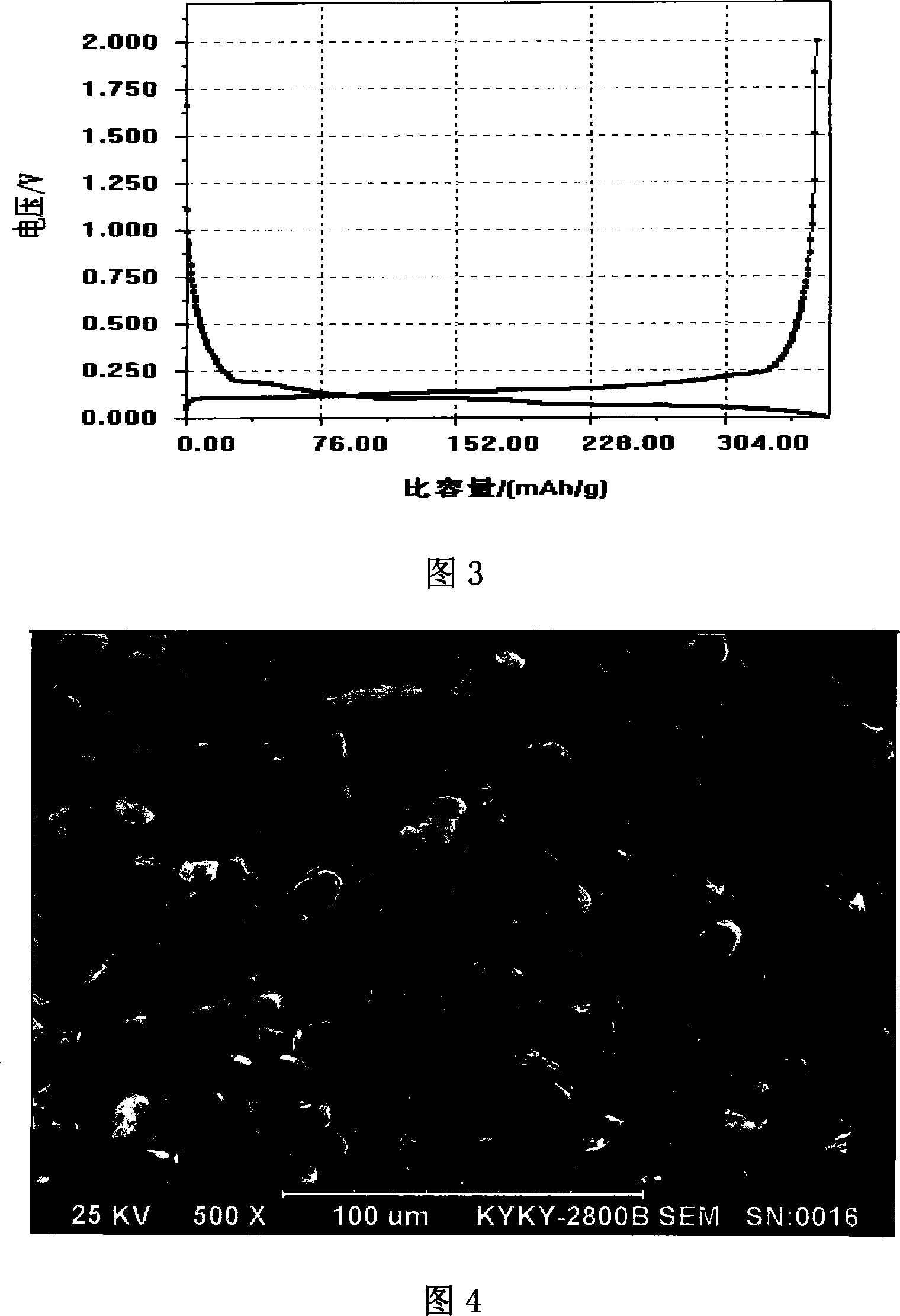

[0038] Example 1: Crushing petroleum-based needle coke to D 50 = about 18 μm, after preheating at 80°C for 2 hours, fully mix with 2.5wt.% boric acid aqueous solution to make a suspension, spray dry and granulate at 180°C, and raise the temperature of the above granules under the protection of nitrogen After reaching 1100°C, keep it warm for 2 hours, and then lower it to room temperature to obtain the artificial graphite negative electrode material, as shown in Figure 1, with an average particle diameter of D 50 18.4μm, specific surface area 2.8m 2 / g, as shown in Figure 2, the crystal layer spacing d 002 0.340nm, as shown in Figure 3, has good charge and discharge performance.

Embodiment 2

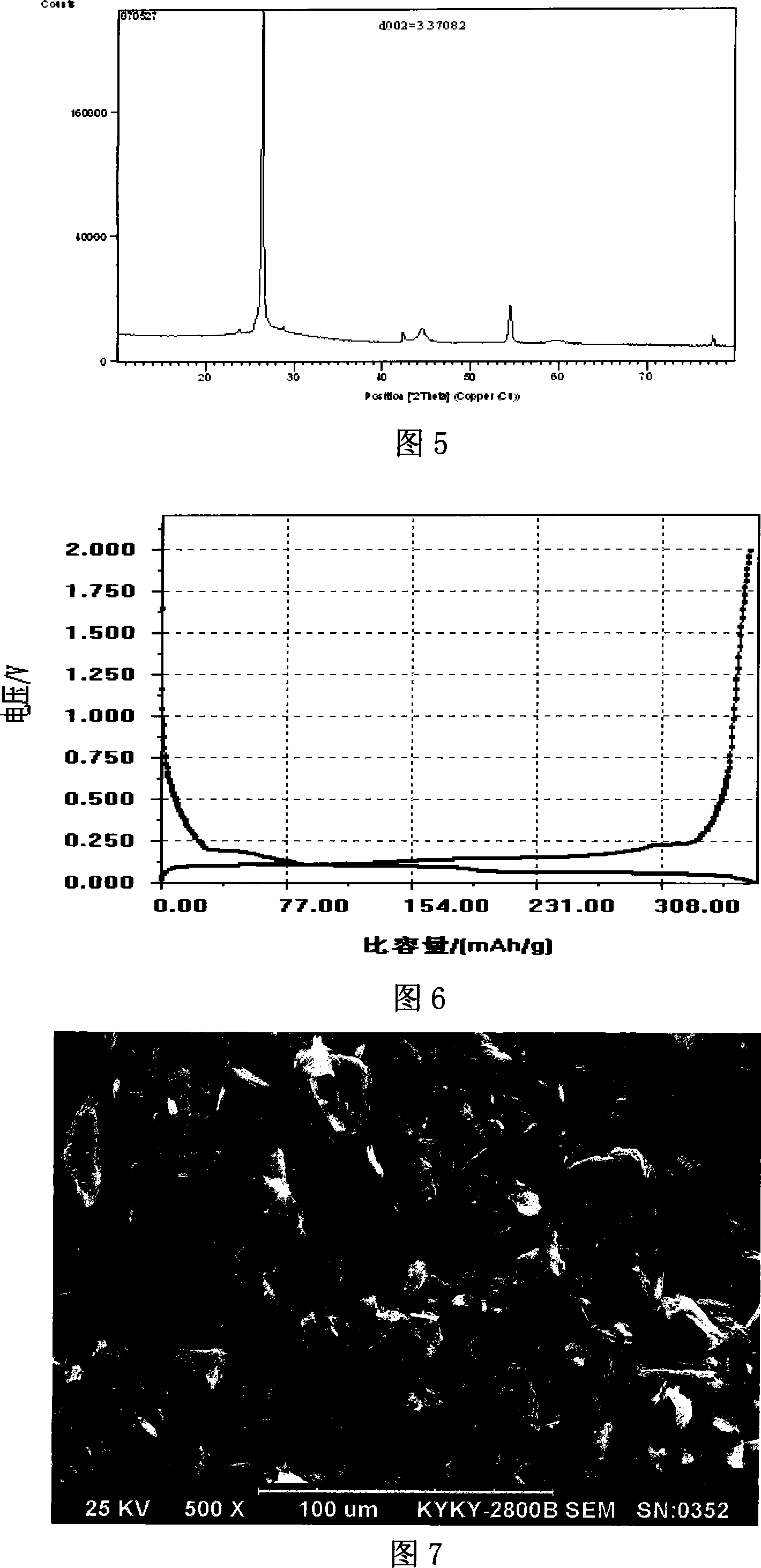

[0039] Example 2: Crushing petroleum-based needle coke to D 50 = about 5 μm, after preheating at 120°C for 4 hours, fully mix with 2wt.% Si, spray dry and granulate at 250°C, and graphitize the above particles at 2500°C for 48 hours under the protection of nitrogen , down to room temperature, the obtained artificial graphite negative electrode material is shown in Figure 4, and its average particle size D 50 5.5μm, specific surface area 1.7m 2 / g, as shown in Figure 5, the crystal layer spacing d 002 It is 0.337nm, as shown in Figure 6, which has good charge and discharge performance.

[0040] As shown in Figure 1, the particle shape of the artificial graphite negative electrode material of the present invention undergoes spray-drying granulation, surface coating modification and heat treatment. , its particle shape is irregular block shape, with more fine powder and larger specific surface area; after modification treatment, the particle shape changes to spherical or nearl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com