Patents

Literature

3391results about "Baking oven" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

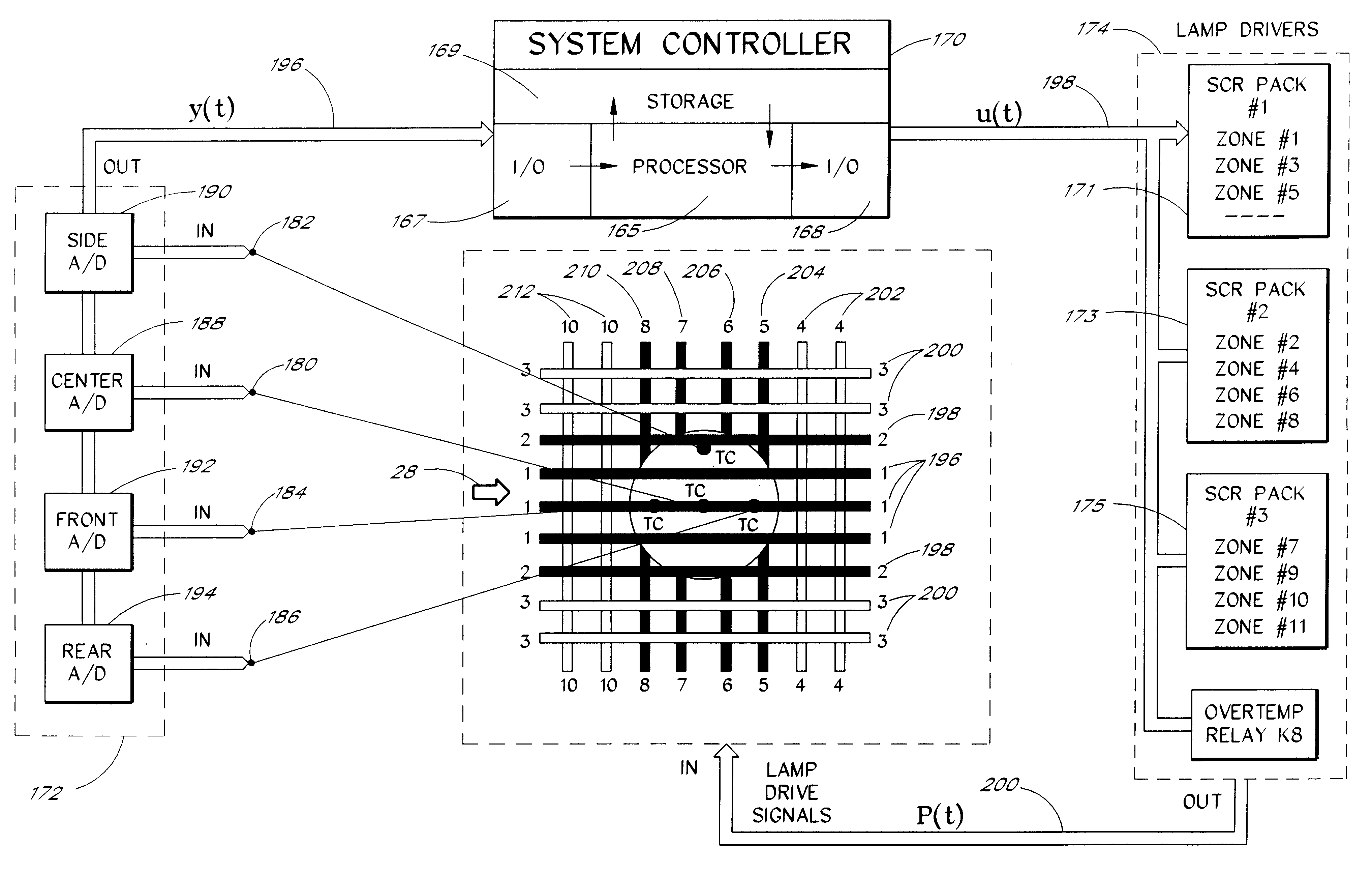

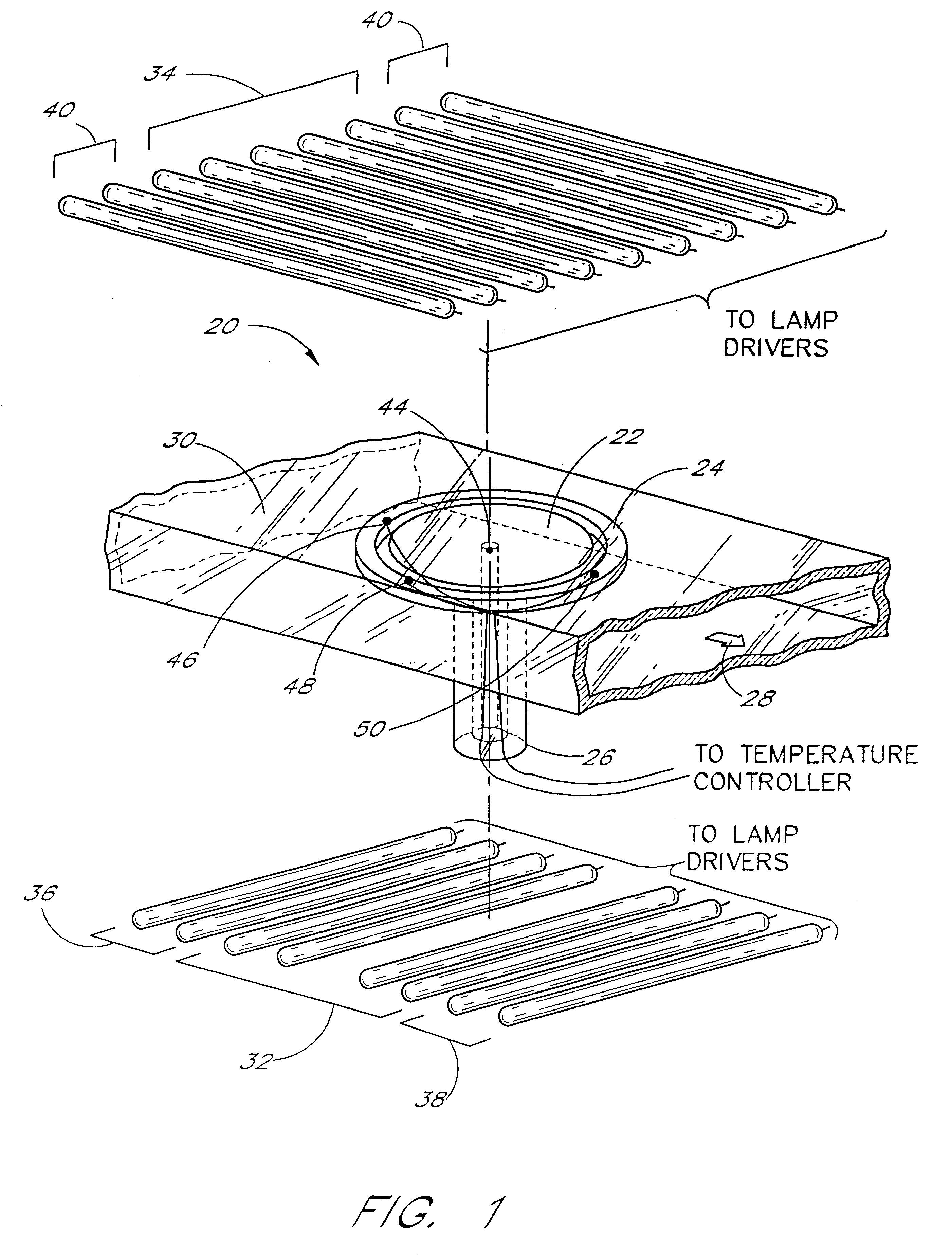

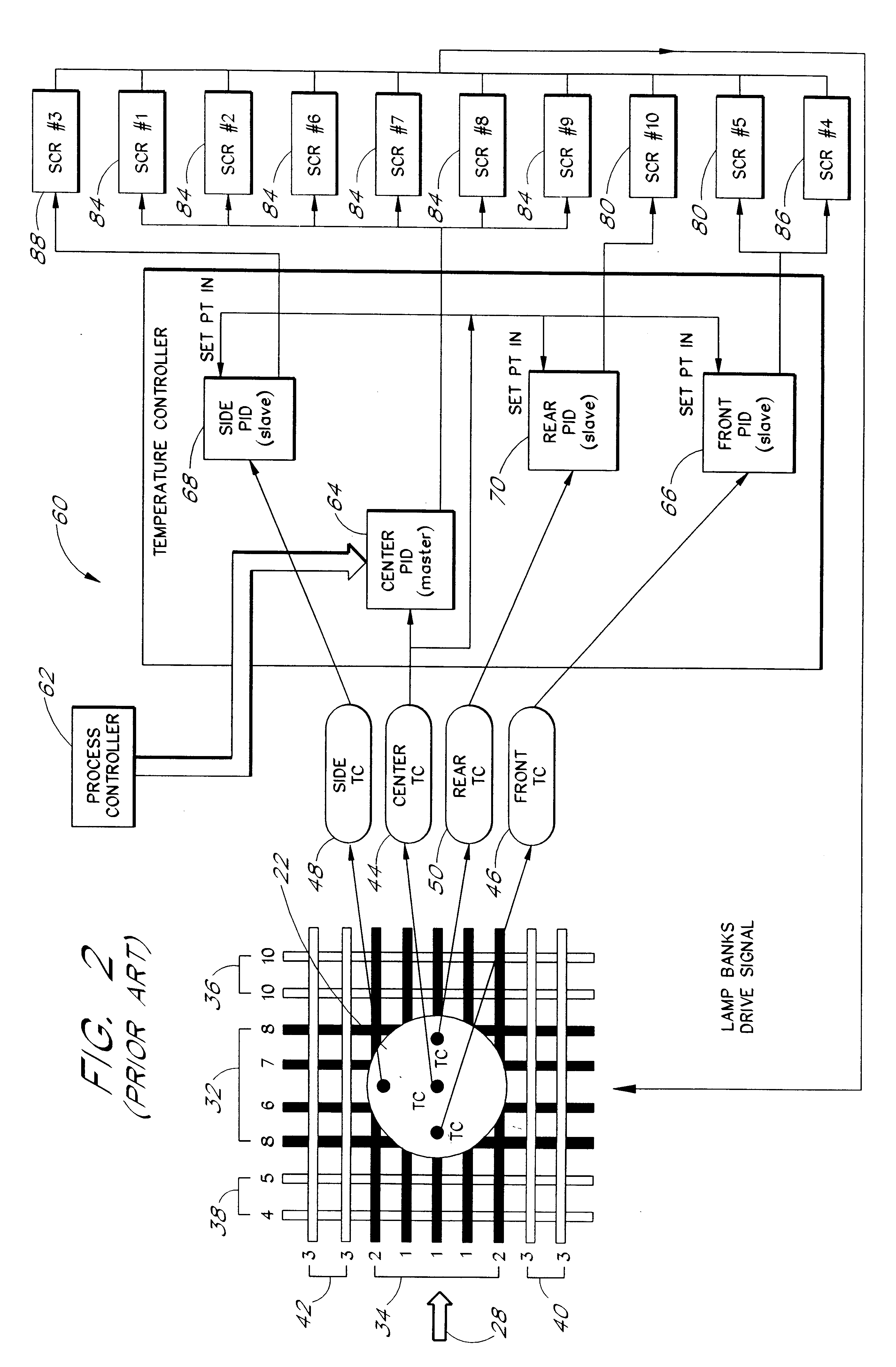

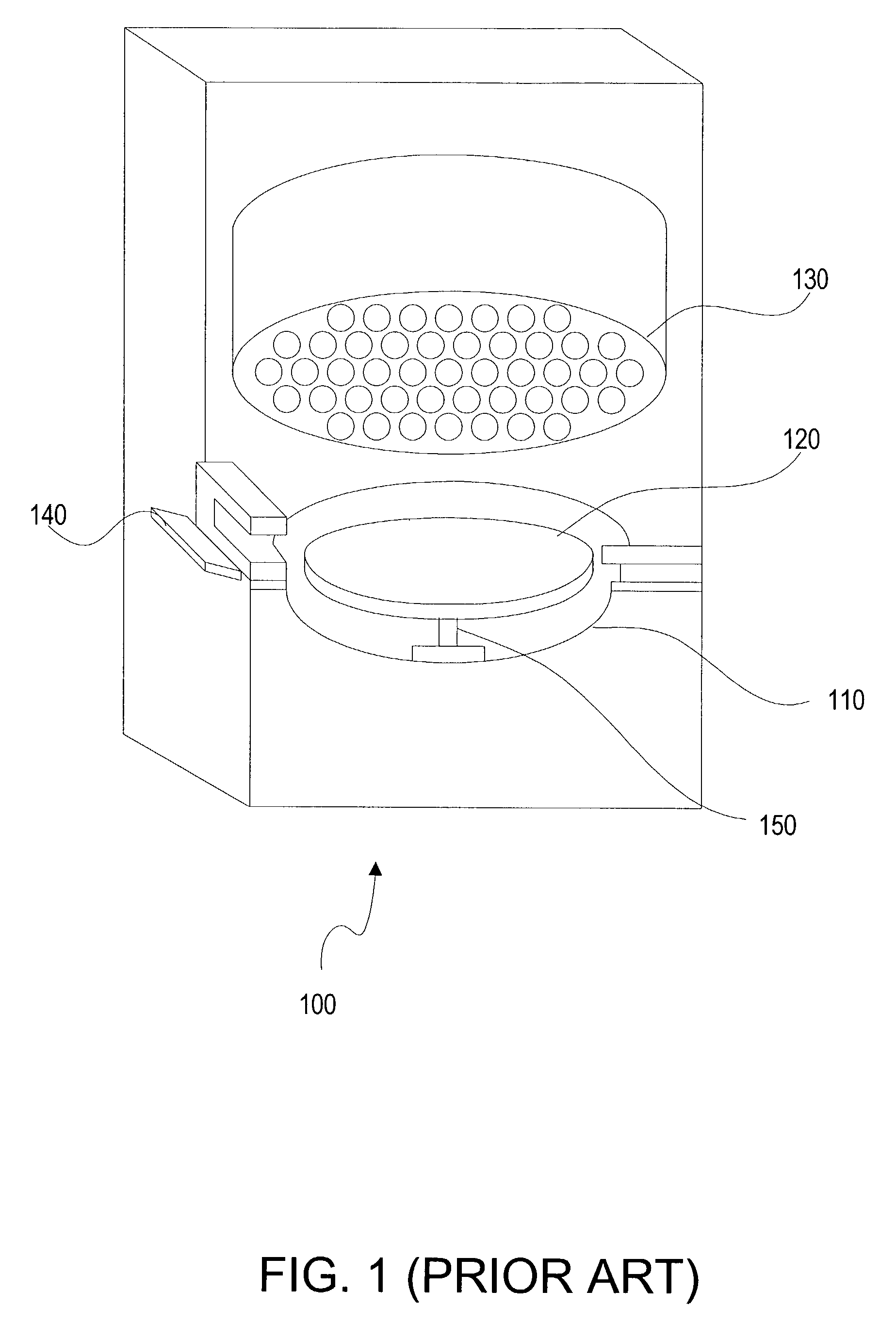

Model-based predictive control of thermal processing

InactiveUS6207936B1Baking ovenSemiconductor/solid-state device manufacturingTemperature controlTemperature response

A nonlinear model-based predictive temperature control system is described for use in thermal process reactors. A multivariable temperature response is predicted using a nonlinear parameterized model of a thermal process reactor. The nonlinear parameterized model is implemented using a neural network. Predictions are made in an auto-regressive moving average fashion with a receding prediction horizon. Model predictions are incorporated into a control law for estimating the optimum future control strategy. The high-speed, predictive nature of the controller renders it advantageous in multivariable rapid thermal processing reactors where fast response and high temperature uniformity are needed.

Owner:ASM AMERICA INC

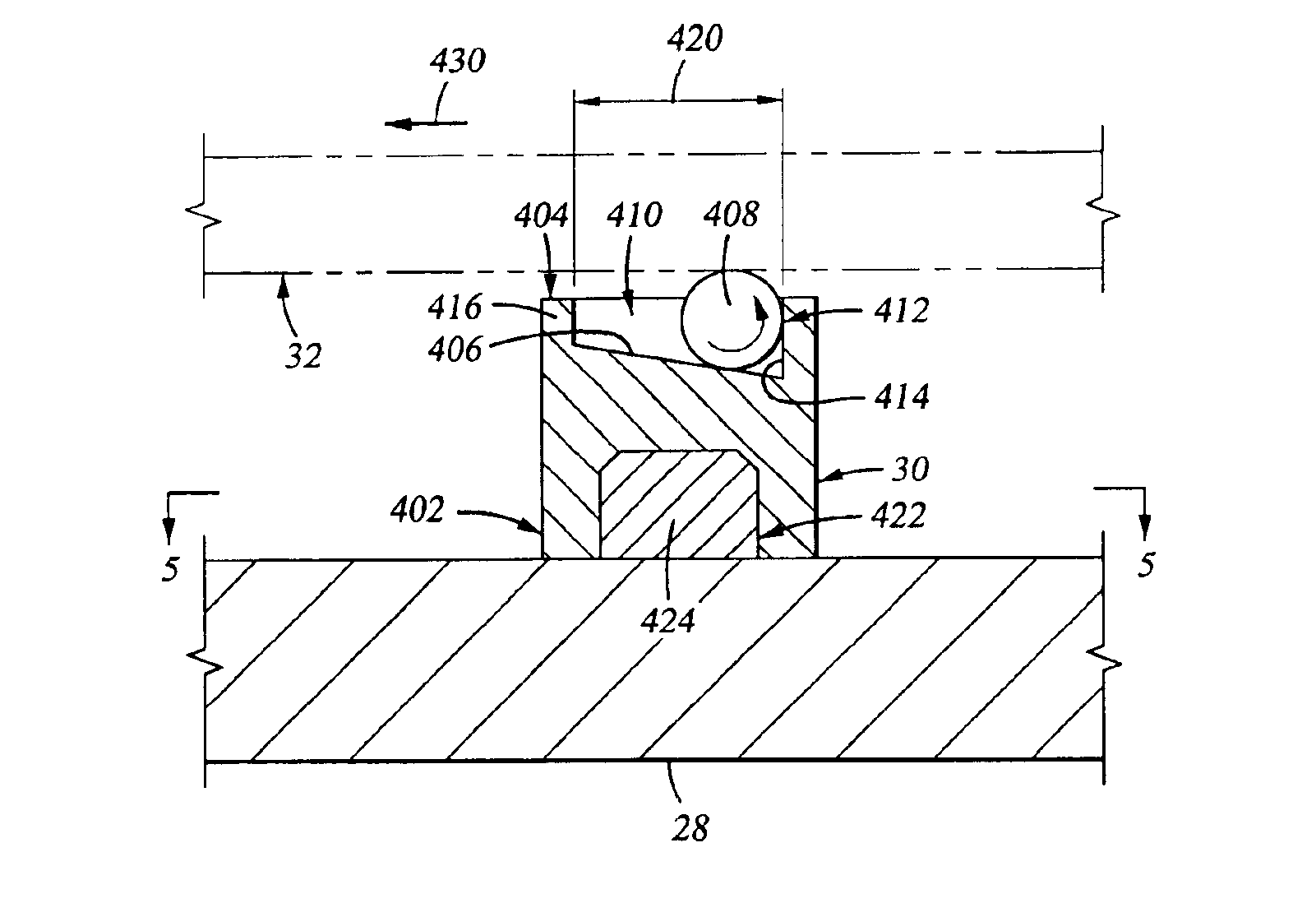

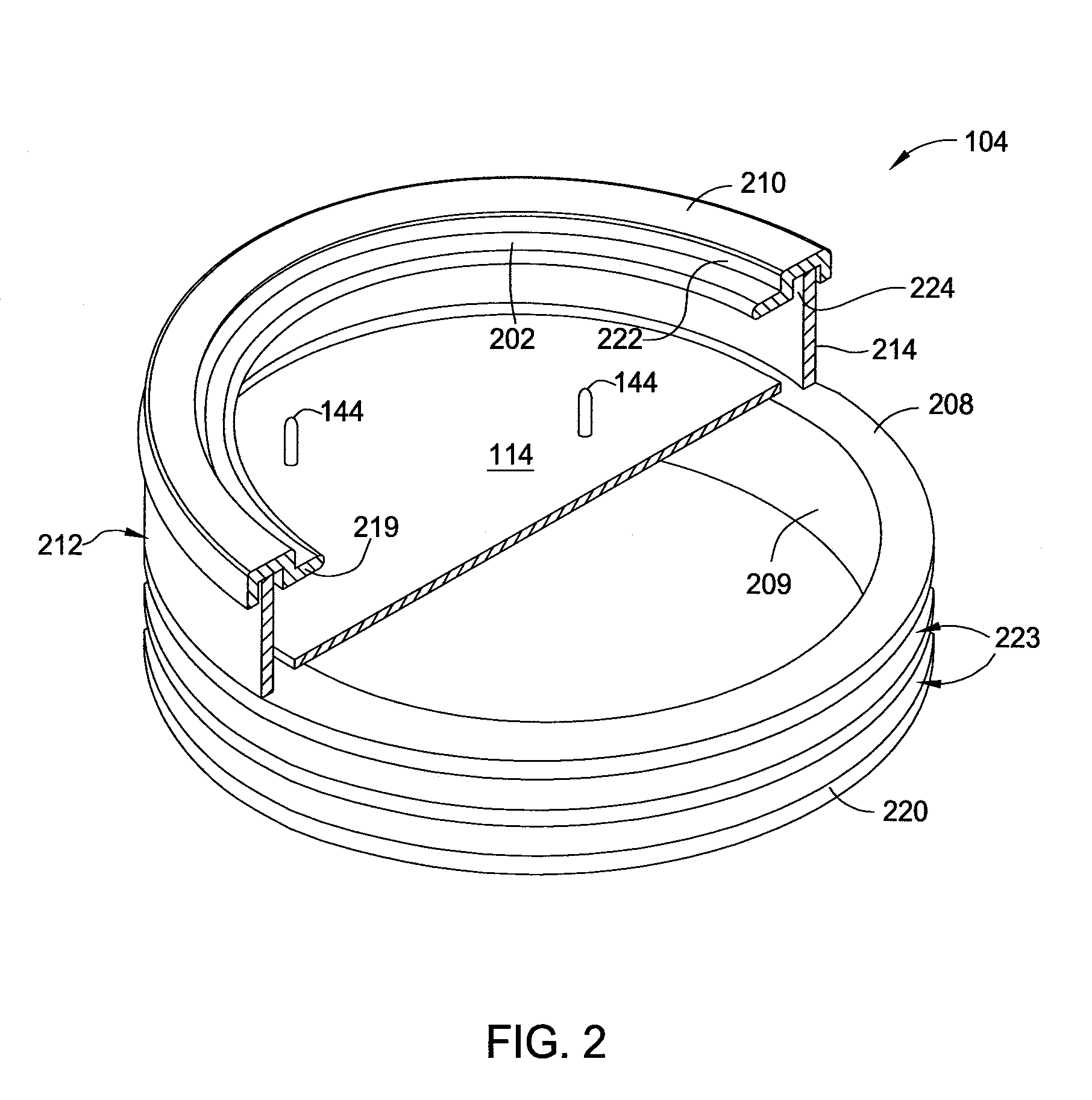

Substrate support

InactiveUS6917755B2Minimize damageProvide spaceDrying solid materials with heatMuffle furnacesSupport surfaceEngineering

An apparatus for supporting a substrate is described that has a ball adapted to minimize damage between the substrate support and the substrate supported thereon. In one embodiment, an apparatus for supporting a substrate includes ball disposed on an inclined ball support surface. The ball support surface is adapted to bias the ball toward one side of the ball support surface thereby providing space for the ball to roll as the substrate supported thereon changes in length when exposed to thermal influences. In another embodiment, the apparatus further comprises a cage adapted to capture the ball to the ball support surface.

Owner:APPLIED MATERIALS INC

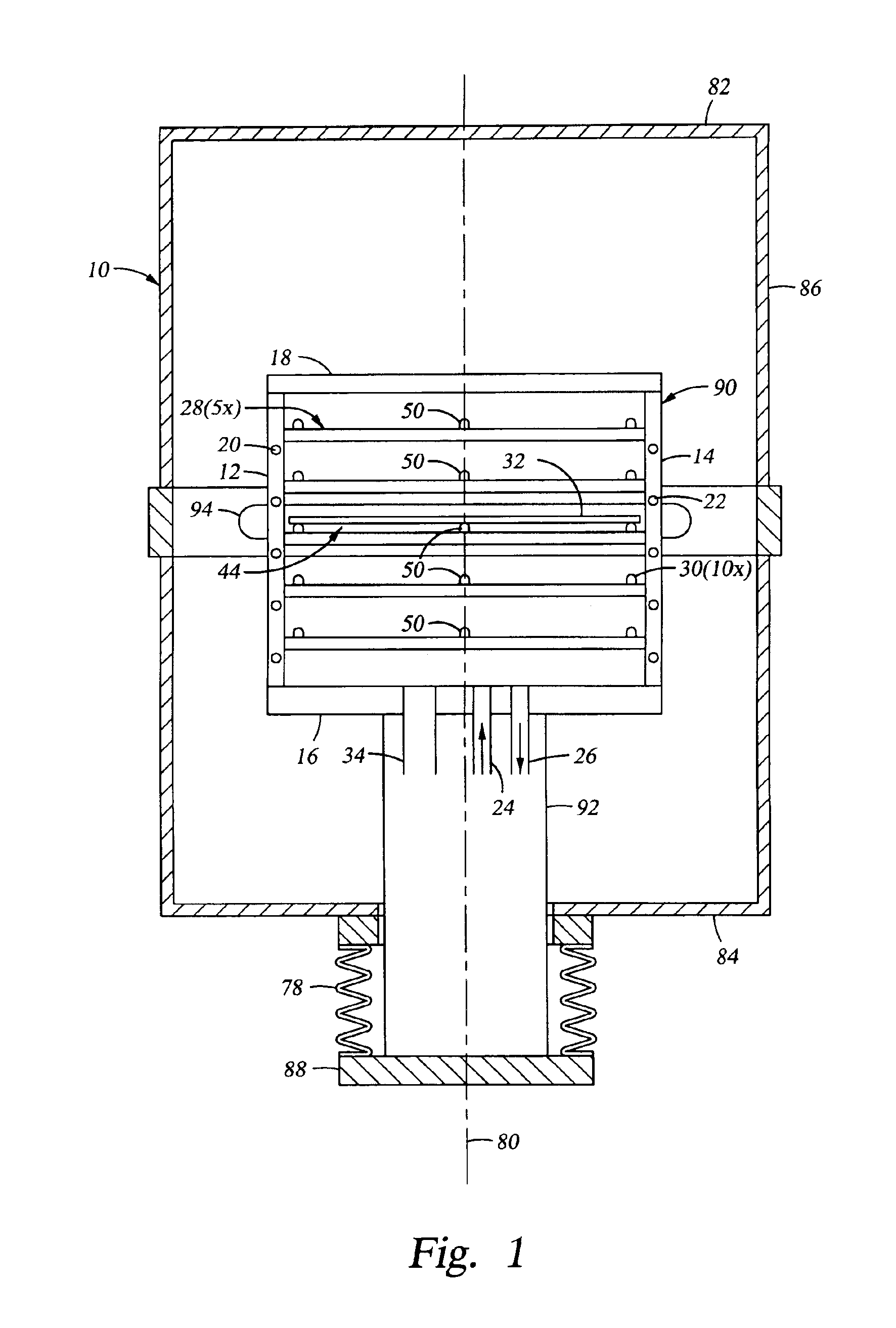

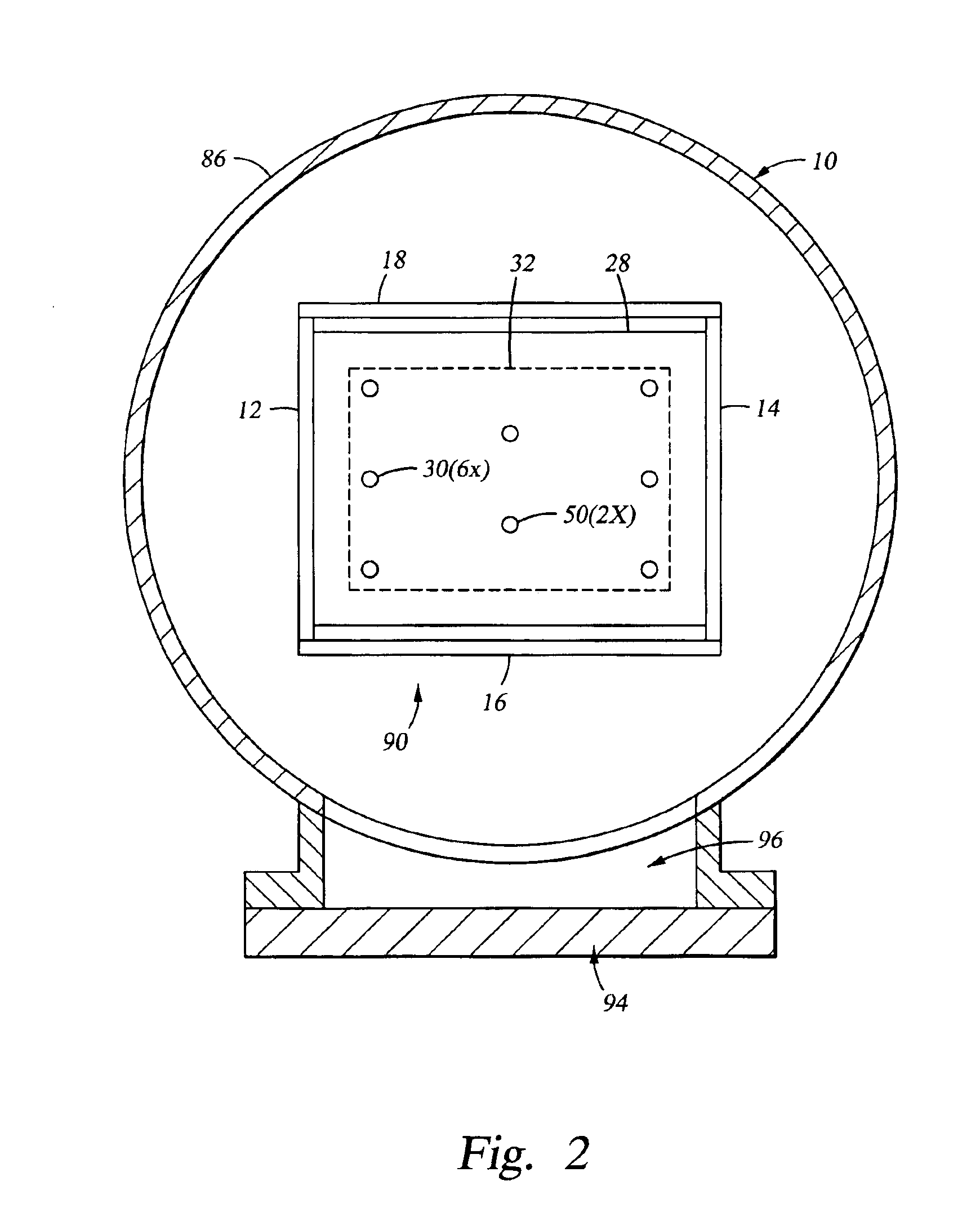

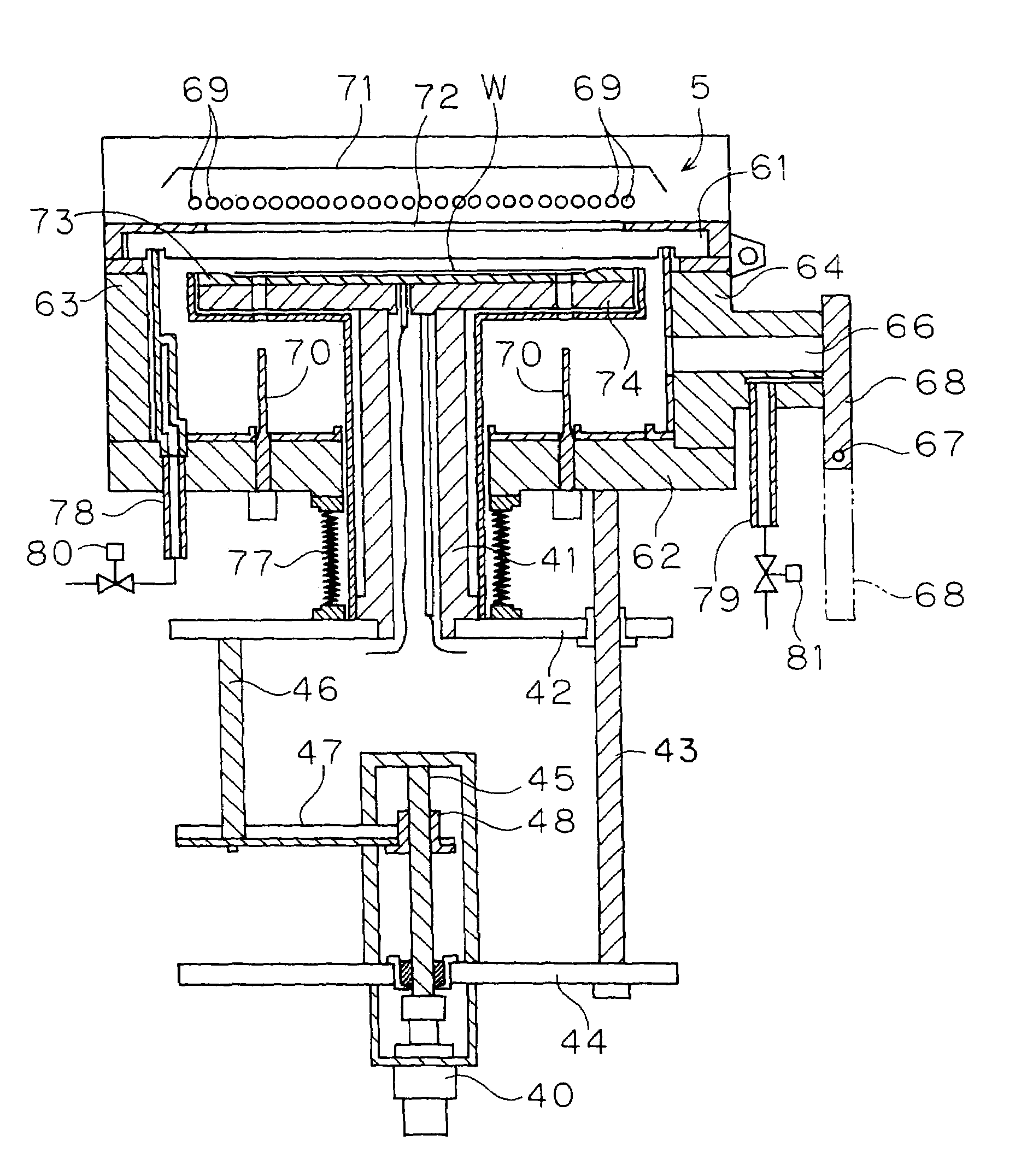

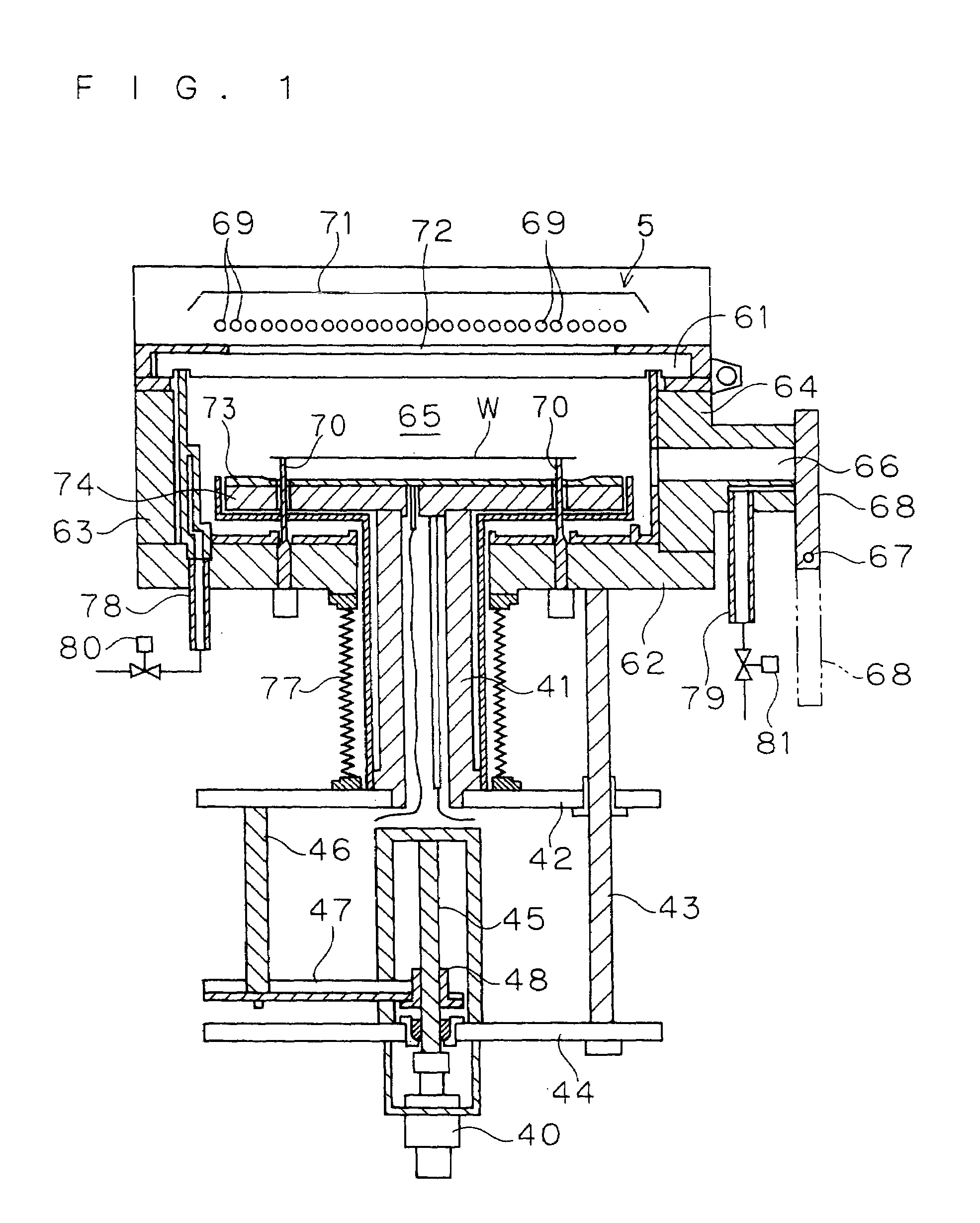

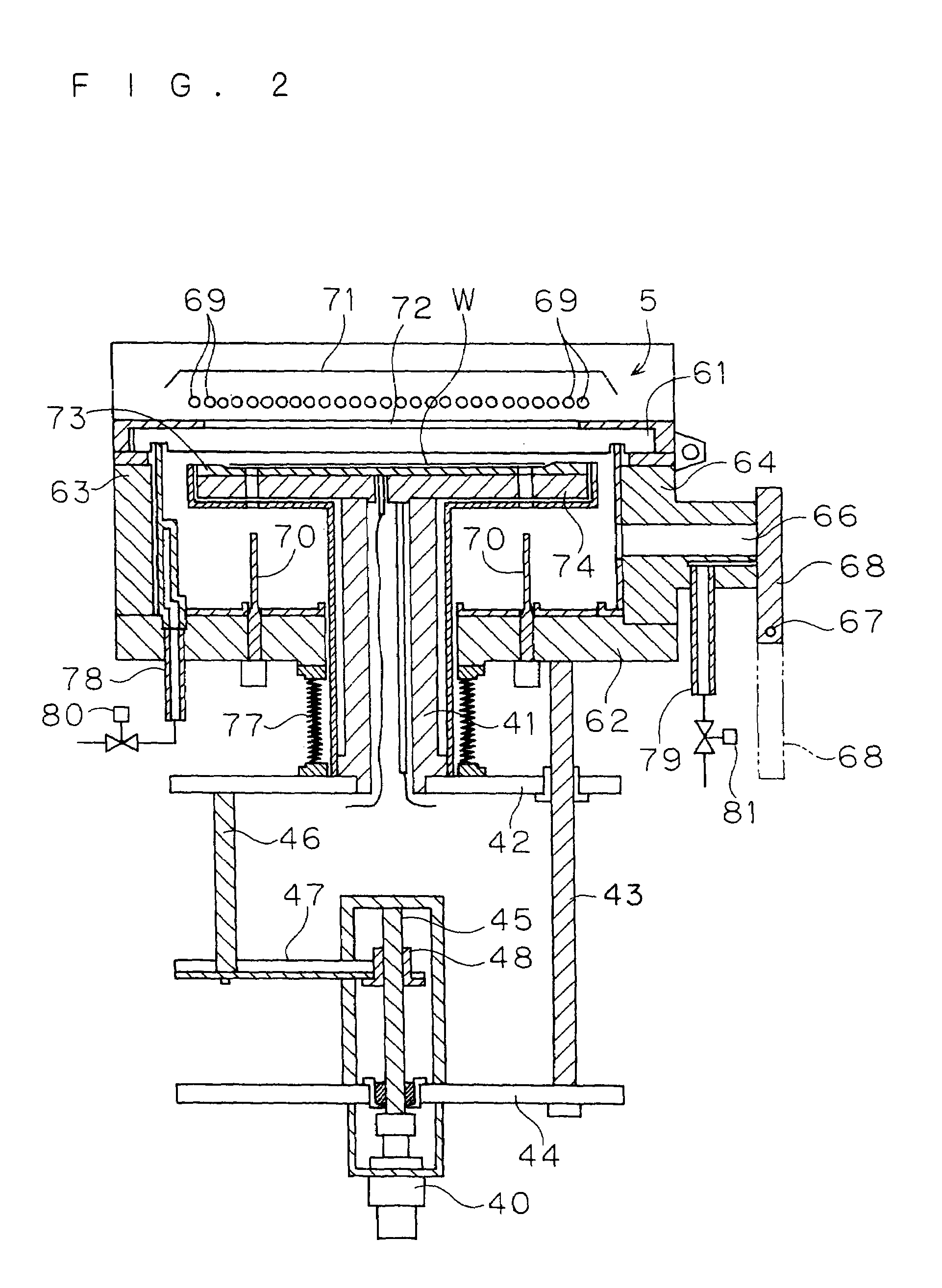

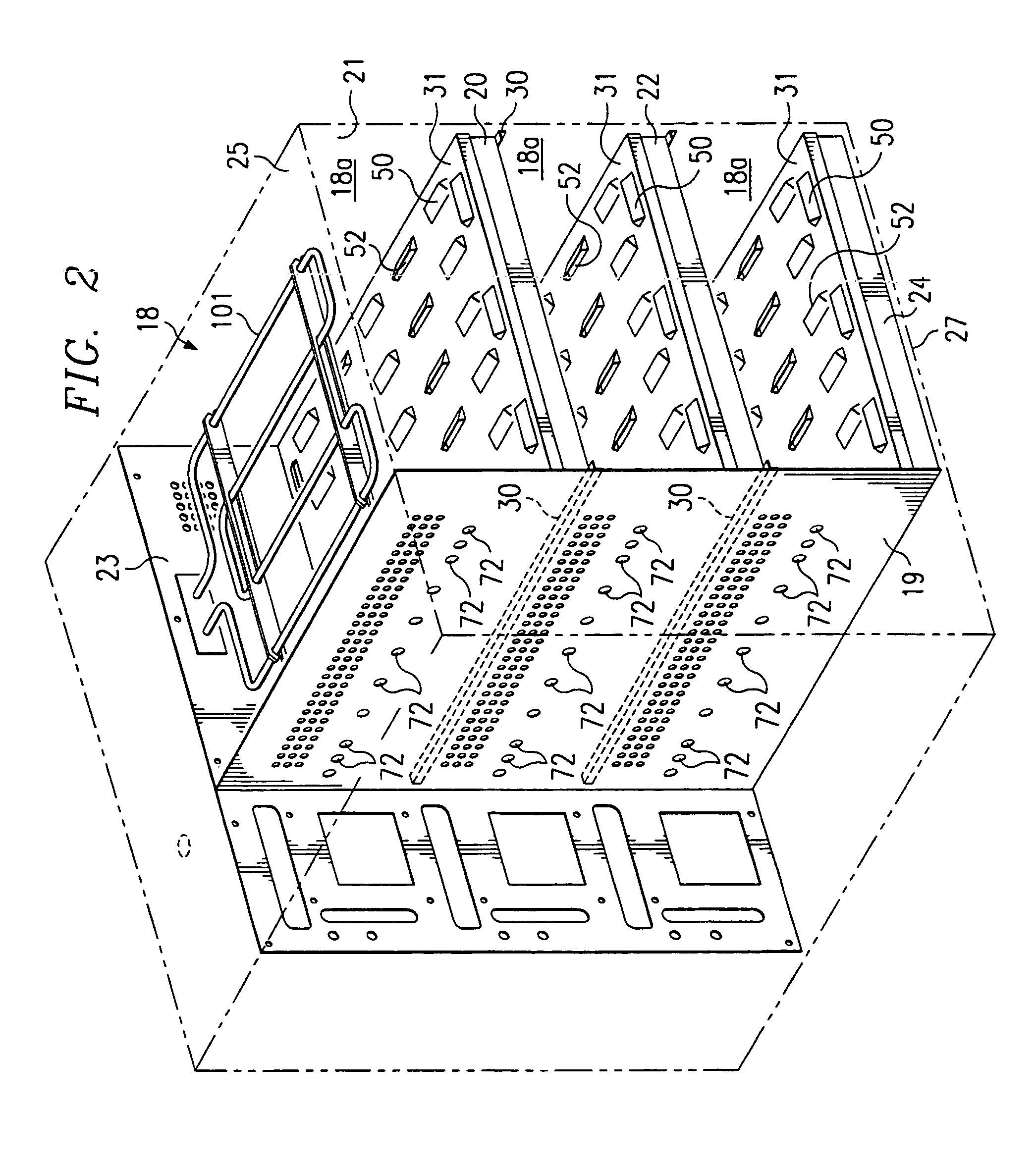

High temperature vacuum chuck assembly

ActiveUS20090179365A1Avoid overall overheatingSleeve/socket jointsMuffle furnacesEngineeringElectrical connector

A vacuum chuck and a process chamber equipped with the same are provided. The vacuum chuck assembly comprises a support body, a plurality of protrusions, a plurality of channels, at least one support member supporting the support body, at least one resilient member coupled with the support member, a hollow shaft supporting the support body, at least one electrical connector disposed through the hollow shaft, and an air-cooling apparatus. The support body has a support surface for holding a substrate (such as a wafer) thereon. The protrusions are formed on and project from the support surface for creating a gap between the substrate and the support surface. The channels are formed on the support surface for generating reduced pressure in the gap. The air-cooling apparatus is used for providing air cooling in the vicinity of the electrical connector.

Owner:APPLIED MATERIALS INC

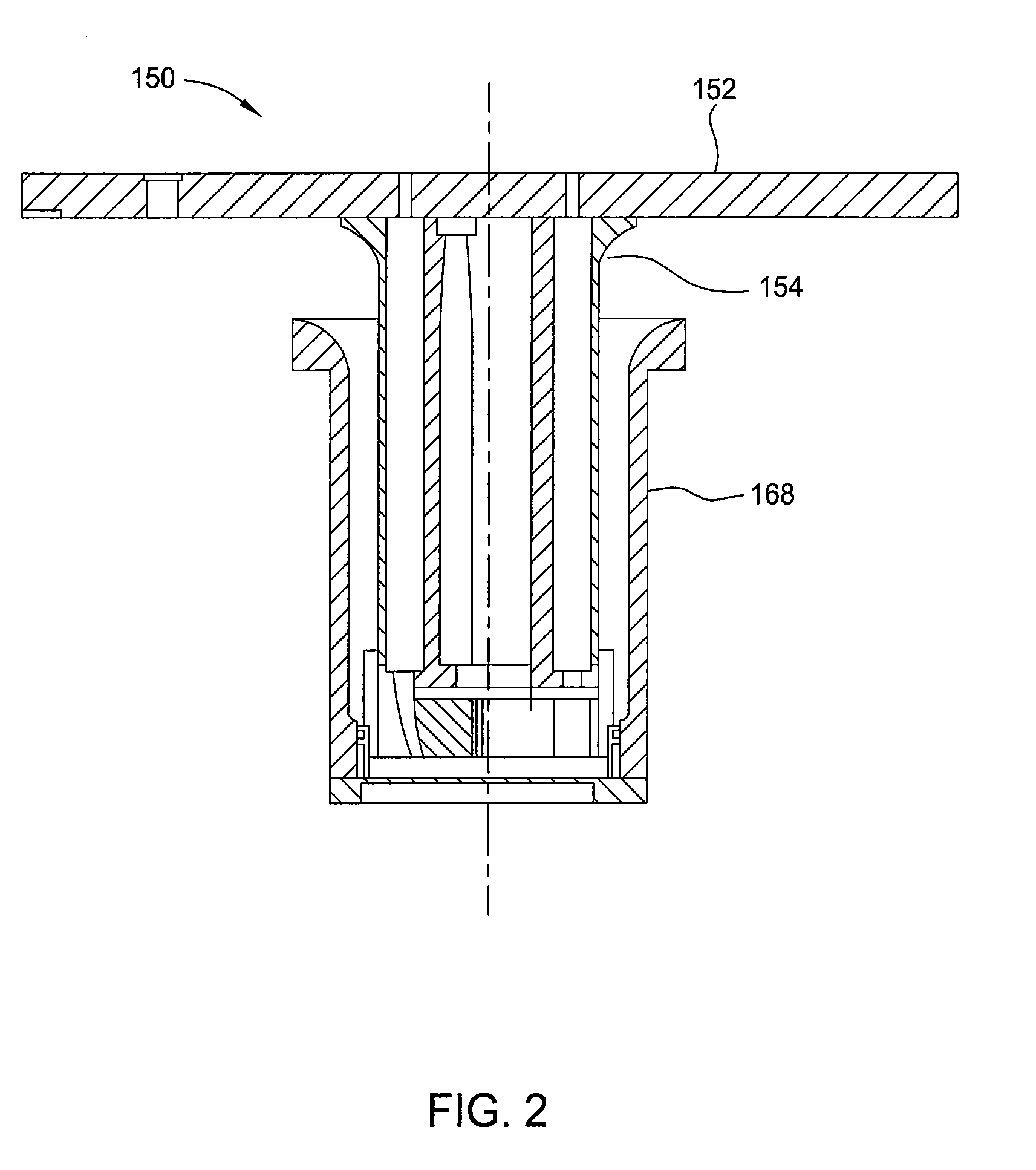

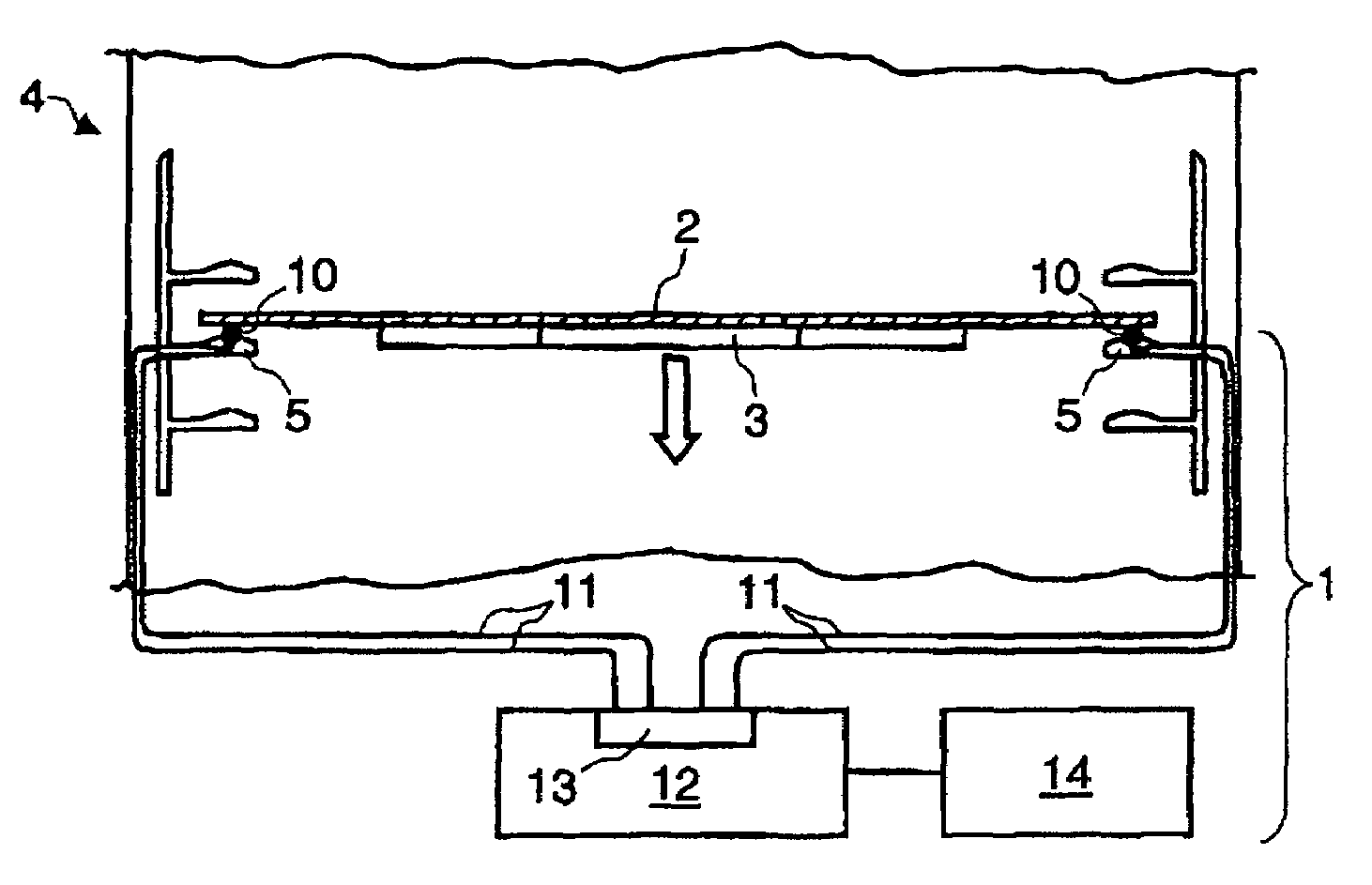

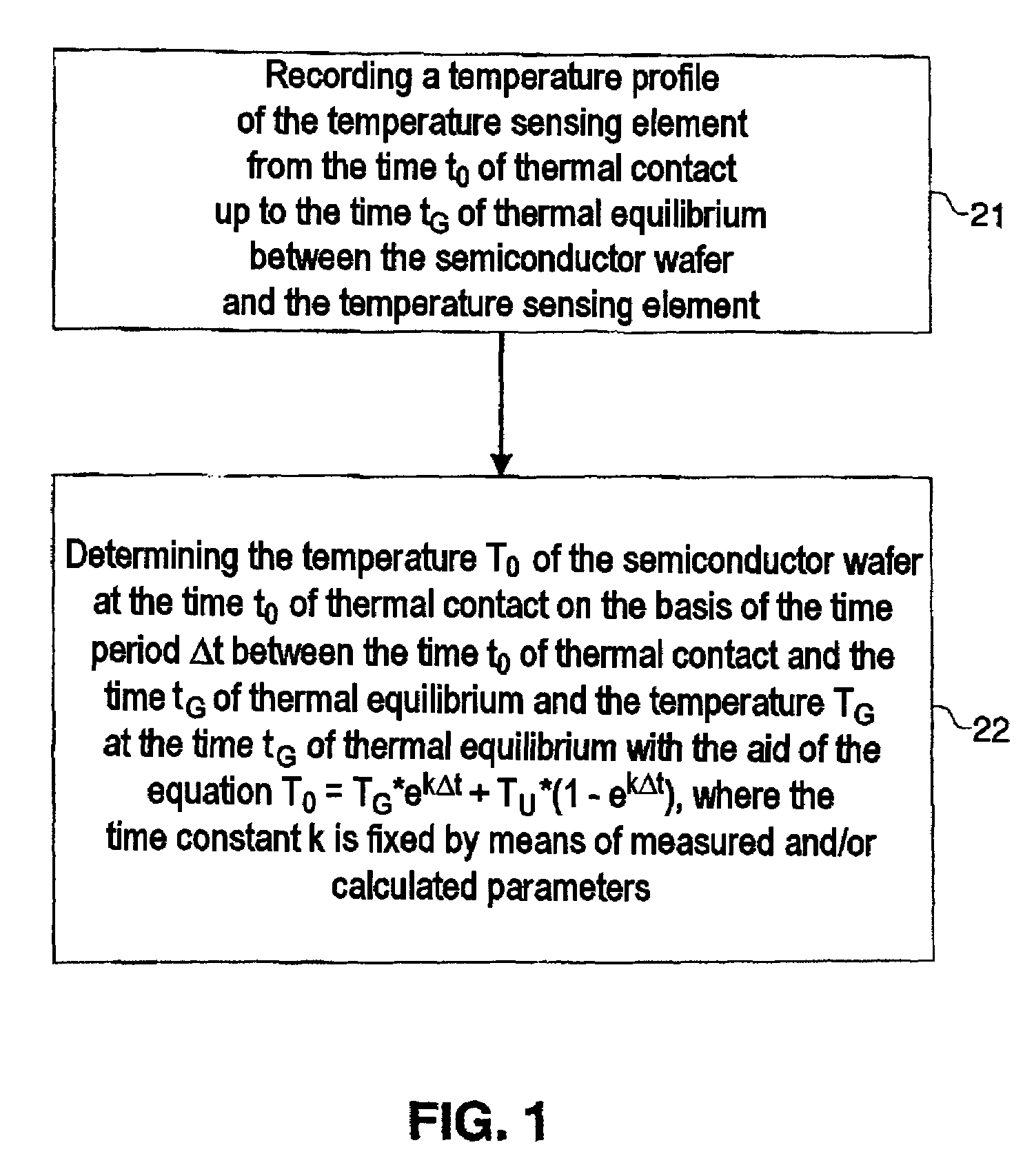

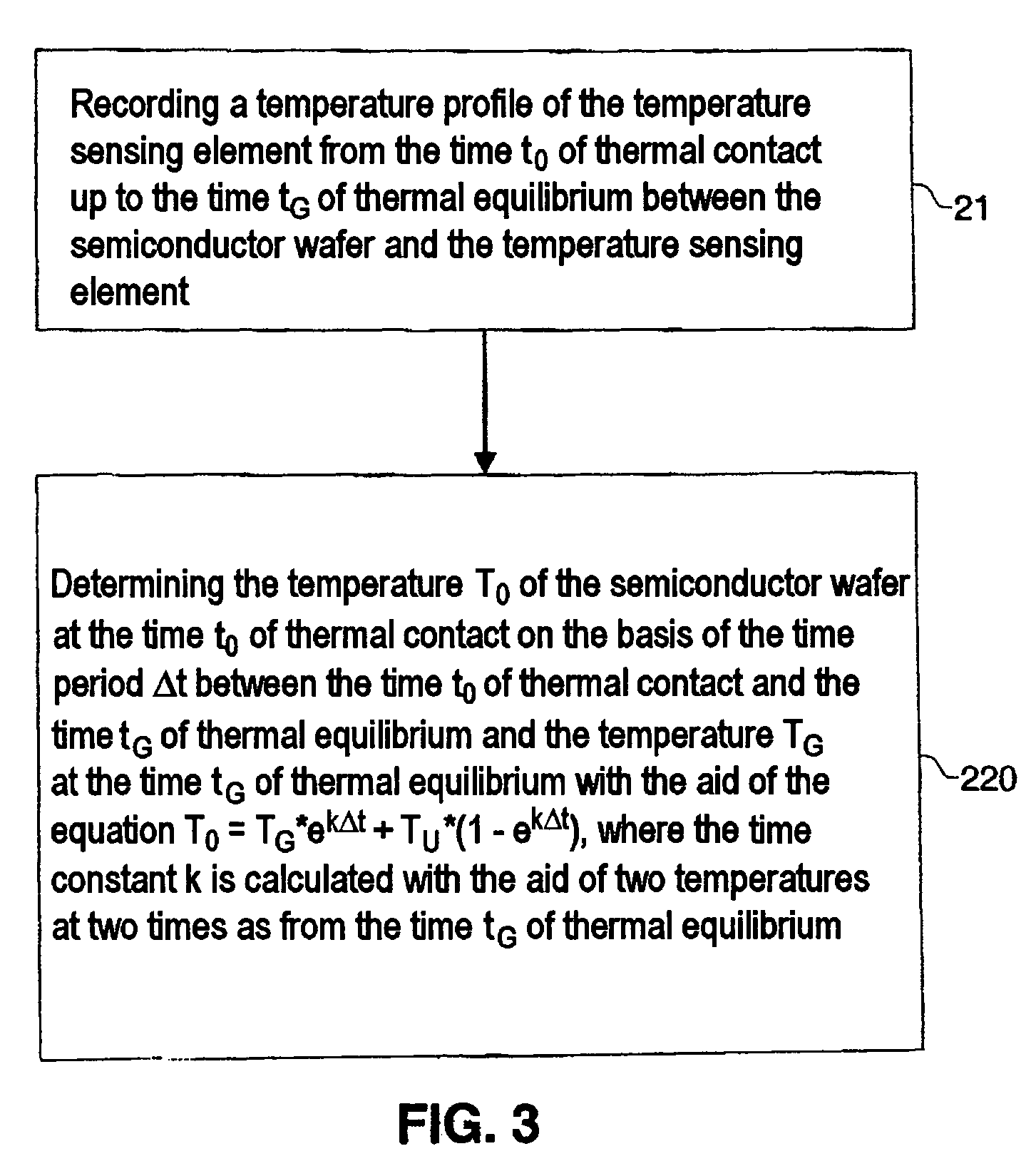

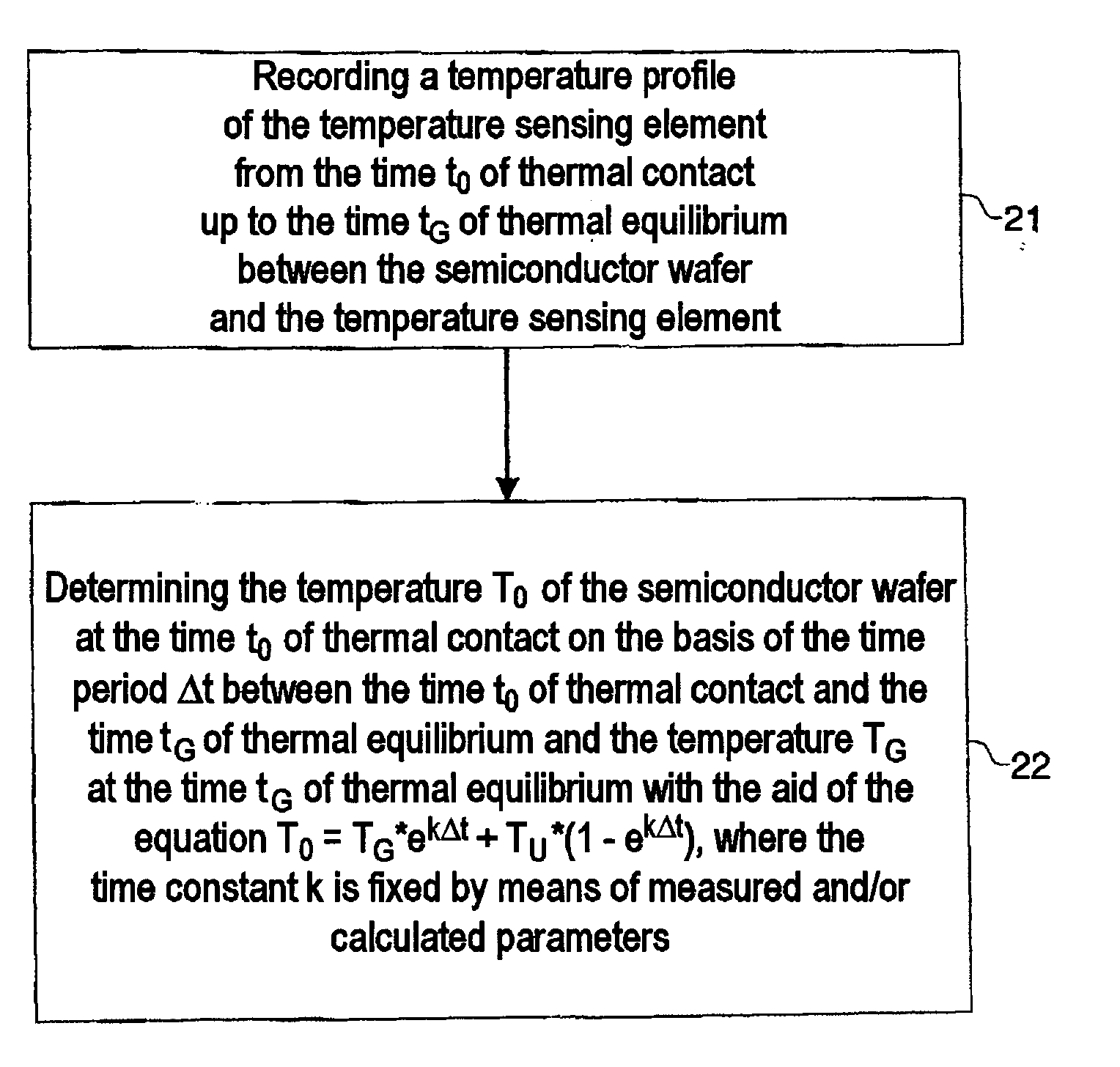

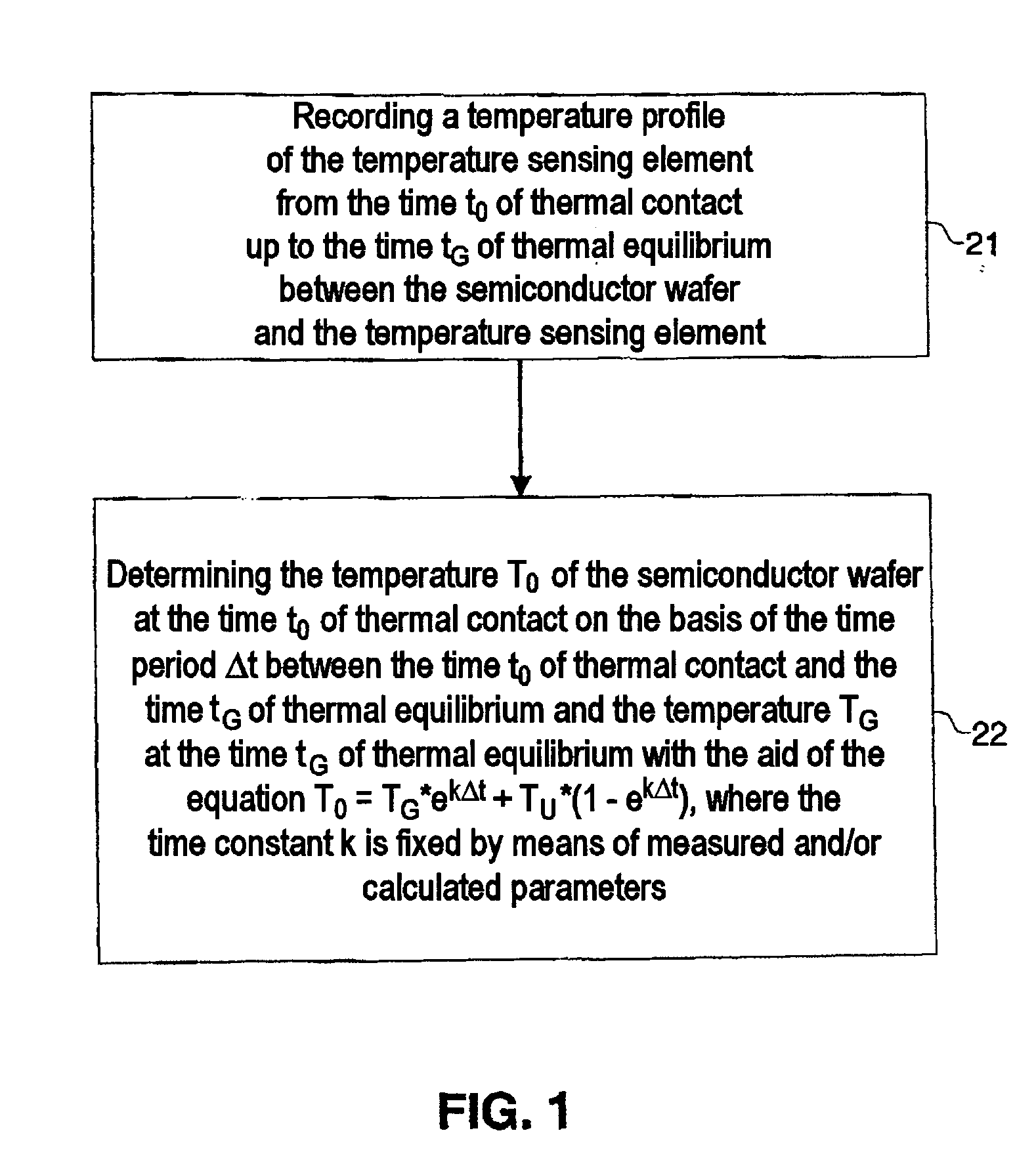

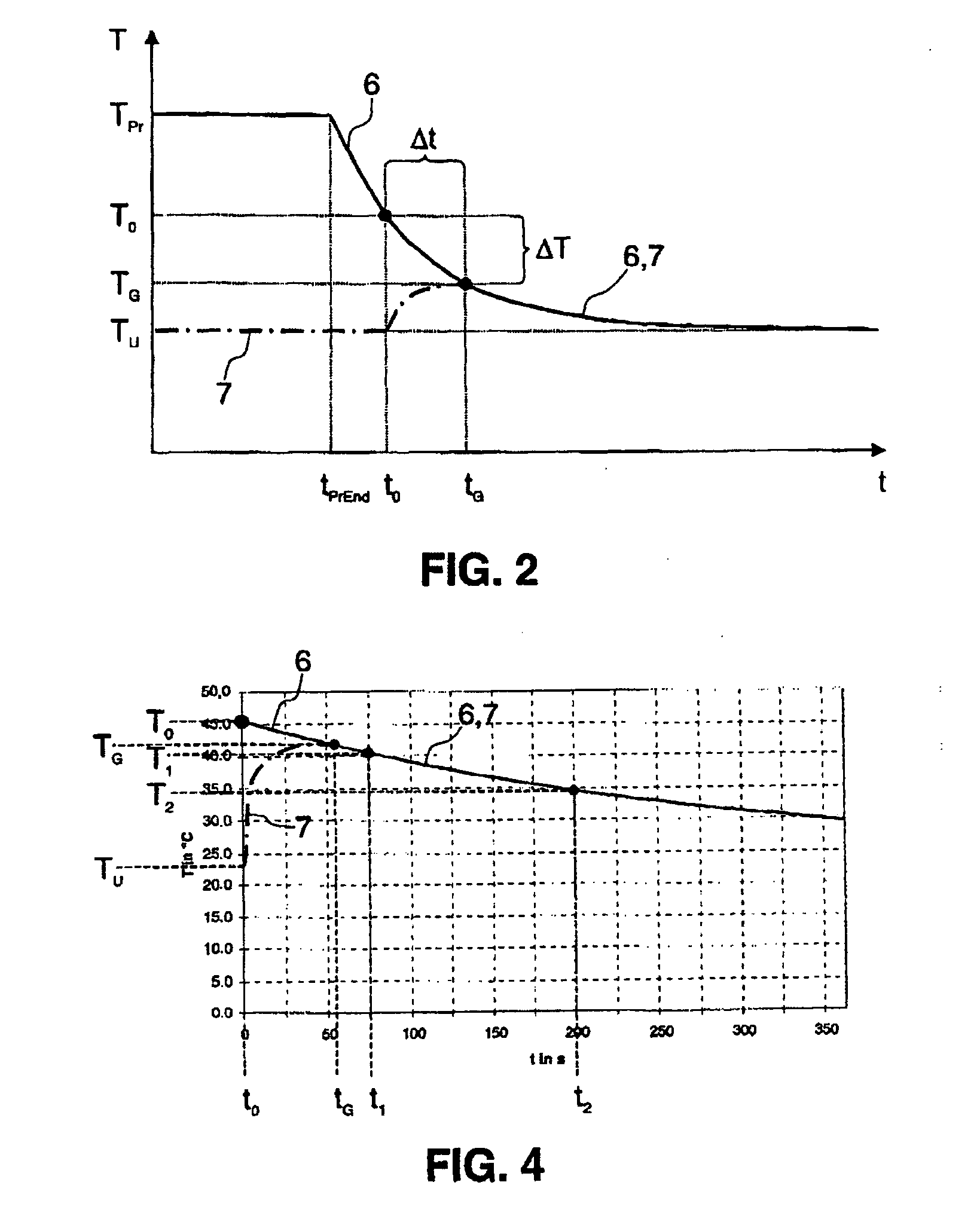

System and method for determining the temperature of a semiconductor wafer

InactiveUS7274867B2High precisionImprove convenienceDrying solid materials with heatSemiconductor/solid-state device testing/measurementTime segmentBack calculation

A system and method for determining the temperature of a semiconductor wafer at the time of thermal contact of the semiconductor wafer with a temperature sensing element. According to the invention, a temperature profile of the temperature sensing element is recorded from the time of thermal contact up to the time of thermal equilibrium between the semiconductor wafer and the temperature sensing element and the temperature of the semiconductor wafer at the time of thermal contact is determined on the basis of a time period between the time of thermal contact and the time of thermal equilibrium and the temperature TG of the semiconductor wafer reached at the time tG of thermal equilibrium is determined by back calculation with the aid of an equation derived from Newton's law of cooling.

Owner:POLARIS INNOVATIONS LTD

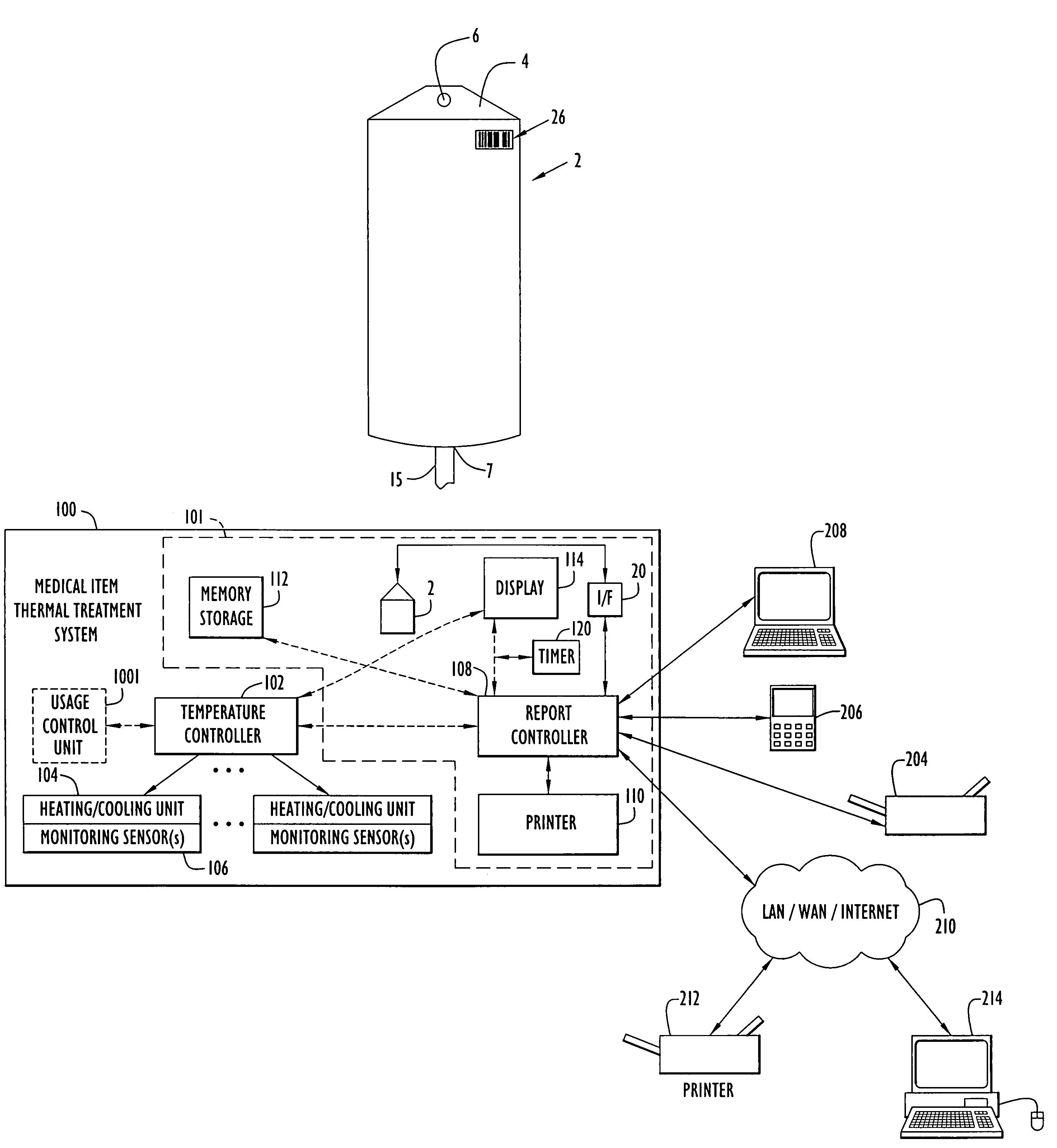

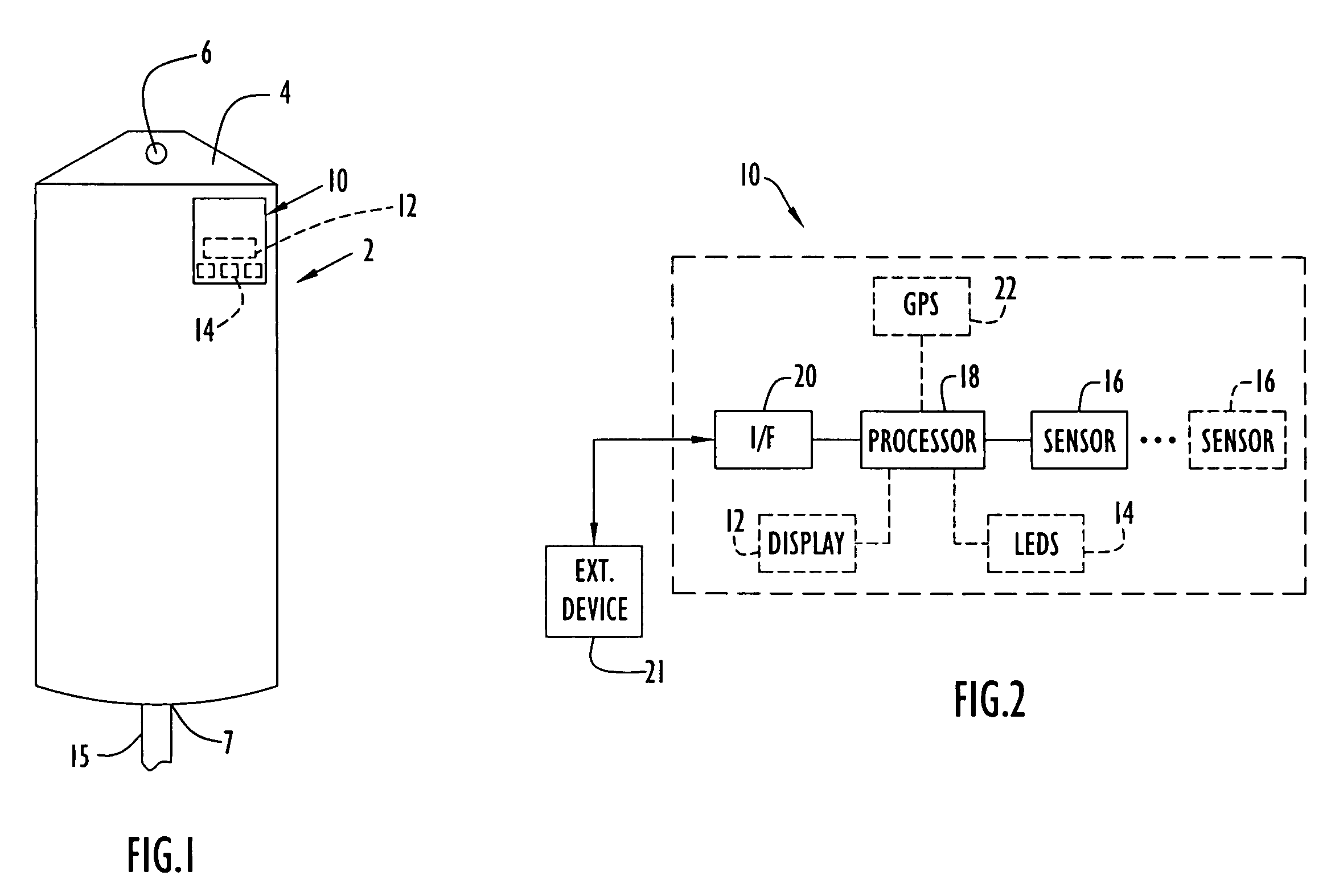

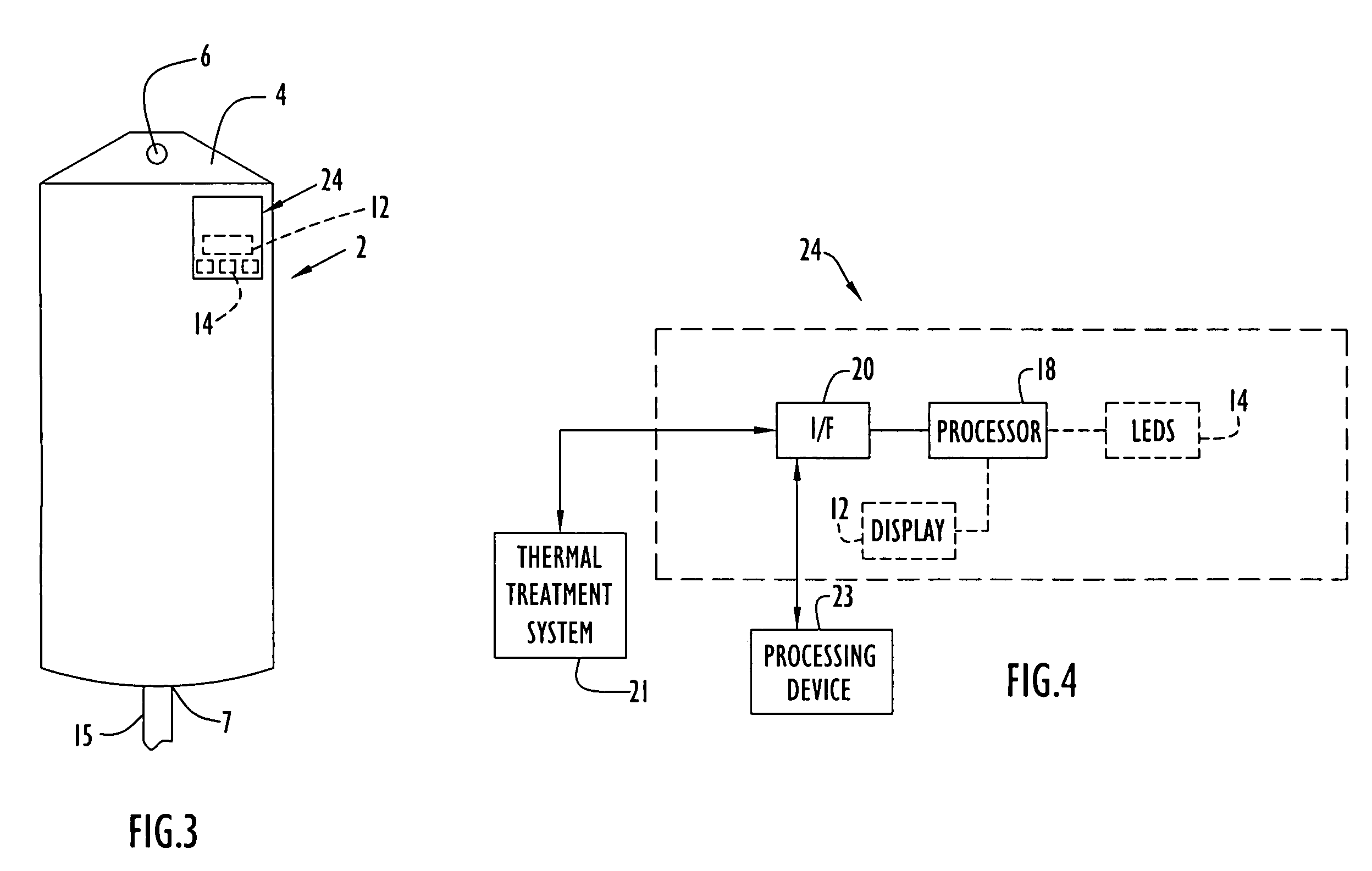

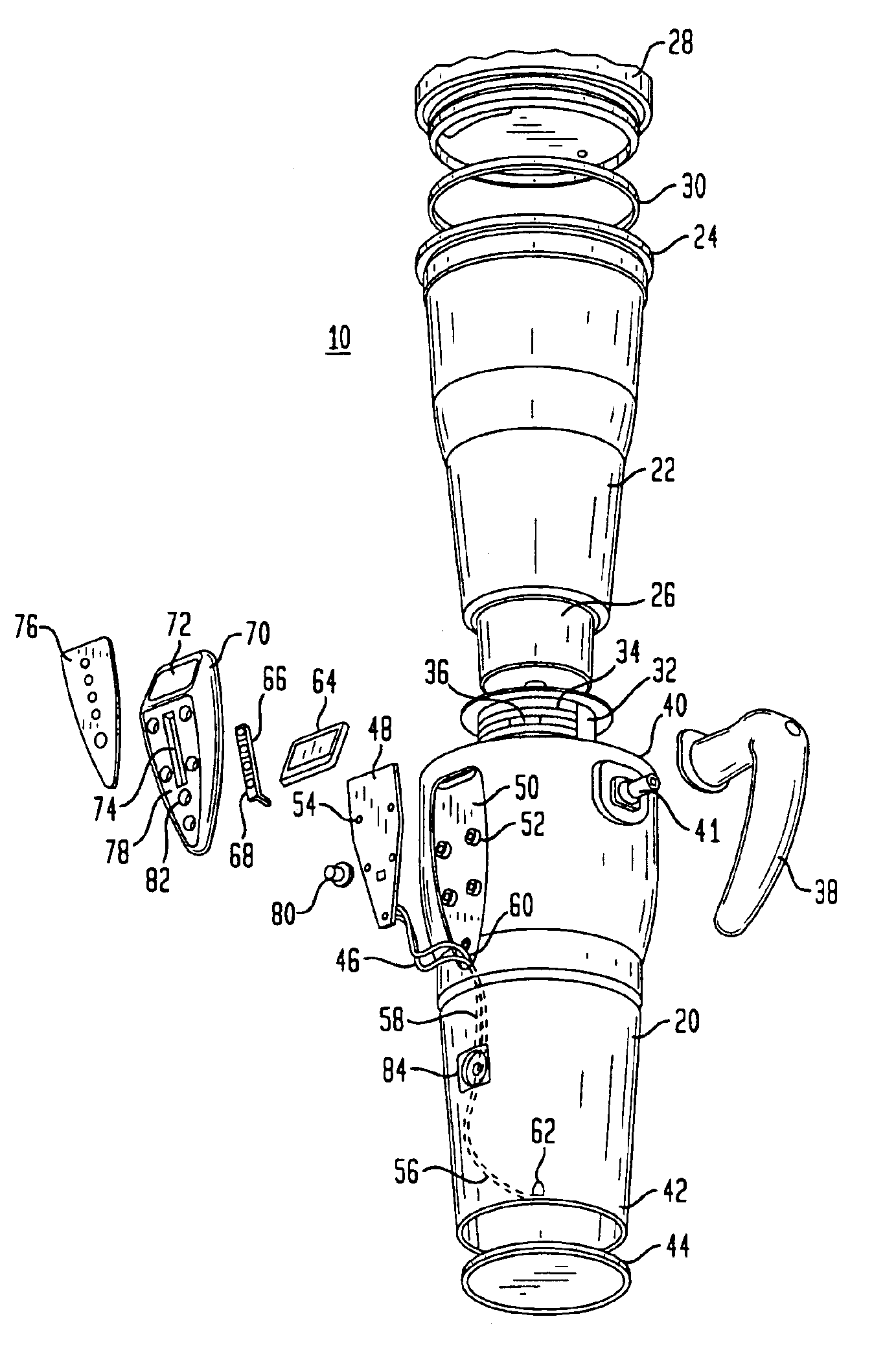

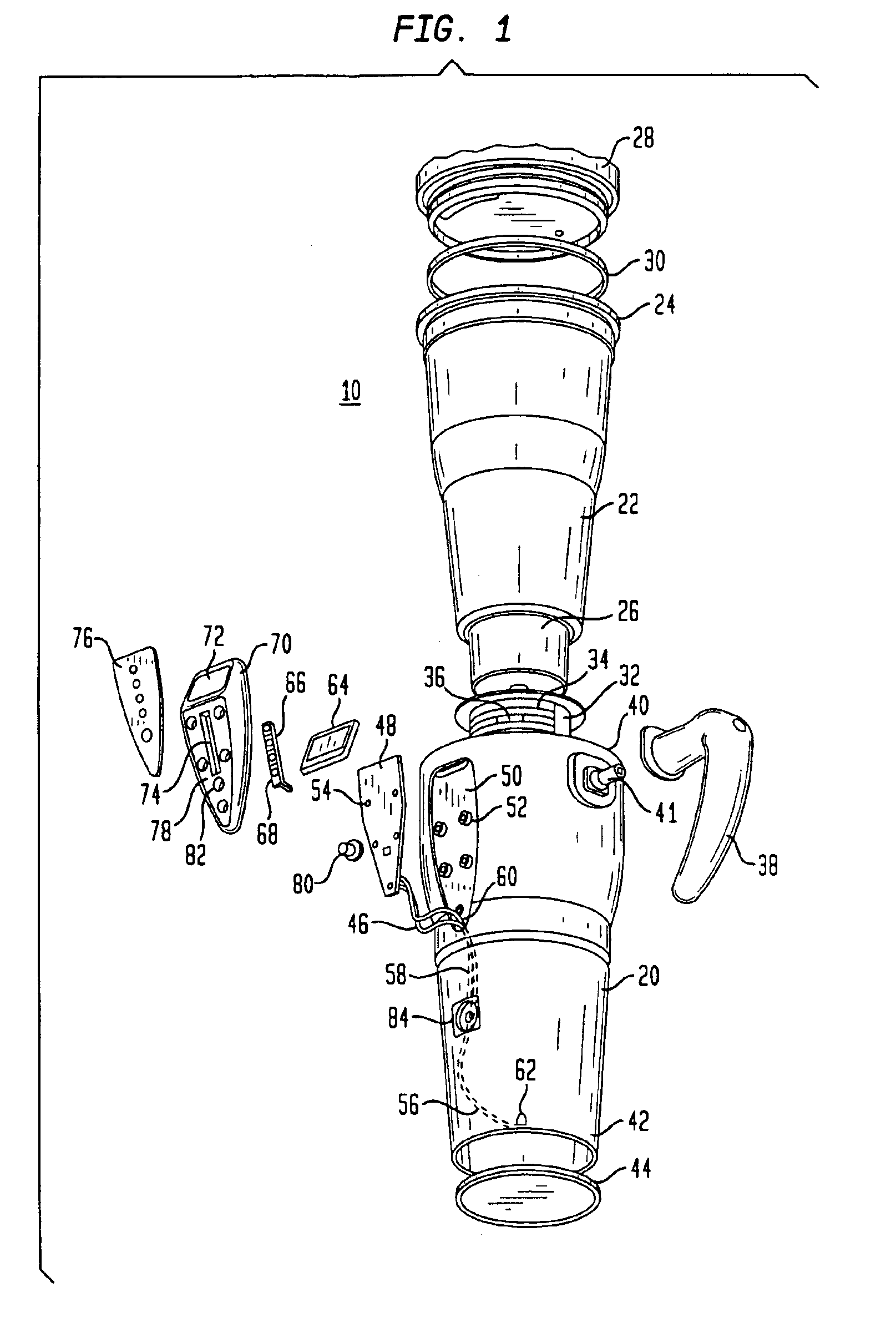

Medical item thermal treatment systems and method of monitoring medical items for compliance with prescribed requirements

Various present invention devices enable adherence to requirements for medical items. A medical item of the present invention includes a monitoring or data recording device to monitor and / or record medical solution conditions. The device may further include indicators to indicate compliance of the medical solution with prescribed requirements (e.g., manufacturer, medical standard or regulation, etc.). The medical item may alternatively include a barcode or transponder to uniquely identify the medical item to a thermal treatment system measuring and storing conditions in a central database. The present invention further includes various thermal treatment systems that monitor medical items for prescribed requirements and display the monitored parameters to medical personnel. In addition, the present invention may place time stamp information on medical items to enable determination by medical personnel of compliance with prescribed requirements.

Owner:PATENTED MEDICAL SOLUTIONS LLC

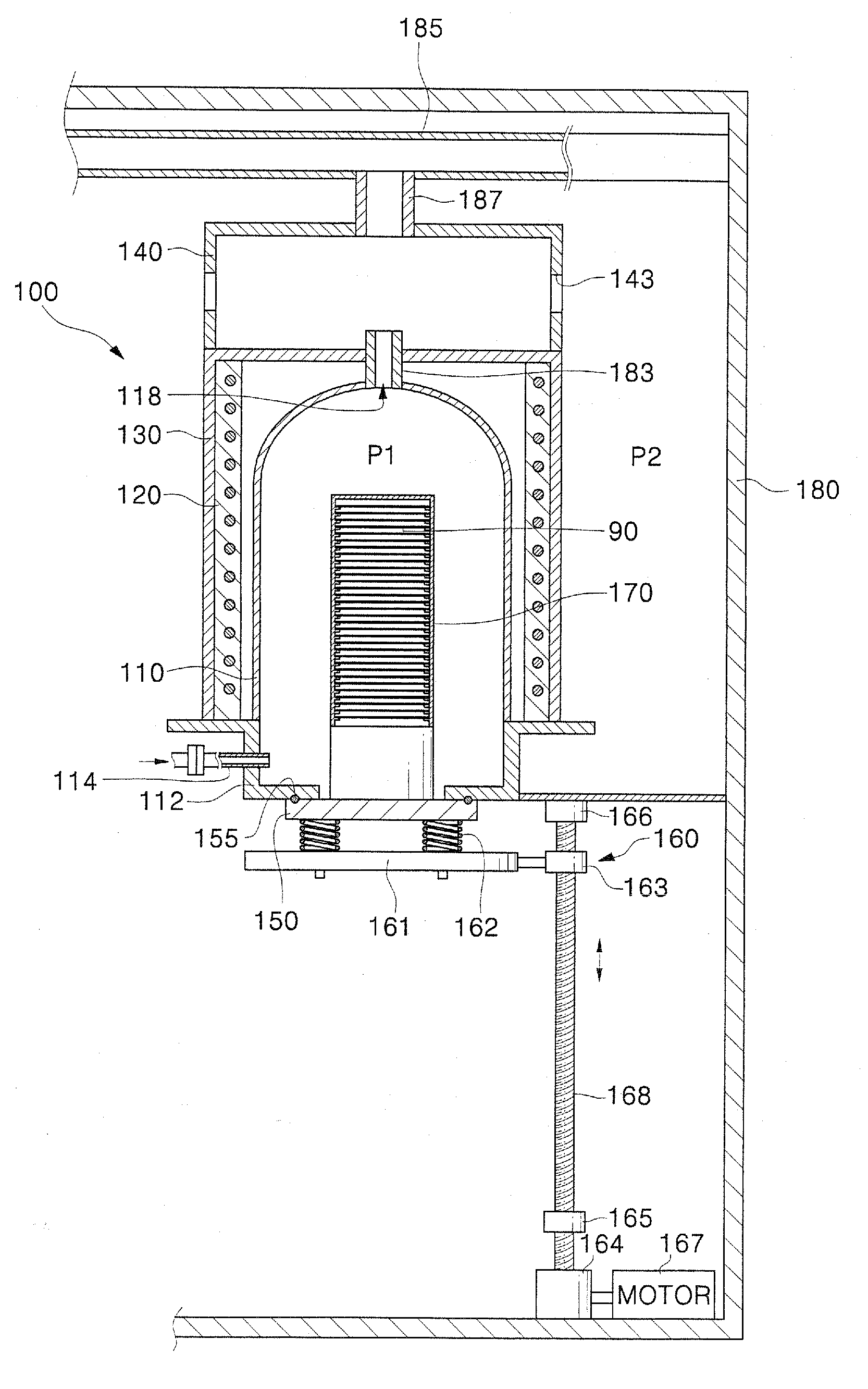

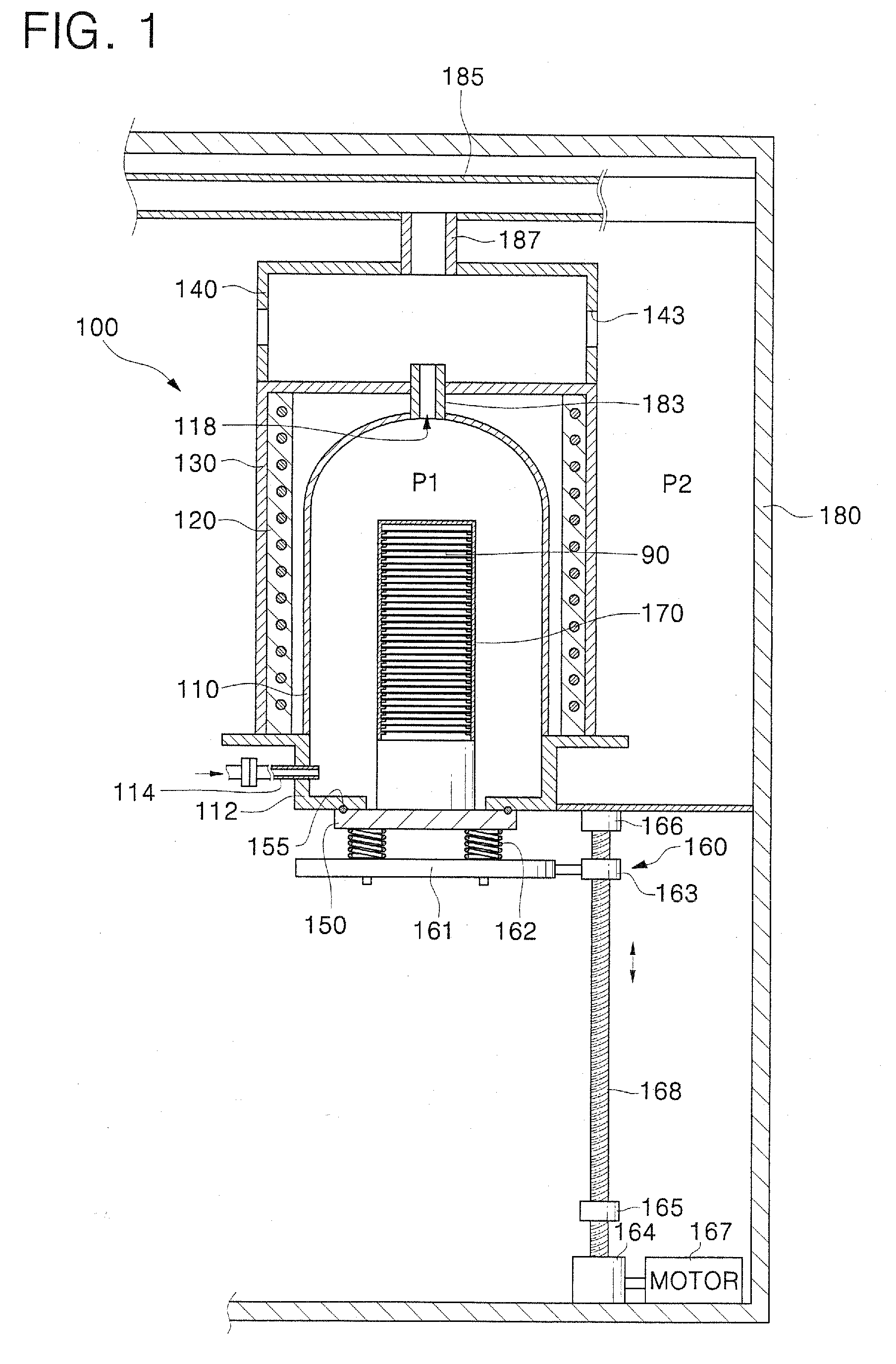

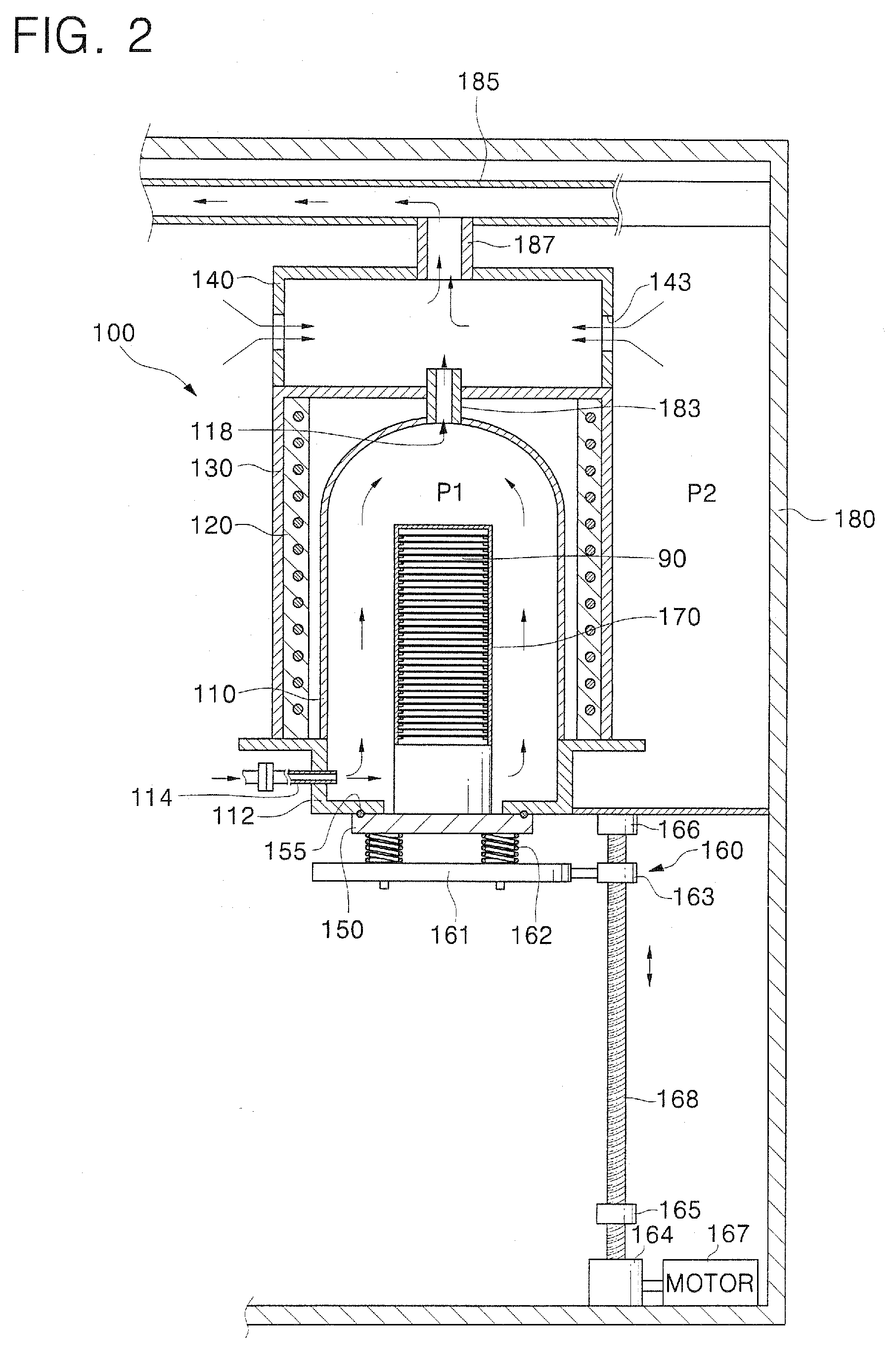

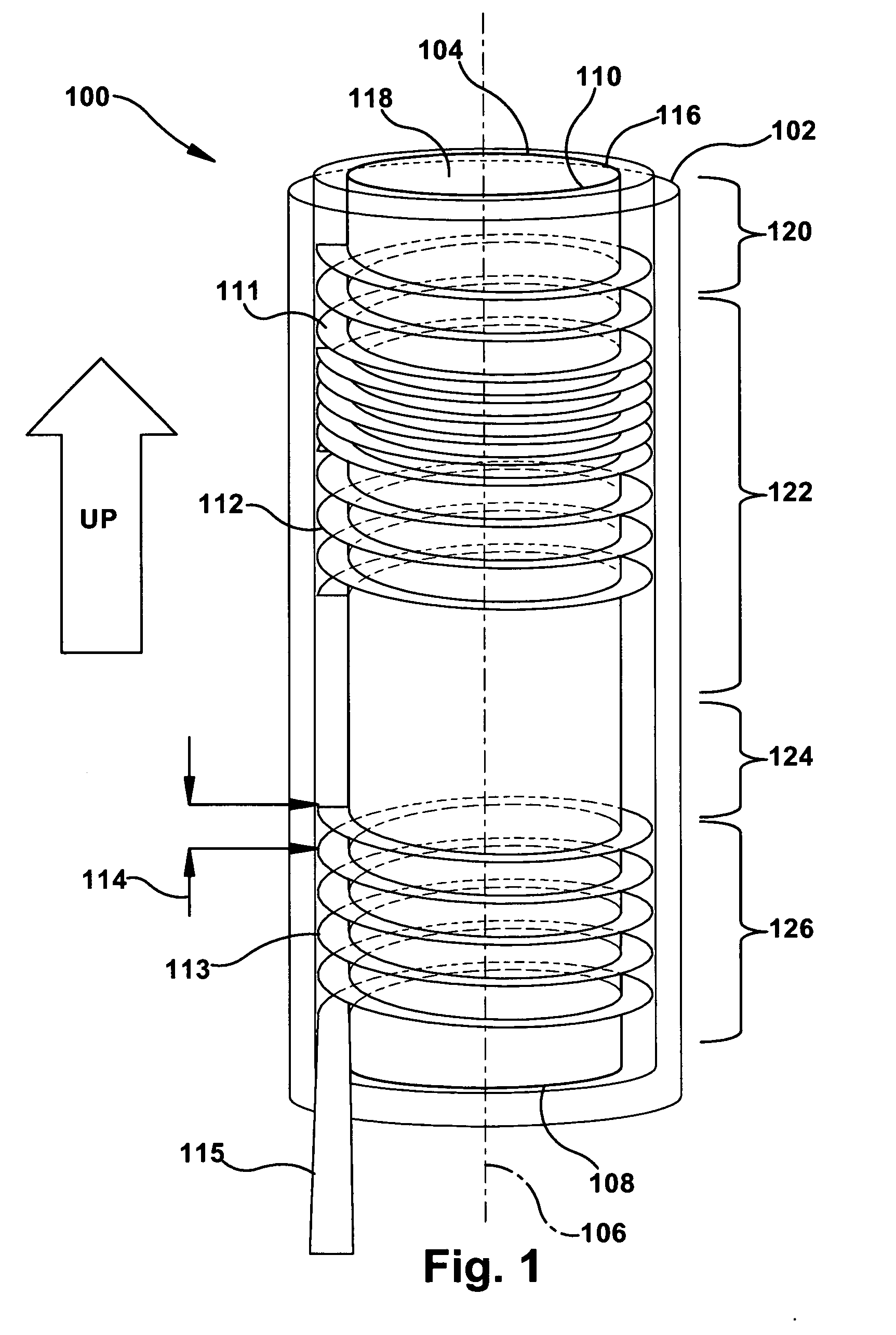

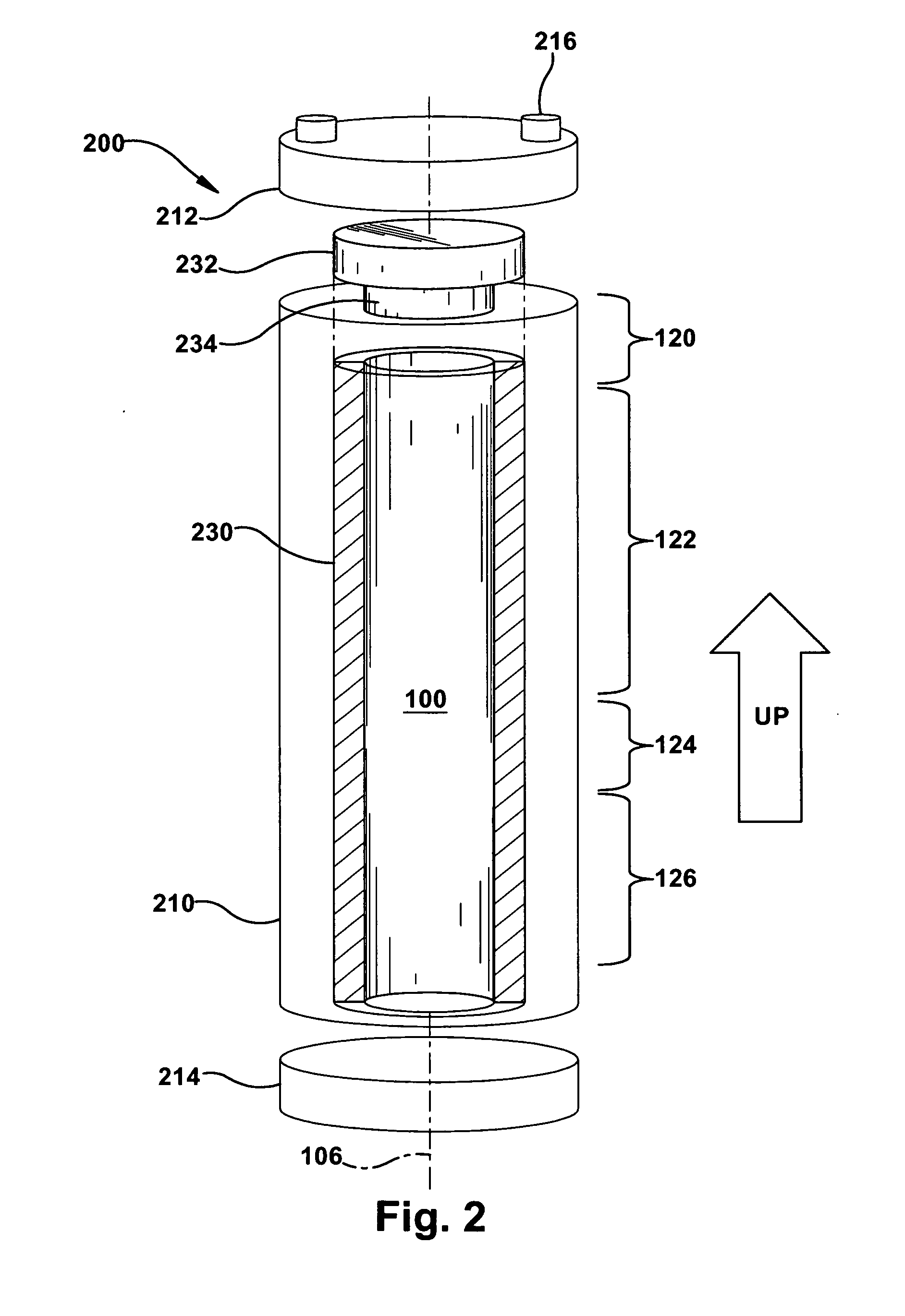

Heat treatment equipment

InactiveUS7850449B2Growth inhibitionReduce processing stepsMuffle furnacesBaking ovenProcess engineeringPressure controlled ventilation

In an embodiment, heat treatment equipment comprises a process tube, an exhaust duct connected to the process tube, and, during operation, exhausting gases present within the process tube. The heat treatment equipment also comprises a hollow pressure control member interposed between the process tube and the exhaust duct, the pressure control member being operatively connected to the process tube and the exhaust duct respectively, and including one or a number of openings. Negative pressure is avoided in the process tube during heat treatment processes so that unwanted gas and impurities cannot enter the process tube from outside.

Owner:SAMSUNG ELECTRONICS CO LTD

System and method for determining the temperature of a semiconductor wafer

InactiveUS20050042778A1High precisionImprove convenienceDrying solid materials with heatSemiconductor/solid-state device testing/measurementBack calculationThermal contact

A system and method for determining the temperature of a semiconductor wafer at the time of thermal contact of the semiconductor wafer with a temperature sensing element. According to the invention, a temperature profile of the temperature sensing element is recorded from the time of thermal contact up to the time of thermal equilibrium between the semiconductor wafer and the temperature sensing element and the temperature of the semiconductor wafer at the time of thermal contact is determined on the basis of a time period between the time of thermal contact and the time of thermal equilibrium and the temperature TG of the semiconductor wafer reached at the time tG of thermal equilibrium is determined by back calculation with the aid of an equation derived from Newton's law of cooling.

Owner:POLARIS INNOVATIONS LTD

Photoirradiation thermal processing apparatus and thermal processing susceptor employed therefor

ActiveUS7062161B2Avoid crackingAvoid actionLiquid surface applicatorsDrying solid materials with heatSusceptorEngineering

A susceptor is formed with a cavity having a tapered surface and a receiving surface. The gradient α of the tapered surface with respect to the receiving surface is set to at least 5° and less than 30°, so that a semiconductor wafer received by the susceptor can be located on the receiving surface through the tapered surface while the semiconductor wafer can be protected against excess stress also when the surface of the wafer abruptly thermally expands due to flashlight irradiation and can be prevented from cracking in thermal processing. Thus provided are a thermal processing susceptor and a thermal processing apparatus capable of preventing a substrate from cracking in thermal processing.

Owner:DAINIPPON SCREEN MTG CO LTD

Radiant shield

InactiveUS20080314892A1Thermometer detailsDrying solid materials with heatTemperature controlMetallurgy

A radiant shield and a furnace employing a radiant shield for controlled heating and treatment of material using infrared radiation. The furnace is capable of improved temperature control where material treated by the furnace may interfere with the quality of a measured temperature signal and temperature control based on that signal.

Owner:DESPATCH INDS

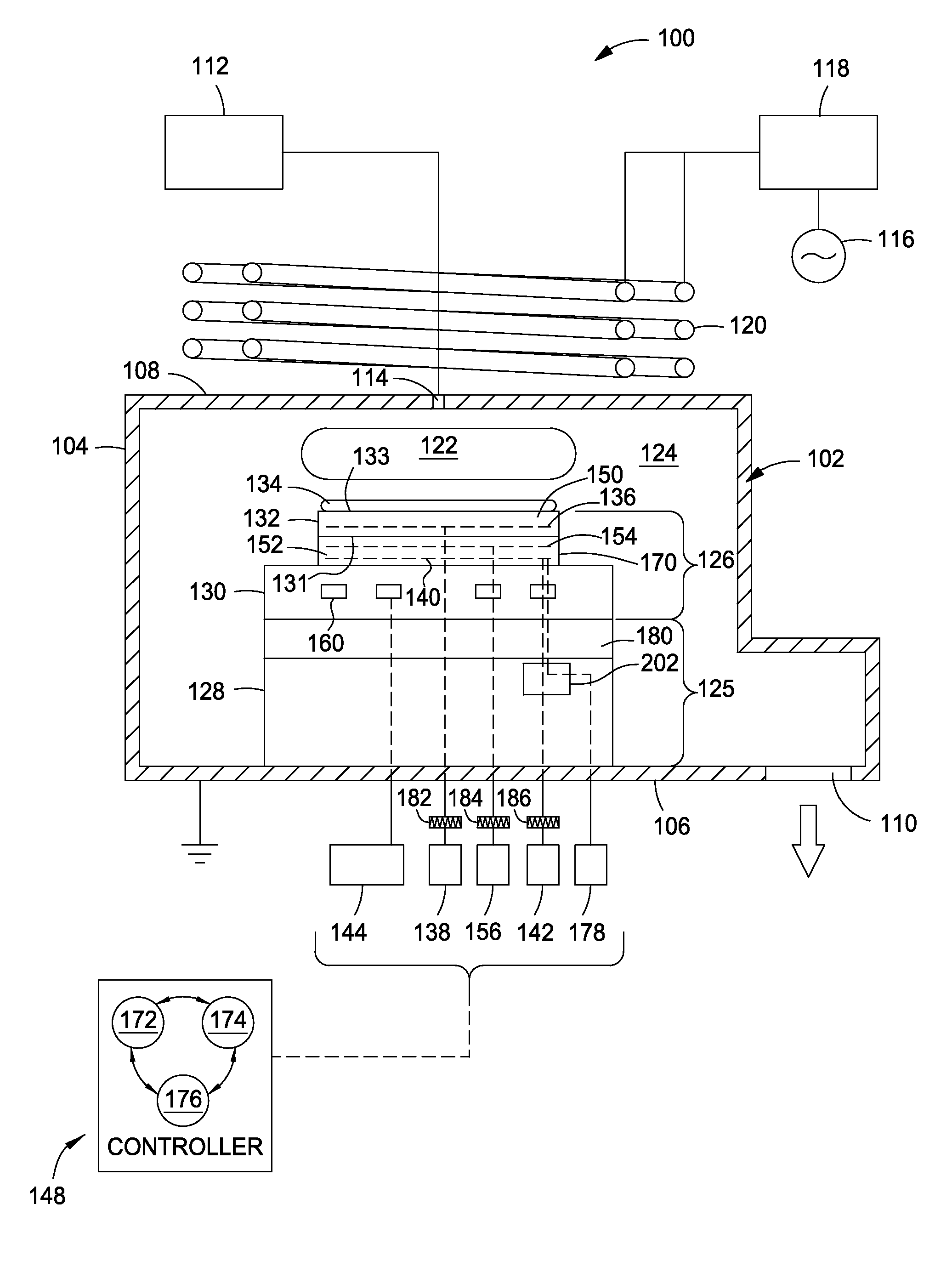

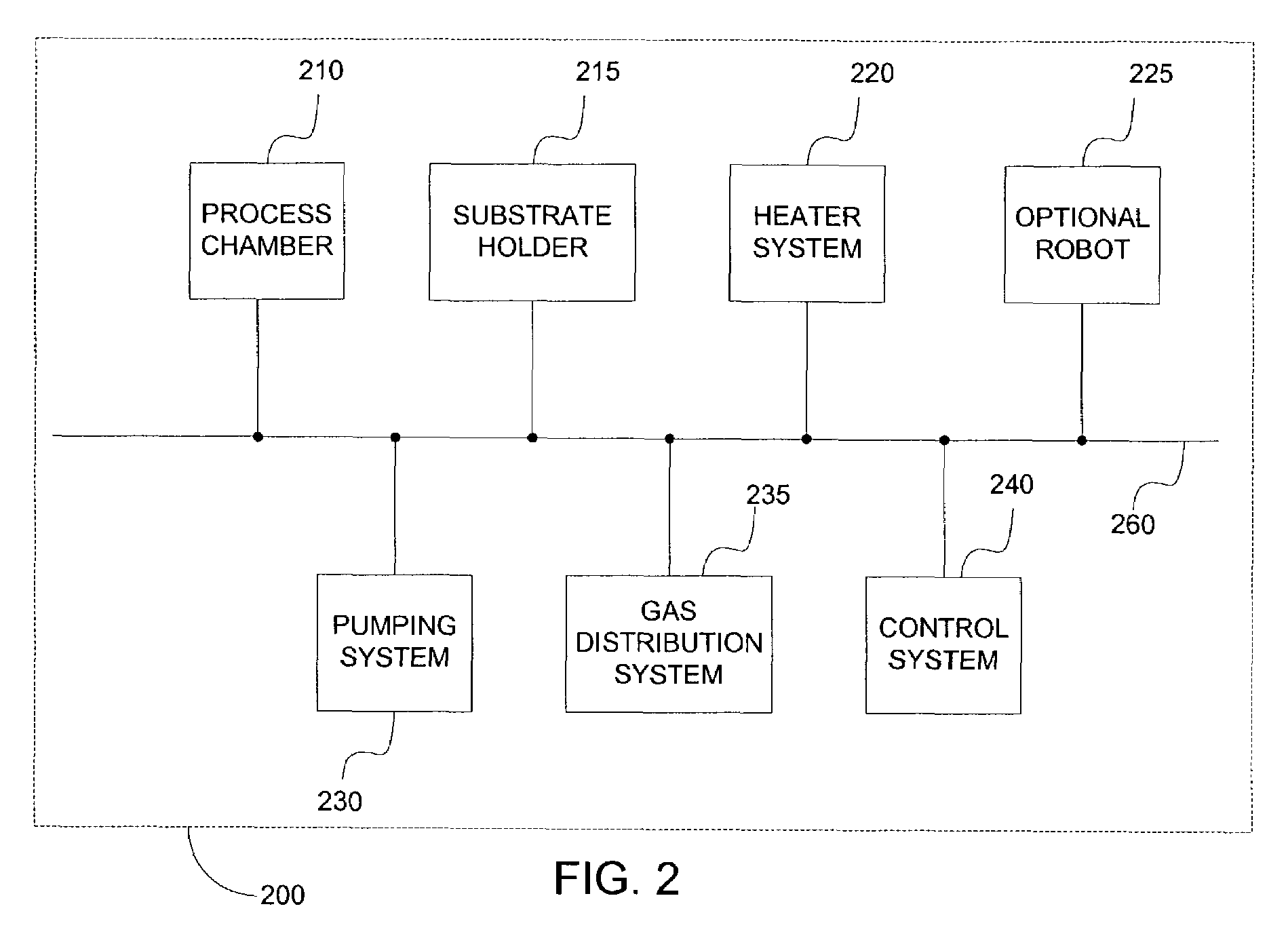

Pixilated temperature controlled substrate support assembly

ActiveUS20150228513A1Charge supportsBaking ovenElectrical resistance and conductanceTemperature control

Implementations described herein provide a pixilated substrate support assembly which enables both lateral and azimuthal tuning of the heat transfer between an electrostatic chuck and a heating assembly. The pixilated substrate support assembly comprises an upper surface and a lower surface; one or more main resistive heaters disposed in the pixilated substrate support; and a plurality of pixel heaters in column with the main resistive heaters and disposed in the substrate support. A quantity of the pixel heaters is an order of magnitude greater than a quantity of the main resistive heaters and the pixel heaters are independently controllable relative to each other as well as the main resistive heater.

Owner:APPLIED MATERIALS INC

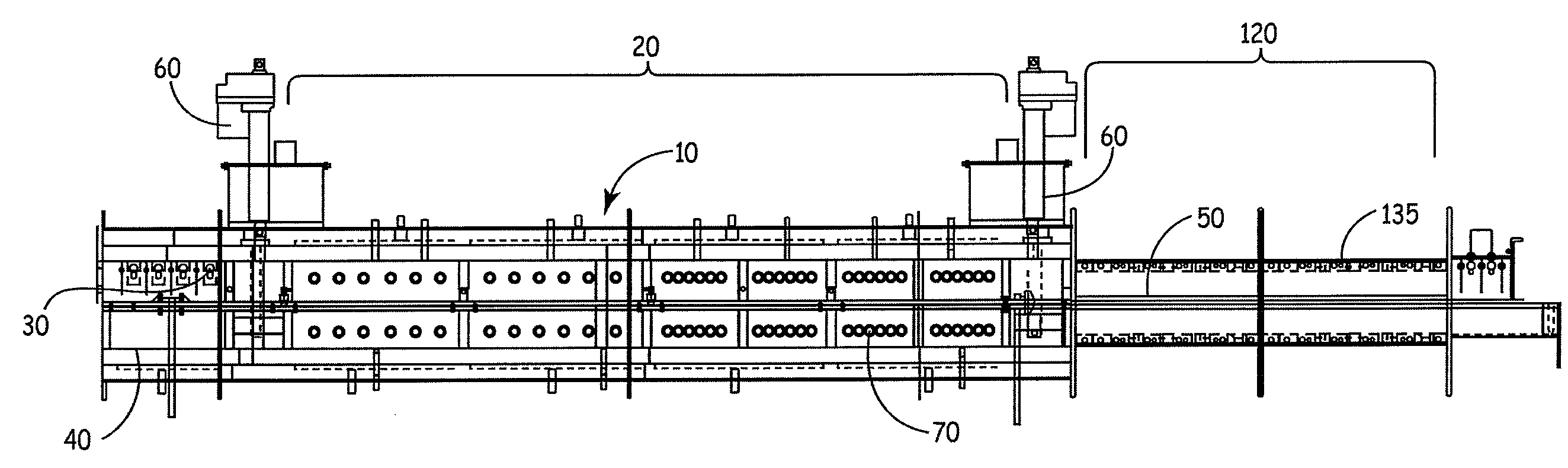

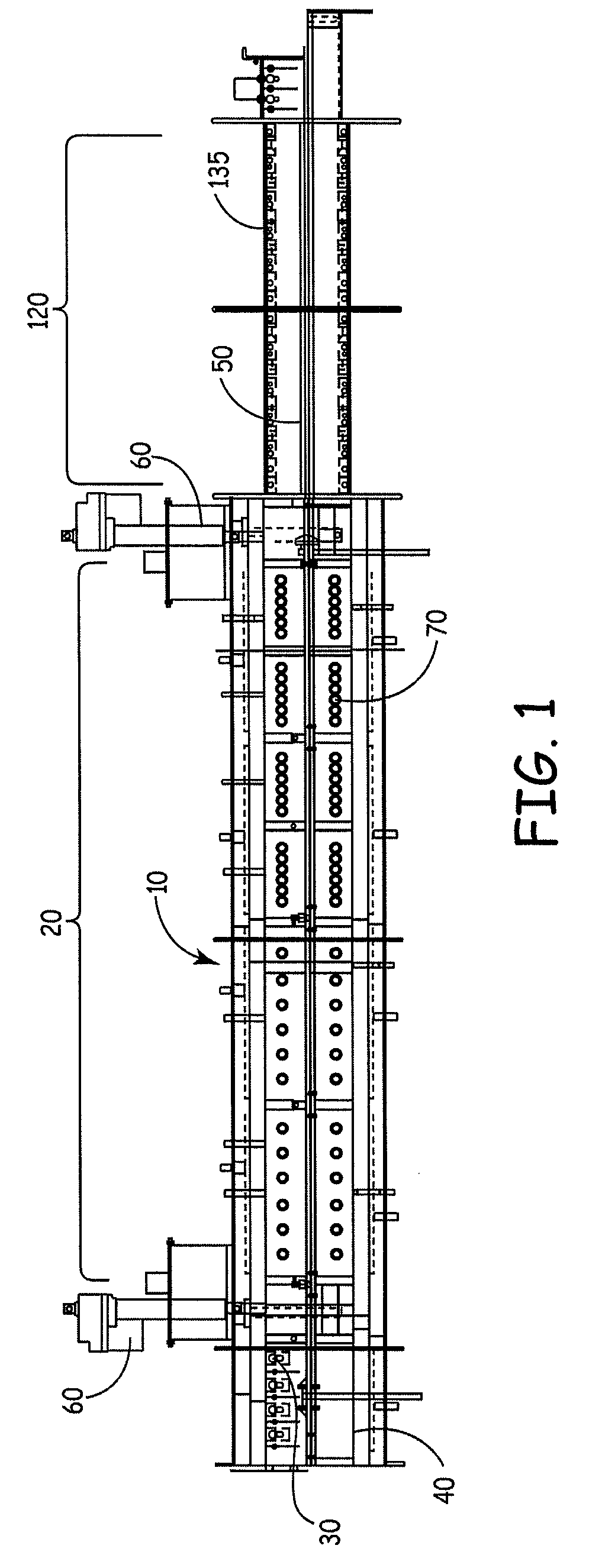

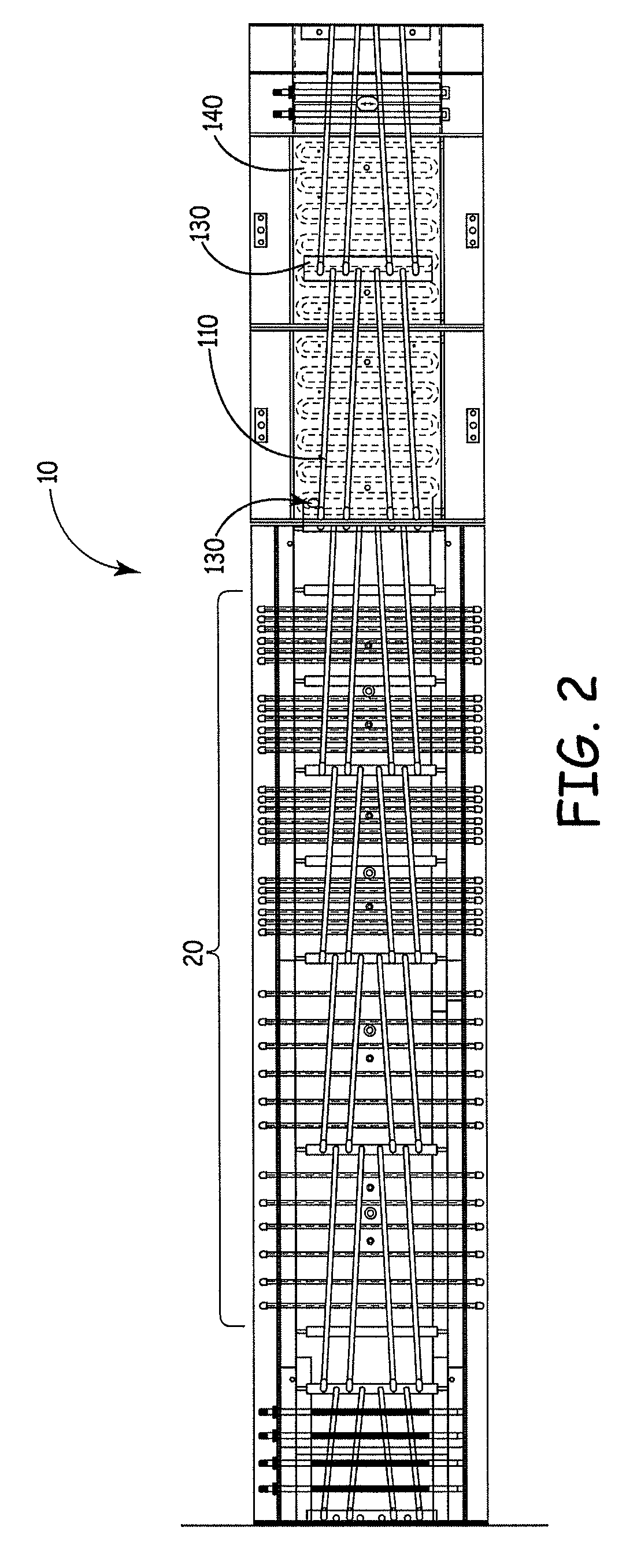

Rapid conductive cooling using a secondary process plane

A method and apparatus for thermally processing a substrate is described. The apparatus includes a substrate support configured to move linearly and / or rotationally by a magnetic drive. The substrate support is also configured to receive a radiant heat source to provide heating region in a portion of the chamber. An active cooling region comprising a cooling plate is disposed opposite the heating region. The substrate may move between the two regions to facilitate rapidly controlled heating and cooling of the substrate.

Owner:APPLIED MATERIALS INC

Vacuum thermal annealer

A vacuum thermal annealing device is provided having a temperature control for use with various materials, such as semiconductor substrates. A vacuum is used to remove air and outgas residual materials. Heated gas is injected planar to a substrate as pressure is quickly raised. Concurrent with the heated gas flow, a chamber wall heater is turned on and maintains a temperature for a proper annealing time. Upon completion of the annealing process, the chamber wall heater shuts down and air is forced around the chamber wall heater. Additionally, cool gas replaces the heated gas to cool the substrate.

Owner:STEED TECH

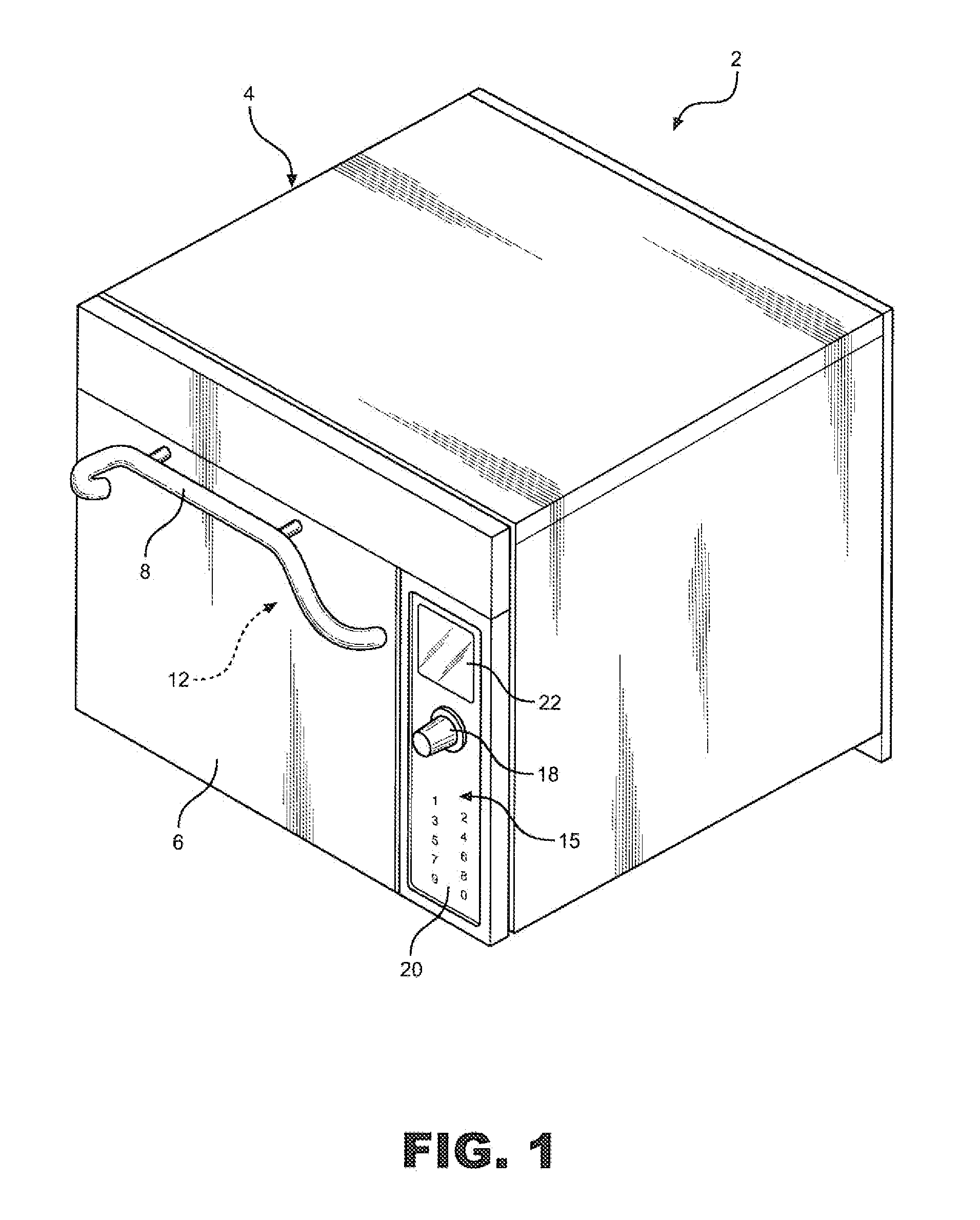

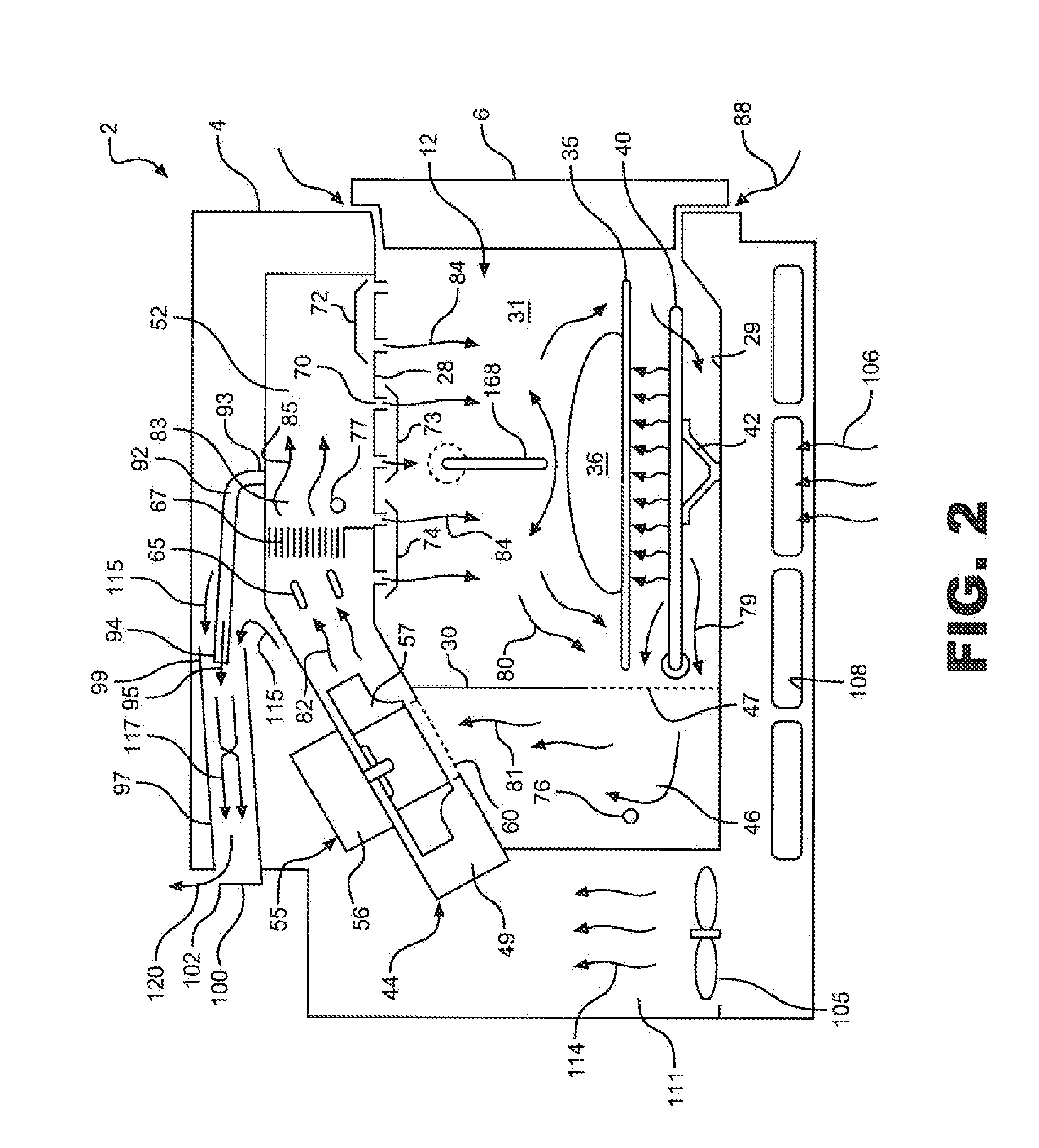

Air Fryer

InactiveUS20080206420A1Improve heat transfer performanceProvide taste and texture and appearance characteristicDomestic stoves or rangesElectrical heating fuelProduct gasProcess engineering

An accelerated cooking air fryer is disclosed comprising a cavity, controller, thermal heating source, blower assembly, gas directing means and a vent assembly. Hot gas is circulated by the blower motor assembly into the air fryer cavity where the hot air is directed in a manner wherein a conflicting, colliding turbulent gas flow is directed at a food product providing for the accelerated cooking of the food product.

Owner:TURBOCHEF TECH INC

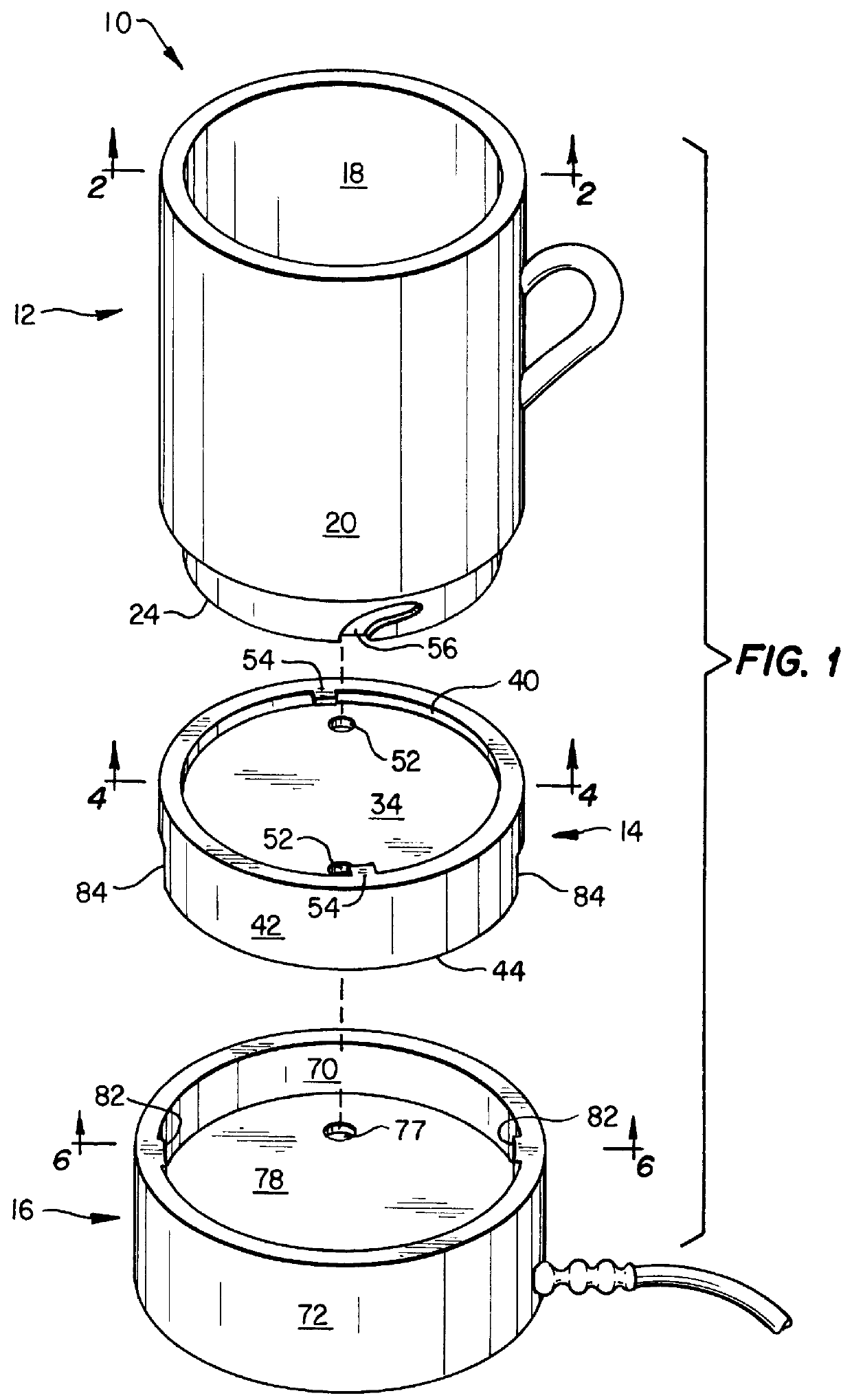

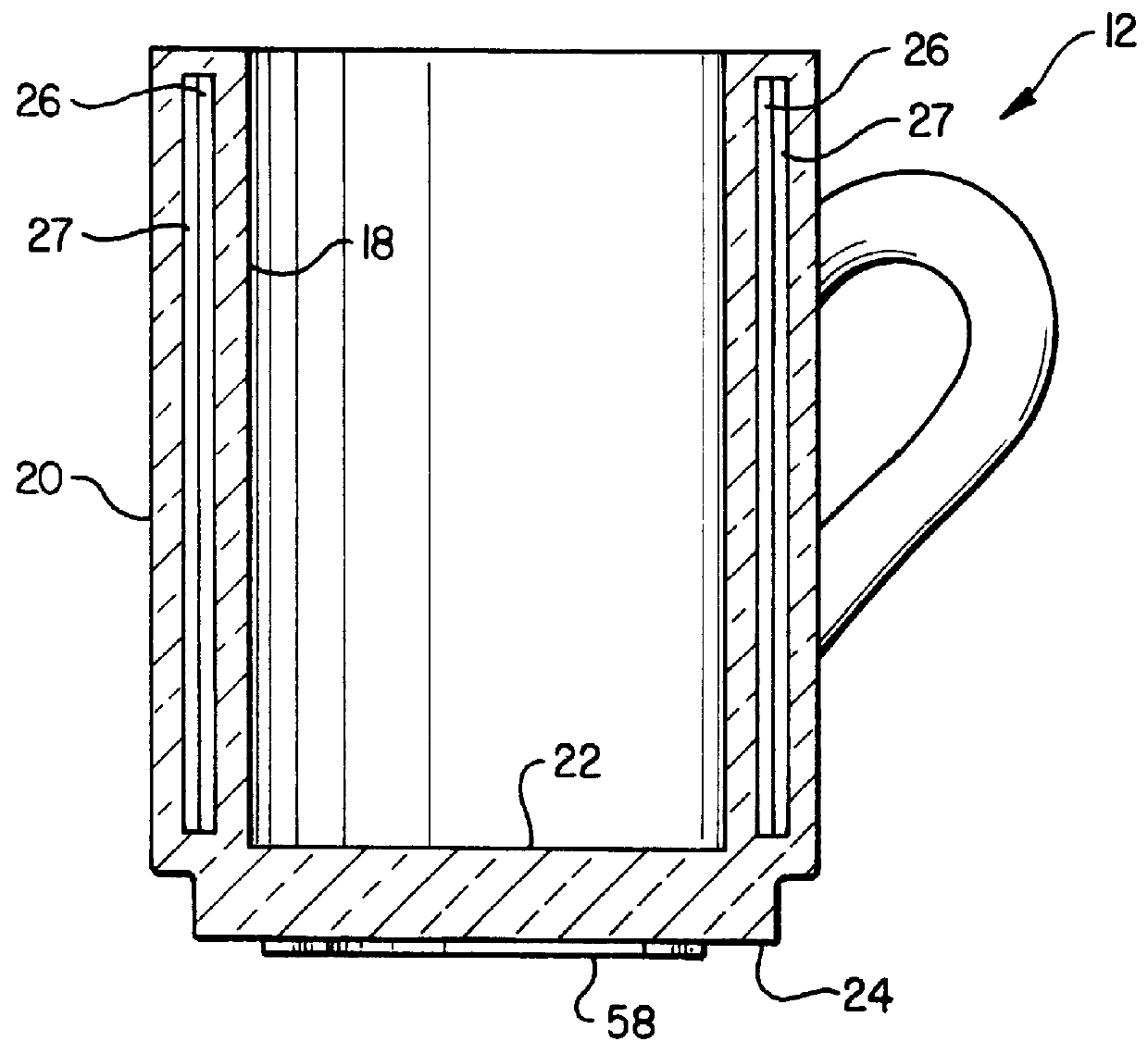

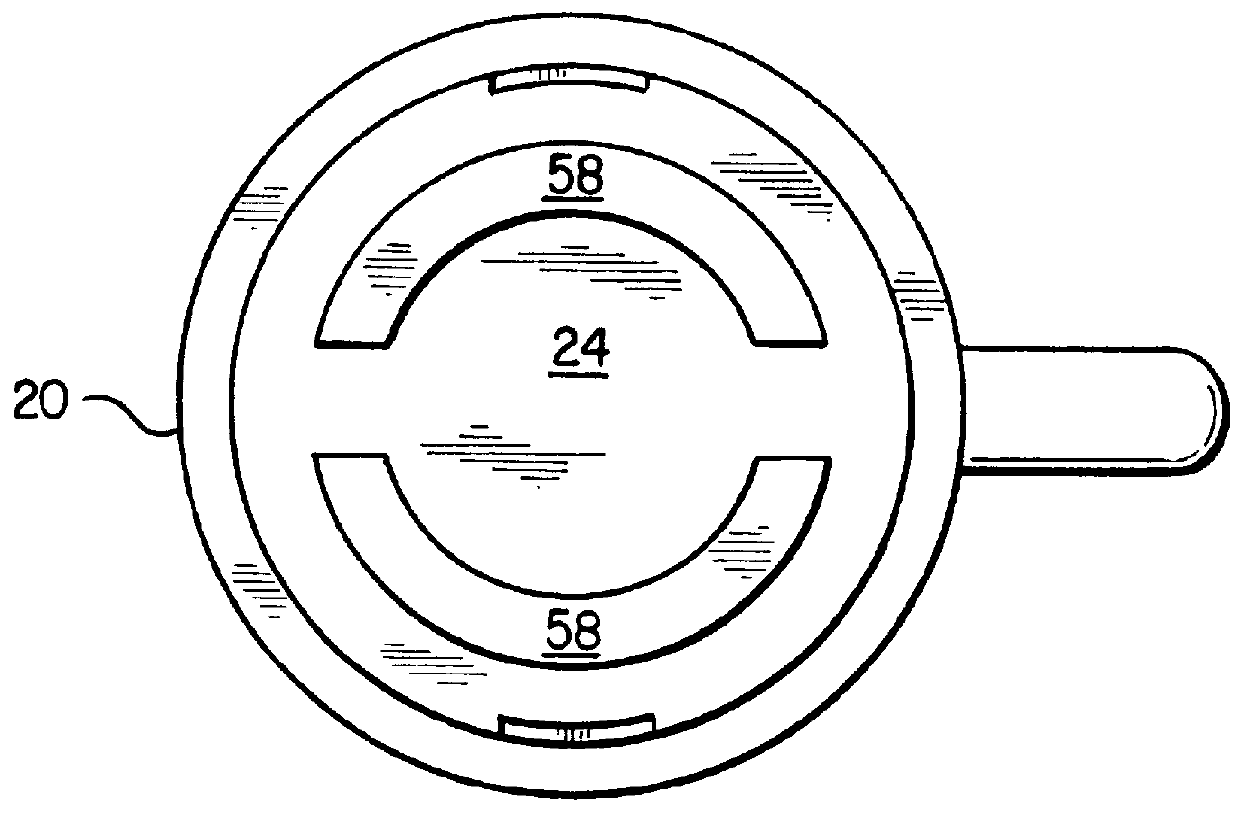

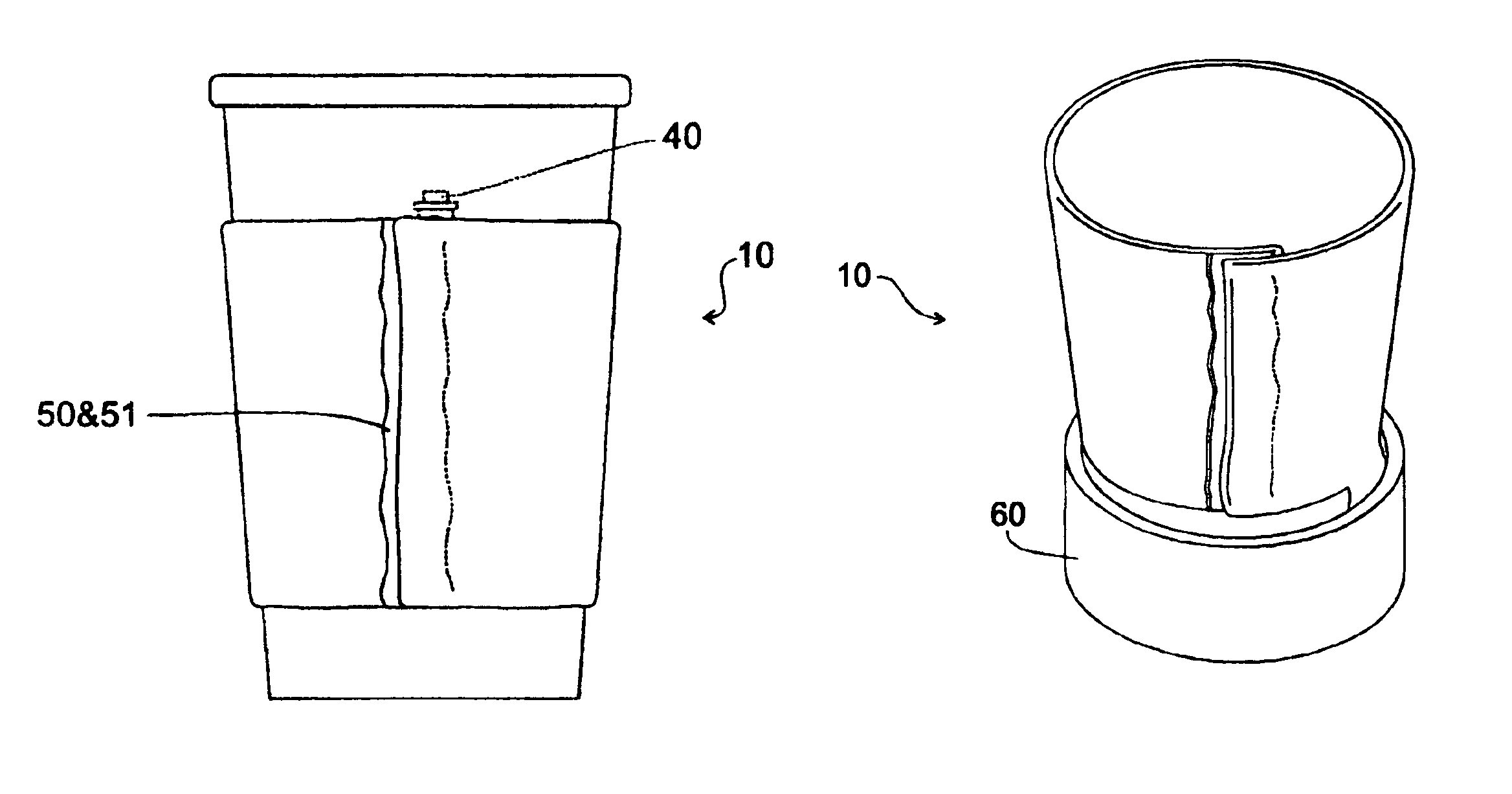

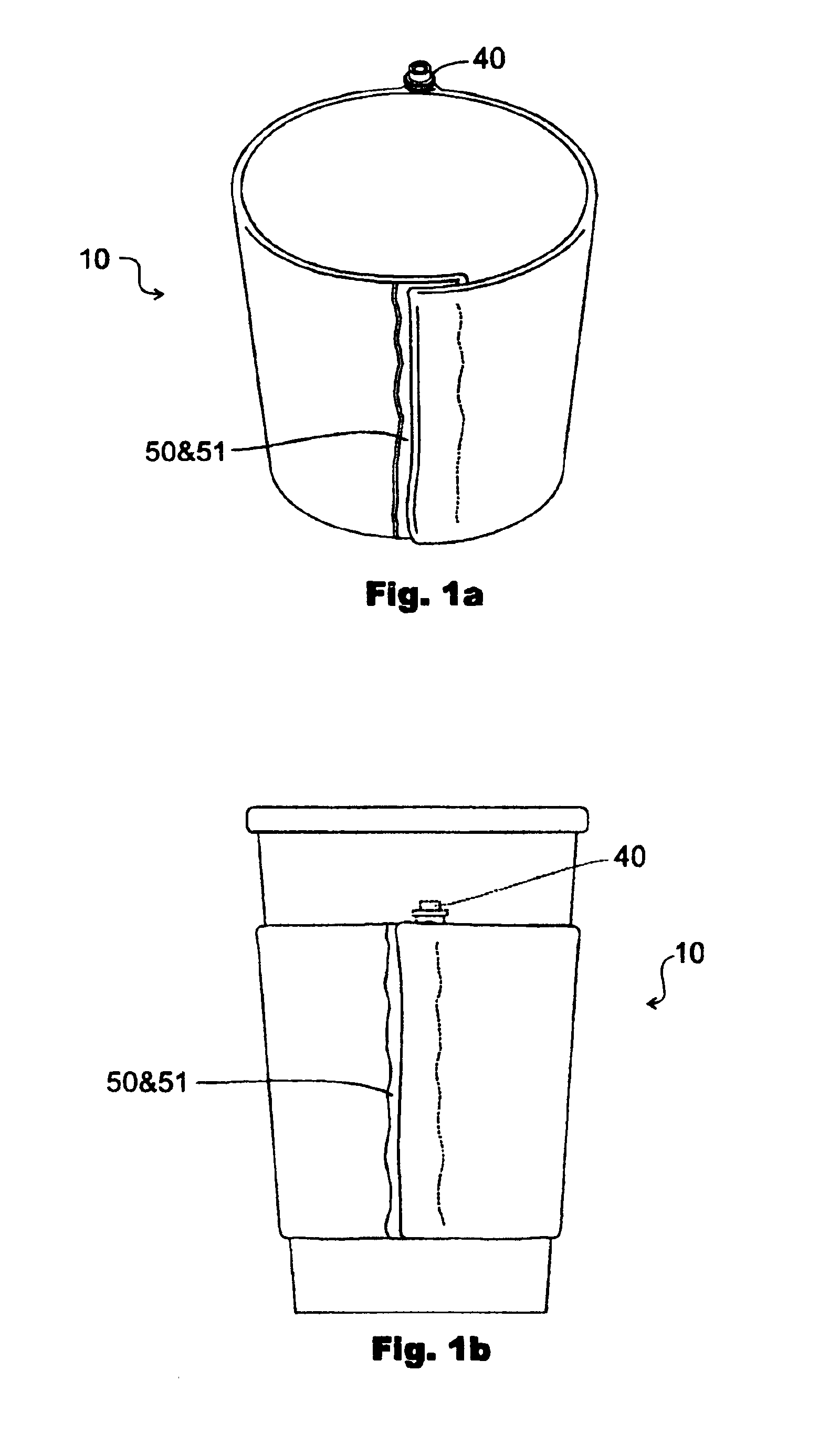

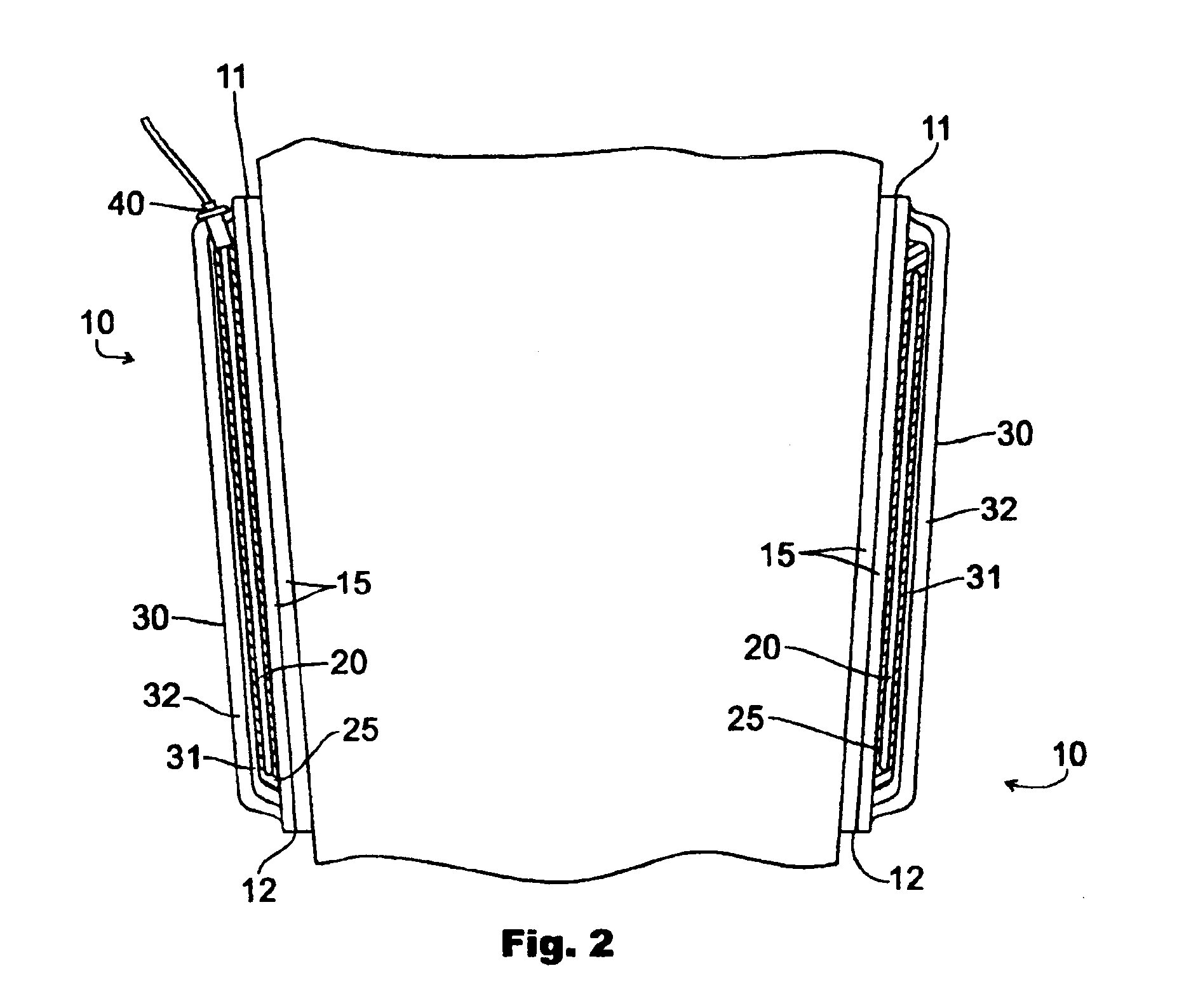

Beverage container

A beverage container is disclosed for keeping liquid evenly heated. The beverage container includes a cup, a heating element, and a removable battery power source. The cup has an inner sidewall surface, an outer sidewall surface, an inner bottom surface, and an outer bottom surface. The inner sidewall surface and inner bottom surface are shaped to hold liquid. The heating element is completely enclosed between the inner sidewall surface and the outer sidewall surface. The heating element heats the inner sidewall surface which then heats the liquid. An insulating layer is included between the heating element and the outer sidewall surface to keep the outer sidewall surface cool while the inner sidewall surface is heated. The battery power source is capable of being temporarily secured to the outer bottom surface of the cup and is utilized to keep the heating element energized to a predetermined level while the battery power source is secured to the cup. When the battery power source is removed, the cup is capable of being submerged in water without damaging the cup. When the battery power source is attached, the beverage container is portable.

Owner:STEIN TODD ANTHONY

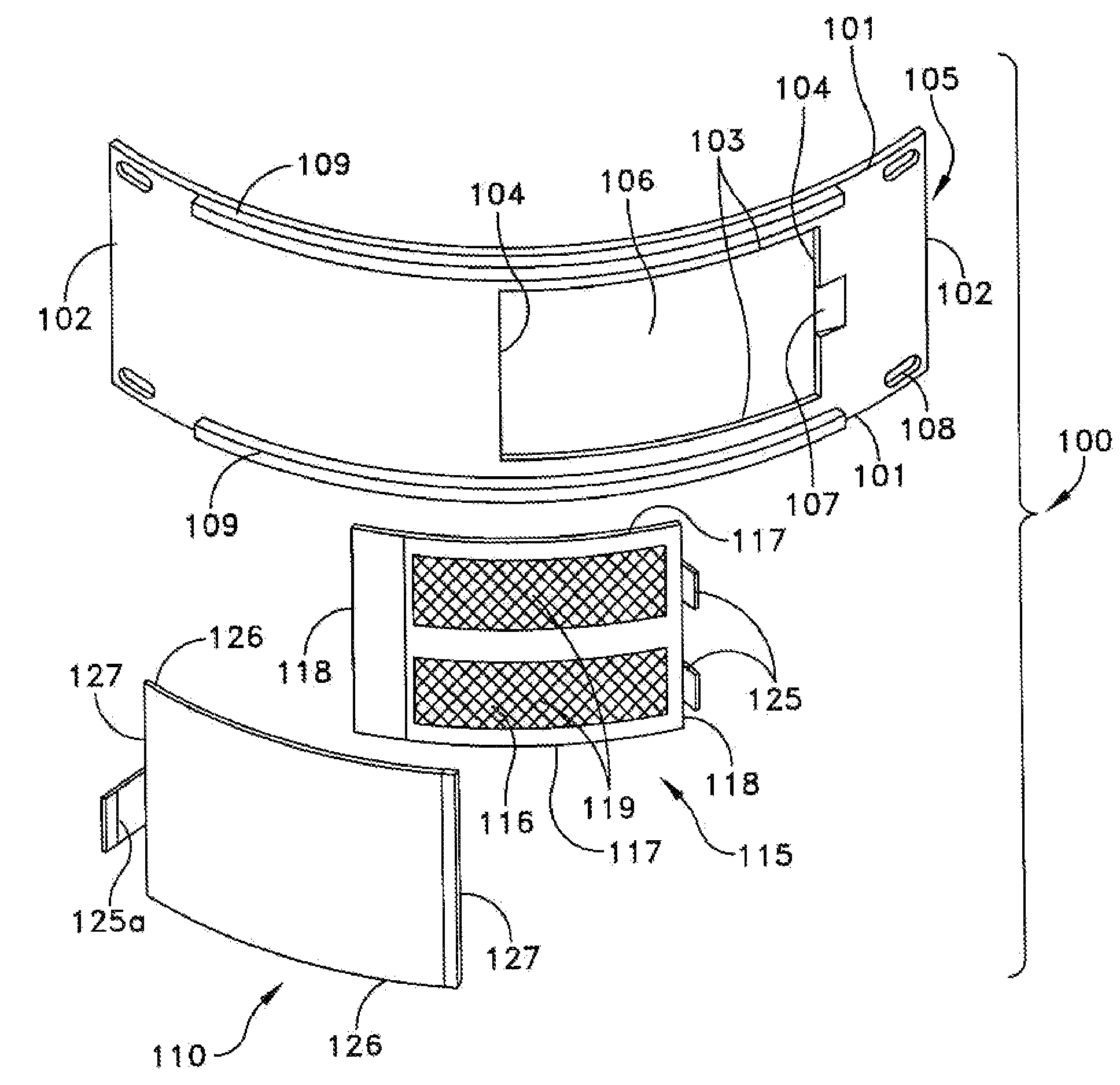

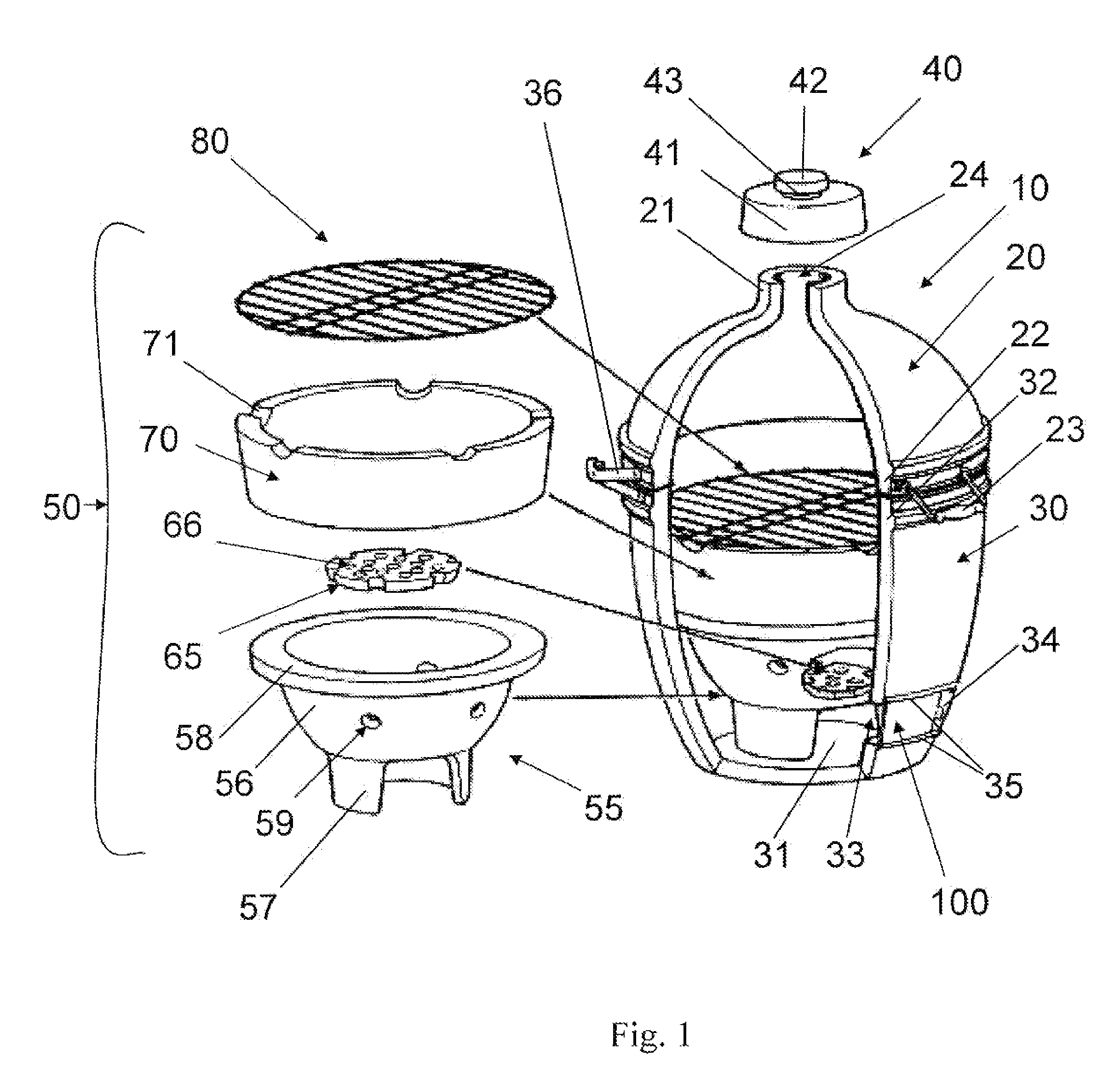

Spark arrestor and airflow control assembly for a portable cooking or heating device

ActiveUS7644711B2Easy to adjustEasy to controlDomestic stoves or rangesBaking ovenSpark arrestorEngineering

A device for arresting spark and ash issuing from, and precisely controlling the ventilation of and temperature inside, a heat source-containing vessel such as a cooking grill, stove, oven, cooker, fireplace, heater, or firebox. The device comprises a spark arrestor assembly including a base plate, a cover plate, and a spark arrestor. The base plate defines an opening. The cover plate and spark arrestor are slidably mated in two channels formed in the base plate around the opening. The cover plate and spark arrestor may be adjusted to extend across or only partway across the opening as selected by a user of the device. Tabs are provided on the cover plate and spark arrestor for easy adjustment thereof. Tabs in the base plate are positioned to define a range of slidable motion of the cover plate and spark arrestor. The spark arrestor assembly engages a fire-containing or heat source-containing vessel over an opening defined by the vessel so that the vessel opening cooperates with the spark arrestor assembly opening.

Owner:THE BIG GREEN EGG

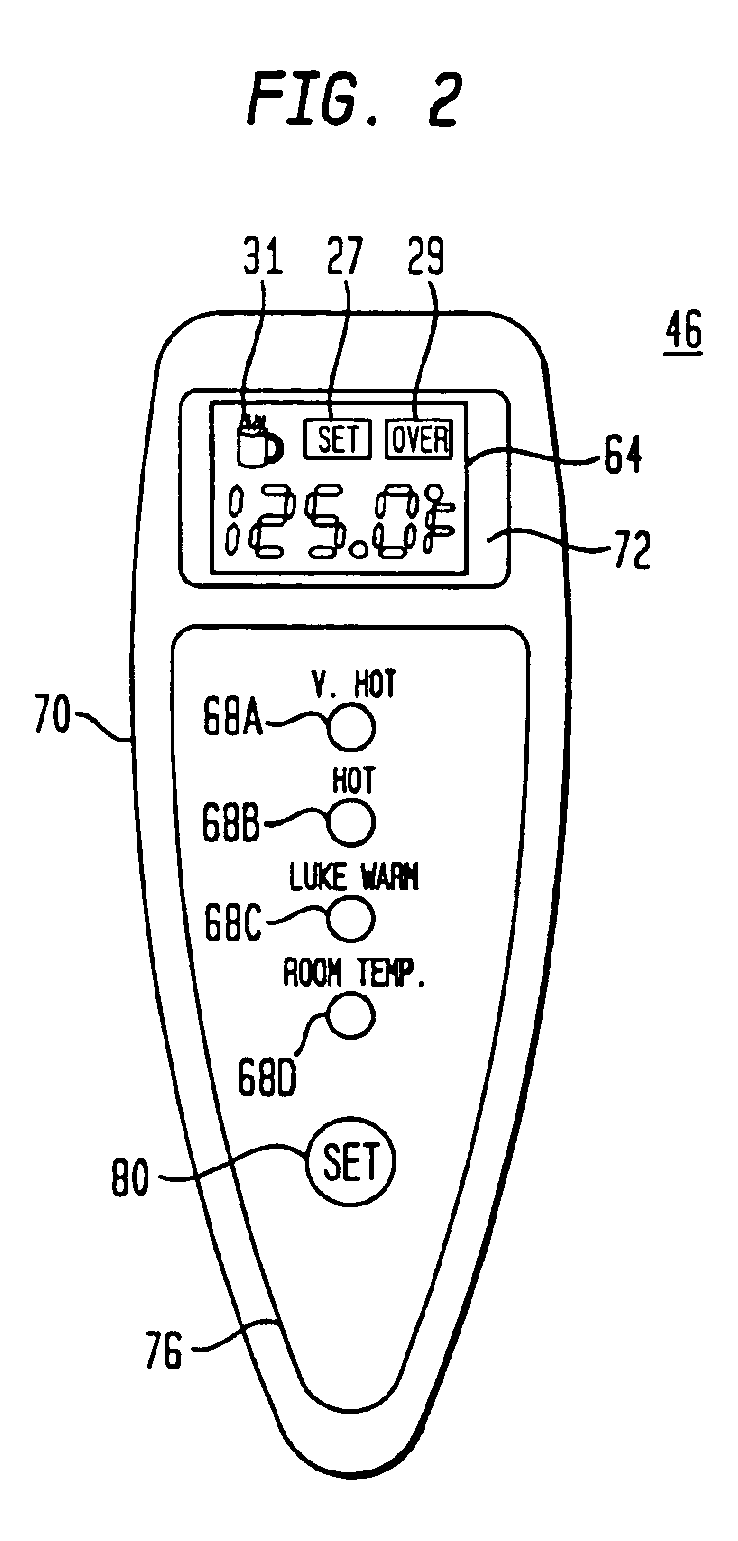

Electronic drinking mug

InactiveUS6864462B2Avoid meltingMinimize the possibilityElectric heatingBaking ovenEngineeringHeating element

An electronic drinking mug includes a heating element in thermal communication with the mug for heating a liquid contained in the mug, a temperture sensoring in communication with the heating element for monitoring a temperature of the liquid, a controller integrally attached to an outer surface of the mug and in communication with the temperature sensor and the heating element for selectively activating and deactivating the heating element so as to heat the liquid in the mug to a desired temperature. In operation, the controller receives temperature readings from the temperature sensor and deactivates the heating element when the monitored temperature of the liquid is greater than or equal to the desired user preset temperature of the liquid. A user interface is integrally attached to the outer surface of the mug and in communication with the controller for establishing the desired temperature of the liquid.

Owner:SOLAR WIDE INDAL

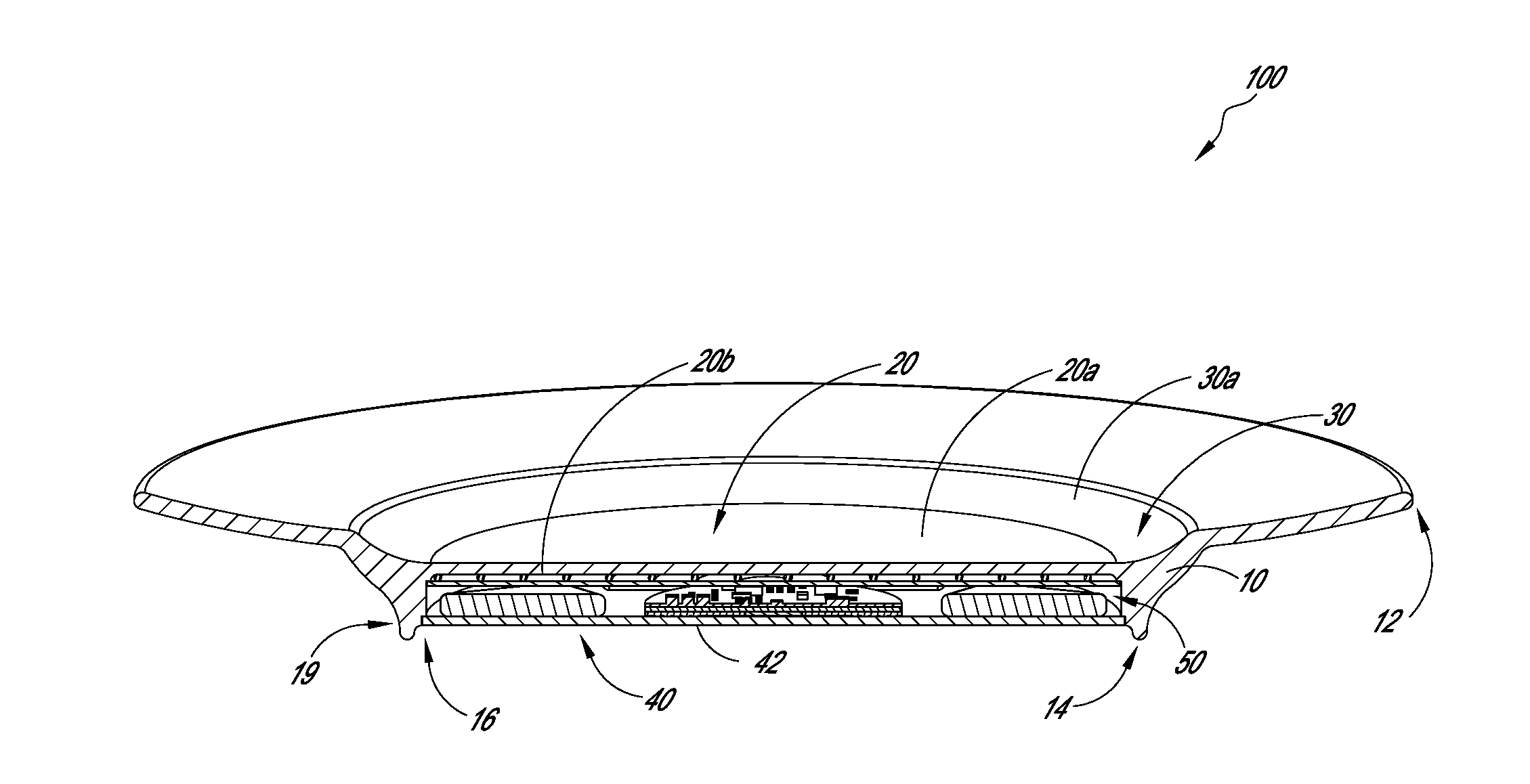

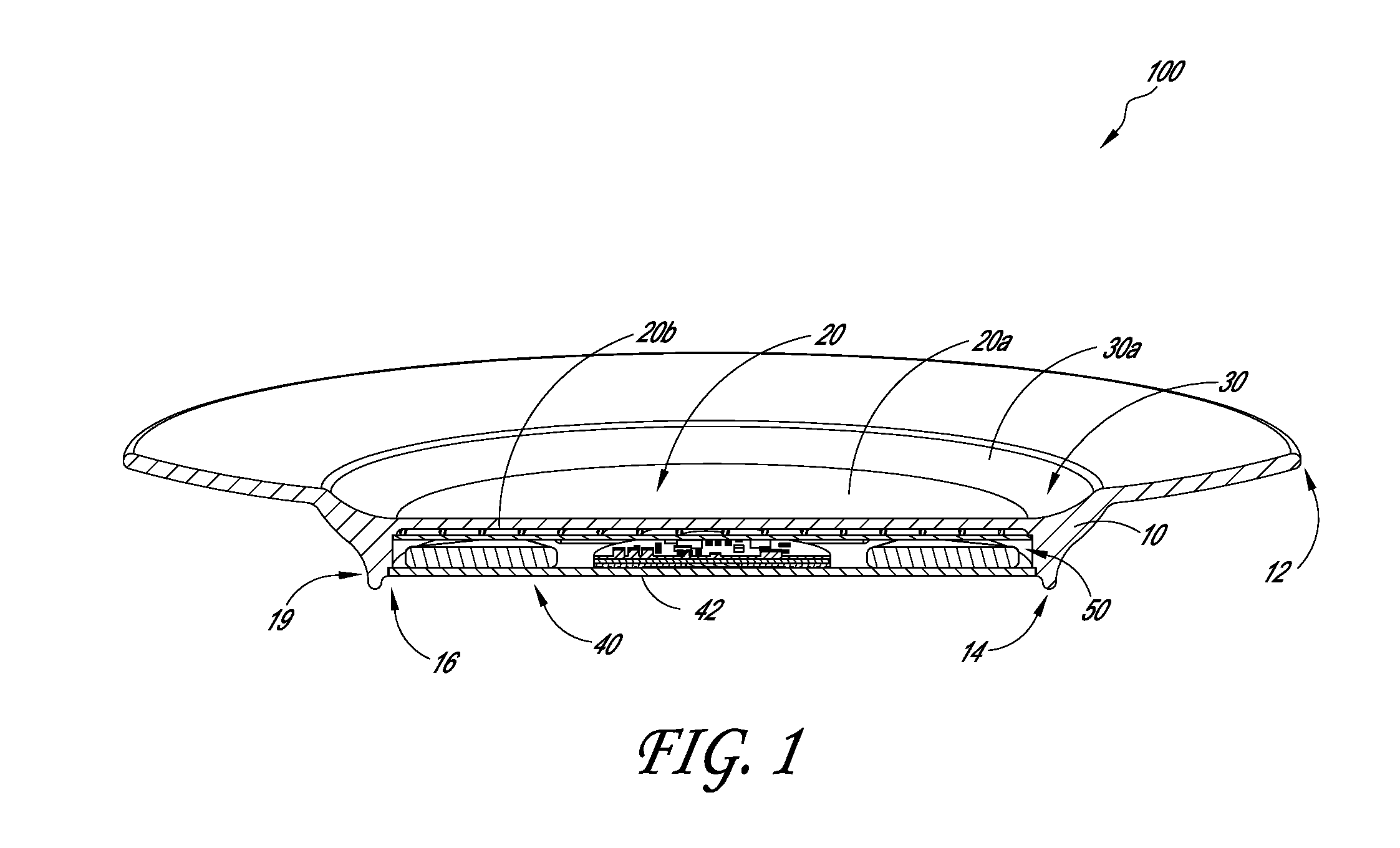

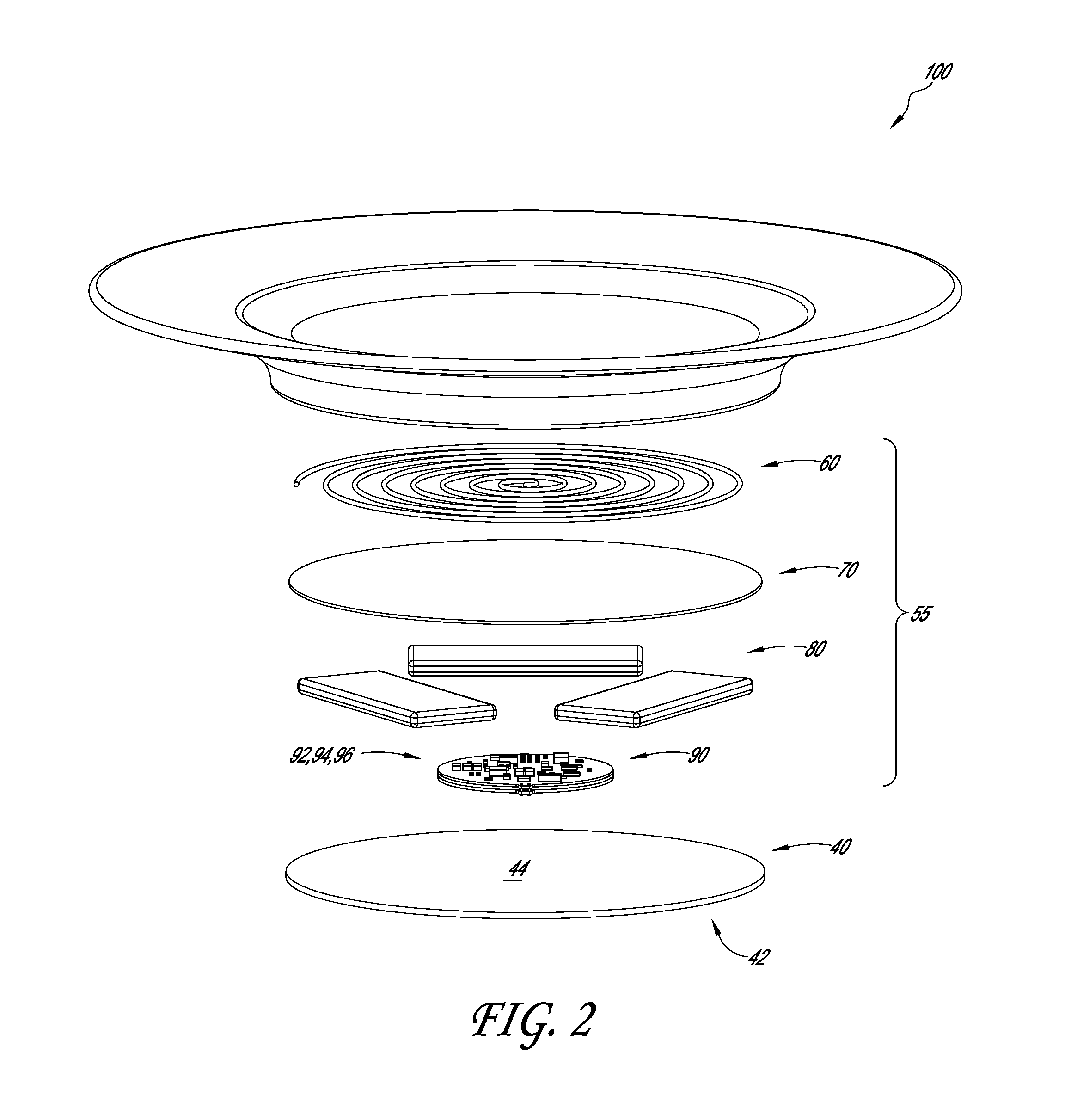

Heated or cooled dishware and drinkware

ActiveUS20150245723A1Uniform liquid temperatureBaking ovenMachines using electric/magnetic effectsElectricityControl circuit

An actively heated mug, travel mug, baby bottle, water bottle or liquid container is provided. The mug, travel mug, baby bottle, water bottle or liquid container can include a body that receives a liquid therein and a heating or cooling system at least partially disposed in the body. The heating or cooling system can include one or more heating or cooling elements that heat a surface of the receiving portion of the body and one or more energy storage devices. The mug, travel mug, baby bottle, water bottle or liquid container can include a wireless power receiver that wirelessly receives power from a power source and control circuitry configured to charge one or more power storage elements and to control the delivery of electricity from the one or more power storage elements to the one or more heating or cooling elements. The mug, travel mug, baby bottle, water bottle or liquid container also can have one or more sensors that sense a parameter of the liquid or sense a parameter of the heating or cooling system and communicates the sensed information to the control circuitry. The control circuitry can turn on, turn off, and / or operate the heating or cooling element to actively heat or cool at least a portion of the body to maintain the liquid in a heated or cooled state generally at a user selected temperature setting based at least in part on the sensed parameter information. The mug, travel mug, baby bottle, water bottle or liquid container can also be paired with a remote device or mobile electronic device to send or receive communications or commands.

Owner:EMBER TECH INC

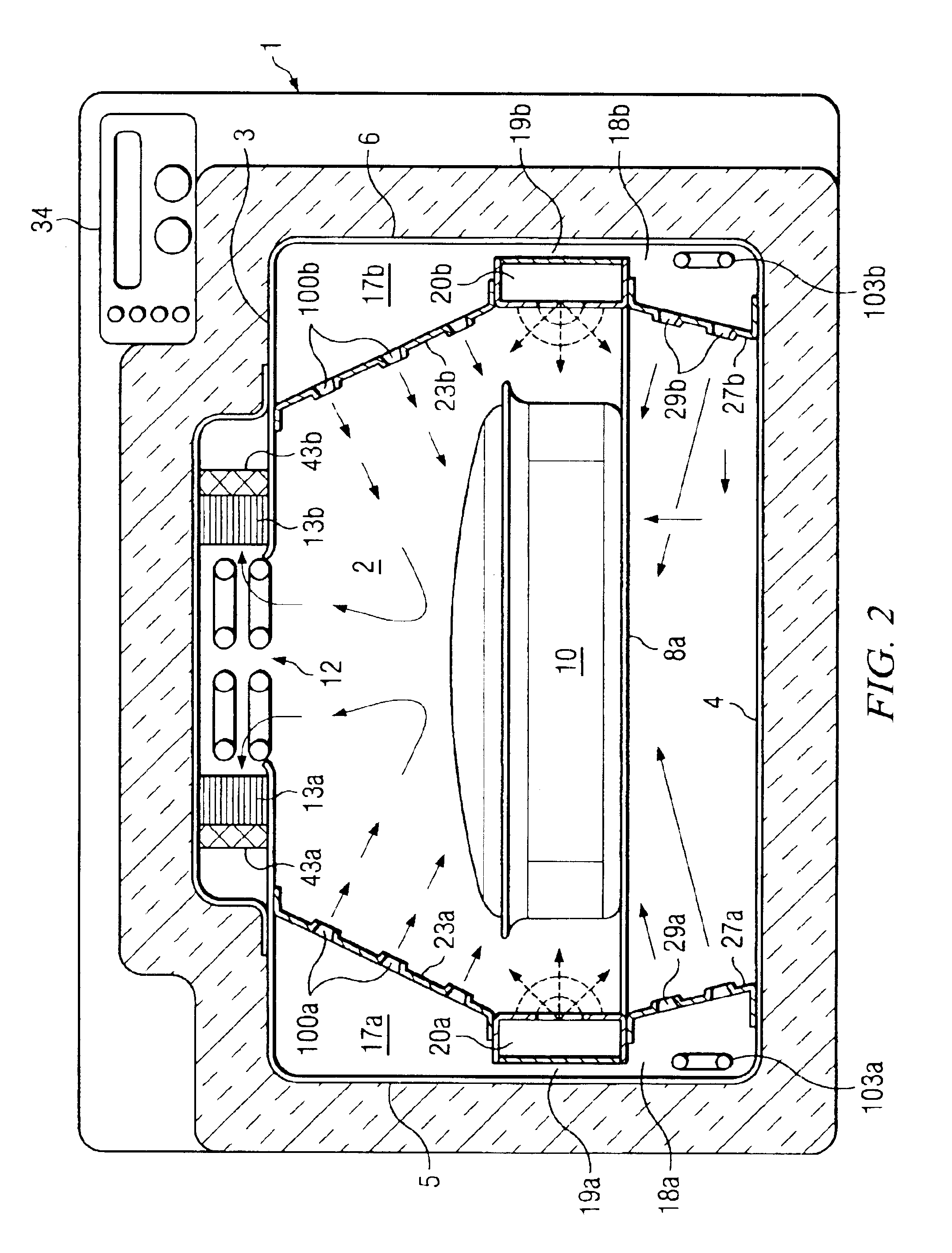

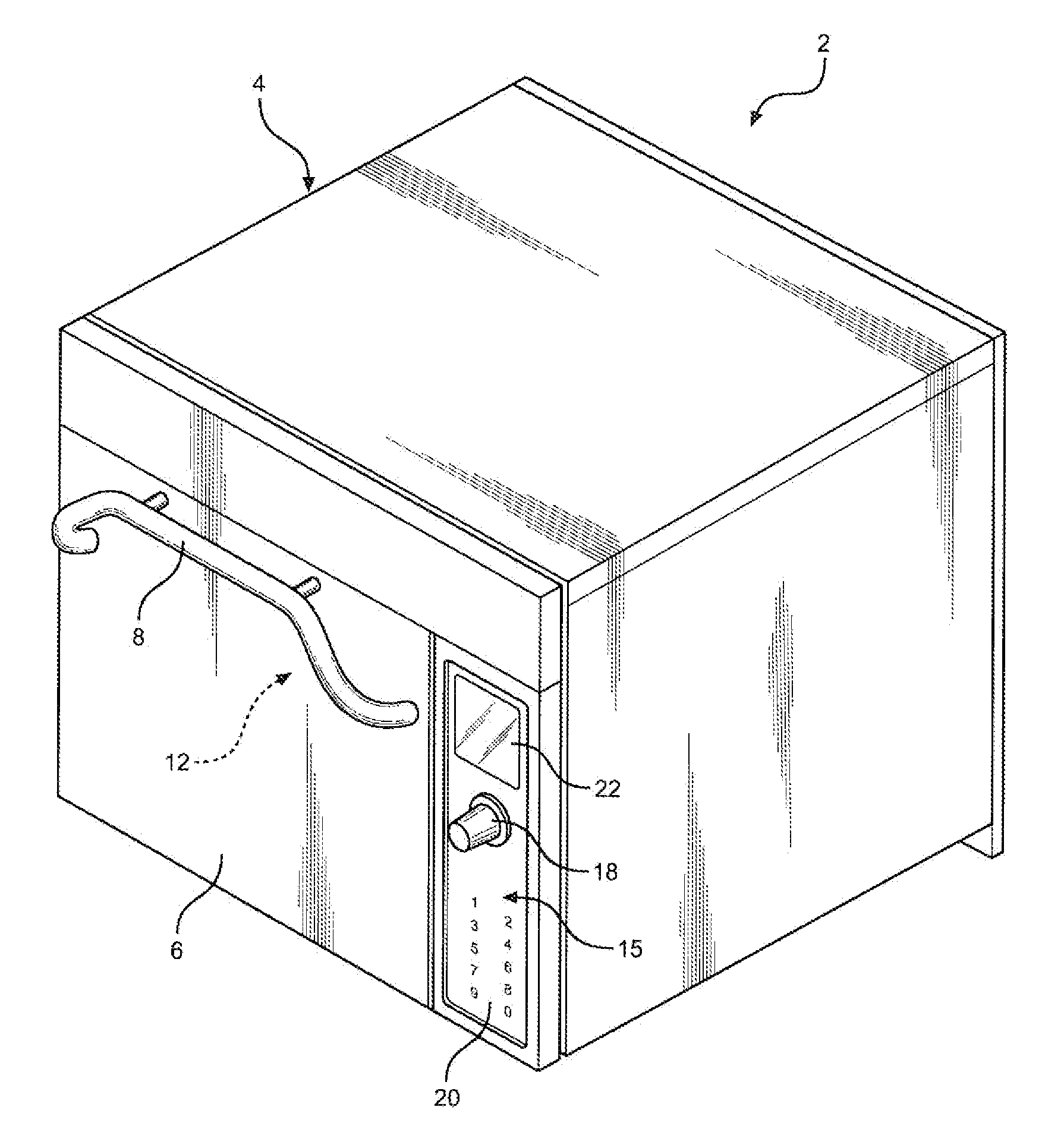

Speed cooking oven

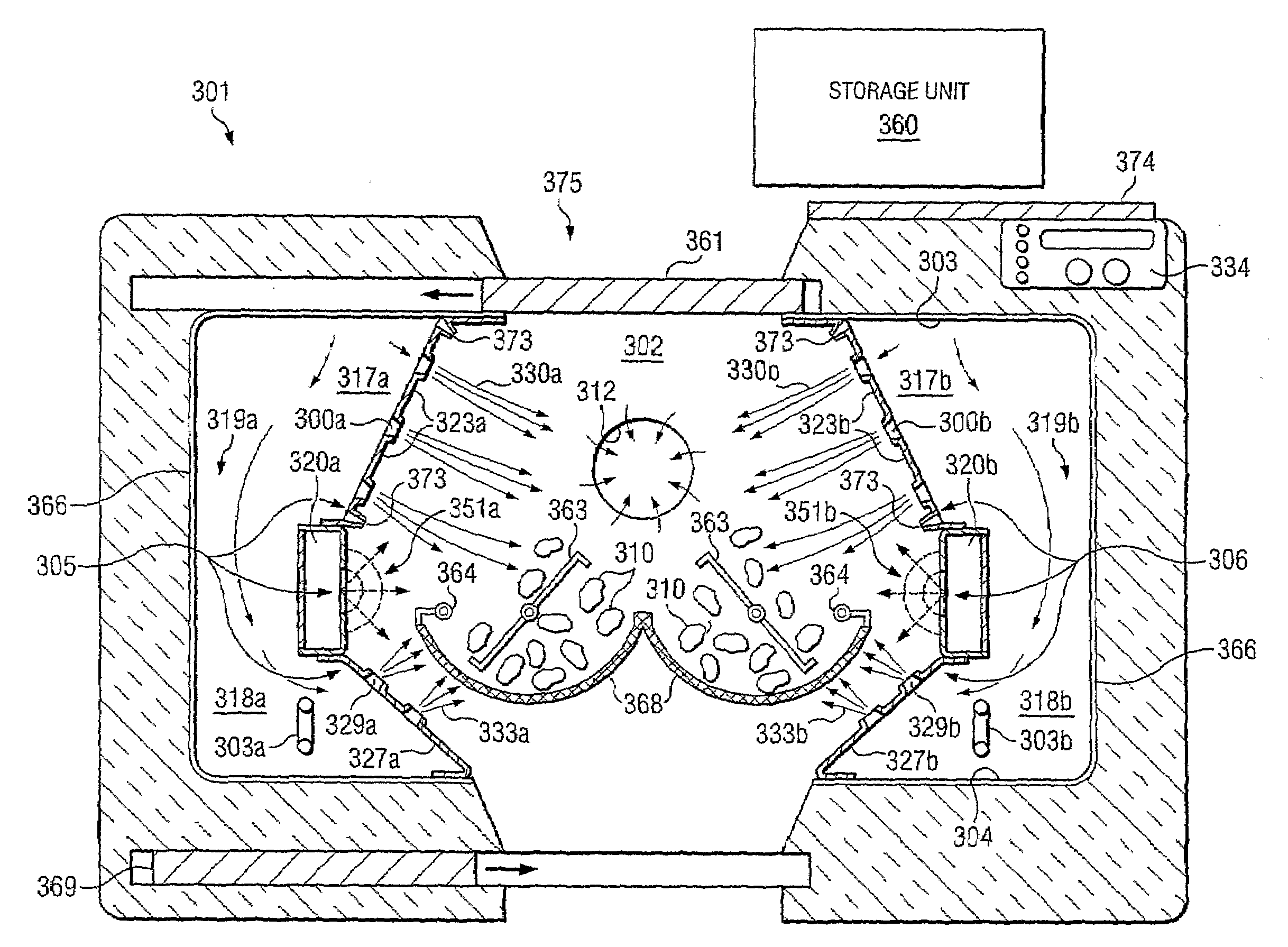

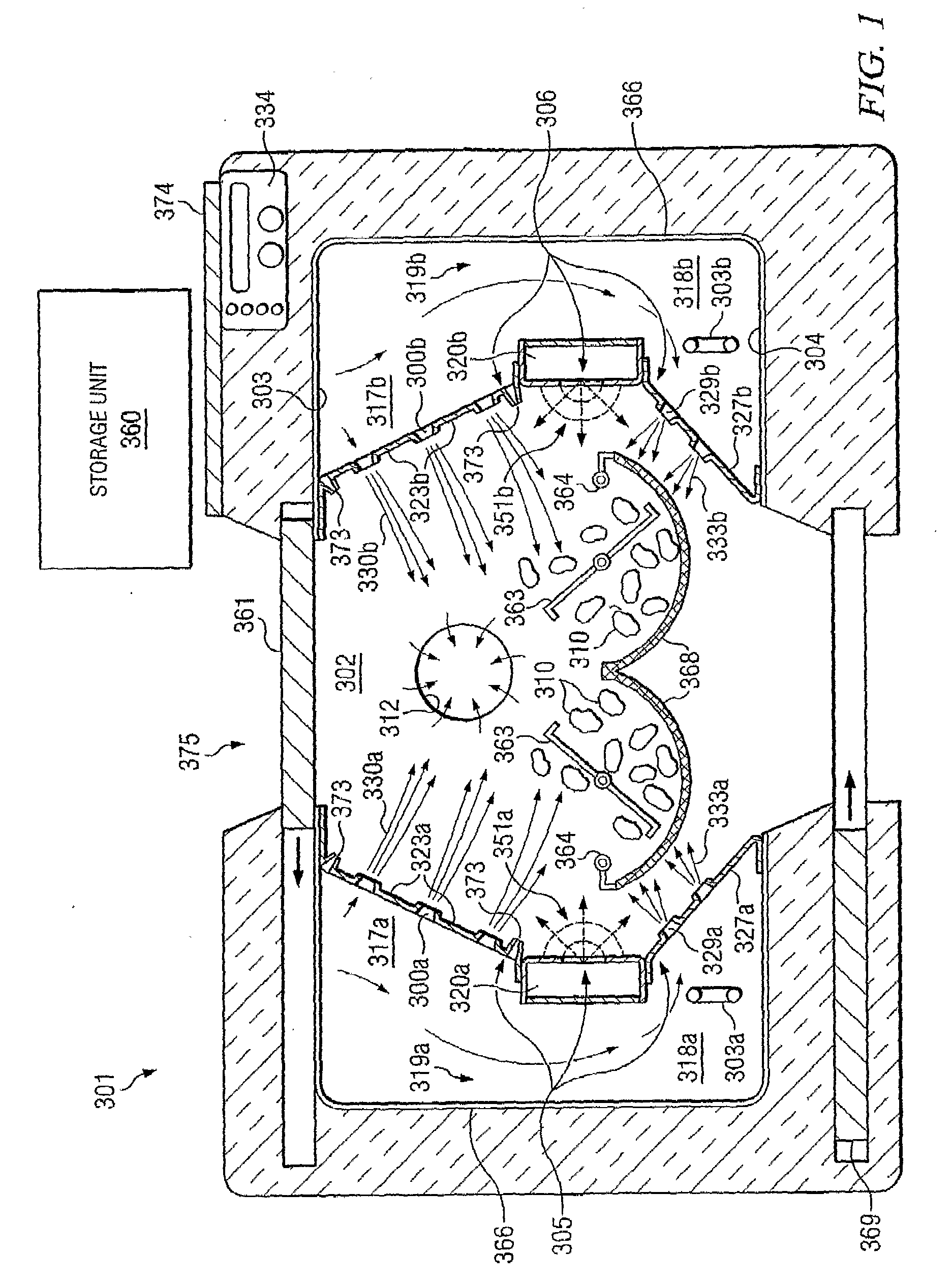

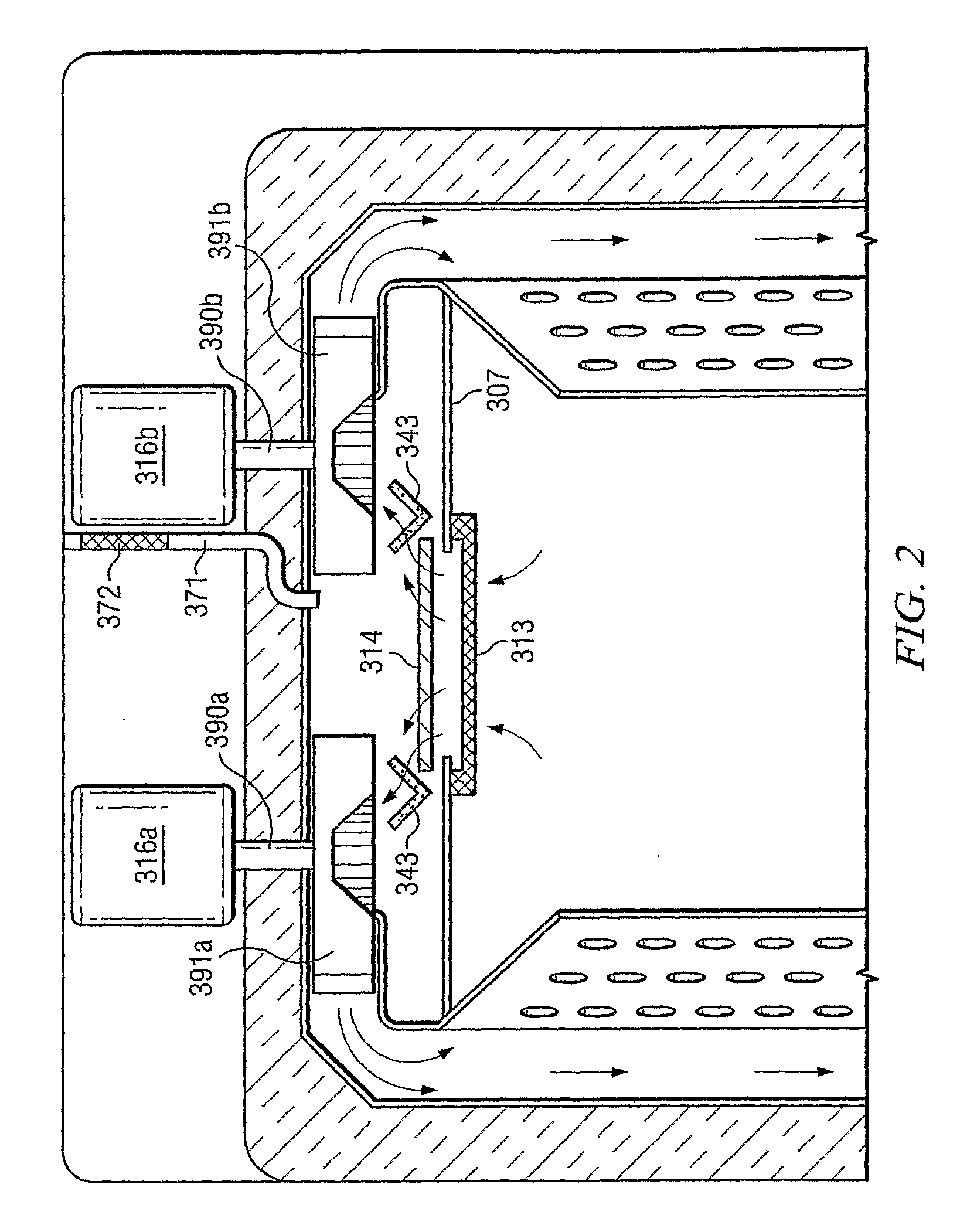

InactiveUS6874495B2Prevent excessive grease build-upSolve the quick installationSelf-cleaning stoves/rangesMeat/fish preservationAir movementProcess engineering

A speed cooking ovens is disclosed comprising a cooking cavity, thermal heating source, air movement and directing means, air flow control means, an air delivery means, and a vent assembly. The speed cooking oven may additionally utilize air flow control mechanisms and be practiced as a single rack speed cooking oven or a multi rack speed cooking oven. Hot gas is circulated to and from the oven cavity via air delivery means, such that turbulently mixed glancing, conflicting and colliding air flows mix at and about the surfaces of the food product. The turbulently mixed air flows are spatially averaged over the surface area of the food product producing high heat transfer and moisture removal rates, thereby optimizing speed cooking of the food product.

Owner:TURBOCHEF TECH INC

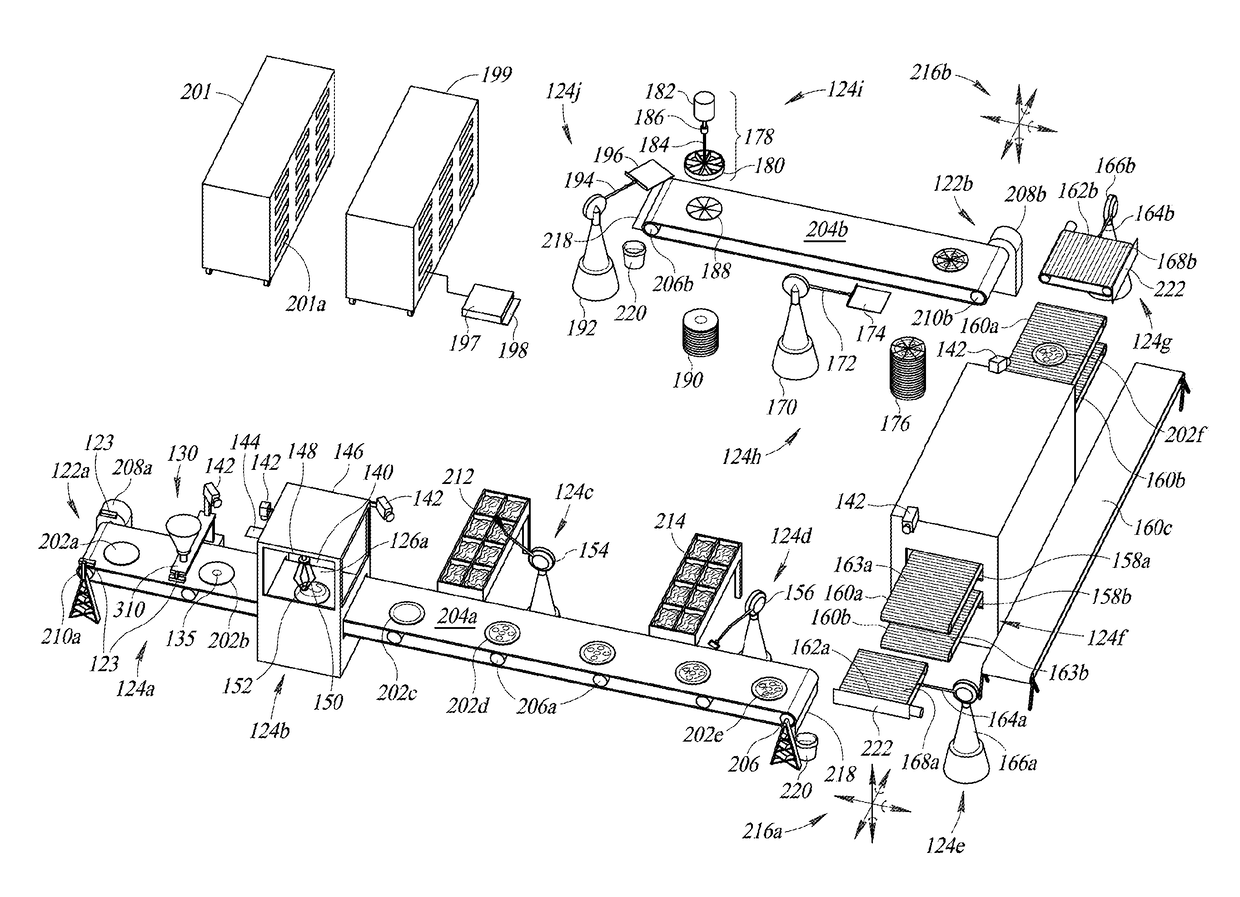

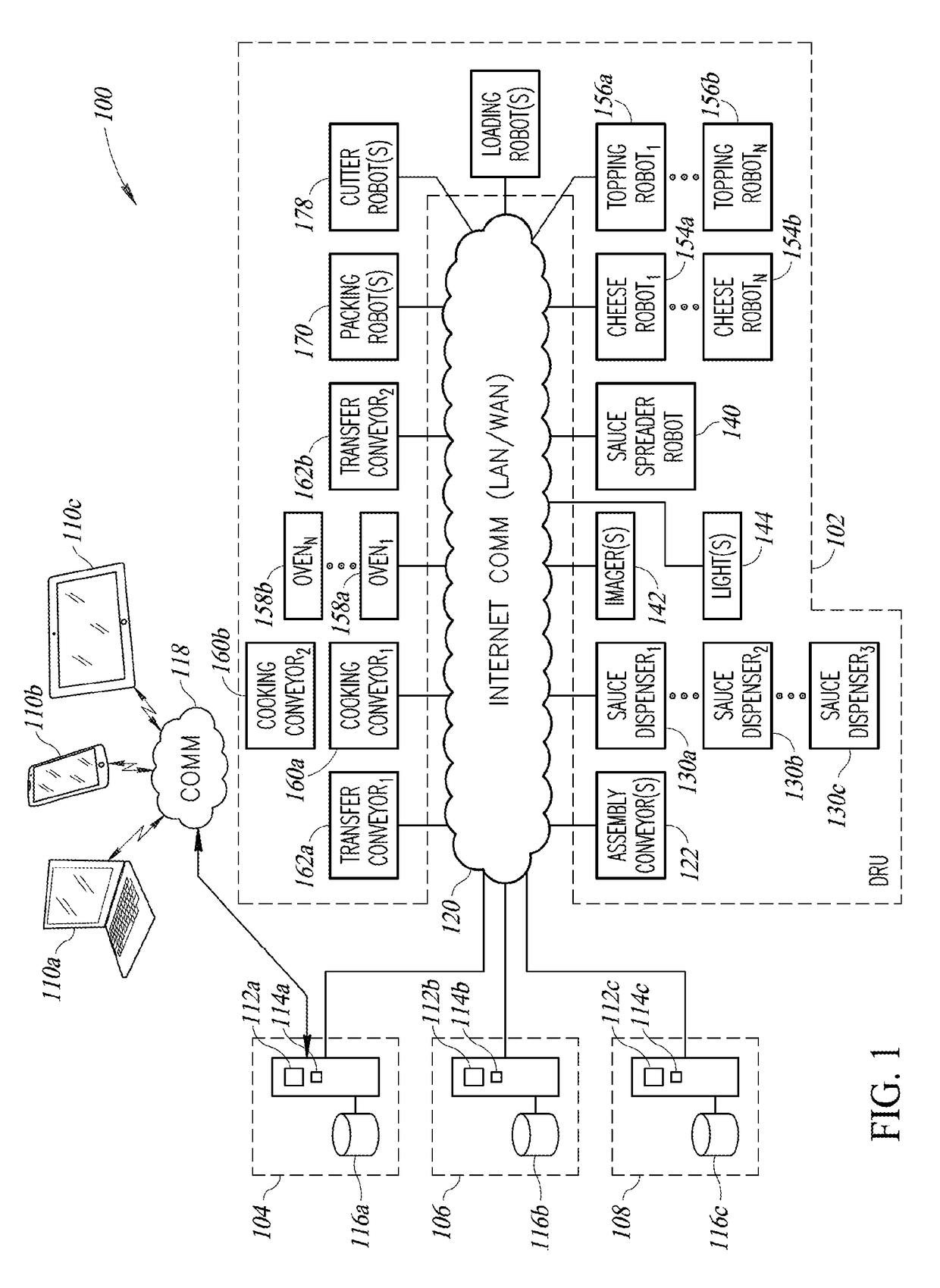

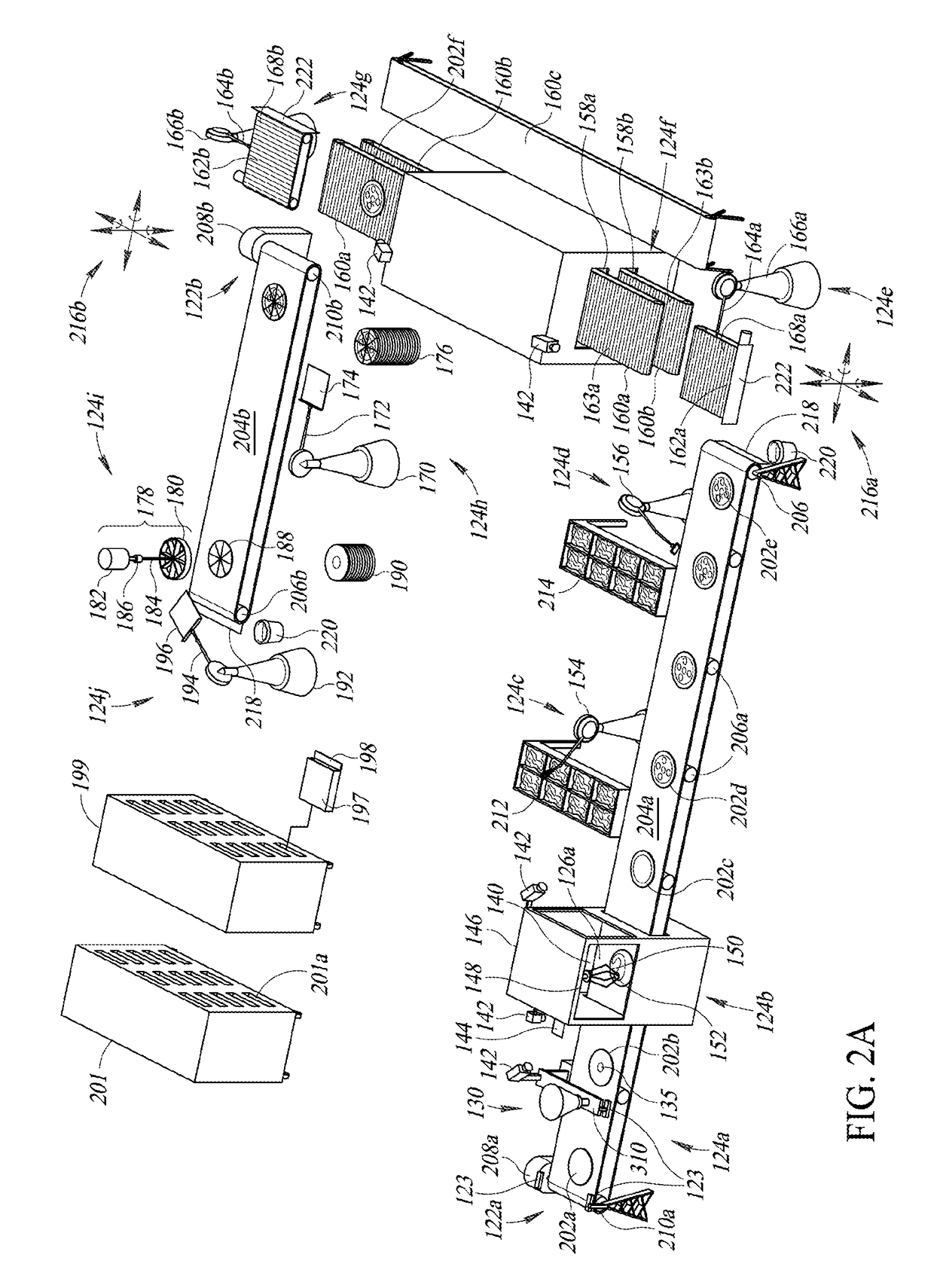

On-demand robotic food assembly and related systems, devices and methods

An on-demand robotic food assembly line can include one or more conveyors and one or more robots, operable to assemble food items in response to received orders for food items, and one or more ovens operable to, for example, partially cook assembled food items. The on-demand robotic food assembly line can optionally package the assembled and partially cooked food items in packaging, and optionally load the packaged partially cooked food items into portable cooking units (e.g., ovens) that are optionally loaded into racks that are, in turn, optionally loaded into delivery vehicles, where the food items are individually cooked under controlled conditions while en route to consumer destinations, such the cooking of each food item is completed just prior to arrival at the consumer destination location. A dynamic fulfillment queue for control of assembly is maintained based at least in part on estimated transit time for orders.

Owner:ZUME INC

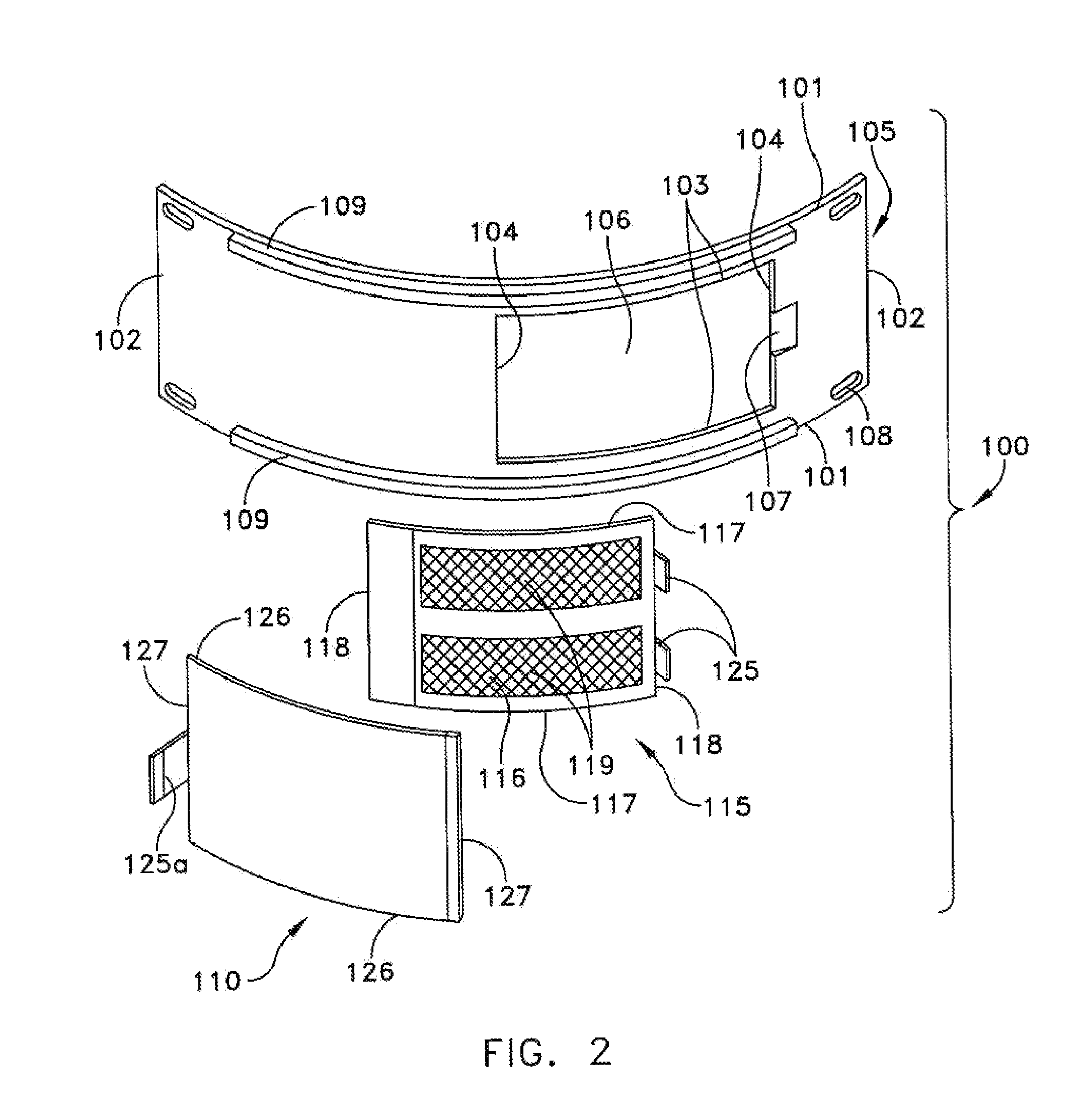

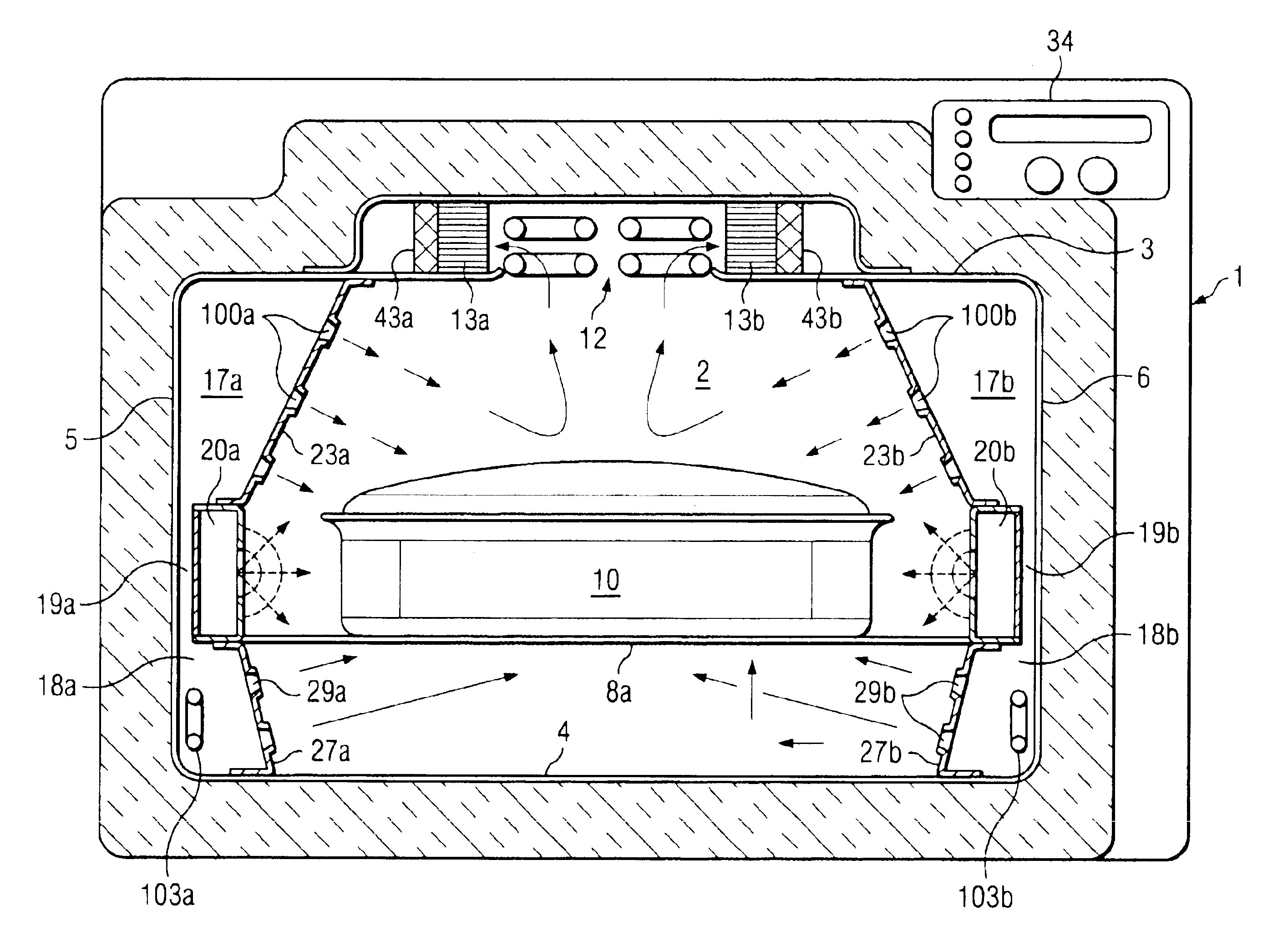

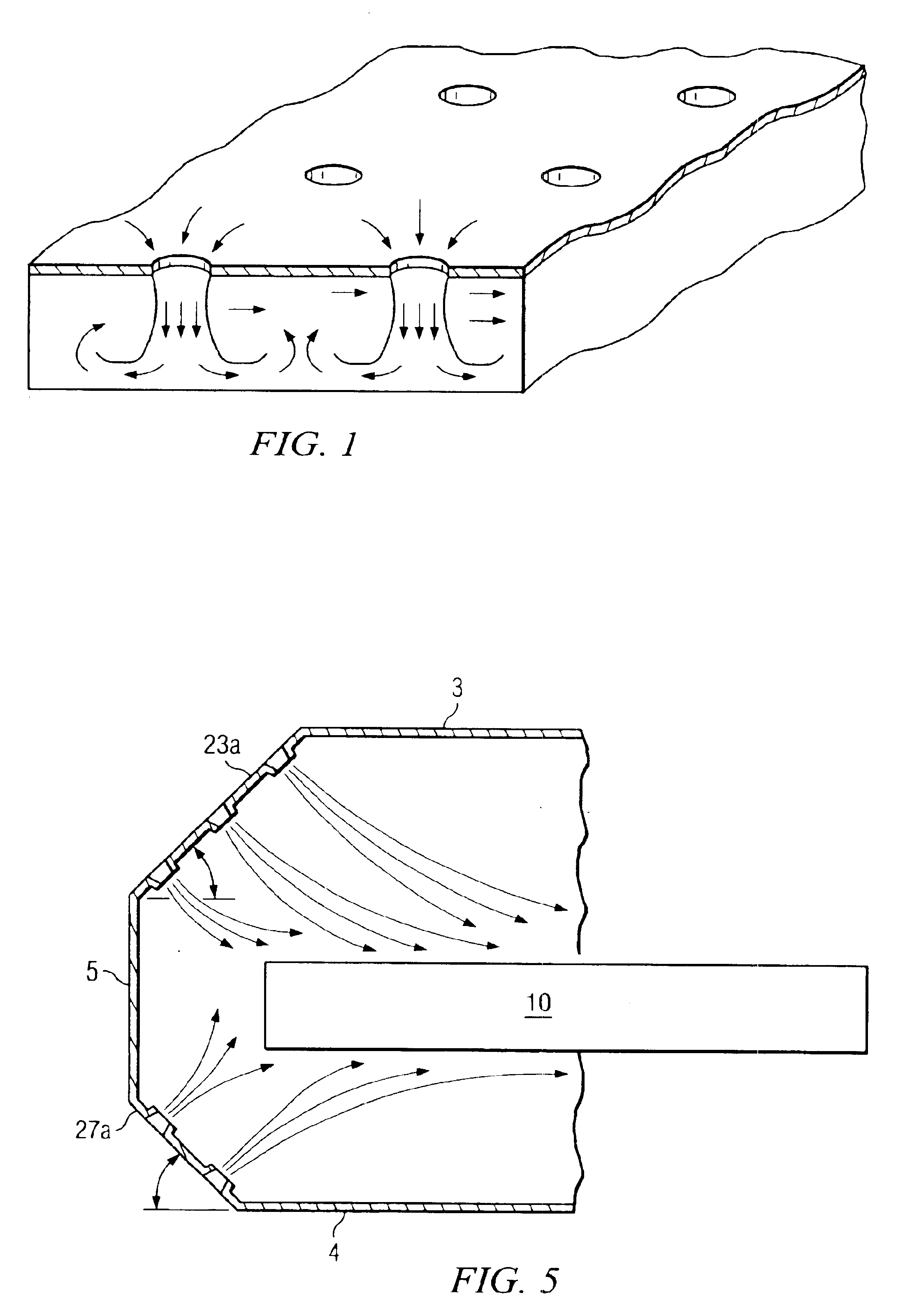

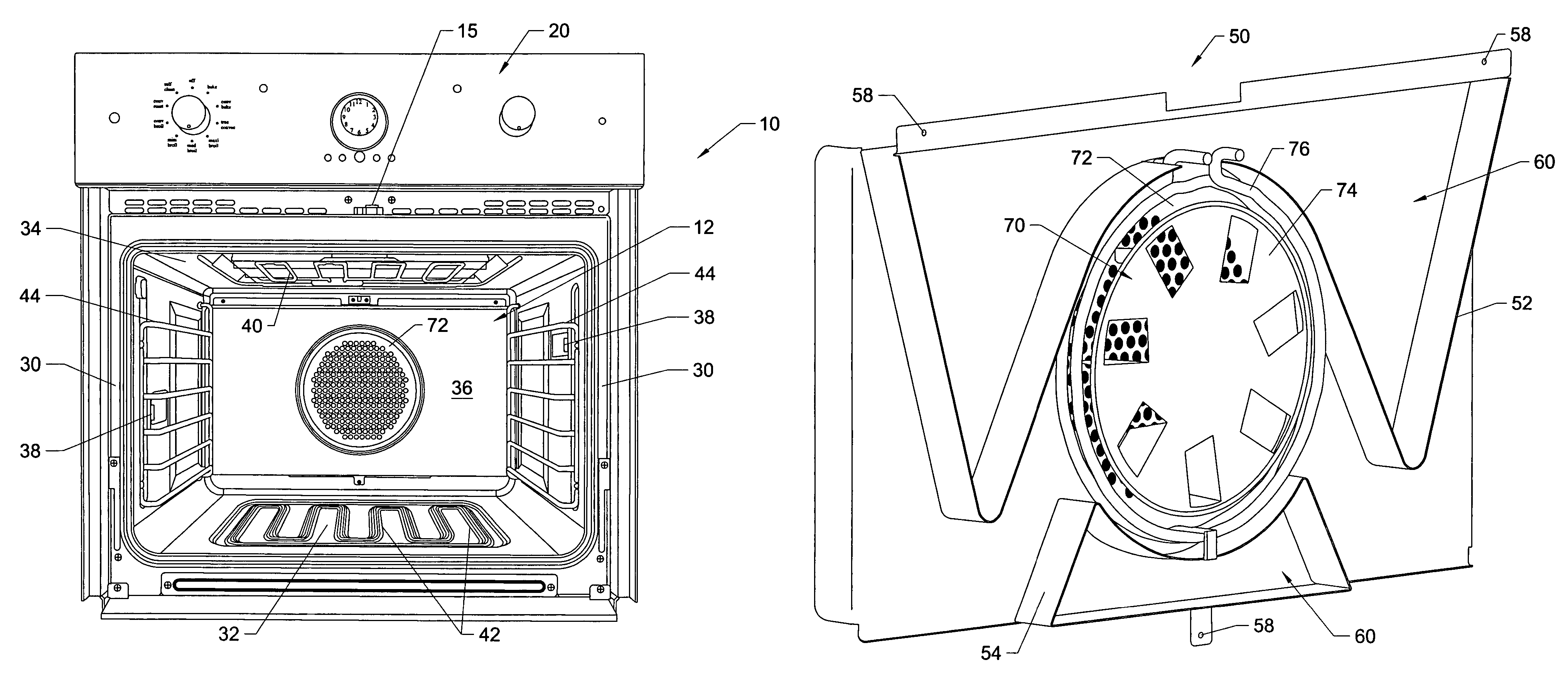

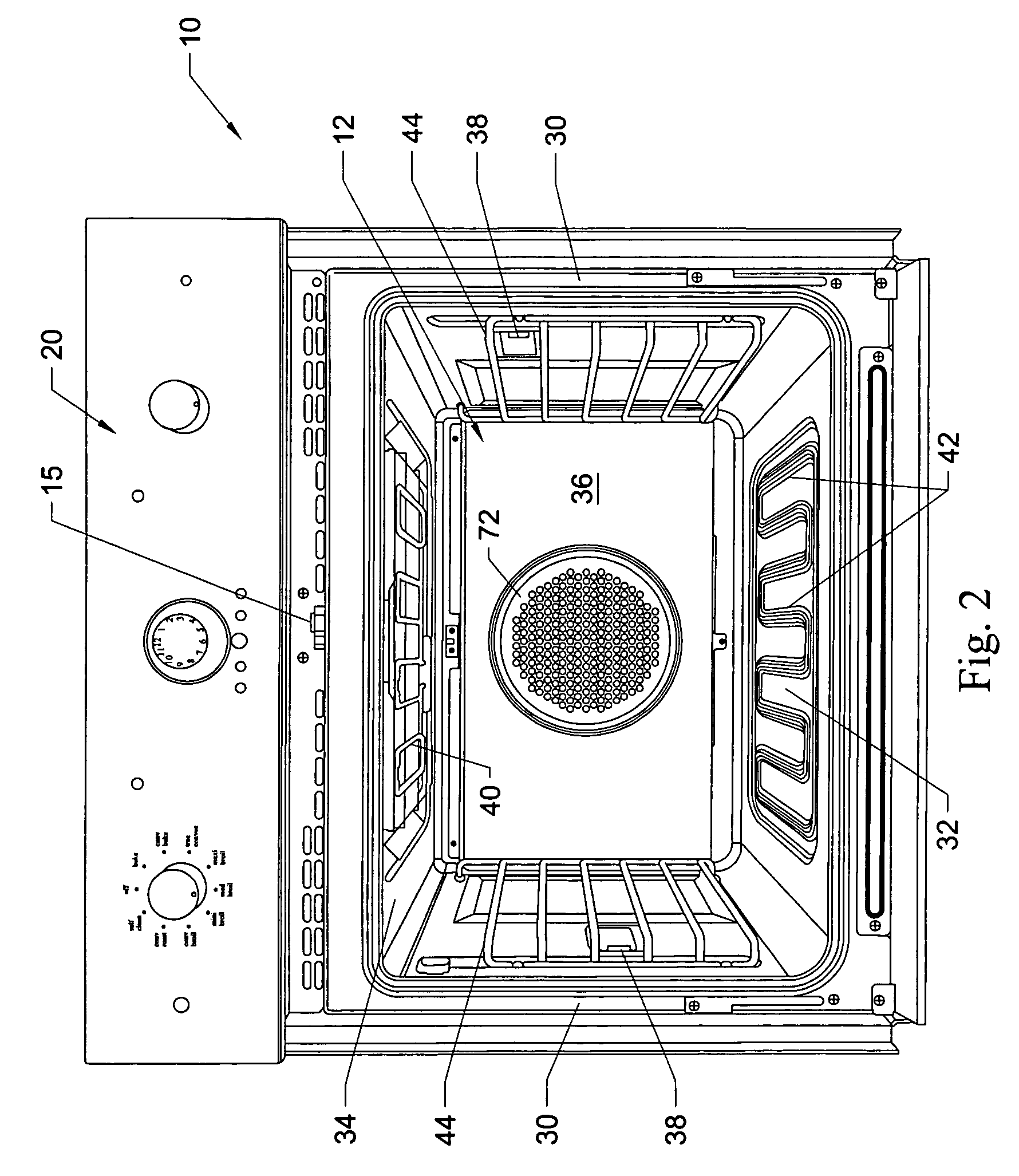

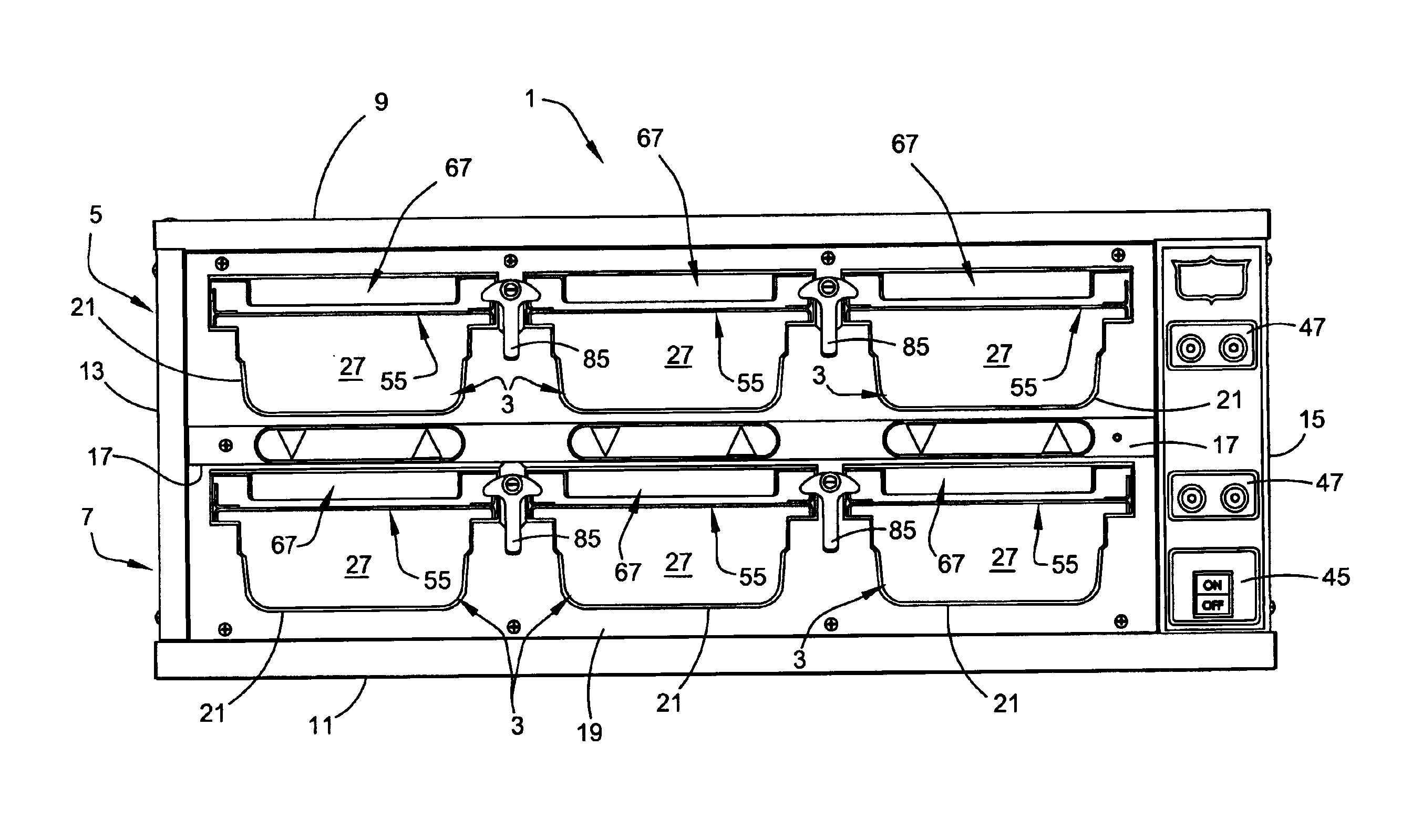

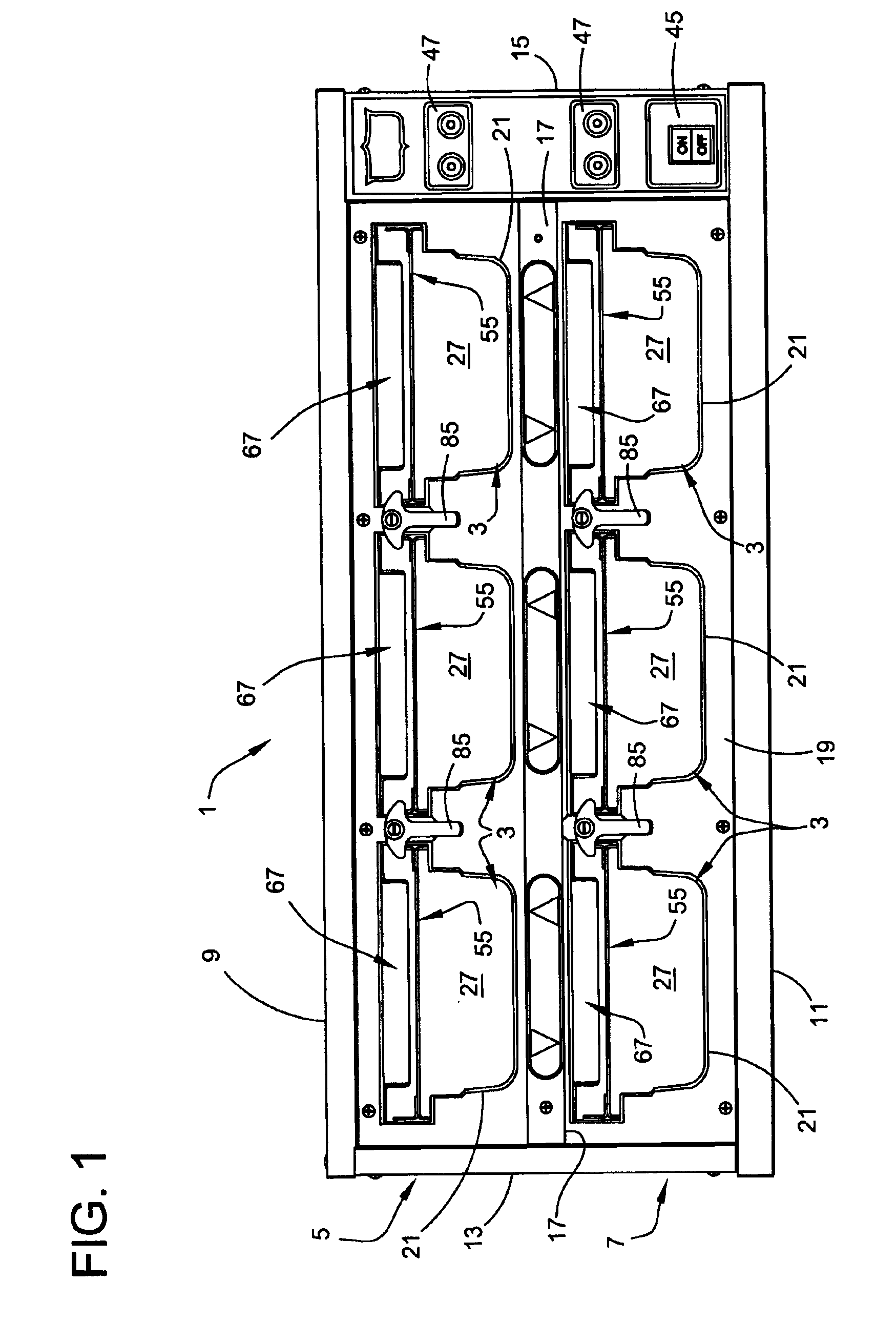

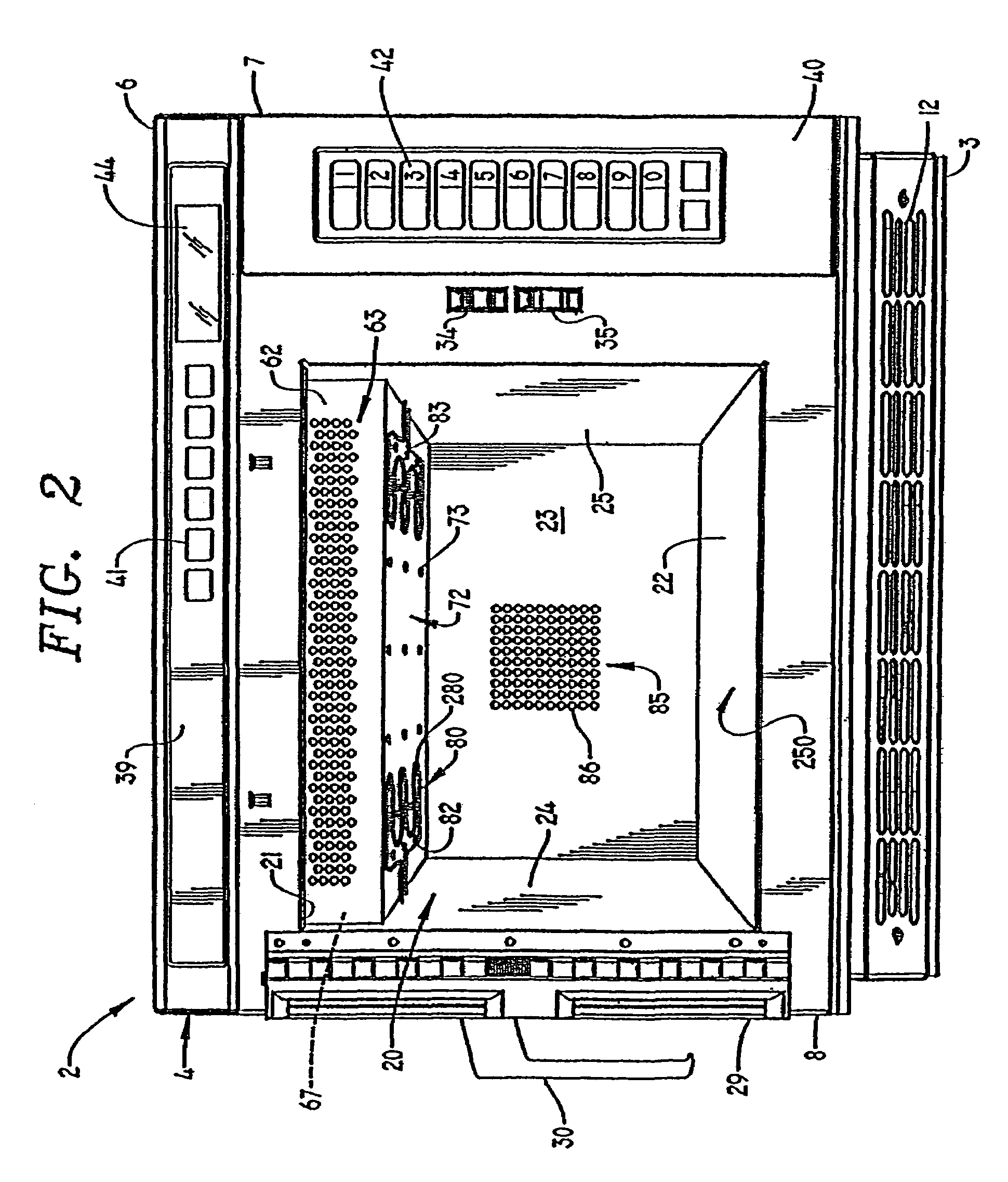

Multi-mode convection oven with flow control baffles

InactiveUS7468495B2Cook food accurately and evenlyEven air distributionAir-treating devicesDomestic stoves or rangesControl systemEngineering

An airflow control system for an oven having an oven cavity and a fan having a first operating mode for generating a first flow of air and a second operating mode for generating a second flow of air is provided. A baffle is included adjacent the fan to direct the first flow of air to a first region of the cavity in the first operating mode and to direct the second flow of air to a second region of the cavity in the second operating mode. A method of controlling airflow in an oven having an oven cavity is also detailed. The method can include different modes of operation, with different clockwise and counterclockwise rotational times for the fan, with different heating elements energized, or a combination of both, depending upon the food to be cooked in the oven.

Owner:VIKING RANGE

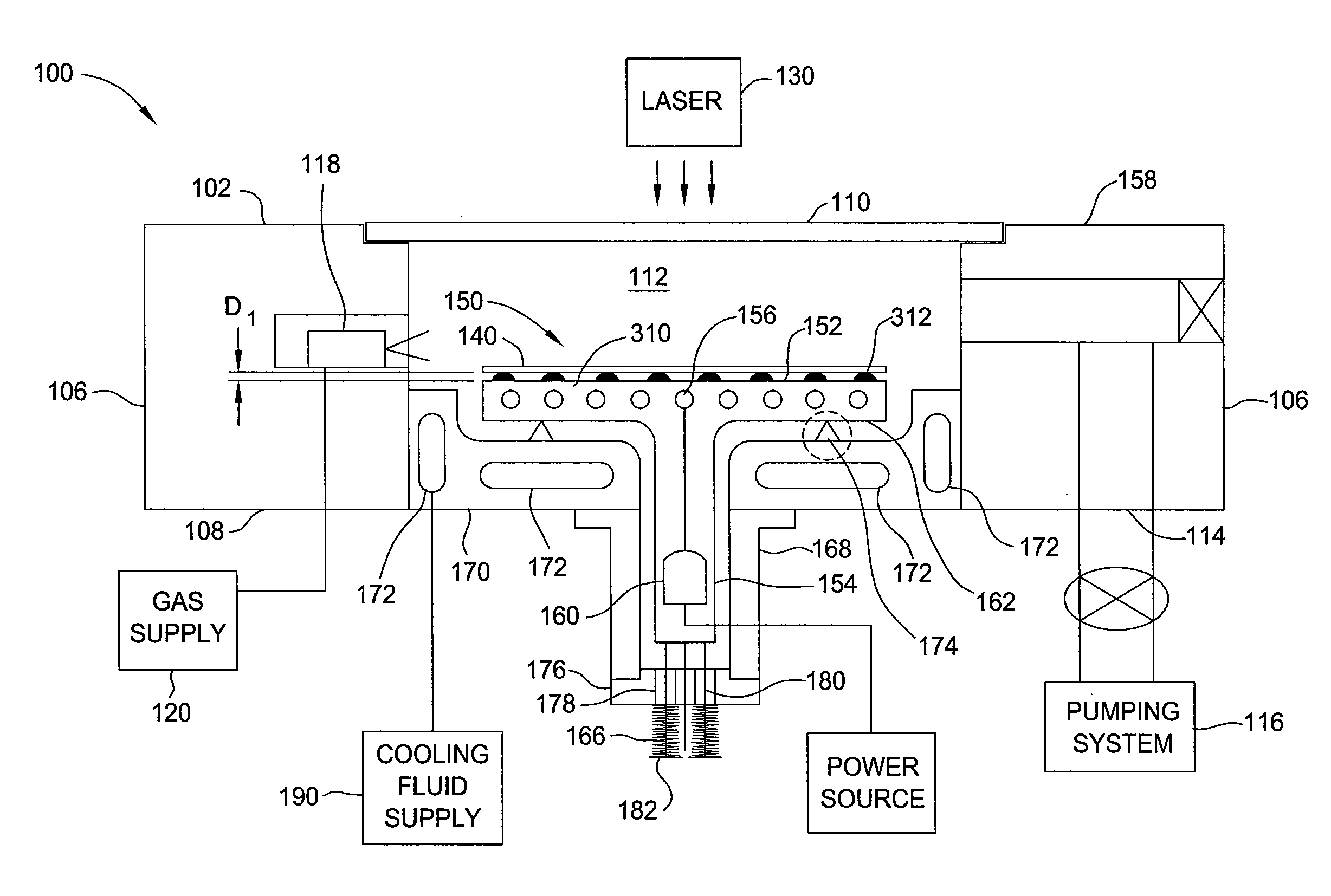

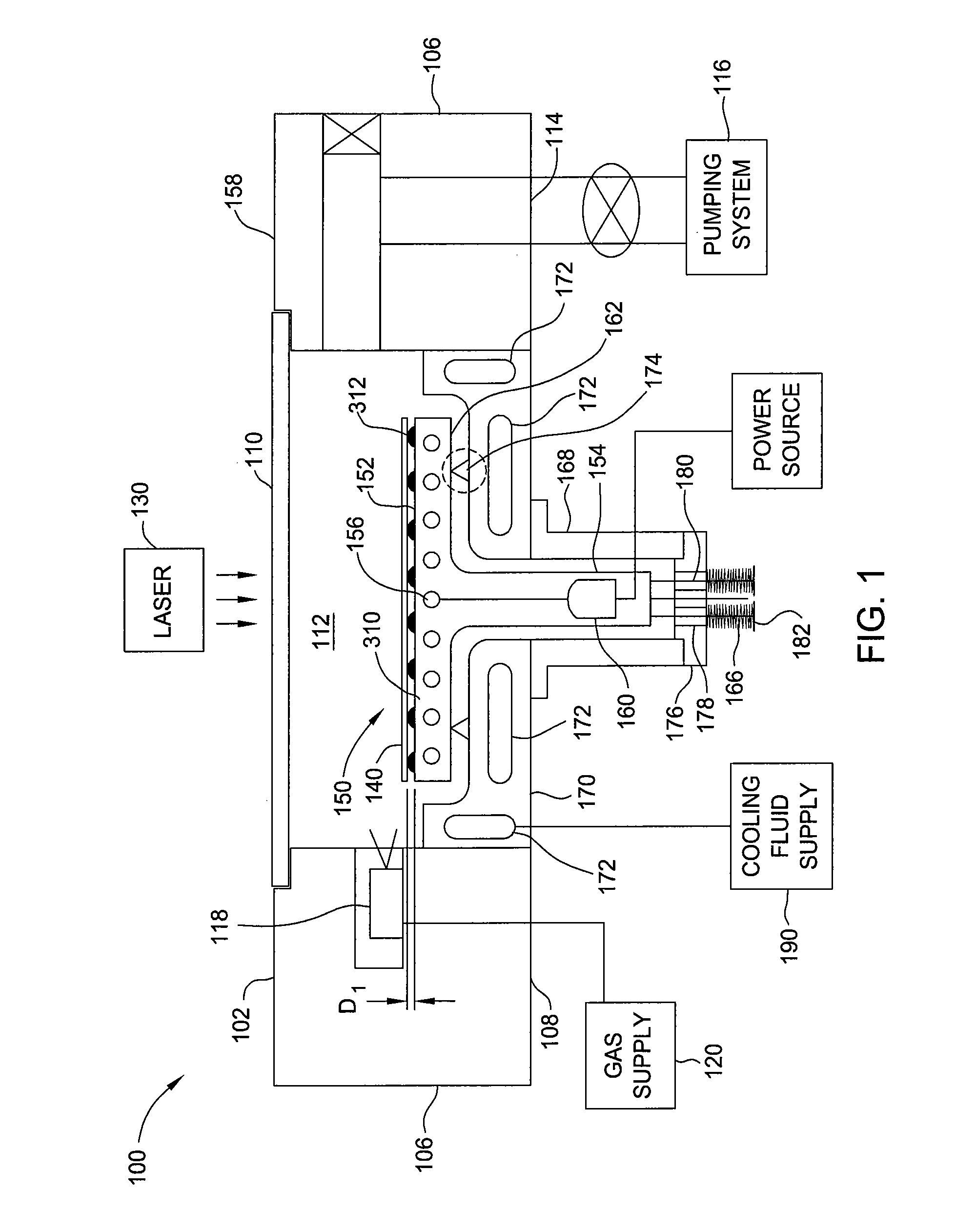

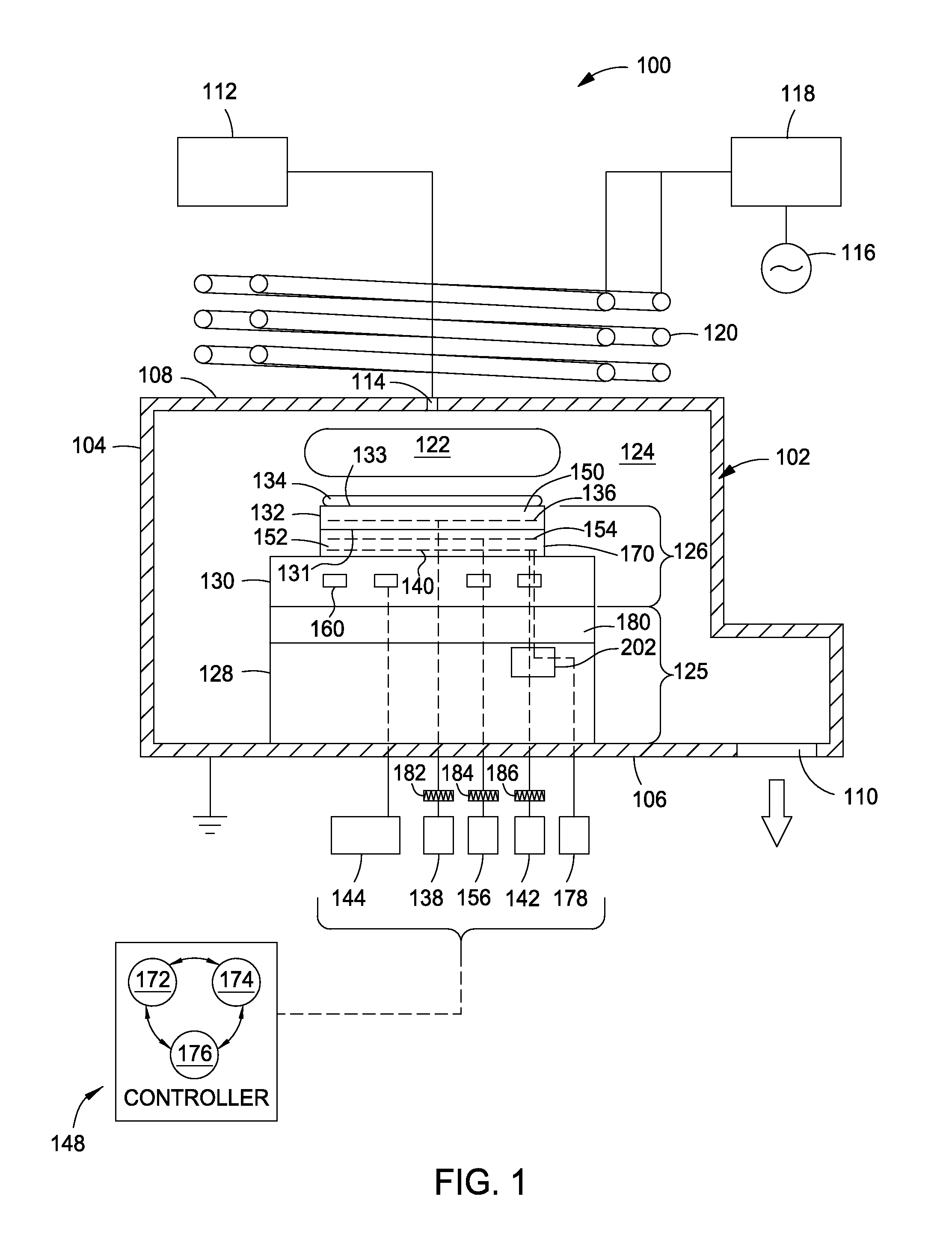

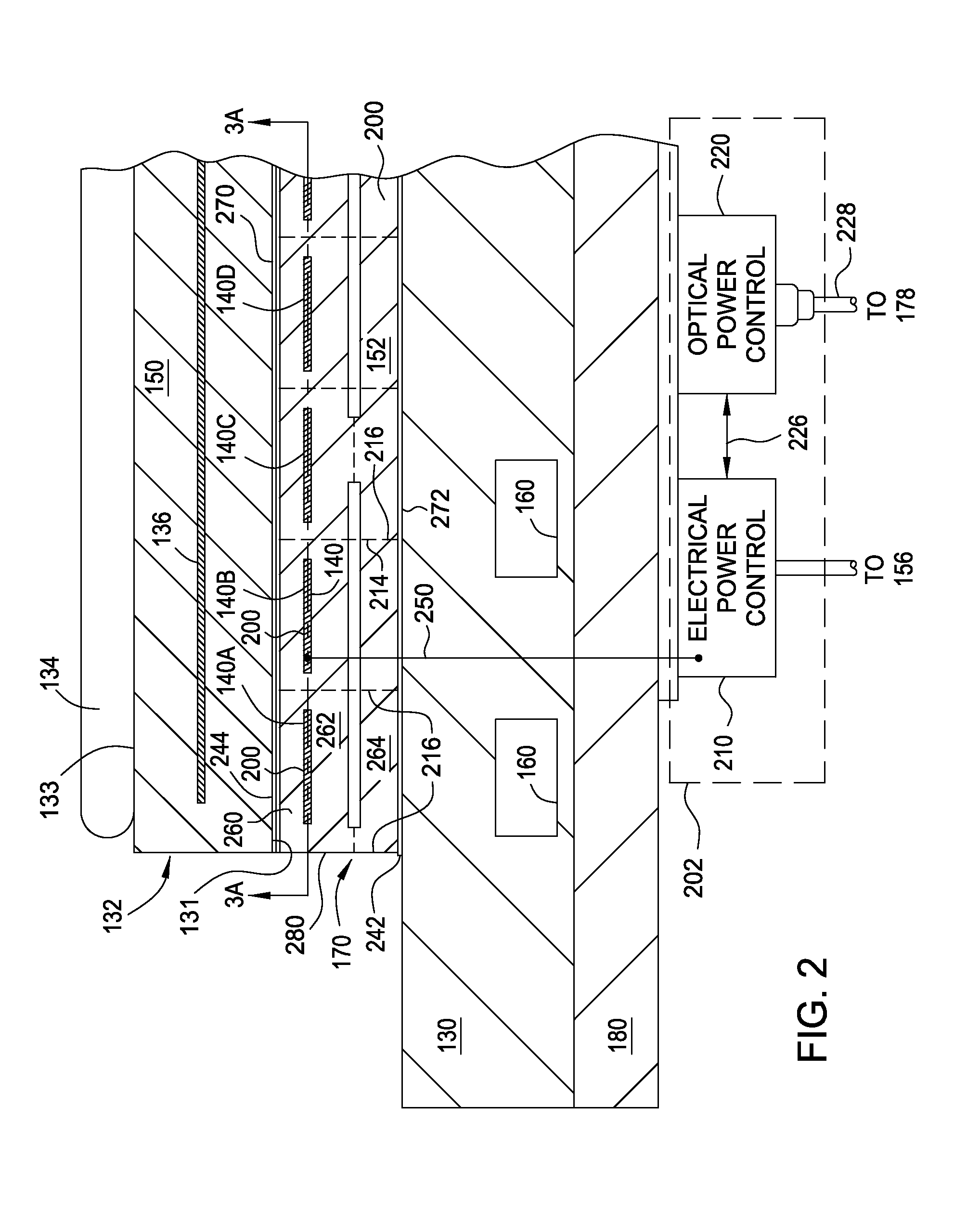

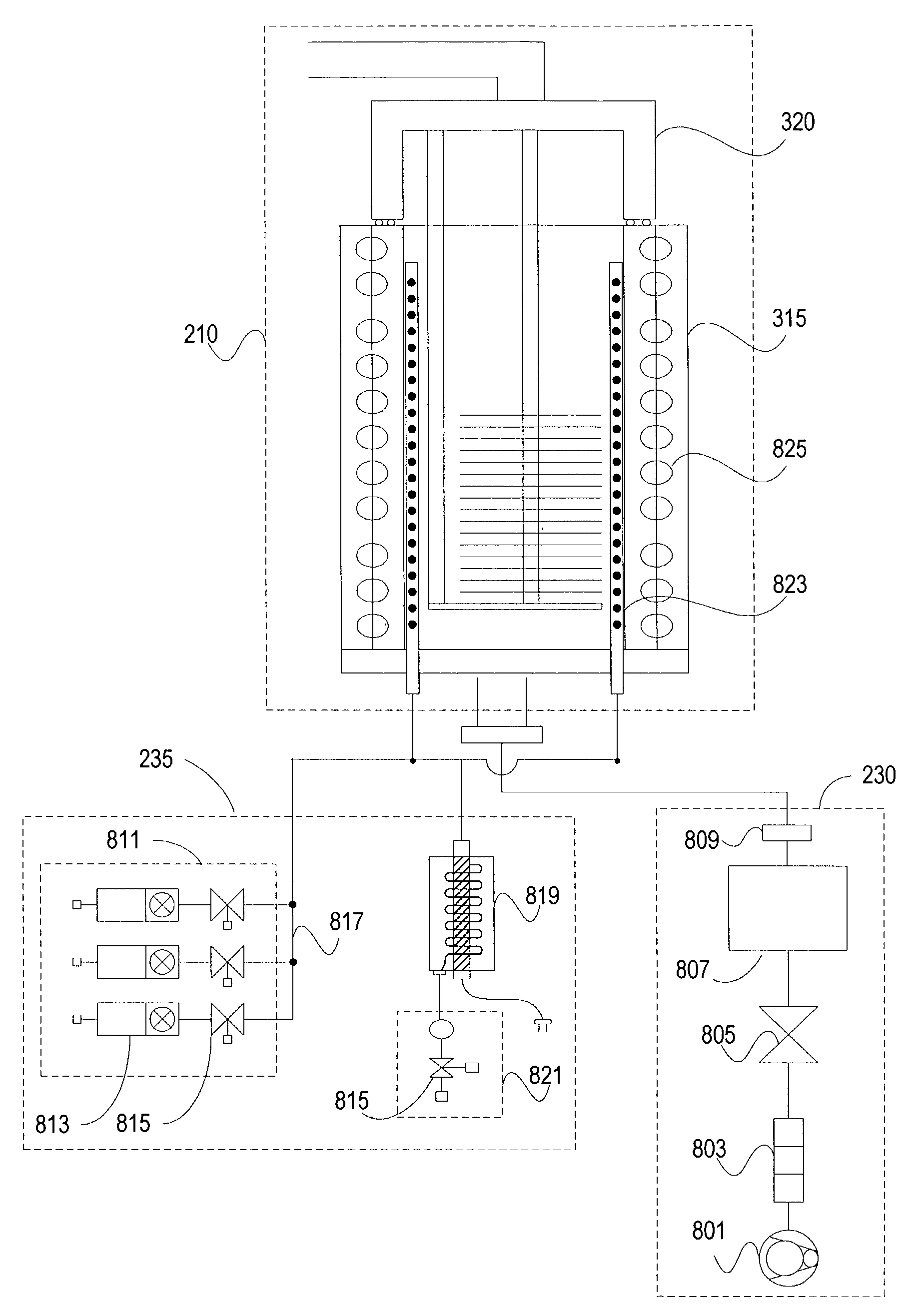

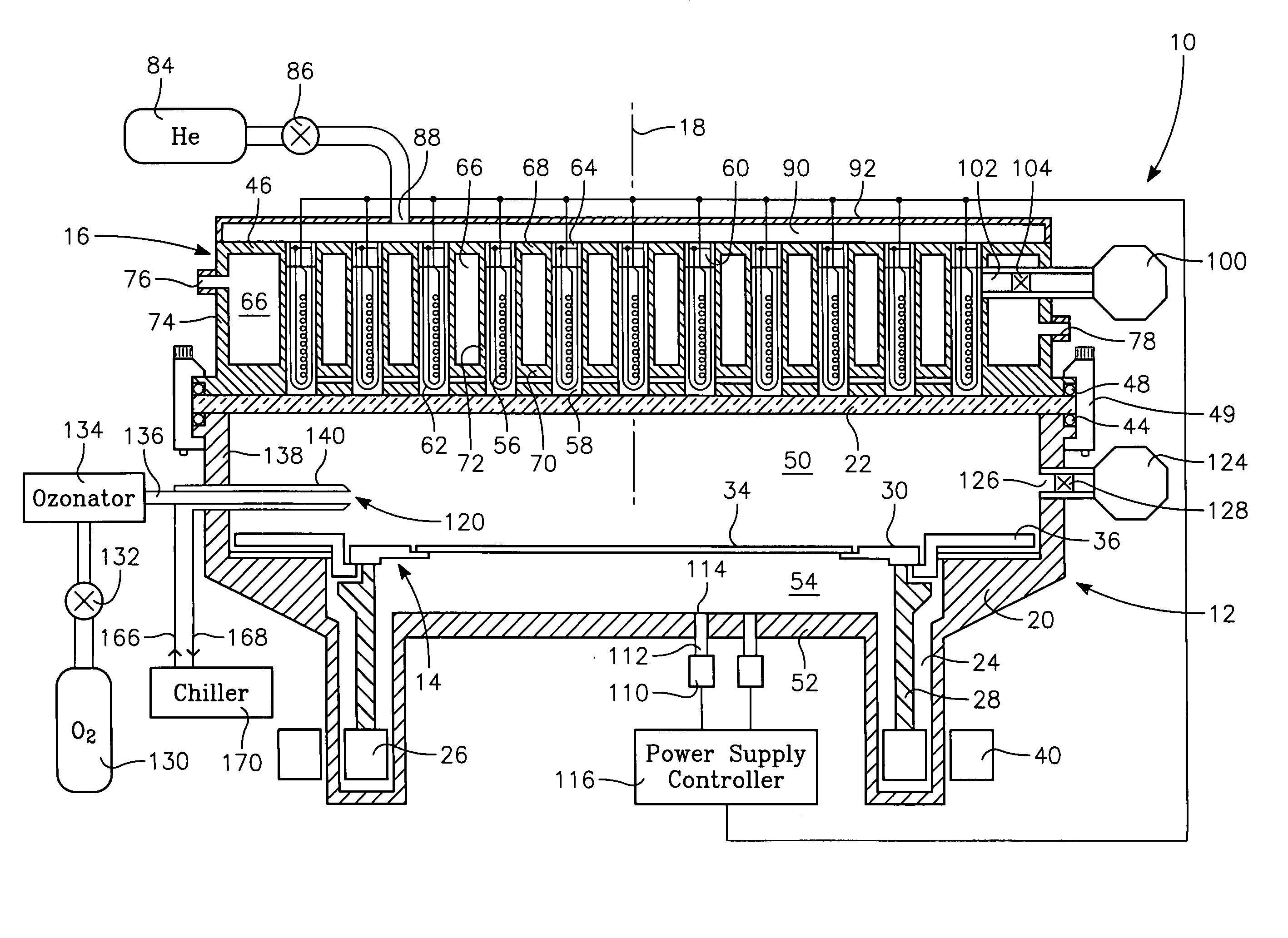

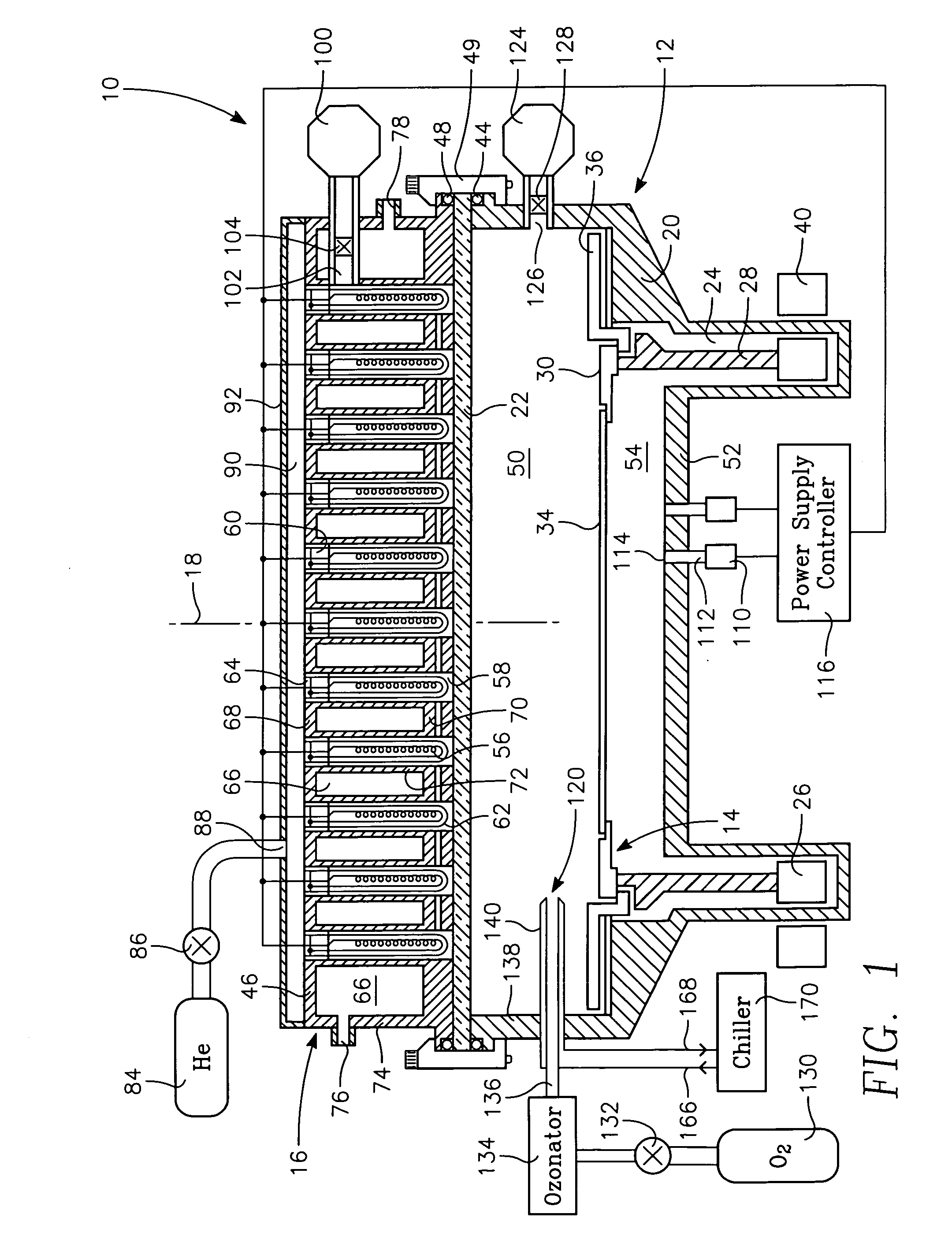

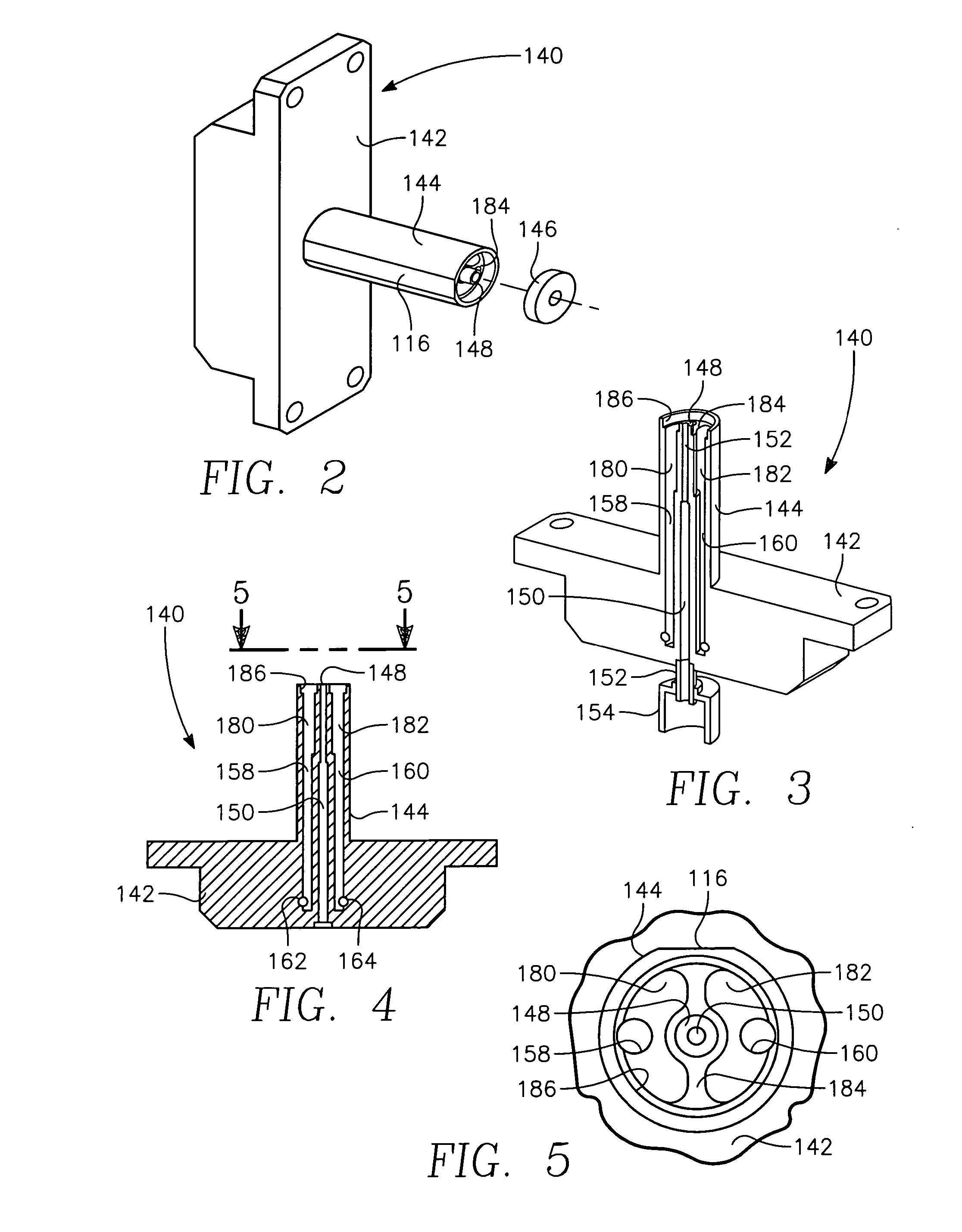

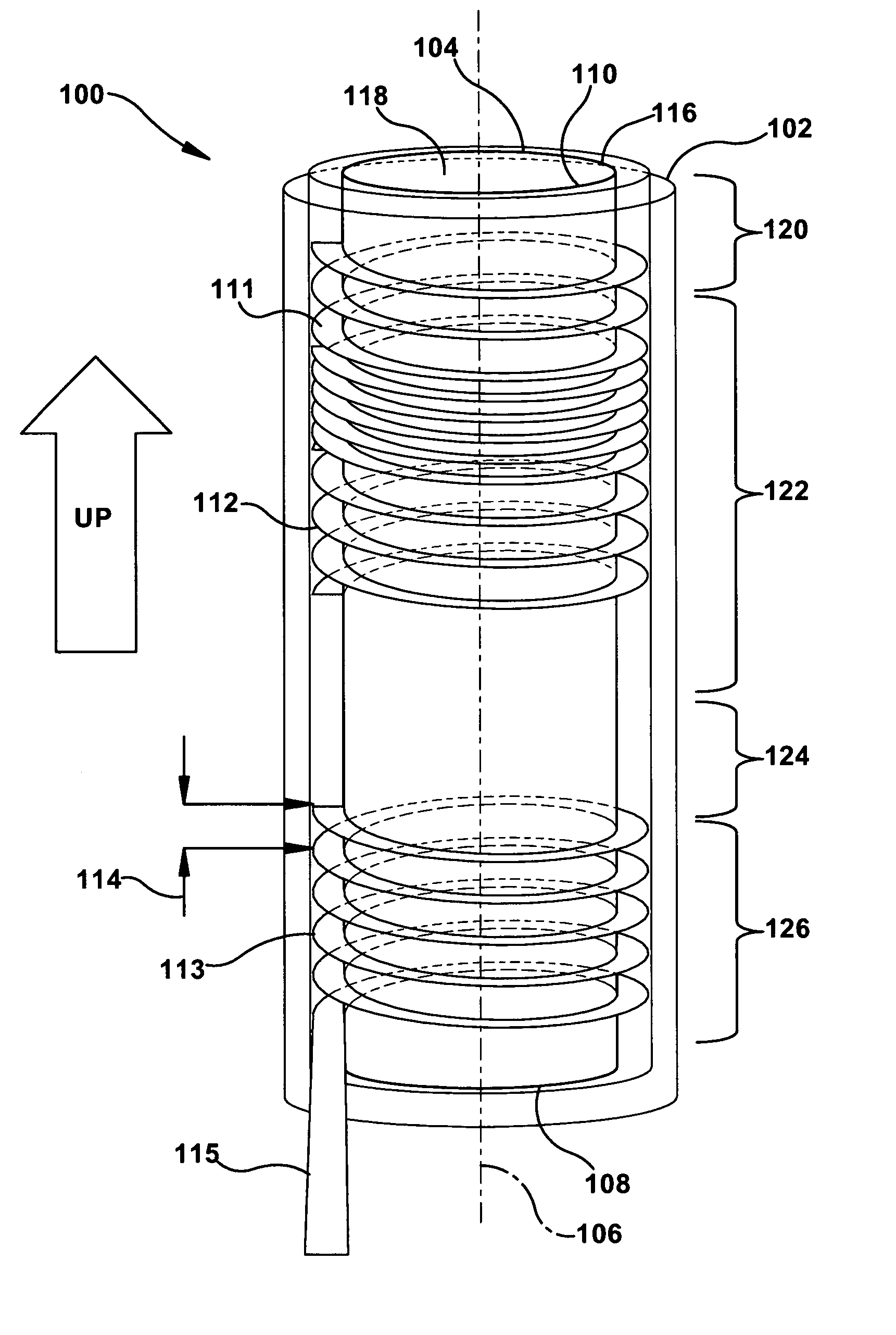

Thermal oxidation of silicon using ozone

A method and apparatus for oxidizing materials used in semiconductor integrated circuits, for example, for oxidizing silicon to form a dielectric gate. An ozonator is capable of producing a stream of least 70% ozone. The ozone passes into an RTP chamber through a water-cooled injector projecting into the chamber. Other gases such as hydrogen to increase oxidation rate, diluent gas such as nitrogen or O2, enter the chamber through another inlet. The chamber is maintained at a low pressure below 20 Torr and the substrate is advantageously maintained at a temperature less than 800° C. Alternatively, the oxidation may be performed in an LPCVD chamber including a pedestal heater and a showerhead gas injector in opposition to the pedestal.

Owner:APPLIED MATERIALS INC

Heater, apparatus, and associated method

A heater that may include an outer housing and an inner tube is provided. The inner tube is in a coaxial relation to and within the outer housing. An inward facing surface of the inner tube defines a volume sufficient to receive a reaction capsule, and the outward facing surface is radially spaced from an inward facing surface of the outer housing sufficient to define a gap. A filler material is disposed within the gap. The filler material responds to pressure such that the filler volume is reduced by less than 5 volume percent at greater than 500 MPa pressure and at greater than 500° C. temperature. One or more heating elements are disposed in the gap. The heating elements are in thermal communication with the inner tube.

Owner:SLT TECH

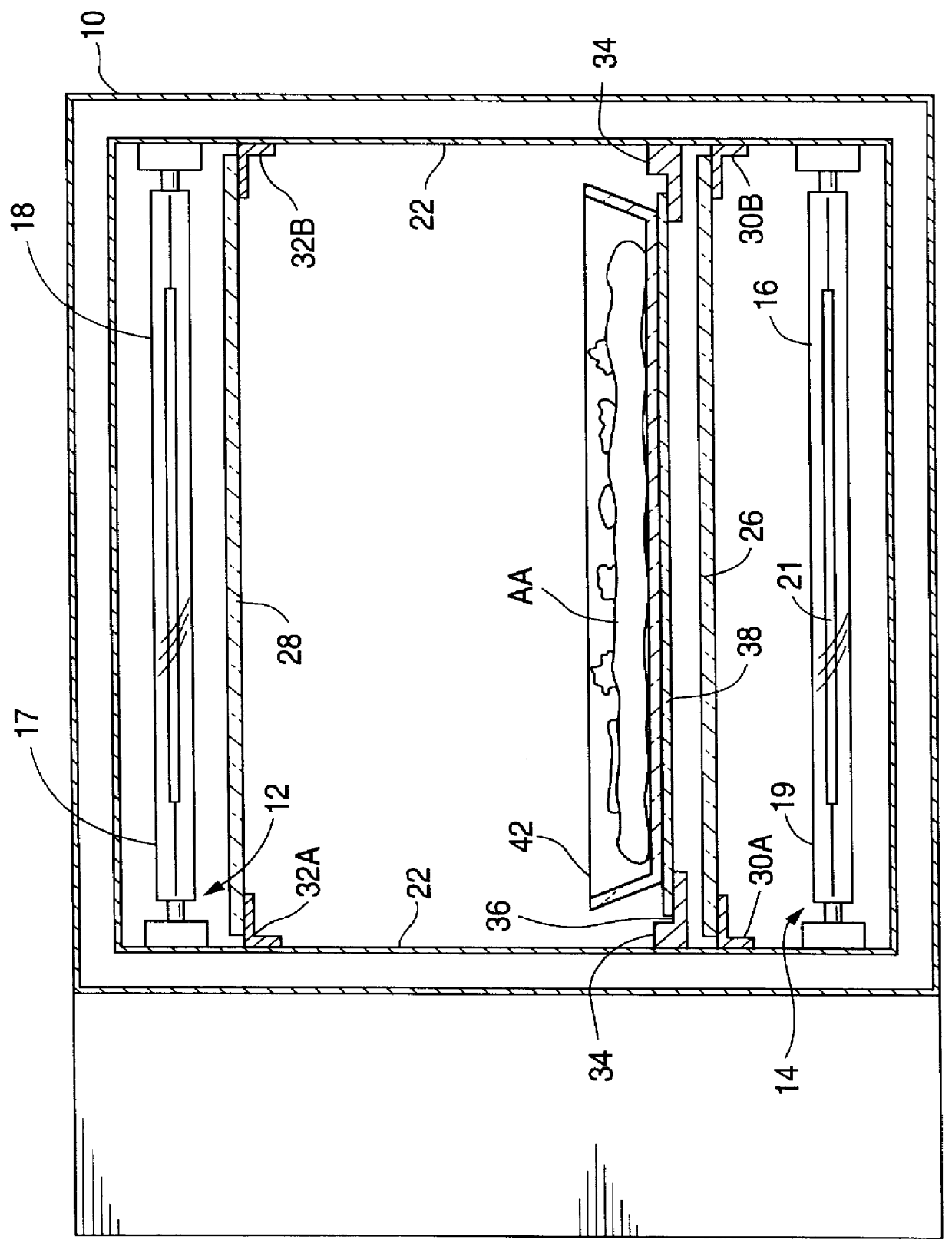

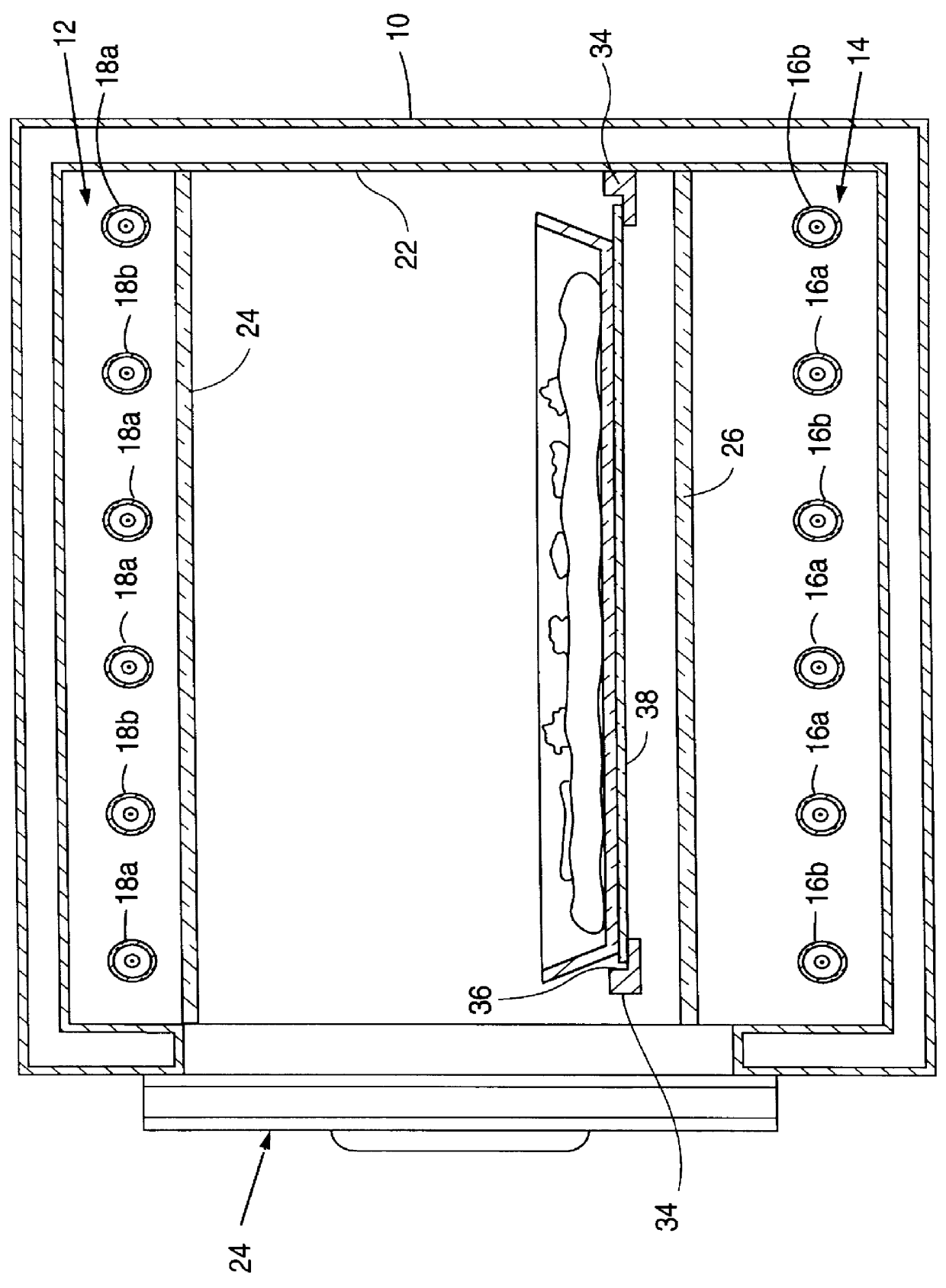

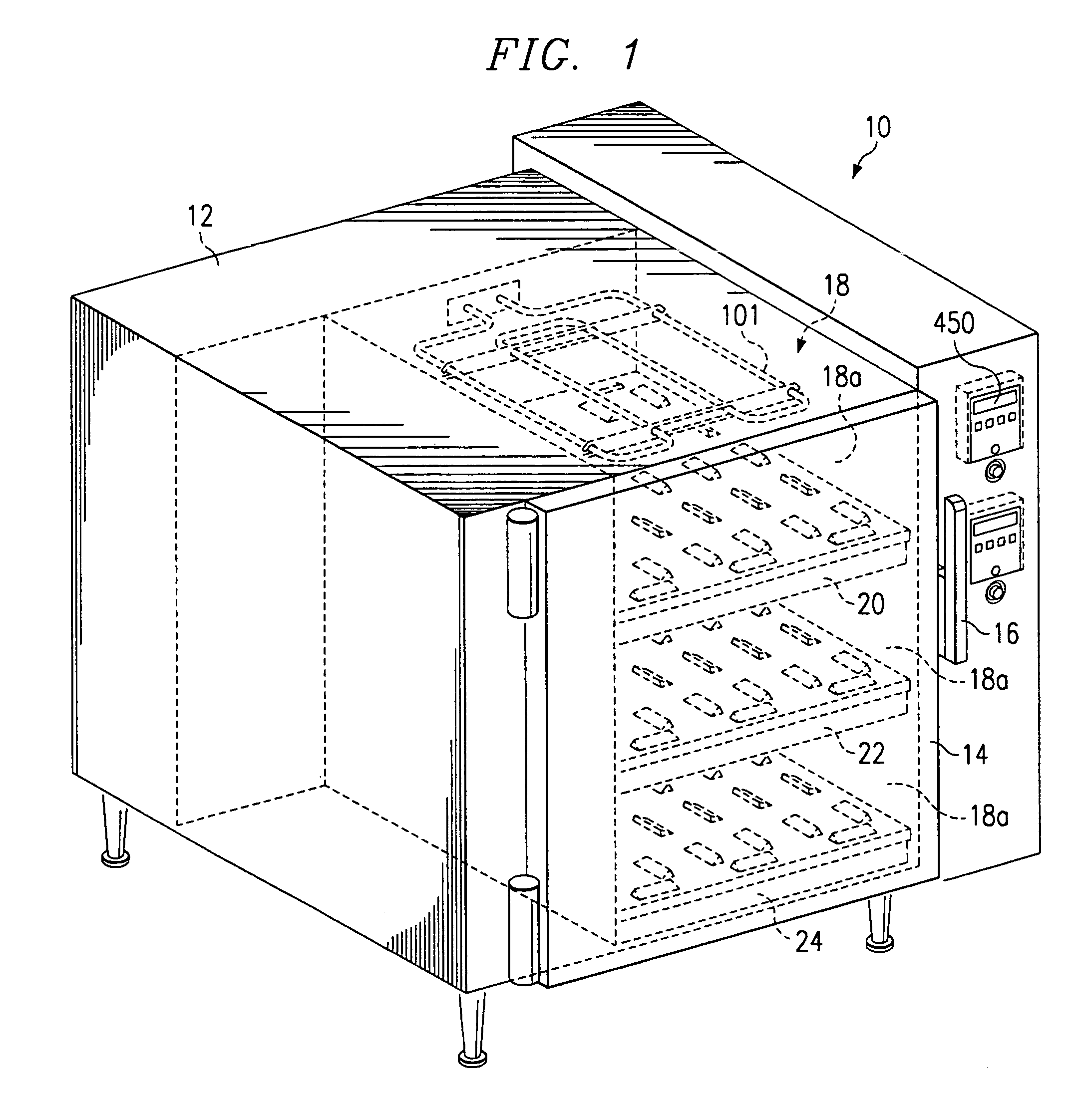

Food warming apparatus and method

InactiveUS7105779B2Less spaceImprove food qualityDomestic stoves or rangesStoves/ranges shelves or racksEngineeringRadiant heat

In general, one embodiment of the invention is directed to food holding apparatus for holding pre-cooked food at a selected holding temperature. The apparatus comprises a cabinet having at least one holding compartment therein, and pre-cooked food in the holding compartment, the food having been previously cooked in a cooking appliance. At least one radiant heat source is spaced above the food a distance less than 12 inches for delivering radiant heat to the food. A control mechanism varies the amount of radiant heat delivered by the heat source to the food to maintain the food at the selected holding temperature. A related method is also disclosed.

Owner:DUKE MANUFACTURING COMPANY

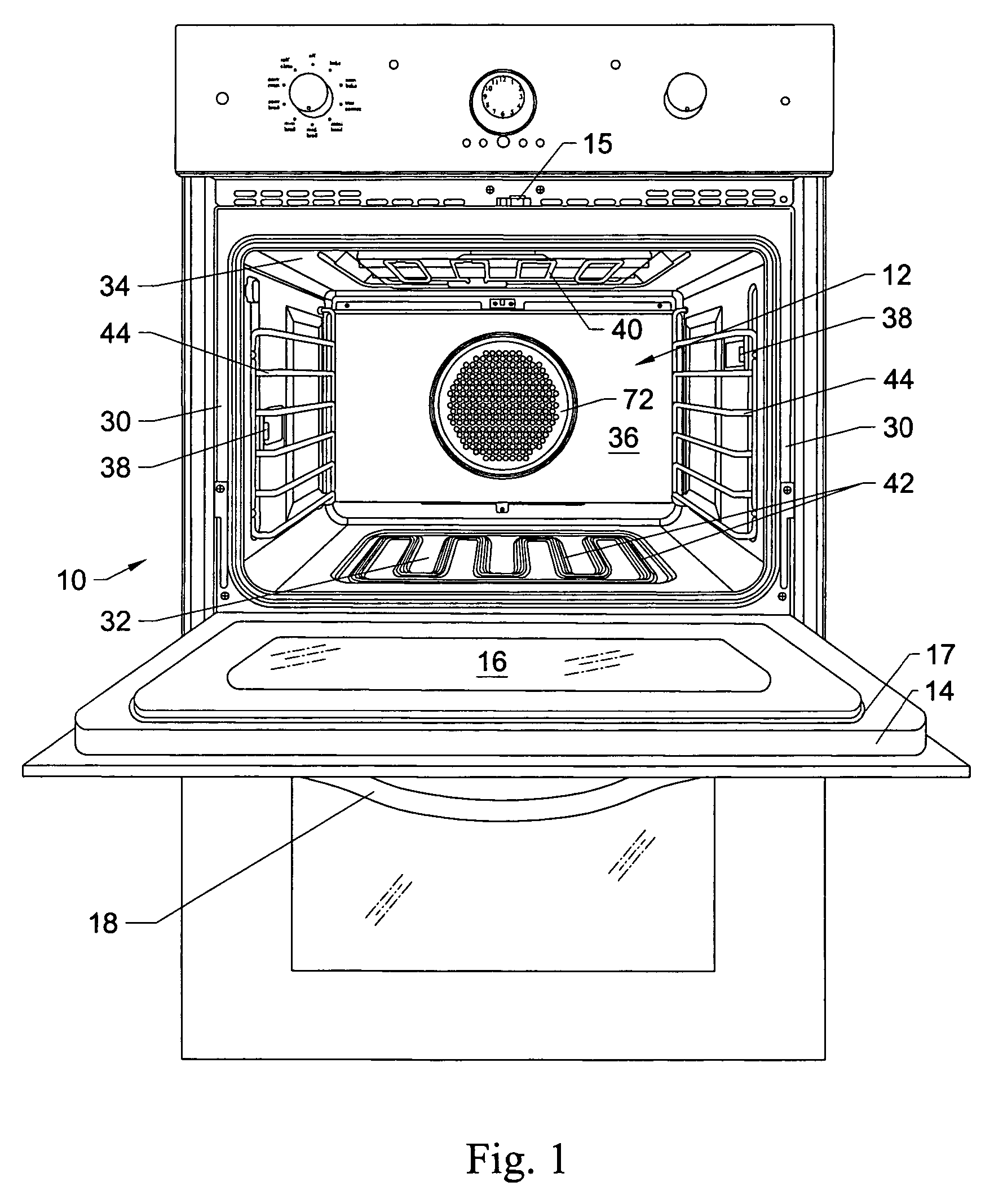

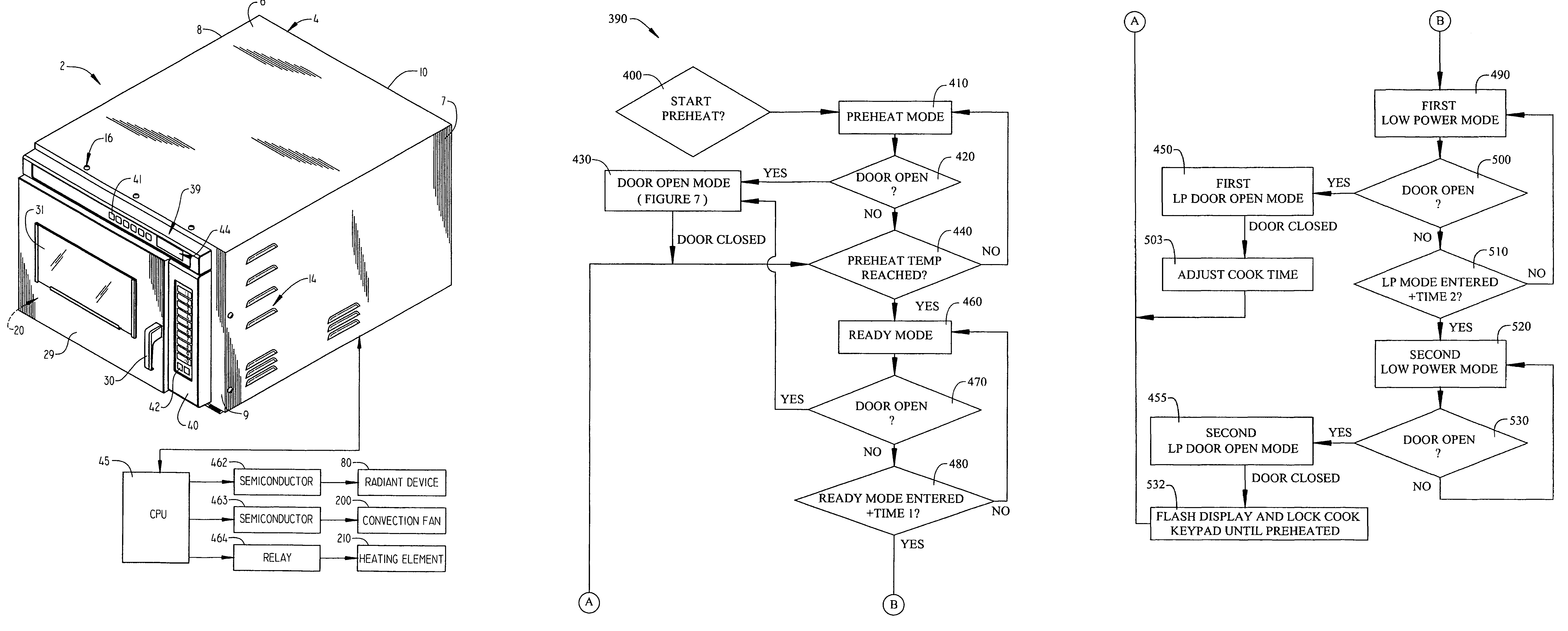

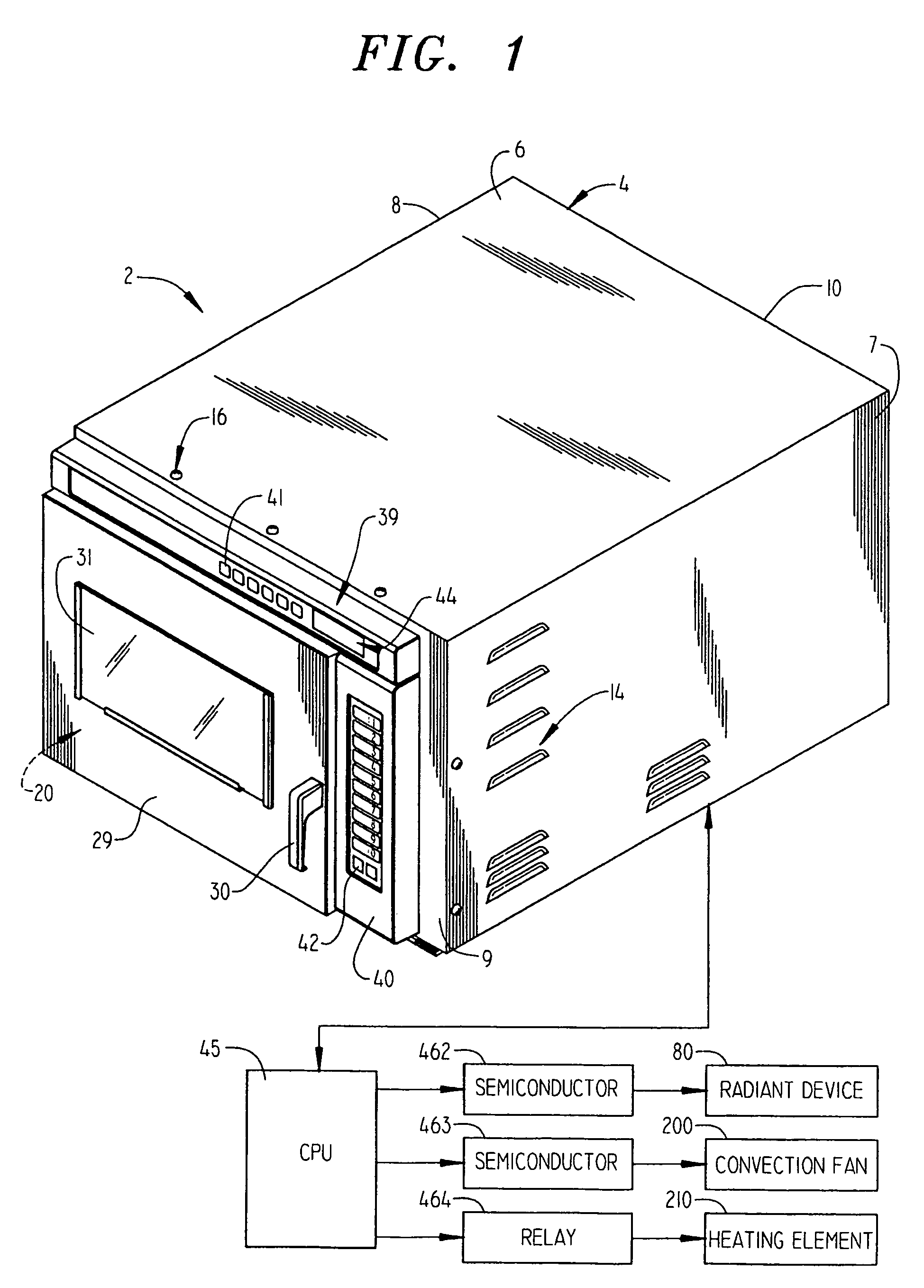

Operational modes for a cooking appliance employing combination cooking technology

A cooking appliance includes a controller for establishing a plurality of operating modes for heating an oven cavity. Specifically, the controller establishes one of a pre-heat mode, a ready mode, a first low power mode and a second low power mode for controlling a temperature of the oven cavity. Upon selecting a temperature for the oven cavity, the controller operates a radiant heating device, a convection fan and a convection heating device at full power to establish the selected temperature. After the selected temperature is achieved, the controller switches to a ready mode and reduces heat output of both the radiant heating device and the convection heating device, while also reducing fan speed. After respective periods of time in which a door of the appliance is not opened, the controller switches to first and second low power modes to conserve energy.

Owner:ACP OF DELAWARE

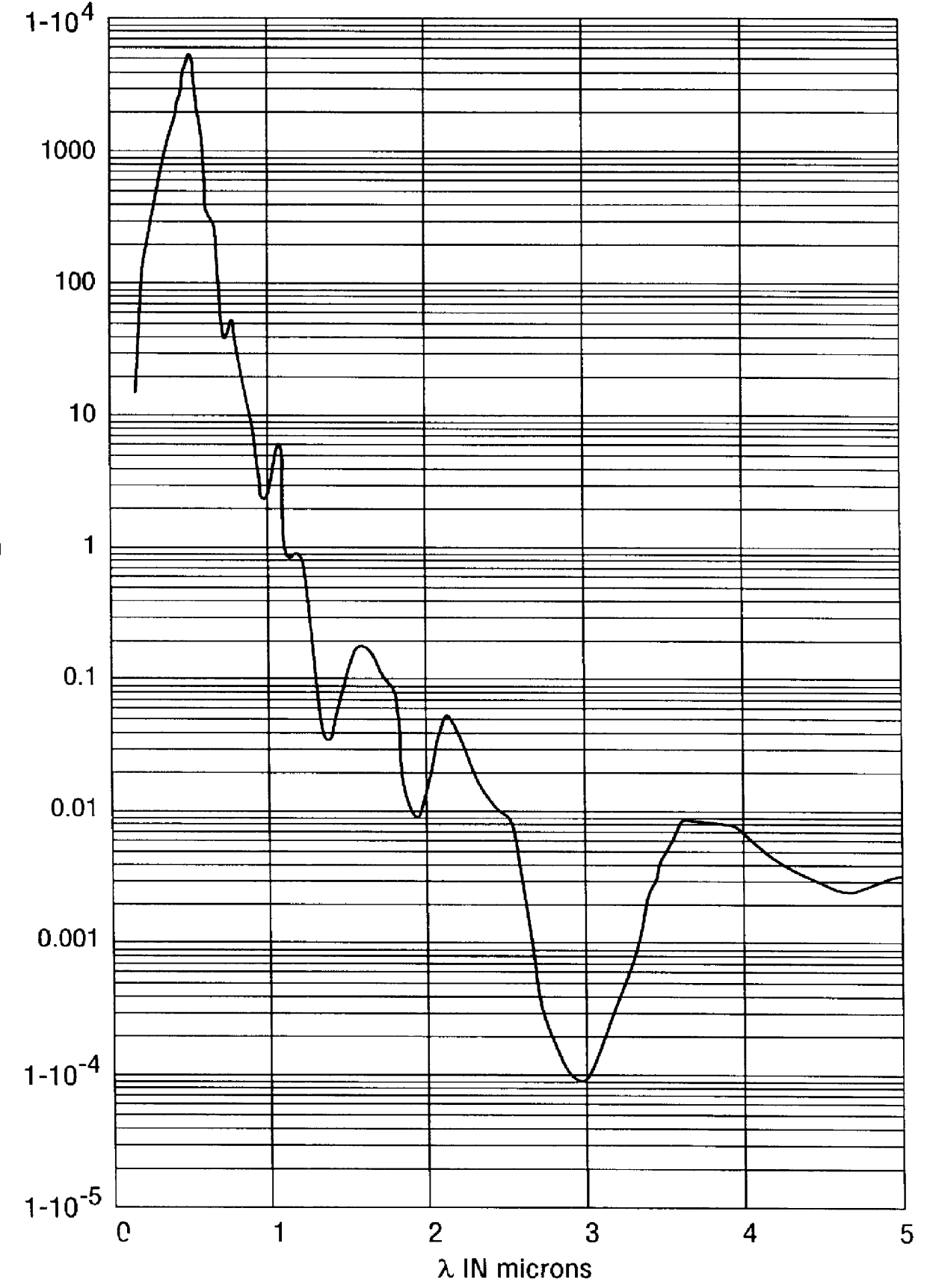

Apparatus and method for cooking food with a controlled spectrum

InactiveUS6069345AHigh strengthIncrease temperatureMilk preparationDomestic stoves or rangesLight energyEngineering

A lightwave oven for cooking with light having wavelengths in the visible, near visible, and infra-red spectral ranges uses one or more quartz halogen tungsten lamps or quartz arc bulbs positioned above and below the food item and delivers light energy in select ranges of the electromagnetic spectrum during select portions of the cooking cycle.

Owner:HAIER US APPLIANCE SOLUTIONS INC

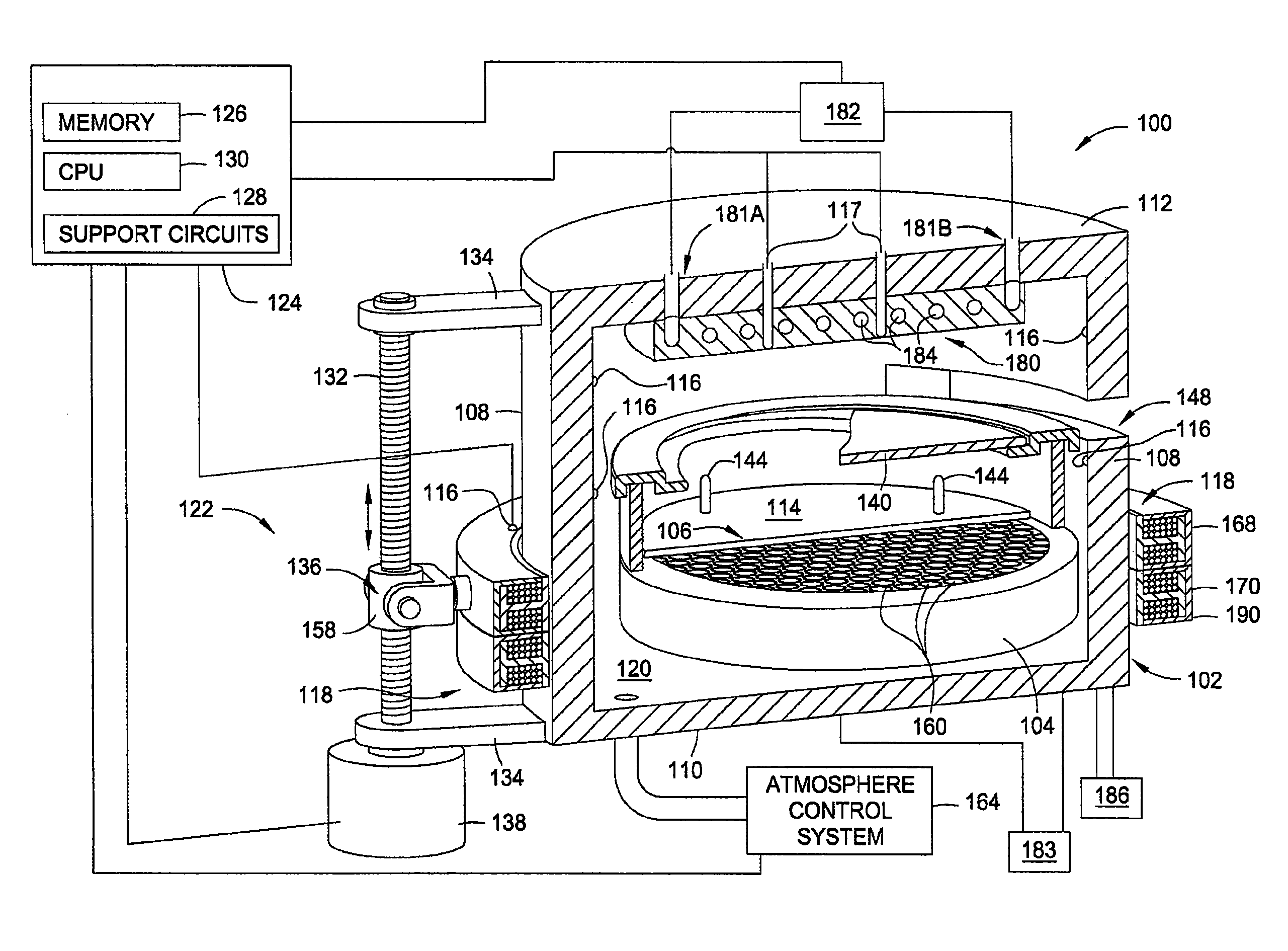

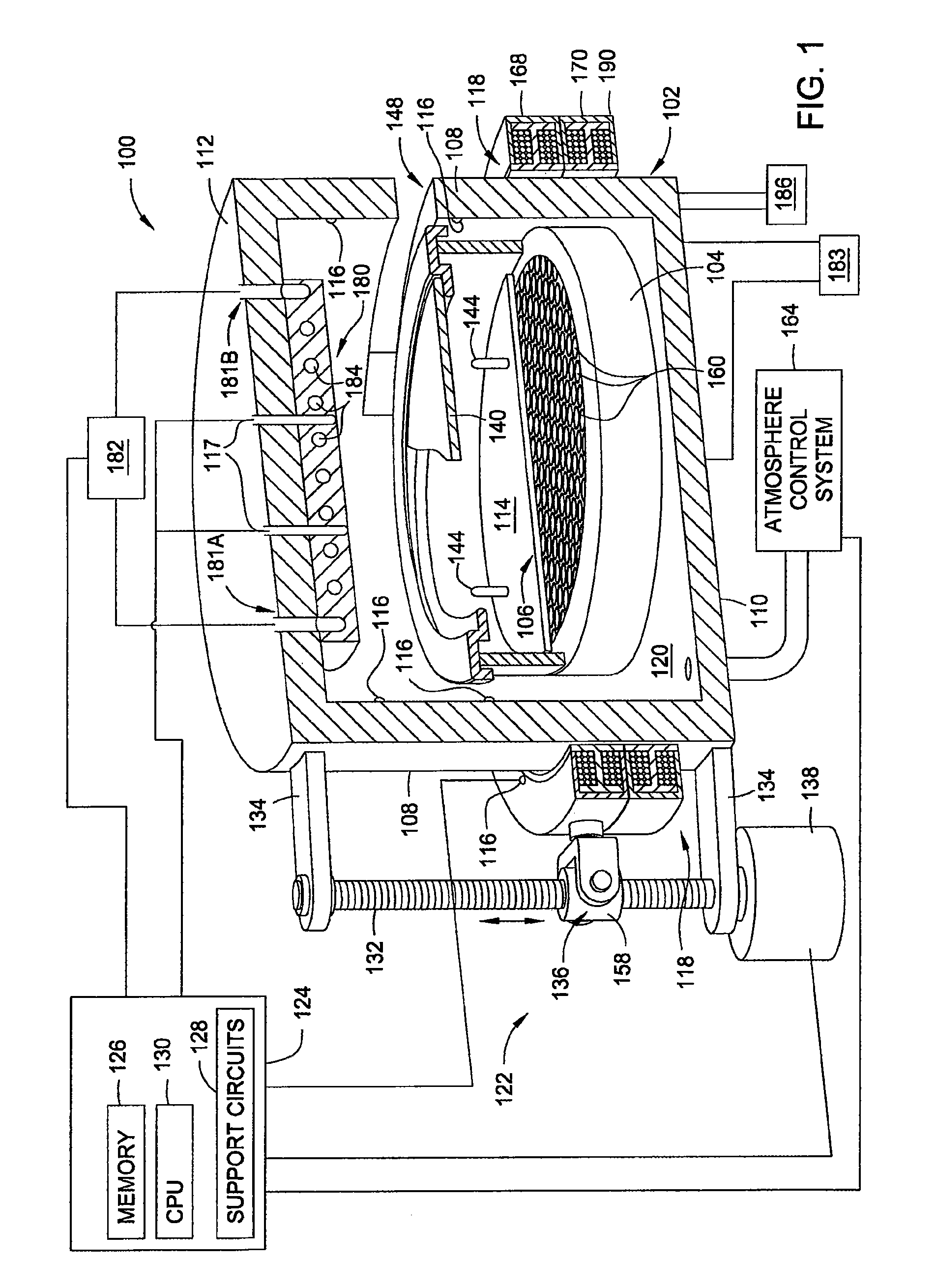

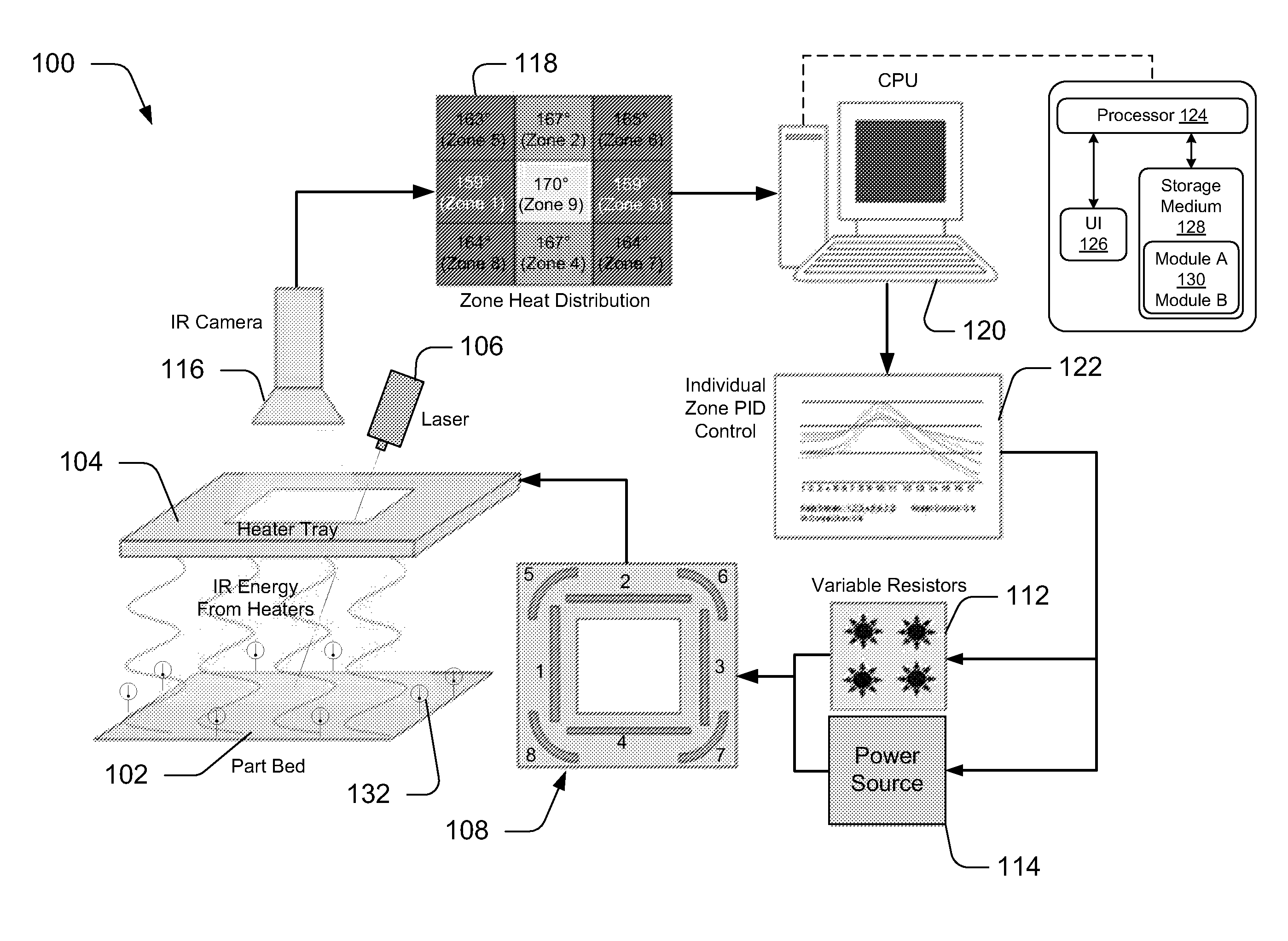

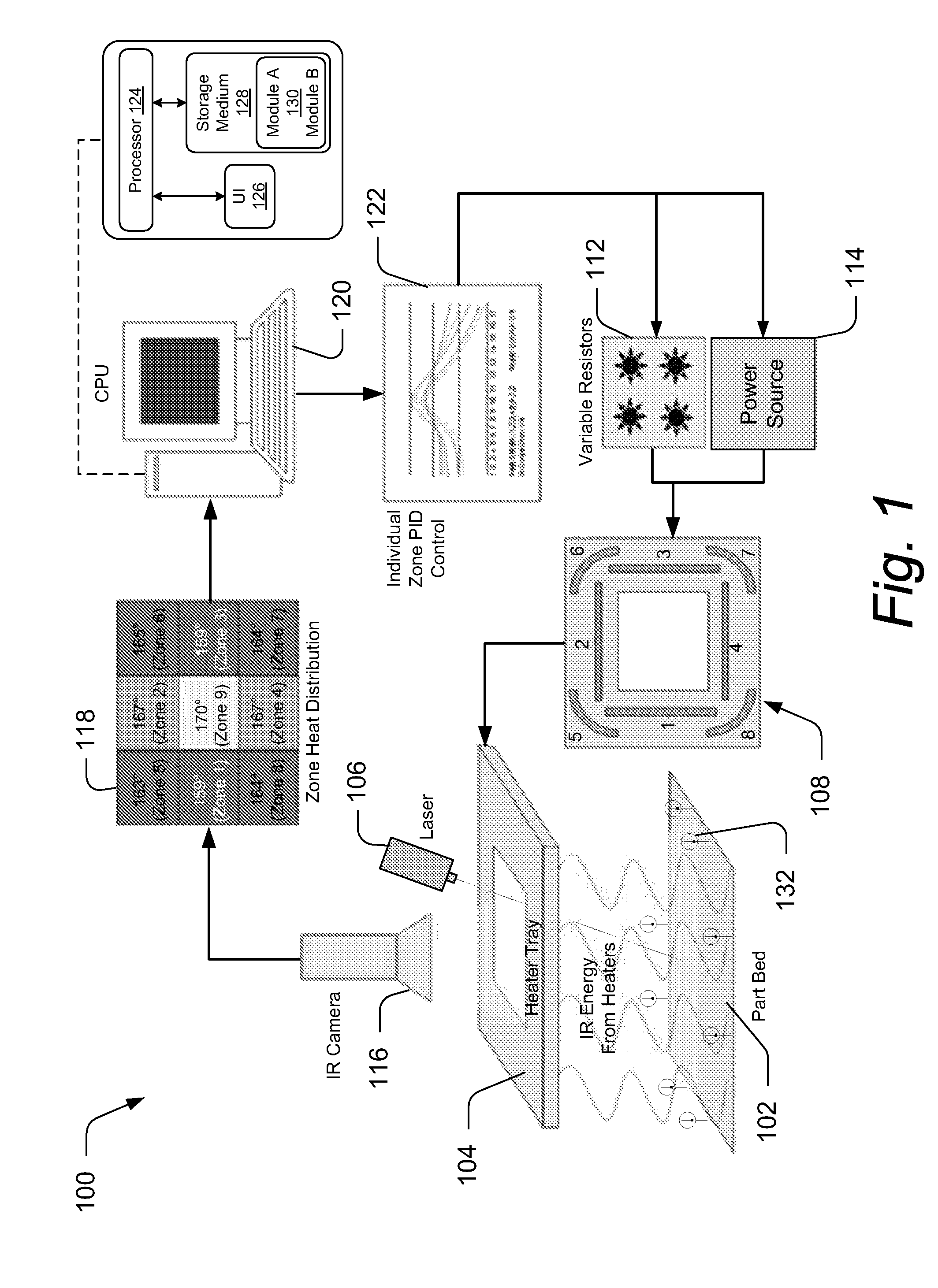

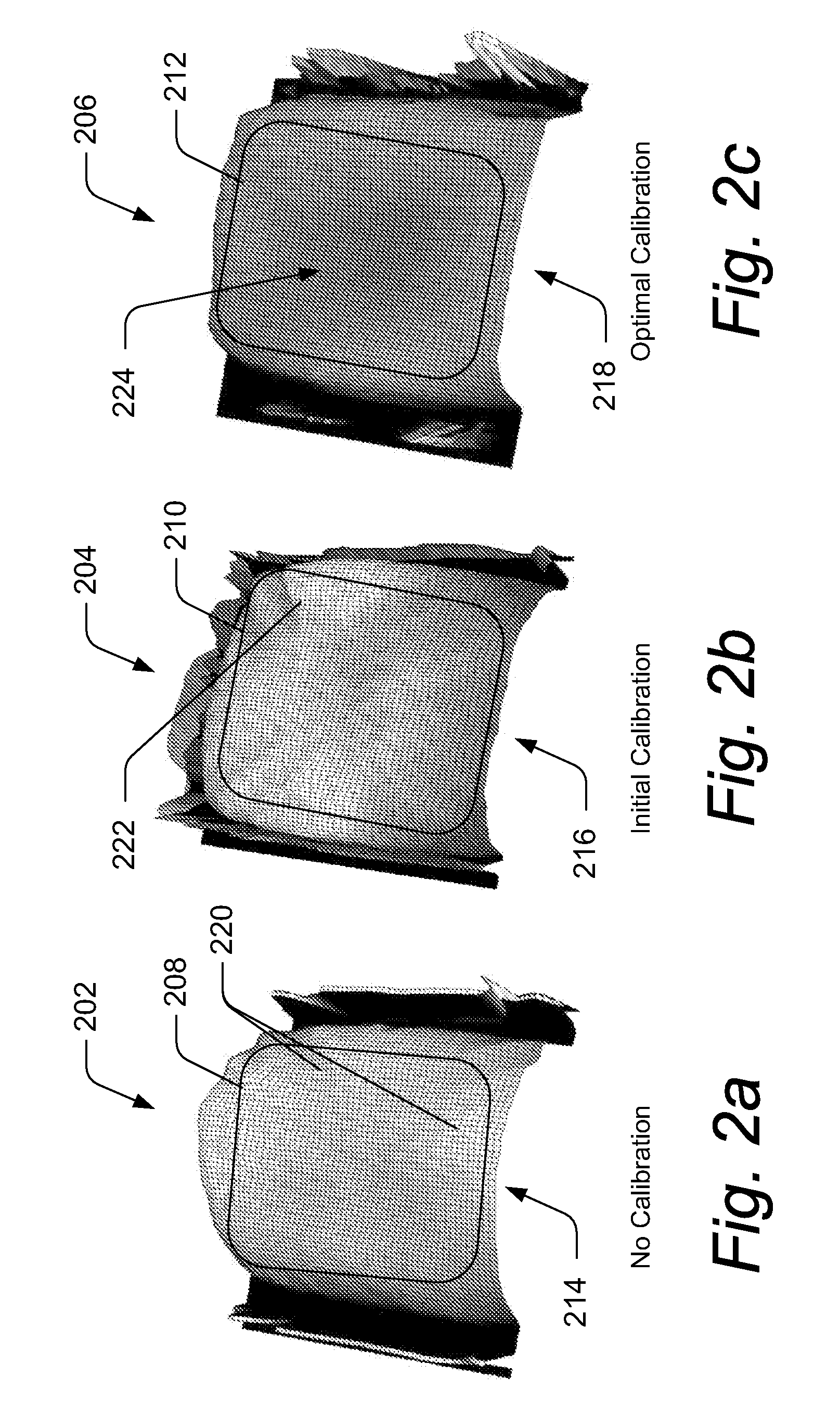

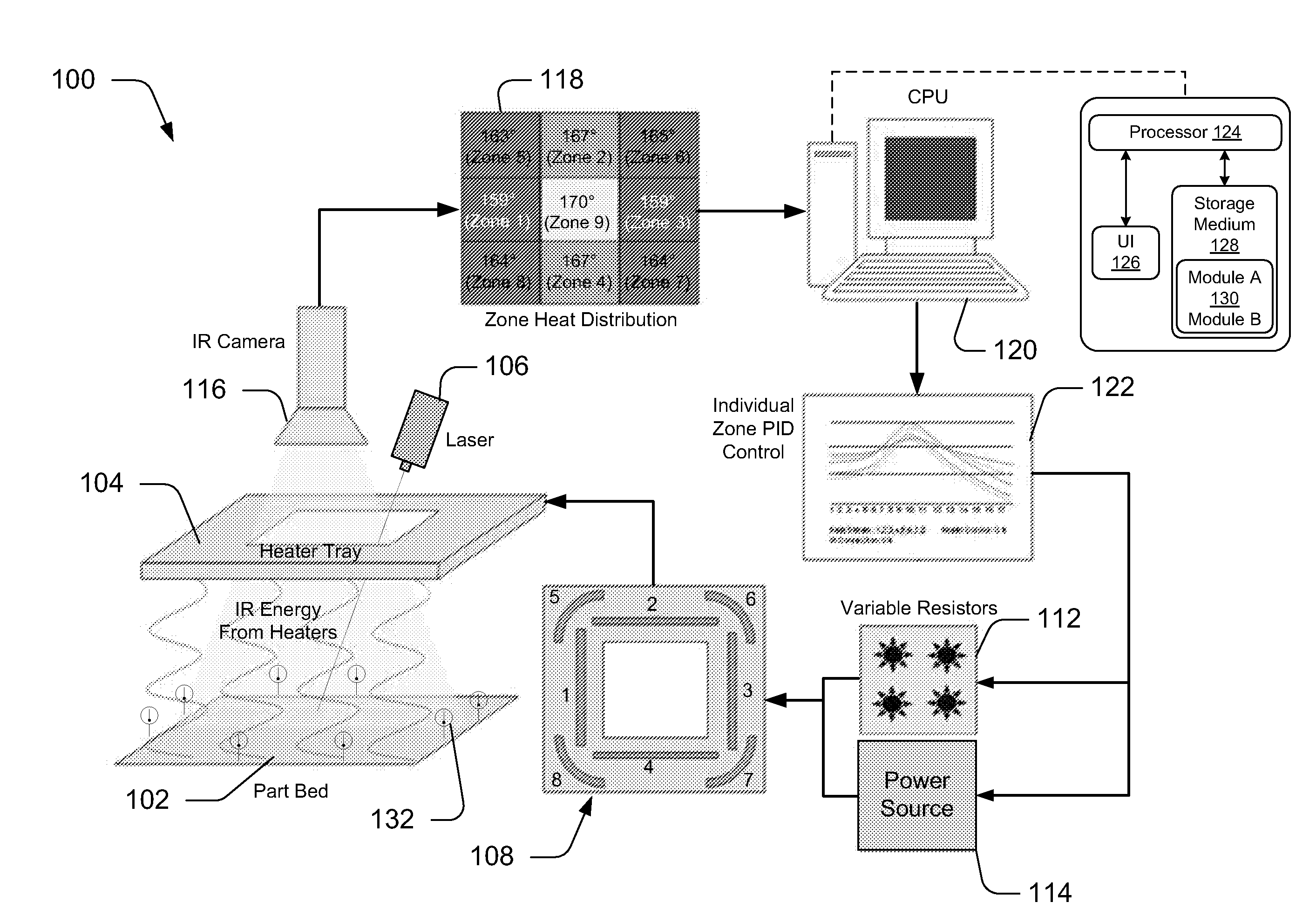

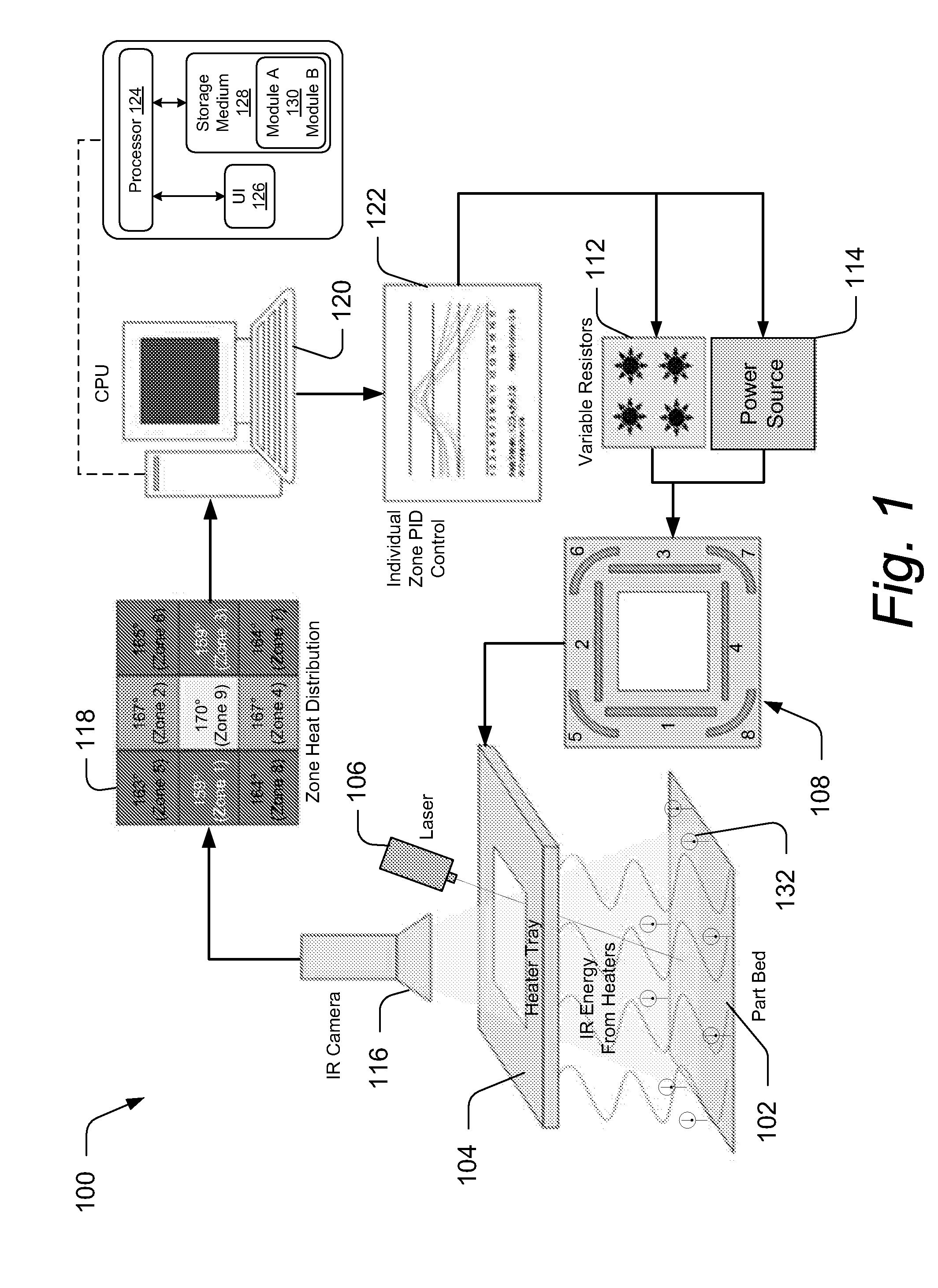

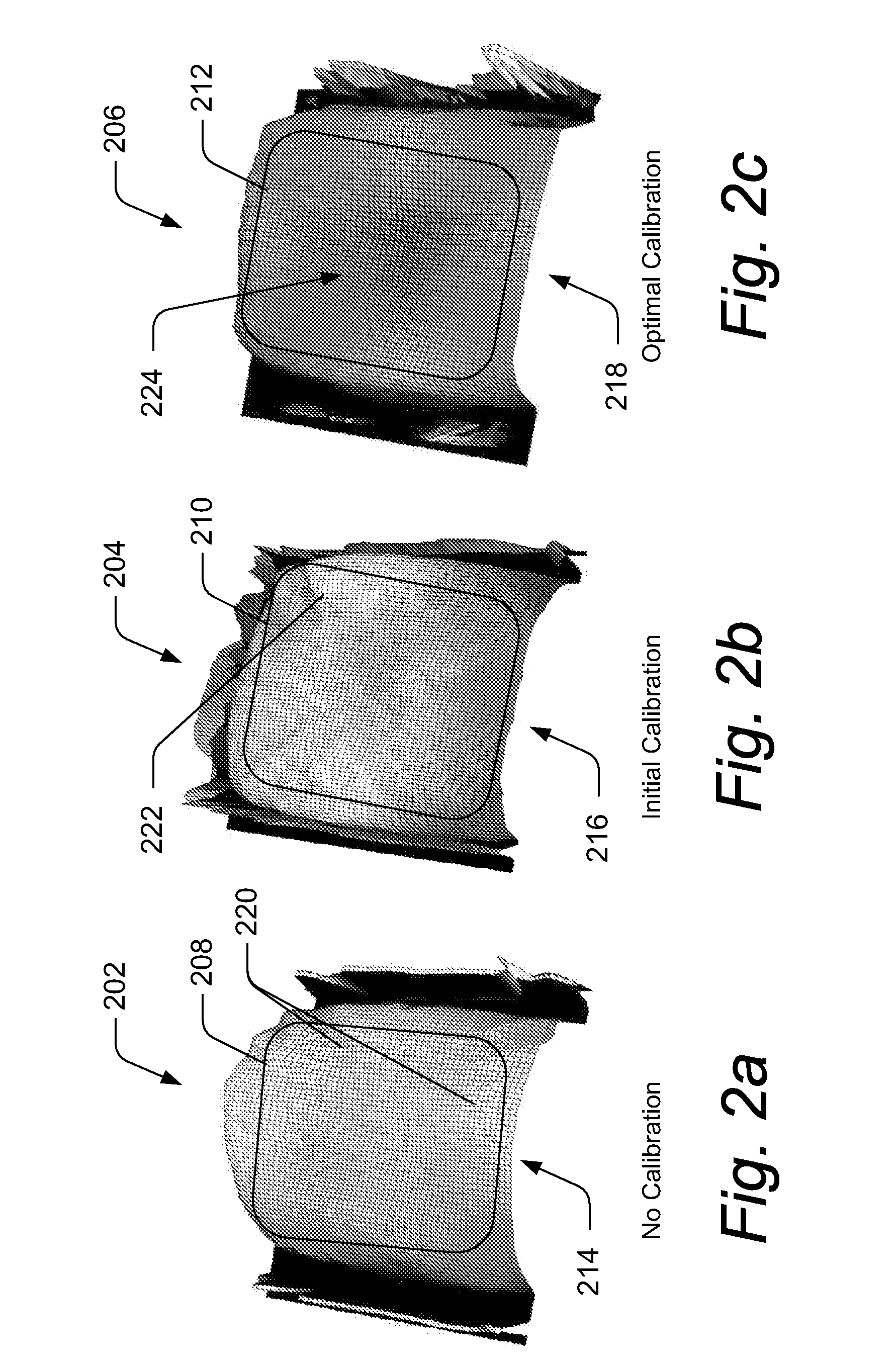

Methods and systems for controlling and adjusting heat distribution over a part bed

Methods and systems for controlling and adjusting heat distribution over a part bed are disclosed. In one embodiment, a technique for providing a calibrated heat distribution over a part bed includes determining the temperature distribution within a part bed, generating a zone heat distribution for a plurality of heat zones from the temperature distribution, analyzing the zone heat distribution to create an adjustment command to calibrate a heater for providing a substantially consistent temperature distribution within the part bed, and adjusting the heater based on the adjustment command.

Owner:THE BOEING CO

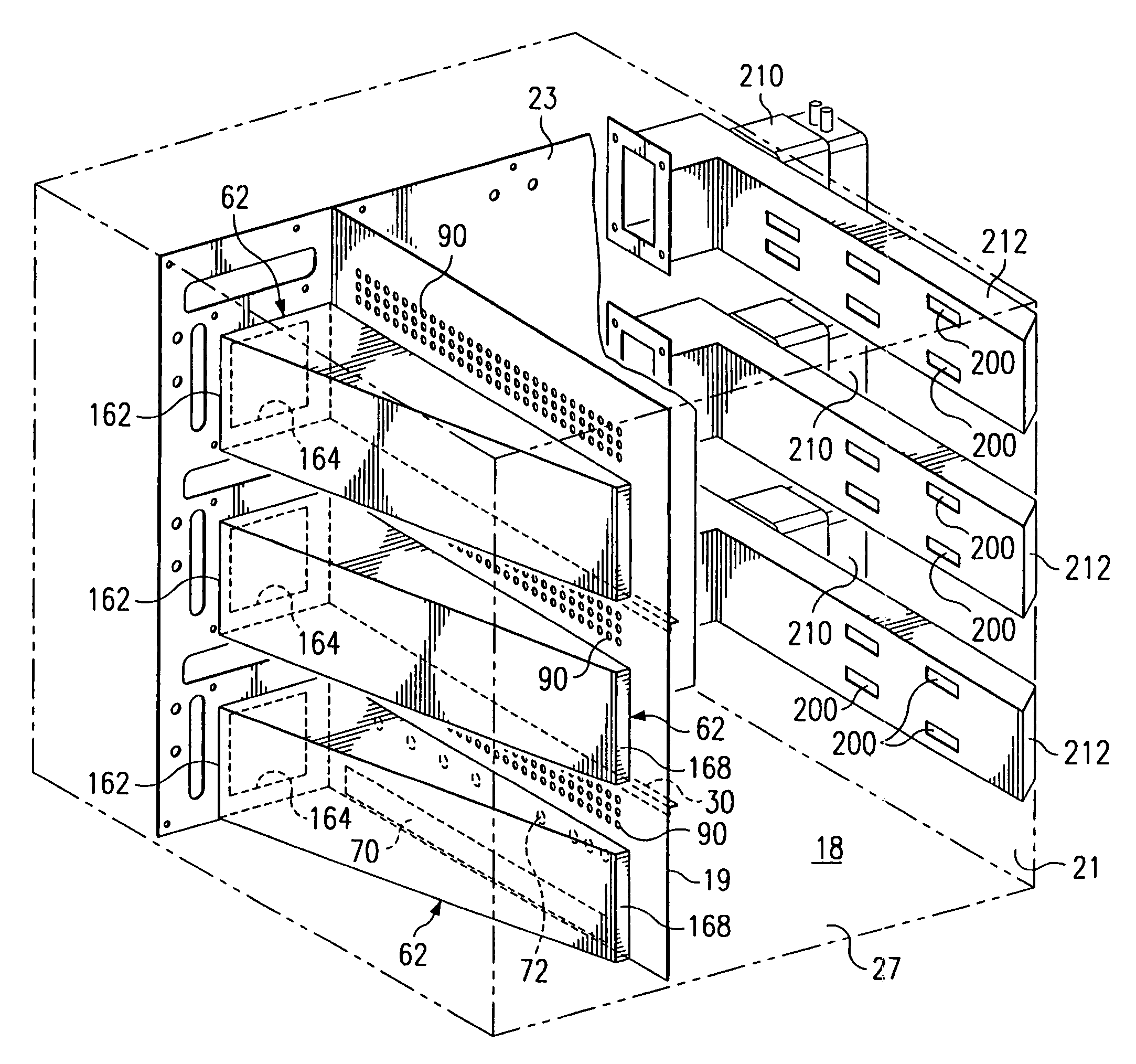

Multi-shelved convection microwave oven

An oven, is provided that includes multiple heat transfer means, including convection and microwave heat transfer means. The oven includes a cooking chamber, a blower and at least a shelf disposed within the cooking chamber. The shelf is designed to act as a food support as well as a conduit through which heated air passes into the cooking chamber. The microwave heating means comprises a microwave source and wave guide through which microwaves travel. The wave guide includes a plurality of openings through which microwaves can pass into said cooking chamber. In the preferred embodiment, the openings in the wave guide are positioned to correspond with the predetermined minima or maxima for the microwave wavelength propagating within the wave guide. An electric heating element may also be disposed within the cooking chamber to provide an alternative heating source.

Owner:ENERSYST DEV CENT

Methods and systems for controlling and adjusting heat distribution over a part bed

ActiveUS20080262659A1Additive manufacturing apparatusRadiation pyrometryEngineeringHeat distribution

Methods and systems for controlling and adjusting heat distribution over a part bed are disclosed. In one embodiment, a technique for providing a calibrated heat distribution over a part bed includes determining the temperature distribution within a part bed, generating a zone heat distribution for a plurality of heat zones from the temperature distribution, analyzing the zone heat distribution to create an adjustment command to calibrate a heater for providing a substantially consistent temperature distribution within the part bed, and adjusting the heater based on the adjustment command.

Owner:THE BOEING CO

Beverage container warmer

ActiveUS6870135B2Increase temperatureConveniently disposedMechanical apparatusDomestic stoves or rangesMobile vehicleElectrical battery

The invention provides an electrically heated jacket to maintain a hot beverage contained in a disposable hot-beverage container at optimum temperature for consumption. Electrical power for heating may be provided, in various embodiments, by household electric power, electric power from a motor vehicle electrical system, or batteries, which may be disposable or rechargeable. The invention also provides a method for keeping a hot beverage warm comprising providing freshly recharged batteries convenient to the point-of-sale of hot beverages.

Owner:HLC EFFICIENCY PRODS

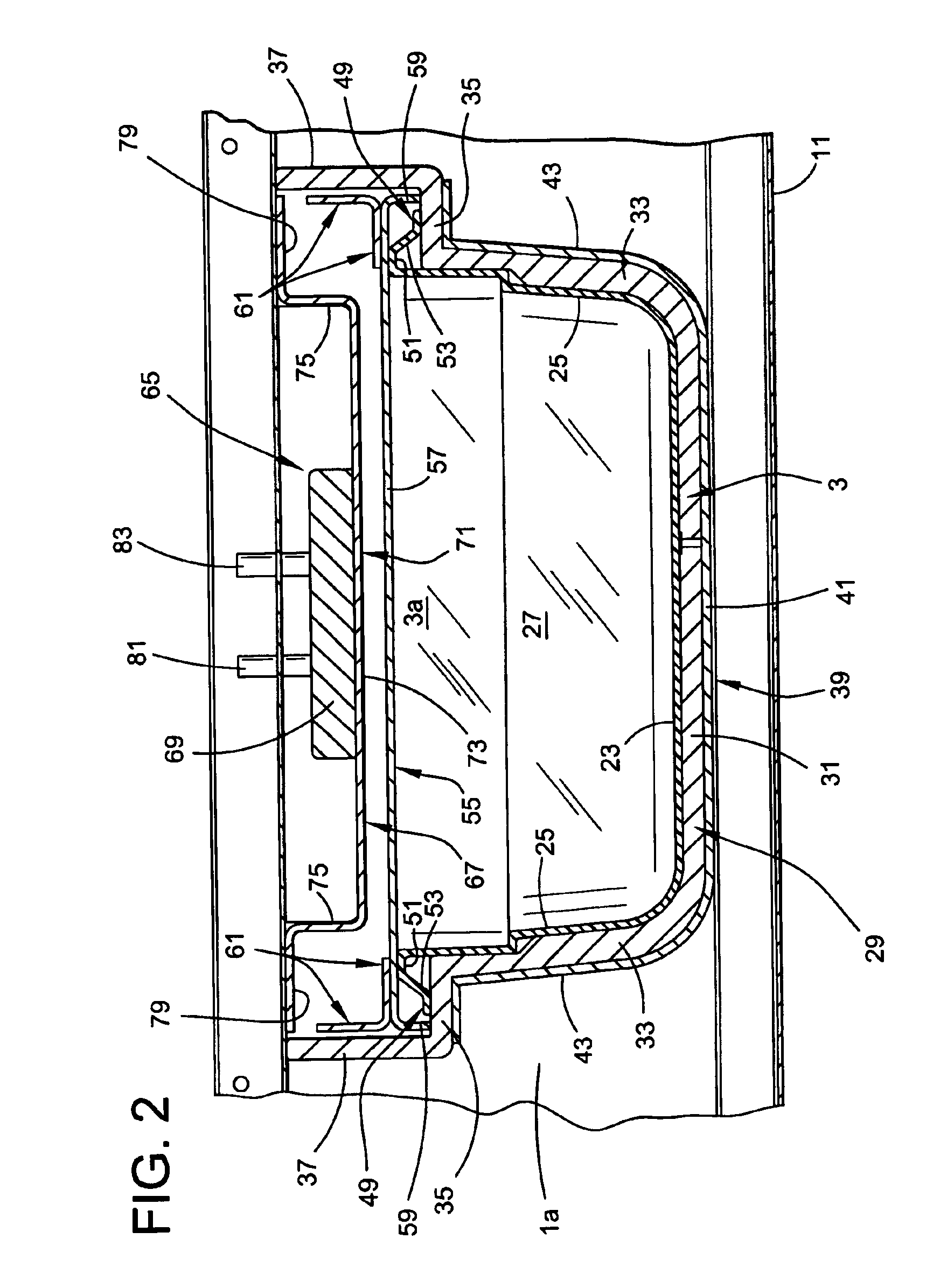

Temperature Control for Cooking Appliance Including Combination Heating System

A combination cooking appliance controls a radiant heating element provided in an oven cavity and a convection heating element provided in an air plenum with a regulating system which receives signals from multiple temperature sensors. More specifically, the appliance includes a first temperature sensor provided in an air return plenum portion for controlling the radiant heating element and a second temperature sensor arranged in a discharge air plenum portion, preferably downstream of a catalyst, for controlling the convection heating element. The heating elements are independently controlled based on the sensed temperatures to establish a desired oven cavity temperature, while accommodating for temperature fluctuations due to the incoming fresh air stream.

Owner:ACP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com