Patents

Literature

239results about "Ball and roller bearings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

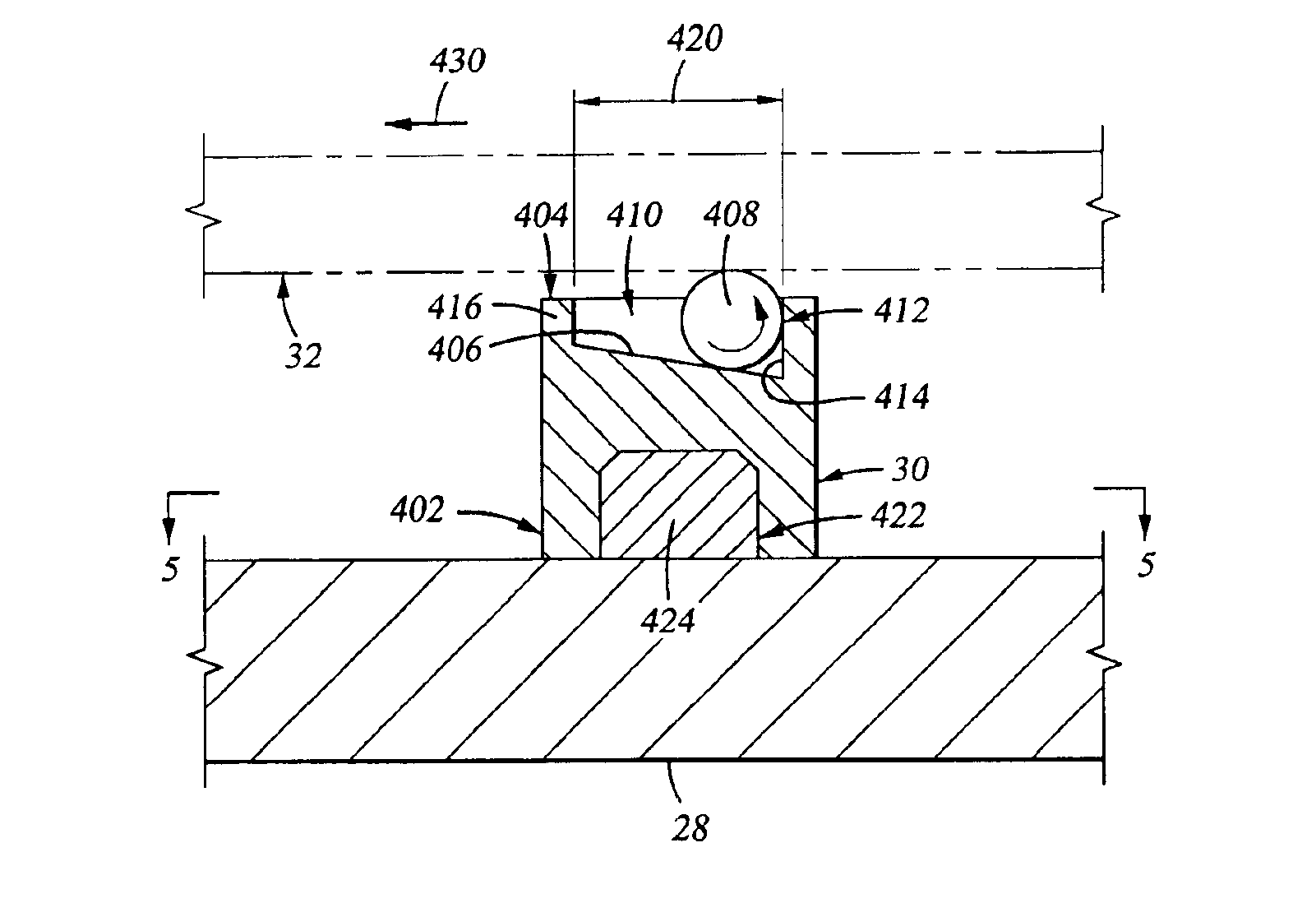

Substrate support

InactiveUS6917755B2Minimize damageProvide spaceDrying solid materials with heatMuffle furnacesSupport surfaceEngineering

An apparatus for supporting a substrate is described that has a ball adapted to minimize damage between the substrate support and the substrate supported thereon. In one embodiment, an apparatus for supporting a substrate includes ball disposed on an inclined ball support surface. The ball support surface is adapted to bias the ball toward one side of the ball support surface thereby providing space for the ball to roll as the substrate supported thereon changes in length when exposed to thermal influences. In another embodiment, the apparatus further comprises a cage adapted to capture the ball to the ball support surface.

Owner:APPLIED MATERIALS INC

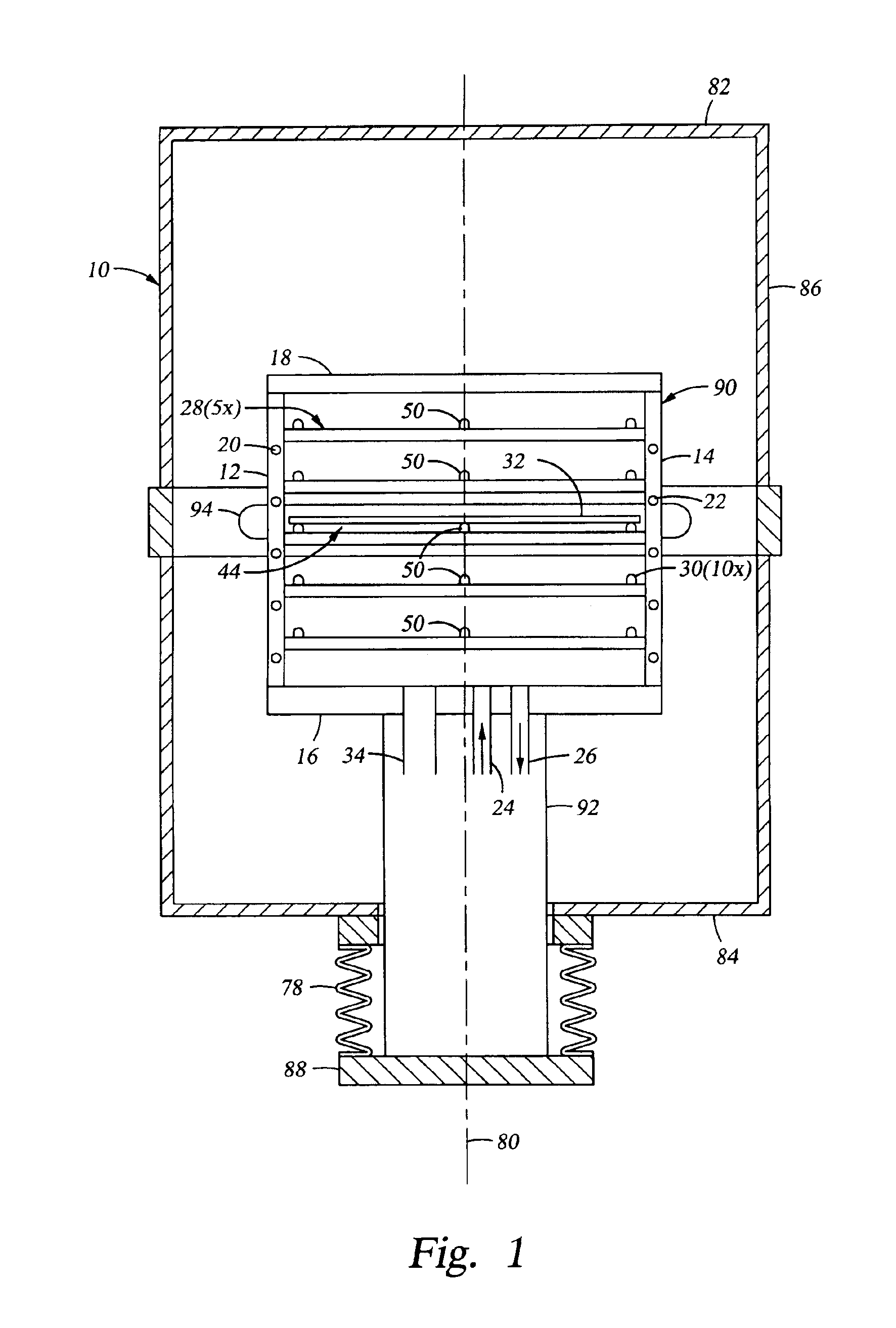

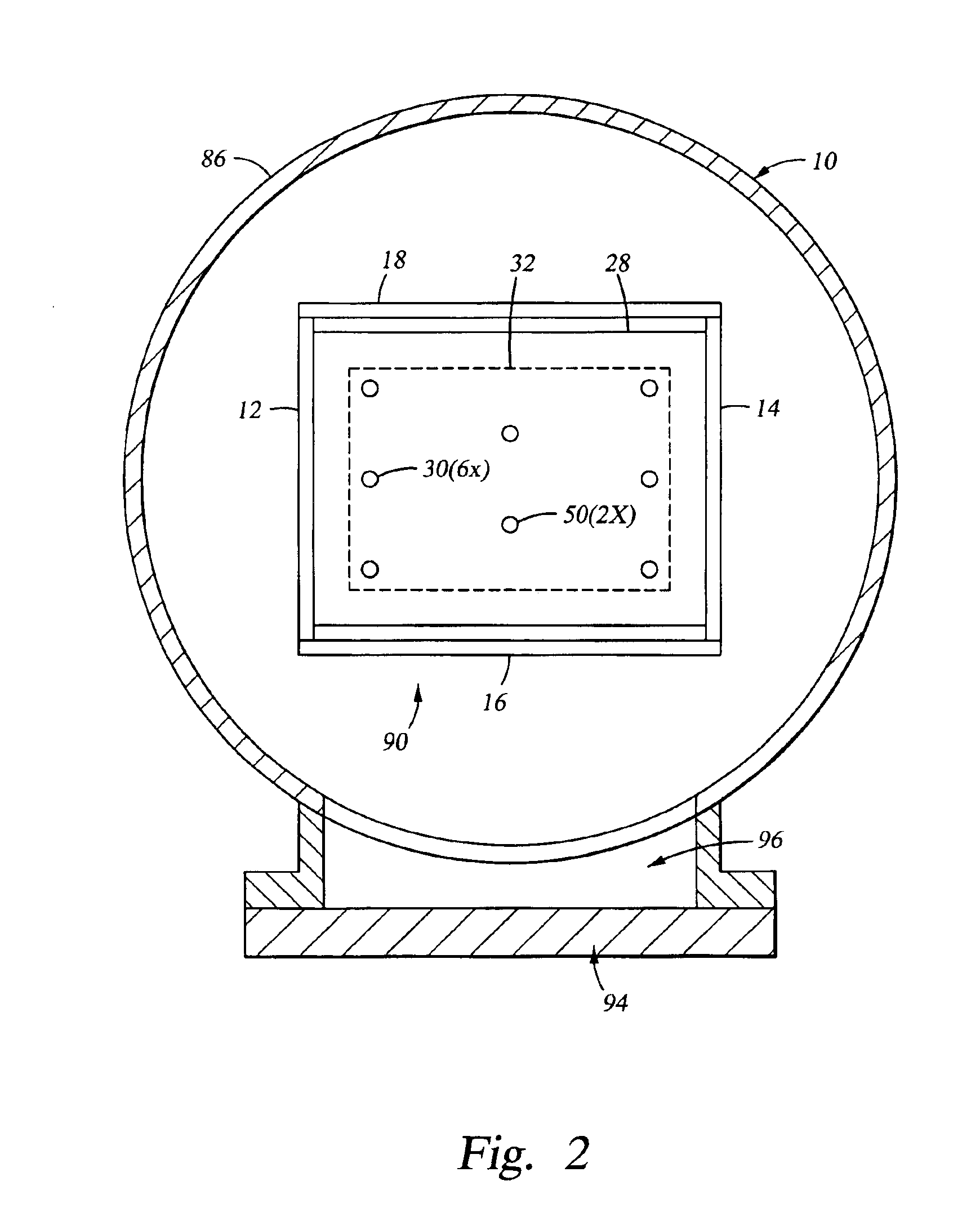

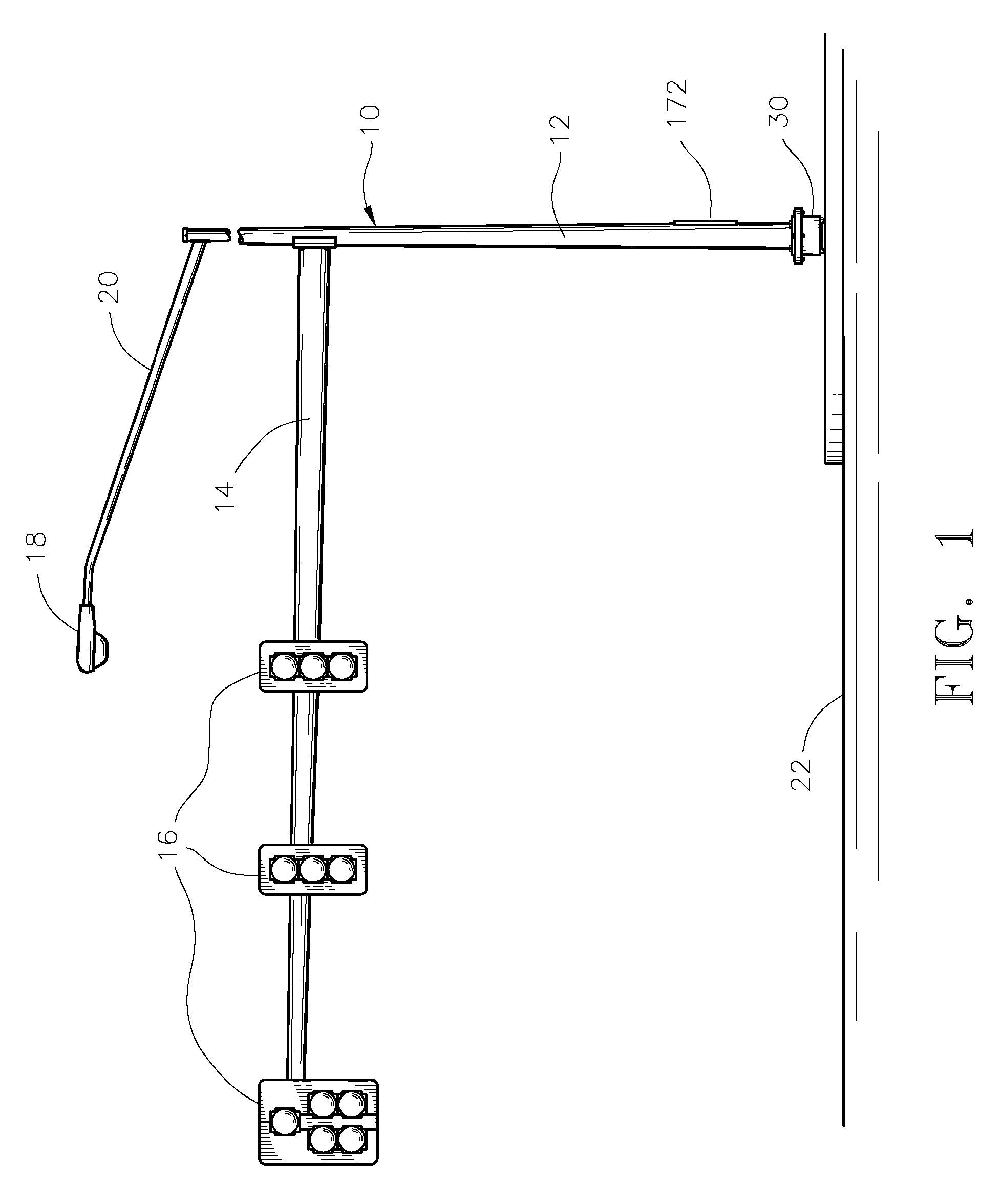

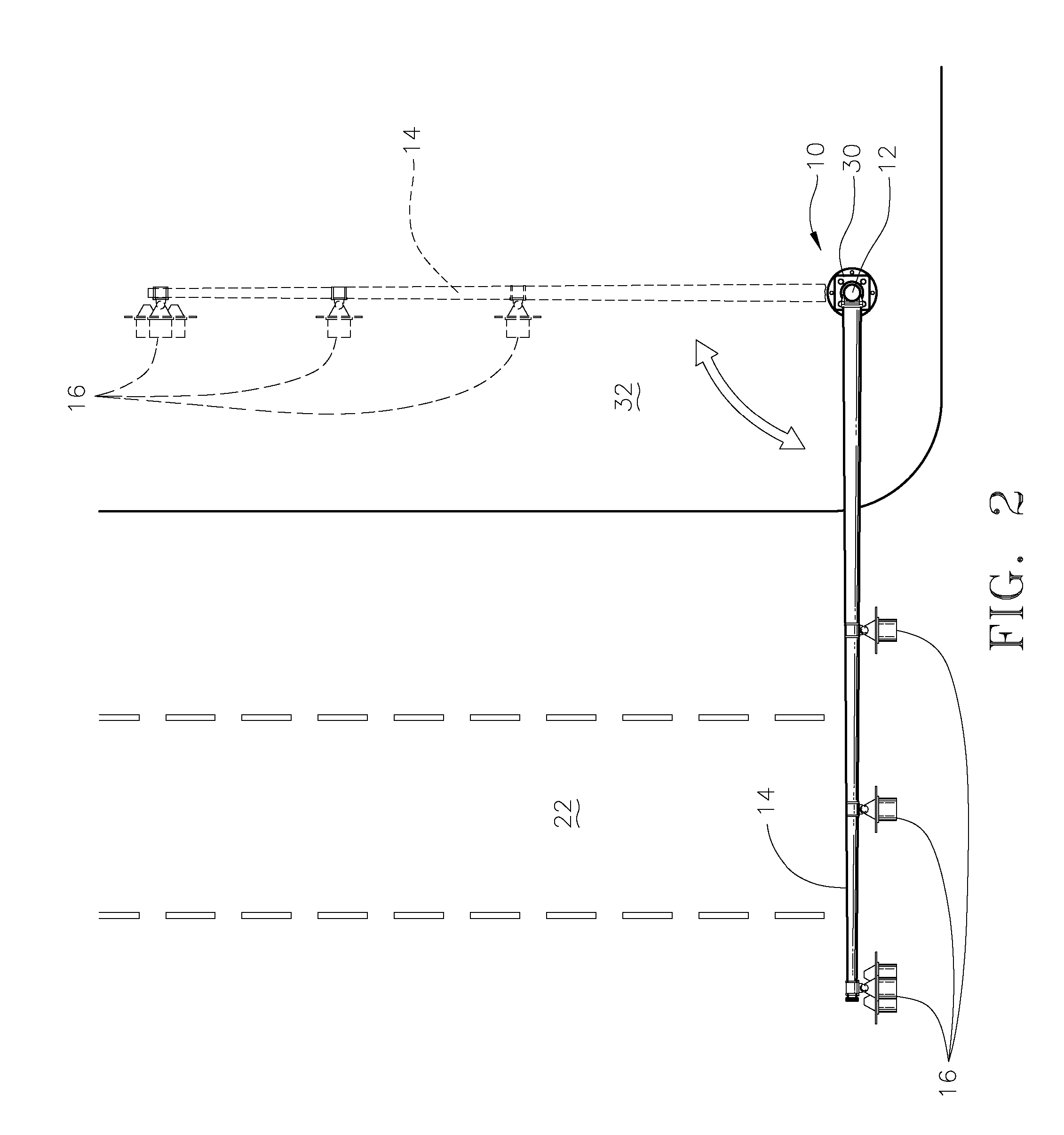

Pivot base assembly for traffic pole

A pivot assembly that can be retrofitted to existing traffic poles. The pivot assembly comprises a bearing assembly disposed between a top plate and a bottom plate. The bottom plate connects to the existing pole foundation with the standard anchor bolt arrangement. Similarly, the top plate connects to the base plate of the traffic pole using additional bolts. Bearings in the pivot assembly allow the pole to rotate relative to the foundation. Preferably, roller bearings are utilized, as these can be contained substantially within the pivot assembly without extending down into the foundation or up into the pole. This means the pivot assembly can be installed in existing, standard traffic poles and foundations without modifying either. The pivot assembly does not interfere with existing wiring or access openings.

Owner:PELCO PRODS

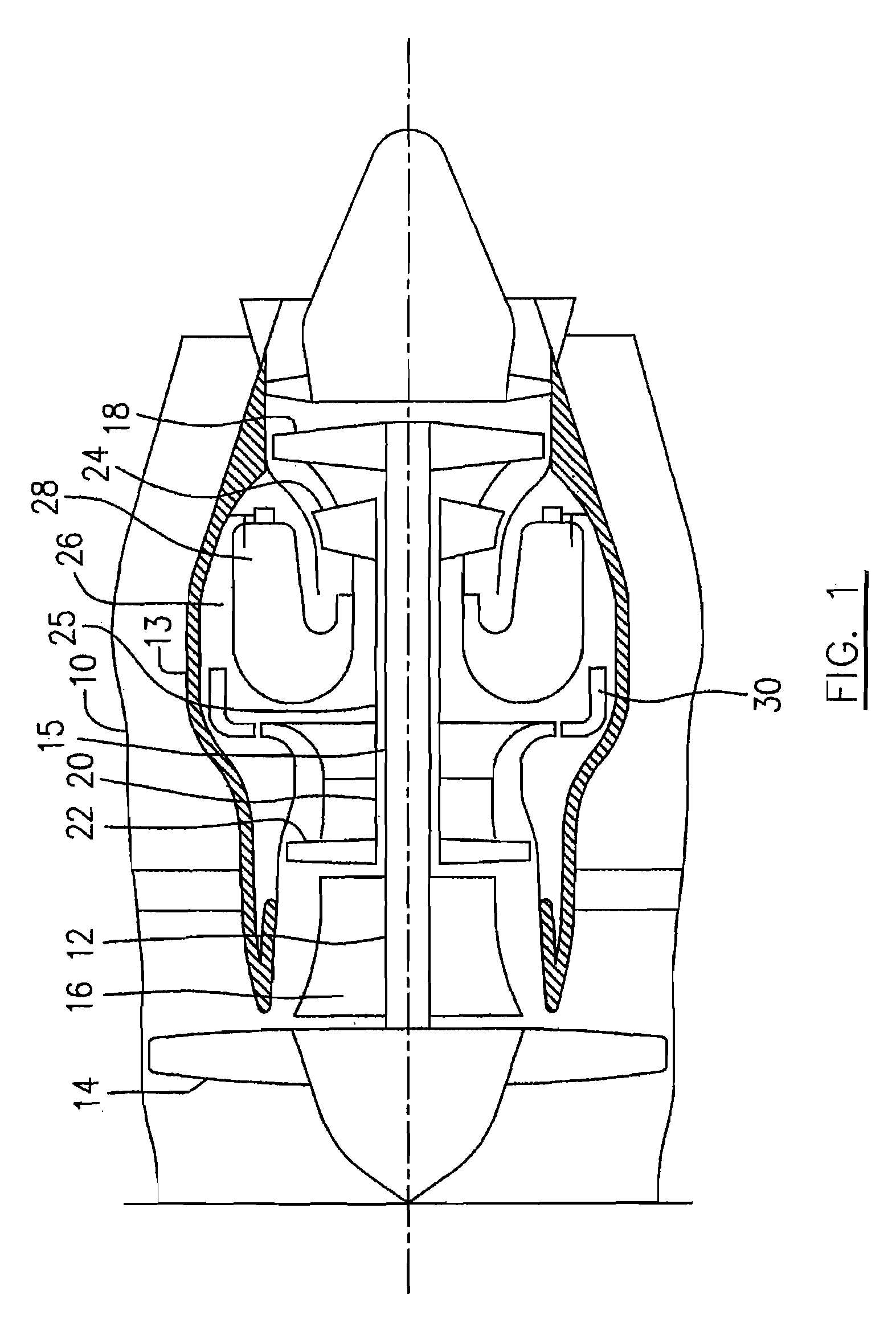

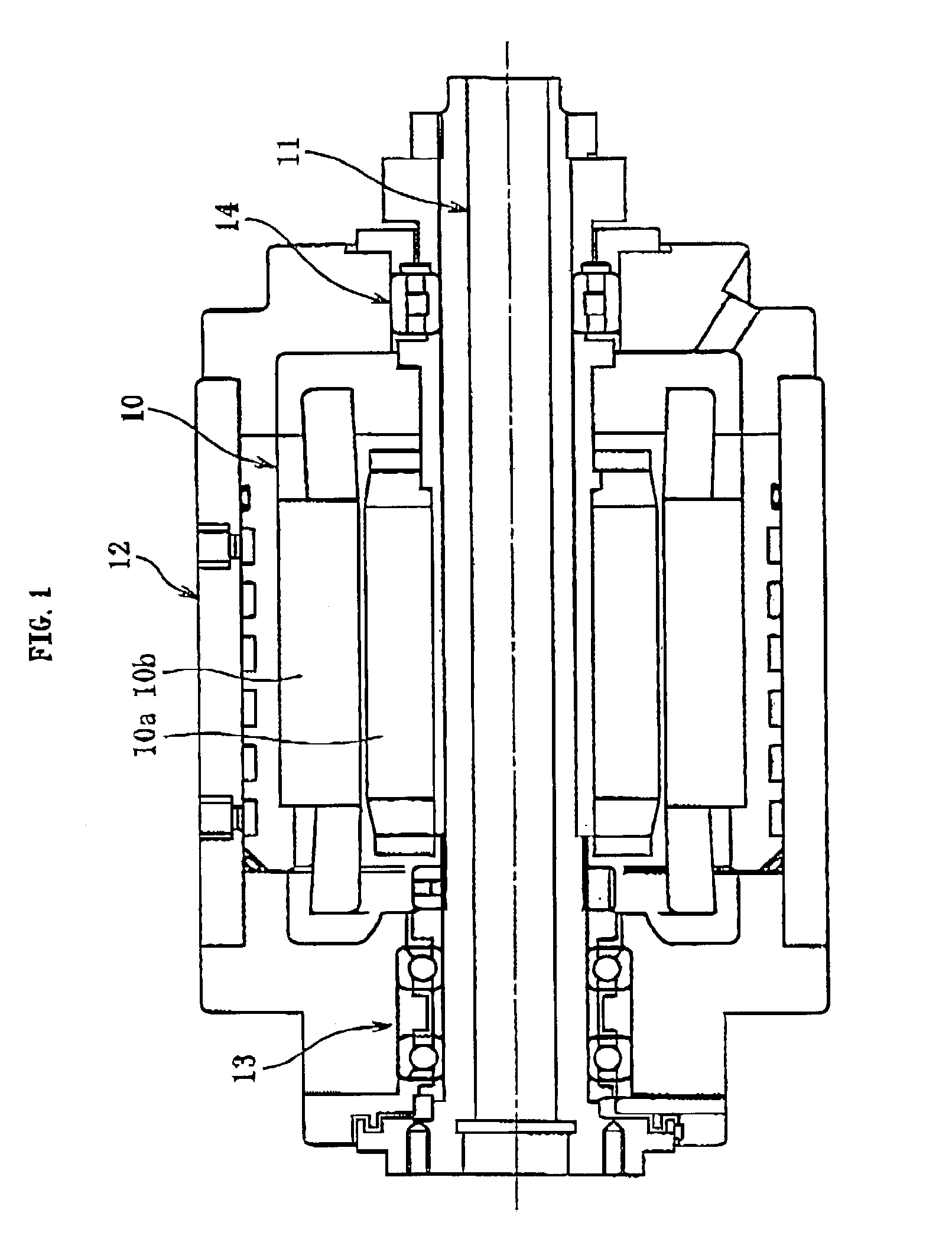

Bearing support apparatus for a gas turbine engine

A bearing support cage includes: an annular forward ring; an annular aft ring; an annular mounting flange disposed between the forward and aft rings; an annular array of axially-extending first spring fingers interconnecting the forward ring and the aft ring; and an annular array of axially-extending second spring fingers interconnecting the mounting flange and the aft ring, wherein the first spring fingers are interdigitated with the second spring fingers. The forward and aft rings, the mounting flange, and the spring fingers are all part of a single monolithic component.

Owner:GENERAL ELECTRIC CO

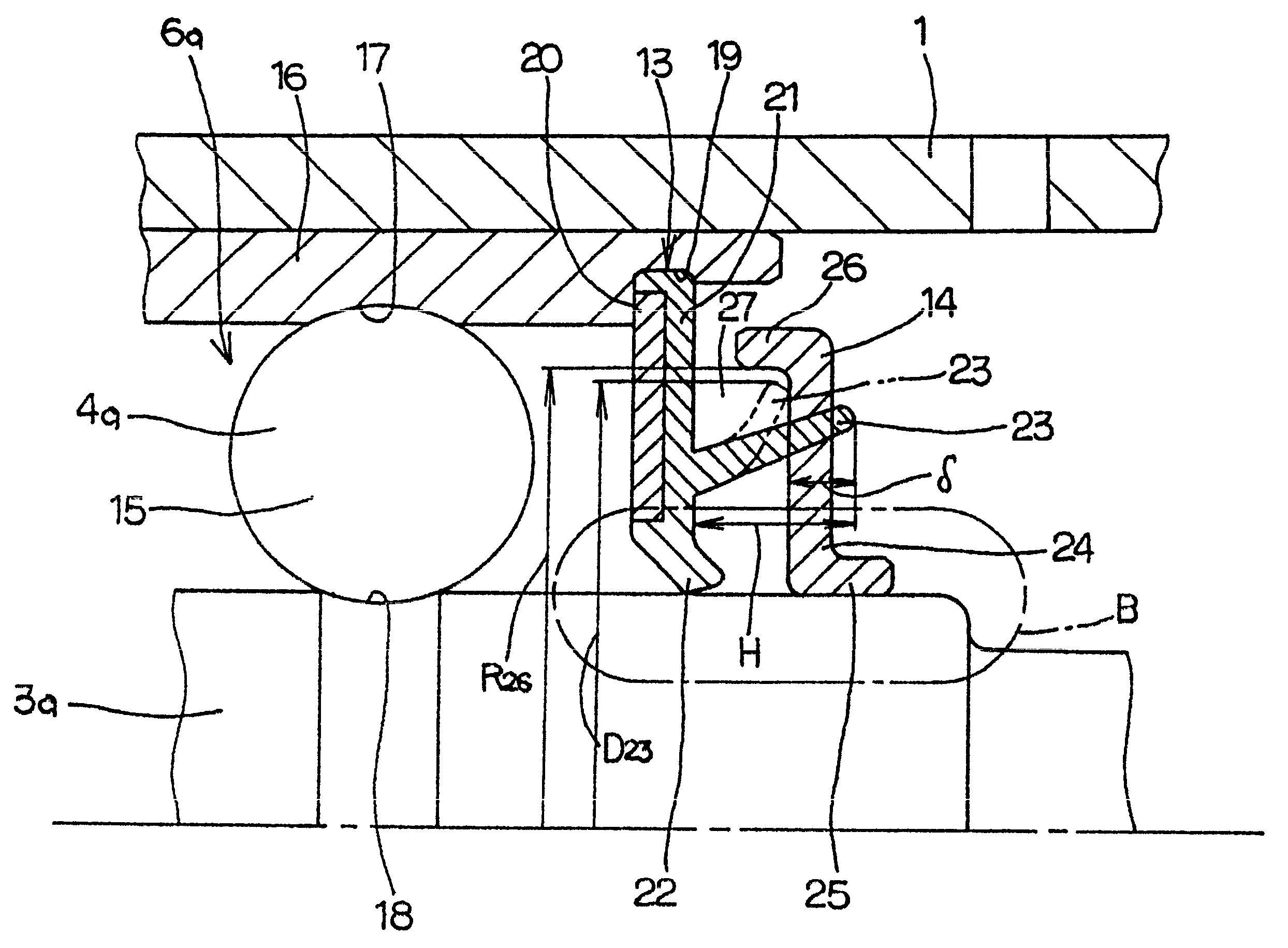

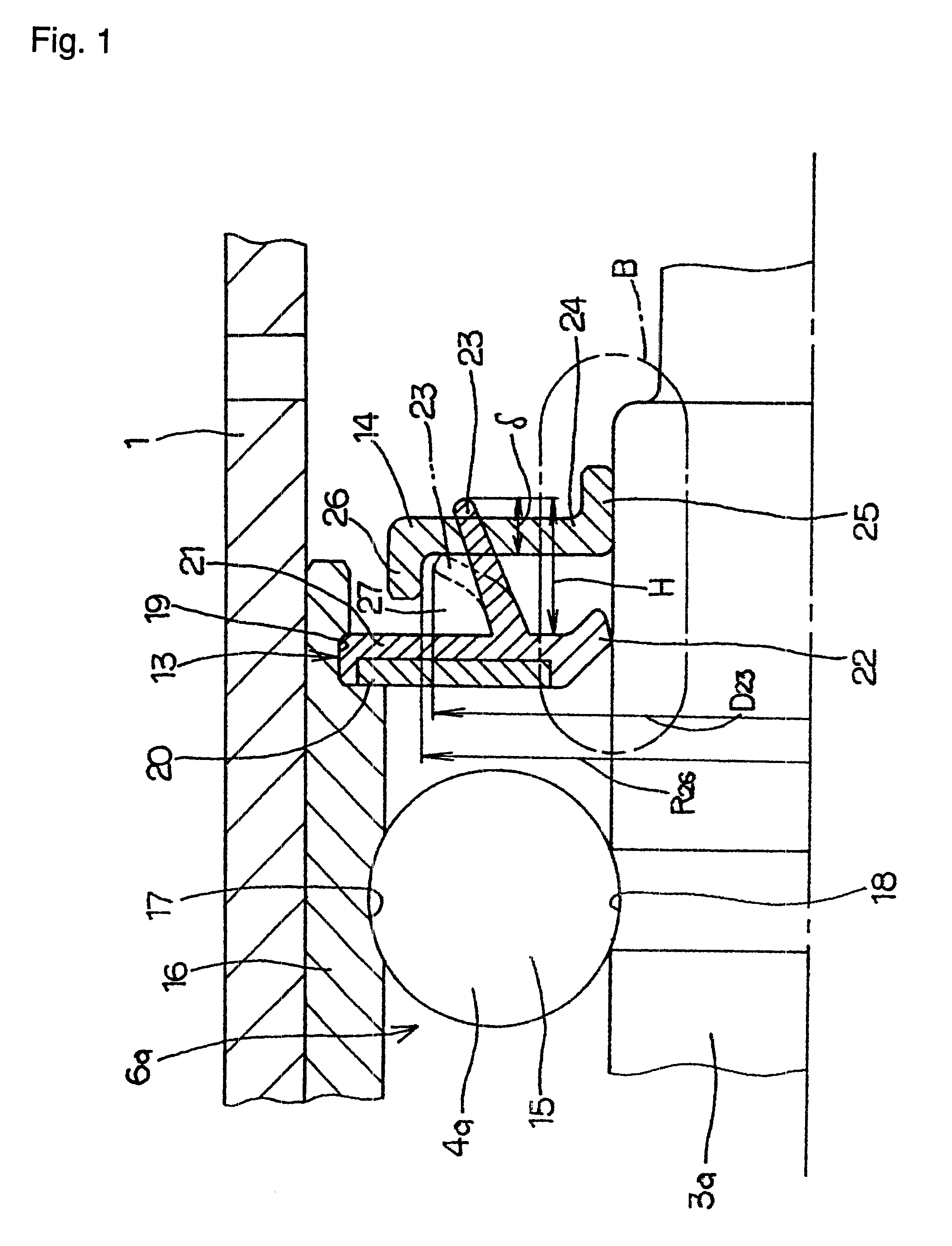

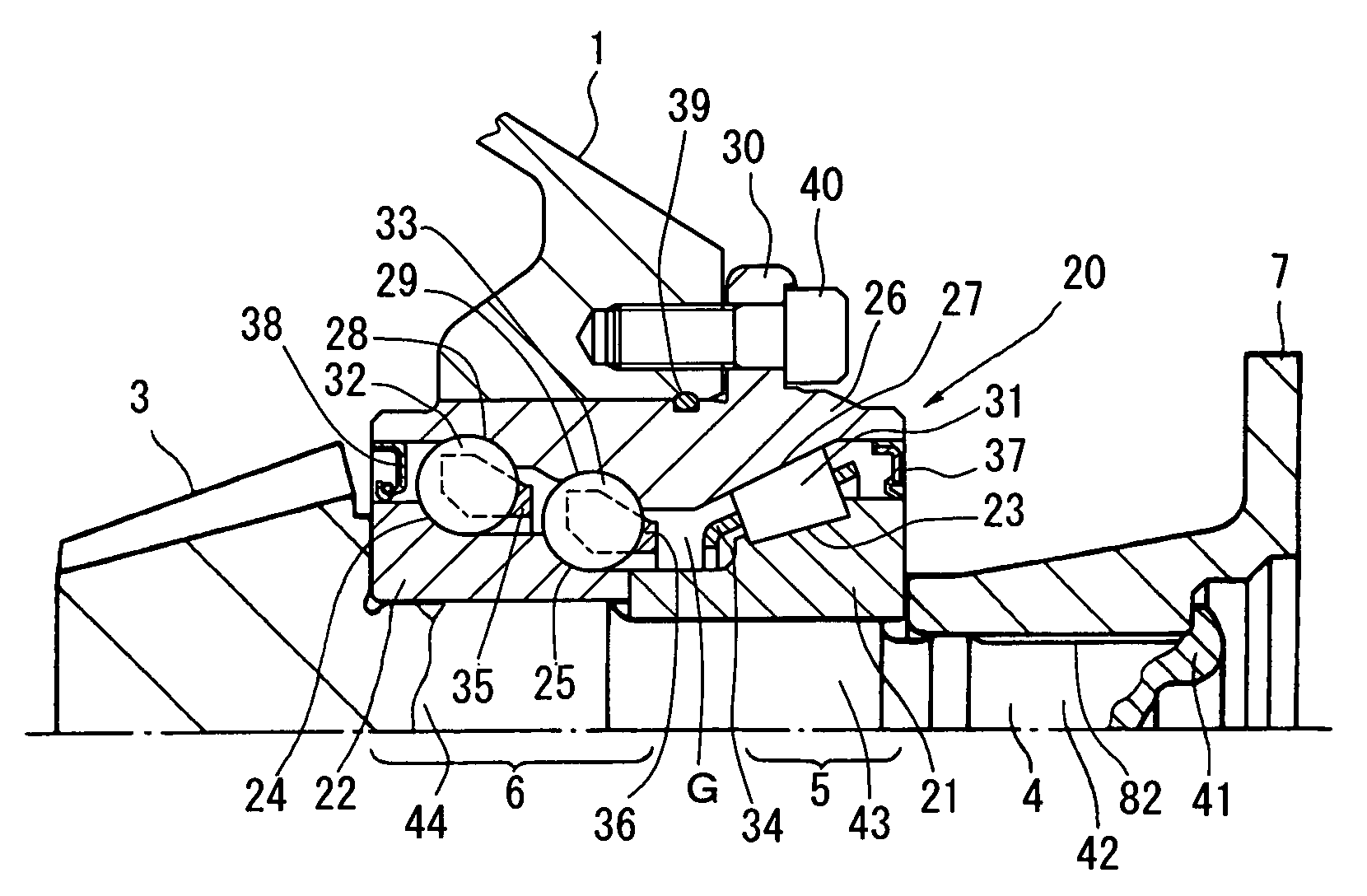

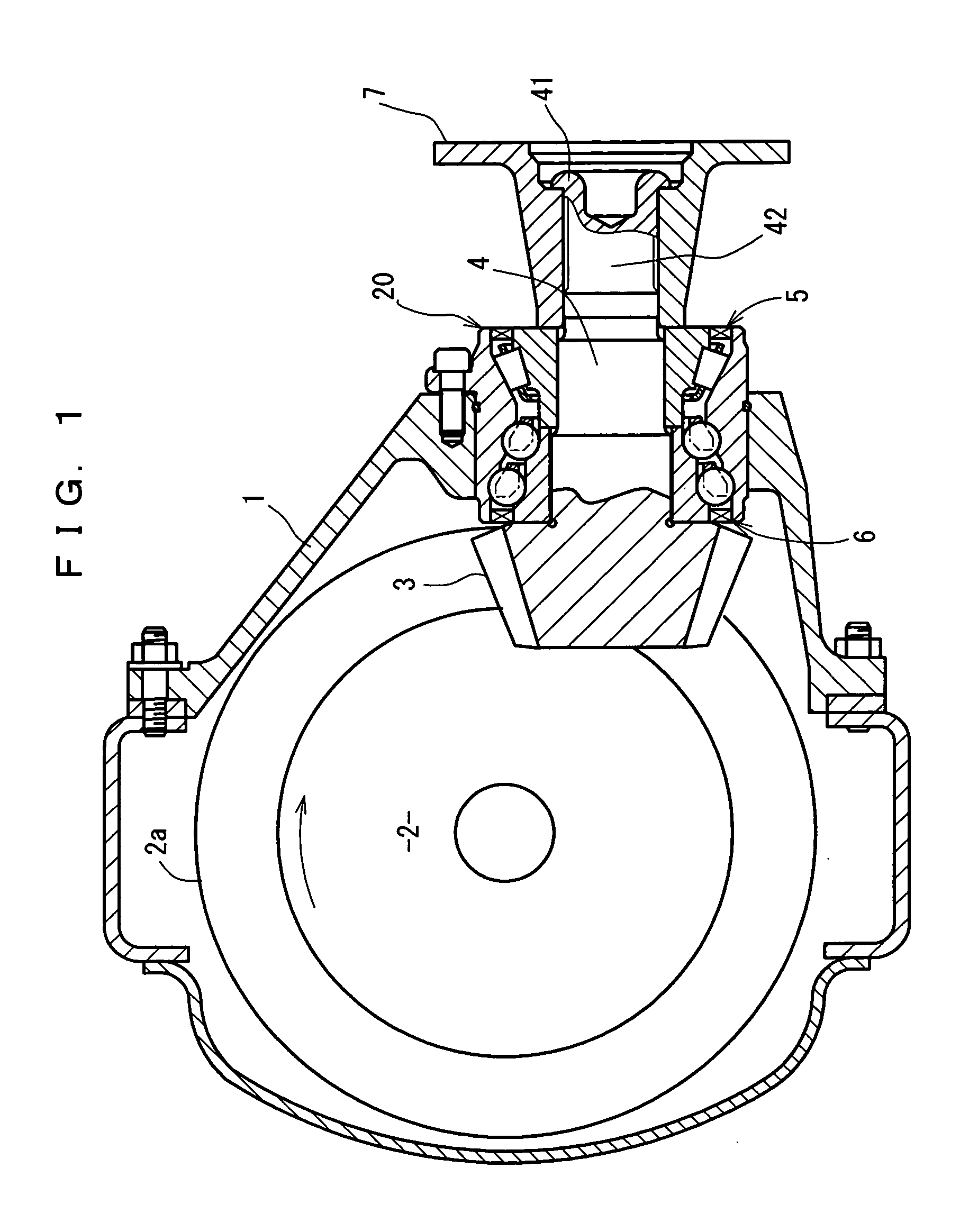

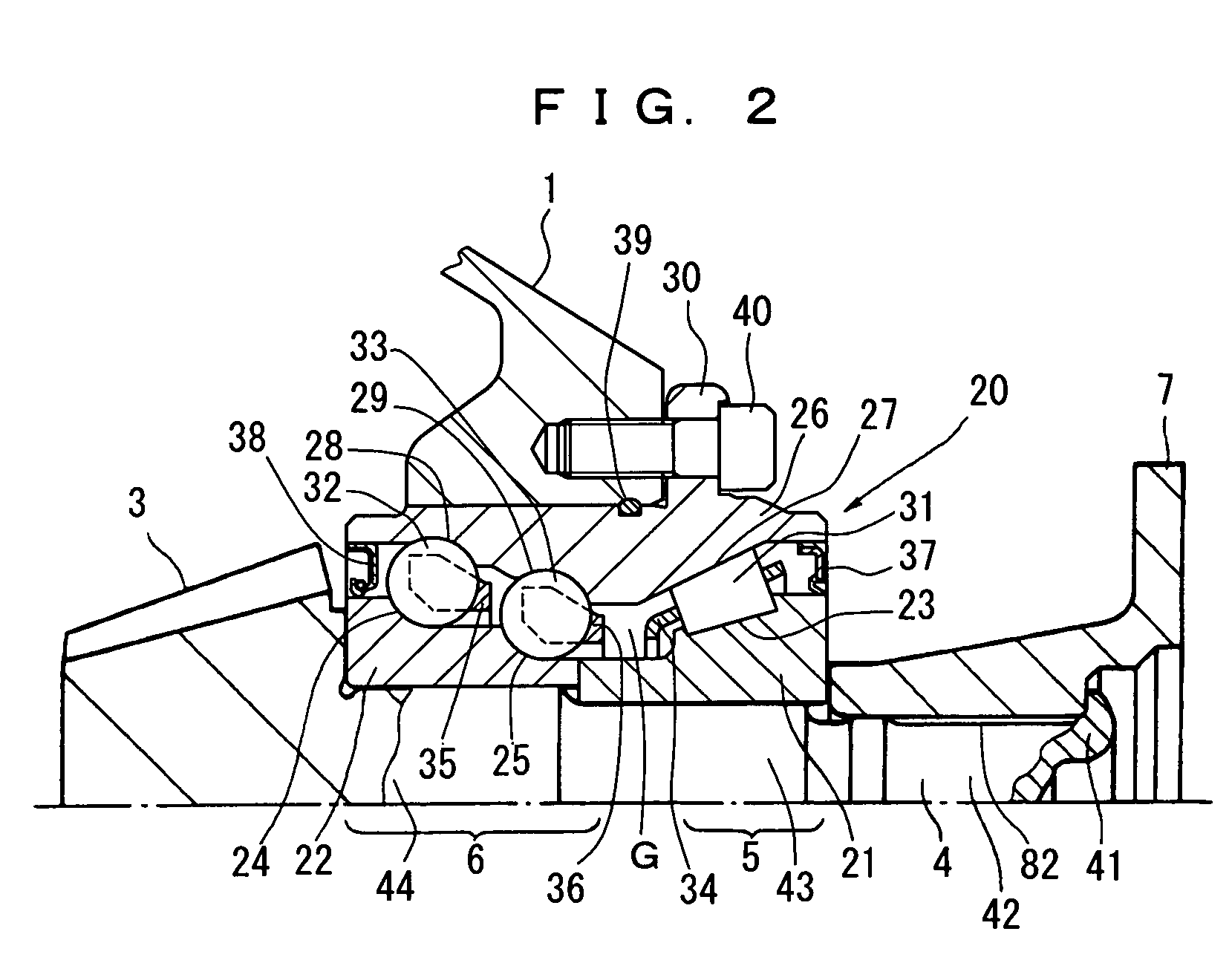

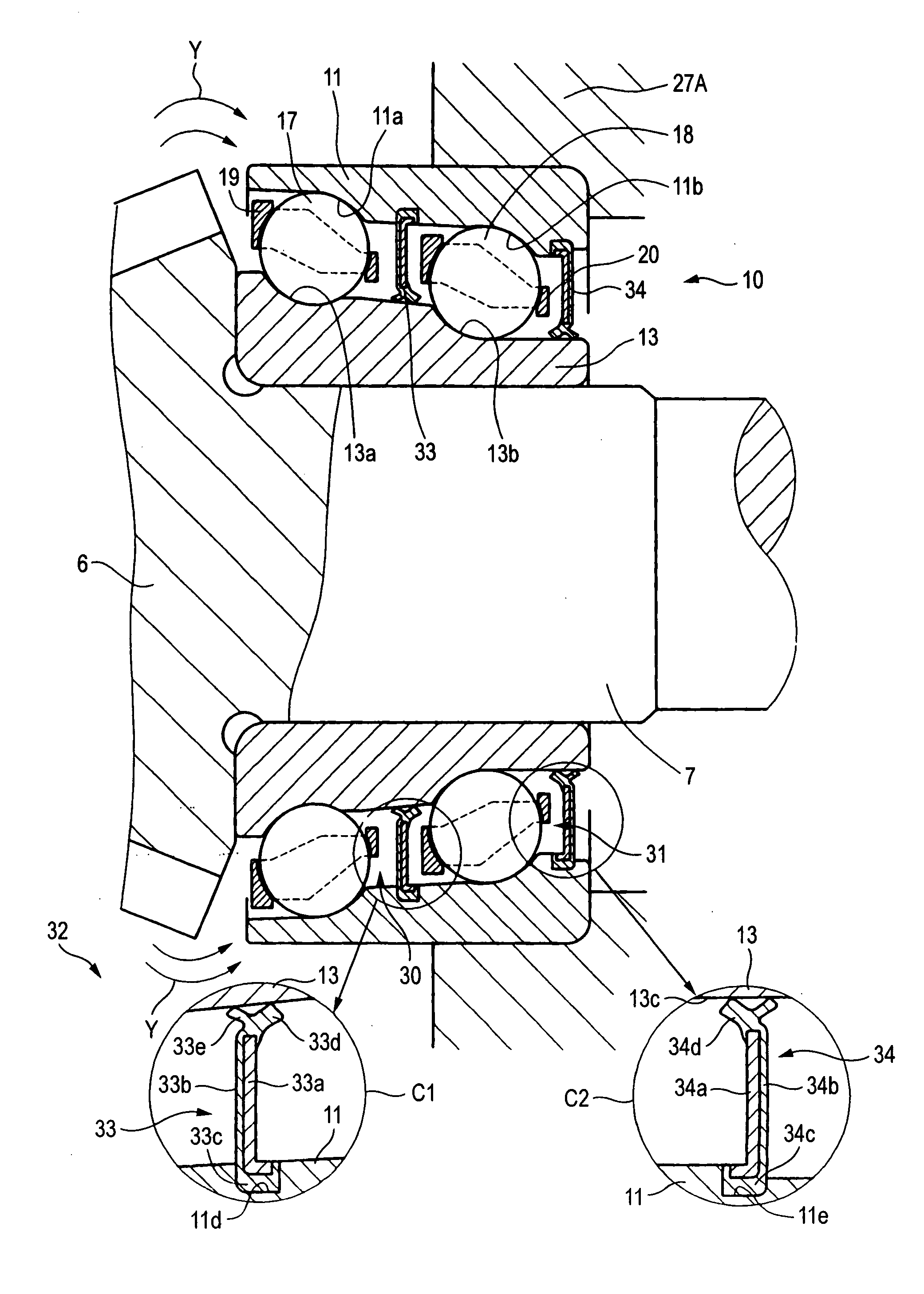

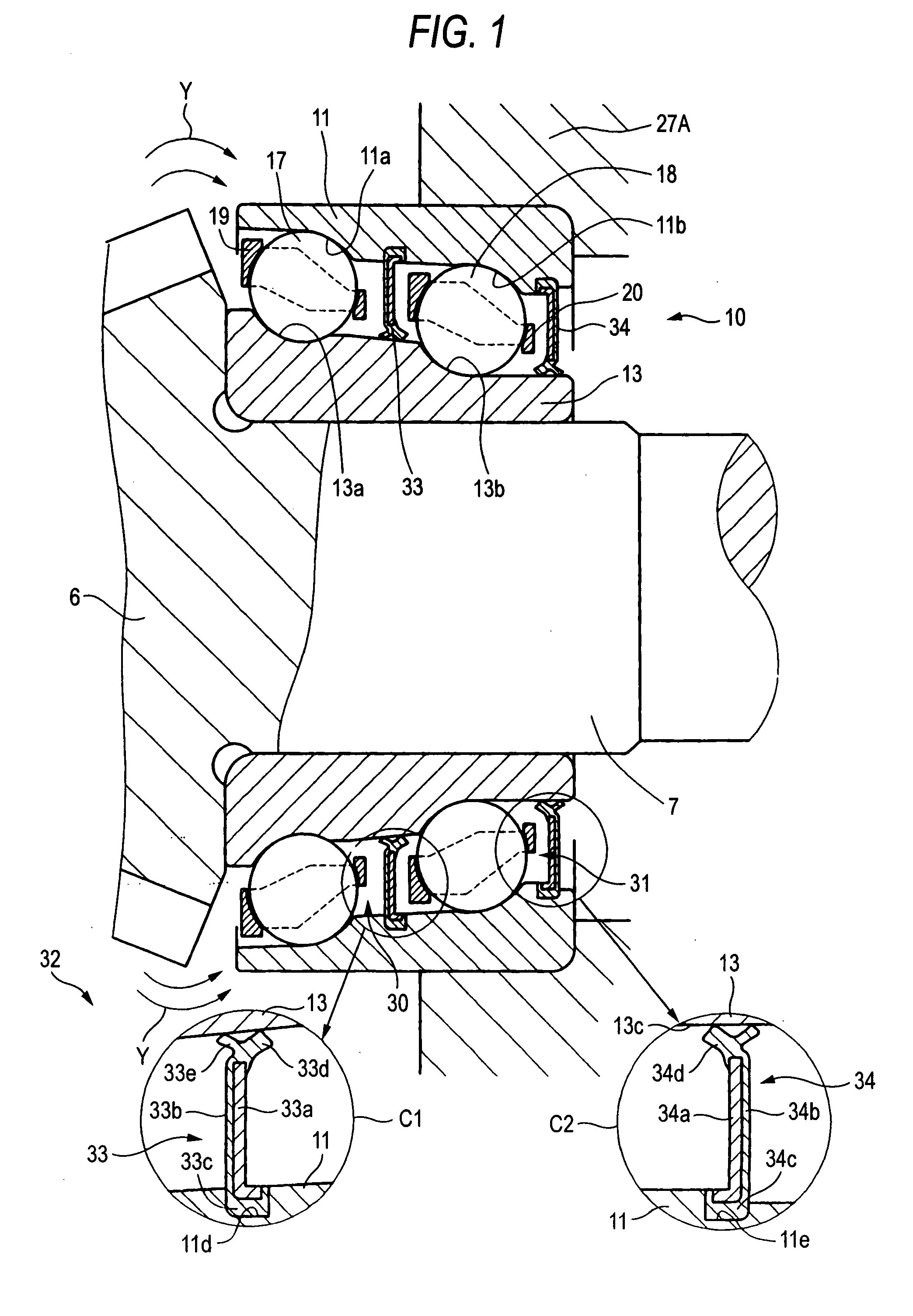

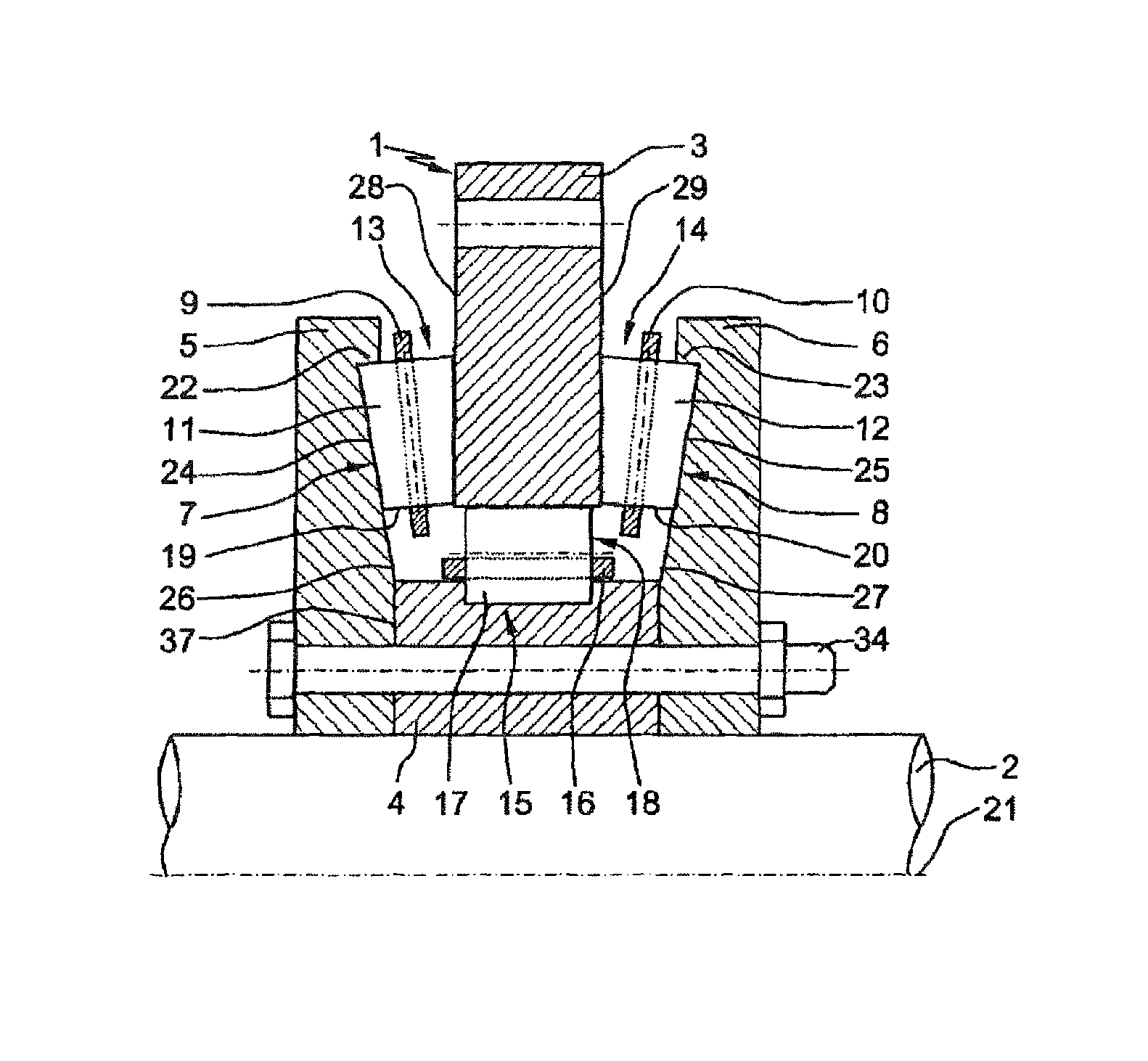

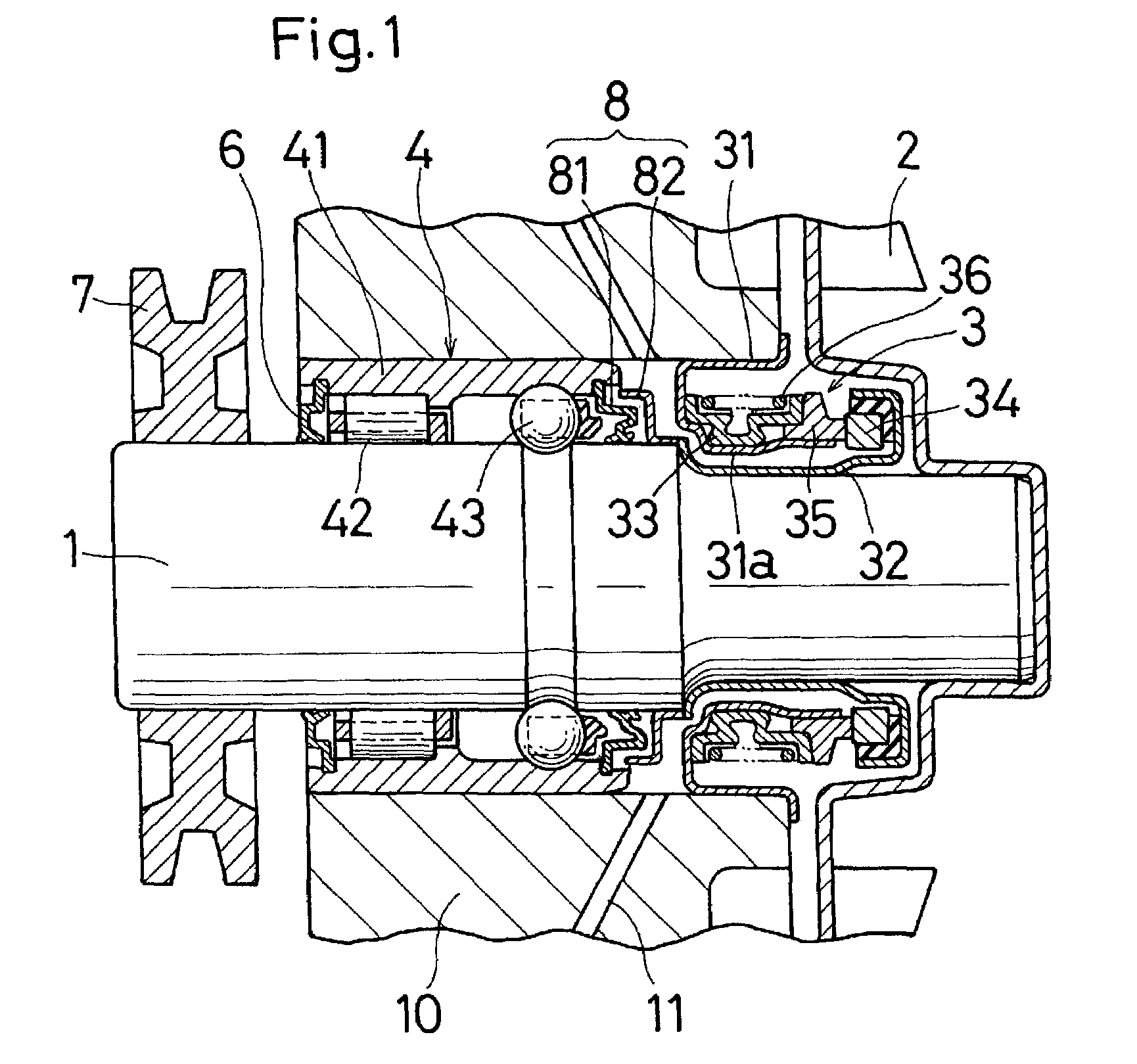

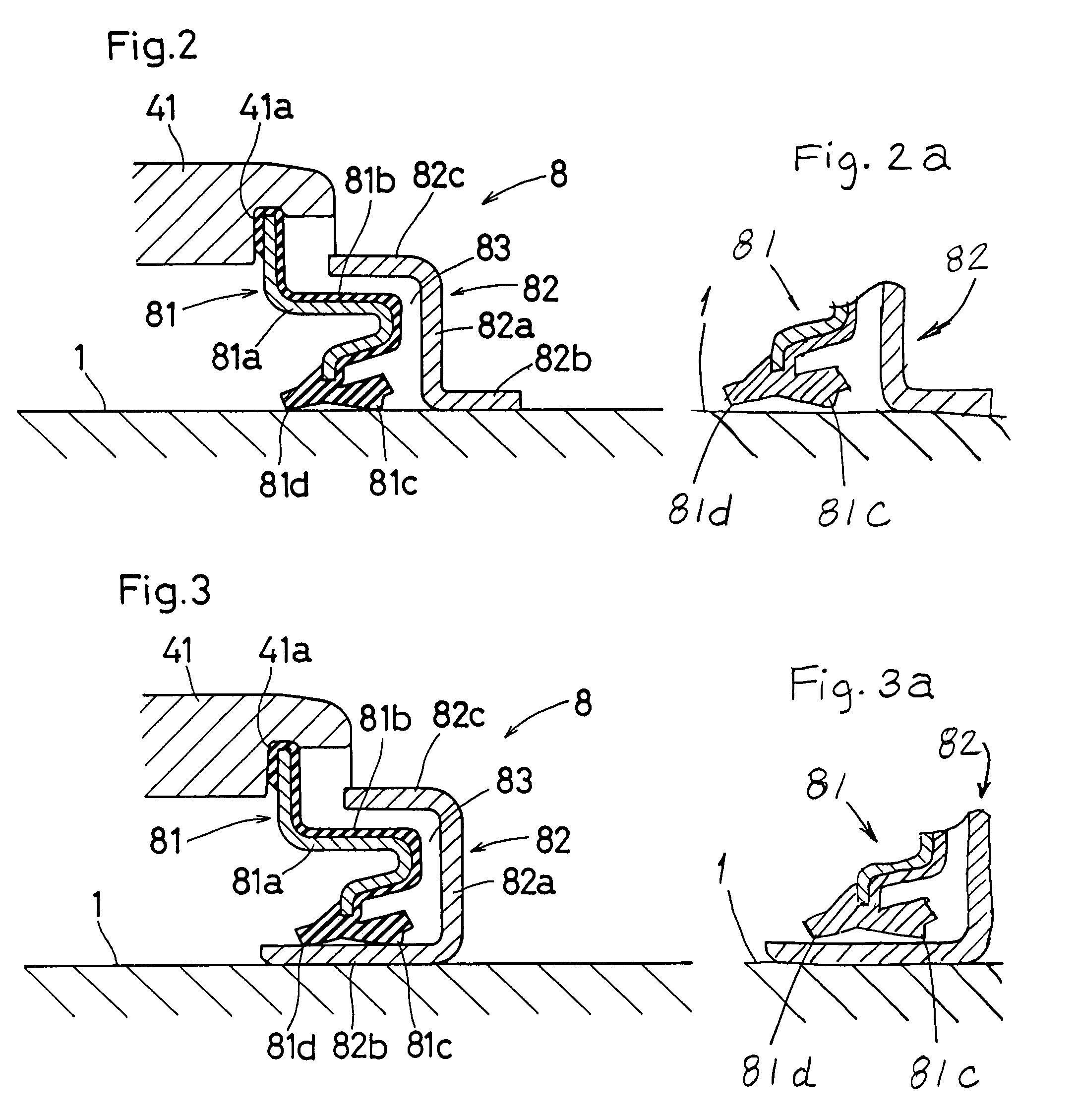

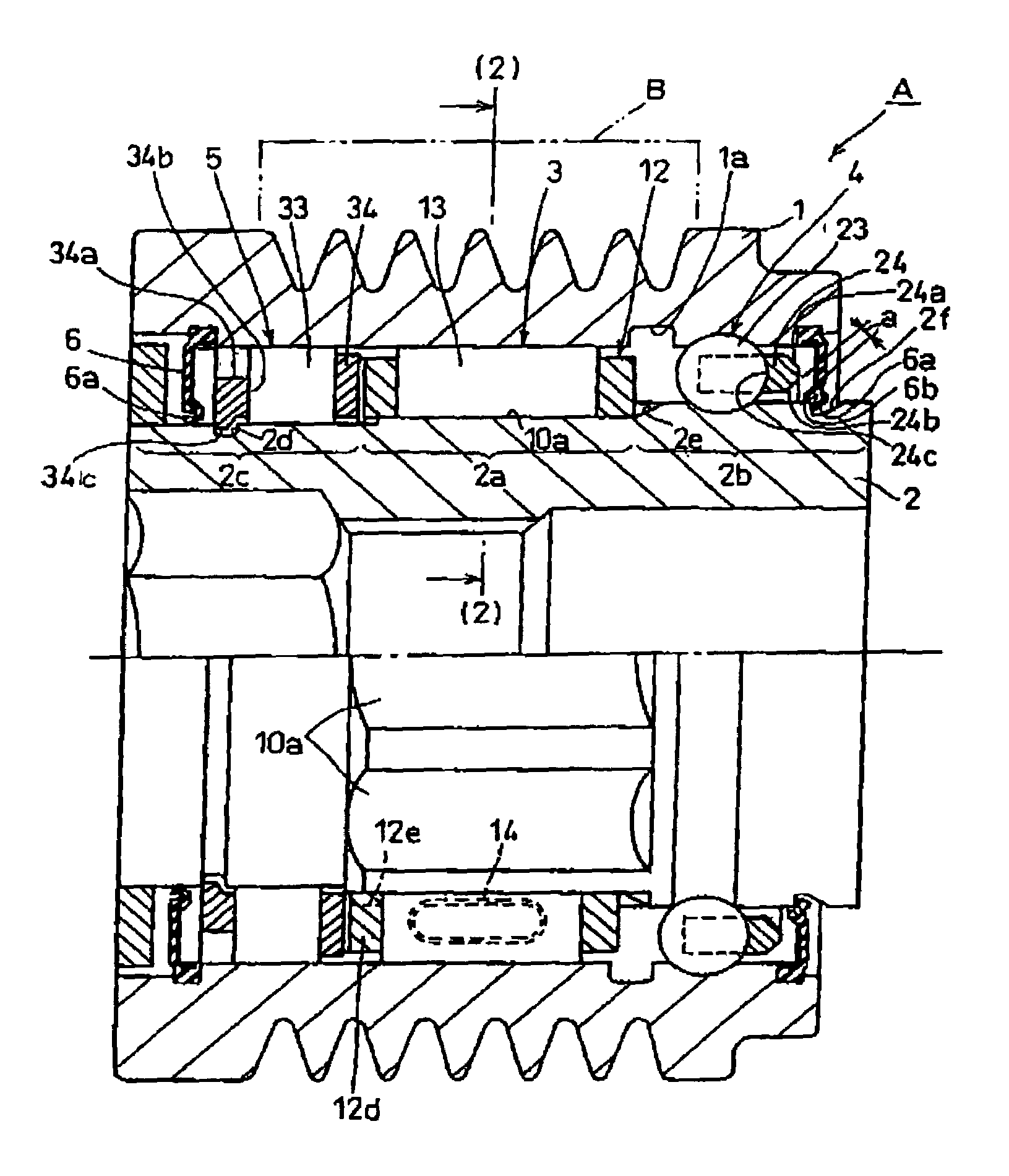

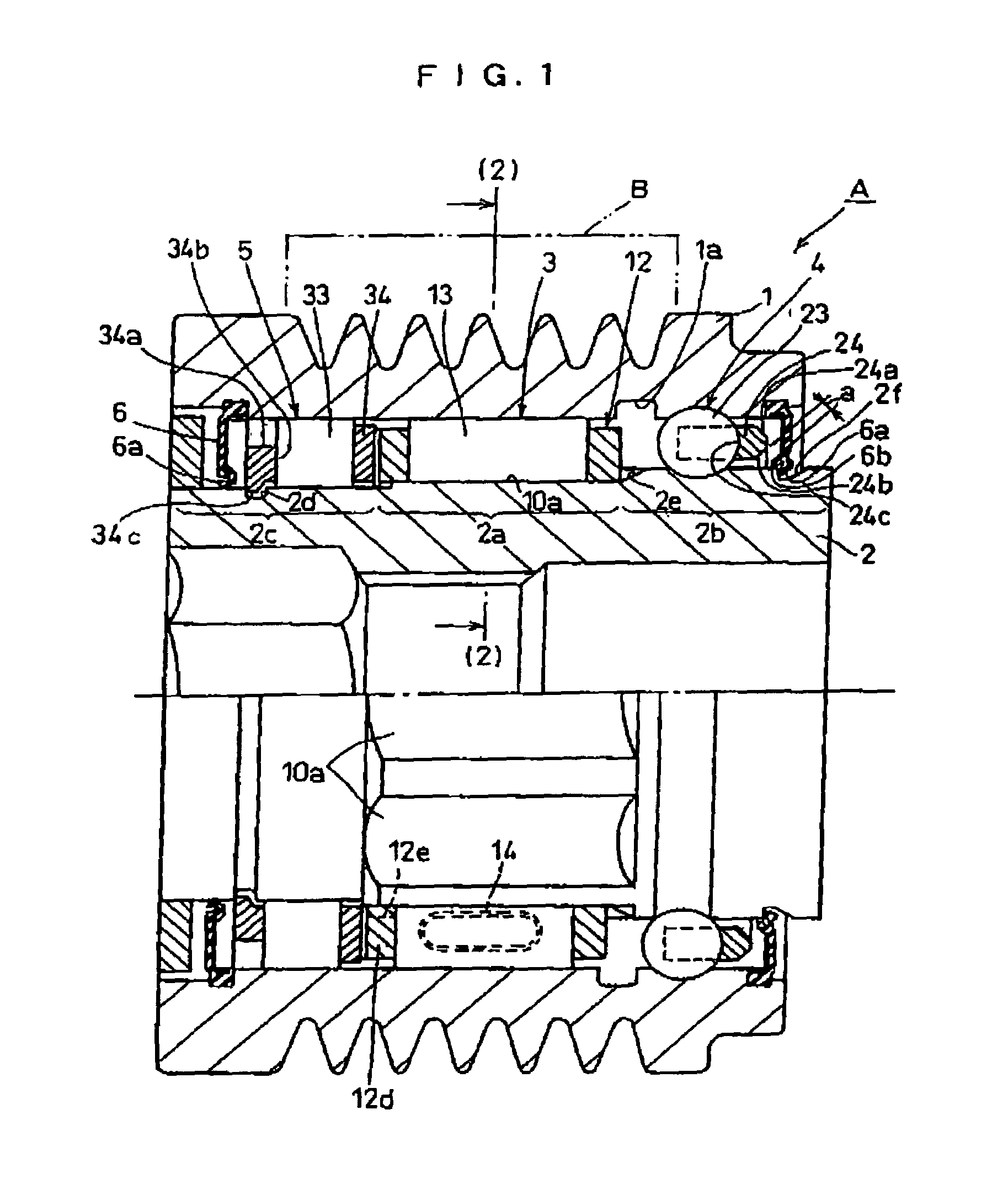

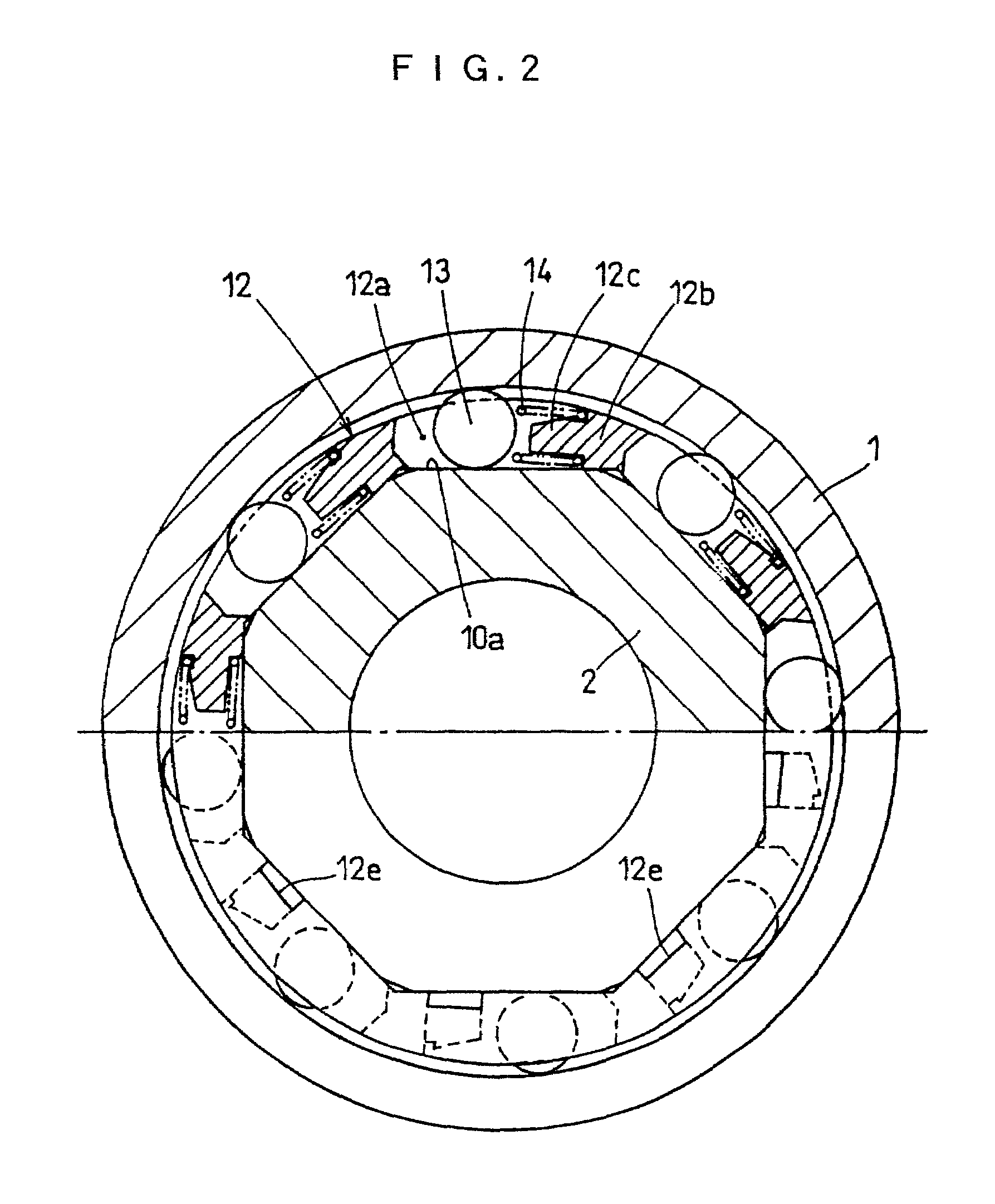

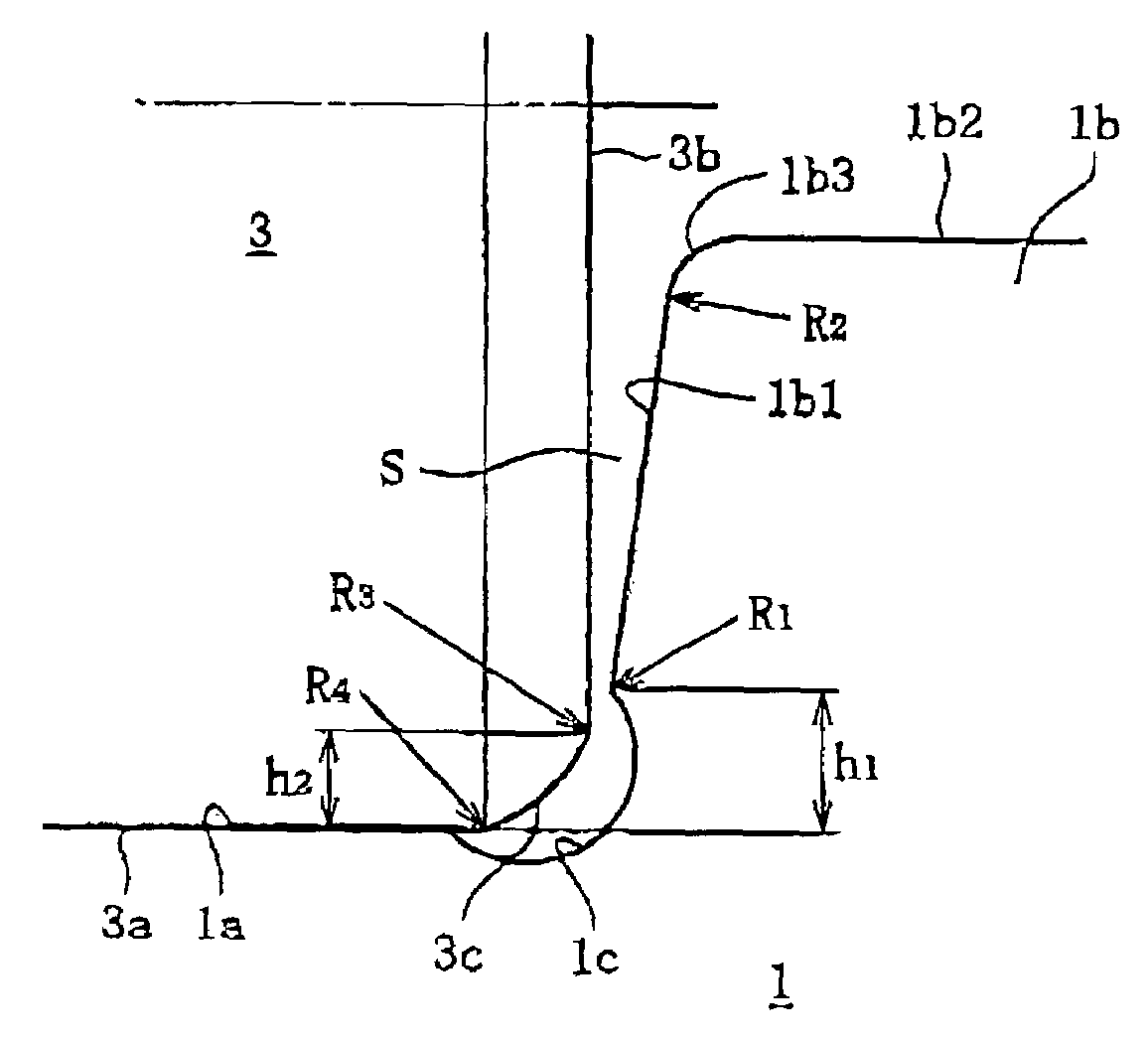

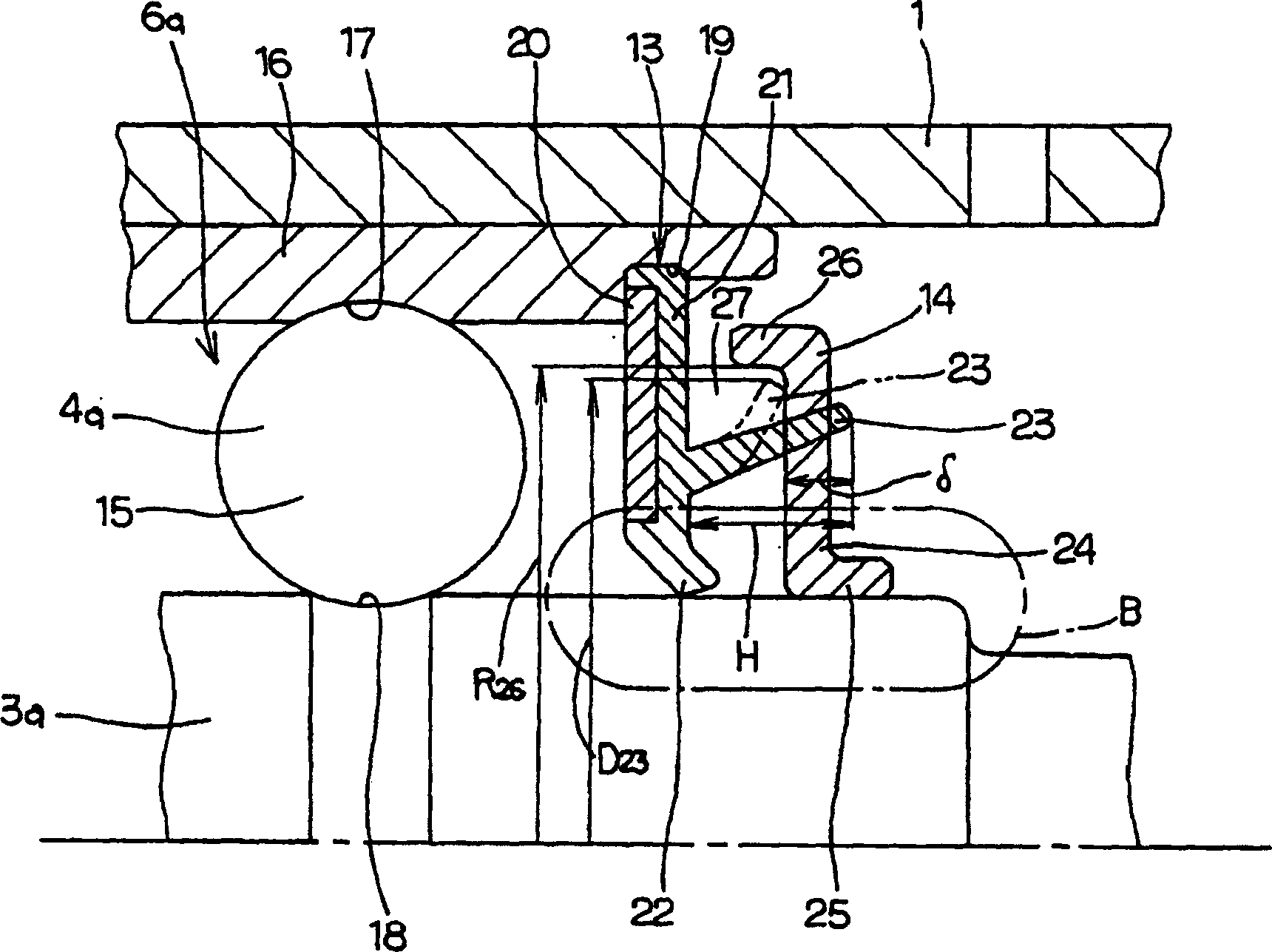

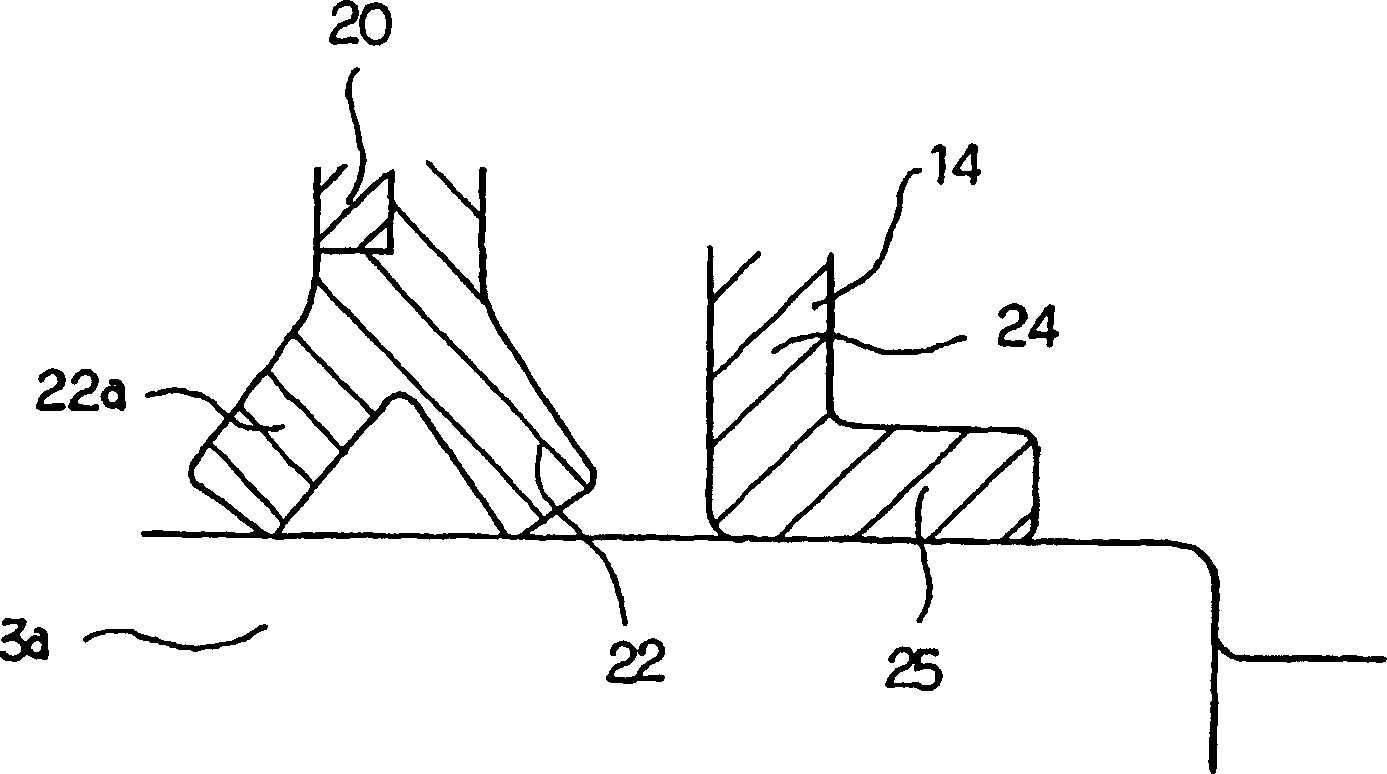

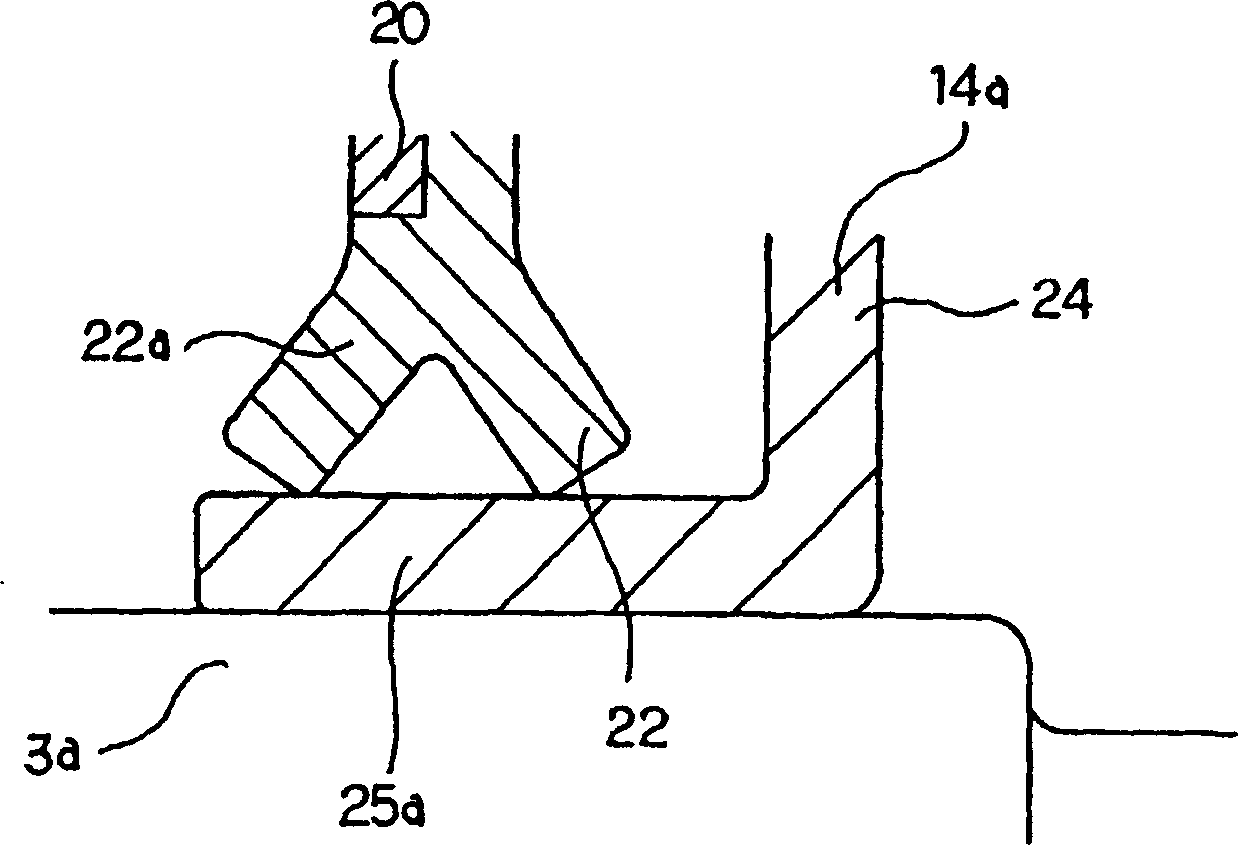

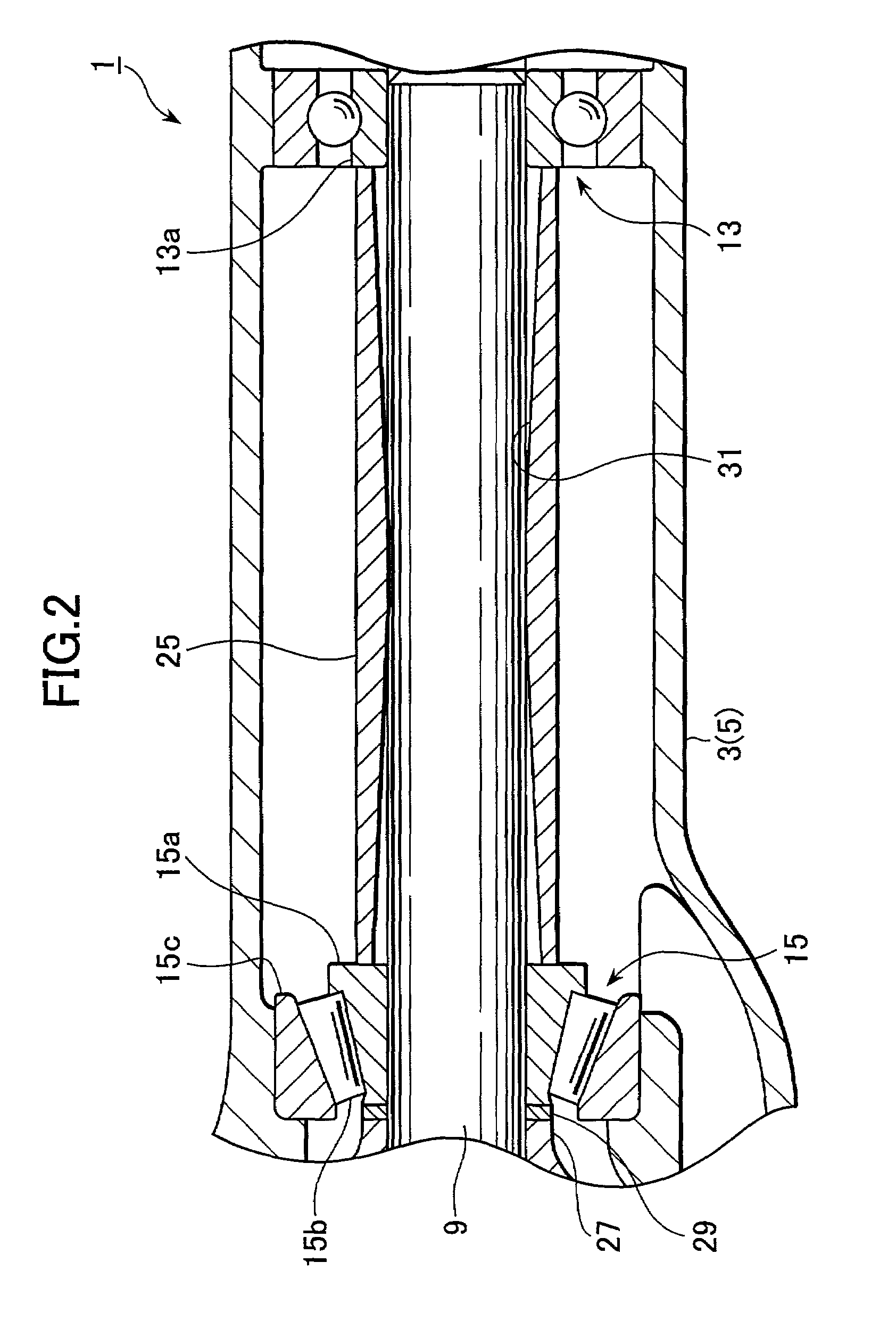

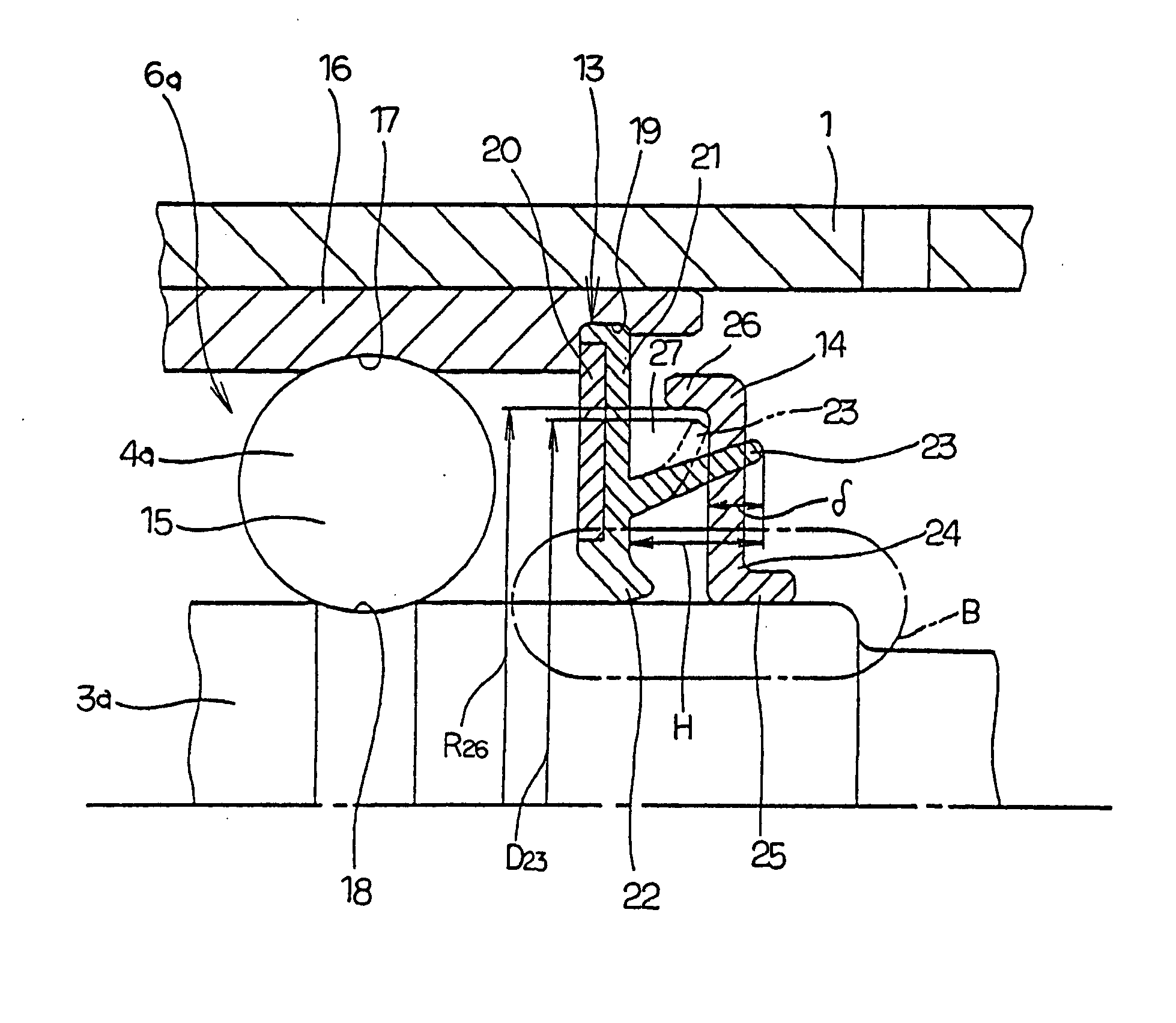

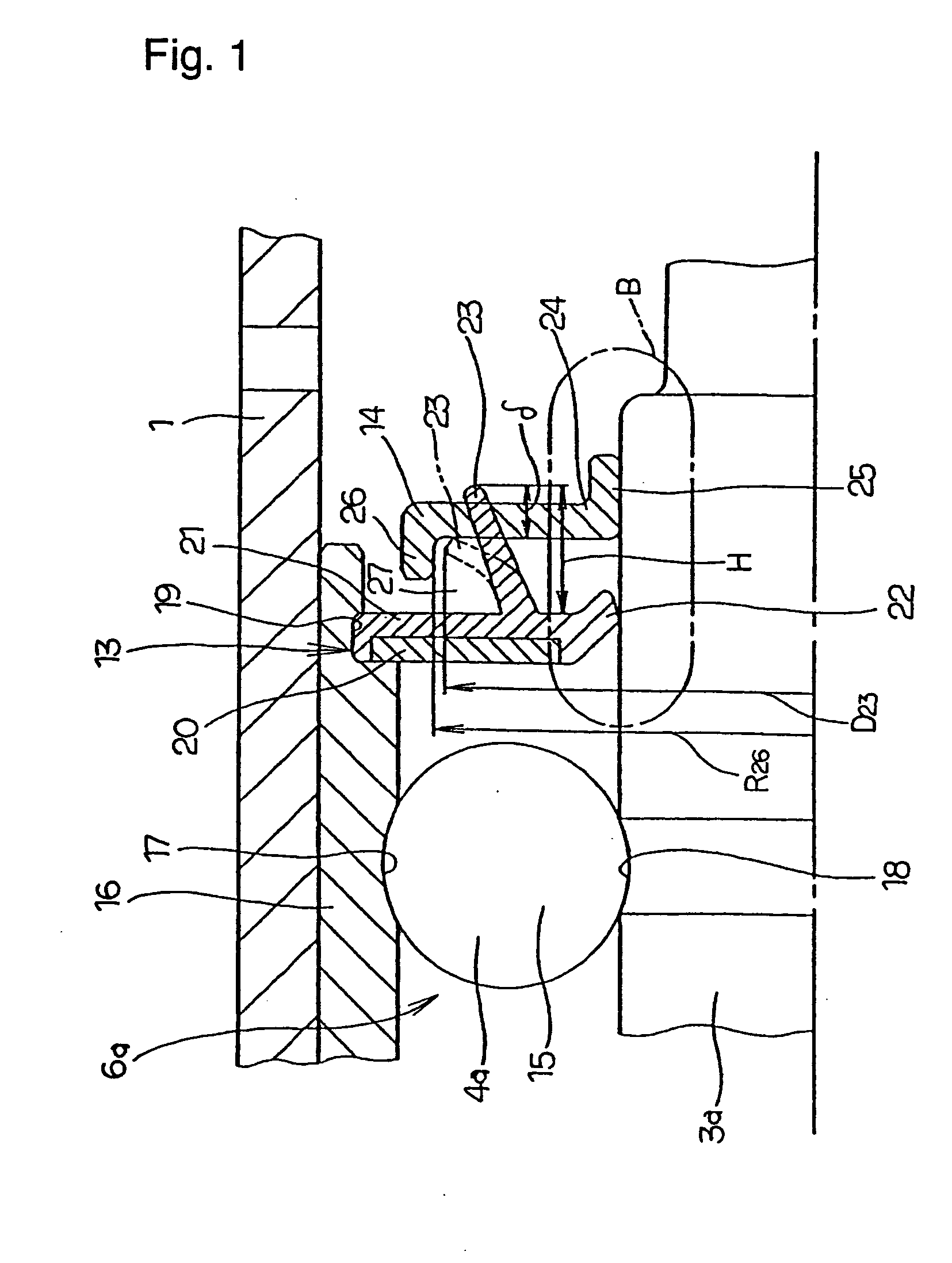

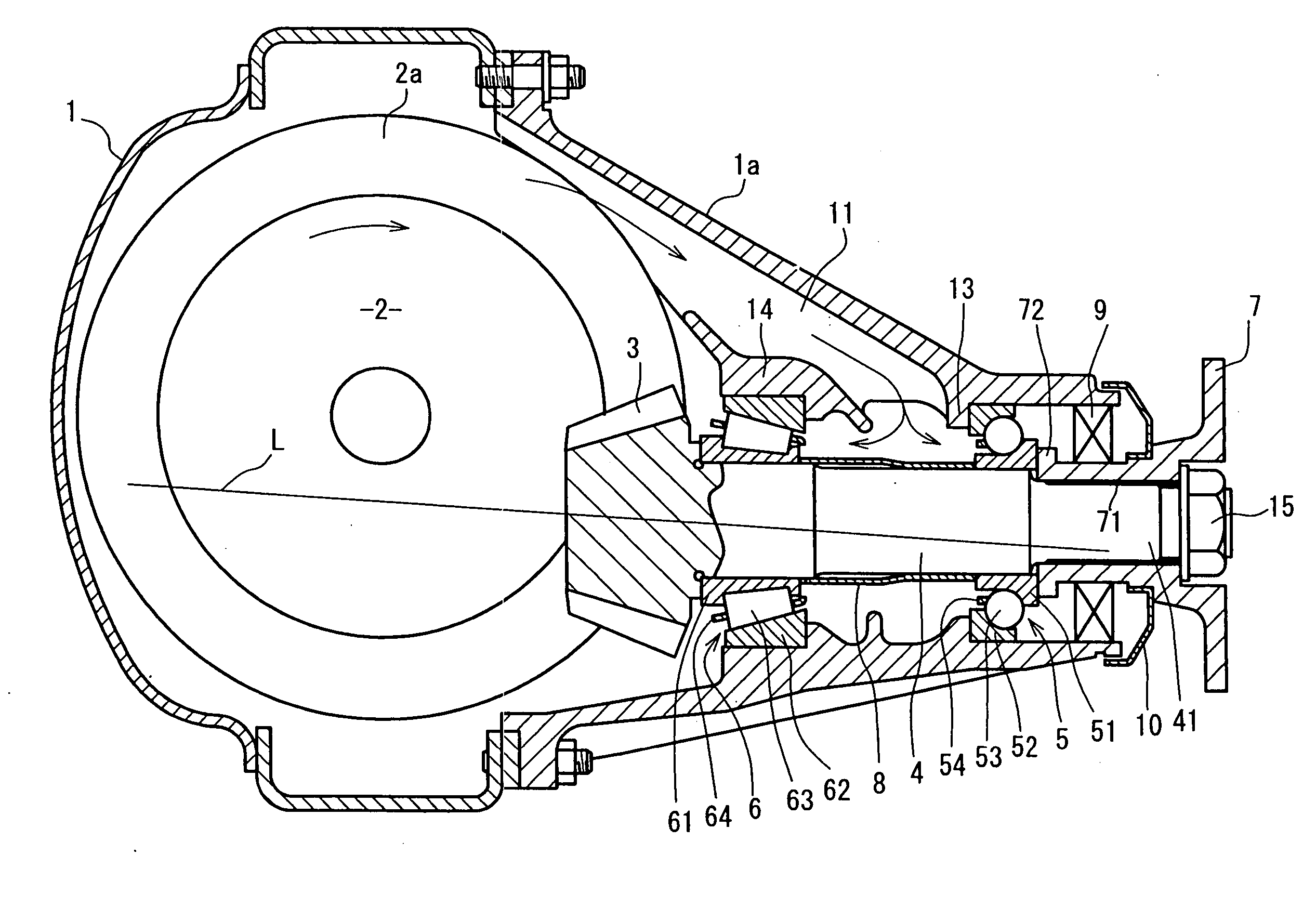

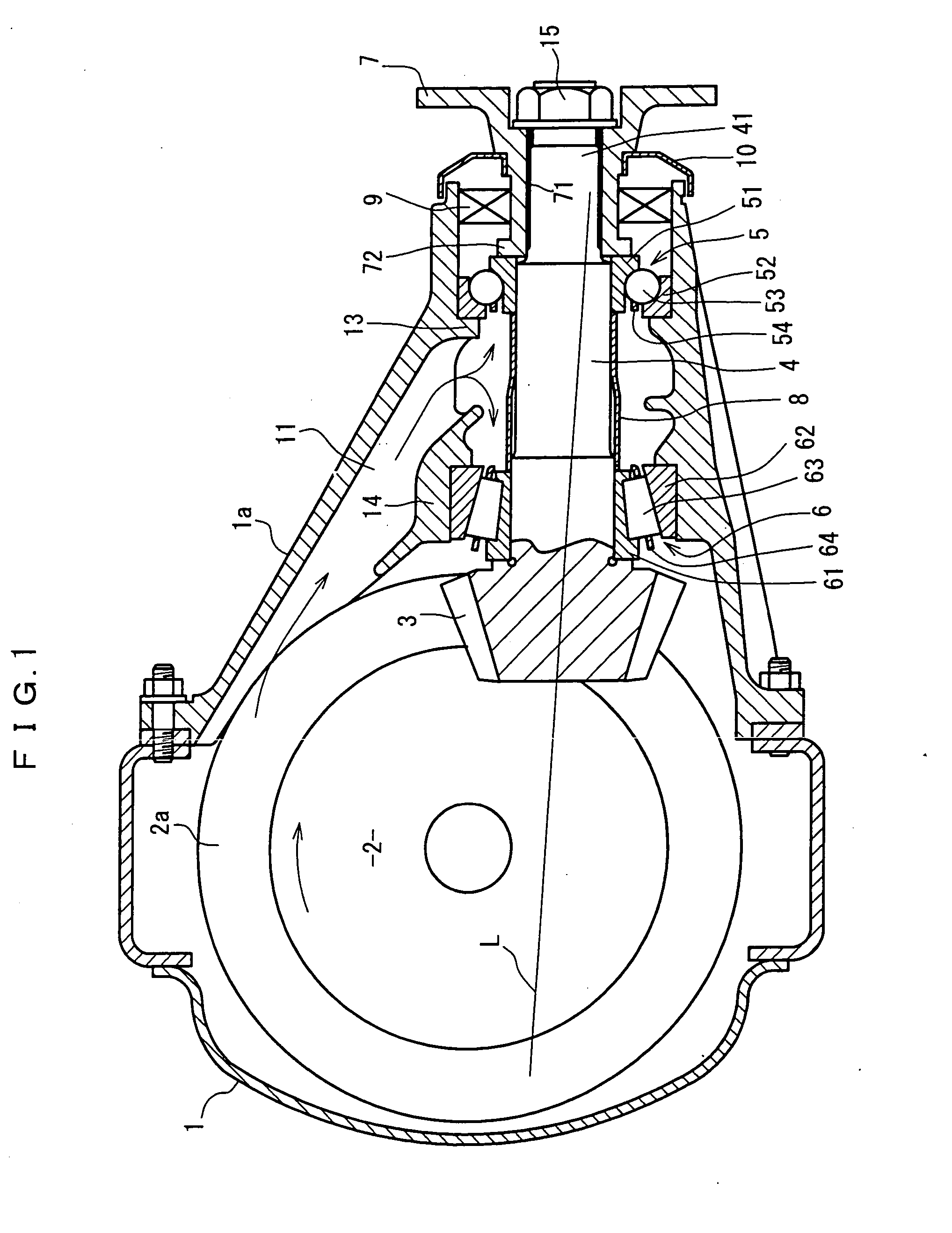

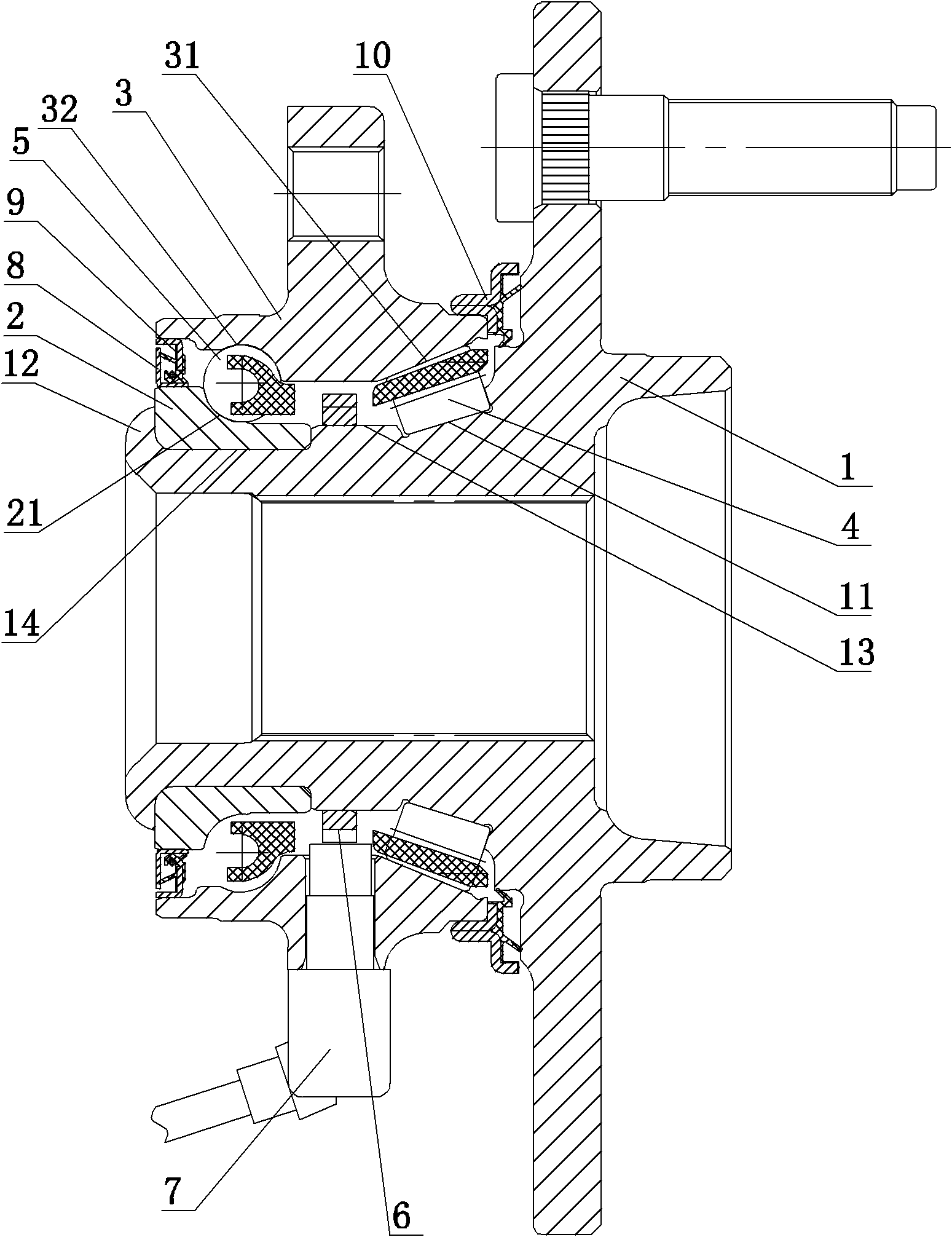

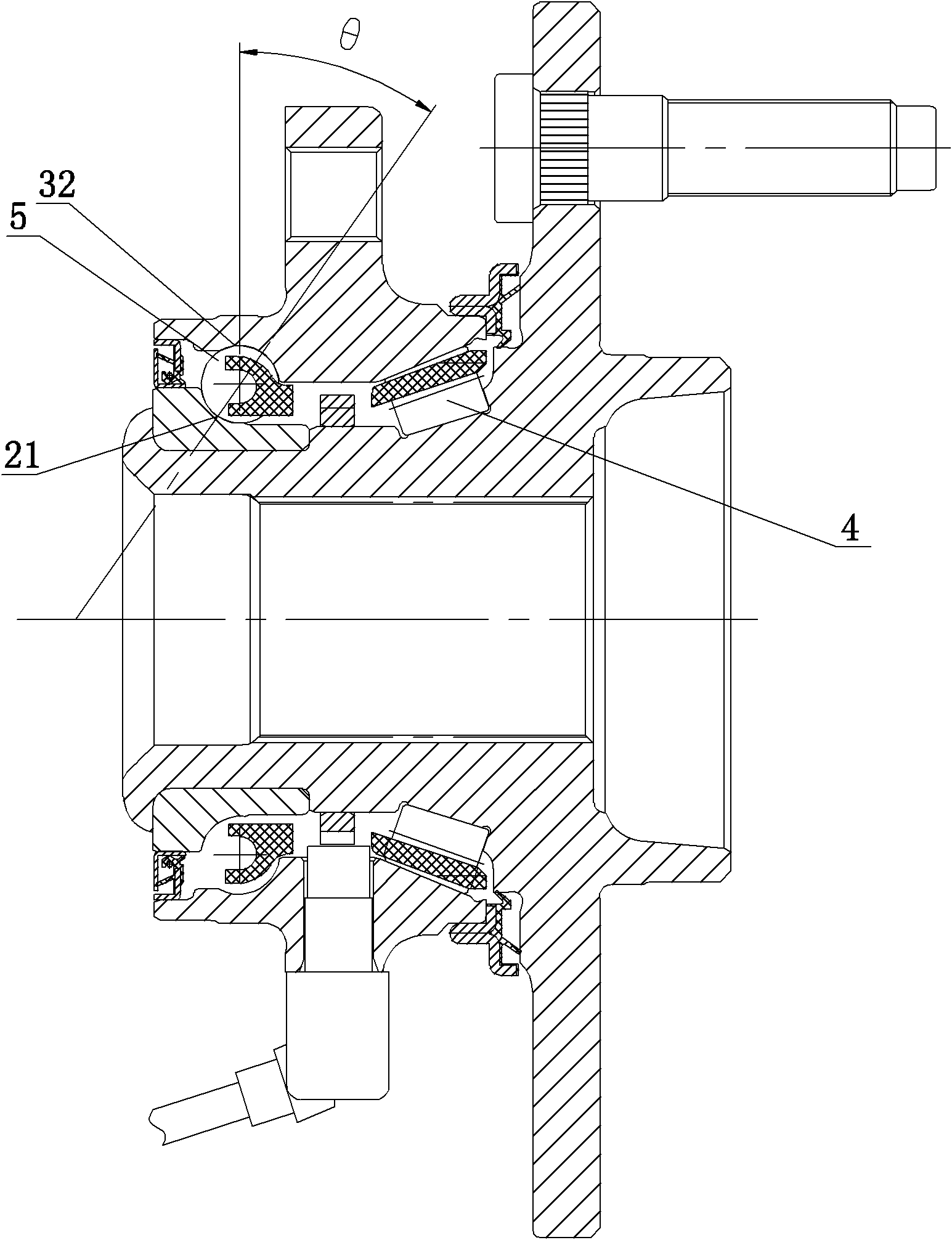

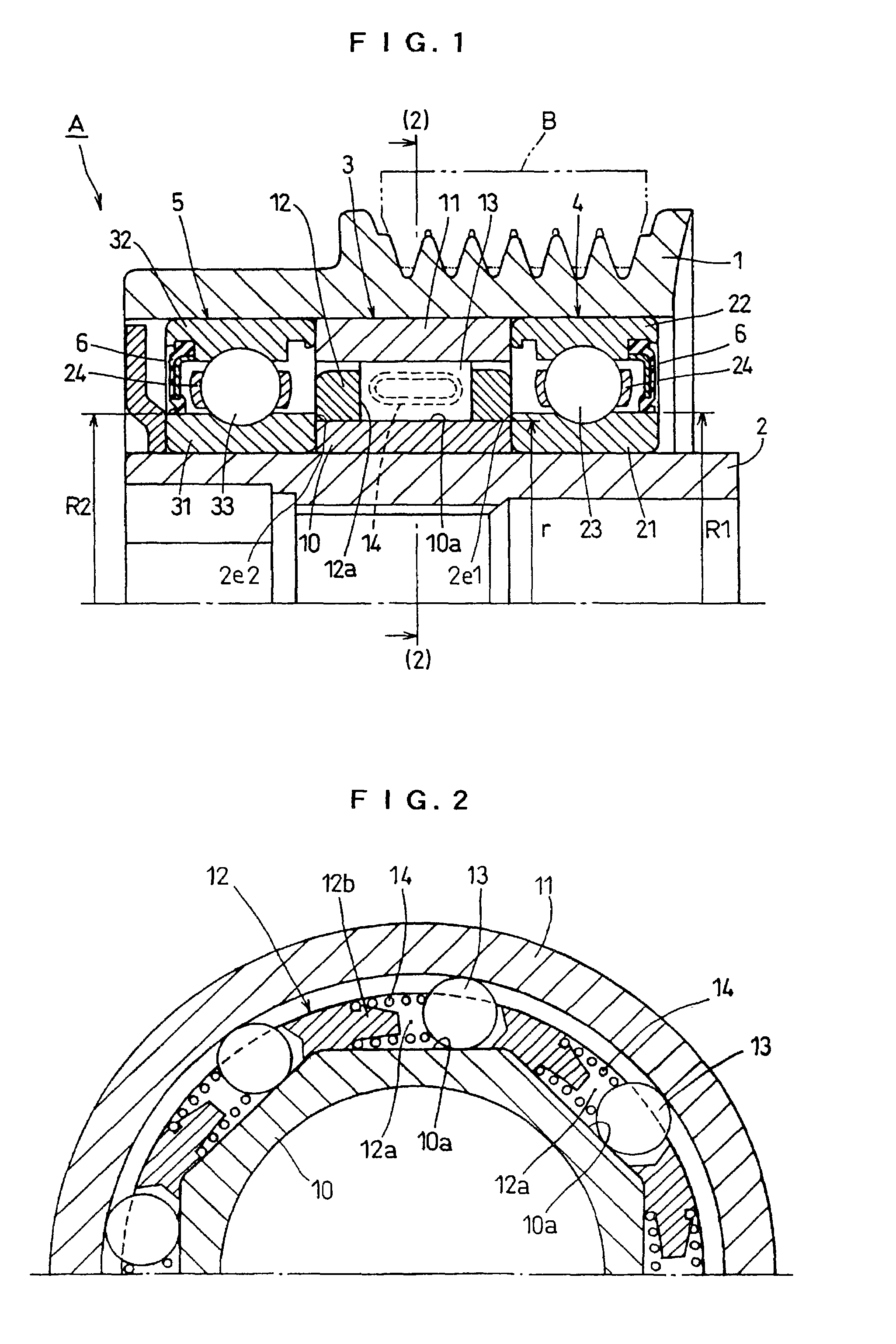

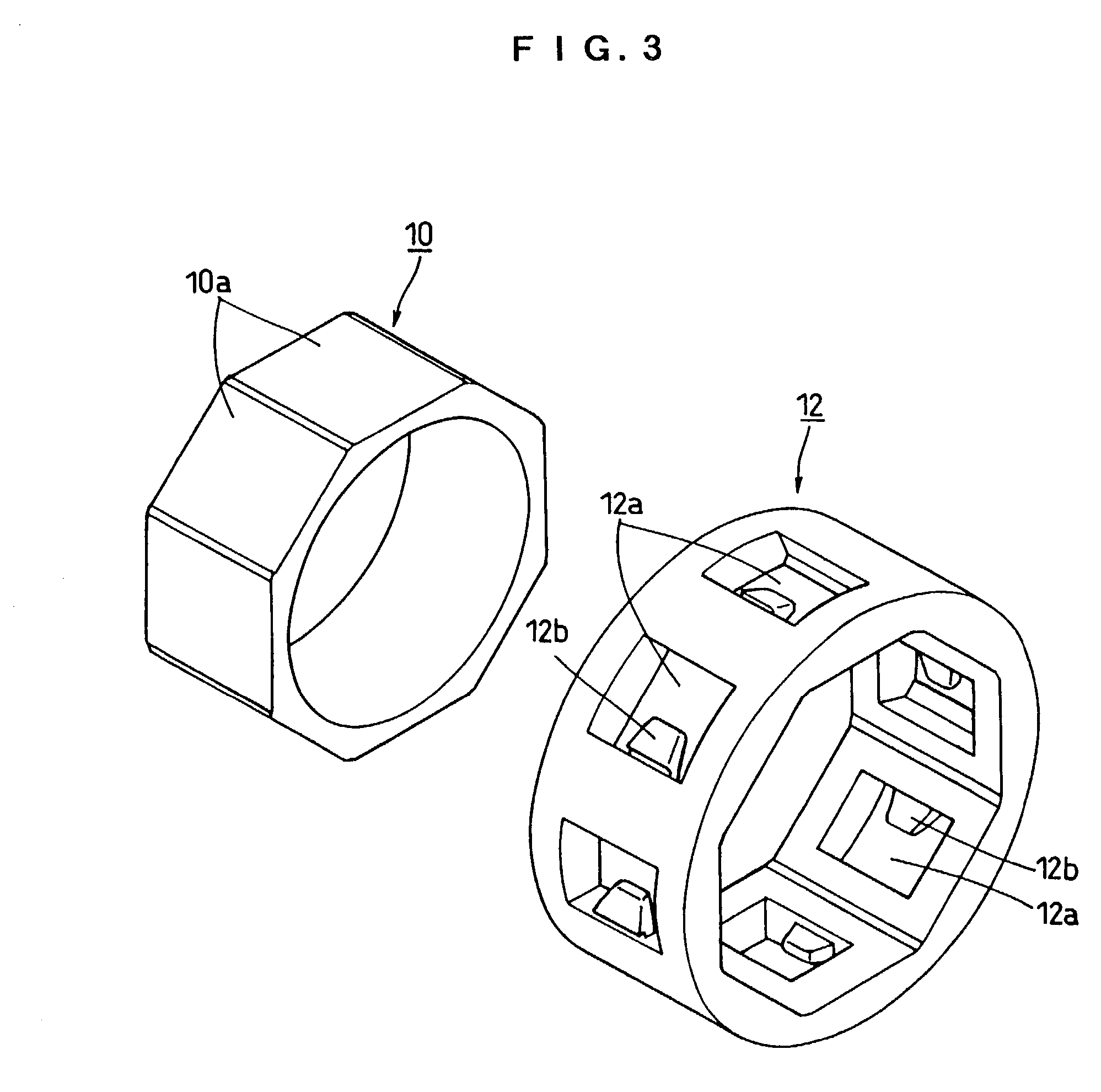

Seal apparatus for a water pump, rotation-support apparatus for a water pump, and a water pump

InactiveUS6485256B1Effectively prevent foreign matter from gettingEngine sealsPump componentsForeign matterFree state

A seal apparatus is comprised of a seal ring 13 and a singer 14 in combination to prevent foreign matter from progressing into the rolling bearing 6a. The amount of compression delta of the second seal lip 23, which occurs when the tip edge of the second seal lip 23 of the seal ring 13 comes in contact with the outside surface of the singer 14, is at least 1 / 10and up to 7 / 10the height of the second seal lip 23 in the free state. In addition, the roughness of a portion of the outside surface of the singer 14 which the tip edge of the second seal lip 23 comes in sliding contact with is from 0.2mum to 2.0mum in the arithmetic mean Ra, or is from 0.8 mum to 8.0 mum in the maximum height Ry. Consequently, a structure of a water pump is provided without increasing the cost thereof, or without enlarging the size to improve the durability of the water pump.

Owner:NSK LTD

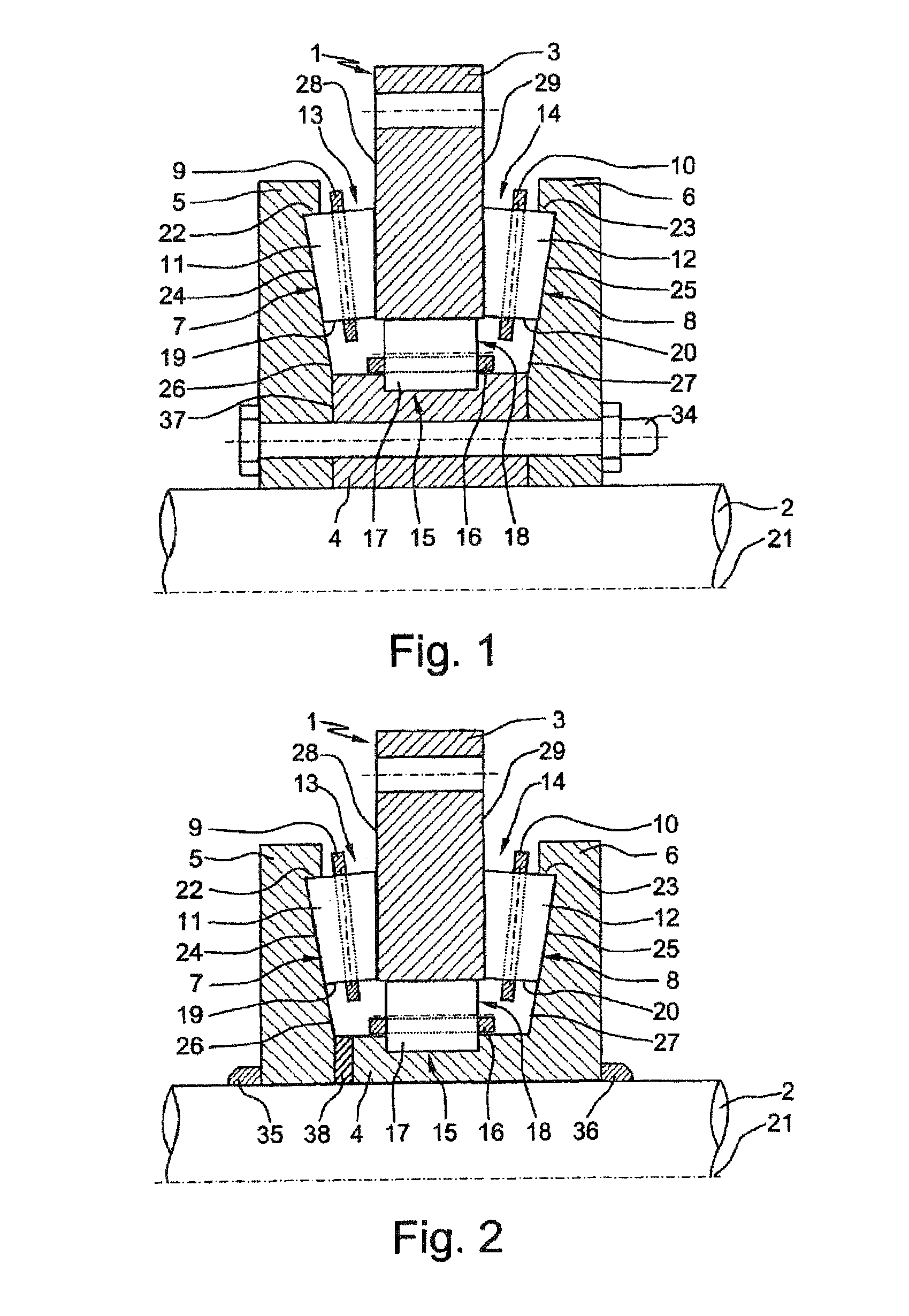

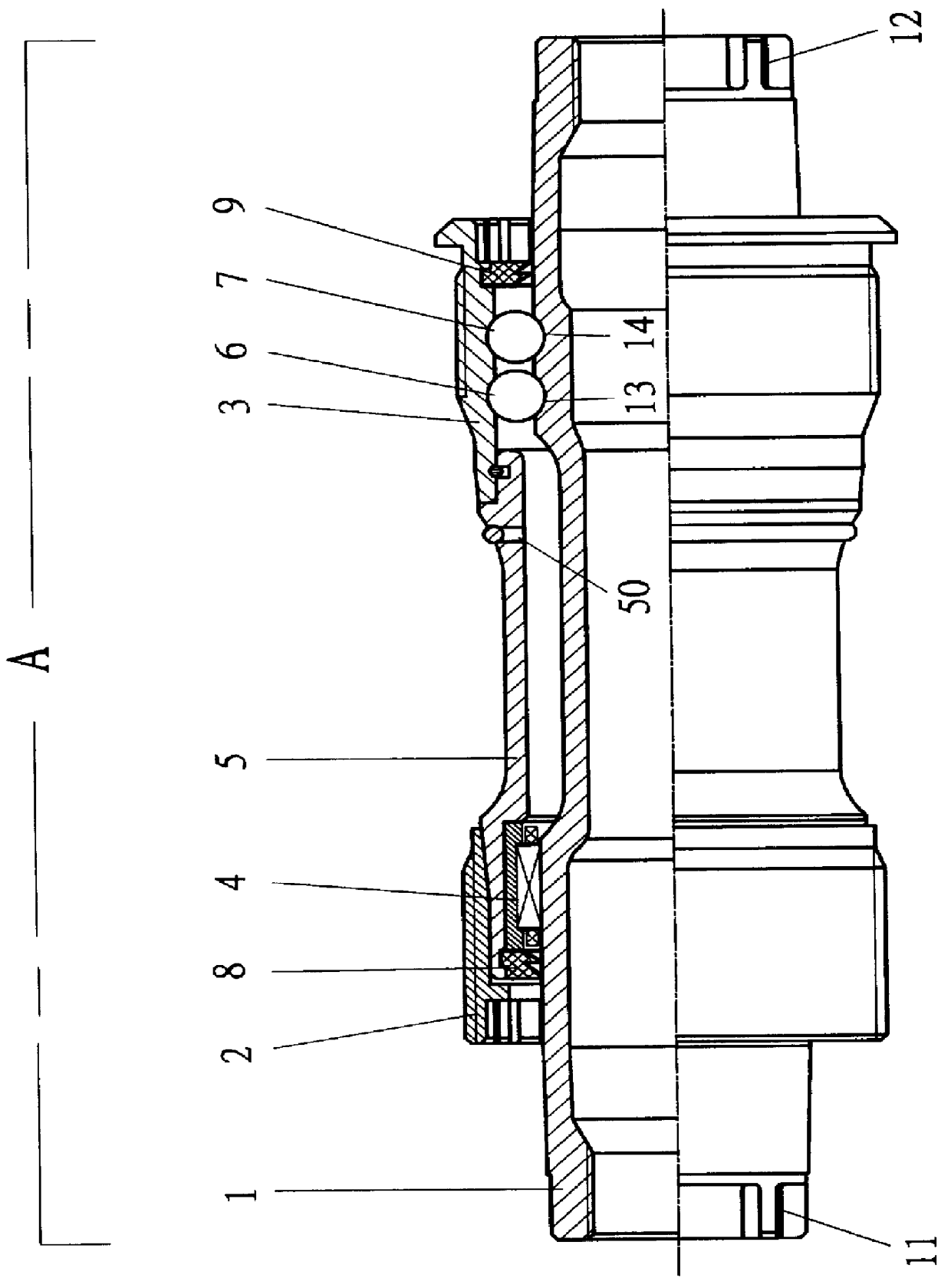

Bearing device for supporting pinion shaft

The present invention relates to a bearing device for supporting a pinion shaft so as to freely rotate with respect to a case. The bearing device comprises a first tilt-contact rolling bearing provided on the connecting-flange-side outer peripheral surface of the pinion shaft and a second tilt-contact rolling bearing formed from an angular ball bearing provided on the pinion-gear-side outer peripheral surface of the pinion shaft, wherein lines of action of the first and second tilt-contact rolling bearings intersect with one another on an outer diameter side, the connecting-flange-side end portion of the first tilt-contact rolling bearing and the pinion-gear-side end portion of the second tilt-contact rolling bearing are respectively sealed with seal members, a sealed space between the seal members is infilled with grease, and the connecting flange is fastened in the pinion-gear direction to thereby preload the first and second tilt-contact rolling bearings.

Owner:JTEKT CORP

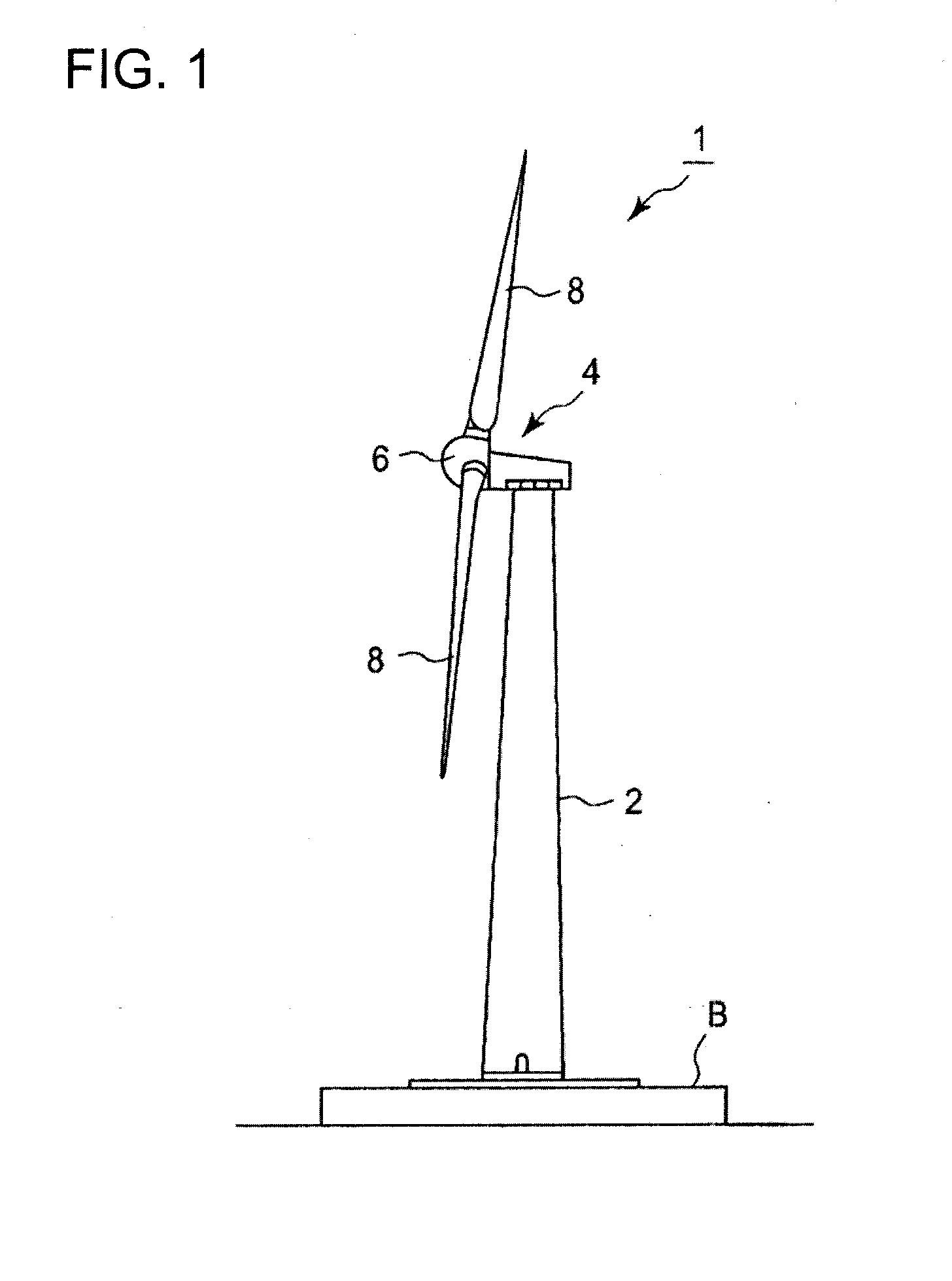

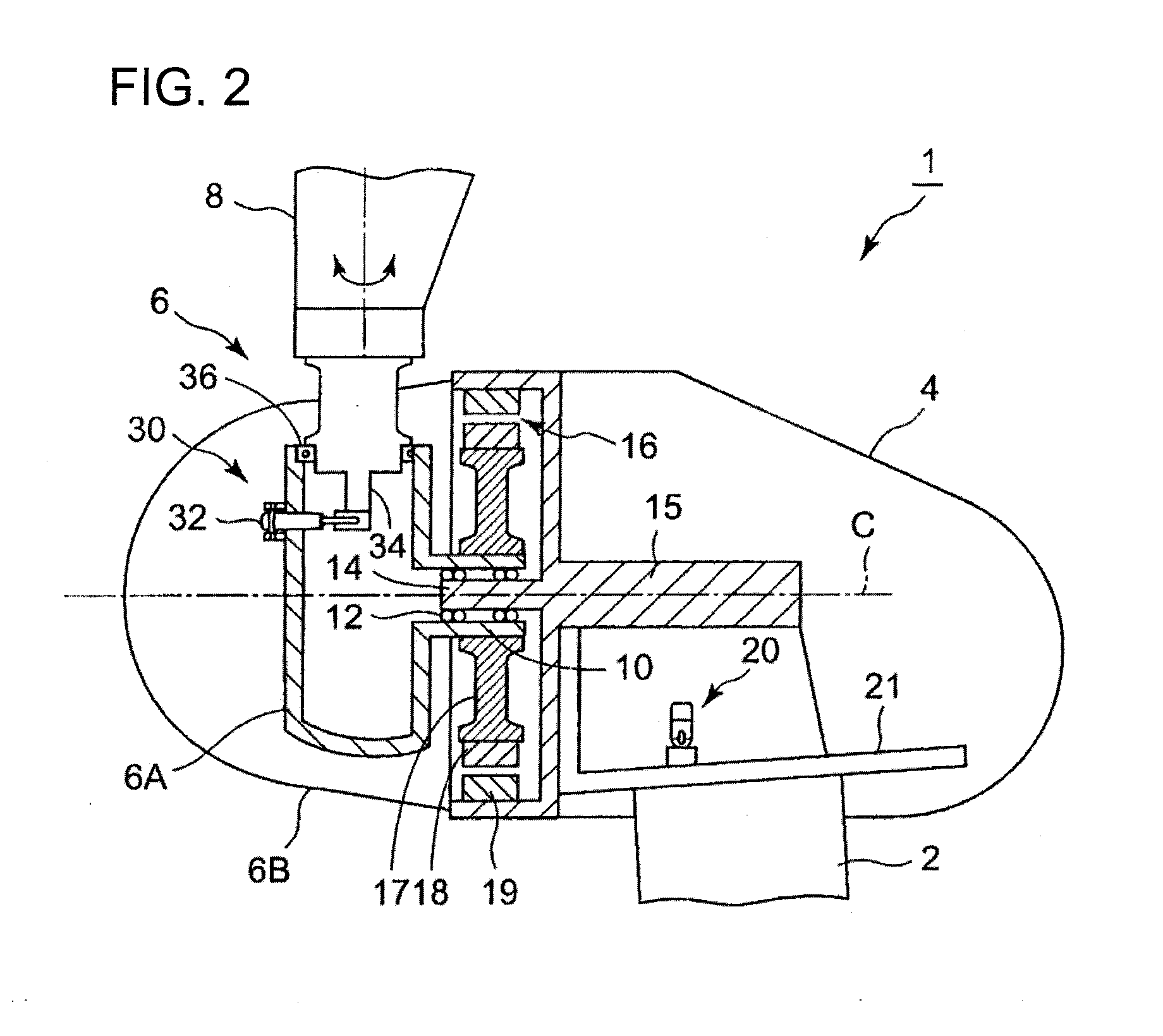

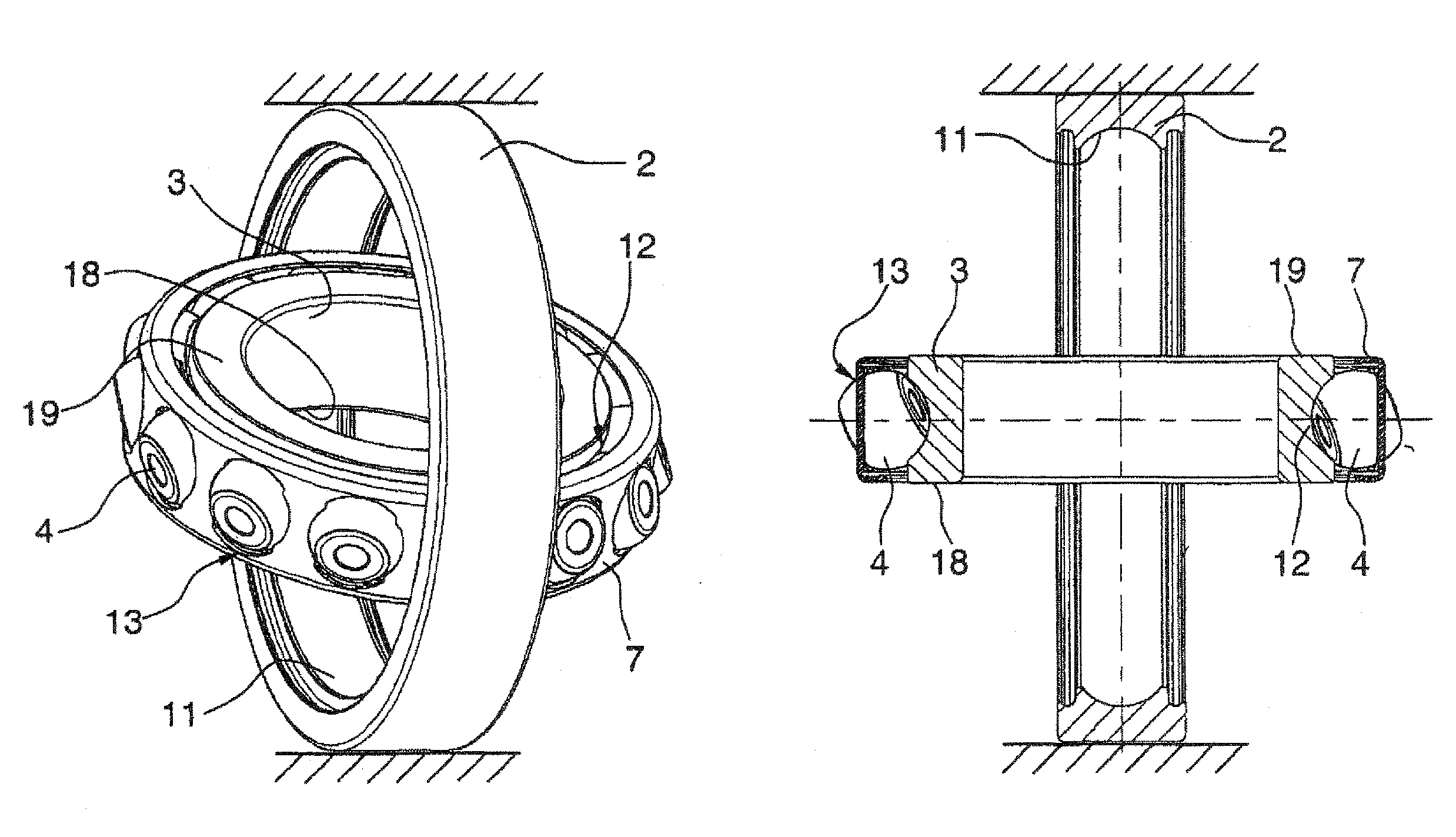

Wind power plant

ActiveUS20120020792A1Improve protectionLong possible service lifeBearing assemblyWind motor controlPeaking power plantFreewheel

Owner:IMO HOLDING GMBH

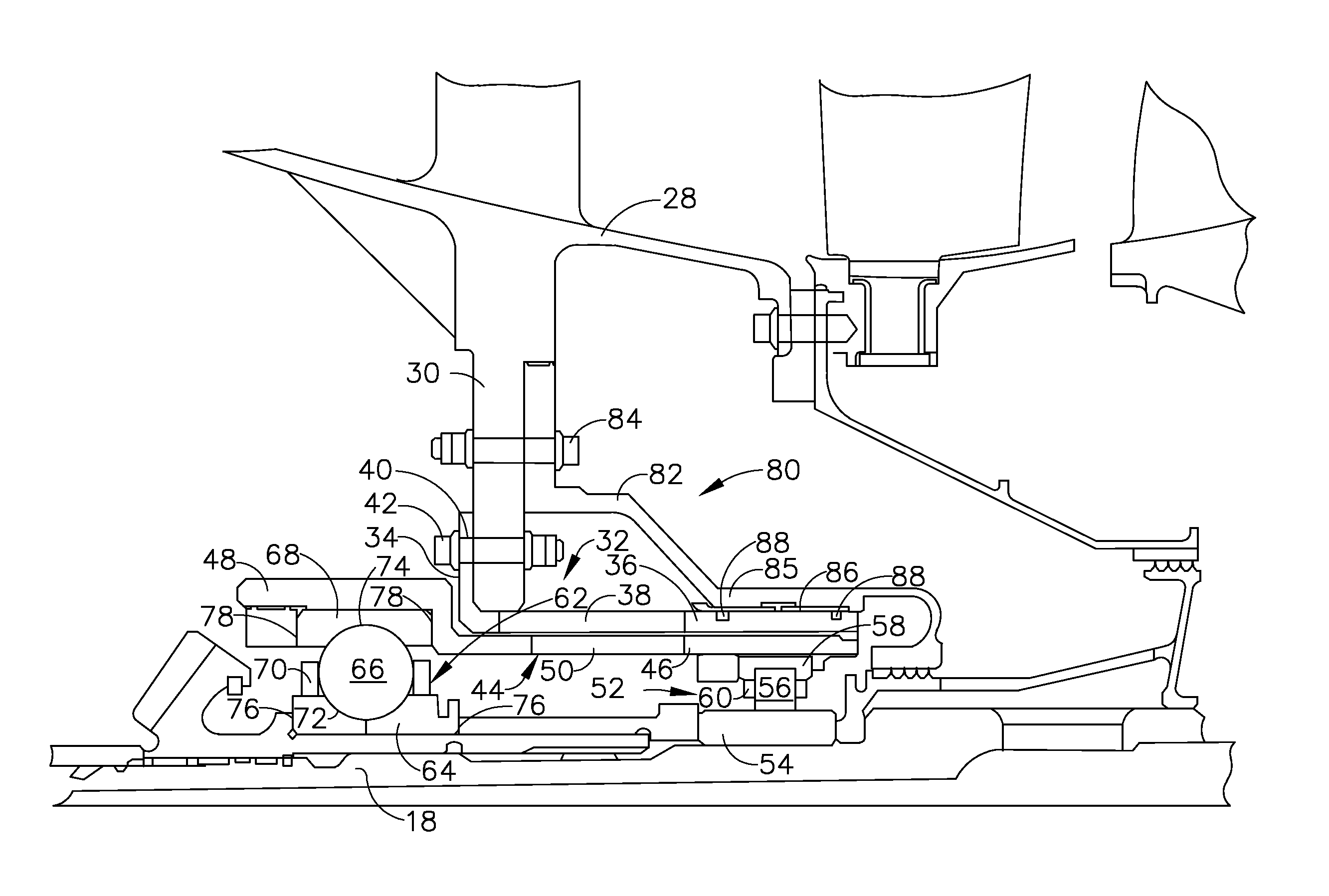

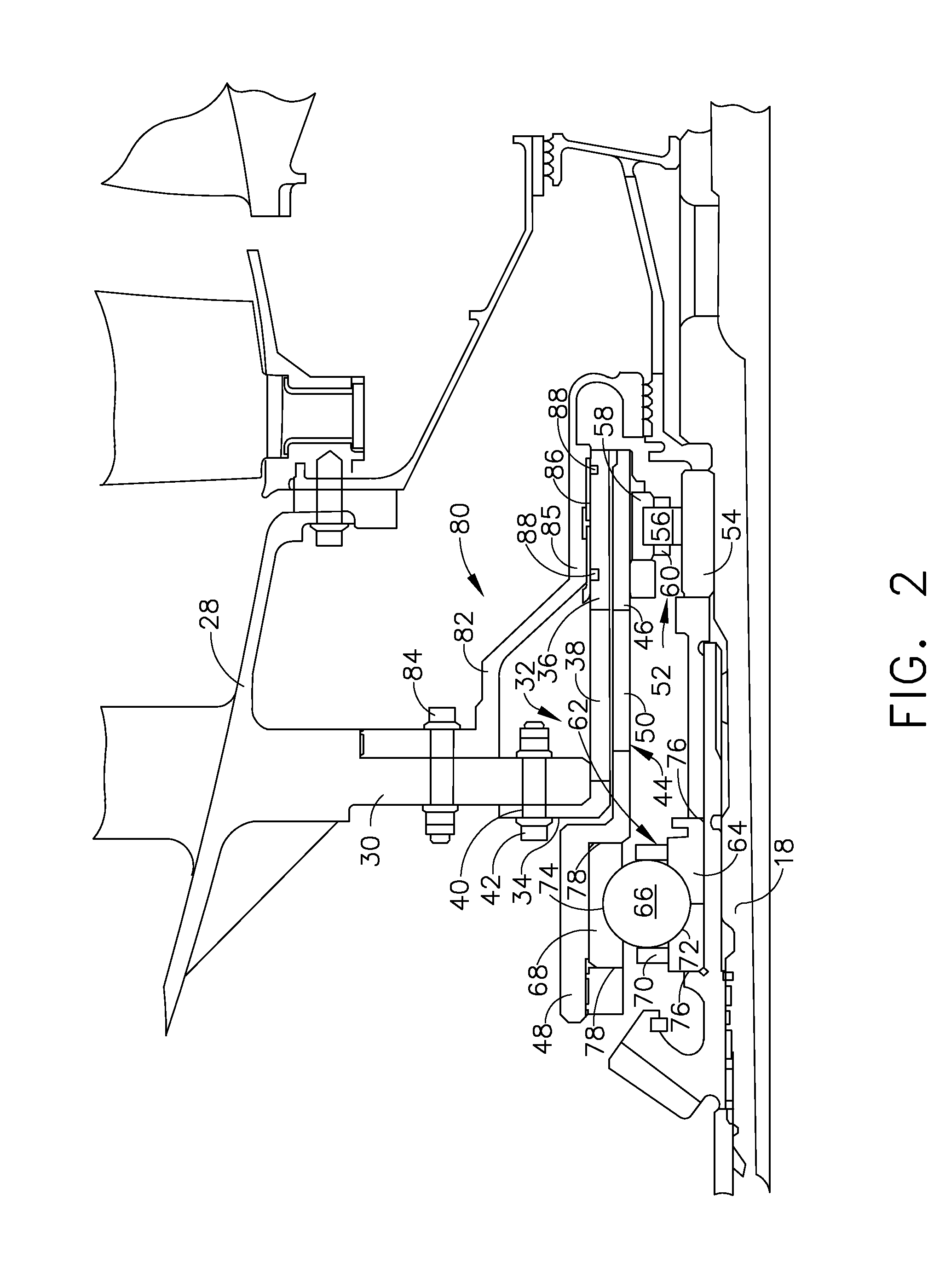

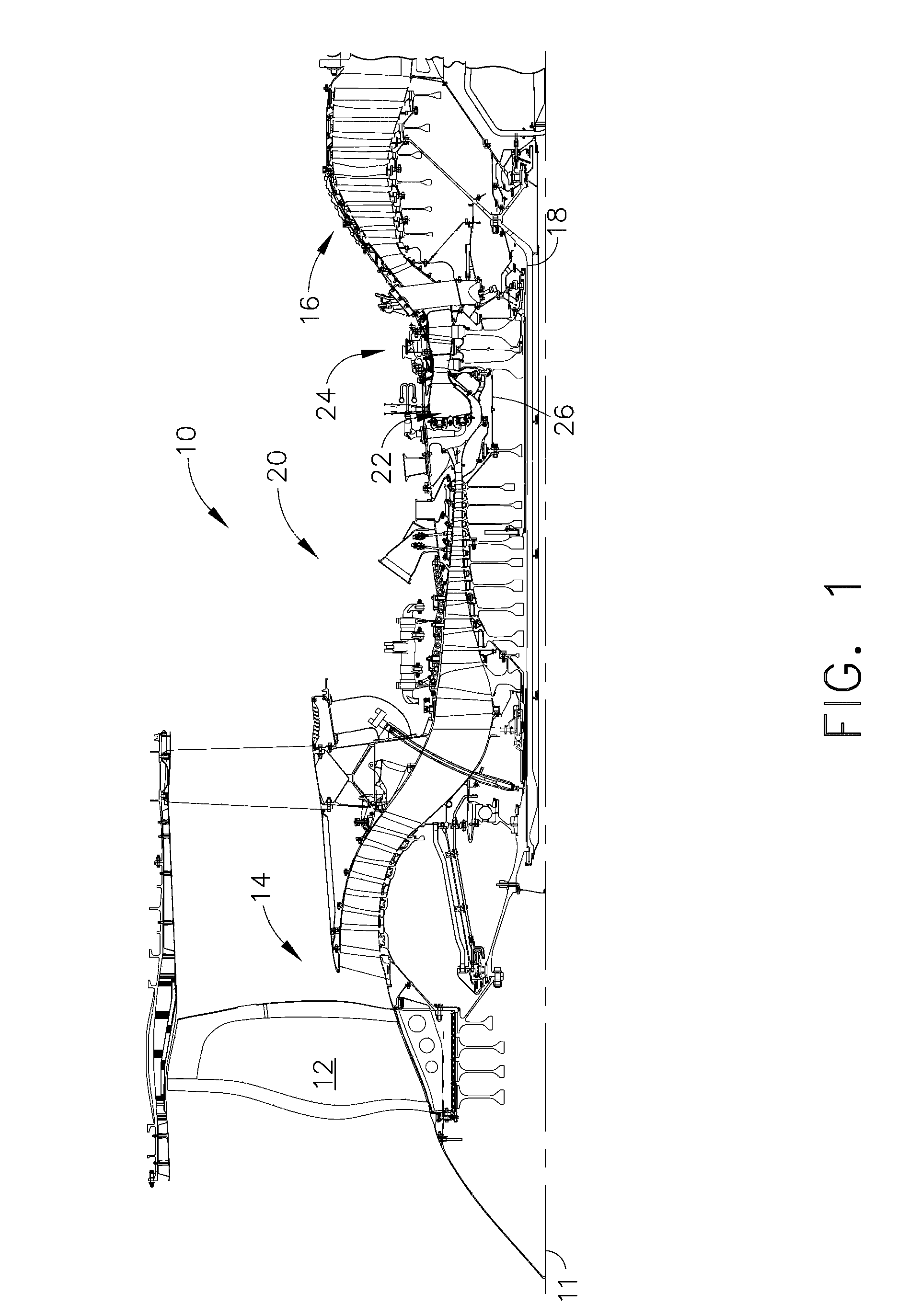

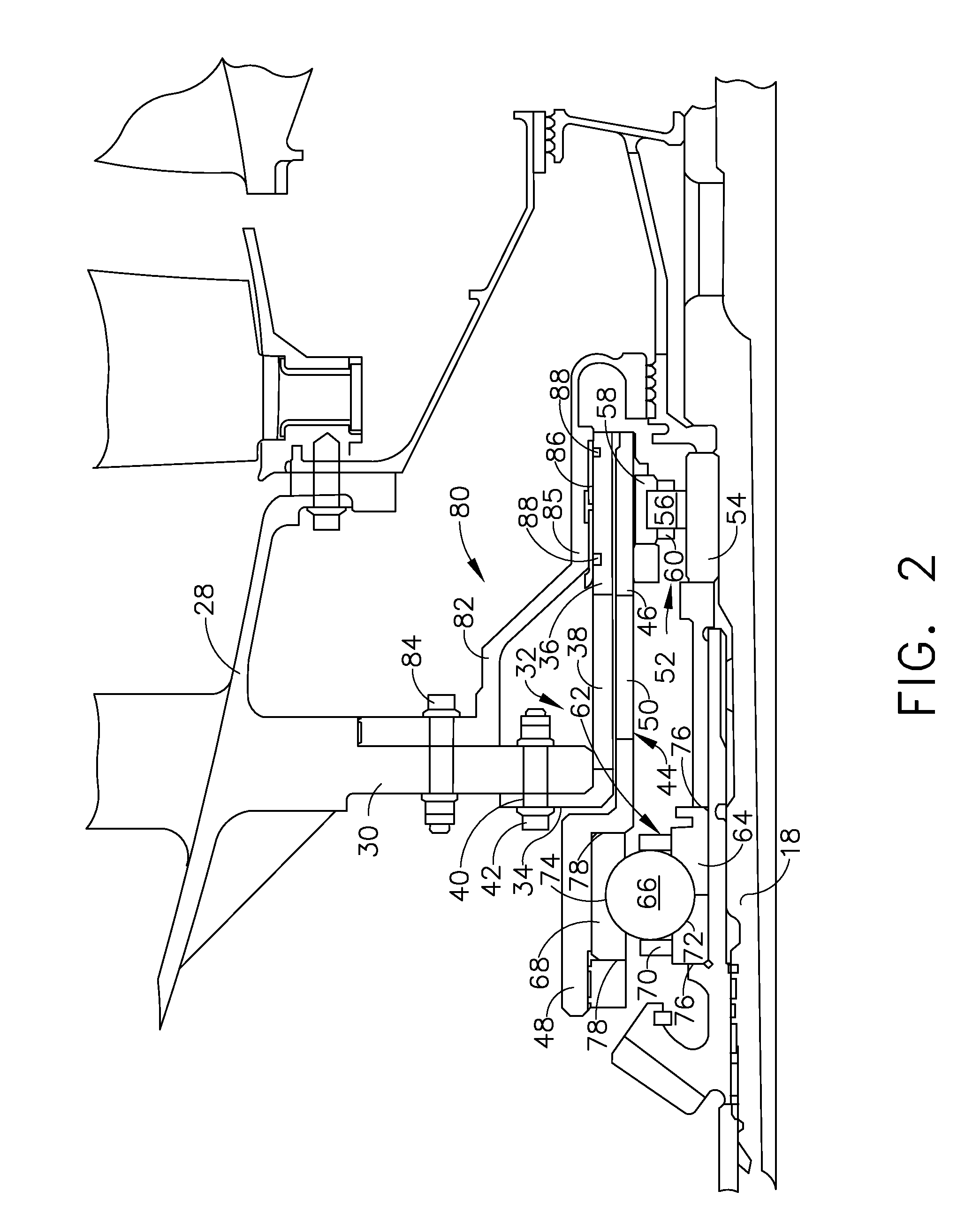

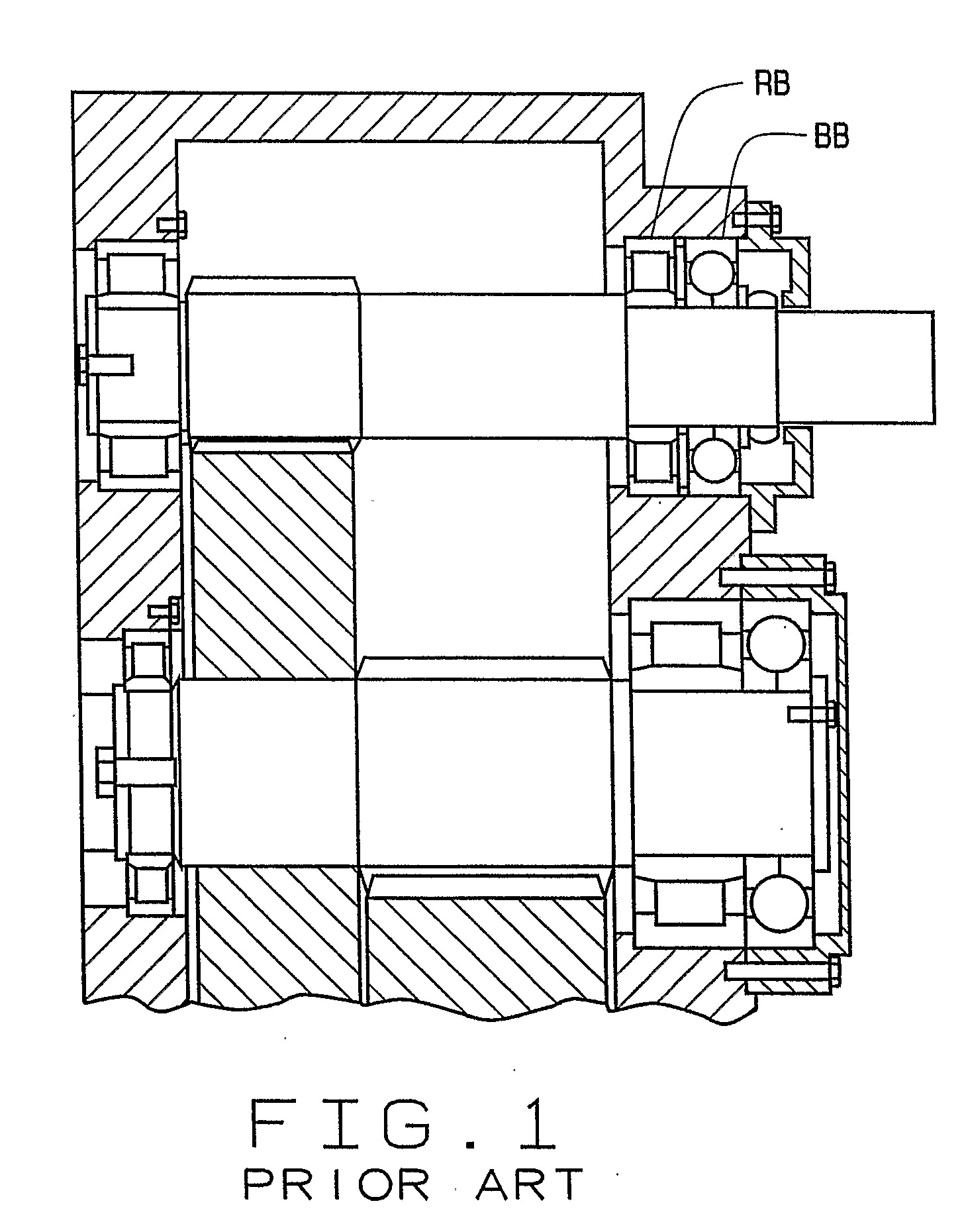

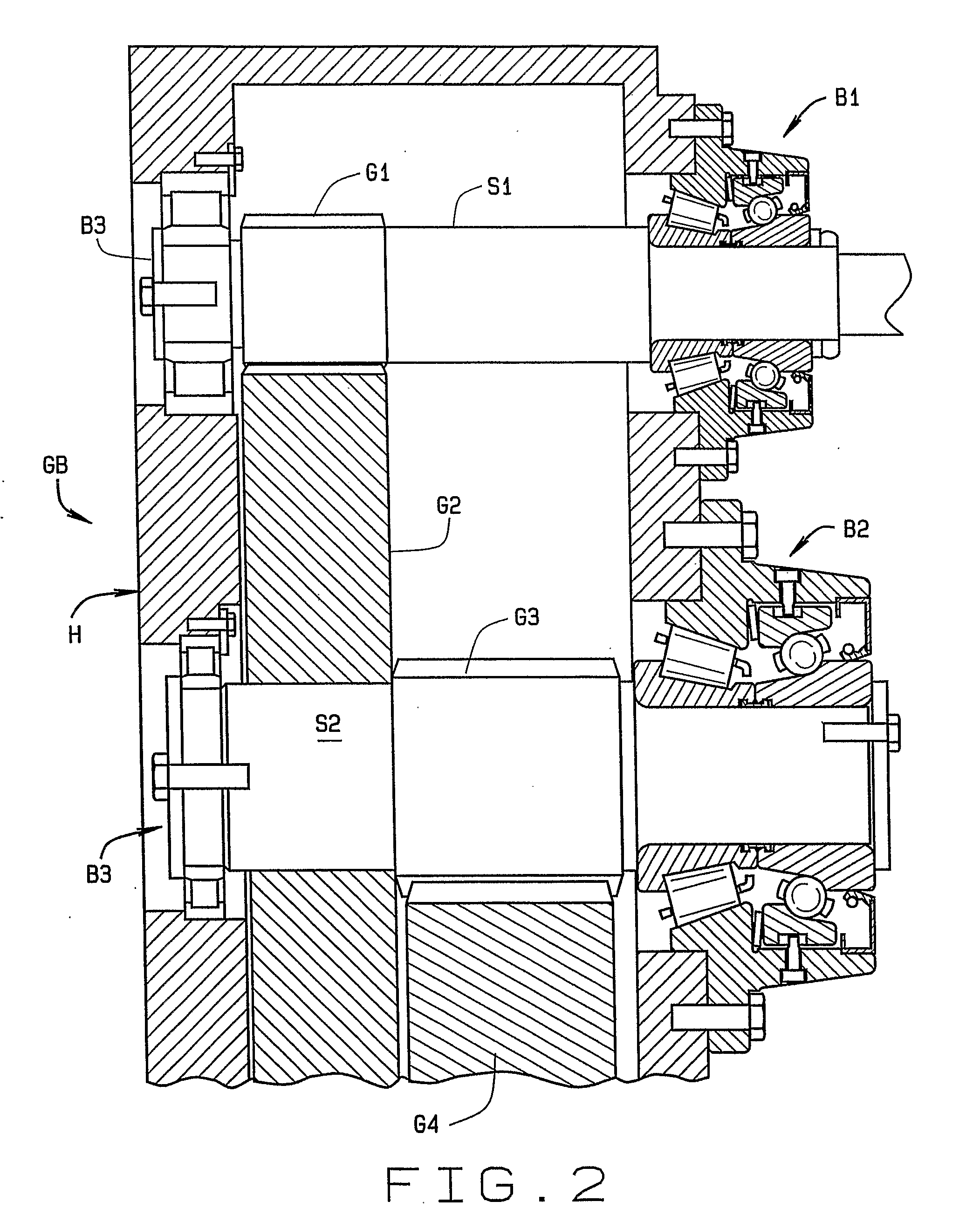

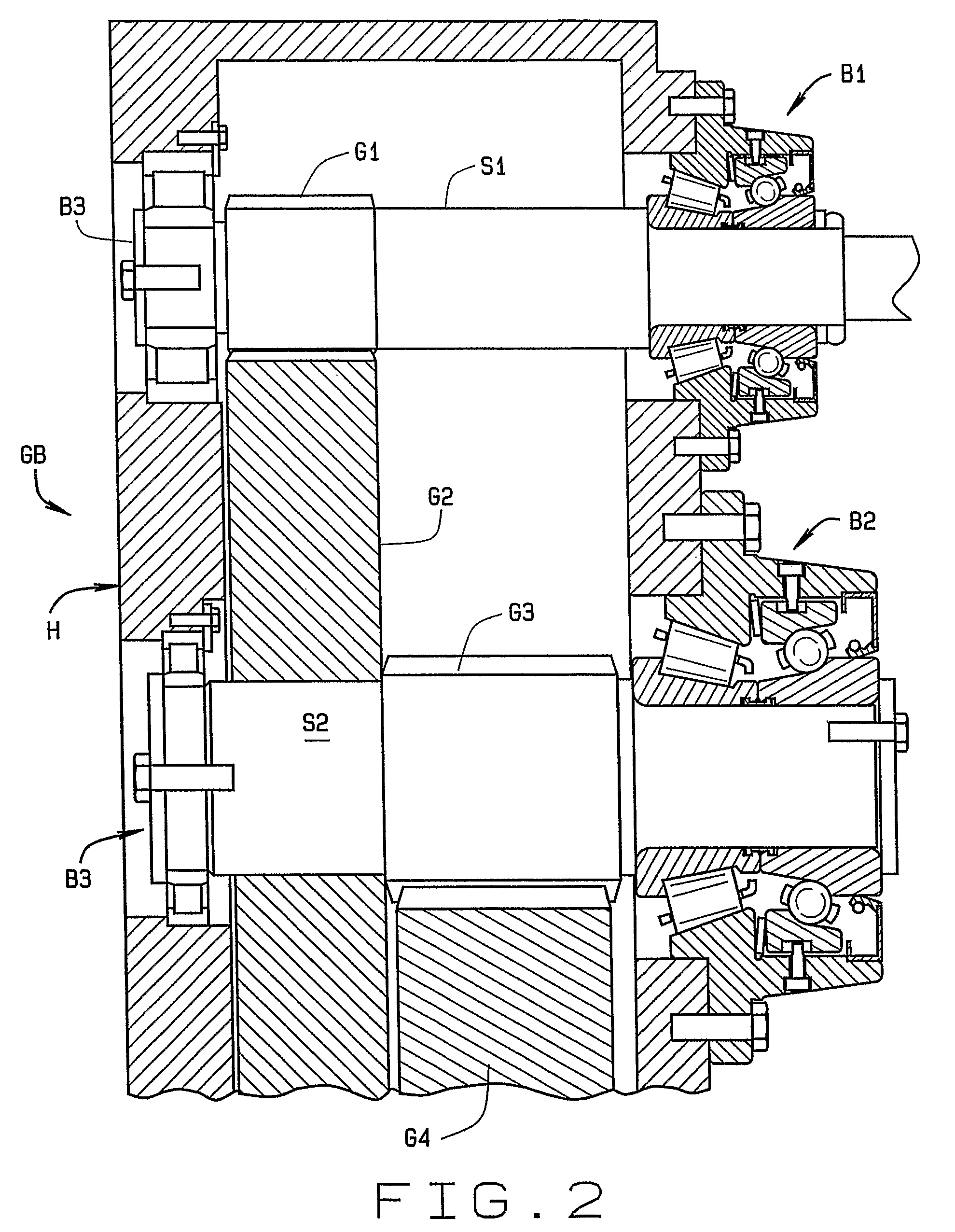

Series bearing support apparatus for a gas turbine engine

A bearing support apparatus for a gas turbine engine, including: a first annular member; a second annular member disposed within the first annular member; first and second axially spaced-apart rolling-element bearings disposed between the first and second annular members so as to enable relative rotation of the first and second members; a first spring element mounting the first bearing to the first member; and a second spring element mounting the second bearing to the first member through the first spring element, such that the first and second bearings are physically supported in series relative to the first member.

Owner:GENERAL ELECTRIC CO

Rolling bearing device for supporting pinion shaft

InactiveUS20070242913A1Improve the rotation effectReducing a torque lossGearboxesShaftsInterior spaceBall bearing

In a bearing device, a double row rolling bearing for supporting a pinion gear-side portion of a pinion shaft on a case (annular wall) is formed by a tandem-type double row angular contact ball bearing. A first row of balls having a larger pitch circle diameter are disposed between inner and outer rings of the double row angular contact ball bearing at a region near to the pinion gear, and a second row of balls having a smaller pitch circle diameter are disposed between the inner and outer rings at a region remote from the pinion gear. A bearing internal space is divided into a first bearing internal space containing the first ball row and open toward the pinion gear and a second bearing internal space containing the second ball row and sealed by partition walls formed respectively by bearing seals, lubricating grease being sealed in the second bearing internal space.

Owner:JTEKT CORP

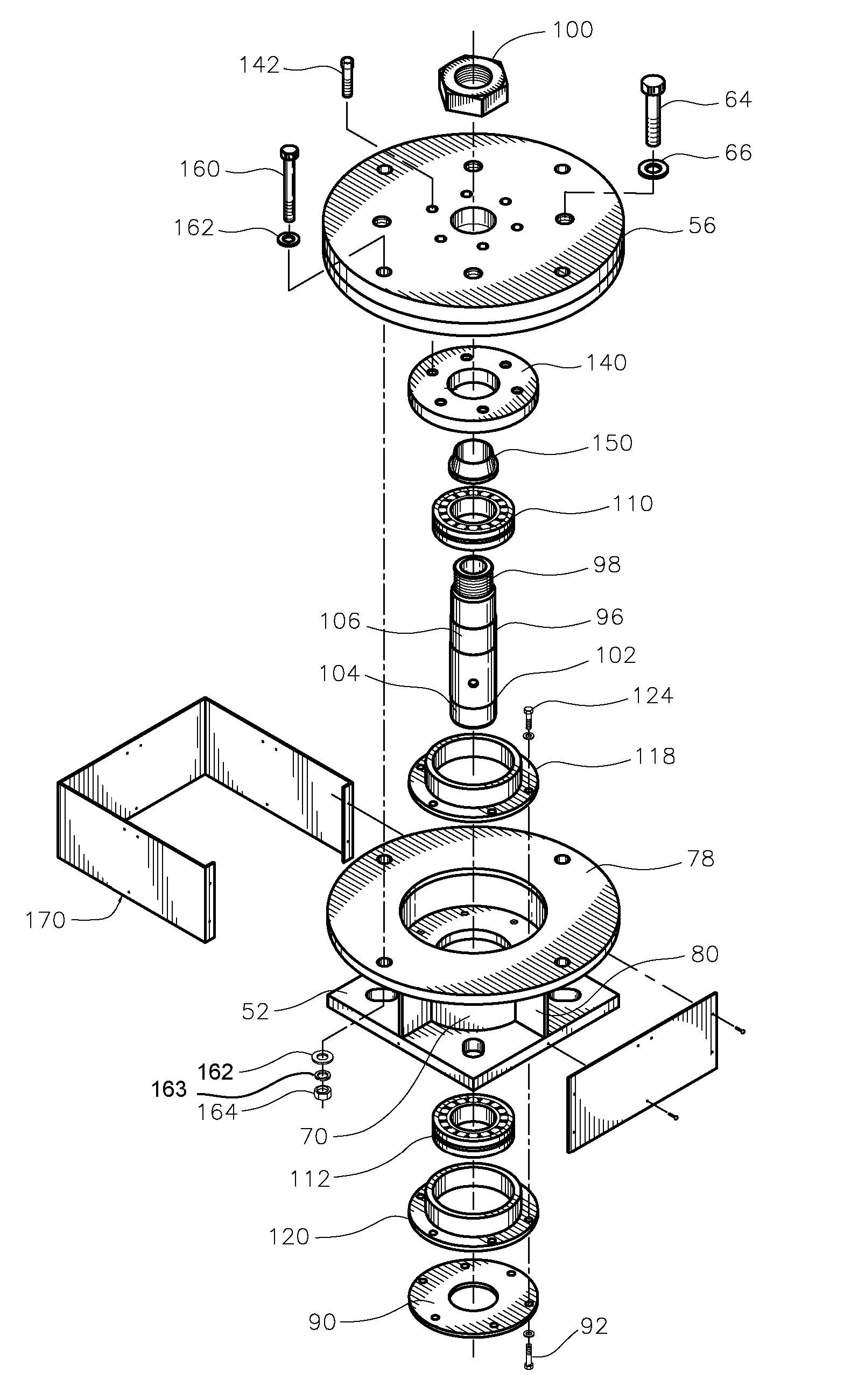

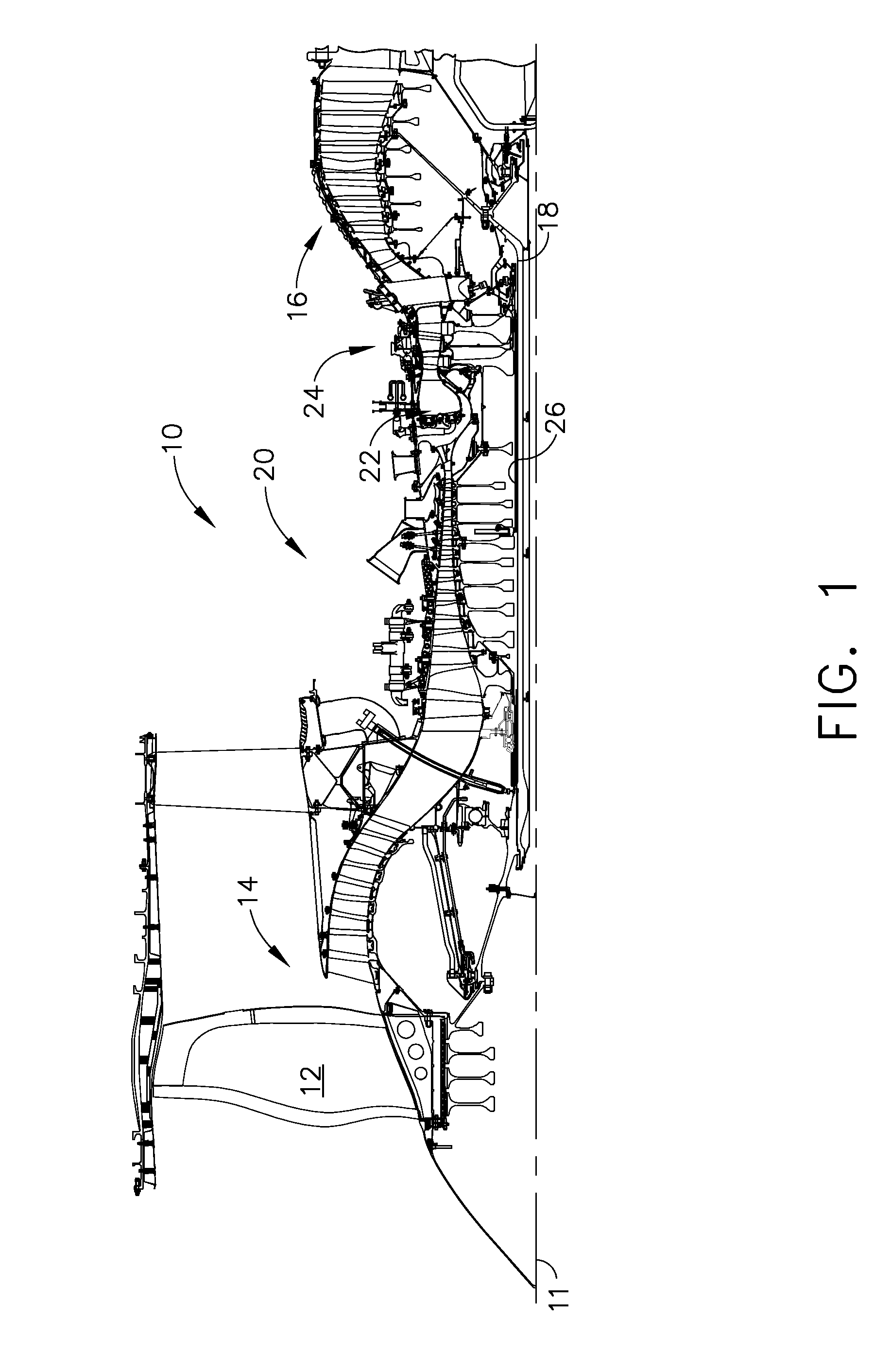

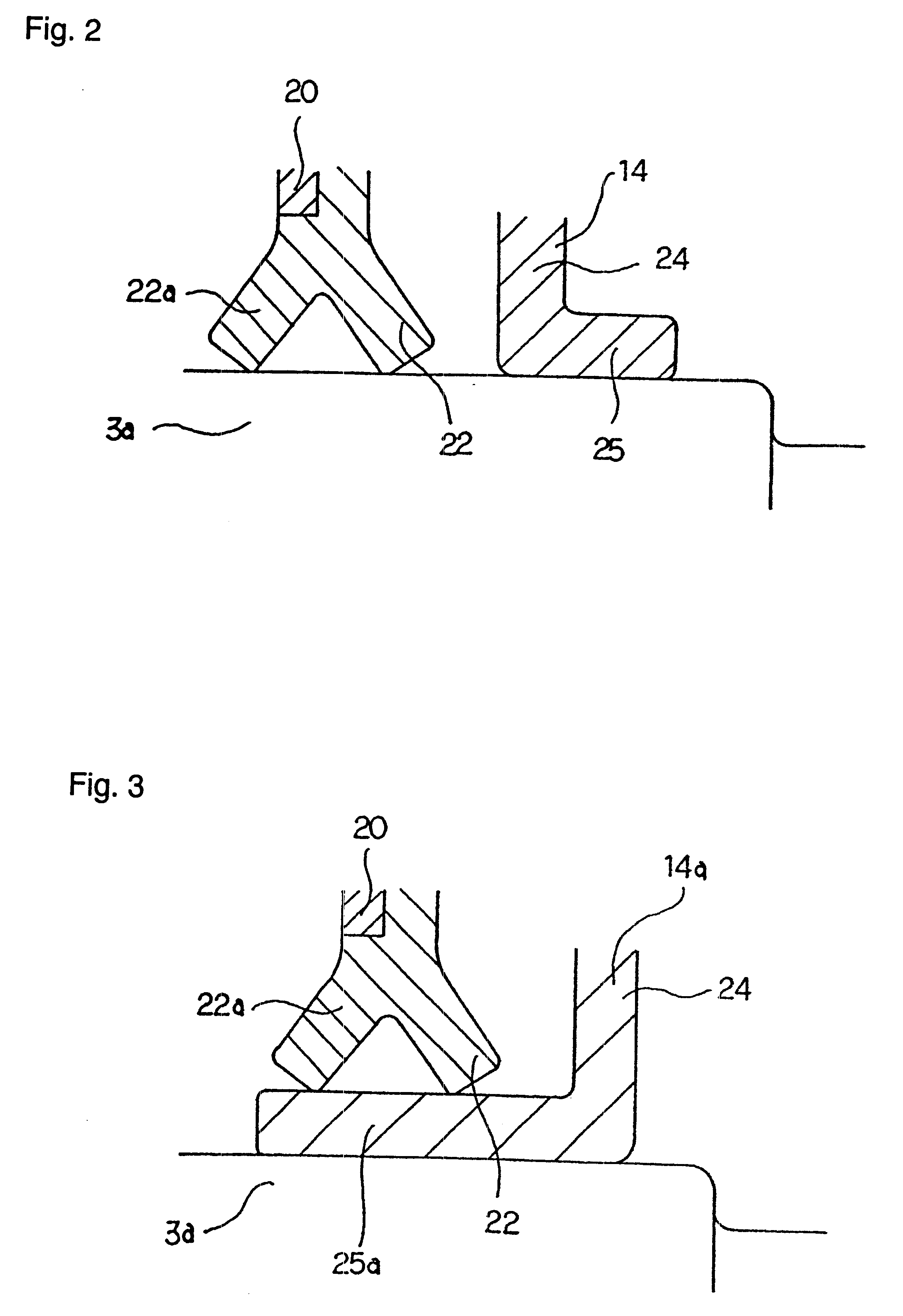

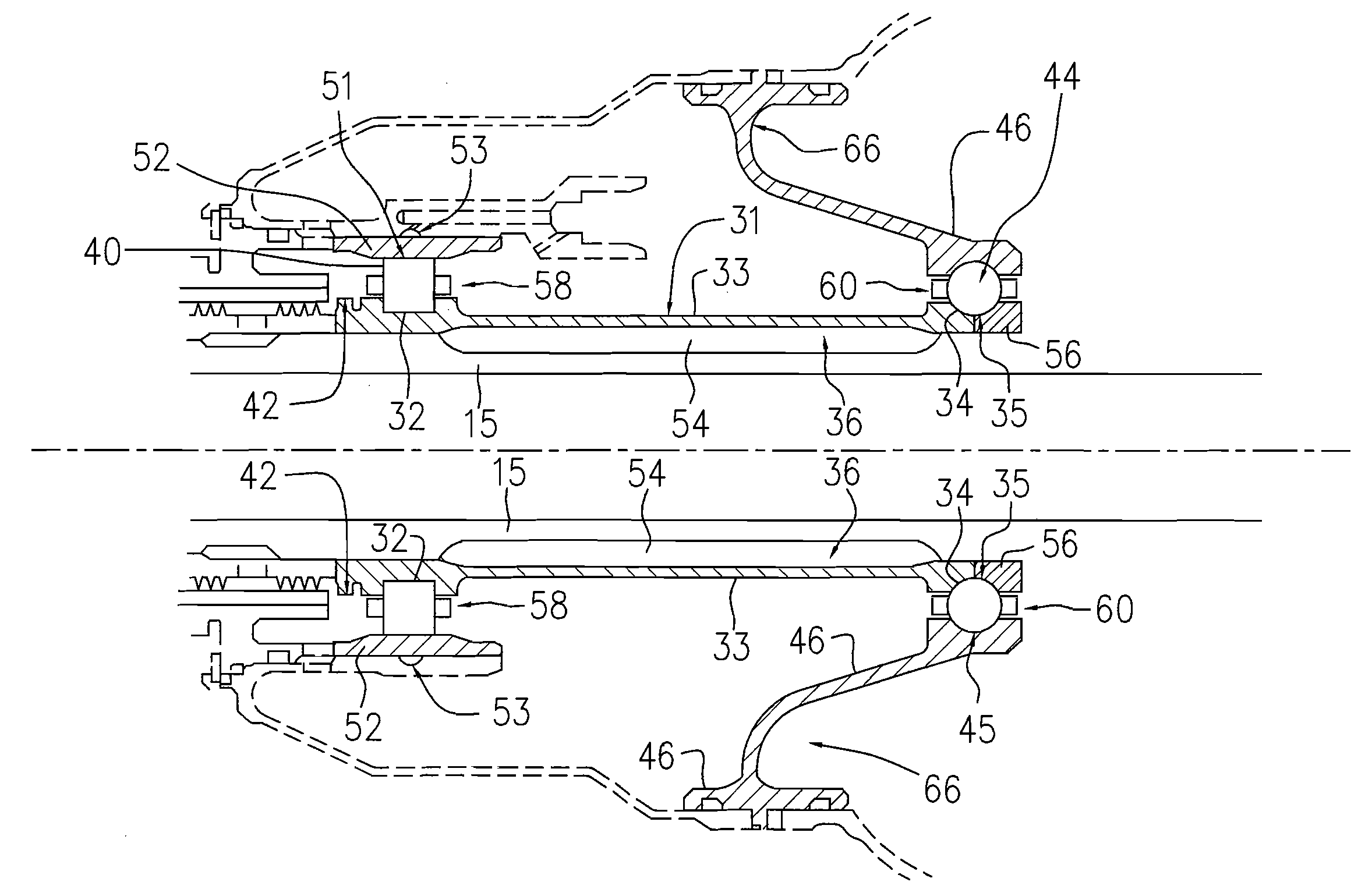

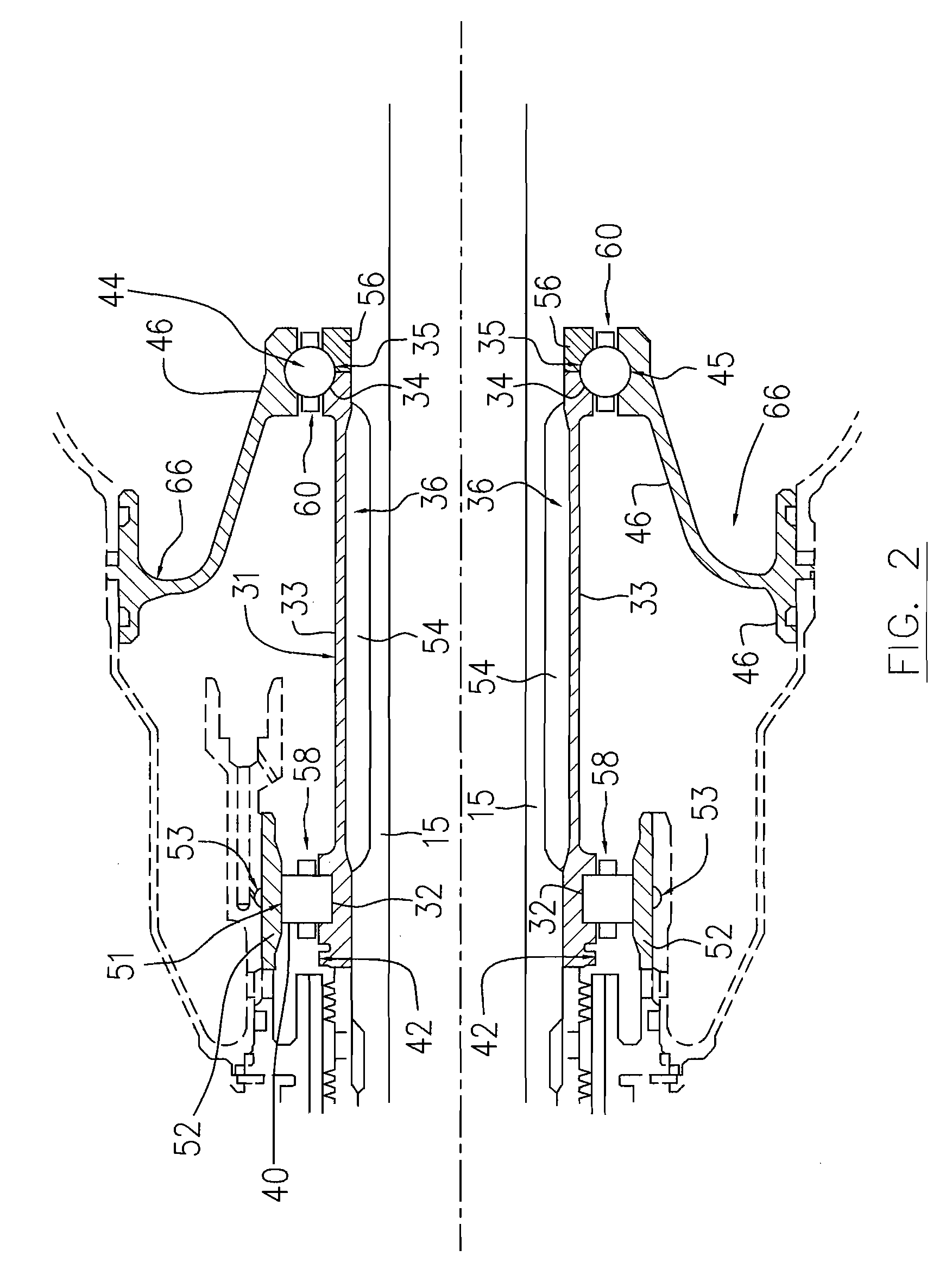

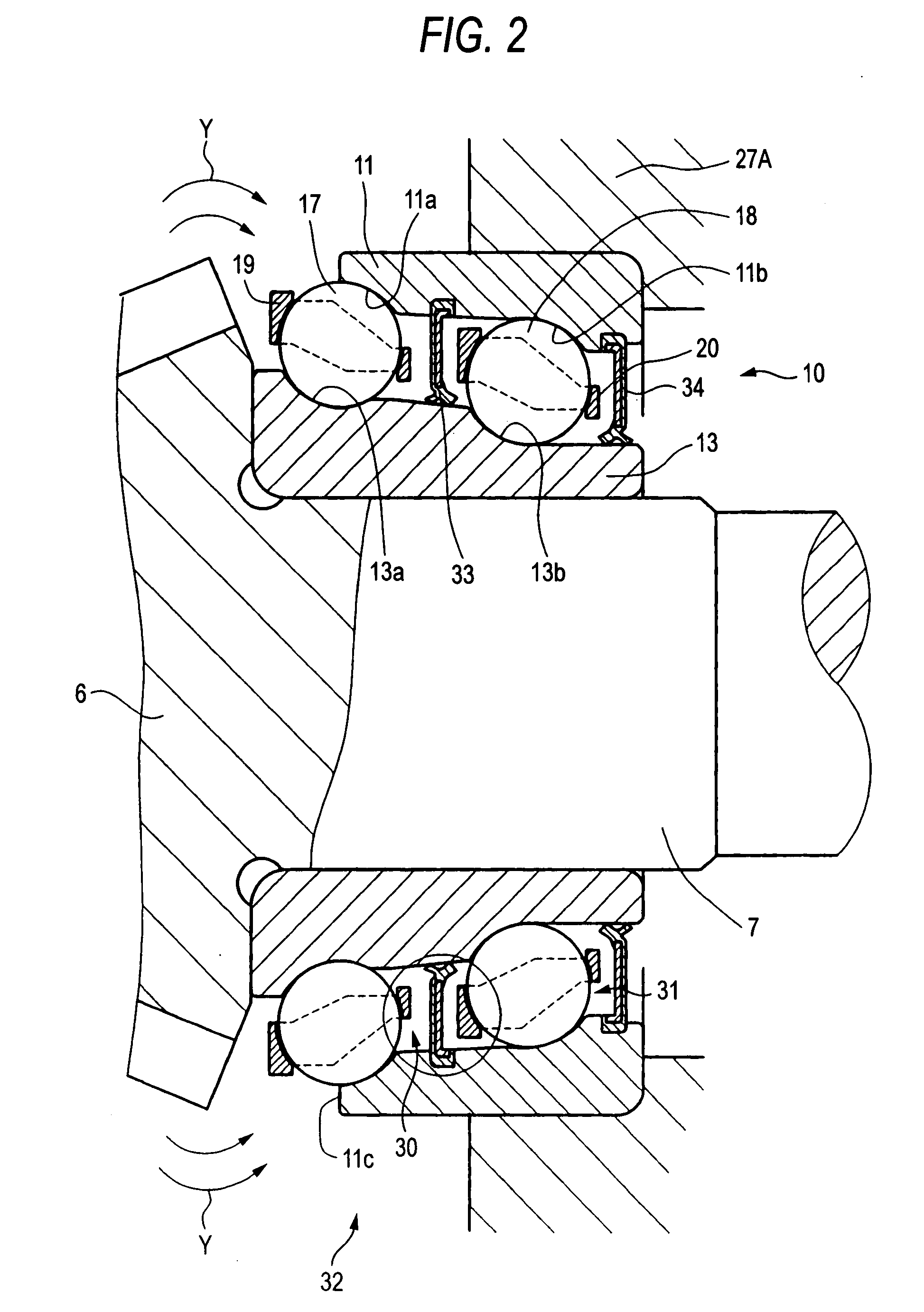

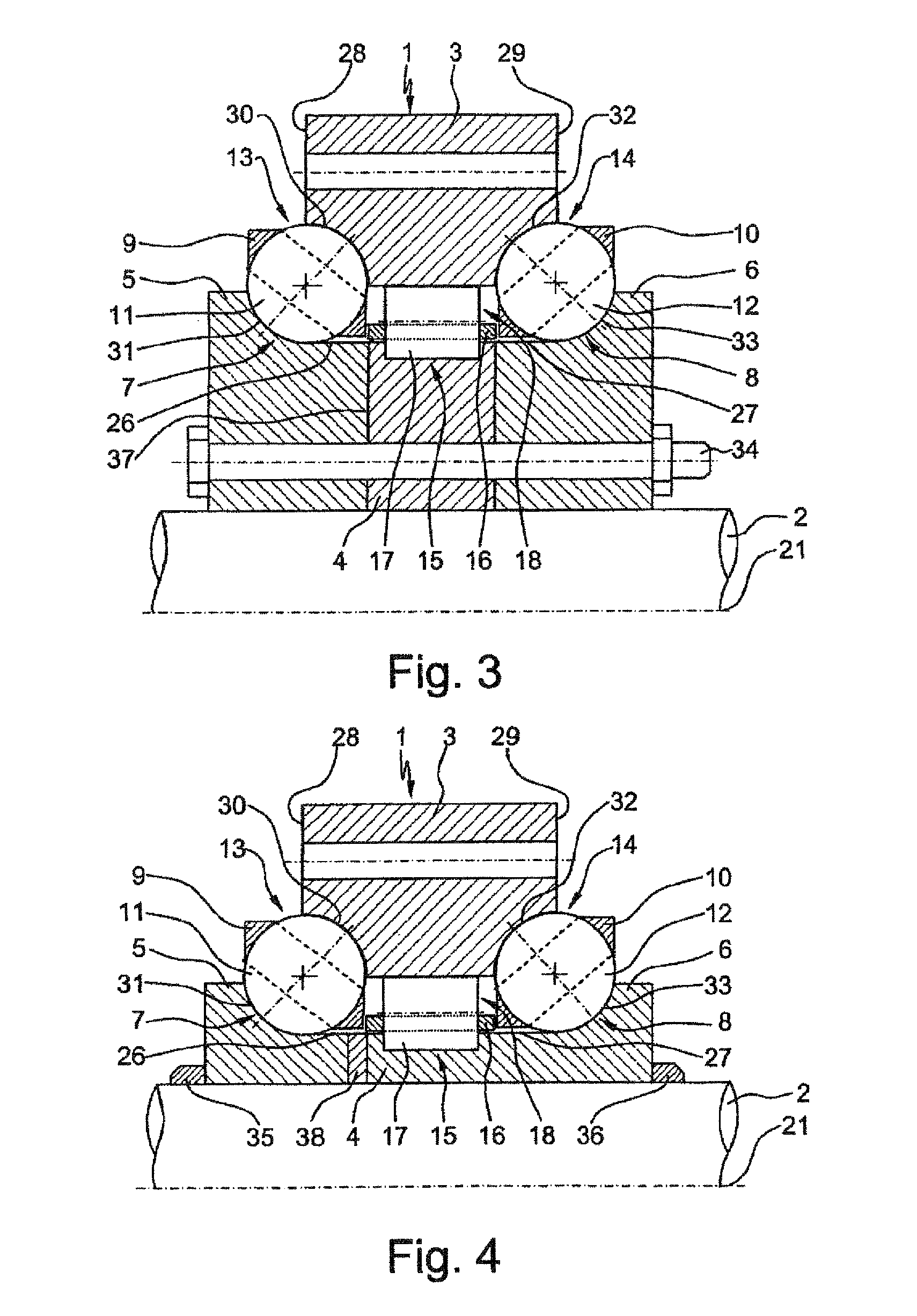

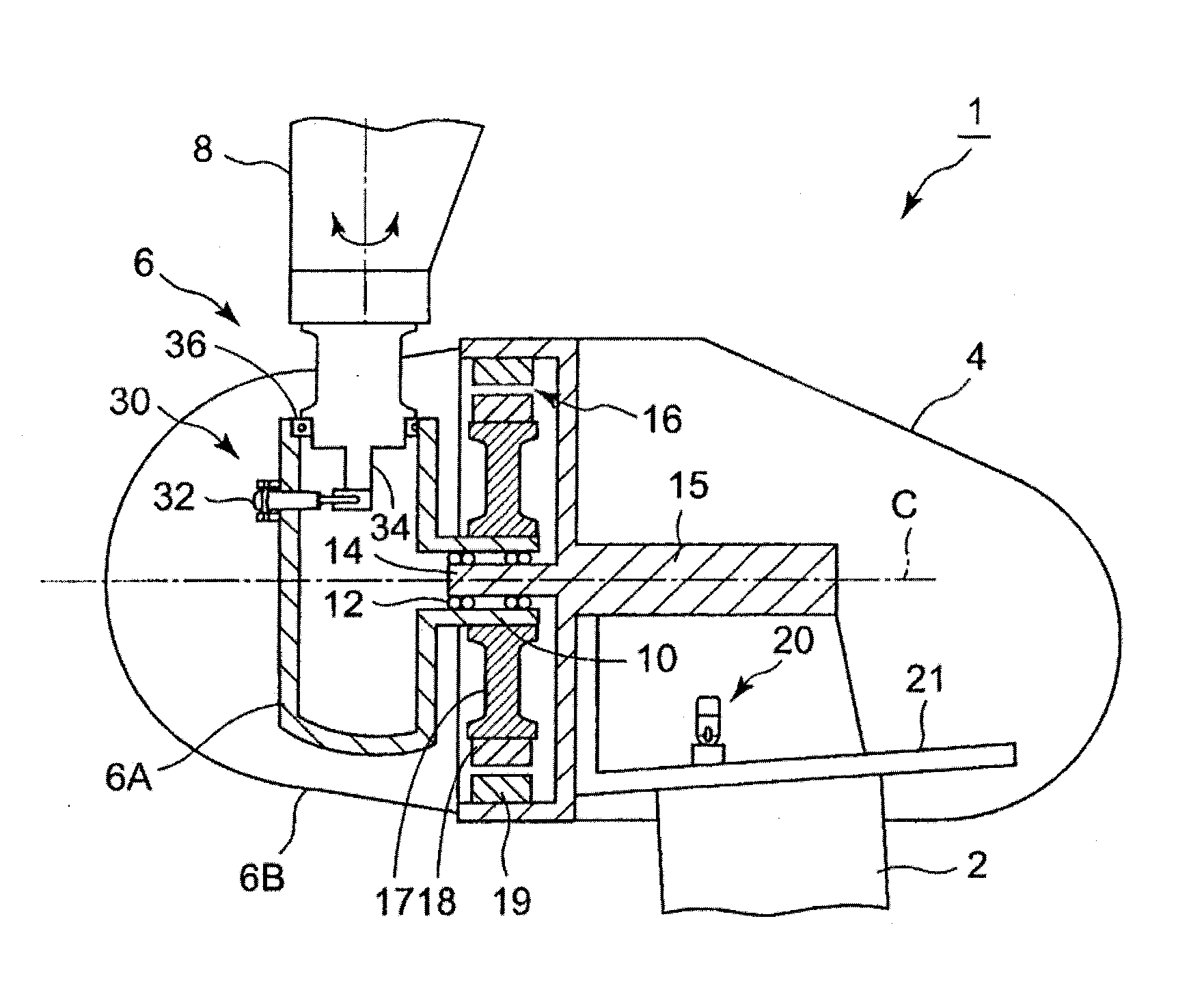

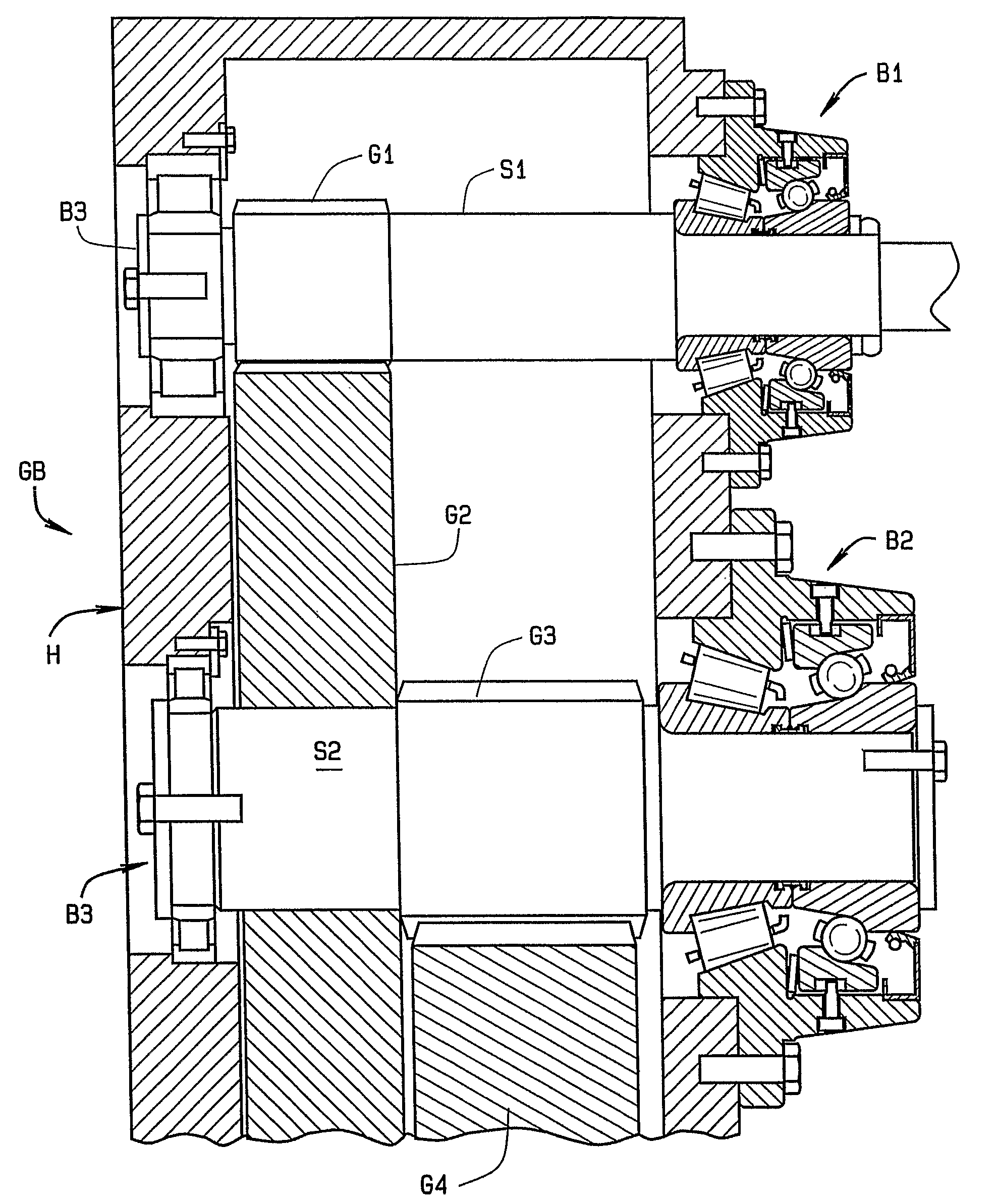

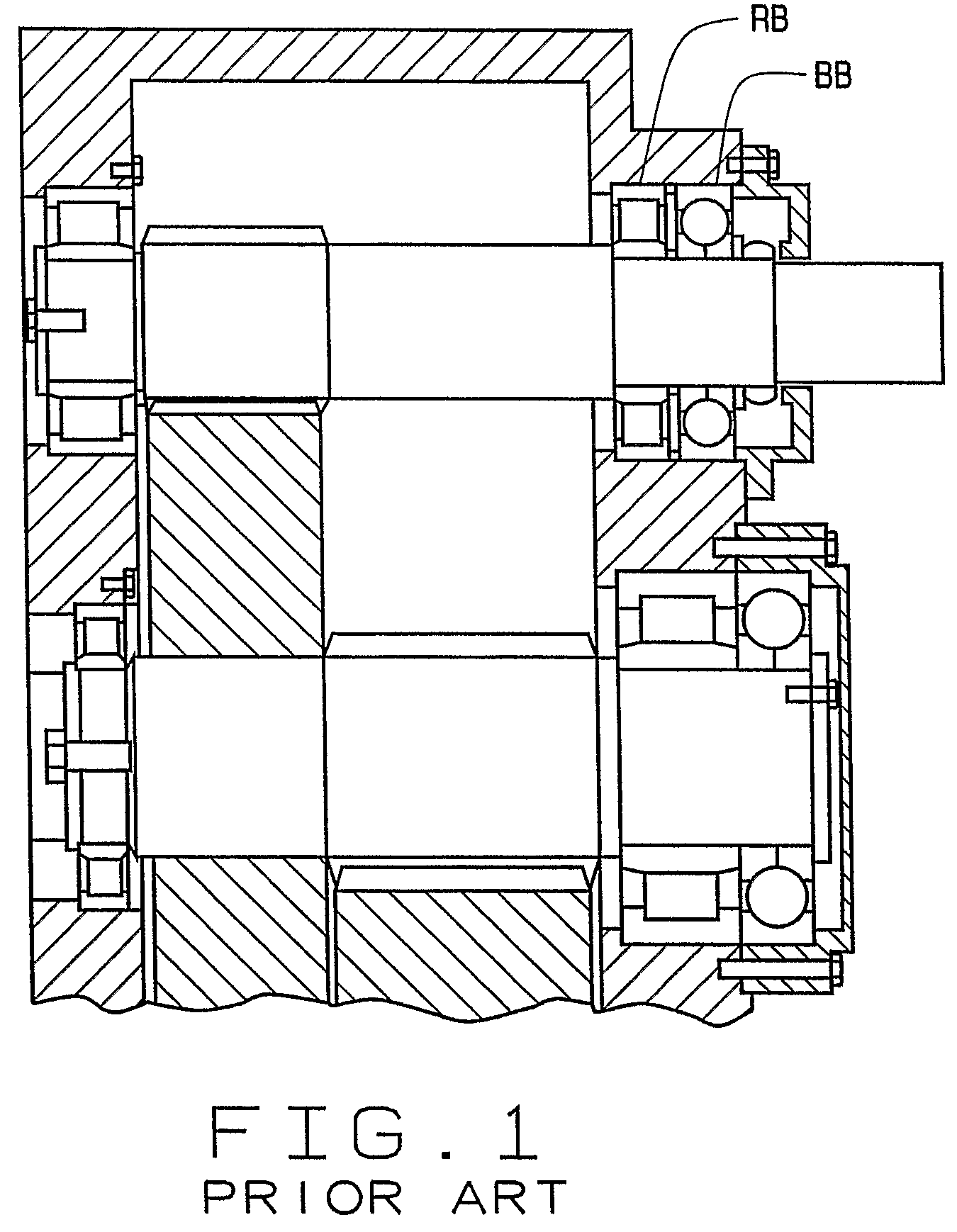

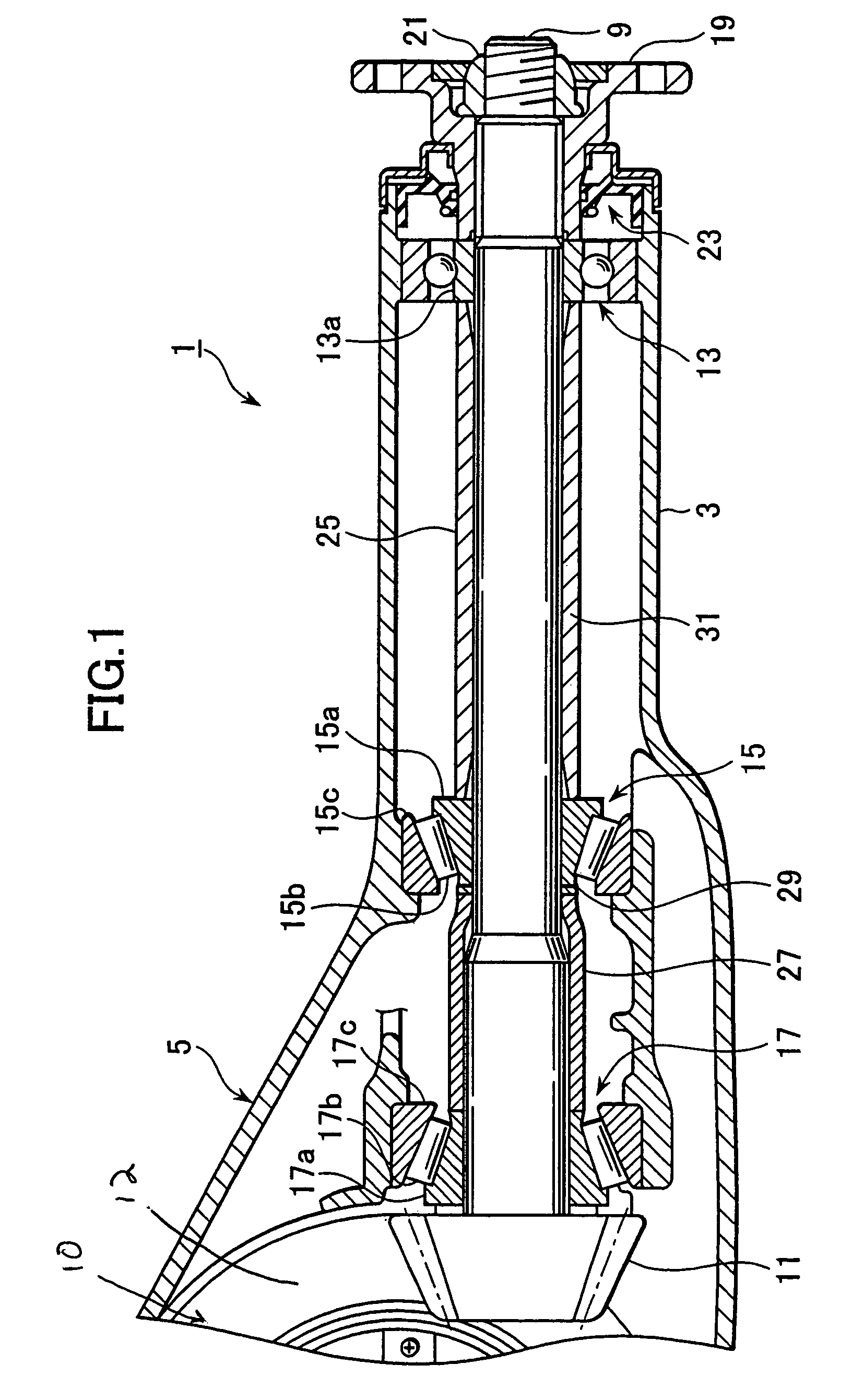

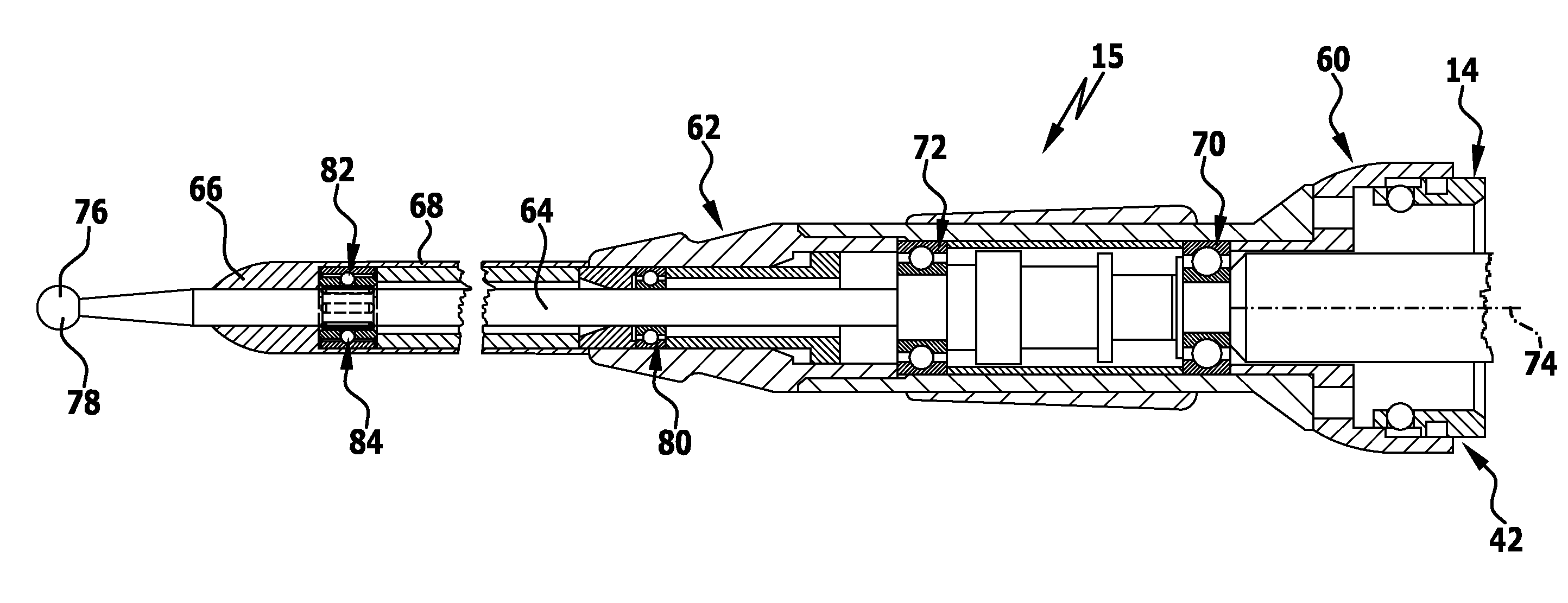

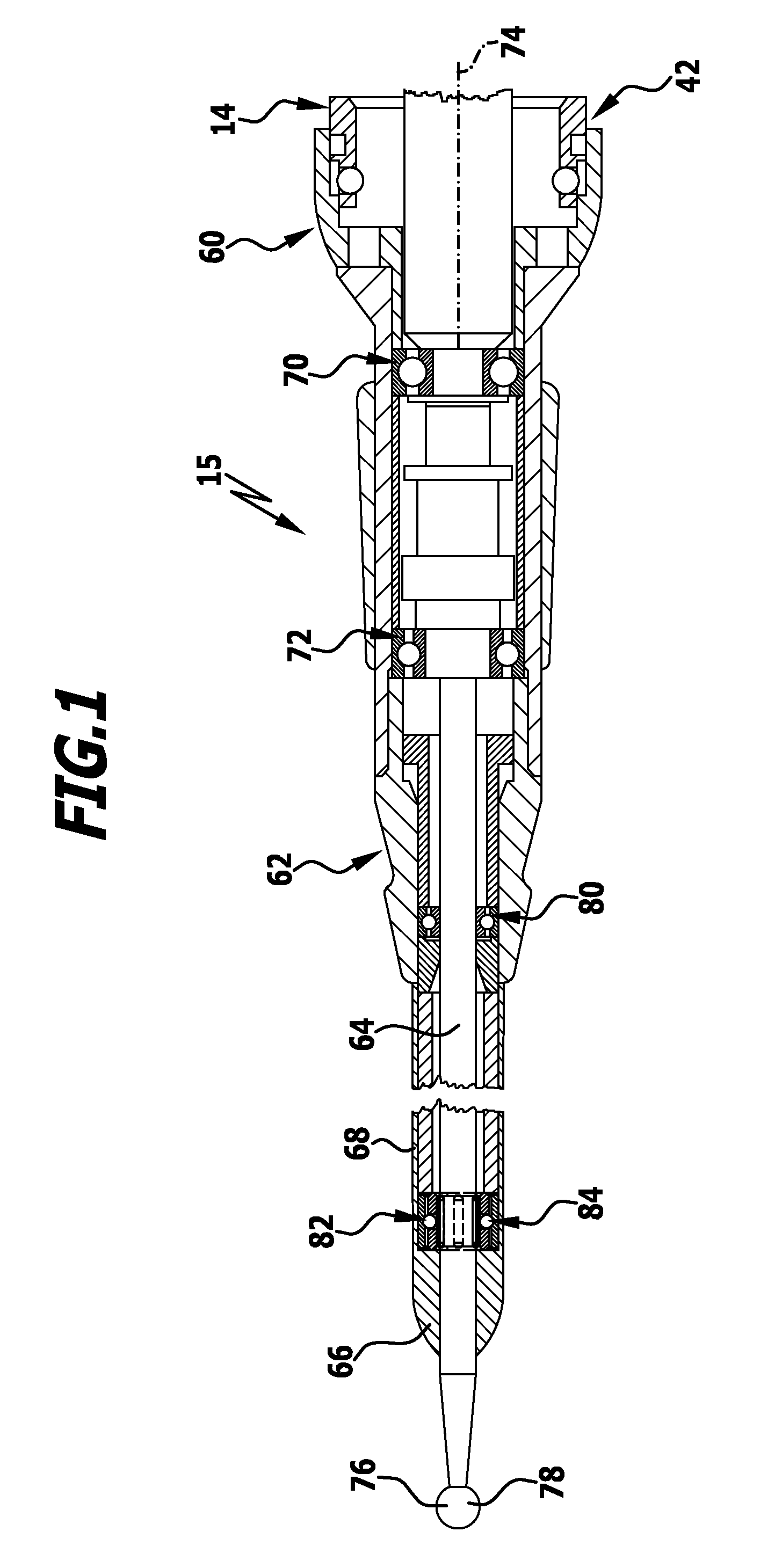

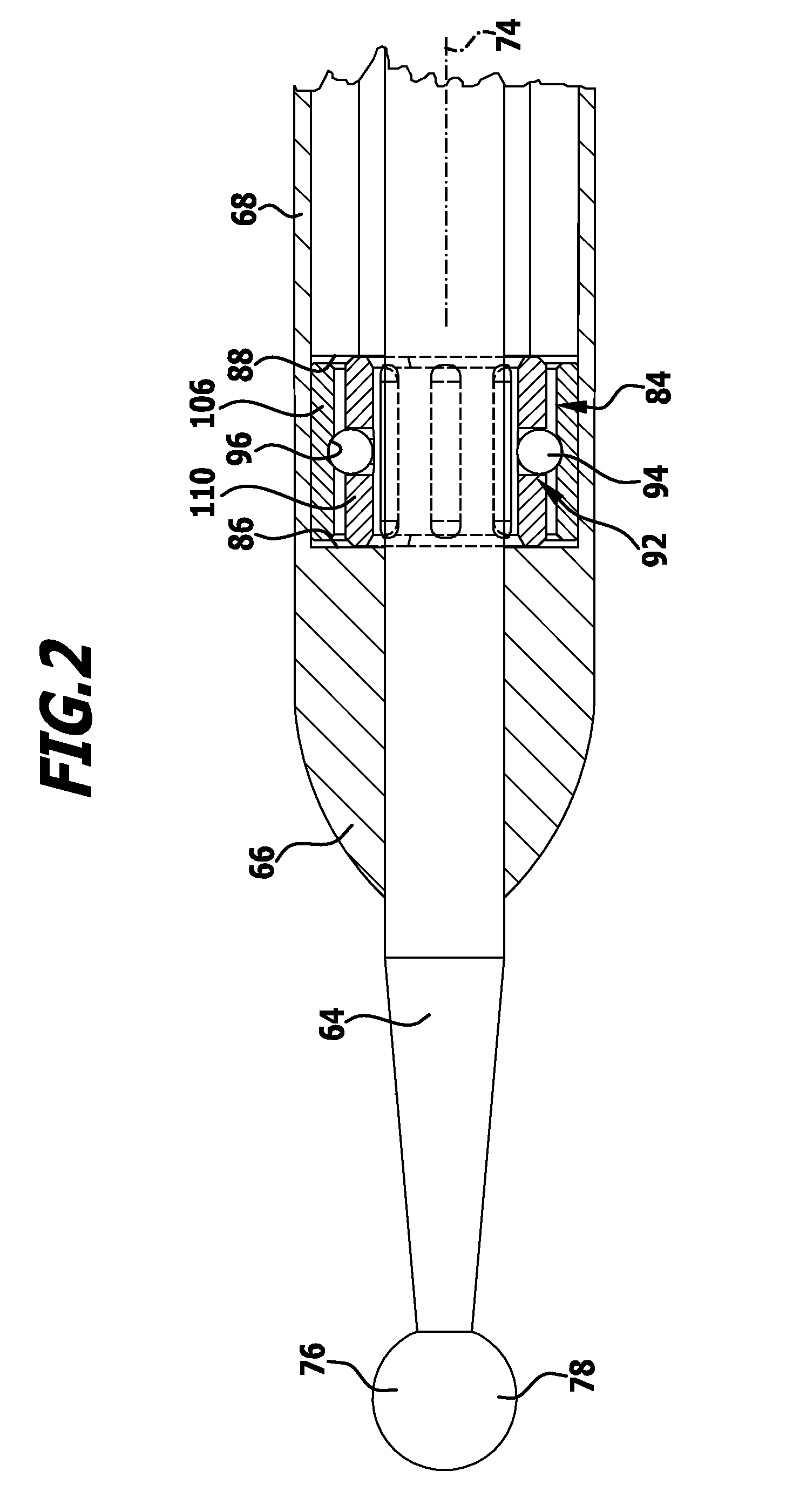

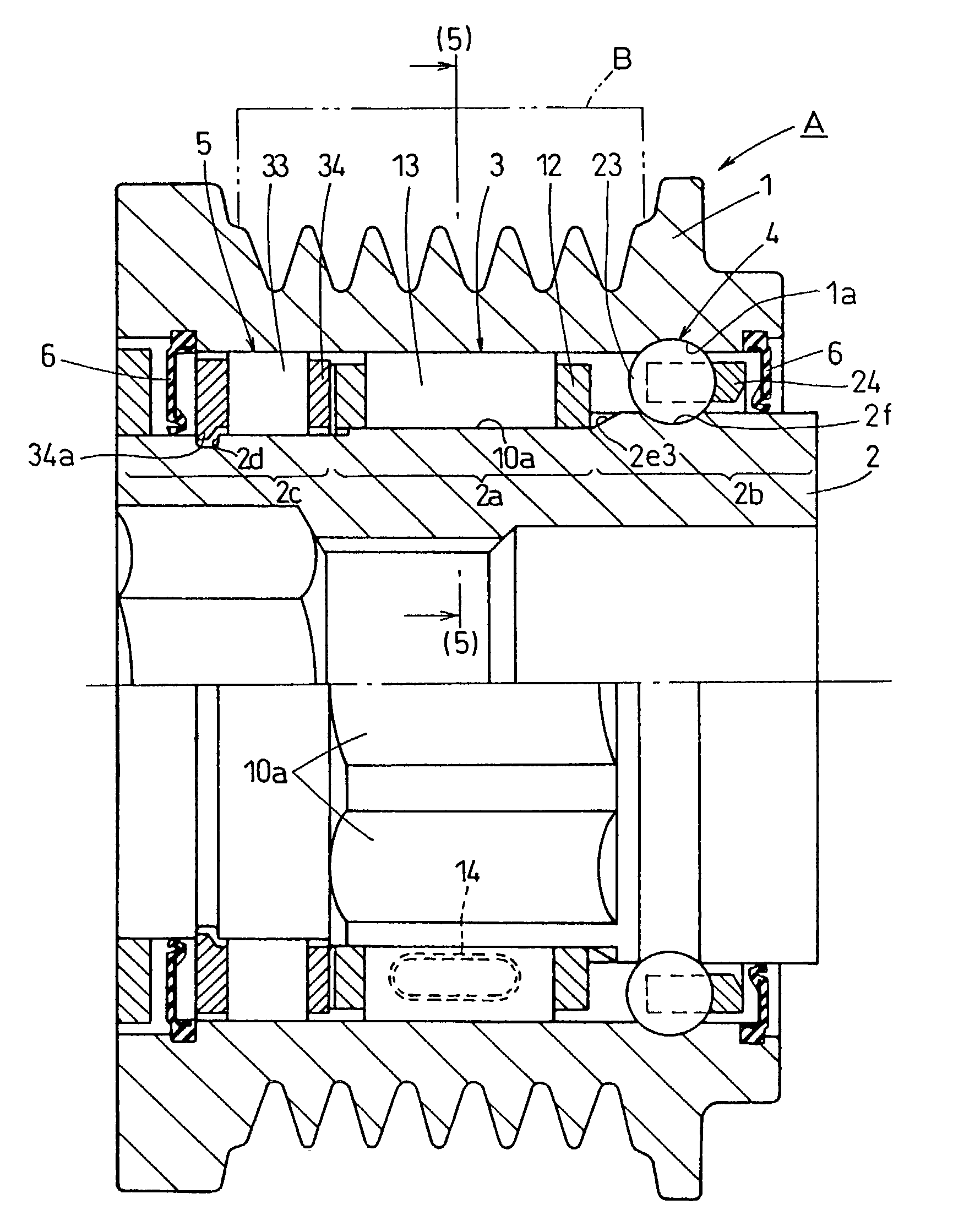

Locating Bearing Assembly for Wind Turbine Gearbox Shaft

InactiveUS20070211976A1Optimize load distributionSufficient loadGearboxesEngine fuctionsBall bearingEngineering

A locating bearing assembly (10) is provided that optimizes load distribution between bearing rows and for all rolling elements within the rows in either positive or negative torque conditions, by combining a single row tapered roller bearing with an angular contact ball bearing. The outer race (60) for the ball bearing is preloaded by a spring element (72) to prevent the balls (26) from floating freely between the ball bearing's inner and outer raceways (16, 64). This will insure that the balls (26) are always sufficiently loaded to roll along a single axis which is off set from the radial direction. The use of the single row tapered bearing and the preloaded angular contact ball bearing provides for a locating bearing assembly (“LBA”) in which the ball bearing supports only reversing axial loads. All radial loads are borne by the tapered roller bearing and transmitted to the bearing assembly housing (30).

Owner:THE TIMKEN CO

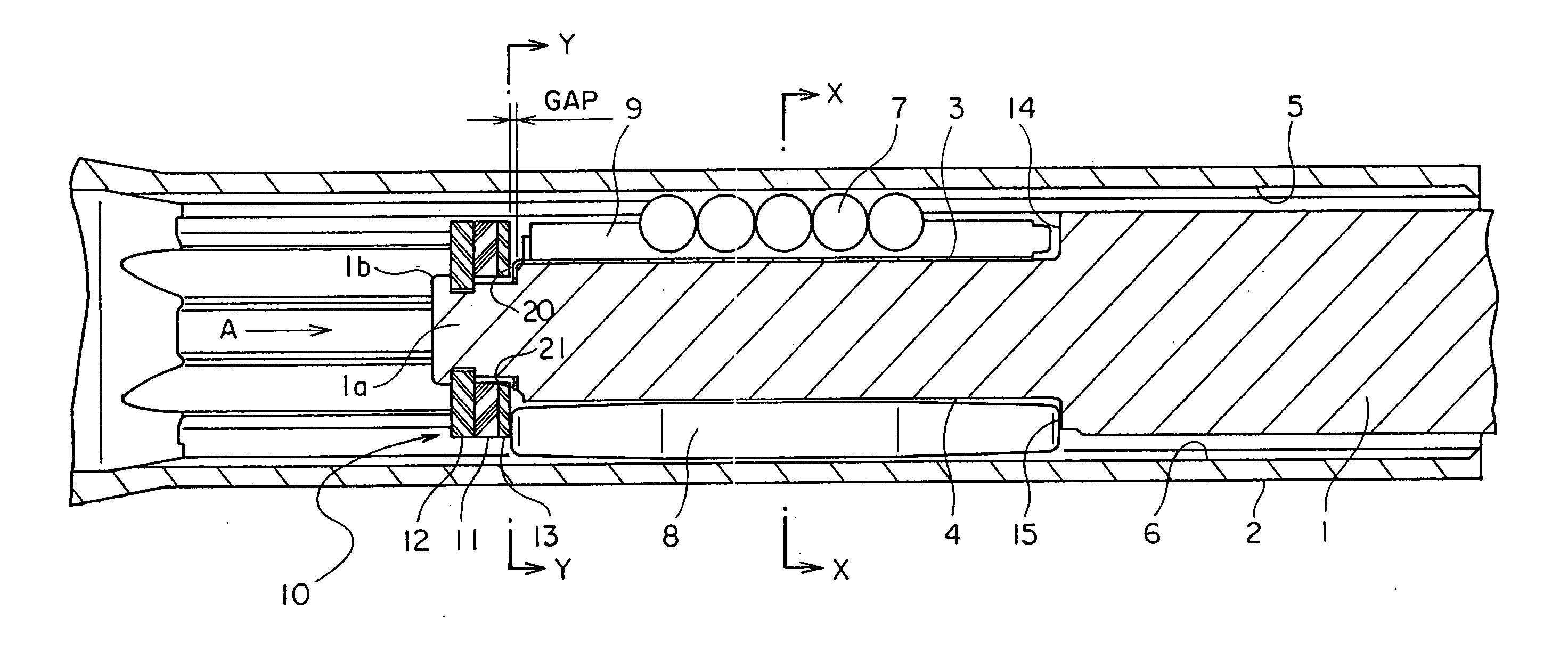

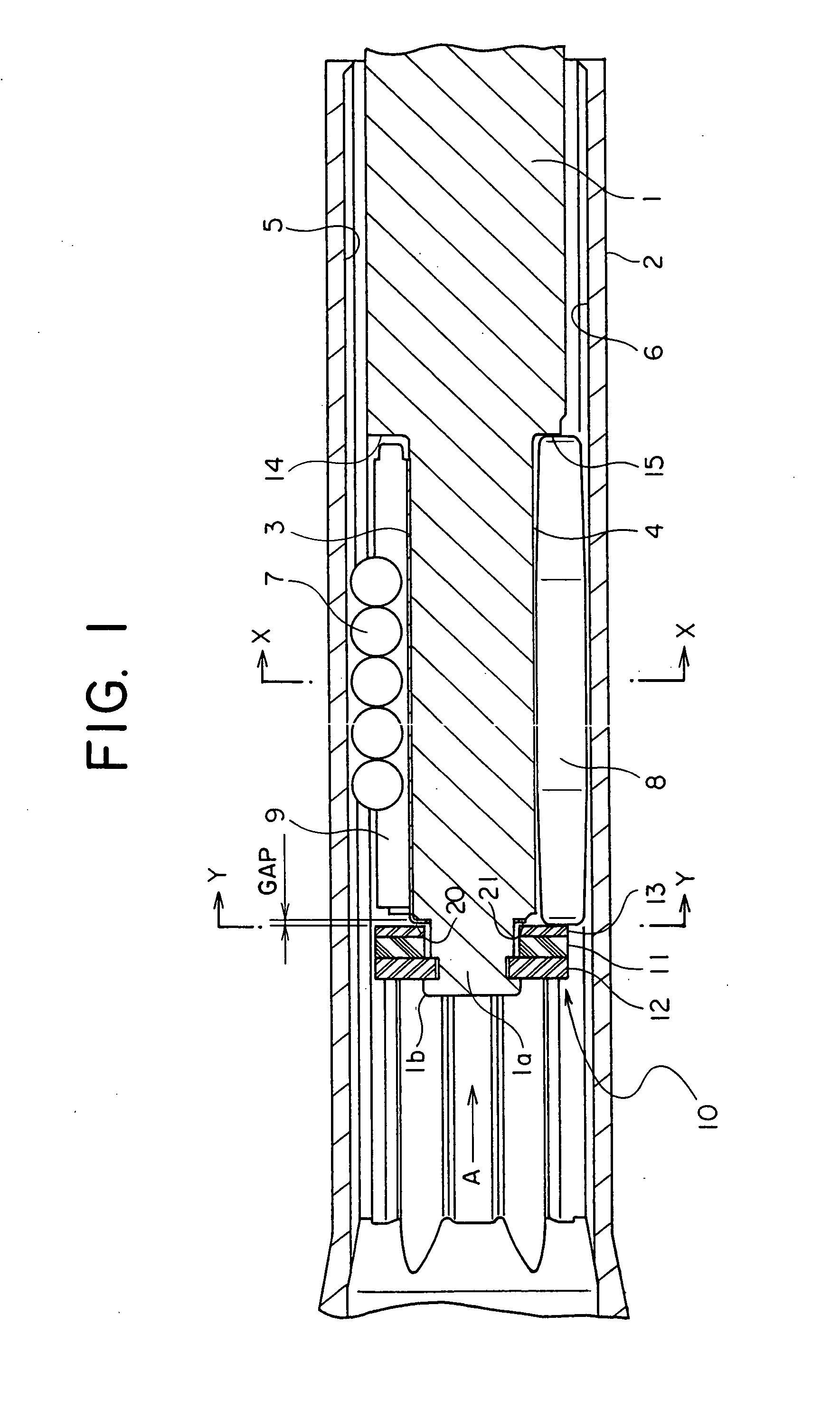

Extendable vehicle steering shaft

ActiveUS20060068924A1Shorten assembly timeLow costYielding couplingLinear bearingsTorque transmissionEngineering

In a telescopic shaft for vehicle steering, assembled in a steering shaft of a vehicle and including a male shaft and a female shaft so fitted as to be mutually incapable of rotating but mutually slidable, at least one set of torque transmission members are disposed in at least one set of accommodating portions formed in an outer peripheral surface of the male shaft and in an inner peripheral surface of the female shaft, and at least the one set of torque transmission members are cylindrical members that gradually decrease in their diameters toward end portions in an axial direction.

Owner:NSK LTD

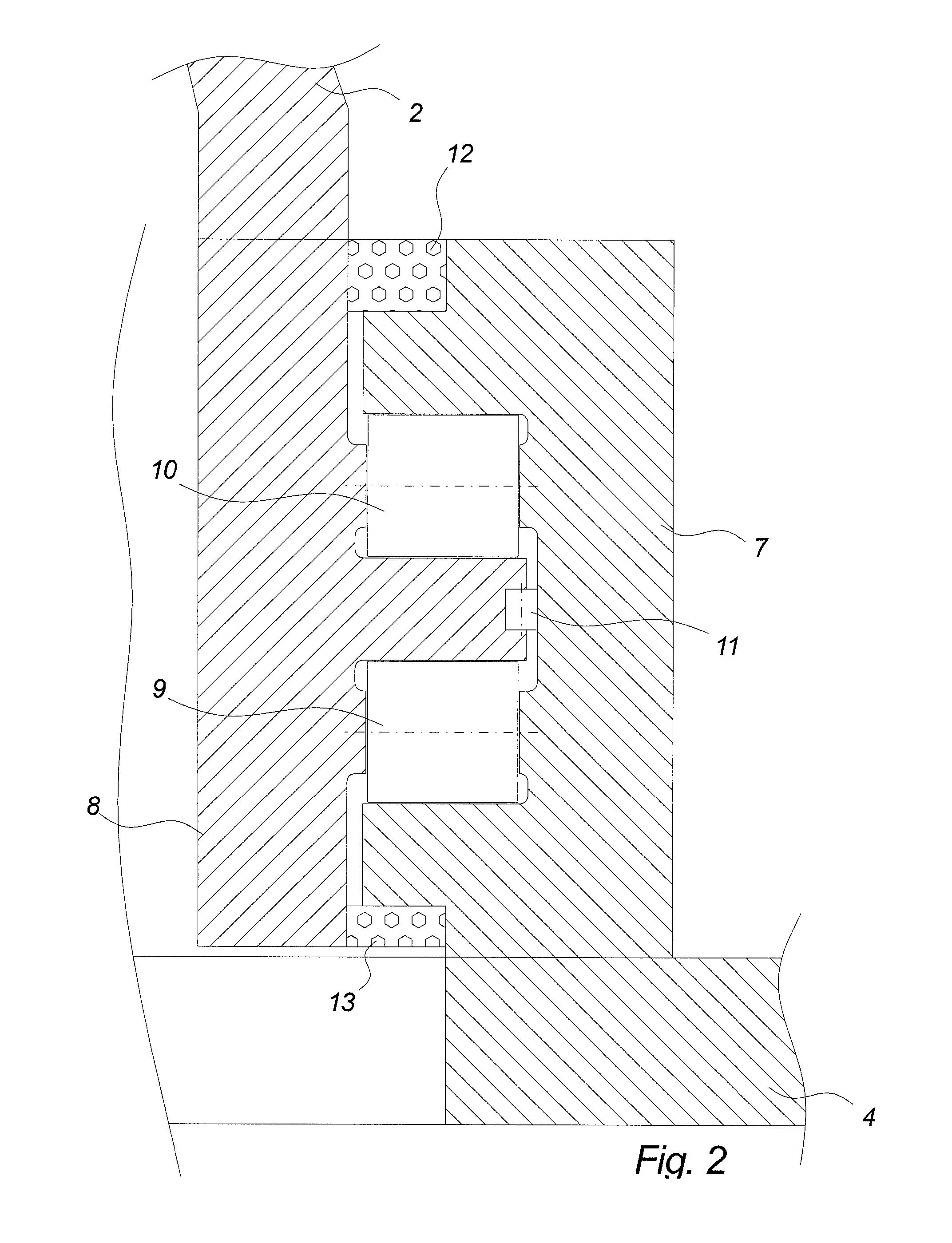

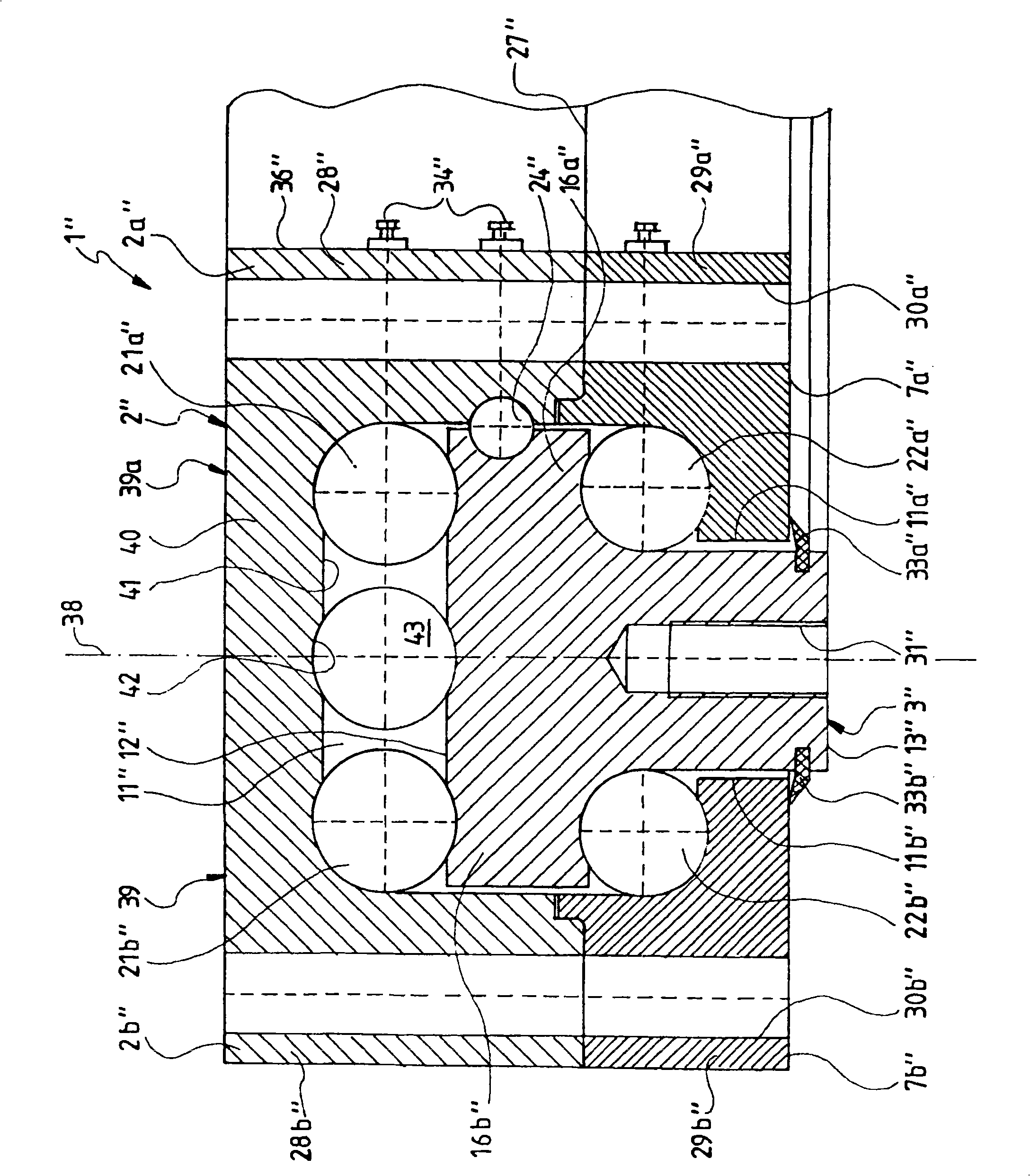

Multiple-row large roller bearing, especially axial radial bearing for the main arrangement of bearings of the rotor shaft of a wind power installation

InactiveUS8523453B2Improved kinematicsEasy to disassembleRoller bearingsBearing assemblyElectricityBall bearing

An axial radial bearing for a rotor shaft of a wind power installation, which has a vertical circular outer disk, inner ring arranged coaxially to the outer disk, and two circular shaft washers axially arranged on both sides of the outer disk. At least one row of rolling bodies, held at equal distances by a bearing cage, extends between the shaft washers and outer disk, forming the rolling bearings for receiving axial forces, while at least one other row of rolling bodies, optionally held at equal distances by another bearing cage, is arranged between the outer disk and inner ring, forming a third rolling bearing for receiving radial forces. The two rolling bearings for receiving radial forces are formed by two tapered roller bearings oriented towards the longitudinal axis of the bearing by the small front sides, or by a double-row angular ball bearing or by two axial ball bearings.

Owner:SCHAEFFLER TECH AG & CO KG

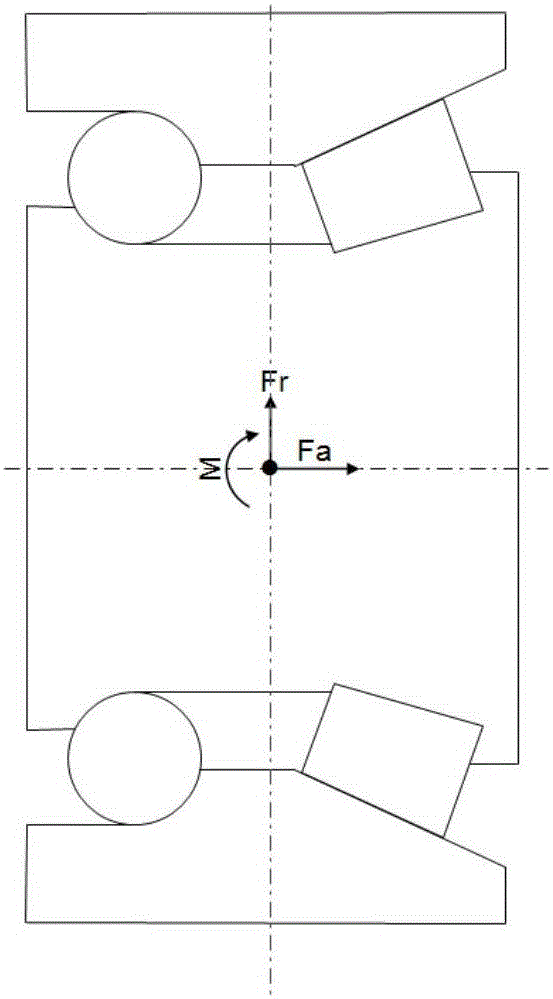

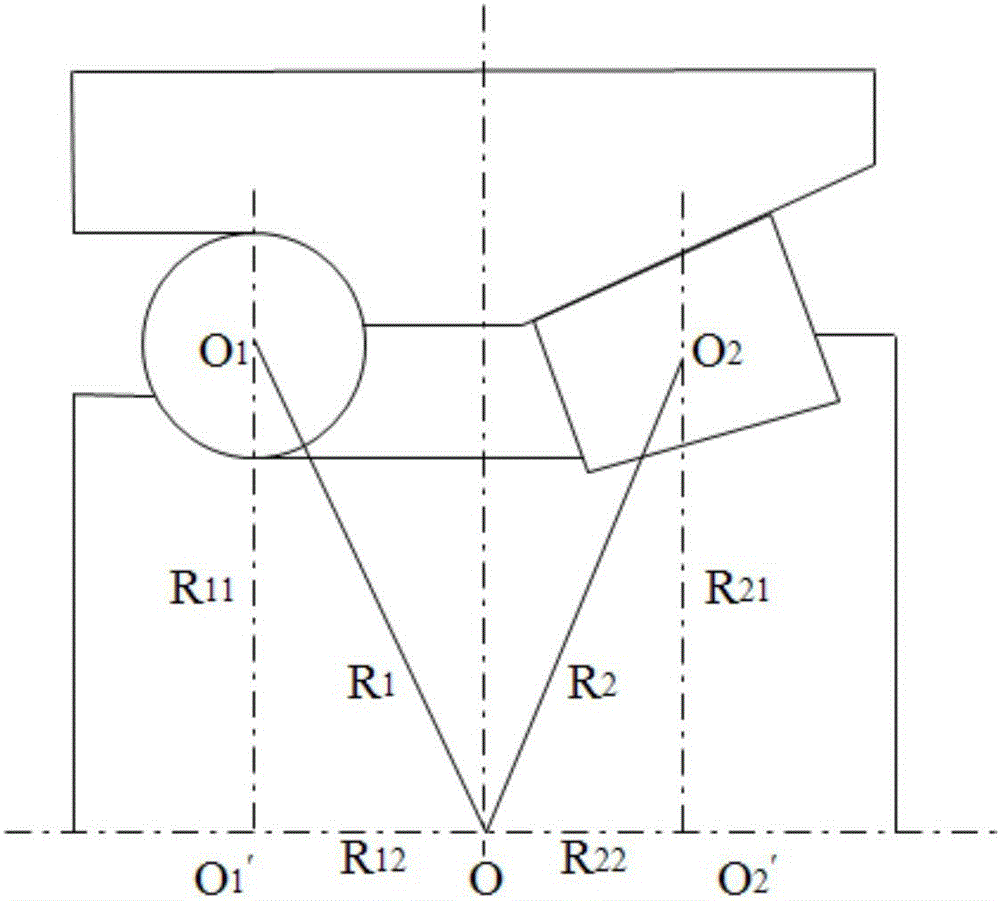

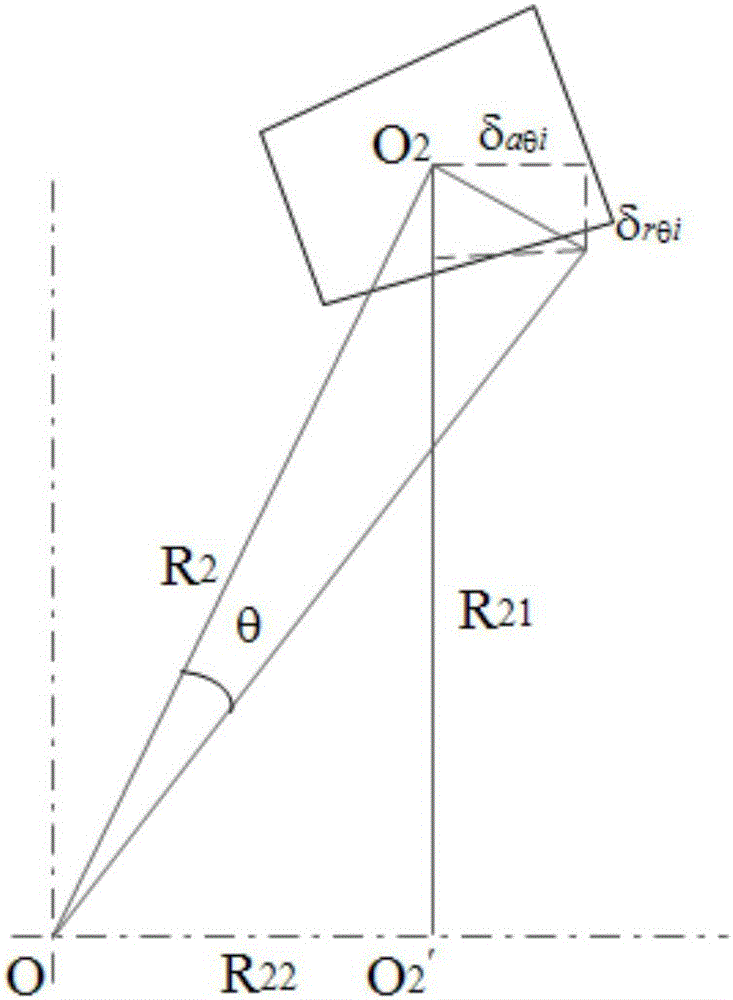

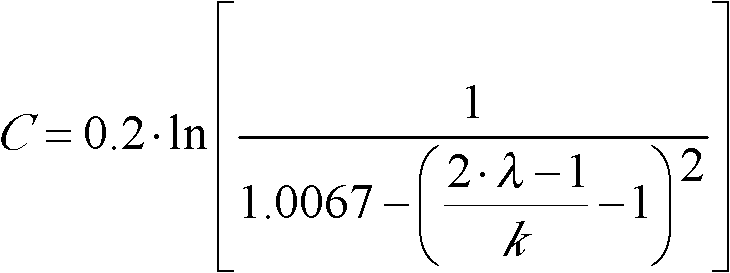

Method and device for obtaining load distribution of ball-cone mixed double-row hub bearing

ActiveCN106089993AQuickly obtain accurate bearing characteristic parametersImprove rationalityGeometric CADBall and roller bearingsAxial displacementPosition angle

The invention relates to a method and a device for obtaining load distribution of a ball-cone mixed double-row hub bearing. Firstly, a normal contact load Q1i in any position angle wi of a steel ball and a normal contact load Q2i in any position angle phi i of a conical roller with an outer ring are derived; then, total radial force Q1r, axial force Q1a and resistance torque M1 generated to the inner ring by the steel ball and total radial force Q2r, axial force Q2a and resistance torque M2 generated by the conical roller to the inner ring are obtained; a mechanical balance equation of the inner ring of the ball-cone mixed double-row hub bearing with delta r, delta a and theta as unknown quantities is built; and a Newton iteration method is applied to solve the balance equation to obtain a radial displacement delta r, an axial displacement delta a and an angular displacement theta of the inner ring of the bearing so as to obtain the load distribution conditions in each row of the bearing. The method can quickly obtain precise bearing characteristic parameters of the ball-cone mixed double-row hub bearing, can directly judge if the structural design of the ball-cone mixed double-row hub bearing is reasonable, and improves the design rationality and accuracy of the ball-cone mixed double-row hub bearing.

Owner:HENAN UNIV OF SCI & TECH

Method of repairing bearing of wind turbine generator

A method of repairing a bearing of a wind turbine generator is provided which is able to more permanently repair a gap which occurred between a constituent member of the wind turbine generator and a bearing ring of the bearing. For example, in the case of repairing the gap 13 between the main shaft outer cylinder 10 of the wind turbine generator 1 and the outer ring 12A of the main bearing 12, the plate 40 is inserted between the main shaft outer cylinder 10 and the outer ring 12A, and also the plate 40 is fixed to an inner circumferential surface of the main shaft outer cylinder 10 by the adhesive agent 41. On the other hand, slip is permitted between the plate 40 and the outer ring 12A of the main bearing 12.

Owner:MITSUBISHI HEAVY IND LTD

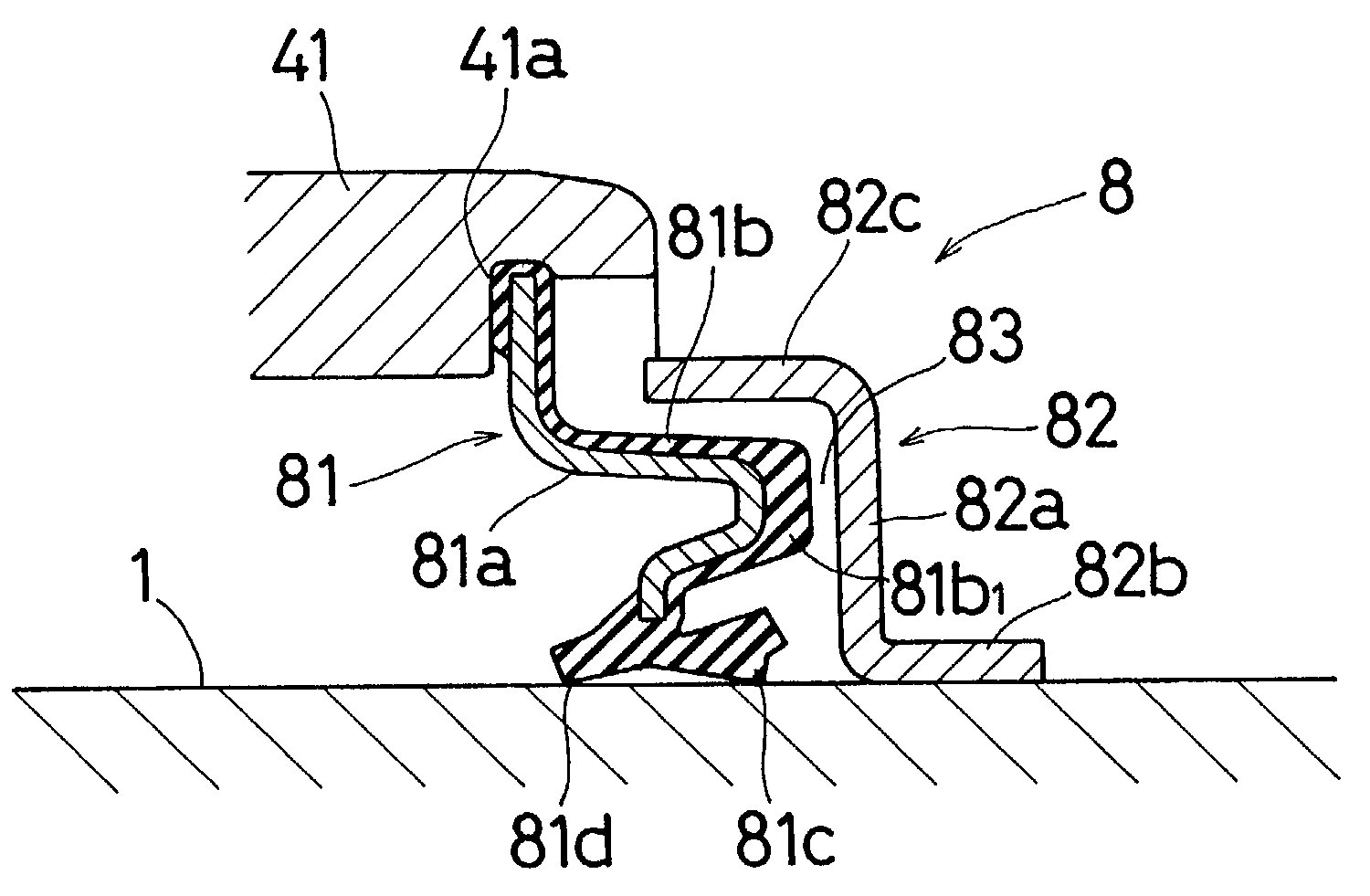

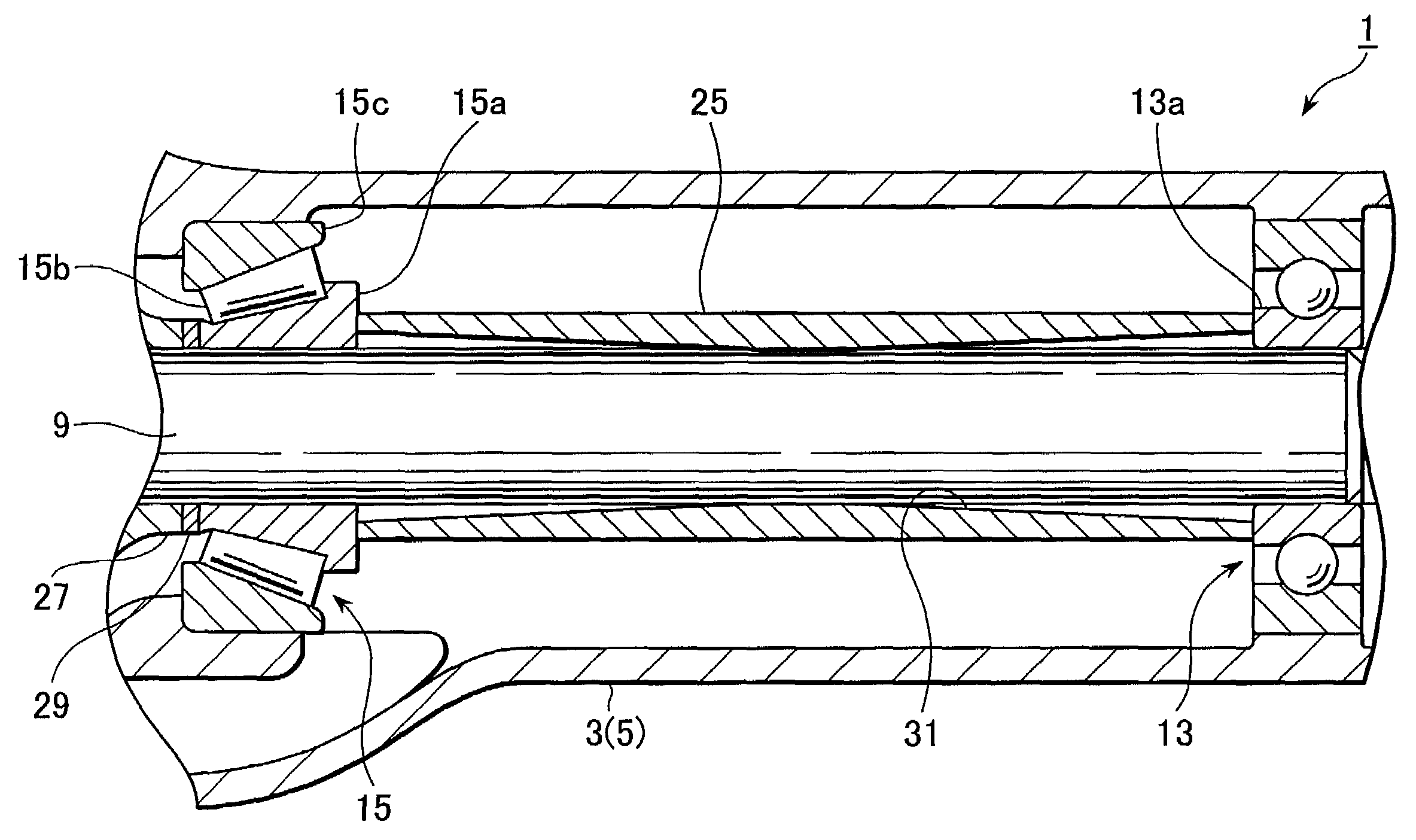

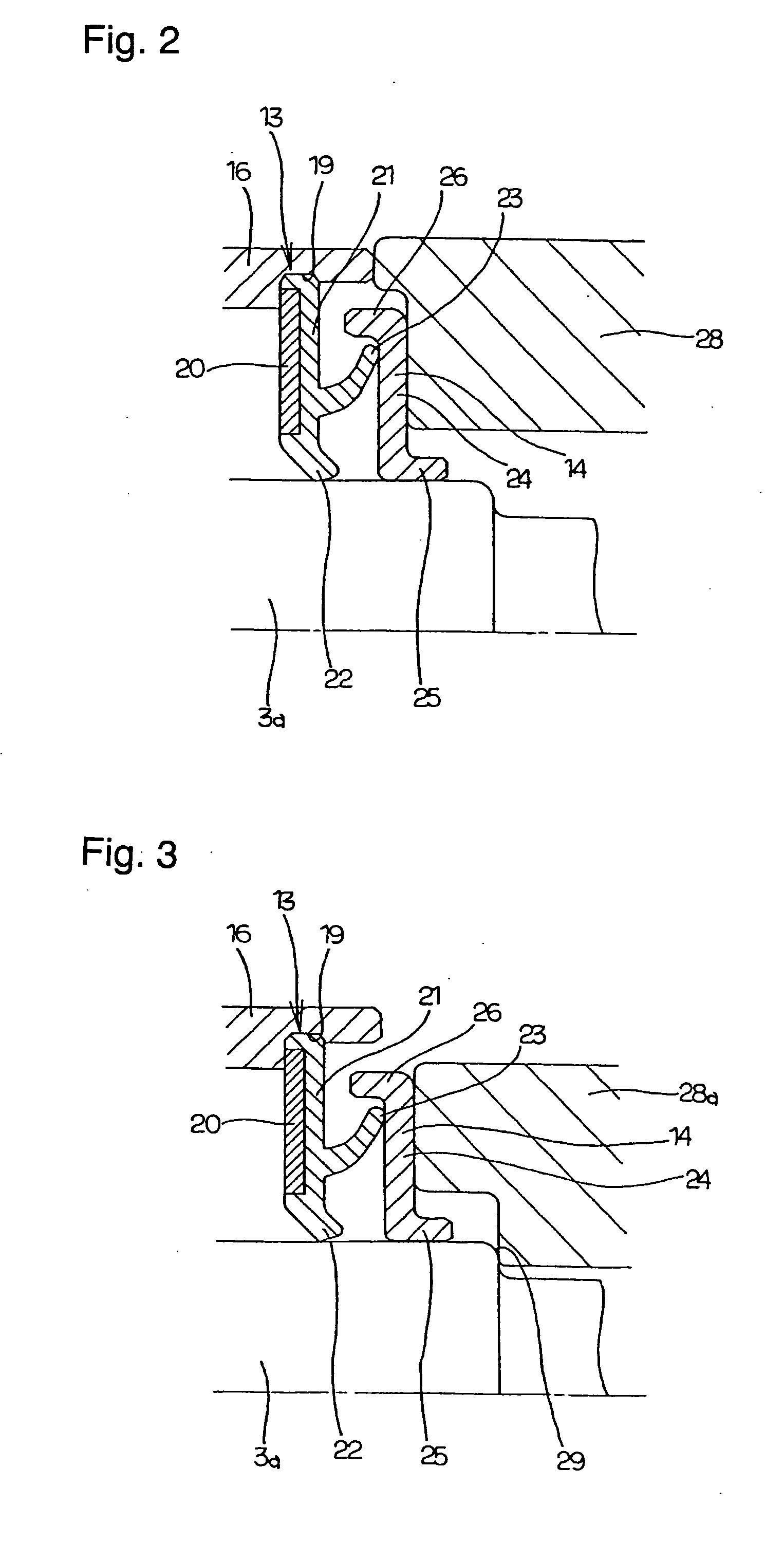

Sealing device for water pump bearings

InactiveUS7066467B2Sufficient seal performanceImprove sealingEngine sealsShaftsEngineeringMechanical engineering

A sealing device for a water pump bearing employs a seal member without an axial lip, and having only a radial lip. The sealing device includes an annular seal member which is fixed to a shoulder portion of one end in an axial direction of an outer race of a water pump bearing and an annular slinger which is positioned on a side of the one end in the axial direction with respect to the seal member and externally fixed to the outer peripheral face of a pump shaft serving as an inner race. The seal member has a section shape which is bent along a disk portion and an outer cylindrical portion of the slinger. A labyrinth seal portion is formed between the seal member, and the disk portion and the outer cylindrical portion of the slinger. Radial lips are formed on an inner periphery of the seal member.

Owner:KOYO SEIKO CO LTD

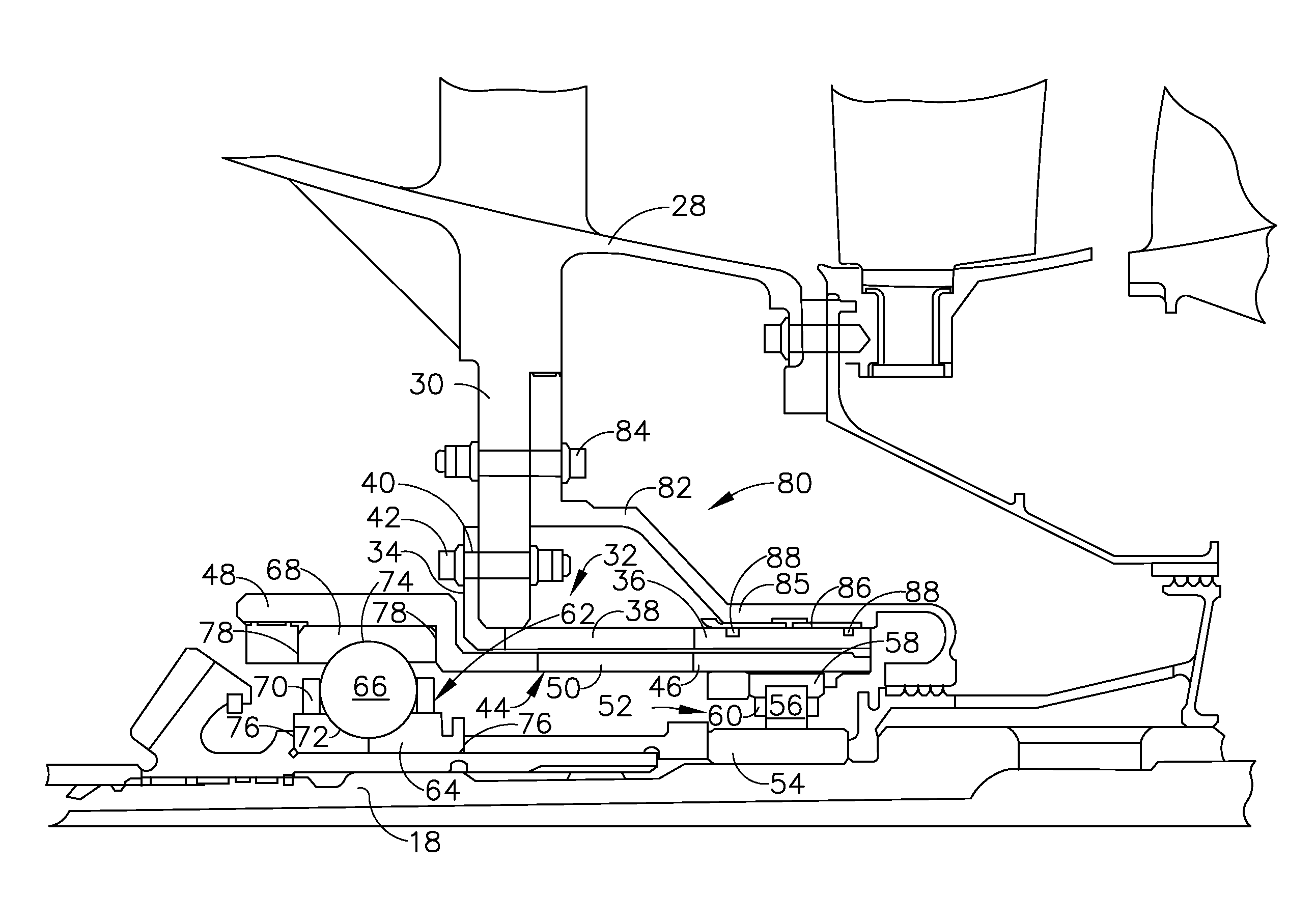

Locating bearing assembly for wind turbine gearbox shaft

A locating bearing assembly (10) is provided that optimizes load distribution between bearing rows and for all rolling elements within the rows in either positive or negative torque conditions, by combining a single row tapered roller bearing with an angular contact ball bearing. The outer race (60) for the ball bearing is preloaded by a spring element (72) to prevent the balls (26) from floating freely between the ball bearing's inner and outer raceways (16, 64). This will insure that the balls (26) are always sufficiently loaded to roll along a single axis which is off set from the radial direction. The use of the single row tapered bearing and the preloaded angular contact ball bearing provides for a locating bearing assembly (“LBA”) in which the ball bearing supports only reversing axial loads. All radial loads are borne by the tapered roller bearing and transmitted to the bearing assembly housing (30).

Owner:THE TIMKEN CO

Pulley unit

InactiveUS7056247B2Improve the lubrication effectImprove abilitiesGearingPortable liftingRolling-element bearingEngineering

A pulley unit includes a pulley and a rotor concentrically disposed for relative rotation, a one-way clutch interposed in an annular space therebetween, rolling bearings provided on opposite sides of the one-way clutch, and a seal ring for sealing the annular space. An inner diametrical surface of the pulley forms an outer ring raceway of the one-way clutch and the rolling bearing, and an outer diametrical surface of the shaft body forms an inner ring raceway of the one-way clutch and the rolling bearing. An outer diameter side of an annular portion of a retainer of the rolling bearing on the side of the seal ring is reduced so as to increase a storage volume of lubricating oil between the rolling bearing and the seal ring.

Owner:KOYO SEIKO CO LTD

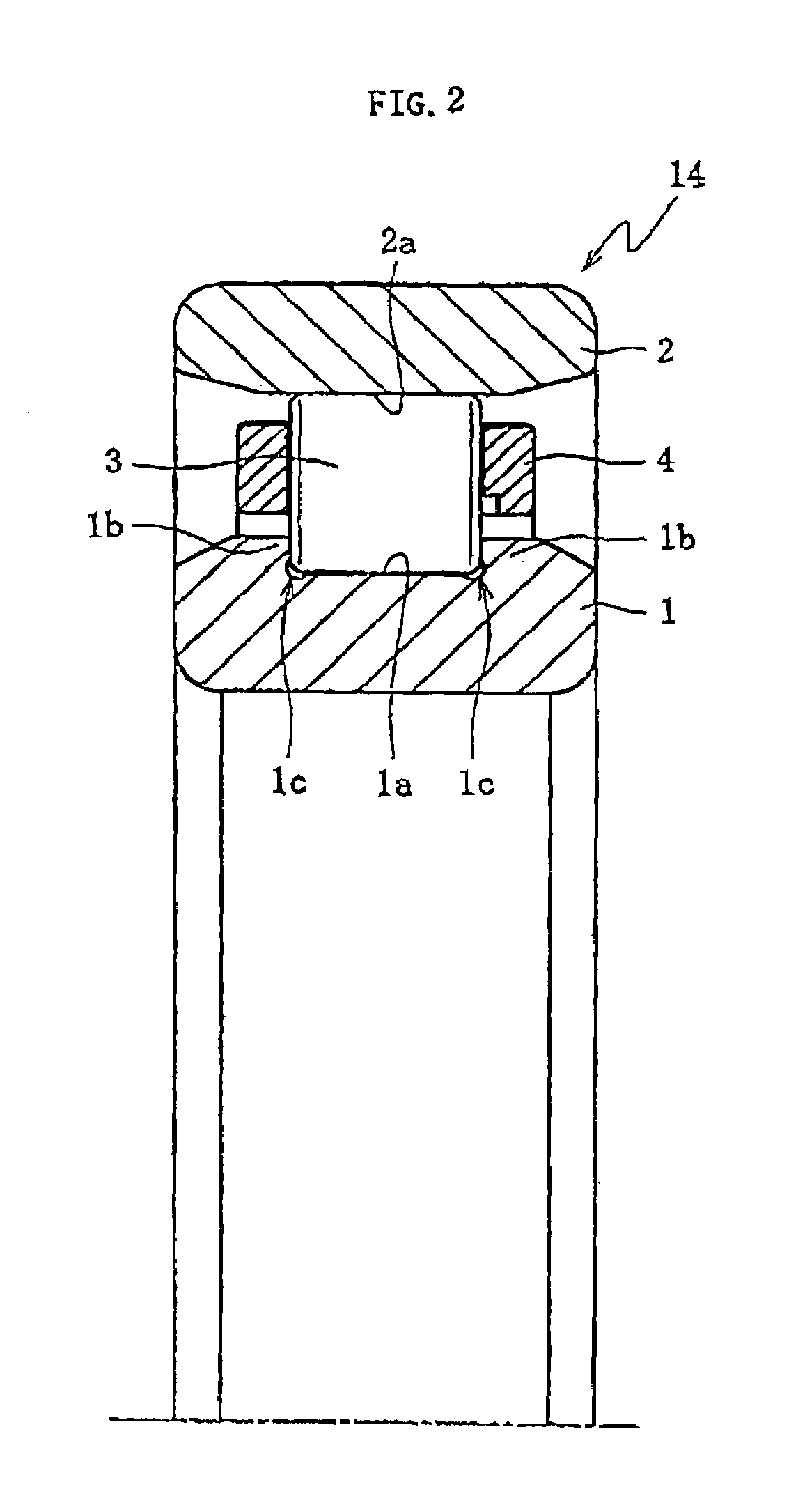

Cylindrical roller bearing

Contact surface pressure P increases rather drastically in proportion to skew angle θ within the range of 0<θ≦θT, but because the critical skew θT is restricted to be small, the contact surface pressure P changes in a low range below a certain level P0 at which wear occurs in contact portions. Thus restricting the critical skew angle θT to a small angle reduces the contact surface pressure P and suppresses heat generation and wear in the contact portions.

Owner:NTN CORP

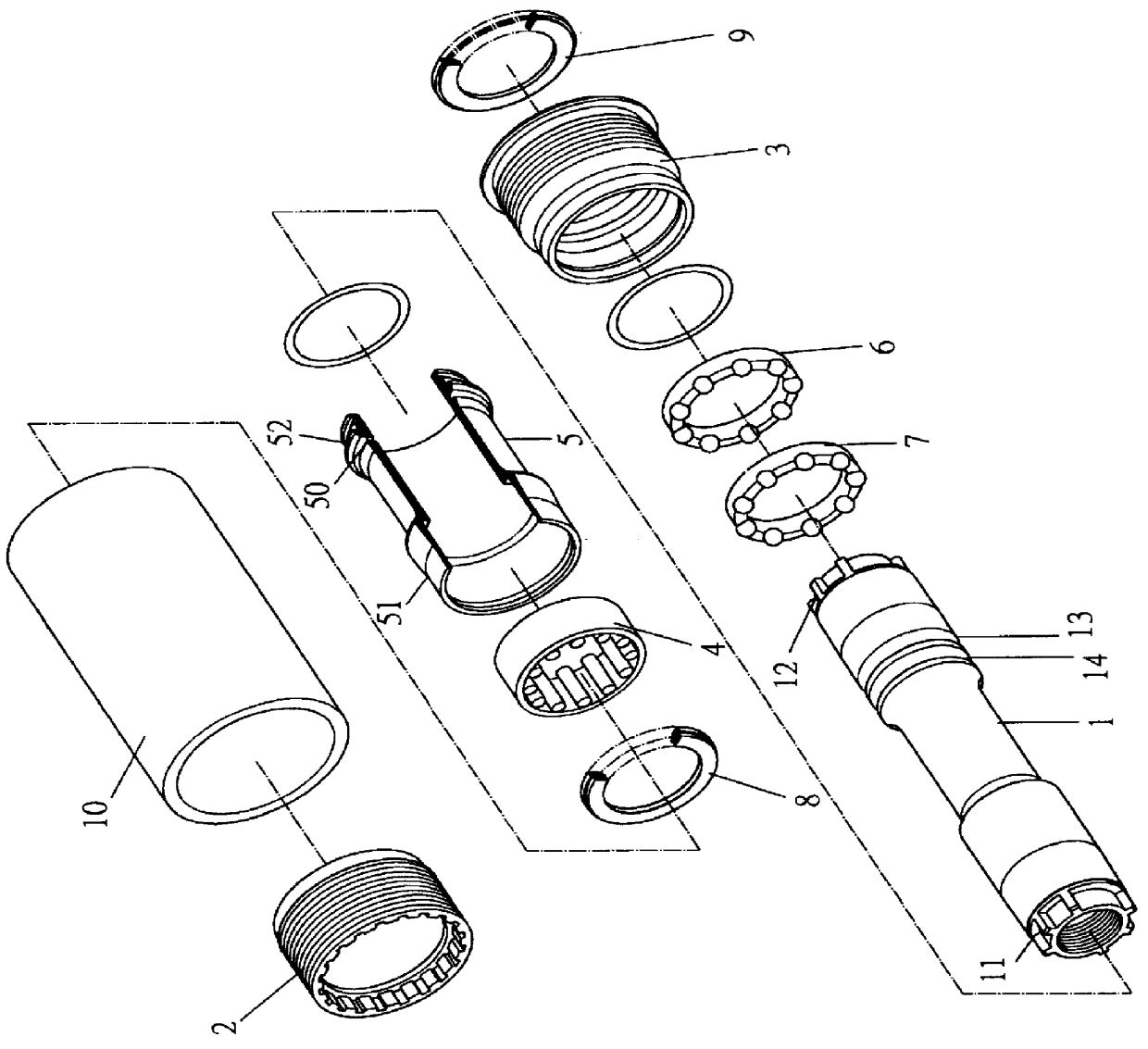

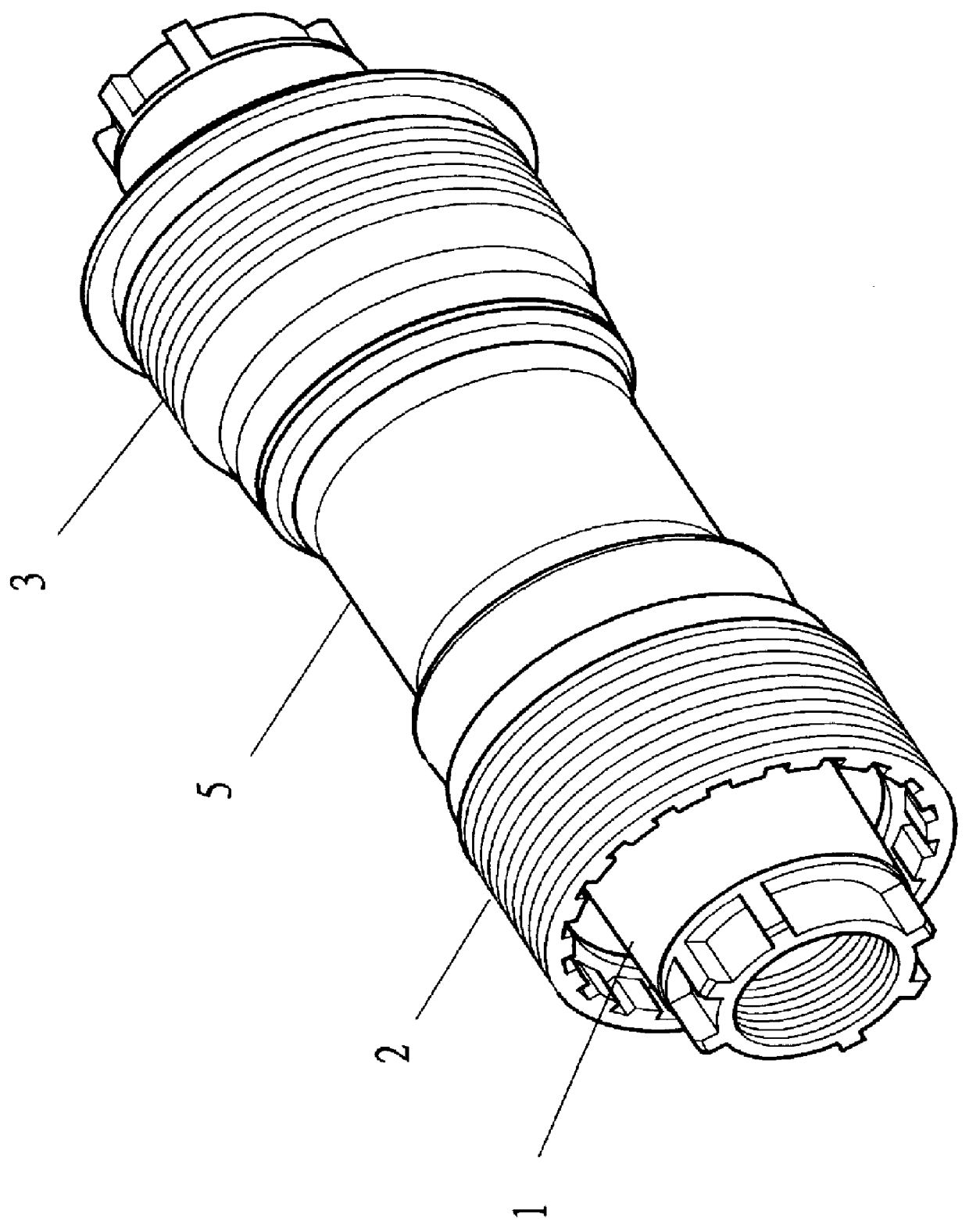

Crank axle for bicycle

An improved crank axle for bicycle is a hollow hub axle provided with a circle of tooth shape key slot at both ends respectively, arranged with a single roller bearing and the two parallel ball bearings and covered with an aluminum alloy cone-shaped sleeve. So that its can reduce the weight, facilitate assembling, keep axle rotation smoothly and receive loading strength well.

Owner:CHIANG DOUGLAS

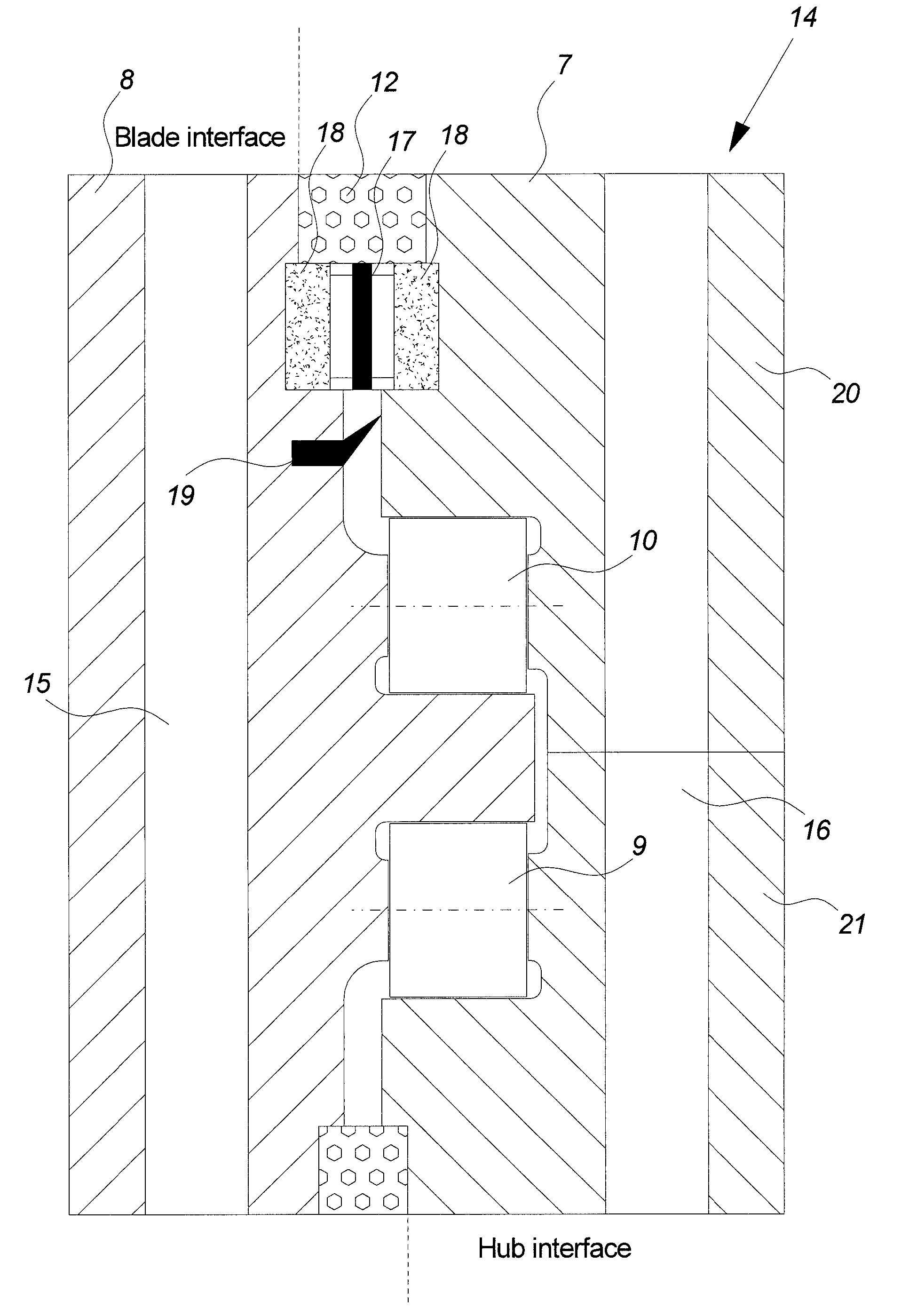

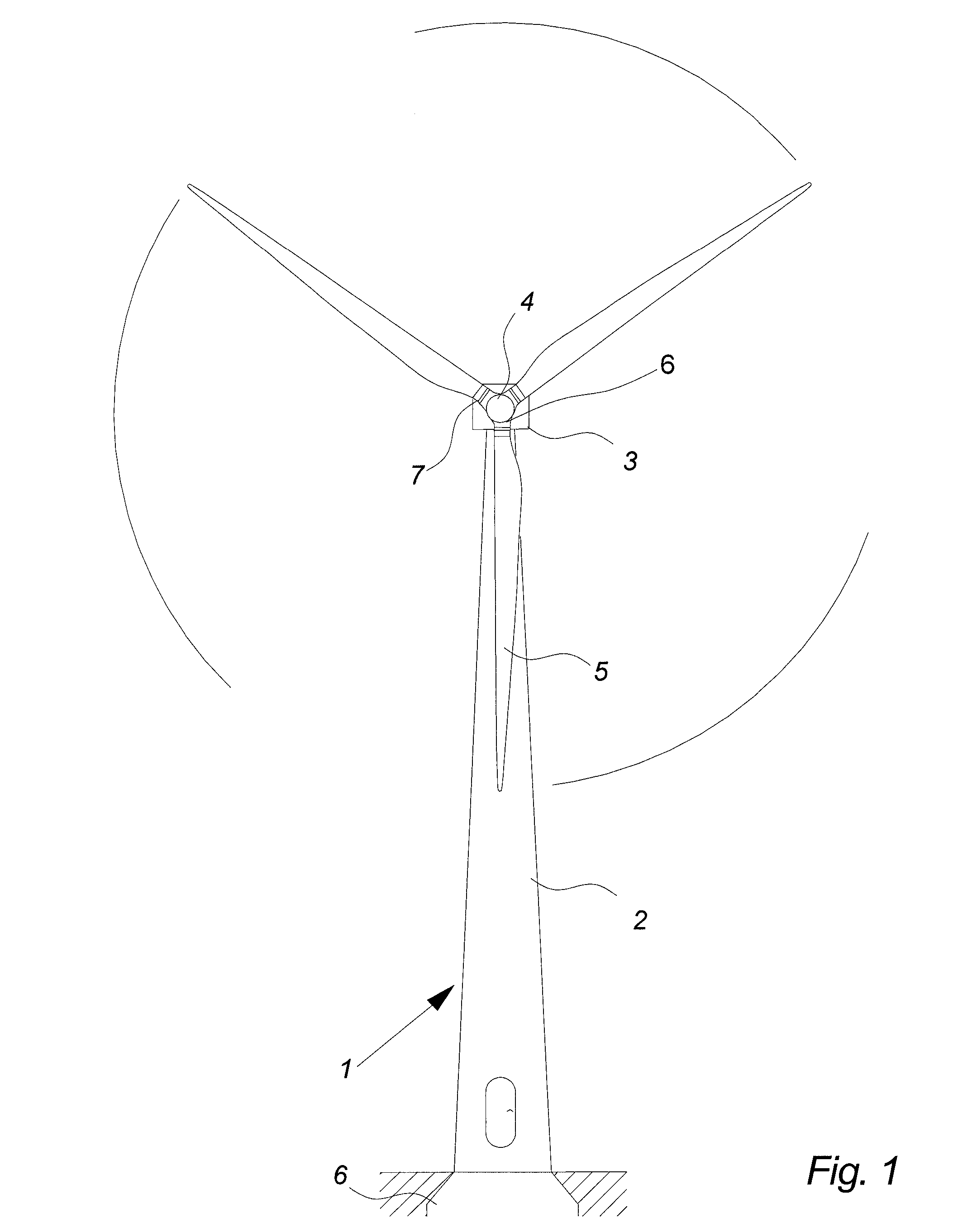

Pitch Bearing For A Wind Turbine, A Wind Turbine And A Method For Servicing A Bearing

InactiveUS20090022442A1Easy to perform serviceLow costRotary combination bearingsRoller bearingsPitch bearing

The invention relates to a pitch bearing for a wind turbine comprising a first and second axial row of bearing rolling elements, said rows being positioned in a distance of each other, and one or more radial rows of bearing elements, where said one or more rows of bearing elements are positioned outside an area defined in between said first and second axial row. The invention also relates to a wind turbine and method for servicing a bearing hereof.

Owner:VESTAS WIND SYST AS

Seal device for water pump rotation supporting device for water pump and water pump

A seal apparatus is comprised of a seal ring 13 and a slinger 14 in combination to prevent foreign matter from progressing into the rolling bearing 6a. The amount of compression delta of the second seal lip 23, which occurs when the tip edge of the second seal lip 23 of the seal ring 13 comes in contact with the outside surface of the slinger 14, is at least 1 / 10 and up to 7 / 10 the height of the second seal lip 23 in the free state. In addition, the roughness of a portion of the outside surface of the slinger 14 which the tip edge of the second seal lip 23 comes in sliding contact with is from 0.2 mu m to 2.0 mu m in the arithmetic mean Ra, or is from 0.8 mu m to 8.0 mu m in the maximum height Ry. Consequently, a structure of a water pump is provided without increasing the cost thereof; or without enlarging the size to improve the durability of the water pump.

Owner:NSK LTD

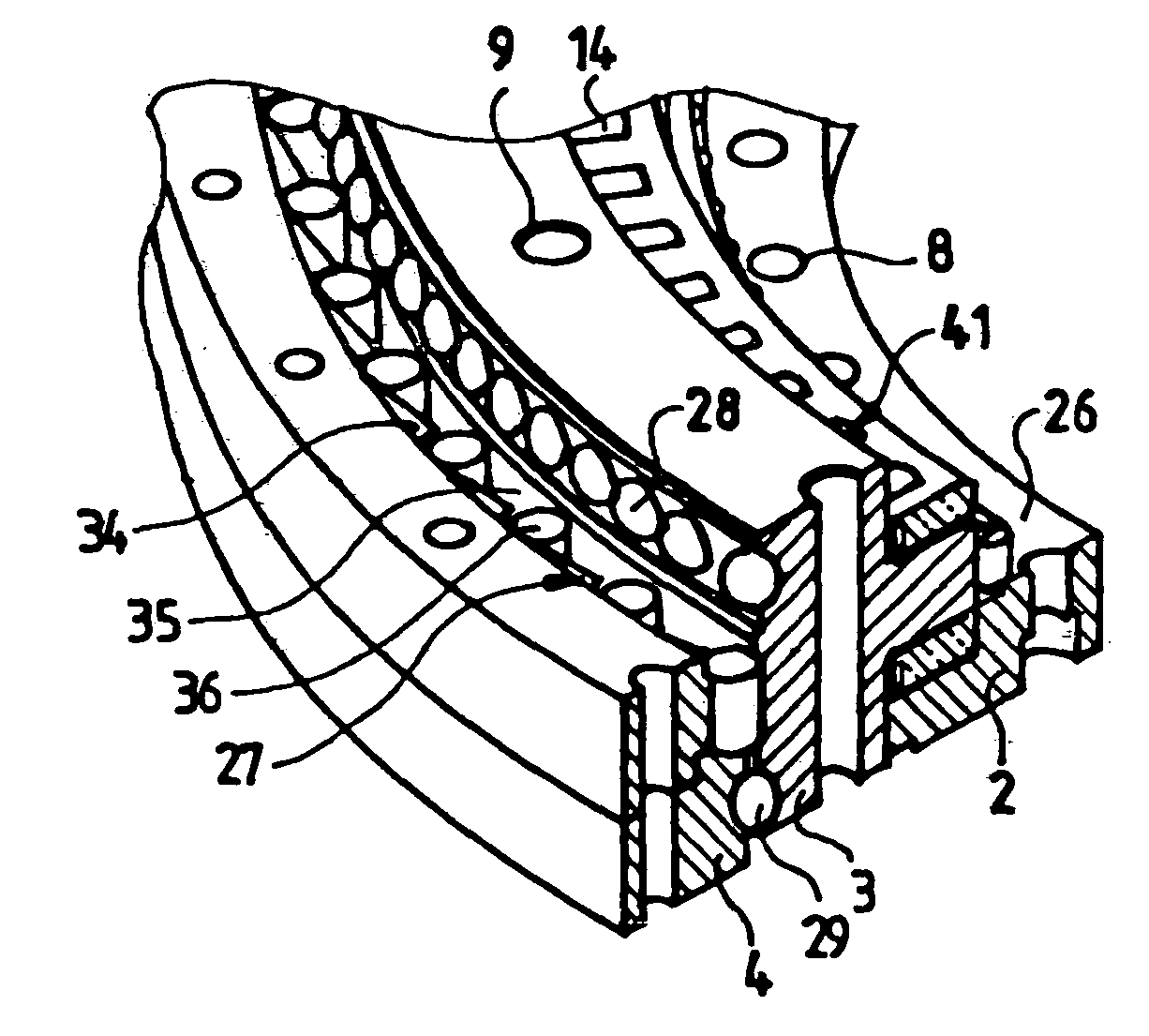

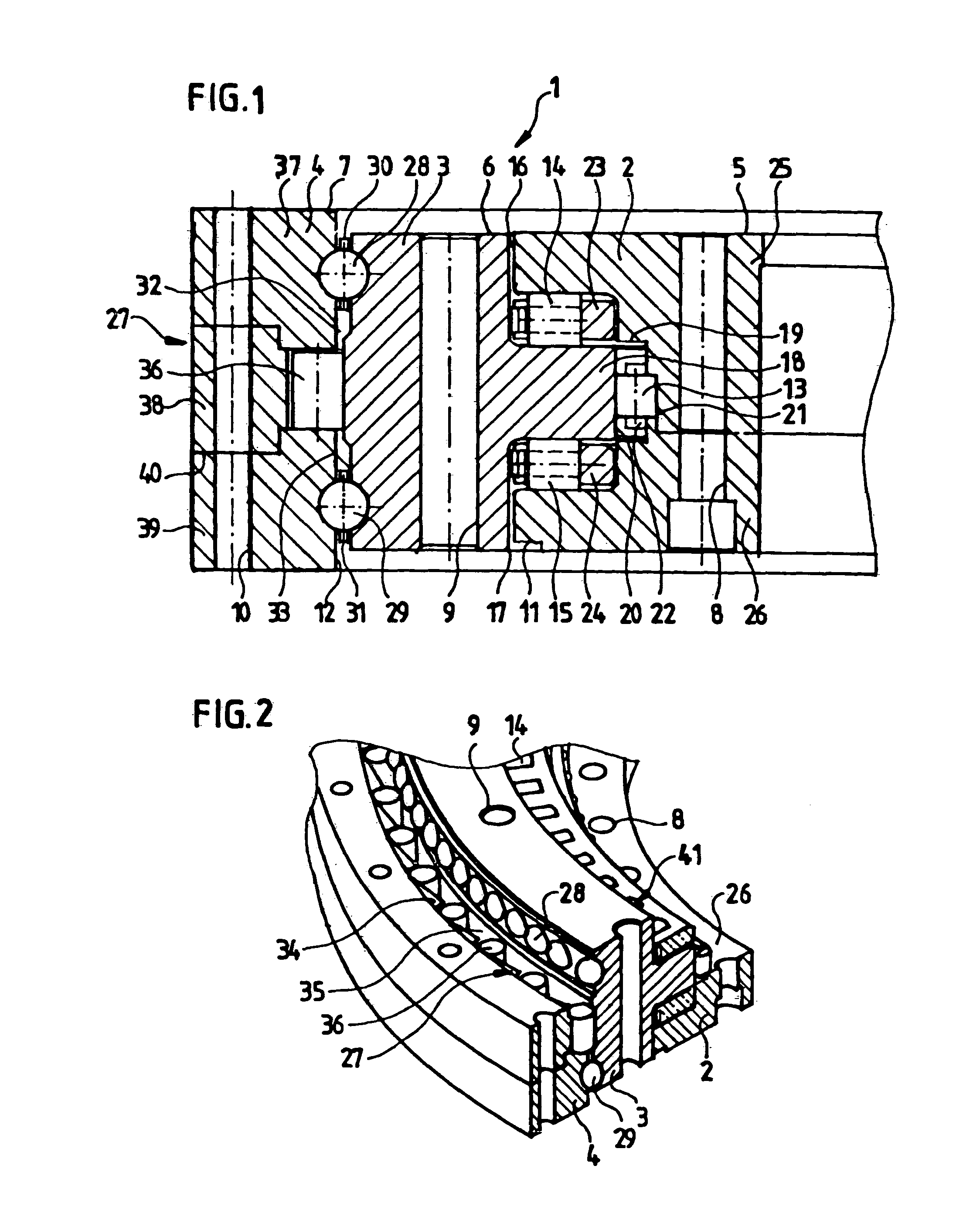

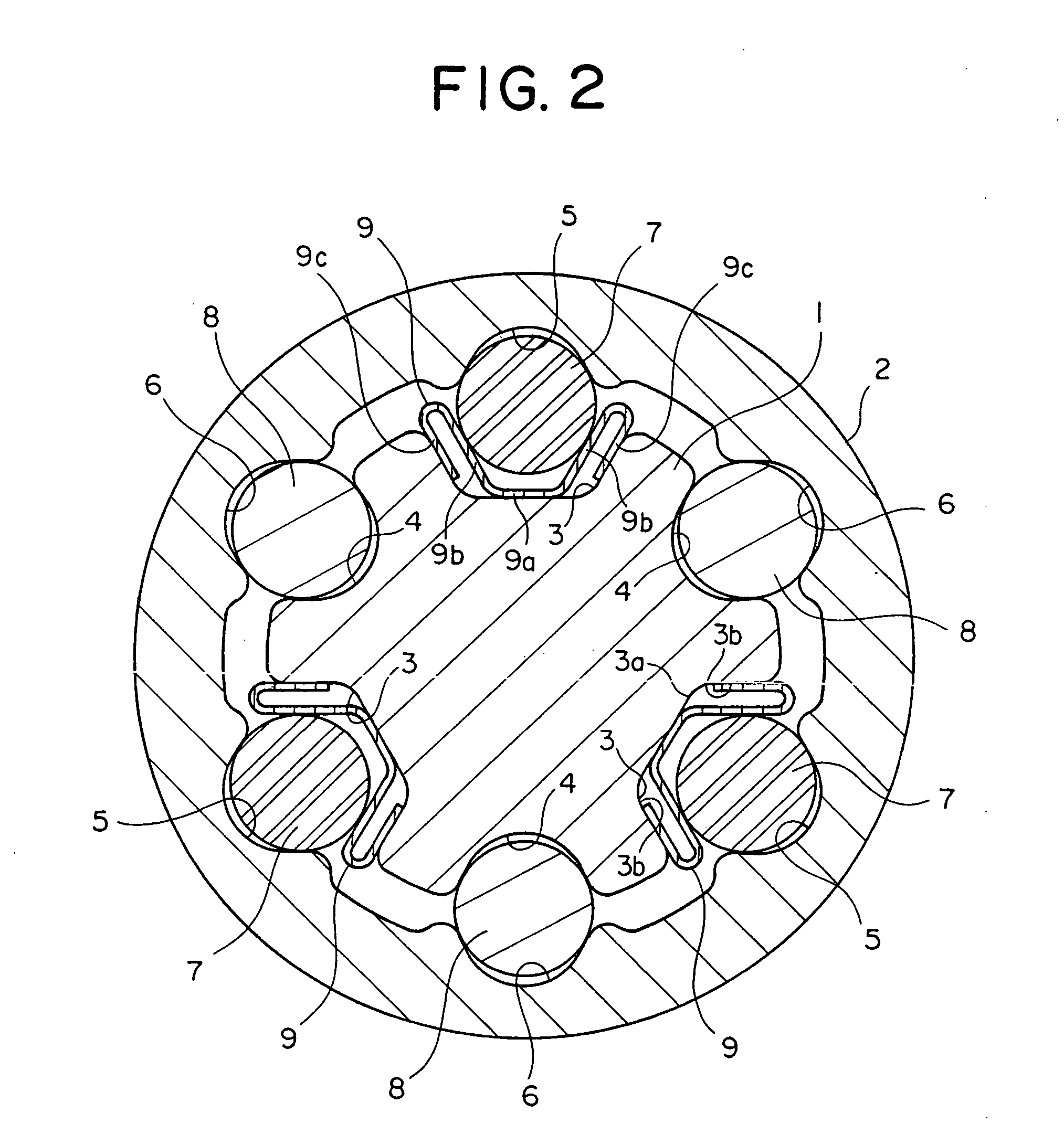

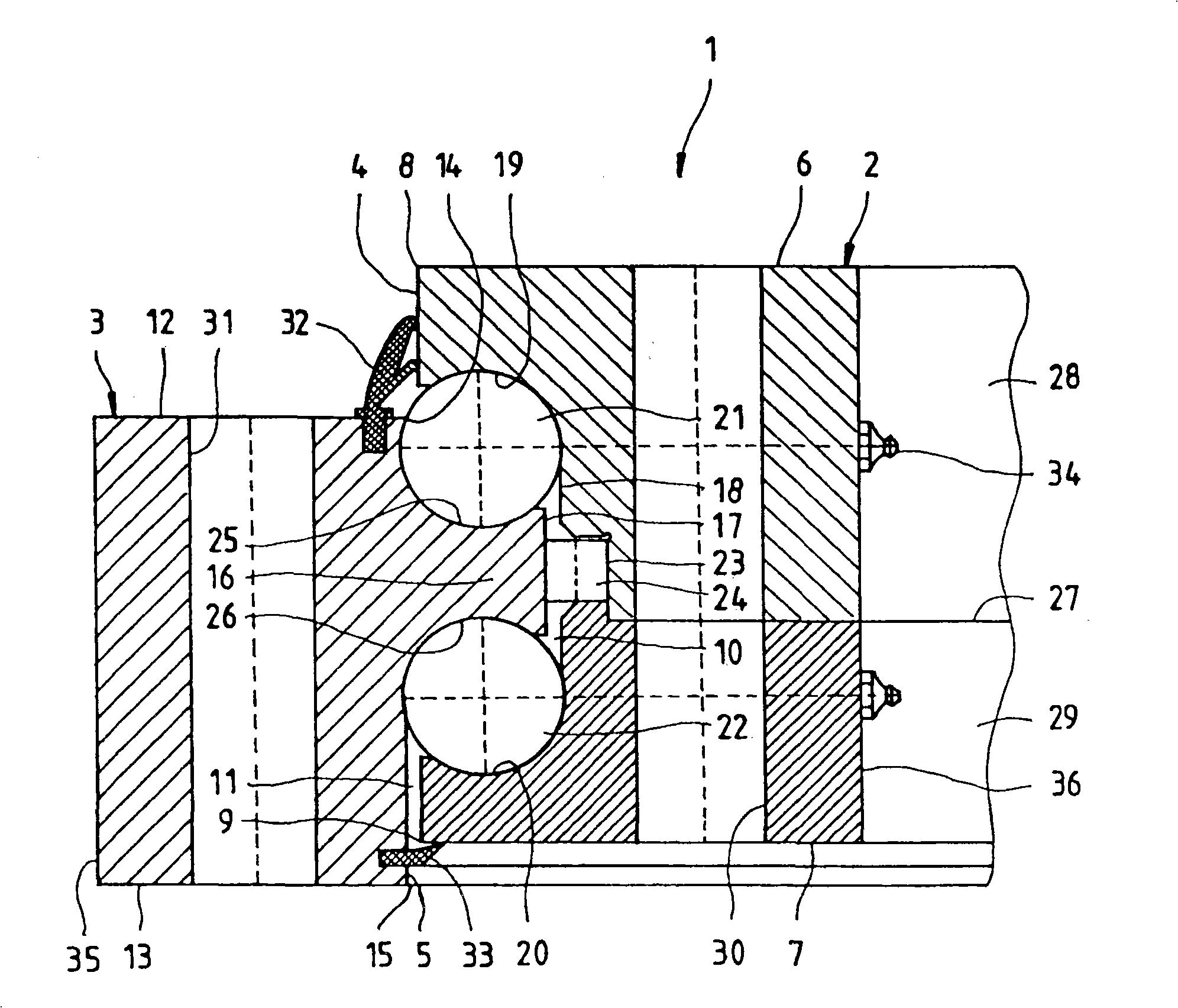

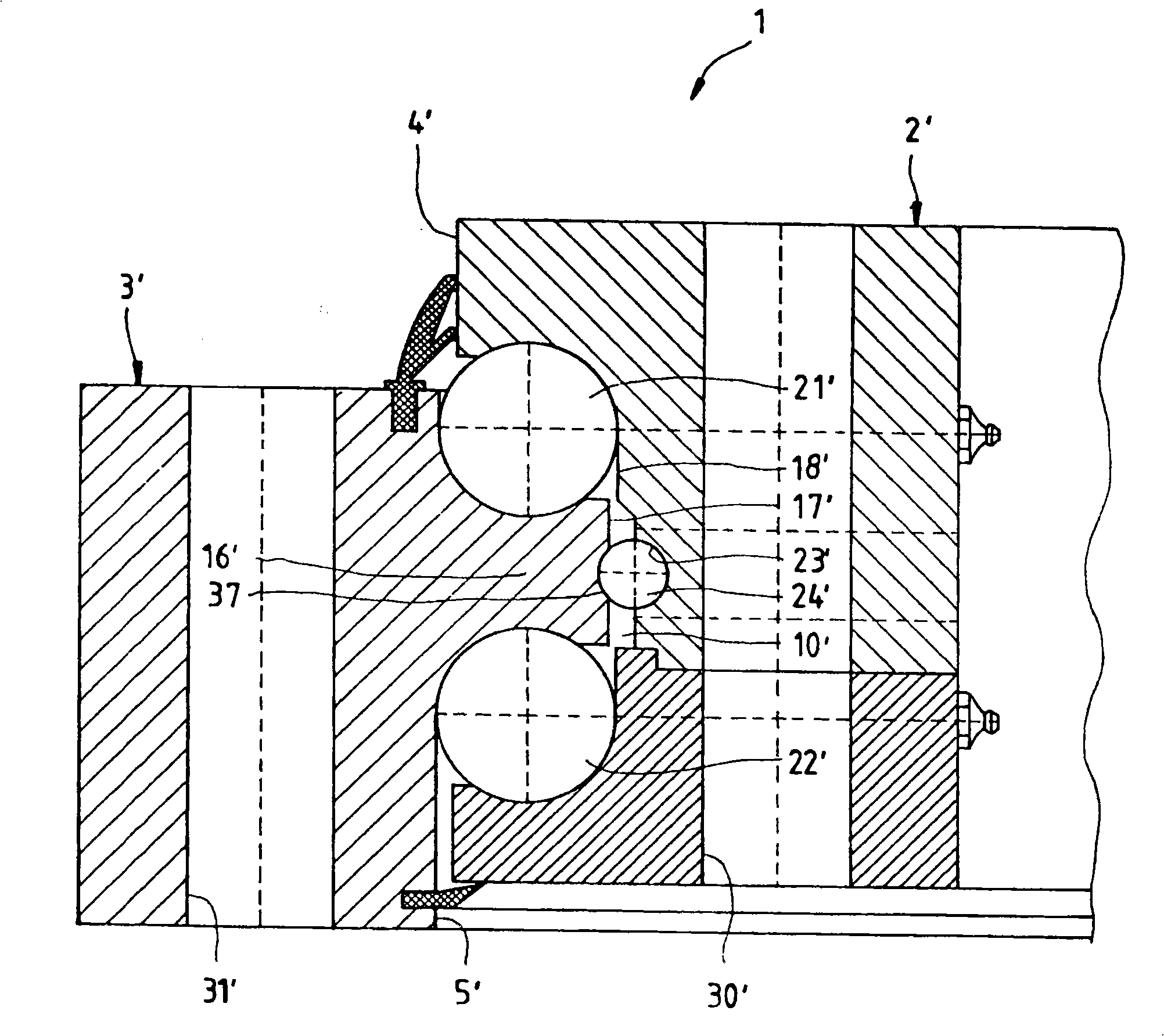

Rolling bearing arrangement

ActiveCN101542145AApplicable loadEvenly distributedBall and roller bearingsMachines/enginesRolling-element bearingMechanical engineering

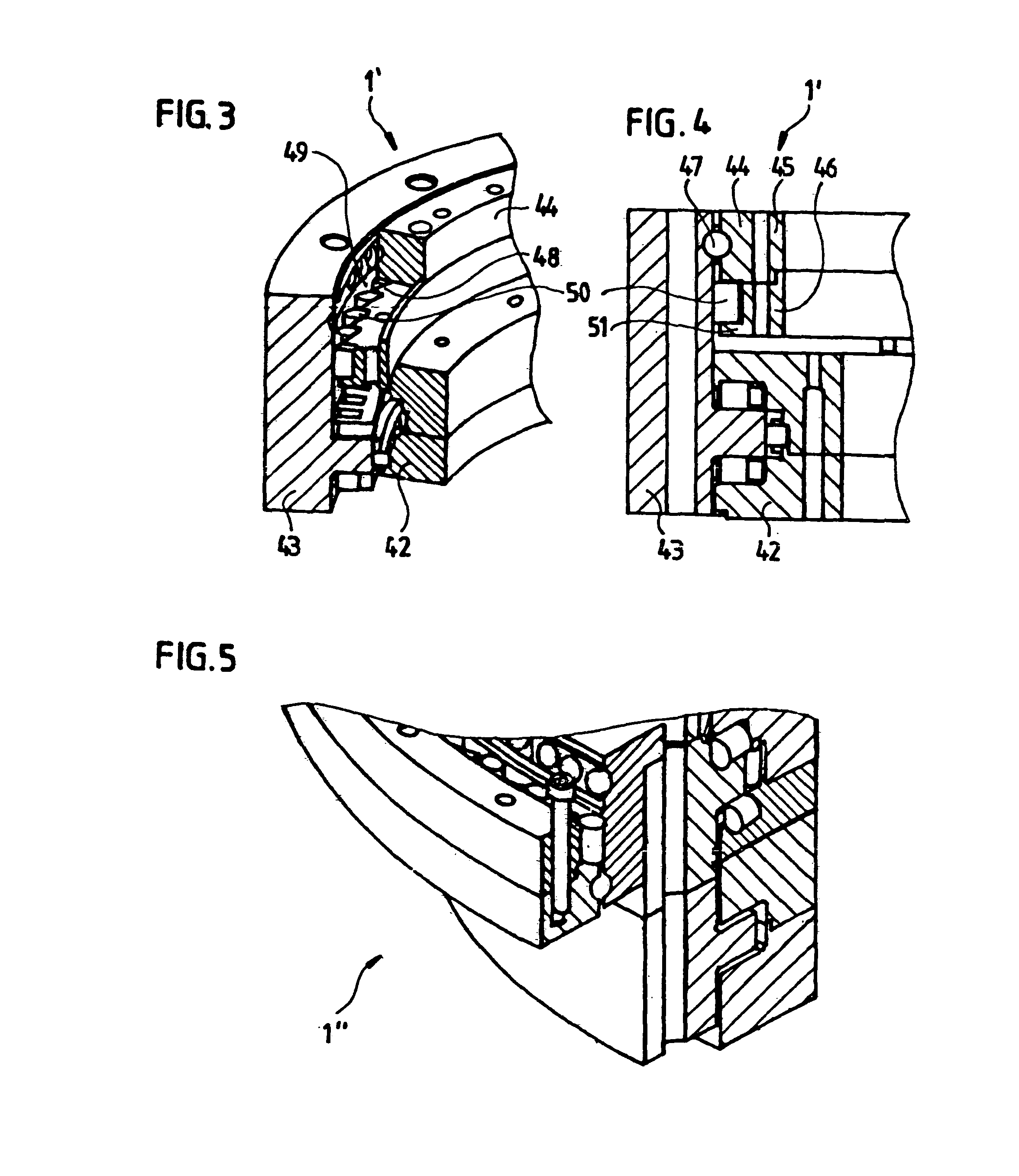

The invention is aimed at a rolling bearing arrangement (1;1',1'') having two annular elements (2,3), which are arranged concentrically with respect to one another and at least in regions one inside the other, for connecting to in each case one of two system parts which are rotatable relative to one another, and having a gap (11) between said connecting elements (2,3), such that said connecting elements (2,3) are rotatable relative to one another about an imaginary axis, which is approximately perpendicular to the ring plane, in the center of the annular connecting elements, wherein at least two rows of rolling bodies (21, 22, 24, 24'') are provided in the region of the gap between the connecting elements, wherein the annular connecting elements completely or partially overlap one another in the radial direction, and one or more raceways (19,20,25,26) for rolling bodies are arranged in radially overlapping regions (10,16) of the annular connecting elements, in such a way that the support angle which the connecting line between the centers of the contact points of a rolling body (21,22) with its two raceways encloses with respect to the annular plane is equal to or greater than 75 DEG , and wherein the rolling bodies (24,24'') of at least one row have a support angle of 15 DEG or less.

Owner:IMO HOLDING GMBH

Differential unit

InactiveUS7036391B2Reduce imbalanceAvoid eccentricityRoller bearingsBall bearingsCircular coneEngineering

A protruding section facing a drive pinion shaft is integrally provided on (or provided as a separate component) a tubular spacer interposed between an inner race of a pilot bearing and an inner race of a tapered roller bearing at an inner section opposite to the drive pinion shaft. In one embodiment, a monolithic protruding section is curved so as to be convex along the overall central axial direction of the spacer, and is arch shaped in cross section. The protruding section protrudes towards the drive pinion shaft along the overall inner peripheral direction of the spacer, and the inner surface of the protruding section comes into contact with or close to the outer surface of the drive pinion shaft. Additional positions include one or a plurality of O-rings interposed between the drive pinion shaft and the inner surface of the tubular spacer.

Owner:SUBARU CORP

Seal device for water pump, rotation supporting device for water pump, and assembly method for water pump

InactiveUS20050062233A1Effectively prevent entryImprove sealingEngine sealsPump componentsEngineeringMechanical engineering

The tip edge of a second seal lip of an elastic member constituting a seal ring is in sliding contact with a side surface of a slinger. When the slinger is fitted onto and fixed to the rotating shaft, the slinger is pressed by a pressing jig. The shape and dimension of the pressing jig are regulated such that when the tip end of the pressing jig is abutted to the end surface of the outer ring, the deformation amount of the second seal lip is made proper. Accordingly, the operation of assembly can be carried out easily in an industrial method while properly regulating the deformation amount of the second seal lip coming into sliding contact with the side surface of the slinger.

Owner:NSK LTD

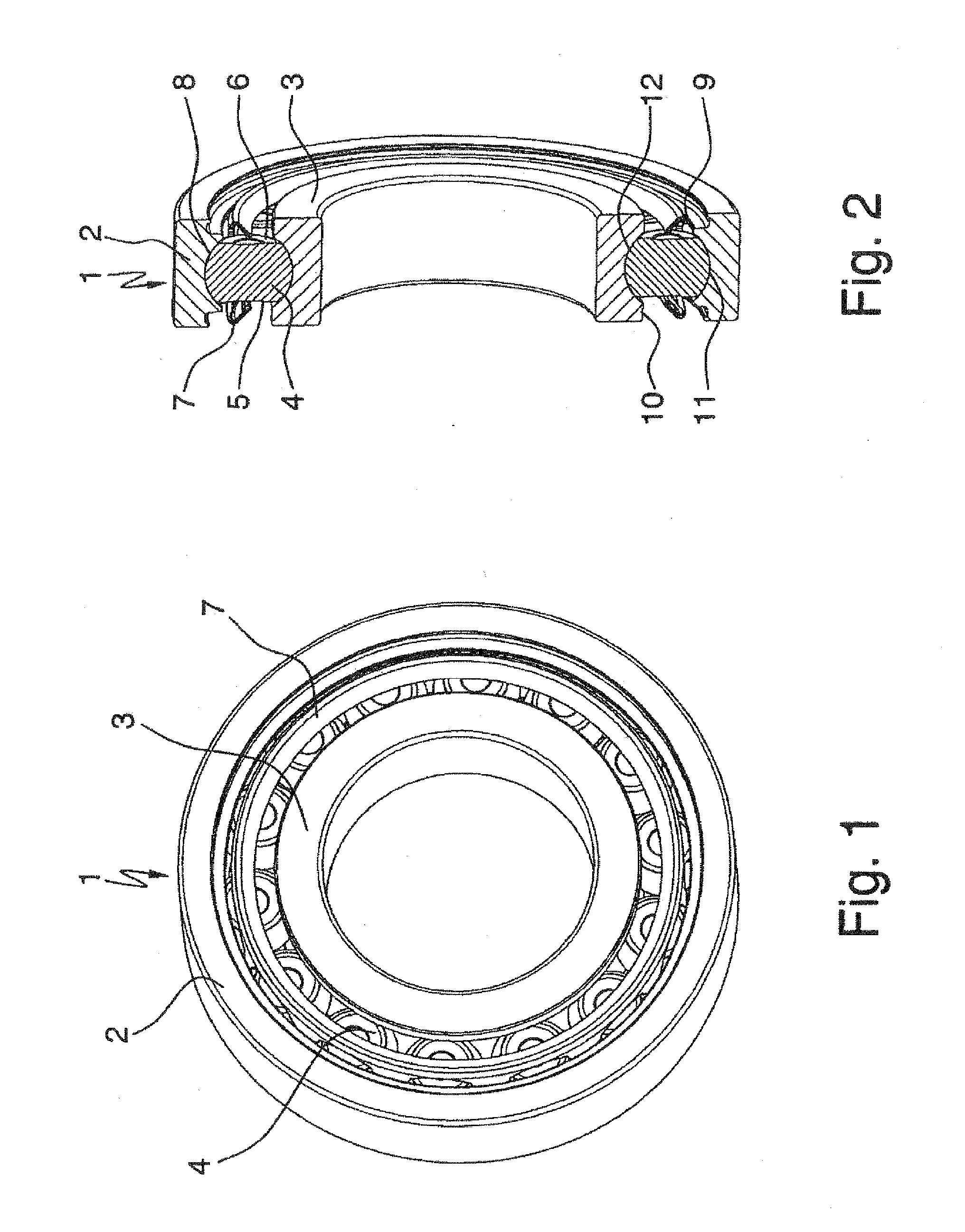

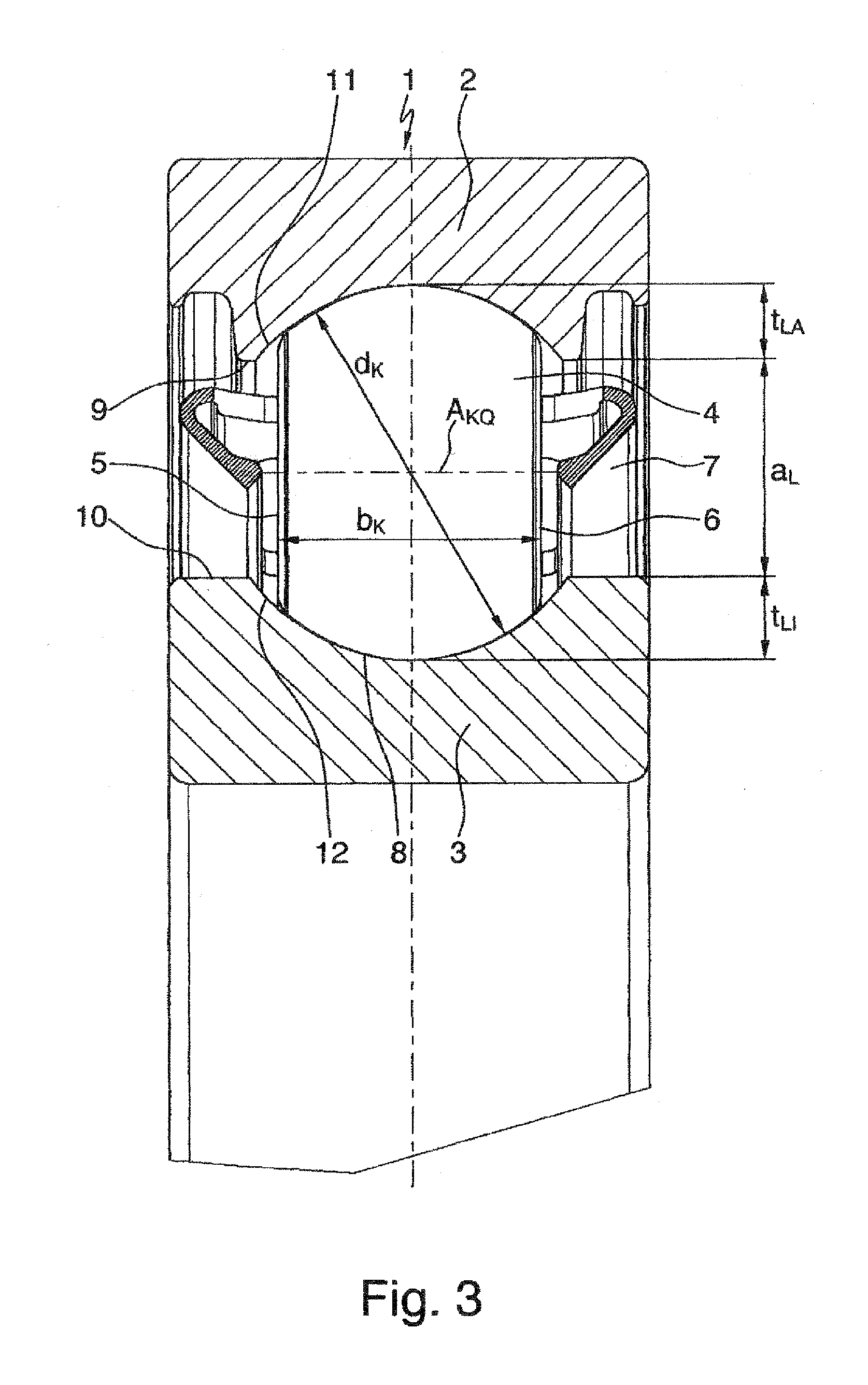

Ball roller bearing and method for the installation of such a ball roller bearing

InactiveUS20110026866A1Improve carrying capacityProlong lifeRoller bearingsBall and roller bearingsNeedle roller bearingBall bearing

A ball roller bearing and to a method for the installation thereof. The ball roller bearing has an outer bearing race, and an inner bearing race, and a plurality of ball rollers, which are disposed between the bearing races and are held at equal distances to each other by a bearing cage. For this purpose, the ball rollers have a width of approximately 70% of the diameter of a spherical shape thereof, and roll with bearing surfaces thereof in two groove-shaped raceways, the depth of which is smaller than the distance between the outer and inner bearing race. The cage pockets of the bearing cage have a cross-sectional contour of a ball roller disposed in the longitudinal and transverse directions to the circumferential direction. The method for installation of the ball roller bearing is a cross / oblique pivot mount between the inner and outer bearing races and the ball rollers.

Owner:SCHAEFFLER TECH AG & CO KG

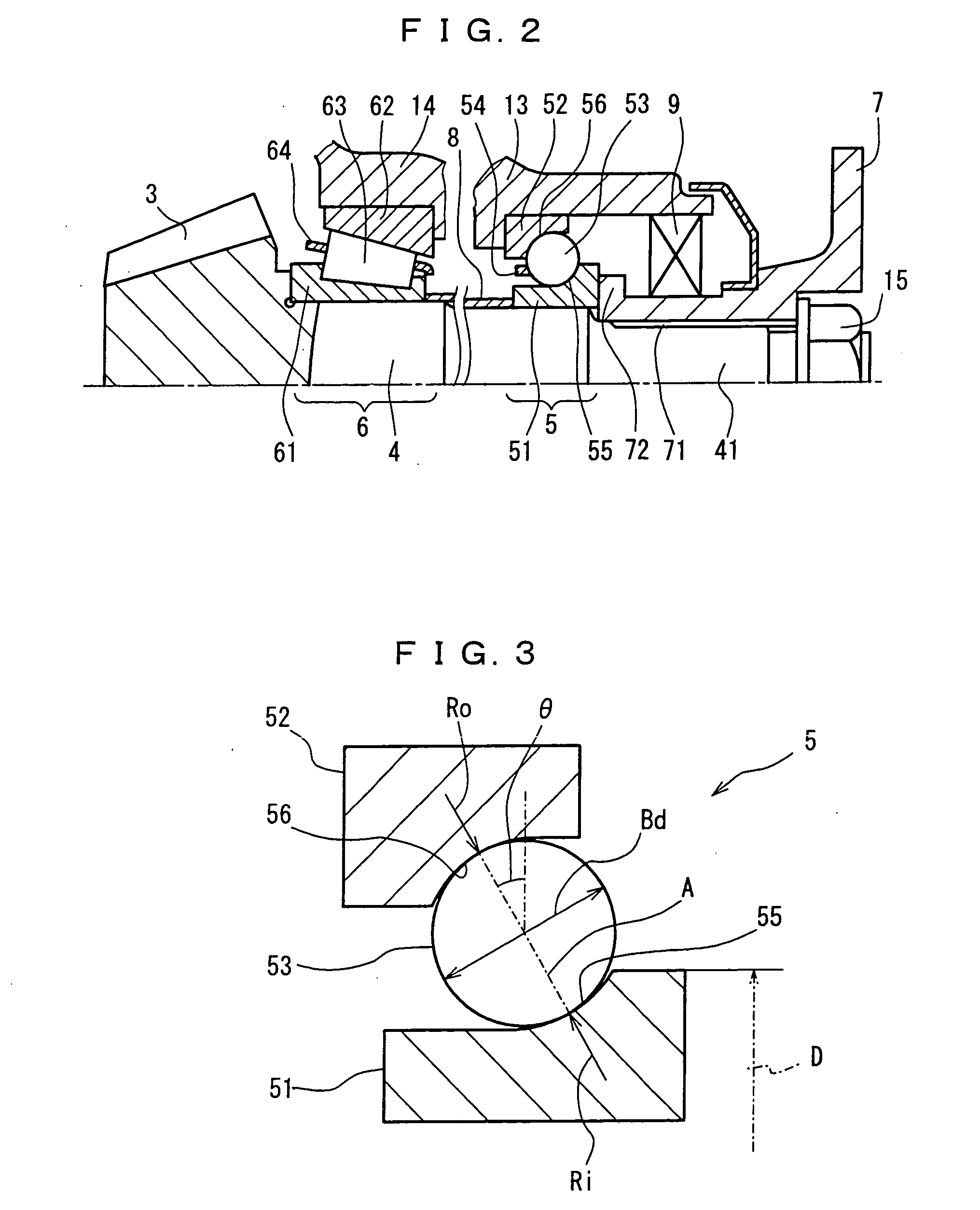

Bearing apparatus for supporting pinion shaft

InactiveUS20070104403A1Improve carrying capacityLarge contact angleShaftsBall bearingsBall bearingRolling-element bearing

A bearing apparatus for supporting a pinion shaft comprises a pair of rolling bearings which rotatably support a pinion shaft to a case and are arranged side by side in a shaft direction between a pinion gear arranged at one end of the pinion shaft, and a companion flange attached outside the other end thereof. The rolling bearing on a companion flange side comprises an angular ball bearing, and a radius of curvature Ri of an inner ring raceway, a radius of curvature Ro of an outer ring raceway, and a ball diameter Bd of the rolling bearing may satisfy a relationship given by equations of Ri<Ro, 0.502×Bd≦Ri≦0.512×Bd, and 0.510×Bd≦Ro≦0.520×Bd.

Owner:JTEKT CORP

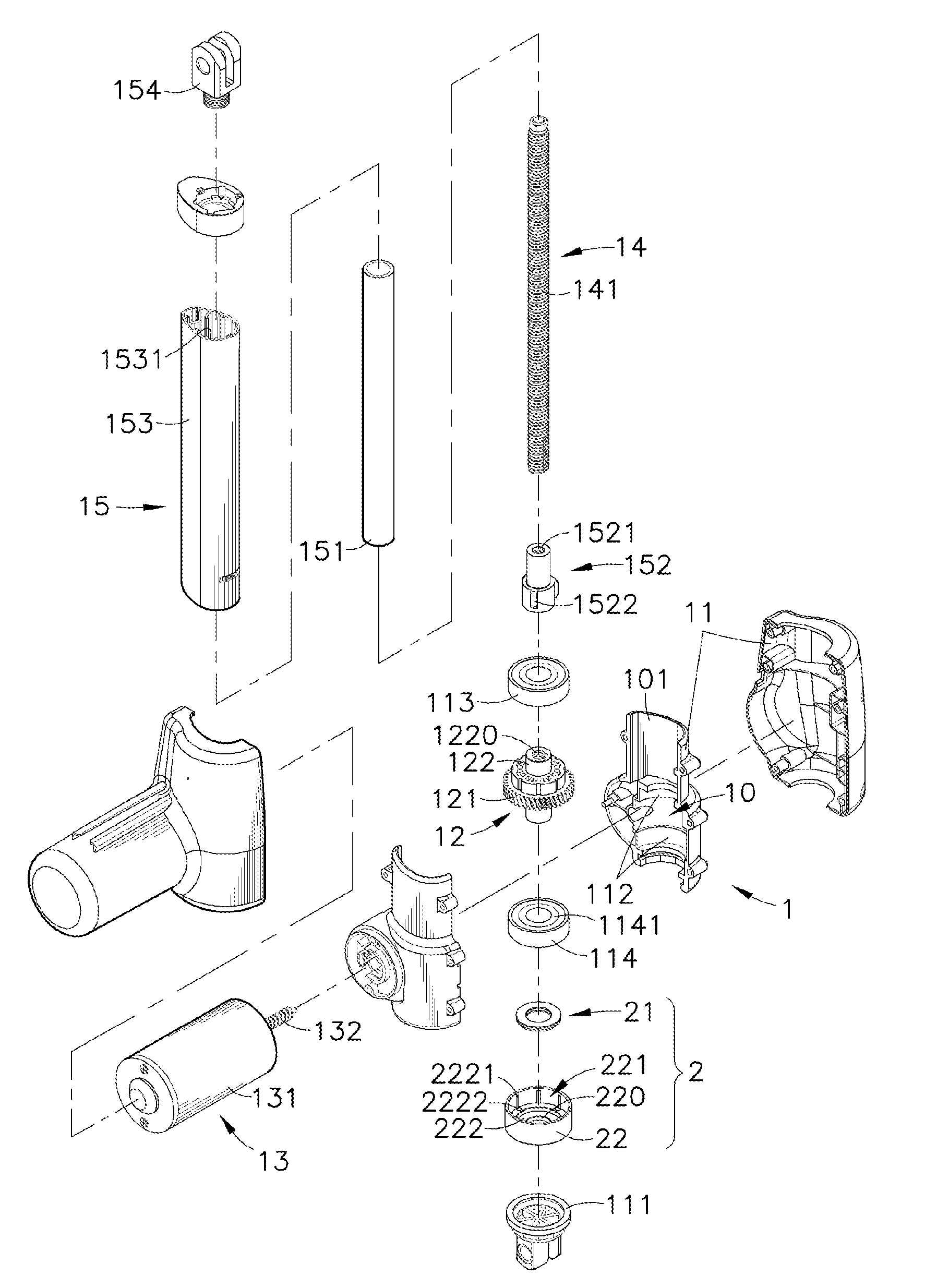

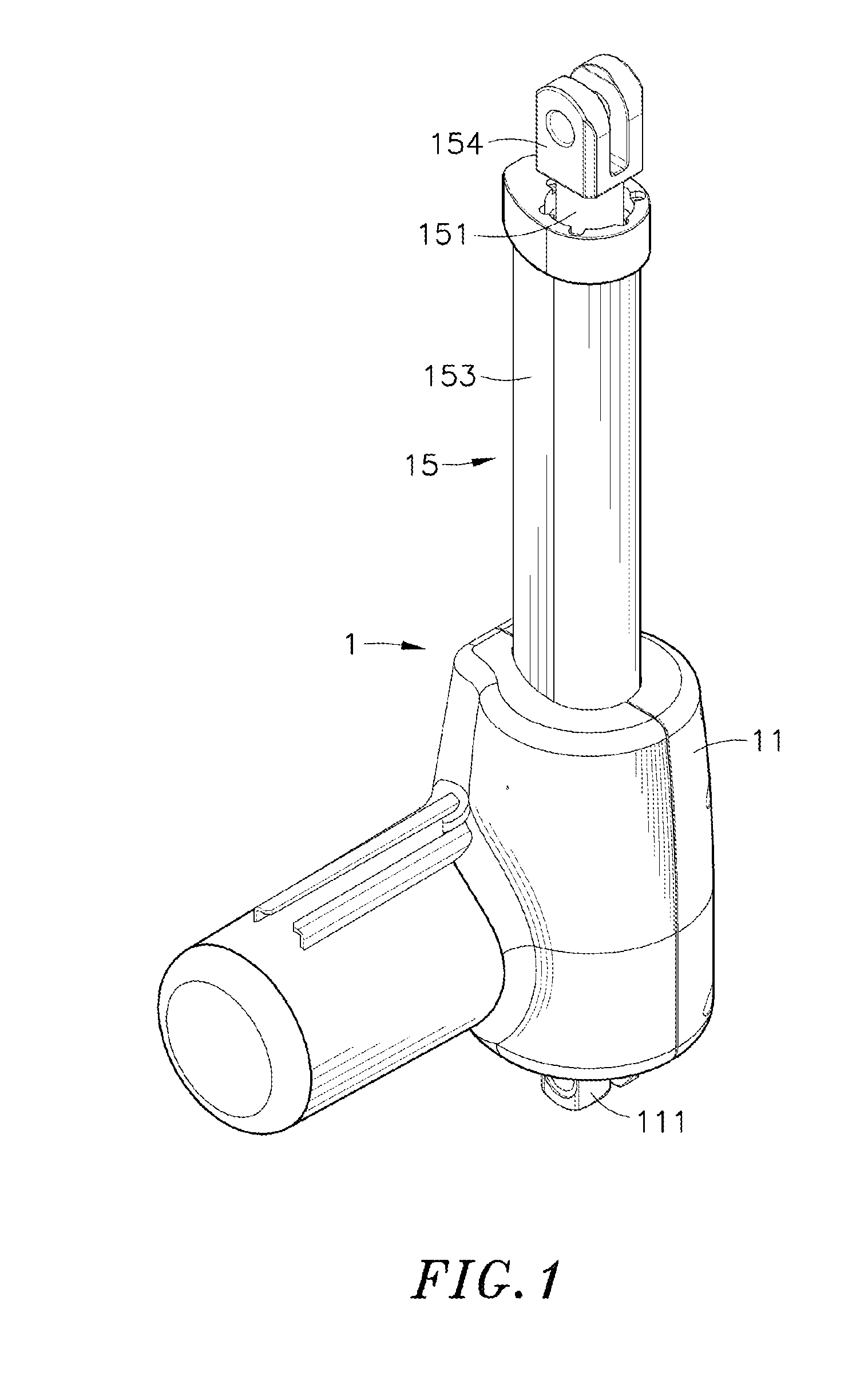

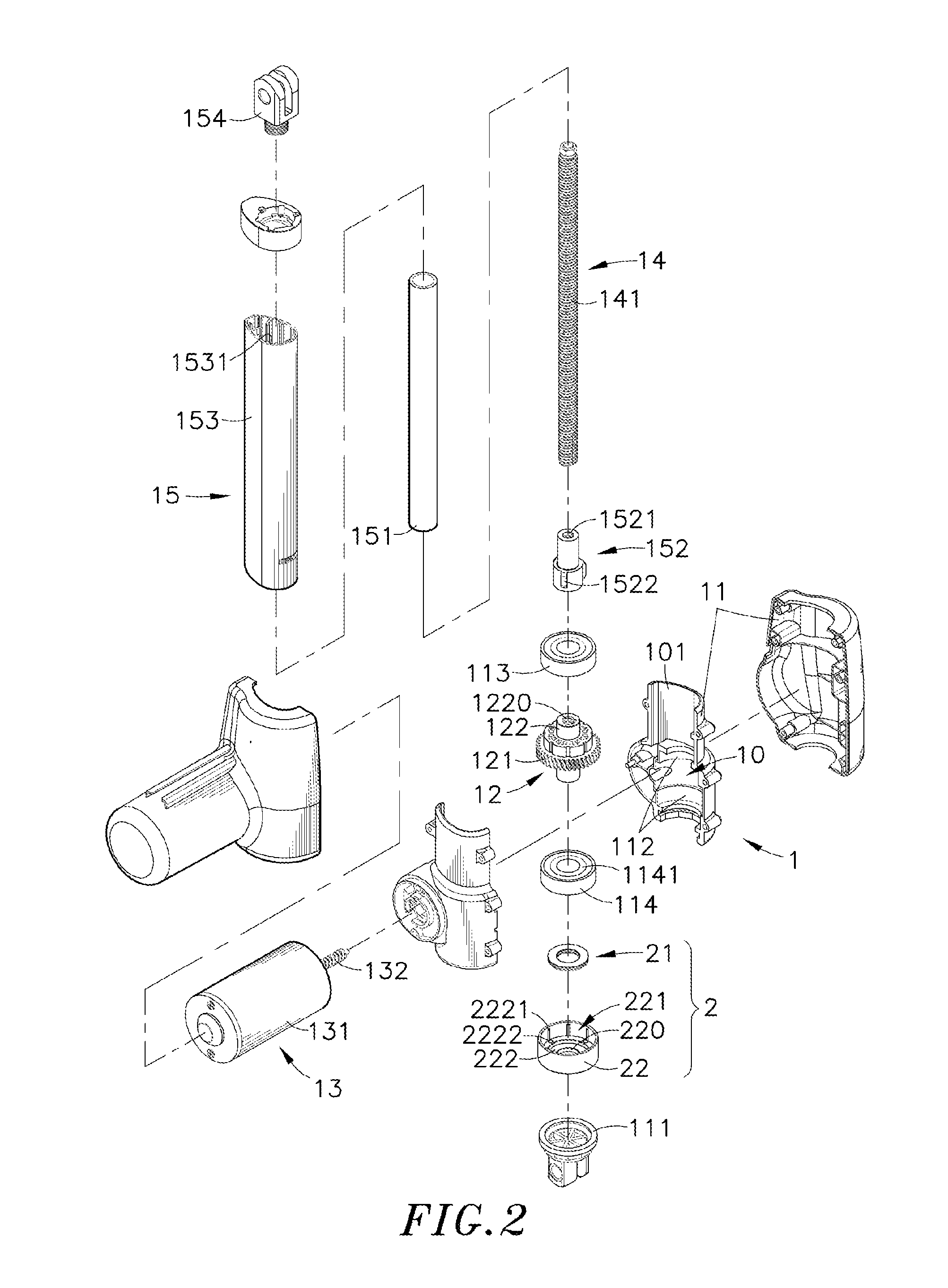

Structure of linear actuator

ActiveUS20160146317A1Simple structureDrawback can be obviatedRoller bearingsToothed gearingsThrust bearingAxial thrust

An improved structure of linear actuator includes an actuator including a gear set having a friction portion located at the periphery of the gear shaft of a driven gear thereof, a one-way bearing mounted on the gear shaft for rubbing against the friction portion to brake the driven gear from reverse rotation, a driver for driving the gear set and a transmission mechanism including a lead screw coaxially coupled to and rotatable by the gear shaft of the driven gear and a retractable tube assembly coupled to the lead screw and movable by the lead screw between an extended position and a received position, and a stopping mechanism including a thrust bearing coupled to the gear shaft of the driven gear and stoppable against an inner race of the one-way bearing inner race to bear an axial thrust load.

Owner:MOTECK ELECTRIC CORP

Surgical instrument, surgical handpiece and surgical drive system

In order to improve a surgical instrument comprising a shank and a drive shaft, which is rotatably mounted in the shank and bears or comprises a tool element at its distal end, wherein in the distal end region of the shank a radial bearing is arranged or configured for the rotatable mounting of the drive shaft on the shank, such that a reliable operation is possible even with increasing miniaturisation of the shanks, it is proposed that the radial bearing is configured in the form of a needle bearing.An improved surgical handpiece as well as an improved surgical drive system are additionally proposed.

Owner:AESCULAP AG

Composite type automobile hub bearing unit

ActiveCN102141080AReduce frictional torqueImprove reliabilityBearing assemblyHubsBall bearingNeck parts

The invention discloses a composite type automobile hub bearing unit which comprises a flange large inner ring, a small inner ring and an outer ring, wherein the end part of the flange large inner ring is provided with a turned edge; the neck part of the flange large inner ring is provided with a step; the small inner ring is fixed on a shaft neck between the turned edge and the step by the turned edge; the step on the neck part of the flange large inner ring is provided with a conical outer roller path; the small inner ring is provided with a spherical outer channel; the inner side of the outer ring is provided with a conical inner roller path and a spherical inner channel; a tapered roller is arranged between the conical outer roller path and the conical inner roller path; and a ball roller is arranged between the spherical outer channel and the spherical inner channel. In the technical scheme of the invention, a bearing with greater stress at the inner side is designed into a tapered roller type, a bearing with smaller stress at the outer side is designed into an angular-contact ball bearing structure, so that the hub bearing unit hardly has early failure, simultaneously the quality risk brought about by the complex manufacturing can be reduced, and the reliability of a unit assembly can be improved better.

Owner:ZHEJIANG ZHAOFENG MECHANICAL & ELECTRONICS CO LTD

Pulley unit

InactiveUS7004861B2Simple preparation procedureSimple structureMechanical actuated clutchesBearing assemblyRolling-element bearingEngineering

A pulley unit improved in axial positioning of a cage of a one-way clutch is provided. An outer radius of an orbital portion of inner rings of two rolling bearings disposed at both axial sides of the cage are designed to be larger than an inner radius of the cage, so that axial movement of the cage is constrained. Due to this structure, projecting and recessing portions disposed on the cage of the one-way clutch and on an inner ring become unnecessary and can be eliminated.

Owner:KOYO SEIKO CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com