Patents

Literature

640results about How to "Avoid eccentricity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

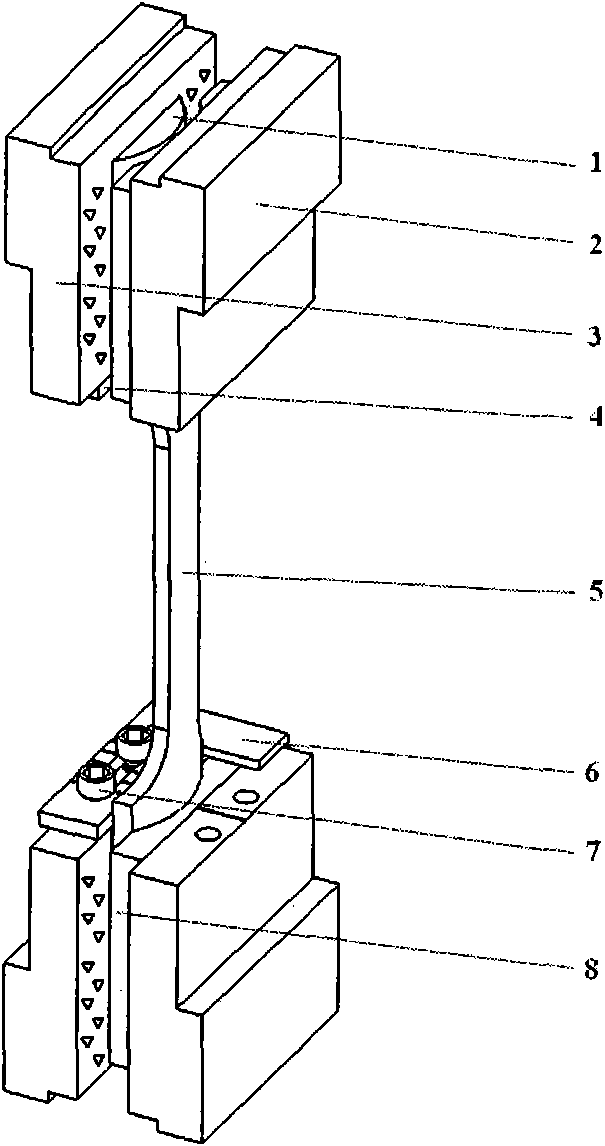

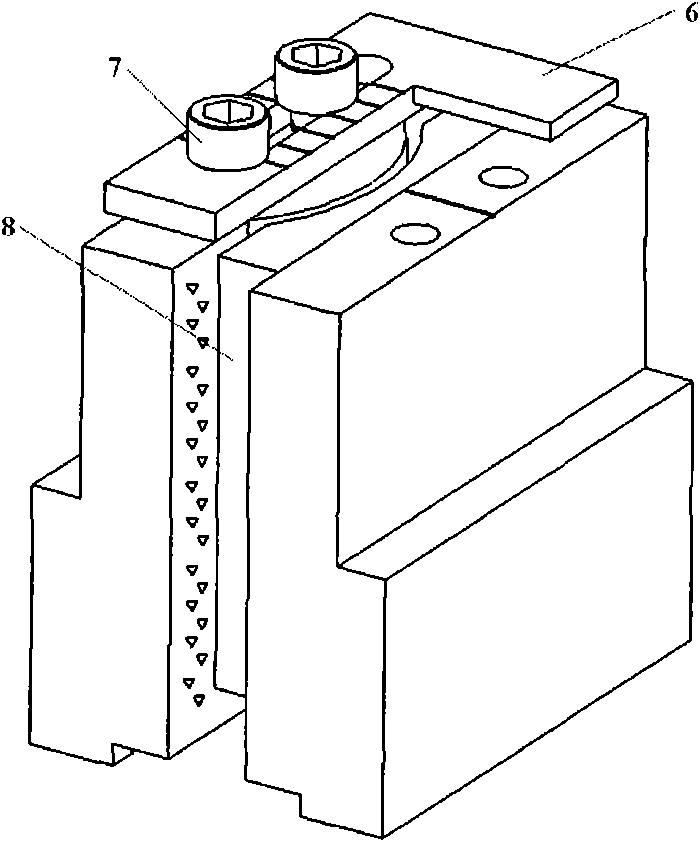

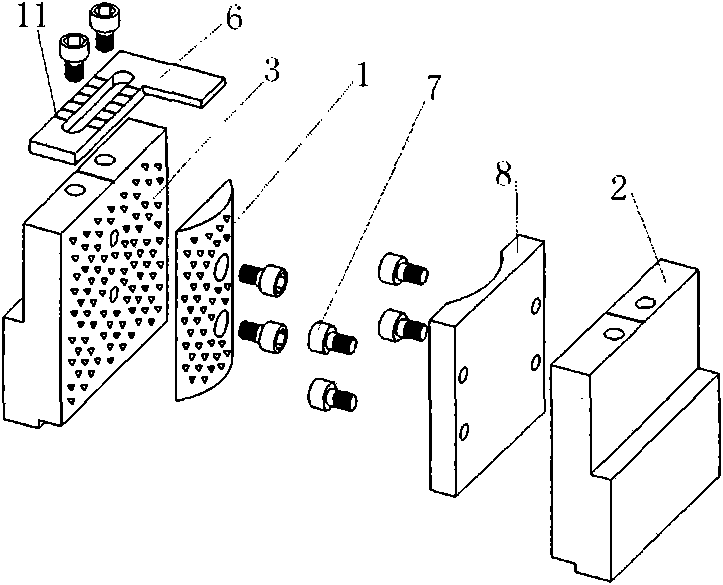

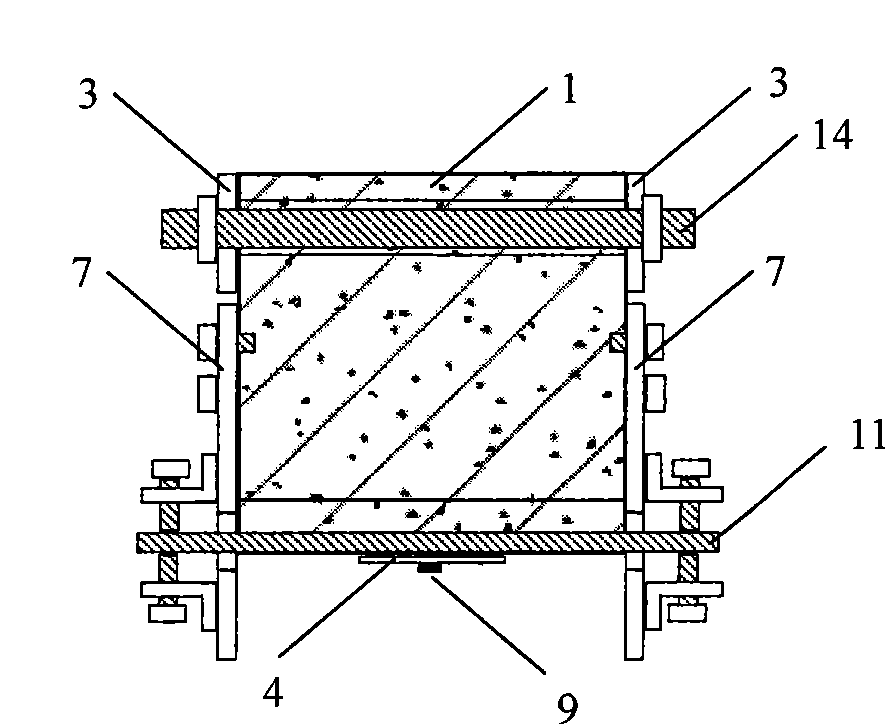

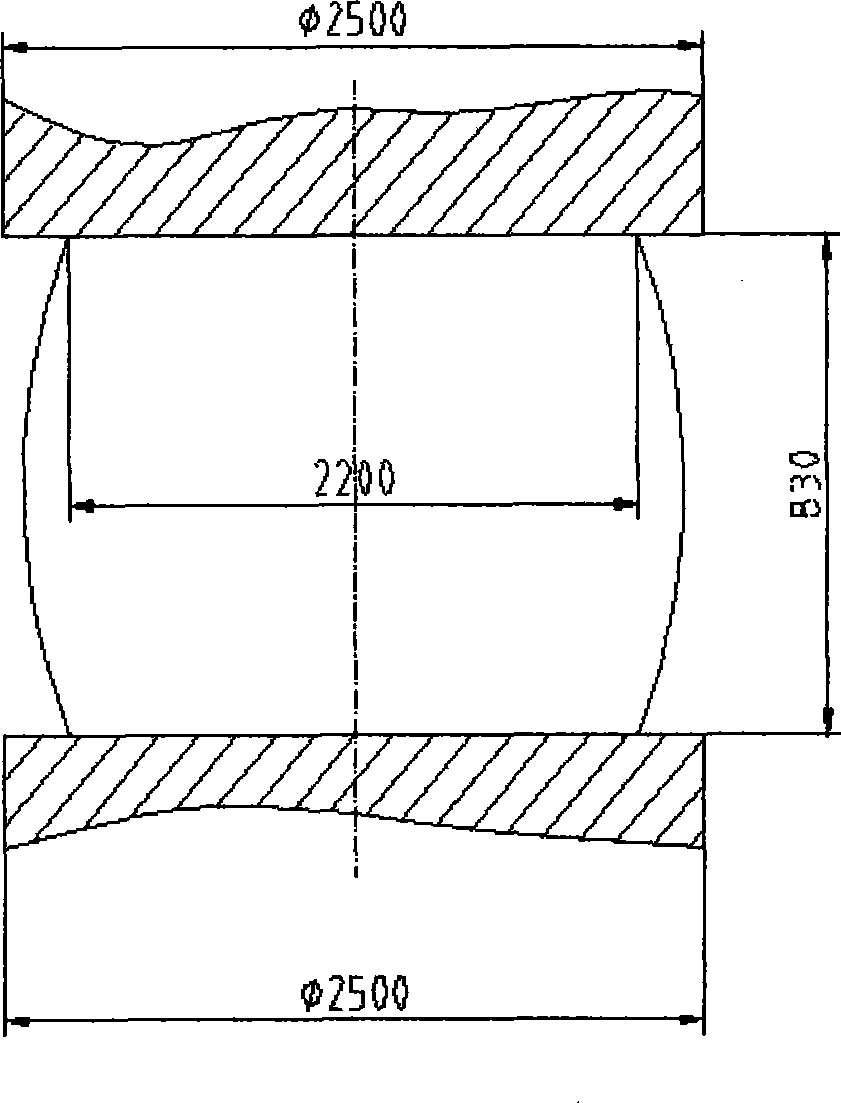

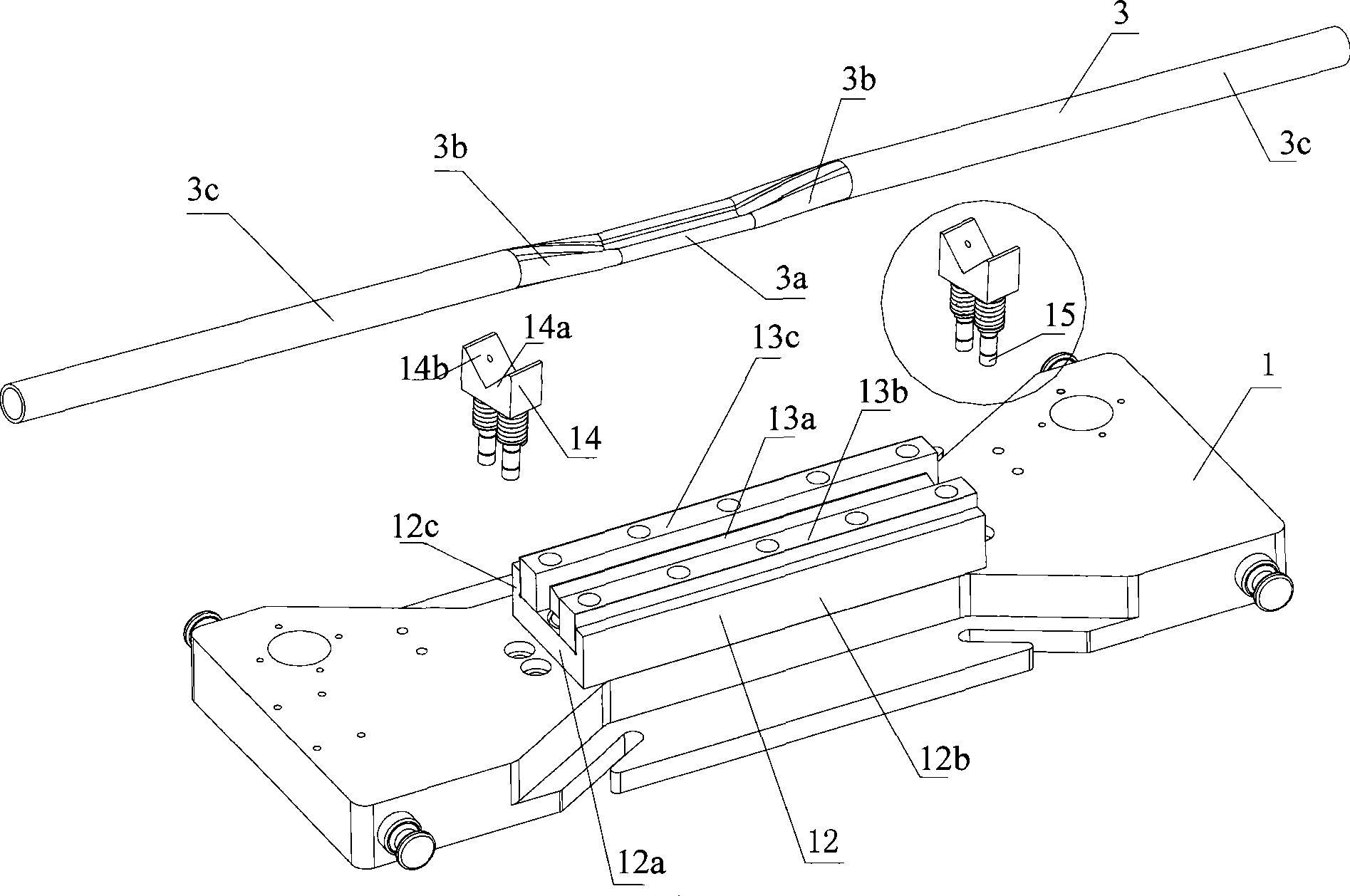

Tensile test fixture used for tubular product sample

InactiveCN101776550APrevent slippingAvoid performance changesMaterial strength using tensile/compressive forcesEngineeringTest fixture

The invention discloses a tensile test fixture used for a tubular product sample, which comprises an integral fixture comprising two concave die fixtures, two concave die cushion blocks, two convex die fixtures and two convex die cushion blocks, an upper positioning plate and a lower positioning plate. The two convex die cushion blocks are respectively fixed on the mounting surfaces of the two convex die fixtures; and the two concave die cushion blocks are respectively fixed on the mounting surfaces of the two concave die fixtures, and the convex arc faces of the convex die cushion blocks and the concave arc faces of the concave die cushion blocks are matched to become a pair of fixtures. The upper positioning plate and the lower positioning plate are respectively fixed on the side surfaces of the two convex die fixtures. The tensile test fixture is connected and positioned with a testing machine by the flanges of the convex die fixtures and the flanges of the concave die fixtures. The invention can firmly fix the tubular product sample and avoids the performance change of a tubular product caused by the condition that both ends of the tubular product sample are flatly clamped, thereby obtaining the accurate tensile property of the tubular product and having the characteristics of simple structure and convenient and reliable use.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

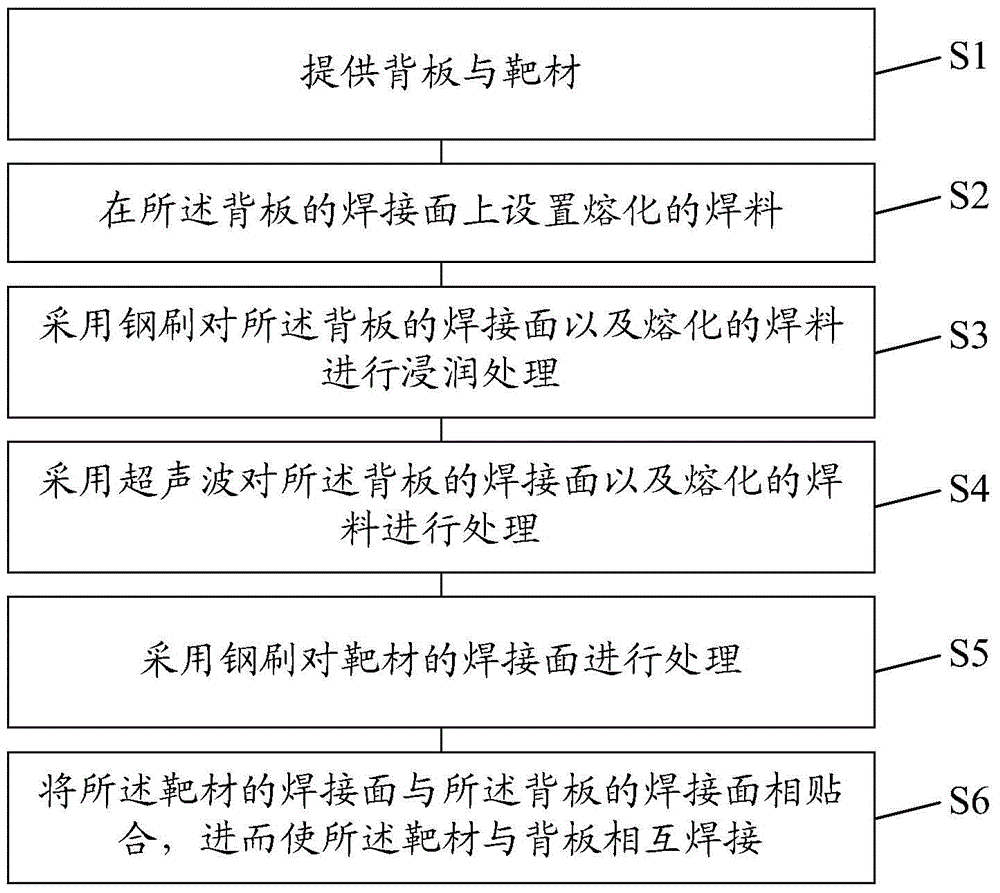

Welding method for target assembly

The invention provides a welding method for a target assembly. The welding method is used for welding a target and a back plate to form the target assembly. The method includes the steps that the back plate and the target are provided; molten solder is arranged on a welding face of the back plate; a steel brush is used for wetting the welding face of the back plate and the molten solder, and ultrasonic waves are used for processing the welding face of the back plate and the molten solder; the steel brush is used for processing a welding face of the target; and the welding face of the target and the welding face of the back plate are attached so as to weld the target and the back plate. The welding method has the beneficial effects that the contact area between the molten solder and the welding face of the back plate is enlarged, atoms of the solder can be conveniently and more quickly dispersed onto the welding face of the back plate, and therefore the molten solder can conveniently wet the surface of the welding face of the back plate, and the welding quality of the target and the back plate is higher.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

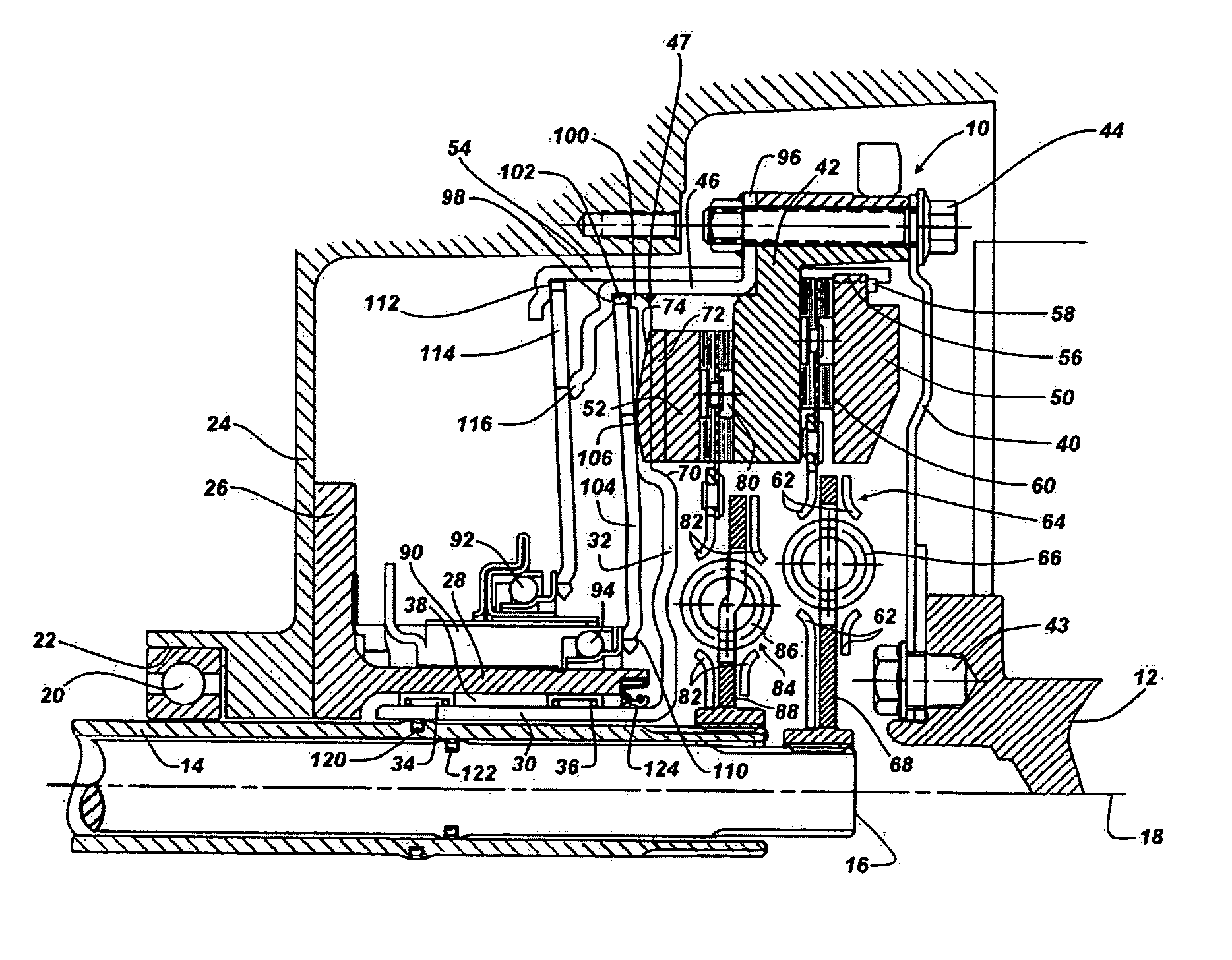

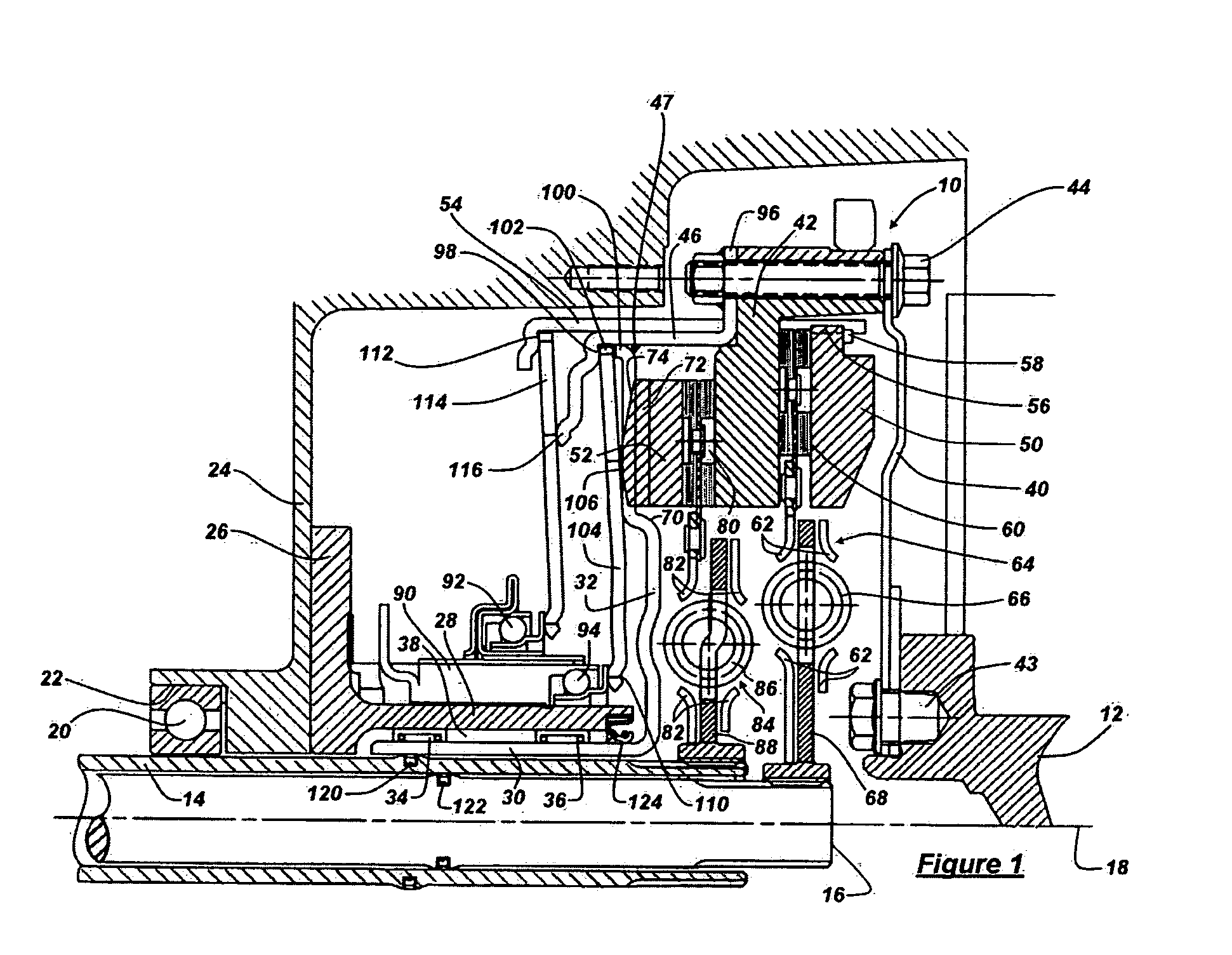

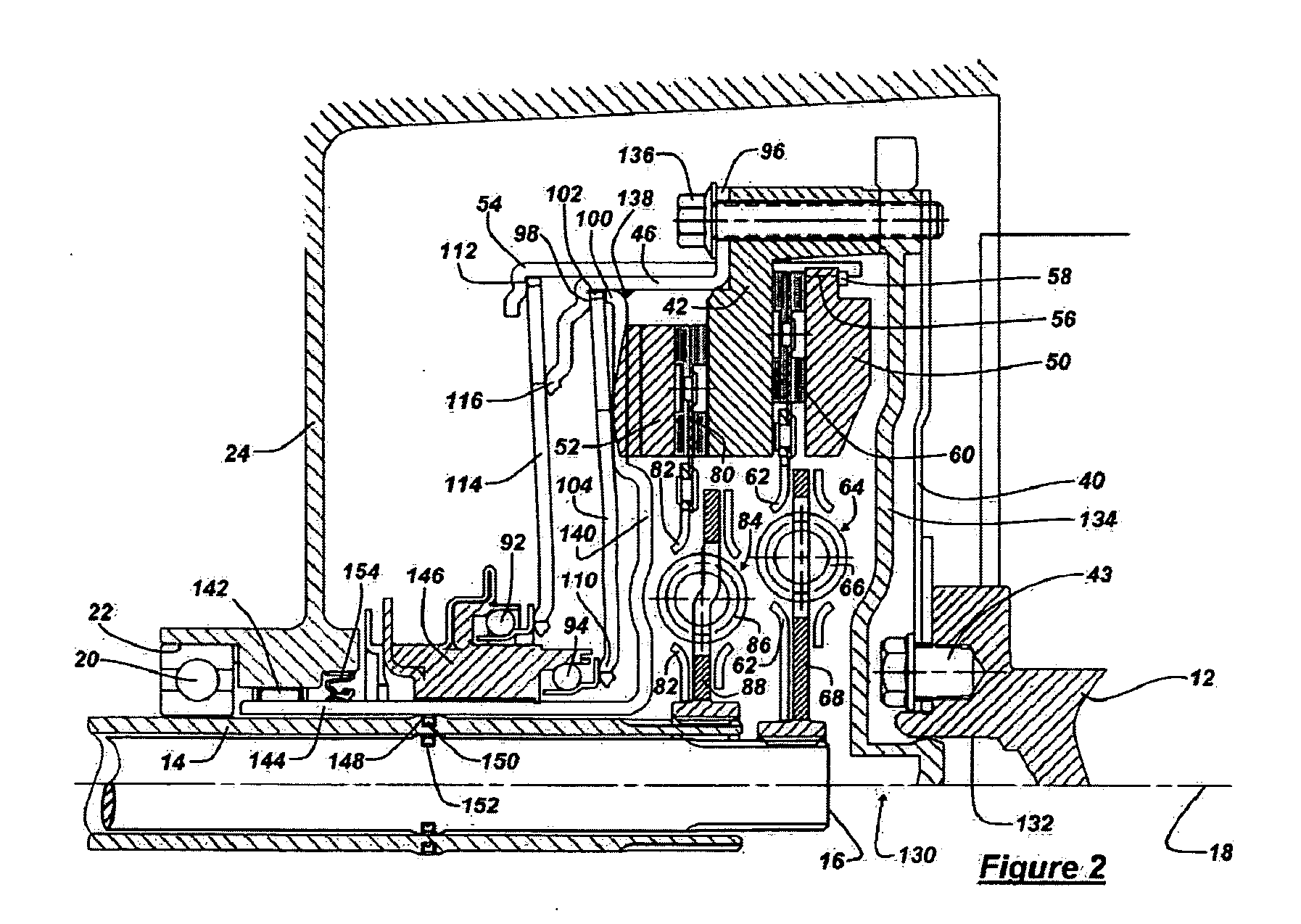

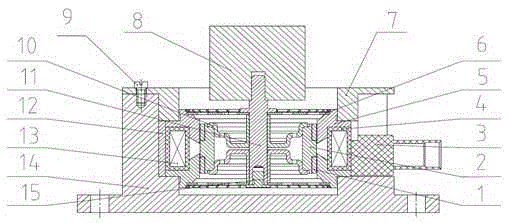

Dual clutch assembly for a motor vehicle powertrain

InactiveUS20050252745A1Firm supportImprove noiseYielding couplingFriction clutchesEngineeringFlywheel

A powertrain assembly for transmitting torque between a power source and a transmission includes an input shaft, a housing on which the input shaft is rotatably supported, a flywheel rotatably supported at two axially spaced locations, at least one of the locations providing support for the flywheel on the housing, and a clutch for driveably connecting and disconnecting the flywheel and the input shaft.

Owner:FORD GLOBAL TECH LLC

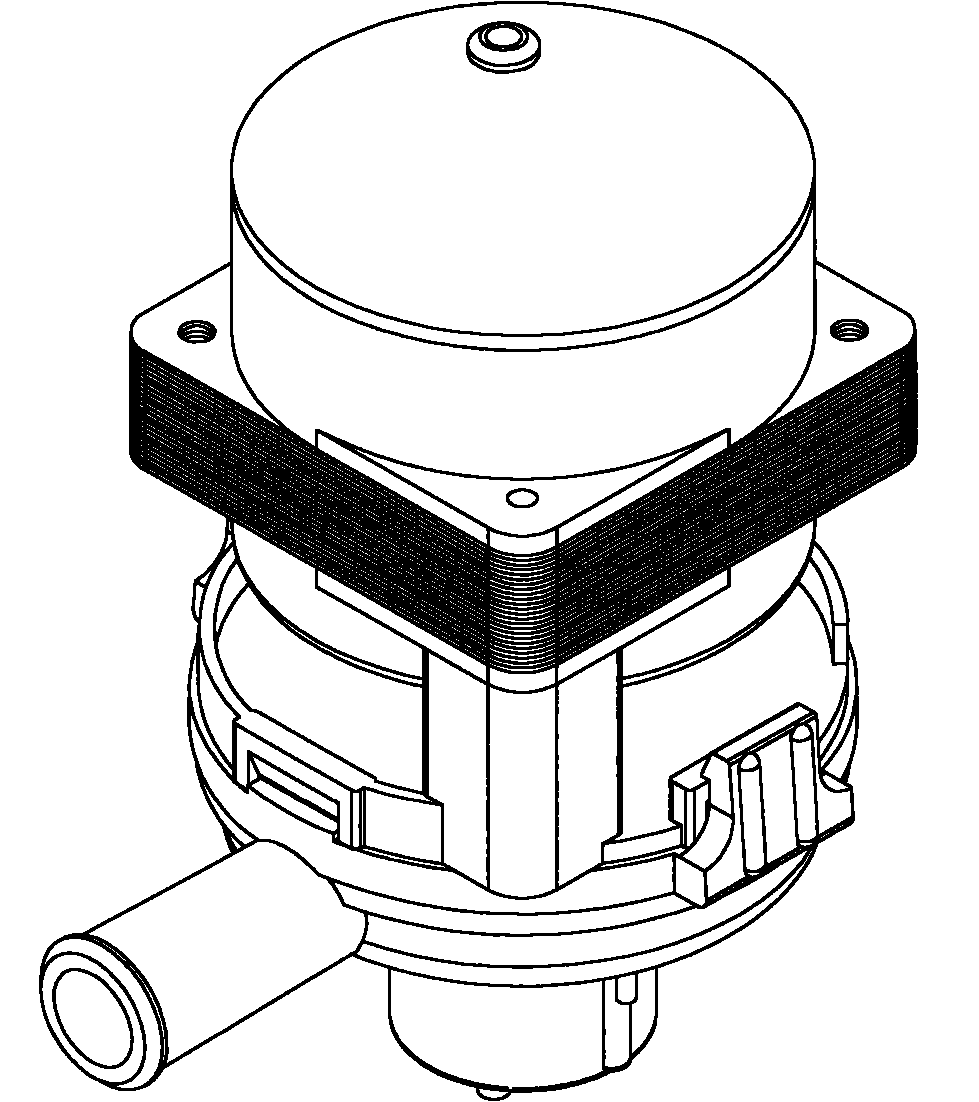

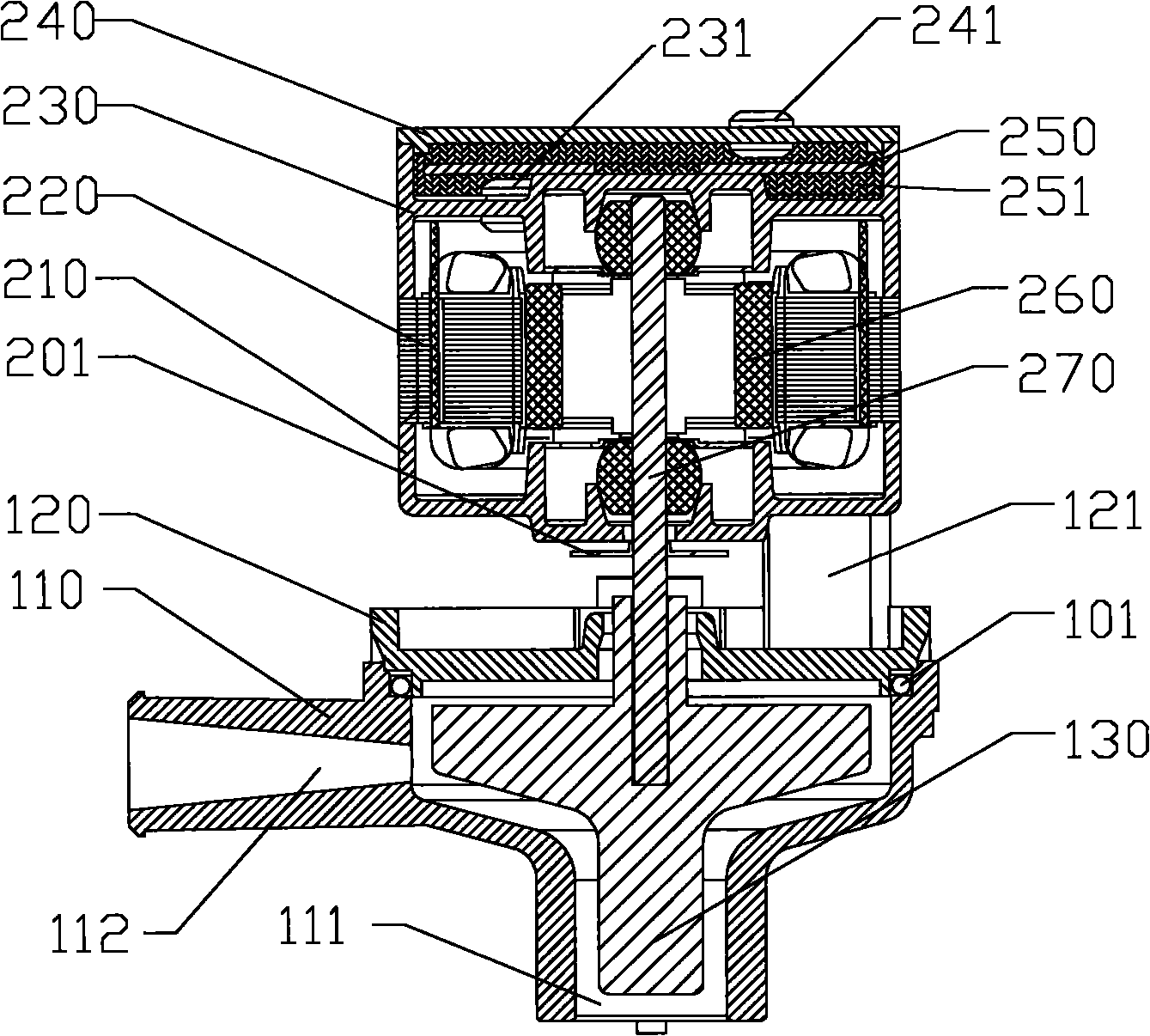

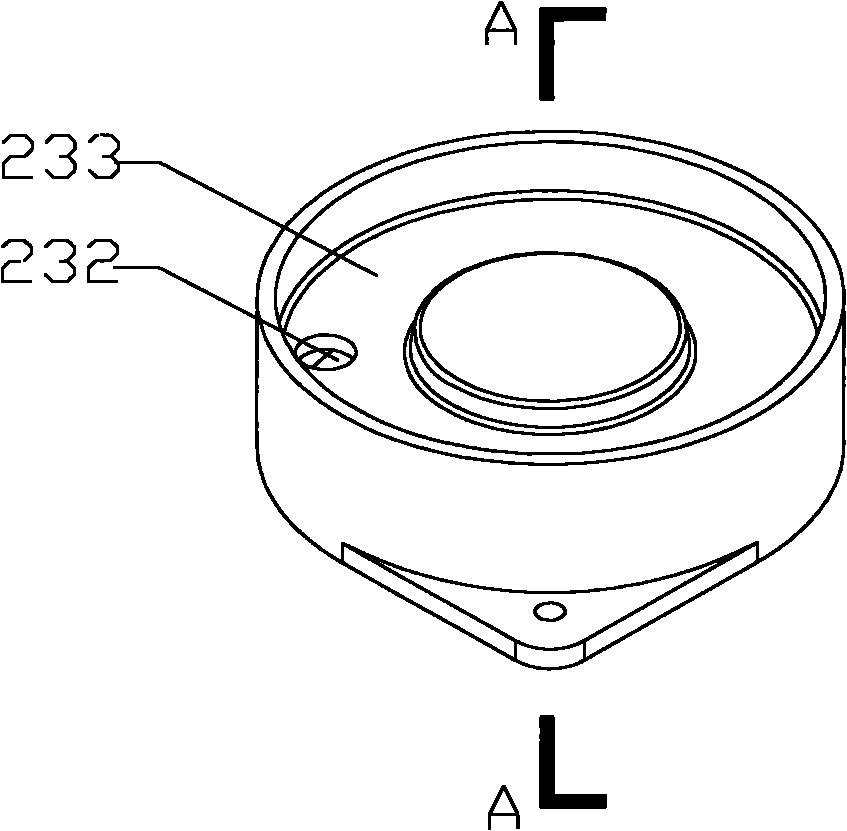

Brushless direct current motor for pump and manufacturing method thereof as well as pump equipped with same

ActiveCN102158034AImprove reliabilitySimple structureManufacturing dynamo-electric machinesPump installationsMotor controlControl circuit

The invention discloses a pump driven by a brushless direct current motor, a pump equipped with the brushless direct current motor as well as a manufacturing method of the brushless direct current motor for driving the pump. The brushless direct current motor of the pump comprises a motor shell and a motor shaft, wherein the motor shell comprises a lower end cover and an upper end cover, a statorpart is fixed between the lower end cover and the upper end cover, the motor shaft passes through the lower end cover and extends downwards, surrounding edges extending upwards are arranged at the periphery of the upper end cover, a circuit board chamber is arranged at the upper side of the upper end cover and is internally provided with a control circuit board and an encapsulating body made of encapsulating material, an internal lead of the control circuit board is connected with a connecting wire of the motor after passing through an internal lead hole on the upper end cover, and an external lead of the control circuit board passes through the encapsulating body and extends outwards. The control circuit board is sealed in the circuit board chamber in the way of encapsulating, and the encapsulating body can protect the control circuit board, ensure the reliability of motor control and operation, simplify the structure of the motor and facilitate the assembly of the motor.

Owner:ZHEJIANG SANHUA COMMERCIAL REFRIGERATION CO LTD

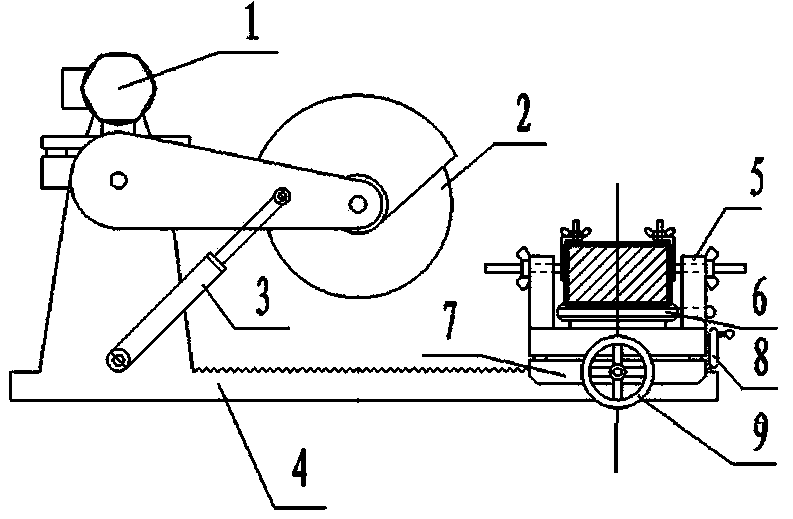

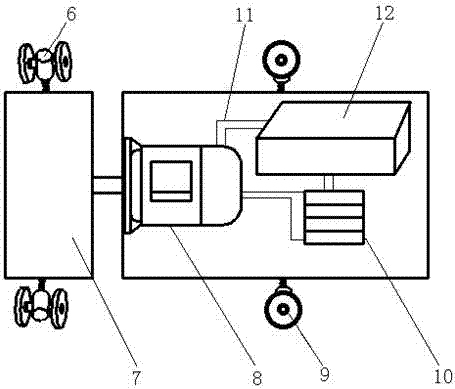

Dry-type joint coal rock sampling device and sampling method thereof

InactiveCN103837368AImprove stabilityAvoid crackingWithdrawing sample devicesCoal briquetteInstability

The invention relates to a dry-type joint coal rock sampling device and a sampling method thereof. The dry-type joint coal rock sampling device comprises a cutting device and a sampling device, wherein the cutting device is provided with a cutting base, one end of a cutting wall is connected with the cutting base, a saw blade is mounted on the other end of the cutting wall, and a height regulating device is mounted between the cutting base and the saw blade; the cutting base further comprises a cutting track; a sliding rail base is connected with the cutting track, the sliding rail base is a two-way sliding rail and capable of moving along the cutting track or in a direction perpendicular to the cutting track, and a base translation control handwheel is mounted on the sliding rail base; a turnplate is mounted at the center of the sliding rail base and is provided with a handwheel, and rock samples are arranged on the turnplate; the sampling device comprises a sampling base, a clamping device, a diamond sampling drill bit, an openable transparent cover, a refrigerating device, an air blowing device and an exhaust fan. The dry-type joint coal rock sampling device is capable of either effectively avoiding coal briquette falling and coal rock cracking due to instability in the coal rock cutting process or accurately controlling the cutting thickness of the coal rock, and therefore, the purpose of accurate cutting is achieved.

Owner:嘉兴骏博精密机械有限公司

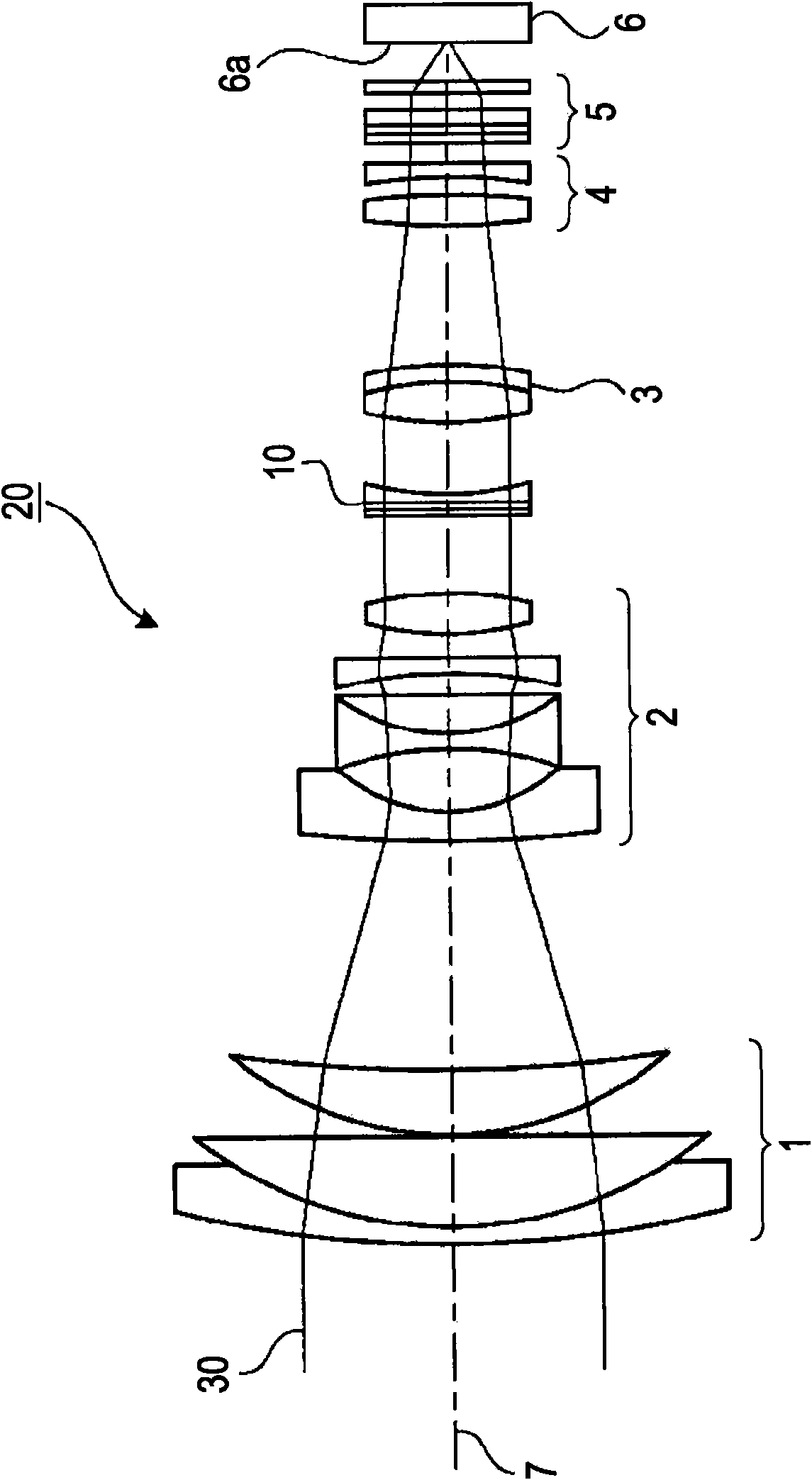

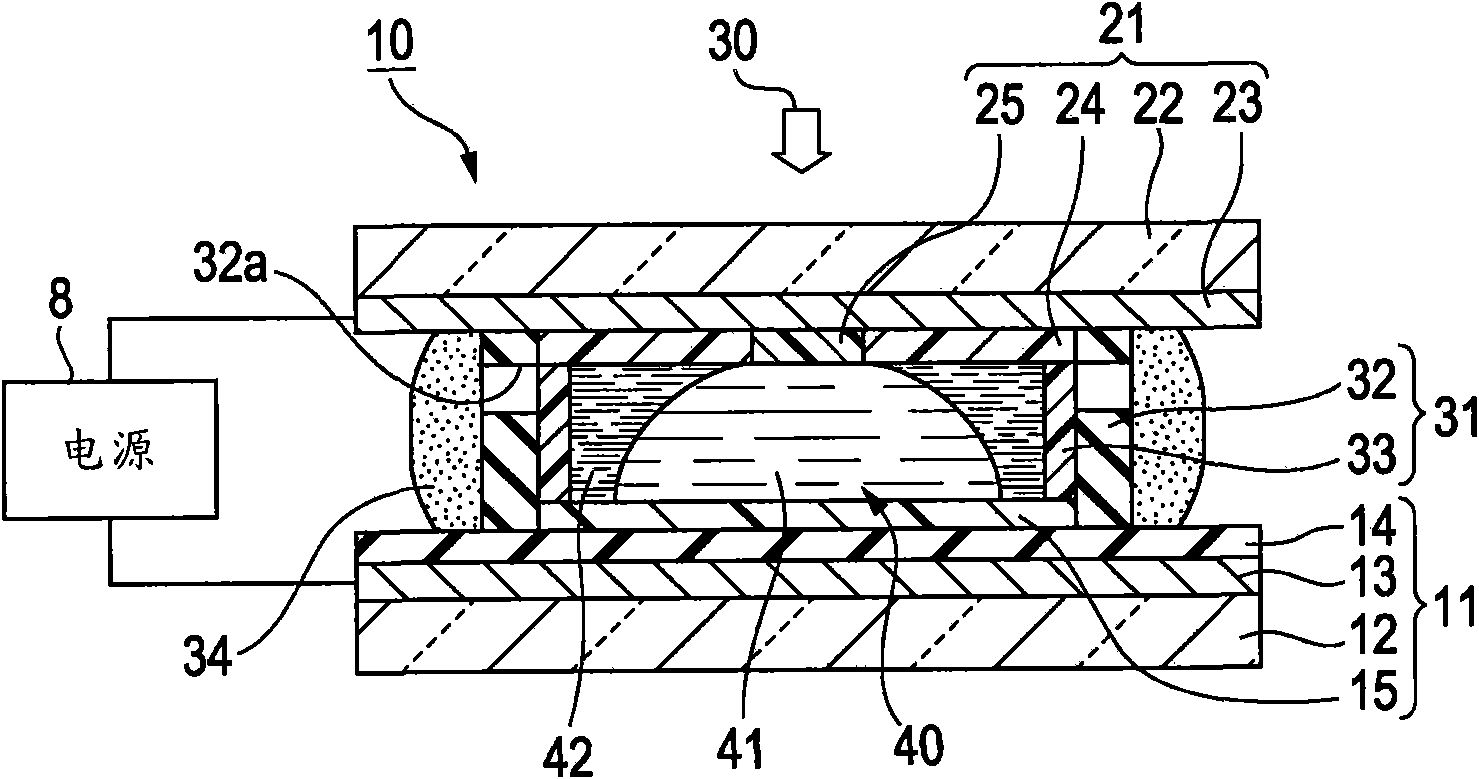

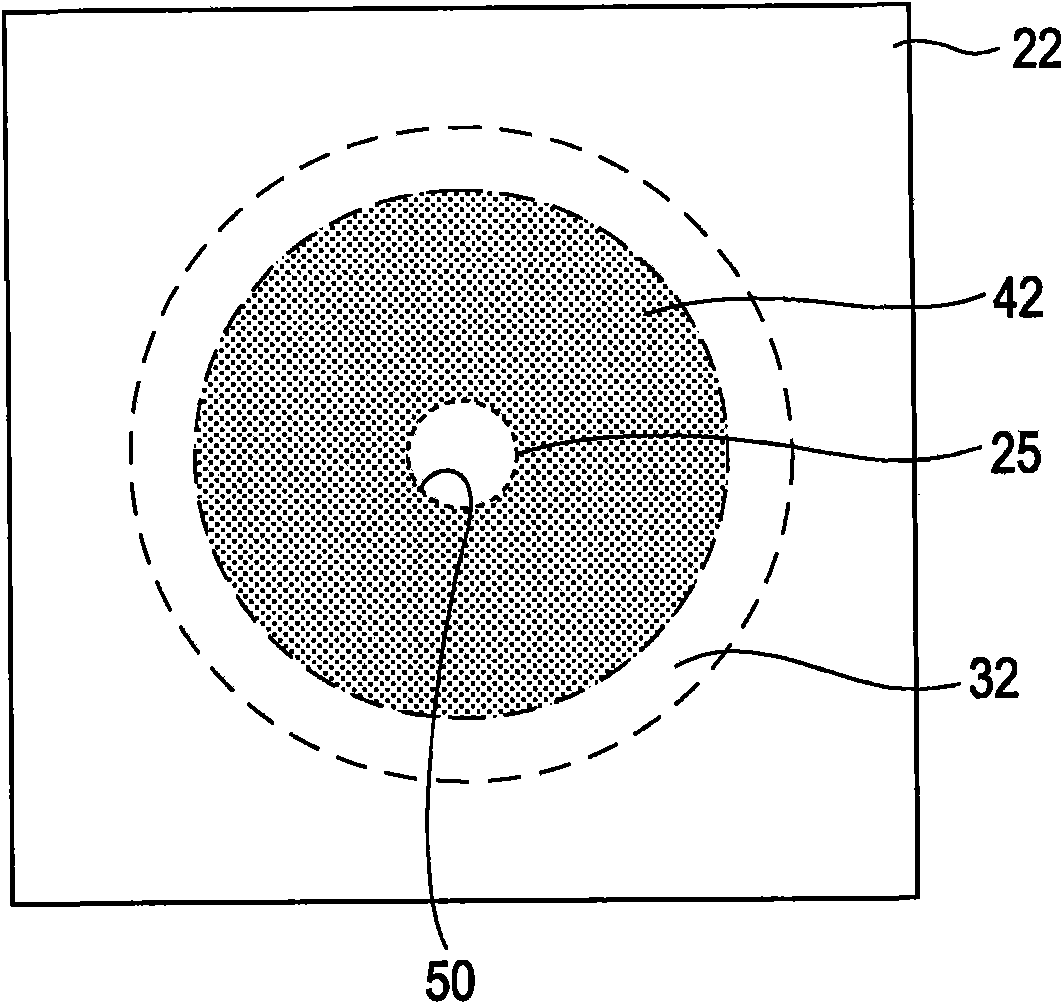

Optical element and imaging device

InactiveCN101685172AAvoid eccentricityTelevision system detailsColor television detailsElectrical polarityEngineering

An optical element includes a first liquid; a second liquid that is immiscible with the first liquid and that has polarity or electrical conductivity; a first substrate portion, a second substrate portion, a sidewall portion; a second electrode disposed on one of the second substrate portion and the sidewall portion; and an accommodating portion constituted by the first substrate portion, the second substrate portion, and the sidewall portion and sealing the first liquid and the second liquid therein. The optical element further includes a first film disposed on the first substrate portion side of the accommodating portion and having high affinity with the first liquid, a second film disposed on the second substrate portion side of the accommodating portion and having high affinity with the second liquid, and a third film disposed at the center of the second film and having high affinity with the first liquid.

Owner:SONY CORP

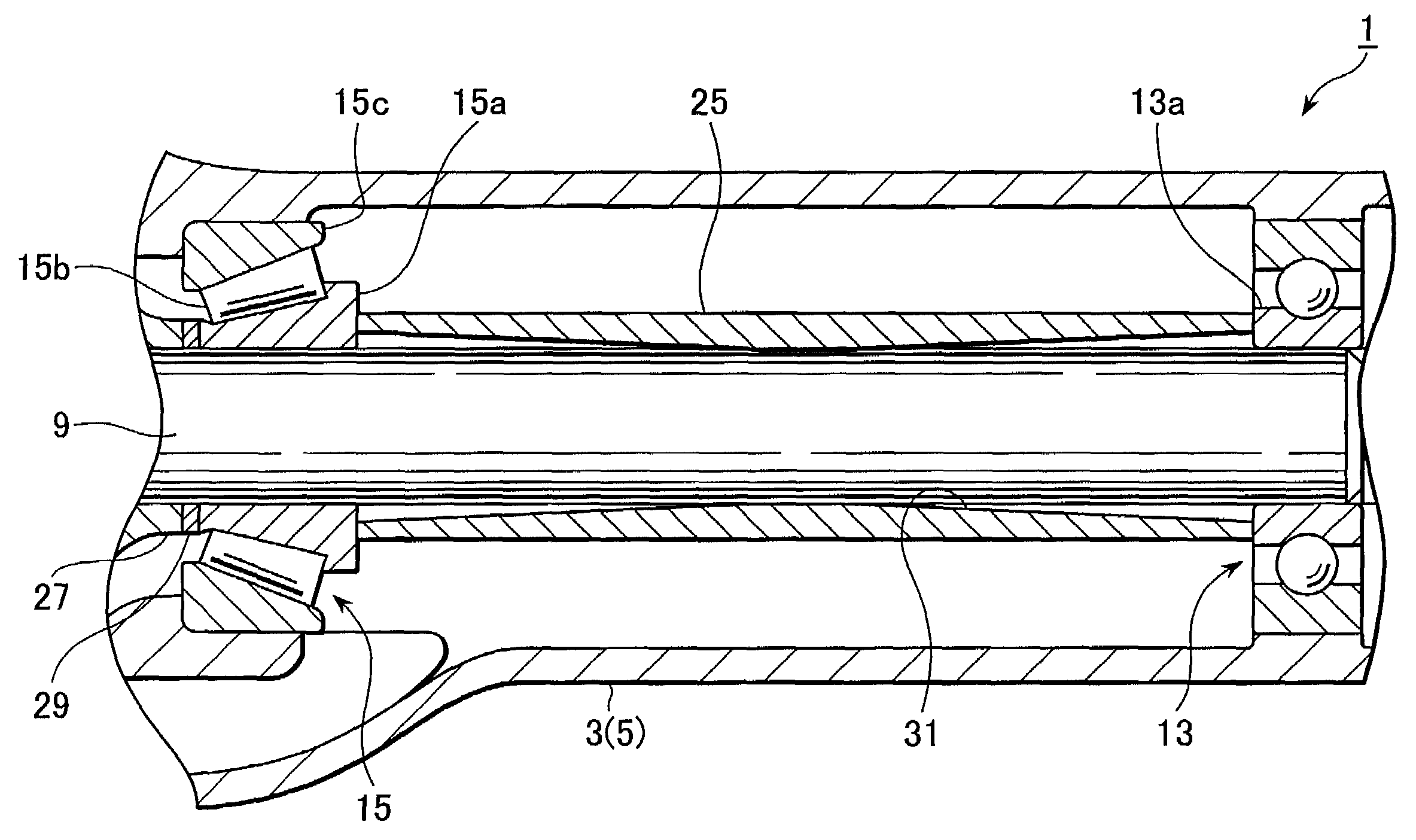

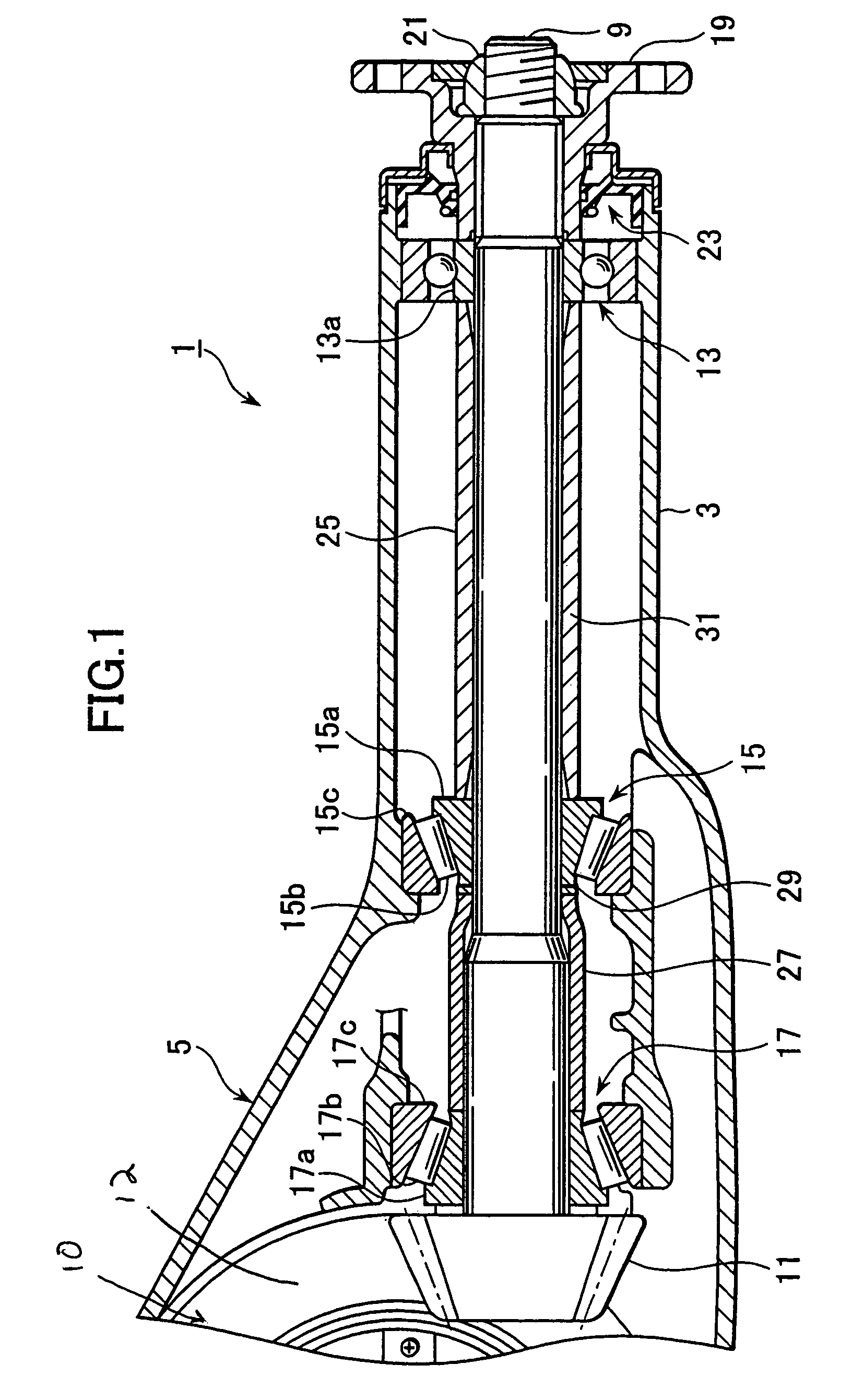

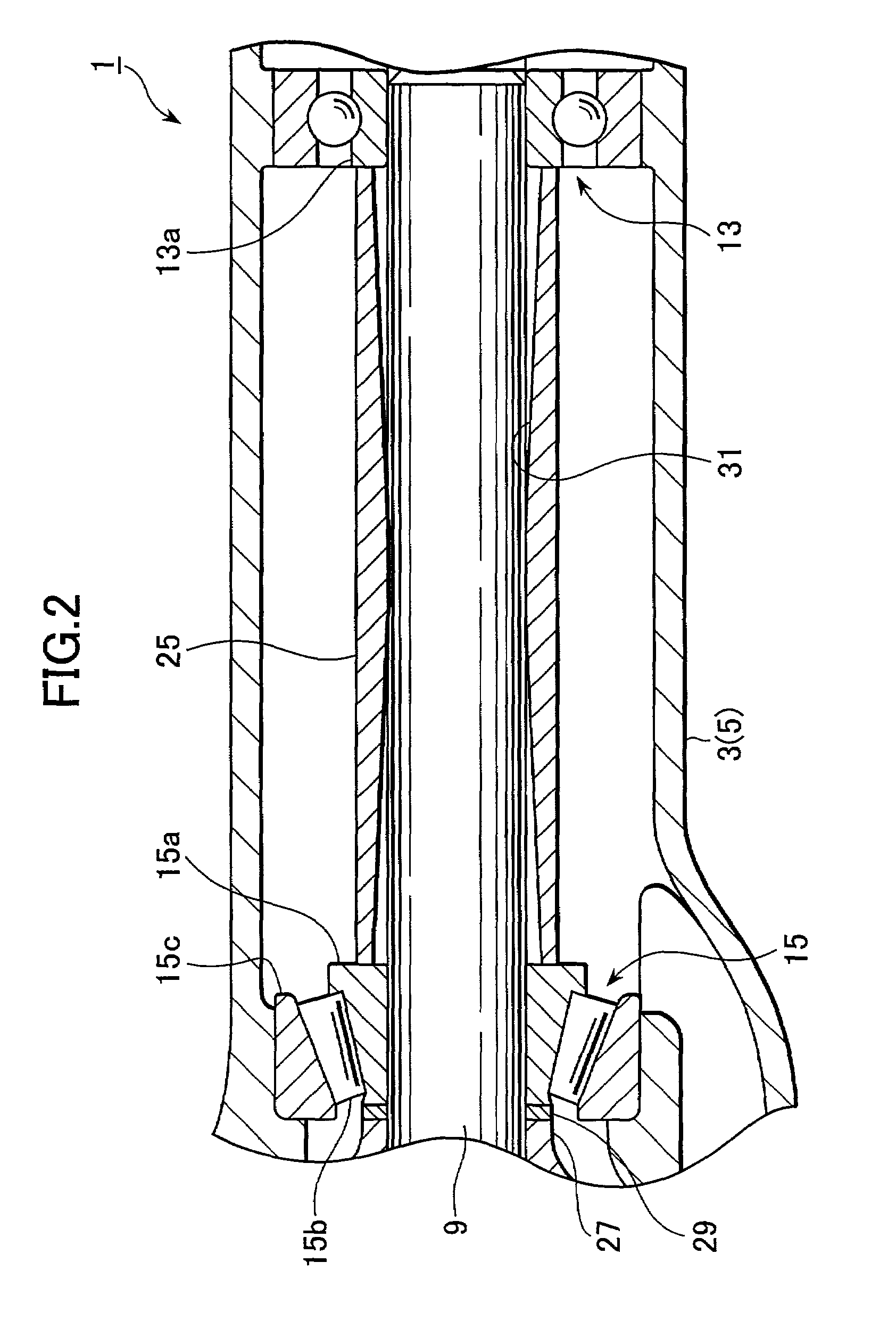

Vibration dumping device

ActiveUS20130116054A1Reduce frequencyImbalance can be reducedRotating vibration suppressionYielding couplingRotational axisReciprocating motion

A vibration damping device capable of reducing a change in an order frequency of a reciprocating motion of a pendulum resulting from eccentricity of rotational members therein. The vibration damping comprises a pendulum damping mechanism having a mass to dampen the torsional vibrations by an oscillating motion thereof resulting from the torsional vibrations. An inertial body is arranged in the prime mover side of the rotary shaft, an elastic damping mechanism is connected with a transmission side of the inertial body in a power transmittable manner, a pendulum damping mechanism is connected with the transmission side of the elastic damping mechanism in a power transmittable manner, and a torque limiter mechanism is connected with the transmission side of the pendulum damping mechanism in a power transmittable manner.

Owner:TOYOTA JIDOSHA KK

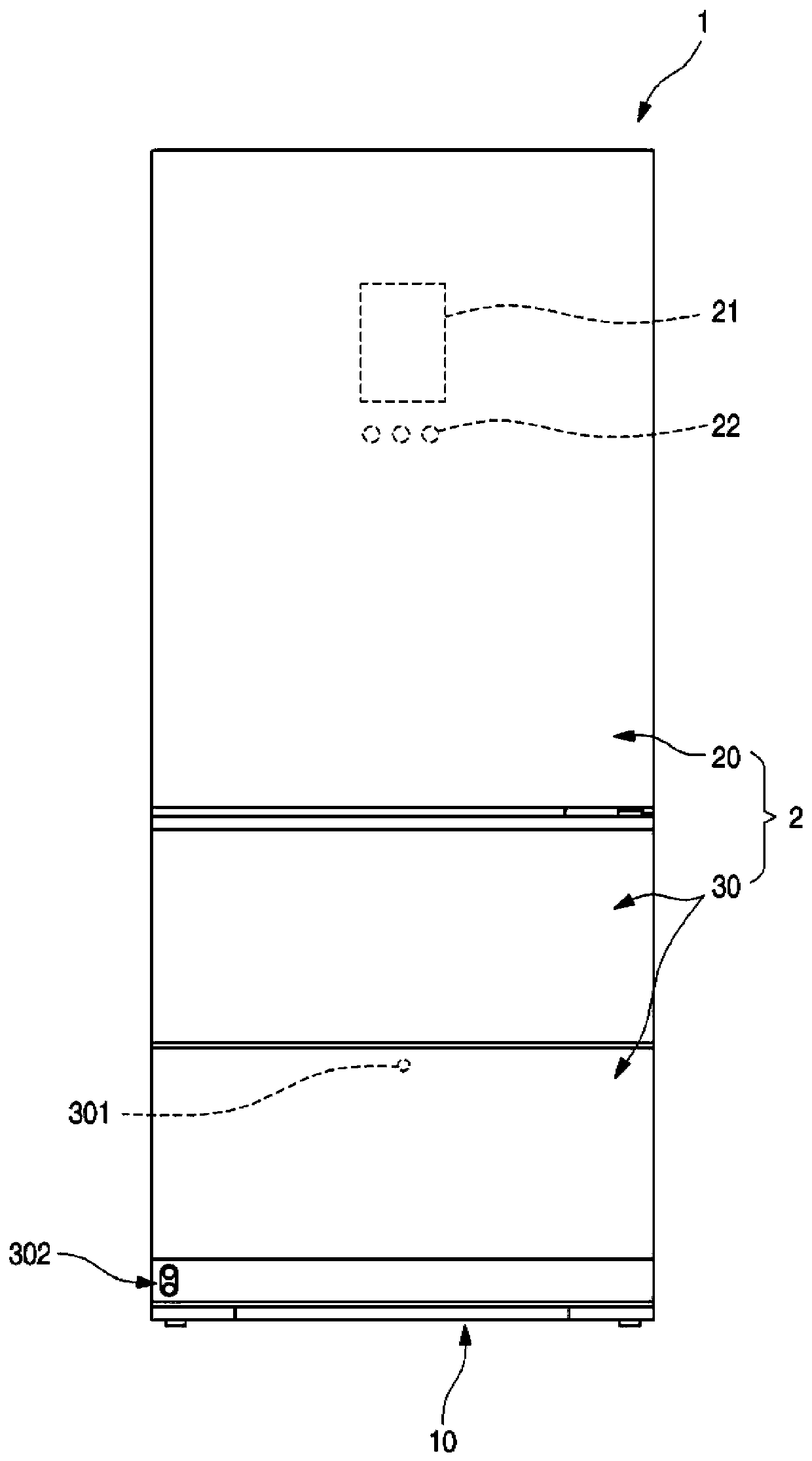

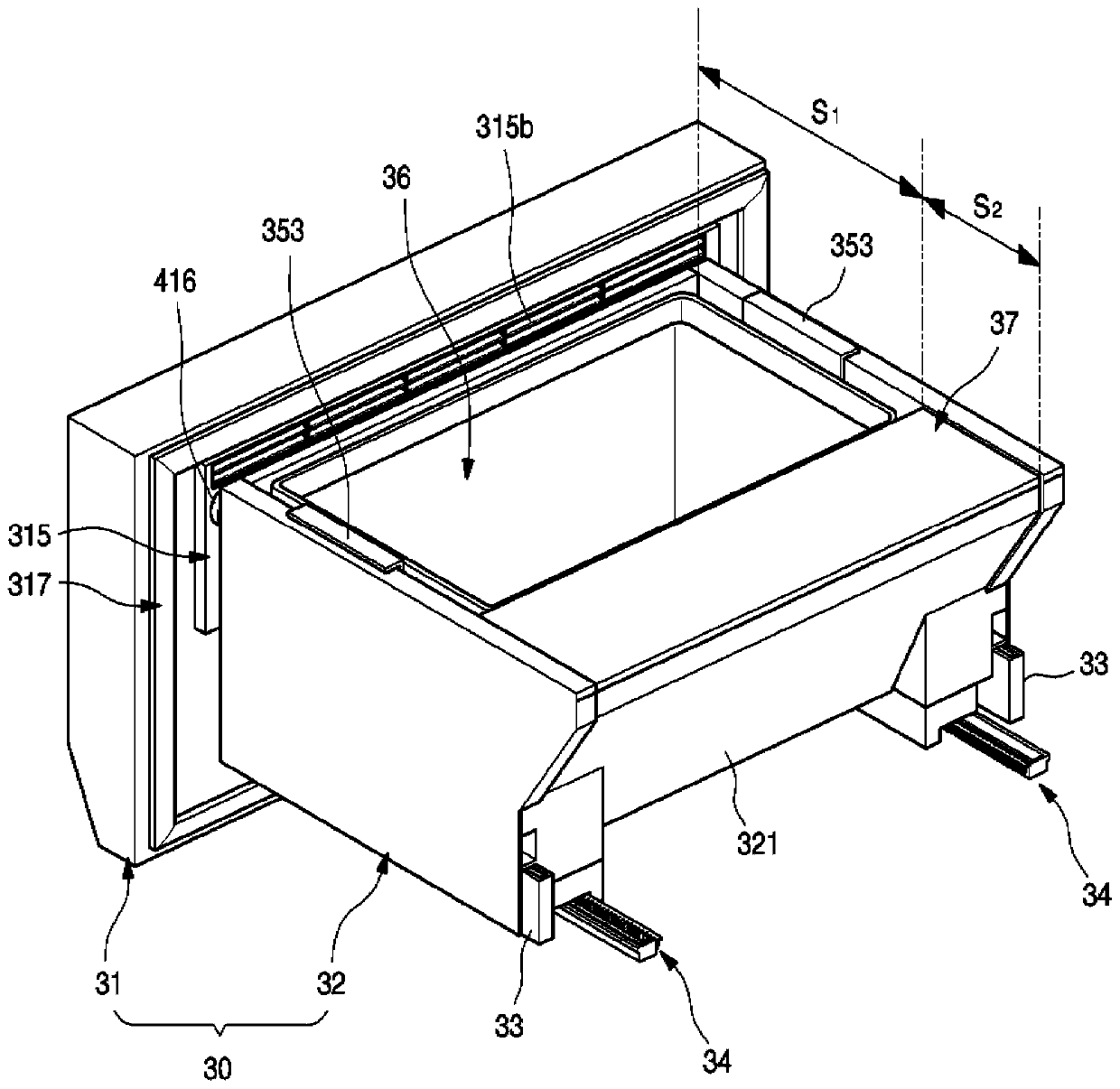

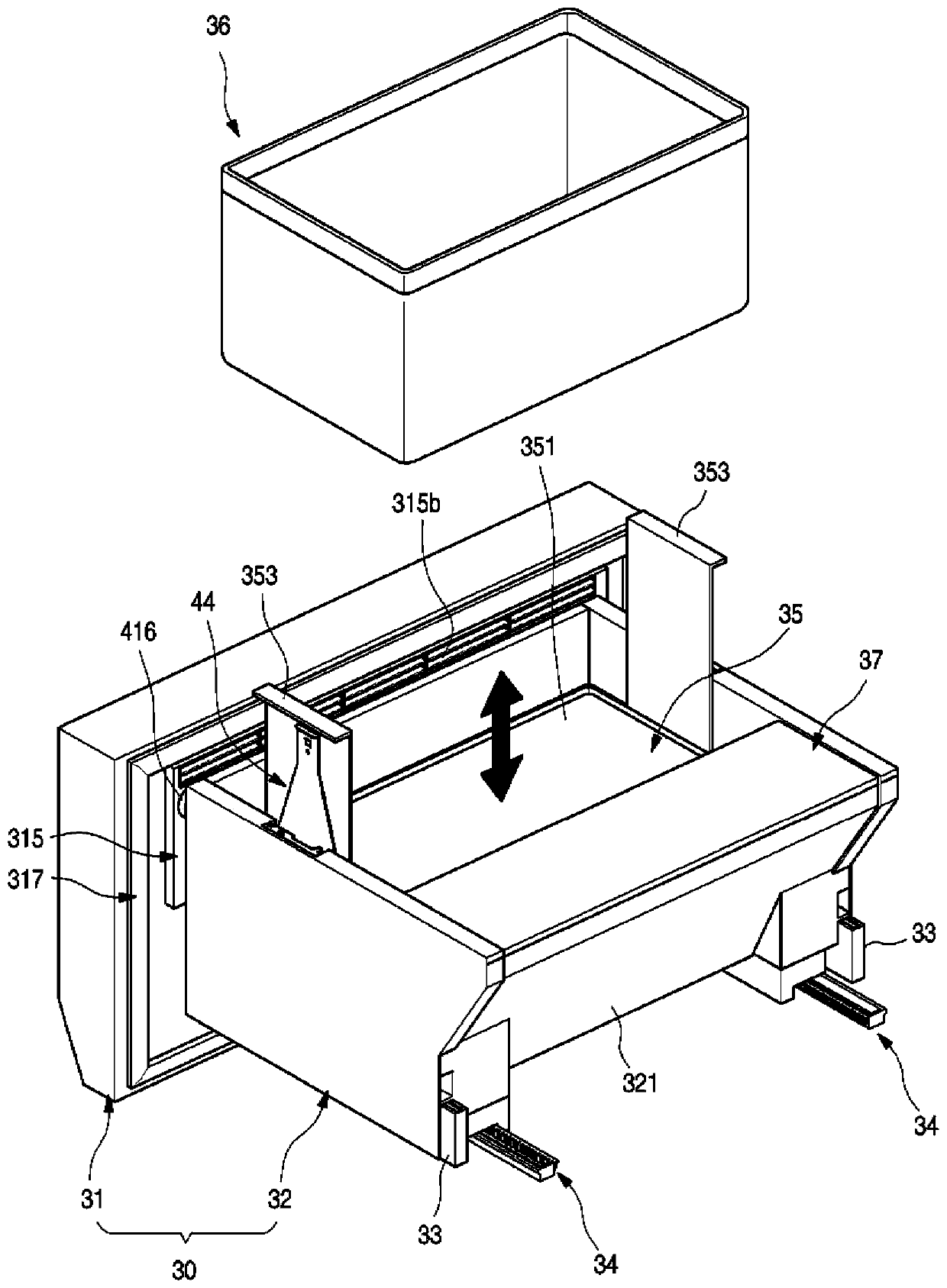

Refrigerator

ActiveCN109990557AImprove ease of useMinimize the loss of storage spaceLighting and heating apparatusSupportStructural engineeringElectrical and Electronics engineering

Owner:LG ELECTRONICS INC

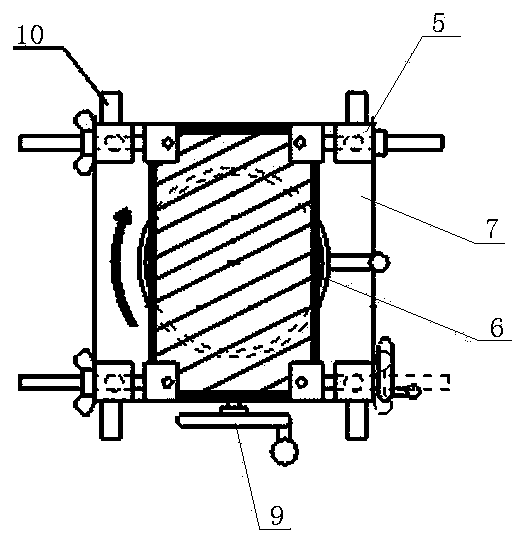

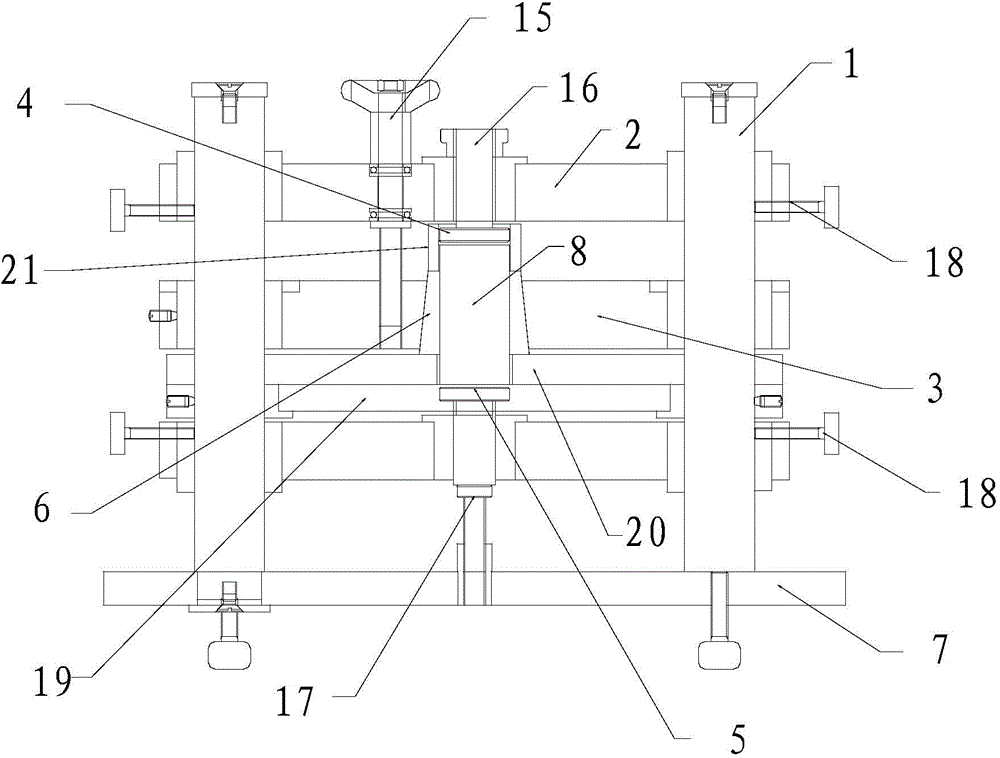

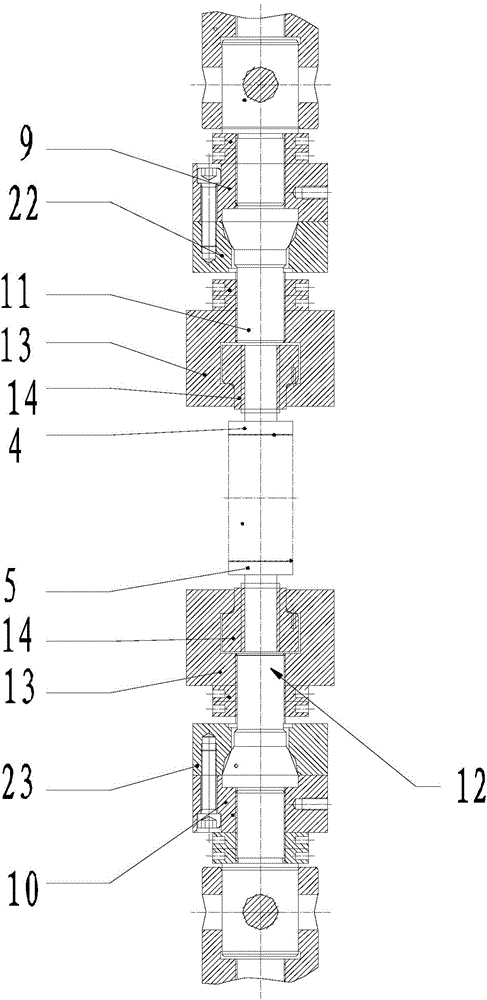

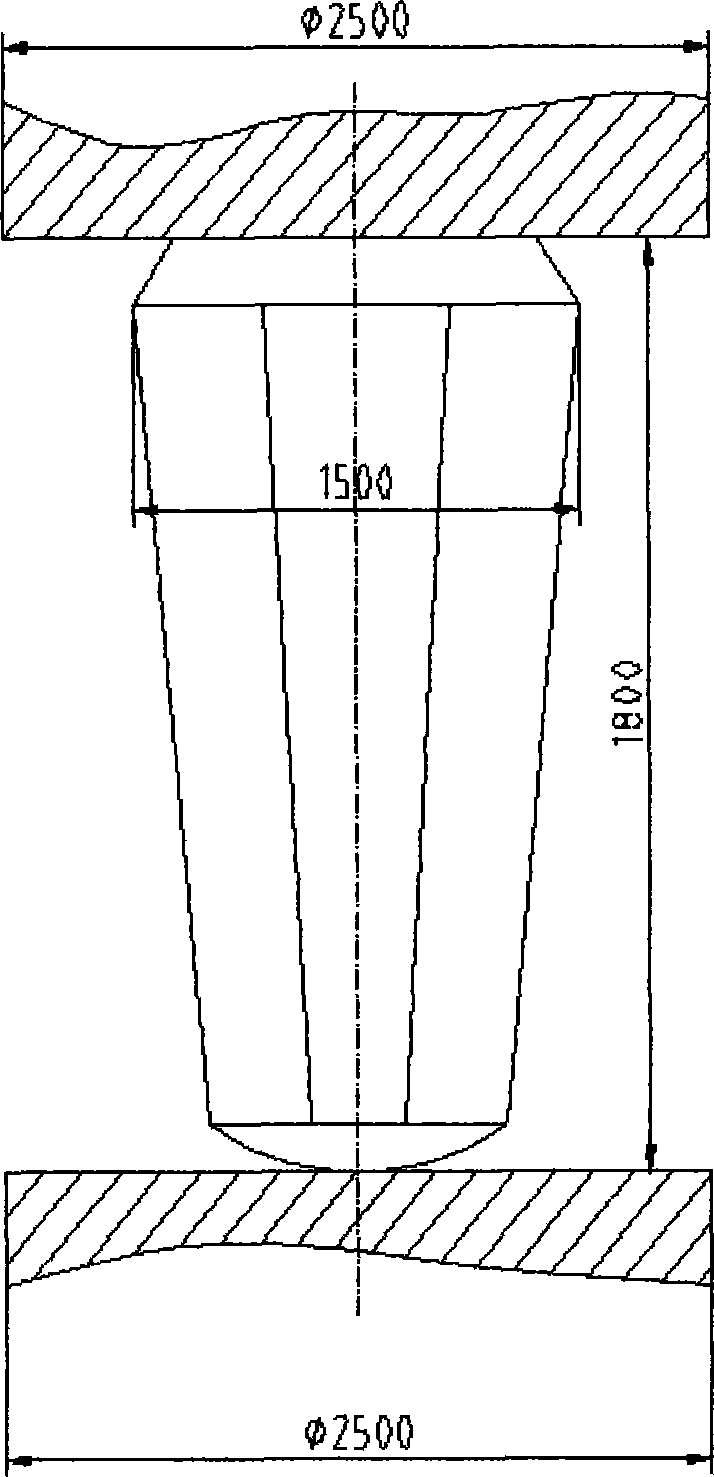

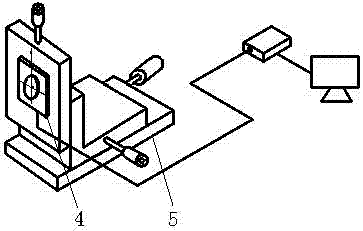

Rock axial tension test device and rock axial tension test device

InactiveCN104596850AAccurate testing of tensile strengthAvoid eccentricityMaterial strength using tensile/compressive forcesAdhesion processEngineering

The invention provides a rock axial tension test device and a rock axial tension test device in the field of material mechanical tests. The invention provides a rock axial tension test device which has a simple structure and can be used for guaranteeing the complete axial alignment of a test piece and upper and lower pull heads in an adhesion process and can also be used for effectively eliminating an eccentric phenomenon in a tension test process. The rock axial tension test device comprises an upright post, an upper positioning sleeve, a lower positioning sleeve, an upper pull head, a lower pull head, a test piece clamping sleeve and a bottom plate, as well as a clamping element, the clamping element comprises an inner side face and an outer side face, the inner side face is cylindrical, the outer side face is a conical surface, a conical surface matched with the outer side face of the clamping element is arranged on the clamping sleeve, and the clamping element is located in the conical surface of the clamping sleeve. The rock axial tension test device provided by the invention is used for solving the eccentric problem of a rock test piece when being pulled, and the rock test piece is aligned in a process of clamping the rock test piece.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

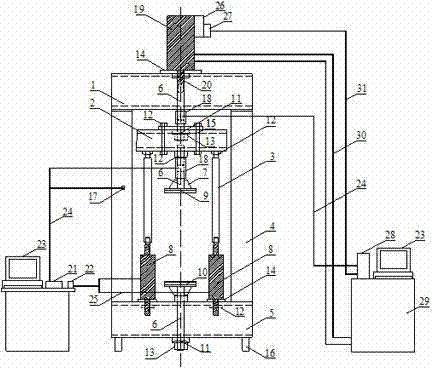

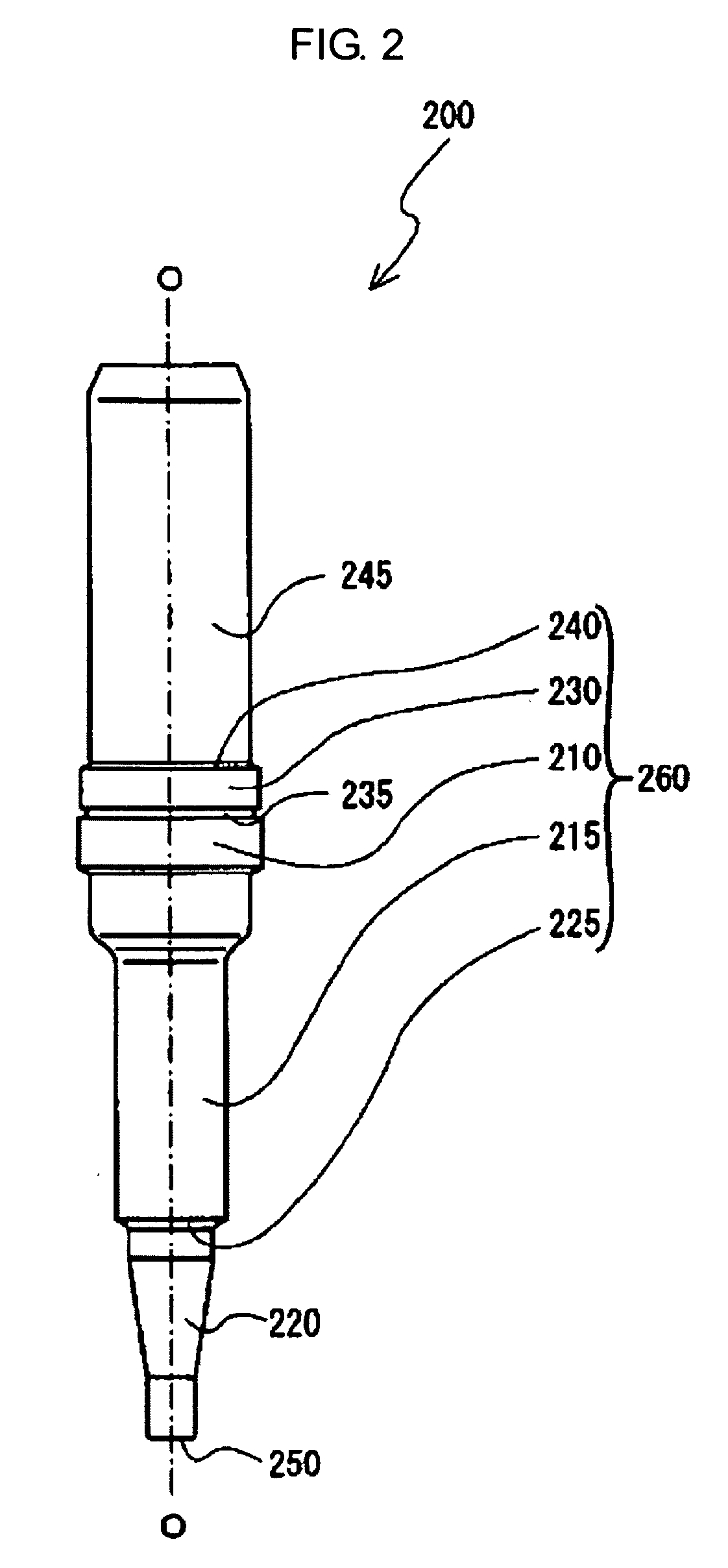

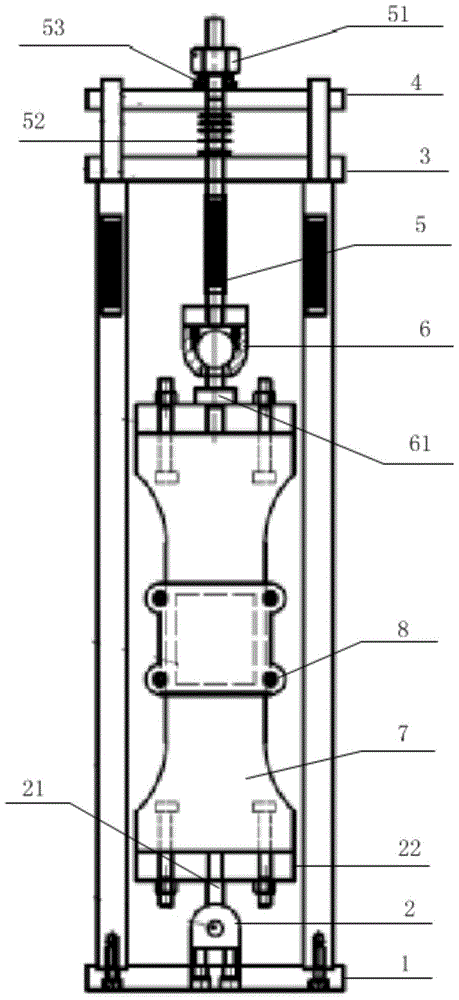

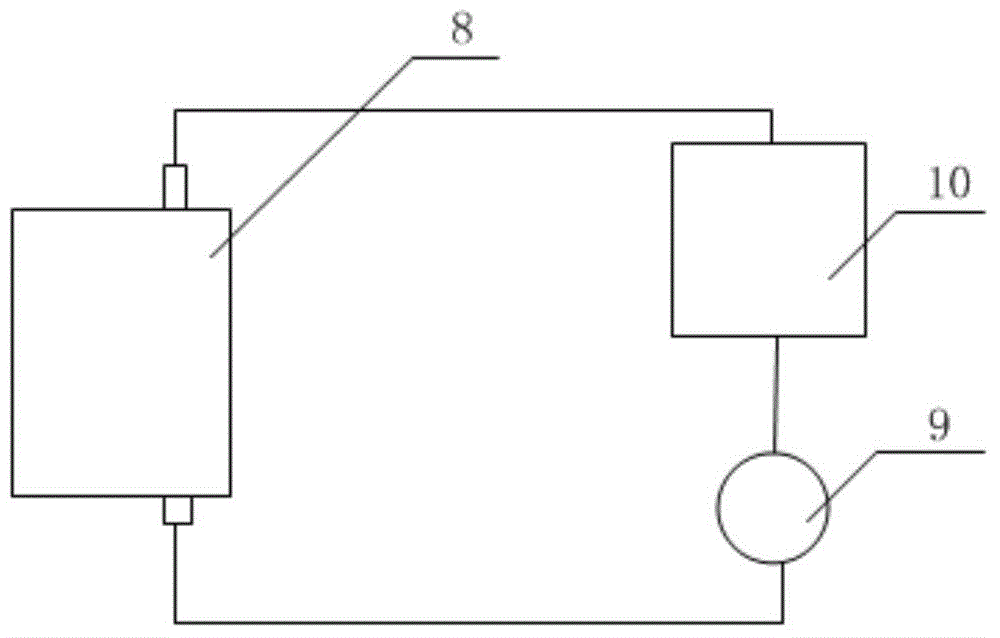

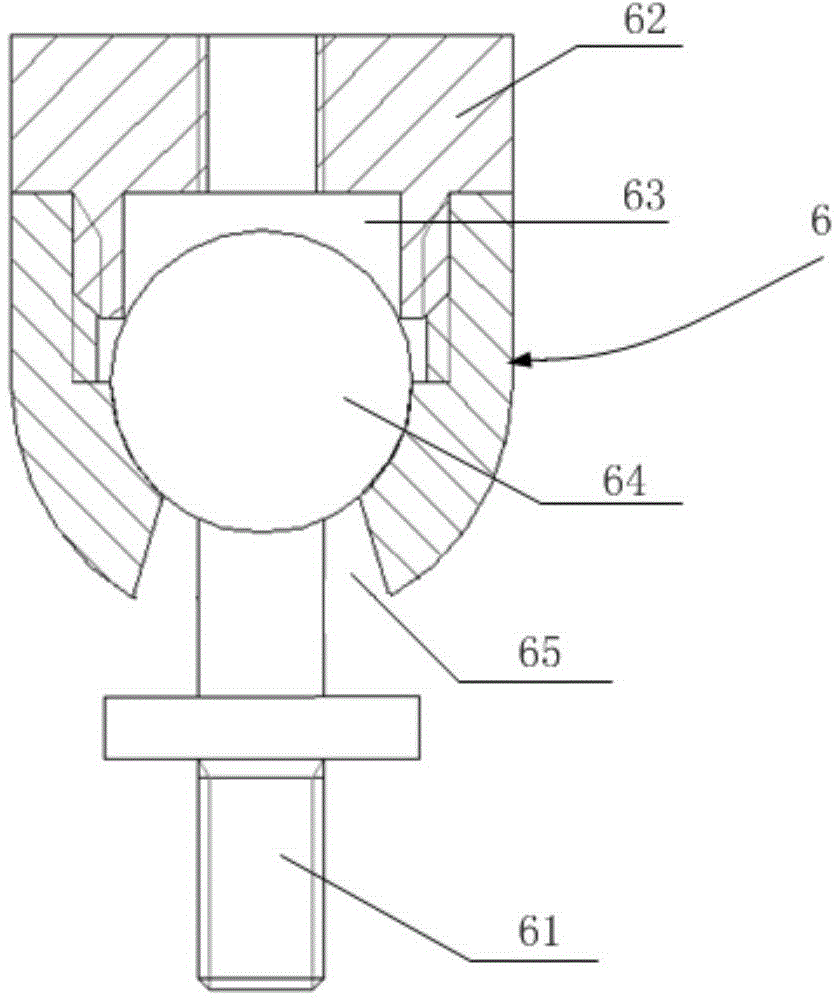

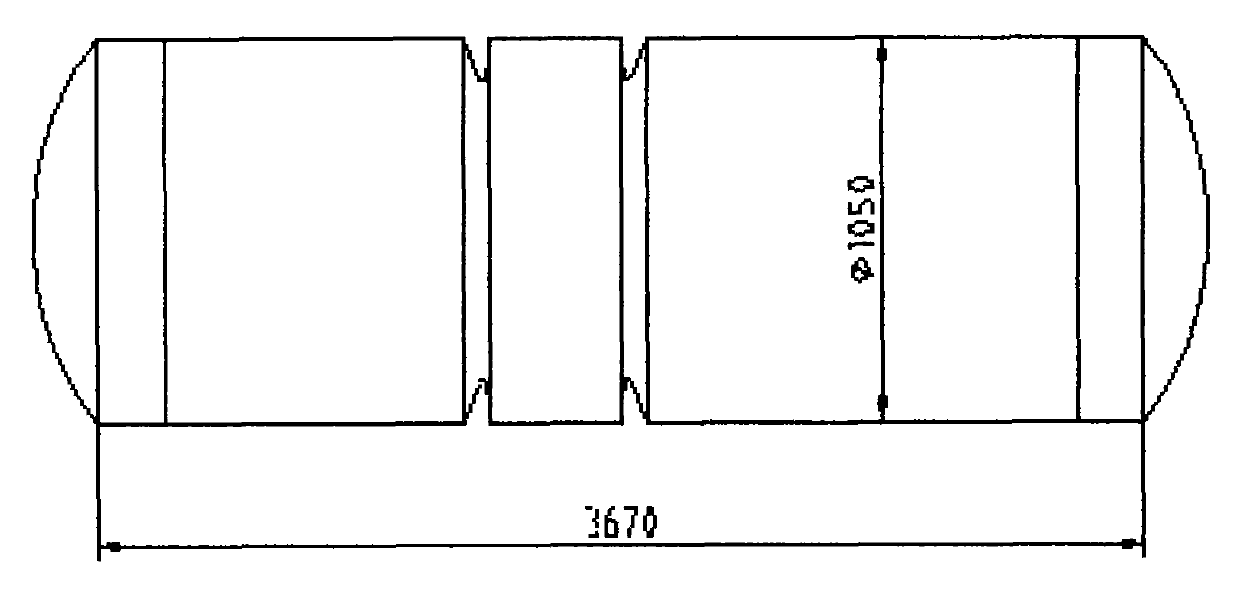

Large-scale fully graded concrete shaft tensile testing machine

InactiveCN102288485AImprove performanceLow priceMaterial strength using tensile/compressive forcesClassical mechanicsMachine

Owner:HOHAI UNIV

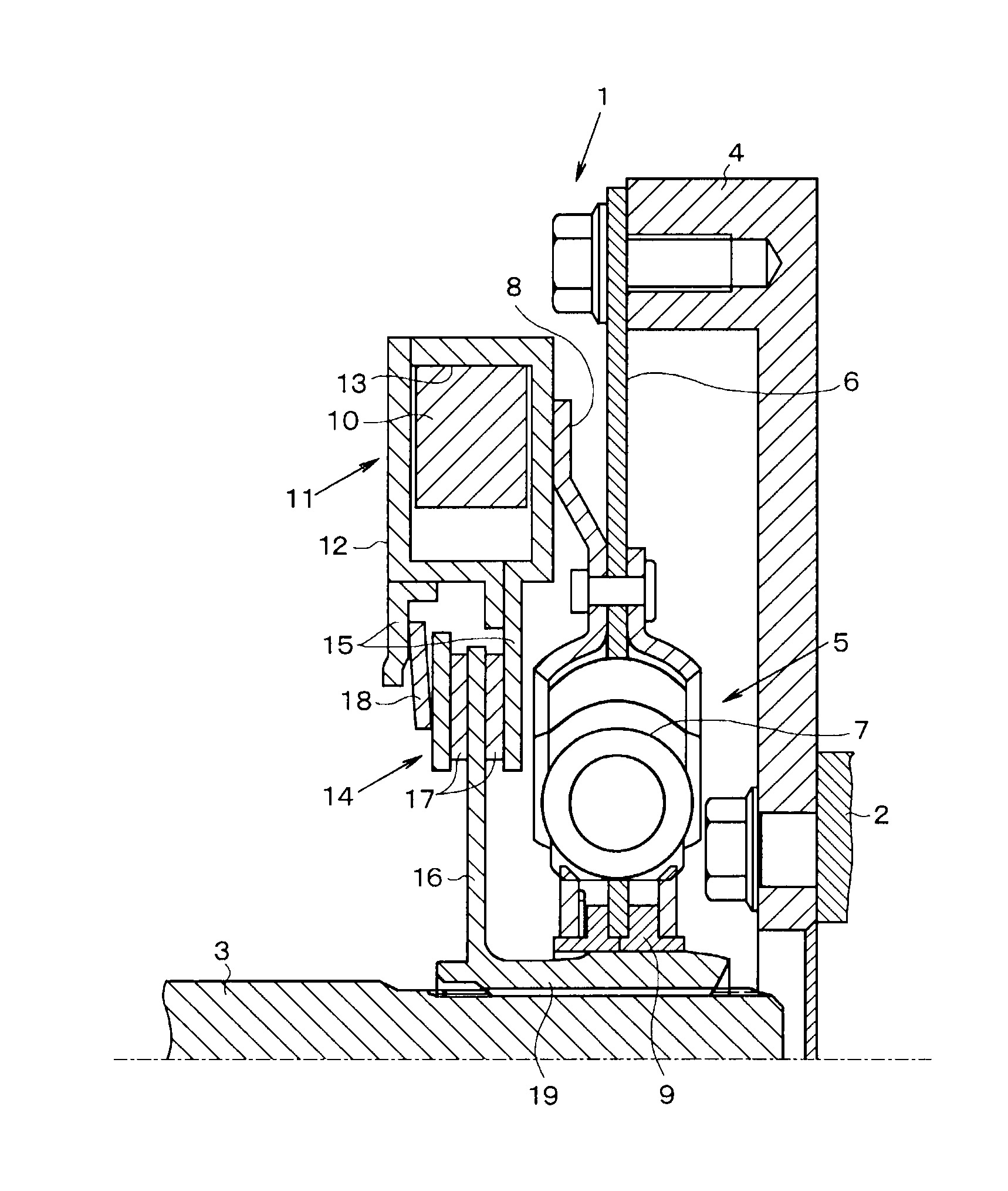

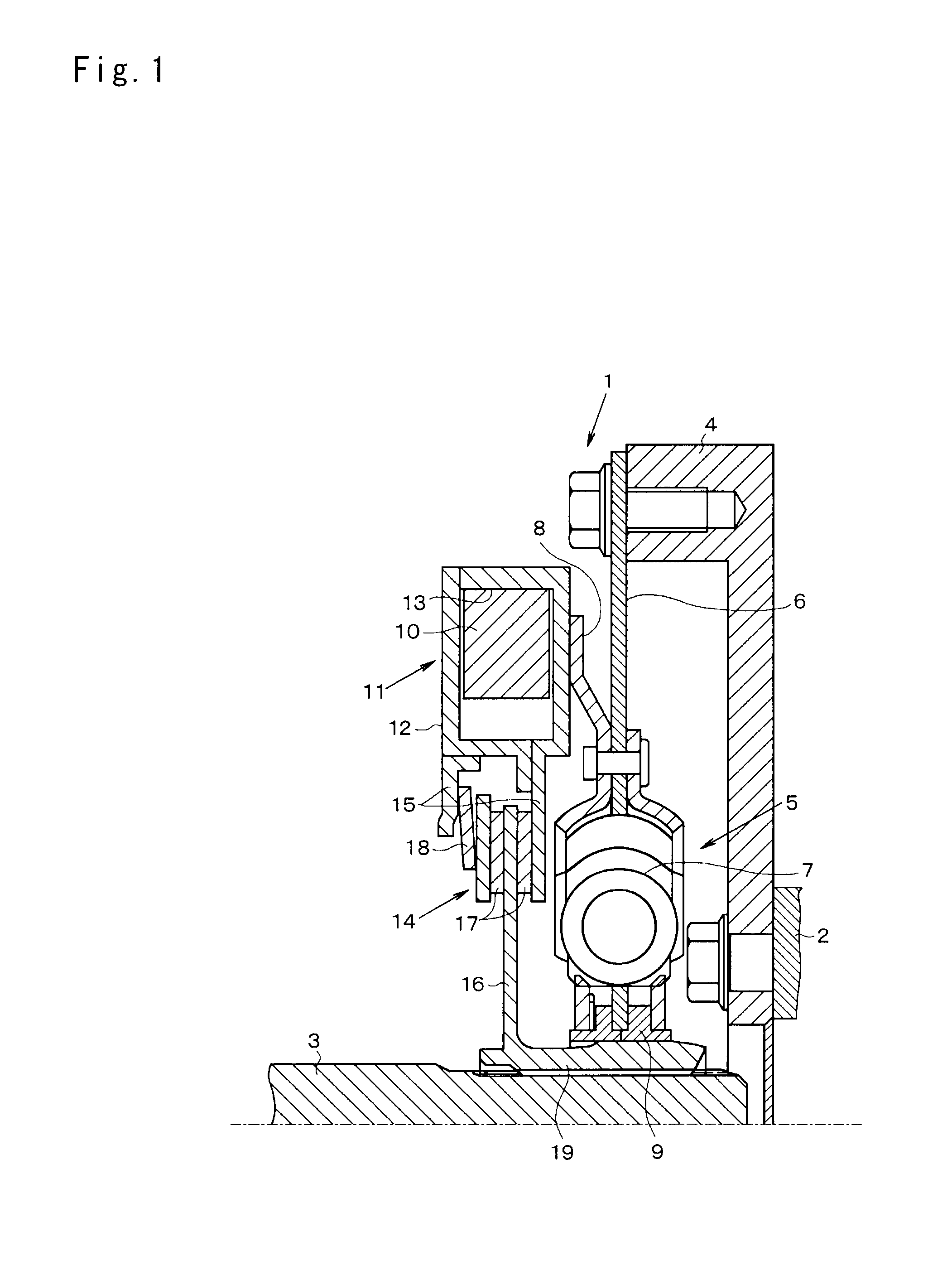

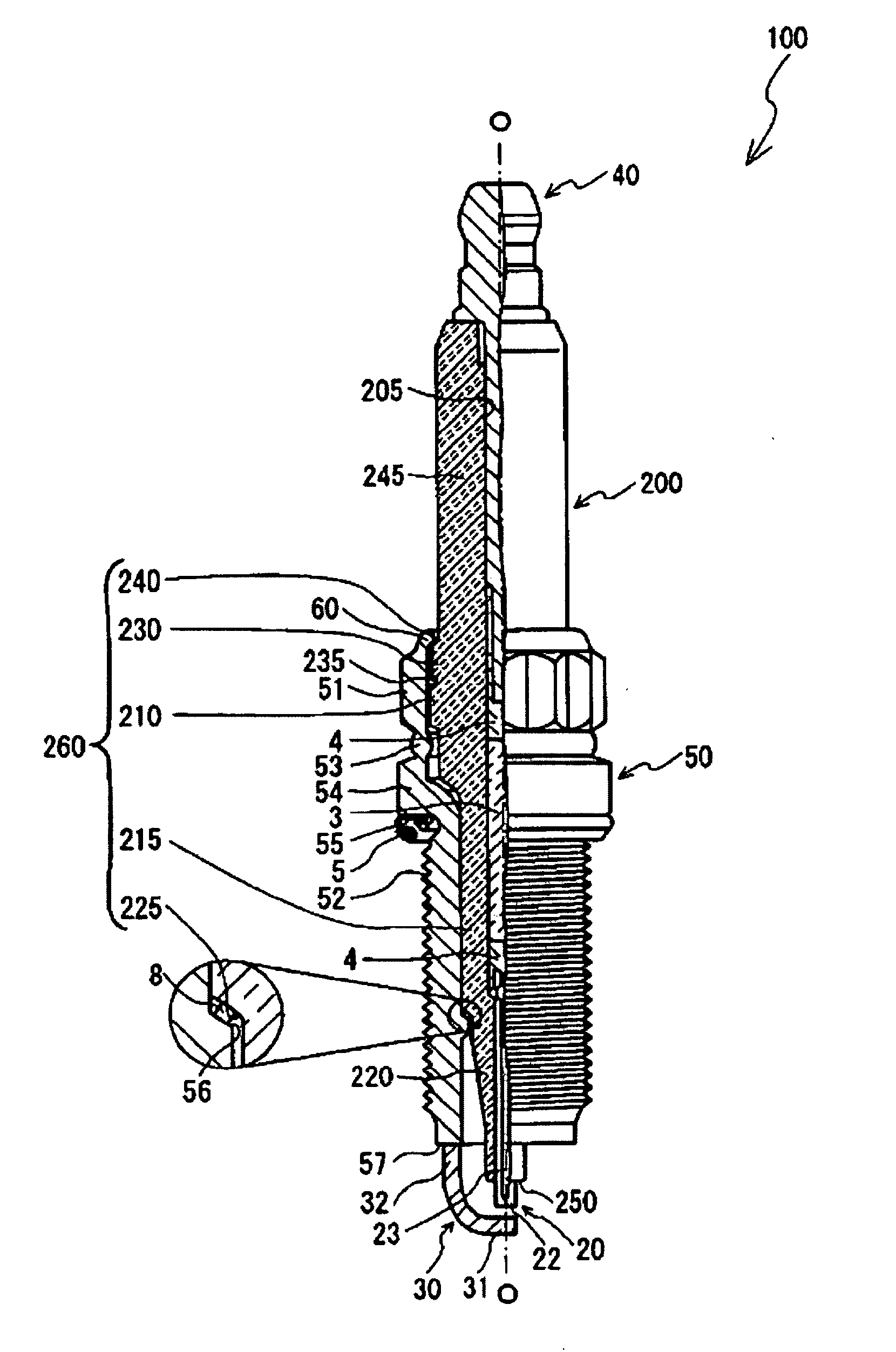

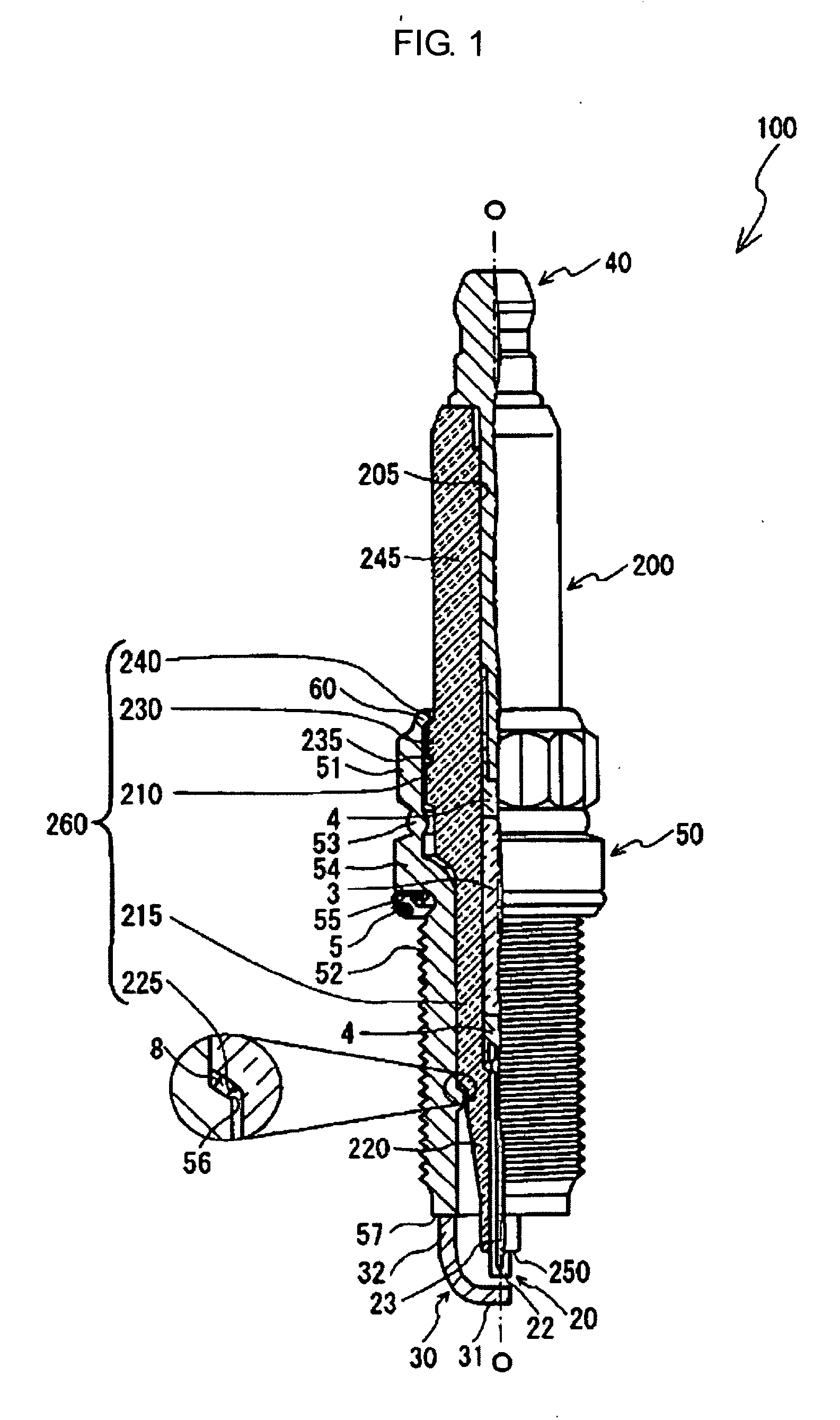

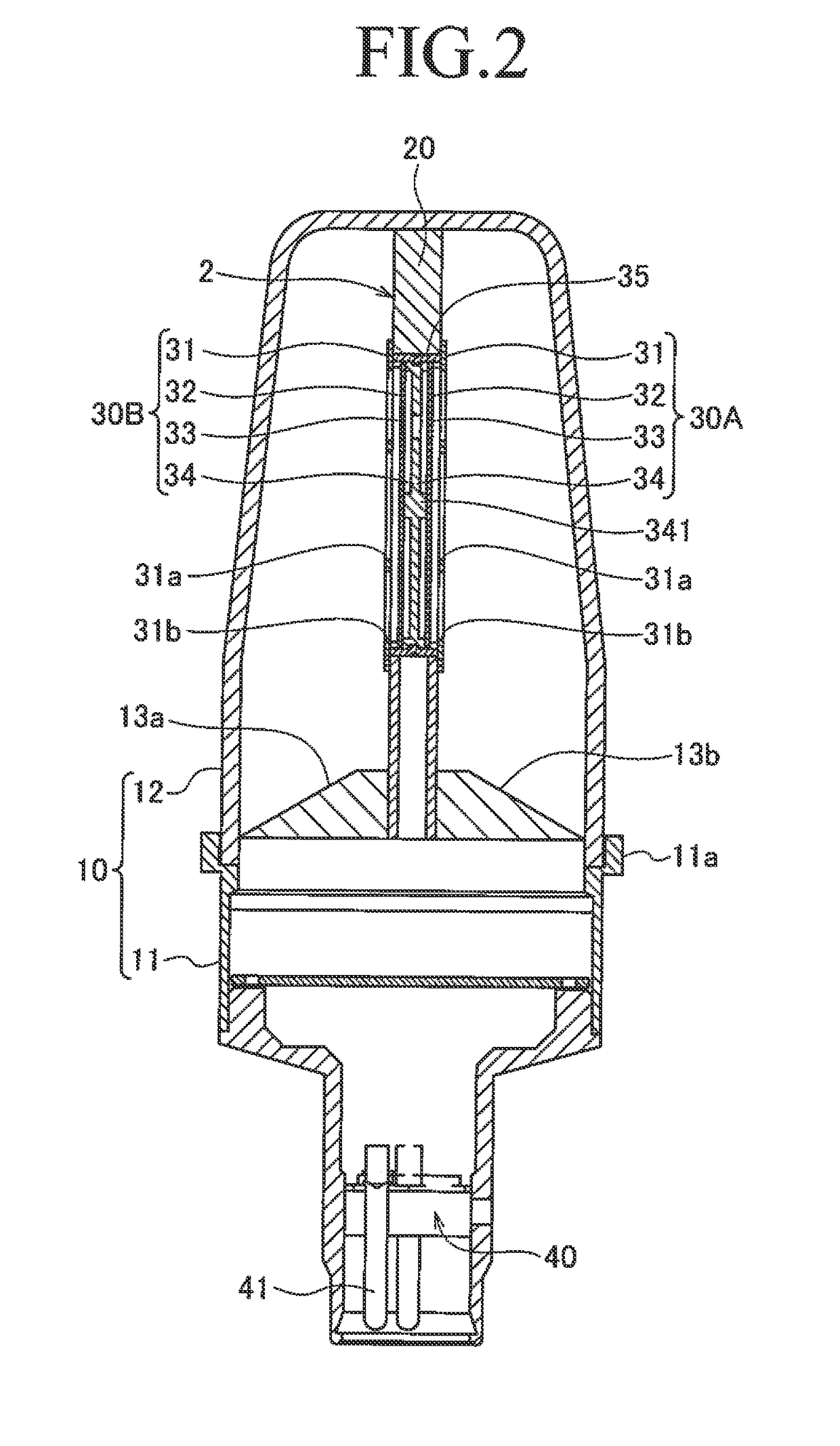

Spark plug

InactiveUS20070040487A1Improve fracture resistanceAvoid eccentricityFuel injection apparatusMachines/enginesMaximum diameterEngineering

A spark plug in which a glaze is applied to a rear trunk portion (245), a shoulder portion (240), and a portion of a intermediate diameter portion (230) of an insulator (200), and glaze firing is performed. Even when the glaze (shown by dots in the drawings) softened by heating flows downwards, the glaze is accommodated within a groove portion (235) formed between the shoulder portion (240) and the maximum diameter portion (210), and does not reach the maximum diameter portion (210). Such structure facilitates assembly of the insulator (200) to a metallic shell in a spark plug manufacturing process.

Owner:NGK SPARK PLUG CO LTD

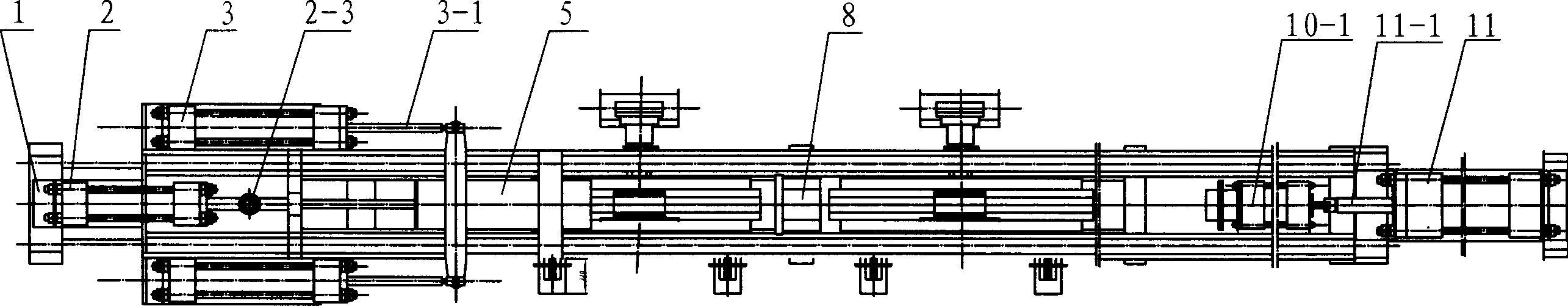

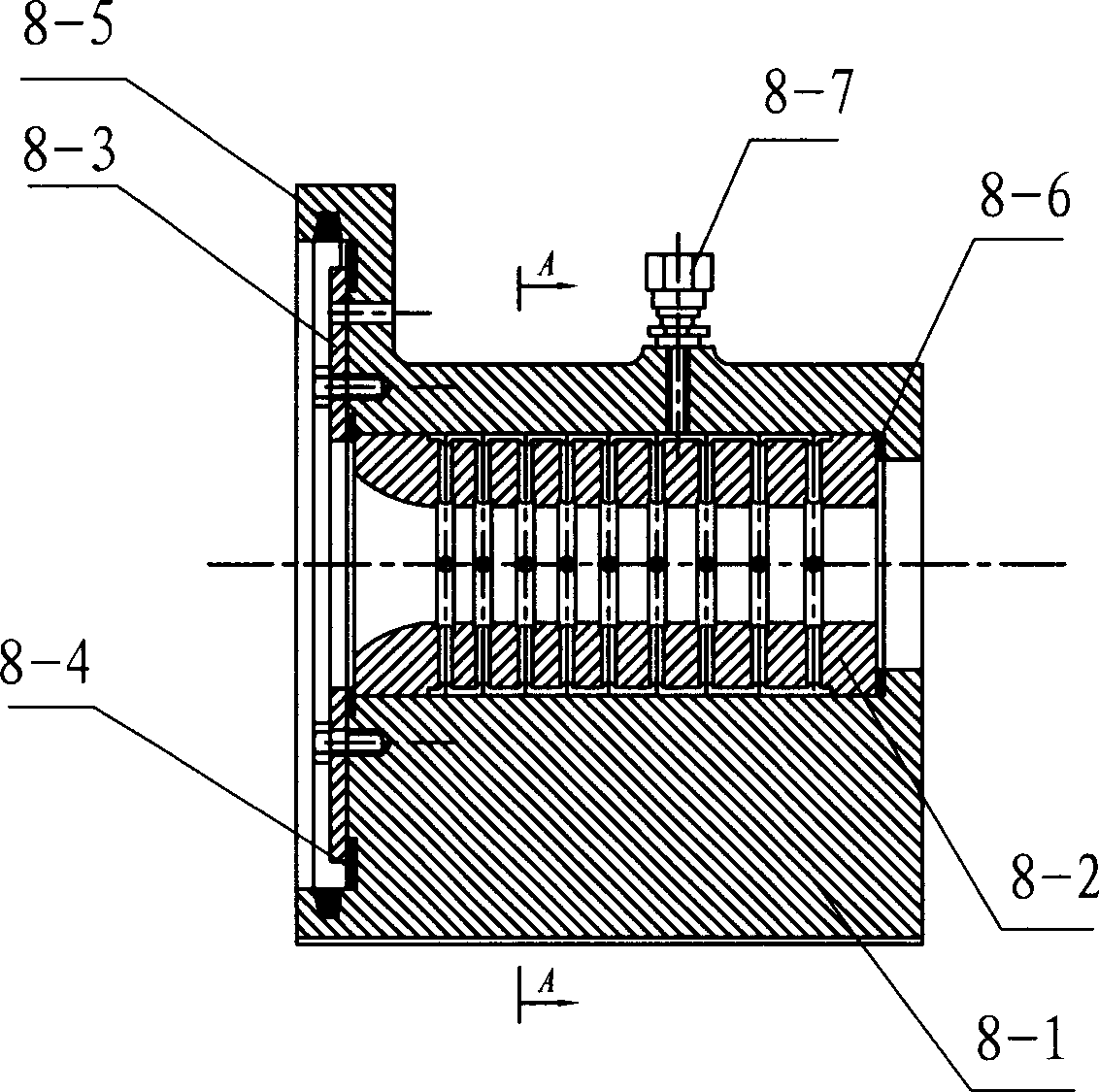

Hydraulic flexible method for producing cold-drawn pipe and apparatus

InactiveCN1803328ALow manufacturing costAvoid vibrationDrawing mandrelsDrawing diesPiston cylinderLubricant

The invention discloses a hydraulic flexible cold-drawing method and equipment in the metallurgical mechanic pipe moulding technique, which comprises the following parts: pushing piston cylinder, pushing core bar cylinder, pushing assembly cylinder, assembly, rail, feeding structure, mould, blanking structure, clamp structure and drawing cylinder. The mould doesn't touch the deformation metal to form the flexible deformation state of mould-hydraulic oil-hollow billet-hydraulic oil-core head, which improves the precision of cold-drawing pipe.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

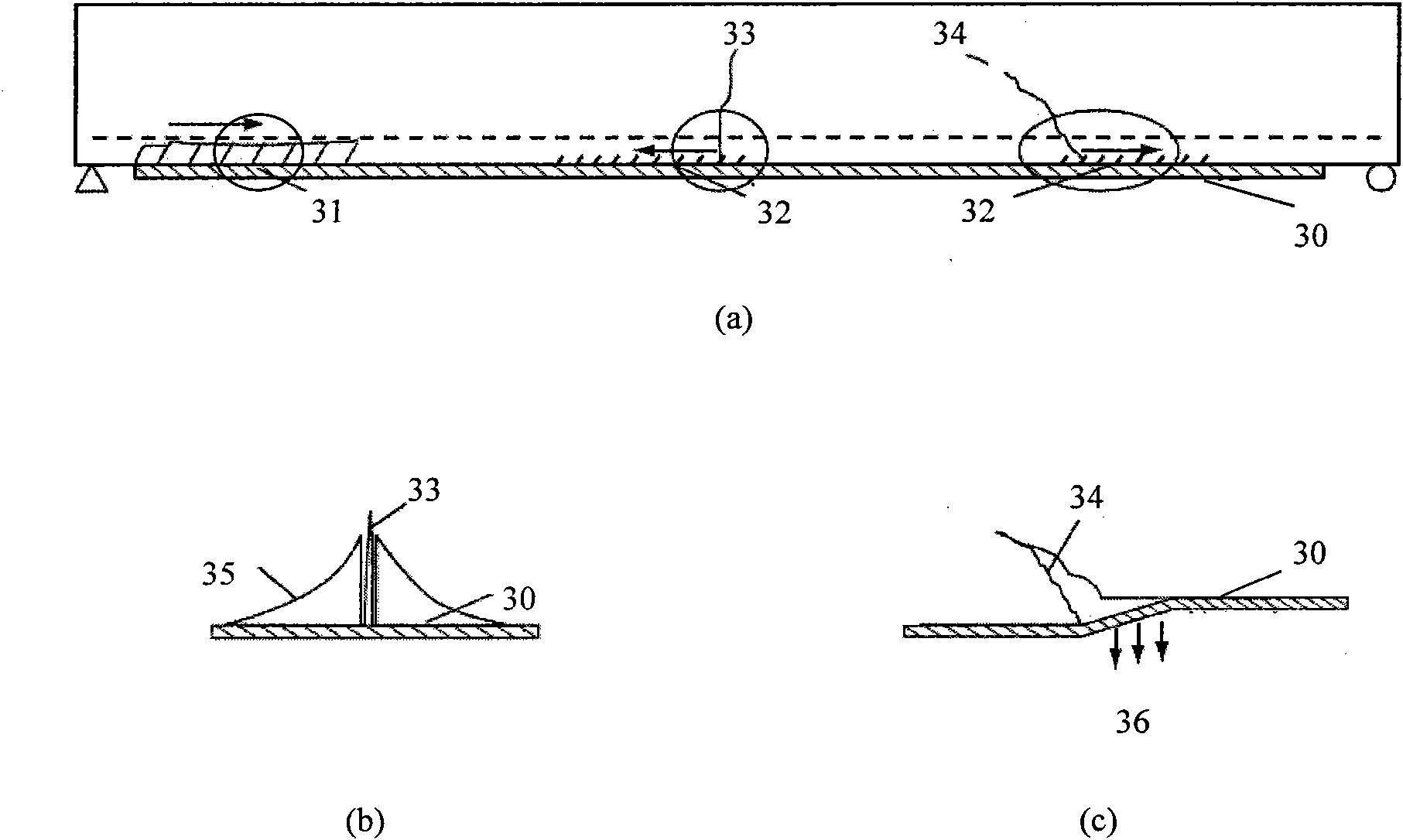

Beam tester of bonding strength of fibre reinforced composite sheet and concrete

InactiveCN101806714AResolve center of gravity shiftSolve the slippage of FRP boardUsing mechanical meansMaterial analysisStructural engineeringUltimate tensile strength

The invention relates to a beam tester of the bonding strength of fibre reinforced composite sheet and concrete. The tester comprises a front compression bar altitude controller, a back compression bar altitude controller, a compression bar, a distributive girder and a steel girder, wherein the distributive girder is arranged above the steel girder, the front and back compression bar altitude controllers are arranged on the sides of the steel girder, the steel girder is connected with a pair of hinge parts, each hinge part is provided with an hinge hole, the inside of the hinge hole is provided with a hinge bar; the front and back compression bar altitude controllers adopt the altitude controllers, each altitude controller contains a base provided with connection holes and a compression bar hole; the inside of each connection hole is provided with a connection bolt, the base is also provided with an upper support and a lower support, a compression bolt is arranged in the upper support, an adjusting bolt is arranged in the lower support; the compression bar hole is arranged between the upper support and the lower support, the compression bar is inserted in the compression bar holes of the front and back compression bar altitude controllers and arranged between the compression bolt and the adjusting bolt, and the front and back compression bar altitude controllers and the pair of hinge parts are arranged on the same side of the steel girder.

Owner:SOUTHEAST UNIV

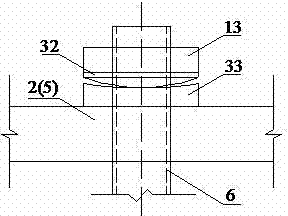

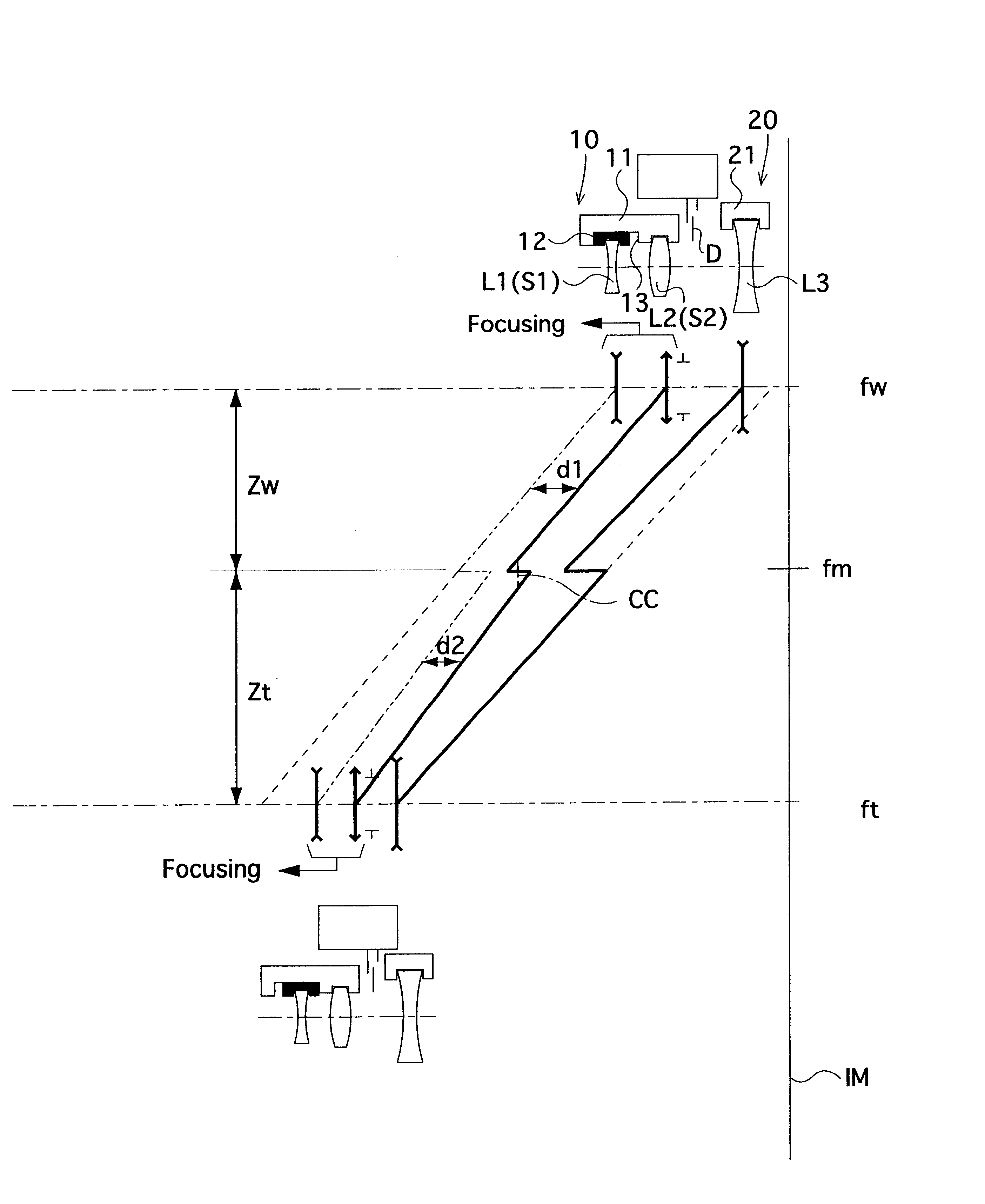

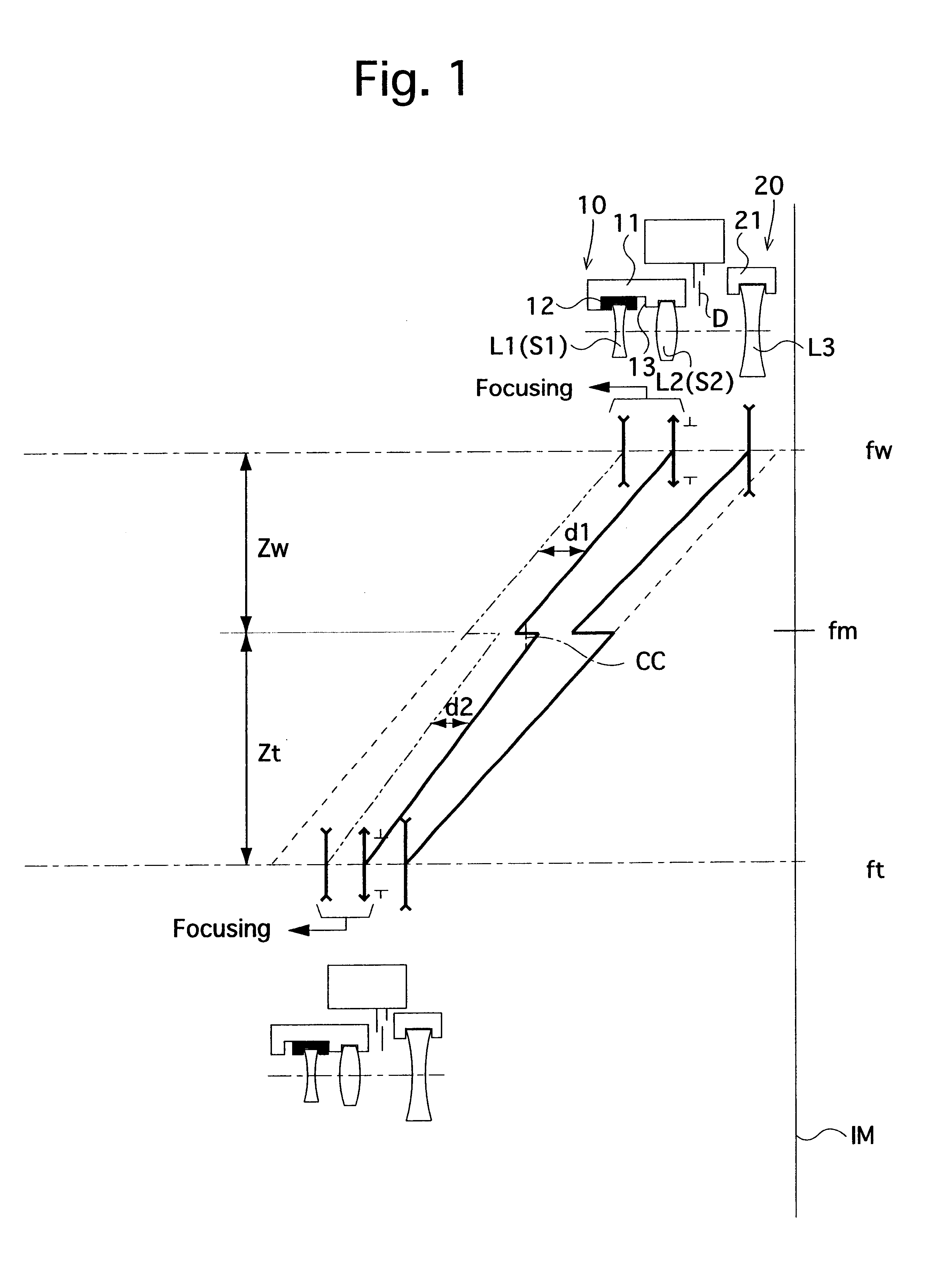

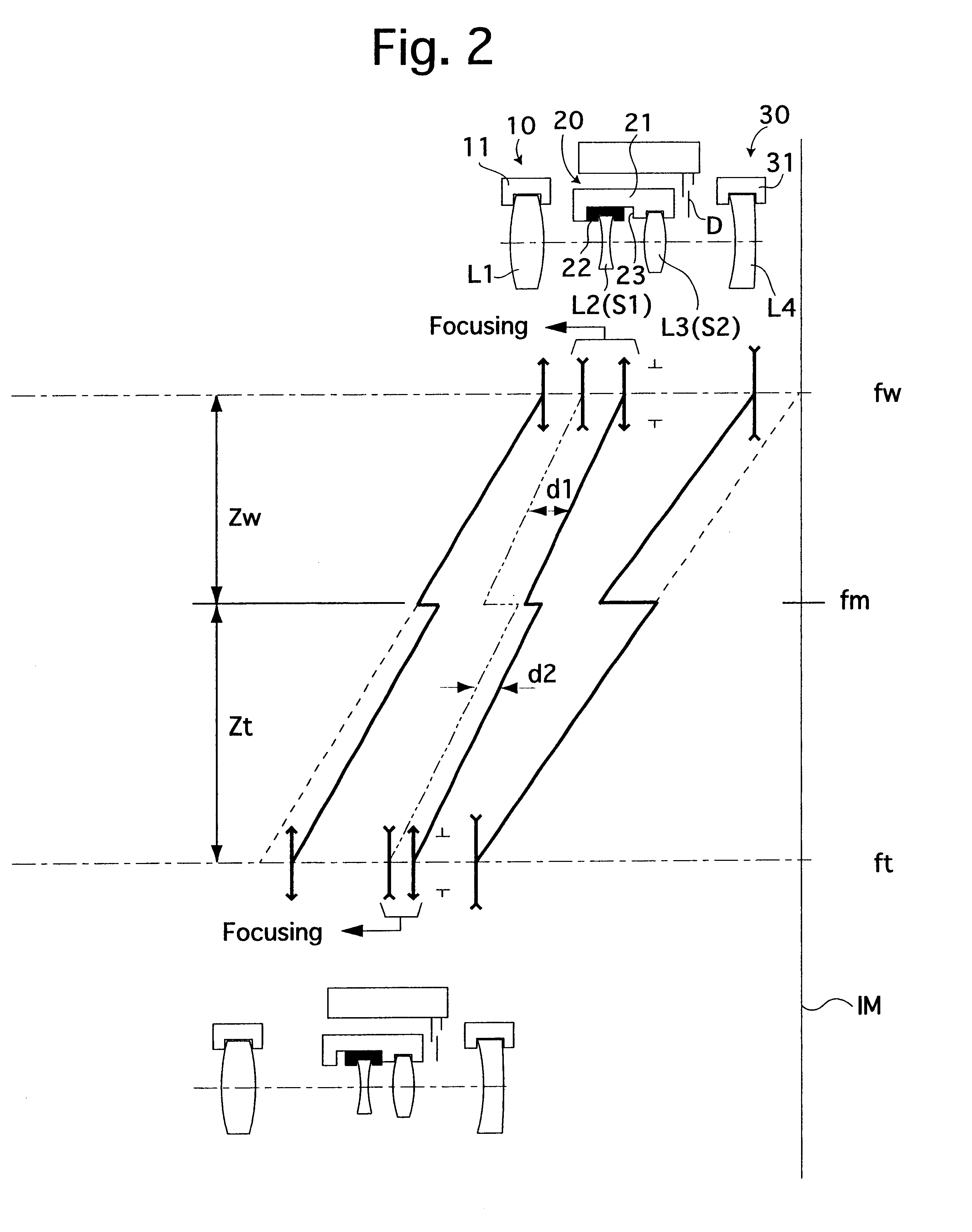

Eccentricity-prevention mechanism for a pair of lens-supporting rings

An eccentricity-prevention mechanism includes a pair of lens-supporting rings for supporting a pair of lens groups, respectively; and a pair of positioning recesses and a follower projection formed on one and the other of opposed surfaces of the pair of lens-supporting rings, such that the follower projection engages with one of the pair of positioning recess to define a relative position of the pair of lens-supporting rings with respect to the optical axis, at a mutually close position and at a mutually distant position. At least three pairs of the positioning recesses and at least three follower projections are provided at different positions in a circumferential direction, so that eccentricity between the pair of lens-supporting rings is eliminated when all of the follower projections are concurrently brought into engagement with corresponding positioning recesses.

Owner:ASAHI KOGAKU KOGYO KK

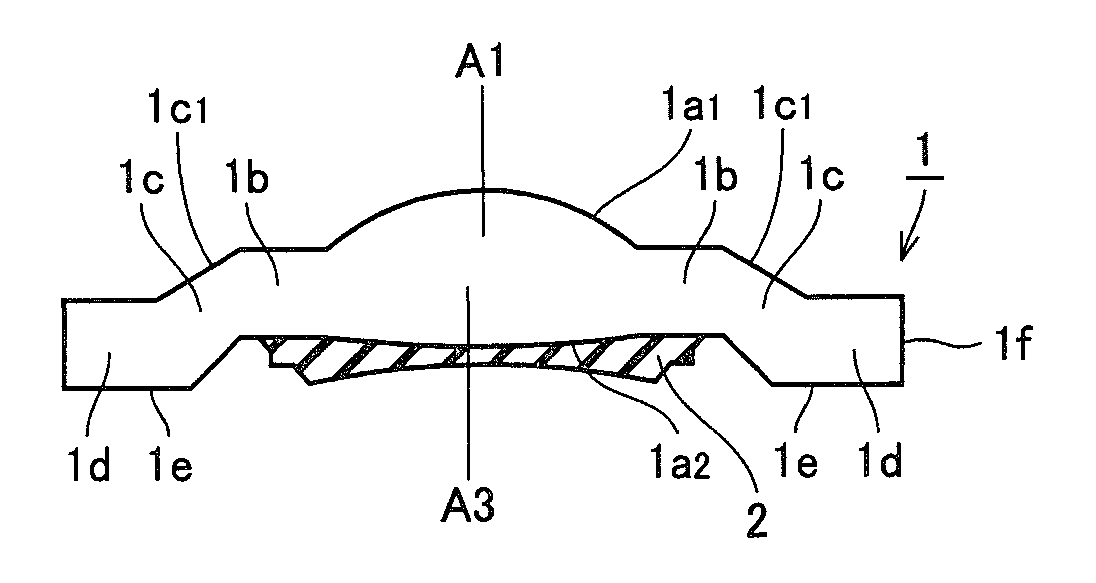

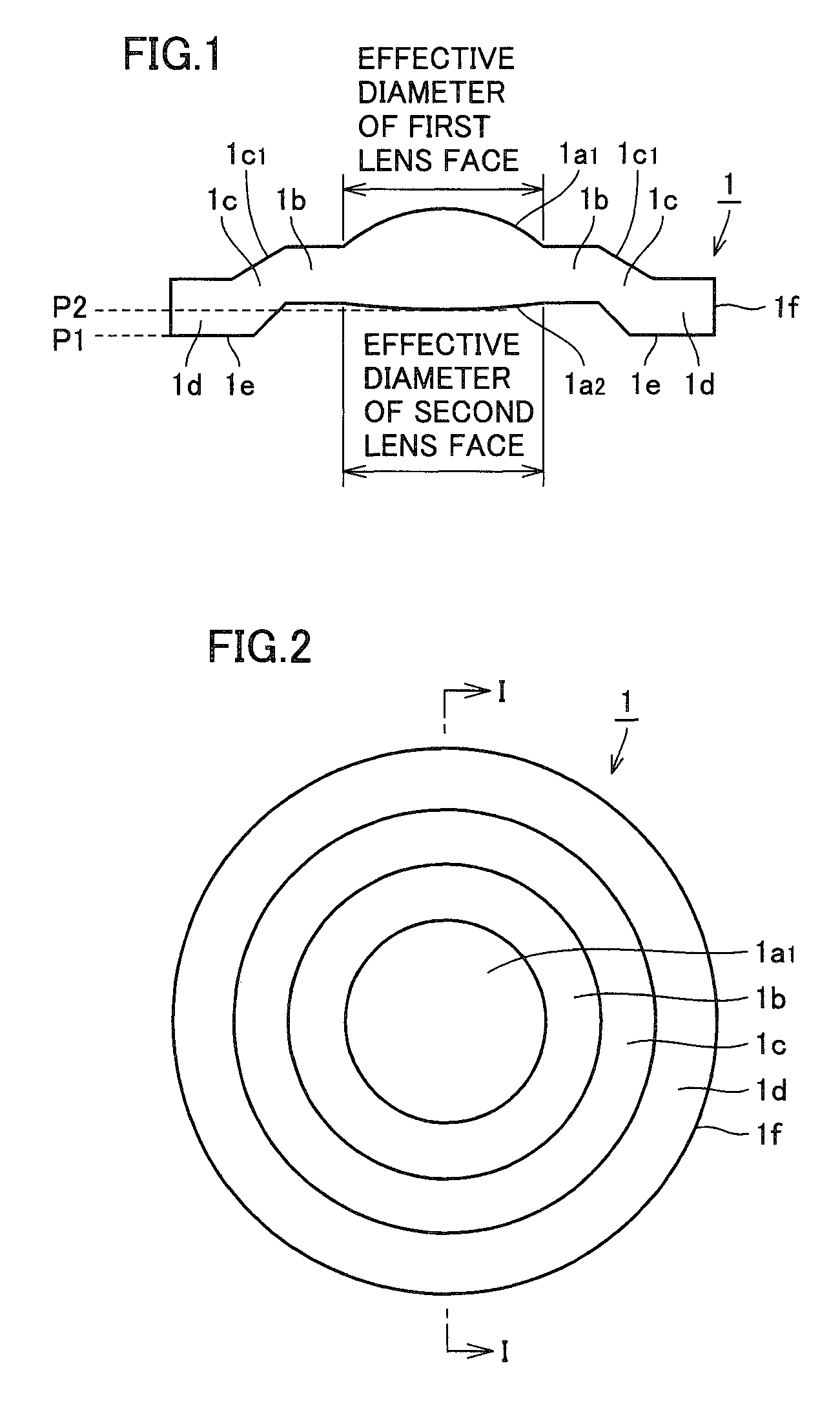

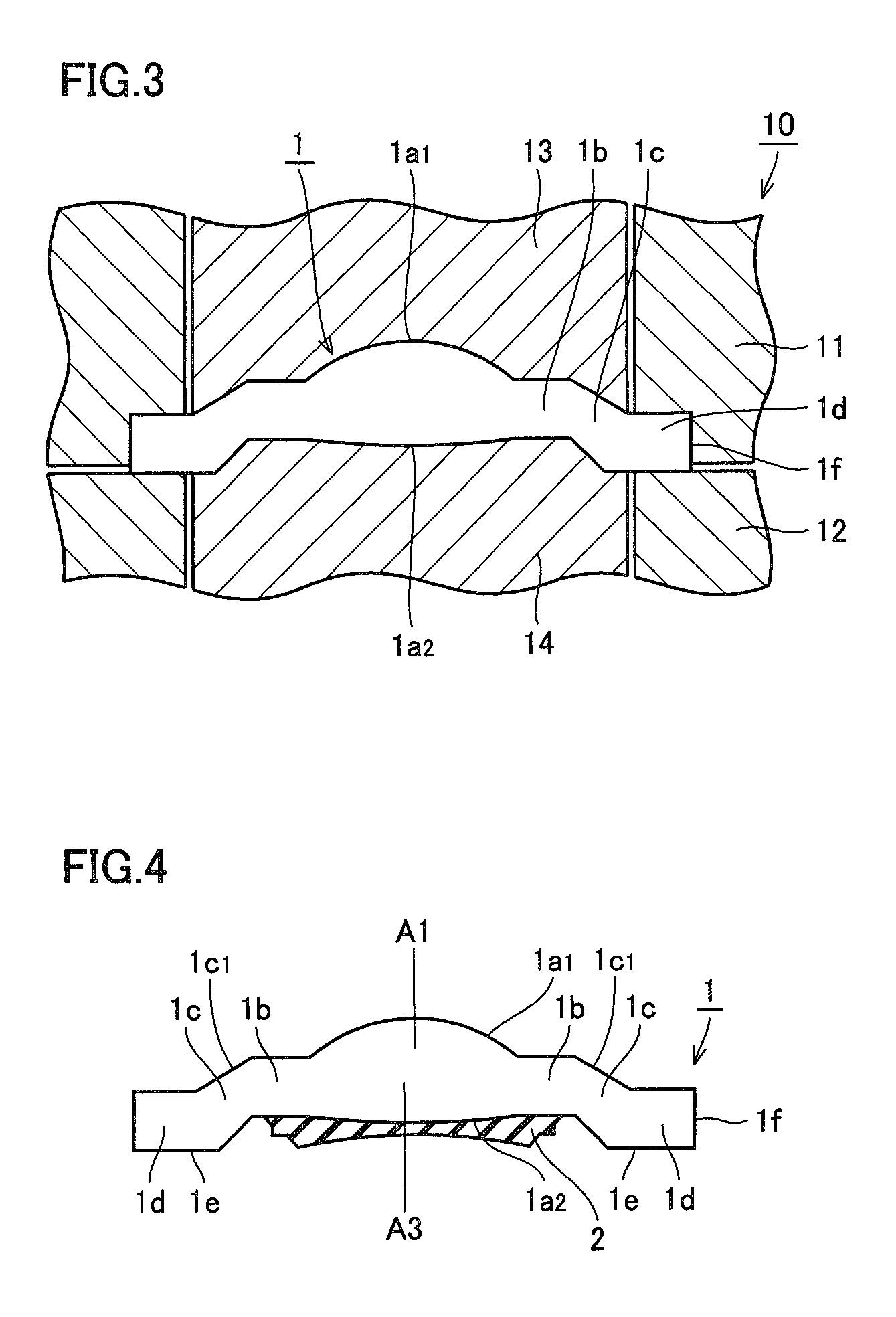

Optical lens, compound lens and method for producing the same, as well as cemented lens and method for producing the same

InactiveUS7474476B2Less susceptible to deformation and chippingAvoid eccentricityOptical articlesTelescopesEngineeringFlange

An optical lens includes a lens effective portion, an inclined portion and a flange portion. The lens effective portion has, on a first side, a lens face with a small radius of curvature and also has, on a second side, a lens face with a large radius of curvature. The inclined portion has, on the first side, an inclined face inclined outwardly from the first side to the second side. The flange portion has, on the second side, a reference face protruding longer than the lens face with the large radius of curvature on the second side. Thus, it is possible to obtain an optical lens which is less susceptible to deformation or chipping and suppresses transmission eccentricity, a compound lens and a method for producing the same, as well as a cemented lens and a method for producing the same.

Owner:HUIZHOU DAYAWAY EVER BRIGHT ELECTRONICS IND CO LTD +2

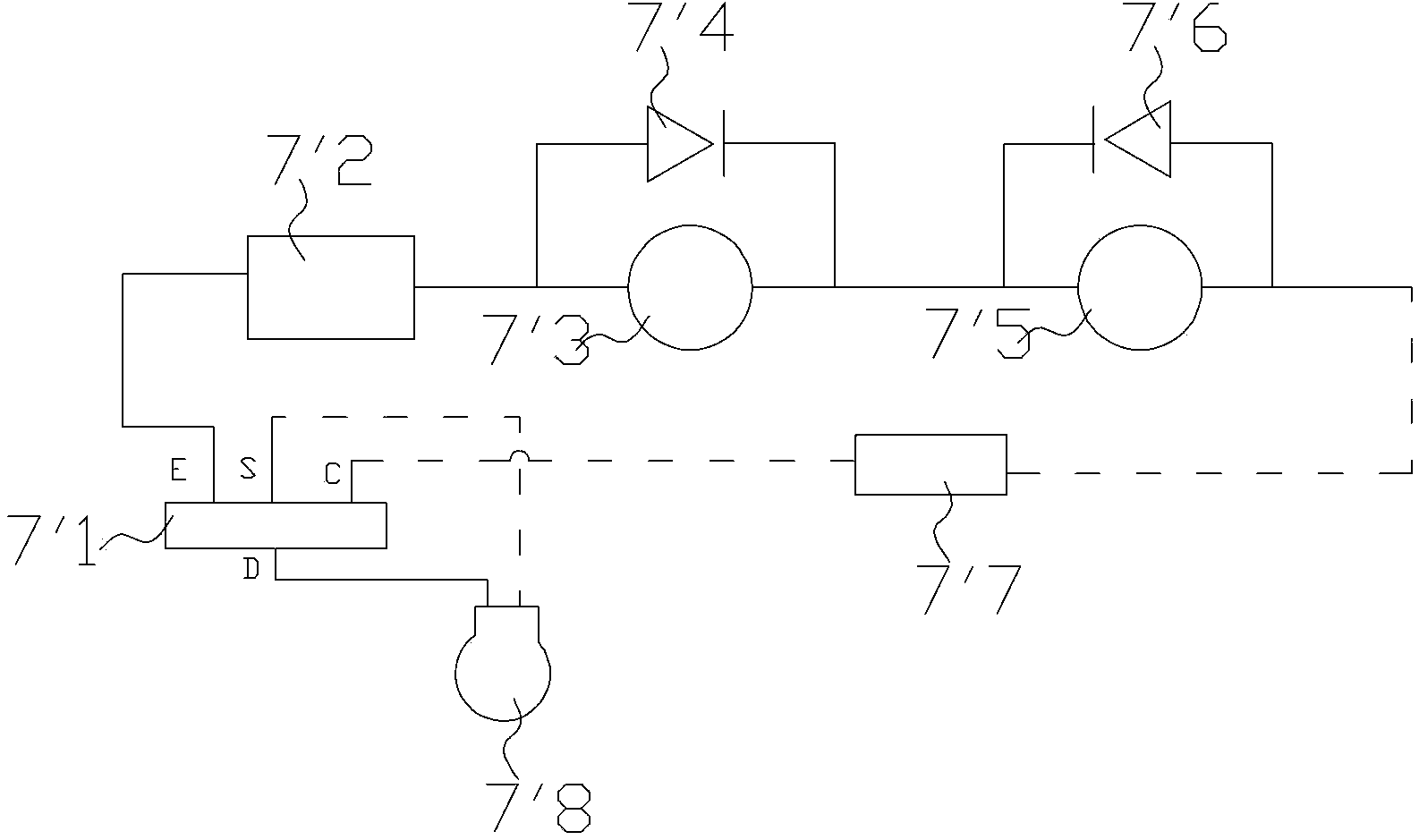

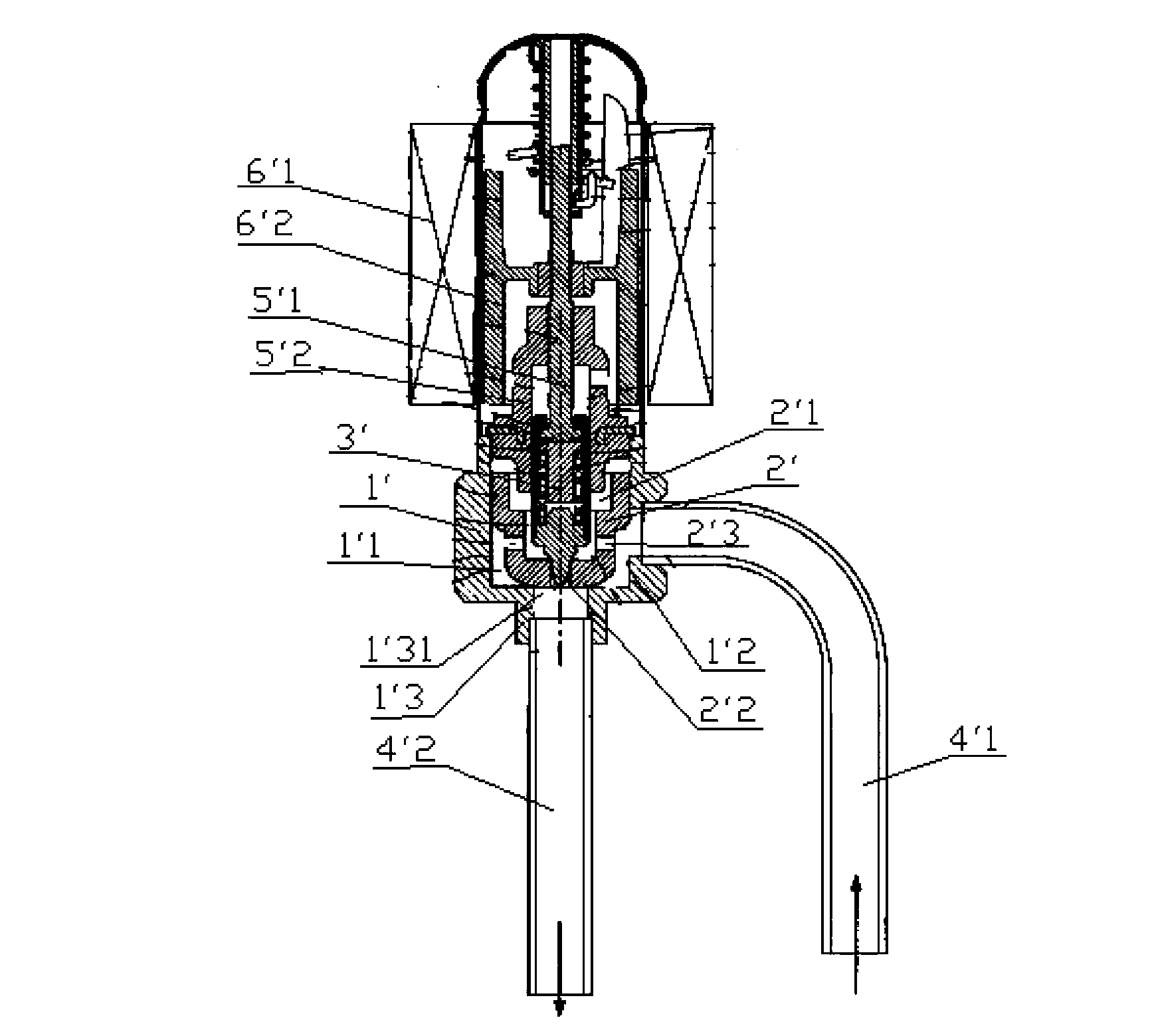

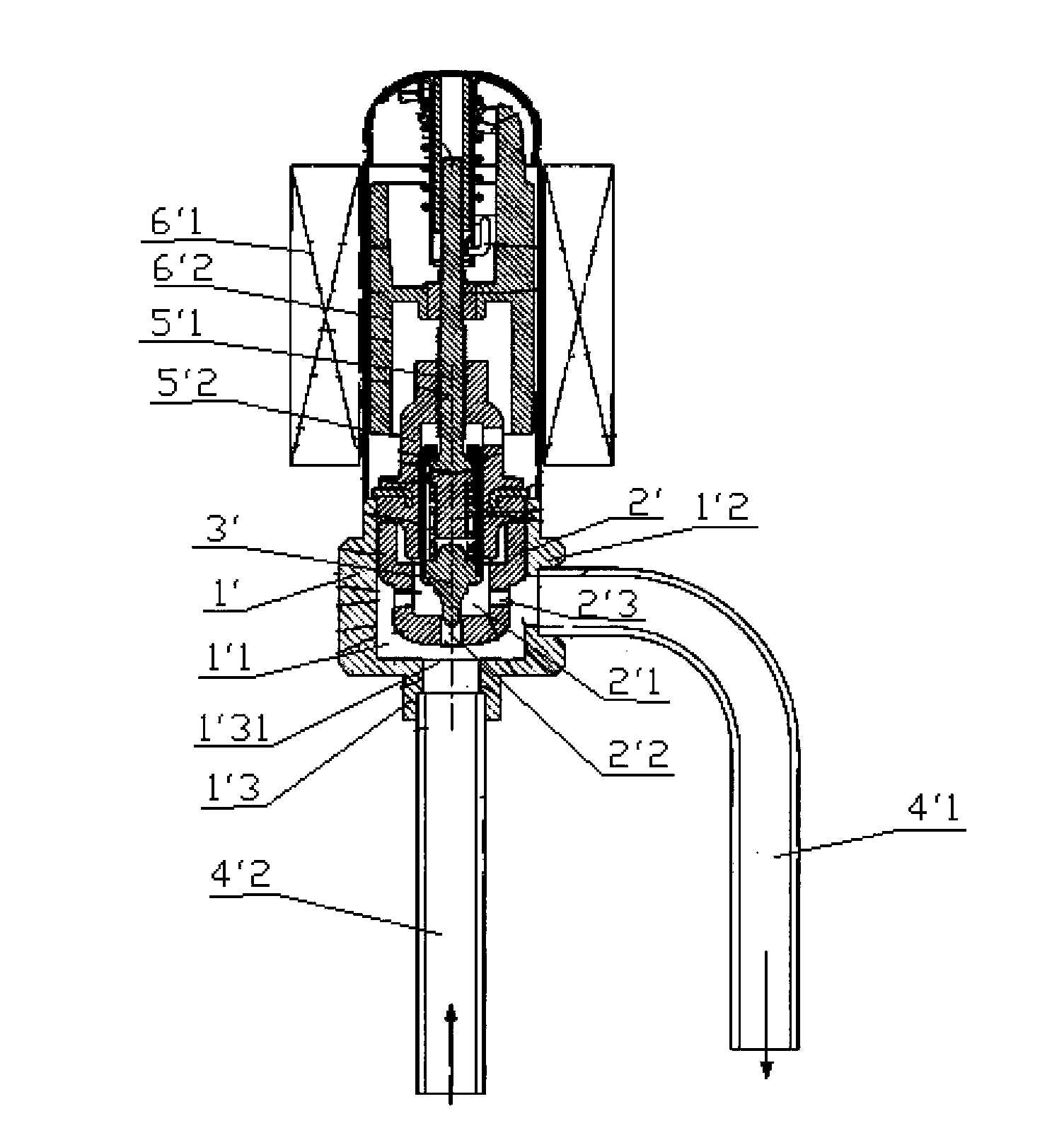

Electronic expansion valve

ActiveCN103453699AReduce shockAvoid eccentricityValve members for absorbing fluid energyEfficient regulation technologiesEngineeringHigh pressure

The invention discloses an electronic expansion valve. A sleeve (4) is fixed in a main valve cavity (11), a valve core seat (2) is movably arranged in the sleeve (4) axially, a sleeve runner (41) is arranged on the peripheral side wall of the sleeve (4), and a valve core seat side hole (24) is formed in the peripheral side wall of the valve core seat (2). When a refrigerant is in forward flowing, the valve core seat (2) closes a main valve port (441) to break off communication between the sleeve runner (41) and the valve core seat side hole (24), and the refrigerant flows to a valve core valve port (21) through the sleeve runner (41); when the refrigerant is in backward flowing, the valve core seat (2) is moved upwards to open the main valve port (441) to communicated the valve core seat side hole (24) with the sleeve runner (41); when the refrigerant is in forward flowing, by the structural design of the electronic expansion valve, high-pressure refrigerant can be avoided from causing overlarge impact on the valve core seat, and eccentric phenomena of the valve core seat can be prevented.

Owner:ZHEJIANG SANHUA INTELLIGENT CONTROLS CO LTD

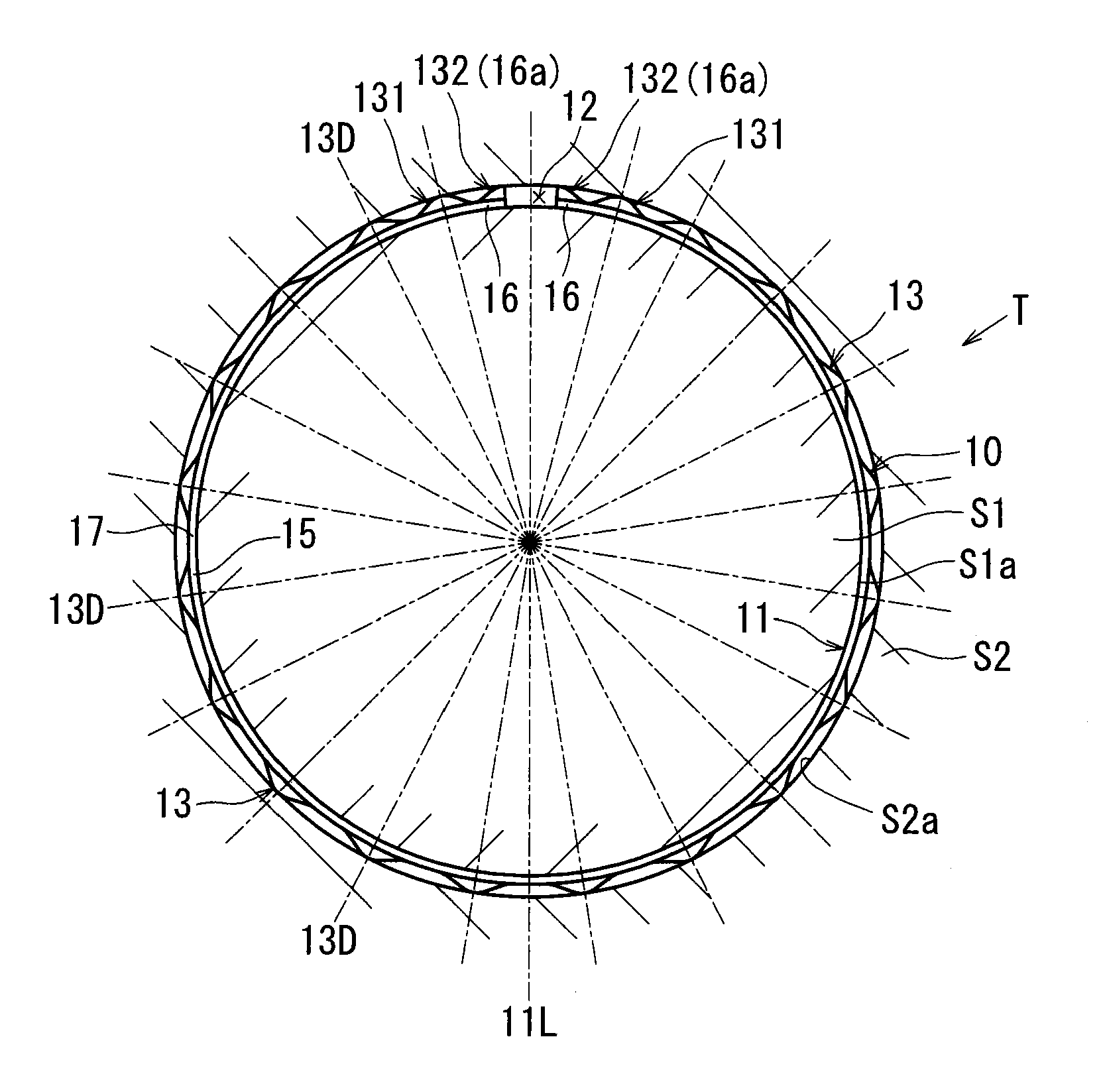

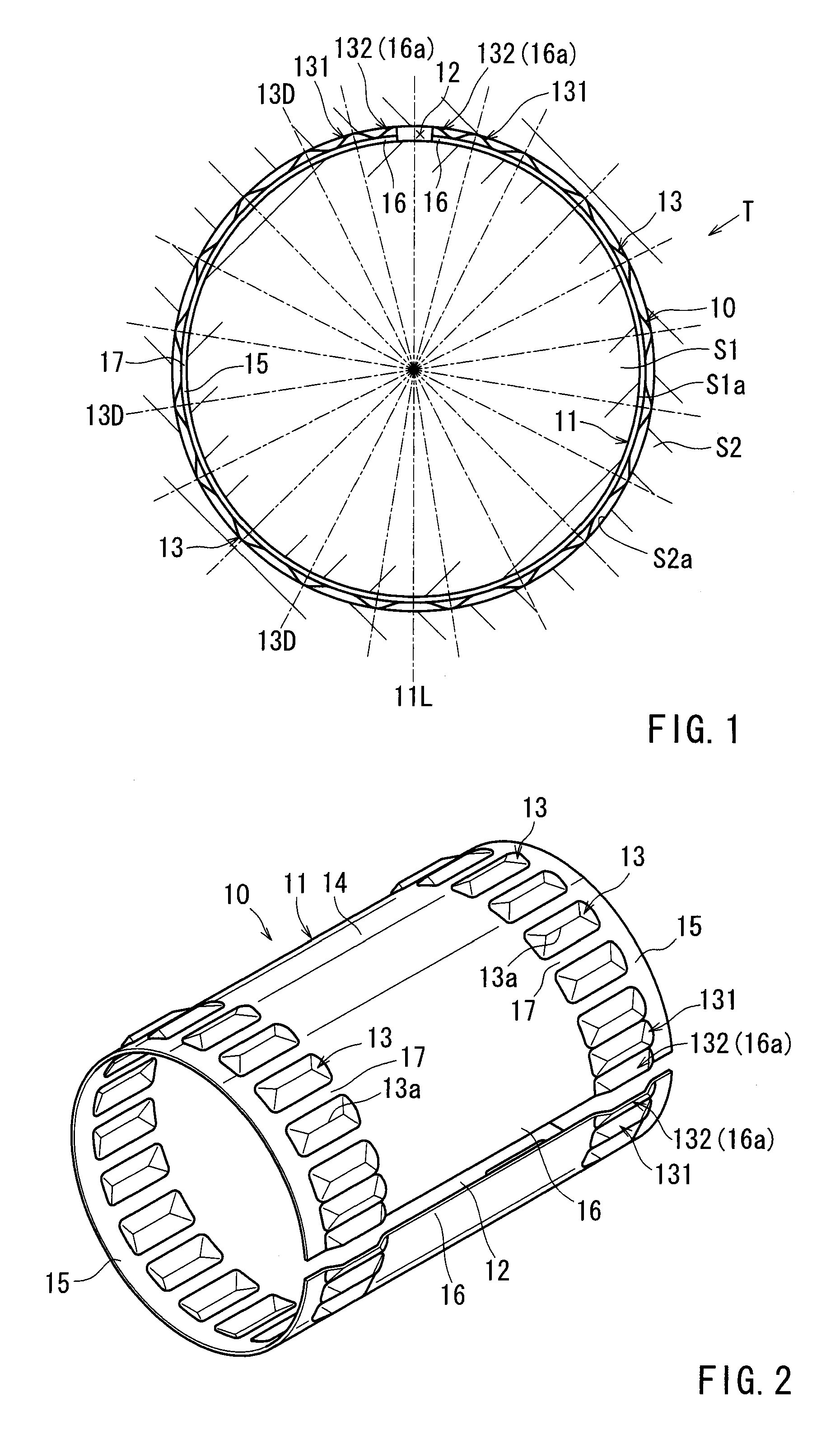

Tolerance ring for torque transmission device

ActiveUS20130105267A1Prevent eccentricityAvoid eccentricityMechanical actuated clutchesSlip couplingEngineeringTorque transmission

This tolerance ring, which is for a torque transmission device, preferably has a ring body that comprises an elastic plate and is roughly a hollow cylindrical shape having a pair of edges that extend in the axial direction. The ring body has: a plurality of protrusions that are arranged along the peripheral direction and preferably protrude in the radial direction; a first region having a number of the protrusions including the pair of protrusions adjacent to the pair of edges; and that is positioned at the diametrically opposite side from the first region. The pair of protrusions has the same rigidity as one of the protrusions of the second region.

Owner:TOGO SEISAKUSYO

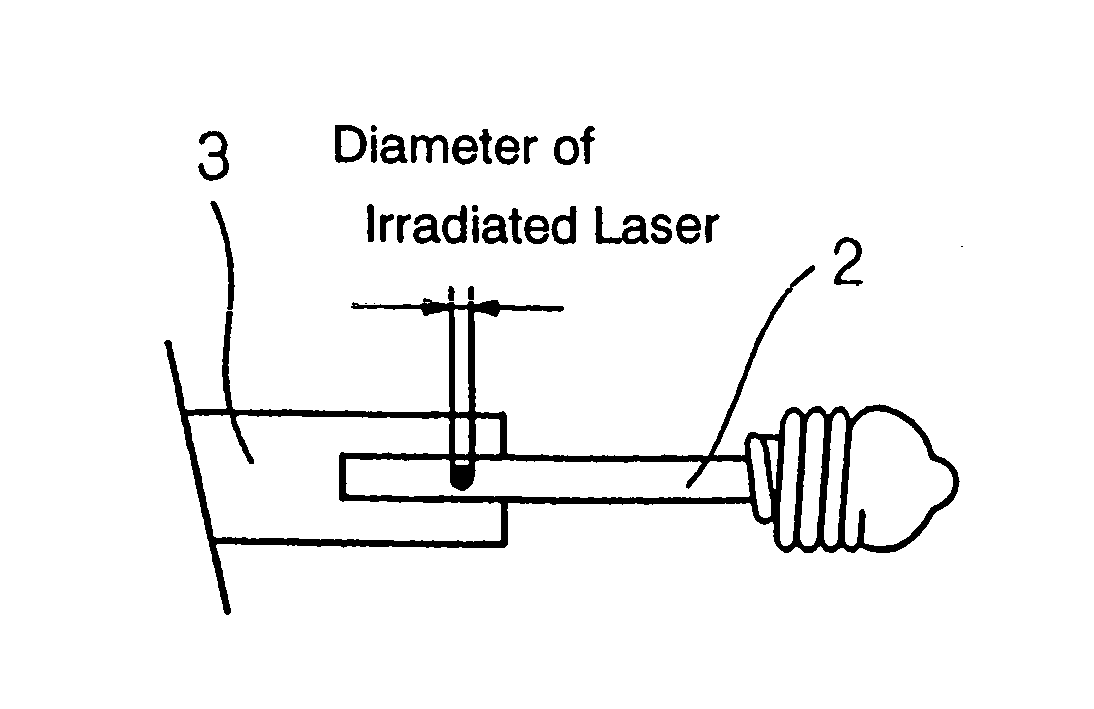

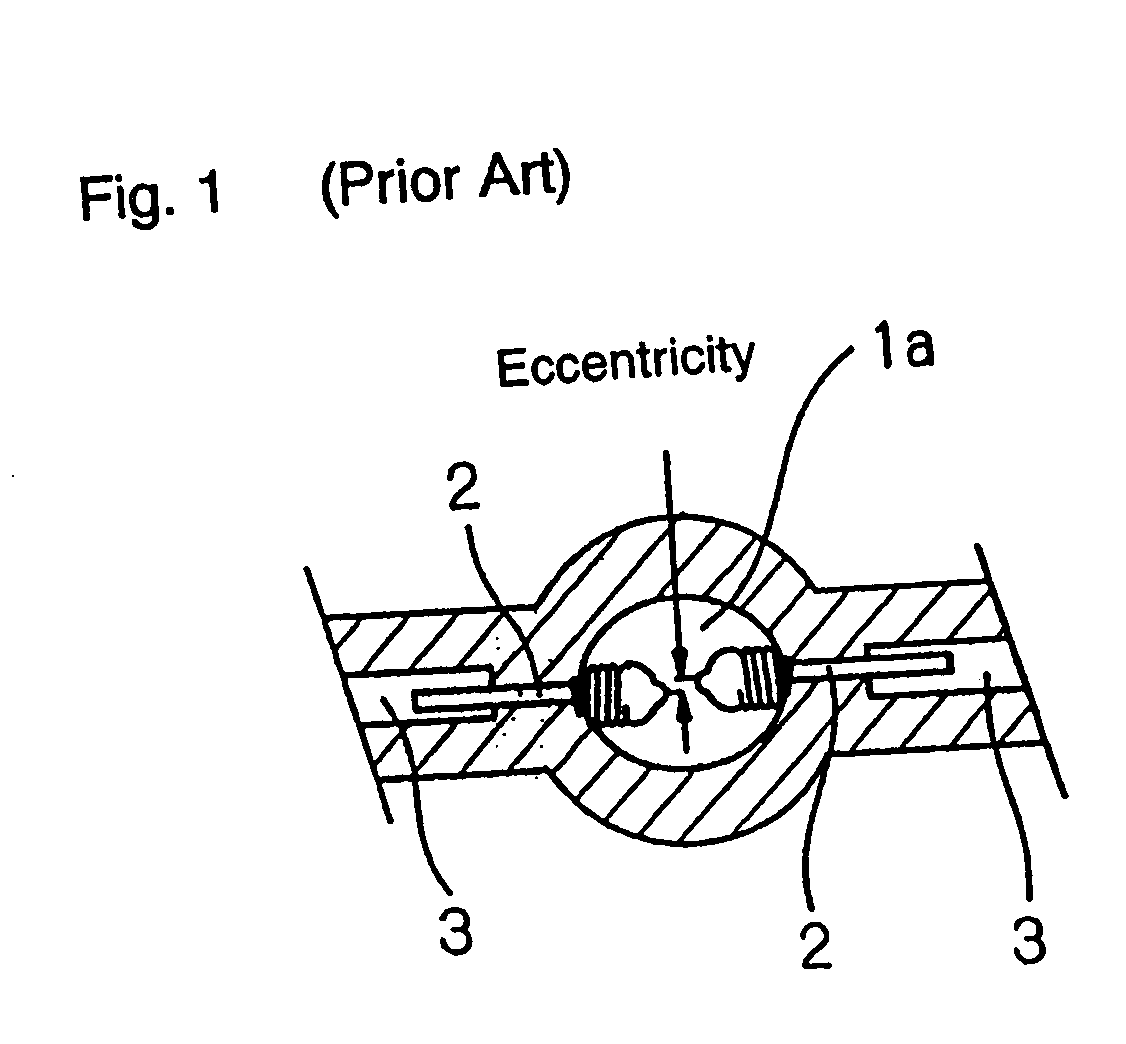

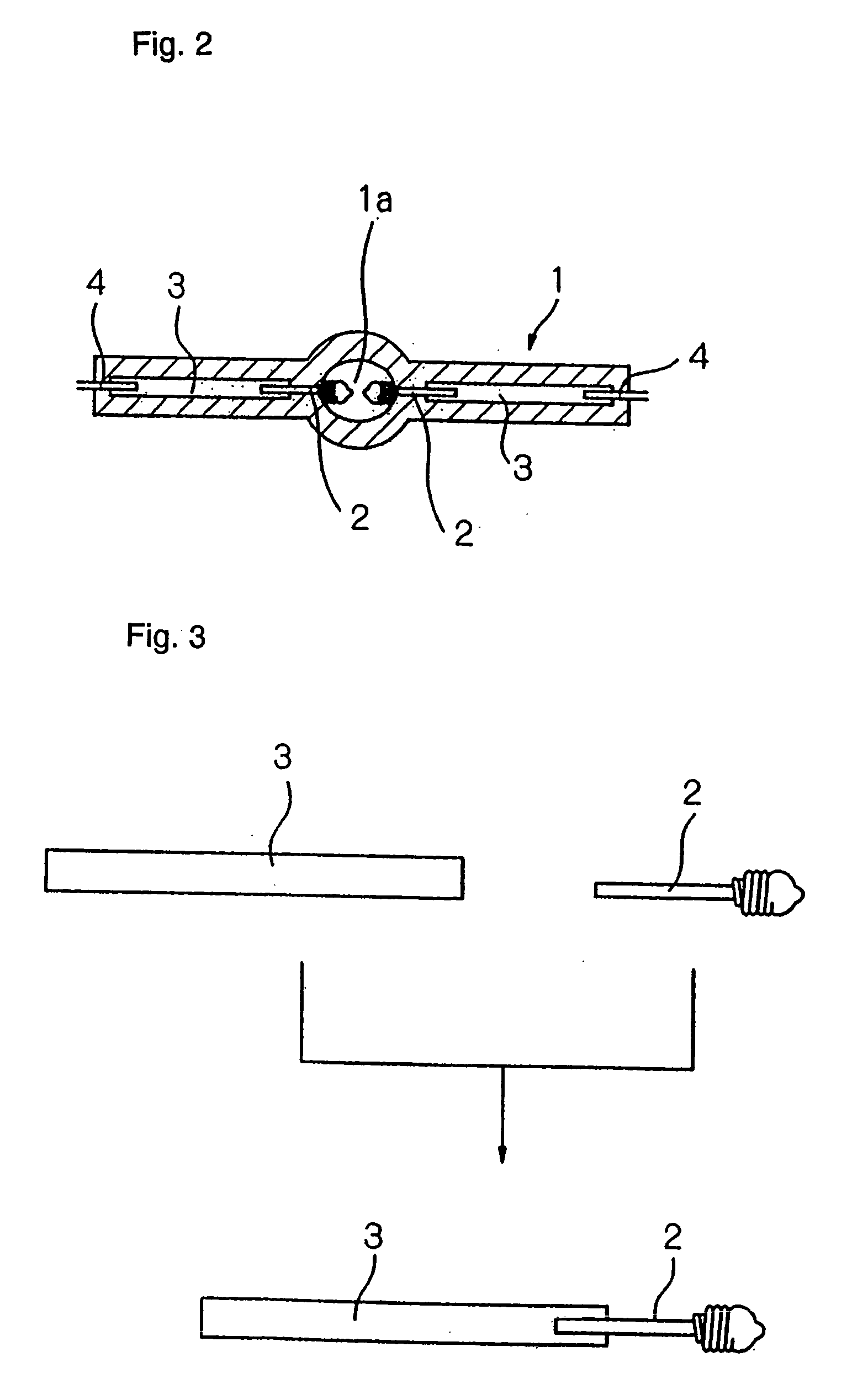

Method of manufacturing a high-pressure discharge lamp

InactiveUS20050003729A1Improve reliabilityEliminate disadvantagesTube/lamp screens manufactureElectroluminescent light sourcesLaser lightLength wave

For manufacturing a high-pressure discharge lamp, a tungsten electrode is welded to a molybdenum foil by bringing a shaft of tungsten electrode into close contact with the molybdenum foil, and by irradiating a laser light, having a metal melting wavelength, to a junction of the molybdenum foil with the tungsten electrode from a location closer to the molybdenum foil to melt both the molybdenum foil and the shaft of the tungsten electrode for bonding.

Owner:USHIO DENKI KK

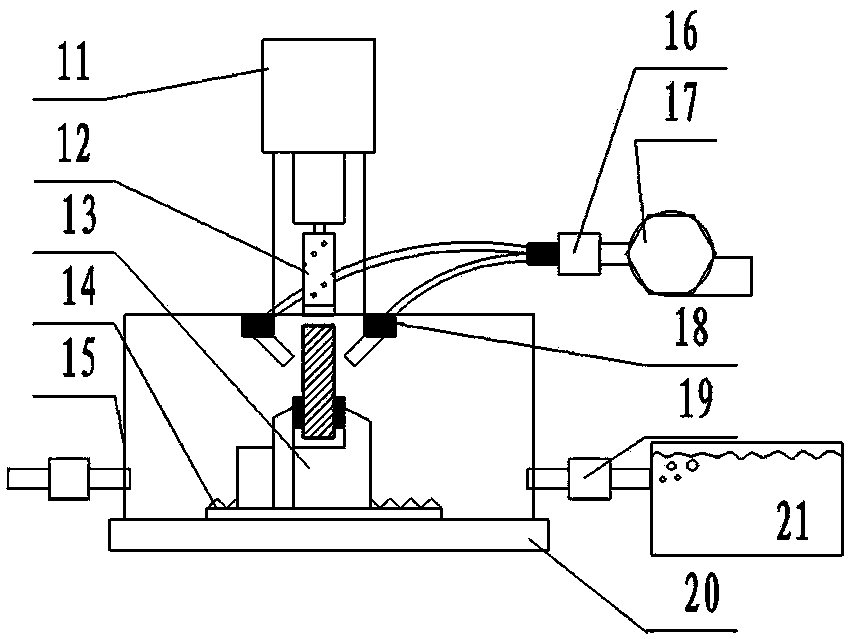

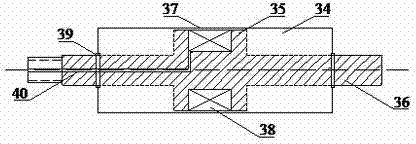

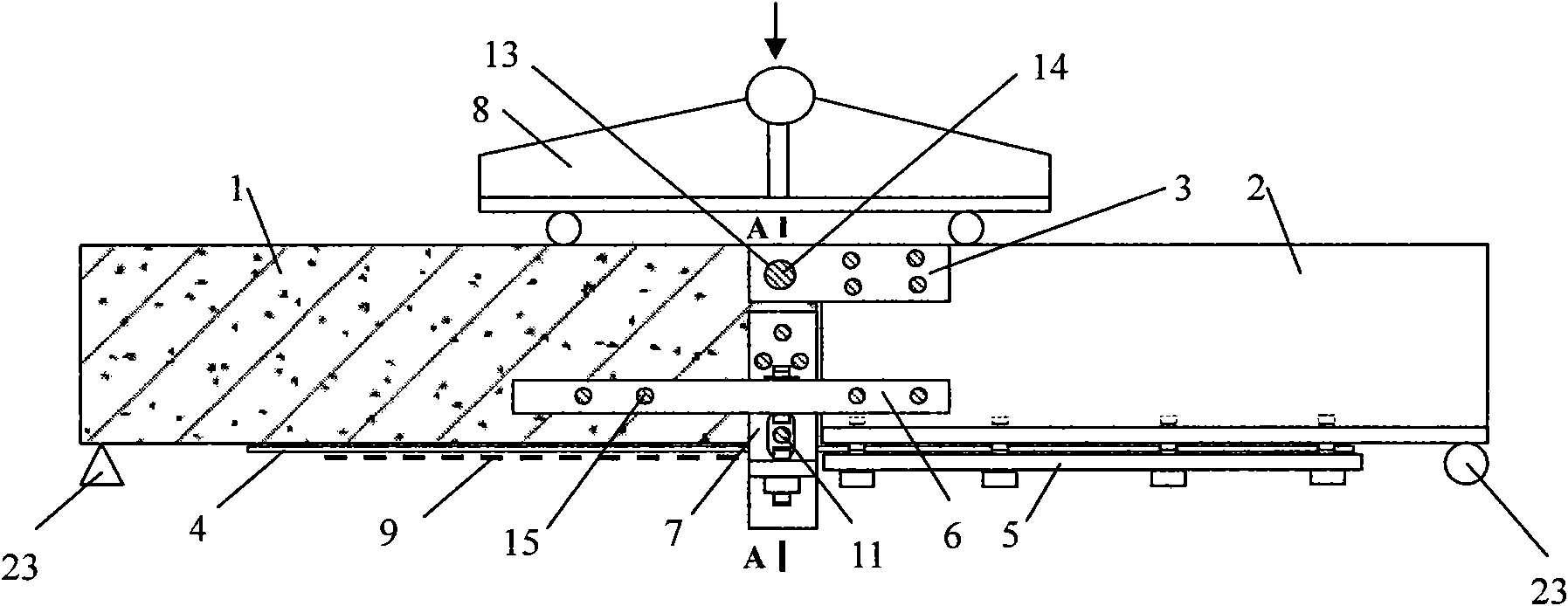

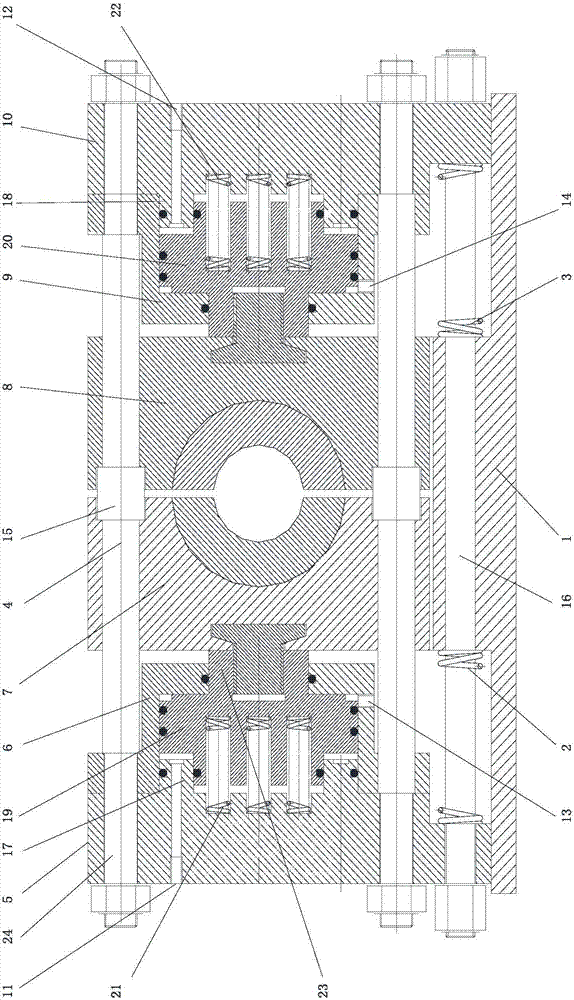

Concrete performance testing device under combined action of constant tensile load and erosion medium

ActiveCN104155185AReduce or eliminate eccentricityAddress stress relaxationWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesConstant stressEngineering

The invention discloses a concrete performance testing device under the combined action of a constant tensile load and an erosion medium, relates to the field of concrete durability testing and solves the problem that an existing testing device cannot implement concrete performance testing under the combined action of a constant stress and medium erosion. The testing device comprises a bottom plate, a connecting base, a first puller, a middle pressure plate, an upper pressure plate, a pull rod, a dish-shaped spring and a medium circulating device, wherein the bottom plate is fixedly connected with an upright; the connecting base is fixed in the middle of the bottom plate; the first puller is hinged to the connecting base and can rotate around the connecting base; the middle pressure plate passes through the upright and is fixed at a limiting point of the upright; the upper pressure plate passes through the upright; the pull rod passes through through holes in the middle pressure plate and the upper pressure plate; one end of the pull rod is connected with a spherical joint; a second puller is connected to the spherical joint; a nut is screwed at the other end of the pull rod; the dish-shaped spring sleeves the pull rod and is positioned between the middle pressure plate and the upper pressure plate; one end of a concrete test piece is connected to the first puller and the other end of the concrete test piece is connected to the second puller.

Owner:CHINA BUILDING MATERIALS ACAD

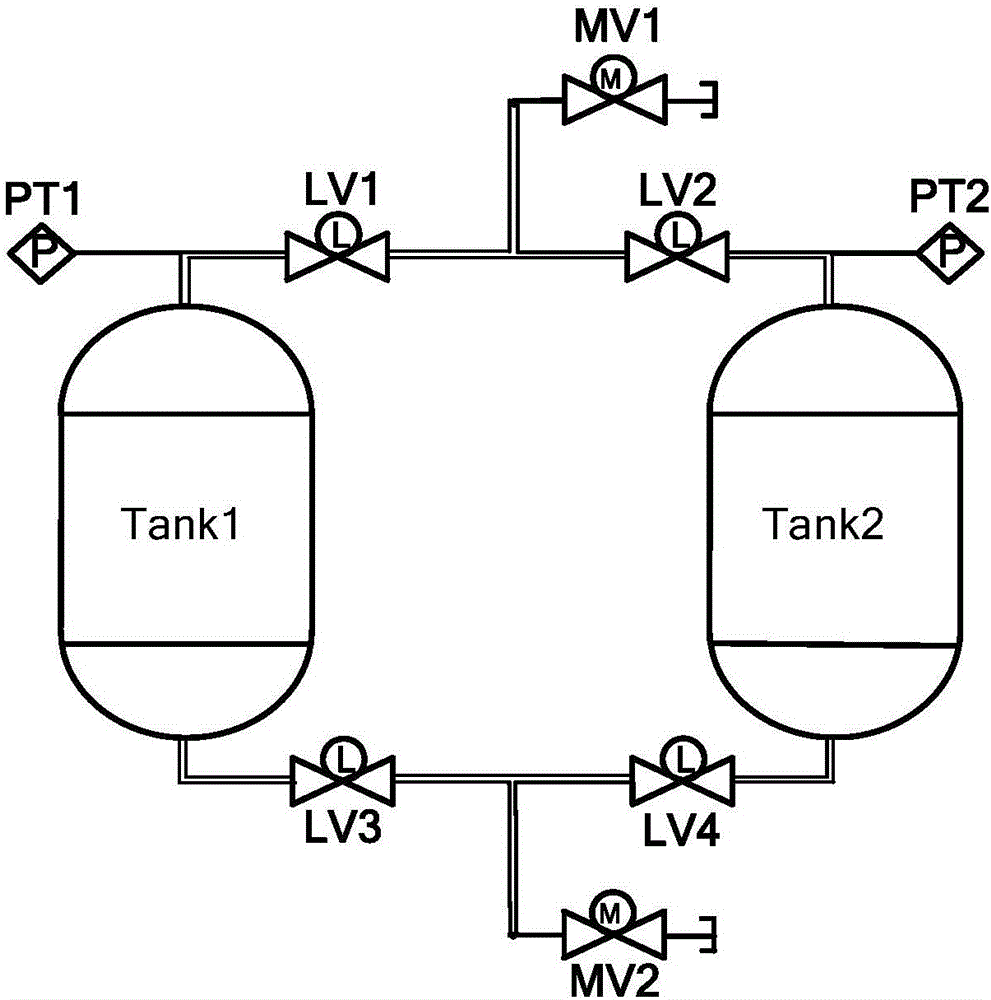

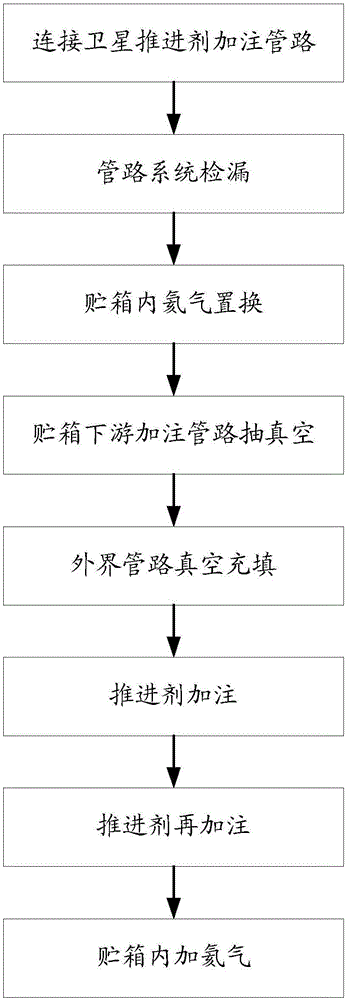

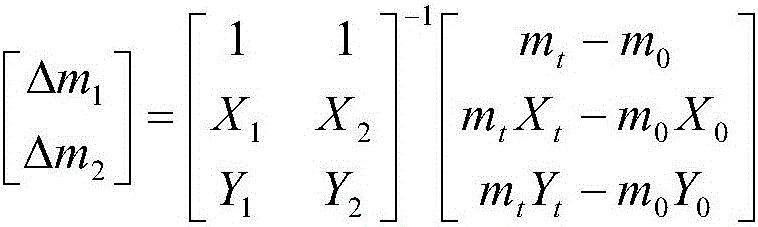

Parallel balanced filling method for high-capacity semi-management surface tension storage tank

ActiveCN106762224AReal-time display of total filling amountReal-time monitoring of parallel balanceLiquid handling installationsCosmonautic propulsion system apparatusEngineeringHelium

A parallel balanced filling method for a high-capacity semi-management surface tension storage tank comprises steps as follows: (1) a satellite propellant filling pipeline is connected, and the leakage rate of a filling pipeline system is ensured to meet the requirements; (2) two parallel storage tanks are simultaneously filled with helium or release helium for replacement until sampled gas is tested to be qualified; (3) the propellant filling pipeline and pipelines at the downstream of the parallel storage tanks are vacuumized; (4) valve ports of filling and drainage valves of the parallel storage tanks are filled with the propellant; (5) the parallel storage tanks are simultaneously and stably filled until 90% or above of the rated filling quantity is reached; (6) refilling is performed on the parallel storage tanks until the filling quantity of each storage tank meets the task requirement; (7) air cushions are added to the storage tanks until required air cushion pressure is reached. By means of the method, parallel balanced filling of the high-capacity semi-management surface tension storage tank can be realized, time for filling the parallel storage tanks with the propellant is shortened, and the reliability and the safety of the satellite filling process are guaranteed.

Owner:BEIJING INST OF CONTROL ENG

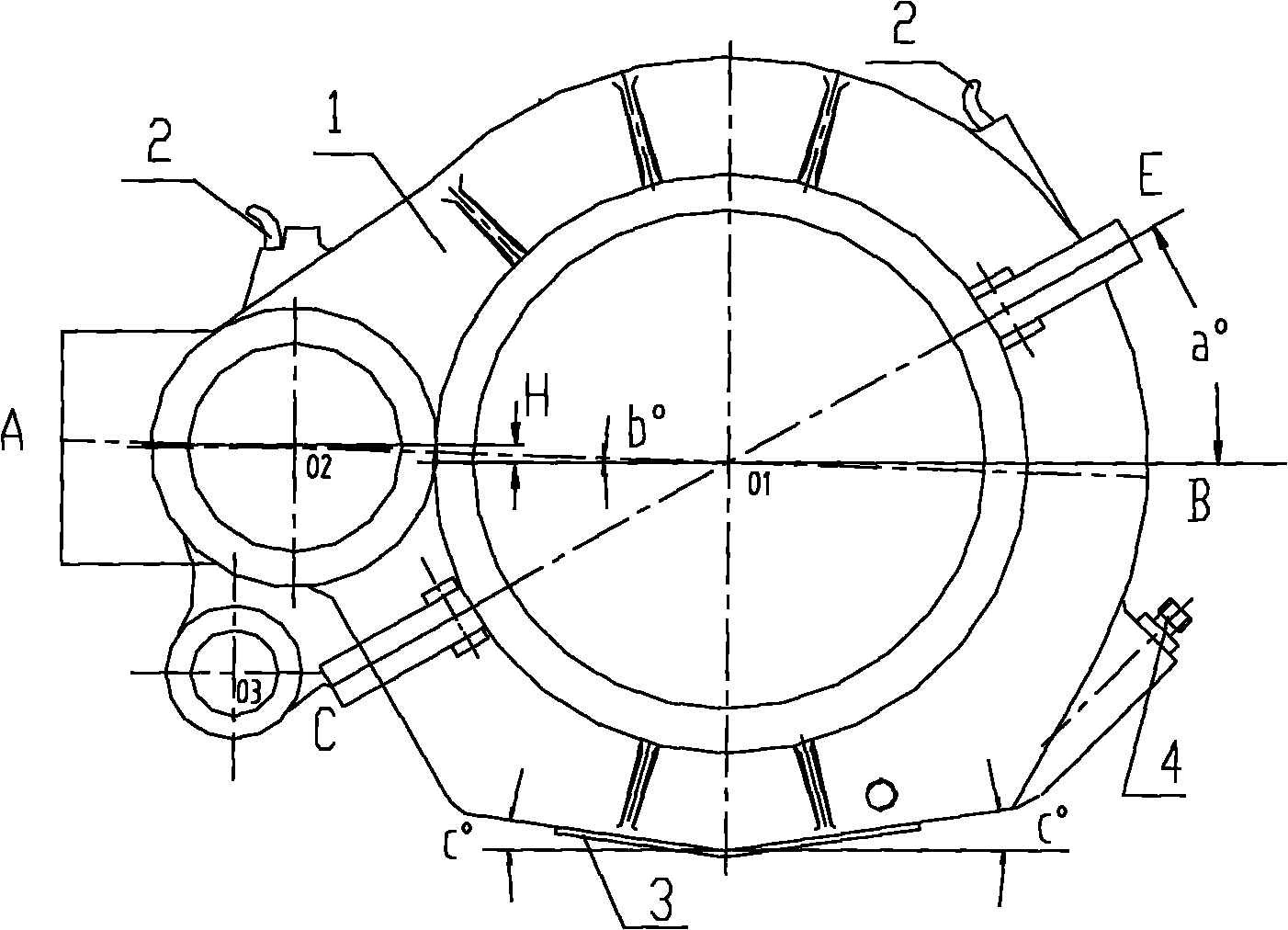

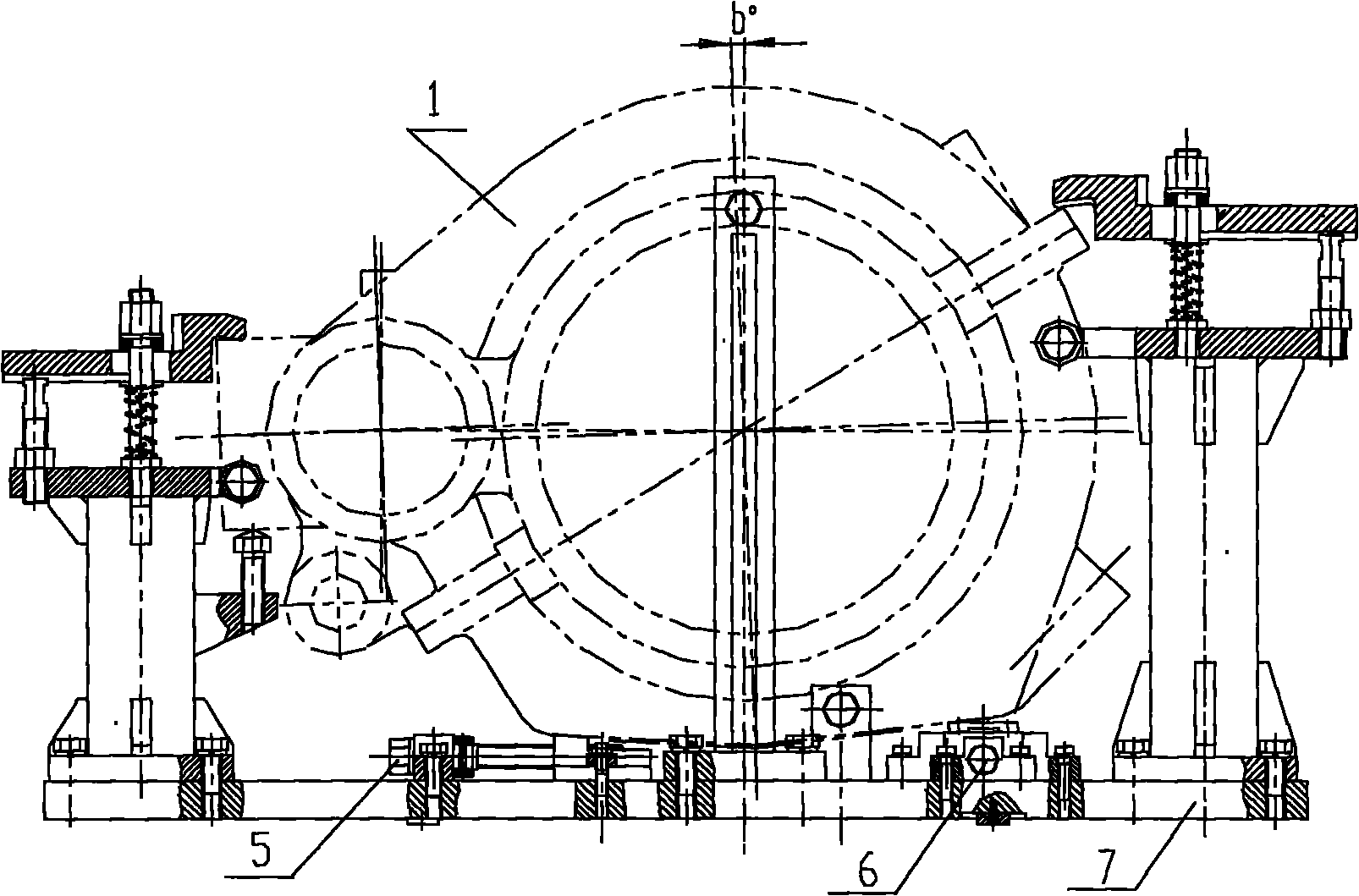

Processing method of gear reducer

InactiveCN101972920AEasy to findImprove processing efficiencyGearboxesGearing detailsPunchingEngineering

The invention relates to a processing method of a gear reducer. The method comprises the following steps of: firstly, scribing the center O2 of a driving gear hole by utilizing a central supporting disk and a centre gauge and using the outer wall of the driving gear hole of a gear reducer as a reference, scribing the center O1 of a driven gear hole of the gear reducer with a scribing template and the central supporting disk, then, prolonging a center connecting line O2O1 of the driven gear hole and the driving gear hole to a point (A) and a point (B) at both ends of the gear reducer body and punching points so as to conveniently calibrate a scribing line; hoisting the gear reducer on a processing clamp, wholly rotating the gear box through the up-and-down movement of a left adjustable support and a right adjustable support so that the center O2 of the driving gear hole and the center O1 of the driven gear hole are connected into a horizontal line, wherein the connecting line is horizontal to a worktable of a machine tool; and roughly processing all parts of a gearbox, processing the surfaces and the holes of a handle, a soleplate, an oil neilsbed, welding, processing and finely processing the driving gear hole and the driven gear hole. The invention reduces error accumulation, comprehends the processing accuracy and processes the gear reducer by utilizing traditional equipment to improve the processing efficiency of the gear reducer and ensure the processing pass rate over 90 percent.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Differential unit

InactiveUS7036391B2Reduce imbalanceAvoid eccentricityRoller bearingsBall bearingsCircular coneEngineering

A protruding section facing a drive pinion shaft is integrally provided on (or provided as a separate component) a tubular spacer interposed between an inner race of a pilot bearing and an inner race of a tapered roller bearing at an inner section opposite to the drive pinion shaft. In one embodiment, a monolithic protruding section is curved so as to be convex along the overall central axial direction of the spacer, and is arch shaped in cross section. The protruding section protrudes towards the drive pinion shaft along the overall inner peripheral direction of the spacer, and the inner surface of the protruding section comes into contact with or close to the outer surface of the drive pinion shaft. Additional positions include one or a plurality of O-rings interposed between the drive pinion shaft and the inner surface of the tubular spacer.

Owner:SUBARU CORP

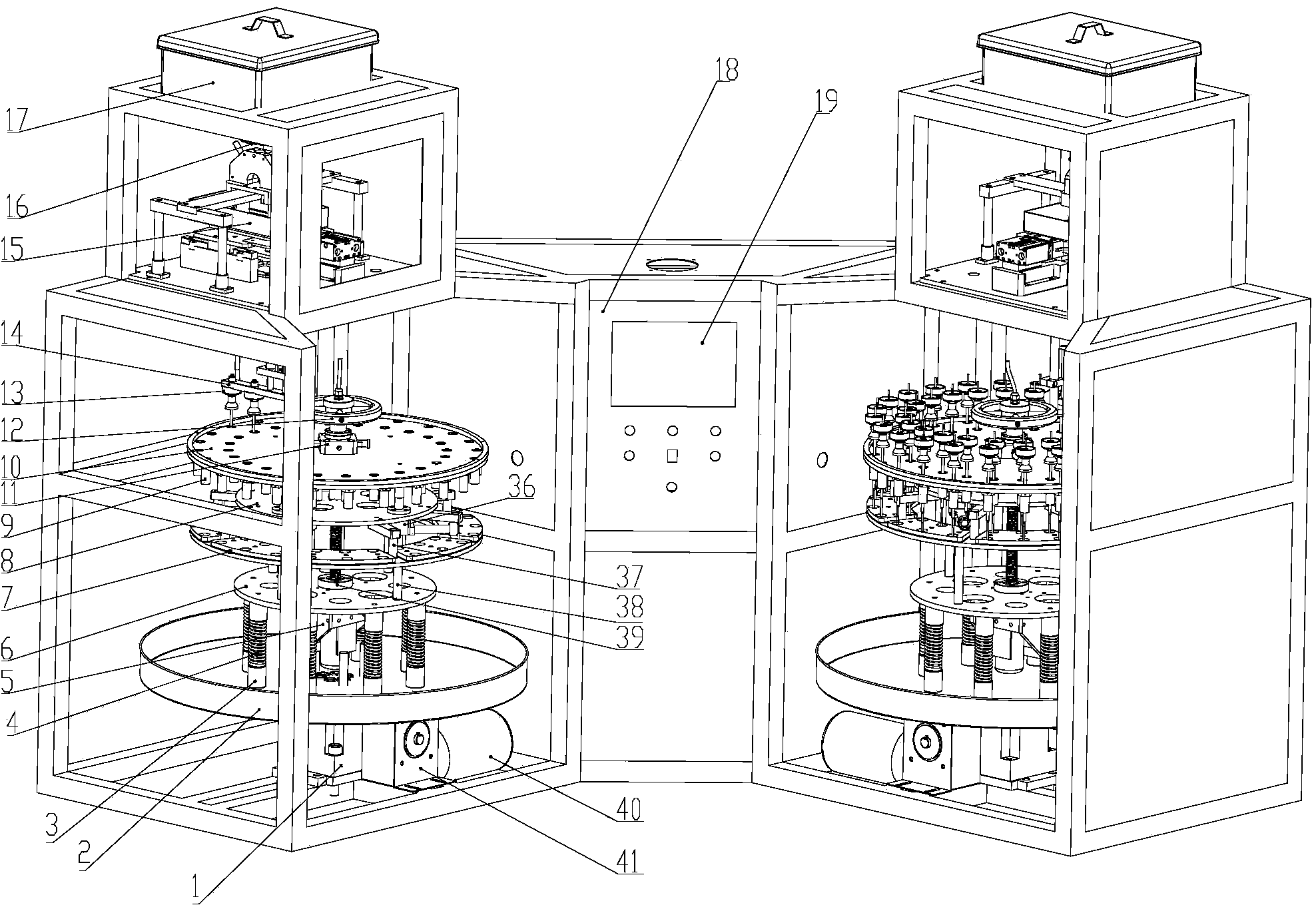

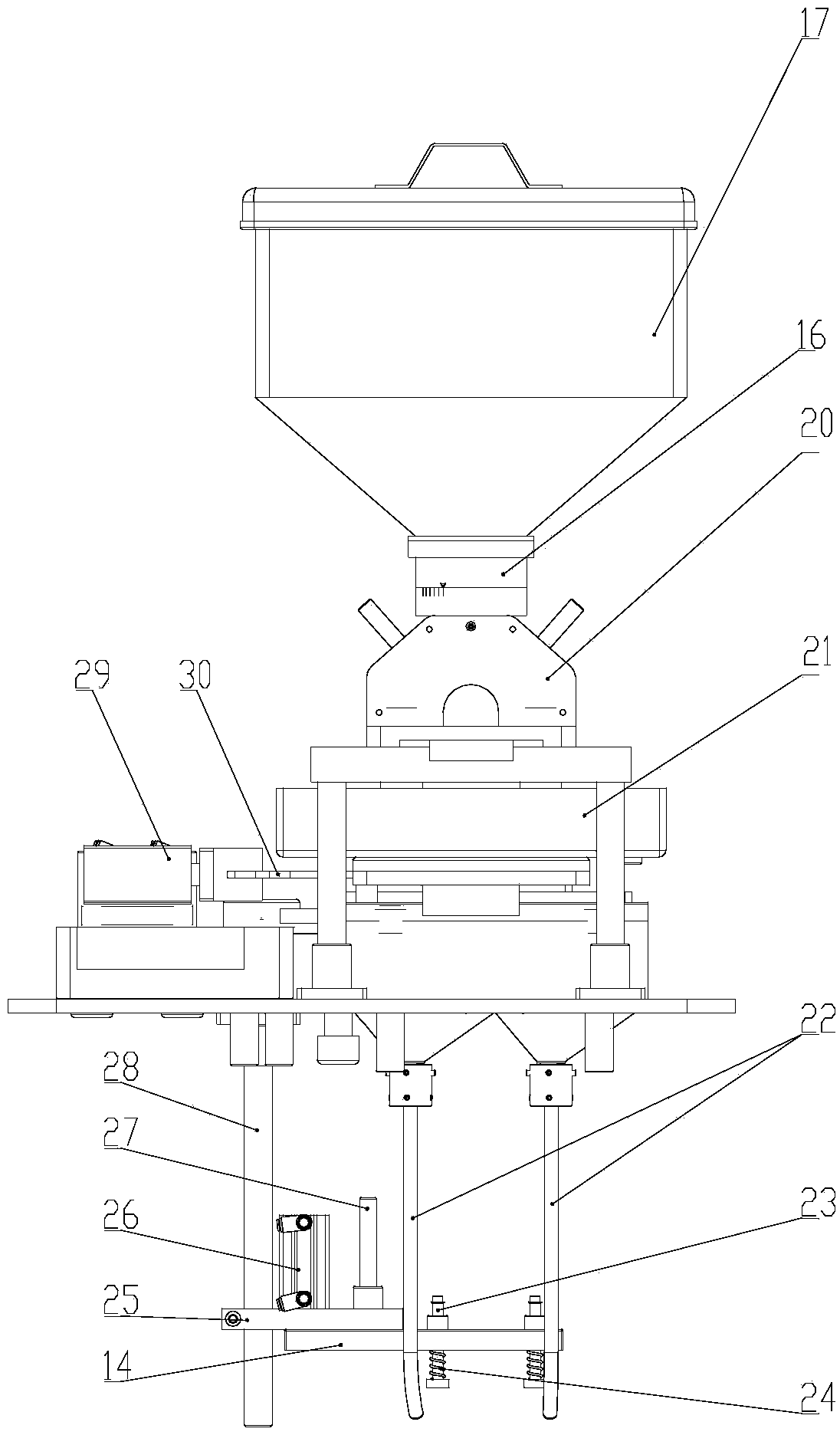

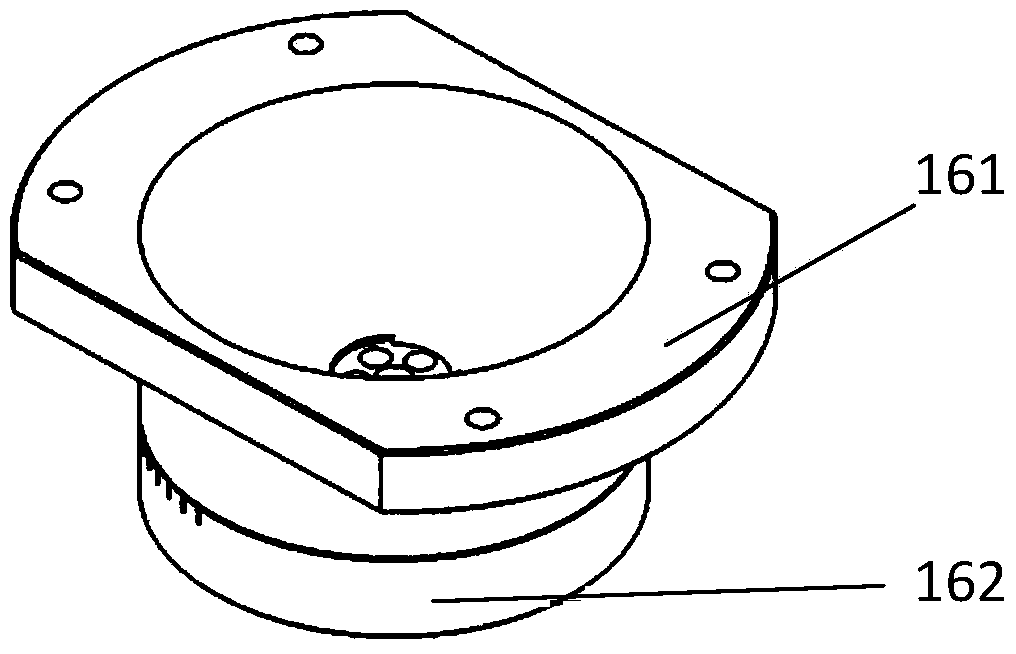

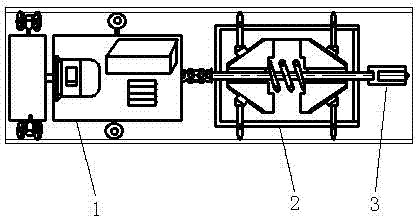

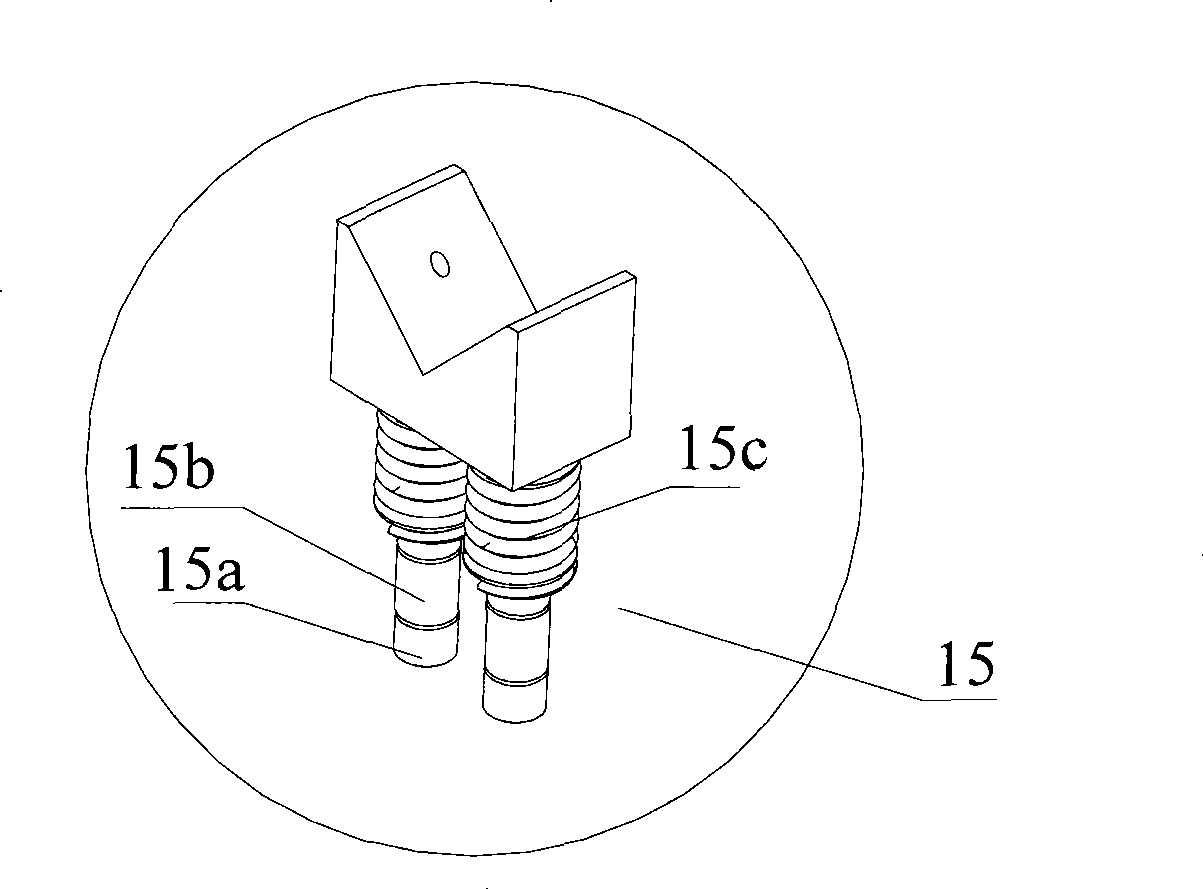

Quantitative powder-filling device for sintering-type heat pipes

The invention discloses a quantitative powder-filling device for sintering-type heat pipes. The quantitative powder-filling device comprises a bilateral symmetry V-shaped rack, a touch screen control panel, a funnel positioning device and two sets of powder-filling core mechanisms, the touch screen control panel is arranged in the middle of the rack, the two sets of powder-filling core mechanisms are arranged on the rack in a bilateral symmetry mode, the powder-filling core mechanisms comprise powder storing tanks, automatic powder inlet mechanisms, pressing mechanisms, powder-filling platform main panels, fixed middle plates, positioning plates, vibrating mechanisms and intermittent rotation devices which are sequentially arranged on the rack from top to bottom, the pressing mechanisms are used for pressing core rods, the powder-filling platform main panels are used for placing the heat pipes, and the touch screen control panel is respectively connected with the vibrating mechanisms, the intermittent rotation devices and the automatic powder inlet mechanisms in a circuit mode. The quantitative powder-filling device for the sintering-type heat pipes has the advantages that the automation degree is high, the controlling is accurate, requirements for operators are low, the labor intensity of the operators is reduced, the operation is convenient, the production efficiency is high, meanwhile, waste of raw materials such as copper powder can be reduced, flying dust is reduced, and the operating environment is improved.

Owner:SOUTH CHINA UNIV OF TECH

All-fiber-texture large-size one-piece flange fan main shaft forging method

ActiveCN104175063ALower fuel consumptionIncrease productivityMetal-working apparatusFurnace typesFiberForging

The invention discloses an all-fiber-texture large-size one-piece flange fan main shaft forging method which comprises the following steps of material selection, heating, primary firing forging, secondary firing forging, heat treatment after forging, rough turning, ultrasonic flaw detection, hardening and tempering, semifinishing, lossless flaw detection, body sampling, mechanical property testing and stable heat treatment. Compared with the conventional twice-forging and welded flange main shaft production method, the all-fiber-texture large-size one-piece flange fan main shaft forging method has the advantages that the welding working procedures are reduced, the time is saved, the raw material consumption is reduced, and the production cost is lowered; a forged flange main shaft is of an all-fiber-texture structure, so that the natural defects that the welded flange is low in balance property and easy to deform and the root is easy to break are totally overcome; a requirement of a large-size fan on the main shaft design is met.

Owner:陕西华威科技股份有限公司

Automatic floating centering hydraulic clamp holder

PendingCN107420051AEliminate wear and tearHigh speedDrilling rodsDrilling casingsSingle degree of freedomEngineering

The invention discloses an automatic floating centering hydraulic clamp holder. The automatic floating centering hydraulic clamp holder comprises a clamping assembly used for clamping a drill rod and a base fixedly matched with a drilling machine rack and used for installing the clamping assembly. The clamping assembly is installed on the base in the radial swing direction of the drill rod in a single-degree-of-freedom sliding mode, and a fixing elastic part used for fixing the clamping assembly to avoid the situation that the clamping assembly slides under the gravity effect is arranged between the base and the clamping assembly in the single-degree-of-freedom sliding direction of the clamping assembly; external force floating centering can be increased, so that the situation that abrasion on the drill rod during clamp holder centering is guaranteed through force generated by rotating of the drill rod is avoided; and meanwhile in a lateral orientation drilling machine, the clamp holder can also be centered under the effect of floating external force, so that the eccentric problem of an existing clamp holder under the gravity effect or the problem that the initial position of the clamp holder is repeatedly adjusted to ensure centering in different orientations is avoided.

Owner:CHINA COAL TECH & ENG GRP CHONGQING RES INST CO LTD

PSD-based deep hole linearity measuring robot

ActiveCN106949856AControl advance and retreatEasy to disassemble and maintainNuclear energy generationUsing optical meansEngineeringLinearity

The invention provides a PSD-based deep hole linearity measuring robot, which comprises an advancing mechanism, a deep hole self-centering mechanism, a laser measuring head, a photoelectric processing system, and a PSD position adjusting mechanism. The deep hole self-centering mechanism comprises a sleeve, an end cap, six support measuring rods, two conical circular truncated cones, a press spring, and a centering shaft. The advancing mechanism is used for pushing the deep hole self-centering mechanism to advance along a deep hole. The laser measuring head is arranged on the other end of the centering shaft. The photoelectric processing system is used for acquiring laser signals of the laser measuring head. The PSD position adjusting mechanism is used for adjusting light receiving positions of the photoelectric processing system. A bidirectional symmetrically wedge-form elastic supporting mechanism is realized, ends of the support measuring rods are supported in a sliding manner, and the conical circular truncated cones are pushed to slide along the centering shaft when the support measuring rods shifts in a radial direction to adapt to changes of the aperture of the hole. Moreover, the central line of the hole and the central line of the centering shaft are always the same line so as to match linearity measuring of the deep hole or a blind hole.

Owner:NANJING COLLEGE OF INFORMATION TECH

Manufacturing process of three-layer co-extrusion nano-modified BOPP matt film

InactiveCN105500889AImprove the interface binding forceImprove wear resistanceLamination ancillary operationsSynthetic resin layered productsHigh rateSurface layer

The invention discloses a manufacturing process of a three-layer co-extrusion nano-modified BOPP matt film. The manufacturing process comprises the following steps: after mixing and drying raw materials of a coring layer, an upper surface layer and a lower surface layer, entering respective single screw extruders to carry out melt plastification, and then entering a die head through a filter and a metering pump; flowing out after converging a three-layer polymer melt at the position of the die head, quickly attaching to the surface of a quenching roller under the effect of an air knife attaching device, forming a solid sheet through quick cooling of the quenching roller and a water channel, then carrying out longitudinal and transverse stretching in sequence, and then instantly carrying out air cooling treatment; then subsequently carrying out online thickness measurement, boundary material cutting, static elimination, automatic rolling, aging treatment and slitting. The manufacturing process adopts a three-layer co-extrusion compounding technology, the BOPP matt film with high extinction property, good abrasion resistance and high rate of finished products is prepared by using an improved raw material formula.

Owner:HAINING CHANGKUN PACKAGING

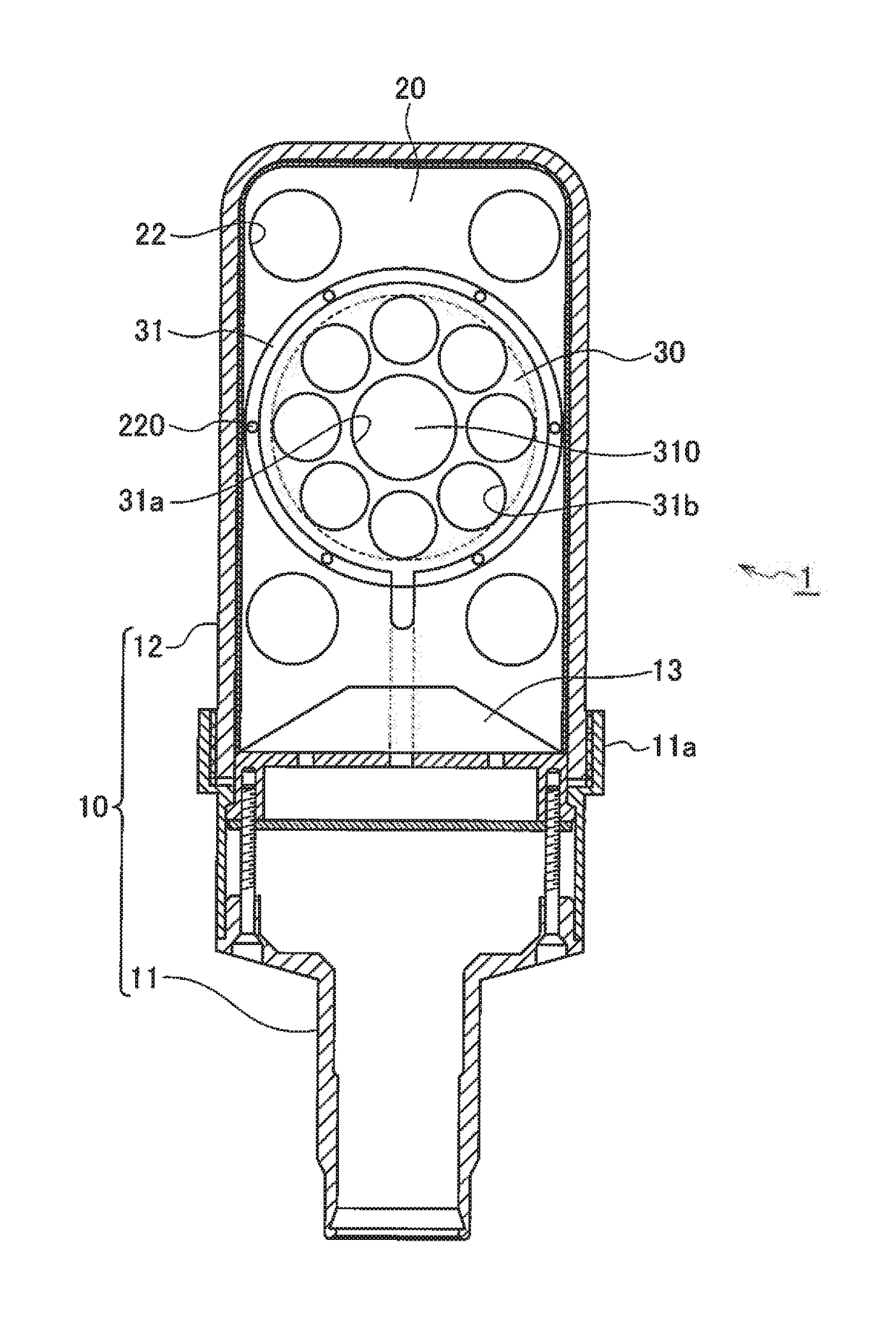

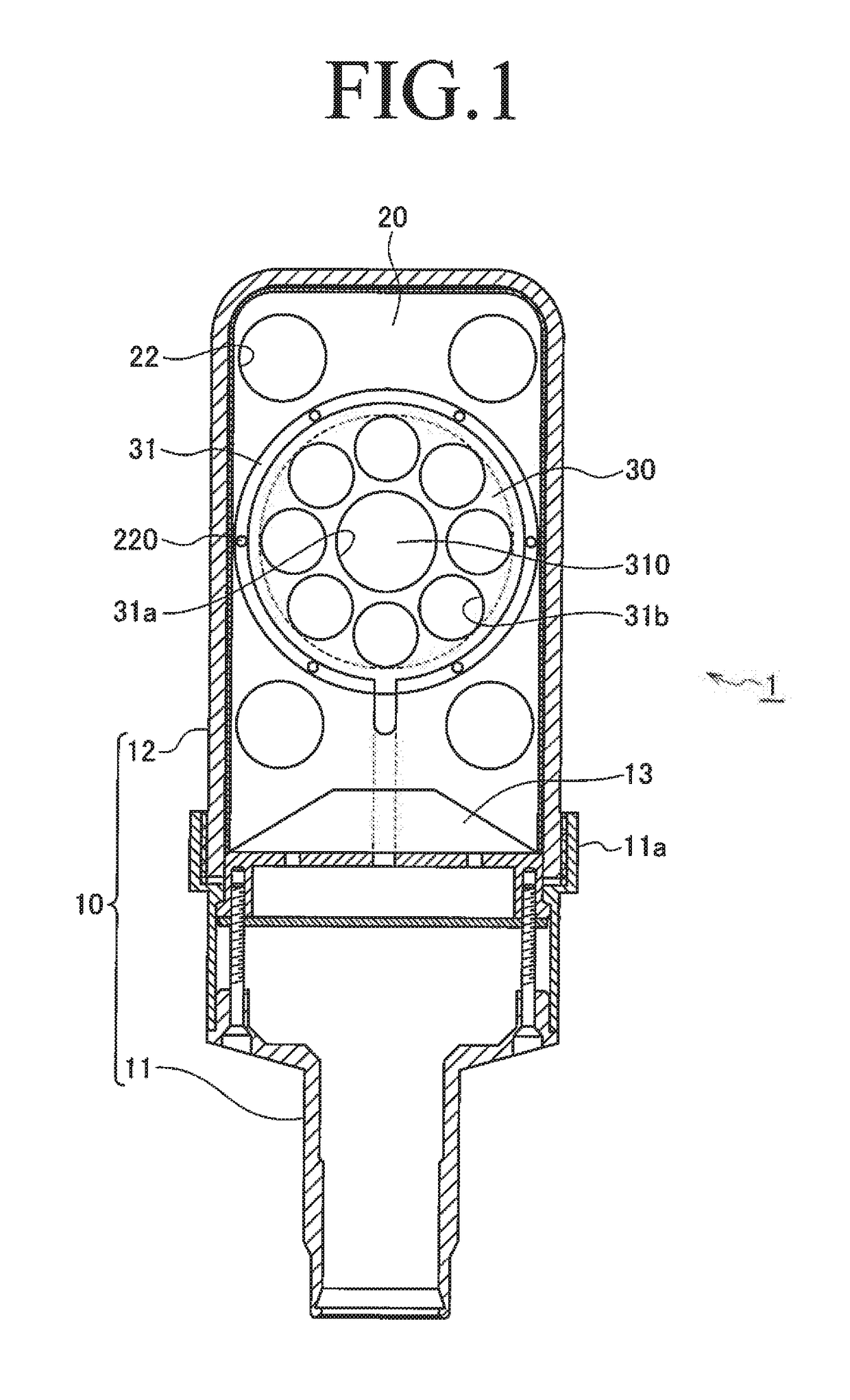

Condenser microphone unit and condenser microphone

ActiveUS20170171670A1Improve assembly accuracyEccentricity is suppressedMicrophone structural associationElectrostatic transducer microphonesCapacitanceEngineering

Provided is a condenser microphone unit that prevents eccentricity as much as possible and achieves improvement of assembly accuracy. A condenser microphone unit including a diaphragm that vibrates upon receiving a sound wave and made by a plurality of configuration components that are assembled, the condenser microphone unit includes a base member including an opening portion to which the plurality of configuration components is attached, and an adjustment member having an outer diameter corresponding to a diameter of the opening portion, and mounted to a side surface of one or more components accommodated in the opening portion, of the plurality of configuration components. The adjustment member is a frame body exhibiting an annular shape and including a notch portion notched to have a pair of end portions, and is fixed in the opening portion in a state of being mounted to the side surface of the one or more components.

Owner:AUDIO-TECHNICA

Electromagnetic type active vibration absorber

ActiveCN106641087ASolve the lack of vibration damping abilityRapid responseSpringsNon-rotating vibration suppressionVibration attenuationLow frequency vibration

The invention discloses an electromagnetic type active vibration absorber which comprises two permanent magnets, a skeleton, two enamelled coils, an insulating sealing shell, a wiring port, two shaft bossings, an ejector pin, screws, two metal springs, a cover plate, a shell and a mass block; the shaft bossings are installed at the two ends of an inner ring of the annular skeleton; the permanent magnets are adhered to the periphery of the skeleton; the enamelled coils are encapsulated in the insulating sealing shell and installed in the shell; the metal springs are of a spring sheet structure with a center hole, are installed on the cover plate in a pressing manner and are installed at the two ends of the shell respectively; the lower end of the ejector pin penetrates through the two shaft bossings and the center holes of the metal springs and is fixed to the metal springs through the screws; the mass block is installed at the upper threaded end of the ejector pin; and the wiring port is adhered to the end of the insulating sealing shell so as to derive the enamelled coils out to be connected with a controller. The electromagnetic type active vibration absorber can better meet the vibration attenuation needs of low-frequency vibration and high-frequency vibration and also has the advantages of compact structure, small energy consumption, sensitiveness in respond, convenience in mounting, strong reliability and the like in engineering application.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

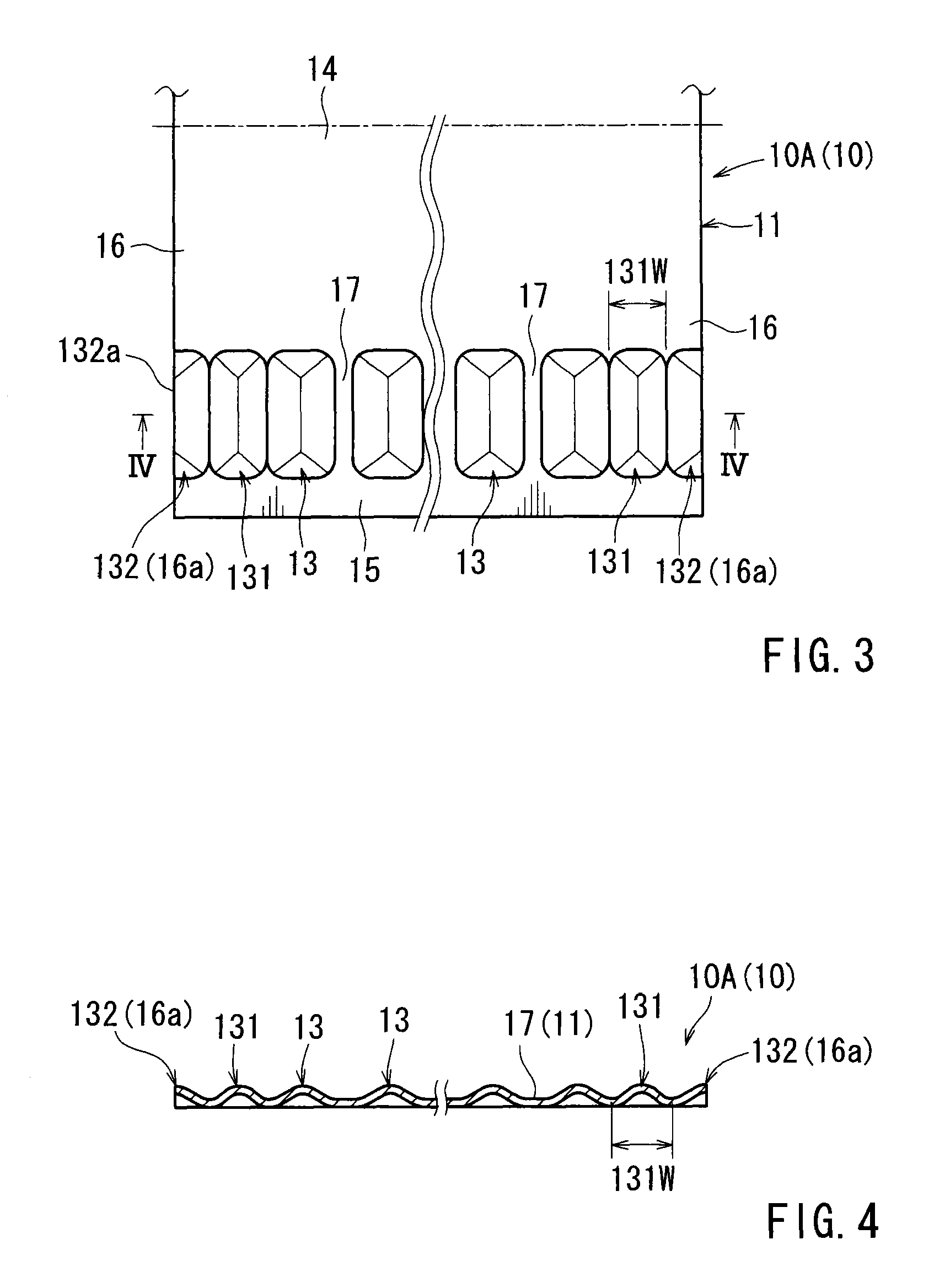

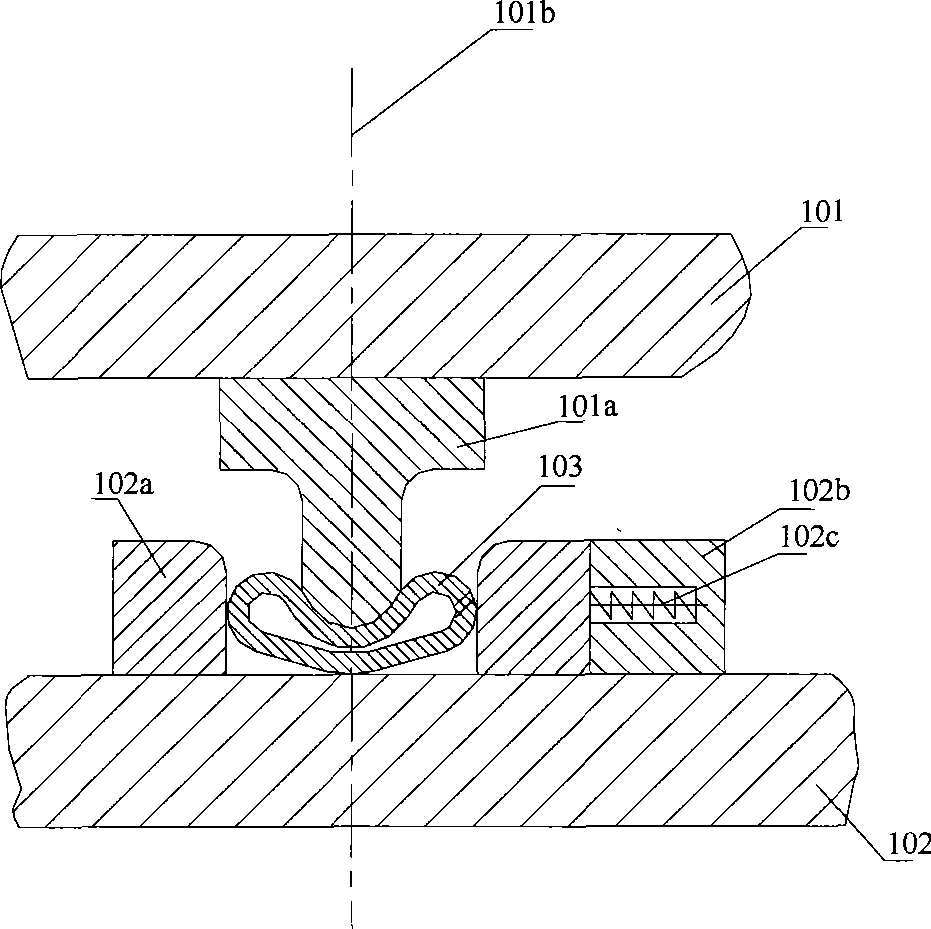

Mold for shaping middle part of cross member

InactiveCN101474654APrevents off-center quality issuesAvoid eccentricityShaping toolsBogie-underframe connectionsVertical planeEngineering

The invention discloses a cross rod middle forming die. The forming die comprises: a convex die which is used for punch forming, wherein, the convex die is fixedly arranged on an upper die plate by an upper die holder; a concave die which is matched with the convex die, wherein, the concave die is fixedly arranged on a lower die plate by a lower die holder; and a pair of liftable follow-up positioning devices which are used for positioning a workpiece to cause the axis of the workpiece and the longitudinal center line of the concave die to be kept at the same vertical plane, wherein, the pair of the positioning devices are respectively arranged at two ends of the concave die. The axis of the workpiece is automatically kept at the same vertical plane with the longitudinal center line of the concave die when the workpiece is placed on the positioning devices before forming, and the convex die moves downwards along with the upper die plate to form the workpiece, which can avoid the quality problems that the eccentric centers and microcracks and the like are formed in the workpiece forming, and improve the fatigue property of a cross fabrication device.

Owner:CRRC QIQIHAR ROLLING CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com