PSD-based deep hole linearity measuring robot

A technology for measuring robot and straightness, applied in measuring devices, instruments, optical devices, etc., can solve the problems of inability to measure the straightness parameters of deep holes and blind holes, and achieve stability, easy disassembly and maintenance, and sliding support. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

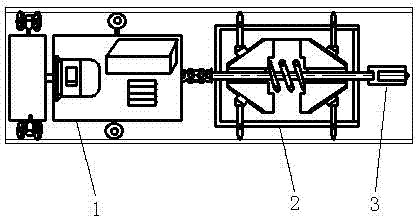

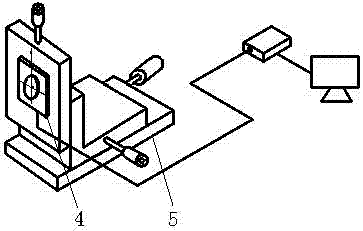

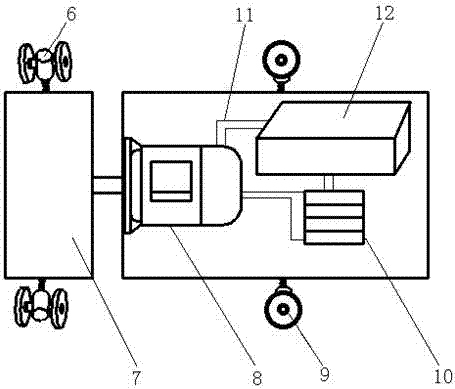

[0022] Such as Figure 1-7 As shown, the present invention discloses a deep hole straightness measurement robot based on PSD, which includes: a traveling mechanism 1 , a deep hole self-centering mechanism 2 , a laser measuring head 3 , a photoelectric processing system 4 and a PSD position adjustment mechanism 5 .

[0023] Wherein, the deep hole self-centering mechanism 2 includes a sleeve 13, an end cover 14, six supporting measuring rods, two conical round tables 18, a compression spring 22 and a centering shaft 21; the end cover 14 is sealed at the port of the sleeve 13; The centering shaft 21 penetrates through the sleeve 13 and the end cover 14 along the axial direction of the sleeve 13; two conical circular platforms 18 are sleeved on the centering shaft 21 through the installation hole at the center, and a centering shaft is provided in the installation hole. Balls 23; the cone bottoms of the two conical round platforms 18 are opposite, and the clip spring 22 is sleeved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com