Energy-saving -type floor intelligent connecting component

An energy-saving, connector technology, applied in the direction of floors, buildings, building structures, etc., can solve the problem of wasting wood and other problems, achieve the elimination of expansion tension, huge manufacturing advantages and energy-saving effects, good shock absorption and buffering effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

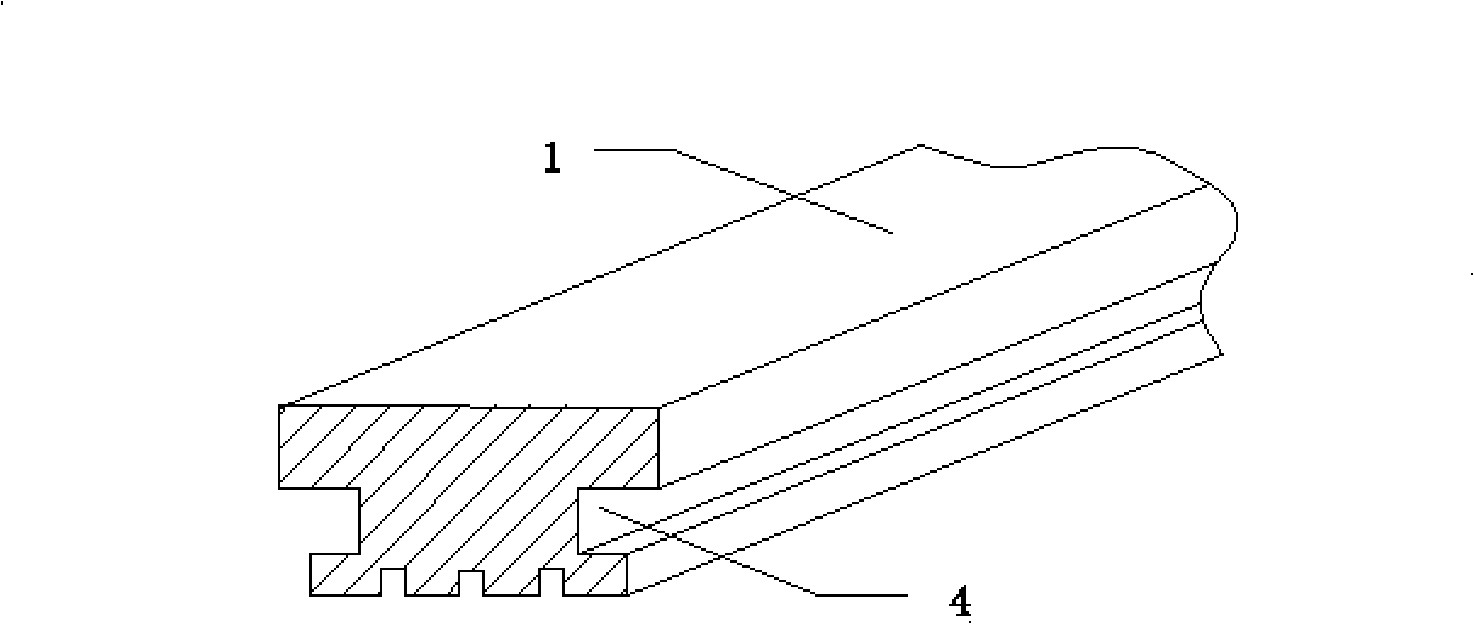

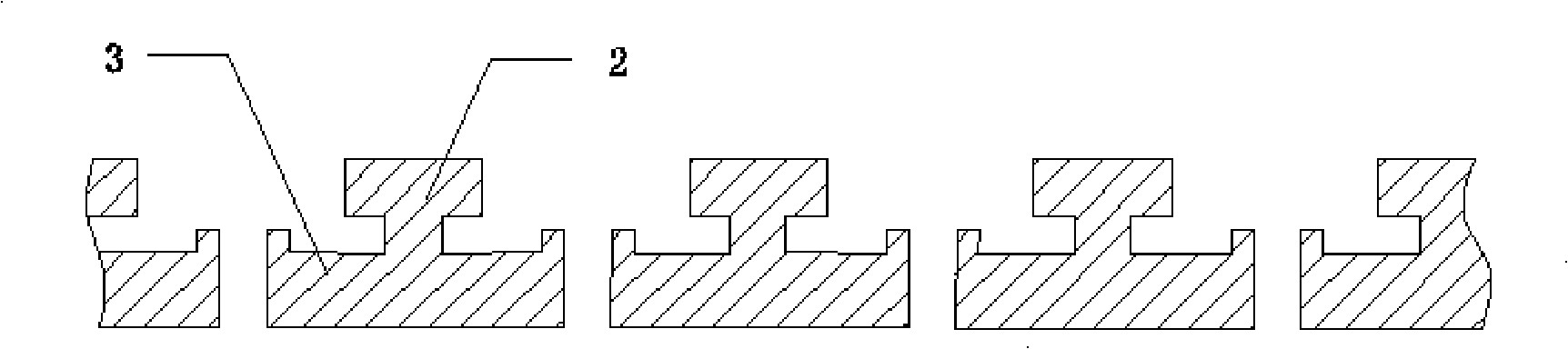

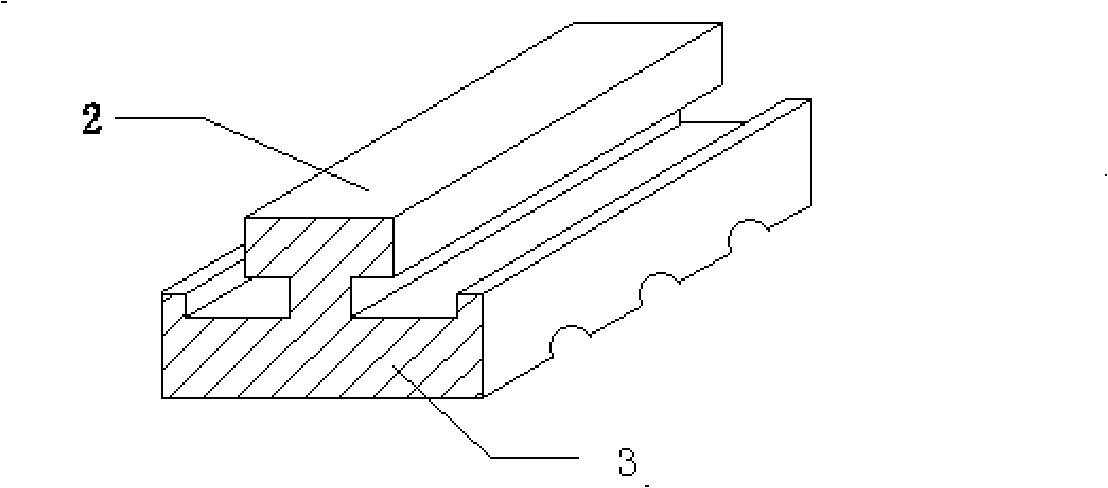

[0029] In the energy-saving floor of the present invention, the two sides of the floor body 1 are provided with symmetrical square horizontal grooves 4, taking a conventional solid wood floor with a width of 96 mm and a thickness of 18 mm or a width of 126 mm and a thickness of 18 mm as an example ,like figure 1 As shown, the opening depth of the horizontal groove 4 is 7 millimeters, and the height is 6 millimeters. The upper surface of the horizontal groove 4 is 7 millimeters away from the top surface of the floor body 1, and the lower surface of the horizontal groove 4 is 5 millimeters away from the bottom surface of the floor body 1. The width of the bottom surface of the floor body 1 is 90 mm or 120 mm. The cross section of the floor body 1 is in the shape of an "I", and the horizontal grooves 4 between adjacent floor bodies 1 form a "T" groove. The bottom of the floor body 1 is provided with 3 to 4 grooves equidistantly along its length direction, such as figure 1 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com