Automatic floating centering hydraulic clamp holder

A hydraulic clamping and automatic technology, applied in drilling equipment, earth-moving drilling, drill pipe, etc., can solve the problems of inability to float, drill pipe wear, increase drill pipe wear, etc., achieve light weight, compact structure, avoid The effect of the eccentricity problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

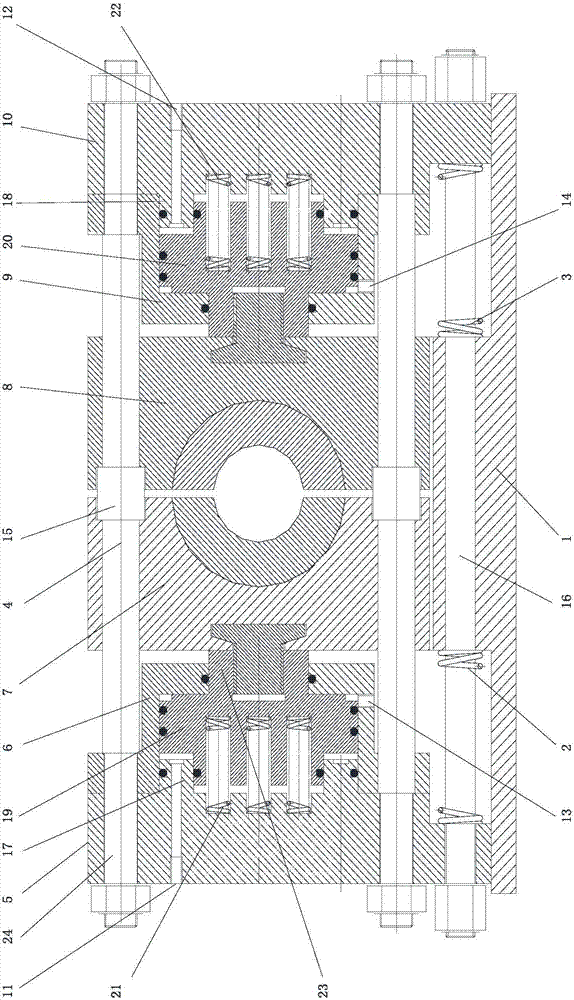

[0023] figure 1 It is a schematic diagram of the structure of the present invention, as shown in the figure, the automatic floating centering hydraulic clamp in this embodiment; includes a clamping assembly for clamping a drill rod and is fixedly matched with the drilling machine frame and used for installing the clamping assembly The base 1; the clamping assembly is installed on the base 1 in a single degree of freedom sliding manner along the radial swing direction of the drill rod; by sliding the clamping assembly on the base 1 in a single degree of freedom along the radial swing direction of the drill rod, The clamping hole of the clamping assembly can be automatically centered with the drill rod, that is, uniform clamping of the drill rod can be realized.

[0024] In this embodiment, a fixed elastic force for fixing the clamping component to prevent the clamping component from sliding under the action of gravity is provided between the base 1 and the clamping component al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com