Patents

Literature

803 results about "Single degree of freedom" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

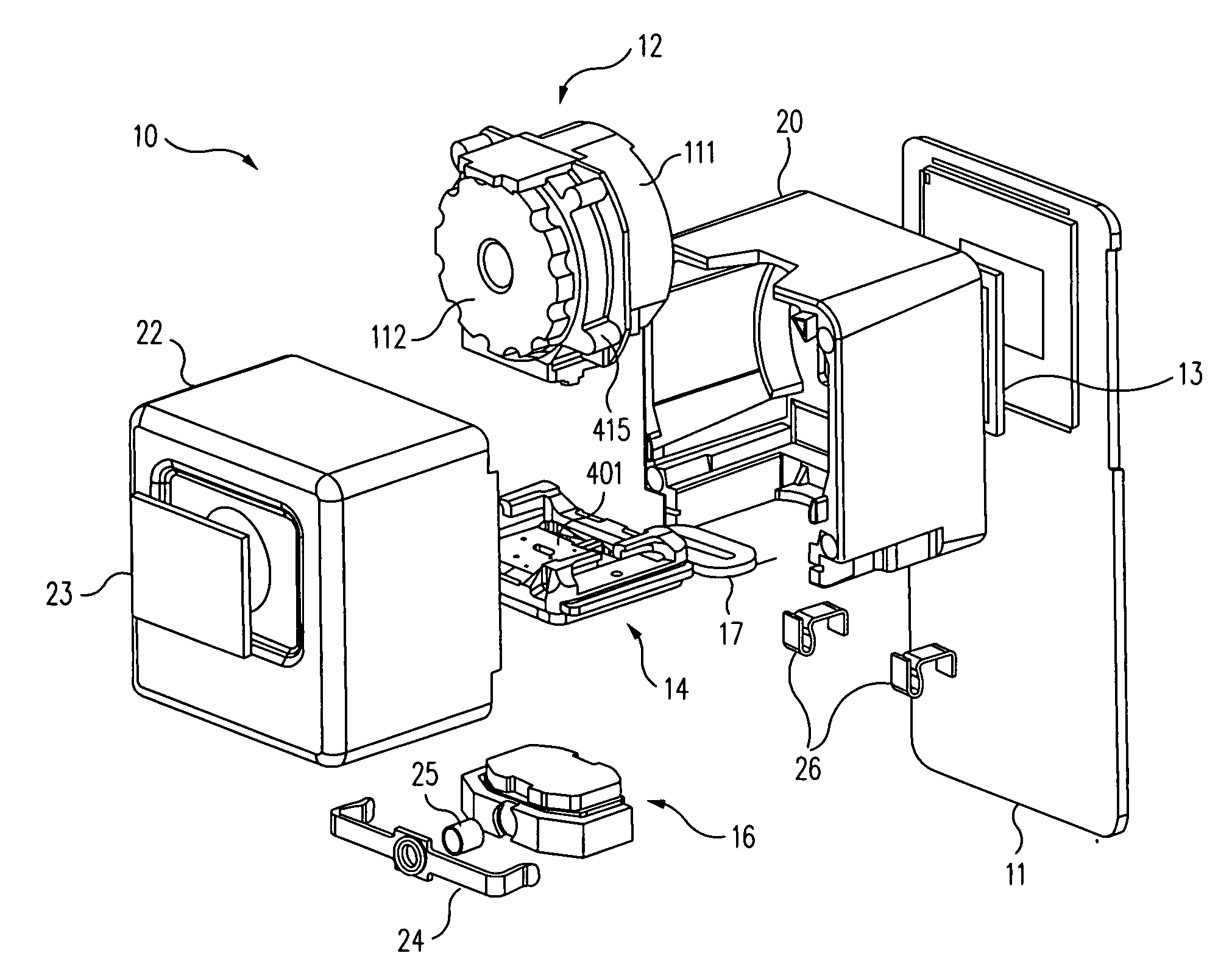

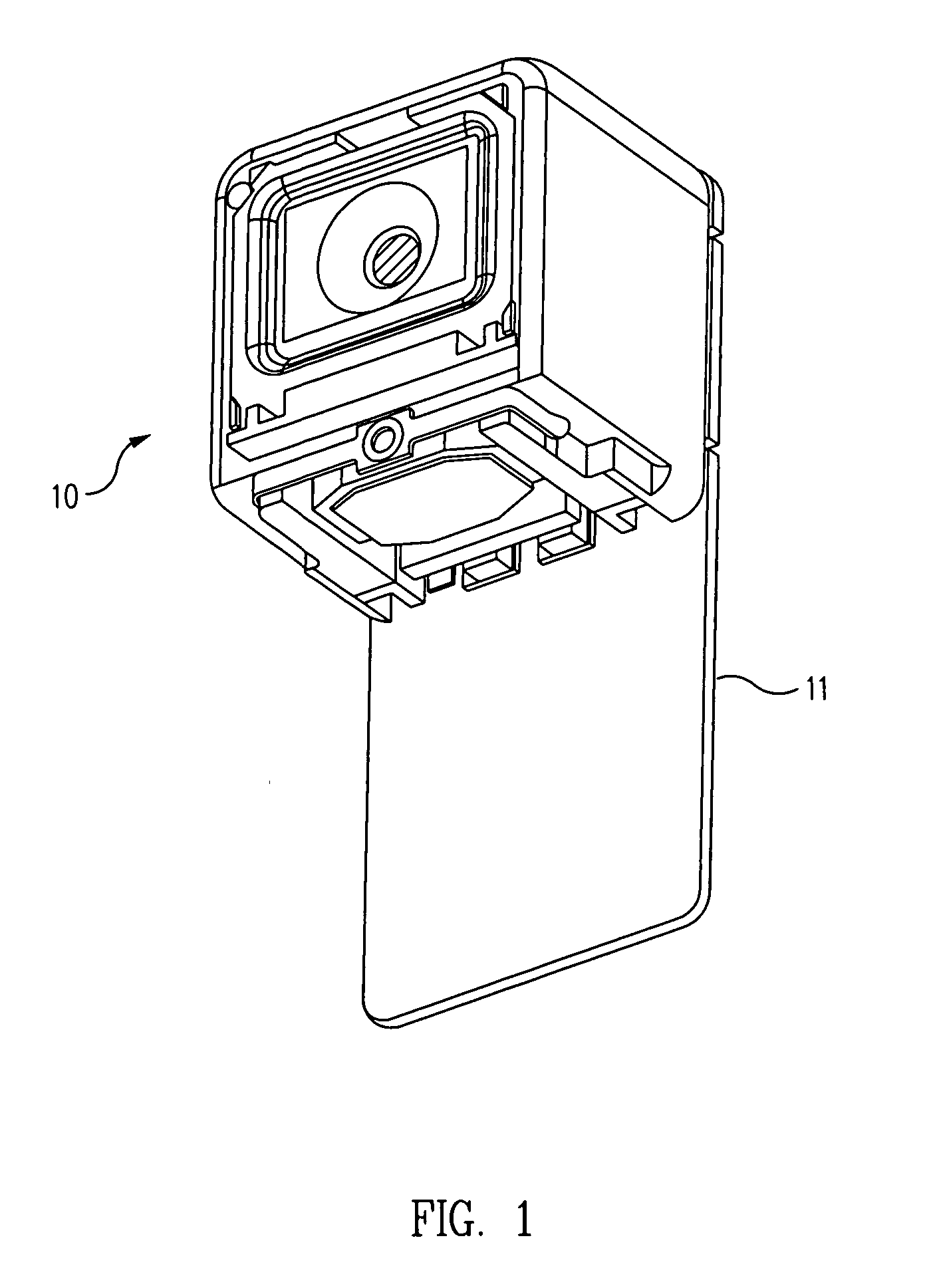

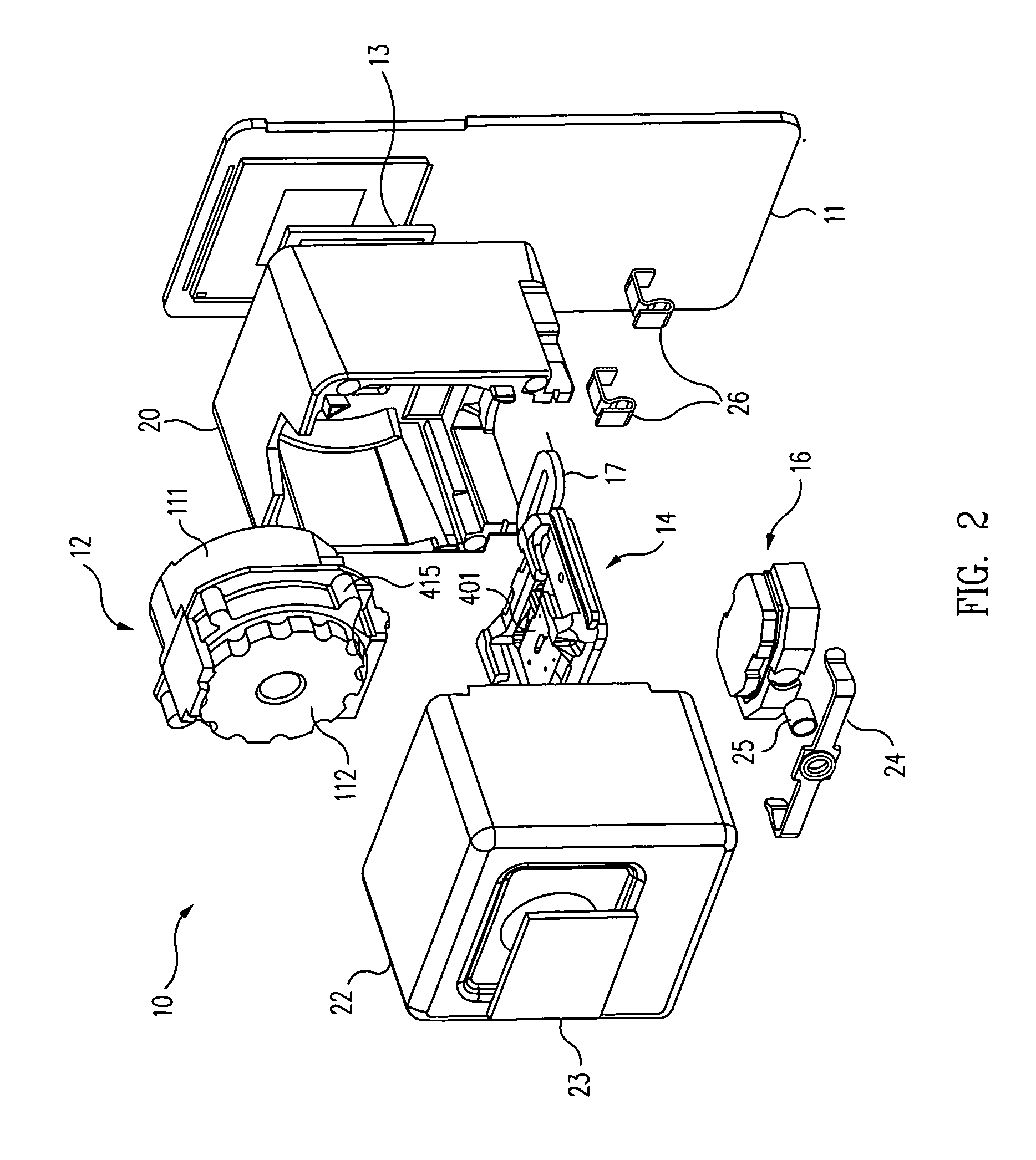

Autofocus camera

ActiveUS20060204242A1Reduce electromagnetic interferenceImprove camera performanceProjector focusing arrangementCamera focusing arrangementSingle degree of freedomElectromagnetic interference

A method and system for facilitating focusing of a miniature camera are disclosed. One or more lenses can be attached to a MEMS stage. The MEMS stage can be moved by a Lorentz actuator. The MEMS stage can be configured to limit movement of the lens(es) to a single degree of freedom to inhibit misalignment thereof with respect to an imaging sensor. The stage can be biased to a predefined position thereof, e.g., for focus at infinity. A metal cover can inhibit electromagnetic interference and can limit movement of the lens(es).

Owner:DIGITALPTICS MEMS

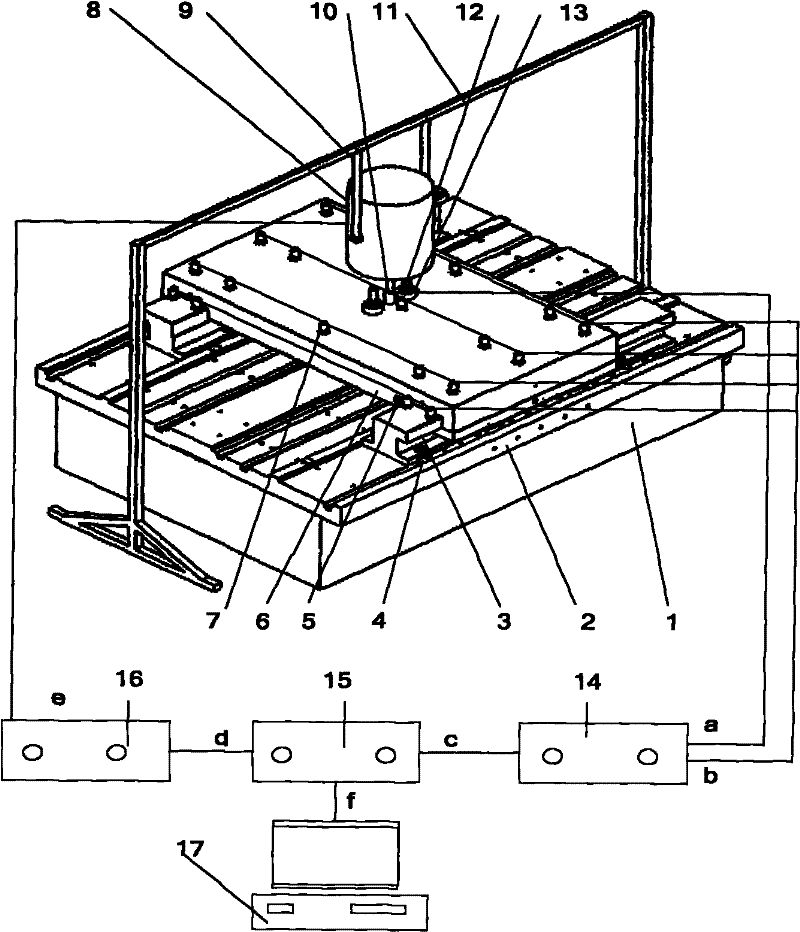

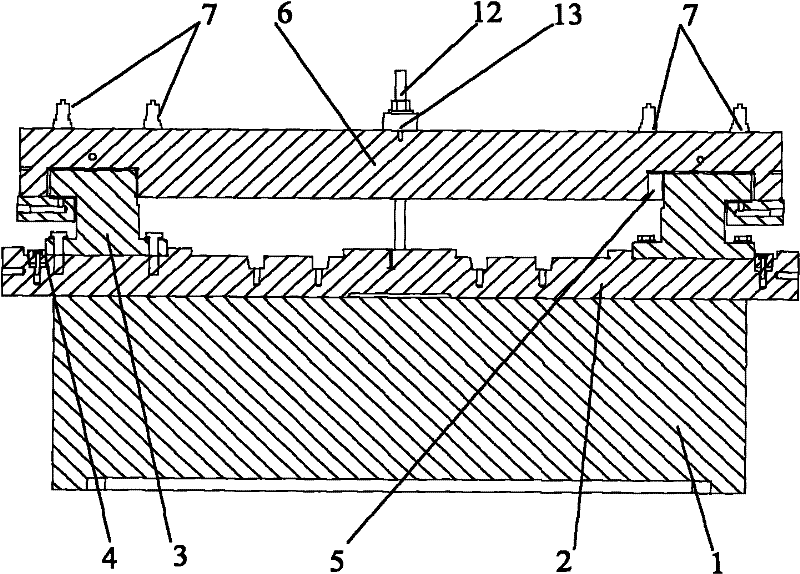

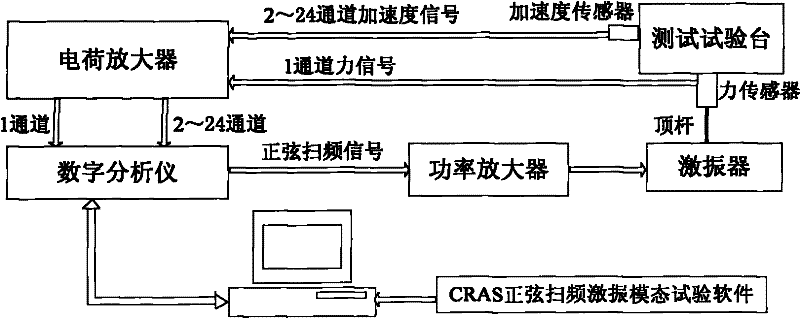

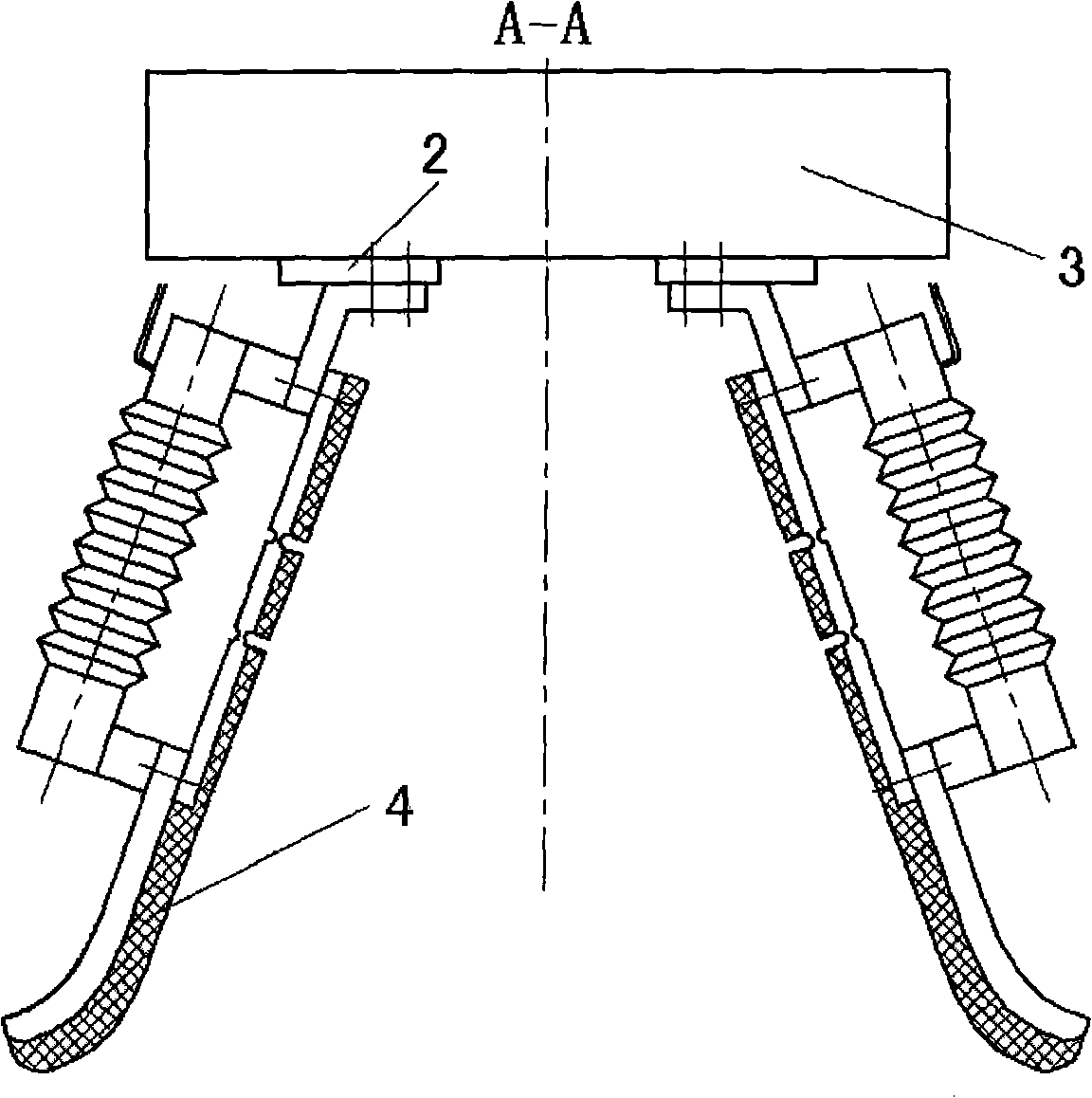

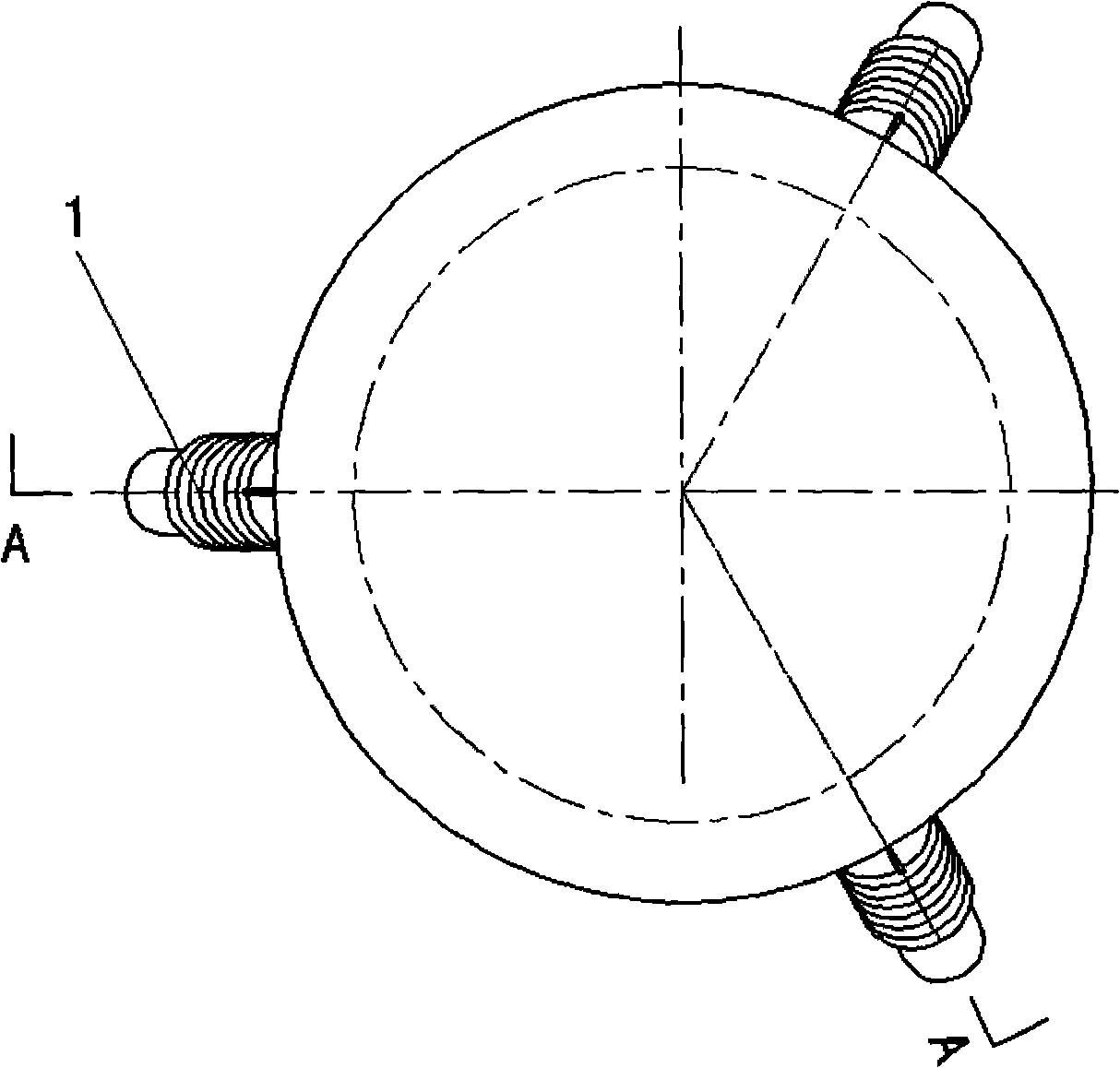

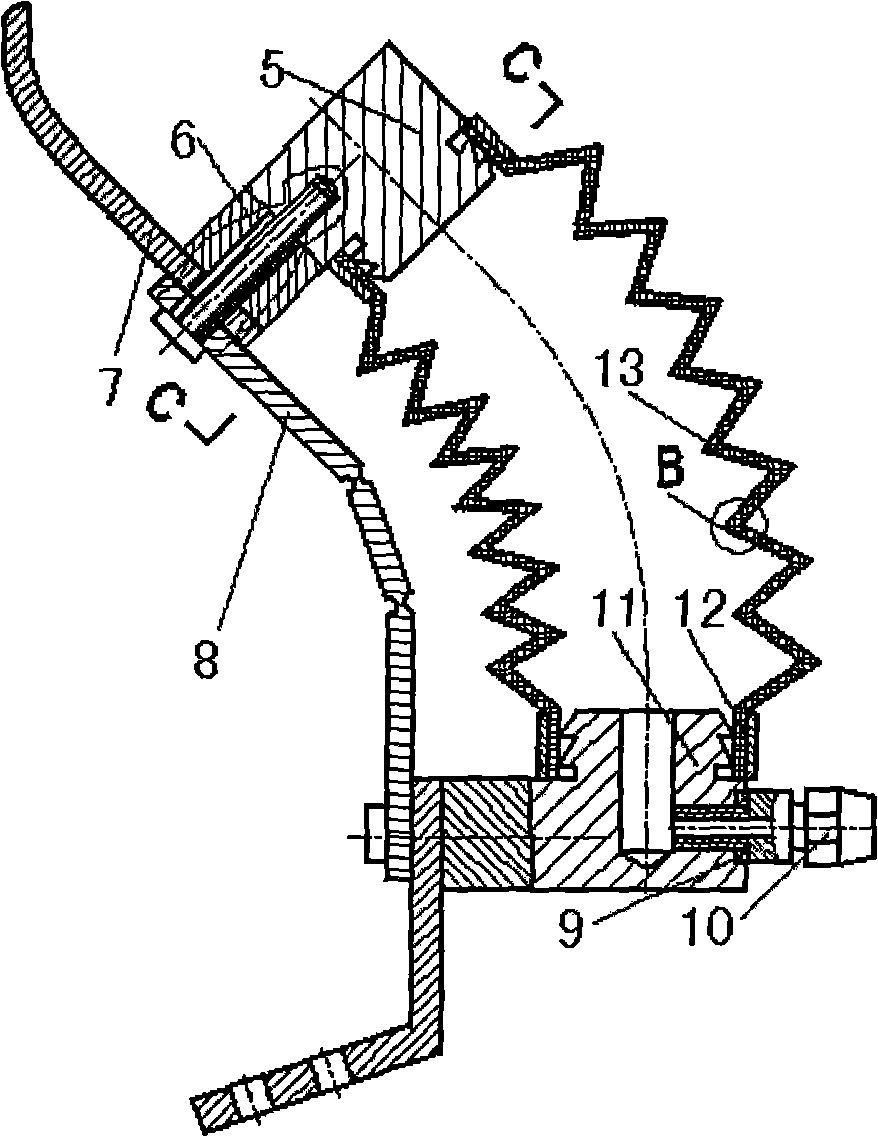

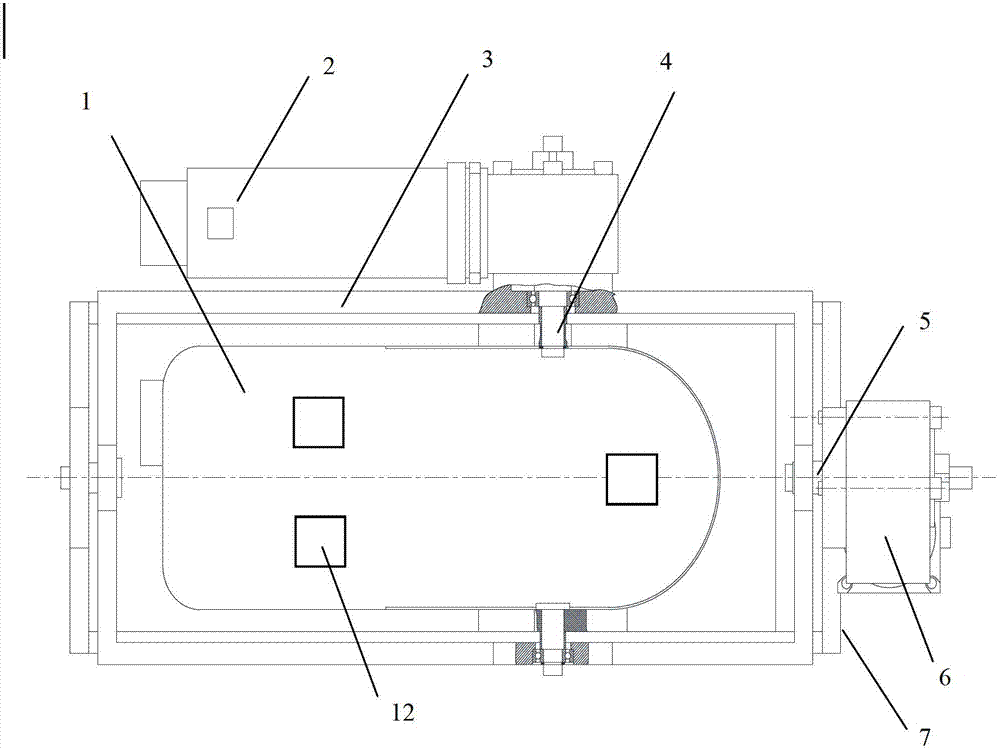

Dynamic characteristic parameter test device and method of sliding guide rail junction surface

InactiveCN102183363AAccurate acquisitionImprove accuracyMachine part testingVibration testingData acquisitionEngineering

The invention relates to a dynamic characteristic parameter test device of a sliding guide rail junction surface, which can be simplified into a single degree of freedom system. The device comprises a base, an installation platform, a fixed guide rail, a wedge-shaped block, an inlaid strip, a sliding block, a plurality of piezoelectric type acceleration sensors, a vibration exciter, an elastic rope, an impedance head, a stand, a normal force applying bolt, a rubber ring, a charge amplifier, a data acquisition unit, a power amplifier and an electronic computer. Compared with the prior art, thedynamic characteristic parameter test device has the advantages that: the structure is compact, the test principle is distinct, dynamic characteristic parameters of the junction surface under different load states can be measured by adjusting the pretightening force of a normal force applying bolt, the vibration exciting force direction passes through the gravity of the sliding block during measurement so that vibration signals of the sliding block and the base can be measured simultaneously, the influence of the vibration signals of the base is eliminated when a frequency response function of a system is calculated, and the characteristics of high efficiency, high stability and high precision are achieved.

Owner:NANJING UNIV OF SCI & TECH

Articulated flexible manipulator

InactiveCN101554730AWith degrees of freedom and flexibilityBufferGripping headsPicking devicesSingle degree of freedomSize change

The invention relates to an articulated flexible manipulator which belongs to the technical field of the robots and the electromechanical integration. The manipulator is provided with three skillful fingers which are respectively arranged on three jaws of a three-jaw chuck, and the three skillful fingers produce chucking force by the function of fluid driving expansion muscle; each skillful fingeris provided with single artificial expansion muscle and a plurality of articulations with single degree of freedom, the artificial expansion muscle is flexible, axially-expandable, each smart fingeris assembled with a hinge framework or flexible hinge framework through the expansion muscle, the smart finger comprising a plurality of articulations with single degree of freedom is designed; the flexibility of the single expansion muscle and the structure of the articulations can realize the flexibility of the degree of freedom and the buffer of the chucking force, the skillful fingers have thecharacteristics of degree flexibility of freedom and chucking force buffer; and the manipulator is applied to chuck breakable brittle bodies and special bodies with shape and size change.

Owner:无锡锦臻自动化技术有限公司

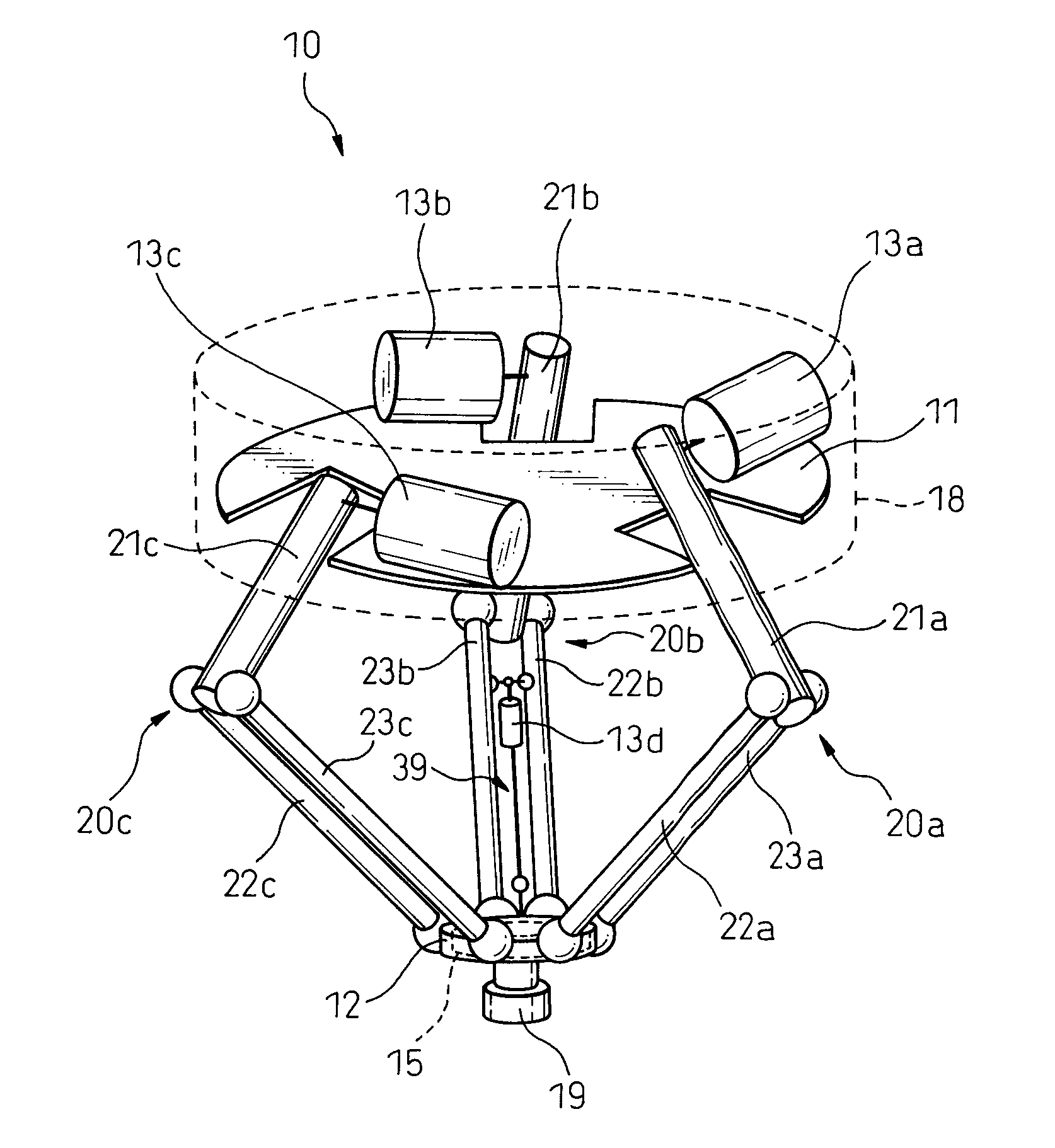

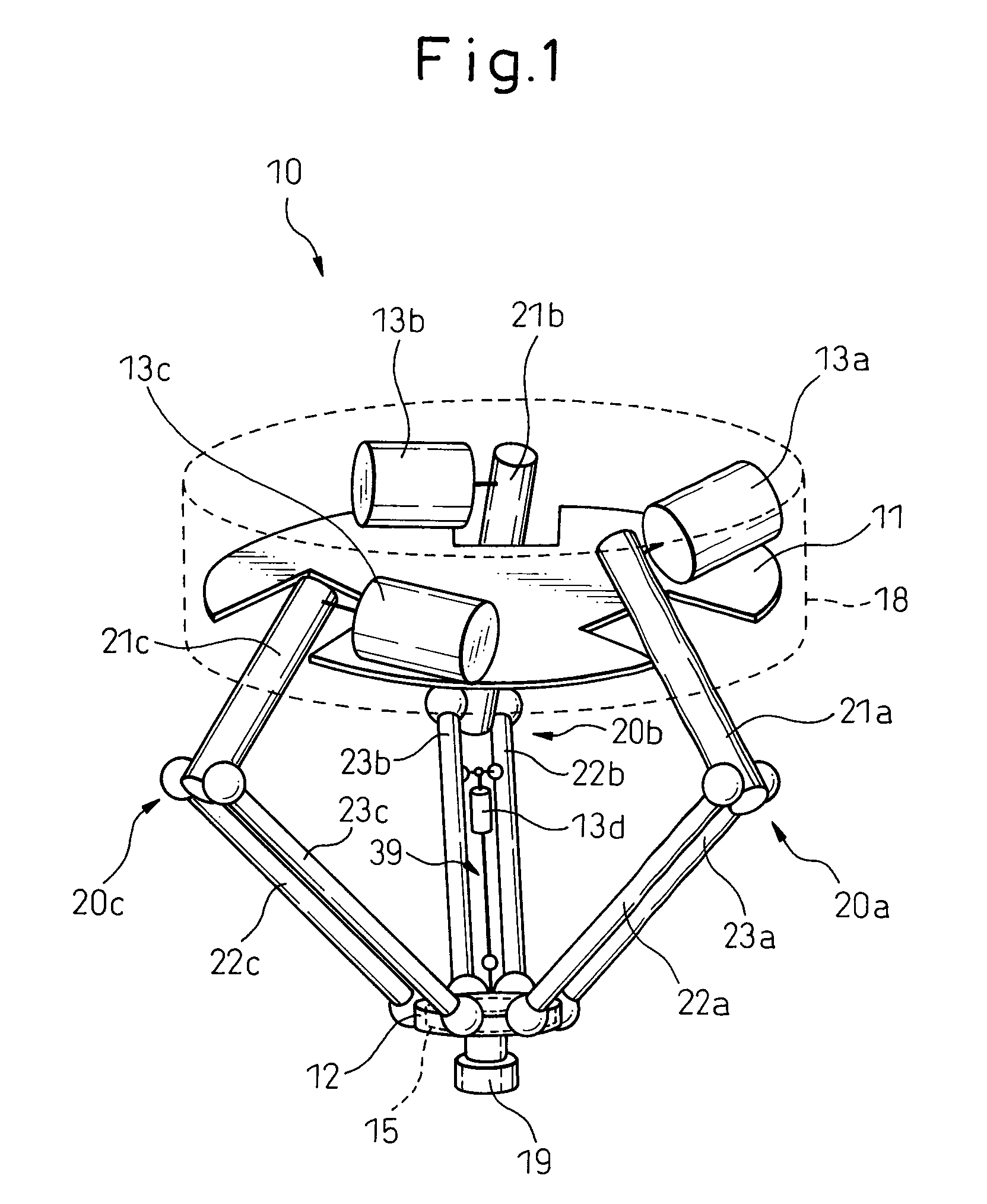

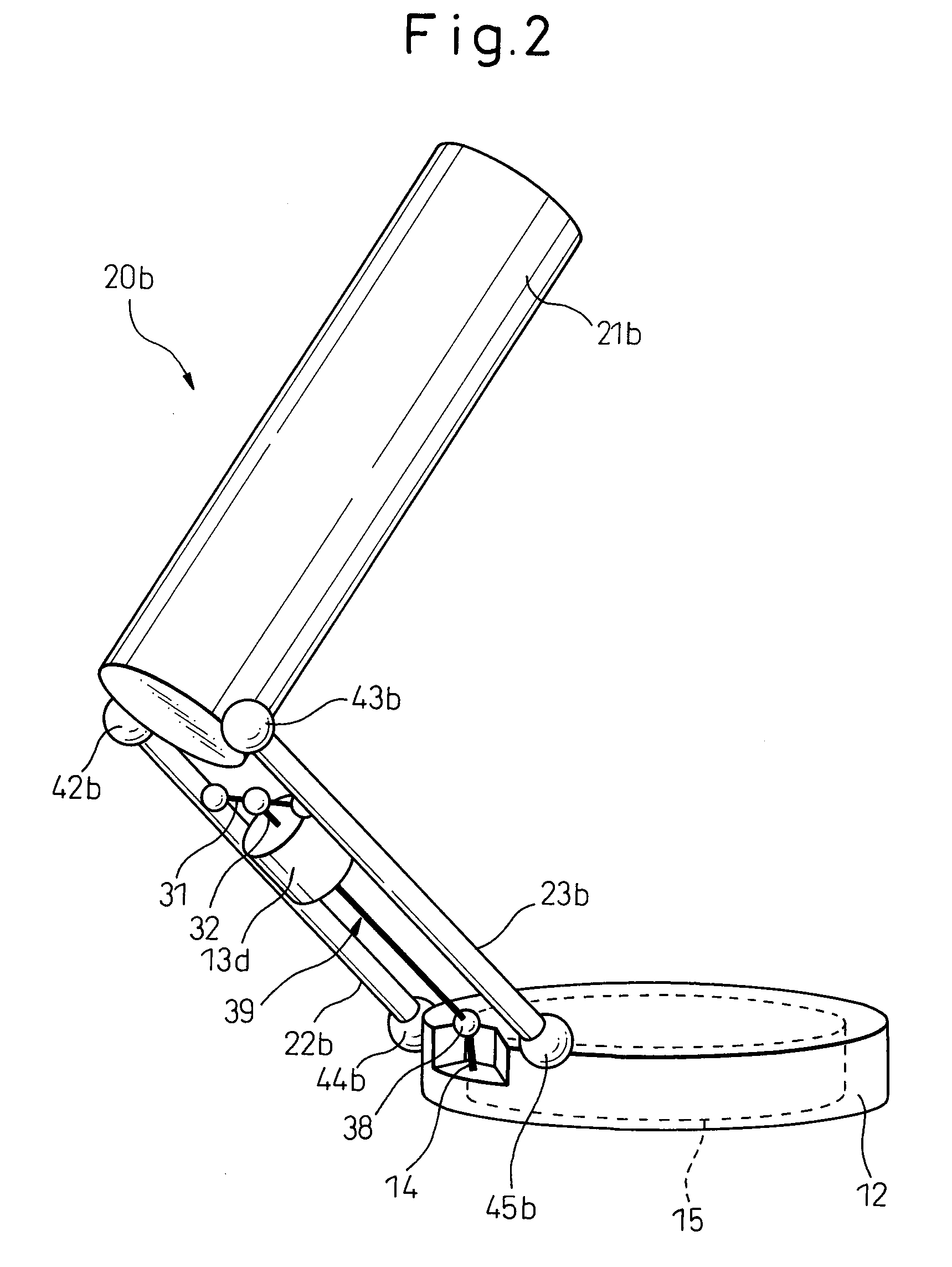

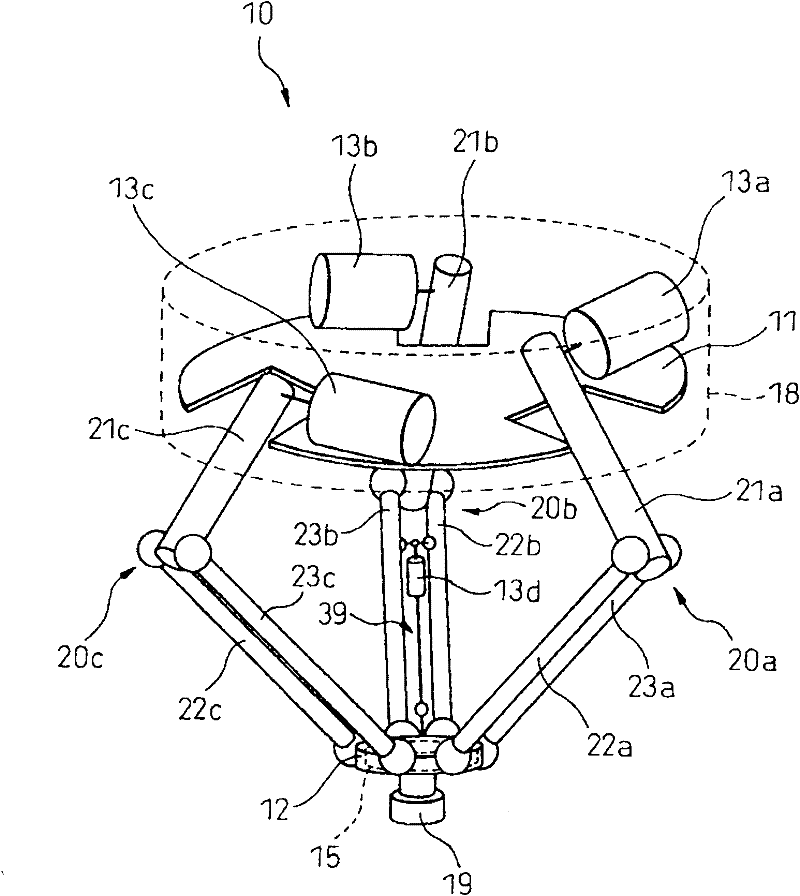

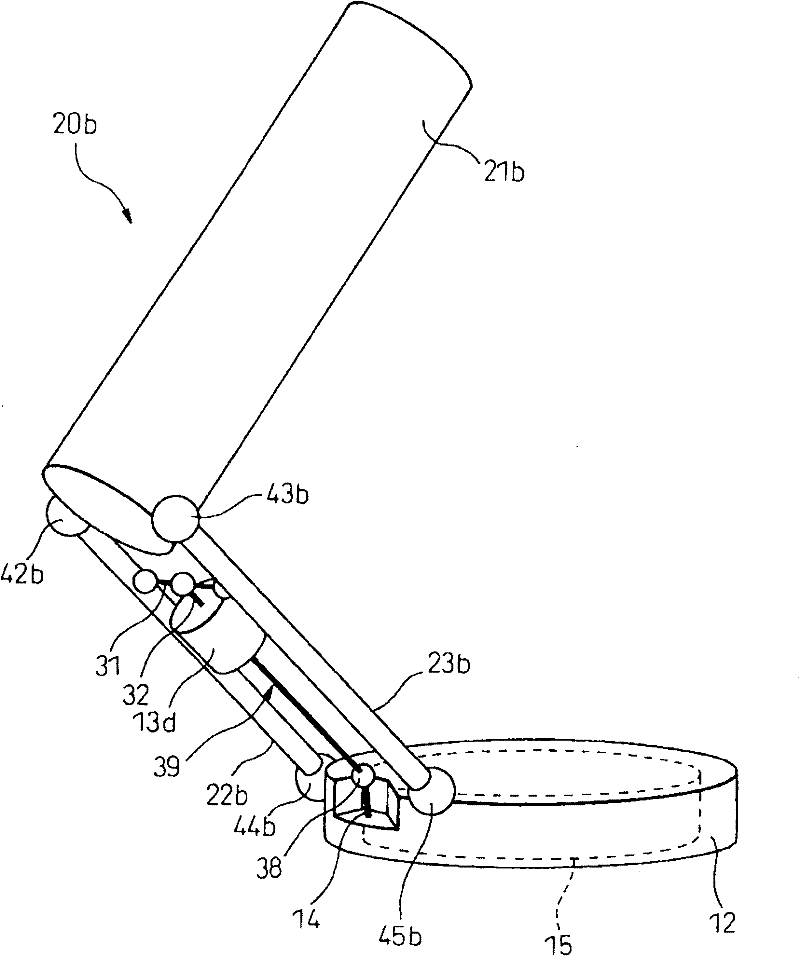

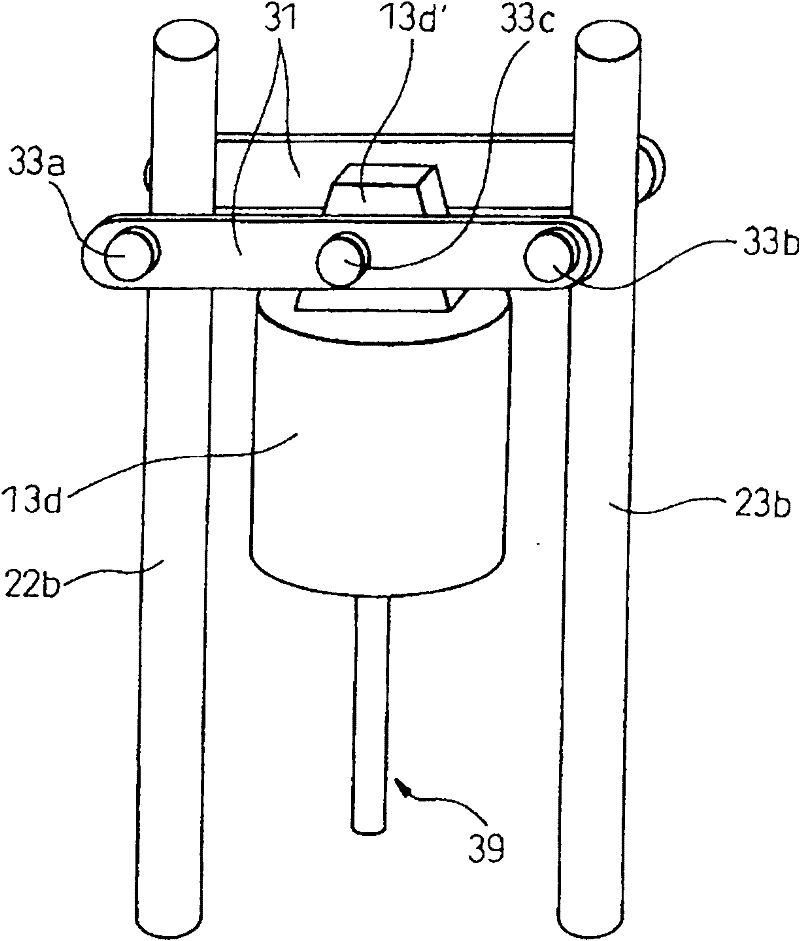

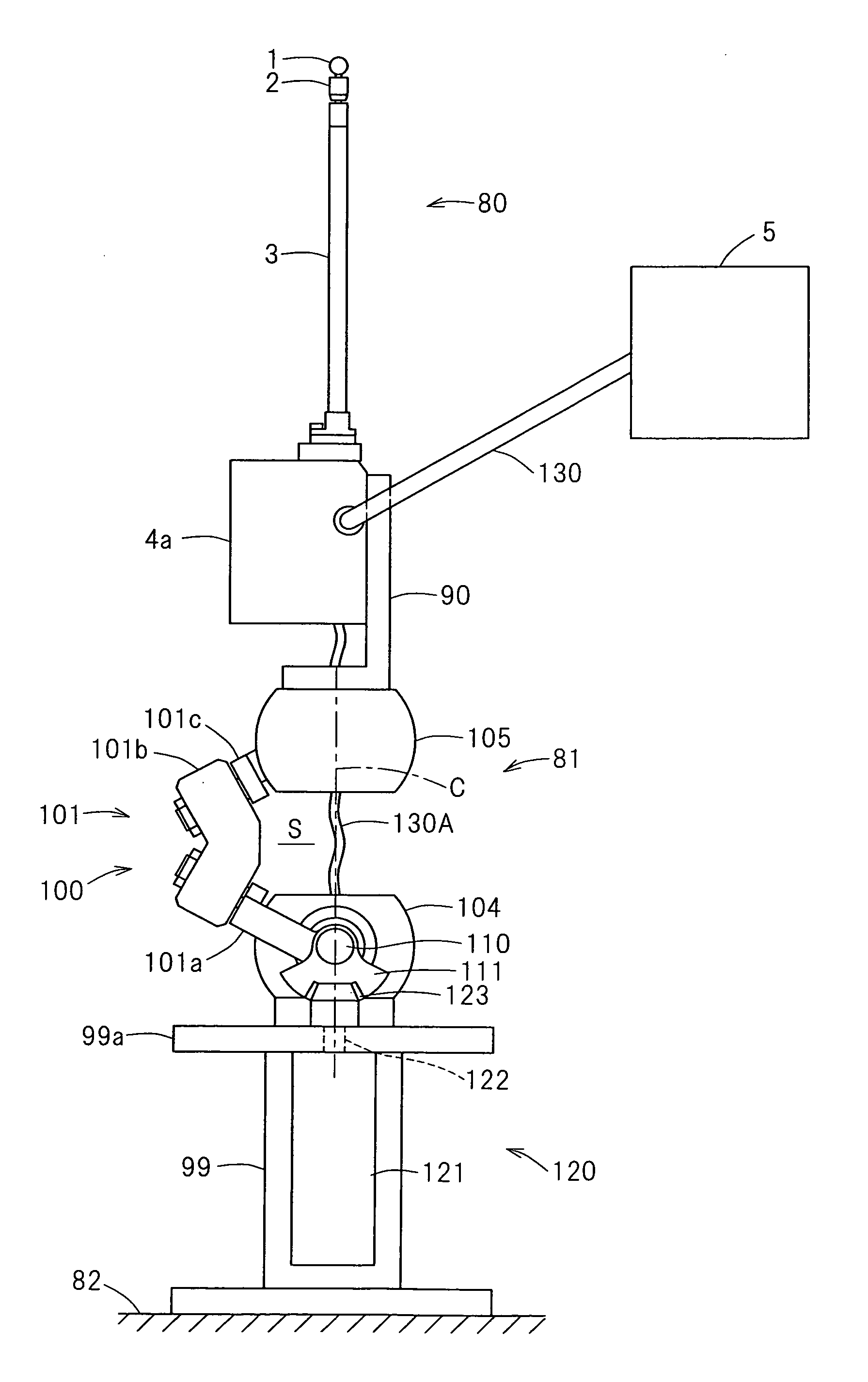

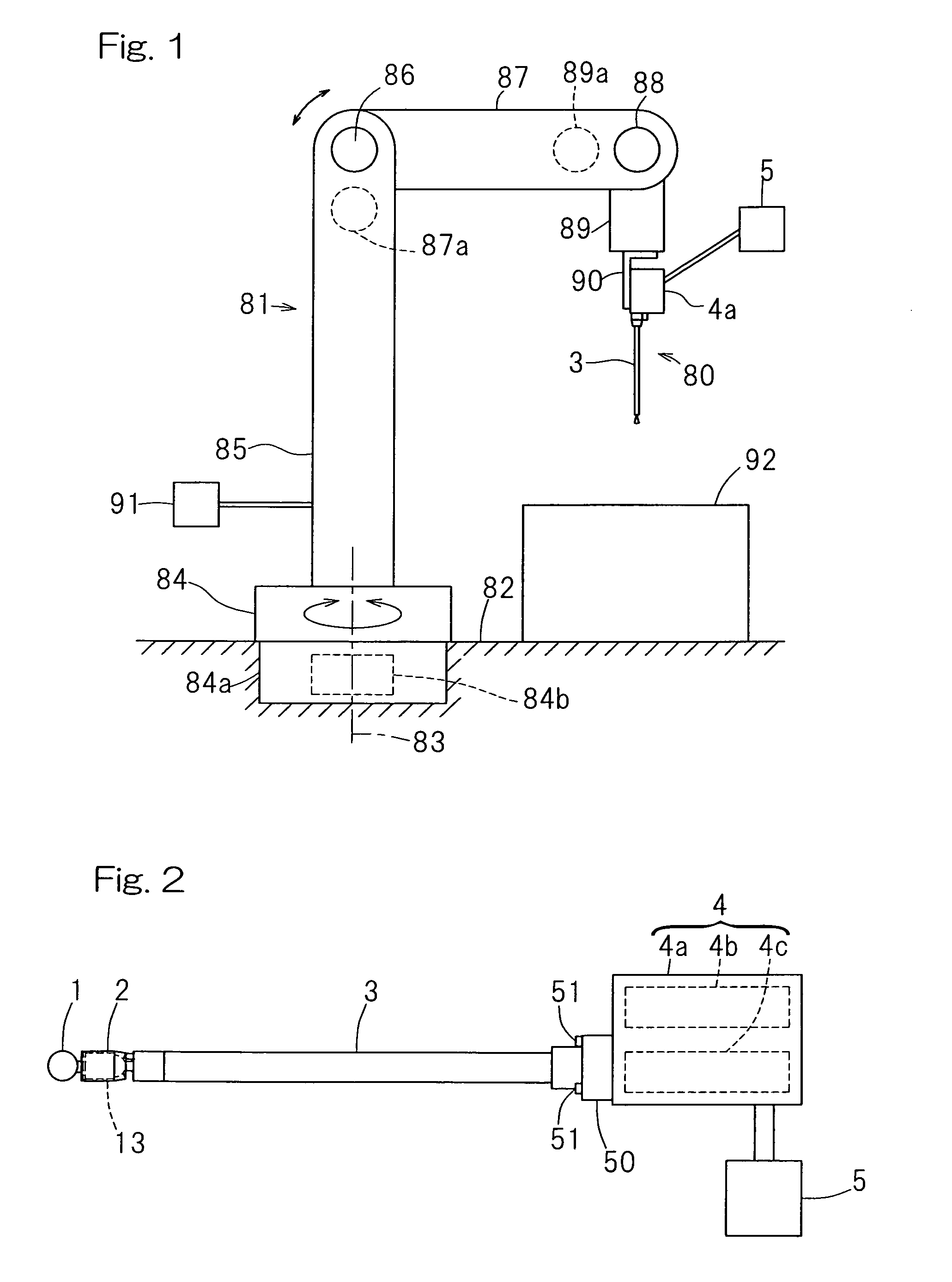

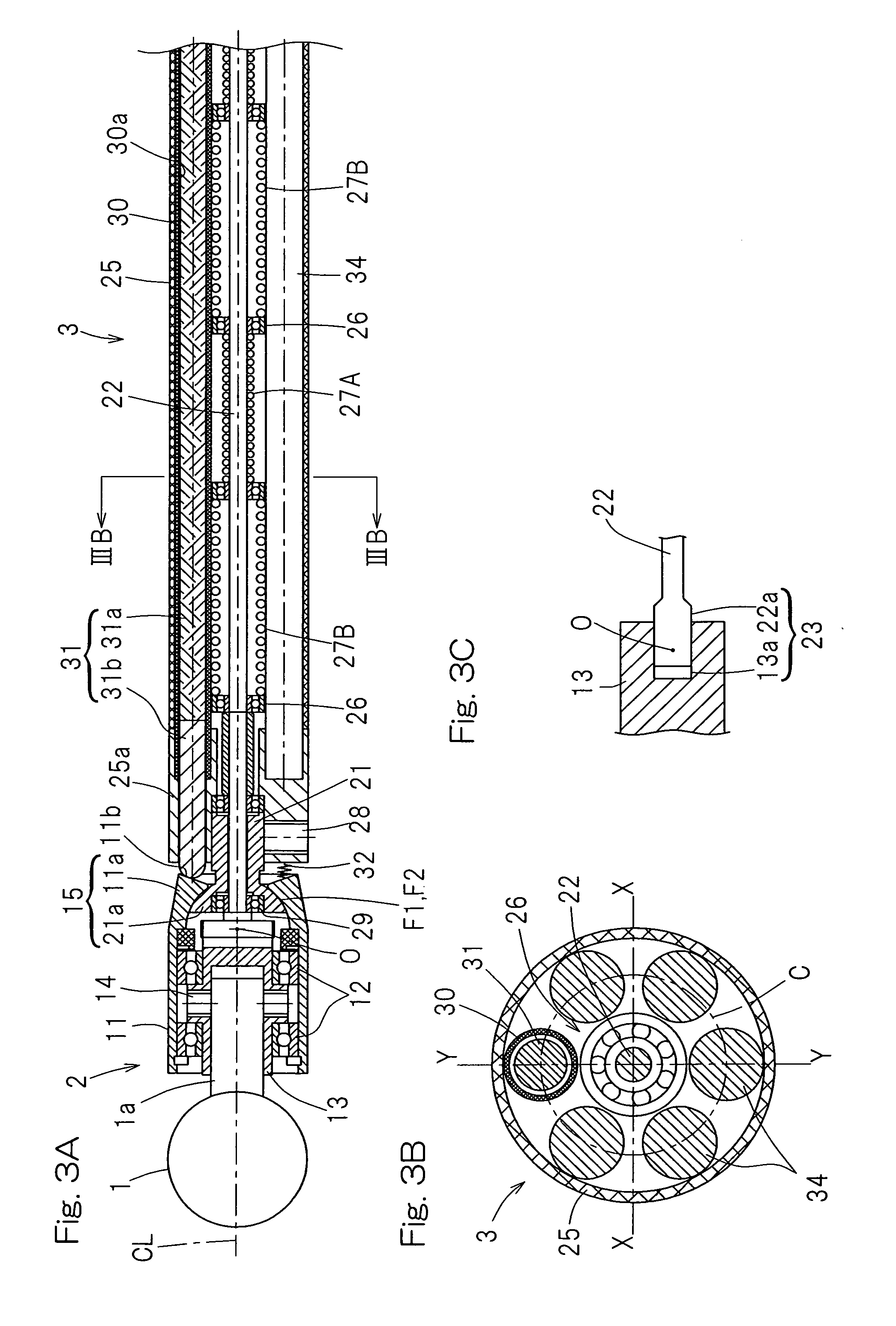

Parallel link robot

ActiveUS20110097184A1Increase the degrees of freedom without narrowing the possible region of operationWithout lowering acceleration/deceleration performanceProgramme-controlled manipulatorMechanical apparatusSingle degree of freedomDegrees of freedom

A parallel link robot (10) provided with a base (11), a moving part (12), three links (20a to 20c) coupling the base and the moving part and having respectively single degrees of freedom with respect to the base, and three actuators (13a to 13c) respectively driving the links, each of the links comprised of a drive link (21a to 21c) coupled with the base and two driven links (22a to 22c, 23a to 23c) coupling the drive link and the moving part and parallel to each other, and further provided with a posture changing mechanism (15) which changes a posture of an element (19) attached to the moving part, an additional actuator (13d to 13f) arranged between the two driven links of at least one link in parallel to these driven links, and a power transmission shaft (39) which extends coaxially from the additional actuator and transmits rotational drive force to the posture changing mechanism. Due to this, it is possible to increase the degrees of freedom without reducing the possible region of operation and the acceleration / deceleration performance.

Owner:FANUC LTD

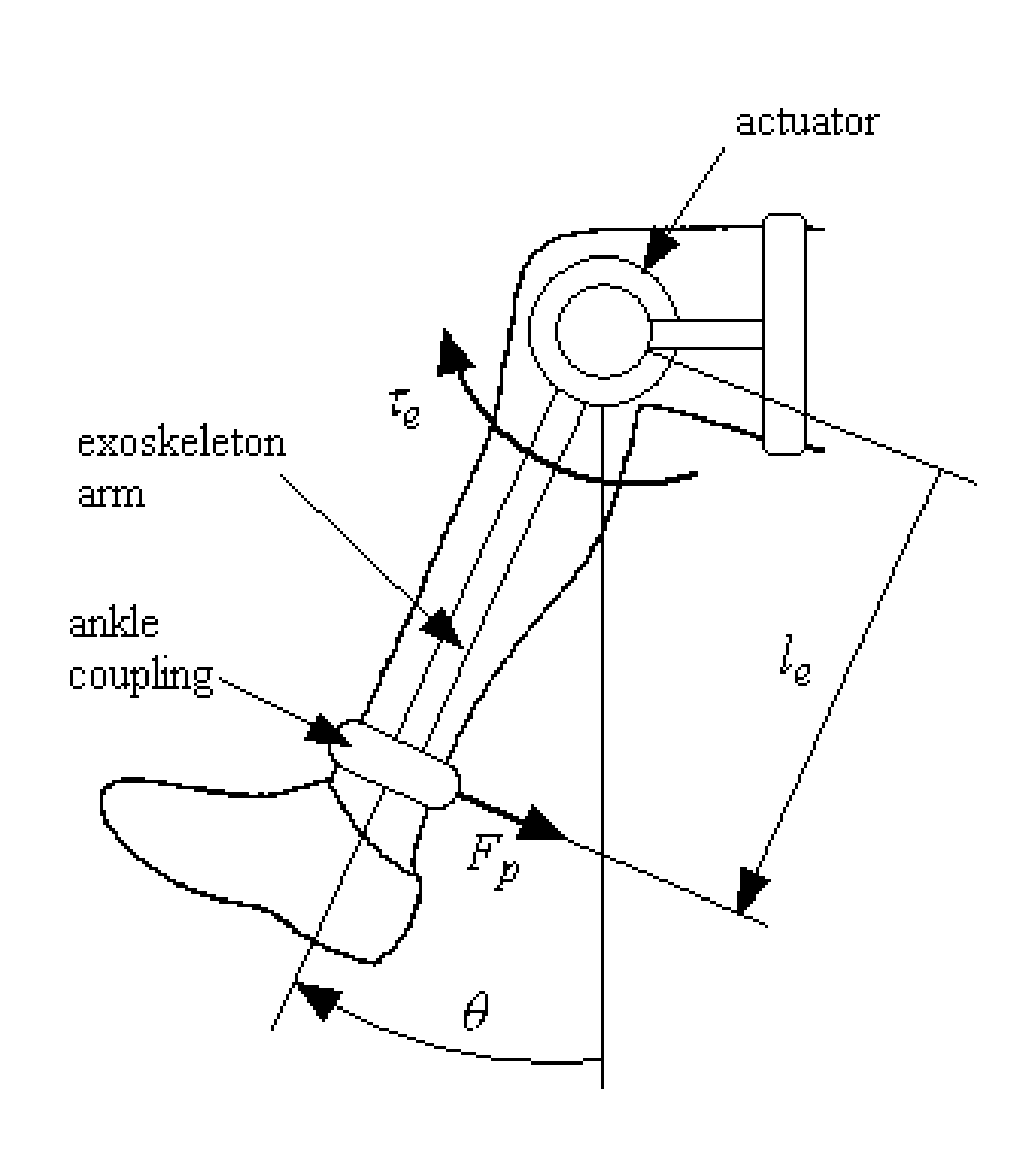

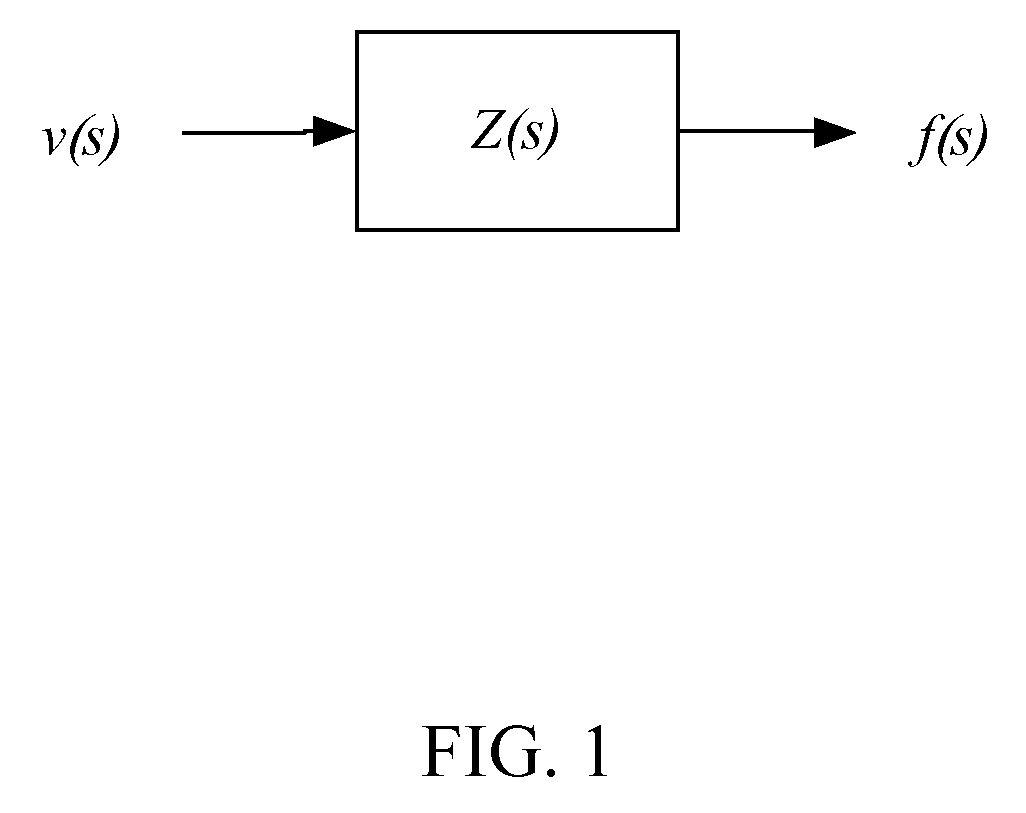

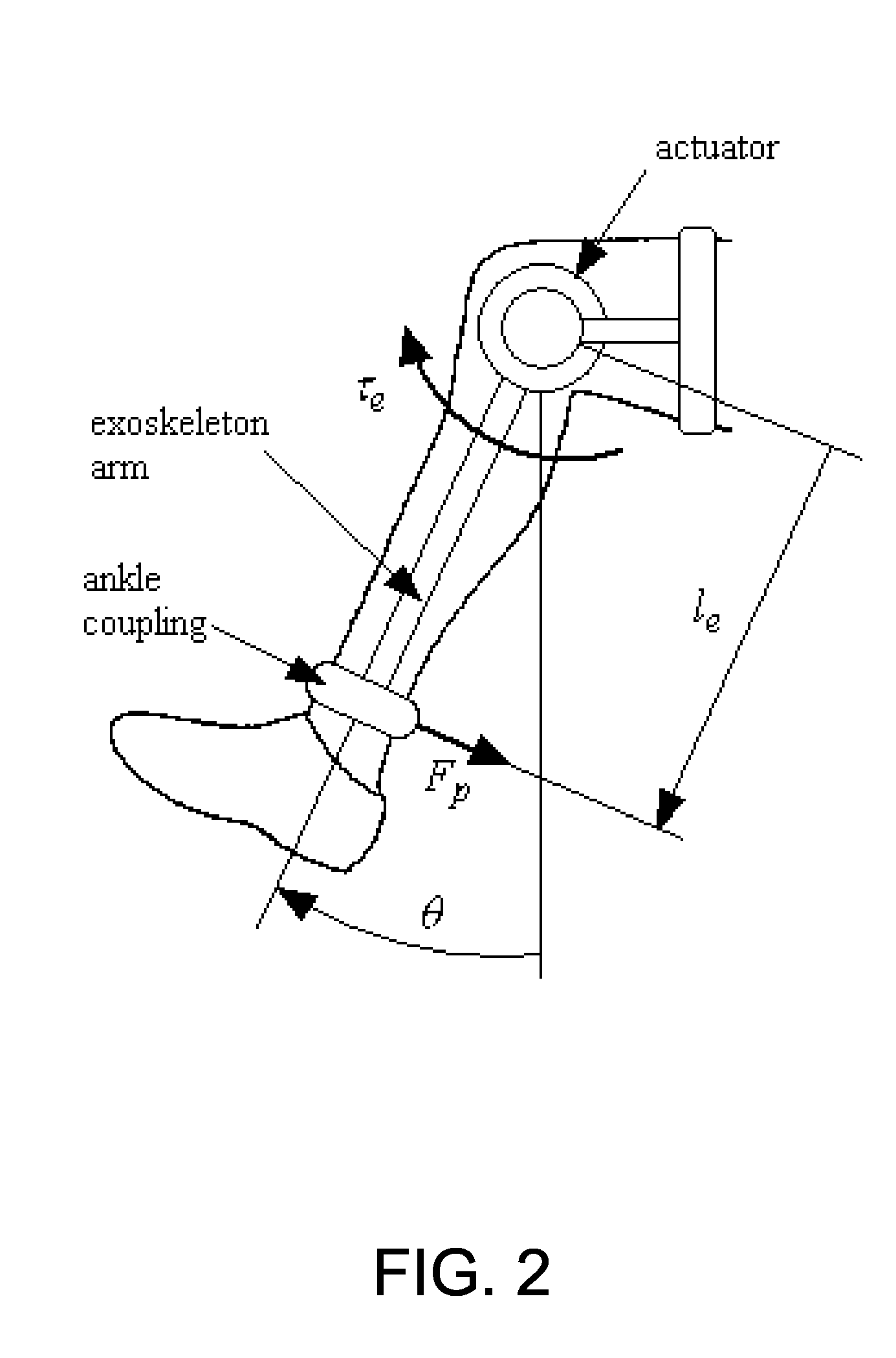

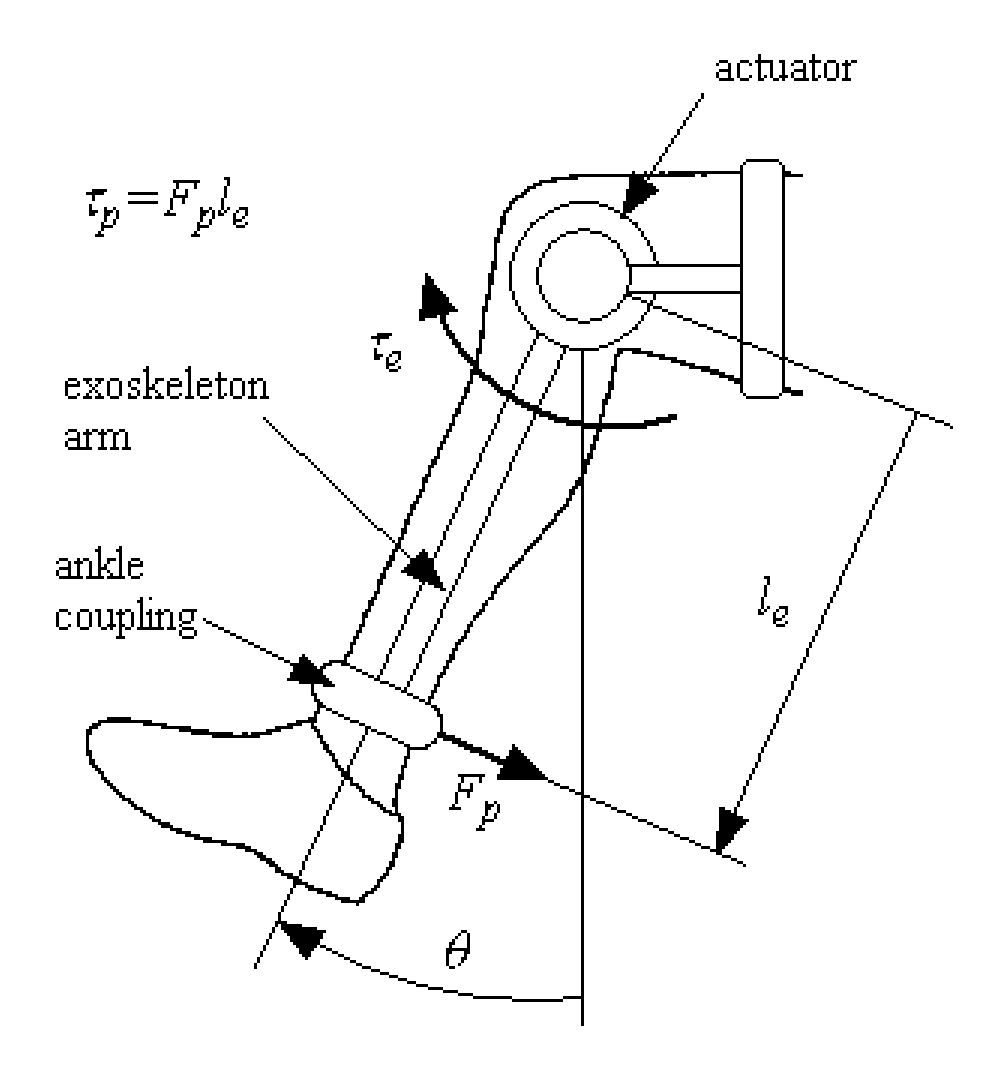

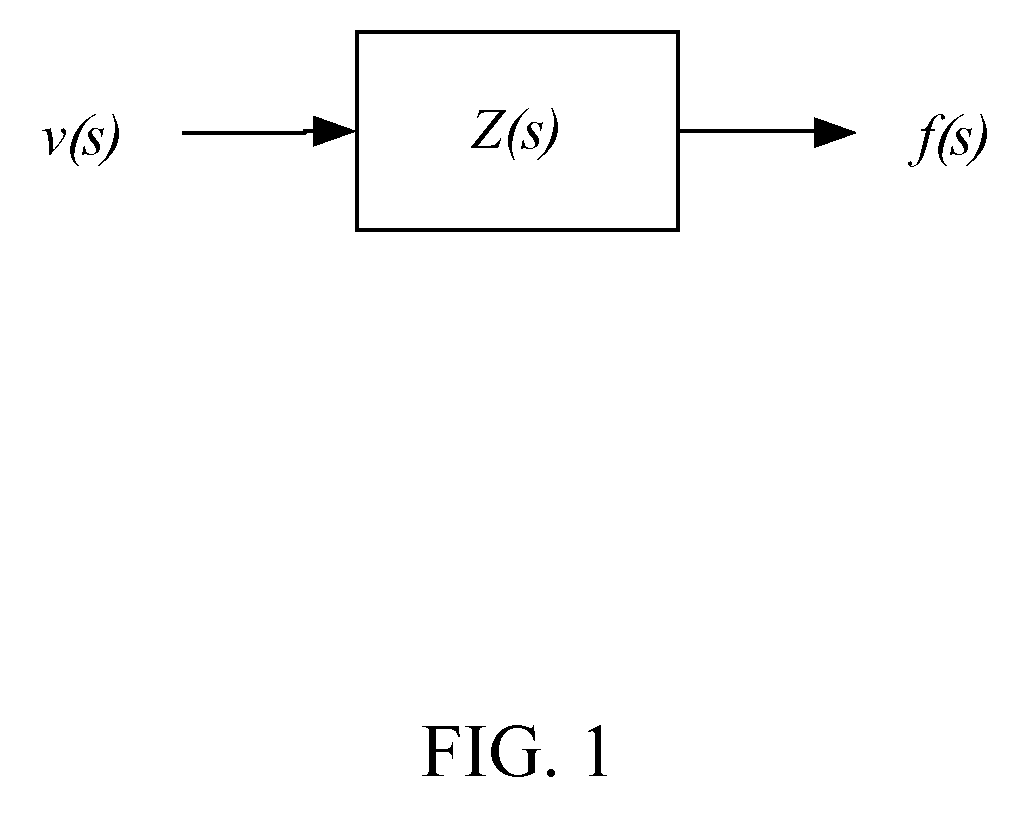

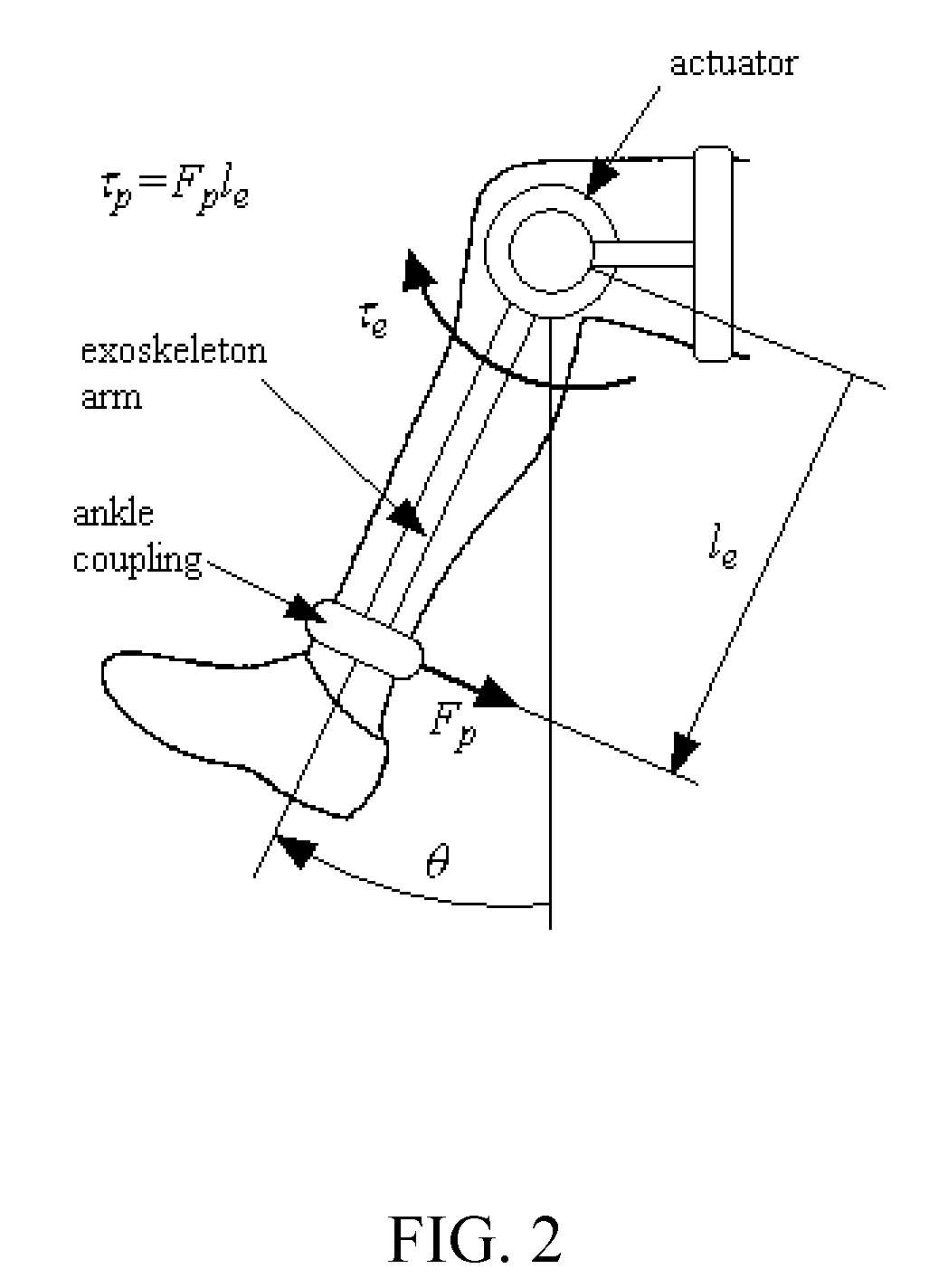

Controller for an assistive exoskeleton based on active impedance

ActiveUS7731670B2Reduce effortElectrotherapyChiropractic devicesMuscle strengthSingle degree of freedom

A system and method are presented to provide assist to a user by means of an exoskeleton with a controller capable of making the exoskeleton display active impedance. The exoskeleton assists the user by reducing the muscle effort required by the user to move his or her extremities. In one embodiment, a single-degree-of-freedom (1-DOF) exoskeleton assists a user with single-joint movement using an active impedance controller. In another embodiment, a multiple-degree-of-freedom (multi-DOF) exoskeleton assists a user with multiple-joint movement using an active impedance controller.

Owner:NORTHWESTERN UNIV +1

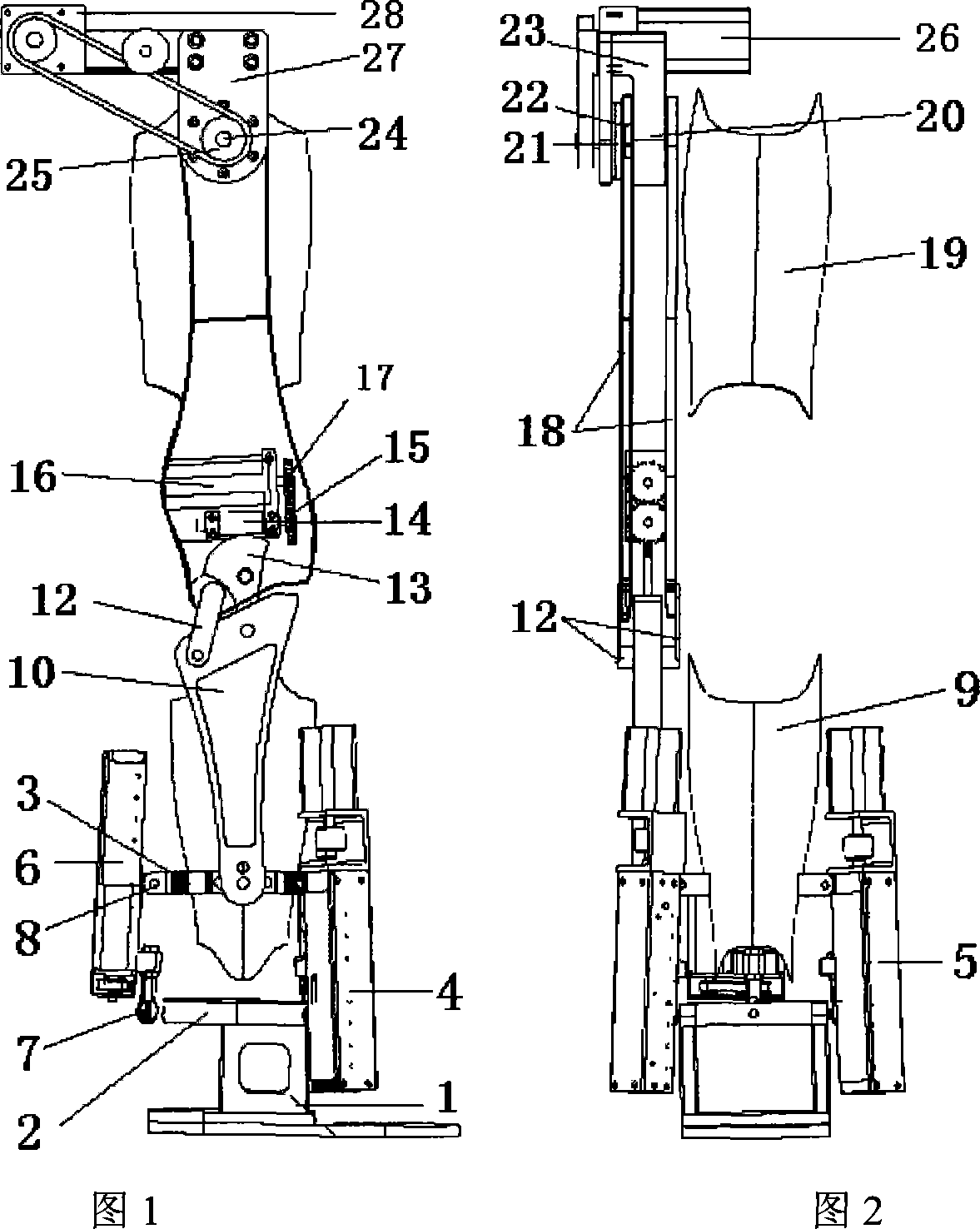

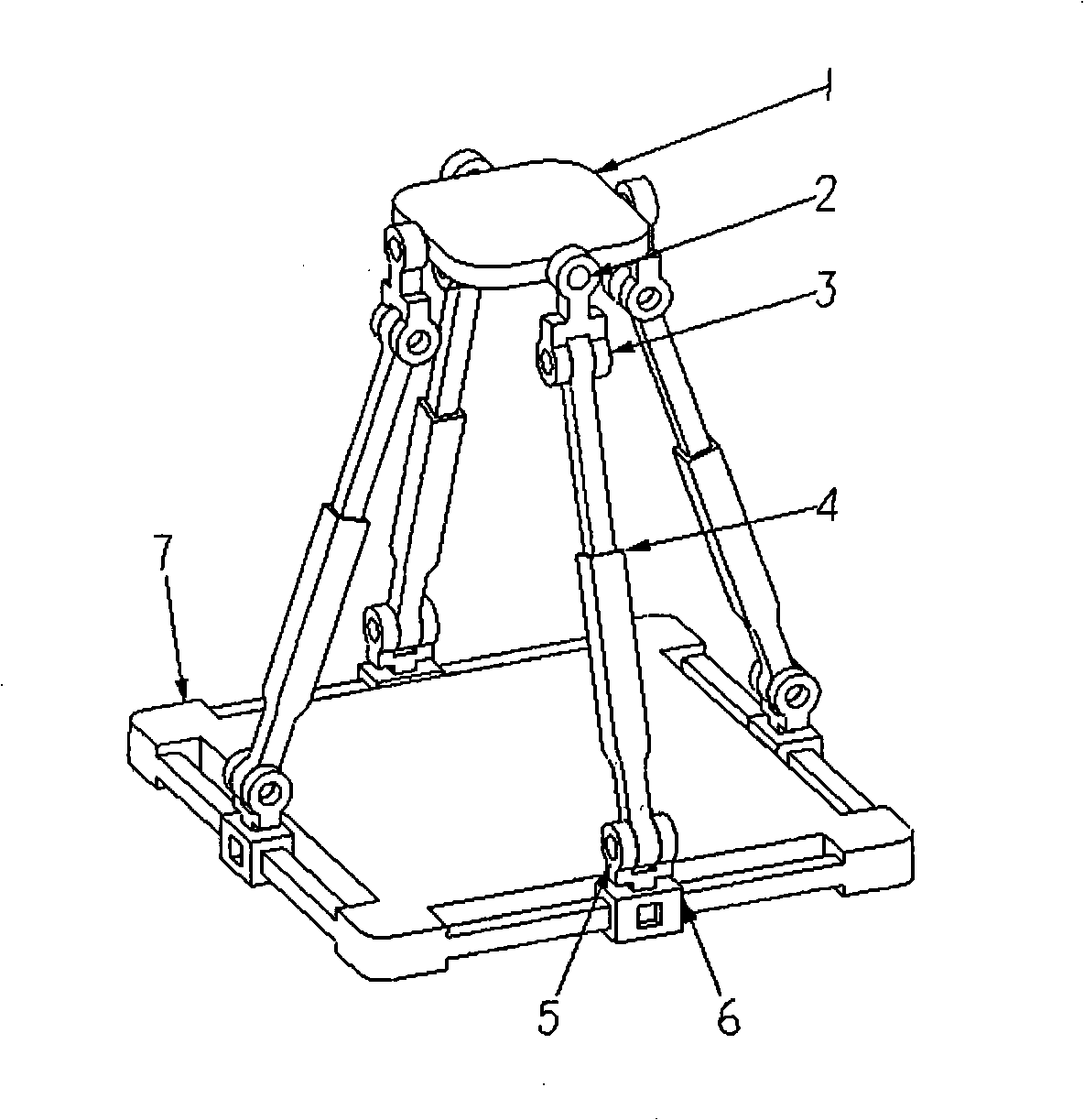

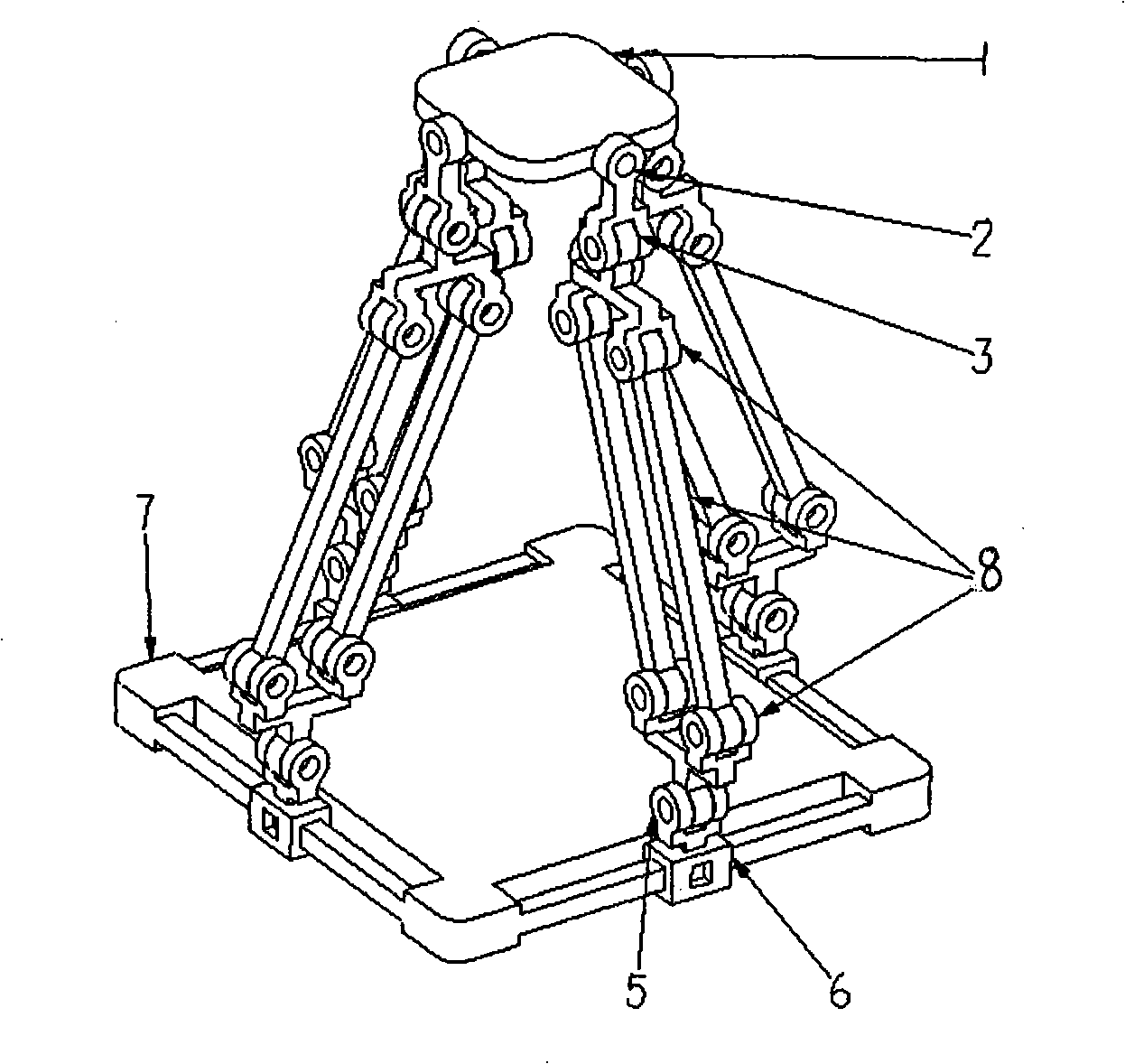

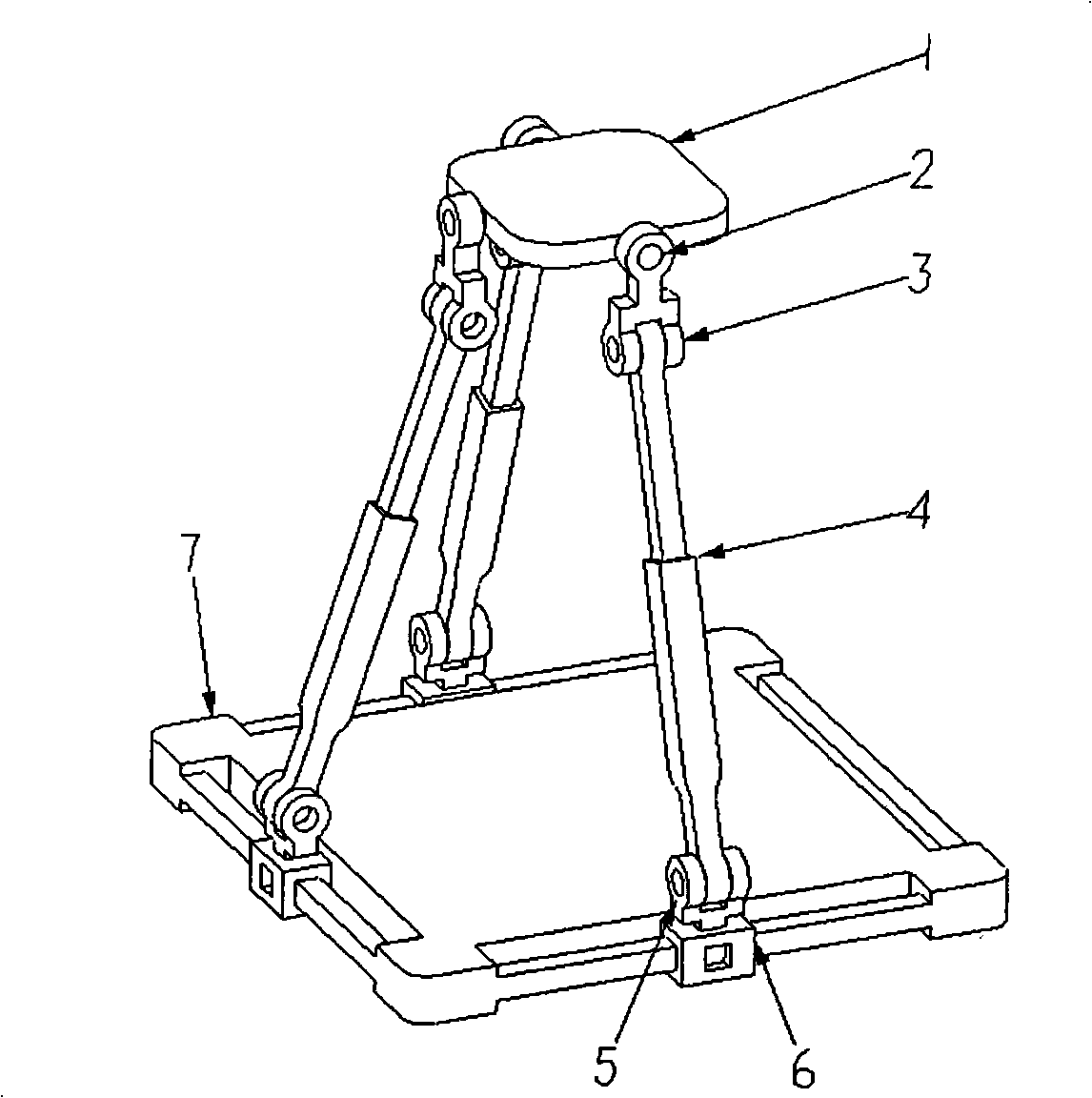

Parallel joint walking-aid exoskeleton artificial limb suitable for paralytic patient

InactiveCN101234043ACompact designLarge range of joint rotationChiropractic devicesWalking aidsHuman bodyKnee Joint

The invention relates to a parallel, joint-type and walk-help ectoskeleton artificial limb applicable to paralytic, which pertains to a rehabilitation engineering technical field and comprises a hip joint, a knee joint and an ankle joint which are connected in sequence to form the ectoskeleton artificial limb structure of human crura. The hip joint comprises a single-degree-of-freedom drive mechanism and a harmonic reducer with a larger drive ratio which can output high torque; the knee joint adopts a four-bar mechanism, worm wheel, a worm and gear mechanism to realize transmission; flection of the ectoskeleton artificial limb is kept by taking advantage of the self-locking property of the worm wheel and worm and simultaneously, the worm wheel and worm can deliver larger torque; the ankle joint adopts a 3-RPS parallel mechanism with three degrees of freedom, which comprises an upper platform, three active branched guide rods, a lower platform and a thenar support part so as to realize dorsiflexion, plantar flexion, inversion and eversion. The artificial limb of the invention has compact structure, large slew range for every joint and can meet the requirements of actual movements of human body.

Owner:JIANGSU MASLECH MEDICAL TECH

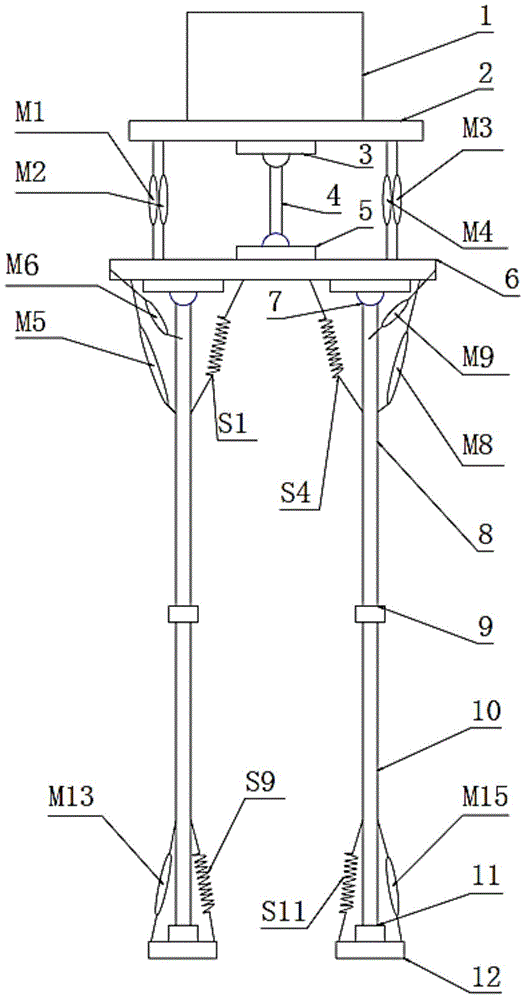

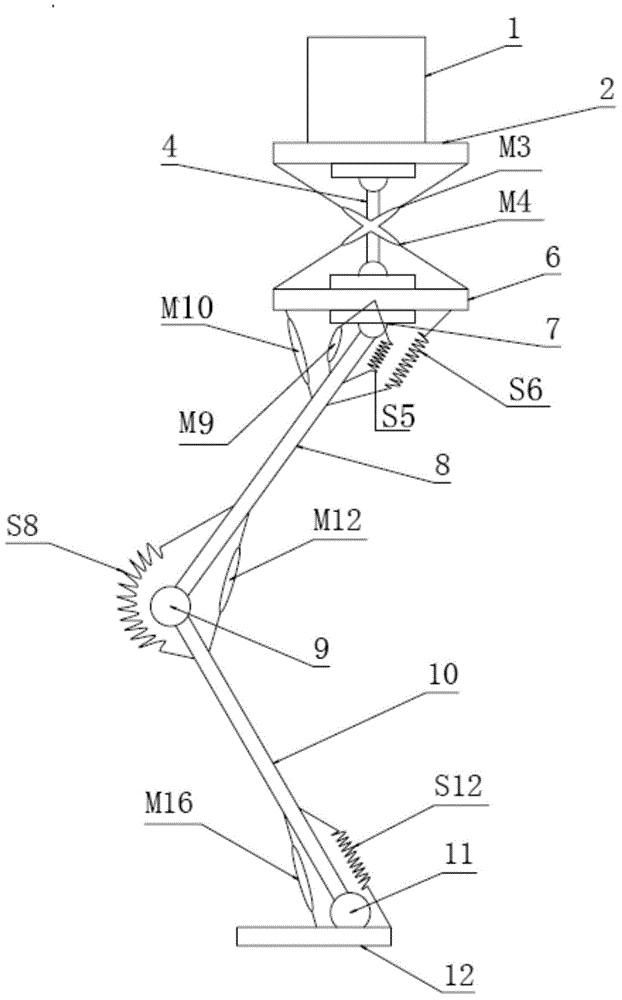

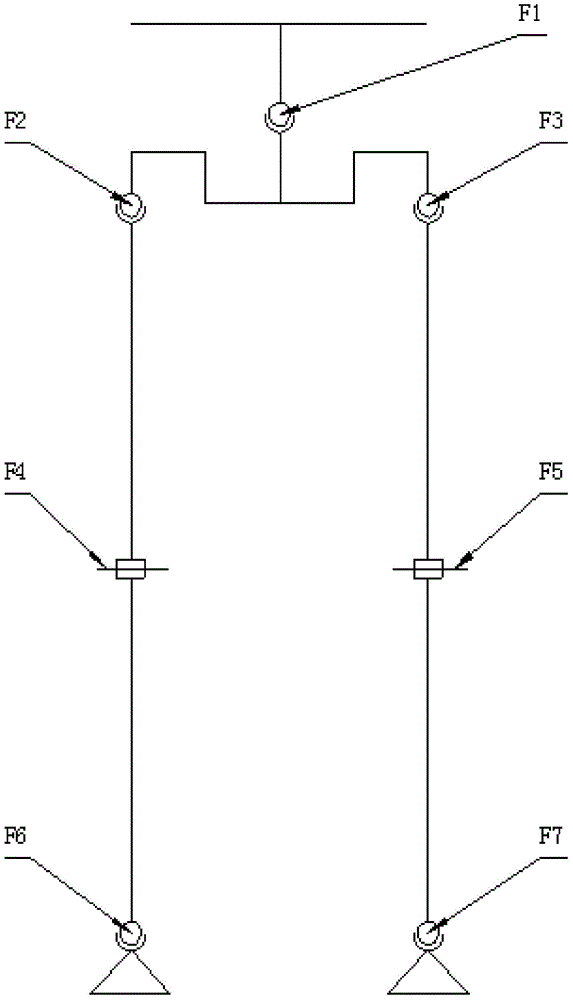

Novel biped humanoid robot system based on pneumatic artificial muscles

ActiveCN104401419AMeet the needs of multidisciplinary scientific research teachingUnique shapeVehiclesSystems designKnee Joint

The invention provides a novel biped humanoid robot system based on pneumatic artificial muscles, belongs to the technical field of robots, and in particular relates to a biped robot having powerful athletic ability and flexible humanoid characteristics. The biped humanoid robot system comprises a mechanical body and an electrical control system; the biped humanoid robot system is characterized in that the mechanical body is mainly composed of seven parts, namely a waist, a hip joint, thighs, knee joints, shanks, feet and the like, and has 13 degrees of freedom in total; in the 13 degrees of freedom, 3 degrees of freedom of the waist are realized by virtue of the cooperation of four pneumatic muscles and the waist spine, and the single degree of freedom of each of the hip joint, the knee joints and the ankle joints is realized by use of one pneumatic muscle and one spring which are pulled to each other to produce opposed rotating force. According to the design of the novel biped humanoid robot system, a control platform is provided; the system relates to the fields of control science and intelligent control in addition to robotics, and is capable of meeting the requirements of scientific research and teaching of a plurality of disciplines.

Owner:廊坊市奥联科技有限公司

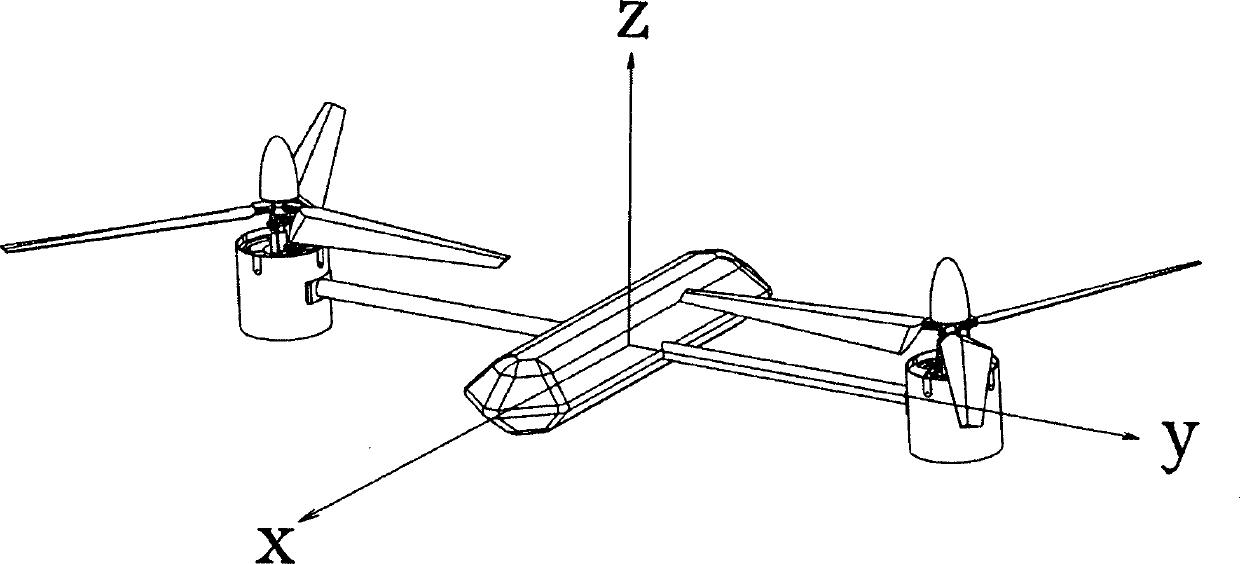

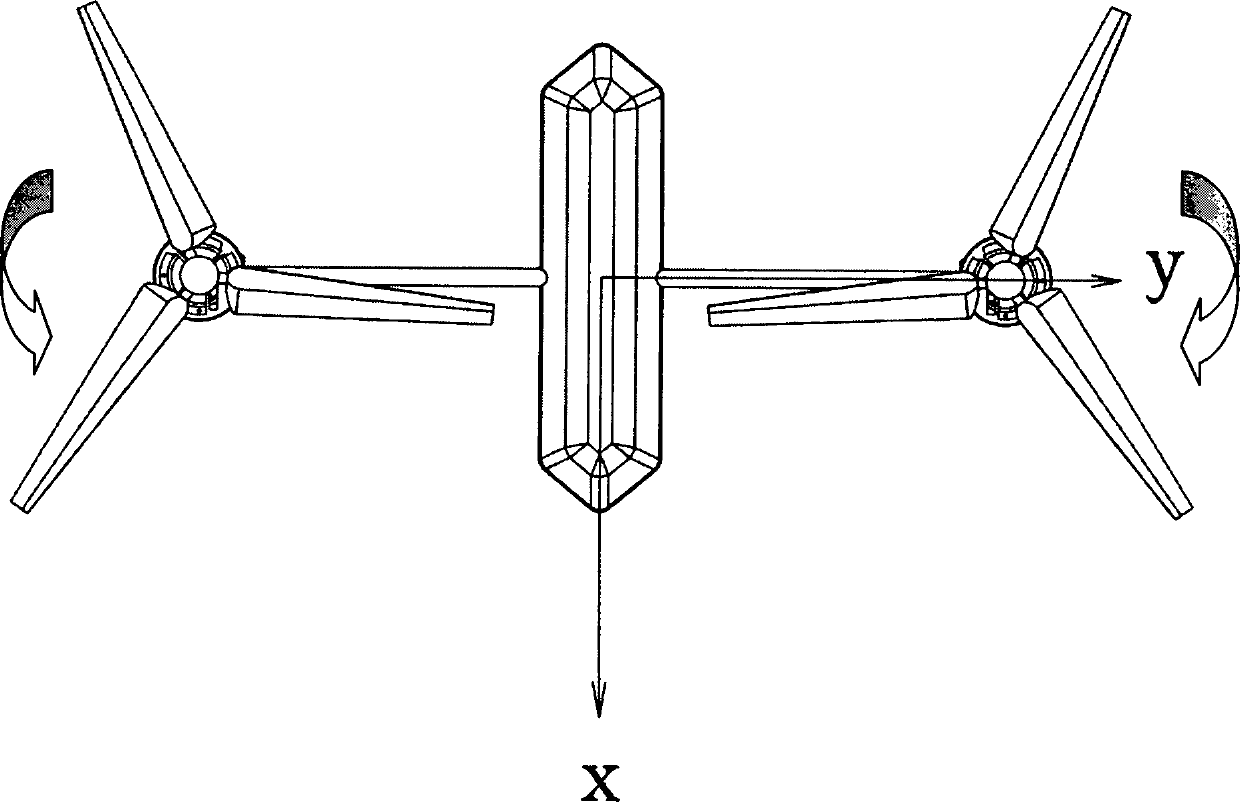

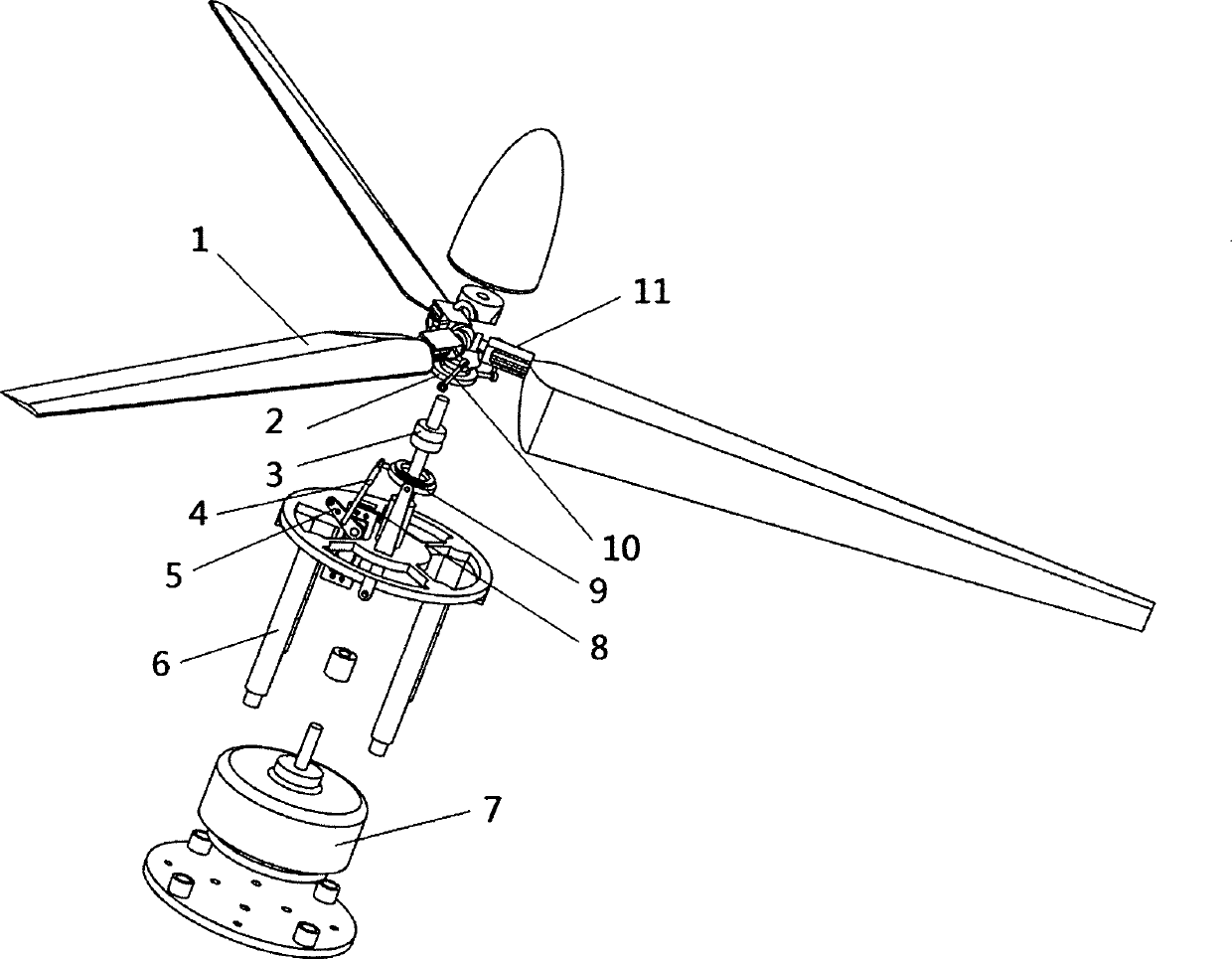

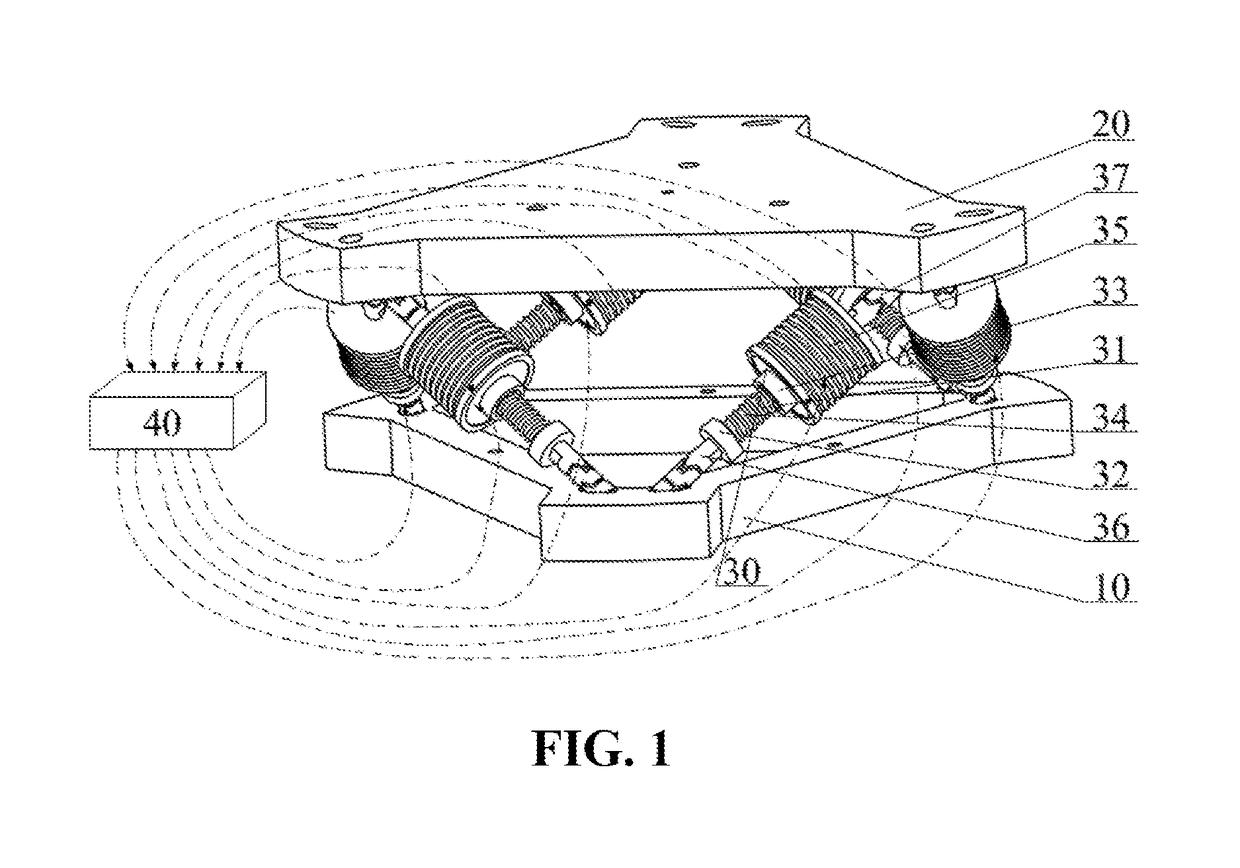

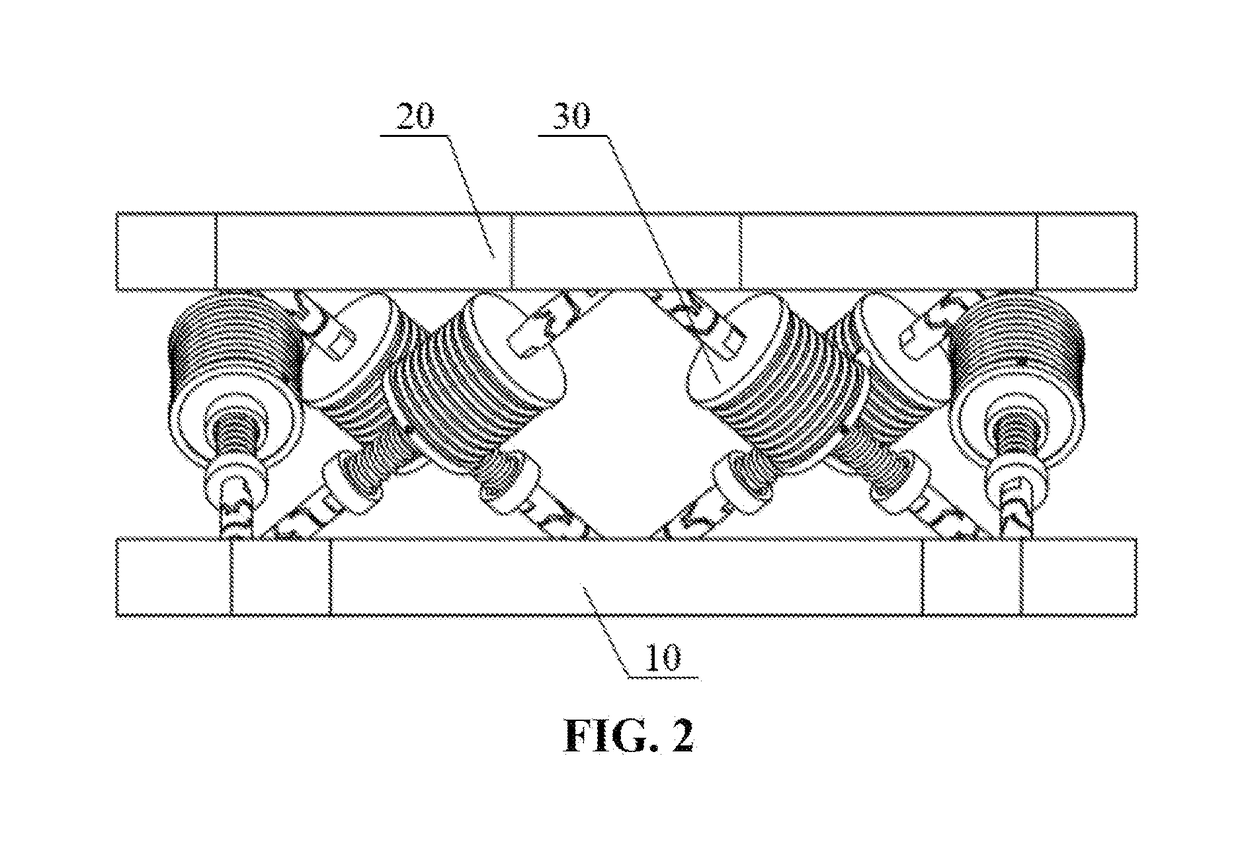

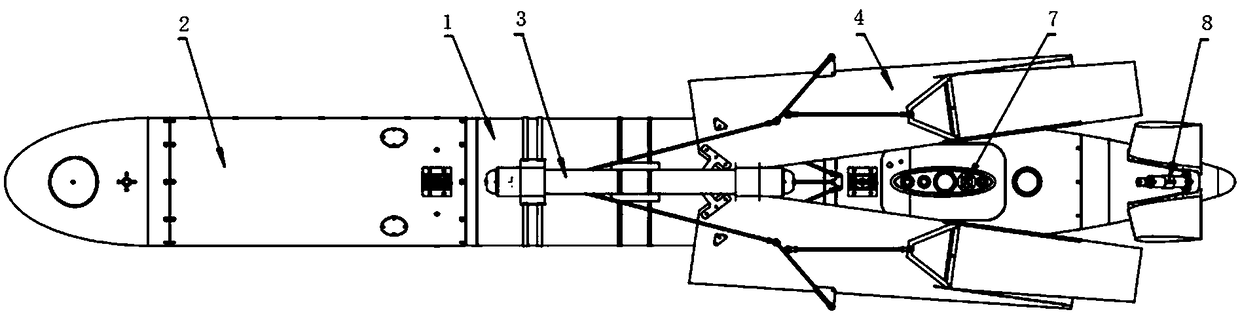

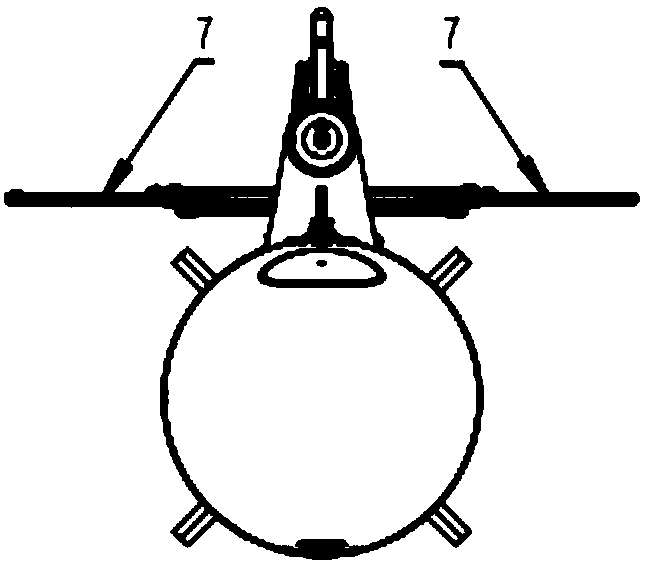

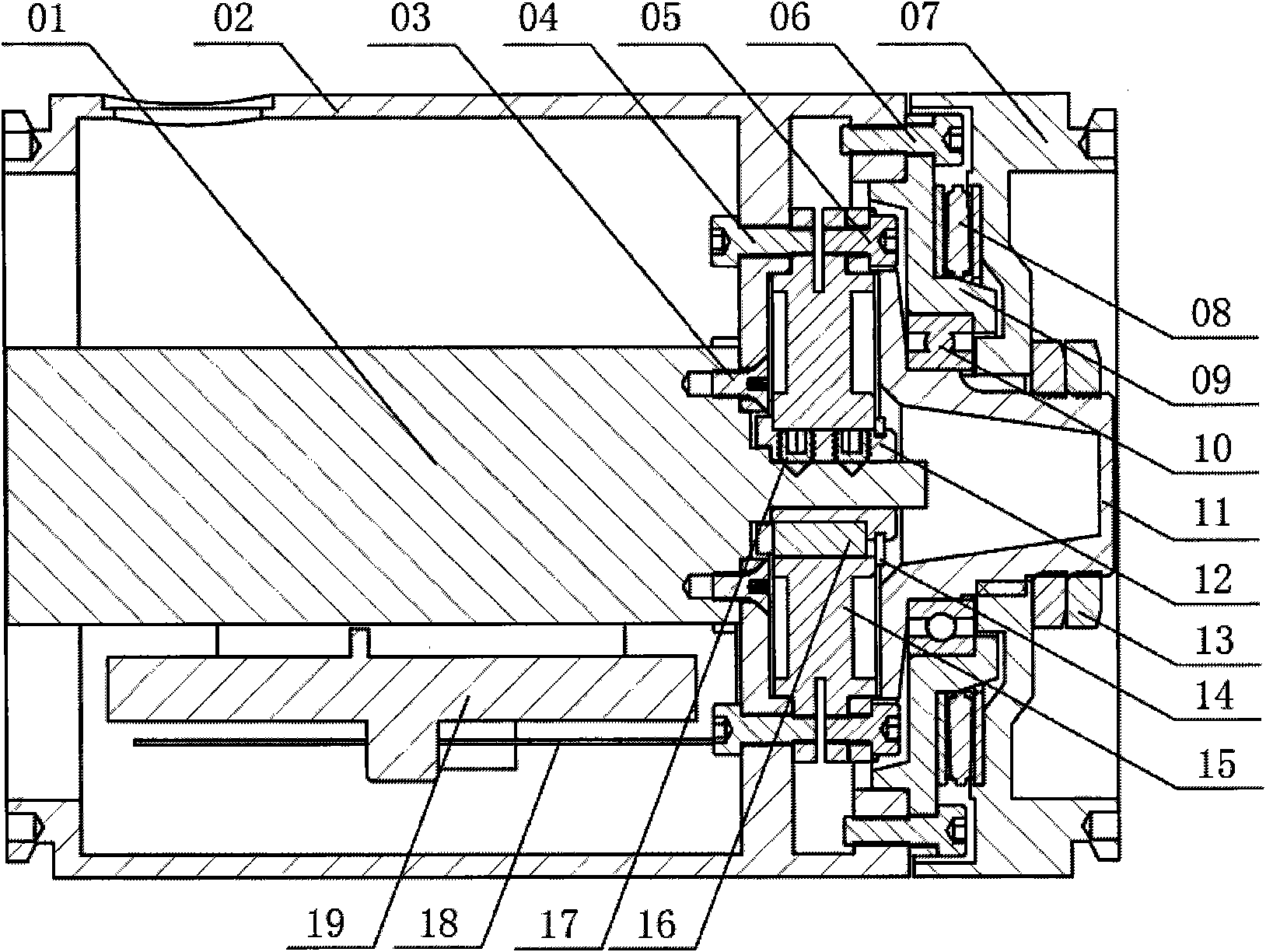

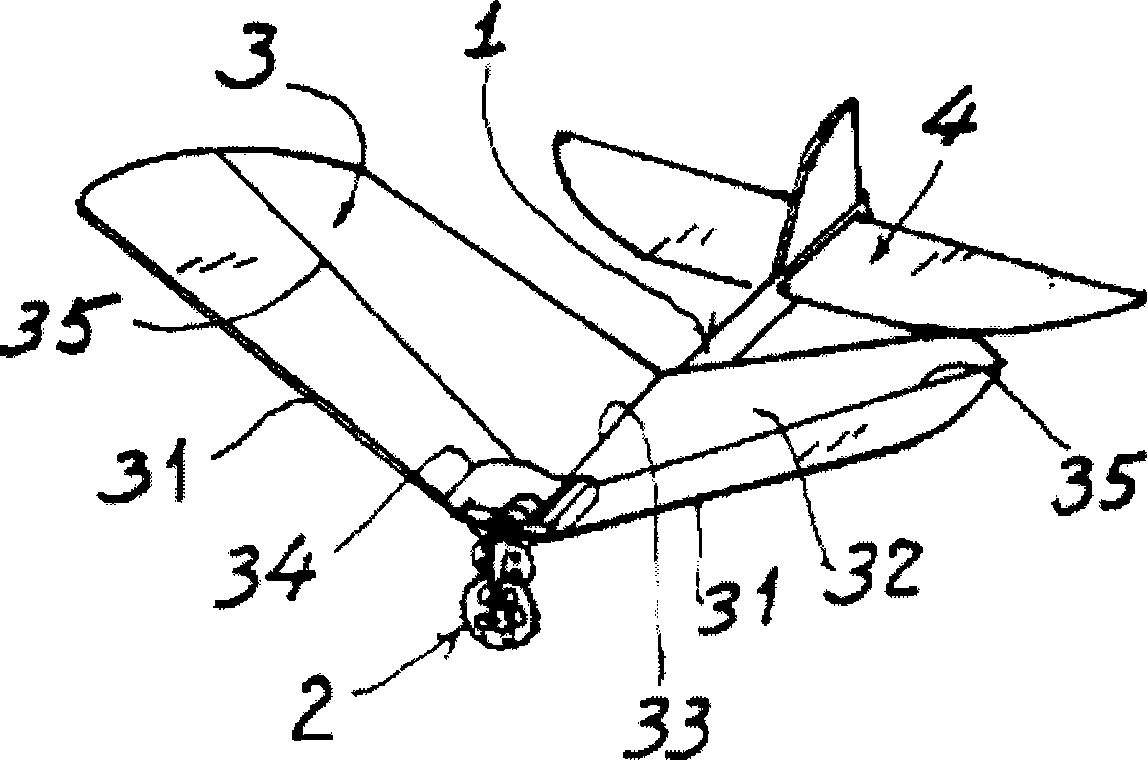

Double-rotor-wing unmanned plane

The invention discloses a double-rotor-wing unmanned plane. Flying control on the double-rotor-wing unmanned plane is realized based on a four-rotor-wing unmanned plane flying control principle by designing a single-degree-of-freedom automatic tilter, semi-rigidity rotor wings and a flying control system. The unmanned plane consists of a stander, a plane body, a power bin, rotor wing systems and a rotor wing system support, wherein the plane body is provided with an equipment bin in which a flight posture sensor group, a PID controller, a lithium battery and an electronic speed controller are arranged; the plane body, the power bin and the rotor wing system support are in rigid fixed connection through the stander; a brushless motor and a steering engine are arranged in the power bin; the steering engine drives a pull rod to operate the single-degree-of-freedom automatic tilter and control the rotor wings to periodically change the distance; the angle of the tilter is measured by a potentiometer, so that precise control is facilitated; the rotor wing systems are symmetrically arranged and are positioned on the same horizontal plane; the rotating directions of the rotor wings are opposite, and the rotor wings are mounted on a total distance hinge so as to be mechanically limited to do waving motion. According to the unmanned plane, the operation mechanism is simplified; the flying quality is good; the requirement on the precision of a theoretical model is low, and an extremely high practical value is achieved.

Owner:NORTHWEST A & F UNIV

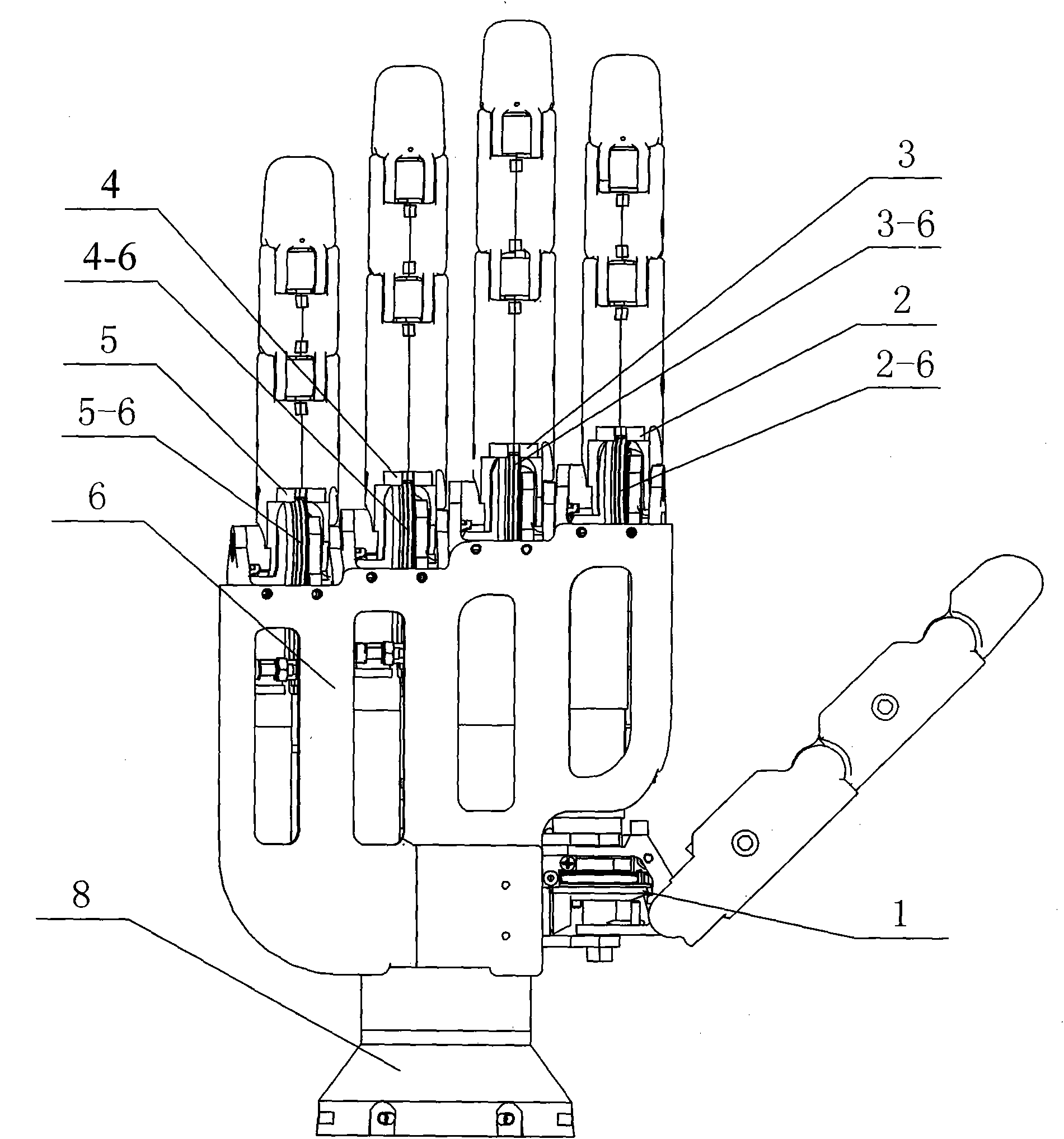

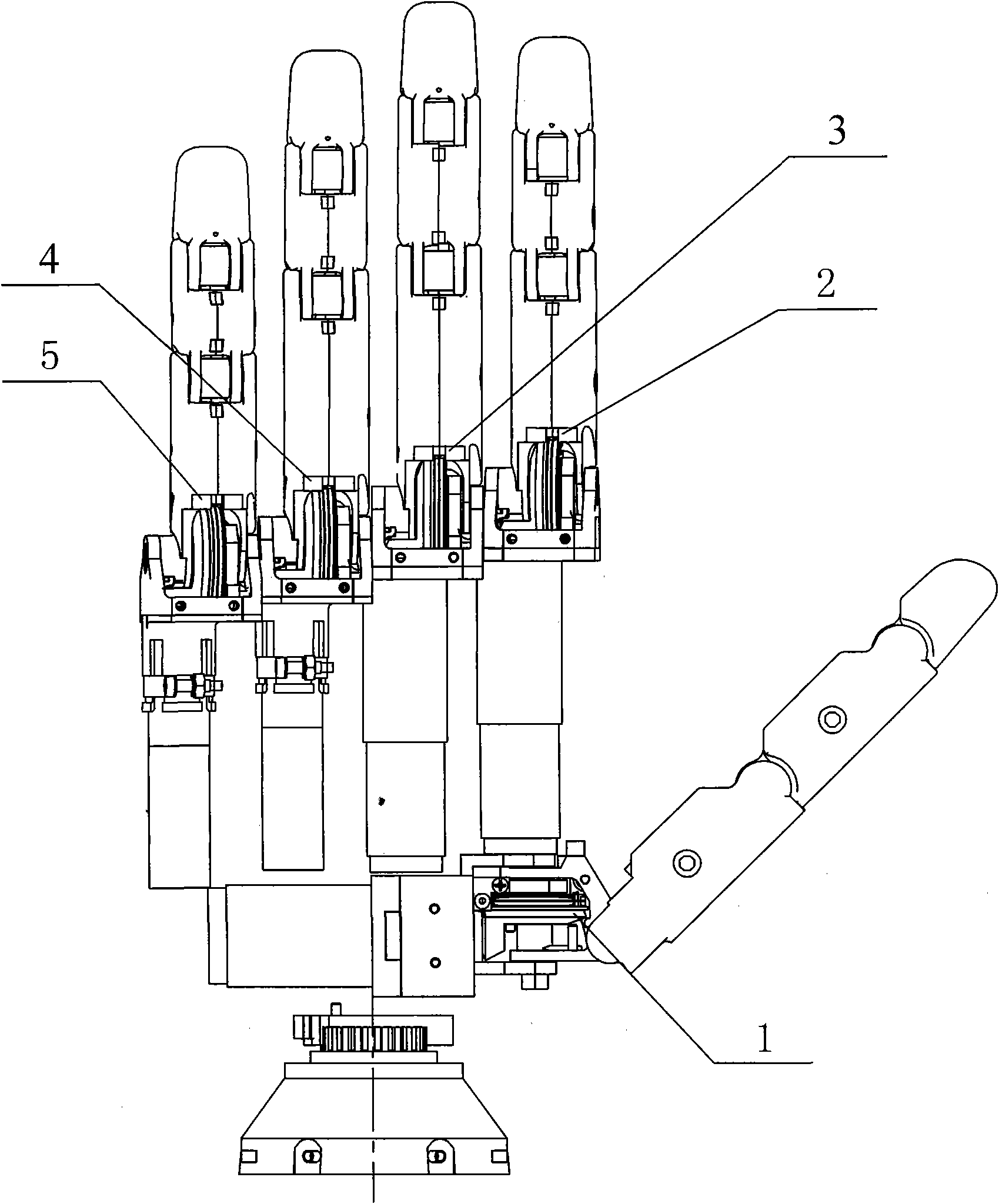

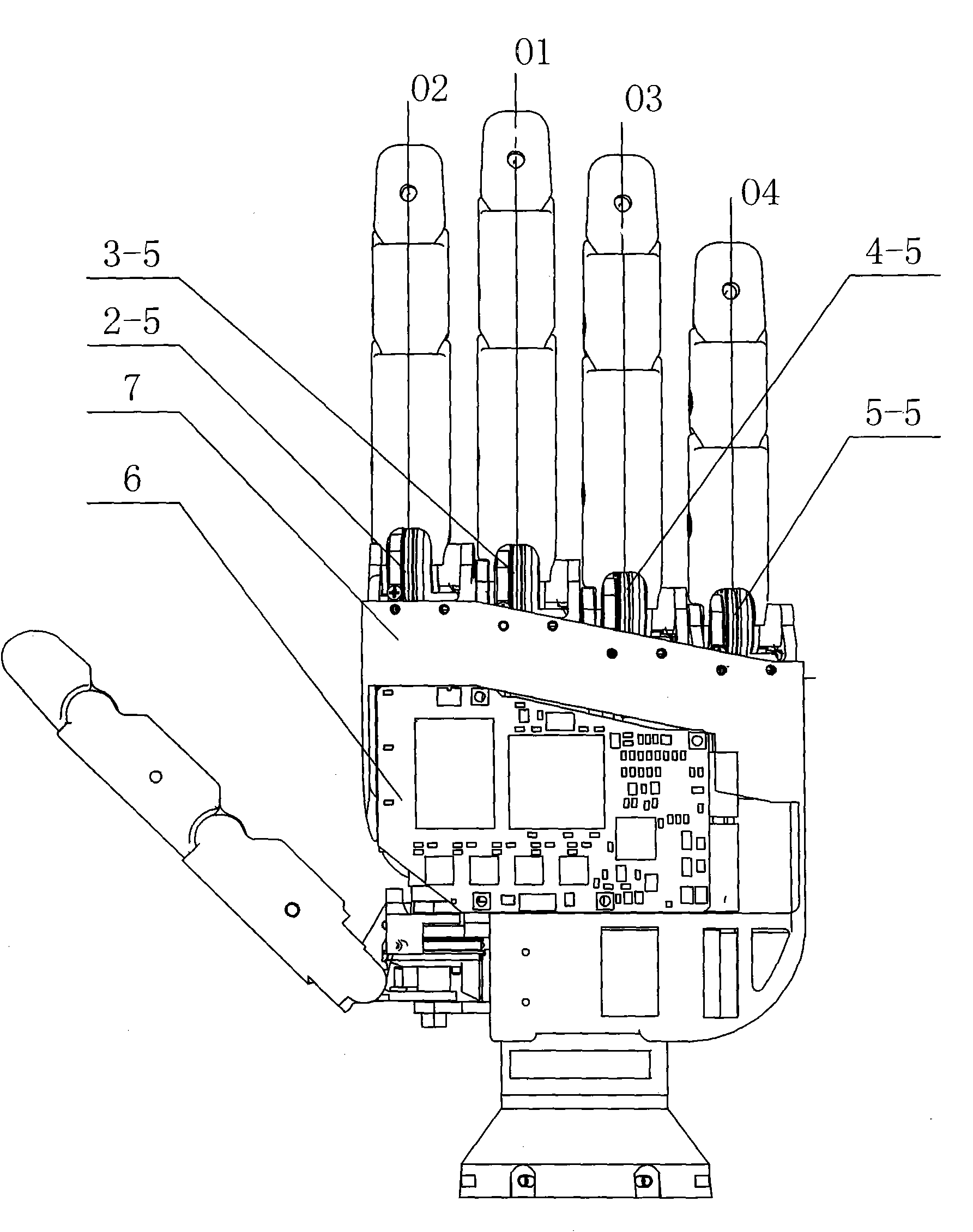

Five-degree-of-freedom artificial hand mechanism

InactiveCN101797749AIncrease freedomAchieve relative motionProgramme-controlled manipulatorArtificial handsReliable transmissionReduction drive

The invention provides a five-degree-of-freedom artificial hand mechanism, relates to an artificial hand mechanism and aims to solve the problems that the conventional artificial hand has single degree of freedom and cannot realize independent movement of each finger. Five drivers, five reducers and a palm circuit board are all integrated in a cavity of a palm; a thumb driver and a thumb reducer are arranged along a width direction of the palm, the four drivers except the thumb driver and the four reducers except the thumb reducer are arranged along a length direction of the palm, and a wrist and the palm are rotatably connected relatively; each driver is in transmission connection with the corresponding reducer, and the reducer is in transmission connection with a corresponding transmission mechanism; and a rotating part of each potentiometer is connected with the corresponding transmission mechanism, and the transmission mechanism is supported on a corresponding substrate. The five-degree-of-freedom artificial hand mechanism has five degree-of-freedom, and improves the flexibility of the artificial hand; and due to the simple and reliable transmission, relative motion of each finger is realized, and adaptive grasping of objects of different shapes and sizes is also realized.

Owner:HARBIN INST OF TECH

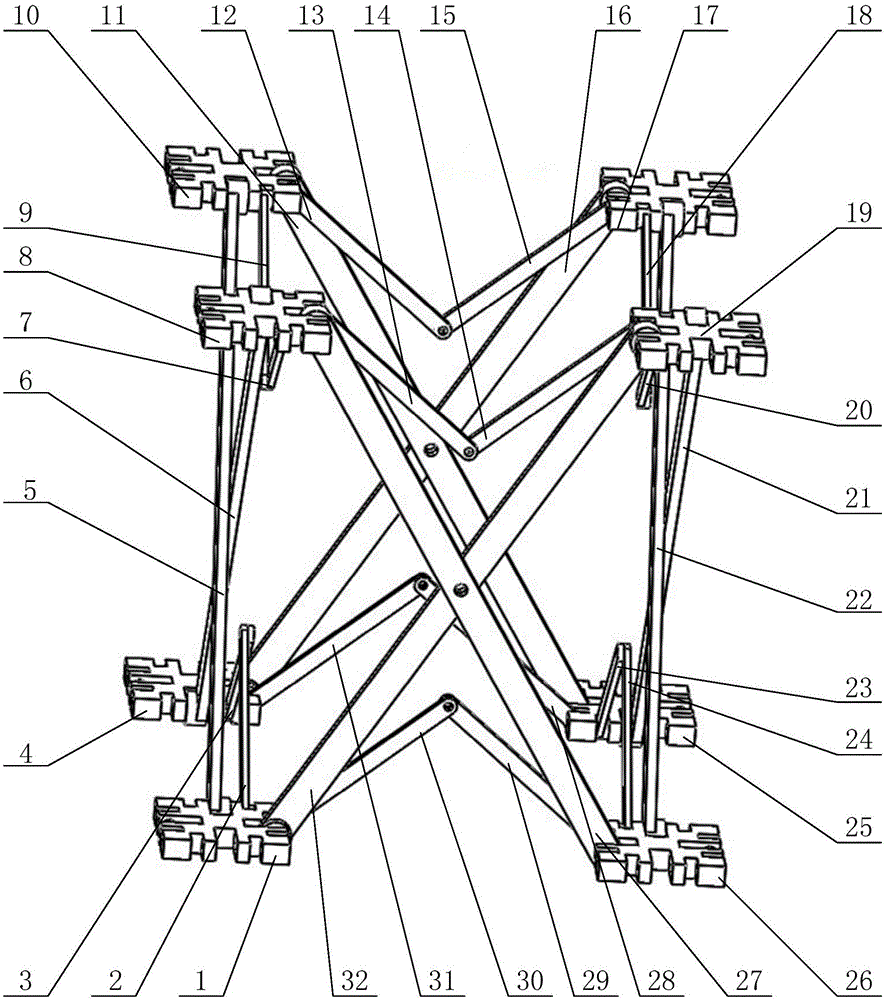

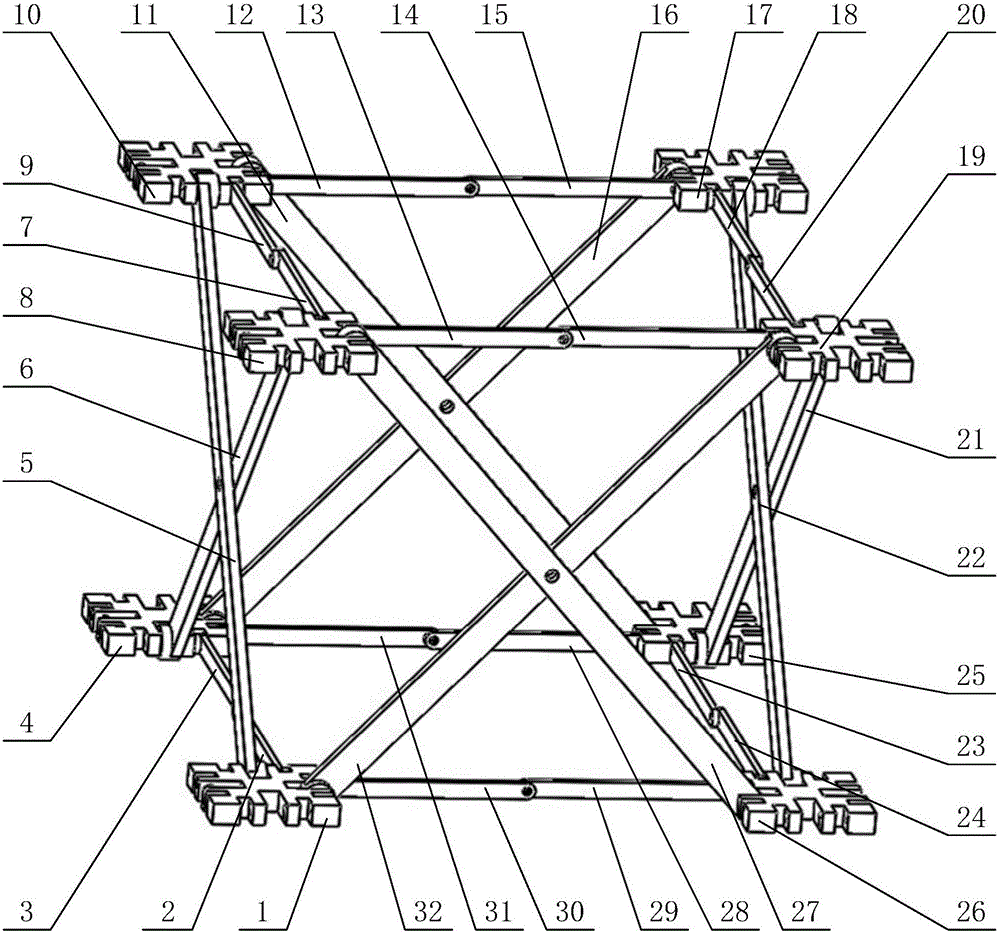

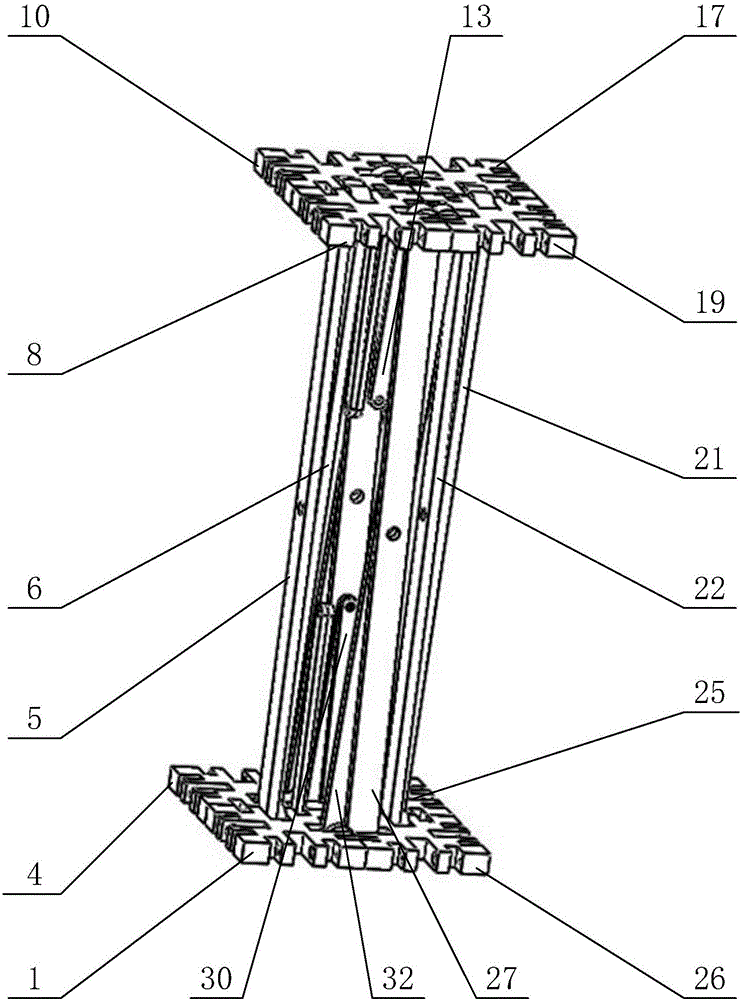

Single-degree-of-freedom overconstrained shear-type deployable unit and space deployable mechanisms composed of same

ActiveCN105799950ALarge folding ratioIncrease stiffnessCosmonautic vehiclesCosmonautic partsStructural symmetrySingle degree of freedom

The invention discloses a single-degree-of-freedom overconstrained shear-type deployable unit and space deployable mechanisms composed of the same. The single-degree-of-freedom overconstrained shear-type deployable unit comprises eight disc chucks, four sets of shear fork folding rods and eight sets of folding connecting rods; one set of the folding connecting rods limit the deployable degree of the basic deployable units by depending on the length of the connecting rods, the other seven sets of the folding connecting rods are all overconstrained connecting rods, and the overconstrained connecting rods can effectively improve the rigidity of the basic deployable units. Accordingly, the basic deployable units can be sequentially arranged in order, every two adjacent deployable units can form the first space deployable mechanism and the second space deployable mechanism by sharing four of the disc chucks and one set of the shear fork folding rods, and the length of the first space deployable mechanism and the size of the second space deployable mechanism can be changed by changing the quantity of the basic deployable units. The single-degree-of-freedom overconstrained shear-type deployable unit is simple in structure, has the high structural symmetry and is suitable for constructing an extendable space mast, a solar battery array support and a satellite plane reflecting antenna.

Owner:YANSHAN UNIV

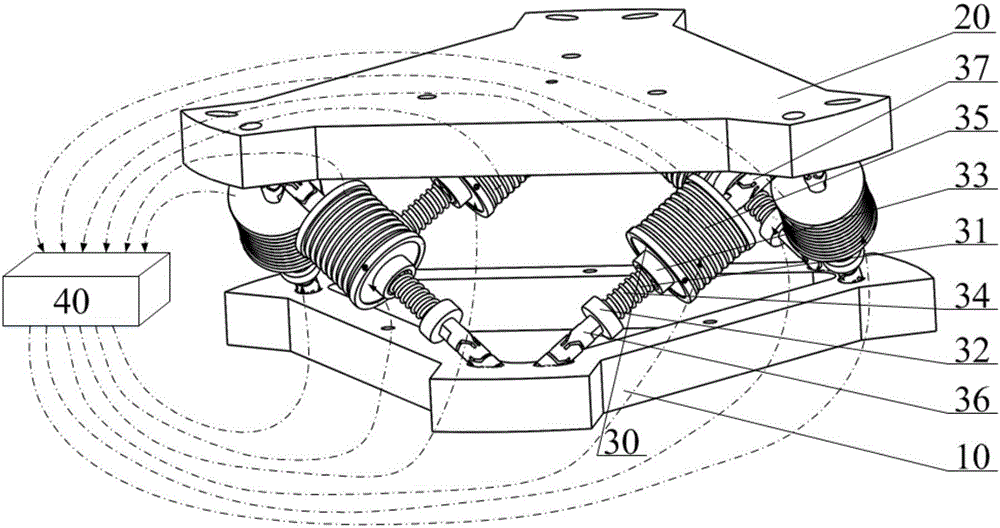

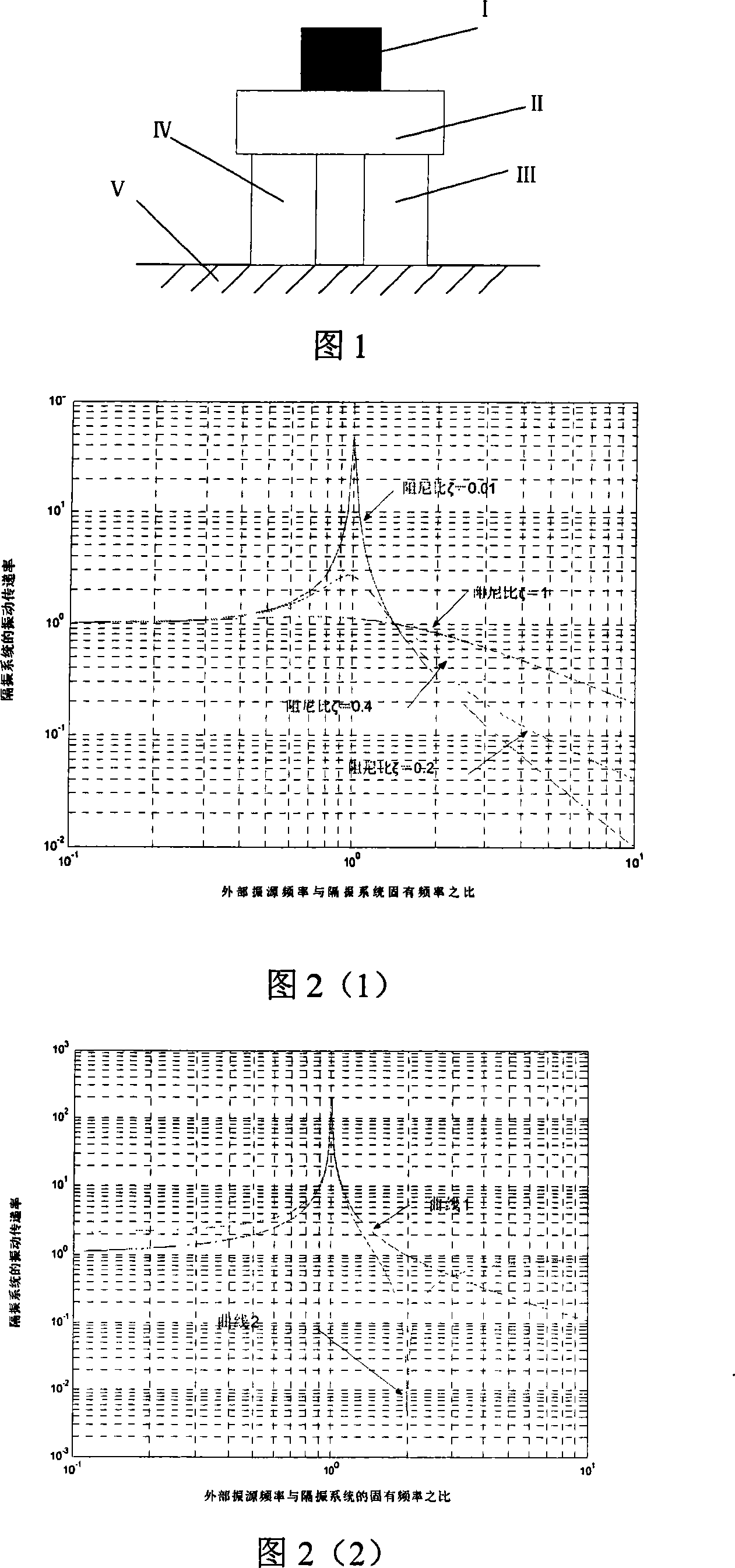

Six-degree-of-freedom micro vibration abatement platform and control method thereof

ActiveCN106286692AChange the stiffnessChange propertiesProgramme controlSpringsControl mannerSingle degree of freedom

Owner:HUAZHONG UNIV OF SCI & TECH

Controller for an Assistive Exoskeleton Based on Active Impedance

ActiveUS20080188907A1Reduce effortElectrotherapyChiropractic devicesMuscle strengthSingle degree of freedom

A system and method are presented to provide assist to a user by means of an exoskeleton with a controller capable of making the exoskeleton display active impedance. The exoskeleton assists the user by reducing the muscle effort required by the user to move his or her extremities. In one embodiment, a single-degree-of-freedom (1-DOF) exoskeleton assists a user with single-joint movement using an active impedance controller. In another embodiment, a multiple-degree-of-freedom (multi-DOF) exoskeleton assists a user with multiple-joint movement using an active impedance controller.

Owner:NORTHWESTERN UNIV +1

Parallel link robot

ActiveCN102049776ADo not reduce the movable areaDoes not degrade acceleration and deceleration performanceProgramme-controlled manipulatorMechanical apparatusSingle degree of freedomDegrees of freedom

A parallel link robot (10) provided with a base (11), a moving part (12), three links (20a to 20c) coupling the base and the moving part and having respectively single degrees of freedom with respect to the base, and three actuators (13a to 13c) respectively driving the links, each of the links comprised of a drive link (21a to 21c) coupled with the base and two driven links (22a to 22c, 23a to 23c) coupling the drive link and the moving part and parallel to each other, and further provided with a posture changing mechanism (15) which changes a posture of an element (19) attached to the moving part, an additional actuator (13d to 13f) arranged between the two driven links of at least one link in parallel to these driven links, and a power transmission shaft (39) which extends coaxially from the additional actuator and transmits rotational drive force to the posture changing mechanism. Due to this, it is possible to increase the degrees of freedom without reducing the possible region of operation and the acceleration / deceleration performance.

Owner:FANUC LTD

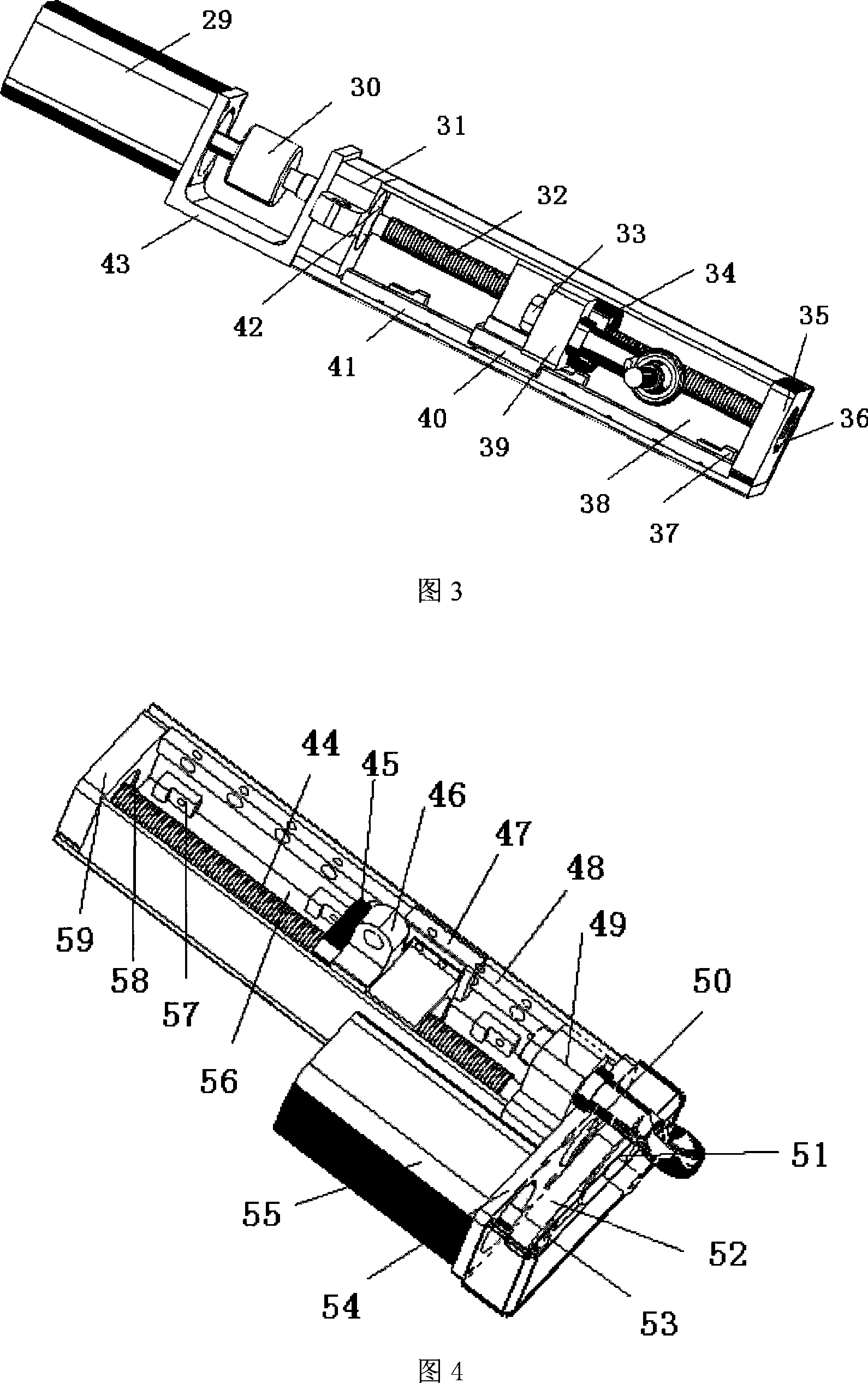

Remote-controlled work robot

ActiveUS20120043100A1Reduce the overall diameterImprove cooling effectProgramme-controlled manipulatorJointsRemote controlCoupling

A remote controlled work robot including a remote controlled actuator and a support device therefor. The remote controlled actuator includes a spindle guide section of an elongated configuration, a distal end member fitted to a distal end of the spindle guide section through a distal end member coupling structure for alteration in attitude, and a drive unit housing connected with a base end of the spindle guide section. The distal end member rotatably supports a spindle for holding a tool. The support device includes a single degree-of-freedom system, in which the remote controlled actuator has a degree of freedom in one direction, or a multi-degrees-of-freedom system, in which the remote controlled actuator has a two or more degrees of freedom relative to a base on which the support device is installed. A drive source and is also provided for driving the degree-of-freedom system.

Owner:NTN CORP

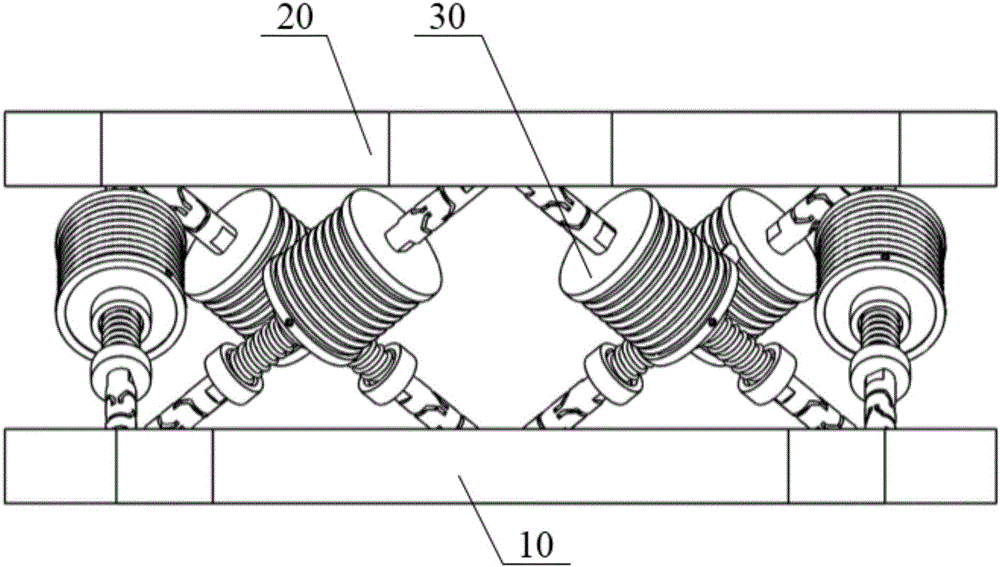

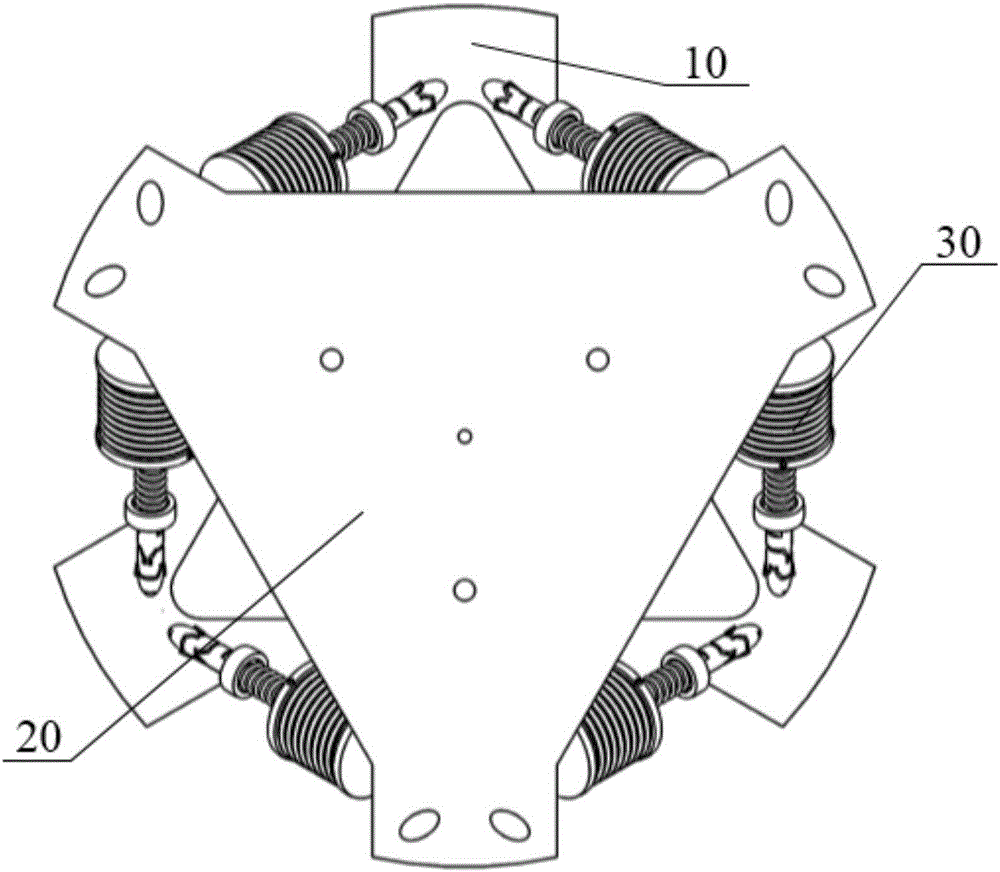

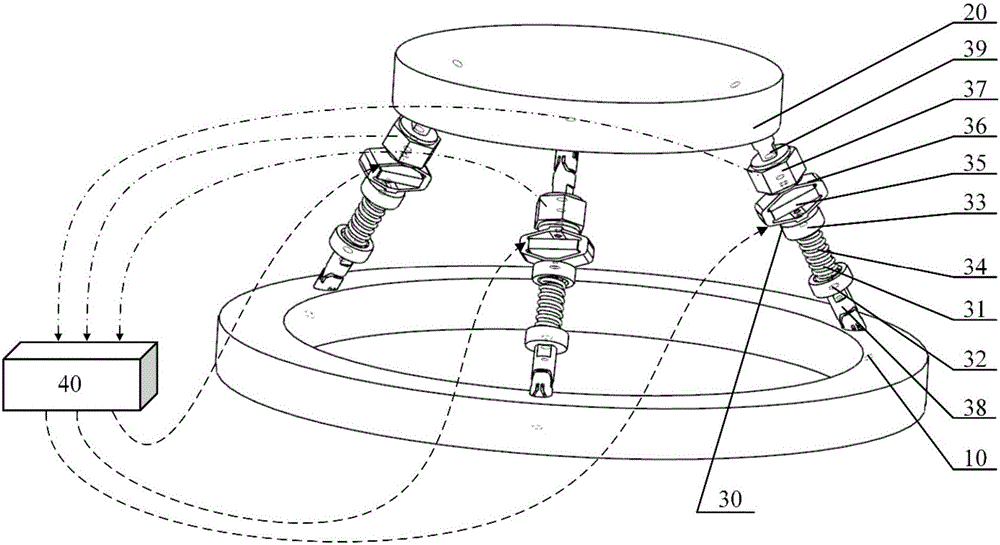

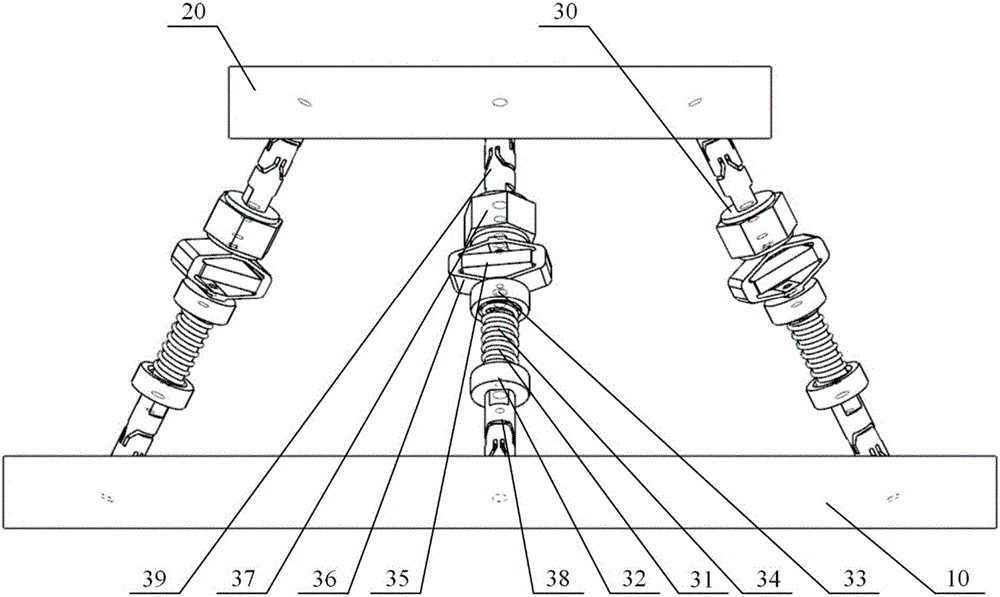

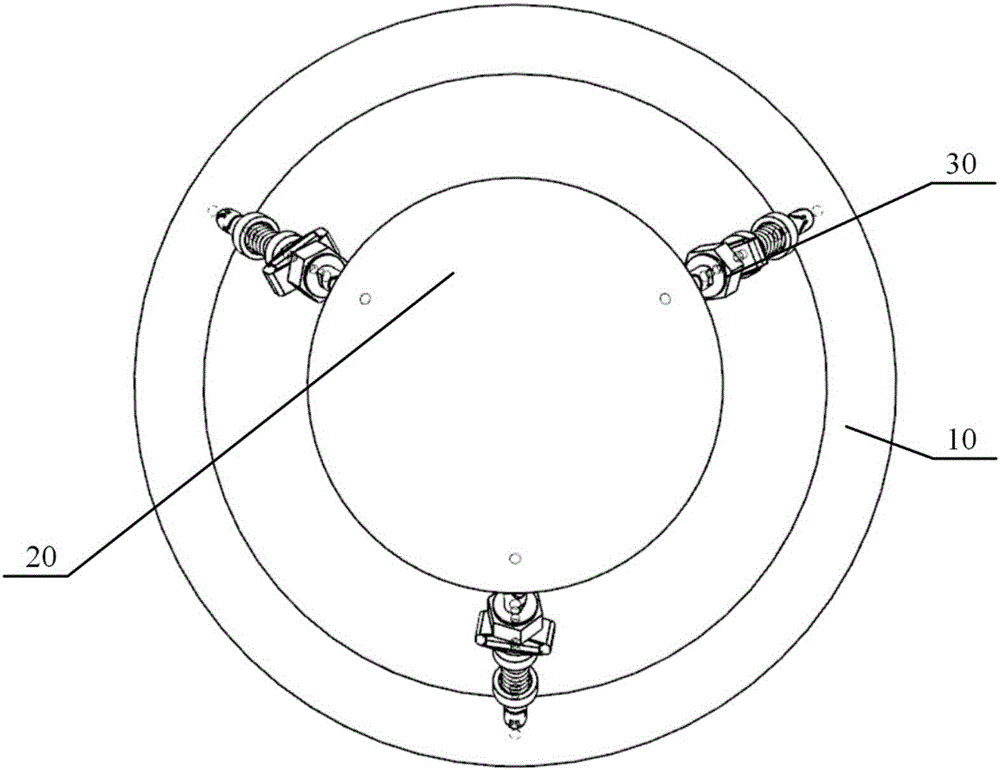

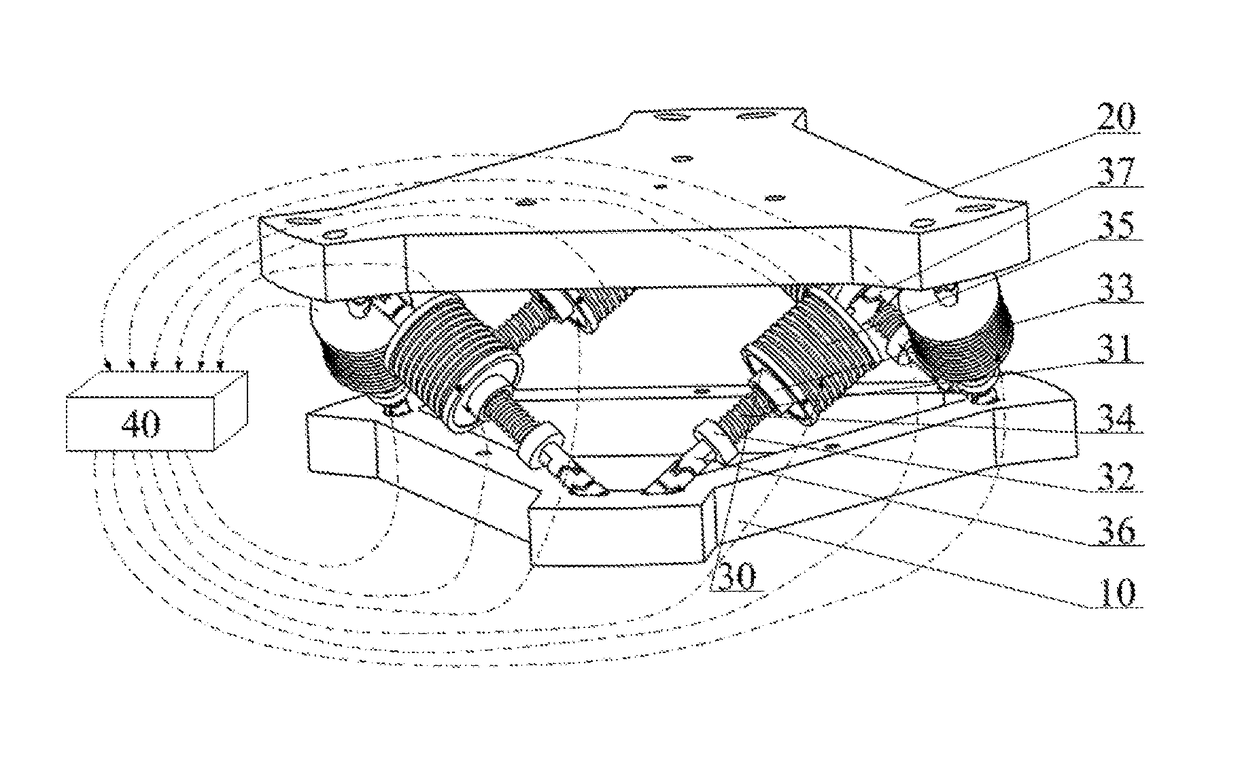

Three degree of freedom micro-vibration suppression platform and control method thereof

ActiveCN105909725AReduce computationSimple Feedback Control StructureControllers with particular characteristicsVibration suppression adjustmentsControl signalControl manner

The invention provides a three degree of freedom micro-vibration suppression platform and a control method thereof, belongs to vibration isolation and suppression devices, and solves problems of complicated structure and complex control method of a prior active-passive composite vibration isolation structure. The platform provided by the invention includes a base platform, a load platform, three sets of single degree of freedom active-passive composite vibration isolation assemblies which are totally identical and a controller. The upper end and the lower end of each single degree of freedom active-passive composite vibration isolation assembly are connected with the load platform and the base platform. The control method provided by the invention includes calculating logic axis translation signals, calculating logic axis control signals, calculating physical axis real time control signals and transmission steps. The platform provided by the invention is simple in structure, adjustable in rigidity, is capable of suppressing and isolating three degree of freedom microvibration in rotation directions of an X axis and a Y axis and a translation direction of a Z axis and is suitable for different occasions. Microvibration of different frequency bands can be dampened effectively and reliable guarantee can be provided for precision machining and measurement equipment in a microvibration environment.

Owner:HUAZHONG UNIV OF SCI & TECH

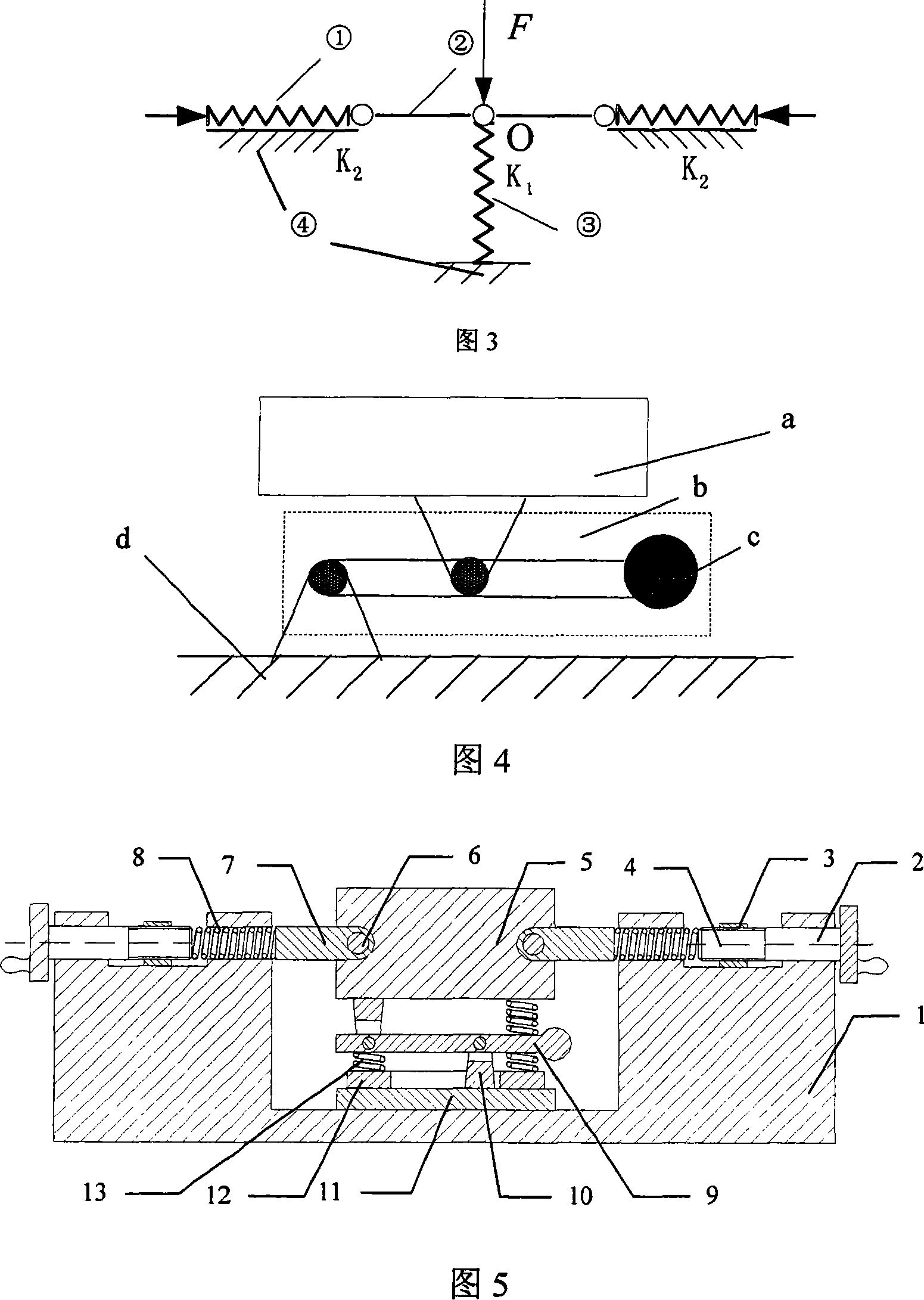

Single-degree-of-freedom ultralow frequency vertical vibration isolation system

InactiveCN101225865AImprove the vibration isolation effectReduce the impactNon-rotating vibration suppressionDynamic stiffnessVertical vibration

The invention relates to a vertical vibration isolation system of single freedom and ultra-low frequency, comprising a mass block, a middle mass block, a zero point generator, a zero stiffness apparatus and a stiffness base. The zero stiffness apparatus invents the dynamic stiffness values of the system at a low cost, which greatly decreases the natural frequency of the system and realizes the passive vibration isolation within the range of ultra-low frequency. The zero point generator reduces the vibration transmissibility in the range of the ultra-low frequency and improves the efficiency of vibration isolation; otherwise, the parameters of the zero point generator can be changed to regulate the system vibration transmissibility according to the actual amplitude and frequency requirements of the vibration isolation. The existing relationship between the zero point generator and the zero stiffness apparatus is: the zero stiffness apparatus decreases the dynamic stiffness value and also brings down the zero value of the zero point generator III and realizes zero within the range of ultra-low frequency.

Owner:XI AN JIAOTONG UNIV

Active and passive type ankle joint rehabilitative apparatus

InactiveCN103041546AMeet Rehabilitation Training RequirementsGuarantee the effect of rehabilitation trainingGymnastic exercisingChiropractic devicesOrthogonal coordinatesThree degrees of freedom

The invention provides active and passive type ankle joint rehabilitative apparatus which uses orthogonal coordinates and three degrees of freedom to respectively achieve dorsal stretch and plantar flexion, inversion and eversion, and intorsion and extorsion motions of ankle joints. Every degree of freedom is respectively driven by a motor so that single degree of freedom motions of ankle joints are achieved and the linkage of three motor can achieve complex motions of ankle joints. Force sensors are arranged on pedals of the ankle joint rehabilitative apparatus. During a rehabilitation process, foot motions of a trainee are controlled by detecting stresses of the pedals so that active and passive type ankle trainings are achieved, besides, stress safety protections are performed and secondary injuries to the trainee are avoided. The active and passive type ankle joint rehabilitative apparatus meets rehabilitative training requirements of single degree of freedom and multiple degrees of freedom motions of ankle joints with a simple and reliable structure. Intelligent control, effect evaluation and intelligent protection are achieved due to an adoption of force sensors so that effects and safety of rehabilitative trainings of a patient are guaranteed.

Owner:三亚哈尔滨工程大学南海创新发展基地

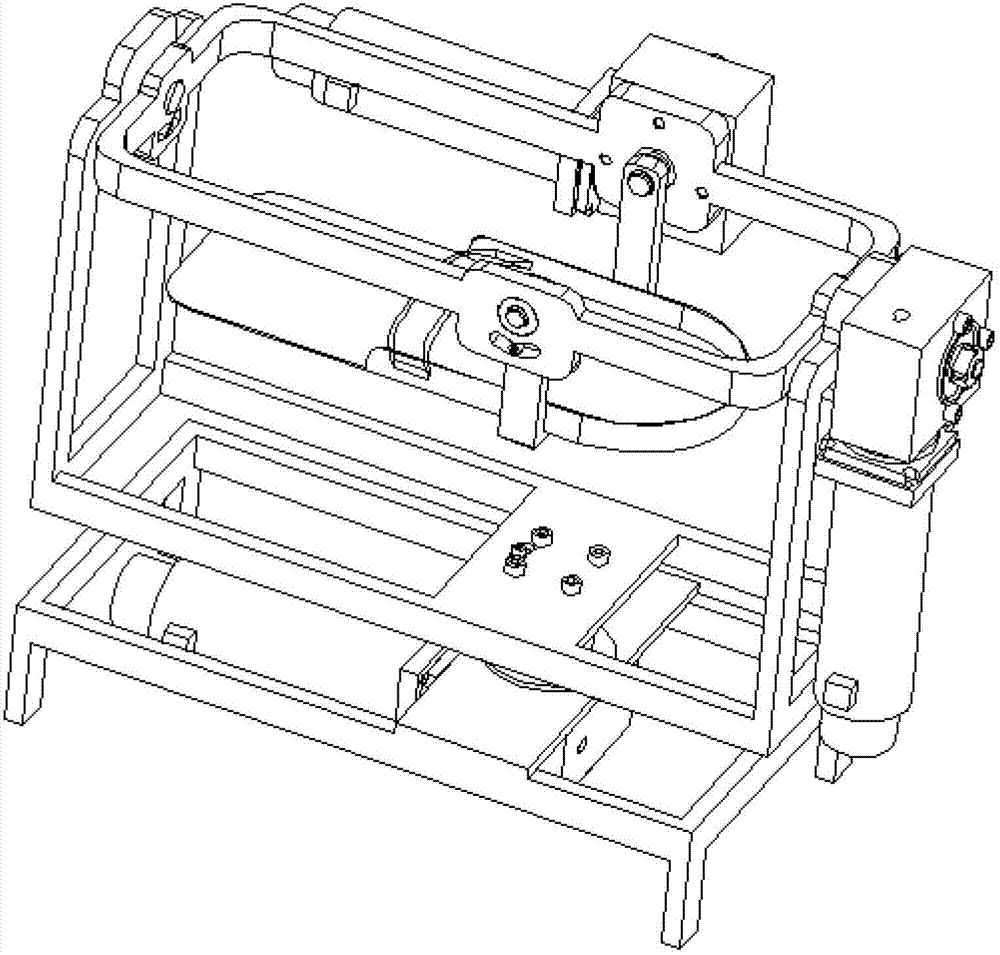

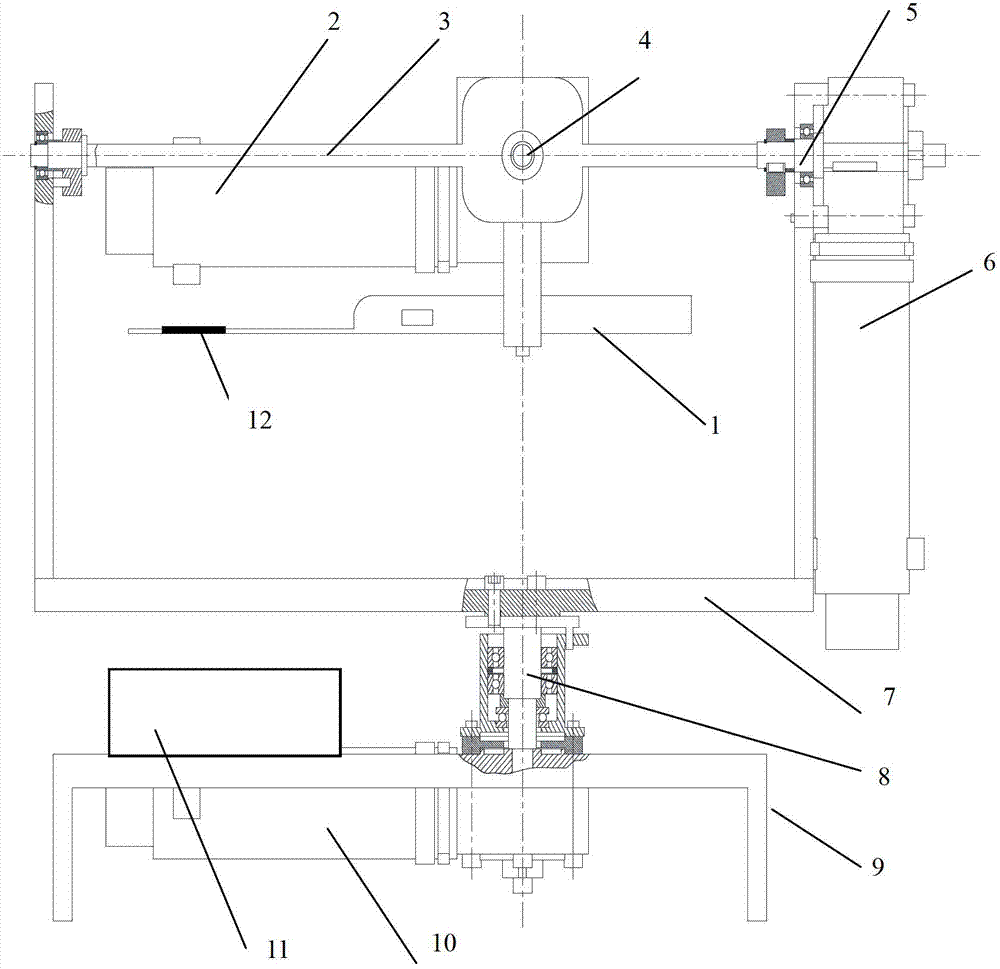

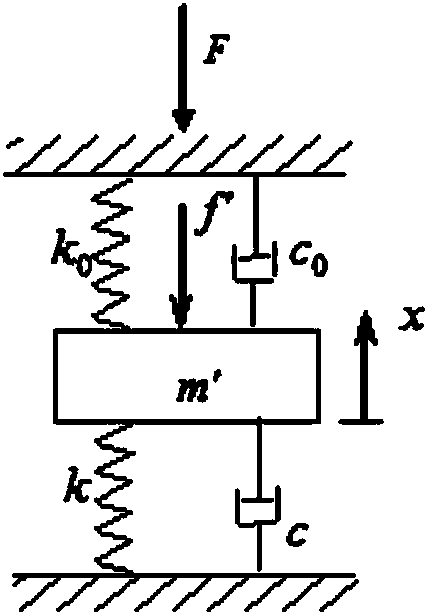

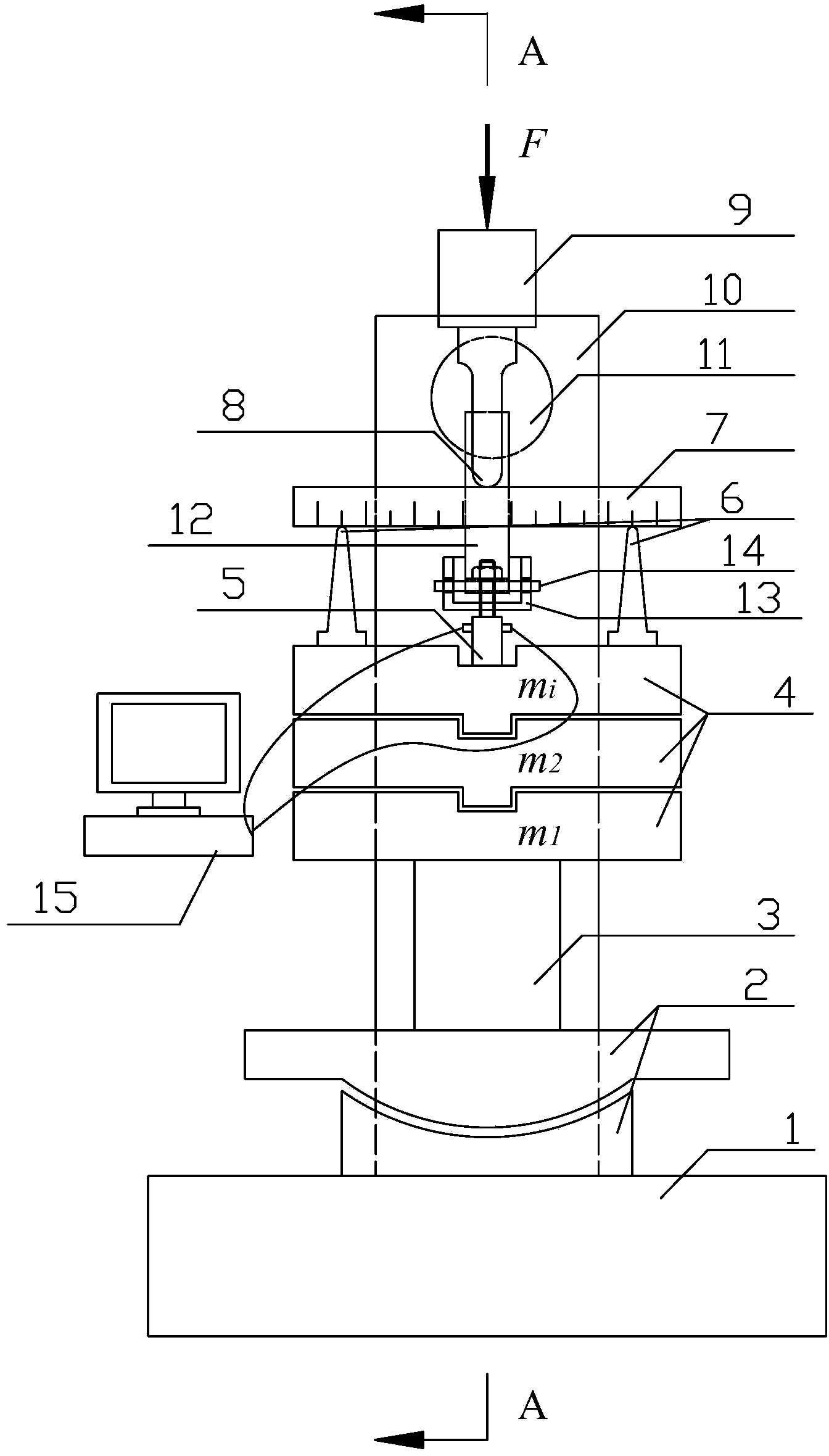

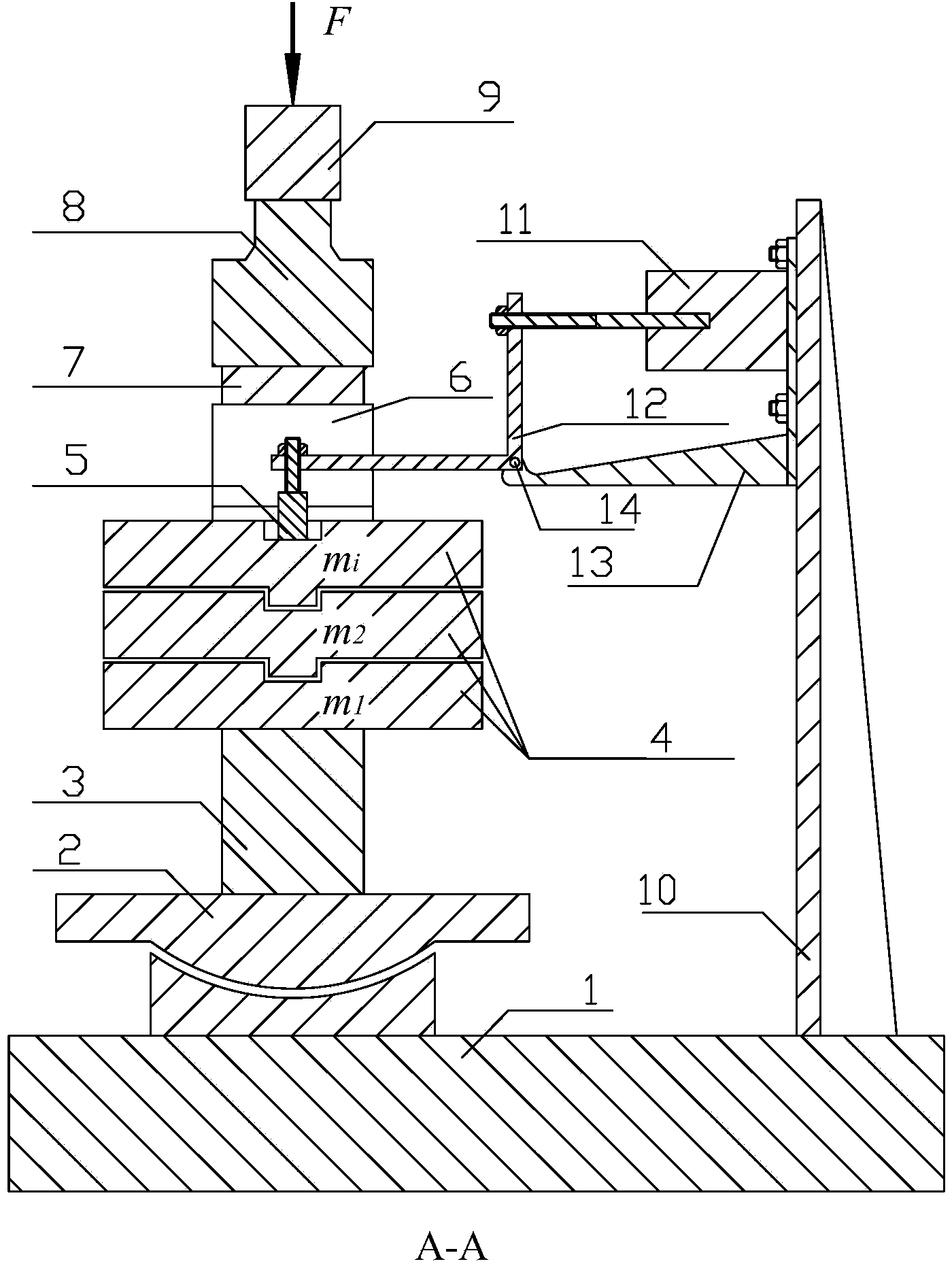

Method and device for testing dynamic stiffness of vibration isolator

InactiveCN103808499ASolve clumsySolve the test costMachine part testingVibration testingDynamic stiffnessHigh rate

The invention discloses a method and a device for testing dynamic stiffness of a vibration isolator. The method comprises the steps of establishing an equivalent test model of a single-degree-of-freedom vibration system in a vibration isolation direction by using a static loading device, a combined vibration mass block and an elastic simply supported beam, measuring a frequency response function of the equivalent test model by an exciting method, and then indirectly obtaining the dynamic stiffness of the vibration isolator by virtue of a vibration equation, the similarity of the vibration system and the characteristics of the single-degree-of-freedom system. The method avoids the problem that the existing methods all need to simulate a rated load or a working load with an equivalent mass block in an ingenious way, and solves the problem that the test system is clumsy, high in test cost and test difficulty and even unachievable if the mass block is used for simulating high rated load or working load; the testing device is light and simple in structure, convenient to operate, and economical and practical; the method and the device are applicable to the dynamic stiffness tests of all single-axis vibration isolators, high in applicability, and especially capable of realizing testing of the dynamic stiffness of a large-rated load vibration isolator and ensuring high precision.

Owner:JIANGSU UNIV OF SCI & TECH

Fork four-freedom parallel connection robot mechanism

InactiveCN101259617AIncrease stiffnessSimple structureProgramme-controlled manipulatorSingle degree of freedomKinematic pair

The invention discloses a parallel robot mechanism with four branched degrees of freedom and consists of a moving platform, a fixed platform and 2 to 4 movable branched chains which are provided with the same structure and is used for connecting the moving platform and the fixed platform; wherein, the movable branched chains comprises a moving pair, a first rotary pair, a kinematic pair with a single degree of freedom, a second rotary pair and a third rotary pair from the fixed platform to the moving platform respectively; the mechanism is provided with three moving degrees of freedom and two rotary degrees of freedom under the initial configuration; the moving platform can rotate around the axial lines of the two rotary pairs respectively and the axial lines are connected with the moving platform by winding two branches adjacent to the moving platform; when the moving platform begins to rotate along one direction, the other rotary direction is automatically locked, that is to say that the mechanism is provided with only three moving degrees of freedom and a rotary degree of freedom after the moving platform rotates from an initial position. The parallel robot mechanism can be widely applied to parallel robots, micro-motion worktables and virtual axial machine tools, etc. and has the advantages of high rigidity, simple structure, moving and rotary decoupling, easy control, good dynamic performance, good processing and assembling performance, etc.

Owner:ZHEJIANG SCI-TECH UNIV

Six-degree-of-freedom micro vibration suppression platform and control method thereof

ActiveUS9777793B1Low dynamic stiffnessNatural frequency can be reducedProgramme controlSpringsSingle degree of freedomControl signal

A six-degree-of-freedom micro vibration suppression platform includes a basic platform, a load platform, six sets of single-degree-of-freedom active and passive composite vibration isolation devices that are exactly the same and a controller. Upper and lower ends of each set of single-degree-of-freedom active and passive composite vibration isolation devices are connected with the load platform and the basic platform, respectively. A control method includes: calculating a logical axis signal, calculating a logical axis control signal, calculating physical axis real-time control signals and a transfer step.

Owner:HUAZHONG UNIV OF SCI & TECH

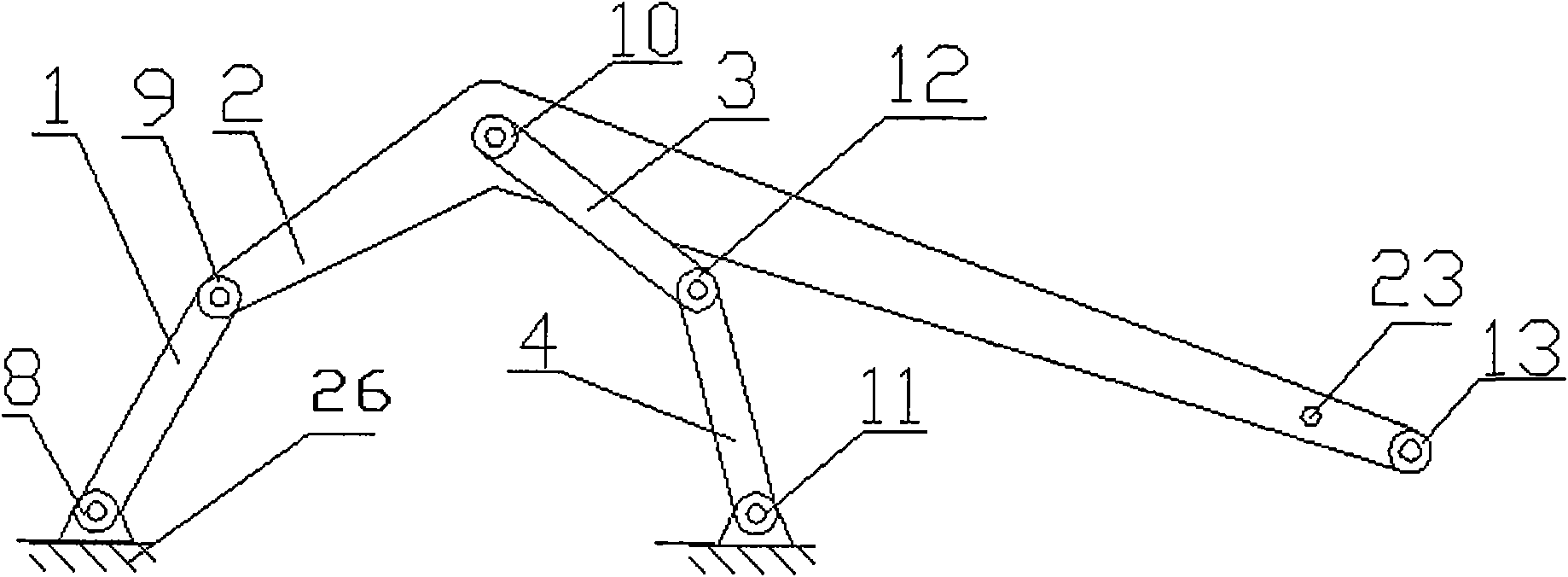

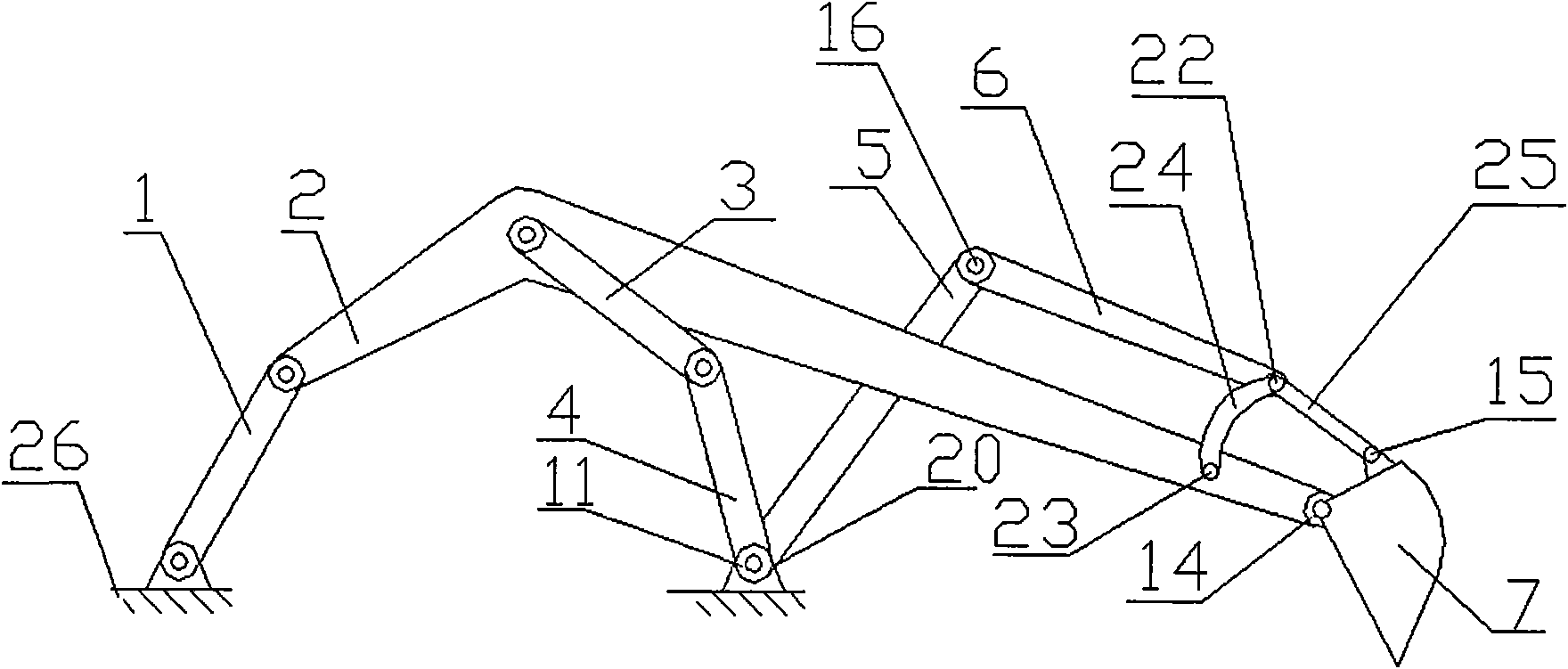

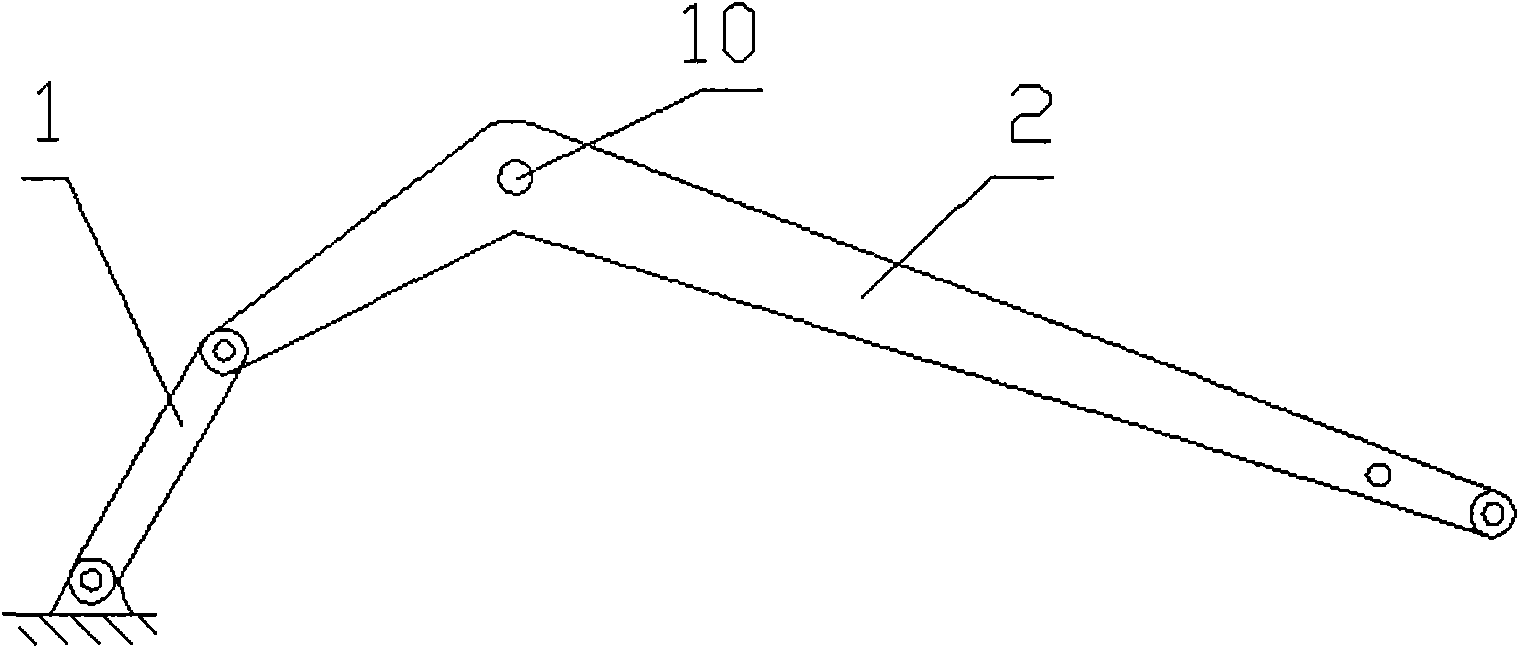

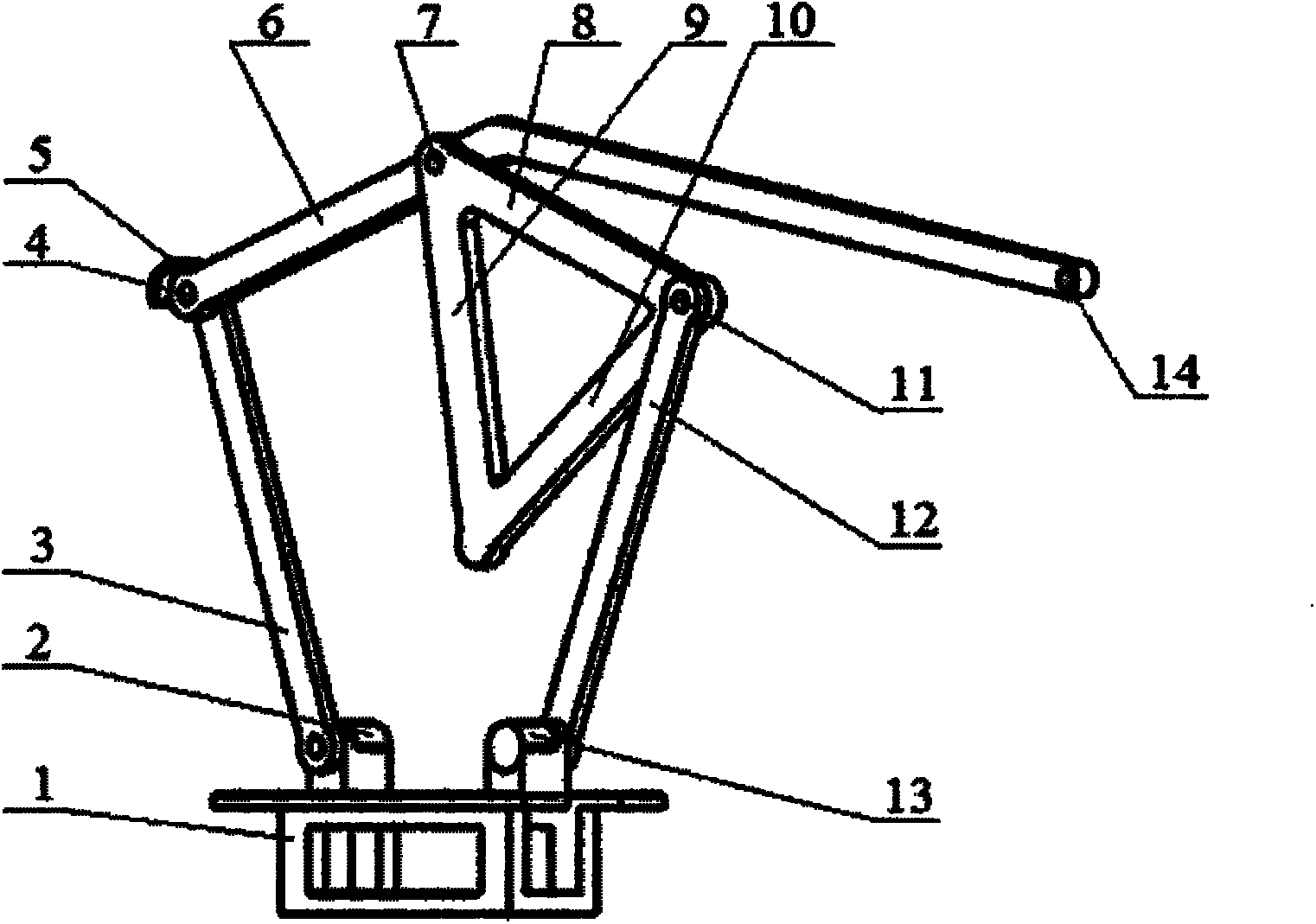

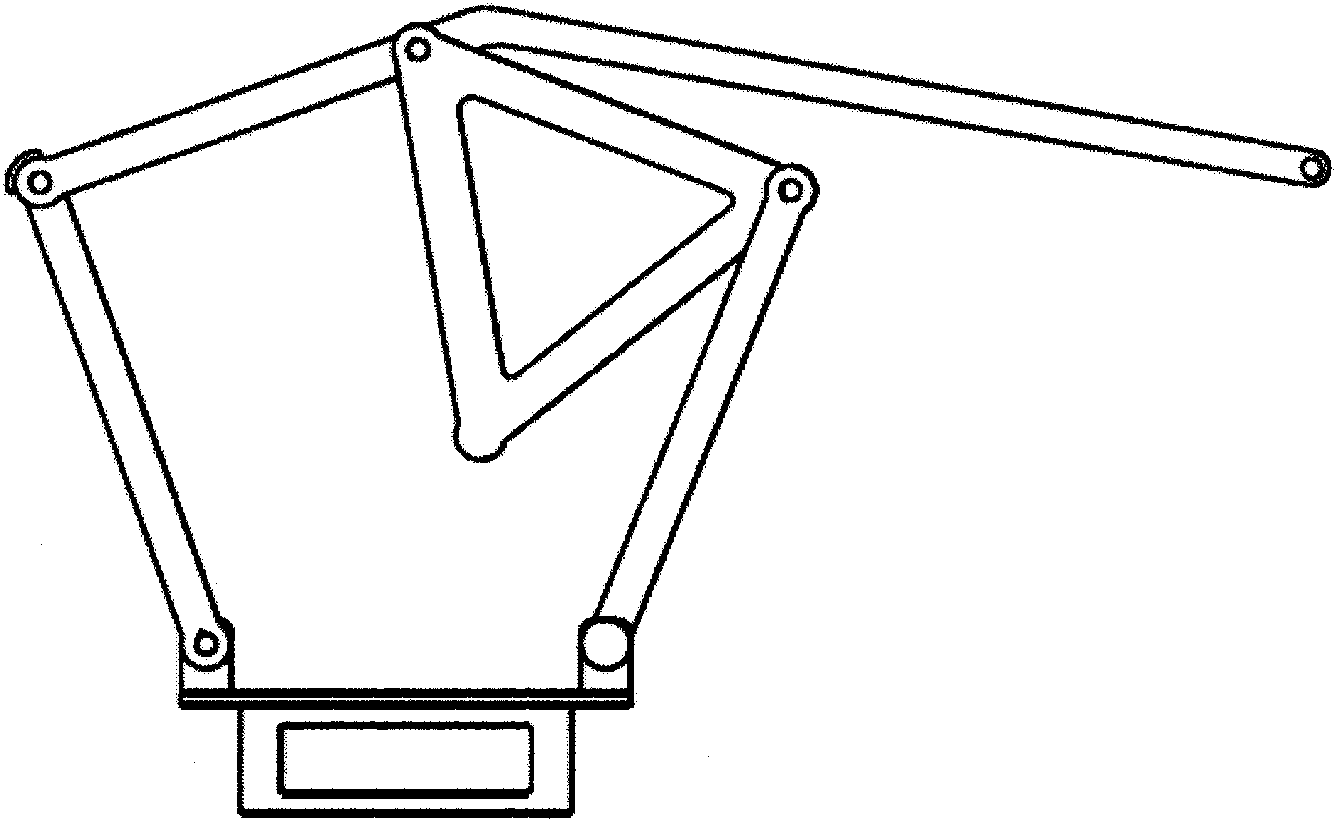

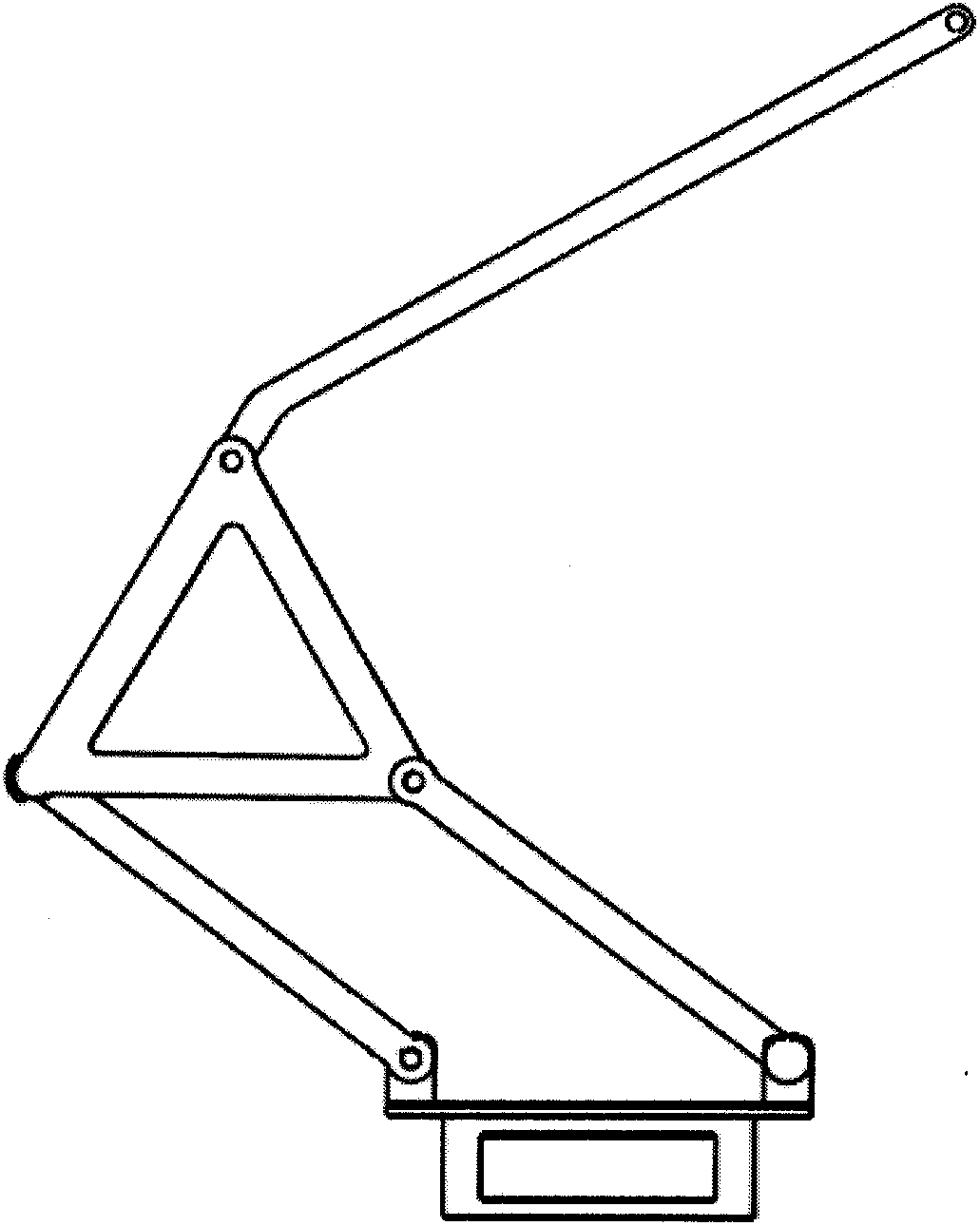

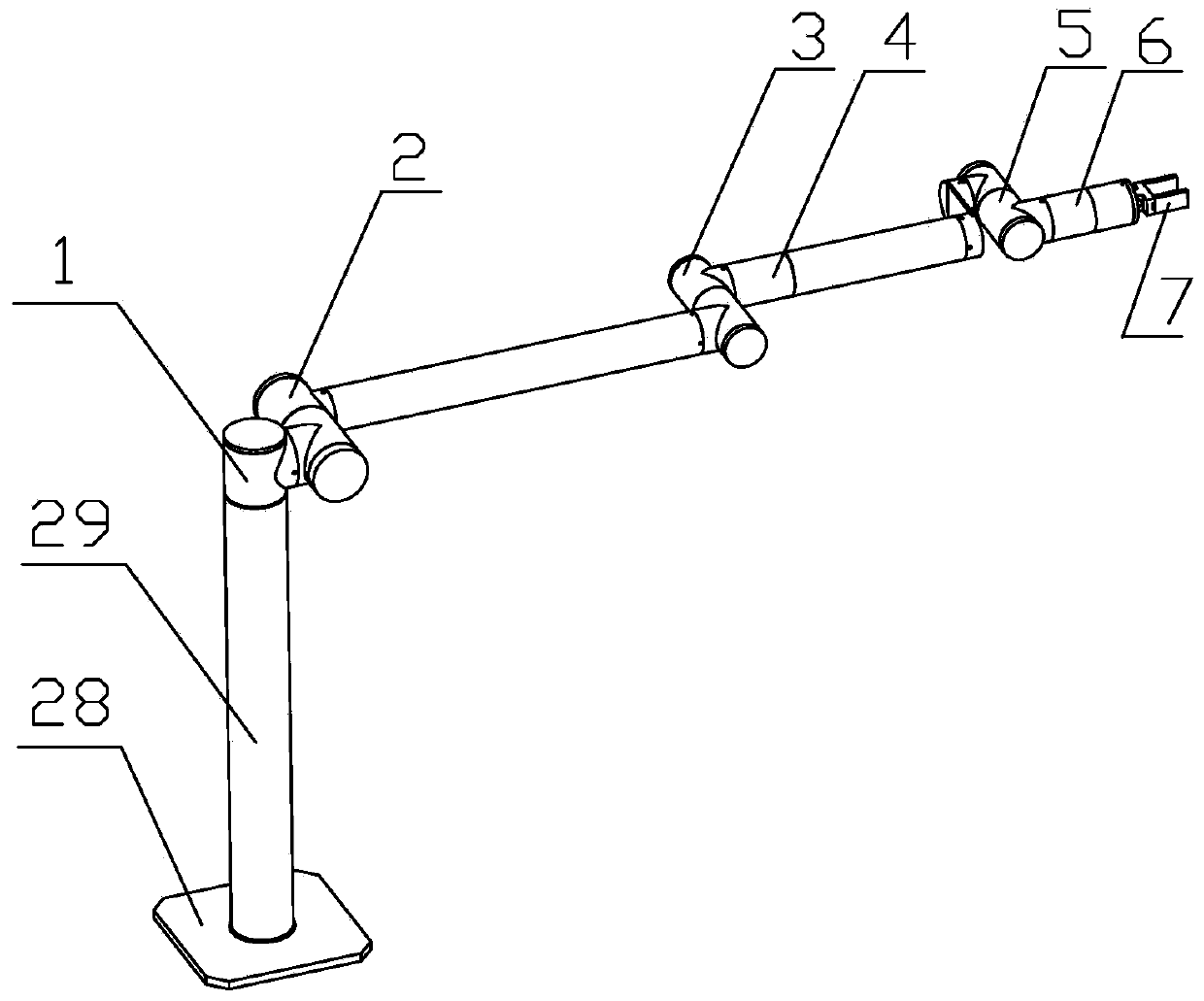

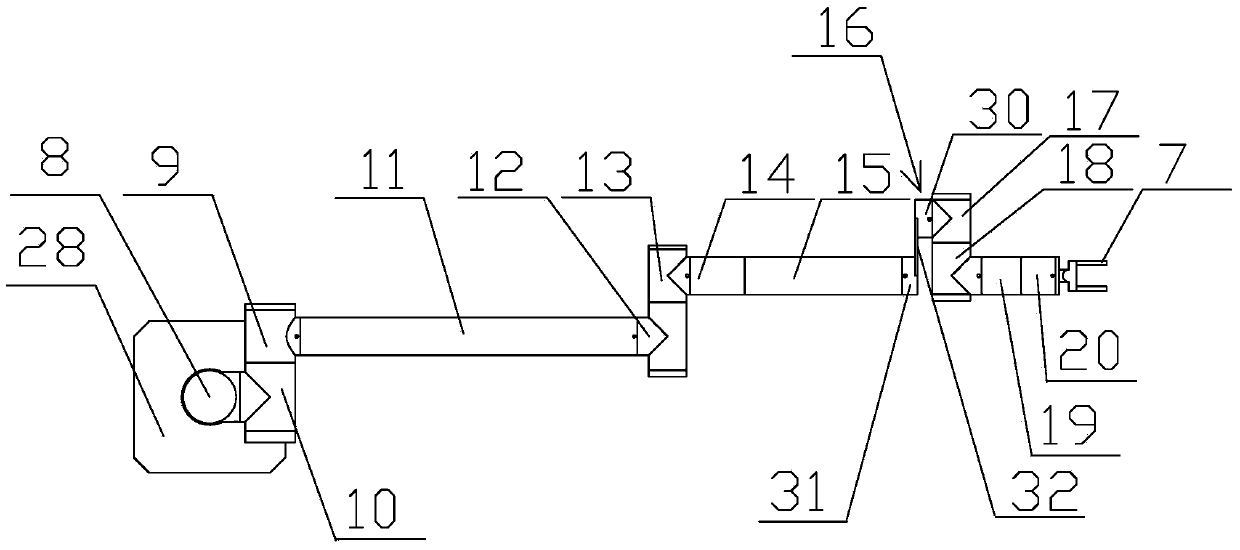

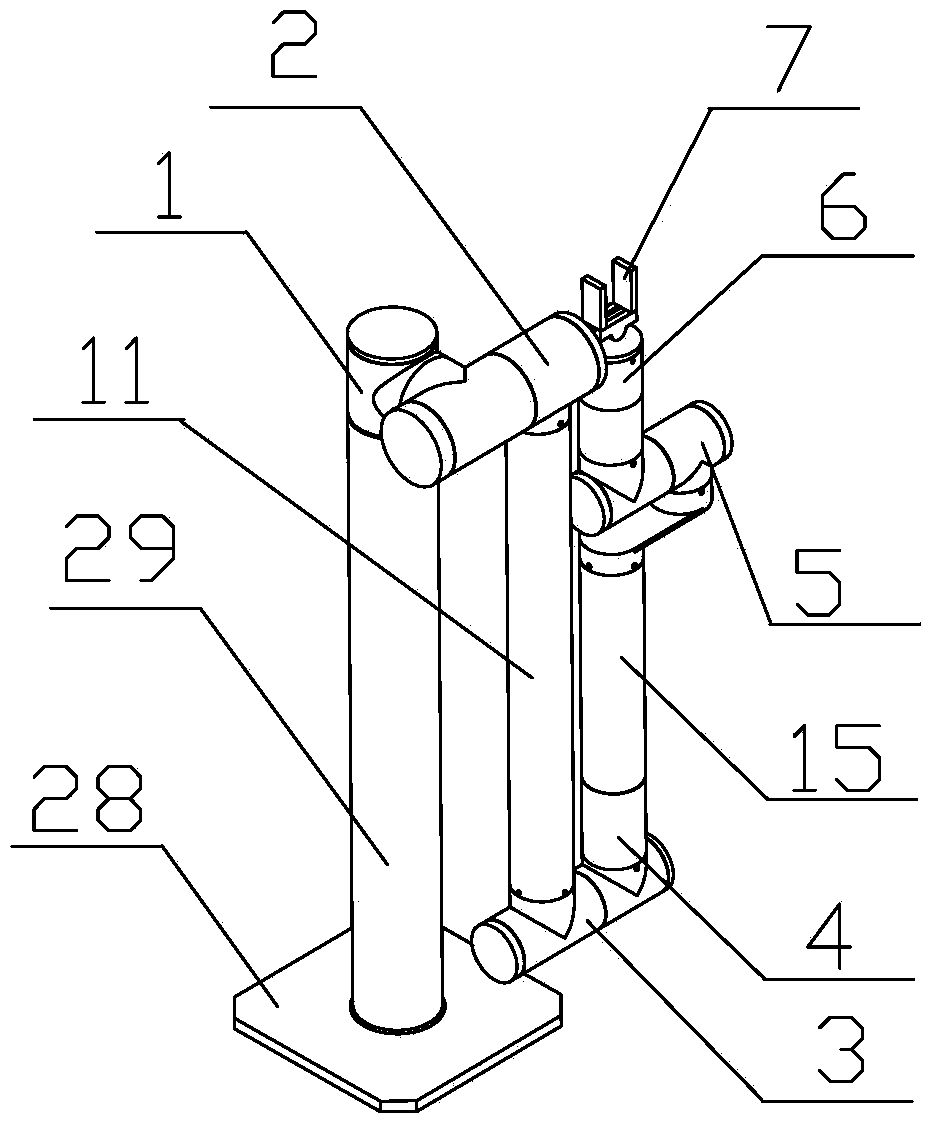

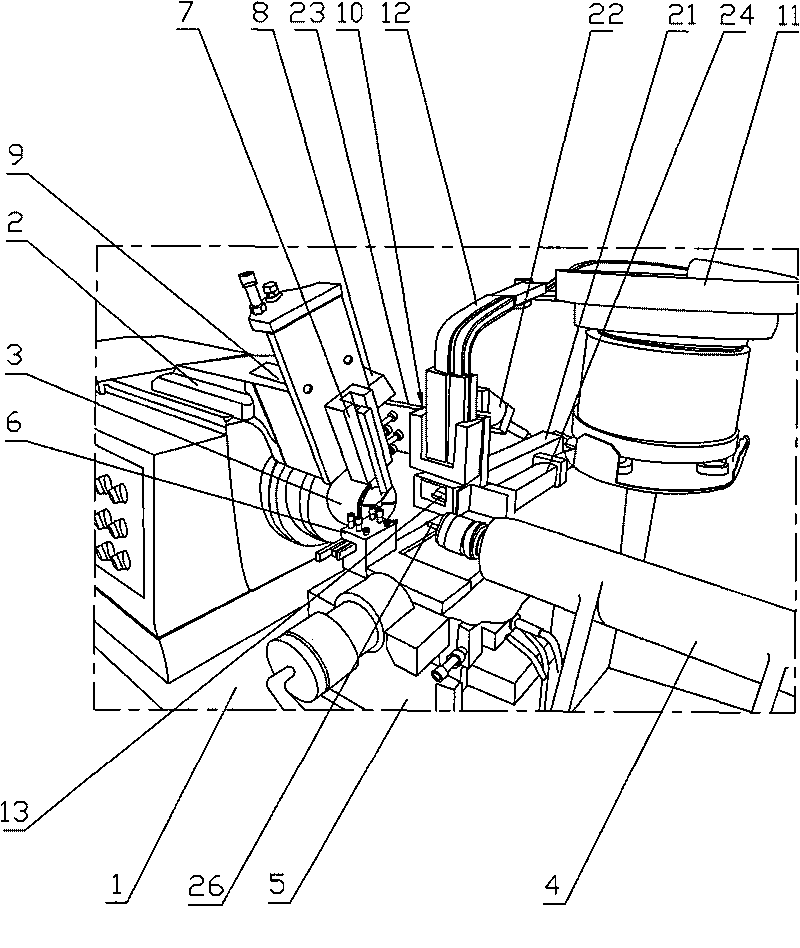

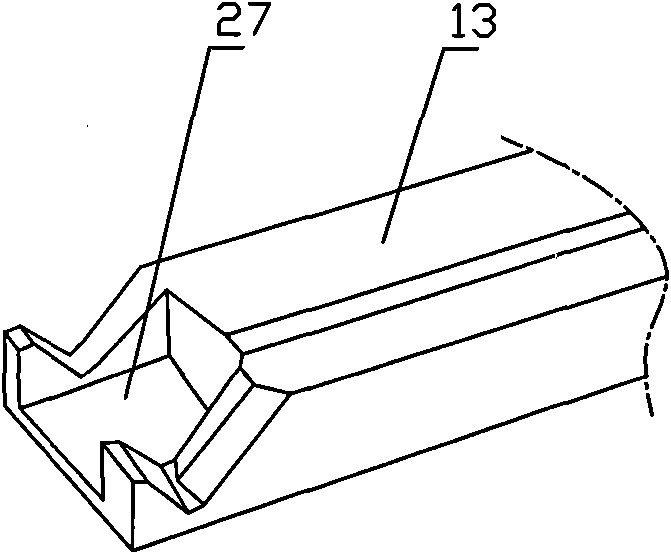

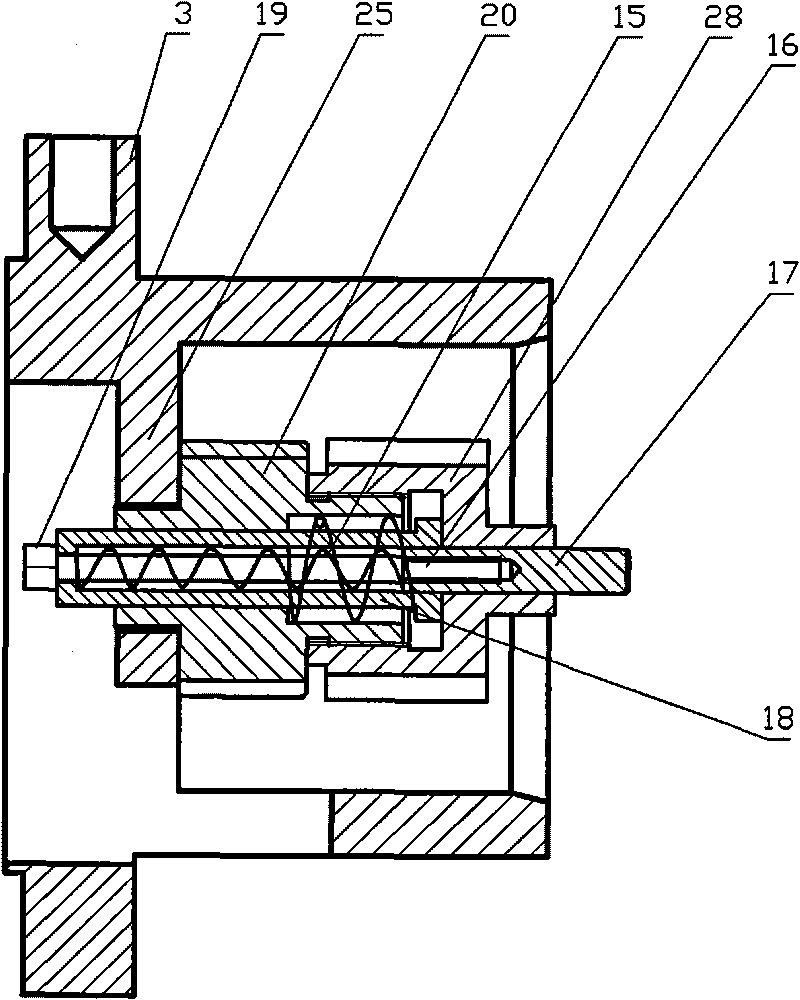

Excavating mechanism of controllable planar three degree of freedom

InactiveCN101666104AReduce weightIncrease digging speedMechanical machines/dredgersThree degrees of freedomSingle degree of freedom

The invention relates to an excavating mechanism of controllable three degree of freedom, comprising an excavating arm, a bucket turning-over mechanism, a backhoe bucket and a stand. The excavating arm is a mechanism of controllable planar two degree of freedom, wherein one end of a driving rod (1) of the mechanism is hinged together with a driven rod (2) through a hinge hole (9), and the other end is hinged on the stand (26) through a hinge hole (8); one end of a driving rod (4) is hinged together with a transmitting rod (3) through a hinge hole (12), and the other end is hinged on the hingehole (11) of the stand (26); and the driven rod (2) is a curved rod which is provided with a hinge hole (10) on the middle curved part and is hinged together with the transmitting rod (3). The invention solves the problems that the traditional mechanical excavating mechanism of single degree of freedom acts simply and the hydraulic excavating mechanism is easy to leak oil.

Owner:GUANGXI UNIV

A Metamorphic Palletizing Robot Mechanism

InactiveCN102275743AWith output flexibilityWith multi-functional phase changeProgramme-controlled manipulatorStacking articlesSingle degree of freedomMulti degree of freedom

The invention discloses a metamorphic mechanism type stacking robot mechanism which comprises a rack, a controllable motor, a side link, an arm rod, a triangular connecting rod component and an arc limiting block, wherein the controllable motor is fixedly connected to the rack; the side link is driven by the controllable motor; the triangular connecting rod component comprises a first side rod, asecond side rod and a third side rod; the tail end of the arm rod is an output end; when the mechanism is in work, limiting is performed by the arc limiting block at the hinged place of a first smooth cylinder, the second side rod of the triangular connecting rod component is partially overlapped with the first smooth cylinder hinge and the second smooth cylinder hinge of the arm rod to realize conversion between a two-degree-of-freedom mechanism and a single-degree-of-freedom mechanism; and the metamorphic mechanism type stacking robot mechanism has performance of controllability, adjustability and output flexibility as well as characteristics of multifunctional stage change, multi-topology structure change and multi-degree-of-freedom change, and adapts to different tasks, occasions and working objects.

Owner:GUANGXI UNIV

Foldable six degrees of freedom light type operating arm with joint axis orthogonal relation

InactiveCN103753528ASimple structureLight in massProgramme-controlled manipulatorArmsSingle degree of freedomDegrees of freedom

A foldable six degrees of freedom light type operating arm with a joint axis orthogonal relation is characterized in that a first rotating joint, a second rotating joint, a large arm connecting rod, a third rotating joint, a forth rotating joint, a fifth rotating joint and a sixth rotating joint are arranged on a foundation base in sequence, an output end of the sixth rotating joint is connected with a tail-end single degrees of freedom paw, wherein an axis of the first rotating joint is arranged coaxially with the foundation base and is perpendicular to an axis of the second rotating joint, the axis of the second rotating joint is parallel to an axis of the third rotating joint, the axis of the third rotating joint is perpendicular to an axis of the forth rotating joint, the axis of the forth rotating joint is perpendicular to an axis of the fifth rotating joint, the axis of the fifth rotating joint is perpendicular to an axis of the sixth rotating joint, and the axis of the forth rotating joint, the axis of the fifth rotating joint and the axis of the sixth rotating joint are intersected at one point in space. By means of the foldable six degrees of freedom light type operating arm with the joint axis orthogonal relation, the integrated structure of an operating arm is simpler and more convenient, and quality is more portable and convenient, so that the optimal operating flexible performance of the tail end of the operating arm can be assured.

Owner:SANITARY EQUIP INST ACAD OF MILITARY MEDICAL SCI PLA

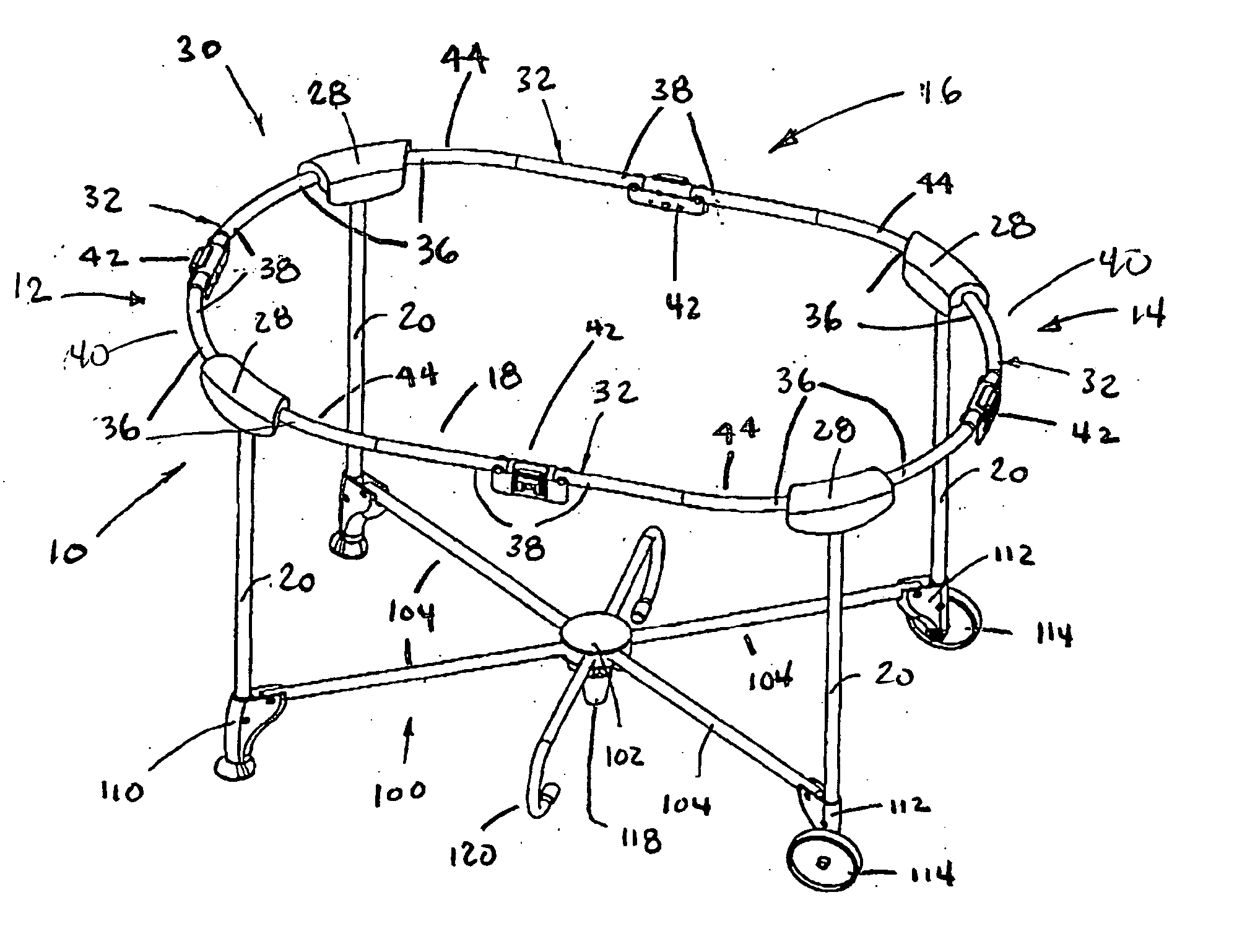

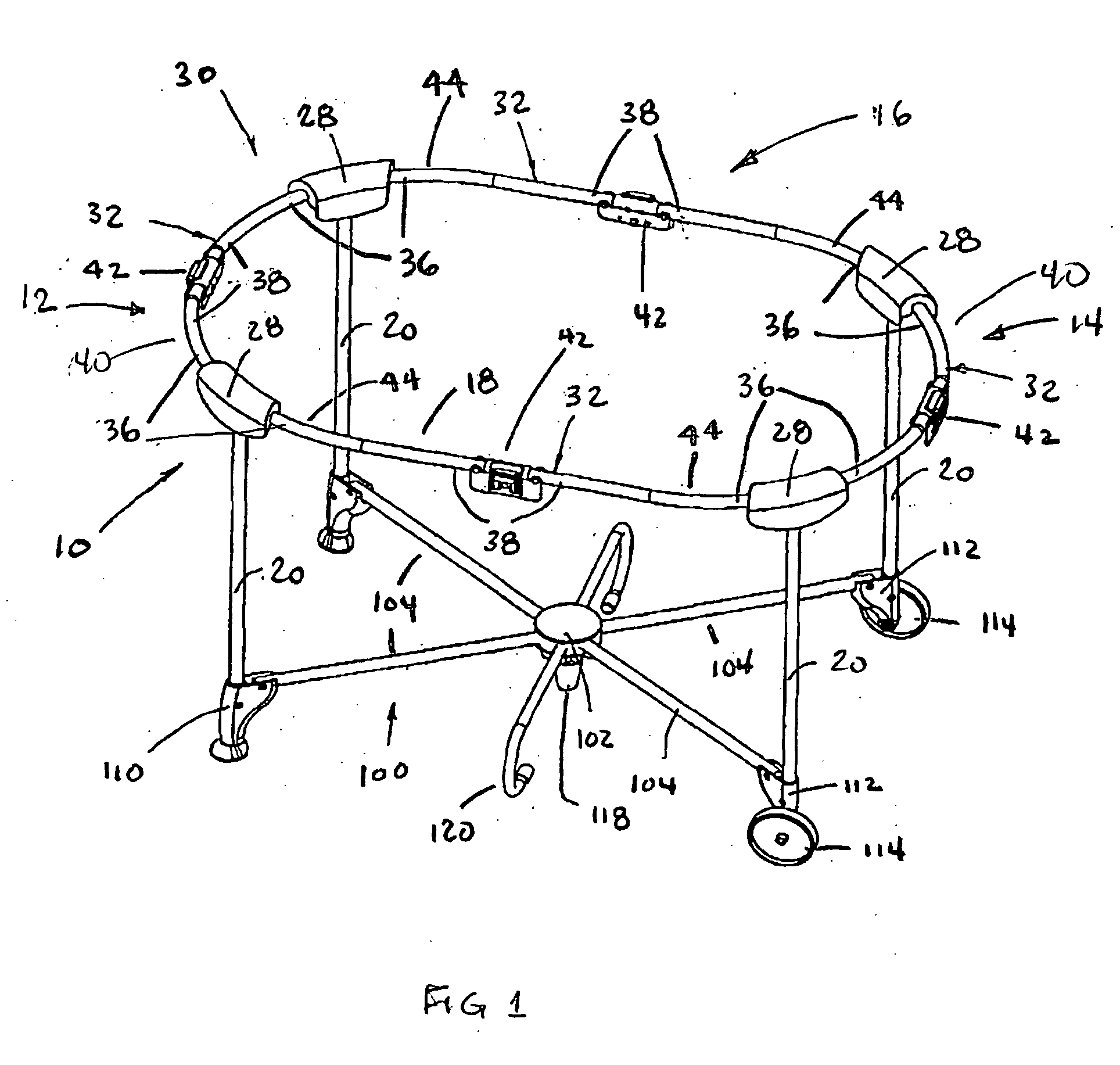

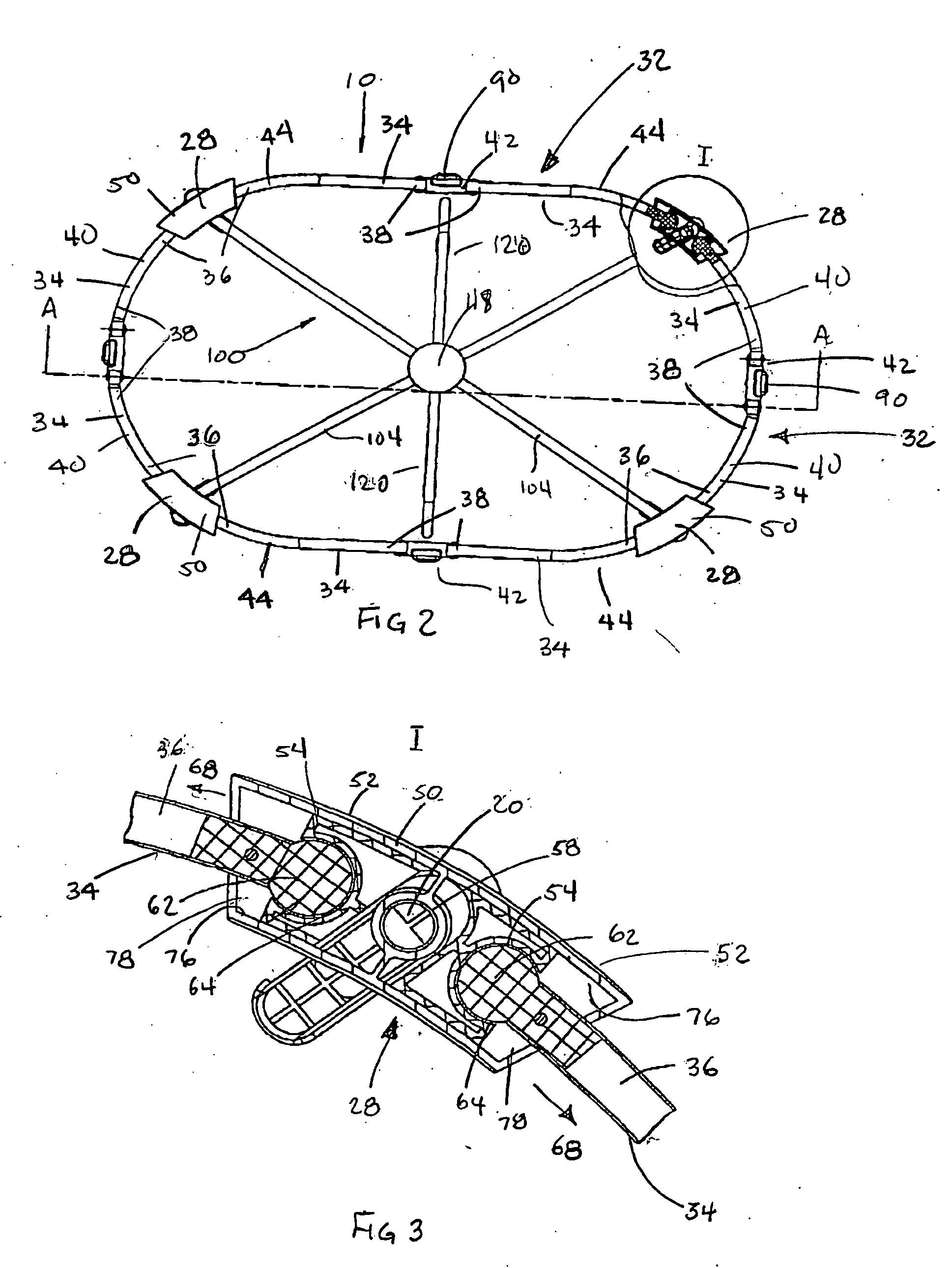

Foldable frame structure for a children's play-yard

A frame structure for a foldable children play-yard adaptable to include a curve side rail to form at least a portion of its upper perimeter. The frame structure comprises a plurality of support members, an upper frame member and a lower frame member. The upper frame member is constructed of a plurality of side segments, which define the upper perimeter of the play-yard and comprise rail members, which can include a curve portion. The rail members are coupled in a rotatable relationship disposed between the adjacent support members. The side segments have opposite distal end portions in engagement with support brackets mounted on the support members, the support brackets are adaptable to affix the side segment when the play-yard is in the open configuration and to permit the side segments to move in more than a single degree of freedom (for example, translational, axial-rotational movement and swivel movements) when the play-yard is being folded. The base frame member comprises a base hub, a plurality of extension members hingedly coupled to the base hub and extending therefrom to engage the lower portions of the support members in a pivotal relationship.

Owner:GOODBABY CHILD PROD CO LTD

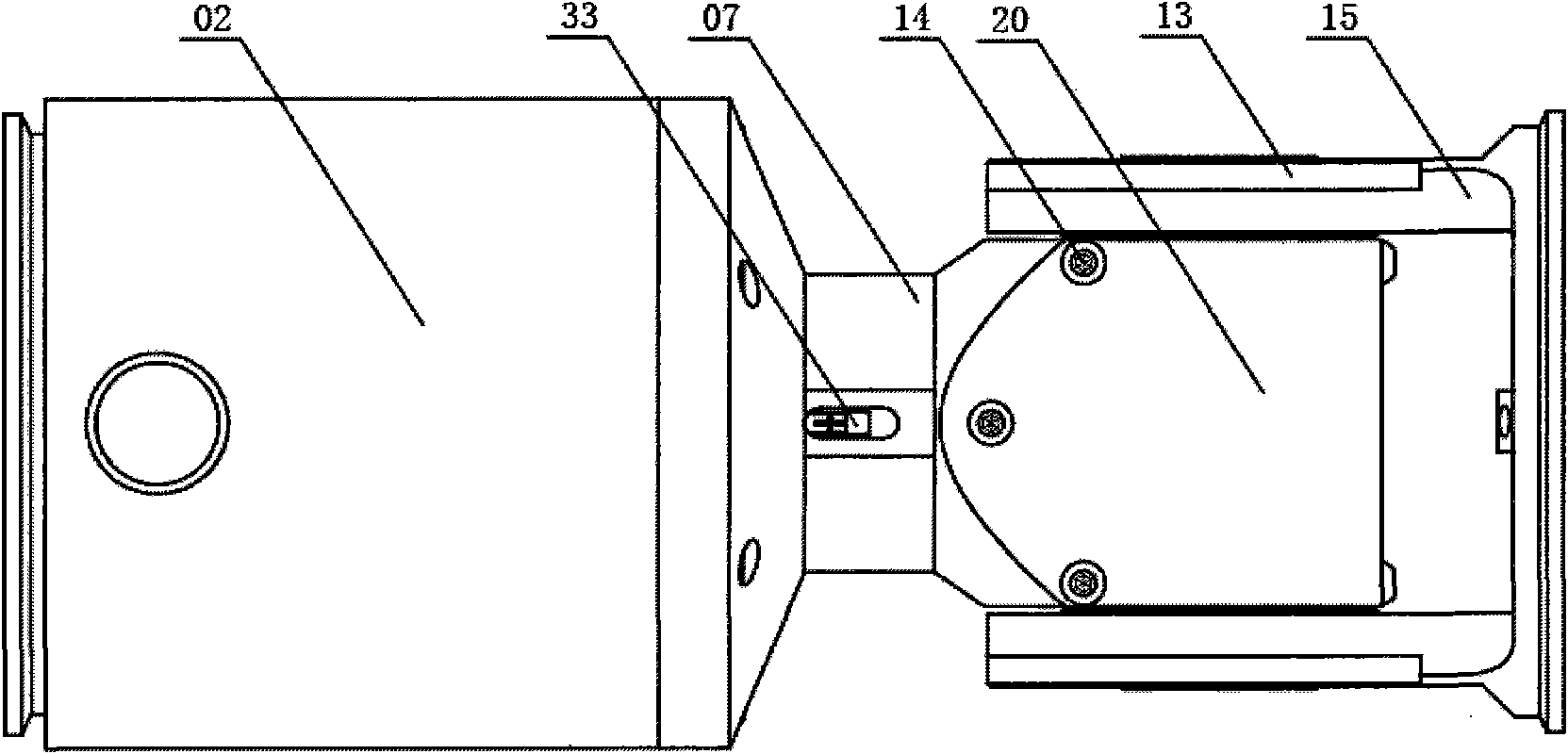

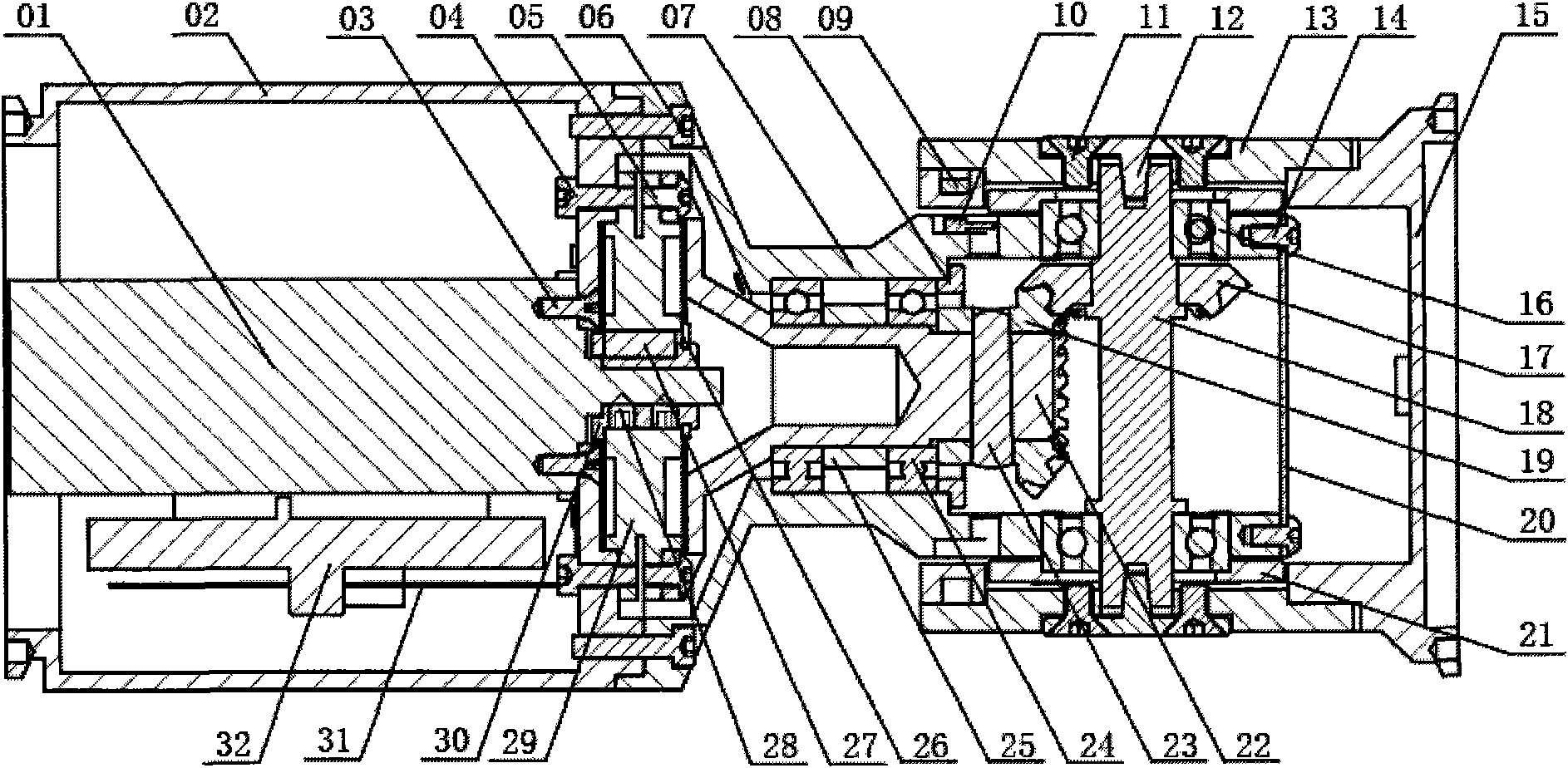

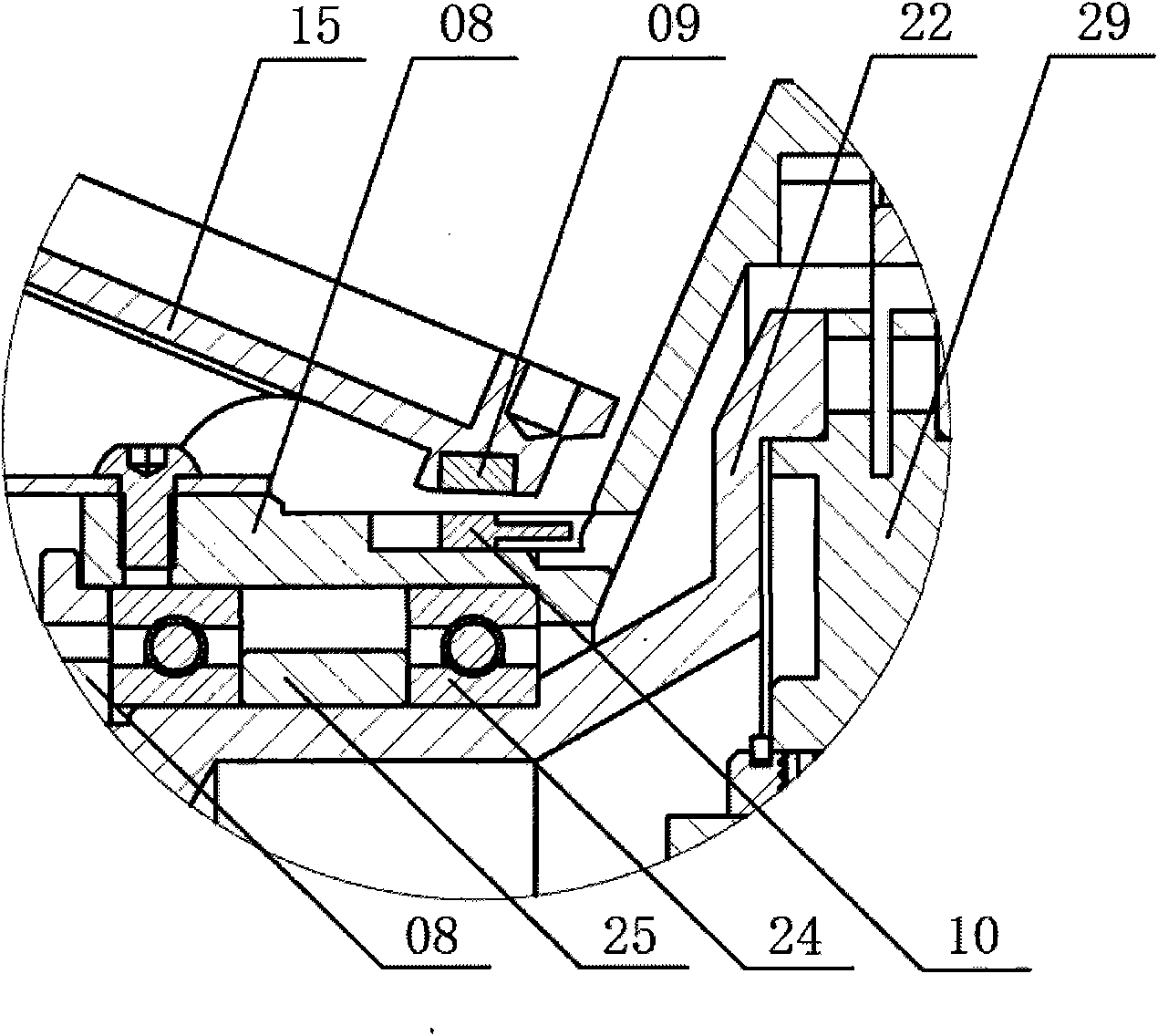

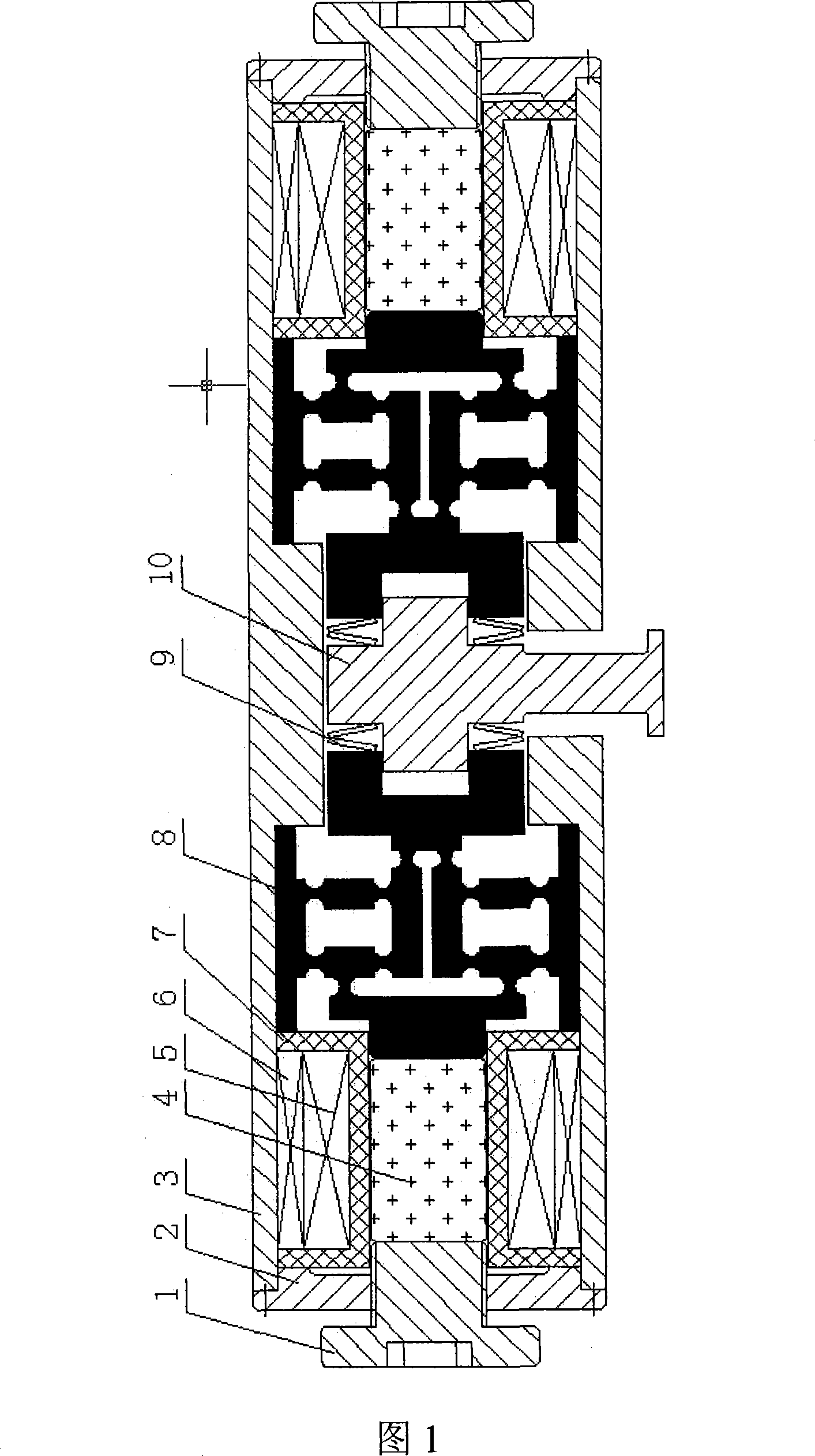

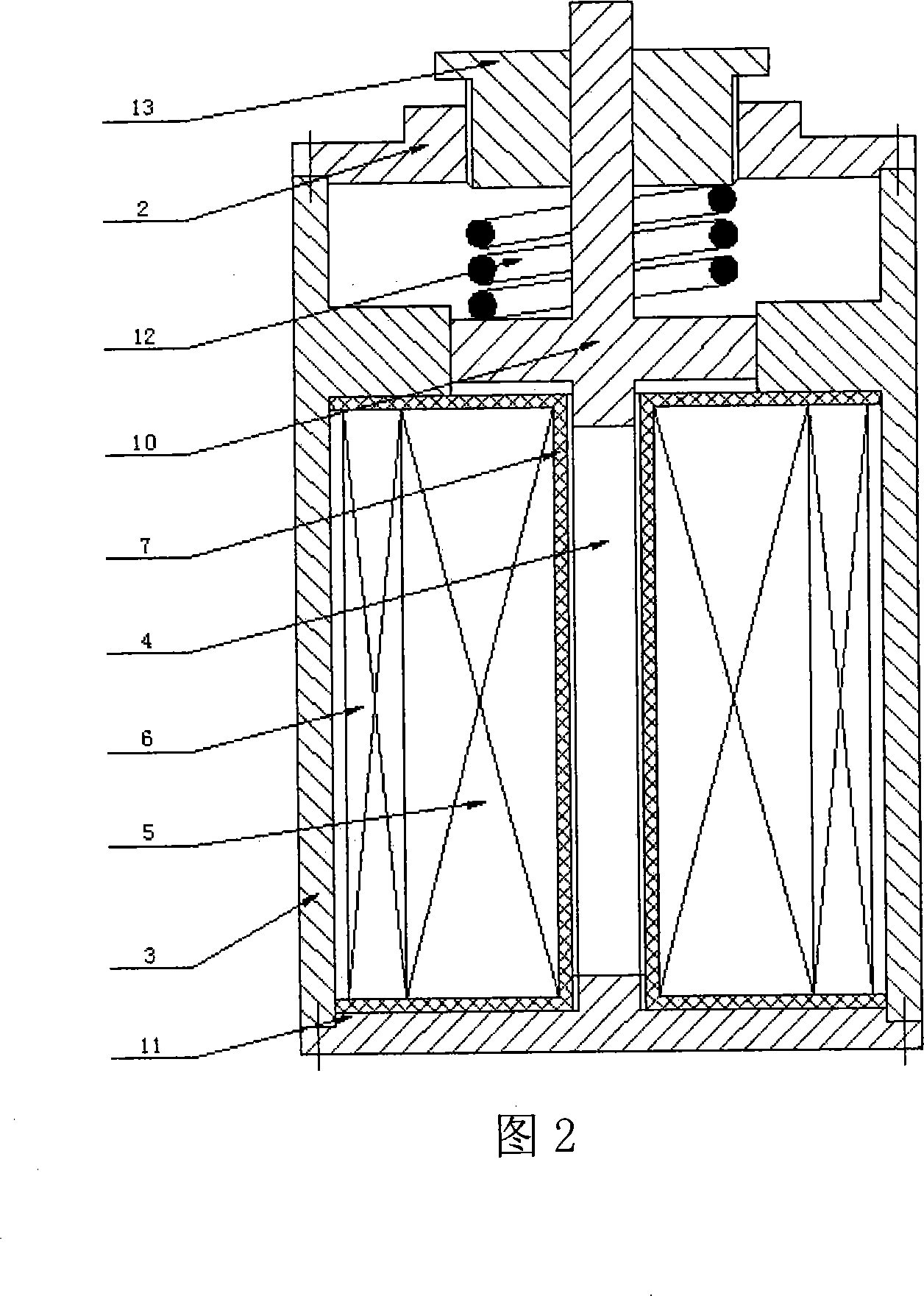

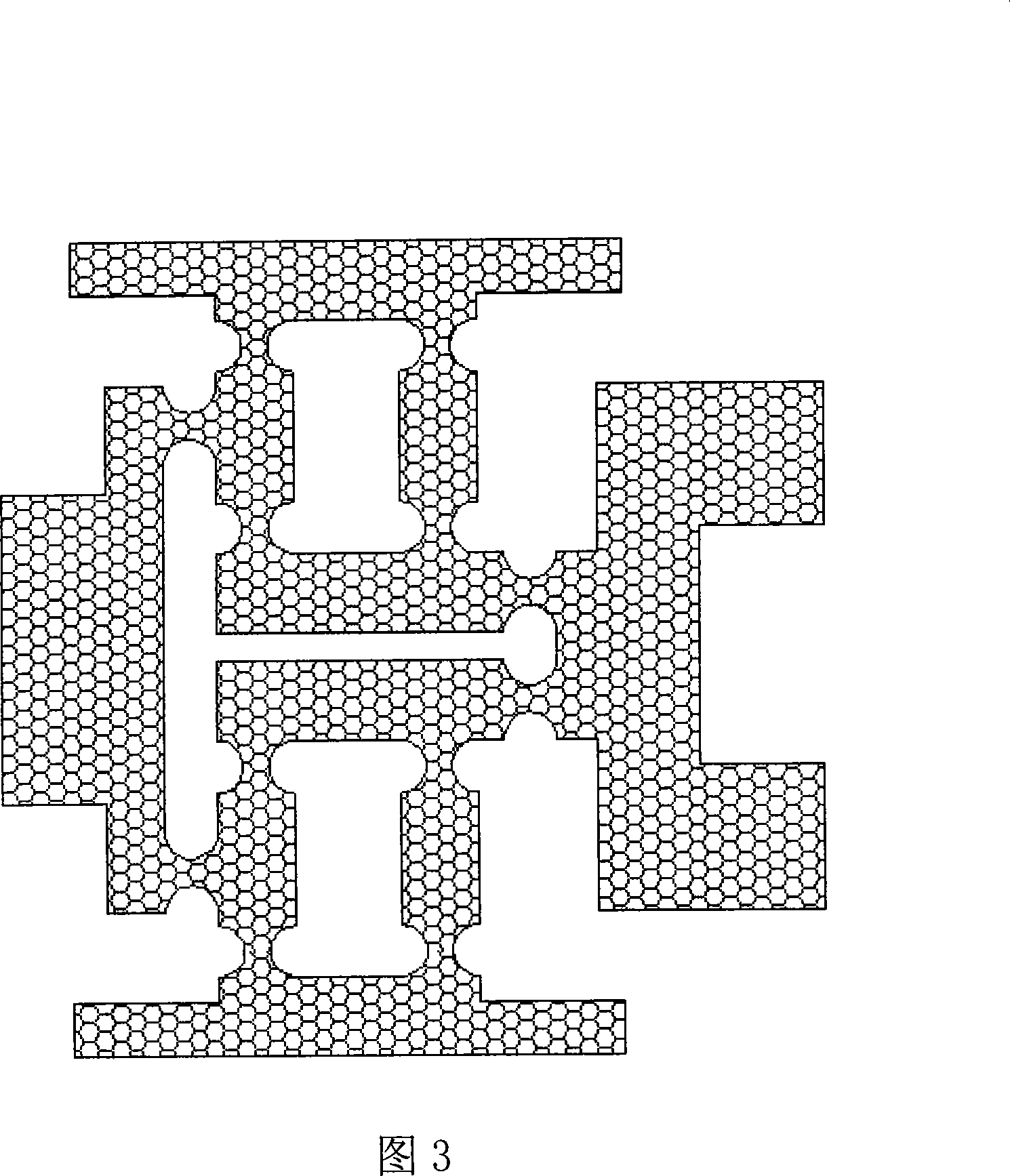

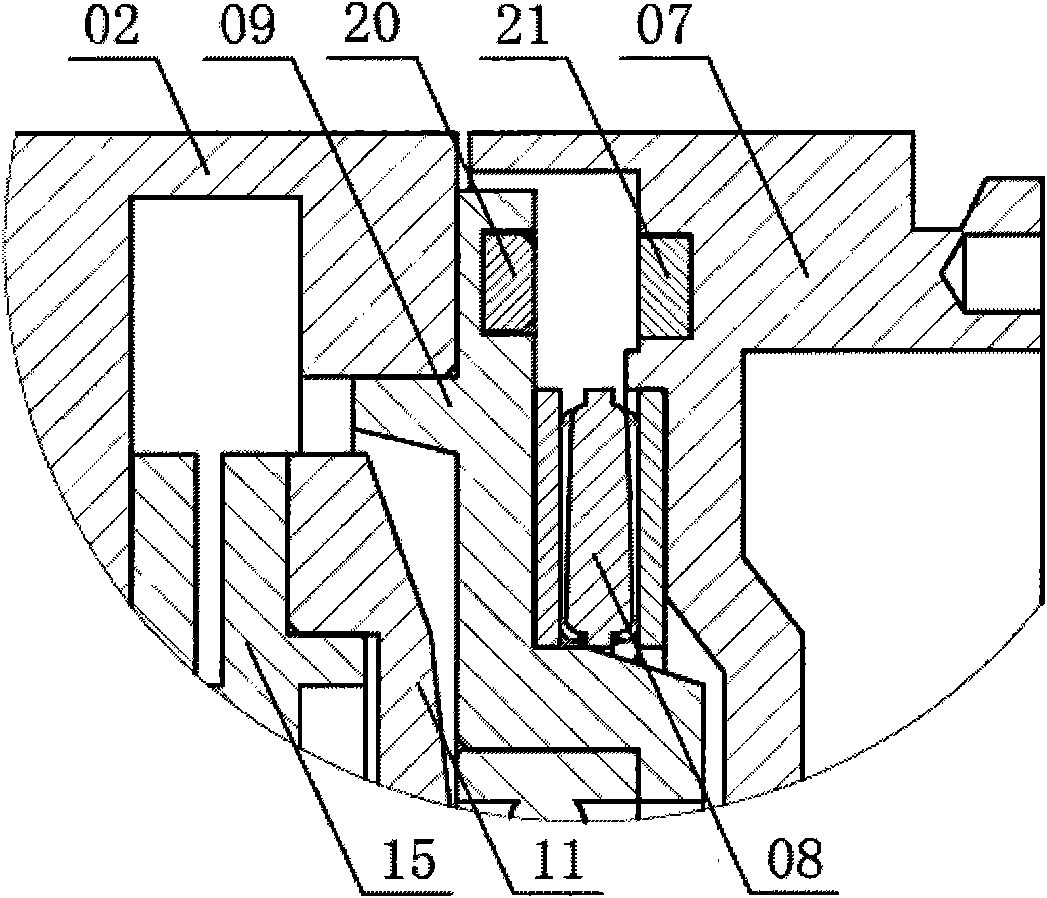

Rotating and swinging joint module of robot of single degree of freedom

The invention relates to a rotating and swinging joint module of a robot of single degree of freedom. The joint module is provided with a rotation degree of freedom, and the joint spindle thereof is vertical to the connection axis of the module to form swinging movement. The joint module is matched with a corresponding control system to realize movement or moment control, and joint parts and limiting position are detected by a Hall switch. The rotating and swinging joint module mainly comprises a servo motor and a photoelectric encoder assembly, a disk-type harmonic wave reducer assembly, a harmonic wave reducer output shaft, a motor base, a joint base, a bearing, a shaft cover, an end cover, a pair of bevel gears, a joint spindle and the like, wherein a motor shaft is connected with the wave generator of the harmonic wave reducer through the shaft sleeve, and the output rigid wheel of the harmonic wave reducer is fixedly connected with an output disk; a pair of bevel gears is arranged between the output disk and the joint spindle; the joint spindle is connected with a joint oscillating piece by a trapezoidal key to finally realize movement and power transmission. The module has compact structure and is convenient to connect with other modules or parts and can be combined and built into various robots or other electromechanical systems.

Owner:SOUTH CHINA UNIV OF TECH

A dual-phase set ultra-magnetism flexible driver and its implementation method

InactiveCN101145742ARealize automatic centering and return functionHigh frequency responsePiezoelectric/electrostriction/magnetostriction machinesDifferential pressureMagnetostrictive actuator

The invention belongs to the field of micro-drive technology. The present invention proposes a new double-phase opposing giant magnetostrictive driver. A pair of disc springs are sleeved on the output assembly and placed in the middle of the housing. Two single giant magnetostrictive drivers with the same structure and size pass through the The disc springs are symmetrically placed on both sides of the output assembly, forming a double-phase structure. Dual sets of thermal compensation mechanisms are used to suppress thermal deformation, and single-degree-of-freedom flexible hinge mechanisms are used to amplify and transmit the output displacement. The driver works through differential pressure (or bias voltage), which can realize the function of automatic centering and return, with high frequency response , high control precision, large output force, large output displacement and other excellent performances, and the structure is simple and easy to miniaturize, it can be widely used in the development of micro drives and the production of sensors, especially suitable for the drive unit of electro-hydraulic servo control valves .

Owner:BEIJING UNIV OF TECH

Guide pipe machining lathe

InactiveCN101698238AImprove work efficiencyReduce processing costsTurning machinesHydraulic cylinderSingle degree of freedom

The invention discloses a guide pipe machining lathe, which comprises a main shaft box, a chuck, a tail seat, a primary tool rest, a secondary tool rest and a secondary tool rest driving hydraulic cylinder. The secondary tool rest driving hydraulic cylinder is fixedly arranged on the main shaft box, a downward inclined track is arranged on the main shaft box, the secondary tool rest is arranged on the track and is driven by the secondary tool rest driving hydraulic cylinder to slide along the track in single degree of freedom, the secondary tool rest is provided with at least two lathe tools along the central line of the chuck, and the tool noses of the lathe tools point to the central line of the chuck obliquely downwards; and the primary tool rest is provided with at least two lathe tools along the central line of the chuck. By arranging the secondary tool rest and the lathe tools on the main shaft box to feed, groove and machine inlet and exhaust guide pipes of a motorcycle engine and arranging the lathe tools on the primary tool rest to longitudinally feed and cut the inlet guide pipes, the purpose of completely machining and shaping machined pieces once is achieved only by clamping the machined pieces once, the work efficiency is greatly improved, and the machining cost is saved. Meanwhile, the machined pieces are automatically fed and clamped and automatically popped and discharged, and the whole machining process realizes full automatic operation.

Owner:CHONGQING ZHIBO POWDER METALLURGY

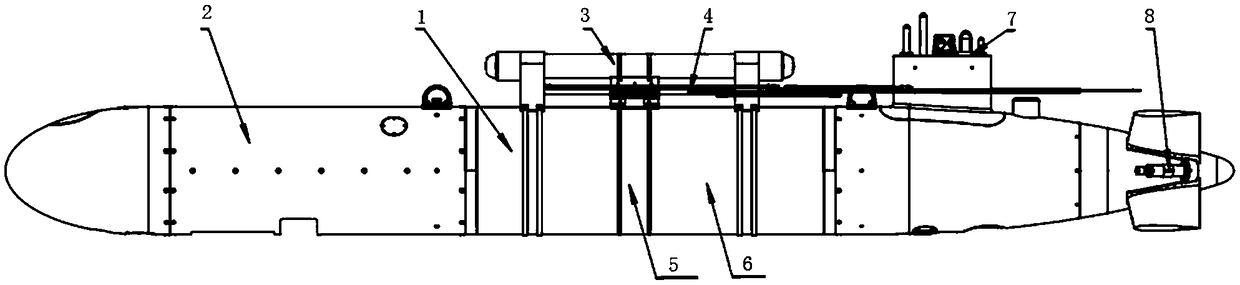

Large-scale heavy-load hybrid driving underwater glider

ActiveCN108639287AImprove performanceEasy to carryUnderwater vesselsUnderwater equipmentAttitude controlUnderwater glider

The invention discloses a large-scale heavy-load hybrid driving underwater glider. The large-scale heavy-load hybrid driving underwater glider comprises a glider body, a buoyancy control device, an attitude adjusting device, a folding wing mechanism, an energy module, a main control system, a navigation communication system and a propeller driving system. The main control system controls the buoyancy control device to adjust the buoyancy of the underwater glider, and the attitude adjusting device is integrally connected above the back of the underwater glider to realize the pitch attitude control of the underwater glider. The folding wing mechanism is arranged as a single degree of freedom and comprises a gas spring mechanism, a connecting rod mechanism, a pair of rotating wings and a pairof telescopic wings, wherein the folding wing mechanism is connected with the attitude adjusting device and is fixed in the middle of the glider body and connected with the glider body as a whole. The pair of rotating wings realizes plane rotation under the drive of the connecting rod mechanism, and the pair of telescopic wings realizes stretching and retracting motion. The navigation communication system is used for setting heading and operation tasks. The main control system controls the propeller driving system to realize the propulsion movement and differential motion turning movement.

Owner:TIANJIN UNIV

Robot revolute joint module with single degree of freedom

The invention relates to a robot revolute joint module with single degree of freedom. The joint module is provided with a rotation degree of freedom, and a rotation shaft of the articulated module is coincident with or parallel to a central axis of the module so as to form revolute motion. A corresponding control system is matched for realizing the control on motion or torque, and a Hall switch is used for zero position detection. The joint module mainly comprises a servo motor and a photoelectric encoder assembly, a disk-type harmonic speed reducer assembly, a harmonic speed reducer output disk, a joint base, an output sleeve, a bearing and a corresponding end cover. The output shaft of the servo motor is connected with the wave generator of a harmonic speed reducer through a sleeve, the output rigid wheel of the harmonic speed reducer is fixedly connected with the output disk through screws, and the output disc is connected with the output sleeve through a spline, therefore, the transmission of motion and power is realized finally. The module has simple and compact structure and convenient connection with other modules or parts, and can be used in combination way to structure various robots or other electromechanical systems.

Owner:SOUTH CHINA UNIV OF TECH

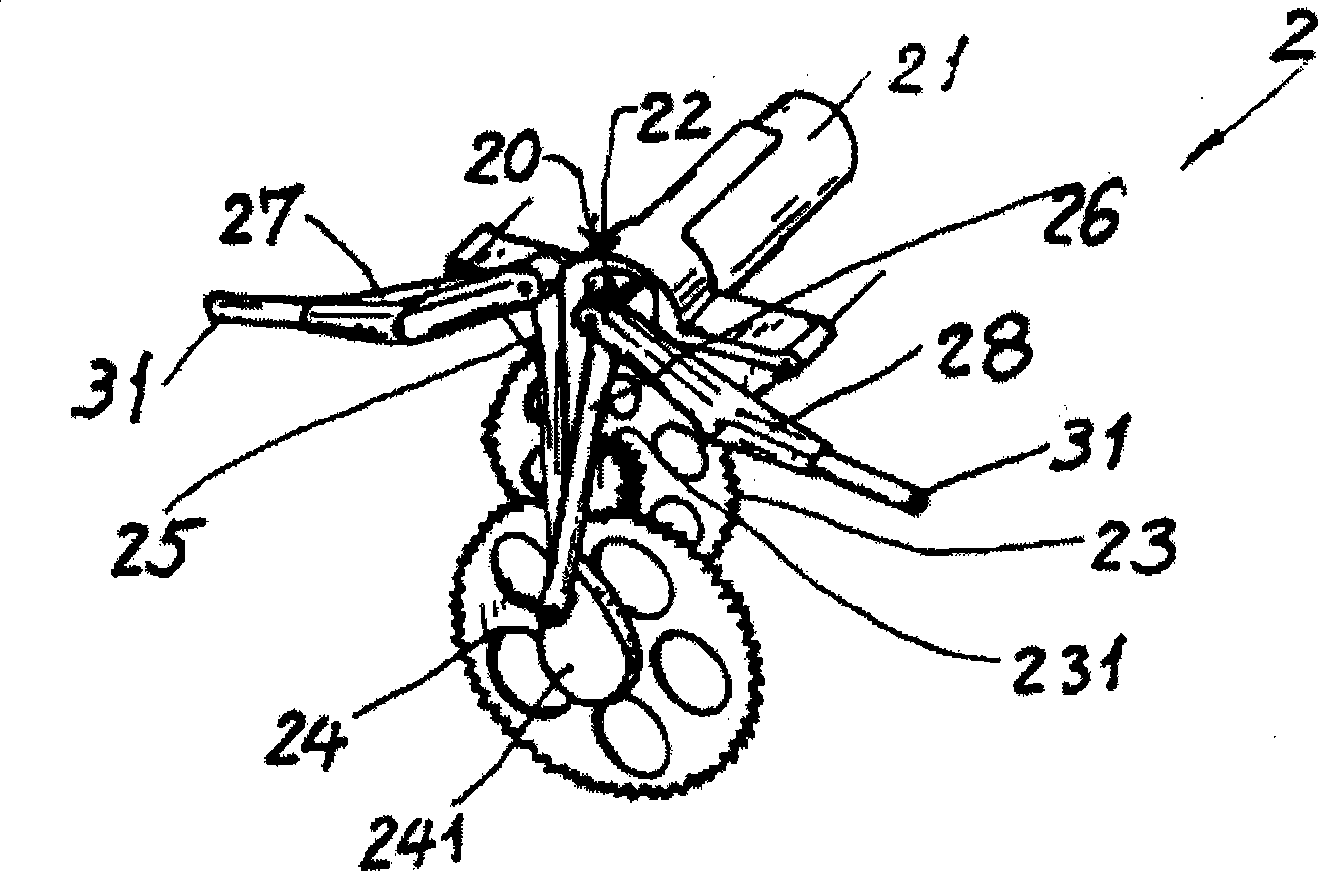

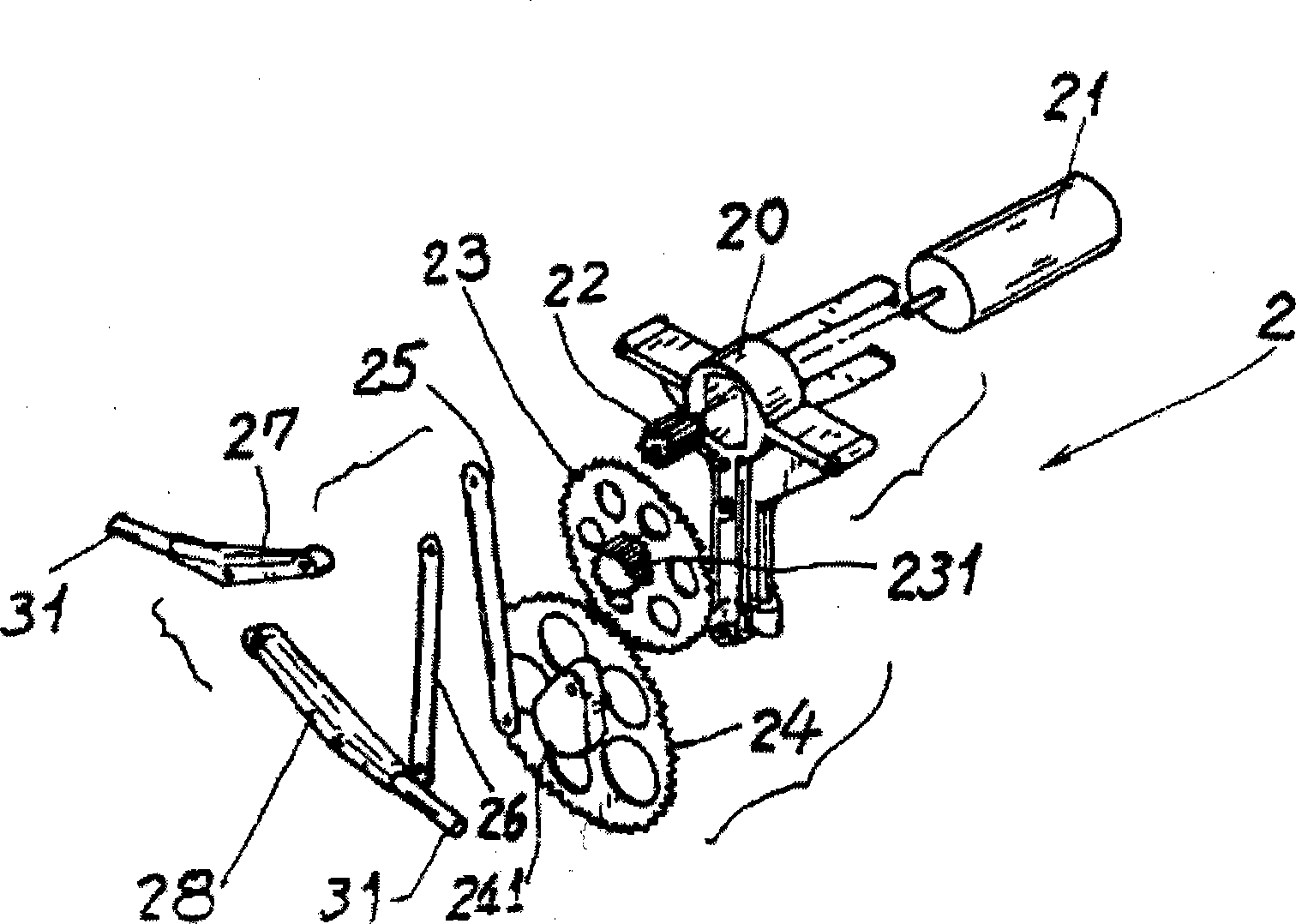

Bionic micro aircraft with figure-of-eight flapping-wing trail

The invention relates to a biomimetic micro air vehicle with 8-shaped flapping tracks, which makes use of a flexible carbon fiber rod and a parylene film as an aerofoil framework and an aerofoil covering skin respectively for a palm-sized micro air vehicle. Even through a flapping (gear connecting rod) driving mechanism is only designed into a single degree of freedom four-bar (mechanism), the linkage of the upward and downward flapping is successfully coupled to flow direction forward and backward vibrations through the material and the shape design of a flexible aerofoil, thus three-dimensional 8-shaped flapping tracks are assembled at the aerofoil tip; and the flapping frequency of the generation of the 8-shaped tracks is close to or even more than 20 Hz, thus a micro air vehicle with a simple structure is formed and can generate the 8-shaped tracks automatically according to the essence of aeroelasticity without getting help from the design of a complicated delicate movement mechanism with multiple degrees of freedom.

Owner:TAMKANG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com