A dual-phase set ultra-magnetism flexible driver and its implementation method

A technology of giant magnetostrictive and giant magnetostrictive rods, which is applied in the direction of piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., and can solve the problem of limiting the application of electro-hydraulic servo control valves , There is no such problem as the key of automatic centering and return, and the output displacement and force of micro-displacement are small, so as to achieve the effect of large output force, large output displacement and improved overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

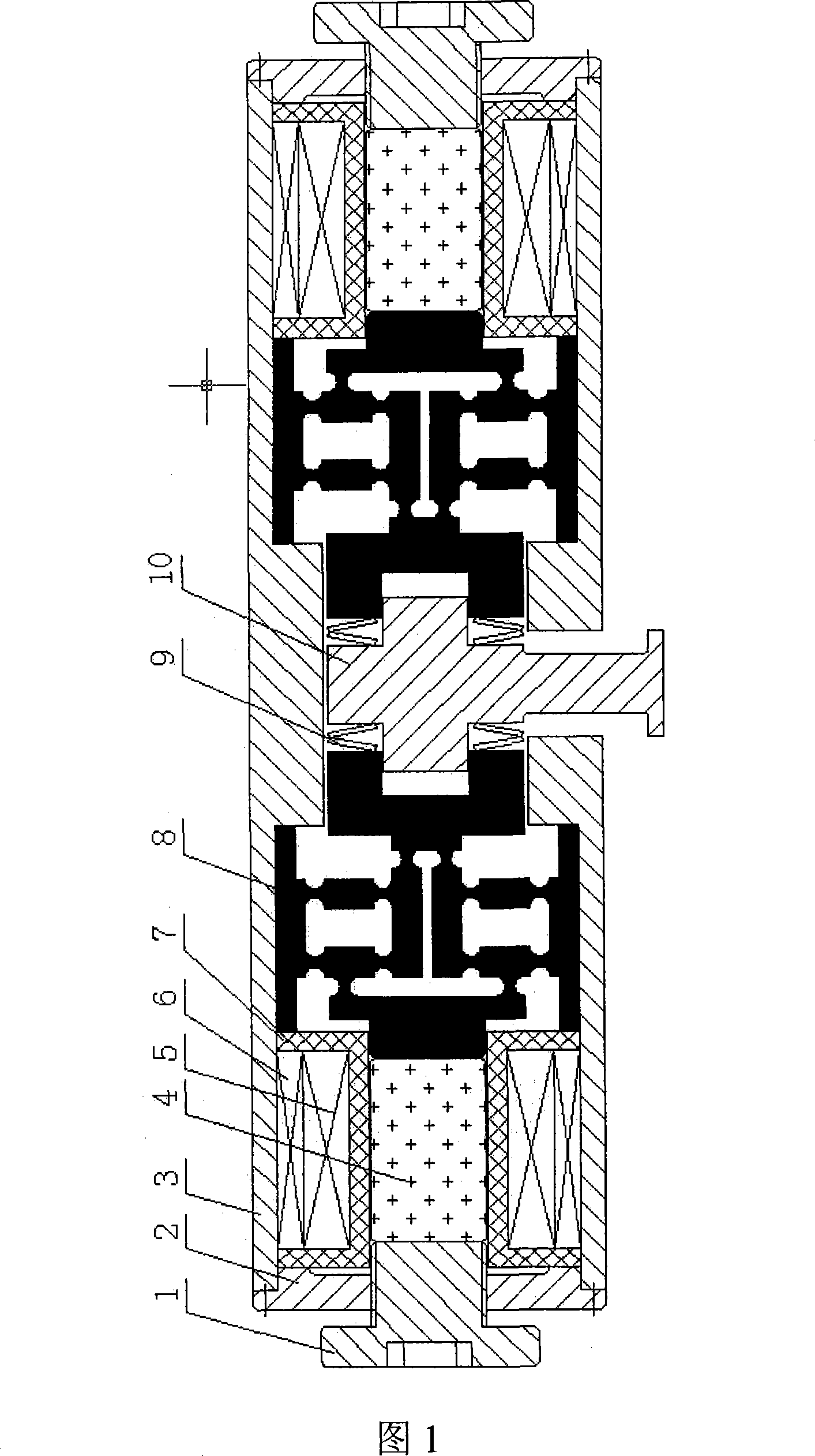

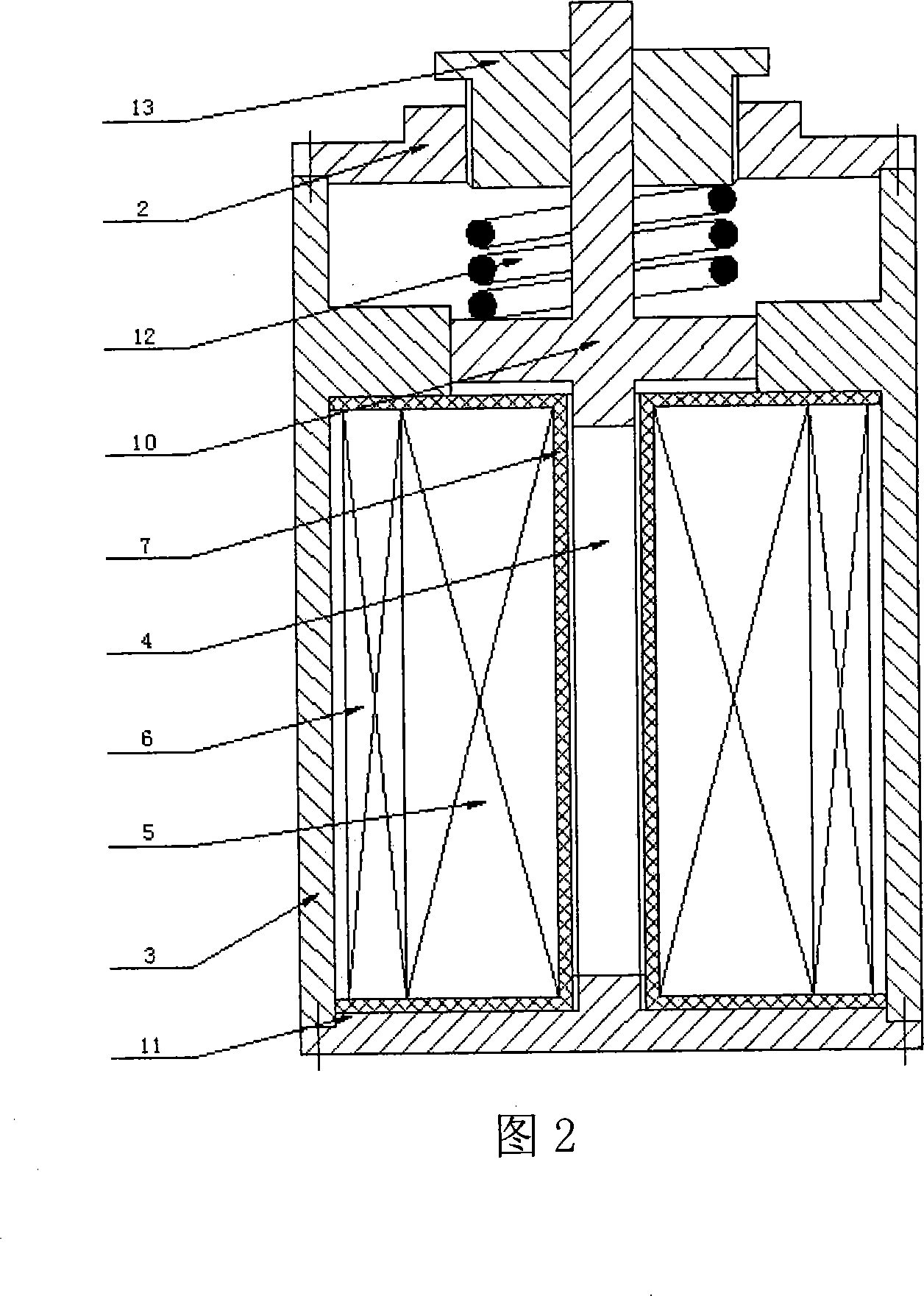

[0020] First check whether the output assembly 10 is centered, if not, adjust it through the adjustment screw 1, input direct current into the bias coil 6, and ensure that the giant magnetostrictive rod 4 works under the selected static pressure state, so that the supermagnetic The telescopic rod 4 works in the linear region.

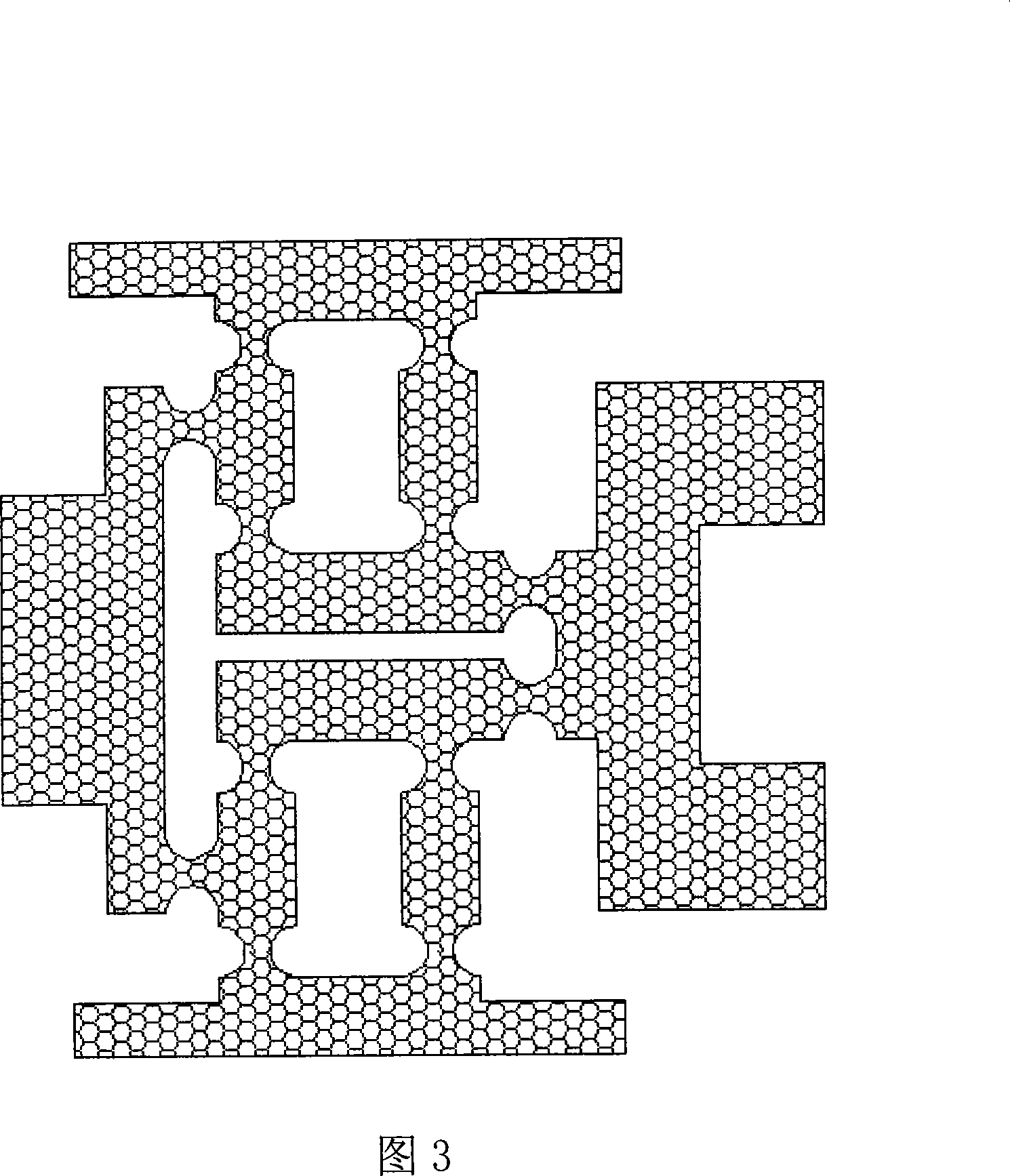

[0021] Non-differential working mode: AC current is passed into the driving coil 5 of the single giant magnetostrictive driver on one side, and a changing magnetic field is generated to magnetize the giant magnetostrictive rod 4, and the length of the giant magnetostrictive rod 4 changes. 4. The outer side is fixed by the adjusting screw 1, and then stretches inward, pushing the micro-displacement amplification mechanism 8 to realize the amplification and transmission of the output displacement, and then output the displacement and force in the output assembly 10 through the disc spring 9; at the same time, the symmetrical side single supermagnetic The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com