Patents

Literature

48results about How to "Reduce offset error" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

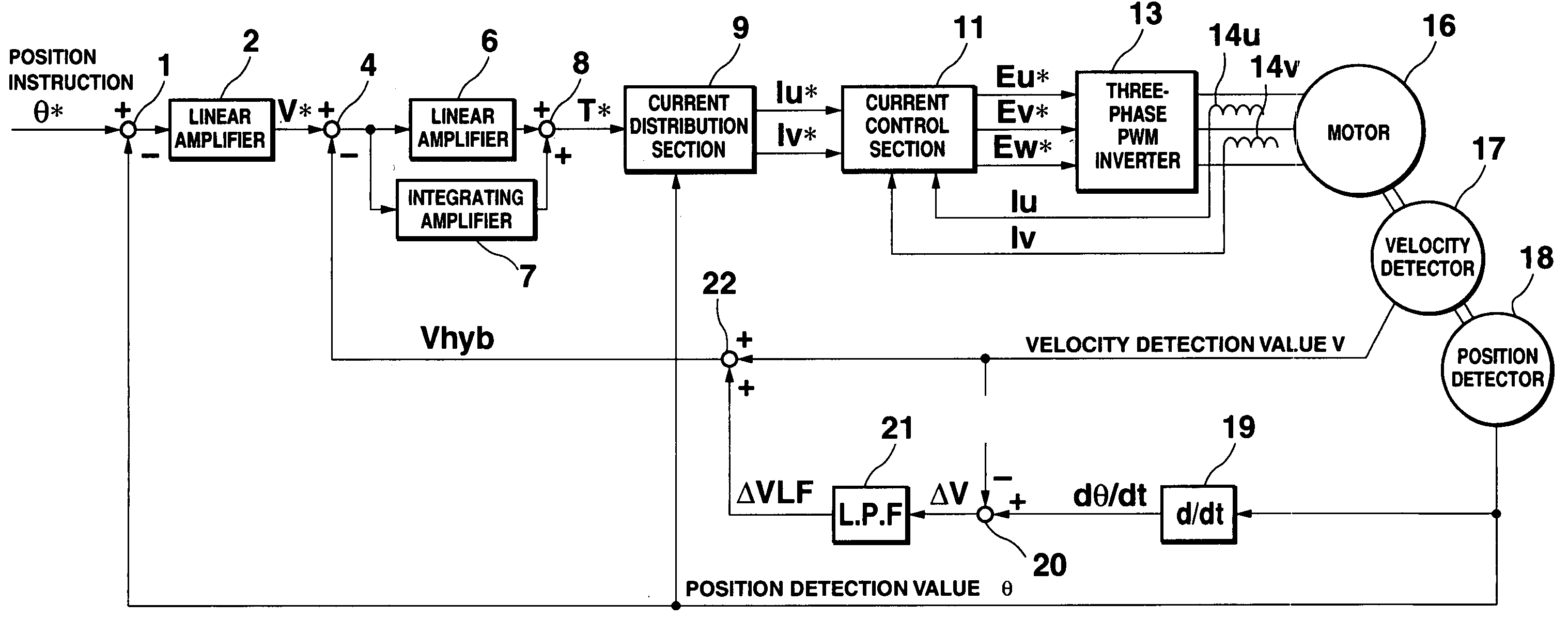

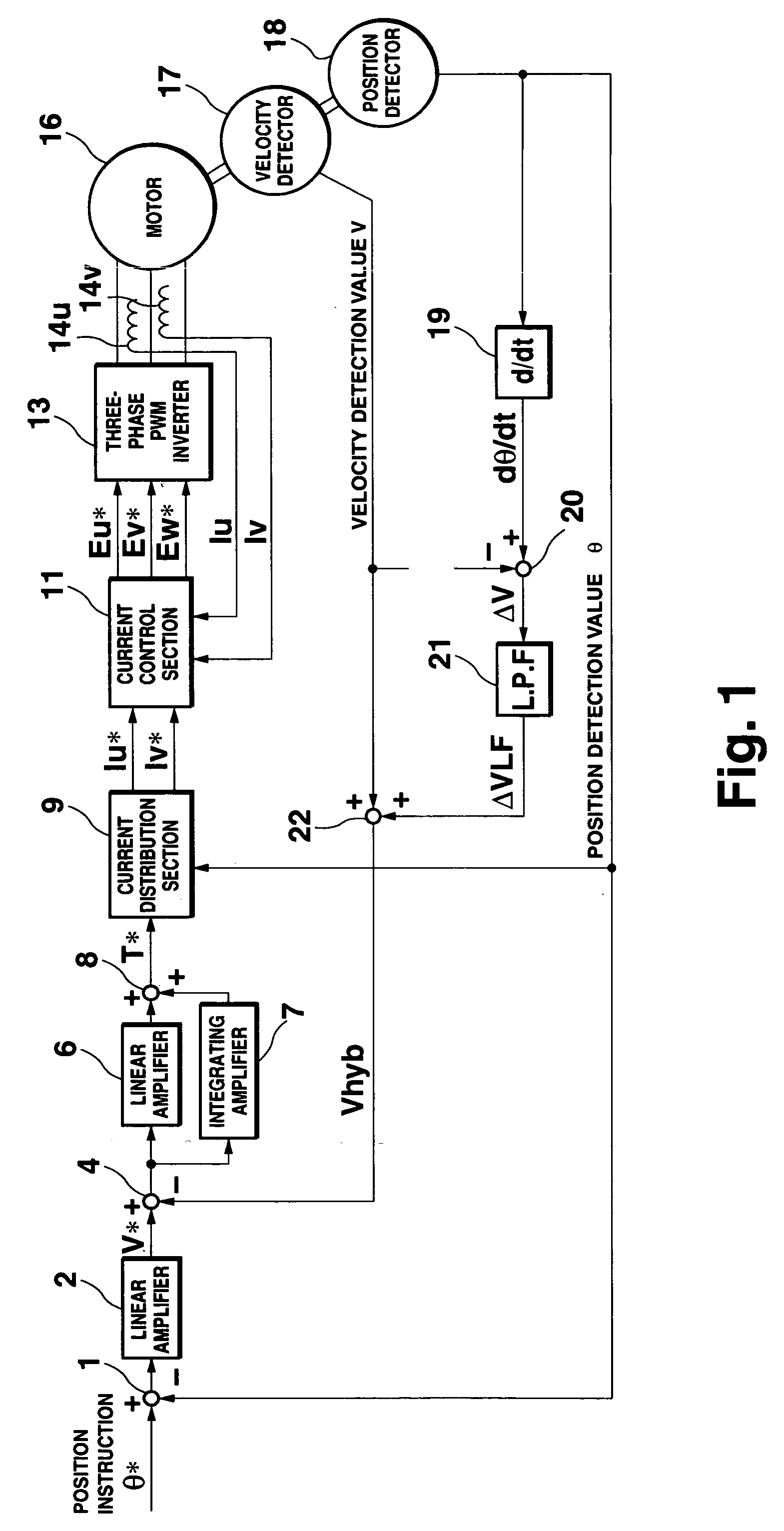

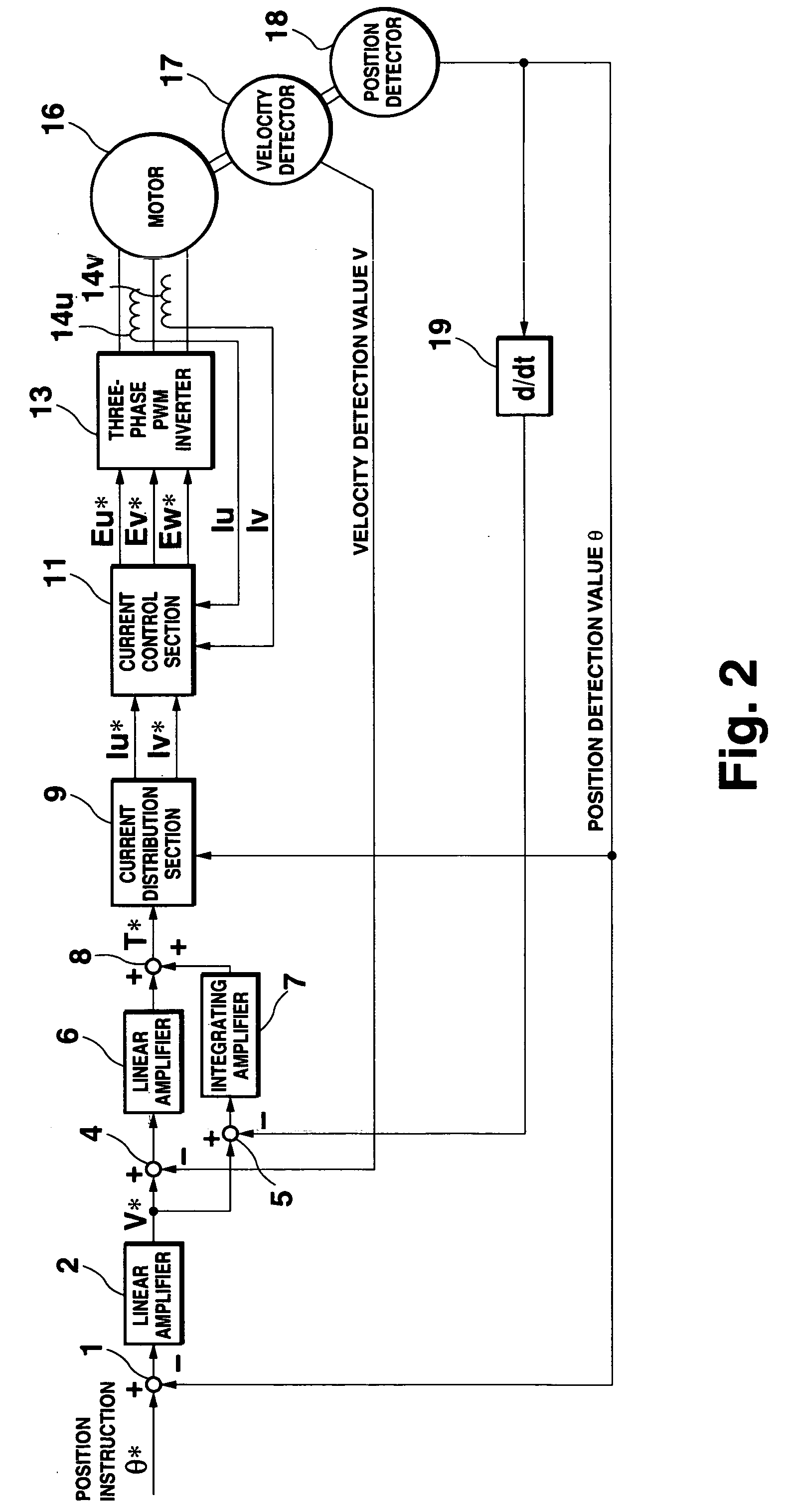

Motor control apparatus for controlling operation of mover of motor

InactiveUS20050067996A1Reduce gain errorReduce offset errorElectronic commutation motor controlElectric motor controlDifferentiatorLinear amplification

A motor control apparatus of the present invention comprises a velocity detector for detecting a rotation velocity of a mover of a motor, a position detector for detecting a position of the mover, a differentiator for performing time differentiation with respect to the position detected by the position detector to obtain a velocity calculation value, a feedback signal generating circuit for generating a feedback signal including the velocity detection value obtained by the velocity detector as a high frequency component and the velocity calculation value obtained by the differentiator as a low frequency component, and a linear amplifier and an integrating amplifier for performing PI control, the linear amplifier and the integrating amplifier performing linear amplification and integrating amplification of a difference between the velocity instruction and the feedback signal, respectively.

Owner:OKUMA CORP

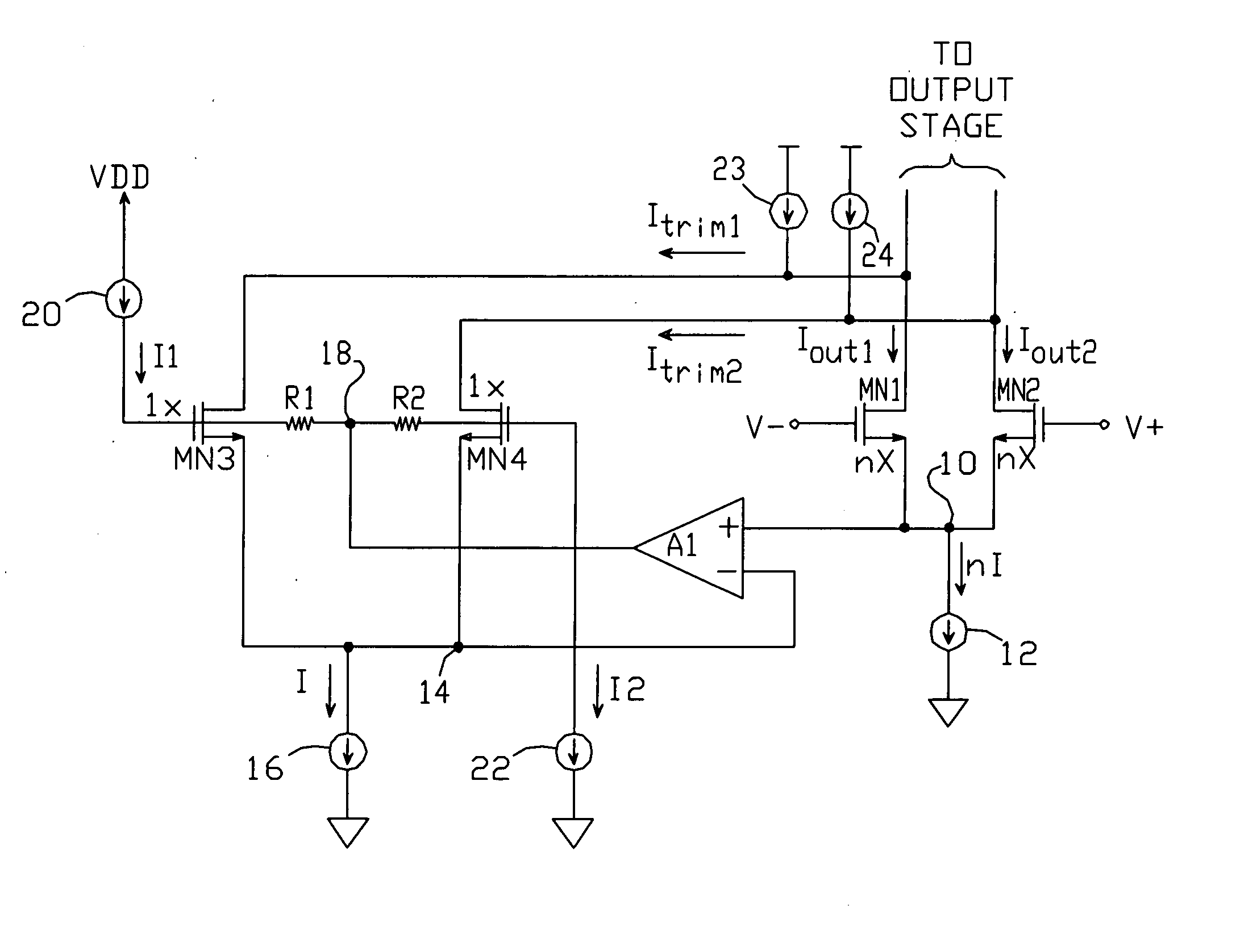

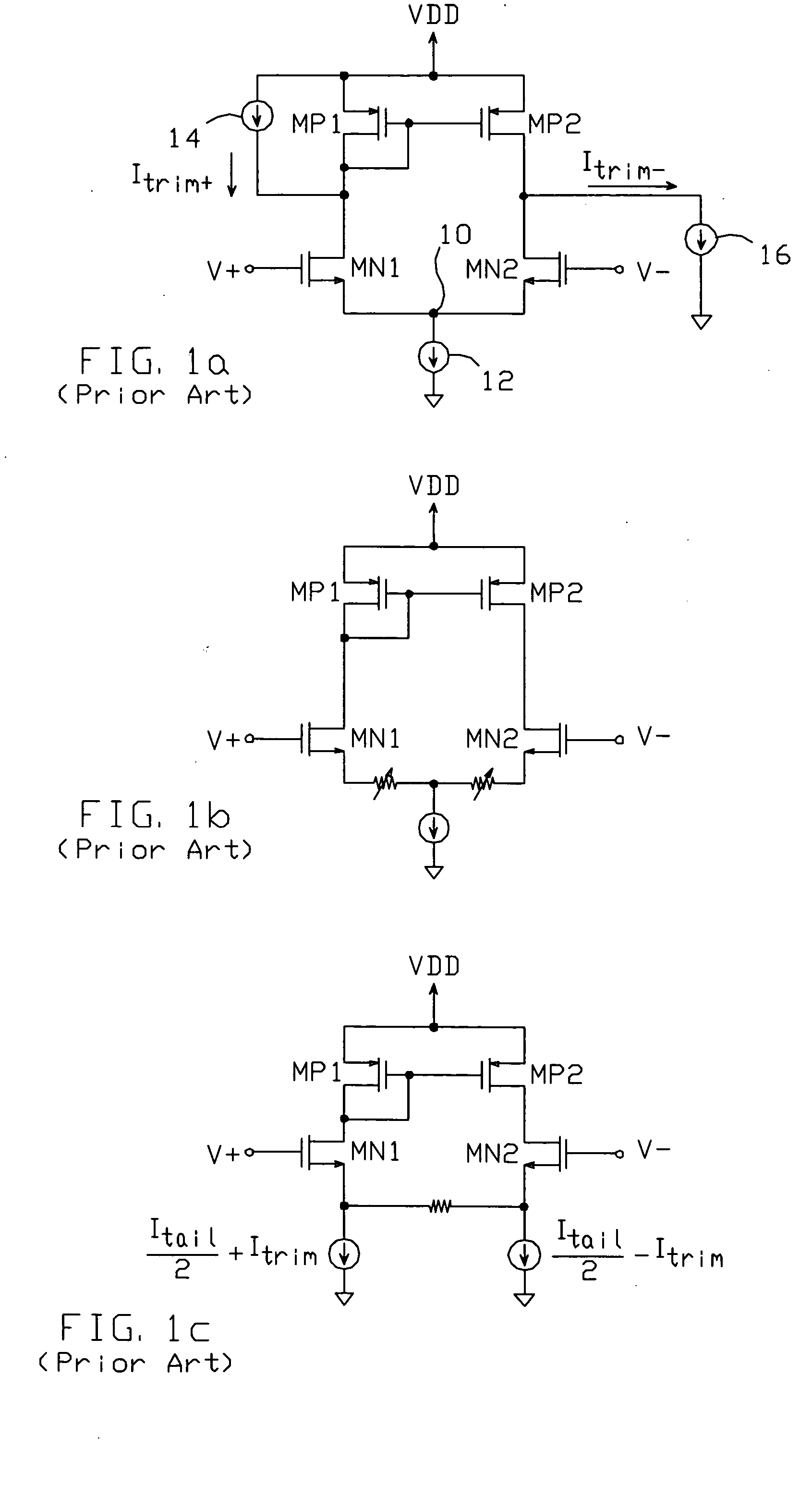

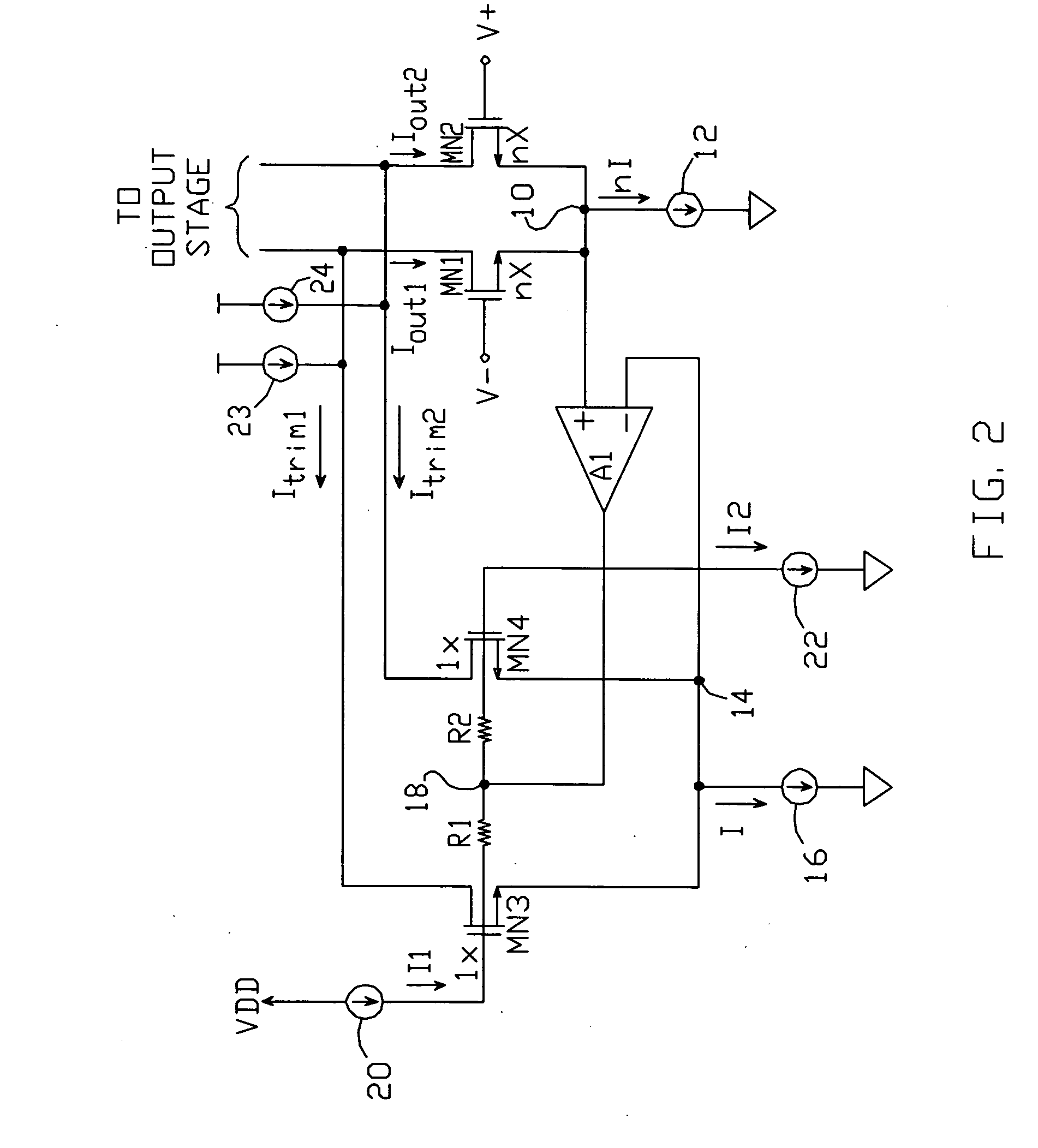

Differential stage voltage offset trim circuitry

ActiveUS20050218980A1Reduce offset errorReduce errorsAmplifier modifications to reduce temperature/voltage variationDifferential amplifiersActive loadVoltage shift

Differential stage voltage offset trim circuitry involves the use of one or more trim circuits, each of which is dedicated to trimming one particular source of voltage offset (Vos) error for a “main” differential pair. One trim circuit may be dedicated to trimming Vos error that arises due to mismatch between the main pairs' threshold voltages, and another trim circuit may be dedicated to trimming Vos error that arises due to mismatch between the main pairs' beta values. Another trim circuit can trim Vos error due to gamma mismatch between the main pair transistors, and respective trim circuits can be employed to trim Vos error that arises due to threshold mismatch and / or beta mismatch between the transistors of an active load driven by the main pair. Several trim circuits may be employed simultaneously to reduce offset errors that arise from each of several sources.

Owner:ANALOG DEVICES INC

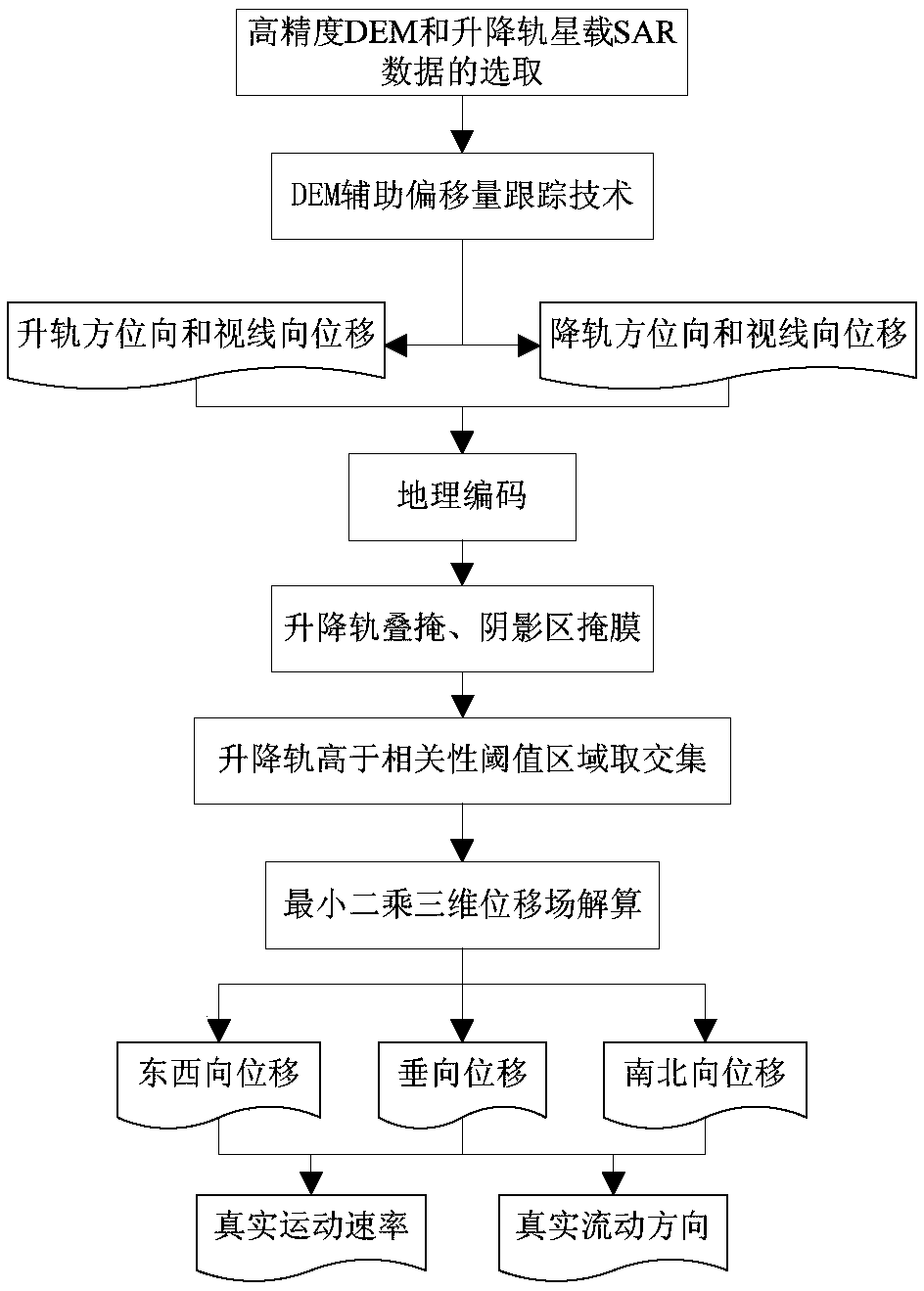

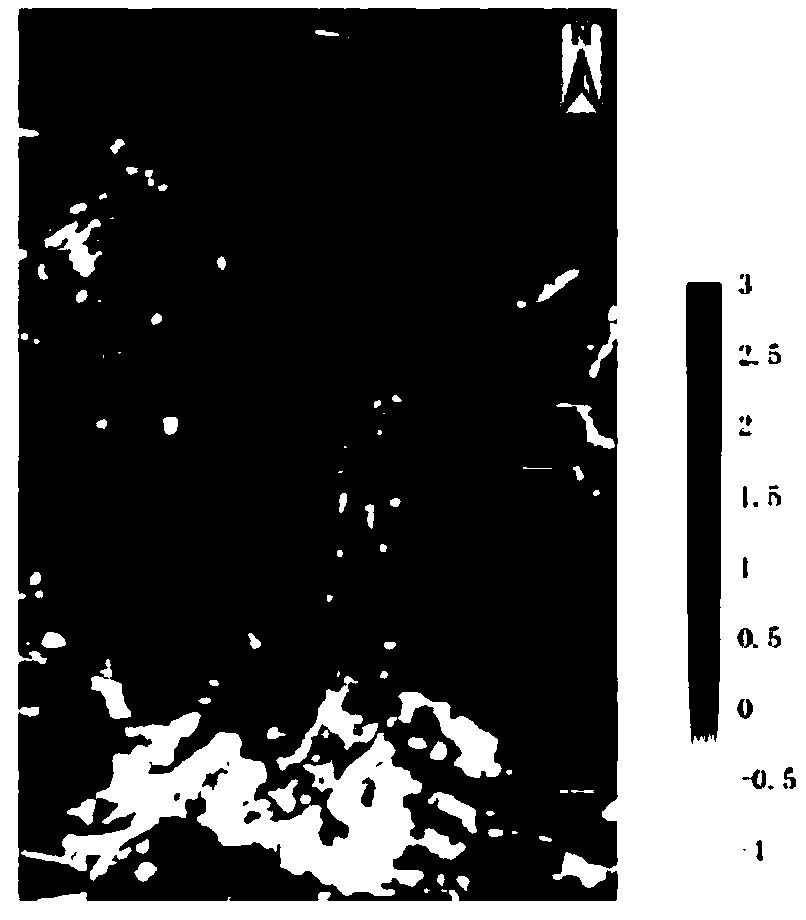

DEM-auxiliary-intensity-related glacier surface motion three-dimensional vector inversion method

ActiveCN108919262AOffset tracking improvedImprove registration accuracyRadio wave reradiation/reflection3D modellingShadowingsTerrain

The invention discloses a DEM-auxiliary-intensity-related glacier surface motion three-dimensional vector inversion method, and relates to the technical field of glacier motion monitoring. Lifting rail SAR image pairs are registered at high precision based on a high-precision DEM, and then displacement observation results in four different directions of a glacier area are obtained by utilizing satellite-borne SAR amplitude information and applying an offset tracking technology; and shadowing and layover areas with the threshold value lower than the offset tracking relativity threshold value are masked, according to the SAR image forming geometrical relationship, the functional equation system between the deformation observation results of the four directions and three-dimensional motion components of three glaciers in the east-west, south-north and vertical directions is built, the three-dimensional motion components are calculated, and then the actual flowing speed and direction of the surfaces of the glaciers are obtained. Actual three-dimensional motion on the surfaces of the glaciers is inversed only through satellite-borne SAR, when the terrain is steep and an SAR image spacebase line is large, the offset error is lowered, and the precision of the offset tracking result is improved.

Owner:CHINA AERO GEOPHYSICAL SURVEY & REMOTE SENSING CENT FOR LAND & RESOURCES

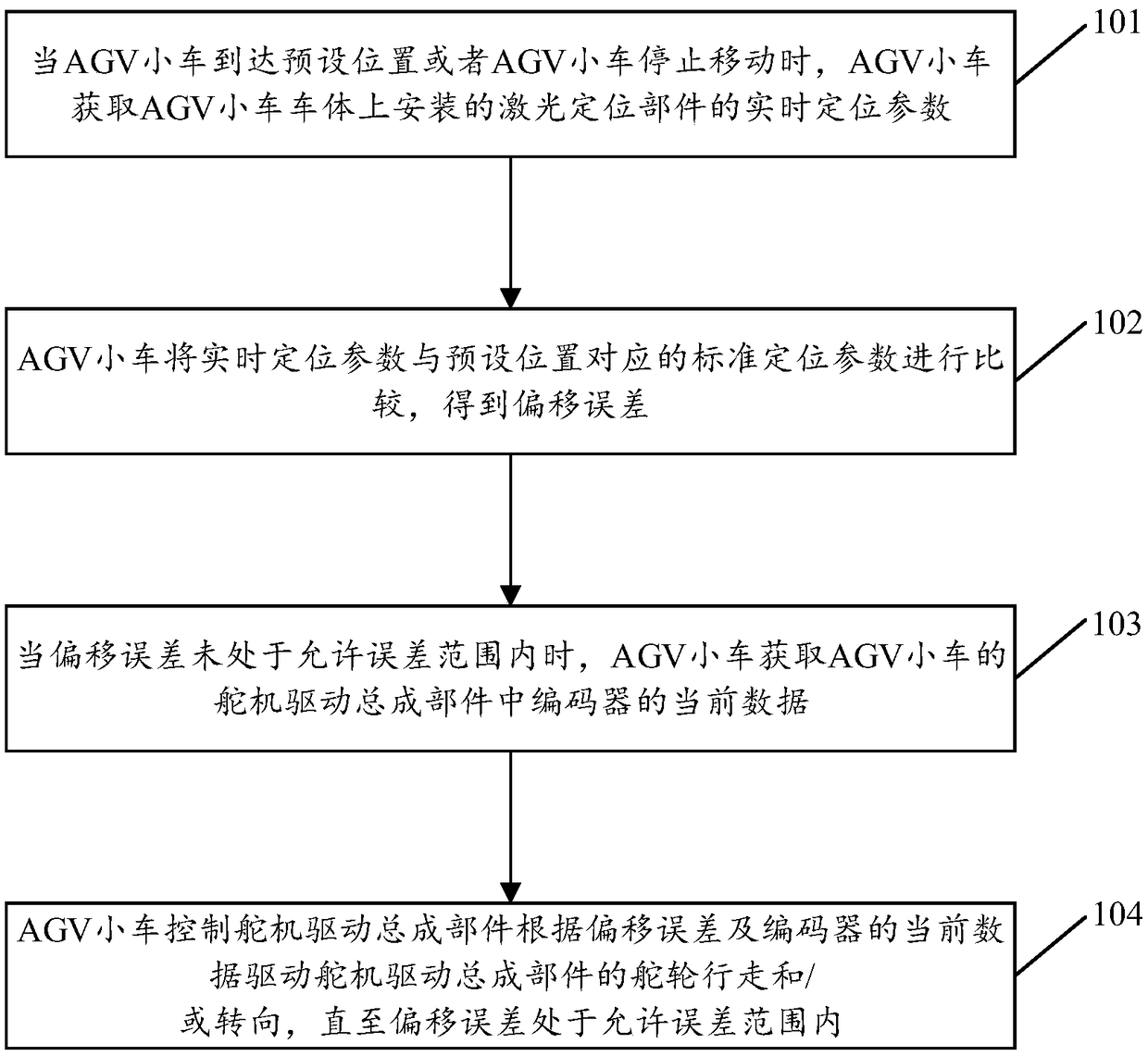

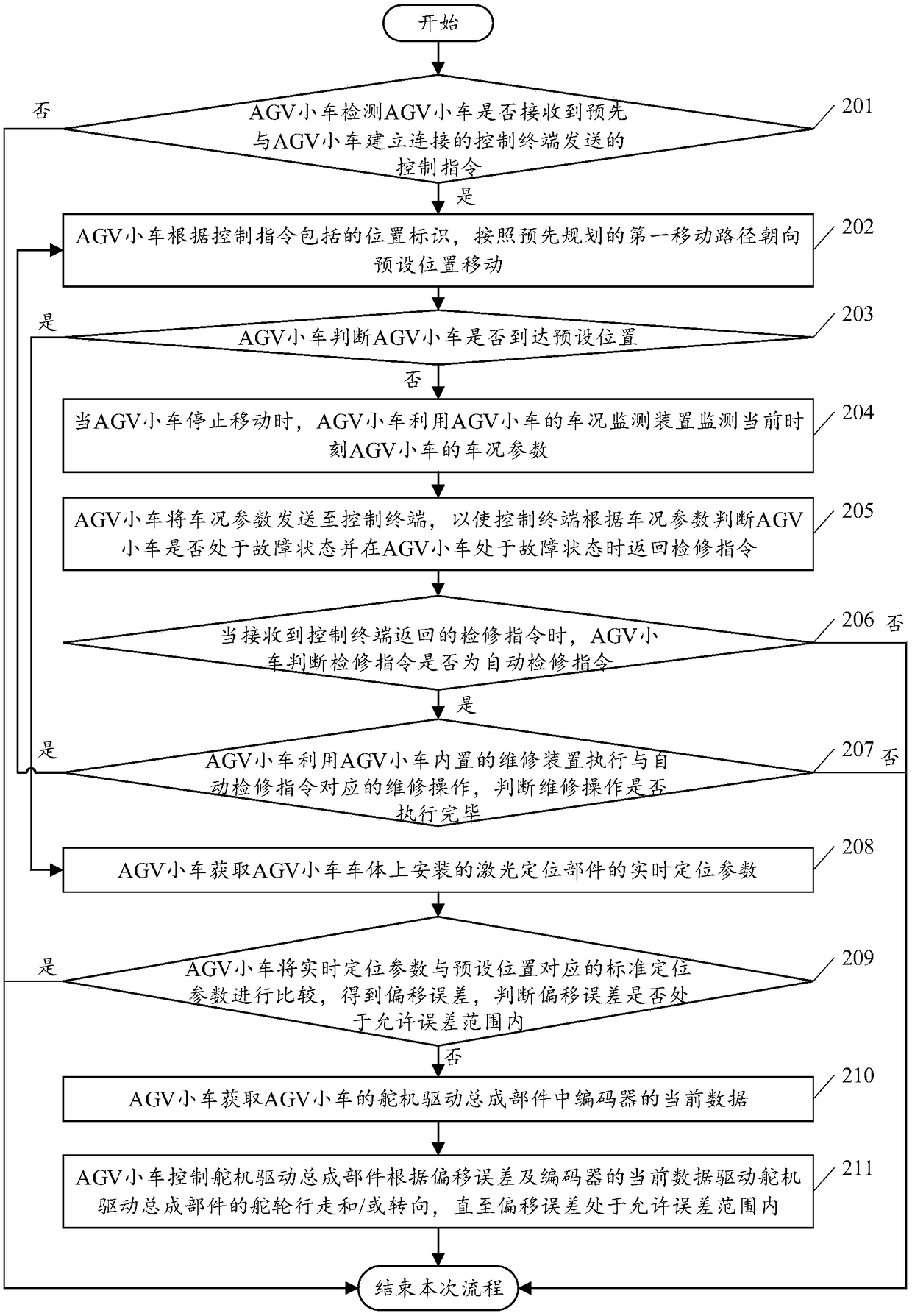

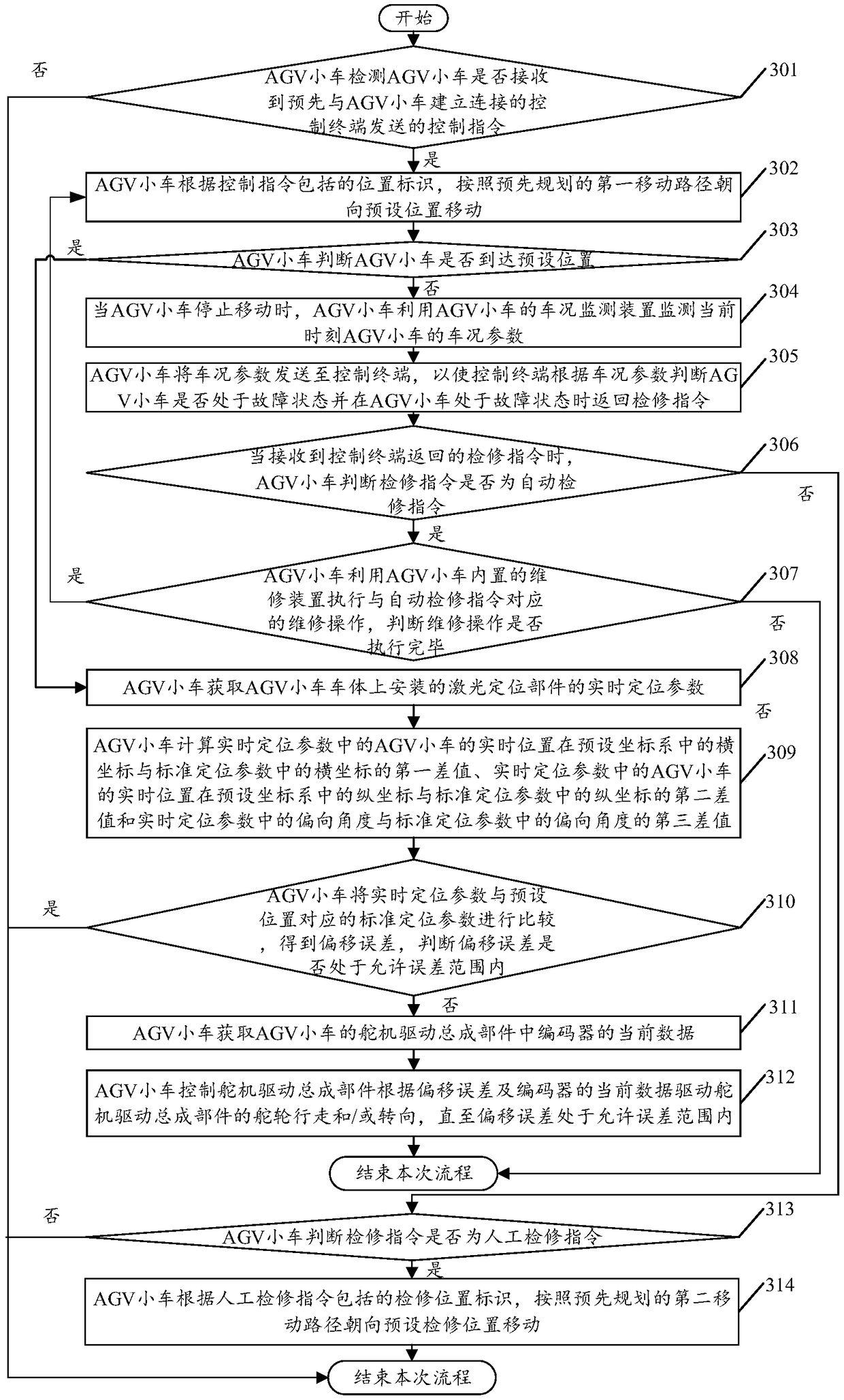

Docking and positioning calibration method based on AGV and AGV

InactiveCN108773433APrecise positioningImprove operating precisionOptical rangefindersVehiclesSteering wheelAutopilot

The invention provides a docking and positioning calibration method based on an AGV and an AGV. The docking and positioning calibration method based on the AGV comprises the steps of obtaining a real-time positioning parameter of a laser positioning part mounted on the an AGV body when the AGV reaches a preset position or the AGV stops moving; comparing the real-time positioning parameter with a standard positioning parameter corresponding to the preset position so as to obtain an offset error; when the offset error is not within an allowed error range, obtaining current data of an encoder ina steering engine driving assembly part of the AGV; and controlling the steering engine driving assembly part to drive a steering wheel of the steering engine driving assembly part to run and / or steeraccording to the offset error and the current data of the encoder till the offset error is within the allowed error range. According to the docking and positioning calibration method based on the AGVand the AGV provided by the embodiment of the invention, an automatic driving route of the AGV can be adjusted for calibration and positioning so that the positioning of the AG is more accurate to reduce an error between the AGV and a storage rack during docking; and therefore, the operation accuracy of the AGV during taking and putting goods or materials is improved.

Owner:YONEGY LOGISTICS AUTOMATION TECH

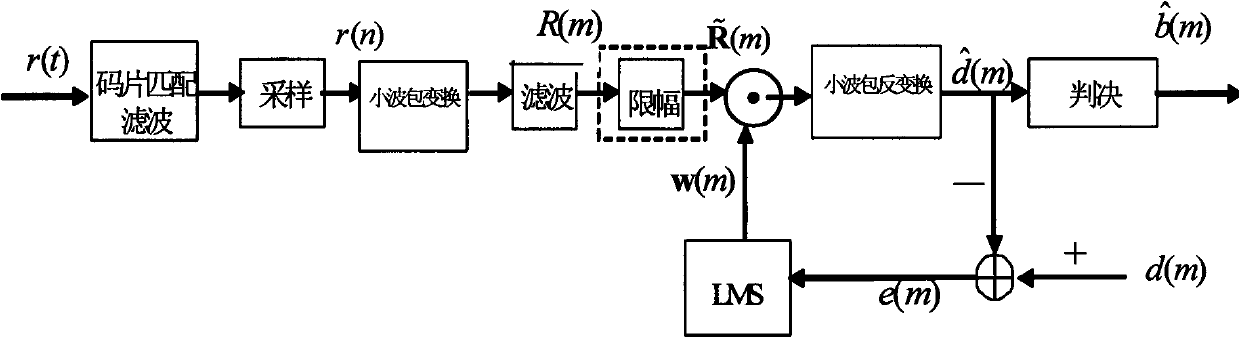

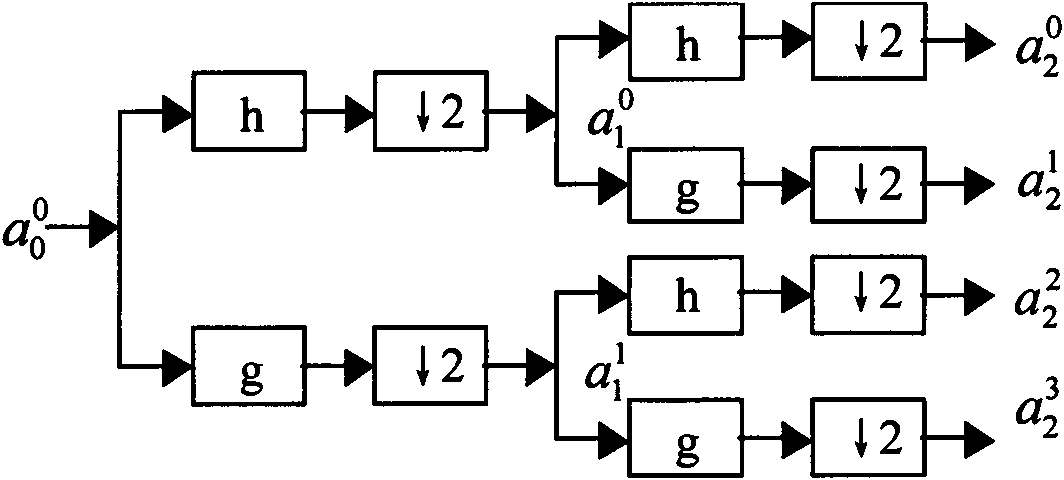

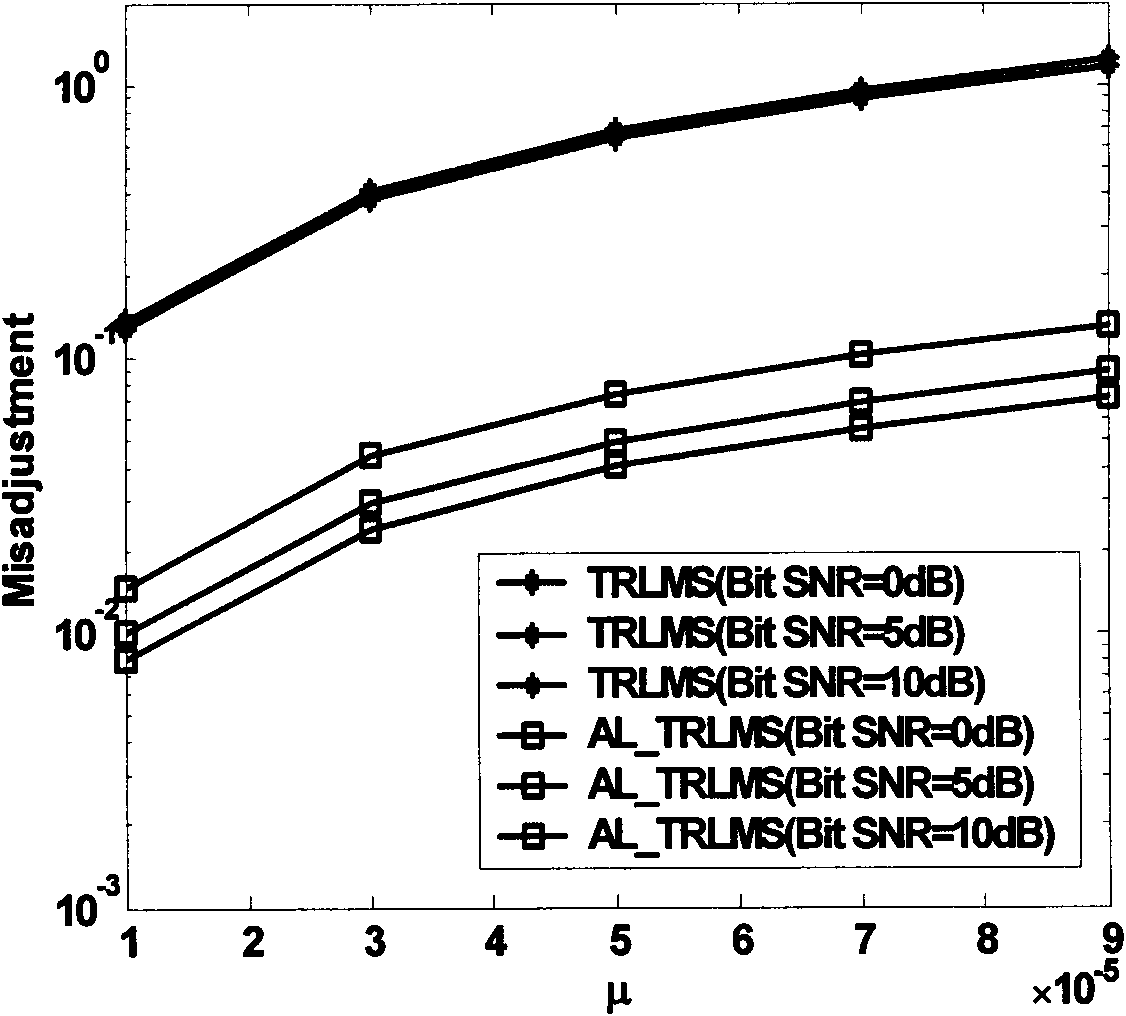

Transform-domain-based narrowband interference inhibiting method in shortwave spread spectrum communication

InactiveCN102122972AGuaranteed convergence speedReduce offset errorTransmissionMean squareWavelet packet transformation

The invention relates to a transform-domain-based narrowband interference inhibiting method in shortwave spread spectrum communication. The method comprises the following steps of performing chip matching filtering, sampling, wavelet packet transformation and filtering on a spread spectrum signal with narrowband interference in shortwave communication; then limiting an amplitude of the transform domain, and performing wavelet packet inverse transformation and lease mean square (LMS) filtering on the signal which is subjected to amplitude limiting; and judging the filtered data to obtain an estimated transmission symbol. By the method, the algorithm offset error is reduced, the algorithm has lower complexity, and the narrowband interference can be effectively located in a certain frequency domain range; and the located 'polluted' frequency range is removed, and then the signal which is subjected to interference inhibition-recovery is synthesized by a wavelet packet. The narrowband interference inhibiting effect is improved in terms of real time property and accuracy.

Owner:COMM ENG COLLEGE SCI & ENGINEEIRNG UNIV PLA

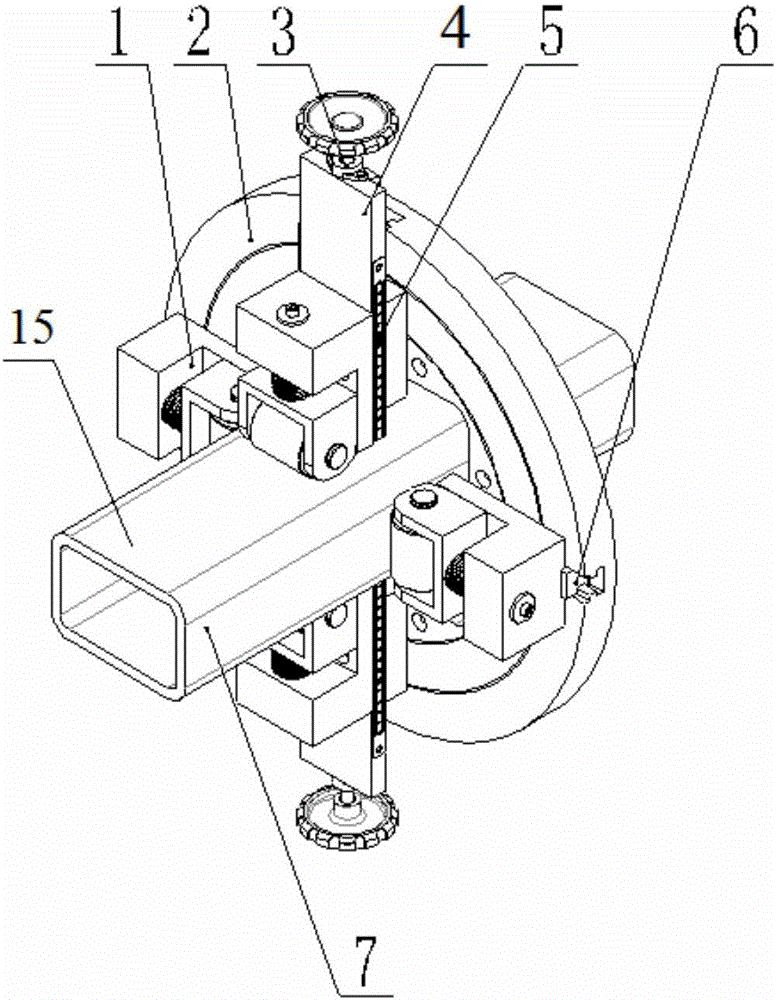

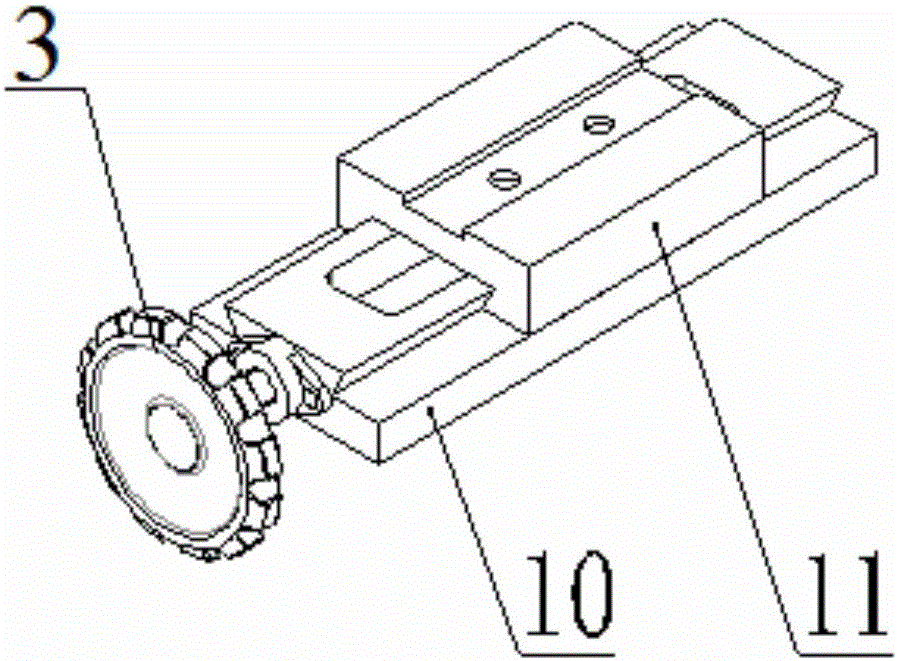

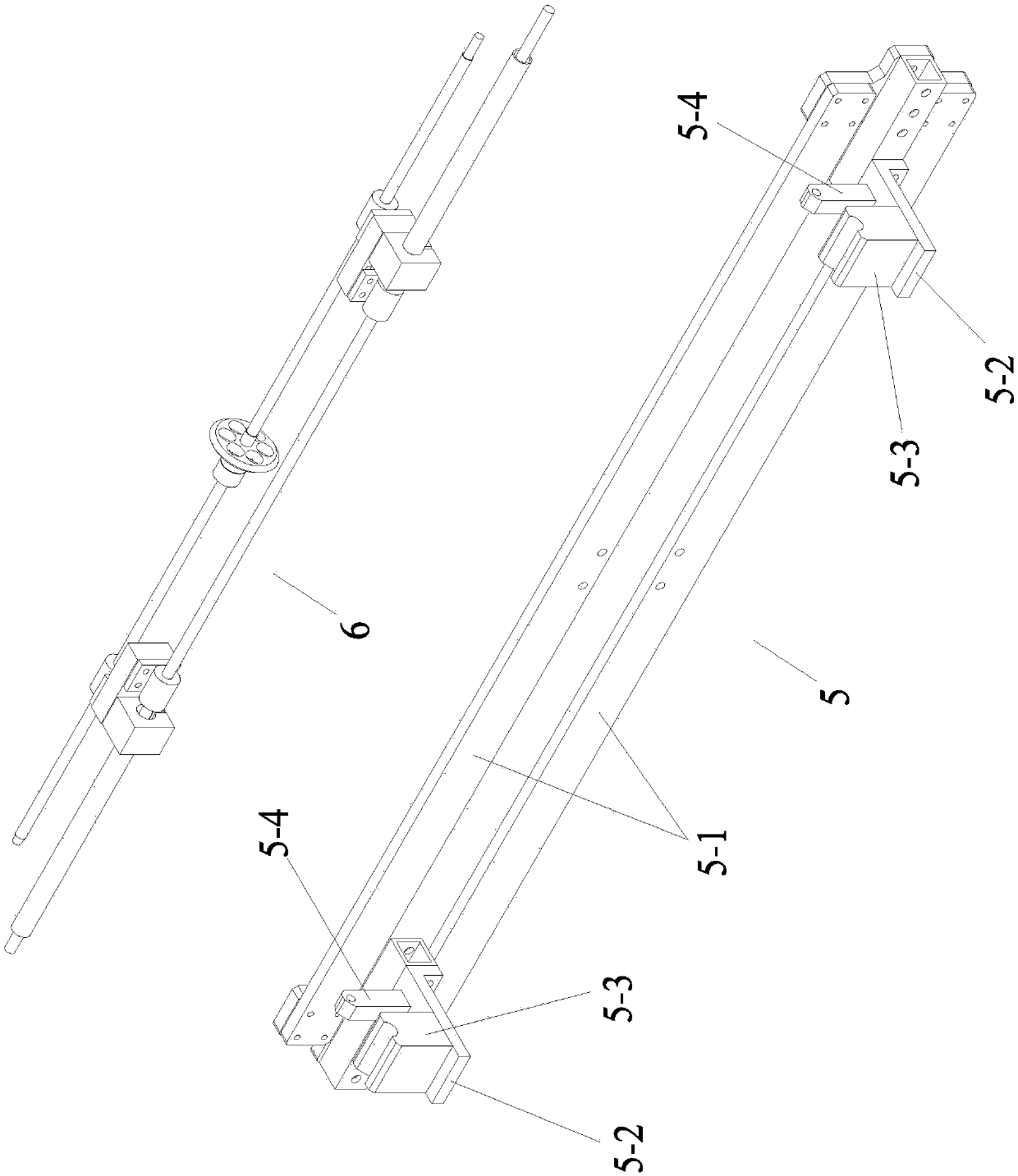

Movable special-shaped pipe clamping device

ActiveCN105880657AAccurateSimple processWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLinkage concept

The invention relates to the technical field of cutting and welding, in particular to a movable special-shaped pipe clamping device. The movable special-shaped pipe clamping device comprises a four-claw chuck. Two sets of opposite base claws of the four-claw chuck are each provided with a roller assembly. The roller assemblies are in contact with the surface of a workpiece, so that the workpiece is clamped, and the workpiece can be adjusted to move in the axial direction of the four-claw chuck. One roller assembly is connected with the corresponding base claw through an adjusting sliding table, and the distance between the roller assembly connected with the adjusting sliding table and the surface of the workpiece can be adjusted through the adjusting sliding table. One of the two roller assemblies mounted on the four-claw chuck is arranged to be capable of being adjusted manually, and therefore the device can adapt to the surface shapes of more special-shaped pipes; the device firstly carries out locating through linkage of the four claws and the roller assemblies, it is guaranteed that the center of the workpiece is accurately aligned to the center of the four-claw chuck, then the workpiece is clamped and reinforced by manually adjusting part of the roller assemblies, and the deviation error of the center of the workpiece and the center of the four-claw chuck generated after clamping is reduced; and the process of adjusting and clamping is simple, and operation is convenient.

Owner:HEBEI FLEXTRONICS ELECTRICAL TECH

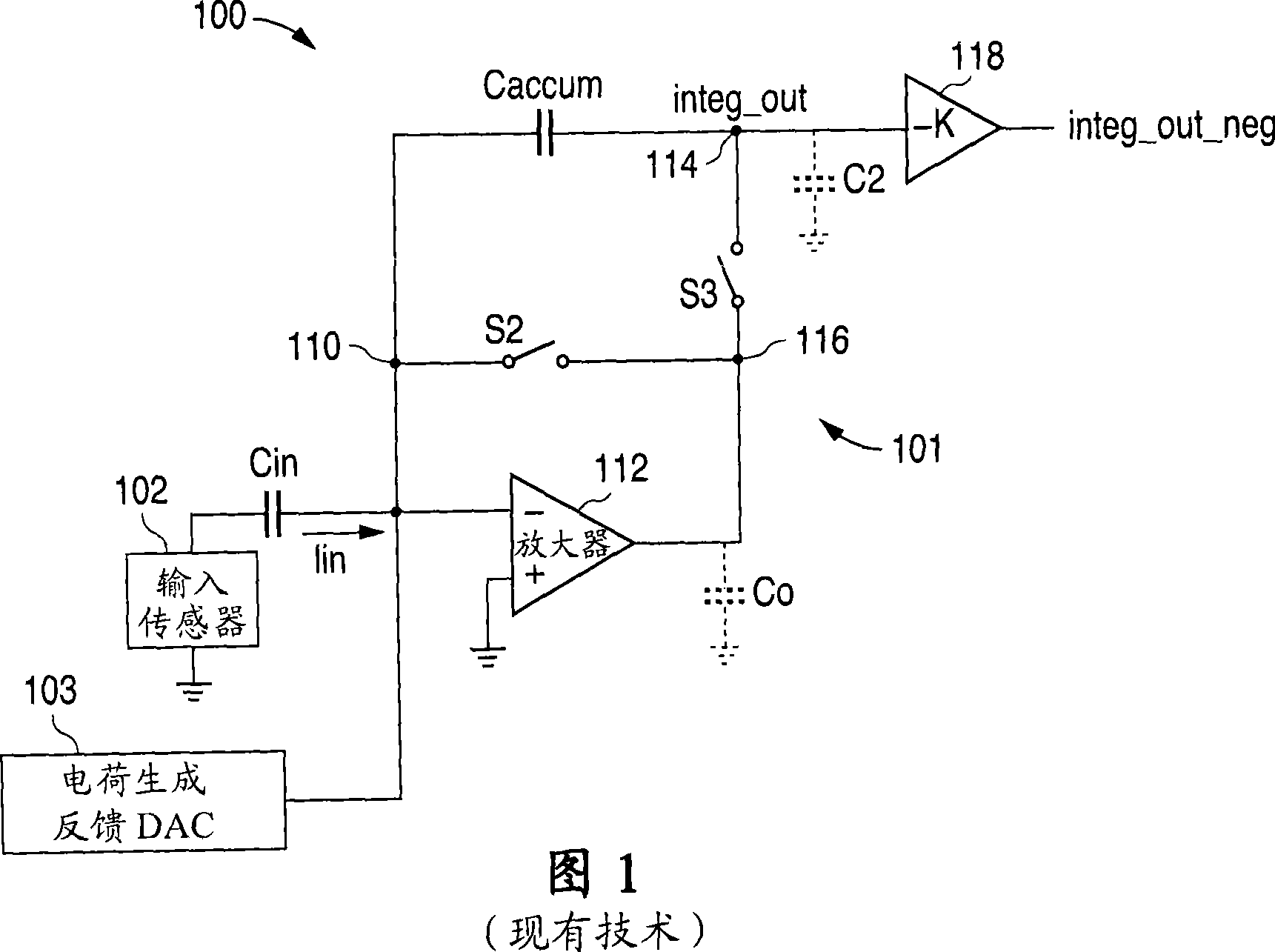

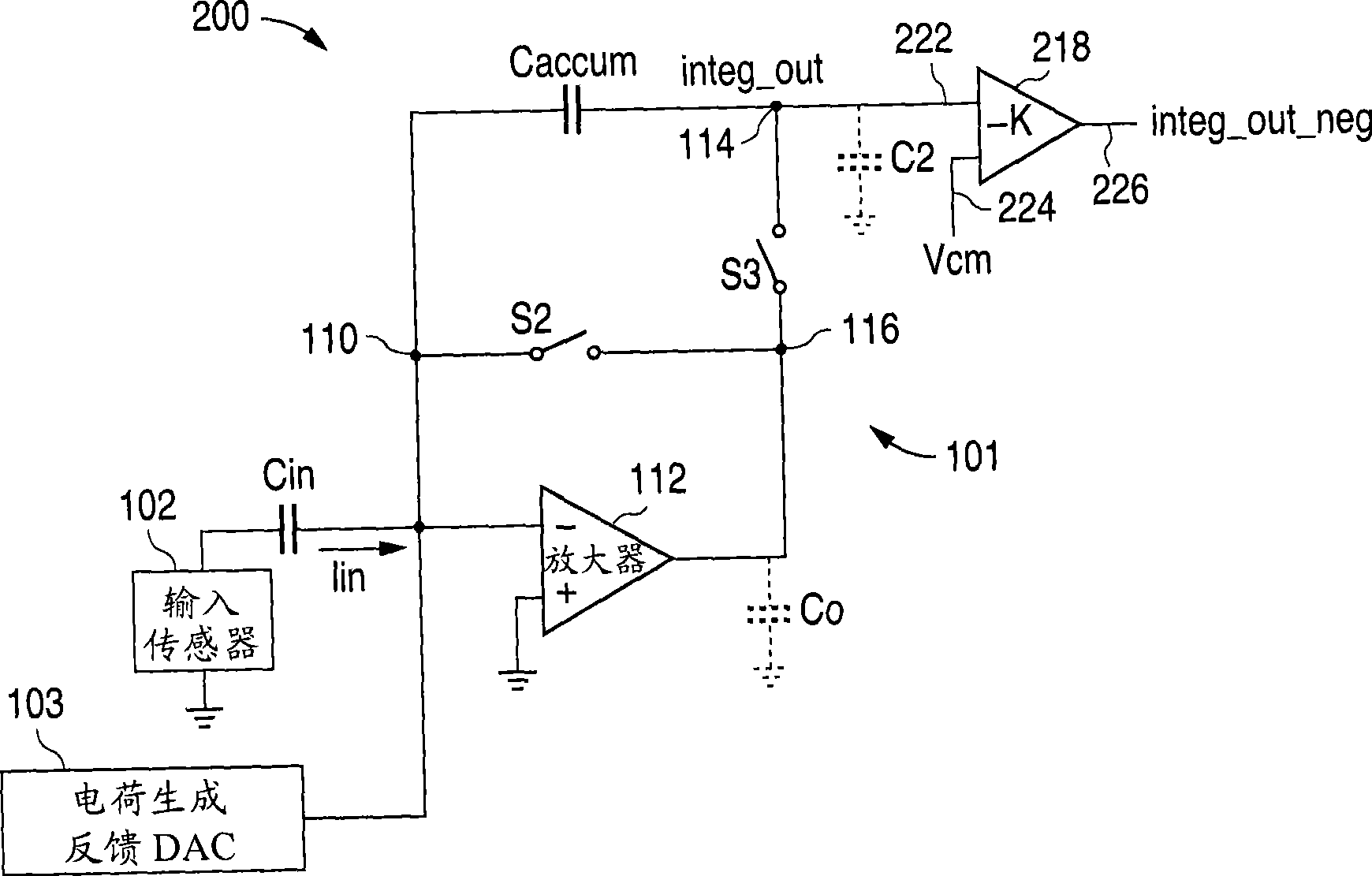

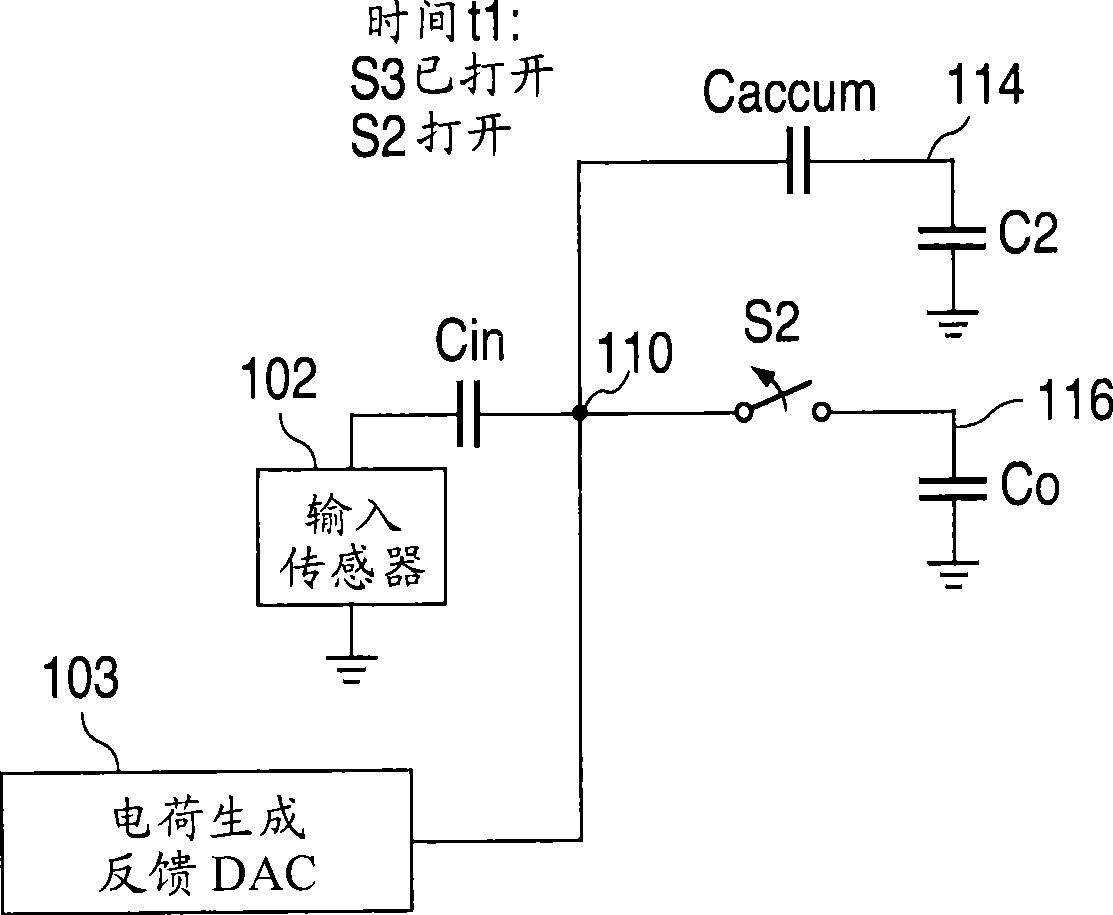

Charge balancing method in current input adc

ActiveCN101394182ASmall voltage errorReduce offset errorAmplifier with semiconductor-devices/discharge-tubesAnalogue-digital convertersCapacitanceIntegrator

A method for charge balancing in a current input ADC including maintaining a low capacitance value at the integrator output node where the capacitance value is independent of the integrator output voltage and operating conditions, generating a first voltage pedestal at a first active device switch at the end of the autozero phase having a first voltage polarity and a first magnitude, generating a second voltage pedestal at a second active device switch at the end of the integration phase having an opposite voltage polarity and the first magnitude, and summing the first voltage pedestal with the second voltage pedestal. The difference between the first voltage pedestal and the second voltage pedestal results in a net voltage error. The first and second voltage pedestals have the first magnitude under all operating conditions of the modulator and the two voltage pedestals cancel to yield a small net voltage error.

Owner:NAT SEMICON CORP

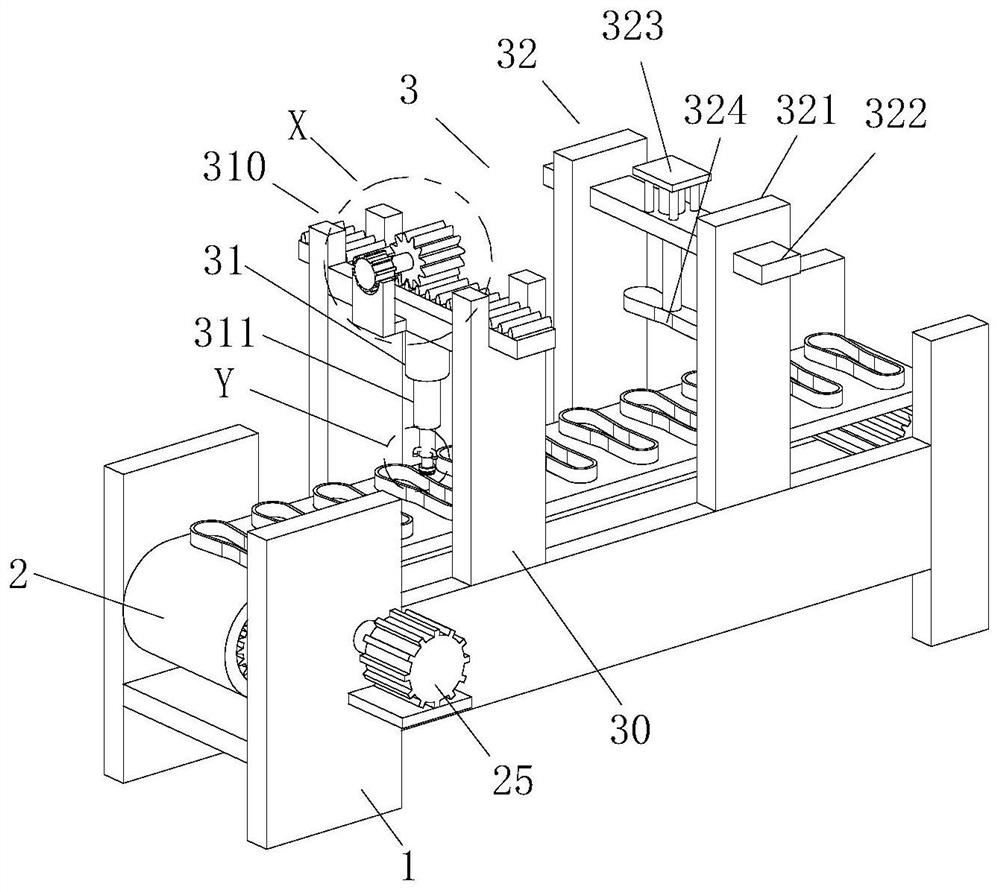

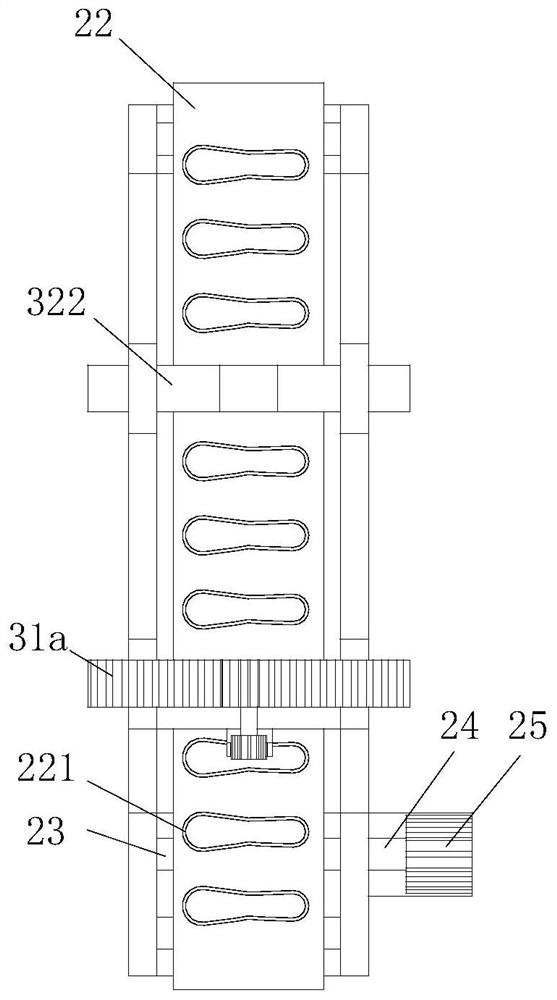

Efficient board positioning cutting device

InactiveCN107322692AImprove flatnessImprove cutting accuracyGripping devicesClamping devicesElectric machineryDrive motor

The invention discloses a high-efficiency plate positioning and cutting device, which relates to the technical field of wood processing equipment and includes a base, a plate clamping device and a cutting device. The base is provided with a guide rail, and a driving trolley is provided in the guide rail. The cutting device includes a cutting motor and a cutting device. The blade and the cutting motor are installed on the driving trolley, and a symmetrical vertical bracket 1 is arranged above the driving trolley. There is a photoelectric switch group and the power-off switch group is arranged symmetrically on both sides of the guide rail. The present invention controls the drive trolley to perform linear reciprocating motion through the signal of the photoelectric switch group, so that the cutting blade can cut the board multiple times, which improves the cutting efficiency. The flatness of the surface, the clamping of the plate is realized by the cylinder, the offset error caused by the mechanical vibration is reduced, and the cutting accuracy and cutting efficiency of the large-size plate are improved.

Owner:涟水县佳兴木材加工厂

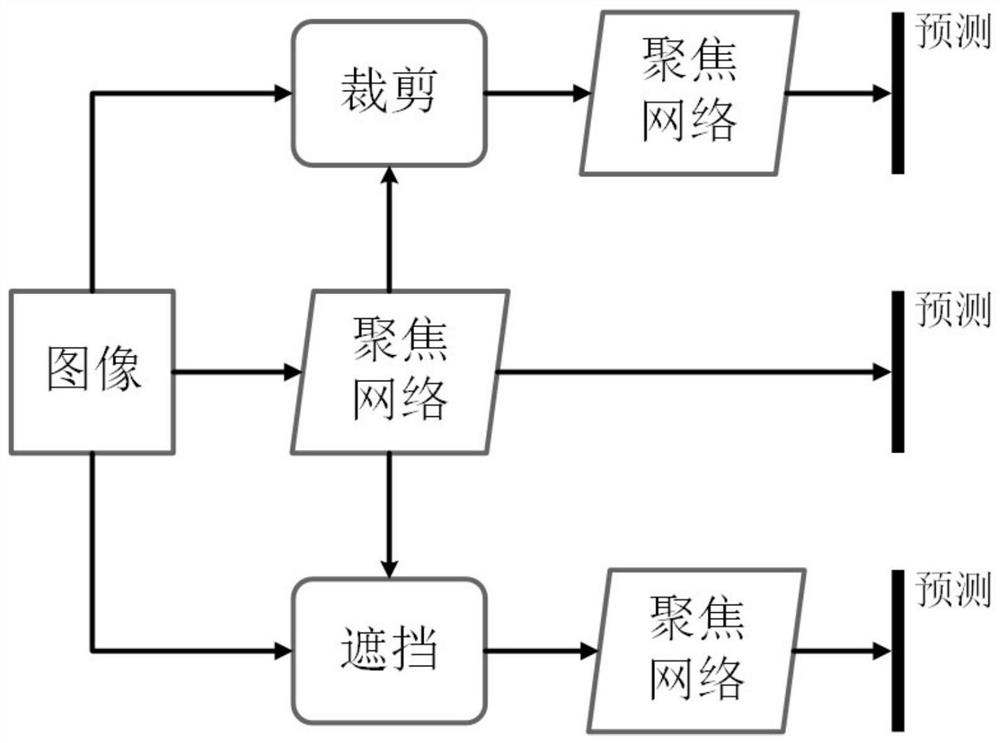

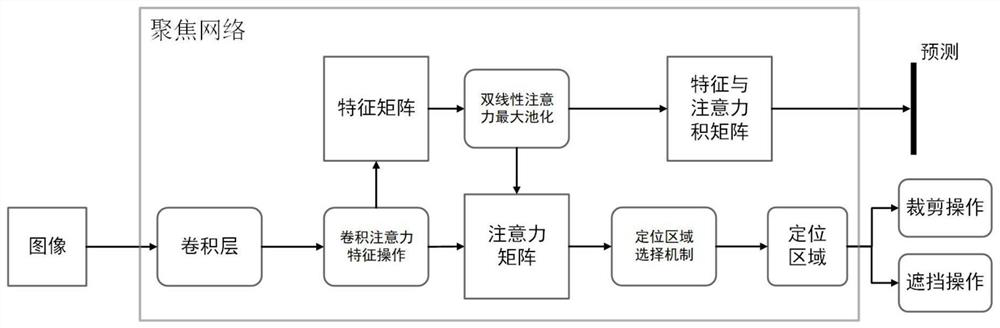

Fine-grained image classification method based on multilayer focusing attention network

ActiveCN112686242AImprove generalization abilityImprove robustnessImage analysisCharacter and pattern recognitionVisual technologyClassification methods

The invention relates to a fine-grained image classification method based on a multilayer focusing attention network, and belongs to the technical field of computer vision. The method comprises the following steps: firstly, accurately and effectively focusing on an identification local area and generating a positioning area through a first-layer focusing network; cutting and shielding the original image according to the positioning area and then inputting into a focusing network of the next layer to be trained and classified, wherein a single-layer focusing network focuses an effective positioning area through a convolution attention feature module and a positioning area selection mechanism on the basis of an InceptionV3 network; then extracting features of each local part by using bilinear attention maximization pooling; and finally performing classification prediction. Experimental results show that the classification accuracy of the method is higher than that of a current mainstream method.

Owner:KUNMING UNIV OF SCI & TECH

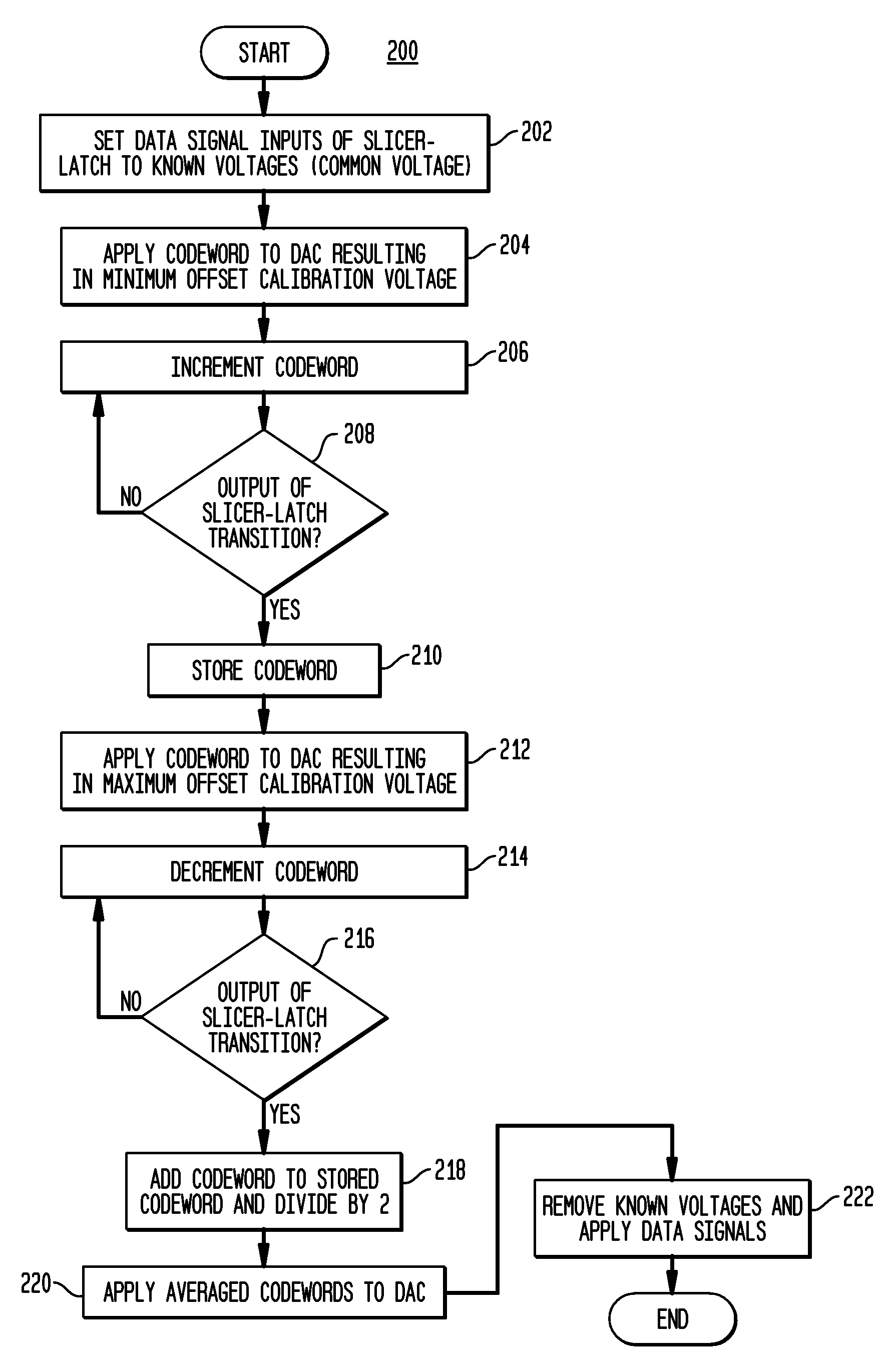

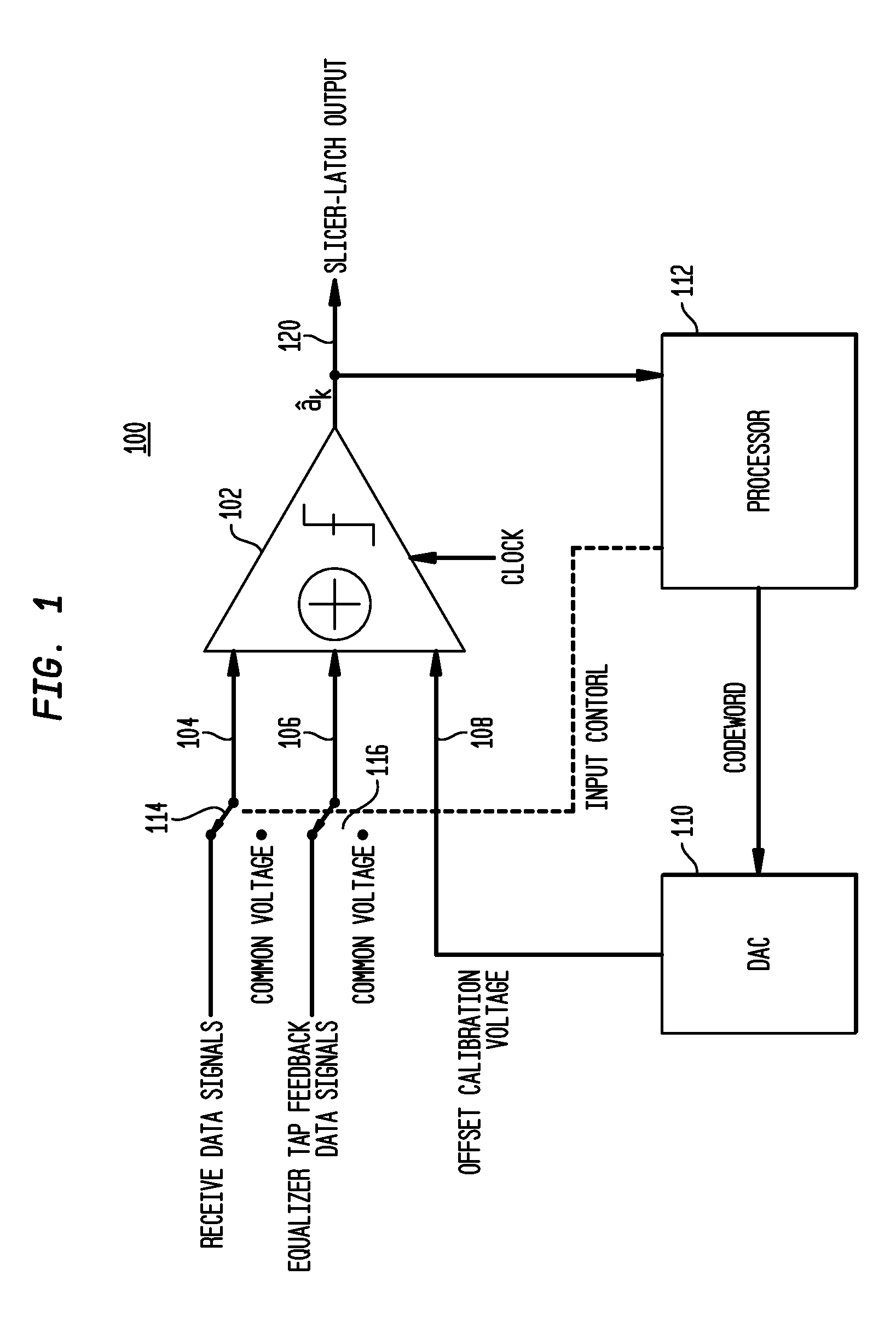

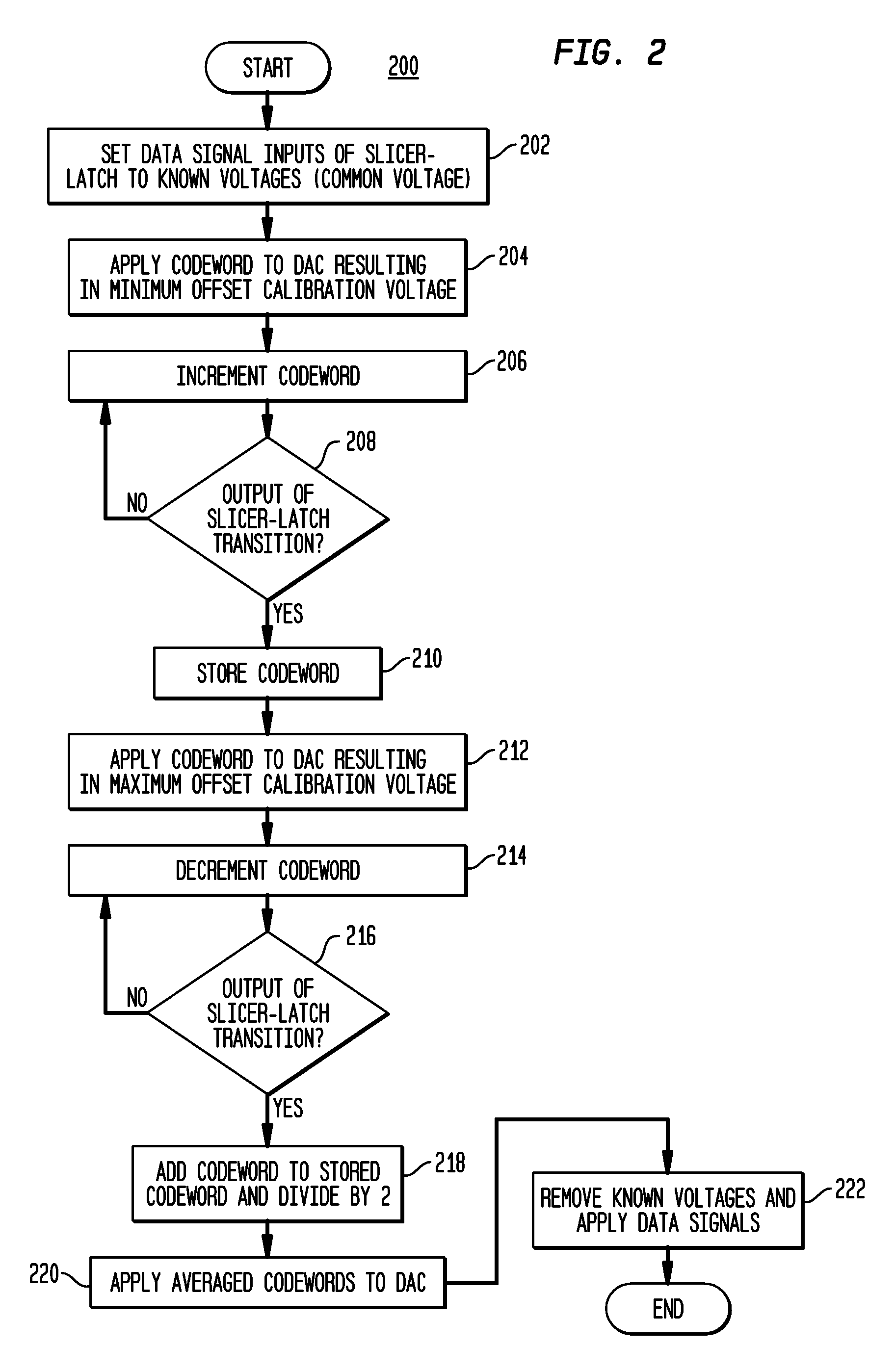

Method of calibrating a slicer in a receiver or the like

InactiveUS9100229B2Reduce offset errorDc level restoring means or bias distort correctionTransmitter/receiver shaping networksEngineeringVoltage

A method of calibrating data slicer-latches in a receiver to remove offset errors in the slicer-latches. A known voltage is applied to all but one of the inputs of the slicer-latch. The remaining input receives an offset cancelation voltage from a DAC is stepped upward from a minimum voltage until the slicer-latch output transitions by incrementing a codeword to the DAC and the codeword that resulted the transition is saved. Then the offset cancelation voltage is swept downward in steps from a maximum voltage until the slicer-latch output transitions and the codeword that caused the transition is averaged with the stored codeword. The average of the codewords is applied to the DAC to generate the offset cancelation voltage used during normal operation of the receiver.

Owner:AVAGO TECH INT SALES PTE LTD

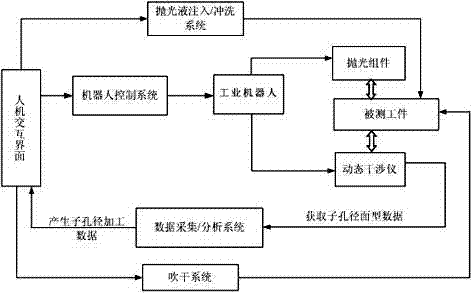

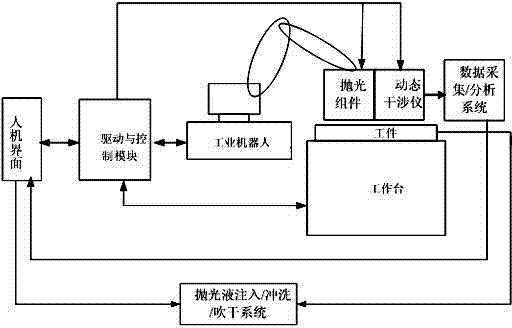

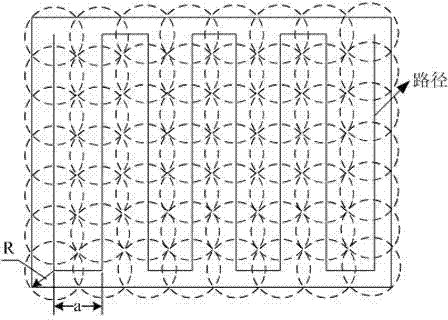

Real-time grinding and polishing method based on dynamic interferometer

InactiveCN103862373AAvoid measurement errorsReal-time measurementGrinding feed controlManufacturing technologyOptical measurements

The invention belongs to the technical field of modern optical measurement and manufacture and particularly relates to a real-time grinding and polishing method based on a dynamic interferometer. The real-time grinding and polishing method comprises the specific steps: (1) according to the placement position coordinate of a workpiece, the equation of a curved surface to be measured and the sizes of corresponding hole diameters measured by the dynamic interferometer at different measuring distances, software is utilized for analyzing the number, the sizes, the positions and the moving paths needing to be measured by the dynamic interferometer; (2) measurement and processing of sub hole diameters are carried out on the curved surface to be measured by a polishing component or the interferometer according to the set measuring path, the measured surface shape data are used for determining the residence time in the measured sub hole diameters and the setting of the moving trail of a grinding head in real time; (3) after washing and blow-drying the surface shape in the range of the measured hole diameters, the workpiece is polished / ground by an industrial robot. The real-time grinding and polishing method has the advantages that the cost of a used system is low, the universality and the practicability are good, dynamic online measurement and processing of multiple surface shapes can be realized and the polishing accuracy and the conformity of the polished surface shapes are high.

Owner:FUDAN UNIV

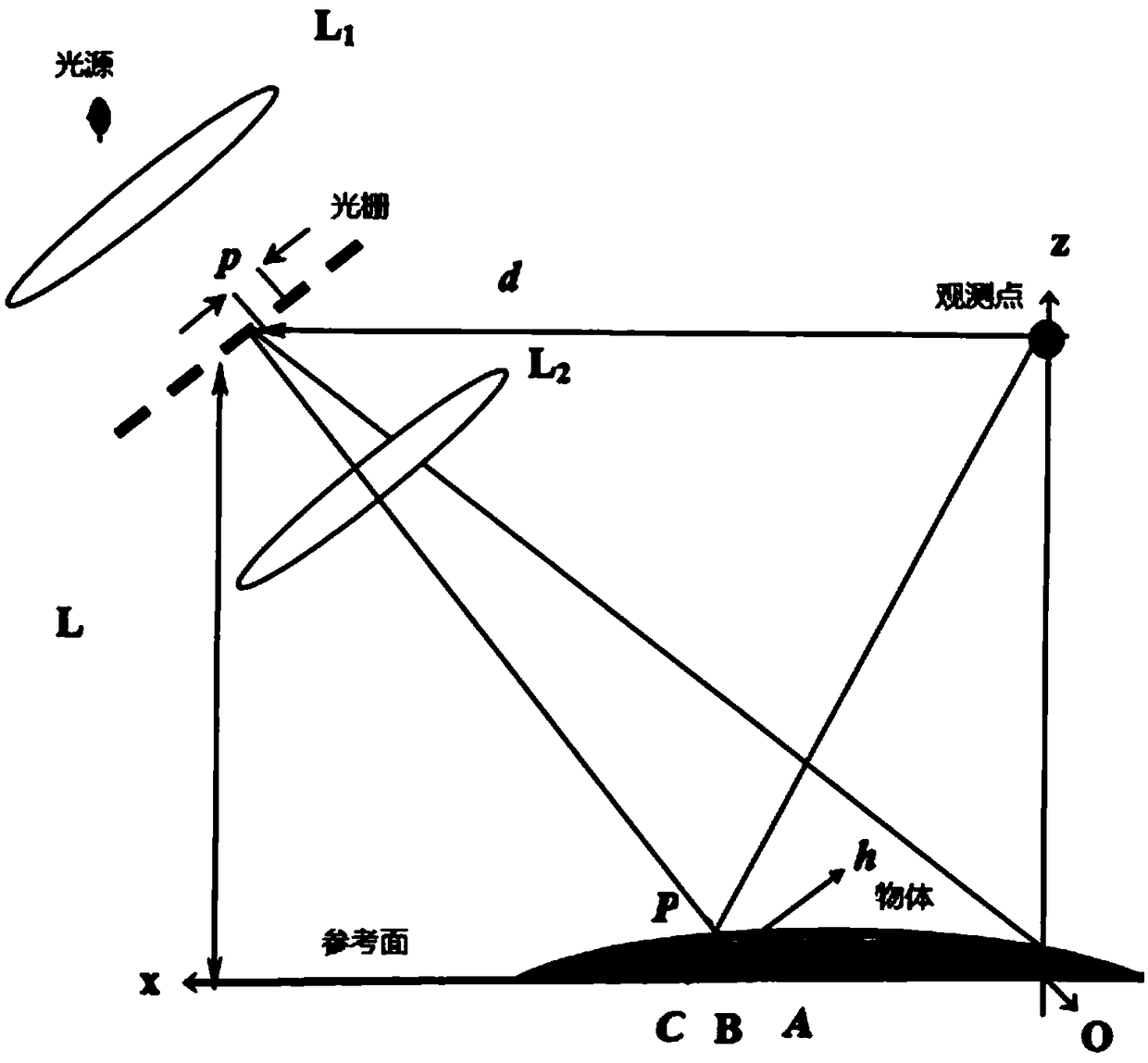

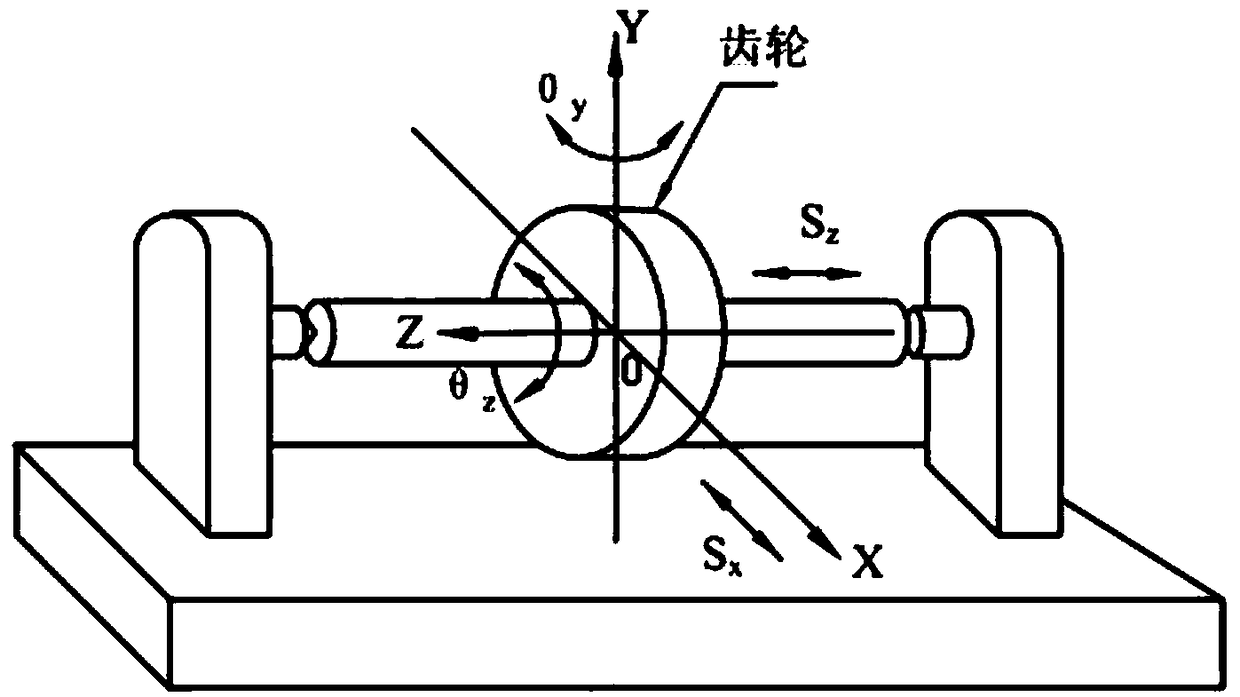

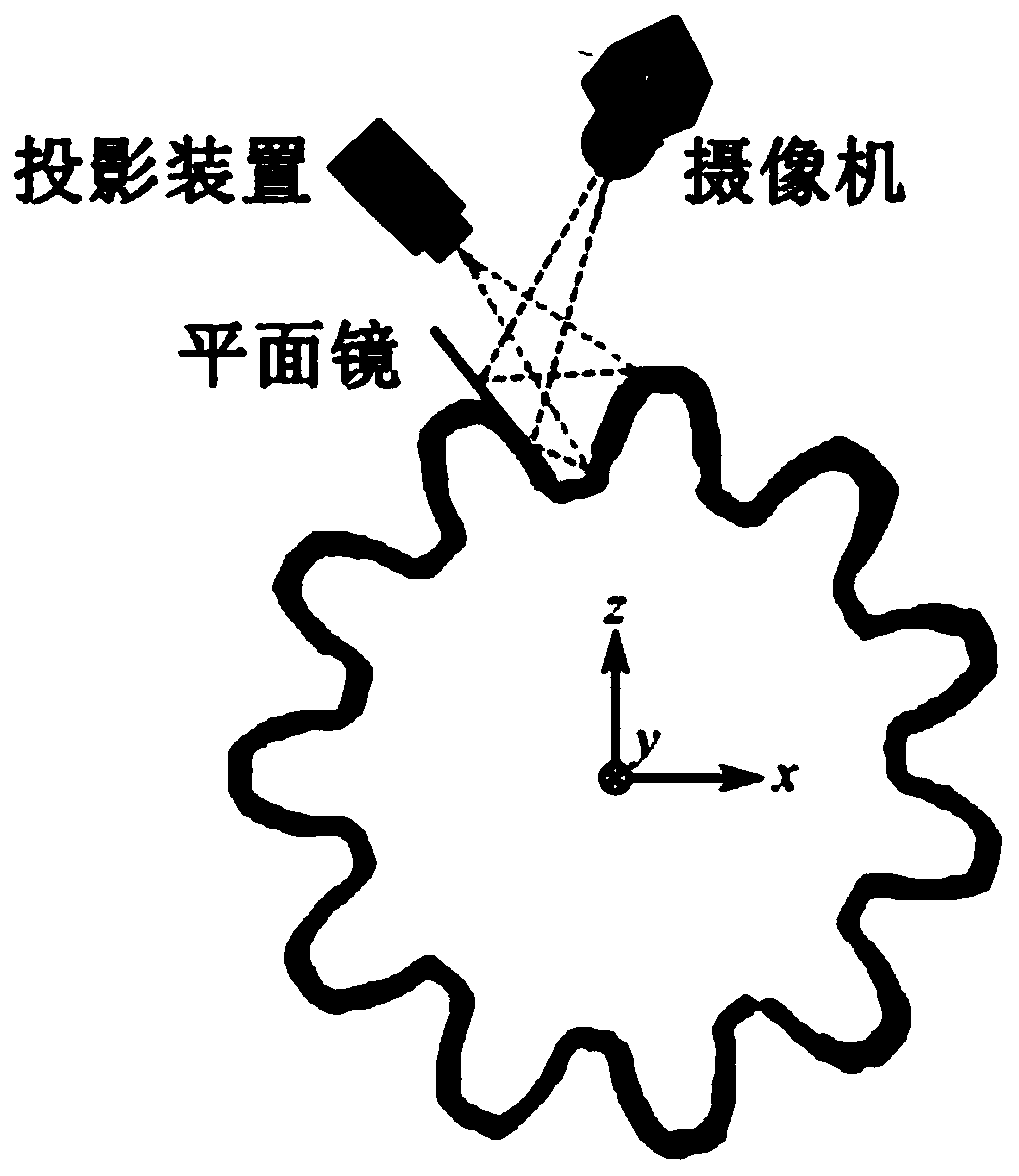

Three-dimensional shape characterization method for gear tooth surface

The invention provides a three-dimensional shape characterization method for a gear tooth surface in real grating projection. The method uses a plane moving grating to introduce a uniform phase shiftfor the measurement field of view, and constructs a random phase shift technique to eliminate the offset error in the phase demodulation process. The method uses the phase as the measurement feature,and uses its invariance characteristics to construct a phase-height difference look-up table to quickly recover the three-dimensional measurement surface, and finally provides a way to construct a fast, high-precision gear three-dimensional contour measurement technology. The method of the invention provides an effective way for non-contact measurement of spur gears and helical gears.

Owner:XIAN TECHNOLOGICAL UNIV

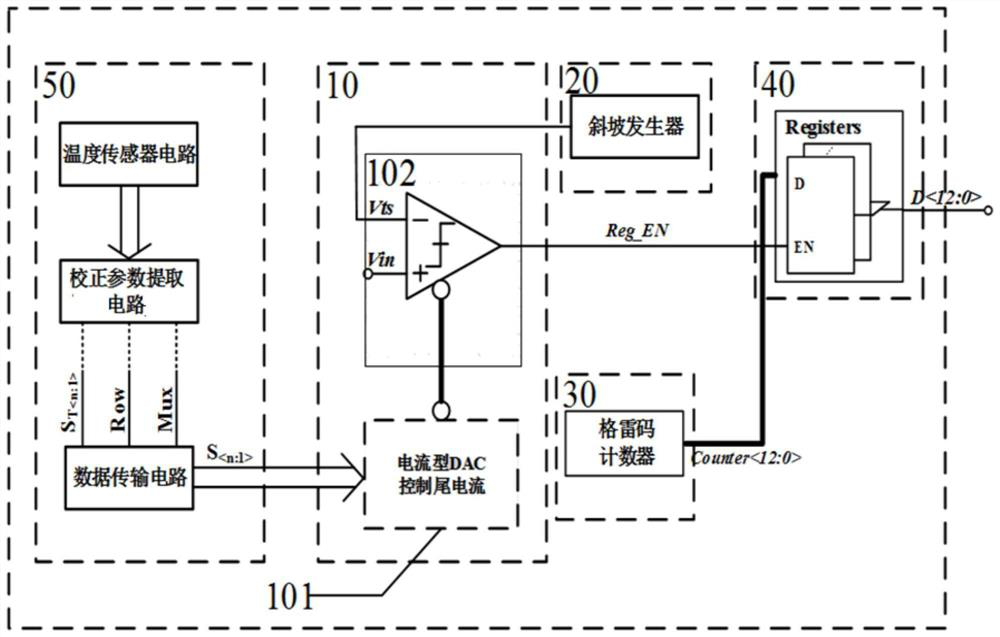

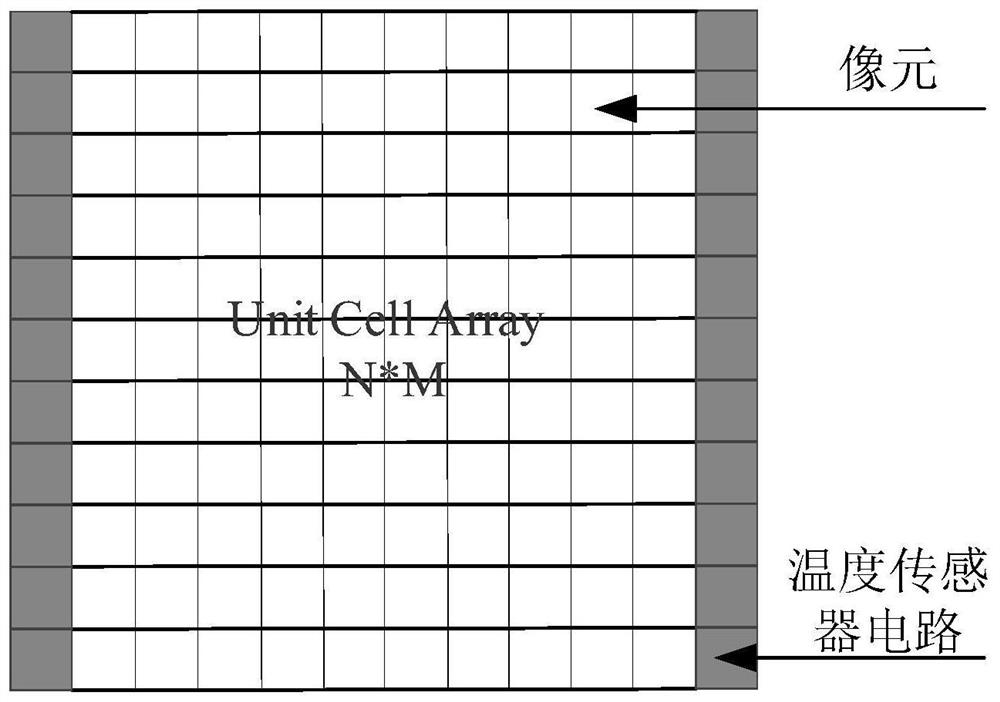

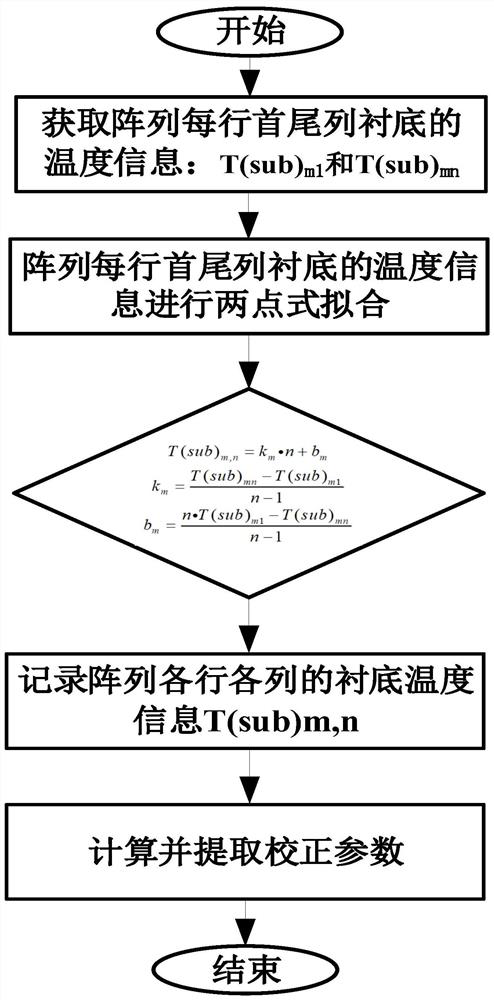

Analog-to-digital conversion device and method with substrate temperature compensation for infrared focal plane

ActiveCN112003617AReduce offset errorImprove uniformityPhysical parameters compensation/preventionA d converterEngineering

The invention discloses an analog-to-digital conversion device with substrate temperature compensation for an infrared focal plane. The analog-to-digital conversion device comprises a substrate temperature acquisition and correction module and a comparator module with substrate temperature compensation, and the comparator module with the substrate temperature compensation function comprises a comparator and a current type DAC. The substrate temperature acquisition and correction module acquires substrate temperature data of the infrared focal plane array and extracts corresponding related correction parameters based on the substrate temperature data; the substrate temperature acquisition and correction module applies the related correction parameter signal to a current type DAC, and the current type DAC regulates and controls the tail current of the comparator based on the related correction parameter signal to perform substrate temperature compensation. According to the scheme, the substrate temperature acquisition and correction module is additionally arranged based on the comparator, compensation of the substrate temperature of the comparator is realized by matching with the current type DAC, the problem of inconsistent overturning delay of the comparator caused by different temperatures is effectively eliminated, the offset error of the analog-to-digital converter is reduced, and the precision and the signal-to-noise ratio of the conversion device are improved, so that the uniformity of an output image is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

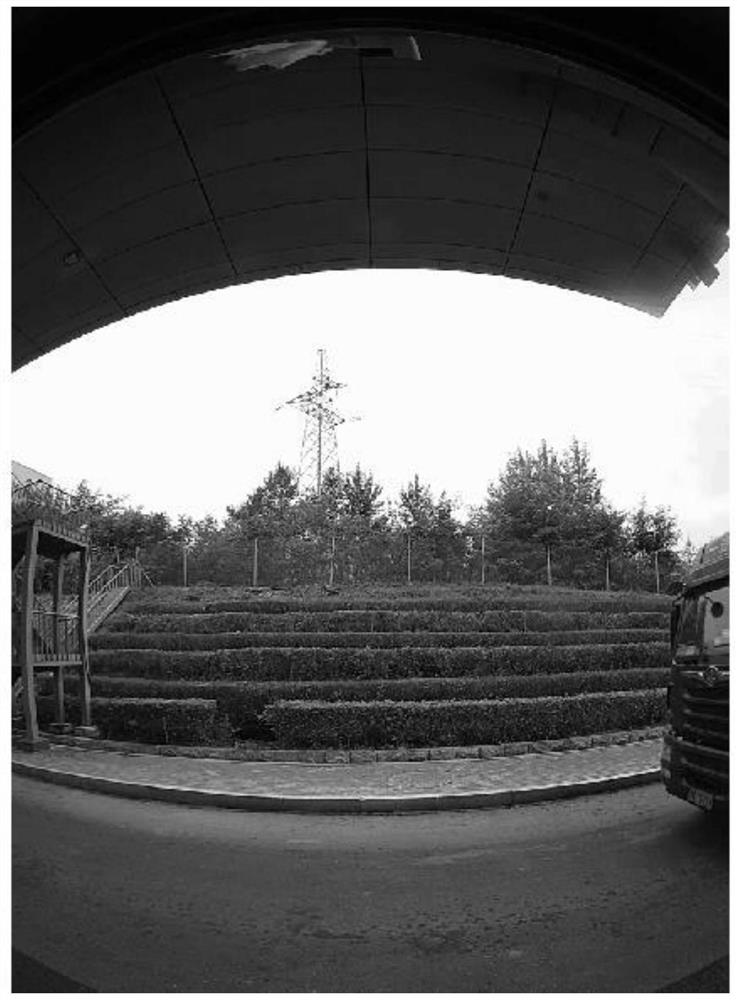

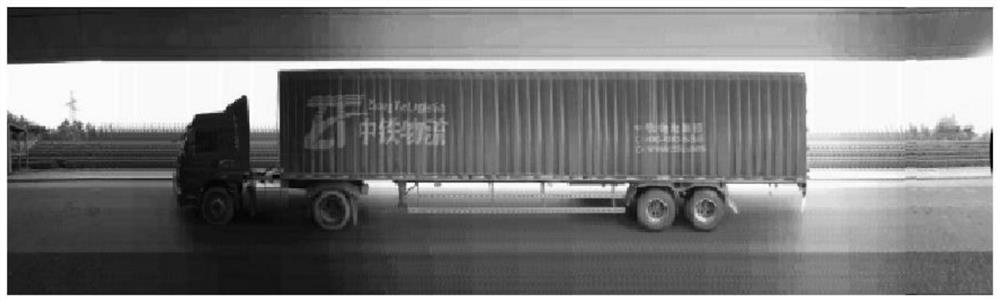

Large vehicle panoramic splicing method

PendingCN114007023AEasy to handleImprove stitching accuracyTelevision system detailsImage enhancementComputer graphics (images)Radiology

The invention relates to the field of image data processing, in particular to a large vehicle panoramic stitching method, which comprises the following steps: acquiring video data of at least one camera, and preprocessing based on the type of the camera to obtain a video frame; obtaining processing data based on image feature point matching of the video frame; horizontally splicing the processed data; and outputting the spliced image. One or more cameras are arranged so that all data of the appearance of a large vehicle can be obtained, a wide-angle camera is generally adopted for one camera, and a flat-angle camera is generally adopted for multiple cameras, so that corresponding video images can be matched to obtain processing data of a video frame with a complete section of the vehicle, and then horizontal splicing is carried out to obtain the complete appearance of the vehicle, so that the vehicle can be better shot and processed, and the measurement and detection efficiency is improved.

Owner:GUANGDONG UNIV OF TECH

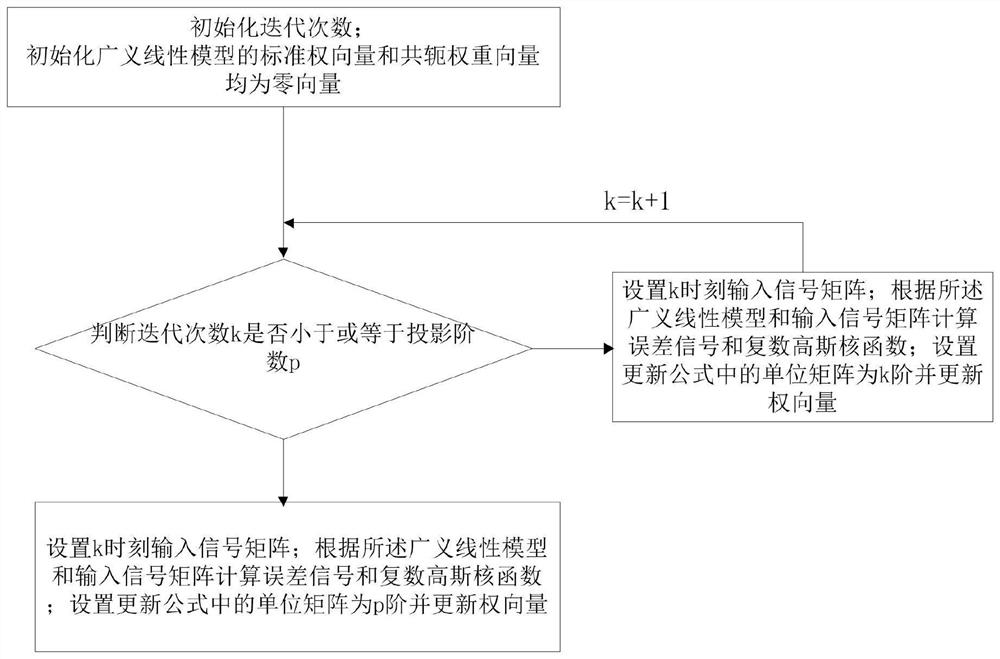

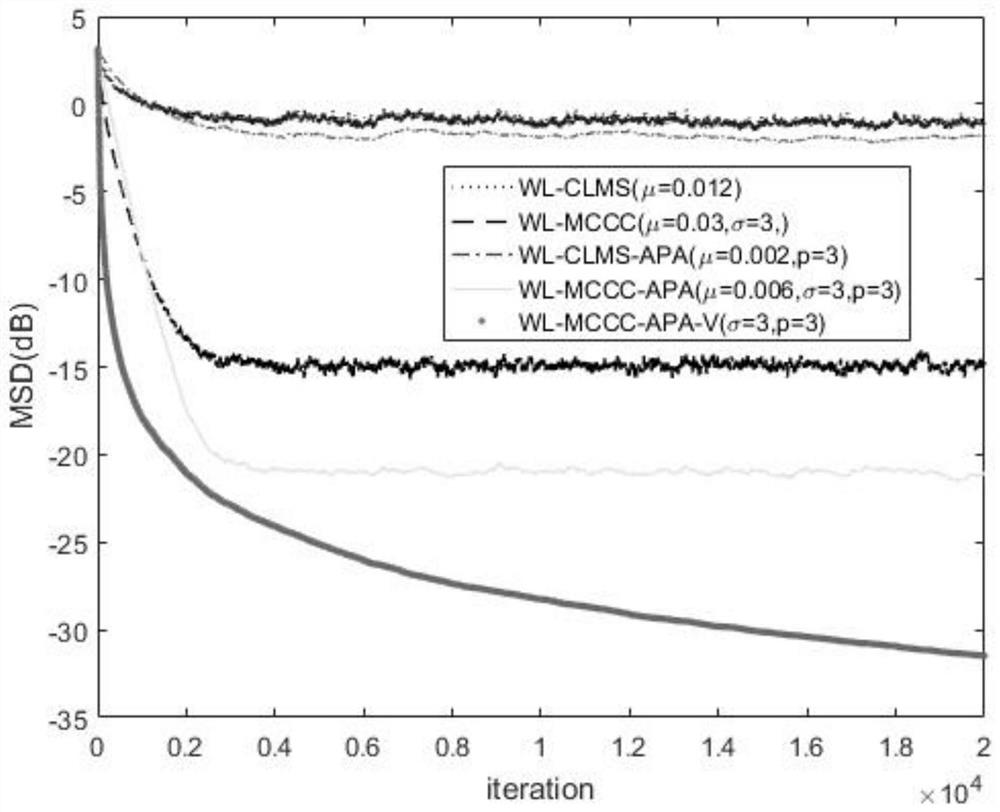

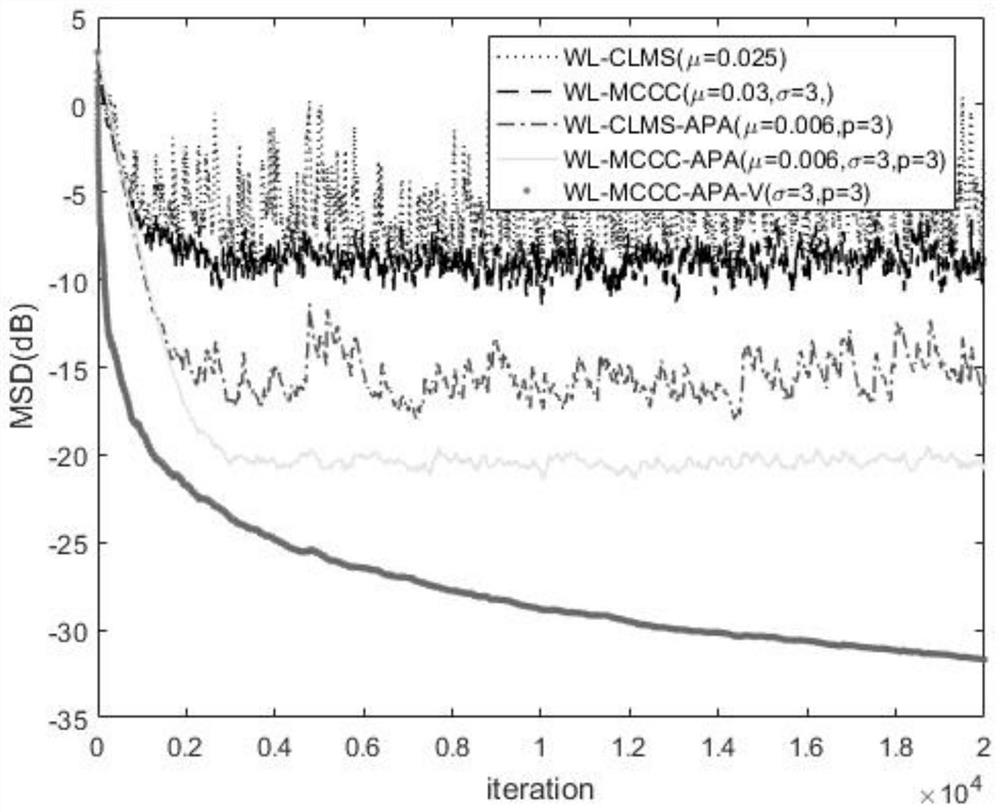

Complex affine projection adaptive signal processing method based on kernel function

PendingCN113872567AImprove signal qualityImprove stabilityAdaptive networkAffine projectionSelf adaptive

The invention discloses a complex affine projection adaptive signal processing method based on a kernel function, a complex Gaussian kernel function is applied to a generalized linear affine complex projection algorithm, and the robustness of an adaptive filtering system is improved by using the excellent performance of the Gaussian kernel function in a non-Gaussian environment, especially an impulse noise environment. When the number k of iterations is small, the unit matrix in the formula is updated to k order; when k is large, the unit matrix in the formula is updated to be p-order, and the accuracy of weight vector calculation is improved; and a variable step size method is used, so that the convergence speed is improved, and the offset error is reduced.

Owner:SOUTHWEST UNIV

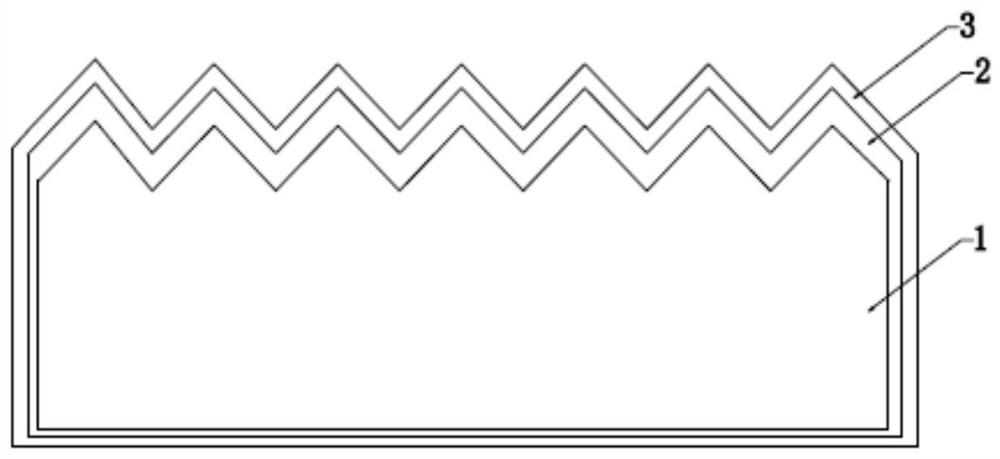

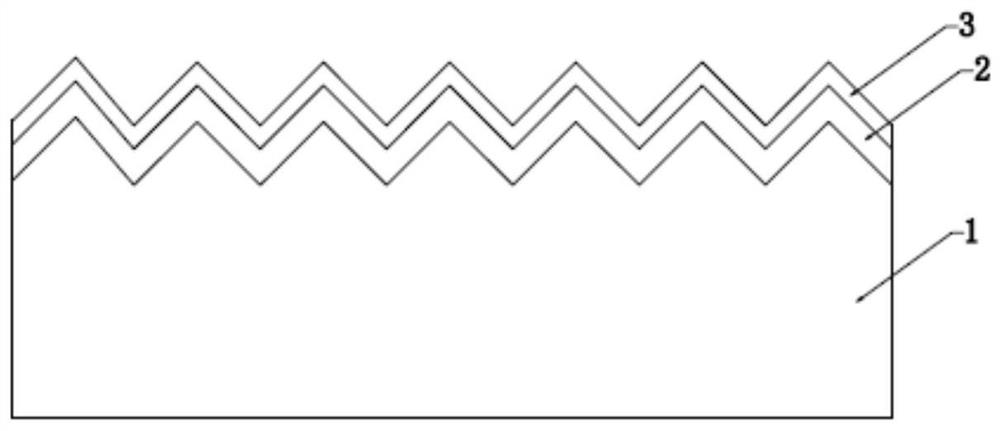

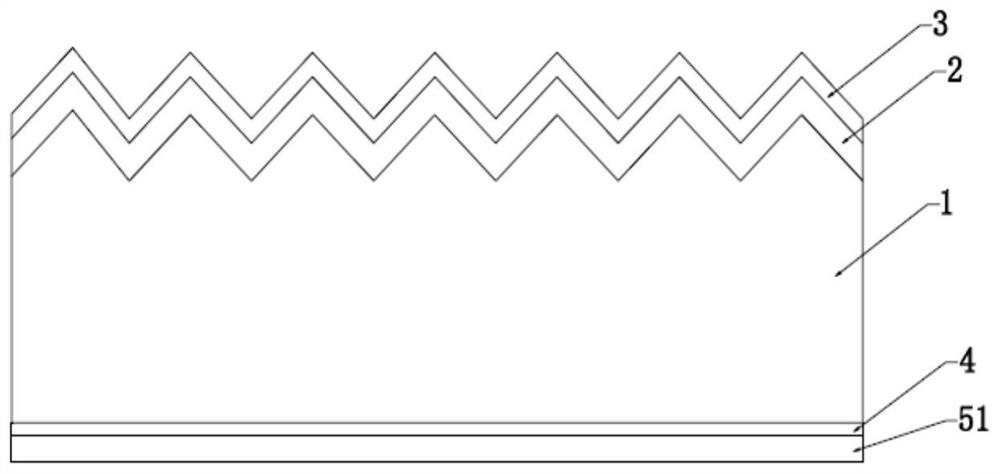

Local back surface field passivation contact cell and preparation method thereof

ActiveCN113471336AReduced Auger RecombinationReduce parasitic absorptionFinal product manufacturePhotovoltaic energy generationChemical physicsBack surface field

The invention discloses a local back surface field passivation contact cell and a preparation method thereof. The cell comprises a silicon wafer main body, a boron diffusion layer, a front passivation film, a positive electrode, a tunneling oxide layer, a field passivation layer, a back passivation film and a back electrode; the boron diffusion layer, the front passivation film and the positive electrode are sequentially laid on the front surface of the silicon wafer main body; the tunneling oxide layer, the field passivation layer, the back passivation film and the back electrode are sequentially laid on the back surface of the silicon wafer main body; and the field passivation layer is provided with a first region and a second region which are different in doping concentration. The field passivation layer is provided with the first region and the second region which are different in doping concentration, the first region is in contact with the back electrode of the cell, namely a metal contact area, the high doping concentration is achieved, and it is guaranteed that the first region has small electrode contact resistance and electron tunneling resistance; and the second region is not in contact with the back electrode of the cell, namely a non-metal contact region, so that the doping concentration is relatively low, auger recombination of the non-metal contact region is reduced, parasitic absorption of the non-metal contact region is further reduced, and the conversion efficiency of the tunneling oxidation passivation contact cell is improved.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

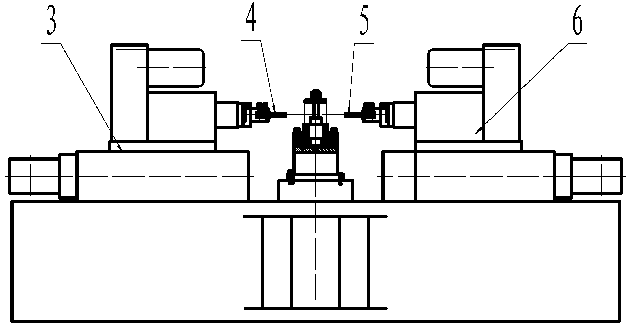

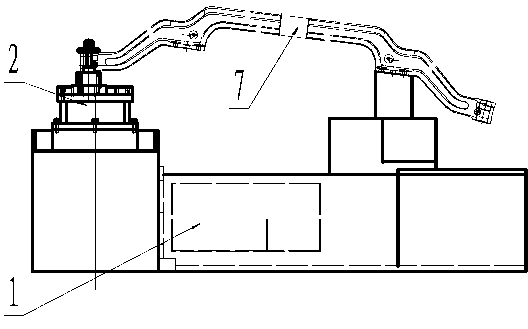

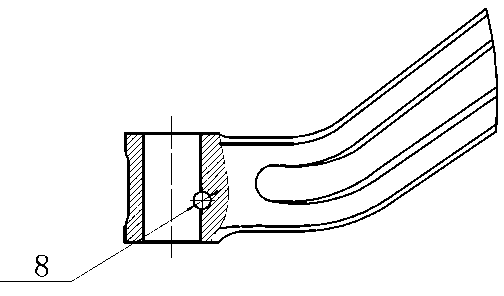

Device for processing side pin hole of front shaft

InactiveCN103302332AReduce offsetMeet the surface qualityBoring/drilling machinesEngineeringUltimate tensile strength

The invention relates to a device for processing a side pin hole of a front shaft. According to the device, a first power feed unit (3) and a second power feed unit (6) are arranged on two sides of a combined lathe bed (1) respectively; a first short-hole drill (4) and a second short-hole drill (5) used for processing the side pin hole of the front shaft are arranged on the first power feed unit (3) and the second power feed unit (6) respectively; a tool (2) is arranged on the combined lathe bed (1), and is positioned between the first short-hole drill (4) and the second short-hole drill (5); and a workpiece (7) is clamped on the tool (2). The device solves the problem of cutter relieving displacement due to one side cutting when processing the side pin hole of the front shaft, accurately and efficiently controls the form and location deviation of two through holes, reduces the labor intensity of a worker, improves the working efficiency, and improves the product quality.

Owner:王庆

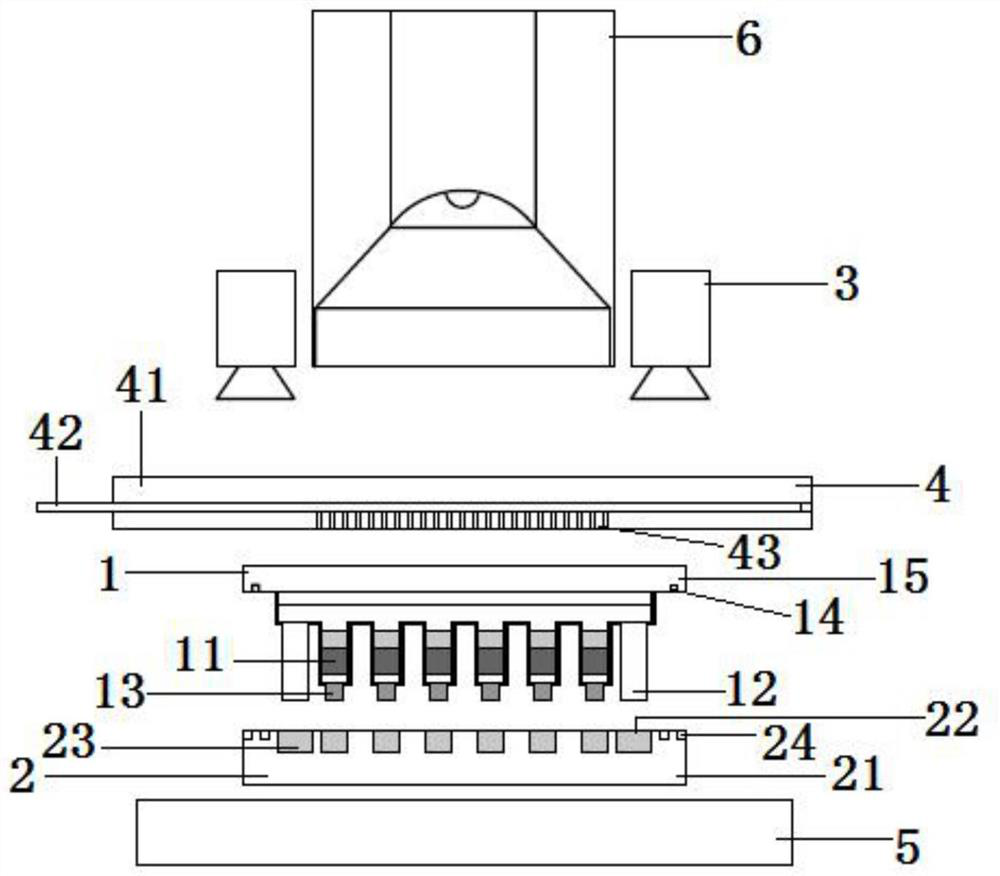

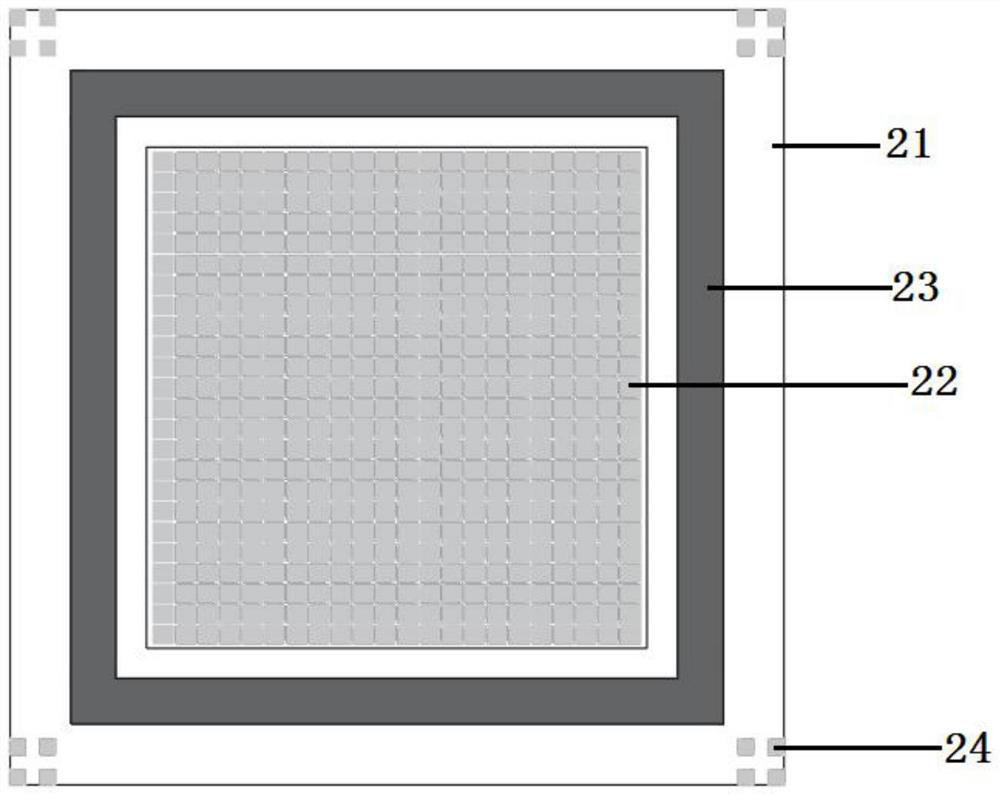

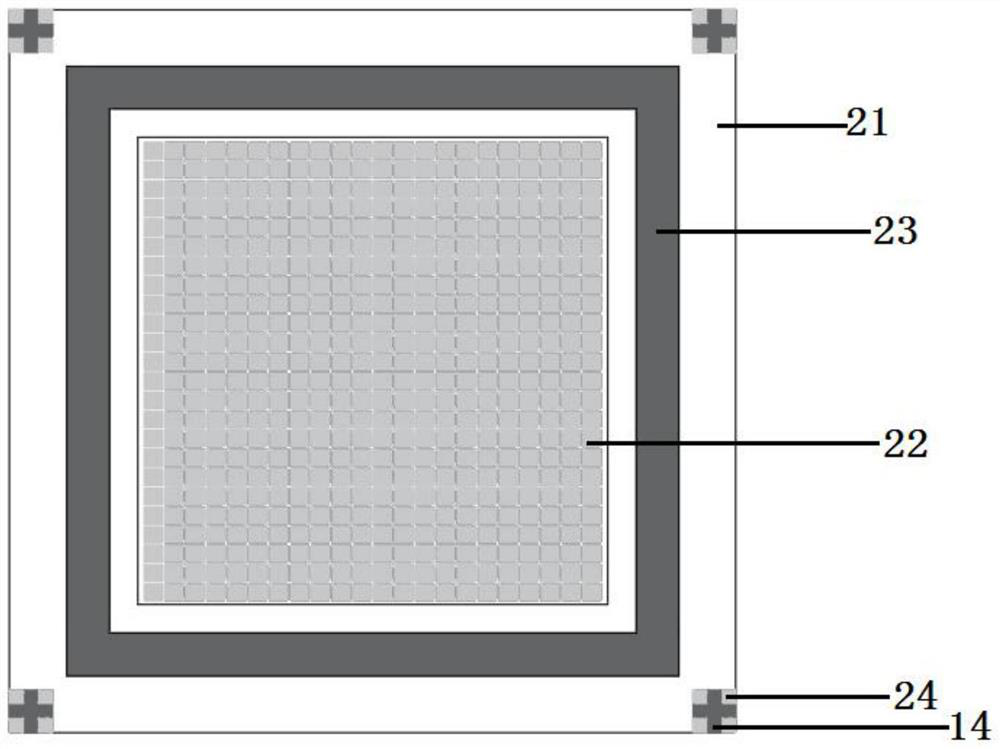

Laser eutectic welding device for miniature LED chip and control substrate

PendingCN113451456APrecise temperature controlAvoid damageWelding/cutting auxillary devicesSemiconductor/solid-state device manufacturingWaferingLaser heating

The invention discloses a laser eutectic welding device for a miniature LED chip and a control substrate. A plurality of LED wafers in the miniature LED chip (1) and the control substrate (2) are welded together through laser. The laser eutectic welding device comprises a negative pressure adsorption unit (4) used for adsorbing the micro LED chip (1) and placing the micro LED chip (1) on the control substrate (2), and a laser emitting system (6) which is positioned above the micro LED chip (1) and is used for heating welding points of a plurality of first positive electrodes (13) and a plurality of second positive electrodes (22) as well as a first negative electrode (12) and a second negative electrode (23) by emitting laser to finish simultaneous eutectic welding. According to the device, the temperature of a heating area can be accurately controlled by adopting laser heating temperature, so that micro LED modular transfer eutectic welding is realized, and secondary melting of a single transfer eutectic welding point of the single Micro LED is avoided. Meanwhile, eutectic welding is transferred in an array mode through MicroLED modularization, the speed is high, and the eutectic speed is effectively increased.

Owner:乙力国际股份有限公司

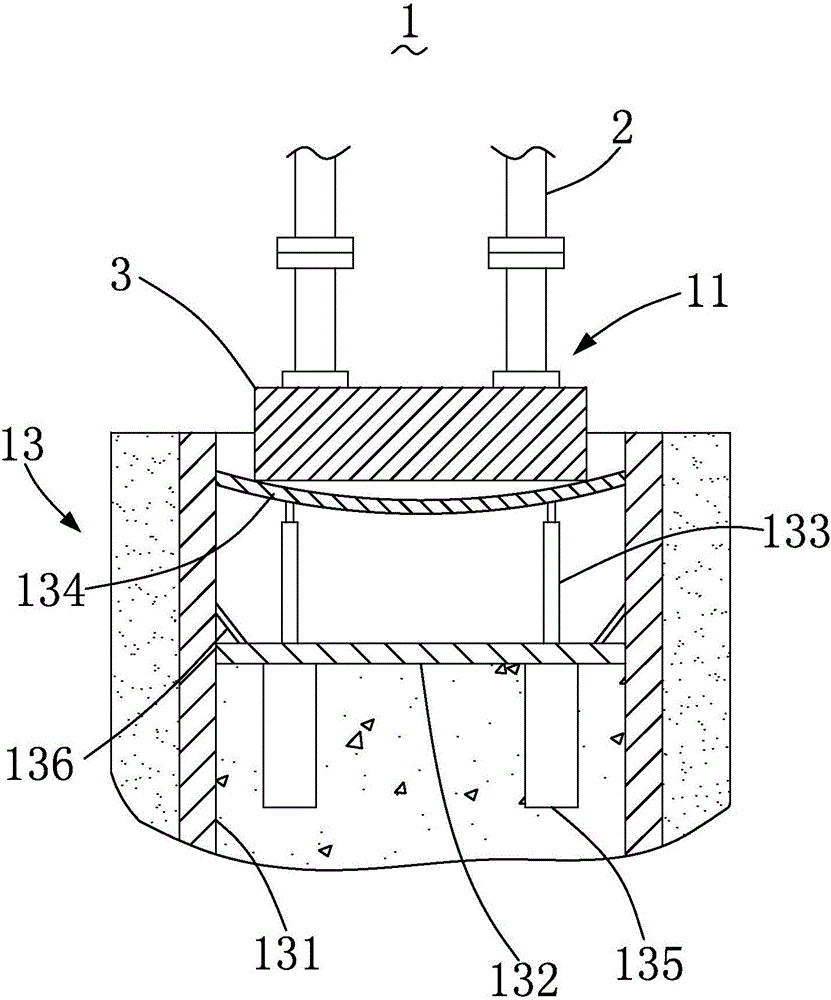

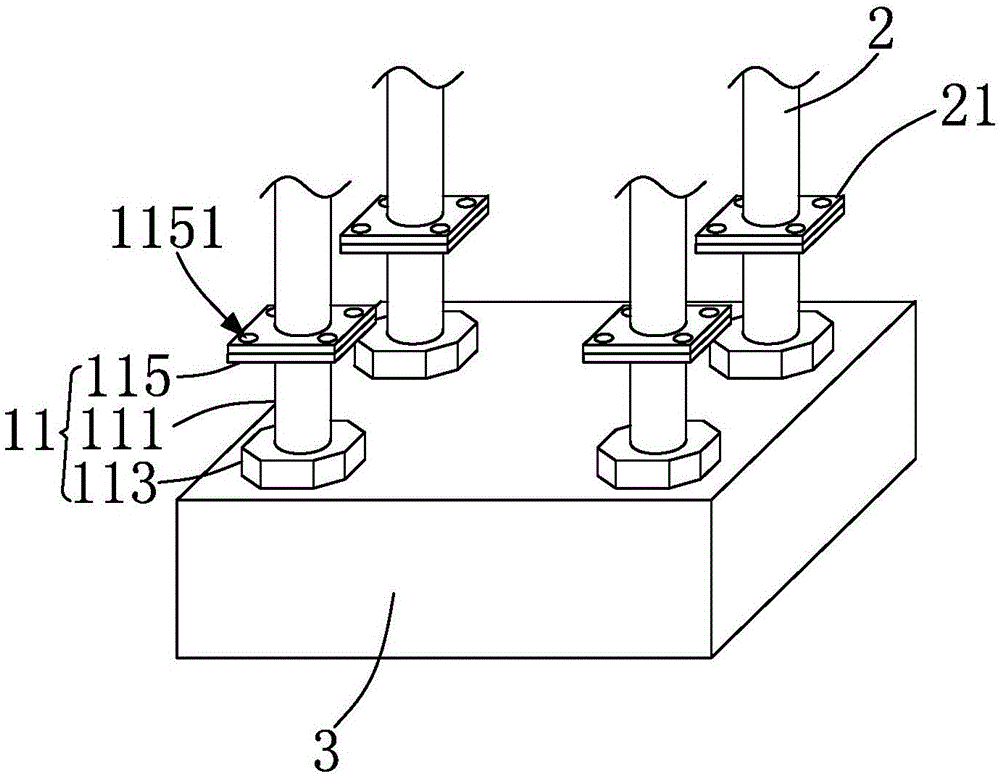

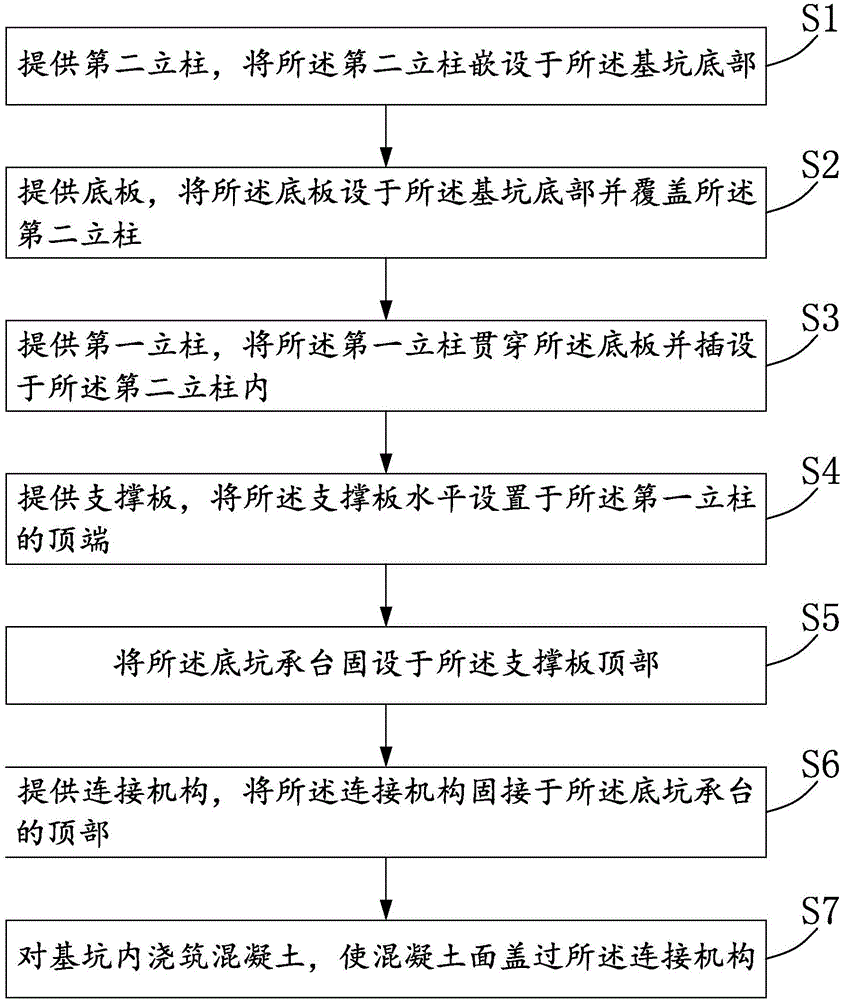

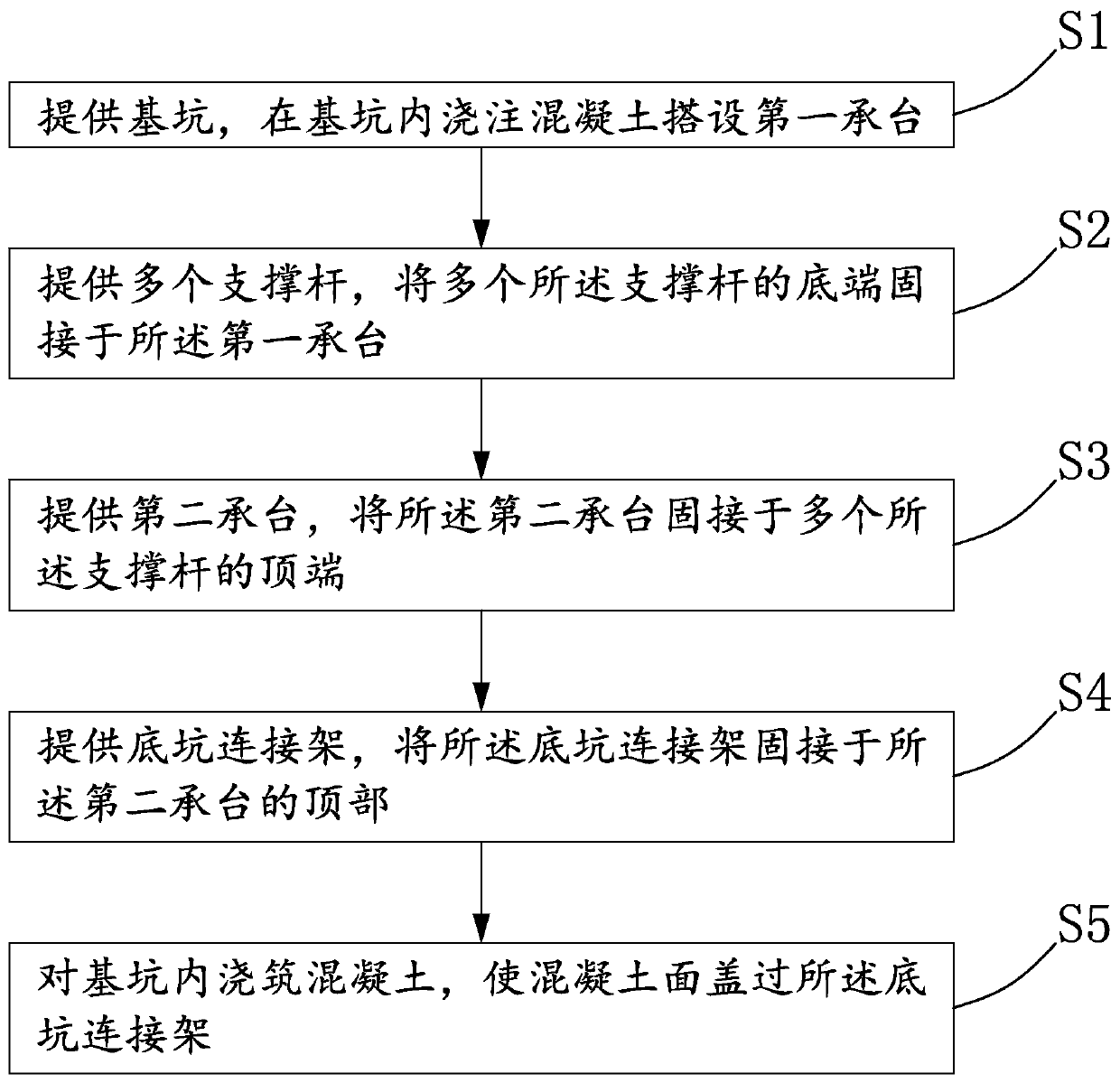

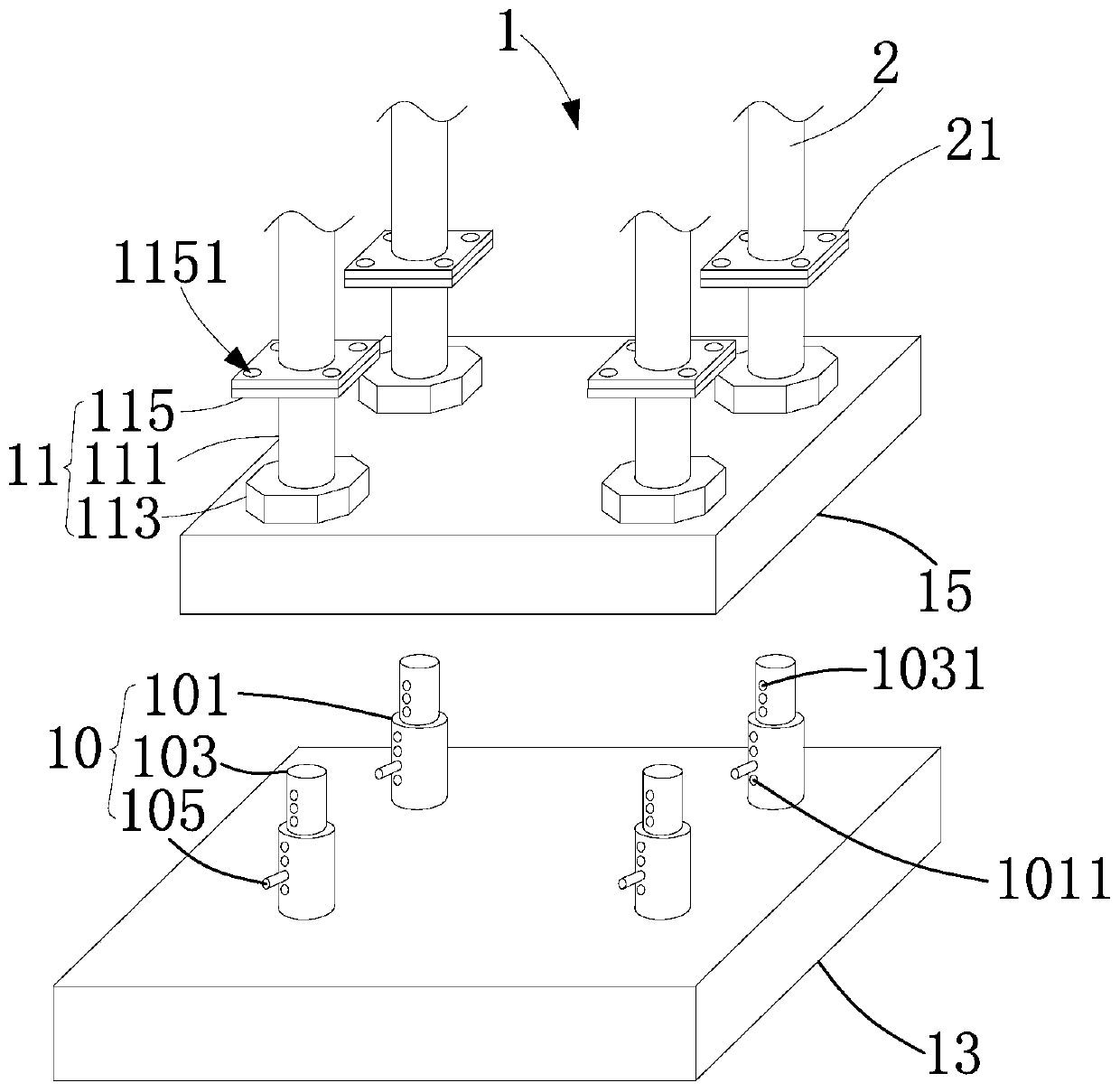

Pit structure mounting method

ActiveCN106592623AEnsure stabilityPrevention of landslidesFoundation engineeringBuilding liftsStructural engineering

Owner:安徽亿力电力设备有限公司

Sneaker producing and manufacturing process

InactiveCN112773054AImprove manufacturing efficiencyQuality is not affectedSolesHeelsGear driveGear wheel

The invention provides a sneaker producing and manufacturing process, the sneaker producing and manufacturing process adopts the following equipment for production, the equipment comprises I-shaped frames, conveying devices and an assembling device, the lower ends of the I-shaped frames are connected with the existing ground, the I-shaped frames are arranged in a bilateral symmetry mode, the conveying devices are arranged between the I-shaped frames which are right opposite in the left-right direction, and the assembling device is arranged above the conveying devices. According to the invention, through mutual cooperation of a first motor, a rotating shaft, a fixed shaft and an incomplete gear, a first gear drives a conveyor belt to do intermittent circulating motion, so that the function of intermittent assembly line operation can be realized; therefore, the production and manufacturing efficiency of sneakers is improved, and the quality of the sneakers is not affected.

Owner:文成

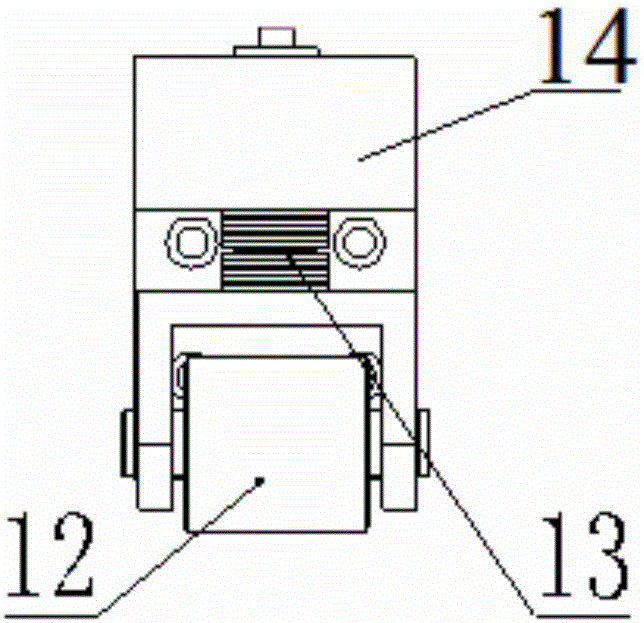

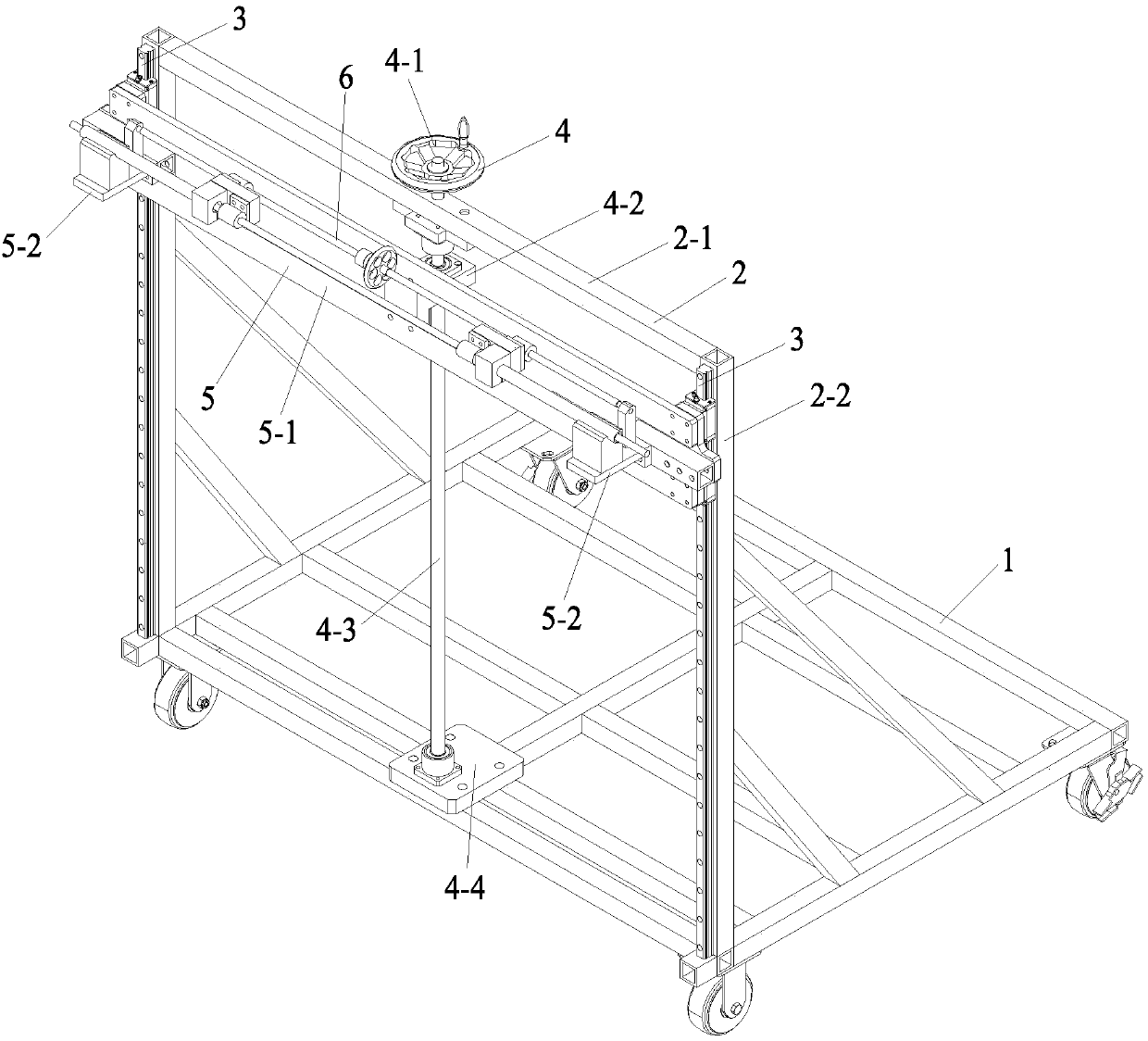

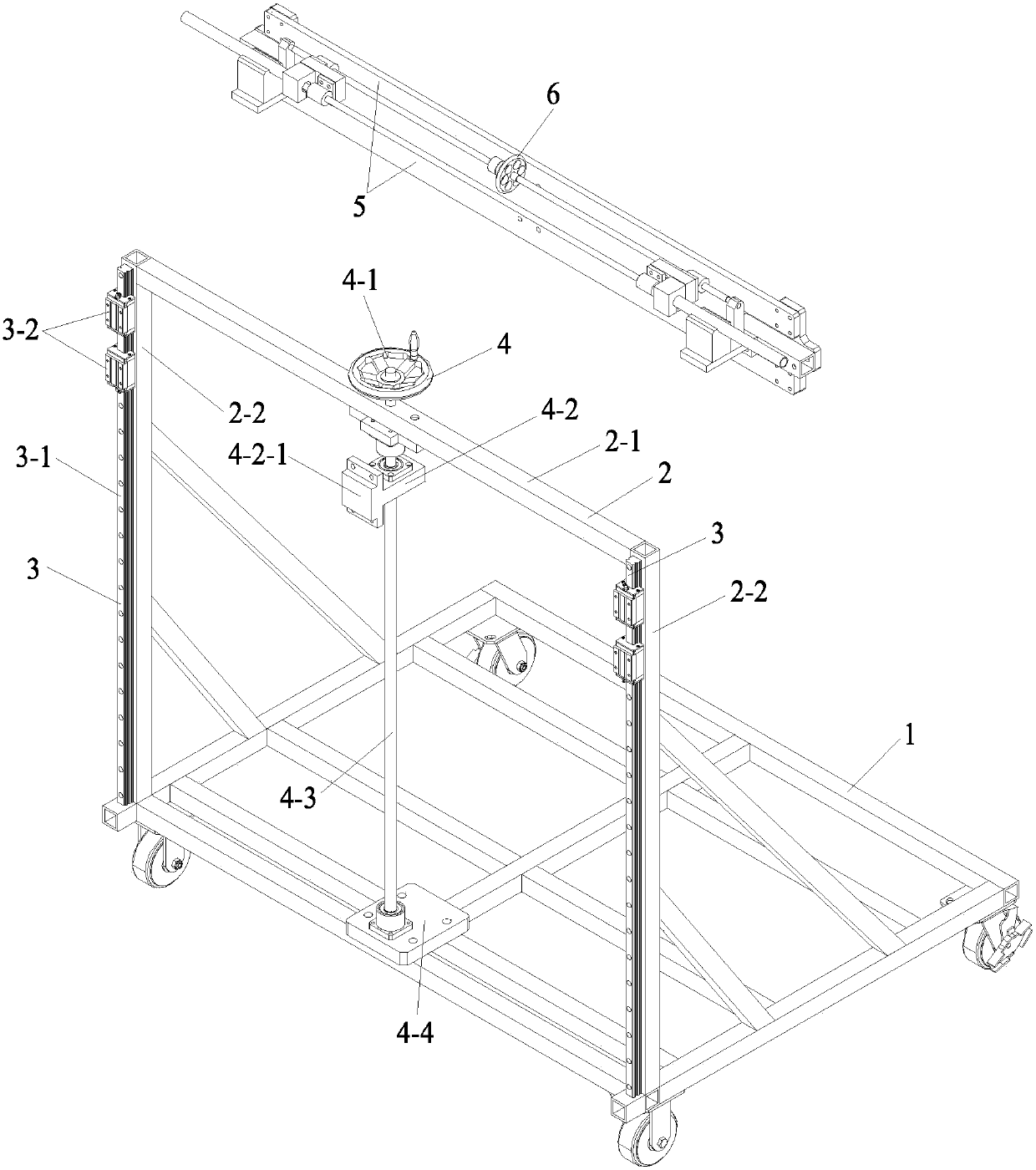

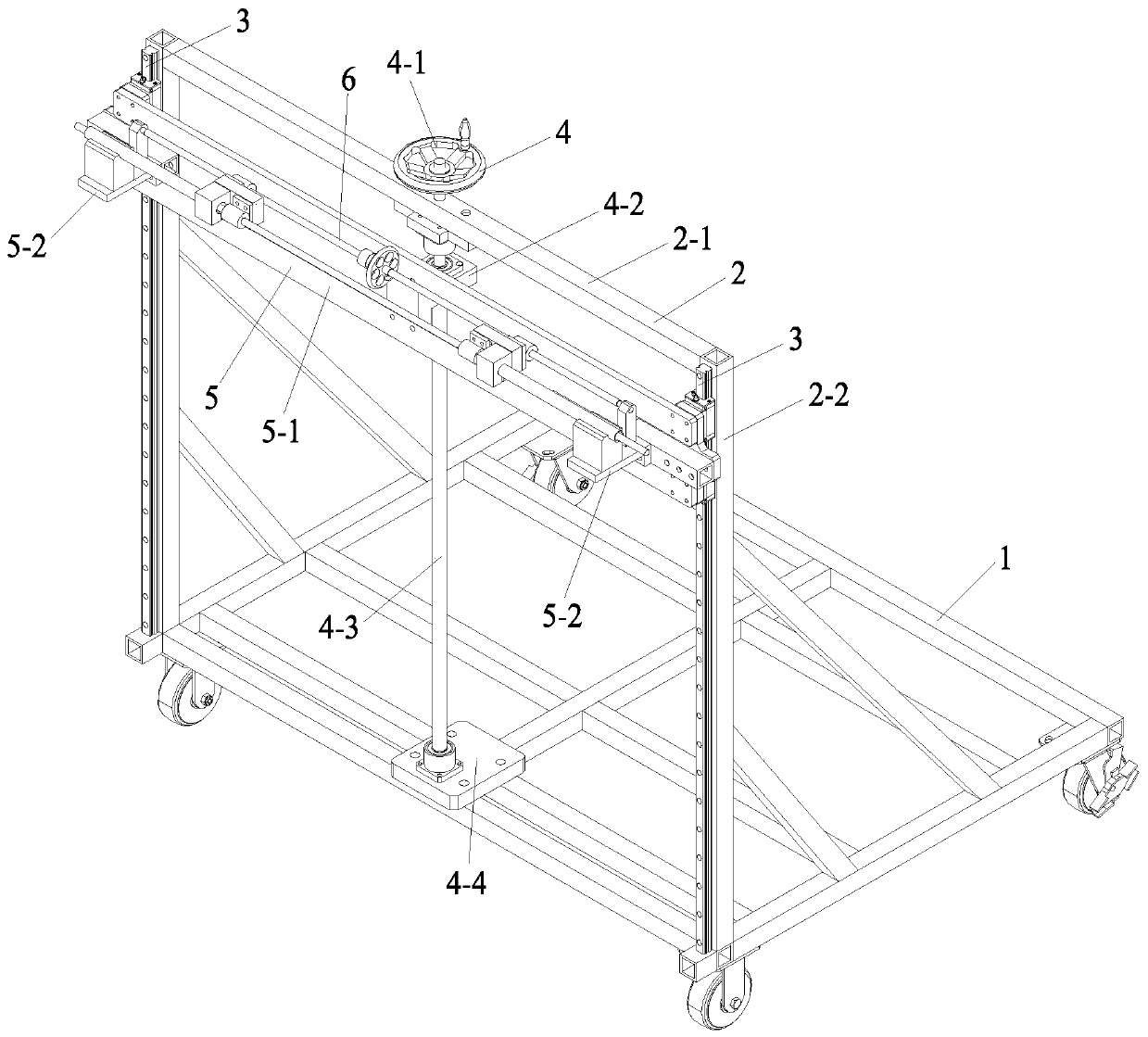

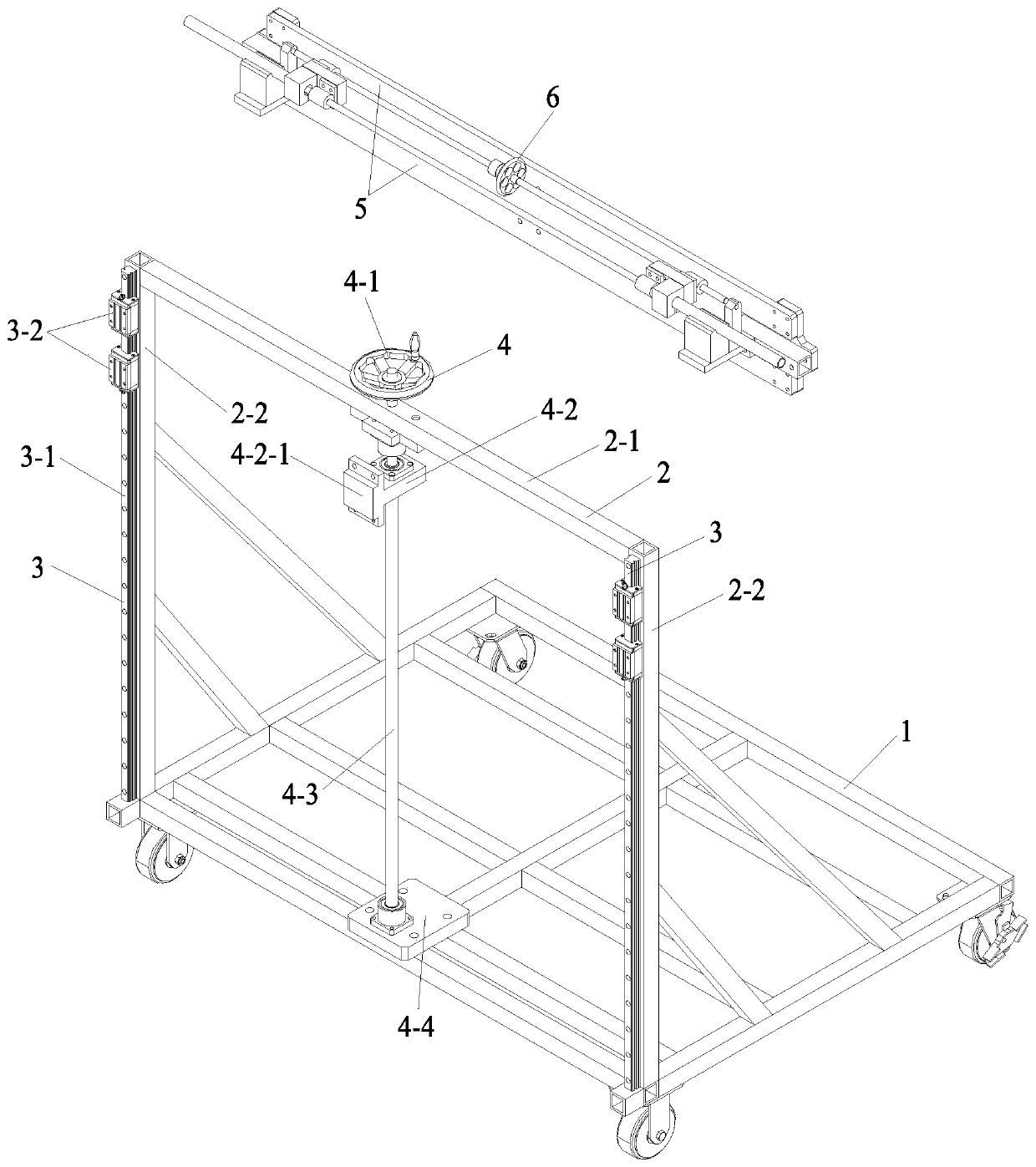

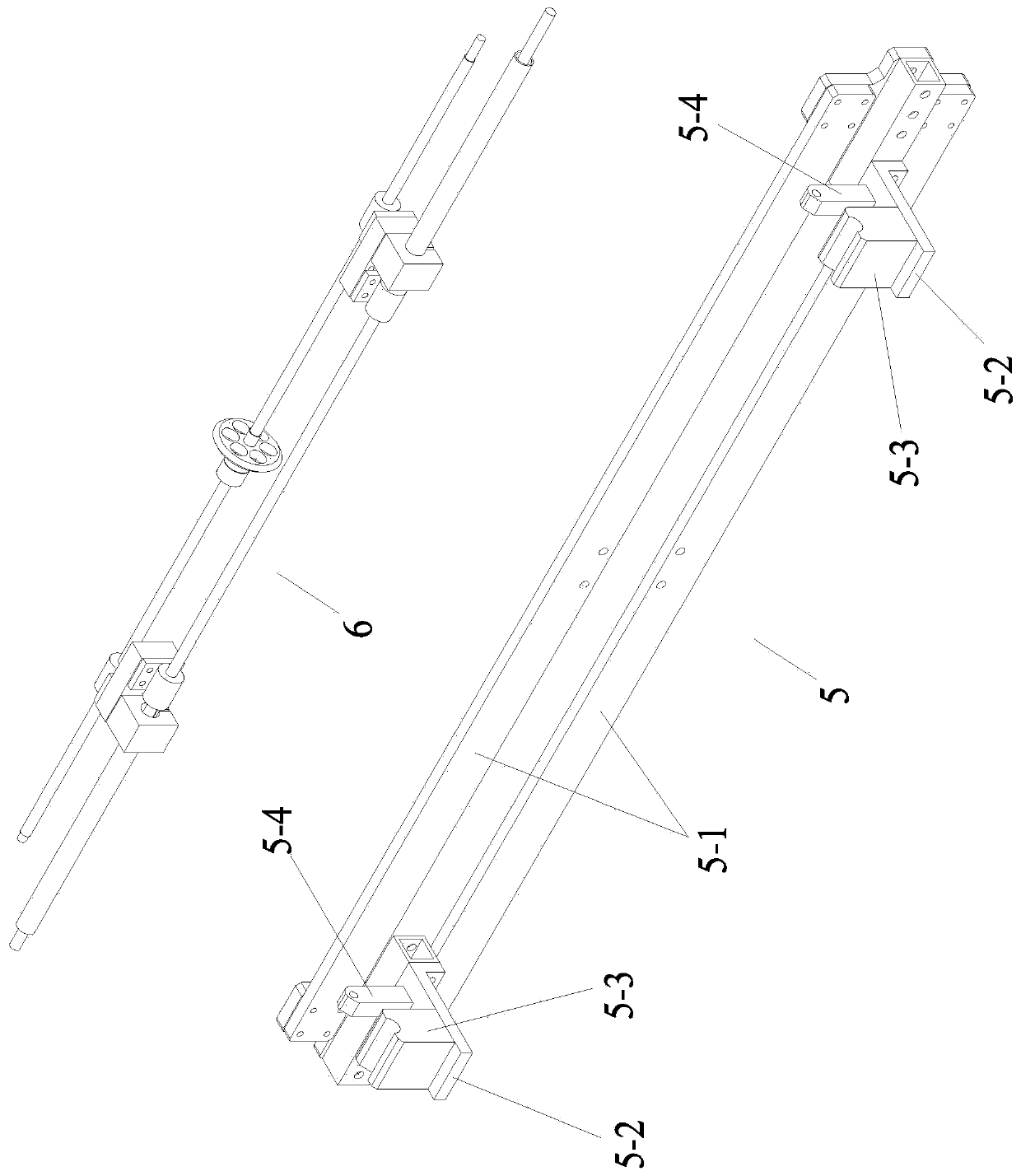

Centering positioning device suitable for vehicle indoors with different internal widths

The invention discloses a centering positioning device suitable for vehicle indoors with different internal widths, and belongs to the field of positioning devices of central planes of the indoor transverse width of railway vehicles. The centering positioning device comprises a four-wheel trolley, a door-shaped frame, two sets of vertical slide rail mechanisms, a vertical lifting screw rod mechanism and a wide-direction central plane centering system, wherein the wide-direction central plane centering system comprises a vertical lifting platform and a horizontal centering mechanism, and the door-shaped frame comprises a horizontal cross beam and two vertical stand columns which are integrally formed. According to the centering positioning device, the problems that the operation process iscomplex, the workload is large, the surveying and mapping efficiency is low and the universality is low due to the fact that a traditional surveying and mapping method used the modes of measuring by adrawing ruler and marking and scribing by a mark pen to determine the center plane in the width direction of the vehicle indoor are overcome, so that deviation errors caused by measuring by the ruleand scribing on the center of all parts of a vehicle are reduced, the quality problems that the center is inaccurate and the position is offset existing in the aspect of vehicle body manufacturing areeffectively solved, and size precision, the assembling quality and the working efficiency in the overall assembly construction process of the urban rail vehicle body are improved.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

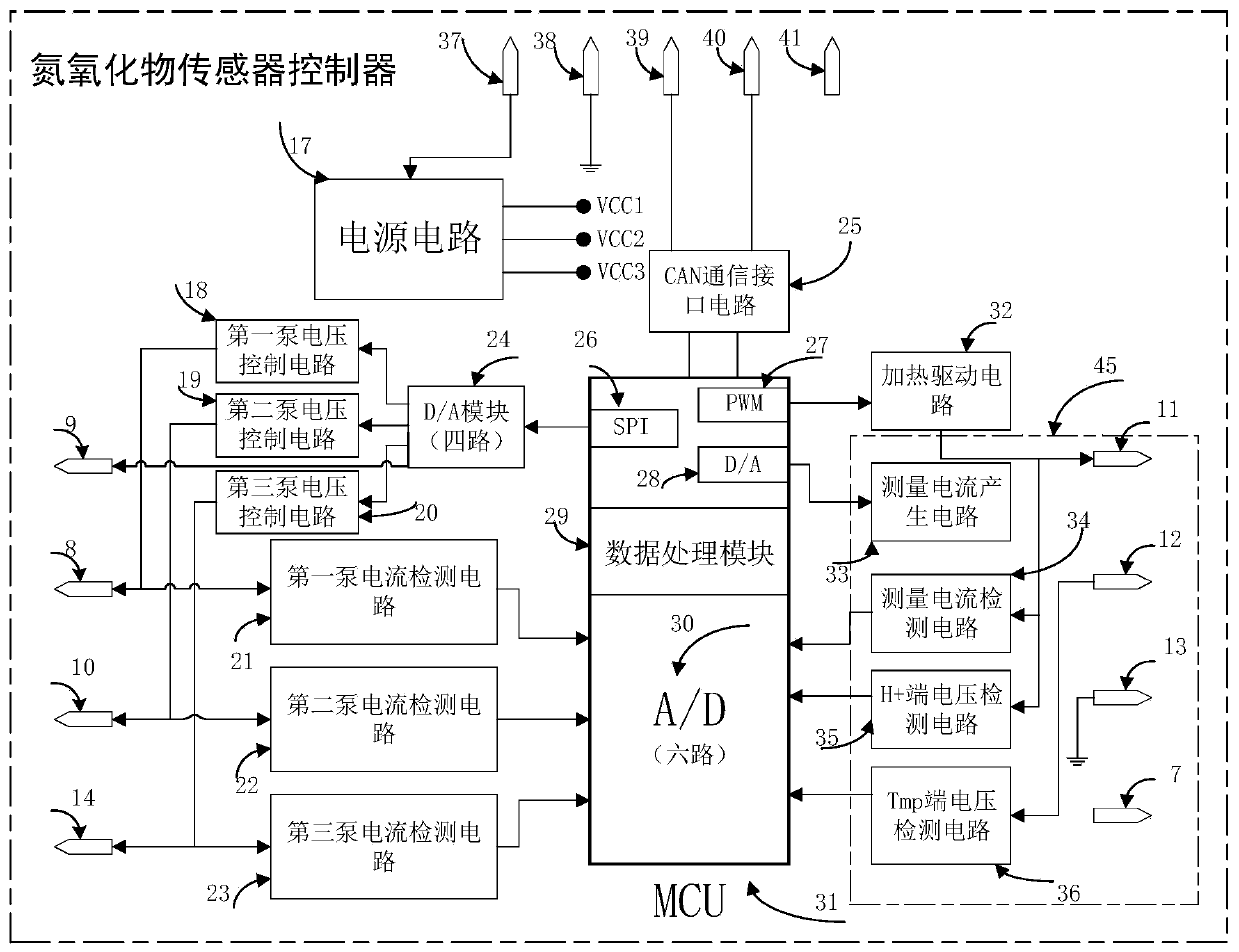

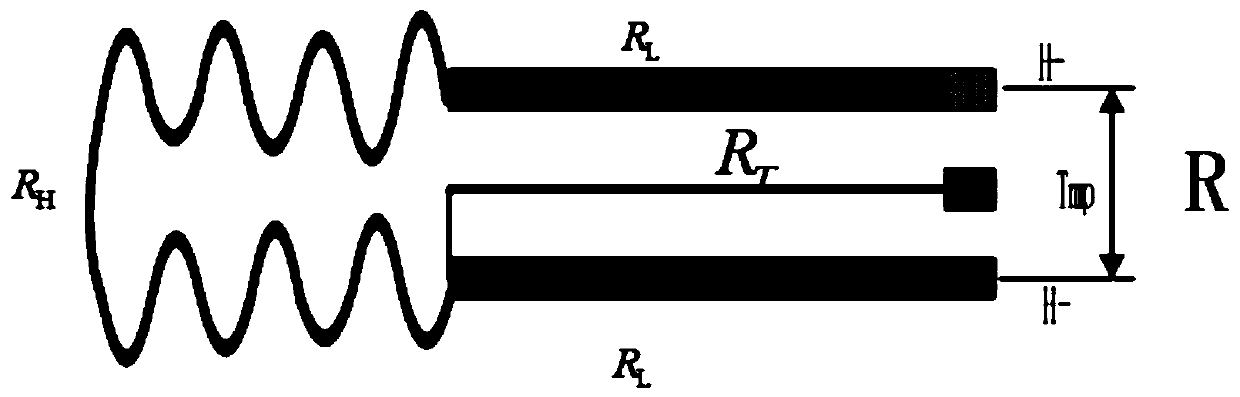

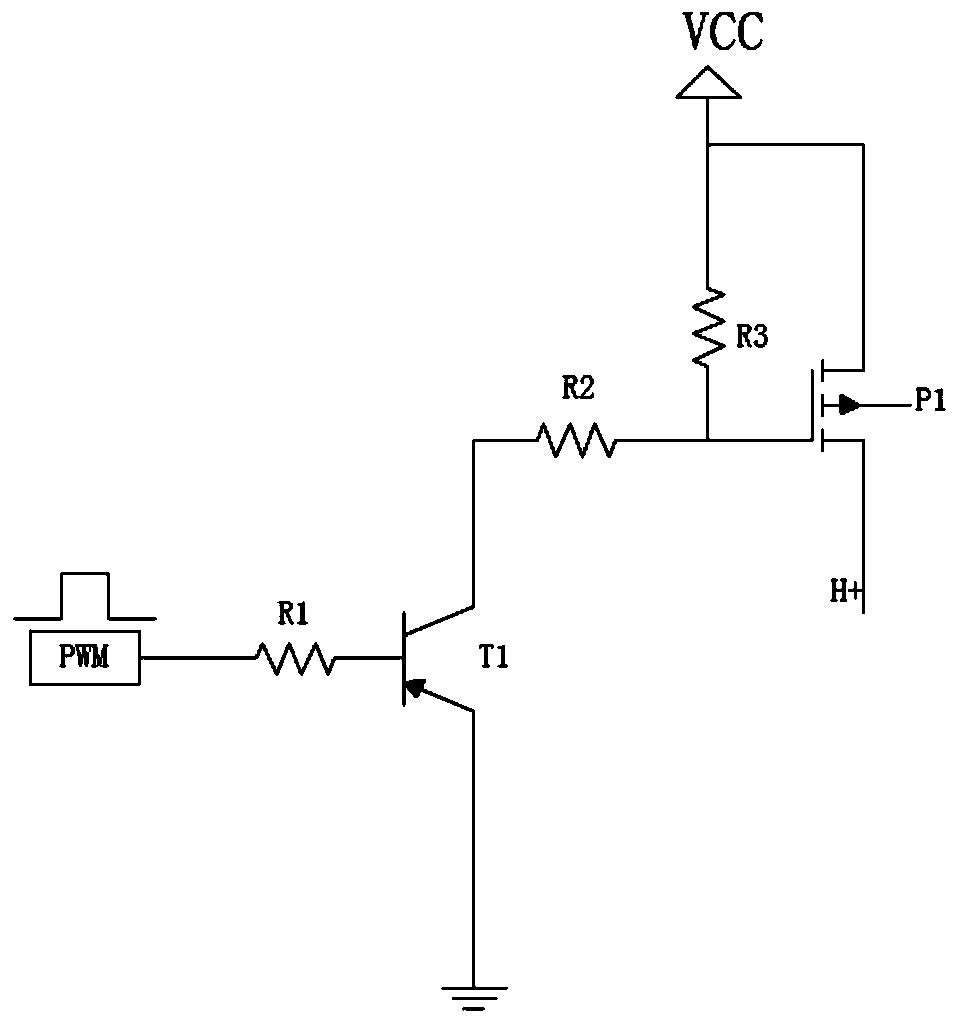

A nitrogen oxide sensor controller

ActiveCN110735699BHigh measurement accuracyImprove reliabilityInternal combustion piston enginesExhaust apparatusMicrocontrollerControl cell

Owner:HUAZHONG UNIV OF SCI & TECH +1

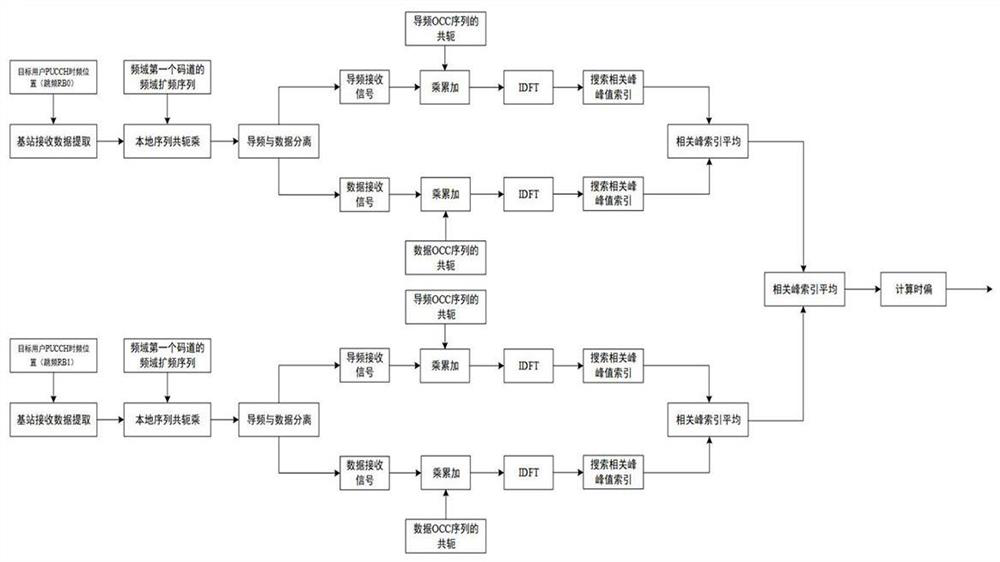

Time offset estimation method and system for NR uplink control channel

ActiveCN114884538AReduce offset errorImproved accuracy of time offset estimationTransmission path divisionPilot signal allocationFrequency domainReal-time computing

The invention discloses a time offset estimation method and system for an NR uplink control channel. The method comprises the following steps of: acquiring a PUCCH (Physical Uplink Control Channel) receiving signal extracted in a current time slot of a base station; performing conjugate multiplication operation on the signal and a local spread spectrum sequence of a current symbol frequency domain code channel 0 to obtain a conjugate receiving signal; separating pilot frequency from data; removing an OCC sequence; the pilot frequency and data correlation peak indexes are averaged, the time offset value of each user is calculated, and the method effectively improves the time offset estimation precision of the PUCCH multi-user multiplexing scene.

Owner:四川创智联恒科技有限公司

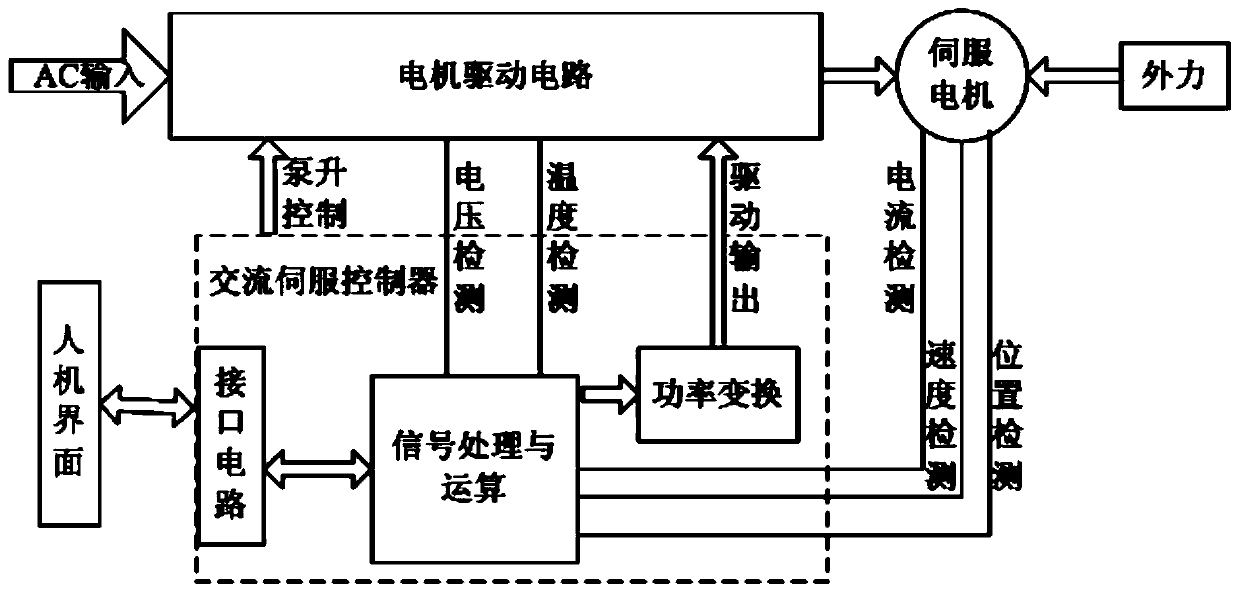

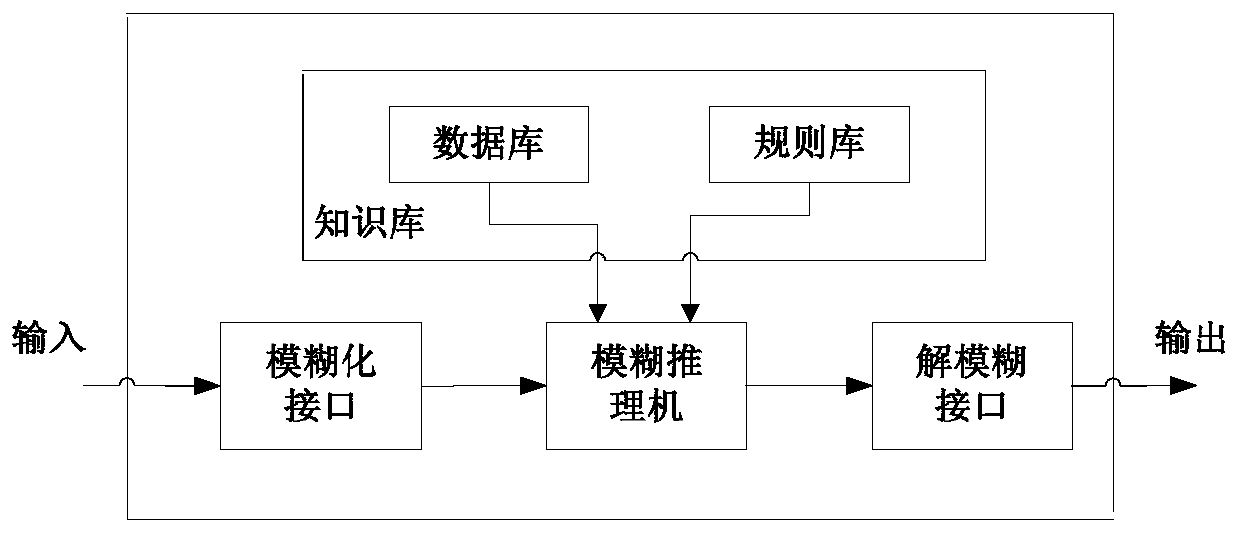

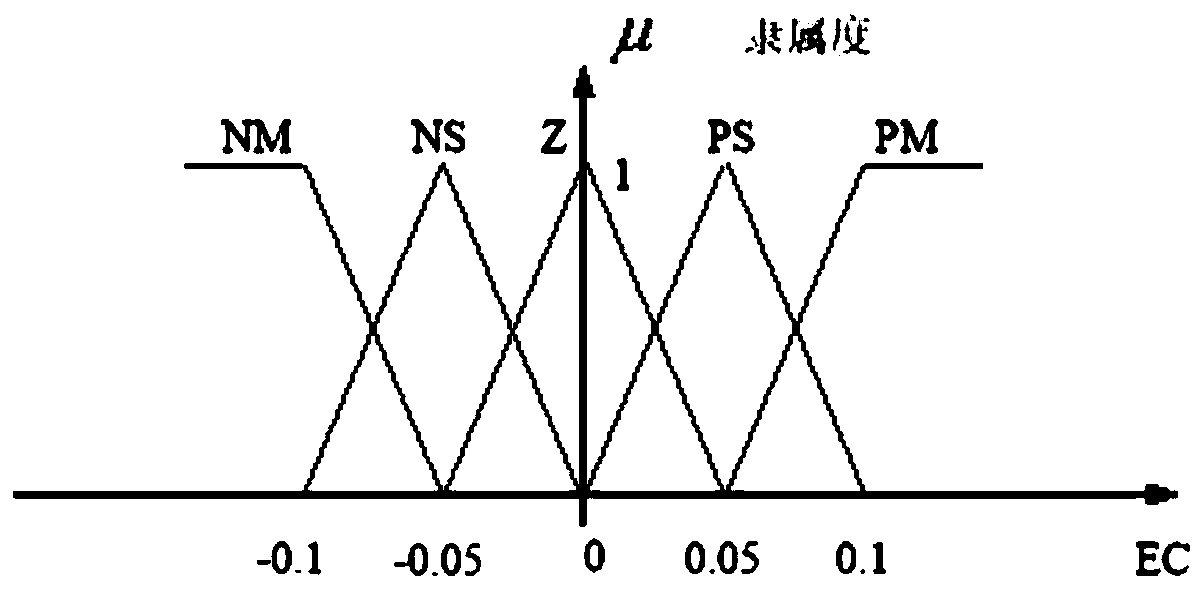

Fitness equipment intelligent control system based on servo technology

InactiveCN111558207AGuaranteed uptimeImprove dynamic stabilityFrictional force resistorsAdaptive controlHuman–machine interfaceControl engineering

The invention discloses a fitness equipment intelligent control device based on a servo technology. The fitness equipment intelligent control device comprises a fitness equipment frame, a servo motor,a servo motor driving unit, a sensor, a servo motor connector, a touch display, a fuzzy controller, a control circuit and a human-computer interface. In the aspect of user experience, due to the factthat the actual torque offset is reduced, the offset error is reduced, a user pulls the servo motor to run more smoothly in the exercise process of using the fitness equipment, and the stagnation feeling before a fuzzification algorithm is applied is eliminated.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

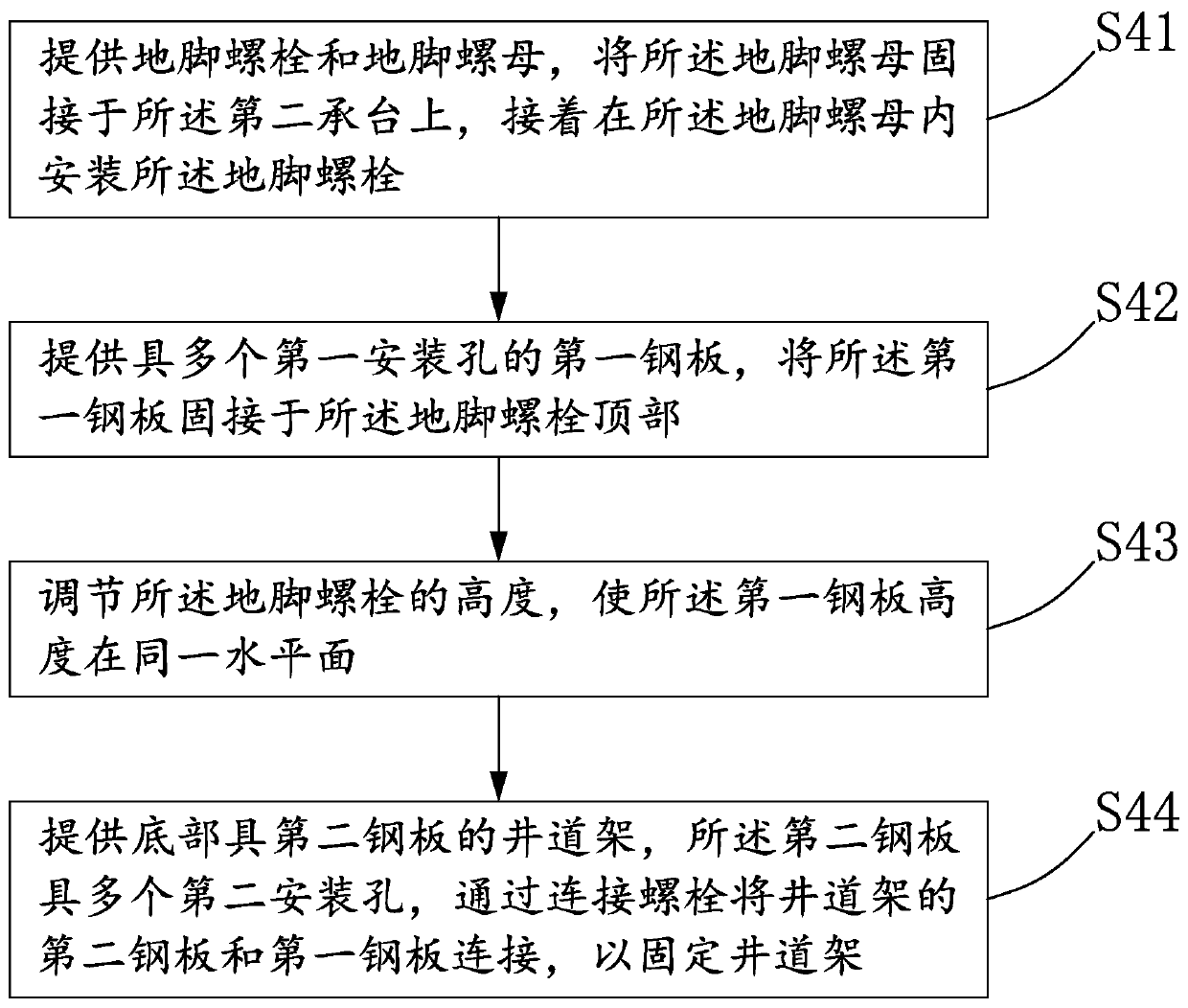

Pit structure installation method

ActiveCN106499048BAdjust levelAccurate and stable connectionCellarsStructural engineeringSurface cover

Owner:ZHEJIANG CANYUAN HOME TEXTILE

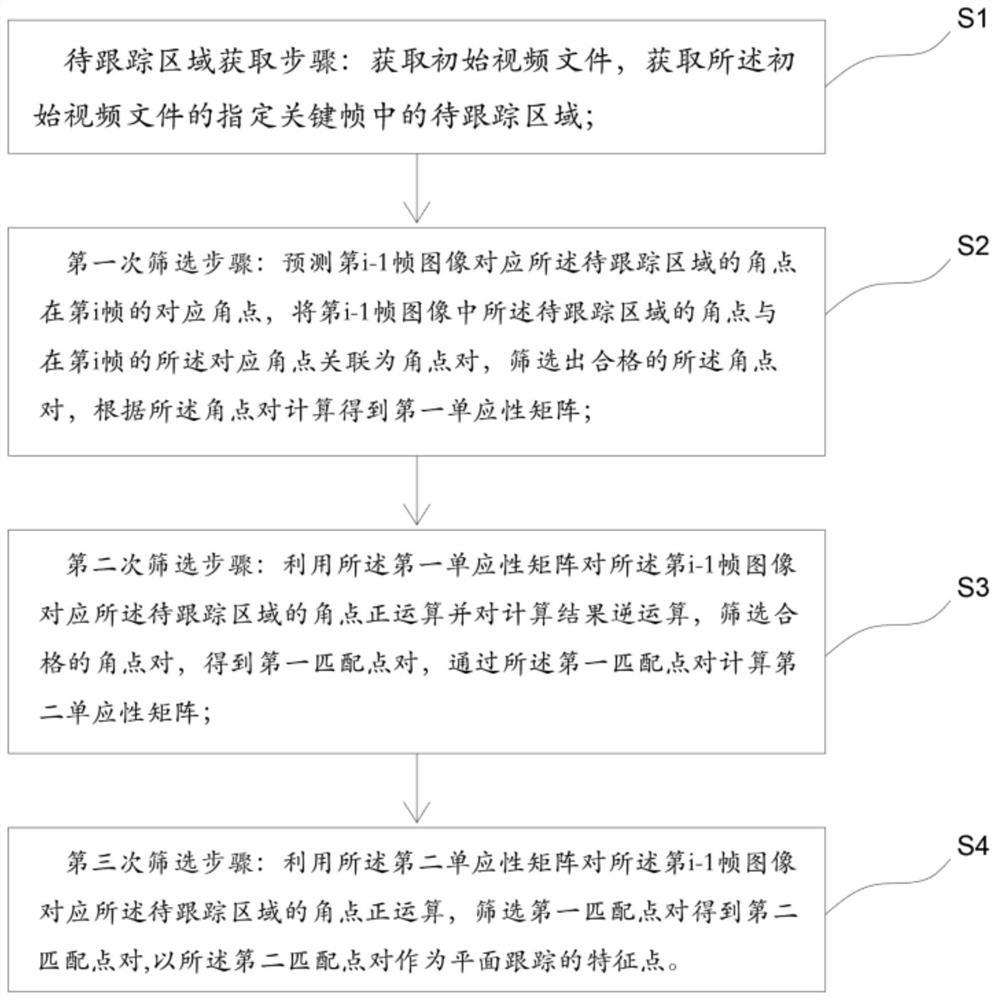

A feature point optimization method and system suitable for plane tracking

ActiveCN113689467BStable trackingTracking Algorithm Tracking StationaryImage enhancementImage analysisAlgorithmKey frame

The invention relates to a feature point optimization method and a system suitable for plane tracking, comprising the following steps: a step of obtaining an area to be tracked: obtaining an initial video file, and obtaining the area to be tracked in a designated key frame of the initial video file; A screening step: predict that the corner point of the i-1th frame image corresponding to the to-be-tracked area is at the corresponding corner point of the i-th frame, screen out the qualified pair of corner points, and calculate the first corner point according to the pair of corner points. A homography matrix; the second screening step: using the first homography matrix to perform positive operations on the corners of the i-1th frame image corresponding to the to-be-tracked area and inverse operations on the calculation results, and filter qualified Corner point pair; the third screening step: using the second homography matrix to perform a positive operation on the corner points of the i-1th frame image corresponding to the area to be tracked, and filter the first matching point pair to obtain a second matching Right.

Owner:GAODING XIAMEN TECH CO LTD +1

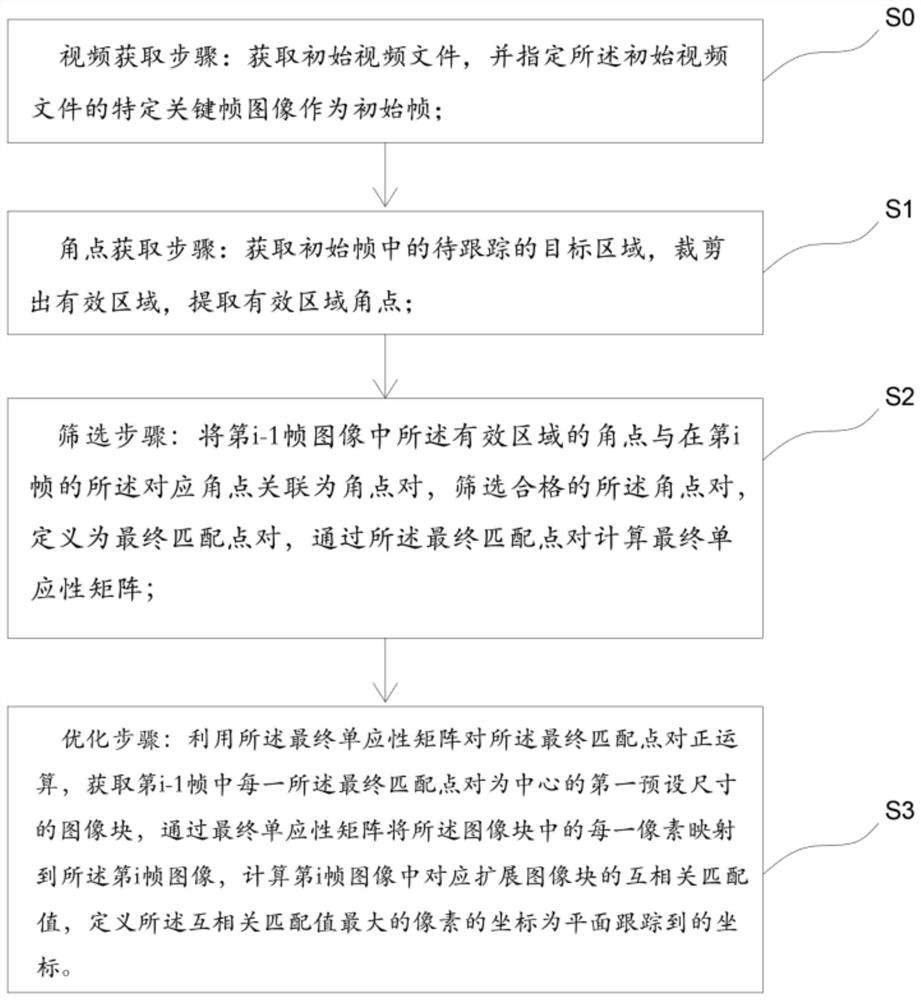

A feature point-based plane tracking method and system

ActiveCN113689466BReduce offset errorImprove stabilityImage enhancementImage analysisComputer graphics (images)Imaging algorithm

The invention relates to a feature point-based plane tracking method and a system thereof, comprising the following steps: obtaining an initial video file; a corner point obtaining step: obtaining a target area to be tracked in an initial frame, cutting out an effective area, and extracting the effective area Corner point; Screening step: associate the corner point of the effective area in the i-1th frame image with the corresponding corner point in the i-th frame as a corner point pair, and filter the qualified corner point pair, which is defined as the final Matching point pairs, calculating the final homography matrix through the final matching point pairs; optimization step: calculating the cross-correlation matching value of the corresponding extended image block in the i-th frame image through the image algorithm, and defining the pixel with the largest cross-correlation matching value The coordinates are the coordinates tracked by the plane.

Owner:GAODING XIAMEN TECH CO LTD +1

Indoor centering and positioning device suitable for trains with different inner widths

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

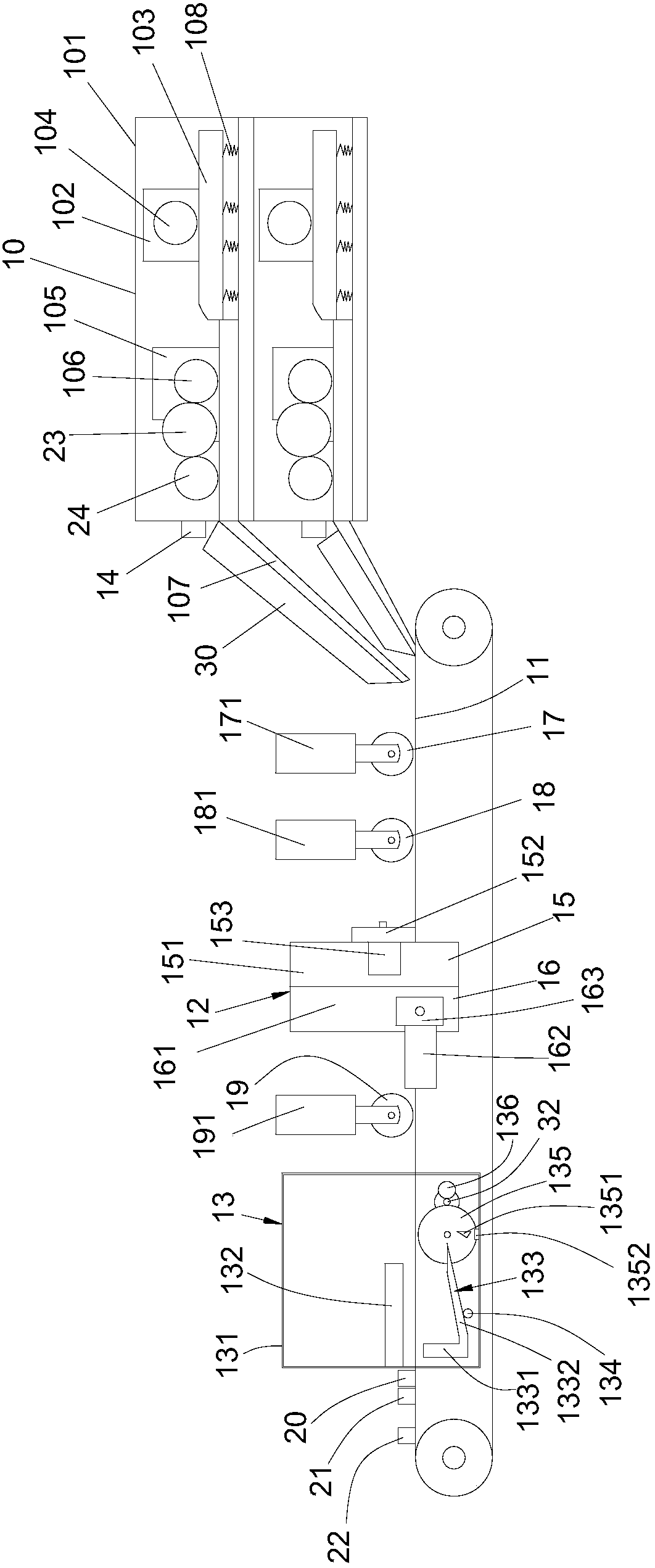

A full-process automatic binding machine

ActiveCN106799897BReduce investmentNeatly boundArticle feedersSheet bindingButt jointPulp and paper industry

The invention relates to a full-process automatic binding machine. The full-process automatic binding machine comprises at least one paper drawing and conveying device used for drawing and conveying paper, a conveying belt used for conveying the paper, a steering engine system used for arranging the paper in order, a binding device used for binding the paper, and a controller used for controlling the automatic binding machine to operate. The paper drawing and conveying device comprises a box body, a first motor, a paper placing block, a first paper conveying roller, a second motor, a second paper conveying roller and a paper discharging rail. A paper outlet of the box body is provided with a first sensor used for sensing whether the paper exits or not. The lower portion of the paper discharging rail is in butt joint with the conveying belt. The steering engine system comprises a transverse paper blocking mechanism and a side paper blocking mechanism. By the adoption of the binding machine provided by the invention, full-automatic paper feeding and paper binding can be achieved, the manpower resource input is greatly reduced, and the working efficiency is further improved.

Owner:FUQING BRANCH OF FUJIAN NORMAL UNIV

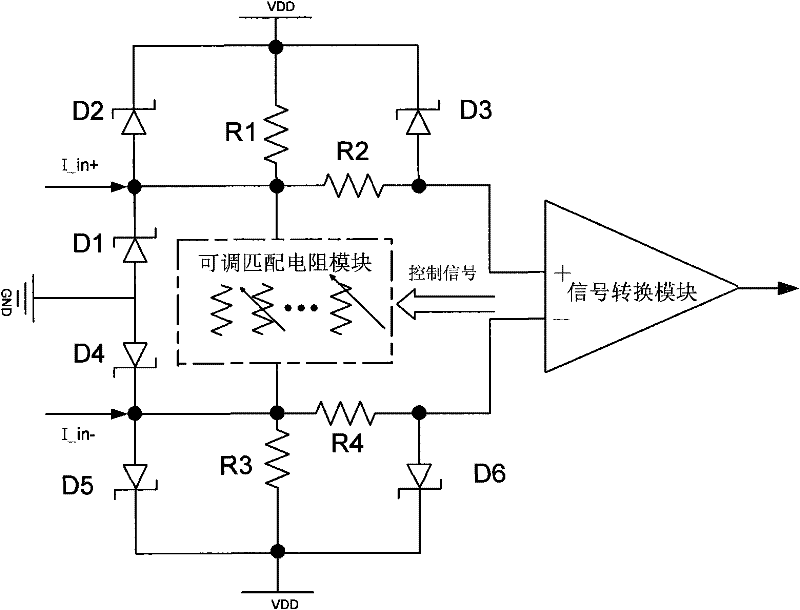

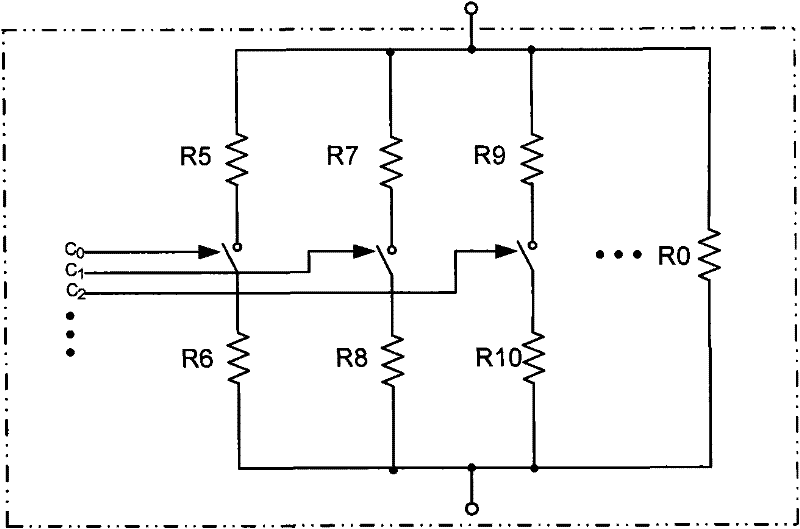

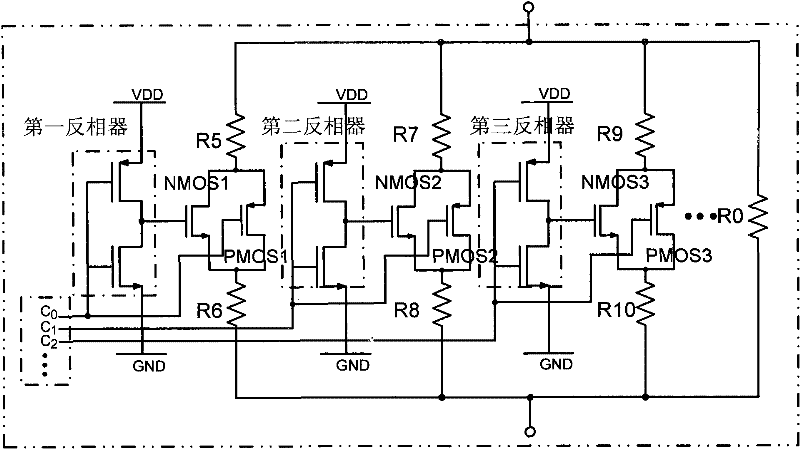

A lvds receiving circuit with adjustable input resistance

InactiveCN101751902BReduce reflectionAchieve Impedance MatchingCathode-ray tube indicatorsControl signalSoftware engineering

Owner:BEIJING MXTRONICS CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com