Patents

Literature

52results about How to "Accurate and stable connection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

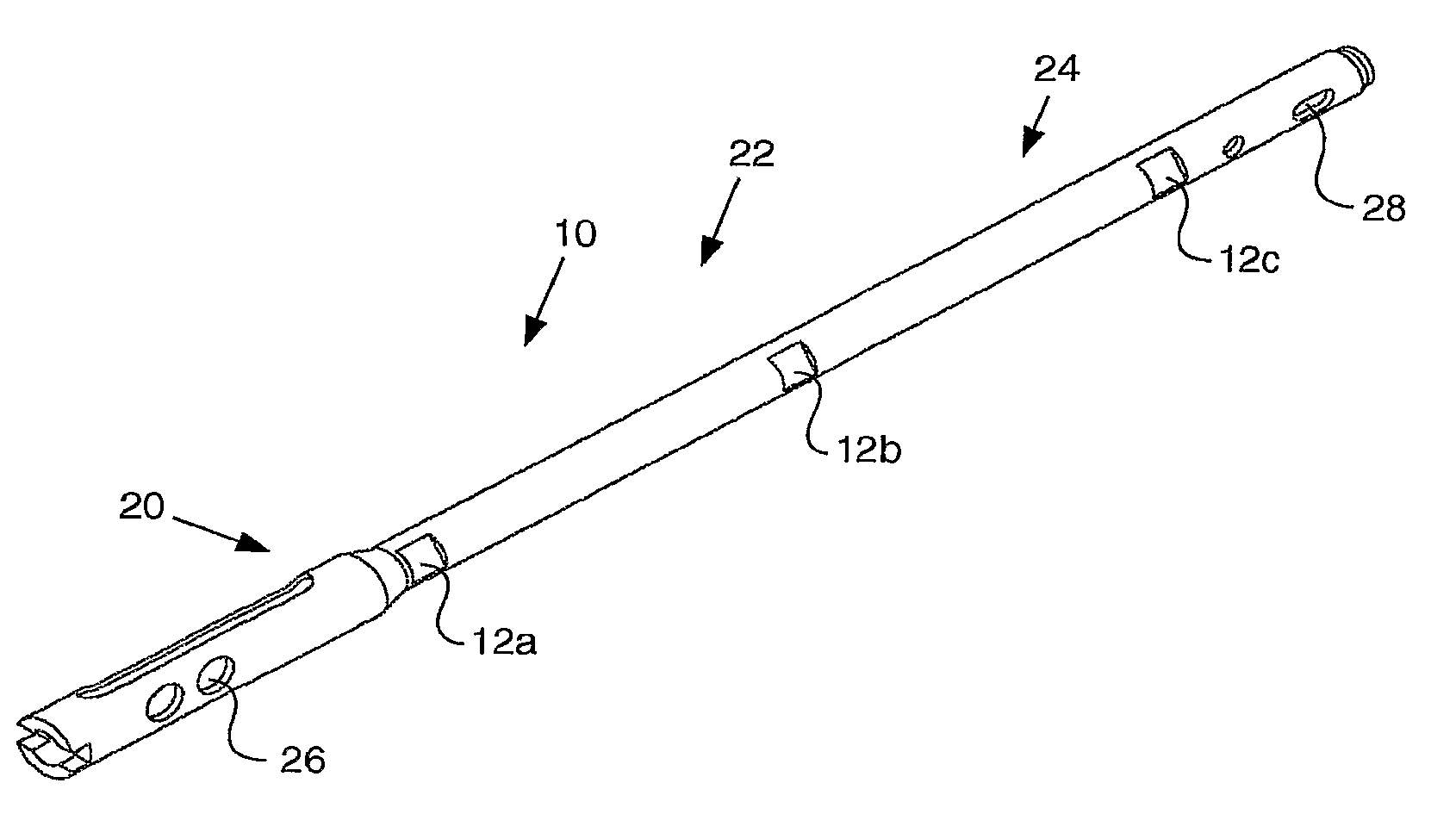

Processing sensed accelerometer data for determination of bone healing

ActiveUS20100152621A1Accurate and stable connectionSuitable for mass productionPerson identificationInertial sensorsAccelerometer dataTime domain

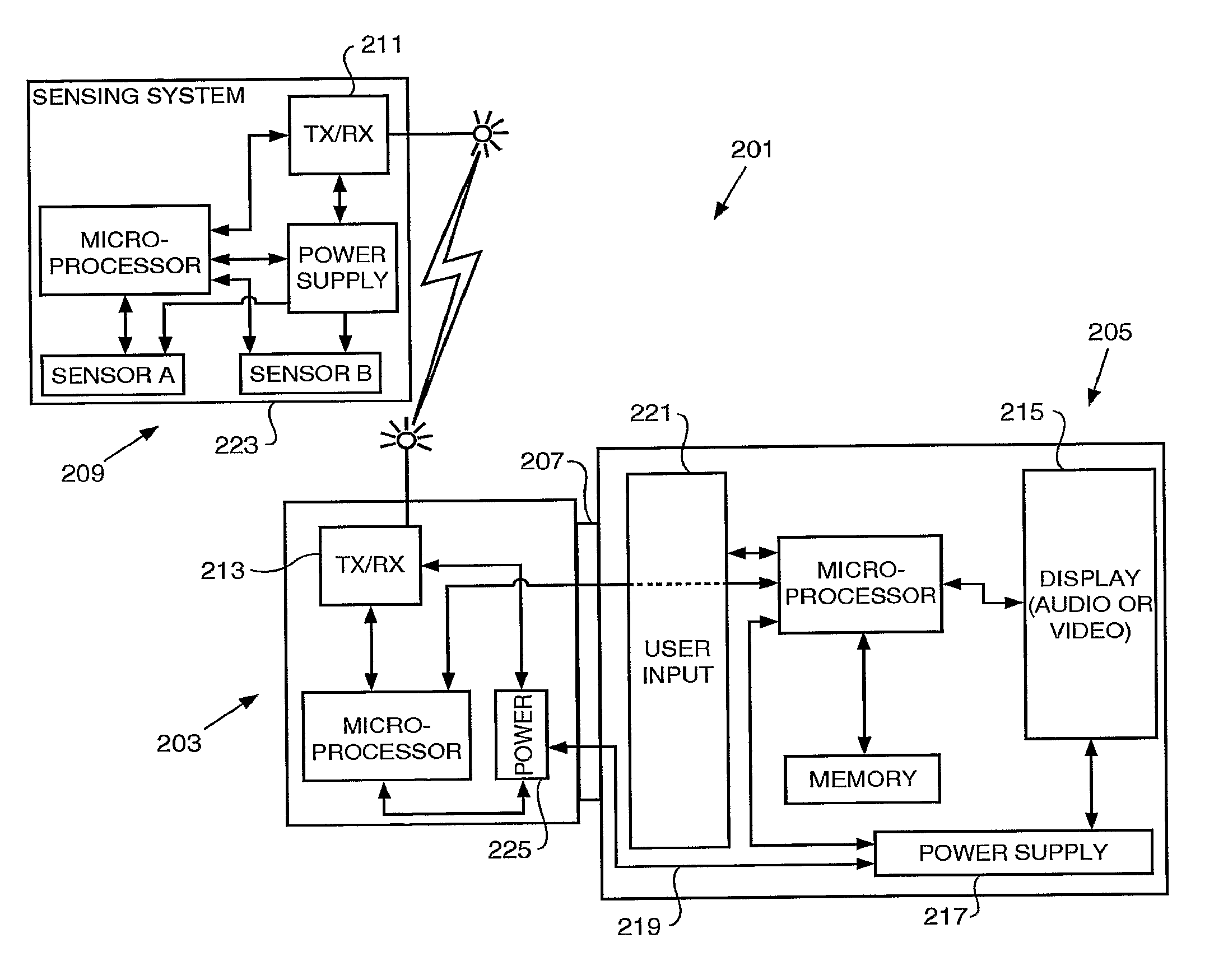

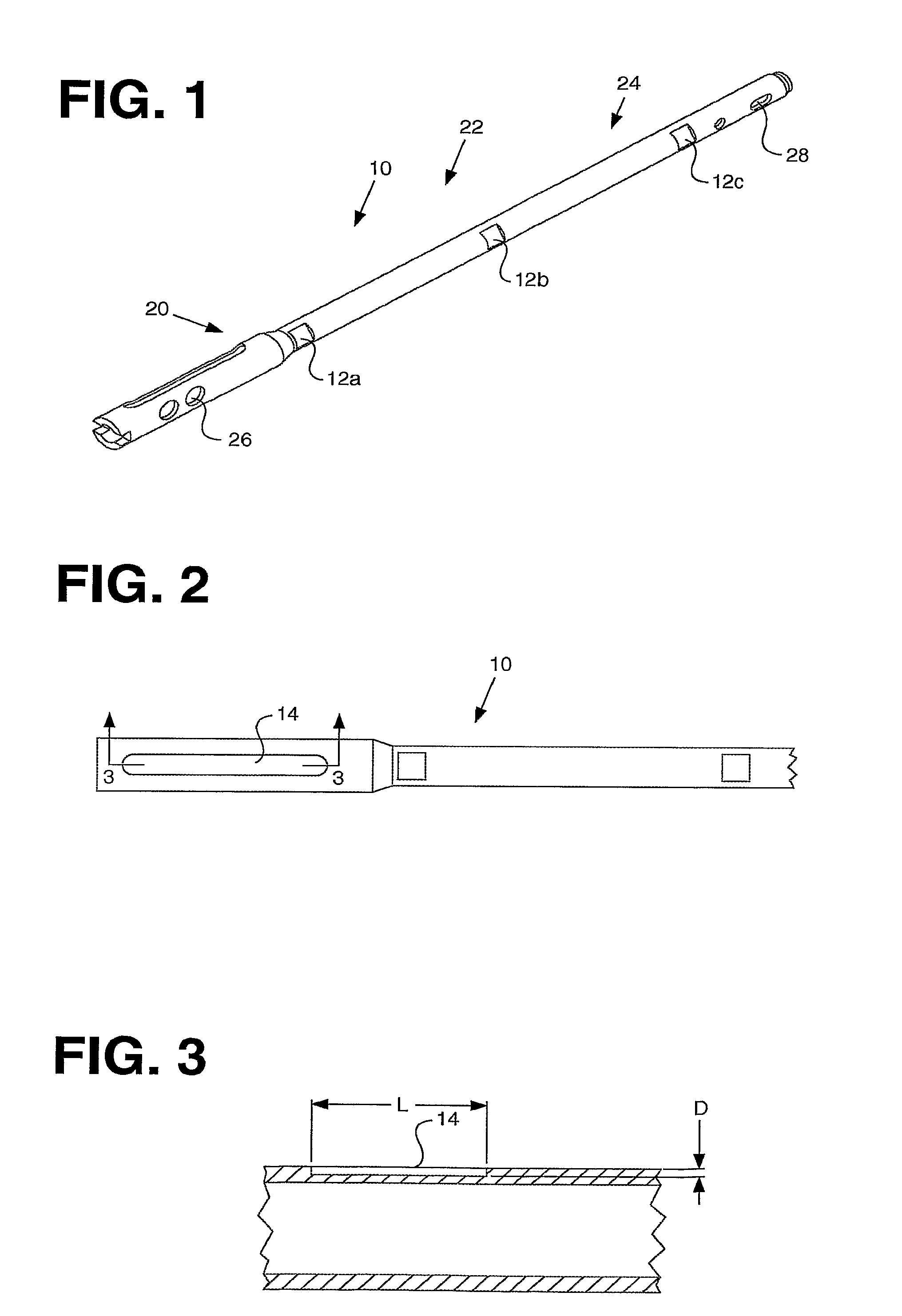

A system (800) for processing accelerometer data is disclosed. The system (800) includes an accelerometer (806), a first processor (810), a power supply (816), and a second processor (804). The accelerometer (806) measures a physiological acceleration parameter. The first processor (810) is operatively connected to the accelerometer (806). The first processor (810) is configured to receive the acceleration parameter from the accelerometer (806) and configured to output machine readable acceleration data. The machine readable acceleration data includes time domain accelerometer data. The power supply (816) is electrically connected to the first processor (810). The second processor (804) is configured to receive the machine readable acceleration data and transform the time domain accelerometer data into frequency domain accelerometer data. The frequency domain accelerometer data may be used to estimate patient healing status.

Owner:SMITH & NEPHEW INC

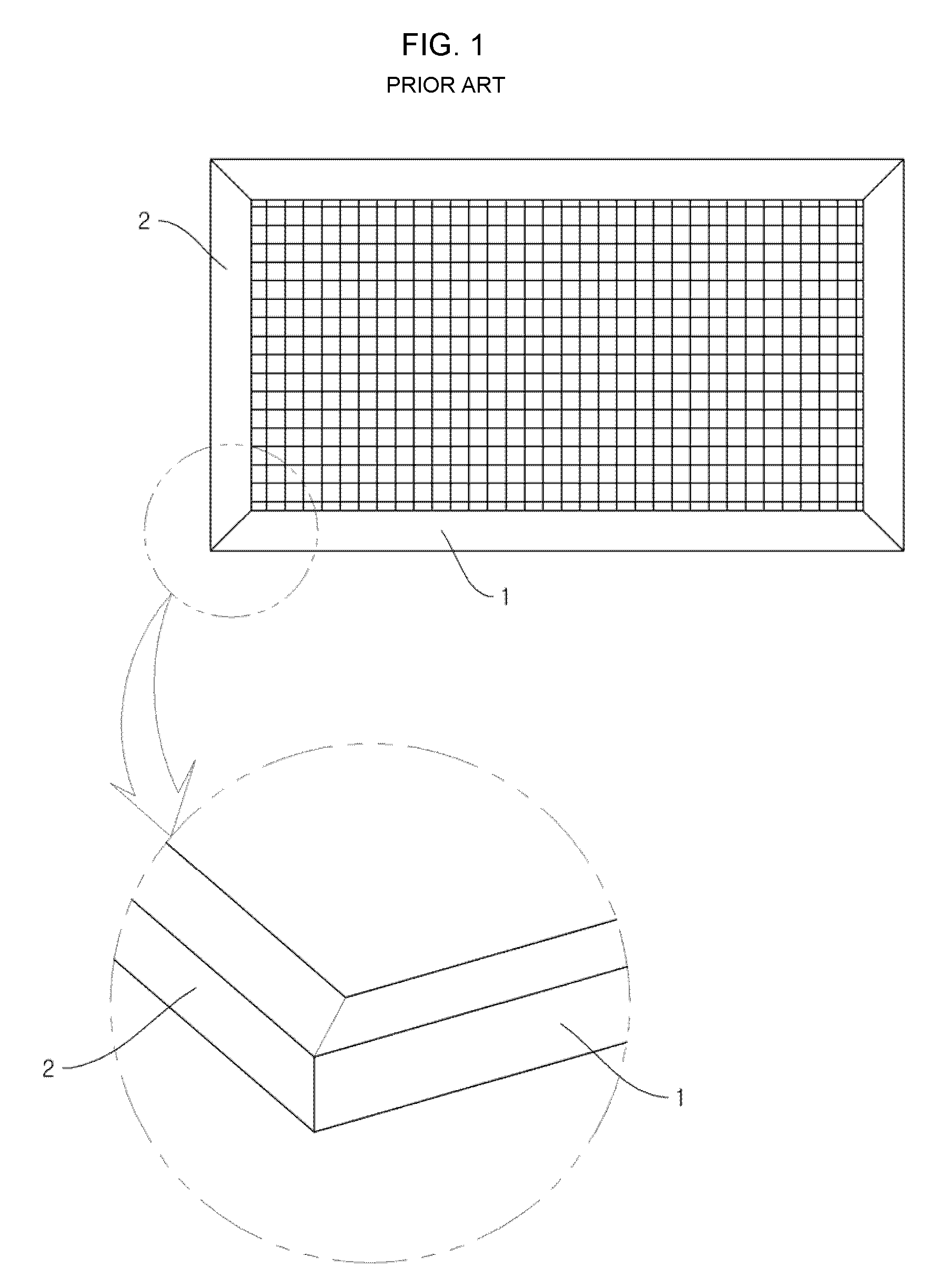

Photovoltaic module frame

InactiveUS20110259404A1Avoid damageQuality improvementSolar heating energySolar heat devicesCouplingEngineering

An apparatus for a photovoltaic module frame assembly comprising a frame member including a vertical member and horizontal member that cover the outer circumference the photovoltaic module, which transforms solar energy into electric energy, and corner member that performs connections and fixation between the horizontal member and vertical member, which provides a solution to alleviate traditional frame structure issues that relate to the sharpness of the corner so that any accidents that may be caused by the corner can be prevented and enhance safety. Also a groove is included to fix the frame onto the corner member that, which covers the photovoltaic module and does not have any sides, and allows accurate coupling by fitting into the frame member so that various designs and formations can be provided.

Owner:DAEJU SYST

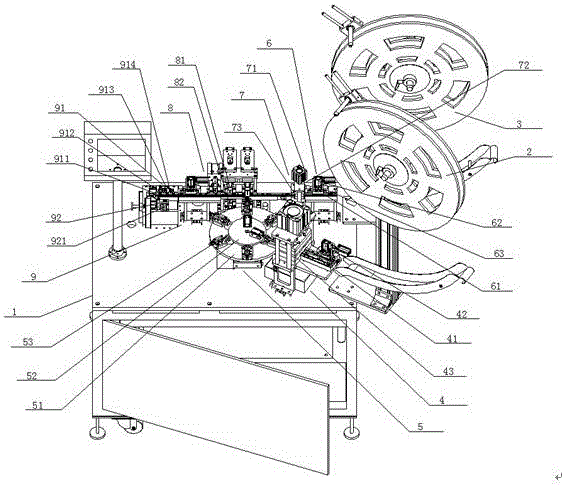

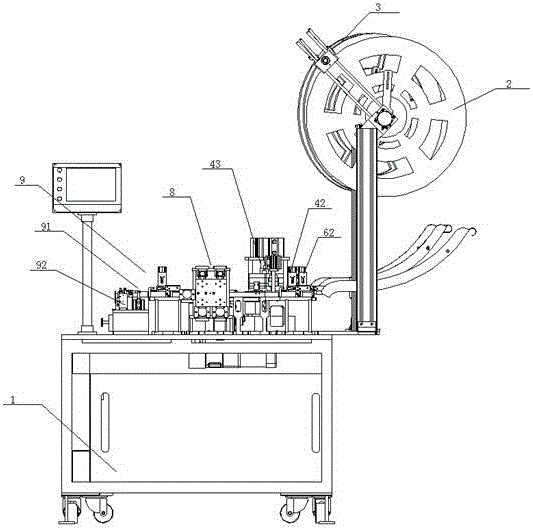

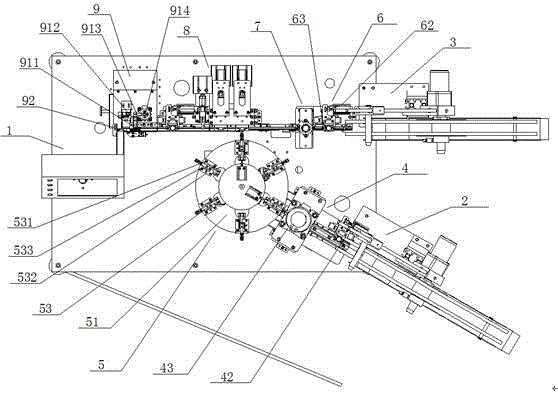

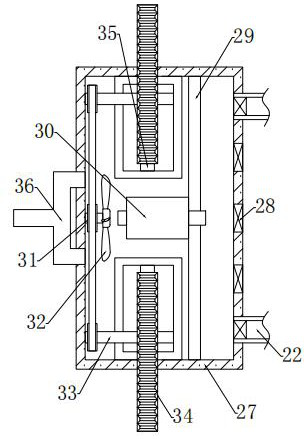

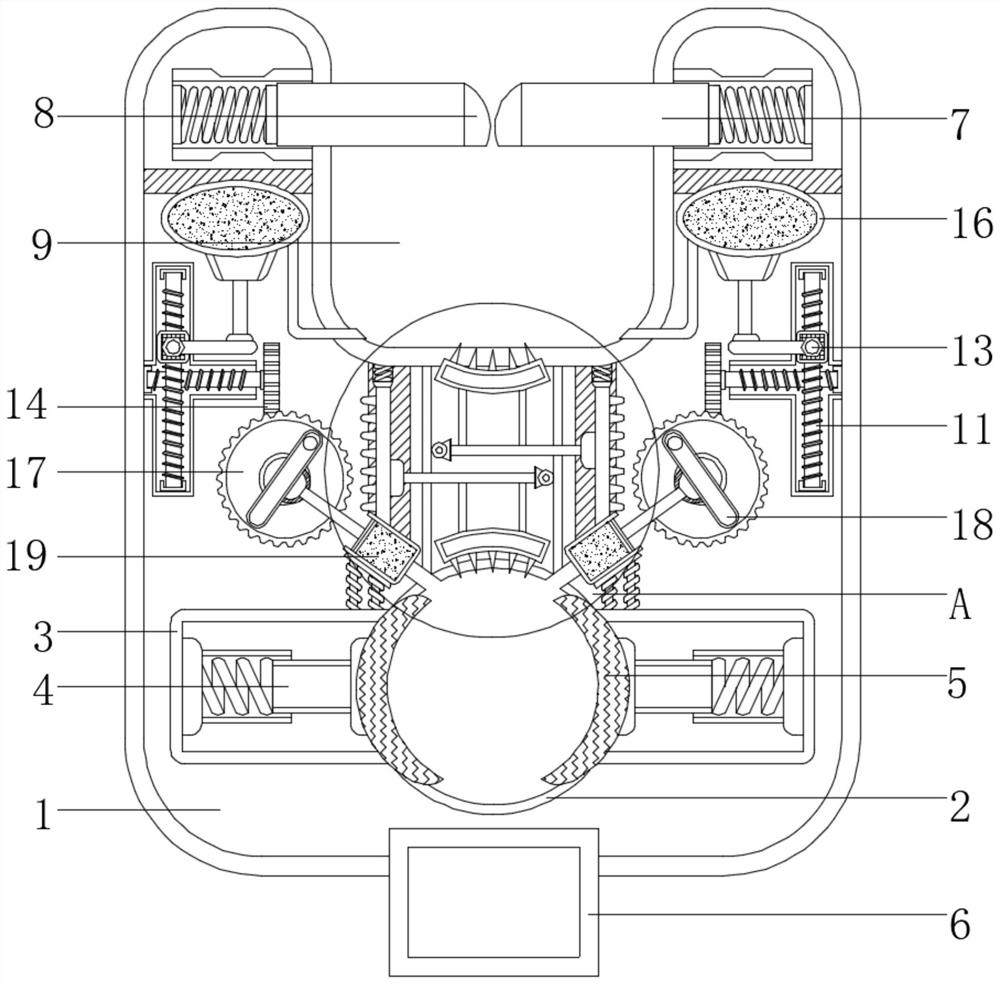

Universal USB connector assembly machine

InactiveCN106654799AReduce manufacturing costFast assemblyContact member cases/bases manufactureContact member assembly/disassemblyEconomic benefitsWork in process

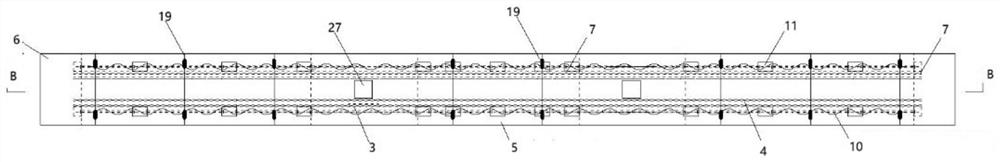

The invention discloses a universal USB connector assembly machine, which comprises a rack, an iron shell discharge plate, a semi-finished product discharge plate, an iron shell feeding and cutting mechanism, a product carrier mechanism, a material strip feeding mechanism, a material strip bending mechanism, a riveting assembly mechanism and a finished product work station, wherein the iron shell discharge plate, the semi-finished product discharge plate, the iron shell feeding and cutting mechanism, the product carrier mechanism, the material strip feeding mechanism, the material strip bending mechanism, the riveting assembly mechanism and the finished product work station are intensively arranged on the rack; the iron shell discharge plate cuts an iron shell through the iron shell feeding and cutting mechanism and then conveys the iron shell to the product carrier mechanism; and the semi-finished product discharge plate conveys a semi-finished product to the material strip bending mechanism through the material strip feeding mechanism, and the semi-finished product is nested with the iron shell through the riveting assembly mechanism and then is conveyed to the finished product work station. The semi-finished product is automatically nested and locked with the iron shell to complete finished product assembly of a USB connector, full-automatic work is adopted in the whole process, the assembly speed is high, connection is accurate and firm, the production efficiency is greatly improved, the universal USB connector assembly machine can be suitable for finished product assembly of different types of USB connectors and is good in universality and good in economic benefit, and the enterprise production cost is reduced.

Owner:苏州市宏越自动化机械设备有限公司

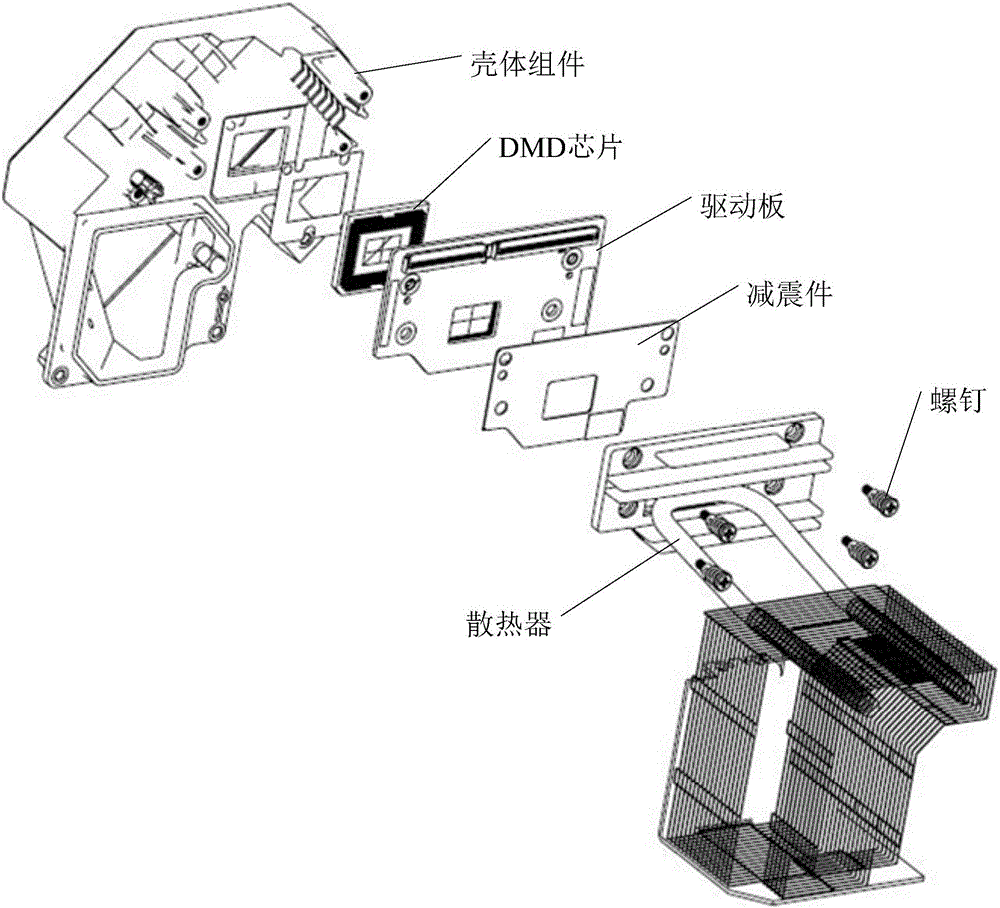

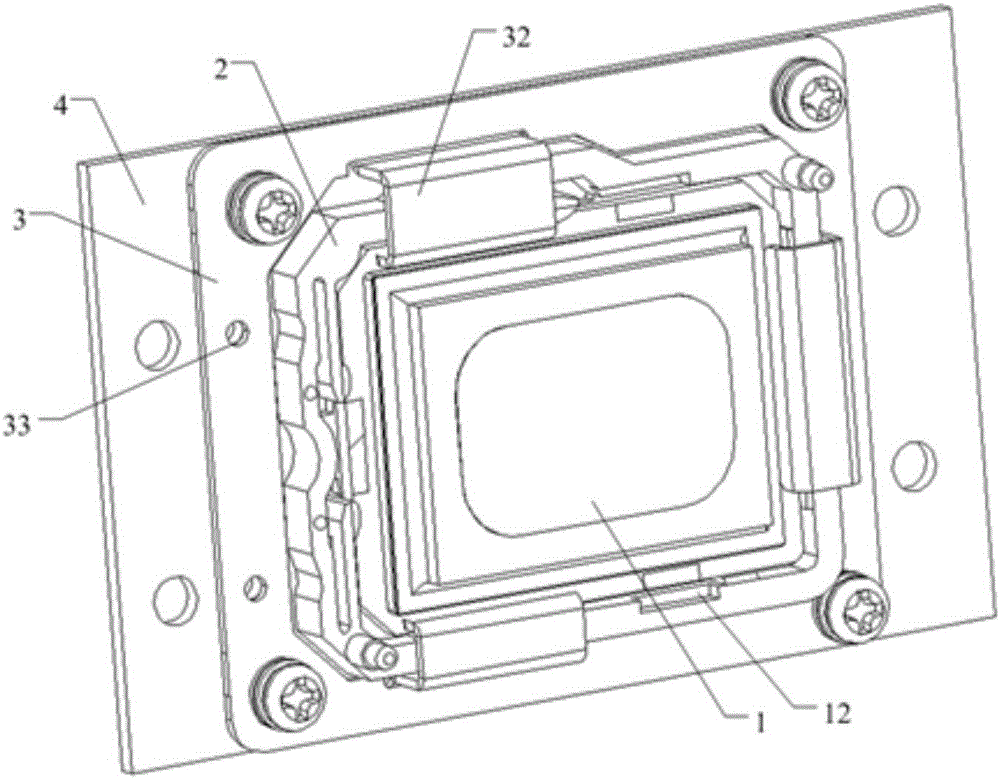

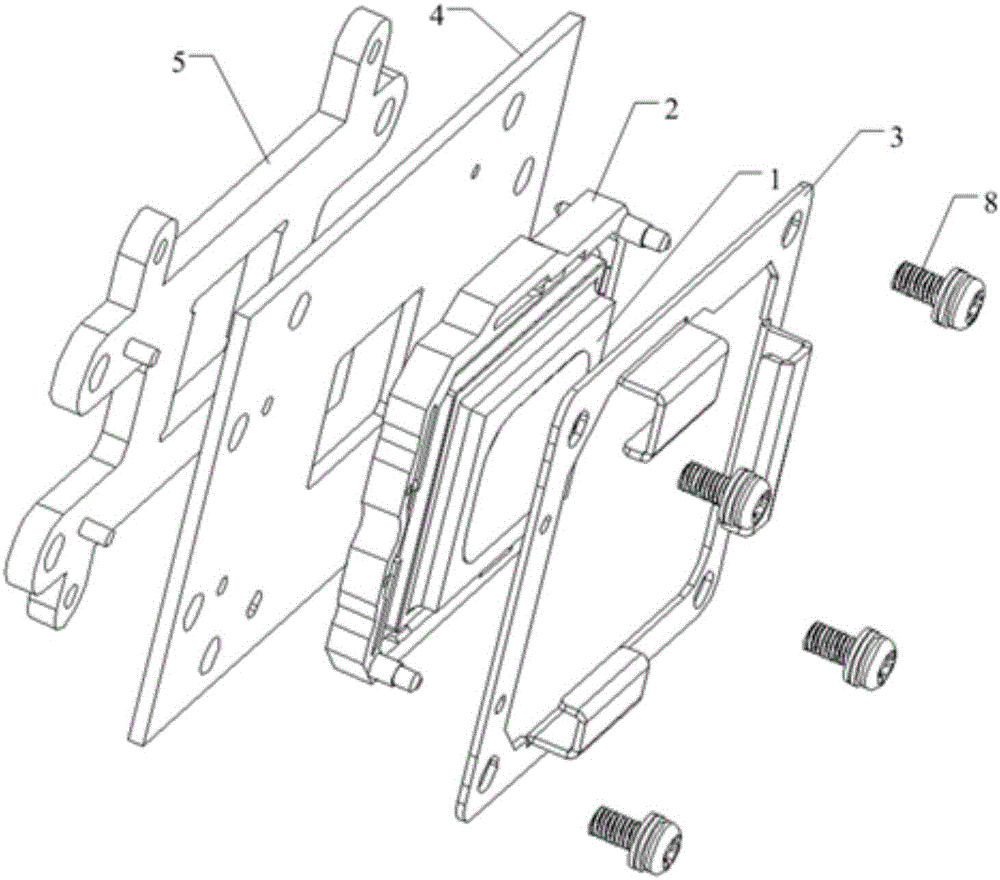

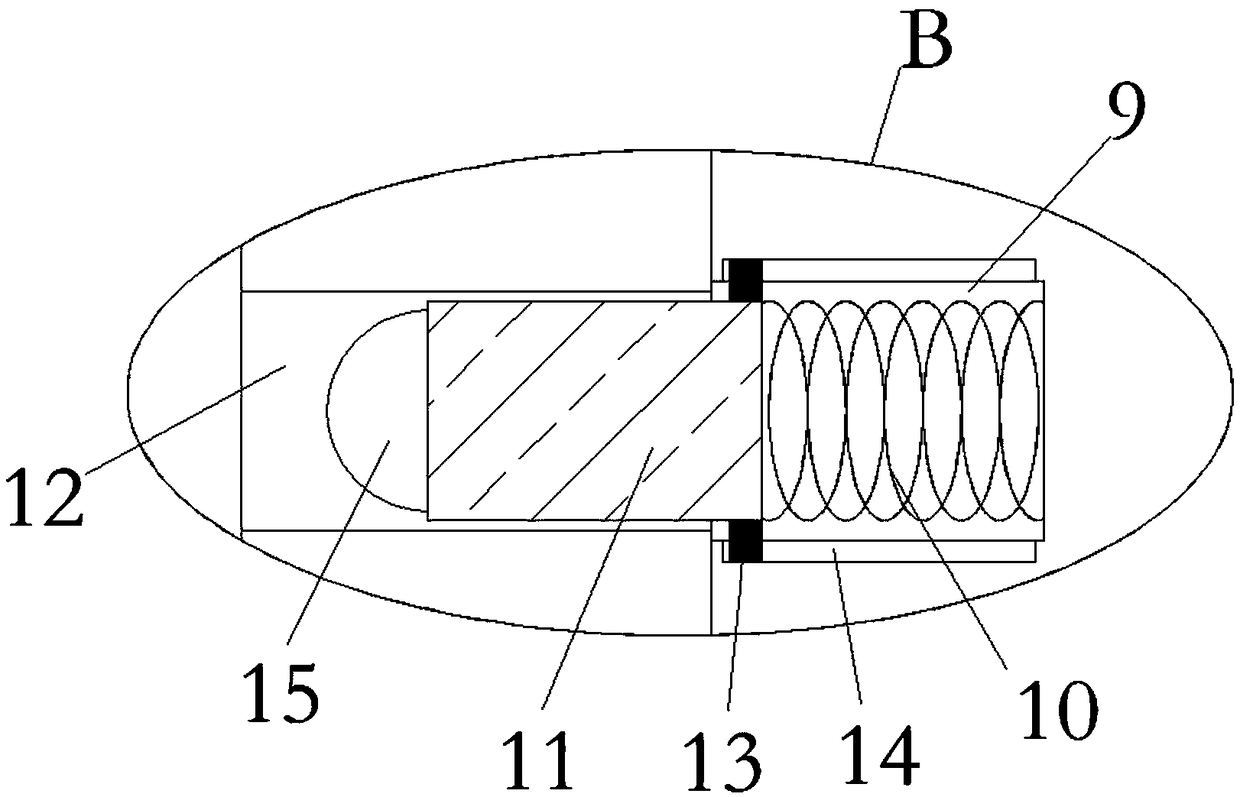

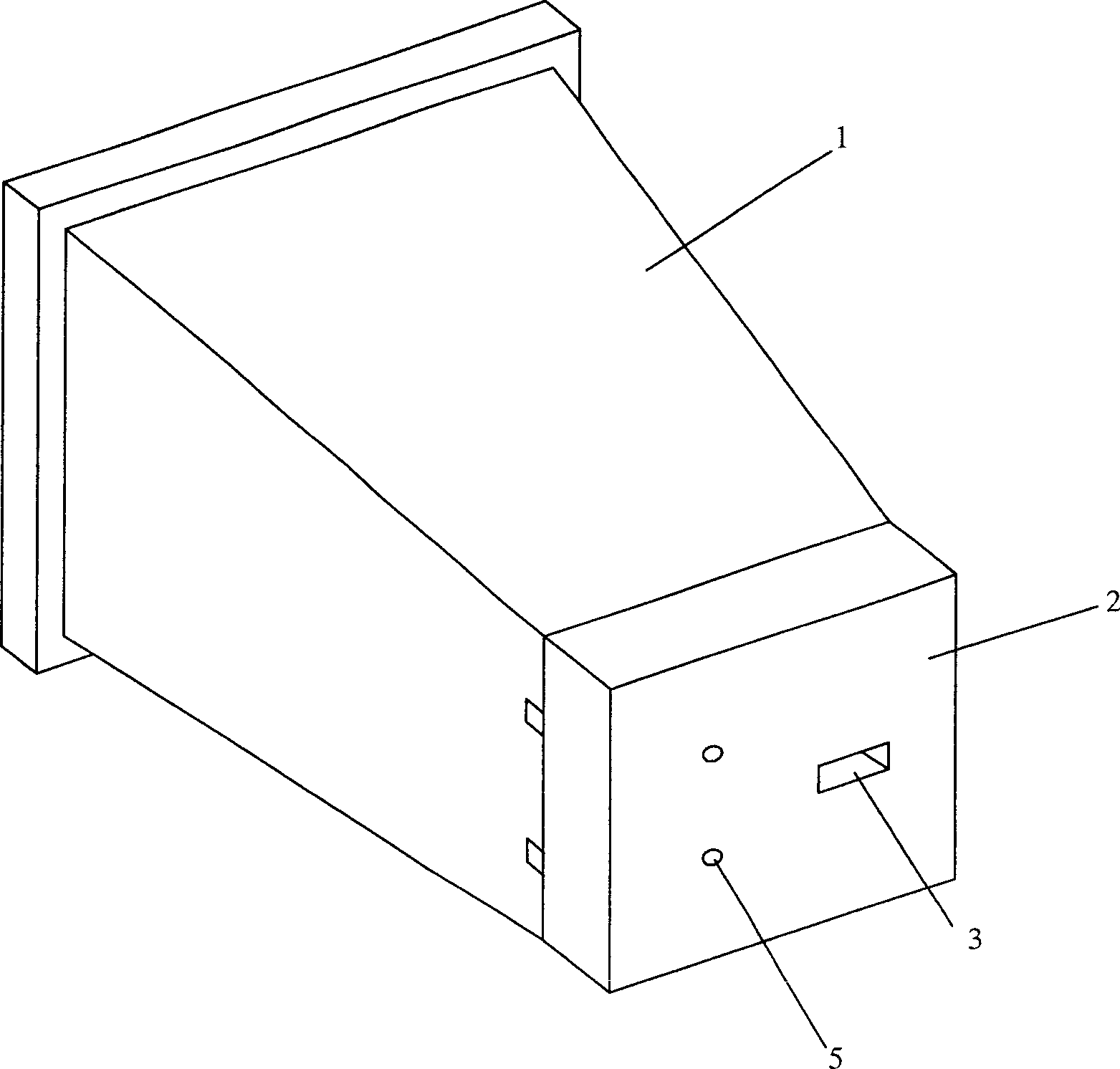

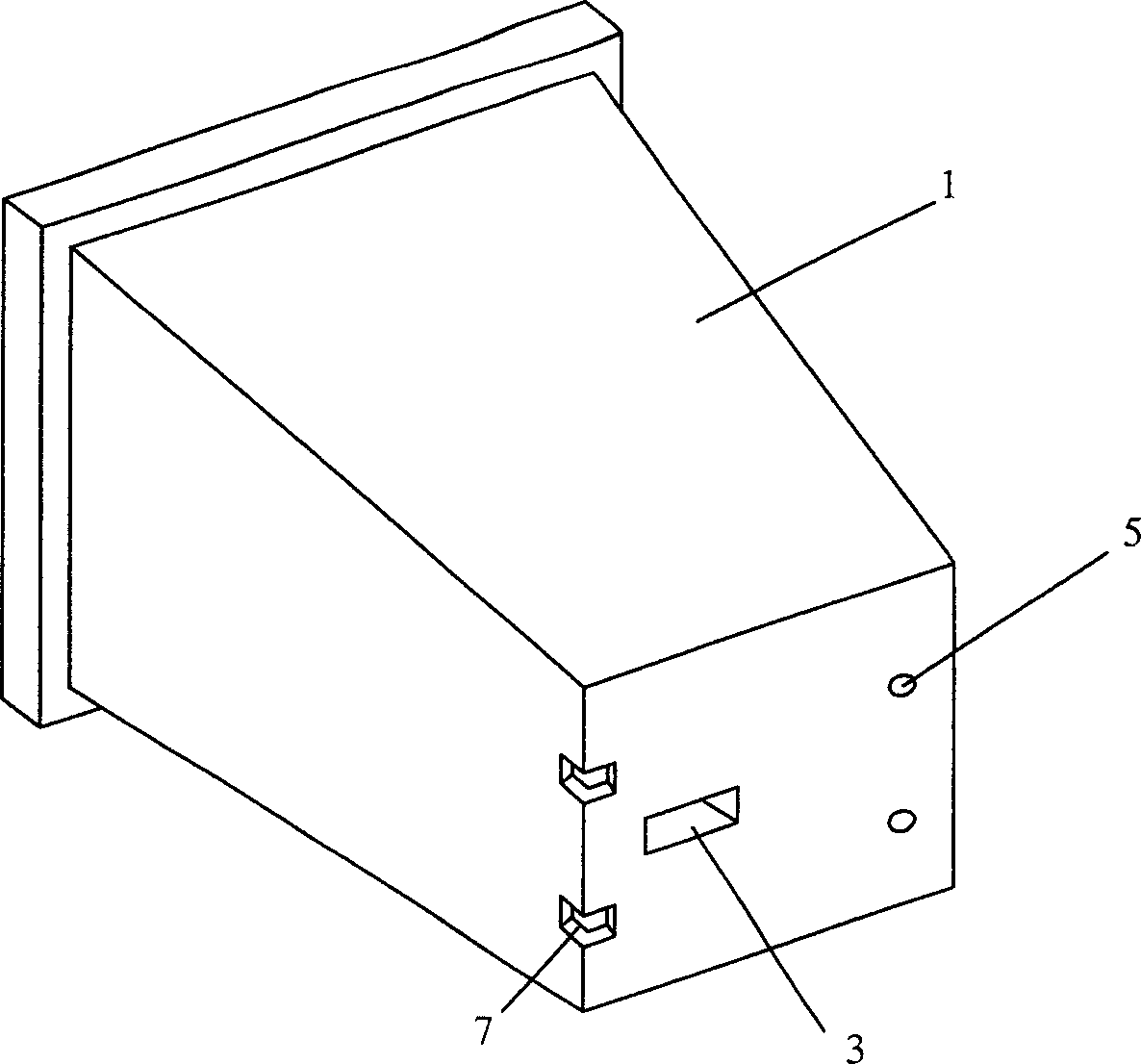

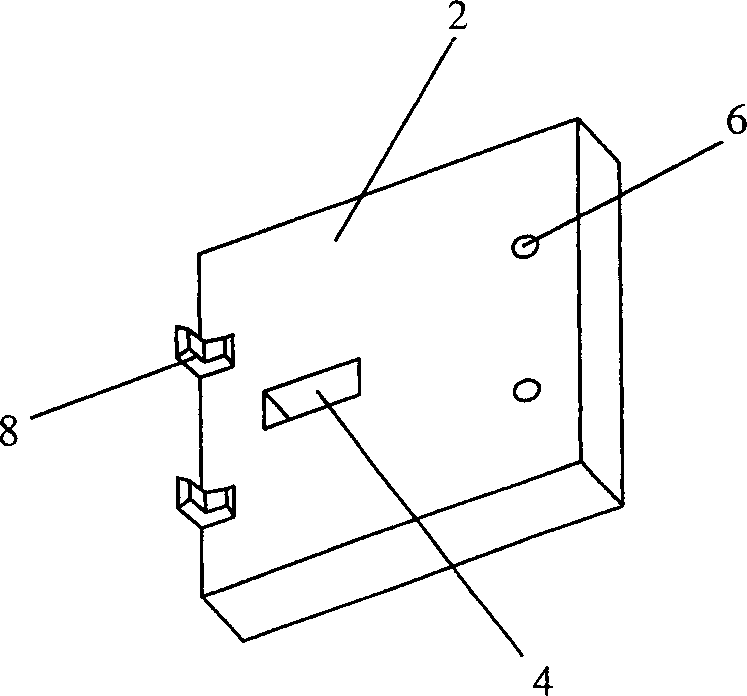

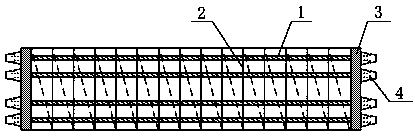

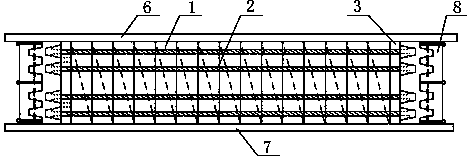

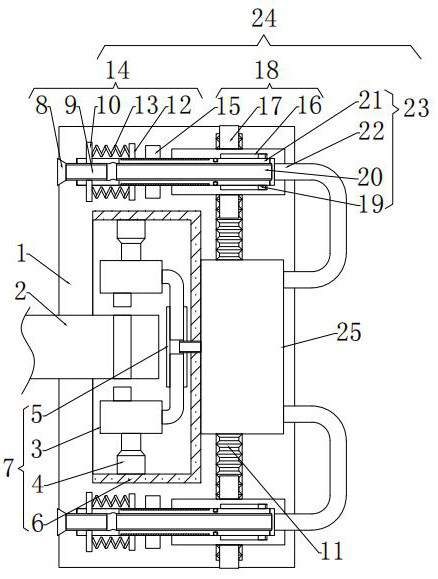

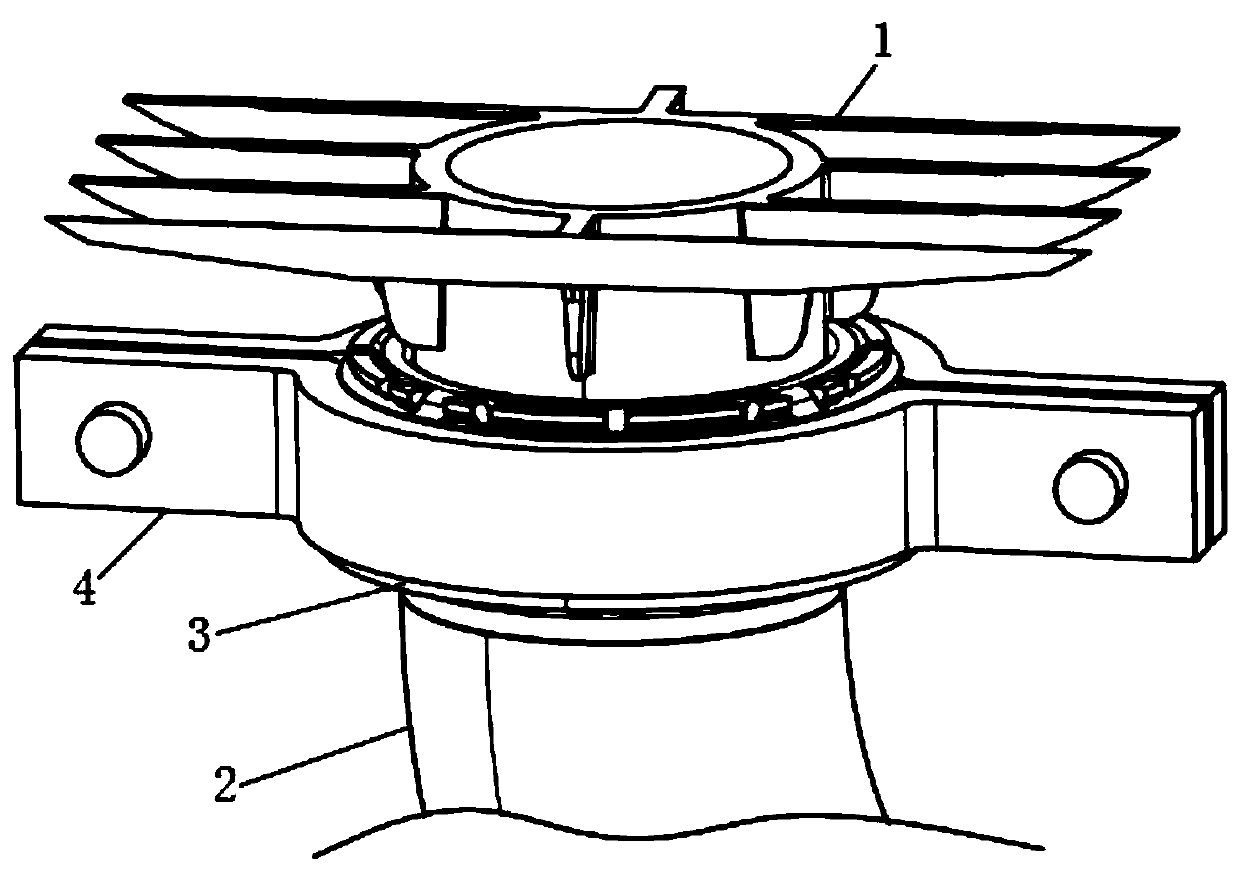

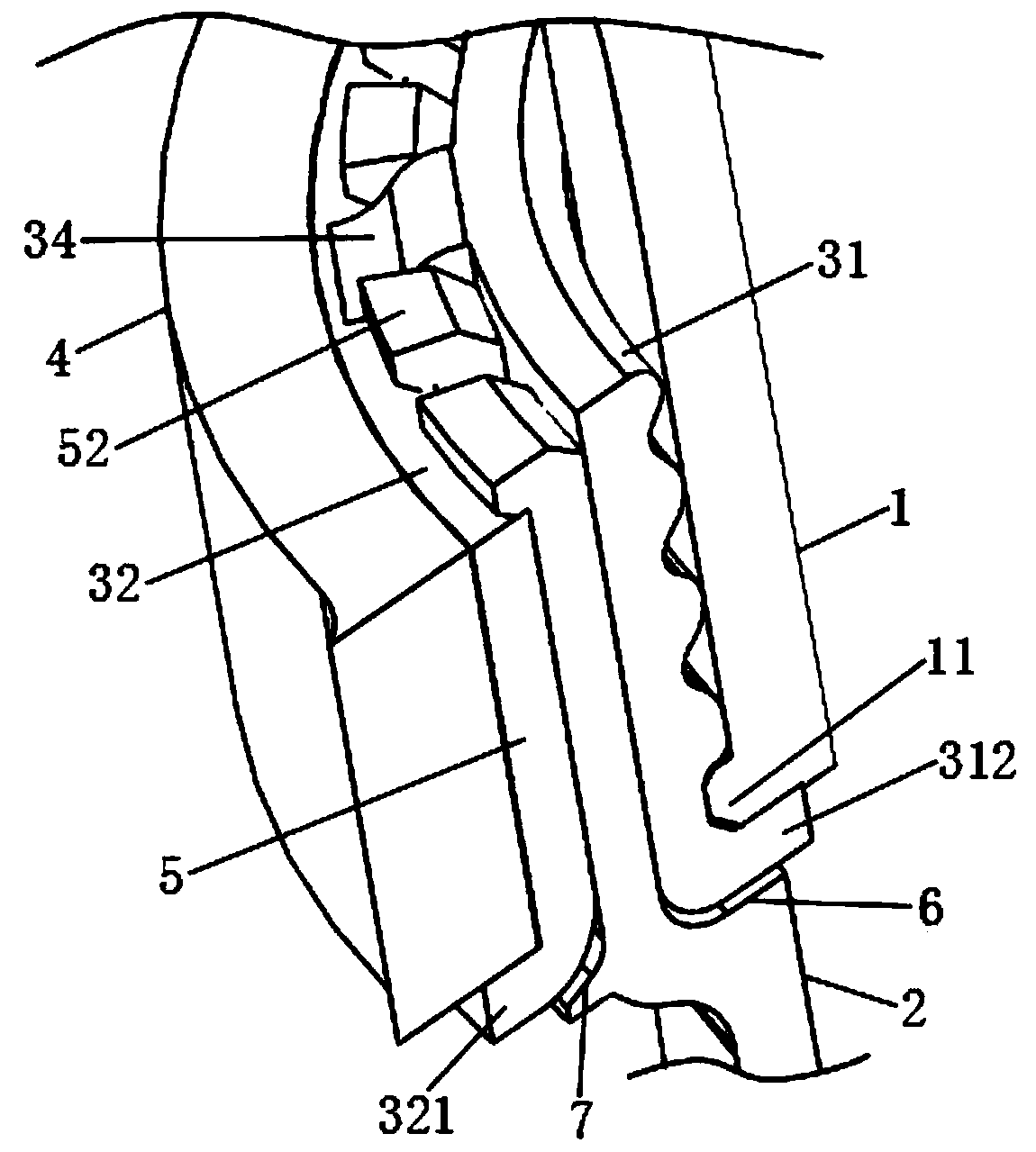

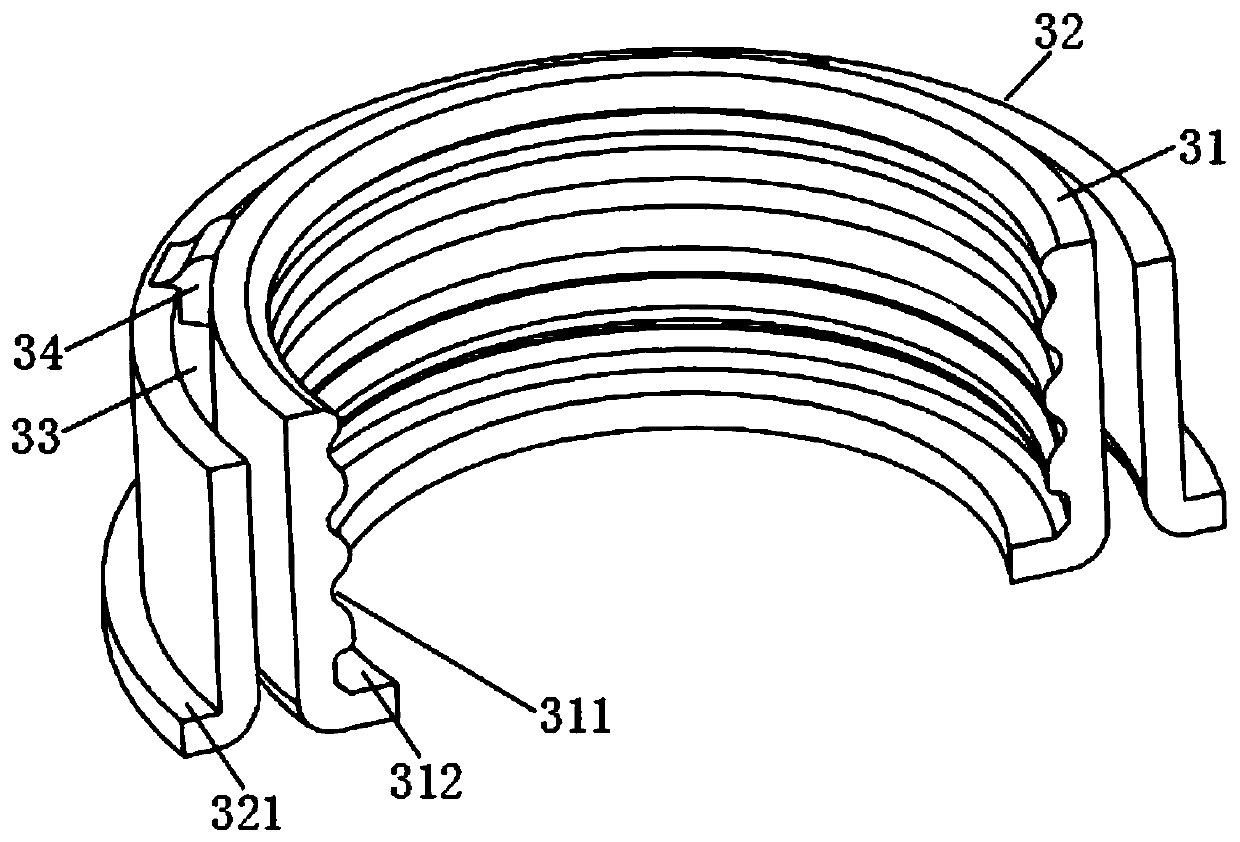

DMD component, DLP light machine and DLP projection device

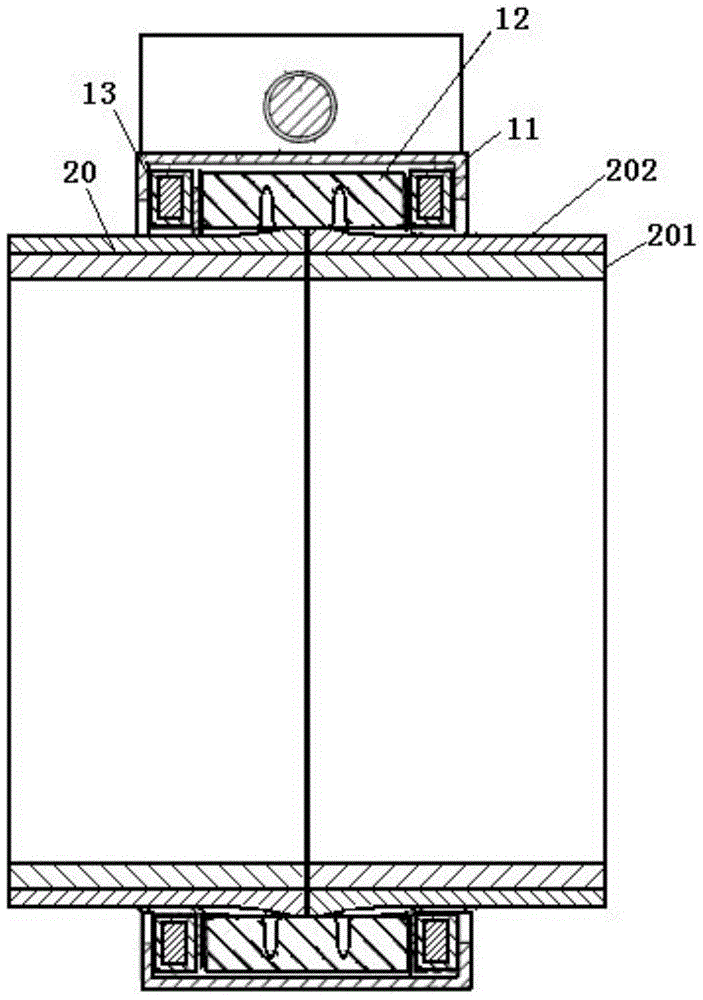

The invention relates to the technical field of optics and projection, and particularly relates to a DMD component, a DLP light machine and a DLP projection device. The DMD component comprises a base with an accommodation groove on one side, a driving plate, a DMD chip which is arranged in the accommodation groove, a supporting plate and a fixation frame with an embedded through hole. A number of elastic hooks are arranged on the edge of one side of the embedded through hole. The driving plate is fixedly clamped between the fixation frame and the supporting plate through a fastener. The base is embedded into the embedded through hole from one side, which is close to the driving plate, of the fixation frame, and the elastic hooks on the other side hook the edge of the inner wall of the accommodation groove and contact the surface of the DMD chip. According to the invention, the accuracy and stability of the contact between the DMD chip and the contact of the driving plate are ensured; the quality of the final projection screen is improved; the difficulty of disassembly and assembly and the requirement on the size of associated structural members are reduced; the efficiency of processing and production is improved; and the production cost is reduced.

Owner:QINGDAO HISENSE LASER DISPLAY CO LTD

Processing sensed accelerometer data for determination of bone healing

ActiveUS9445720B2Accurate and stable connectionSuitable for mass productionPerson identificationInertial sensorsTime domainAccelerometer data

A system (800) for processing accelerometer data is disclosed. The system (800) includes an accelerometer (806), a first processor (810), a power supply (816), and a second processor (804). The accelerometer (806) measures a physiological acceleration parameter. The first processor (810) is operatively connected to the accelerometer (806). The first processor (810) is configured to receive the acceleration parameter from the accelerometer (806) and configured to output machine readable acceleration data. The machine readable acceleration data includes time domain accelerometer data. The power supply (816) is electrically connected to the first processor (810). The second processor (804) is configured to receive the machine readable acceleration data and transform the time domain accelerometer data into frequency domain accelerometer data. The frequency domain accelerometer data may be used to estimate patient healing status.

Owner:SMITH & NEPHEW INC

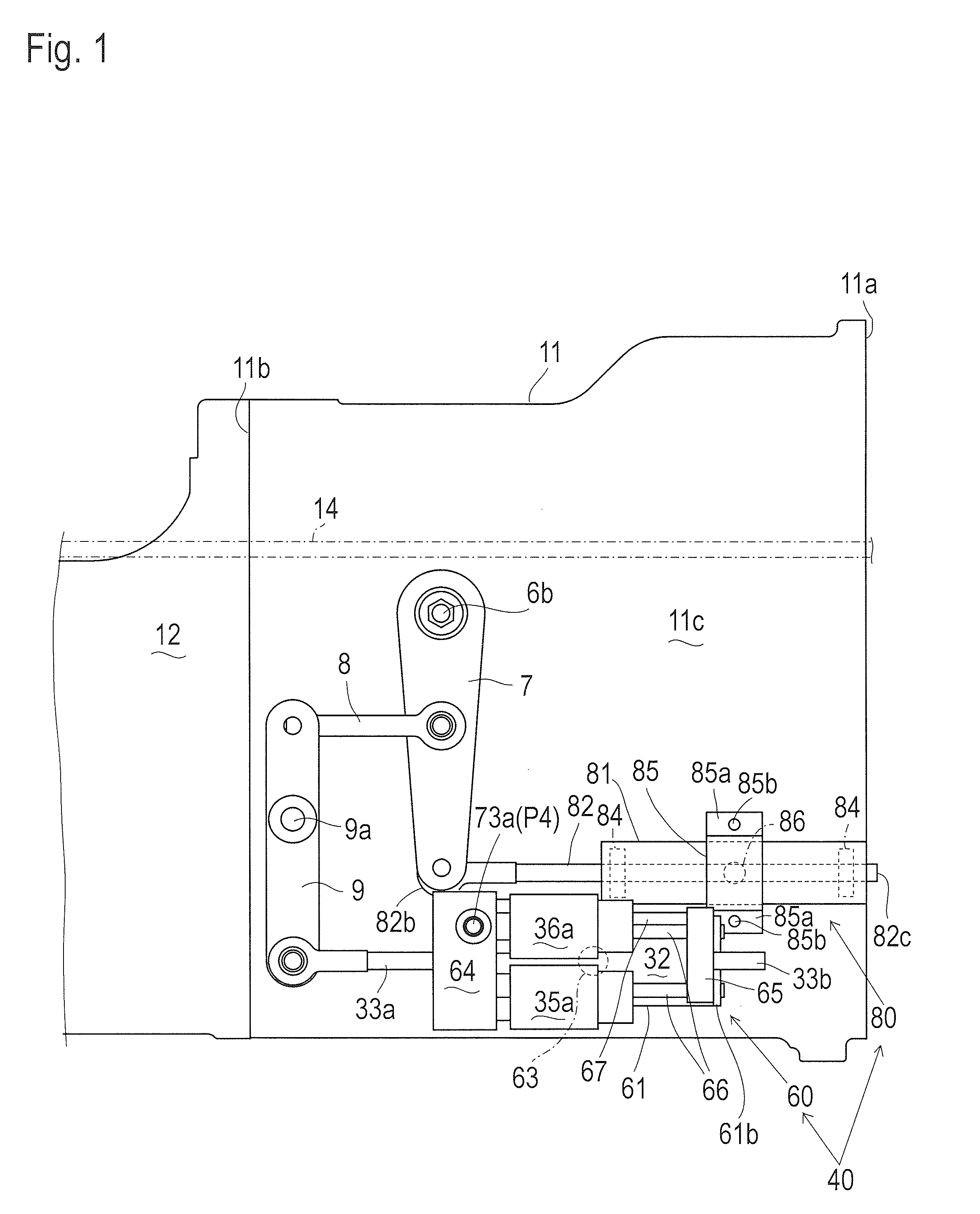

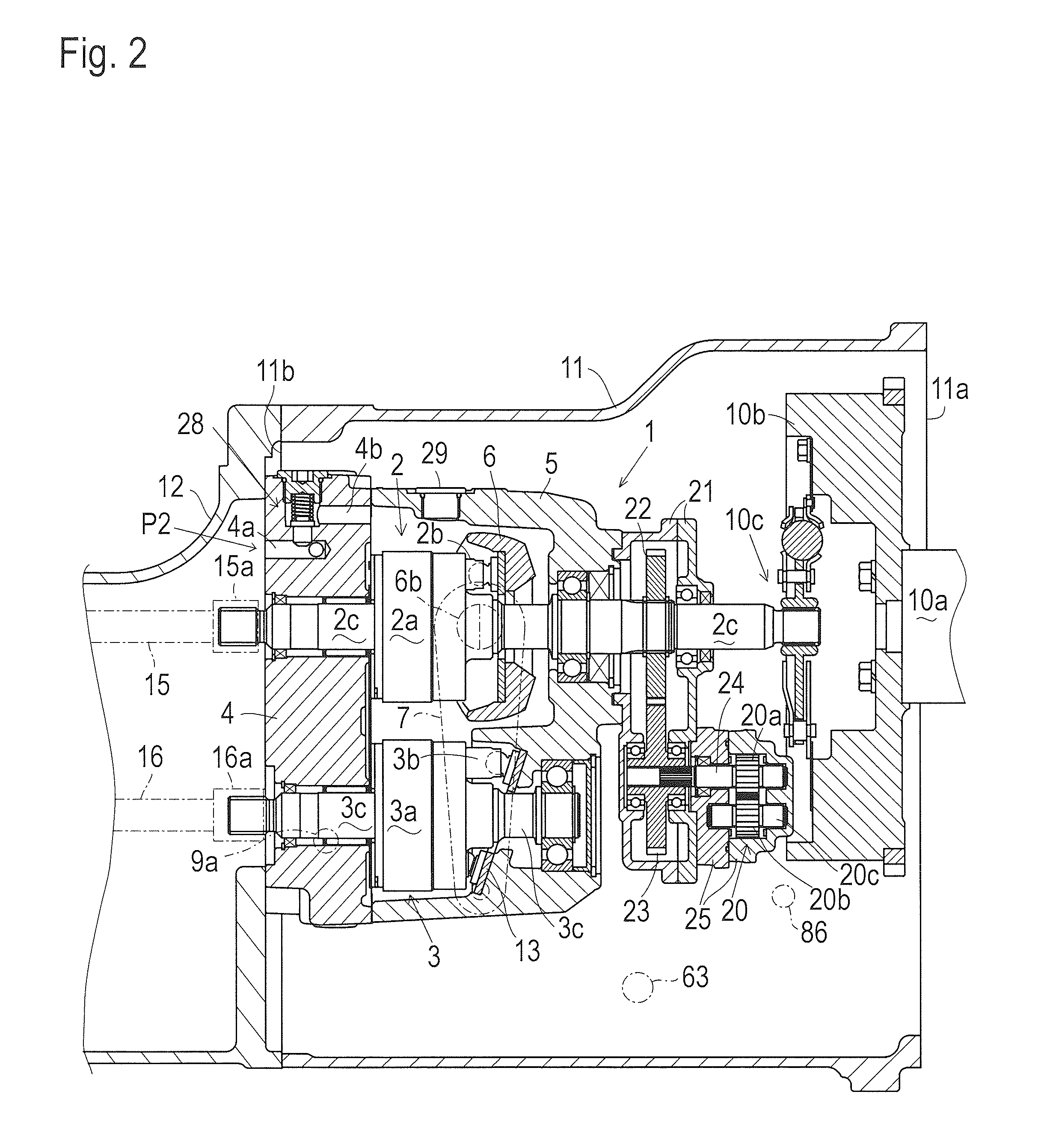

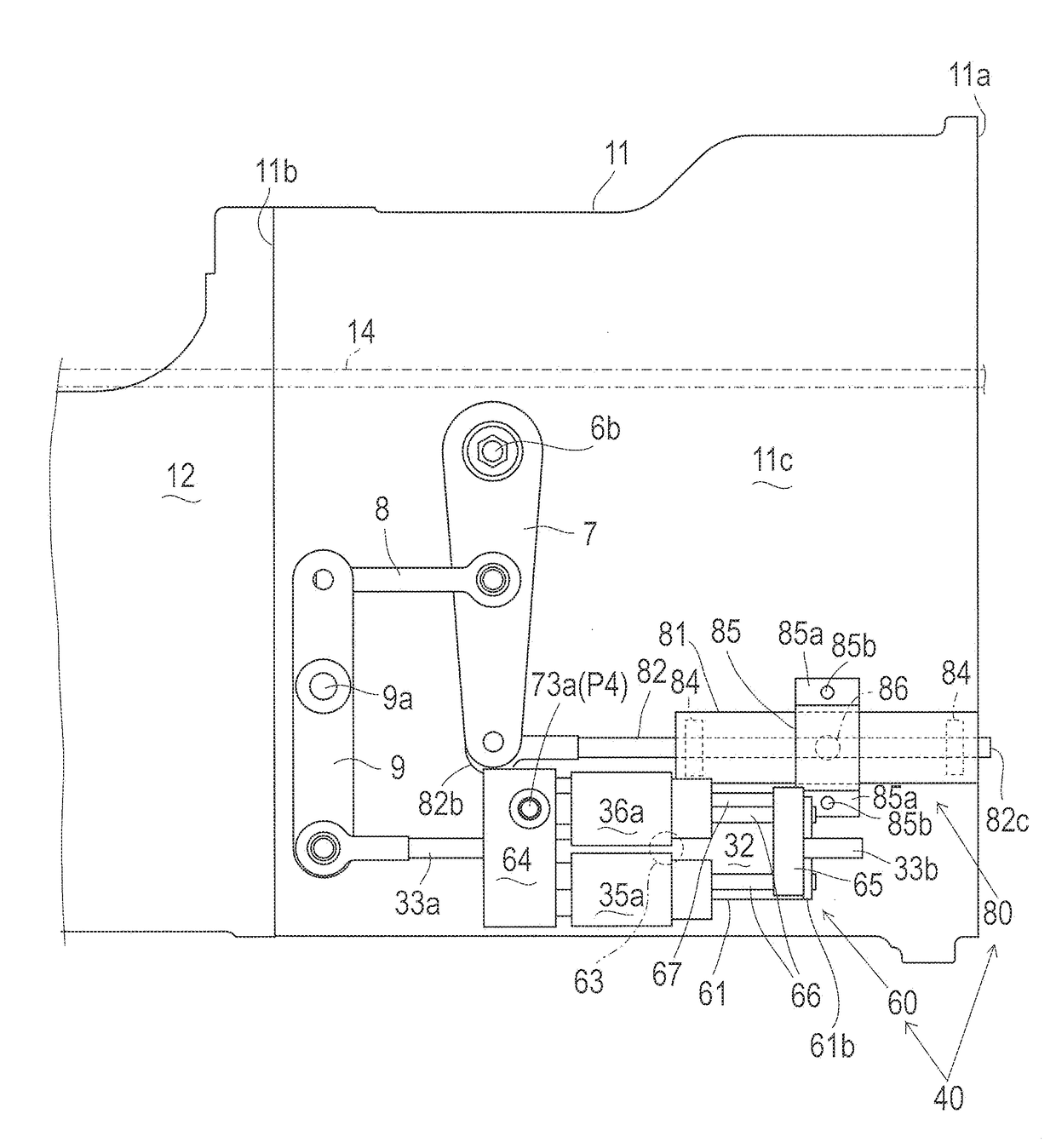

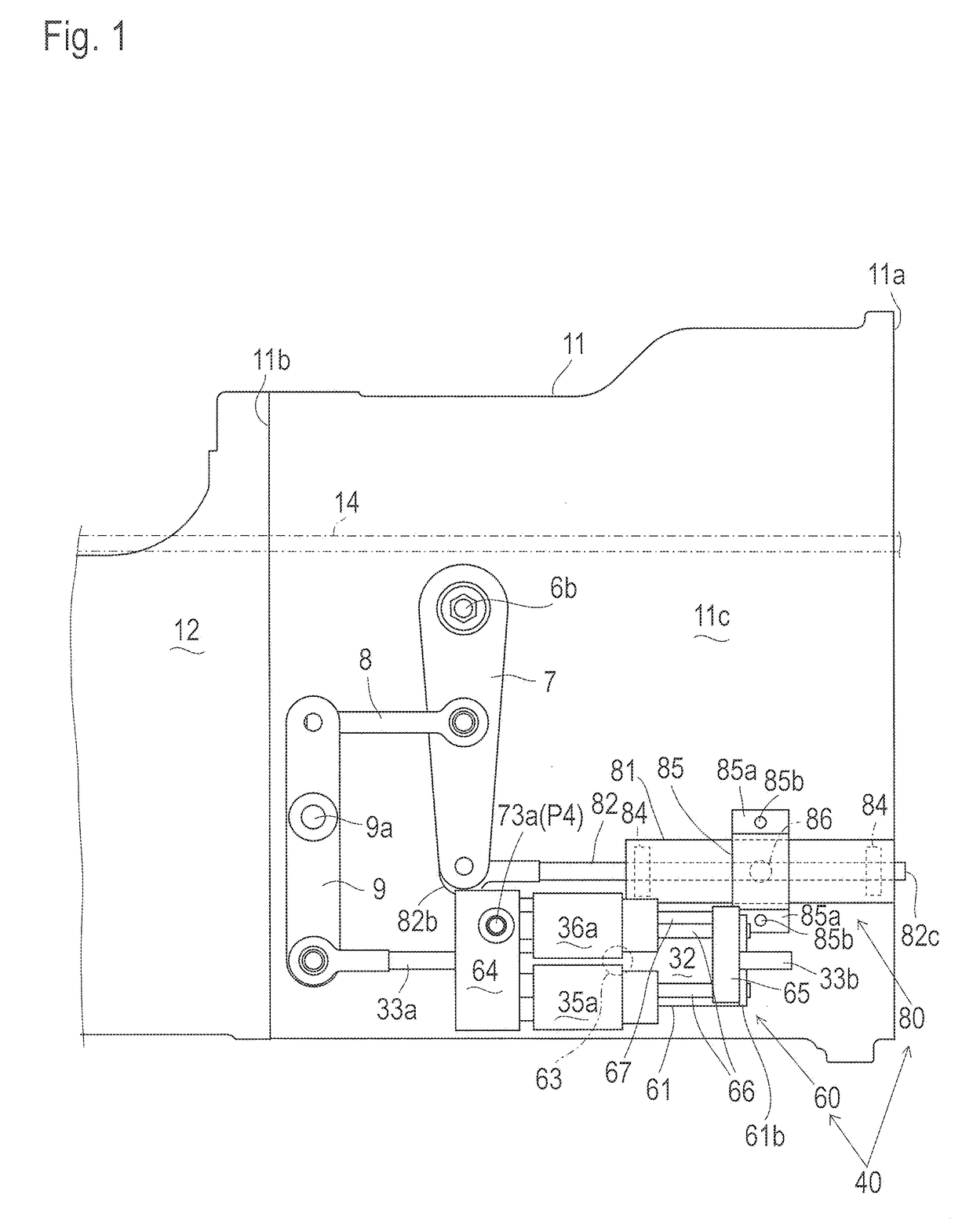

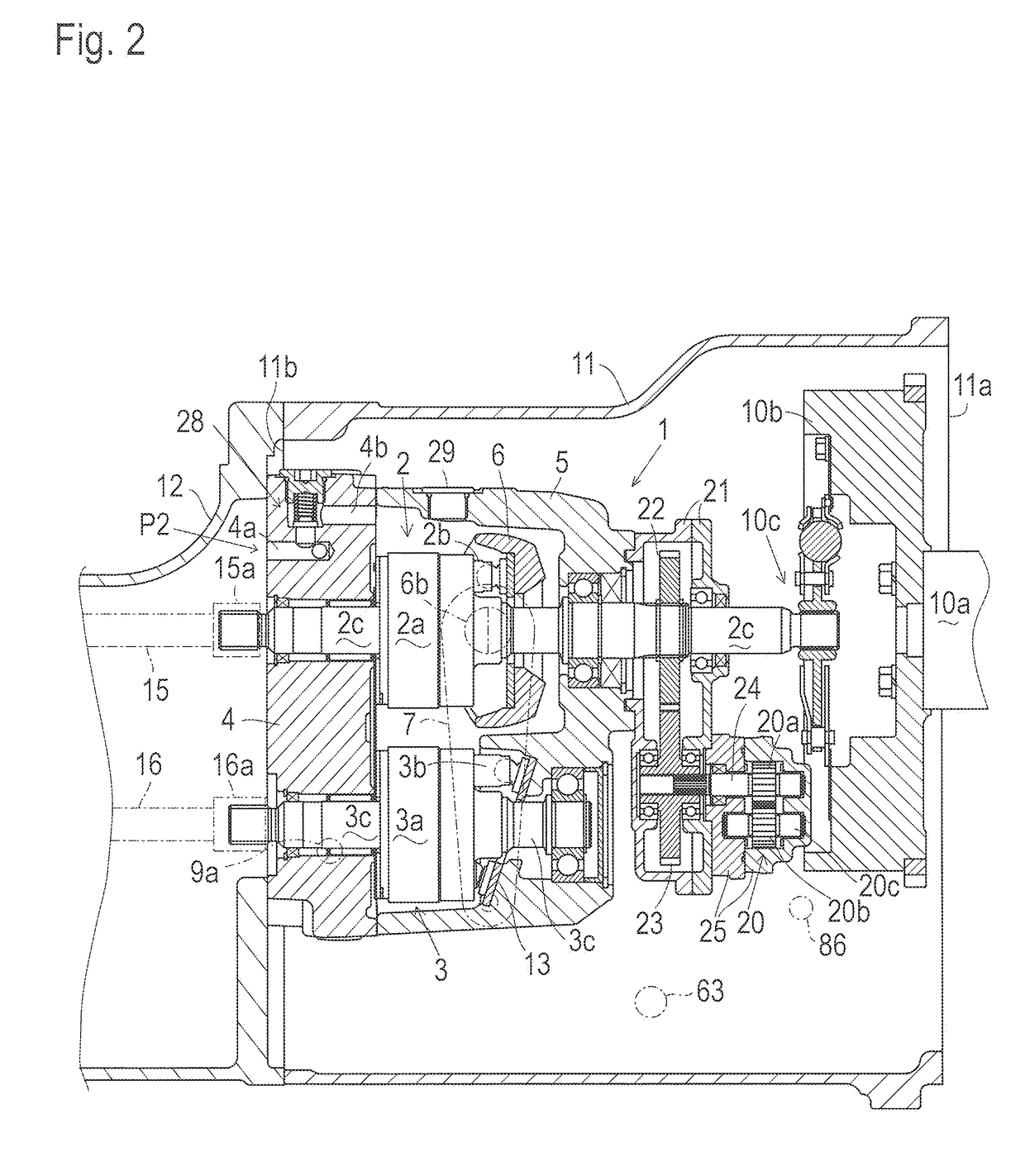

Control mechanism for hydrostatic transmission

InactiveUS20160040691A1Easy to provideSimple configurationFluid couplingsGearing controlActuatorControl theory

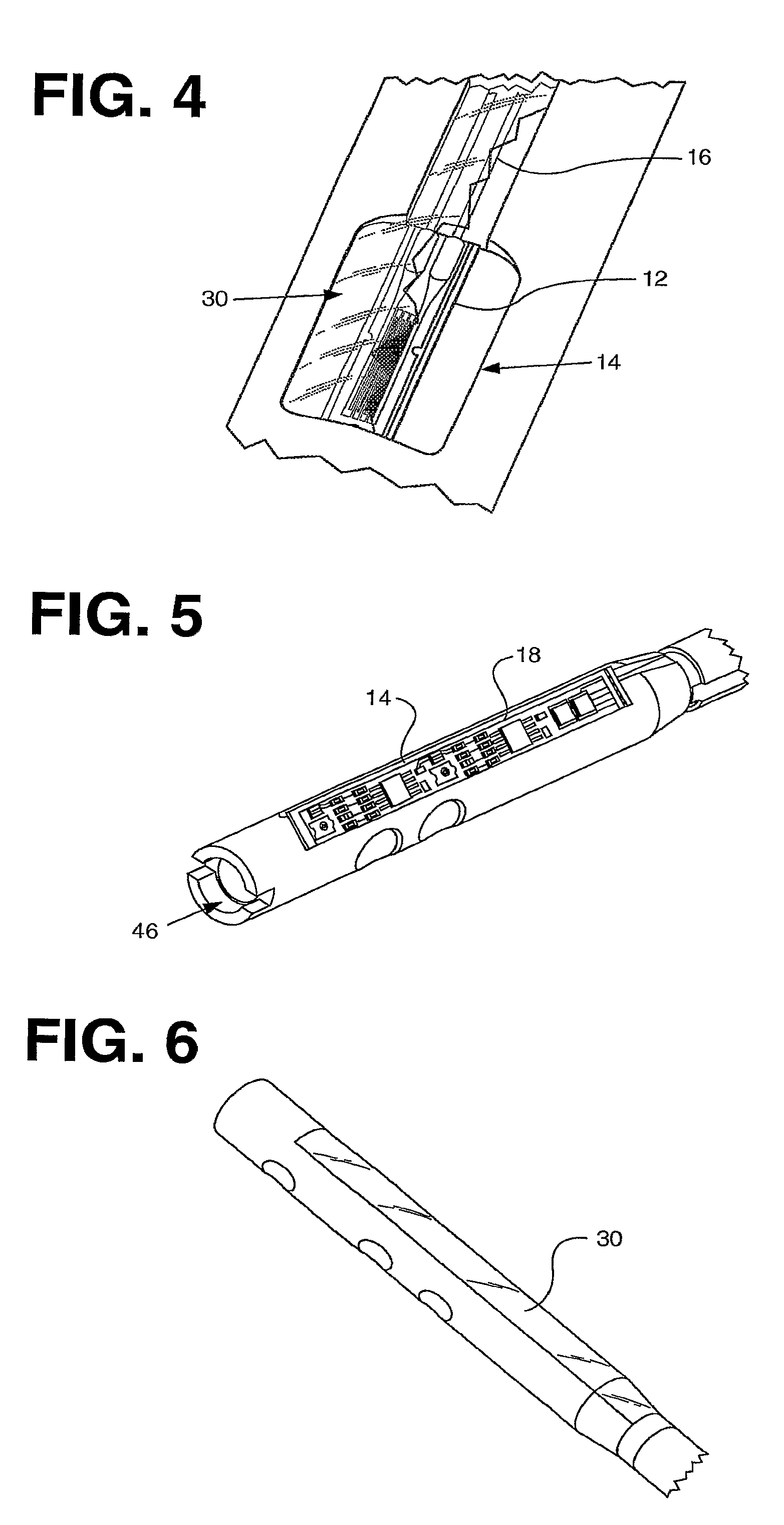

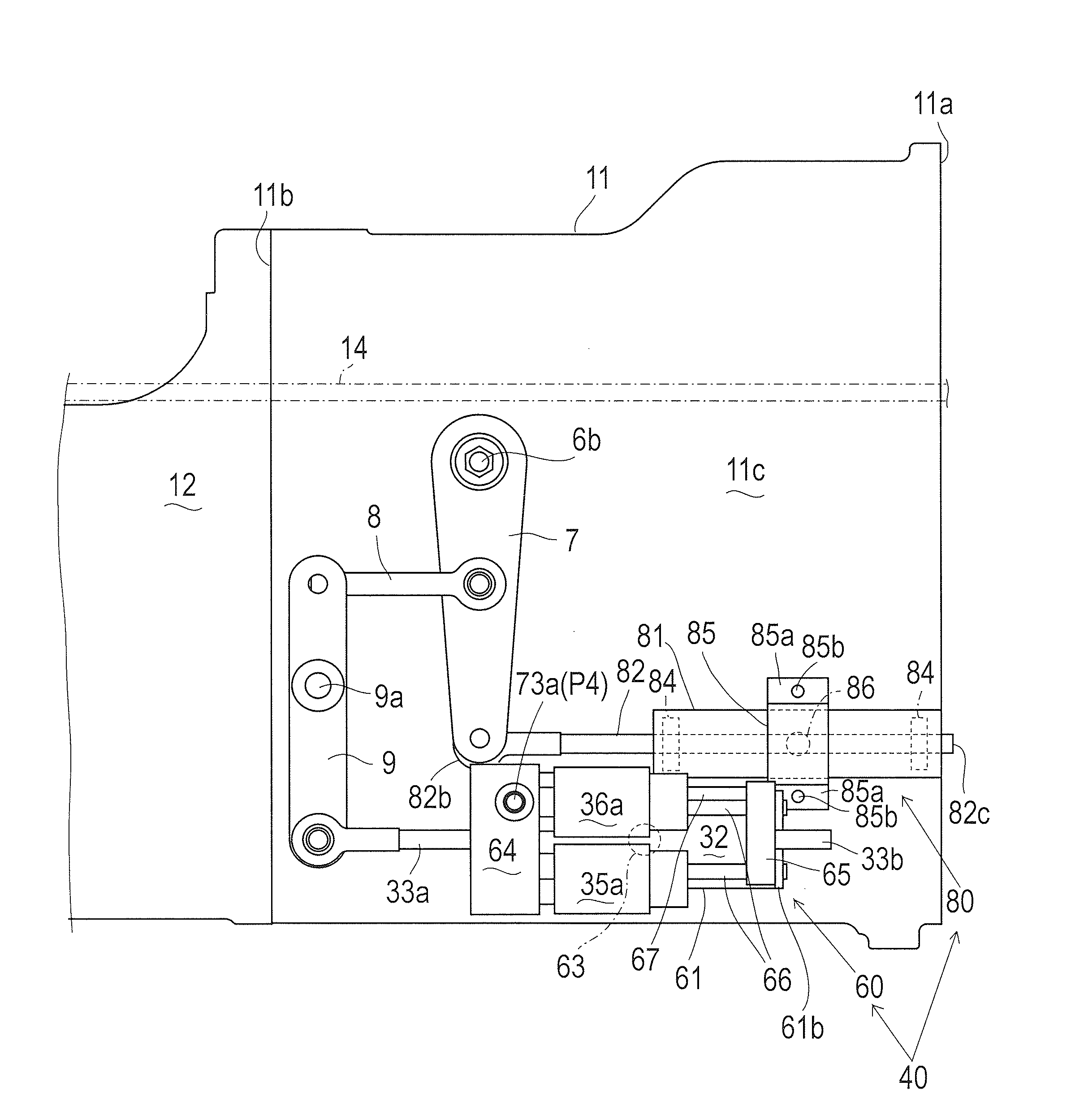

An HST control mechanism includes a rotary member, a servo unit, a telescopic member, and a biasing device. The rotary member for controlling a displacement of a hydrostatic transmission (HST) is pivoted outside of a casing incorporating the HST. The servo unit includes a telescopically movable actuator and a valve controlling the telescopic movement of the actuator. The actuator is interlockingly connected to the rotary member. The servo unit is pivotally supported on the casing via a first pivot. The servo unit rotates centered on the first pivot as the rotary member rotates according to the telescopic movement of the actuator hydraulically controlled by the valve. The telescopic member is pivotally supported on the casing via a second pivot. The telescopic member is provided with the biasing device that biases the telescopic member and the rotary member toward a position corresponding to a neutral state of the HST.

Owner:KANZAKI KOKYUKOKI MFG

OCV valve for VVT engine

PendingCN109339895AEasy to assemble and disassembleAccurate connectionValve arrangementsMachines/enginesEngineering

Owner:JIANGSU PACIFIC PRECISION FORGING +1

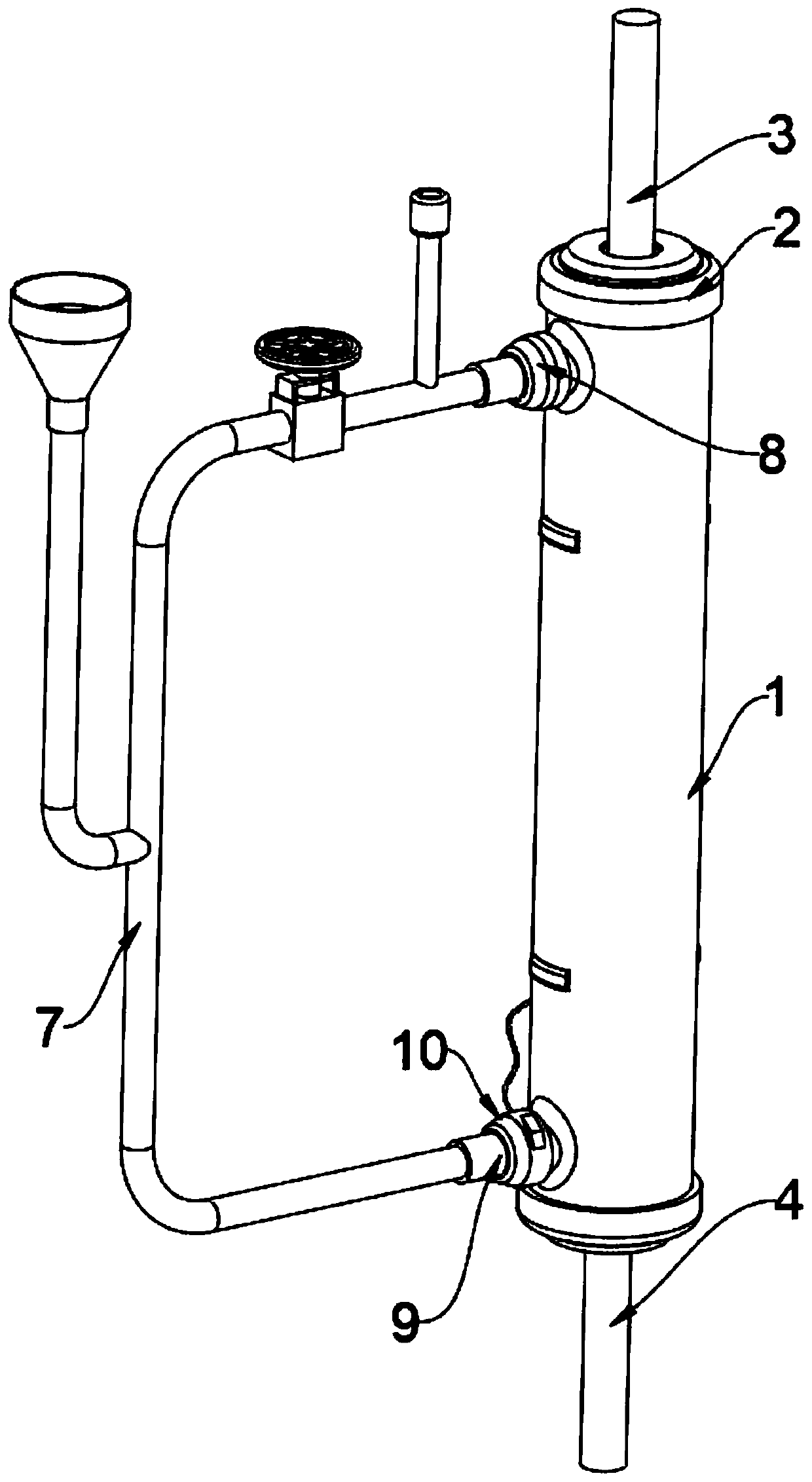

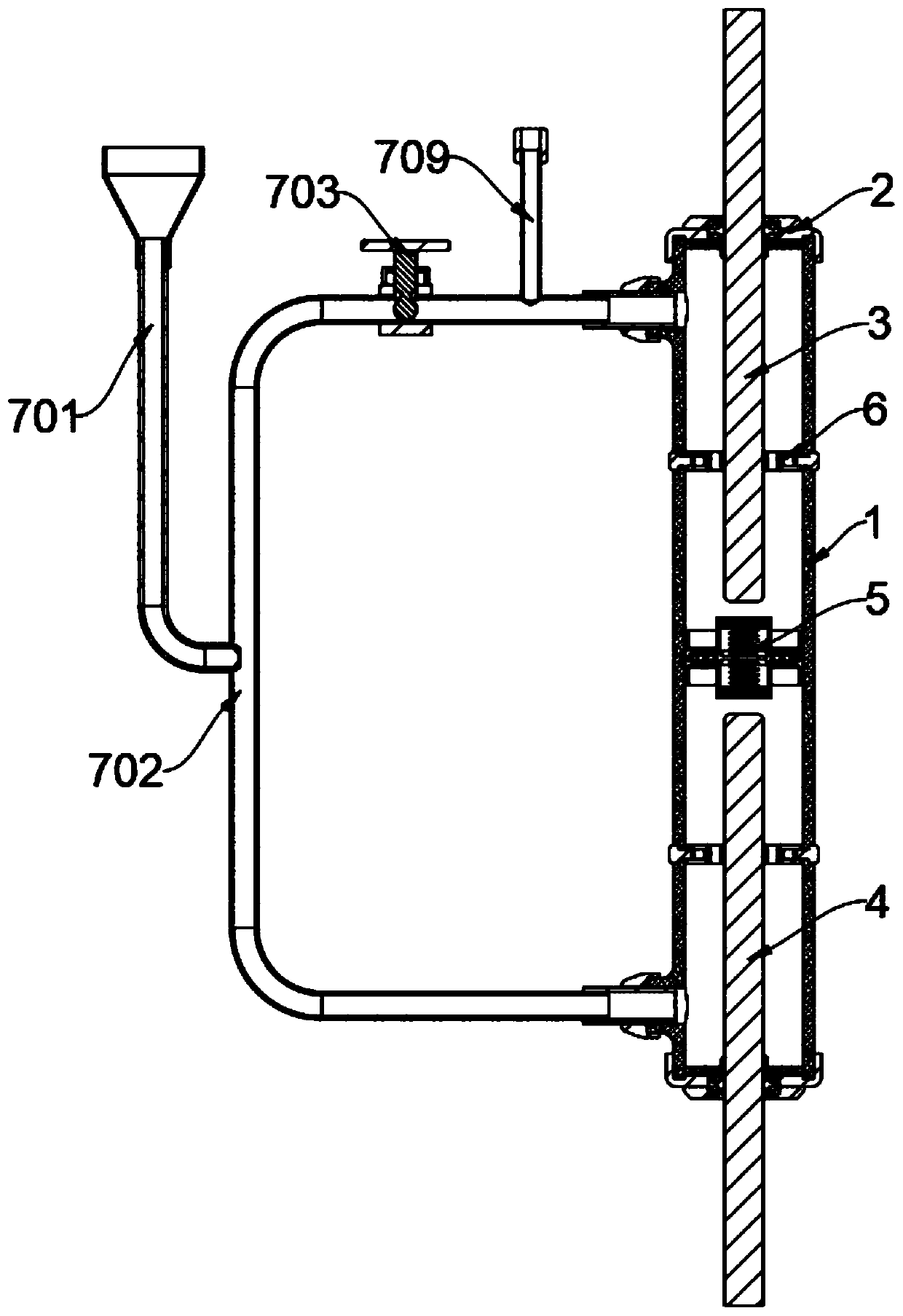

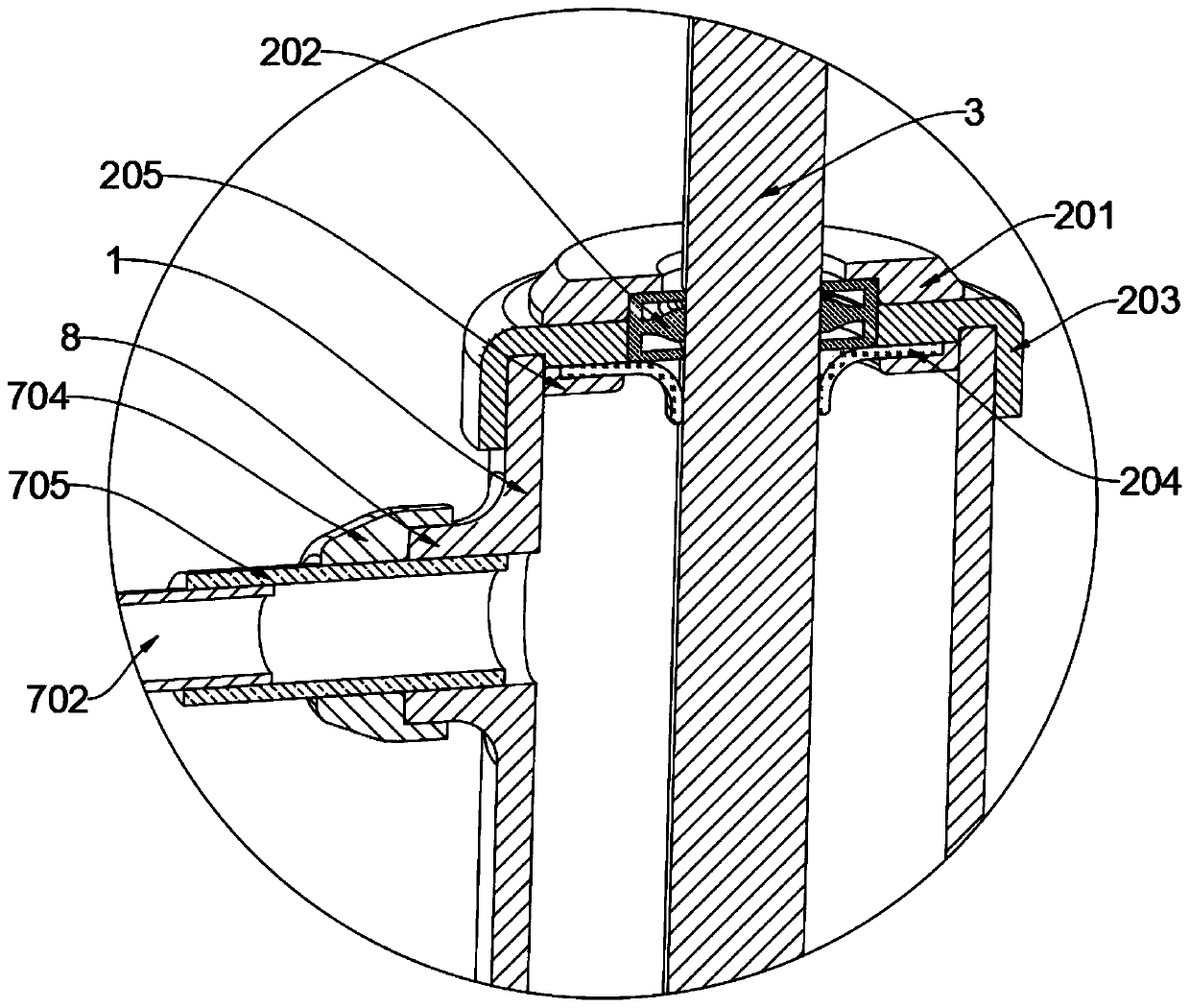

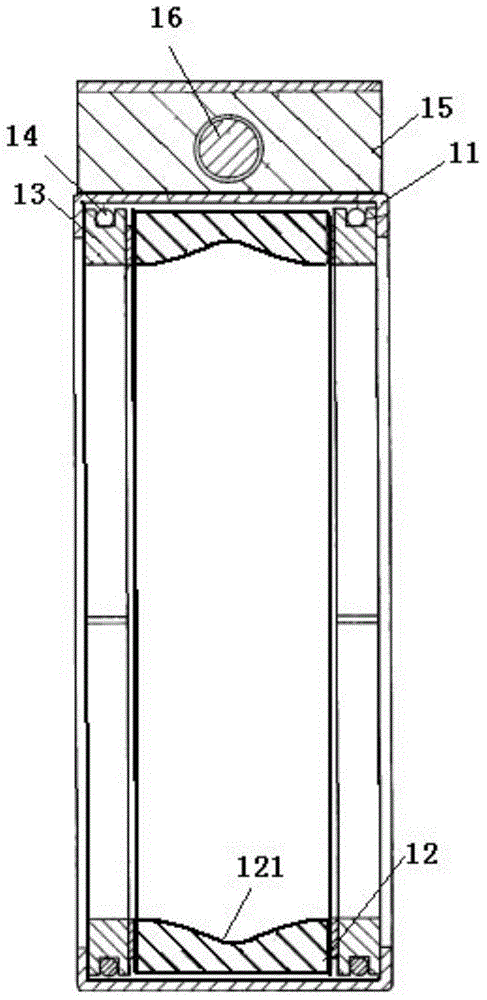

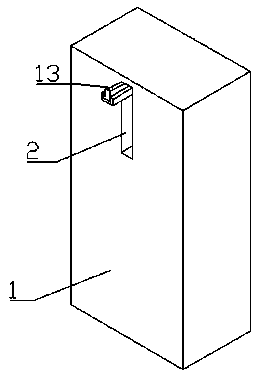

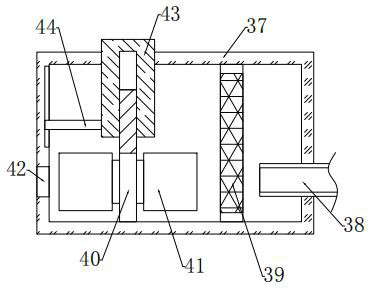

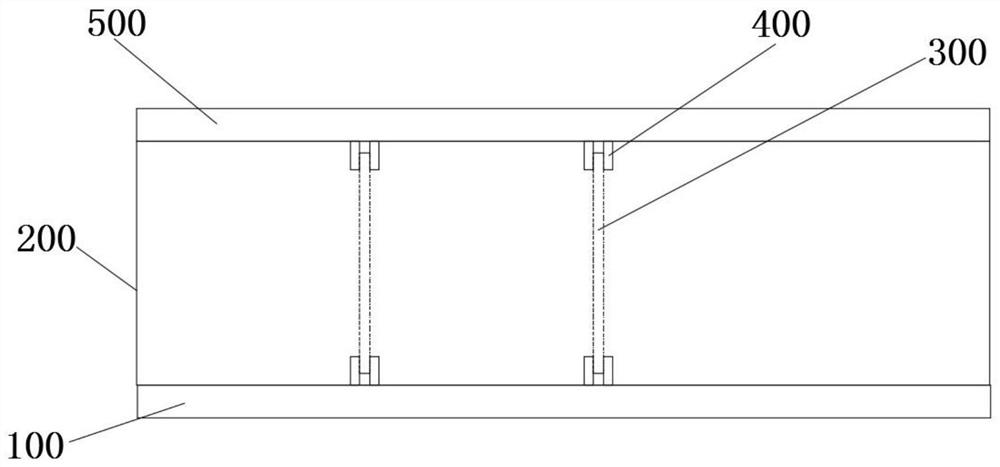

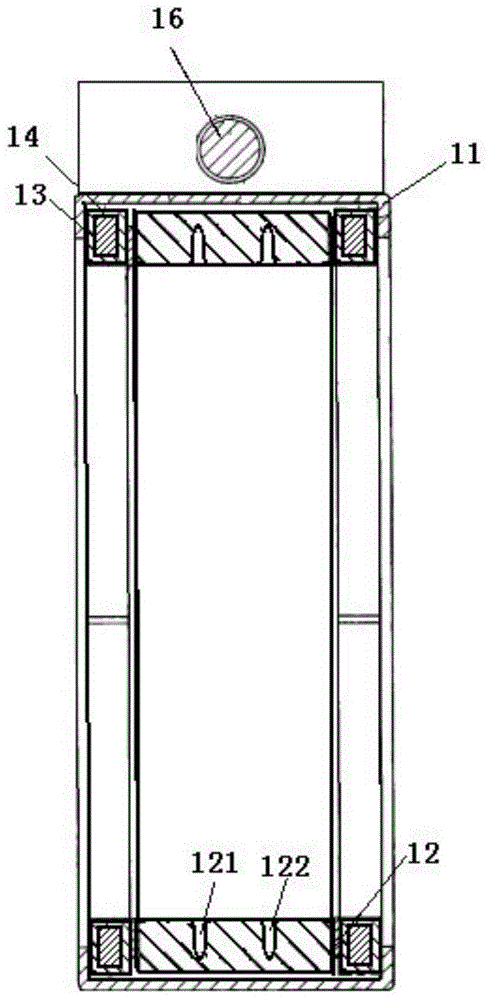

Quantitative-type grouting device of sleeve of PC component and with reinforcement positioning and sealing functions

ActiveCN111270814AEasy to navigateGuaranteed to be fullBuilding reinforcementsBuilding material handlingSlurryMechanical engineering

The invention discloses a quantitative-type grouting device of a sleeve of a PC component and with reinforcement positioning and sealing functions, relates to the technical field of sleeve grouting, and solves the problem of difficult control of grouting amount in the grouting process of an existing sleeve and poor positioning and sealing effects of the sleeve for a reinforcement. The quantitative-type grouting device of the sleeve of the PC component and with reinforcement positioning and sealing functions comprises a sleeve main body, a grouting port is formed in the outer side of the sleevemain body, a slurry outlet is formed above the grouting port, and a grouting pipe mechanism is mounted on the outer side of one end of the slurry outlet and comprises a slurry inlet pipe, a connecting circulating pipe, a blocking rod, a connecting protective sleeve, a connecting pipe, a fixed blocking seat, a regulating plate, a rotary handle and a slurry outlet pipe. According to the quantitative-type grouting device, centering and positioning can be conducted on a connecting reinforcement in the sleeve, quantitative-type grouting operation and slurry sealing can be conducted on the sleeve,the control of grouting amount and accurate positioning of the reinforcement can be achieved, and the connection quality of the sleeve is effectively guaranteed.

Owner:SHIJIAZHUANG TIEDAO UNIV +1

Circuit extension method

InactiveCN1901291AMeet the extended requirementsAvoid damageCoupling device detailsElectrical apparatus contructional detailsExtension methodElectrical and Electronics engineering

This invention provides a circuit expansion method characterizing that a signal connecting device is set on the shell of a containing circuit for transferring signals and / or inputting supply and a signal connecting device matched to it is set on the expnding shell of a containing expanding circuit correspondingly and the devices are connected with circuits in their shells separately, the circuits are connected to each other via the connecting devices and transmit signals or supplies and a locating device and the connecting device are set on the two shells correspondingly to be fixed and connected by the devices.

Owner:北京爱博精电科技有限公司

Shakeproof lift-preventing anti-bending preformed pile and manufacturing process of preformed pile

ActiveCN103386709AAccurate and stable connectionNeutral goodShaping reinforcementsProtective foundationPre stress

The invention relates to a shakeproof lift-preventing anti-bending preformed pile and a manufacturing process of the preformed pile. The preformed pile is characterized by comprising a plurality of prestress main bars, concrete, end plates on both sides and circular truncated cones matched with the prestress main bars, wherein the prestress main bars are uniformly arranged in the preformed pile, and adjacent prestress main bars encircle a circle through stirrups. The concrete is filled around the prestress main bars and the stirrups to form the preformed pile. The end plates are provided with through holes threaded with the prestress main bars which pass through the through holes on the end plates and are matched and connected with the circular truncated cones arranged on the other sides of the end plates. The invention provides the novel preformed pile and the manufacturing process thereof. Demands such as connection and piling of piles are realized through special connectors. The preformed pile has the advantages that the performed pile is simple in structure, convenient to operate and quick to construct, and the preformed piles can be firmly and accurately connected, so that the work efficiency is greatly improved, and the performed pile is labor-saving and the like.

Owner:MINGYE CONSTR GRP

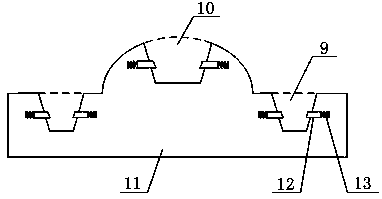

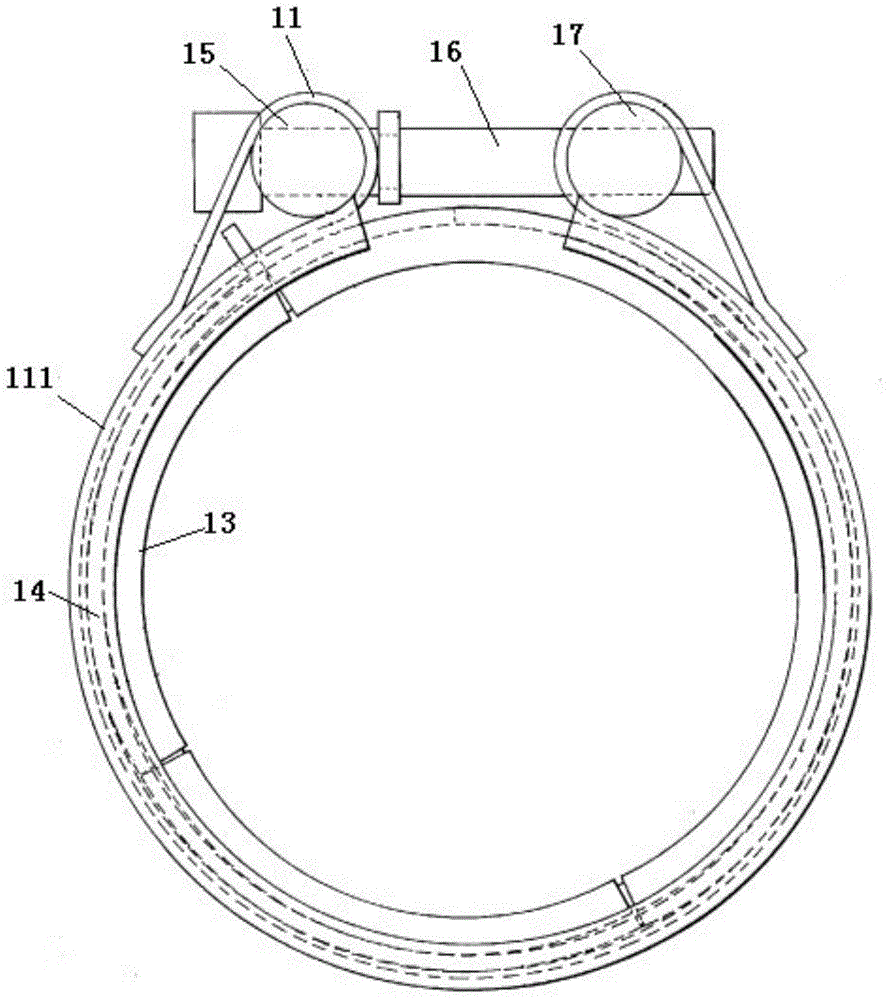

Pressure backfill type pipe connection piece

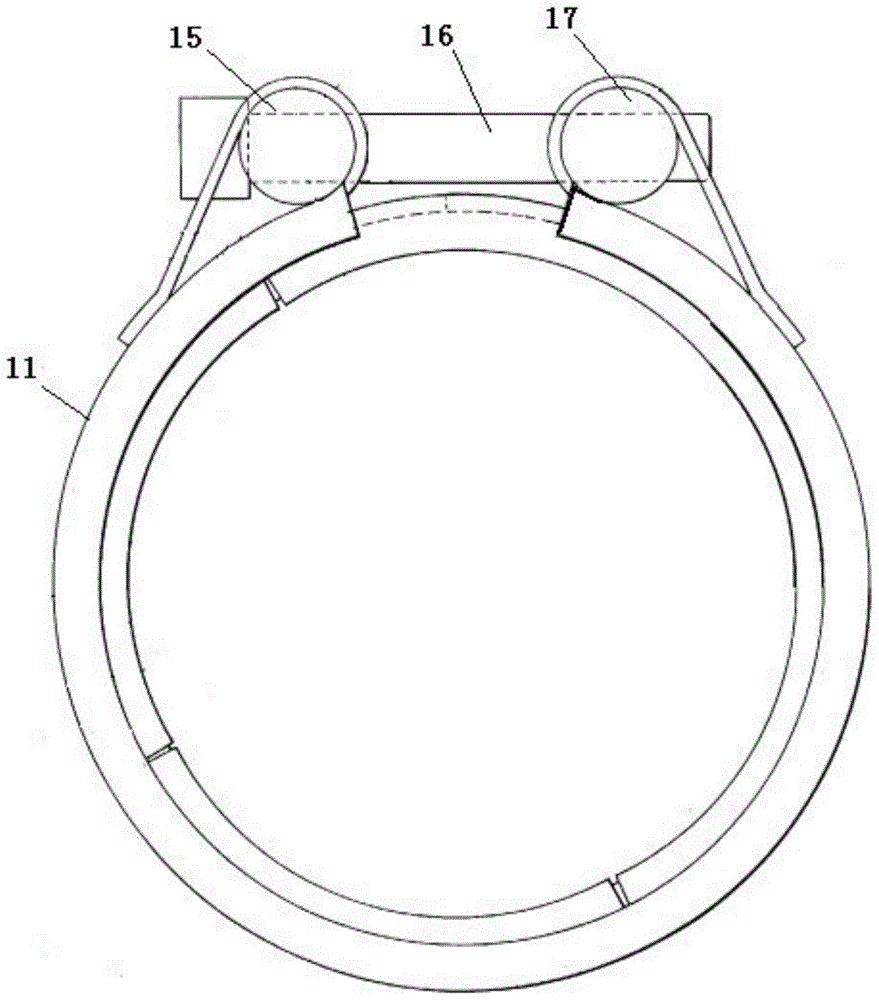

ActiveCN104455827AQuick connectionSimple structureSleeve/socket jointsElastic compressionArchitectural engineering

A pressure backfill type pipe connection piece comprises a clamping piece and an elastic compression ring, wherein the clamping piece is in an opened annular shape, the section of the clamping piece is in a U shape, and the elastic compression ring is located on the inner edge of the clamping piece. The pressure backfill type pipe connection piece further comprises a clamping bolt, a left fixing rod and a right fixing rod, wherein the left fixing rod and the right fixing rod are transversely fixed to the two sides of an opening of the clamping piece respectively. Fixing rings are arranged on the two sides of the elastic compression ring respectively. A chrome-steel alloy pipe serves as the clamping piece, and the inner surface and the outer surface of the clamping piece, the outer surface of the left fixing rod, the outer surface of the clamping bolt and the outer surface of the right fixing rod are each coated with an anti-corrosion coating with the thickness of 0.1 mm to 0.5 mm. In this way, the pressure backfill type pipe connection piece is simple in structure, pressure backfill type pipe connection pieces can be conveniently matched, operation is convenient, pipes can be rapidly connected, the anti-corrosion effect is good, and the service life is prolonged.

Owner:SINOHYDRO BEREAU 10 CO LTD

Domestic appliance switch

PendingCN108615640AAvoid Electric Shock Safety AccidentsWide range of controlElectric switchesElectrical conductorEngineering

The invention discloses a domestic appliance switch. The domestic appliance switch comprises a box body, a handle sliding channel, a switch sliding groove, connecting pieces, connecting rings, a connector, inserting grooves, an insulating rubber shell, a connecting groove, a metal conductor, a spring and a control handle; the domestic appliance switch is characterized in that the handle sliding channel is formed in the outer wall of the front surface of the box body; the cylindrical switch sliding groove is formed in the box body; three connecting rings are arranged on the upper part of the inner wall of the switch sliding groove at equal spacings; the insulating rubber shell is arranged at the bottom of the switch sliding groove; the connecting rings are arranged in the insulating rubbershell; the connecting rings are connected with the connector through the connecting pieces; the connecting rings and the connecting pieces are integrally formed; the connecting rings and the connecting pieces are molten and casted in the box body; and inserting grooves are formed in the upper ends of the connecting pieces at the upper part of the switch sliding groove at equal spacings. The domestic appliance switch is convenient to operate and capable of improving equipment safety and preventing a user electric shock safety accident effectively.

Owner:山东亲橙里教学用品有限公司

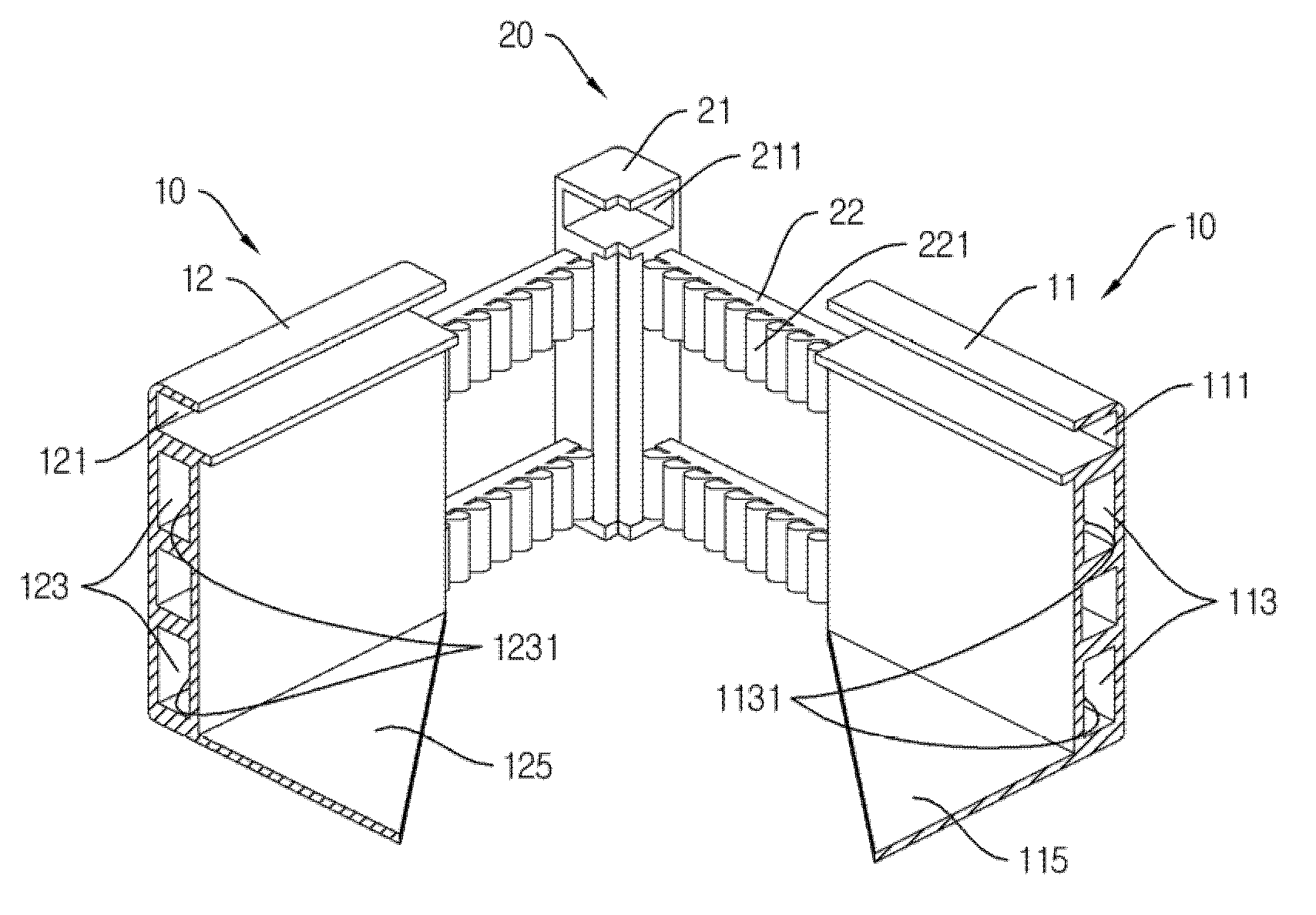

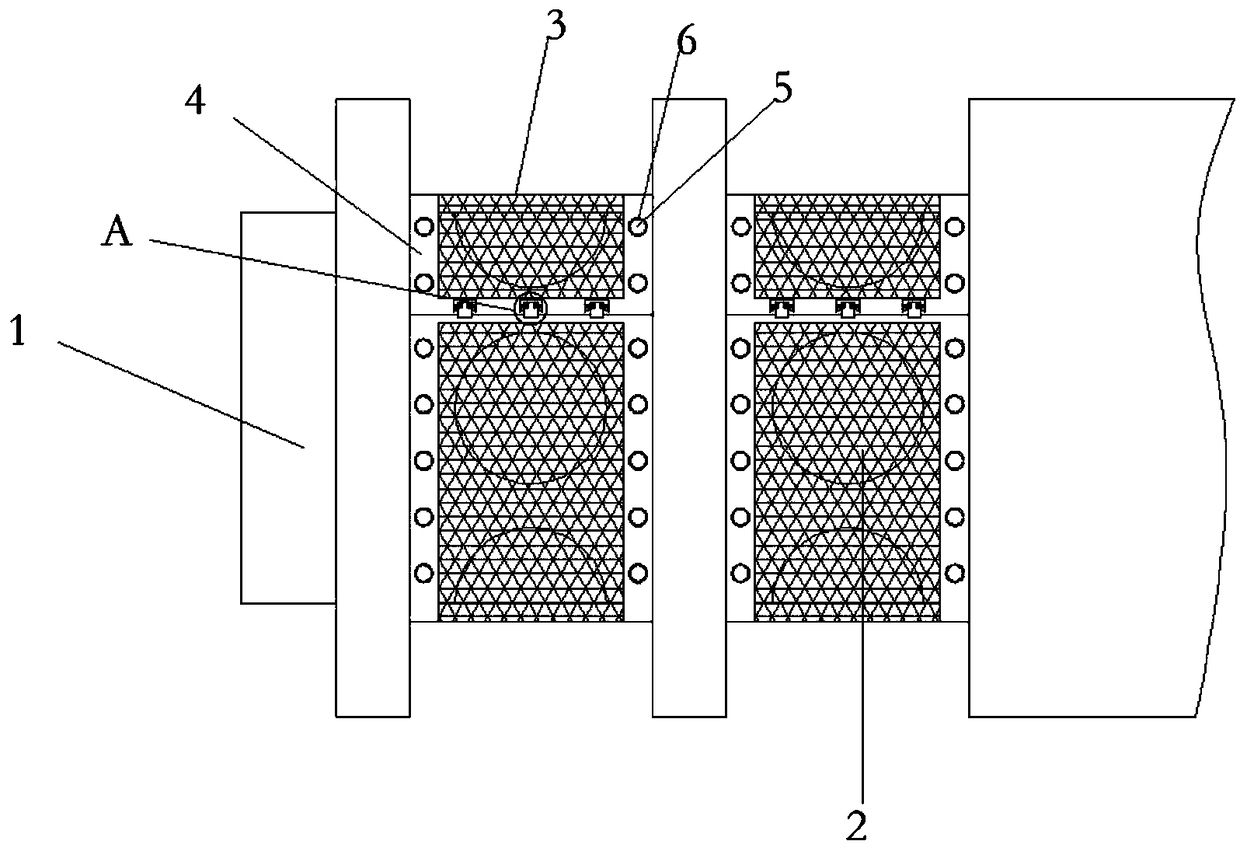

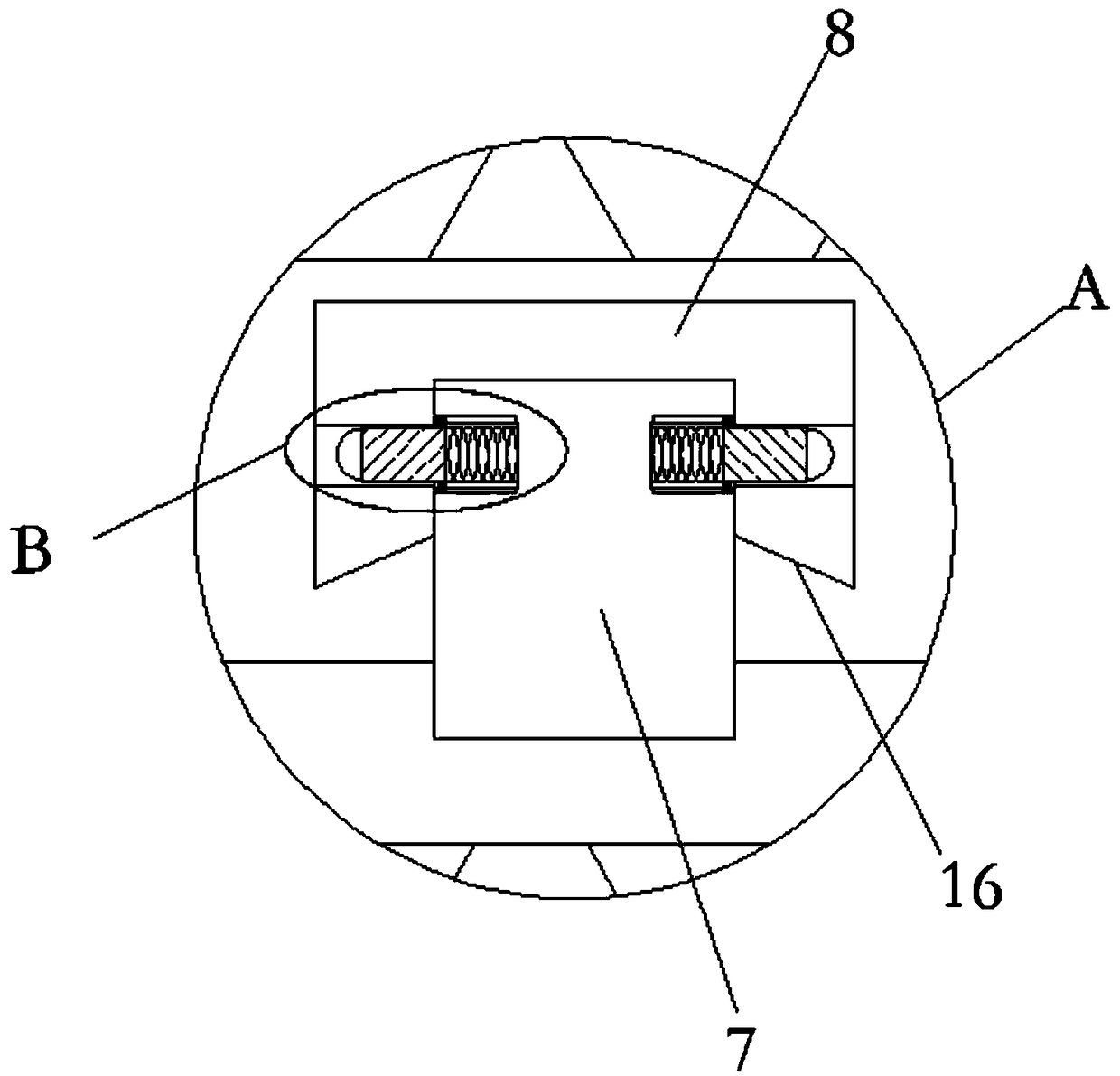

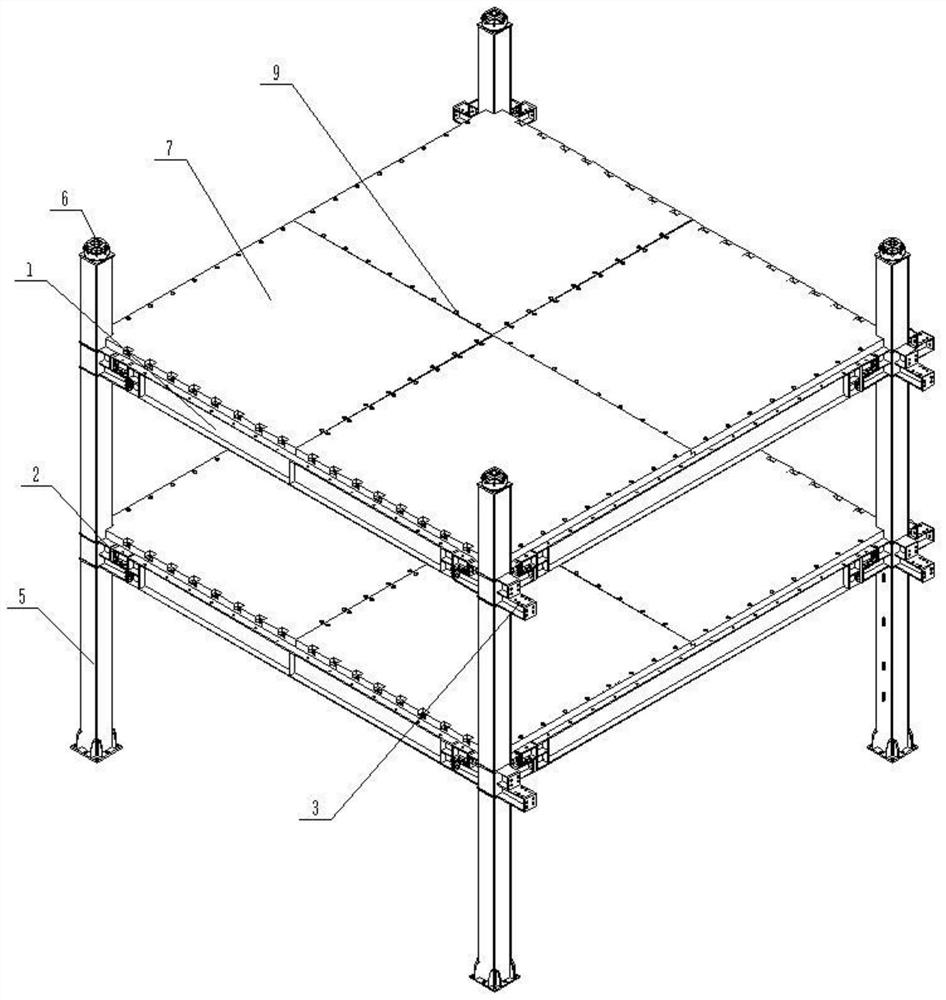

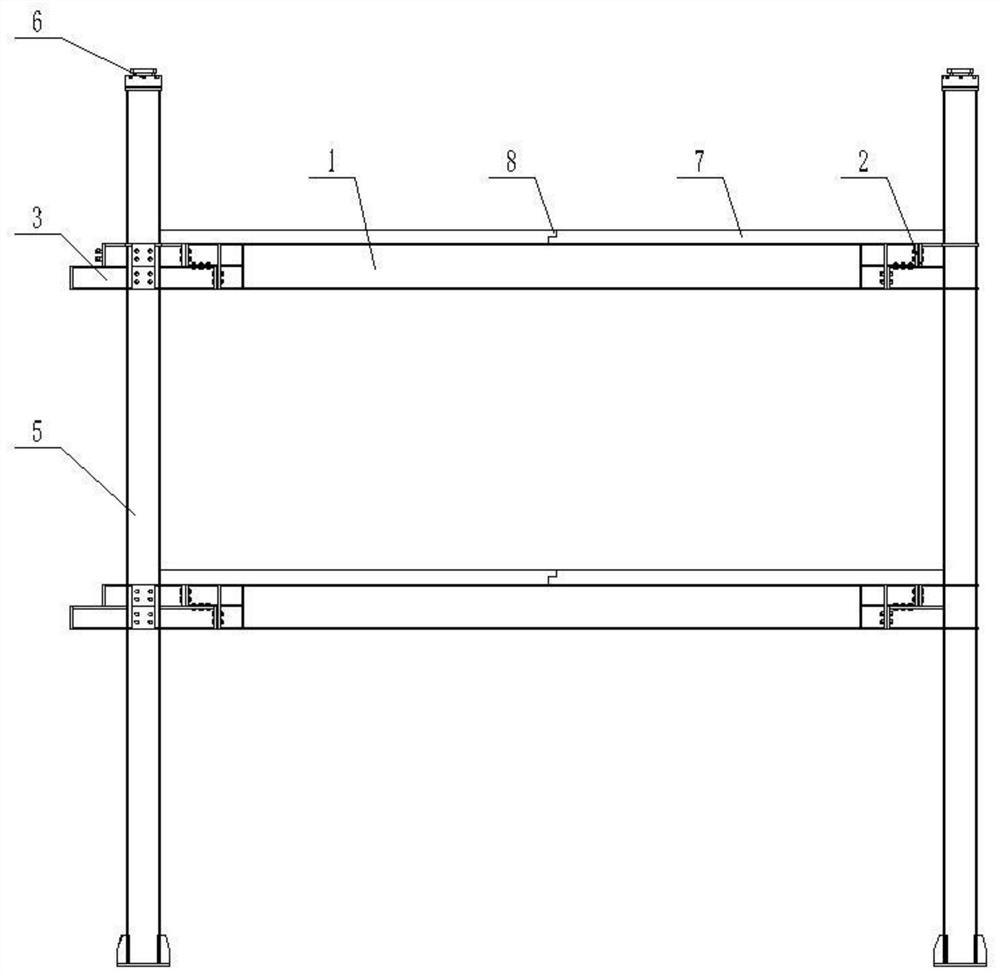

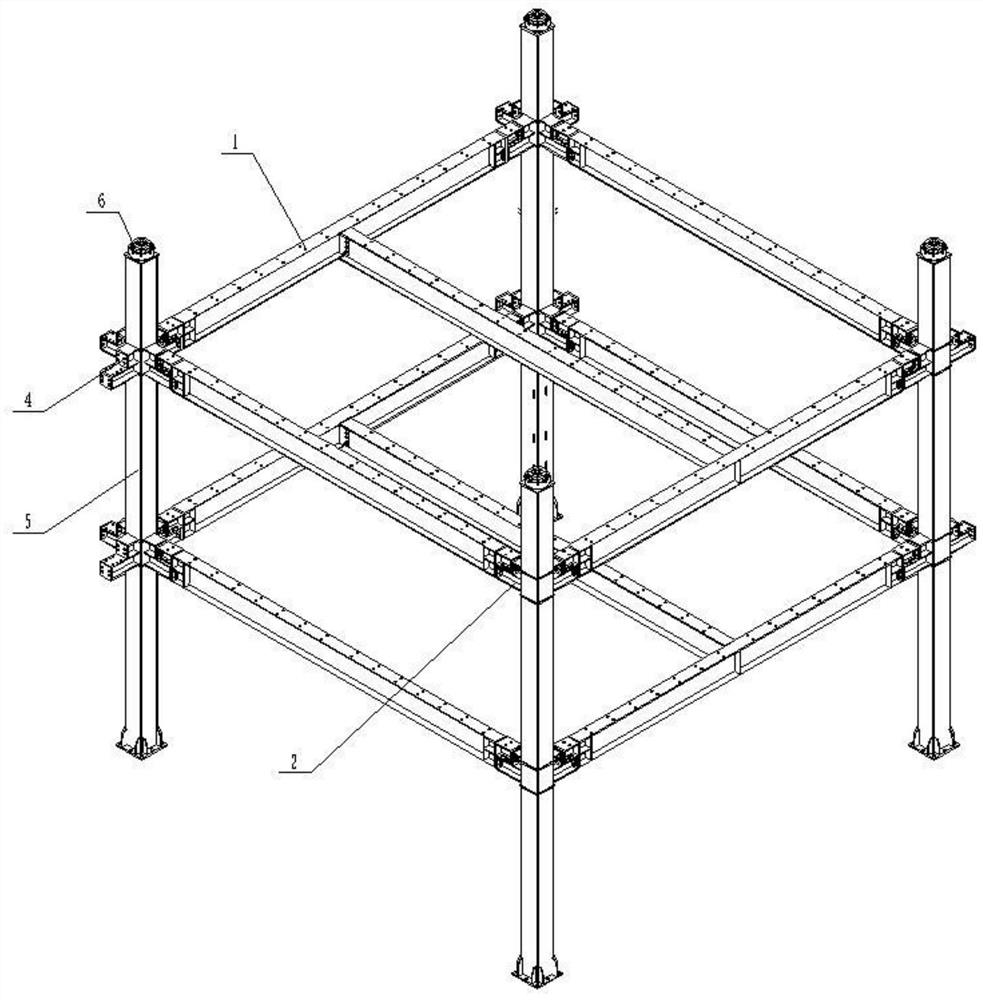

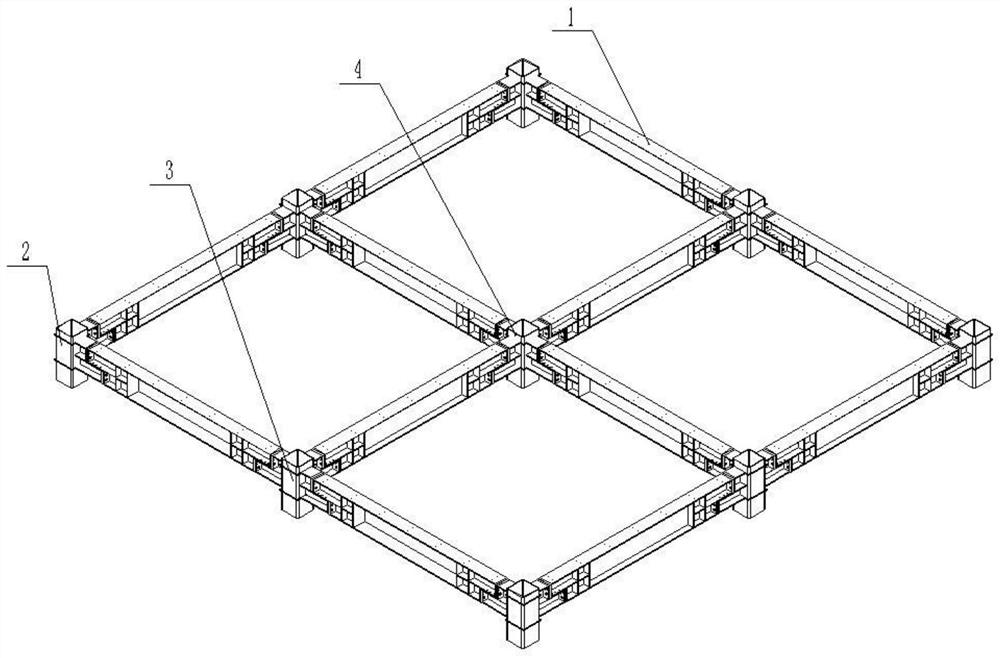

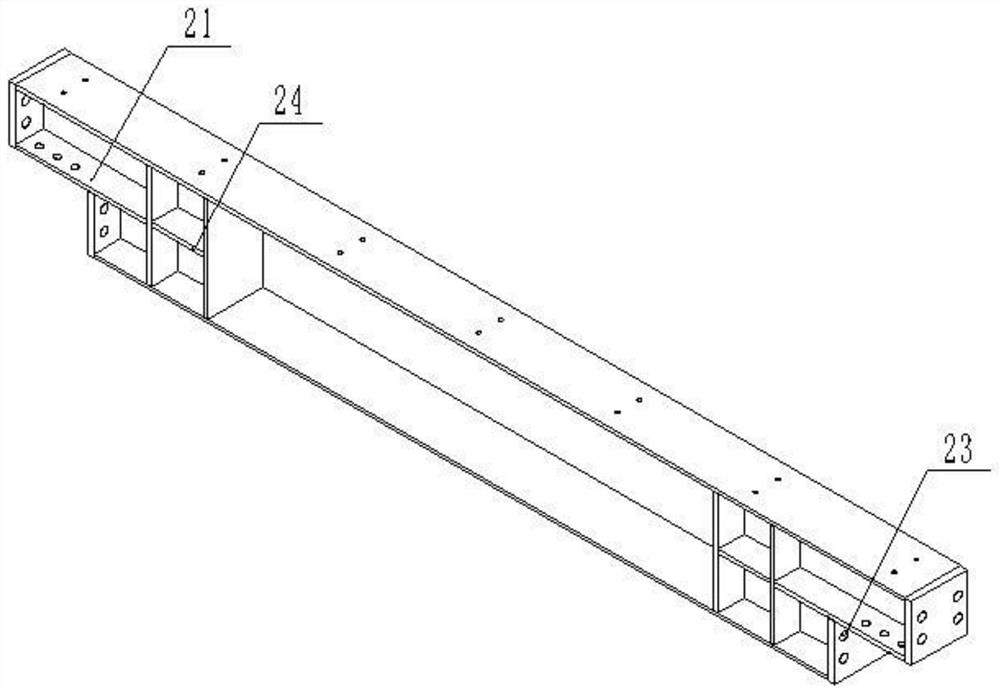

Fabricated building structure

The invention discloses a fabricated building structure. The problem of frame beam column splicing in large-scale assembly is solved, the connecting quality is ensured, and the assembly efficiency is improved. According to the adopted technical scheme, a cross-shaped joint structure is located in the center of a Chinese character 'Tian', L-shaped joint structures are located at the four corners of the Chinese character 'Tian', T-shaped joint structures are located in the middles of the side edges of the Chinese character 'Tian', and cross beams are connected between the L-shaped joint structures and the T-shaped joint structures and between the T-shaped joint structures and the cross-shaped joint structure; the upper end and the lower end of a columnar frame body are sleeved with stand columns, the stand columns are limited by supporting tables, stand column connecting joints are arranged on the stand columns at intervals, and the outer end faces of mother joints and child joints are fixedly connected with beams or columns to be connected; and stepped connecting ends are arranged on one sides of floor plate bodies, a plurality of holes are sequentially formed in the other three sides of the floor plate bodies in the edge direction, holes are formed in all stepped faces of the connecting ends, and the steps of every two adjacent floor plate bodies can be matched, connected and fixed together.

Owner:山西宏厚装配式建筑科技发展有限公司

Tractor device for agricultural machine manufacturing

ActiveCN113501054AImprove stabilityFixed and accurateTractorsTowing devicesMachine buildingAgricultural engineering

The invention relates to the technical field of tractor devices, in particular to a tractor device for agricultural machinery manufacturing. The tractor device comprises a tractor body; a positioning mechanism which is fixedly connected with the tractor body; a control mechanism which is arranged on the outer side of the positioning mechanism and is connected with the tractor body; and an adsorption mechanism which is connected with the control mechanism, wherein the adsorption mechanism comprises an adsorption assembly; a connecting assembly which is arranged between the adsorption assembly and the control mechanism; a transmission assembly which is arranged between the connecting assembly and the control mechanism, the positioning mechanism and the adsorption mechanism are arranged, and the control mechanism is used for driving and connecting the positioning mechanism and the adsorption mechanism, so that the device not only can realize accurate fixation between the agricultural machinery body and the tractor body, and the connection reliability of the two parts is greatly improved.

Owner:徐州市飞虎建筑机械有限公司

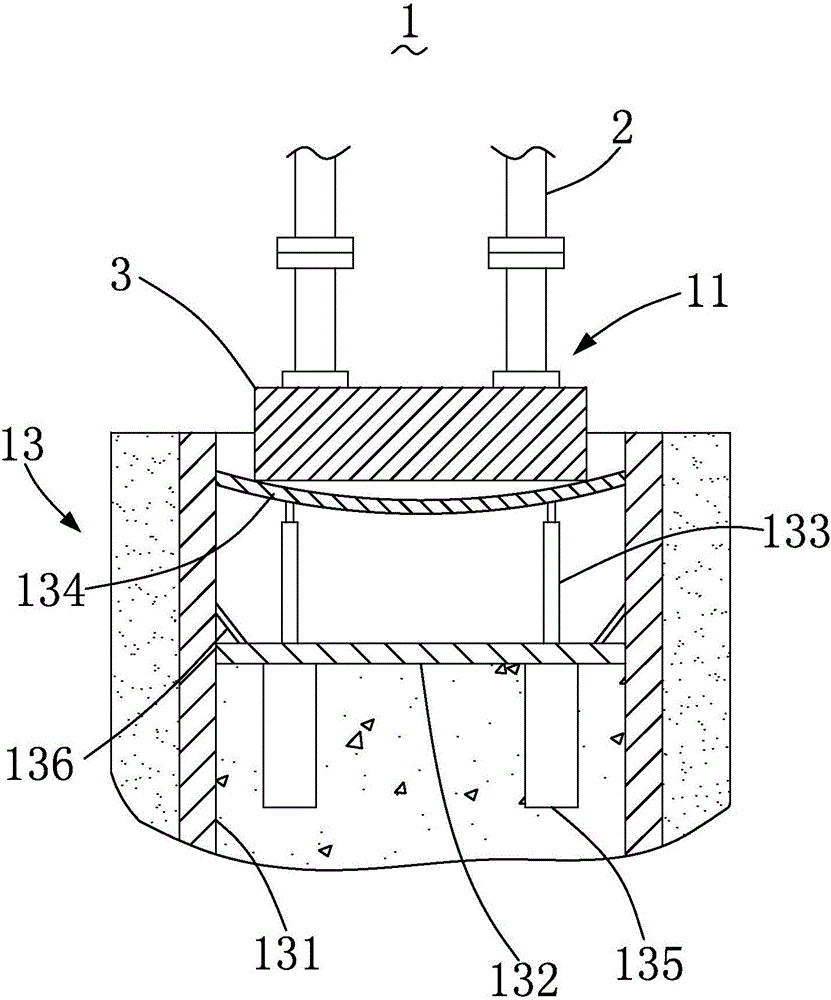

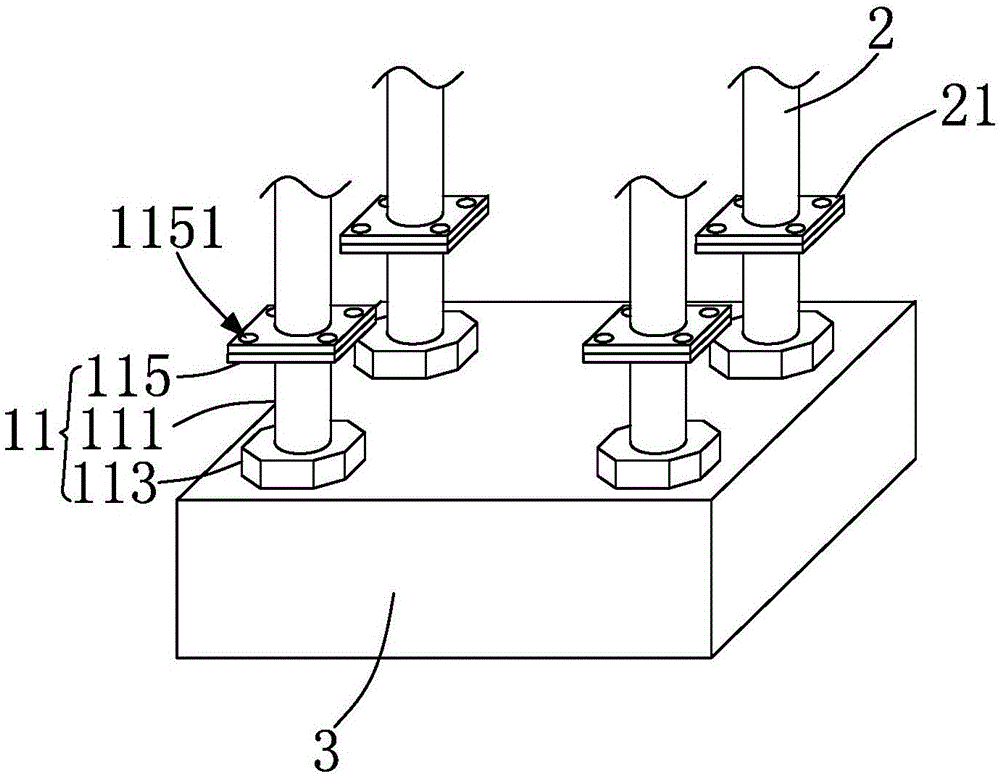

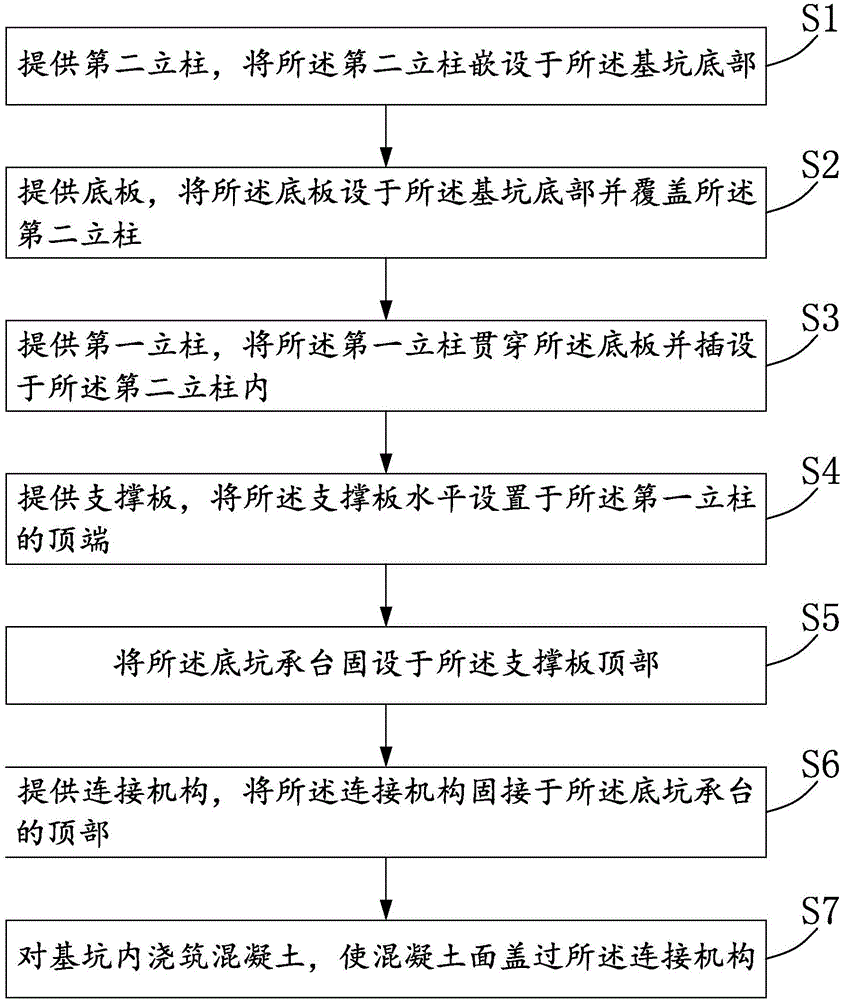

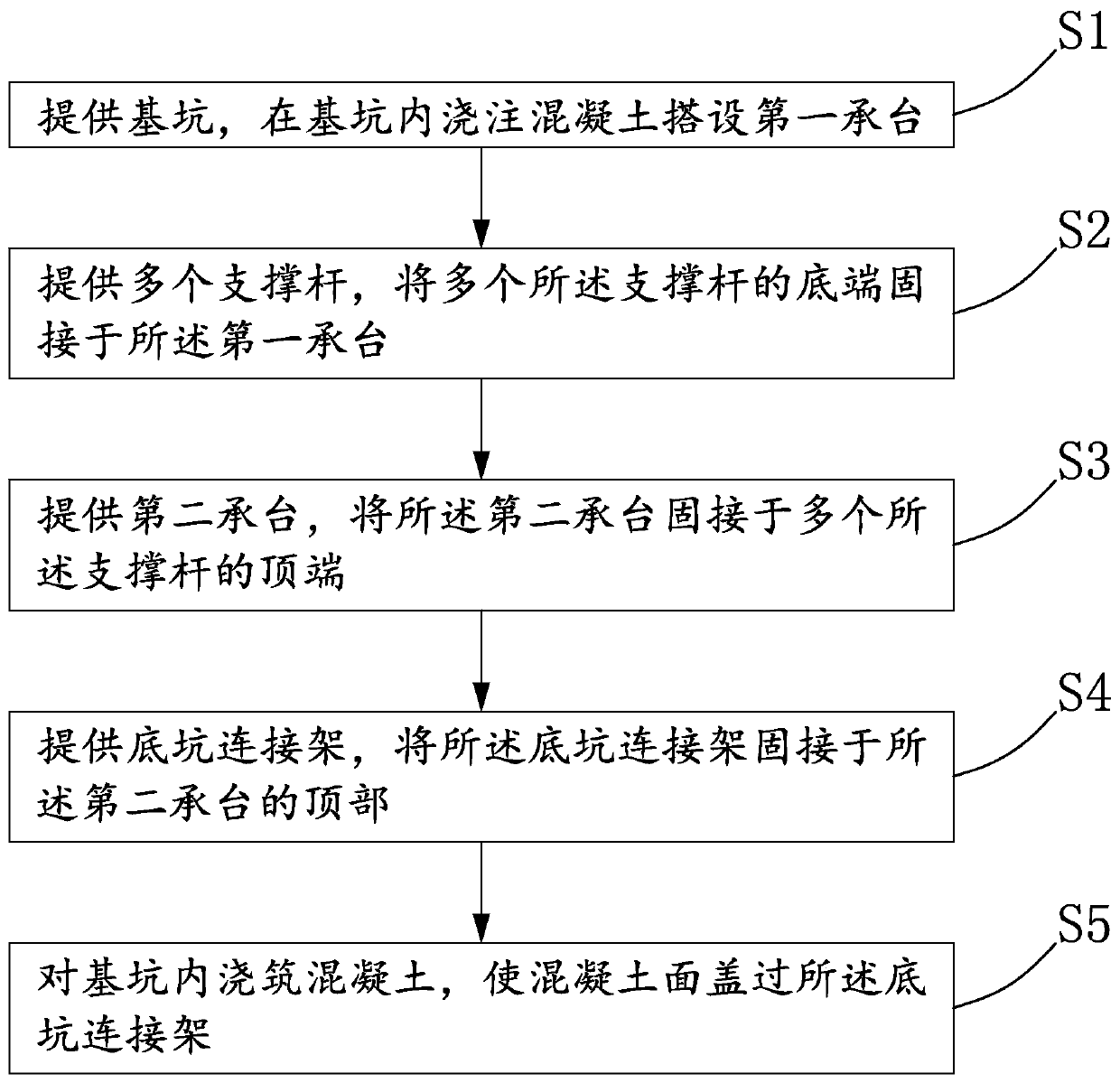

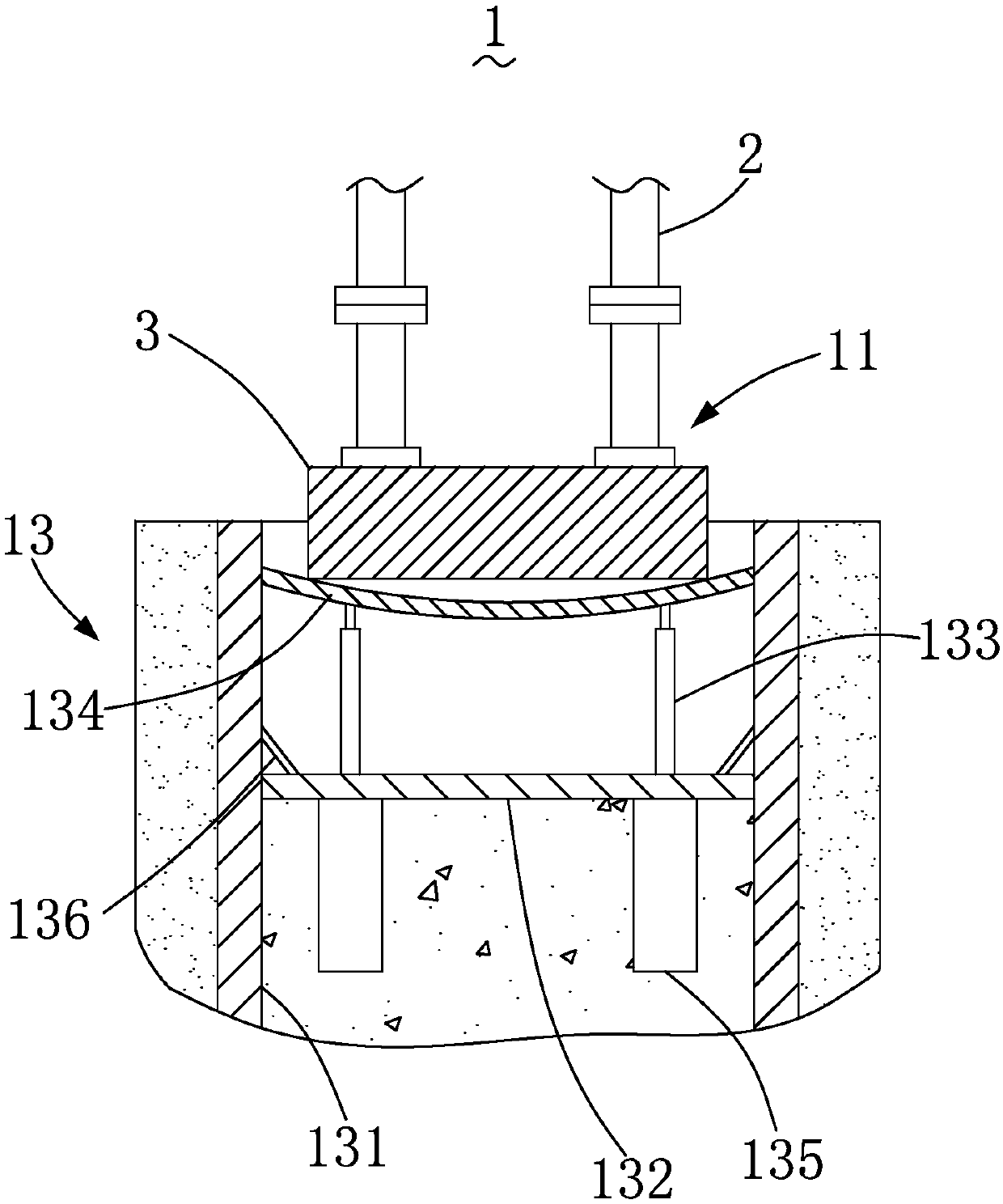

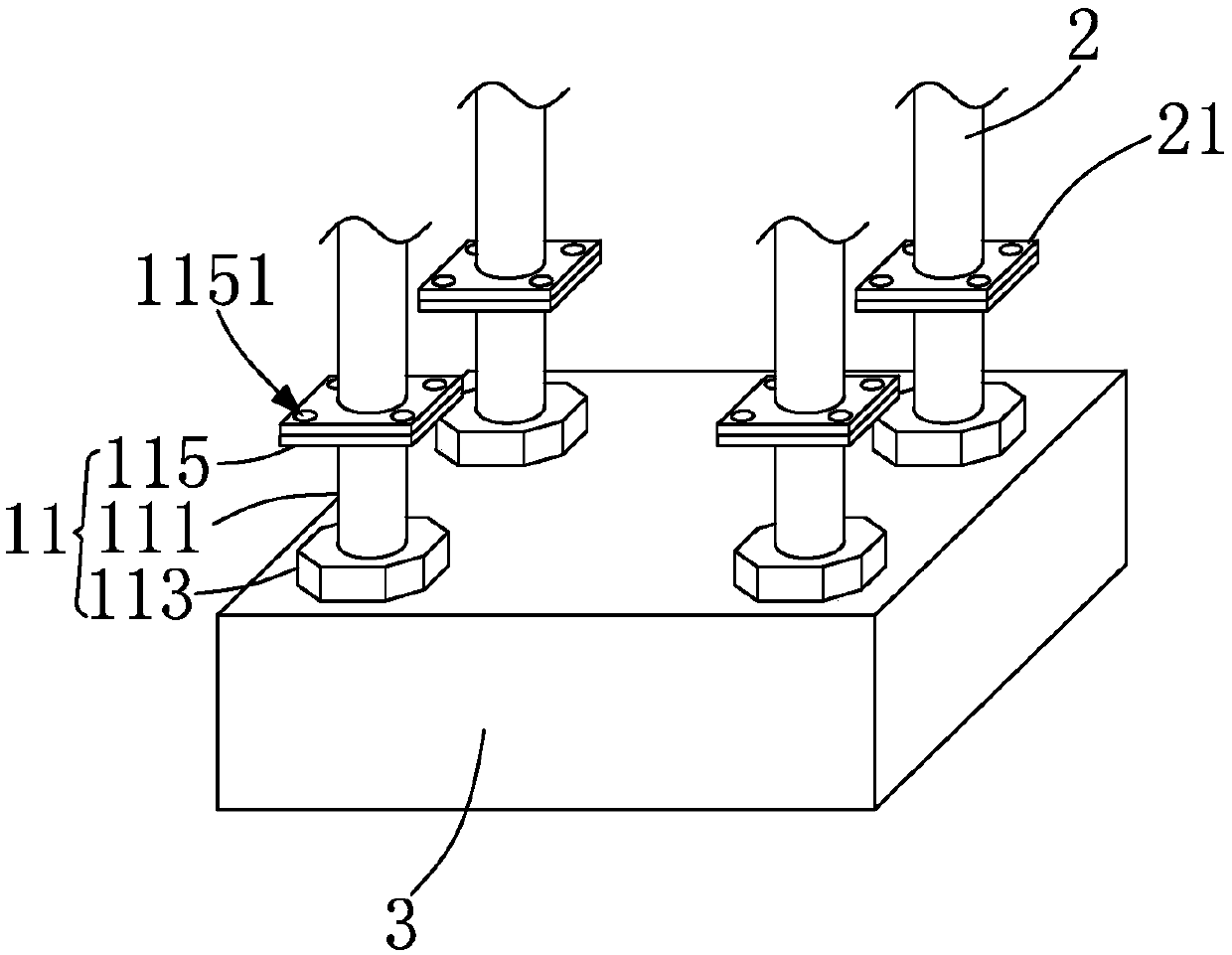

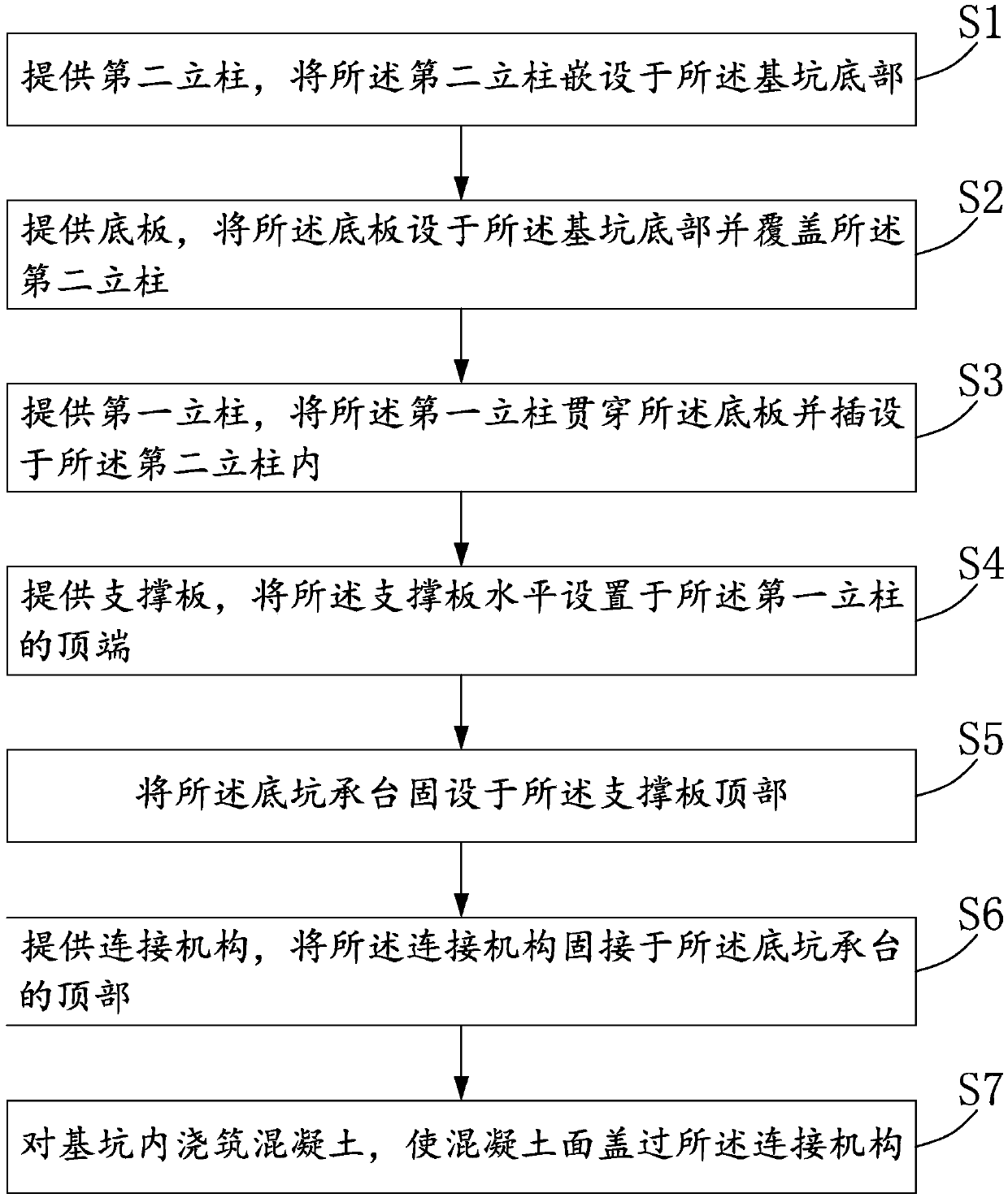

Pit structure mounting method

ActiveCN106592623AEnsure stabilityPrevention of landslidesFoundation engineeringBuilding liftsStructural engineering

Owner:安徽亿力电力设备有限公司

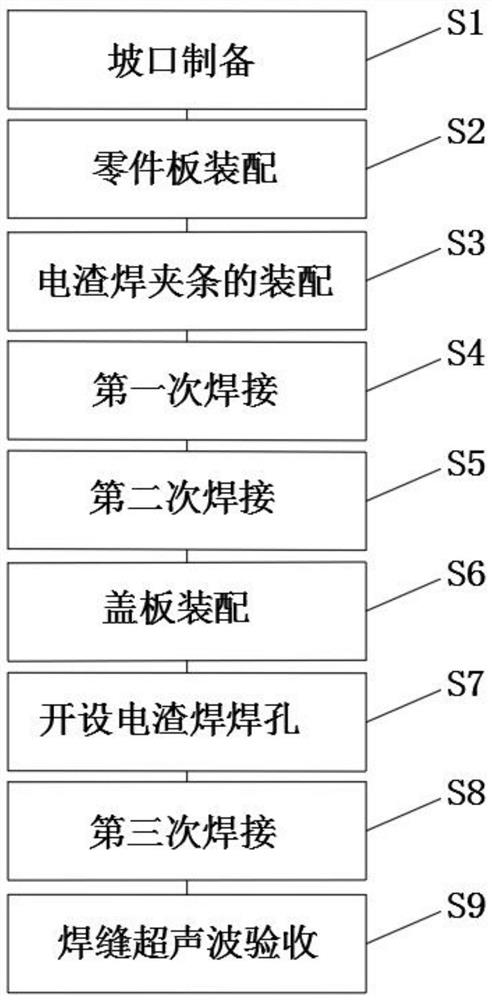

Process for welding bent box type

The invention provides a process for welding a bent box type. The process for welding the bent box type comprises the following steps: S1, groove preparation: forming grooves in a box body wall plate and a part plate; S2, part plate assembling: placing a flange plate on an assembling jig frame, then assembling webs on two sides of the flange plate, finally, assembling an inner partition plate in the middle of the flange plate, to complete the part plate assembling action; S3, assembling an electroslag welding holding strip; S4, performing welding for the first time; S5, performing welding for the second time; S6, assembling a cover plate; S7, forming electroslag welding holes; S8, performing welding for the third time; and S9, performing ultrasonic acceptance inspection for a weld joint. According to the process, stable assembly of the bending box type is achieved through assembly of all the structures, then all the structures are stably welded together through electroslag welding operation, and accurate and stable connection between a partition plate and the flange plate when the angle between the partition plate and the flange plate is not 90 degrees is achieved.

Owner:SHENZHEN JINXIN GREEN CONSTR LTD BY SHARE LTD

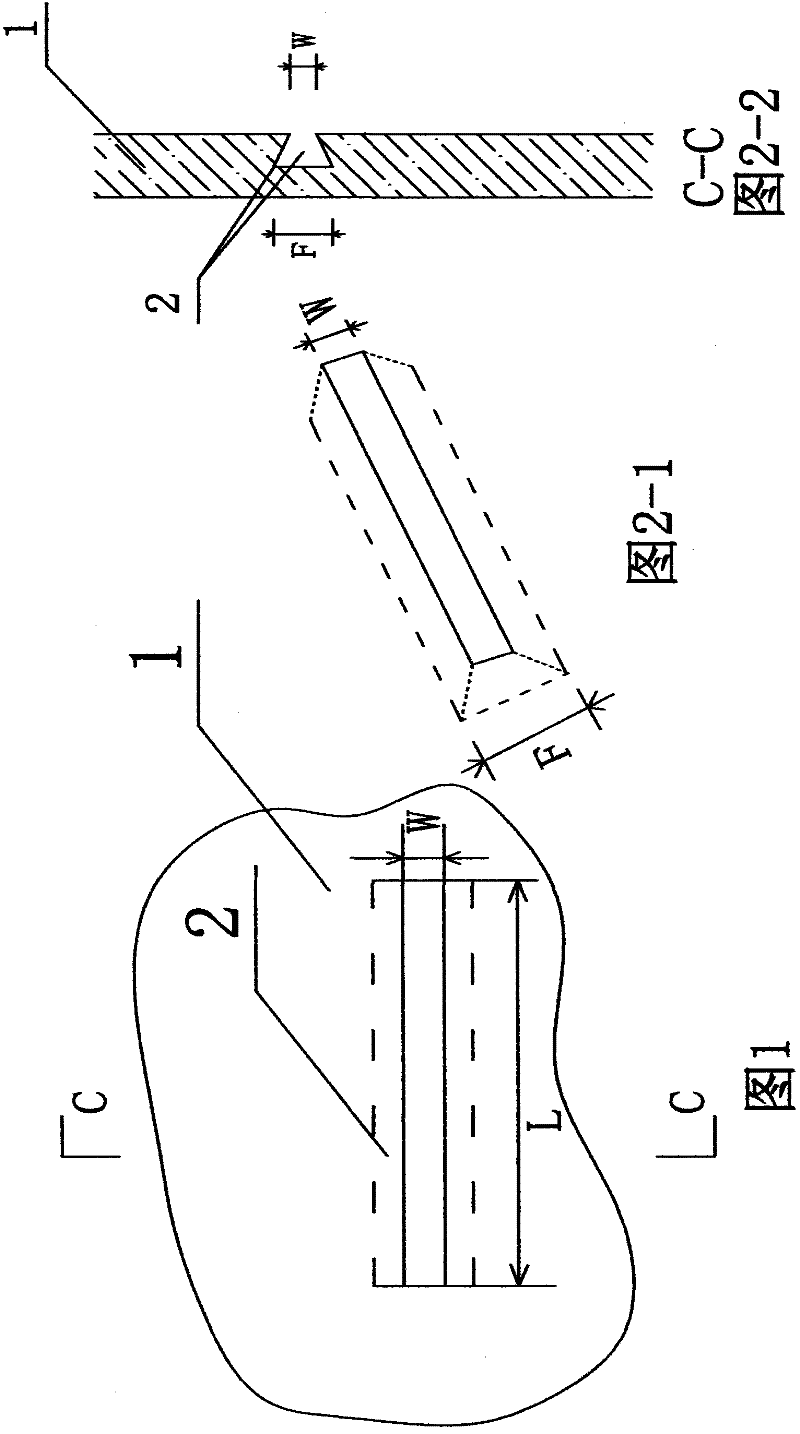

Device and method for mounting wire rope of architectural veneer

The invention discloses a device and method for mounting a wire rope of an architectural veneer. The device for mounting the wire rope of the architectural veneer comprises the veneer and is characterized in that: a connecting groove with a small opening and a large inside is arranged on the back of the veneer, not close to the edge; a connecting piece can be arranged in the connecting groove with a small opening and a large inside arranged on the back of the veneer, not close to the edge; the shape and the size of the cross section of the connecting piece are matched with those of the cross section of the connecting groove arranged on the back of the veneer, not close to the edge; the connecting piece is transversely inserted into the connecting groove; the direction of the connecting piece is changed from transverse to vertical so as to reach the top position of the connecting piece; the top position of the connecting piece is just positioned at a position with largest width in the connecting groove, and thus the connecting piece is buckled into the connecting groove; and one end of the wire rope is fixedly connected with the connecting piece, and the other end of the wire rope is connected with a building body. Therefore, perforating positions of the veneer and the building body do not need to be too precise and can be subjected to fine adjustment through the deformation ofthe wire rope when the veneer and the building body are connected with each other, thereby the accurate positioning and the firm connection between the veneer and the building body can be achieved. Moreover, the device for mounting the wire rope of the architectural veneer has the characteristics of simple structure, convenient construction and installation, and the like.

Owner:福建省兴雅达建设发展有限公司

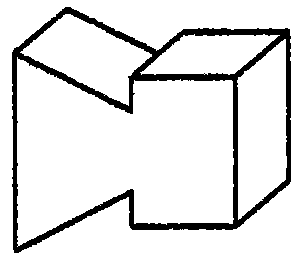

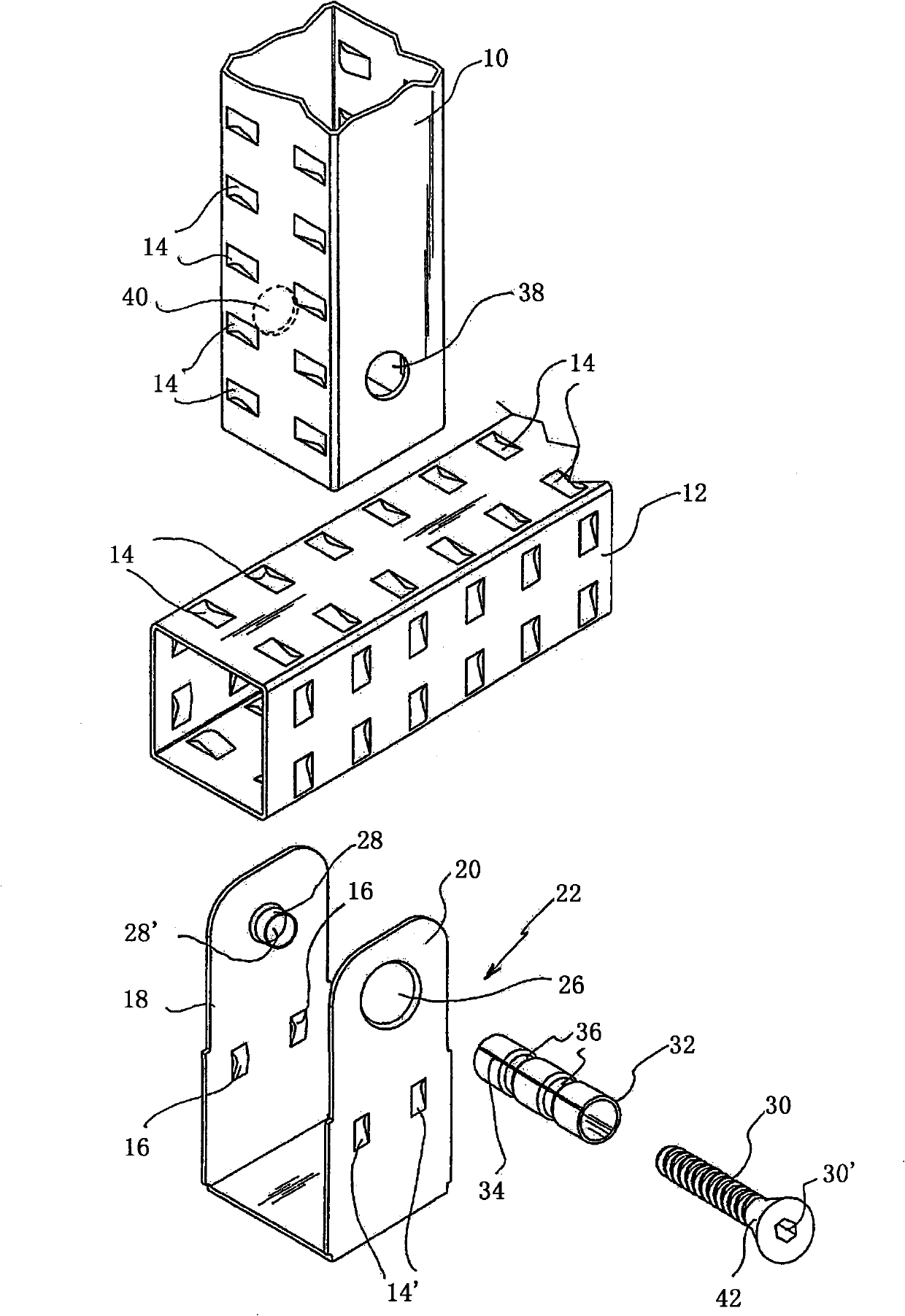

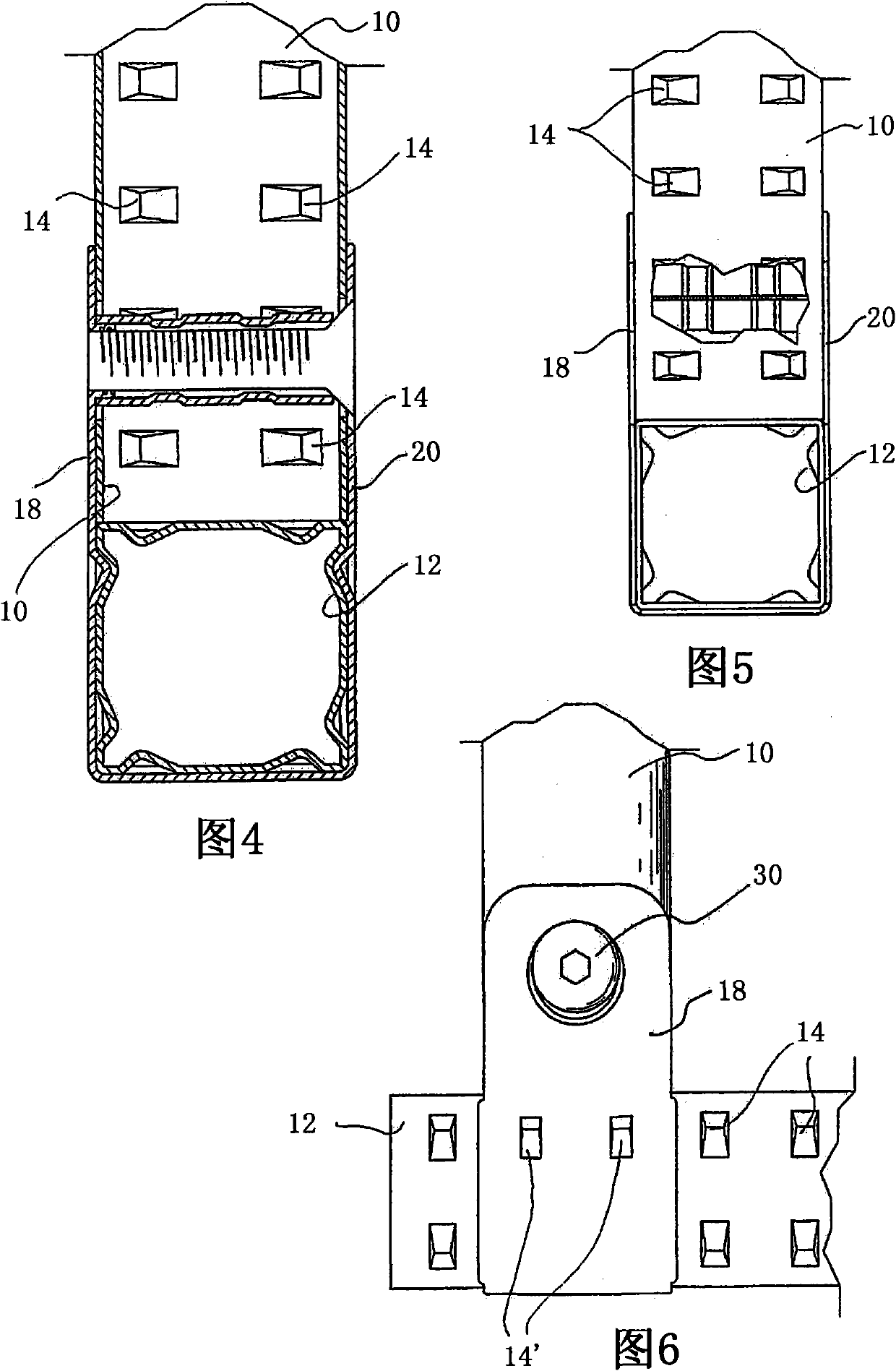

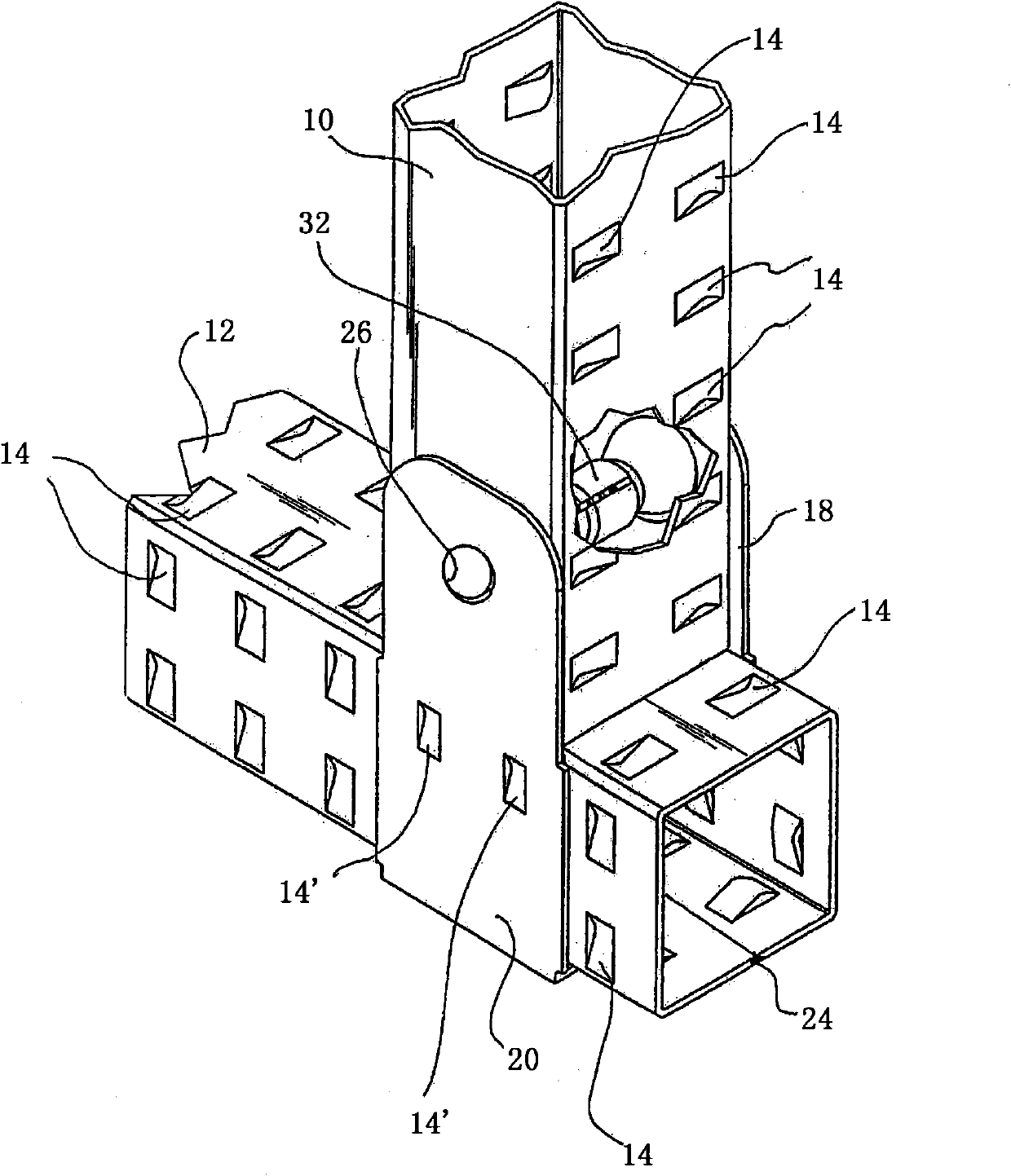

A device for the forced locking of two elements oriented orthogonally to one another

ActiveCN101949405AAccurate and stable connectionRod connectionsDismountable cabinetsEngineeringScrew thread

Owner:METALSISTEM

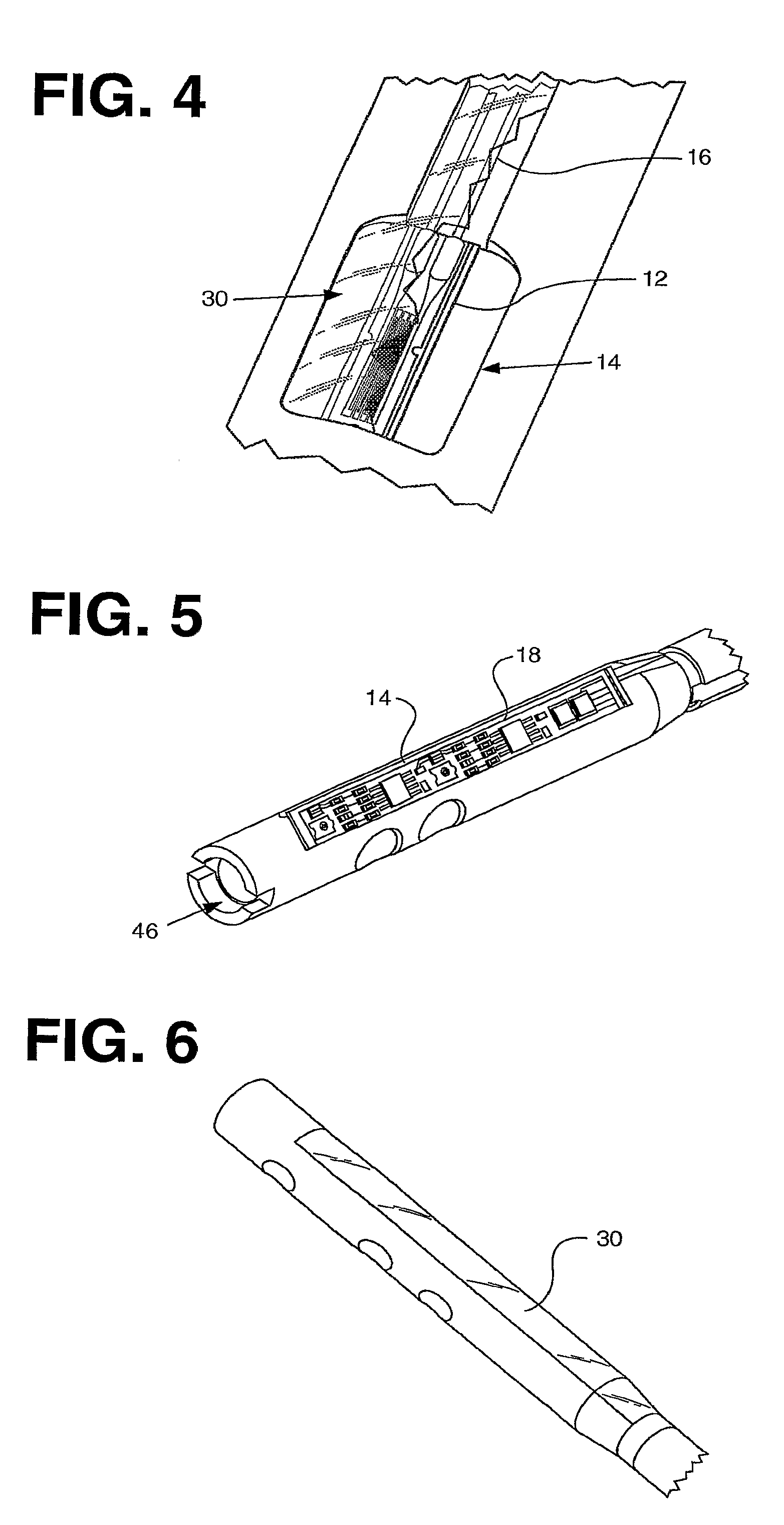

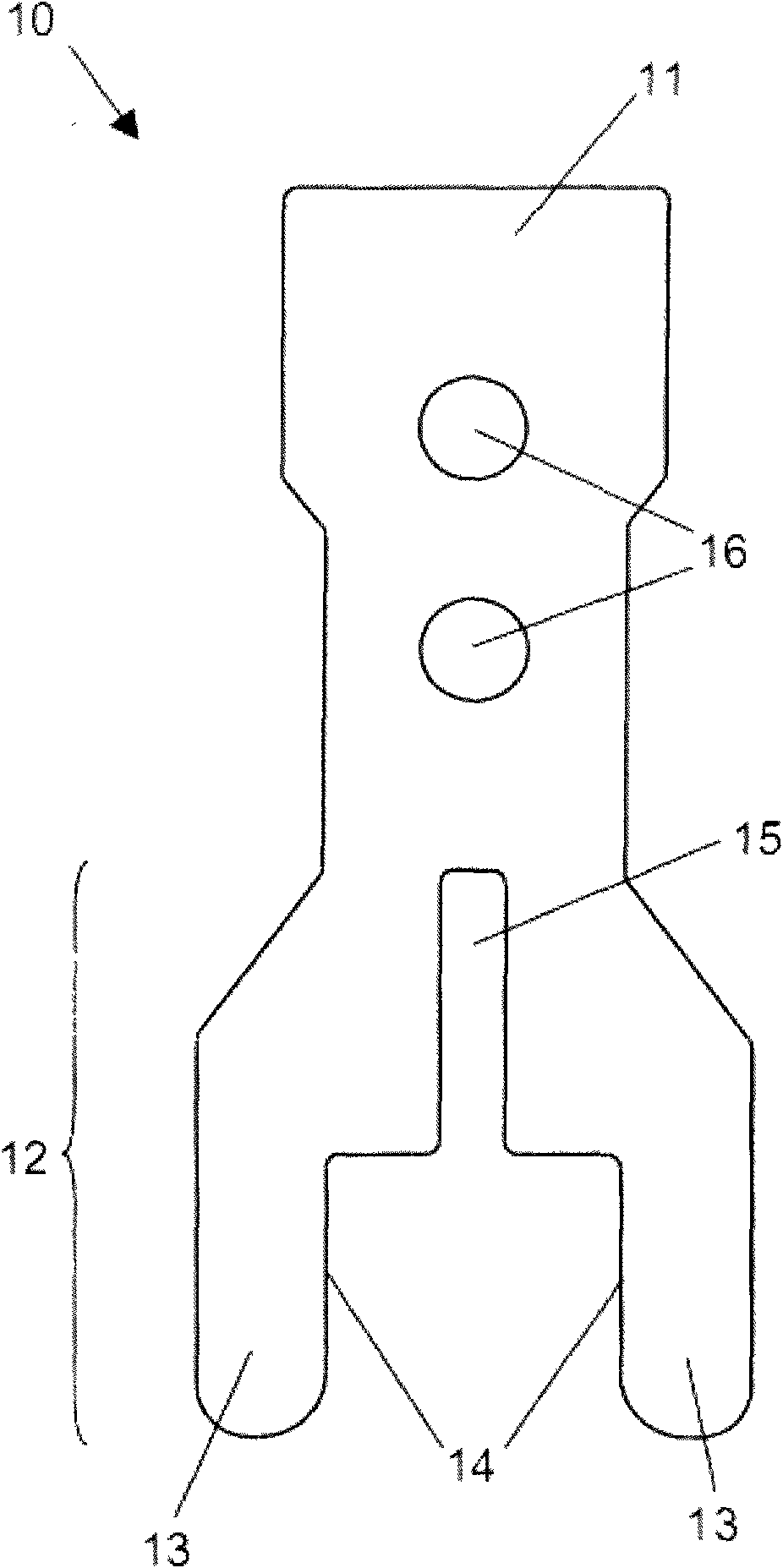

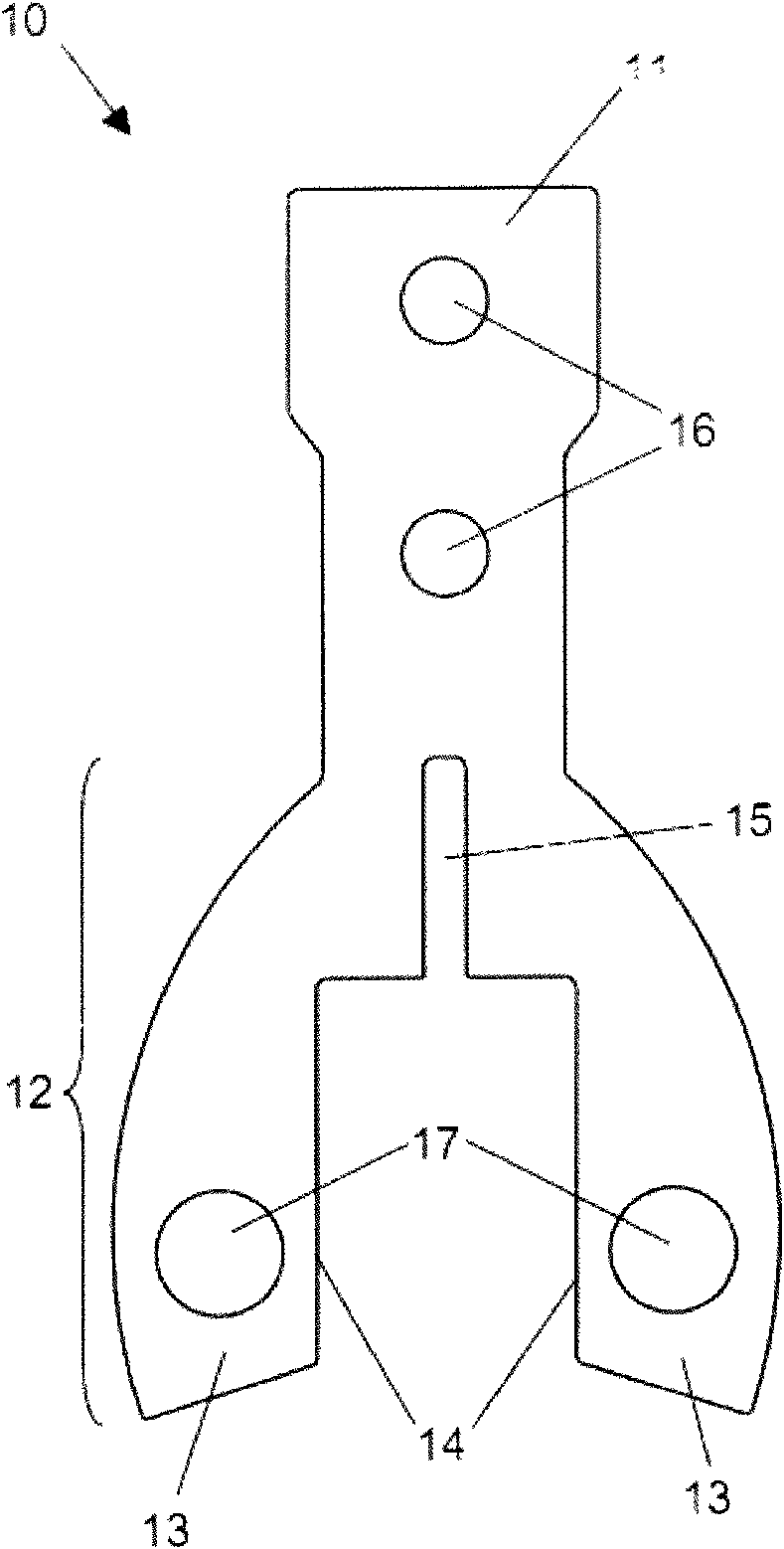

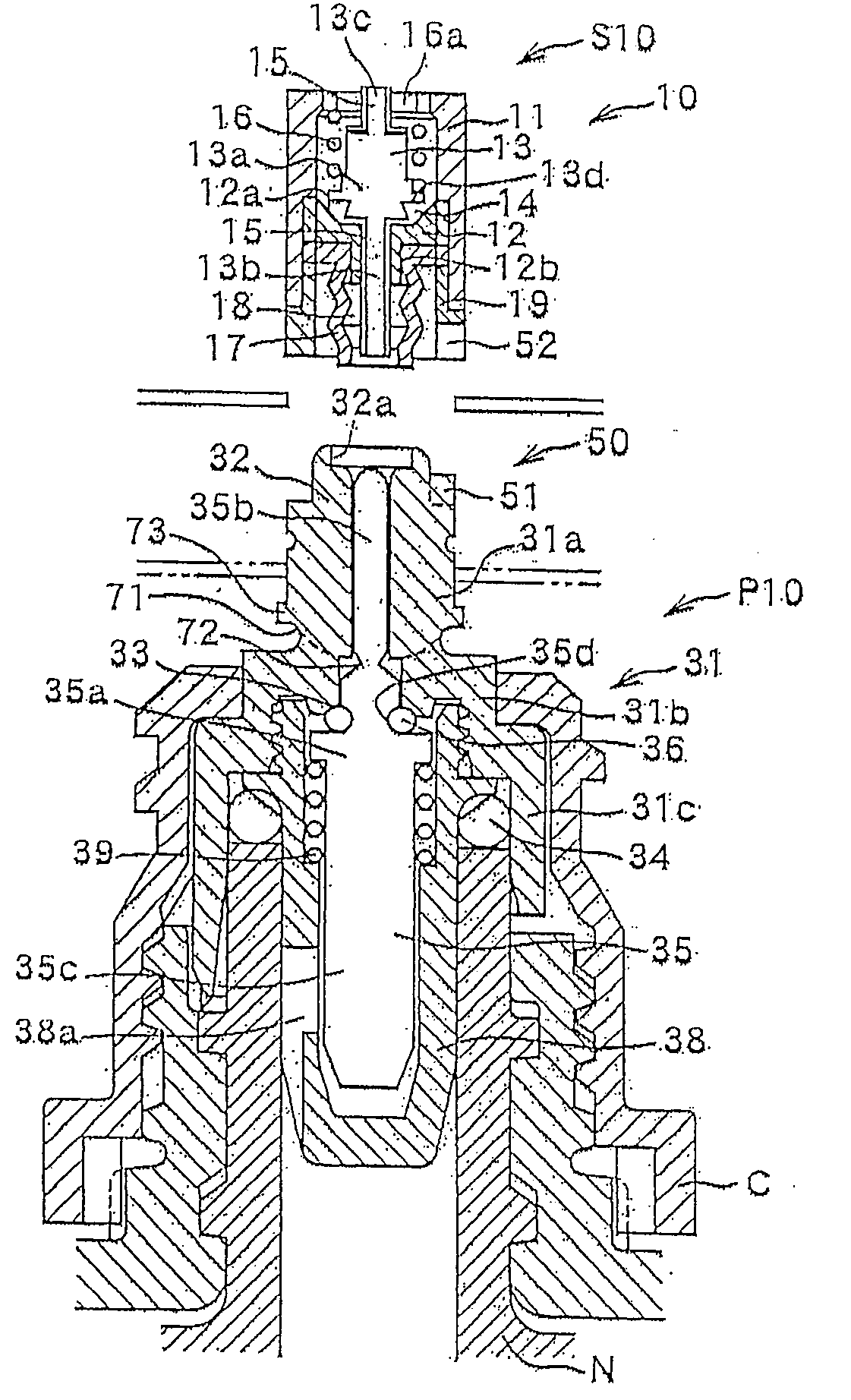

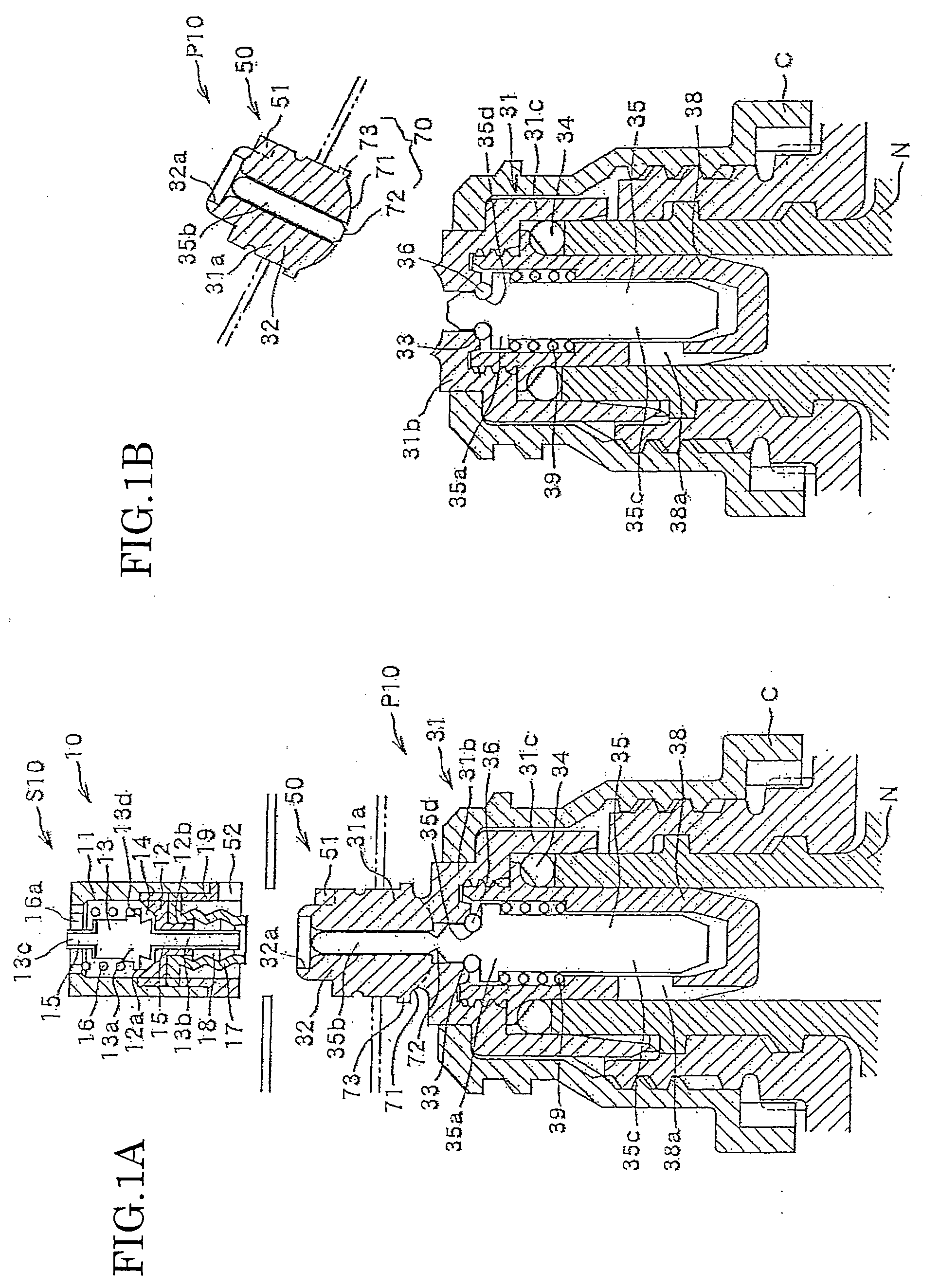

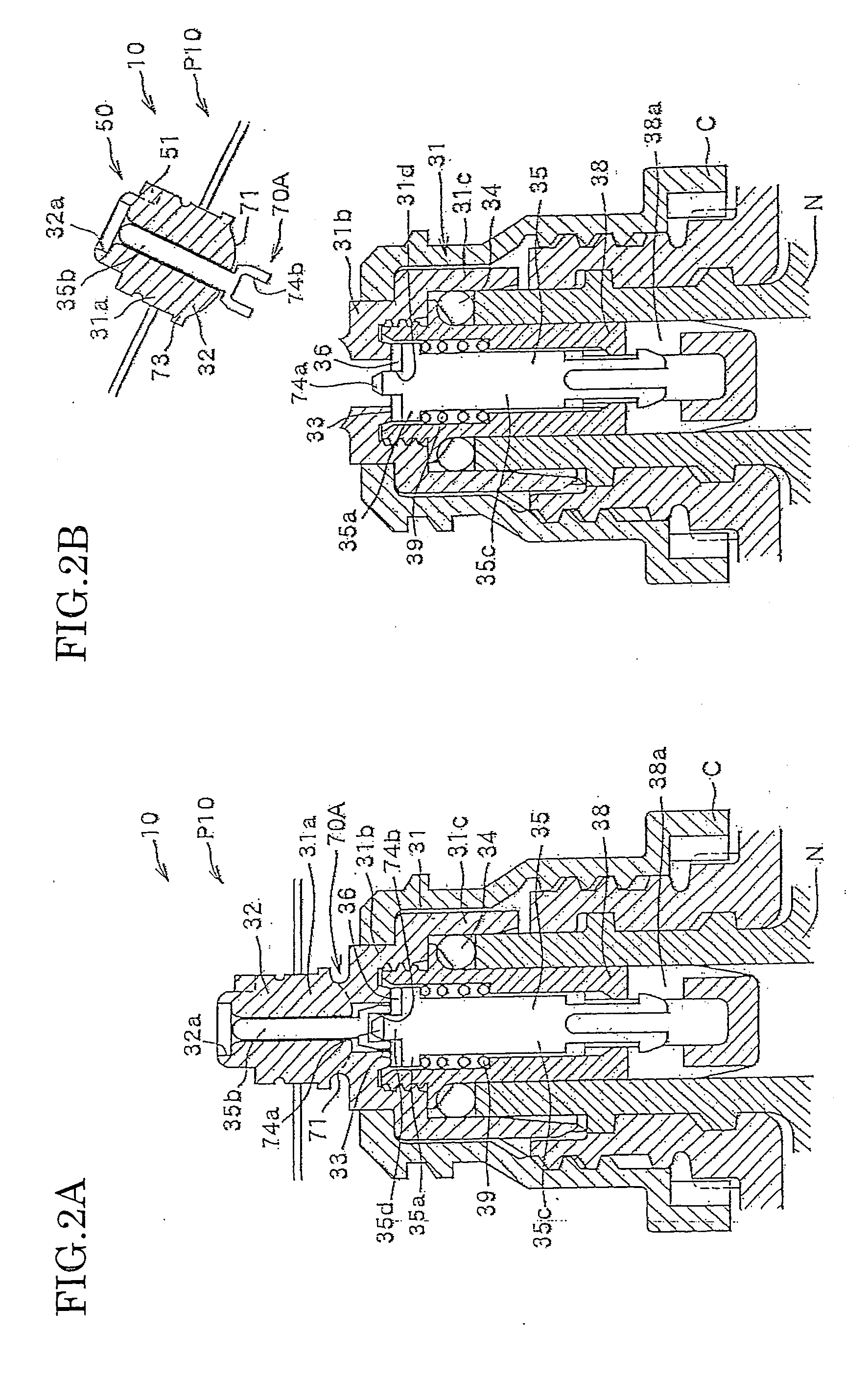

Plug Structure of a Coupler

InactiveUS20090229680A1Easy to carryAccurate and stable connectionLiquid fuel feeder/distributionReactant parameters controlEngineeringValve stem

A projecting connecting portion 32 which is fitted to a socket S10 and a valve seat 33 are provided in a plug main body 31 of a plug P10. The valve main body 31 having a valve head 35 which is urged to the valve seat 33 for sealing is provided in the plug main body 31 and the projecting connecting portion 32. Breaking starting portions 71 and 72 are provided in at least a part of the projecting connecting portion 32 and / or the valve stem 35b. A position at which breaking occurs when an excessive force exceeding a normal range of use is applied is set at a predetermined position whereby, when breakage occurs, the sealed state between the valve seat 33 and the valve head 35a can be maintained.

Owner:TOYO SEIKAN KAISHA LTD +1

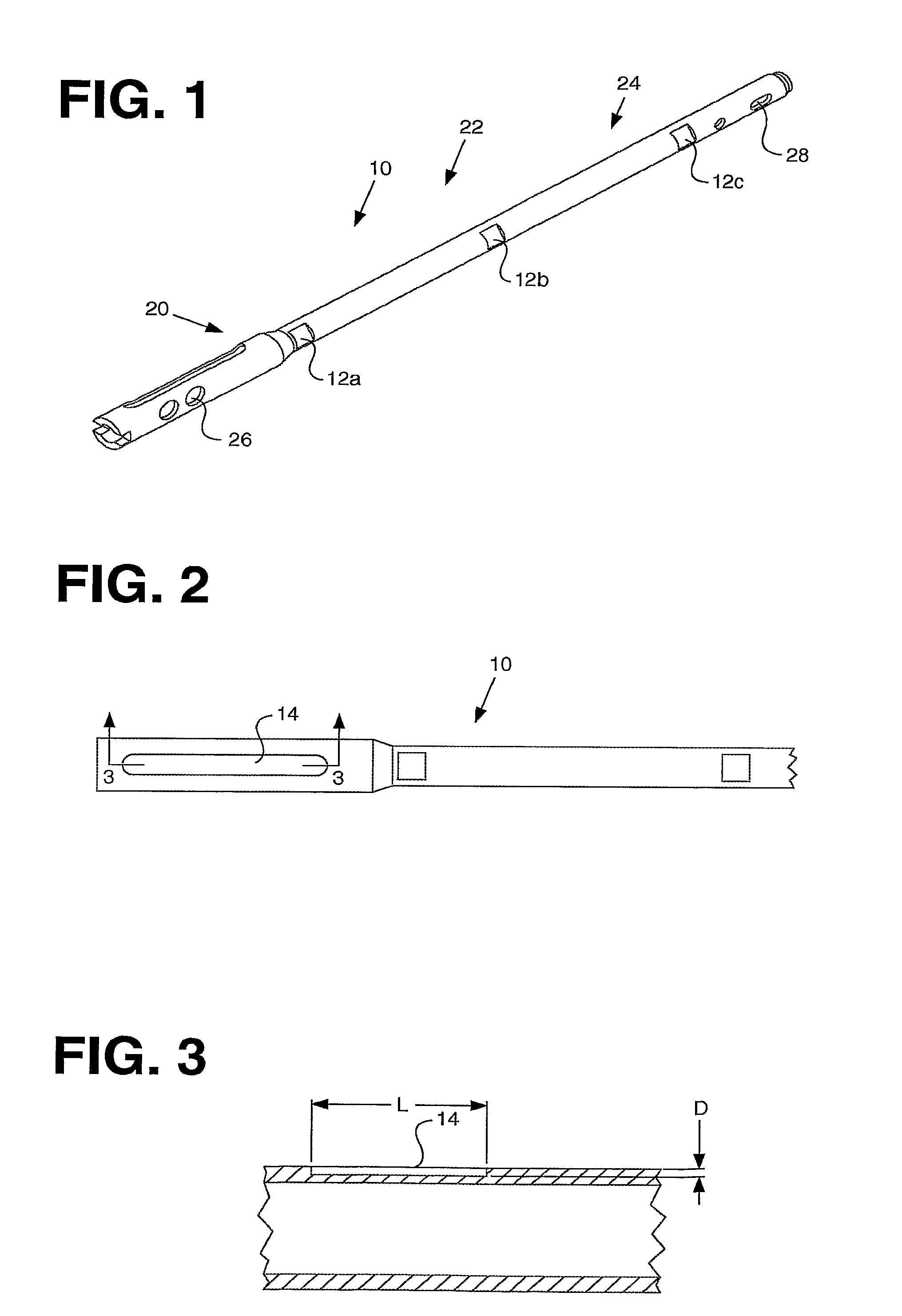

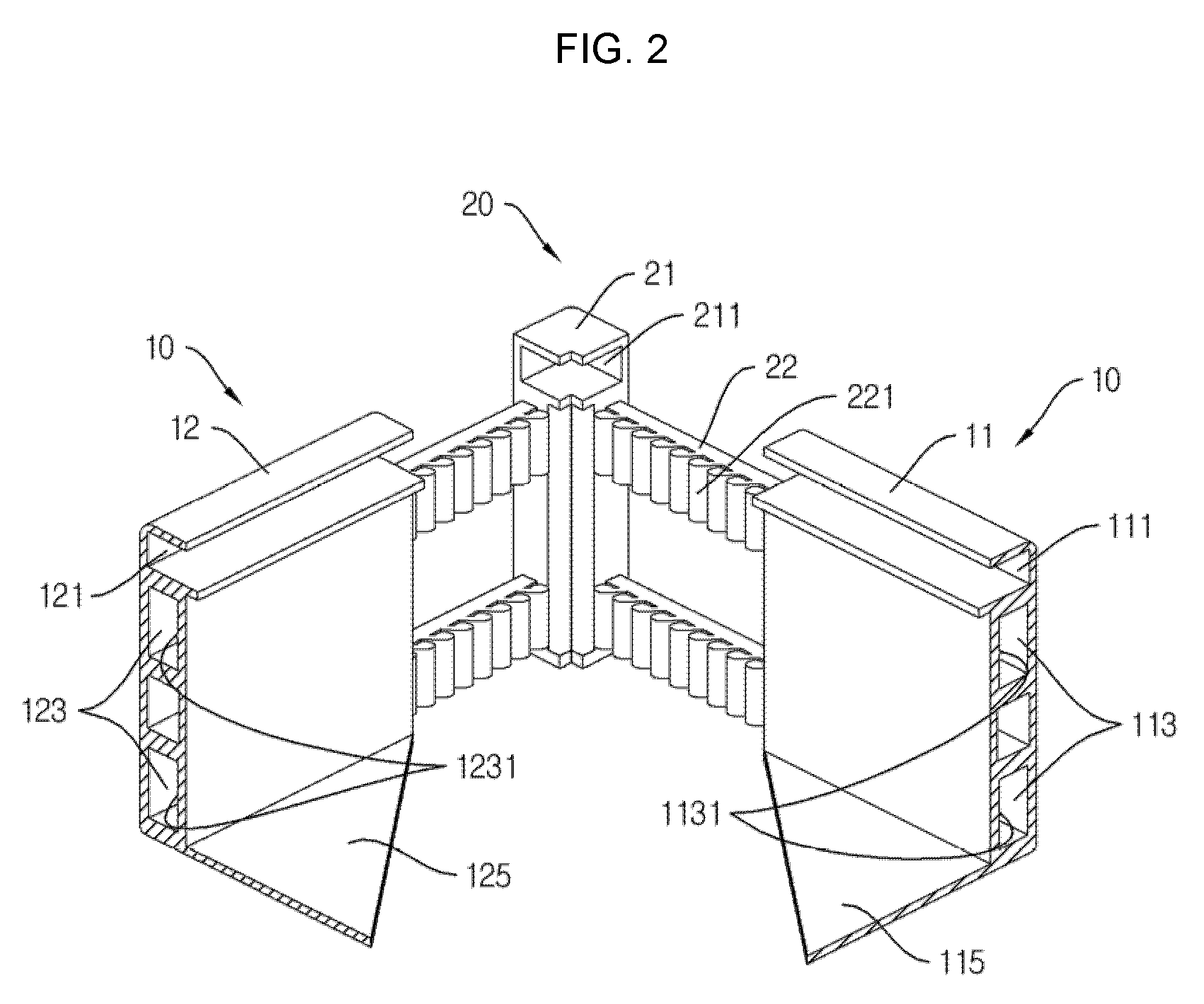

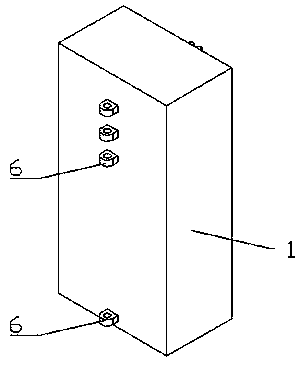

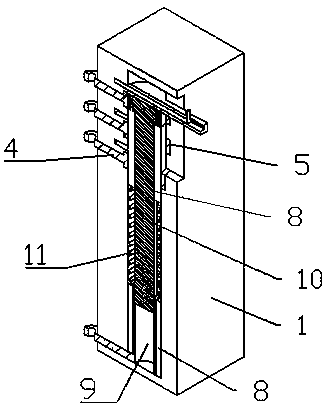

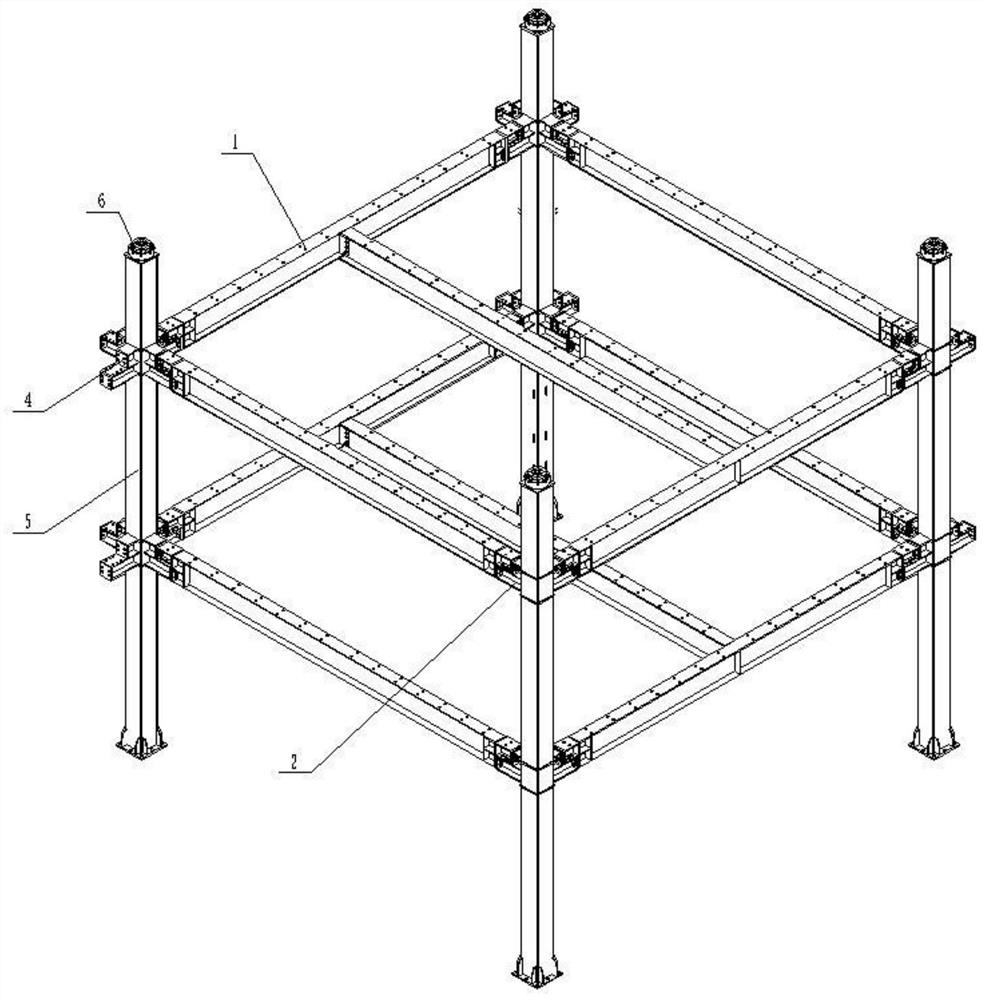

Fabricated building main body frame structure

PendingCN112900625AAccurate and stable connectionGuaranteed connection qualityFloorsCruciformChinese characters

The invention discloses a fabricated building main body frame structure. The problem of frame beam column splicing in large-scale assembly is solved, the connecting quality is ensured, and the assembly efficiency is improved. According to the technical scheme, the fabricated building main body frame structure is characterized in that a cross-shaped joint structure is located at the center of a Chinese character 'Tian', L-shaped joint structures are located at the four corners of the Chinese character 'Tian', T-shaped joint structures are located in the middles of the side edges of the Chinese character 'Tian', and cross beams are connected between the L-shaped joint structures and the T-shaped joint structures and between the T-shaped joint structures and the cross-shaped joint structure; and the upper end and the lower end of a cylindrical frame body are sleeved with stand columns, the stand columns are limited by supporting tables, stand column connecting joints are arranged on the stand columns at intervals, each stand column connecting joint comprises a mother joint, a child joint, a plurality of F-shaped buckles and a plurality of inclined wedges, the mother joints and the child joints are connected into a whole in an embedded and locked mode through the F-shaped buckles and the inclined wedges, and the outer end faces of the mother joints and the outer end faces of the child joints are fixedly connected with beams or columns to be connected.

Owner:山西宏厚装配式建筑科技发展有限公司

Actuator unit for controlling hydraulic pump

ActiveUS20170307075A1Simple configurationAccurate and stable connectionGearing controlFluid gearingsValve actuatorHydraulic pump

An HST control mechanism includes a rotary member, a servo unit, a telescopic member, and a biasing device. The rotary member for controlling a displacement of a hydrostatic transmission (HST) is pivoted outside of a casing incorporating the HST. The servo unit includes a telescopically movable actuator and a valve controlling the telescopic movement of the actuator. The actuator is interlockingly connected to the rotary member. The servo unit is pivotally supported on the casing via a first pivot. The servo unit rotates centered on the first pivot as the rotary member rotates according to the telescopic movement of the actuator hydraulically controlled by the valve. The telescopic member is pivotally supported on the casing via a second pivot. The telescopic member is provided with the biasing device that biases the telescopic member and the rotary member toward a position corresponding to a neutral state of the HST.

Owner:KANZAKI KOKYUKOKI MFG

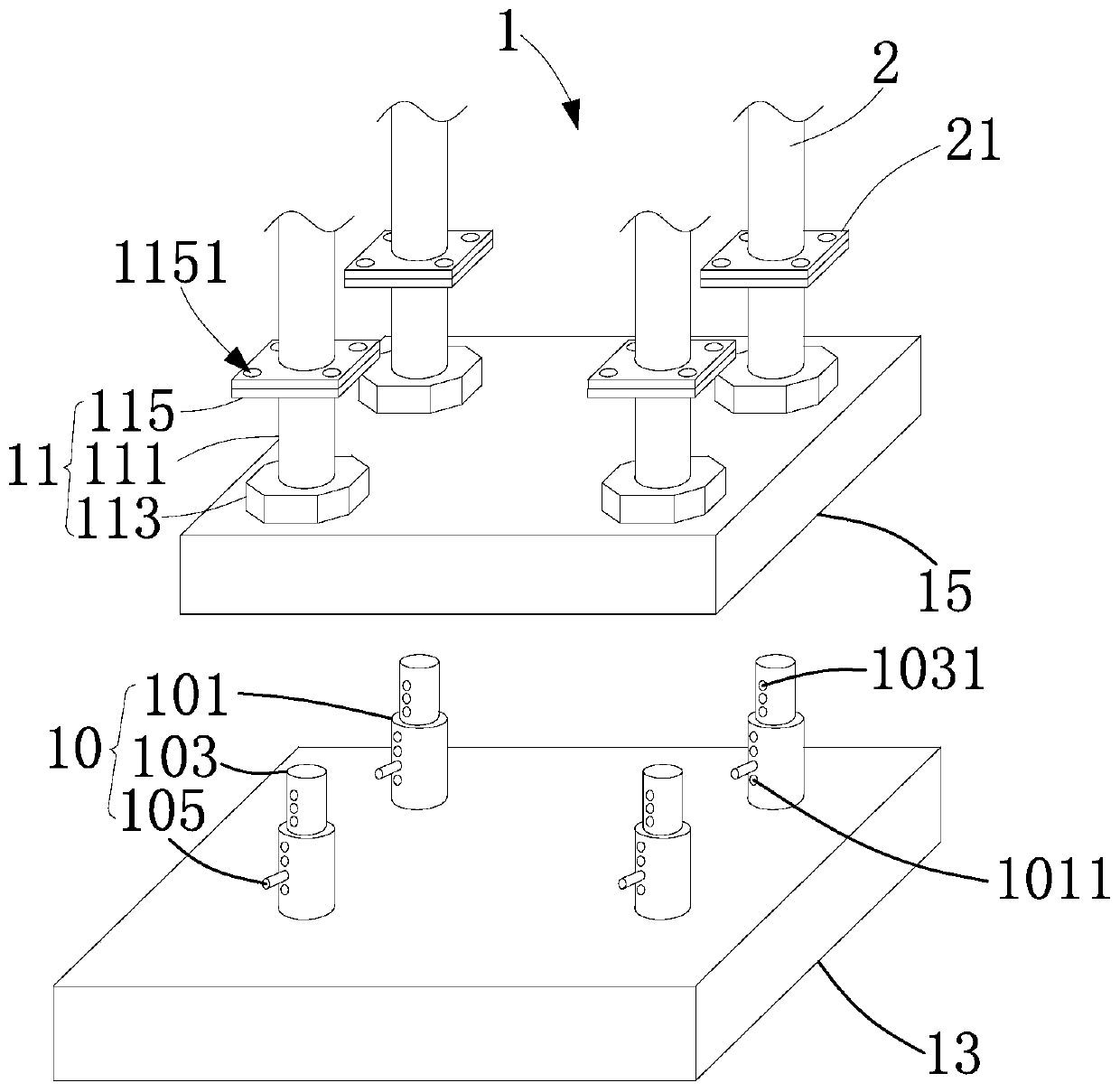

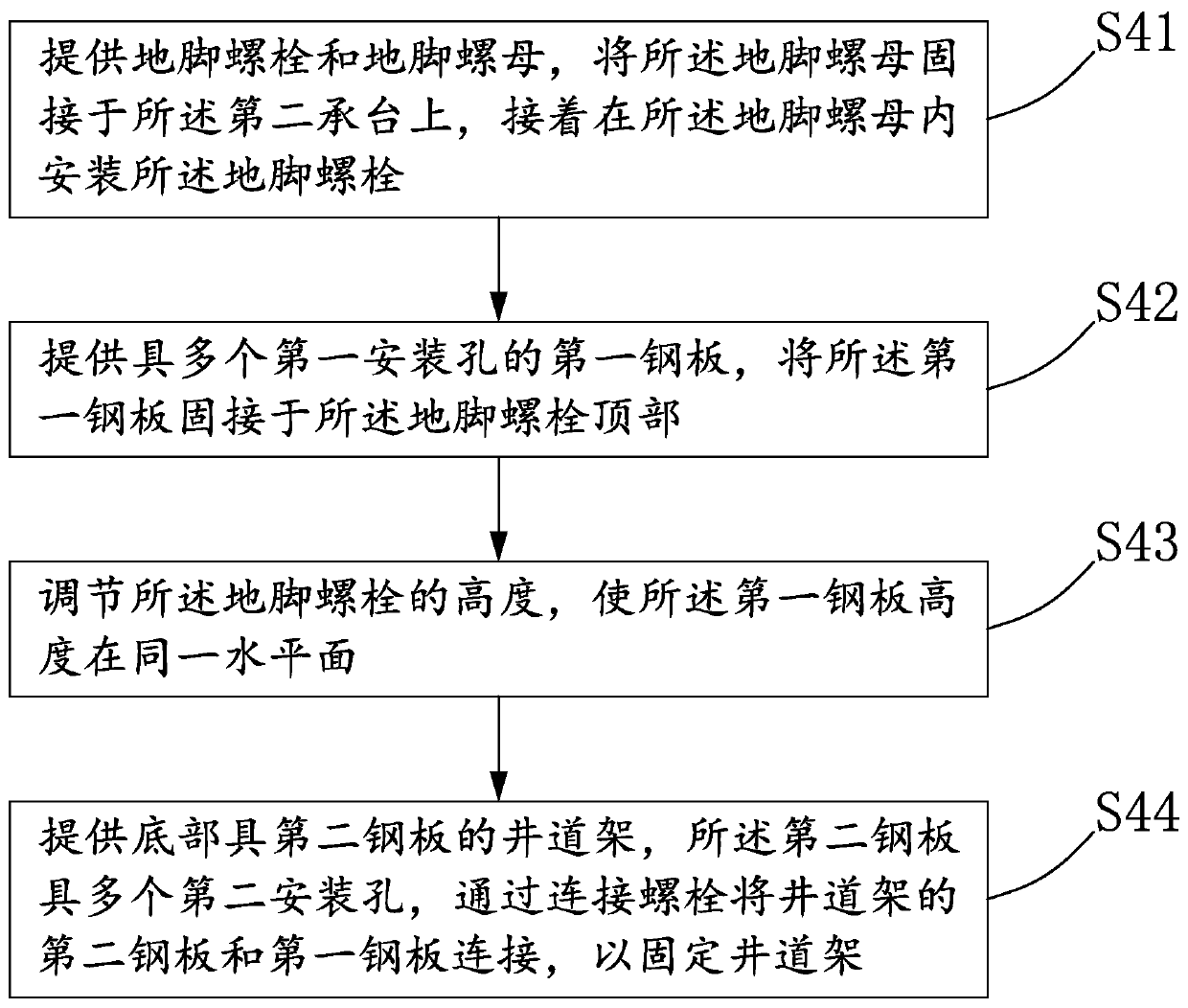

Pit structure installation method

ActiveCN106499048BAdjust levelAccurate and stable connectionCellarsStructural engineeringSurface cover

Owner:ZHEJIANG CANYUAN HOME TEXTILE

Connecting structure for short joint and used for fuel cell system

PendingCN110985779ALocking pressure equalizationImprove the tightnessSleeve/socket jointsReactant parameters controlAdhesive glueStructural engineering

The invention discloses a connecting structure for a short joint and used for a fuel cell system, relates to the technical field of sealed connecting structures of vehicle fuel cell systems, and solves the problems of low fastening degree and poor durability in the prior art. The connecting structure comprises a first connector and a second connector, and further comprises a sealing connector, thesealing connector comprises an inner sleeve and an outer sleeve, a plug-in slot is formed between the inner sleeve and the outer sleeve, the first connector is in inserted connection within the innersleeve, the second connector is in inserted connection within the plug-in slot, and a locking piece is arranged on the outer side of the sealing connector. The connecting structure is reasonable in structure and reliable in connection, the two joints can be firmly connected, the fastening degree is high, the durability and the sealing performance are high, and the possible aging problem of glue after using of the glue is avoided.

Owner:GUANGXI YUCHAI MASCH CO LTD

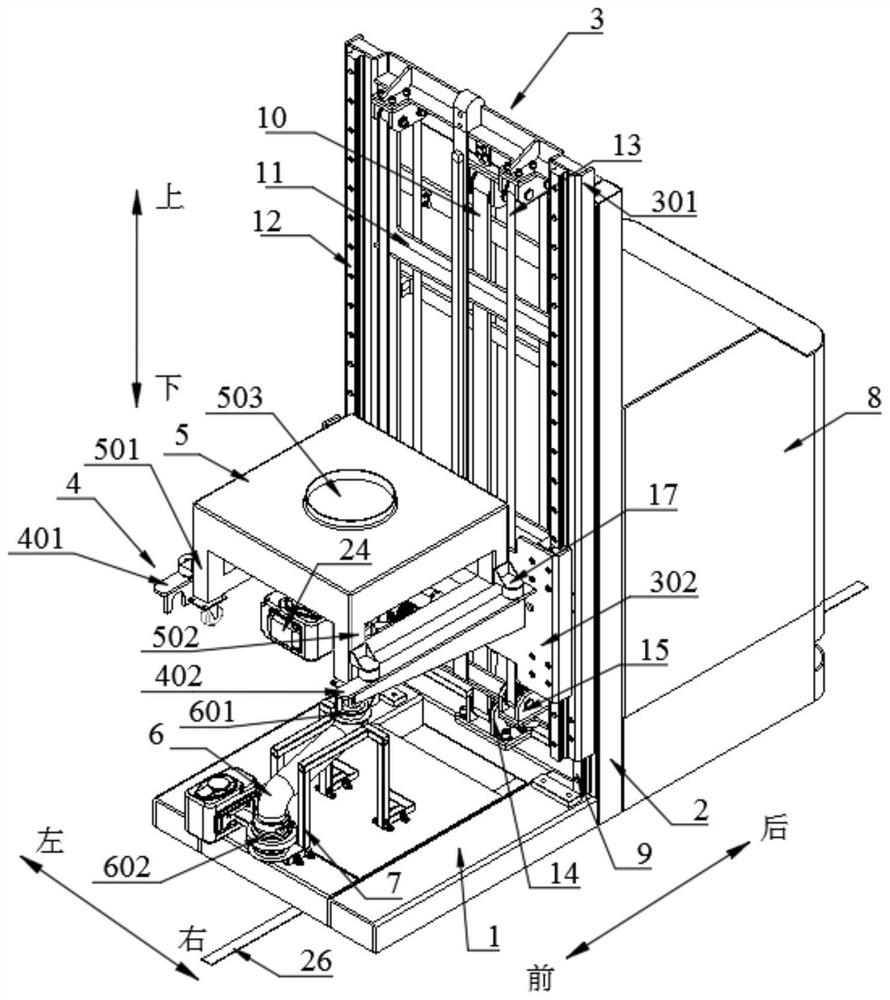

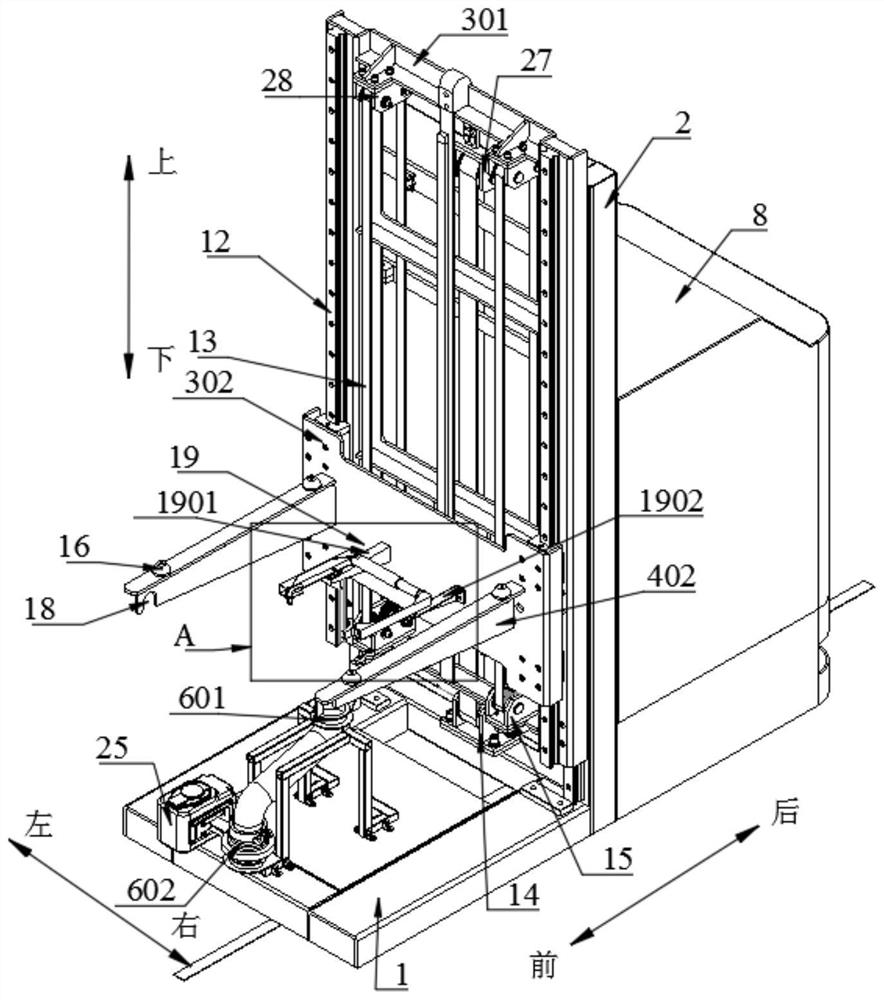

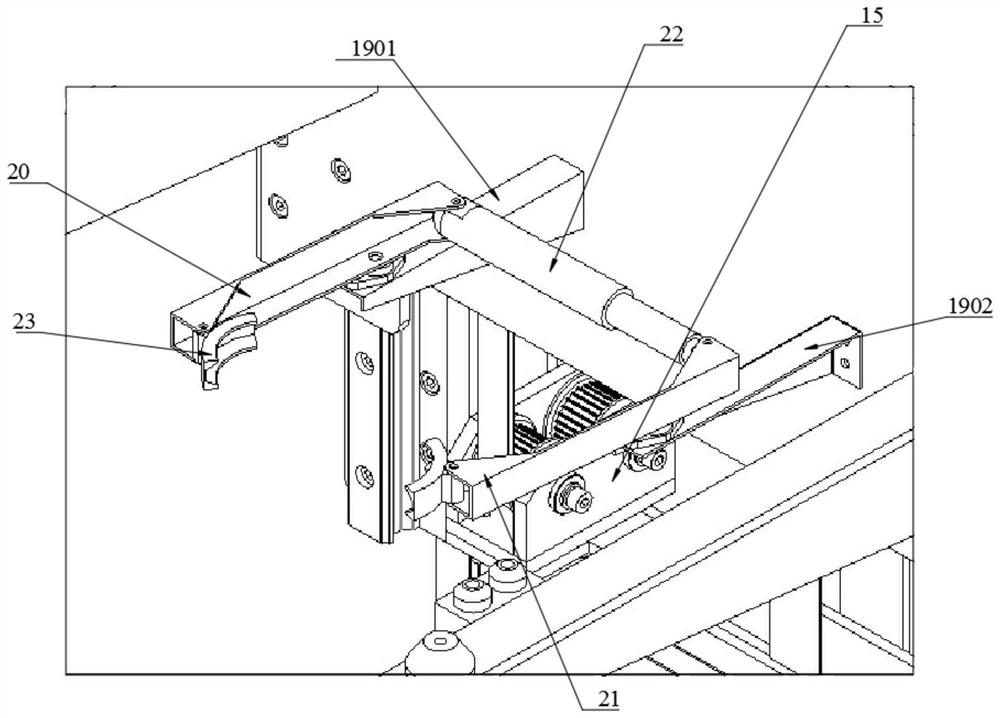

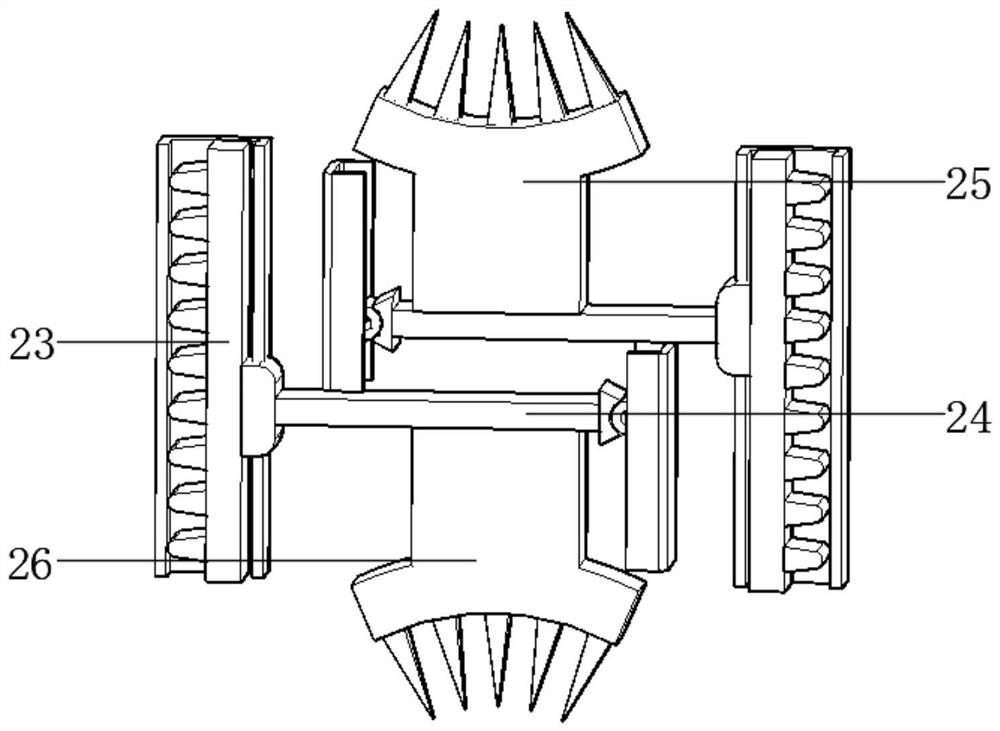

A material transfer device

ActiveCN111717612BIncrease working radiusIncrease heightControl devices for conveyorsLifting devicesParticulatesDrive wheel

The invention relates to a material transfer device. The device includes a transfer platform, a lifting mechanism, a fork, a material transfer mechanism and an electrical control module. A driving wheel for walking and a supporting wheel for supporting are arranged under the transfer platform. The driving wheel consists of Driven by a power source; the lifting mechanism is telescopically arranged in the vertical direction and includes a fixed part and a climbing part. The fixed part is vertically installed on the upper end of the transfer platform, and the climbing part is slidingly connected to the fixed part; The transmission mechanism includes a transfer material barrel arranged on the fork and a feeding pipe arranged under the fork. The transfer material barrel is provided with a material inlet and a material outlet. The feeding pipe is fixed on the transfer platform through the first bracket. The feeding pipe A first opening and a second opening are provided, and the first opening is located directly below the discharge port. The invention can realize automatic transfer of granular materials, reduce labor intensity, improve work efficiency, avoid dust pollution, and improve work environment quality.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

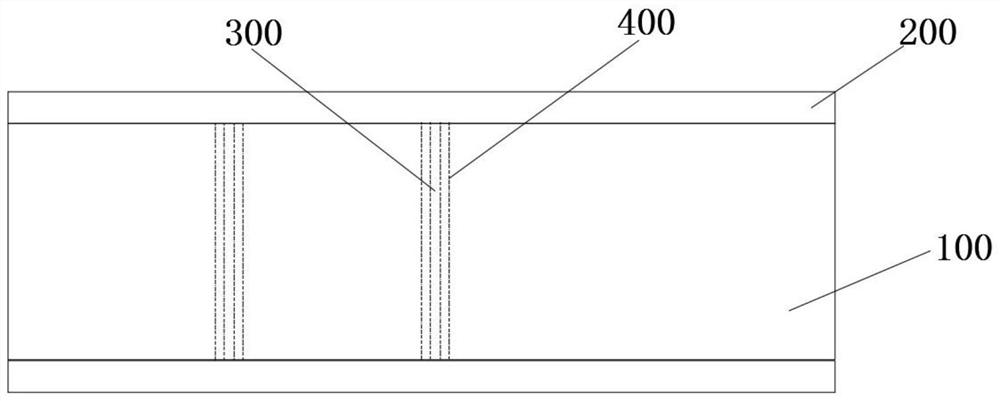

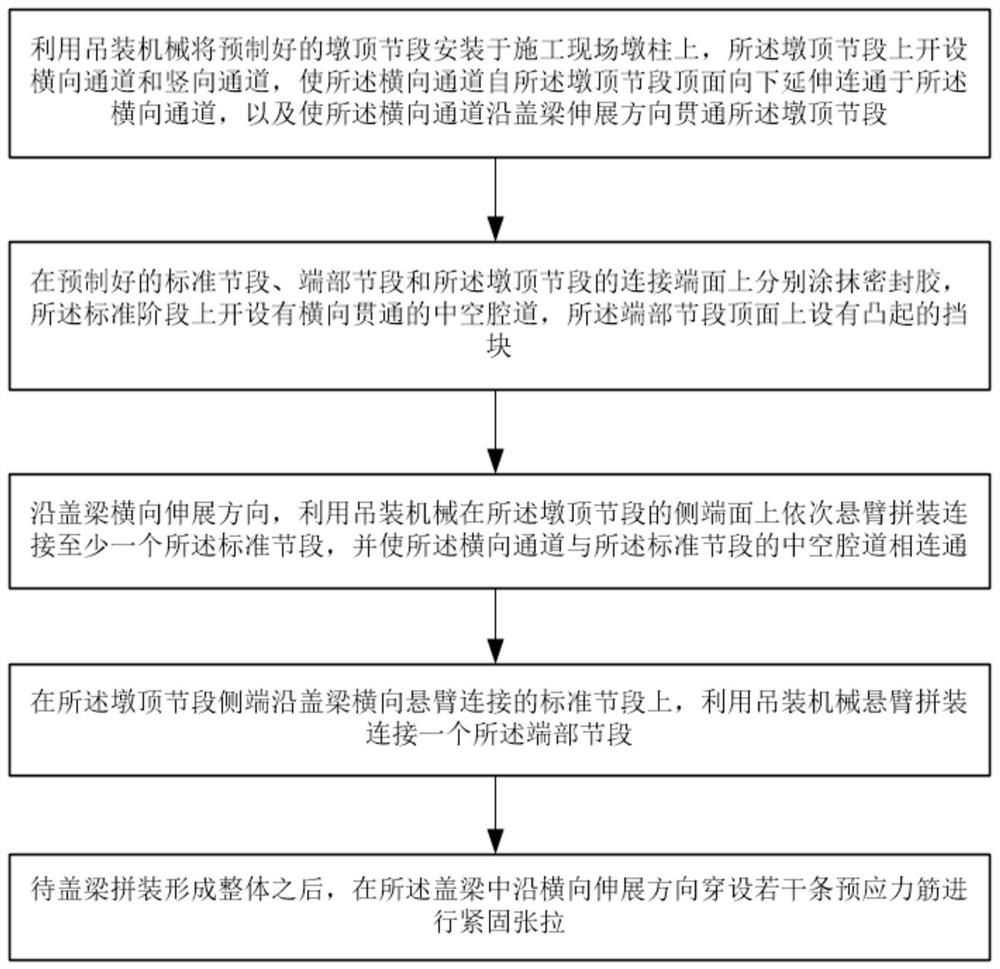

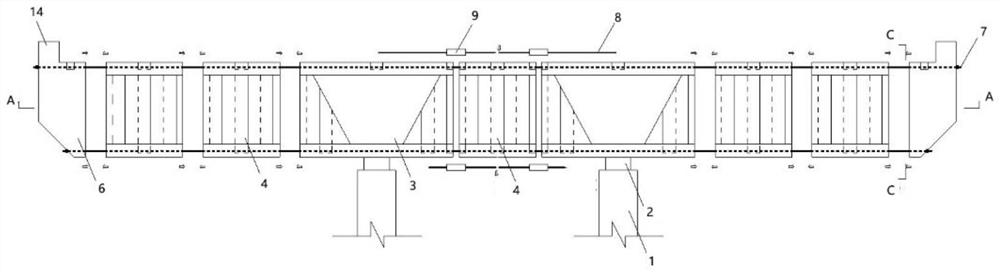

Assembling process of light segment prefabricated assembling bent cap

The invention discloses an assembling process of a light segment prefabricated assembly bent cap, which belongs to the technical field of bent cap construction, and comprises the following steps of: mounting a prefabricated pier top segment on a pier column on a construction site by using a hoisting machine, respectively smearing sealant on the connecting end surfaces of a prefabricated standard segment, an end segment and the pier top segment, and sealing the prefabricated standard segment, the end segment and the pier top segment; in the transverse extending direction of the bent cap, at least one standard section is sequentially spliced and connected to the side end face of the pier top section in a cantilever mode through a hoisting machine, and the transverse channel communicates with a hollow cavity channel of the standard section; splicing and connecting an end section on a standard section which is connected with the side end of the pier top section along a transverse cantilever of the bent cap by utilizing a hoisting mechanical cantilever; and after the bent cap is assembled into a whole, arranging a plurality of prestressed tendons in the bent cap in a penetrating mode in the transverse stretching direction for fastening and tensioning. According to the assembling process, the light prefabricated sections are adopted, a large number of supporting frames and formworks do not need to be adopted, and the weight of each section and dependence on heavy machinery are reduced.

Owner:JSTI GRP CO LTD +1

Surface shallow buried pipe connection structure

ActiveCN104405976BQuick connectionSimple structureSleeve/socket jointsCorrosion preventionElastic compressionEngineering

The invention discloses a shallowly-buried-in-surface type pipe connection structure. The structure comprises a pipe connection piece and a buried pipe, wherein the buried pipe is a double-layer metal pipe and comprises an inner pipe and an outer pipe; the outer pipe sleeves the outer edge of the inner pipe; the inner pipe is a steel pipe; the outer pipe is a copper-chromium alloy pipe; the inner wall of the inner pipe is coated with an anti-corrosion resin coating; a progressive protrusion part is arranged at the outer edge of the end part of the outer pipe, gradually extends outwards from a position, and is progressively protruded to the end part all the time, and certain distance exists between the position and the end part; the pipe connection piece at least comprises a tight holding piece and an elastic compression ring; the tight holding piece is of an opening ring shape, and the section of the tight holding piece is of a U shape shown as a figure; the elastic compression ring is positioned at the inner edge of the tight holding piece; a first recess and a second recess are formed in the inner edge of the elastic compression ring. Therefore, the shallowly-buried-in-surface type pipe connection structure has the advantages of simple structure, convenience in mutual matching and convenience in operation; pipes can be quickly connected; moreover, the connection performance and the sealing performance of the pipes are better, so that the connection piece is prevented from being corroded and destroyed, and the service life is prolonged.

Owner:SINOHYDRO BEREAU 10 CO LTD

Pit structure installation method

ActiveCN106592623BEnsure stabilityPrevention of landslidesFoundation engineeringBuilding liftsStructural engineering

Owner:安徽亿力电力设备有限公司

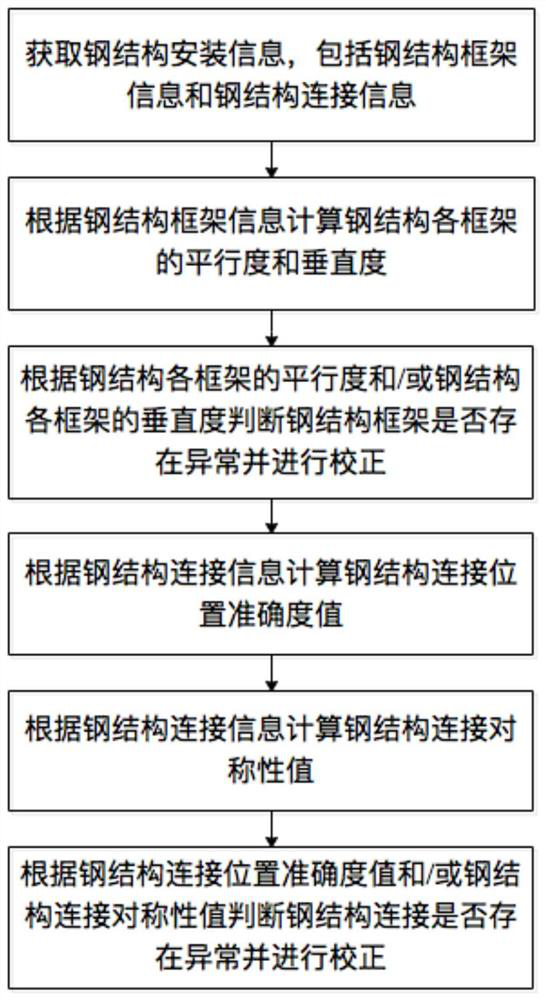

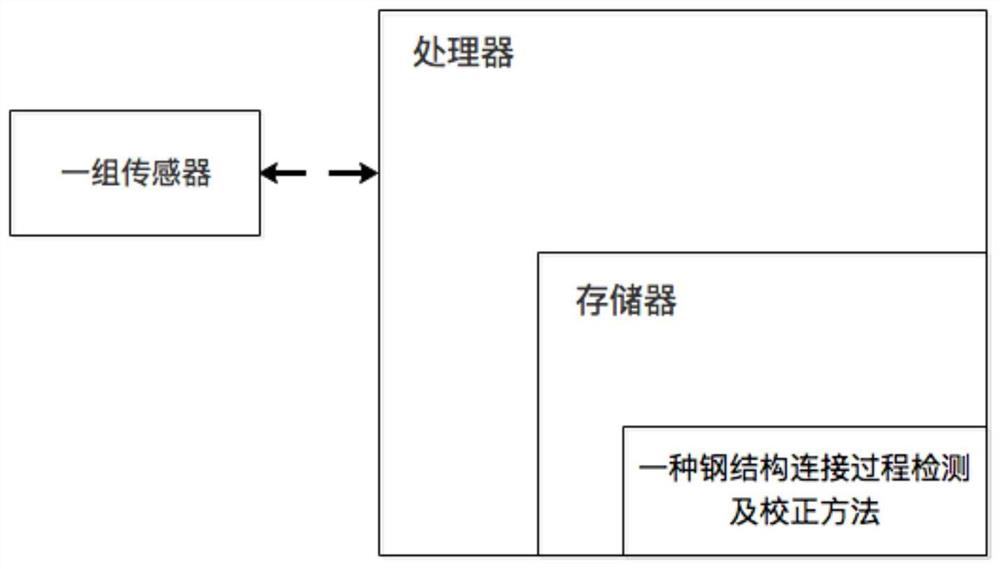

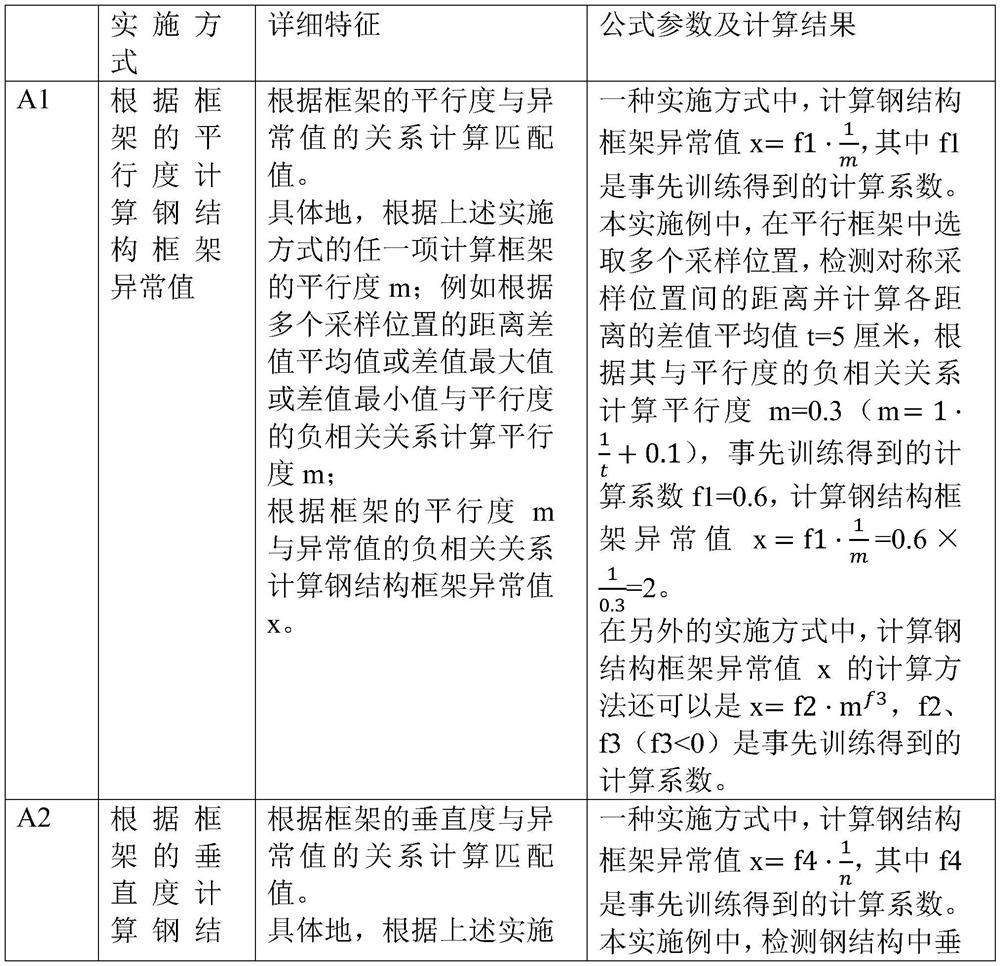

Steel structure connection process detection and correction method and system

InactiveCN112948918AEffectively reflect the connection relationshipEffective correctionGeometric CADDesign optimisation/simulationMechanical engineeringSteel structures

The invention discloses a steel structure connection process detection and correction method and system, and the method comprises the steps: obtaining steel structure installation information, which comprises steel structure frame information and steel structure connection information; calculating the parallelism and perpendicularity of each frame of the steel structure according to the frame information of the steel structure; according to the parallelism of each frame of the steel structure and / or the perpendicularity of each frame of the steel structure, judging and correcting whether the steel structure frame is abnormal or not; calculating a steel structure connection position accuracy value and a steel structure connection symmetry value according to the steel structure connection information; and judging whether the steel structure connection is abnormal or not according to the steel structure connection position accuracy value and / or the steel structure connection symmetry value, and correcting. The problem of how to detect and correct whether the relative position between the steel structure frames in the steel structure connection process is abnormal or not and whether the steel structure connection position is abnormal or not is solved.

Owner:HANGZHOU HOUBO TECH CO LTD

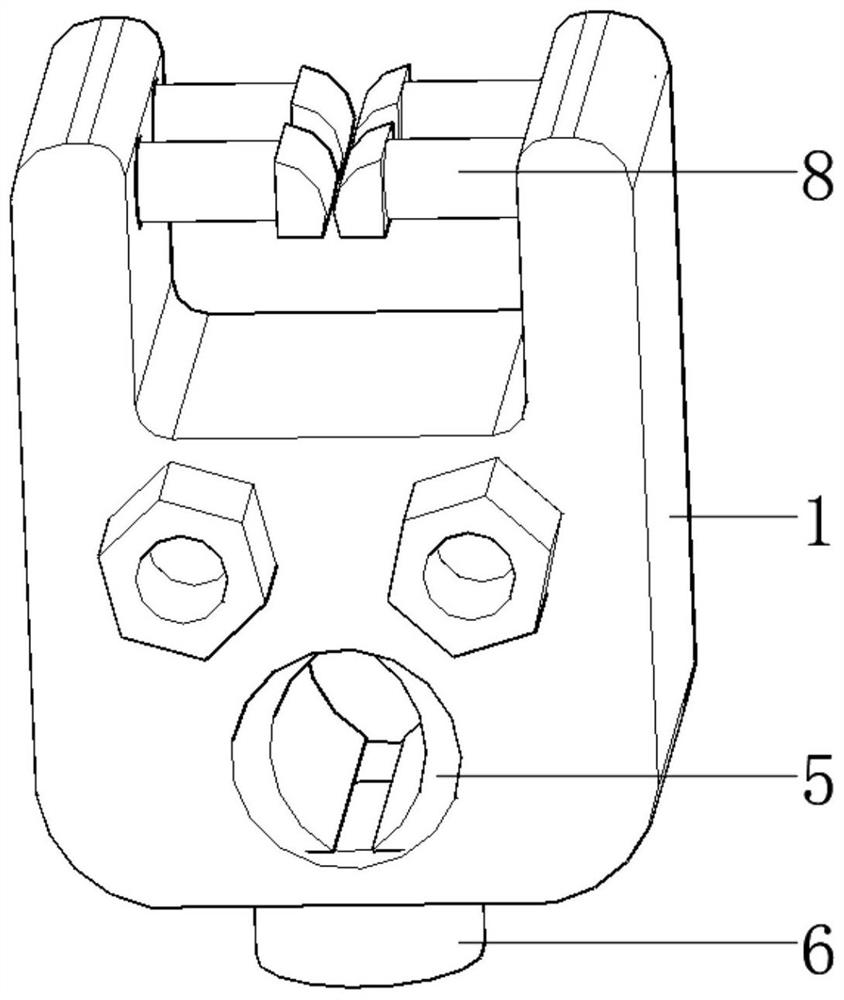

Puncture wire clamp and method for overhauling overhead power distribution equipment without power outage

InactiveCN113937518AImprove sealing and waterproof performanceQuick and stable installationOverhead installationElectrically conductive connectionsElectric power equipmentEngineering

The invention relates to the technical field of power equipment, and discloses a puncture wire clamp for overhauling overhead power distribution equipment without power outage The puncture wire clamp comprises a shell and a socket spanner, a branch wire groove is formed in the bottom of the shell, clamping grooves are formed in the left side and the right side of the bottom of the shell, and telescopic rods are fixedly connected in the clamping grooves; a crescent plate is fixedly connected to the end, close to the branch wire groove, of the telescopic rod, a mounting block is fixedly connected to the bottom end of the shell, stop levers are fixedly connected to the interiors of the left side and the right side of the top end of the shell, touch plates are fixedly connected to the ends, close to the interior, of the stop levers, and the main wire groove is formed in the top of the shell.Through the action of the stop levers, the contact plate and the return spring, the installation is more stable and quick. When the bolt is screwed, the rotating wheel can drive the upper bayonet teeth to pierce the insulating layer of the main wire upwards and drive the lower bayonet teeth to pierce the insulating layer of the branch wire downwards, meanwhile, silicone grease in the air bag and the piston chamber can be squeezed into the main wire groove and the branch wire groove respectively, and waterproof sealing treatment is conducted on the main wire and the branch wire respectively.

Owner:李玉常

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com