Shakeproof lift-preventing anti-bending preformed pile and manufacturing process of preformed pile

A prefabricated pile and prestressed technology, applied in sheet pile wall, foundation structure engineering, reinforcement forming, etc., can solve problems such as endangering the safety of buildings, people's lives and property, impact on the integrity of piles, falling off of prefabricated piles, etc. Influenced by unfavorable factors, convenient and fast installation, accurate and firm connection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Below in conjunction with accompanying drawing, the present invention will be further described:

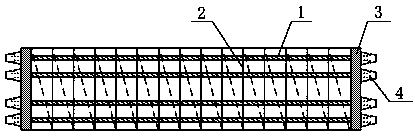

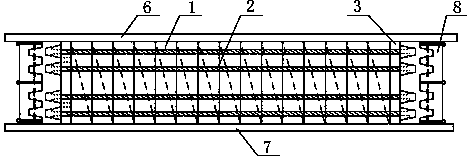

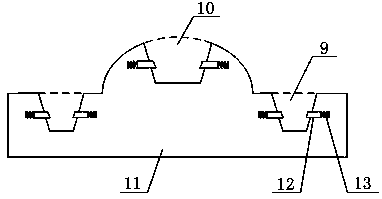

[0037] An anti-seismic, pullout, and bending-resistant prefabricated pile, the prefabricated pile is a hollow structure, a top connector 11 is arranged at the top of the prefabricated pile, a bottom connector 28 is arranged at the bottom of the prefabricated pile, and a transition connector 16 is arranged between adjacent prefabricated piles, When piling, the top of the prefabricated pile is provided with a piling connector 8; the prefabricated pile includes a number of prestressed main reinforcement 1, concrete, end plates 3 on both sides and a round platform 4 matched with the prestressed main reinforcement, and the prestressed main reinforcement 1 is evenly arranged in the prefabricated pile , the adjacent prestressed main reinforcement 1 is surrounded by the stirrup 2 to form a circle, and concrete is filled around the prestressed main reinforcement and the stirrup to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com