Pit structure installation method

An installation method and pit technology, which are used in infrastructure engineering, transportation and packaging, construction, etc., can solve problems such as rough and simple installation methods, unstable connections, and deviation errors, and achieve the elimination of hidden safety hazards, prevention of landslides, The effect of reducing the offset error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below with reference to the drawings and embodiments.

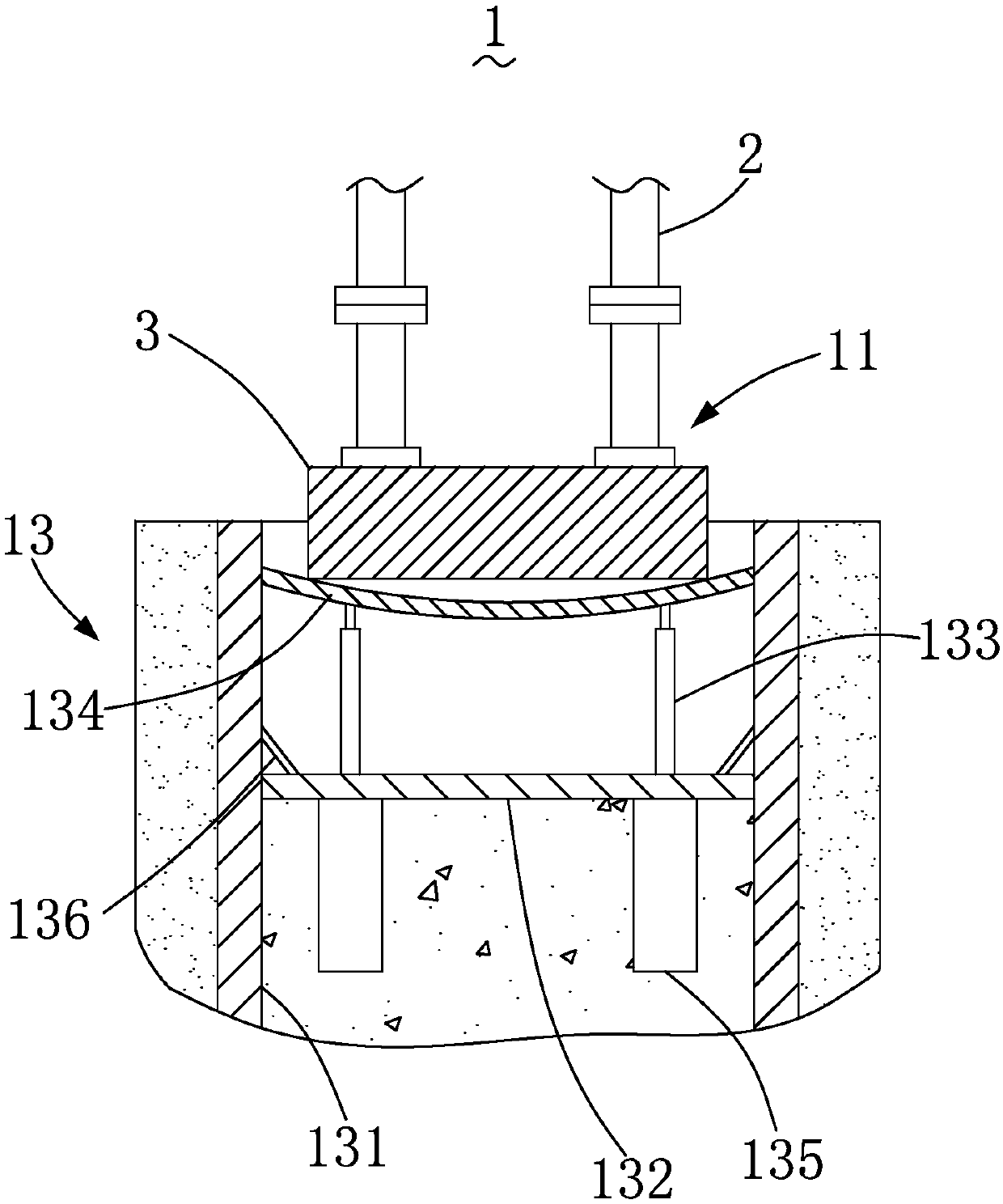

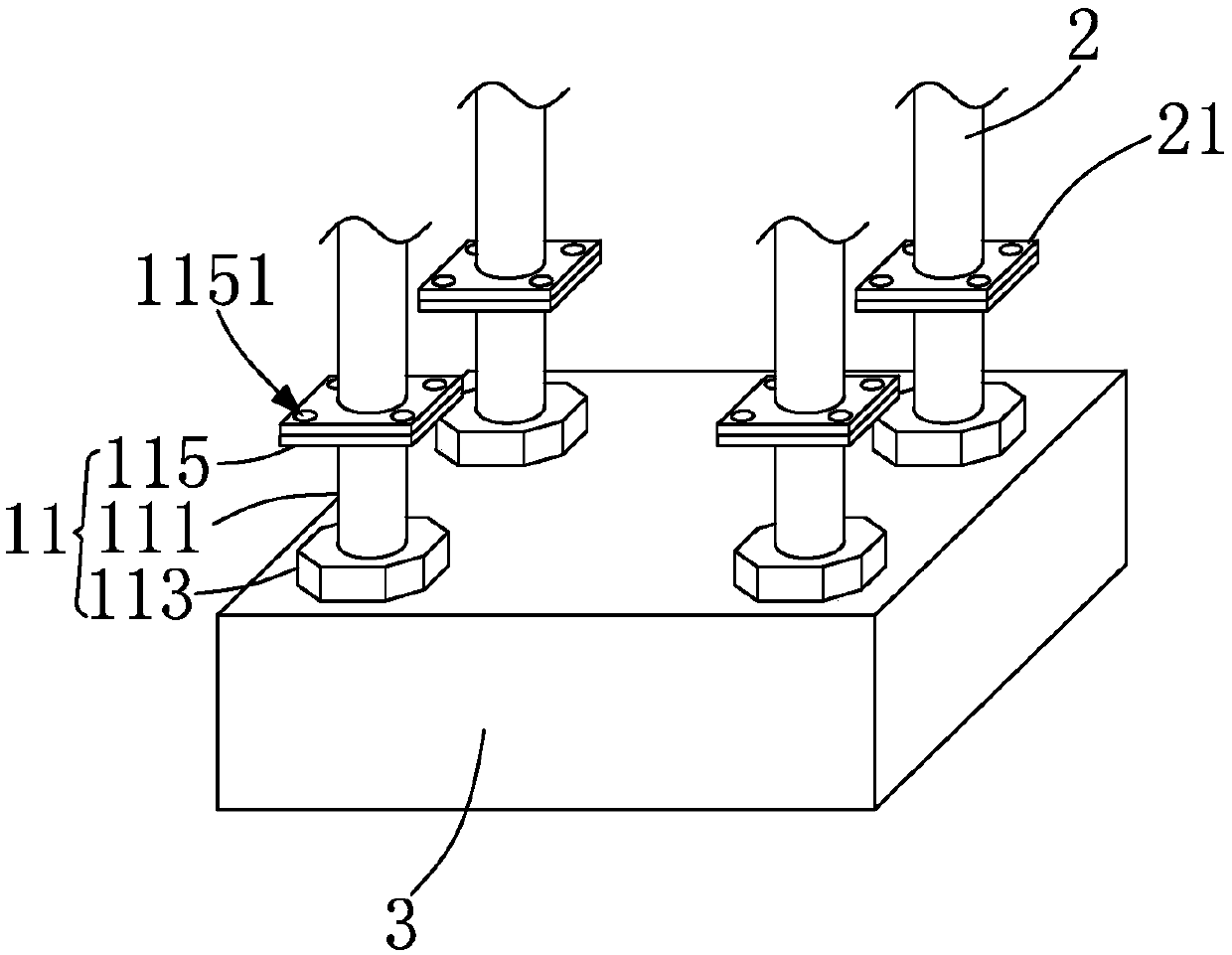

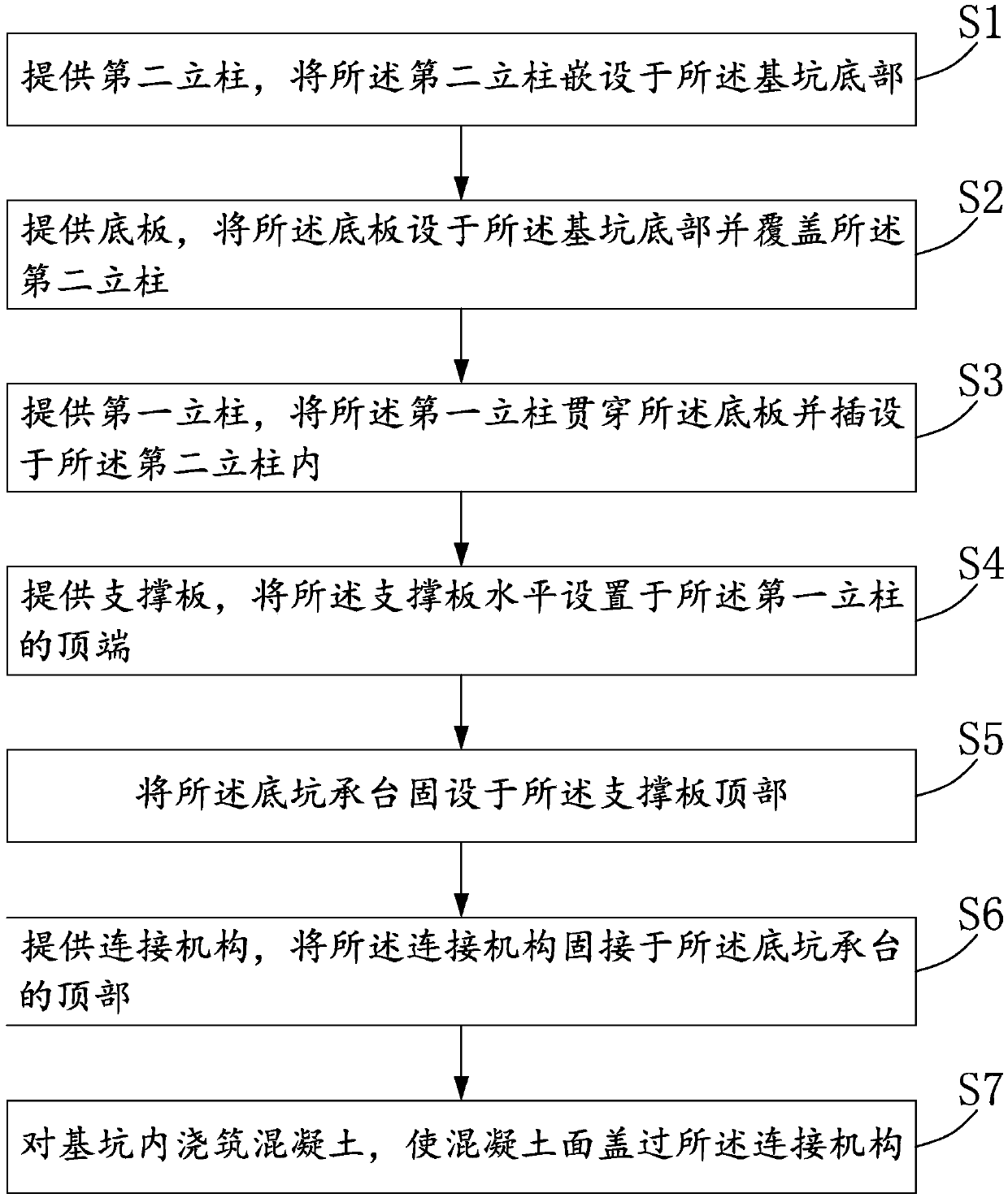

[0034] See figure 1 , Is a flow chart of the steps of the method for installing the pit structure of the present invention. The method for installing the pit structure includes the following steps of fixing the pit cap and connecting the hoistway frame through a fixing mechanism provided at the bottom of the pit cap and a connecting mechanism provided at the top of the pit cap :

[0035] Step S1, providing a second upright post, and embedding the second upright post on the bottom of the foundation pit;

[0036] Step S2, providing a bottom plate, and setting the bottom plate at the bottom of the foundation pit and covering the second upright post;

[0037] Step S3, providing a first upright post, and inserting the first upright post through the bottom plate and inserted into the second upright post;

[0038] Step S4, providing a supporting plate, and placing the supporting pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com