Surface shallow buried pipe connection structure

A shallow-buried, pipe connection technology, applied in sleeve/socket connections, pipes/pipe joints/fittings, pipeline protection, etc., can solve problems such as corrosion and sealing effects, achieve good connection and sealing performance, and avoid detachment , the effect of mutual cooperation and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

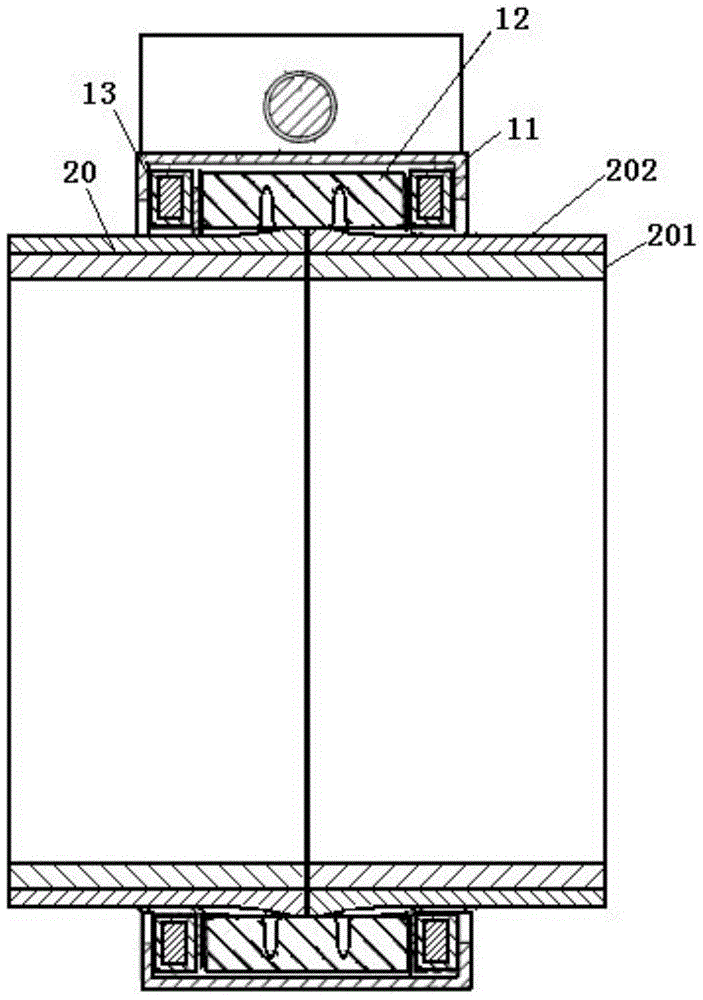

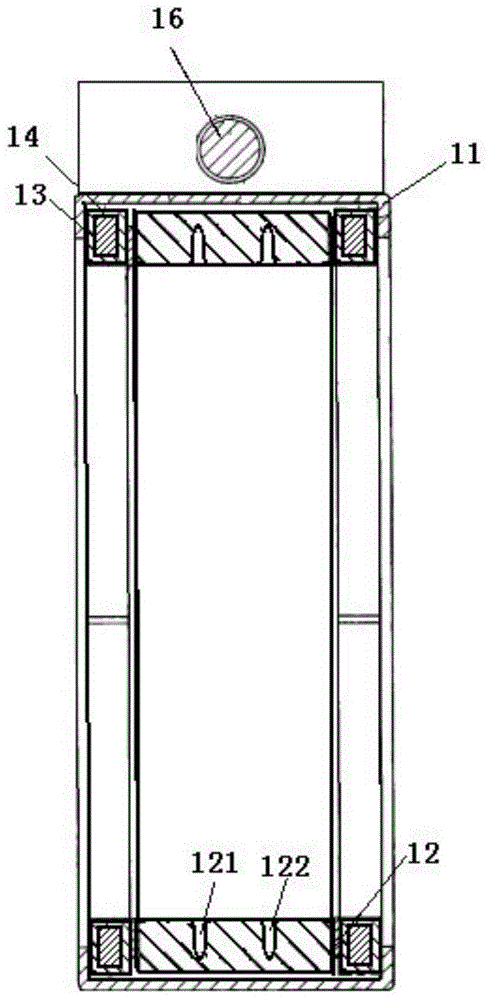

[0026] see figure 1 , shows the surface shallow buried pipe connection structure of the present invention.

[0027] The surface shallow-buried pipe connection structure mainly includes pipe connectors and buried pipes. The buried pipe 20 is a double-layer metal pipe, which includes an inner pipe 201 and an outer pipe 202 fitted on the outer edge of the inner pipe 201, wherein the The inner tube 201 can be a steel pipe, and the outer tube 202 is a copper-chromium alloy tube, so as to improve the corrosion resistance and wear resistance of the outer tube on the basis of maintaining the good elasticity of copper.

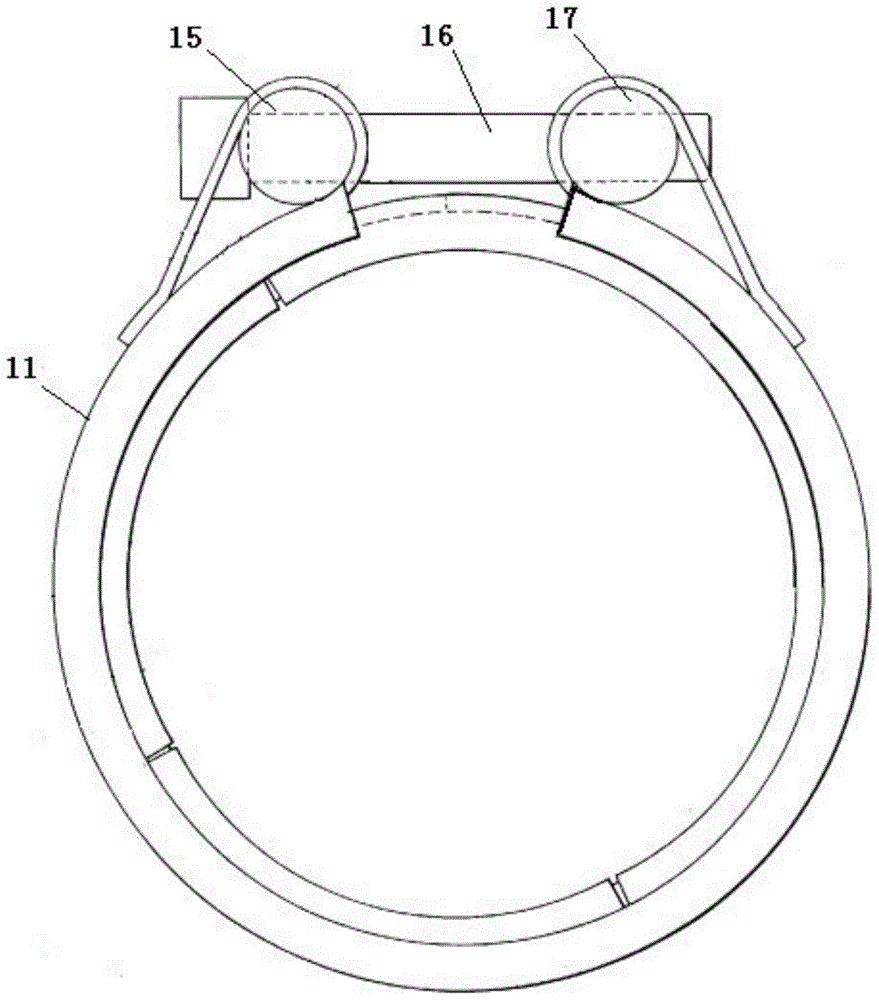

[0028] Wherein, the inner wall of the inner tube 201 is coated with an anti-corrosion resin coating, wherein, the outer edge of the end of the outer tube 202 is provided with a progressive protrusion, and the progressive protrusion gradually starts from a certain distance from the end. Extending vertically outwards, it is gradually raised to the end. The progressive r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com