Assembling process of light segment prefabricated assembling bent cap

A prefabricated assembly and segment technology, applied in the erection/assembly of bridges, bridges, bridge construction, etc., can solve the problems of high requirements, numerous construction procedures, and high hoisting costs, reduce the dependence of heavy machinery, and simplify the assembly operation. , Improve the effect of connection stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

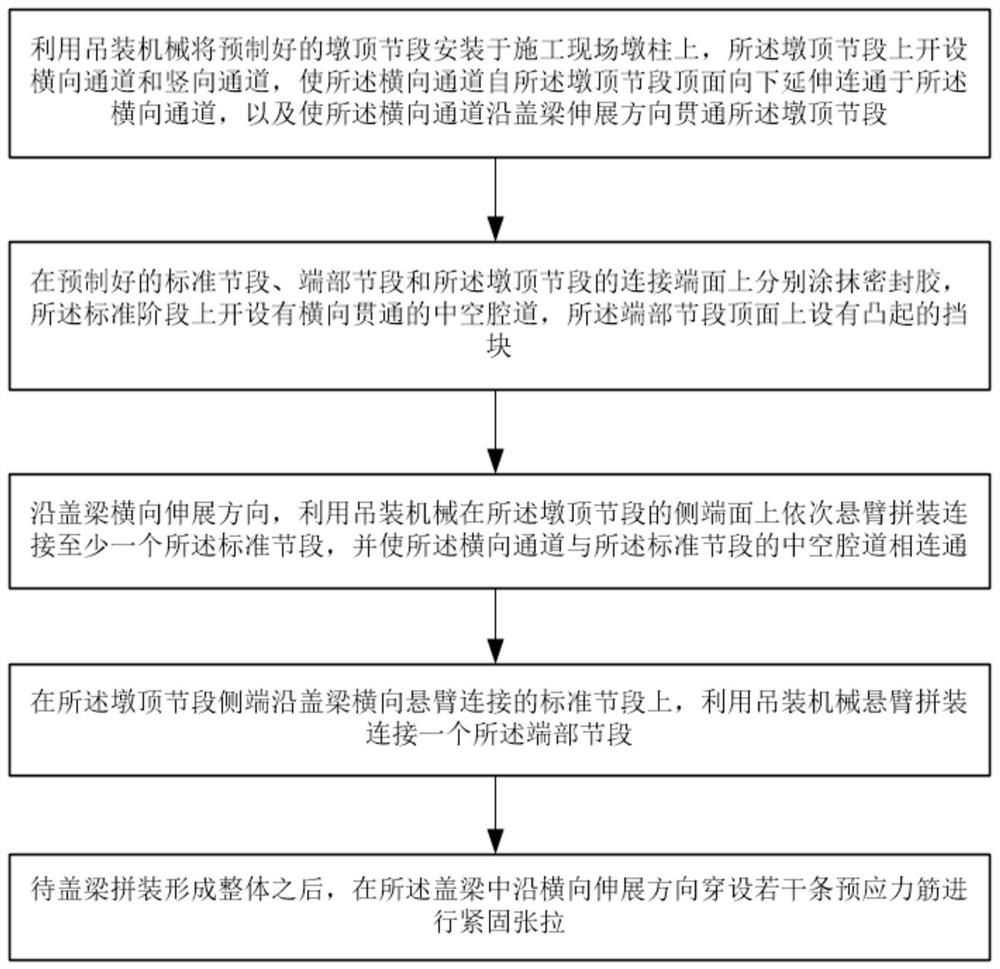

Method used

Image

Examples

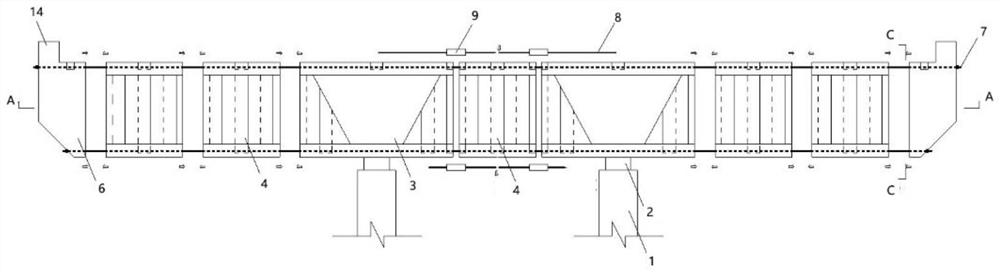

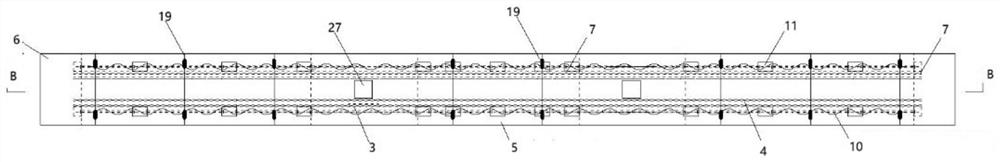

Embodiment 1

[0129] The single pier column 1 light section prefabricated assembled cover beam is assembled on site, and the specific operation process is as follows:

[0130] In the first step, the pier top section 3 is hoisted above the support 2 according to the construction requirements, and the sealant 19 is applied to the side ends of the concrete top plate and the concrete bottom plate of the pier top section 3;

[0131] At the same time, insert the finish-rolled threaded steel bar into the anchor hole 10 of the pier top section 3 connected with the anchor groove 11 of the pier top section 3 .

[0132] In the second step, the standard segments 4 are assembled symmetrically at both ends.

[0133] The specific steps are:

[0134] Use a small crane to lift the standard section 4 and move to the pier top section 3 from the left and right directions. Alignment of fine-rolled threaded steel rods;

[0135] When the standard section 4 is close to the pier top section 3, use anchor bolts t...

Embodiment 2

[0149] Based on the on-site assembly of light-duty segmental prefabricated assembled cap beams with multi-column piers, the specific operation process is as follows:

[0150] In the first step, refer to the on-site assembly steps of the top section 3 and the standard section 4 of the single-column pier light section cover beam pier in Example 1, until the symmetrical cantilever is assembled to the closing section 5.

[0151] In the second step, the finish-rolled threaded steel rods are placed symmetrically in the anchor holes 10 connected to the anchor grooves 11 on the standard segment 4 to be closed and the closed segment 5 respectively.

[0152] The third step is to use a small crane to vertically hoist the closing section 5 to the section to be closed, and use a steel sleeve 9 to connect the standard section 4 to be closed with the fine-rolled threaded steel rod in the gap groove 30 on the closing section 5 , use anchor bolts to fix the finish-rolled threaded steel rod in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com