Steel structure connection process detection and correction method and system

A technology of connection process and correction method, applied in special data processing applications, geometric CAD, design optimization/simulation, etc., can solve problems such as inability to effectively judge whether the relative position is abnormal, whether the position of the steel structure connection is abnormal, etc., to achieve accurate connection. And stable and effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The preferred embodiments of the present invention will be described in detail below.

[0050] The steel structure connection process detection and correction method of the present invention can be applied to different application scenarios, such as prefabricated building construction, traditional building construction, bridge and road repair and other scenarios, to obtain steel structure information in the construction area for different application scenarios in different ways.

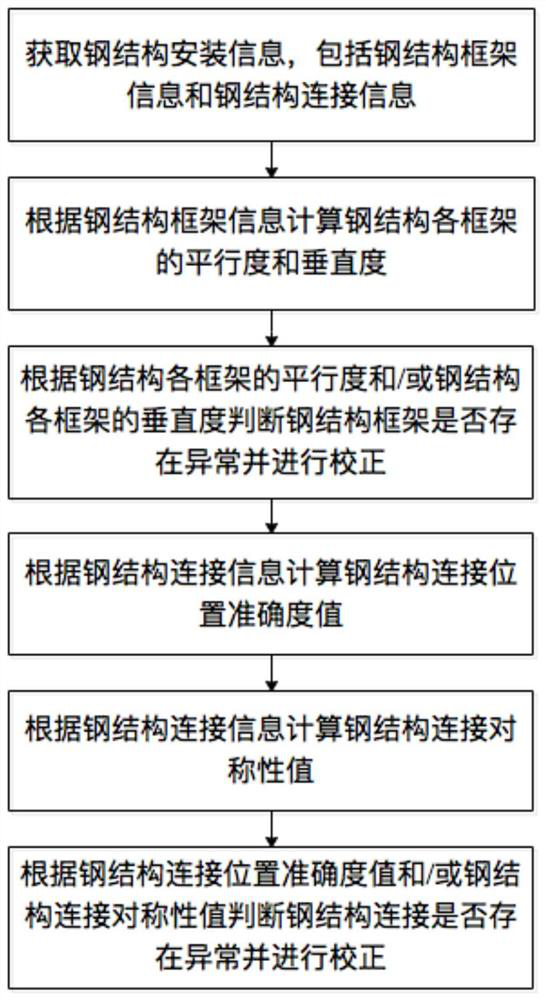

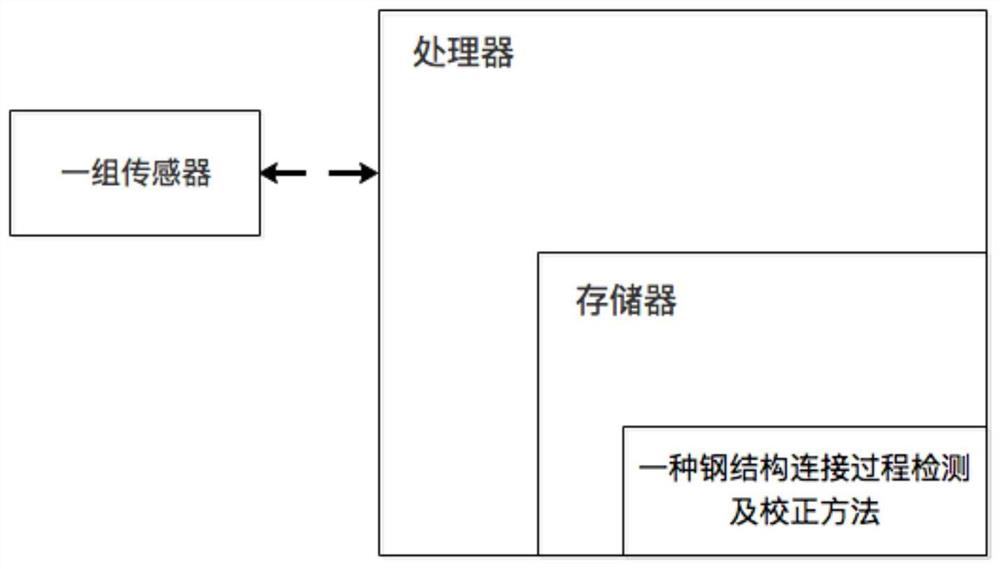

[0051] The embodiment of the steel structure connection process detection and correction method of the present invention is characterized in that:

[0052] Obtain steel structure installation information, including steel structure frame information and steel structure connection information;

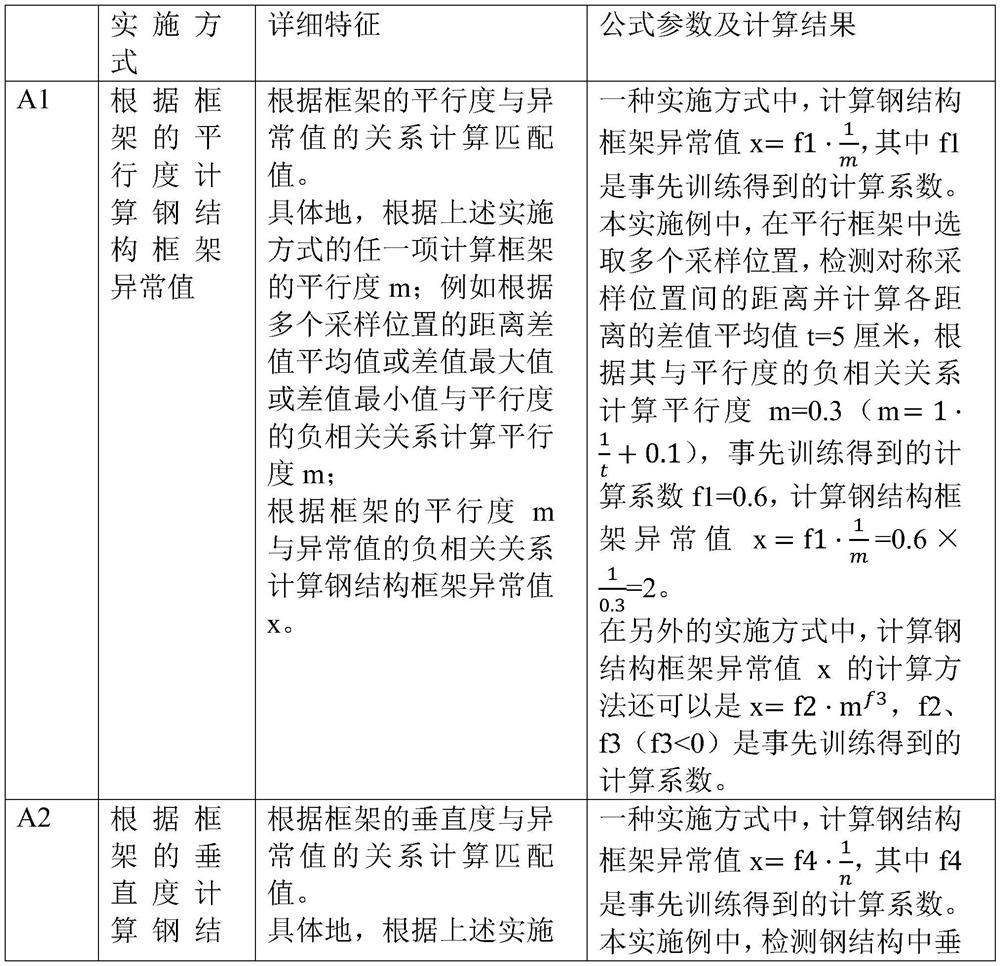

[0053] Calculate the parallelism and perpendicularity of each frame of the steel structure according to the information of the steel structure frame;

[0054] According to the parallelism of each frame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com