Patents

Literature

136results about How to "Corrected spherical aberration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

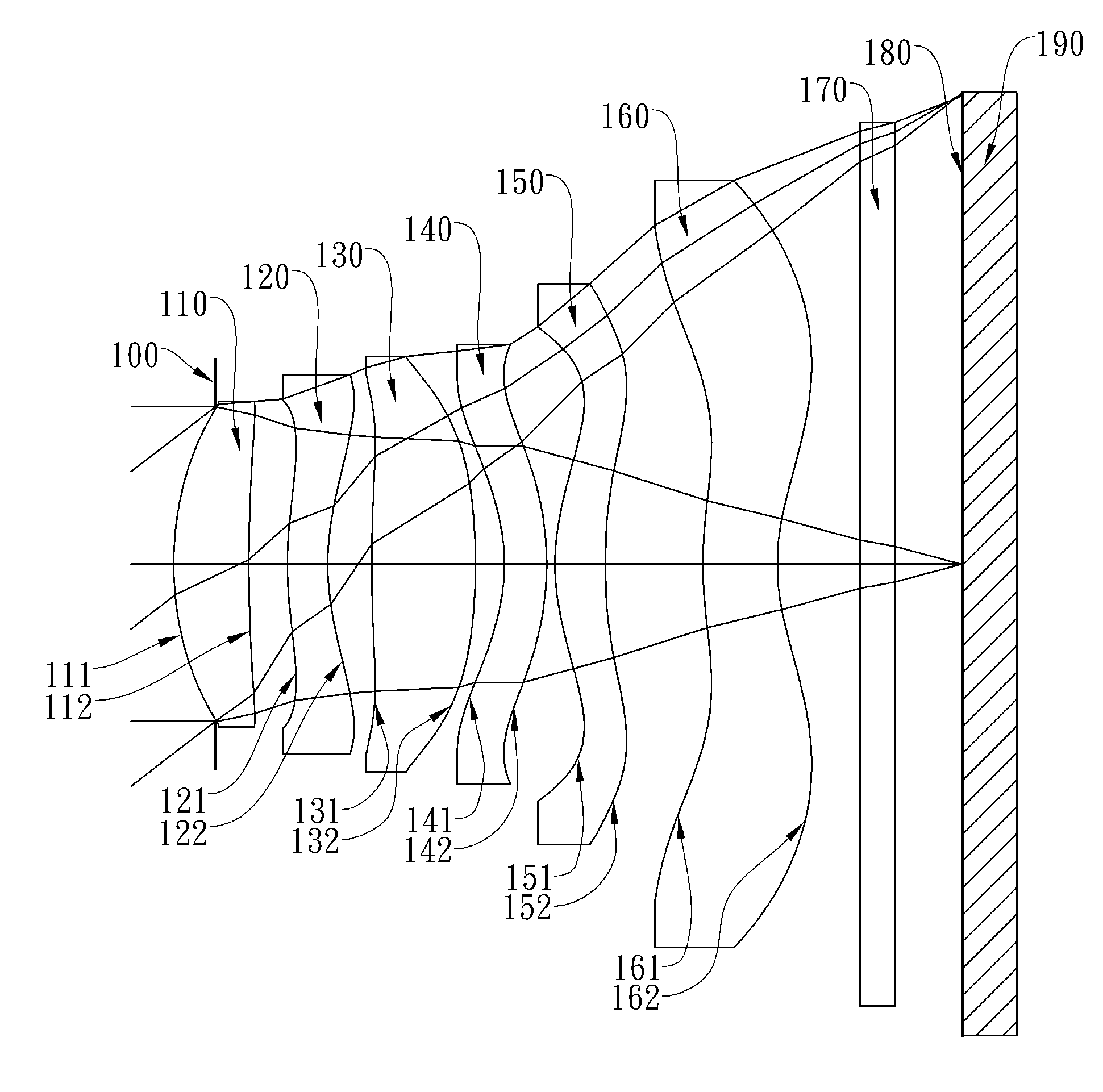

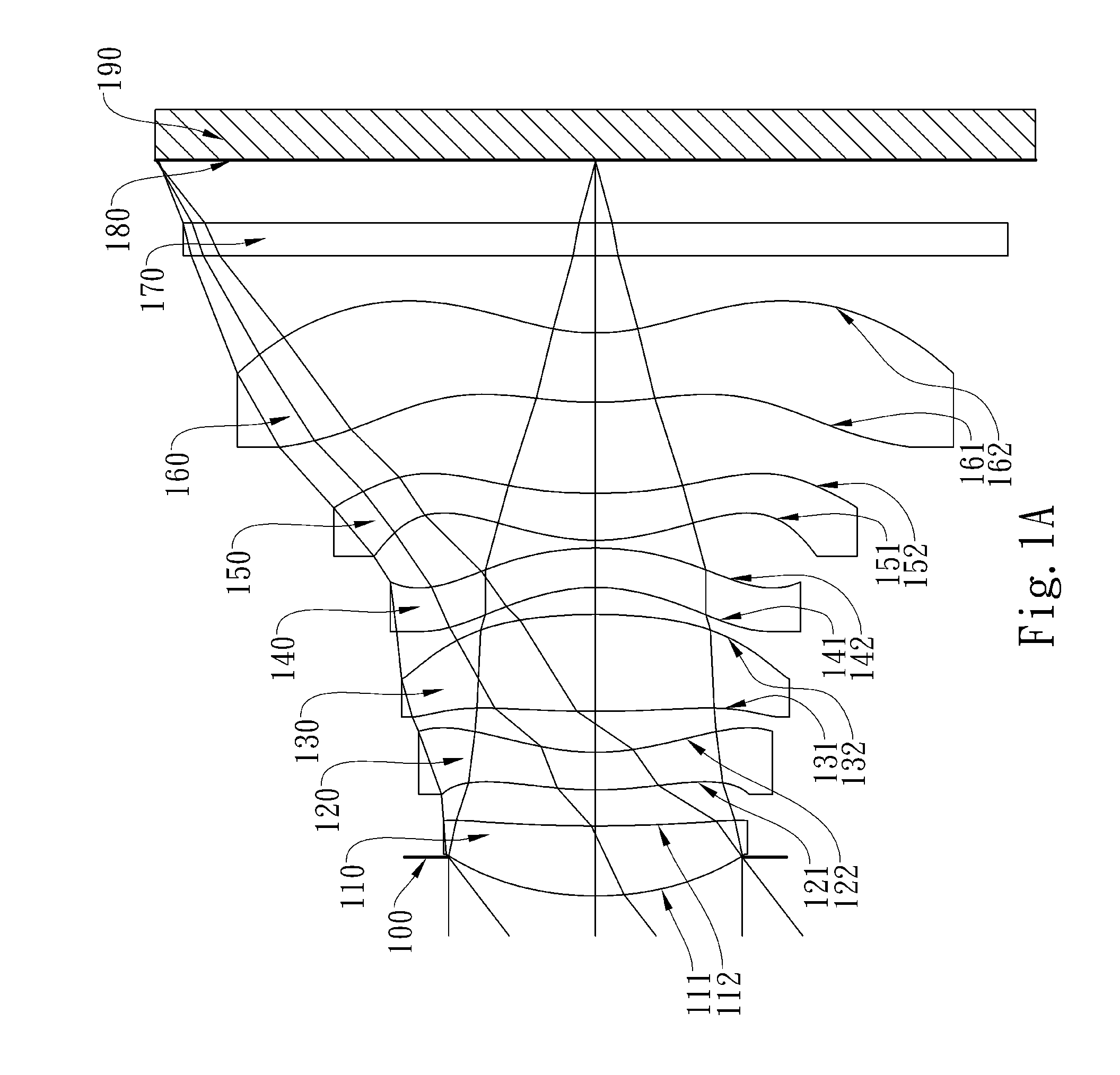

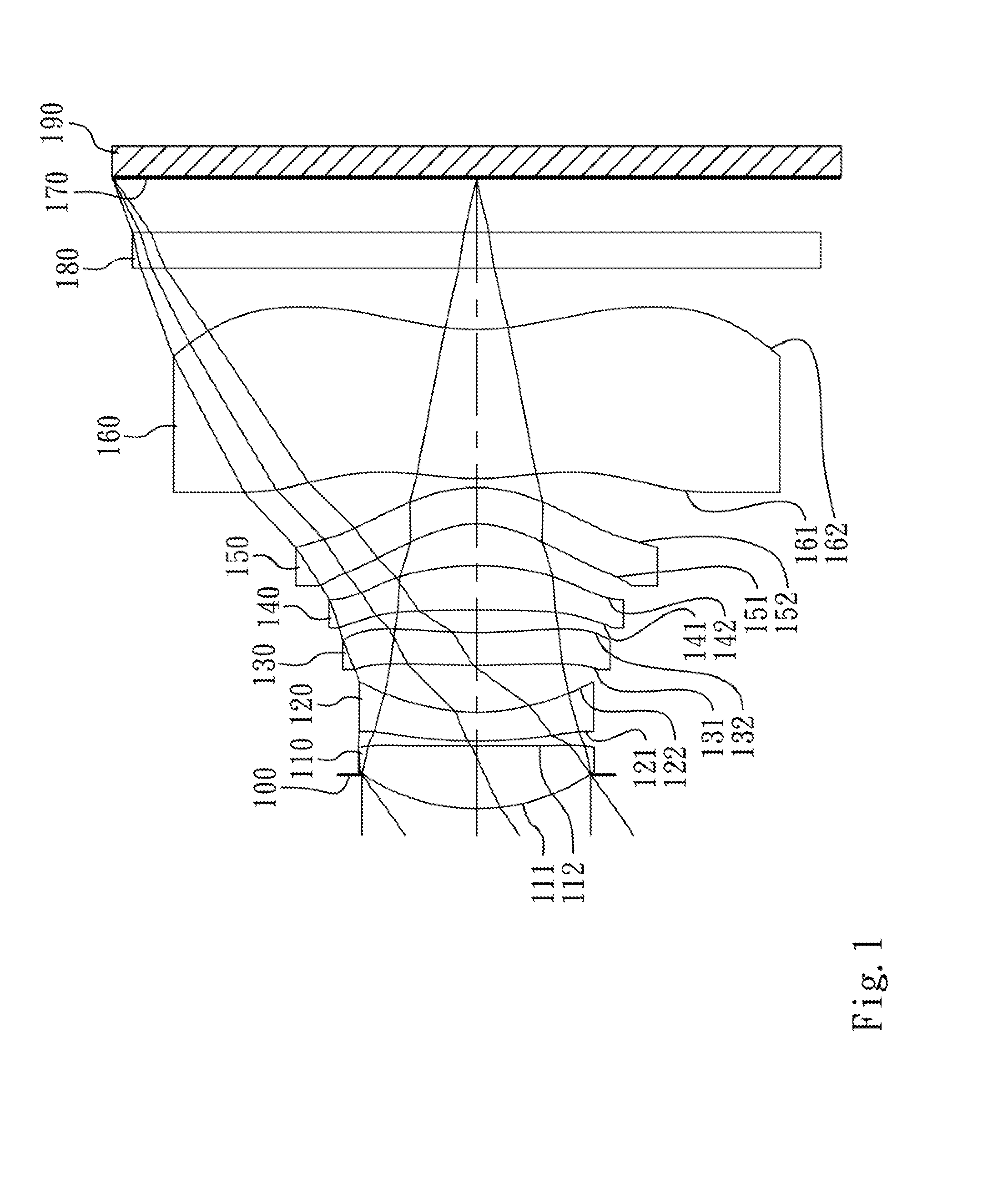

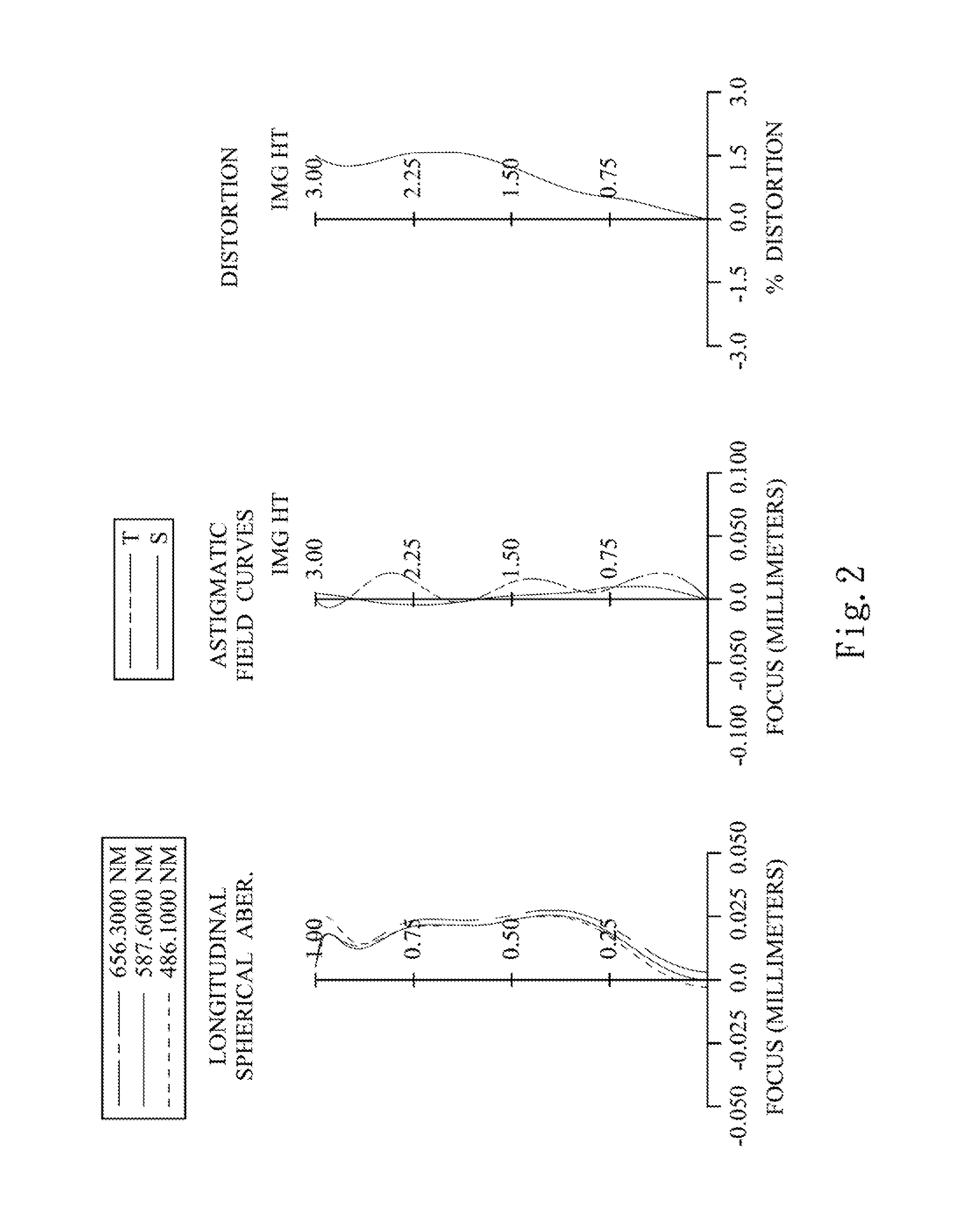

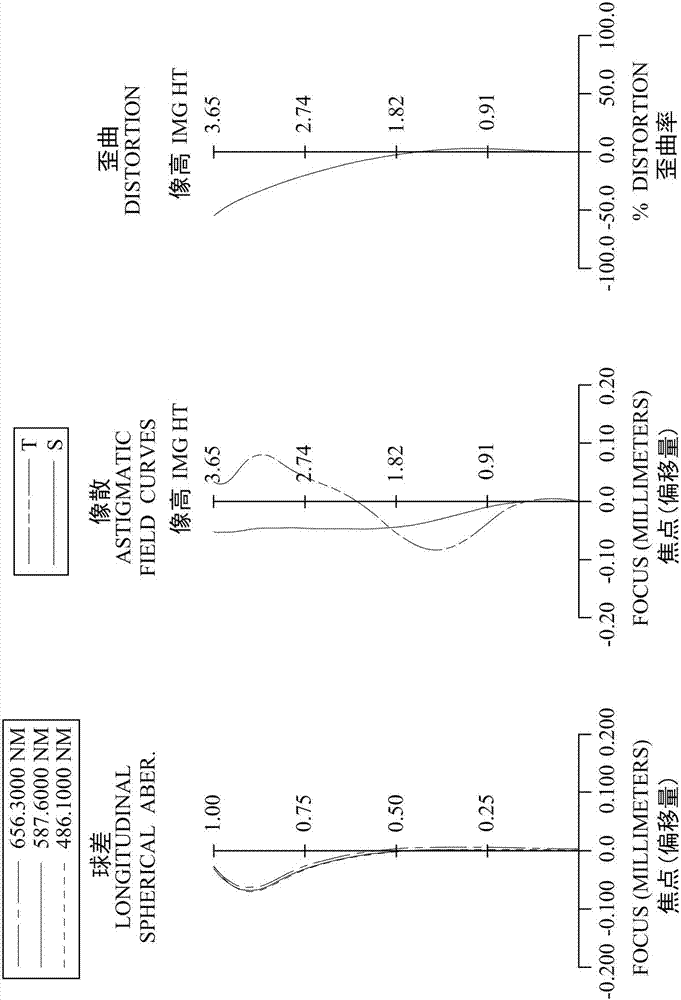

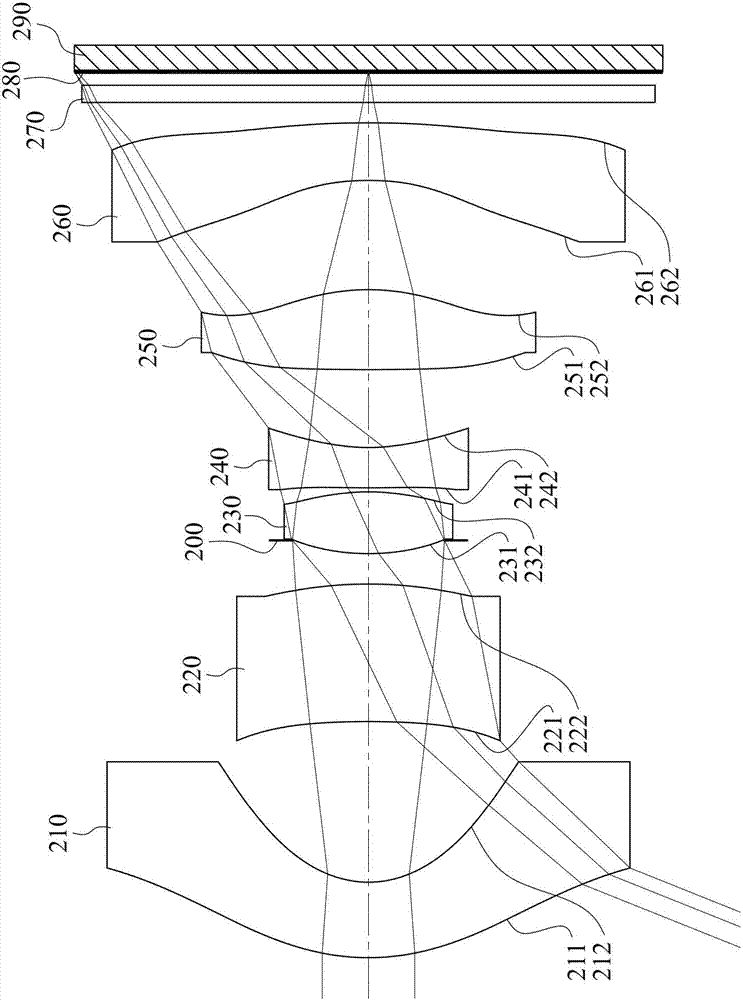

Optical image capturing lens assembly

An optical image capturing lens assembly includes, in order from an object side to an image side, a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element, and a sixth lens element. The first lens element with positive refractive power has a convex object-side surface. The object-side surface and the image-side surface of the fifth lens element are aspheric and at least one of the object-side surface and the image-side surface has at least one inflection point formed thereon. The sixth lens element with negative refractive power has a concave object-side surface and a convex image-side surface, wherein the object-side surface and the image-side surface of the sixth lens element are aspheric.

Owner:LARGAN PRECISION

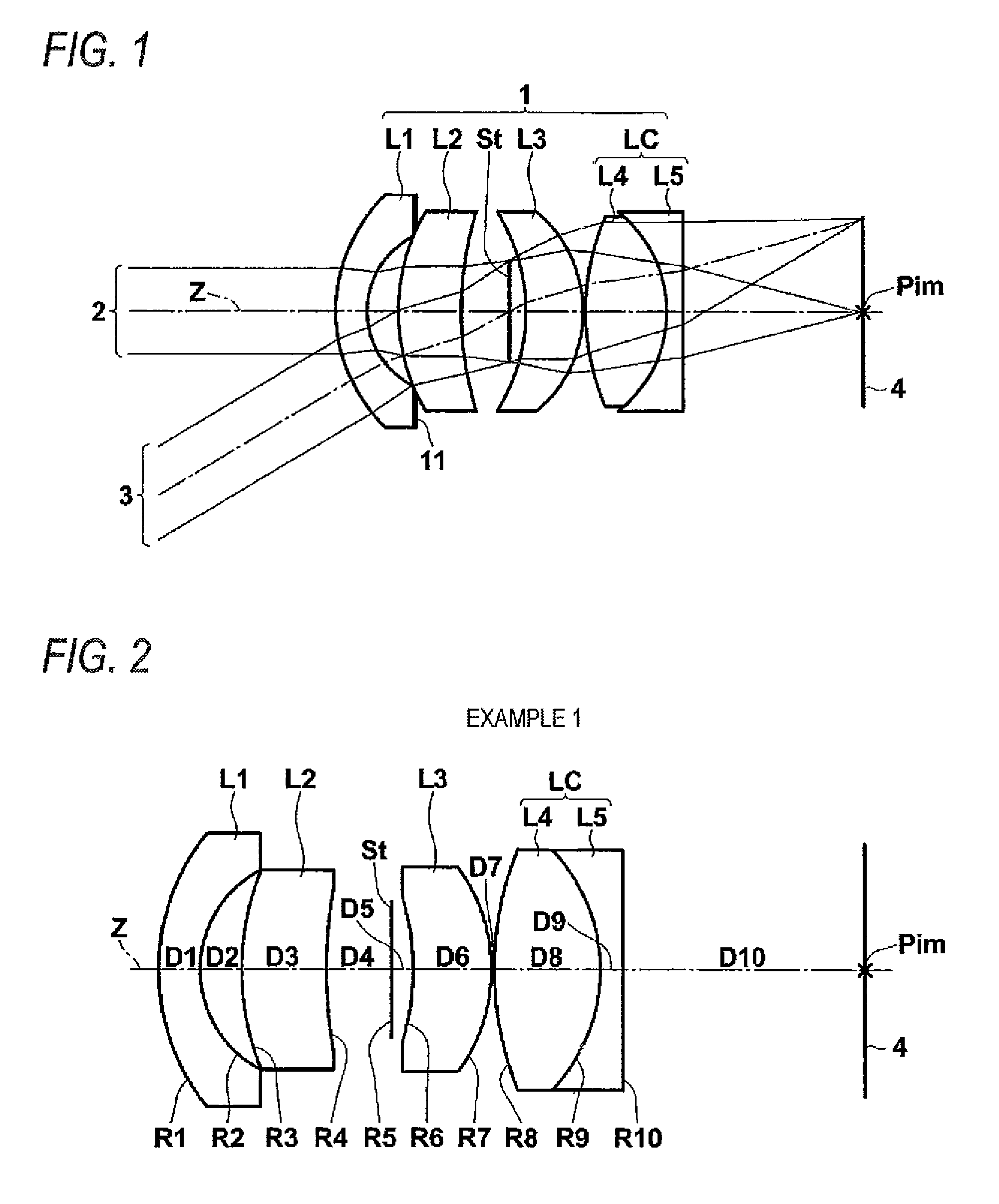

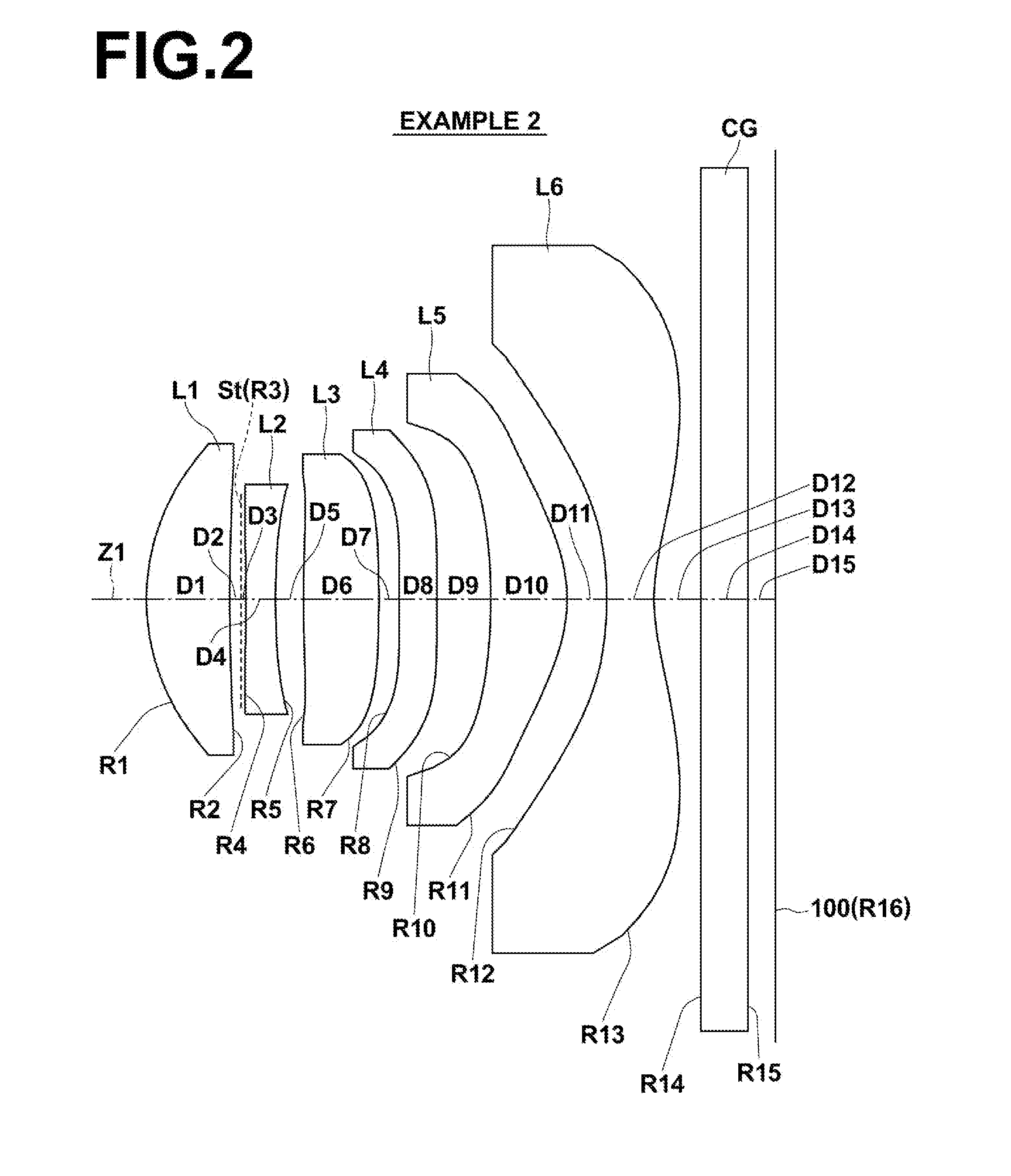

Imaging lens and image pickup apparatus

ActiveUS7746572B2Corrected spherical aberrationAberration correctionOptical elementsOptical axisConditional expression

An imaging lens comprises, in order from an object side: a first lens that has a negative refractive power and is convex toward the object side; a second lens that has a positive refractive power and is a meniscus lens convex toward the object side; a stop; a third lens that has a positive refractive power and is convex toward an image side; and a cemented lens that has a positive refractive power as a whole and is formed by cementing a fourth lens and a fifth lens, wherein assuming that an Abbe number of the second lens with respect to d-line is ν2, a distance on an optical axis from a vertex of a surface of the first lens facing toward the object side to an image plane of the imaging lens is L, a focal length of the imaging lens is f, and a back focus of the imaging lens is Bf, the following conditional expressions (1) to (3) are satisfied:ν2>30 (1),2.5<L / f<4.0 (2), and0.5<Bf / f<1.3 (3).

Owner:TIANJIN OFILM OPTO ELECTRONICS CO LTD

Image capturing optical lens system

An image capturing optical lens system includes, in order from an object side to an image side, a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element, and a sixth lens element. The first lens element with positive refractive power has a convex object-side surface. The second lens element has negative refractive power. The third lens element has refractive power. The fourth lens element has refractive power, wherein at least one surface of the fourth lens element is aspheric. The fifth lens element with negative refractive power has a concave object-side surface and a convex image-side surface, and the surfaces thereof are aspheric. The sixth lens element with refractive power has an image-side surface changing from concave at a paraxial region thereof to convex at a peripheral region thereof, and the surfaces thereof are aspheric.

Owner:LARGAN PRECISION

Optical image lens system

This invention provides an optical image lens system comprising: a positive first lens element having a convex object-side surface; a second lens element; a positive third lens element; a fourth lens element; a positive plastic fifth lens element having a convex object-side surface and a concave image-side surface, at least one of the object-side and image-side surfaces is aspheric; and a negative plastic sixth lens element having a concave image-side surface, at least one of the object-side and image-side surfaces is aspheric, wherein the shape of the image-side surface changes from concave at the paraxial region thereof to convex while away from the paraxial region thereof.

Owner:LARGAN PRECISION

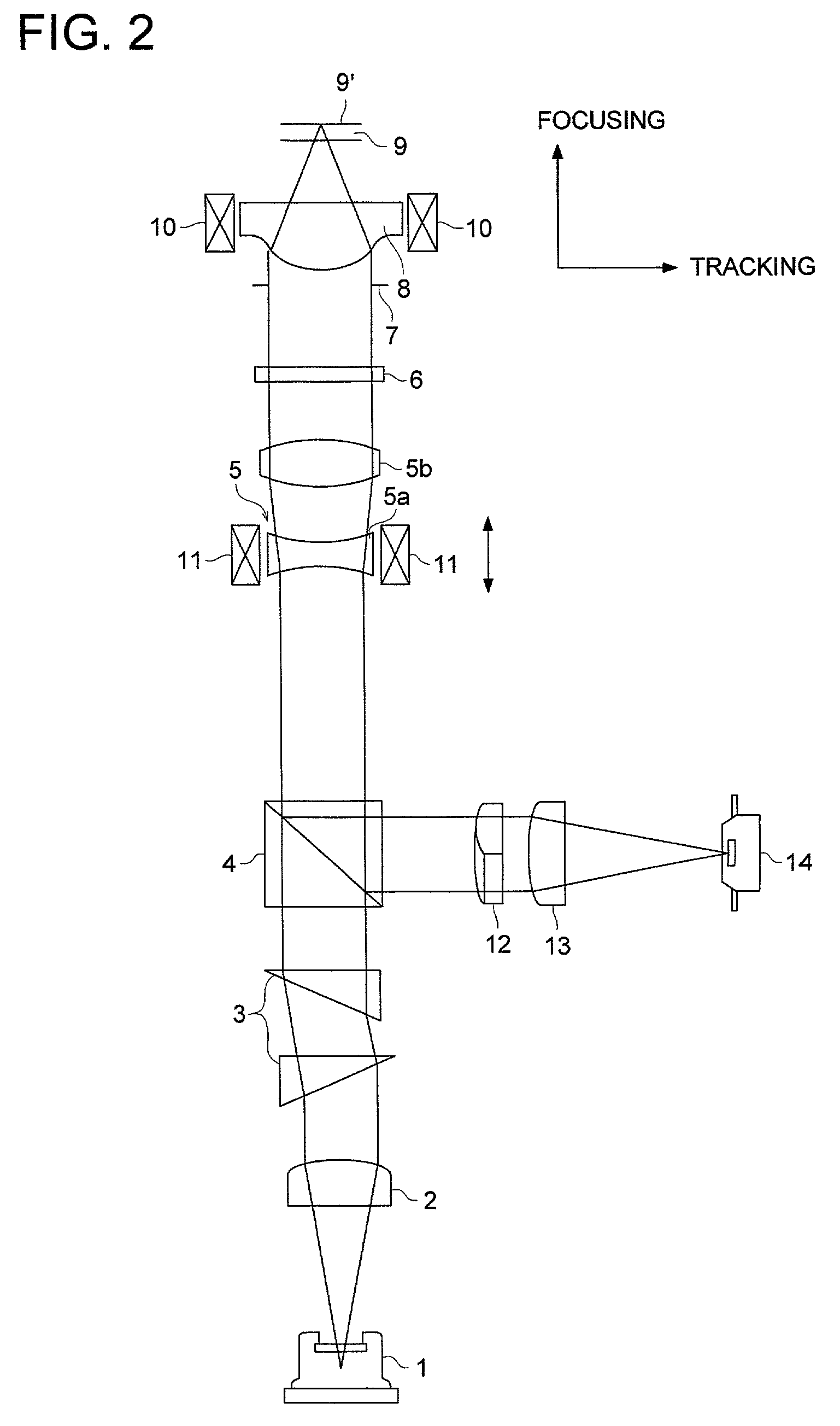

Optical element and optical pickup

InactiveUS20060273284A1Exclude influencePrevent degradationLiquid crystal compositionsRecord information storageOptical pickupElectrical conductor

On one side of a liquid crystal layer, a first electrode is provided, and, on the other side of the liquid crystal layer, a second electrode, composed of a plurality of individual electrodes, and a third electrode are provided. The second and third electrodes have holes that are increasingly small away from the liquid crystal layer. When the potential at the third electrode is set equal to or lower than the potential at the second electrode, the liquid crystal layer acts as a convex lens; when the potential at the third electrode is set higher than the potential at the second electrode, the liquid crystal layer acts as a concave lens. The range in which the focal length can be varied depends on the diameters of the holes, and giving the holes of the different electrodes varying diameters helps widen the range. Moreover, conductors can be laid to reach the electrodes at the outer edges thereof so as not to directly face the liquid crystal layer. This helps eliminate the influence of the conductors on the electric field distribution in the liquid crystal layer.

Owner:KONICA MINOLTA INC

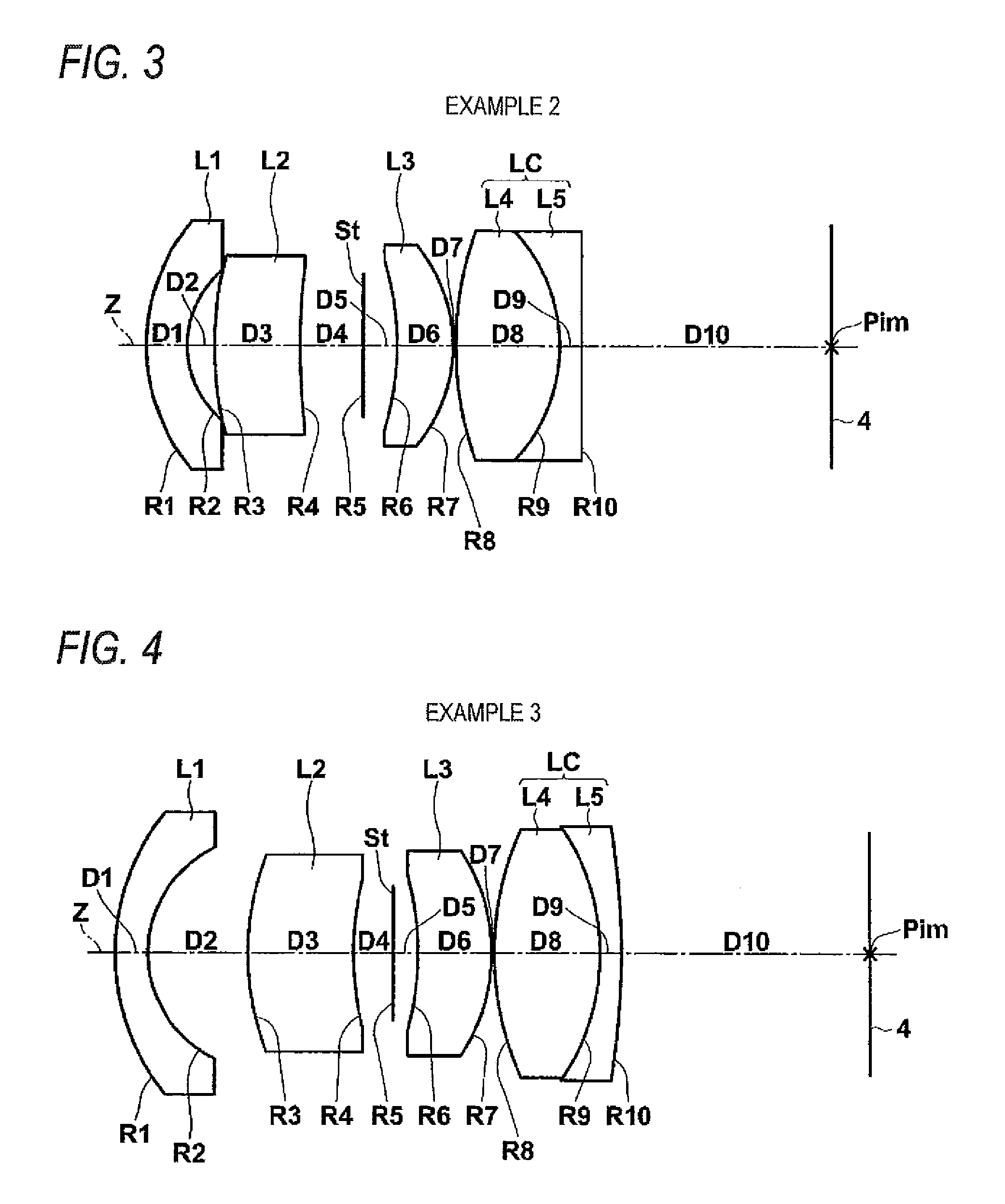

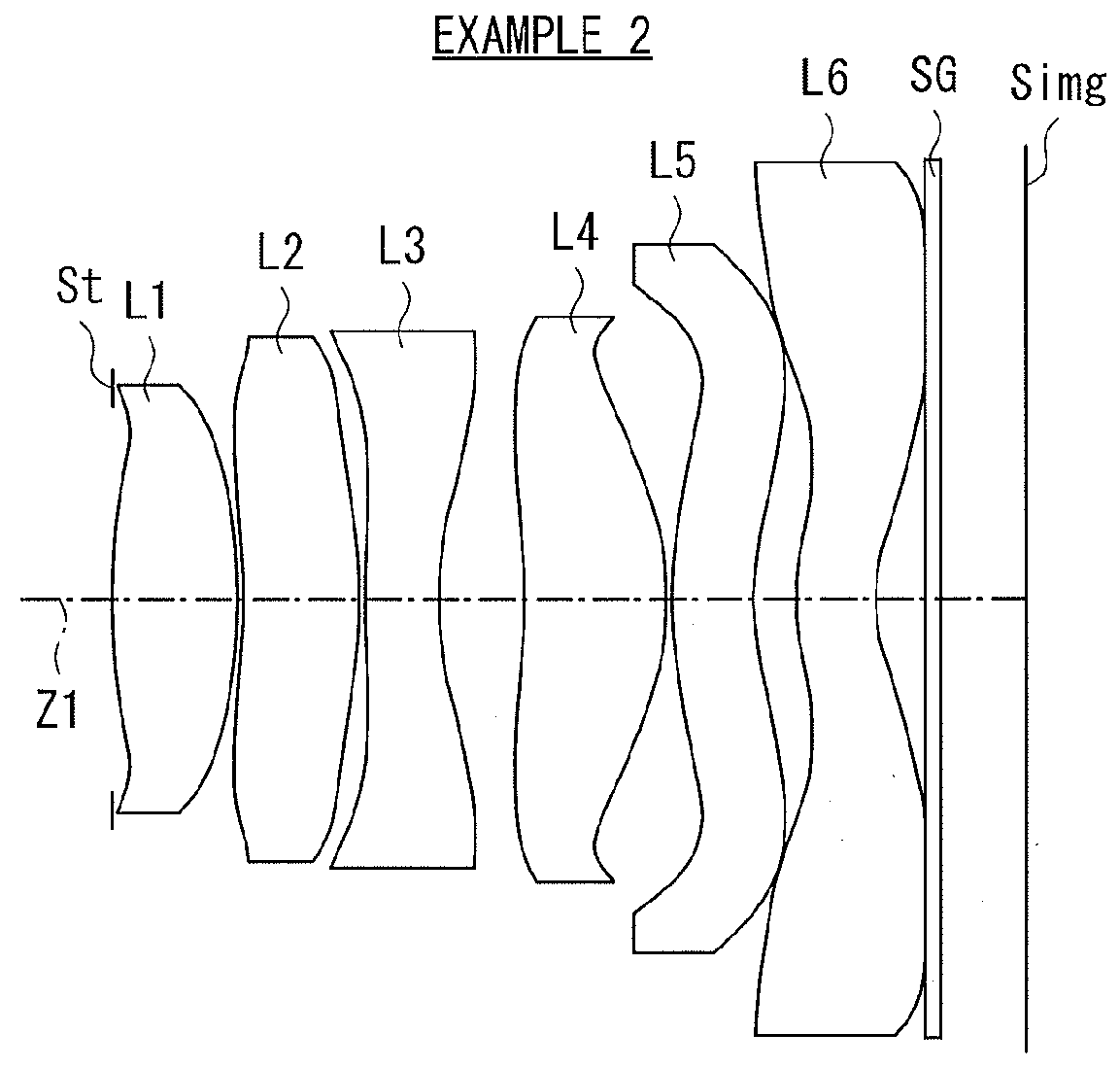

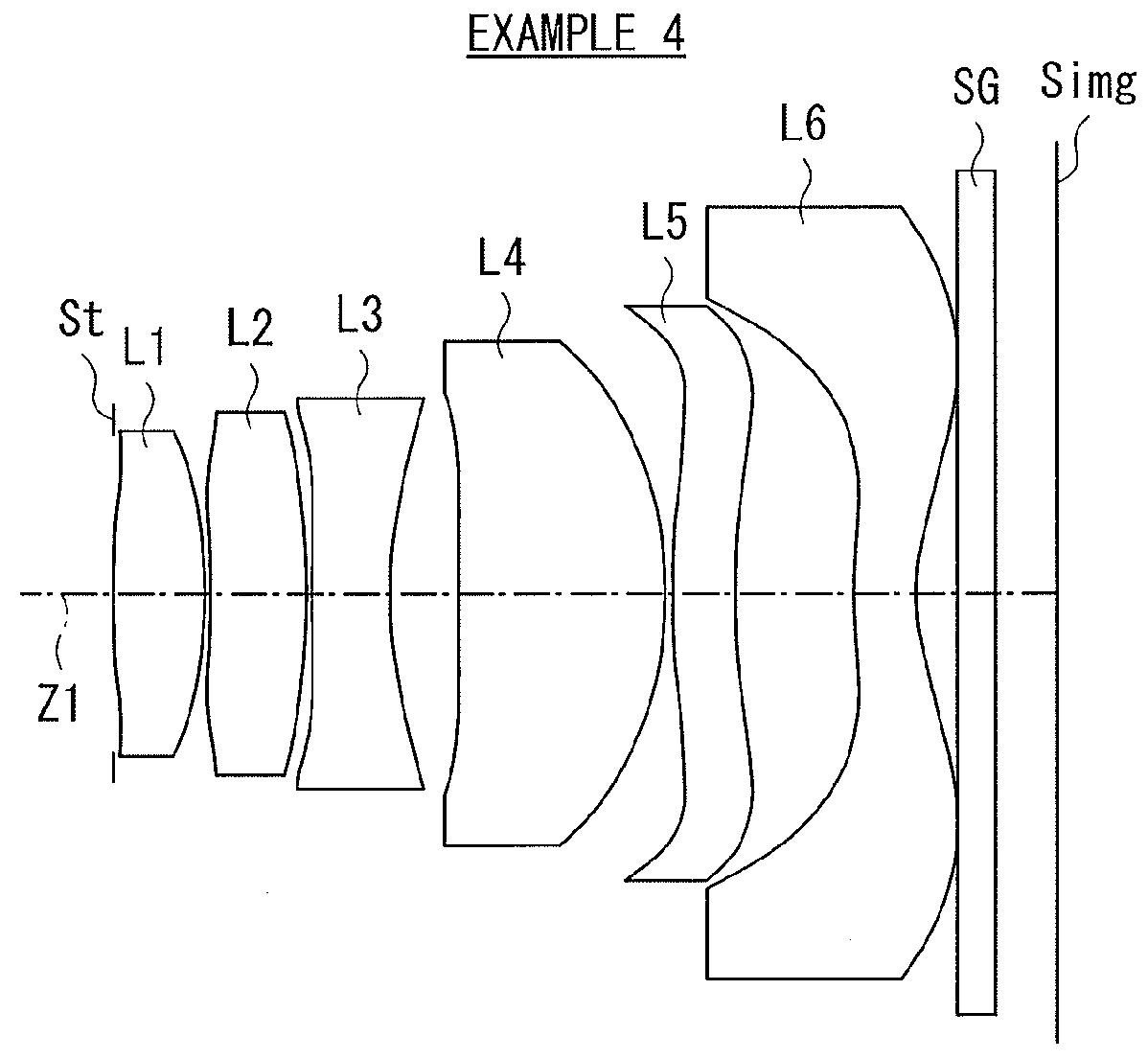

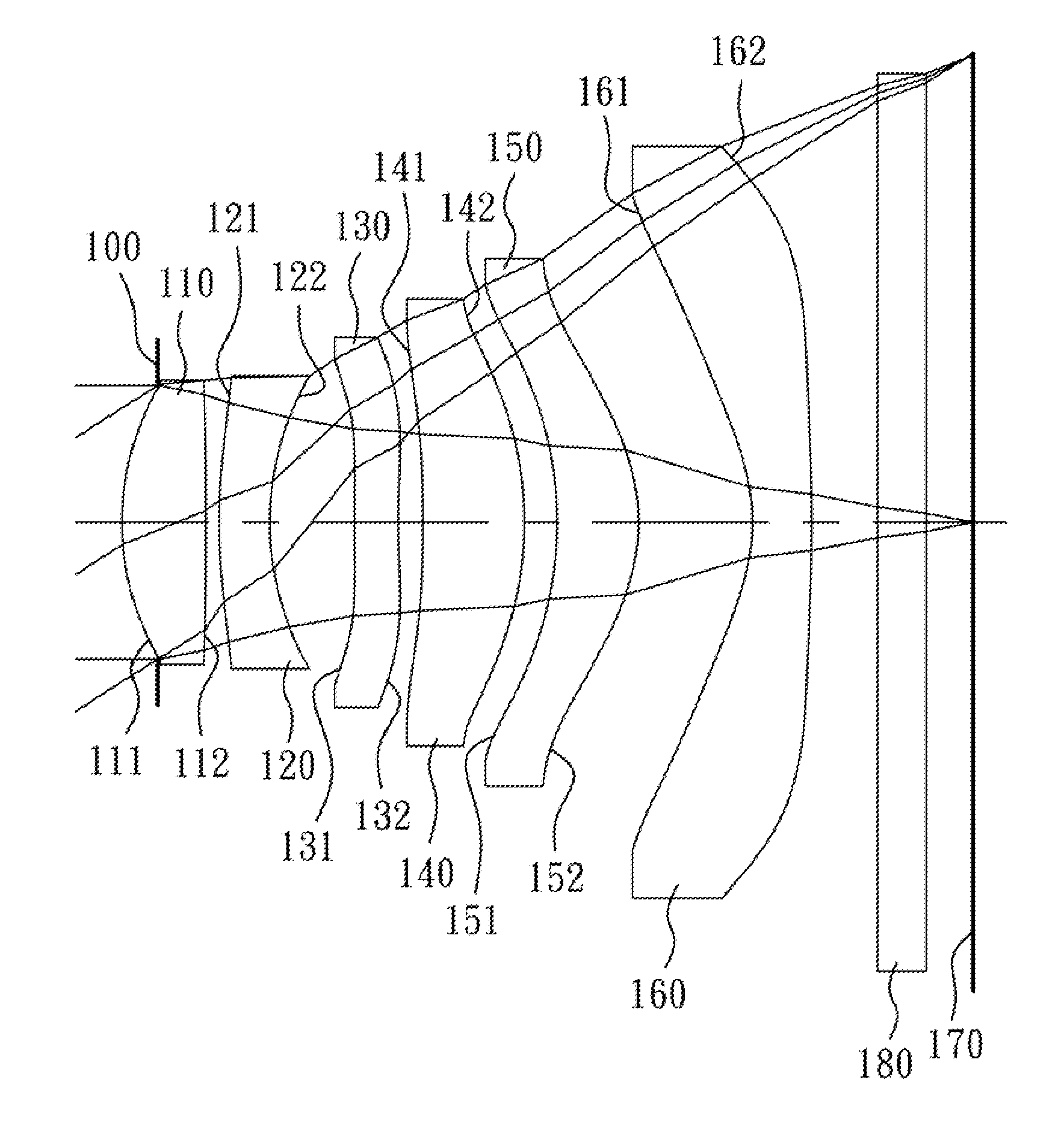

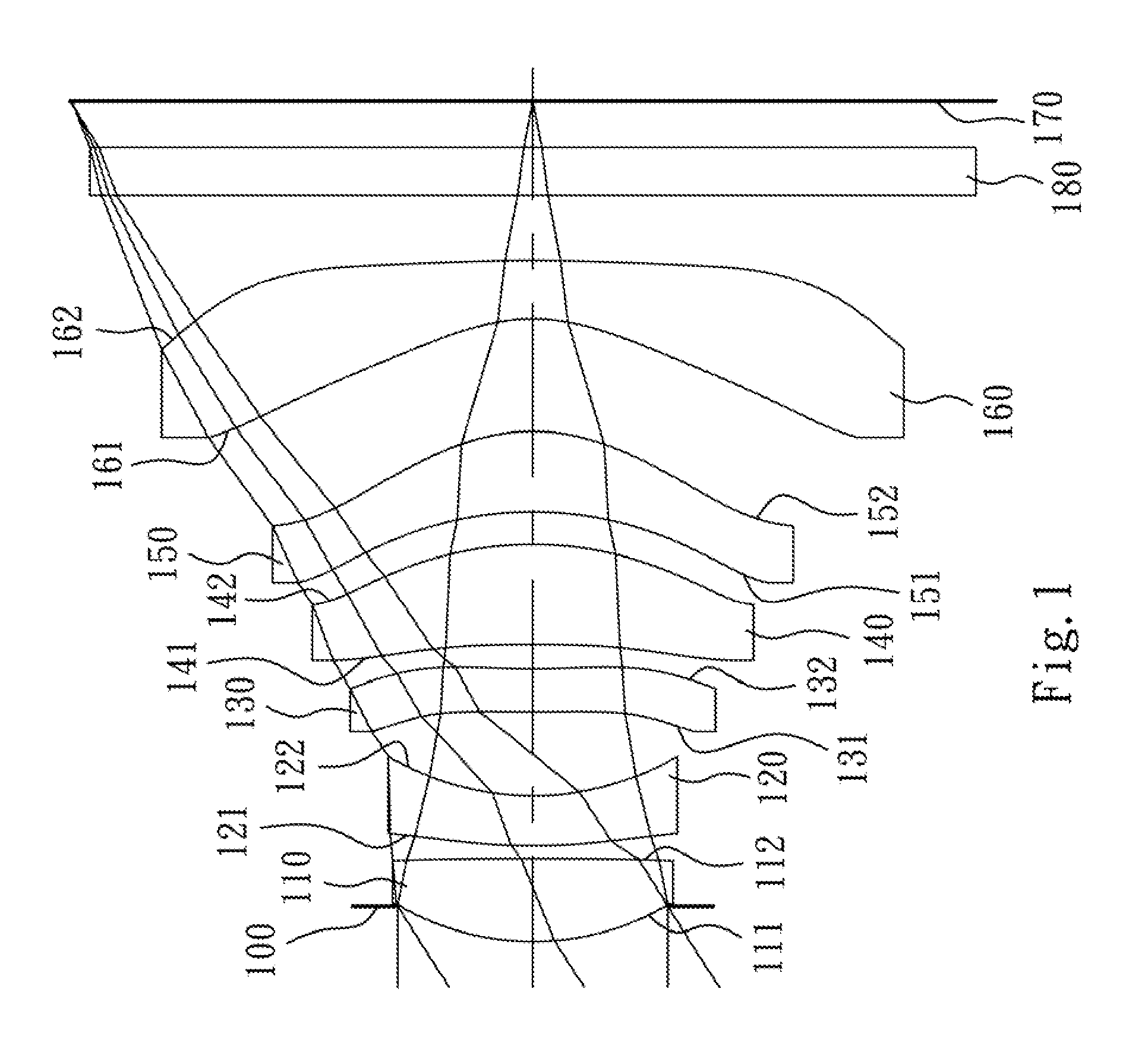

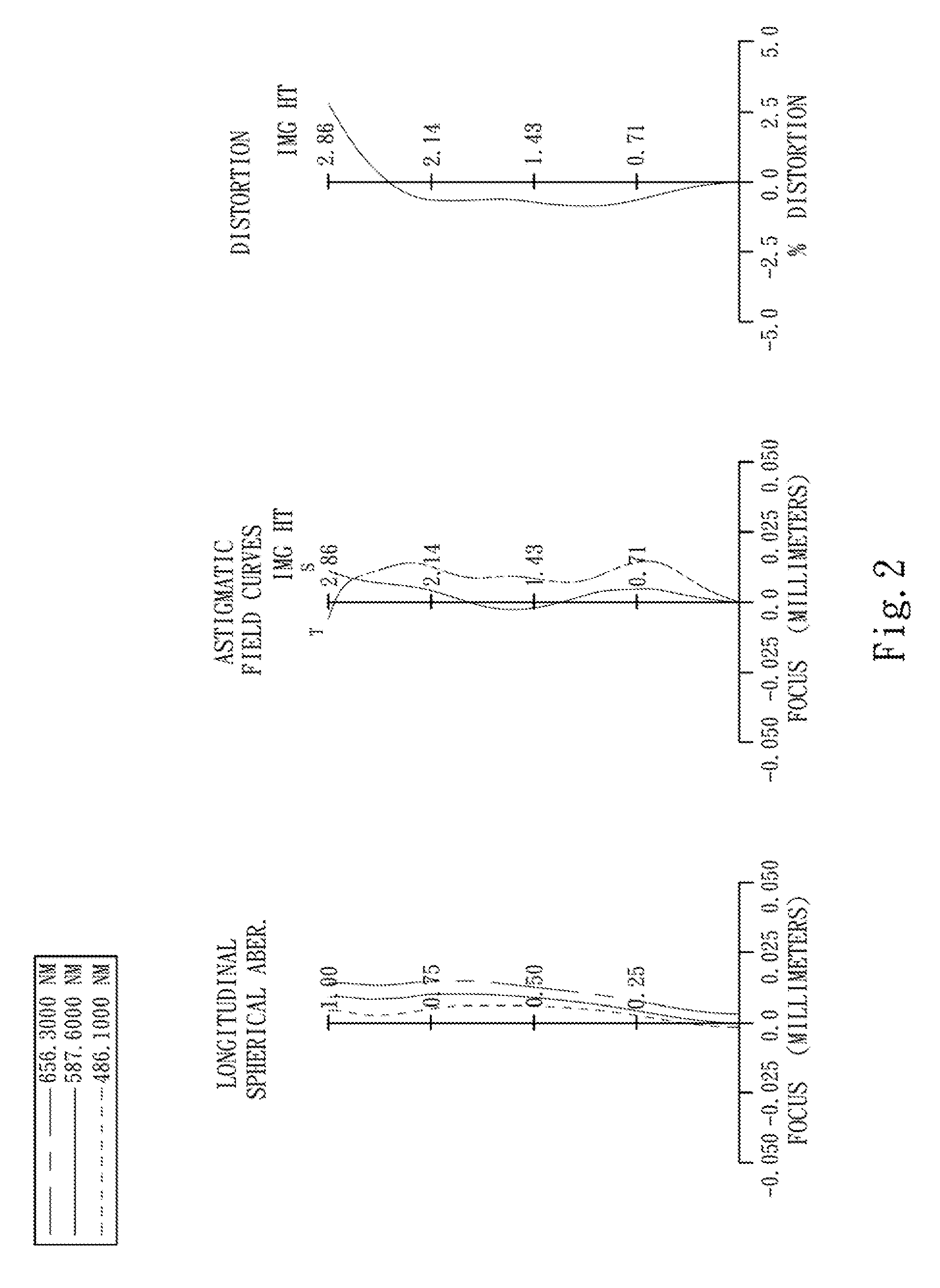

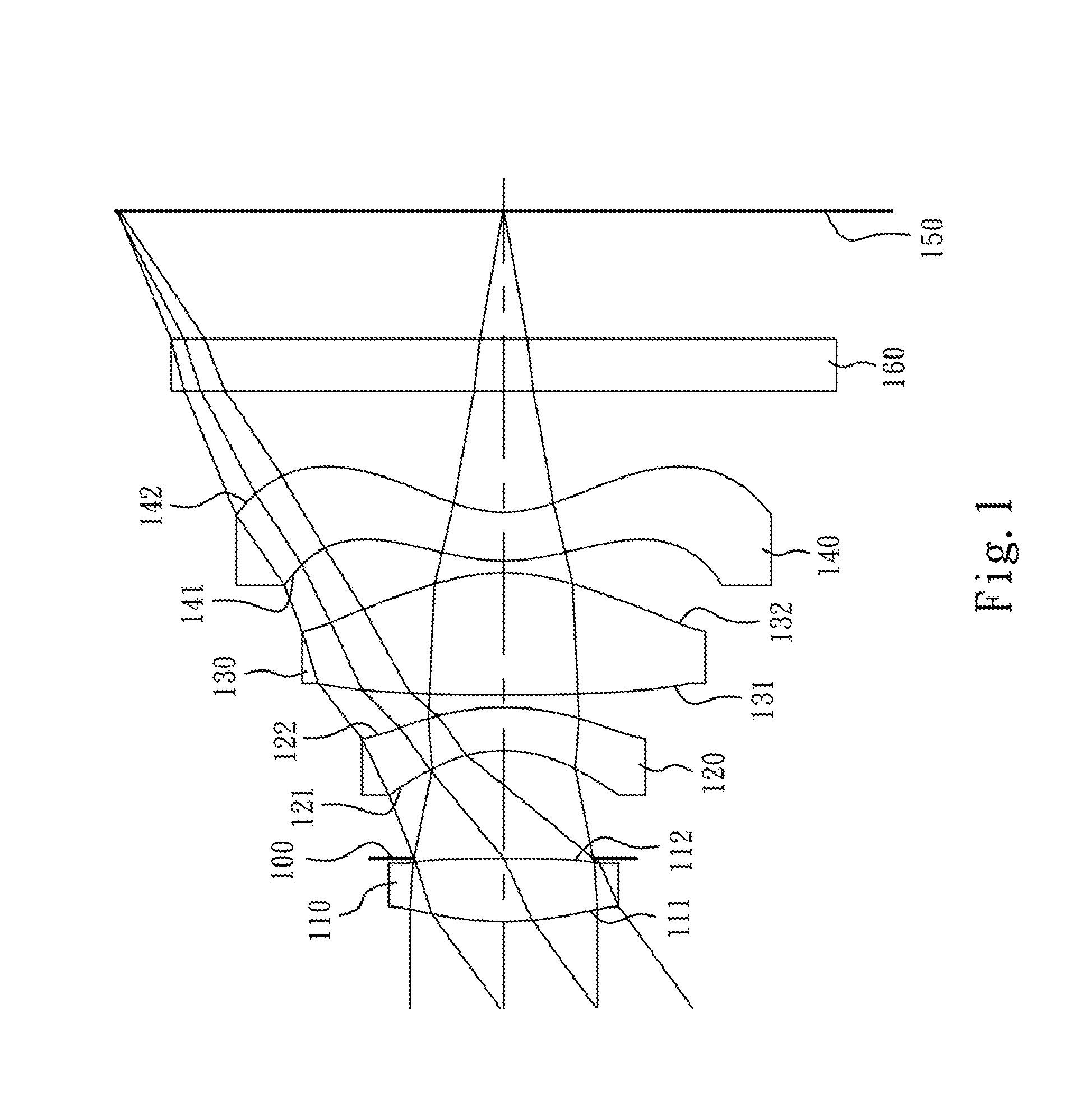

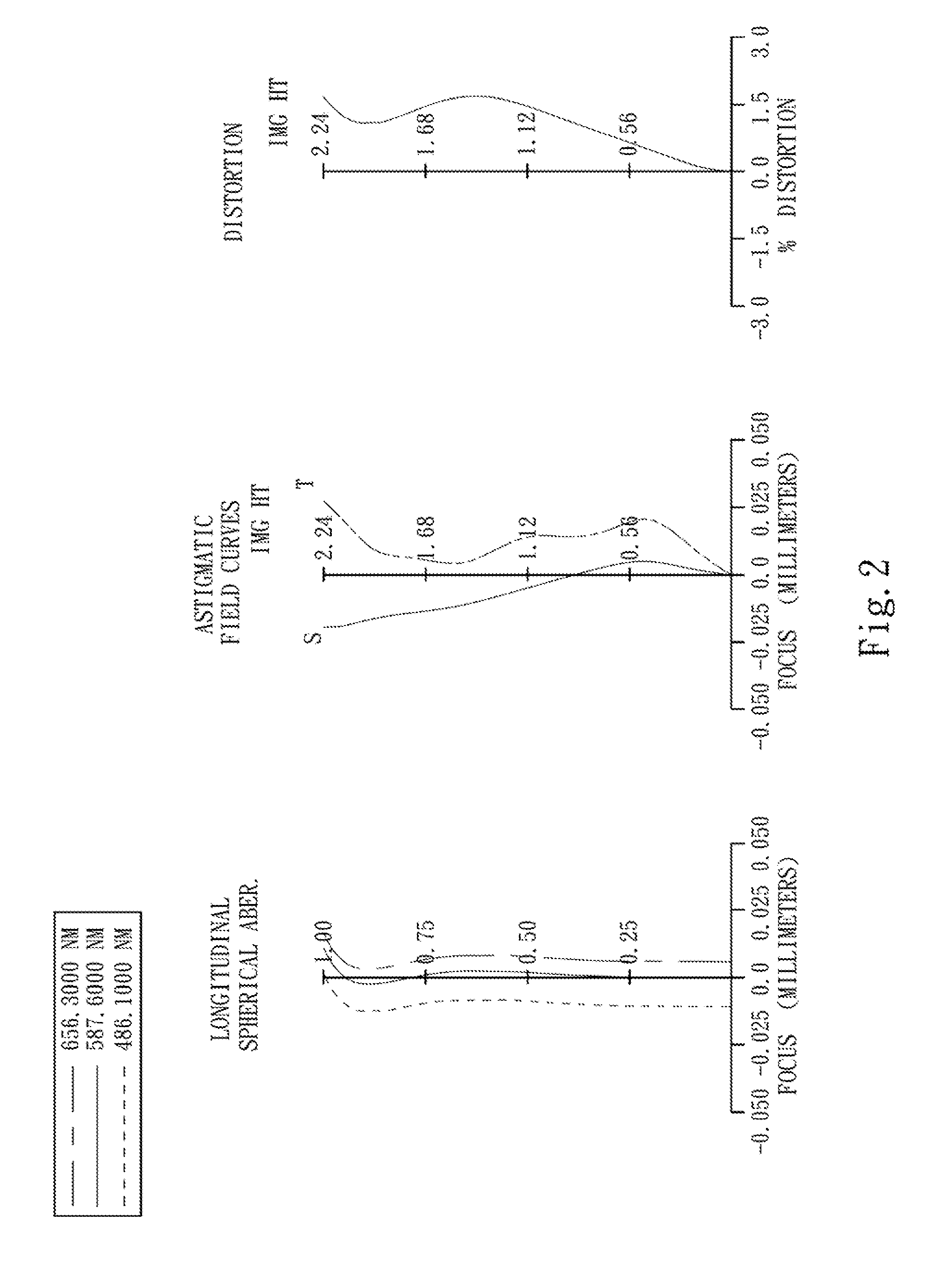

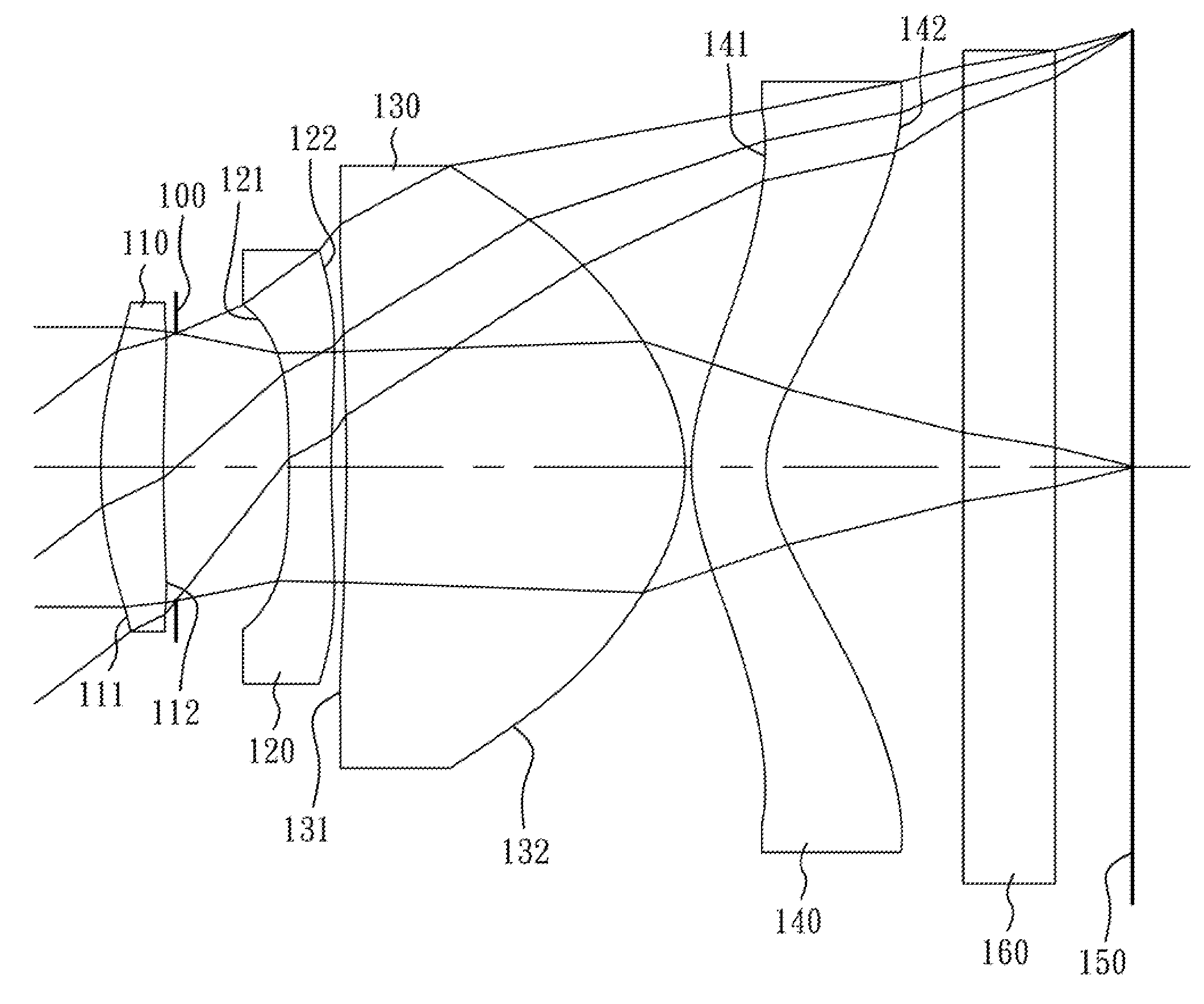

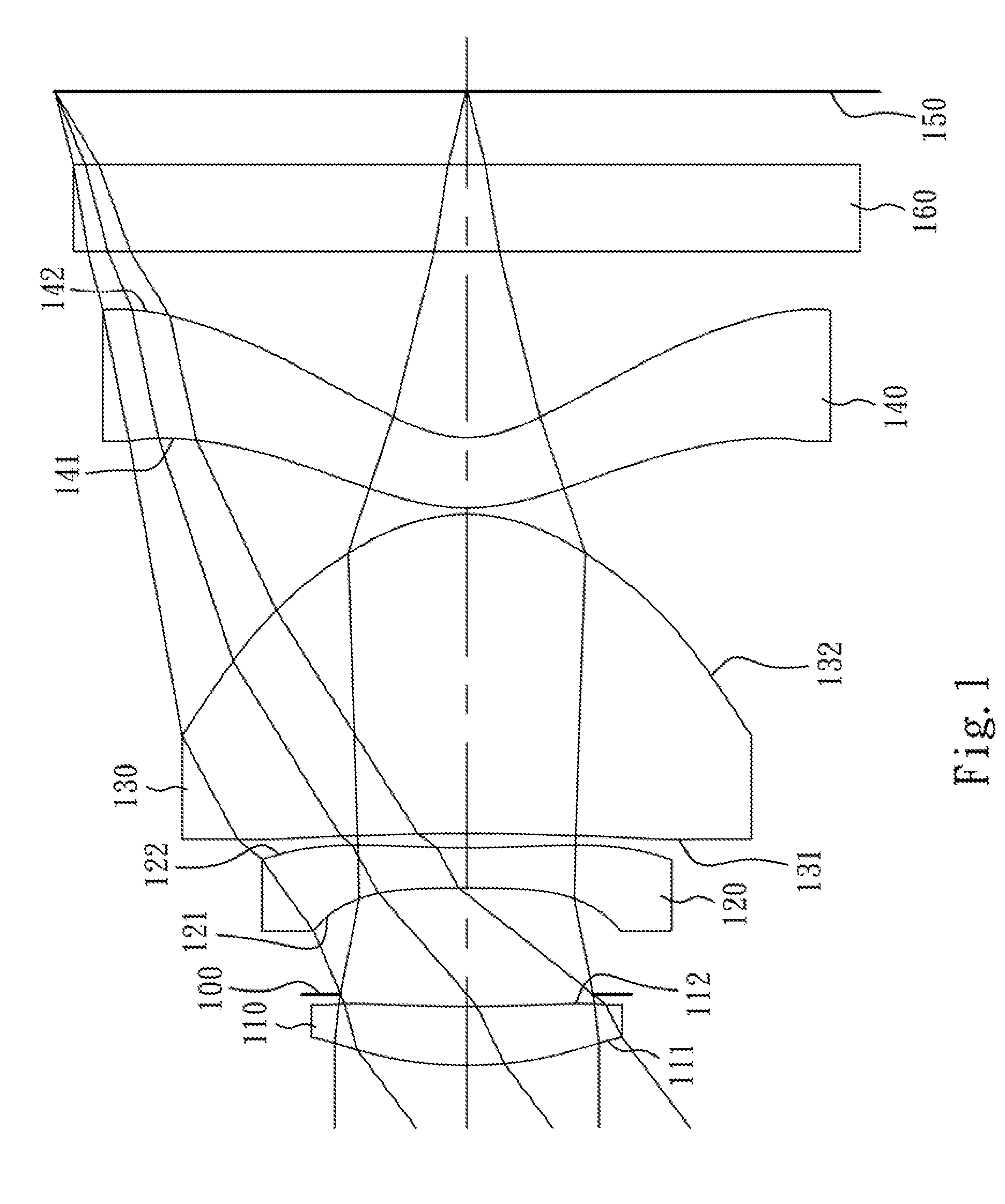

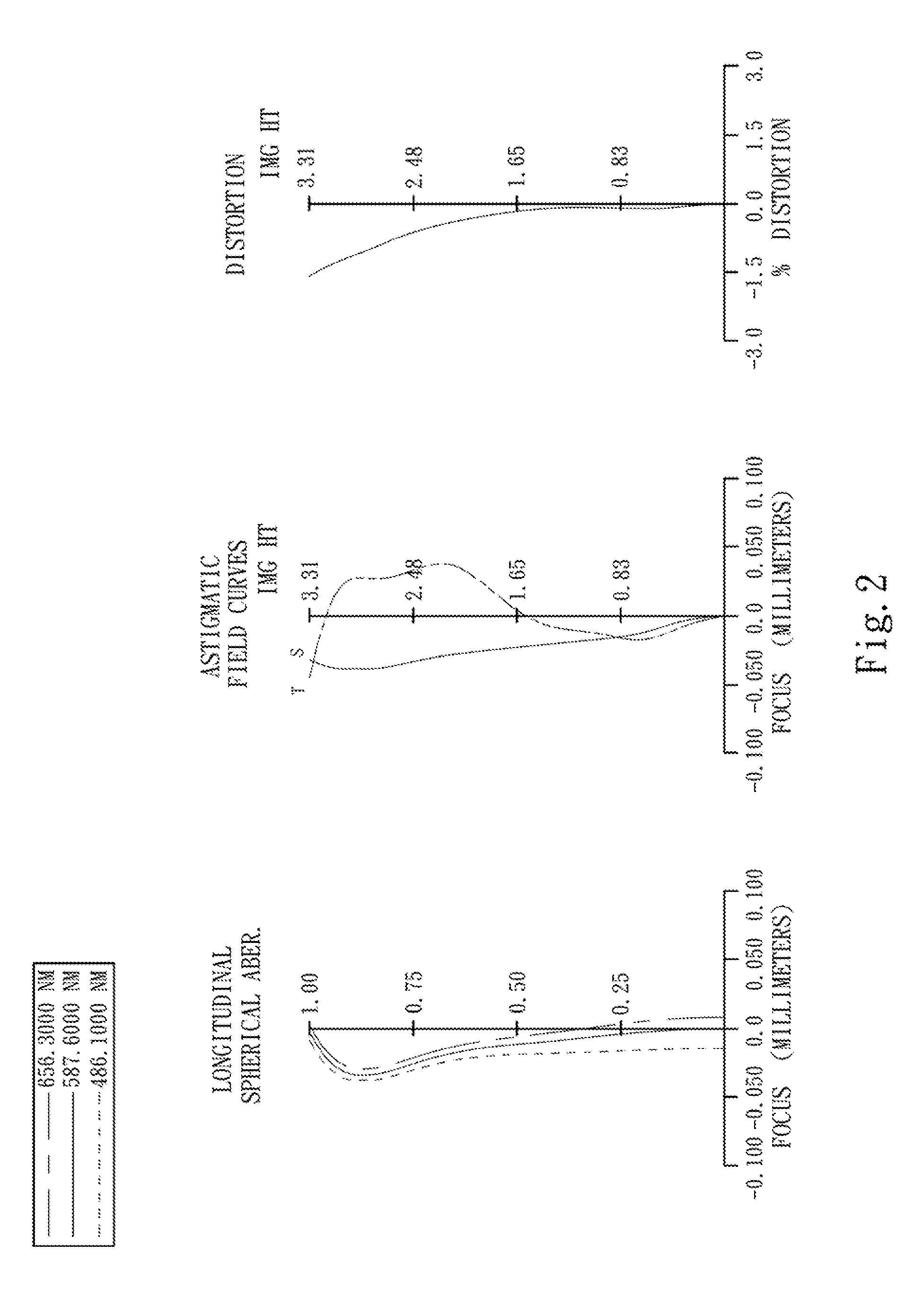

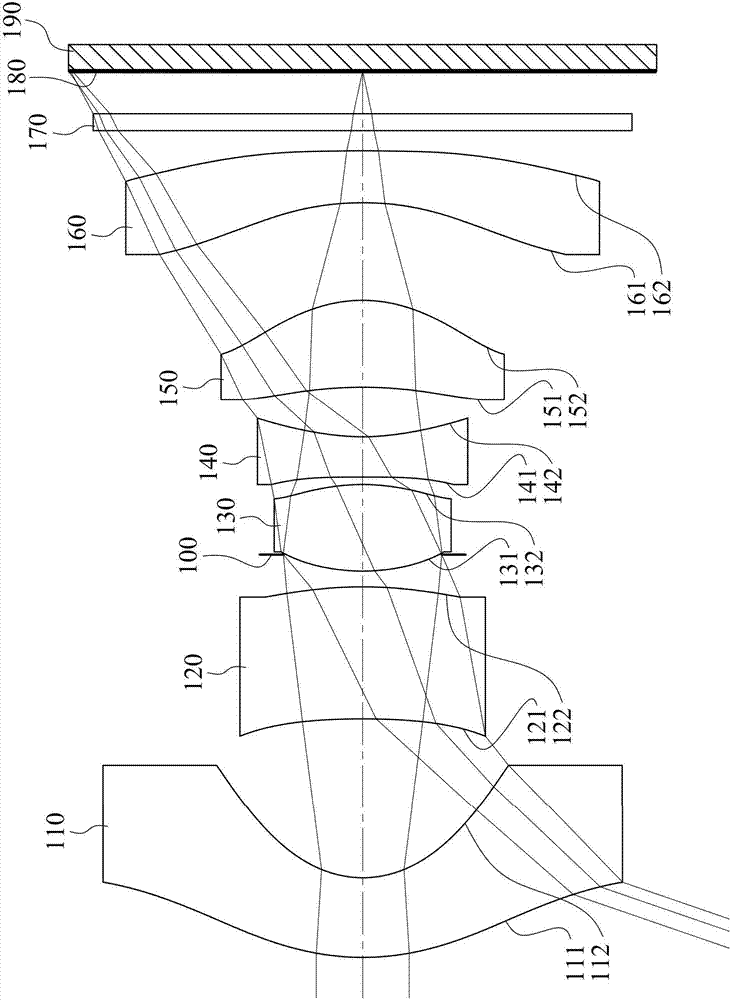

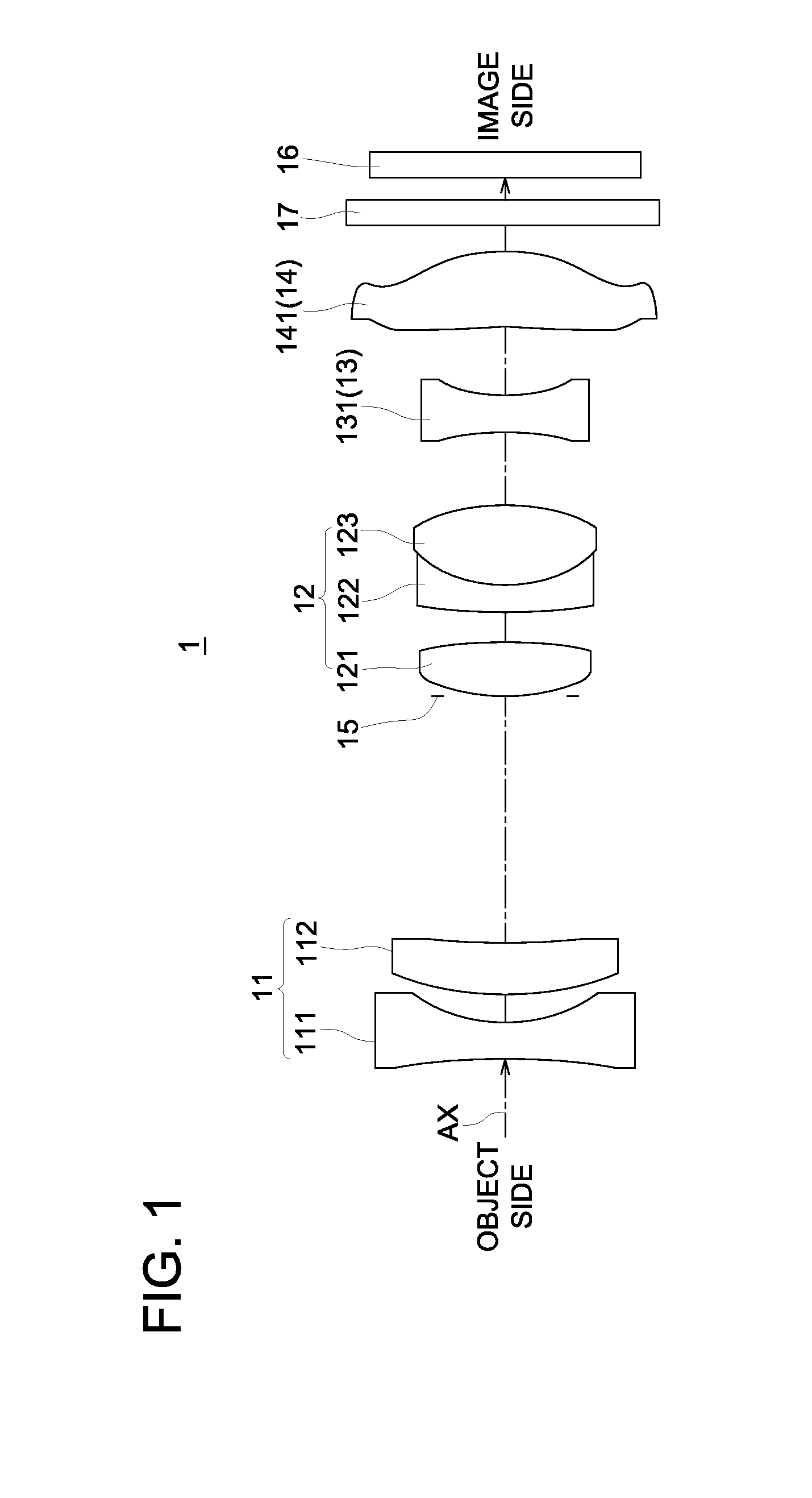

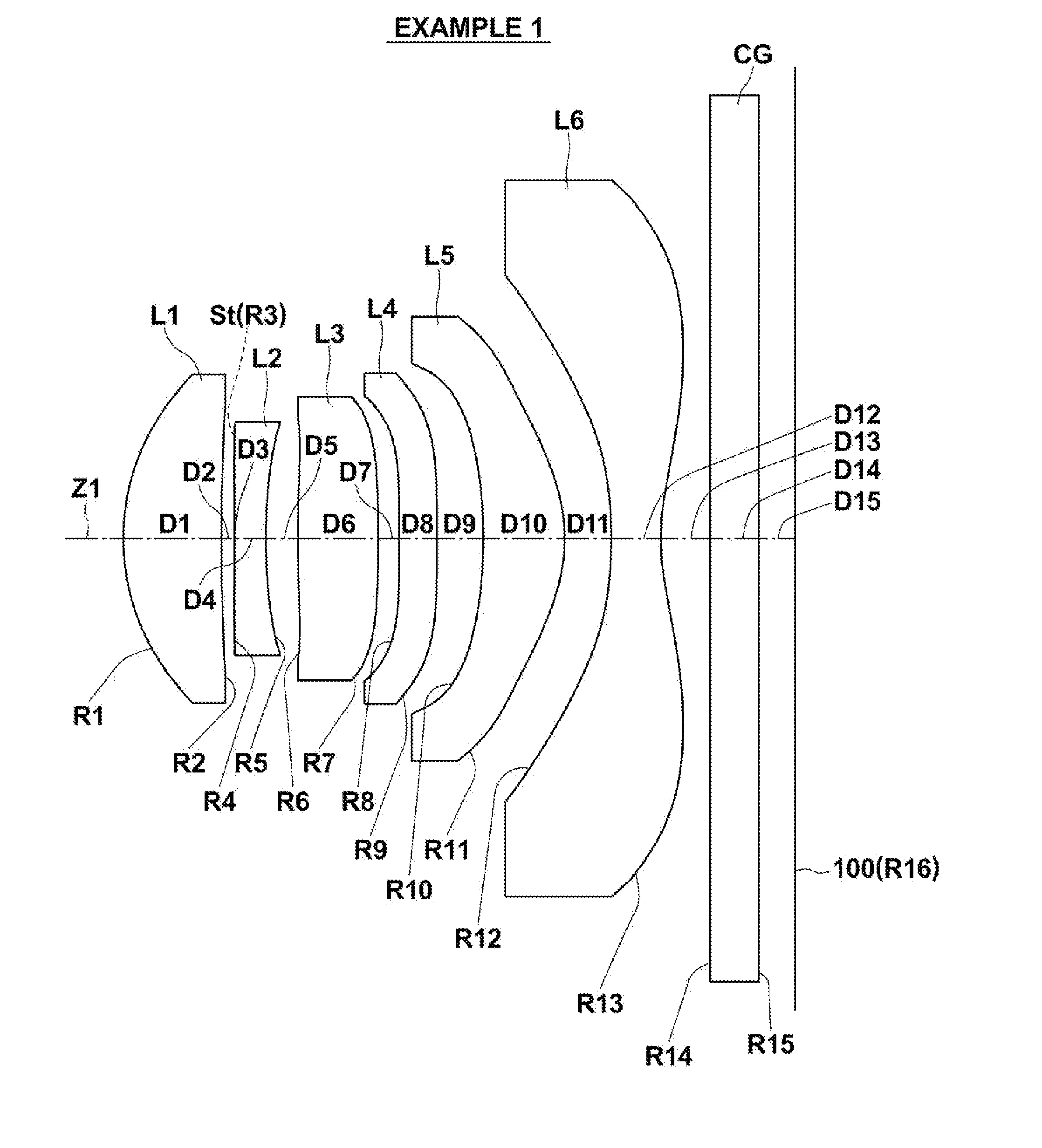

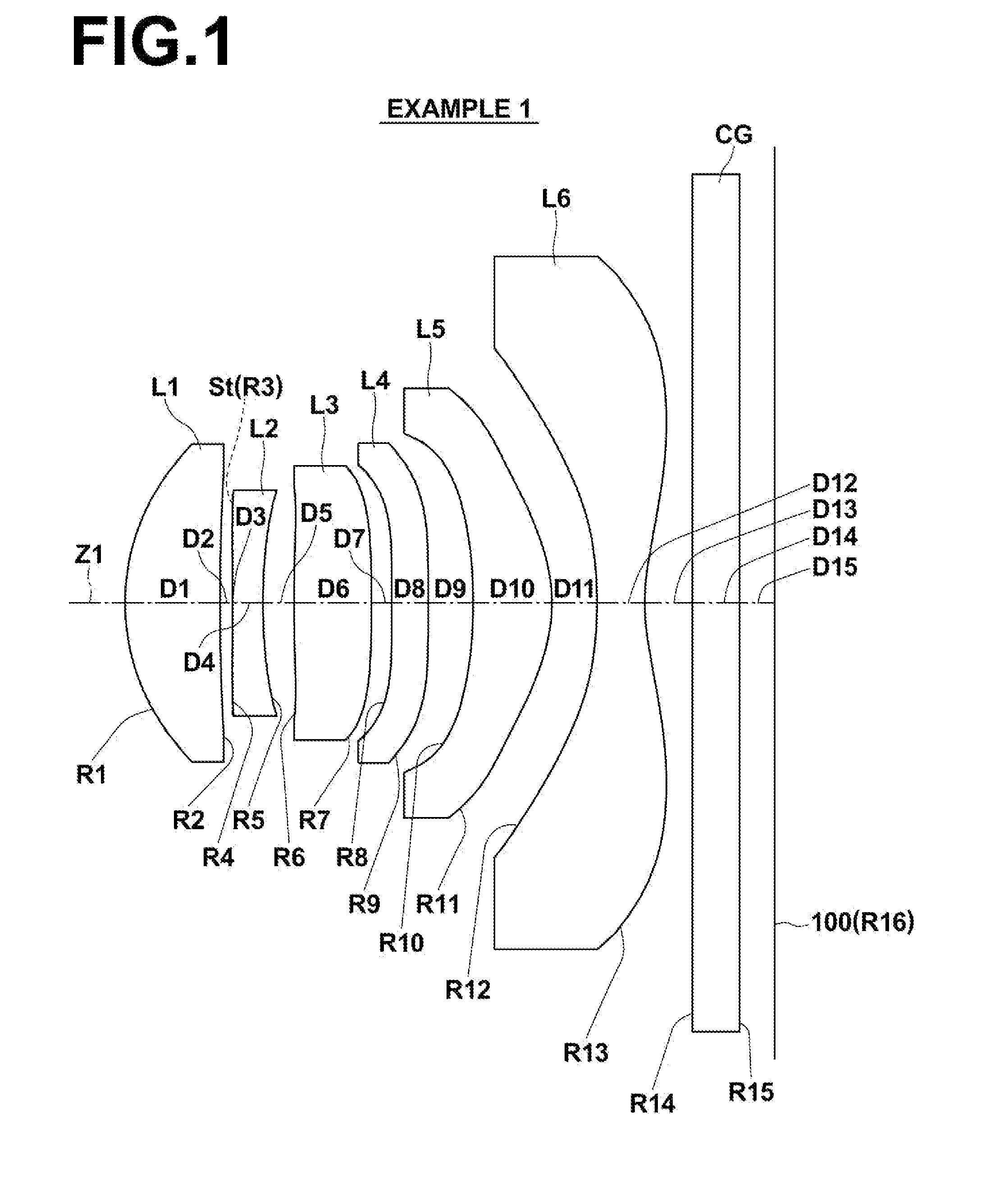

Imaging lens and imaging unit

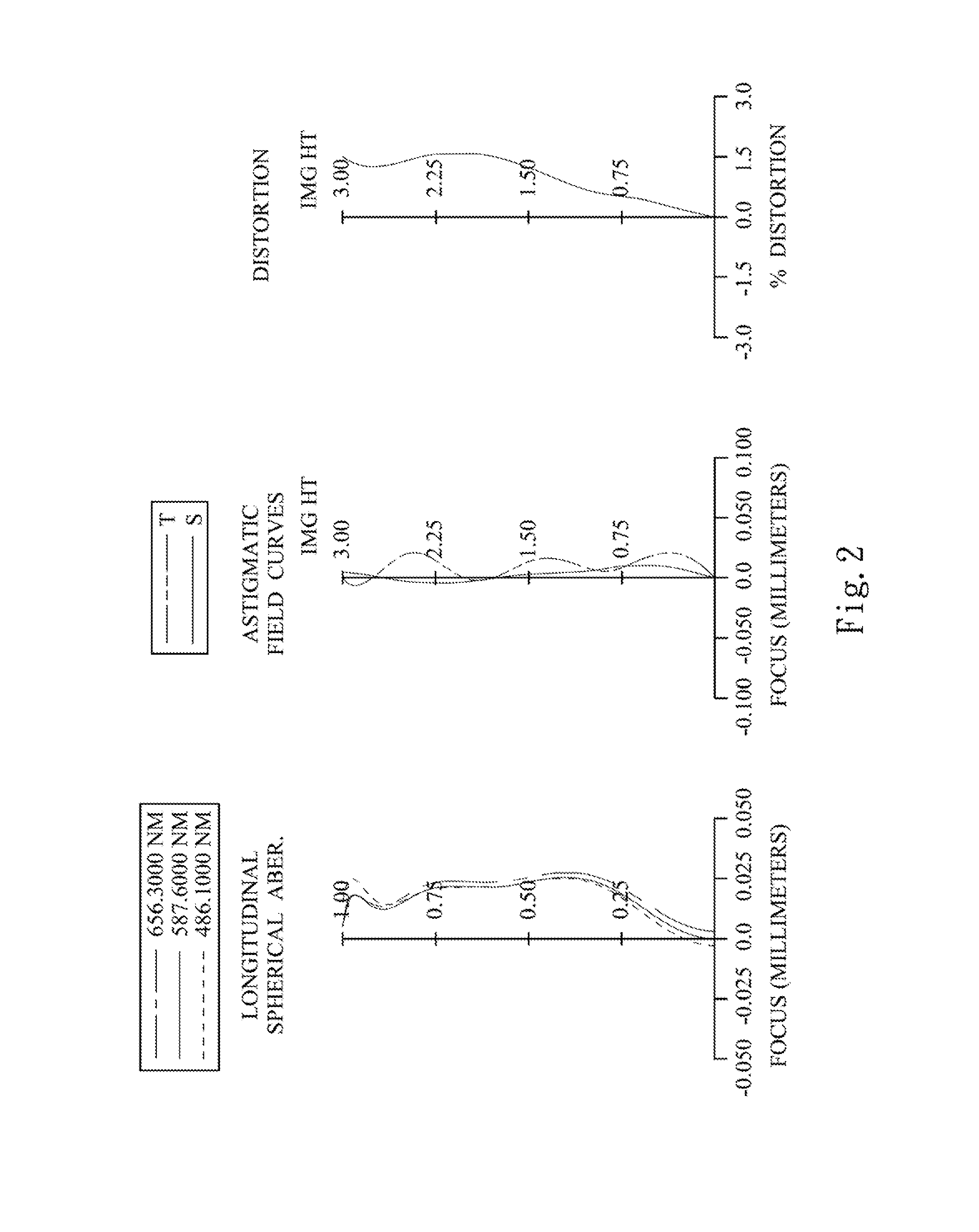

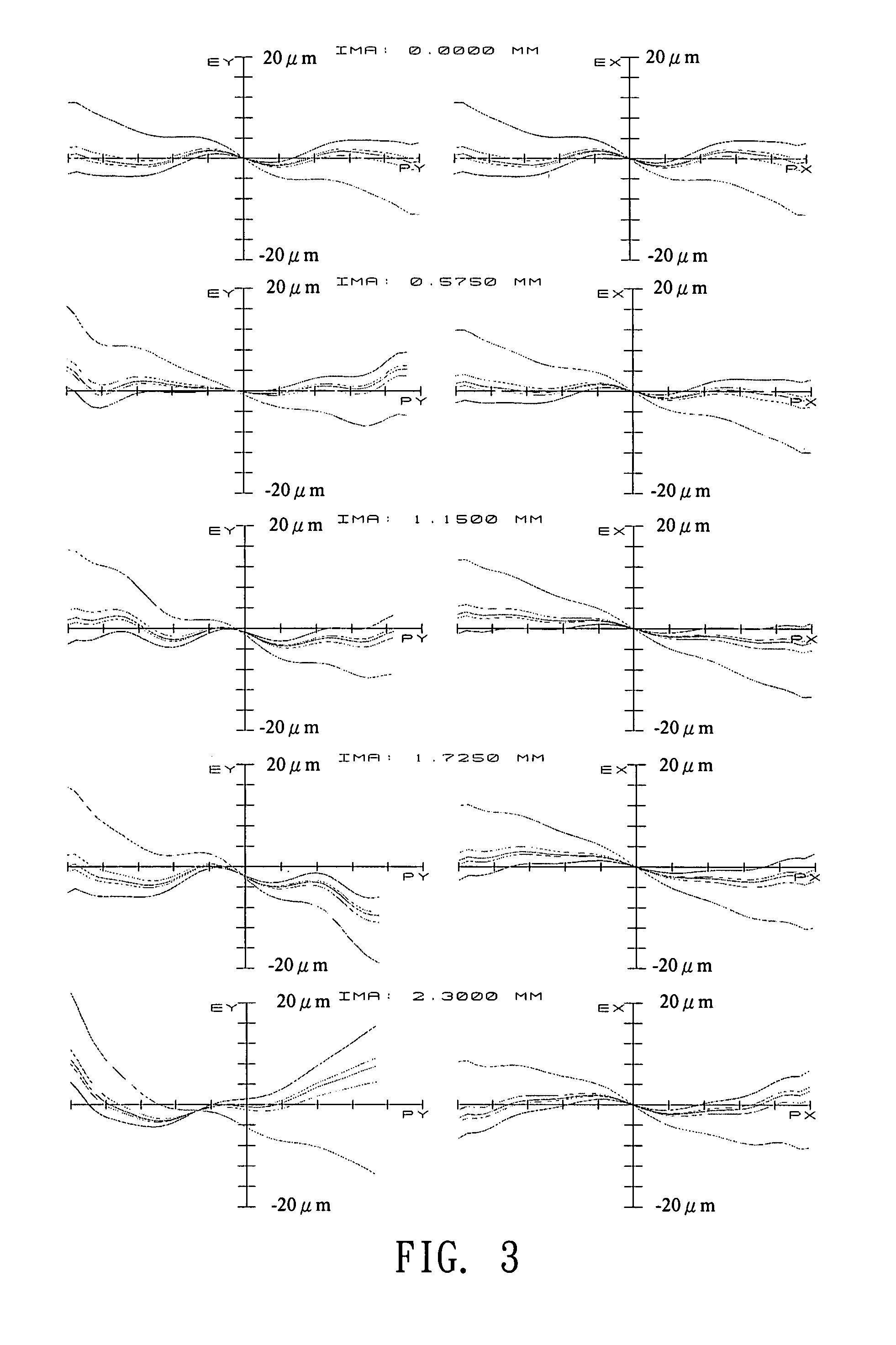

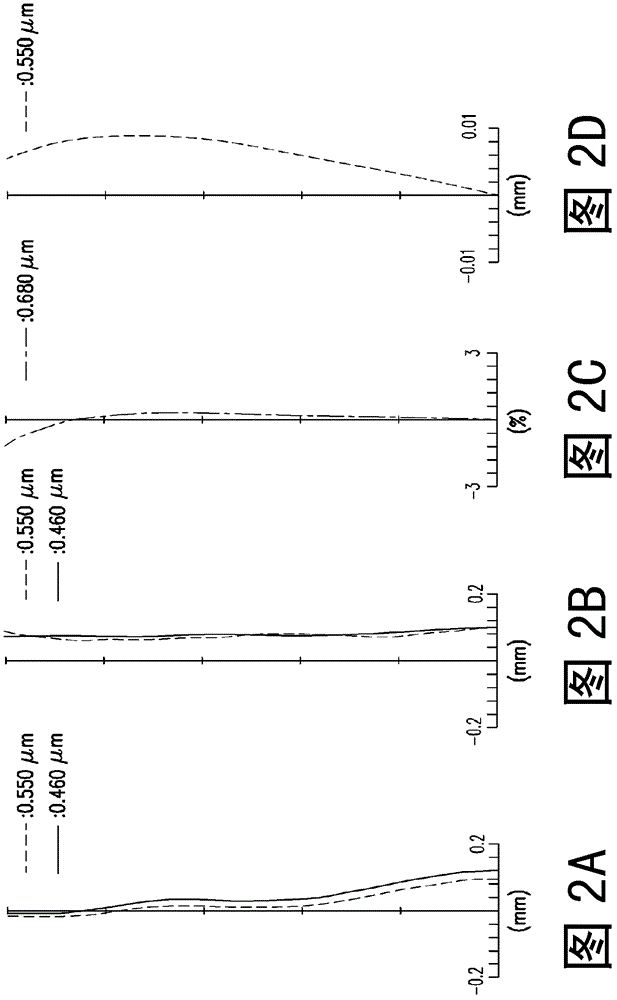

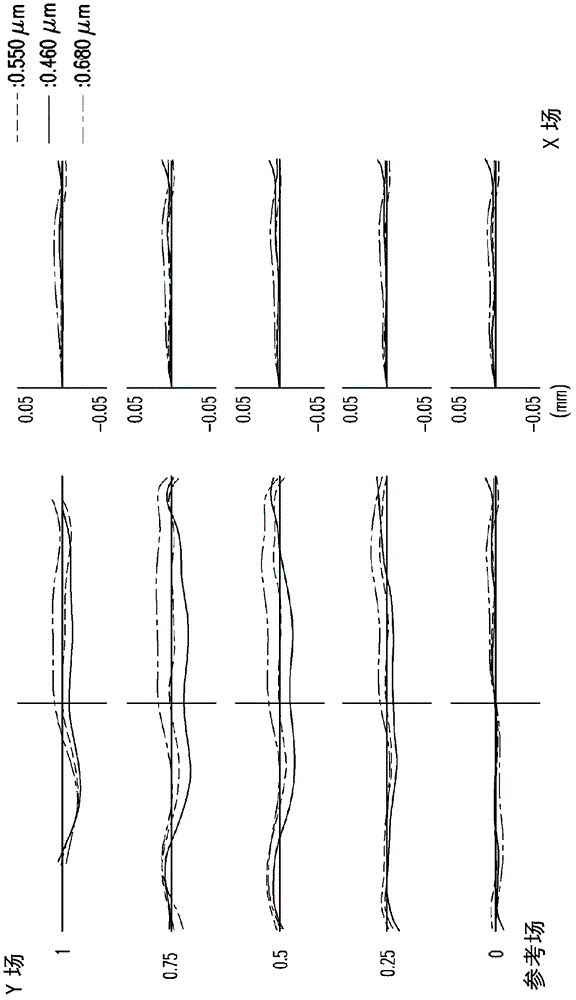

ActiveUS20160054543A1Good optical performanceCorrected spherical aberrationLensOptical axisImaging lens

An imaging lens includes: a first lens having positive refractive power; a second lens having positive refractive power; a third lens having negative refractive power; a fourth lens having positive refractive power; a fifth lens having negative refractive power; and a sixth lens having positive or negative refractive power in vicinity of an optical axis, a peripheral portion of a surface on an image side of the sixth lens including one or more inflection points, the first to sixth lenses being provided in order from an object side.

Owner:SONY CORP

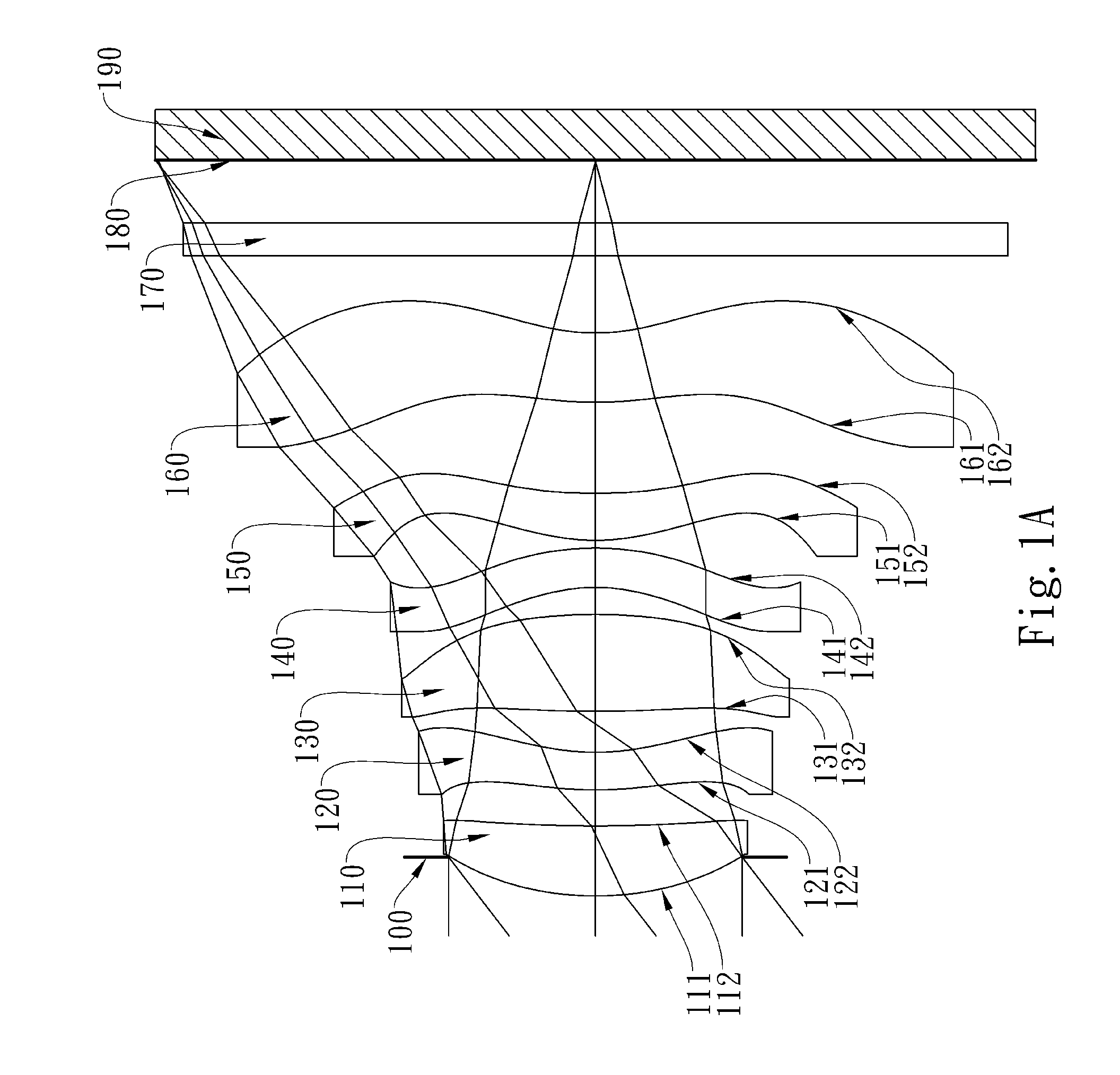

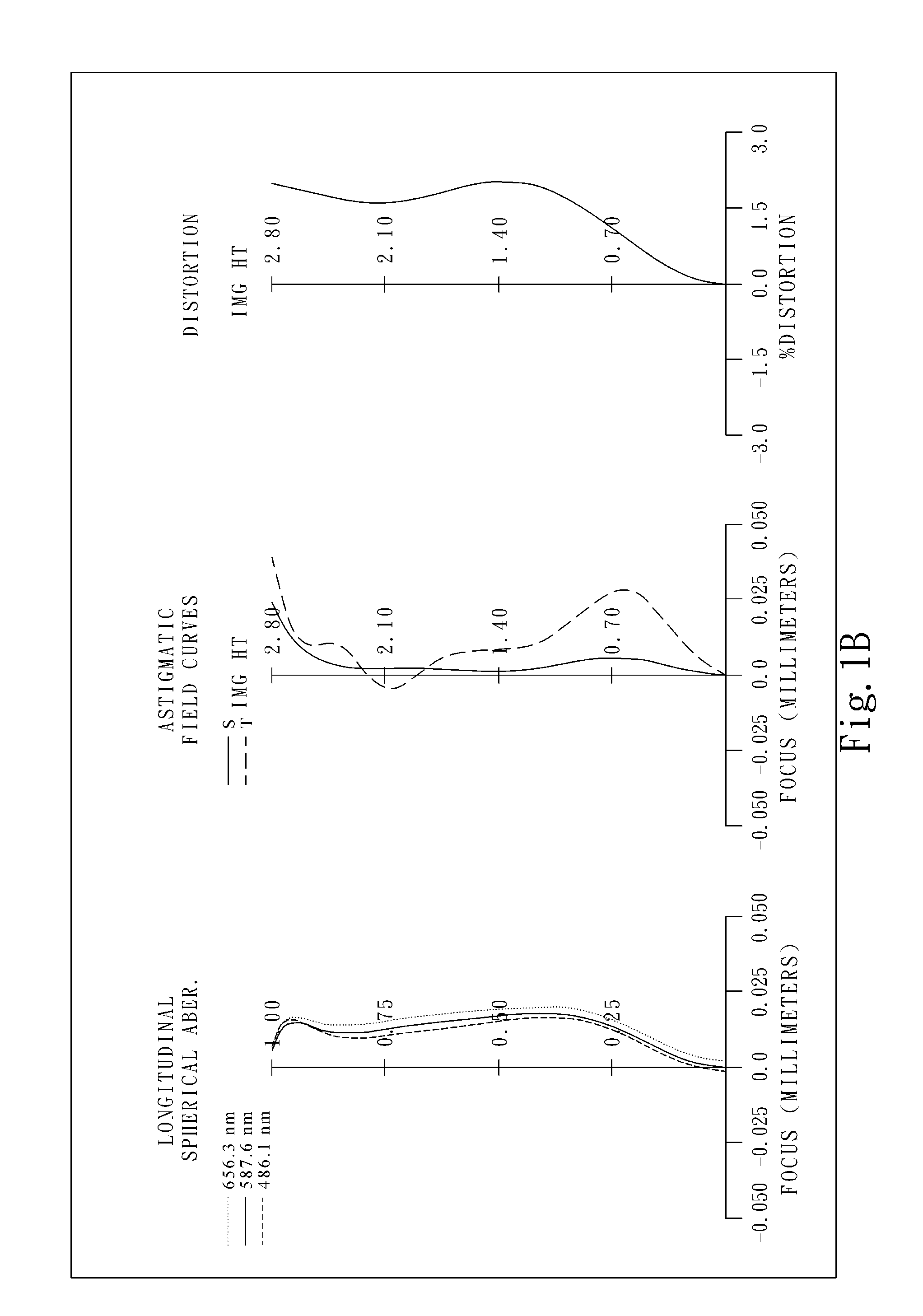

Optical image lens system

ActiveUS8717685B2Suppressing the field curvatureReduce sensitivityStereoscopic photographyLensSurface changePhysics

This invention provides an optical image lens system comprising: a positive first lens element having a convex object-side surface; a second lens element; a positive third lens element; a fourth lens element; a positive plastic fifth lens element having a convex object-side surface and a concave image-side surface, at least one of the object-side and image-side surfaces is aspheric; and a negative plastic sixth lens element having a concave image-side surface, at least one of the object-side and image-side surfaces is aspheric, wherein the shape of the image-side surface changes from concave at the paraxial region thereof to convex while away from the paraxial region thereof.

Owner:LARGAN PRECISION

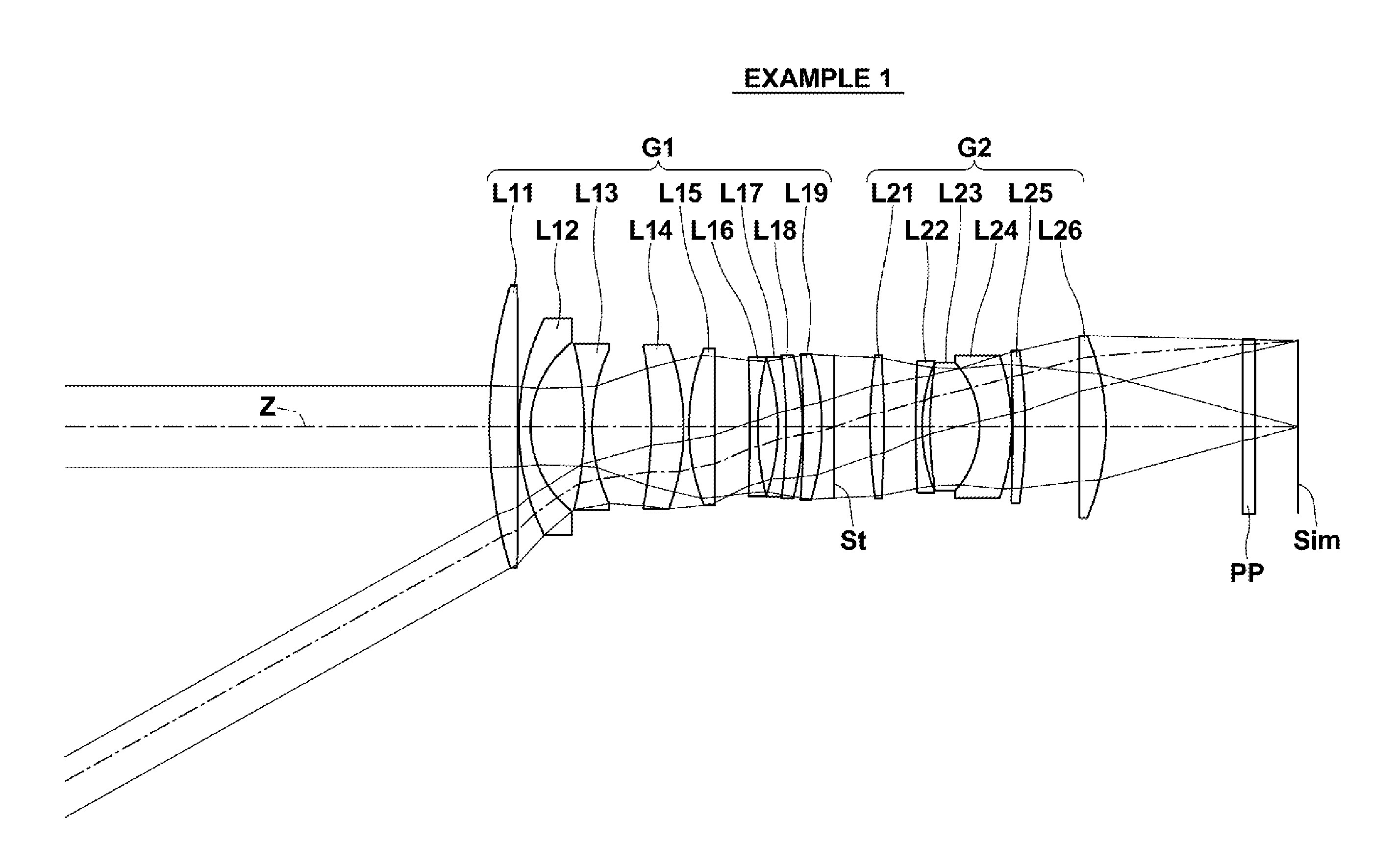

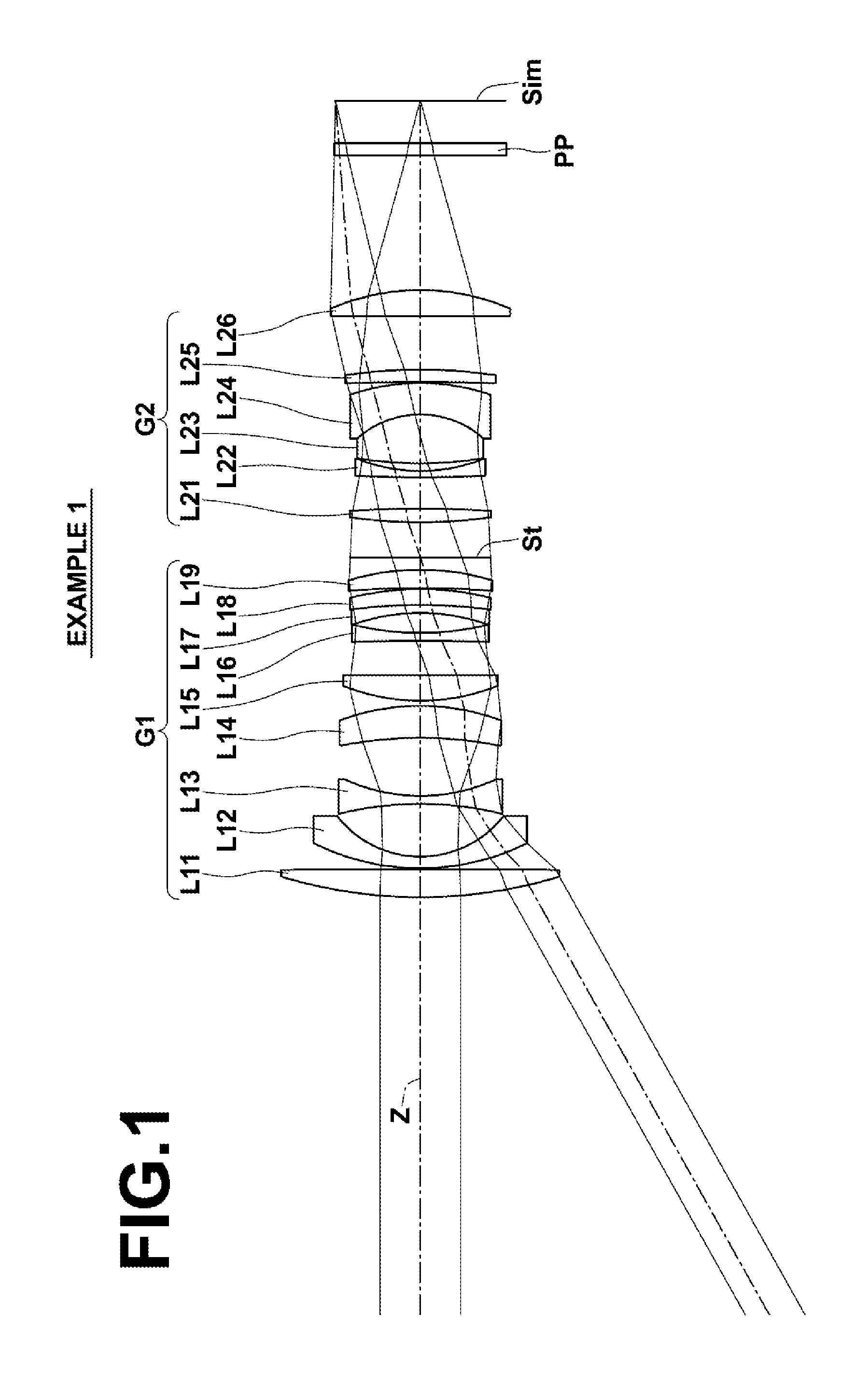

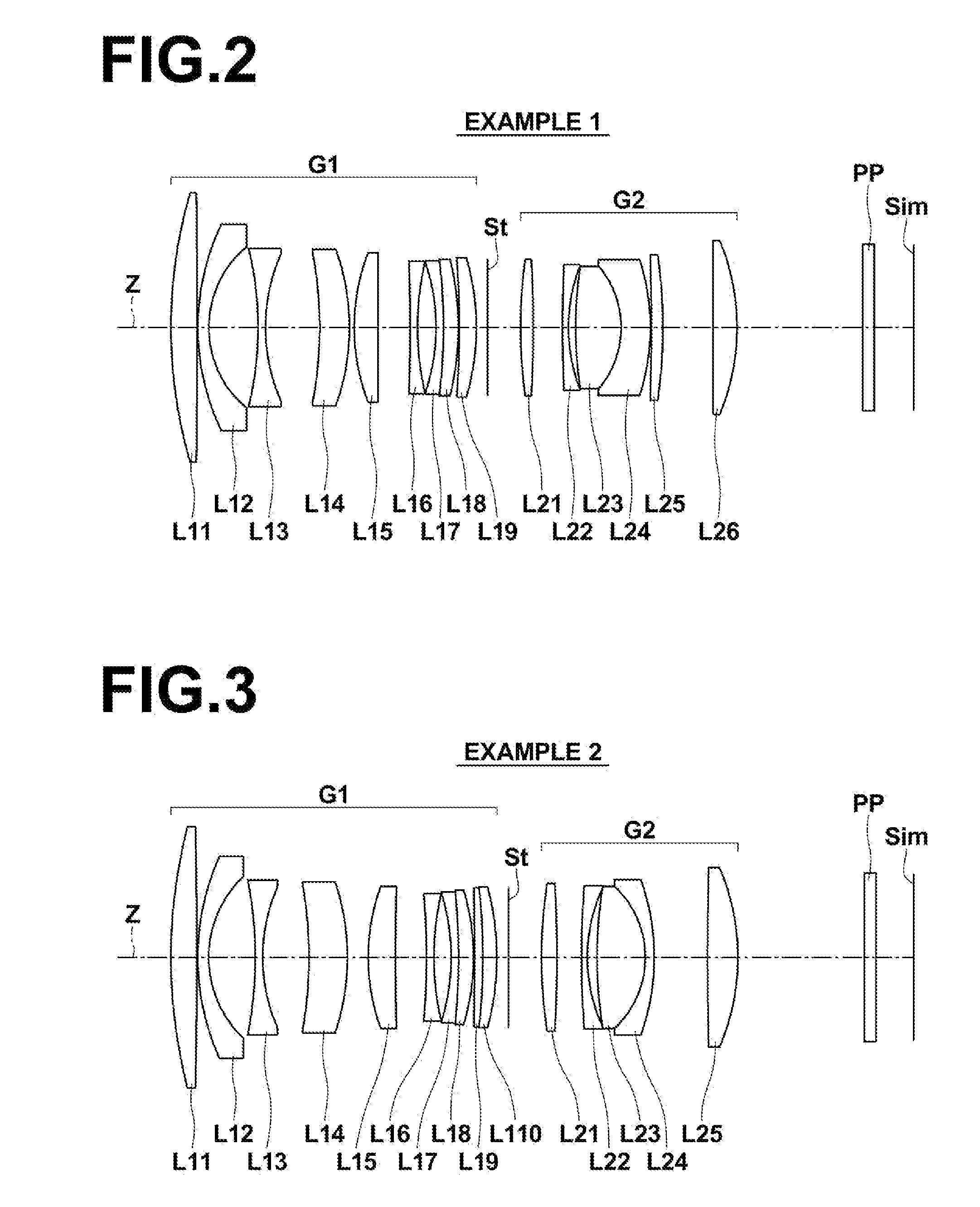

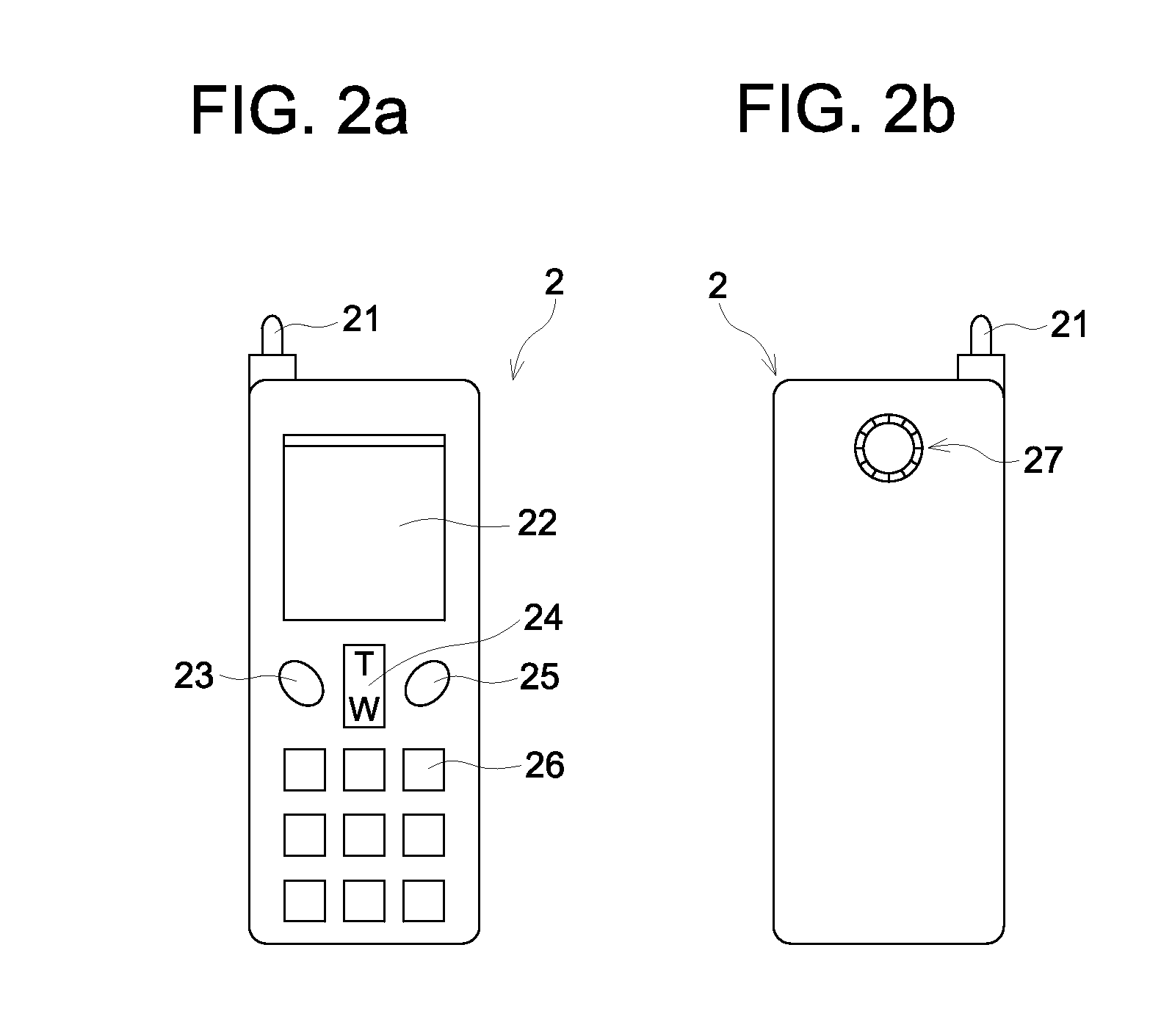

Zoom lens, camera, and portable information terminal device

InactiveUS6839183B2Increase freedomCorrected spherical aberrationTelevision system detailsColor television detailsTerminal equipmentMagnification

A zoom lens includes a negative first group optical system, and a positive second group optical system, which are sequentially arranged from an object side, and an aperture stop disposed on the object side of the second group optical system moving integrally therewith. During change of magnification from a short focal end to a long focal end, the second group optical system monotonously moves from the image side to the object side, and the first group optical system moves so as to correct displacement of an image plane position in accordance with the change of magnification.

Owner:RICOH KK

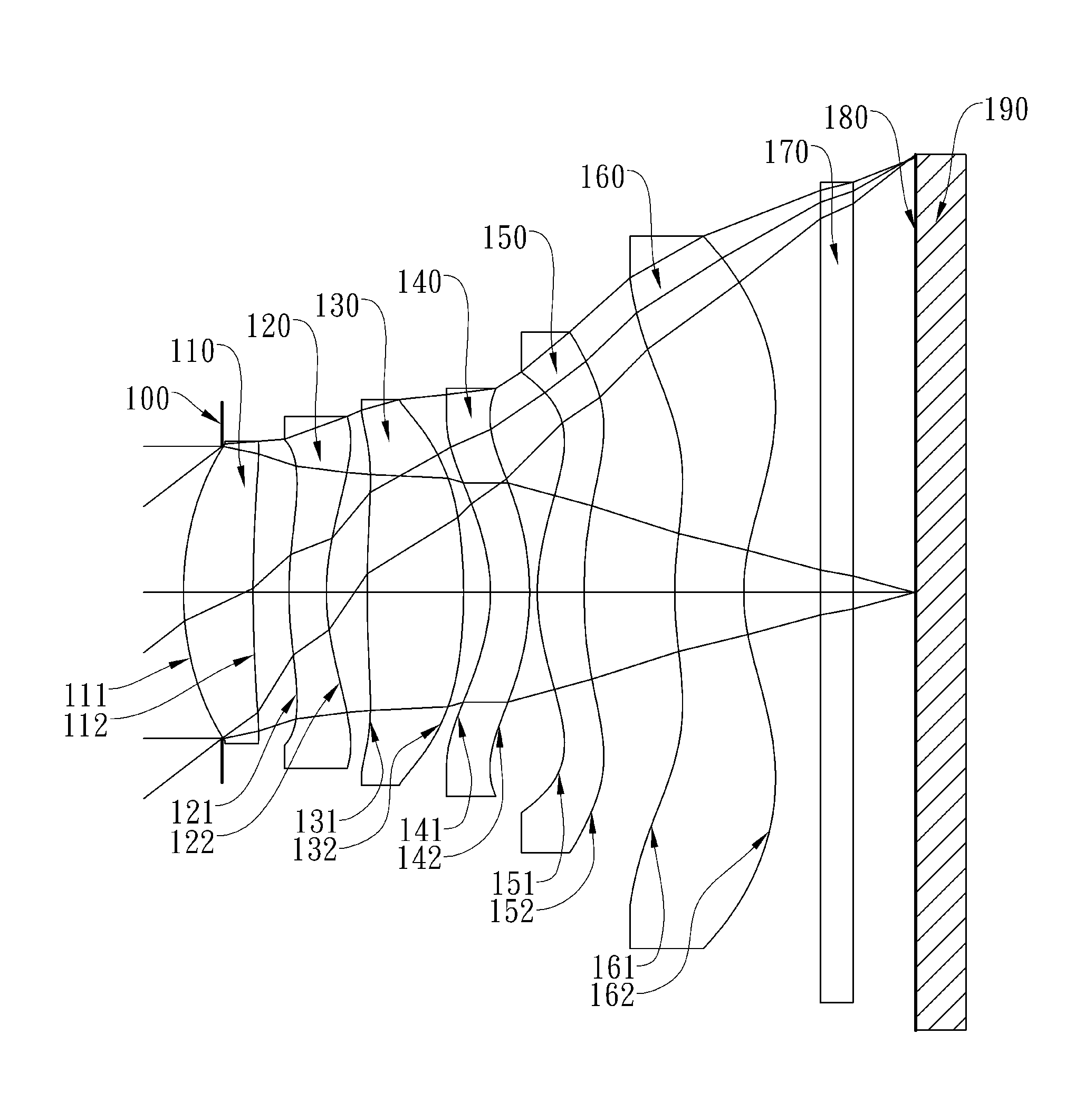

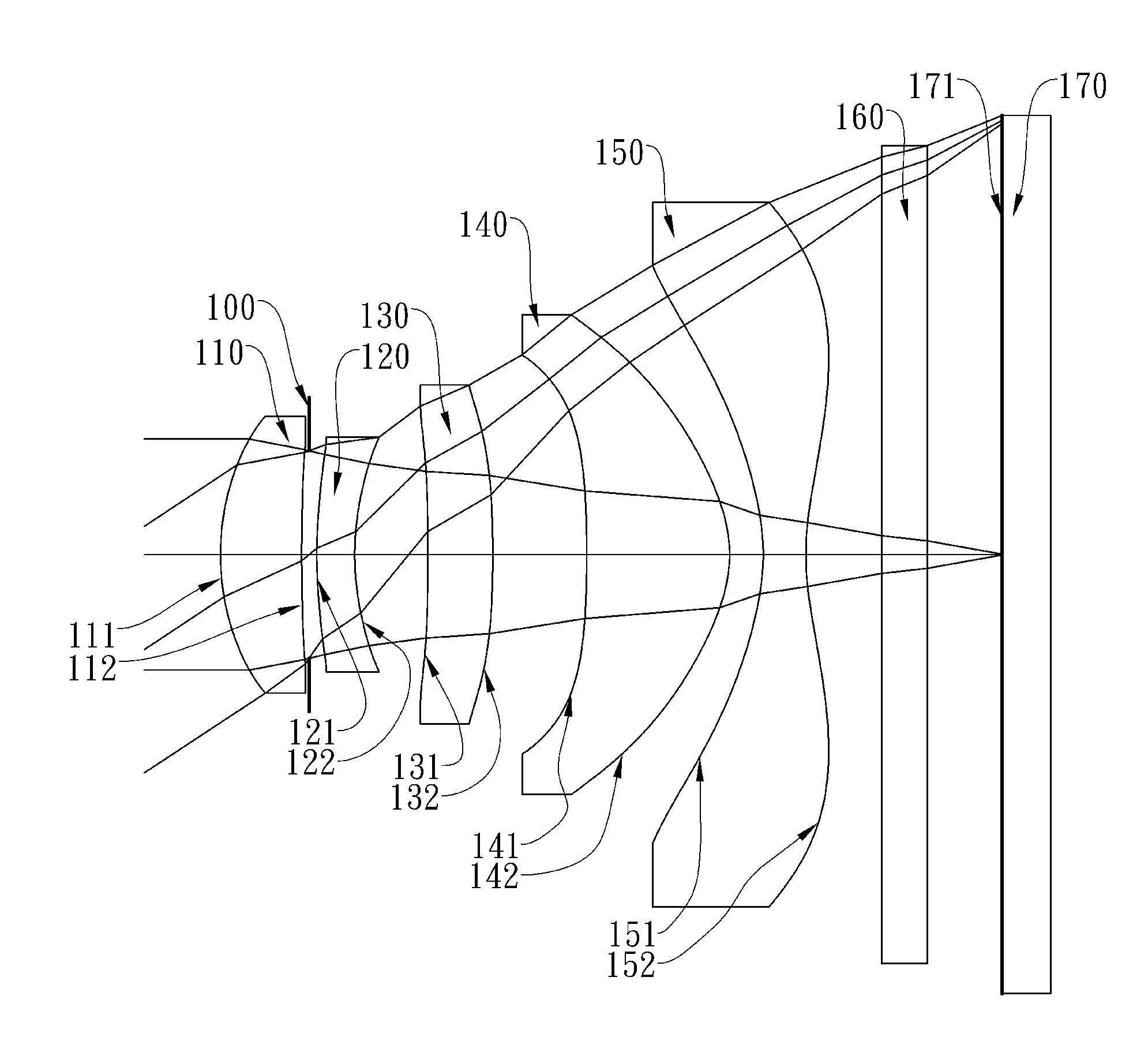

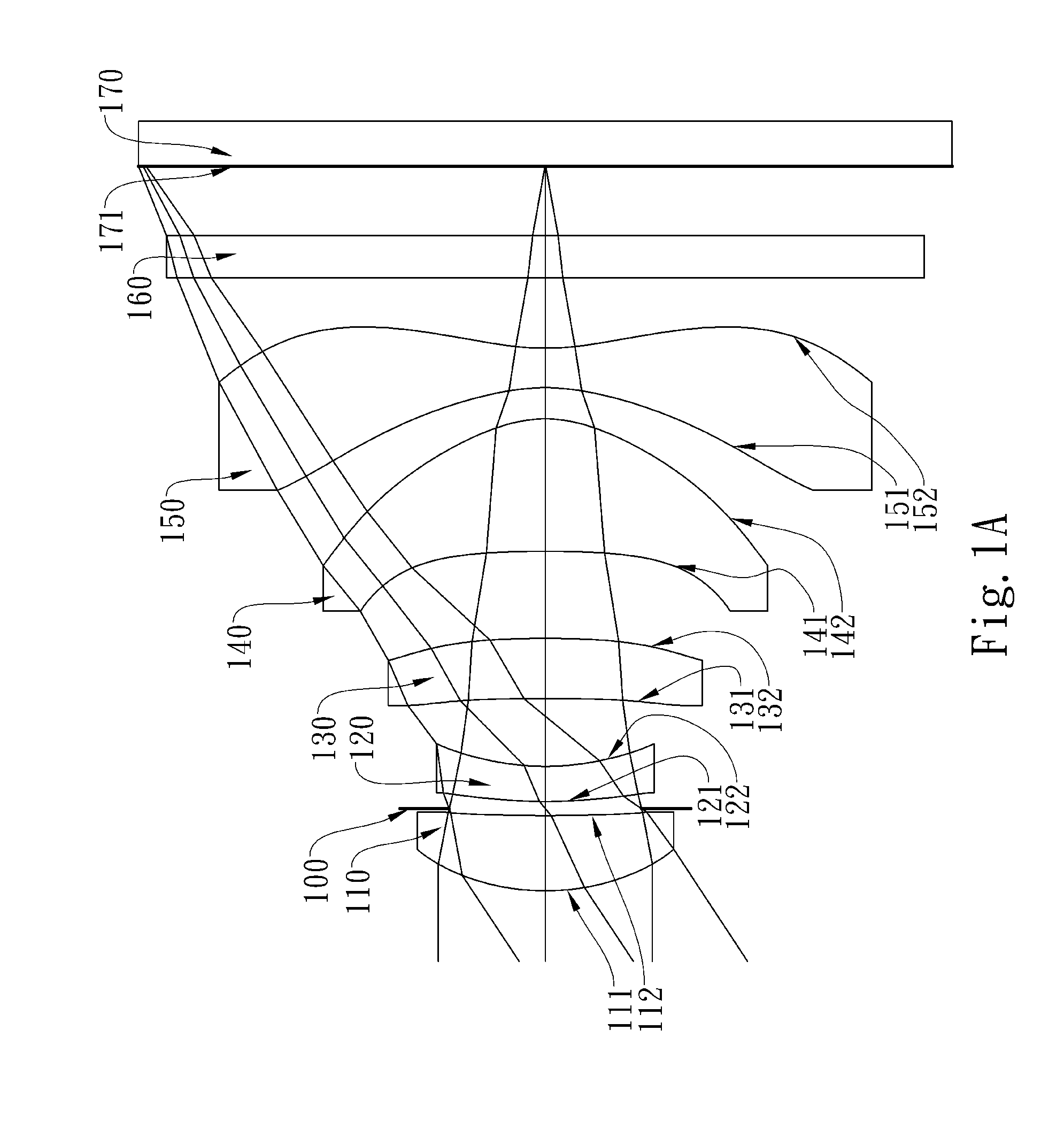

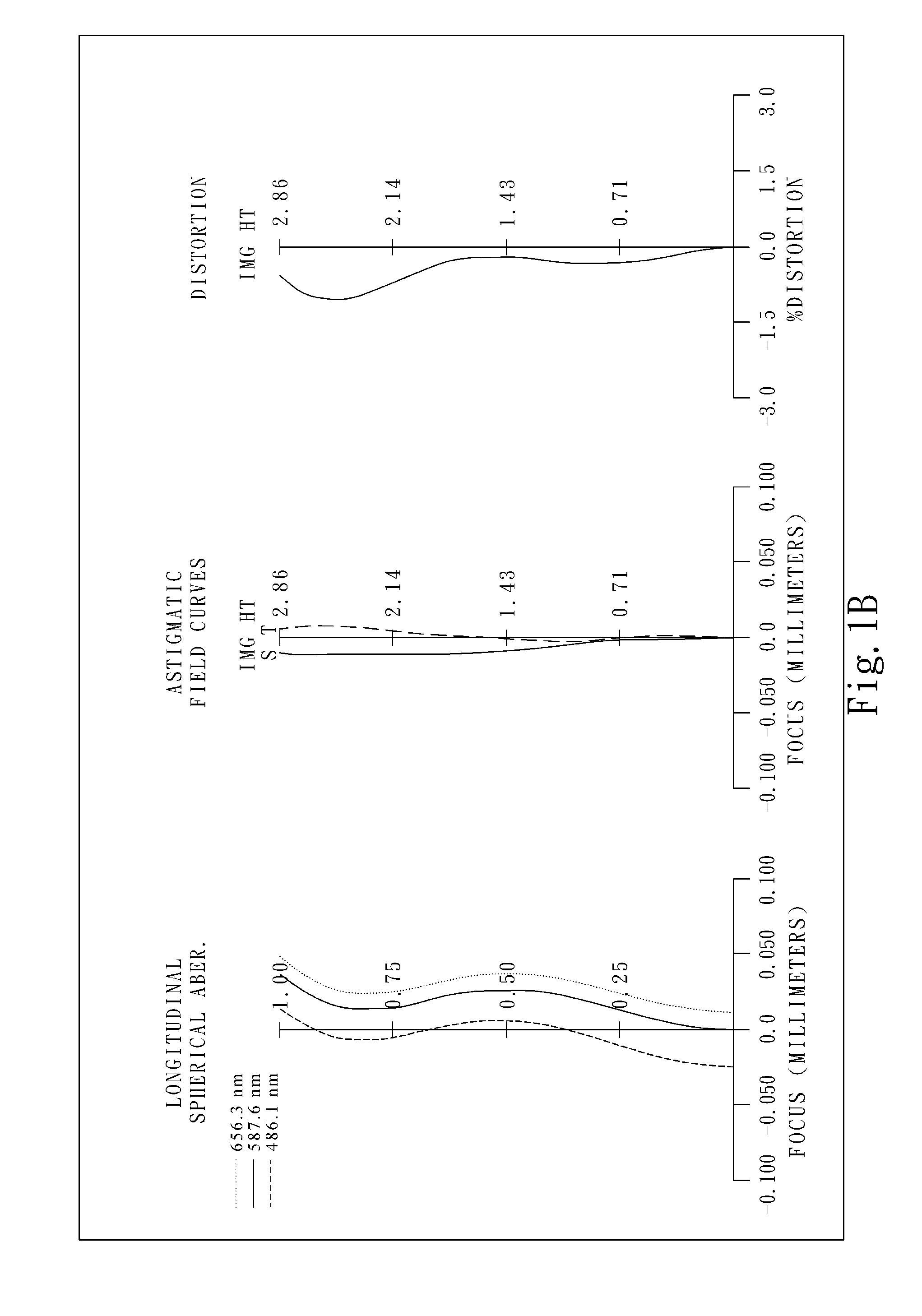

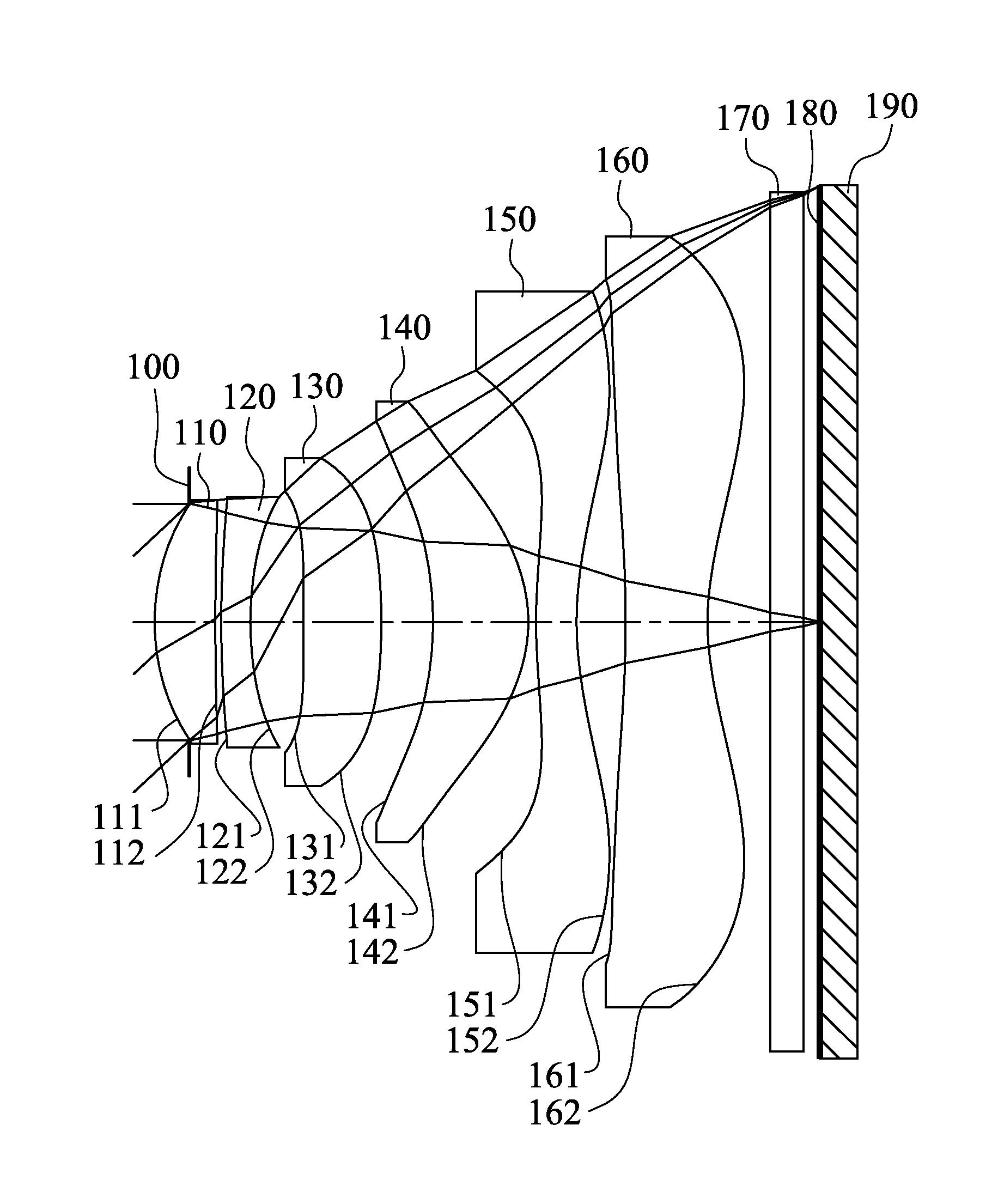

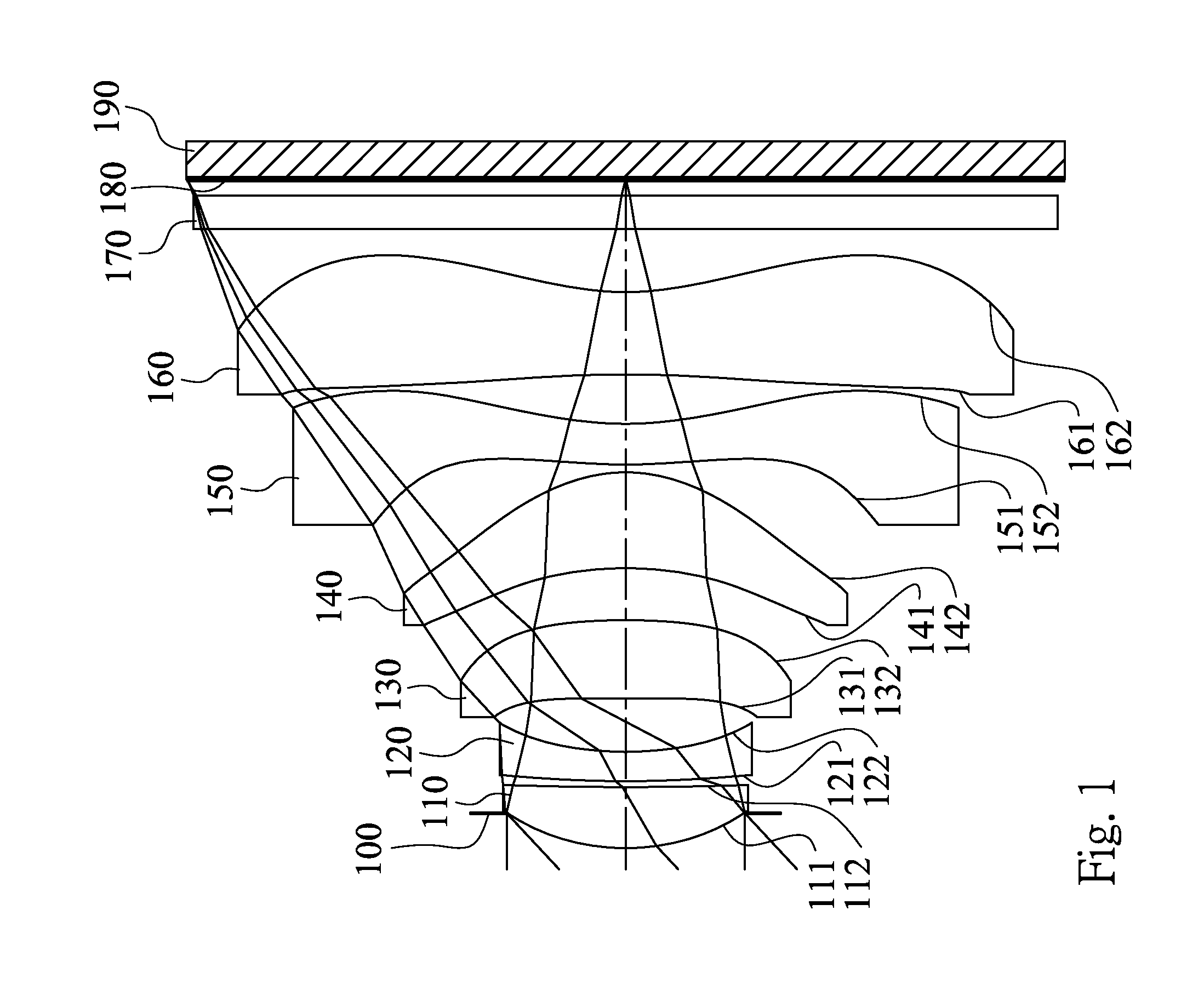

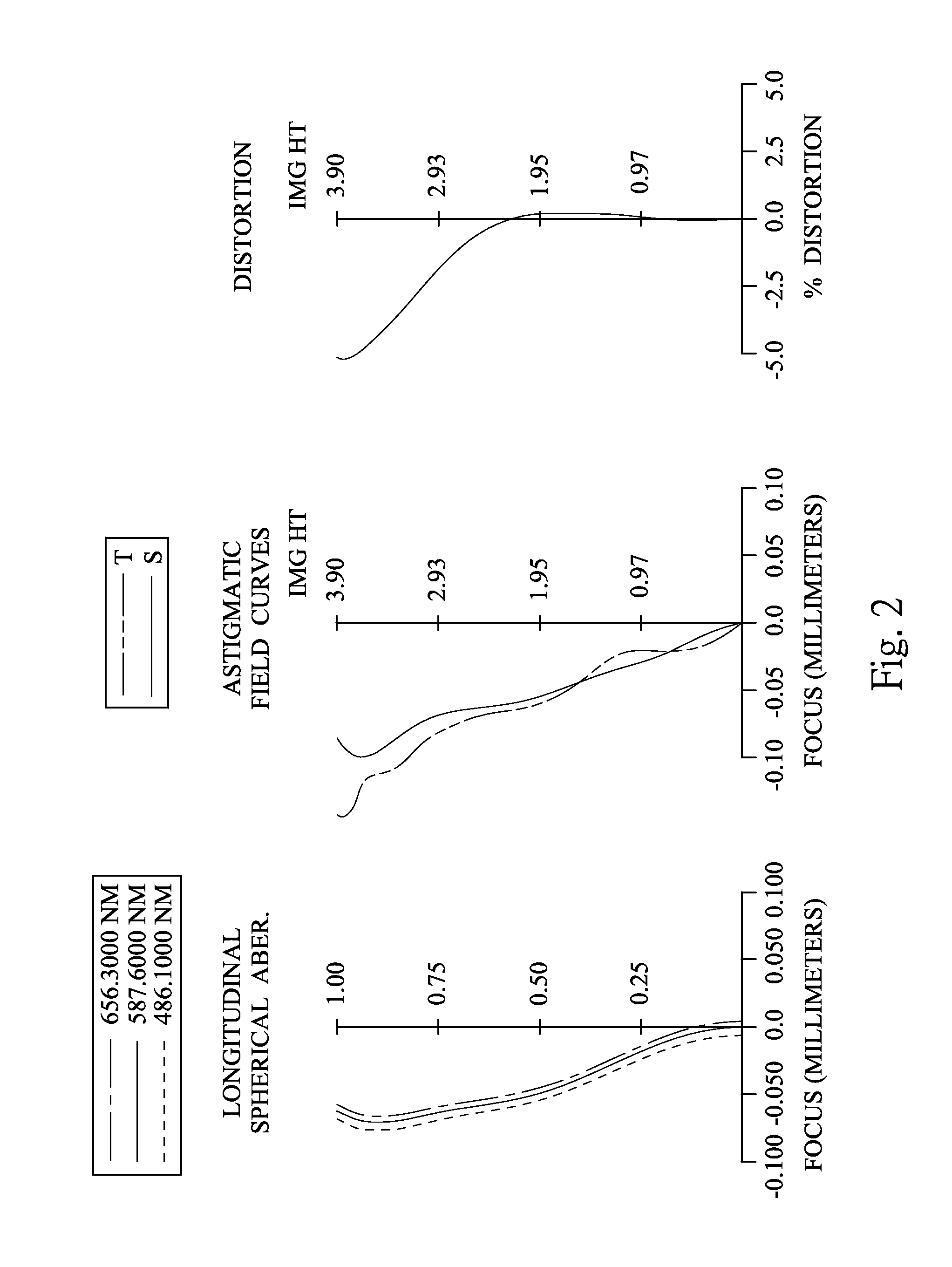

Optical image capturing lens assembly

An optical image capturing lens assembly includes, in order from an object side to an image side, a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element, and a sixth lens element. The first lens element with positive refractive power has a convex object-side surface. The object-side surface and the image-side surface of the fifth lens element are aspheric and at least one of the object-side surface and the image-side surface has at least one inflection point formed thereon. The sixth lens element with negative refractive power has a concave object-side surface and a convex image-side surface, wherein the object-side surface and the image-side surface of the sixth lens element are aspheric.

Owner:LARGAN PRECISION

Image capturing optical lens system

An image capturing optical lens system includes, in order from an object side to an image side, a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element, and a sixth lens element. The first lens element with positive refractive power has a convex object-side surface. The second lens element has negative refractive power. The third lens element has refractive power. The fourth lens element has refractive power, wherein at least one surface of the fourth lens element is aspheric. The fifth lens element with negative refractive power has a concave object-side surface and a convex image-side surface, and the surfaces thereof are aspheric. The sixth lens element with refractive power has an image-side surface changing from concave at a paraxial region thereof to convex at a peripheral region thereof, and the surfaces thereof are aspheric.

Owner:LARGAN PRECISION

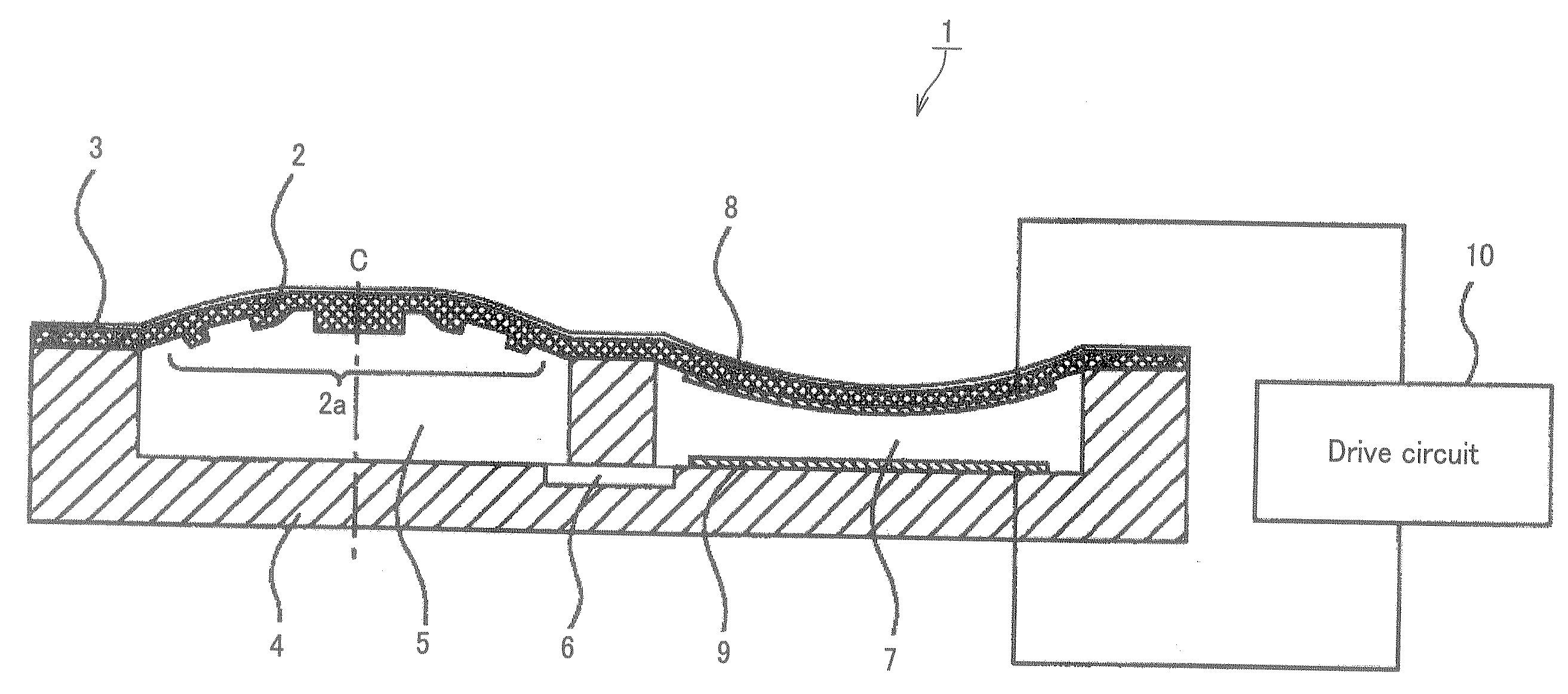

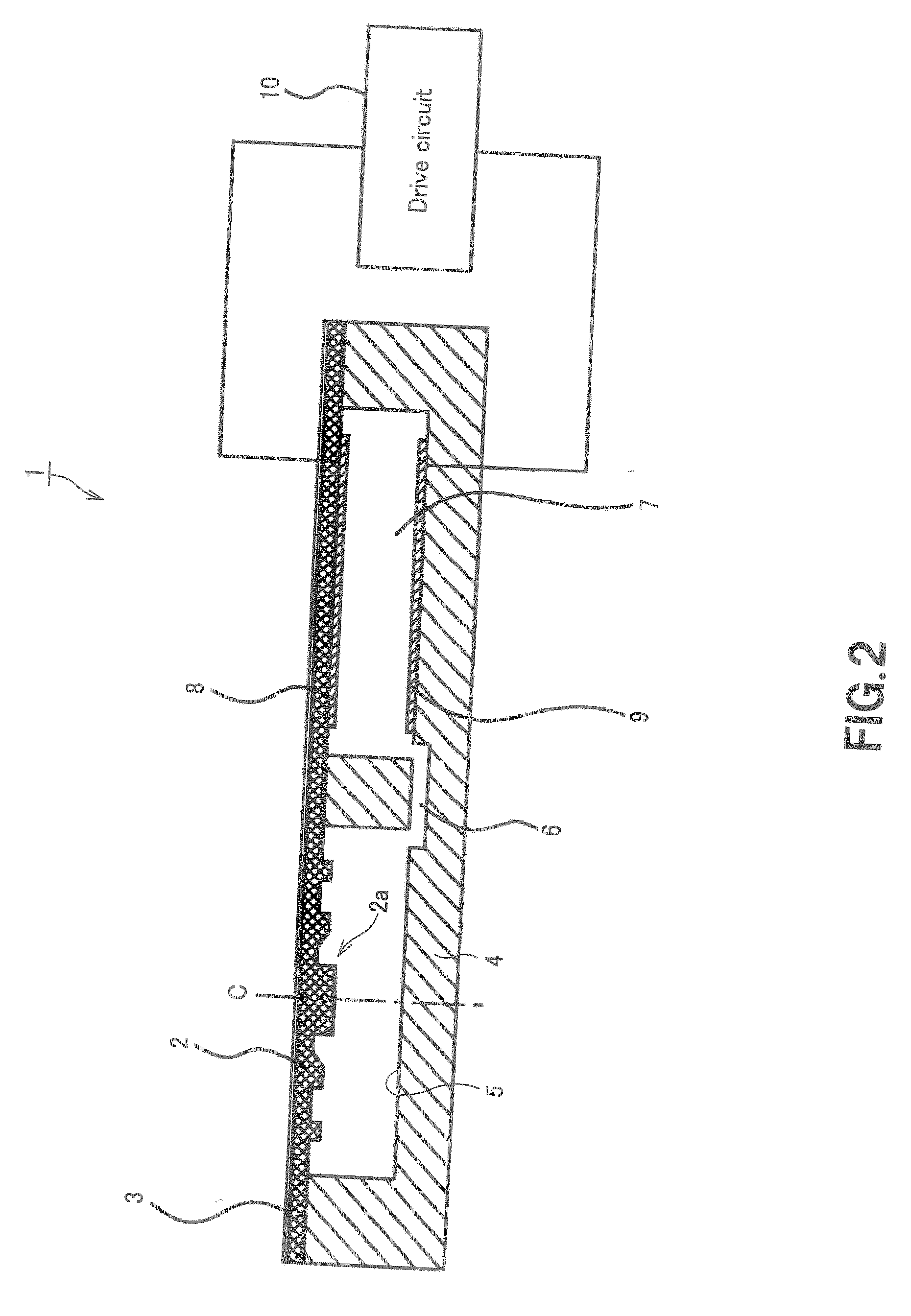

Deformable mirror device, deformable mirror plate

InactiveUS20070165312A1Corrected spherical aberrationMirrorsRecord information storageDistribution patternEngineering

A deformable mirror device compensates the spherical aberration caused by the difference of thickness of the cover layers covering recording layers of an optical disc. Circular projections are concentrically arranged on a flexible member (2) where a mirror surface (3) is formed to produce a strength distribution pattern (2a). Attractive force is generated as electrostatic force between an upper electrode (8) and a lower electrode (9) according to the voltage applied from a drive circuit (10) so as to contract the second space (7) and accordingly expand the first space (5) in order to deform the mirror surface. At this time, the profile of the mirror surface is deformed to show a desired profile that can compensate the spherical aberration by the pattern formed on the flexible member (2) as strength distribution pattern (2a). With this arrangement, only a single drive actuator (10) is needed to deform the mirror surface to simplify the configuration and the control operation. The mirror surface can be deformed stepwise to show predetermined deformed profiles depending on the pattern formed as strength distribution pattern (2a). Then, it is possible to compensate the spherical aberration for each of the three or more than three recording layers of the optical disc.

Owner:SONY CORP

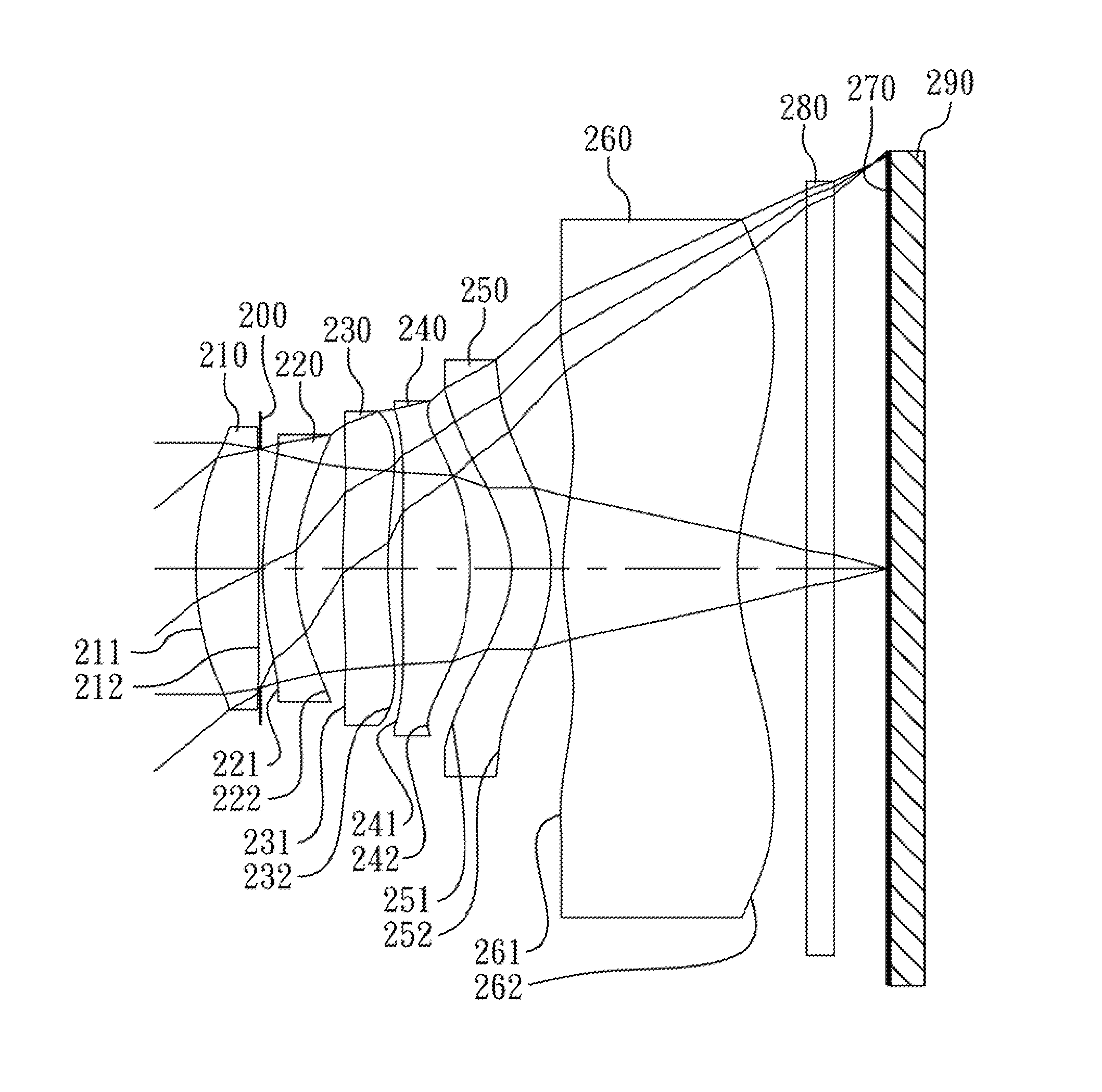

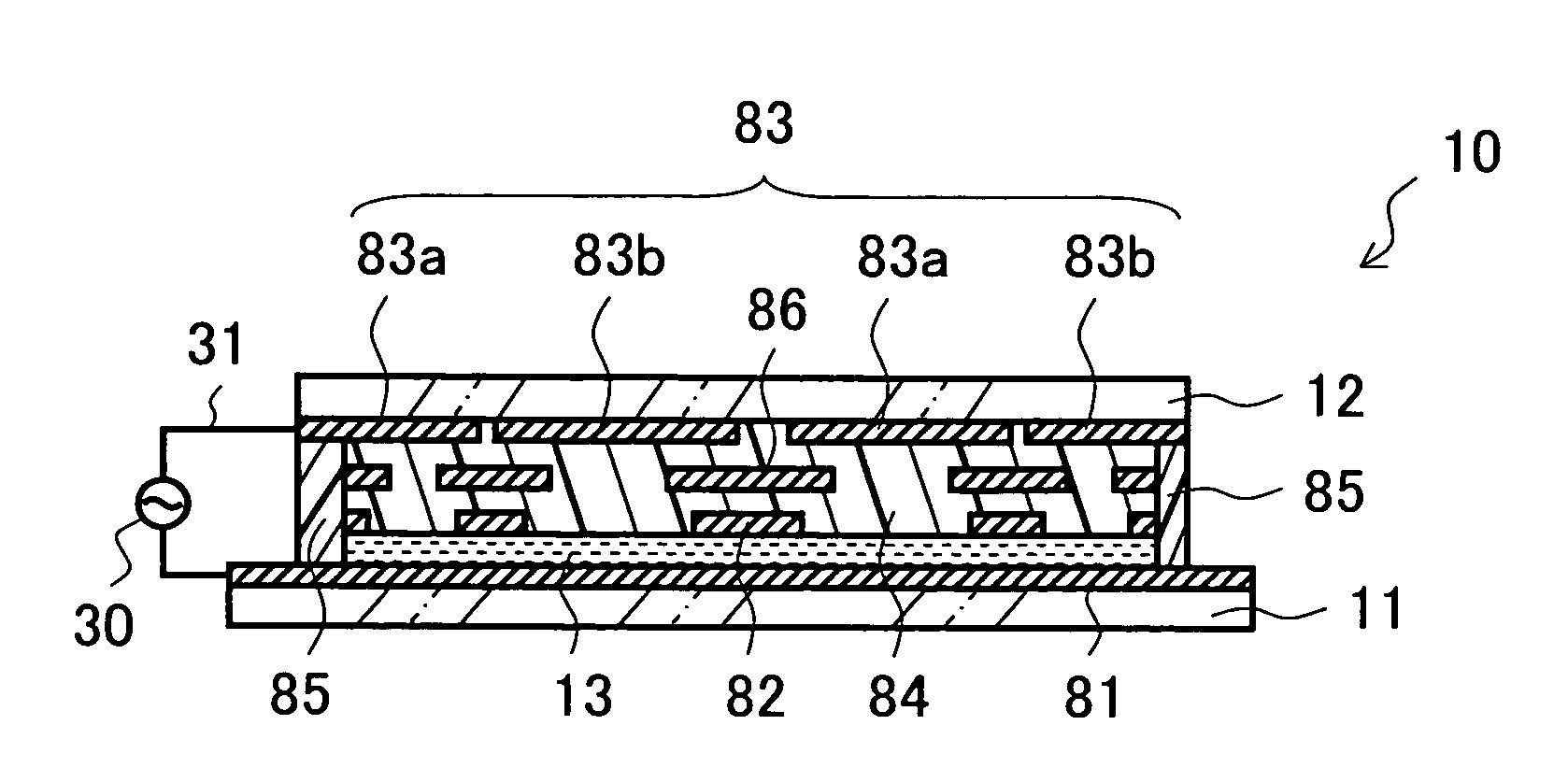

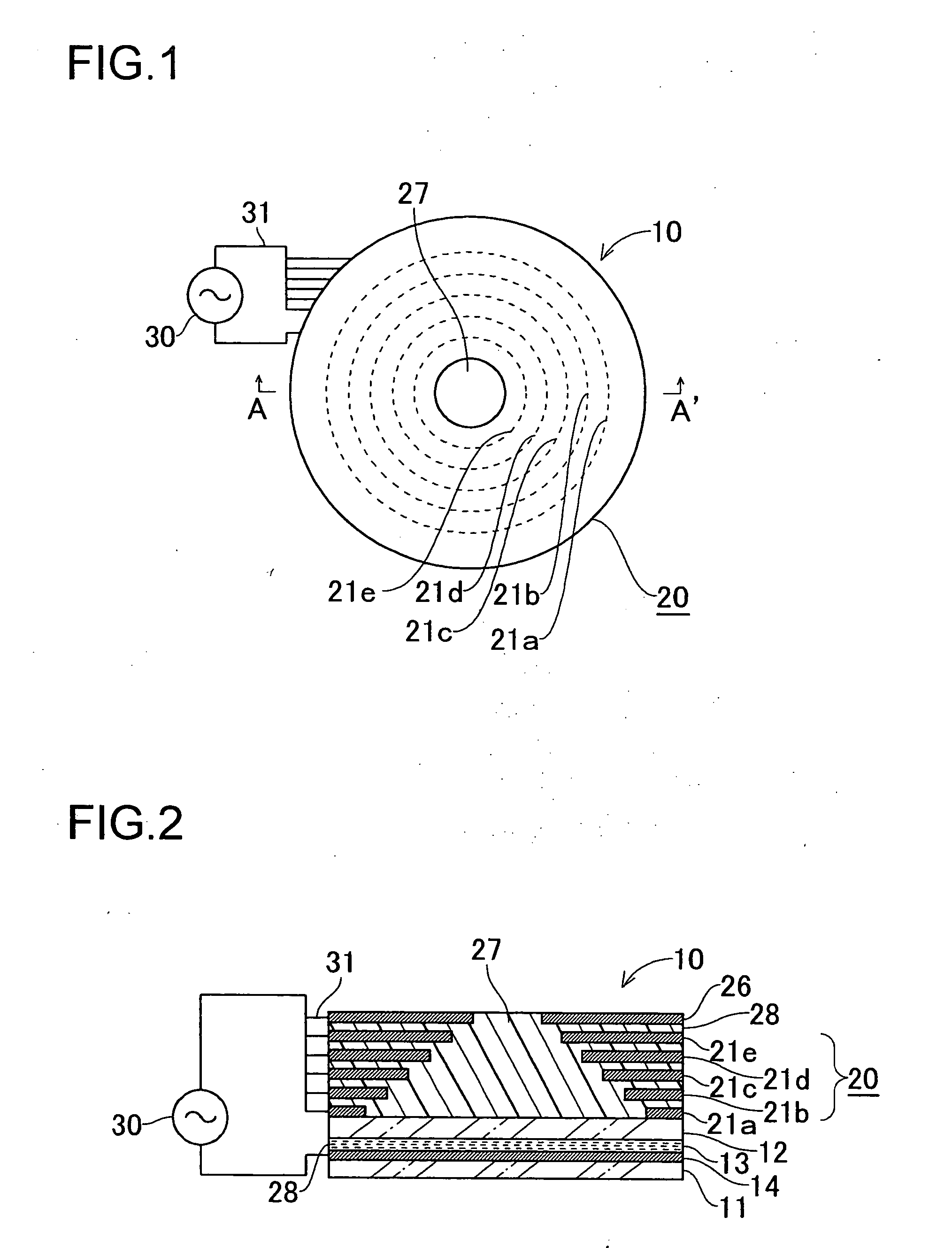

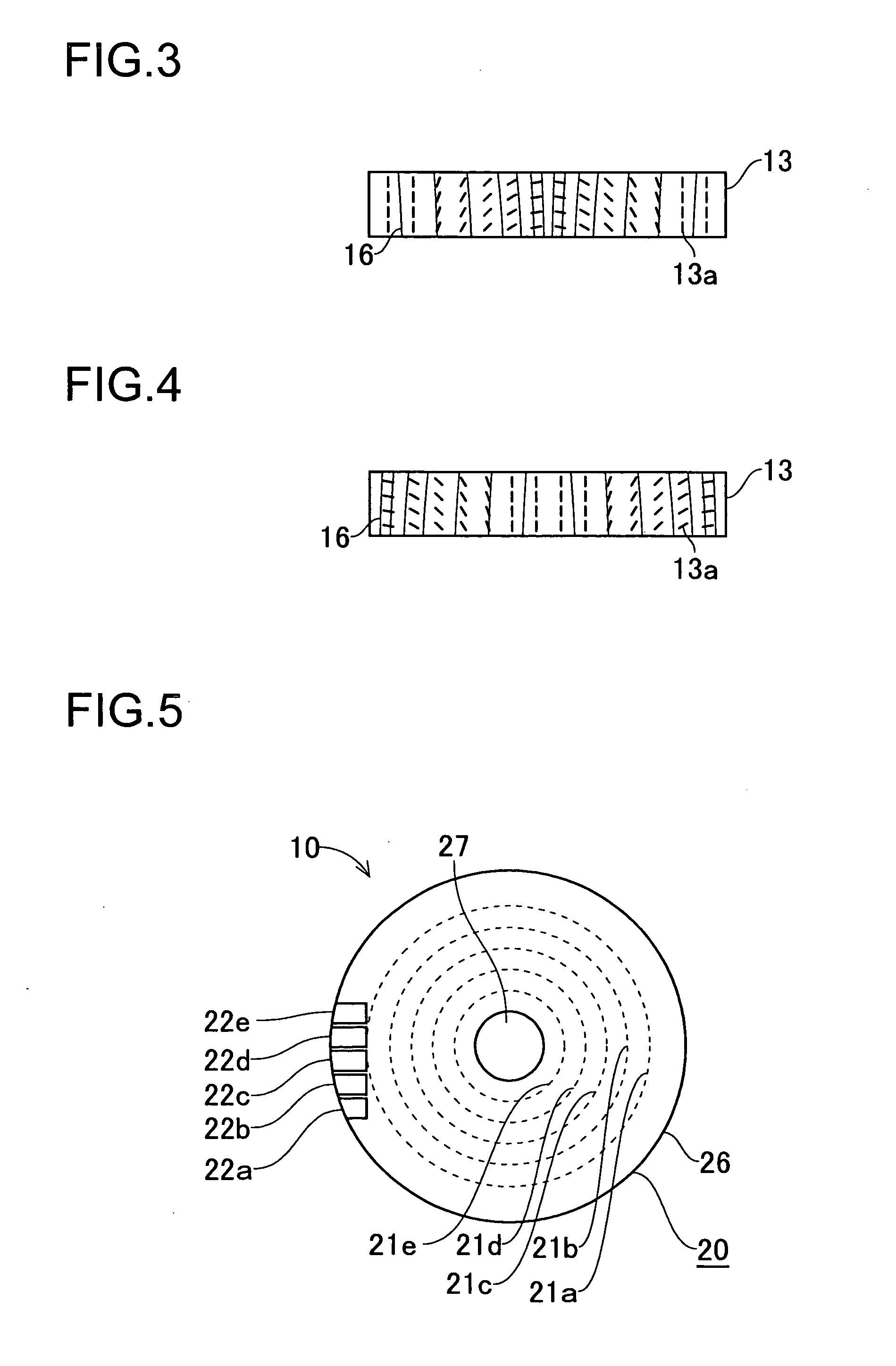

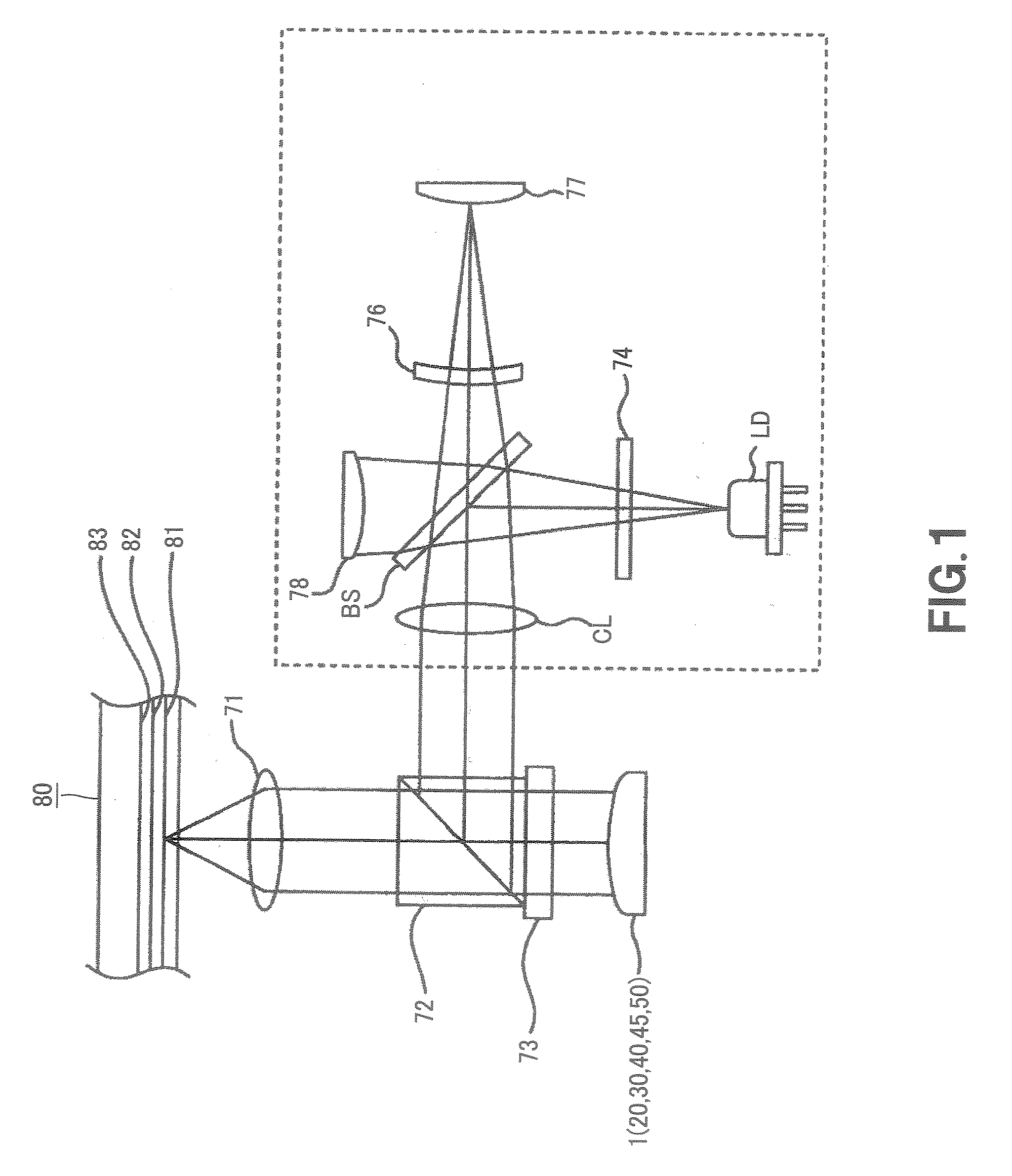

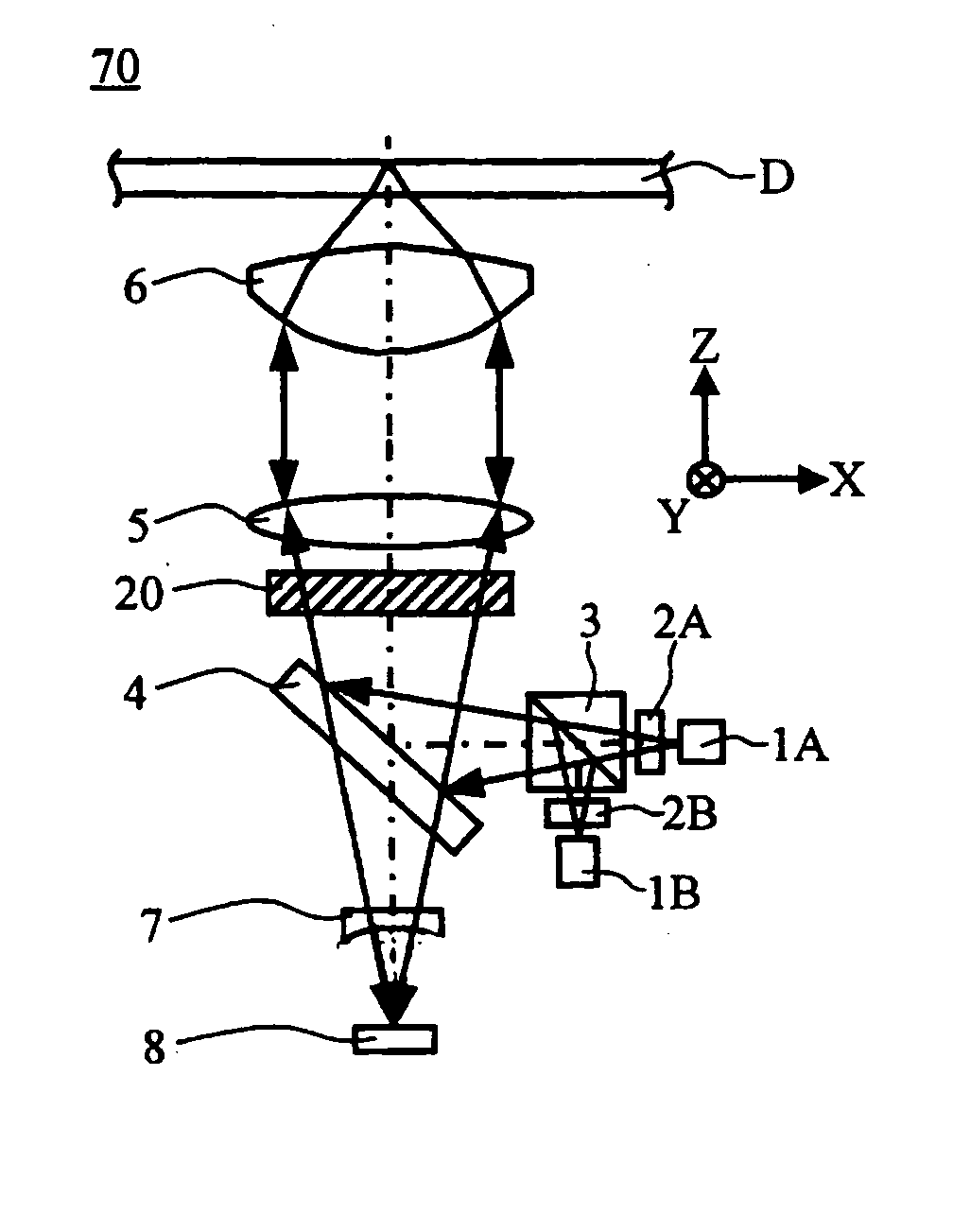

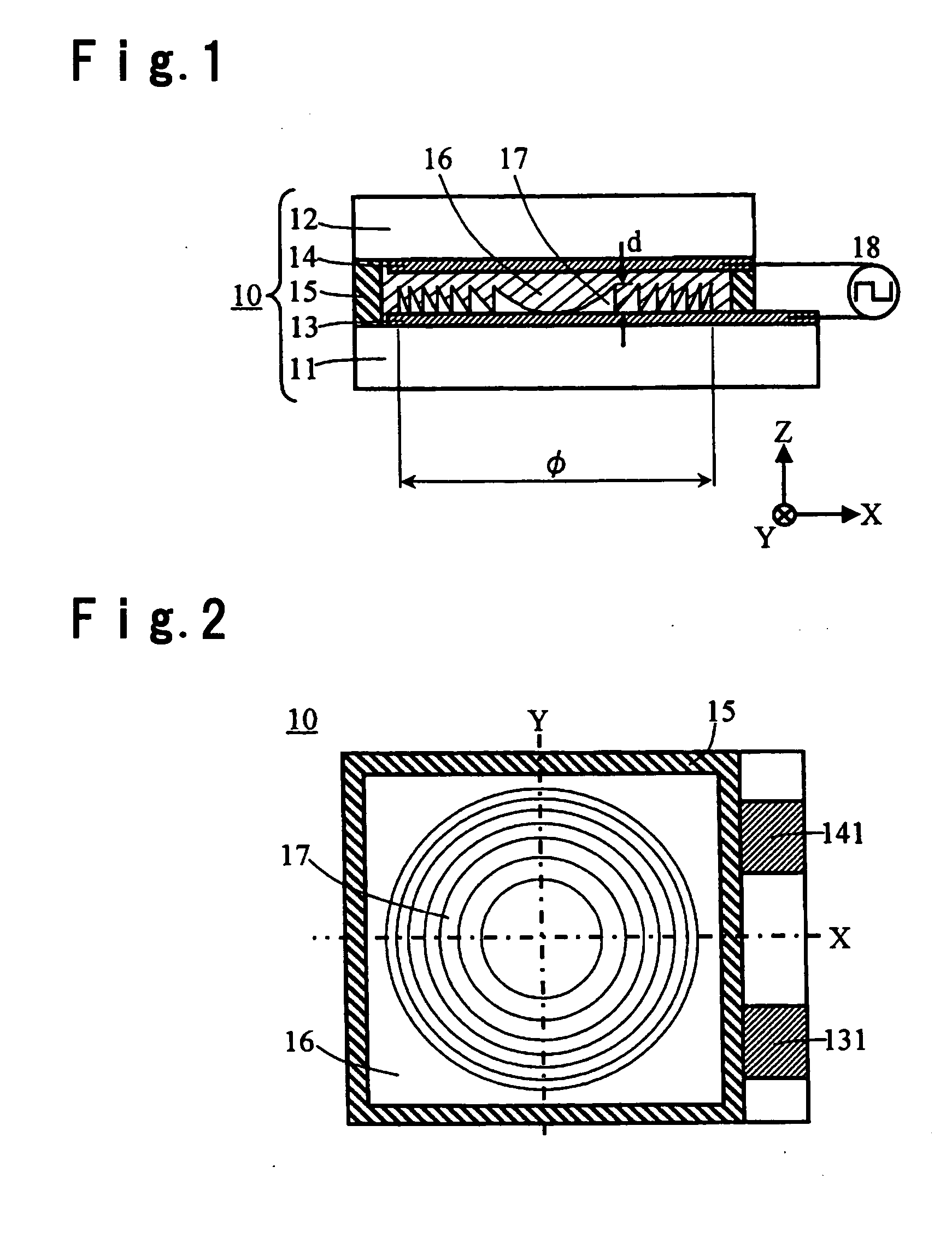

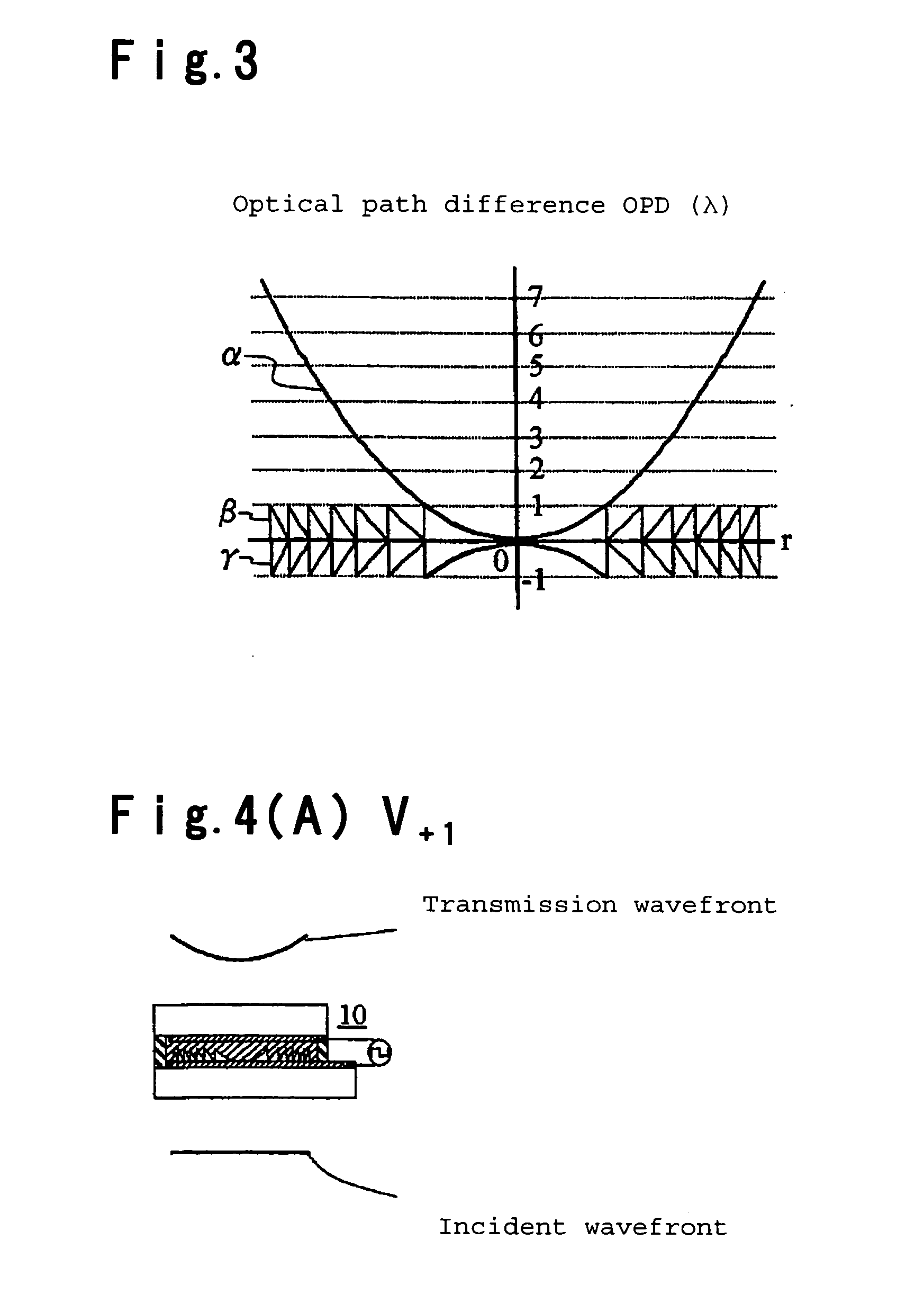

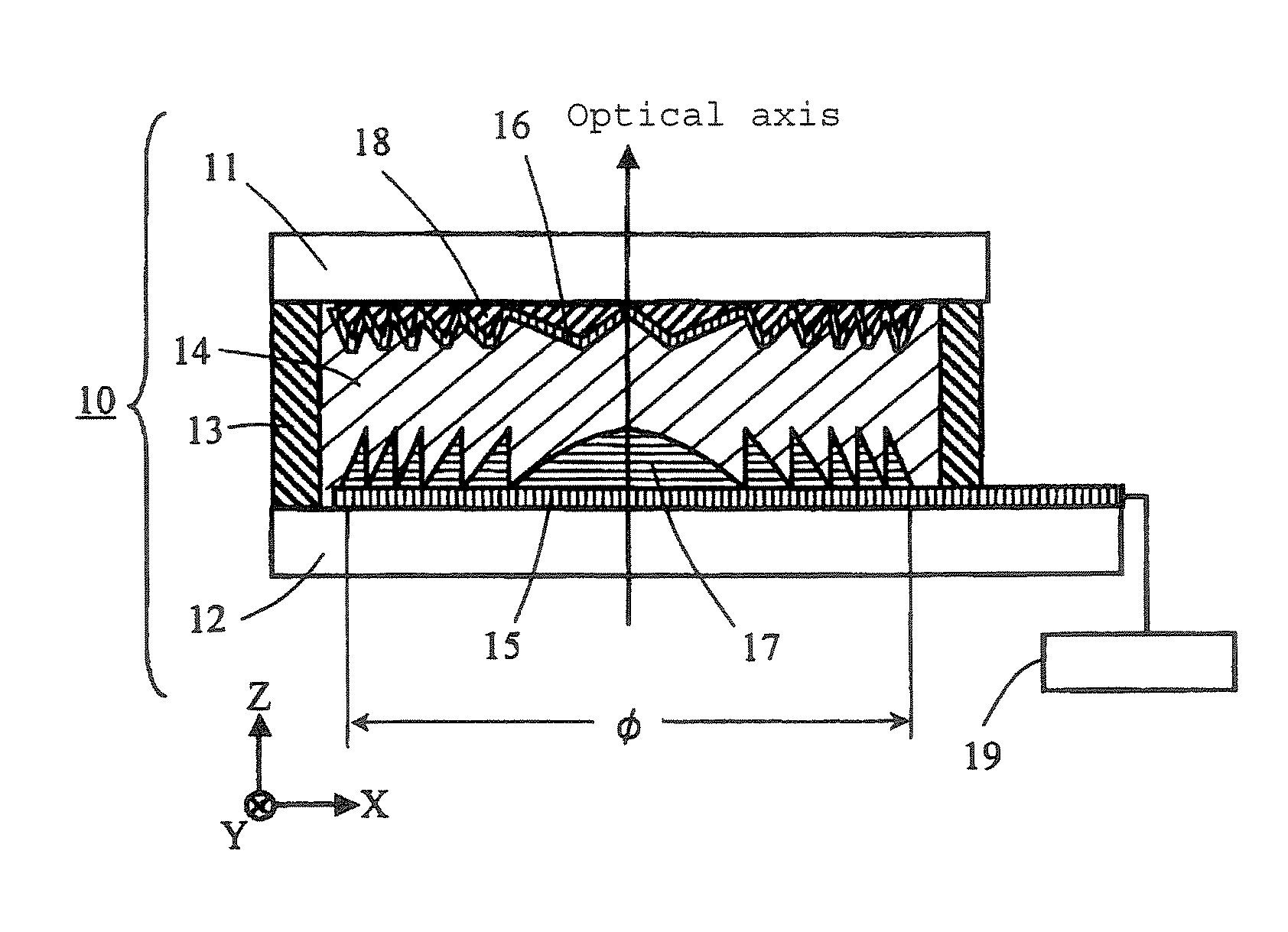

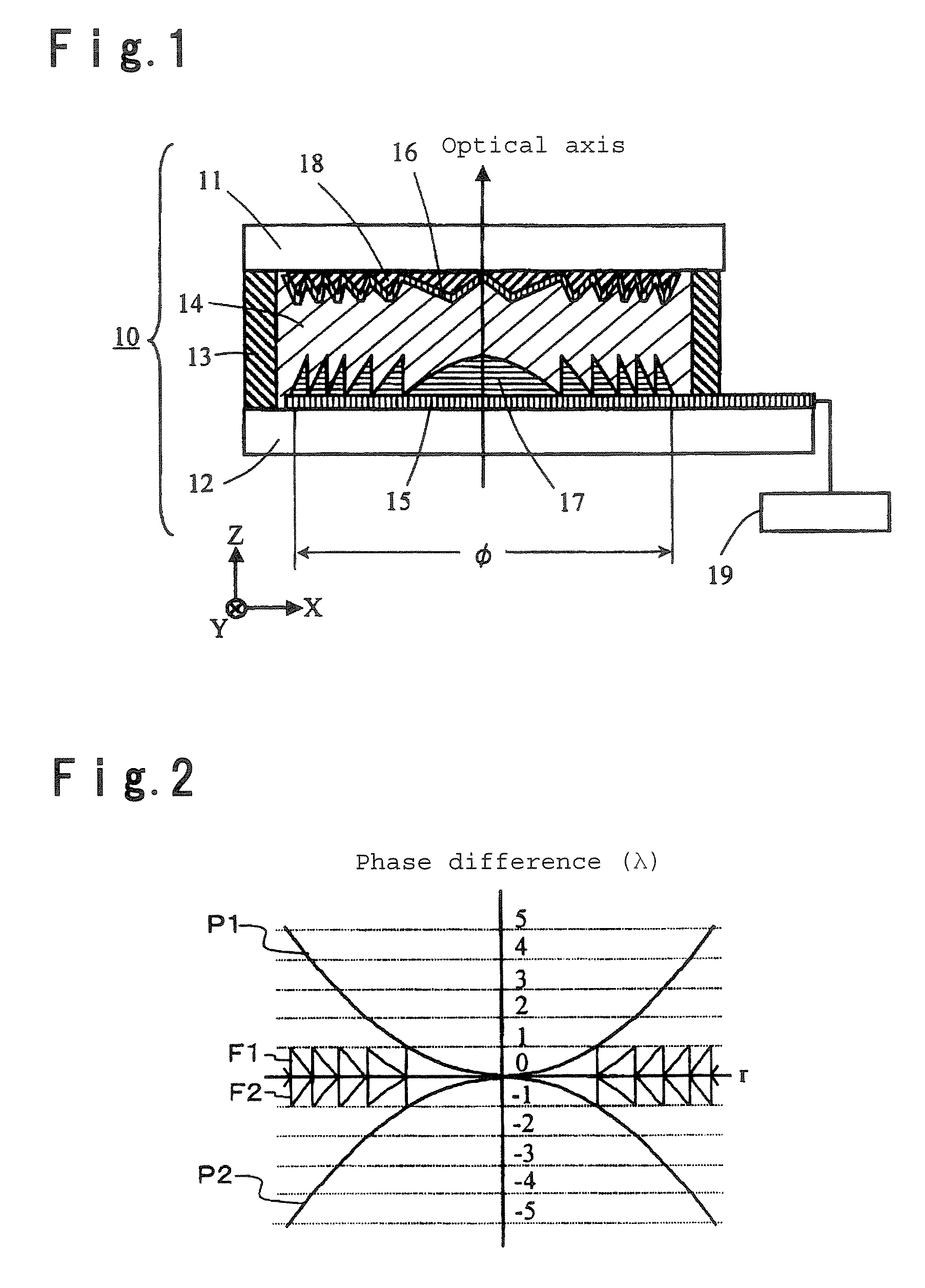

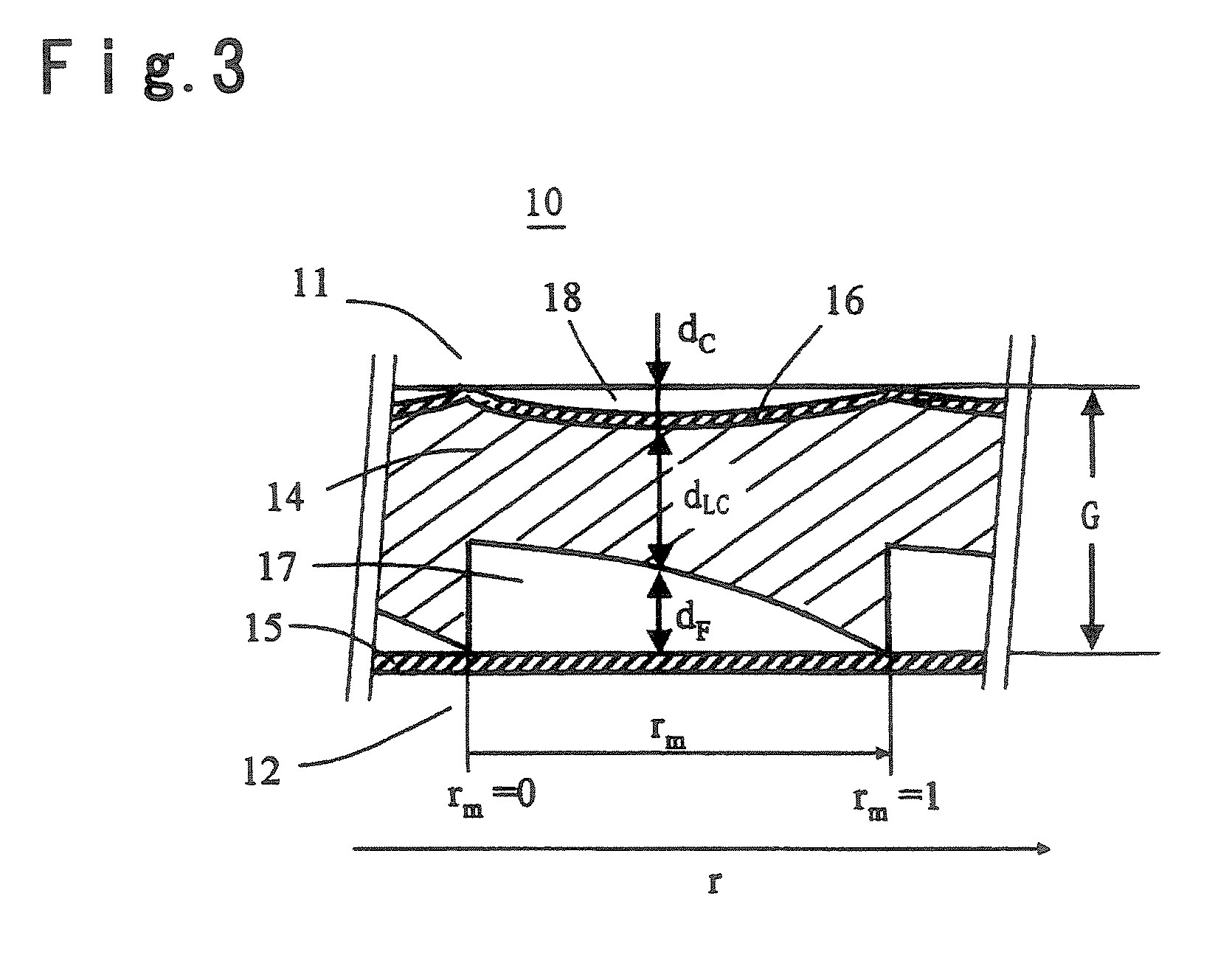

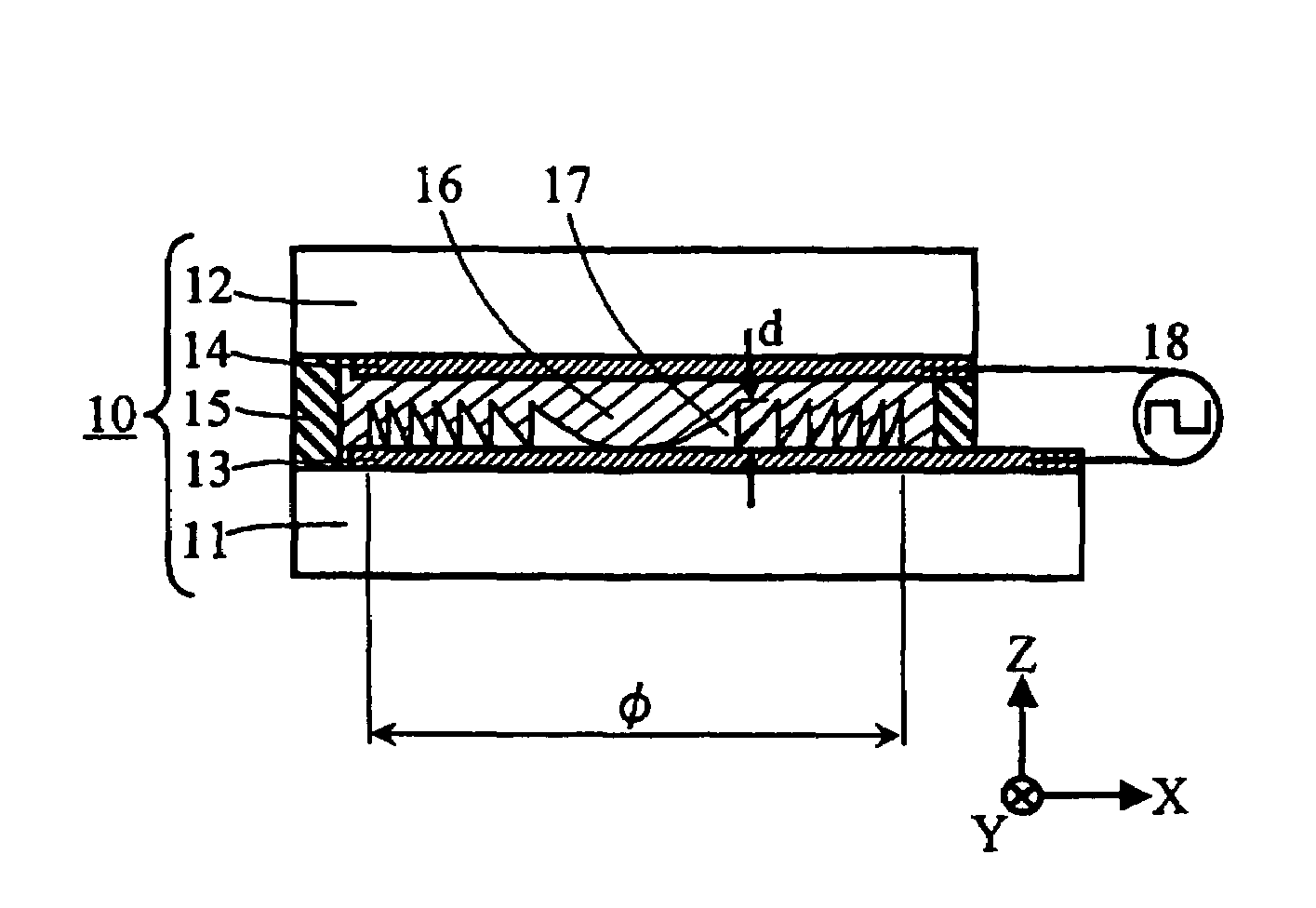

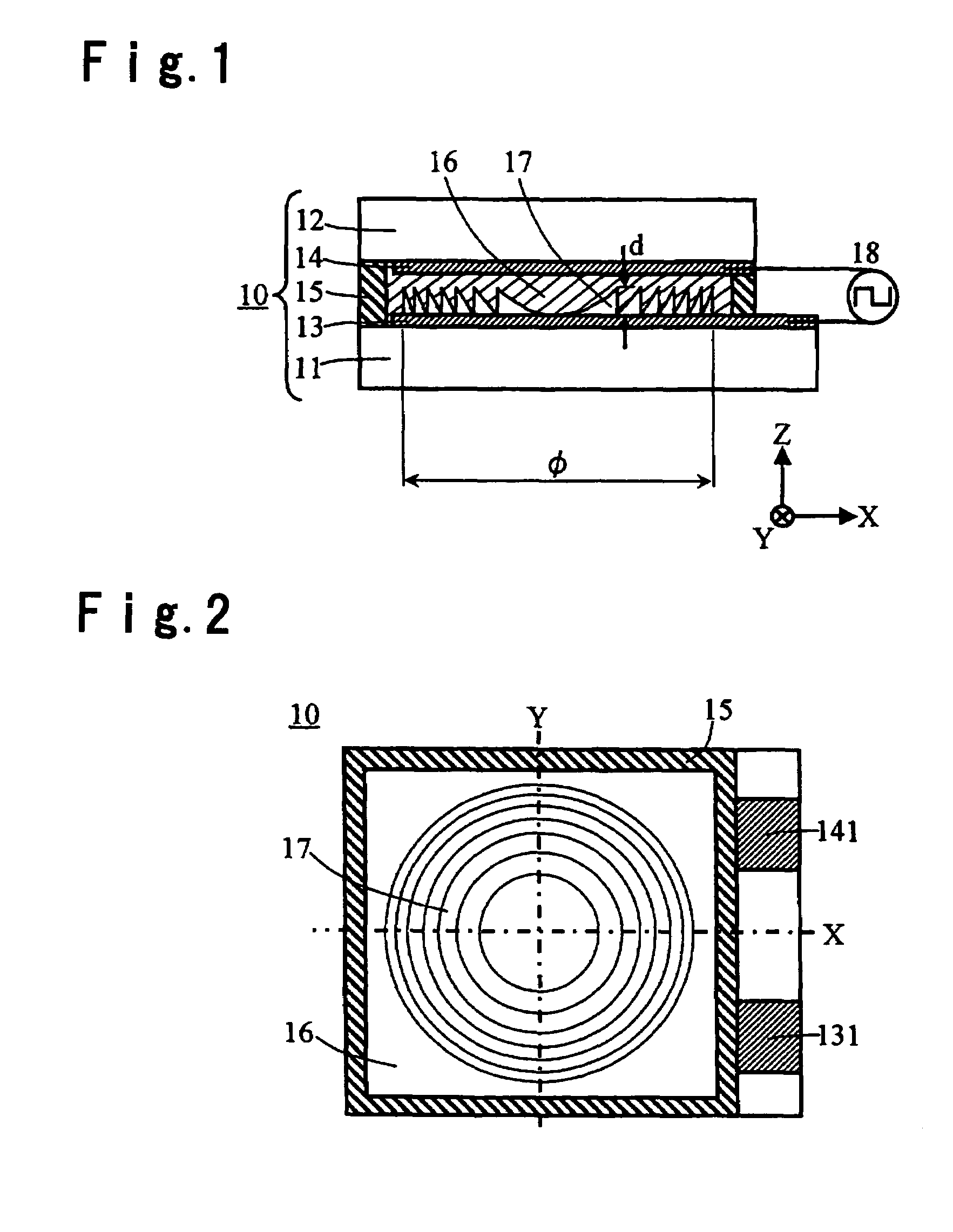

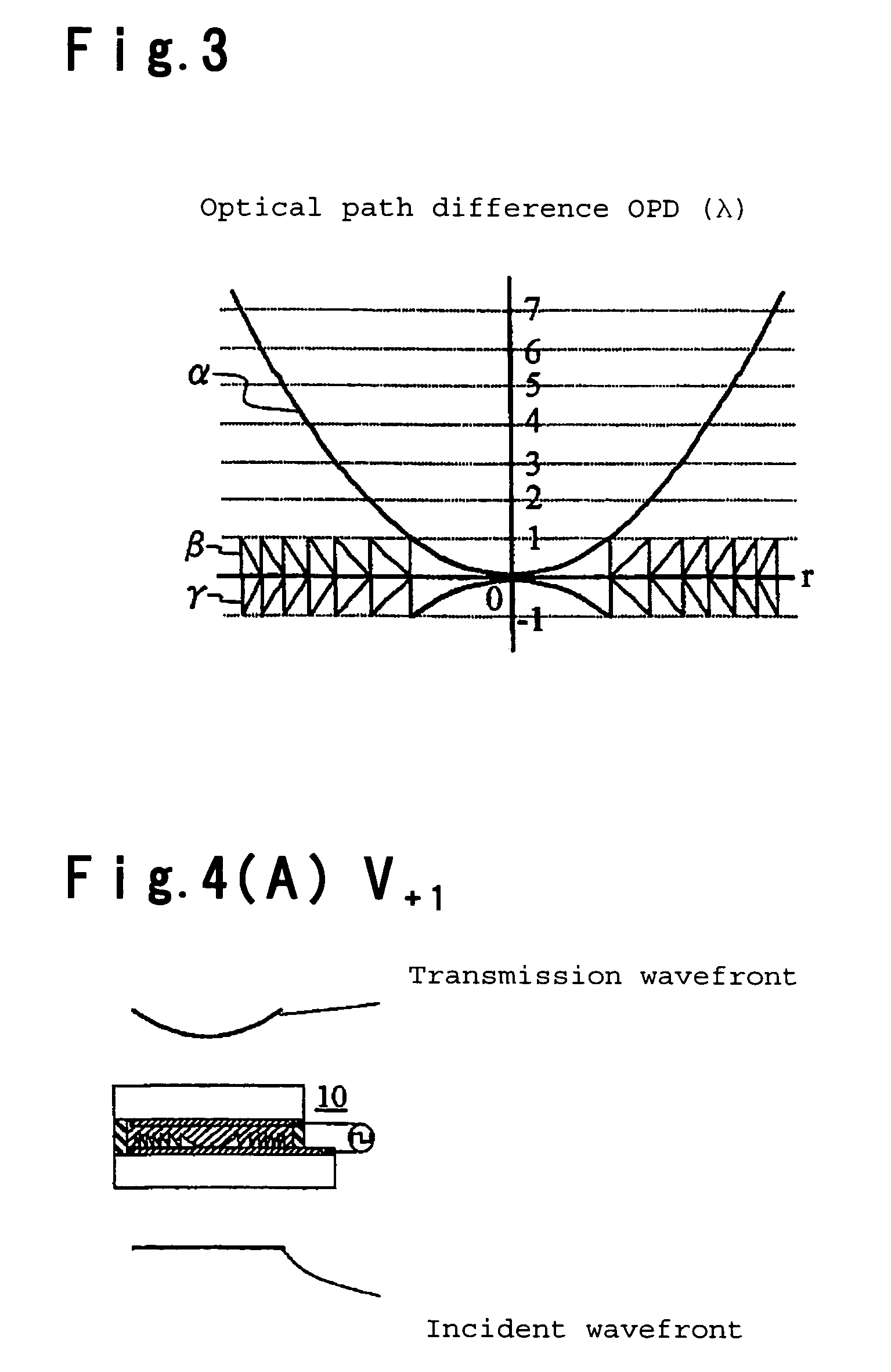

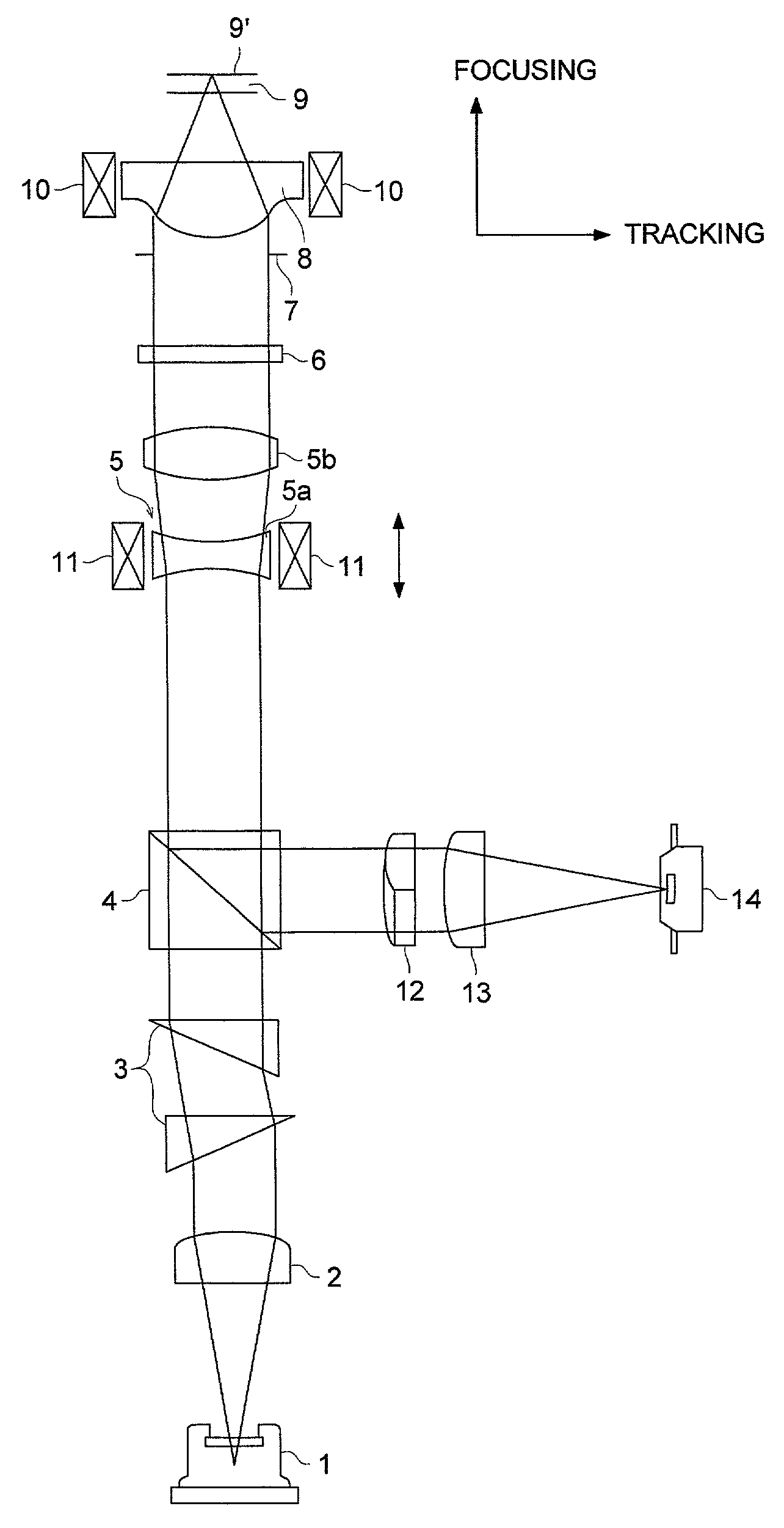

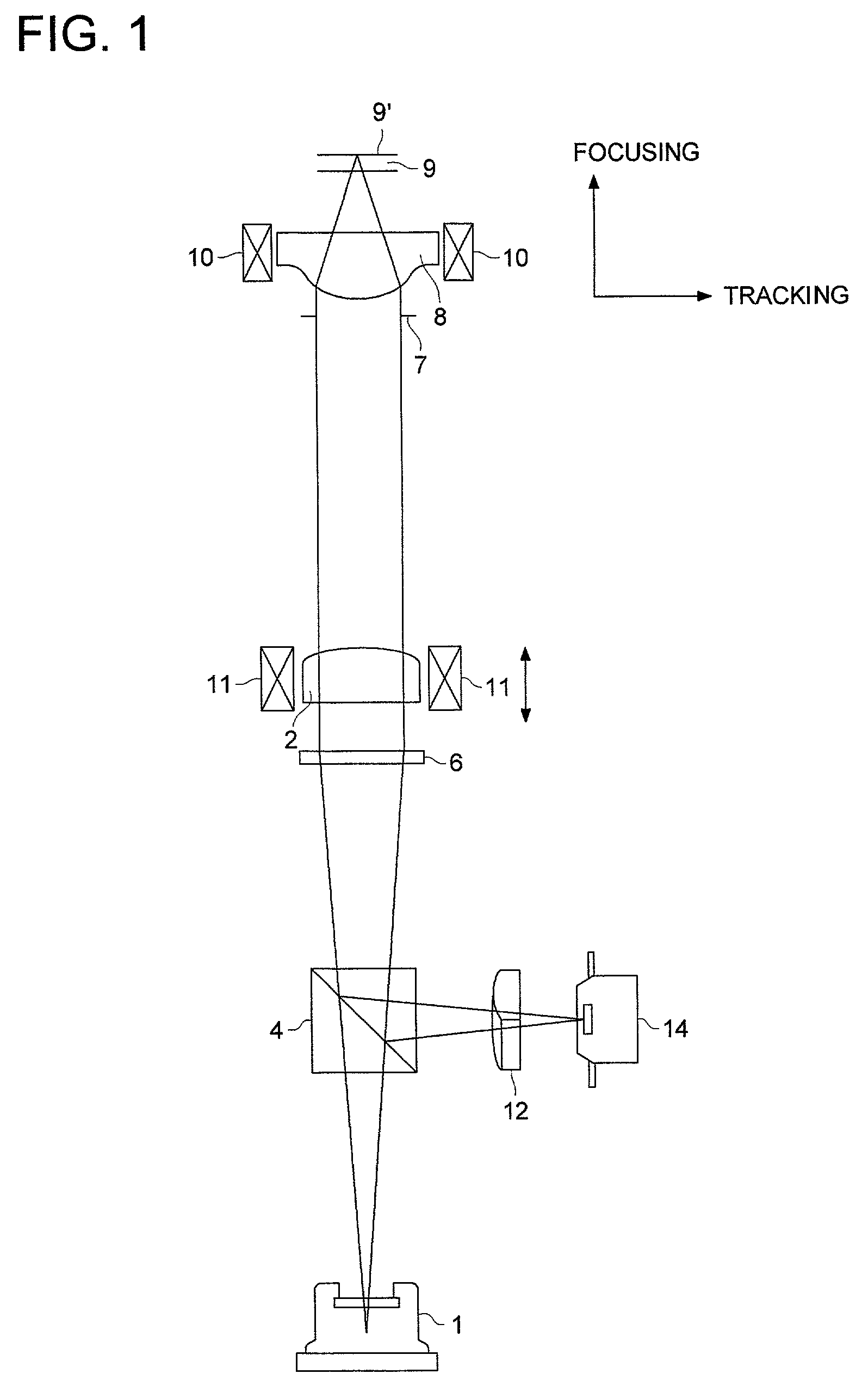

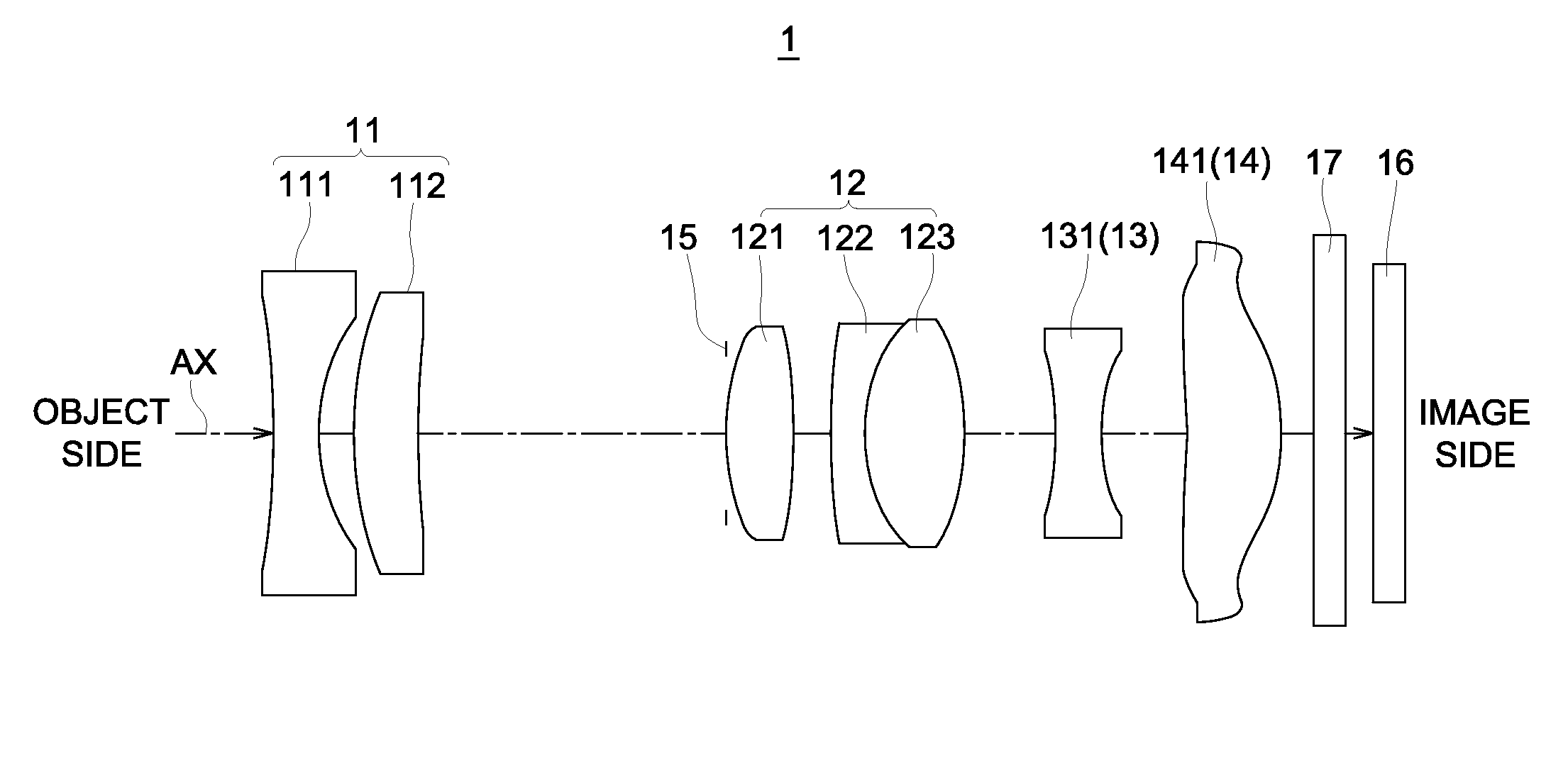

Liquid crystal lens element and optical head device

ActiveUS20060280100A1Guaranteed uptimeLow voltage drivingOptical beam sourcesRecord information storageOptical axisRefractive index

A liquid crystal lens element having a lens function is provided, which is small sized without having moving part, and which can stably carry out correction of spherical aberration containing a power component corresponding to focal point change of incident light. A liquid crystal lens element which changes a focal length of light transmitted through a liquid crystal 16 according to the magnitude of the voltage applied to the liquid crystal 16 sandwiched between a pair of transparent substrates 11 and 12, which comprises transparent electrodes 13 and 14 provided on the respective transparent substrates 11 and 12 for applying a voltage for the liquid crystal 16, and a concave-convex portion 17 having a saw-tooth-shaped cross-sectional shape having a rotational symmetry about an optical axis and formed on one surface of the transparent electrode 13 with a transparent material, wherein at least concave portions of the concave-convex portion 17 are filled with the liquid crystal 16 so as to change the substantial refractive index of the liquid crystal 16 according to the magnitude of applied voltage.

Owner:ASAHI GLASS CO LTD

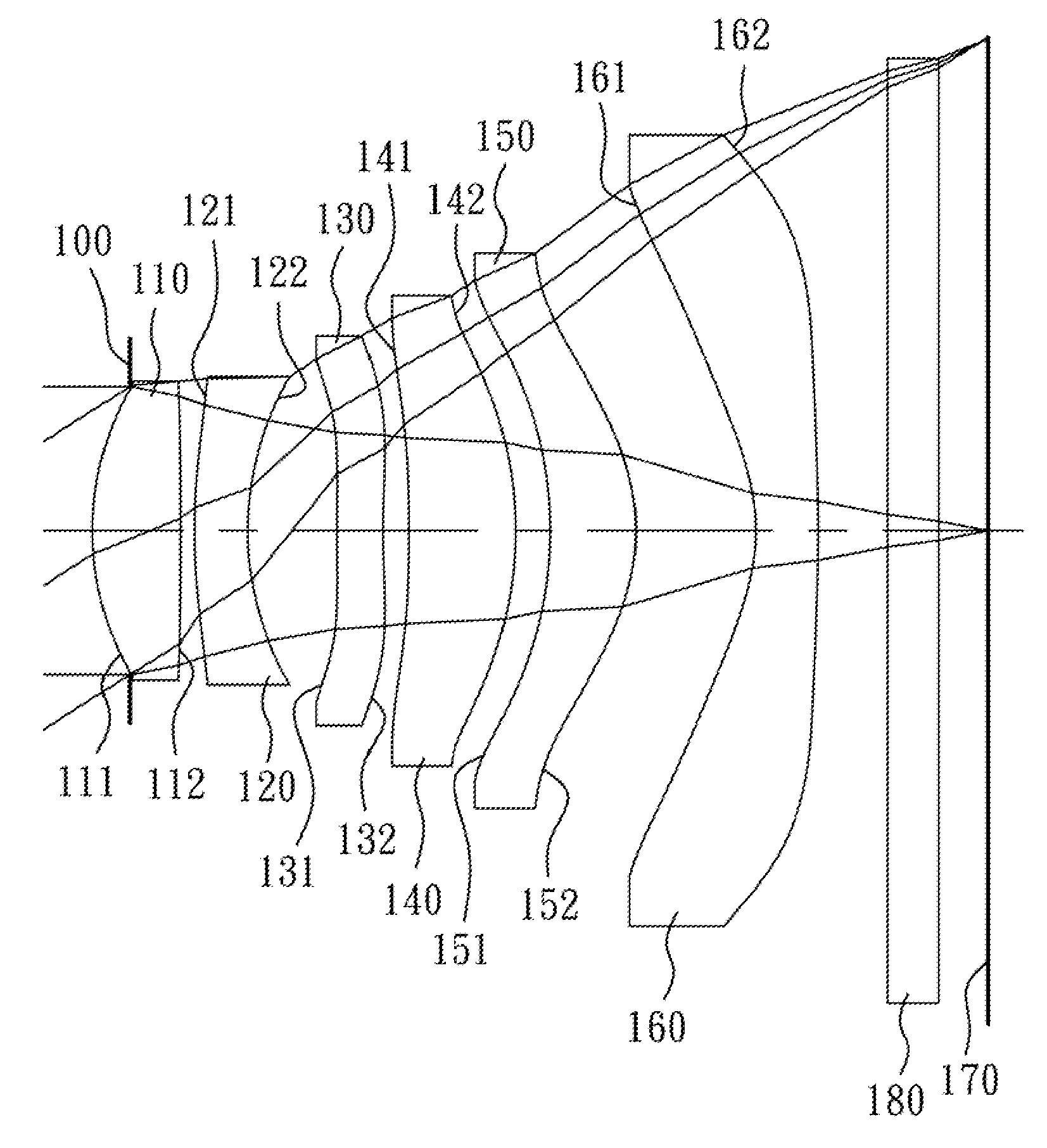

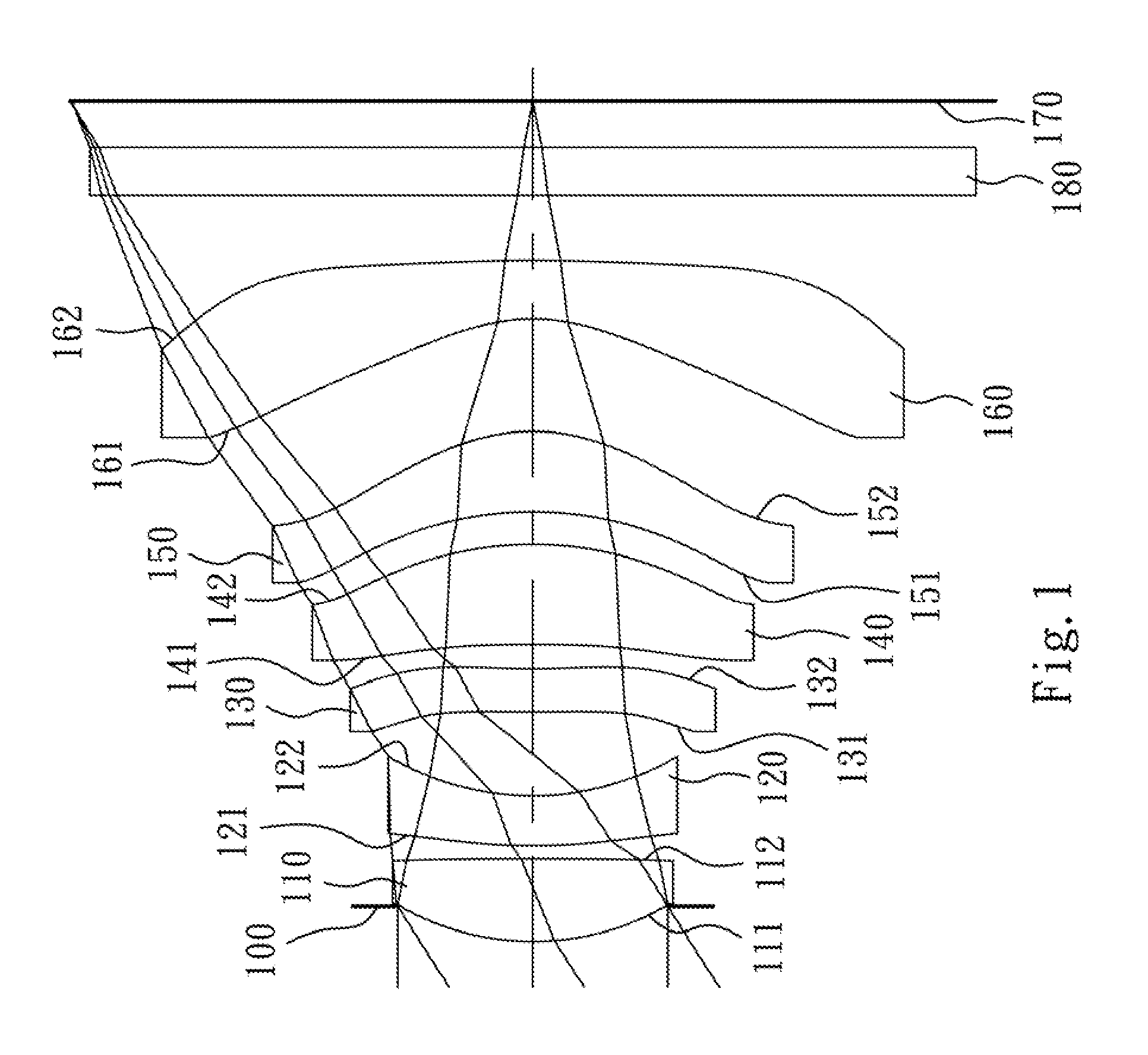

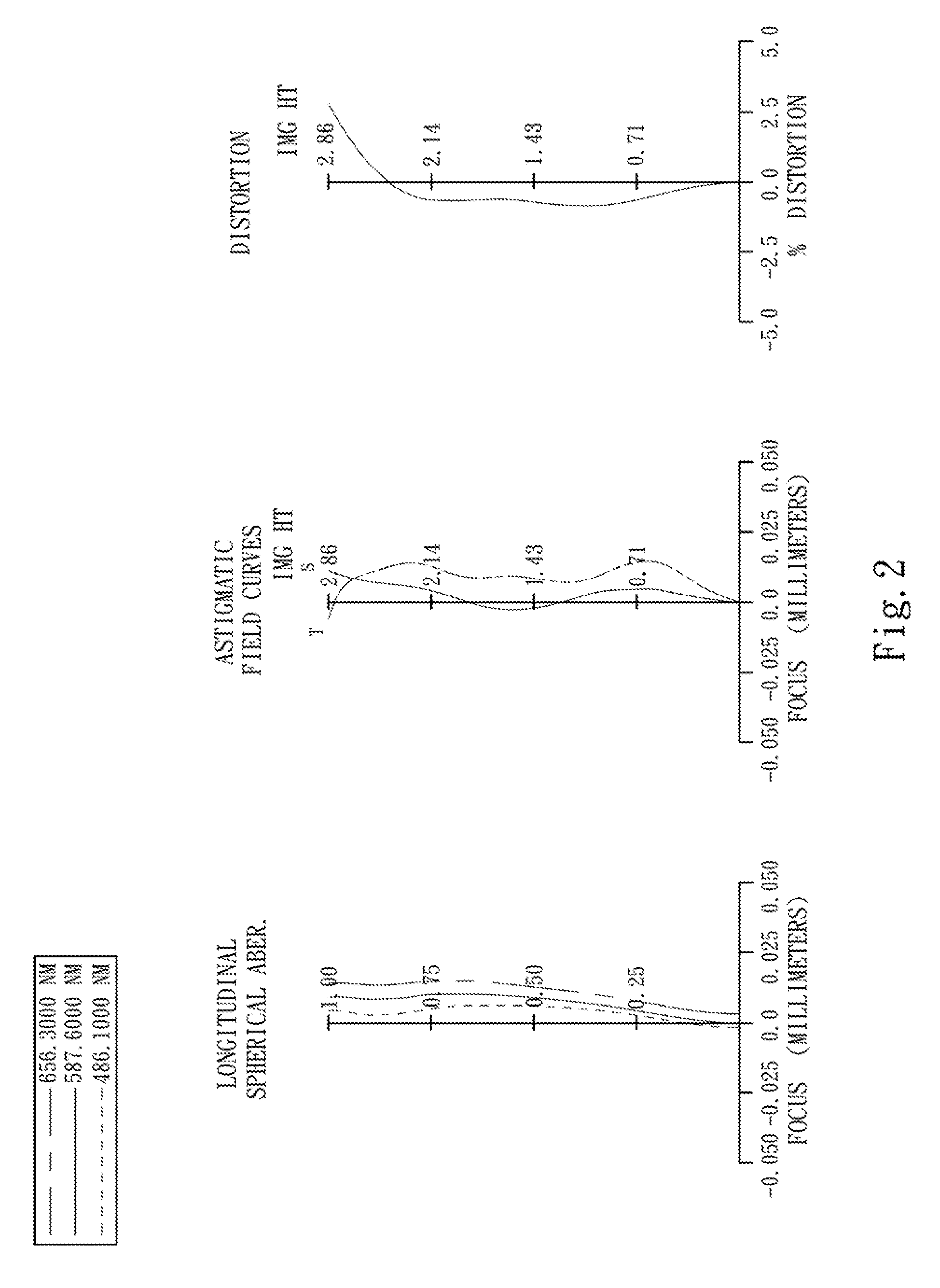

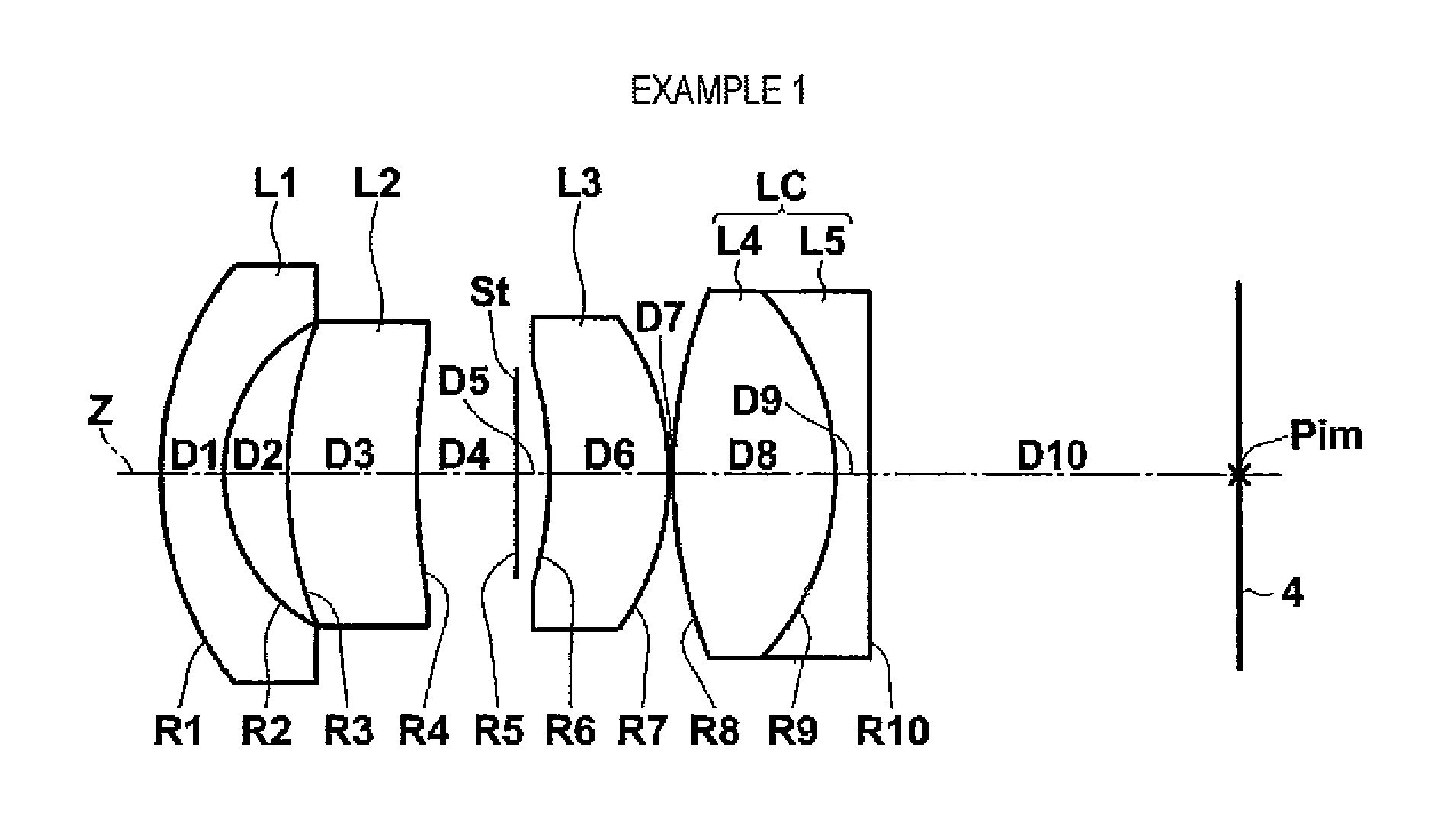

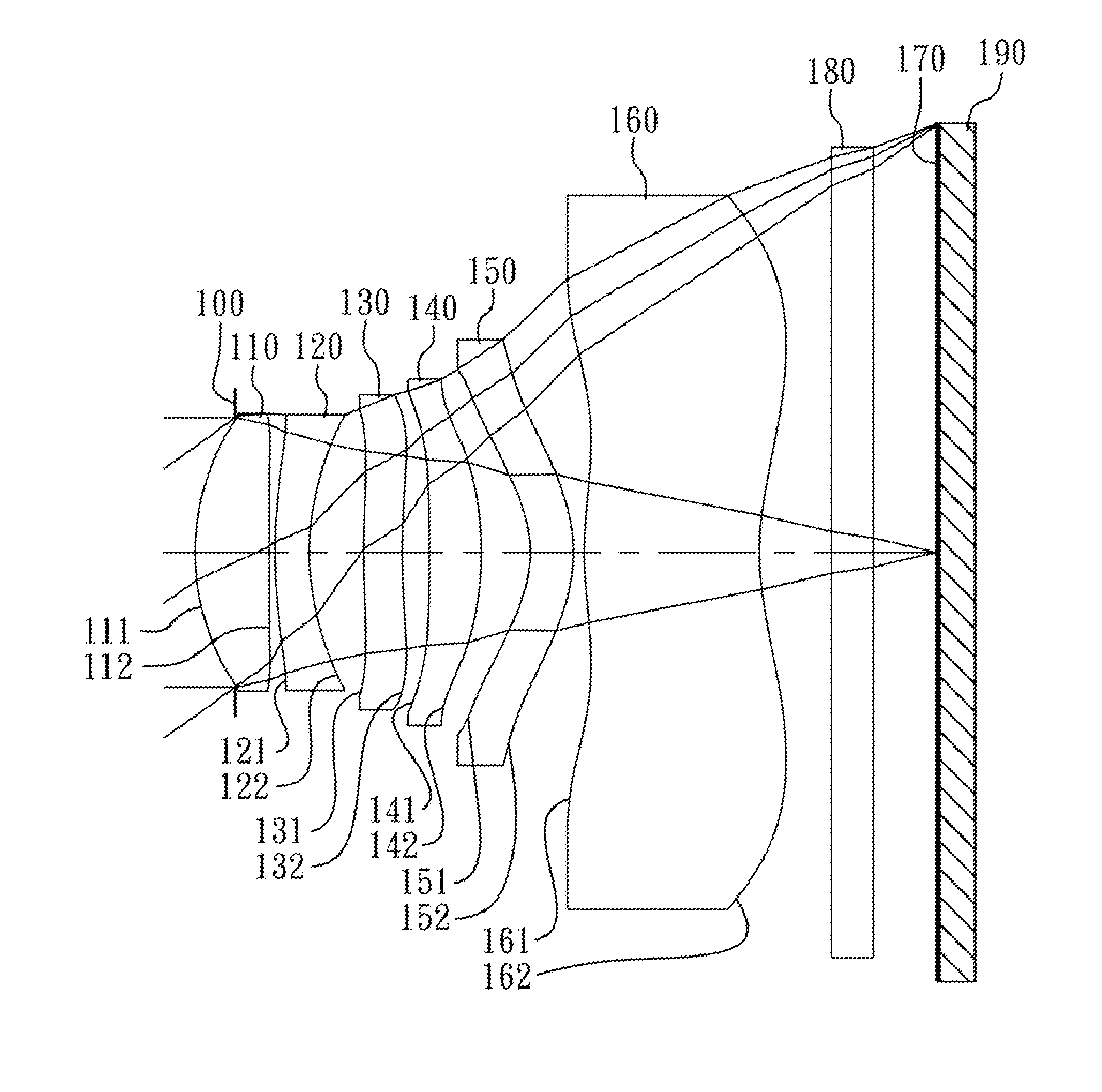

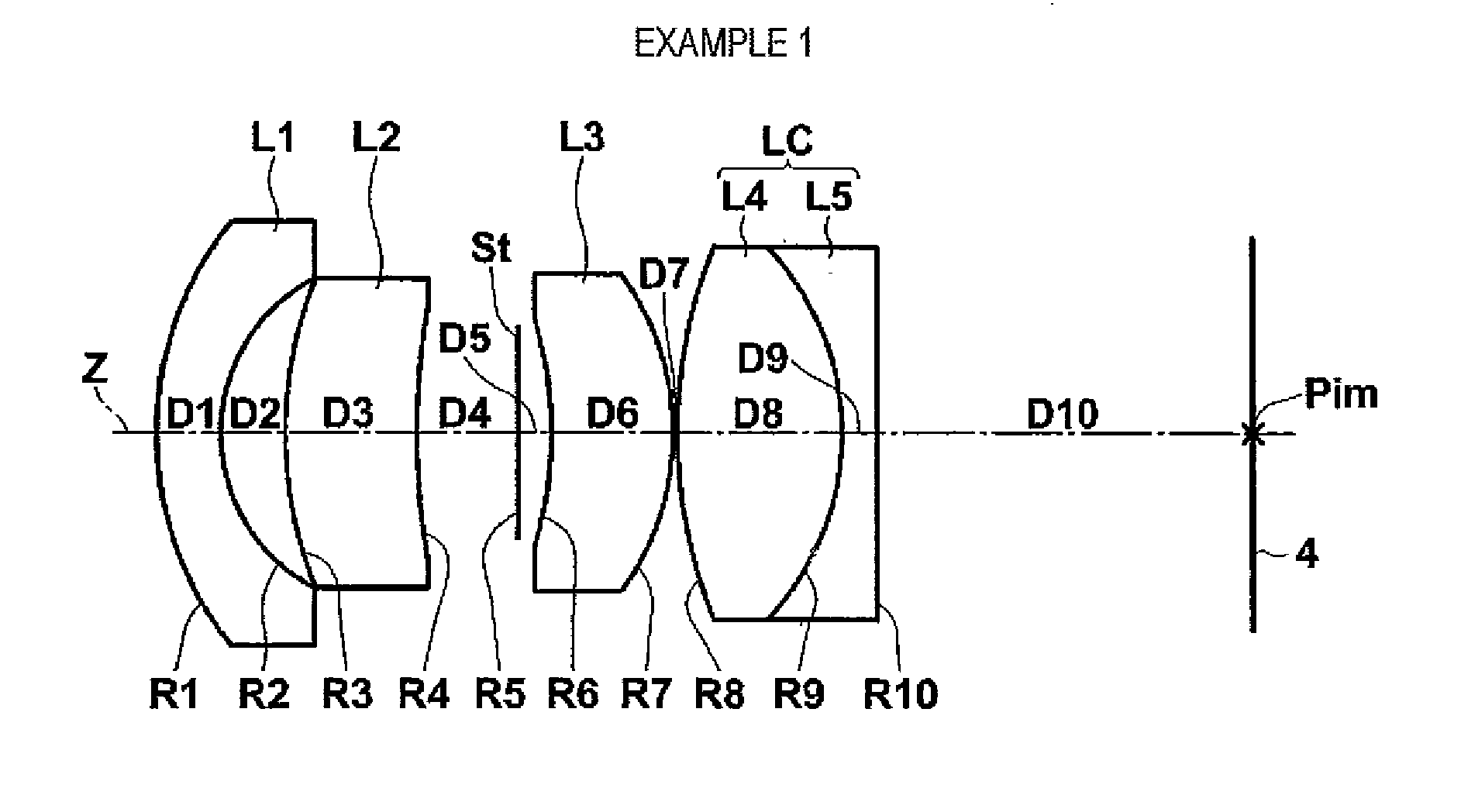

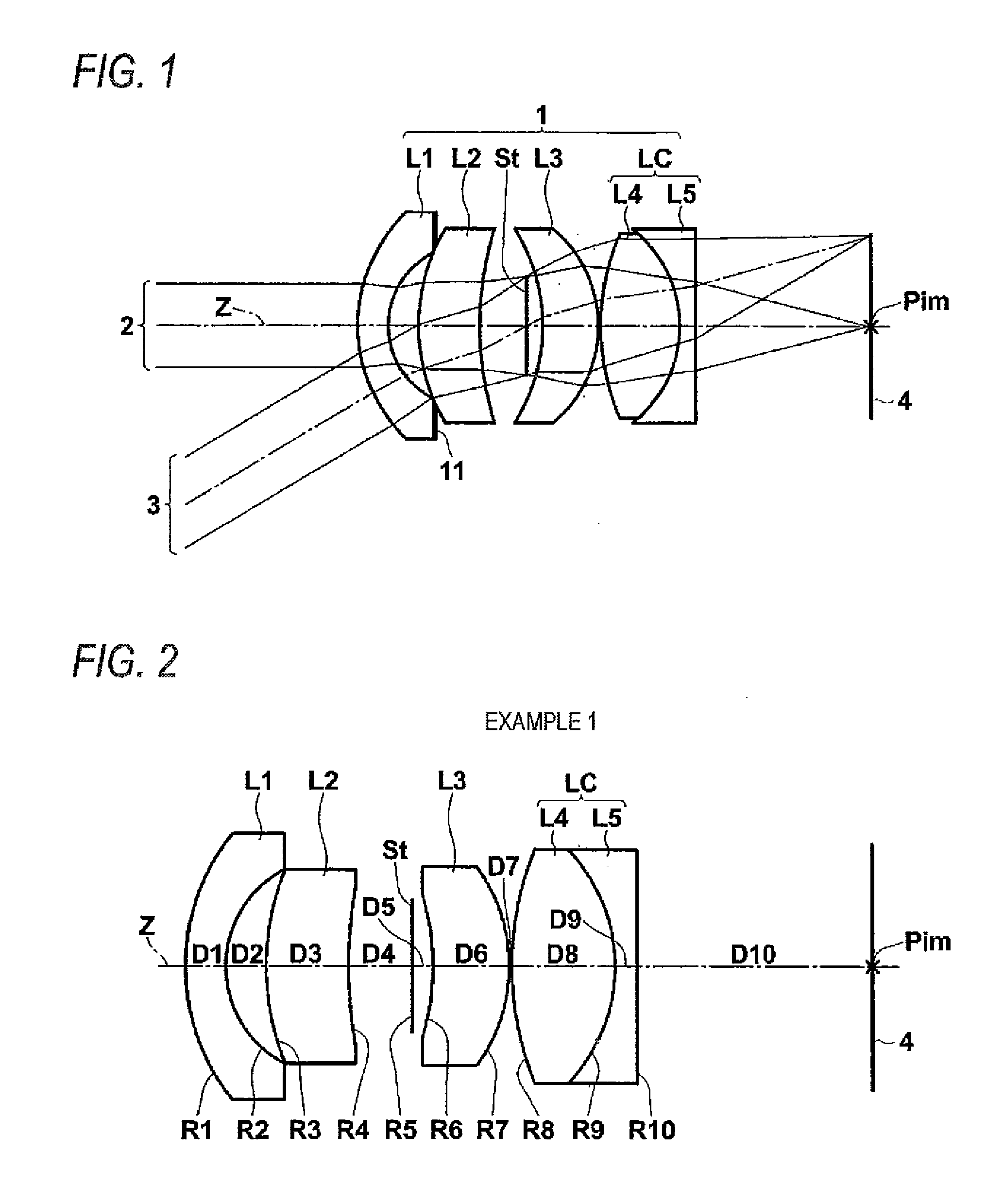

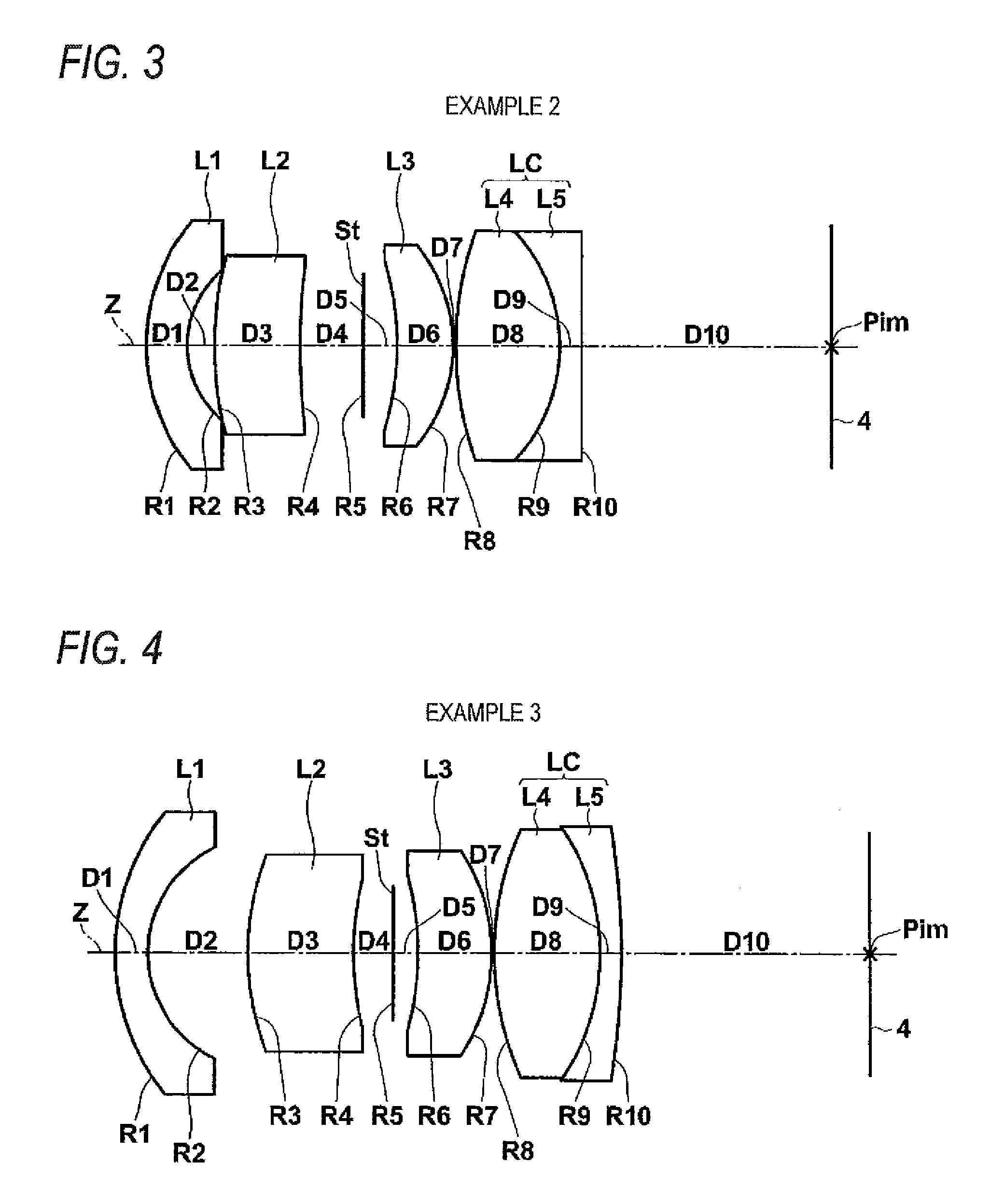

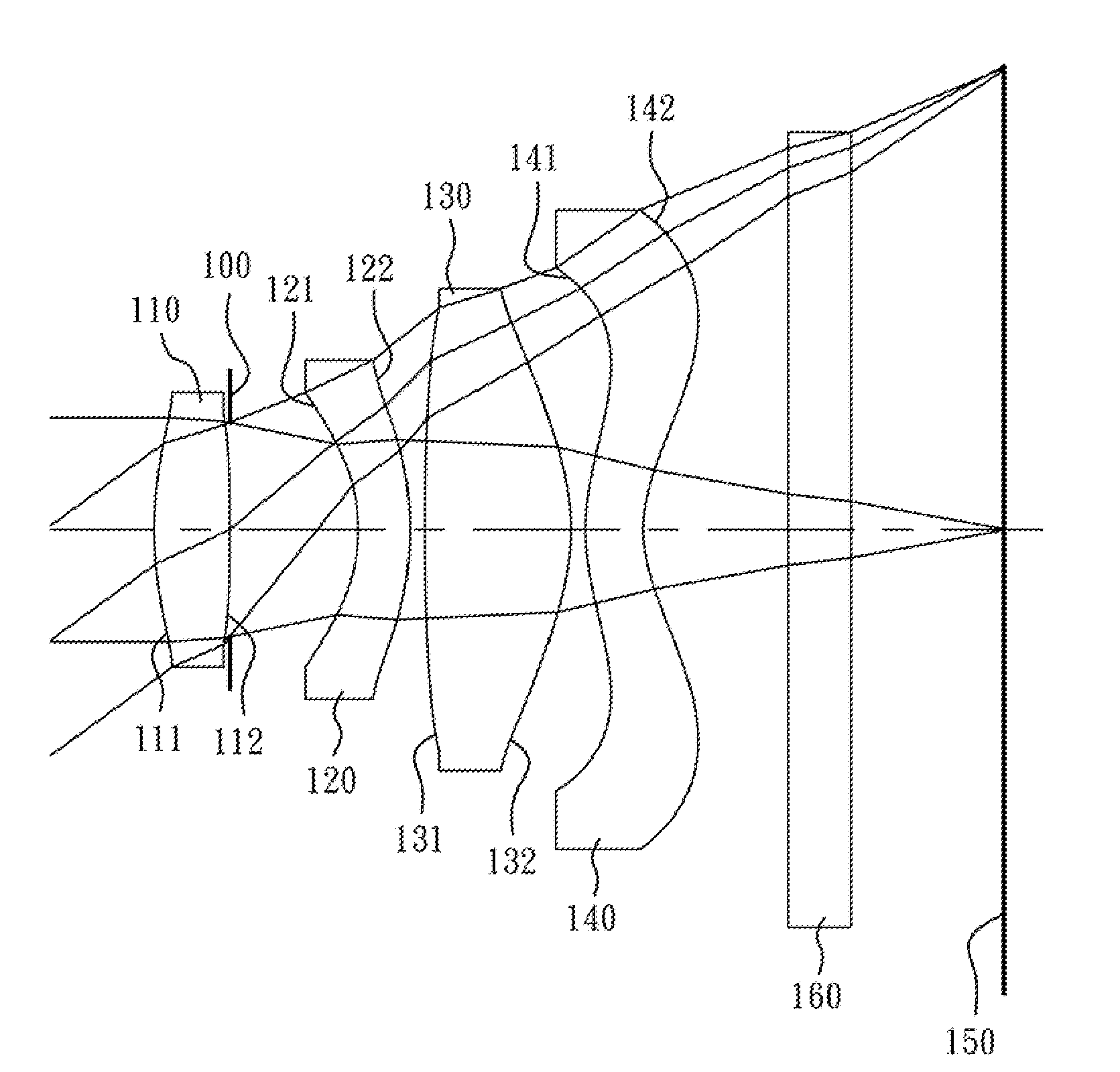

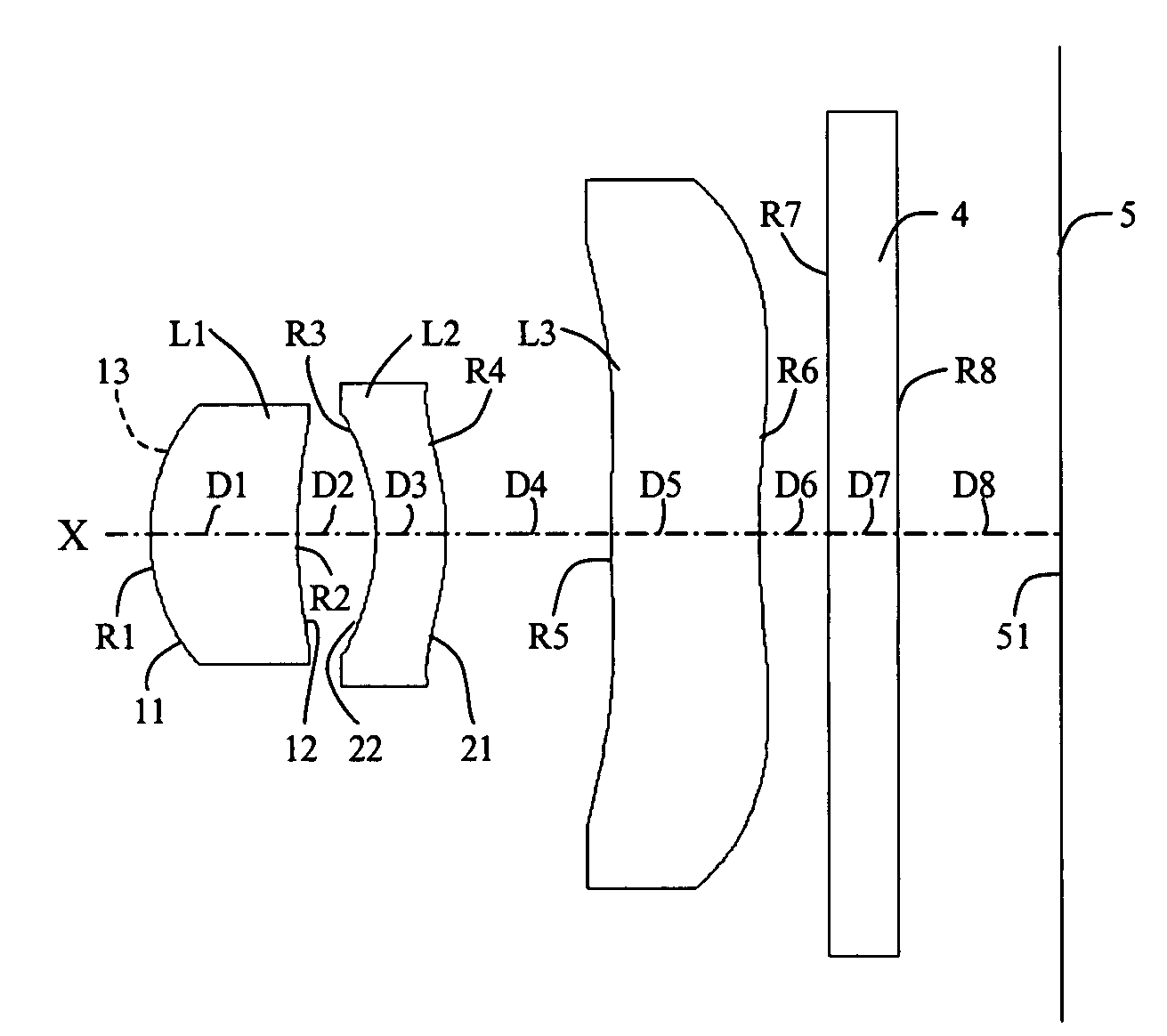

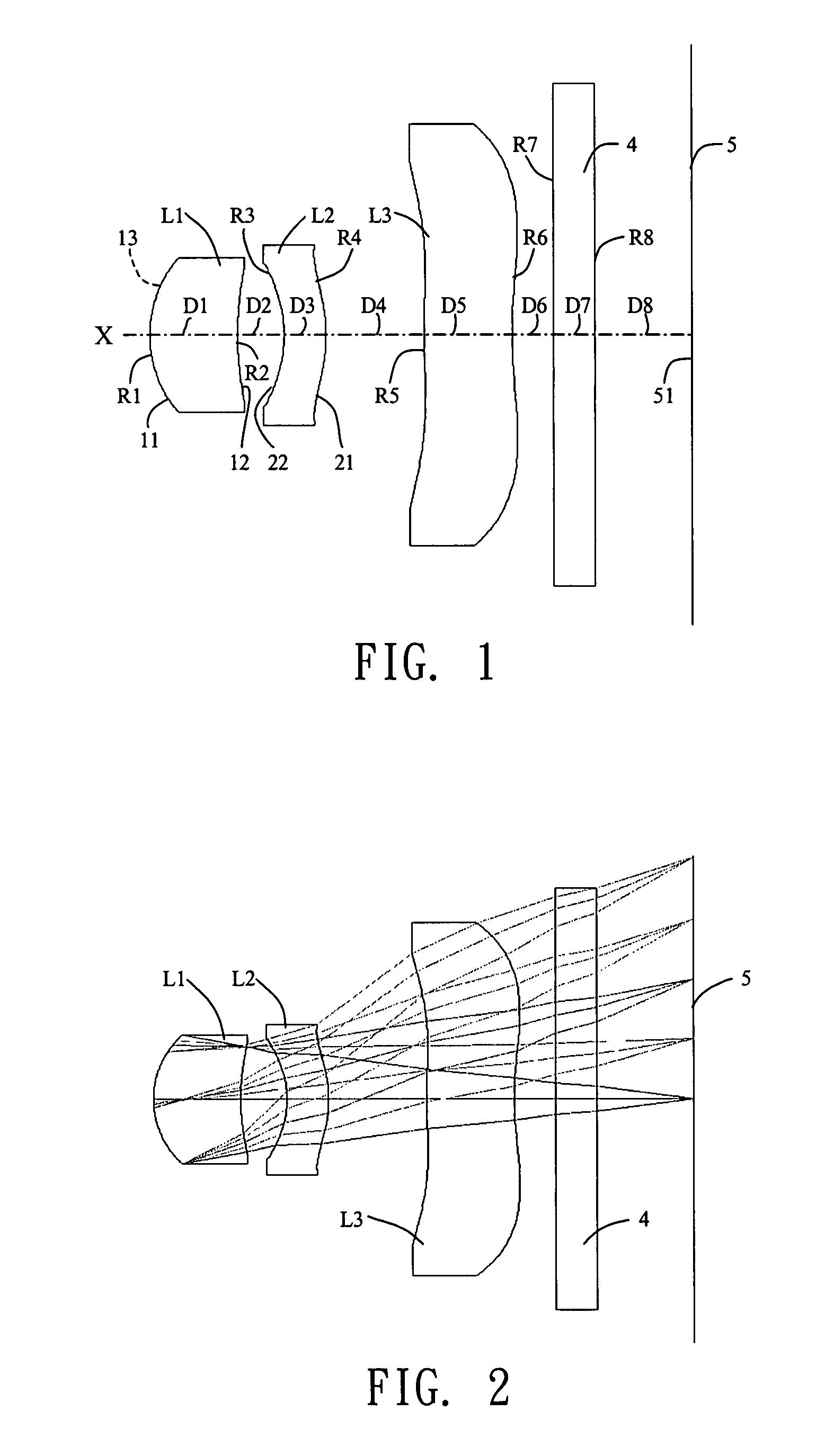

Imaging lens and image pickup apparatus

ActiveUS20090052061A1Good optical performanceSmall sizeOptical elementsOptical axisConditional expression

An imaging lens comprises, in order from an object side: a first lens that has a negative refractive power and is convex toward the object side; a second lens that has a positive refractive power and is a meniscus lens convex toward the object side; a stop; a third lens that has a positive refractive power and is convex toward an image side; and a cemented lens that has a positive refractive power as a whole and is formed by cementing a fourth lens and a fifth lens, wherein assuming that an Abbe number of the second lens with respect to d-line is ν2, a distance on an optical axis from a vertex of a surface of the first lens facing toward the object side to an image plane of the imaging lens is L, a focal length of the imaging lens is f, and a back focus of the imaging lens is Bf, the following conditional expressions (1) to (3) are satisfied:ν2>30 (1),2.5<L / f<4.0 (2), and0.5<Bf / f<1.3 (3).

Owner:TIANJIN OFILM OPTO ELECTRONICS CO LTD

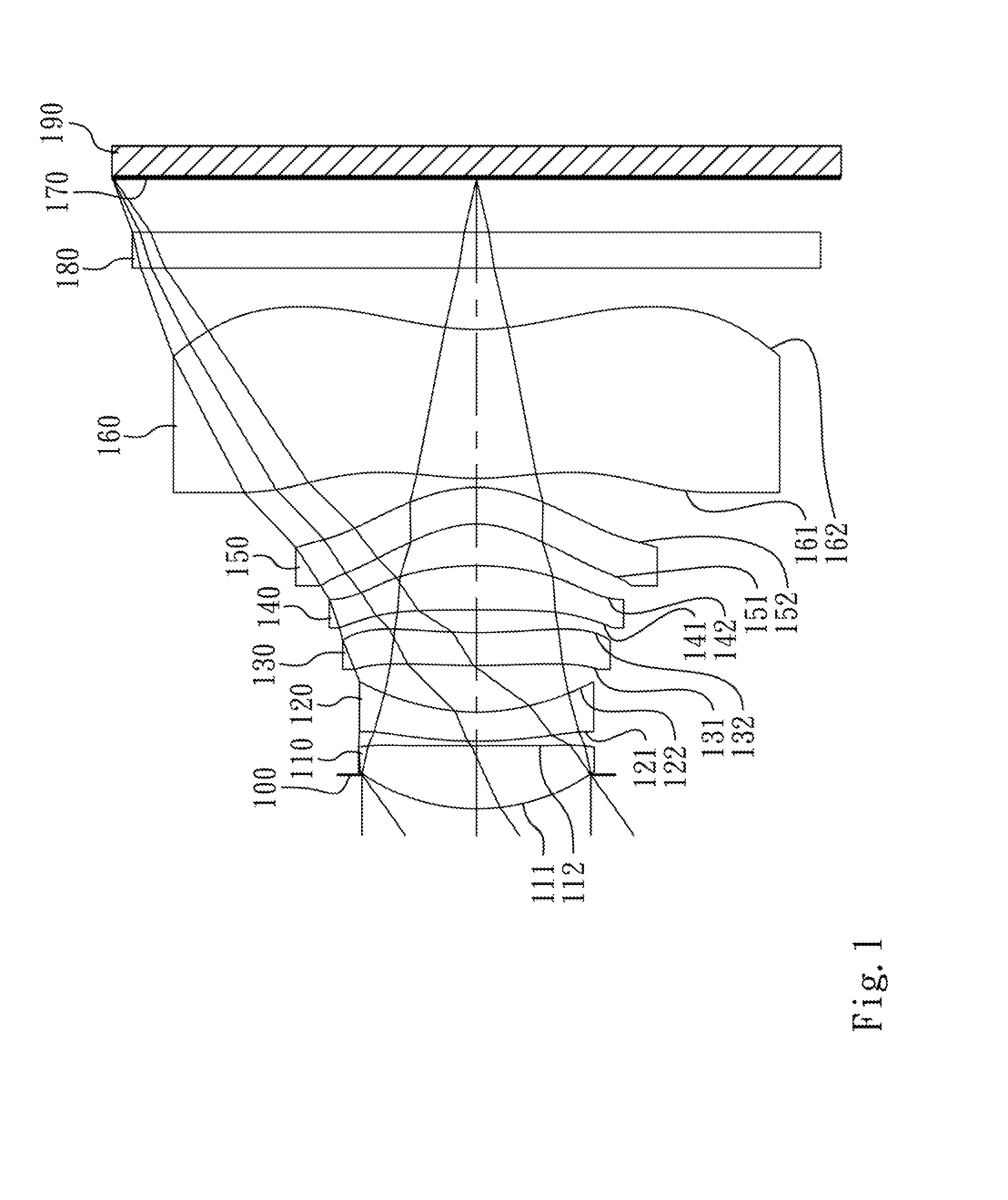

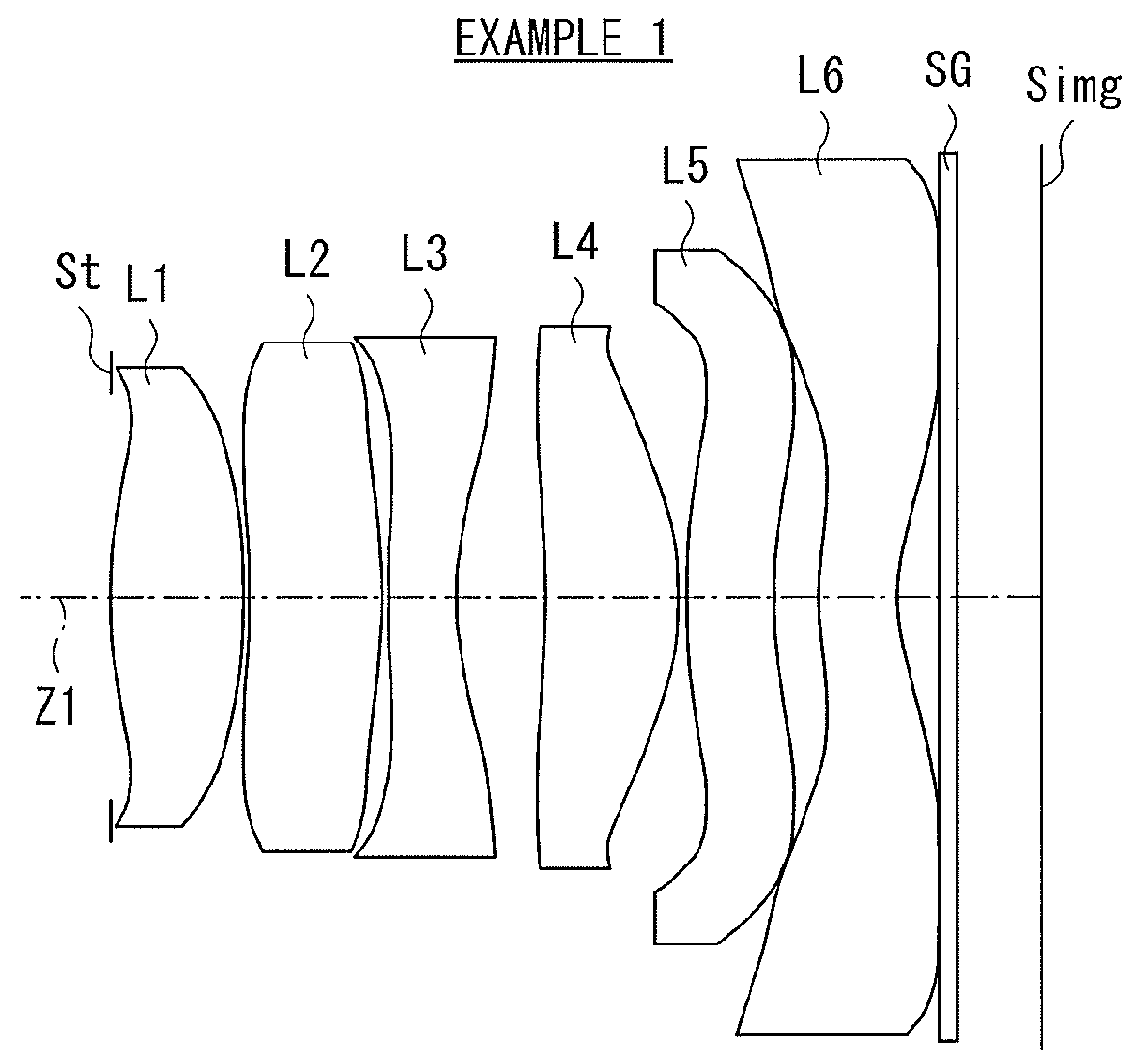

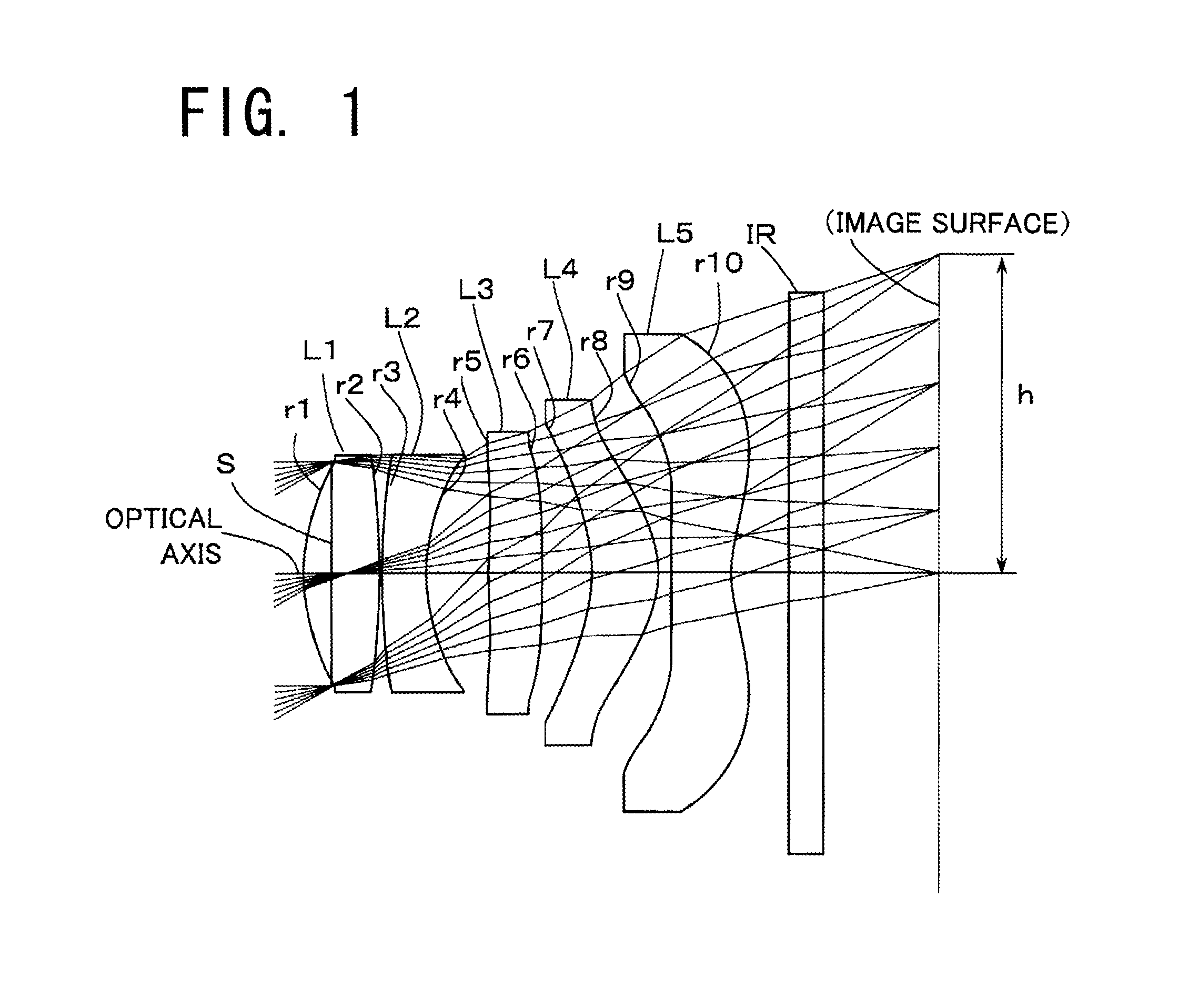

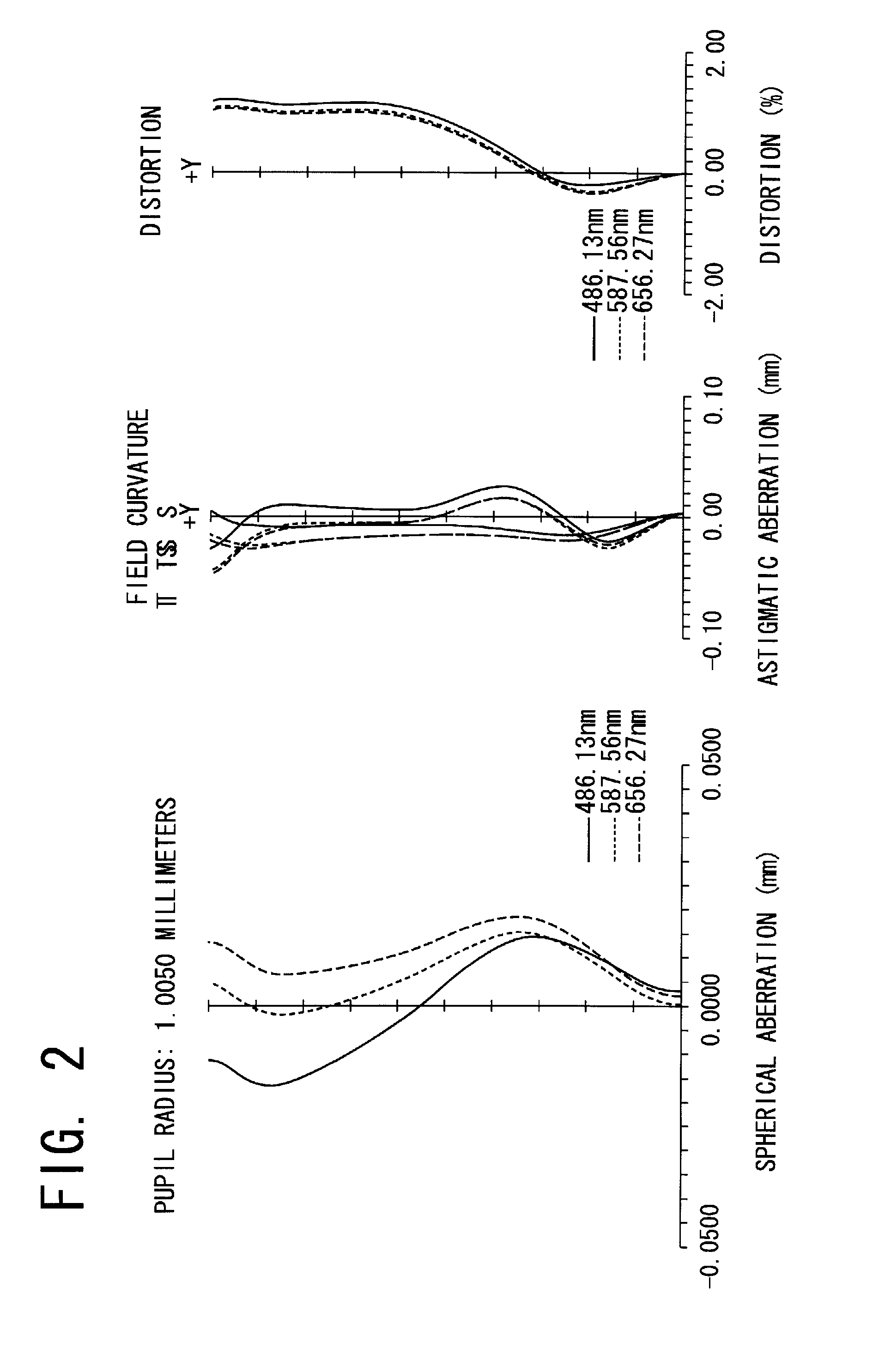

Imaging lens

ActiveUS20120250167A1Small and high-performanceCorrected spherical aberrationLensCamera lensConditional expression

An imaging lens includes: an aperture stop; a biconvex first lens directing convex surfaces toward an object and an image; a second lens directing a convex surface toward the object near the optical axis and having negative refractive power; a biconvex third lens directing convex surfaces toward the object and the image near the optical axis; a fourth lens directing a concave surface toward the object near the optical axis and having positive refractive power; and a fifth lens directing a convex surface toward the object near the optical axis and having negative refractive power. The aperture stop and the first to fifth lenses are arranged in this order from the object side, and a conditional expression 1 being 0.50<f1 / f<0.76 is satisfied, where f1 represents the focal length of the first lens and f represents the focal length of the entire imaging lens.

Owner:TOKYO VISIONARY OPTICS CO LTD

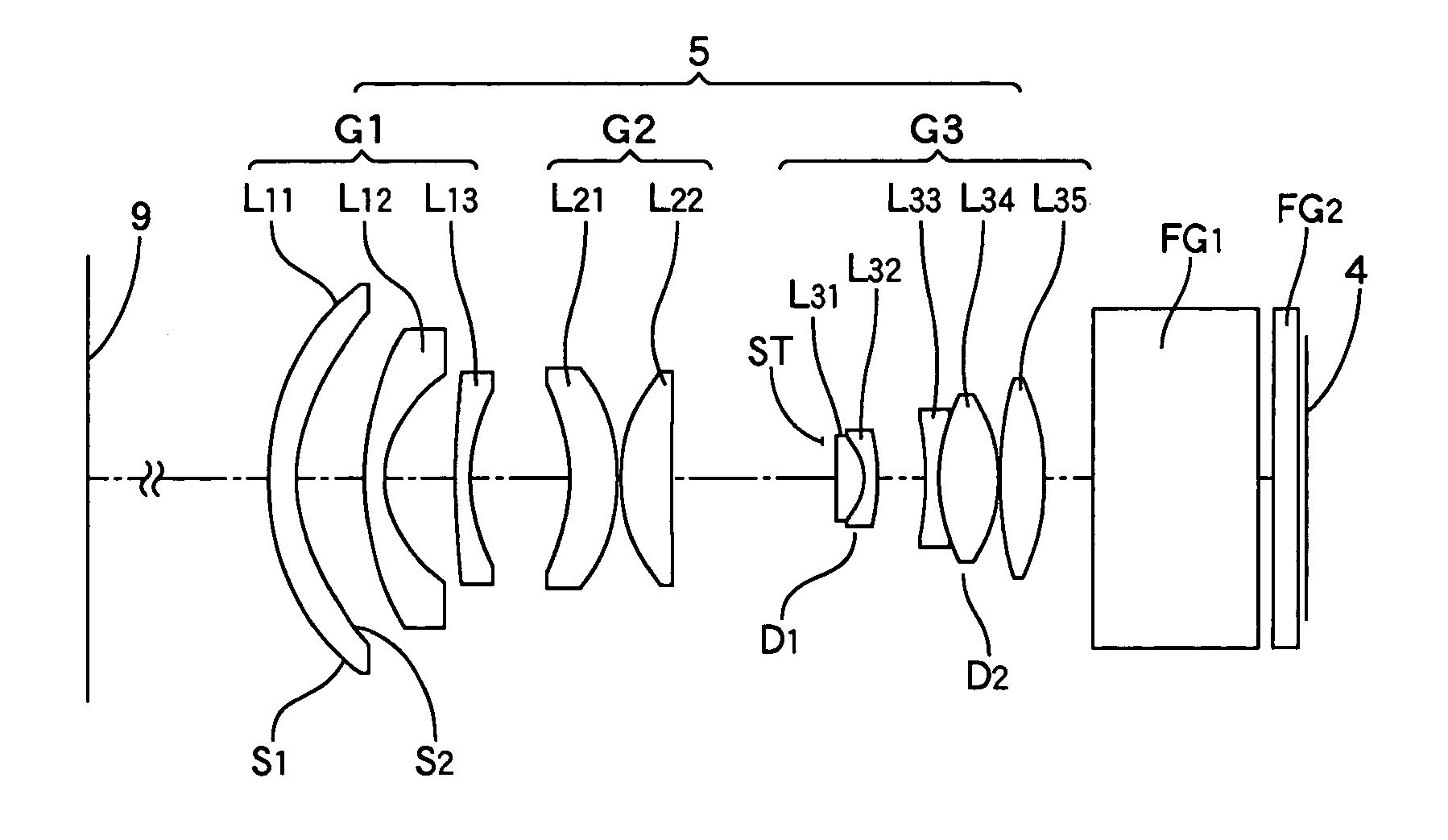

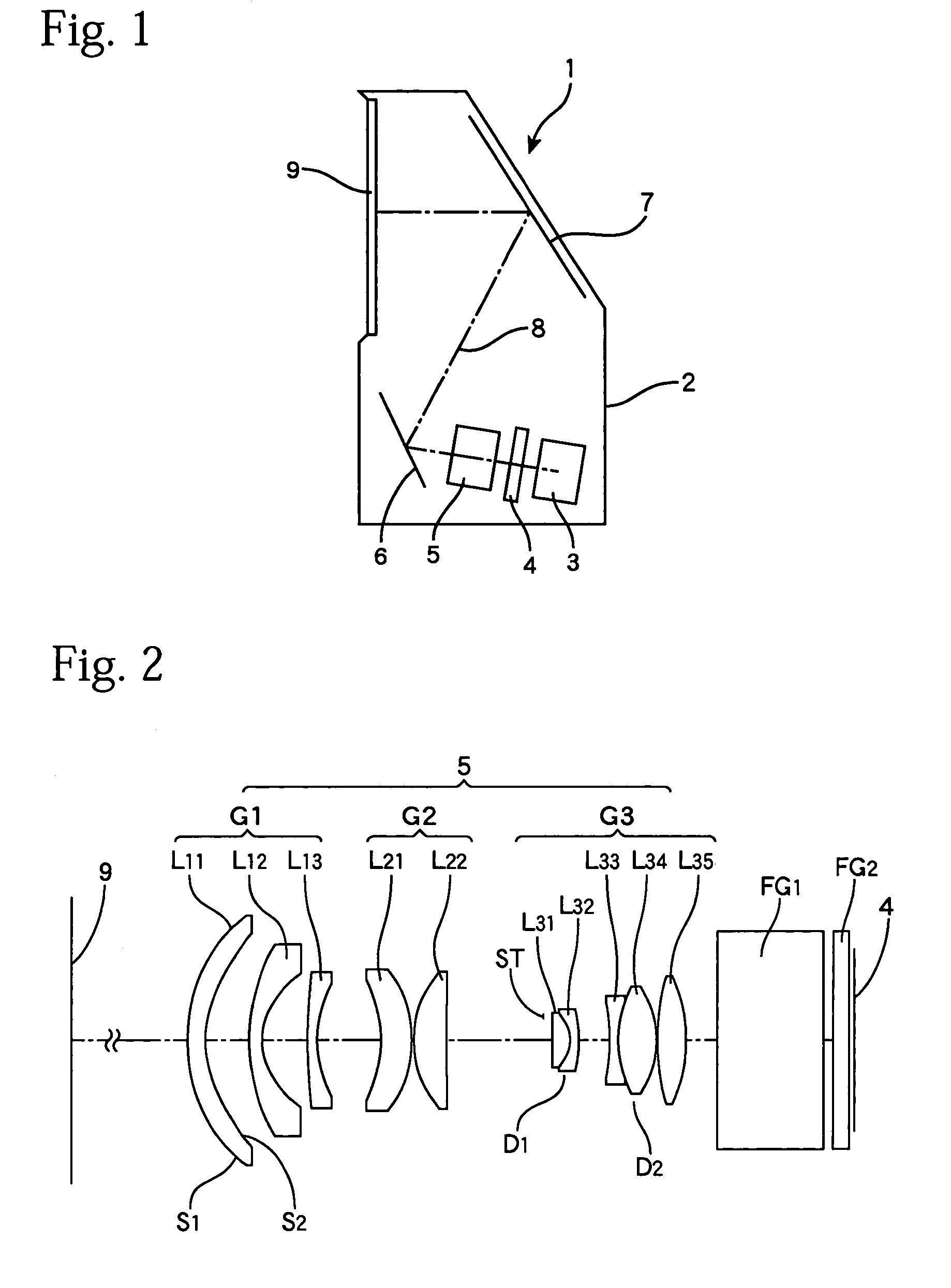

Projection lens system and projector

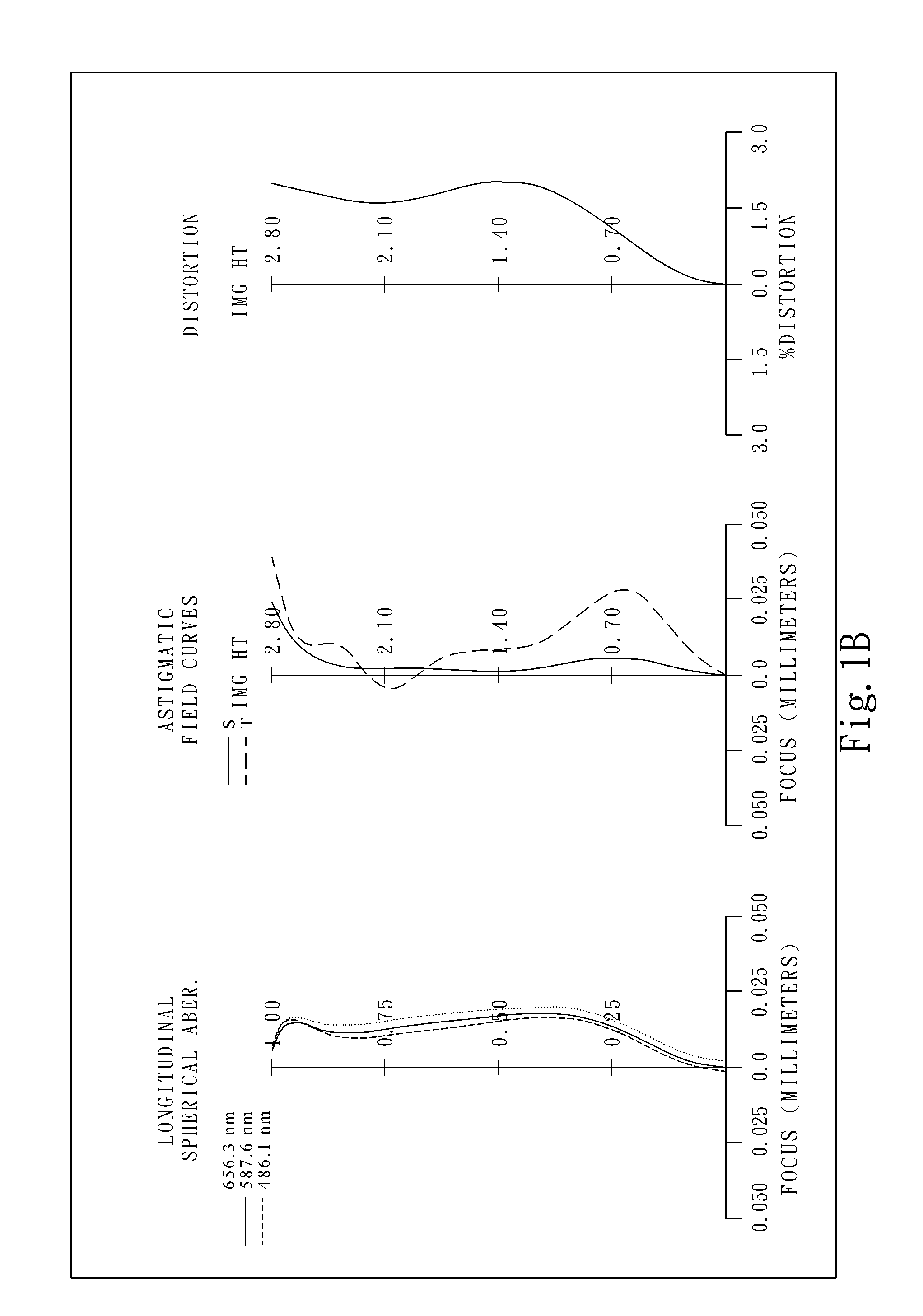

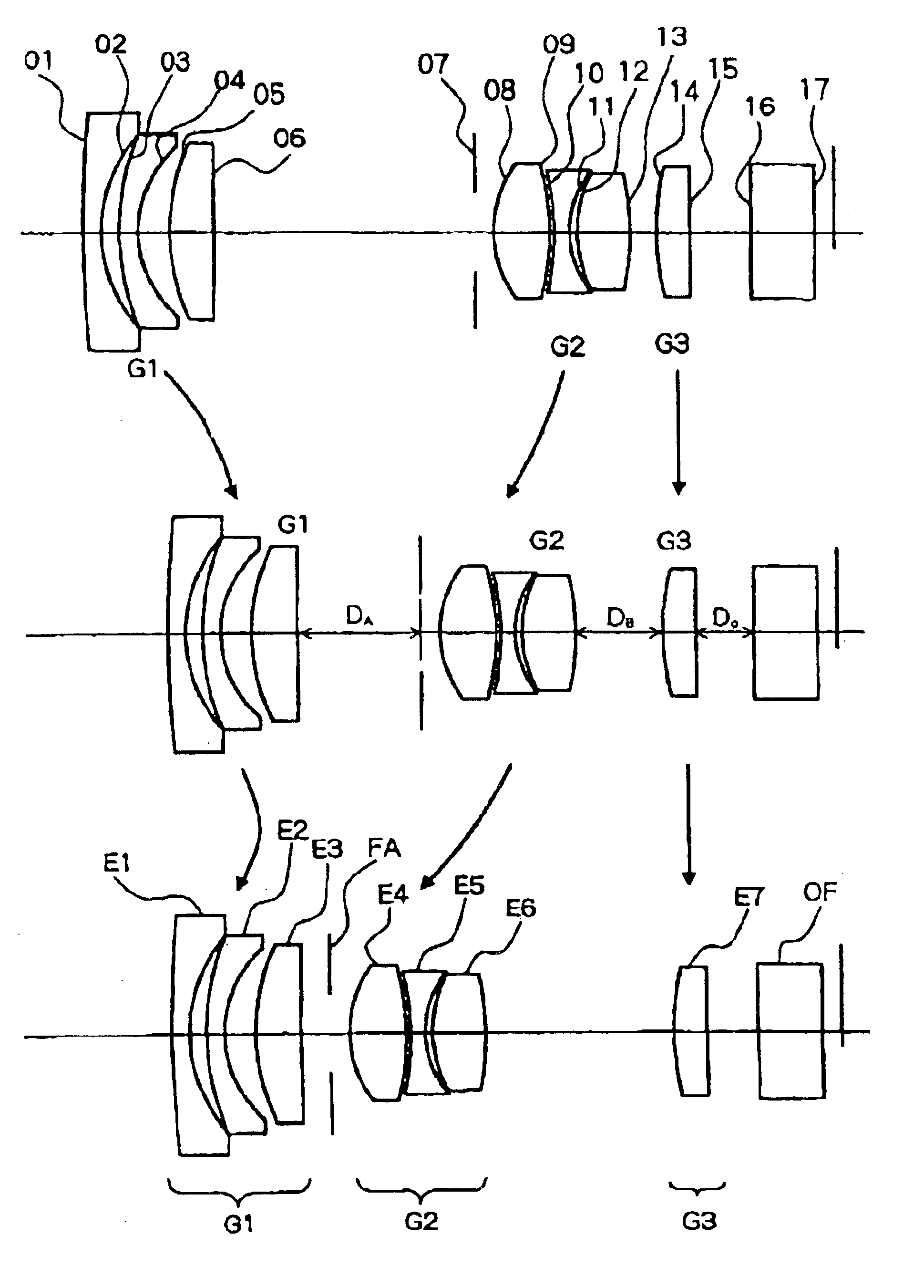

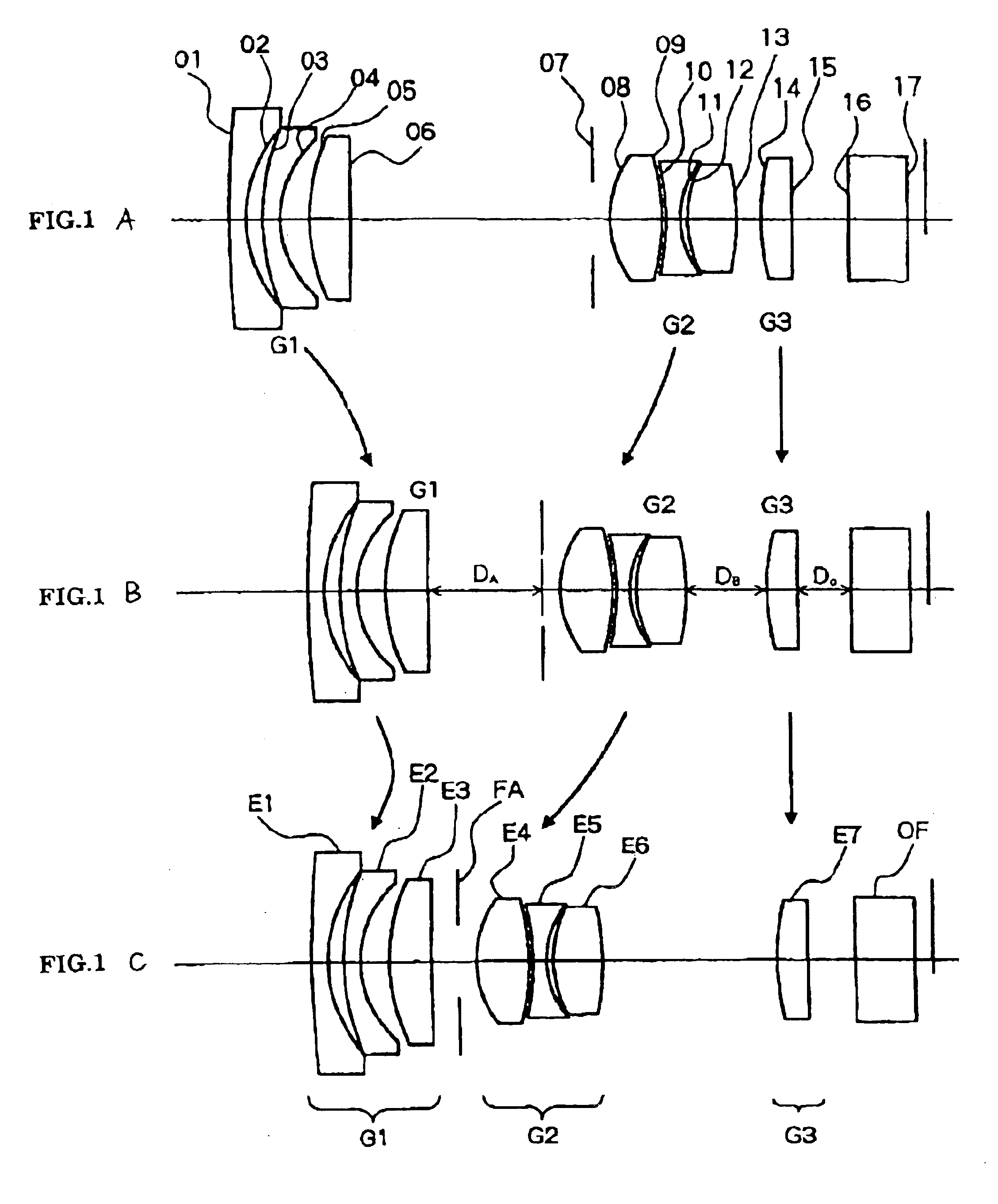

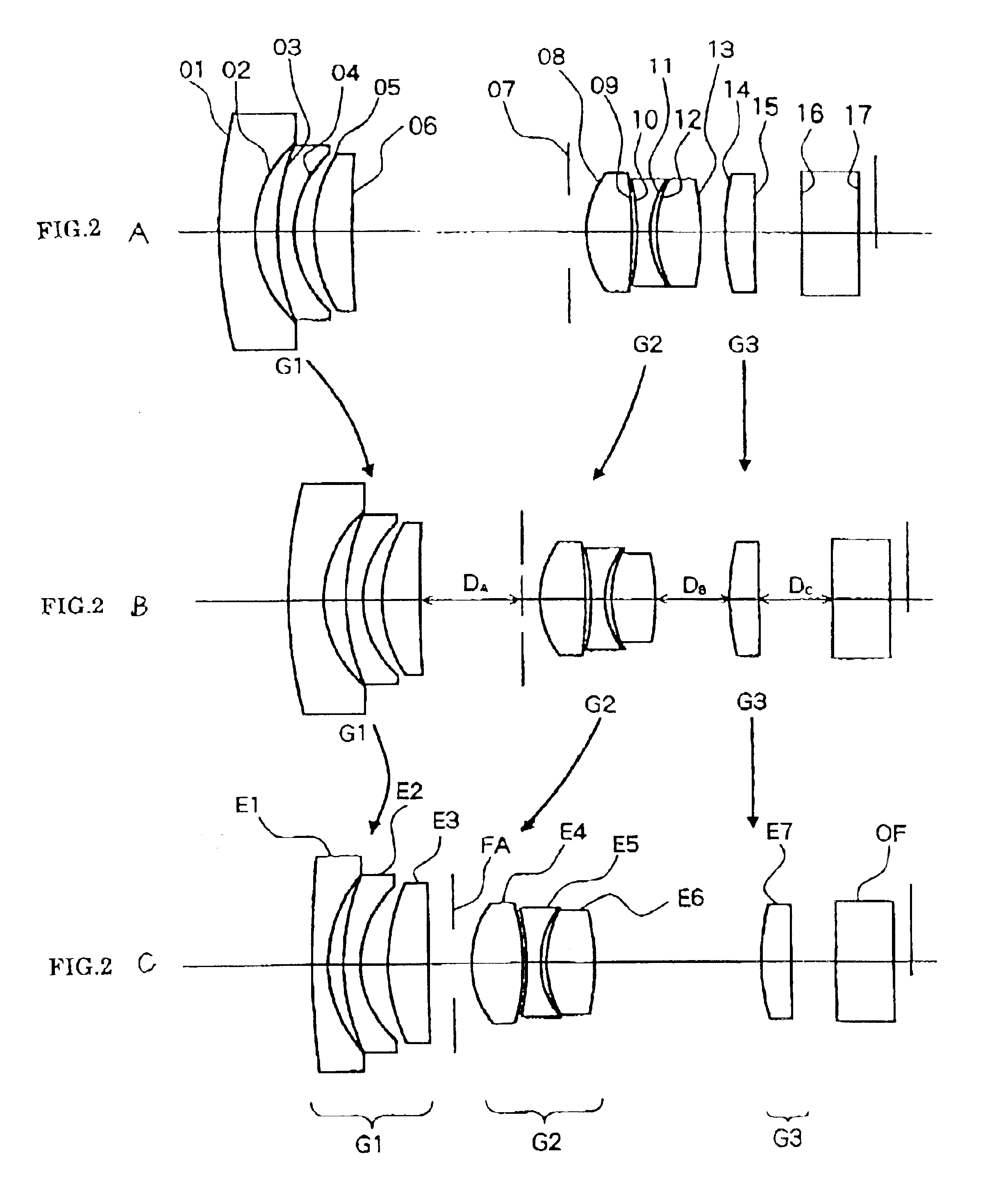

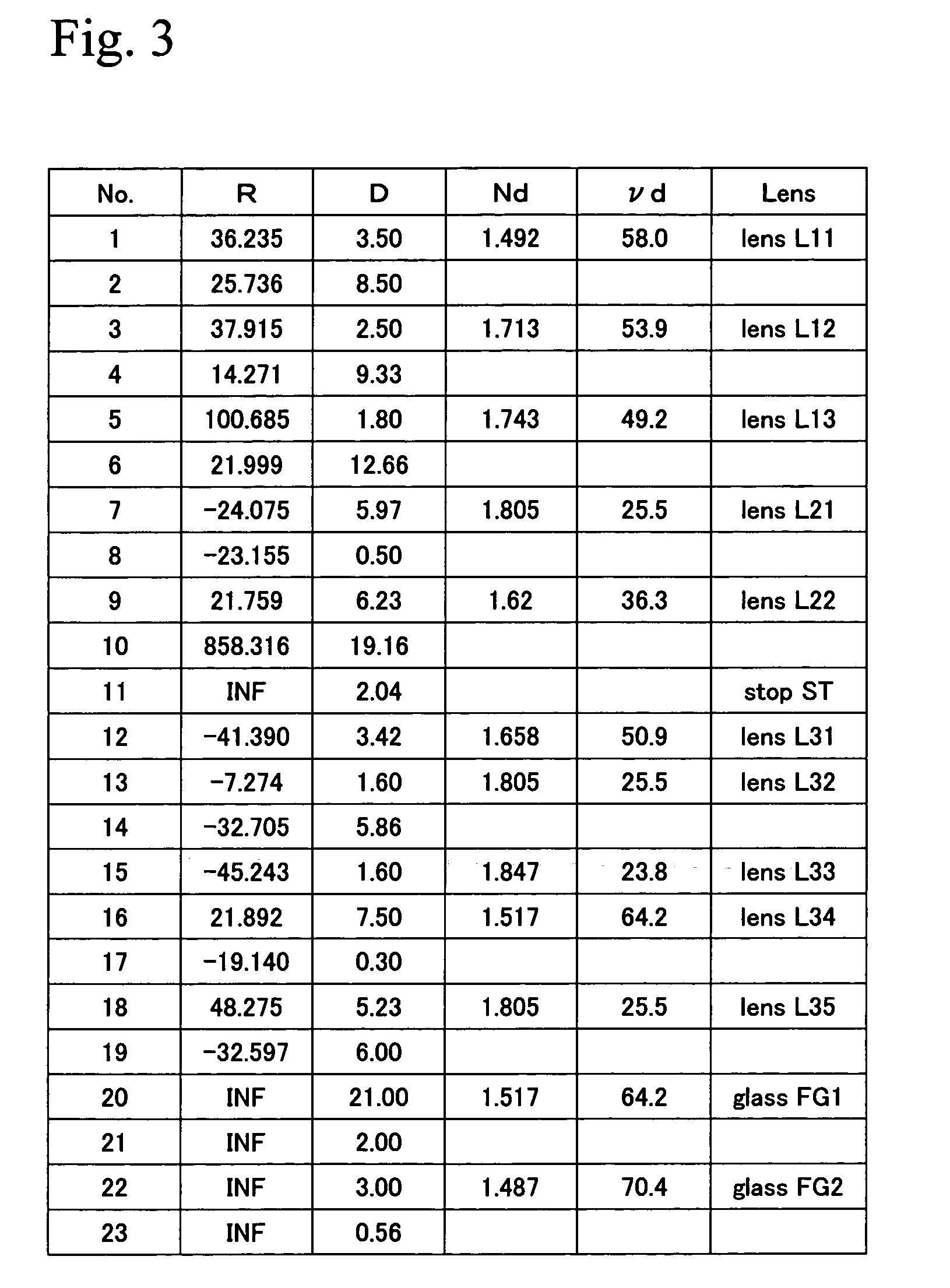

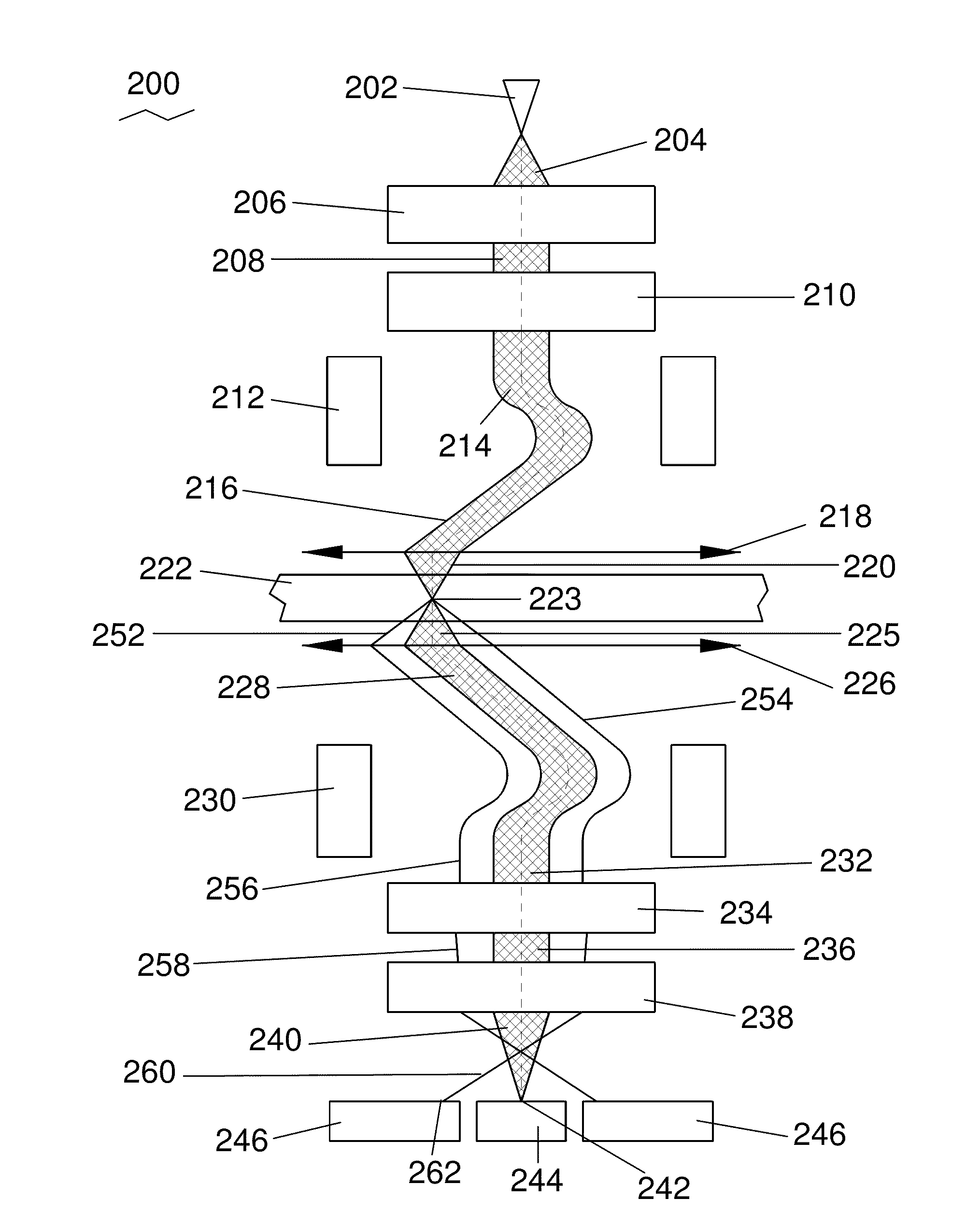

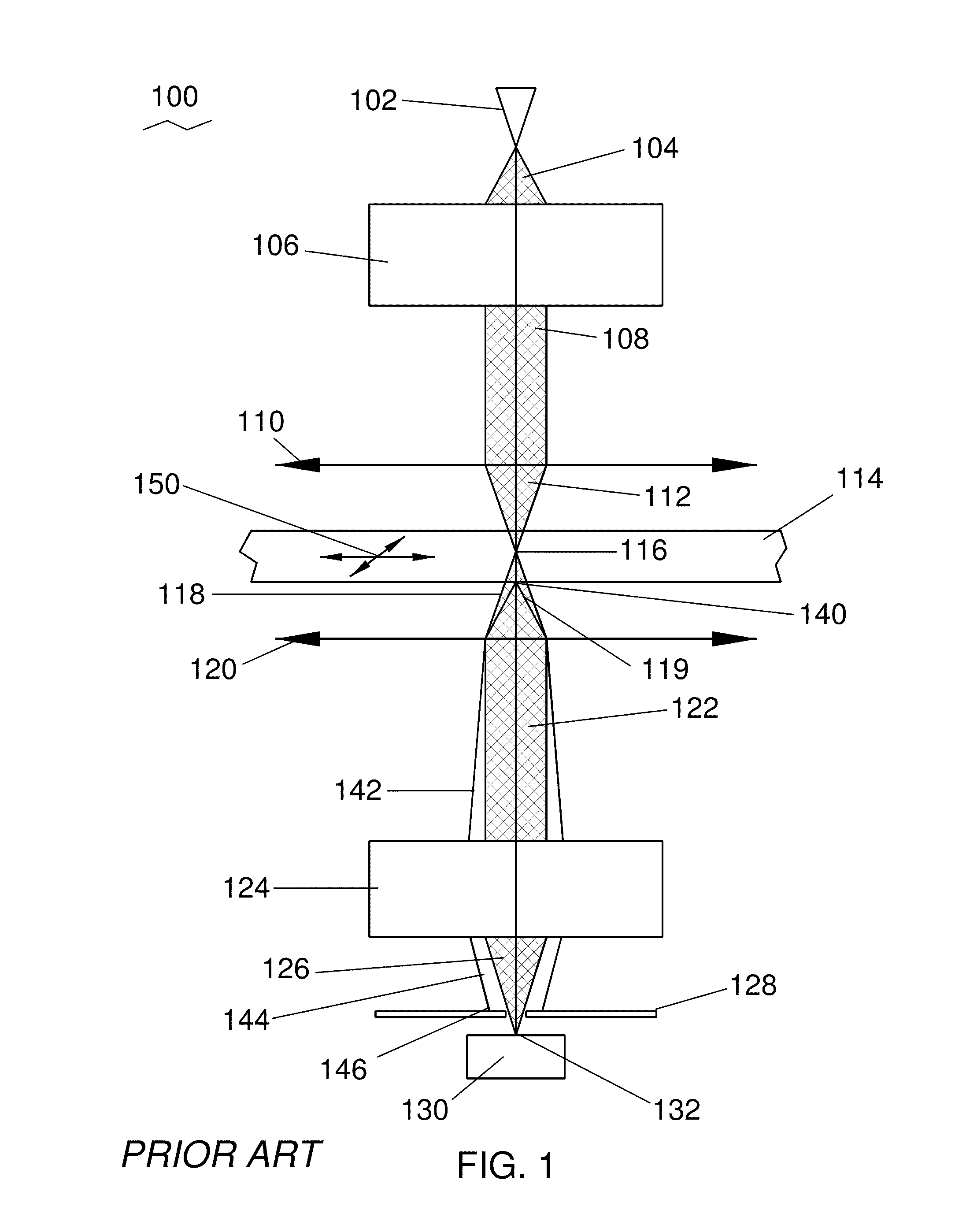

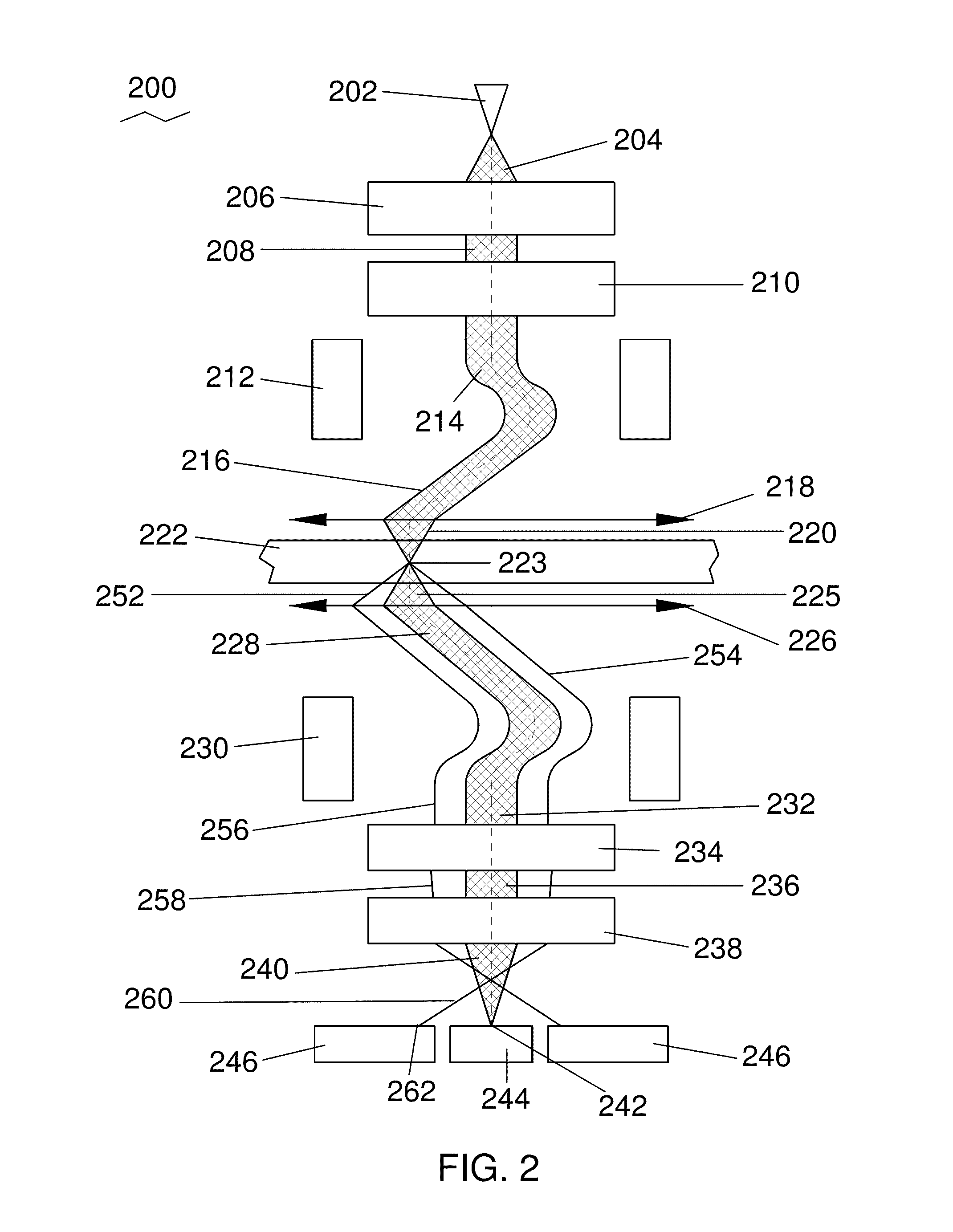

InactiveUS7057825B2Improve performanceEasy to correctTelevision system detailsBuilt-on/built-in screen projectorsCamera lensImaging quality

A projection lens system that projects projected light from a light modulator to a screen, comprising in order from a screen side: a first lens group with a negative refractive power; a second lens group with a positive refractive power; and a third lens group with a positive refractive power is provided. The third lens group includes at least two cemented lenses and a lens with a positive refractive power positioned on an opposite side of the cemented lenses to the screen. Since the projection lens system achieves a sufficiently high correcting performance for various aberrations using fewer aspherical lenses, it is suitable lens system for a rear projector with high image quality.

Owner:NITTO OPTICAL CO LTD

Contrast for Scanning Confocal Electron Microscope

ActiveUS20120012747A1Increase contrastImprove image contrastElectric discharge tubesMaterial analysis by transmitting radiationScanning confocal electron microscopyImage resolution

A scanning confocal transmission electron microscope includes a descan deflector and a corrector below the sample. The microscope uses a detector that is preferably significantly larger than the resolution of the microscope and is positioned in the real image plane, which provides improved contrast, particularly for light elements.

Owner:FEI CO

Image capturing optical system

This invention provides an image capturing optical system in order from an object side to an image side comprising: a first lens element with positive refractive power having a convex object-side surface; a second lens element; a third lens element; a fourth lens element with both the object-side and image-side surfaces thereof being aspheric, and the fourth lens element is made of plastic; and a fifth lens element with negative refractive power, both the object-side and image-side surfaces thereof being aspheric, at least one inflection point is formed on at least one of the object-side and image-side surfaces thereof, and the fifth lens element is made of plastic. By such arrangement, photosensitivity and total track length of the system can be reduced, and better image quality can be obtained.

Owner:LARGAN PRECISION

Liquid crystal lens element and optical head device

InactiveUS7710535B2Reduce thicknessImprove overall utilizationRecord information storageNon-linear opticsPhase correctionFresnel lens

Owner:ASAHI GLASS CO LTD

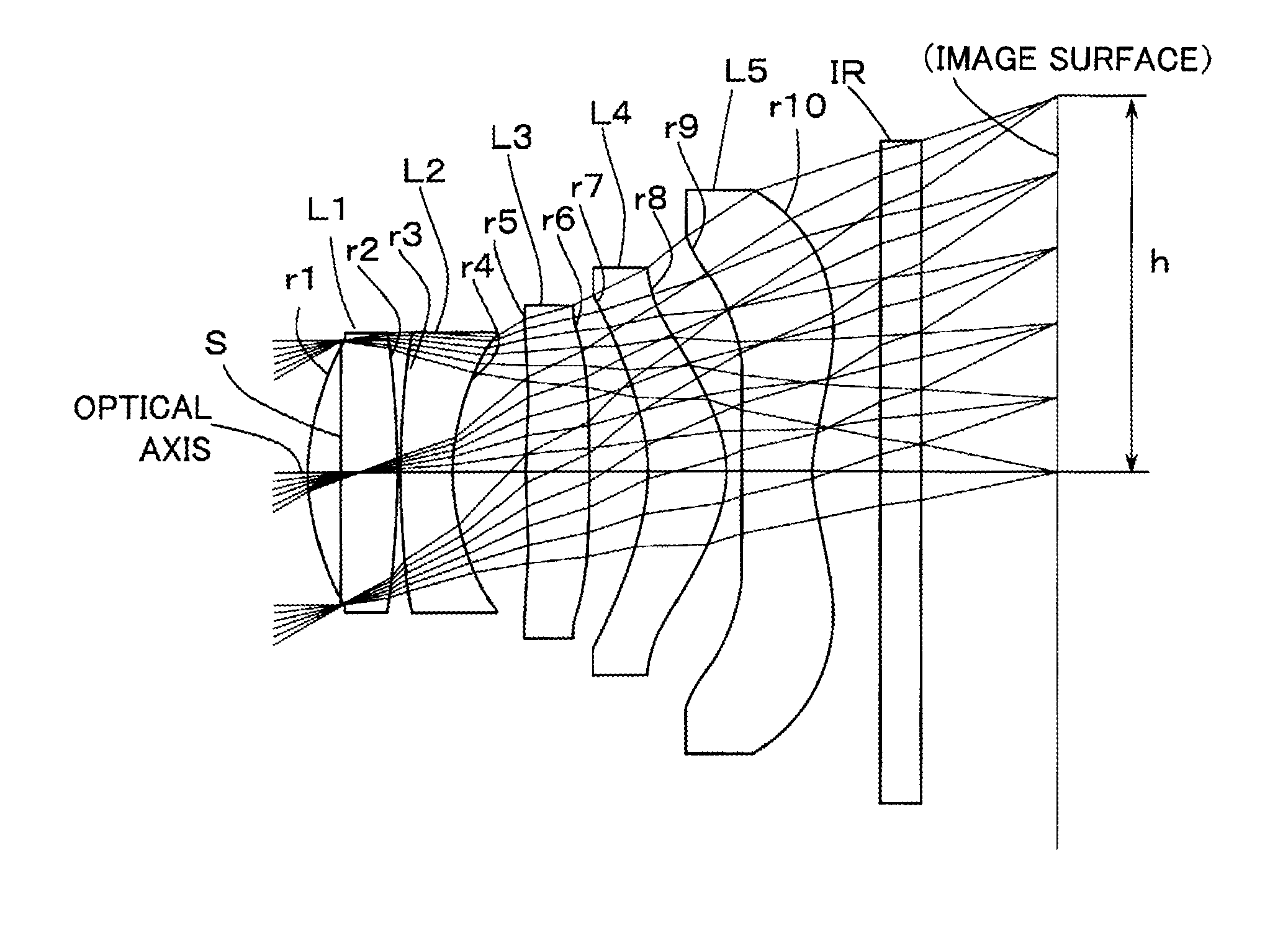

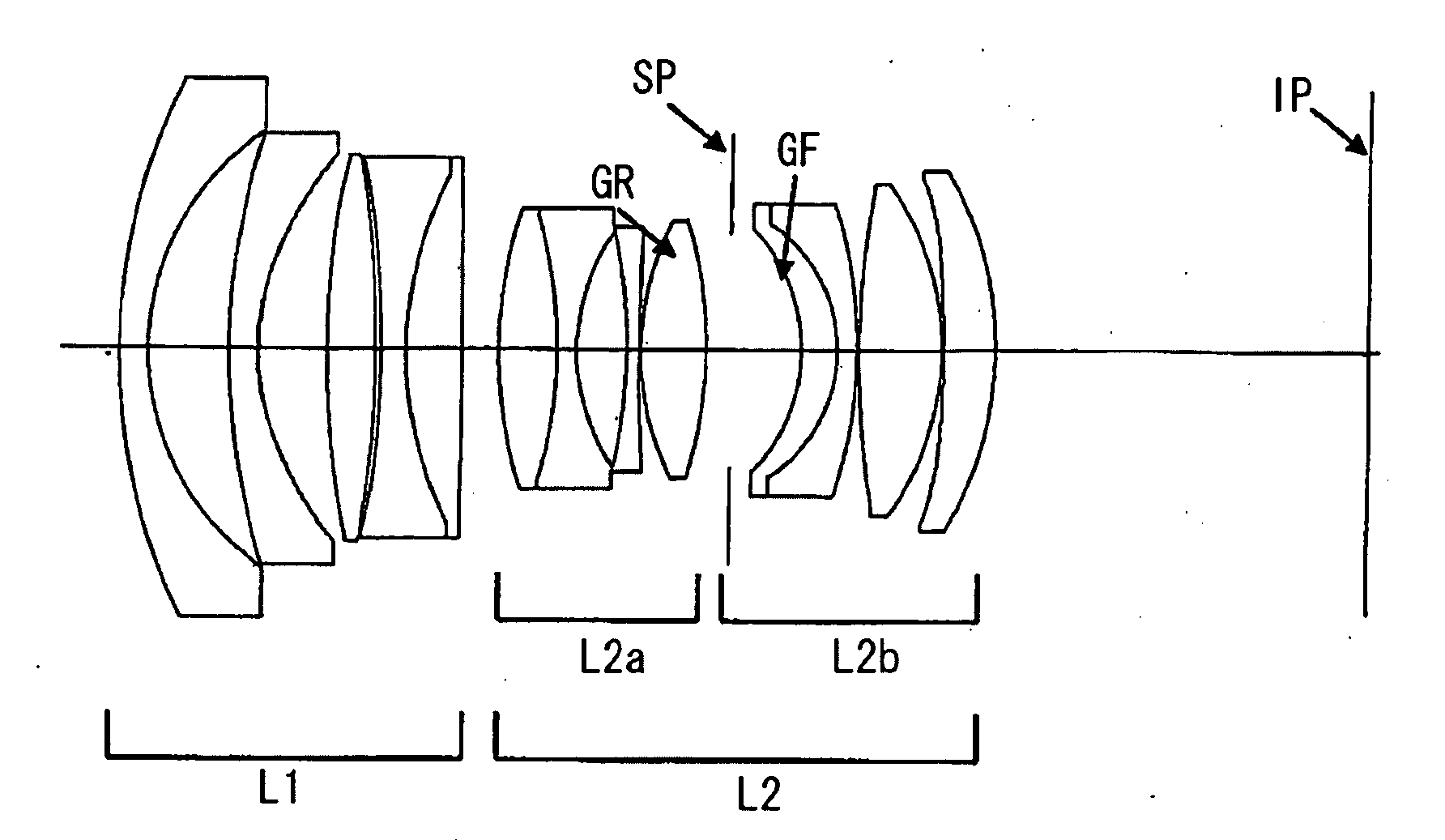

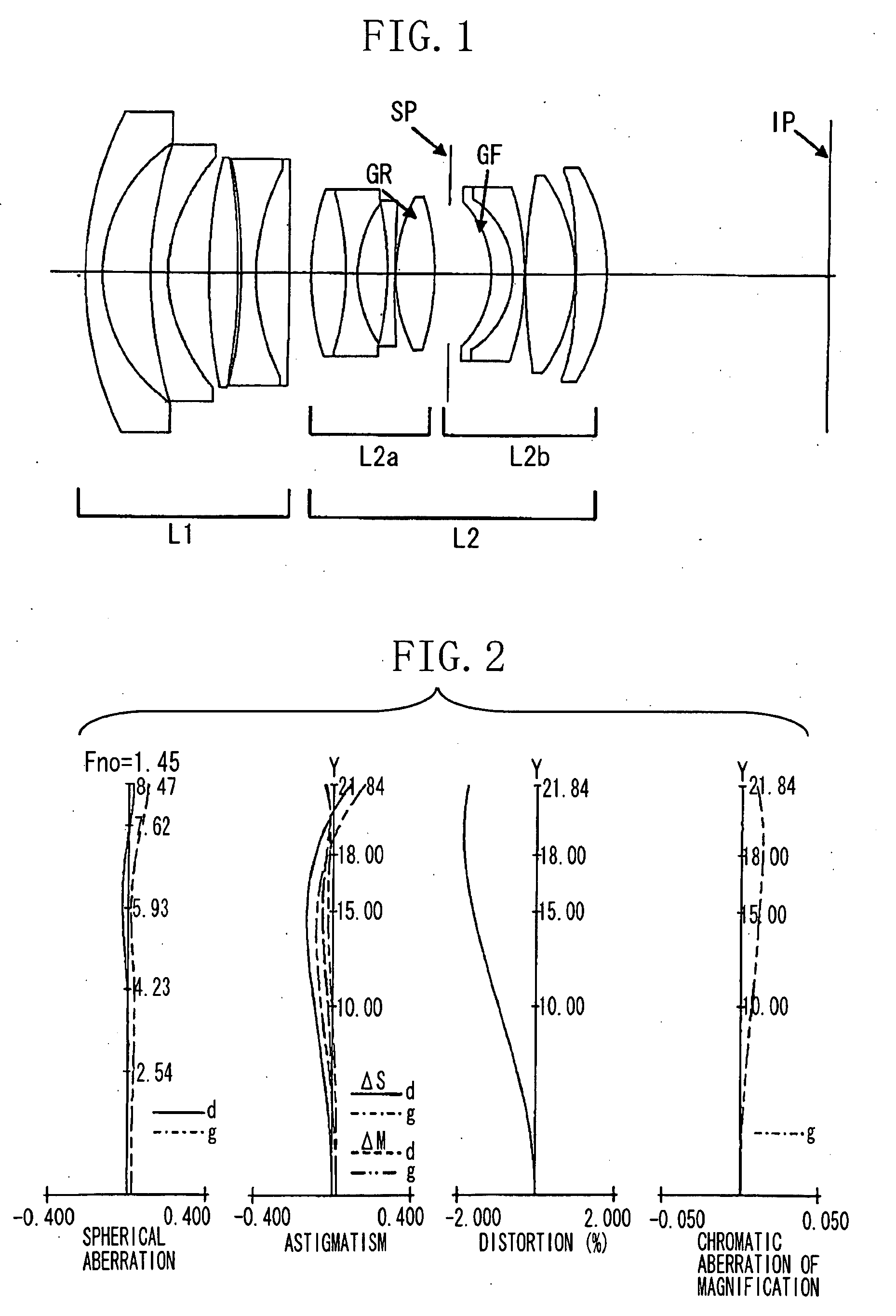

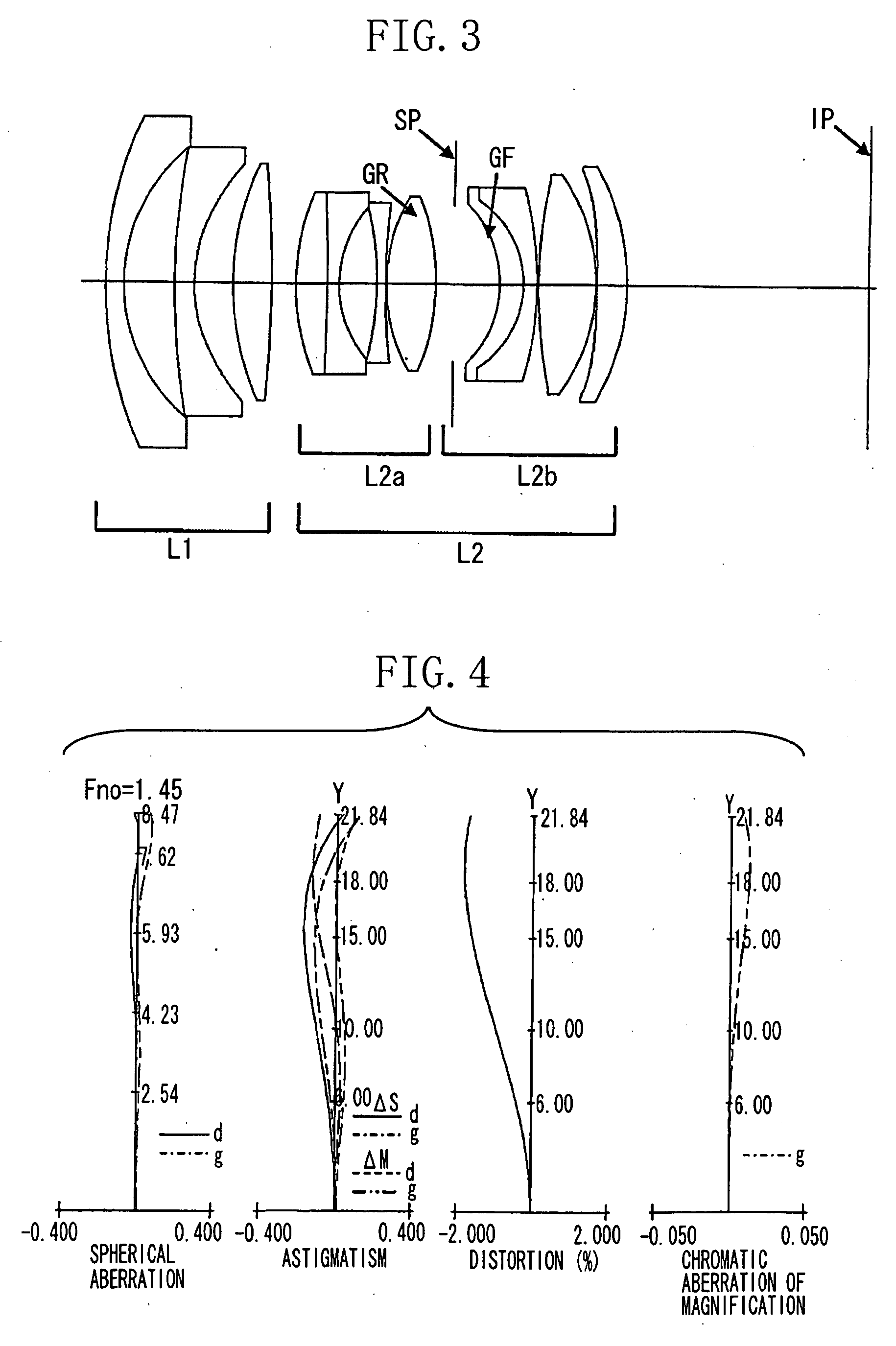

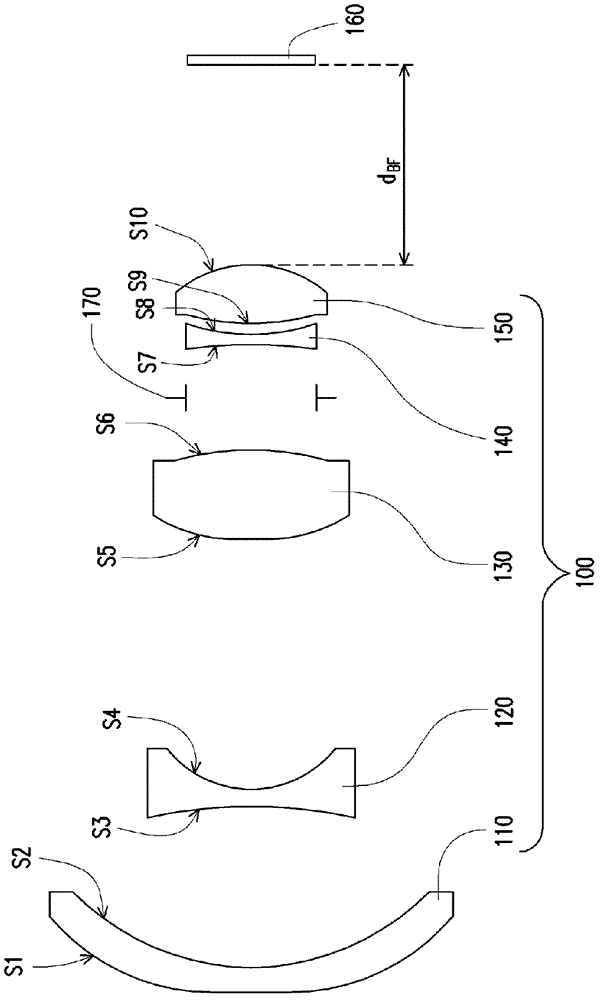

Optical system and image pickup apparatus using the same

ActiveUS20090109551A1Corrected spherical aberrationVarious aberrationOptical elementsObject pointOptoelectronics

An optical system includes a first lens unit having a negative refractive power and a second lens unit having a positive refractive power. The second lens unit includes a front lens unit, a stop, and a rear lens unit. The front lens unit includes a biconvex positive lens located closest to the image side. A back focus during focusing on an infinitely-distant object point (BF), a focal length of the entire optical system (f), a focal length of the positive lens of the front lens unit located closest to the image side (fp), a focal length of the front lens unit (f2a), a refractive power of a surface of the rear lens unit located closest to the object side (φf), and a refractive power of the entire optical system (φ) satisfy the following conditions:1.0<BF / f<3.00.1<fp / f2a<0.50.7<|φf / φ|<1.5.

Owner:CANON KK

Liquid crystal lens element and optical head device

ActiveUS7388822B2Small sizeGuaranteed uptimeOptical beam sourcesRecord information storageOptical axisRefractive index

A liquid crystal lens element having a lens function is provided, which is small sized without having moving part, and which can stably carry out correction of spherical aberration containing a power component corresponding to focal point change of incident light.A liquid crystal lens element which changes a focal length of light transmitted through a liquid crystal 16 according to the magnitude of the voltage applied to the liquid crystal 16 sandwiched between a pair of transparent substrates 11 and 12, which comprises transparent electrodes 13 and 14 provided on the respective transparent substrates 11 and 12 for applying a voltage for the liquid crystal 16, and a concave-convex portion 17 having a saw-tooth-shaped cross-sectional shape having a rotational symmetry about an optical axis and formed on one surface of the transparent electrode 13 with a transparent material, wherein at least concave portions of the concave-convex portion 17 are filled with the liquid crystal 16 so as to change the substantial refractive index of the liquid crystal 16 according to the magnitude of applied voltage.

Owner:ASAHI GLASS CO LTD

Photographing optical lens, image capturing device and electronic device

Owner:LARGAN PRECISION

Optical image capturing assembly

An optical image capturing assembly includes, in order from an object side to an image side, a first lens element, a second lens element, a third lens element and a fourth lens element. The first lens element with positive refractive power has a convex object-side surface. The second lens element with negative refractive power has a concave object-side surface and a convex image-side surface. The third lens element with positive refractive power is made of plastic material, and has a convex object-side surface and a convex image-side surface. The fourth lens element with negative refractive power is made of plastic material, and has a convex object-side surface and a concave image-side surface. The object-side surfaces and the image-side surfaces of the third lens element and the fourth lens element are aspheric. The fourth lens element has at least one inflection point formed on at least one surface thereof.

Owner:LARGAN PRECISION

Three-piece type optical lens

A three piece type optical lens includes a first lens element with positive refractive power, a second lens element with negative refractive power, a third lens element with negative refractive power, an IR cut-off filter and an image sensor arranged along an optical axis in sequence from an object side. The first lens element and the second lens element are both meniscus aspherical lens while a convex surface of the first lens element is on the object side and a convex surface of the second lens is on the image side. The third lens element is an M-shaped aspherical lens whose object side and image side are both M-shaped and a central surface of the optical axis can be a convex surface or a concave surface. A pre-aperture is disposed or a center-aperture is arranged on the optical lens.

Owner:E PIN OPTICAL IND

Imaging lens and imaging apparatus

The imaging lens substantially consists of a first lens group having a positive refractive power and a second lens group having a positive refractive power, in which the entire second lens group moves along the optical axis to perform focusing. In the imaging lens, the first lens group comprises a positive first lens, a negative second lens, a negative third lens, a positive fourth lens, and a positive fifth lens in this order from the object side. When the Abbe number of the second lens with respect to the d-line is νd2 and the Abbe number of the third lens with respect to the d-line is νd3, conditional formula (1) below is satisfied:2.0<νd2 / νd3 (1).

Owner:FUJIFILM CORP

Image capturing lens assembly

An image capturing lens assembly comprises, in order from an object side to an image side, a first lens element with positive refractive power having a convex object-side surface, a second lens element with refractive power, a third lens element with positive refractive power having a convex image-side surface, and a fourth lens element with refractive power having a convex object-side surface and a concave image-side surface. The object-side surface and the image-side surface of the fourth lens element are aspheric and have at least one inflection point.

Owner:LARGAN PRECISION

Photographing optical lens system, image capturing apparatus and electronic device

ActiveCN107462979AEffective shape controlCorrected spherical aberrationOptical elementsOptical axisConvex side

A photographing optical lens system includes, in order from an object side to an image side, a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element and a sixth lens element. The first lens element has negative refractive power. The second lens element has an image-side surface being convex in a paraxial region thereof. The third lens element has positive refractive power. The fourth lens element has negative refractive power. The sixth lens element with negative refractive power has an object-side surface being concave in a paraxial region thereof and an image-side surface being planar or convex in a paraxial region thereof.

Owner:LARGAN PRECISION

Objective lens, optical pickup apparatus, and recording and/or reproducing apparatus

InactiveUS7110344B2Increase the number ofHigh density recordingOptical beam sourcesRecord information storageOptical pickupOptical axis

An objective lens for recording and / or reproducing information of an optical information recording medium, comprises at lest one aspherical surface. The objective lens is a single lens and satisfies the following formulas:0.85<NA<0.980.80<d / f<3.000.5<Φ1<5.8whereNA is an optical information recording medium side numerical aperture,d is a thickness (mm) on an optical axis,f is a focal length (mm) for an object locating at an infinite distance, andΦ1 is an effective diameter (mm) of a light source side surface.

Owner:KONICA CORP

Variable-power optical system, image pickup device, and digital apparatus

ActiveUS20100045808A1Compact configurationEffective correctionTelevision system detailsColor television detailsConditional expressionOptical power

A variable-power optical system includes, in order from an object side thereof: a first lens group with a negative optical power; a second lens group with a positive optical power; a third lens group with a negative optical power; and a fourth lens group with a positive optical power. An interval between the first lens group and the second lens group decreases when a power of the variable-power optical system varies from a wide-angle end to a telephoto end. The second lens group includes at least one aspheric surface. The variable-power optical system satisfies the predetermined conditional expressions.

Owner:KONICA MINOLTA OPTO

Imaging lens and imaging apparatus equipped with the imaging lens

An imaging lens is constituted essentially by six lenses, including: a first lens having a positive refractive power and a convex surface toward the object side; a second lens having a negative refractive power; a third lens having a positive refractive power and a convex surface toward the image side; a fourth lens having a positive refractive power; a fifth lens having a positive refractive power; and a sixth lens having a negative refractive power, provided in this order from the object side. The imaging lens satisfies a predetermined conditional formula.

Owner:FUJIFILM CORP

Projection lens

InactiveCN103064175AQuality improvementCorrected spherical aberrationOptical elementsImaging qualityRefractive index

A projection lens comprises a first lens, a second lens, a third lens, a fourth lens and a fifth lens, wherein the first lens, the second lens, the third lens, the fourth lens and the fifth lens are arranged in order from the enlargement side to the diminution side. Diopter of the first lens, the second lens, the third lens, the fourth lens and the fifth lens is respectively negative, negative, positive, negative and positive. The diopter of the fourth lens is larger than that of the first lens and the second lens. Refractive index of the fourth lens is Nd and focal length of the fourth lens is f4. The focal length of fifth lens is f5. Due to the fact that the projection lens meets 0.45<|f4 / (f5*Nd)|<1.2, the projection lens has the advantages of being good in imaging quality and small in size.

Owner:CORETRONIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com