Patents

Literature

35results about How to "Reduce track length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

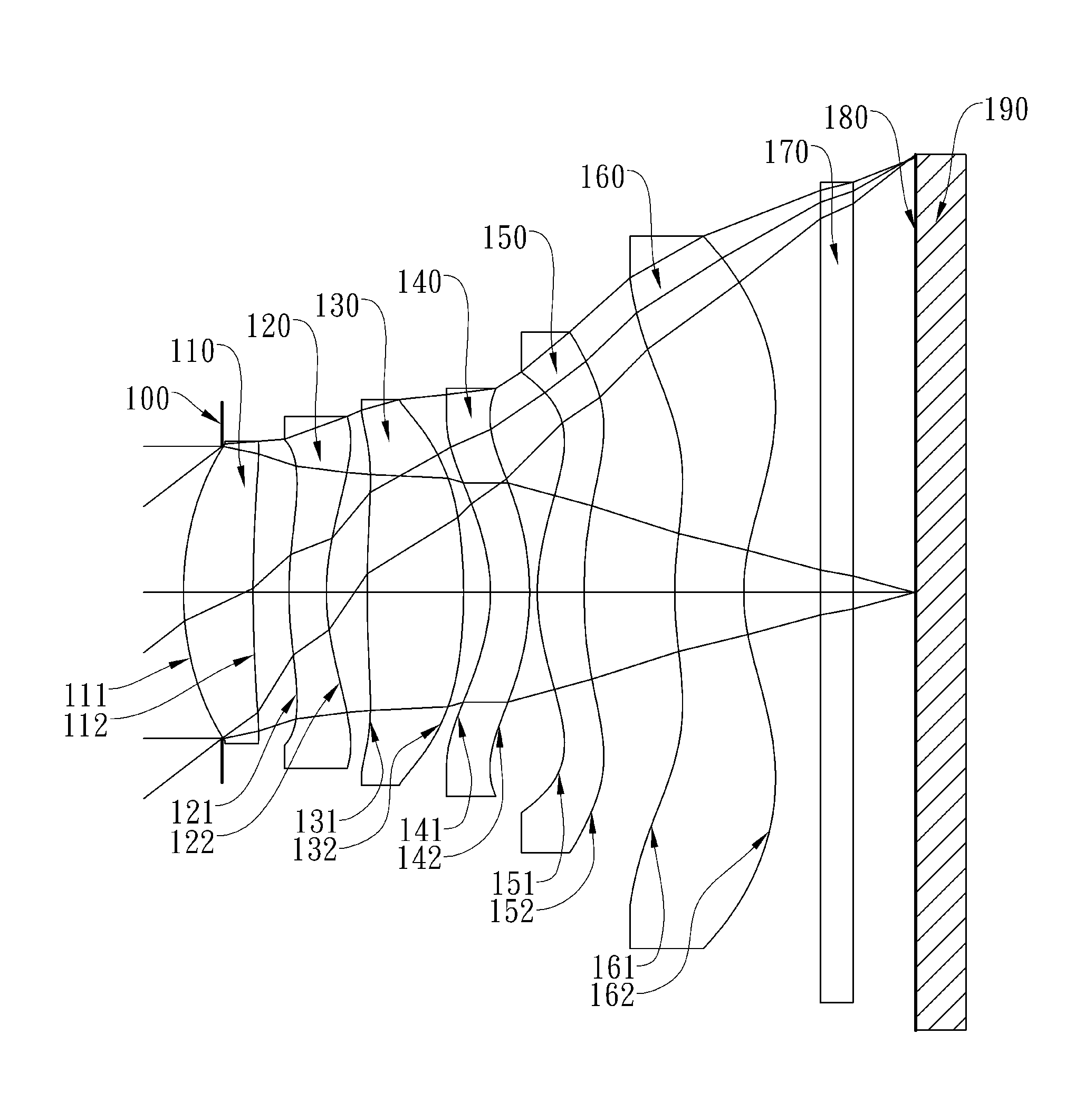

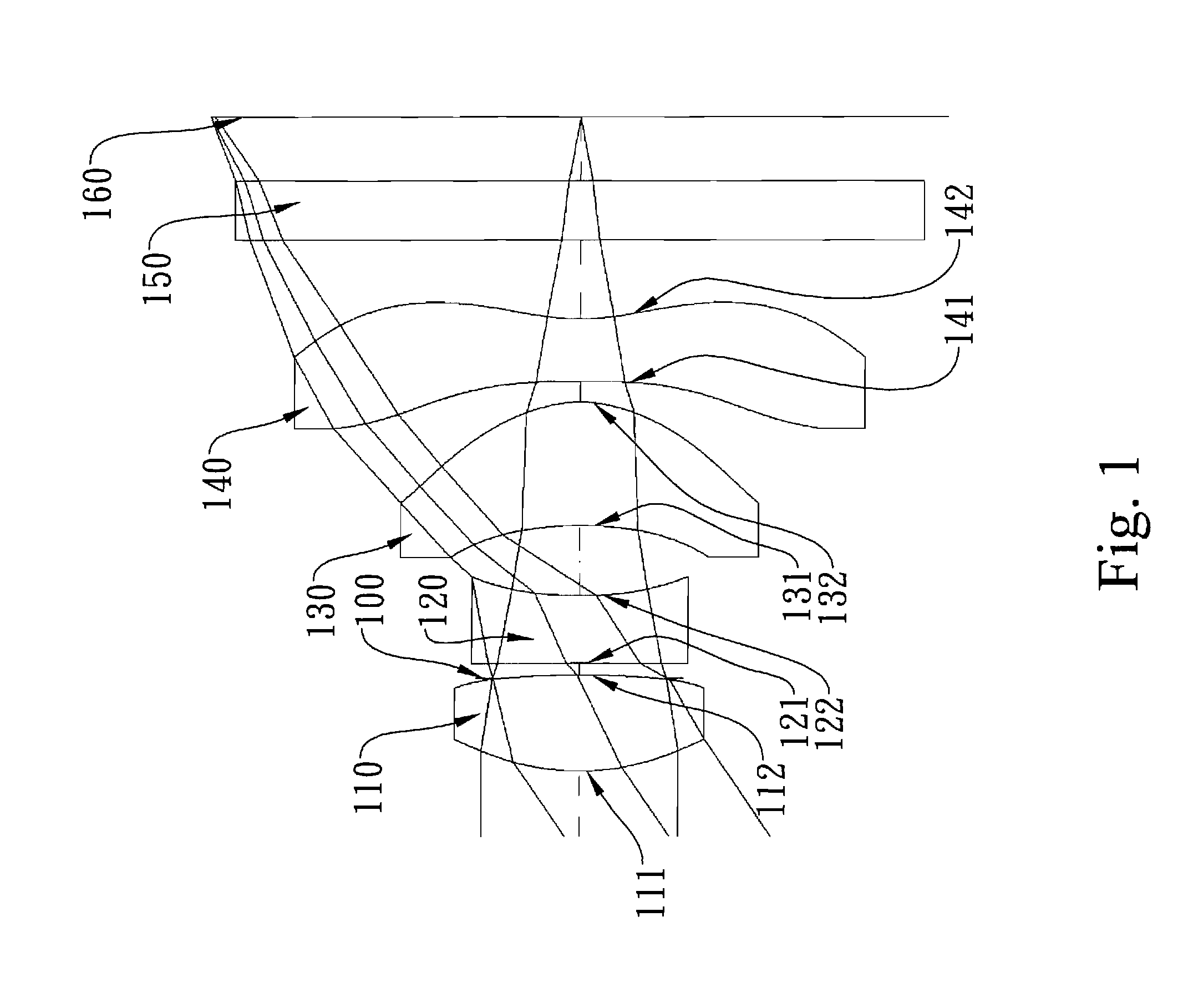

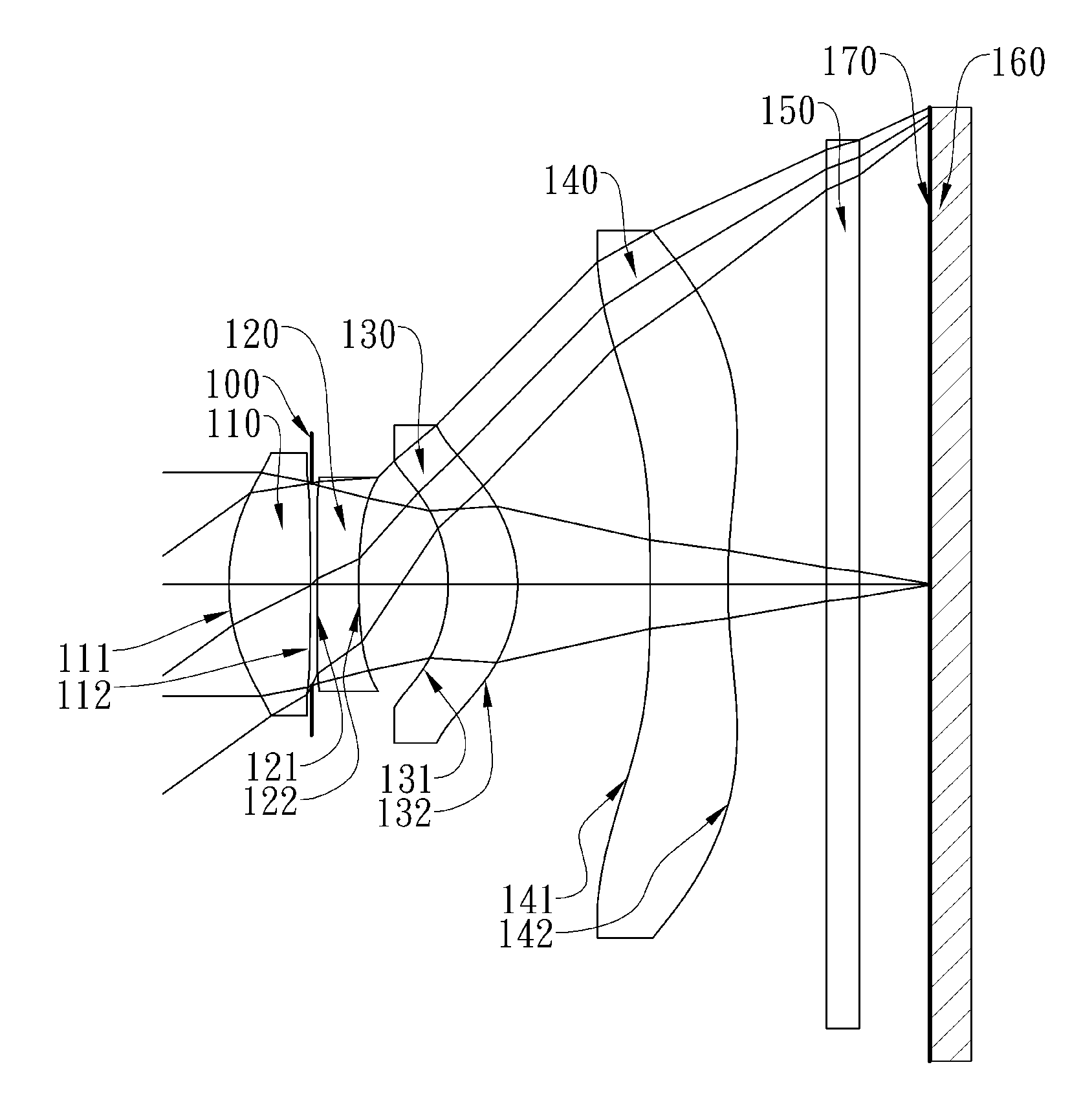

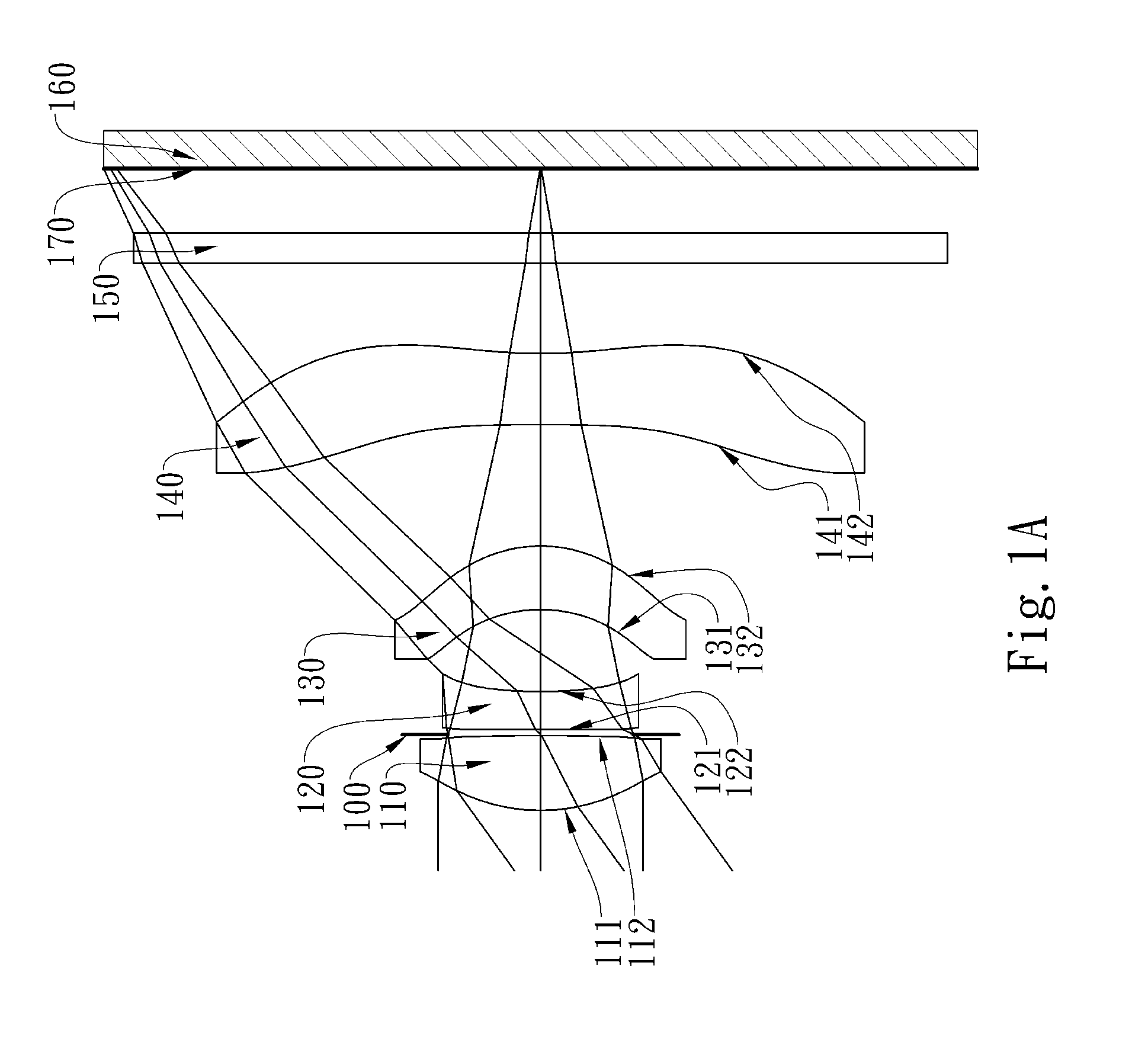

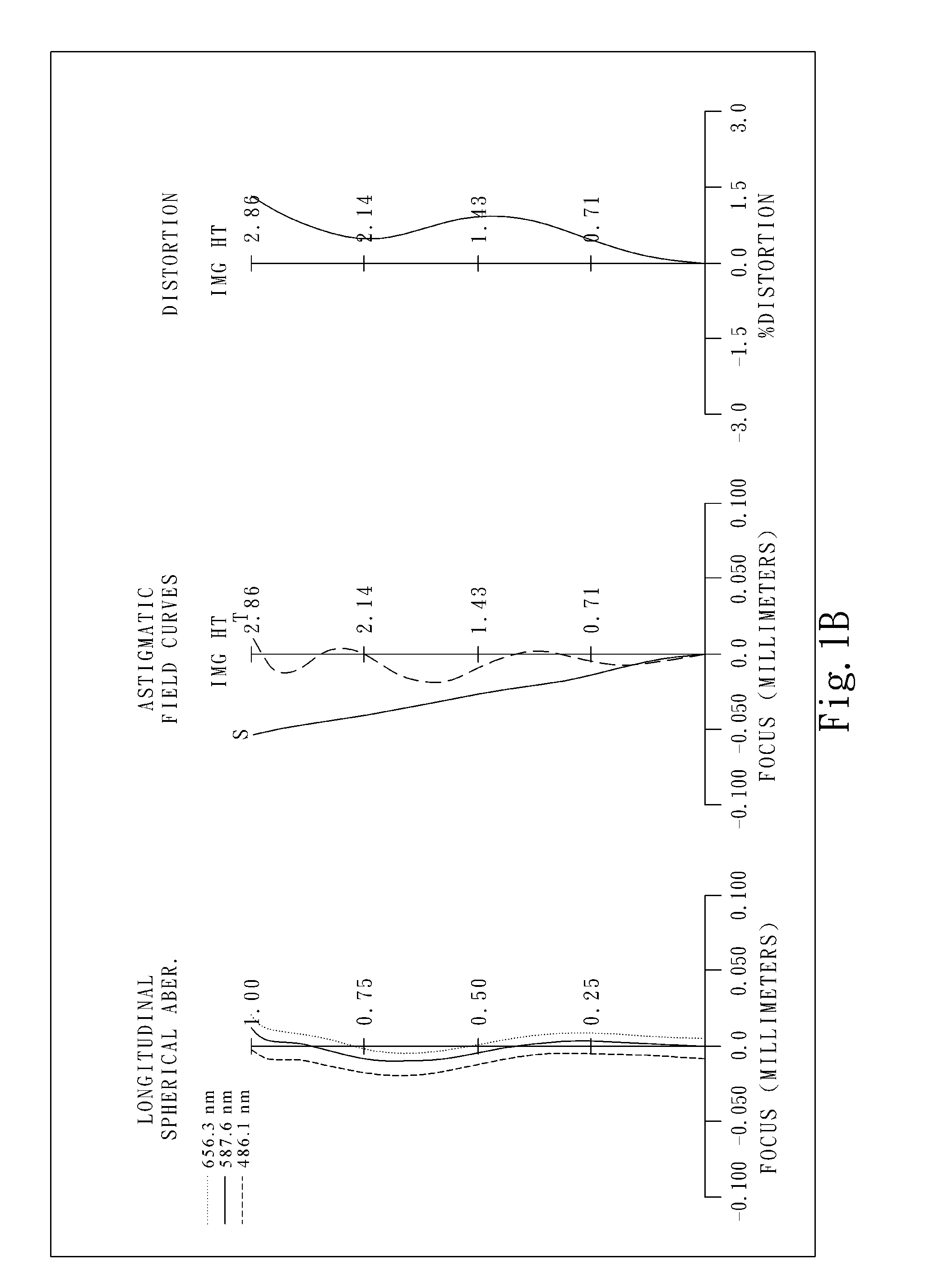

Folded camera lens systems

ActiveUS20150253647A1Well-corrected and balanced minimal residual aberrationReduce track lengthTelevision system detailsColor television detailsCamera lensImage resolution

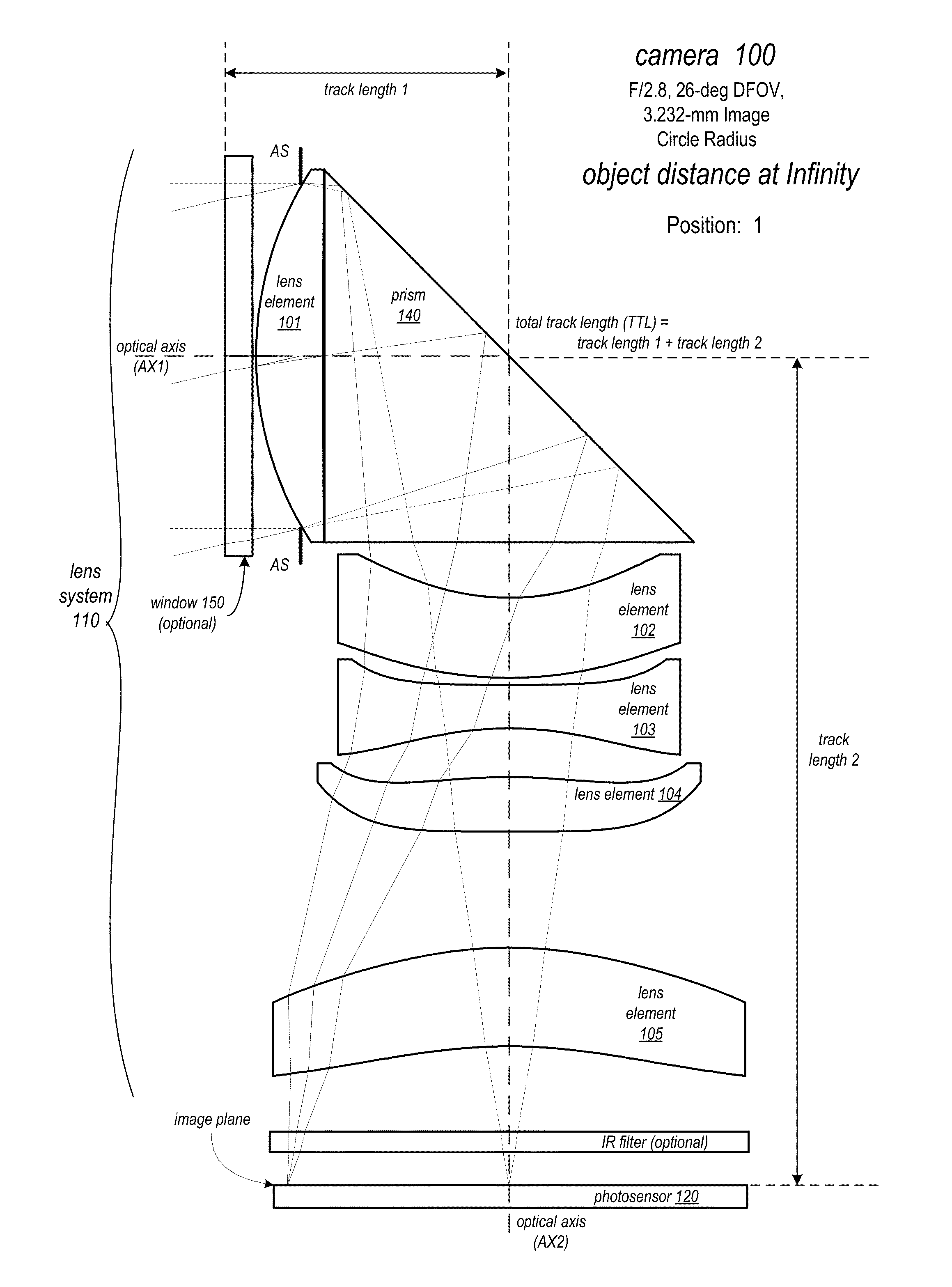

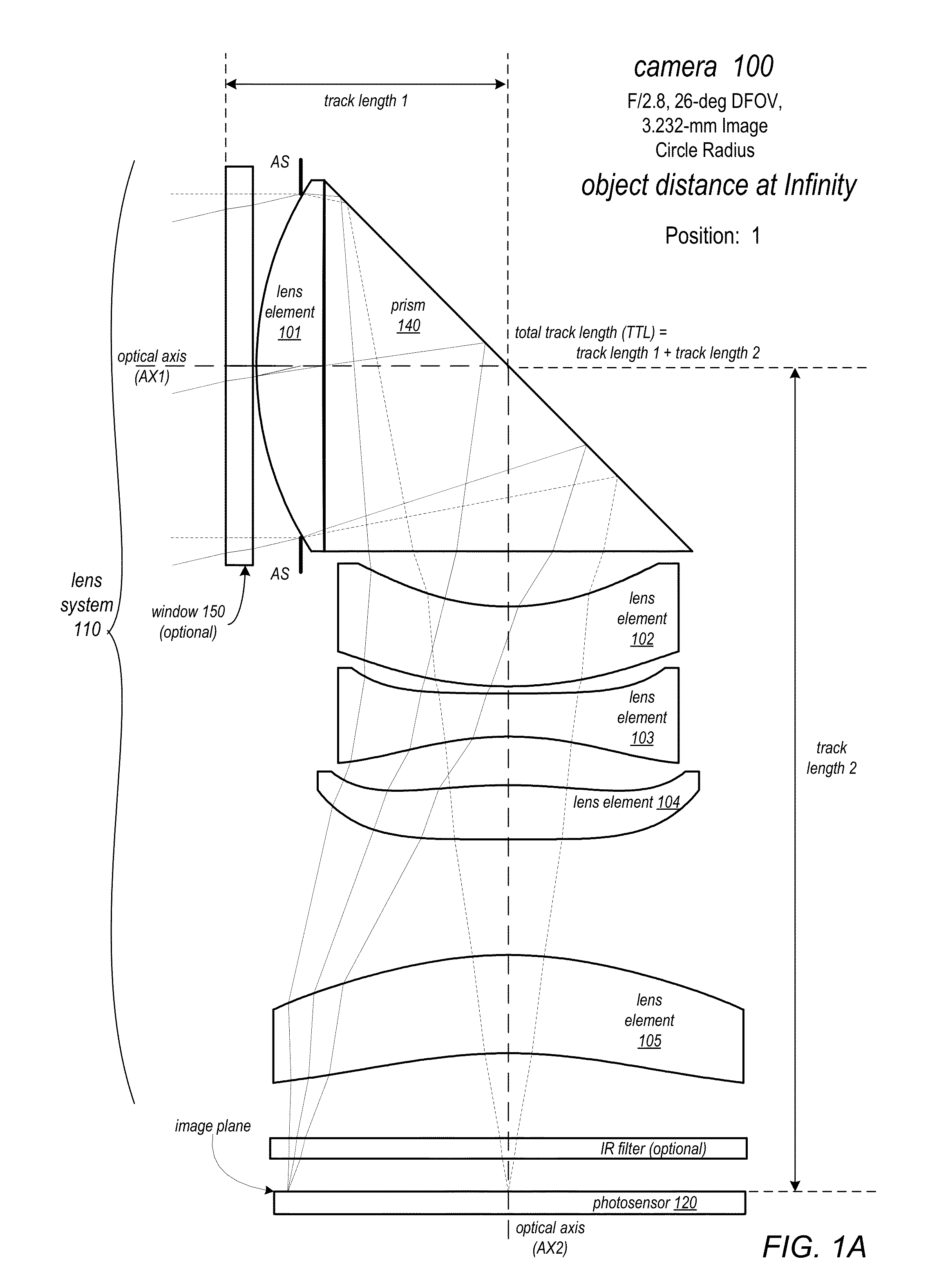

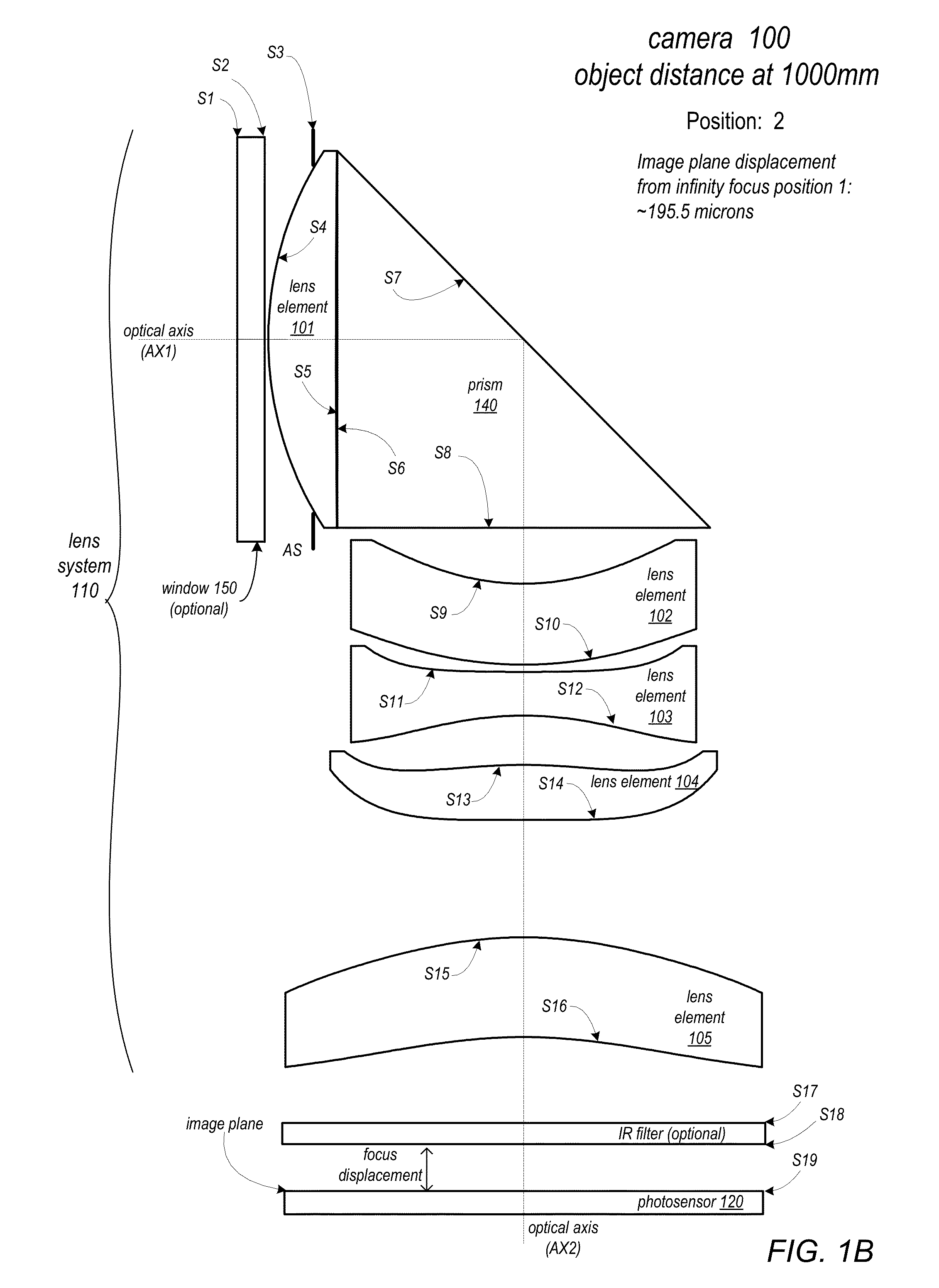

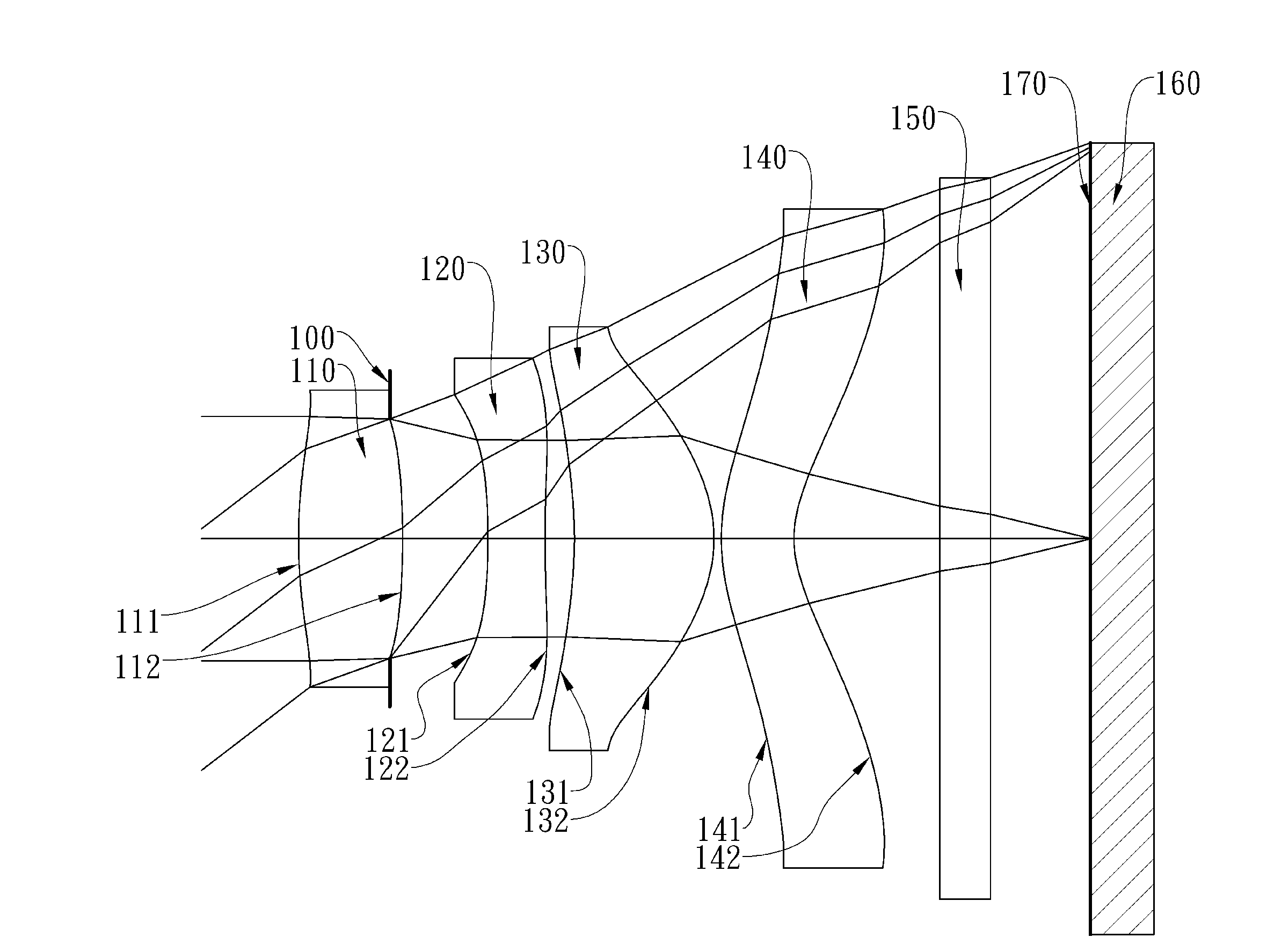

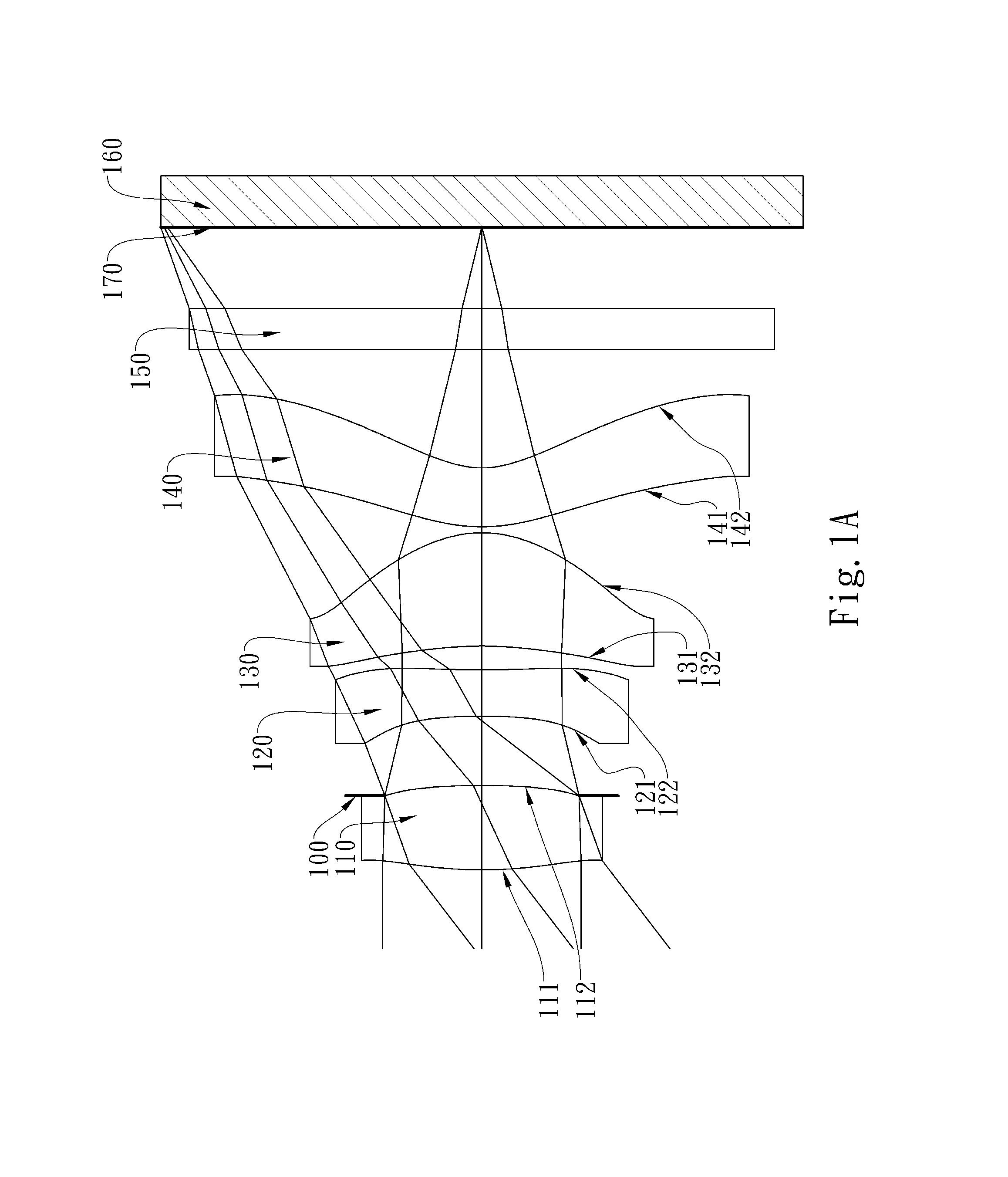

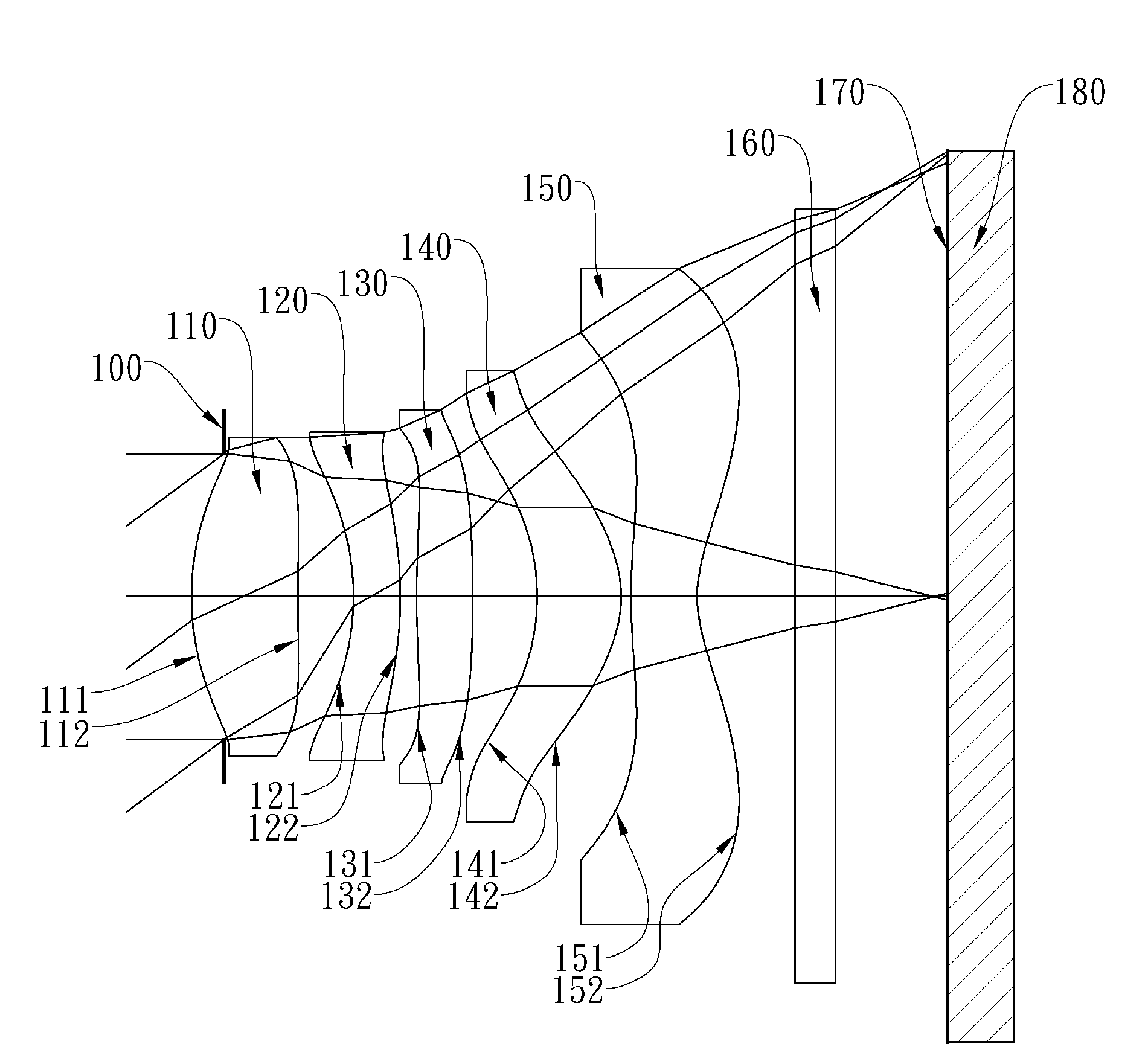

A folded lens system may include multiple lenses with refractive power and a light path folding element. Light entering the camera through lens(es) on a first optical path or axis is refracted to the folding element, which changes direction of the light onto a second optical path or axis with lens(es) that refract the light to form an image plane at a photosensor. At least one of the object side and image side surfaces of at least one of the lens elements may be aspheric. Total track length (TTL) of the lens system may be 16.0 mm or less. The lens system may be configured so that the telephoto ration |TTL / f| is greater than 1.0. Materials, radii of curvature, shapes, sizes, spacing, and aspheric coefficients of the optical elements may be selected to achieve quality optical performance and high image resolution in a small form factor camera.

Owner:APPLE INC

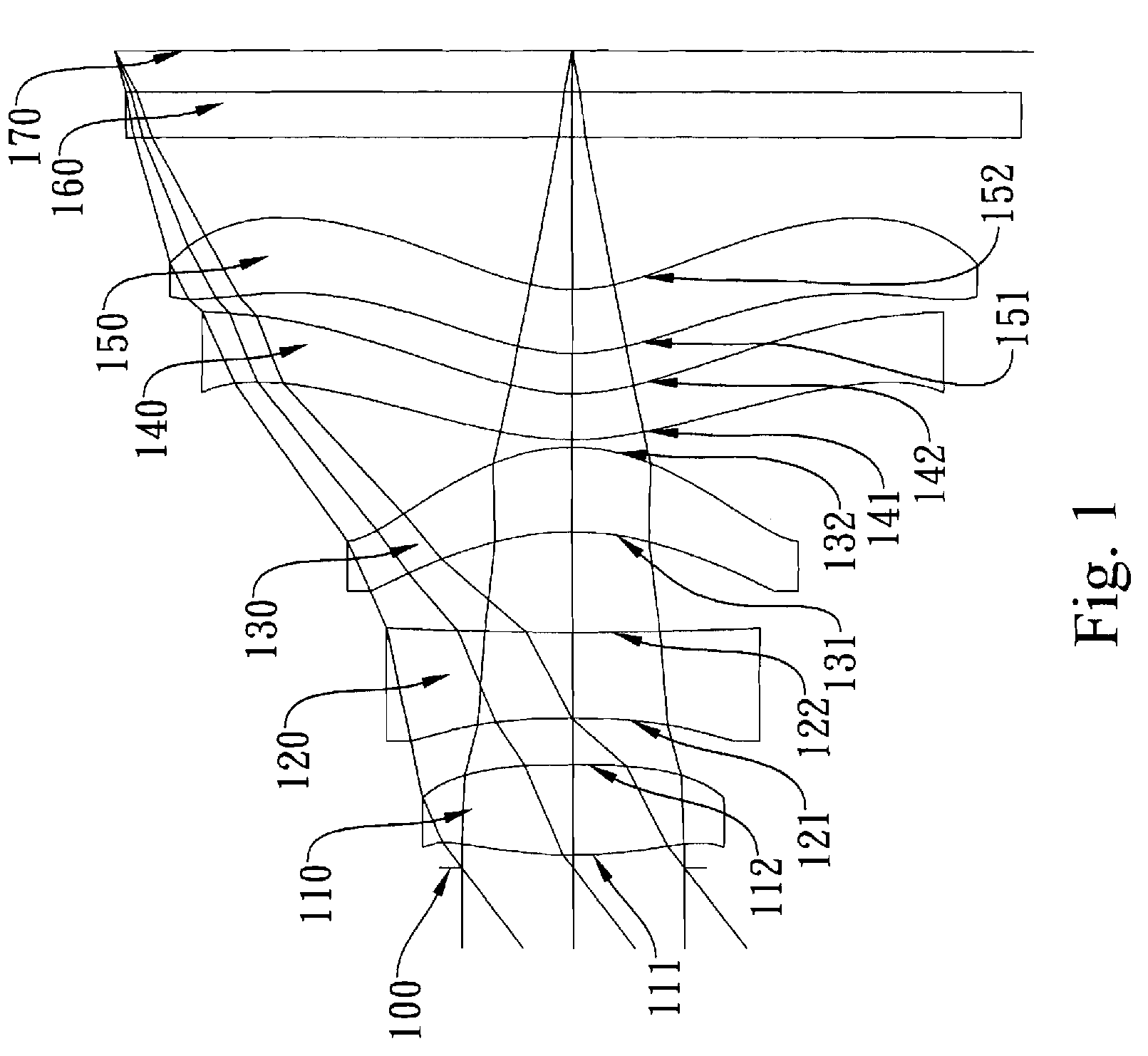

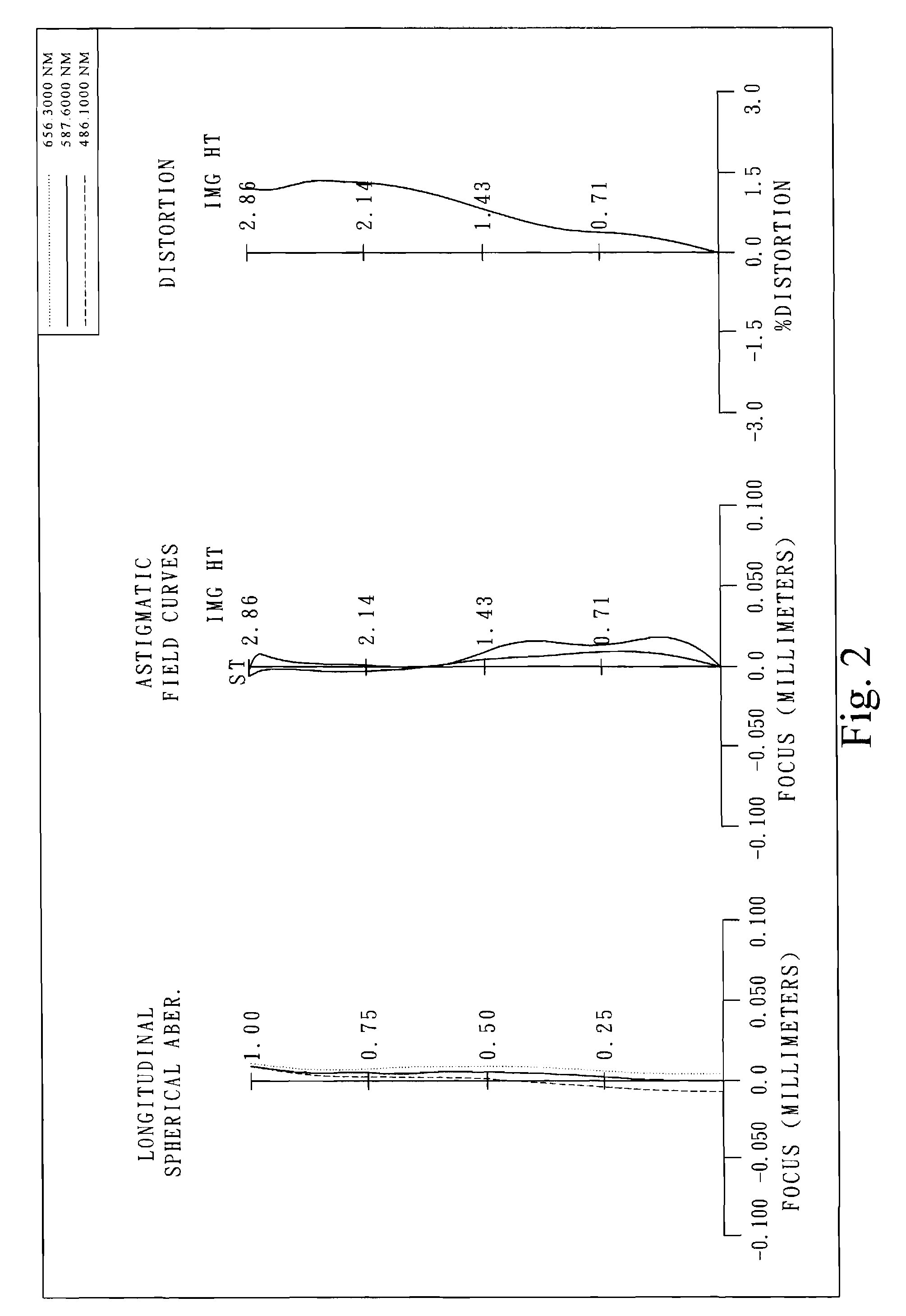

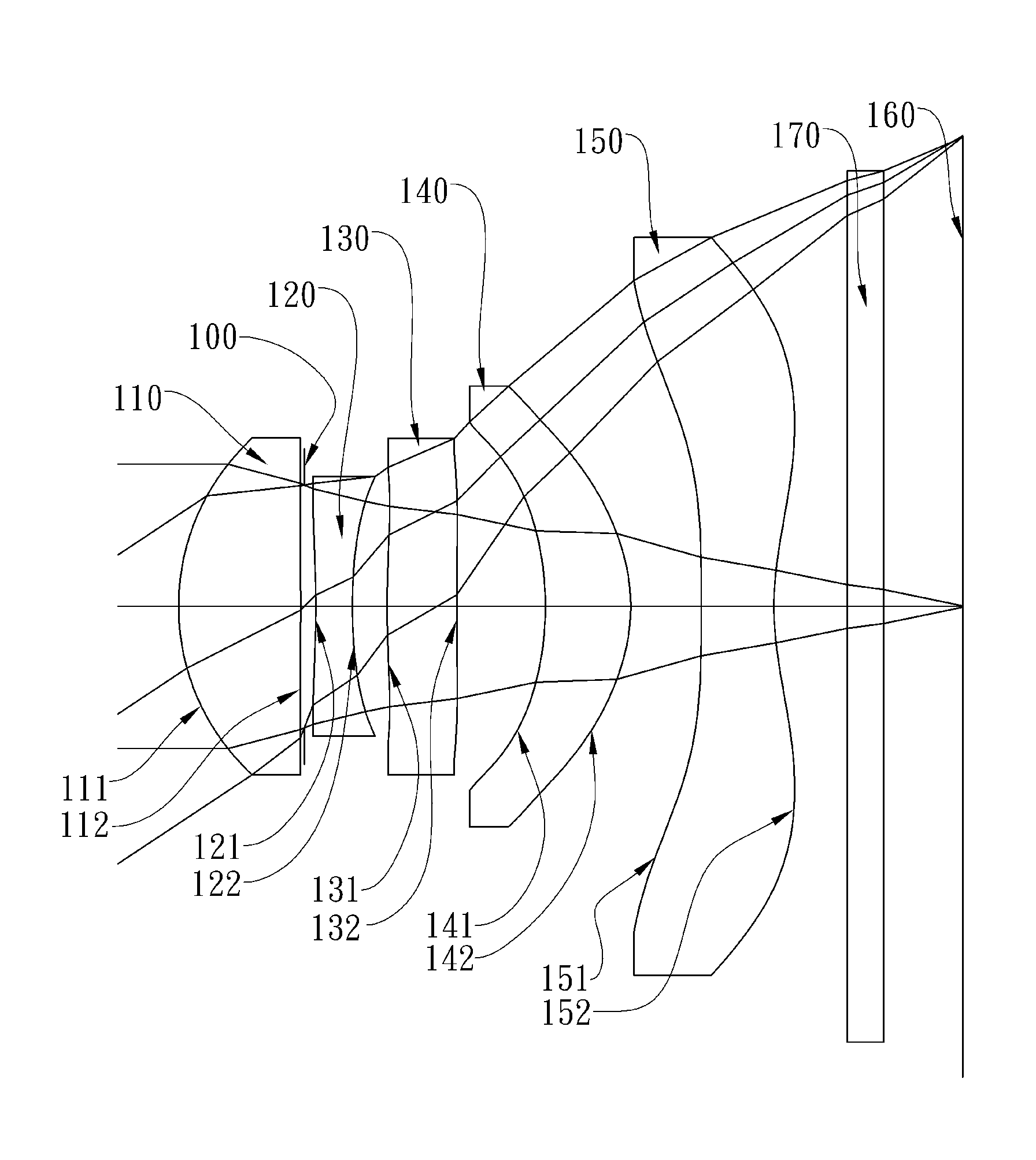

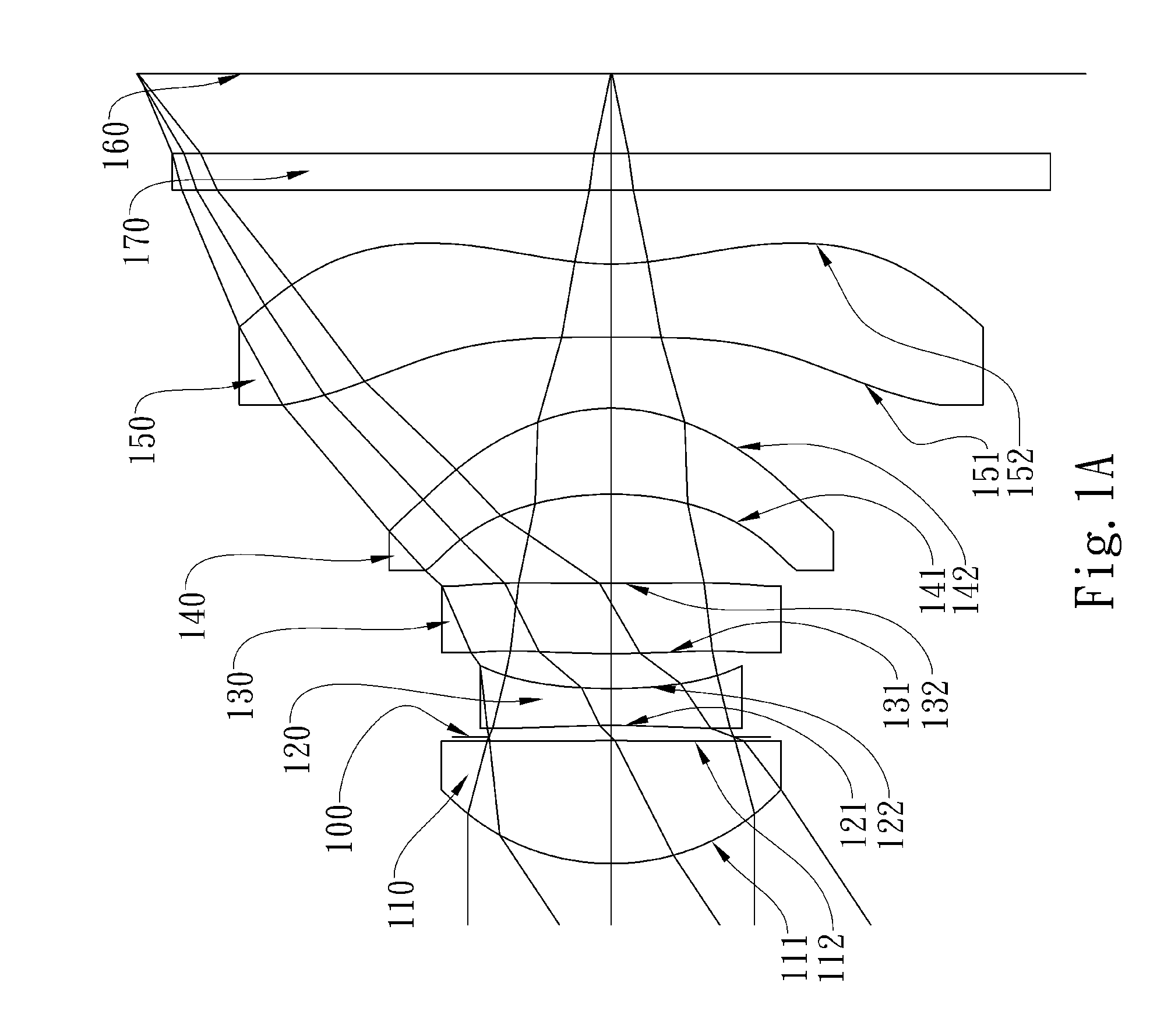

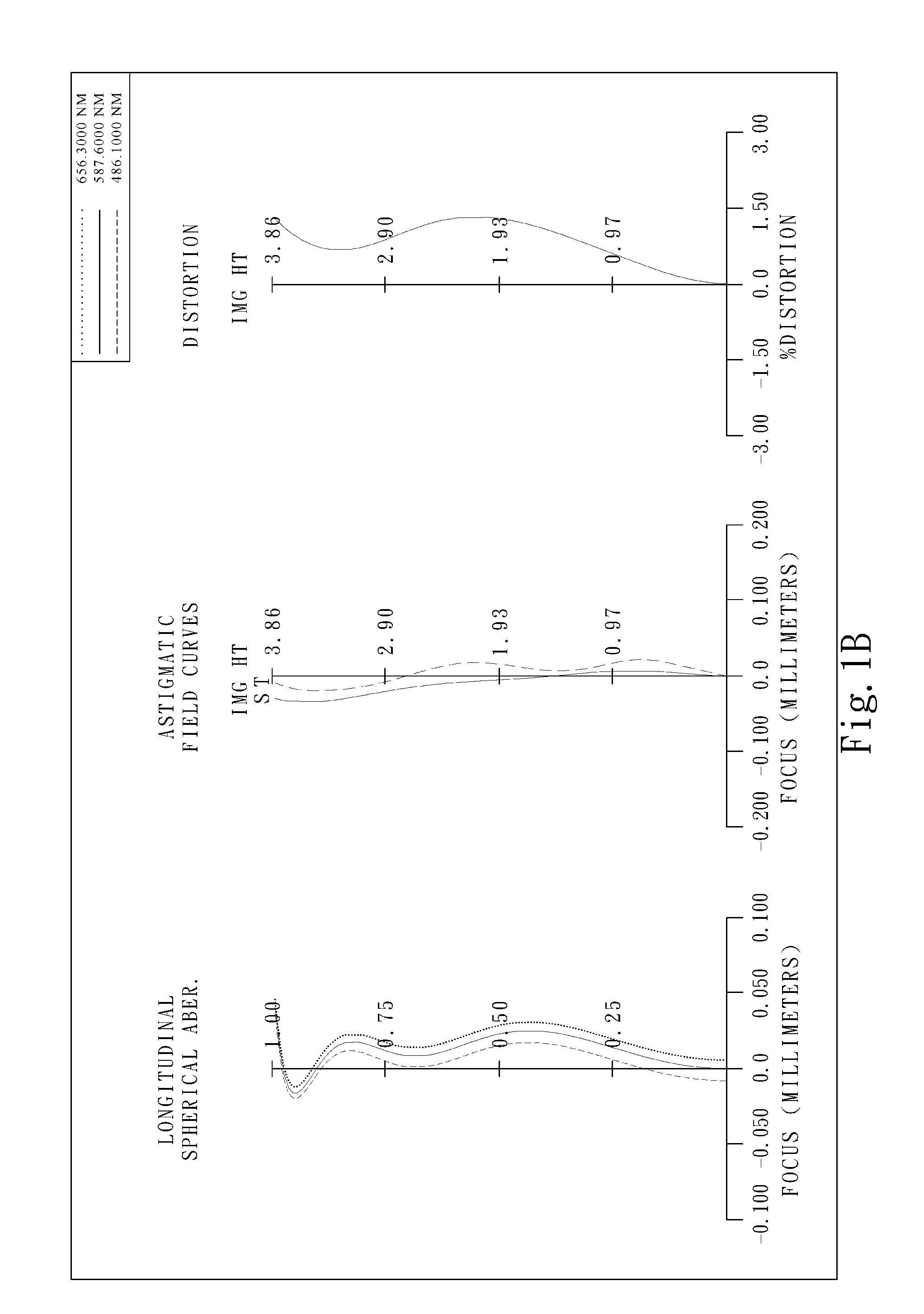

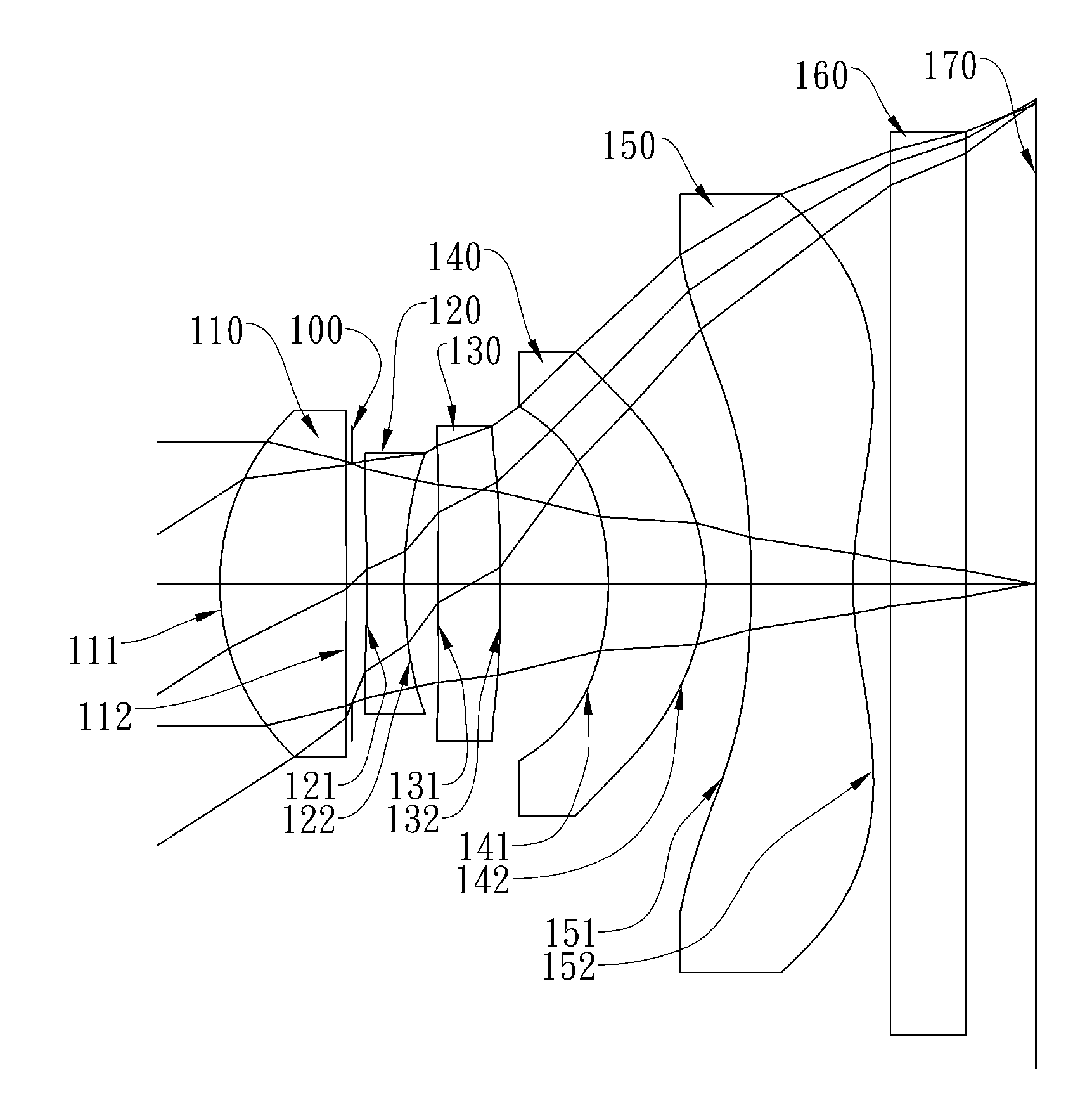

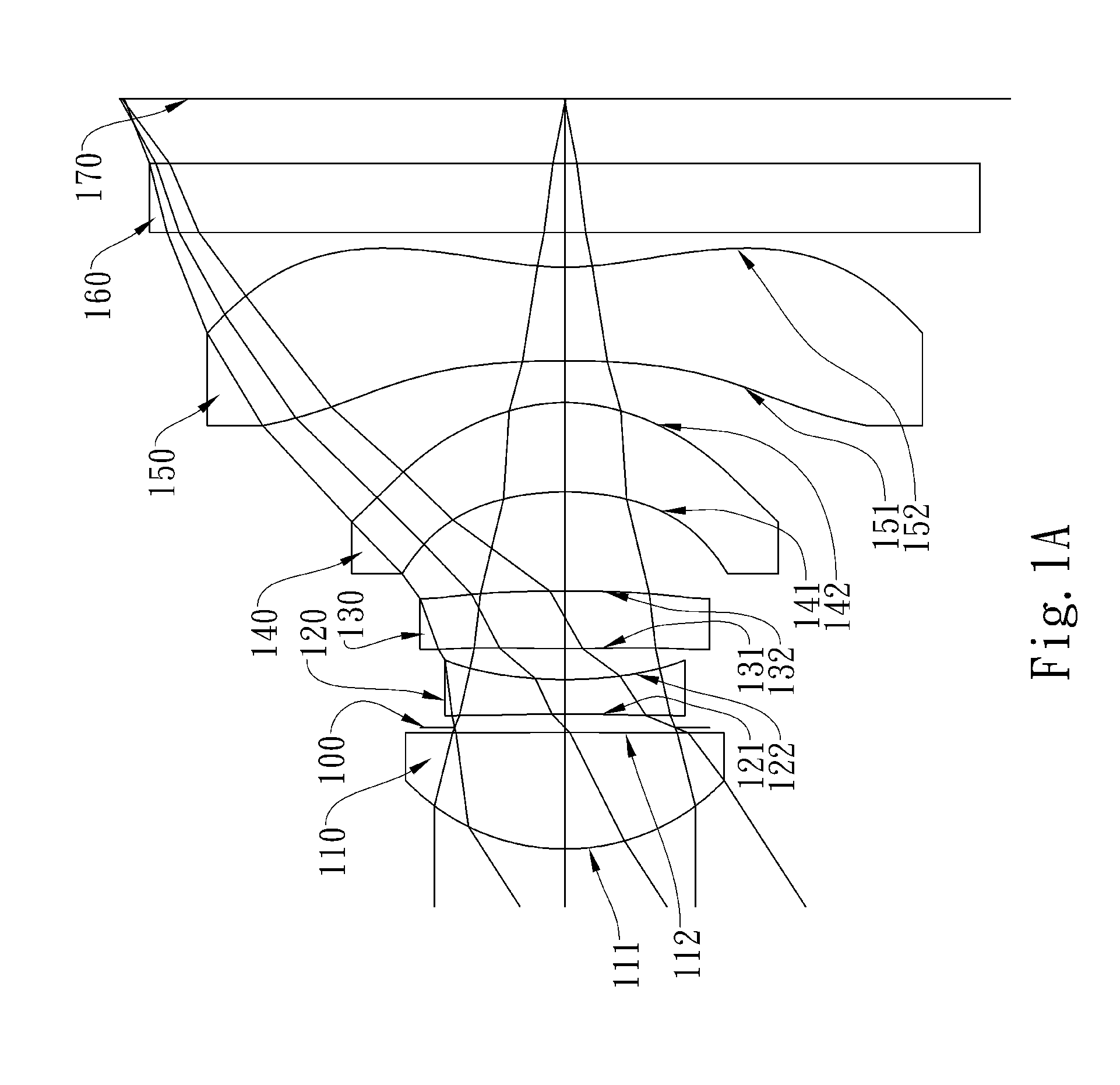

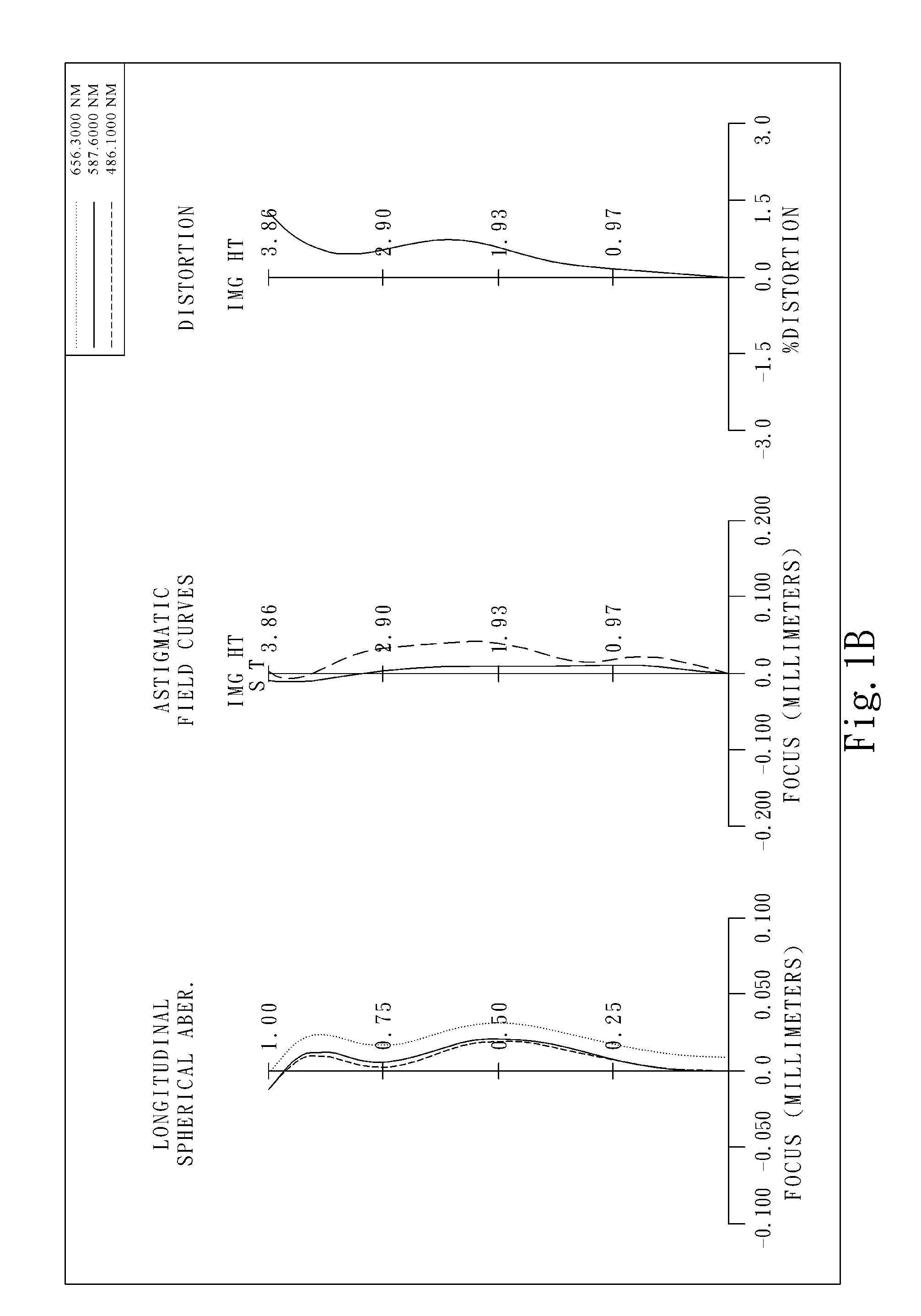

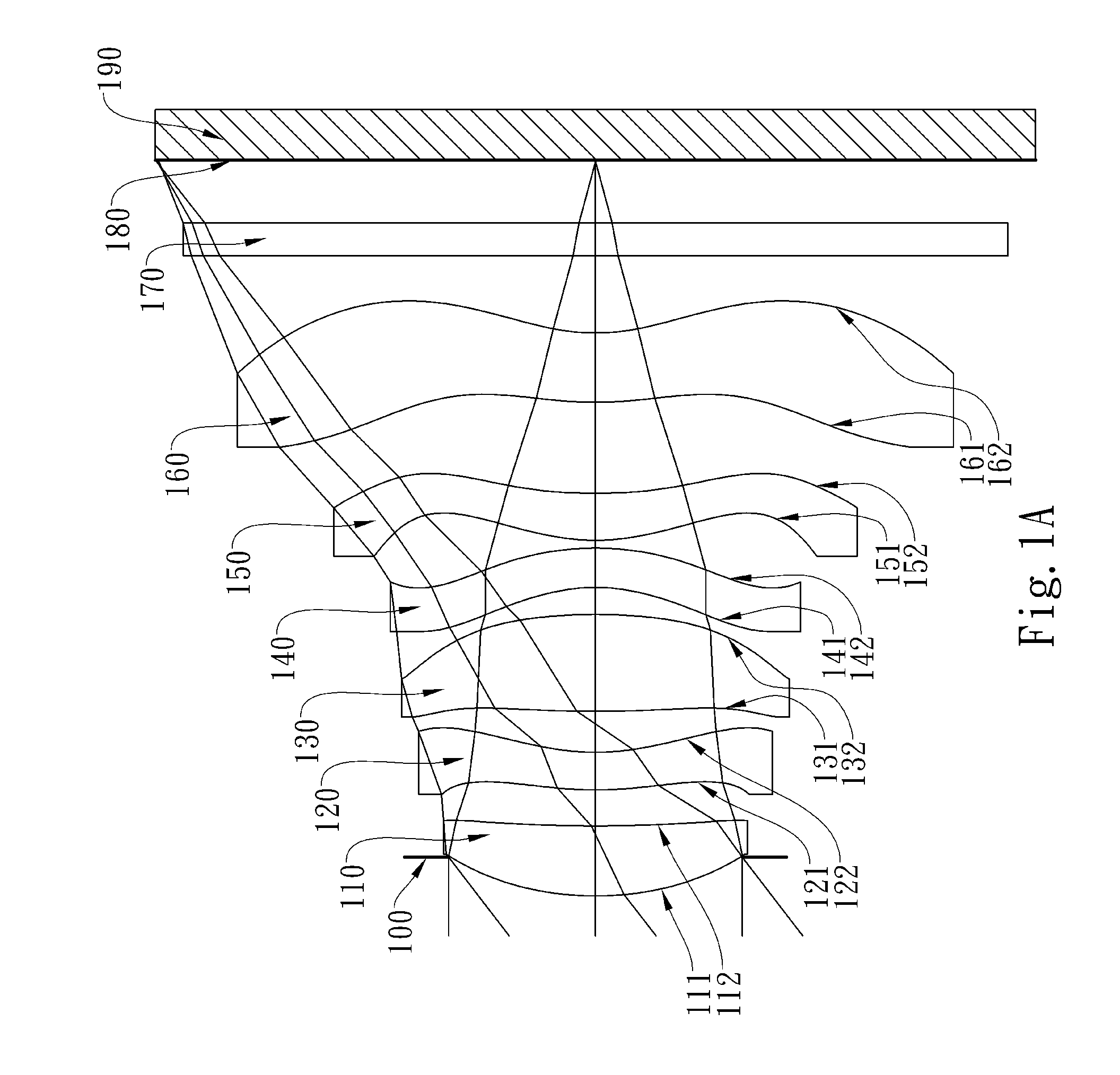

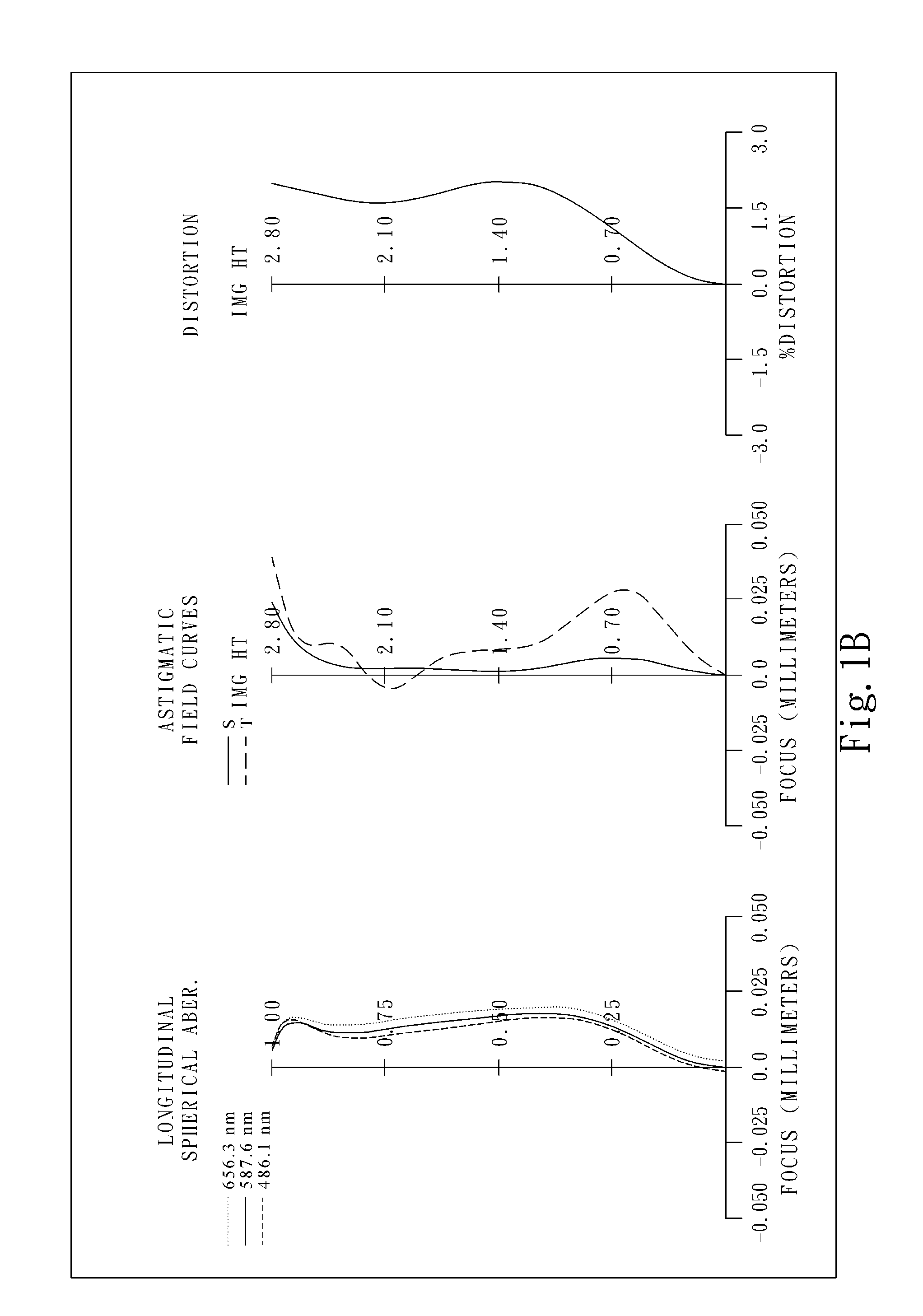

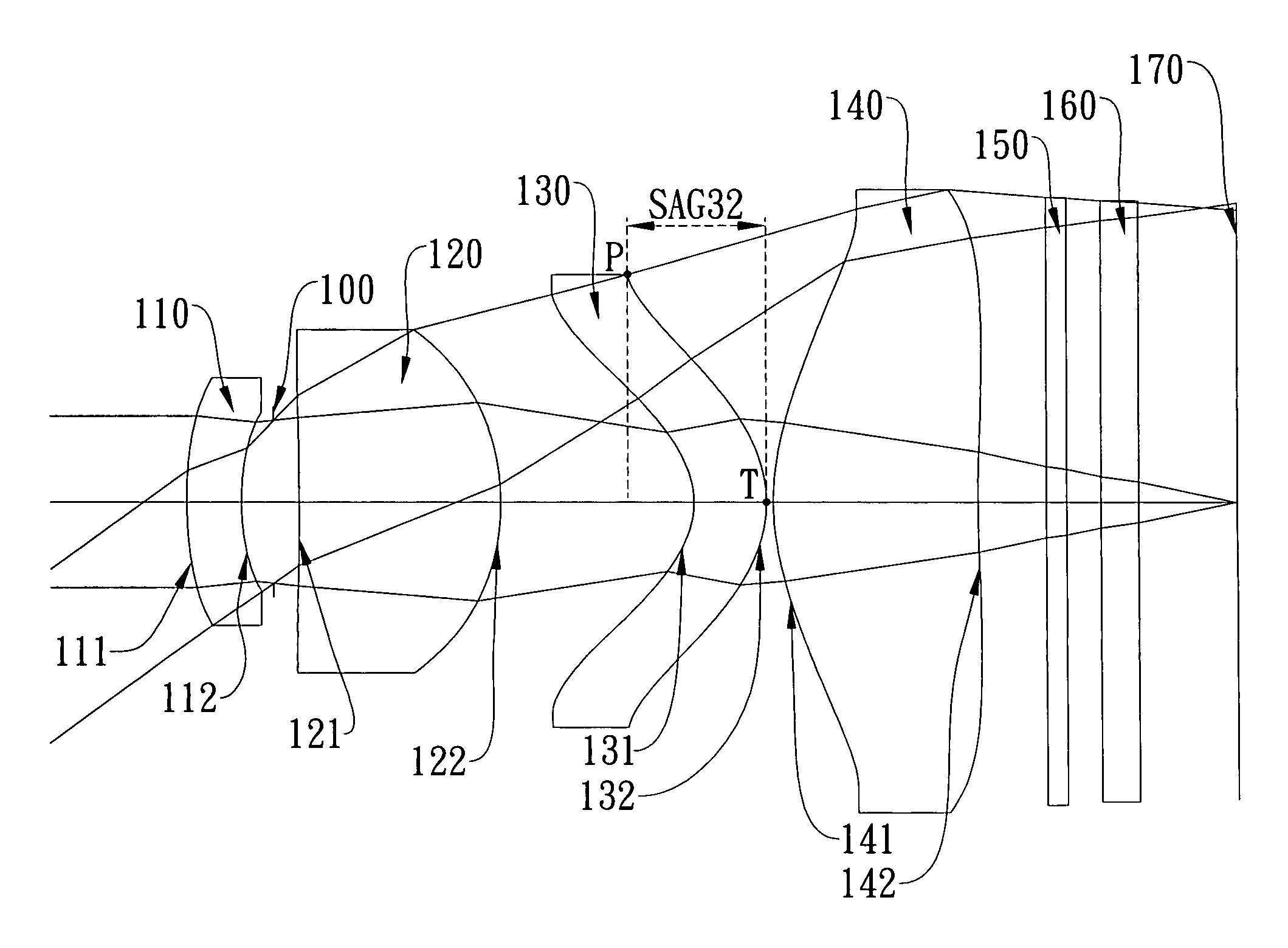

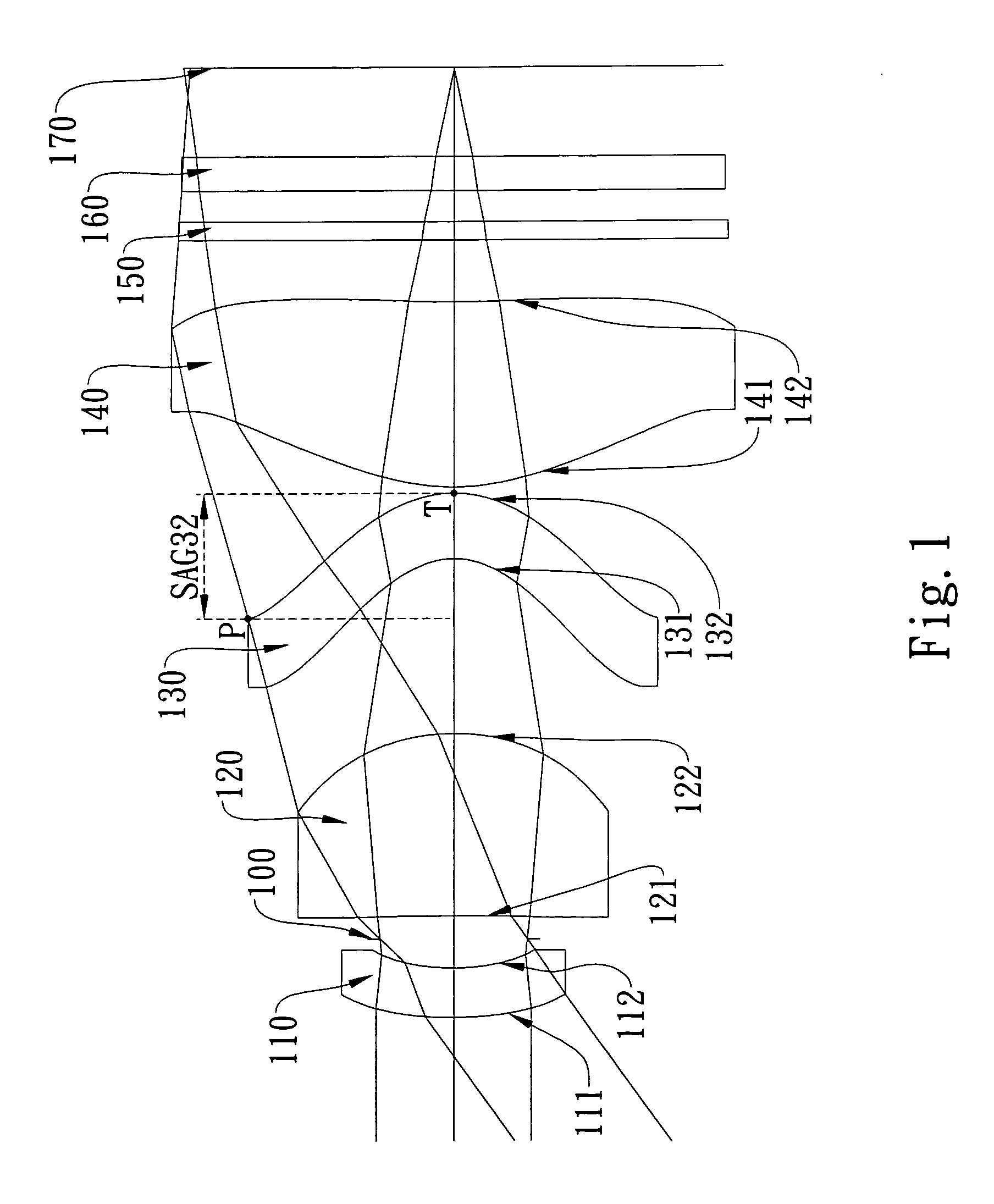

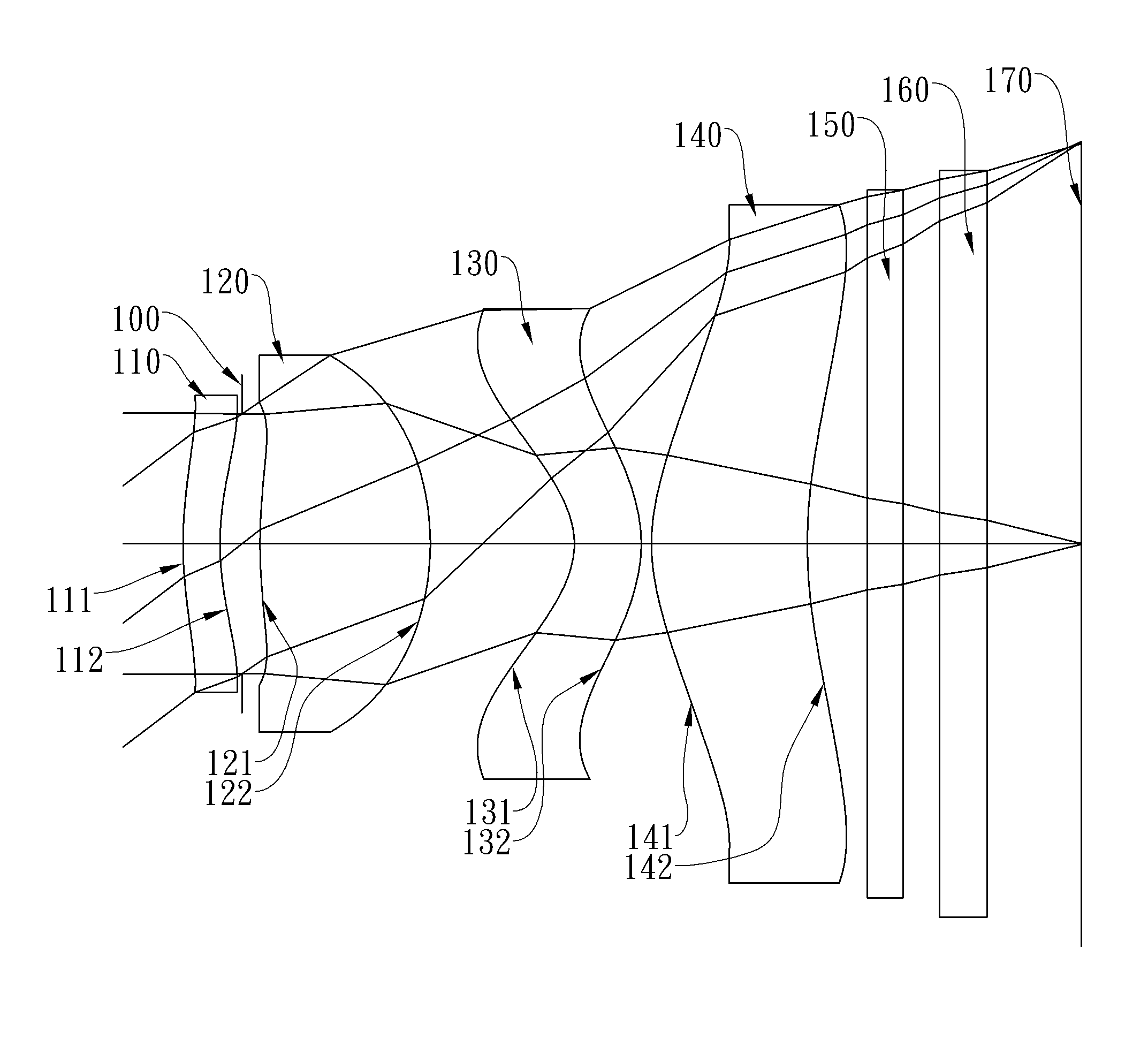

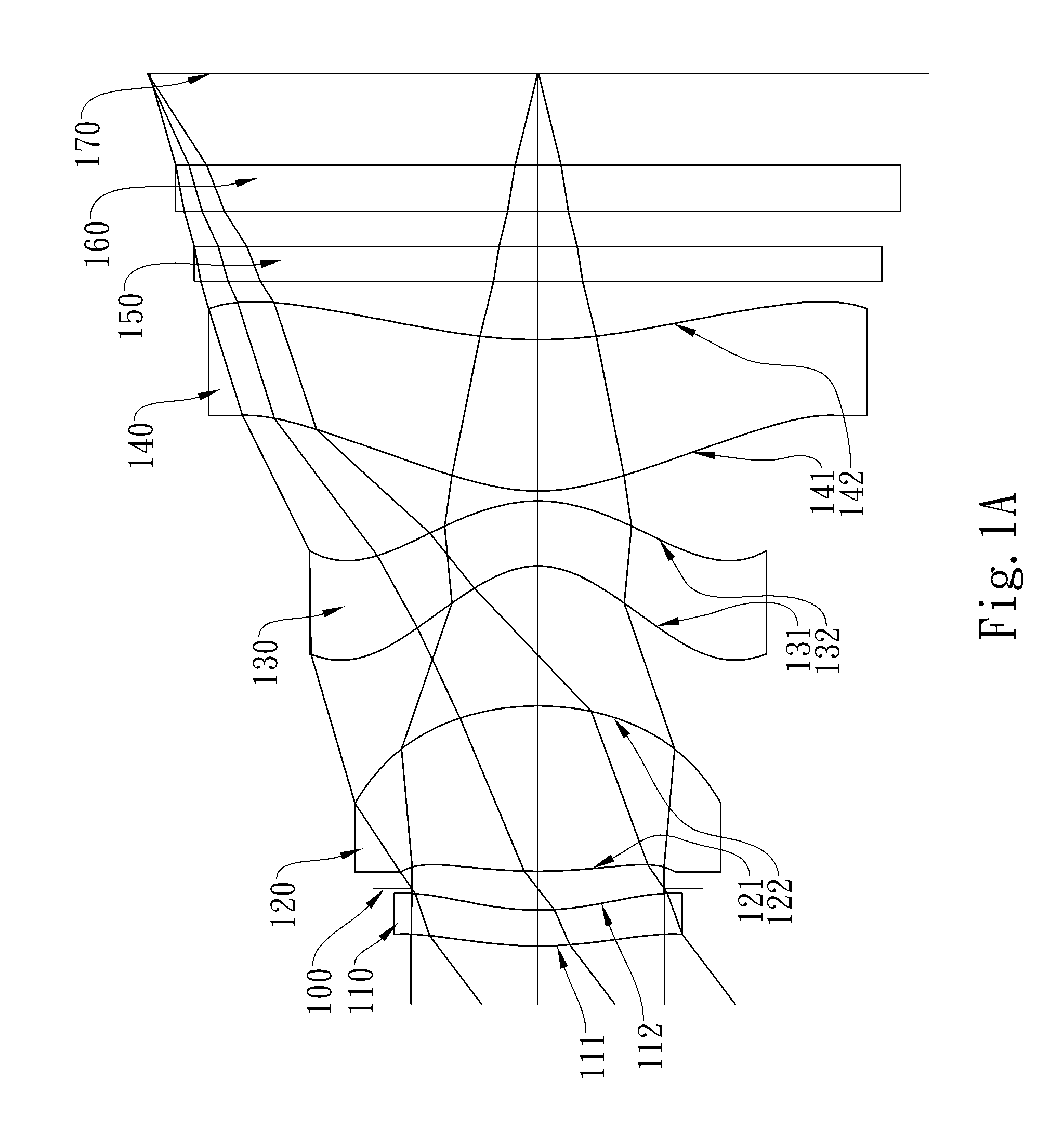

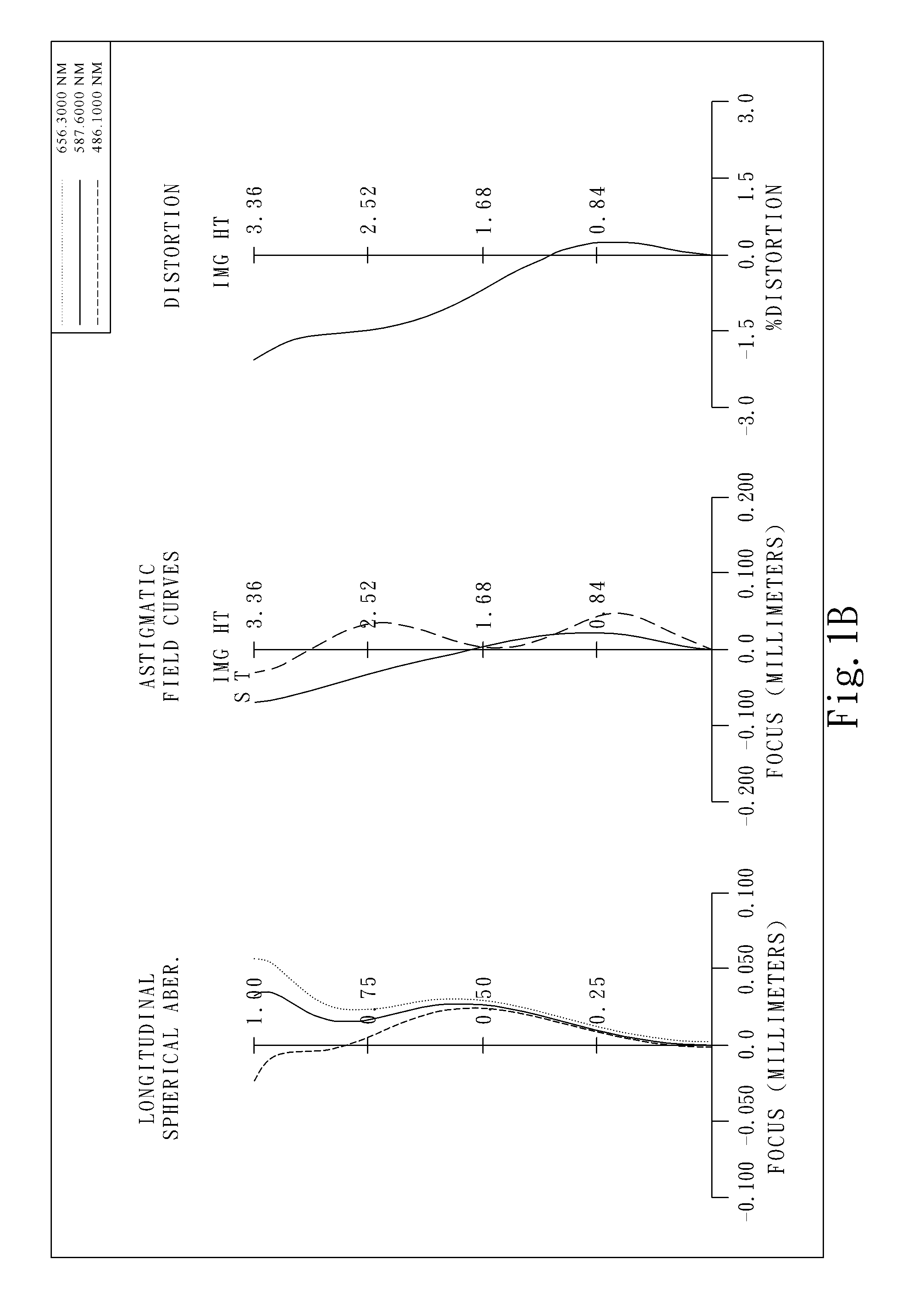

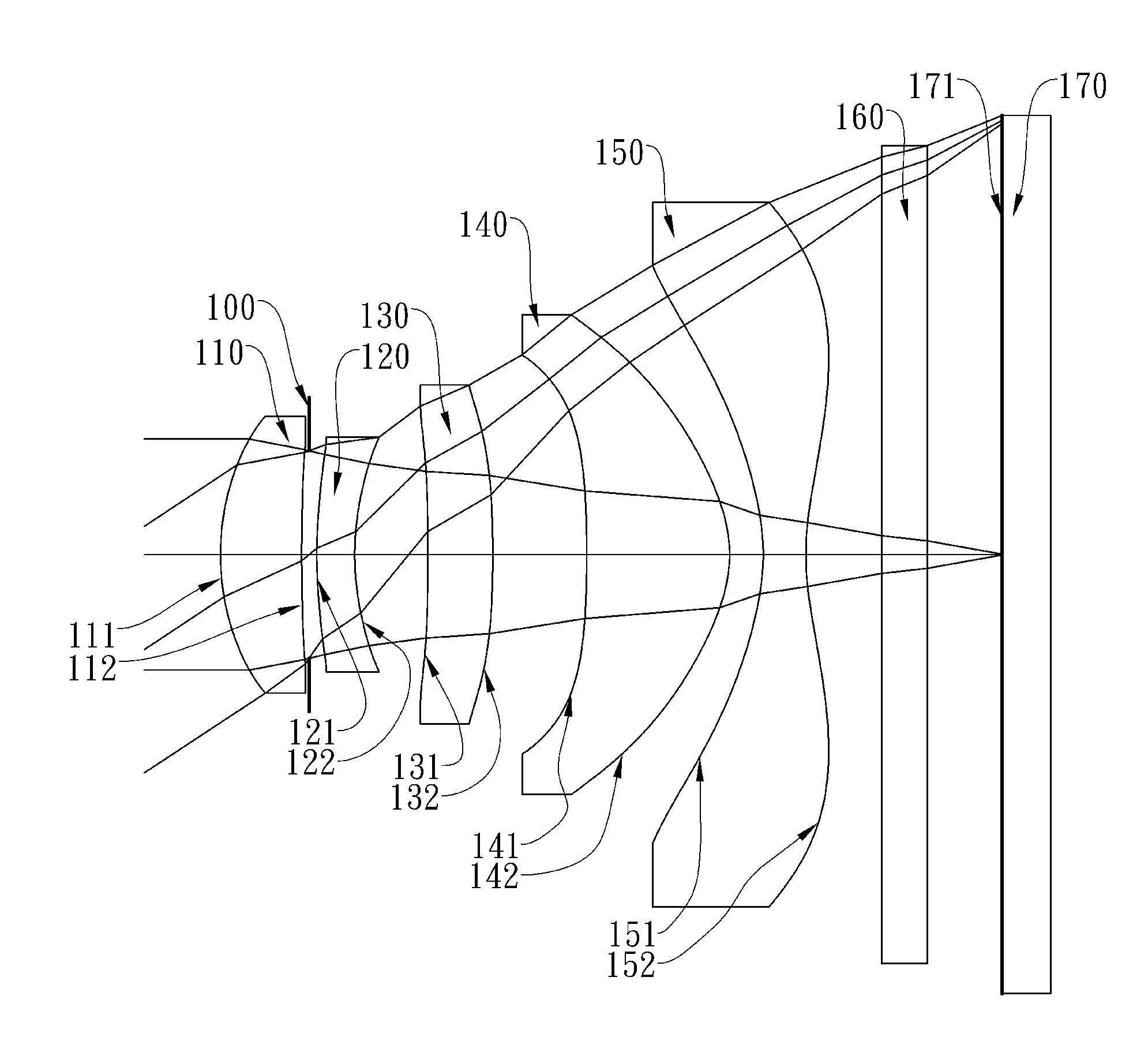

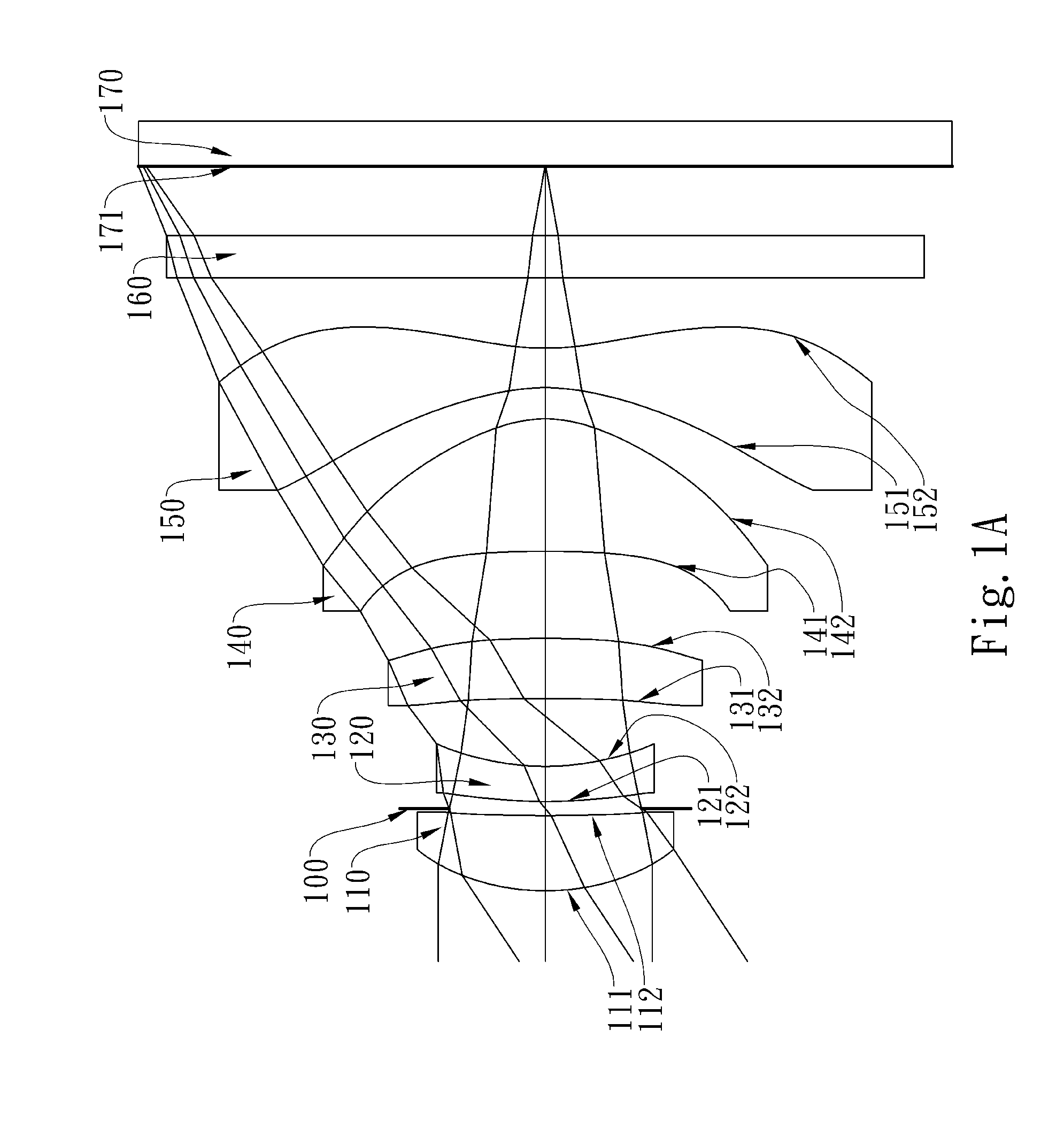

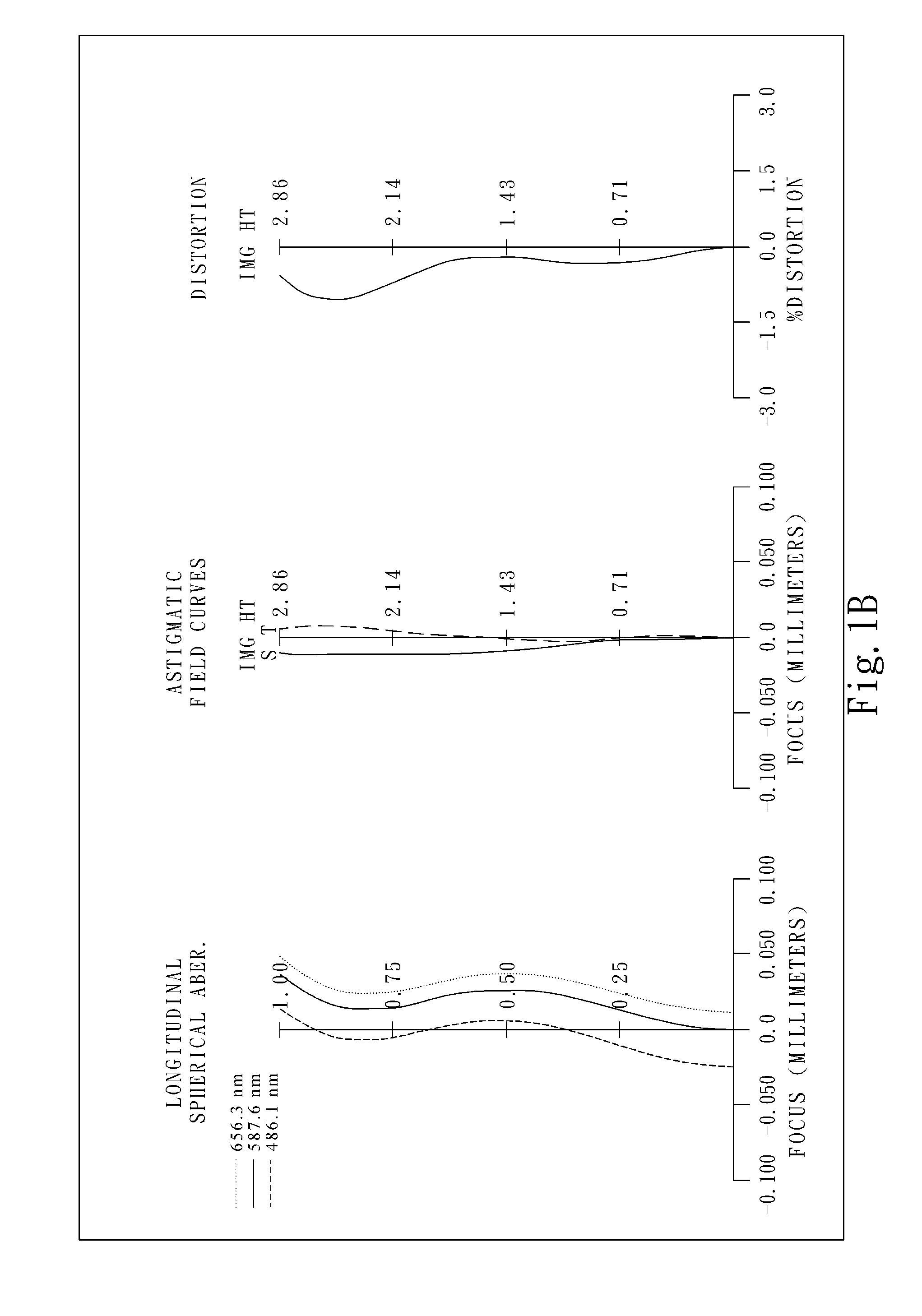

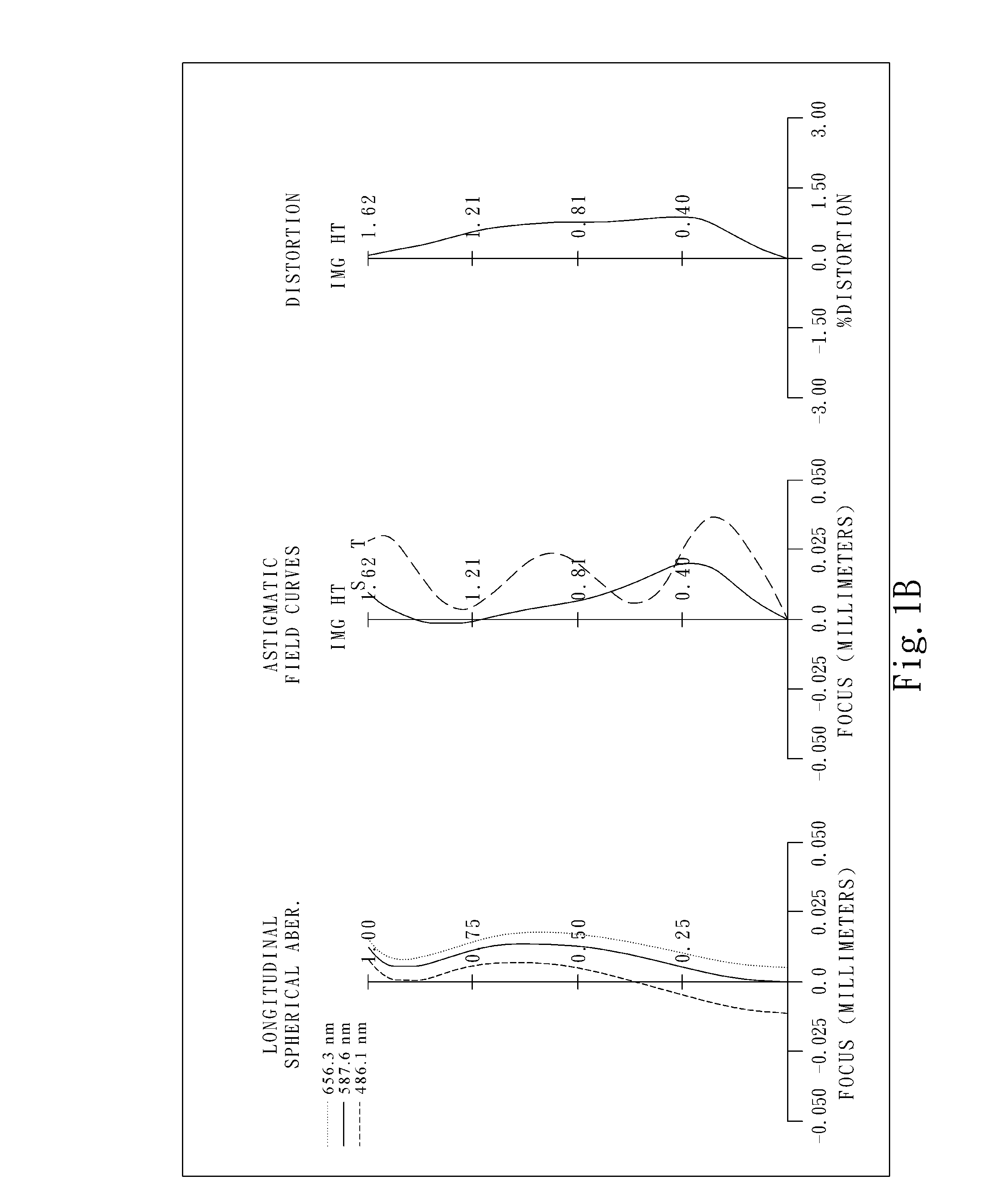

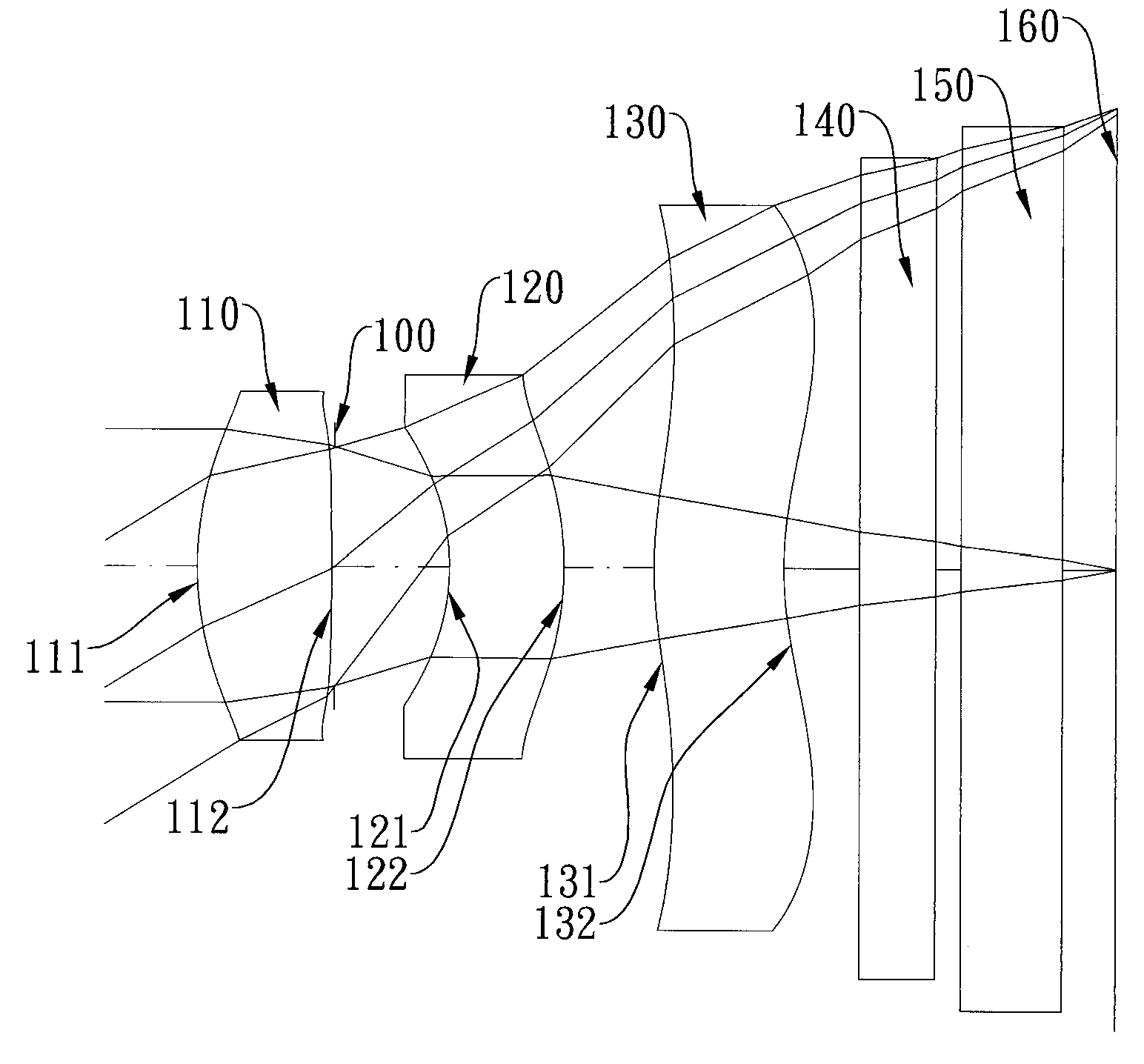

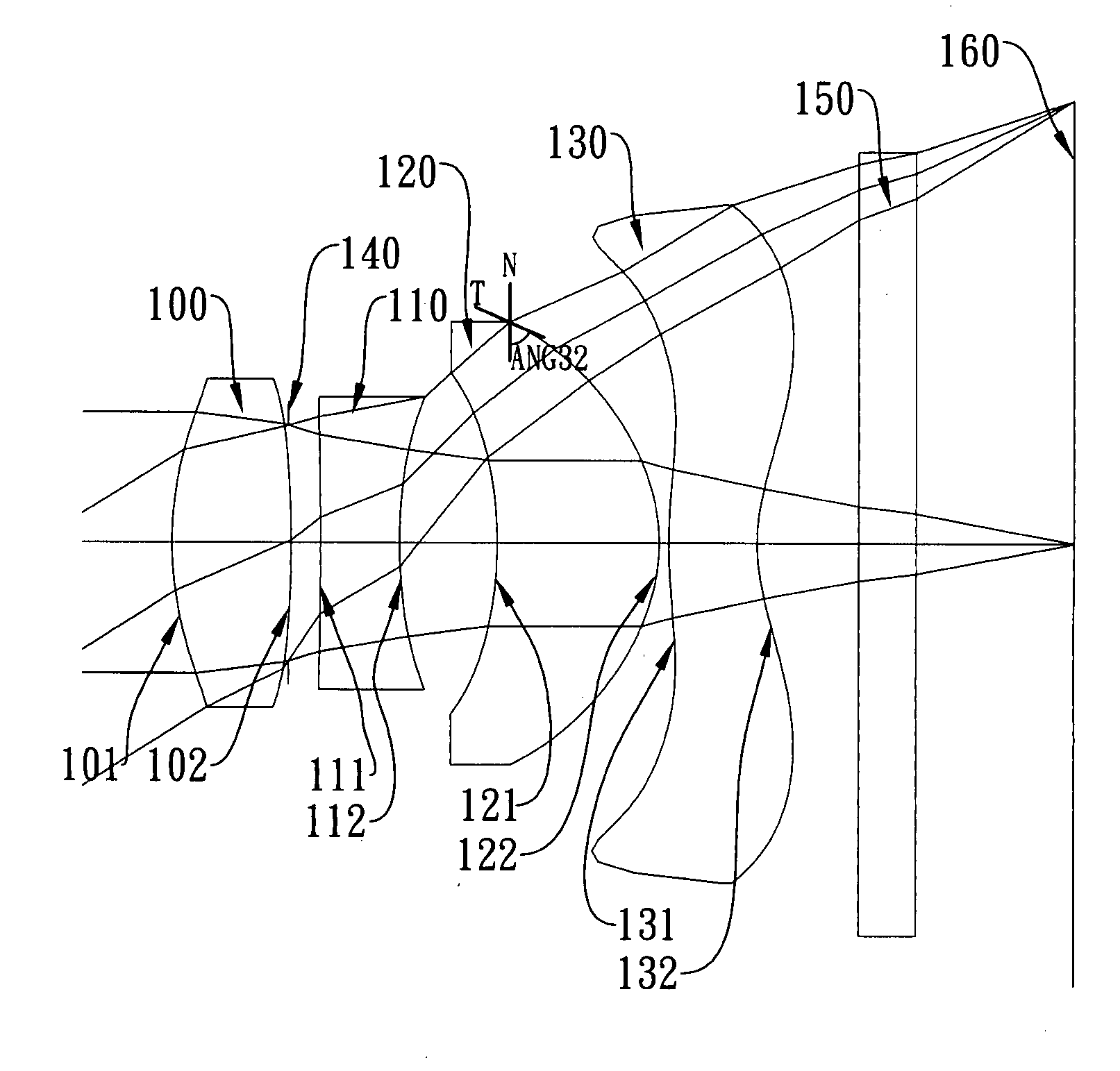

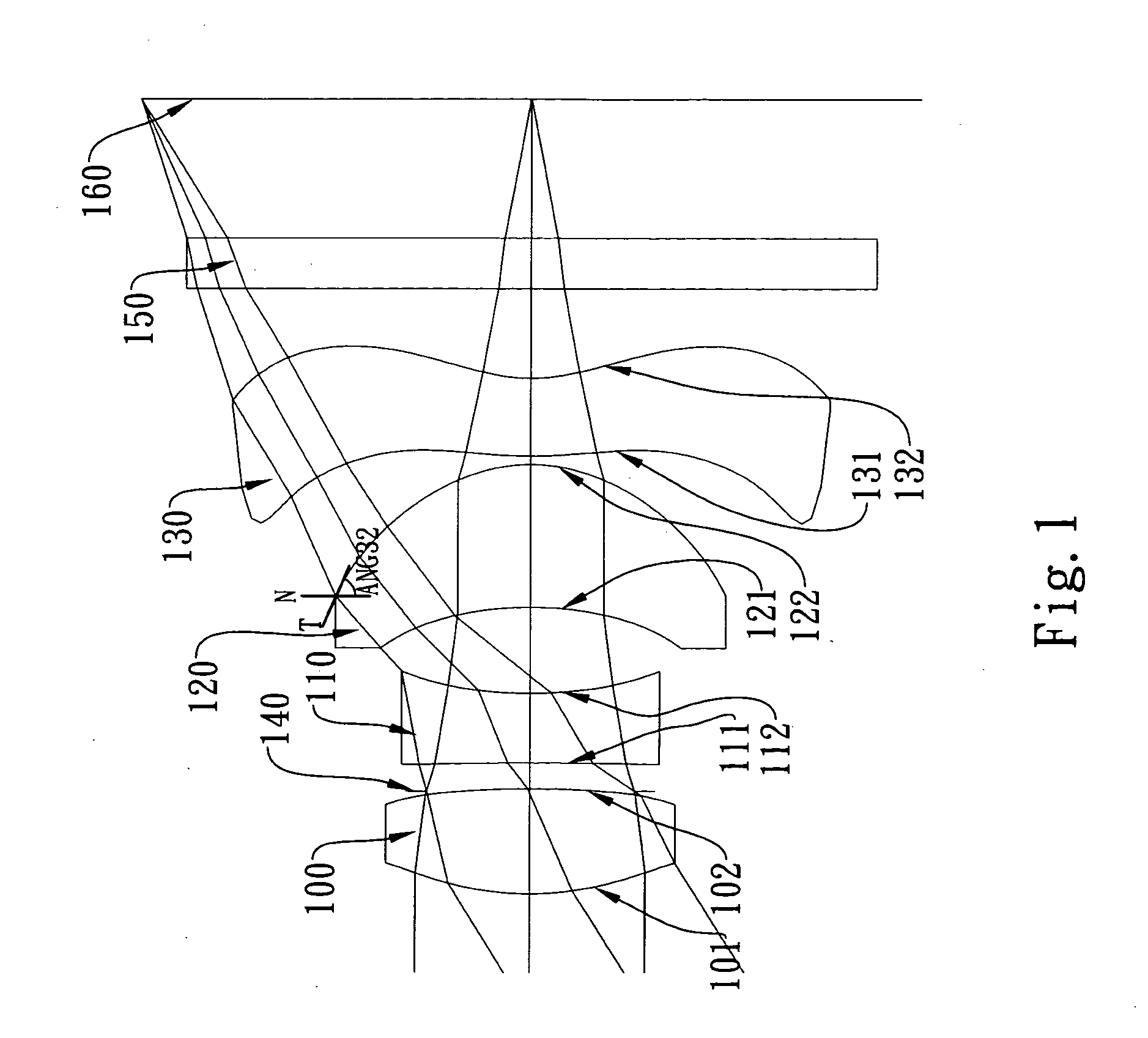

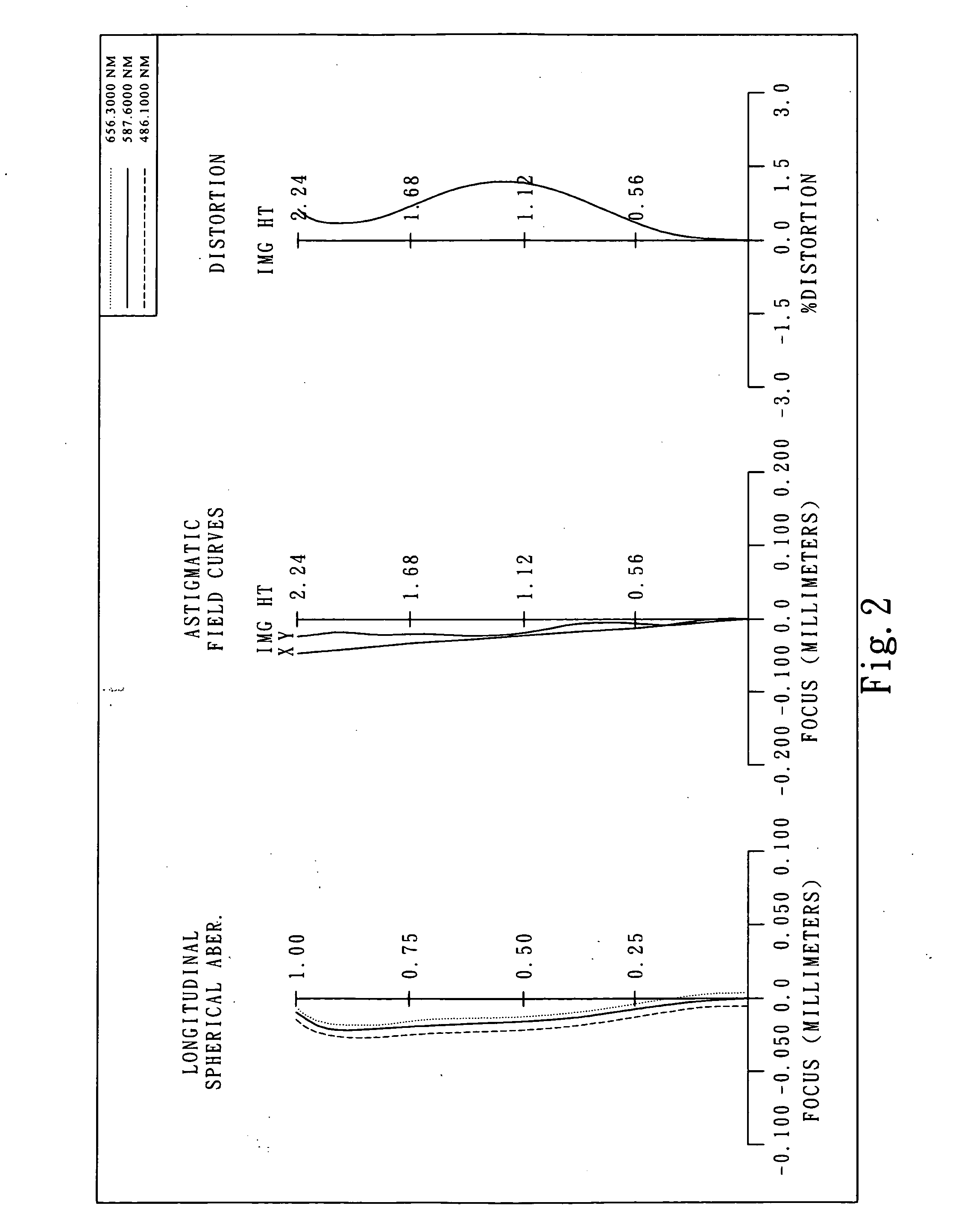

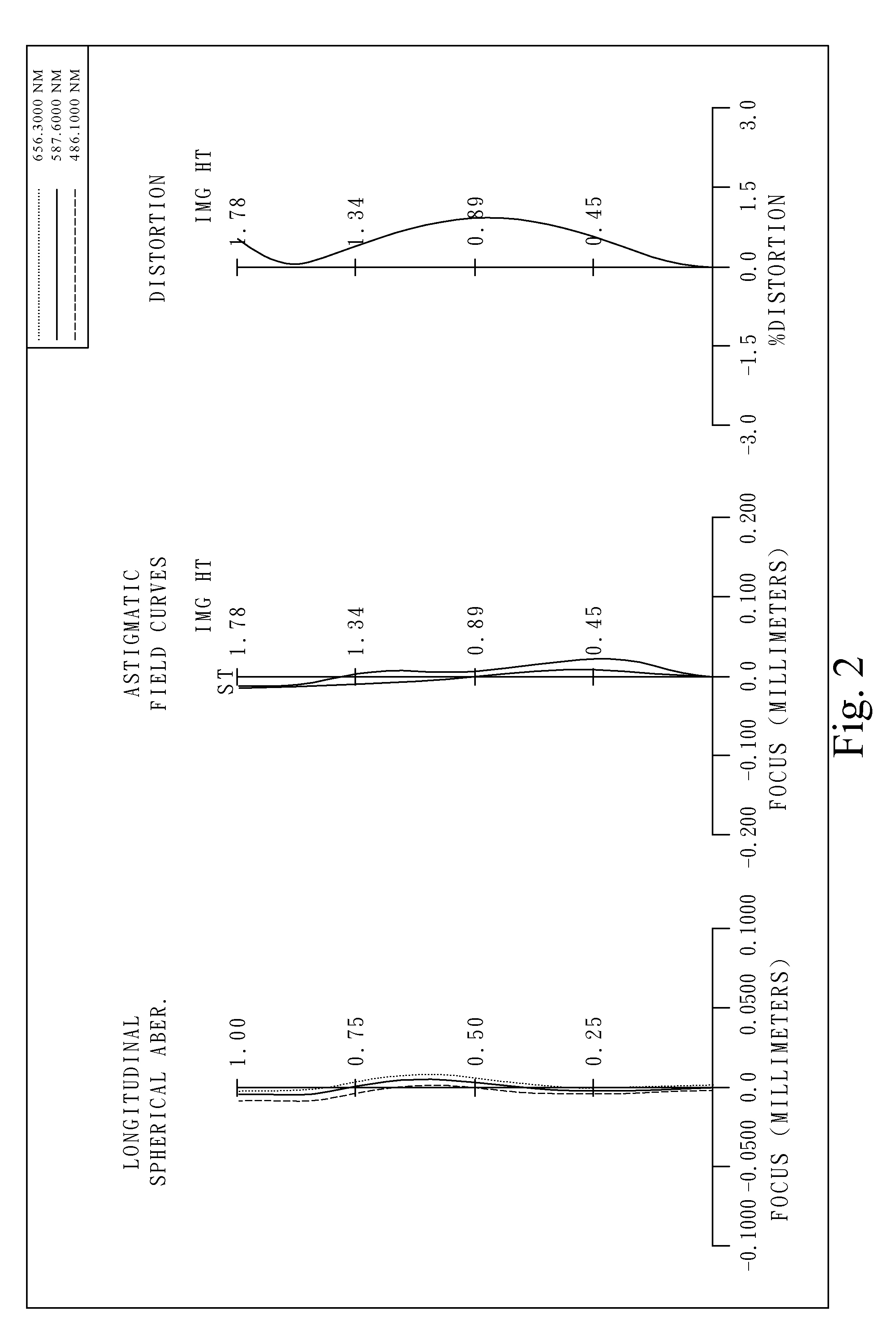

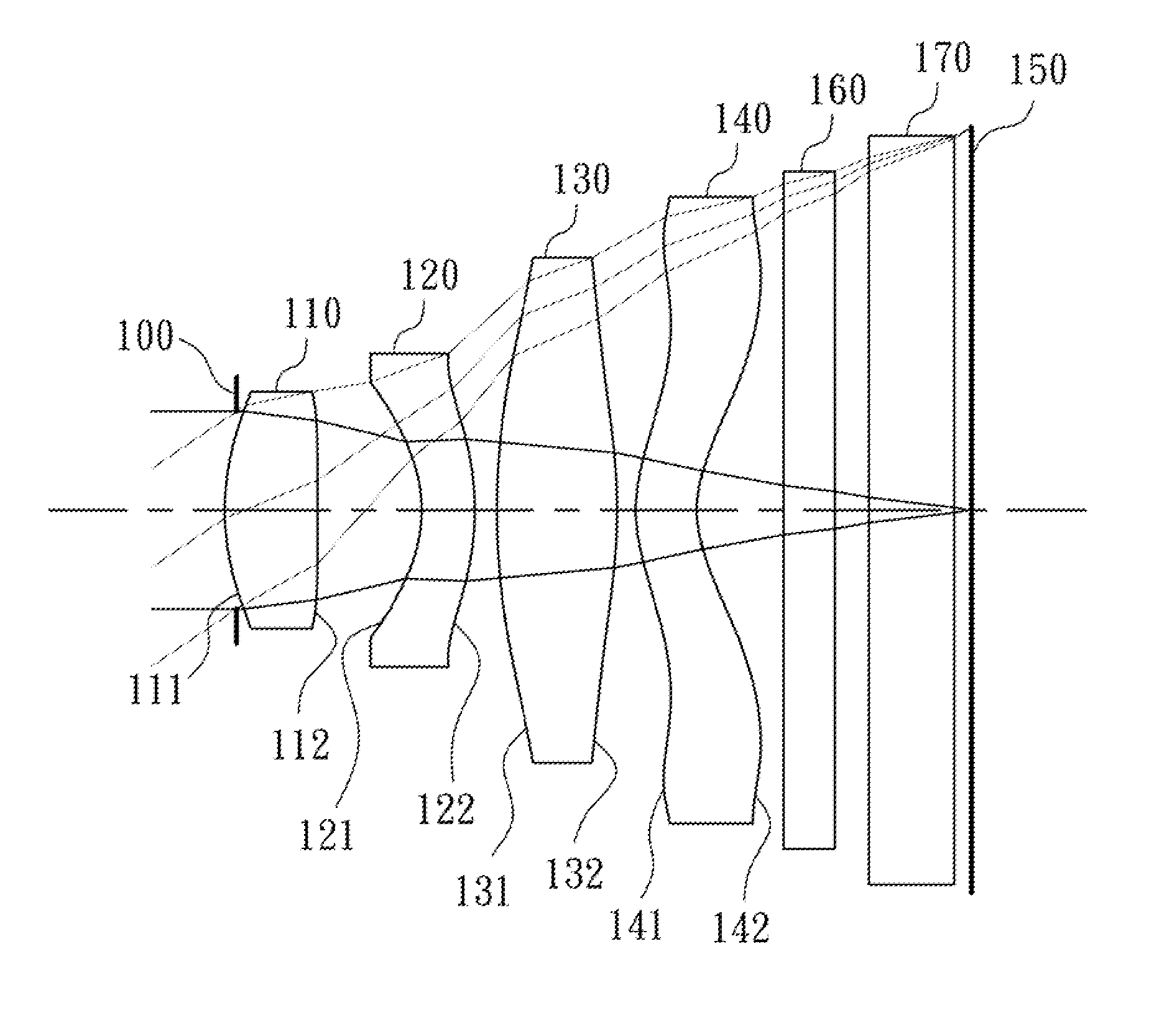

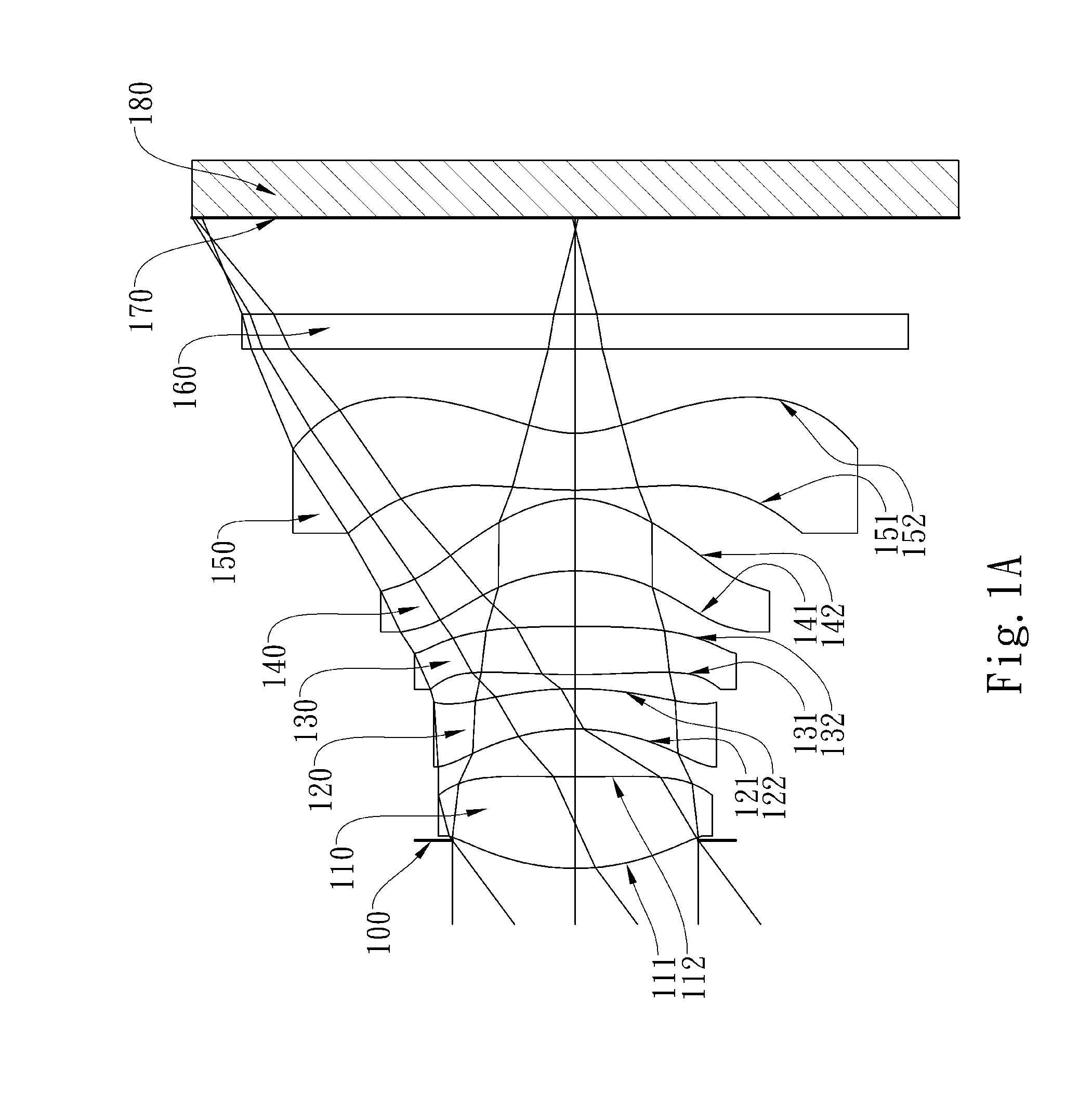

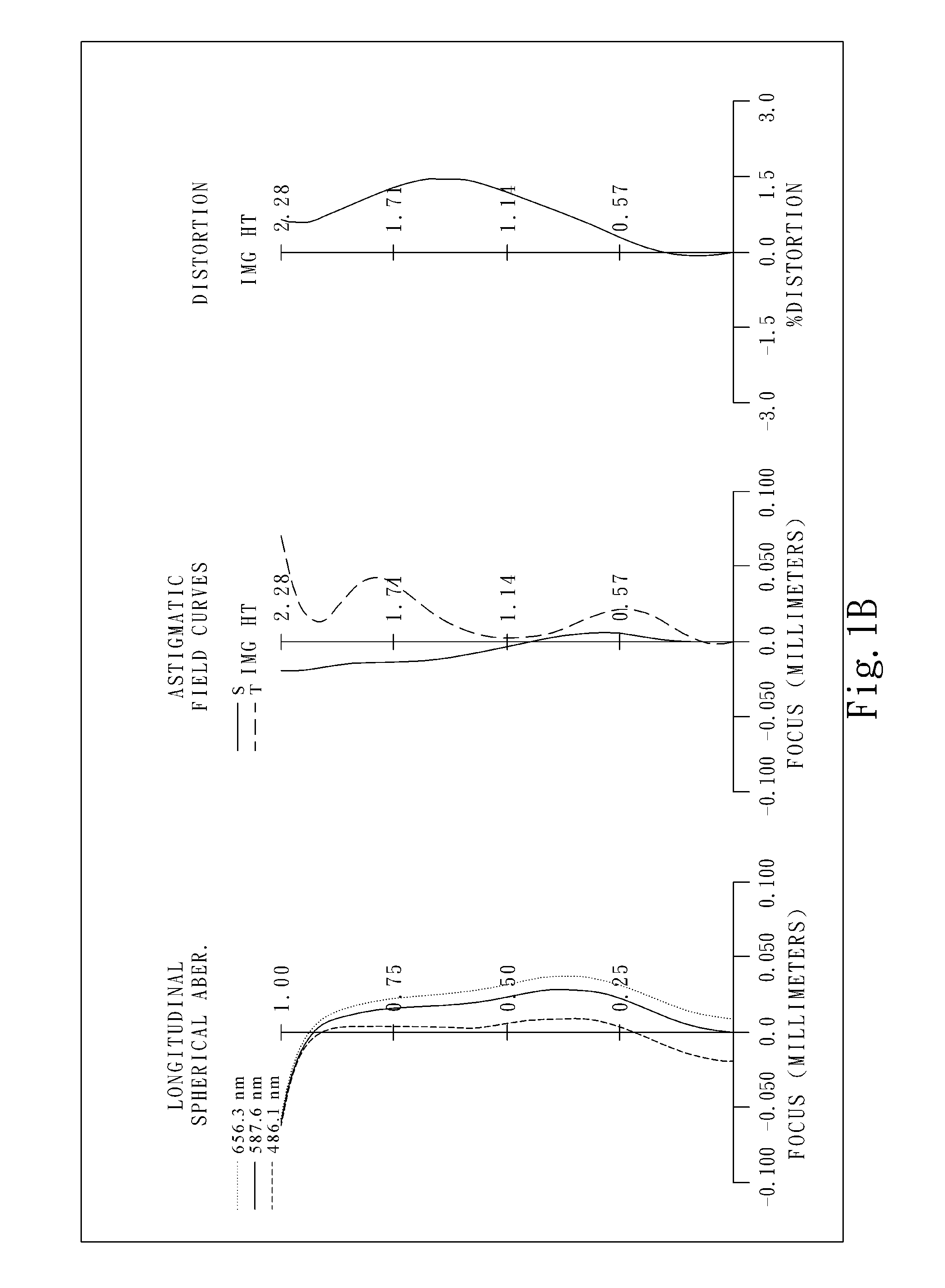

Photographing optical lens assembly

This invention provides a photographing optical lens assembly including, in order from an object side toward an image side: a first lens element with positive refractive power having a convex object-side surface, a second lens element with negative refractive power having a concave object-side surface and a concave image-side surface, a third lens element with positive refractive power, a fourth lens element with negative refractive power having a convex object-side surface and a concave image-side surface, and at least one of surfaces thereof being aspheric, a plastic fifth lens element having a convex object-side surface and a concave image-side surface with at least one inflection point. An aperture stop is positioned between an imaged object and the third lens element. The photographing optical lens assembly further comprises an electronic sensor on which the object is imaged.

Owner:LARGAN PRECISION

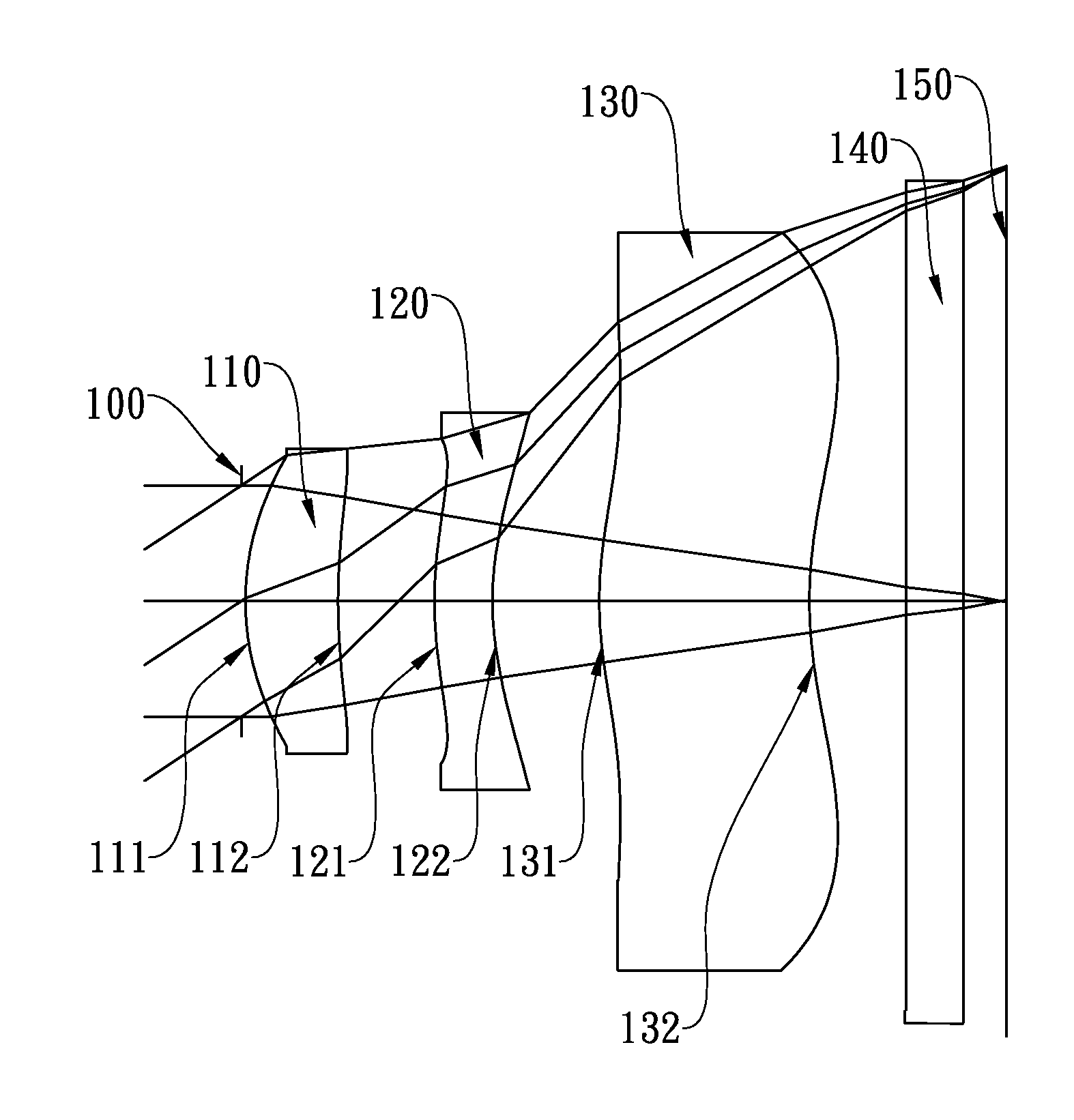

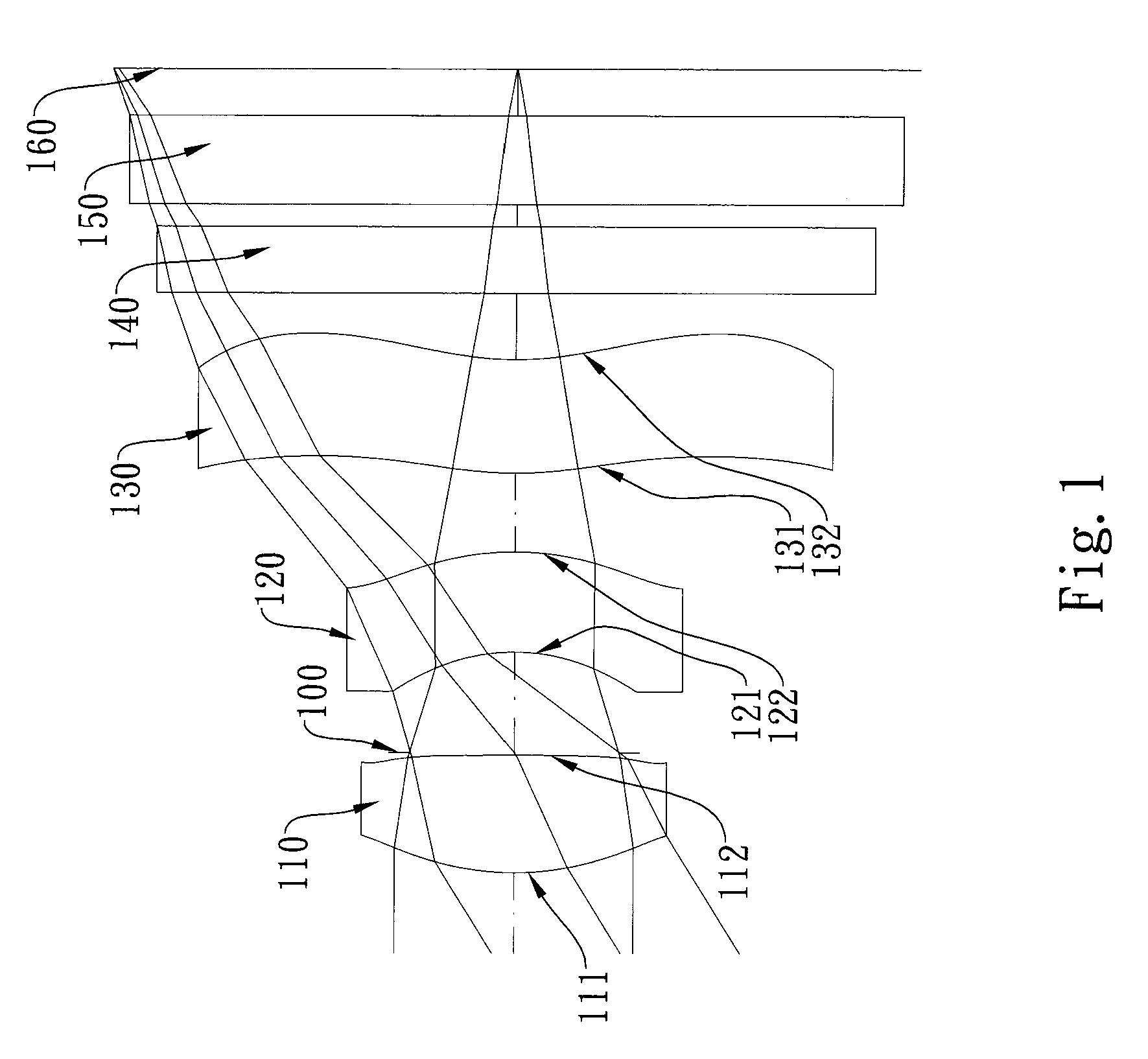

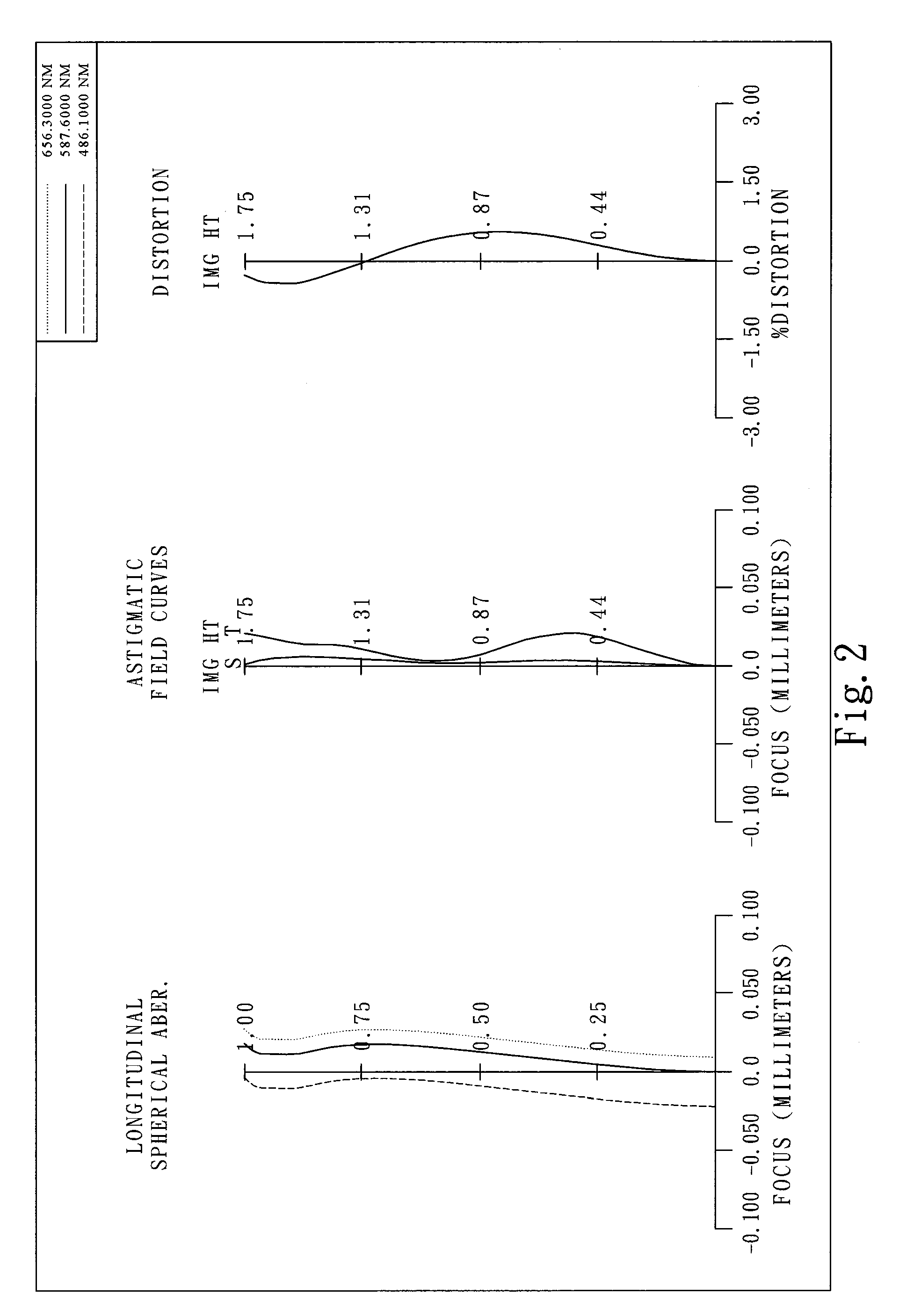

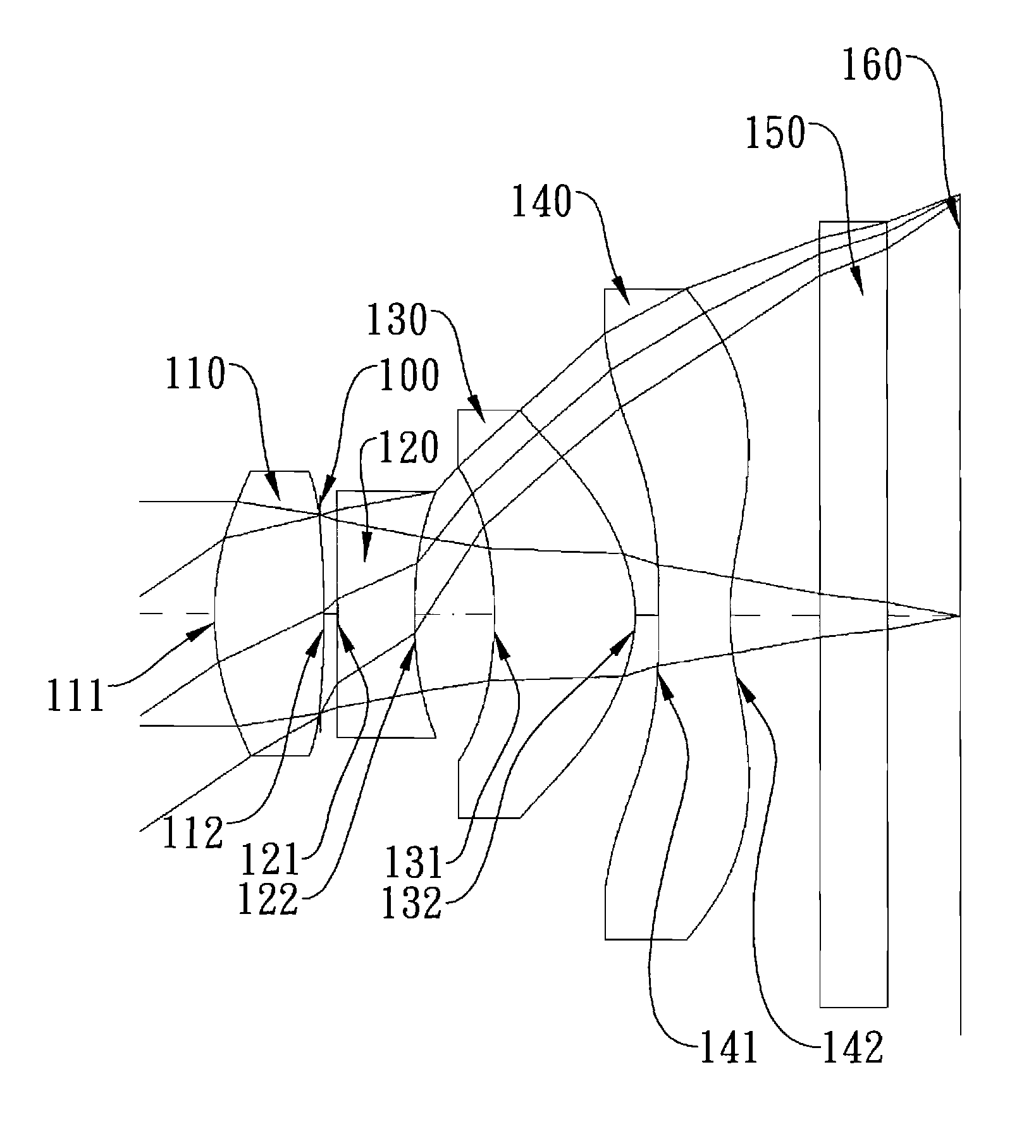

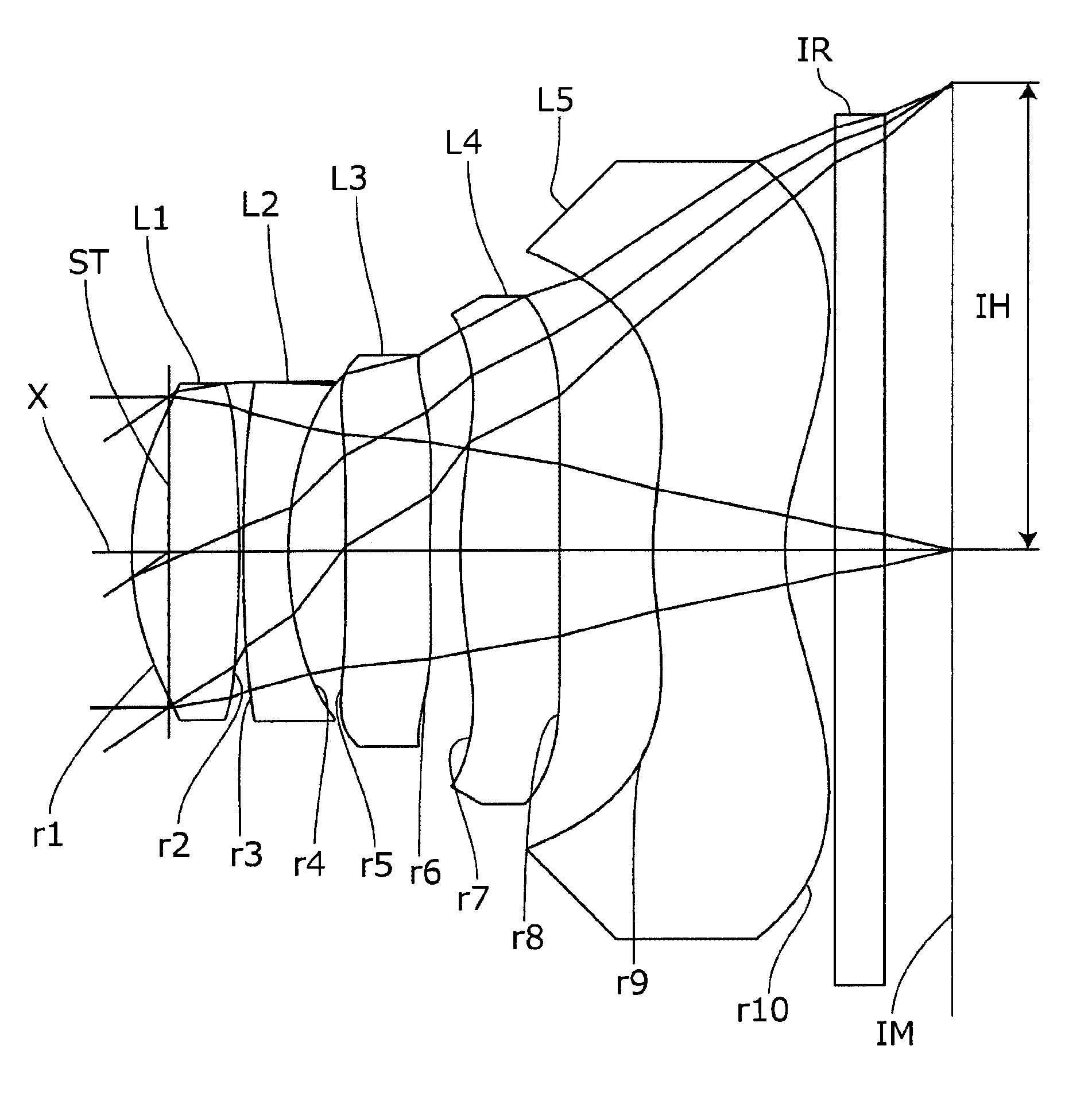

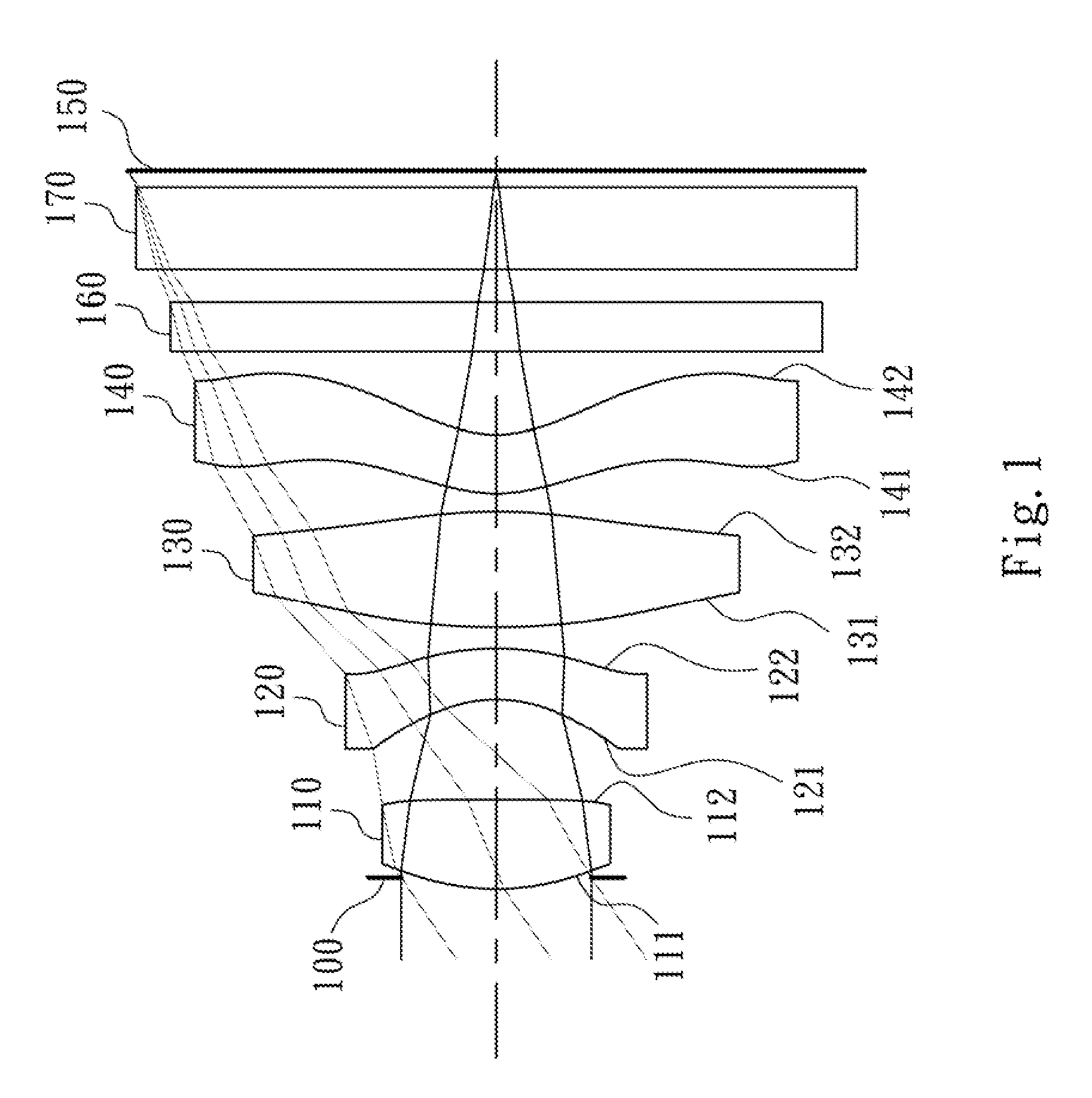

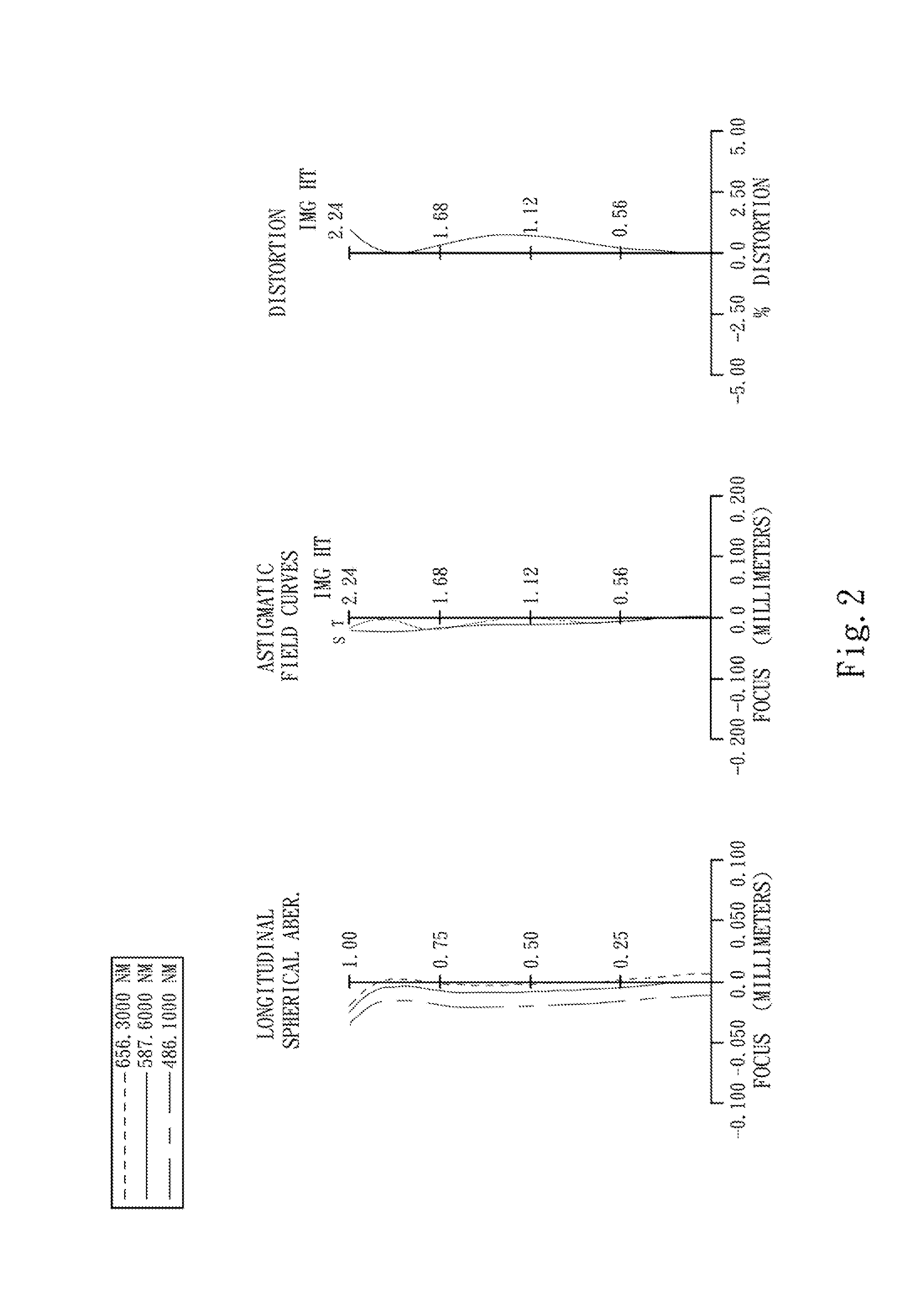

Optical imaging lens system

This invention provides an optical imaging lens system including five lens elements with refractive power, in order from an object side toward an image side: a first lens element with positive refractive power having a convex object-side surface, a second lens element with negative refractive power, a third lens element having a convex object-side surface and a concave image-side surface, a fourth lens element having both surfaces being aspheric, a fifth lens element having a concave image-side surface with at least one inflection point formed thereon. By such arrangement, the total track length and the sensitivity of the optical imaging lens system can be reduced while achieving high image resolution.

Owner:LARGAN PRECISION

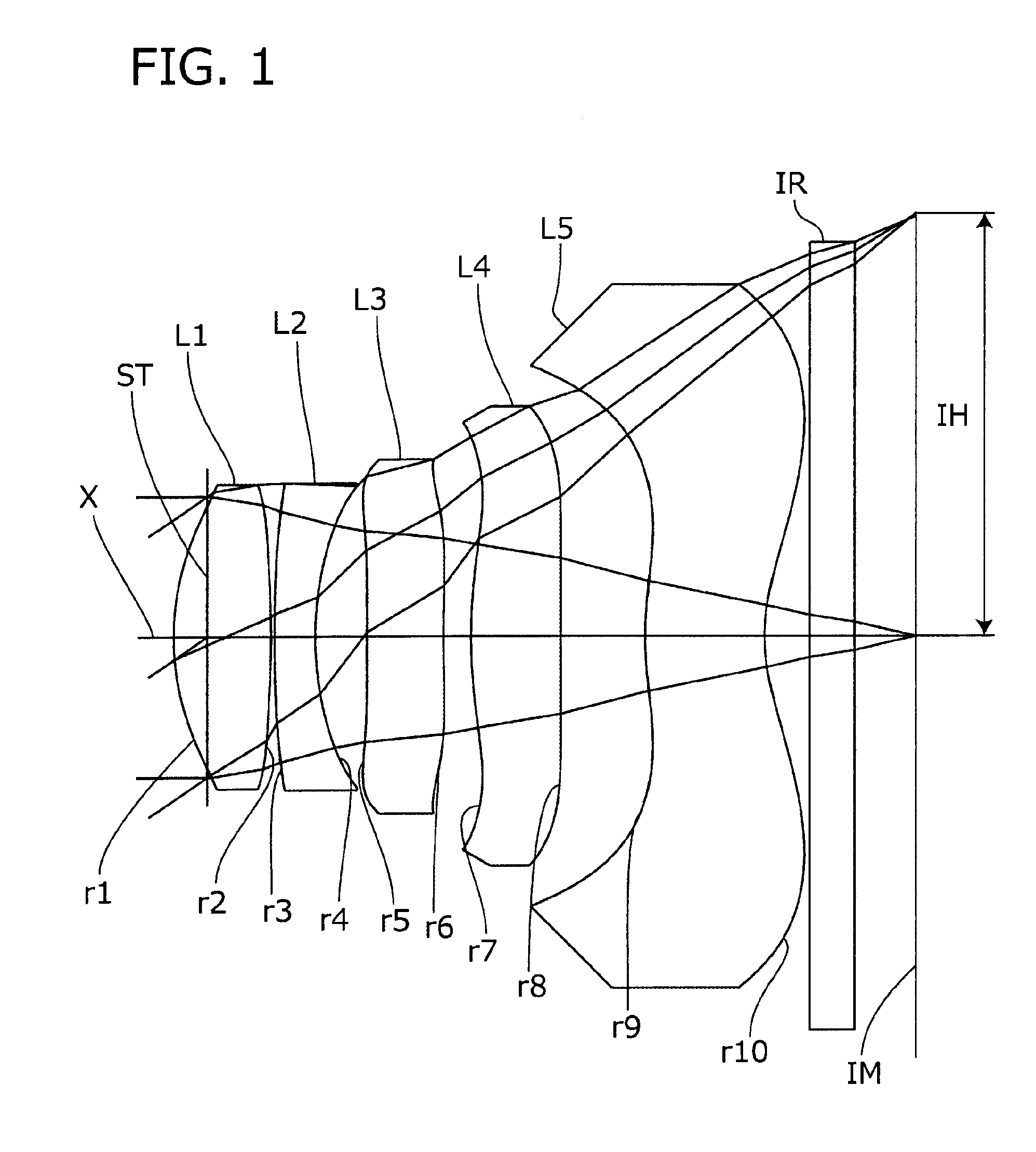

Optical lens system

The present invention provides an optical lens system comprising, in order from an object side to an image side: a first lens element with positive refractive power having a convex object-side surface; a second lens element with negative refractive power; a third lens element with positive refractive power having a convex object-side surface and a convex image-side surface; a fourth lens element; and a fifth lens element having a convex object-side surface and a concave image-side surface, the object-side and image-side surfaces thereof being aspheric and at least one inflection point being formed on the image-side surface. Such arrangement of optical elements can effectively minimize the size of the optical lens system, lower the sensitivity of the optical system, and obtain higher image resolution.

Owner:LARGAN PRECISION

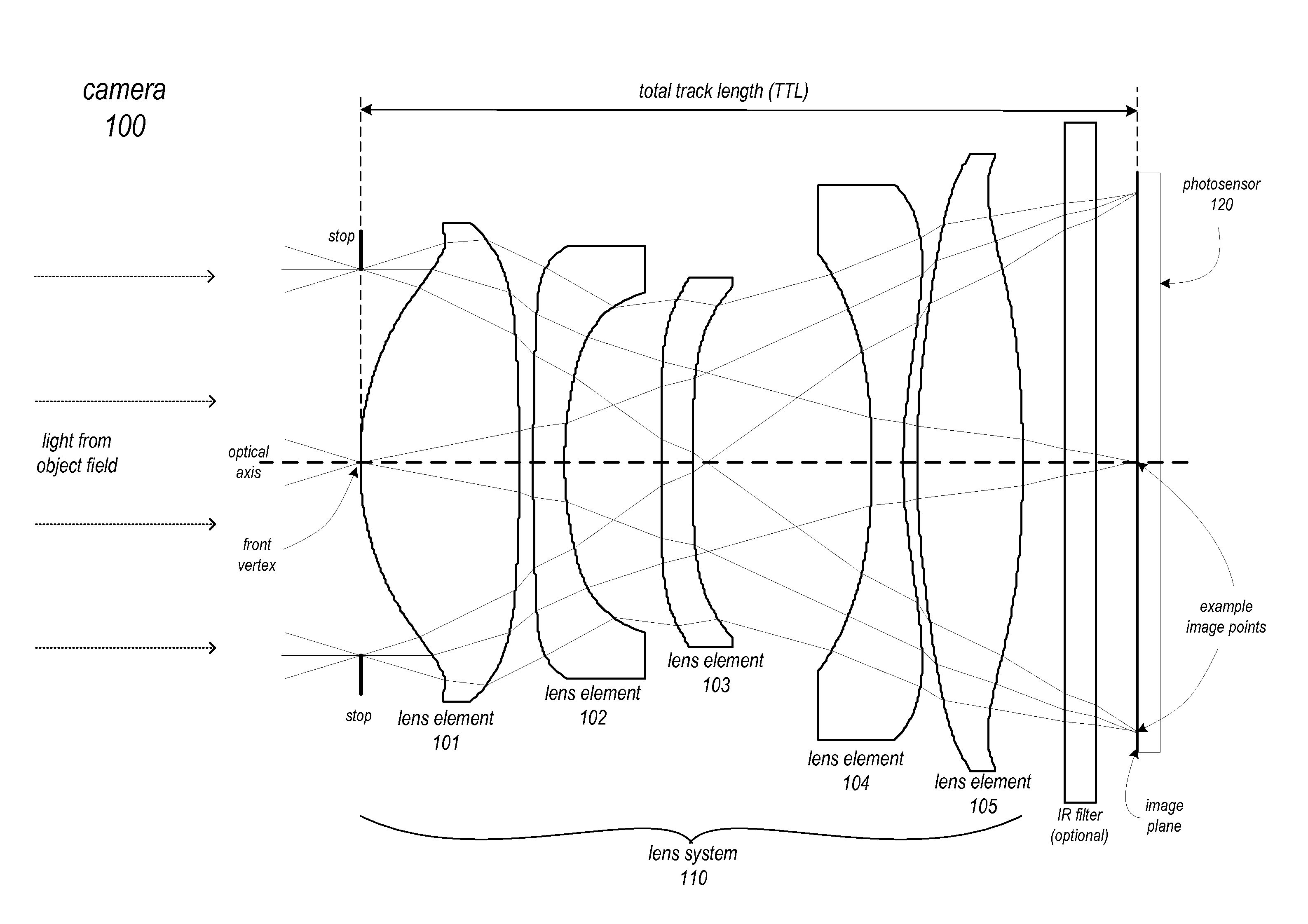

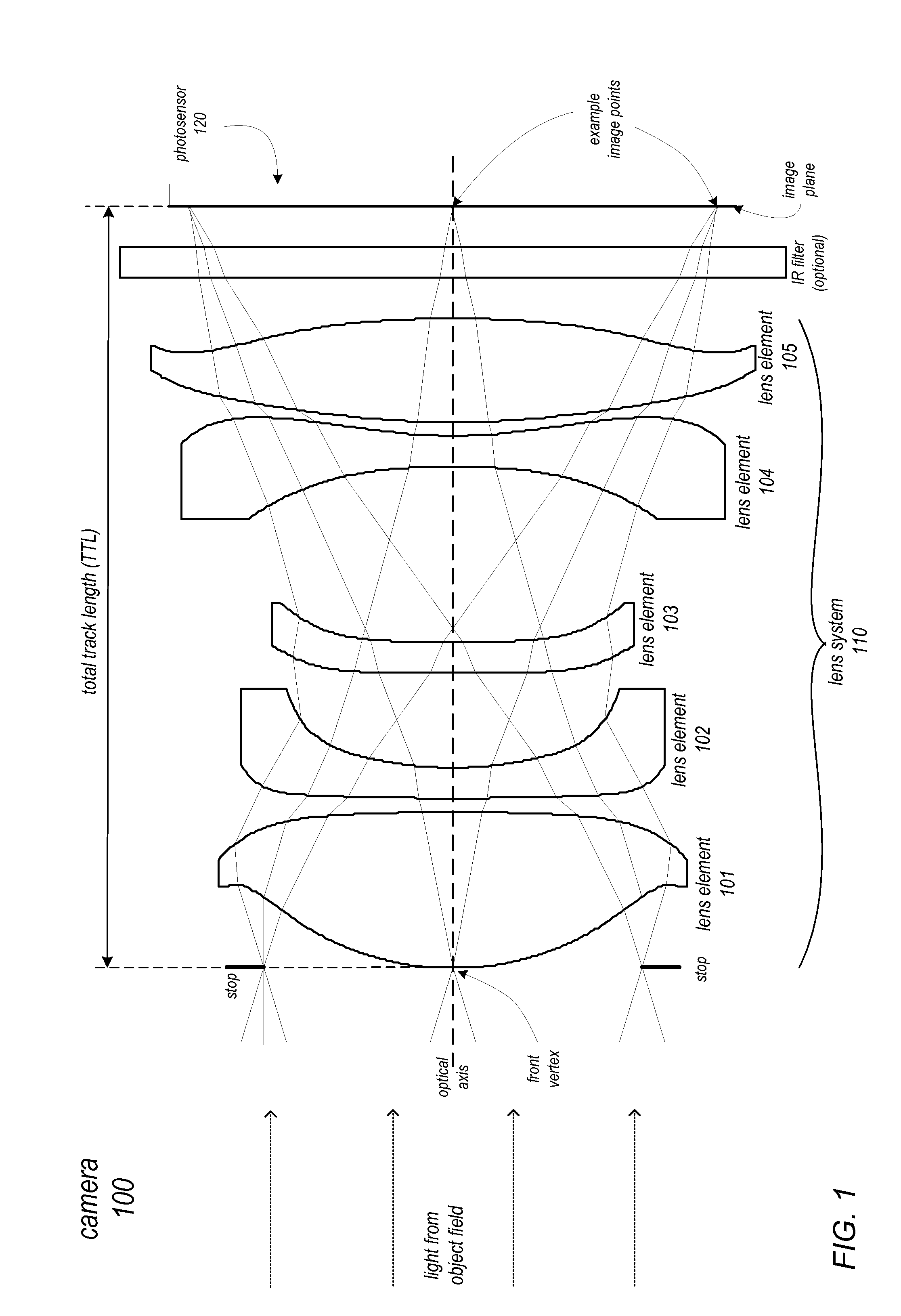

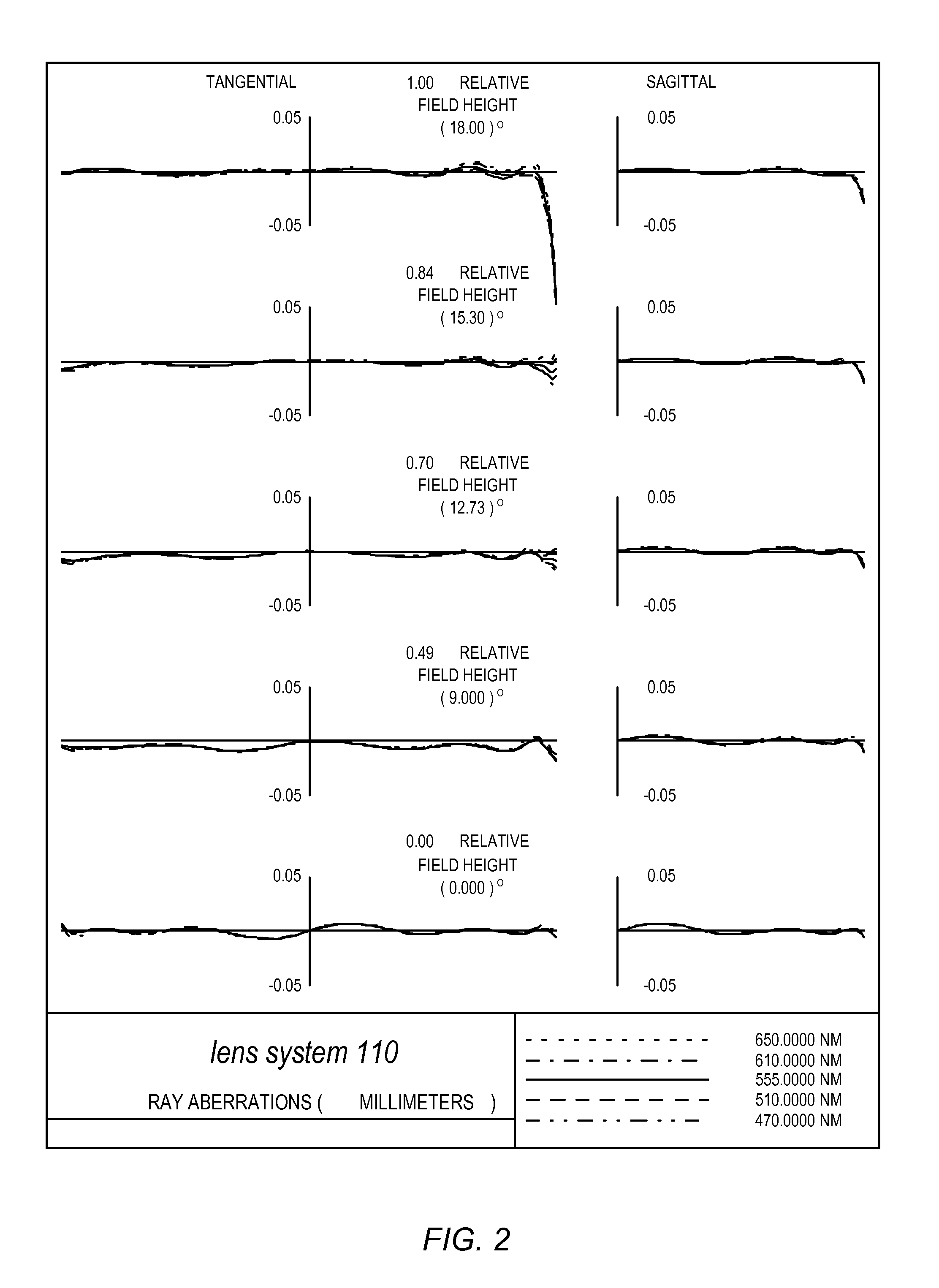

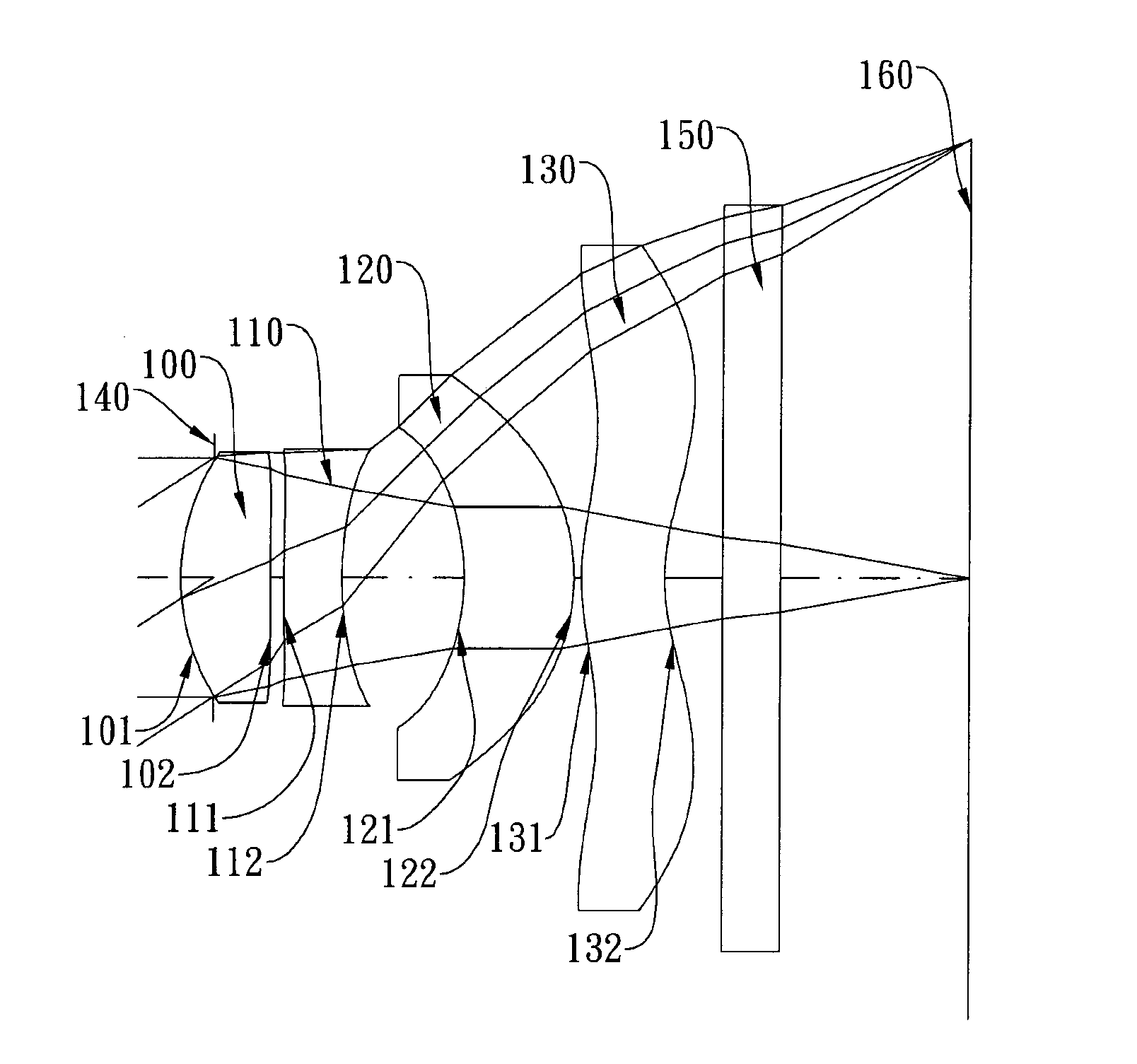

Small form factor telephoto camera

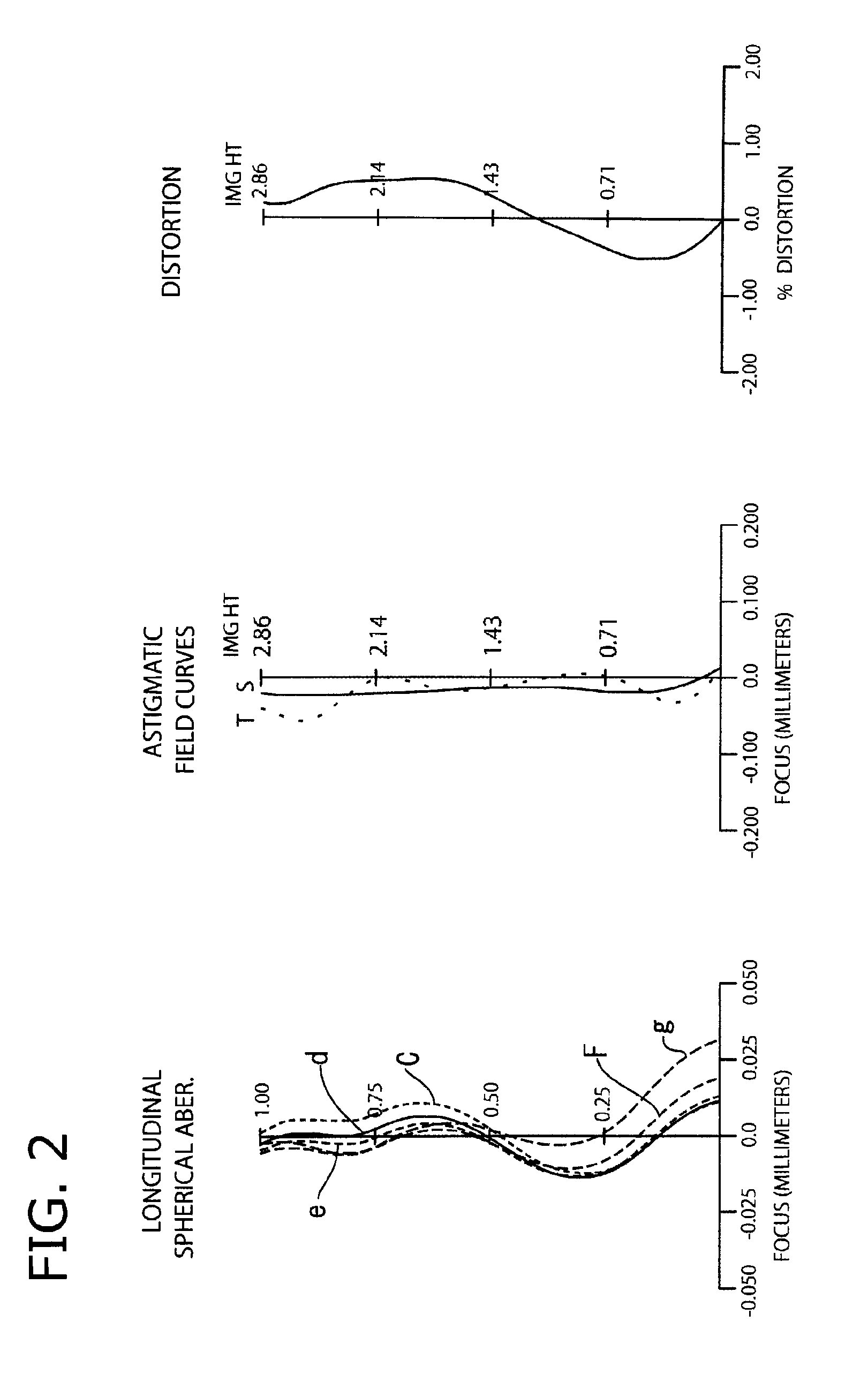

ActiveUS20150116569A1Well-corrected and balanced minimal residual aberrationReduce track lengthTelevision system detailsColor television detailsImage resolutionTelephoto lens

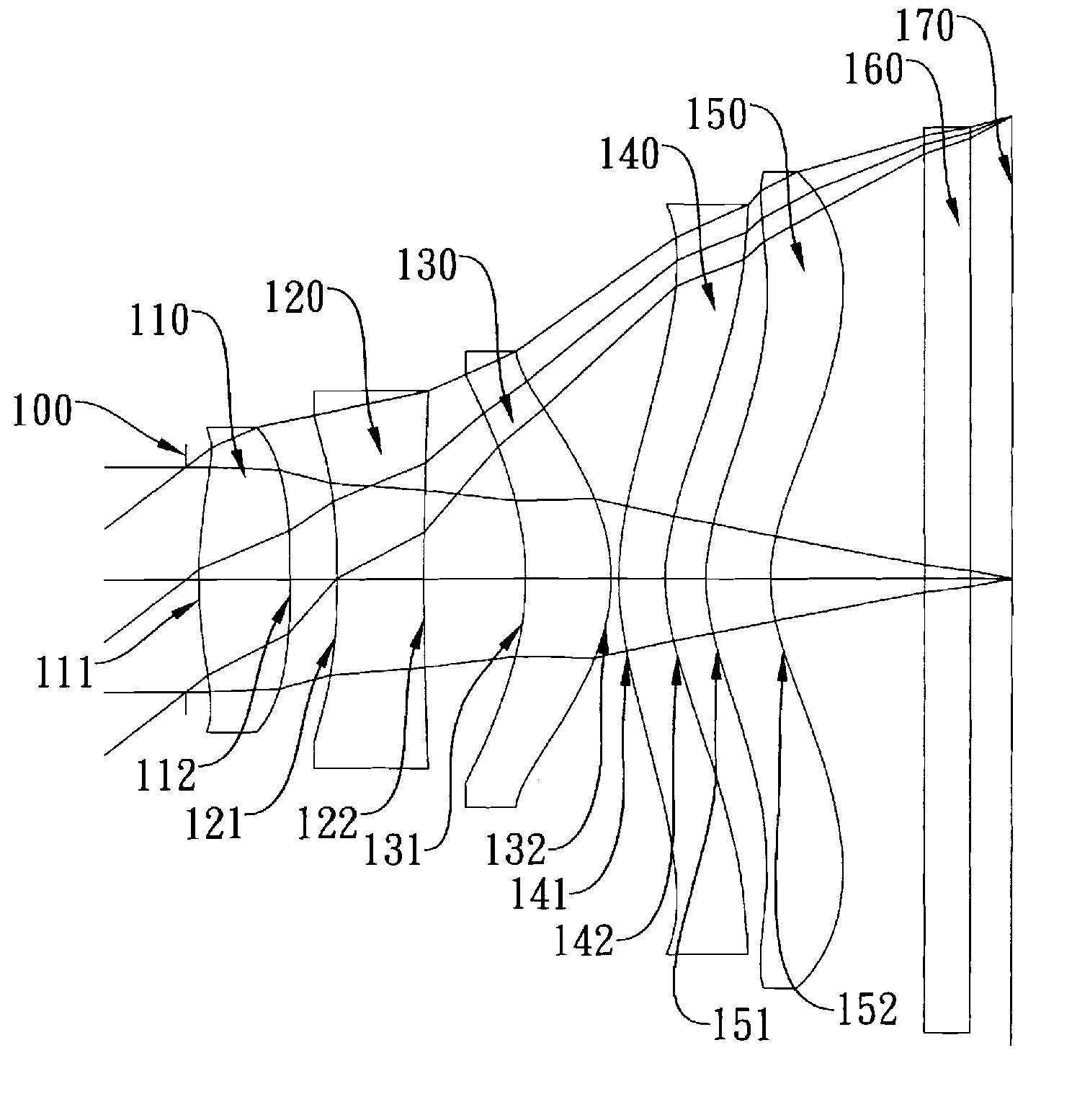

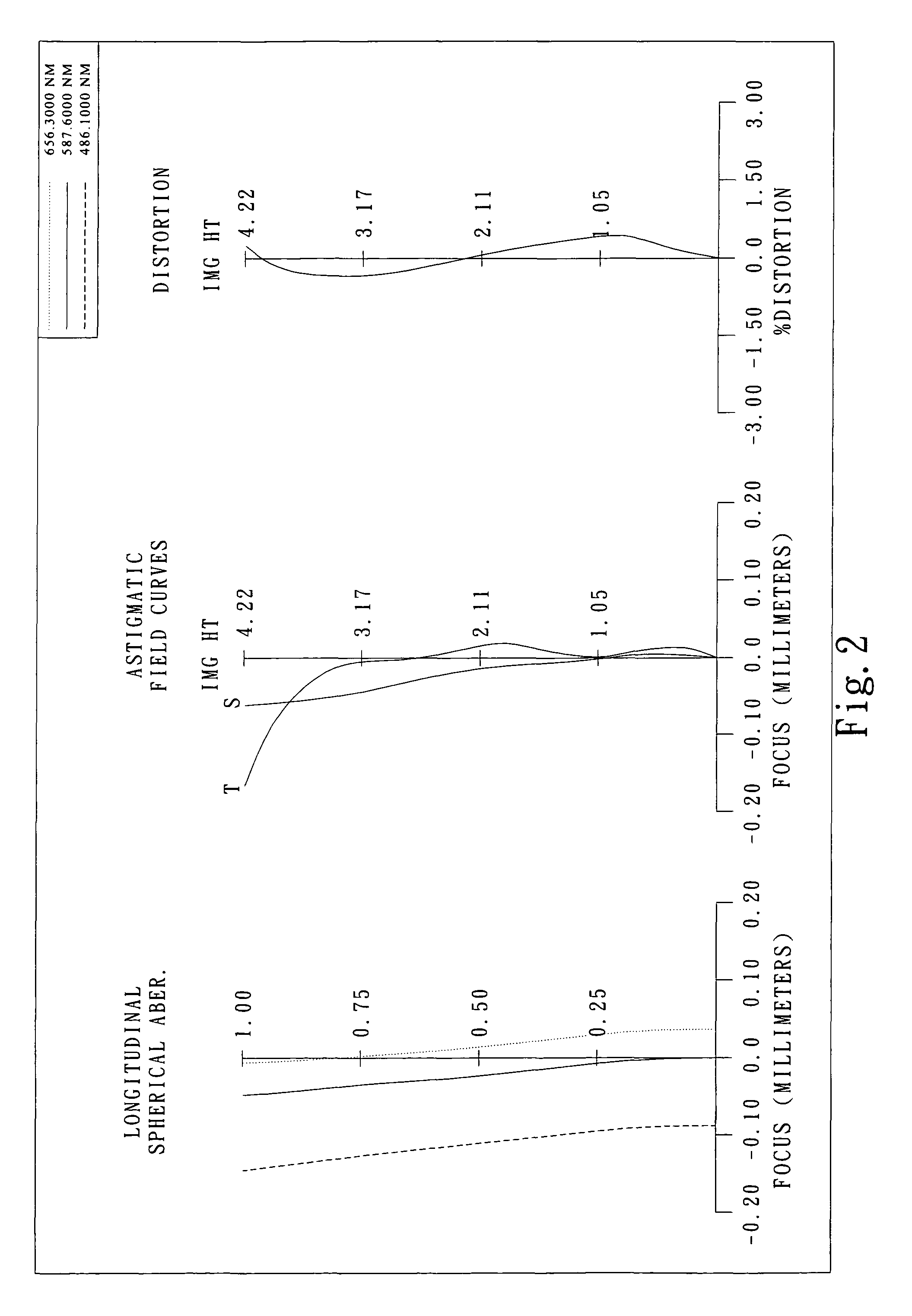

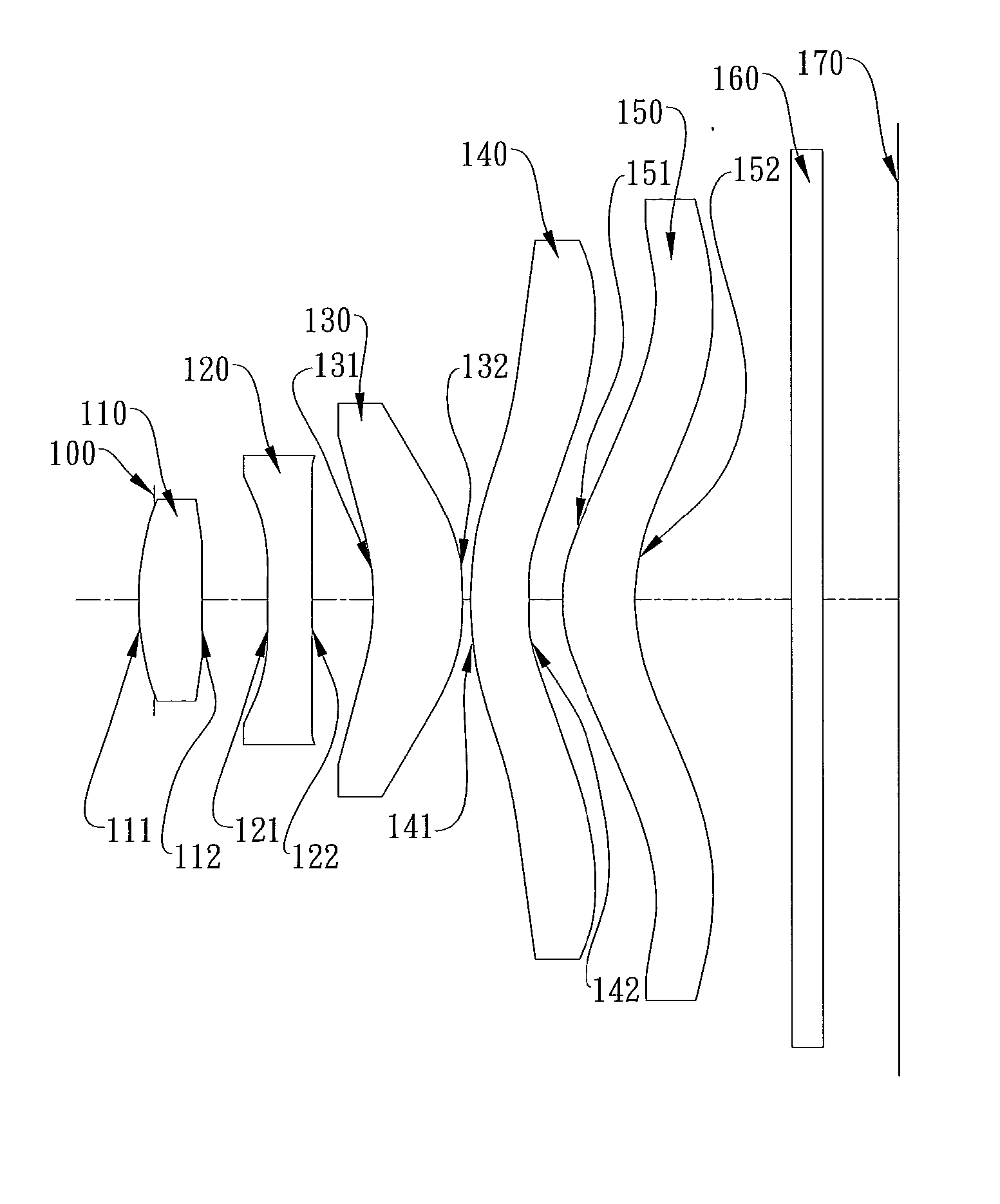

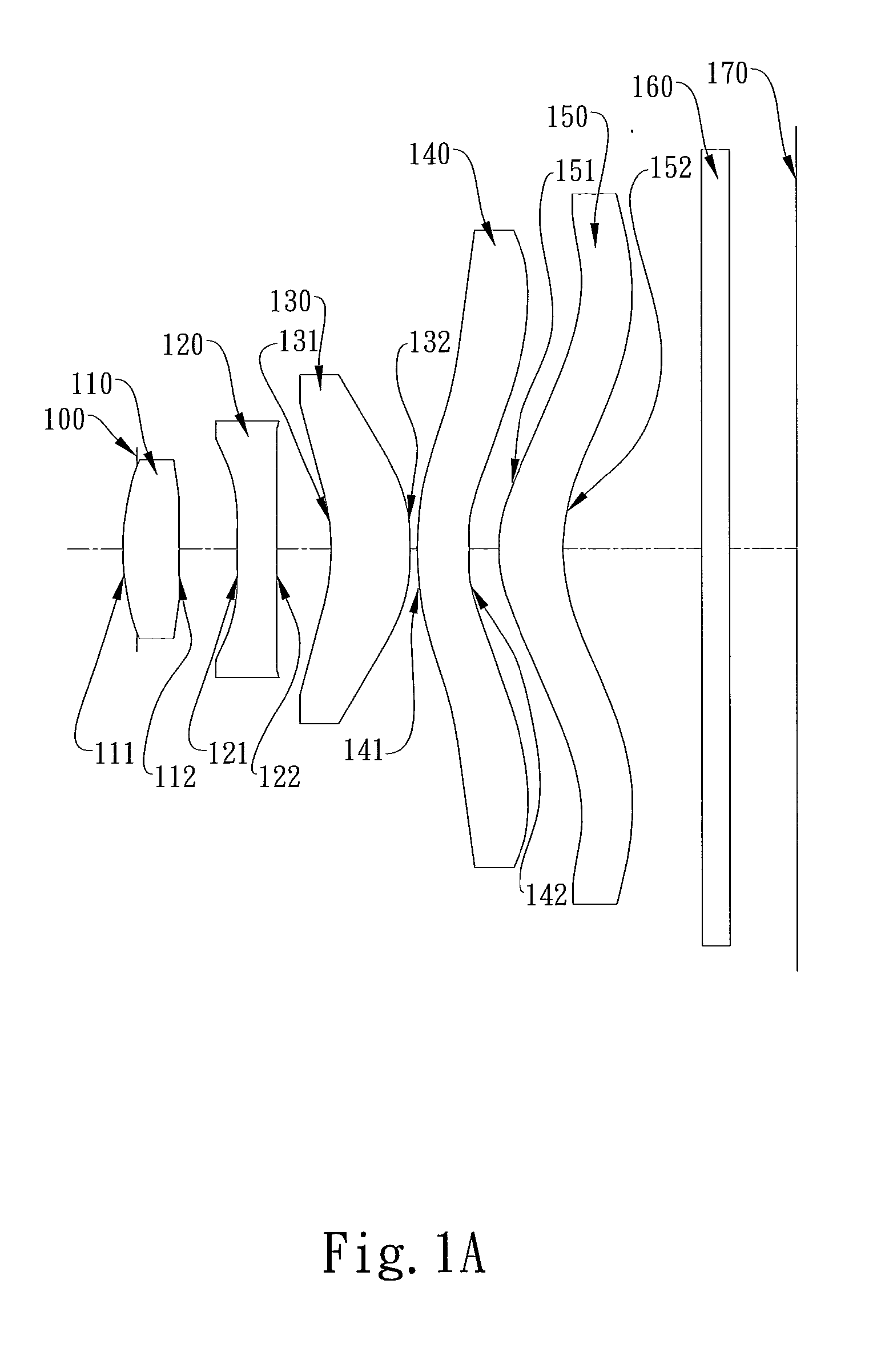

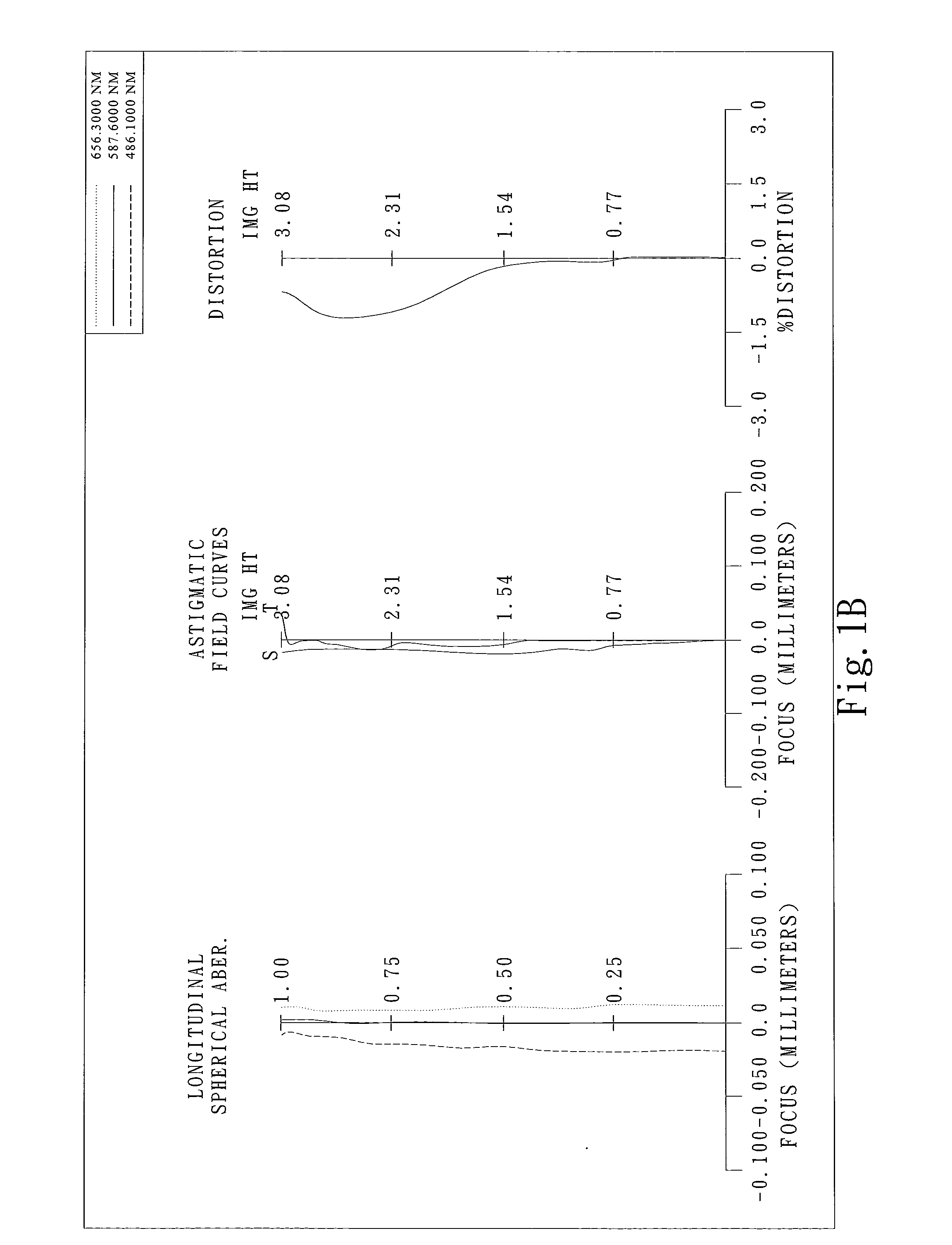

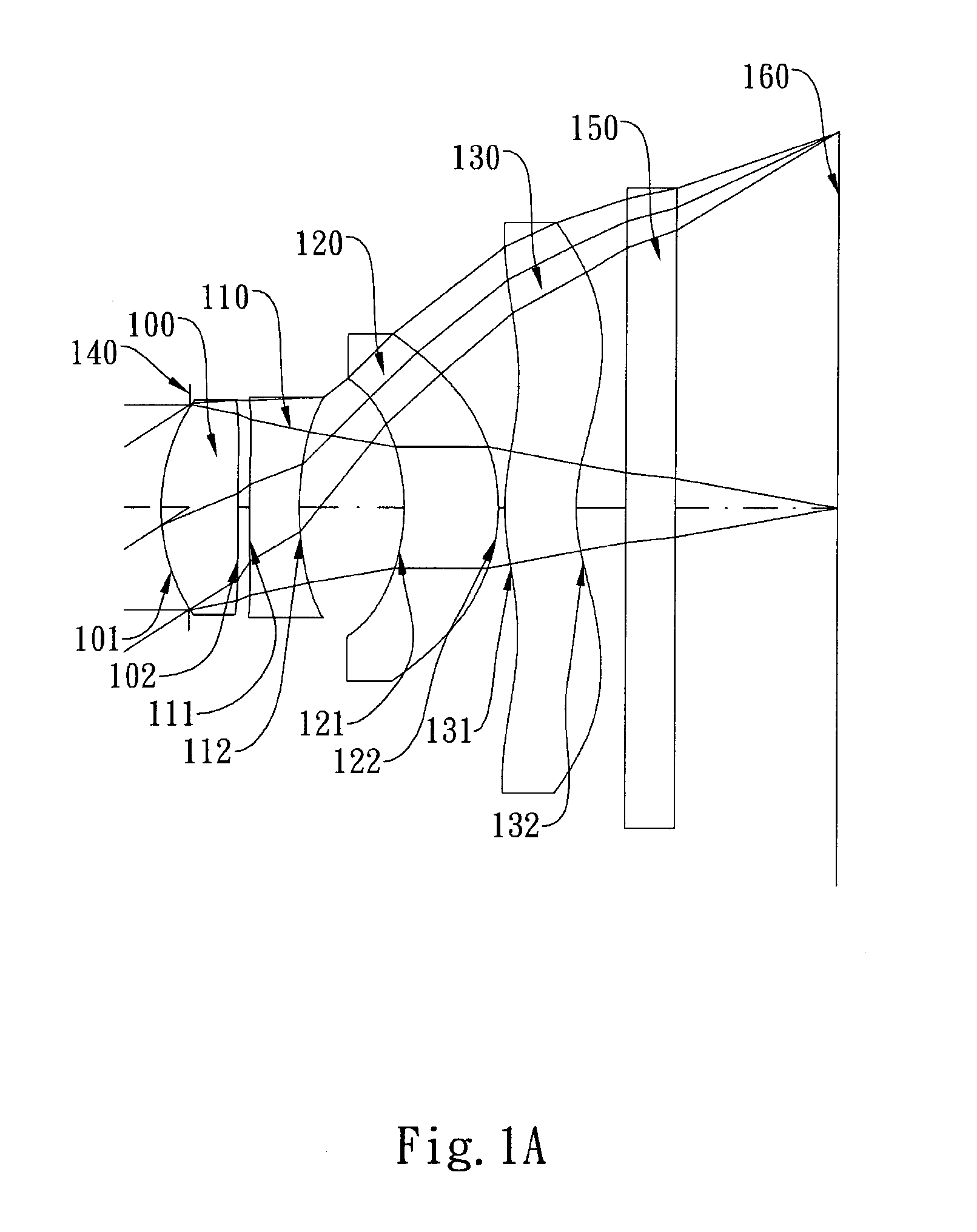

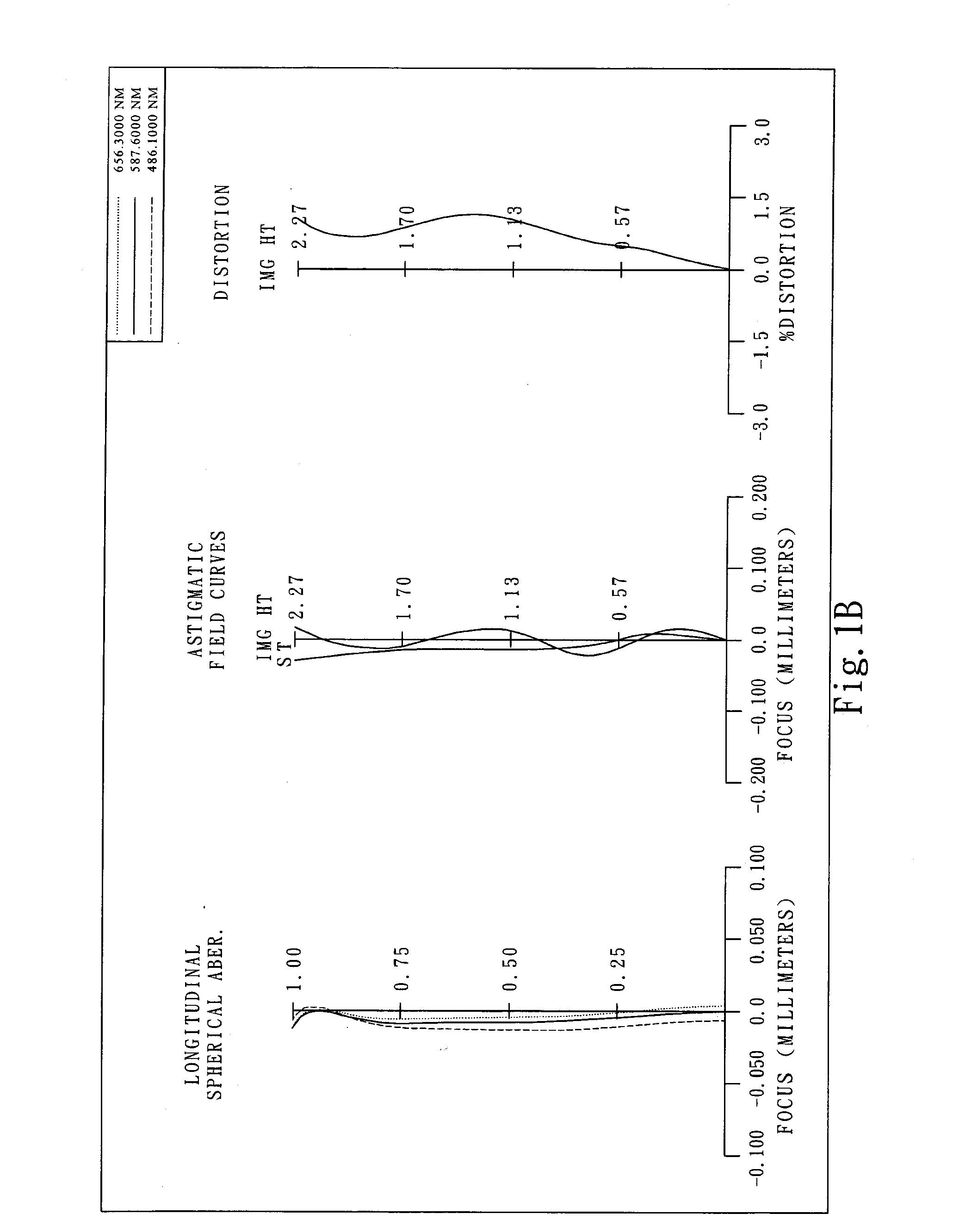

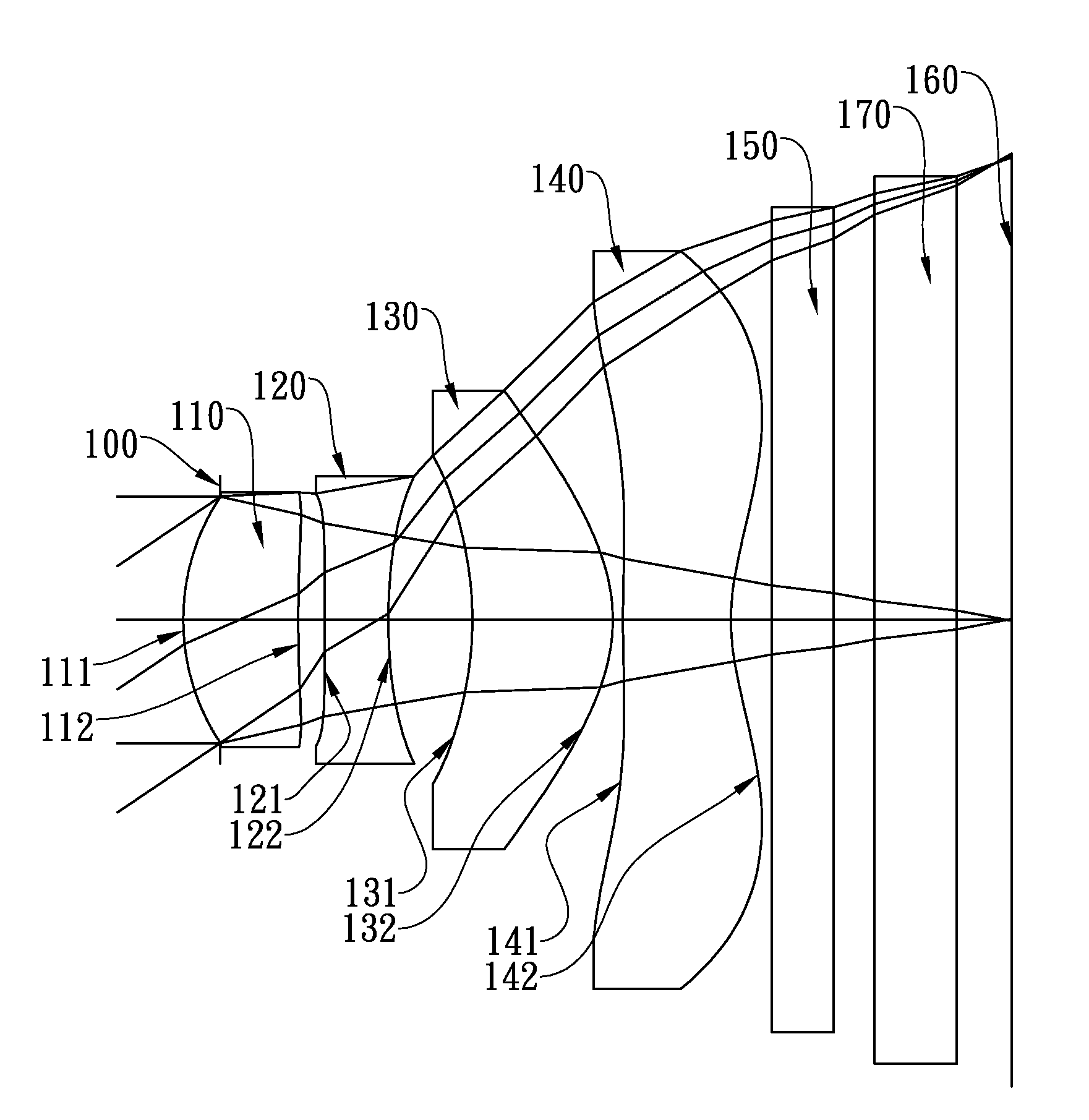

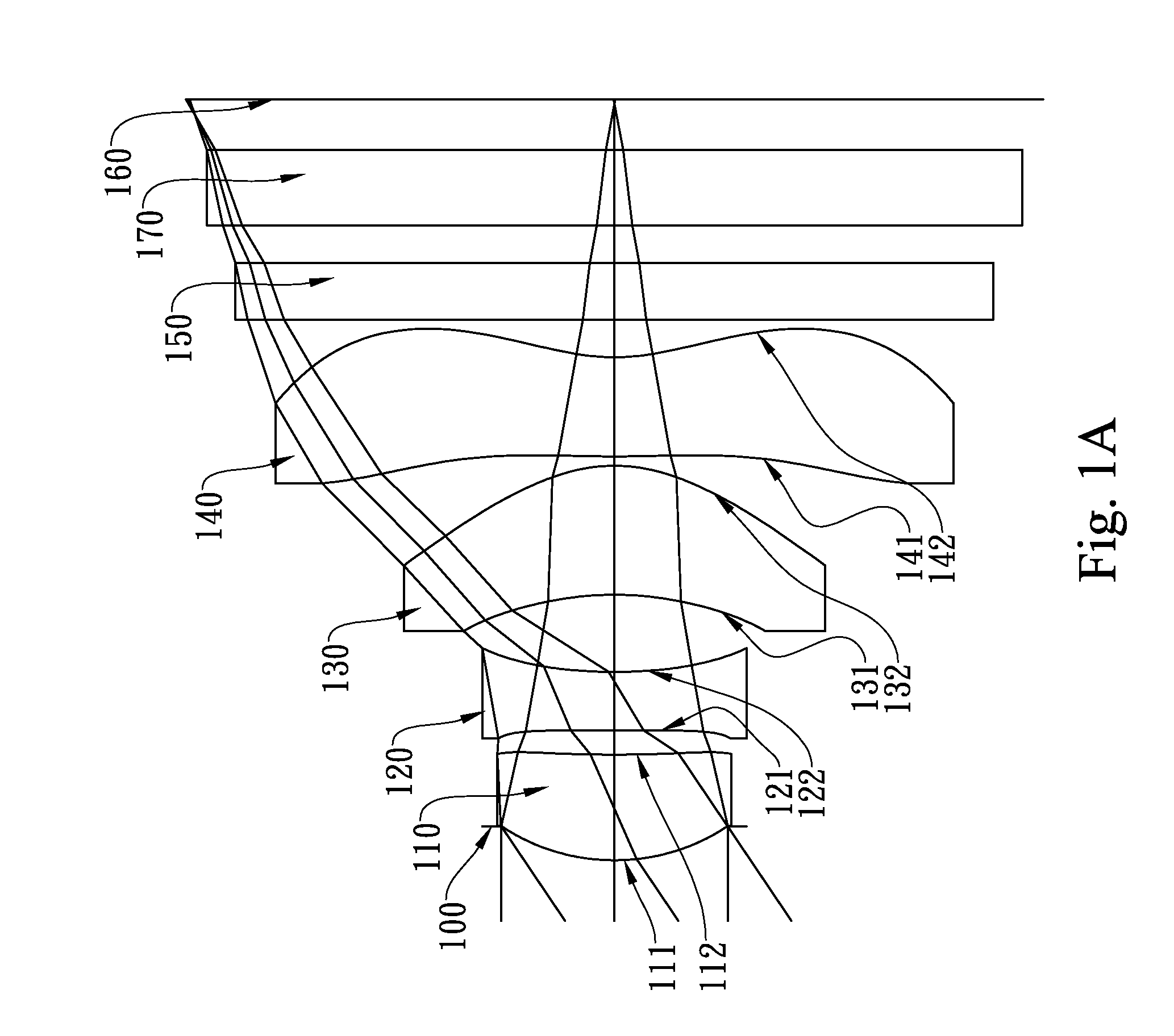

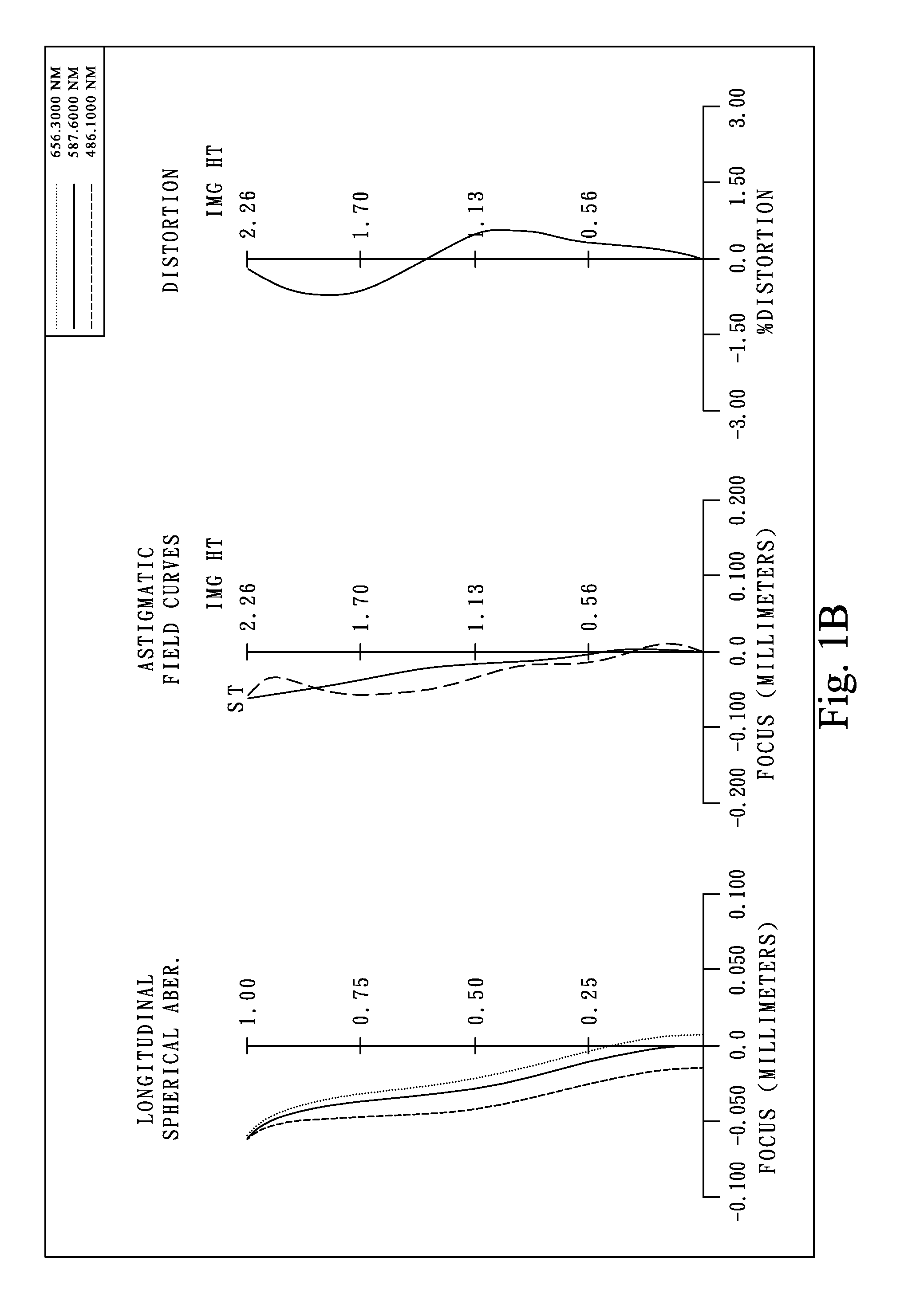

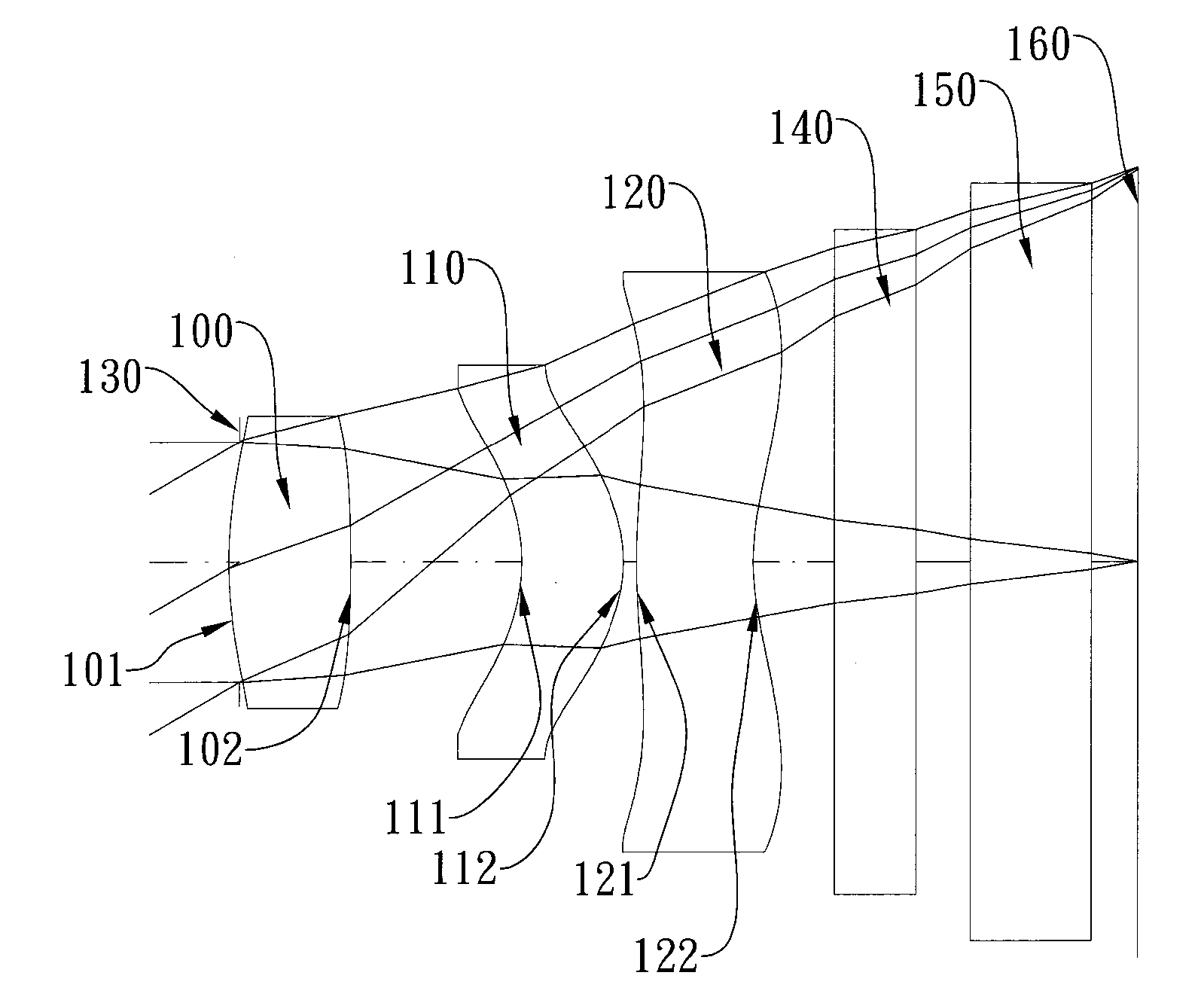

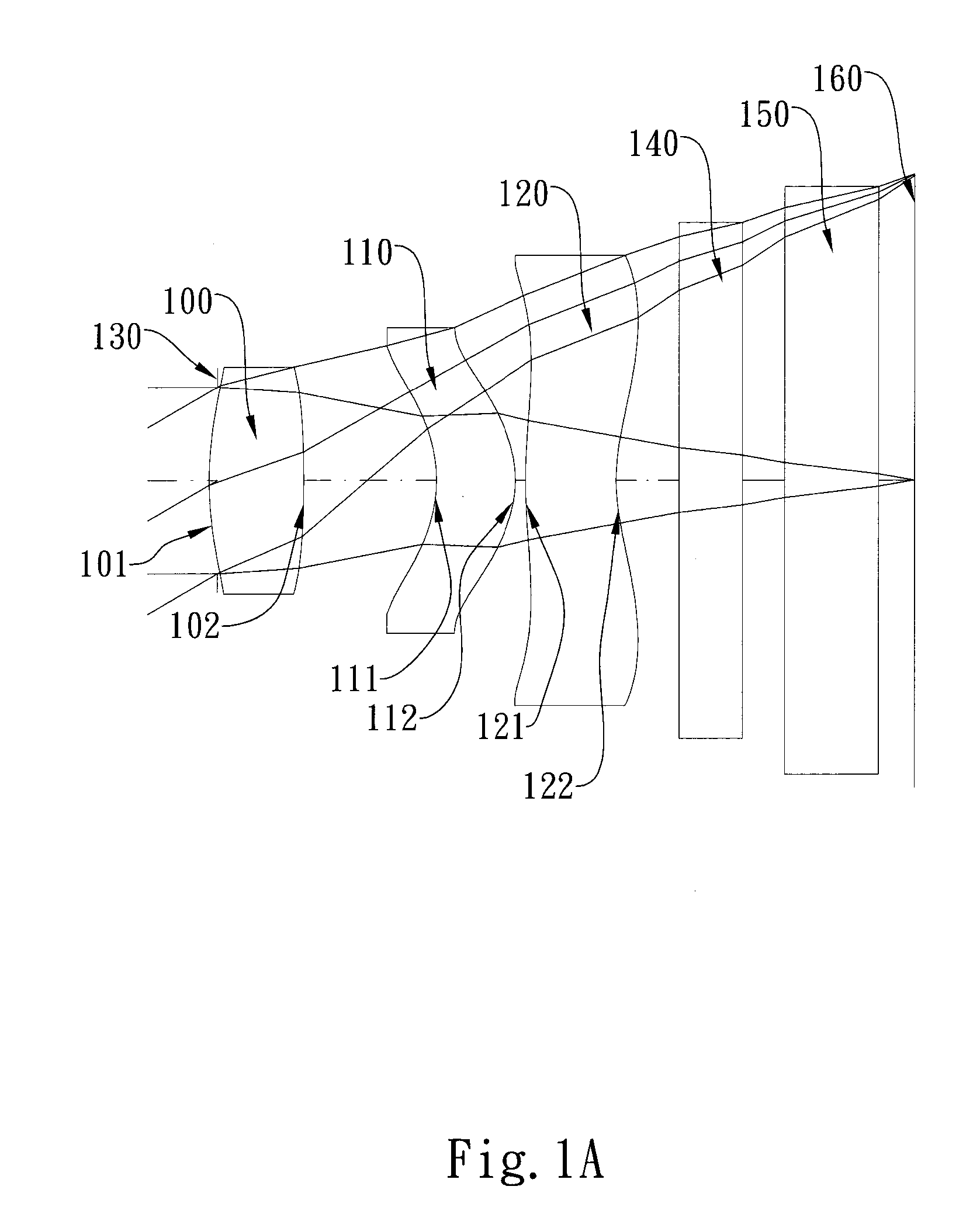

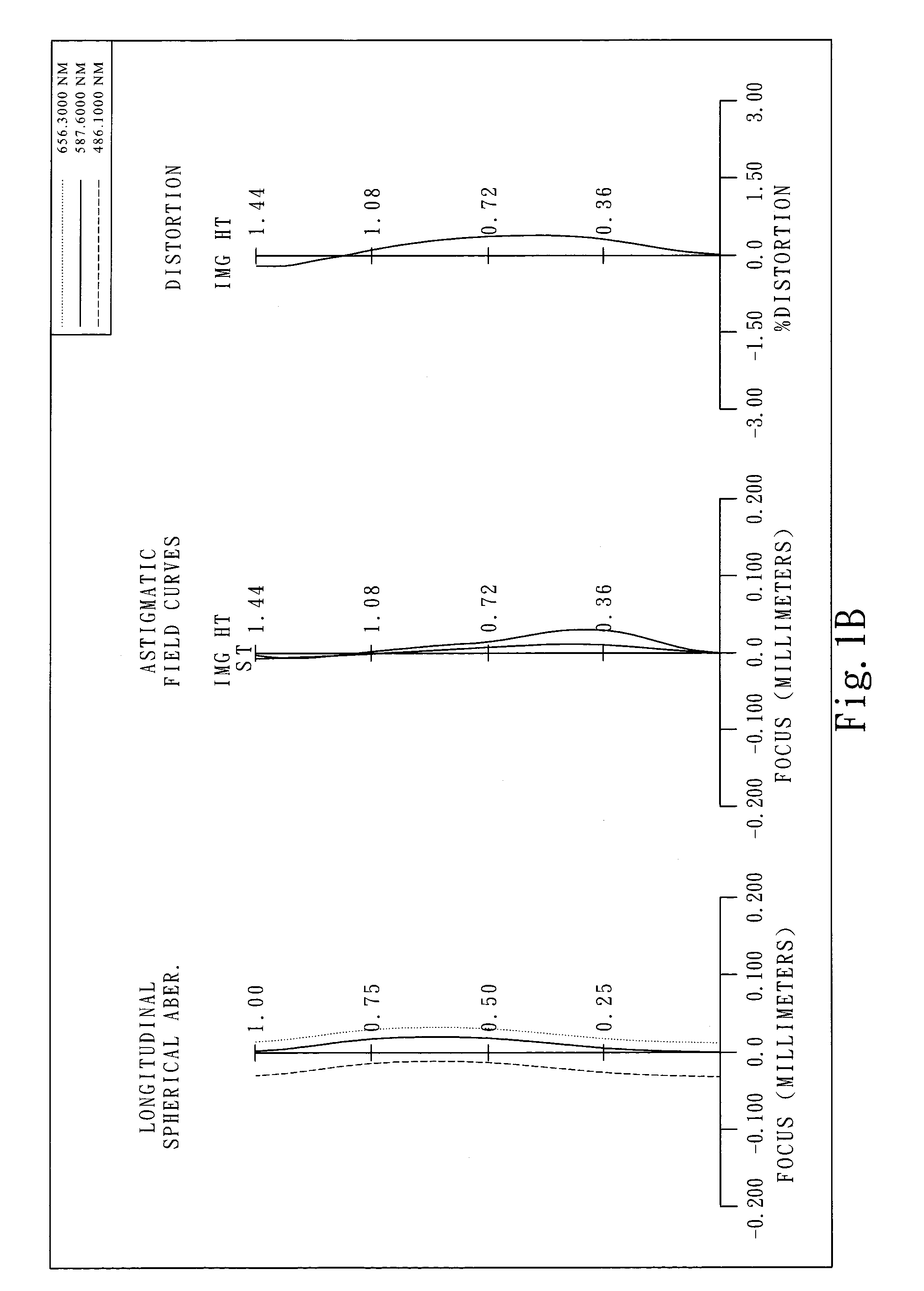

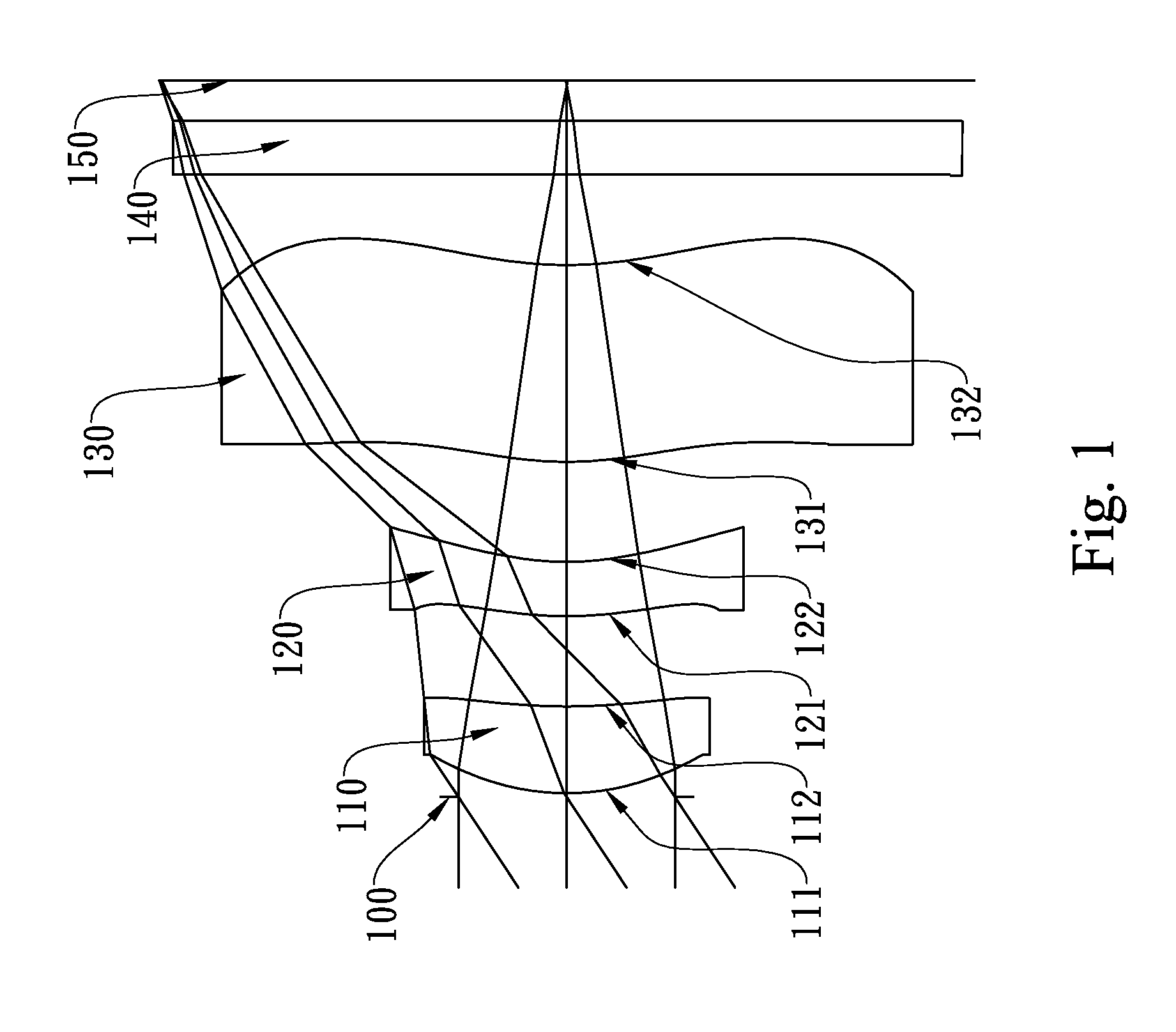

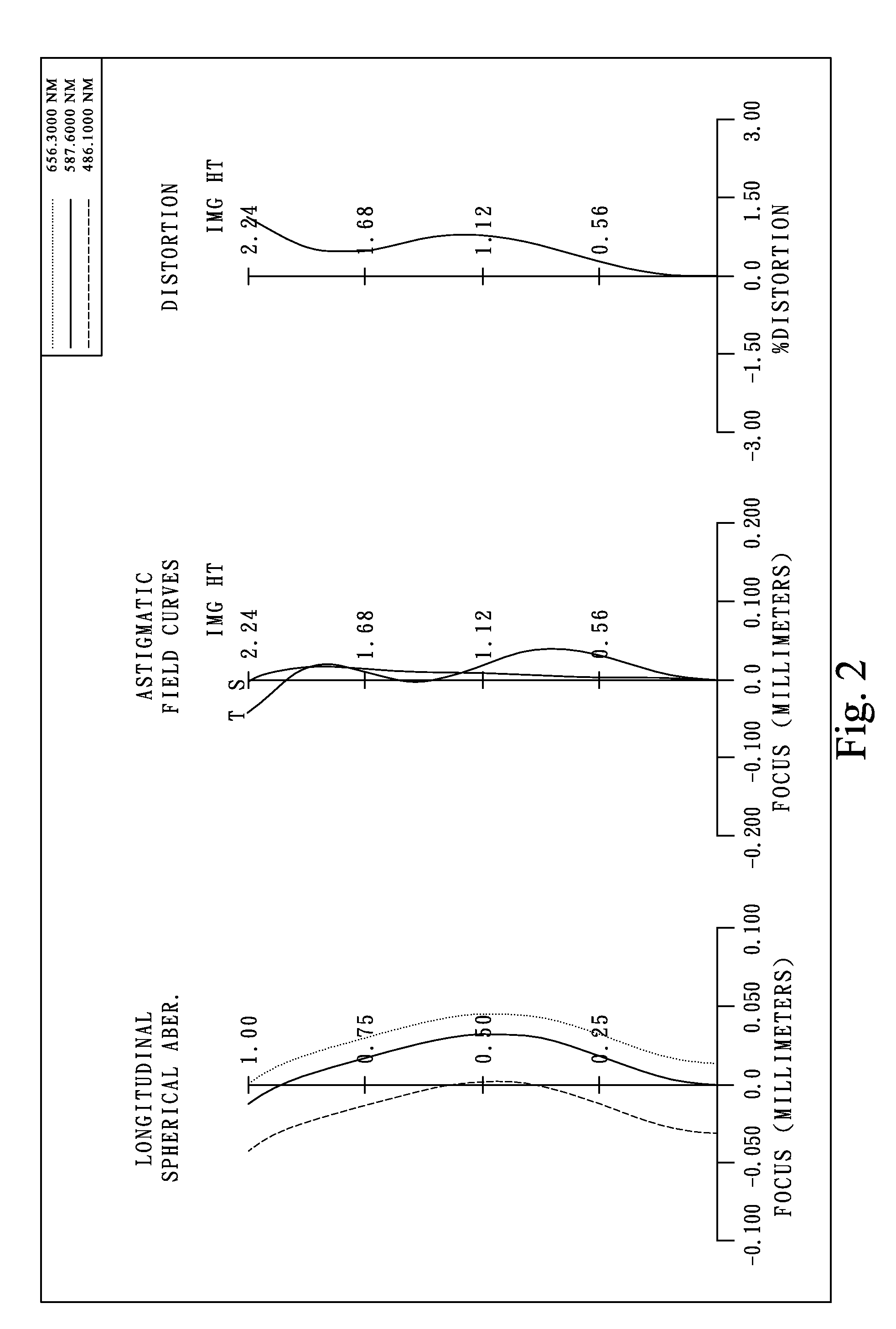

A compact telephoto lens system that may be used in a small form factor cameras. The lens system may include five lens elements with refractive power. Alternatively, the lens system may include four lens elements with refractive power. At least one of the object side and image side surfaces of at least one of the lens elements is aspheric. Total track length (TTL) of the lens system may be 6.0 mm or less. Focal length f of the lens system may be at or about 7.0 mm (for example, within a range of 6.5-7.5 mm). Lens elements are selected and configured so that the telephoto ratio (TTL / f) satisfies the relation 0.74<TTL / f<1.0. Materials, radii of curvature, shapes, sizes, spacing, and aspheric coefficients of the lens elements may be selected to achieve quality optical performance and high image resolution in a small form factor telephoto camera.

Owner:APPLE INC

Optical image lens system

This invention provides an optical image lens system comprising: a positive first lens element having a convex object-side surface; a second lens element; a positive third lens element; a fourth lens element; a positive plastic fifth lens element having a convex object-side surface and a concave image-side surface, at least one of the object-side and image-side surfaces is aspheric; and a negative plastic sixth lens element having a concave image-side surface, at least one of the object-side and image-side surfaces is aspheric, wherein the shape of the image-side surface changes from concave at the paraxial region thereof to convex while away from the paraxial region thereof.

Owner:LARGAN PRECISION

Imaging lens assembly

This invention provides an imaging lens assembly comprising, in order from an object side to an image side: a first lens element with negative refractive power having a convex object-side surface and a concave image-side surface; a second lens element with positive refractive power having a convex image-side surface; a third lens element with negative refractive power having a concave object-side surface and a convex image-side surface, both being aspheric; a fourth lens element with positive refractive power having a convex object-side surface, both its two surfaces being aspheric; and a stop disposed between the first and second lenses.

Owner:LARGAN PRECISION

Imaging lens assembly

The present invention provides an imaging lens assembly, comprising in order from an object side toward an image side, a first lens element with positive refractive power having a convex object-side surface, a second lens element with negative refractive power having a concave object-side surface and a convex image-side surface, a third lens element with positive refractive power having a concave object-side surface and a convex image-side surface, a fourth lens element with negative refractive power, a fifth lens element with positive refractive power, and an aperture stop positioned between an imaged object and the first lens element. The above lens arrangement shortens the total track length effectively, enabling a high performance imaging lens assembly with a wide field of view.

Owner:LARGAN PRECISION

Optical photographing system

ActiveUS8014080B1Reduce track lengthIncrease photosensitivityLensMagnifying glassesImage resolutionView angle

This invention provides an optical photographing system comprising four lens elements with refractive power, in order from an object side to an image side: a first lens element; a second lens element with positive refractive power, and at least one of the object-side and image-side surfaces thereof being aspheric; a third lens element with negative refractive power having a concave object-side surface and a convex image-side surface, and both of the object-side and image-side surfaces thereof being aspheric; a fourth lens element with positive refractive power, and both of the object-side and image-side surfaces thereof being aspheric; wherein the optical photographing system further comprises an aperture stop positioned between an object and the second lens element. By such arrangement, total track length of the optical photographing system can be effectively reduced. Wide view-angle and high image resolution are also obtained.

Owner:LARGAN PRECISION

Image-capturing lens assembly

ActiveUS20110115962A1Small sizeReduce sensitivityTelevision system detailsColor television detailsImage resolutionOptic system

This invention provides an image-capturing lens assembly comprising, in order from an object side to an image side: a first lens element with positive refractive power having a convex object-side surface; a second lens element with negative refractive power; a third lens element with positive refractive power having a concave object-side surface and a convex image-side surface, the object-side and image-side surfaces thereof being aspheric; a fourth lens element with negative refractive power having a concave image-side surface on which at least one inflection point is formed, the object-side and image-side surfaces thereof being aspheric; and a stop disposed between an imaged object and the first lens element; wherein there are four lens elements with refractive power. Such an arrangement of optical elements can effectively reduce the size of the lens assembly, mitigate the sensitivity of the optical system and enable the lens assembly to obtain a higher resolution.

Owner:LARGAN PRECISION

Optical imaging lens assembly

This invention provides an optical imaging lens assembly, in order from an object side toward an image side including: a first lens element with positive refractive power having a convex object-side surface, a second lens element with negative refractive power having a concave object-side surface and a concave image-side surface, a third lens element with positive refractive power having a concave object-side surface and a convex image-side surface, a fourth lens element with negative refractive power having a concave image-side surface, and the two surfaces being aspheric; wherein the optical imaging lens assembly further comprises an aperture stop disposed between an imaged object and the first lens element, and there are four lens elements with refractive power.

Owner:LARGAN PRECISION

Photographing optical lens assembly

ActiveUS20110096221A1Small sizeReduce sensitivityTelevision system detailsColor television detailsImage resolutionOptic system

This invention provides a photographing optical lens assembly comprising, in order from an object side to an image side: a first lens element with positive refractive power having a convex object-side surface and a convex image-side surface; a second lens element with positive refractive power having a concave object-side surface and a convex image-side surface, both of the two surfaces being aspheric; a third lens element with negative refractive power having a concave image-side surface on which at least one inflection point is formed, both of the two surfaces being aspheric; and a stop disposed between an imaged object and the second lens element; wherein there are only three lens elements with refractive power. Such an arrangement of optical elements can effectively reduce the size of the lens assembly, mitigate the sensitivity of the optical system and enable the lens assembly to obtain a higher resolution.

Owner:LARGAN PRECISION

Image capturing optical system

This invention provides an image capturing optical system in order from an object side to an image side comprising: a first lens element with positive refractive power having a convex object-side surface; a second lens element; a third lens element; a fourth lens element with both the object-side and image-side surfaces thereof being aspheric, and the fourth lens element is made of plastic; and a fifth lens element with negative refractive power, both the object-side and image-side surfaces thereof being aspheric, at least one inflection point is formed on at least one of the object-side and image-side surfaces thereof, and the fifth lens element is made of plastic. By such arrangement, photosensitivity and total track length of the system can be reduced, and better image quality can be obtained.

Owner:LARGAN PRECISION

Photographing optical system

ActiveUS20110228157A1Reduce track lengthReduce sensitivityTelevision system detailsColor television detailsPhysics

This invention provides a photographing optical system comprising: in order from an object side to an image side: a first lens with positive refractive power having a convex object-side surface; a second lens with negative refractive power having a convex object-side surface and a concave image-side surface, at least one of the object-side and image-side surfaces thereof being aspheric; a third lens having at least one inflection point formed thereon and both surfaces thereof being aspheric. A stop is positioned between an imaged object and the first lens element. The photographing optical system further comprises an electronic sensor on which an object is imaged, and there are three lens elements of the photographing optical system with refractive power.

Owner:LARGAN PRECISION

Image lens system

This invention provides an image lens system comprising: a first lens element with positive refractive power; a second lens element with negative refractive power having a concave object-side surface and a concave image-side surface, both the object-side and image-side surfaces thereof being aspheric and made of plastic; a third lens element with positive refractive power; and a fourth lens element with negative refractive power, and at least one inflection point is formed on at least one of the object-side and image-side surfaces thereof; wherein, the region of the image-side surface of the second lens element near the optical axis is concave, but the off-axis region thereof is convex. By such arrangement, not only the photosensitivity and total track length of the system can be reduced, but also better image quality can be obtained.

Owner:LARGAN PRECISION

Imaging lens assembly

This invention provides an imaging lens assembly including: in order from an object side toward an image side: a first lens with positive refractive power having a convex object-side surface and a convex image-side surface, a second lens with negative refractive power having at least one of its object-side surface and image-side surface being aspheric, a third lens with negative refractive power having a concave image-side surface, and both of its object-side surface and image-side surface being aspheric. An aperture stop is positioned between the first lens element and second lens element. The imaging lens assembly further comprises an electronic sensor on which an object is imaged, and there are three lens elements with refractive power.

Owner:LARGAN PRECISION

Imaging lens assembly

ActiveUS20110075271A1Reduce sensitivitySmall sizeTelevision system detailsColor television detailsConvex sideImaging lens

This invention provides an imaging lens assembly comprising: in order from an object side to an image side: a first lens with positive refractive power having a convex object-side surface and a convex image-side surface; a second lens with negative refractive power having a concave object-side surface; a third lens with positive refractive power having a convex image-side surface, at least one of both surfaces thereof being aspheric; and a fourth lens with negative refractive power having a convex object-side surface and a concave image-side surface on which at least one inflection point is formed; wherein there are four lenses with refractive power, an on-axis spacing between an aperture stop and an electronic sensor provided therein is SL, an on-axis spacing between the object-side surface of the first lens and the electronic sensor is TTL, they satisfy the relation: 0.75<SL / TTL<0.90.

Owner:LARGAN PRECISION

Photographing optical lens assembly

This invention provides a photographing optical lens assembly, from an object side to an image side in order, comprising a first lens element with positive refractive power having a convex object-side surface, a second lens element with negative refractive power having a concave image-side surface, a third lens element with positive refractive power, a fourth lens element with negative refractive power having a concave image-side surface, both the two surfaces of the fourth lens thereof being aspheric. And an aperture stop is positioned between the first element and the second lens element. There are four lens elements with refractive power in the lens assembly.

Owner:LARGAN PRECISION

Imaging lens

An imaging lens includes five lenses for a solid-state image sensor, arranged in order from the object side to the image side, a first lens with positive refractive power having a convex object side surface, a second lens with negative refractive power having a concave image side surface, a third lens with positive or negative refractive power, a fourth lens with positive refractive power as a double-sided aspheric lens having a concave image side surface near an optical axis, and a fifth lens with negative refractive power as a double-sided aspheric lens having a concave image side surface near the optical axis, wherein the first lens and second lens satisfy conditional expressions below:45<ν1<90 (1)22<ν2<35 (2)2.0<ν1 / ν2<2.6 (3)whereν1: first lens Abbe numberν2: second lens Abbe number.

Owner:TOKYO VISIONARY OPTICS CO LTD

Photographing optical lens assembly

ActiveUS20120099014A1Improve image qualityReduce sensitivityTelevision system detailsColor television detailsPhysics

A photographing optical lens assembly includes, in order from an object side to an image side, a first lens element with positive refractive power having a convex object-side surface, a second lens element with negative refractive power having a concave object-side surface and a convex image-side surface, a third lens element with positive refractive power having a convex object-side surface and a convex image-side surface, and a fourth lens element having a convex object-side surface and a concave image-side surface with both surfaces thereof being aspheric.

Owner:LARGAN PRECISION

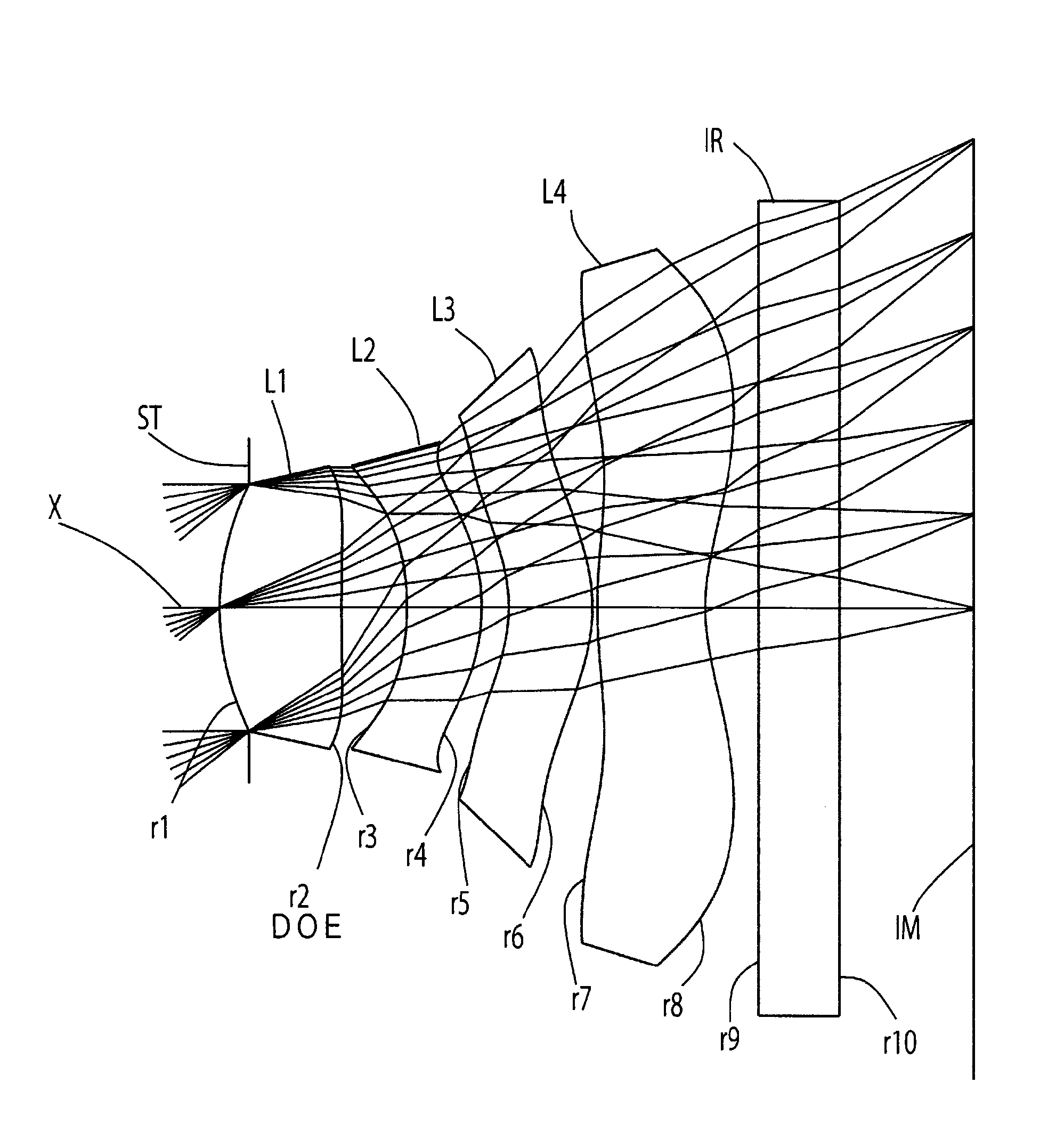

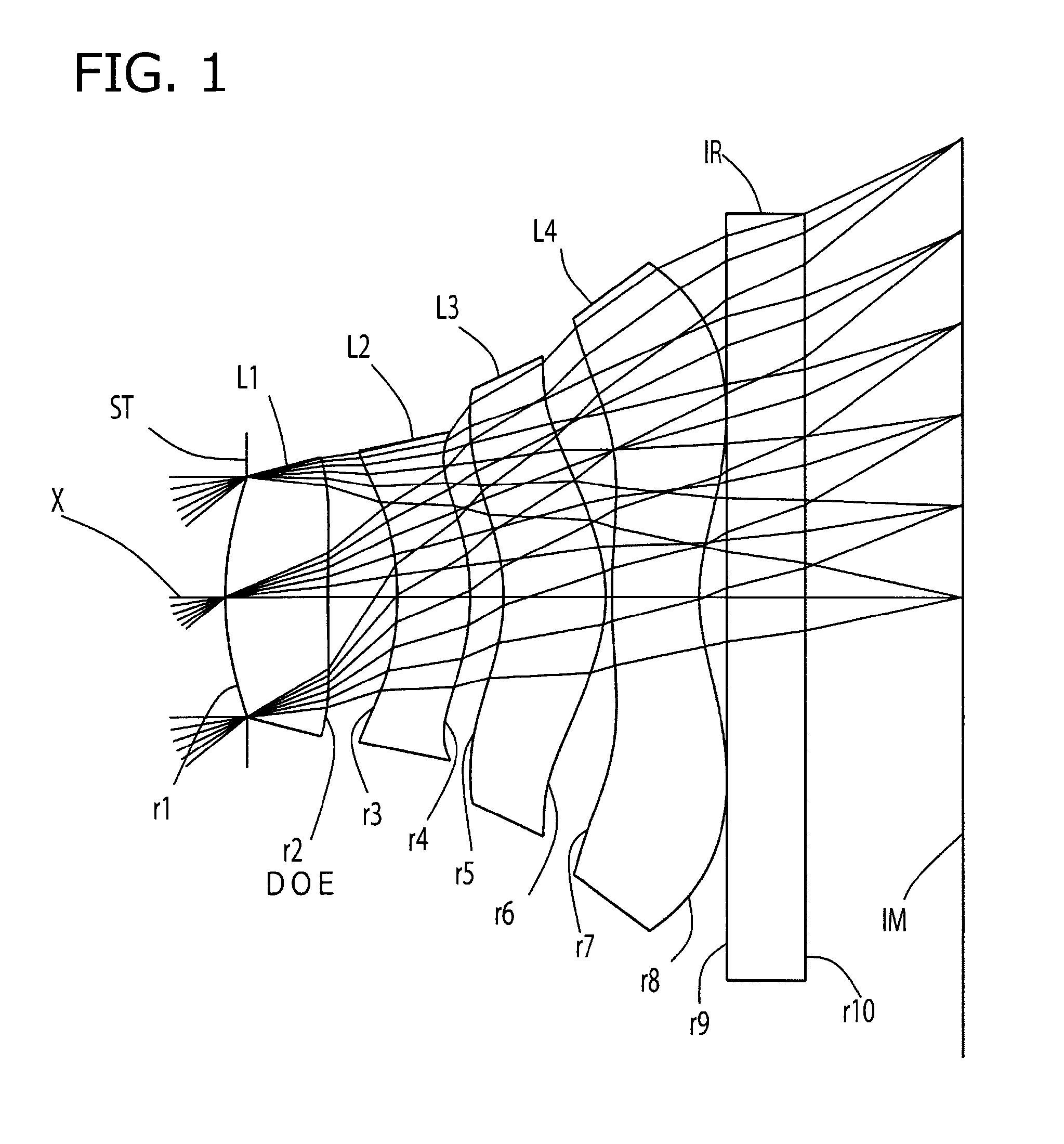

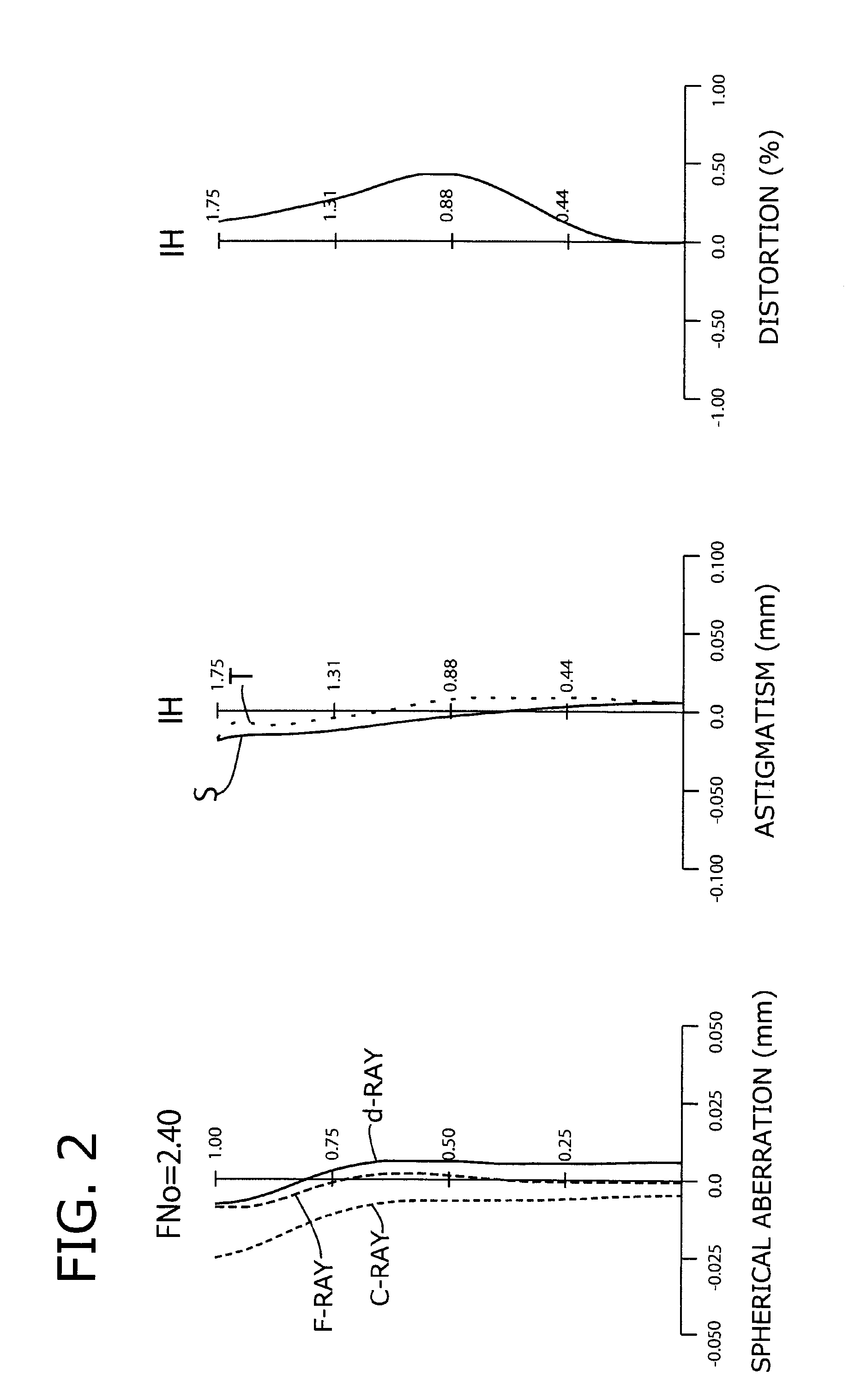

Imaging lens

ActiveUS20130321920A1Reduce distanceImprove batch productivityDiffraction gratingsOptical axisPlastic materials

An imaging lens includes, from the object side to the image side, an aperture stop, a first lens with positive refractive power having a convex object-side surface near an optical axis, a second lens with positive refractive power having a convex image-side surface near the axis, a third lens with positive refractive power having a convex image-side surface near the axis, and a fourth lens with negative refractive power having a concave image-side surface near the axis, wherein all lens surfaces are aspheric, all lenses are made of plastic material, a diffractive optical surface is formed on at least one of the lens surfaces from the first lens image-side surface to the second lens image-side surface, and at least one of the three positive lenses satisfies expression (1):1.58<Ndi (1)whereNdi: refractive index of the i-th positive lens at d-ray.

Owner:TOKYO VISIONARY OPTICS CO LTD

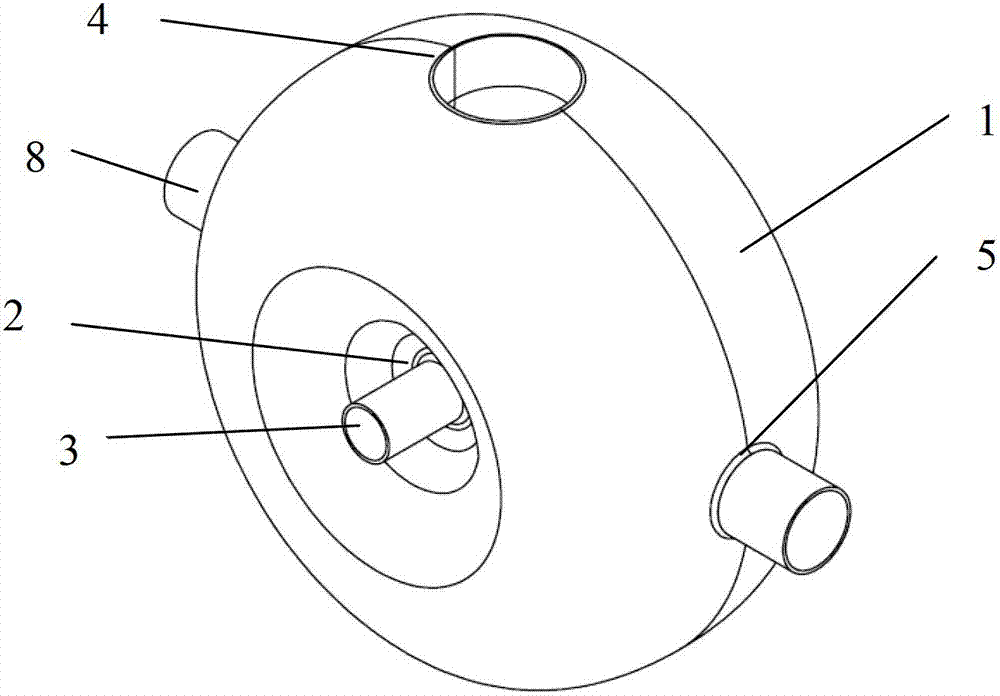

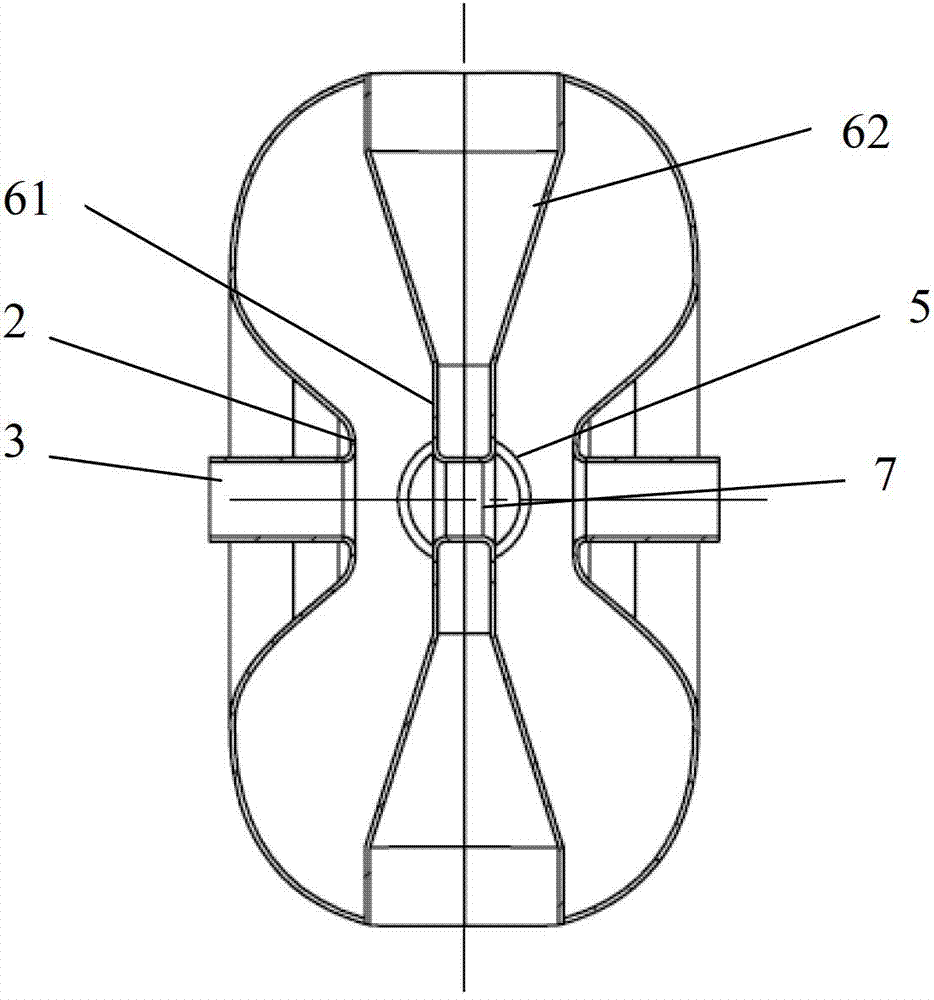

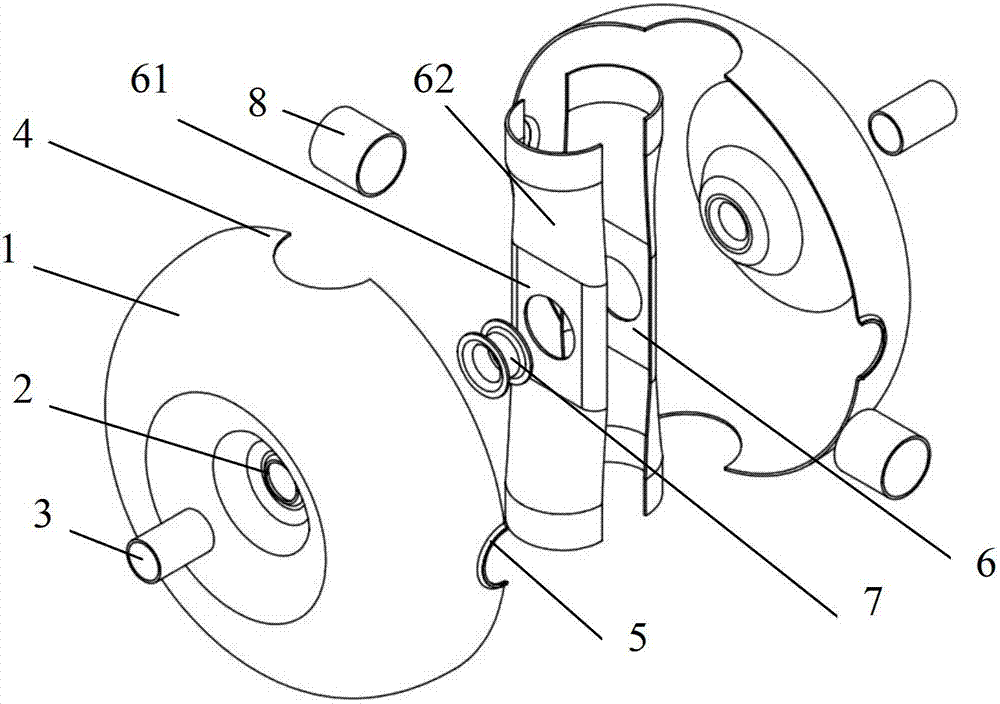

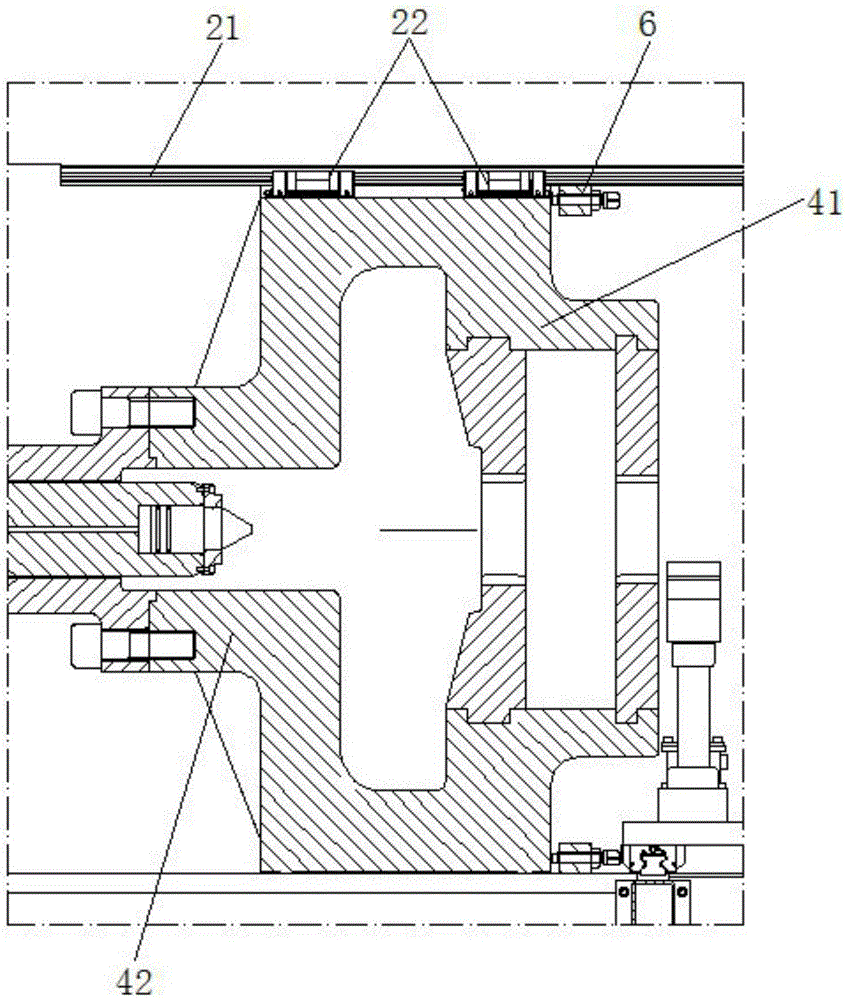

Single-mandril spoke type superconduction accelerating cavity and manufacture method thereof

InactiveCN103167718AReduce intensityReduce difficultyLinear acceleratorsElectron beam welding apparatusPhysicsThin walled

The invention relates to a single-mandril spoke type superconduction accelerating cavity and a manufacture method thereof, wherein an optimal beta range is 0.1-0.1. The single-mandril spoke type superconduction accelerating cavity comprises a cavity body. The cavity body is formed by two semi-cavity bodies with the same shape in a welding mode. The outline of the cavity body is in an ellipsoid shape. A pair of beam tube holes is symmetrically formed in the center of the cavity body. A beam tuber is welded in each of the two beam tube holes. A flange is welded on the outer side of each of the two beam tubes. A pair of mandril holes is symmetrically formed in the cavity body and is perpendicular to the direction of the connecting line of the two beam tubes. A pair of cleaning holes is symmetrically formed in the cavity body and is 90 degrees away from the two mandril holes. A mandril which is formed by two half thin-wall cavities in a welding mode is welded in the two mandril holes. The middle section of the mandril is in straight barrel shape, and two ends of the mandril are in a symmetrical hopper shape. The two hopper-shaped end openings are respectively welded on the corresponding mandril holes. A center beam tube penetrates through and is welded on the middle section of the mandril. The center beam tube is located on the same axis with the beam tubes at the two ends. A cleaning tube is welded in each of the two cleaning holes. A flange is welded on the outer side of each of the two cleaning tubes, and the flanges are connected with an external device. The single-mandril spoke type superconduction accelerating cavity can be well applied to an injector of an accelerator transmutation system.

Owner:PEKING UNIV

Image capturing lens system

This invention provides an image capturing lens system in order from an object side to an image side comprising four non-cemented lens elements with refractive power: a first lens element with positive refractive power having a convex object-side surface; a second lens element with negative refractive power having a concave image-side surface; a plastic third lens element having a concave object-side surface and a convex image-side surface, both the object-side and image-side surfaces thereof being aspheric; and a plastic fourth lens element with negative refractive power having a concave image-side surface, both the object-side and image-side surfaces thereof being aspheric, and at least one inflection point is formed on at least one of the object-side and image-side surfaces thereof; wherein the image capturing lens system comprises a stop positioned between the first lens element and the second lens element.

Owner:LARGAN PRECISION

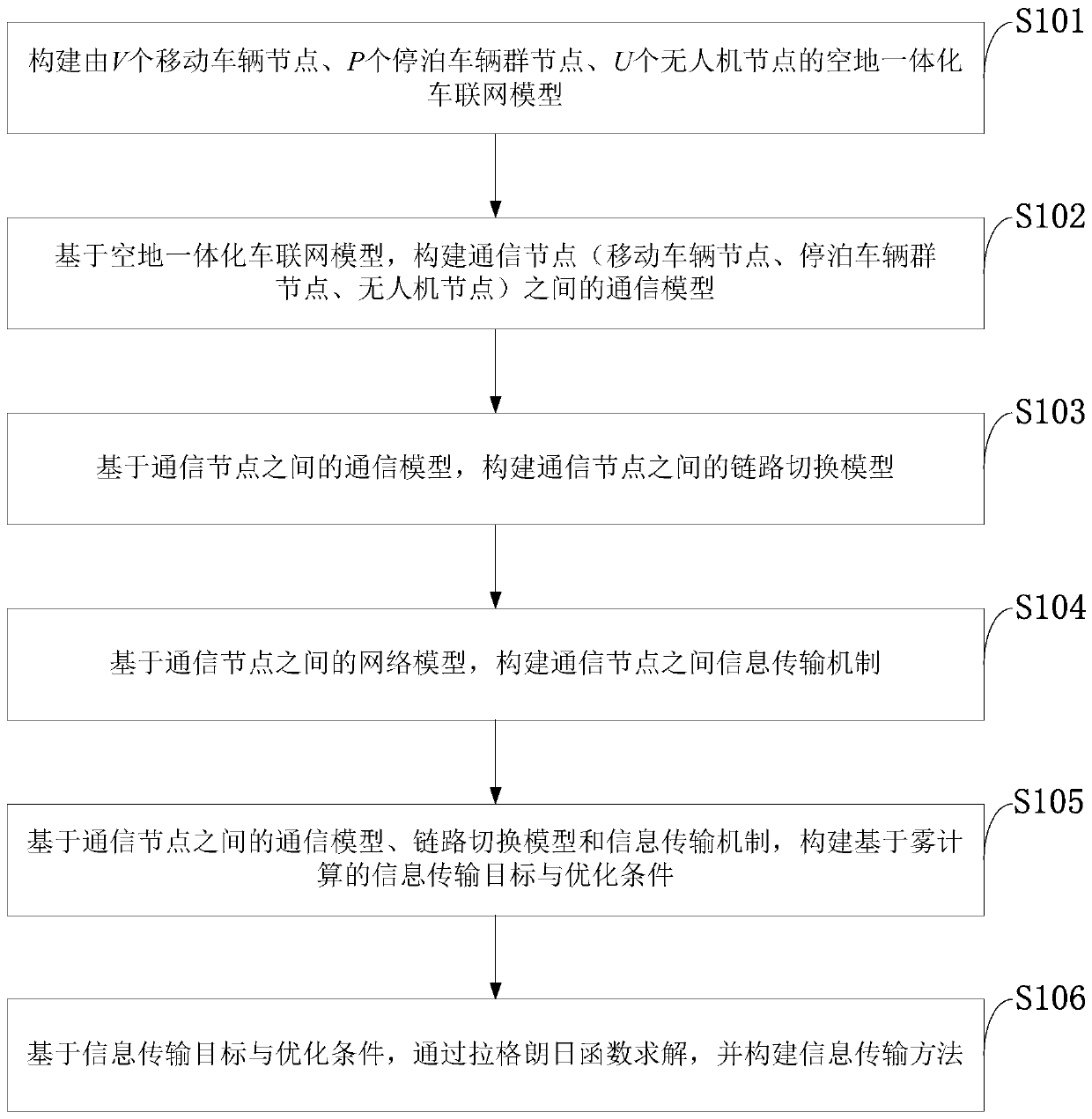

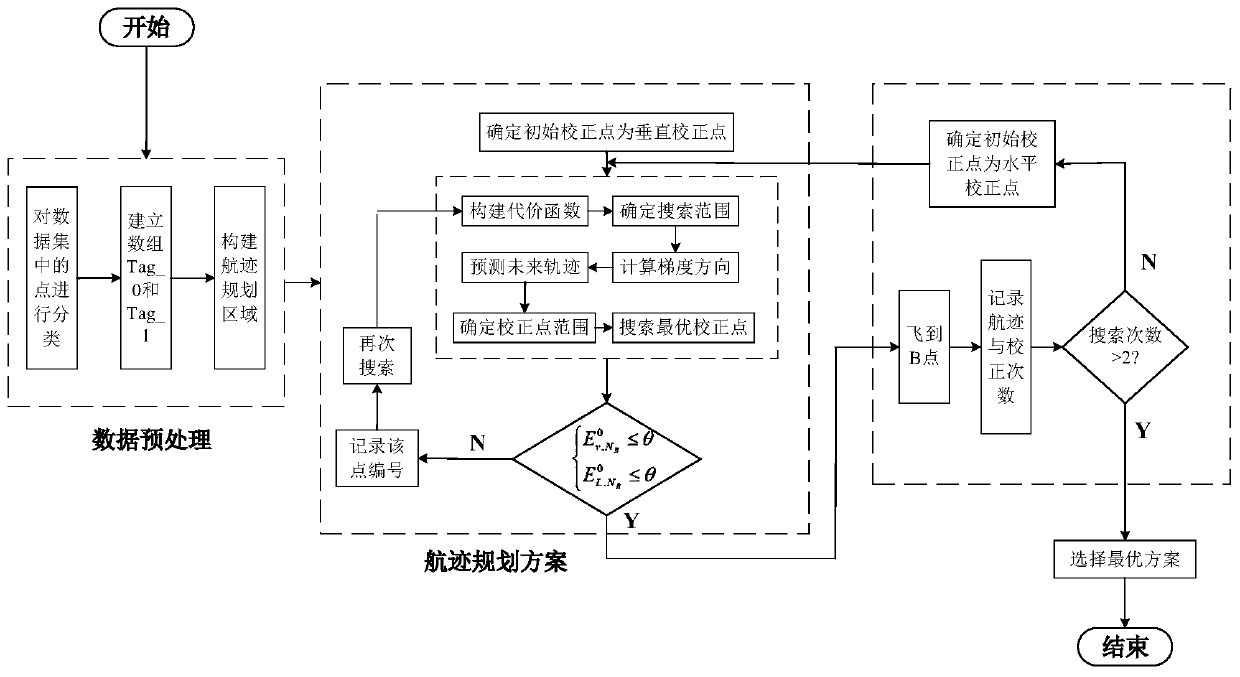

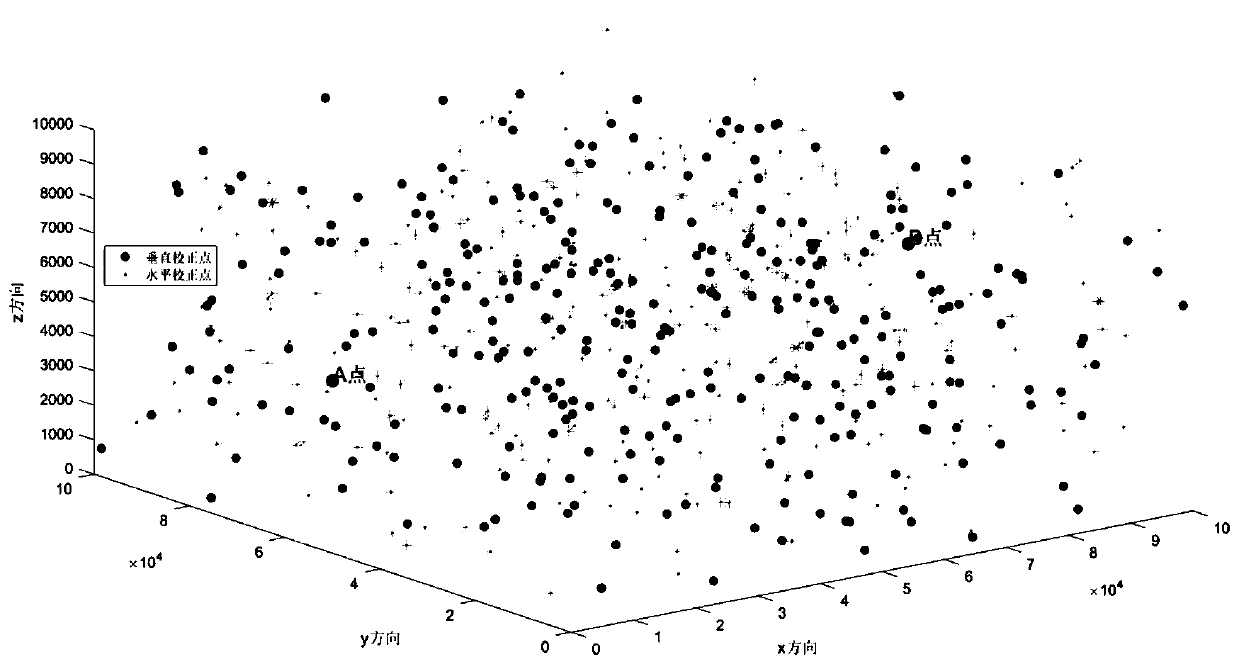

Unmanned aerial vehicle route planning method based on positioning error correction

ActiveCN111595343ATimely correctionFast track planningInternal combustion piston enginesNavigational calculation instrumentsSimulationUncrewed vehicle

The invention belongs to the technical field of unmanned aerial vehicle route planning and discloses an unmanned aerial vehicle route planning method based on positioning error correction. On the basis of a mathematical modeling thought and an optimization method theory, because of problems existing in the prior art, a route planning problem is formalized into a multi-objective optimization problem with the route length and the correction frequency as optimization objectives and a positioning error threshold value as constraint conditions. The optimization problem considers the influence of the dynamic change of the flight environment of the unmanned aerial vehicle on the route planning, and the length of the route is optimized on the premise of ensuring that the positioning error is effectively corrected. Meanwhile, an A * algorithm and a Q-learning method are adopted to solve the model and correct errors; the flight positioning precision of the unmanned aerial vehicle can be effectively ensured, the route length of the unmanned aerial vehicle is reduced; and compared with other unmanned aerial vehicle route planning methods, the method is more suitable for actual scene application, and rapid unmanned aerial vehicle route planning under multi-constraint conditions is realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

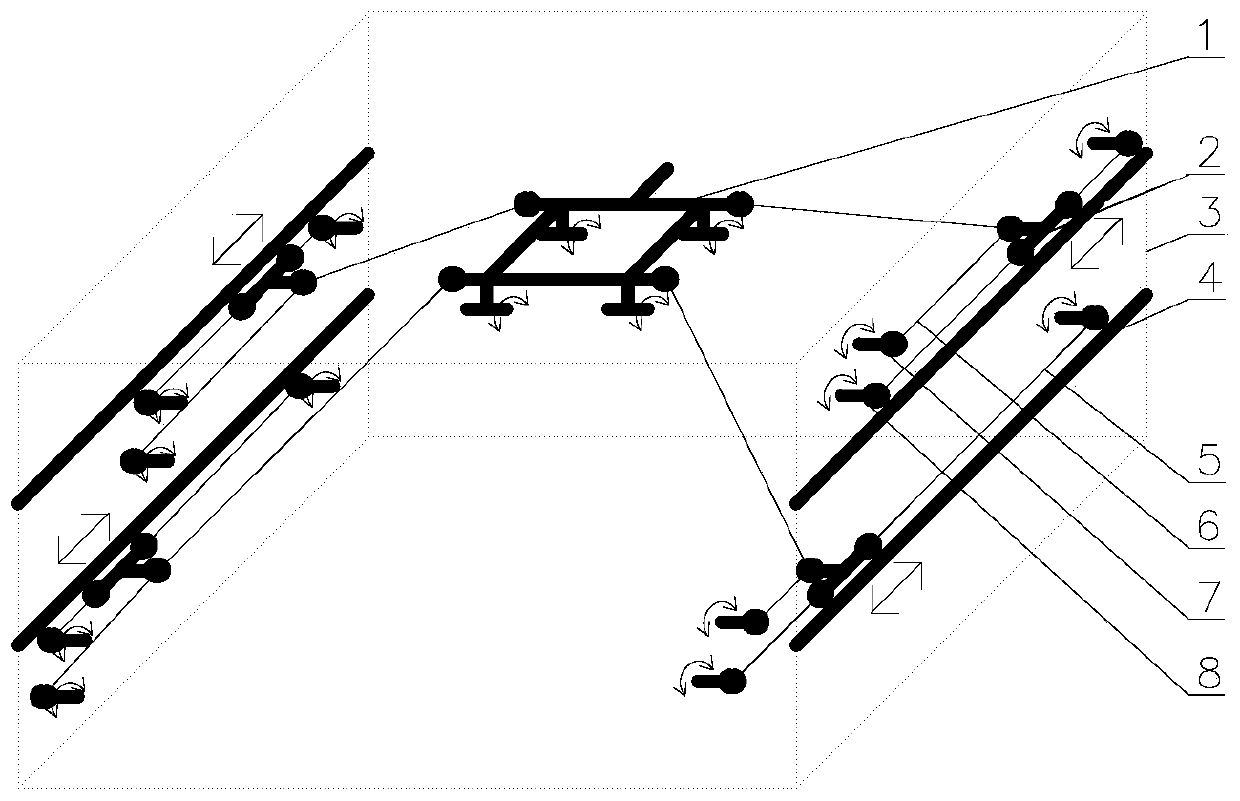

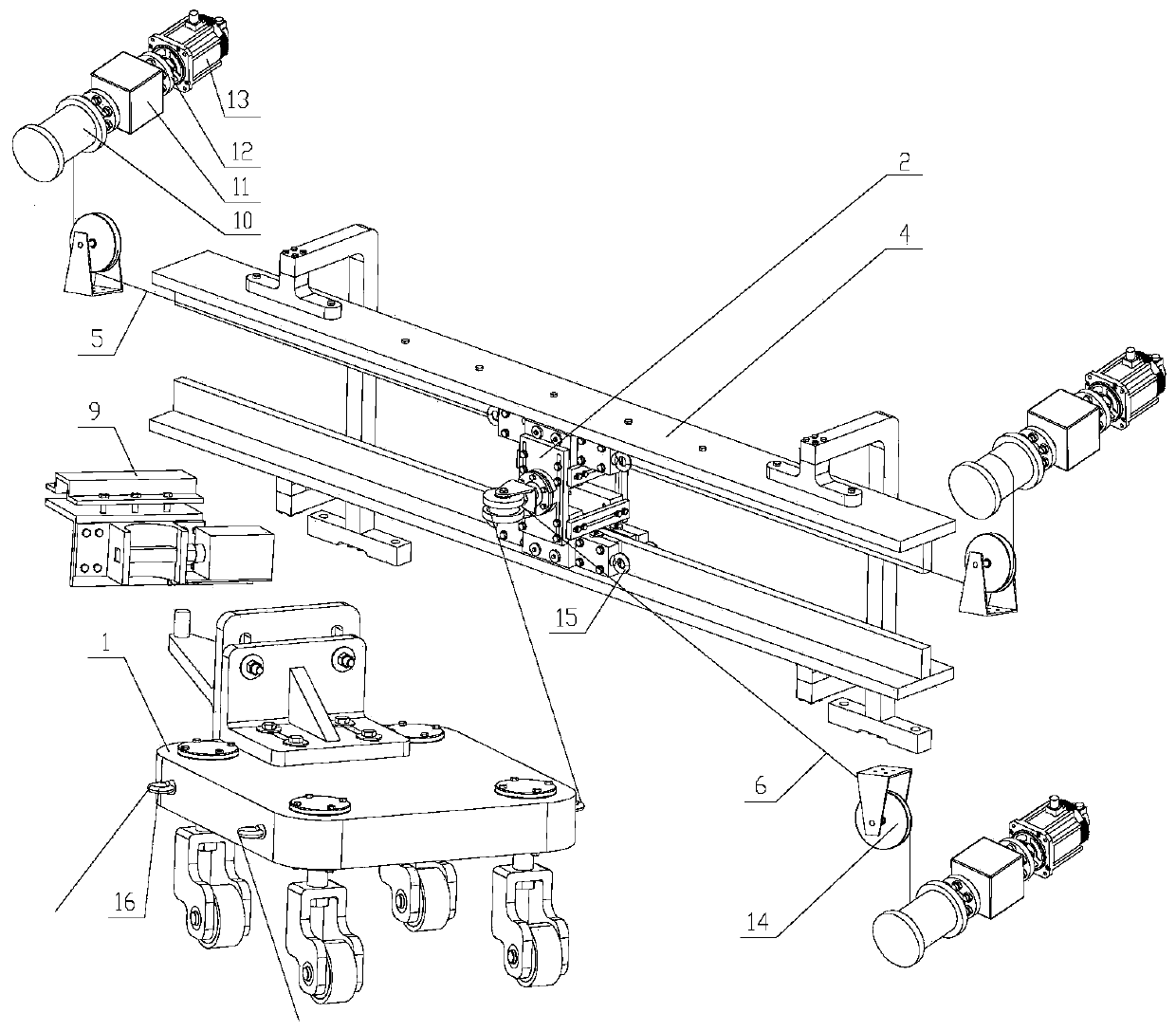

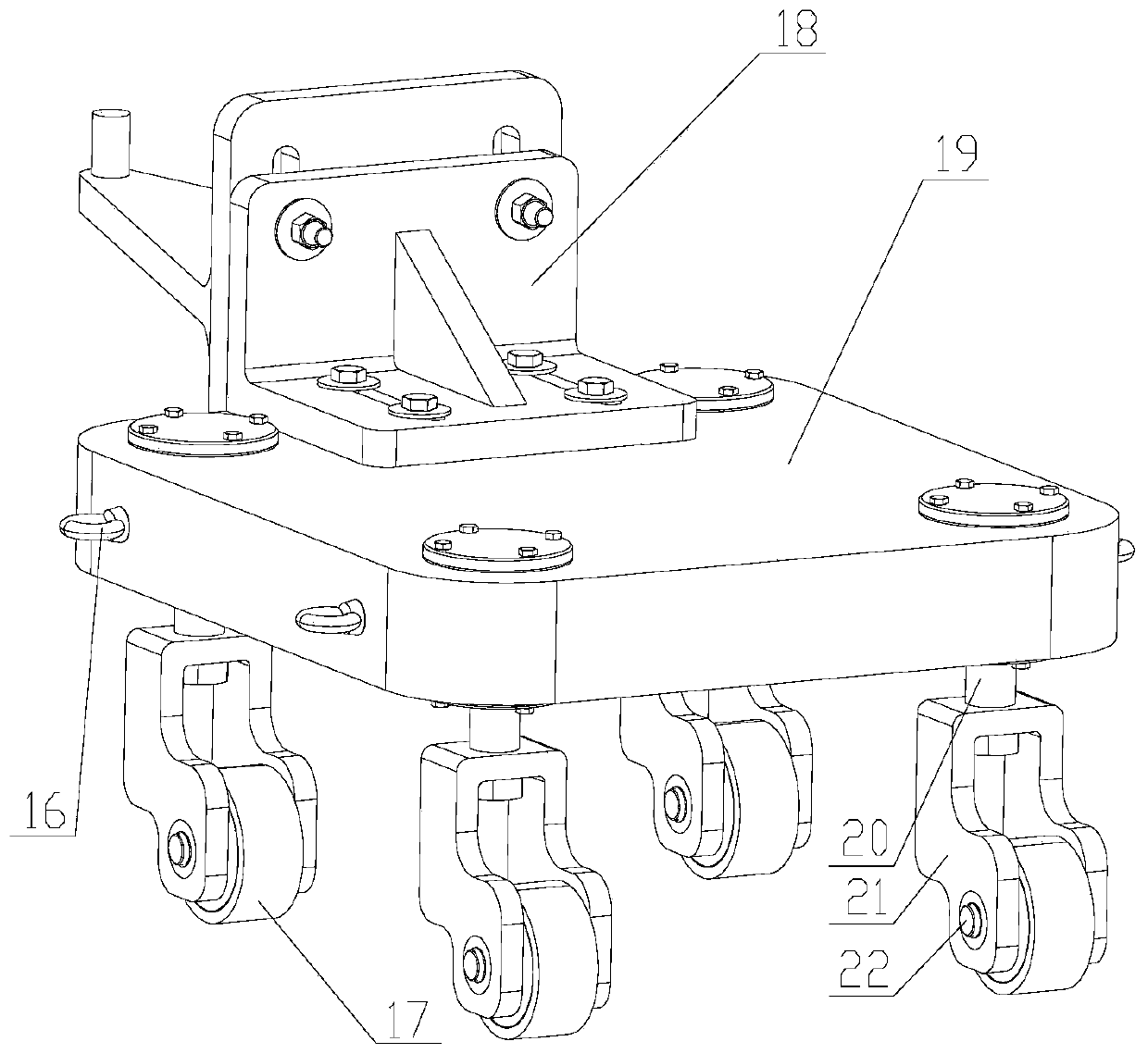

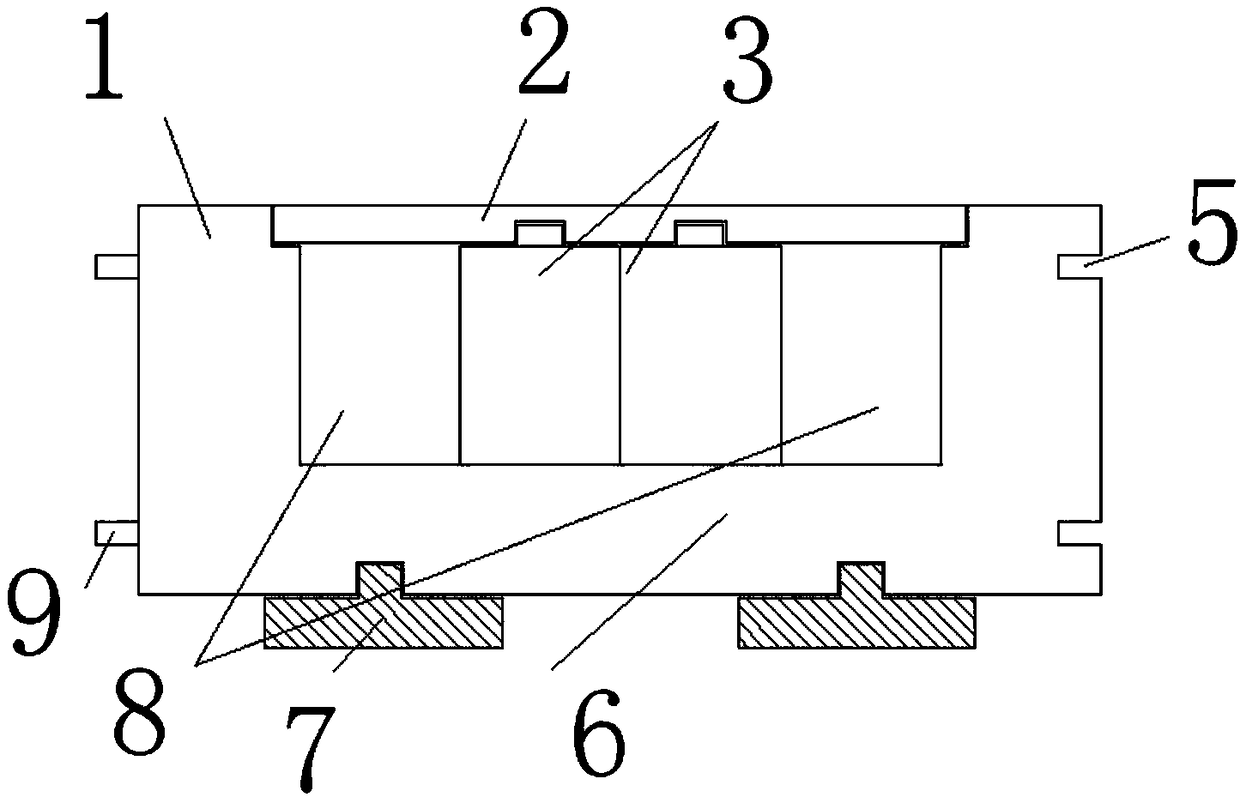

Variable-structure rope traction parallel robot for automobile collision test

PendingCN110154003AVariety of test itemsLarge working spaceProgramme-controlled manipulatorVehicle shock testingTraction systemEngineering

The invention provides a variable-structure rope traction parallel robot for an automobile collision test. The robot comprises a machine frame, a tail end actuator and two traction rope driving branches which are oppositely arranged in pair, each group of traction rope driving branches comprises a universal hinge point, a guide rail assembly, a tail end actuator driving assembly, a universal hingepoint driving assembly, a tail end actuator traction rope and universal hinge point traction ropes, the universal hinge point are arranged on the guide rail assembly in a sliding mode, the two ends of the universal hinge point are connected with the universal hinge point driving assembly through the universal hinge point traction ropes, one end of the tail end actuator traction rope is connectedwith the tail end actuator, the other end of the tail end actuator traction rope is connected with the tail end actuator driving assembly through a universal hinge point, and the tail end actuator isconnected with a test vehicle through a connecting device. The variable-structure rope traction parallel robot has the advantages of being high in response speed, diversified in test project and largein working space, and the defects that a conventional track type test traction system is single in function, small in motion space of a test object, difficult to adjust speed and slow in response speed are overcome.

Owner:LUOYANG INST OF SCI & TECH

Image capturing lens system

This invention provides an image capturing lens system comprising: a positive first lens element having a convex object-side surface; a negative second lens element having a concave object-side surface and a convex image-side surface; a third lens element with refractive power; a positive fourth lens element having a convex image-side surface, both of the object-side and image-side surfaces being aspheric; a fifth lens element with refractive power having a concave image-side surface, both of the object-side and image-side surfaces being aspheric, at least one inflection point is positioned on the image-side surface thereof. When some particular relations are satisfied, the light-focusing spots of various wavelengths can be favorably adjusted for extending the depth of field; therefore, the present image capturing lens system shall be suitable for compact electronic products with Extended Depth of Field (EDOF) function.

Owner:LARGAN PRECISION

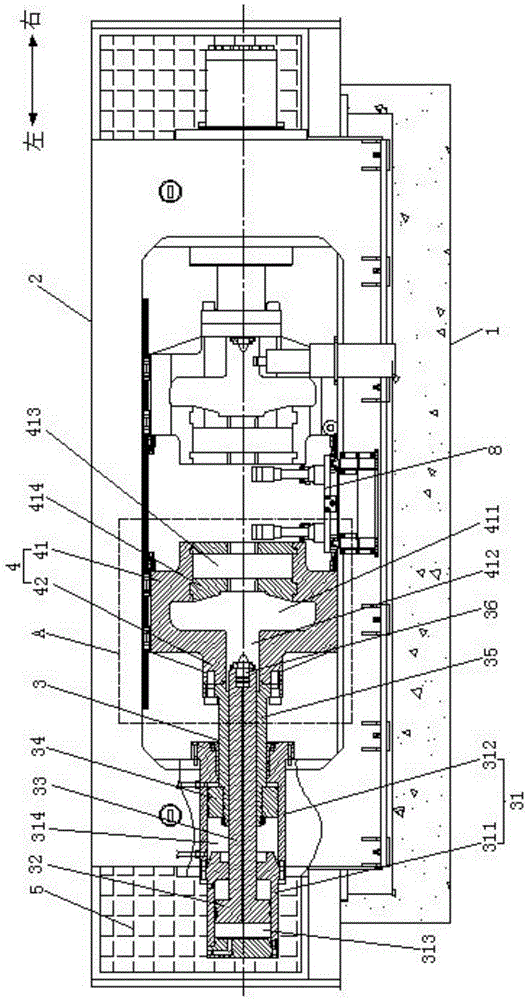

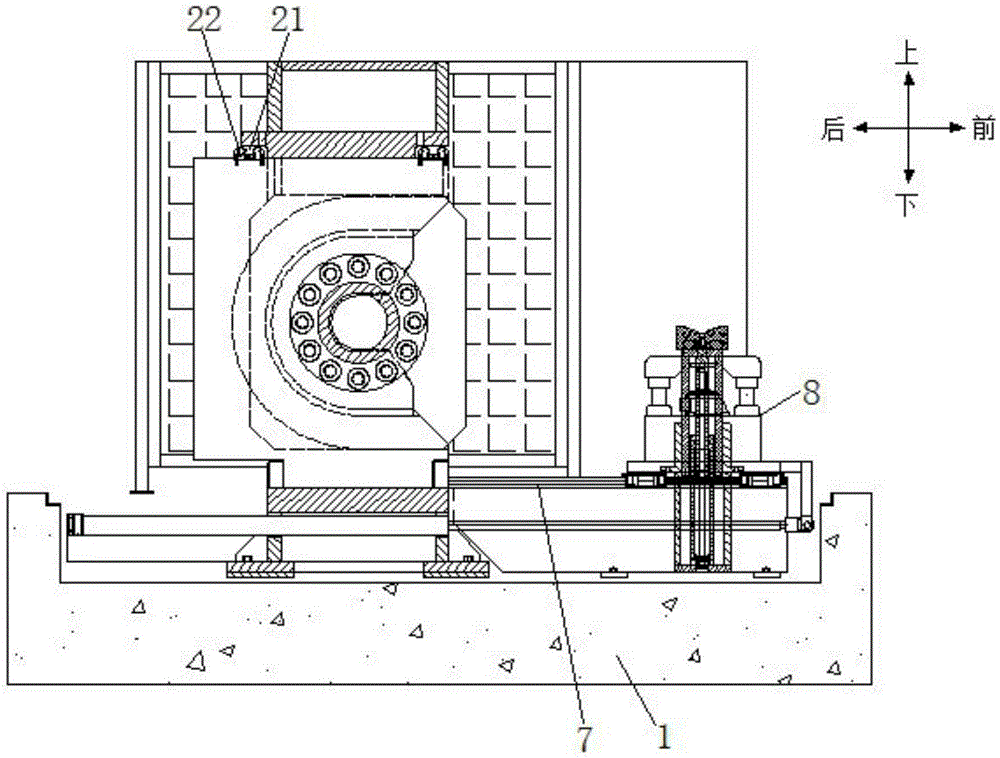

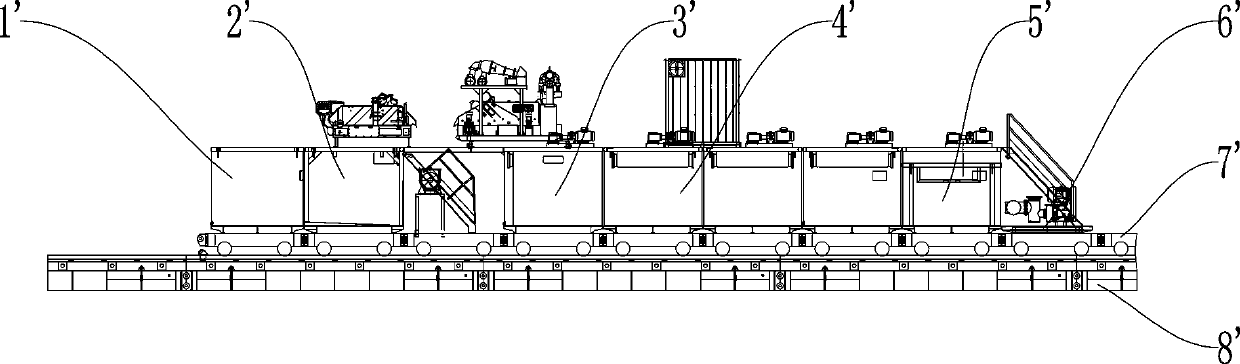

Wheel set dismantlement press-fit machine for rail transit rolling stock

ActiveCN105382520AReduce labor intensityAvoid thickeningMetal working apparatusEngineeringMechanical engineering

The invention discloses a wheel set dismantlement press-fit machine for a rail transit rolling stock. The machine comprises a machine base, a machine frame, a wheel axle positioning telescoping mechanism, a wheel clamping driving mechanism and a wheel clamping mechanism, wherein the machine frame is installed on the machine base, the wheel axle positioning telescoping mechanism is installed on the machine frame to be used for clamping and moving a wheel axle of a wheel set to be subjected to dismantlement press-fitting, the wheel clamping driving mechanism is installed on the machine frame to be used for driving the wheel clamping mechanism to move in the axial direction, and the wheel clamping mechanism is connected with the wheel clamping driving mechanism to be used for clamping wheels of the wheel set to be subjected to dismantlement press-fitting. The machine has the advantages that the structure is simple, operation and use are convenient, dismantlement press-fitting of two wheel sets can be conducted independently or simultaneously, automatic feeding and discharging of wheel sets can be achieved, the labor intensity of workers can be relieved, and wheel set dismantlement time can be shortened; besides, force is applied to a shaft body rather than a shaft end during dismantlement, so that heading and damaging of the shaft end is effectively avoided during dismantlement.

Owner:BEIJING SHEENLINE GRP CO LTD

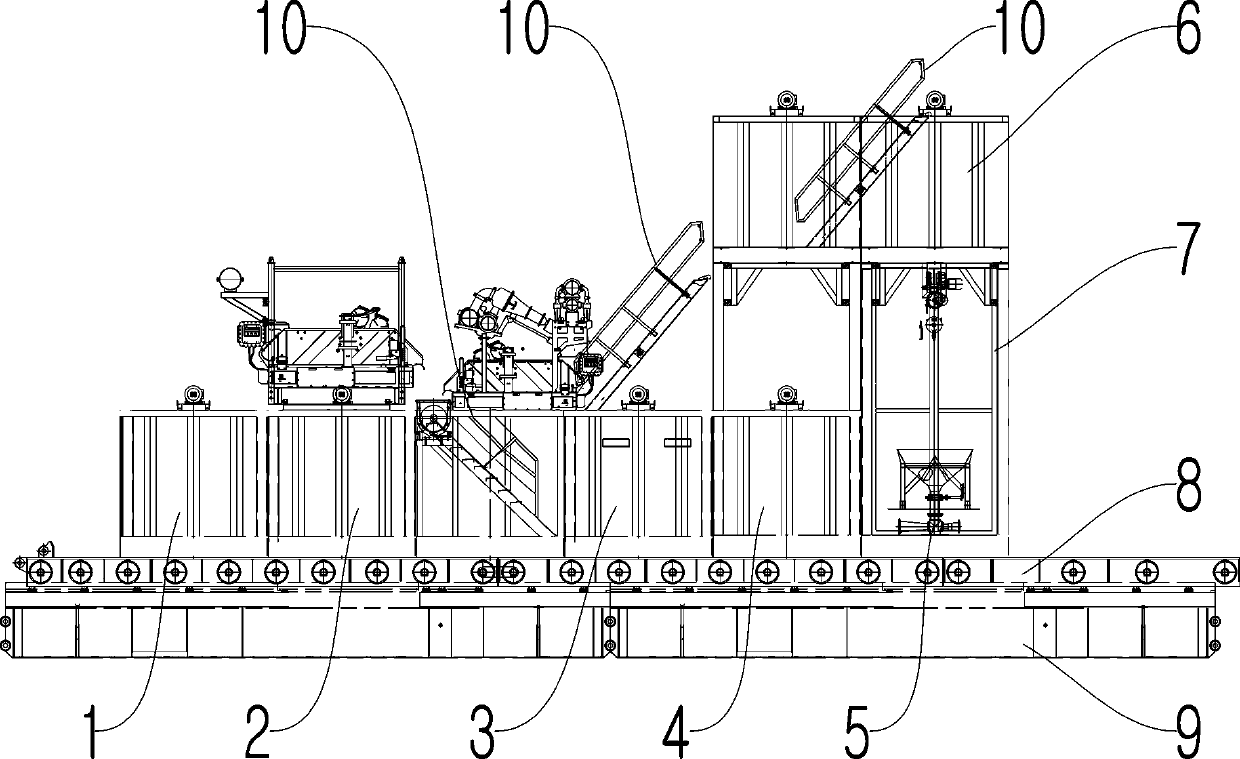

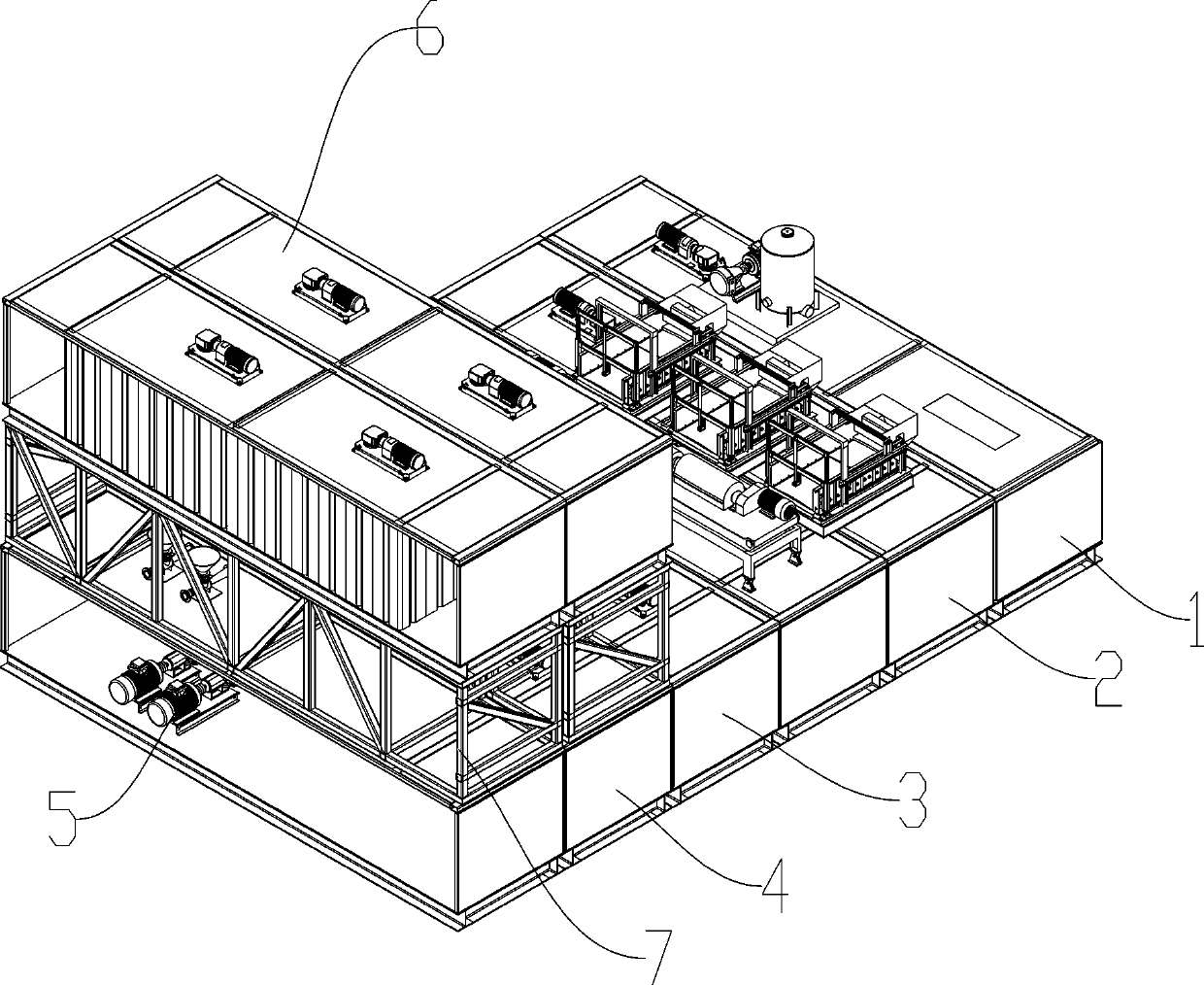

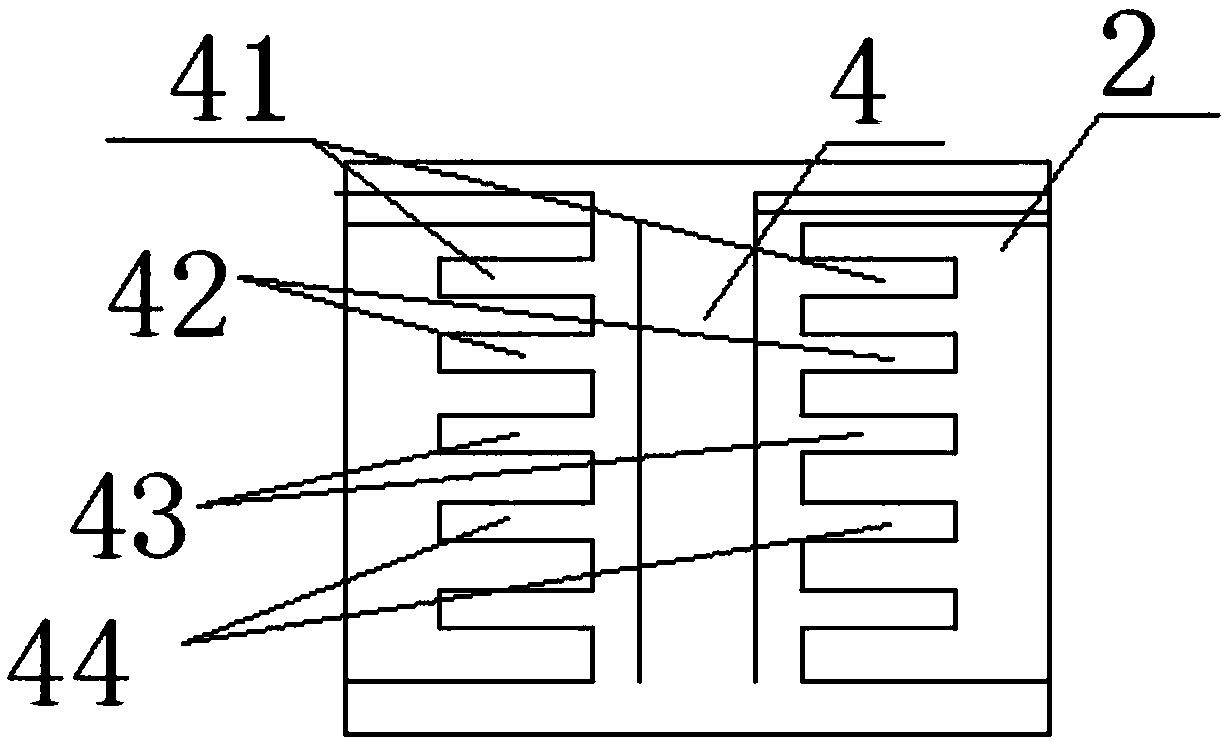

Double-layer solid control system

The invention relates to the technical field of oil and natural gas drilling equipment, in particular to a double-layer solid control system with a small covering area. The double-layer solid controlsystem comprises a track fixedly connected to a foundation, a pry movably connected to the track, a supply tank, a vibrating screen tank, a centrifuge tank, a suction tank, a cast-in-place pry, an intermediate support and a reserve tank, wherein the supply tank, the vibrating screen tank, the centrifuge tank, the suction tank and the cast-in-place pry are fixedly connected with the pry correspondingly, the bottom of the intermediate support is fixedly connected with the tops of the suction tank and the cast-in-place pry, and the reserve tank is fixed to the top of the intermediate support. According to the double-layer solid control system with the small covering area, the structure is simple, the track length covered by the whole solid control system is shortened by about 7 meters, and the covering area is reduced.

Owner:SICHUAN HONGHUA PETROLEUM EQUIP

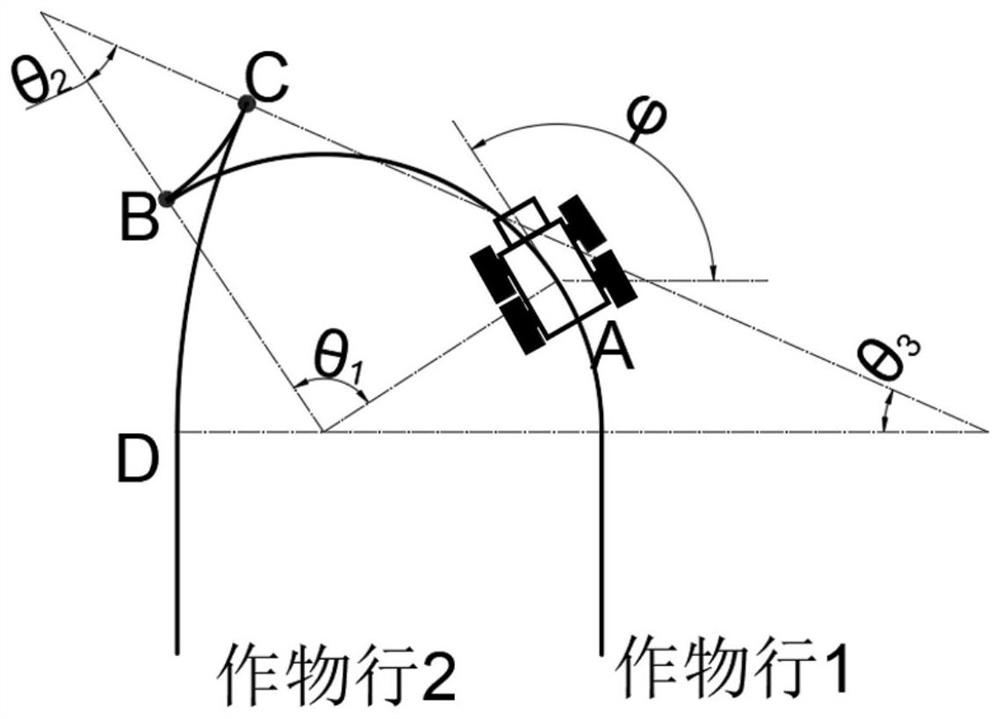

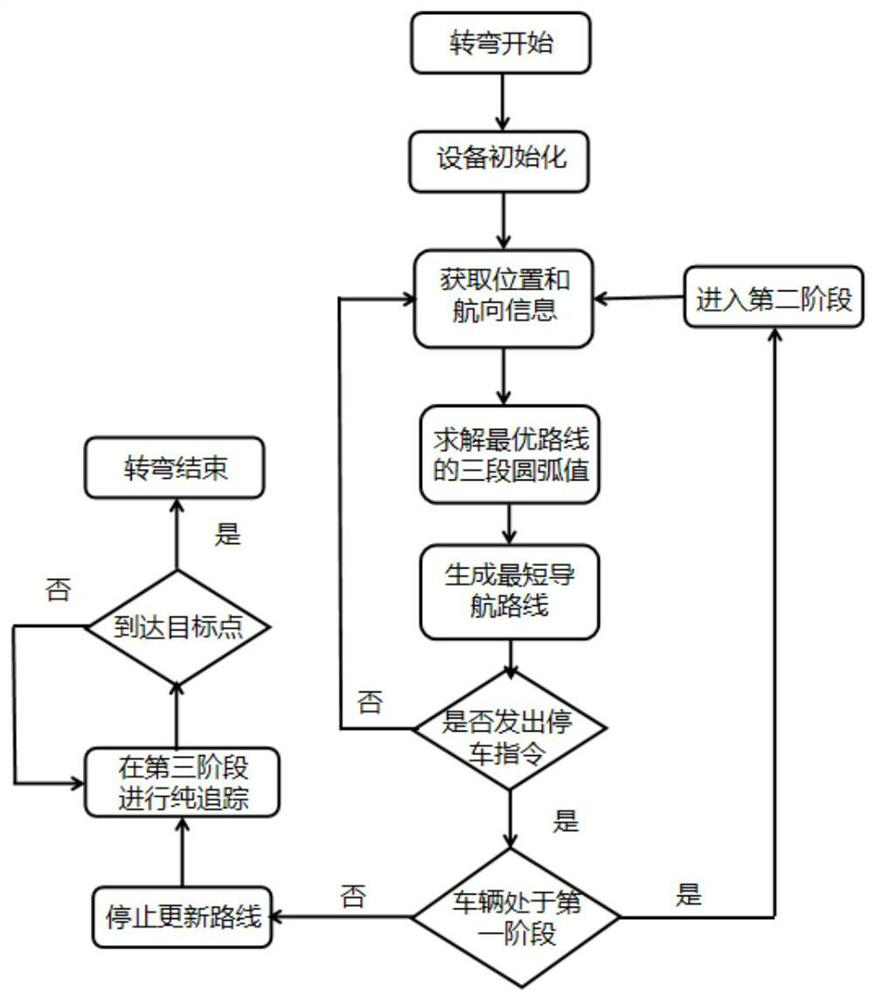

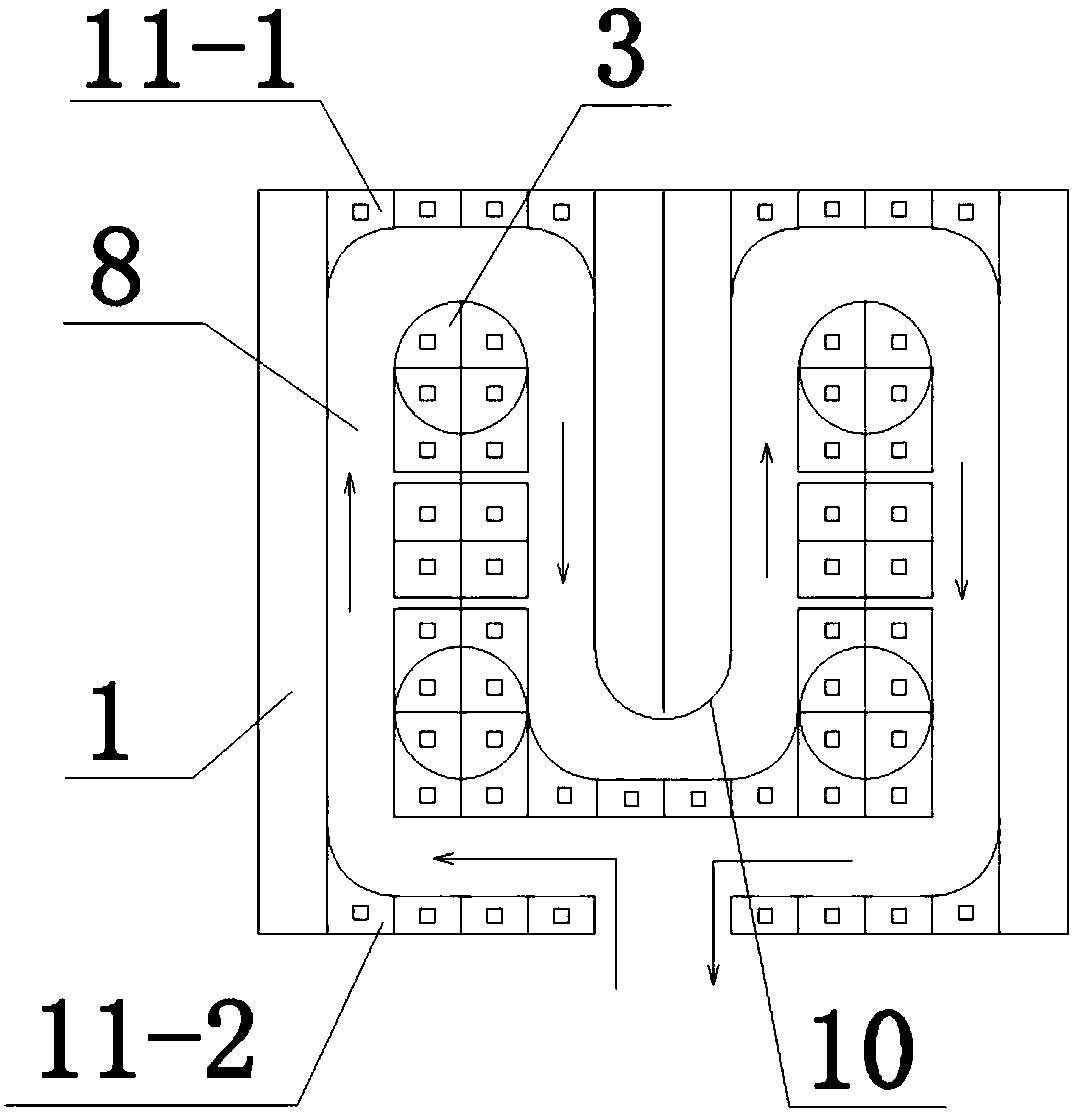

A real-time path planning and control method for headland steering of agricultural unmanned vehicles

ActiveCN113406960BReduce track lengthImprove accuracyPosition/course control in two dimensionsVehiclesControl engineeringSteering control

The invention discloses a real-time path planning and control method for agricultural unmanned vehicles turning to the ground, which comprises the following steps: (1) the vehicle starts to turn and initializes equipment; Input information; (3) generate the shortest planned route with the current position as the starting point by inputting information; (4) judge whether to issue a parking instruction according to the distance between the position of the current stage of the vehicle and the end point of the real-time update of this stage; (5) If a parking command is issued, enter the next stage; if a reverse command is not issued, then return to step (2) to continue updating the route. The invention can effectively solve the problems of track length increase, accuracy reduction and energy consumption increase after yaw in the existing turning route planning and control, and simultaneously solve the problems of frequent steering control and acceleration and deceleration control.

Owner:ZHEJIANG UNIV

Intelligent capsule type floor heating system

InactiveCN108151124AReduce track lengthSave thermal resourcesLighting and heating apparatusSpace heating and ventilation detailsHeating systemEngineering

The invention provides an intelligent capsule type floor heating system. The intelligent capsule type floor heating system comprises a combined type floor heating track, a capsule type intelligent floor heating heater, a ground control commanding device and a ground heating pile, wherein a plurality of track modules are combined and installed to form the combined type floor heating track; the capsule type floor heating heater moves to heat the indoor space; advancing and movement of the capsule type floor heating heater are achieved through the ground control commanding device; and heating units are heated through the ground heating pile. The intelligent capsule type floor heating system is easy and convenient to install, and the modularized capsule type floor heating system is invented innovatively.

Owner:重庆中贝仪胜科技有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com