Single-mandril spoke type superconduction accelerating cavity and manufacture method thereof

A technology of superconducting accelerating cavity and manufacturing method, which is applied in the direction of manufacturing tools, linear accelerators, metal processing equipment, etc., and can solve the problems of limiting the application prospect of single core rod and spoke type superconducting cavity, unstable operation of accelerator, strong X-ray radiation, etc. problem, to achieve the effect of simplifying the number of electron beam welding, reducing the strength and reducing the difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

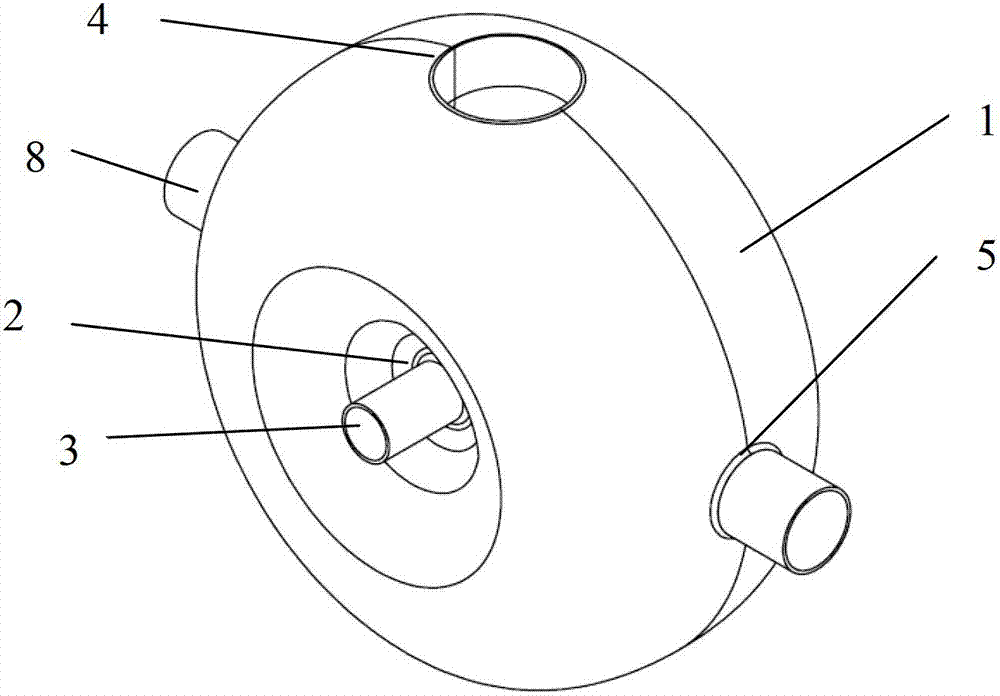

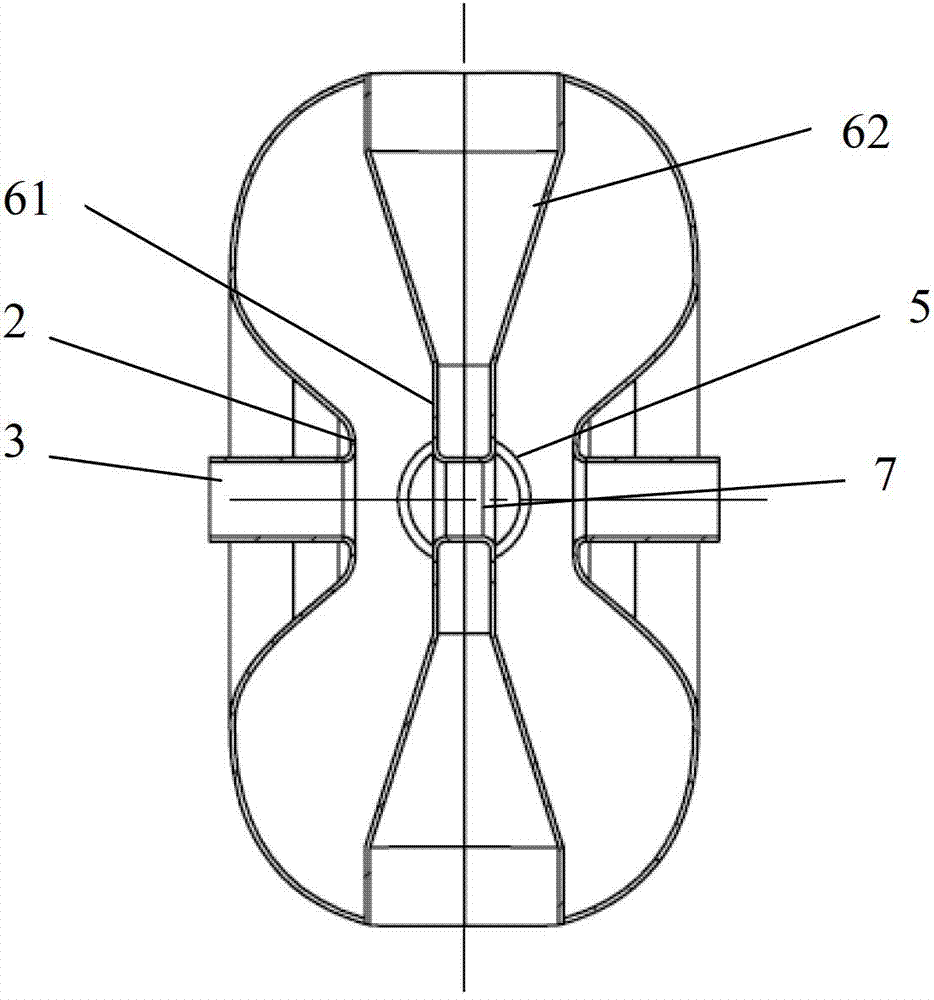

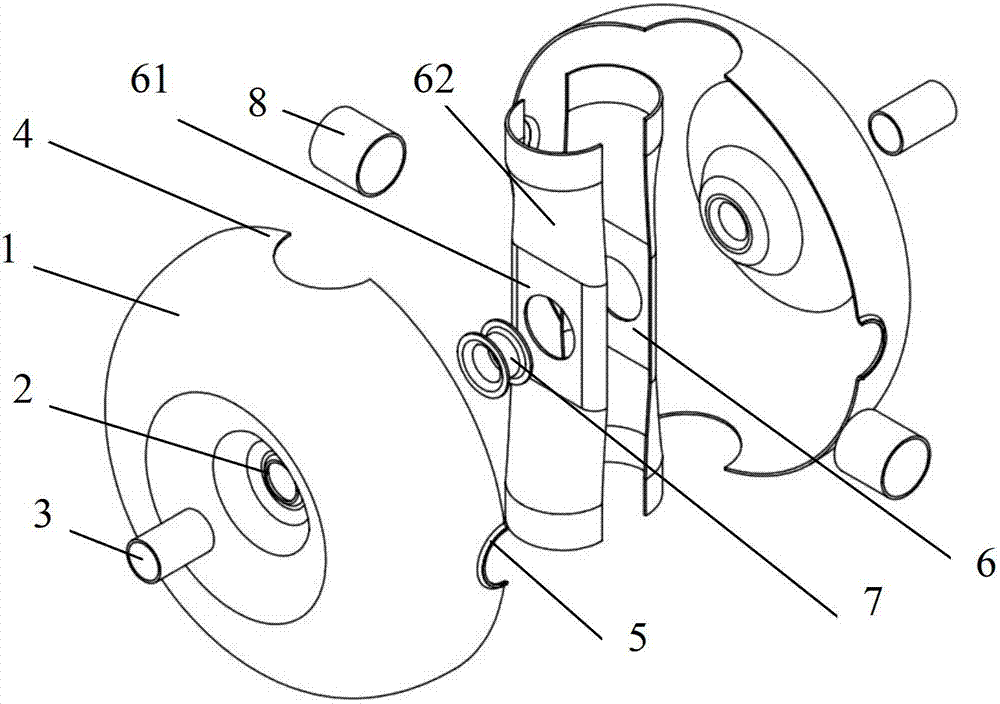

[0020] like Figure 1 ~ Figure 3 As shown, the device of the present invention includes a cavity 1, which is welded by two half-cavities 1 with exactly the same shape. A pair of bundle tube holes 2 are arranged symmetrically in the central recess of the cavity 1, a bundle of tubes 3 are respectively welded in the two bundles of tube holes 2, and a flange (not shown in the figure) is welded on the outside of the two bundles of tubes 3 respectively. The flange can be connected with external devices. A pair of mandrel holes 4 are symmetrically arranged on the cavity perpendicular to the connecting direction of the two bundles of tubes 3 , and a pair of cleaning holes 5 are symmetrically arranged on the cavity 1 separated from the two mandrel holes 4 by 90°. In the two mandrel holes 4, there is a mandrel 6 welded by two halves of the thin-walled cavity....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com