Intelligent capsule type floor heating system

A capsule and floor heating technology, applied in the field of intelligent capsule floor heating system, can solve the problems of consumption of heat resources, inability to maintain, and high operating costs, and achieve the effects of reducing operating costs, reducing track length, and saving thermal resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the embodiments of the present invention will be described clearly and in detail below with reference to the drawings in the embodiments of the present invention. The described embodiments are only some of the embodiments of the invention.

[0031] The technical scheme that the present invention solves the problems of the technologies described above is:

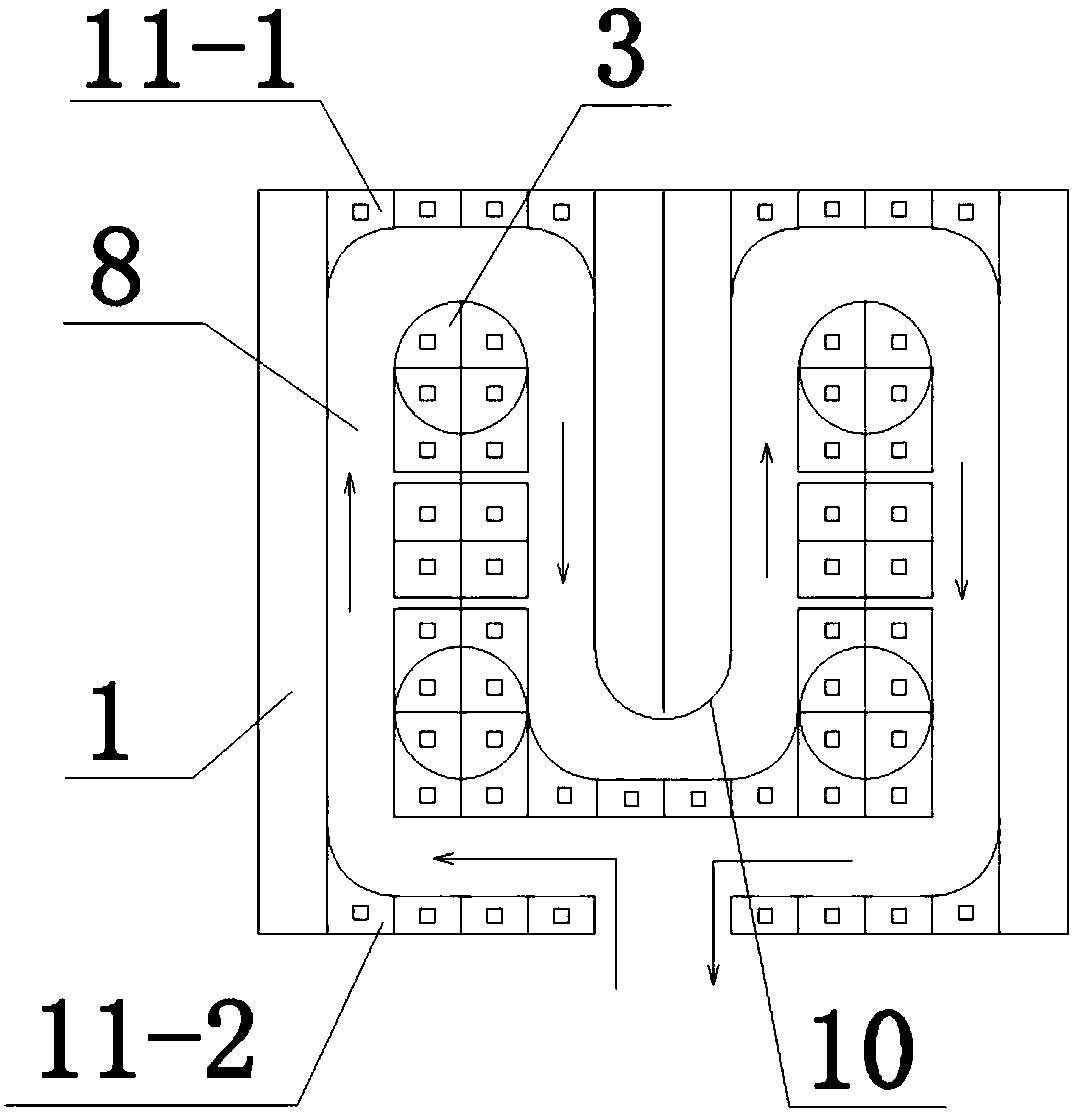

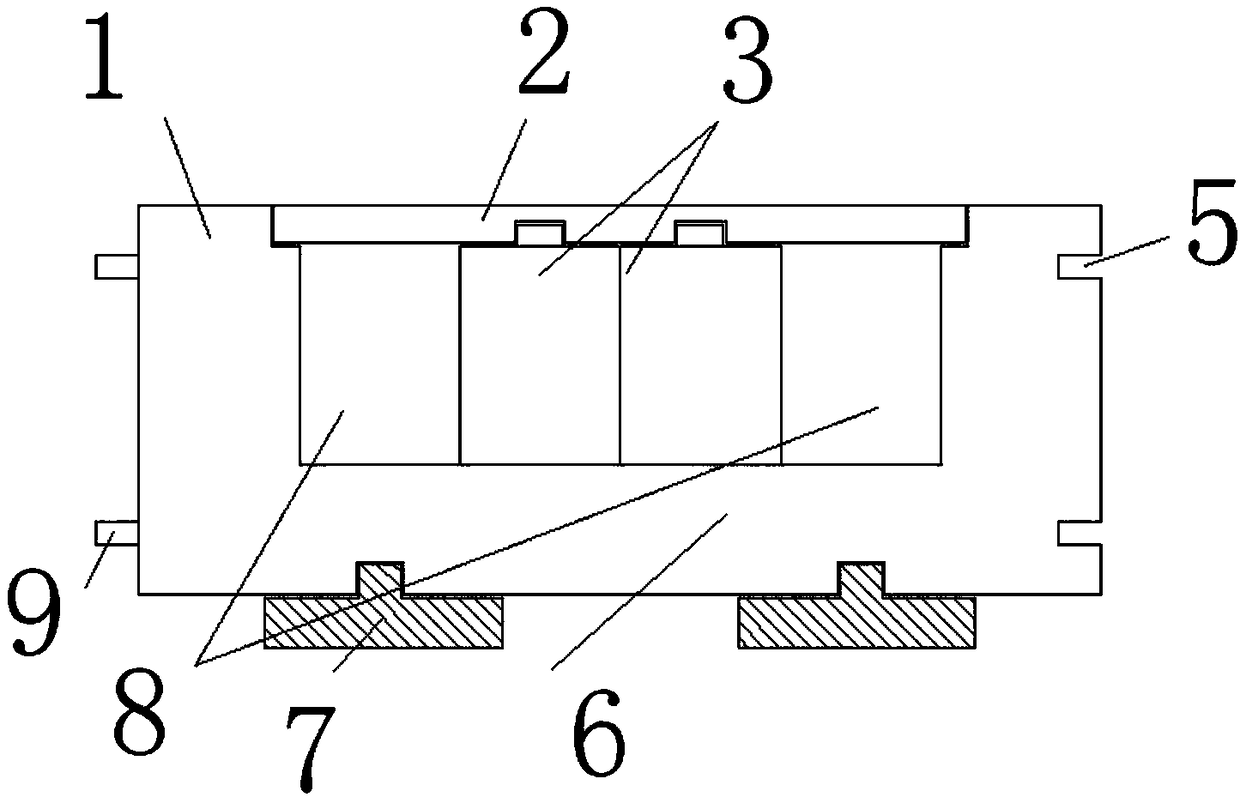

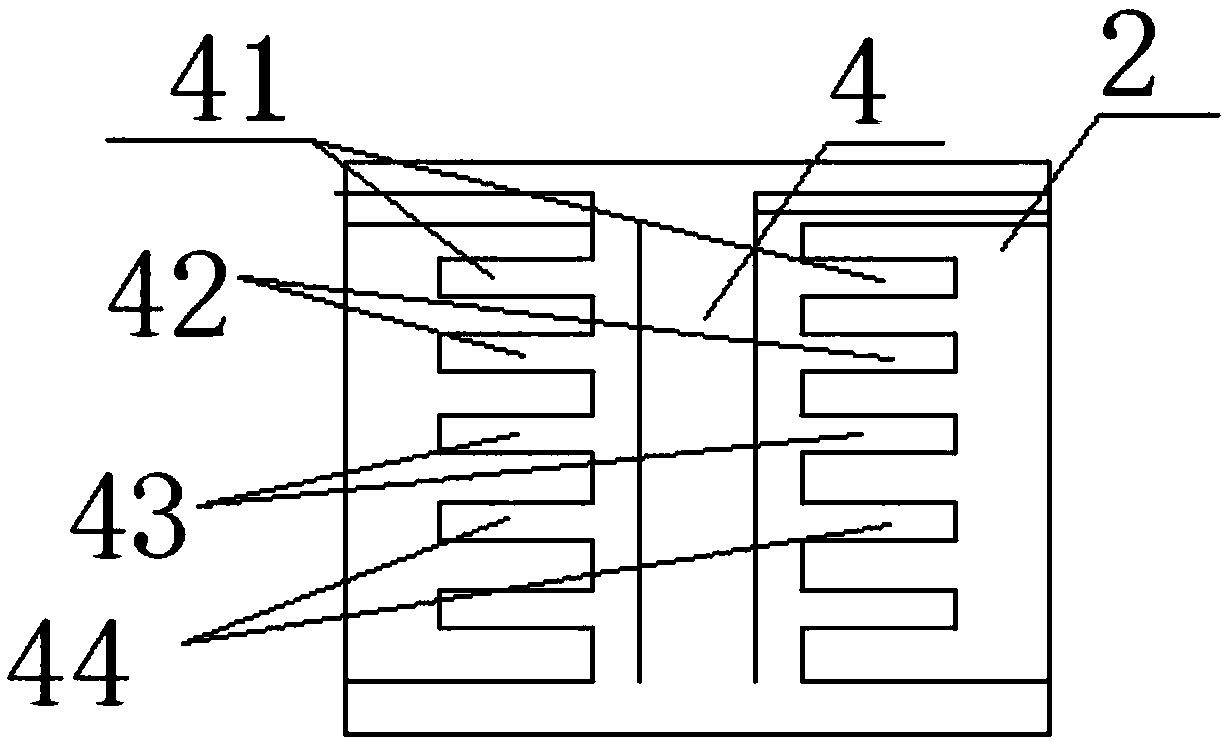

[0032] Such as Figure 10 Shown is a capsule floor heating system, which includes a combined floor heating track, a capsule floor heating intelligent heating device, a ground control command device, and a ground heating pile. The combined floor heating track is assembled and installed by several track modules to form a floor heating track. The indoor space is heated through the movement of the capsule floor heating intelligent heating device, the ground control command device realizes the advancement and movement of the capsule floor heating device, and the heating unit is heated through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com