Patents

Literature

109results about How to "Reduce photosensitivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

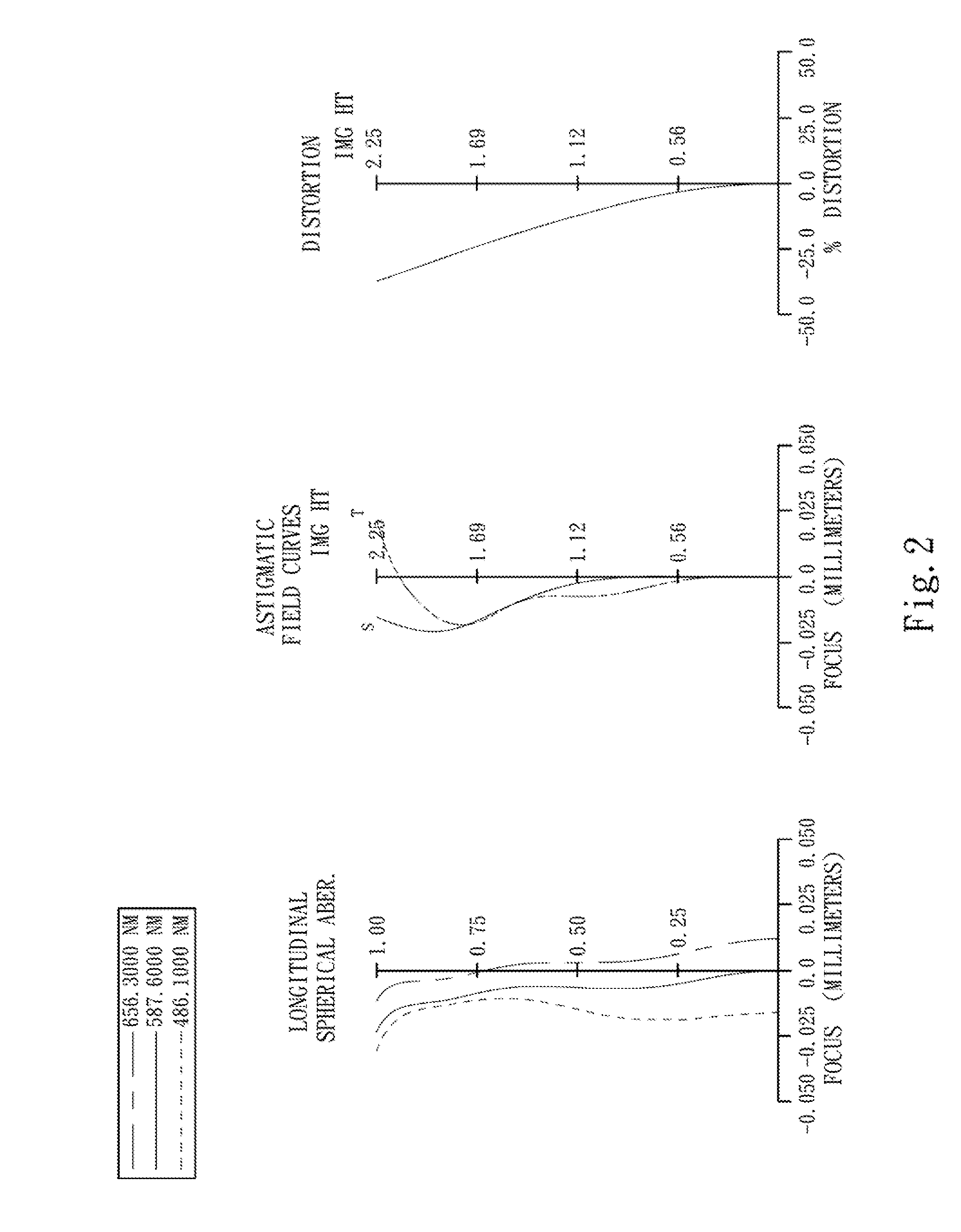

Image lens assembly and image capturing device

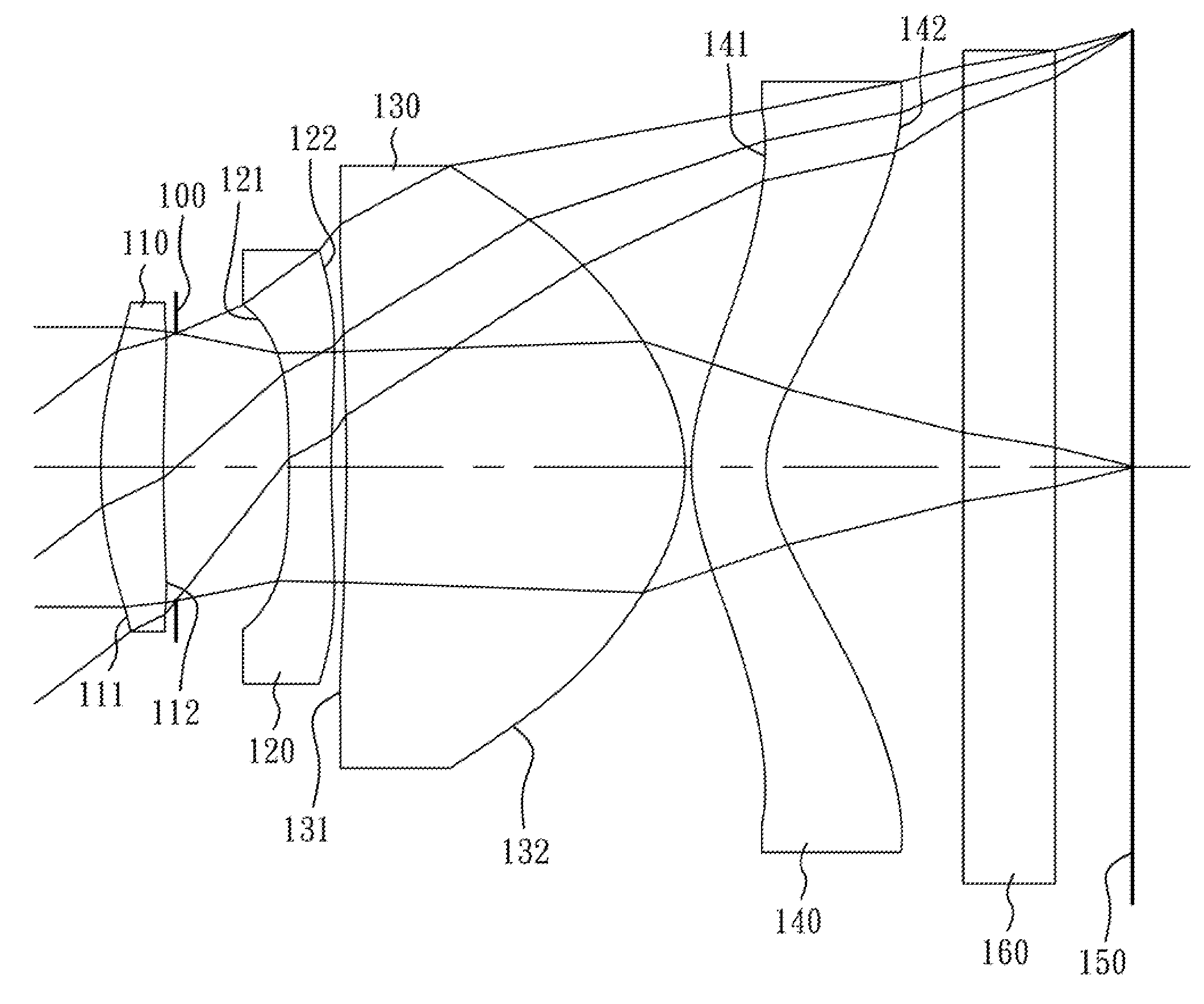

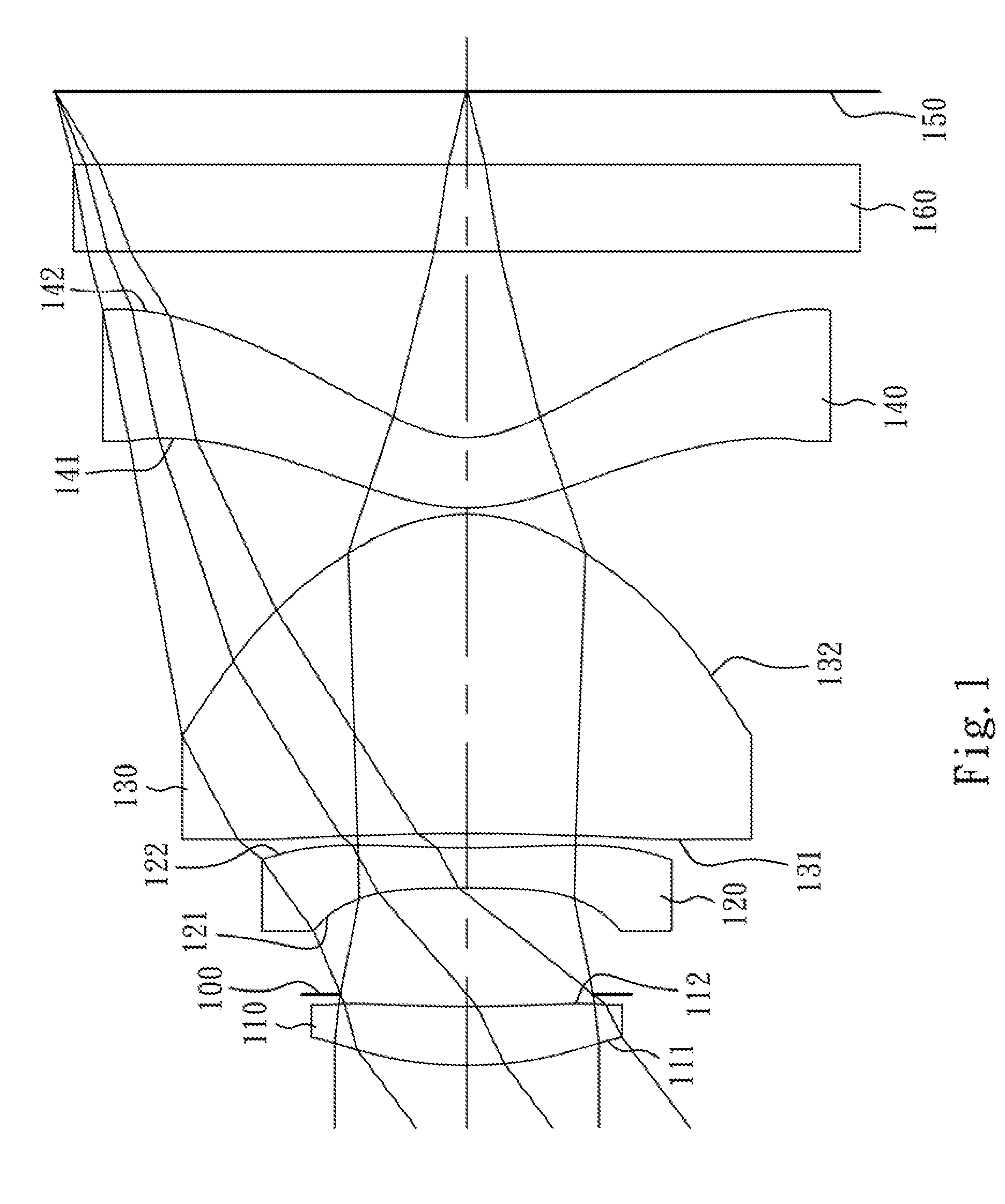

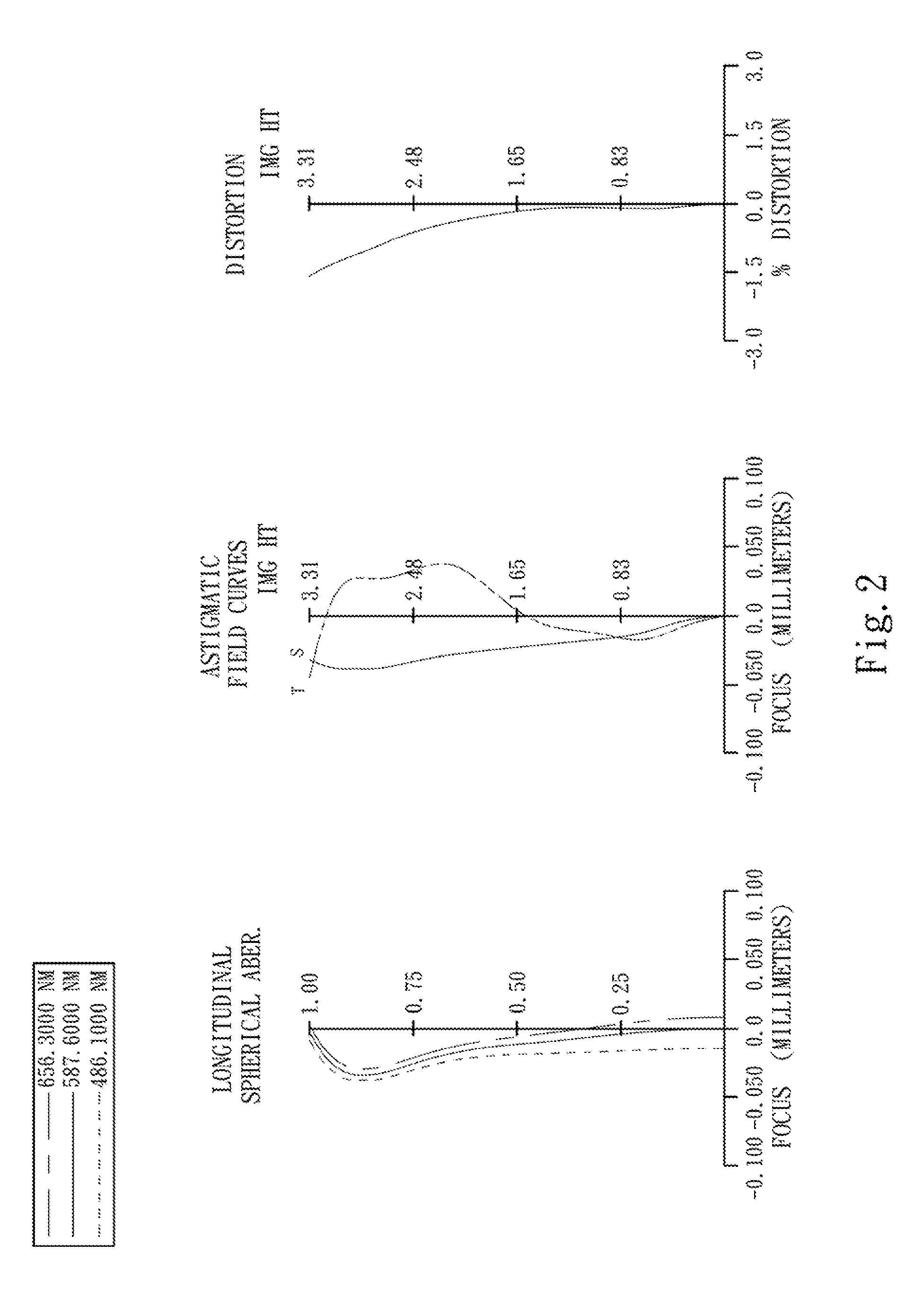

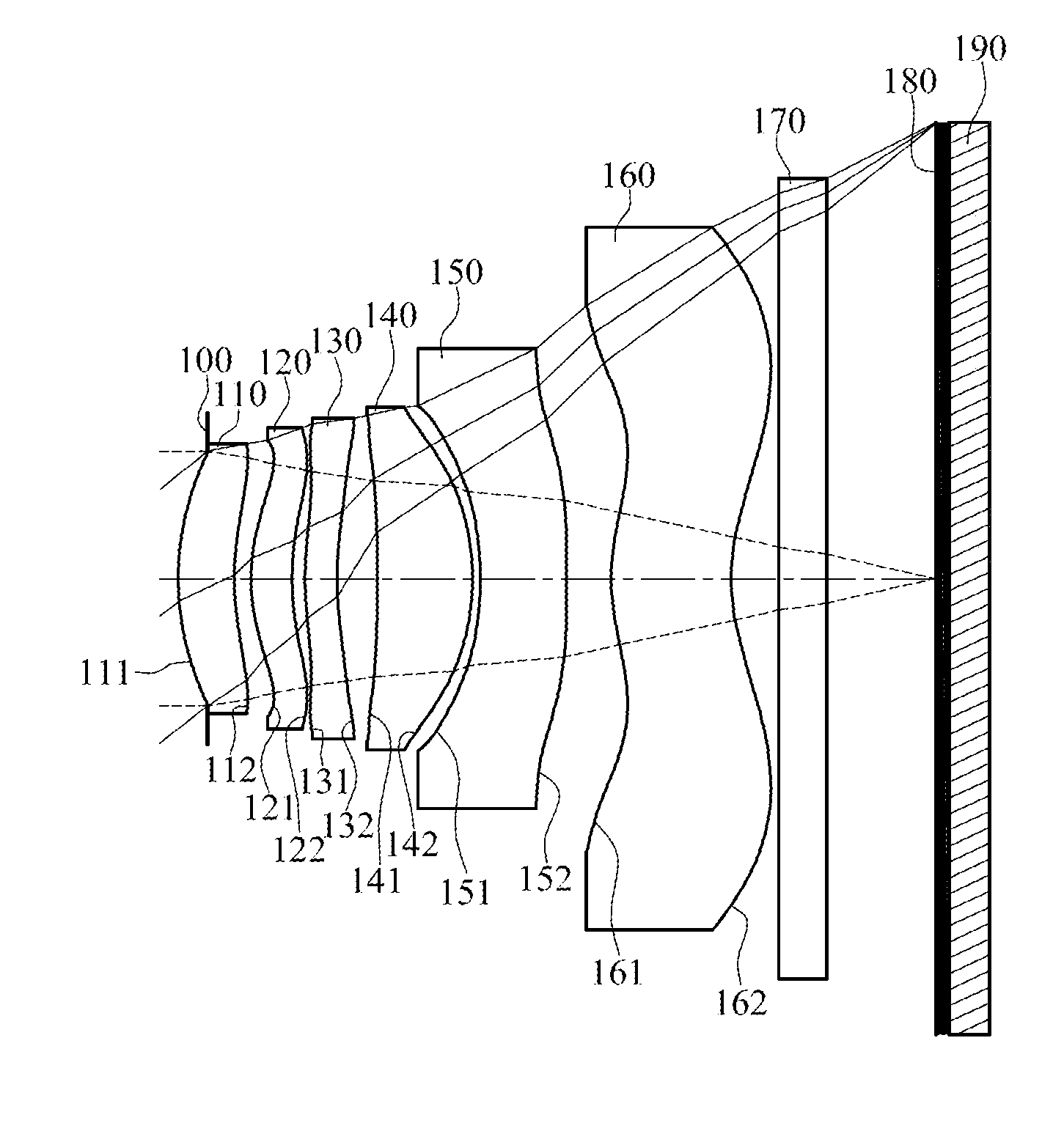

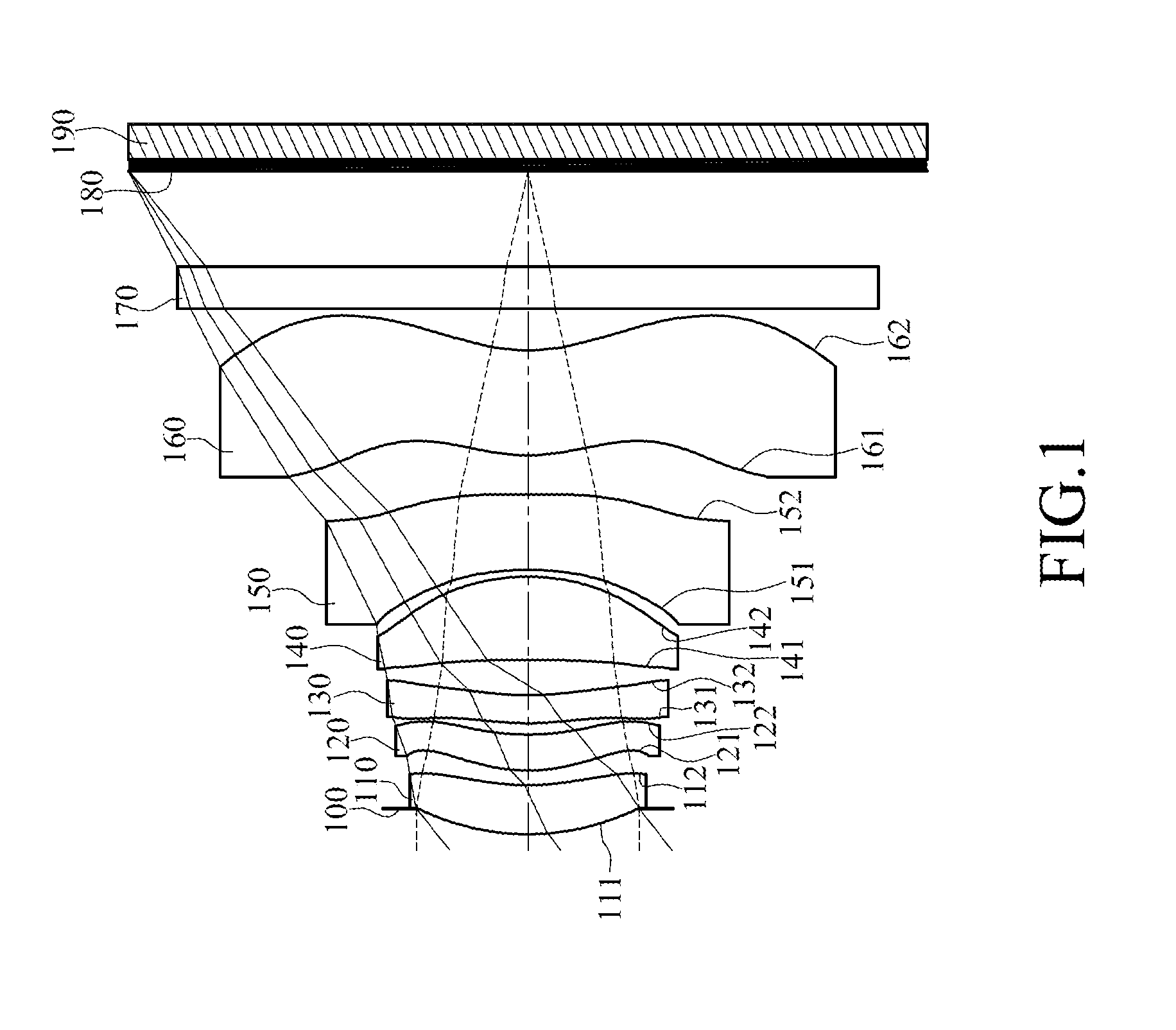

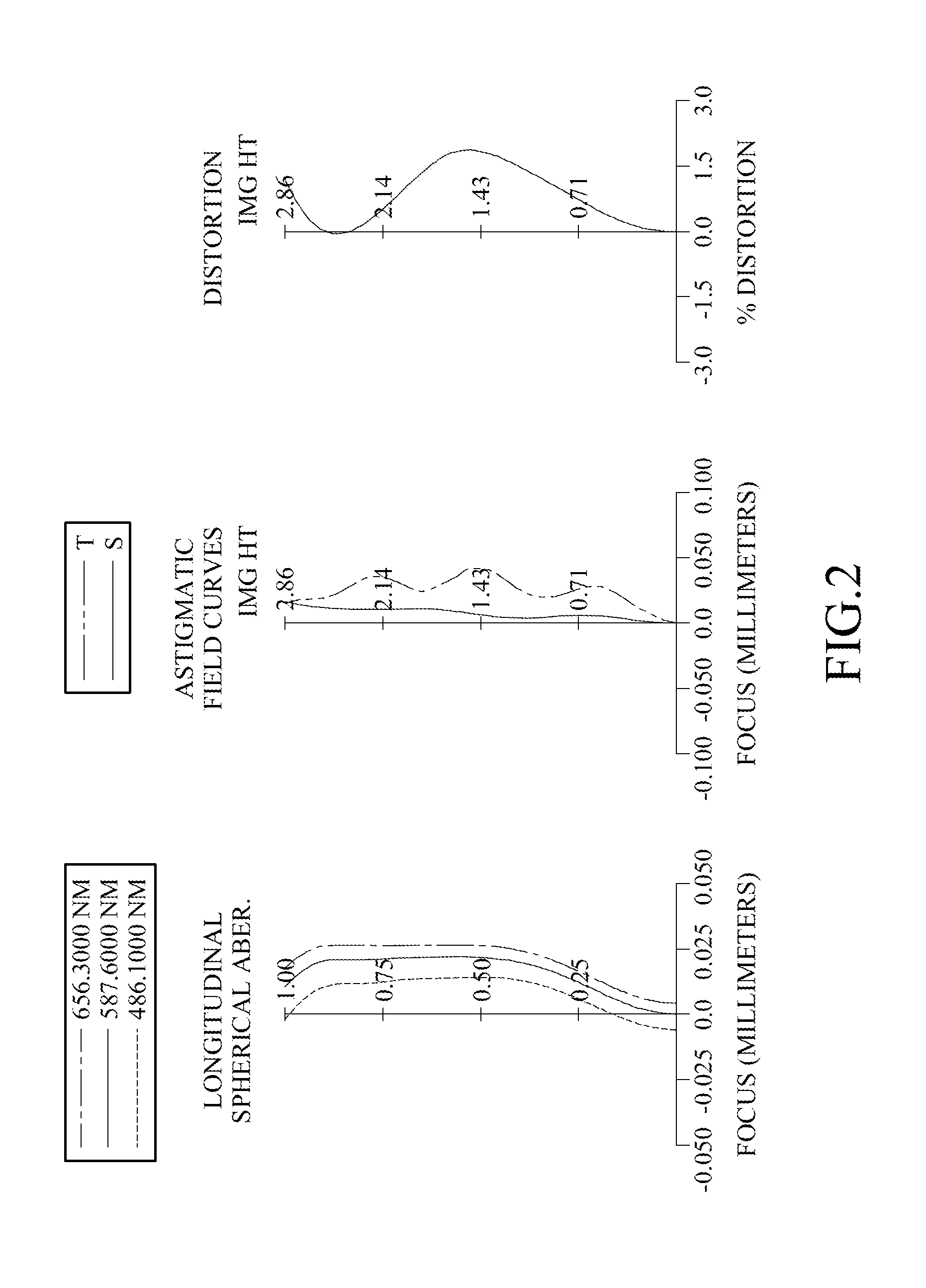

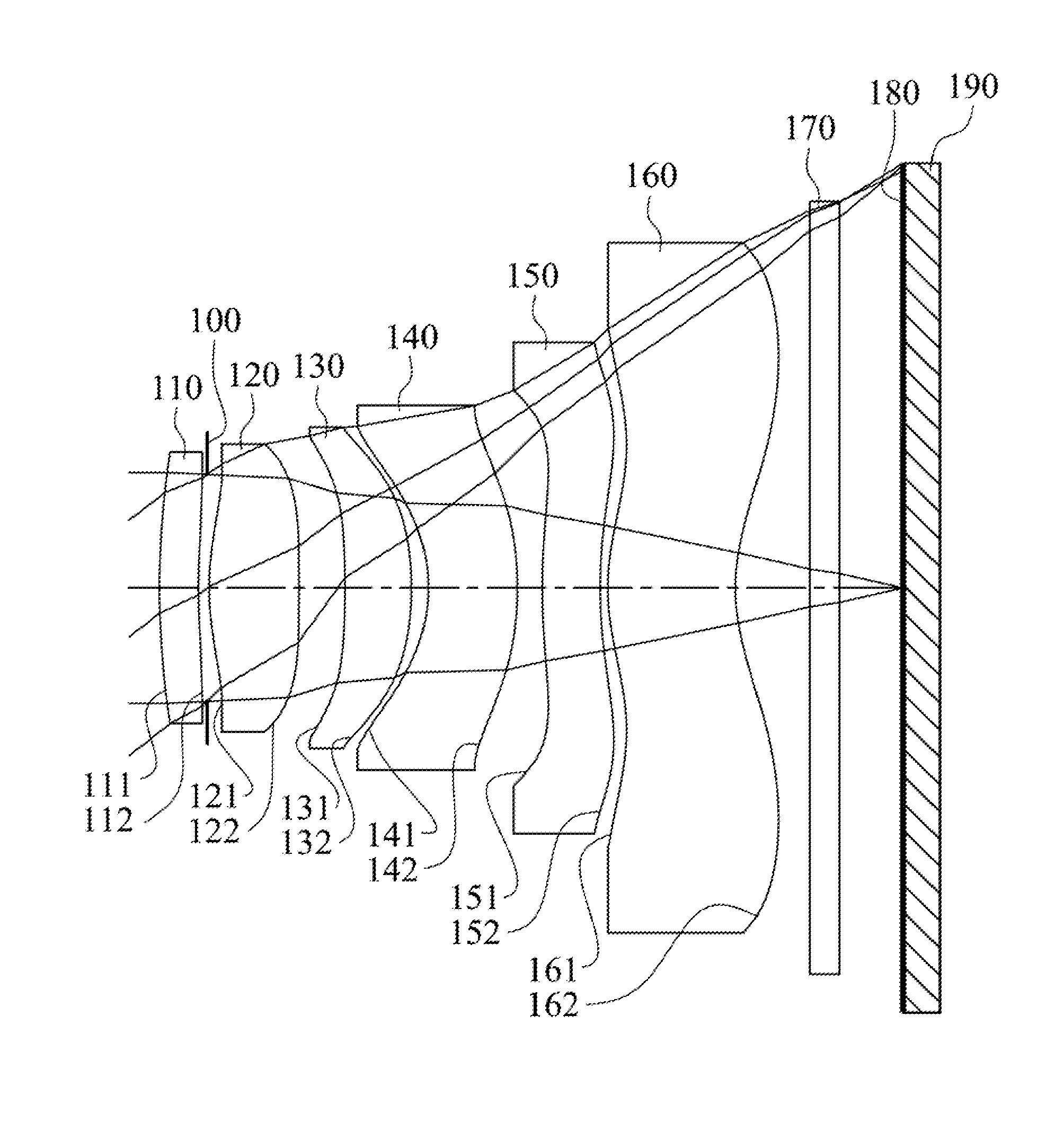

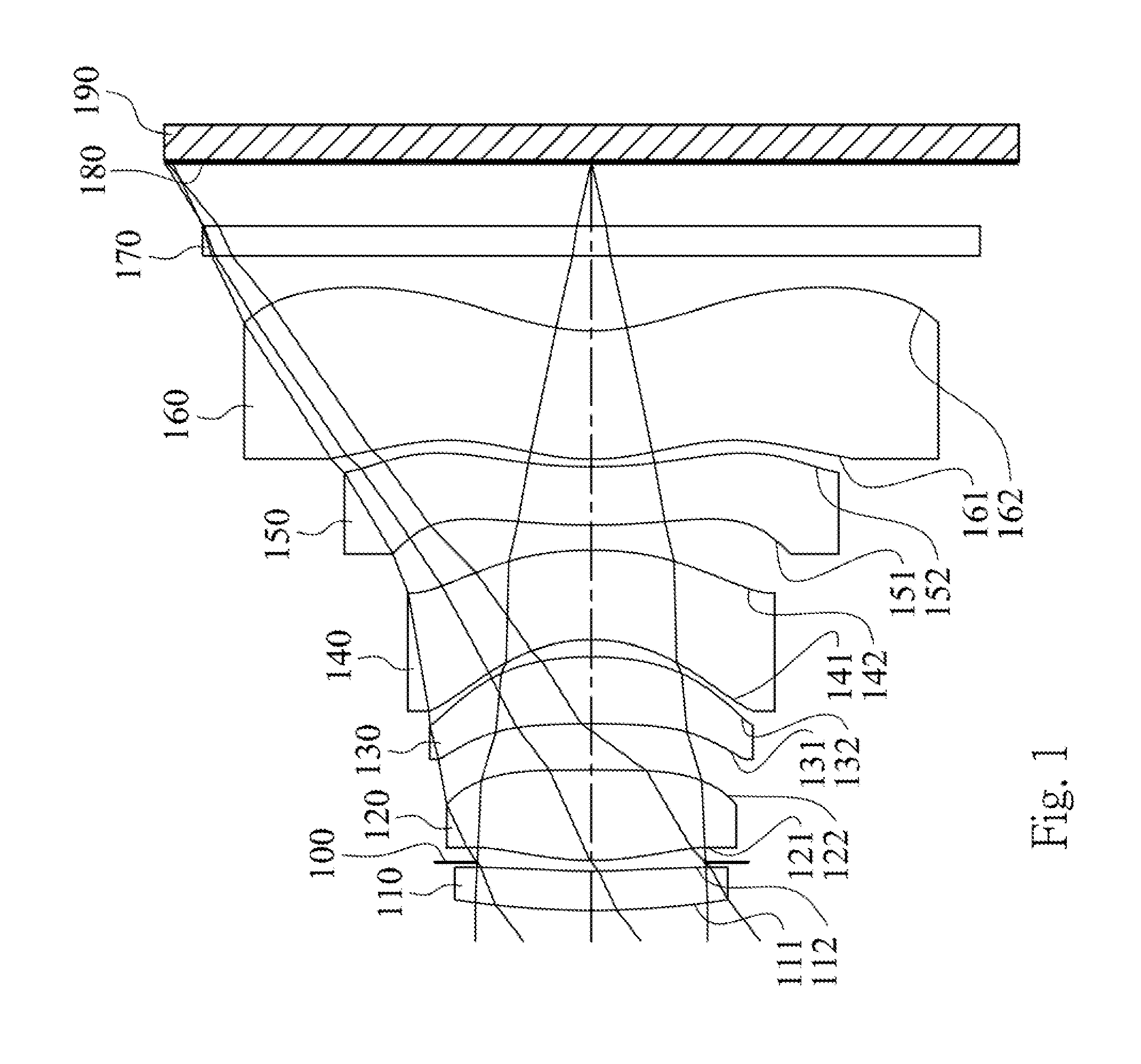

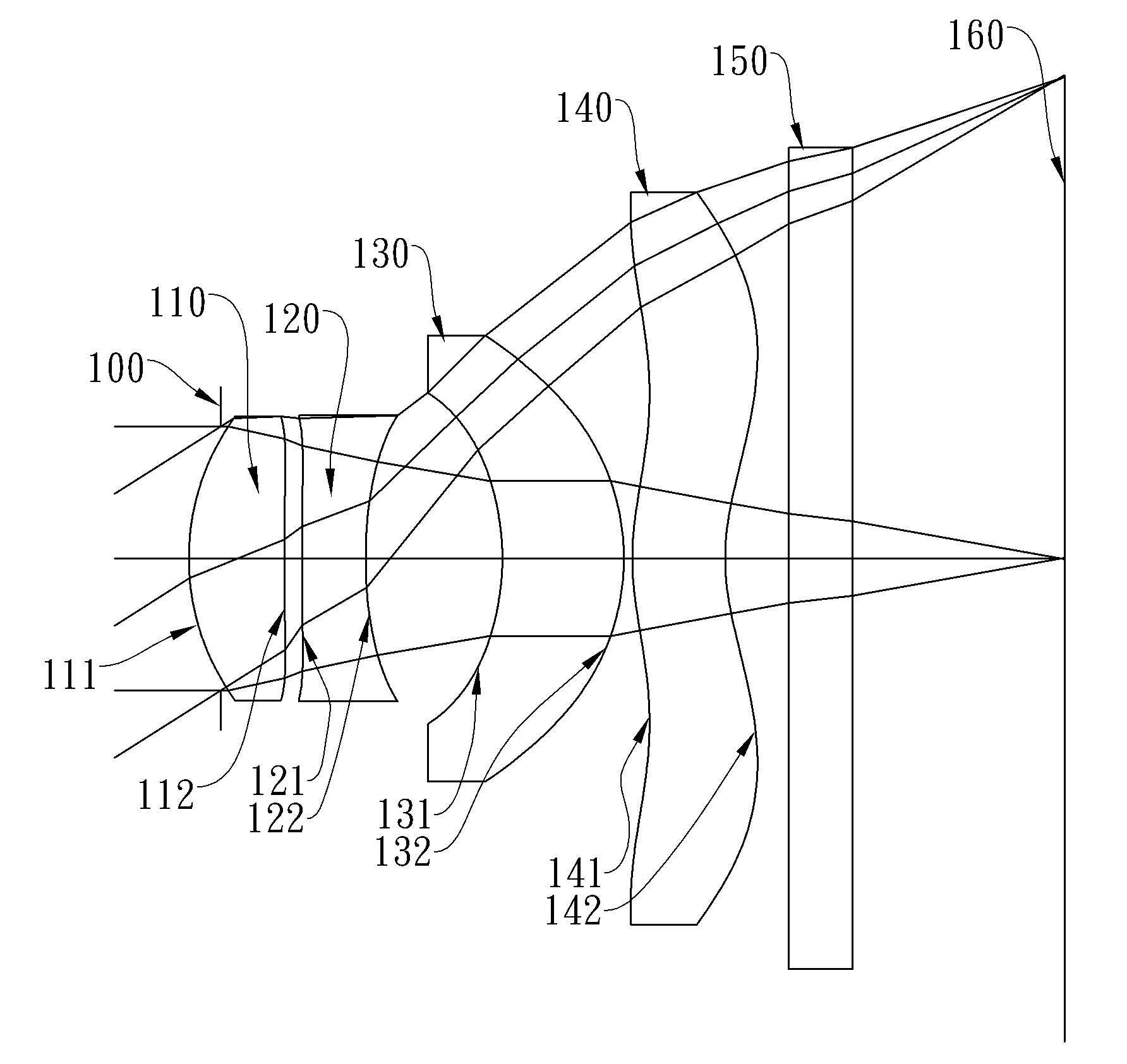

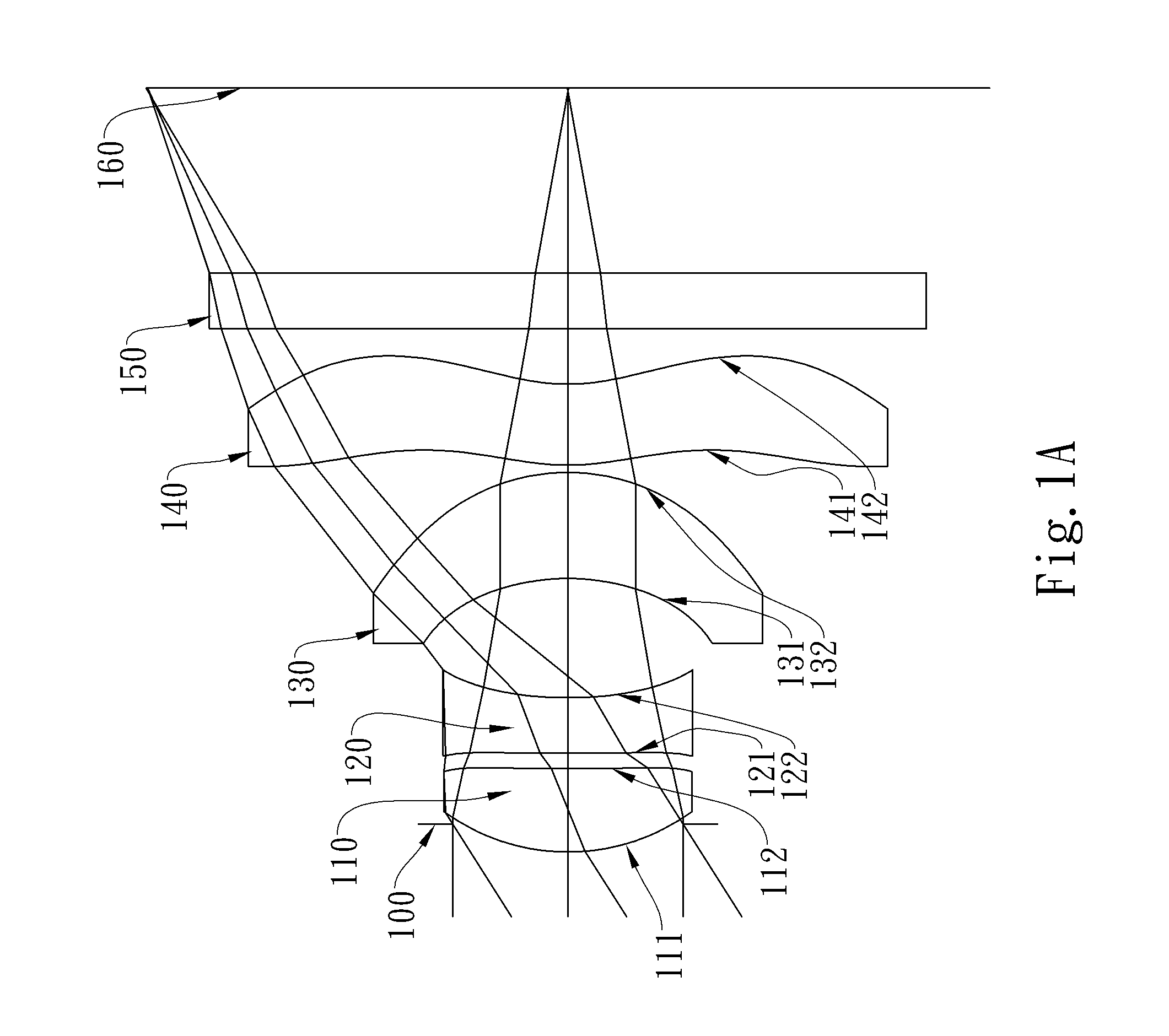

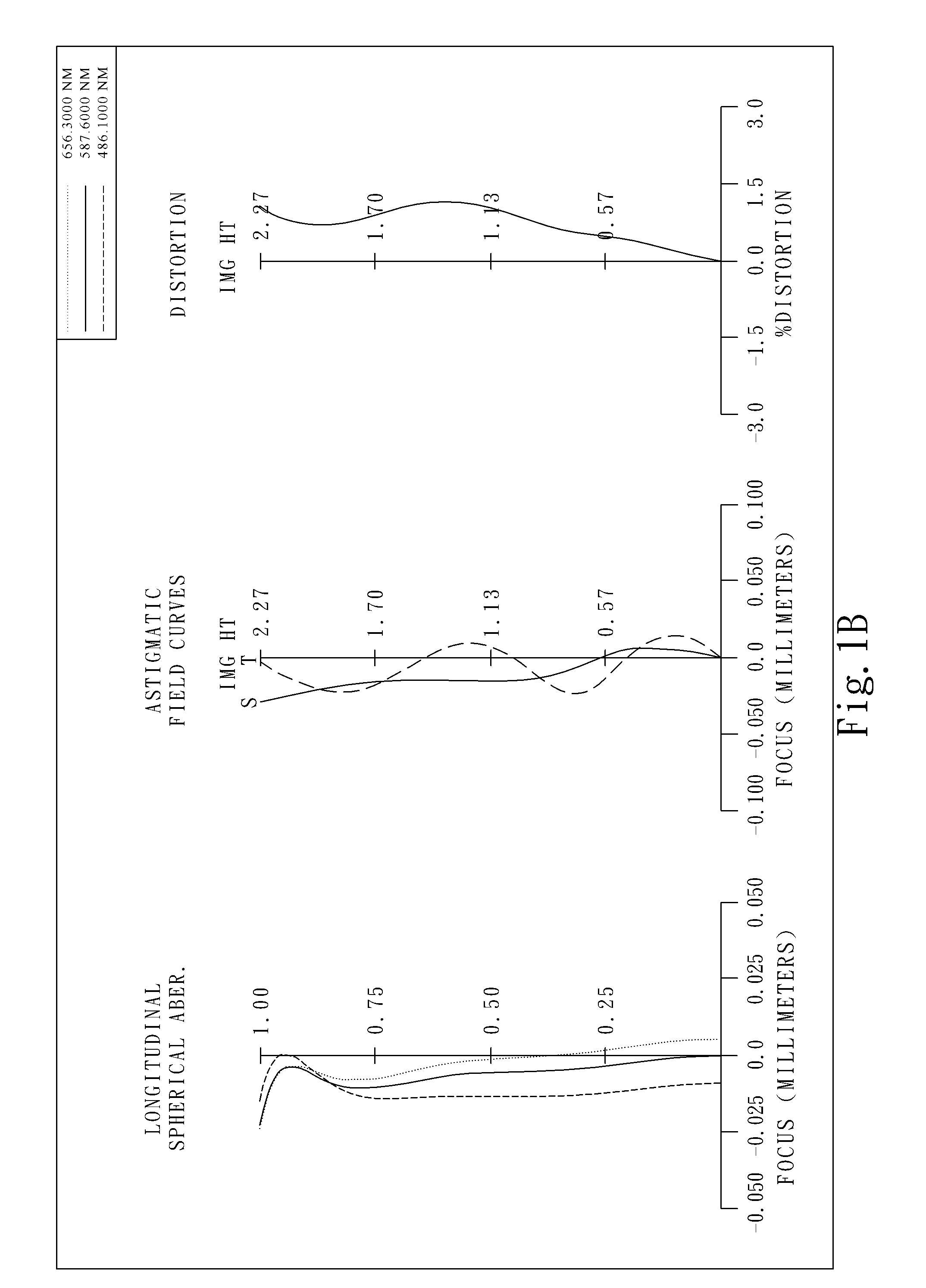

An image lens assembly includes, in order from an object side to an image side, a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element and a sixth lens element. The first lens element with positive refractive power has a convex object-side surface. The second lens element has positive refractive power. The third lens element has refractive power. The fourth lens element has refractive power. The fifth lens element with negative refractive power has a concave object-side surface, wherein both of the surfaces of the fifth lens element are aspheric. The sixth lens element with refractive power has a concave image-side surface, wherein the image-side surface thereof has at least one inflection point, and both of the surfaces of the sixth lens element are aspheric. The image lens assembly has a total of six lens elements with refractive power.

Owner:LARGAN PRECISION

Image capturing lens assembly

An image capturing lens assembly includes, in order from an object side to an image side: the first lens element with positive refractive power, the second lens element with refractive power, the third lens element with positive refractive power, the fourth lens element with refractive power, the fifth lens element with refractive power, and the sixth lens element with refractive power, at least one surface of the sixth lens element thereof being aspheric and having at least one inflection point. By such arrangement, total track length and the photosensitivity of the image capturing lens assembly can also be effectively reduced while retaining high image quality.

Owner:LARGAN PRECISION

Photocurable Compositions

ActiveUS20070205528A1Reduce Shrinkage ProblemsHigh Tg cured propertyAdditive manufacturing apparatusNanostructure manufacturePhysicsRadiation exposure

An optical moulding process is disclosed comprising the sequential steps of: (a)(y) forming a layer of a photocurable composition; and (bXz) irradiating selected areas of the composition in the layer with radiation from a radiation source, thereby curing the composition in said selected areas and repeating the steps a) and b) on top of an earlier cured layer to form a three dimensional structure, wherein the radiation source used in step b) is a non-coherent source of radiation and wherein the photocurable composition comprises at least two curable components: (i) 45%-95% (and preferably at least 50%, more preferably at least 60%, e.g. at least 70%) by weight of the total curable components in the composition is a first component that is photocurable and that is such that, when cured in the presence of a photocuring initiator by exposure to UV radiation having an energy of 30 mJ / cm2, at least 90% of the component is cured within 50 milliseconds; and (ii) 5% to 55% (and preferably 10-40%, more preferably 15 to 30%, e.g. about 20%) by weight of the total curable components in the composition is a second component that results in the composition, on curing, shrinking, in a linear direction, by less than 3% and preferably that results in the composition having, after cure, a Tg of greater than 50° C., preferably at least 100° C. and more preferably at least 120° C.

Owner:3D SYST INC

Image capturing lens assembly

An image capturing lens assembly includes, in order from an object side to an image side: the first lens element with positive refractive power, the second lens element with refractive power, the third lens element with positive refractive power, the fourth lens element with refractive power, the fifth lens element with refractive power, and the sixth lens element with refractive power, at least one surface of the sixth lens element thereof being aspheric and having at least one inflection point. By such arrangement, total track length and the photosensitivity of the image capturing lens assembly can also be effectively reduced while retaining high image quality.

Owner:LARGAN PRECISION

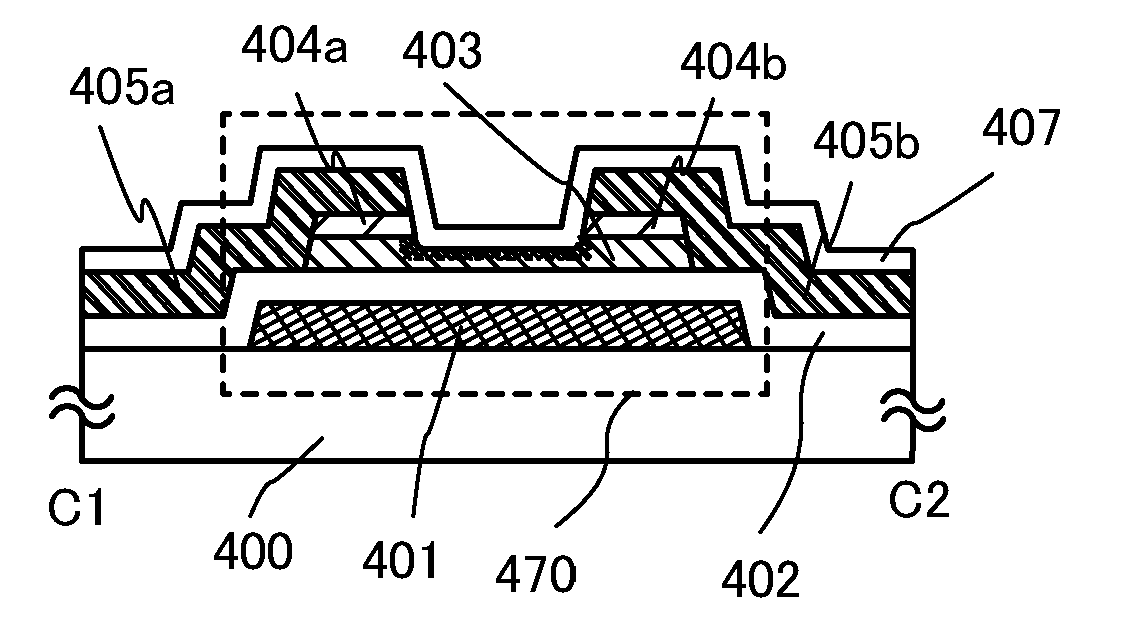

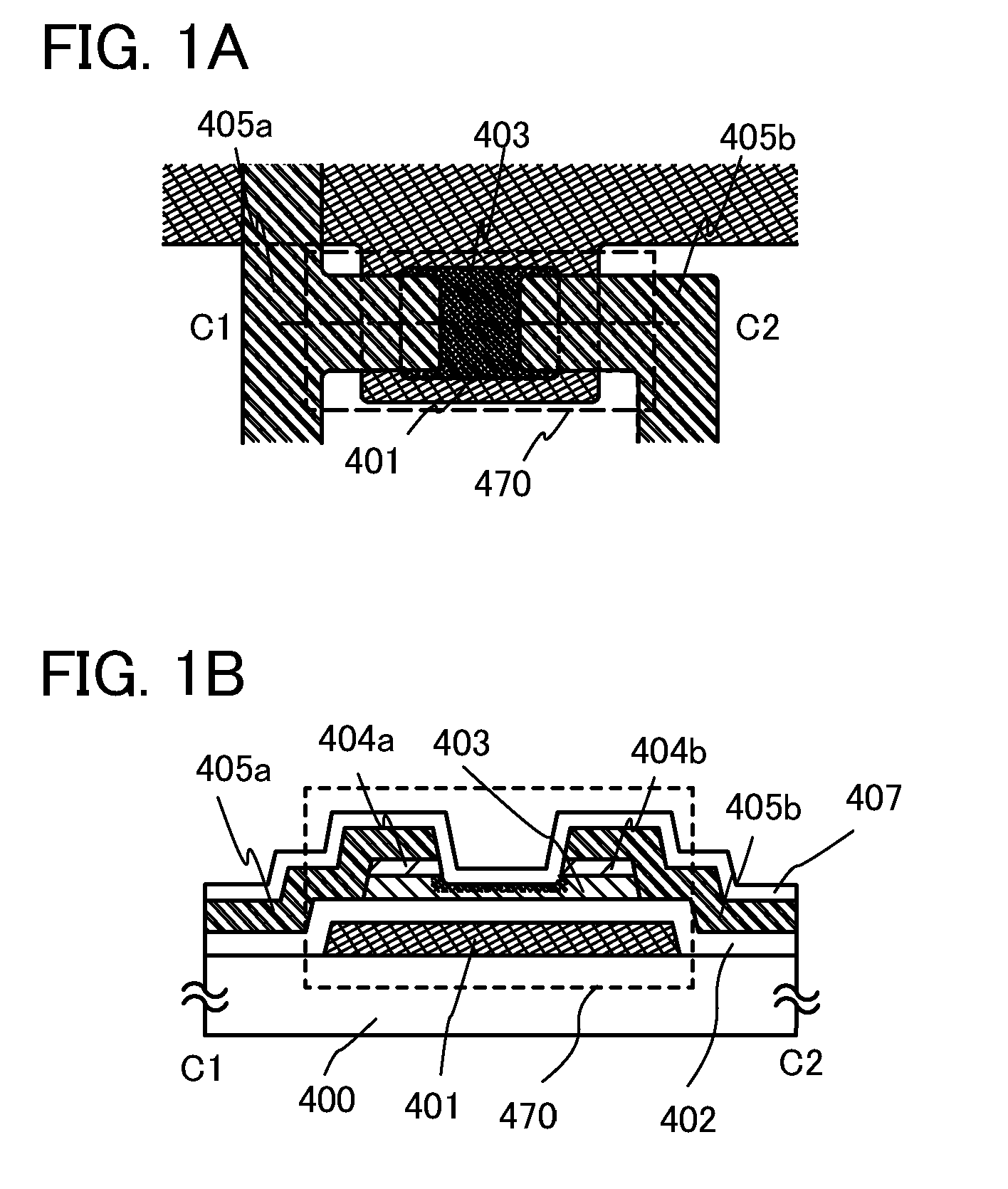

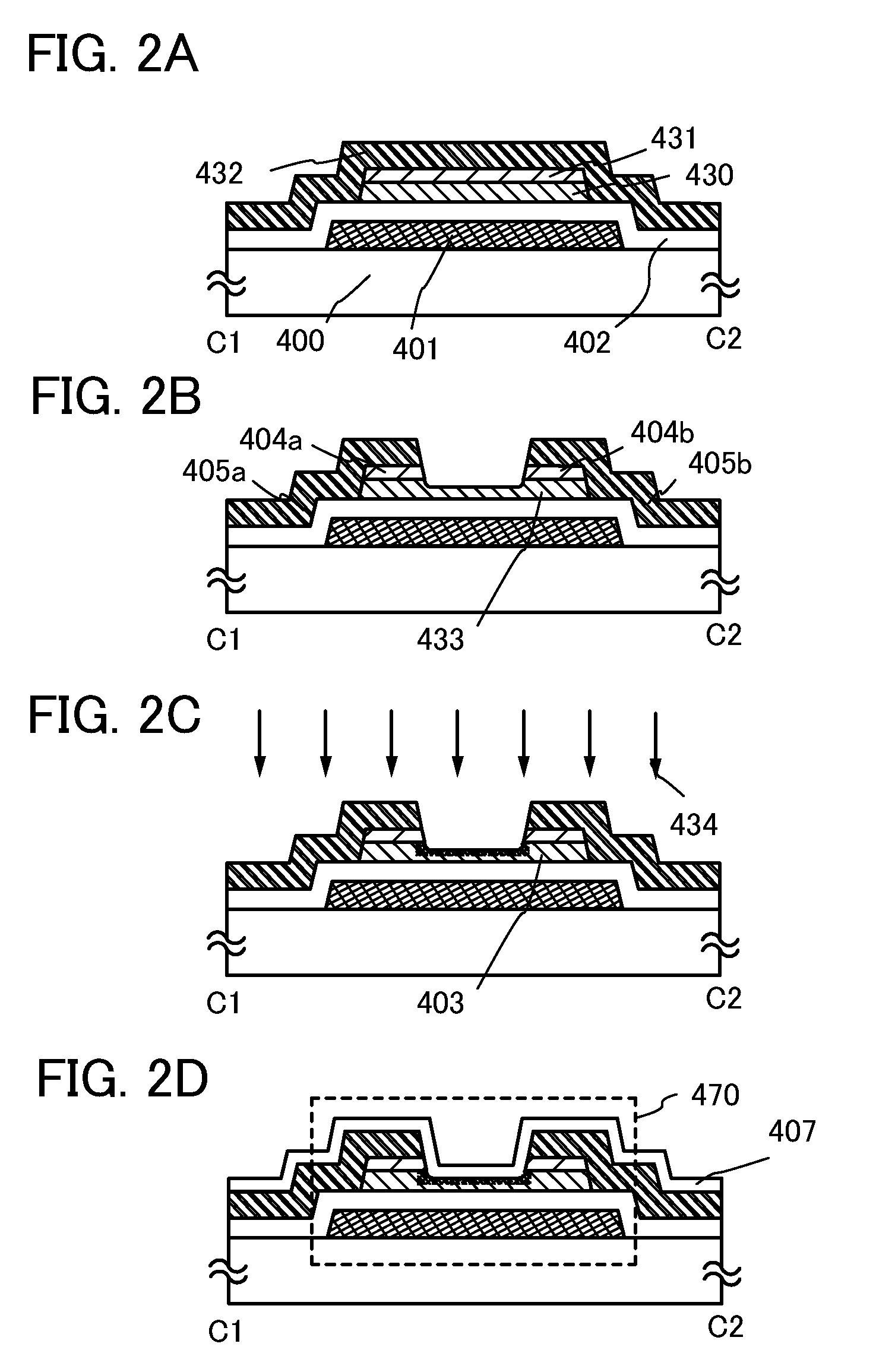

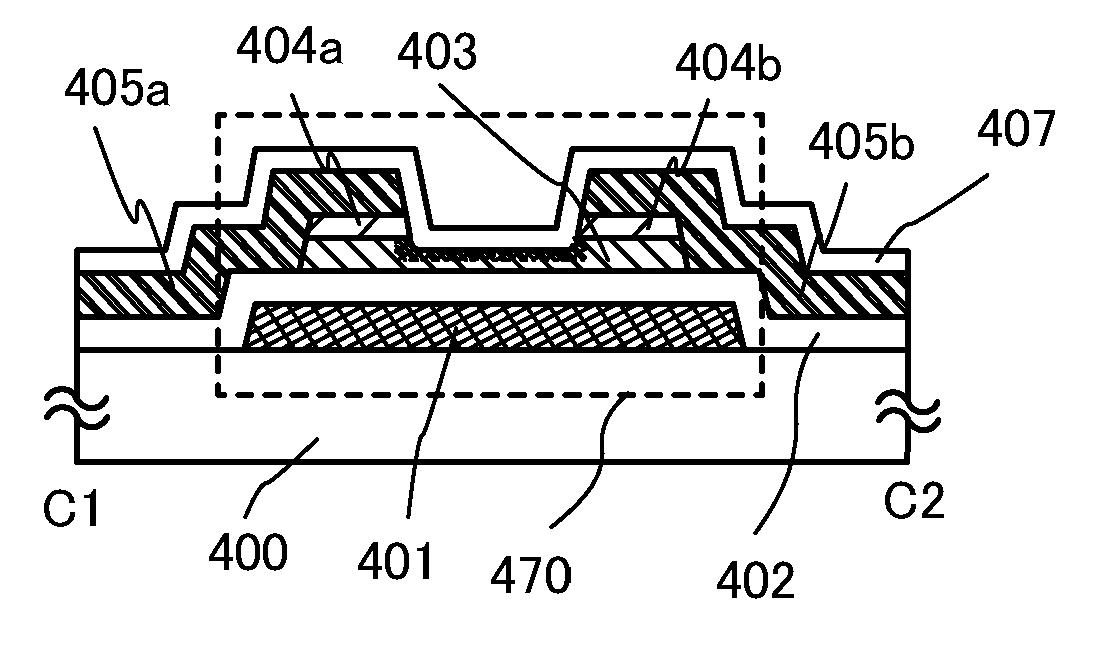

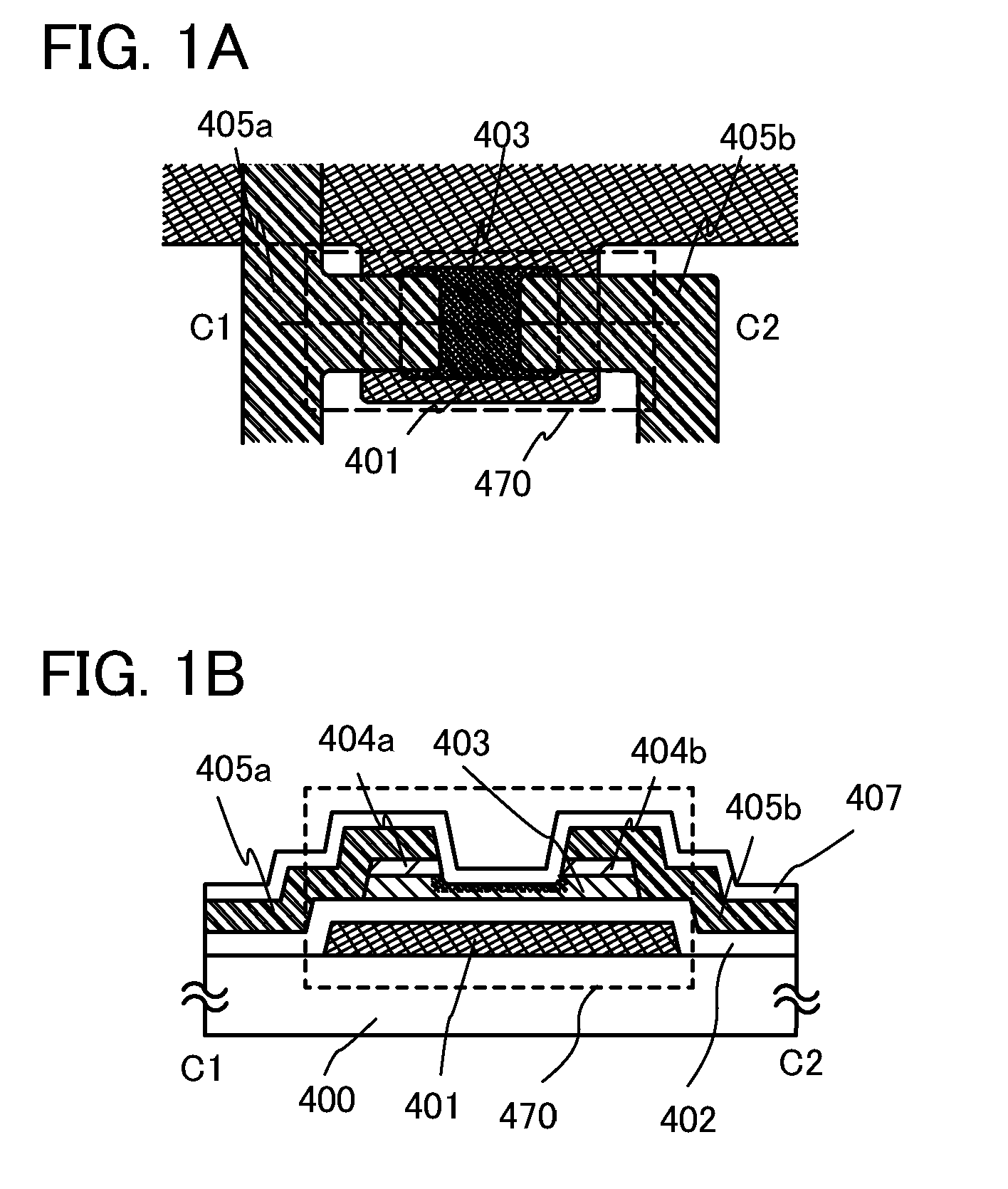

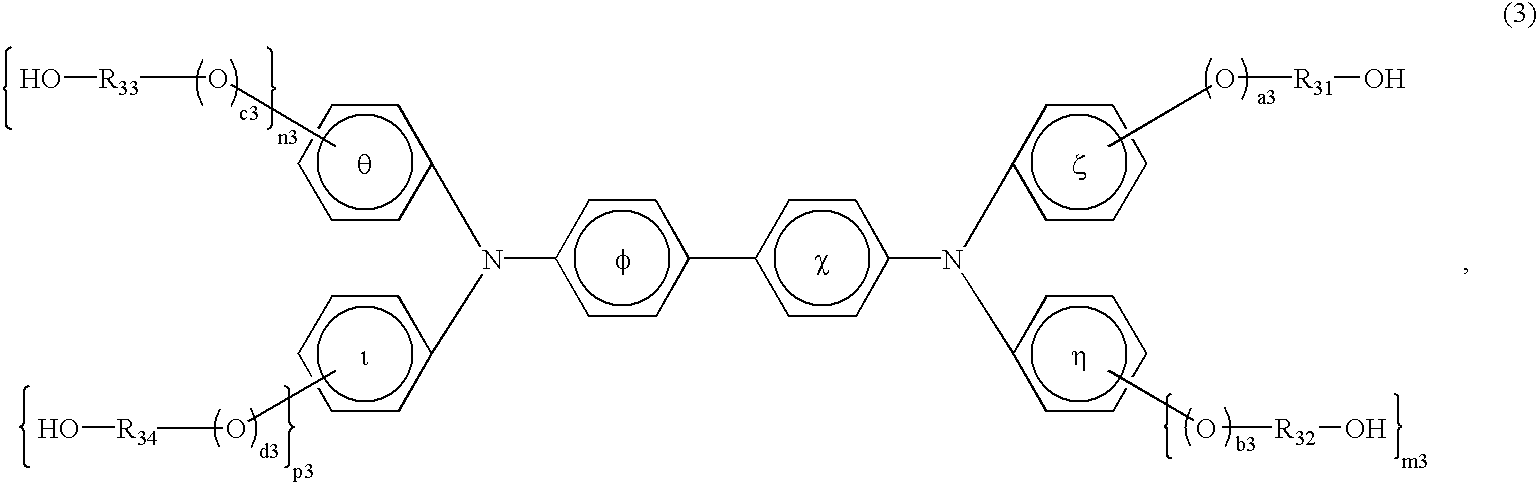

Semiconductor device and method for manufacturing the same

ActiveUS20100117074A1Stable electrical characteristicsImprove dynamic characteristicsTransistorSolid-state devicesIndiumNiobium

It is an object to provide a highly reliable semiconductor device including a thin film transistor whose electric characteristics are stable. In addition, it is another object to manufacture a highly reliable semiconductor device at low cost with high productivity. In a semiconductor device including a thin film transistor, a semiconductor layer of the thin film transistor is formed with an oxide semiconductor layer to which a metal element is added. As the metal element, at least one of metal elements of iron, nickel, cobalt, copper, gold, manganese, molybdenum, tungsten, niobium, and tantalum is used. In addition, the oxide semiconductor layer contains indium, gallium, and zinc.

Owner:SEMICON ENERGY LAB CO LTD

Photographing optical lens assembly, image capturing unit and mobile device

ActiveUS20150316749A1Reduce the angle of incidenceHigh sensitivityTelevision system detailsColor television detailsMobile devicePhysics

A photographing optical lens assembly includes, in order from the object side to the image side, a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element and a sixth lens element. The first lens element, the second lens element and the fourth lens element have positive refractive power. The third lens element has refractive power. The fifth lens element has negative refractive power. The sixth lens element with refractive power has an image-side surface being concave in a paraxial region thereof and having at least one convex shape in an off-axis region thereof. An object-side surface and an image-side surface of the sixth lens element both are aspheric. Both of an absolute value of a focal length of the fourth lens element and that of the fifth lens element each are greater than those of the other lens elements.

Owner:LARGAN PRECISION

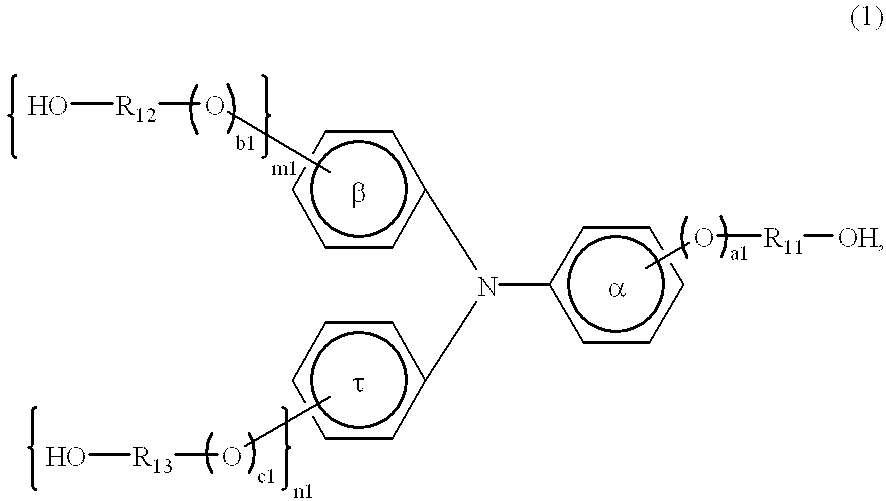

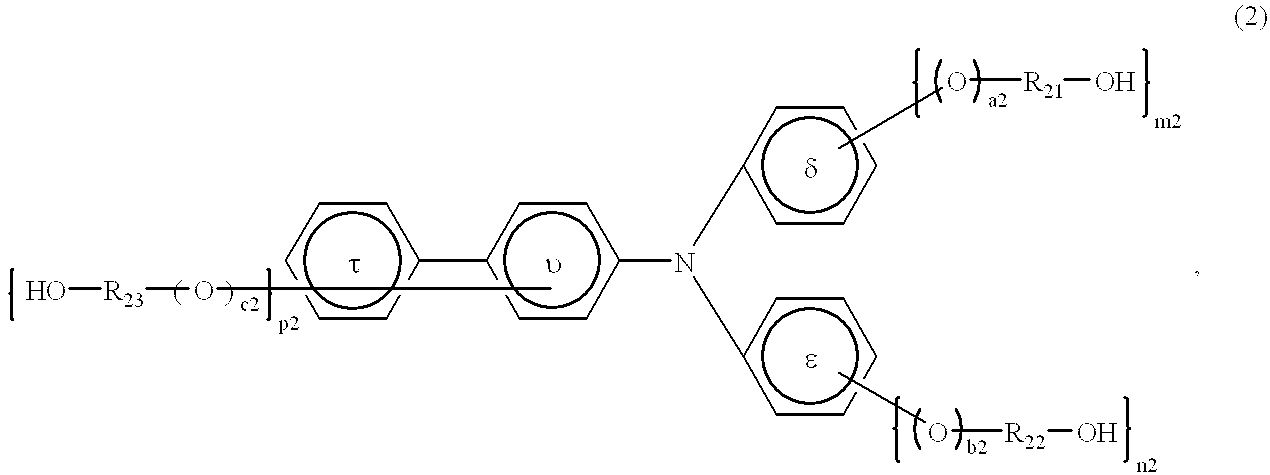

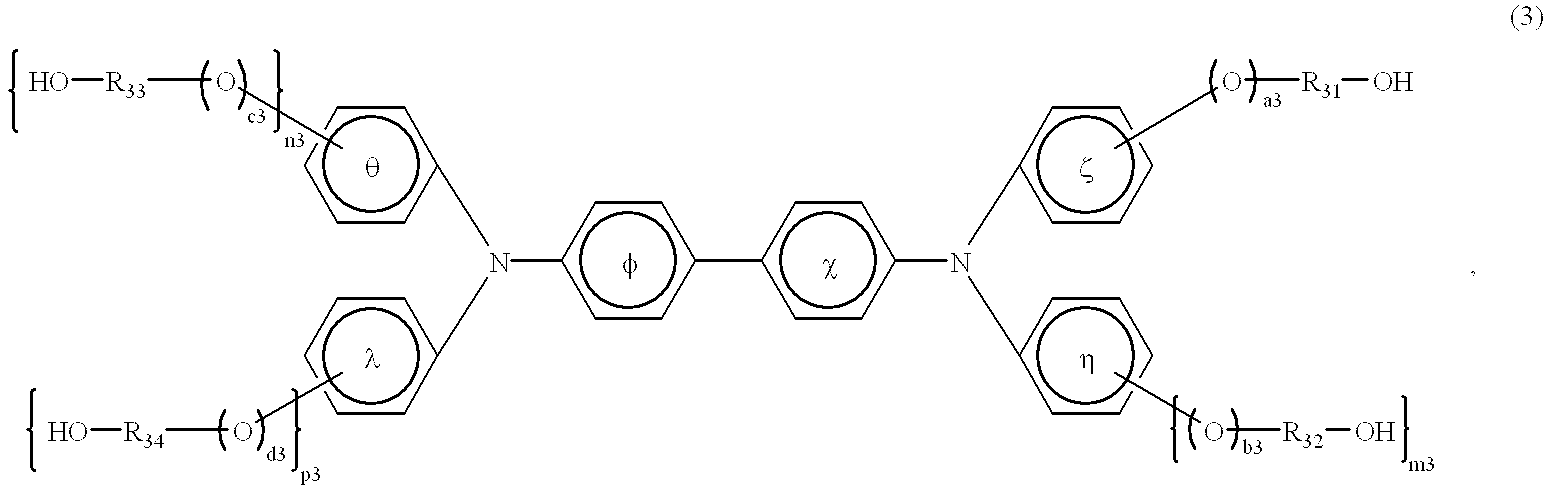

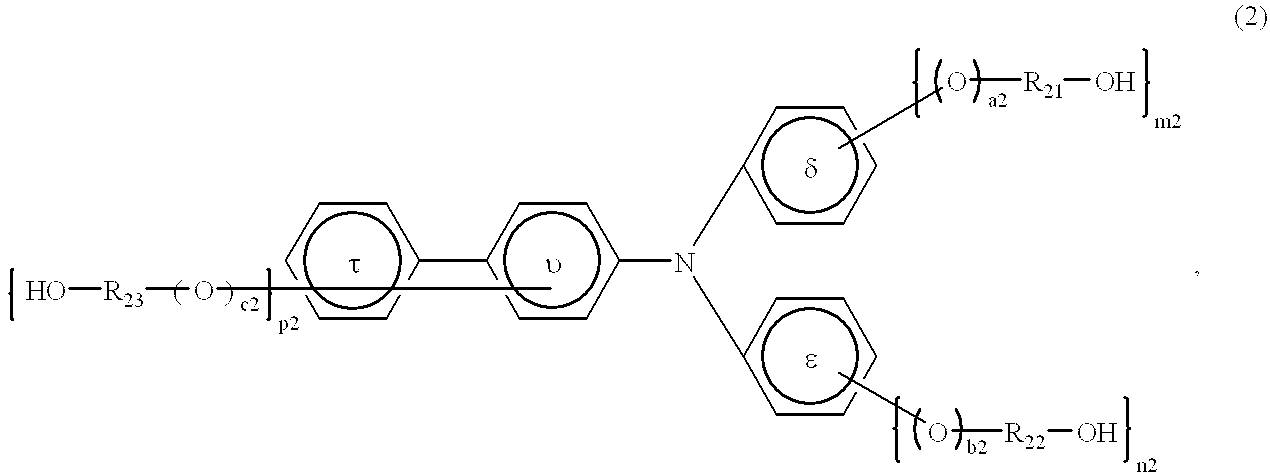

Electrophotographic photosensitive member, process cartridge and electrophotographic apparatus

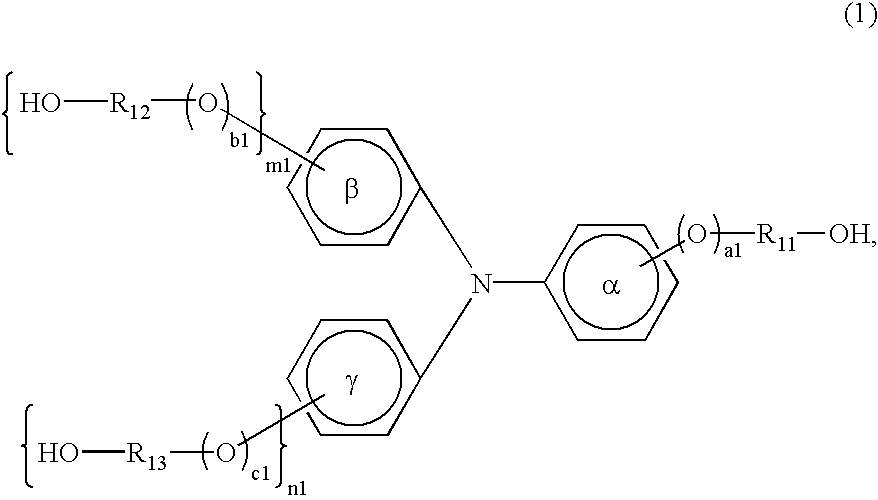

InactiveUS20020119382A1Reduce photosensitivityIncrease in residual potentialElectrographic process apparatusCorona dischargeProtection layerElectric charge

An electrophotographic photosensitive member exhibiting a good durability and stable electrophotographic performances regardless of environmental change is provided by coating the photosensitive layer with a specific protective layer. The protective layer comprises a cured phenolic resin and a charge-transporting compound having at least one group selected from the group consisting of hydroxyalkyl groups, hydroxyalkoxy groups and hydroxyphenyl groups capable of having a substituent.

Owner:CANON KK

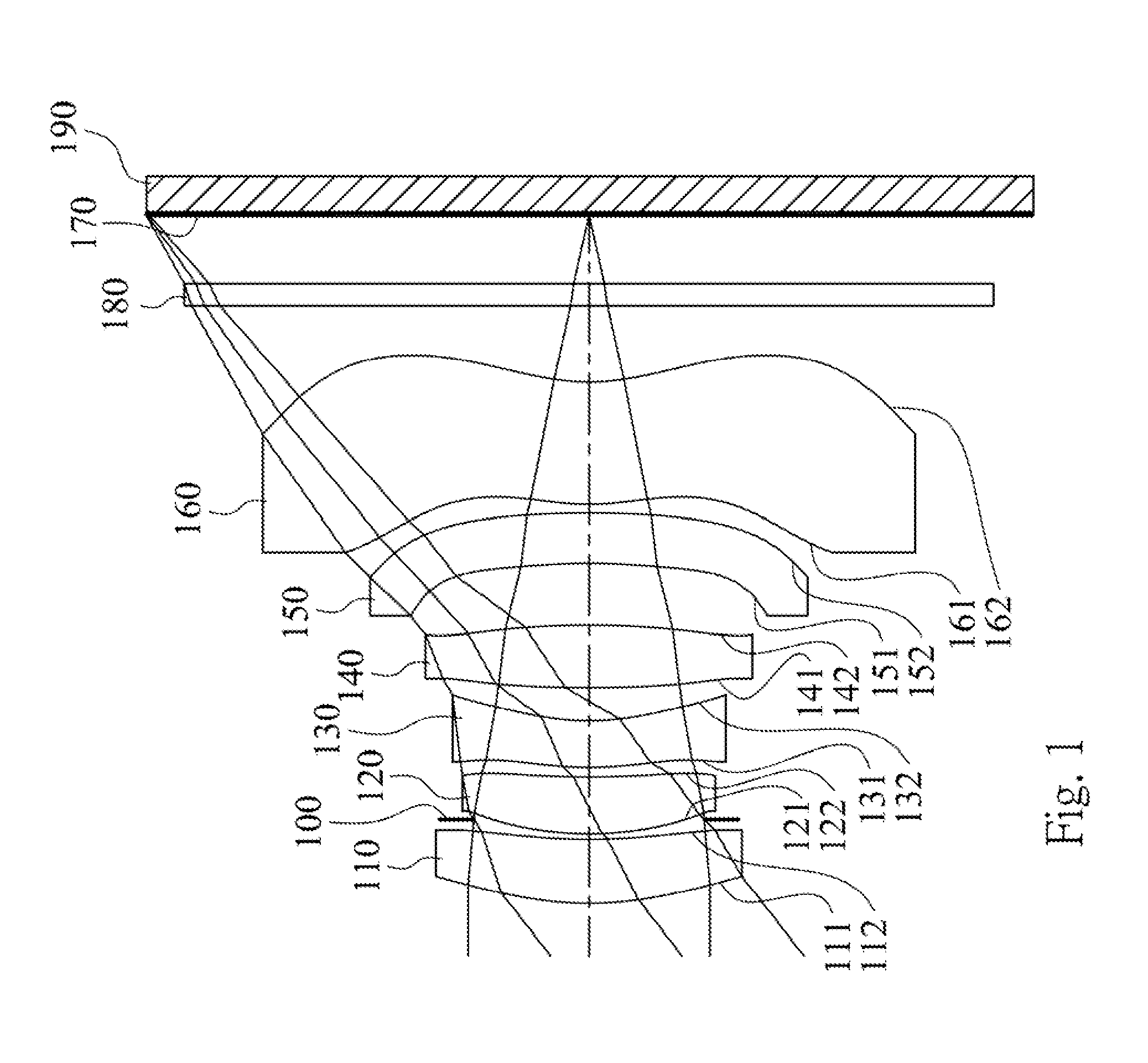

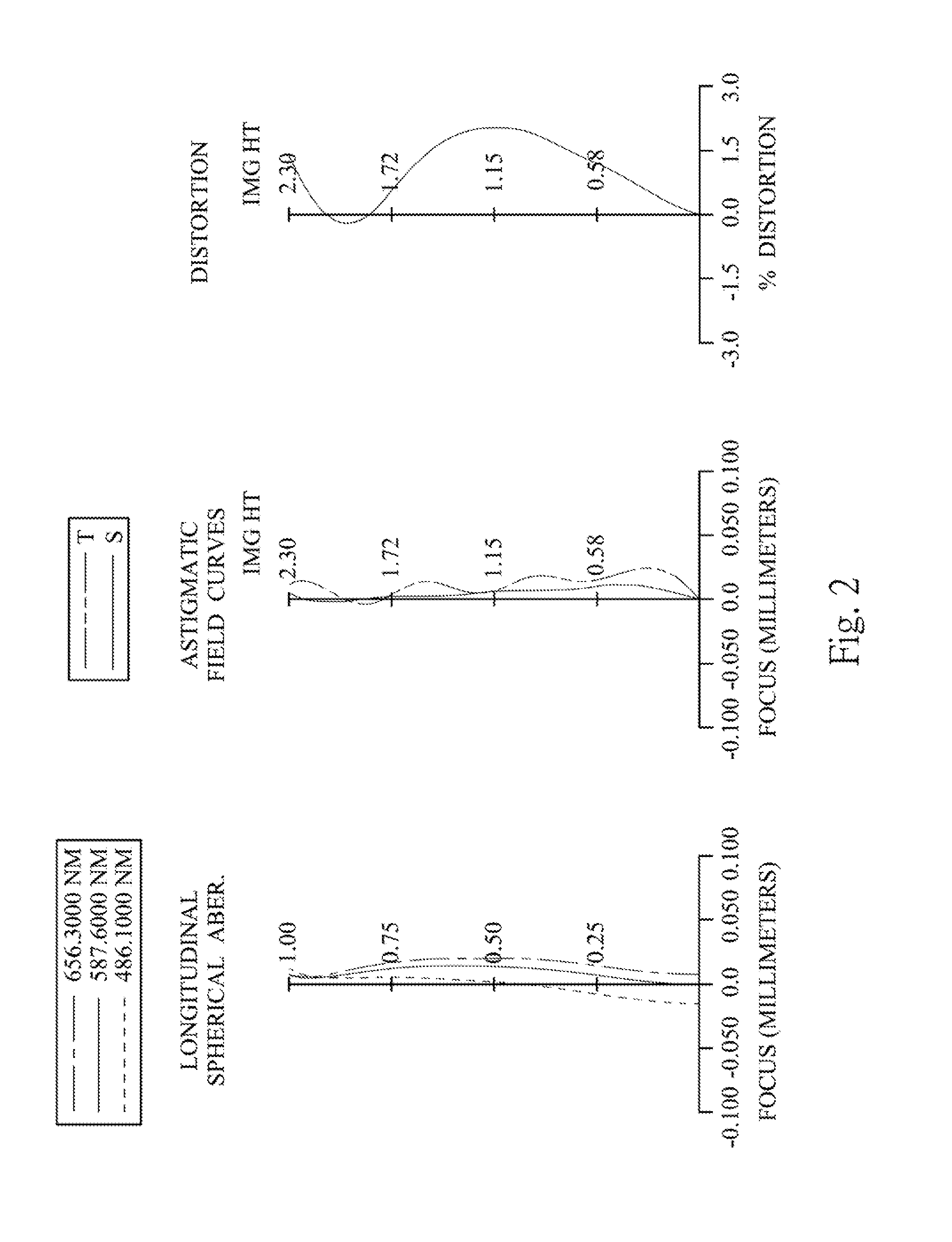

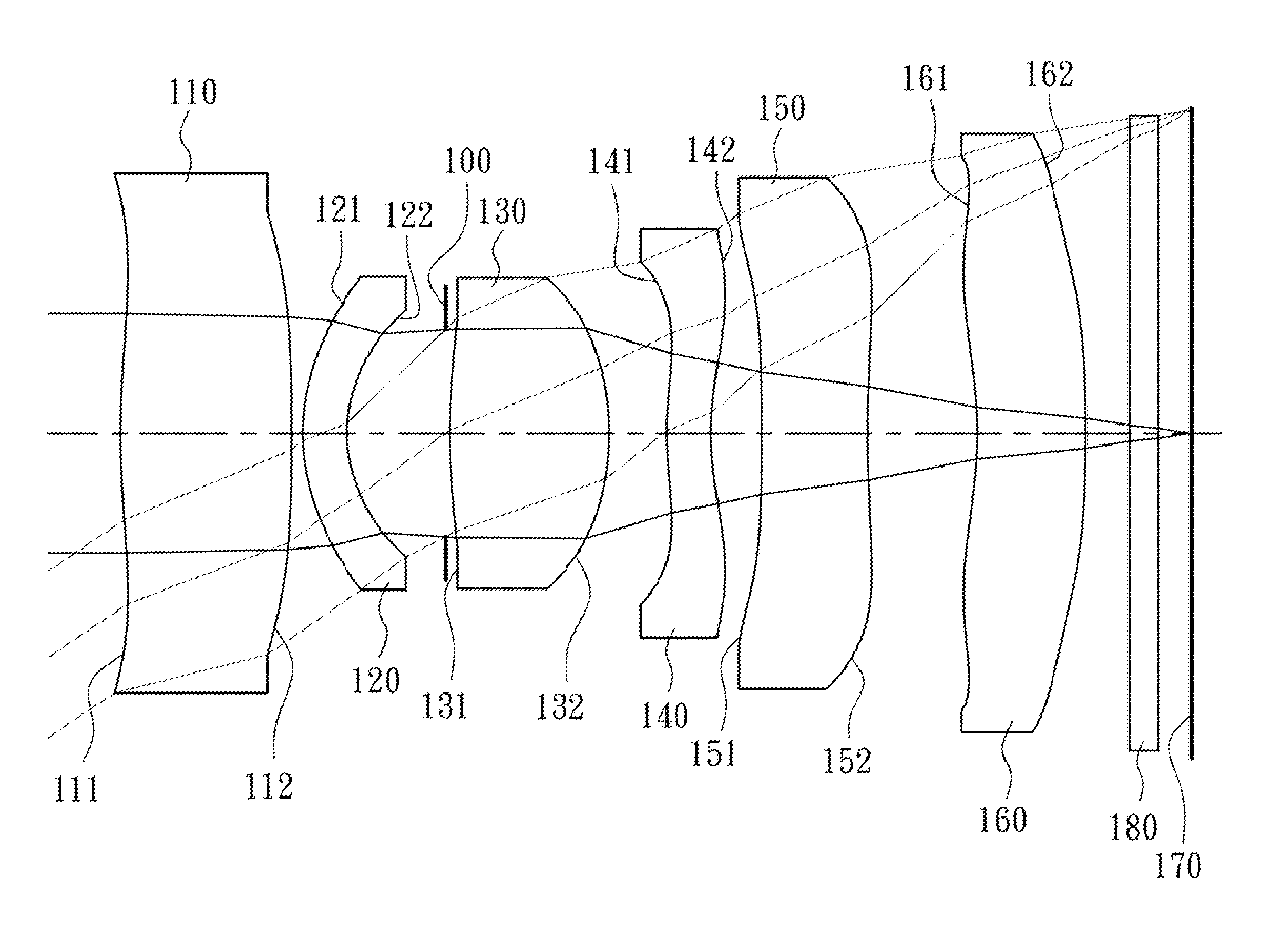

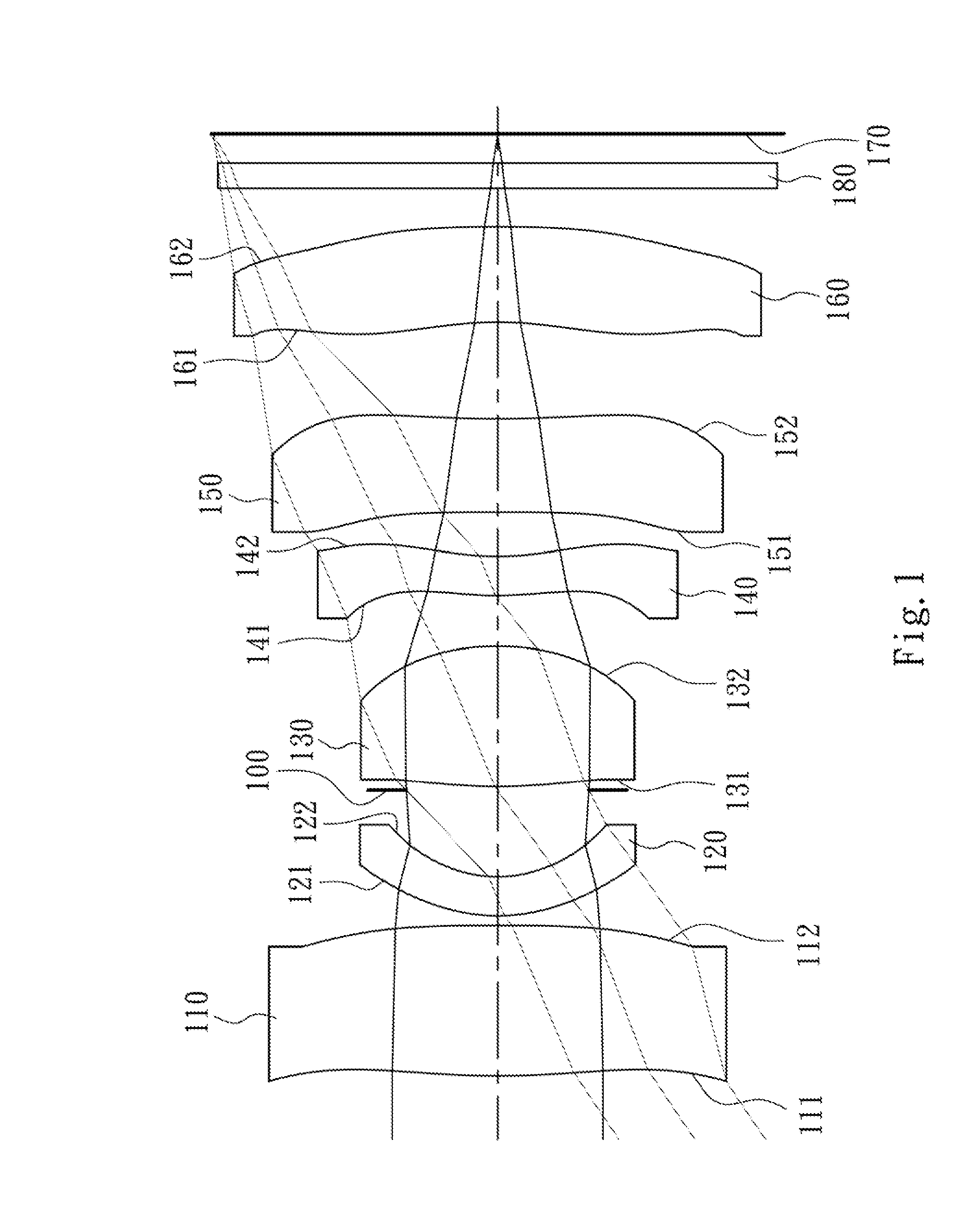

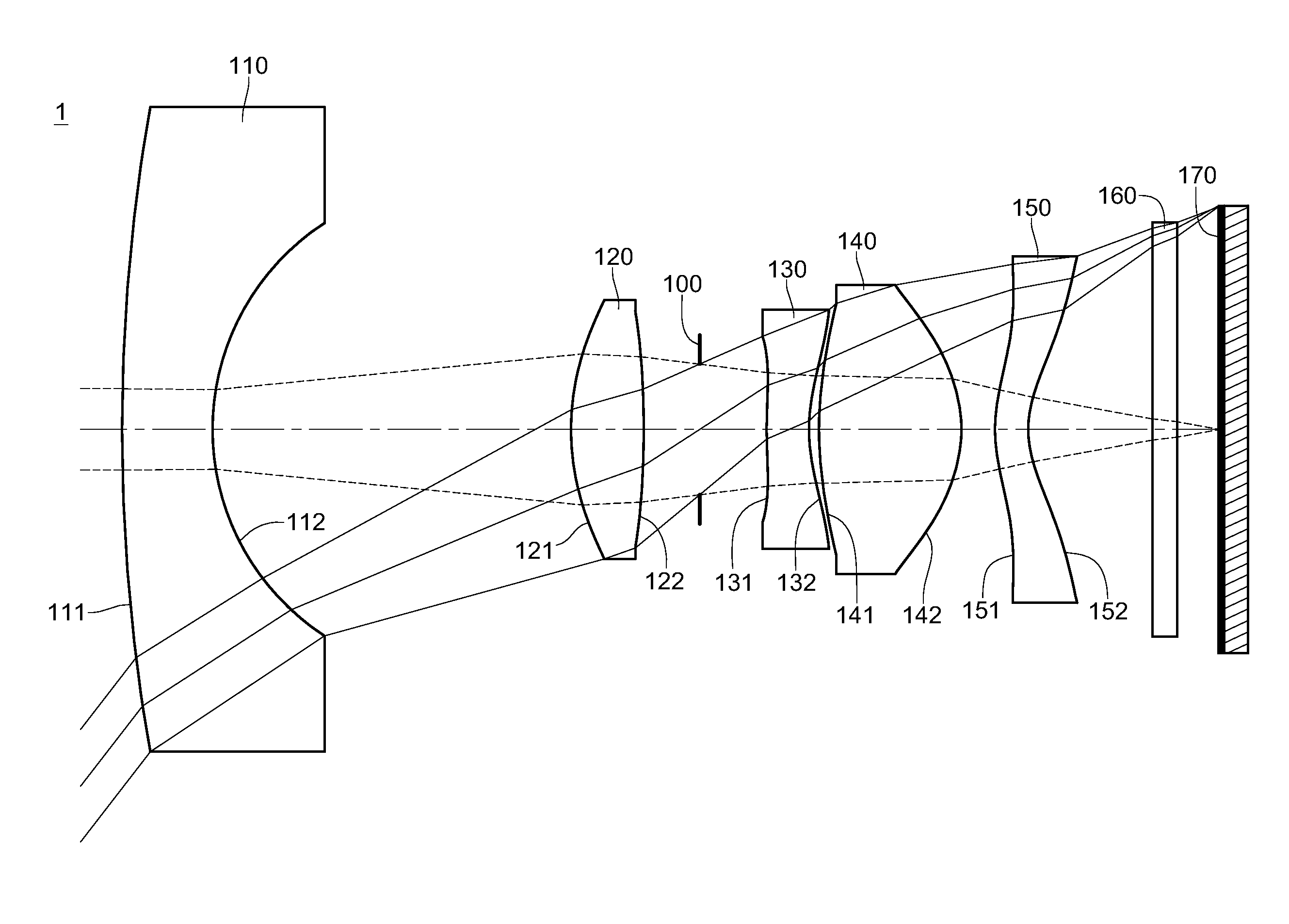

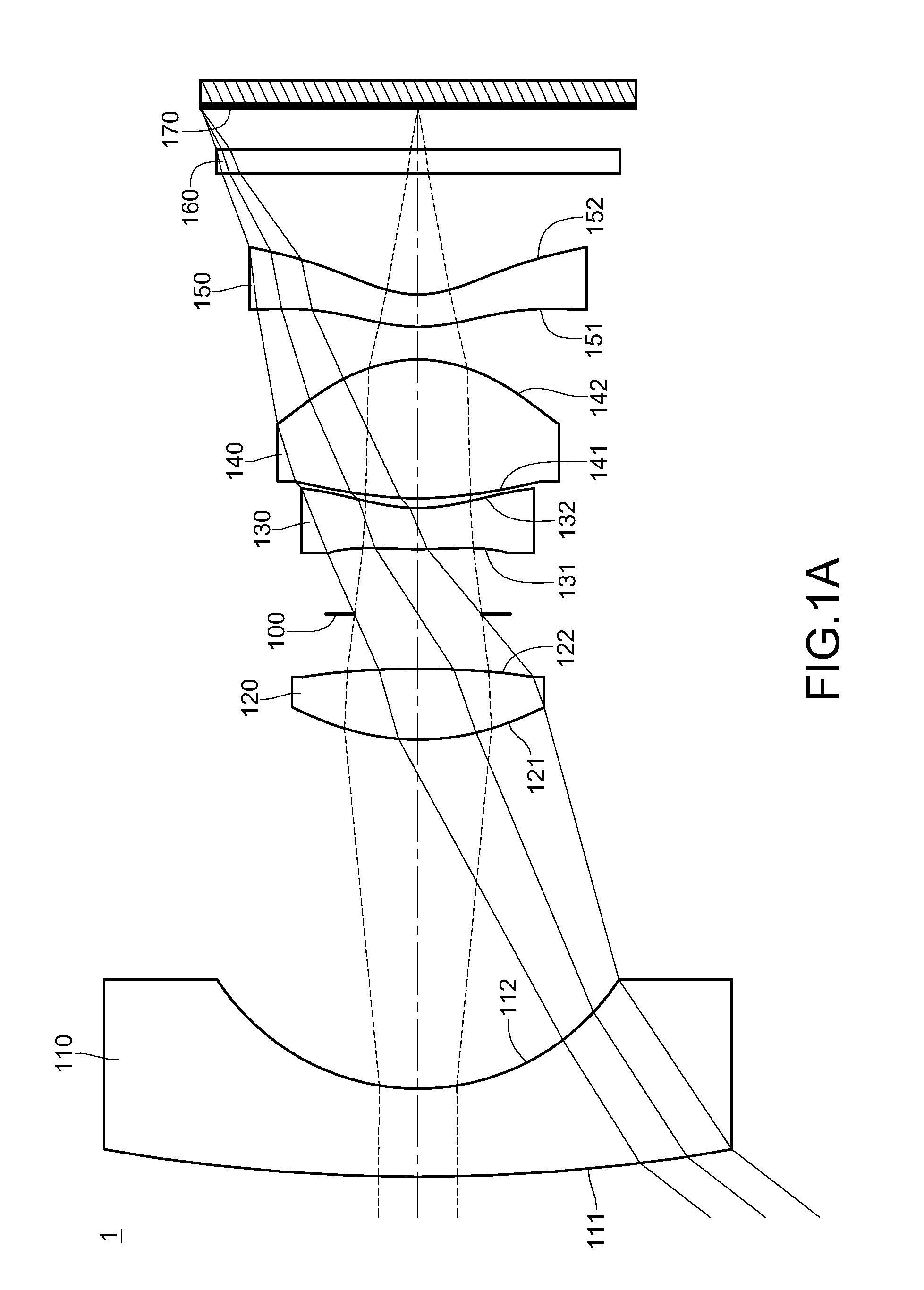

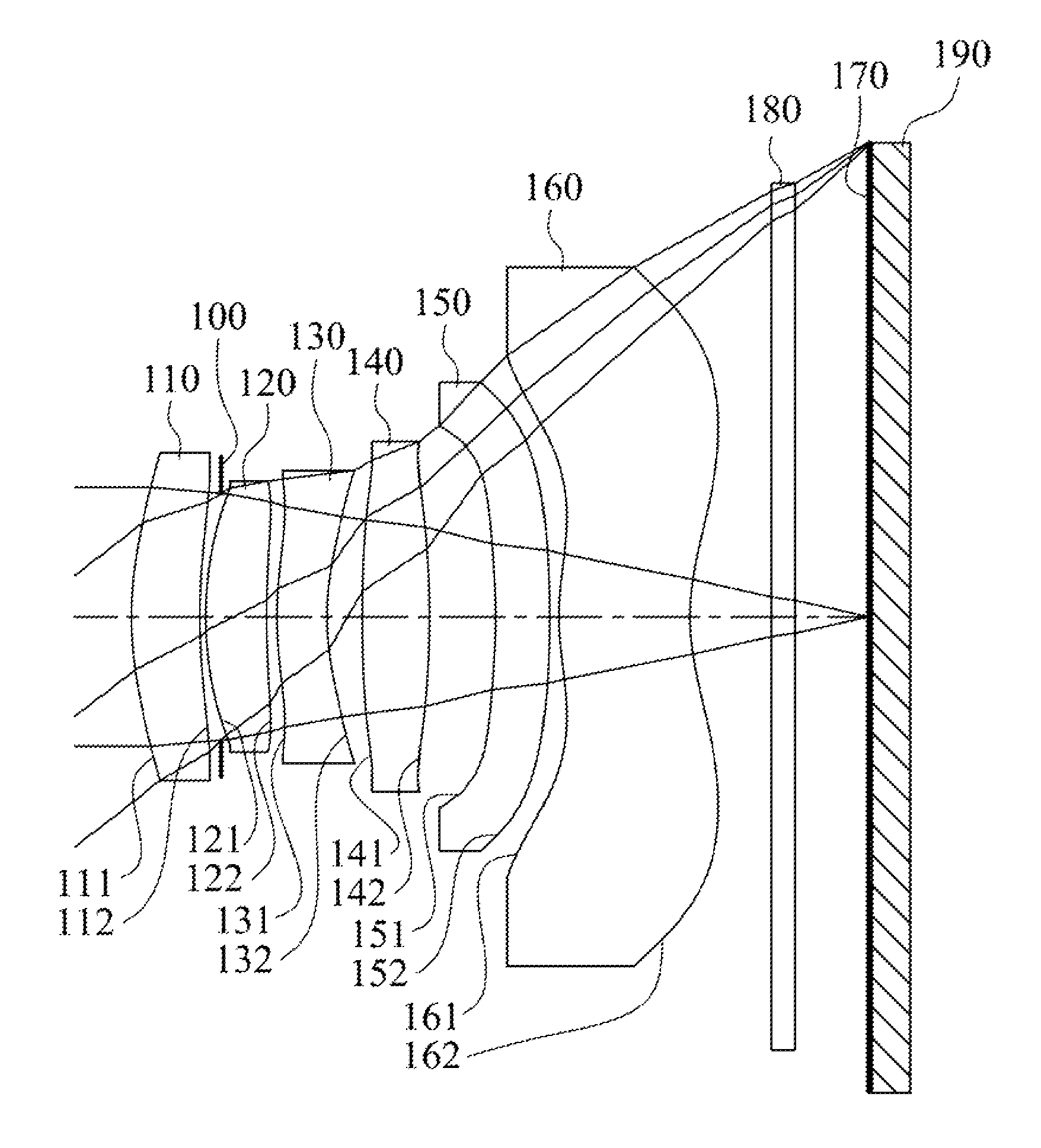

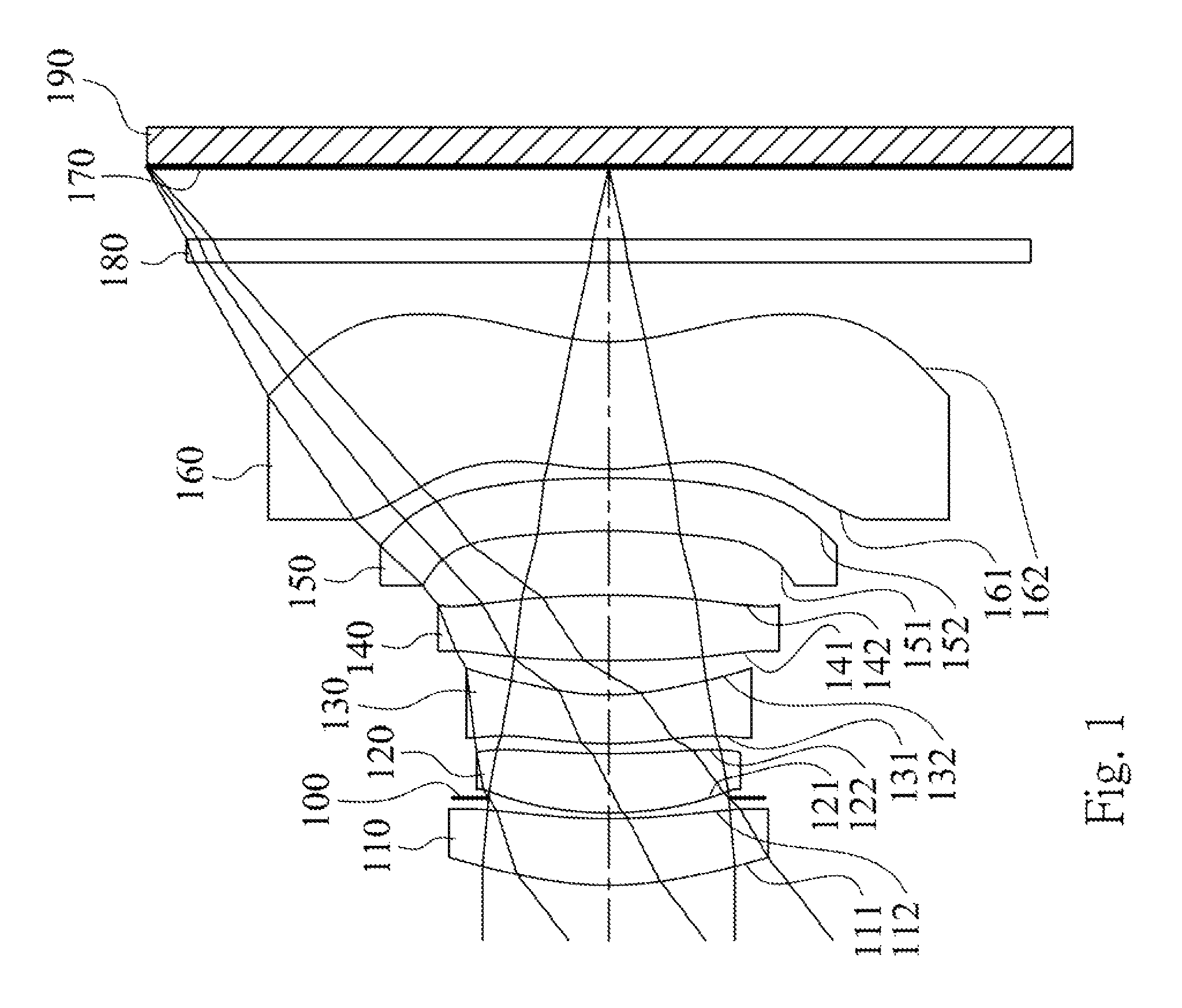

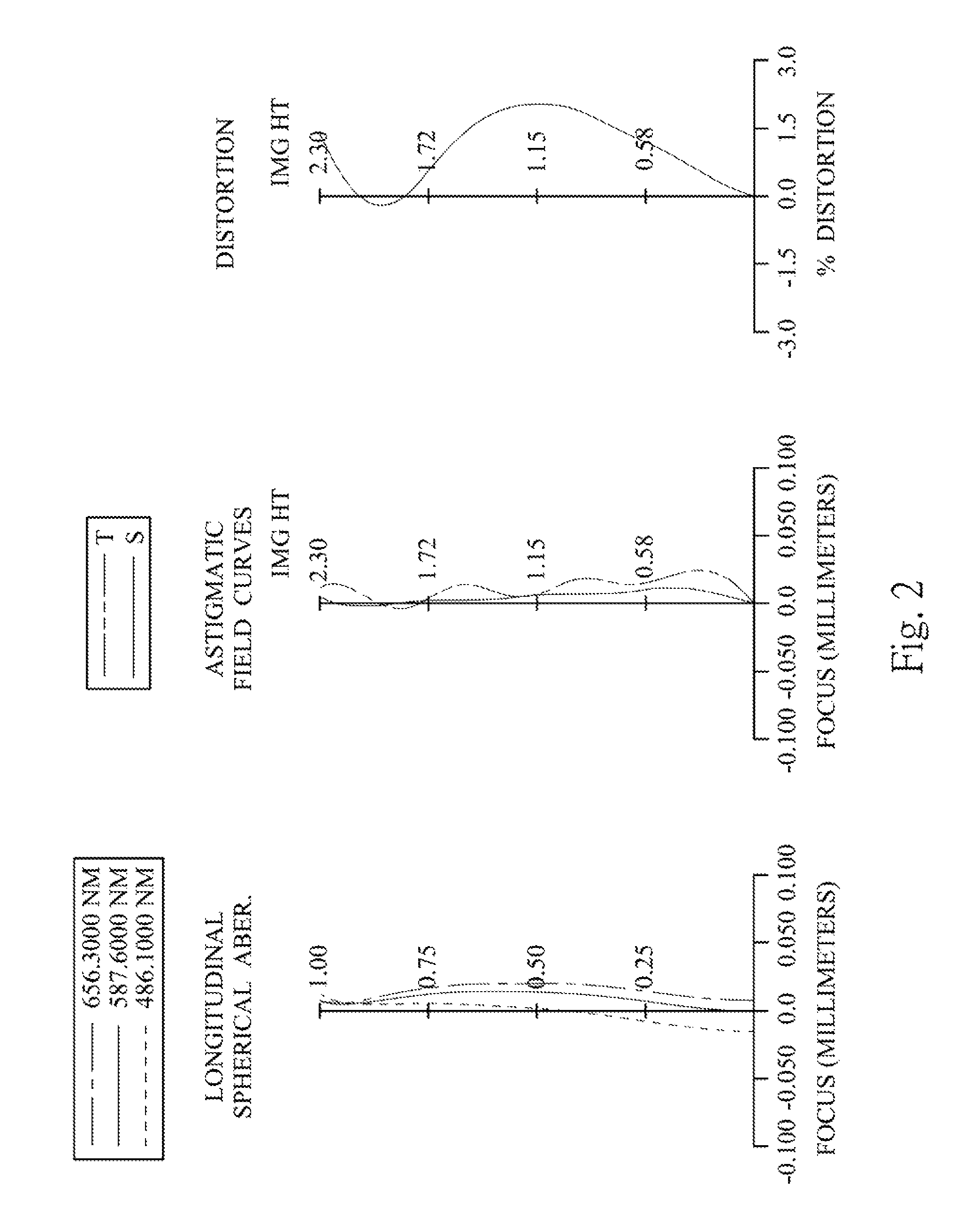

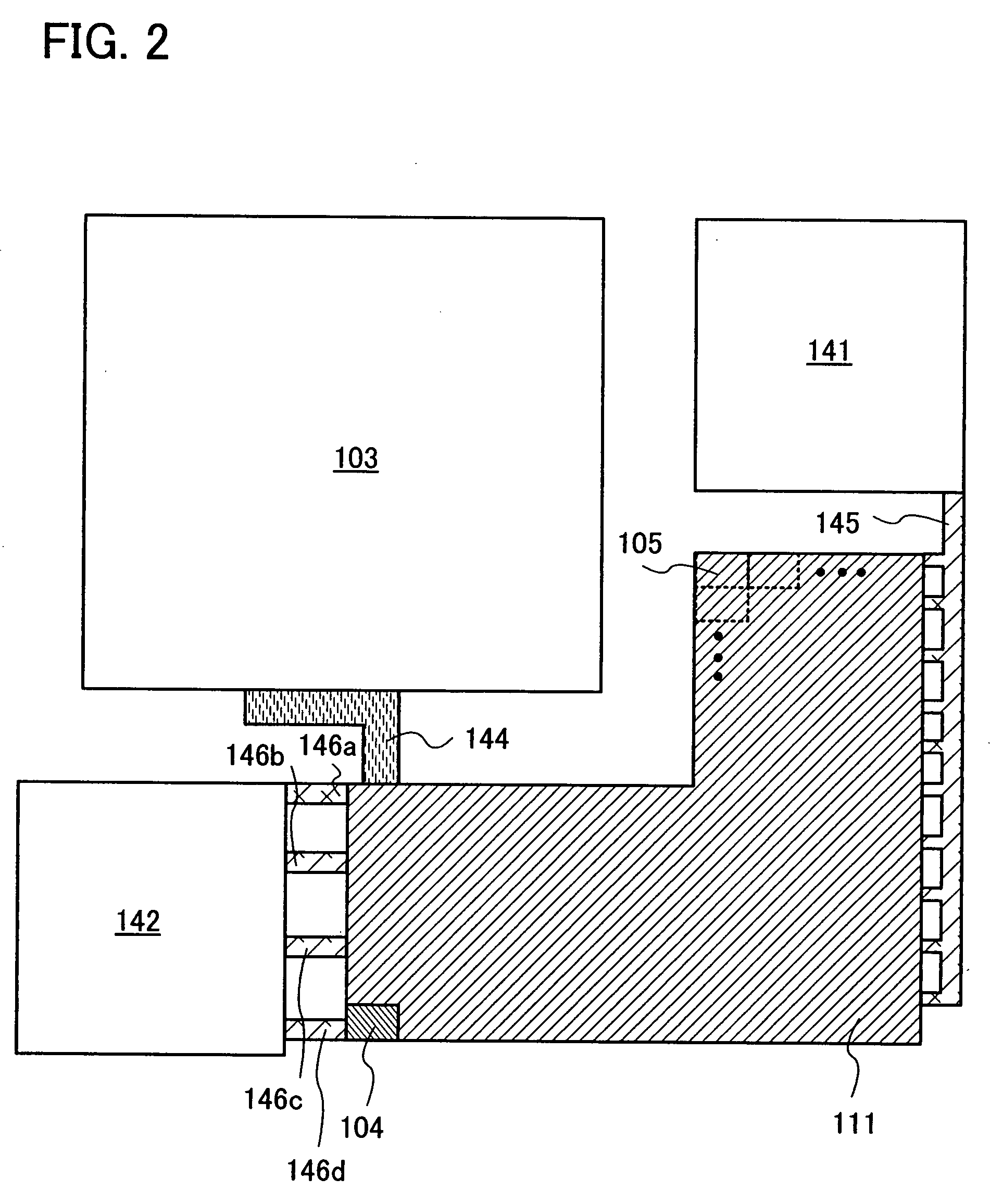

Optical imaging lens assembly, image capturing device and mobile terminal

ActiveUS20150241659A1Reduce photosensitivityImprove yieldTelevision system detailsColor television detailsPhysicsOptical imaging

An optical imaging lens assembly includes, in order from an object side to an image side, a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element, and a sixth lens element. The first lens element has negative refractive power. The second lens element has positive refractive power. The third lens element has refractive power. The fourth lens element with refractive power has an object-side surface being concave in a paraxial region thereof. The fifth lens element with refractive power has an object-side surface being convex in a paraxial region thereof and an image-side surface being concave in a paraxial region thereof. The sixth lens element with refractive power has an image-side surface being concave in a paraxial region thereof. The optical imaging lens assembly has a total of six lens elements with refractive power.

Owner:LARGAN PRECISION

Image lens system

An image lens system includes, in order from an object side to an image side, a first lens element with negative refractive power including a concave image-side surface; a second lens element with positive refractive power including a convex object-side surface; a third lens element with negative refractive power including an object-side surface and a concave image-side surface, the object-side surface and the image-side surface being aspheric; a fourth lens element with positive refractive power including a convex object-side surface and a convex image-side surface; and a fifth lens element with negative refractive power including a convex object-side surface and a concave image-side surface, the object-side surface and the image-side surface being aspheric, the fifth lens element having at least one inflection point.

Owner:LARGAN PRECISION

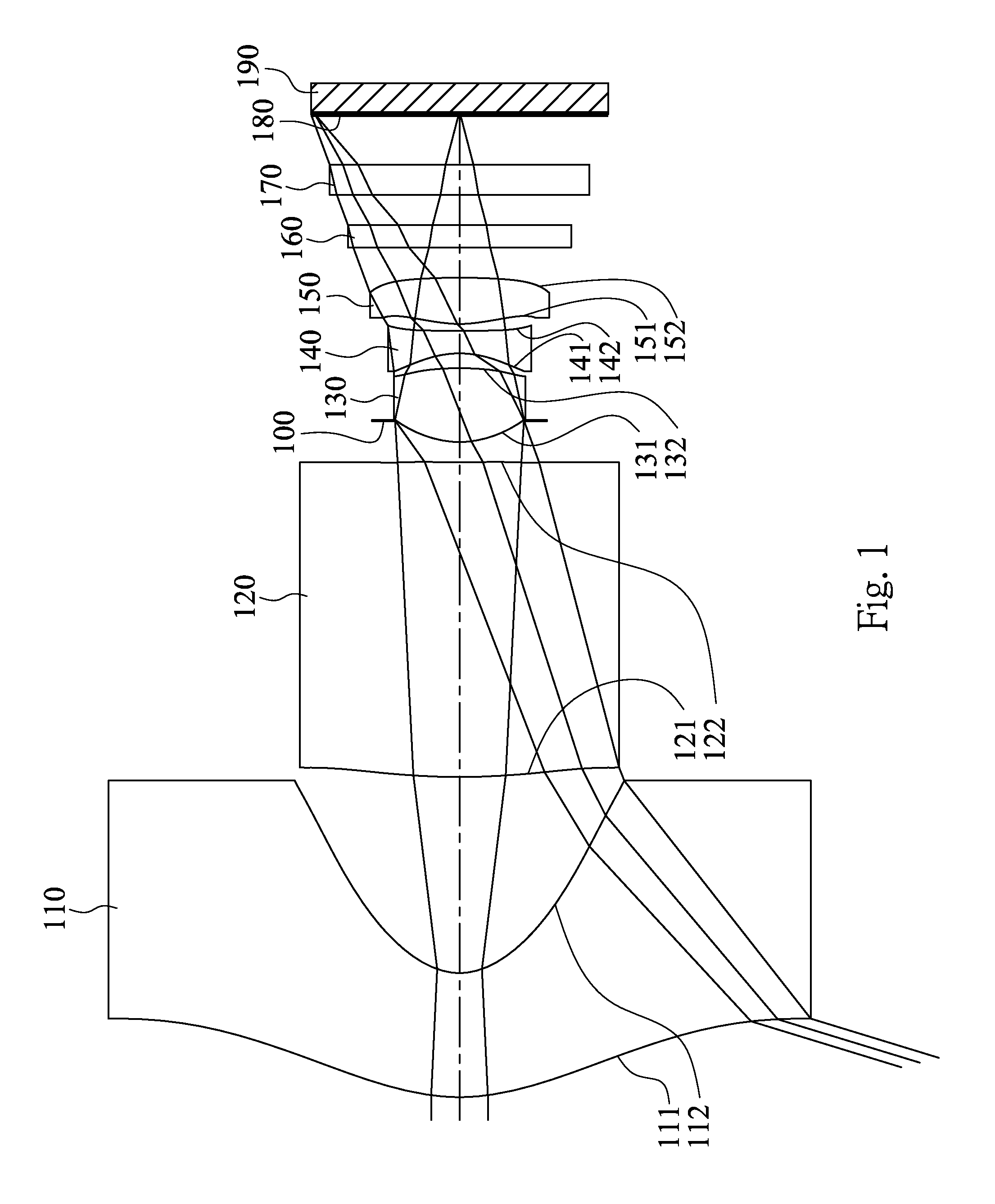

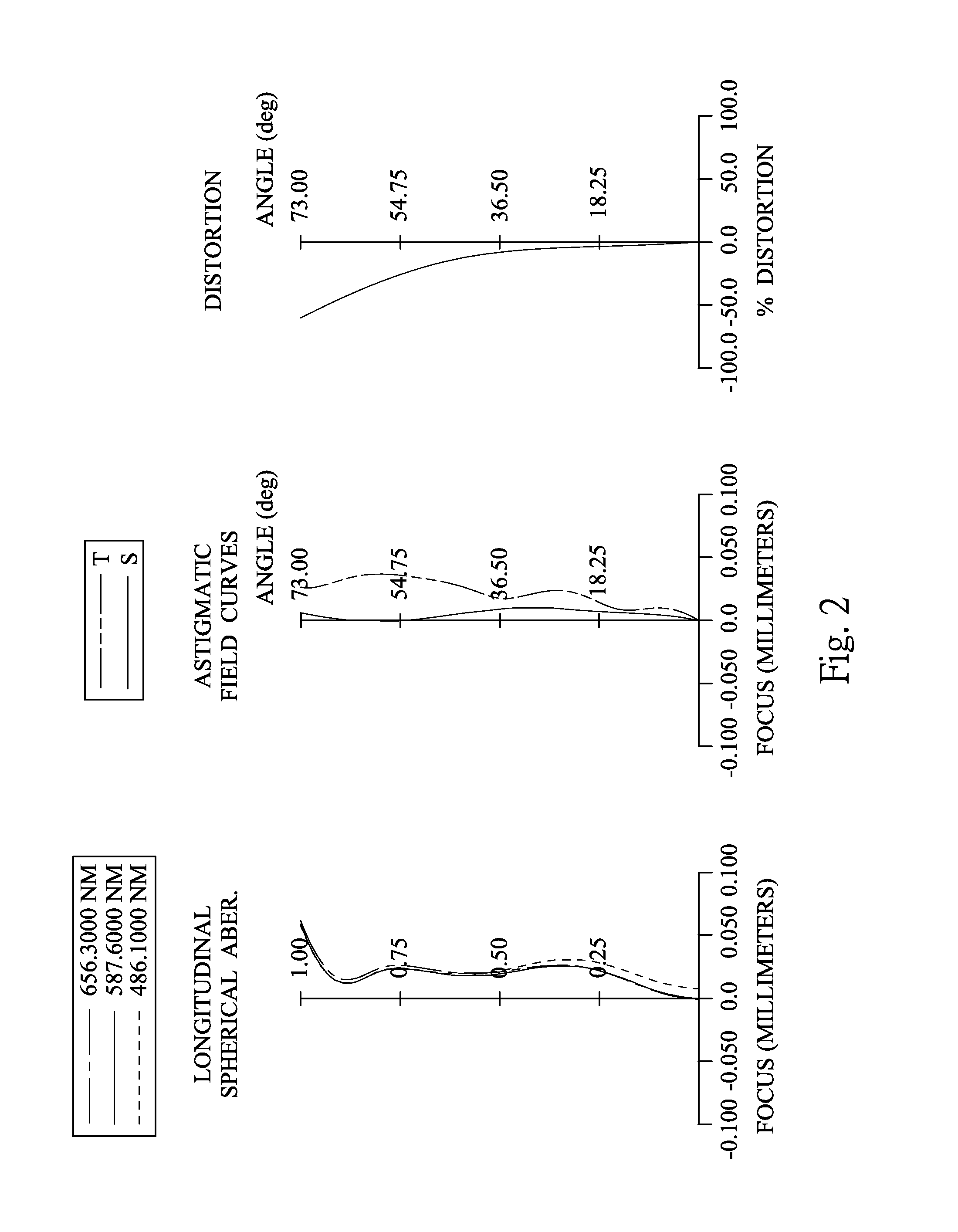

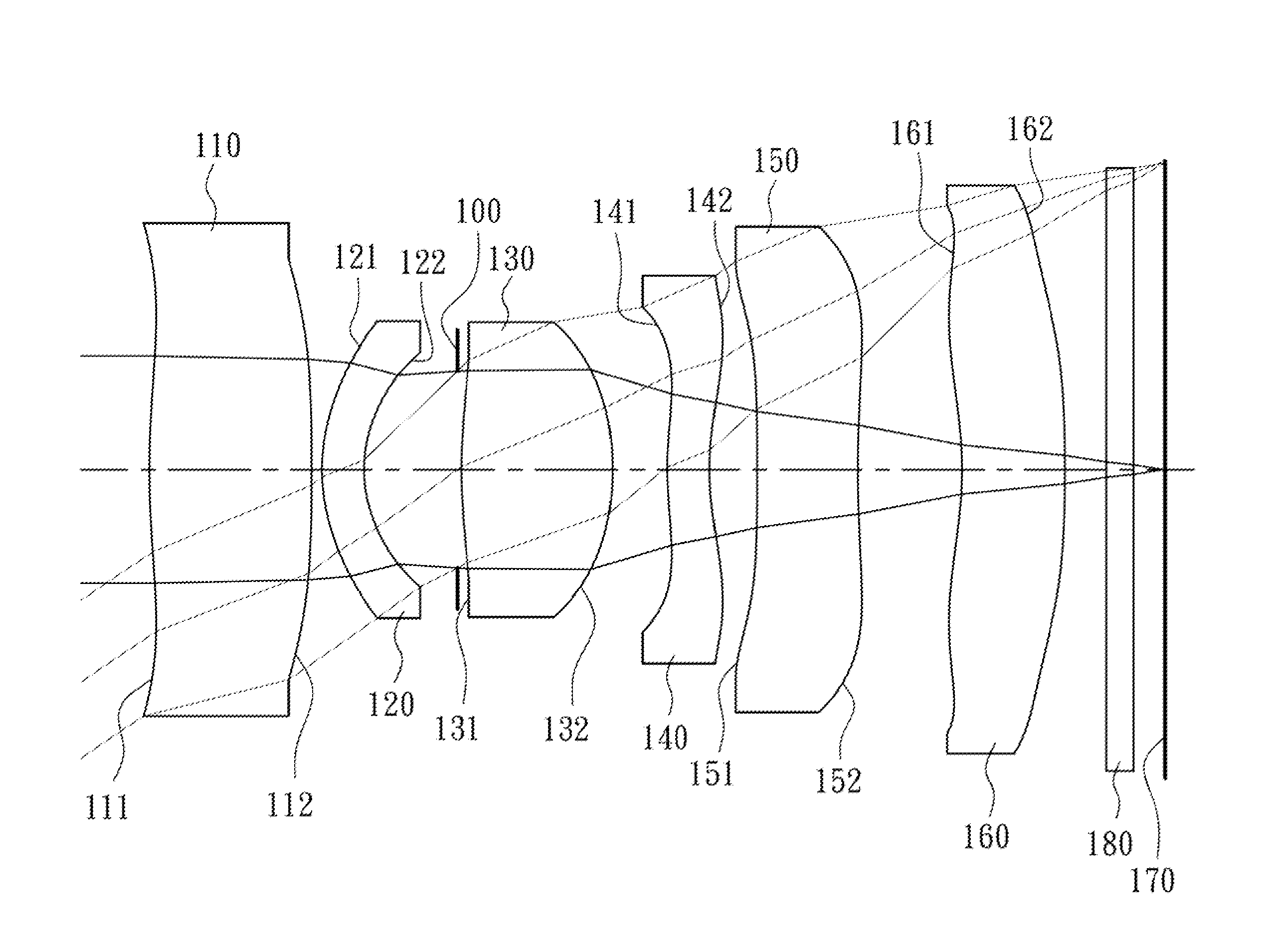

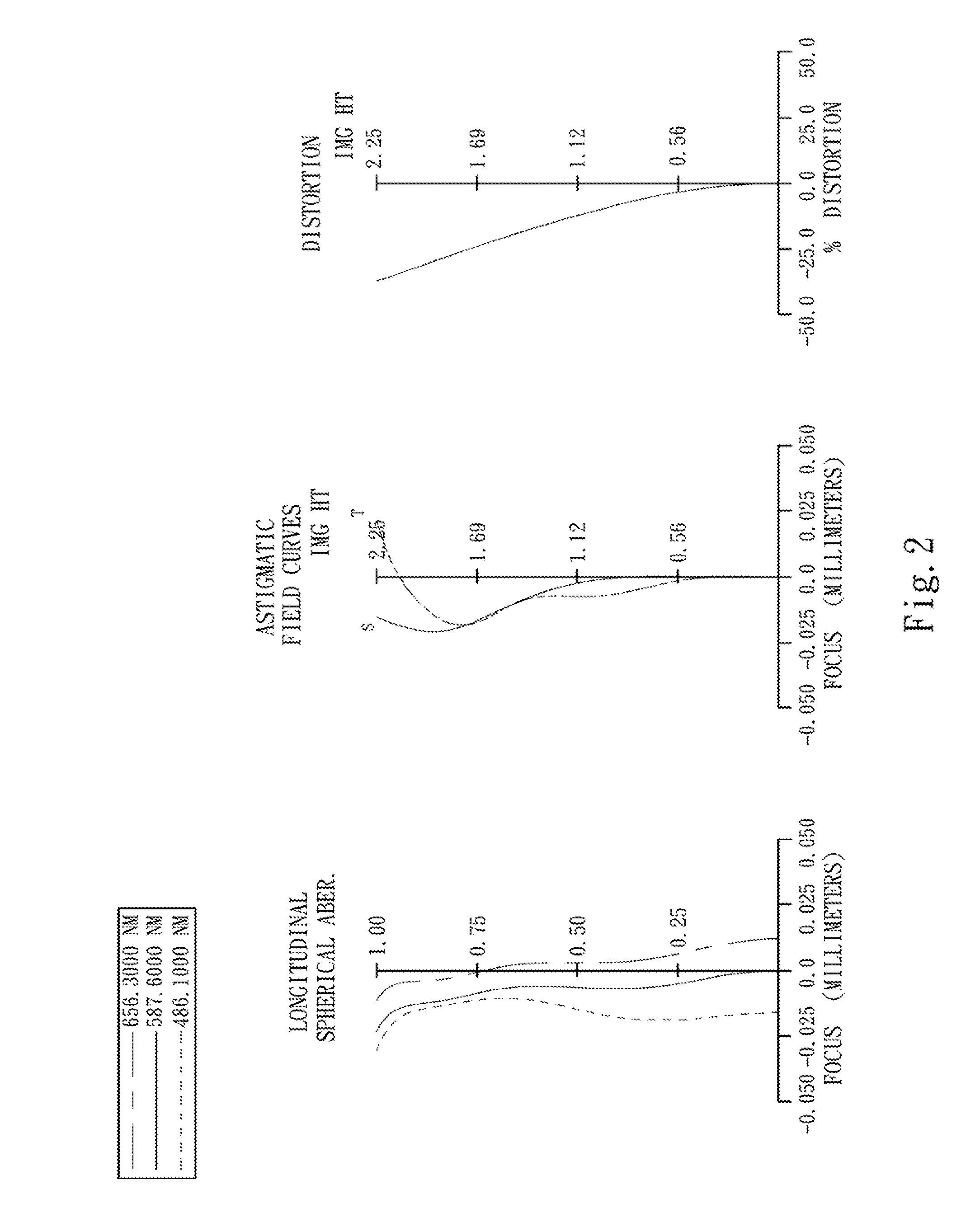

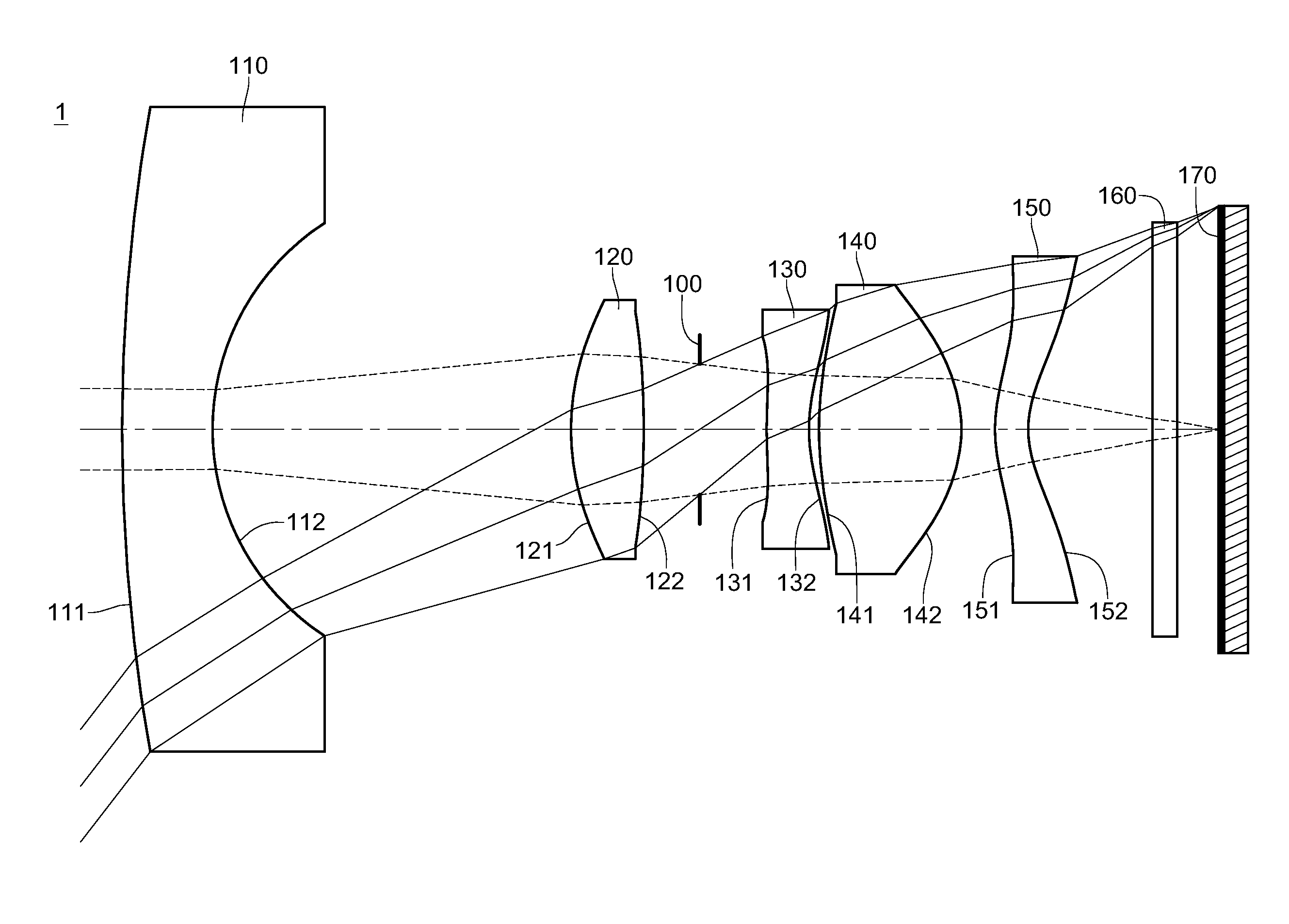

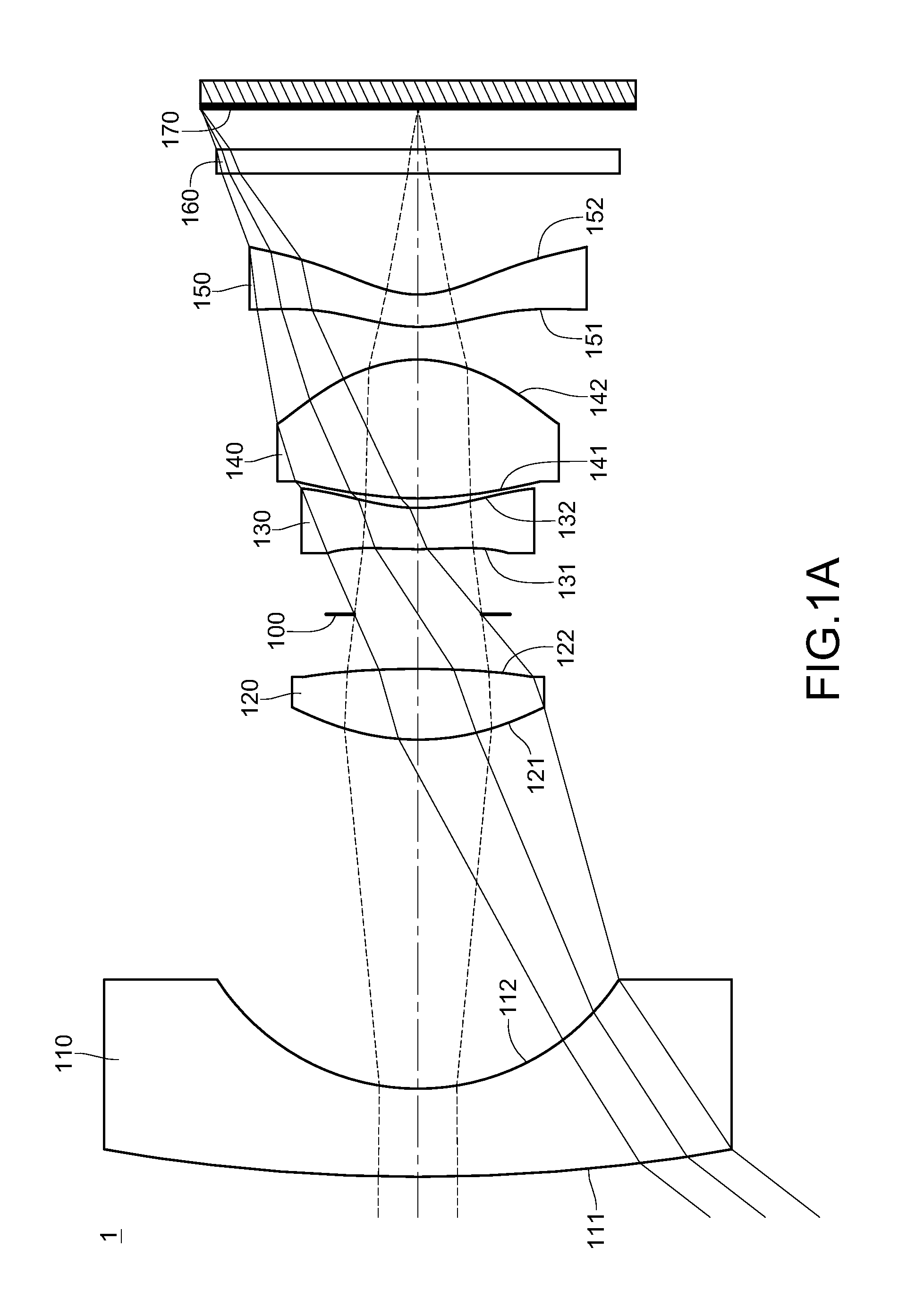

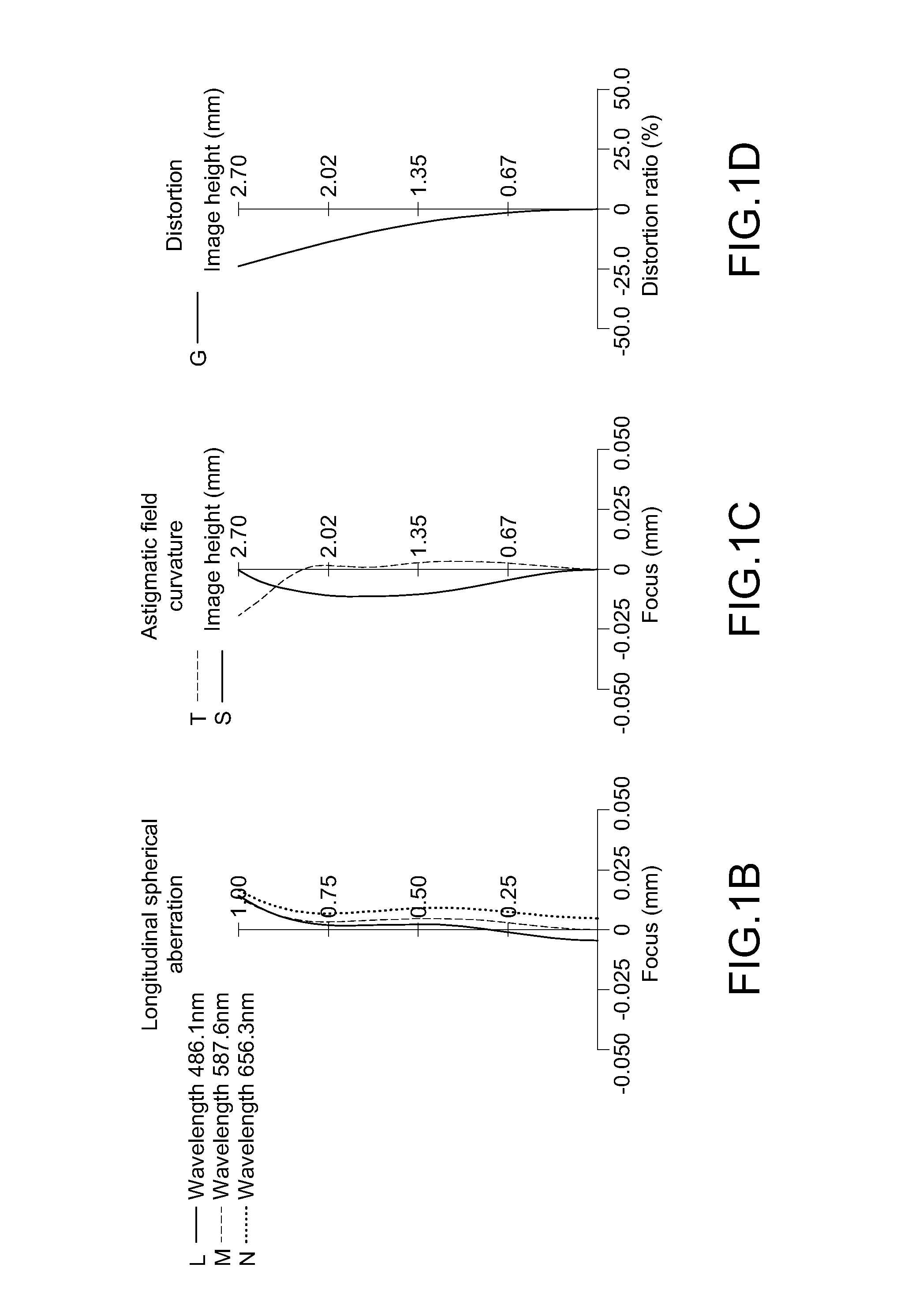

Image lens assembly and image capturing device

ActiveUS9036272B2Avoiding excessive spherical aberrationReduce photosensitivityTelevision system detailsLensPhysics

An image lens assembly includes, in order from an object side to an image side, a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element and a sixth lens element. The first lens element with positive refractive power has a convex object-side surface. The second lens element has positive refractive power. The third lens element has refractive power. The fourth lens element has refractive power. The fifth lens element with negative refractive power has a concave object-side surface, wherein both of the surfaces of the fifth lens element are aspheric. The sixth lens element with refractive power has a concave image-side surface, wherein the image-side surface thereof has at least one inflection point, and both of the surfaces of the sixth lens element are aspheric. The image lens assembly has a total of six lens elements with refractive power.

Owner:LARGAN PRECISION

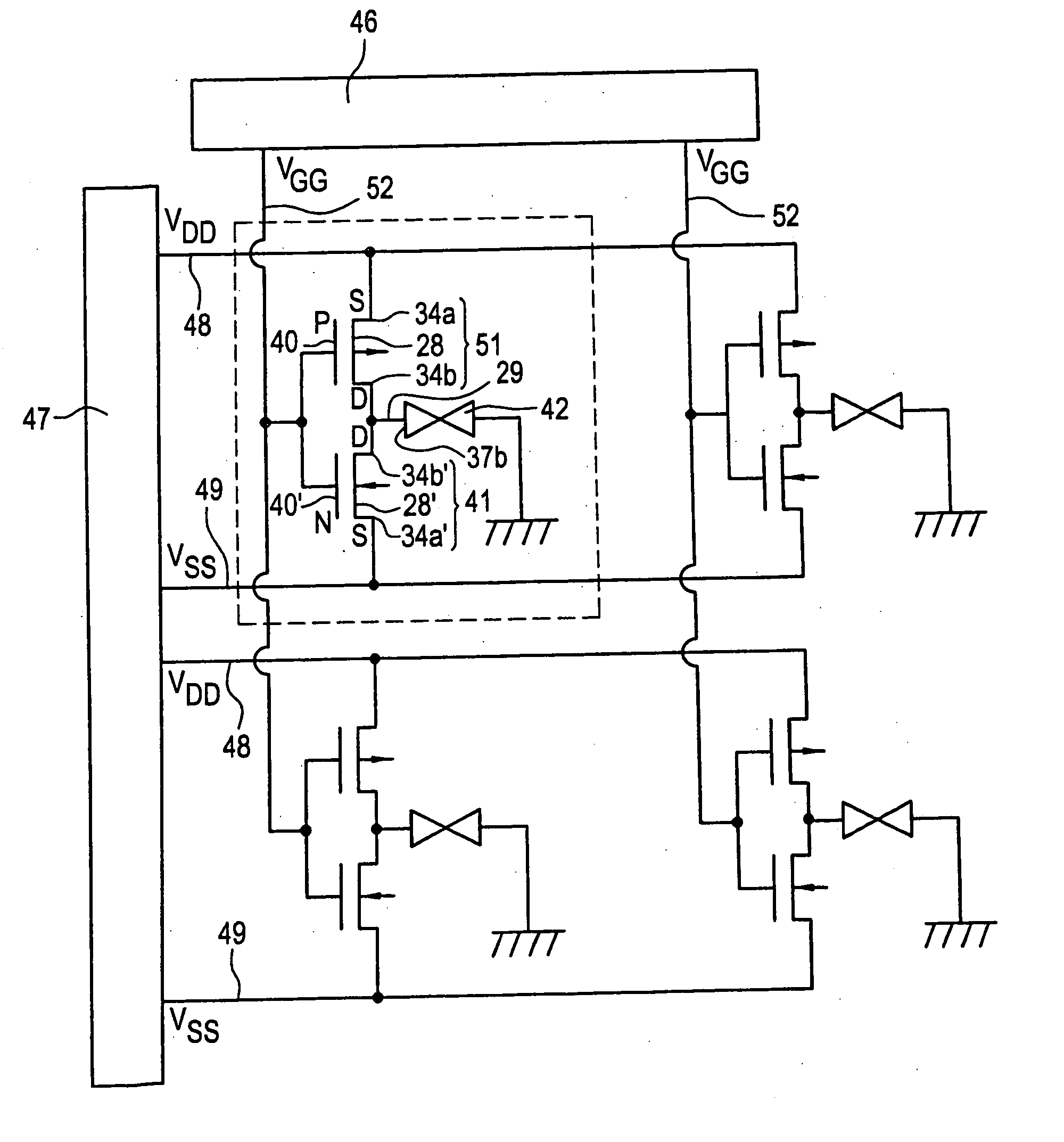

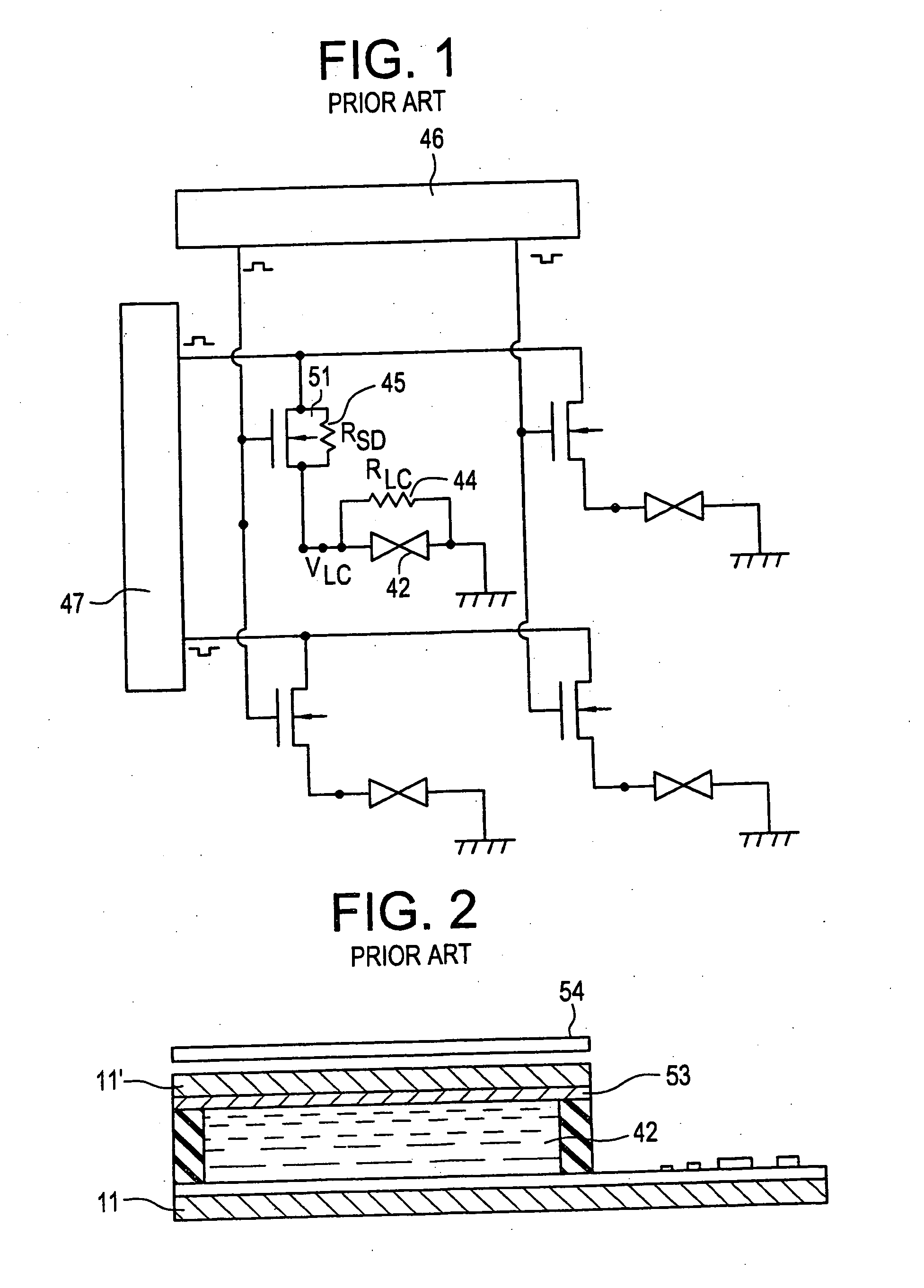

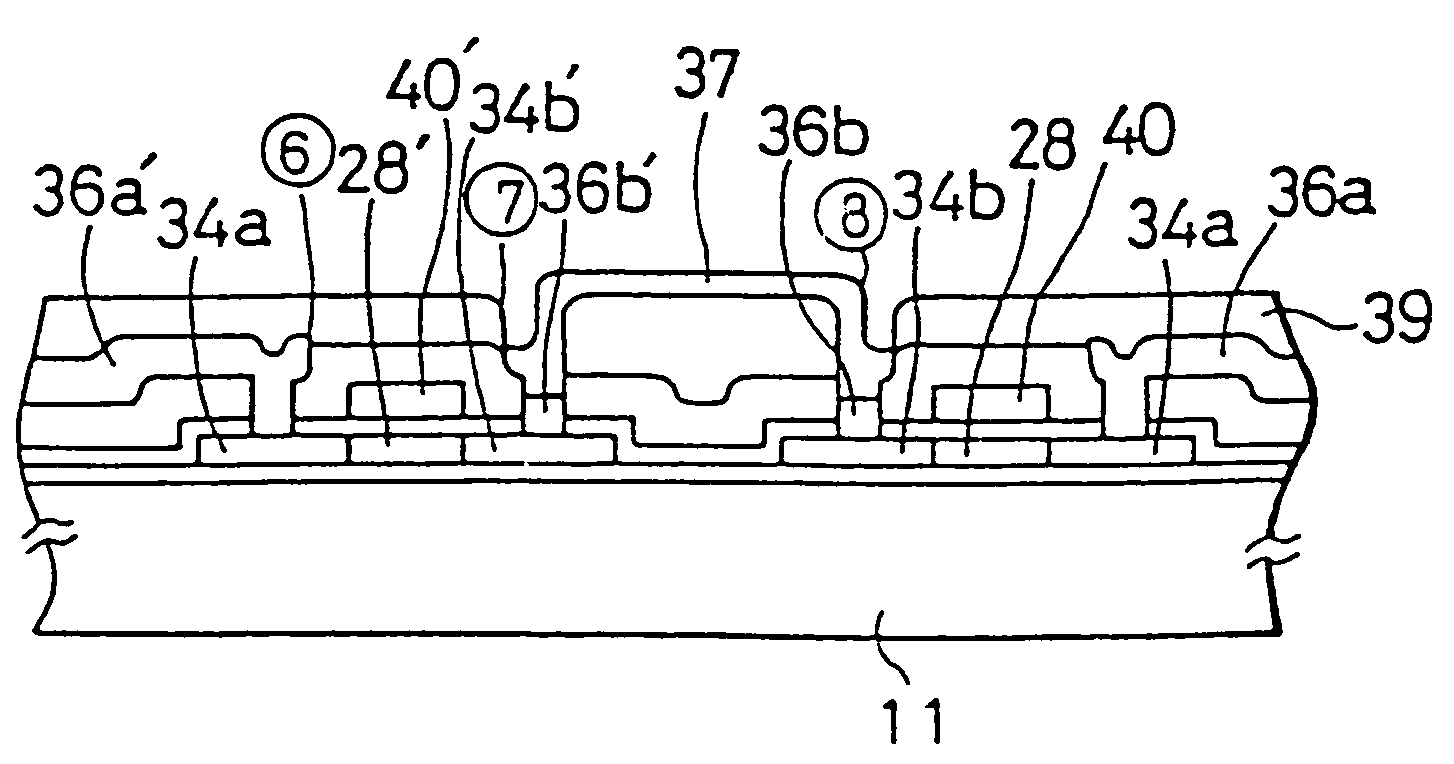

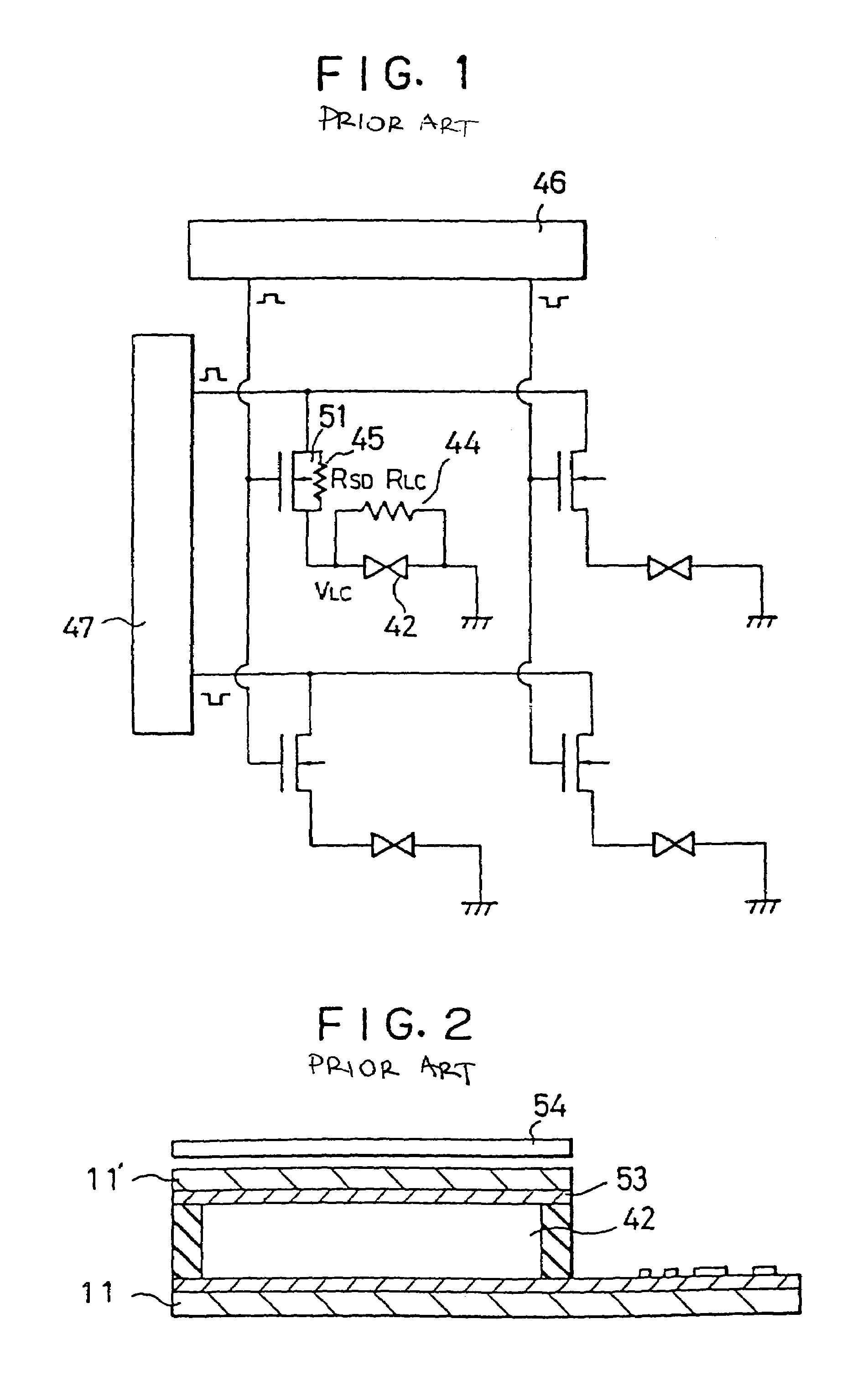

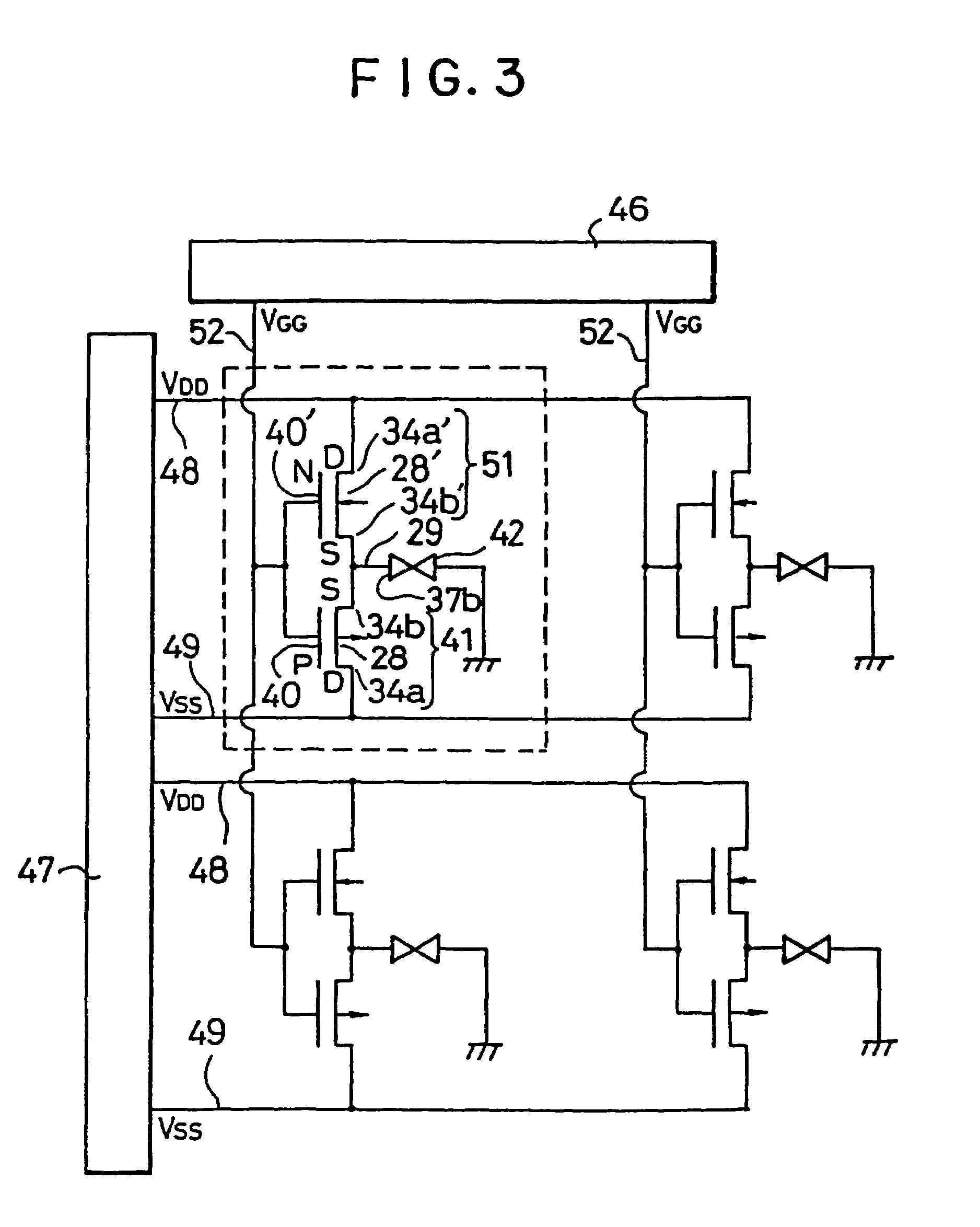

Electro-optical device and driving method for the same

InactiveUS20050237442A1Voltage level of each pixel during its operation is prevented from fluctuatingEliminate bad effectsStatic indicating devicesSolid-state devicesControl signalDisplay device

A display and a driving method for the same capable of constructing clear visual images is described. In the display, a plurality of conductive pads are opposed to a back electrode with a light influencing medium such as a liquid crystal layer. Control signals are supplied to the conductive pads through complimentary transistors comprise a p-channel field effect transistor and an n-channel field effect transistor connected between VDD and VSS lines of a control circuit, which also supplies a bias voltage to the back electrode and gate control signals to the gate terminals of the p-channel field effect transistor and the n-channel field effect transistor. During operation, the bias voltage is inverted in order to invert the polarity of control signal applied across the light influencing medium.

Owner:SEMICON ENERGY LAB CO LTD

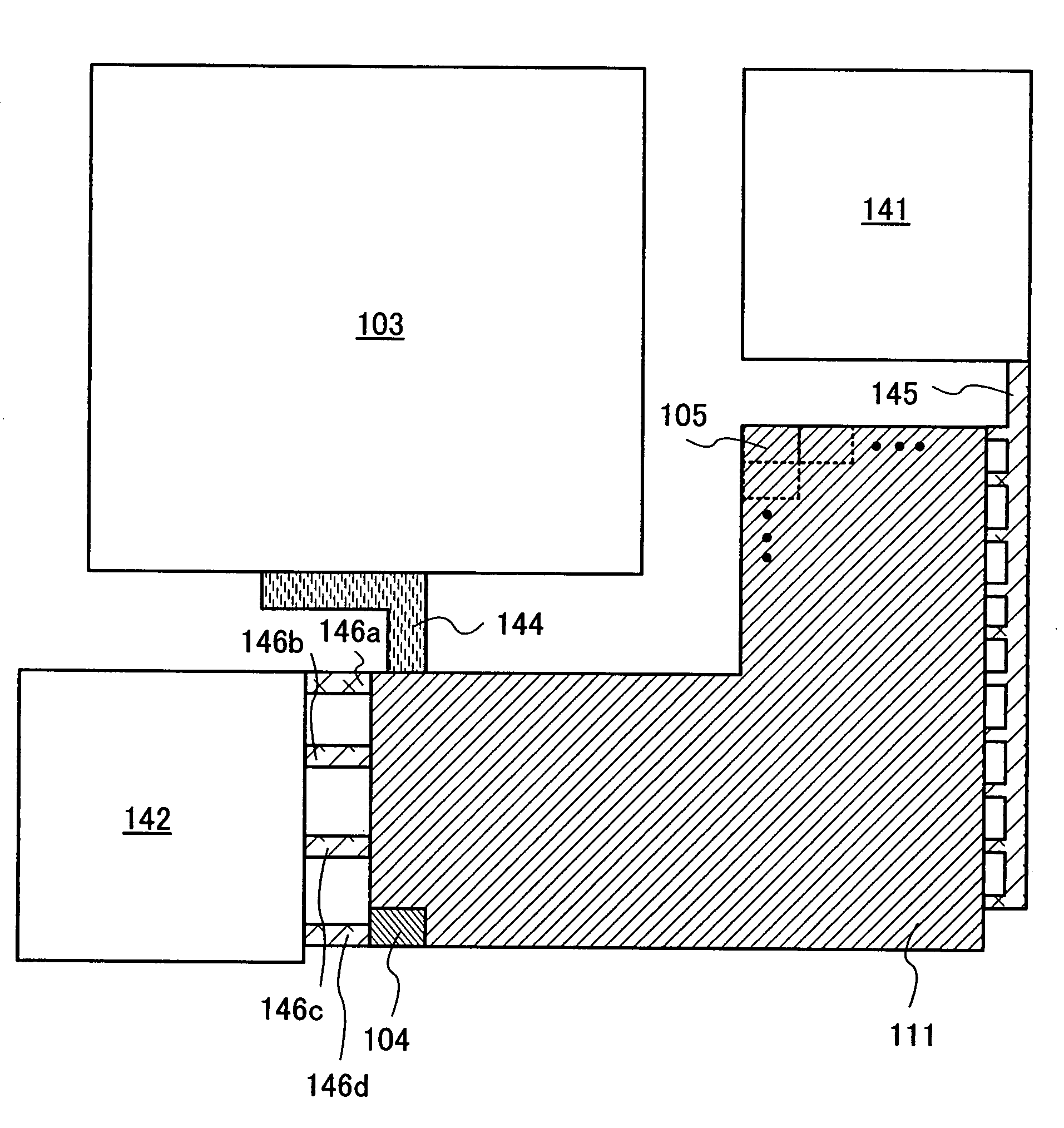

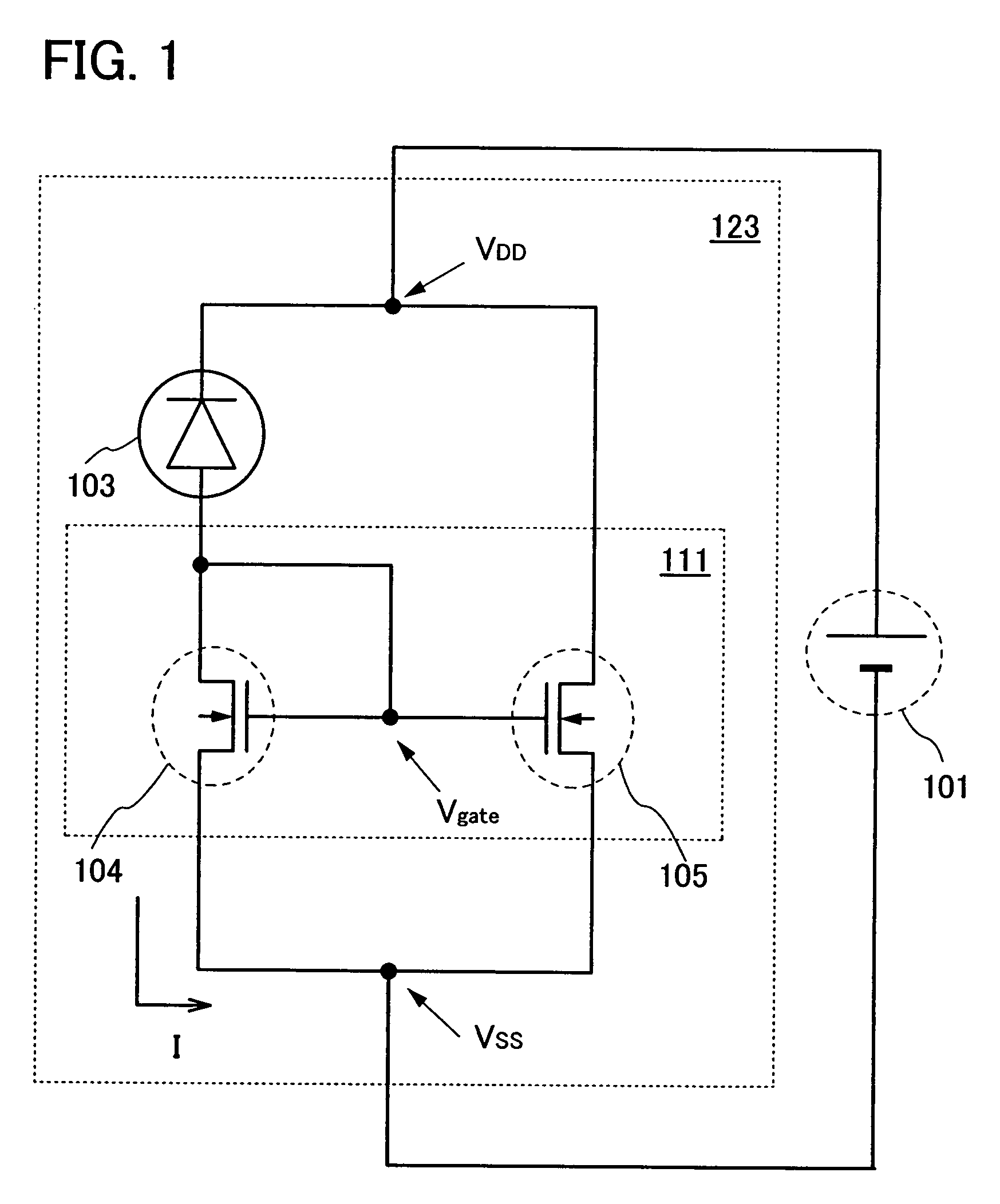

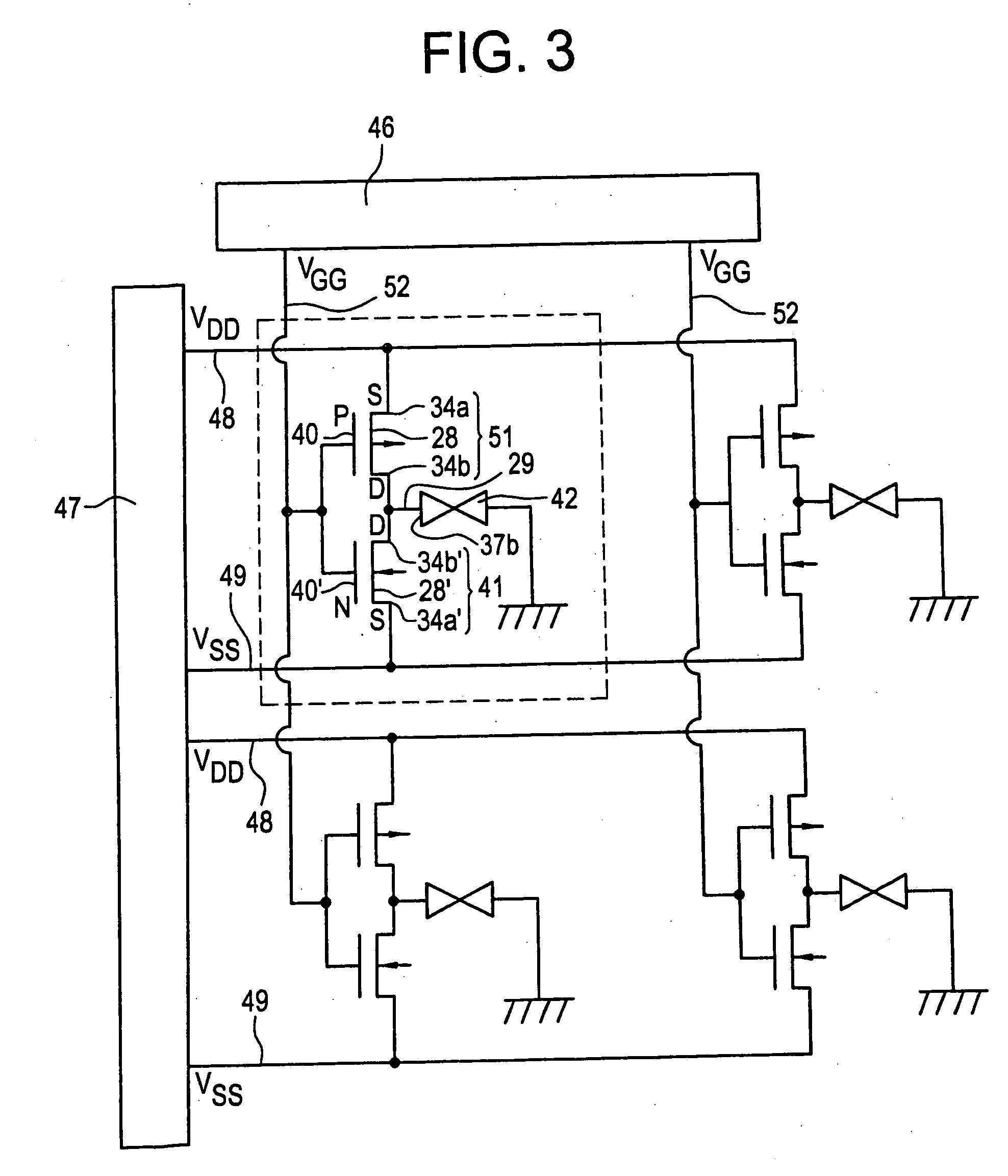

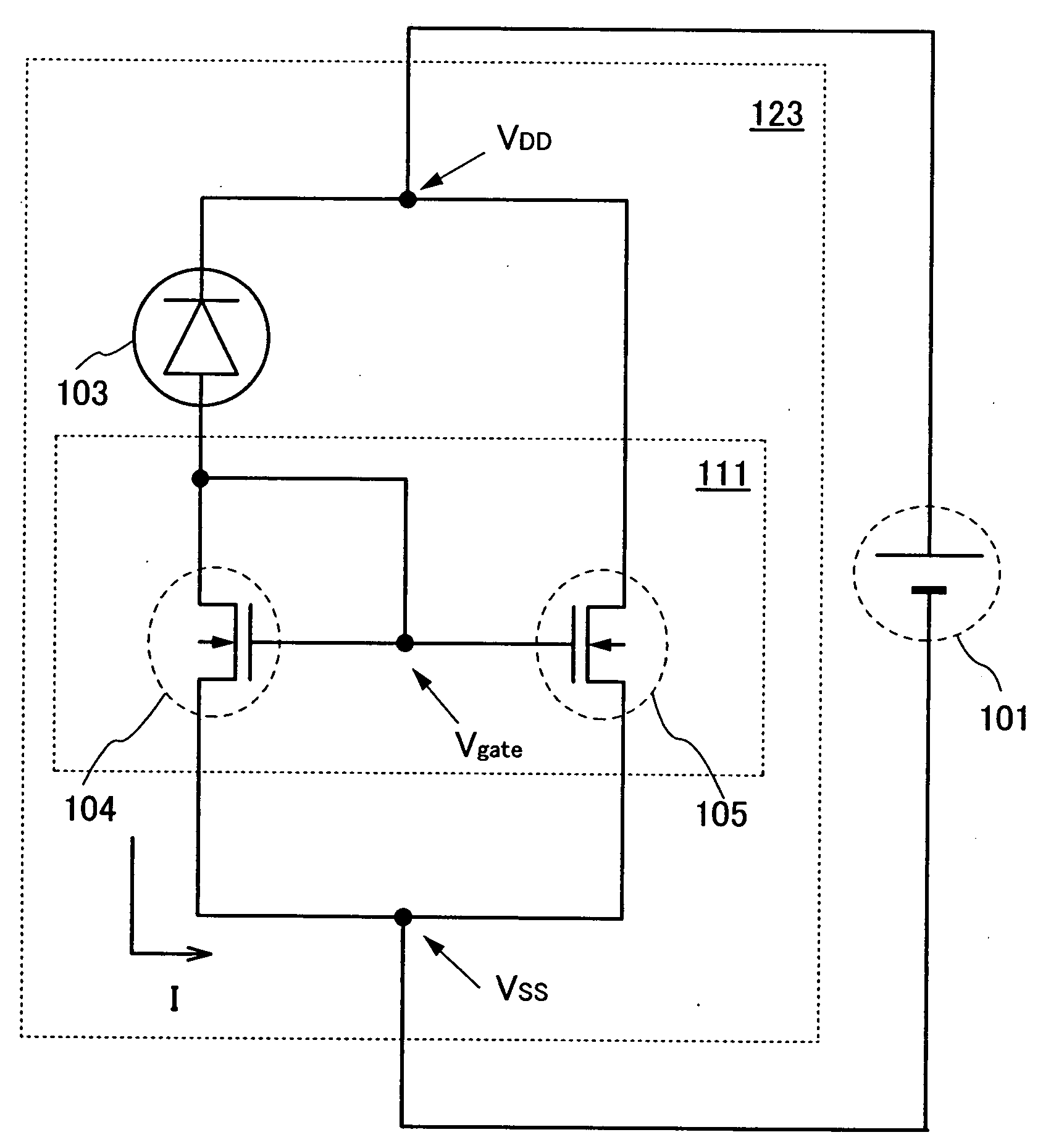

Semiconductor device

InactiveUS20080078923A1Reduce photosensitivityStable circuit operationTransistorTelevision system detailsAudio power amplifierPhotoelectric conversion

To suppress a decrease in photosensitivity of a photoelectric conversion element provided in a semiconductor device by reducing the parasitic resistance of an amplifier circuit. In addition, the amplifier circuit which amplifies the output current of the photoelectric conversion element is operated stably. A semiconductor device includes a photoelectric conversion element, a current mirror circuit having at least two thin film transistors, a high-potential power supply electrically connected to each of the thin film transistors, and a low-potential power supply electrically connected to each of the thin film transistors. When a reference thin film transistor is an n-type, the reference thin film transistor is placed closer to the low-potential power supply than an output thin film transistor is. When a reference thin film transistor is a p-type, the reference thin film transistor is placed closer to the high-potential power supply than an output thin film transistor is.

Owner:SEMICON ENERGY LAB CO LTD

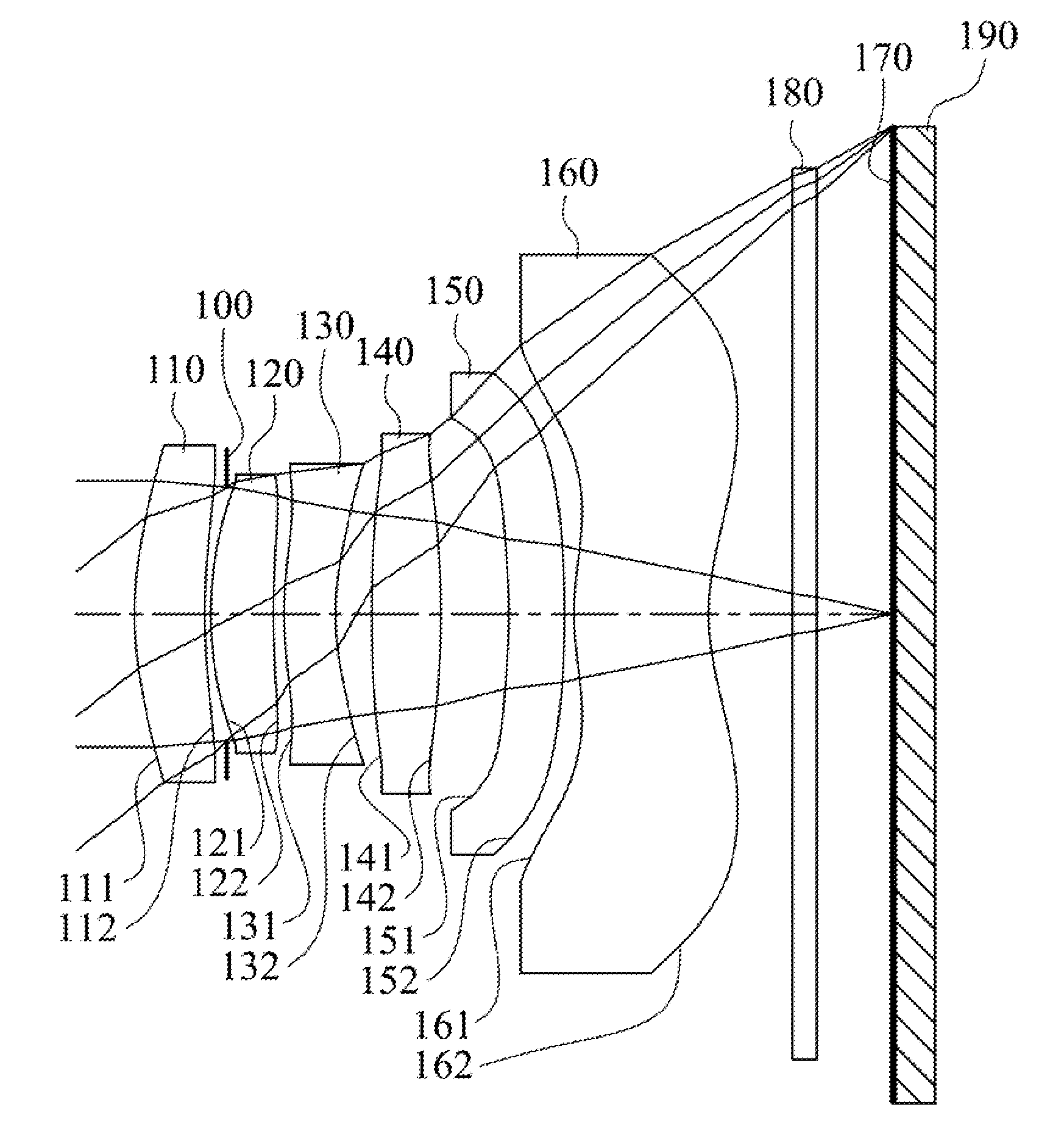

Photographing optical lens assembly, image capturing device and mobile terminal

A photographing optical lens assembly includes, in order from an object side to an image side, a first lens element, a second lens element, a third lens element, a fourth lens element, a fifth lens element, and a sixth lens element. The first lens element with positive refractive power has an object-side surface being convex in a paraxial region thereof. The second lens element has negative refractive power. The third lens element has refractive power. The fourth lens element has refractive power. The fifth lens element with refractive power has an object-side surface being concave in a paraxial region thereof. The sixth lens element with positive refractive power has an object-side surface being convex in a paraxial region thereof, and an image-side surface being concave in a paraxial region thereof. The photographing optical lens assembly has a total of six lens elements with refractive power.

Owner:LARGAN PRECISION

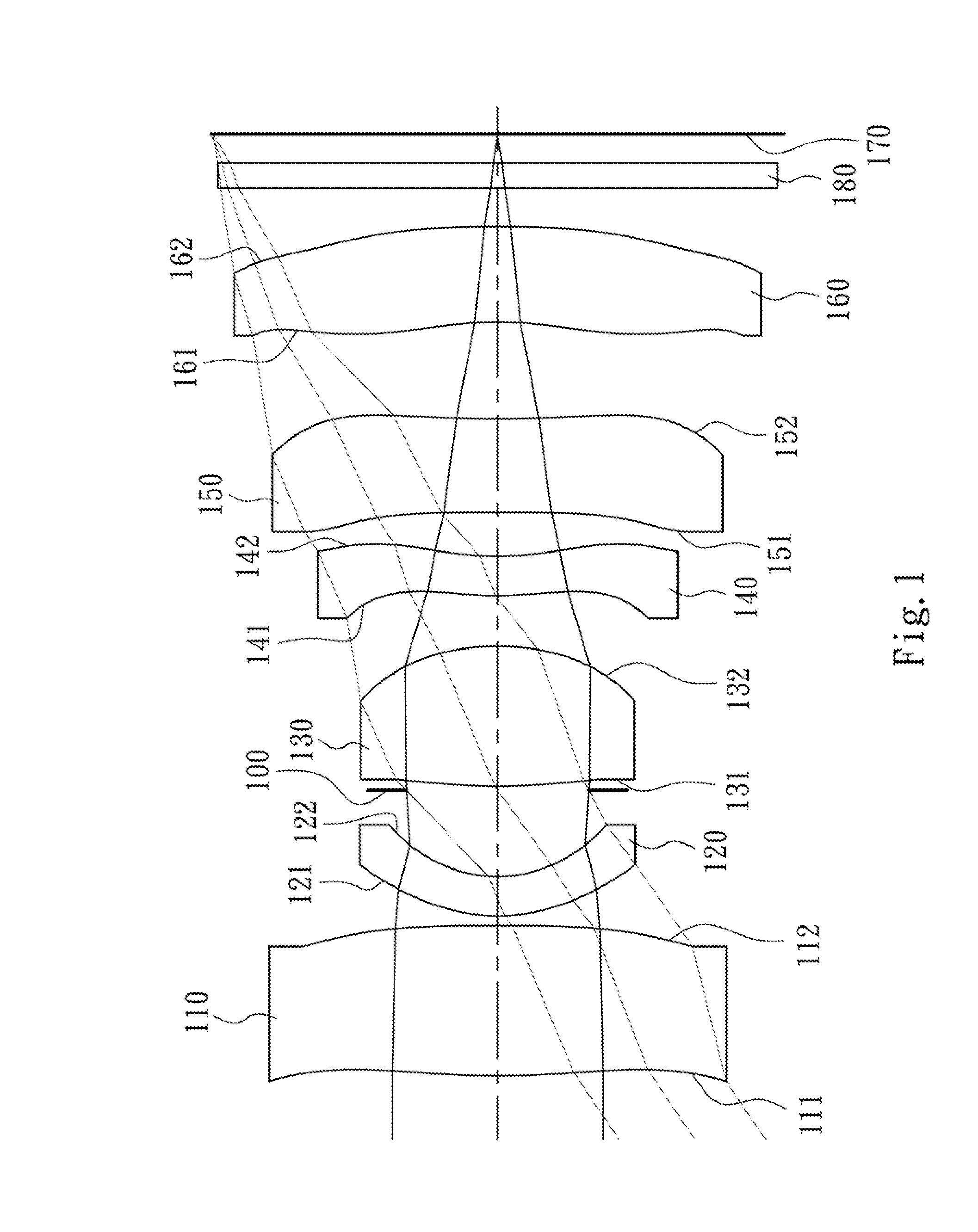

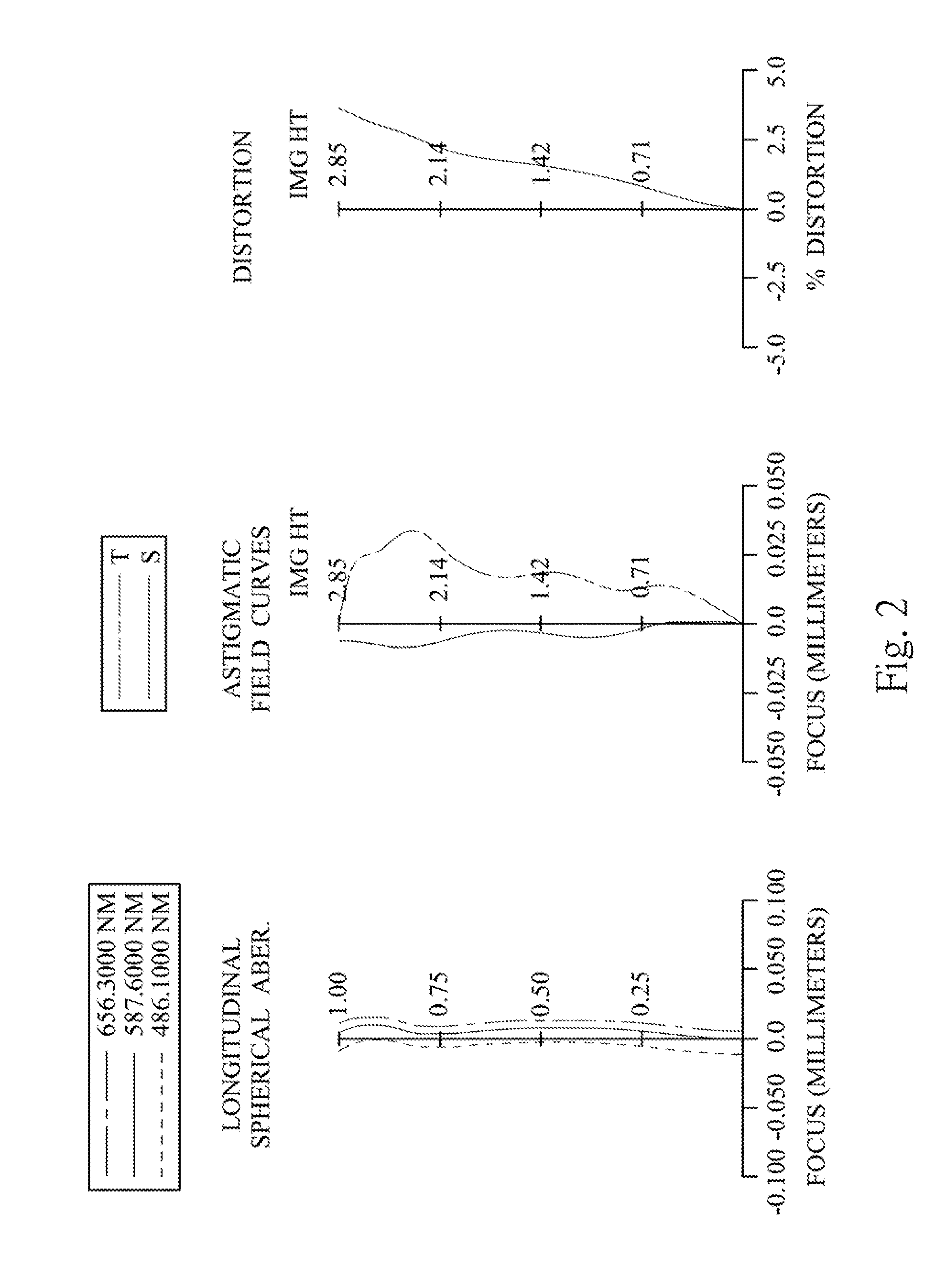

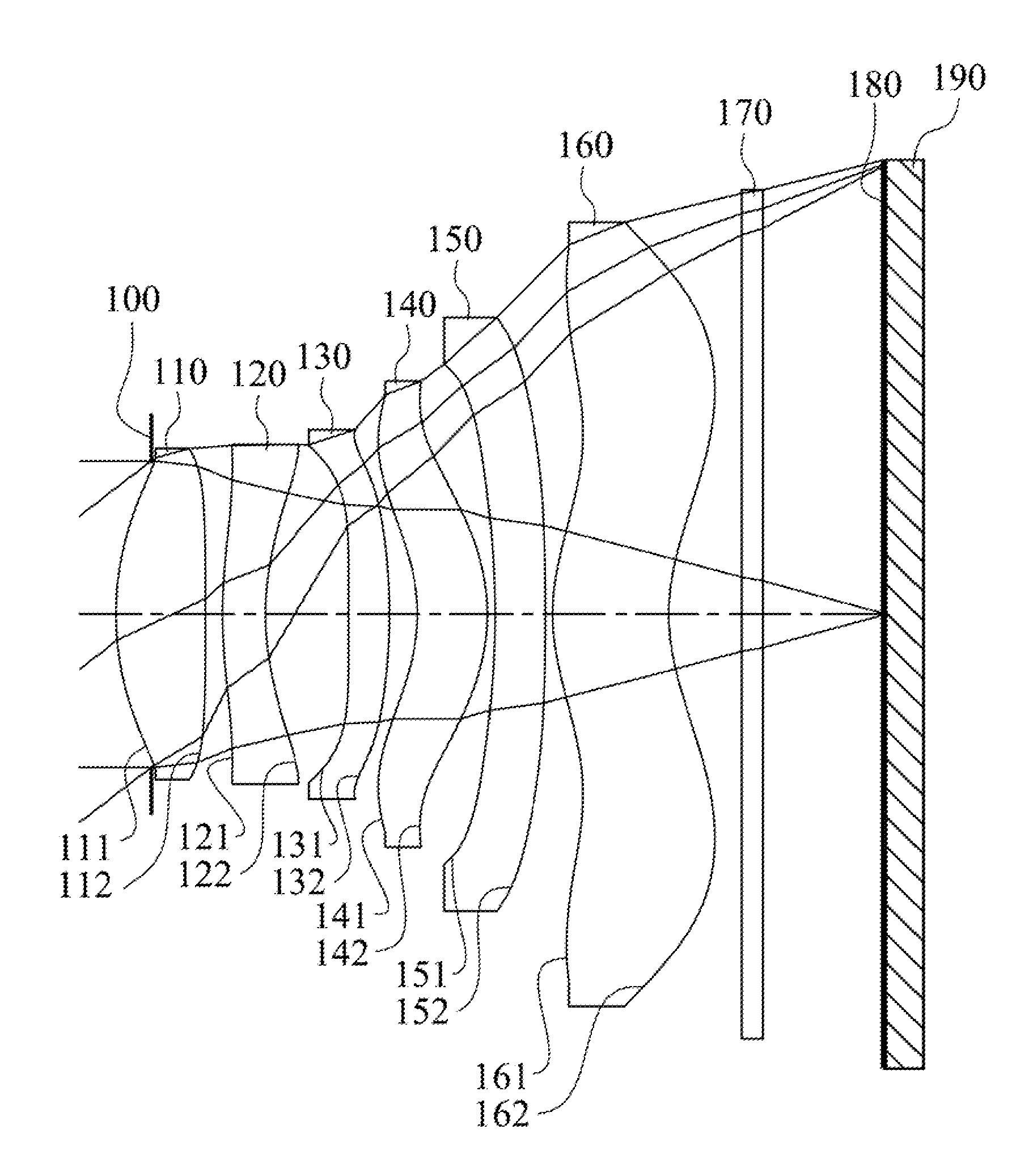

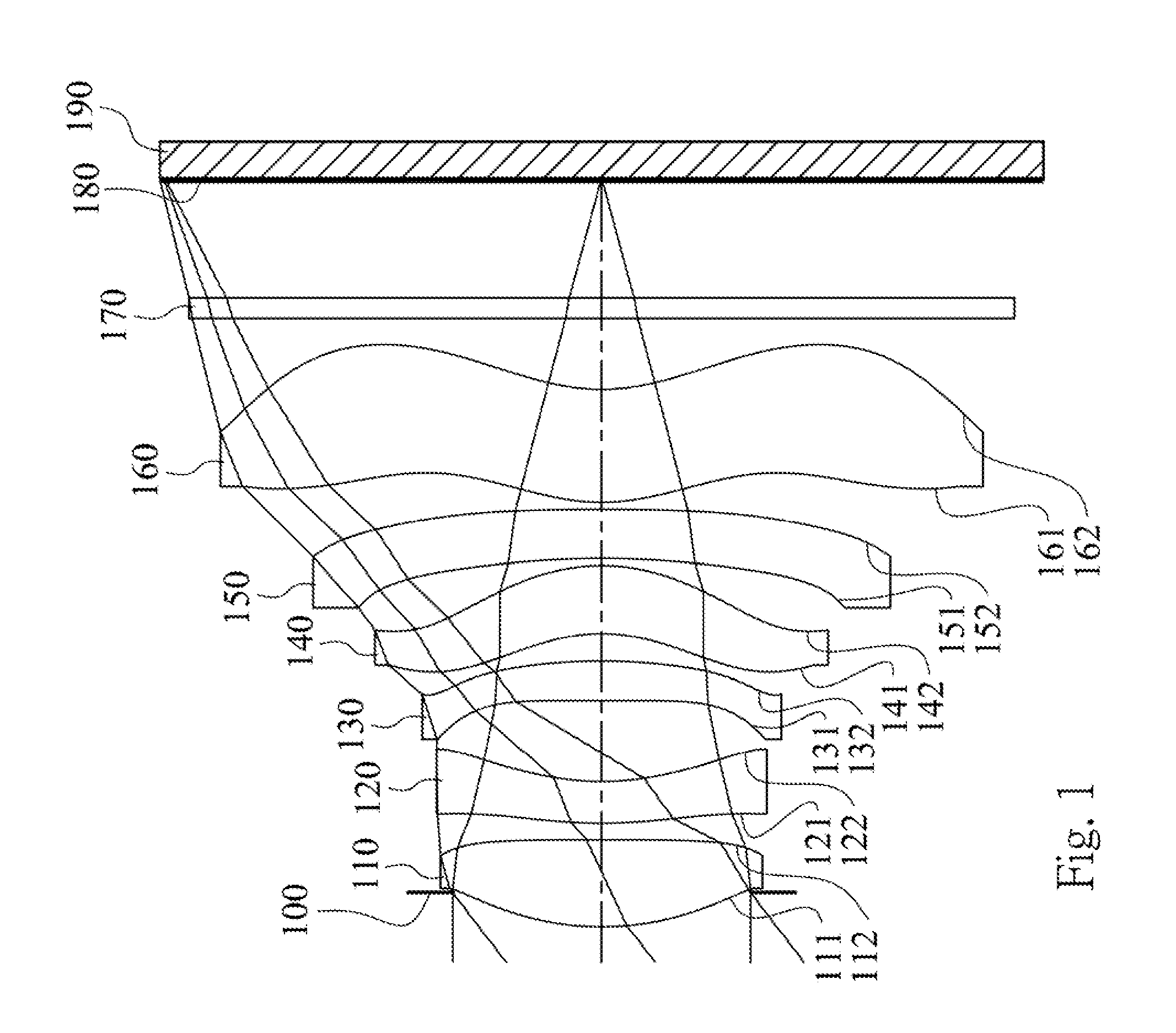

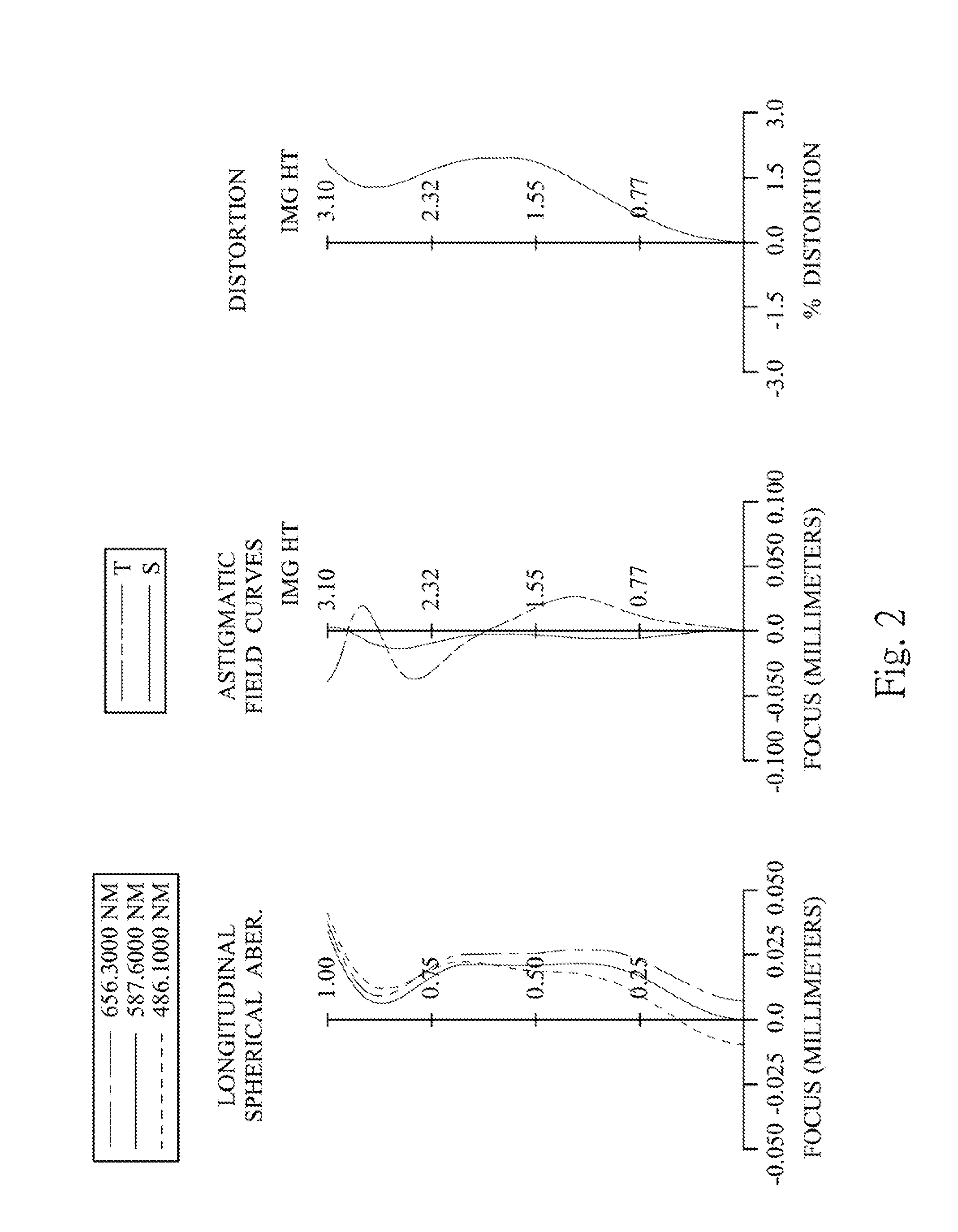

Optical imaging lens system

ActiveUS20120086848A1Shorten the lengthReduce photosensitivityTelevision system detailsColor television detailsImaging qualityImage quality

This invention provides an optical imaging lens system in order from an object side to an image side including: a first lens element with positive refractive power having a convex object-side surface and a concave image-side surface, a second lens element with negative refractive power having a convex object-side surface and a concave image-side surface, a third lens element with positive refractive power, and a fourth lens element having a concave image-side surface, and at least one of the object-side and image-side surfaces thereof being aspheric; wherein the optical imaging lens system further comprises an aperture stop and an electronic sensor on which an object is imaged, and the aperture stop is positioned between an object and the first lens element; wherein there are four lens elements with refractive power. By such arrangement, total track length and photosensitivity of the optical imaging lens system can be effectively reduced while retaining high image quality.

Owner:LARGAN PRECISION

Electrophotographic photosensitive member, process cartridge and electrophotographic apparatus

InactiveUS6555279B2Reduce photosensitivityIncrease in residual potentialElectrographic process apparatusCorona dischargeProtection layerChemistry

An electrophotographic photosensitive member exhibiting a good durability and stable electrophotographic performances regardless of environmental change is provided by coating the photosensitive layer with a specific protective layer. The protective layer comprises a cured phenolic resin and a charge-transporting compound having at least one group selected from the group consisting of hydroxyalkyl groups, hydroxyalkoxy groups and hydroxyphenyl groups capable of having a substituent.

Owner:CANON KK

Electro-optical device and driving method for the same

InactiveUS7154147B1Clear imagingAccurate operationStatic indicating devicesSolid-state devicesControl signalDisplay device

A grey tone display and a driving method are described. The display comprises a light influencing layer, an electrode pad located adjacent to the layer at one side of the layer in order to define a pixel in the layer, an n-channel field effect transistors connected to the electrode pad at its source terminal, a p-channel field effect transistors connected to the electrode pad at its source terminal, a first control line connected to the drain terminal of the n-channel field effect transistor, a second control line connected to the drain terminal of the p-channel field effect transistor, a third control line connected to the gate terminals of the n-channel field effect transistor and the p-channel field effect transistor, and a control circuit for supplying control signals to the first, second and third control lines. By this configuration, the voltage of the electrode pad can be arbitrarily controlled by adjusting the input level at the gate terminals.

Owner:SEMICON ENERGY LAB CO LTD

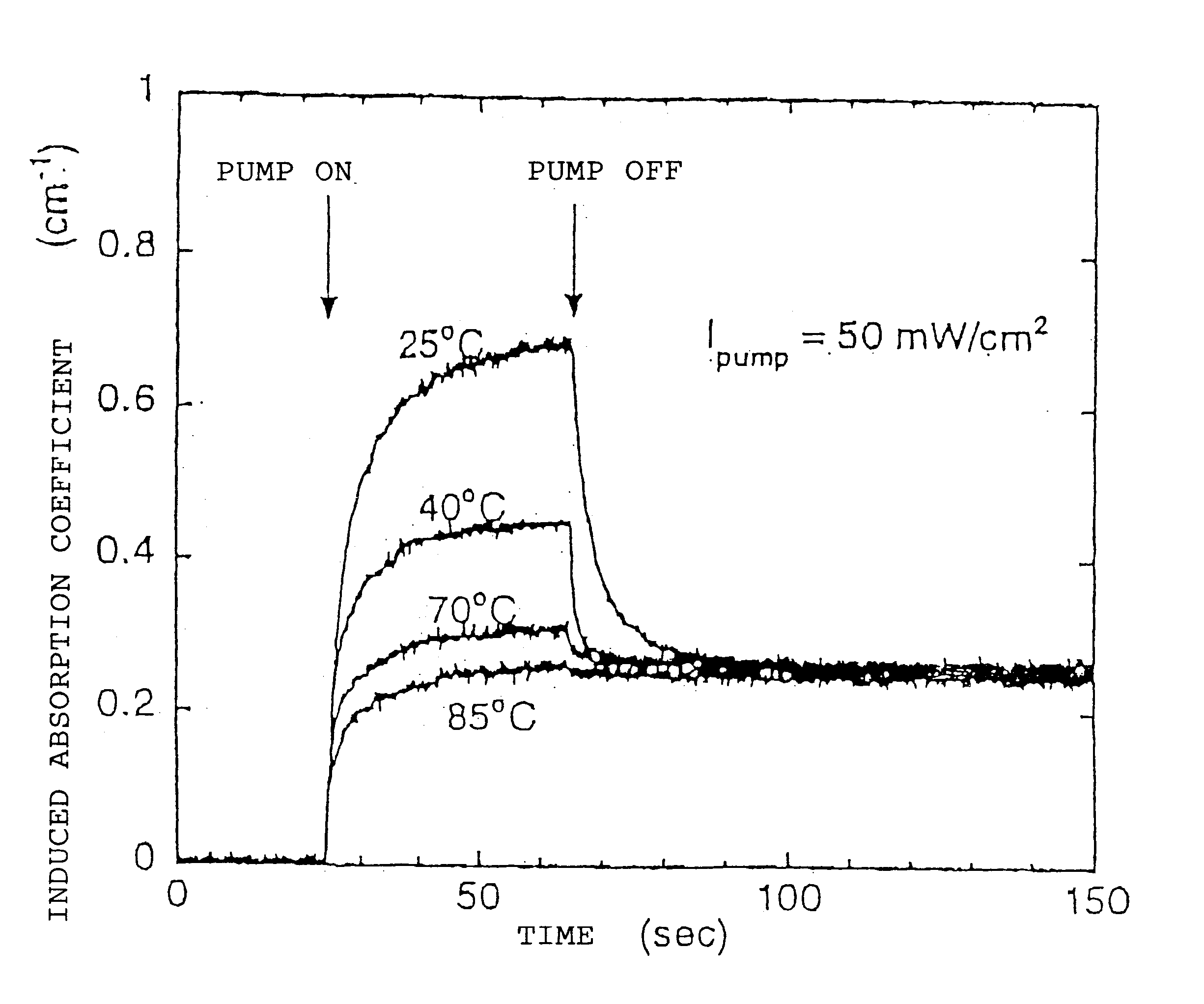

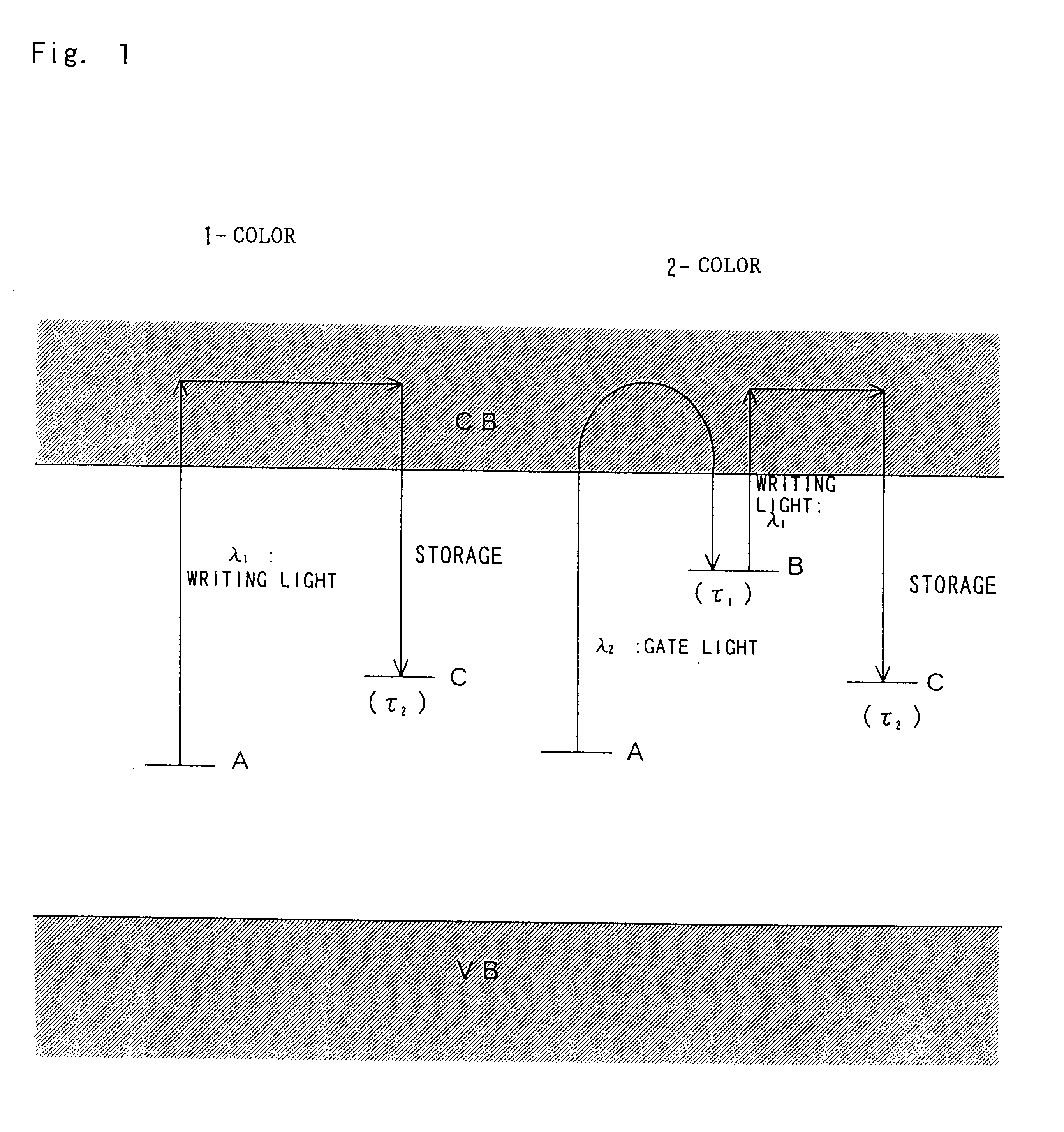

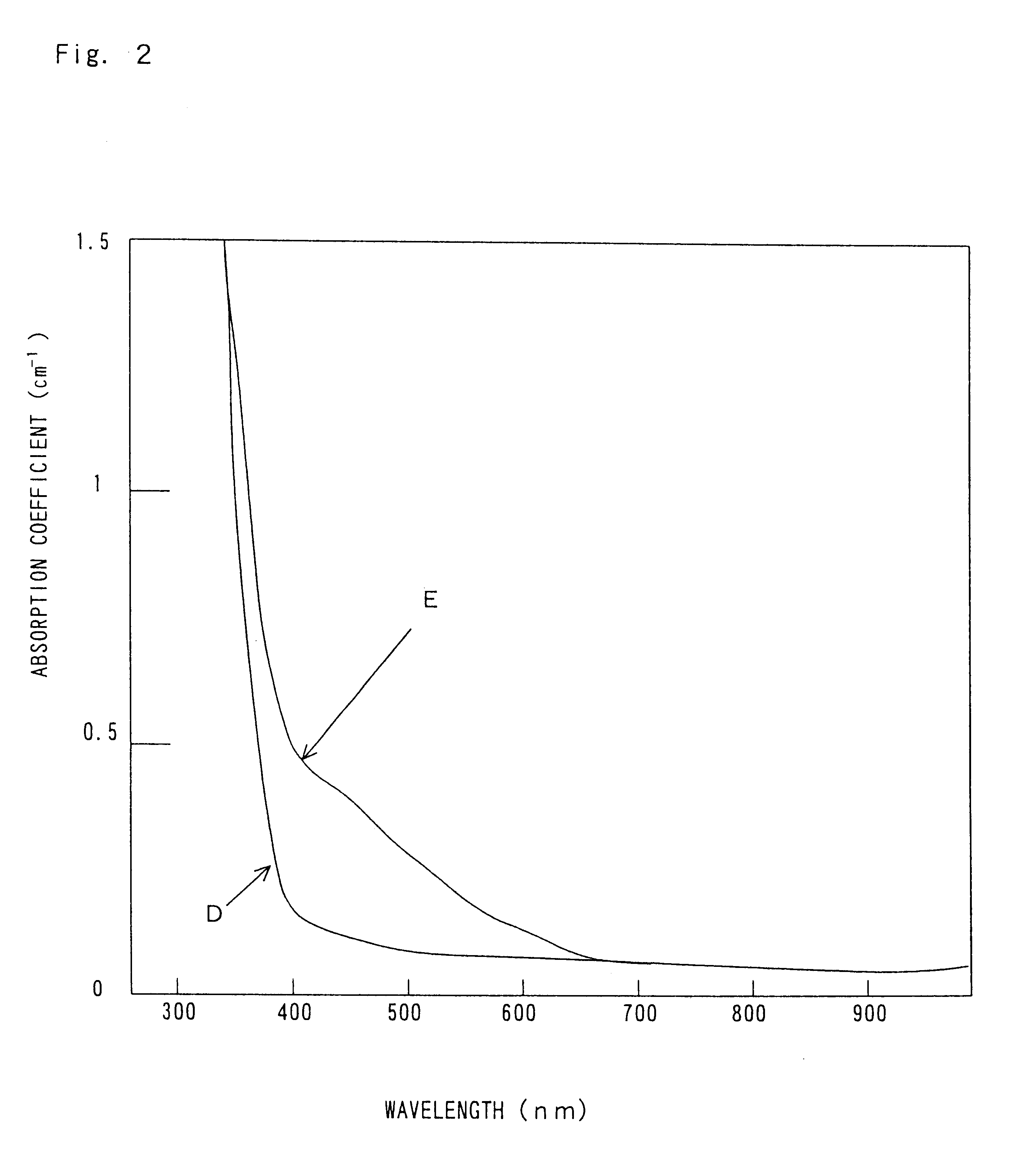

Photorefractive material

InactiveUS6670079B1Reduce photosensitivityPhotomechanical apparatusDigital storageTerbiumSingle crystal

A photorefractive material provides a high photosensitivity without reduction. The material comprises a single crystal of terbium (Tb)-doped niobate or tantalate. The single crystal is a single crystal of lithium niobate (LiNbO3) whose molar fraction of [Li2O] / ([Li2O]+[Nb2O5]) lies in a range of 0.482 to 0.505, or a single crystal of lithium tantalate (LiTaO3) whose molar fraction of [Li2O] / ([Li2O]+[Ta2O5]) lies in a range of 0.482 to 0.505. The amount of terbium added in the photorefractive material ranges from 10 weight ppm to 1000 weight ppm.

Owner:DIRECTOR GEN OF NAT INST FOR RES & INORGANIC MATERIALS +1

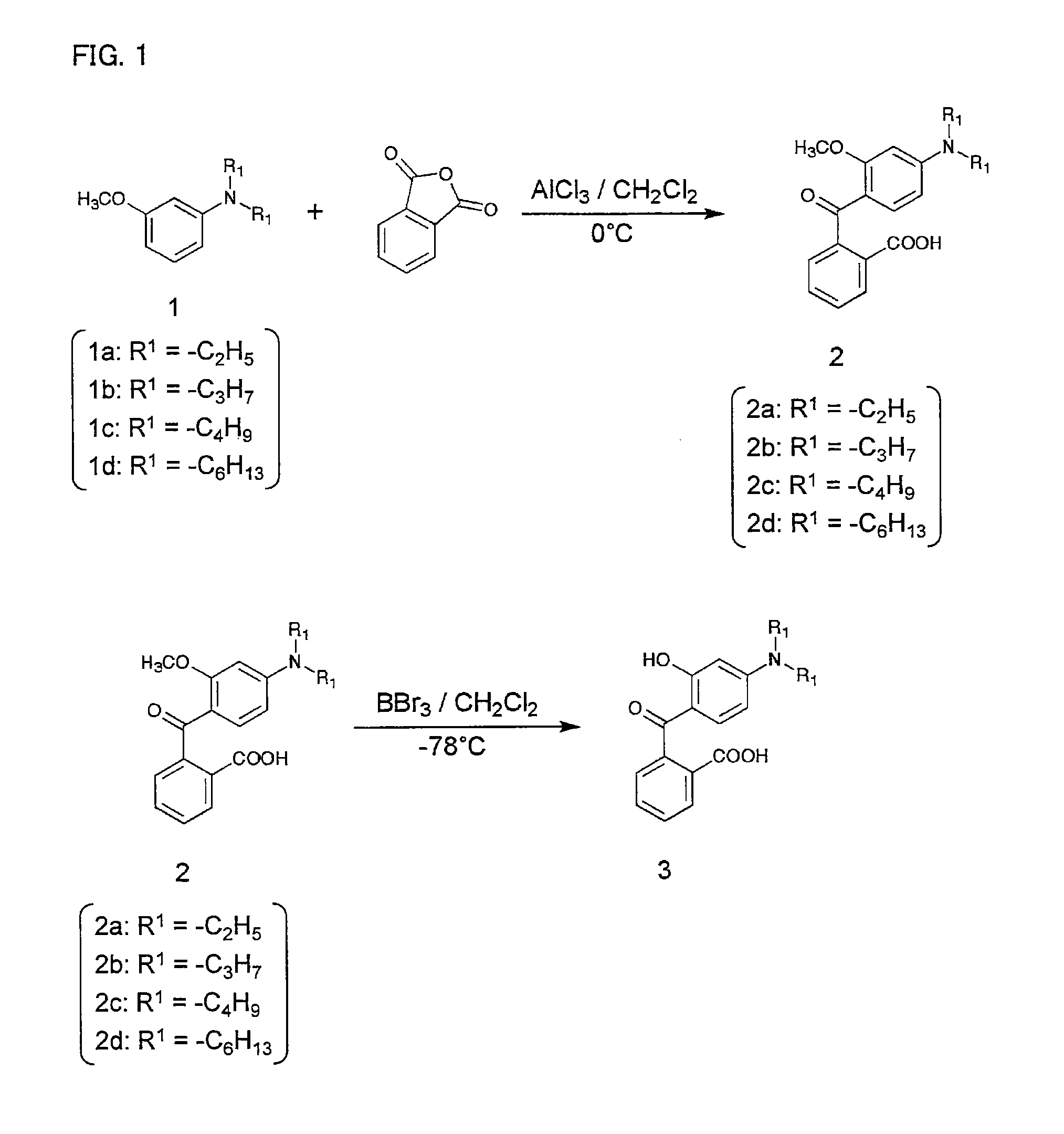

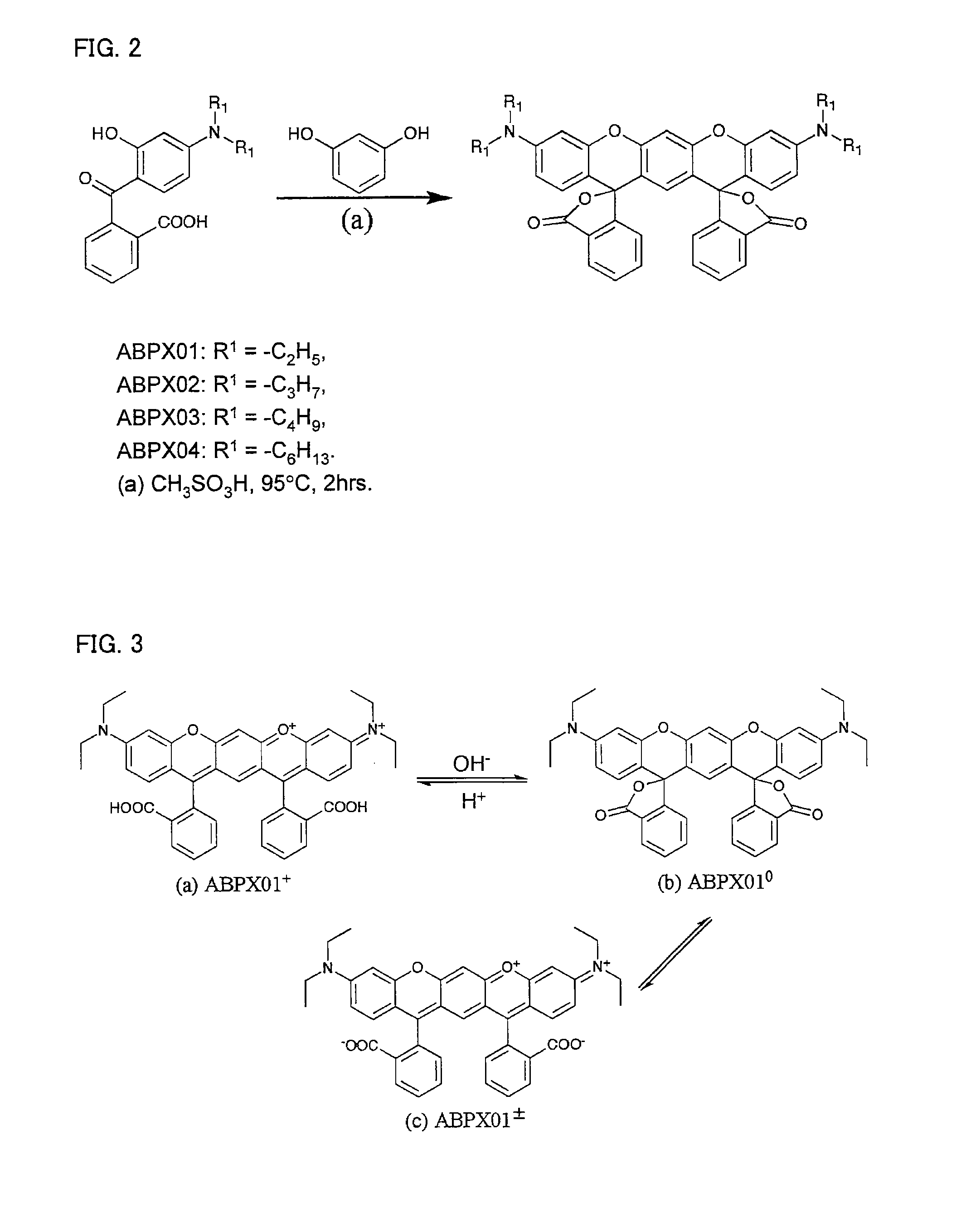

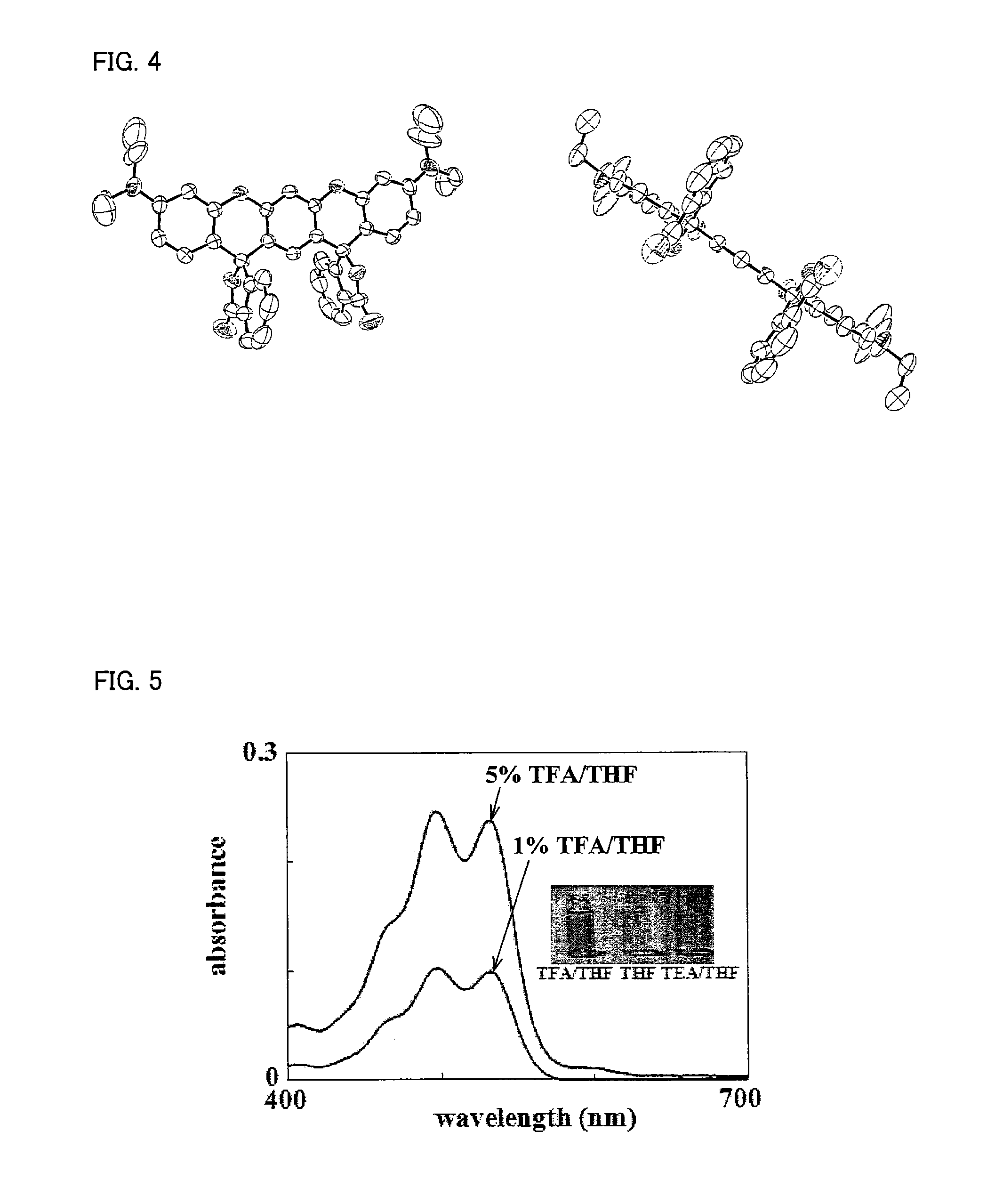

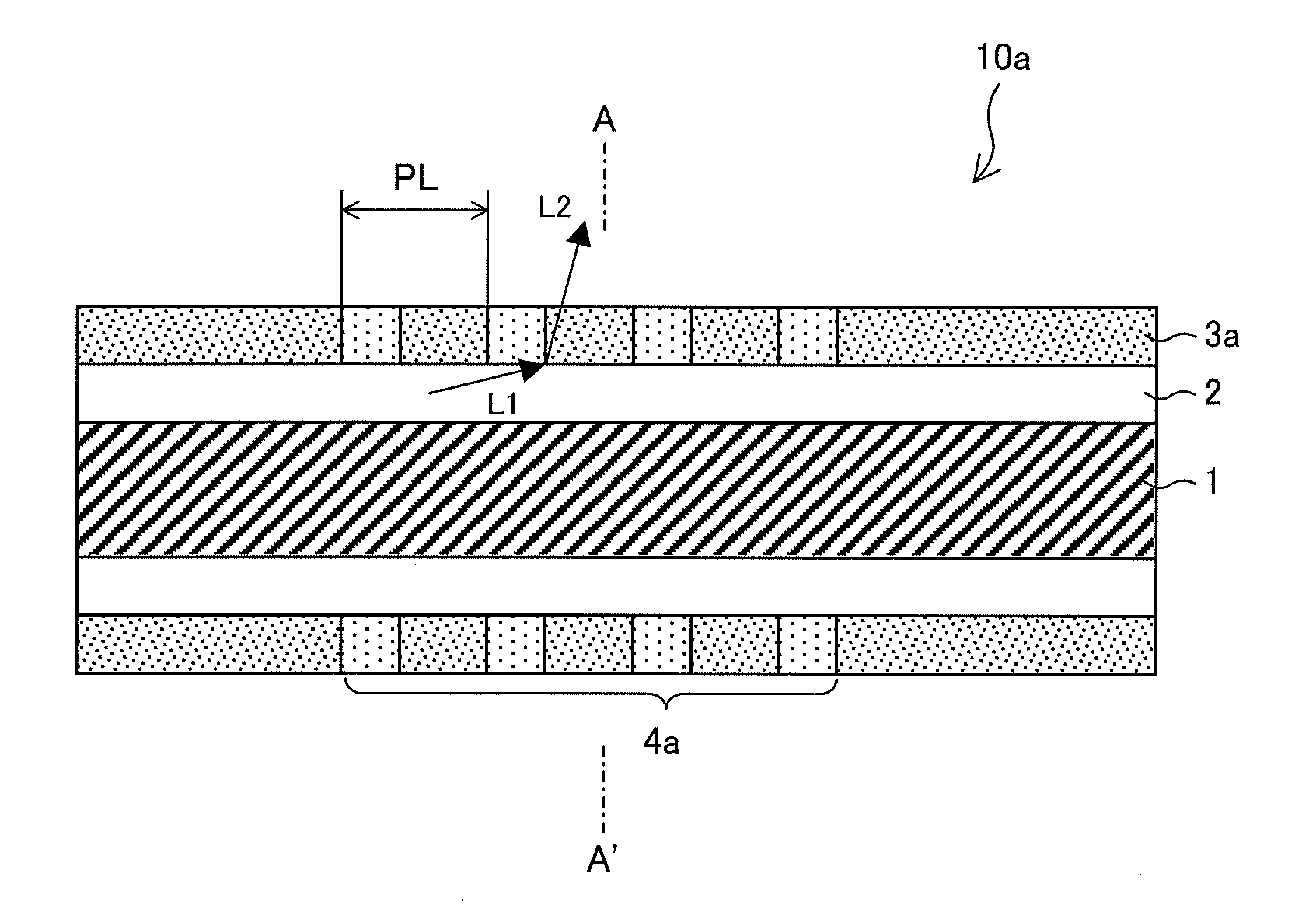

Compound and use thereof

ActiveUS8134017B1Solve low luminous efficiencyReduce photosensitivityUltrasonic/sonic/infrasonic diagnosticsBiocideMedicinal chemistry

Owner:RIKEN

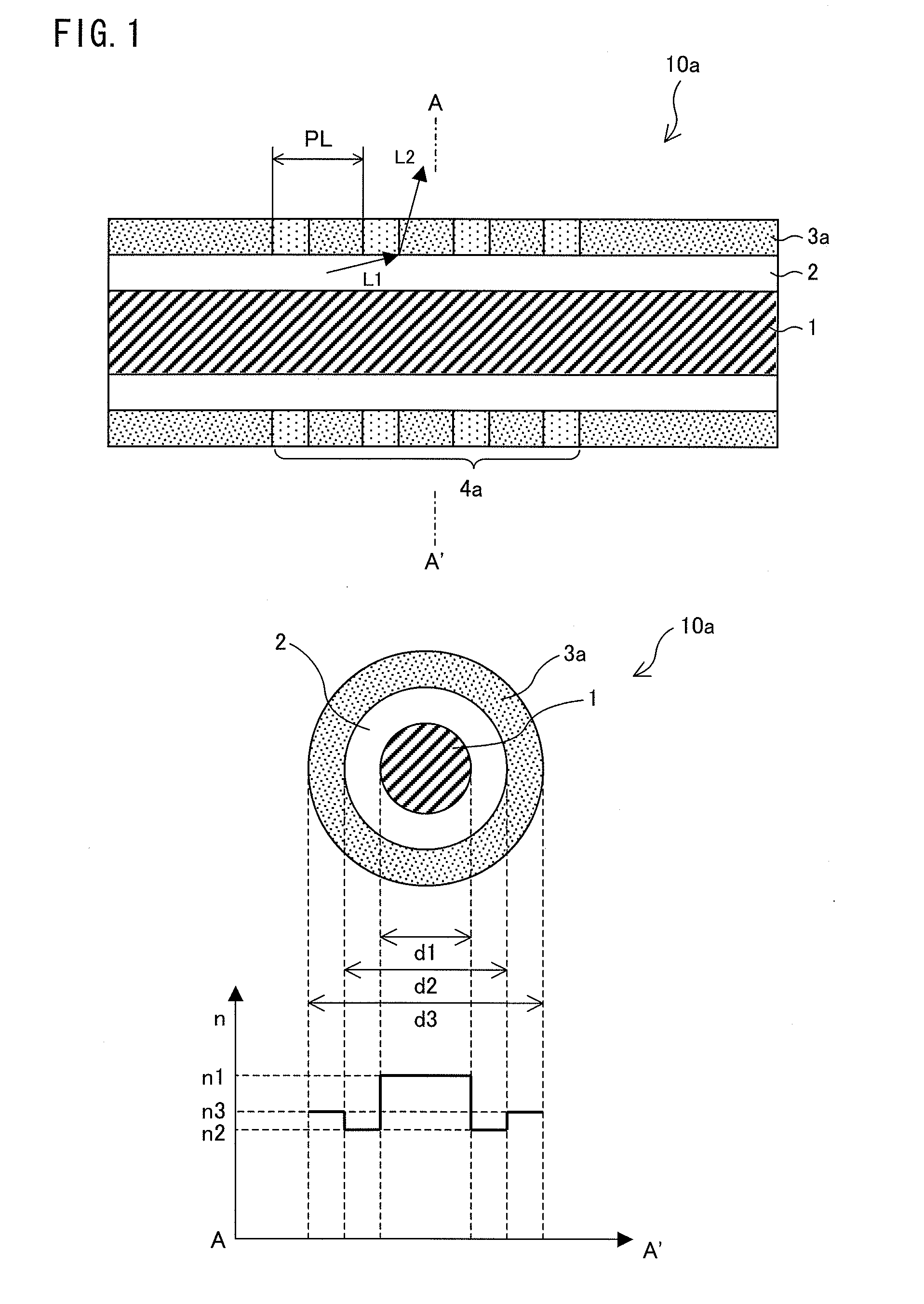

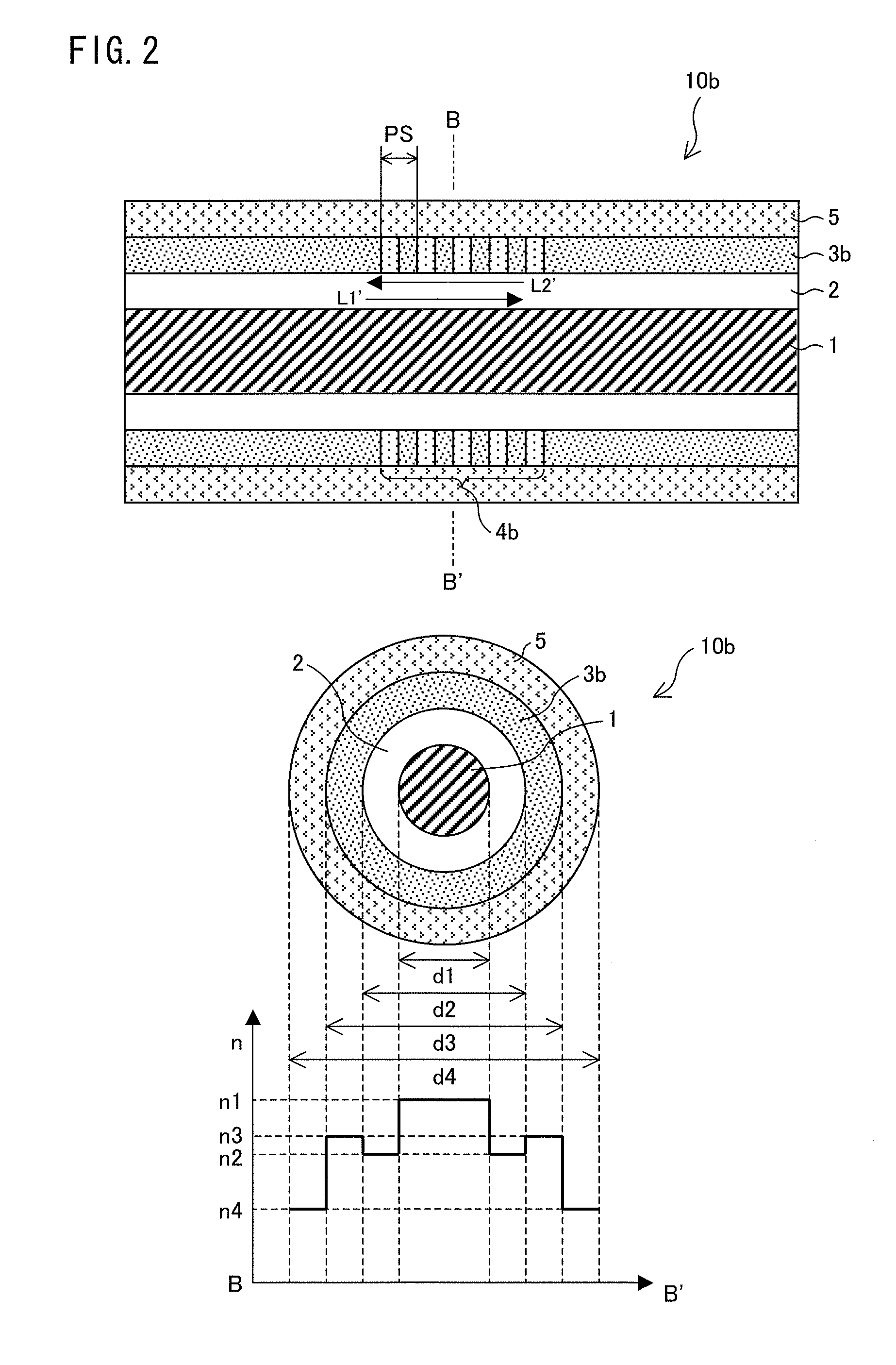

Optical fiber-type optical element, laser diode module, and fiber laser

InactiveUS20130016742A1Reduce photosensitivityEasy to understandGlass optical fibreLaser using scattering effectsLaser fiberRefractive index

There are provided: a core section provided so as to extend in a light-guiding direction in which incident light propagates; a photosensitive layer provided so as to extend in the light-guiding direction and peripherally enclose the core section, the photosensitive layer including a grating formed therein by irradiation of ultraviolet light having a predetermined wavelength; and a first cladding section provided between the core section and the photosensitive layer, the first cladding section having a lower refractive index than the core section and a lower photosensitivity than the photosensitive layer, the photosensitivity being a property in which a refractive index changes in response to irradiation with the ultraviolet light.

Owner:THE FUJIKURA CABLE WORKS LTD

Image lens system

Owner:LARGAN PRECISION

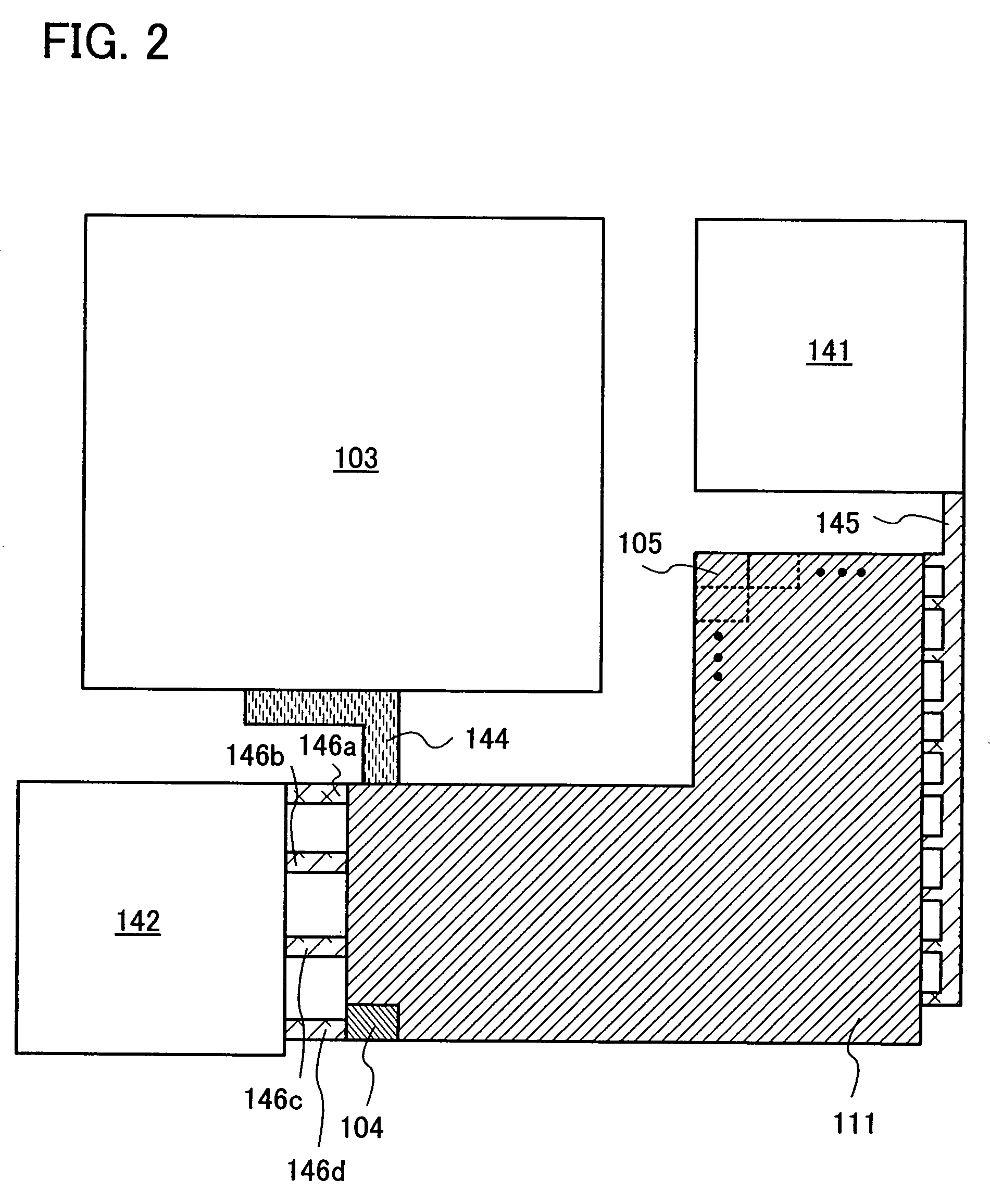

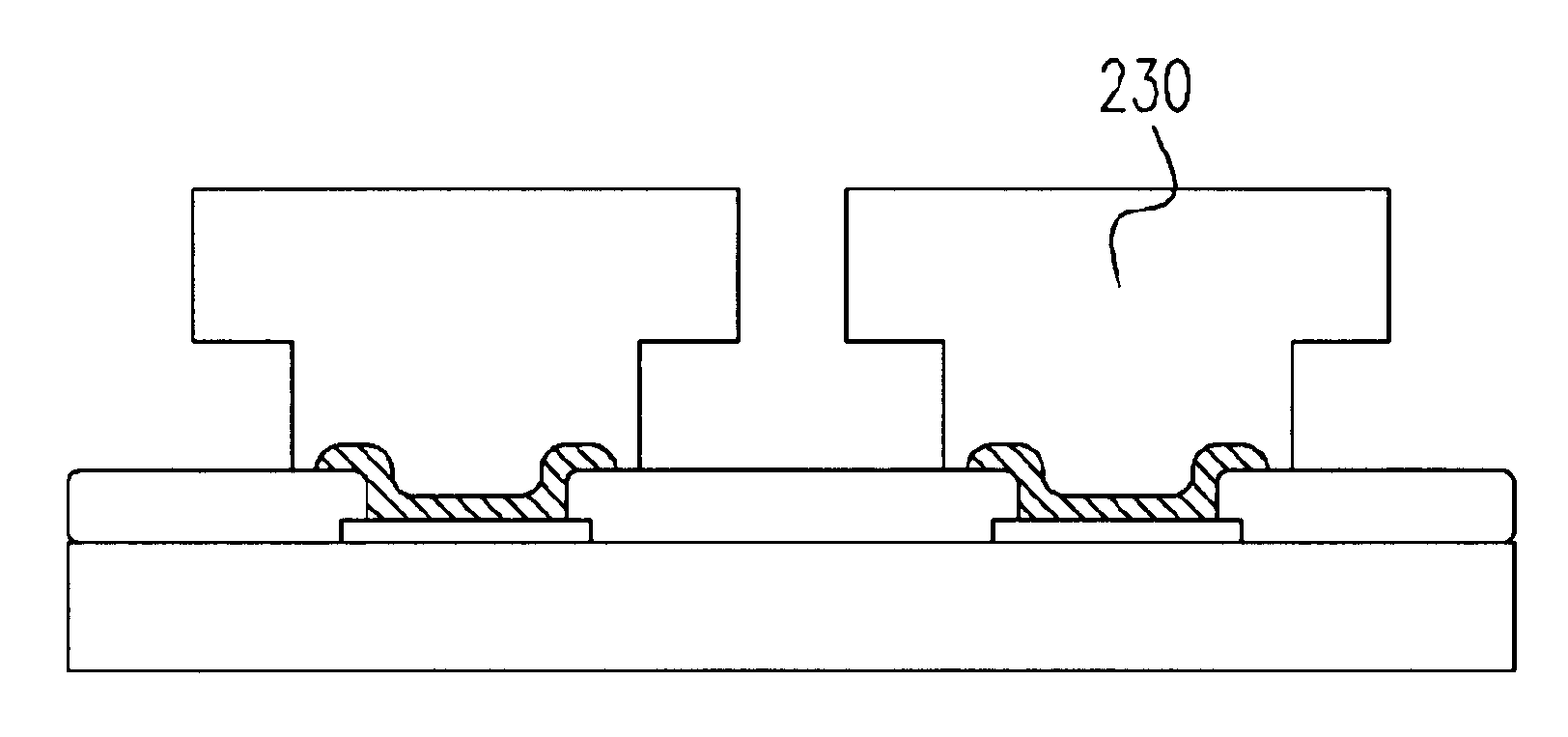

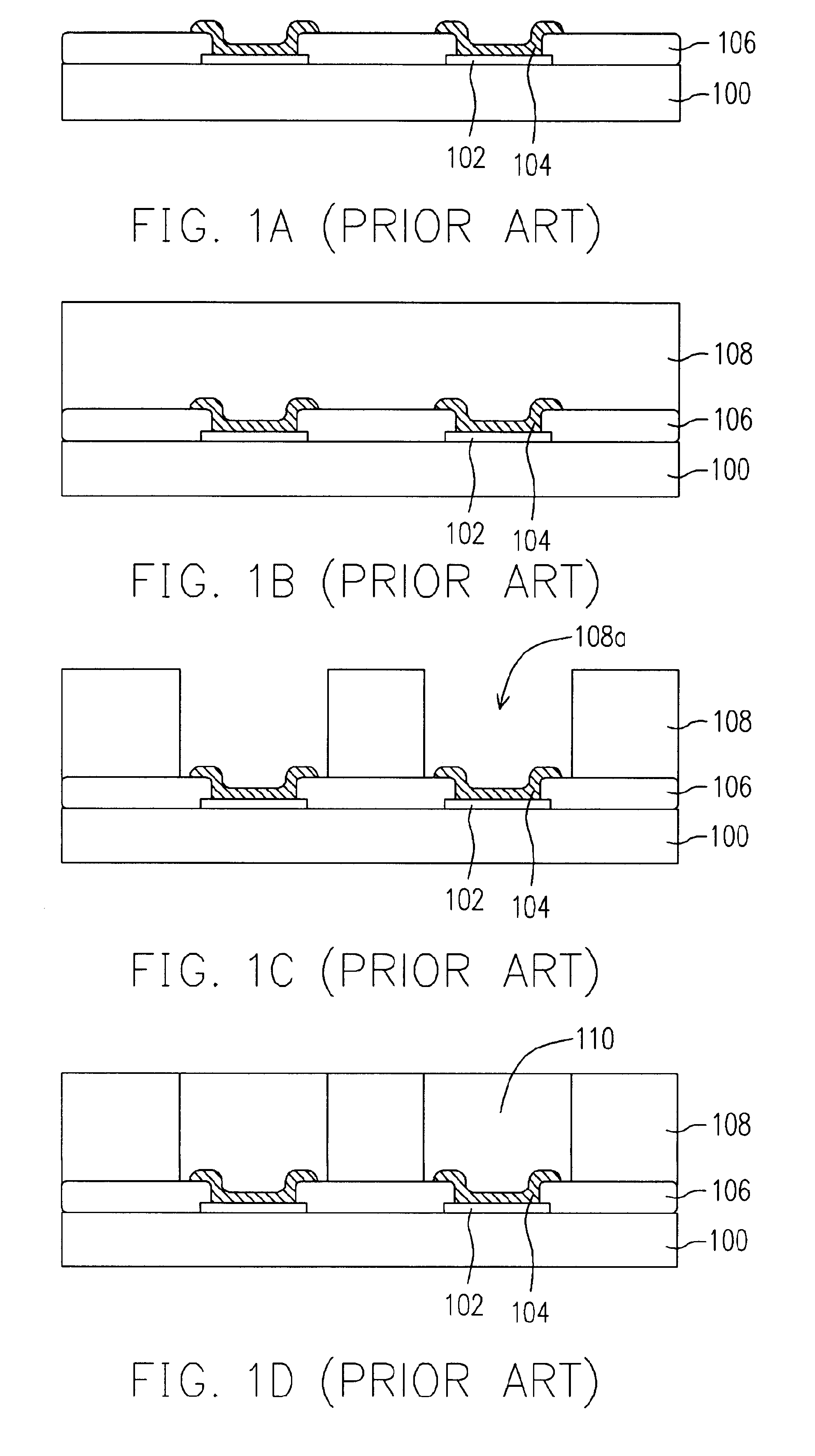

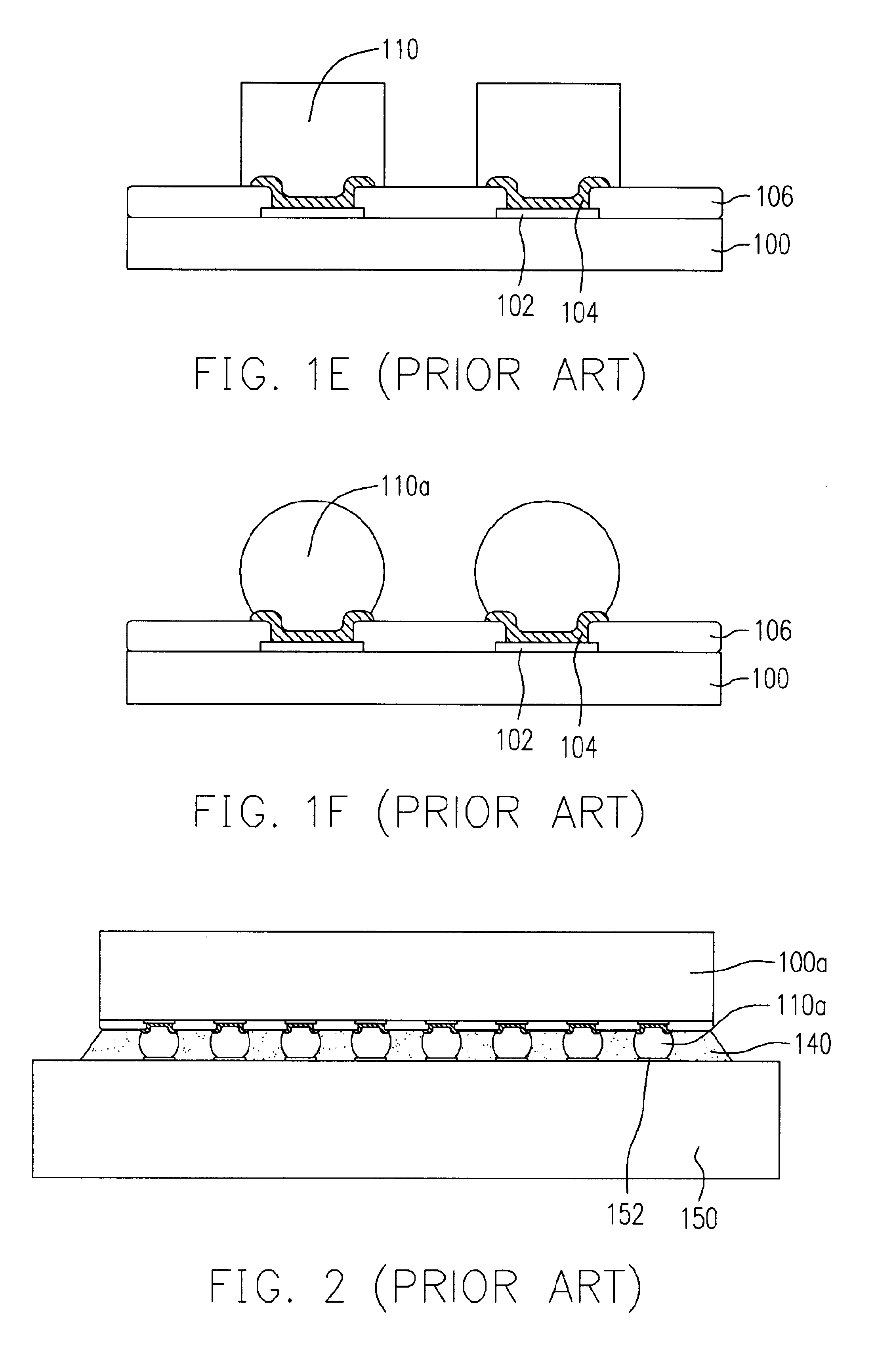

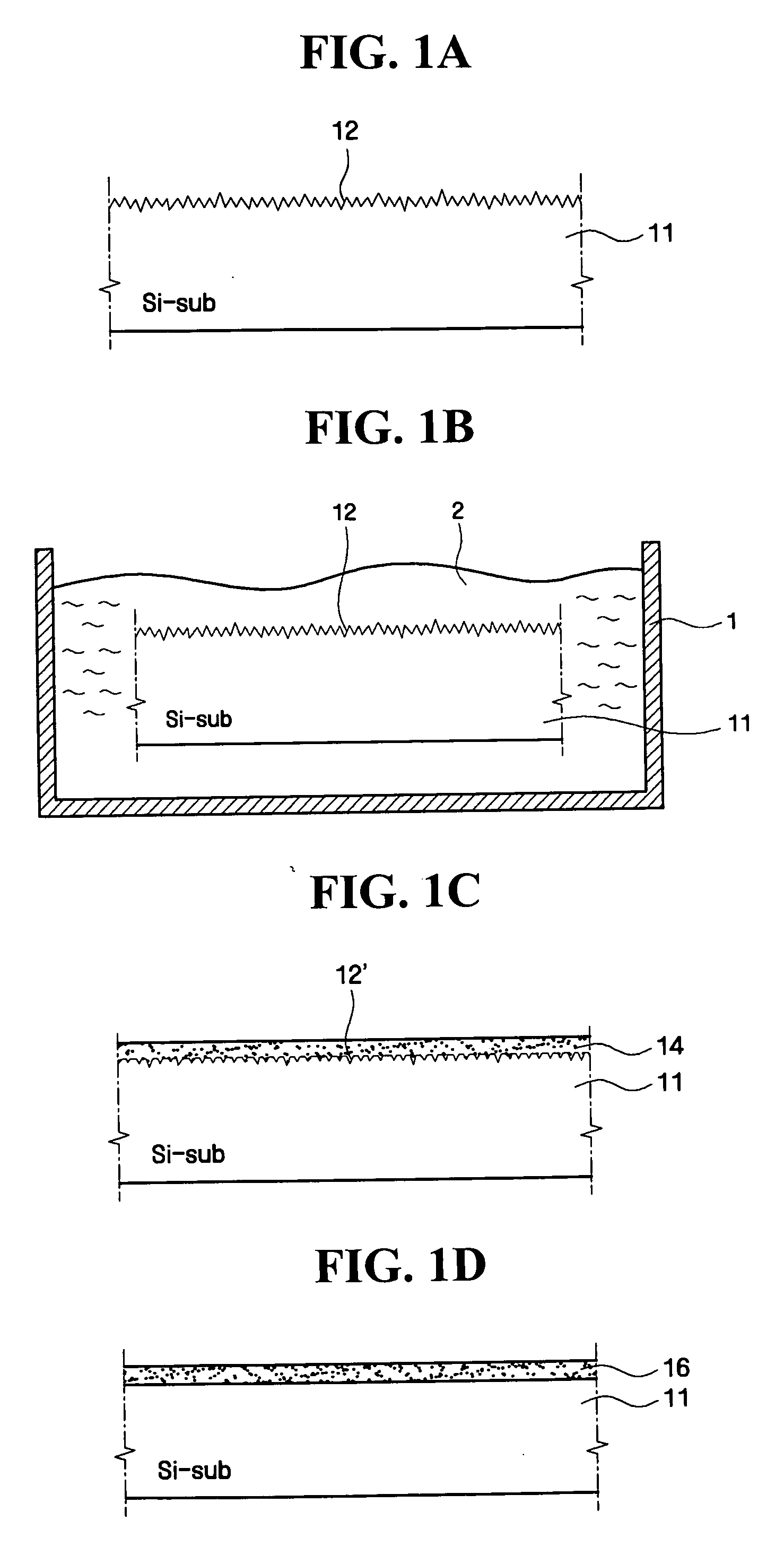

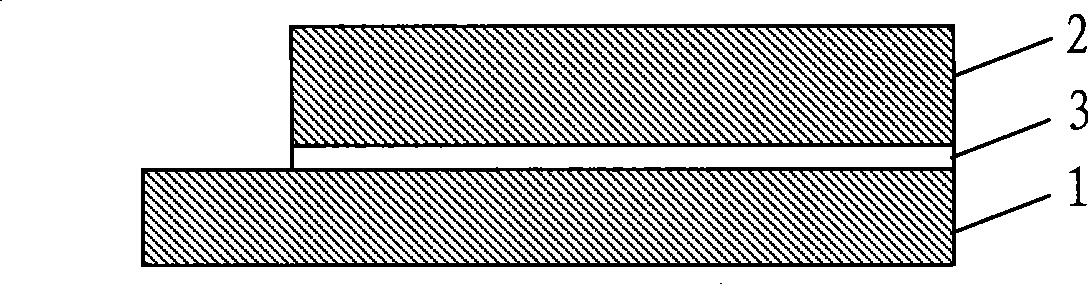

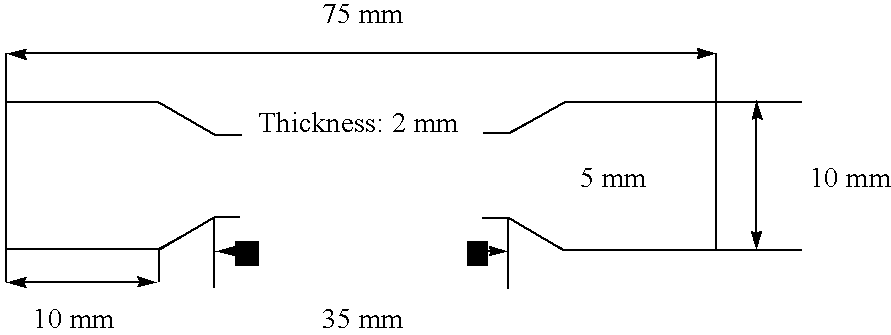

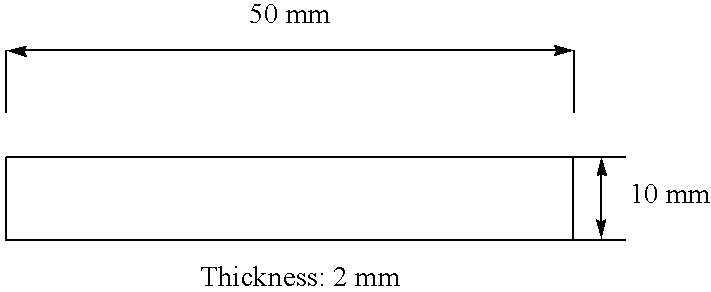

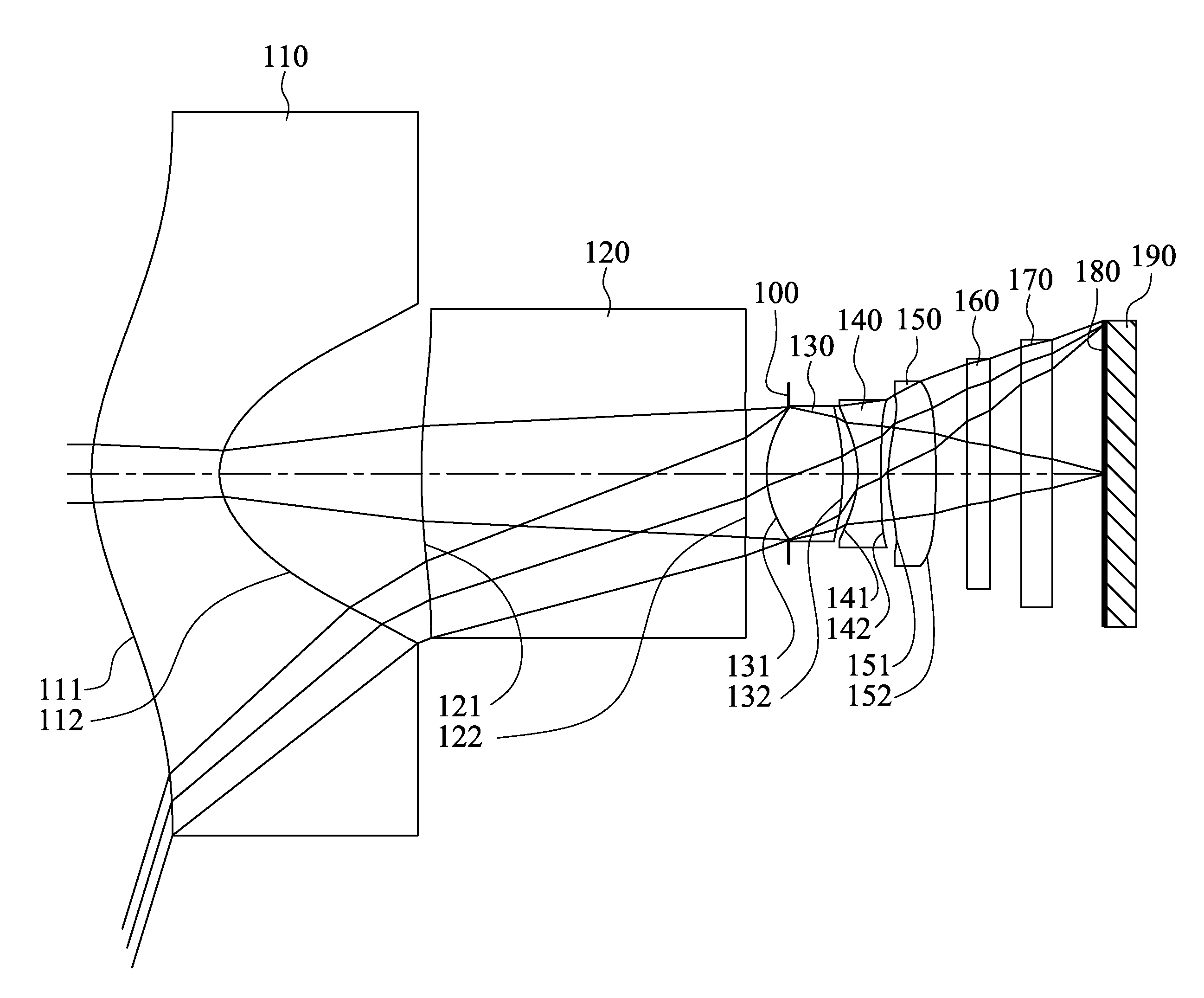

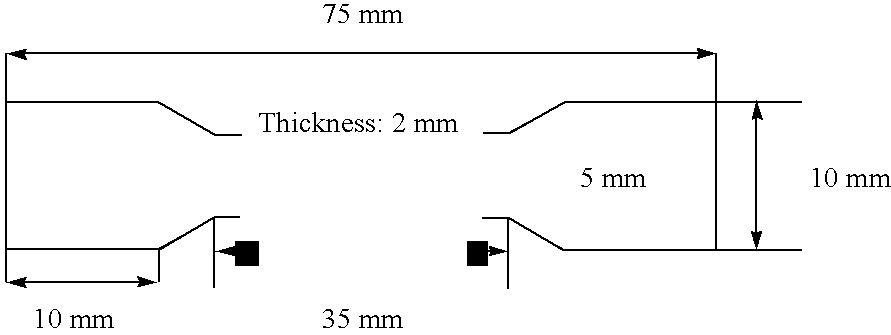

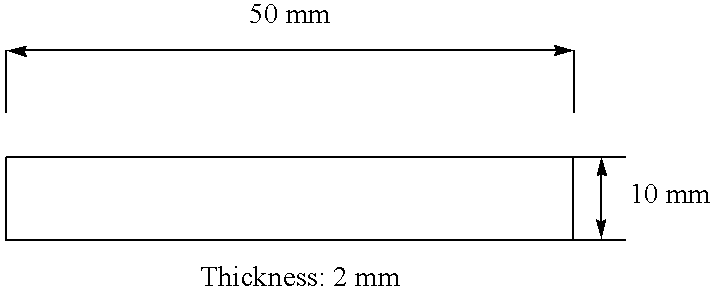

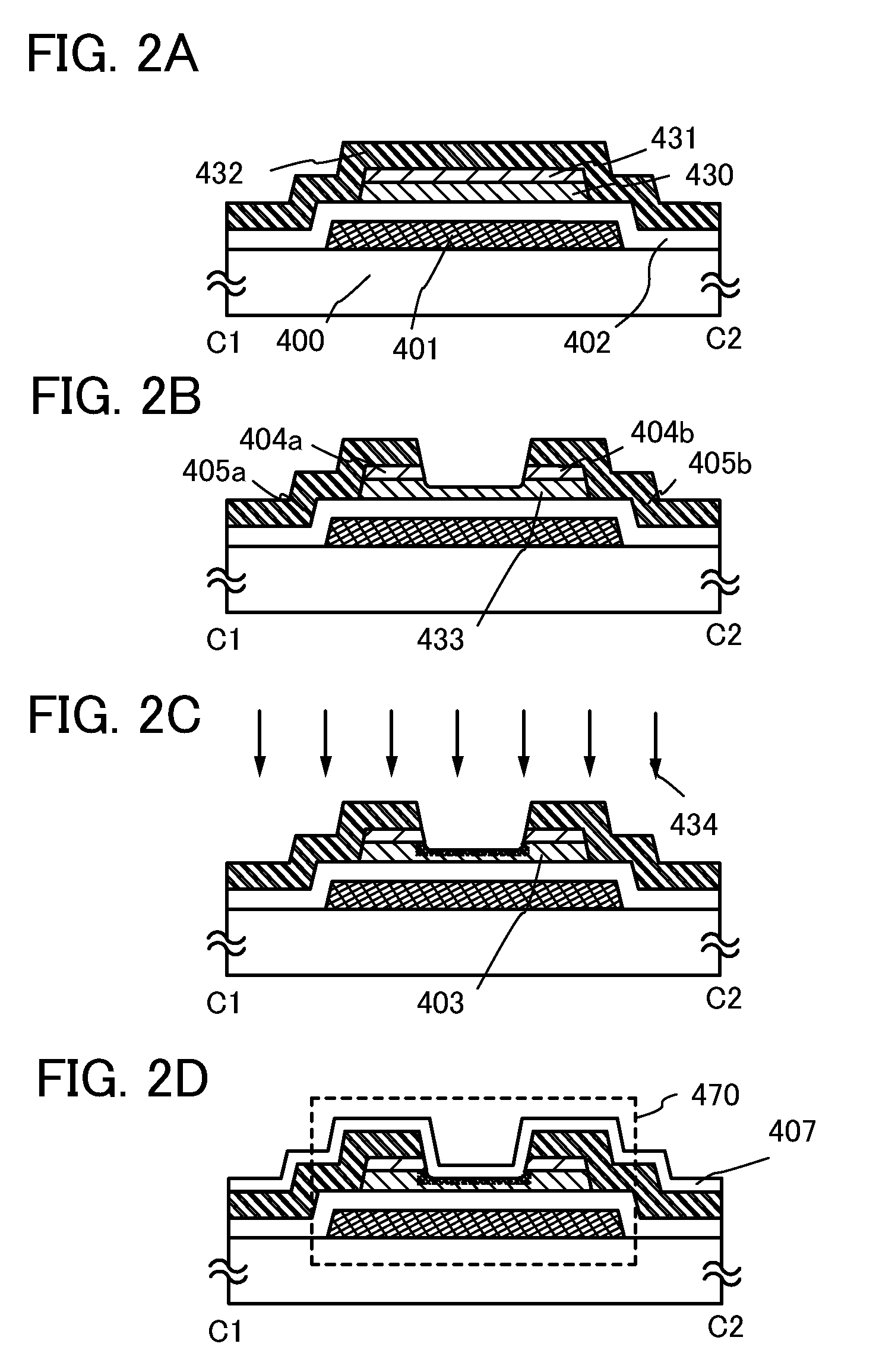

[bumping process]

ActiveUS20050020050A1Taller in heightLow costSemiconductor/solid-state device detailsSolid-state devicesSingle exposureEngineering

A bumping process is disclosed. The bumping process comprises the steps of: providing a wafer having a plurality of bonding pads and a passivation layer, wherein the passivation layer exposes the bonding pads; forming an UBM layer over the wafer to cover the bonding pads; forming two or more photoresist layers over the wafer, wherein the photoresist layers have different exposure and development characteristics; forming at least one or more stair-shaped openings in the photoresist layers by a single exposure corresponding to the bonding pads; filling solder into the stair-shaped openings to form a plurality of solder bumps; removing the entire photoresist layer. The bumping process can provide bumps with higher heights, so that the connection between chips and carriers becomes more reliable.

Owner:ADVANCED SEMICON ENG INC

Image capturing lens assembly

An image capturing lens assembly comprises, in order from an object side to an image side, a first lens element with positive refractive power having a convex object-side surface, a second lens element with refractive power, a third lens element with positive refractive power having a convex image-side surface, and a fourth lens element with refractive power having a convex object-side surface and a concave image-side surface. The object-side surface and the image-side surface of the fourth lens element are aspheric and have at least one inflection point.

Owner:LARGAN PRECISION

Semiconductor device and method for manufacturing the same

ActiveUS8395148B2Easy to makeLow reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingIndiumNiobium

It is an object to provide a highly reliable semiconductor device including a thin film transistor whose electric characteristics are stable. In addition, it is another object to manufacture a highly reliable semiconductor device at low cost with high productivity. In a semiconductor device including a thin film transistor, a semiconductor layer of the thin film transistor is formed with an oxide semiconductor layer to which a metal element is added. As the metal element, at least one of metal elements of iron, nickel, cobalt, copper, gold, manganese, molybdenum, tungsten, niobium, and tantalum is used. In addition, the oxide semiconductor layer contains indium, gallium, and zinc.

Owner:SEMICON ENERGY LAB CO LTD

Semiconductor device comprising photoelectric conversion element and high-potential and low-potential electrodes

InactiveUS7791012B2Reduce sensitivitySuppression resistanceTransistorTelevision system detailsElectrical resistance and conductanceAudio power amplifier

Owner:SEMICON ENERGY LAB CO LTD

Bumping process

ActiveUS6930031B2Increase heightBondingSemiconductor/solid-state device detailsSolid-state devicesSingle exposureEngineering

A bumping process is disclosed. The bumping process comprises the steps of: providing a wafer having a plurality of bonding pads and a passivation layer, wherein the passivation layer exposes the bonding pads; forming an UBM layer over the wafer to cover the bonding pads; forming two or more photoresist layers over the wafer, wherein the photoresist layers have different exposure and development characteristics; forming at least one or more stair-shaped openings in the photoresist layers by a single exposure corresponding to the bonding pads; filling solder into the stair-shaped openings to form a plurality of solder bumps; removing the entire photoresist layer. The bumping process can provide bumps with higher heights, so that the connection between chips and carriers becomes more reliable.

Owner:ADVANCED SEMICON ENG INC

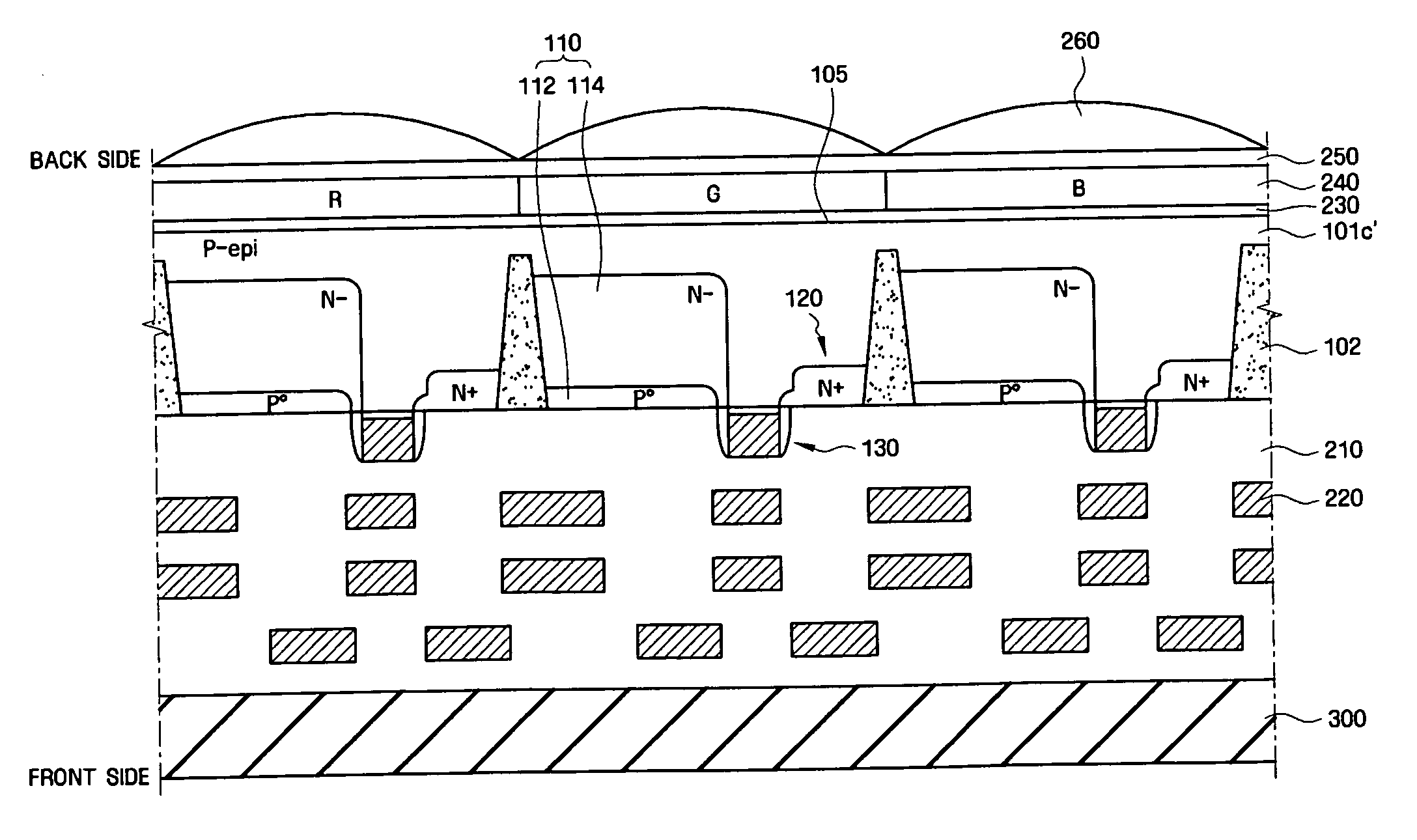

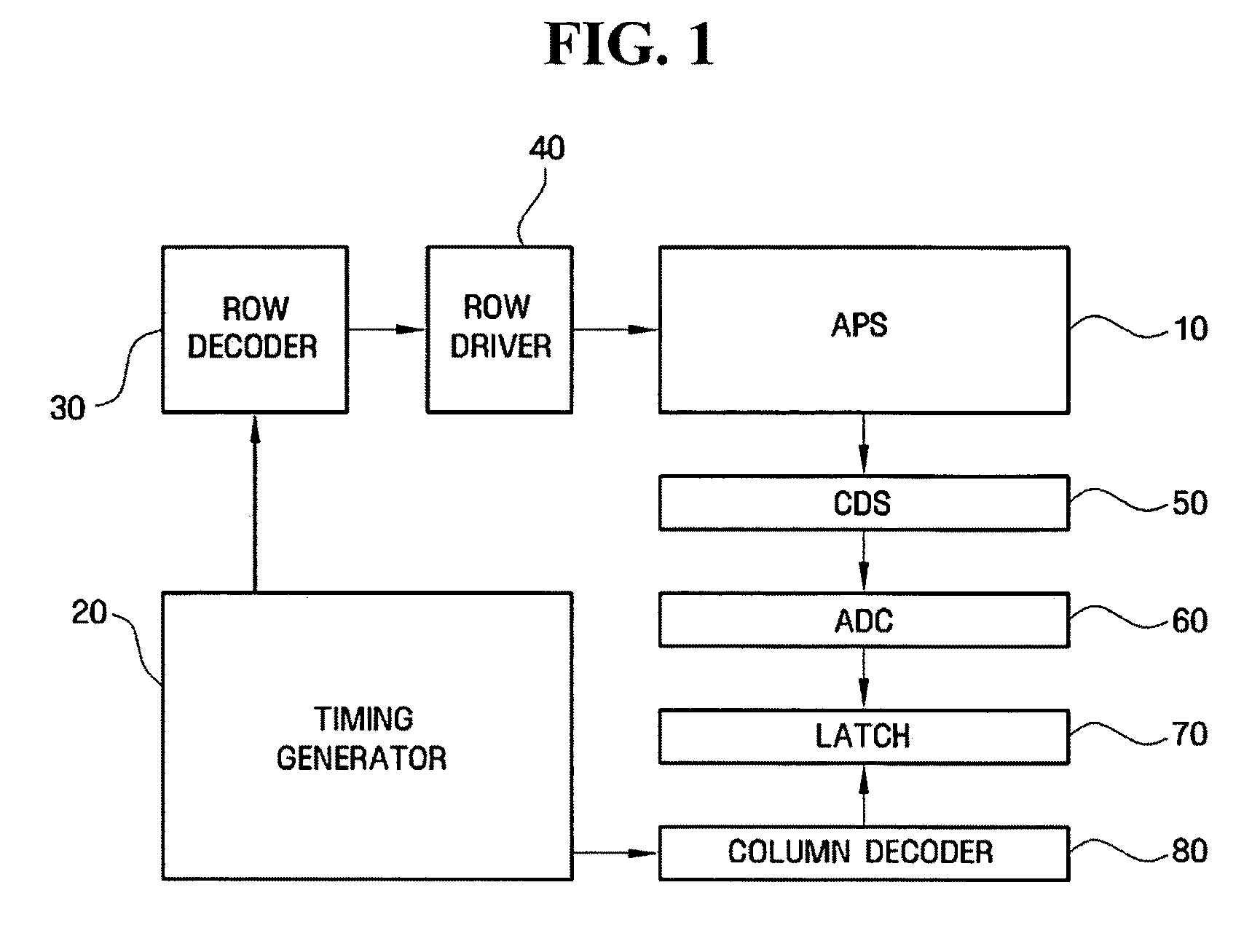

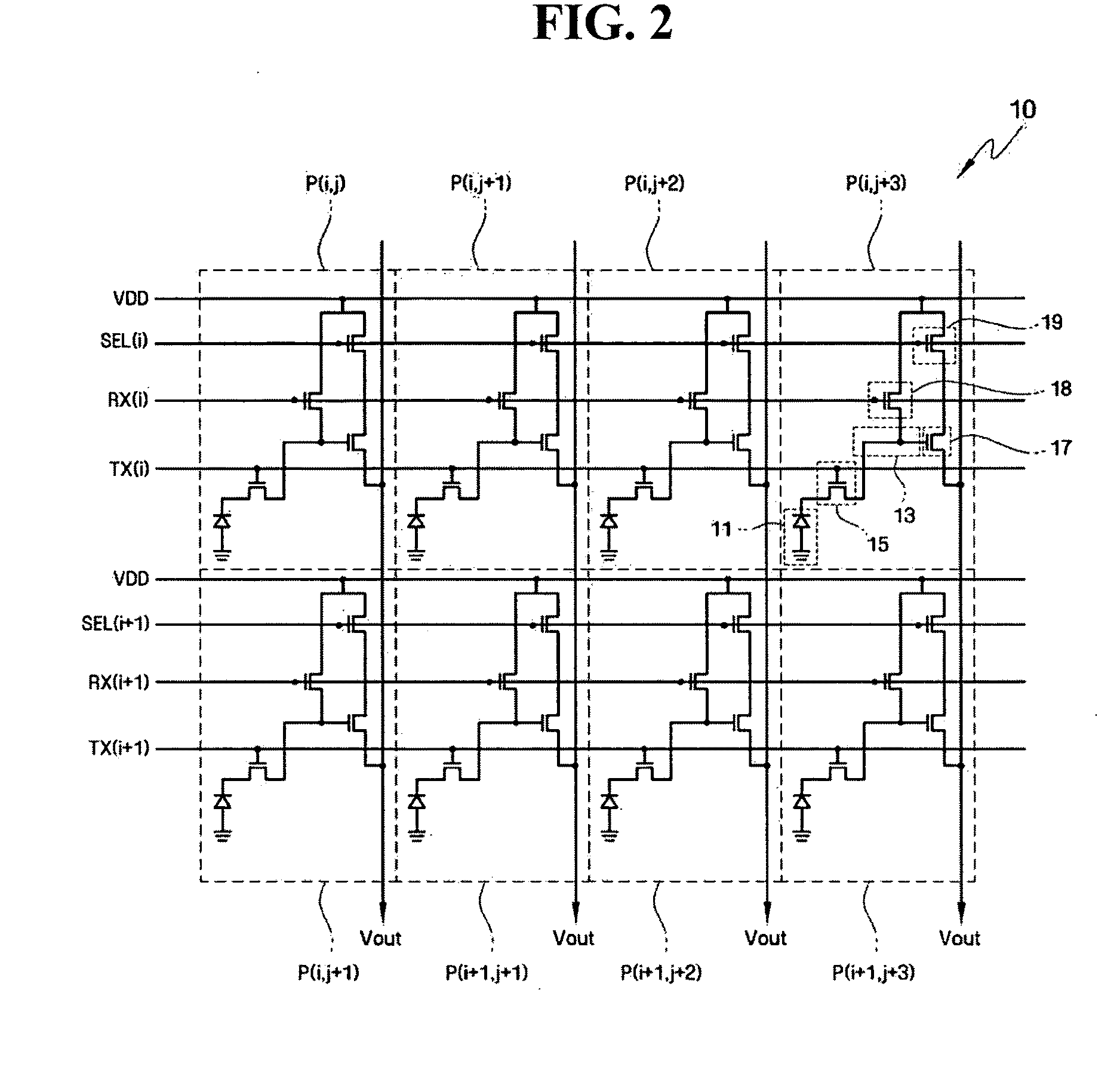

Treatment method for surface of substrate, method of fabricating image sensor by using the treatment method, and image sensor fabricated by the same

InactiveUS20090197365A1Reduce photosensitivityQuantity of light is reducedSolid-state devicesSemiconductor/solid-state device manufacturingChemical solutionSemiconductor

Provided may be a treatment method to remove defects created on the surface of a substrate, a method of fabricating an image sensor by using the treatment method, and an image sensor fabricated by the same. The treatment method may include providing a semiconductor substrate including a surface defect, providing a chemical solution to a surface of the semiconductor substrate, and removing the surface defect by consuming the surface of the semiconductor substrate and forming a chemical oxide layer on the semiconductor substrate.

Owner:SAMSUNG ELECTRONICS CO LTD

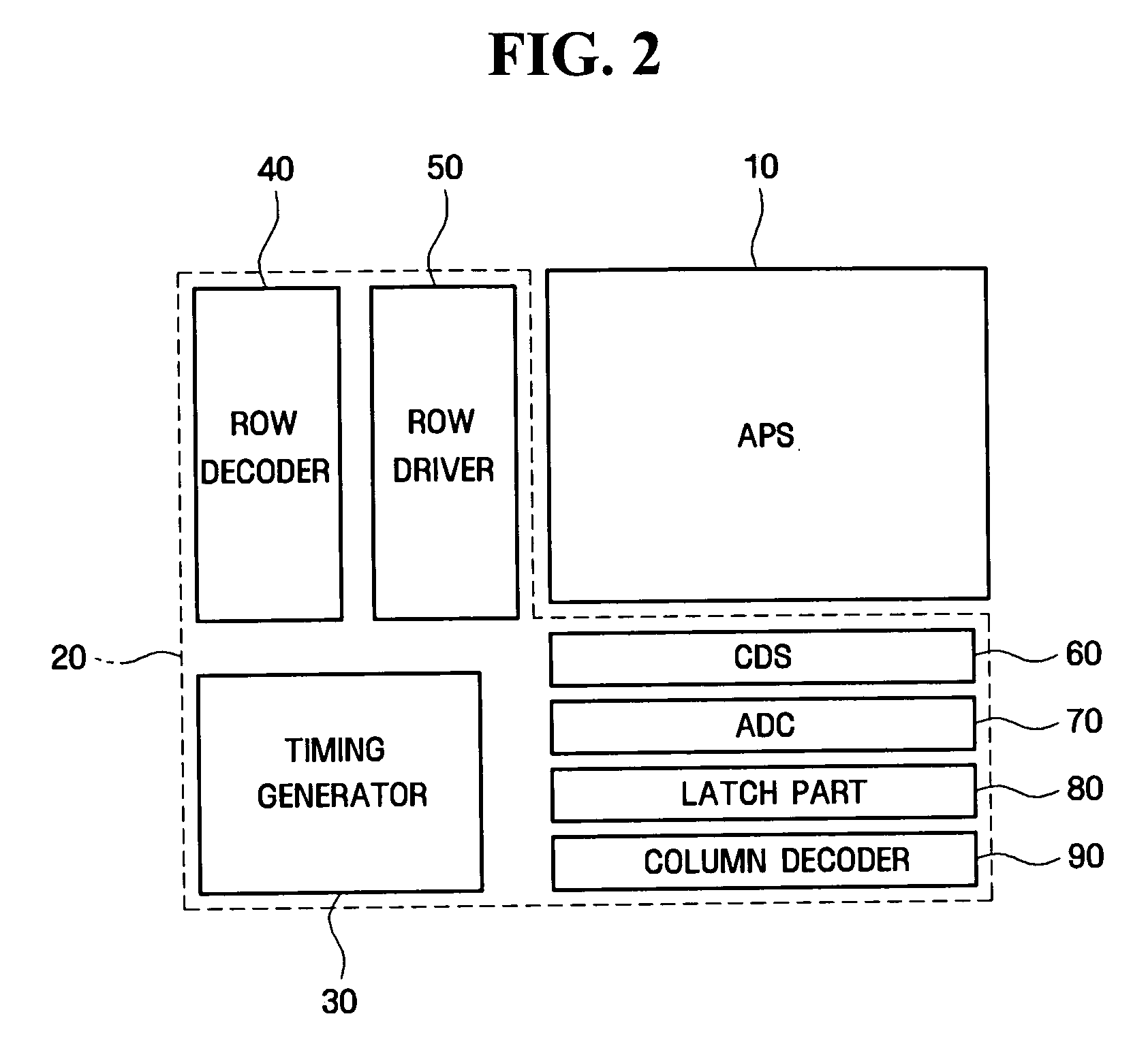

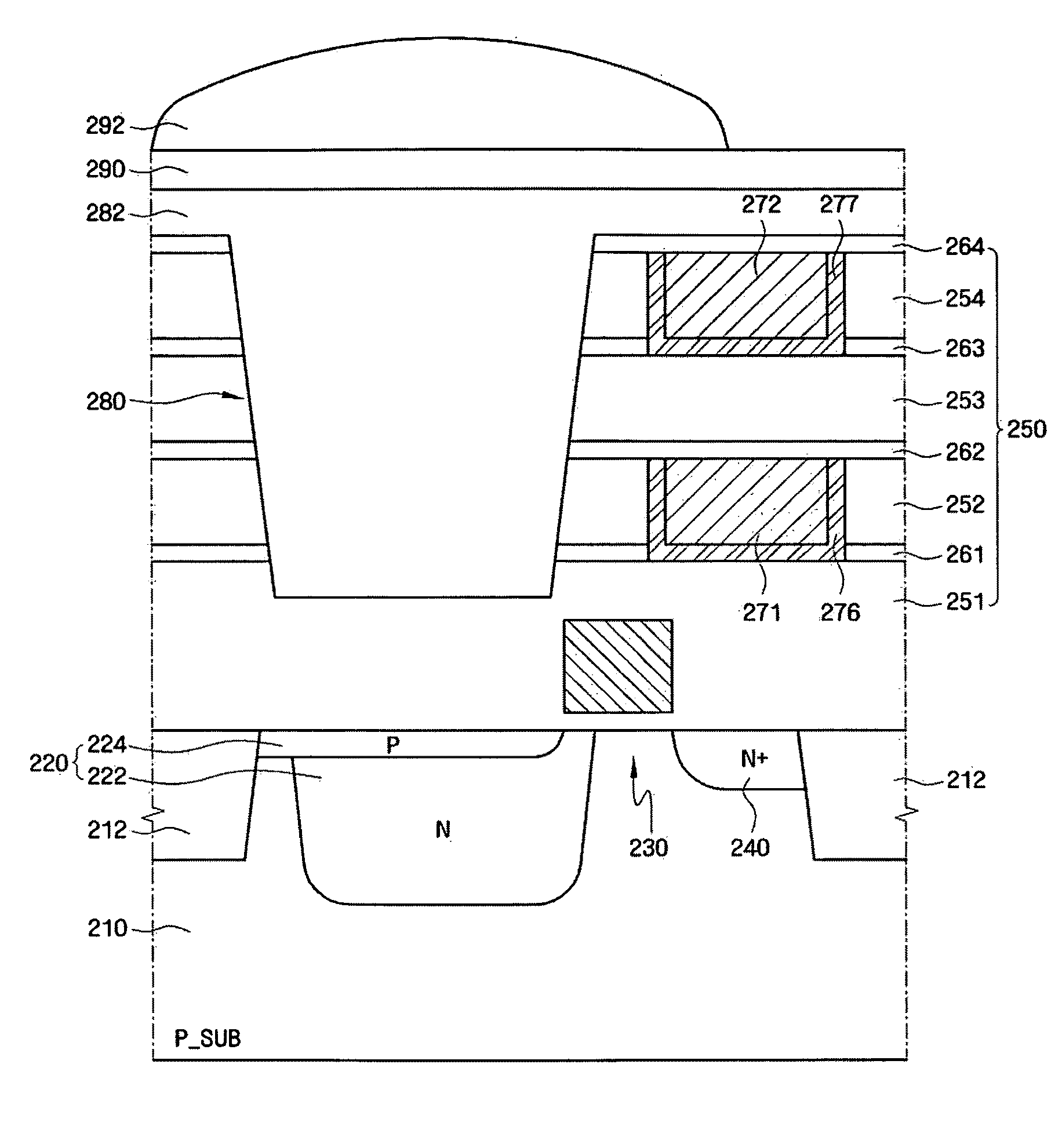

Method of fabricating image sensor

ActiveUS20090130792A1Reduce photosensitivityLow lightSolid-state devicesSemiconductor/solid-state device manufacturingImage sensorDielectric layer

A method of fabricating an image sensor includes forming a photoelectric transformation device on a substrate and forming a dielectric layer structure on the substrate. The dielectric layer structure includes multi-layer interlayer dielectric layers and multi-layer metal interconnections which are located between the multi-layer interlayer dielectric layers. A cavity which penetrates the multi-layer interlayer dielectric layers on the photoelectric transformation device is formed. A heat treatment is performed on the substrate on which the cavity is formed.

Owner:SAMSUNG ELECTRONICS CO LTD

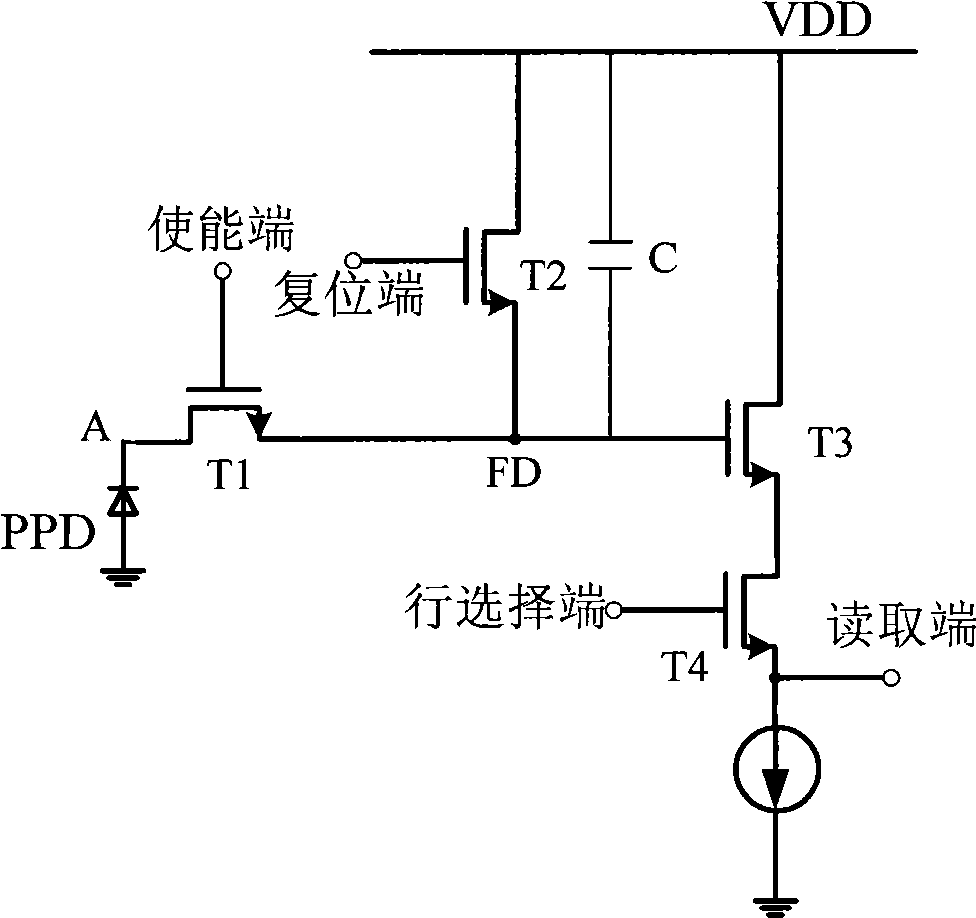

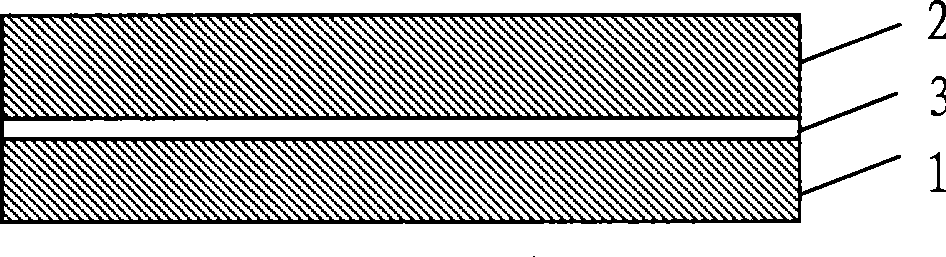

Semiconductor device, metal-insulator-metal capacitor and method for manufacturing same

ActiveCN101533767ALow costDoes not affect sizeSemiconductor/solid-state device detailsSolid-state devicesMetal-insulator-metalCapacitance

The invention provides a semiconductor device, a metal-insulator-metal (MIM) capacitor and a method for manufacturing the same, wherein the method comprises the following steps: depositing a first metal layer on a semiconductor substrate and patterning the metal layer; depositing a passivation layer on the first metal layer and forming a connecting line hole thereon by etching; depositing a dielectric layer on the surfaces of the passivation layer and the connecting line hole and etching part of the dielectric layer; covering and depositing a second metal layer on the surfaces of the dielectric layer and the passivation layer; and using the first metal layer as a lower electrode plate and the second metal layer as an upper electrode plate. The MIM capacitor combines the upper electrode plate metal layer with a metal interconnection layer, reduces the space occupied in the semiconductor device, avoids influencing the photosensitive property of edge pixels in a pixel array, and can achieve the aim of reducing lateral light crosstalk by arranging the position and the number of the connecting line hole reasonably.

Owner:BRIGATES MICROELECTRONICS KUNSHAN

Photocurable compositions

ActiveUS8097399B2Fast curingGood physical propertiesAdditive manufacturing apparatusNanostructure manufactureFluenceNon coherent

An optical moulding process is disclosed comprising the sequential steps of: (a)(y) forming a layer of a photocurable composition; and (bXz) irradiating selected areas of the composition in the layer with radiation from a radiation source, thereby curing the composition in said selected areas and repeating the steps a) and b) on top of an earlier cured layer to form a three dimensional structure, wherein the radiation source used in step b) is a non-coherent source of radiation and wherein the photocurable composition comprises at least two curable components: (i) 45%-95% (and preferably at least 50%, more preferably at least 60%, e.g. at least 70%) by weight of the total curable components in the composition is a first component that is photocurable and that is such that, when cured in the presence of a photocuring initiator by exposure to UV radiation having an energy of 30 mJ / cm2, at least 90% of the component is cured within 50 milliseconds; and (ii) 5% to 55% (and preferably 10-40%, more preferably 15 to 30%, e.g. about 20%) by weight of the total curable components in the composition is a second component that results in the composition, on curing, shrinking, in a linear direction, by less than 3% and preferably that results in the composition having, after cure, a Tg of greater than 50° C., preferably at least 100° C. and more preferably at least 120° C.

Owner:3D SYST INC

Photographing lens system, image capturing device and electronic terminal

A photographing lens system includes, in order from an object side to an image side, a first lens element, a second lens element, a third lens element, a fourth lens element and a fifth lens element. The first lens element with negative refractive power has a concave image-side surface. The second lens element has refractive power. The third lens element with positive refractive power has a convex object-side surface and a convex image-side surface. The fourth lens element with negative refractive power has a concave image-side surface, wherein an object-side surface and the image-side surface of the fourth lens element are aspheric. The fifth lens element with positive refractive power has a convex object-side surface and a convex image-side surface, wherein the object-side surface and the image-side surface of the fifth lens element are aspheric.

Owner:LARGAN PRECISION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![[bumping process] [bumping process]](https://images-eureka.patsnap.com/patent_img/5749955a-dd74-4133-b803-7b01ab7fd782/US20050020050A1-20050127-D00000.png)

![[bumping process] [bumping process]](https://images-eureka.patsnap.com/patent_img/5749955a-dd74-4133-b803-7b01ab7fd782/US20050020050A1-20050127-D00001.png)

![[bumping process] [bumping process]](https://images-eureka.patsnap.com/patent_img/5749955a-dd74-4133-b803-7b01ab7fd782/US20050020050A1-20050127-D00002.png)