Patents

Literature

285 results about "Tantalate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tantalate is an tantalum-containing anion or a salt of such an anion. A commercially important example is heptafluorotantalate (TaF₇²⁻) and its potassium salt (K₂TaF₇). Many oxides of tantalum are called tantalates. They are viewed as derivatives of "tantalic acid", hypothetic compounds with the formulas Ta₂O₅·nH₂O or HTaO₃). Examples of such tantalates are lithium tantalate (LiTaO₃), lutetium tantalate (LuTaO₄) and lead scandium tantalate (PST or Pb(ScₓTa1-x)O₃. Polyoxometallates containing tantalum provide examples of discrete tantalum oxides that exist in solution.

Method to protect internal components of semiconductor processing equipment using layered superlattice materials

InactiveUS20060040508A1Imparting corrosion resistanceElectric discharge tubesSemiconductor/solid-state device manufacturingStrontiumCompound (substance)

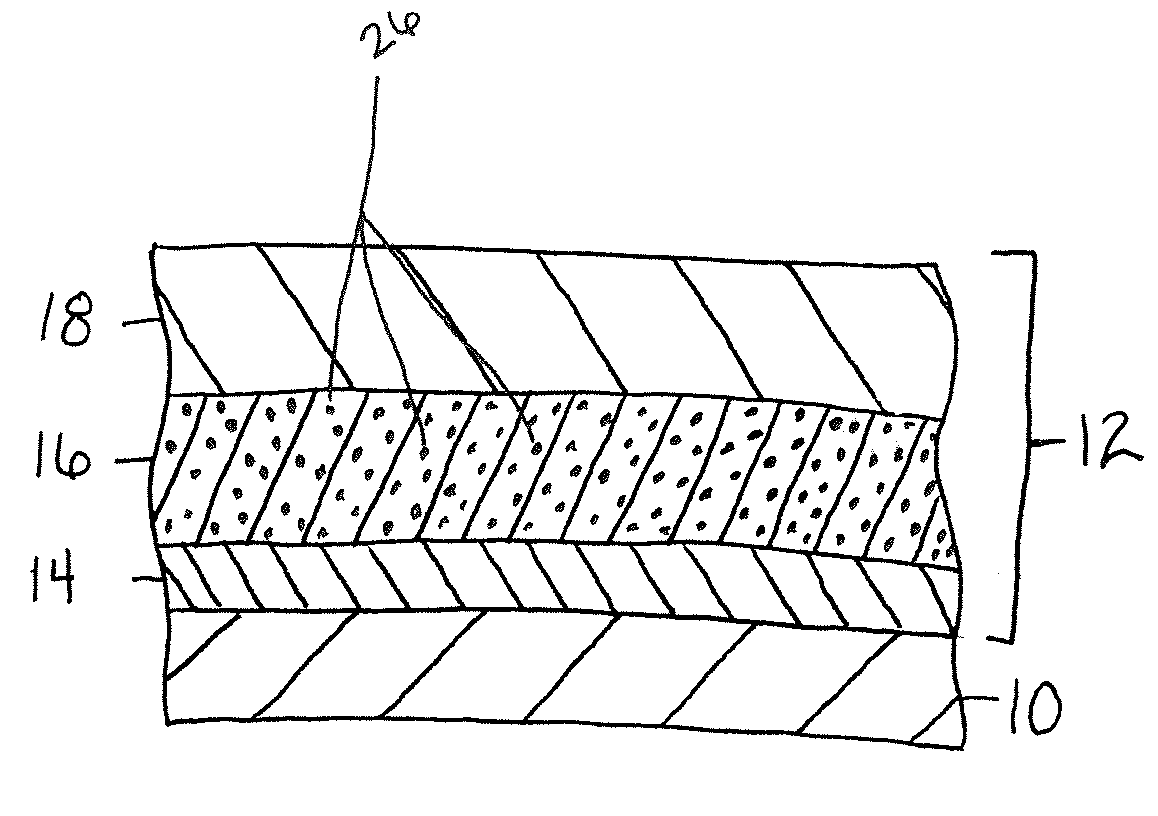

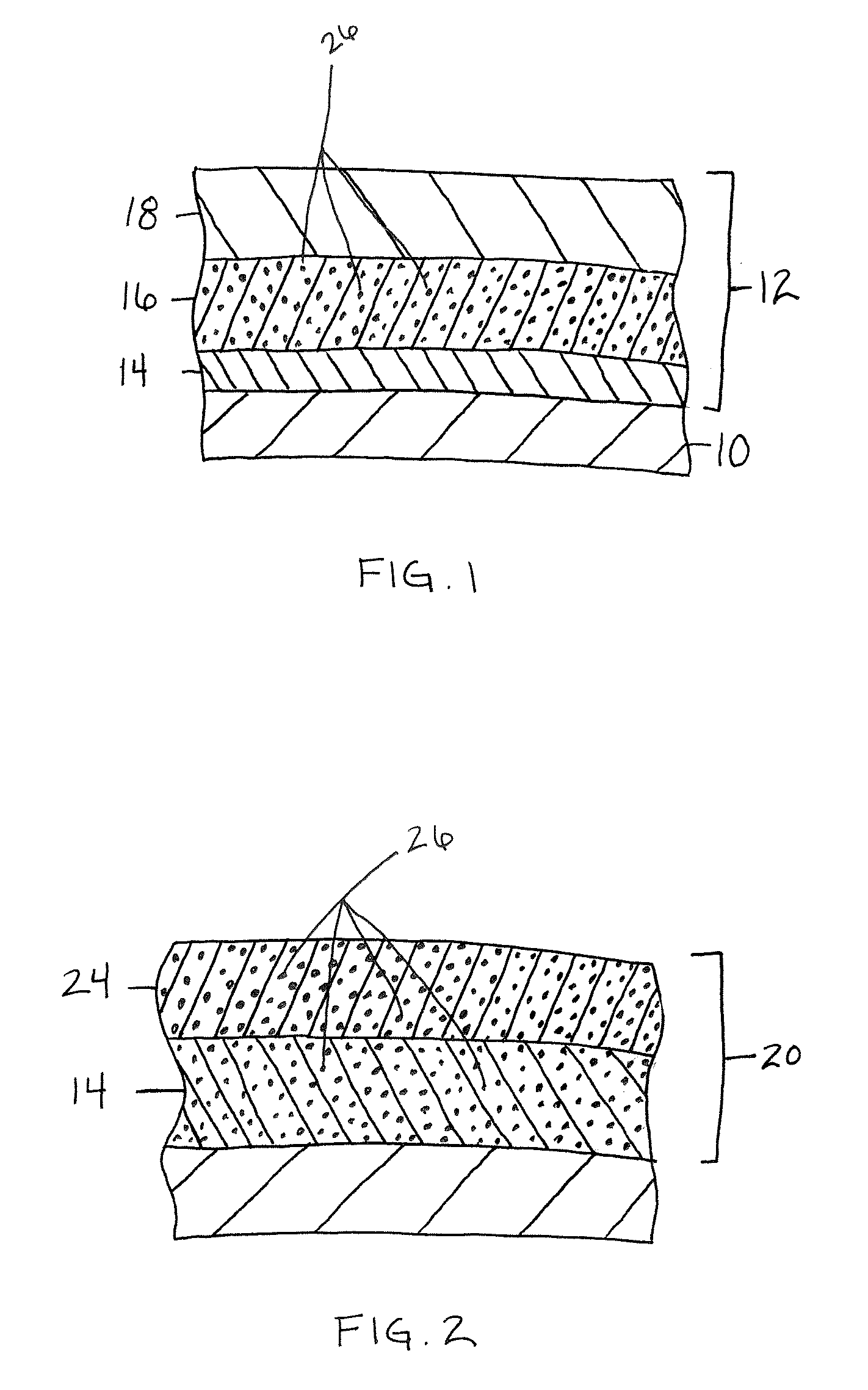

This invention relates to apparatus and a method to protect the internal components of semiconductor processing equipment such as a plasma reactor or a reactive species generator against physical and / or chemical damages during etching and / or cleaning processes. Layered superlattice materials having three or more metal elements such as strontium bismuth tantalate (SBT) are used to form a protective barrier on the surfaces of the internal components of a reaction chamber.

Owner:AIR PROD & CHEM INC

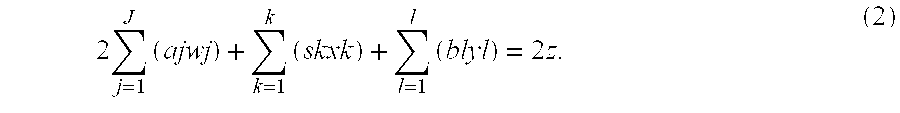

Catalyst for decomposing hydrogen sulfide by photocatalysis and preparation method of hydrogen and liquid sulfur by employing same

ActiveCN101590410ARealize comprehensive utilizationHigh activityDispersed particle separationSulfur preparation/purificationAlkaline earth metalVanadate

The invention relates to a catalyst for decomposing hydrogen sulfide by photocatalysis and a preparation method of hydrogen and liquid sulfur by employing same. The catalyst comprises a carrier, active component and assistant and has the characteristics that the carrier is one or more selected from vanadate, niobate and tantalate, the active component is one or more selected from alkali metal hydroxide, alkaline earth metal hydroxide, alkali metal nonmetal oxysalt, alkali metal nonoxysalt, alkaline earth metal nonmetal oxysalt and alkaline earth metal nonoxysalt and the assistant is lanthanide oxide or VIII group oxide. The catalyst of the invention can be used for preparing hydrogen and liquid sulfur so that the produced sulfur is easy to be separated from the catalyst, the catalyst can be recycled and the sulfur contained in hydrogen sulfide can be fully recycled, thus realizing the comprehensive utilization of hydrogen sulfide.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

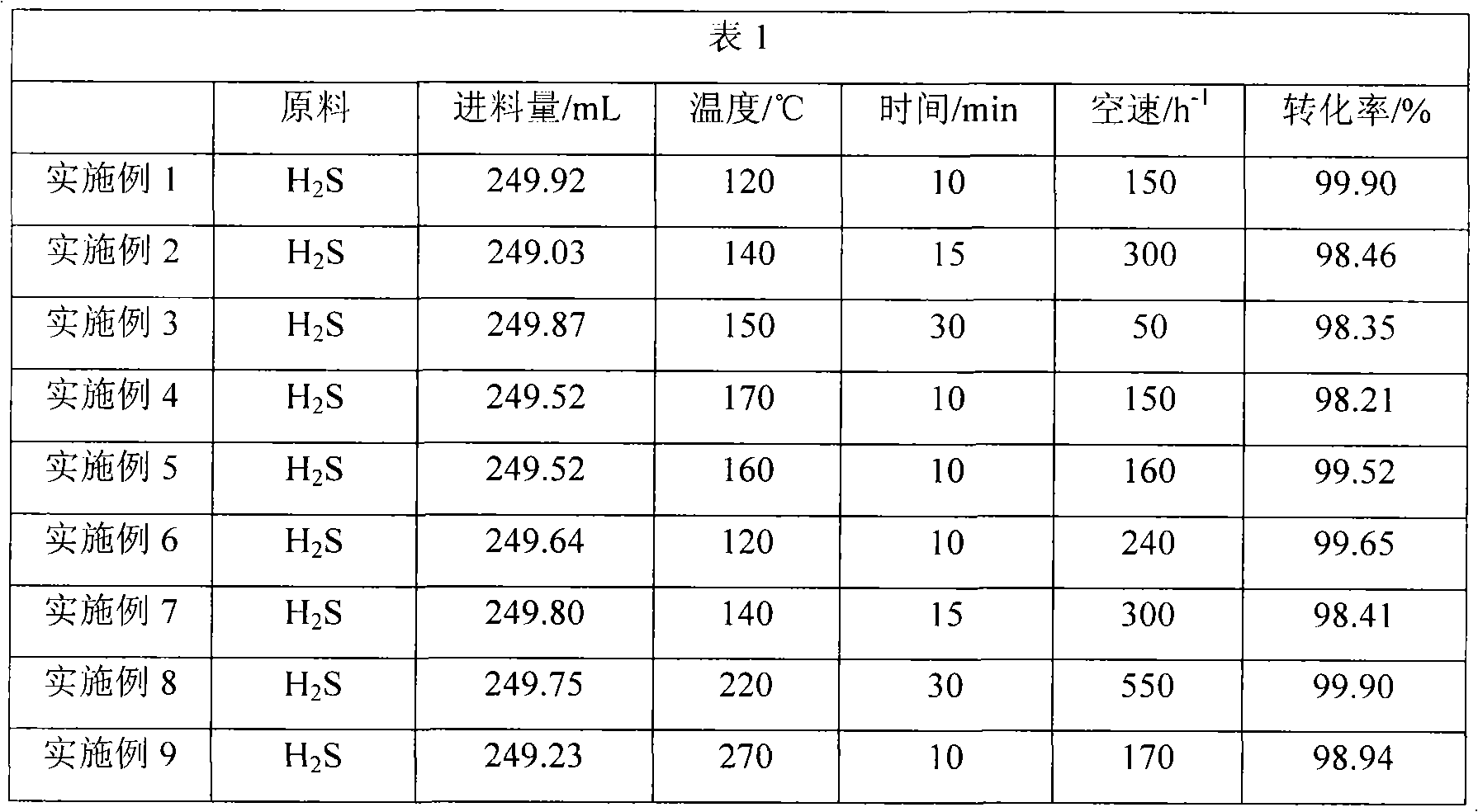

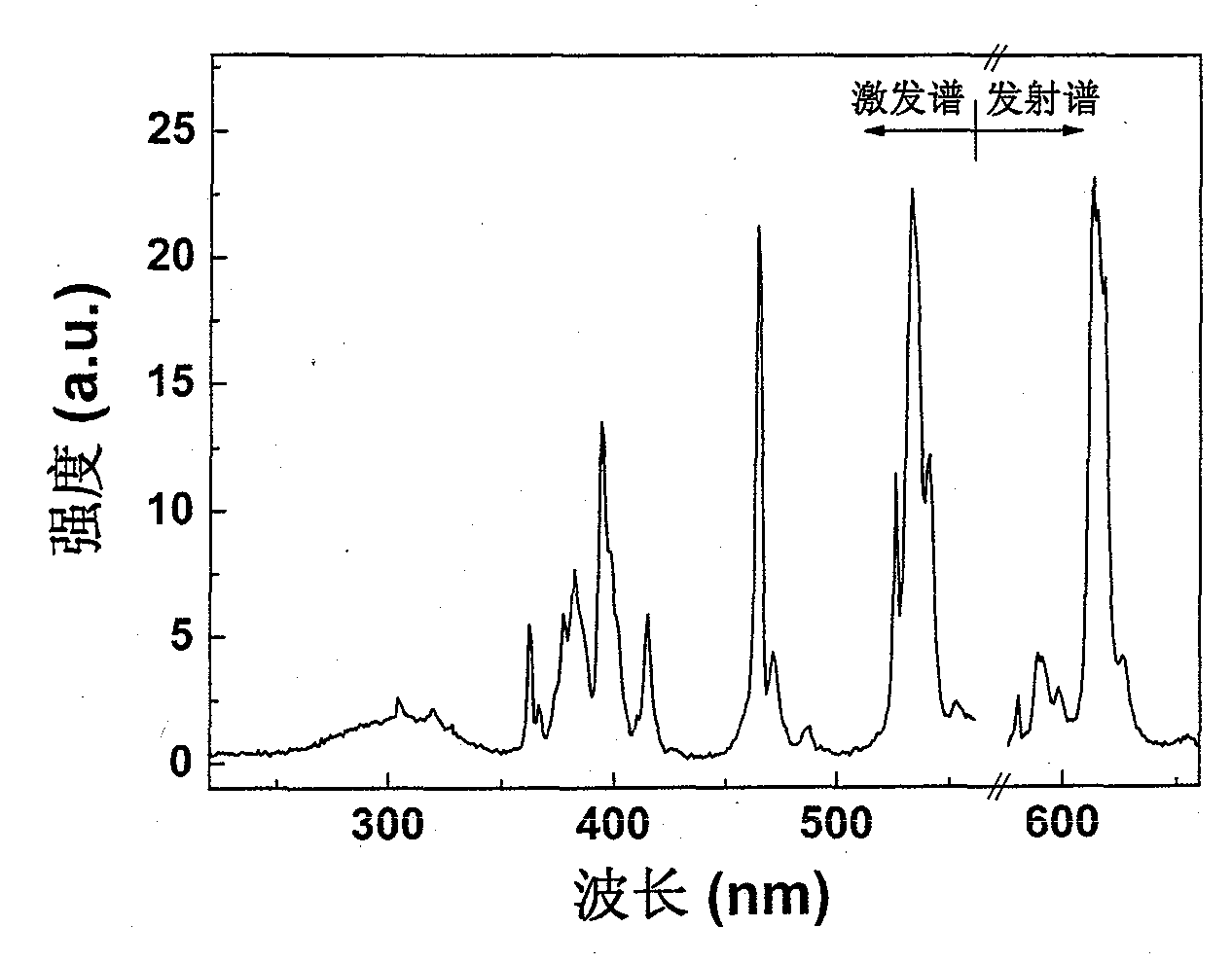

Niobate or tantalite fluorescent material used for white light LED and preparation method thereof

InactiveCN101921589AVariable crystal structureAdjustable Crystal Field StrengthGas discharge lamp usageLuminescent compositionsRare-earth elementEffect light

The invention relates to a niobate or tantalite fluorescent material used for a white light LED and a preparation method thereof. The material comprises the following components: non-doped niobate or tantalite, transition metal doped niobate or tantalite, T1 like ion doped niobate or tantalite with an s2 configuration, rare-earth element doped niobate or tantalite and T1 like ion and rear earth codoped niobate or tantalite. The materials in the invention can be used for the white light LED and related display and lighting devices. The invention has cheap and easy available materials, simple preparation process, stable material chemical property and excellent luminescence performance, and the prepared niobate or tantalite flourescent material is an ideal fluorescent powder candidate material for the white light LED.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Amorphous dielectric capacitors on silicon

InactiveUS6255122B1Improve conformityReduce leakage currentTransistorSemiconductor/solid-state device manufacturingLead zirconate titanateMaterials science

High-capacity capacitors and gate insulators exhibiting moderately high dielectric constants with surprisingly low leakage using amorphous or low temperature films of perovskite type oxides including a titanate system material such as barium titanate, strontium titanate, barium strontium titanate (BST), lead titanate, lead zirconate titanate, lead lanthanum zirconate titanate, barium lanthanum titanate, a niobate, aluminate or tantalate system material such as lead magnesium niobate, lithium niobate lithium tantalate, potassium niobate and potassium tantalum niobate, a tungsten-bronze system material such as barium strontium niobate, lead barium niobate, barium titanium niobate, and Bi-layered perovskite system material such as strontium bismuth tantalate, bismuth titanate deposited directly on a silicon surface at temperatures about 450° C. or less.

Owner:GLOBALFOUNDRIES INC

Methods for making barrier coatings comprising taggants and components having the same

Methods for making barrier coatings including a taggant involving providing a barrier coating, and adding from about 0.01 mol % to about 30 mol % of a taggant to the barrier coating wherein the taggant comprises a rare earth element selected from lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, ytterbium, and lutetium, salts thereof, silicates thereof, oxides thereof, zirconates thereof, hafnates thereof, titanates thereof, tantalates thereof, cerates thereof, aluminates thereof, aluminosilicates thereof, phophates thereof, niobates thereof, borates thereof, and combinations thereof.

Owner:GENERAL ELECTRIC CO

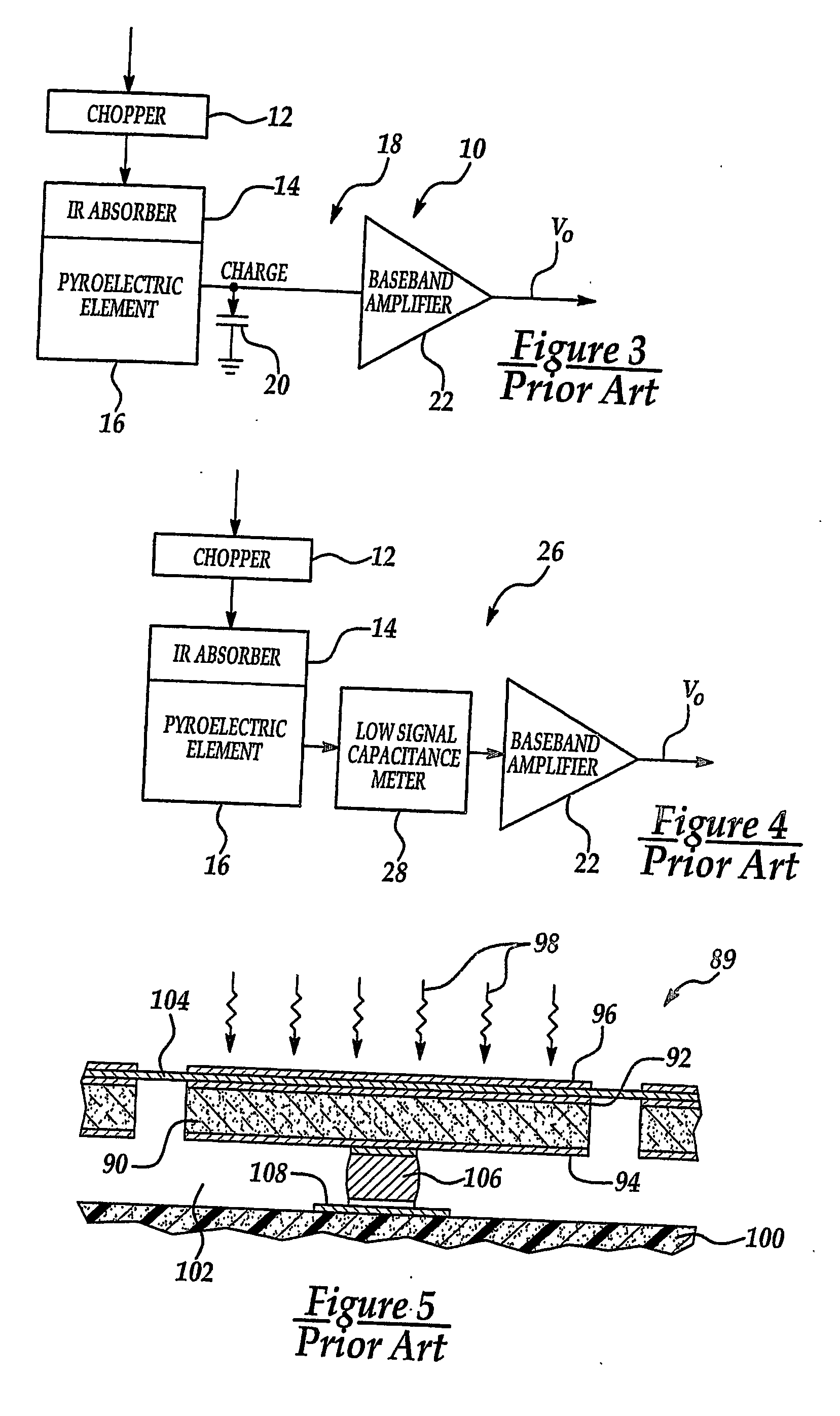

Pyroelectric sensor

ActiveUS20070108385A1Environmentally friendlyEnvironmentally robustMaterial analysis by optical meansPyrometry using electric radation detectorsHysteresisEngineering

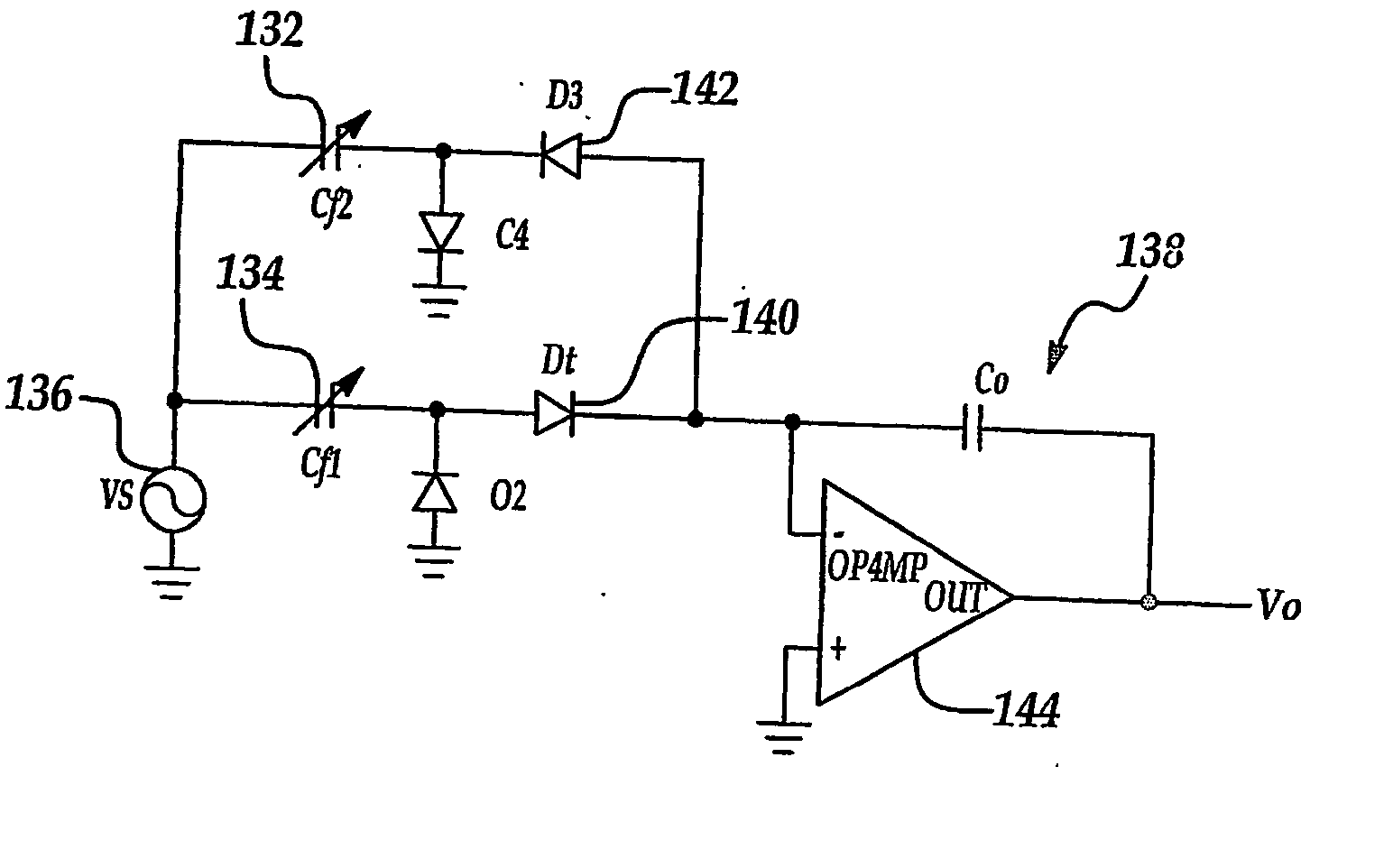

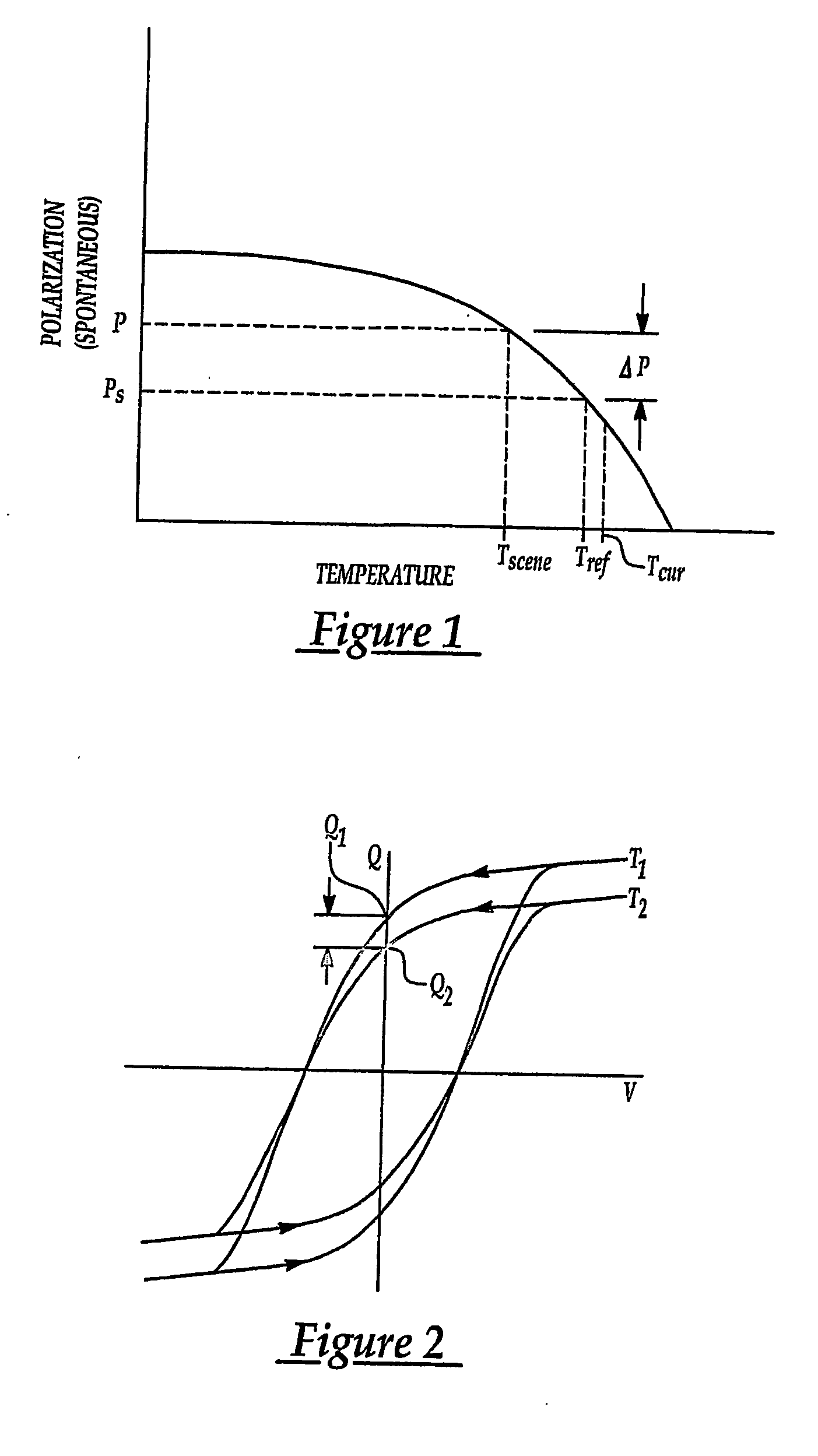

A ferroelectric / pyroelectric sensor employs a technique for determining a charge output of a ferroelectric scene element of the sensor by measuring the hysteresis loop output of the scene element several times during a particular time frame for the same temperature. An external AC signal is applied to the ferroelectric scene element to cause the hysteresis loop output from the element to switch polarization. Charge integration circuitry, such as a combination output capacitor and operational amplifier, is employed to measure the charge from the scene element. Preferably, the ferroelectric of the scene element is made of an economical and responsive strontium bismuth tantalate, SBT, or derivative thereof, disposed directly between top and bottom electrodes. Because of the frequency characteristics of the sensor, created by the external AC signal, the element need not be thermally isolated from the silicon substrate by a traditional air bridge, which is difficult to manufacture, and instead is preferably thermally isolated by spin-on-glass, SOG. To prevent saturation of an output signal voltage of the sensor by excessive charge accumulation in an output capacitor, the sensor preferably has a reference element configured electrically in parallel with the scene element. When the voltage of the AC signal is negative the output capacitor is discharged by flowing current through the reference element thus interrogating the polarization of the reference element which is compared to and subtracted from the polarization of the scene element for each cycle. The polarization difference measured for each cycle over a set time period are summed by an integrating amplifier to produce a signal output voltage.

Owner:APTIV TECH LTD +1

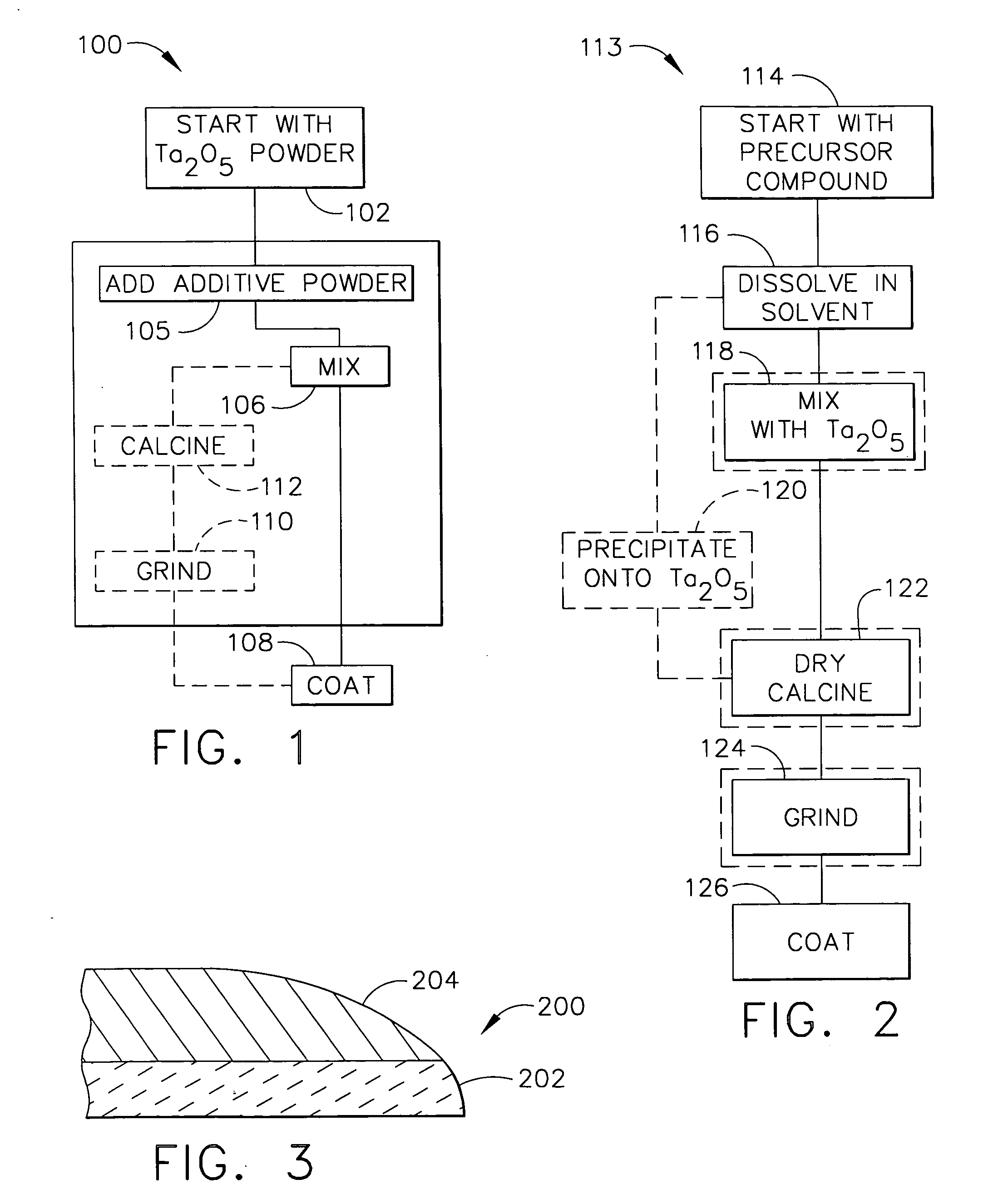

Protective coating for ceramic components

InactiveUS20060099358A1Envelopes/bags making machineryEfficient propulsion technologiesRare-earth elementCombustion

A protective coating for a component comprising a ceramic based substrate, and methods for protecting the component, the protective coating adapted for withstanding repeated thermal cycling. The substrate may comprise silicon nitride or silicon carbide, and the protective coating may comprise at least one tantalate of scandium, yttrium, or a rare earth element. The protective coating may further comprise one or more metal oxides. The coating protects the substrate from combustion gases in the high temperature turbine engine environment. The coating may be multi-layered and exhibits strong bonding to Si-based substrate materials and composites.

Owner:HONEYWELL INT INC

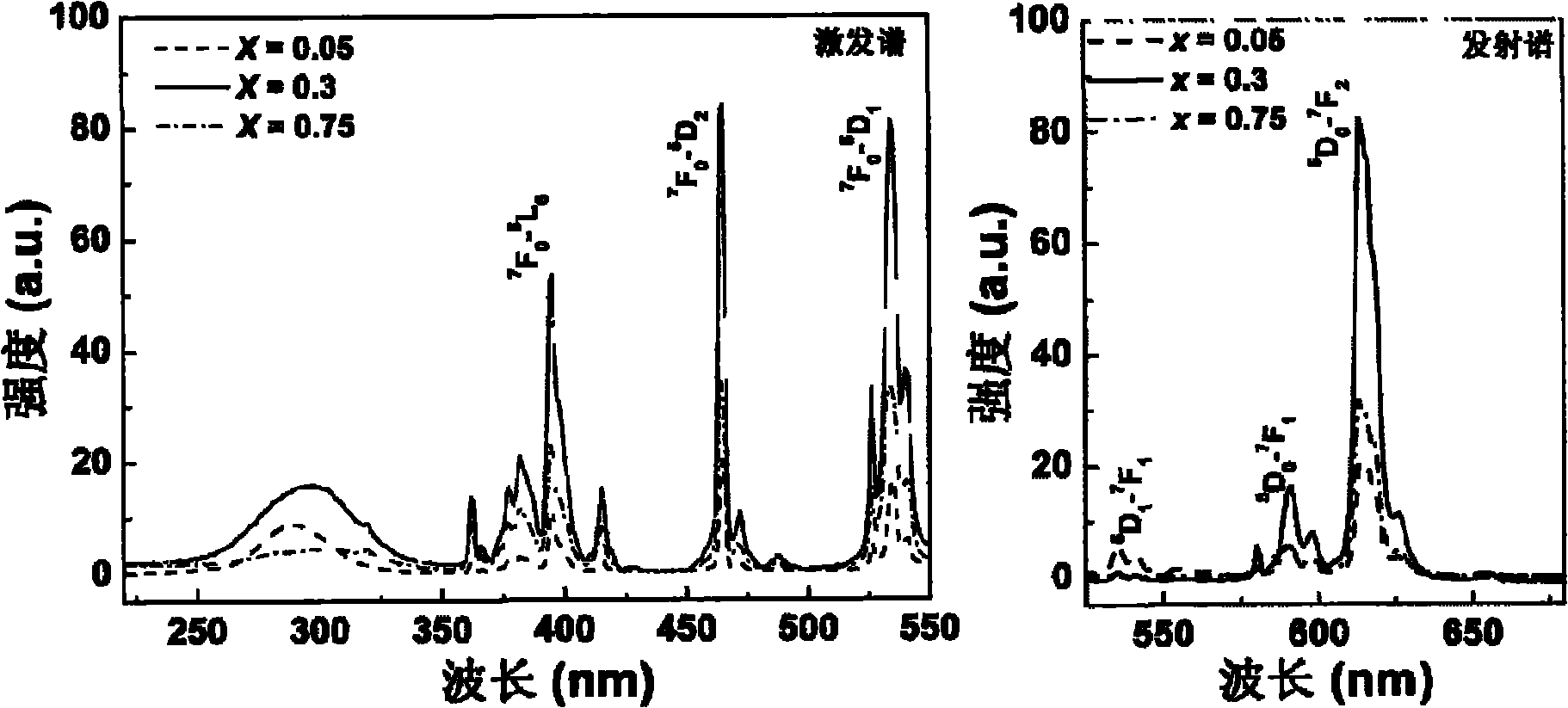

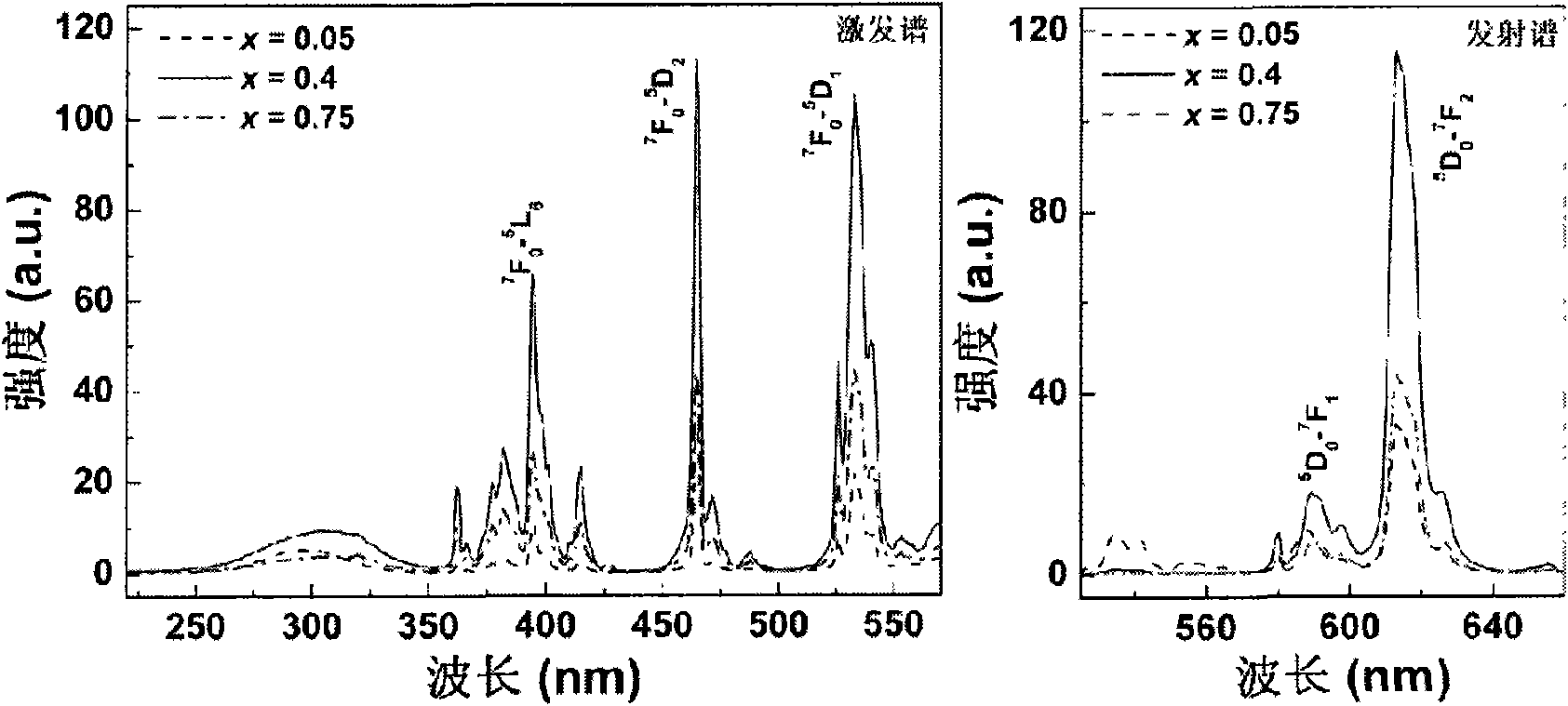

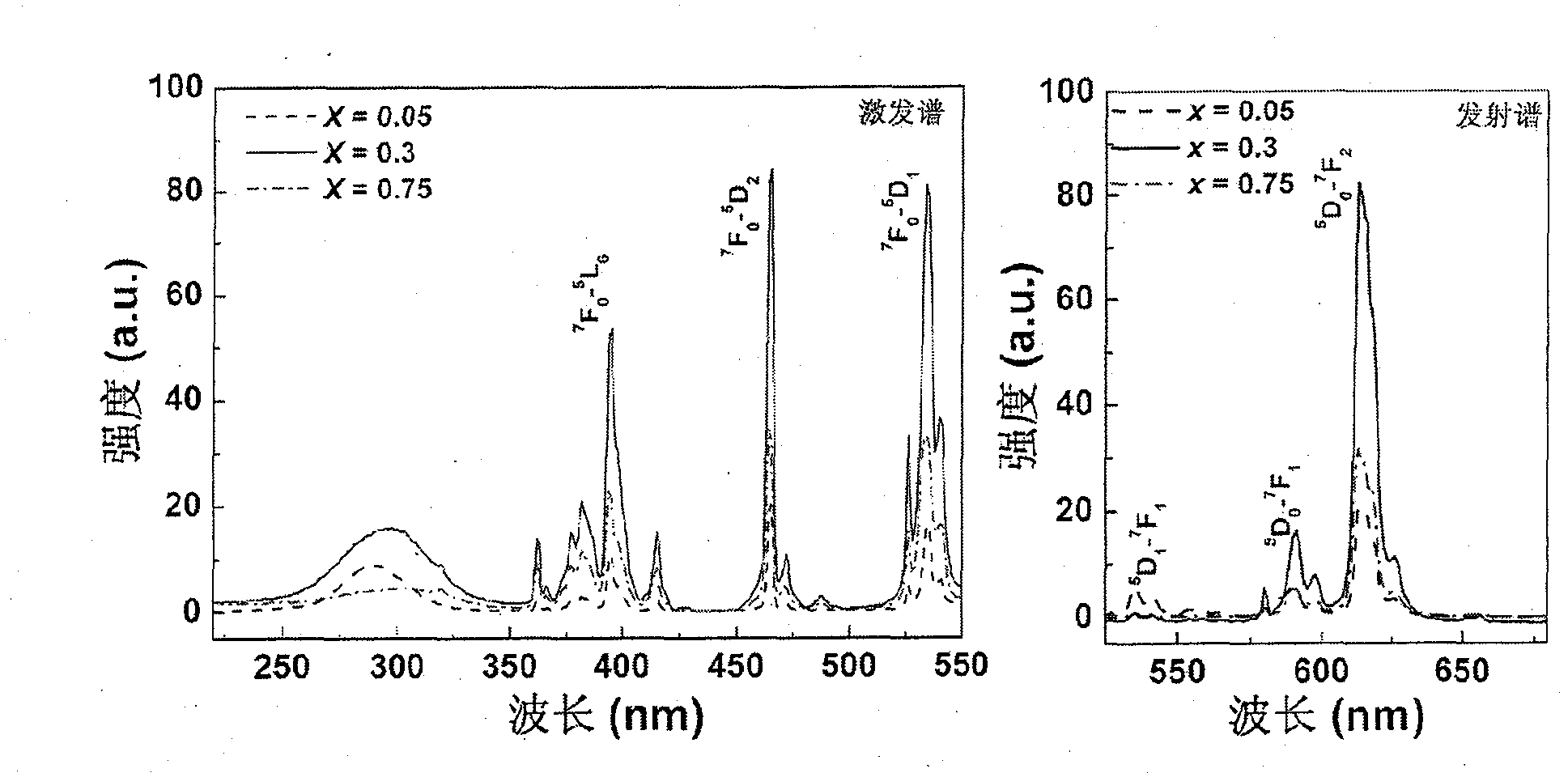

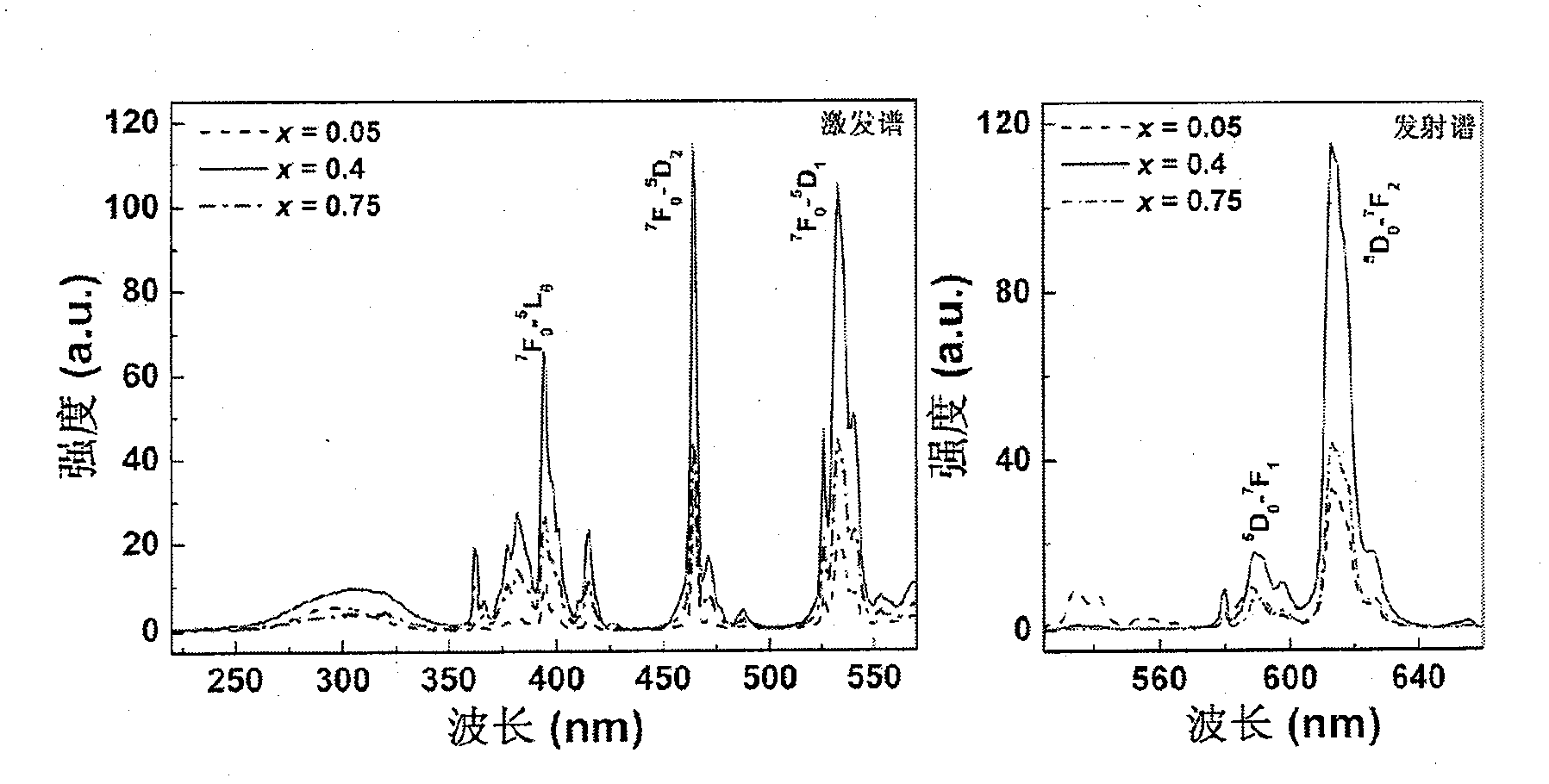

Luminescent material doped with niobate, tantalate and the mischcrystal thereof, and crystal growth method thereof for the melt process

InactiveCN101445727APolycrystalline material growthLuminescent compositionsCzochralski methodHigh energy

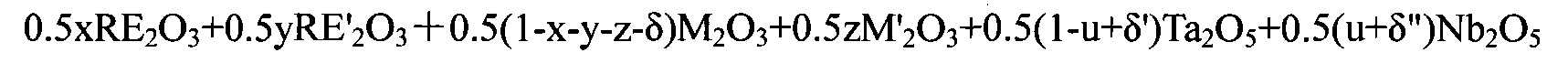

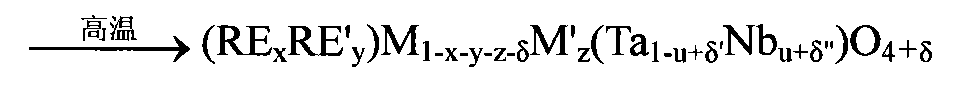

The invention discloses a luminescent material doped with niobate, tantalate and the mischcrystal thereof, and a crystal growth method thereof for the melt process. The molecular formula of the compound is (RExRE'y) M1-x-y-z-deltaM'z (Ta1-u+delta' Nbu+delta') O4+delta (x equals to 0 to 0.5, y equals to 0 to 0.5, 0 is smaller than x+y and x+y is smaller than and equal to 0.5, z equals to 0 to 0.5, delta equals to -0.4 to 0.4, and delta'+delta' equals to delta), wherein, the RE and the RE' are Yb, Nd, Er, Tm, Ho, Ce, Pr, Eu, Bi, Ti and Cr, and the M and the M' are Sc, Y, Gd and Lu. The well prepared raw material becomes the starting material of crystal growth after uniformly mixing, pressing molding and high temperature sintering; the starting material for crystal growth is put into a crucible and sufficiently heated and fused to form an initial melt for melt process growth, and then the melt methods can be used for crystal growth such as a Czochralski method, a Bridgman-Stockbarge method, a TGT method and other melt methods; and the (RExRE'y) M1-x-y-z-deltaM'z (Ta1-u+delta' Nbu+delta') O4+delta can be used as the detection material for the working laser material, the high-energy rays, the high-energy particle, and the like.

Owner:ANHUI INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

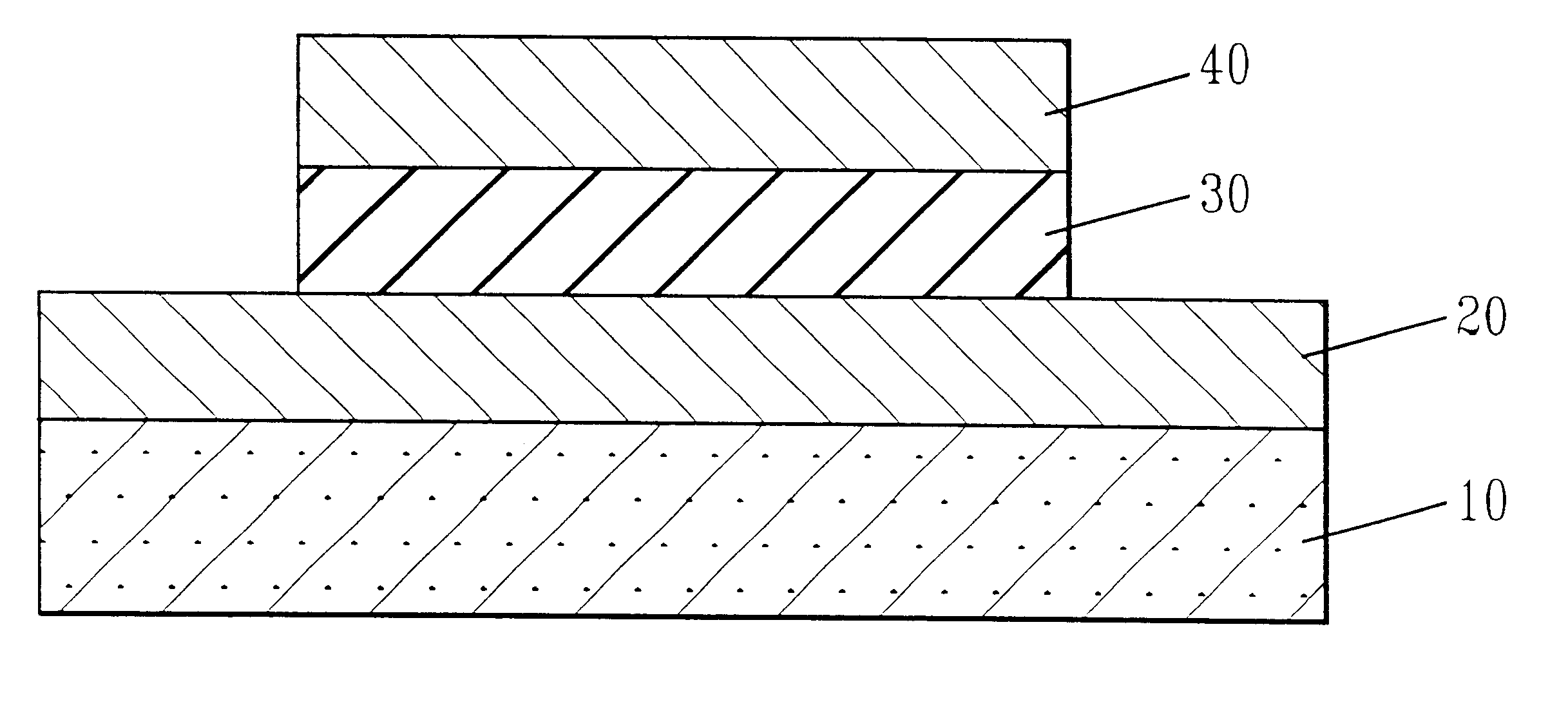

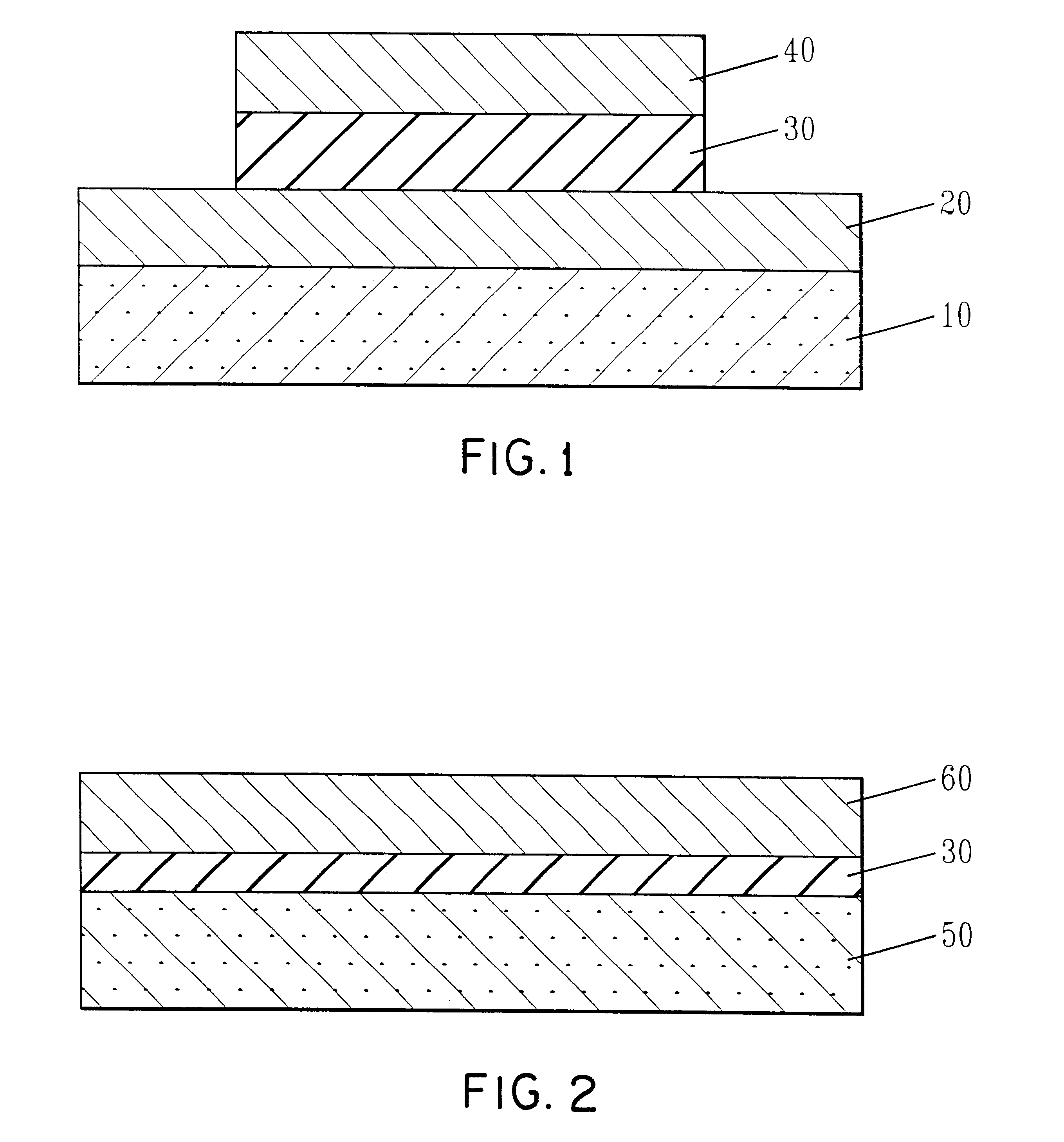

Method of making layered superlattice material with improved microstructure

InactiveUS20040048455A1Solid-state devicesSemiconductor/solid-state device manufacturingCooking & bakingStrontium

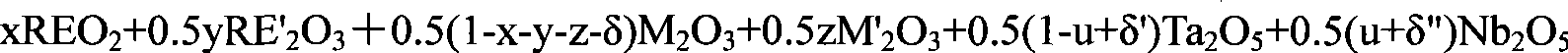

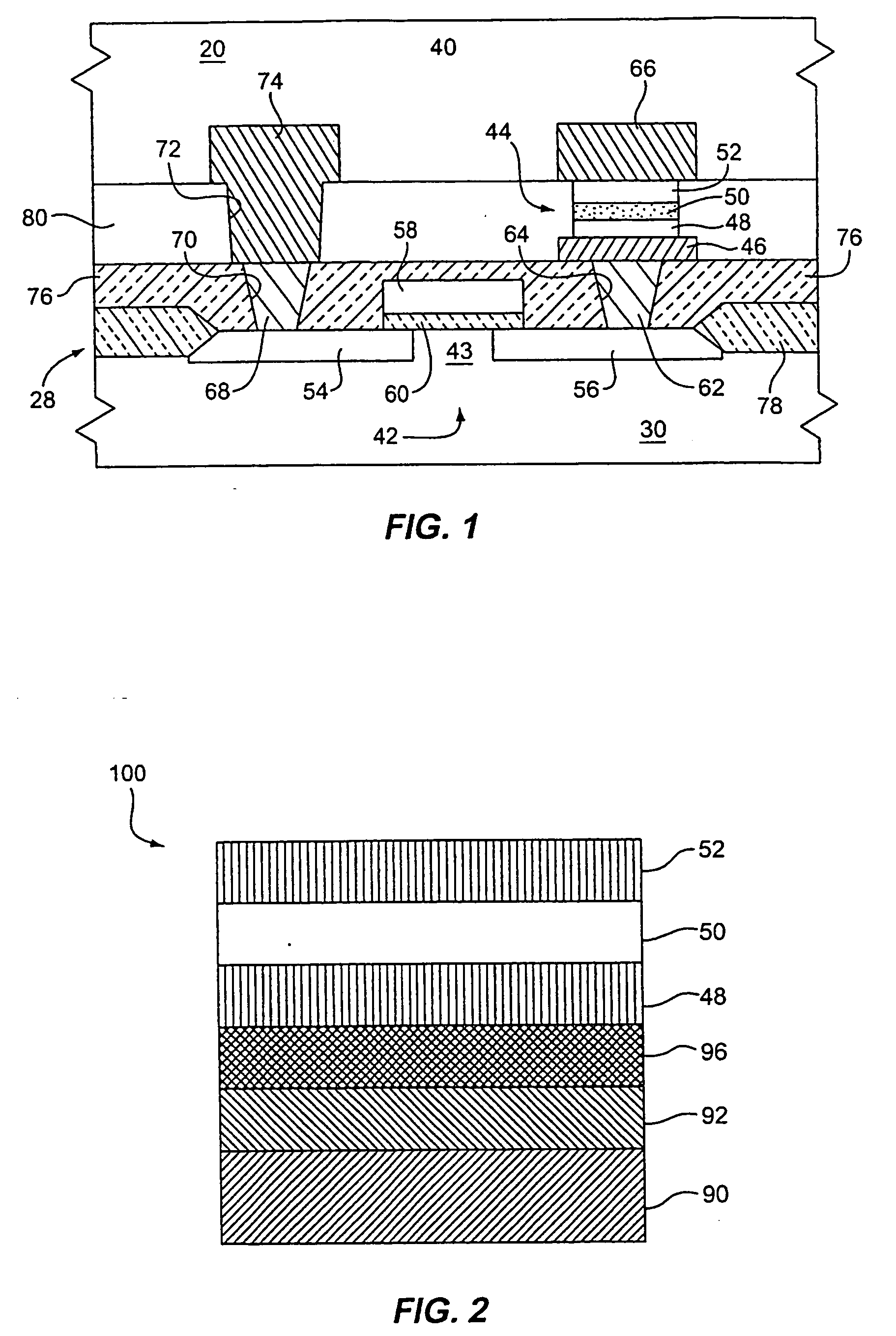

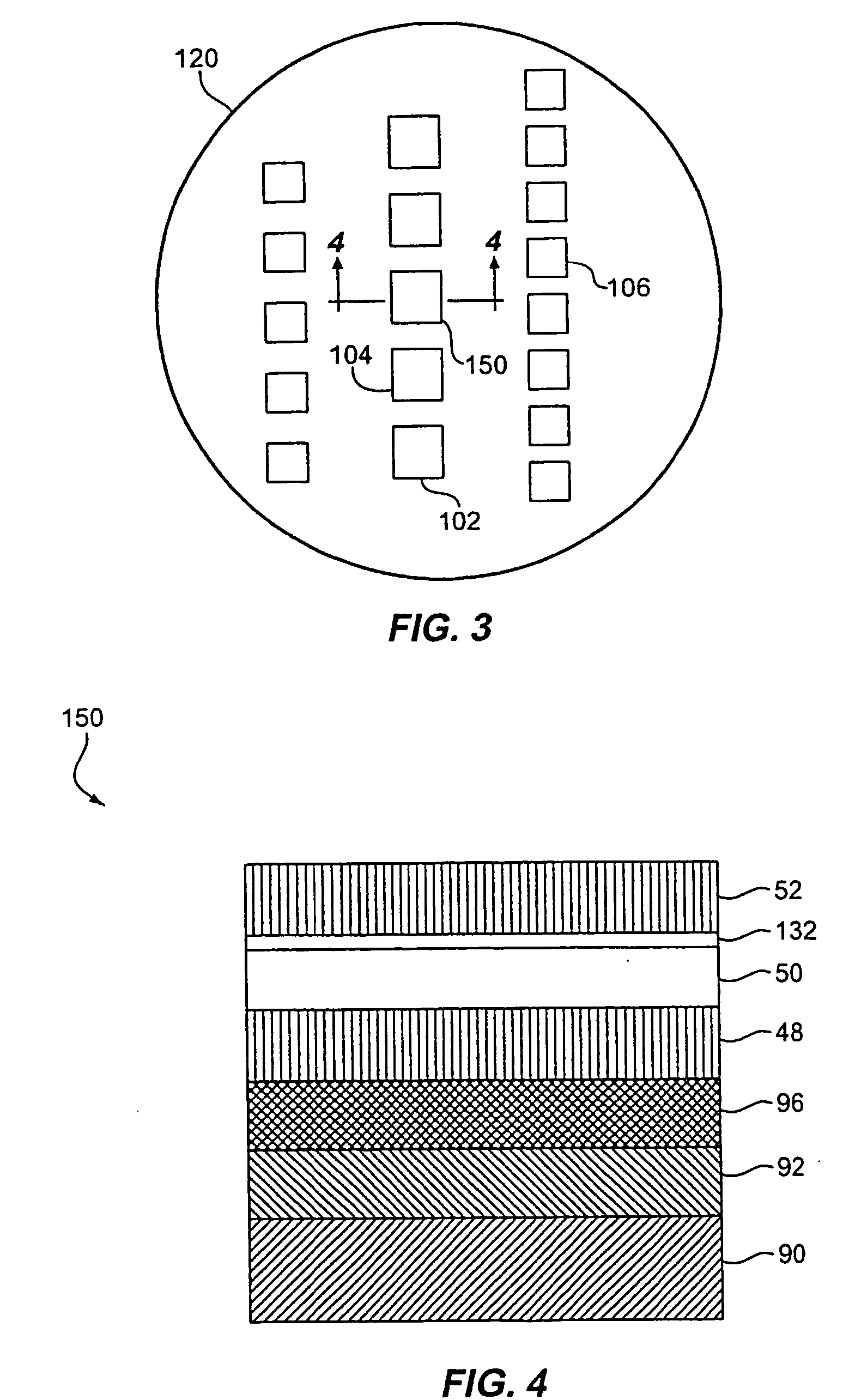

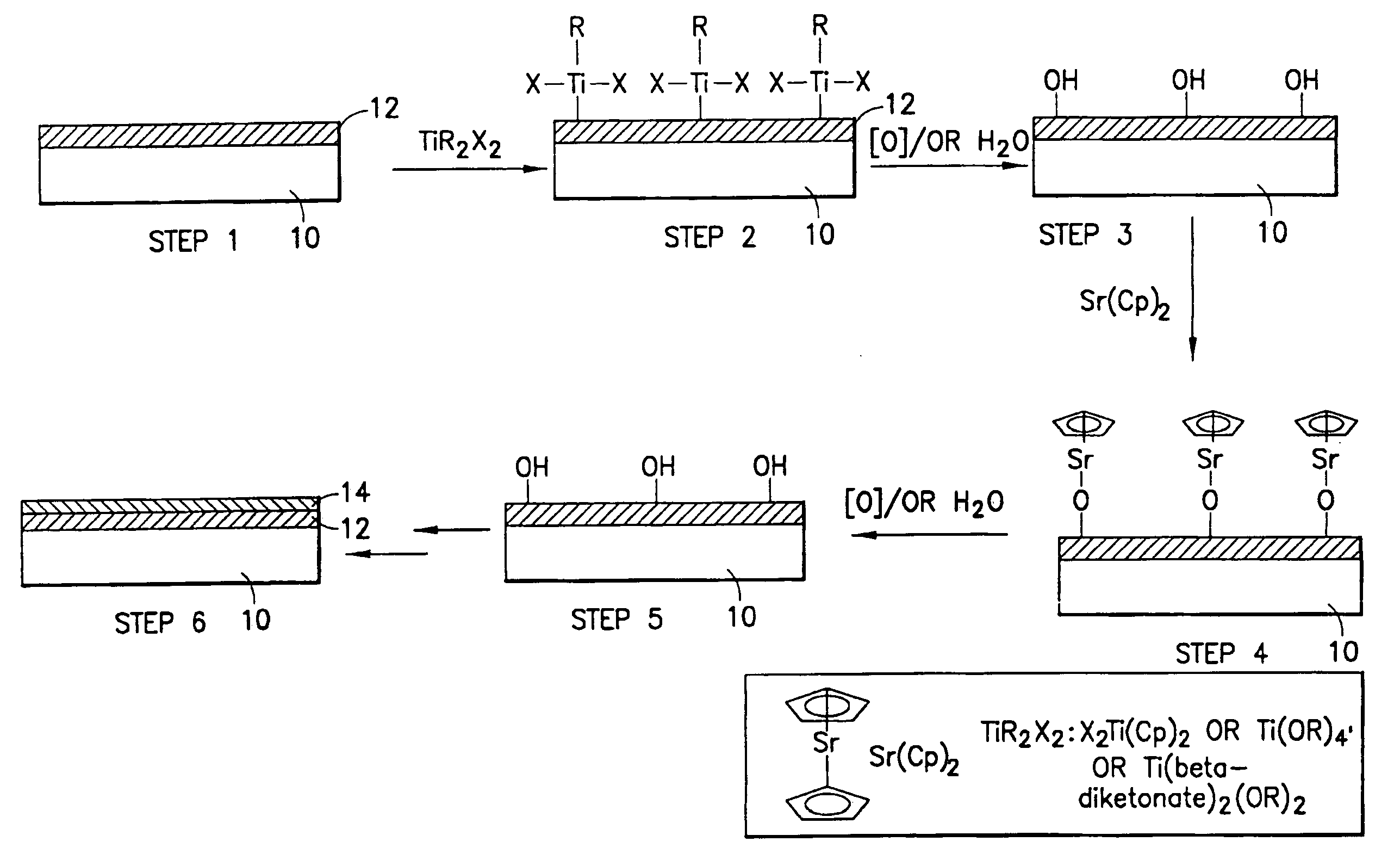

In the manufacture of an integrated circuit, a first electrode (48) is formed on a substrate (28). In a first embodiment, a strontium bismuth tantalate layer (50) and a second electrode (52) are formed on top of the first electrode (48). Prior to the final crystallization anneal, the first electrode (48), the strontium bismuth tantalate layer (50) and the second electrode (52) are patterned. The final crystallization anneal is then performed on the substrate (28). In a second embodiment, a second layer (132) of strontium bismuth tantalate is deposited on top of the strontium bismuth tantalate layer (50) prior to the forming of the second electrode (52) on top of the first and second layers (50), (132). In a third embodiment, a carefully controlled UV baking process is performed on the strontium bismuth tantalate layer (50). In a fourth embodiment, an additional rapid thermal annealing process is performed on a substrate subsequent to the patterning process and prior to the final crystallization annealing process.

Owner:SYMETRIX +1

Precursor compositions for atomic layer deposition and chemical vapor deposition of titanate, lanthanate, and tantalate dielectric films

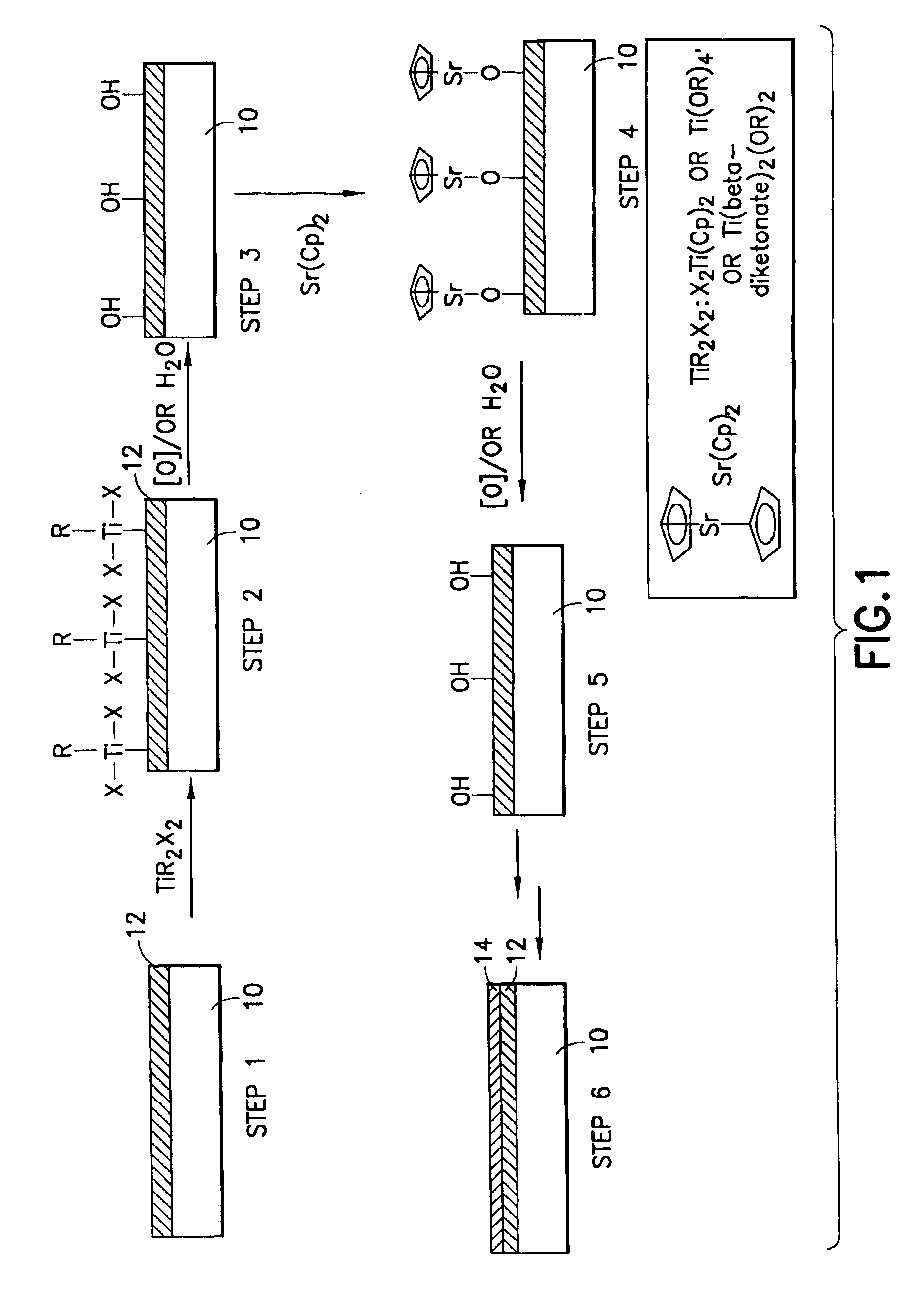

Barium, strontium, tantalum and lanthanum precursor compositions useful for atomic layer deposition (ALD) and chemical vapor deposition (CVD) of titanate thin films. The precursors have the formula M(Cp)2, wherein M is strontium, barium, tantalum or lanthanum, and Cp is cyclopentadienyl, of the formula (I), wherein each of R1-R5 is the same as or different from one another, with each being independently selected from among hydrogen, C1-C12 alkyl, C1-C12 amino, C6-C10 aryl, C1-C12 alkoxy, C3-C6 alkylsilyl, C2-C12 alkenyl, R1R2R3NNR3, wherein R1, R2 and R3 may be the same as or different from one another and each is independently selected from hydrogen and C1-C6 alkyl, and pendant ligands including functional group(s) providing further coordination to the metal center M. The precursors of the above formula are useful to achieve uniform coating of high dielectric constant materials in the manufacture of flash memory and other microelectronic devices.

Owner:ENTEGRIS INC

Low thermal budget fabrication of ferroelectric memory using RTP

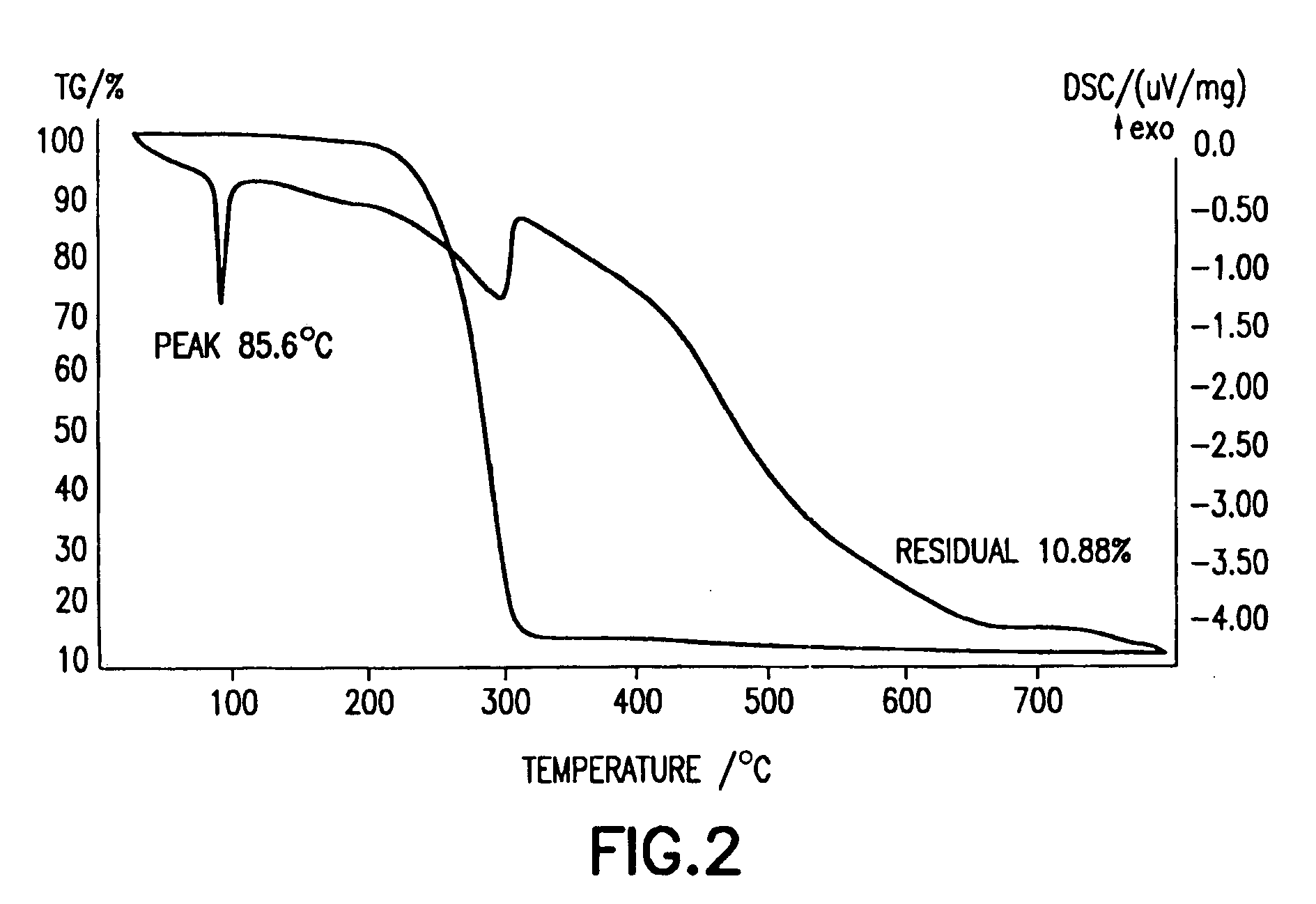

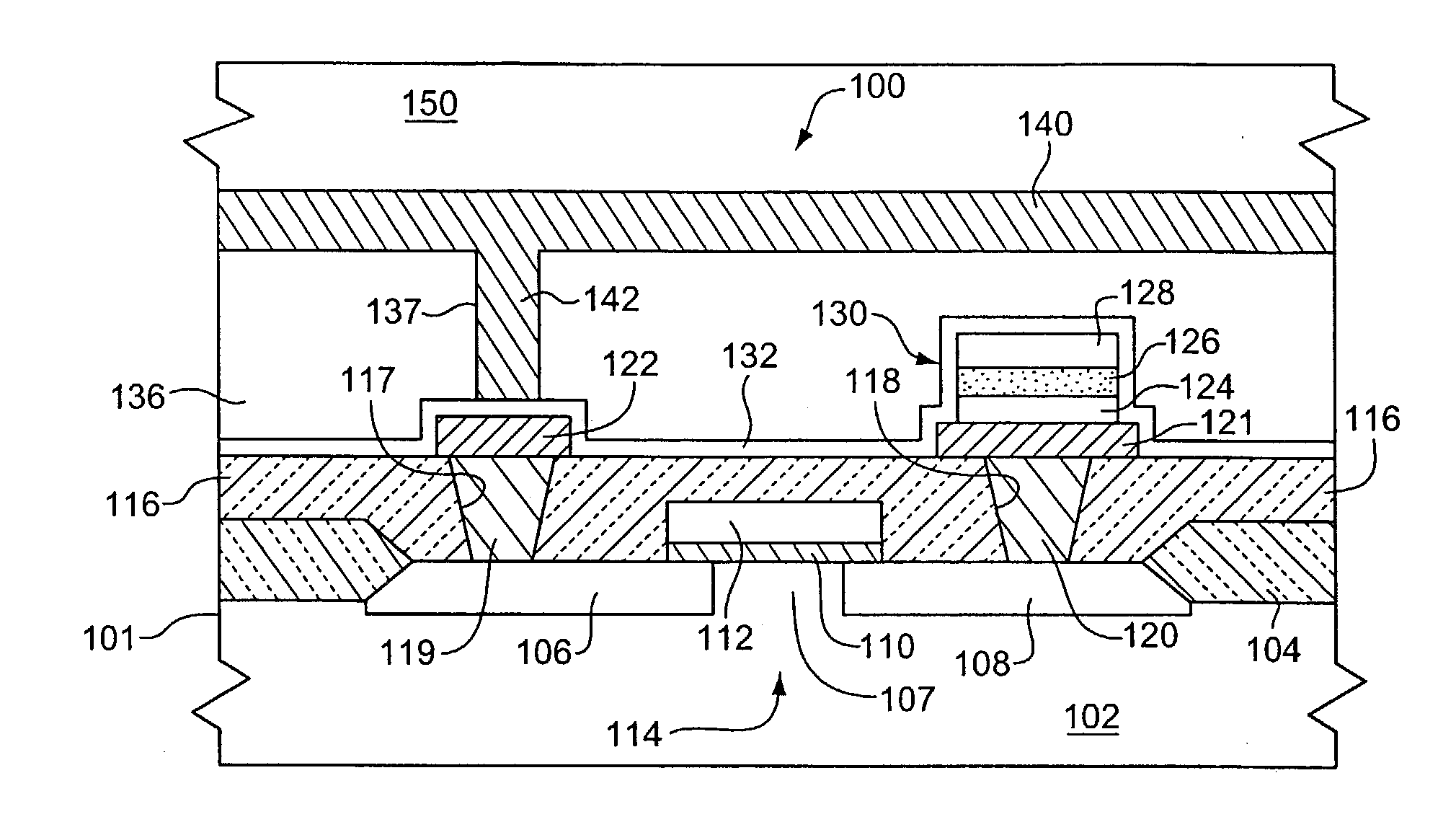

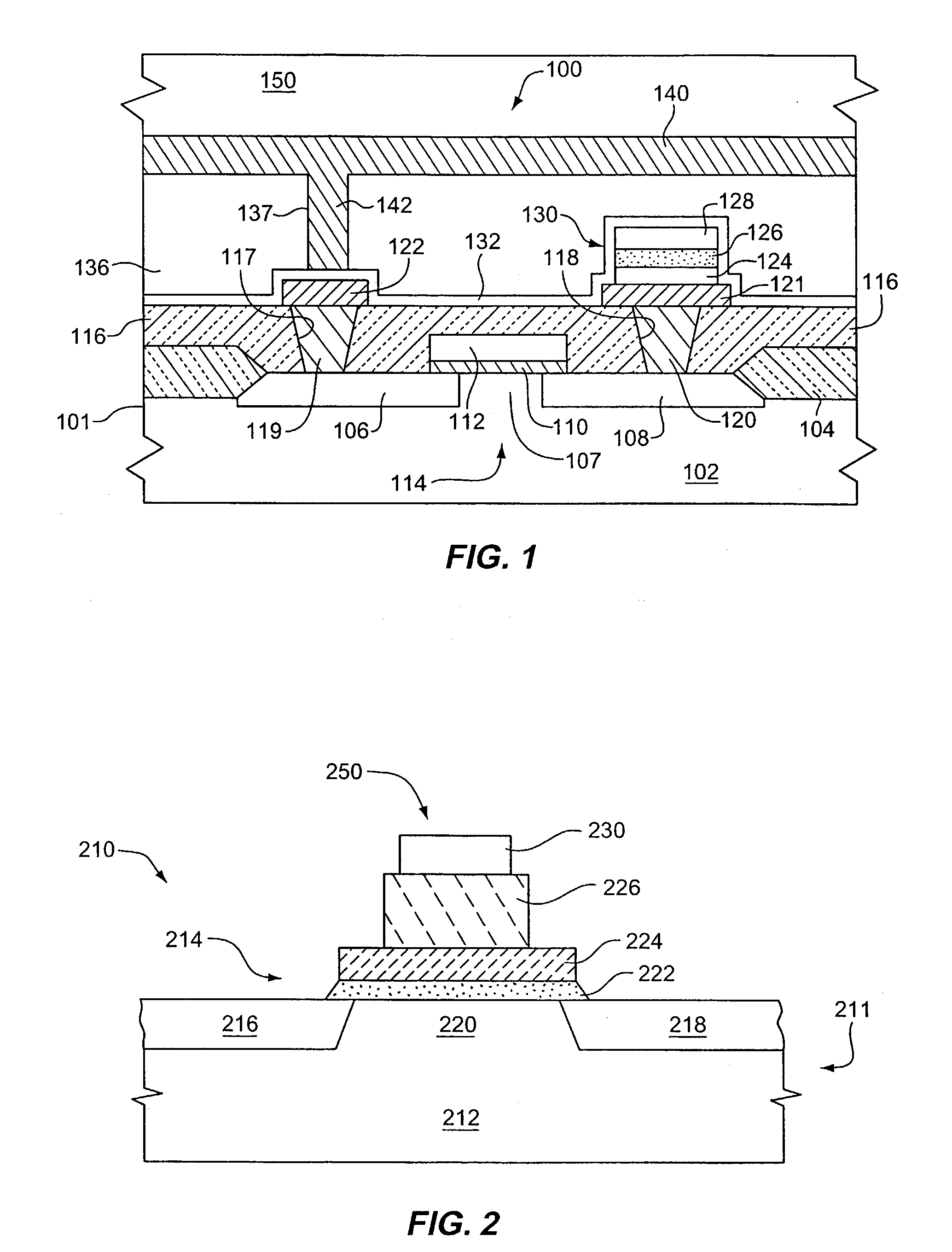

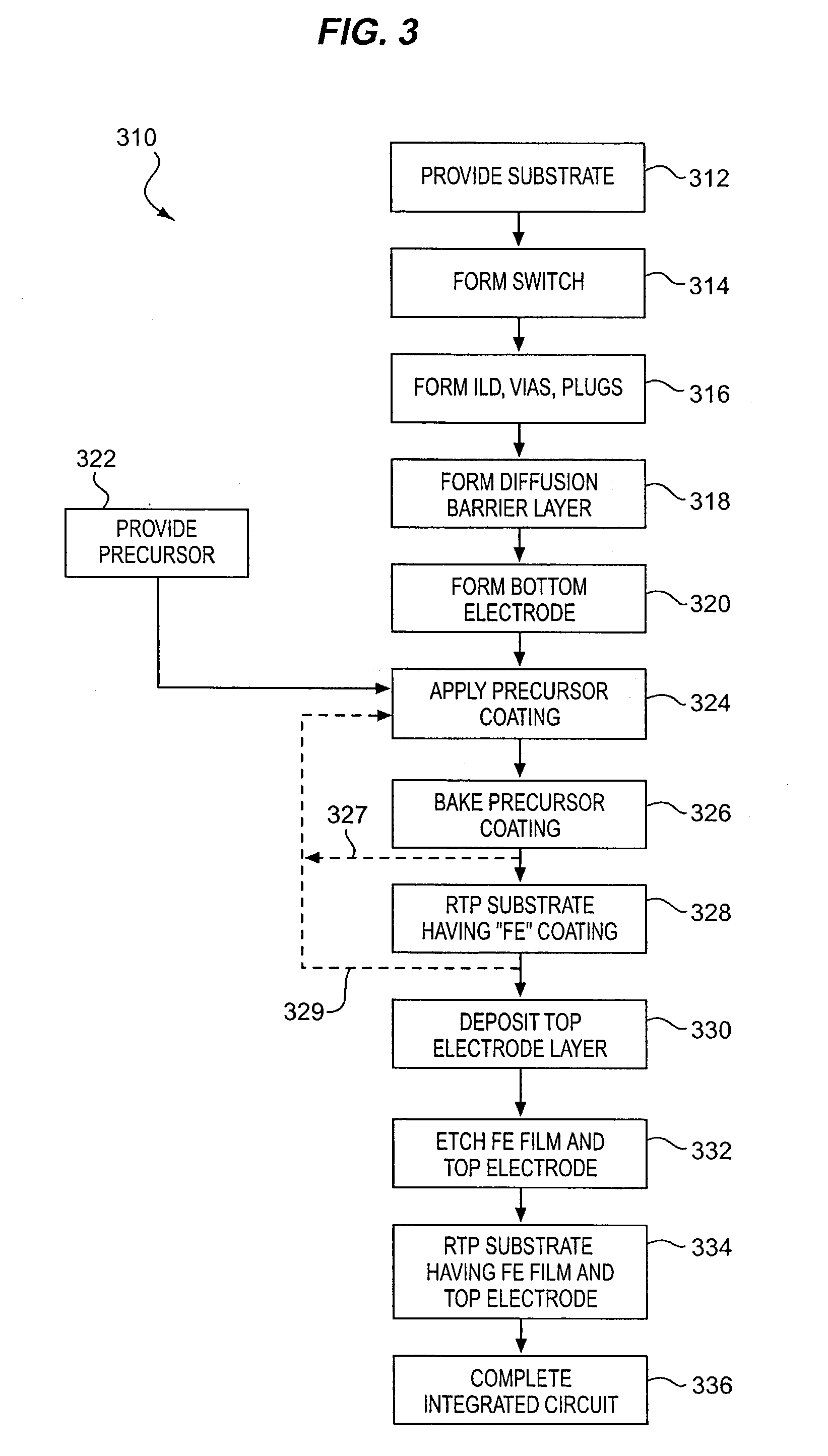

InactiveUS20040101977A1Budget is reducedReduce the temperaturePolycrystalline material growthSemiconductor/solid-state device manufacturingOxygenHeat treated

A precursor for forming a thin film of layered superlattice material is applied to an integrated circuit substrate. The precursor coating is heated using rapid thermal processing (RTP) with a ramping rate of 100° C. / second at a hold temperature in a range of from 500° C. to 900° C. for a cumulative heating time not exceeding 30 minutes, and preferably less than 5 minutes. In fabricating a ferroelectric memory cell, the coating is heated in oxygen using RTP, then a top electrode layer is formed, and then the substrate including the coating is heated using RTP in oxygen or in nonreactive gas after forming the top electrode layer. The thin film of layered superlattice material preferably comprises strontium bismuth tantalate or strontium bismuth tantalum niobate, and preferably has a thickness in a range of from 25 nm to 120 nm. The process of fabricating a thin film of layered superlattice material typically has a thermal budget value not exceeding 960,000° C.-sec, preferably less than 50,000° C.-sec.

Owner:SYMETRIX

Magnesium removal from magnesium reduced metal powders

A method of producing a refractory metal powder that includes providing a metal powder containing magnesium tantalate or magnesium niobate; and heating the powder in an inert atmosphere in the presence of magnesium, calcium and / or aluminum to a temperature sufficient to remove magnesium tantalate or magnesium niobate from the powder and / or heating the powder under vacuum to a temperature sufficient to remove magnesium tantalate or magnesium niobate from the powder, the heating steps being performed in any order. The metal powder can be formed into pellets at an appropriate sintering temperature, which can be formed into electrolytic capacitors.

Owner:TANIOBIS GMBH

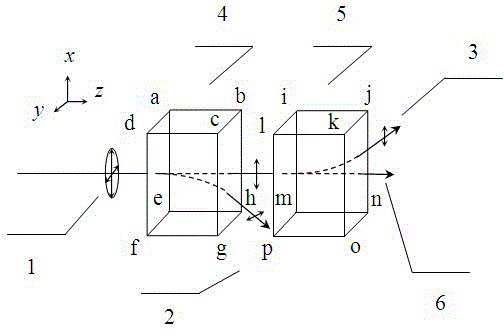

Optical switching method capable of using electronic control quadratic electro-optical effect for deflecting incident light

InactiveCN103605217APolarization direction achievedReduce volumeNon-linear opticsOptical polarizationMaterials science

The invention provides an optical switching method capable of using the electronic control quadratic electro-optical effect for deflecting incident light, belongs to the technical field of optics, and aims to solve the problem in the existing optical switching technology that a broadband range and quick responses cannot be realized. The optical switching method specifically comprises the following steps: a quadratic electro-optical effect potassium tantalate niobate crystal is used; when laser radiation is needed, an external electric field is not applied to the crystal, and lasers directly penetrate through the crystal; when laser radiation is not needed, the external electric field is applied to the crystal in the two directions perpendicular to the incident lasers, and the quadratic electro-optical effect is used for making polarized components in the incident lasers be polarized sequentially after the polarized components pass through the crystal, wherein the polarization direction of the polarized components is parallel to the direction of the externally applied electric field; finally, the polarized components deviate from the original propagation direction, and the purpose of switching on and off is achieved. An optical switch manufactured by the adoption of the optical switching method has the advantages of being small in size, low in cost, easy to process, and high in response speed (at a nanosecond level), so that the application prospect of the optical switch is quite broad.

Owner:HARBIN INST OF TECH

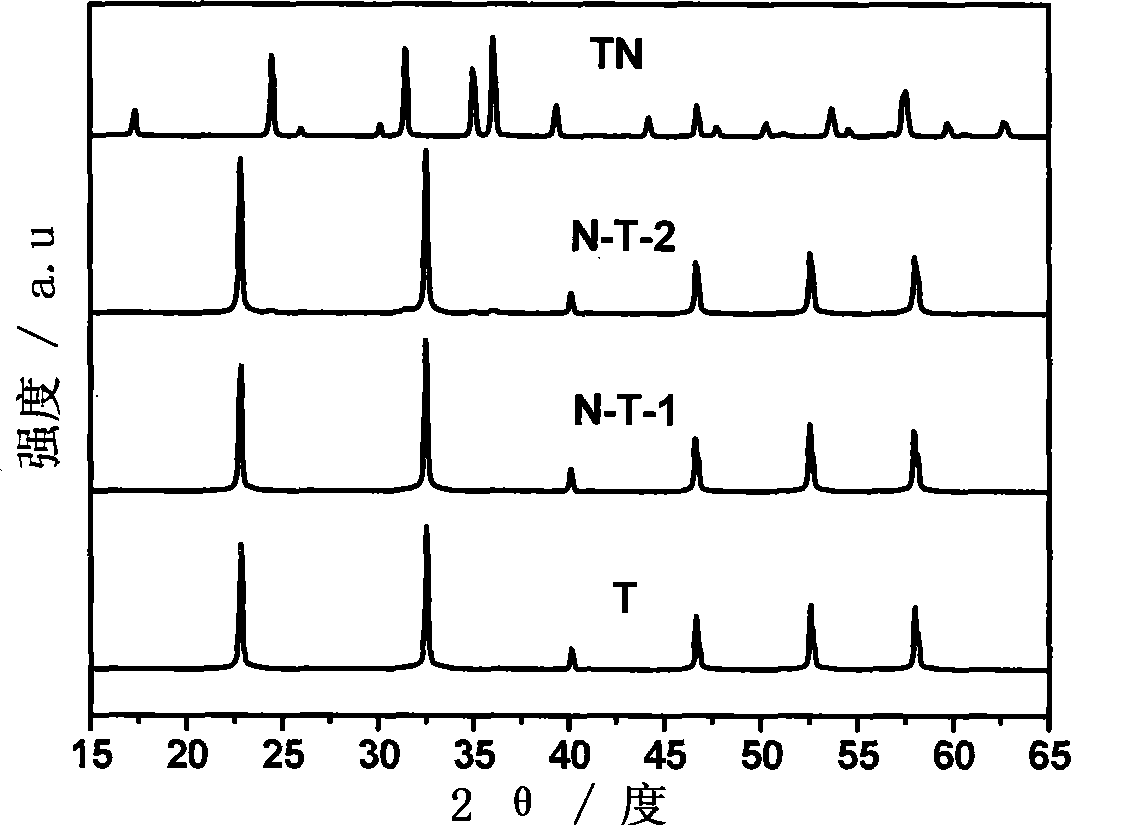

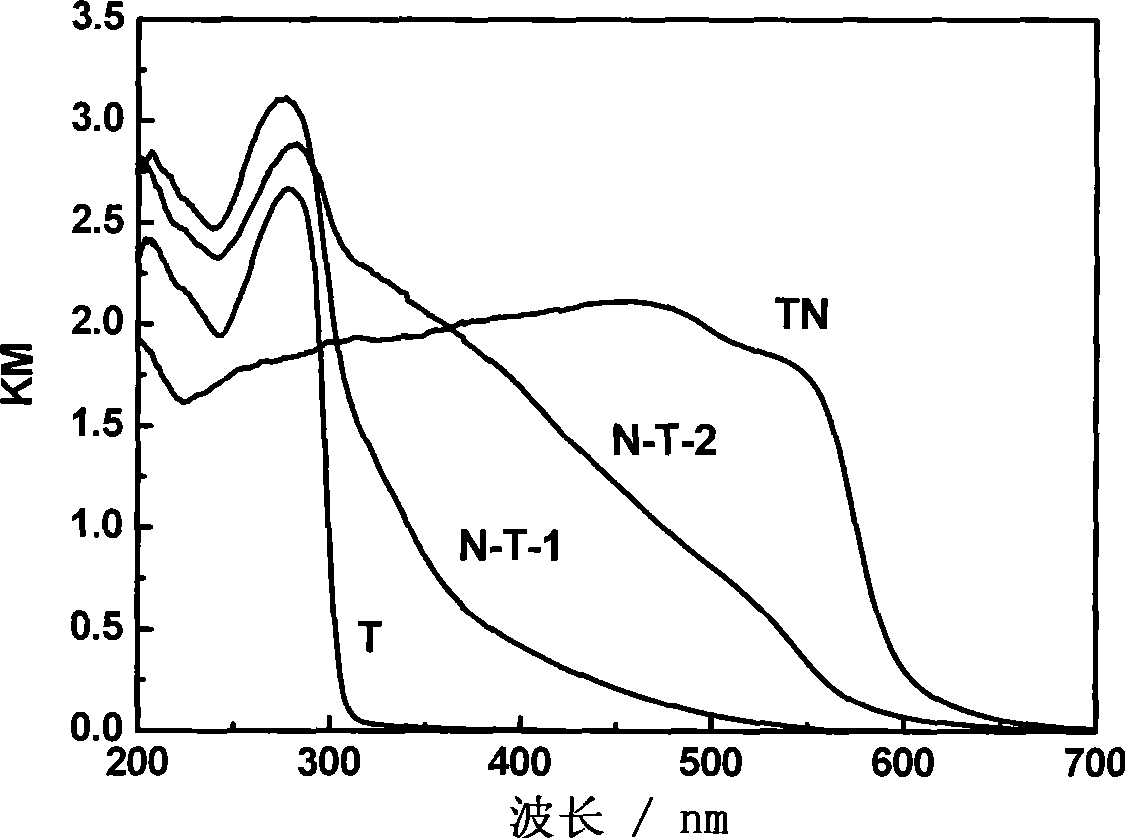

Preparation method of alkali metal tantalate composite visible-light photocatalyst for hydrogen production from photodissociation of water

InactiveCN101474558AAchieve dopingIt can be seen that the absorption is goodHydrogen productionMetal/metal-oxides/metal-hydroxide catalystsNitrogen dopedHeat treated

The invention relates to a preparation method for an alkali tantalate based composite visible-light photocatalyst in hydrogen production by water splitting, in particular to a method that ammonia is used as the nitrogen source to perform nitrogen doping on the alkali tantalate at high temperature. The method has the following steps: (1) dissolving the tantalum-containing precursor in the surfactant acidic solution to produce a uniform tantalum salt solution; (2) adjusting the PH value to 6-9 and adding the hydroxide of an alkali metal to produce a suspension; (3) water-heating the produced suspension in a reaction kettle to produce the alkali tantalate crystal and (4) treating the crystal with the ammonia to produce the alkali tantalate, and then obtaining the nitrogen doped alkali tantalate. The photocatalyst treats the alkali tantalate by high-temperature ammonolysis, which realizes nitrogen doping to the alkali tantalate. The experiment shows that the alkali tantalate is nitrogen doped in the preparation process which has good visible light catalysis and solves the problem of nitrogen doping to the alkali tantalate.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

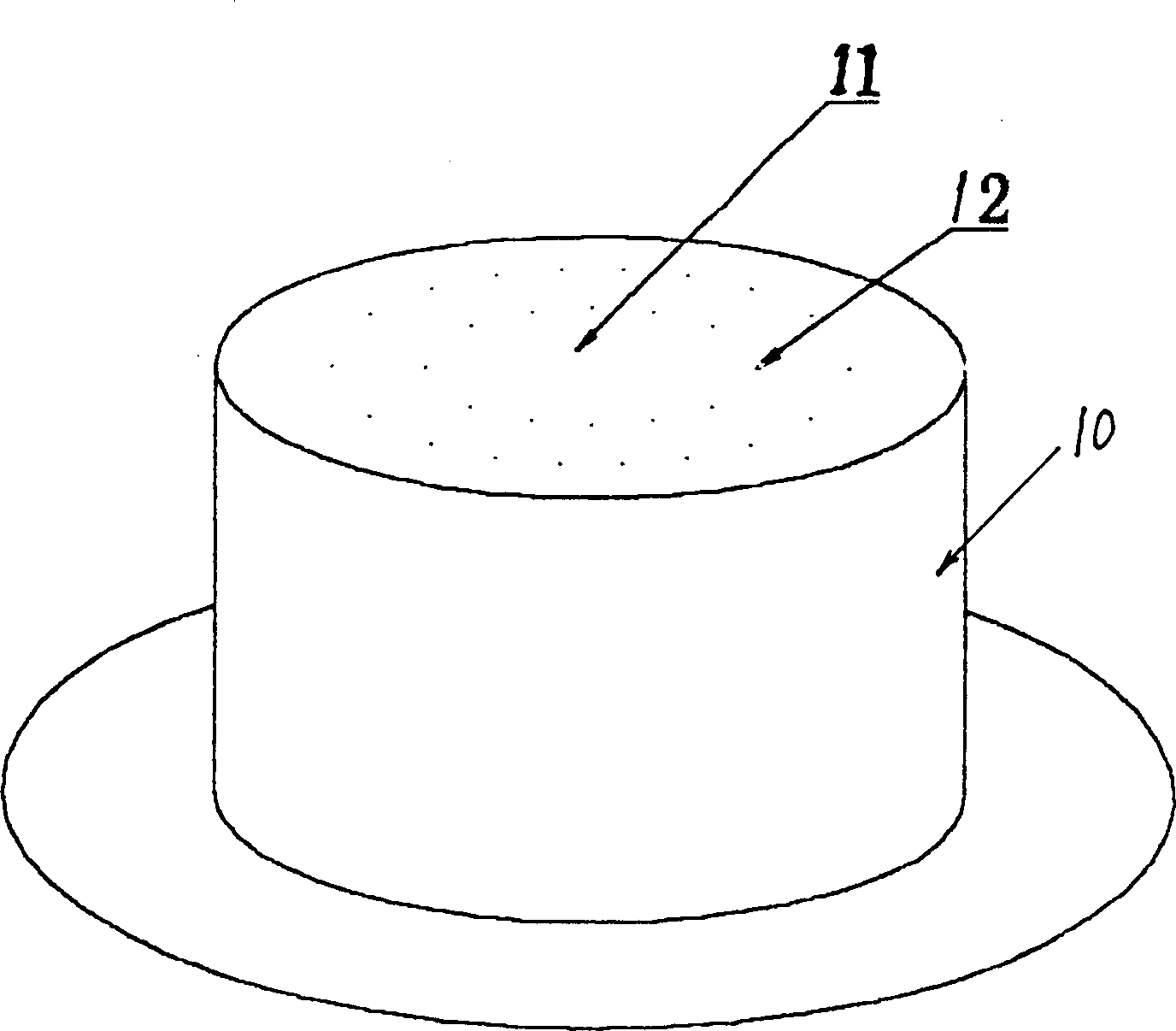

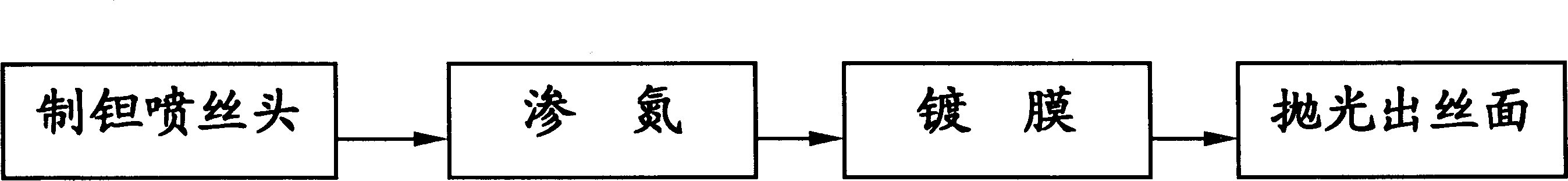

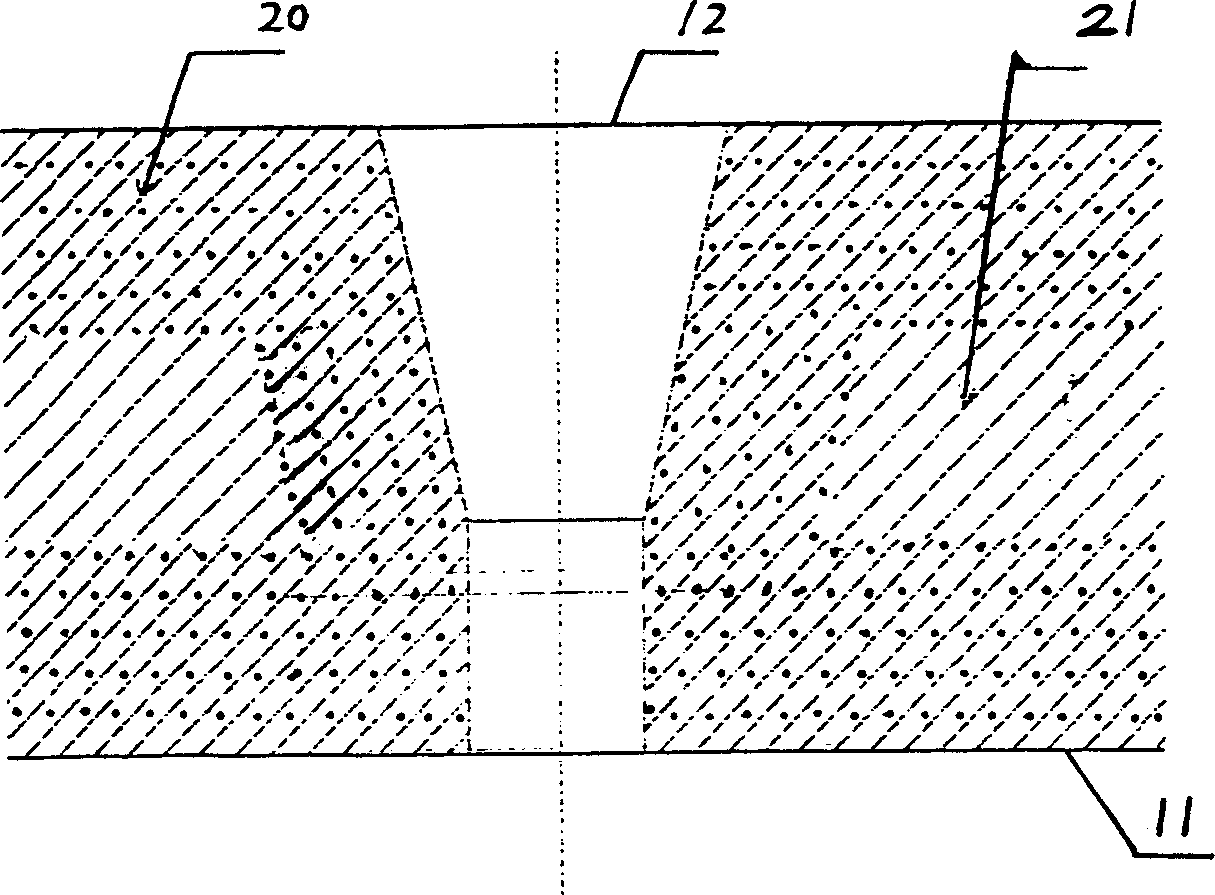

Surface treatment method of tantalum sprayer for wet spinning

InactiveCN1380450AImprove scratch resistanceImprove wear resistanceSpinnerette packsElectrolytic inorganic material coatingSprayerFilm coating

The surface treatment method of tantalum spinneret for wet spinning includes the following steps: a. making metal tantalum plate into tantalum spinneret; b. using ion nitridizing furnace to form nitridation layer on the surface of tantalum spinneret; c. adopting fused-salt electrochemical method to make tantalum spinneret undego the process of film-coating treatment to form a layer of film layer containing lithium tantalate on tantalum spinneret; and d. polishing the surface of nozzle to remove insulated film layer containing tithium tantalate and remain transition layer of tantalum.

Owner:BEIJING HUAYU CHUANGXIN SCI & TRADE CO LTD +1

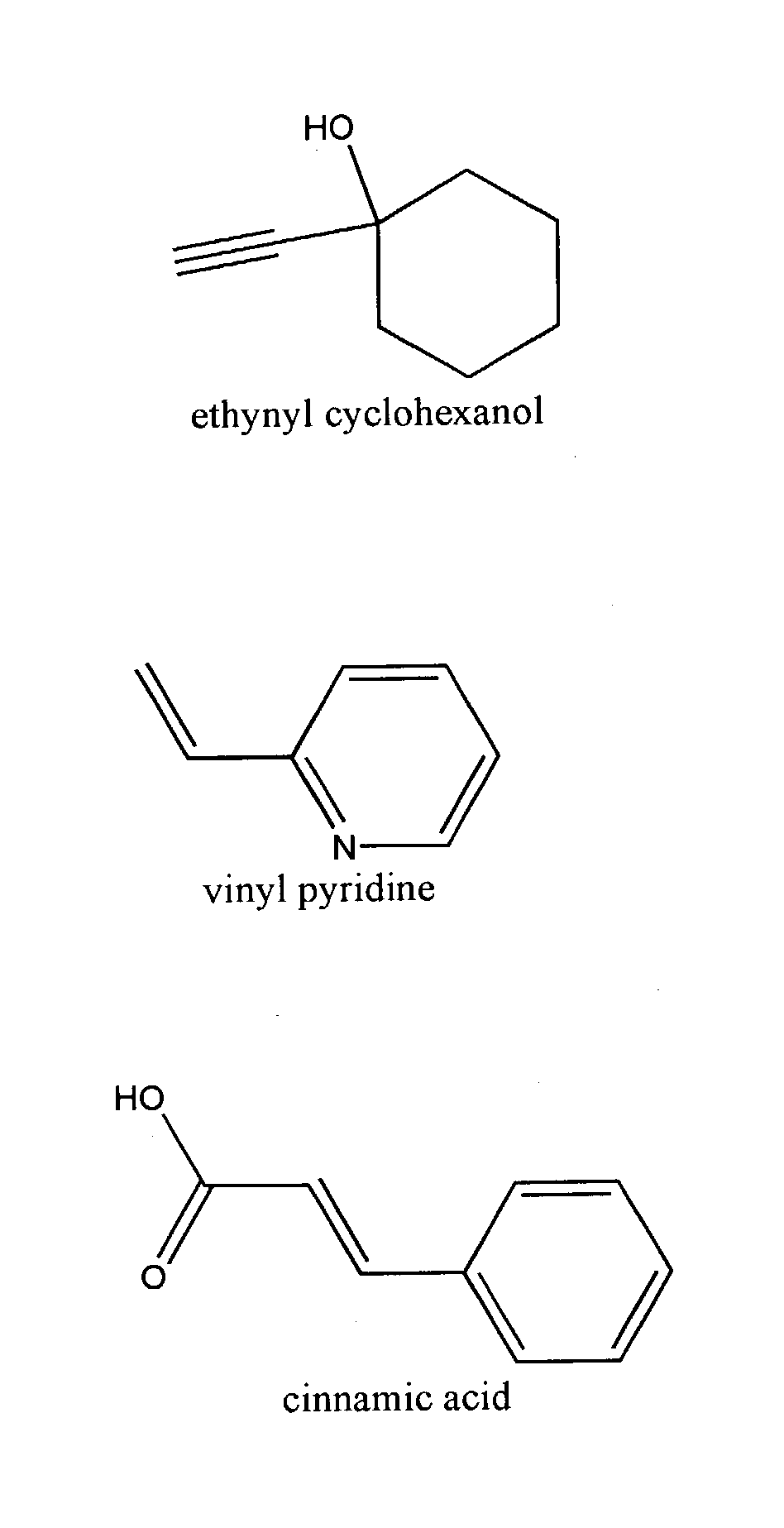

Process for improving the adhesion of polymeric materials to metal surfaces

InactiveUS7186305B2Improve adhesionReduce the amount requiredInsulating substrate metal adhesion improvementOther chemical processesNitro compoundNiobium

A process is described for treating metal surfaces with a composition comprising an oxidizer, an acid, a corrosion inhibitor, an unsaturated alkyl substituted with an aromatic or non-aromatic cyclic groups, and optionally but preferably a source of adhesion enhancing species selected from the group consisting of molybdates, tungstates, tantalates, niobates, vanadates, isopoly or heteropoly acids of molybdenum, tungsten, tantalum, niobium, vanadium, and combinations of any of the foregoing, an organic nitro compound, and a source of halide ions in order to increase the adhesion of polymeric materials to the metal surface.

Owner:MACDERMID ACUMEN INC

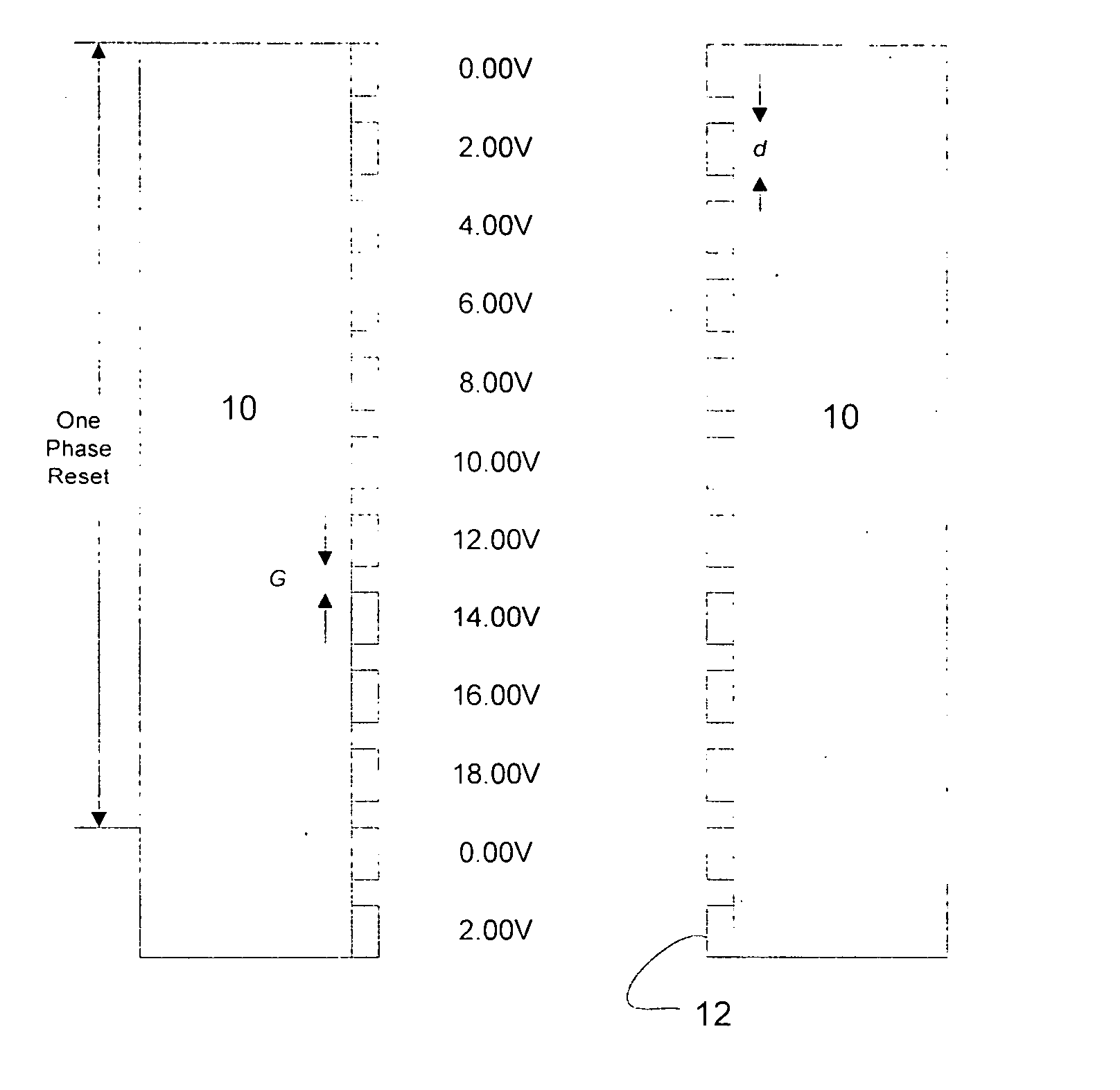

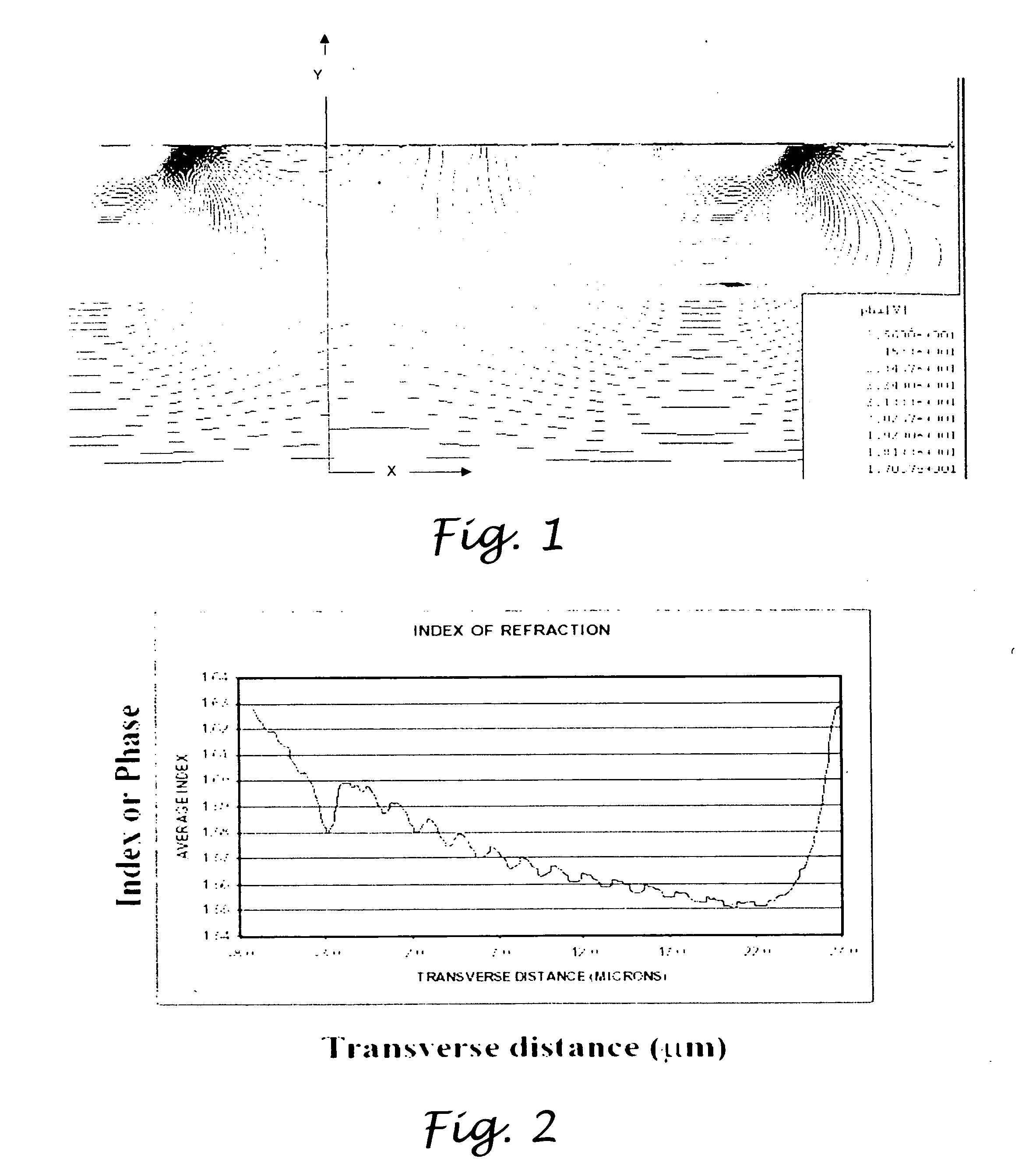

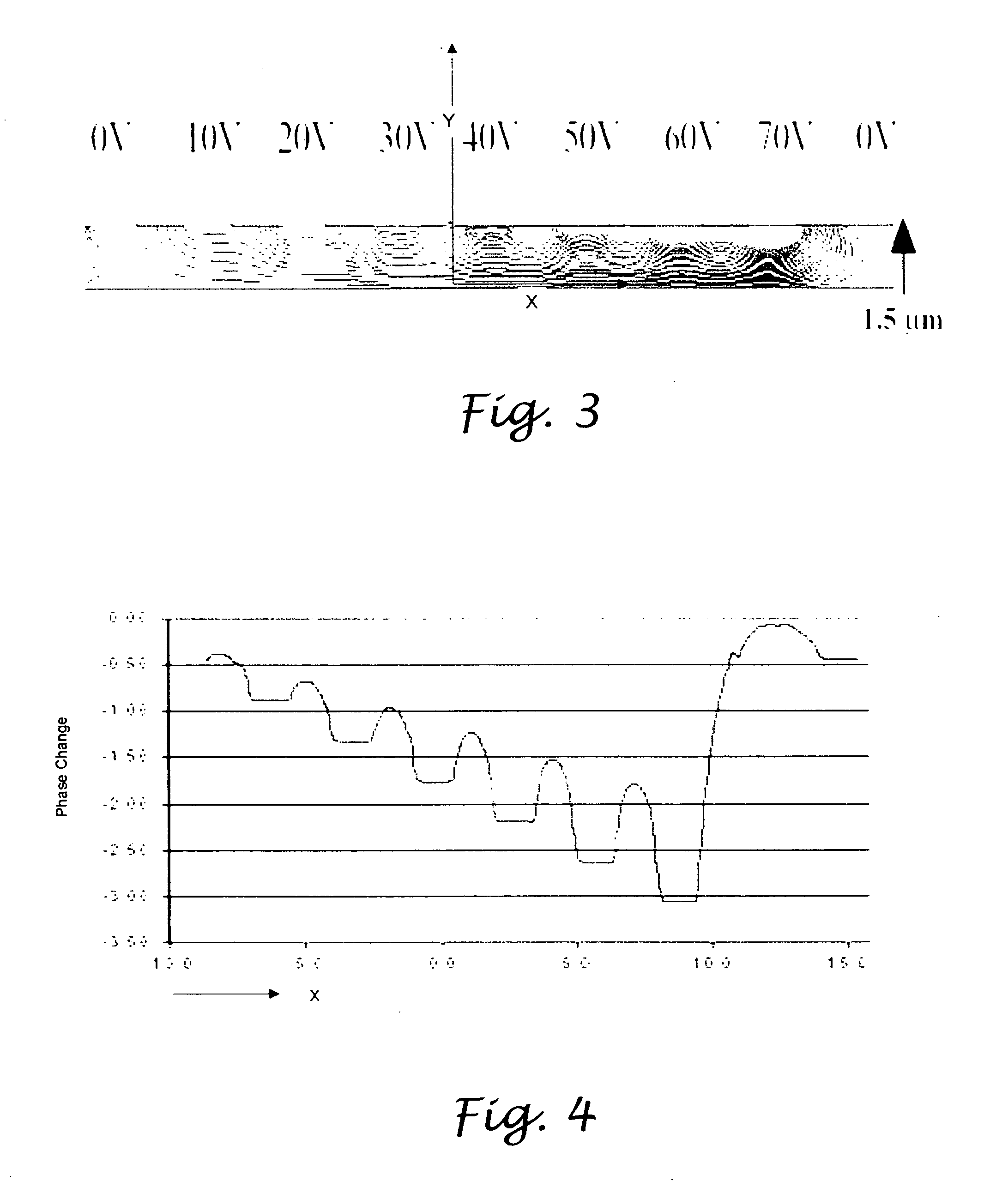

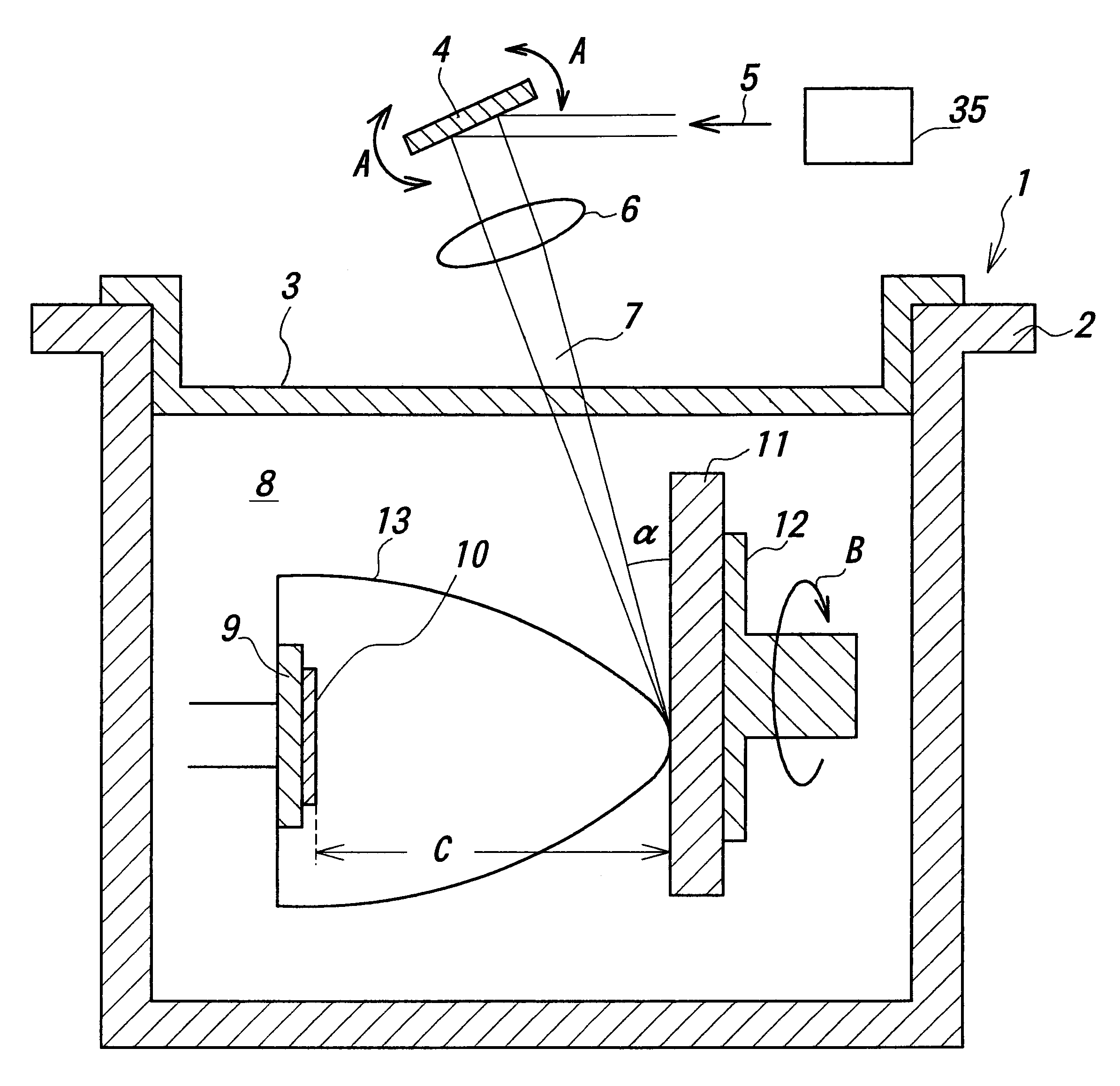

Electro-optic crystal, diffraction-based, beam-steering element

A beam-steering element made of a more optically-active material, potassium tantalate niobate, with an improved diffraction efficiency, having a plurality of electrode layers and one electro-optic crystal layer interposed between every two adjacent electrode layers. Each electro-optic crystal layer and the electrode layer adjacent thereto have an aspect ratio of about 1:1. The electrode layers and the electro-optic crystal layers are interposed between two substrates. Preferably, the substrates are transparent to an incoming beam to be modulated by the electro-optic crystal layer.

Owner:NORTHROP GRUMMAN SYST CORP

Rare-earth doped tantalic acid salt transparent luminous thin-film and preparation thereof

InactiveCN1613960AEasy to getSynthesis temperature is lowLuminescent compositionsField electron emissionRare earth

The invention relates to a transparent-shining film of rare-earth choleric acid salt and its production method. The chemical formula is (Ln1-xREx)TaO4(0<x<0.1); Ln=Gd,Lu; RE=Eu,Tb. The process is low cost, simple, and convenience. The film is of transparent, compact and good adhesion. It simplifies conditions of experiment and shortens preparation period. It can be used for the microradiology imaging screen of high space resolution factor and screen of high resolution factor cathode-ray, field emission, plasma display.

Owner:TONGJI UNIV

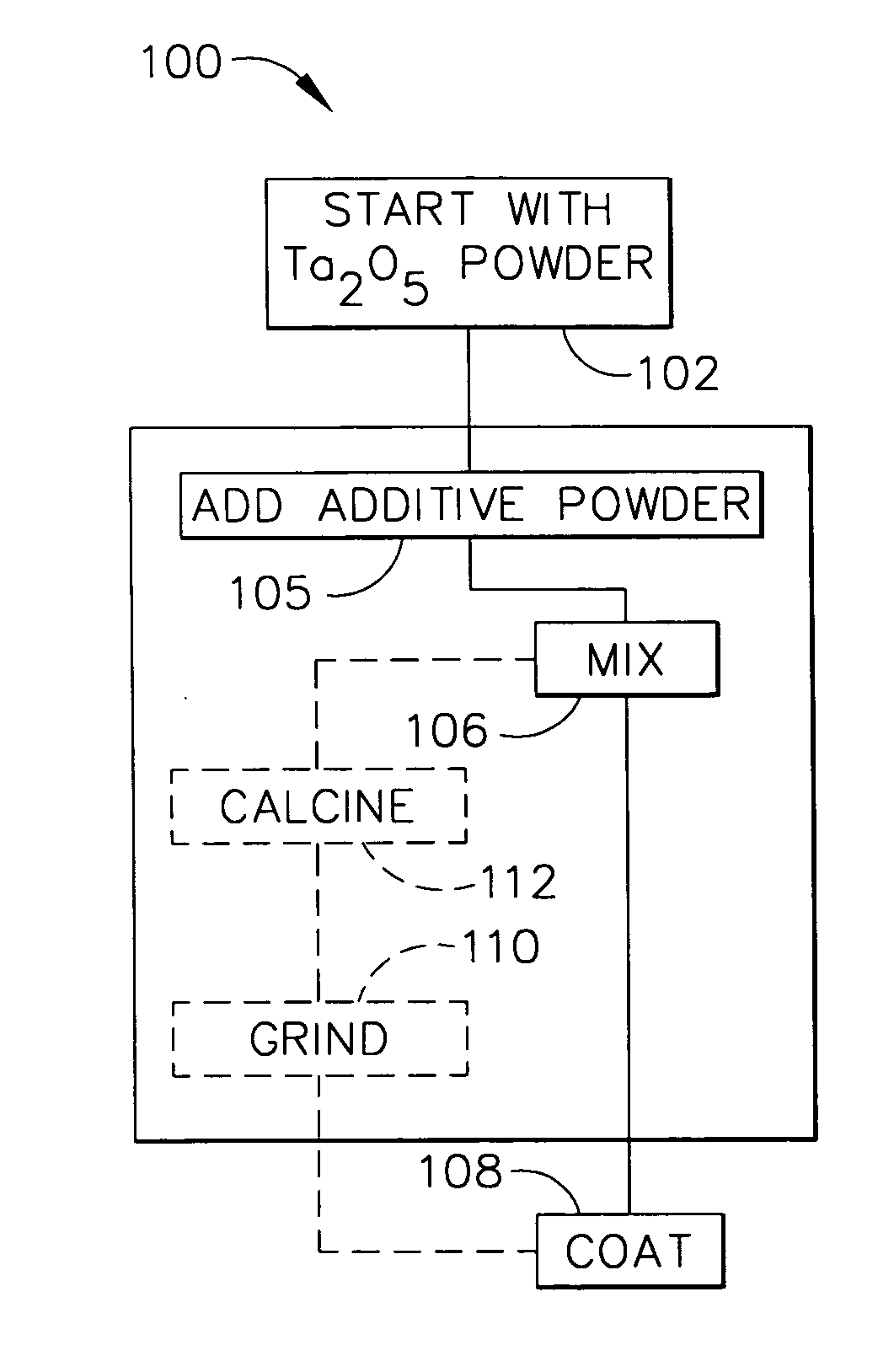

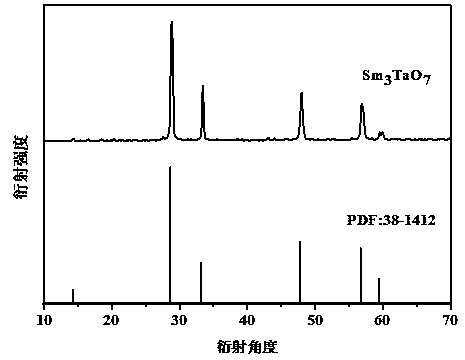

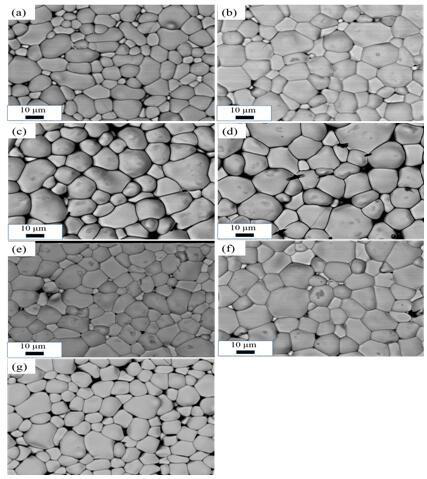

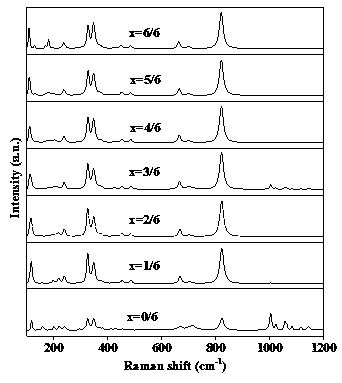

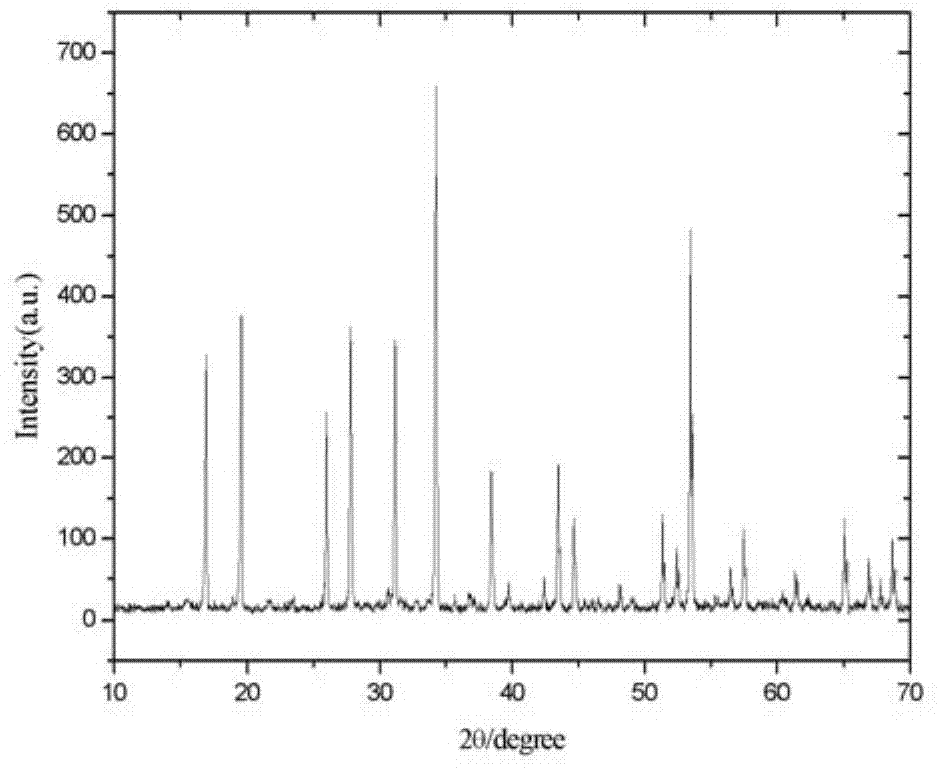

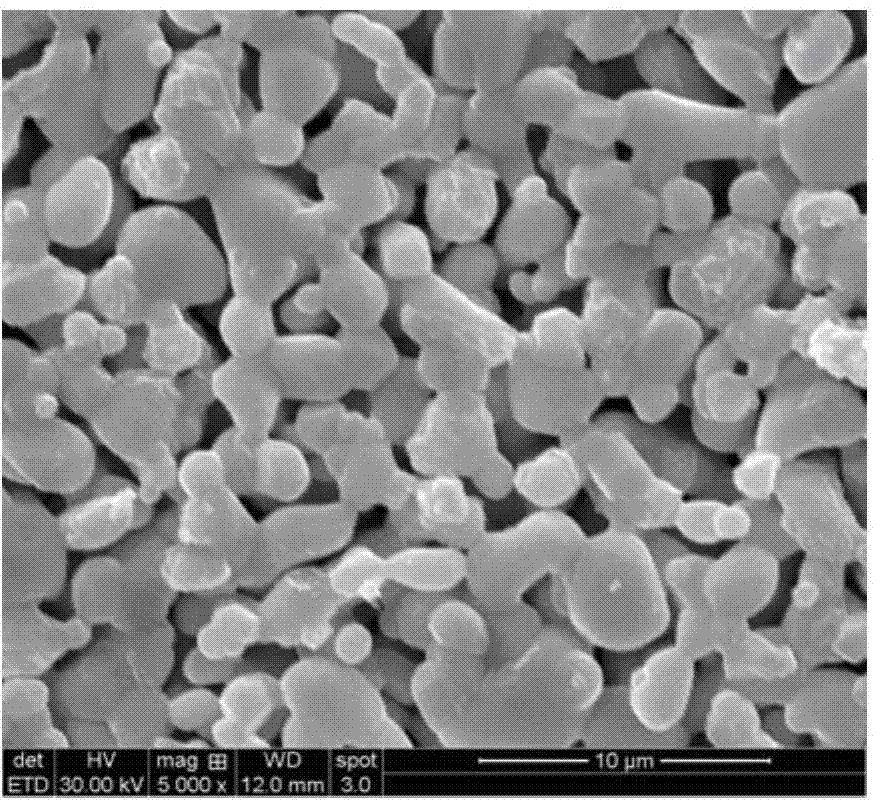

Preparation method of dense rare earth tantalate high temperature ceramic

ActiveCN107602120AEffective control of crystal structureLow thermal diffusivityRare earthCopper oxide

The invention relates to a preparation method of dense rare earth tantalate high temperature ceramic and belongs to the technical field of high temperature materials. The preparation method comprisesweighing rare earth oxide RE2O3 and tantalum pentoxide according to the stoichiometric ratio of rare earth tantalate RE3TaO7, carrying out ball milling mixing on the rare earth oxide RE2O3, tantalum pentoxide, titanium oxide and copper oxide to obtain uniform mixed powder A, screening the mixed powder A, putting the mixed powder A into a mold, carrying out compaction, carrying out carbon sprayingtreatment and carrying out pressure-keeping sintering to obtain the dense rare earth tantalate high temperature ceramic. The dense rare earth tantalate high temperature ceramic has the characteristicsof high process purity, less impurity content, high compactness and uniform crystal grain size.

Owner:陕西天璇涂层科技有限公司

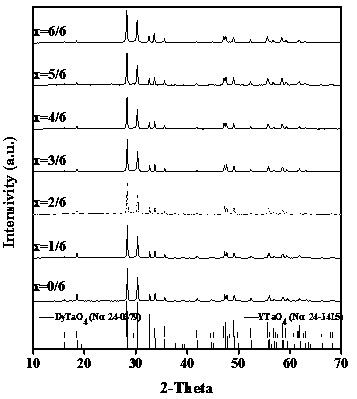

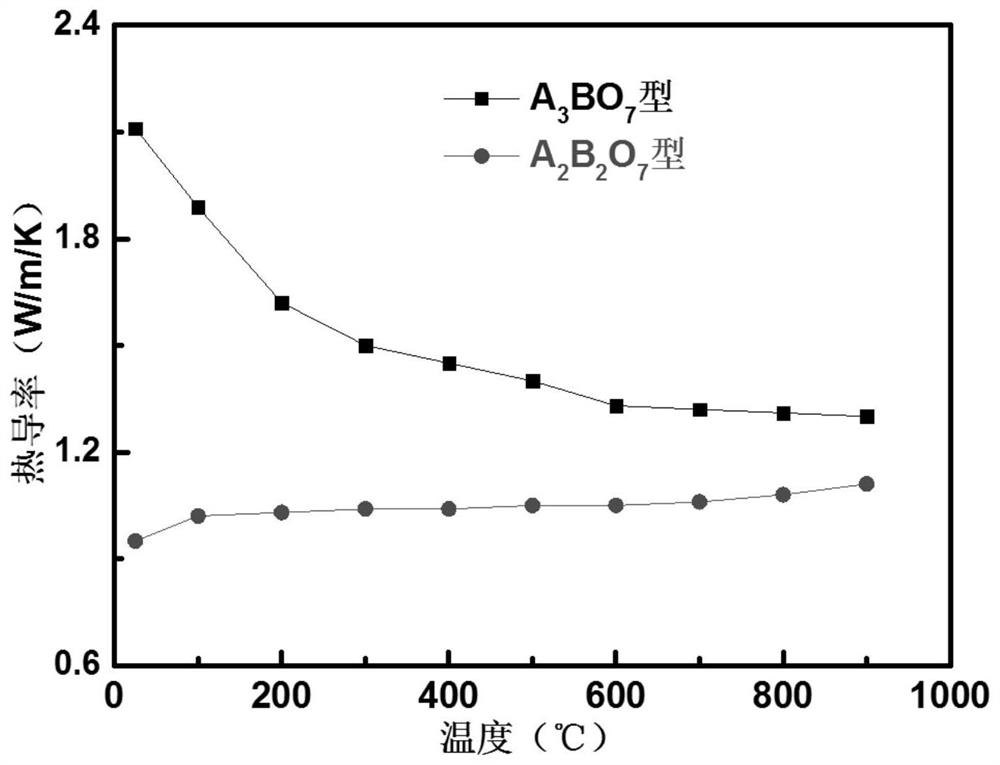

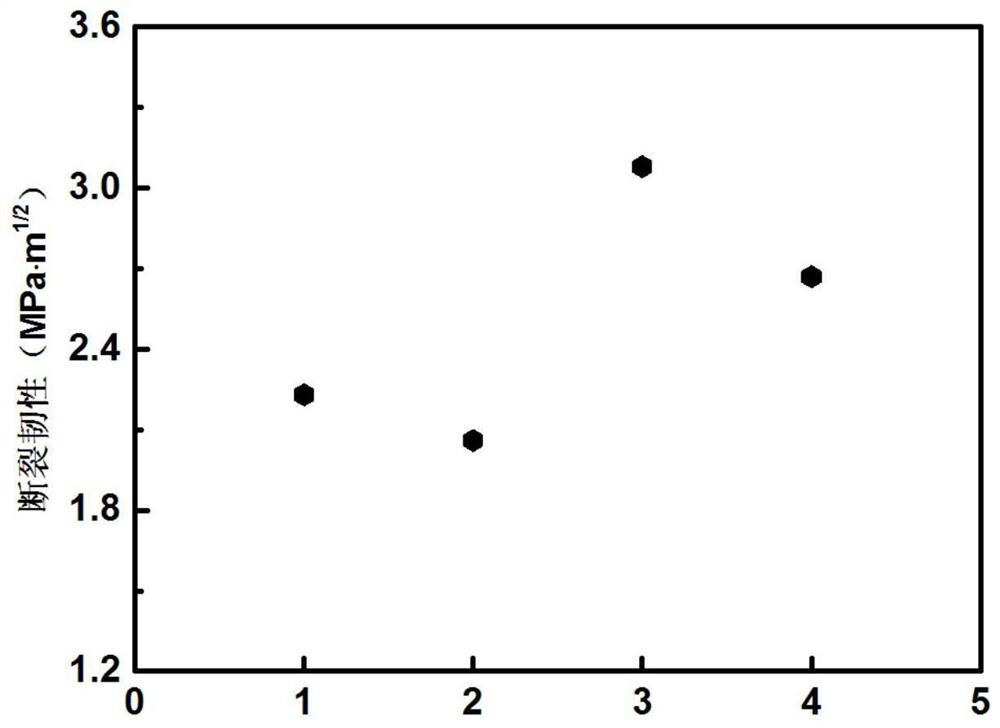

Compact ferroelastic dual rare earth tantalate solid solution high-temperature ceramic and preparation method thereof

The invention discloses compact ferroelastic dual rare earth tantalate solid solution high-temperature ceramic and a preparation method thereof, and belongs to the technical field of high temperatureresistant material of thermal barrier ceramic coating. The structural formula is (Y1-xDyx)TaO4 (x=0.1-0.9). Previously dried rare earth oxides (Y2O3, Dy2O3) and tantalum pentoxide (Ta2O5) are weighedaccording to the stoichiometric ratio required. Then, the materials are ball milled with ethanol as a solvent to obtain mixed powder A; the mixed powder A is sieved and compacted in a mold, and then ablank undergoes isostatic cool pressing to prepare a compact blank; and finally, the compact blank undergoes pressureless sintering to obtain the compact dual rare earth tantalate solid solution high-temperature ceramic. The dual rare earth tantalate solid solution high-temperature ceramic prepared by the method has characteristics of high process purity, low impurity content, high compactness, uniform grain size, low heat conductivity, large coefficient of thermal expansion, good toughness and the like.

Owner:KUNMING UNIV OF SCI & TECH

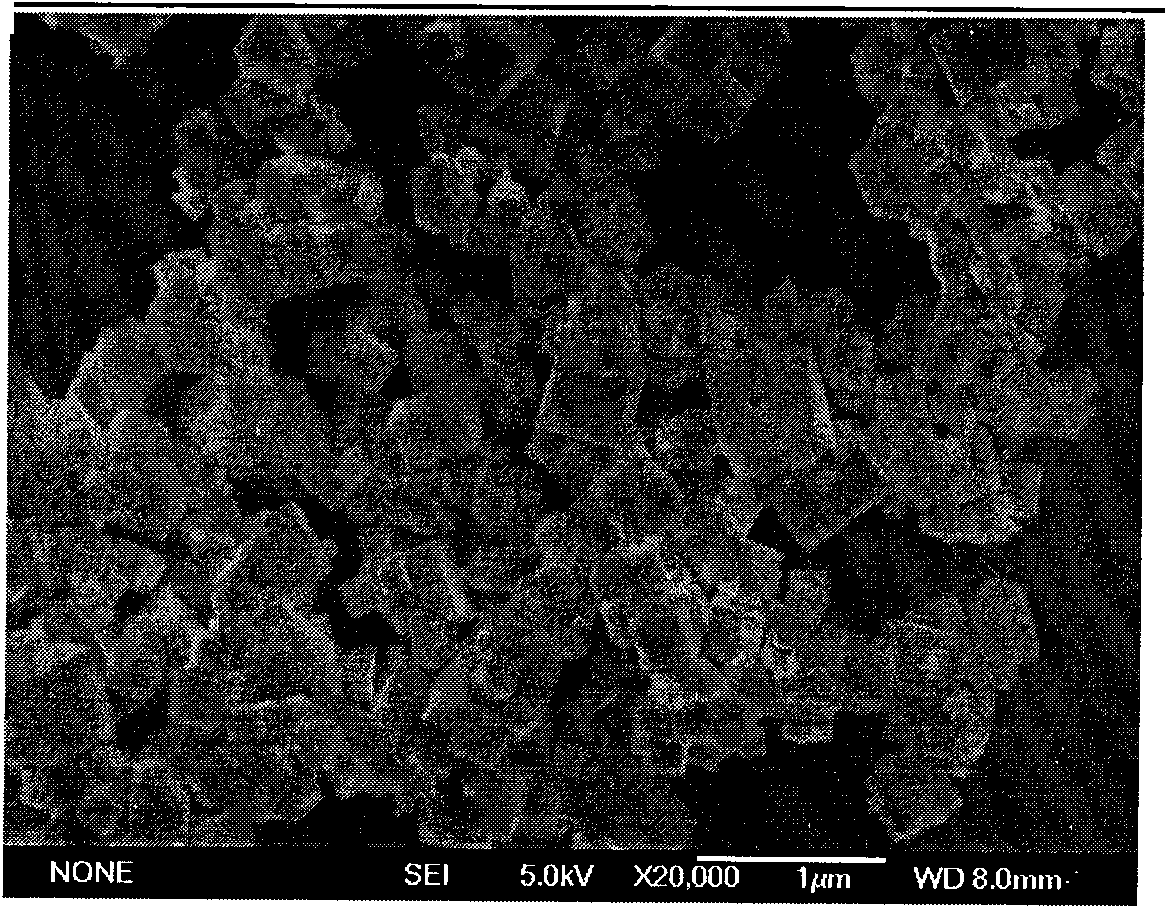

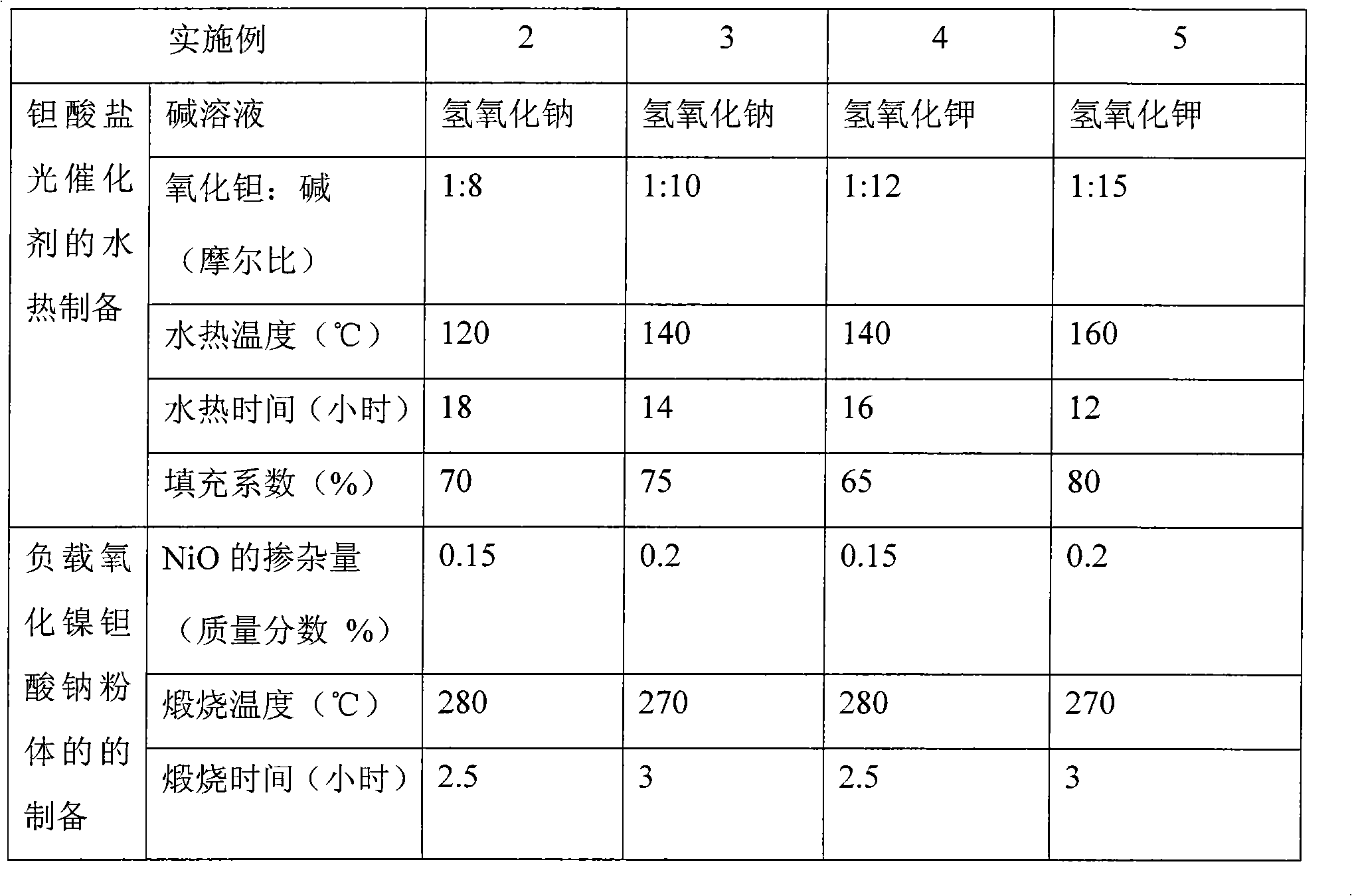

Method for preparing high efficiency photocatalyst of nickel oxide supported tantalate

InactiveCN101602002ALess structural defectsLow reaction temperatureWater/sewage treatment by irradiationCatalyst activation/preparationTantaliteMuffle furnace

The invention provides a method for preparing a high efficiency photocatalyst of nickel oxide supported tantalate, comprising the following steps: (1) uniformly dispersing tantalum oxide into excessive aqueous alkali and placing the mixture into a reaction kettle; (2) keeping the reaction kettle for a period of time at the set temperature to ensure full hydrothermal reaction; (3) after the hydrothermal reaction, fully washing and filtering the product in the reaction kettle until eluate is neutral, and preparing tantalate nano powder after drying; (4) uniformly dispersing certain amount of the tantalate nano powder into proper amount of nickel nitrate solution and evaporating the mixed solution at the constant temperature to obtain pressed powder; (5) putting ground pressed powder into a Muffle furnace for calcining to obtain the final product. The method adopts cheap raw materials and has simple equipment and process. The prepared photocatalyst of the tantalate has few structural defects, small grain size and good dispersibility, and the tantalate is endowed with good photocatalytic activity.

Owner:QINGDAO UNIV OF SCI & TECH

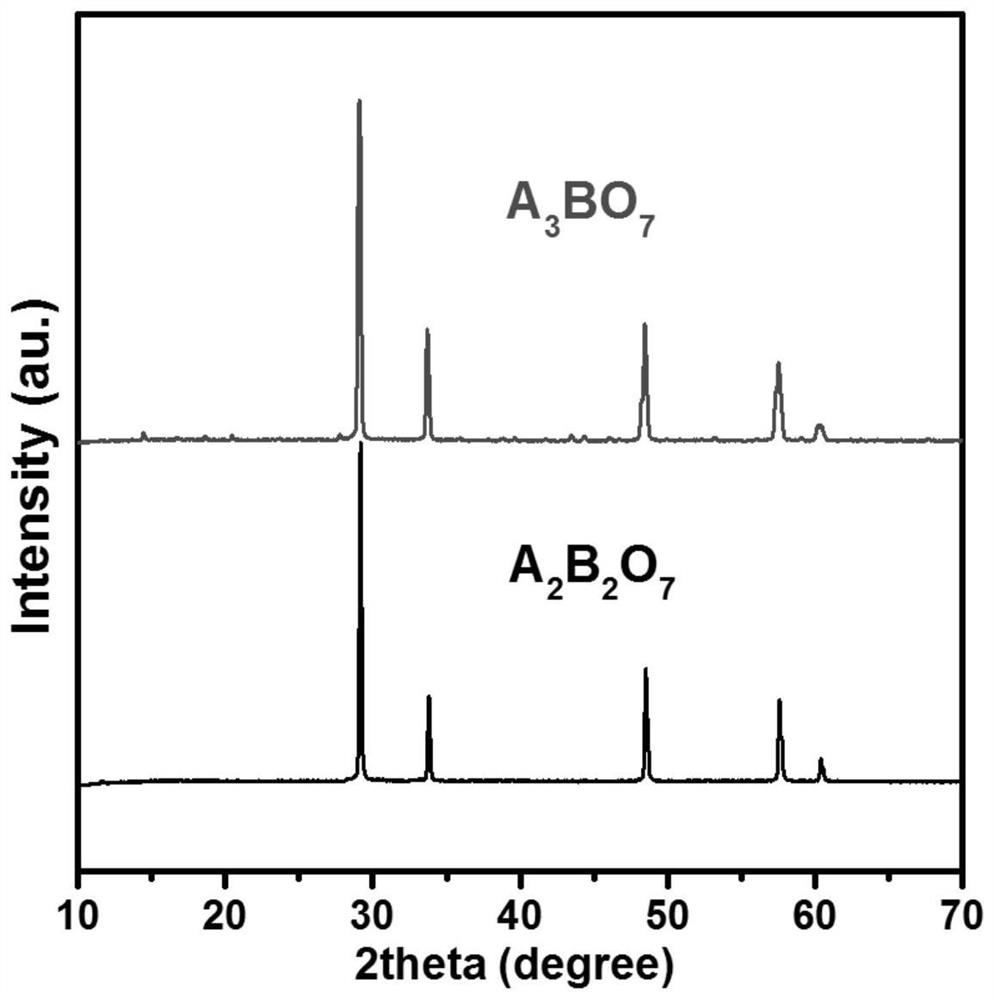

High-entropy stable rare earth tantalate/niobate ceramic and preparation method thereof

The invention discloses a high-entropy stable rare earth tantalate / niobate ceramic and a preparation method thereof, and the preparation method comprises the following steps: taking rare earth oxide RE2O3, tantalum oxide Ta2O5, niobium oxide Nb2O5 and MO2 oxide as raw materials, and taking A3BO7 type rare earth tantalate / niobate RE<3>Ta<1-x> Nb<x>O<7> ceramic as a matrix, and adding three or more MO2 oxides to equivalently replace rare earth and tantalum / niobium elements at positions A and B to obtain the novel high-entropy stable rare earth tantalate / niobate ceramic material RE < 3-y > Ta < 1-y / 2-x > Nb < x-y / 2 > M < 2y > O<7>. The ceramic material prepared by the invention has the characteristics of low thermal conductivity, high thermal expansion coefficient, high hardness, high fracture toughness, controllable crystal structure and the like, and can be used as a high-temperature protection material for thermal barrier coatings, environmental barrier coatings, nuclear material storages and the like.

Owner:KUNMING UNIV OF SCI & TECH

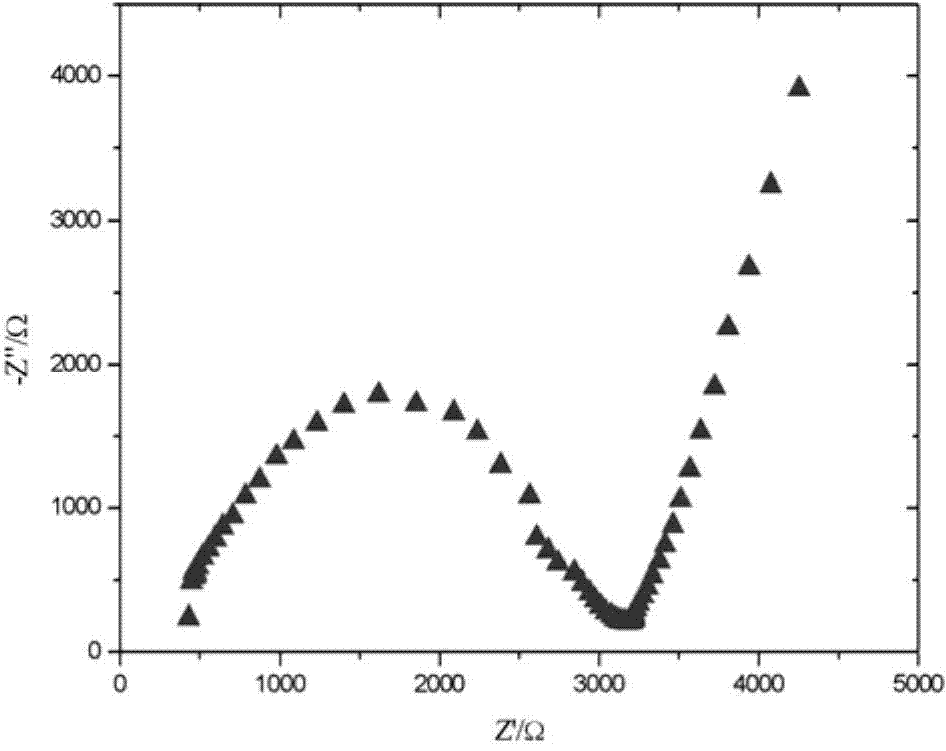

Garnet-structure lithium lanthanum tantalate-based solid electrolyte material and preparation method thereof

InactiveCN103594726AWill not cause churnImprove electrochemical performanceFinal product manufactureElectrolyte accumulators manufactureLanthanumElectrochemistry

The invention discloses a garnet-structure lithium lanthanum tantalate-based solid electrolyte material and a preparation method thereof. The lithium lanthanum tantalate-based solid electrolyte material is a compound of Li5La3Ta2O12 doped at the lanthanum site and / or tantalum site; and the preparation method comprises the following steps: dissolving tantalum pentoxide in a H2C2O4 solution; adding lithium salt and lanthanum slat and the salt of a lanthanum site-doped compound and / or the salt of a tantalum site-doped compound, and mixing to obtain a solution; adding EDTA into the obtained mixed solution for reaction until transparent and clear sol appears; adding a water-soluble high-molecular polymer and continuously reacting until gel appears; drying the obtained gel and calcining; performing mould pressing of the calcined particles to obtain a blank; and further calcining the blank to obtain the solid electrolyte material. The preparation method is mild in conditions, simple in process and simple to operate, and can realize industrial production; the prepared solid electrolyte material has good electrochemical stability and relatively high electrical conductivity, and can be used for preparing an all-solid-state lithium ion battery.

Owner:CENT SOUTH UNIV

Columbate or tantalate fluorescence material used in white-light LED, and its preparation method

InactiveCN103205253AVariable crystal structureAdjustable Crystal Field StrengthGas discharge lamp usageLuminescent compositionsRare-earth elementFluorescence

The invention relates to a columbate or tantalate fluorescence material used in white-light LED, and its preparation method. The columbate or tantalate fluorescence material comprises undoped columbate or tantalite, transition metal doped columbate or tantalite, Tl-like ion doped columbate or tantalite having an s<2> configuration, rare earth element doped columbate or tantalite, and Tl-like ion and rare earth ion co-doped columbate or tantalite. The material can be used in the white-light LED, and relevant display and illumination devices. The columbate or tantalate fluorescence material has the advantages of cheap and easily available raw materials, simple preparation technology, stable chemical properties, and excellent luminescence performance, and is an ideal phosphor candidate material for the white-light LED.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

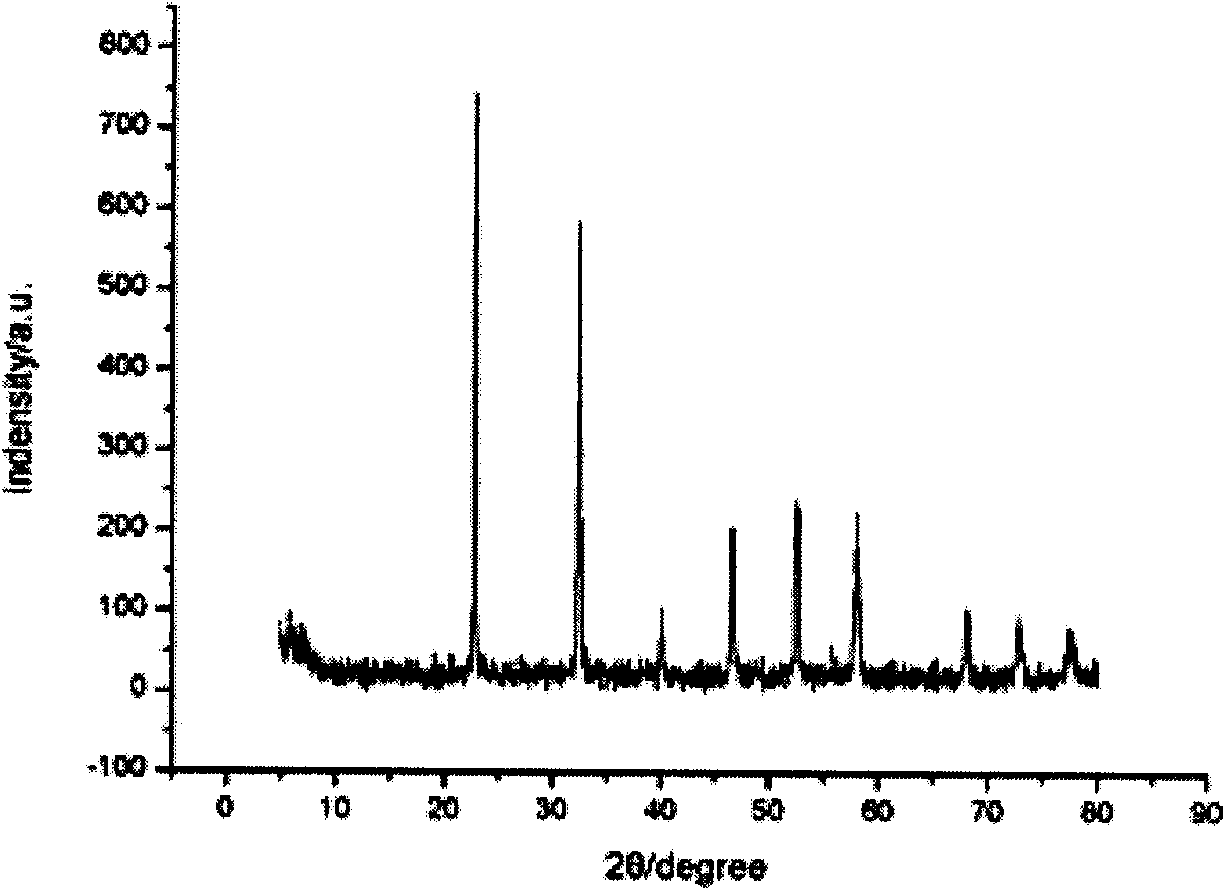

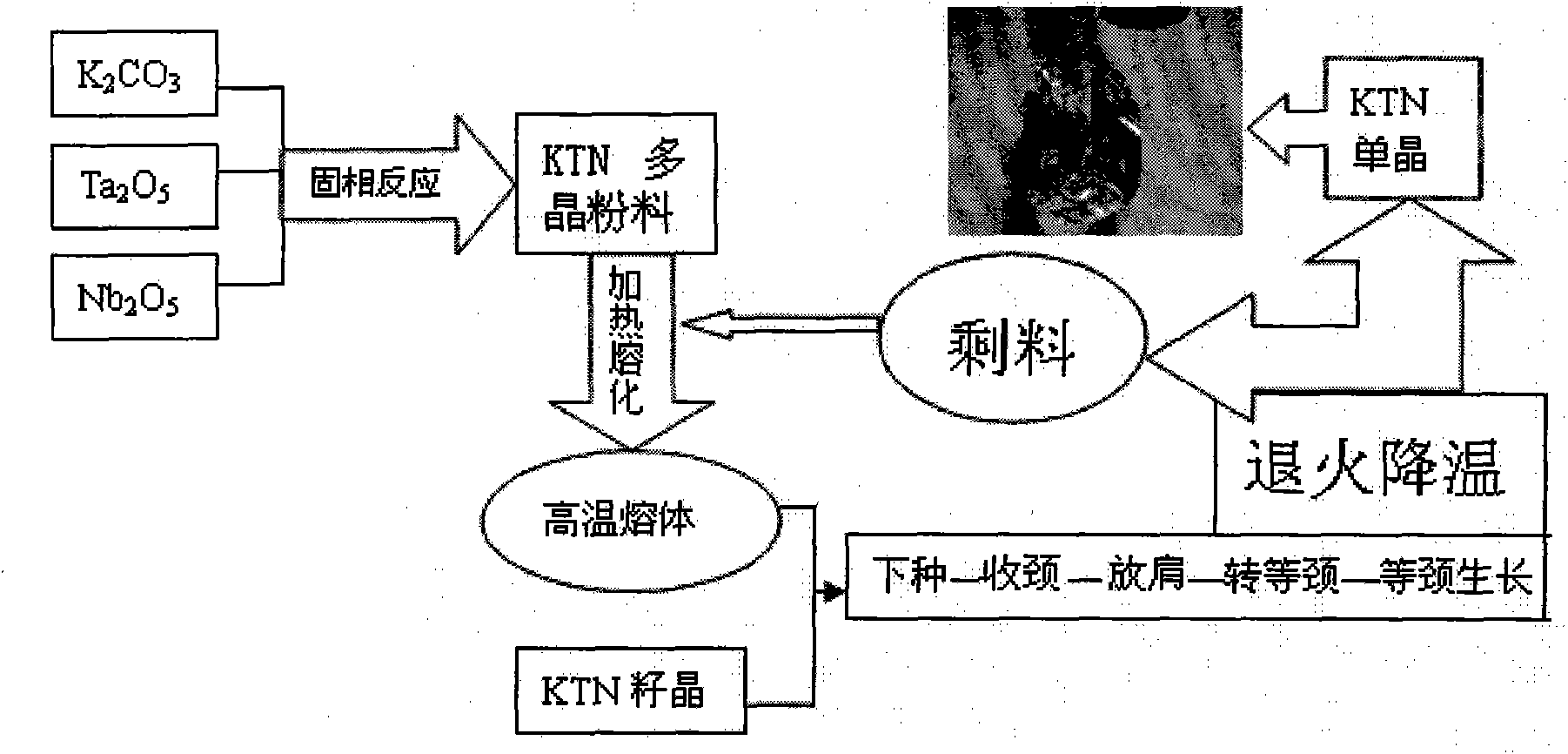

Preparation method of growing potassium tantalate-niobate series monocrystal materials by fused mass pulling method

InactiveCN101864598AGood repeatabilityEasy to industrializePolycrystalline material growthBy pulling from meltRoom temperaturePotassium

The invention discloses a preparation method of growing potassium tantalate-niobate series monocrystal materials by a fused mass pulling method. The invention starts from the preparation of potassium tantalate-niobate polycrystal powder materials. The preparation method comprises the following steps: using K2CO3, Ta2O5 and Nb2O5 as raw materials to obtain KTN polycrystal powder materials through the processes of grinding, uniform mixing, press forming and sintering; then, raising the temperature of the KTN polycrystal powder materials to a temperature near the melting point; continuously raising the temperature after the heat preservation until all raw materials are melted; lowering the temperature to the melting point of the crystal after the constant-temperature overheating; lifting the crystals from the liquid level after the processes such as seeding, neck contraction, shouldering, equal neck steering and equal neck growth; and lowering the temperature to the room temperature to obtain KTN monocrystals. The invention overcomes the defects of high cost, long period and the like of the KTN crystal growth by high-temperature solvents. Under the condition without using the solvent, the fused mass pulling technology is used as the basis, the technical process of the crystal growth is reasonably designed, the stable and repeated growth of large-dimension and high-quality KTN crystals is realized, and the growth period of the crystals can be shortened.

Owner:NEW MATERIAL INST OF SHANDONG ACADEMY OF SCI

Method to protect internal components of semiconductor processing equipment using layered superlattice materials

InactiveUS7119032B2Electric discharge tubesSemiconductor/solid-state device manufacturingCompound (substance)Strontium

This invention relates to apparatus and a method to protect the internal components of semiconductor processing equipment such as a plasma reactor or a reactive species generator against physical and / or chemical damages during etching and / or cleaning processes. Layered superlattice materials having three or more metal elements such as strontium bismuth tantalate (SBT) are used to form a protective barrier on the surfaces of the internal components of a reaction chamber.

Owner:AIR PROD & CHEM INC

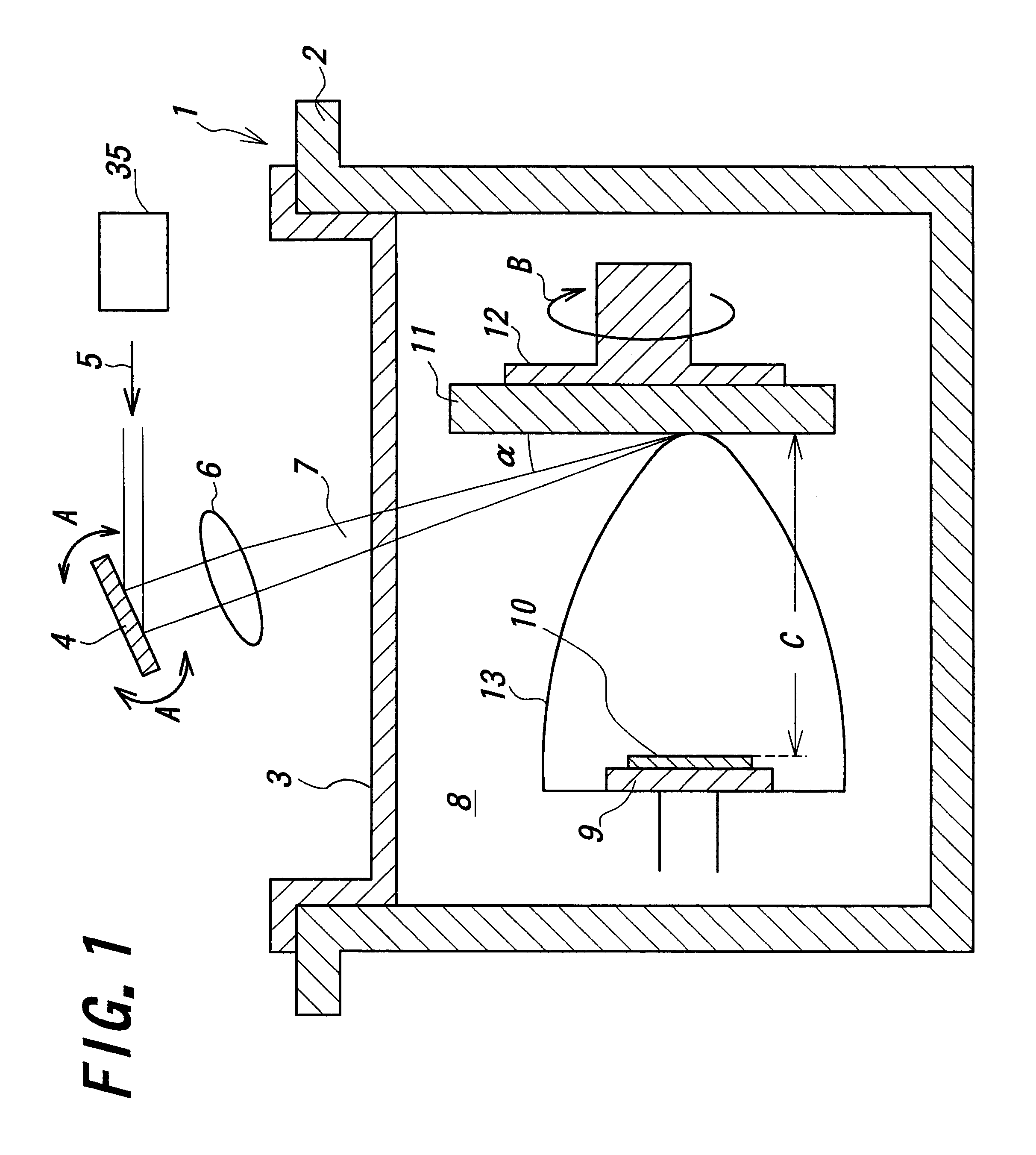

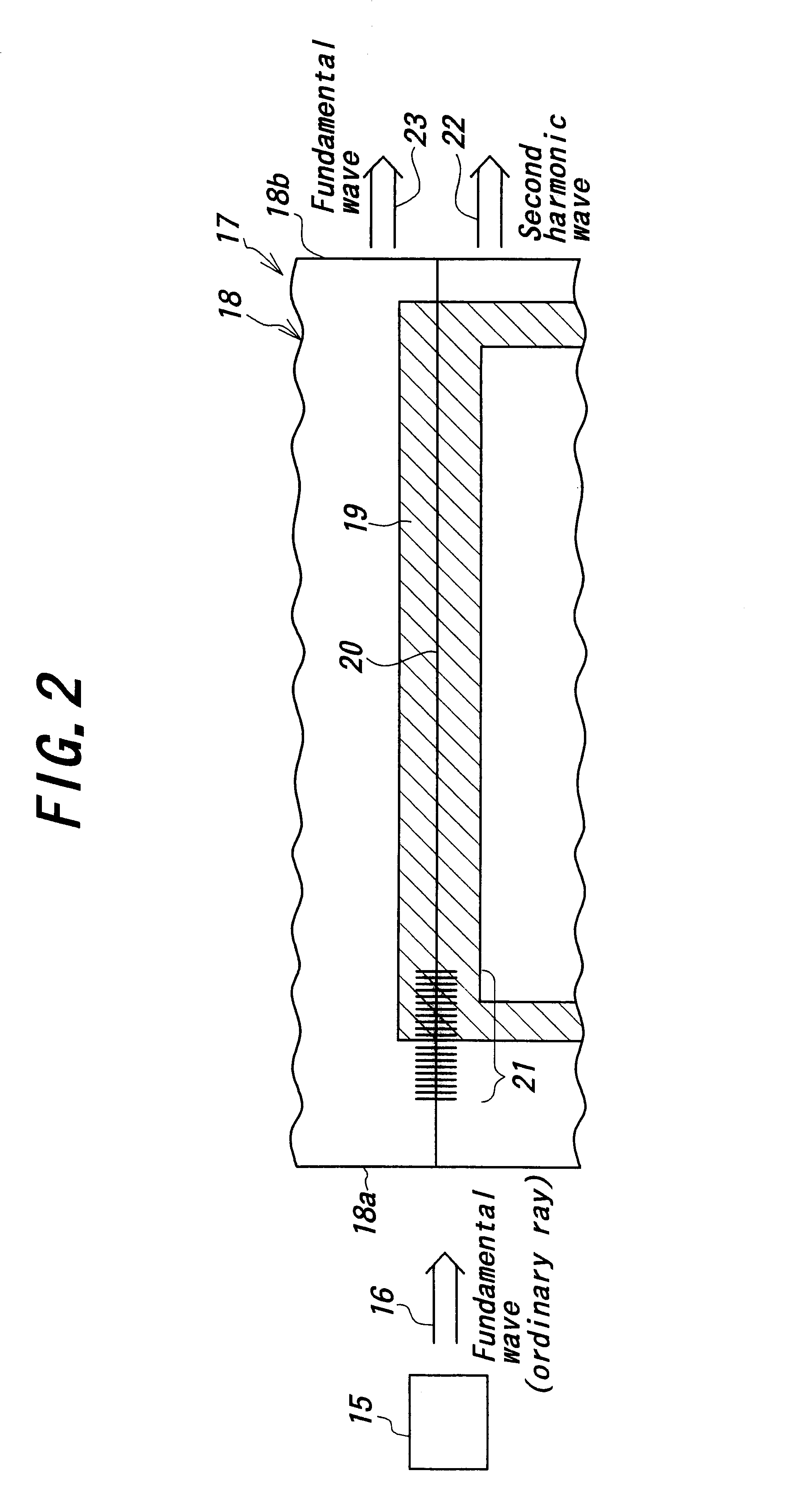

Method for producing a single-crystalline film of KLN or KLNT

InactiveUS6447606B2Improve featuresImprove conversion efficiencyPolycrystalline material growthSemiconductor/solid-state device manufacturingLithiumPotassium

Owner:NGK INSULATORS LTD

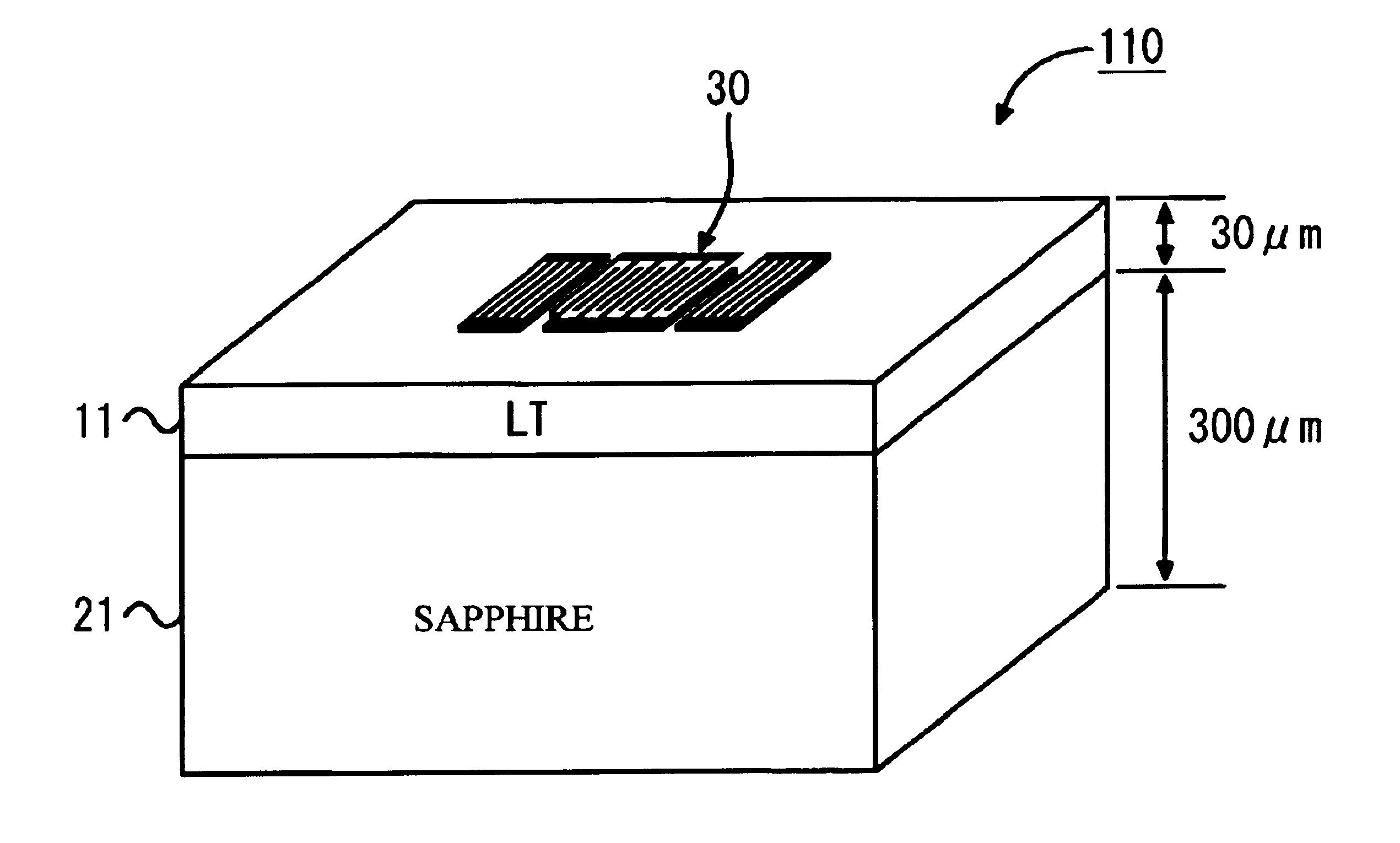

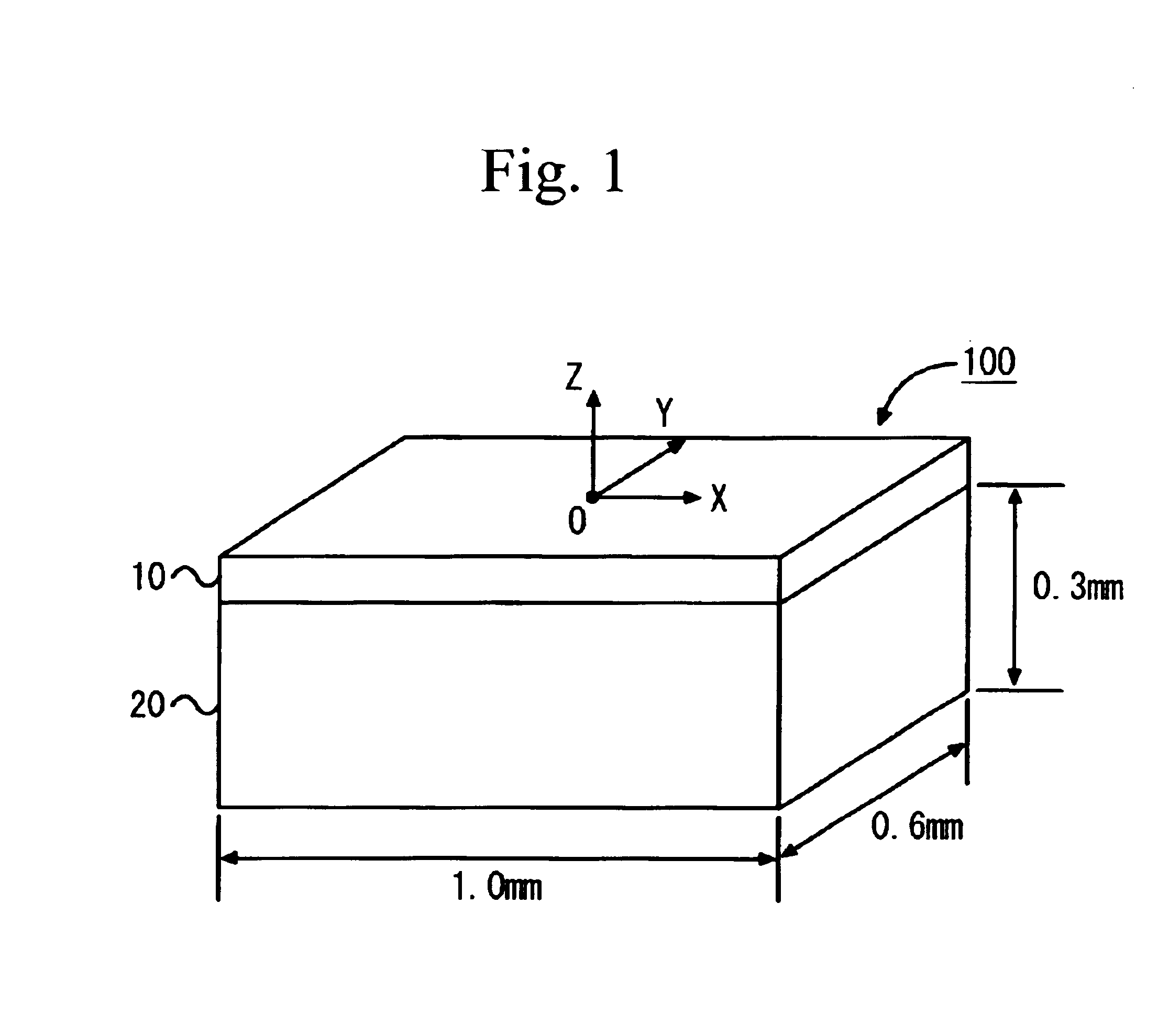

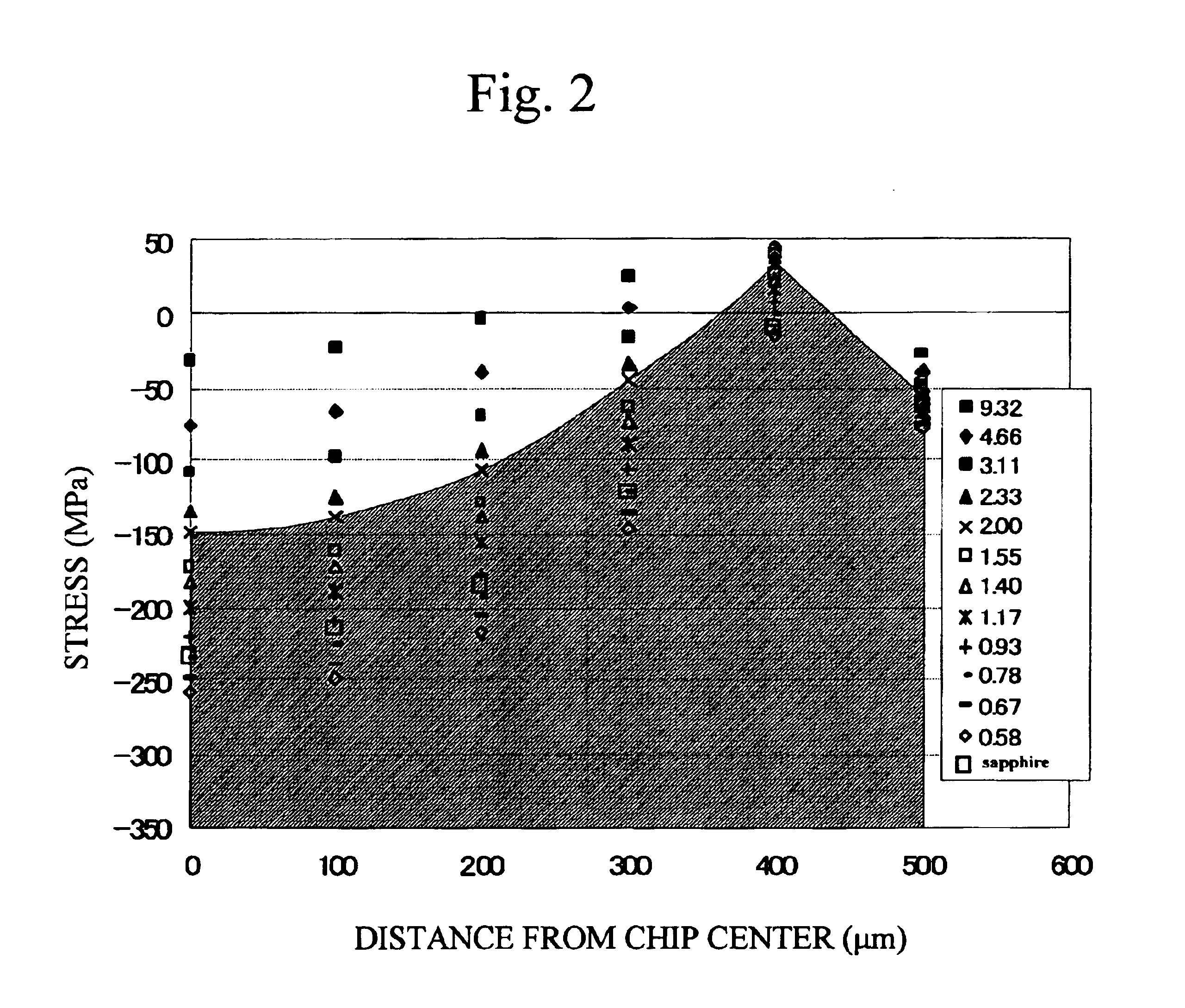

Surface acoustic wave device with lithium tantalate on a sapphire substrate and filter using the same

InactiveUS6933810B2Reduce frequency differenceImprove featuresImpedence networksPiezoelectric/electrostriction/magnetostriction machinesLithiumAcoustic wave

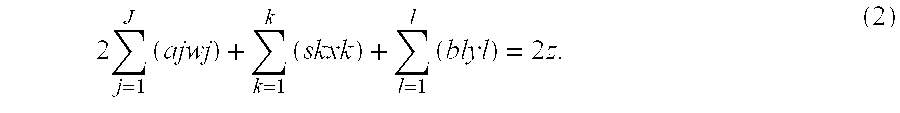

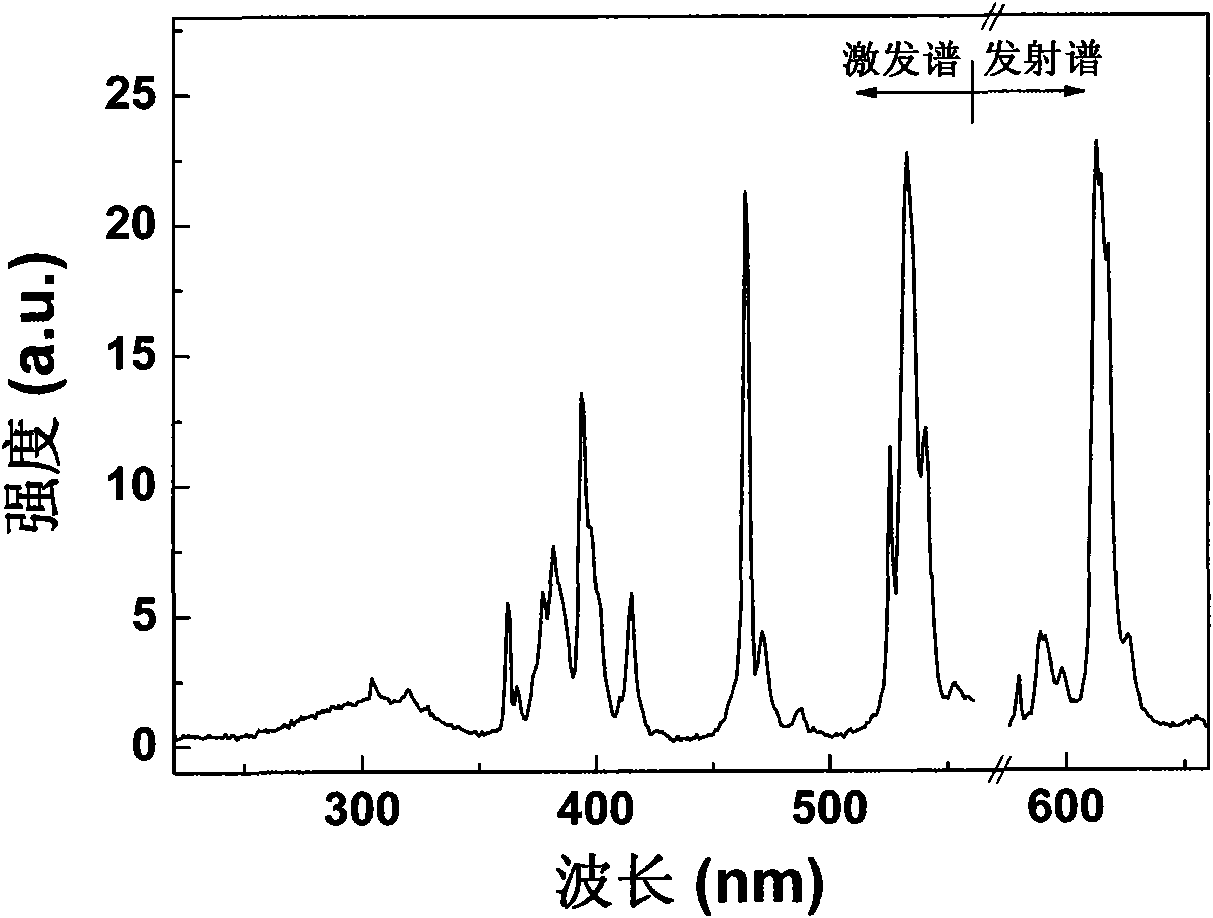

A surface acoustic wave device includes a piezoelectric substrate having a first surface on which comb-like electrodes are formed, and a second surface, and a support substrate joined to the second surface of the piezoelectric substrate. The piezoelectric substrate is made of lithium, tantalate, and the support substrate is made of sapphire. The following expressions being satisfied:T / t<⅓ (1)T / λ>10 (2)where T is a thickness of the piezoelectric substrate, t is a thickness of the support substrate, and λ is a wavelength of a surface acoustic filter, propagated along the first surface of the piezoelectric substrate.

Owner:FUJITSU MEDIA DEVICES +1

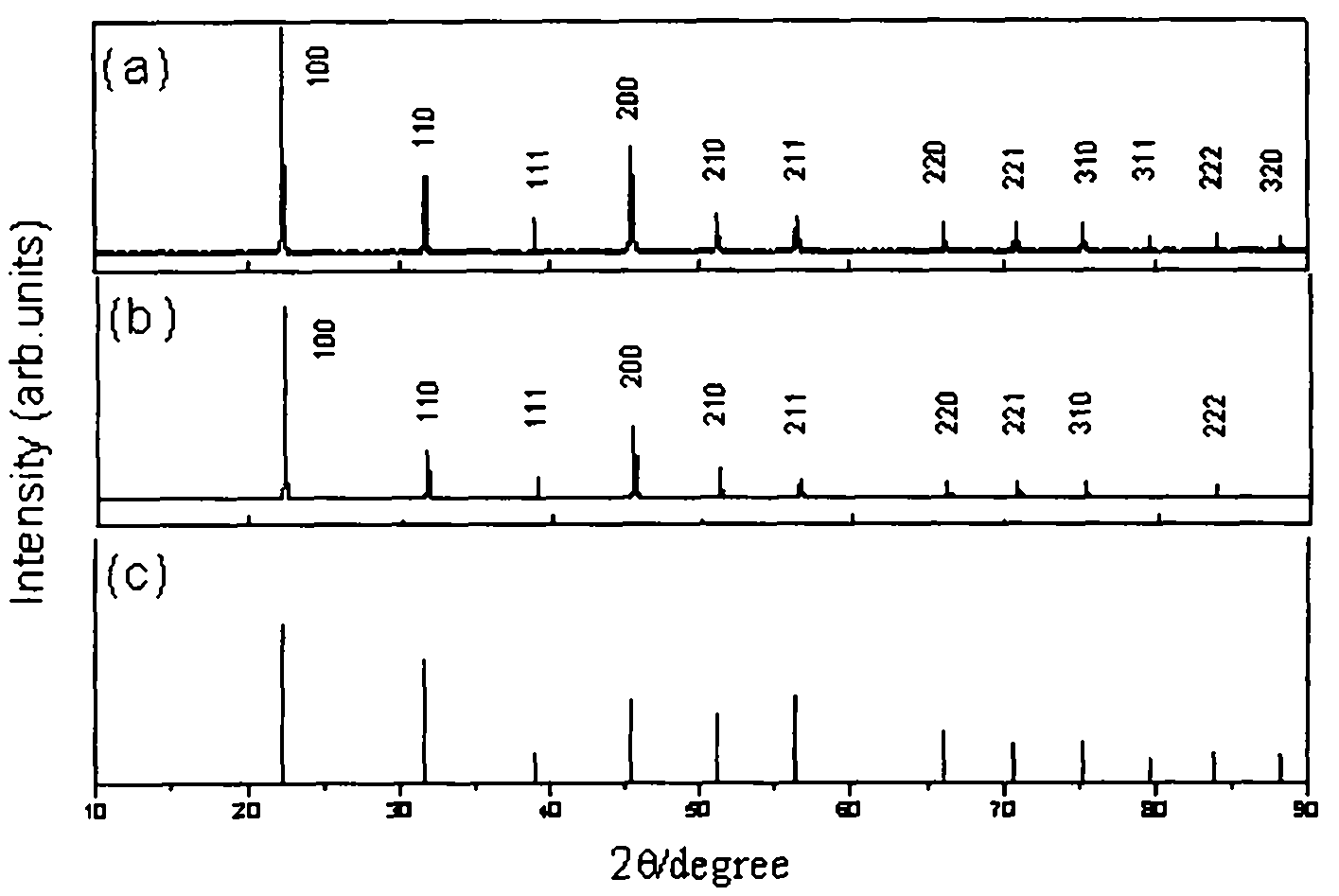

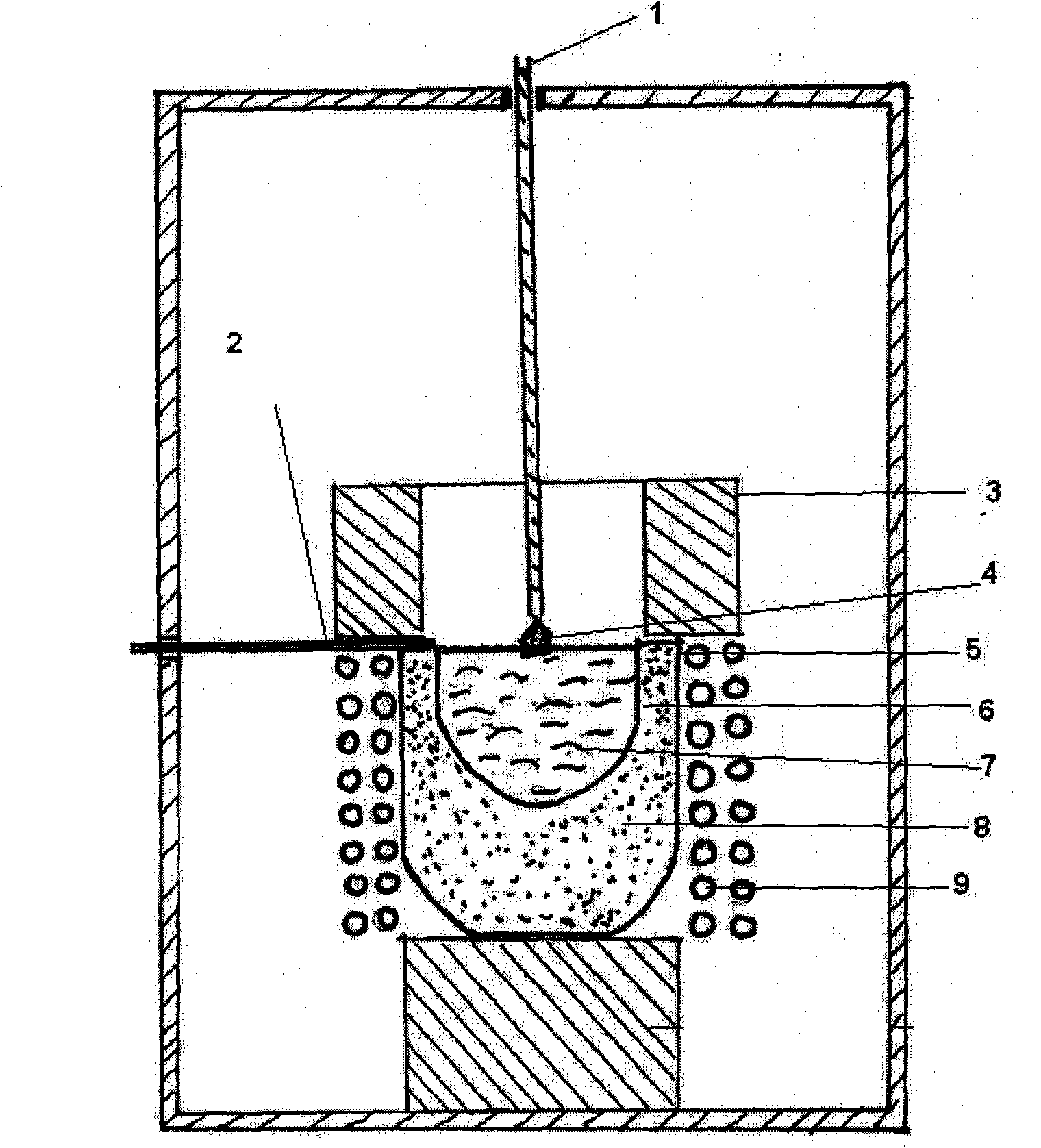

Crystal growth way of crystal pulling method for tantalate

This invention relates to a Czochralski method for growing tantalite crystal. The molecular formula of the grown compound is RE1-xDxTa1-yNbyO4, wherein, RE = Lu, Gd or Y; D = Bi, Ce, Eu or Tb; x and y = 0-1. The raw materials, Ta2O5, Nb2O5, Lu2O3, Gd2O3, Y2O3, Bi2O3, Eu2O3 and Tb4O7 are prepared from other compounds of Ta, Nb, Lu, Gd, Y, Bi, Eu and Tb. The Czochralski method comprises: mixing the raw materials, pressing in a mold into disc shape, and / or sintering at 750-1300 deg.C for 10-24 h to obtain the starting material for RE1-xDxTa1-yNbyO4 crystal. The method can obtain large-size single crystal of Nb5+, Bi3+, Tb3+ or Eu3+-doped RETaO4, which can be used in high-energy physics and nuclear medicine.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

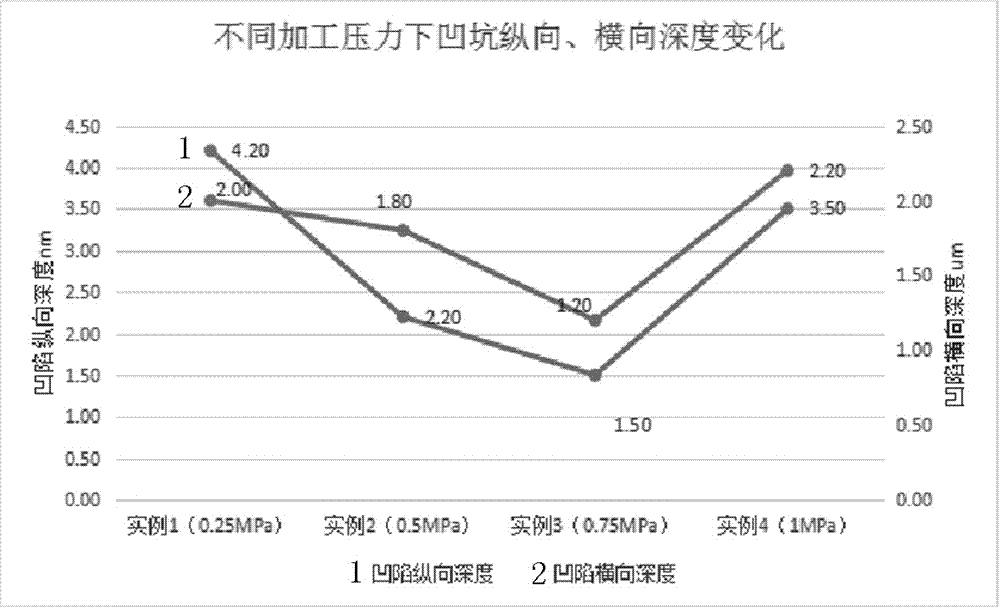

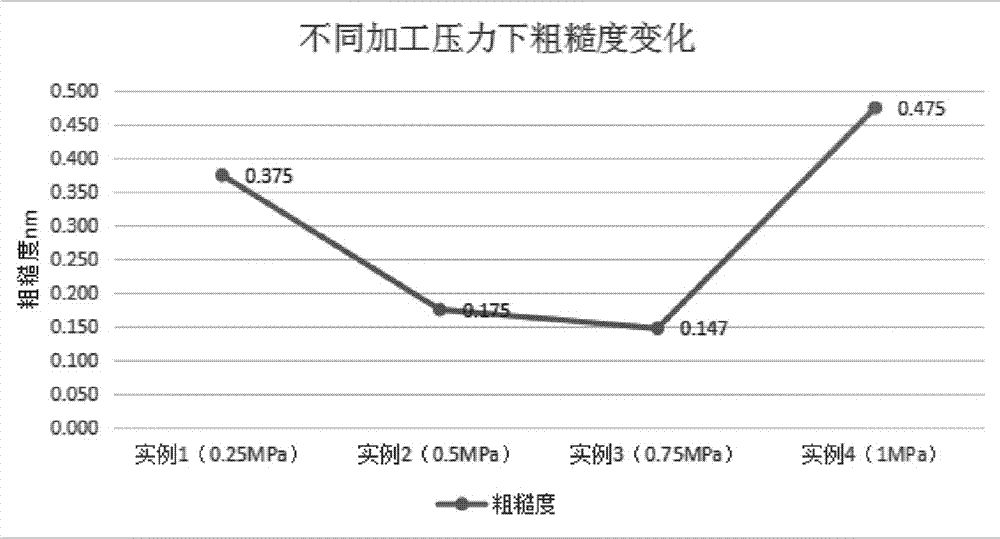

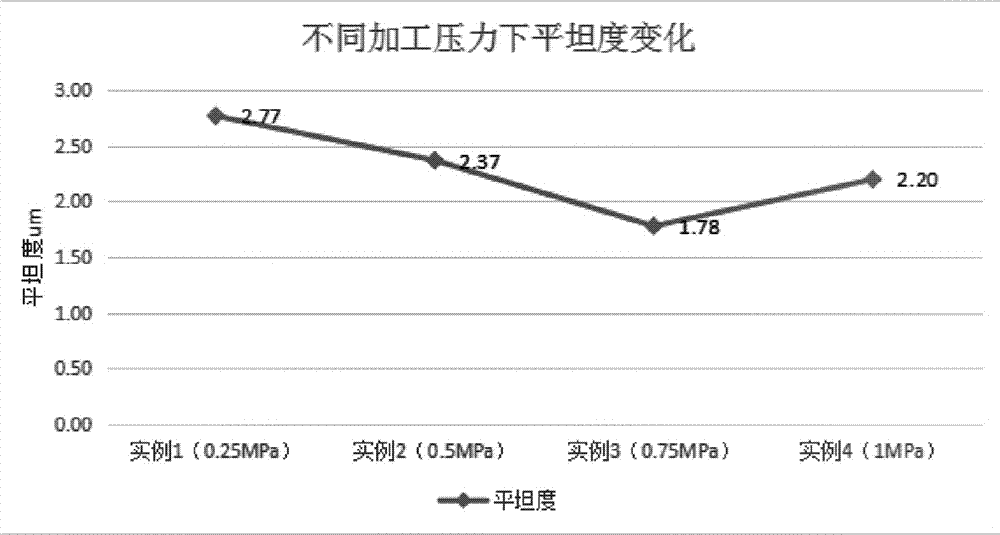

Polishing method for lithium tantalate substrate

The invention discloses a polishing method for a lithium tantalate substrate. The method includes the steps of 1, grinding a cut tantalate lithium wafer with an abrasive material with the particle size of 5-20 microns, and obtaining a lithium tantalate grinding sheet with the surface of a rough structure; 2, directly conducting chemical corrosion on the lithium tantalate grinding sheet in a sealed container filled with the mixed acid of nitric acid and hydrofluoric acid, wherein the roughness of the tantalate lithium wafer is smaller than 200 nm, and the flatness is smaller than 5 microns; obtaining a lithium tantalate corrosion sheet with the surface of a random disordered pit structure; 3, conducting single-side polishing on the lithium tantalate corrosion sheet with a single-polishing machine and a polishing liquid, wherein the polishing pressure is 0.005-1 MPa, the roughness of the tantalate lithium wafer is smaller than 0.5 nm, and the flatness is smaller than 3 microns; obtaining a lithium tantalite polishing sheet. The polishing method has the advantages of one-time polishing, batch production and high polishing efficiency, and the produced lithium tantalate substrate has high surface flatness which determines that the lithium tantalate substrate is not easily broken in the application of devices; the material utilization is high, and the processing yield is high.

Owner:TDG HLDG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com