Preparation method of growing potassium tantalate-niobate series monocrystal materials by fused mass pulling method

A technology of potassium tantalum niobate and single crystal material, which is applied in the field of research on the preparation process of functional single crystal materials, can solve the problems of crystal research and application limitations, increase the cost of crystal growth, corrode quartz and refractory materials, etc. Compared with the design, the effect of reducing oxygen vacancy defects and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

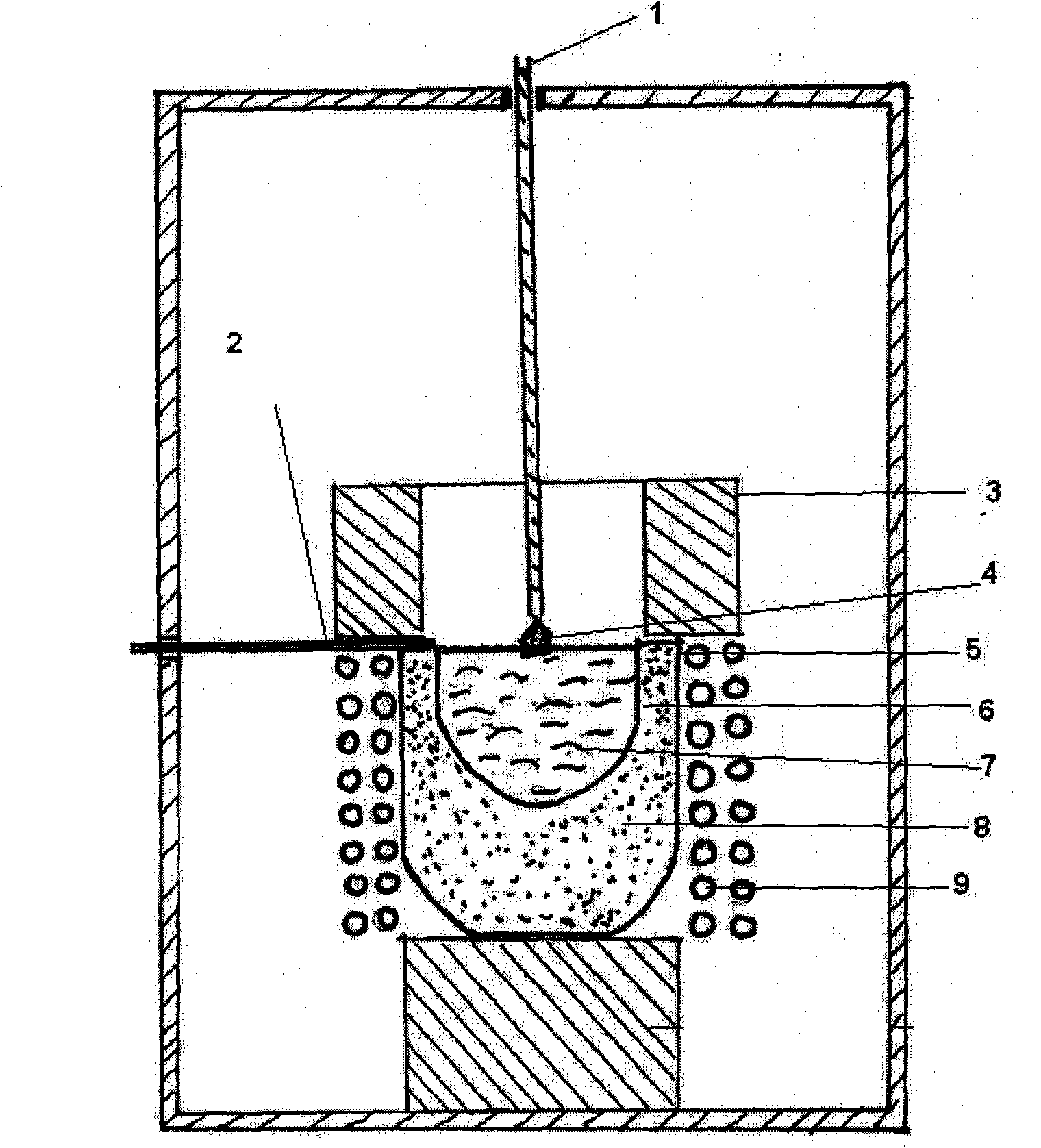

Method used

Image

Examples

Embodiment 1

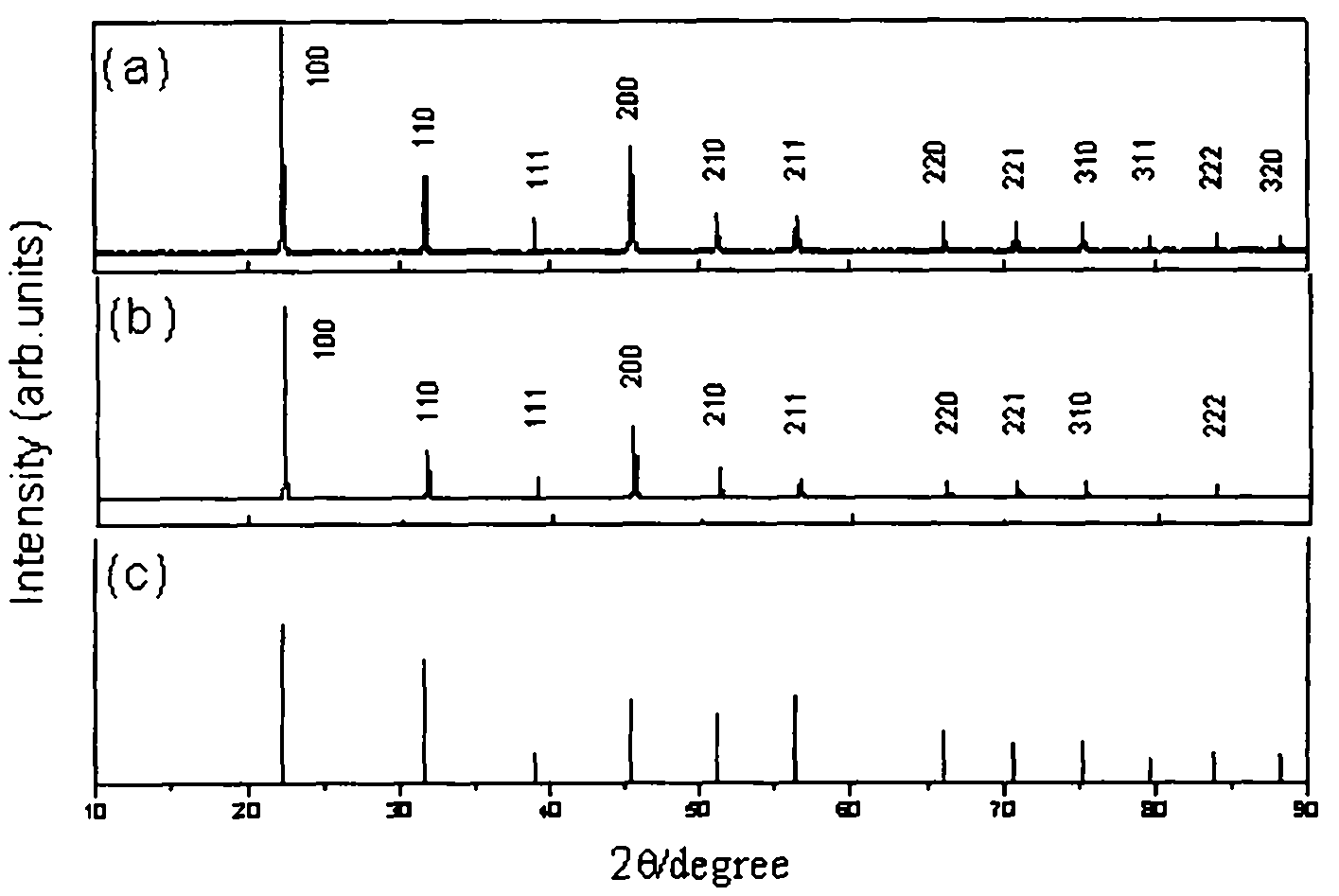

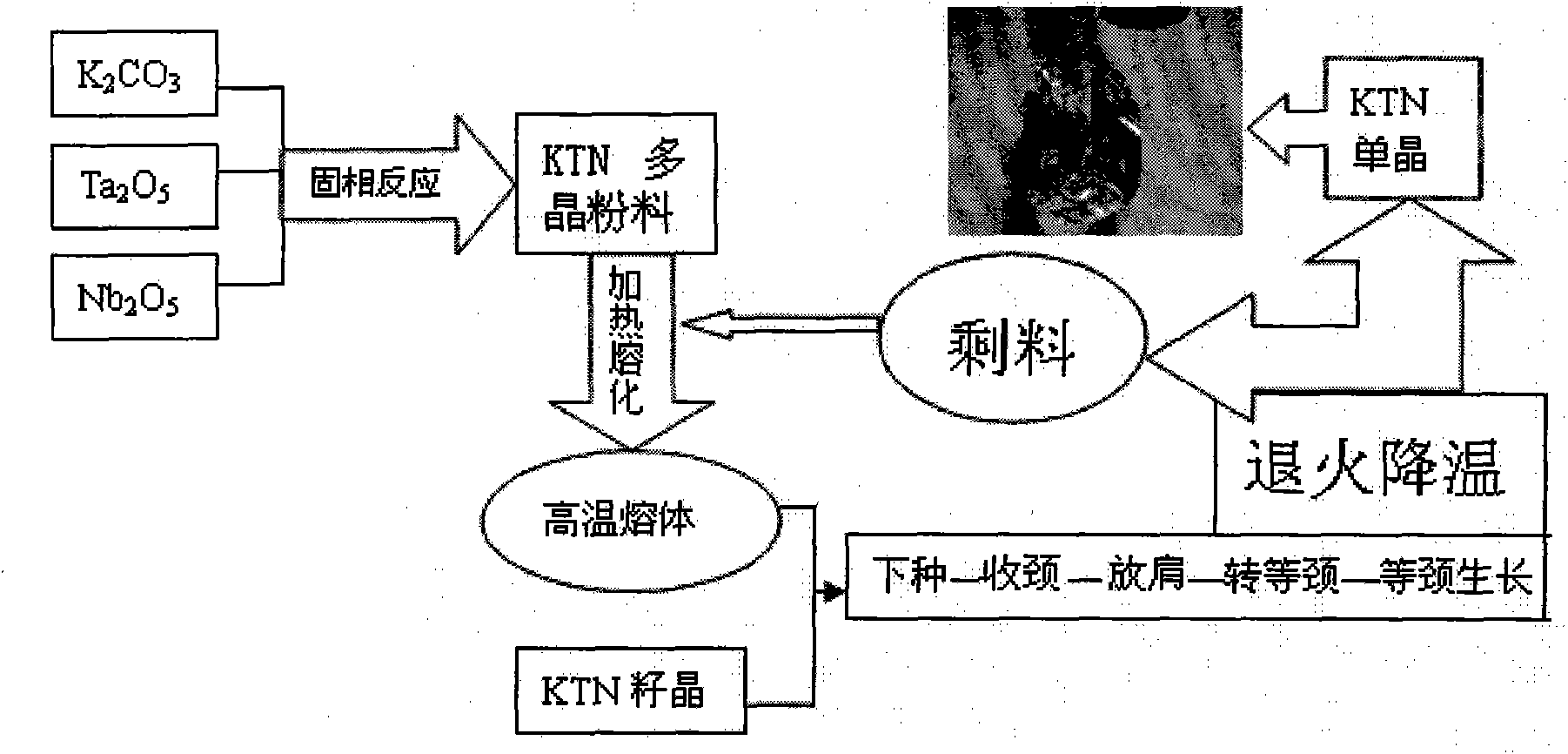

[0032] Example 1: KTaO 3 crystal growth

[0033] KT crystal is a special case of KTN crystal with zero Nb content. high purity K 2 CO 3 (99.99%) and Ta 2 o 5 (99.99%) is prepared according to the molar ratio of 1.05: 1, weighed and put into a nylon material mixing bottle, which is equipped with zirconia grinding balls (mass ratio of material balls is 1: 2), and the mixing The feed bottle is installed on a mixer, ground and mixed for 10 hours, the average particle size of the obtained powder is below 1 micron, and the speed of the mixing bottle is 200 rpm.

[0034] Put the raw material into the stainless steel powder forming mold, and the mold and the raw material need to be protected by a plastic film to prevent contact pollution. Slowly increase the pressure on the press so that the gas between the powders overflows to 10 8 Pa stop pressurization, take out raw material, this moment raw material is columnar. Put the columnar raw material into a platinum crucible and pu...

Embodiment 2

[0038] Example 2: KTa 0.61 Nb 0.39 o 3 Crystal Growth Preparation

[0039] K Ta 0.61 Nb 0.39 o 3 The crystal is a KTN crystal whose Curie phase transition point is near room temperature. Because KTN crystal has significantly superior electro-optical and other physical properties near the phase transition point, while KTa 0.61 Nb 0.39 o 3 The Curie point of the crystal is about 25°C, which is beneficial to the research and development and design of KTN crystal electro-optical components that can be applied at room temperature.

[0040] Take high purity K 2 CO 3 (purity 99.99%), high-purity Ta 2 o 5 (purity 99.99%), high-purity Nb 2 o 5 (Purity 99.99%) The raw materials are weighed according to the molar ratio of 1.03:0.3:0.7, and the raw materials are placed in a nylon material mixing bottle, which is equipped with zirconia grinding balls (mass ratio of the balls is 1:2), after sealing Put the mixing bottle on the mixer, grind and mix for more than 10 hours, and t...

Embodiment 3

[0044] Example 3: KTa 0.5 Nb 0.5 o 3 crystal growth

[0045] In addition to raw material molar ratio K 2 CO 3 : Ta 2 o 5 : Nb 2 o 5 Adjusted to 1.025:0.2:0.8, the sintering temperature was reduced to 920°C, and the crystal growth temperature was about 1075°C, KTa 0.5 Nb 0.5 o 3 The crystal raw material configuration and growth parameter control are the same as in Example 2.

[0046] Also note that KTa 0.5 Nb 0.5 o 3 The crystal is in the tetragonal phase at room temperature, and the Curie point of the crystal is about 150°C. After the crystal growth process, the cooling process is slower than that of Example 2, not higher than 20°C / h. Keep the temperature constant for more than 5 hours, then slowly drop to room temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com