Method for preparing high efficiency photocatalyst of nickel oxide supported tantalate

A technology of photocatalyst and tantalate, which is applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc. Large diameter and other problems, to achieve the effect of high photocatalytic performance, low reaction temperature, and less structural defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

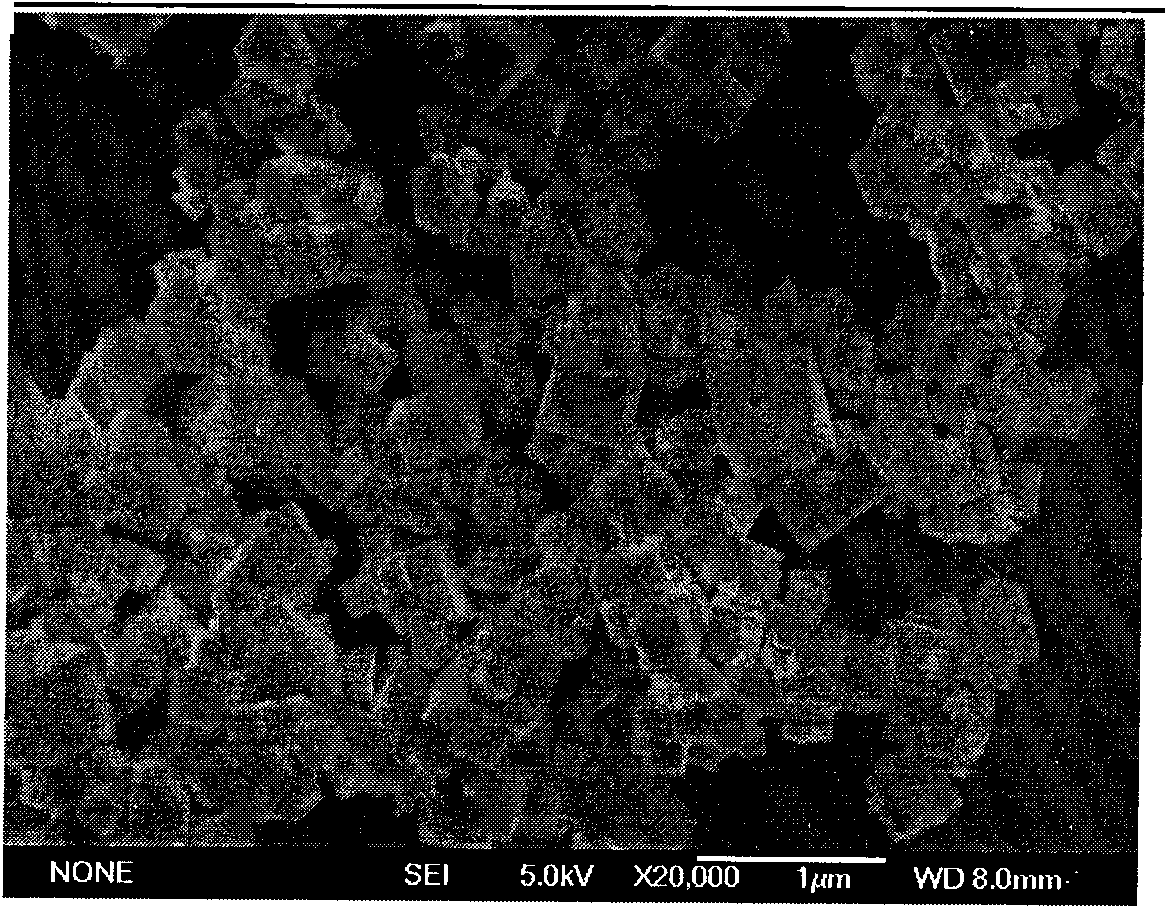

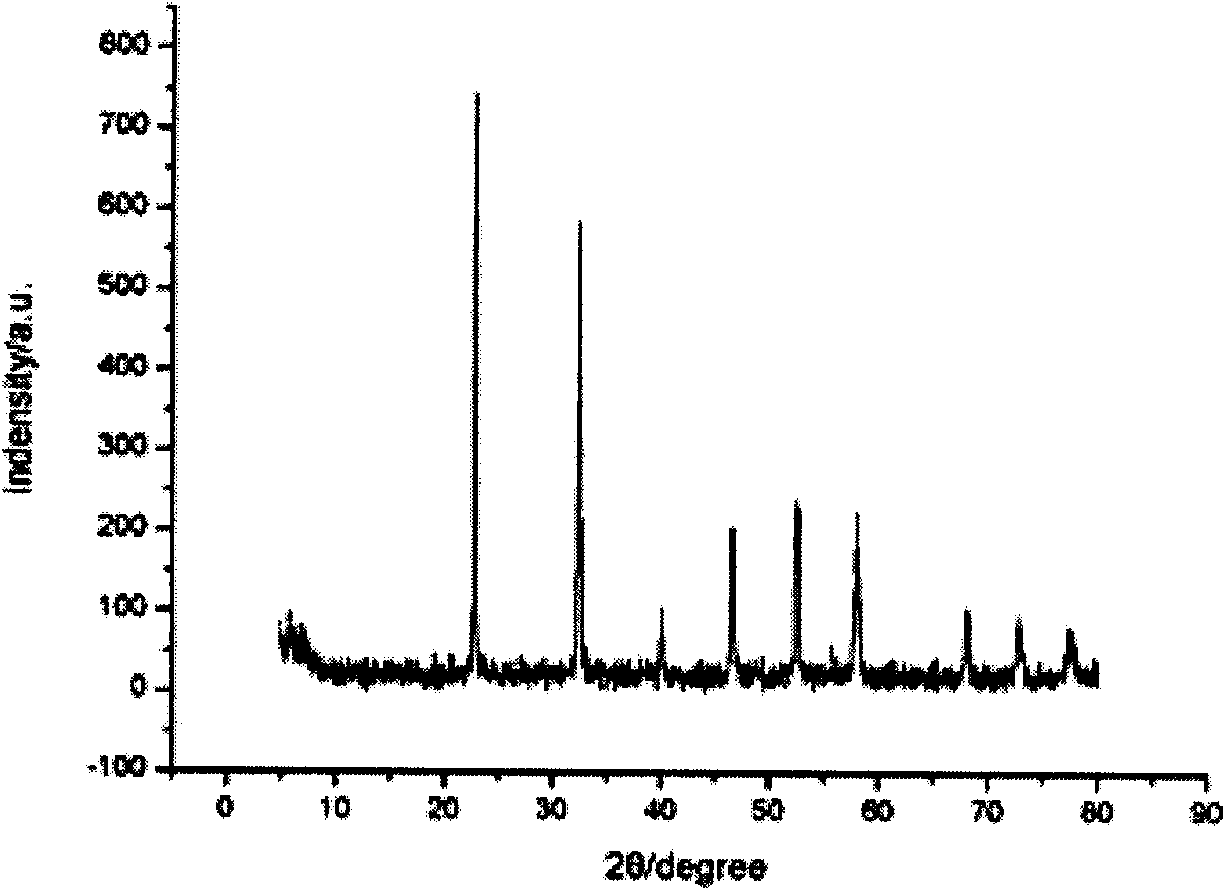

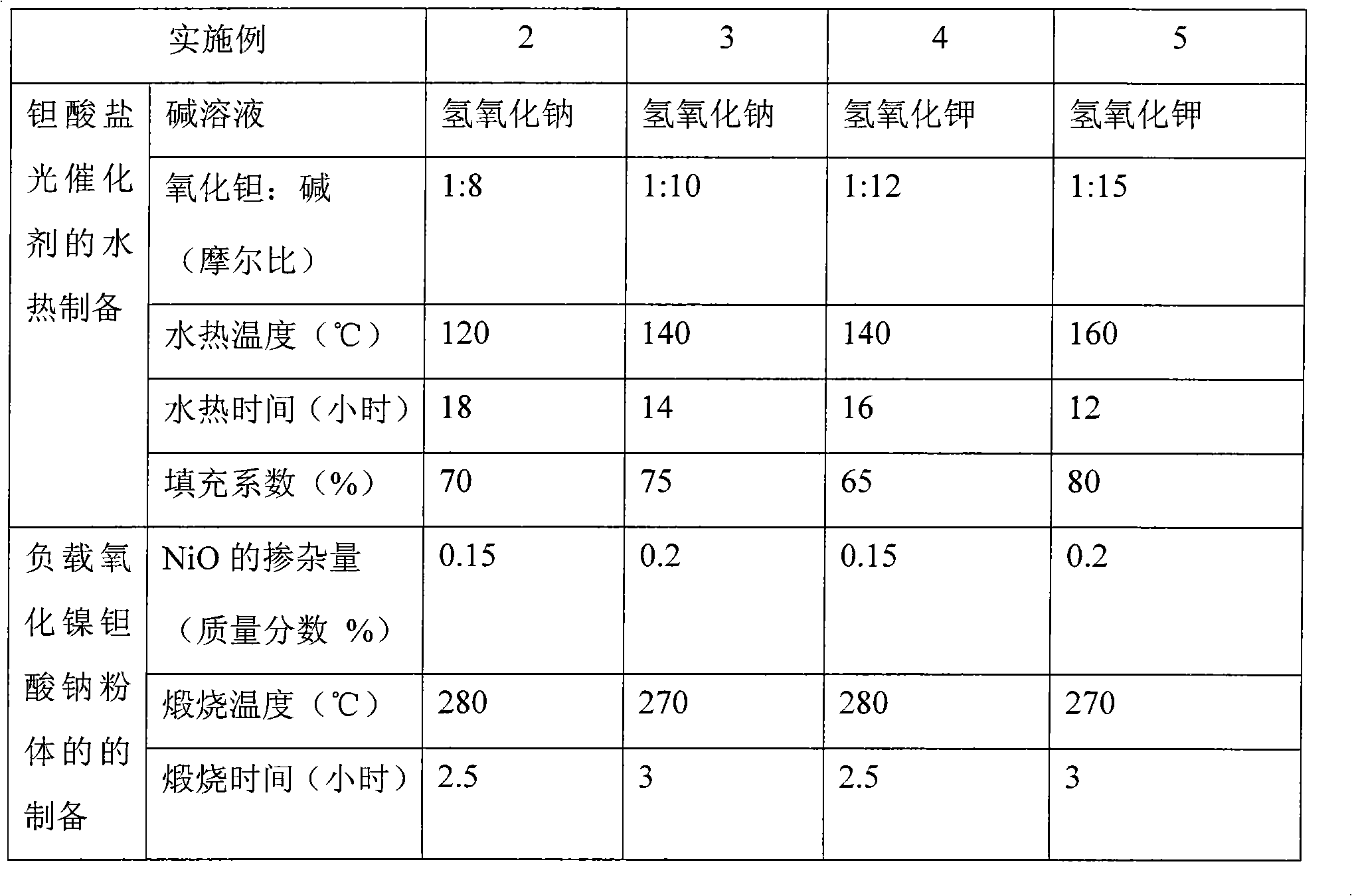

[0021] The hydrothermal preparation method of nanometer sodium tantalate photocatalyst of the present invention is as follows:

[0022] (1) Add 0.4420g Ta 2 o 5 and 0.6gNaOH to make sodium hydroxide excessive, then add 25ml of distilled water to dissolve;

[0023] (2) Put the polytetrafluoroethylene liner in an ultrasonic cleaner for ultrasonic dispersion for 15 minutes, so that tantalum oxide is evenly dispersed in the sodium hydroxide solution;

[0024] (3) Put the liner into a stainless steel reaction kettle, and put it in an oven for 12 hours at a constant temperature of 140°C;

[0025] (4) Naturally cool to room temperature, take out the inner tank of the reaction kettle, pour the supernatant liquid, pour the remaining slurry into the sand core funnel, filter the powder with vacuum suction, wash with a large amount of distilled water, remove excess NaOH, until washed out liquid is neutral;

[0026] (5) Dry the sample in an oven at 80°C for 6 hours, and collect the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com