Patents

Literature

302results about How to "Less structural defects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

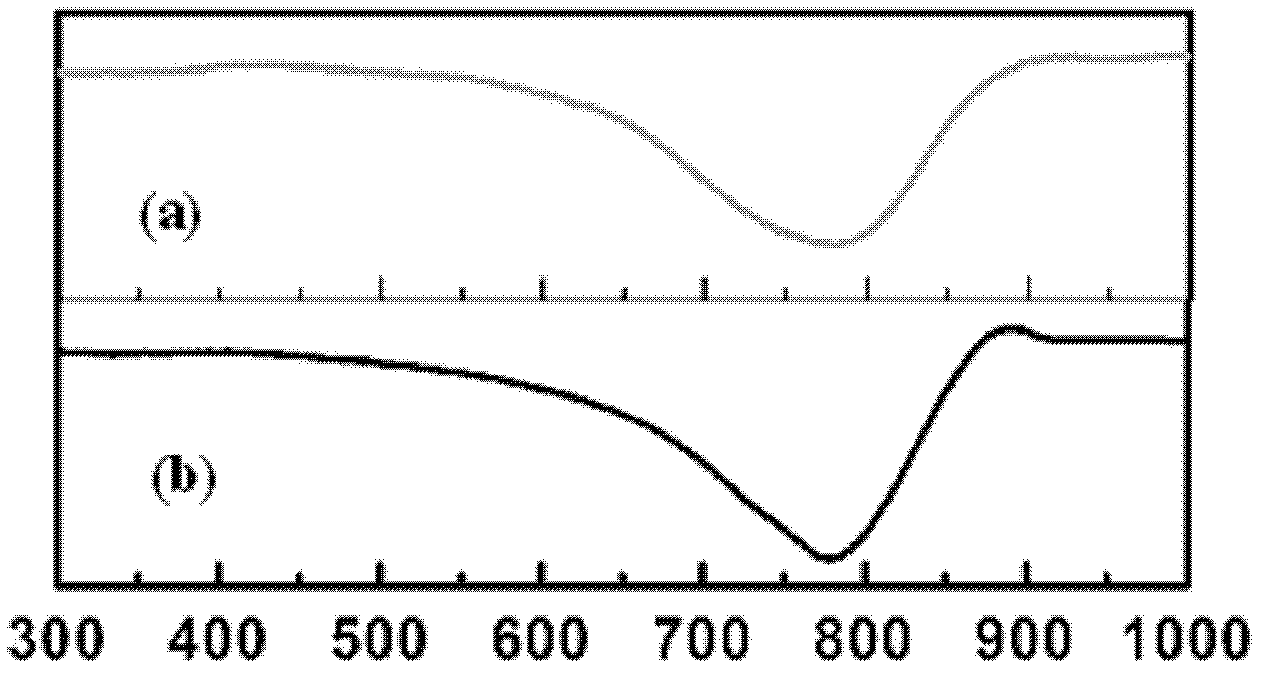

Electrochromic polymers and polymer electrochromic devices

InactiveUS6791738B2Increase the gapLess structural defectsPhotosensitive materialsElectrography/magnetographyPolymer scienceGas phase

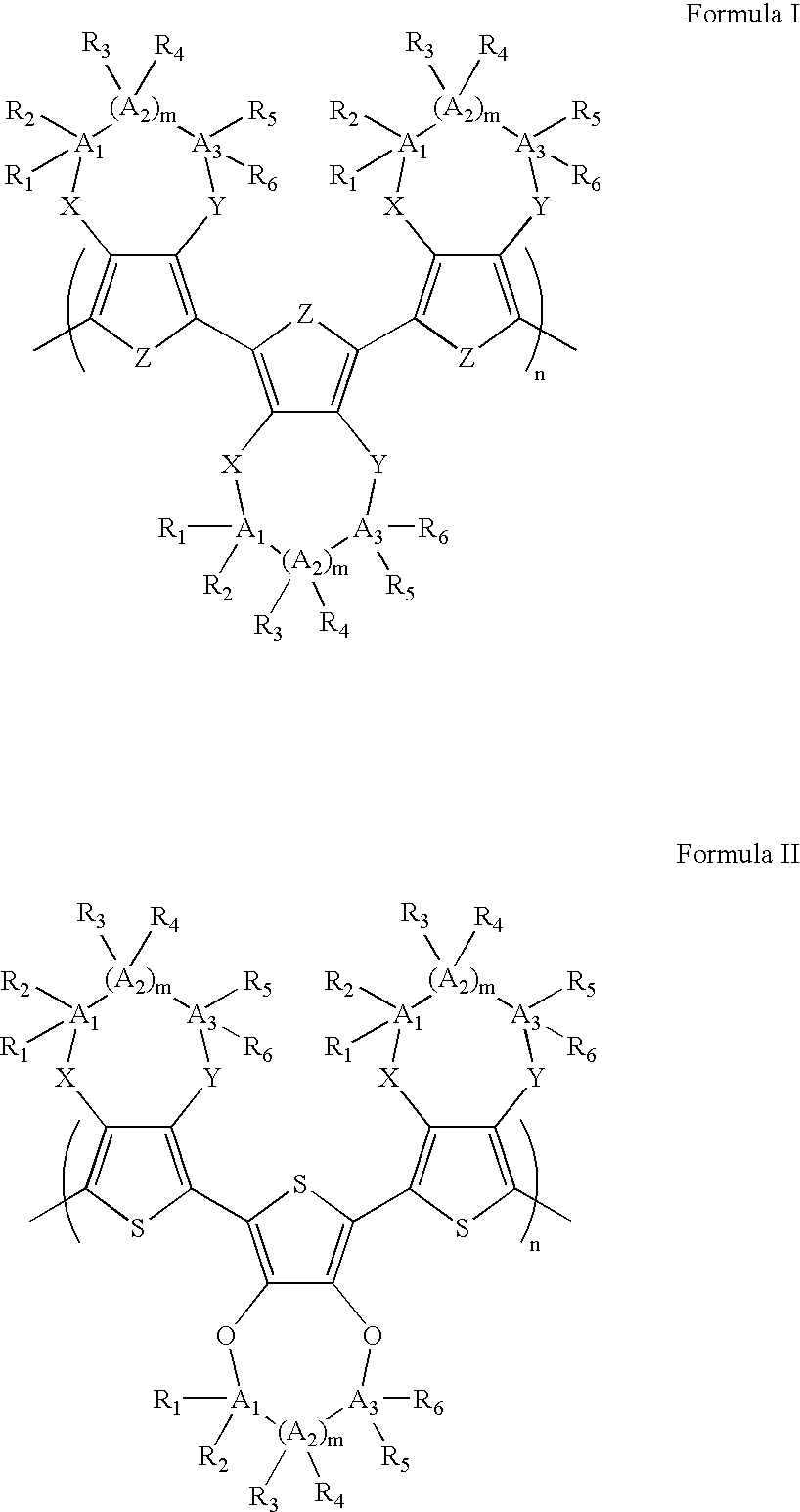

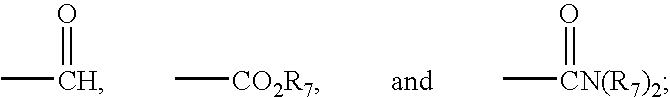

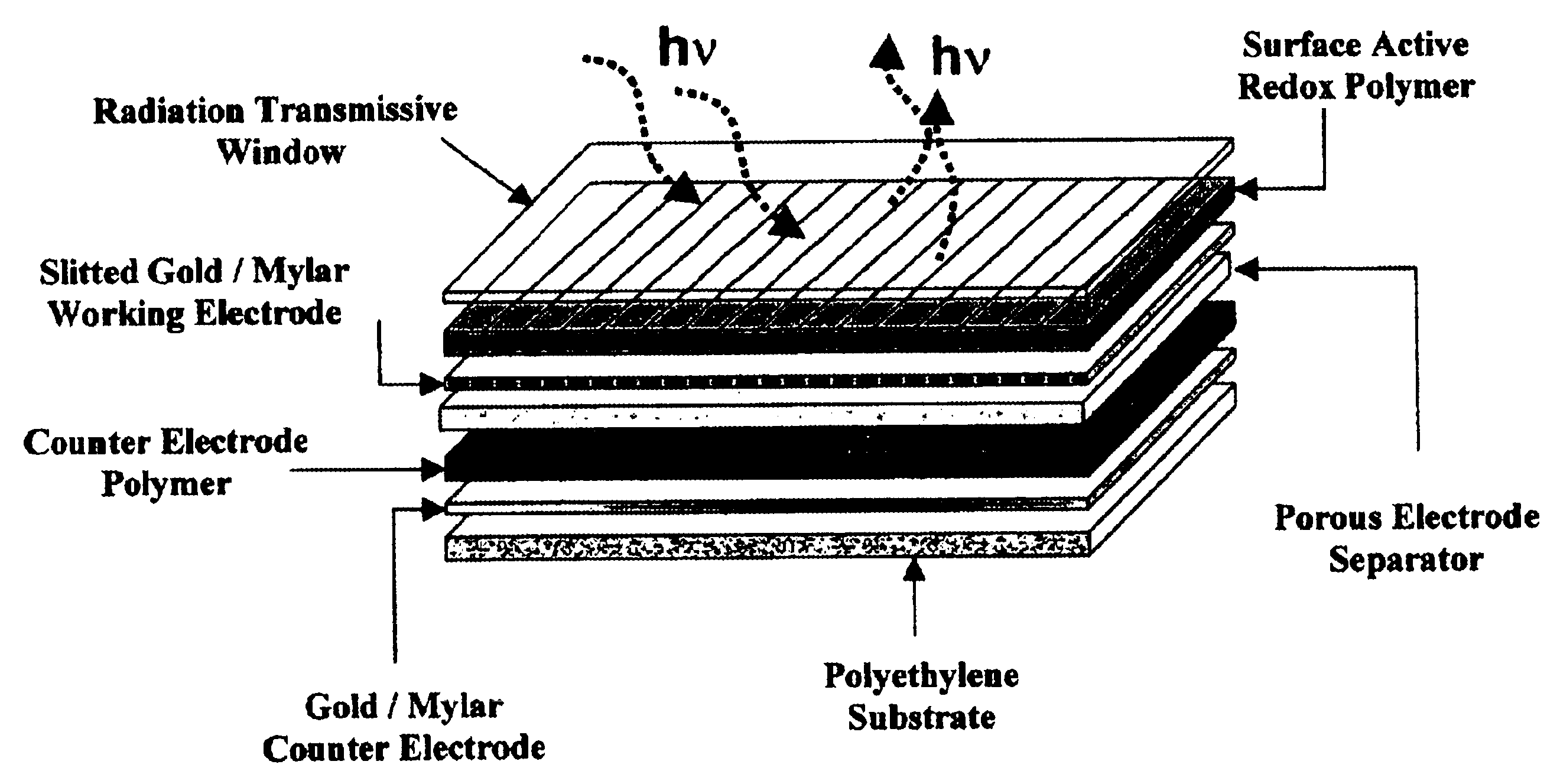

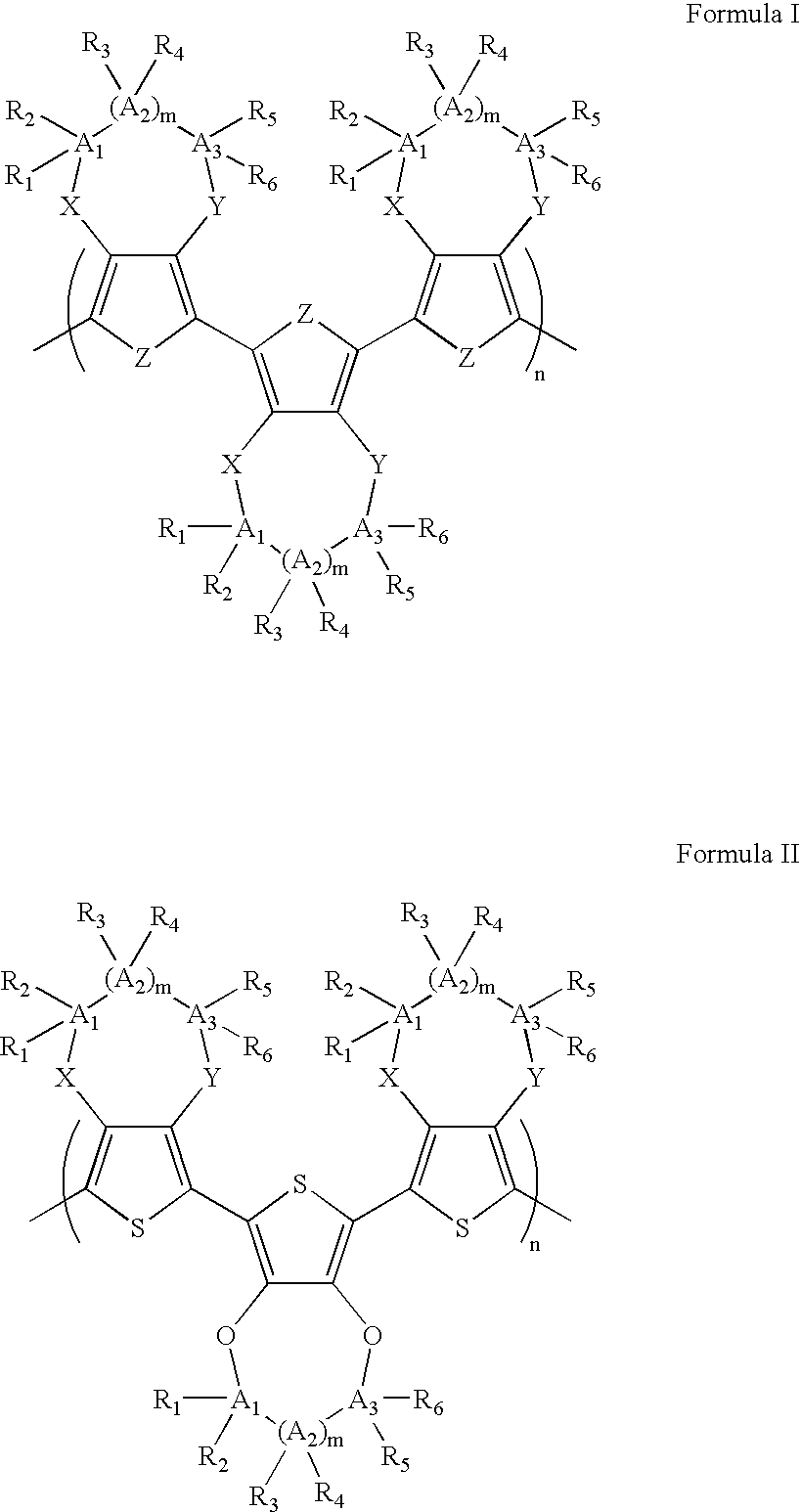

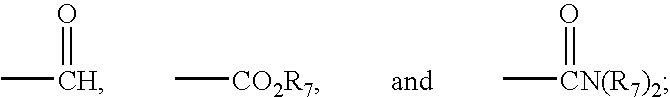

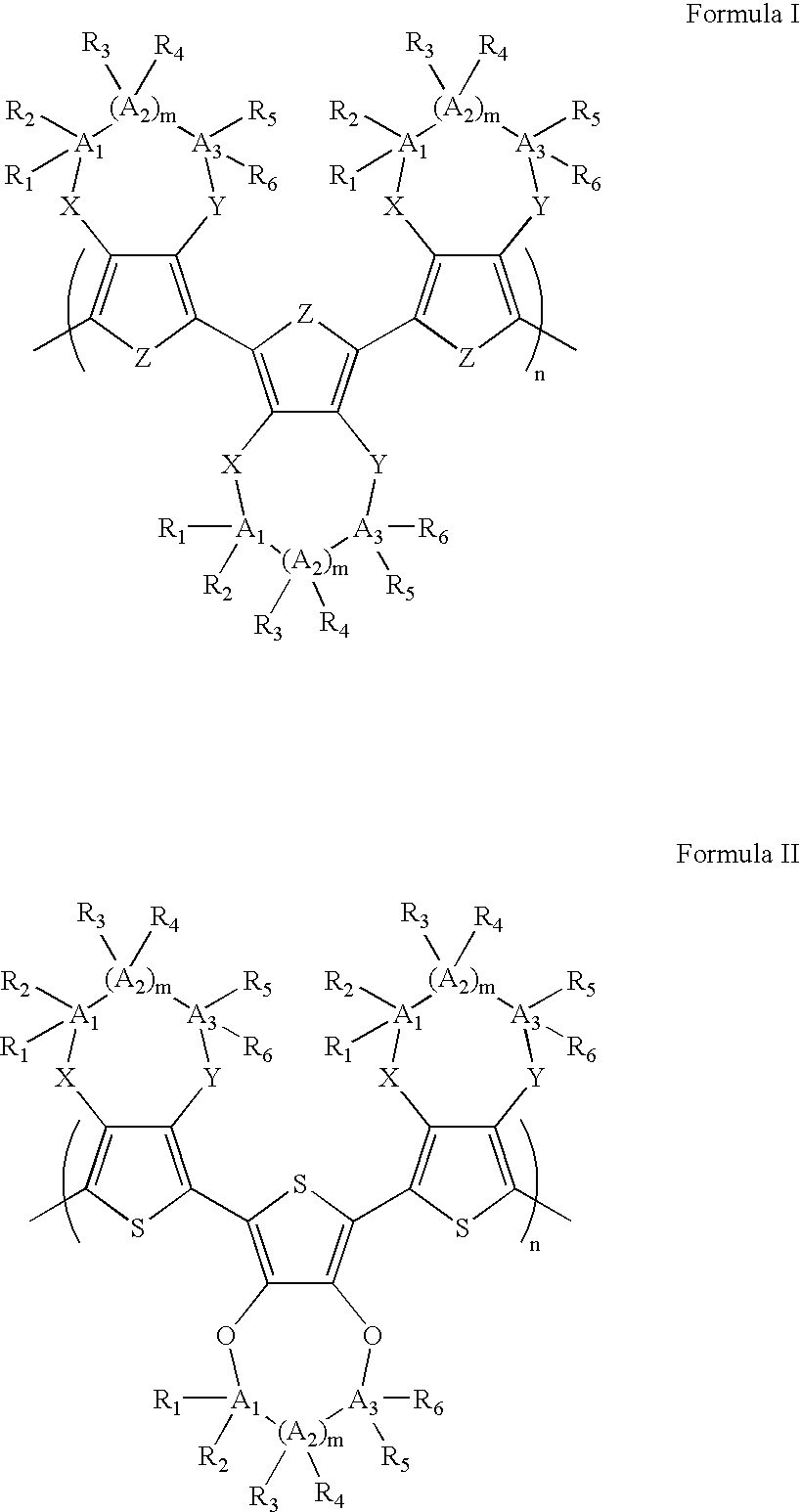

The subject invention pertains to electrochromic polymers and polymer electrochromic devices. In a specific embodiment, two complementary polymers can be matched and incorporated into dual polymer electrochromic devices. The anodically coloring polymers in accordance with the subject invention can allow control over the color, brightness, and environmental stability of an electrochromic window. In addition, high device contrast ratios, high transmittance changes, and high luminance changes can be achieved, along with half-second switching times for full color change. Also provided are electrochromic devices such as advertising signage, video monitors, stadium scoreboards, computers, announcement boards, warning systems for cell phones, warning / information systems for automobiles, greeting cards, electrochromic windows, billboards, electronic books, and electrical wiring. The subject invention also provides for the use of complementary electrochromic polymers in the manufacture of electrochromic devices. In some embodiments, the devices of the invention can be prepared using metal vapor deposition or line patterning.

Owner:FLORIDA UNIV OF A FLORIDA

Electrochromic polymers and polymer electrochromic devices

InactiveUS20030174377A1Increase the gapLess structural defectsPhotosensitive materialsElectrography/magnetographyPolymer scienceGas phase

The subject invention pertains to electrochromic polymers and polymer electrochromic devices. In a specific embodiment, two complementary polymers can be matched and incorporated into dual polymer electrochromic devices. The anodically coloring polymers in accordance with the subject invention can allow control over the color, brightness, and environmental stability of an electrochromic window. In addition, high device contrast ratios, high transmittance changes, and high luminance changes can be achieved, along with half-second switching times for full color change. Also provided are electrochromic devices such as advertising signage, video monitors, stadium scoreboards, computers, announcement boards, warning systems for cell phones, warning / information systems for automobiles, greeting cards, electrochromic windows, billboards, electronic books, and electrical wiring. The subject invention also provides for the use of complementary electrochromic polymers in the manufacture of electrochromic devices. In some embodiments, the devices of the invention can be prepared using metal vapor deposition or line patterning.

Owner:FLORIDA UNIV OF A FLORIDA

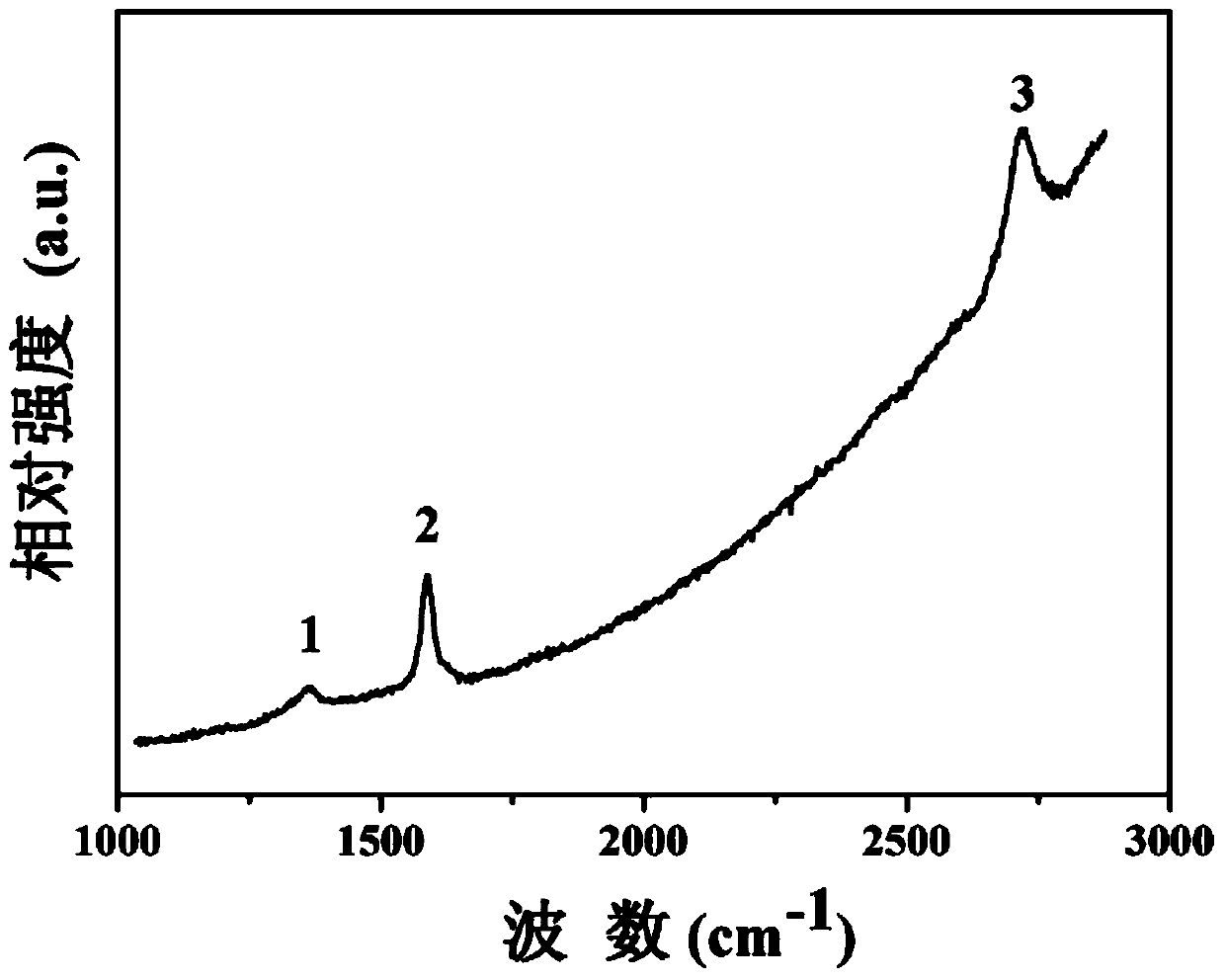

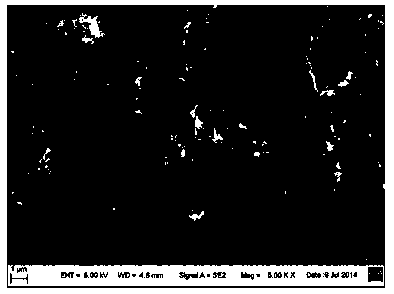

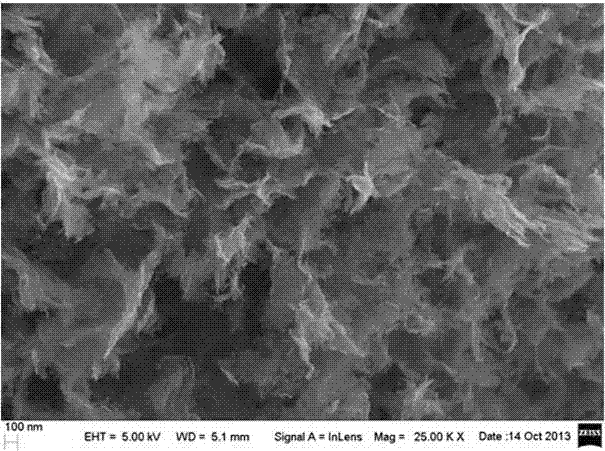

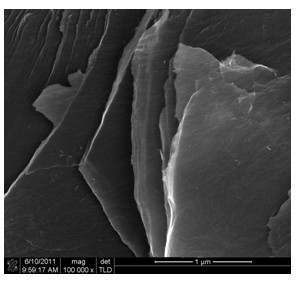

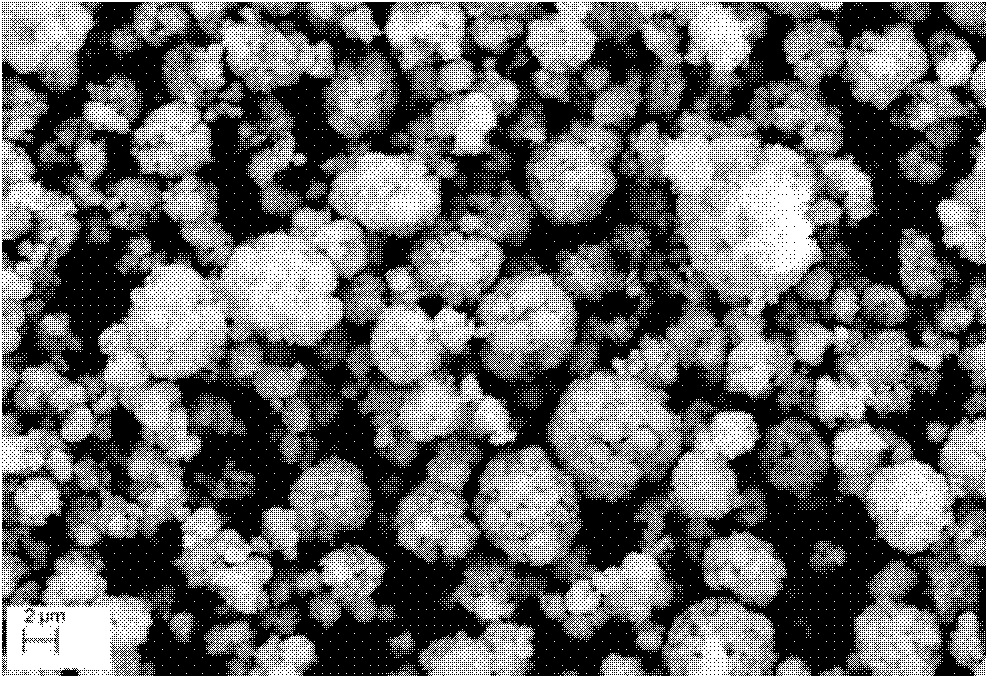

Efficient in-situ preparation method of graphene reinforced copper-based composite material

The invention discloses an efficient in-situ preparation method of a graphene reinforced copper-based composite material, and relates to a method for preparing a graphene reinforced copper-based composite material and the method can be used for solving the problems of poor uniform dispersion, poor structure integrity of grapheme and complex process in the existing preparation method of the graphene reinforced copper-based composite material. The efficient in-situ preparation method of the graphene reinforced copper-based composite material comprises the following steps: putting copper powder in a plasma reinforced chemical vapor deposition vacuum device, introducing hydrogen, preserving heat at high temperature, then introducing argon and carbon source gas, depositing, stopping introducing the carbon source gas after ending the deposition, and finally, cooling below the room temperature to obtain grapheme / copper composite powder, and then primarily pressing, sintering and secondarily pressing the grapheme / copper composite powder to obtain the graphene reinforced copper-based composite material. The method is an efficient in-situ preparation method of a graphene reinforced copper-based composite material.

Owner:HARBIN INST OF TECH

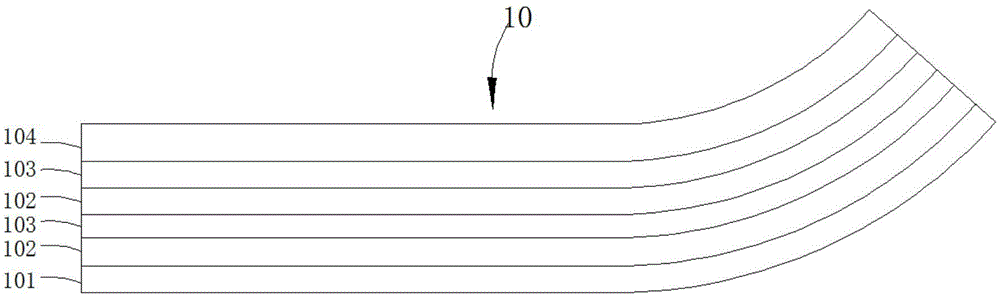

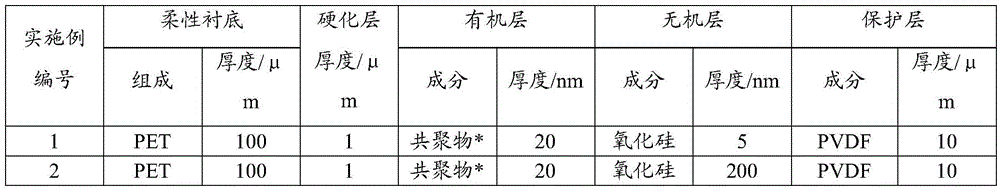

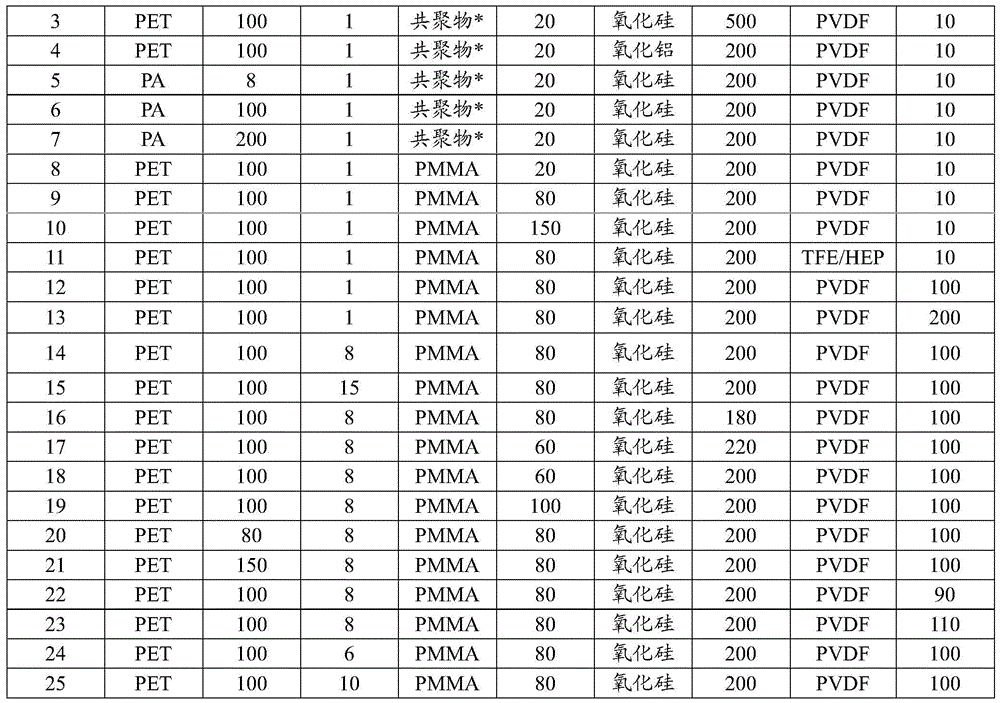

Flexible transparent barrier film and preparation method thereof

InactiveCN106711345ALess structural defectsHigh light transmittanceSolid-state devicesSemiconductor/solid-state device manufacturingTransmittanceOptical thin film

The invention relates to an optical thin film, and particularly relates to a flexible transparent barrier film and a preparation method thereof, so as to solve the problems that low transmittance is likely to happen to a composite barrier film and barrier performance generated after rolling drops. The barrier film comprises a flexible substrate; a barrier layer is arranged on the flexible substrate; a protection layer is arranged on the barrier layer; the flexible substrate is a transparent thin film; the barrier layer comprises at least two organic layers and at least two inorganic layers; the organic layers and the inorganic layers are arranged alternately; and the flexible substrate is connected with the organic layers in the barrier layer. The flexible transparent barrier film has good transmittance, and the barrier performance is still excellent after multiple times of rolling.

Owner:NINGBO CHANGYANG TECH

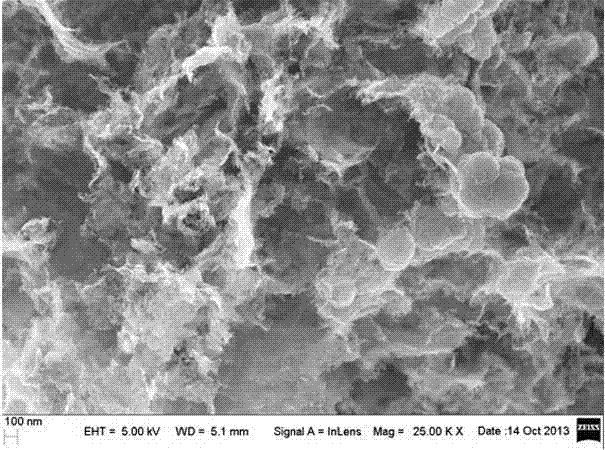

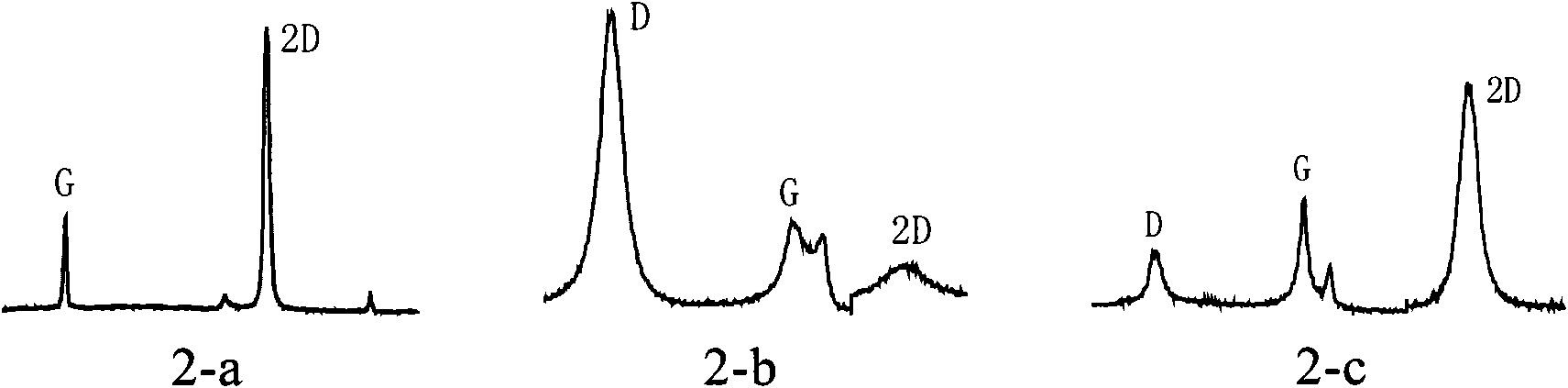

Method for preparing graphene

ActiveCN102757038AQuality improvementIncrease productionGrapheneNanotechnologyGas phaseLithium-ion battery

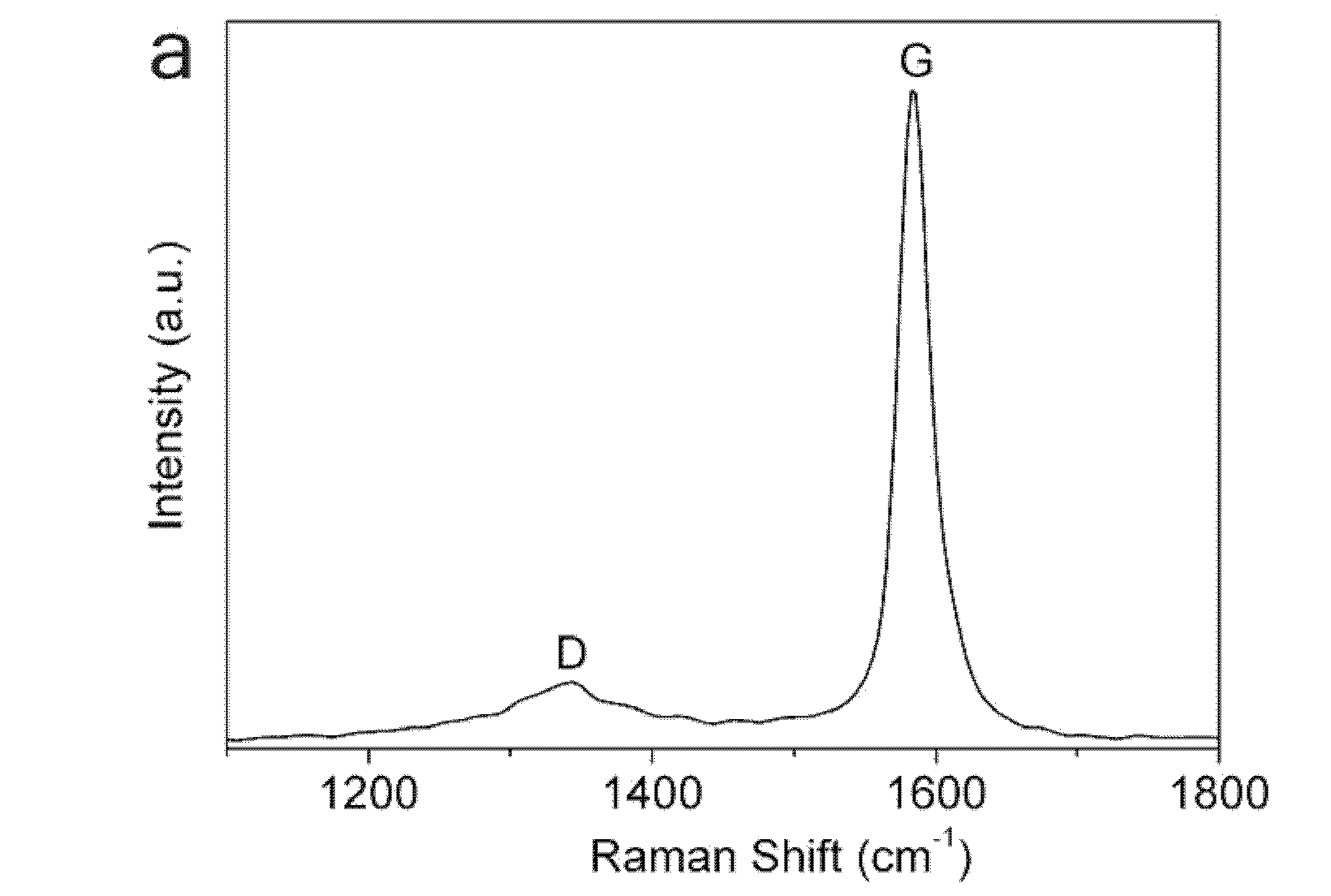

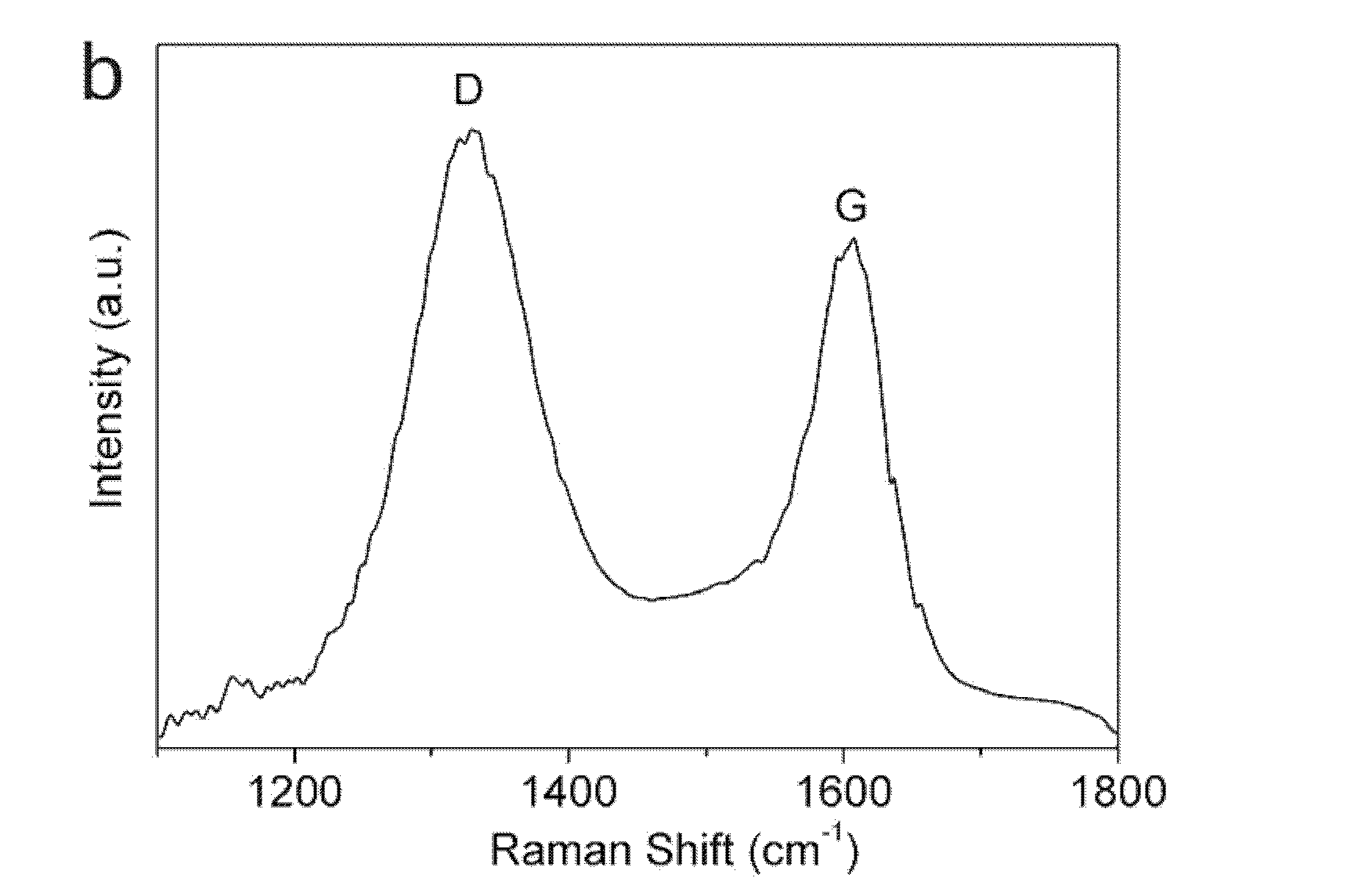

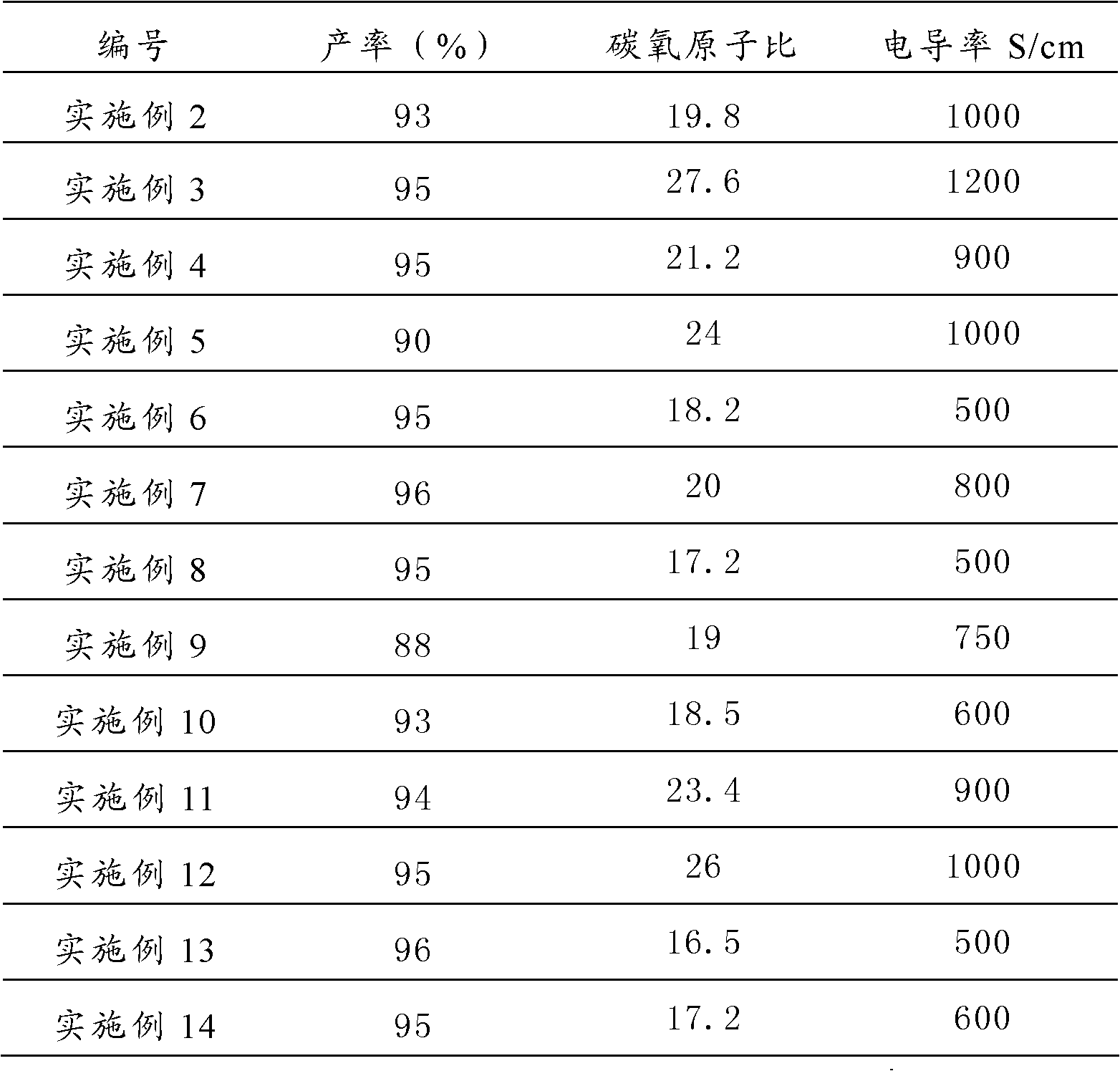

The invention provides a method for preparing graphene. The method includes that graphite reacts in acid solution with an oxidant to obtain the graphene. Compared with the prior art, the method has the advantages that the graphene prepared by the method is good in quality, yield is greatly increased and productivity is greatly improved as compared with a mechanical exfoliation method, an epitaxial growth method and a chemical vapor deposition method; the quality of the graphene is greatly enhanced, structural defects of the graphene are greatly reduced, and electrical conductivity of the graphene is obviously improved as compared with a solution-phase oxidation reduction method; and the preparation process is simple, conditions are mild, cost is low, and large-scale production is realized easily. In addition, the graphene prepared by the method has an extremely broad prospect in fields of lithium ion batteries, super-capacitors, functional composites, transparent conductive thin films, microelectronic devices and the like.

Owner:NINGBO MORSH TECH

Preparation method of low-cost porous graphene

Owner:FUZHOU UNIV

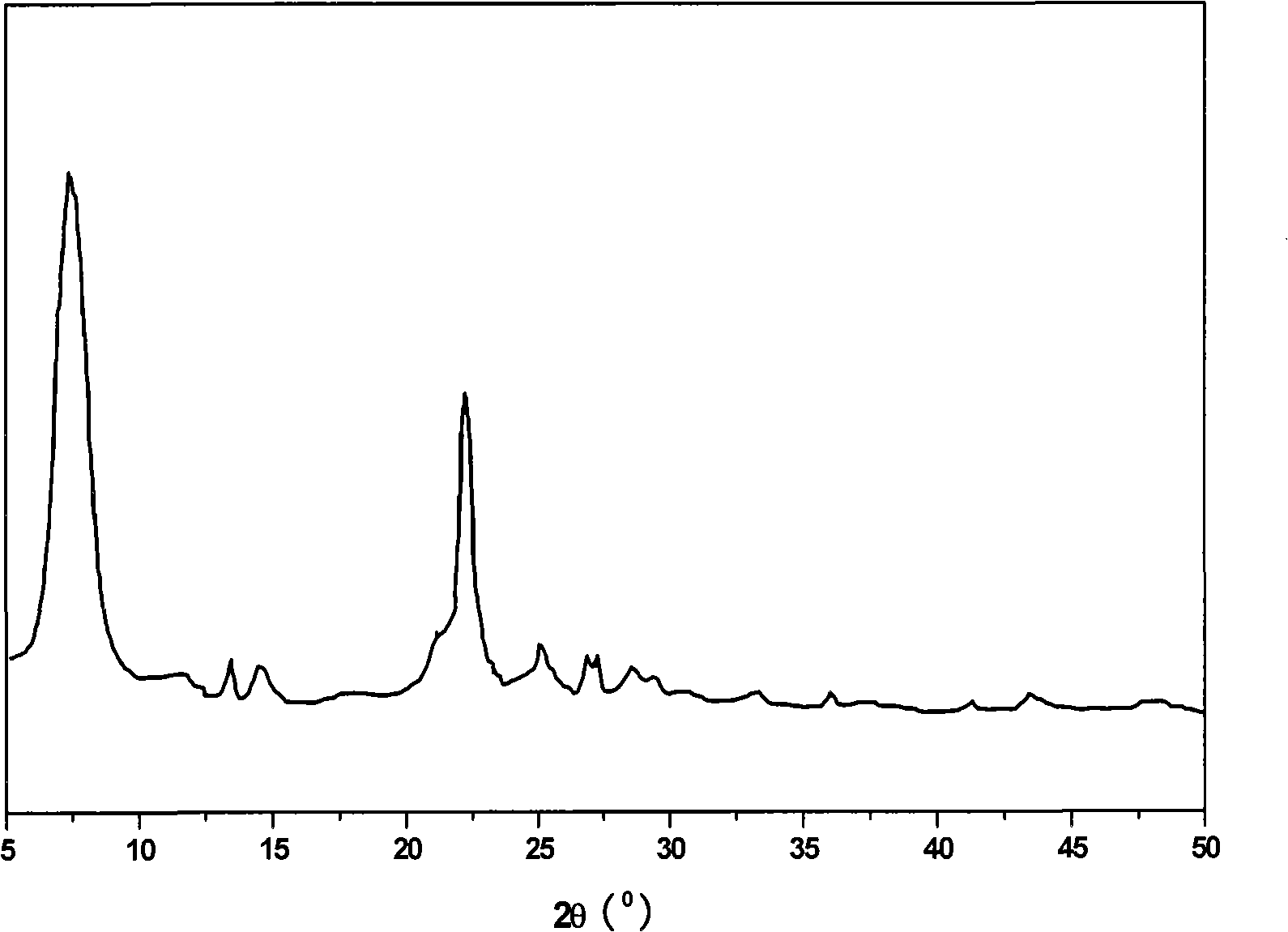

Synthetic method of Ti-beta molecular sieve

ActiveCN101353169AHigh crystallinityLess structural defectsCrystalline aluminosilicate zeolitesMolecular sieveAlcohol

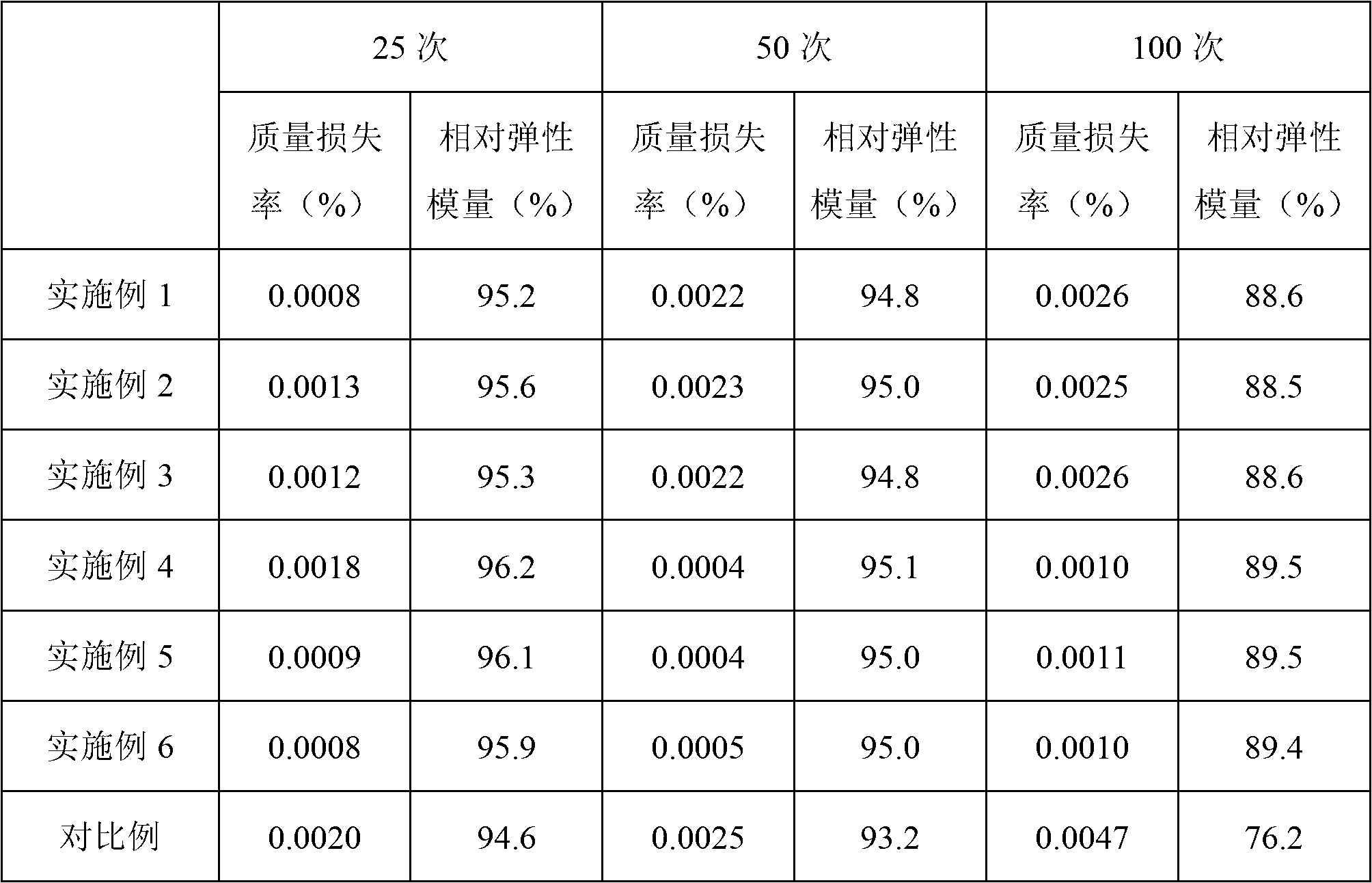

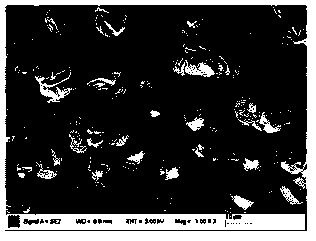

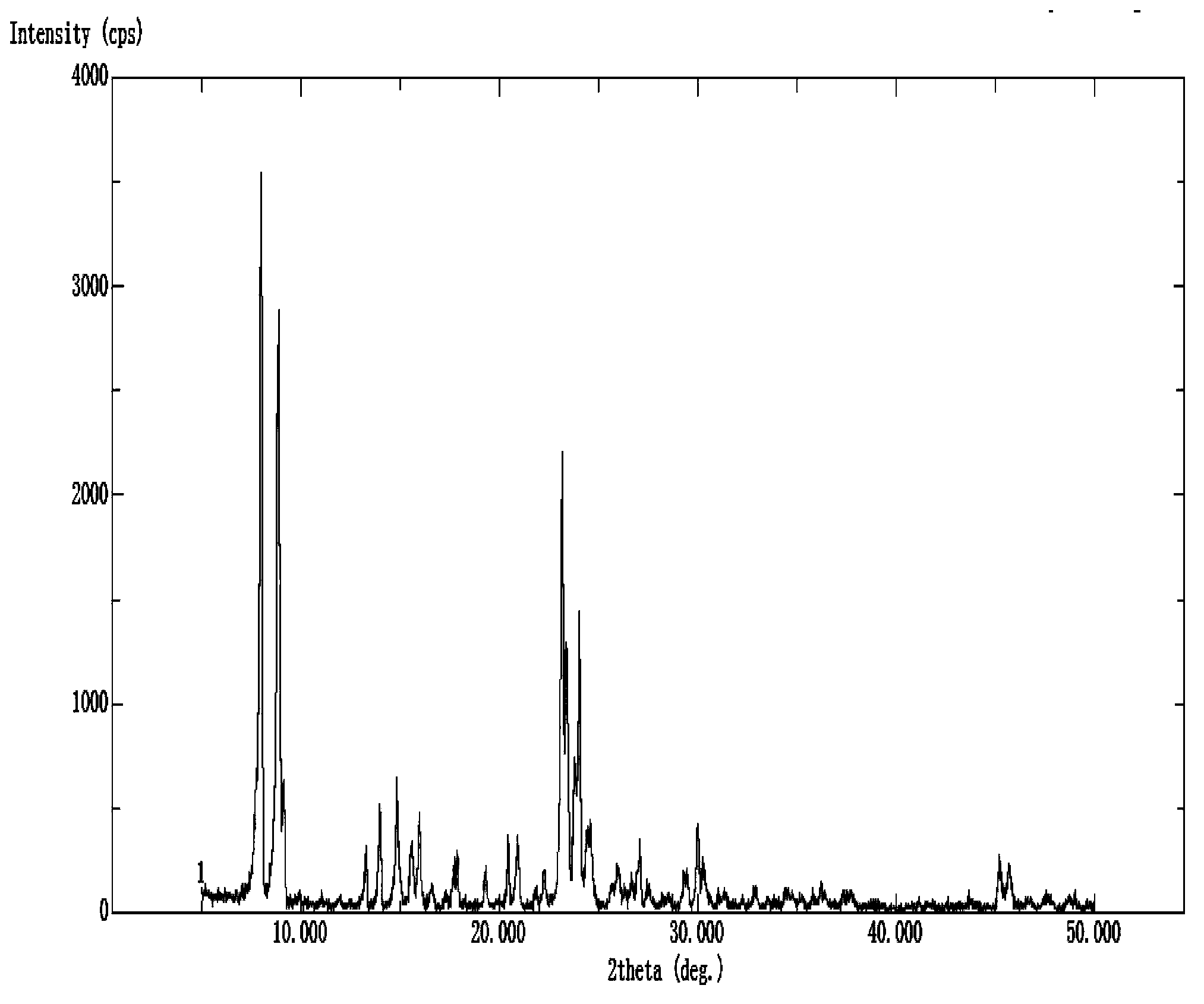

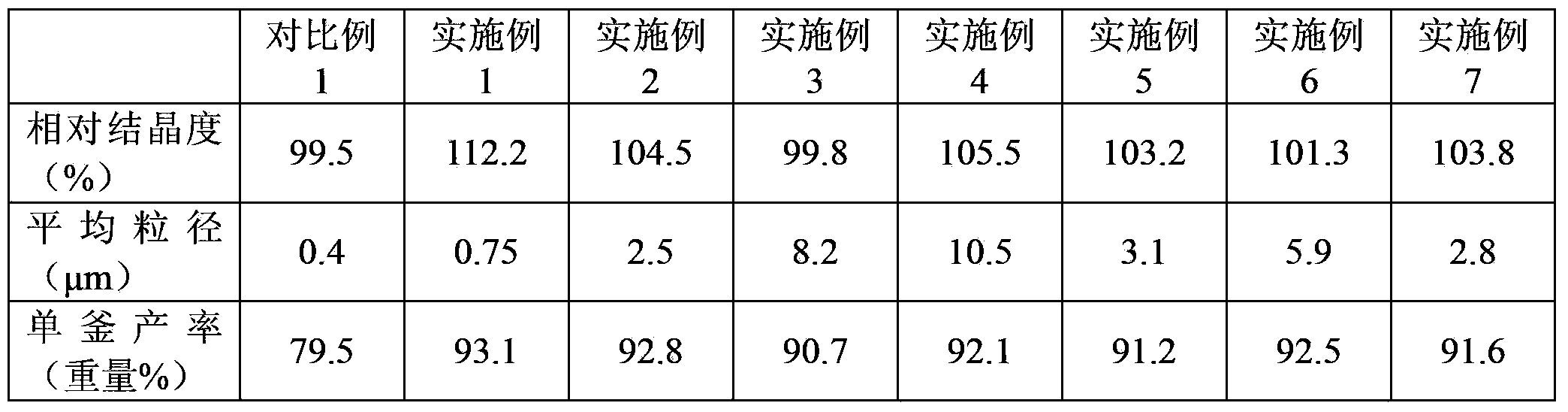

A synthetic method of TI-beta zeolite comprises the steps as follows: (1) silicate ester, titanate ester and butanol are evenly mixed according to the mol ratio that SiO2: TiO2: alcohol equals 1: (0.01-0.05): (4.0-15.0), and then NaOH solution is added for reaction at the room temperature of 120 DEG C, and kanemite is obtained by roasting; (2) the kanemite (counted based on SiO2), a template agent and water are evenly mixed according to the mol ratio that the SiO2: the template agent: the water equals 1: (0.1-1.0): (2.0-8.0) at the temperature of 120-170 DEG C, and crystallized for 2-15 days to obtain raw powder of a titanium silicalite molecular sieve with BEA skeleton structure; (3) the raw powder of the titanium silicalite molecular sieve obtained in the step (2) is washed by acid; and (4) the product washed by acid is roasted to obtain a Ti-beta molecular sieve product. The Ti-beta molecular sieve synthesized by the method in the invention contains little non-skeleton Ti, contains no Al, and is characterized by high relative crystallinity, few structural defects, good thermal stability, and nano crystal grain dimension.

Owner:CHINA PETROLEUM & CHEM CORP +1

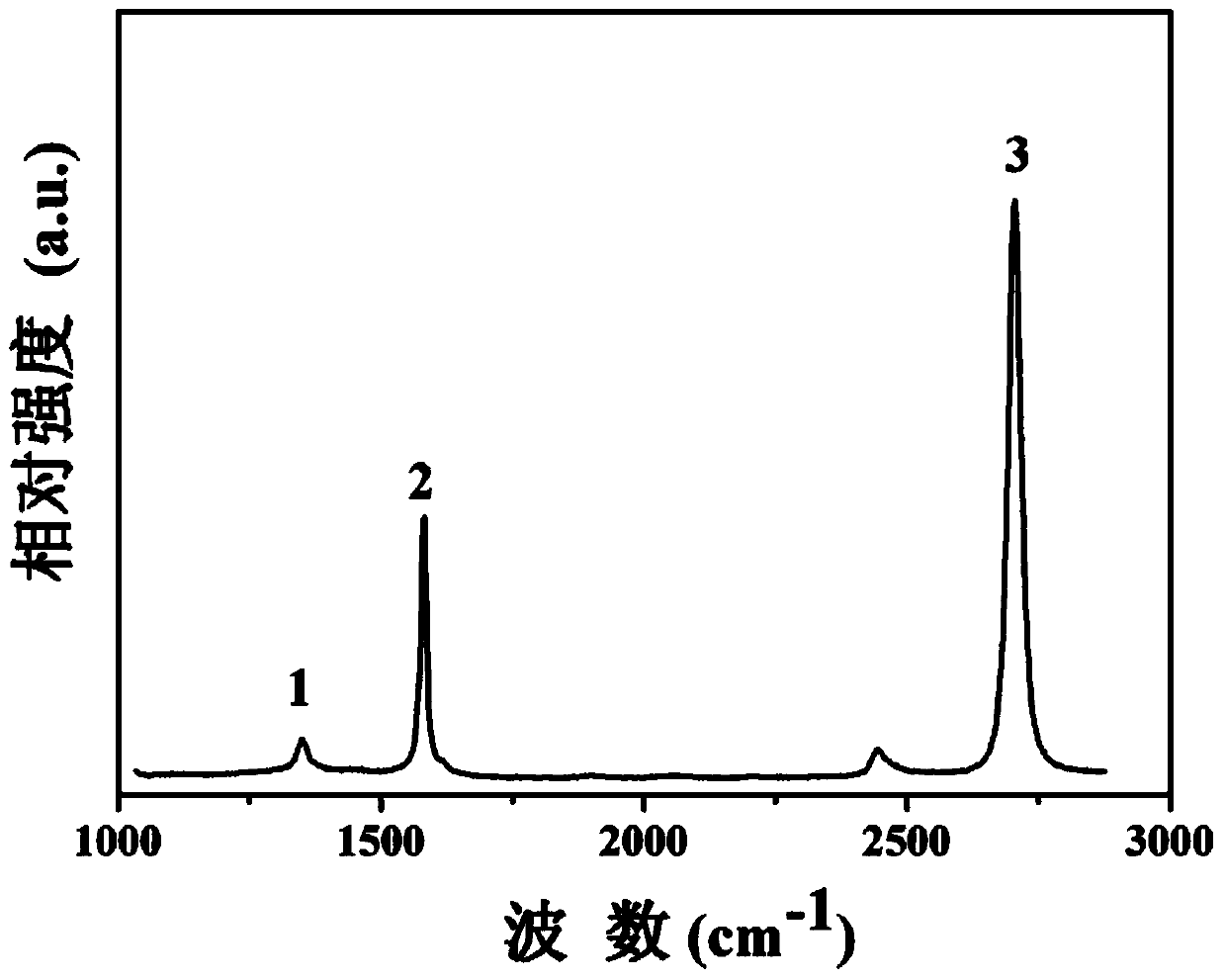

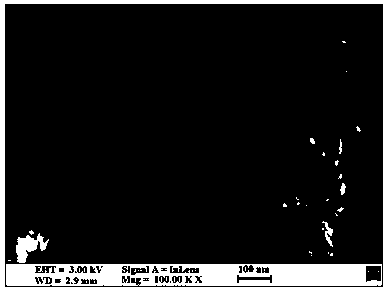

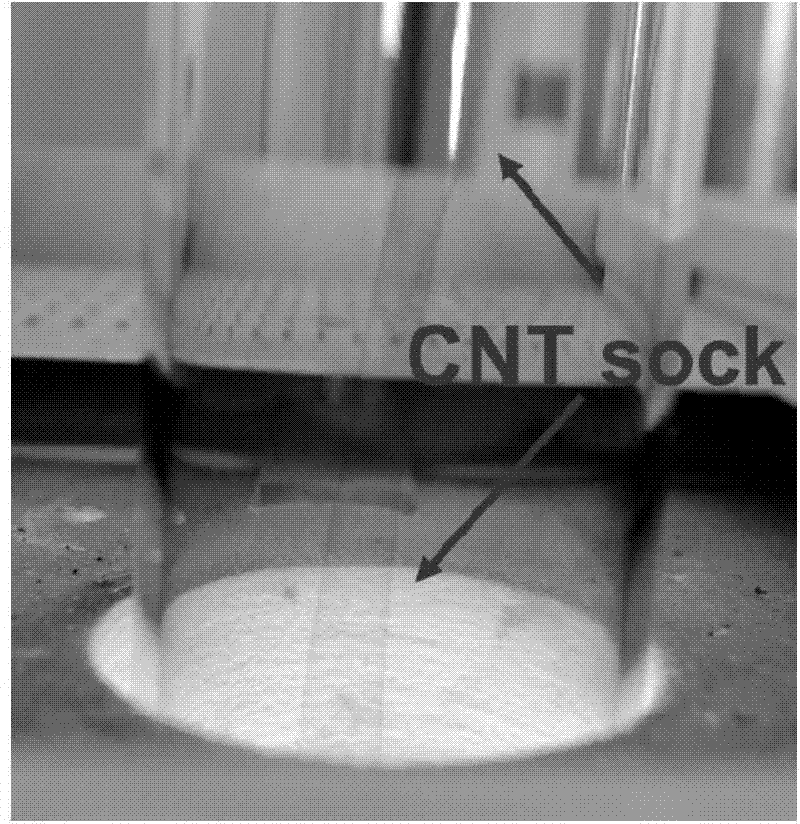

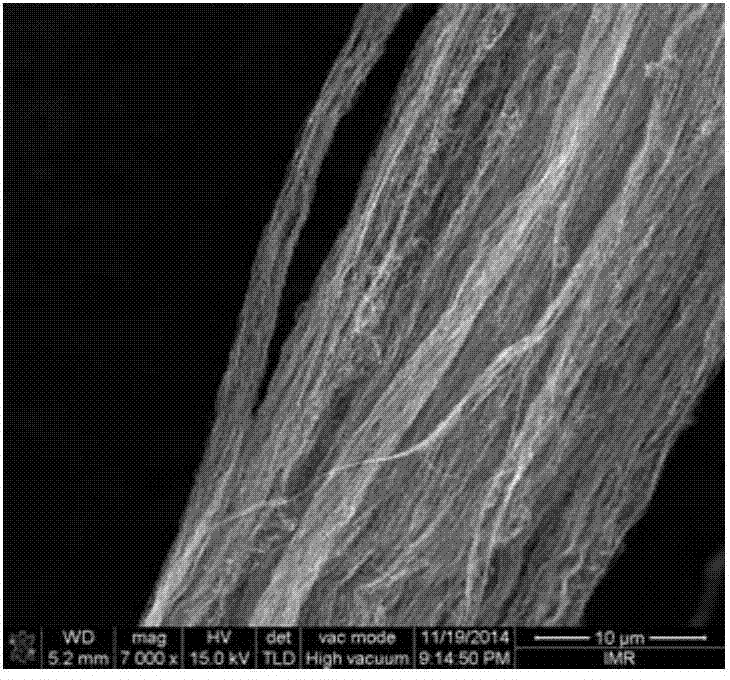

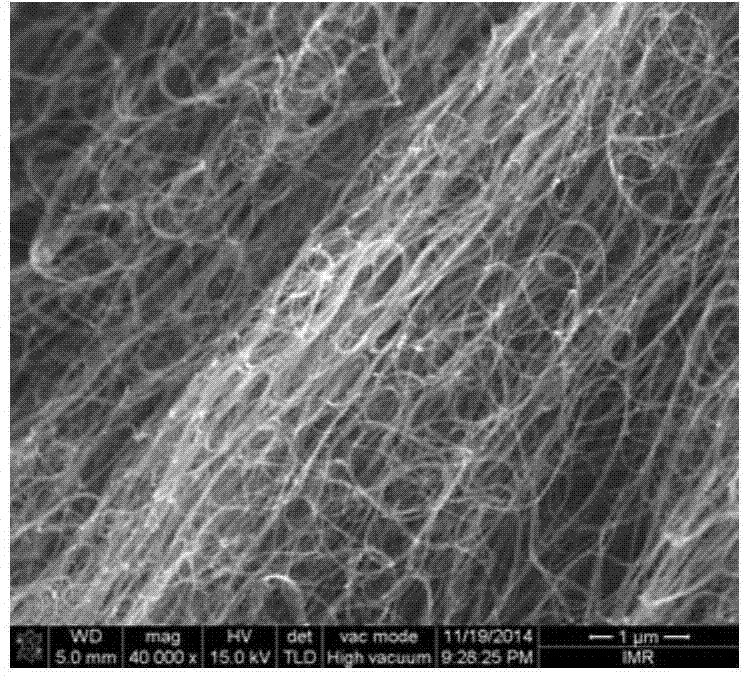

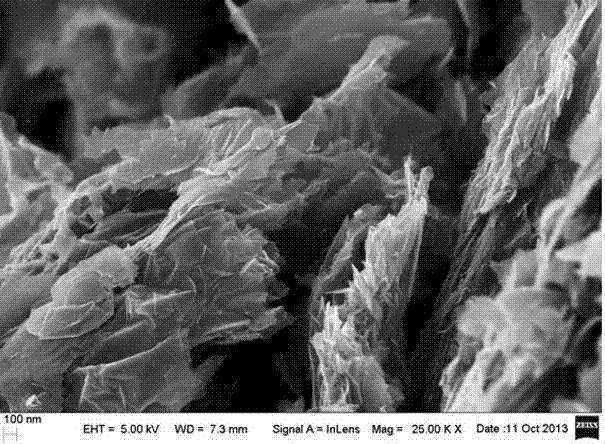

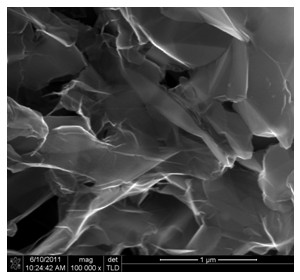

Method for preparing single-wall carbon nanotube fiber by using mixed gaseous carbon source

The invention relates to the field of direct, massive, and controllable preparation of a high-quality single-wall carbon nanotube, and particularly provides a method for massively preparing a high-quality high-purity single-wall carbon nanotube fiber via a CVD method by using a floating catalyst of a mixed gaseous carbon source. A volatile organometallic compound, such as ferrocene, is taken as a precursor of the catalyst; sulfur powder and a sulfur-contained organic compound are taken as growth promoters; methane and a second low-carbon hydrocarbon are taken as carbon sources; a mixed gas of argon / hydrogen is taken as a carrier gas; and the growth of the single-wall carbon nanotube fiber is achieved at a temperature of 1000-1200 DEG C. The impurity content of the obtained single-wall carbon nanotube fiber is less than 15%; the concentrated oxidation temperature of the single-wall carbon nanotube is over 800 DEG C; and the G / D ratio of the single-wall carbon nanotube is more than 100. During the growth process of the single-wall carbon nanotube via the CVD method by using the floating catalyst, methane and a second low-carbon hydrocarbon are taken as carbon sources; and the massive, continuous, and controllable growth of the high-quality high-purity single-wall carbon nanotube fiber is realized in the presence of a low-flow protective gas mixed by argon and hydrogen.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Preparation method of graphene lubricating additive

The invention provides a preparation method of a graphene lubricating additive. The preparation method comprises the following steps of adopting a biomass carbon source as a main raw material; performing high temperature carbonization to form a carbon source precursor with a porous structure; dispersing the carbon source precursor in a modified chitosan solution to improve the dispersing power of the material; shearing and peeling by a microfluidizer; crushing and breaking the carbon source by using a high-speed shearing action formed by a huge pressure gradient to form a graphene material; then stirring and mixing the graphene material with nano mircropore clay; enabling graphene to be uniformly dispersed in a micropore structure of nanoclay to improve the stability of the graphene and reduce the aggregation of the graphene; filtering and drying to obtain the graphene lubricating additive for lubricating oil. According to the graphene lubricating additive prepared by adopting a mechanical stripping method, structure defects are small; after the graphene lubricating additive is added into the lubricating oil, the graphene lubricating additive is high in dispersing power, is not easy to aggregate and good in lubricating effect; in addition, the whole preparation process has the advantages of safe and reliable process, low cost, environmental protection and significant market application value.

Owner:深圳市天润石墨烯材料科技股份有限公司

Sodium-ion battery anode material as well as preparation method and application thereof

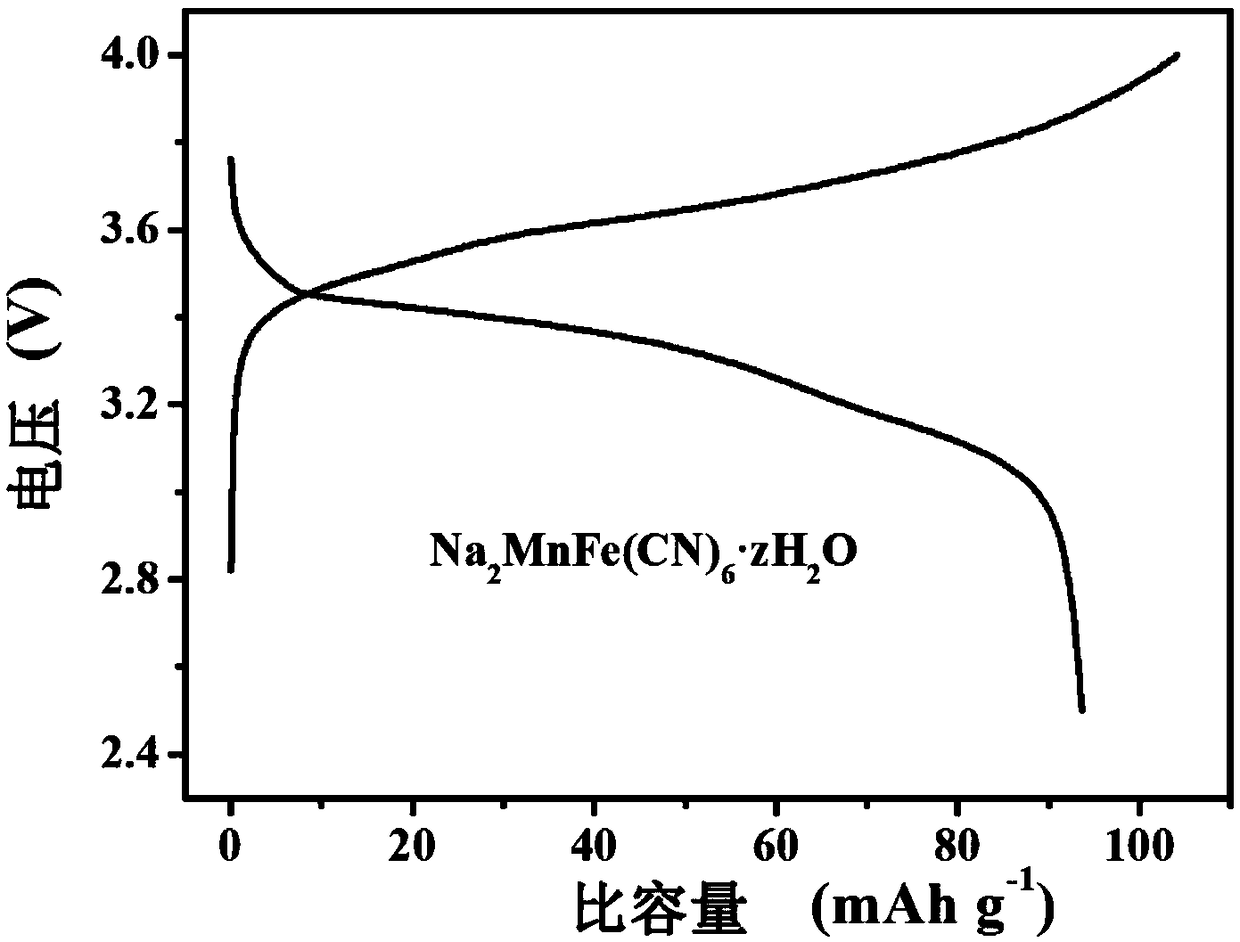

ActiveCN108258239ALess structural defectsCrystallization intactSecondary cellsPositive electrodesIonCharge and discharge

The invention provides a sodium-ion battery anode material as well as a preparation method and application thereof. The anode material comprises doped prussian blue, wherein the prussian blue comprises a sodium element; the anode material is free of water. The preparation method of the anode material provided by the invention comprises the following steps: (1) mixing a solution A and a solution Bso as to obtain a suspension, wherein the solution A is a mixed solution of sodium ferrocyanide and sodium chloride; the solution B is a mixed solution of a doping source and a complexing agent; (2) performing solid-liquid separation on the suspension of the step (1), and collecting and drying a solid, thereby obtaining the anode material. The sodium-ion battery anode material provided by the invention has a univoltage platform, is excellent in charge and discharge property, is free of water and thus is particularly applicable to anodes of solid sodium ion batteries. The preparation method ofthe anode material provided by the invention is simple in process, low in cost and applicable to industrial application.

Owner:济宁中科恩吉科创新产业园管理有限公司

Bend-insensitive radiation-resistant single-mode fiber

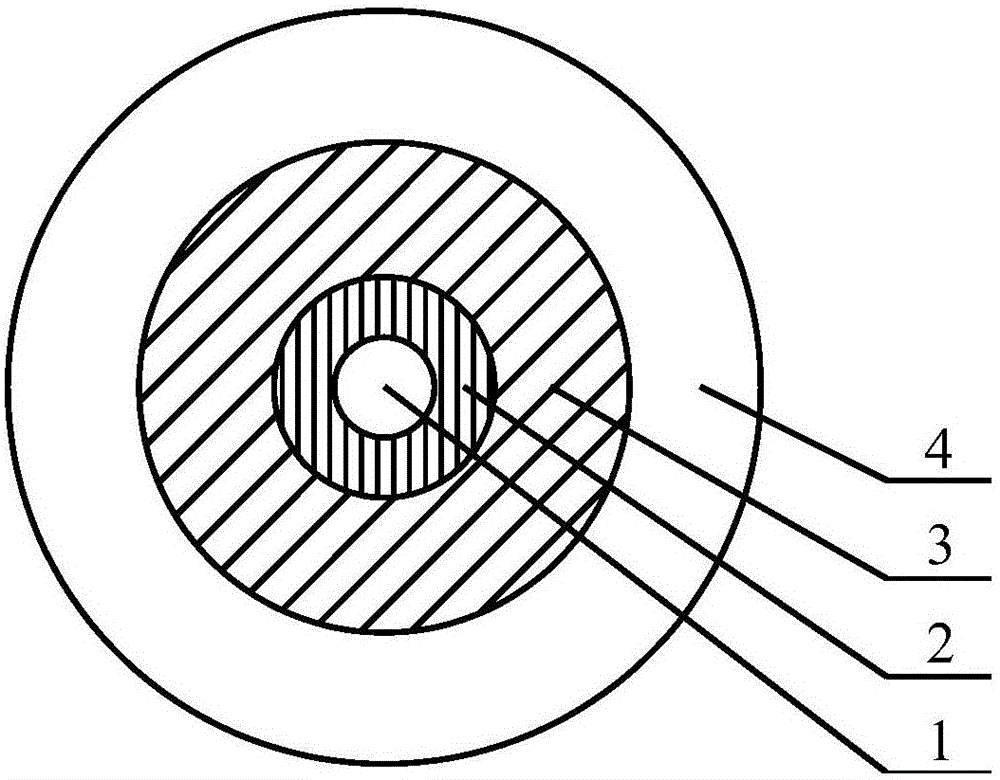

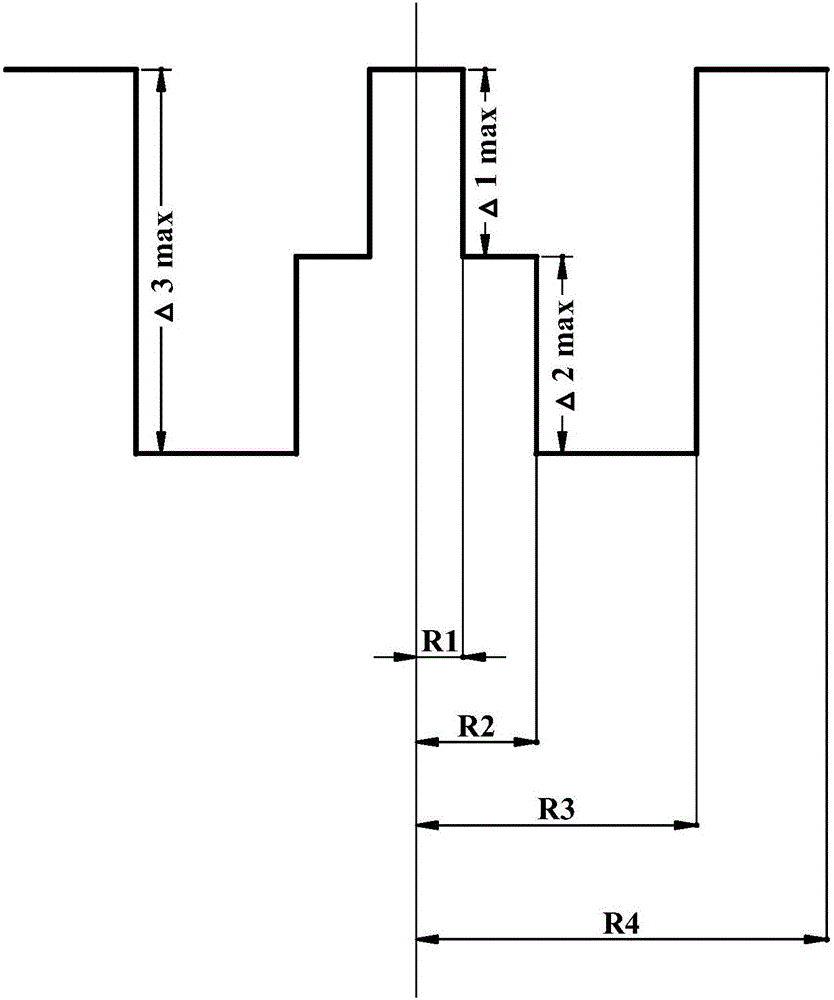

ActiveCN105676349AReduce additional lossStrong bending resistanceGlass optical fibreOptical fibre with multilayer core/claddingRadiation resistantMetal impurities

The invention discloses a bend-insensitive radiation-resistant single-mode fiber and relates to the field of a single-mode fiber. The single-mode fiber comprises a core layer, an inner wrapping layer and an outer wrapping layer, which are arranged in sequence from the inside out. The core layer, the inner wrapping layer and the outer wrapping layer are made of quartz material. The inner wrapping layer comprises a first fluorine-doped inner wrapping layer and a second fluorine-doped inner wrapping layer arranged in sequence from the inside out. The core layer and the first fluorine-doped inner wrapping layer are germanium-undoped, and other metal impurities and phosphorus concentration are lower than 0.1 ppm; in mass percent, the doped fluorine content in the core layer is 0-0.45%, and chlorine content is 0.01%-0.10 %; fluorine content in the first fluorine-doped inner wrapping layer is 1.00%-1.55%; and the fluorine content in the second fluorine-doped inner wrapping layer is 3.03%-5.00%. Compared with an existing radiation-resistant single-mode fiber, additional loss of the single-mode fiber under a bending state is greatly reduced, and bending-resistant performance thereof is better, that is, the single-mode fiber is insensitive to bend; and meanwhile, the radiation-resistant capability of the single-mode fiber is better.

Owner:WUHAN POST & TELECOMM RES INST CO LTD +1

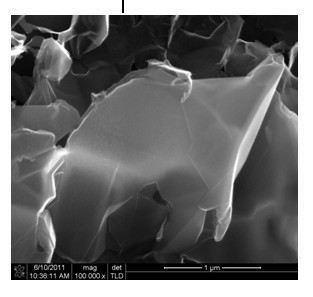

Low-cost carbon graphene sheet and preparation method thereof

The invention discloses a low-cost carbon graphene sheet and a preparation method thereof. The preparation method comprises the following steps of: mixing a carbon material (coal, coke, resin carbon, graphite, bamboo charcoal or active carbon) as a raw material and an additive; then preparing the graphene sheet through processes, namely vacuum carbonization, pickling, ball milling, and the like, at low cost. The graphene sheet prepared through the preparation method disclosed by the invention has the advantages of less structural defect, low preparation cost, easiness for operation, greenness, environmental protection, easiness for industrialization and outstanding economic and social benefits.

Owner:FUZHOU UNIV

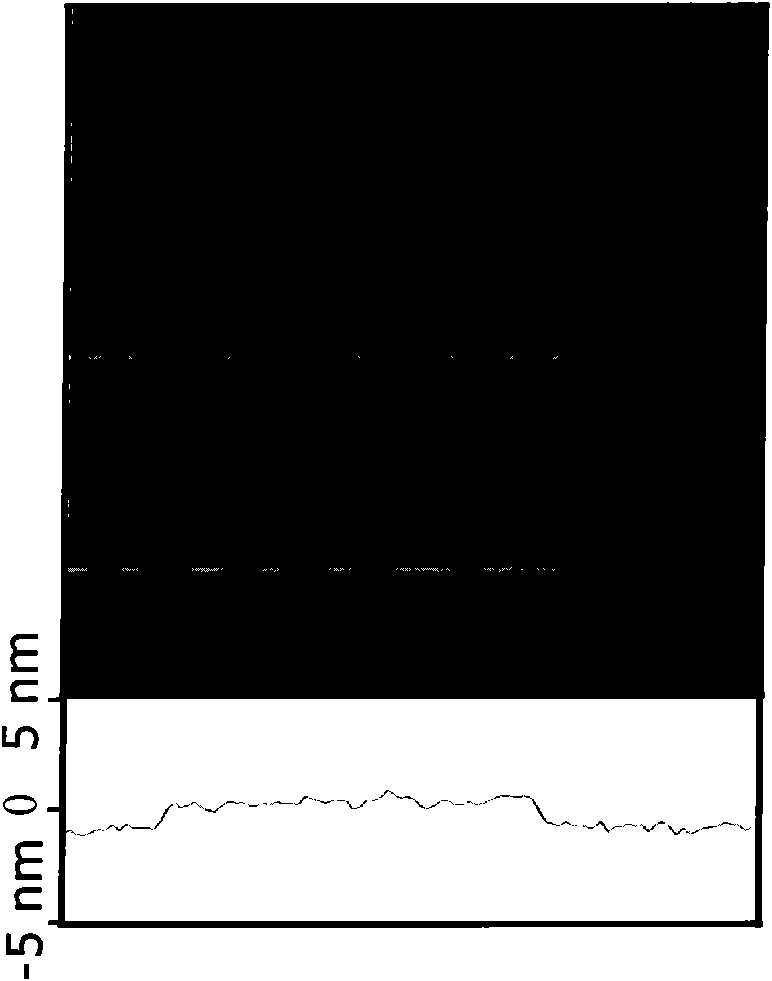

Graphene film and preparation method thereof

The invention relates to a preparation method of a graphene film, which comprises the following steps: (1) dispersing graphene oxide in a solvent to obtain a mixture; (2) pouring the mixture into a knifing machine, carrying out continuous knifing on a substrate at a speed V, and sending the film and substrate into a blast drying tunnel at the speed V to perform drying, thereby obtaining a substrate-bearing graphene oxide film; (3) continuously sending the substrate-bearing graphene oxide film into a pipe furnace at the speed V, and carrying out graphitizing in an inert atmosphere to reduce the graphene oxide and repair the structure defects on the surface, thereby obtaining a substrate-bearing graphene film; and (4) rolling the substrate-bearing graphene film from the pipe furnace, and peeling the substrate to obtain the graphene film. The invention also relates to a graphene film.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method of production of multilayer ceramic electronic device

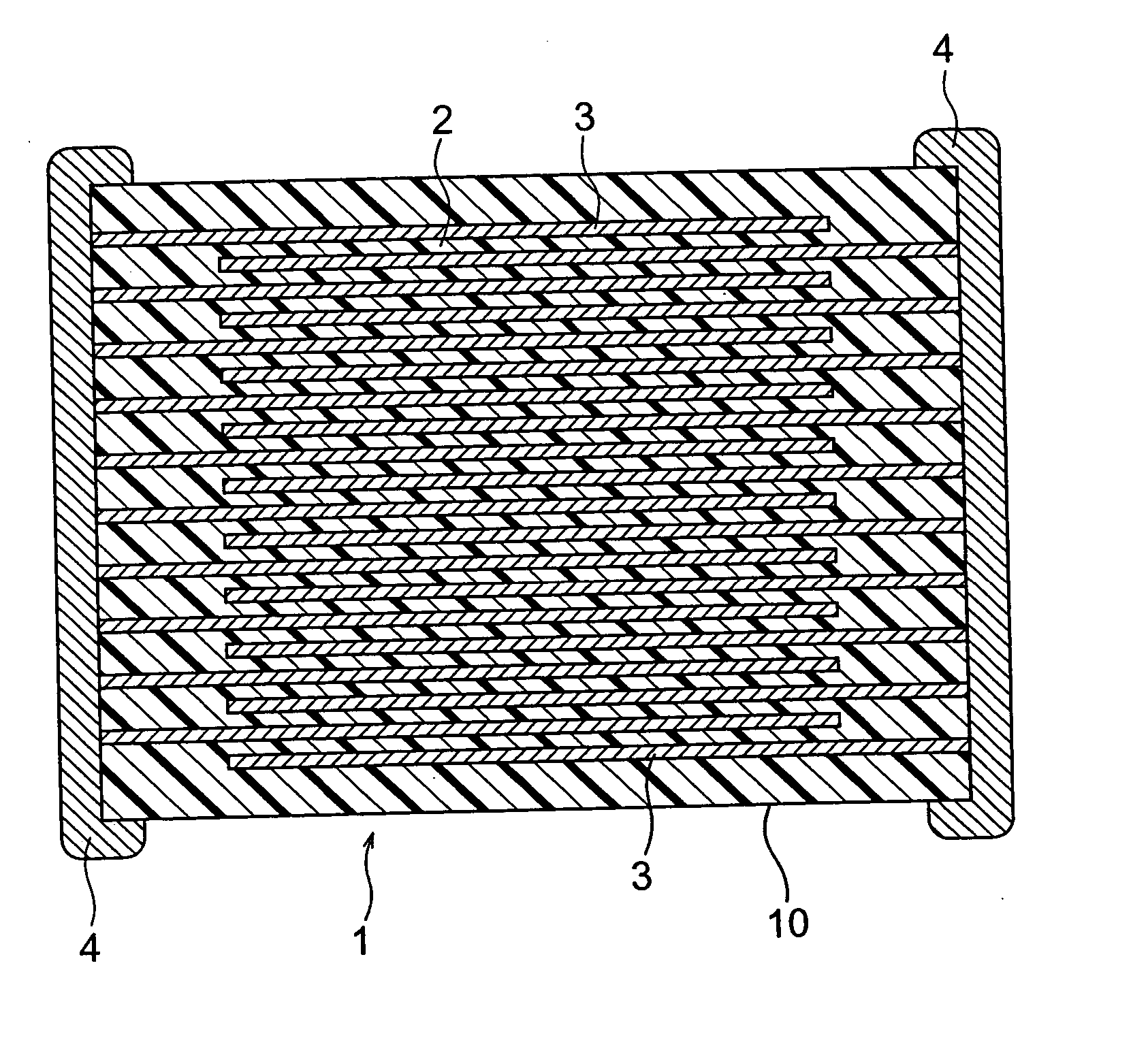

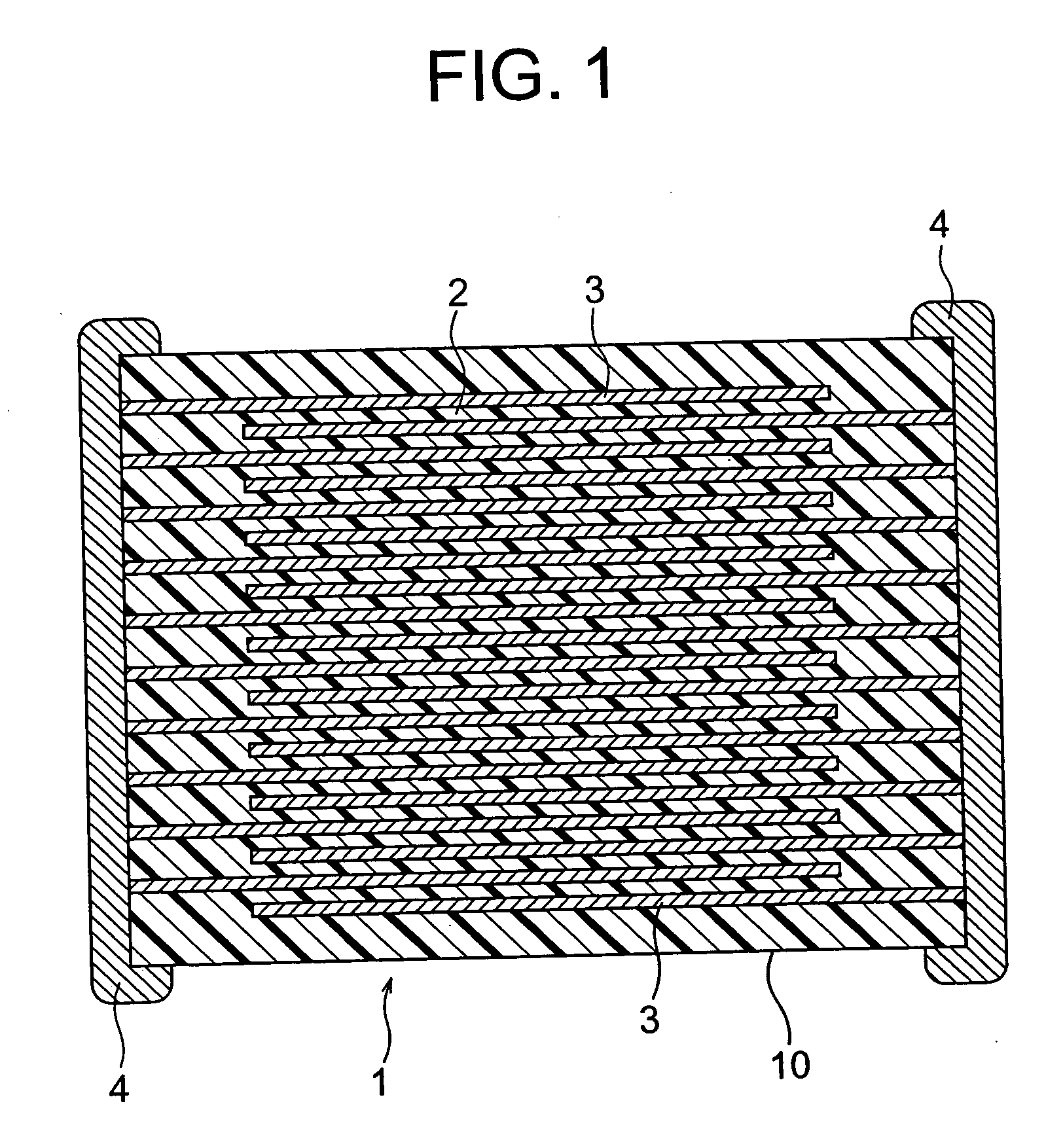

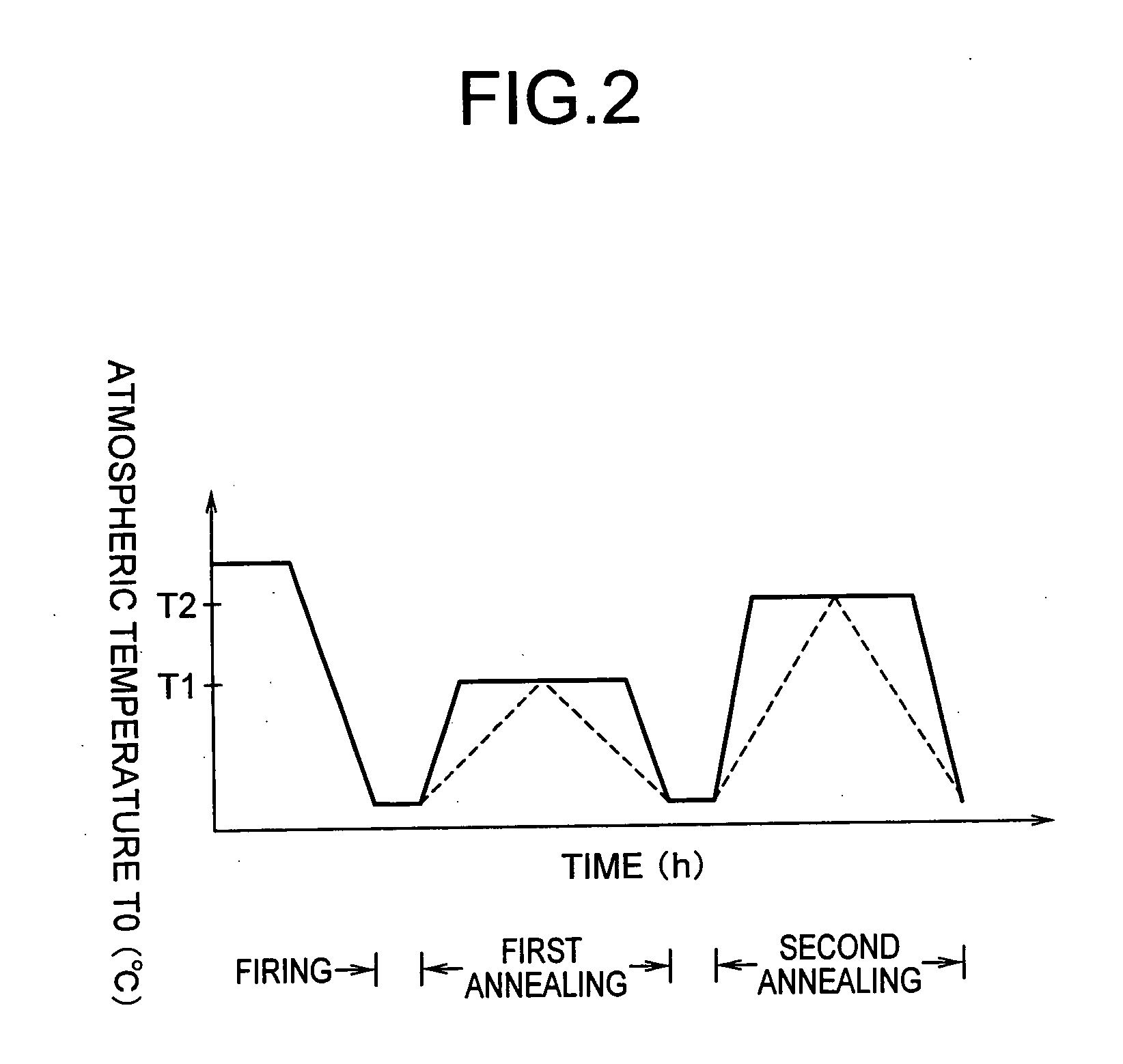

ActiveUS20050095851A1Few structural defectLess structural defectsFixed capacitor dielectricStacked capacitorsBase metalMethods of production

A method of production of a multilayer ceramic capacitor or other multilayer ceramic electronic device with few structural defects and improved highly accelerated life, that is, a method of production of a multilayer ceramic electronic device having a firing step of firing a stack comprised of a dielectric layer paste and an internal electrode layer paste including a base metal alternately arranged in a plurality of layers, a first annealing step of annealing, at a temperature T1 of 600 to 900° C., the stack after firing and a second annealing step of annealing, at a temperature T2 of 900 to 1200° C. (however, excluding 900° C.), the stack after said first annealing.

Owner:TDK CORPARATION

Method for numerously preparing asphalt-based graphene material with low cost

The invention discloses a method for numerously preparing a graphene material, which takes asphalt as a raw material and comprises the processes of preparing, pyrolyzing and carrying out carbonization. Compared with the conventional preparation of the graphene material, the method disclosed by the invention has low preparation cost, little equipment investment, simplicity for operating, no pollution, and easiness for realizing industrialization; and in addition, the purity of a product is high, the structure defect of the product is little, and the performance of the product is excellent.

Owner:FUZHOU UNIV

Method for preparing graphene nanoplatelets special for thermal conductive plastic

The invention provides a method for preparing graphene nanoplatelets special for thermal conductive plastic. Natural flake graphite is taken as the main material, intercalation modification is conducted by means of urea, shear stripping is conducted by means of a twin-screw vibration extruder, a large amount of gas is discharged through quick decomposition of urea under the heating condition to achieve stripping of a large number of graphitic layers, and flake graphite is stripped layer by layer into the graphene nanoplatelets through temperature control in different stages, so that the structure defect of the graphene nanoplatelets is reduced and the heat conducting property of graphene is improved; then the graphene nanoplatelets are coated by means of organic microcapsules, so that the electrical conductivity of graphene is reduced, compatibility between the graphene nanoplatelets and thermal conductive plastic macromolecules is improved, the utilization rate of graphene is increased, and the application cost of graphene in thermal conductive plastic is reduced. The graphene nanoplatelets prepared with the mechanical stripping method are small in structure defect and high in heat conducting property, the whole process is safe and reliable, cost is low, environment friendliness is realized, and the market application value is remarkable.

Owner:内蒙古石墨烯材料研究院

Preparation method of doped graphene and application of doped graphene

InactiveCN102486993AHas semi-metallic propertiesControl electrical propertiesSemiconductor/solid-state device manufacturingDoped grapheneCvd graphene

The invention provides a preparation method of doped graphene and a product prepared by using the method. The method comprises the following steps of: (1) processing graphene so that the graphene has defects; and (2) annealing the graphene processed in the step (1) in an atmosphere containing a doped element. The method provided by the invention can be used for controlling the electric property of graphene, is simple and reliable and is suitable for mass production. The invention also provides the application of the doped graphene prepared by using the method.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

Lead-free high-dielectric-constant microwave dielectric ceramic material and preparation method thereof

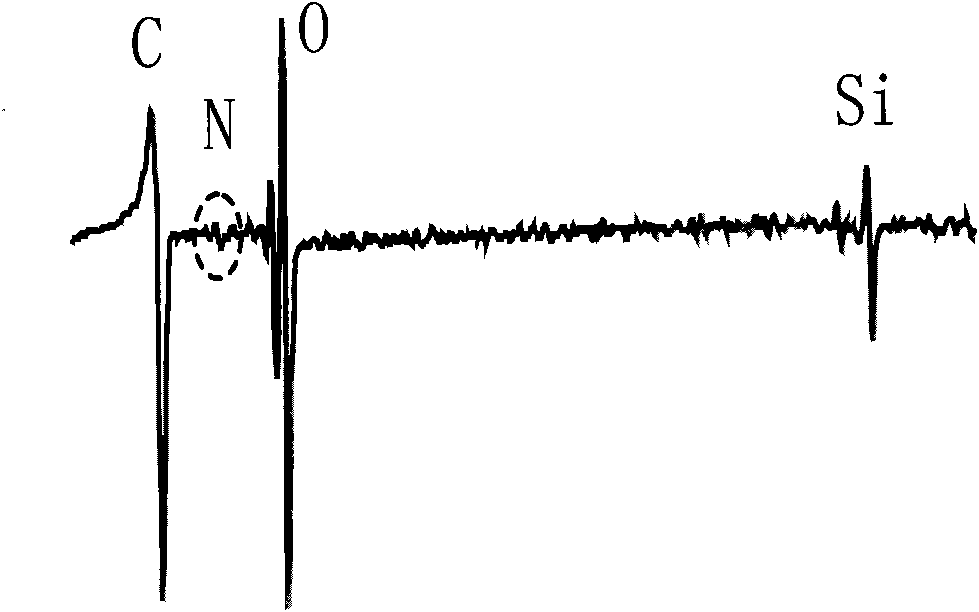

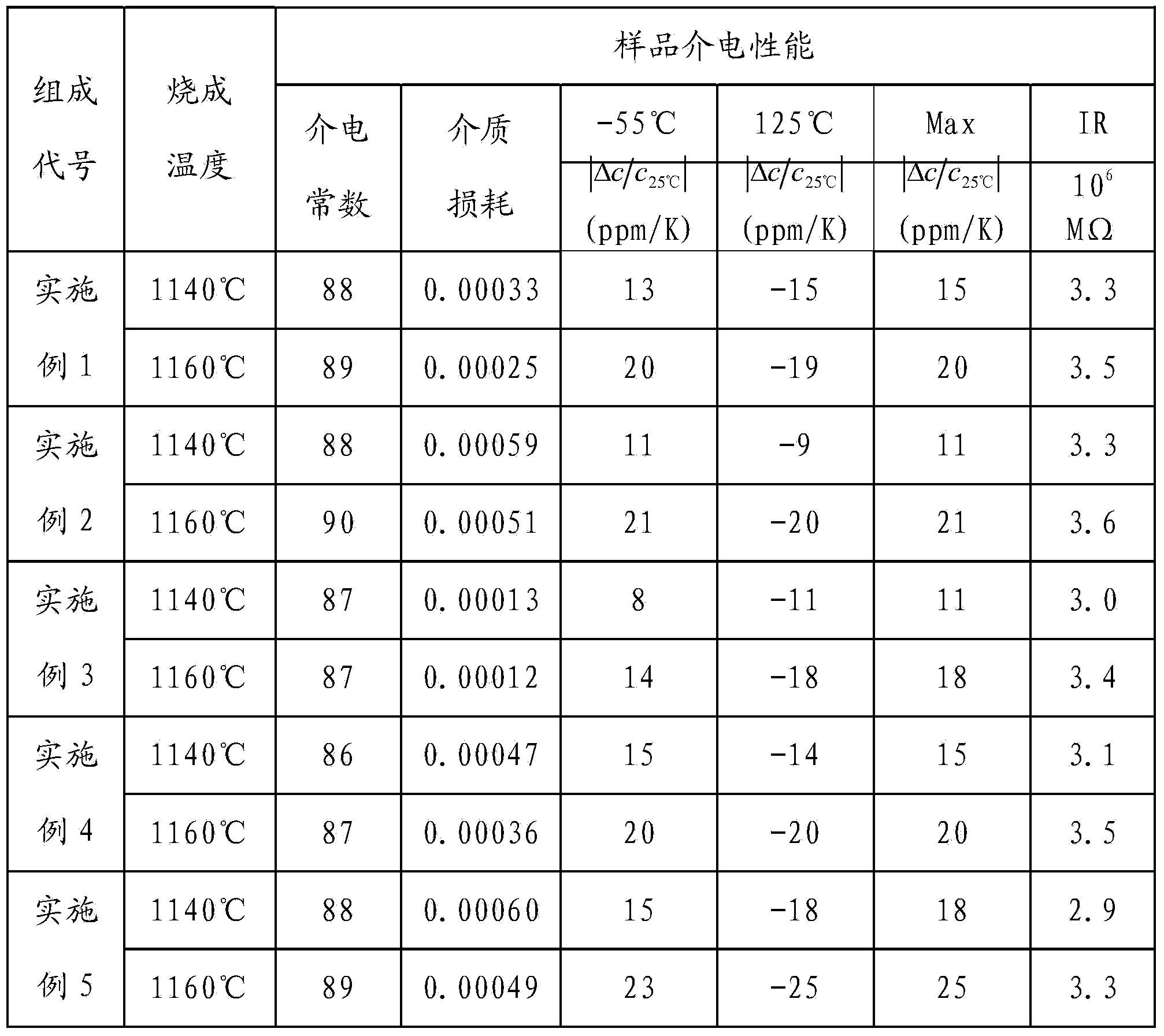

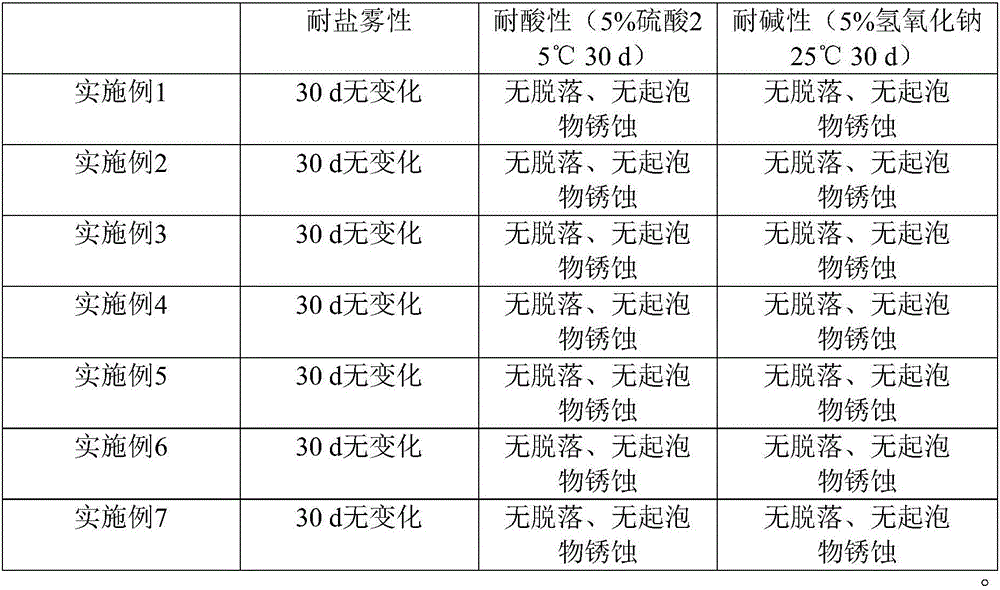

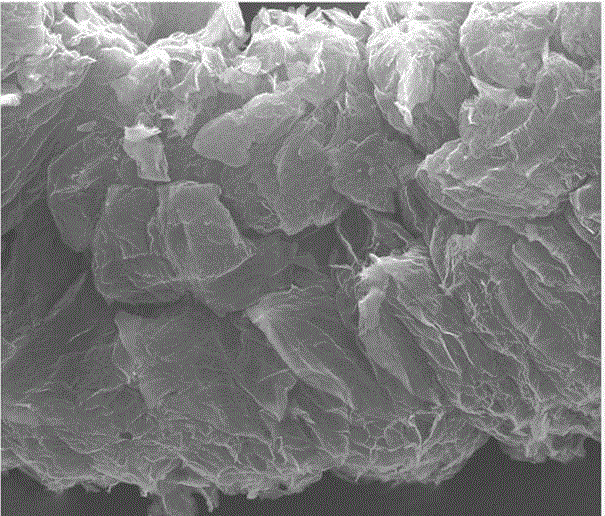

ActiveCN104058740AReduce material structural defectsReduce the number of free electronsAir atmosphereTitanium

The invention provides a lead-free high-dielectric-constant microwave dielectric ceramic material and a preparation method of the lead-free high-dielectric-constant microwave dielectric ceramic material. The lead-free high-dielectric-constant microwave dielectric ceramic material mainly comprises an xBaO yNd2O3 zTiO2 compound, a bismuth titanium compound, MTiO3, a silicon zinc compound and NB2O4. The preparation method of the material includes the steps that xBaO yNd2O3 zTiO2 is used as a main base material, the bismuth titanium compound, the MTiO3, the silicon zinc compound and the NB2O4 are used as auxiliary materials, water is used as a dispersion medium, ball-milling, drying, crushing and pelleting are conducted, pelletized powder is pressed into wafer green bodies, the wafer green bodies are heated to the temperature from1100 DEG C to 1200 DEG C in an air atmosphere and sintered for 2 h to 4 h at the temperature, and then the lead-free high-dielectric-constant microwave dielectric ceramic material is prepared. The prepared ceramic material can be used for manufacturing a monolithic ceramic capacitor with high frequency and good thermal stability, is environmentally friendly and has great market value.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

Anticorrosive coating material with physically stripped graphene and method for preparing anticorrosive coating material

ActiveCN105969025AImproves Structural IntegrityLess structural defectsAnti-corrosive paintsPolyether coatingsSolventDefoaming Agents

The invention belongs to the field of anticorrosive coating, and particularly relates to an anticorrosive coating material with physically stripped graphene and a method for preparing the anticorrosive coating material. An anticorrosive component in the anticorrosive coating material is physically stripped graphene powder. The anticorrosive coating material comprises, by weight, 3-12 parts of the physically stripped graphene powder, 21-54 parts of matrix resin, 0.6-1.8 parts of leveling agents, 0.6-1.8 parts of defoaming agents, 0.6-1.8 parts of dispersing agents, 0.6-1.8 parts of coupling agents and 40-70 parts of solvents. The anticorrosive coating material and the method have the advantages that the physically stripped graphene is added into the anticorrosive coating material in procedures for preparing the anticorrosive coating material, accordingly, permeation of moisture and other corrosive molecules can be effectively obstructed, and physical anticorrosive effects can be realized; the physically stripped graphene is excellent in electric conductivity, accordingly, anodic reaction and corrosion of metal base materials can be effectively prevented, and electrochemical anticorrosive effects can be realized.

Owner:上海多希石墨烯材料科技有限公司

Method for preparing graphene sheet

ActiveCN102942177AQuality improvementQuick and effective sheddingGrapheneMicro nanoThermal dilatation

The invention discloses a method for preparing a graphene sheet. The graphene sheet is prepared through the following steps: (1) expansible graphite is subjected to thermal expansion treatment so as to form wormlike graphite, the wormlike graphite is then soaked in alkaline solution, is subjected to suction filtration, is washed and then is put in the solvent to be subjected to ultrasonic dispersion, so that a micro-nano graphene sheet is obtained; (2) the micro-nano graphene sheet which is obtained in the step (1) is dispersed in inorganic strong protonic acid to be soaked, is subjected to suction filtration, is then transferred into H2O2 solution to be soaked and is subjected to suction filtrating, washing and drying; (3) the micro-nano graphene sheet which is treated through the step (2) is transferred into the solvent to be dispersed, is enabled to stand at constant temperature, and is then subjected to suction filtrating or drying to be secondarily expanded; and (4) the micro-nano graphene sheet which is treated in the step (3) is transferred into the solvent to be subjected to ultrasonic dispersion, is filtered, dried and transferred to a furnace in a reduction protective atmosphere and is subjected to high temperature deoxygenation reduction, so the graphene sheet is obtained. The method can be used for preparing the high quality pure graphene sheet in batches and is easy to popularize and apply.

Owner:浙江东盛慧谷投资发展有限公司

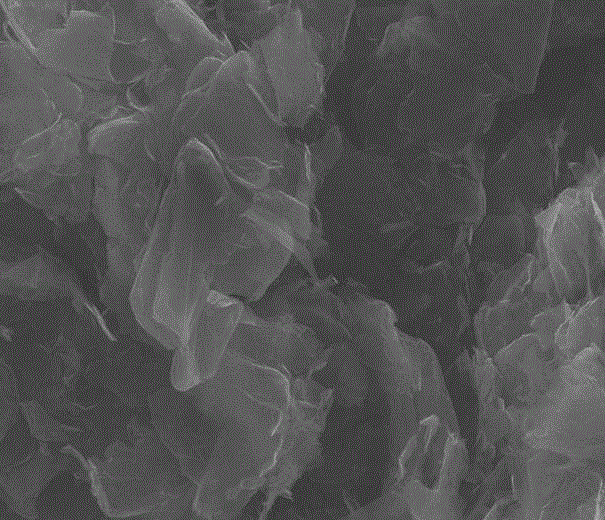

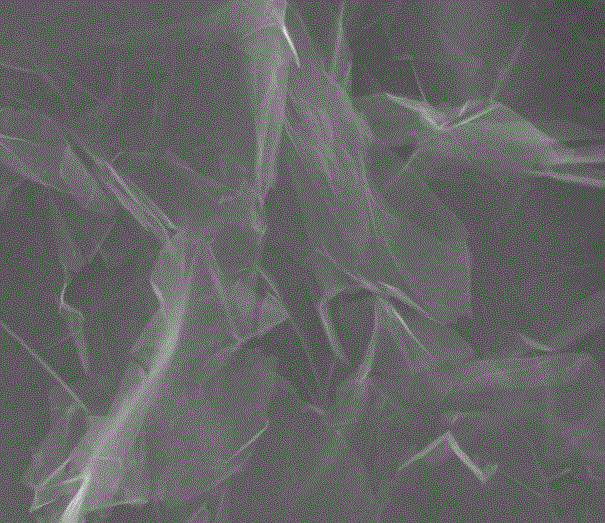

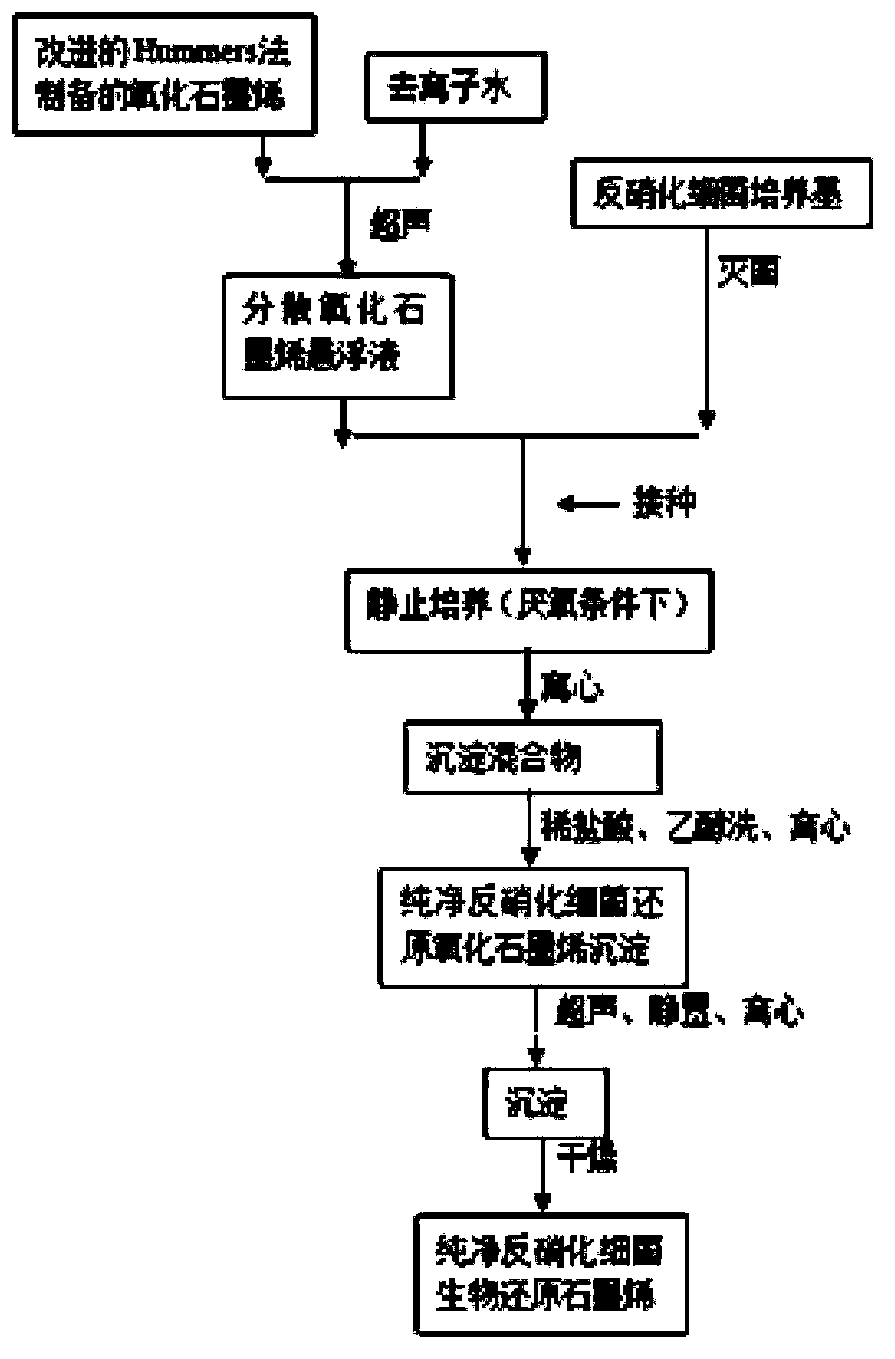

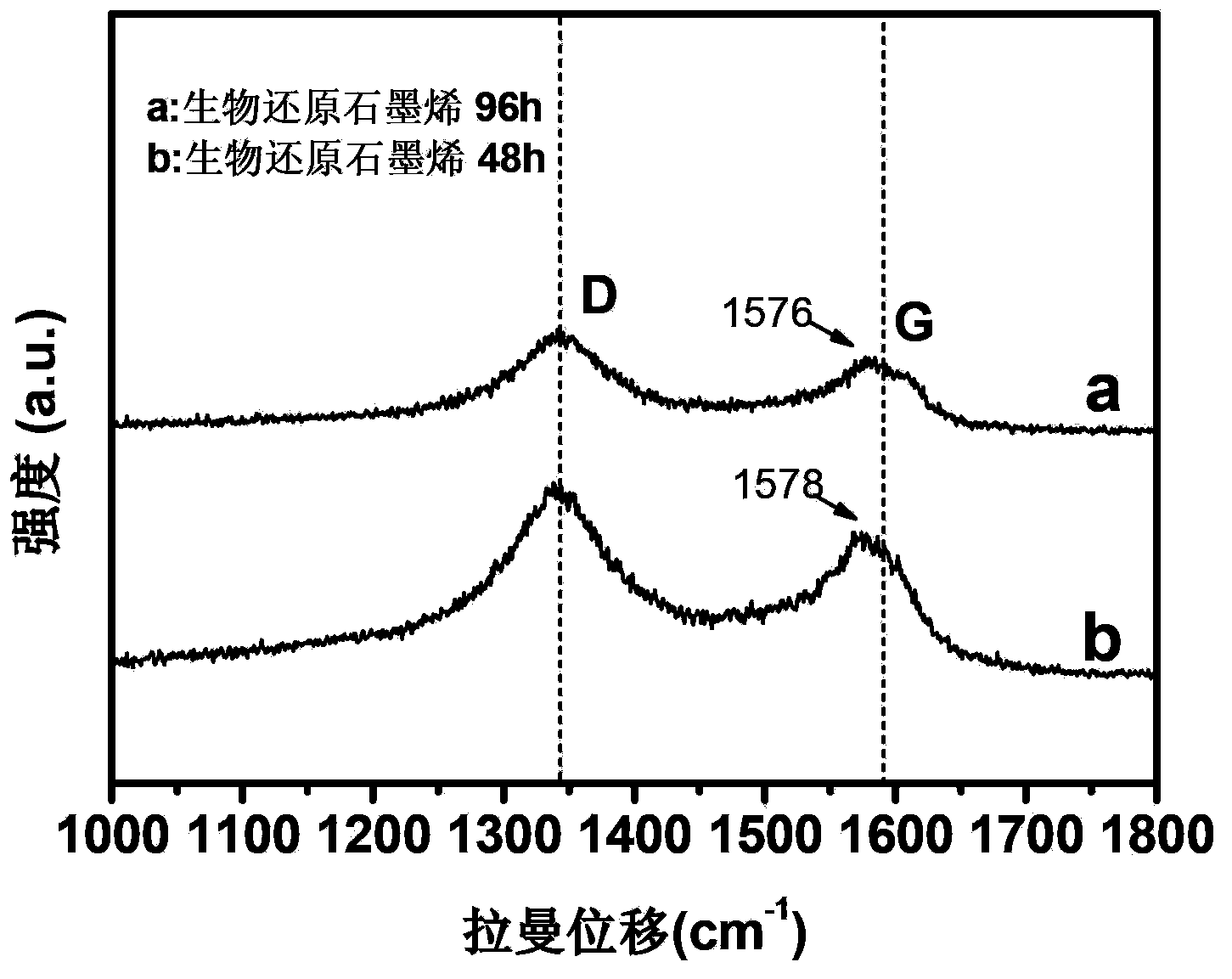

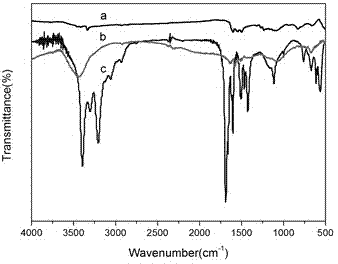

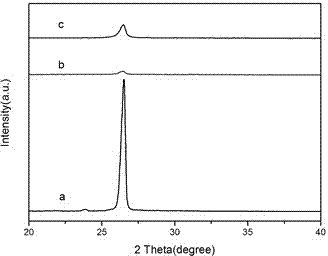

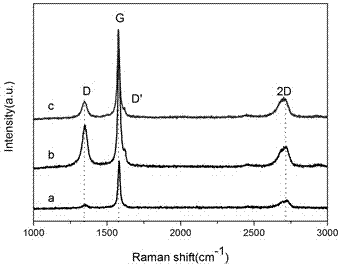

Microbial reduction of graphene oxide and preparation method for graphene

The invention discloses a microbial reduction of graphene oxide and a preparation method for graphene. The method comprises the following steps: dispersing graphene oxide in water to form a graphene oxide suspending solution with better dispersion; mixing denitrifying bacteria culture medium being subjected to sterilization and cooling with the graphene oxide suspending solution; inoculating a seed solution; culturing in still standing state in anaerobic condition for a few days, removing the oxygen-containing functional group of the dispersed graphene oxide with the effect of denitrifying bacteria to form graphene; after finishing the culturing, using hydrochloric acid, alcohol, and deionized water to remove bacterial cells, metabolite, and other ions produced in the reduction process, using water to cleaning until the water is neutral finally, and drying to obtain pure graphene. The method using microorganism denitrifying bacteria capable of reducing high valence state inorganic nitrogen and carbon as the microbial strain to conduct microbial reduction on graphene oxide; compared with similar reducing bacteria of Shewanella, the denitrifying bacteria has the advantages that the environmental safety is good, the reaction condition is mild and controllable, the medium component is simple, and the graphene obtained by preparation has less defects and layers.

Owner:NANJING UNIV OF SCI & TECH

Method for preparing few-layer graphene by using auxiliary reagent

The invention discloses a method for preparing few-layer graphene by using an auxiliary reagent. The method specifically comprises the following steps: (a) adding graphite and the auxiliary reagent into a ball-milling tank for ball-milling; (b) adding a dispersing solvent into the mixture, and performing suction filtration on the obtained upper-layer dispersion liquid; (c) adding the dispersing solvent into the filtrate, stirring, leaving the mixture to stand, and centrifuging the upper-layer dispersion liquid twice; (d) performing suction filtration to the upper-layer suspension, and drying so as to obtain a dried product, that is, the few-layer graphene. The few-layer graphene obtained by using the method disclosed by the invention is complete in plane structure, small in structural defects and relatively high in conductivity, heat conduction and mechanical property, and meanwhile the reagents used in the method are all ordinary chemical reagents, so that the method is simple to operate and easy to popularize and use.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

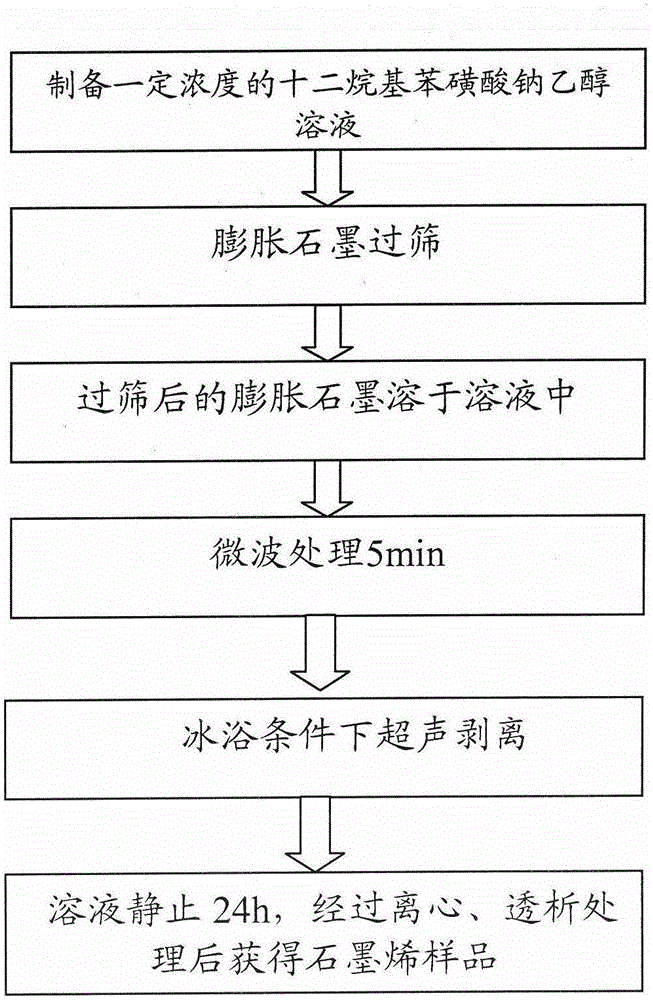

Method adopting a liquid phase stripping method to prepare grapheme and grapheme

InactiveCN105110326ALess structural defectsImprove conductivityStructure analysisSODIUM DODECYL BENZENE SULFONATE

The invention provides a method adopting a liquid phase stripping method to prepare grapheme, which comprises steps: 1 sodium dodecyl benzene sulfonic acid ethanol solution in a certain concentration is prepared; 2 expanded graphite is screened; 3 the expanded graphite after being screened are dissolved into the sodium dodecyl benzene sulfonic acid ethanol solution which is prepared in the step 1 by being stirred through magnetic force; 4 the expanded graphite which is prepared in the step 3 is treated for 5mins through microwaves; 5 the sodium dodecyl benzene sulfonic acid ethanol solution which is treated through the microwaves is peeled through ultrasound in ice bath conditions; and 6 the sodium dodecyl benzene sulfonic acid ethanol solution which is treated through the ultrasound is statically placed for 24h, thereby obtaining graphene samples after centrifugal and dialysis treatment. The grapheme is extremely thin in layers through pattern analysis and structural analysis, smaller than 10 in layer number, small in structural defect and excellent in conductivity.

Owner:朱振业

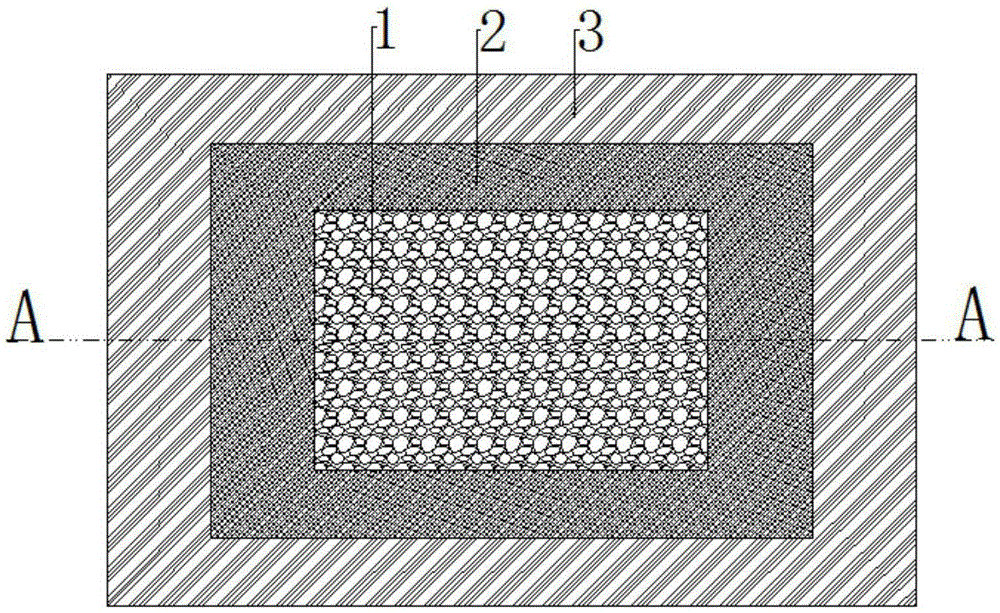

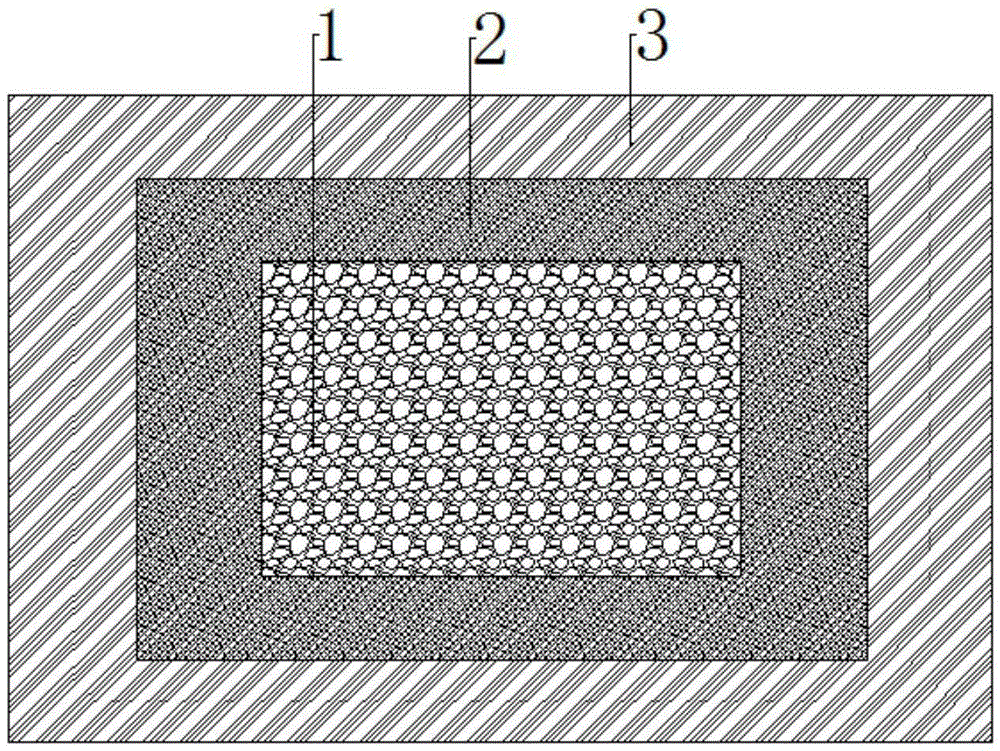

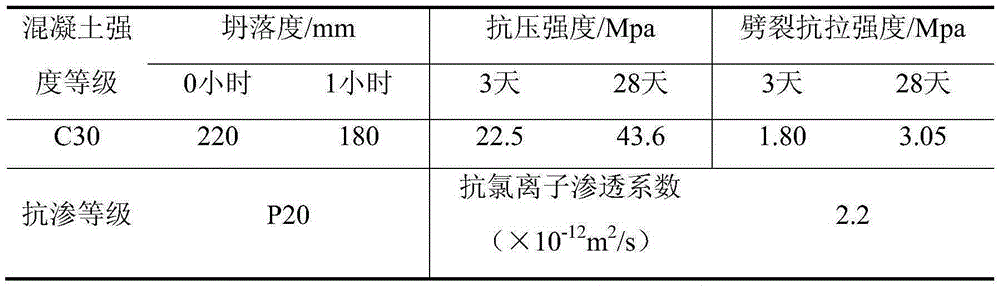

Temperature gradient controlled mass concrete for bridges

ActiveCN105418006AImprove densification performanceLimit crackingBridge engineeringMaterials science

The invention discloses a temperature gradient controlled mass concrete for bridges. The mass concrete comprises an inner layer of low-temperature rise anti-crack concrete I, a middle layer of low-temperature rise anti-crack concrete II and an outer layer of high-tenacity high-crack resistance concrete from the inside to the outside. According to the mass concrete disclosed by the invention, under combination of the low-temperature rise anti-crack concrete (the inner layer of low-temperature rise anti-crack concrete I and the middle layer of low-temperature rise anti-crack concrete II) and the high-tenacity high-crack resistance concrete structure, hydration heat of cementing materials on various layers is respectively absorbed through the characteristics of a high phase-transition temperature of a composite temperature control material in the inner layer of low-temperature rise anti-crack concrete and a low phase-transition temperature of a composite temperature control material in the middle layer of low-temperature rise anti-crack concrete; the inside and the middle temperatures of the concrete are lowered; meanwhile, different thicknesses and layout forms of two concrete materials are optimized and designed; reduction of the temperature difference between the layers is achieved; the overall temperature stress level is reduced; the technical problem of crack of the mass concrete widely existing in bridge engineering can be effectively solved; and the temperature gradient controlled mass concrete for the bridges is applicable to popularization and application.

Owner:HUBEI UNIV +1

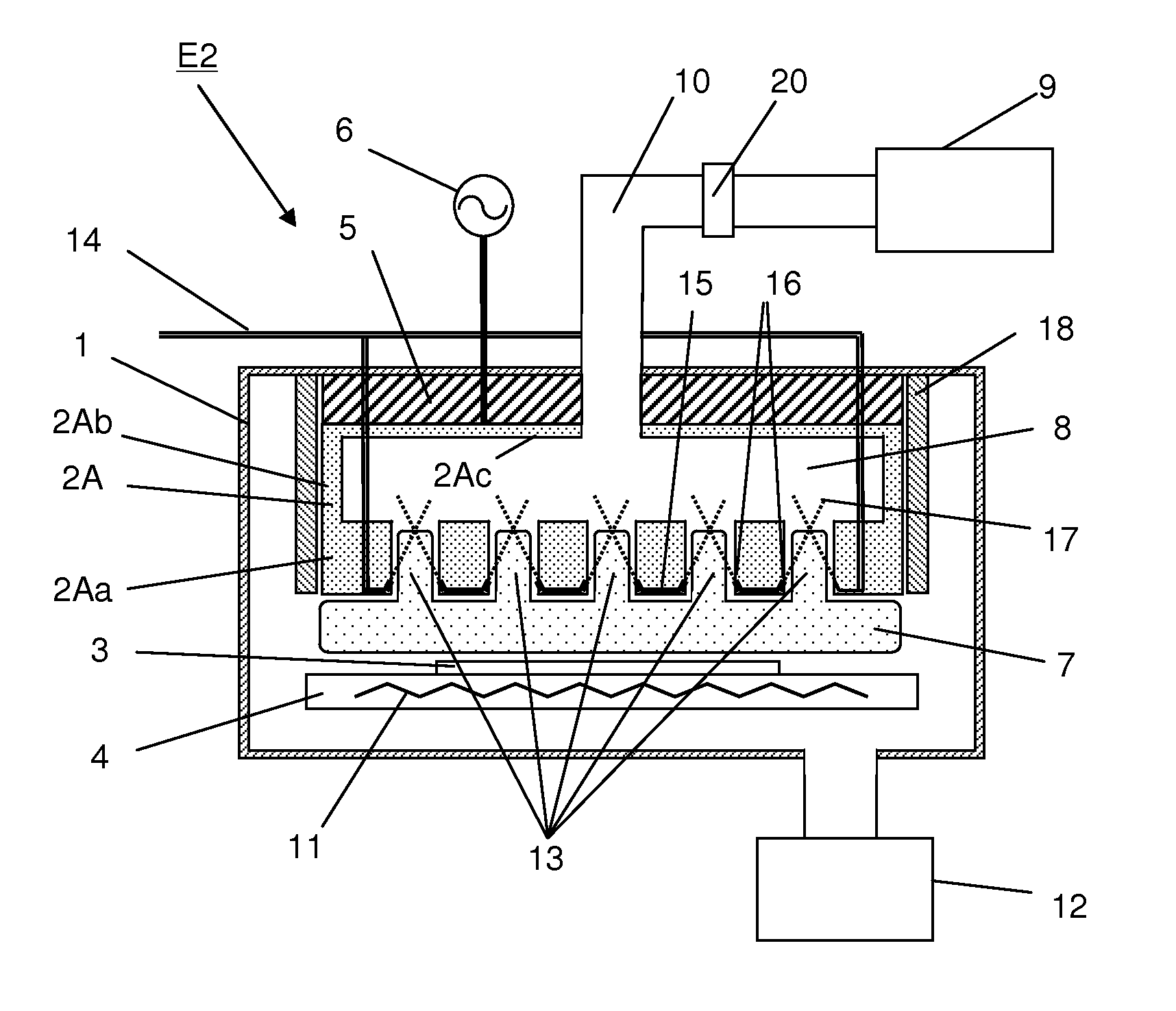

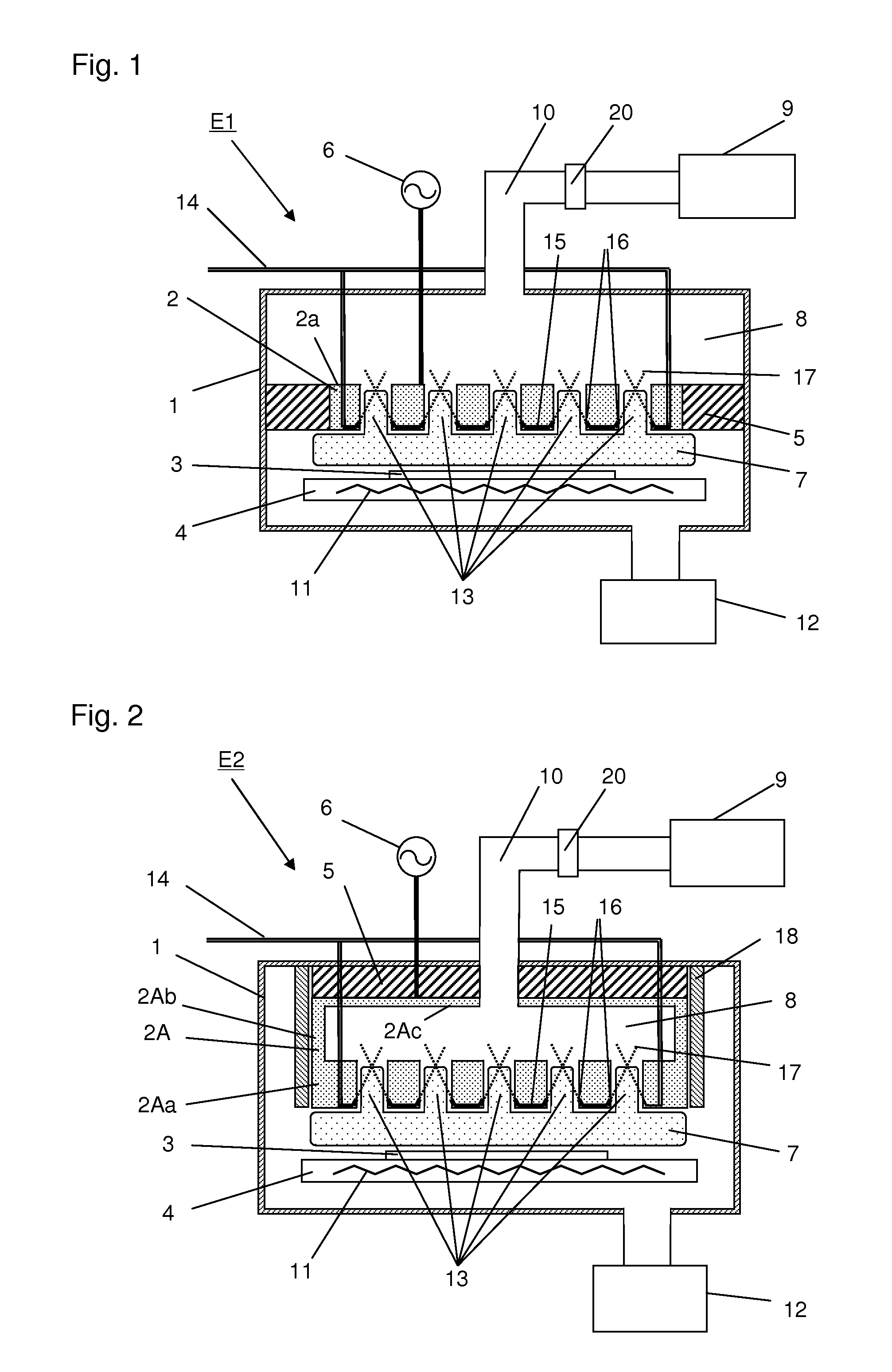

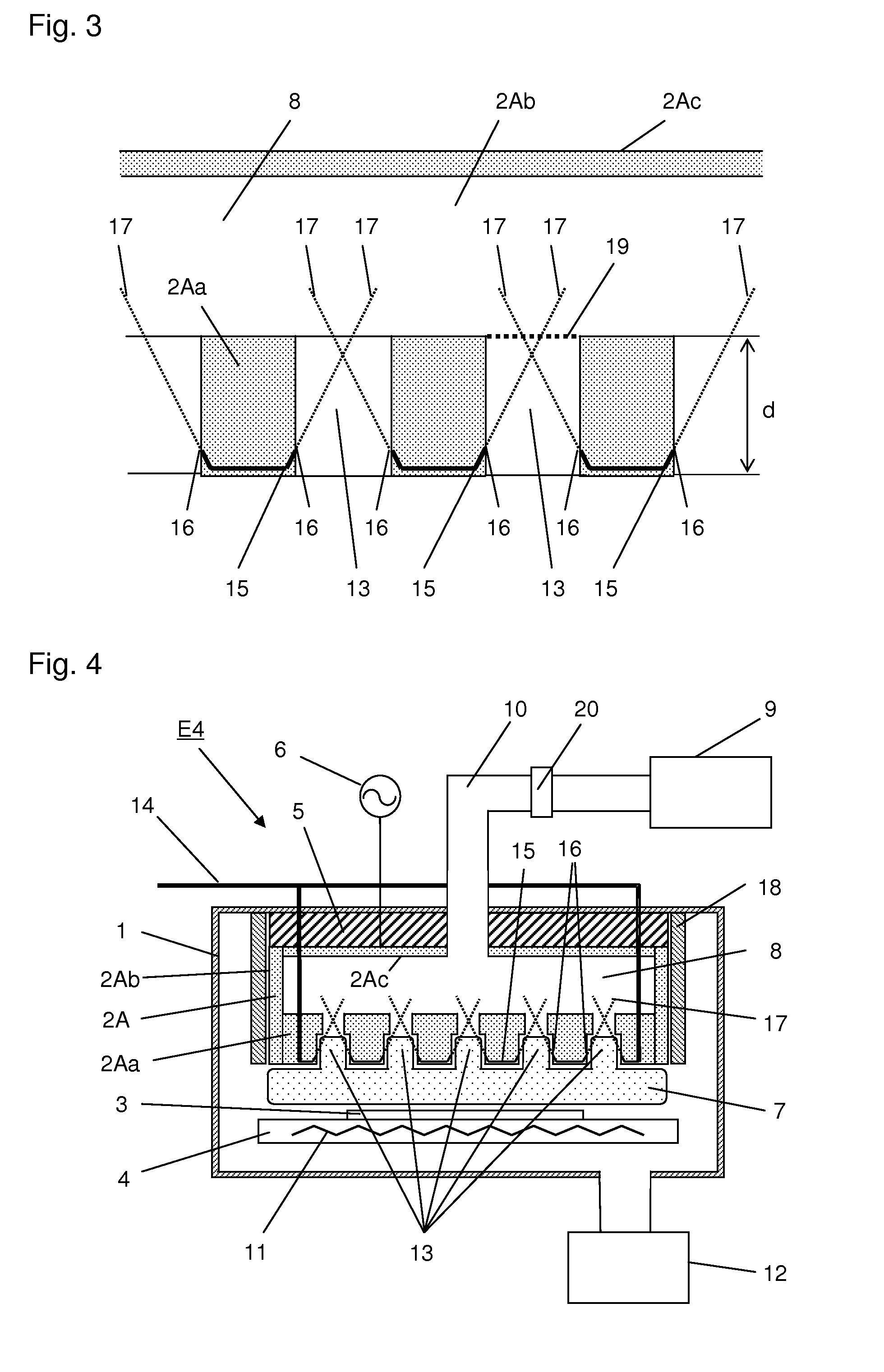

Plasma processing apparatus and method of producing amorphous silicon thin film using same

InactiveUS20120115314A1Efficient removalFew defectElectric discharge tubesFinal product manufactureAmorphous siliconEngineering

Disclosed is a plasma processing apparatus, wherein a plasma-generating electrode has a plurality of gas exhaust holes which run through the plasma-generating electrode from the surface facing a substrate held by a substrate-holding mechanism, and reach a gas exhaust chamber; gas-feeding pipes, provided connected to a gas-introducing pipe, have gas-feeding ports for discharging source gas toward the inside of the plurality of gas exhaust holes; and the gas-feeding pipes and the gas-feeding ports are arranged in a manner such that extended lines, representing the direction of the flow of the source gas discharged from the gas-feeding ports, intersect the end surface open regions at the interface of the gas exhaust chamber to the gas exhaust holes. Also disclosed is a method of producing the amorphous silicon thin film using the plasma processing apparatus.

Owner:TORAY IND INC

Preparation of cellulose carbamate and low-temperature dissolution spinning method of cellulose carbamate

InactiveCN104072622ALess structural defectsImprove mechanical propertiesArtificial filaments from cellulose solutionsCelluloseFiber

The invention discloses preparation of cellulose carbamate and a low-temperature dissolution spinning method of the cellulose carbamate. The method comprises the following steps: adding cellulose into a sodium hydroxide solution, stirring uniformly, immersing, taking out the cellulose, washing with water to a neutral state to obtain alkalified cellulose, adding urea, stirring uniformly, putting in a drying oven, heating, reacting and drying to obtain the cellulose carbamate; pulverizing the cellulose carbamate into powder, adding the powder into a mixing kettle, adding double solvents of sodium hydroxide, thiocarbamide and deionized water, and stirring uniformly; and carrying out extrusion, deaeration and filtration on the raw material in the mixing kettle, spraying by spinneret orifices of a spinneret, sequentially sending into a first coagulation bath and a second coagulation bath to obtain a solid, washing with water in a water tank, and carrying out stretching and winding by a spinning component to obtain the cellulose carbamate fiber. The method is suitable for preparing the cellulose carbamate by an industrialized large-scale production process route, and has important meanings for implementing low-temperature dissolution spinning engineering and industrialized production of cellulose.

Owner:DONGHUA UNIV

Improved method for preparing layered enriched lithium-manganese-nickel oxide by low-heat solid-phase reaction

ActiveCN102219262APromote growthSimple processCell electrodesManganese oxides/hydroxidesMANGANESE ACETATEOXALIC ACID DIHYDRATE

The invention provides an improved method for preparing layered enriched lithium-manganese-nickel oxide by low-heat solid-phase reaction. The method comprises the following steps: weighing lithium hydroxide monohydrate, nickel acetate and manganese acetate, and oxalic acid dihydrate according to the stoichiometry as follows: Li1+xMnyNi1-x-yO2, x being more than 0 and less than or equal to 1 / 3, y being more than 0 and less than 1, and x+y being more than 0 and less than 1 (wherein the mole ratio of LiOH.H2O to C2H2O4.2H2O is 1:1-1.2), and adding into a ball milling tank together for balling milling for 0.5-2h; obtaining slurry, adding deionized water in the slurry to adjust concentration, spraying and drying the slurry, and roasting the dried powder to obtain the final product -Li1+xMnyNil-x-yO2. The improved method has the following advantages: the process flow is short, the component of the material can be accurately controlled, the problems of material loss and inaccurate stoichiometry caused by repeatedly washing the product in a liquid phase method are overcome, the generation of a large quantity of waste water is avoided; simultaneously, the shape and particle size of a synthesized material can be controlled, the engineering index requirement can be achieved, the impurity pollution caused by dependence of a synthetic material by a solid phase method on crushing process can be overcome, the enriched lithium-manganese-nickel oxide has typical layered structure property, the particle size is 3-12mum, the specific capacity is high, and the cyclic performance is stable.

Owner:湖南金富力新能源股份有限公司

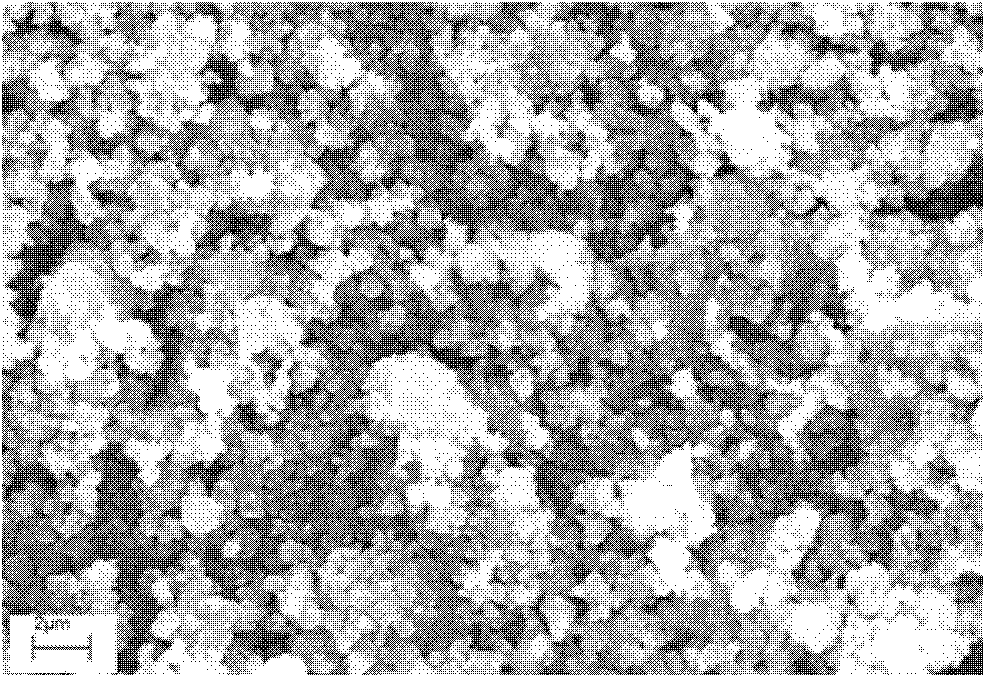

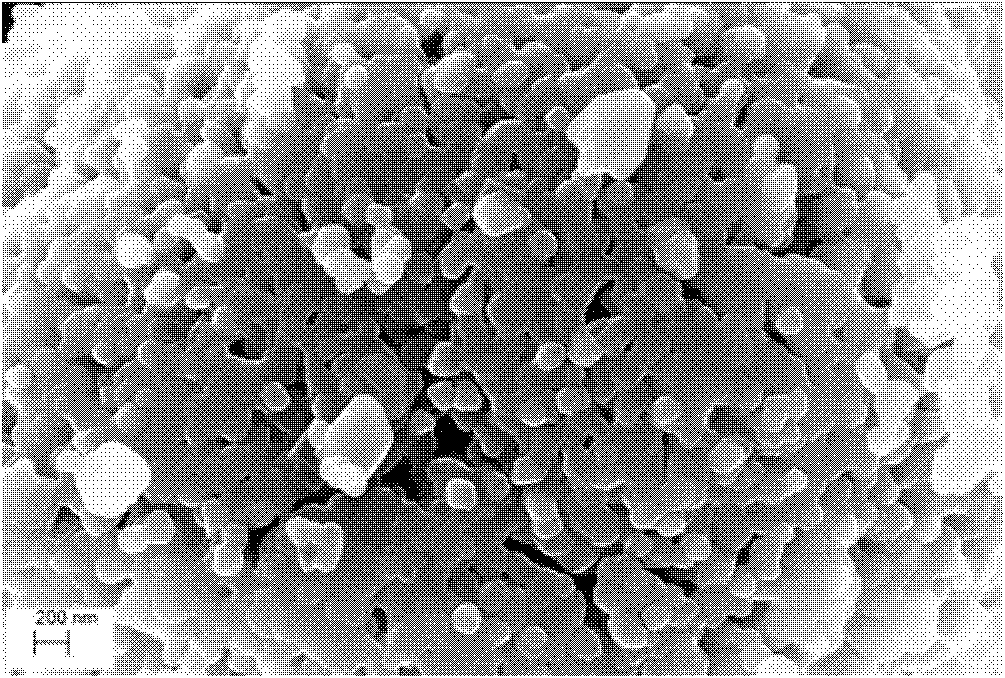

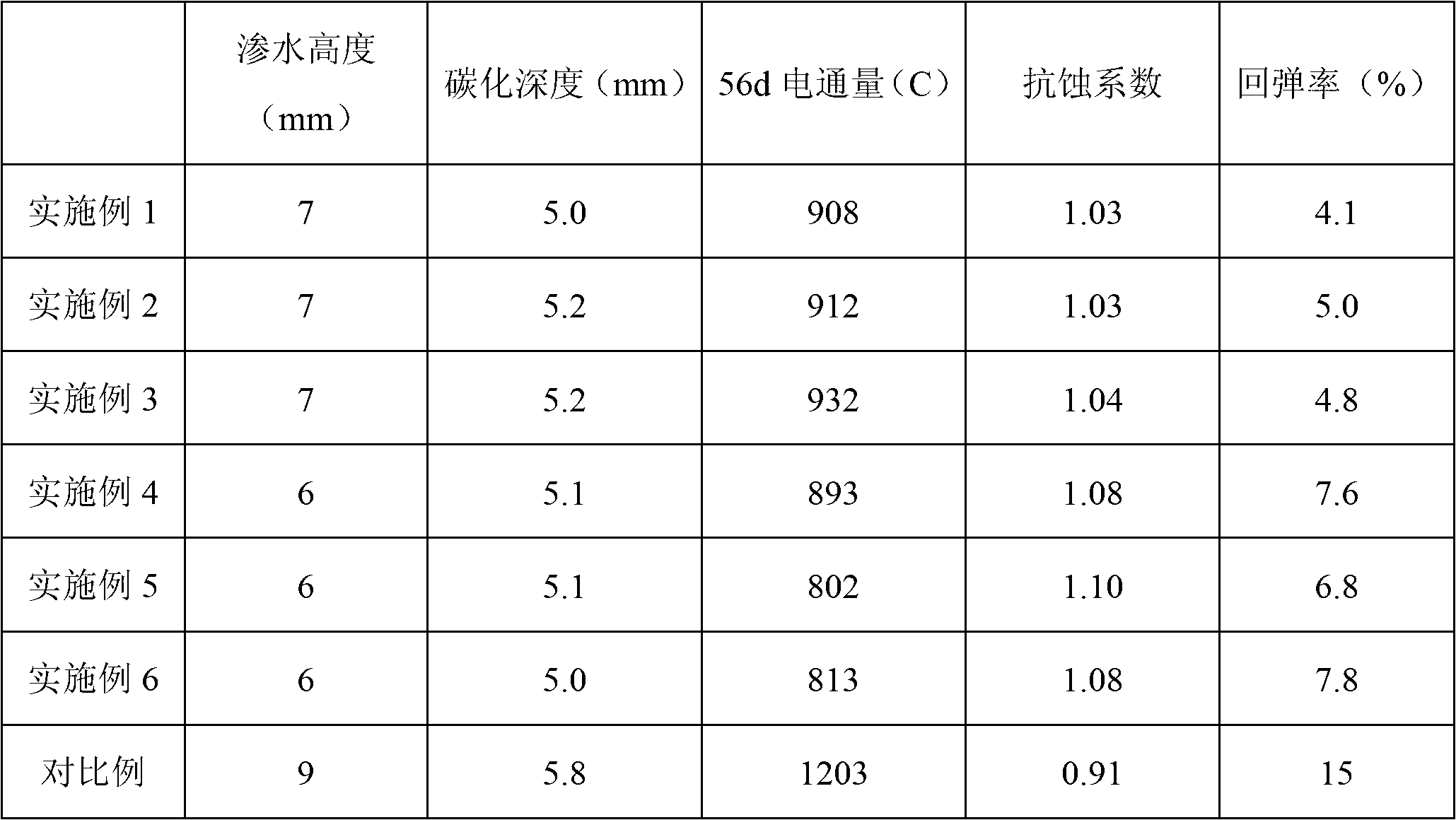

High-performance concrete gel material for tunnel and application thereof

The invention discloses a concrete gel material which comprises cement and silica solution. The invention further discloses a high-performance concrete for tunnel prepared through the concrete gel material provided by the invention. The high-performance concrete is suitable to be applied to injecting concrete, moulding concrete and others. Through the adoption of the concrete gel material or the high-performance concrete for the tunnel provided by the invention for injecting the concrete, the rebound ratio can be effectively reduced and even reduced to 4.1% to the minimum; and the concrete gel material or the high-performance concrete is good in working performance; the obtained concrete finished product is high in early strength, and good in freezing resistance; the waterproof performance and the wearable performance are improved; the quantity of used cement can be reduced; the carbon emission can be reduced; and good economic benefit and environment-friendly benefit are brought.

Owner:中铁西南科学研究院有限公司

ZSM-5 molecular sieve and preparation method thereof

InactiveCN104229826AHigh crystallinityParticle size control means simplifiedPentasil aluminosilicate zeolitePotassiumPetrochemical

The invention relates to a ZSM-5 molecular sieve and a preparation method thereof. The preparation method comprises the following steps: according to the amounts of SiO2 of a silicon source, Al2O3 of an aluminum source, the TPA<+> of a template agent and the K<+> of a potassium source, uniformly mixing the silicon source, the aluminum source, the template agent, the potassium source and water in a mole ratio of 1: (0-0.075):(0.02-1):(0-5):(5-100), crystallizing for 8-180 hours at 120-200 DEG C, washing a solid product which is obtained through crystallization till the filtrate is neutral, drying and calcining, thereby obtaining the ZSM-5 molecular sieve, wherein the template agent is tetrapropylammonium hydroxide. According to the method, K<+> is adopted to effectively introduce the aluminum source into a zeolite molecular sieve, the crystal particle size of the prepared product is 500nm to 50mu m, the particle size is controllable and uniform, the silicon-aluminum ratio can be adjusted from 27 to pure silicon, the crystallization degree of the product is high, and the material can be widely used in multiple fields such as petrochemical engineering, adsorption separation and catalytic synthesis.

Owner:PETROCHINA CO LTD

Controllable preparation method of high-oxidation-resistance high-purity single/double-wall carbon nanotube

ActiveCN102320593AOvercoming problems such as difficulty in large-scale productionImprove antioxidant capacityNanotechnologyDouble wallOxidation resistant

The invention relates to the field of the controllable preparation of high-oxidation-resistance single / double-wall carbon nanotubes, in particular to a controllable preparation method of high-oxidation-resistance high-purity single / double-wall carbon nanotubes. The controllable preparation method comprises the following steps of: introducing carbon-source gas by utilizing a floating-catalyst chemical vapor-deposition method and using ferrocene as a catalyst precursor and sulfur powder as a growth promoter at a higher temperature, growing the high-oxidation-resistance carbon nanotubes under a high hydrogen-gas carrier-gas flow quantity, and simultaneously realizing the controlled growth of the single-wall or double-wall carbon nanotubes by regulating and controlling the quantity of the added growth promoter for sulfur to obtain the high-purity high-oxidation-resistance single / double-wall carbon nanotubes, wherein the single-wall or double-wall carbon nanotubes account for more than 90 percent of the total content of carbon tubes, and the highest oxidation-resisting temperatures of the single-wall and double-wall carbon nanotubes are respectively 770 DEG C and 785 DEG C. The single / double-wall carbon nanotubes with high crystallization degrees, fewer structural defects and high purity are obtained by the method, have the characteristics of excellent electrical conductivity, highelasticity, high strength and the like and are expected to be applied to transparent conductive films and the related devices of the transparent conductive films.

Owner:唯碳纳米科技(沈阳)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com