Anticorrosive coating material with physically stripped graphene and method for preparing anticorrosive coating material

A technology of physical peeling and anti-corrosion coating, applied in anti-corrosion coatings, coatings, polyester coatings, etc., can solve the problems of reducing graphene hydrophobicity, poor electrochemical anti-corrosion ability, unfavorable electrochemical anti-corrosion, etc., and achieve high practicability , good corrosion resistance, less structural defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

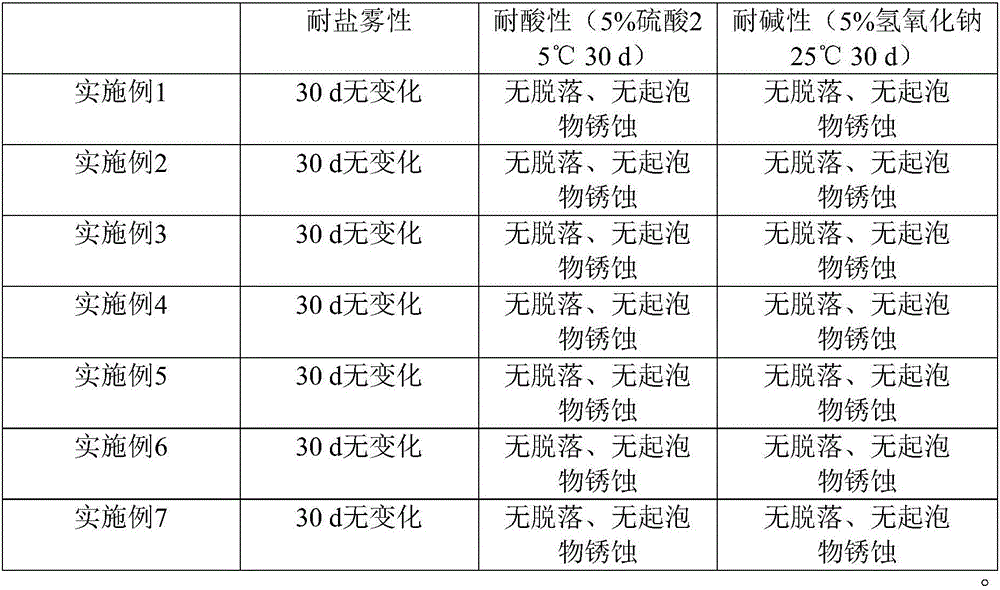

Embodiment 1

[0029] Weigh 80 parts of polyvinylpyrrolidone and dissolve in N-methylpyrrolidone. Take 10 parts of 50-mesh high-quality physically exfoliated graphene powder and add N-methylpyrrolidone to sonicate for 2 hours, with an ultrasonic power of 500W and an ultrasonic temperature of 30°C. Mix polyvinylpyrrolidone solution and graphene slurry after ultrasonication, add 2 parts of dispersant (BYK161), 2 parts of leveling agent (BYK361), 3 parts of defoamer (BYK088), 3 parts of coupling agent (KH550 ) high-speed disperser, the dispersion speed is 2000r / min, and the dispersion time is 30min; the anti-corrosion coating material is prepared, and its anti-corrosion performance is shown in Table 1.

Embodiment 2

[0031] Weigh 54 parts of epoxy resin E44 (Baling Petrochemical) and dissolve in 40 parts of acetone. Take 3 parts of 50-mesh high-quality physically exfoliated graphene powder and add 300 acetone to ultrasonic for 2 h, ultrasonic power 500 W, ultrasonic temperature 30 °C. Mix the epoxy resin solution with the graphene slurry after ultrasonication and add 1 part of dispersant (BYK111), 1 part of leveling agent (BYK356), 1 part of defoamer (BYK057), 2 parts of coupling agent (KH550 ) high-speed disperser, the dispersion speed is 2000r / min, and the dispersion time is 30min; the anti-corrosion coating material is prepared, and its anti-corrosion performance is shown in Table 1.

Embodiment 3

[0033] Weigh 21 parts of polyvinyl alcohol and dissolve in 20 parts of water. Take 12 parts of 50-mesh high-quality physically exfoliated graphene powder and add it into 40 water for ultrasonication for 10 hours. The ultrasonic power is 100W and the ultrasonic temperature is 30°C. Mix the polyvinyl alcohol solution with the graphene slurry after ultrasonication and add 0.6 parts of dispersant (BYK161), 0.8 parts of leveling agent (BYK361), 0.8 parts of defoamer (BYK088), 1.8 parts of coupling agent (KH570 ) high-speed disperser, the dispersion speed is 1000r / min, and the dispersion time is 90min; the anti-corrosion coating material is prepared, and its anti-corrosion performance is shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com