Patents

Literature

176results about How to "Permeation barrier" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy resin-oxidized graphene composite coating and application method thereof

InactiveCN104356860AImprove corrosion resistanceImprove adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyCoated surface

The invention provides an epoxy resin-oxidized graphene composite coating. The composite coating is prepared by using oxidized graphene as a packing and adding the packing to epoxy resin coating. A coating layer prepared on the surface of a matrix by utilizing the composite coating is excellent in binding force of the matrix, and further greatly improved in corrosion resistance, so as to effectively obstruct a corrosive medium from penetrating from the surface of the coating layer to the path of the matrix. Therefore, the epoxy resin-oxidized graphene composite coating is good in application prospect, and in particular suitable for the matrix in a highly-corrosive severe environment.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method for graphene modified anticorrosive paint

InactiveCN105778716AStrong adhesionHigh strengthAnti-corrosive paintsEpoxy resin coatingsSolventCvd graphene

The invention discloses a preparation method for graphene modified anticorrosive paint. The preparation method comprises the following steps: (1) adding resin into a solvent to dissolve, adding a stabilizer and graphene powder into the resin after the resin is dissolved, uniformly mixing, and treating by adopting a dispersing process, thereby obtaining graphene-resin composite slurry; (2) additionally getting resin to mix with the solvent and a filler to obtain a mixture, adding a dispersing agent into the uniformly-mixed mixture, and treating by adopting a dispersing process, thereby obtaining color paste, wherein the type of the additionally-got resin is the same as that of the resin in the step (1); and (3) adding the color paste prepared in the step (2) into the graphene-resin composite slurry prepared in the step (1), and filtering after grinding and dispersing, thereby obtaining the finished paint. According to the preparation method, a path of adding a corrosive medium to protected matrix is added, so that the protection time of a coating on the matrix is prolonged, and the purpose of long-acting corrosion prevention is achieved; and the defects of poor weather resistance, low barrier property, short service life and the like of the current paint are overcome.

Owner:DEYANG CARBONENE TECH

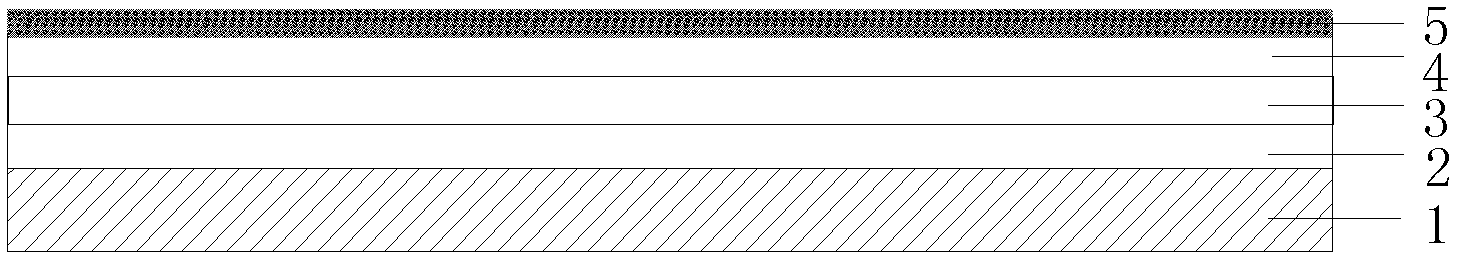

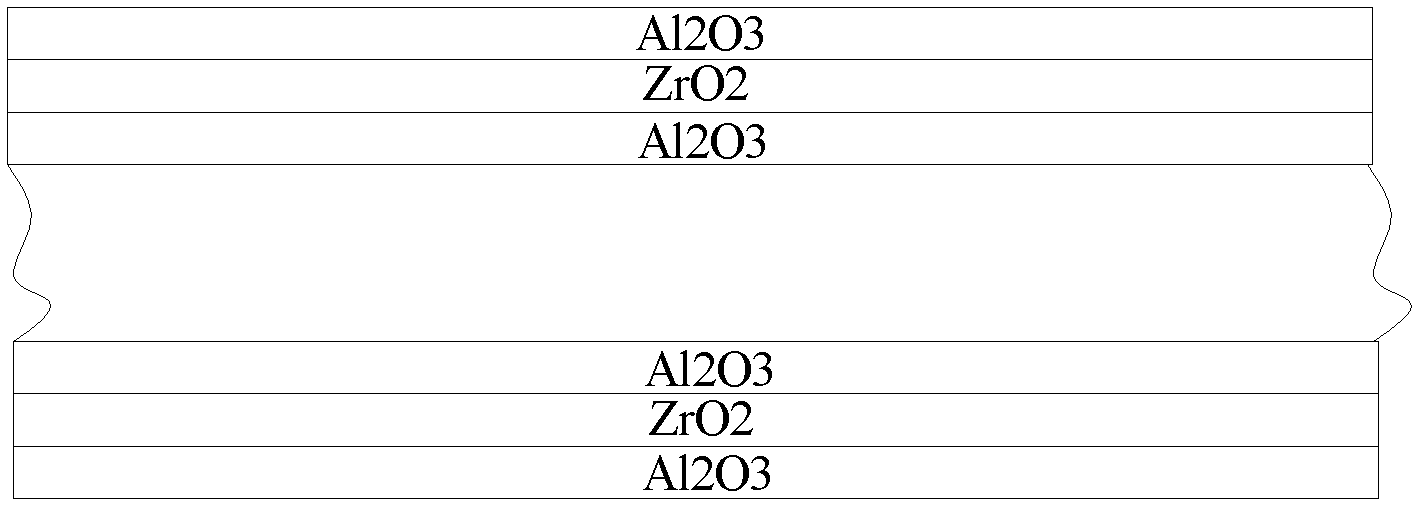

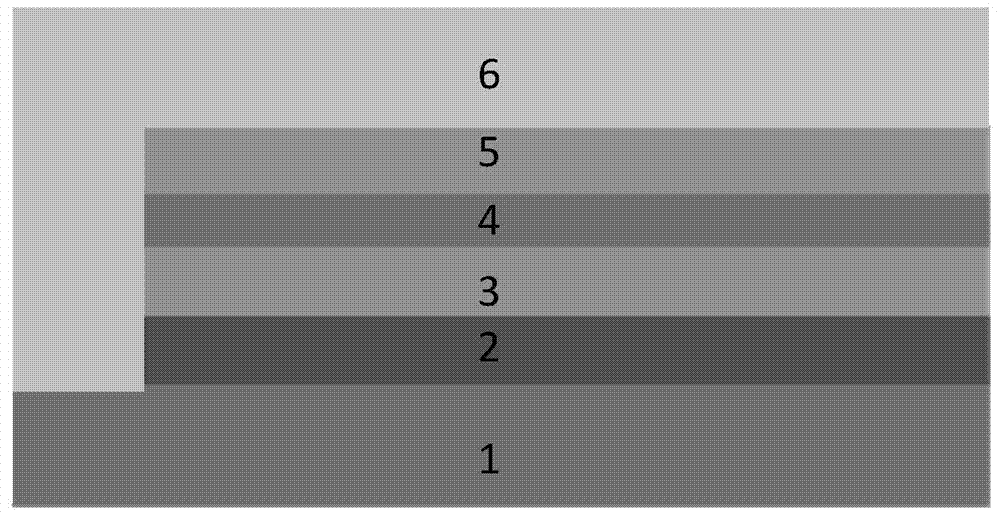

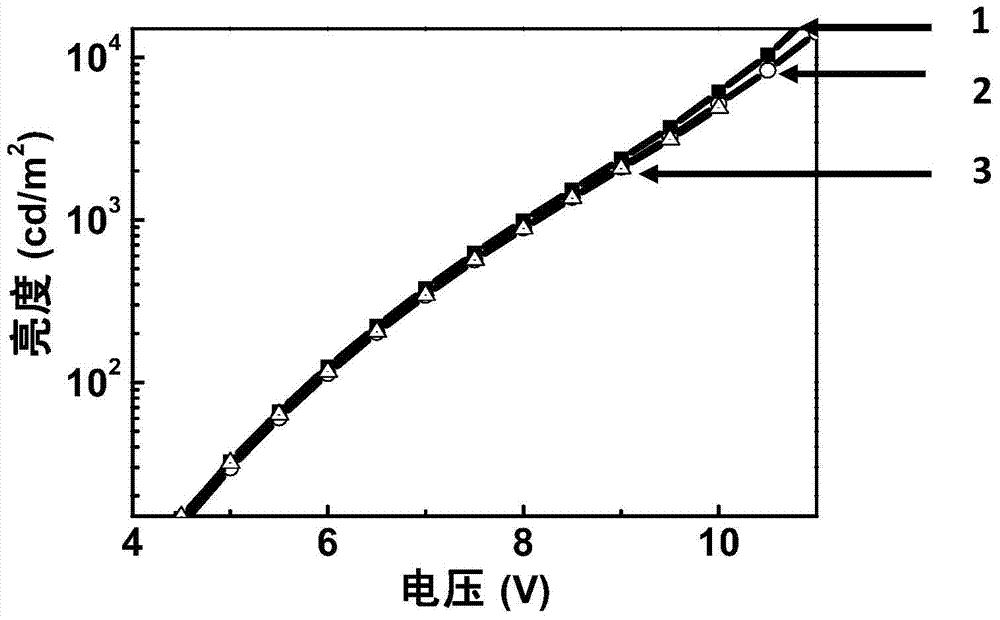

Packaging structure of OLED

InactiveCN102437288ALow deposition temperatureSave floor space and equipment investment costsSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceOrganic film

The invention relates to a packaging structure of an OLED. The structure comprises a substrate of the OLED. One side of the substrate is provided with an anode of the OLED, an organic layer and a cathode. The outboard of the cathode is at least provided with a packaging layer. The packaging layer is a multilayer composite membrane structure which is formed by alternative deposition of two inorganic insulating materials through an atomic layer deposition system. The packaging structure of the OLED in the invention has a low deposition temperature. The organic layer of a luminescent device can not be damaged. Other organic film formation equipment is not needed. Equipment investment costs and land occupation areas can be saved. The inorganic film layer structure alternatively prepared by using an atomic layer deposition method is compact. Pinholes are less. Water and oxygen can be effectively avoided to penetrate into a device. A protection layer is processed on the packaging layer so as to effectively protect the packaging layer and obstruct the water and the oxygen.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

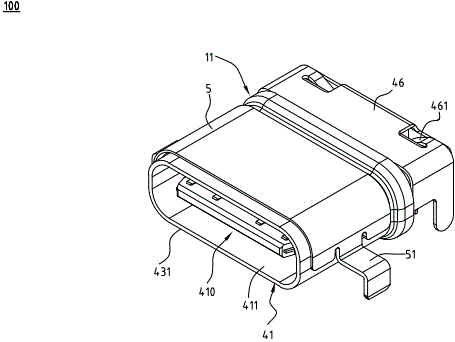

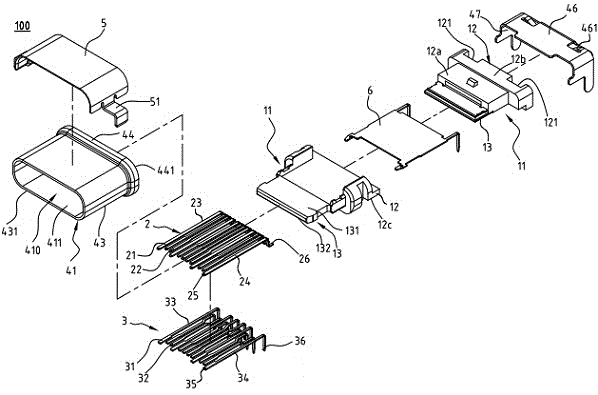

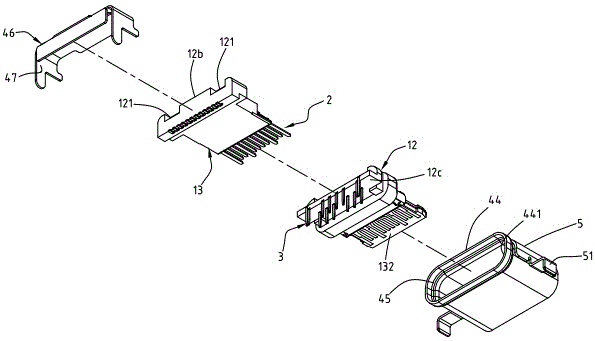

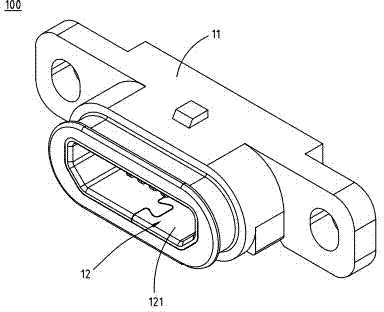

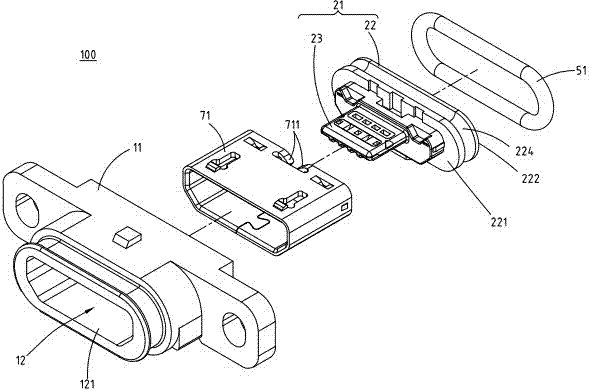

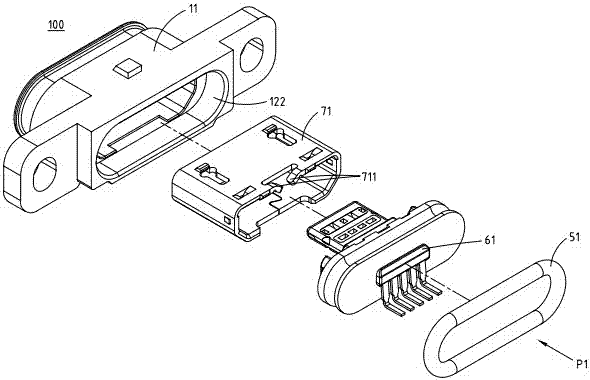

Waterproof socket electric coupler

ActiveCN104538781APermeation barrierPrevent penetrationCoupling contact membersCouplings bases/casesMechanical engineering

A waterproof socket electric coupler comprises an insulating body, a shielding shell and sealing bodies made of sealing materials (like waterproof rubber blocks). The insulating body comprises a base and a tongue plate, and the tongue plate extends from one side of the base. The shielding shell comprises an annular wall and an outer ring wall, the outer ring wall extends from the draft annular wall to the rear side of the annular wall, the inner diameter of the outer ring wall is larger than that of the annular wall, and an annular sealing channel filling groove is formed between the inner wall face of the outer ring wall and the corresponding outer side face of the base. The sealing bodies made of the sealing materials are formed in the annular sealing channel filling groove, and a gap between the inner wall face of the outer ring wall and the outer side face of the base and the bottom region of the base are filled with the sealing bodies.

Owner:LIANZHAN TECH ELECTRONICS KUNSHAN CO LTD

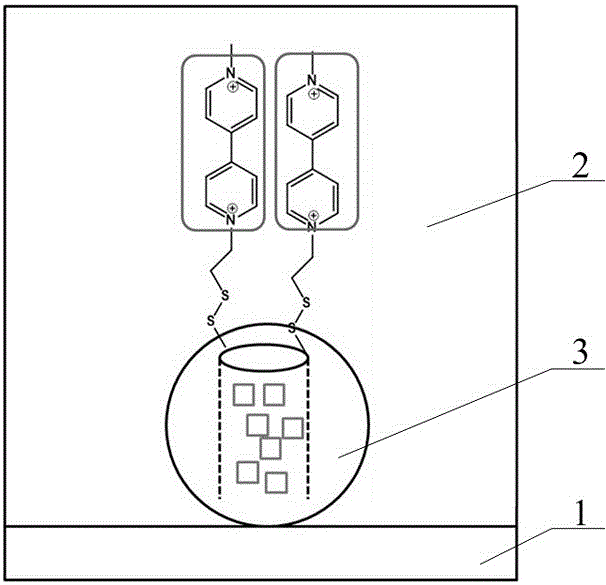

Self-corrosion potential response type self-repairing anti-corrosion coating, preparation method and application

ActiveCN105925129APermeation barrierNot easy to peel offAnti-corrosive paintsEpoxy resin coatingsSilanesMesoporous silica

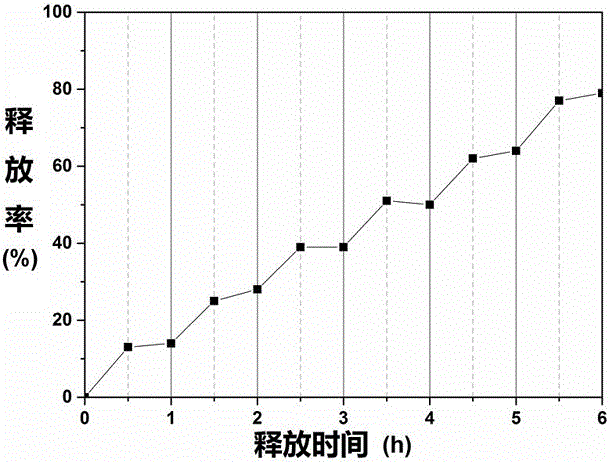

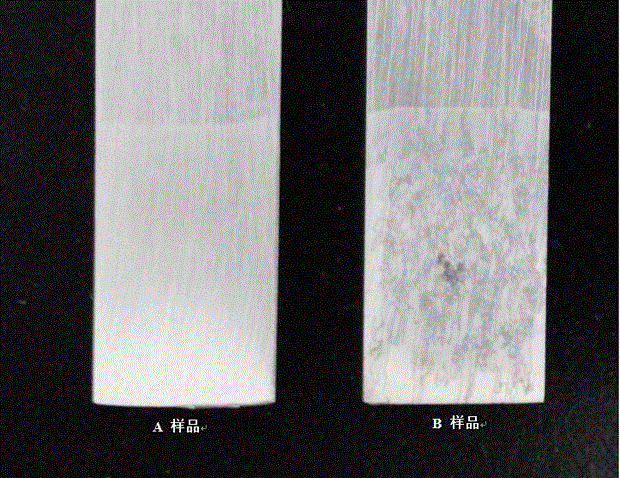

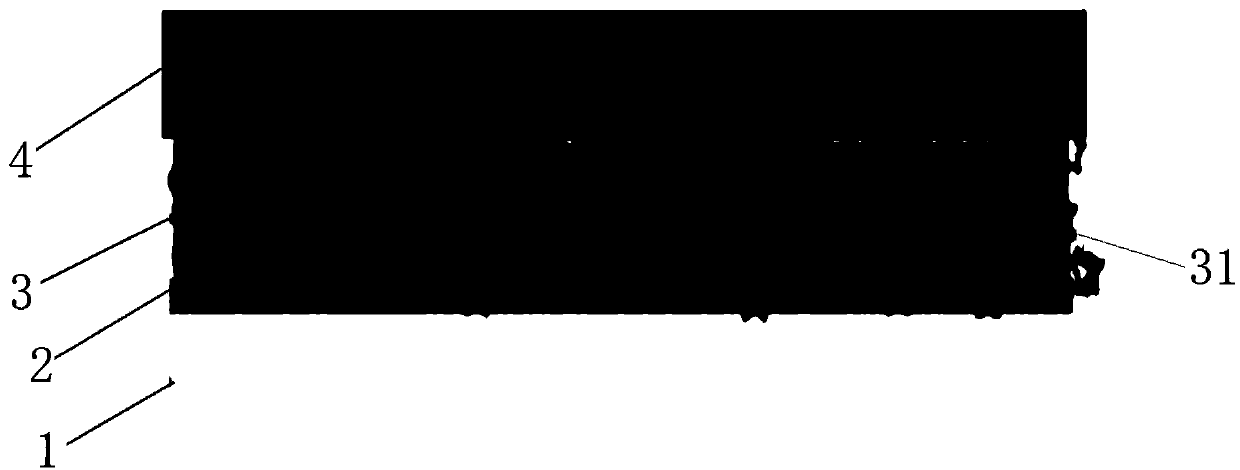

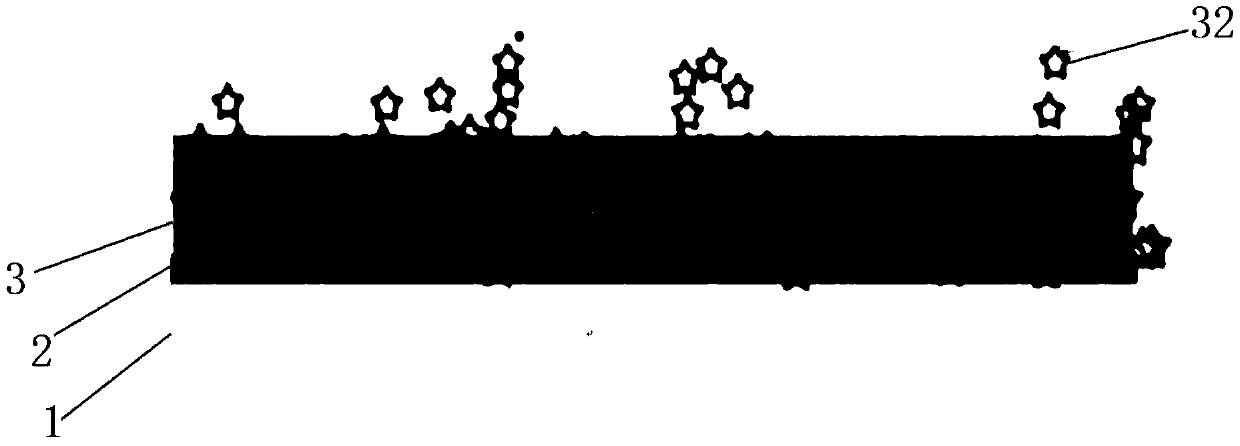

The invention discloses a self-corrosion potential response type self-repairing anti-corrosion coating and belongs to the field of the metal anti-corrosion technology. The self-corrosion potential response type self-repairing anti-corrosion coating is composed of an epoxy-silane composite coating and a mesoporous silica nano-container doped in the epoxy-silane composite coating. The preparation process includes the steps that an epoxy-silane composite coating substrate is prepared; the mesoporous silica nano-container is prepared; the mesoporous silica nano-container is dispersed in the epoxy-silane composite coating and then attached to the surface of a basic material, and the self-corrosion potential response type self-repairing anti-corrosion coating is formed after high-temperature drying. The self-corrosion potential response type self-repairing anti-corrosion coating is high in sensitivity and short in response time, microcell corrosion on the surface of metal can be actively and rapidly detected, corrosion inhibitor molecules are released and adsorbed on the surfaces of corrosion microcells to generate a self-repairing effect, and good application prospects are achieved in the metal anti-corrosion technology. The invention further discloses a preparation method and application of the self-corrosion potential response type self-repairing anti-corrosion coating.

Owner:JIANGSU GUGELANSHAN PROTECTIVE FACILITIES CO LTD +2

Metal bipolar plate and preparation method thereof and fuel cell

ActiveCN109560290AImprove corrosion resistanceLarge specific surface areaCell electrodesFuel cellsFuel cellsBinding force

The invention discloses a metal bipolar plate and a preparation method thereof and a fuel cell, and relates to the technical field of the fuel cell. An adopted technical scheme is as follows: the metal bipolar plate comprises a metal substrate, a conducting coating, and an anti-corrosion coating; the conducting coating is deposited on the metal substrate; the anti-corrosion coating is deposited onthe conducting coating; and the material of the conducting coating is the conductive metal oxide. The metal dipolar plate further comprises an amorphous carbon film deposited on the anti-corrosion coating. The fuel cell comprises the above metal bipolar plate. The metal bipolar plate is mainly used for improving the binding force of the metal substrate and the coating in the metal bipolar plate,the coating is hard to fall off after being used for a long time, and the corrosion resistance of the metal bipolar plate is improved.

Owner:浙江锋源氢能科技有限公司

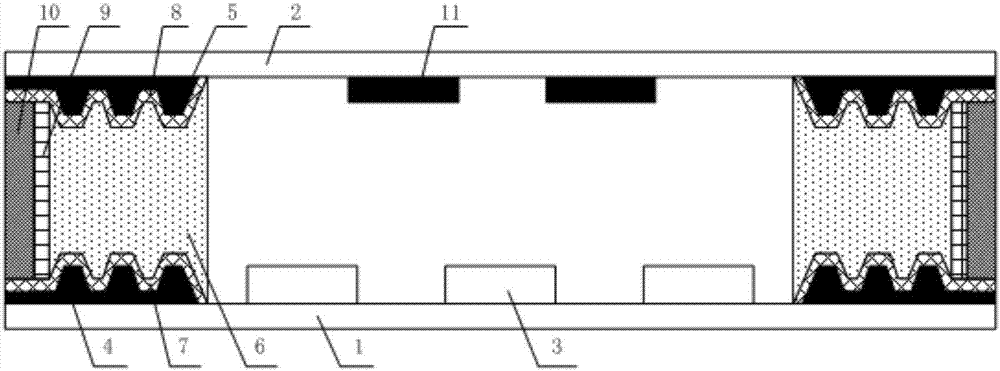

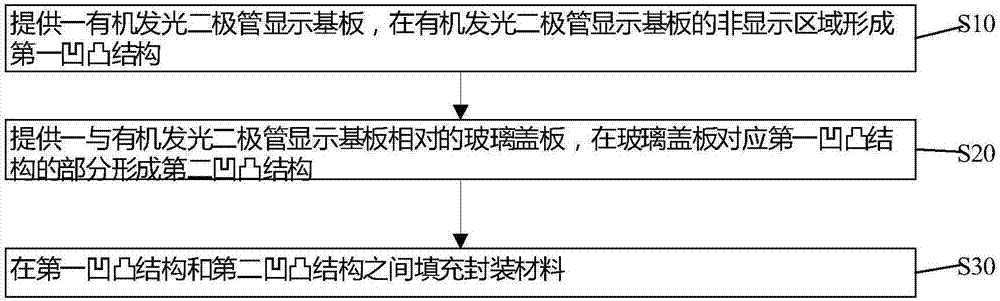

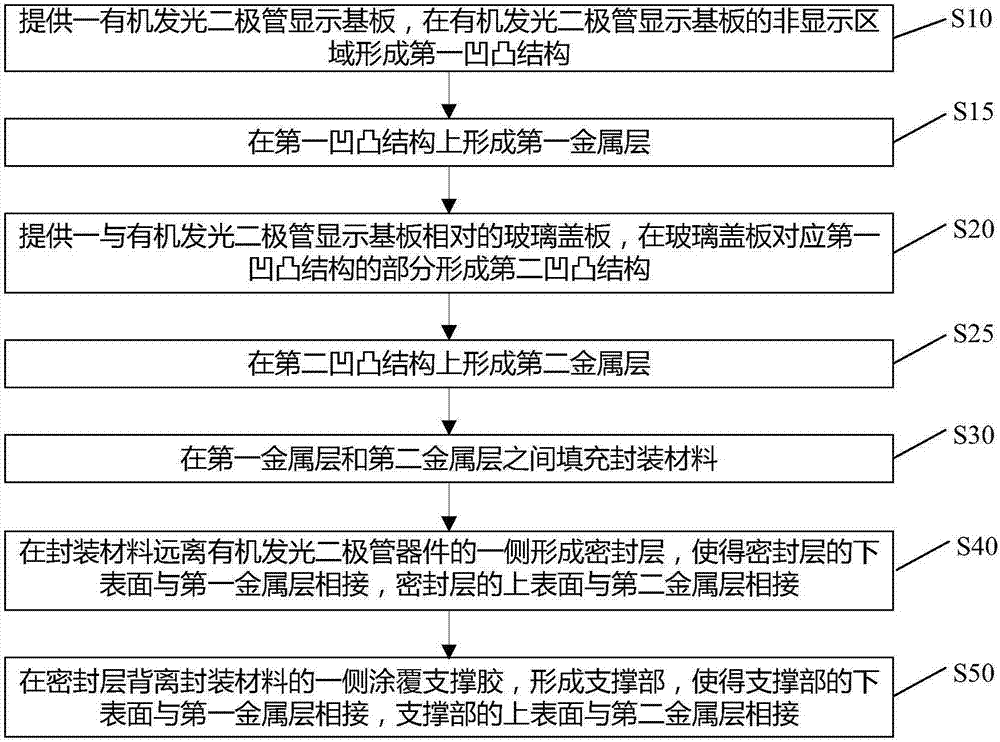

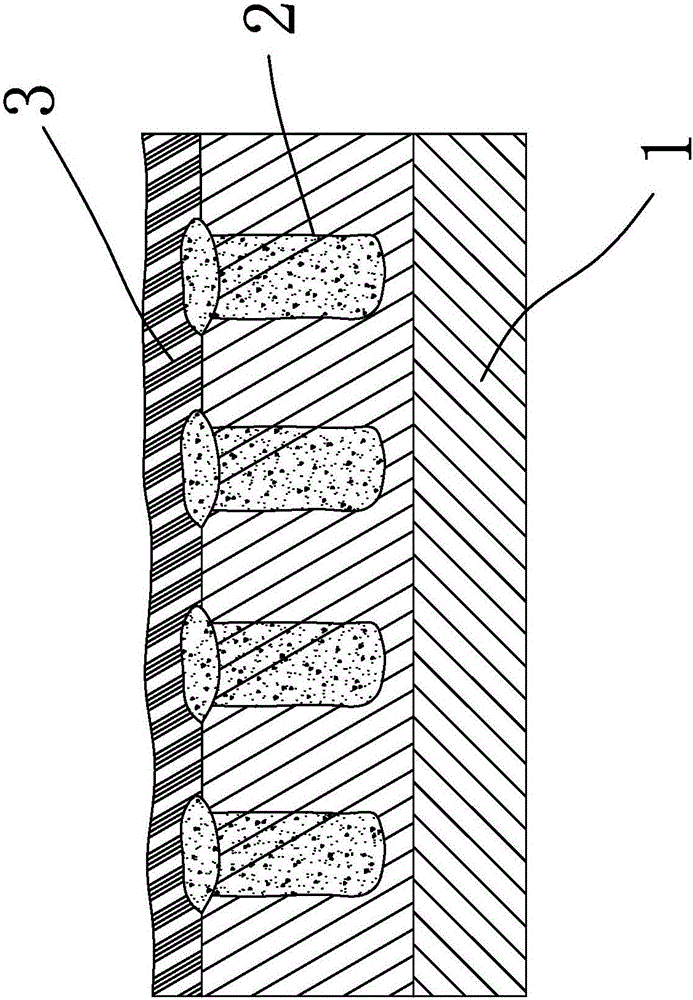

Organic light-emitting diode (OLED) display panel encapsulation structure, manufacturing method of OLED display panel encapsulation structure, and display device

ActiveCN107104201AIncrease contact areaImprove fit reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingConvex structureGlass cover

The invention relates to the field of display technologies, and discloses an organic light-emitting diode (OLED) display panel encapsulation structure, a manufacturing method of the OLED display panel encapsulation structure, and a display device, which are used to improve the sealing reliability of OLED device encapsulation and prolong the service life of OLED devices. The OLED display panel encapsulation structure comprises an OLED display substrate and a glass cover plate which are oppositely arranged, wherein encapsulation parts are arranged between non-display areas of the OLED display substrate and parts of the glass cover plate corresponding to the non-display areas; and each encapsulation part comprises a first concave-convex structure arranged on the OLED display substrate, a second concave-convex structure arranged on the glass cover plate, and encapsulation materials arranged between the first concave-convex structure and the second concave-convex structure. The OLED display panel encapsulation structure, the manufacturing method of the OLED display panel encapsulation structure, and the display device provided by the invention are used for an OLED display device.

Owner:BOE TECH GRP CO LTD +1

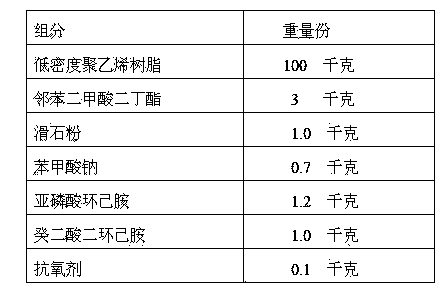

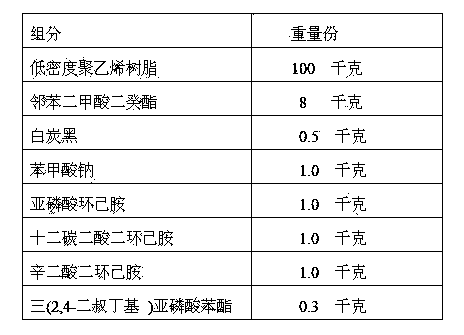

Vapor phase antirust blown polyethylene film and making method thereof

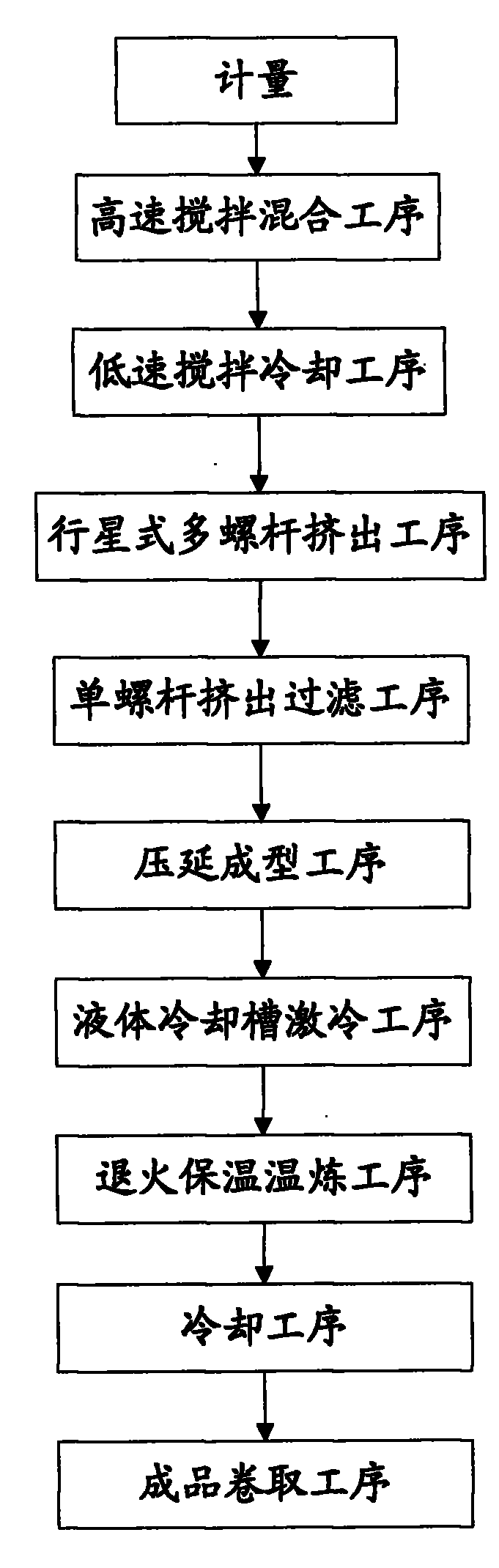

The invention discloses a vapor phase antirust blown polyethylene film and a making method thereof. The vapor phase antirust blown polyethylene film comprises low density polyethylene resin, a plasticizer, an auxiliary filler, sodium benzoate, cyclohexylamine phosphate, amine salt of aliphatic dibasic acid, and an antioxidant. Polyethylene materials comprising vapor phase antirust agents are utilized to make the vapor phase antirust blown polyethylene film through a blowing production process in order to realize convenient production and vapor phase antirust effects. The vapor phase antirust agents adopted in the invention are different from traditional nitrite vapor phase antirust agents, are in favor of realizing environmental protection and benefiting the health of human bodies. The film made in the invention has the advantages of composite structure, obstruction of the outward penetration of the vapor phase antirust agents, antirust effect increase and antirust time prolongation.

Owner:YANTAI HENGDIKE ENERGY TECH

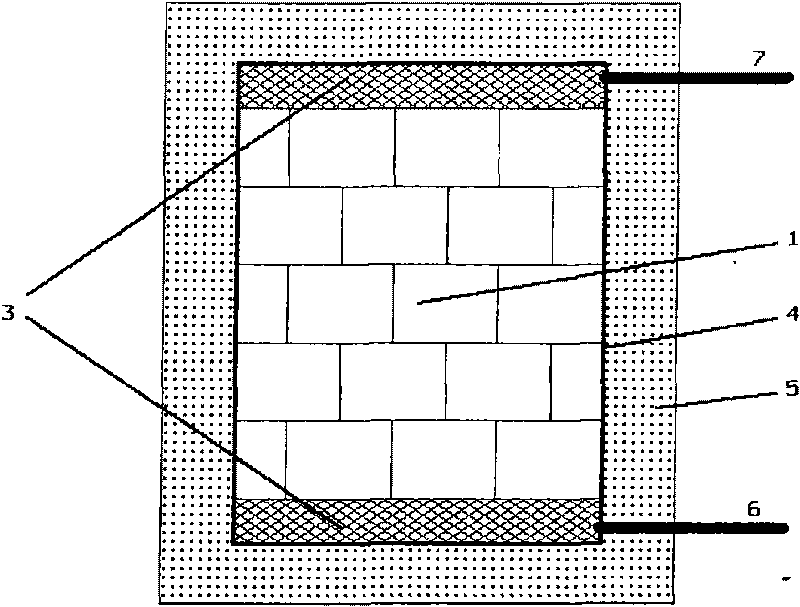

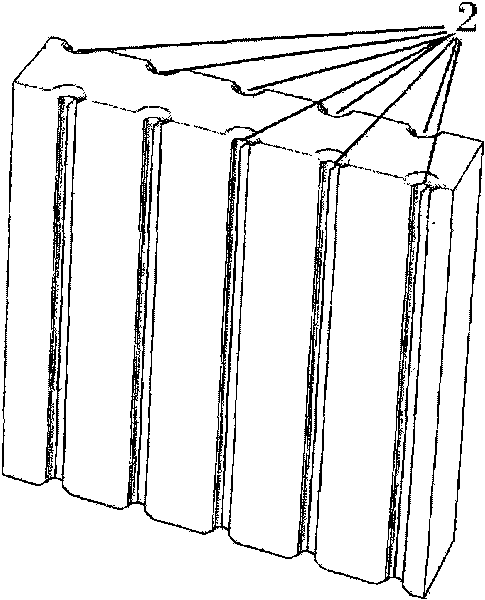

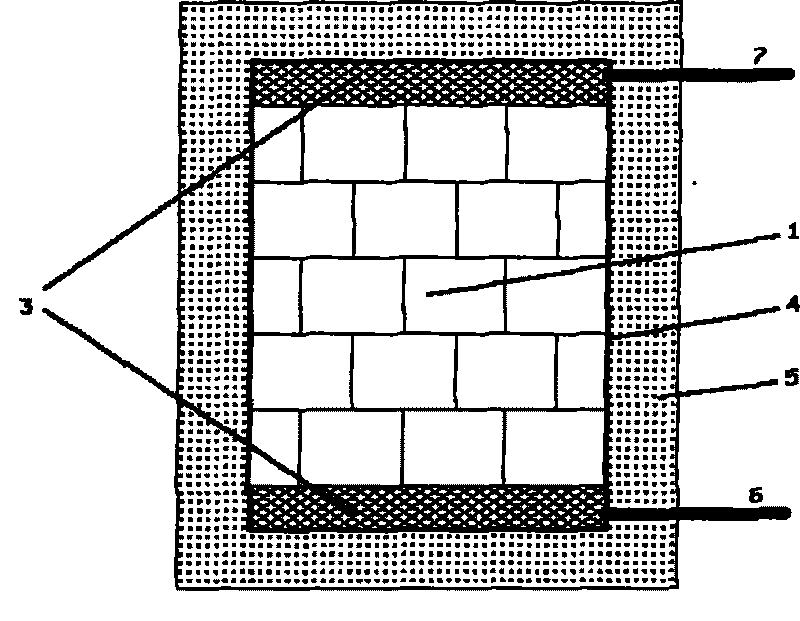

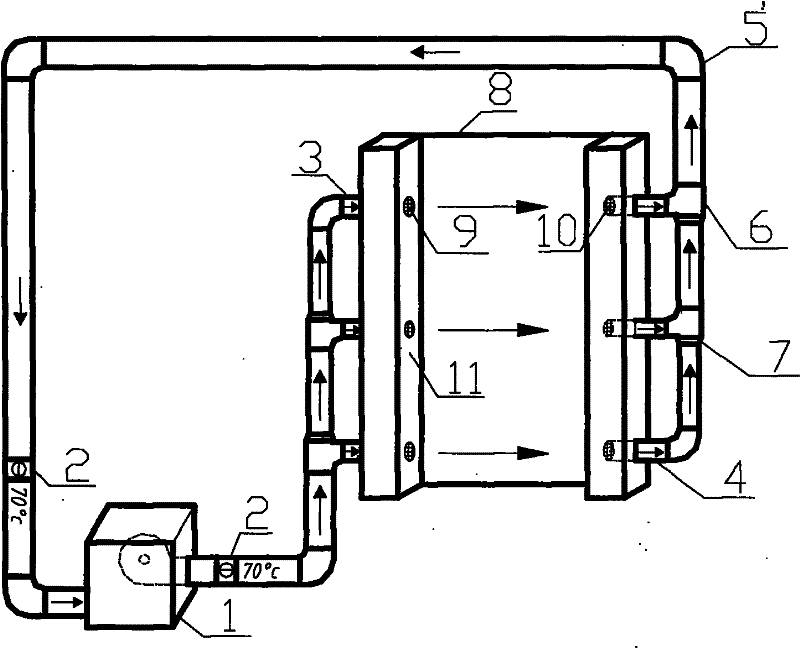

Solar energy heat storage device and preparation method thereof

InactiveCN101737969APermeation barrierReduce consumptionSolar heating energySolar heat devicesNitrateBrick

The invention discloses a solar energy heat storage device. The device is characterized in that the heat storage device has a sealed metal shell, the metal shell is provided with two heat-conducting liquid outlets, wherein one is a cold end outlet, the other is a hot end outlet; solid heat storage medium is arranged in the metal shell, the solid heat storage medium comprises a plurality of solid heat storage bricks, the heat storage bricks are made of glass or a mixture of glass and sandstone; the inside or surface of each heat storage brick is provided with at least two pore paths, grooves or gaps used for the flowing of the heat-conducting liquid, the paths grooves or gaps can be used to form connecting channels which are used for the flowing of the heat-conducting liquid in each heat storage brick or between two adjacent heat storage bricks. The solving approach provided by the invention is to adopt the special bricks which are directly immersed in the flowing and high temperature heat-conducting liquid (heat-conducting oil, molten nitrate or the like) as the solid heat storage medium while metal pipes for separation are not needed to add. The bricks are characterized in that the surfaces of the bricks are made of glass material; the glass material barely has pores and can effectively prevent the penetration of the heat-conducting liquid, therefore the liquid consumption caused by the pores in the bricks which are soaked in the heat-conducting liquid and the fouling problem caused by the pollution of the heat-conducting liquid can not be caused.

Owner:SHANGHAI SHENXI SOLAR TECH

Novel wind-curtain device for refrigerator

InactiveCN102374602AShort rangeReduce energy consumptionLighting and heating apparatusAir currents for screeningStore foodEngineering

The invention relates to a novel wind-curtain device for a refrigerator. The device comprises a fan set, a fireproof valve, a wind-supplying pipe, a wind-returning pipe, a bend, a three-way pipe, an increasing pipe, a PVC (Poly Vinyl Chloride) curtain, a wind-supplying opening grid, a wind-returning opening grid and a curtain wall. The PVC curtain and an air curtain of the device can perform the double heat-insulating actions for the refrigerator, and meanwhile, a door curtain can be used for blocking the air curtain from being directly contacted with an external environment, thereby the probability of garbage entering a wind pipe is decreased. Mosquitoes, flies, insects and mice are effectively prevented from entering the refrigerator from the side of the air curtain with a smaller wind speed through uniform air flows formed at a refrigerator door by a wind-supplying and returning system, thereby the storage safety of the refrigerator is improved, and the uniform wind speed is favorable to blocking the penetration of cold wind. The device can be used for sufficiently blocking the penetration of the cold wind in the refrigerator, and insect prevention and dust prevention are achieved. A wind curtain disclosed by the invention has the characteristics of energy saving, high efficiency, cleanliness, simple structure, low cost and the like and is particularly suitable for large refrigerators for storing foods.

Owner:SHANGHAI OCEAN UNIV

Composite adhesive specially for heat insulating polystyrene outer-wall board

InactiveCN1403522AImprove adhesionImprove aging resistanceHydrocarbon polymer adhesivesPolymer scienceAdhesive

The composite adhesive is prepared with styrene and acrylic acid copolymer emulsion, which is inorganic silica gel and organosilicon modified and has low vitrification point and high adhesion, as main adhesive component and through adding quartzite, asbestos and other reinforcing material and some assistants. The composite adhesive has high adhesion effect, high adhesion strength, good antiaging performance, high hardness and high water resistance.

Owner:上海丰慧节能环保科技有限公司

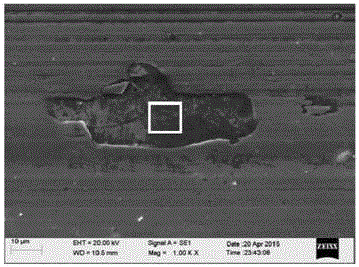

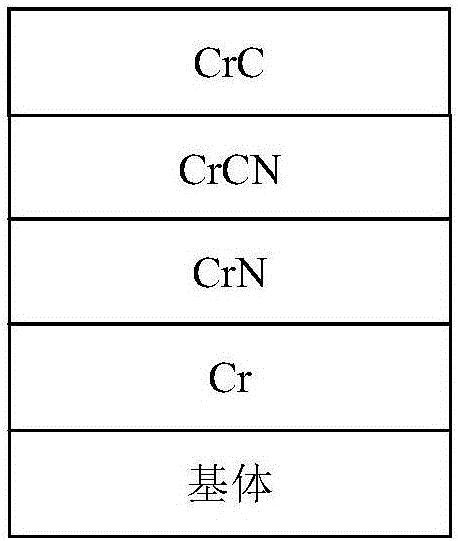

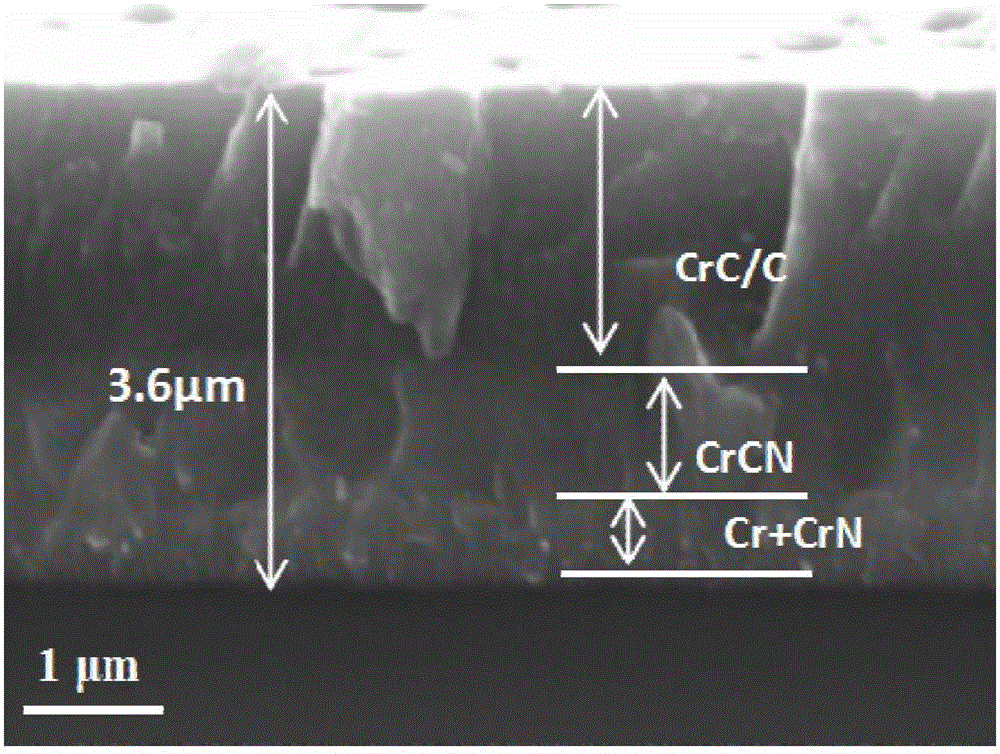

Multilayered gradient composite chromium carbide coating on substrate surface and preparation method of multilayered gradient composite chromium carbide coating

ActiveCN106544631APermeation barrierHigh bonding strengthVacuum evaporation coatingSputtering coatingChromium carbideSubstrate surface

The invention provides a multilayered gradient composite chromium carbide coating on a substrate surface. The composite coating comprises a Cr layer, a CrN layer, a CrCN layer and a CrC layer that are upwards laminated in sequence on the substrate surface. Compared with an existing single-layer CrC coating, the multilayered gradient structure can alleviate the differences of the coating and a substrate in constitution, structure and physical property, reduce the stress of the coating and remarkably improve the frictional wear performance of the coating. The invention also provides a method for preparing the multilayered gradient composite chromium carbide coating by adopting a multi-arc ion plating technique in which the metal Cr is taken as a target material, high-purity Ar is taken as a working gas and C2H2 and N2 are taken as reacting gases; and the constituents and structure of each layer can be controlled by regulating the flow rate of each type of gas.

Owner:宁波奥深科技有限公司

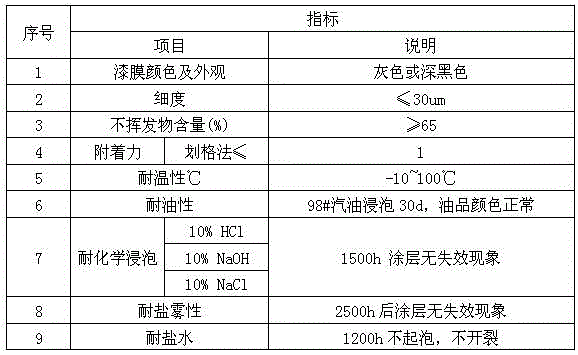

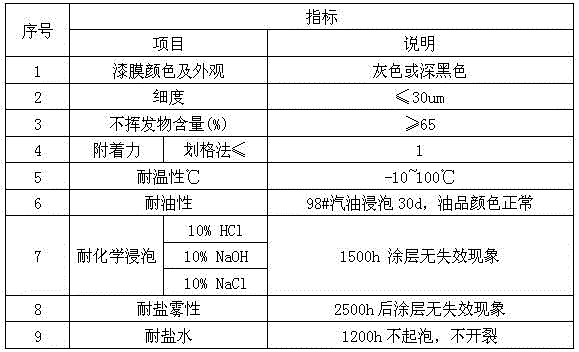

Composite coating on surface of anti-alkali anti-corrosion aluminum alloy and technology

ActiveCN104962974APermeation barrierStrong alkali resistanceSynthetic resin layered productsSurface reaction electrolytic coatingEpoxyOrganosilicon

The invention belongs to the technical field of processing of metal surfaces, and provides a composite coating on the surface of an anti-alkali anti-corrosion aluminum alloy and a technology. The composite coating comprises aluminum or an aluminum alloy matrix and an anode oxide film layer coated on the aluminum or the aluminum alloy matrix, wherein an organosilicon coating is coated outside the anode oxide film layer, and the organosilicon coating is a composite layer consisting of epoxy modified organic silicon resin and methyl methacrylate. The organosilicon coating is firmly coated on the surface on which anodic oxidation is performed through construction of a mixing method and a spraying method, soaking, diffusion and closing on oxide film holes and solidification at 180 DEG C for 20-25min after flash drying of the surface layer of the organosilicon coating, infiltration of corrosive substances or alkaline substances on the inner-layer oxide film and the aluminum matrix is insulated, an aluminum alloy product processed by the technology disclosed by the invention has a good anti-alkali property and a good anti-corrosion property, the high temperature resistant property can be improved to 180 DEG C, so that cracks do not exist, and performance standard requirements can be satisfied under the condition that original appearance requirements are not changed.

Owner:NINGBO MINTH AUTOMOTIVE PARTS RES&DEV CO LTD

Use of plastic film or plastic composite film as architecture component protective film or decorative film

InactiveCN1884753AConstruction is inconvenientSolve the durability problemBuilding insulationsTectorial membraneComposite film

The invention relates to the application of plastic film or plastic composite film, used as building element protective film or decorating film, wherein the invention coats adhesive or polymer on the surface of building element, then adheres the plastic film or plastic composite film on the said surface. The invention has the advantages that: it can prolong the service life of decorate element, with low cost and simple operation, while the polymer is made by mixing adhesive and other stuff on site.

Owner:吴淑环

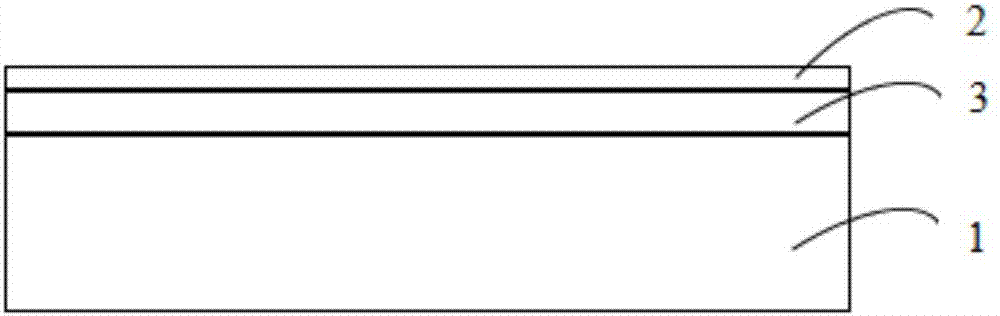

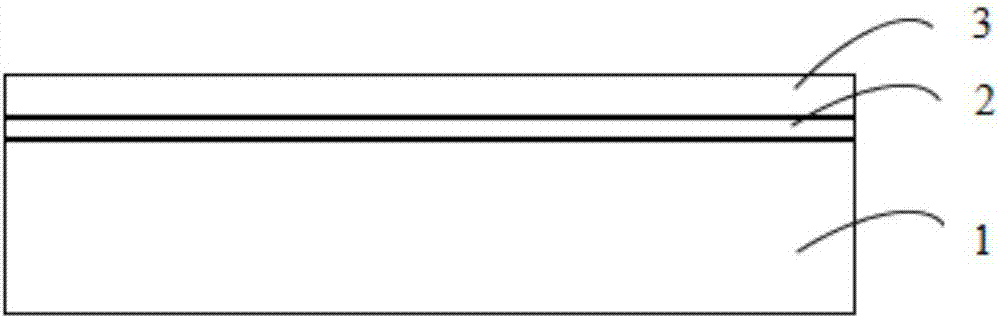

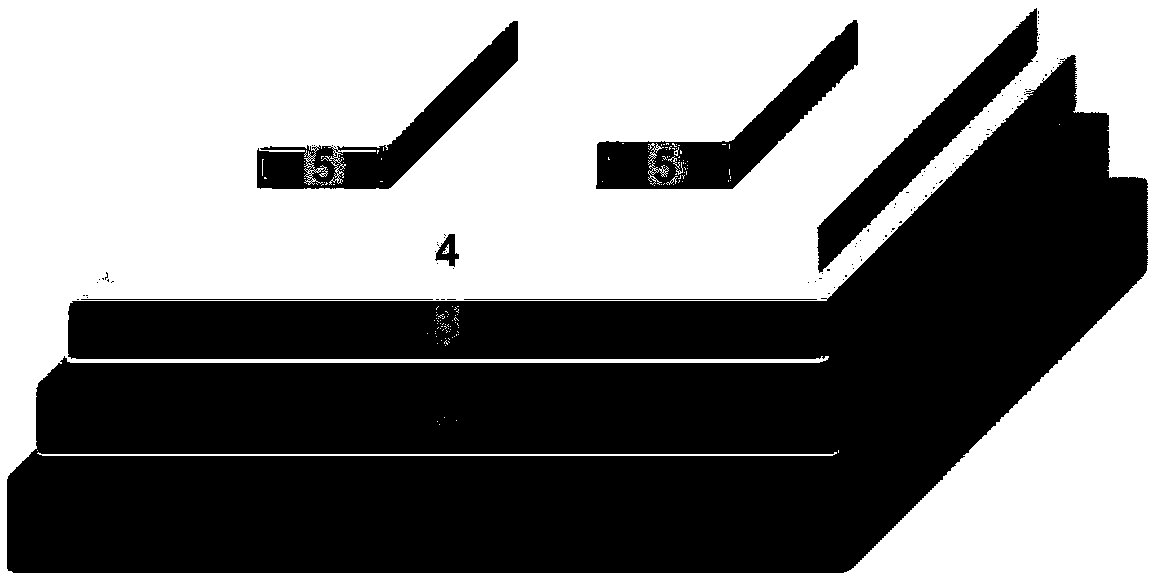

Flexible conductive film

InactiveCN107230514APermeation barrierBarrier erosionMaterial nanotechnologyConductive layers on insulating-supportsTransmittanceEngineering

The invention provides a flexible conductive film which comprises a flexible base layer, a flexible conductive layer and a flexible water vapor barrier layer. The flexible base layer, the flexible conductive layer and the flexible water vapor barrier layer are laminated to each other and are combined to form the flexible conductive film. The flexible conductive film is not easy to break, has the advantages of scrape resistance, scratch resistance, bending folding resistance, high light transmittance, low haze, water vapor resistance and the like, can be widely used in a variety of optoelectronic devices, and especially optoelectronic devices with flexible demand and waterproof demand.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

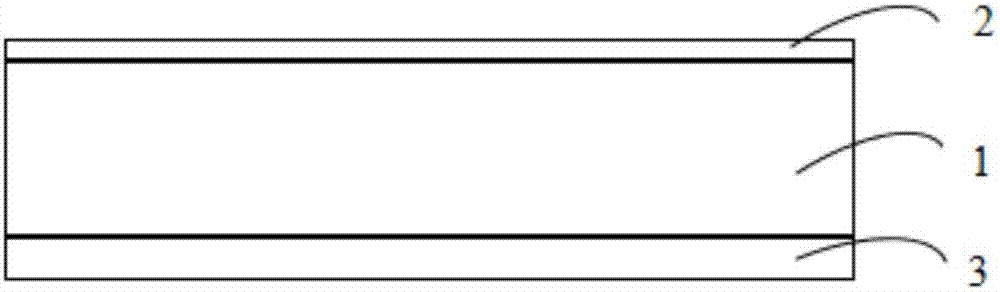

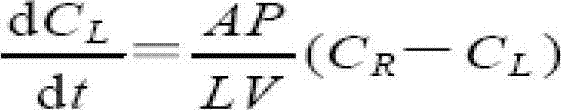

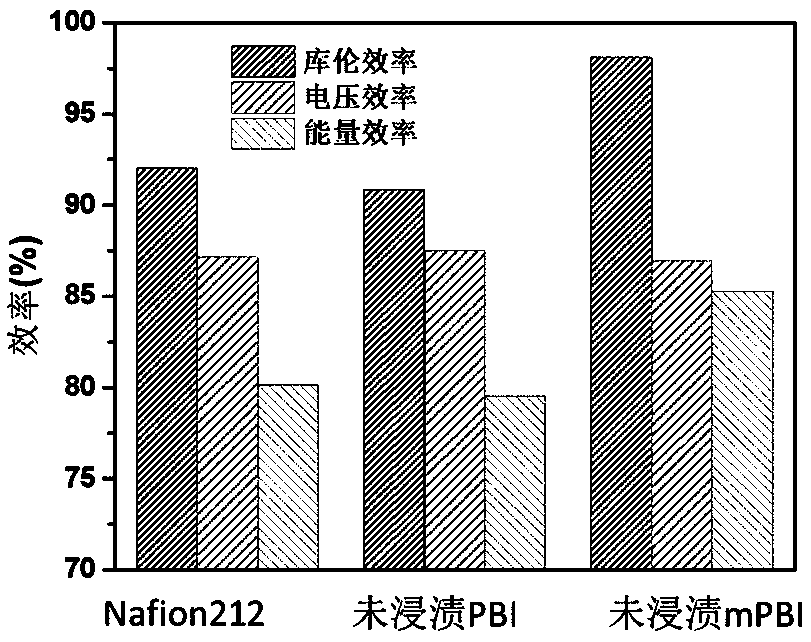

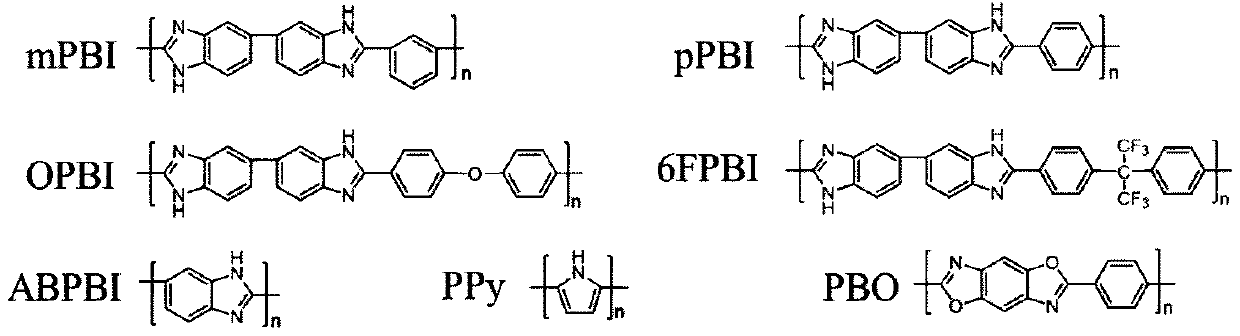

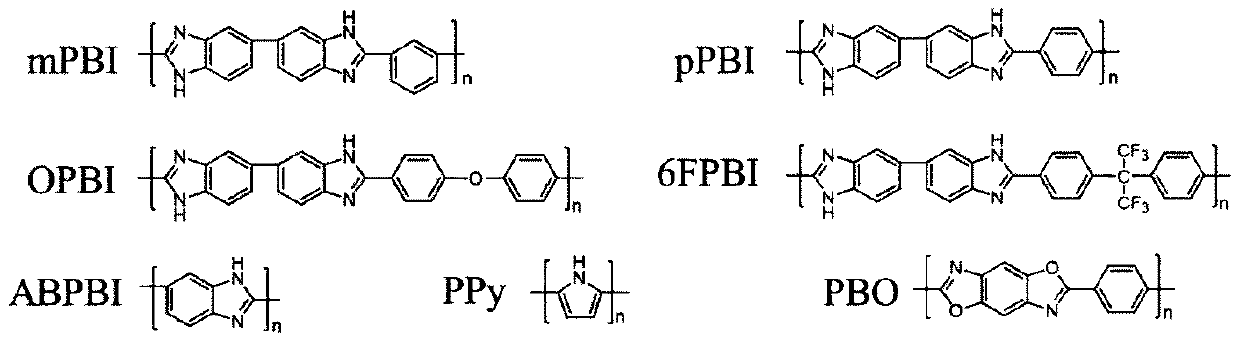

Blending membrane for all-vanadium redox flow battery and preparation method for blending membrane

ActiveCN102881853AHigh modulusGood dimensional stabilityCell component detailsCooking & bakingVanadium redox battery

The invention relates to the field of ion exchange membranes for all-vanadium redox flow batteries (VRB), in particular to a blending membrane for a VRB and a preparation method for the blending membrane. The blending membrane comprises A weight percent of perfluorosulfonate (PFSA) ion exchange resin and B weight percent of sulfonated polybenzimidezole (SPBI), wherein A is more than 75 percent and less than or equal to 100 percent, and B is more than 0 percent and less than or equal to 25 percent. The method comprises the following steps of: dissolving the PFSA ion exchange resin and the SPBI into a solvent respectively, mixing the PFSA ion exchange resin and the SPBI according to a certain proportion, magnetically stirring the mixed solution, performing ultrasonic treatment for a certain time to uniformly mix the PFSA ion exchange resin and the SPBI, spreading the uniform solution on a clean glass plate, preserving heat for a certain time at low temperature in a baking oven, raising the temperature, preserving heat for a certain time, and performing temperature reduction to obtain the blending membrane. The method is simple; and the prepared blending membrane is low in swelling, high in dimensional stability, strong in mechanical strength, low in vanadium ion permeability, high in chemical and thermal stability and applicable to the VRB.

Owner:辽宁科京新材料有限公司

Antioxidant coating for surface of aluminum oxide-silicon carbidee-carbon brick

The invention relates to an antioxidant coating for the surface of an aluminum oxide-silicon carbidee-carbon (ASC) brick. The antioxidant coating is aqueous paste substance formed by mixing a component A and a component B by a weight part proportion of 100:101.5-102.5, wherein the component A is powder formed by mixing 50-70 parts by weight of glaze powder, 2-5 parts by weight of alpha-AL2O3 micro-powder, 1-7 parts by weight of bentonite powder, 1-3 parts by weight of SiO2 micro-powder and 26-35 parts by weight of silicon carbide powder; the component B viscous fluid formed by dissolving 1.5-2.5 parts by weight of carboxymethyl cellulose into 100 parts by weight of water, and the glaze powder in the component A is fine powder prepared by drying and grinding an material formed by mixing, melting and quenching 40-60 parts by weight of borax, 12-18 parts by weight of quartz, 8-15 parts by weight of sodium carbonate, 12-15 parts by weight of calcite and 8-12 parts by weight of albite. After coated with the antioxidant coating, ASC bricks of the lining of a torpedo type mixed iron car has the service life prolonged at least for 50 heating numbers, which saves the refractory material.

Owner:常州市武进第一耐火材料有限公司

Waterborne epoxy graphene zinc anticorrosive coating and preparation method and application thereof

InactiveCN109762446AIncrease the conductive pathIncrease profitAnti-corrosive paintsEpoxy resin coatingsEpoxyEmulsion

The invention discloses a waterborne epoxy graphene zinc anticorrosive coating. The waterborne epoxy graphene zinc anticorrosive coating comprises a first component and a second component, wherein thefirst component is prepared from the following components in parts by weight: 5-10 parts of a waterborne epoxy resin curing agent, 0.5-1 part of a dispersant, 1-3 parts of an anti-settling agent, 1-3parts of a coalescing agent, 10-15 parts of body pigment, 42-65 parts of zinc powder and 4.5-5 parts of graphene dispersion slurry. The second component is prepared from the following components in parts by weight: 30-40 parts of aqueous epoxy emulsion, 1-2 parts of an anti-flash rust agent, 5-15 parts of water and 0.2-0.8 part of a defoaming agent. The waterborne epoxy graphene zinc anticorrosive coating has high utilization rate of zinc powder and is easy to prepare, and the formed coating has excellent comprehensive properties, such as good compactness, excellent cathodic protection performance and shielding performance, anticorrosive performance is remarkably improved, and the waterborne epoxy graphene zinc anticorrosive coating has wide application prospects in the field of marine equipment anticorrosion.

Owner:宁波中科银亿新材料有限公司 +1

Ceramic silicone rubber composite with excellent burning resistance

The invention belongs to the field of macromolecular rubber materials, and relates to a silicone rubber composition, in particular to a ceramic silicone rubber composite with excellent burning resistance. The ceramic silicone rubber composite is prepared from, by weight, 100 parts of silicone rubber, 20-60 parts of formed ceramic filling, 5-15 parts of fluxing agent and 2-4 parts of vulcanizing agent, wherein the formed ceramic filling is the mixture of alumina silicate fibers and needle-like wollastonite, and the mass ratio of the alumina silicate fibers to the needle-like wollastonite is (15-25):(30-40). According to the ceramic silicone rubber composite with the excellent burning resistance, the compound of the alumina silicate fibers and the needle-like wollastonite is adopted as the formed ceramic filling to improve the thermal stability and burning resistance of the ceramic silicone rubber.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

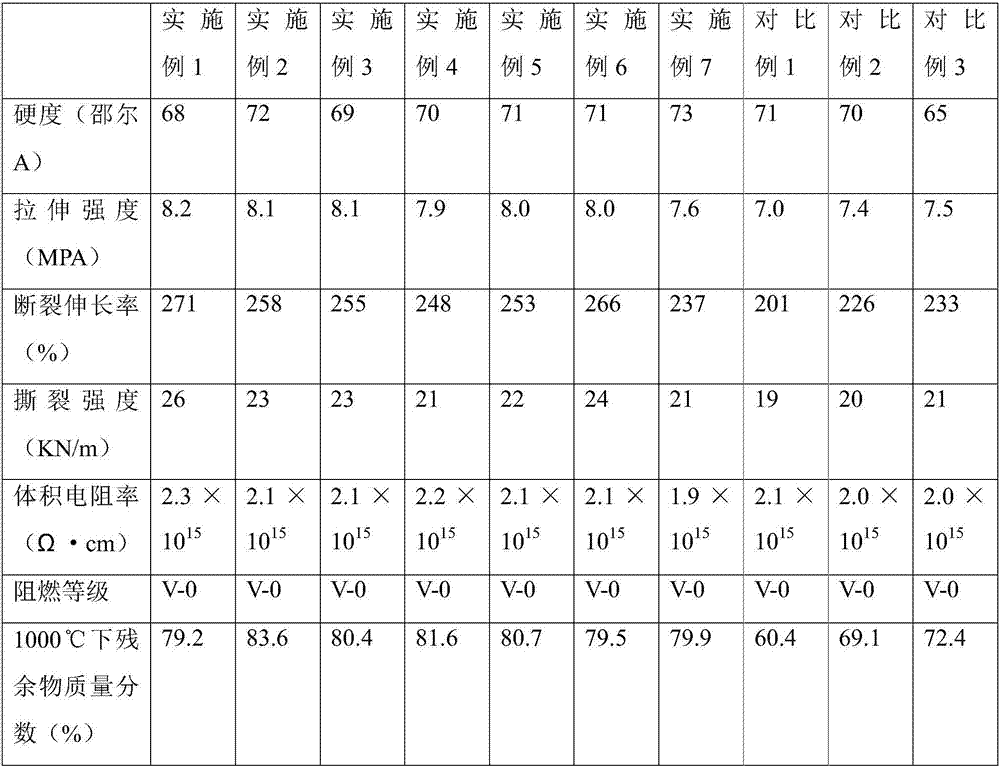

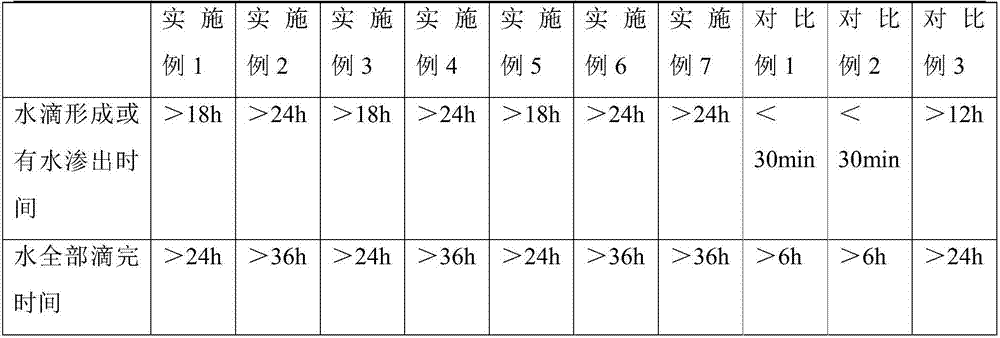

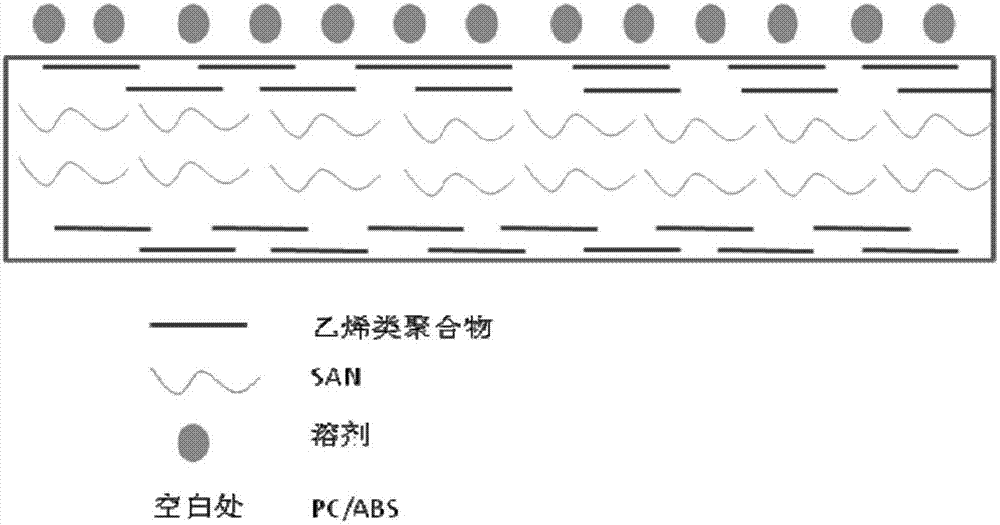

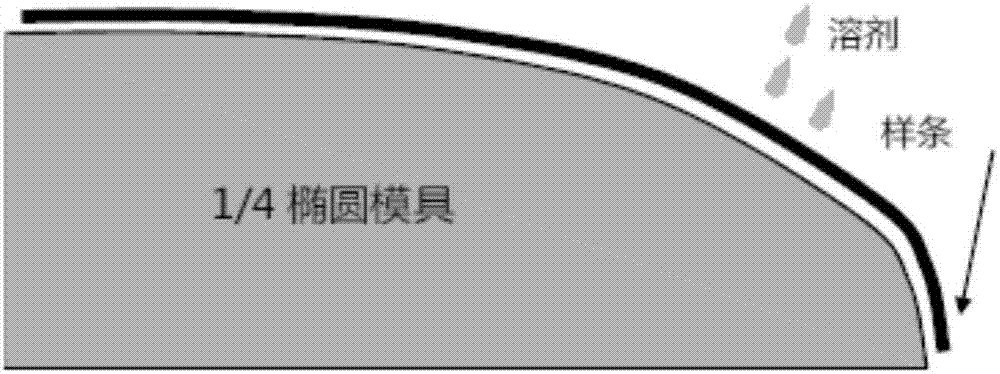

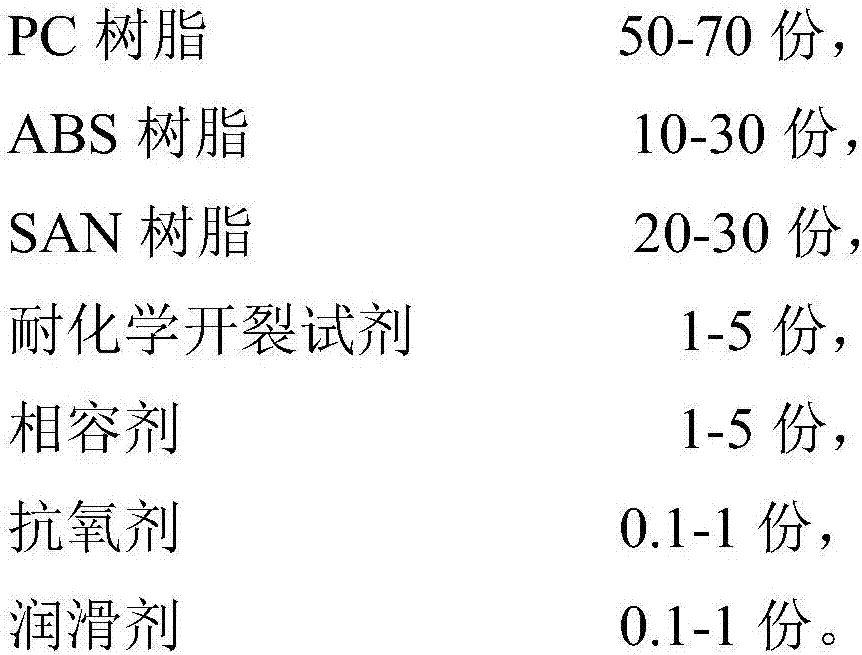

PC/ABS alloy with excellent automotive paint crack resistance and preparation method thereof

The invention relates to the field of high polymer materials, in particular to PC / ABS alloy with excellent automotive paint crack resistance. The PC / ABS alloy is prepared from the following components in parts by weight: 50-70 parts of PC resin, 10-30 parts of ABS resin, 20-30 parts of SAN resin, 1-5 parts of a chemical crack resistant reagent, 1-5 parts of compatibilizer, 0.1-1 part of antioxidant and 0.1-1 part of lubricant. The invention further provides a preparation method for the PC / ABS alloy with excellent automotive paint crack resistance. According to the PC / ABS alloy with excellent automotive paint crack resistance, through synergistic use of ethylene polymer and polystyrene-acrylonitrile with high nitrile (AN) content, very good paint crack resistance is achieved on the surface layer of PC / ABS and inside PC / ABS, so that the PC / ABS does not have a bad cracking phenomenon as a result of poor solvent resistance in a paint spraying process, and therefore, the product yield in the paint spraying process is greatly increased.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

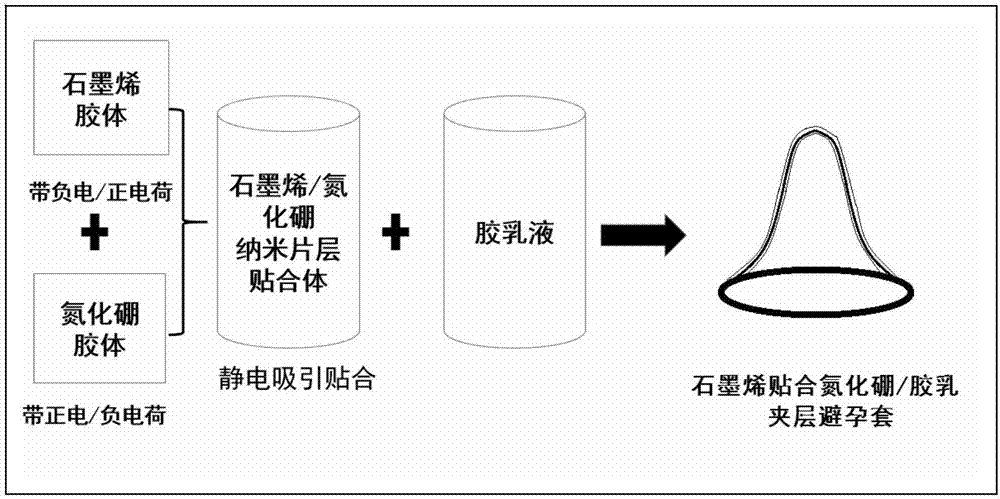

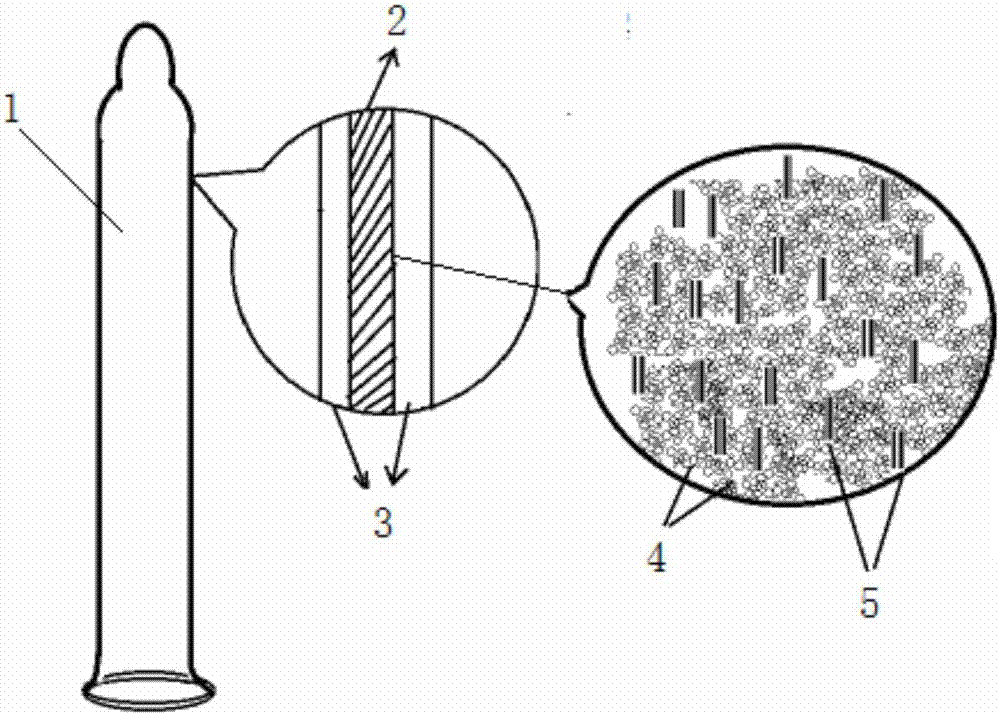

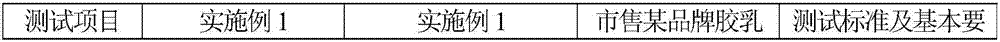

Method of producing sandwich-structure sensitization-free isolating condom from graphene laminating nano boron nitride compounded latex

The invention relates to the field of composite materials and medical appliances, and particularly provides a method of producing a sandwich-structure sensitization-free high-isolating condom from graphene laminating nano boron nitride compounded latex. The method includes the steps of: a) laminating and compounding graphene treated in an electric field and modified hexagonal nano-lamella boron nitride according to weight mass ratio of 5-2000%; b) compounding the compound in the step a) with latex according to solid mass ratio of 0.005-1%, wherein the prepared compound latex liquid is used in a second impregnation step, while in the first and third impregnation steps, a normal latex material is applied for impregnation, thereby finally producing the sensitization-free high-isolating condom having a sandwich structure. The condom in the invention has a stable transparent color and is not liable to have defects, such as graying, darkening, allergy of skin contact, and poor weather-resistant stability, due to deterioration of graphene. When the graphene is laminated with the nano-lamella boron nitride, which is also called white graphene, the tensile strength, flexibility and heat conductivity of latex are improved and permeation of virus liquid is effectively isolated.

Owner:辽宁格莱菲尔健康科技有限公司

Waterproof-socket electric connector

A waterproof-socket electric connector comprises a rubber core shell, an insulated body, plural terminals, a waterproof gasket, and a piece of sealing material (for example, a waterproof rubber block). The rubber core shell comprises a hollow opening. The insulated body is located in the hollow opening and comprises a pedestal and a tongue plate. The pedestal comprises an inner side surface and an outer side surface. The inner side surface faces the hollow opening while the outer side surface faces the exterior of the hollow opening. The tongue plate extends on the inner side surface. The plural terminals penetrate through the pedestal, and each terminal comprises a contacting end and a welding end which are connected with each other. Each contacting end extends on the tongue plate while each welding end penetrates out of the external side surface. The waterproof gasket is butted against the pedestal and the inner wall surface of the hollow opening. The sealing material (for example, the waterproof rubber block) is formed on the outer side surface and fills gaps between the plural terminals and the pedestal.

Owner:LIANZHAN TECH ELECTRONICS KUNSHAN CO LTD

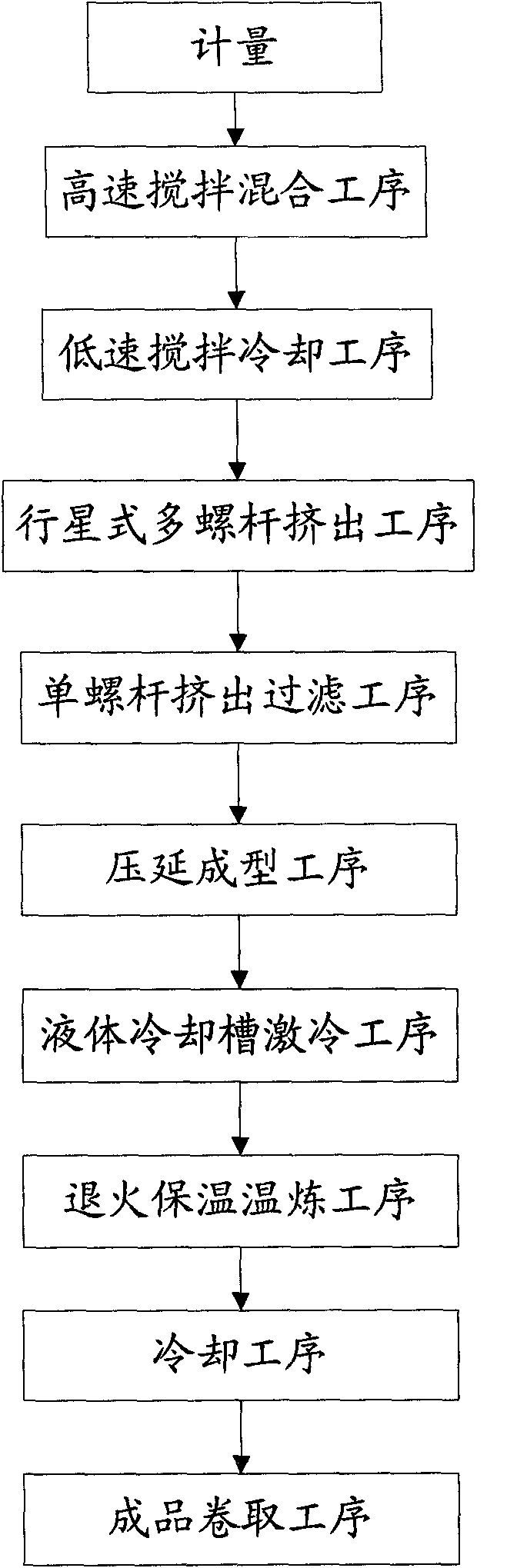

Hard polrvinyl chloride product and preparation method thereof

ActiveCN101792562AAvoid the phenomenon of surface sensitive water whiteningProtect the surfaceThiolPlasticizer

The invention discloses a hard polrvinyl chloride product, which contains the following components in parts by weight: 100 parts of polrvinyl chloride, 1.6-2.2 parts of organotin thiol, 0.6-1.0 part of internal lubricant, 0.2-0.5 part of external lubricant, 6-14 parts of impact-resistant modifier, 0.2-0.5 part of waterproof modifier, and proper amount of pigment is added. The invention also discloses a preparation method of the hard polrvinyl chloride product. The formula of the hard polrvinyl chloride product does not add any plasticizer, thus avoiding the phenomenon that the surface of the polrvinyl chloride product is water-sensitive and becomes white due to the influence of ester group of the plasticizer. In addition, the formula of the hard polrvinyl chloride product adds the waterproof modifier containing hydrophobic group, thus obviously improving the solvent resistance and the impermeability of the polrvinyl chloride product, effectively isolating the corrosion of external water or steam, protecting the surface of the polrvinyl chloride product, and leading the polrvinyl chloride product to have good appearance performance.

Owner:ANHUI TIANAN NEW MATERIAL CO LTD

Preparation method of ion exchange membrane and application thereof

ActiveCN110783591APermeation barrierReduce thicknessFinal product manufactureRegenerative fuel cellsPolymer resinPhysical chemistry

The invention relates to a preparation method of an ion exchange membrane and an application thereof, belongs to the technical field of ion exchange membrane preparation process, and mainly solves thetechnical problems of low ion conductivity, poor mechanical stability and the like existing in the present ion exchange membrane. The technical scheme of the invention is as follows: the preparationmethod of the ion exchange membrane comprises the following steps: 1) dissolving a perfluorosulfonic acid resin in a high boiling point polar solvent to prepare a perfluorosulfonic acid resin solution; 2) coating the perfluorosulfonic acid resin solution on a clean polytetrafluoroethylene porous mesh cloth through casting, dipping or scraper to prepare a mesh cloth supported perfluorosulfonic acidmembrane; and 3) soaking the mesh cloth supported perfluorosulfonic acid membrane in the nitrogen-containing heterocyclic polymer resin solution, then thoroughly drying the membrane, rinsing with water for many times and drying the membrane so as to obtain the ion exchange membrane. The preparation method has the advantages of high ion selectivity, high mechanical and chemical stability and the like.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

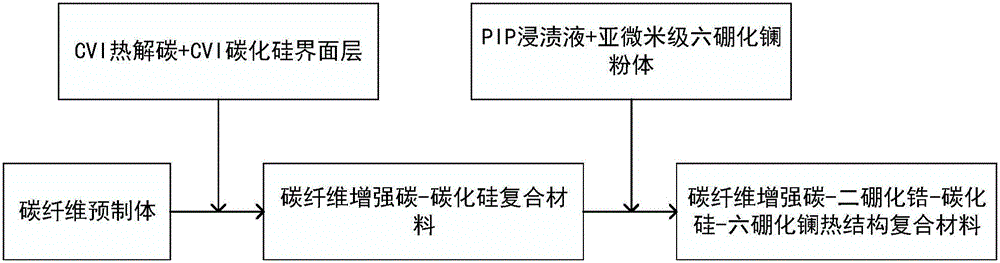

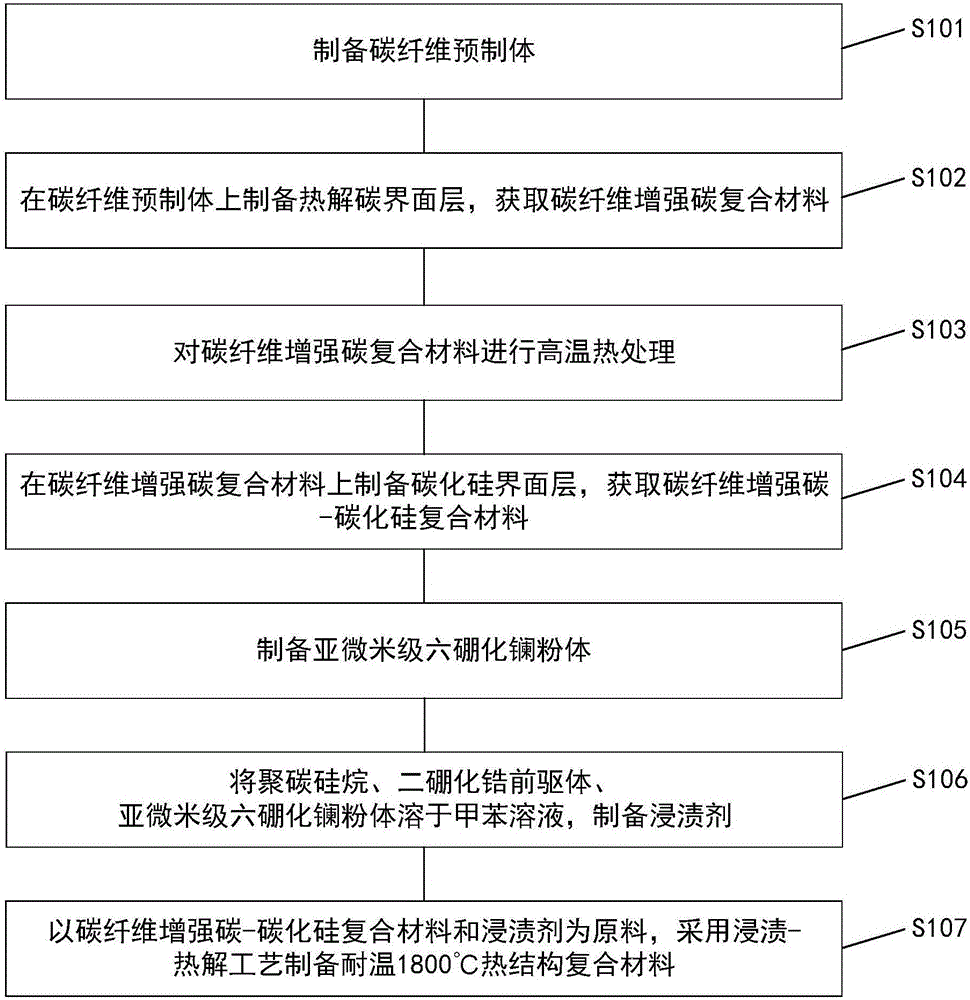

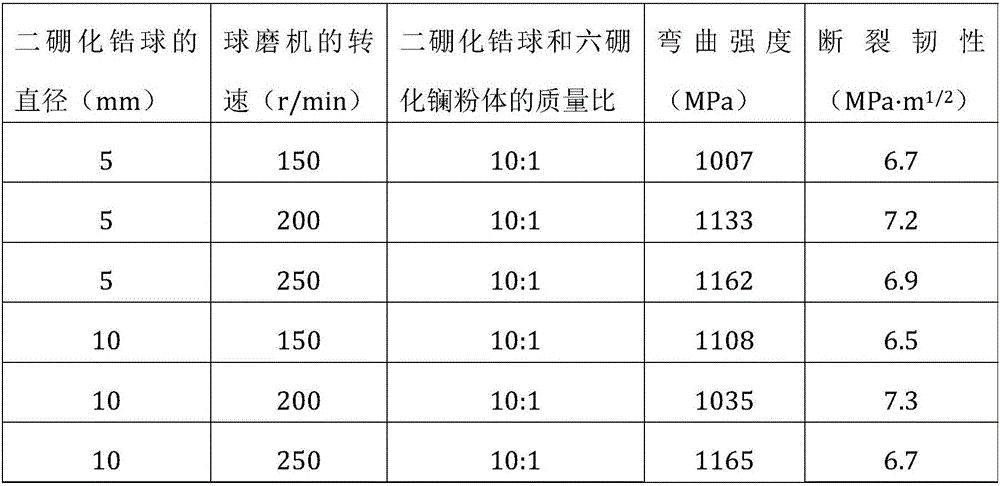

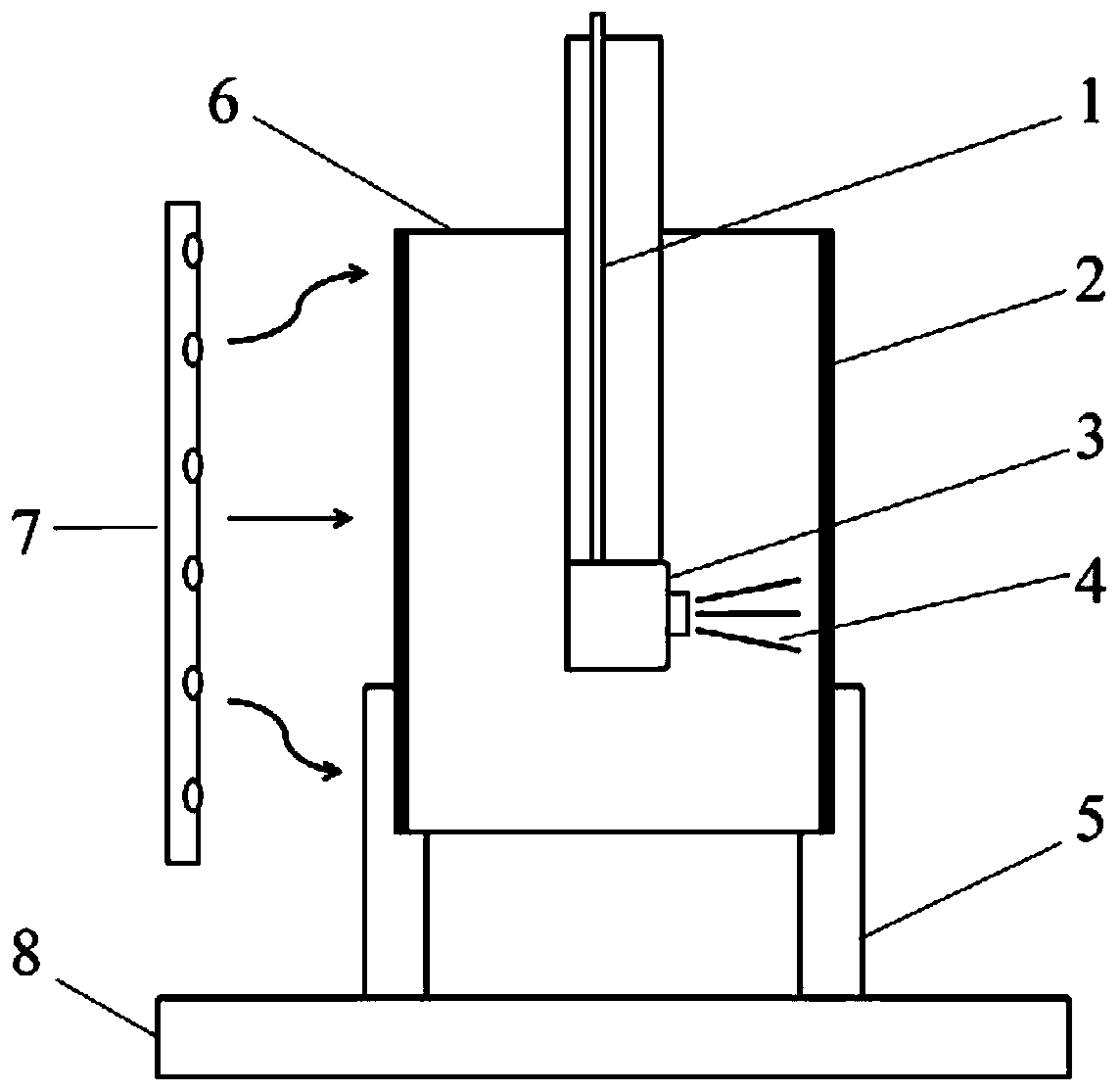

Preparation method for thermo-structure composite capable of resisting temperature of 1800 DEG C

The invention provides a preparation method for a thermo-structure composite capable of resisting a temperature of 1800 DEG C. A carbon fiber reinforced carbon-zirconium diboride-silicon carbide-lanthanum hexaboride composite, which is prepared with carbon fiber as a reinforcement body and a high-temperature-resistant multiphase ceramic composite as a matrix, integrates the advantages of both a carbon fiber reinforced carbon composite and the multiphase ceramic composite. The thermo-structure composite prepared by the preparation method has the advantages of low density, excellent mechanical property, high oxidation resistance and high ablation resistance; carbon, zirconium diboride, silicon carbide and lanthanum hexaboride in the matrix coexist; in the high temperature oxidation process, the substances are oxidized in sequence to generate a protective film for blocking oxygen diffusion and seeping, and a mechanism for alternately or jointly suppressing oxygen is formed to protect reinforced fibers from oxidation erosion; and through combination of zirconium diboride, silicon carbide and lanthanum hexaboride, the mechanical property and high temperature oxidation resistance of the thermo-structure composite are greatly improved.

Owner:BEIHANG UNIV

Cylinder sleeve inner wall heat insulation wear-resistant composite coating layer and preparation method thereof

InactiveCN109778104AWith wear resistanceImprove insulation performanceMolten spray coatingInsulation layerWear resistant

The invention belongs to the field of coating layers and particularly relates to a cylinder sleeve inner wall heat insulation wear-resistant composite coating layer and a preparation method thereof. The coating layer is arranged on the inner surface of a cylinder sleeve and comprises ceramic heat-insulation layers and metal wear-resistant layers which are alternately arranged. In the method, an inner hole plasma spraying system with a double-path powder feeder is adopted to perform preparation of the coating layer, metal powder and ceramic powder are sent into a plasma arc flame flow at the same time, the cylinder sleeve rotates around the axis self, an inner hole spray gun head of the inner hole plasma spraying system extends into the cylinder sleeve to move up and down in a reciprocatingmanner through a control program, powder parameters and powder feeding parameters are adjusted, a trajectory is adjusted and controlled, and the composite coating layer with a layered structure is obtained. The alternate layered coating layer is capable of insulating heat and resisting corrosion, enables the cylinder sleeve to perform heat dissipation by conducting the heat to a matrix along thecoating layer and a temperature of the interior of the cylinder sleeve to be maintained within a certain range, so that severe high-temperature wear cannot be caused by heat insulation in a severe high-temperature environment, the abrasion loss of the cylinder sleeve can be effectively reduced, and the heat efficiency of an engine can be improved.

Owner:YANGZHOU UNIV

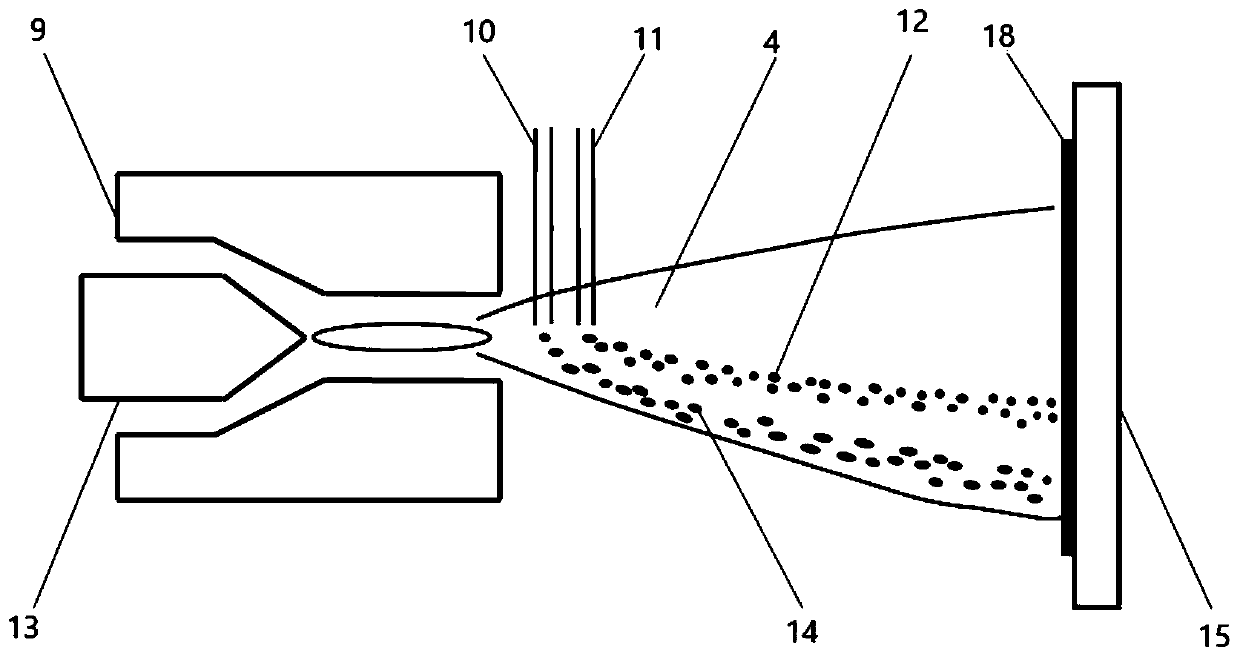

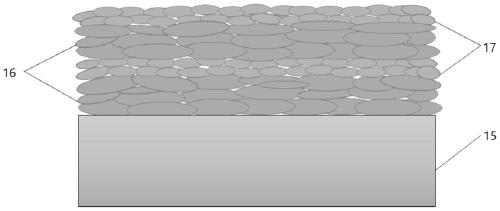

Method for utilizing photo-crosslinking polymers to conduct thin film packaging on organic electronic device

InactiveCN103579503APermeation barrierPackage suitable forSolid-state devicesSemiconductor/solid-state device manufacturingChemistryPhoto crosslinking

The invention provides a method for utilizing photo-crosslinking polymers to conduct thin film packaging on an organic electronic device, and belongs to the technical field of organic electronic devices. According to the method for utilizing the photo-crosslinking polymers to conduct thin film packaging on the organic electronic device, permeation of water vapor and oxygen into the organic electronic device can be effectively obstructed. Thin films formed through the method have stable chemical and physical properties, and the thin films are suitable for the flexible organic electronic device due to the potential material property of the thin films. The method includes the steps that the organic electronic device with an anode, a functional layer and a metallic cathode structure is manufactured on a substrate; then, the photo-crosslinking polymers are dripped to a metallic cathode of the organic electronic device in a hanging mode, and an organic packaging thin film is acquired through a spin coating method; eventually the organic electronic device coated with the organic packaging thin film is cured under the ultraviolet condition, and then the organic electronic device is packaged.

Owner:JILIN UNIV

Three-layer tetrafluoroethylene resin film-wound fuel hose and manufacturing method thereof

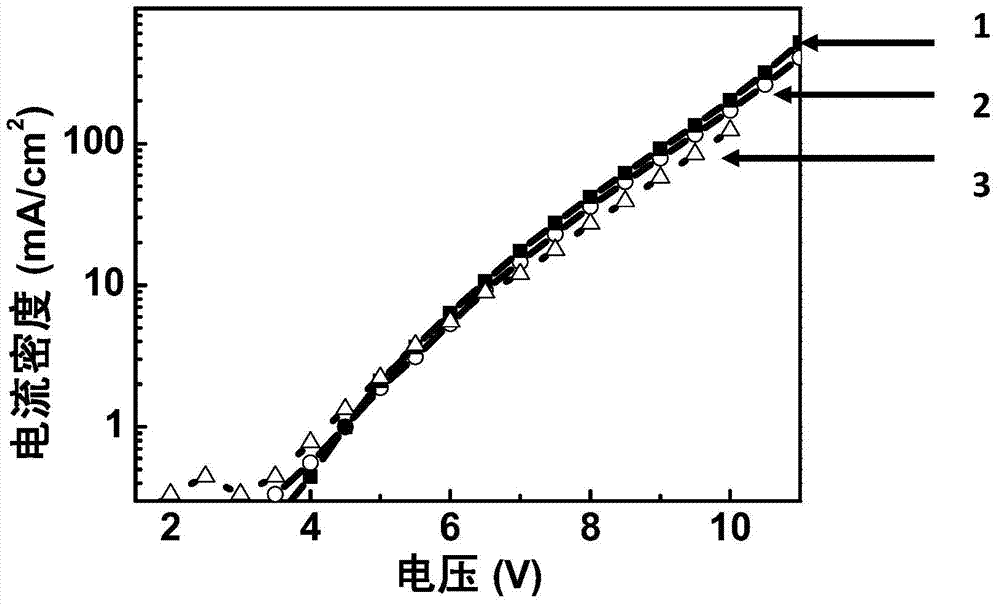

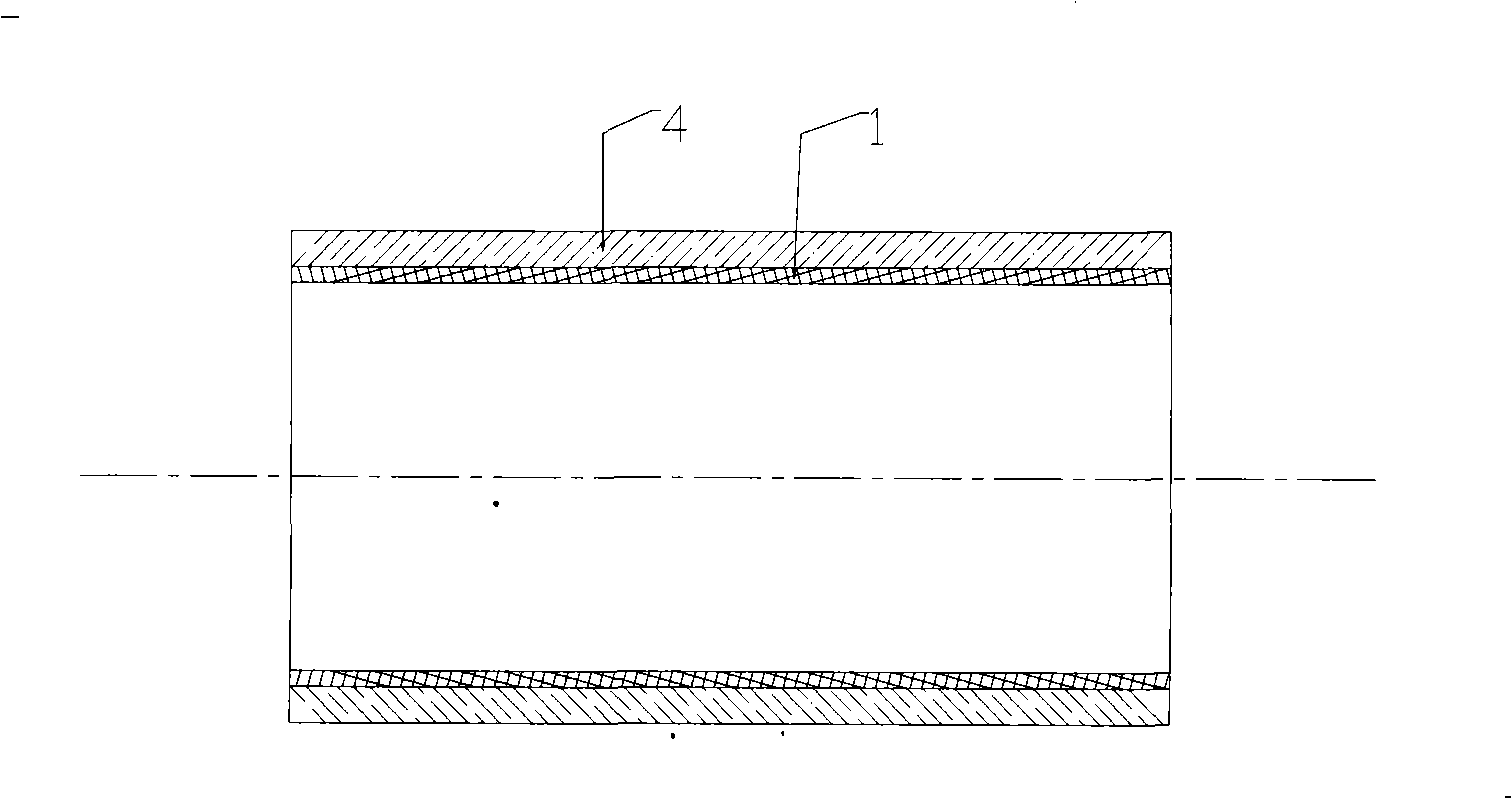

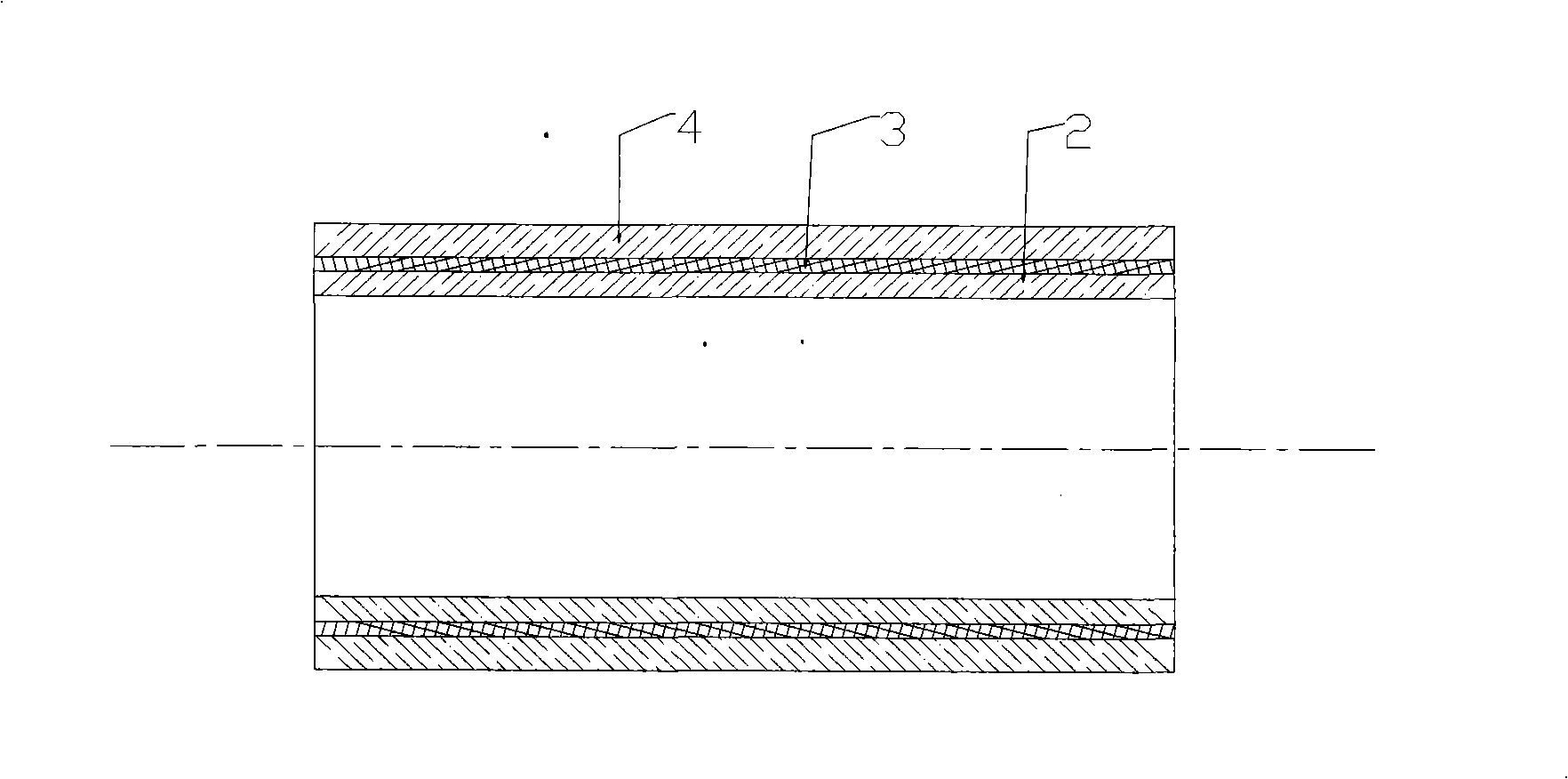

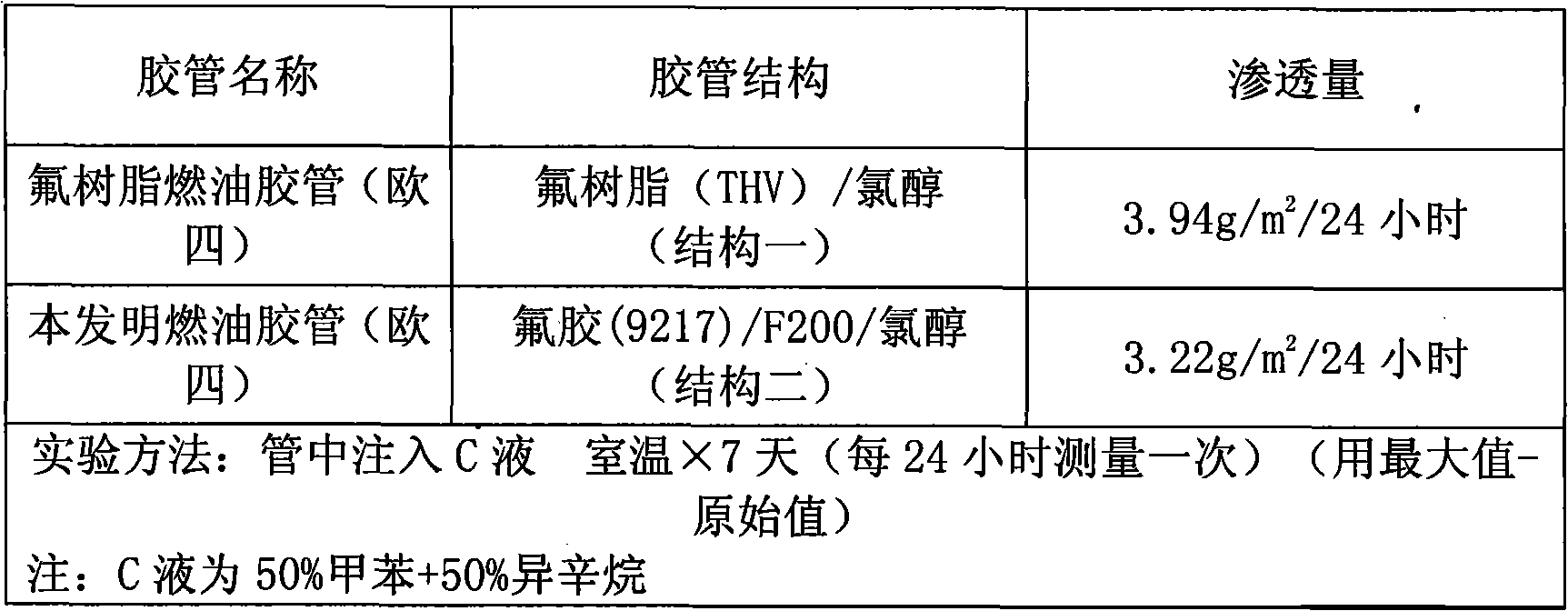

The invention relates to a three-layer tetrafluoroethylene resin film-wound fuel hose and a manufacturing method thereof. The invention proposes the method of extruding an inner rubber layer of the hose, winding an F200 fluororesin thin film and then coating an outer layer of the hose, so as to obtain a structure with a fluororubber layer 2, an F200 layer 3 and an outer rubber layer 4, while the thickness of each layer is as follows: the fluororubber layer is 0.5-1.0mm, the F200 layer is 0.05mm or 0.1mm, and the outer rubber layer is 1.0-2.5mm, and the range of the inner diameter of the hose is 7.3mm-50.0mm. The structural pipeline prepared by selecting the materials and the basic process not only plays the role of blocking the penetration of fuel and achieves the penetration requirements of Europe IV, but also solves the problems that the prior shaping of large-diameter Europe IV fuel pipeline is difficult and the flexibility of the hose is poor.

Owner:TIANJIN PENGYI GRP CO LTD

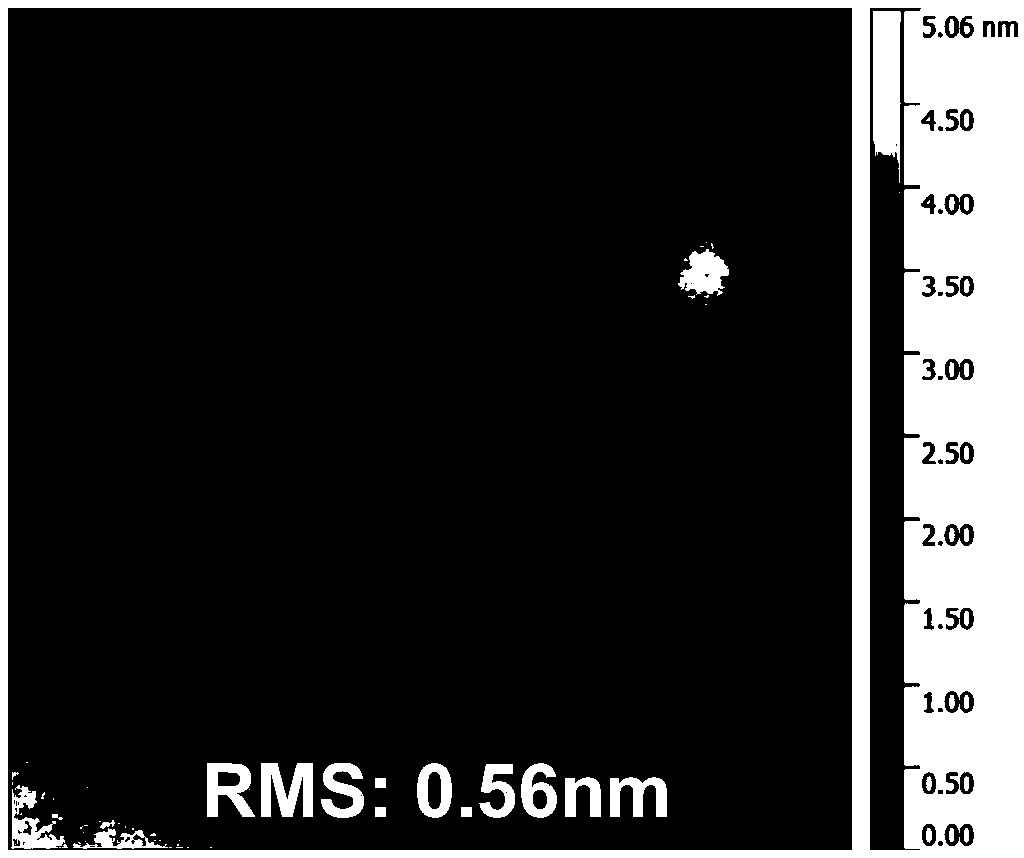

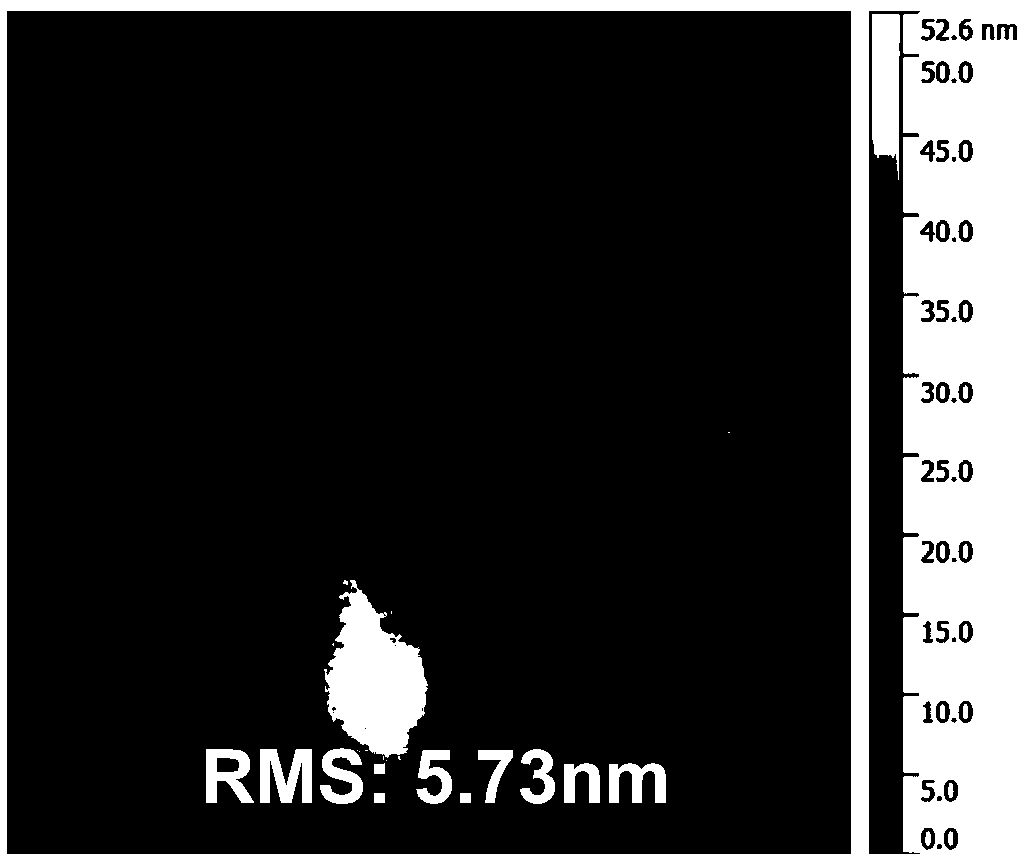

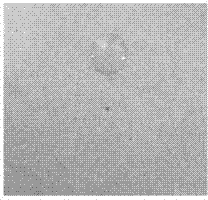

Flexible organic thin film transistor and fabrication method thereof

ActiveCN109638158AReduce roughnessReduce energy consumptionFinal product manufactureSolid-state devicesCross-linkPolyethylene terephthalate glycol

The invention discloses a flexible organic thin film transistor and a fabrication method thereof. The flexible organic thin film transistor sequentially comprises a flexible substrate, a gate electrode, an insulation layer, a semiconductor layer and a source-drain electrode, wherein the flexible substrate is polyimide, polyethylene terephthalate, polyethylene naphthalate or paper, the gate electrode is one of an indium tin oxide thin film, aluminum-doped zinc oxide, silver or nanometer silver wire thin film, a conductive polymer PEDOT:PSS or PEDOT:PSS and an AgNWs composite thin film, the insulation layer is a cross-linking agent obtained by esterification reaction of poly4-vinyl-phenol and 4,4'-(hexaisopropenylancetylene) phthalic anhydride, the semiconductor layer is C8-BTBT, and the source-drain electrode is gold, or silver, or nanosilver or PEDOT:PSS. The flexible organic thin film transistor has the advantages of high mobility, low working voltage, ideal switch ratio, favorable flexibility and the like, and a solution method is simple in preparation process and good in economic benefit and can be suitable for production on a large scale.

Owner:CENT SOUTH UNIV

Oil-repellent coated corrugated case and preparation method thereof

InactiveCN104775324AGuaranteed bonding strengthGuaranteed StrengthNon-fibrous pulp additionPaper coatingEnvironmental resistanceEngineering

The invention provides an oil-repellent coated corrugated case and a preparation method thereof. Firstly, the surface of one side of the body paper of a corrugated board adopted for the corrugated case is coated with oil-repellent coating; secondly, pressure is exerted to the oil-repellent coating under the condition of a temperature ranging from 160 to 170 DEG C so that the oil-repellent coating can be partially pressed in the body paper of the corrugated board, and the rest part of the oil-repellent coating forms an oil-repellent film on the surface of the body paper of the corrugated board. The oil-repellent coated corrugated case is an environment-friendly product, and does not contain heavy metal and does not pollute the environment; the oil-repellent coated corrugated case can be recycled and reutilized to conform to the European Union RoHs decrees. The case is coated with a layer of imported oil-repellent coating, and when the coating amount is about 15g / m<2>, the penetration of oil can be thoroughly obstructed, and a remarkable effect can be achieved and the cost is low.

Owner:DACHENG PACKAGING PROD SUZHOU +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com