Organic light-emitting diode (OLED) display panel encapsulation structure, manufacturing method of OLED display panel encapsulation structure, and display device

A technology of light-emitting diodes and display panels, which is applied in the manufacture of semiconductor/solid-state devices, semiconductor devices, electrical components, etc., and can solve the problems of reducing the service life of organic light-emitting diode devices, easily breaking glass retaining walls, and easily reducing adhesion, etc. Achieve the effects of improving packaging reliability, improving bonding reliability, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further illustrate the packaging structure of the organic light emitting diode display panel provided by the embodiments of the present invention, its manufacturing method, and the display device, a detailed description will be given below in conjunction with the accompanying drawings.

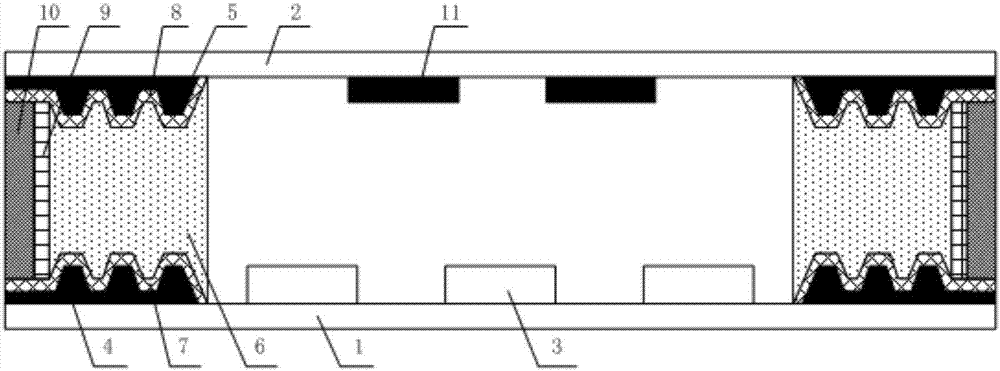

[0030] refer to figure 1 , the organic light emitting diode display panel packaging structure provided by the embodiment of the present invention includes an organic light emitting diode display substrate 1 and a glass cover plate 2 arranged oppositely, the non-display area of the organic light emitting diode display substrate 1 and the corresponding non-display area of the glass cover plate 2 An encapsulation part is provided between the parts, and the organic light emitting diode device 3 of the organic light emitting diode display substrate 1 is located in a sealed cavity surrounded by the organic light emitting diode display substrate 1, the glass cover plate 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com