PC/ABS alloy with excellent automotive paint crack resistance and preparation method thereof

A paint and performance technology, applied in the field of PC/ABS alloy and its preparation, can solve the problems of cracking, strong corrosion, etc., and achieve high product yield, good resistance to acetone and ethyl acetate, and good resistance to paint cracking. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

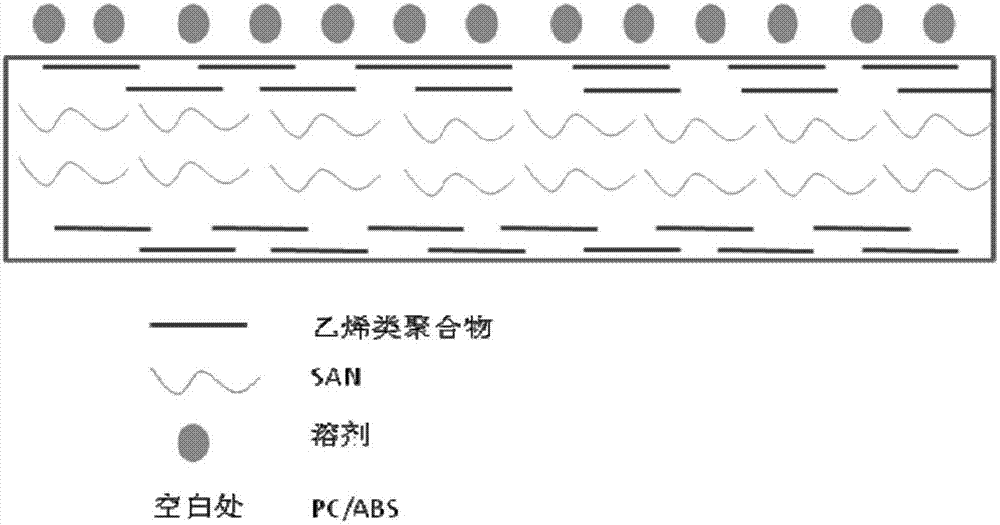

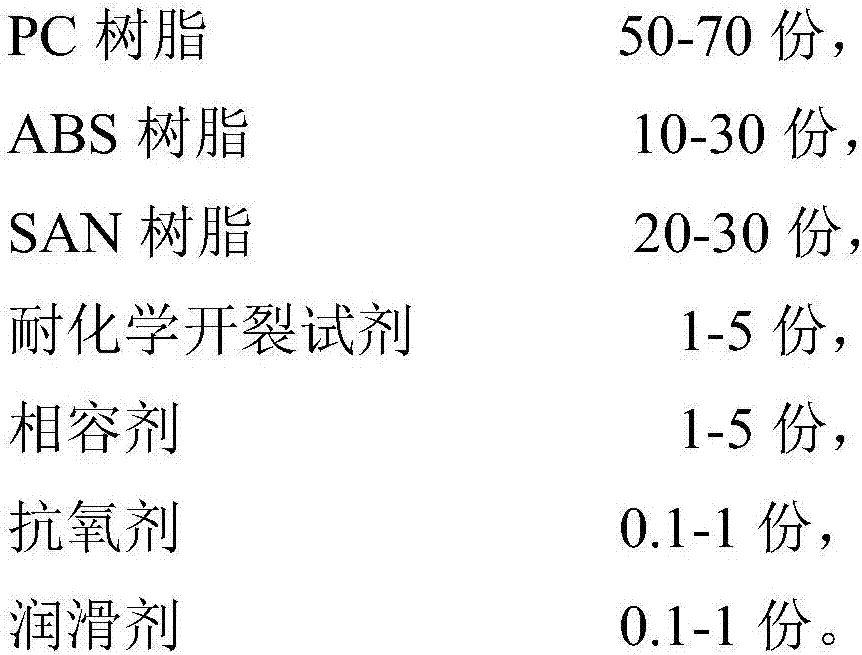

Method used

Image

Examples

Embodiment 8

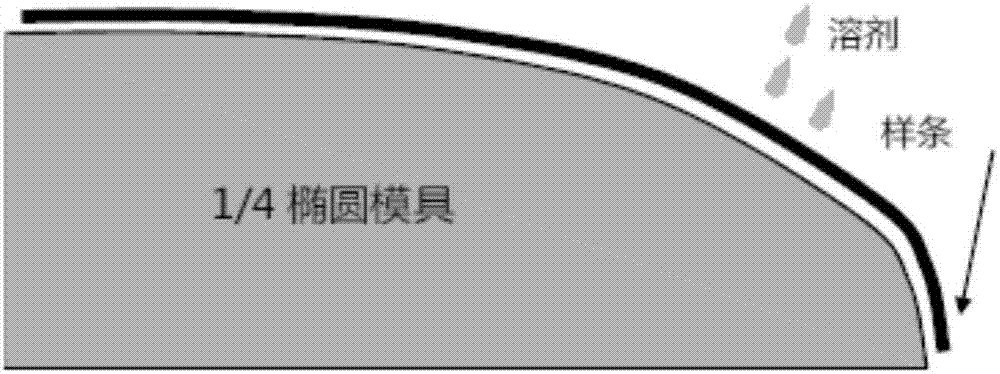

[0061] Embodiment 8: Evaluation of implementation effect

[0062] The PC / ABS prepared in the above Comparative Examples 1-3 and Examples 1-6 were subjected to related tests: melting was tested according to ISO1133; notched impact strength was tested according to ISO 179; Vicat softening temperature was tested according to ISO 306; mold shrinkage was tested according to Tested according to ISO 294-4; chemical resistance performance evaluation, fixed on a 1 / 4 elliptical mold with a tensile spline, and then evenly coated acetone / ethanol and ethyl acetate / ethanol on the surface of the spline at a ratio of 1:1 The mass ratio of mixed solvents was used to observe the time for cracks to appear on the surface of the spline. After the actual painting verification, after the solvent is applied, the cracking time of the spline exceeds 20 minutes is a qualified product. It can be seen from comparative examples 1 to 3 that the chemical resistance of PC / ABS can be improved by adding silico...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com