Patents

Literature

130results about How to "Improve cracking performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

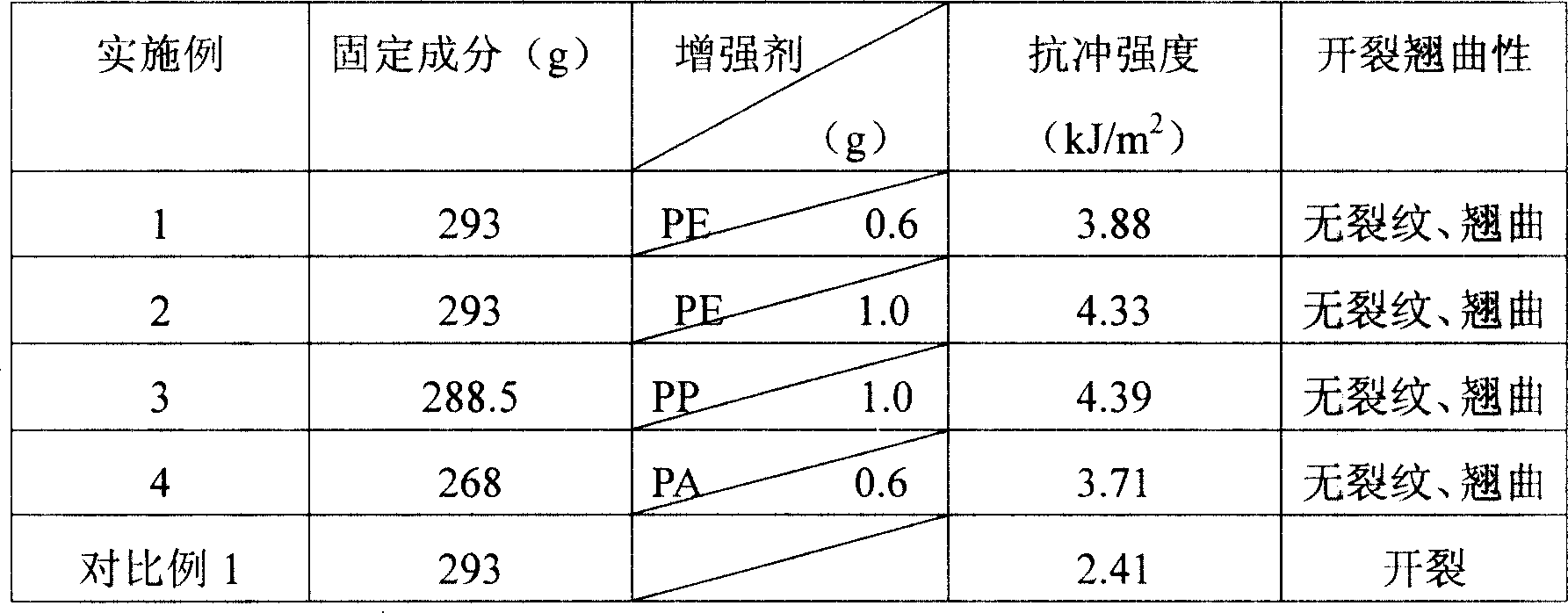

Artwork with modified urea-formaldehyde resin as adhesive and preparing method thereof

InactiveCN101012360AHigh impact strengthImprove cracking performanceDecorative surface effectsOrnamental structuresAqueous solutionPoly methacrylate

The invention discloses a binder and making method of modified urea-formaldehyde resin, which comprises the following steps: adopting urea-formaldehyde resin, fill, reinforcer, deoxidation agent, formaldehyde catching agent, anti-aging agent, anti-shrinking agent, hardener and auxiliary reinforcer; adopting modified copolymer of acrylic acid, sodium acrylate, N, N-dimethylamino propyl methyl acrylamide as anti-shrinking agent; making polyacrylamide solution reacted by acrylamide and ammonium persulphate as formaldehyde catching agent; allocating each component according to proportion; blending evenly; casting; extracting into vacuum; stripping; stewing; drying naturally; coating a layer of polymethacrylate paint on the surface of product; proceeding colorful paint; obtaining the product.

Owner:XIAMEN UNIV

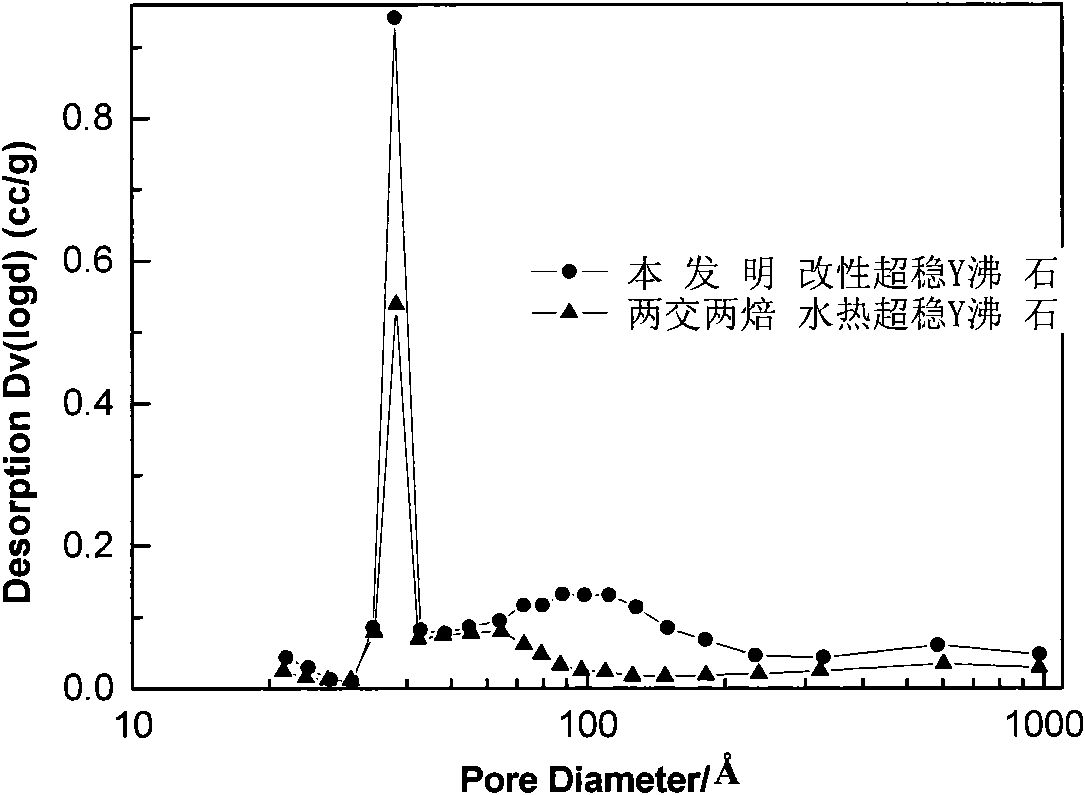

Super-stable Y zeolite, preparation method and application thereof

ActiveCN102020289AHigh crystallinityIncrease the areaCatalytic crackingMolecular sieve catalystsOrganic acidGasoline

The present invention provides a super-stable Y zeolite and the preparation method thereof. The ratio of silicate to aluminum in the super-stable Y zeolite is 6-11. The lattice constant of the zeolite is 2.446 to 2.458 nanometers. The percentage of non-skeleton aluminum in total aluminum in the zeolite is not higher than 30% by weight. The diameter of secondary pores with diameter of 2 to 100 nanometers in the zeolite shows a double probable distribution. The most probable diameter of the secondary pores with comparatively large diameter is 6-15 nanometers. The proportion of secondary pores with diameter between 8 to 100 nanometers in total secondary pores is 35% to 60%. The preparation method of the zeolite includes the step of making the super-stable Y zeolite come into contact with a solution containing organic acids and inorganic acids in the atmosphere of inert gases and / or nitrogen. The modified super-stable Y zeolite provided in the invention is applied to catalytic cracking; therefore the following effects can be realized: the cracking ability of heavy oil is strong, the selectivity of gasoline is high, and the selectivity of dry gas and carbon coke is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

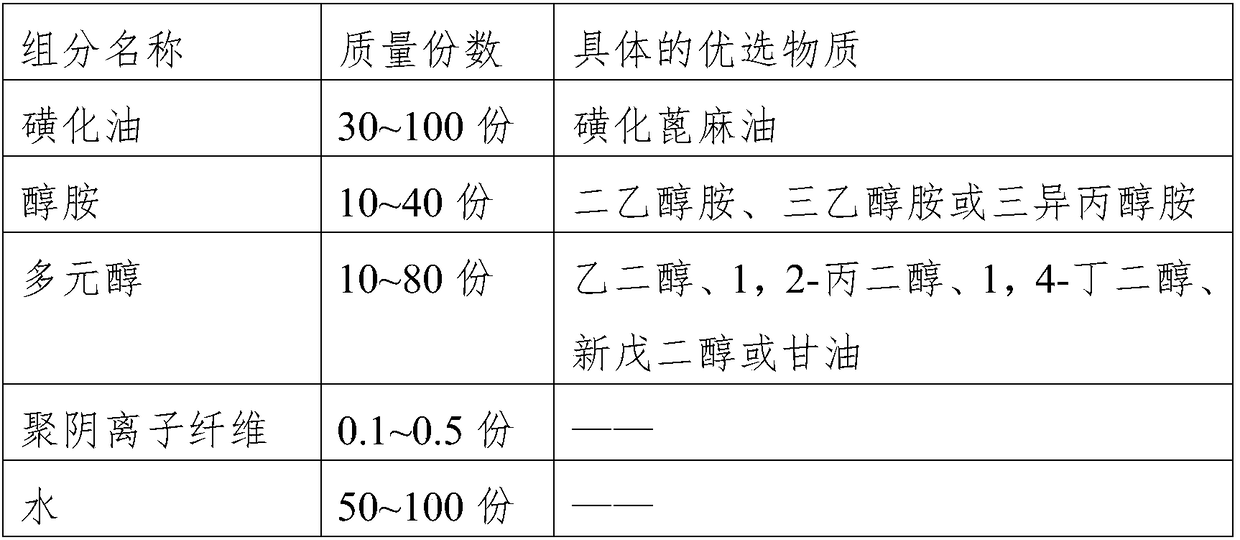

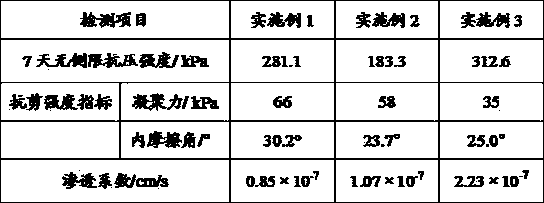

Curing agent capable of rapidly curing sludge at room temperature and use method thereof

The invention discloses a curing agent capable of rapidly curing sludge at room temperature and a use method thereof. The curing agent is prepared from, by weight, 48%-70% of inorganic micro powder, 28%-50% of emulsion, 0.05%-1.8% of high-performance water-absorbent resin and 0.05%-0.5% of triethanolamine. The emulsion can react with the inorganic micro powder and activated silicon dioxide and aluminum oxide in the sludge to form a zeolite-like crystalline substance of a silicon (aluminum)-oxygen tetrahedron structure. The sludge curing agent is capable of improving the curing strength of the sludge and shortening the curing time, small in air shrinkage and good in water resistance, and dosing of materials can be particularly adjusted according to components of the sludge, so that curing of the sludge is not limited by time, the strength, the stability and the like meet the actual engineering requirements, the cost is low, pollution does not exist, and the curing agent can be widely applied and promoted.

Owner:GUANGZHOU INSTITUTE OF BUILDING SCIENCE CO LTD

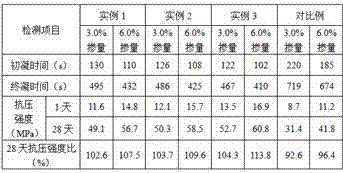

Chlorine-free and alkali-free liquid setting accelerator and preparation method thereof

The invention belongs to the technical field of preparation of additives, and in particular relates to a chlorine-free and alkali-free liquid setting accelerator and a preparation method thereof. The preparation method comprises the steps of adding aluminum sulfate and aluminum hydroxide into deionized water, and heating to obtain mother liquor of aluminate; then, adding magnesium fluosilicate and disodium ethylenediamine tetraacetate into the deionized water, and heating to obtain a magnesium fluosilicate solution; mixing the magnesium fluosilicate solution with the mother liquor of aluminate, then adding organic amine, organic acid and a stabilizer, and stirring to obtain the chlorine-free and alkali-free liquid setting accelerator. The setting accelerator prepared by the method has the characteristics of being small in mixing amount and good in setting acceleration effect; furthermore, after the setting accelerator is used, the mechanical properties of the concrete are improved, and the compressive strength of the concrete is increased; therefore, the chlorine-free and alkali-free liquid setting accelerator is an ideal concrete additive.

Owner:常州文诺纺织品有限公司

Modified epoxide resin pouring sealant and preparation method thereof

InactiveCN103059788AReduce moisture absorption performanceReduce the coefficient of expansionNon-macromolecular adhesive additivesEpoxy resin adhesivesEpoxySealant

The invention relates to the technical field of pouring sealant, in particular to modified epoxide resin pouring sealant and a preparation method of the modified expoxide resin pouring sealant. The modified epoxide resin pouring sealant achieves improvement based on the prior art. The pouring sealant is composed of a component A and a curing agent. The weight ratio of the component A to the curing agent is 100 to 3-15, wherein the component A comprises, by weight, 1.0-8.0% of thinner, 25.0-39.0% of nano filler, 0.5-4.5% of flexibilizer, 0.08-0.45% of coupling agent, 0.08-0.45% of pigment, and the balance grapheme modified epoxide resin, and the total weight is equal to 100%. Compared with the prior art, due to addition of the grapheme modified epoxide resin and the nano filler, the pouring sealant is capable of improving high and low temperature resistant impact properties, capable of reducing hygroscopicity and a dilatation coefficient, capable of prolonging storage time, capable of strengthening dehiscence resisting capacity, and capable of having great value of industrial application.

Owner:东莞市松山湖微电子材料研发中心

Melt treating method of high-vanadium high-speed steel roller material for various rolling machines

The invention discloses a melt processing method of high-speed steel rolls containing high vanadium used for various rolling mills. When molten steel in transportation, ferrovanadium granules are added with flowing, the addition amount of the ferrovanadium granules is 0.80-1.20 percent of total weight of the molten steel. Before the molten steel is poured over a pouring ladle, yttrium based rare earth magnesium alloy, nitriding ferrochrome, potassium salt and metal aluminum are added into the pouring ladle in advance; wherein, the addition amount of the yttrium based rare earth magnesium alloy is 0.30-0.80 percent of the weight of the molten steel, the addition amount of the nitriding ferrochrome is 0.20-0.50 percent of the weight of the molten steel, the addition amount of the potassium salt is 0.30-0.80 percent of the weight of the molten steel and the addition amount of the metal aluminum is 0.30-0.60 percent of the weight of the molten steel. When the temperature of the molten steel reaches between 1450-1480 DEG C, the molten steel in a centrifuge is directly cast into rollers; during the process of casting molten steel, the ferrovanadium granules and ferrotitanium granules with granule dimension between 5mm-8mm are added with flowing, wherein, the addition amount of the ferrovanadium granules and the ferrotitanium granules is respectively 0.30-0.80 percent and 0.40-1.00 percent of the total weight of the molten steel. The centrifugal casting high-speed steel rolls containing high vanadium of the invention has less segregation, no casting cracks, high rigidity and good abrasion resistance.

Owner:XI AN JIAOTONG UNIV

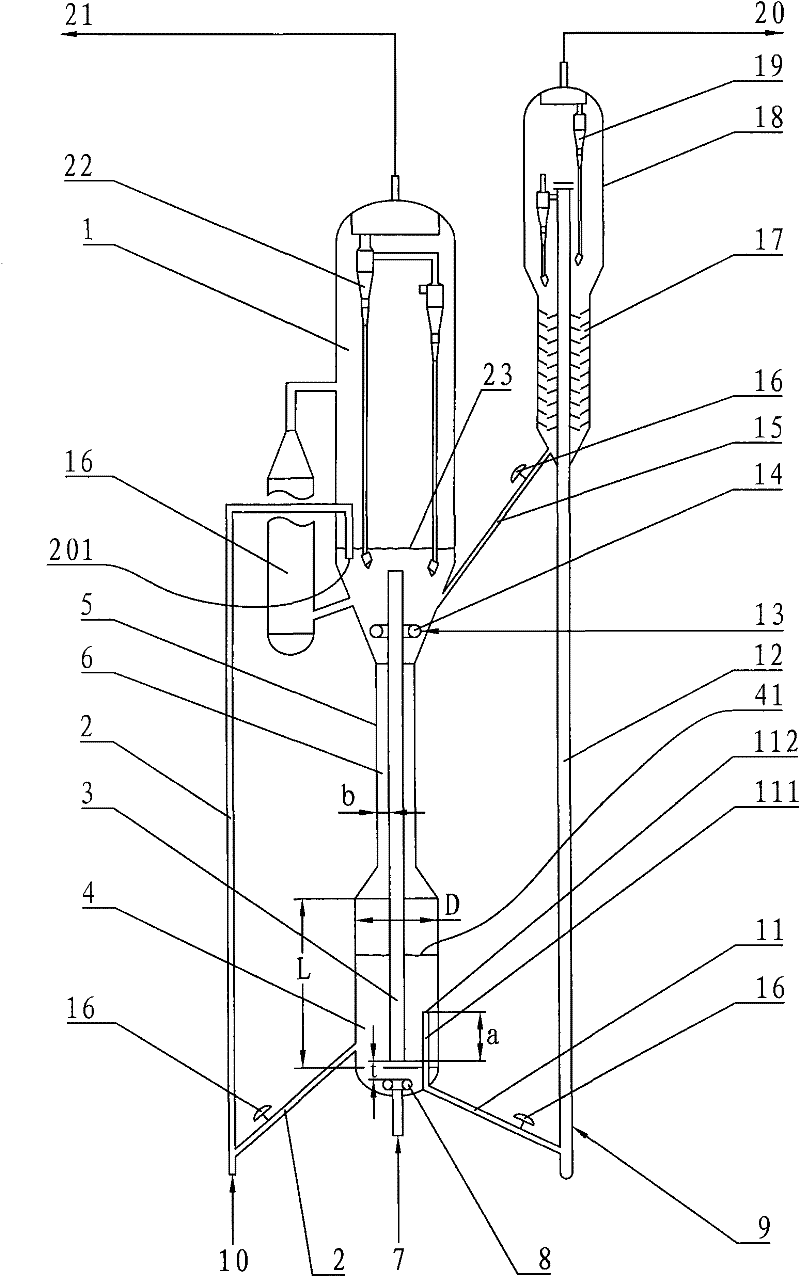

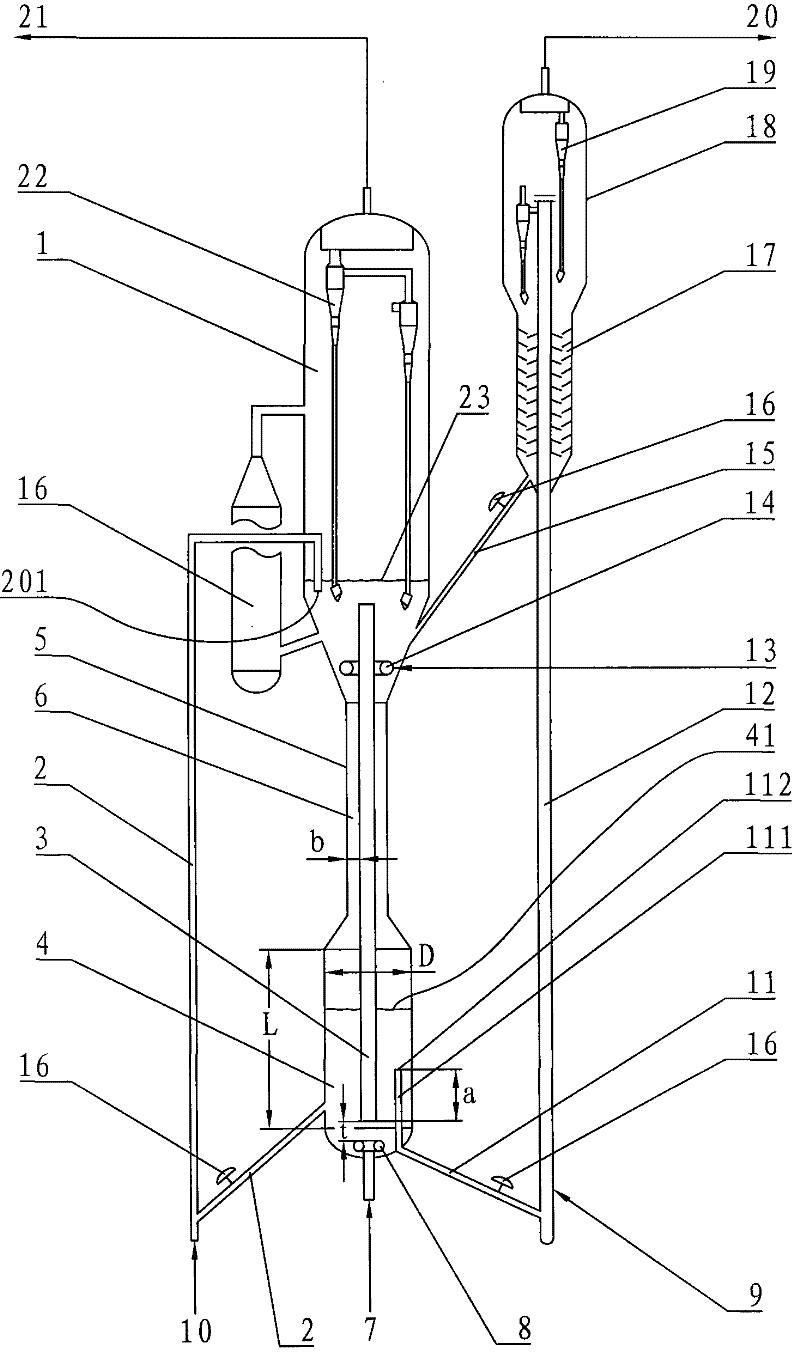

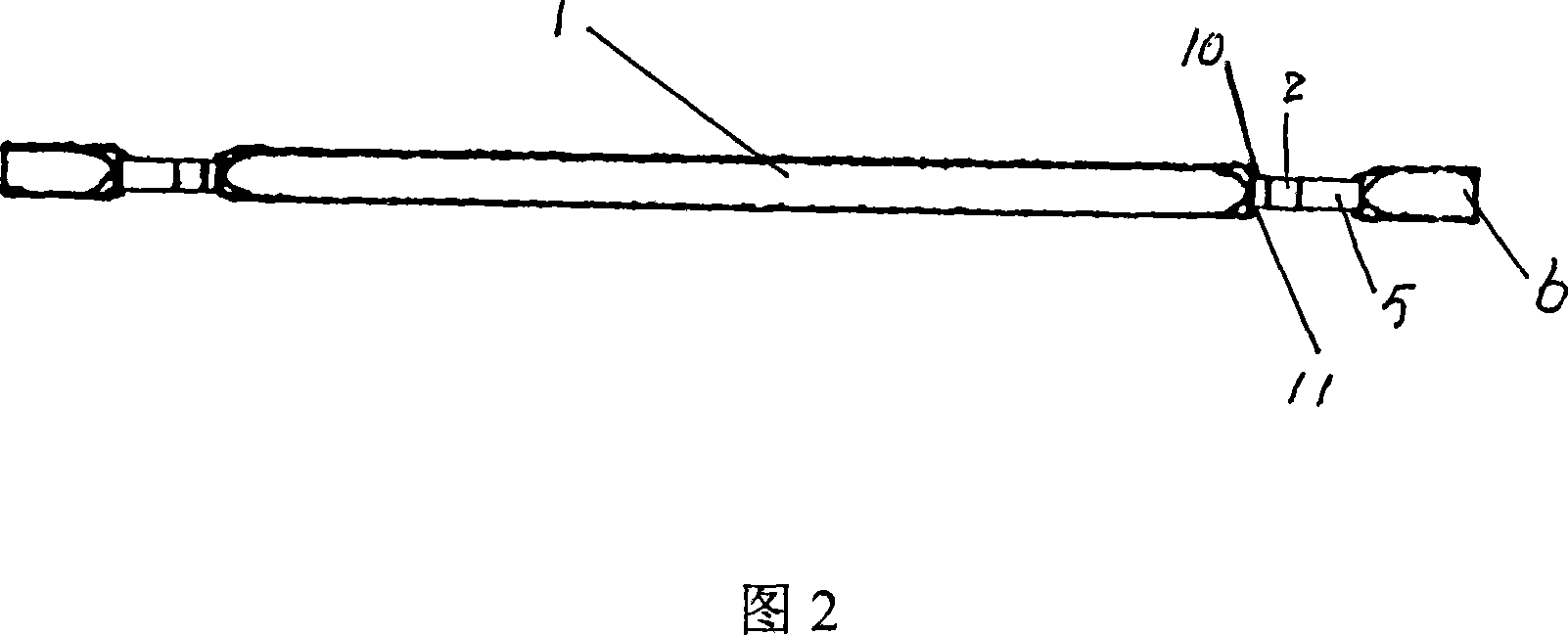

Device and method for reducing the temperature of catalytic cracking regenerated catalyst

Owner:CHINA PETROCHEMICAL CORP +1

Device and method for reducing the temperature of catalytic cracking regenerated catalyst

ActiveCN101575534AWide range of applicationsReduce carbon contentCatalytic crackingPetrochemicalPetroleum

The invention discloses a device and a method for reducing the temperature of catalytic cracking regenerated catalyst in the field of petrochemical industry catalytic cracking and aims to solve the problems that the method for reducing the temperature of catalytic cracking regenerated catalyst has a small application range in the prior art, and the like. The device comprises a regenerated catalyst cooler (4) arranged below a regenerator (1) and the bottom head of the cooler is internally provided with a cooling main air distributor (8). A sleeve (5) is arranged between the top of a taper section of the regenerated catalyst cooler and the bottom of the regenerator and provided with a regenerated catalyst conveying pipe (3) internally, and an annular space (6) is formed between the sleeve and the conveying pipe. A regenerated inclined pipe (11) is arranged between the regenerated catalyst cooler and a heavy oil riser reactor (12) of a catalytic cracking device. The invention also discloses a method for reducing the temperature of catalytic cracking regenerated catalyst by adopting the device. The device and the method can be used for setting a catalytic cracking device of a single heavy oil riser reactor and a plurality of riser reactors.

Owner:CHINA PETROCHEMICAL CORP +1

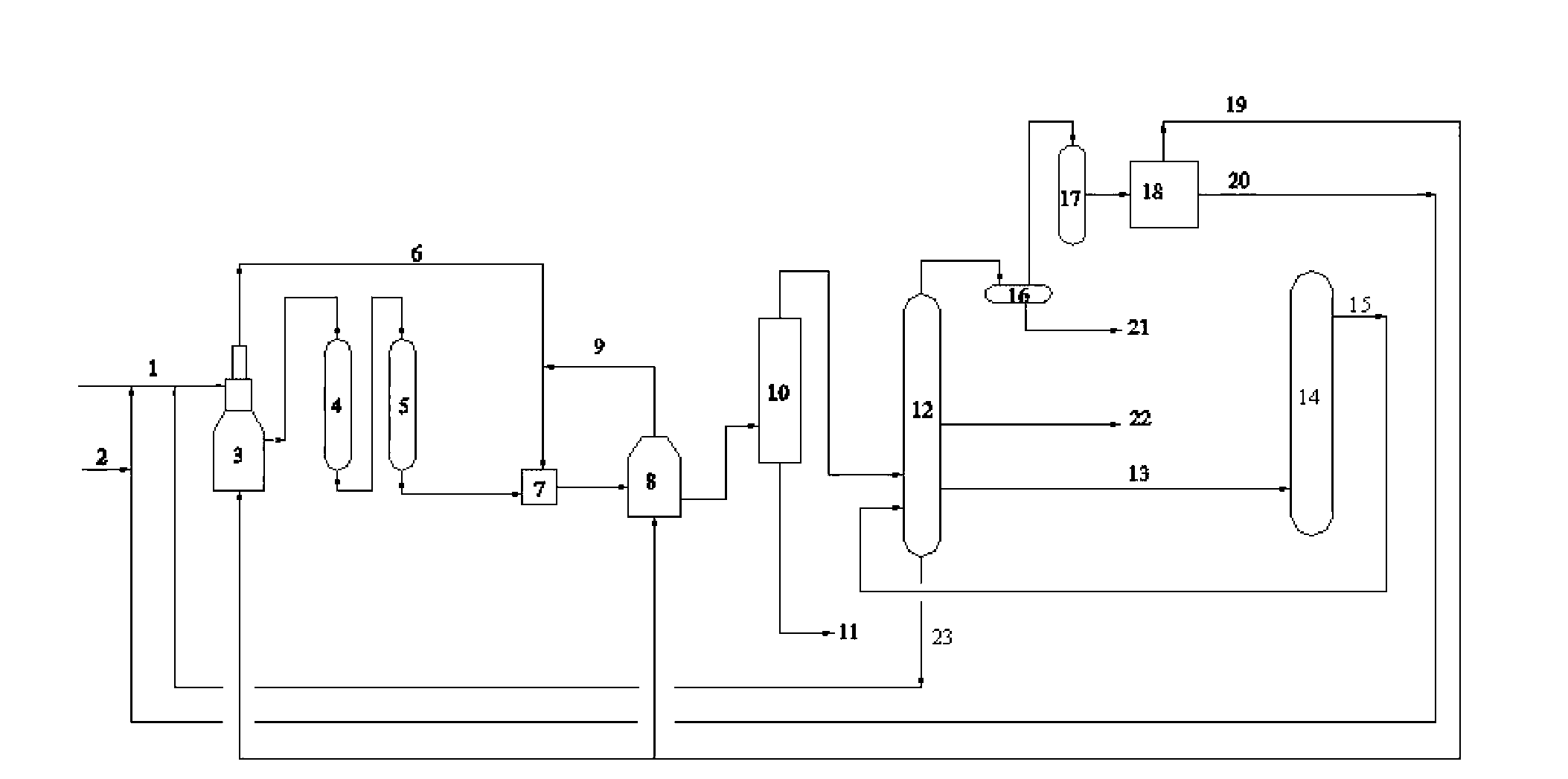

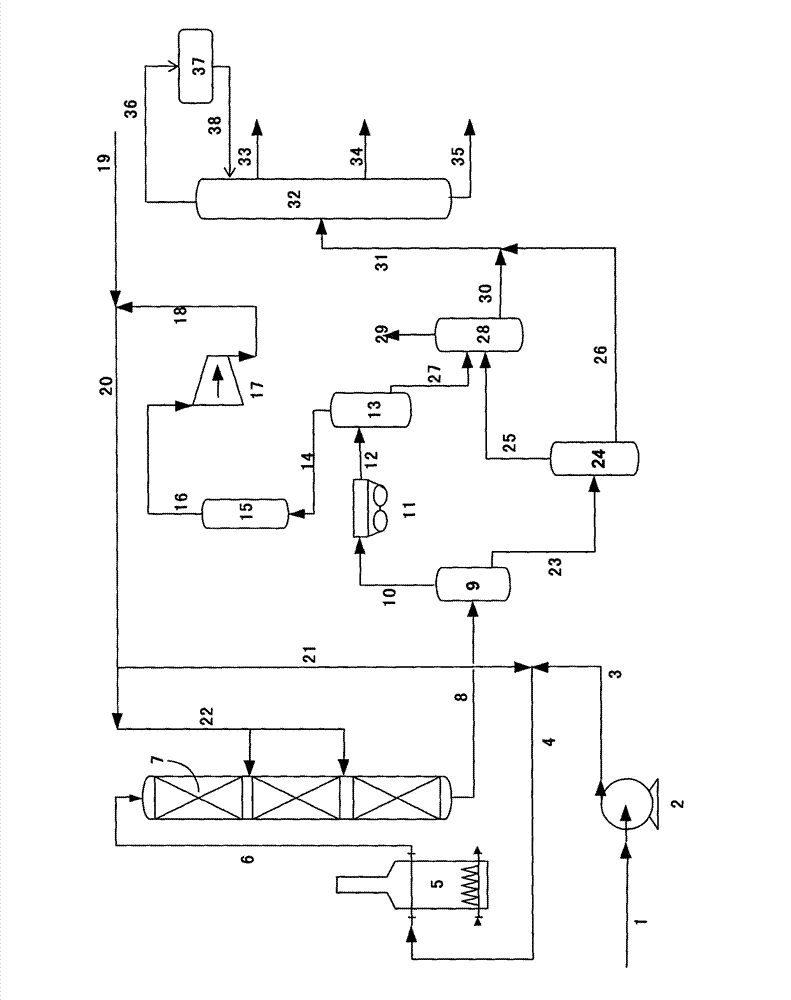

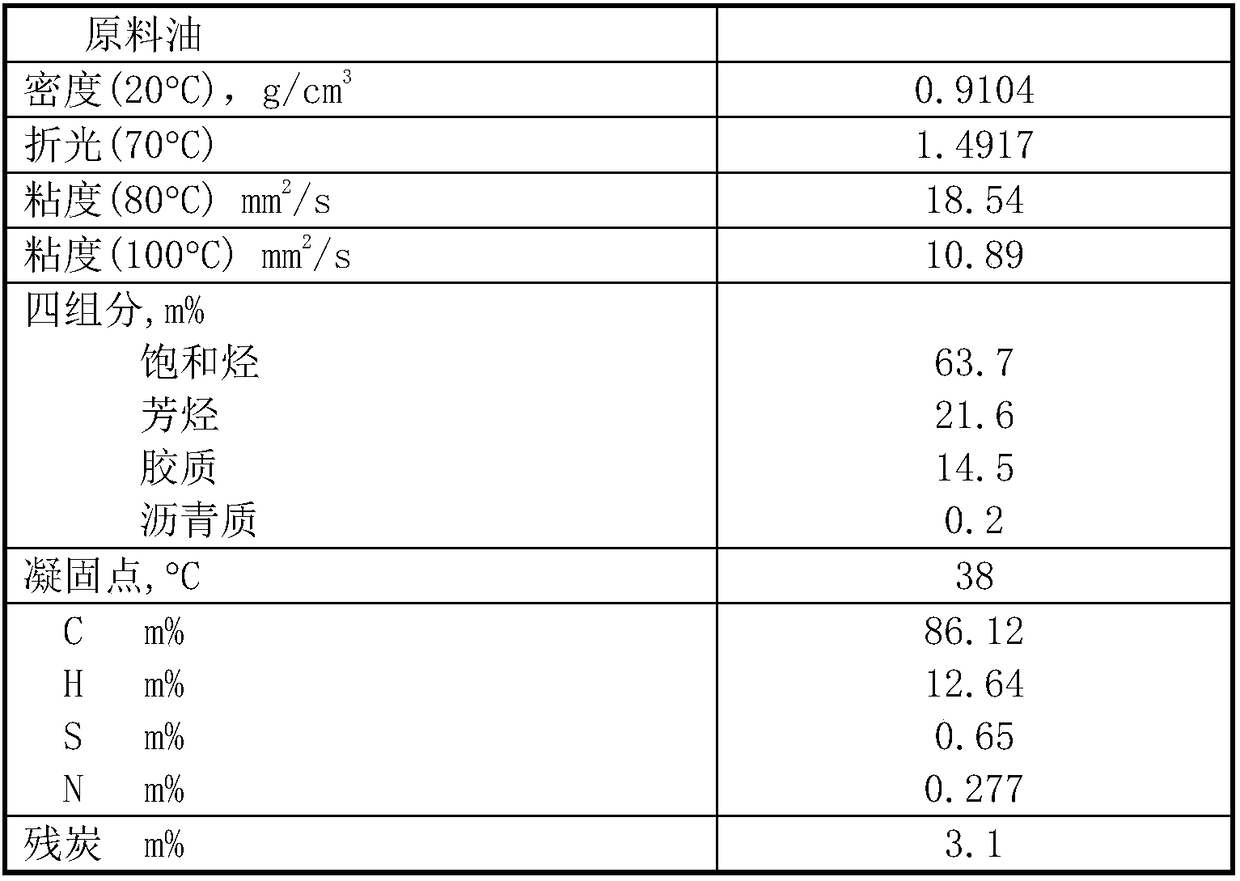

Combined process method of lightening residual oil/ medium and low temperature coal tar

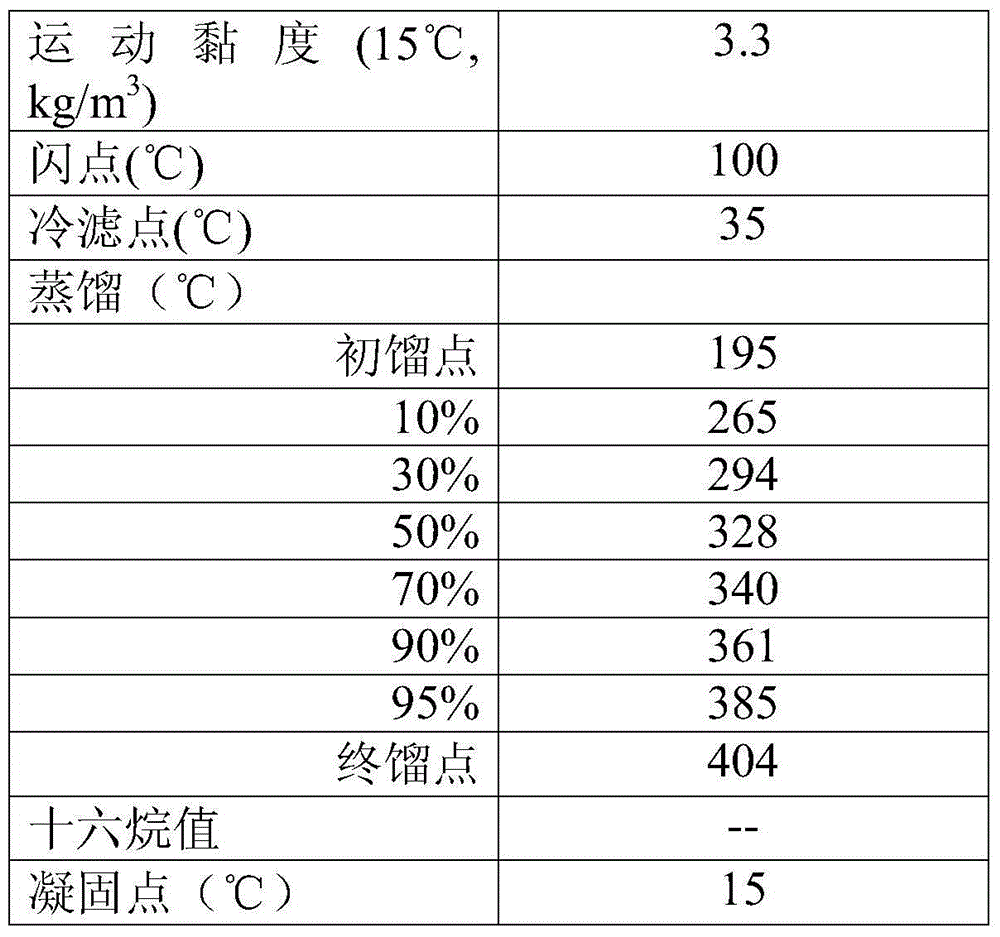

ActiveCN103305271AHigh yieldImprove cracking performanceTreatment with hydrotreatment processesWaxHydrogenation reaction

The invention discloses a combined process method of lightening residual oil / medium and low temperature coal tar. Raw material oil enters a hydrotreating unit after being mixed with hydrogen to perform a hydrogenation reaction in the presence of a hydrogenation catalyst; all hydrogenation products enter a delayed coking unit without being separated to perform a thermal cracking reaction so as to prepare high quality coke; tower top oil gas obtained by a coke chamber of the delayed coking unit enters a fractionating system to be fractionated so as to separate out dry coking gas, gasoline, diesel oil, wax oil and heavy distillate oil; all wax oil enters a catalytic cracking unit to perform a catalytic cracking reaction, the catalytic cracking unit and the delayed coking unit share one fractionating system, and the oil gas obtained by catalytic cracking enters the fractionating system; and the dry coking gas enters a PSA purification unit after being desulfurized, and the obtained hydrogen is recycled in the hydrotreating unit. The method can be used for maximizing the production of light oil, obtaining clean finished product oil, producing high quality coke, simplifying the process procedures, saving the consumption of new hydrogen and reducing overall energy consumption.

Owner:SINOPEC NANJING ENG & CONSTR +1

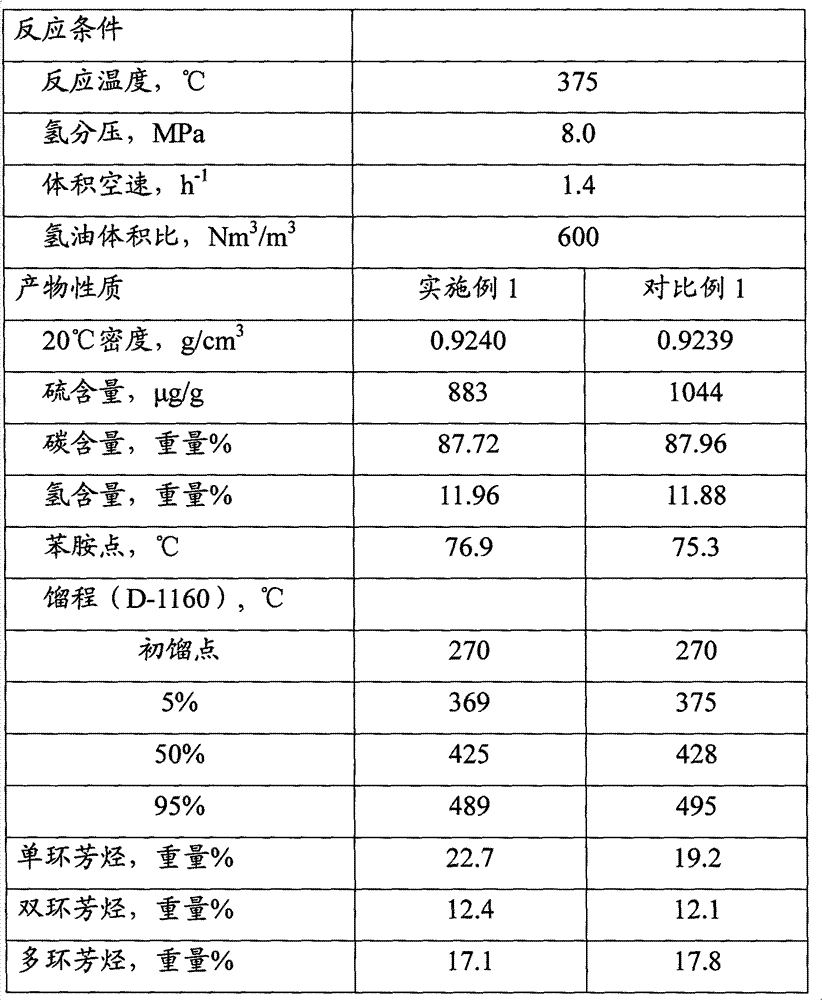

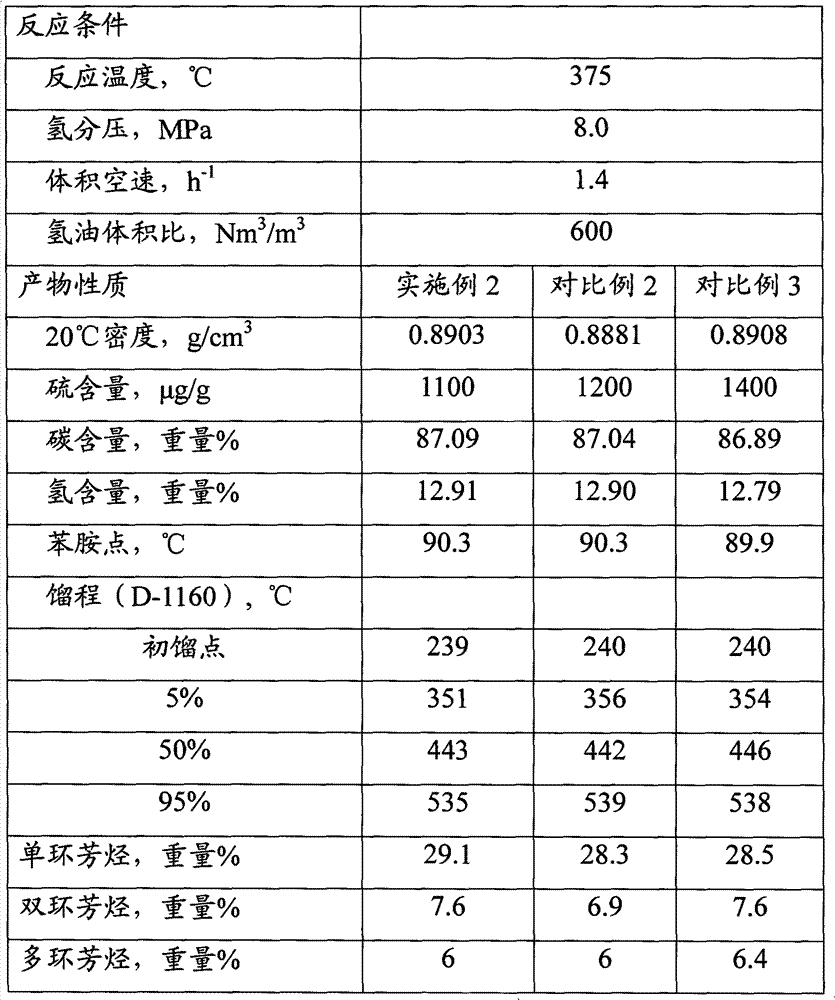

Wax oil hydrotreating method

ActiveCN102899081AAdaptableLow hydrogenation saturation rateTreatment with hydrotreatment processesPartial saturationCobalt

The invention relates to a wax oil hydrotreating method. According to the invention, under a hydrogenation reaction condition, a mixture of raw material oil and hydrogen is sequentially delivered into three hydrogenation reaction zones and is subjected to reactions. A first hydrogenation reaction zone is filled with a hydrogenation protective agent, and is used for removing metal, colloid and asphaltene from the raw material oil. The second hydrogenation reaction zone is filled with a hydrogenation refining catalyst I, and is mainly used for carrying out hydrodenitrogenation and polycyclic aromatic hydrocarbon partial saturation reactions. The active metal of the hydrogenation refining catalyst I is nickel-tungsten, nickel-molybdenum or nickel-molybdenum-tungsten. The third hydrogenation reaction zone is filled with a hydrogenation refining catalyst II, and is mainly used for carrying out a hydrodesulphurization reaction. The active metal of the hydrogenation refining catalyst II is cobalt-molybdenum. With the method provided by the invention, refined wax oil desulphurization rate can be improved, wax oil raw material cracking performance is improved, and conversion rate and light oil yield of a catalytic cracking device are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

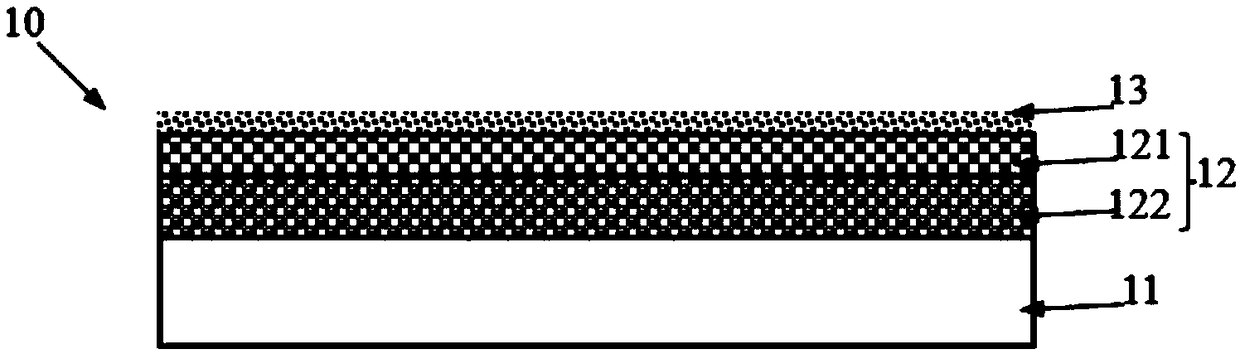

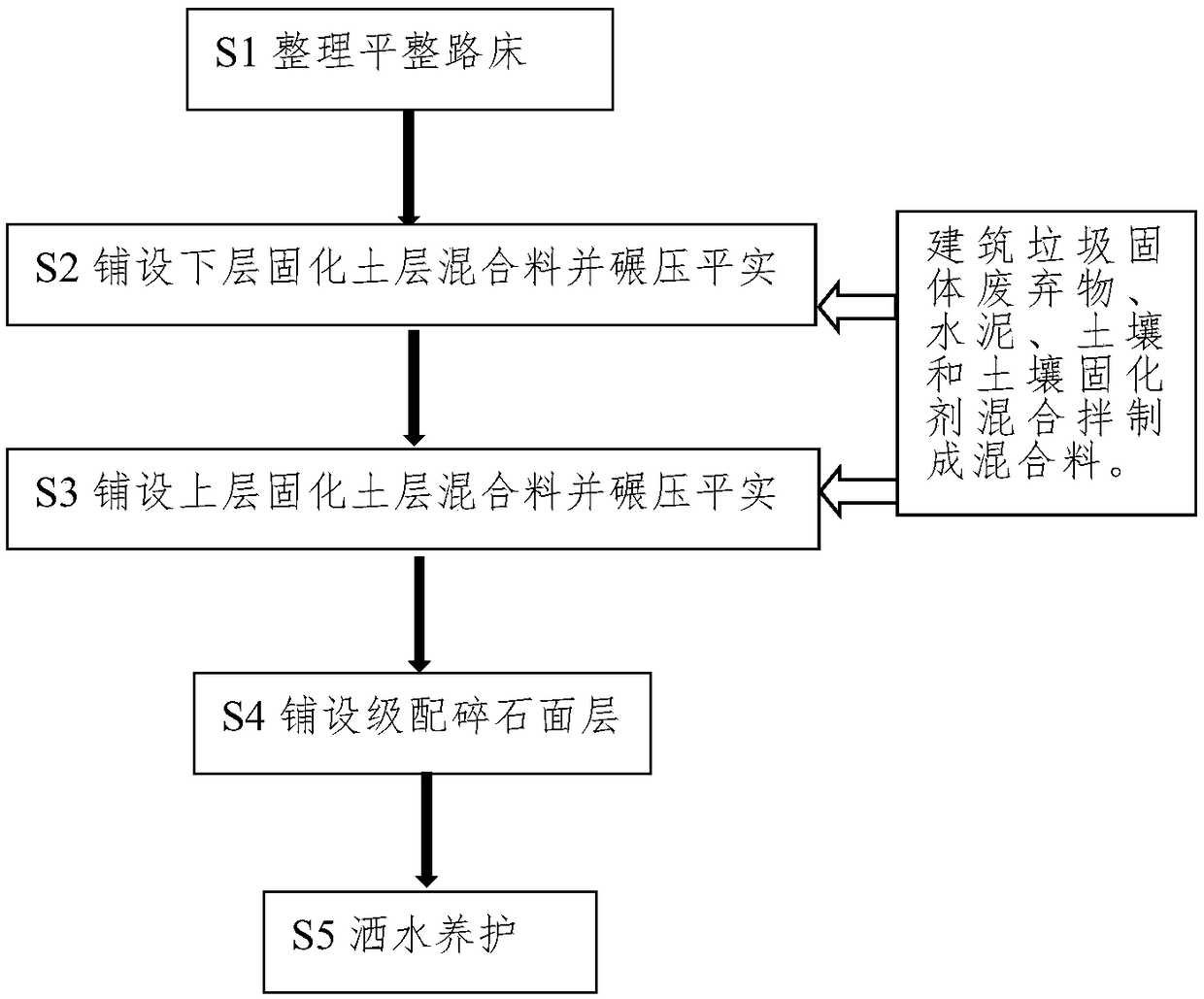

Temporary road pavement structure and road construction method

ActiveCN108842557AIncreased durabilityWide adaptabilityTemporary pavingsChemical reactionSurface layer

The invention discloses a temporary road pavement structure which comprises a roadbed, a base layer and a surface layer from bottom to top in sequence, wherein the base layer is a cured soil layer with cement and a soil curing agent; the surface layer is a macadam floor consisting of graded broken stone. By virtue of properties of the soil curing agent, the soil curing agent is mixed with mixing materials, through a series of physical and chemical reactions, the compactness of a soil body is increased, the soil body is a dense stable soil layer, and thus the bearing capability of the roadbed can be greatly improved. The soil curing agent is wide in adaptability, is capable of effectively curing soil, mud, various solid building wastes and the like, and is applicable to large-scale recycledand reused building wastes. The cured soil layer made of the soil curing agent is used as the road base layer, so that compared with a conventional temporary road, the temperature road made with theroad base layer is high in strength and good in water stability and dry shrinkage resistance, the amounts of conventional road construction materials such as lime, cement, coal ash and macadam can bereduced, and the road construction cost can be effectively reduced.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI

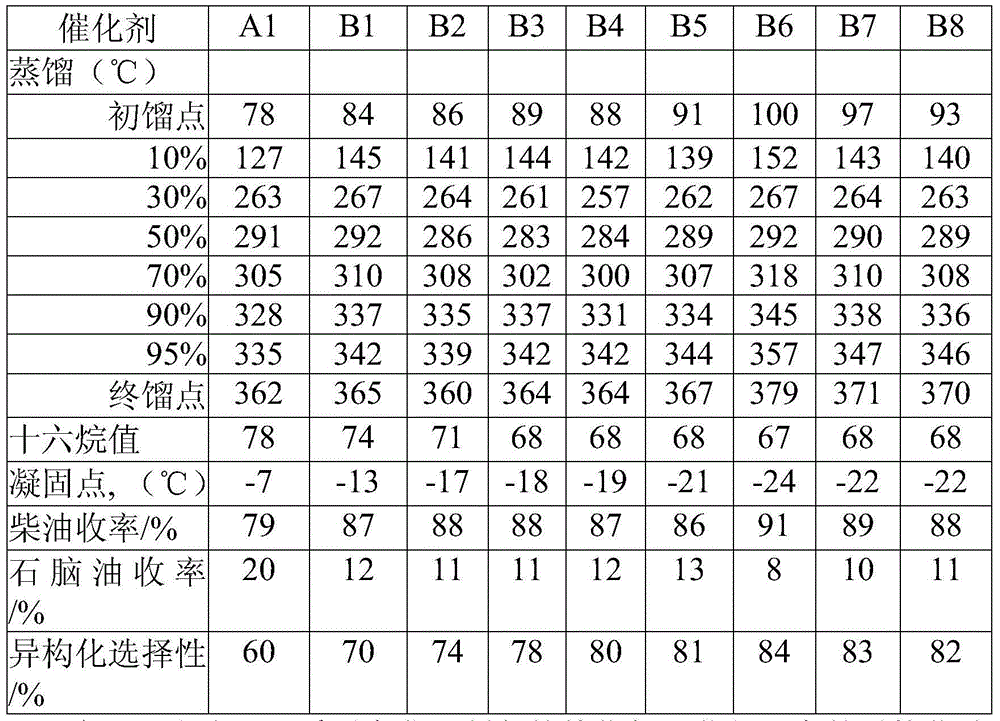

Preparation method of hydroisomerization/cracking catalyst and catalyst

ActiveCN105749964AExcellent isomerization performanceGood cracking performanceMolecular sieve catalystsHydrocarbon oil crackingWaxAmorphous oxide

The invention relates to a preparation method of a hydroisomerization / cracking catalyst. The method specifically comprises the following steps: treating a sodium-type ZSM-23 molecular sieve containing a template agent with an alkaline solution having a certain concentration; washing the obtained product with deionized water, and performing drying and calcination to remove the template agent; performing replacement with an ammonium nitrate solution, performing filtration, washing the obtained product with deionized water, and performing drying and calcination to prepare a hydrogen-type ZSM-23 molecular sieve; mixing the hydrogen-type ZSM-23 molecular sieve with an amorphous oxide and an acid solution, and performing molding and calcination to prepare a carrier; and soaking the carrier in an aqueous solution of soluble salt, and performing drying and calcination to obtain the catalyst. Compared with a catalyst prepared in the prior art, the prepared catalyst can be used in a conversion process of wax in Fischer-Tropsch synthesis, and has favorable catalytic activity and selectivity of target products.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Modified rubber particles for mortar and preparation method of modified rubber particles

Disclosed are modified rubber particles for mortar and a preparation method of the modified rubber particles. The preparation method includes soaking rubber particles in alkali liquor; removing hydrophobic surface layers of the rubber particles so that rough surfaces of the rubber particles are exposed; washing the rubber particles by clear water; adding the treated rubber particles and a coupling modifier into a water bath container to stir the treated rubber particles and the coupling modifier under a water bath environment at the temperature ranging from 40 DEG C to 70 DEG C after the rubber particles are dried; and drying the mixture in the water bath container to obtain the modified rubber particles. The modified rubber particles for mortar and the preparation method have the advantages that affinity of the rubber particles and mortar is obviously enhanced by means of modification, cracking and pull strength of the mortar are improved, the ratio of compressive strength of mortar materials is reduced, and the modified rubber particles can be used as anti-crack components in the mortar in a building project. In addition, the surfaces of the rubber particles are corroded by the aid of alkali liquor treatment, the specific surface area is increased, accordingly, bonding with a coupling agent is enhanced, a modification effect is improved, and shearing force of the modified rubber particles and the mortar is increased.

Owner:北京振利节能环保科技股份有限公司

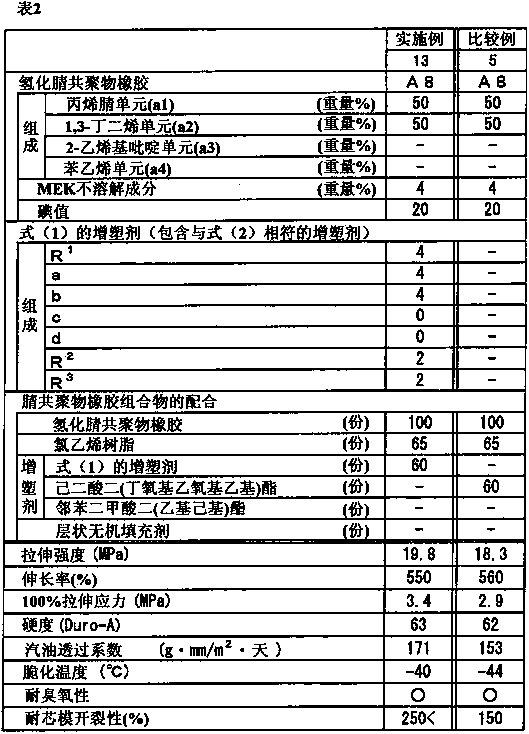

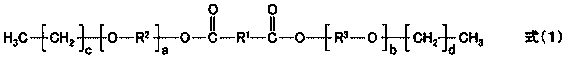

Nitrile copolymer rubber composition and rubber crosslink

ActiveCN103797062AImprove cracking performanceGood gasoline permeation resistanceThin material handlingPolymer sciencePlasticizer

A nitrile copolymer rubber composition of the present invention contains from 35 wt% to 85 wt% of an alpha,beta-ethylenically unsaturated nitrile monomeric unit (a1), from 15 wt% to 65 wt% of a conjugated diene monomeric unit (a2) which may be at least partially hydrogenated, from 0 wt% to 30 wt% of a cationic monomeric unit (a3), and from 0 wt% to 50 wt% of an aromatic vinyl monomeric unit (a4). The present invention contains a nitrile copolymer rubber (A) whose combined content of the alpha,beta-ethylenically unsaturated nitrile monomeric unit (a1) and the aromatic vinyl monomeric unit (a4) is from 35 wt% to 85 wt%, a vinyl chloride resin (B), and a plasticizer (C) having a specific structure.

Owner:ZEON CORP

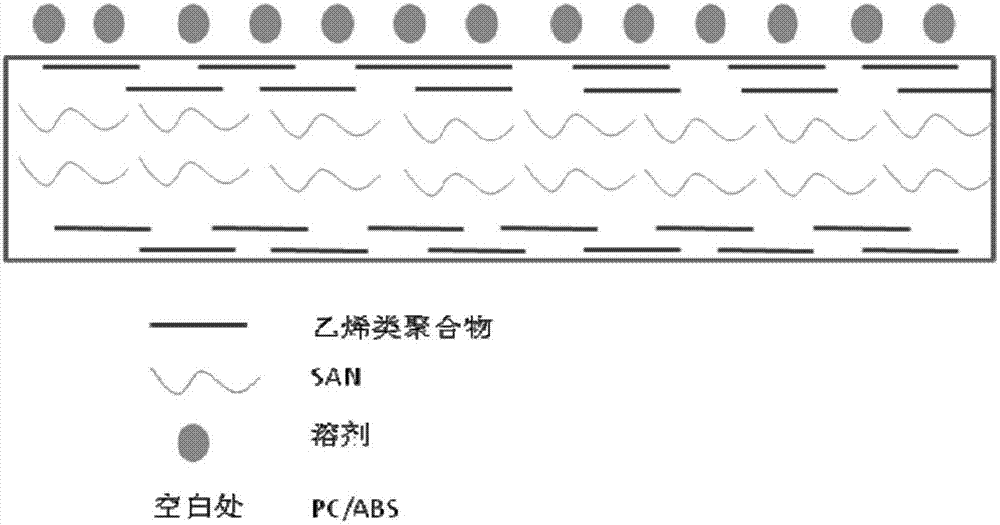

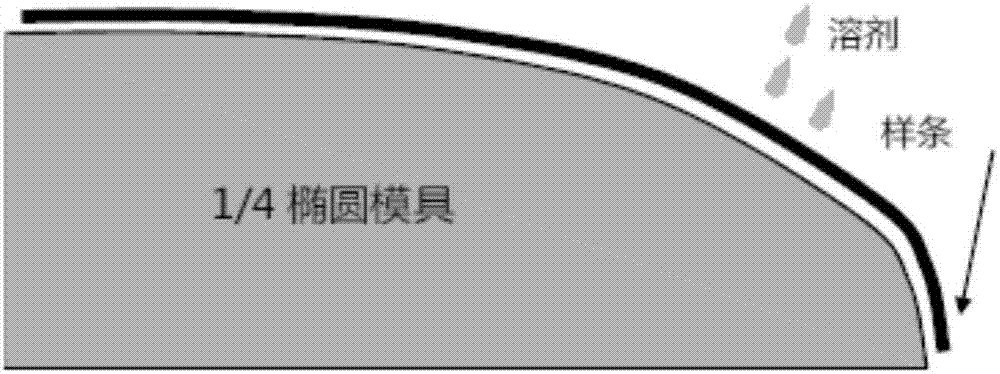

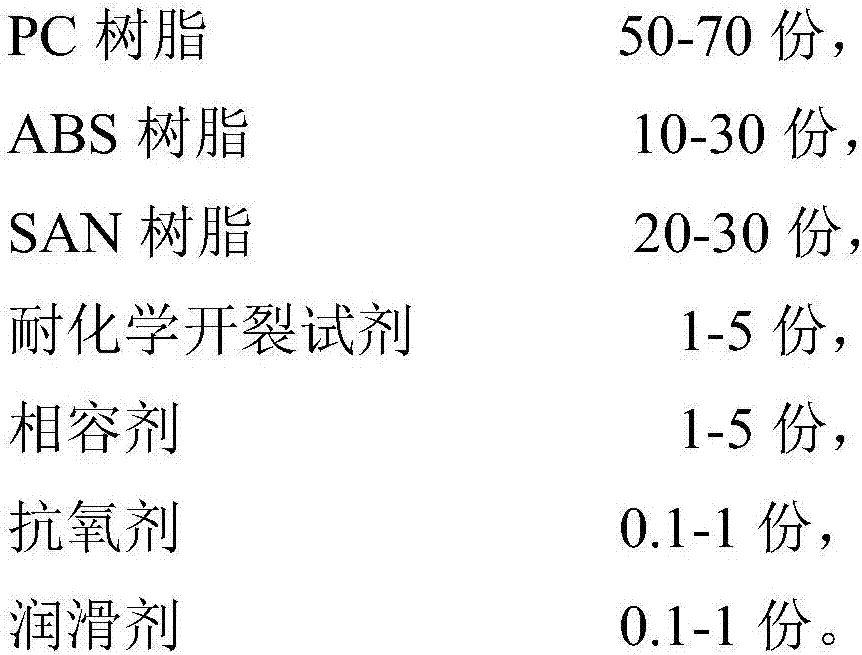

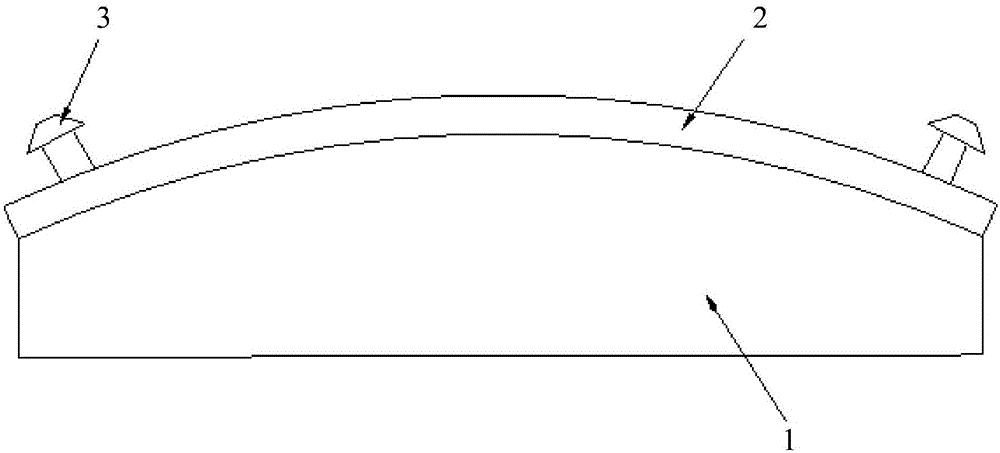

PC/ABS alloy with excellent automotive paint crack resistance and preparation method thereof

The invention relates to the field of high polymer materials, in particular to PC / ABS alloy with excellent automotive paint crack resistance. The PC / ABS alloy is prepared from the following components in parts by weight: 50-70 parts of PC resin, 10-30 parts of ABS resin, 20-30 parts of SAN resin, 1-5 parts of a chemical crack resistant reagent, 1-5 parts of compatibilizer, 0.1-1 part of antioxidant and 0.1-1 part of lubricant. The invention further provides a preparation method for the PC / ABS alloy with excellent automotive paint crack resistance. According to the PC / ABS alloy with excellent automotive paint crack resistance, through synergistic use of ethylene polymer and polystyrene-acrylonitrile with high nitrile (AN) content, very good paint crack resistance is achieved on the surface layer of PC / ABS and inside PC / ABS, so that the PC / ABS does not have a bad cracking phenomenon as a result of poor solvent resistance in a paint spraying process, and therefore, the product yield in the paint spraying process is greatly increased.

Owner:SHANGHAI CHANGWEI JINCI ENG PLASTIC

High temperature-resistant, high-radiation, anti-cracking and energy-saving coating and preparation method

ActiveCN106634570AIncrease temperatureSmall shrinkageFireproof paintsChemical industryMetal fibersSlurry

The invention discloses high temperature-resistant, high-radiation, anti-cracking and energy-saving coating and a preparation method. The high temperature-resistant, high-radiation, anti-cracking and energy-saving coating can be applied to various industrial furnaces and boilers. The high temperature-resistant, high-radiation, anti-cracking and energy-saving coating is prepared from the following components in parts by weight: 30-40 parts of high temperature-resistant and high-radiation powder, 10-20 parts of a high temperature-resistant filler, 1-5 parts of high temperature-resistant fiber filaments, 30-50 parts of a bonding agent and 10-20 parts of a solvent, and further 0.1-0.2 part of a dispersing agent, 0.15-0.3 part of a coupling agent and 0.05-0.15 part of a defoaming agent. The high temperature-resistant, high-radiation, anti-cracking and energy-saving coating is characterized in that metals and non-metallic fiber filaments are introduced into a coating slurry, on one hand, the non-metallic fiber filaments have a certain suspending effect in the coating slurry and can improve the stability of the slurry, and on the other hand, the fiber filaments can hinder the sintering contraction and cracking of the coating and prolong the service life of the coating.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Oil fume resistant polycarbonate material, preparation method and application thereof

The invention discloses an oil fume resistant polycarbonate material, a preparation method and application thereof. The oil fume resistant polycarbonate material is prepared from the following components by mass: 70-90% of polycarbonate; 5-20% of modified nitrile butadiene rubber; 4-15% of a flame retardant; 0.3-3% of an antioxidant, and 0.4%-3% of a lubricating agent. The modified nitrile butadiene rubber is prepared from nitrile butadiene rubber and an ethylene-methyl acrylate copolymer in a mass ratio of 2-5:1. The material has excellent impact toughness, good flame retardant properties and electrical insulation properties, also has well improved oil fume cracking resistance, and is very suitable for preparation of kitchen wall switches and other products. The preparation method of the oil fume resistant polycarbonate material disclosed in the invention adopts existing equipment, the preparation is simple and is easy for industrial production, thus having broad application prospects.

Owner:中广核俊尔(浙江)新材料有限公司 +2

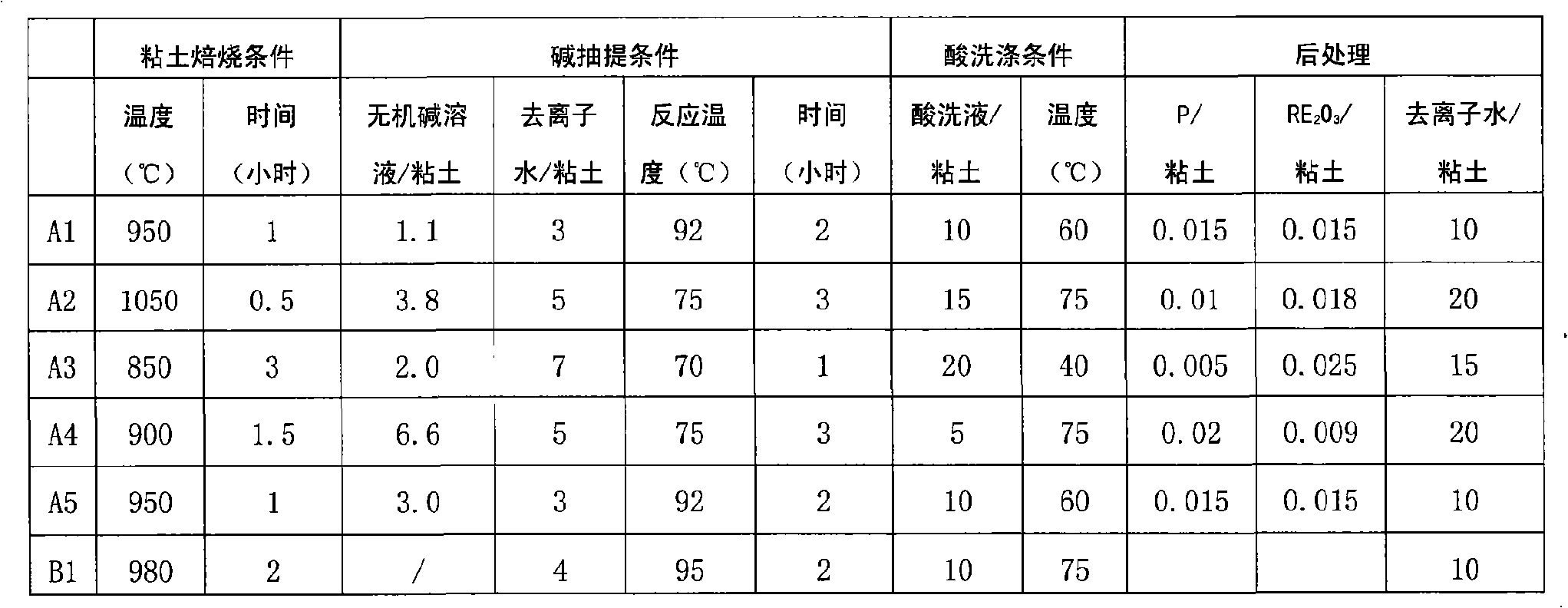

Modified clay and preparation method thereof

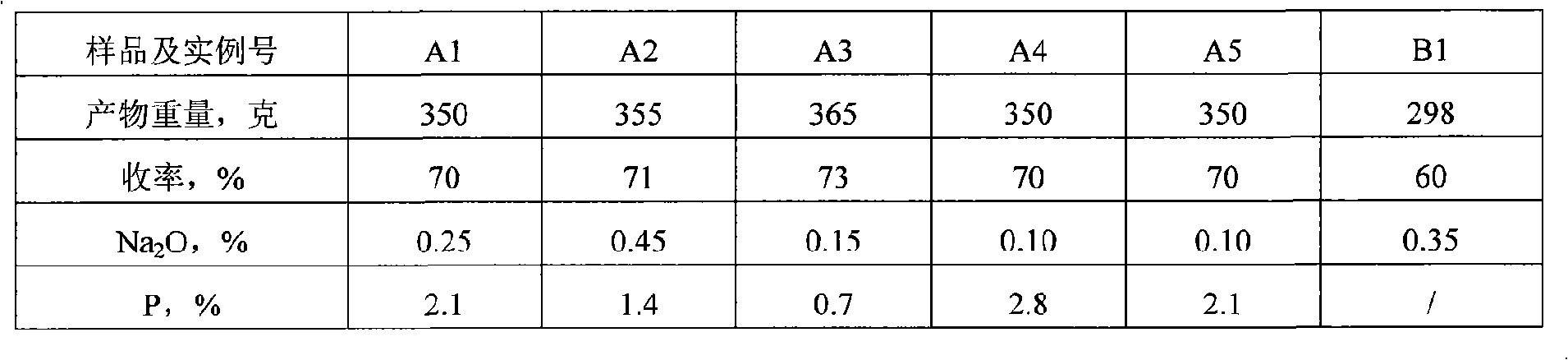

ActiveCN101590432AHigh microreactivityModerate acid strengthCatalyst carriersCatalytic crackingAluminateRare earth

The invention relates to a modified clay and a preparation method thereof. The modified clay is prepared by being roasted at 800-1100 DEG C for 0.3-10h, comprising the following materials by mass percentage: 0.1-3.0 of P, 0.1-4.0 of RE2O3 and 0.1-1.5 of Na2O; the pore volume of the modified clay is 0.1-0.5ML / g, the specific surface is 50-400m / g, and the average grain diameter is 0.5-15mu m. The preparation method comprises the following steps: roasting clay at 800-1100 DEG C for 0.3-10h, mixing the roasted clay and deionized water evenly, adding inorganic alkali solution with 0.5-15 mol / L of OH-concentration in the mixture to react at 50-100 DEG C for 0.1-5h and obtaining clay slurry; filtering the clay slurry,,washing the obtained clay slurry by inorganic acid solution at 30-100 DEG C, introducing phosphorus and rare earth by soaking, separating and drying to obtain the modified clay; wherein, the mass ratio of deionized water to clay (dry basis) is 1.5-10, the mass ratio of inorganic alkali solution to clay (dry basis) is 0.5-8, and the inorganic alkali is selected out of one or more of sodium hydroxide, water glass, ammonia and sodium meta-aluminate.

Owner:PETROCHINA CO LTD

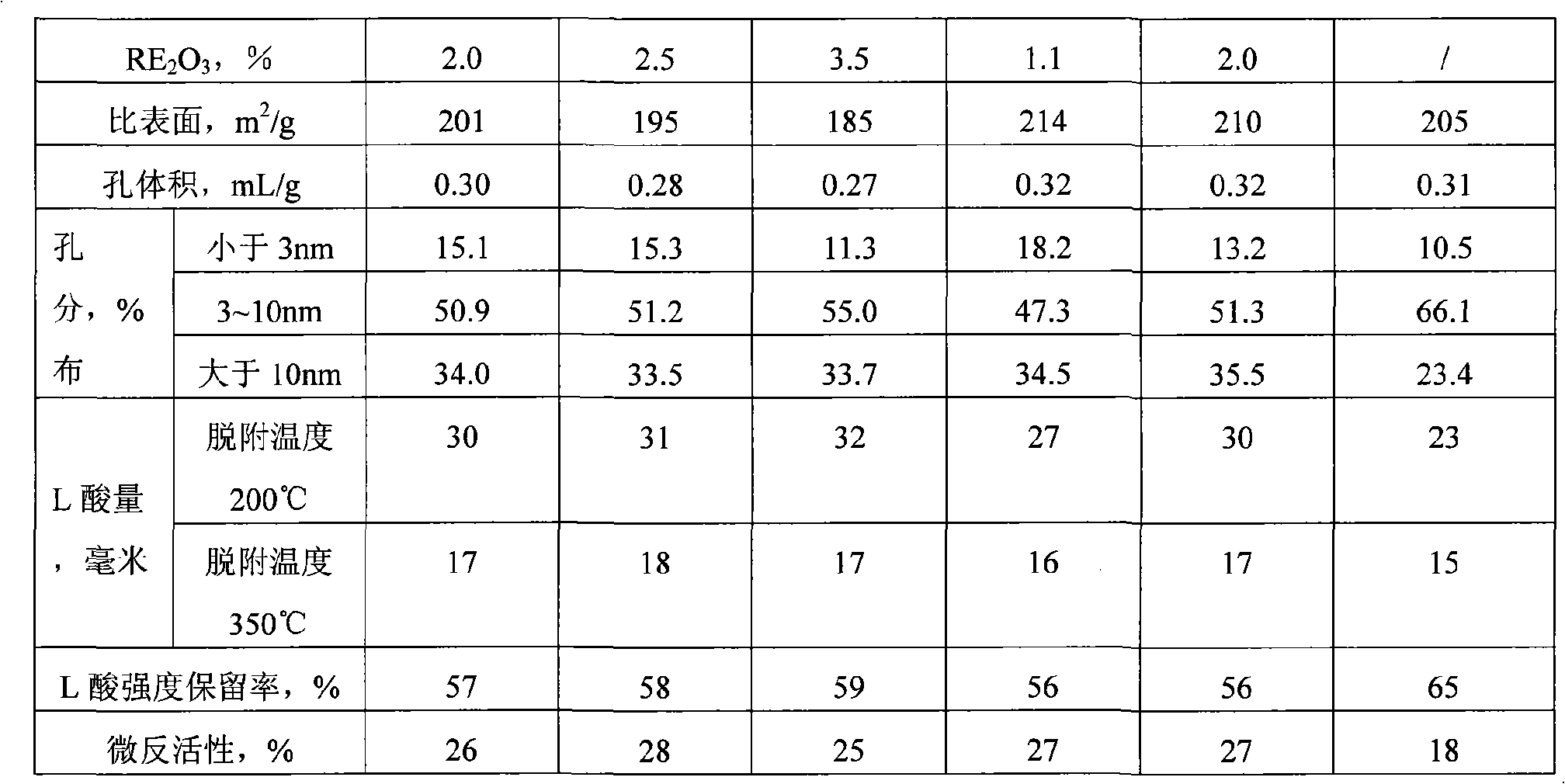

Welded stirrup steel framework beam/pillar

InactiveCN106522467AImprove bearing capacityIncreased shear capacityStrutsPillarsCrack resistanceAssembly line

The invention relates to the field of civil engineering structures, in particular to a welded stirrup-steel framework concrete component. The welded stirrup-steel framework concrete component is a combined structure component formed by welding stirrup on a steel framework and pouring concrete, and shear connectors and longitudinal steel reinforcements of a traditional steel framework concrete component are reduced. Due to the fact that the steel framework is wrapped with the concrete, structural stiffness and shear capacity are improved, and earthquake resistance can be improved remarkably. The steel framework has bearing capacity to a certain extent and is used for bearing loads in the construction stage, a formwork is suspended on the steel framework, formwork erection is omitted, and assembly line production is facilitated. The stirrup in the welded stirrup-steel framework concrete component can improve the crack resistance of the concrete on the one hand, and can be used as a shear part on the other hand, cooperative work of the steel framework and the concrete is ensured, the construction process is simplified, the steel reinforcement net rack binding process is omitted, the manufacturing time is shortened, and industrialized production of components is facilitated.

Owner:SHANDONG UNIV

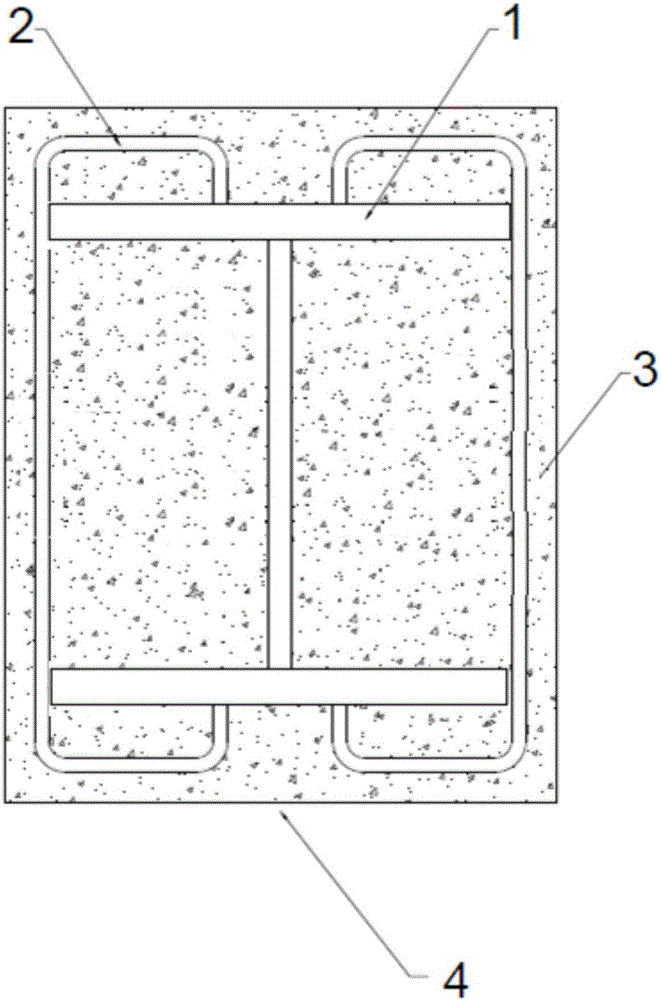

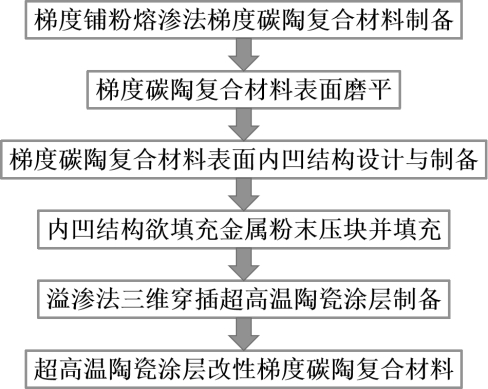

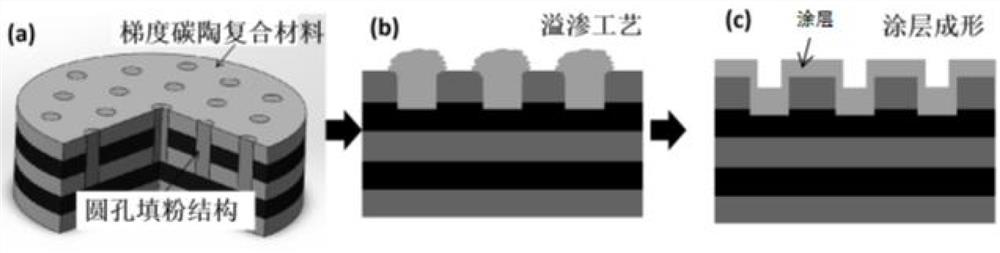

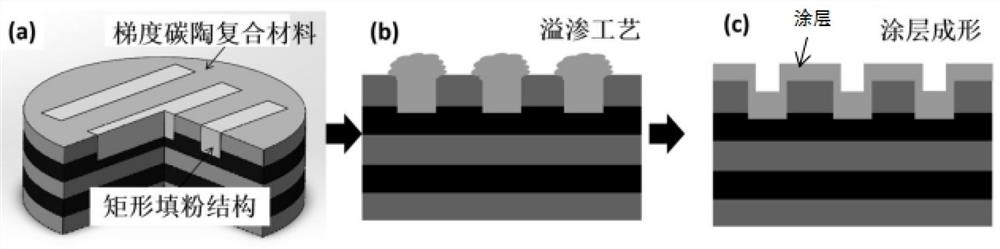

Ceramic coating protection gradient carbon-ceramic composite material and preparation method thereof

ActiveCN113582713AStable high temperature mechanical propertiesImprove high temperature mechanical propertiesCeramic compositeCarbide coating

The invention discloses a ceramic coating protection gradient carbon-ceramic composite material and a preparation method thereof. The ceramic coating protection gradient carbon-ceramic composite material comprises: a gradient carbon-ceramic composite material which is provided with a concave structure on the surface thereof and is a gradient C / C-ZrC-SiC composite material; and an ultrahigh-temperature ceramic coating which is continuously arranged along the surface of the gradient carbon-ceramic composite material and the inner wall surface of the concave structure. The ultrahigh-temperature ceramic coating is an indissolvable metal carbide coating formed by diffusing and infiltrating indissolvable metal along the surface of the gradient carbon-ceramic composite material and reacting the indissolvable metal with the surface of the gradient carbon-ceramic composite material. Therefore, the formed ceramic coating is a three-dimensional jack structure coating, the interfacial strength of the ceramic coating is far higher than that of a two-dimensional plane coating, the surface area of the coating is greatly increased due to the arrangement of the concave structure, meanwhile, the flow resistance of melt on the surface of the composite material can be improved, then the overall temperature resistance of the composite material can be improved, and the risk of coating stripping is reduced.

Owner:CENT SOUTH UNIV

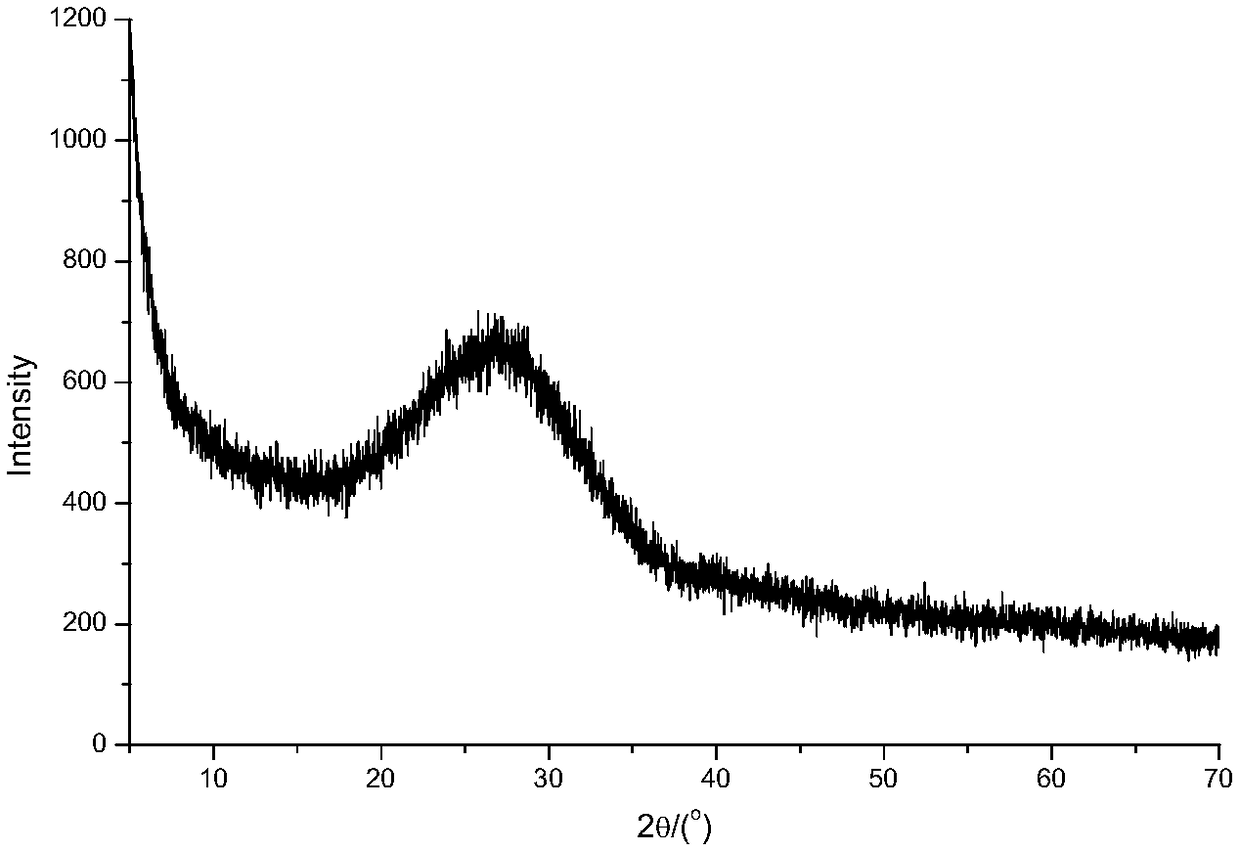

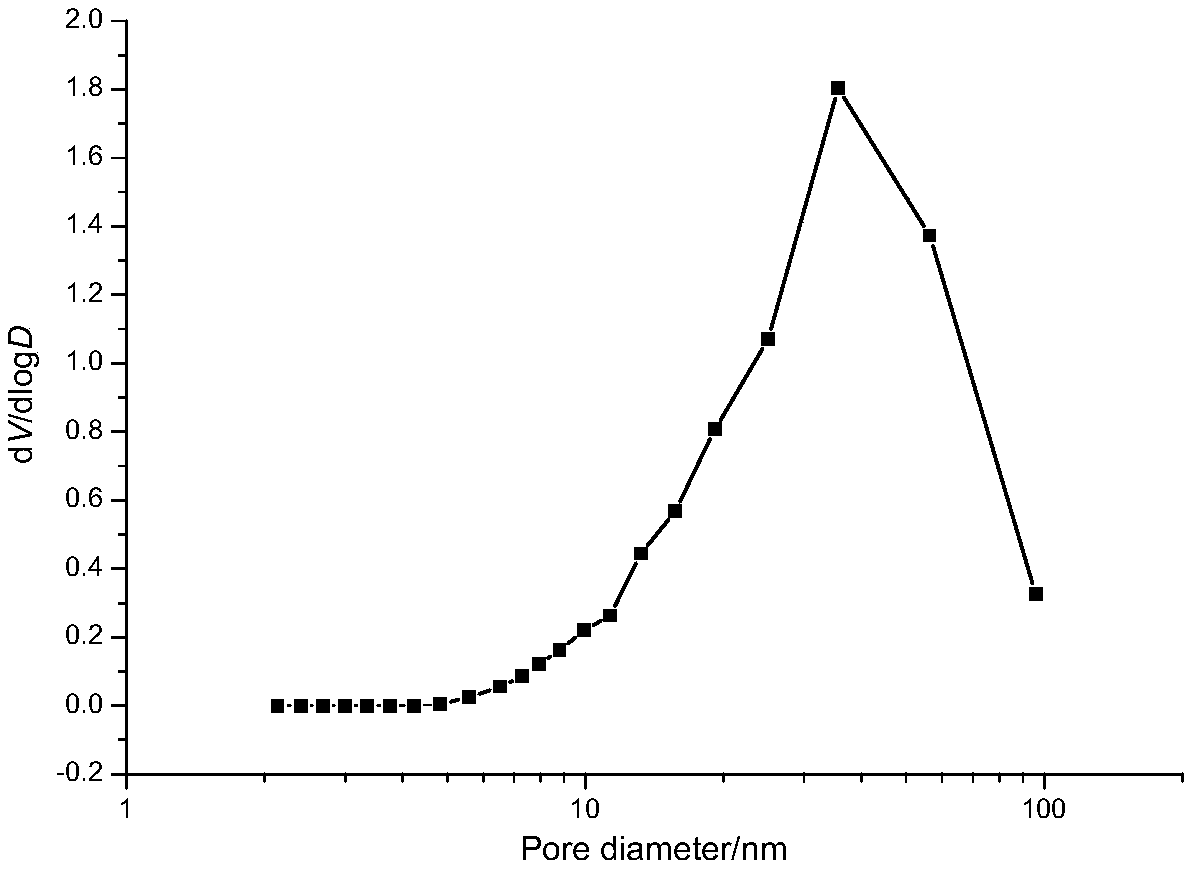

Silicon-aluminum material, preparation method and applications thereof

ActiveCN108499554AGood hydrothermal stabilityImprove cracking performanceCatalytic crackingHeterogenous catalyst chemical elementsChemical compositionPetrochemical

The invention relates to a silicon-aluminum material, wherein the chemical composition measured through an XRF method is (0-0.3)Na2O.(50-80)SiO2.(20-50)Al2O3 based on the weight of the oxide, only theone diffuse diffraction peak appears at 25-27 DEG in the XRD spectrum of the silicon-aluminum material, the probable pore diameter is 20-50 nm, x / y is 0.55-0.75, x represents the Si / Al atomic ratio value measured through an XPS method, and y represents the Si / Al atomic ratio value measured through an XRF method. The silicon-aluminum material of the present invention can be used in petrochemical processes, and has advantages of strong pore channel accessibility good hydrothermal stability and good cracking performance in the being applied as the catalytic material.

Owner:CHINA PETROLEUM & CHEM CORP +1

Curing agent for hydraulic filling of marine mud and curing method thereof

InactiveCN103964809AImprove cracking performanceResolve shrinkageSludge treatment by de-watering/drying/thickeningSolid waste managementSulfateFly ash

The invention discloses a curing agent for hydraulic filling of marine mud and a curing method thereof. The curing agent comprises the following raw materials in parts by weight: 8 to 23 parts of lime, 37 to 45 parts of fly ash, 0.2 to 0.5 part of triethanolamine, 18 to 23 parts of calcium sulfate, 2 to 5 parts of strong base, and 10-16 parts of water glass. The curing method comprises the following steps: the water content of an undisturbed mud sample is controlled by a cutter-suction pump in the range of 80% to 90%, and according to the mechanical stress borne by a soil mass in practical engineering, the curing agent is admixed; the admixture is then maintained for 6 to 8 days under a natural curing condition after admixing. According to the curing agent disclosed by the invention, lime and fly ash are mainly adopted as the main curing agents, auxiliary curing agents are added to improve the cracking property of the lime-fly ash stabilized soil, clay soil with higher plastic index are the main targets for curing, and the problem of greater shrinkage of the lime-fly ash stabilized soil used on the clay soil with higher plastic index is solved.

Owner:ZHEJIANG INST OF HYDRAULICS & ESTUARY +2

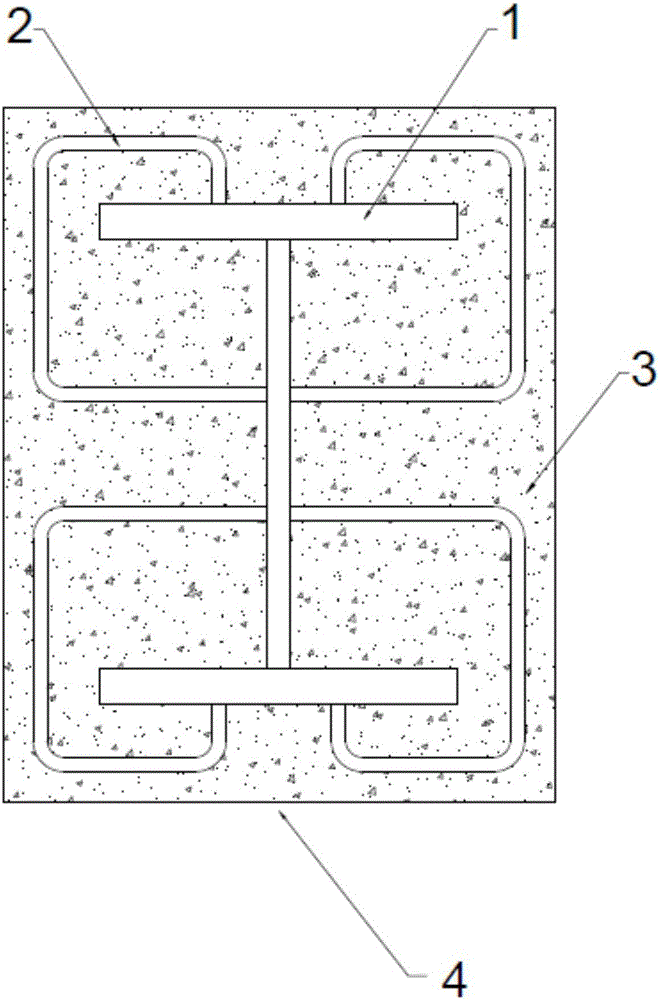

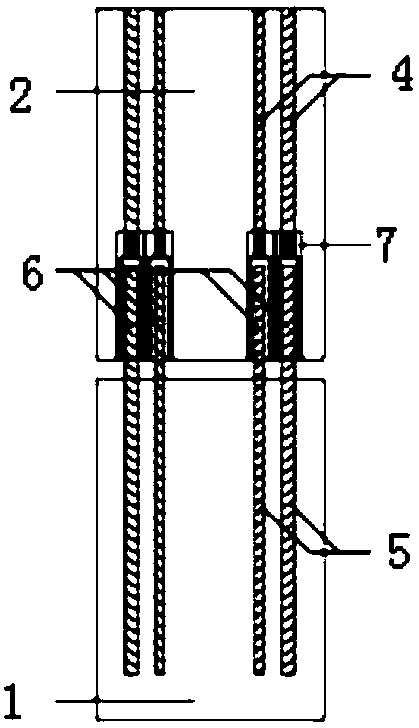

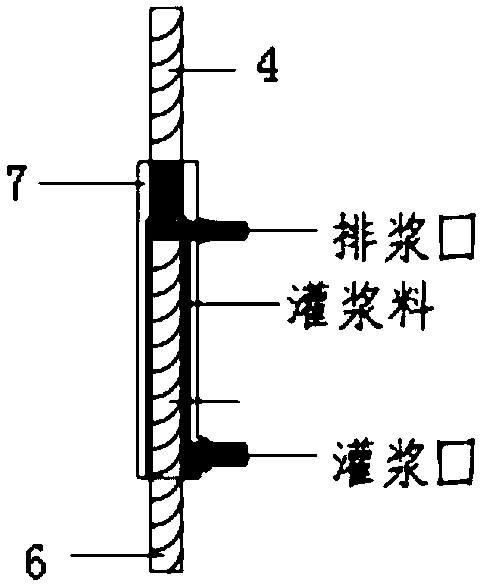

Bridge compound pier stud structure based on orientation ECC and construction process

ActiveCN109338874AImprove cracking performanceImprove seismic performanceBridge structural detailsBridge erection/assemblyReinforced concrete columnRebar

The invention discloses a bridge compound pier stud structure based on an orientation ECC and a construction process. The bridge compound pier stud structure comprises a pier stud plastic hinging areafor connecting a concrete pier stud base and a concrete pier stud. The pier stud plastic hinging area is of a reinforced concrete columnar structure. Concrete adopted in the pier stud plastic hingingarea is an oriented-fiber-enhanced cement-base composite. The oriented-fiber-enhanced cement-base composite is a cement-base composite with fibers in a cement base body arrayed in one direction. Thetending direction of the fibers in the oriented-fiber-enhanced cement-base composite is the same as the axial direction of the pier stud plastic hinging area. A reinforcing steel bar framework adoptedin the pier stud plastic hinging area is formed by binding a plurality of low-yield reinforcing steel bars and a plurality of high-strength reinforcing steel bars through reinforcement stirrups. Thelow-yield reinforcing steel bars and the high-strength reinforcing steel bars are parallel in pairs and located in different planes.

Owner:SHANDONG UNIV

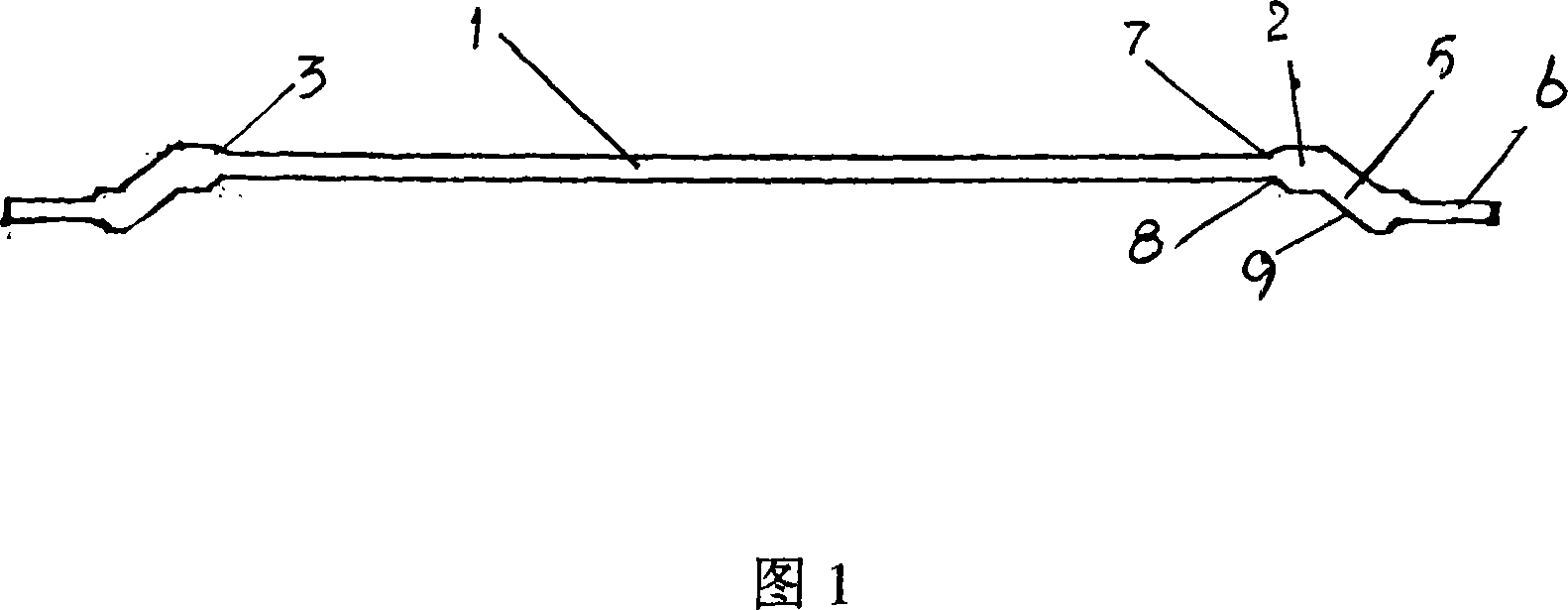

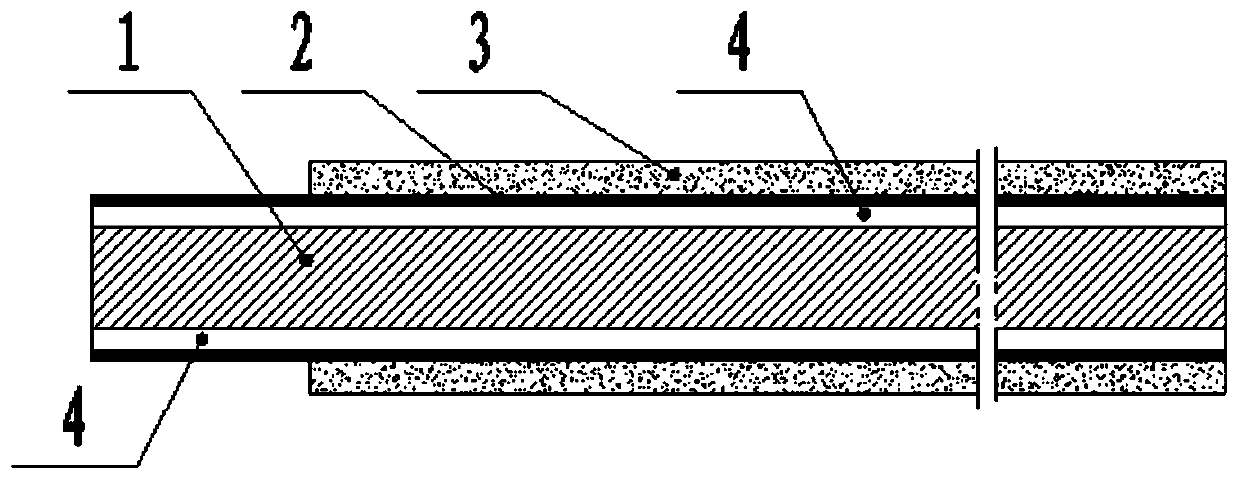

Steel fibre with multi-anchor fixed point

InactiveCN101029531AImprove carrying capacityHigh tensile strengthBuilding reinforcementsEngineeringAnchor point

A steel fiber with multi anchor points includes a middle section with two ends fixed with the first anchor zone extruded out of the first plane, a second anchor zone connected to the first one in an obtuse angle, a third anchor zone connected to the second one with an angle, which is extruded from the second plane.

Owner:武汉新途工程新材料科技有限公司

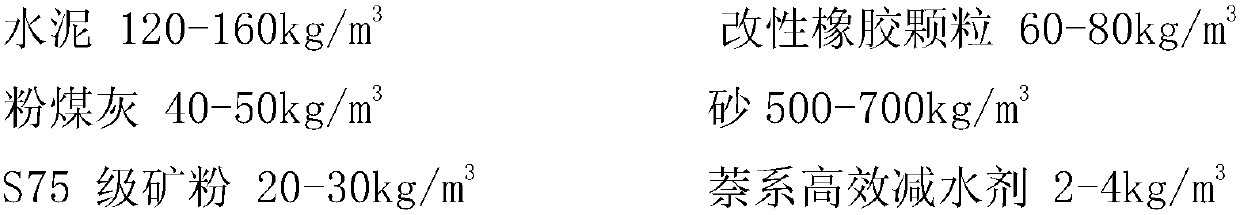

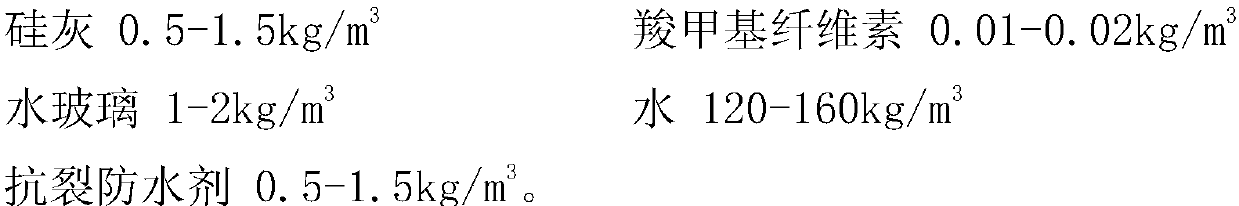

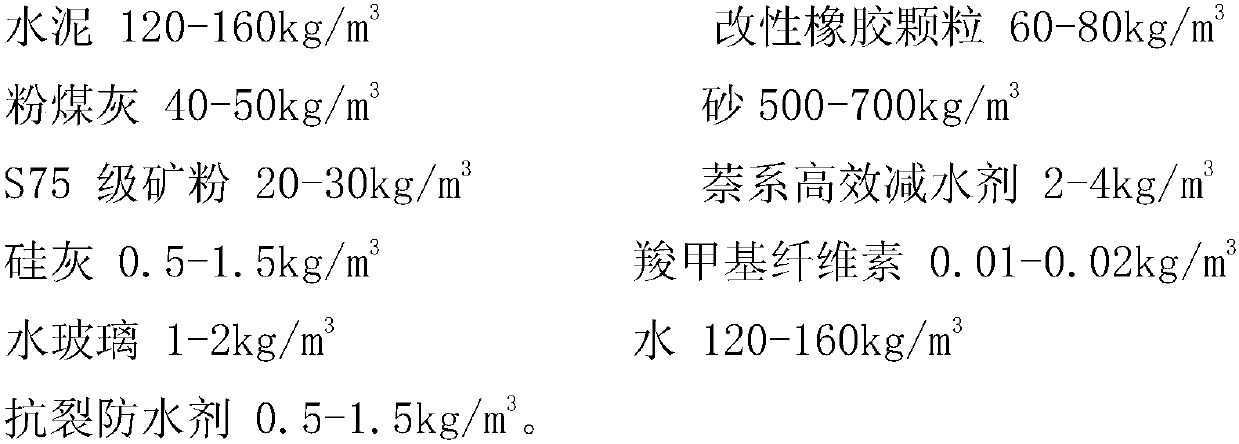

Method for preparing water-resistant thermal insulation mortar from modified rubber particles

The invention discloses a method for preparing water-resistant and heat-retaining mortar with modified rubber particles. The rubber particles are soaked in alkaline solution, rubbed, washed and filtered, and the hydrophobic surface layer is removed to present a rough surface, and then rinsed with clean water and dried. In a water bath environment, add the treated rubber particles and coupling modifier into a water bath container and stir, and obtain modified rubber particles after drying; weigh silica fume and anti-cracking waterproof agent, add water and stir evenly, then add water glass, Mix evenly; pour the prepared modified rubber particles into the above slurry and mix evenly for interface treatment, then cool the modified rubber particles that have been pretreated at the interface until half-dry, and set aside; mix cement, fly ash, After mixing sand, S75 grade mineral powder and modified rubber particles with interface pretreatment, stir in a concrete or mortar mixer; then add water, naphthalene-based high-efficiency water reducer and carboxymethyl cellulose and stir again to obtain Modified rubber particle water-resistant and thermal insulation mortar. The modified rubber particle mortar prepared by the invention has strong water resistance and thermal insulation.

Owner:上海涛瀚橡塑制品有限公司

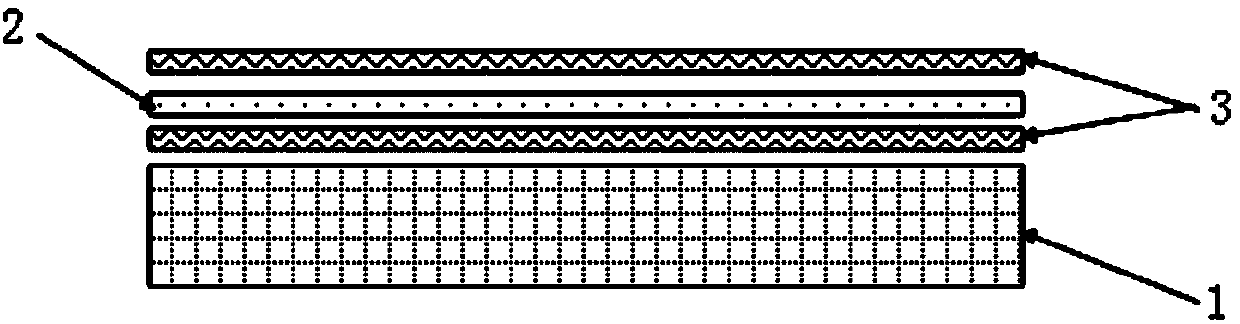

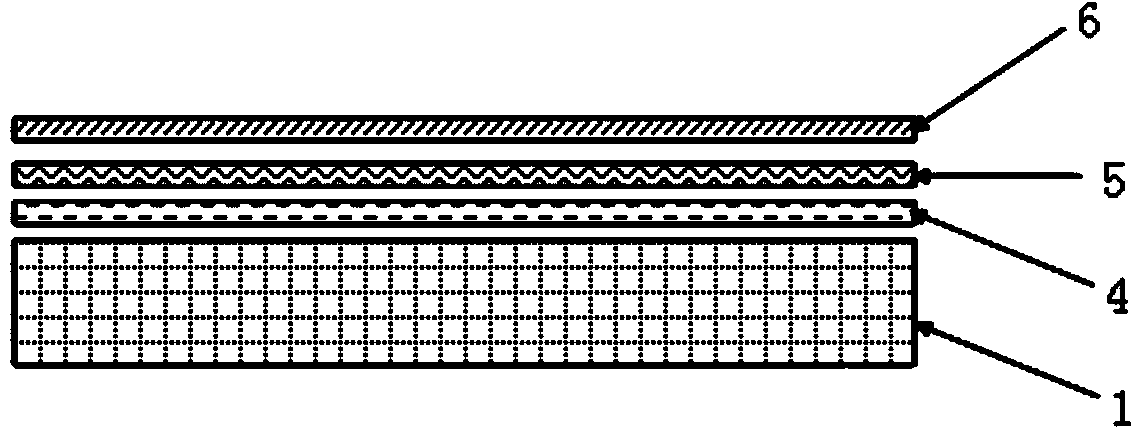

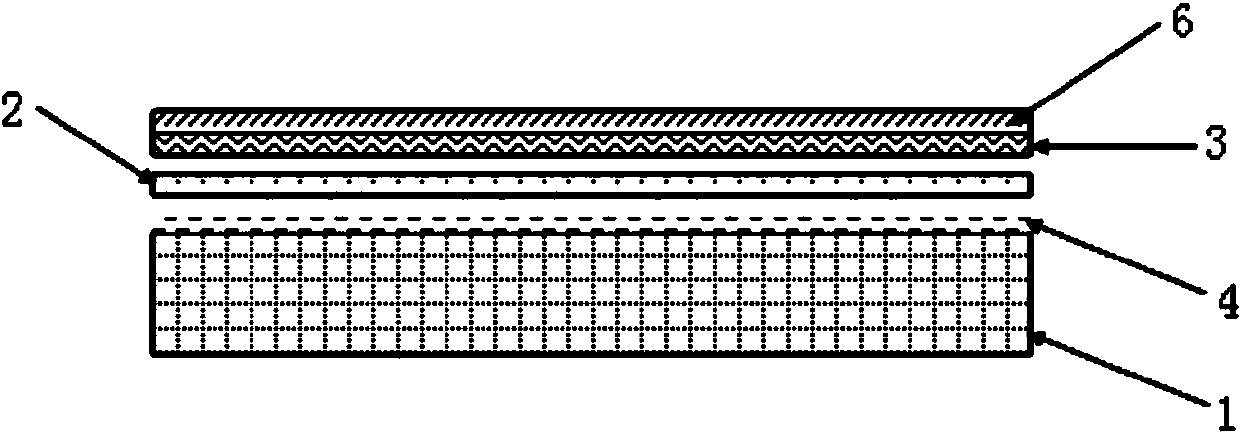

Anti-fracturing solid wood composite board and processing method thereof

InactiveCN104191470AWon't crackAvoid crackingSynthetic resin layered productsLaminationSolid woodFiber

The invention provides an anti-fracturing solid wood composite board and a processing method thereof. At least one non-impregnated fiber layer is arranged on a base material, the upper face and the lower face of the non-impregnated fiber layer are respectively provided with at least one impregnated layer, the non-impregnated fiber layer, the upper impregnated layer and the lower impregnated layer form an anti-fracturing fiber buffering layer, and the fiber buffering layer and the base material are composited in a hot-press mode to form the anti-fracturing solid wood composite board. The anti-fracturing solid wood composite board has the advantages that the fracturing phenomenon caused by different expansion factors is avoided, and surface resin can not fracture due to expansion or shrinkage of the base material; production cost is not increased, the processing method is simple and practical, and the anti-fracturing solid wood composite board can be suitable for industrial mass production.

Owner:濮亮

Stainless steel welding rod capable of resisting redness and cracking of coating

InactiveCN111112882AWeaken ruptureHeat dissipation fastWelding/cutting media/materialsSoldering mediaSodium carboxymethylcelluloseSlag (welding)

The invention belongs to the field of welding materials, and particularly relates to a stainless steel welding rod capable of resisting redness and cracking of coating. The stainless steel welding rodcomprises a stainless steel core wire with a longitudinal V-shaped groove formed in the peripheral surface, a copper-plated layer and the coating, wherein the coating comprises the following dry powder components of 10-12% of rutile, 8%-10% of mica, 8%-10% of calcium carbonate, 8%-10% of magnesium carbonate, 5%-7% of nickel carbonate, 3%-5% of white mud, 2%-4% of zirconium oxide, 8%-10% of fluorite, 1%-3% of spodumene, 4%-6% of ferromanganese, 2%-4% of ferrotitanium, 5%-7% of ferrosilicon, 0.2%-0.3% of sodium alginate, 0.15%-0.25% of carboxymethyl cellulose, 1.5%-2% of nano cerium oxide and / or nano yttrium oxide and / or nano lanthanum oxide, and the balance feldspar. According to the stainless steel welding rod, the core wire is small in volume expansion after being heated, the coating strength is high, the welding arc voltage is high, molten drops are in slag wall and jet combined transition, and reddening resistance and cracking resistance of the coating are high.

Owner:ZHENGZHOU UNIV

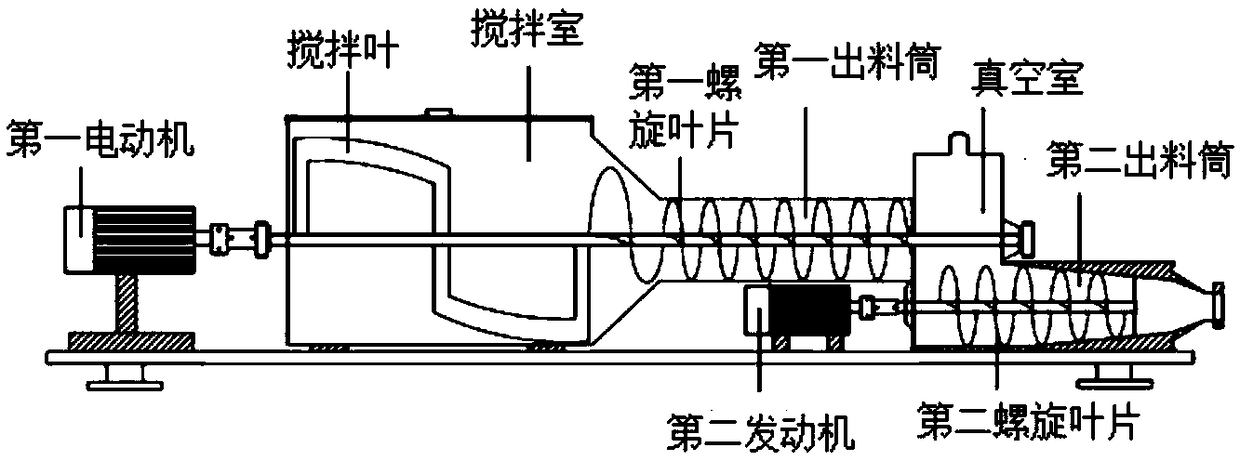

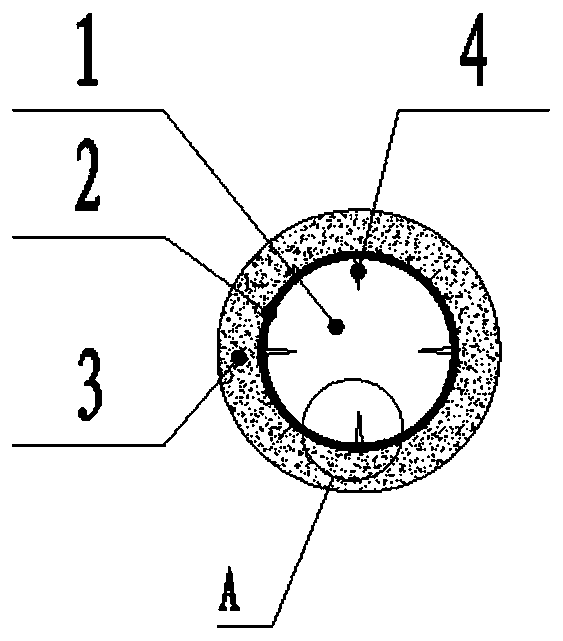

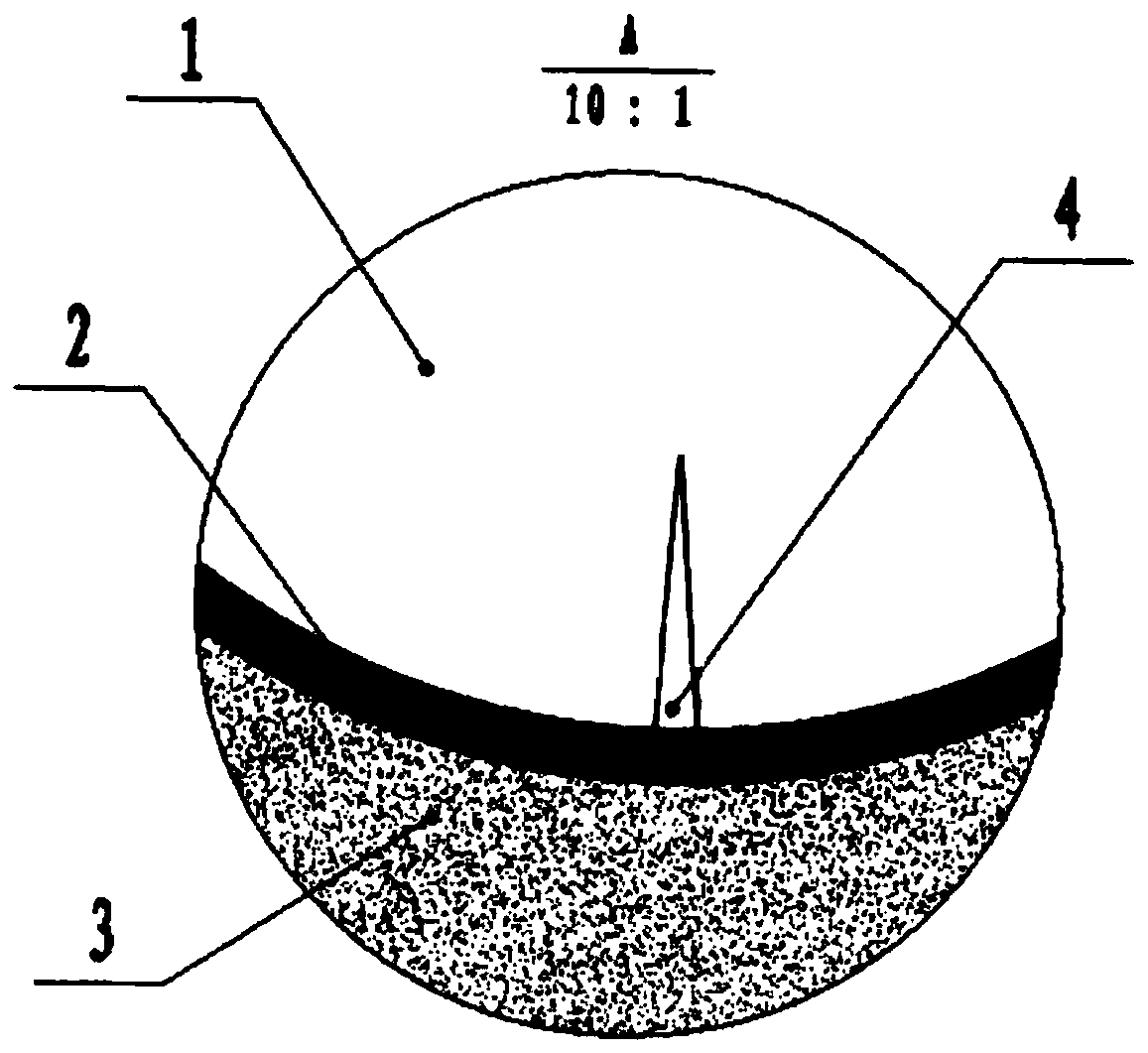

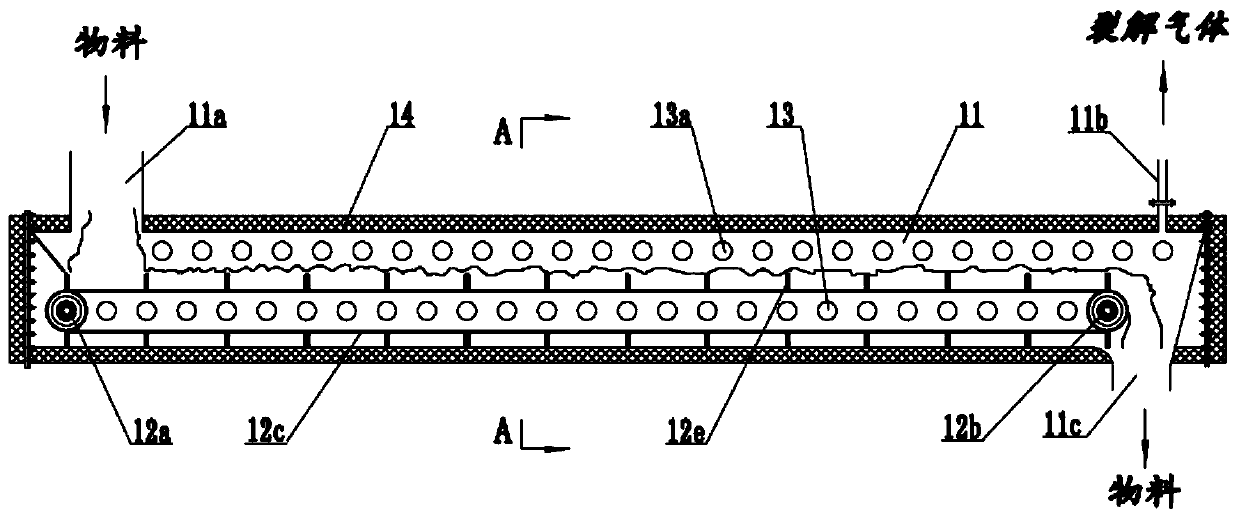

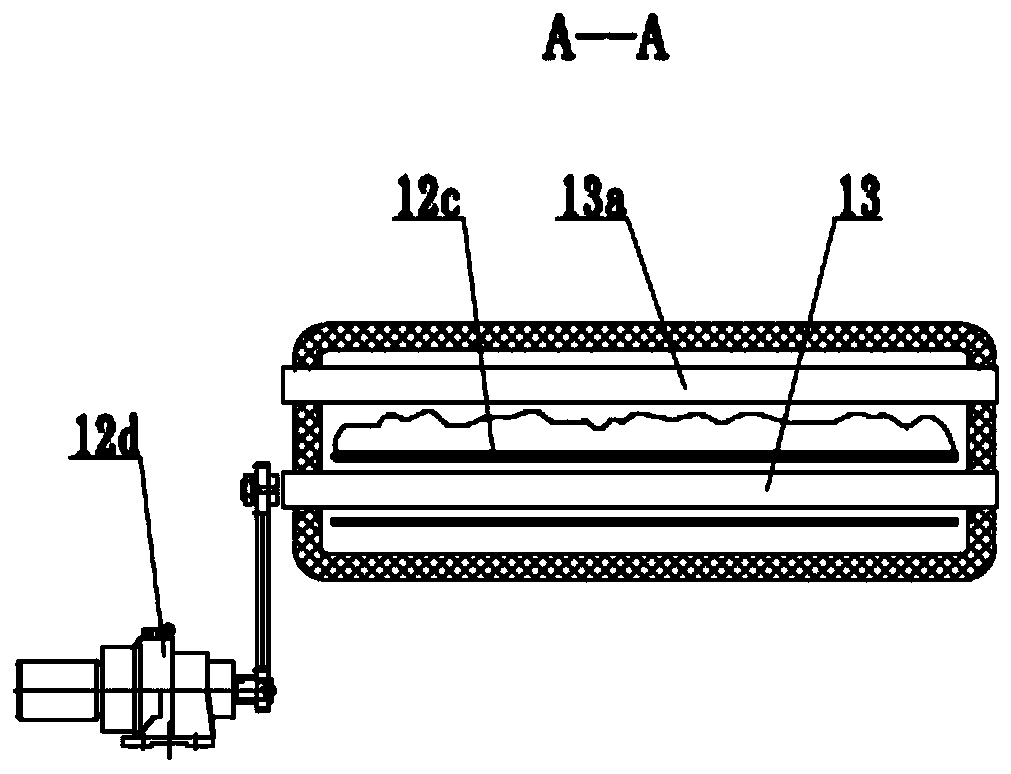

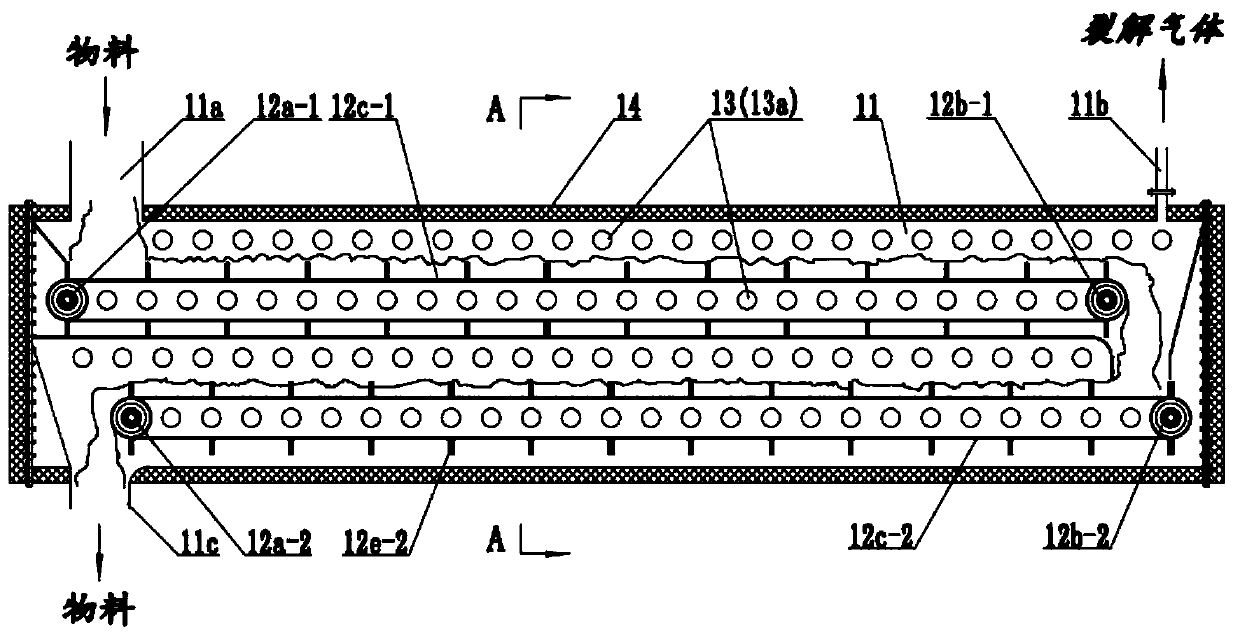

Material treatment device and material treatment system

PendingCN109824228AImprove cracking performanceGuarantee the predetermined temperatureSludge treatment by pyrolysisElectric heatingSprocket

The invention relates to a material treatment device for oil sludge cracking and a material treatment system for oil sludge treatment. The material treatment device comprises a shell, a conveying mechanism and a heating device. The shell comprises an upper wall with a feeding port and an exhaust port and a lower wall with a discharging port. The conveying mechanism comprises a driving chain wheel,a driven chain wheel and a conveying belt engaged with the driving chain wheel and the driven chain wheel, and the conveying belt is configured to receive and convey materials to be treated. The heating device comprises multiple electric heating tubes. The electric heating tubes are evenly arranged in parallel to the conveying belt at preset intervals, the feeding port corresponds to the feedingend of the conveying mechanism, and the discharging port corresponds to the discharging end of the conveying mechanism.

Owner:SHAN DONG HI LINK ELECTRICITY

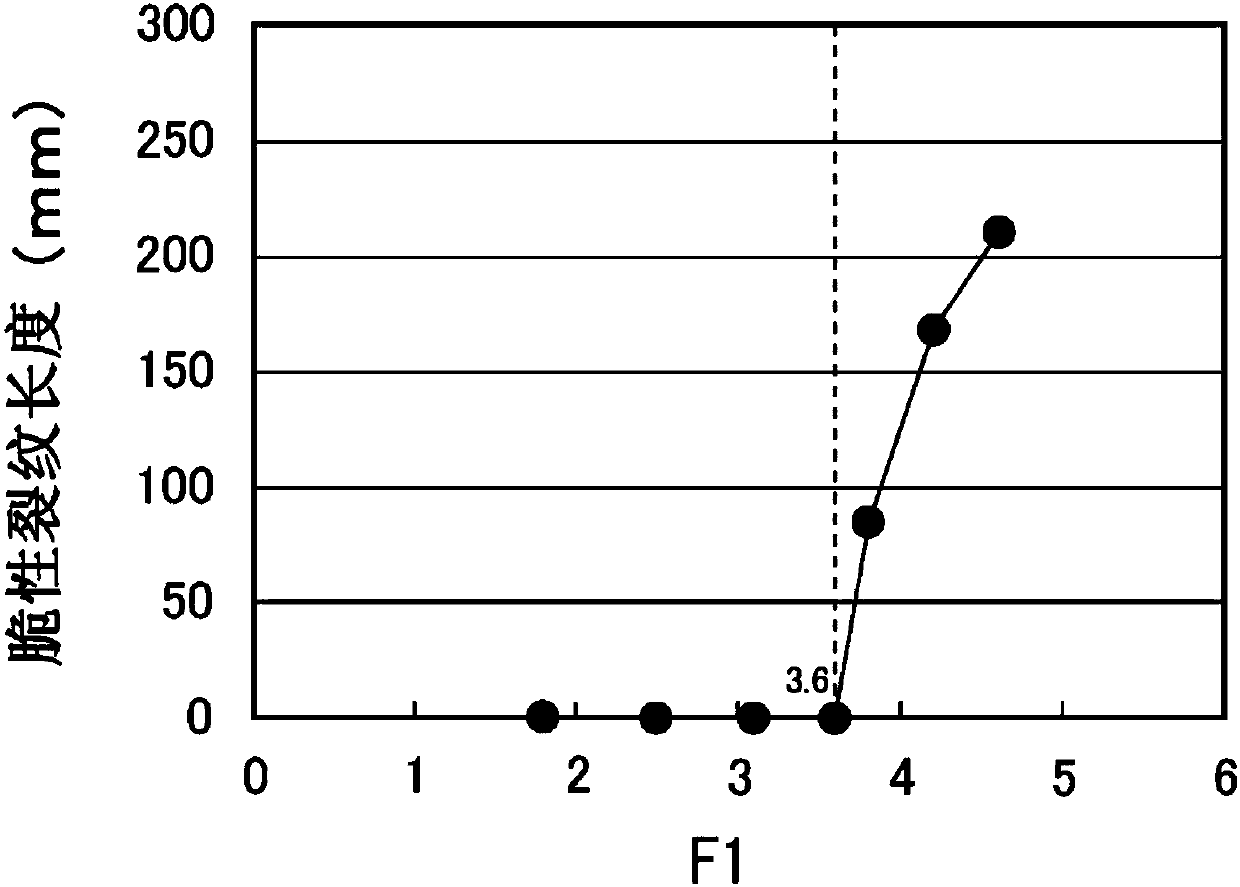

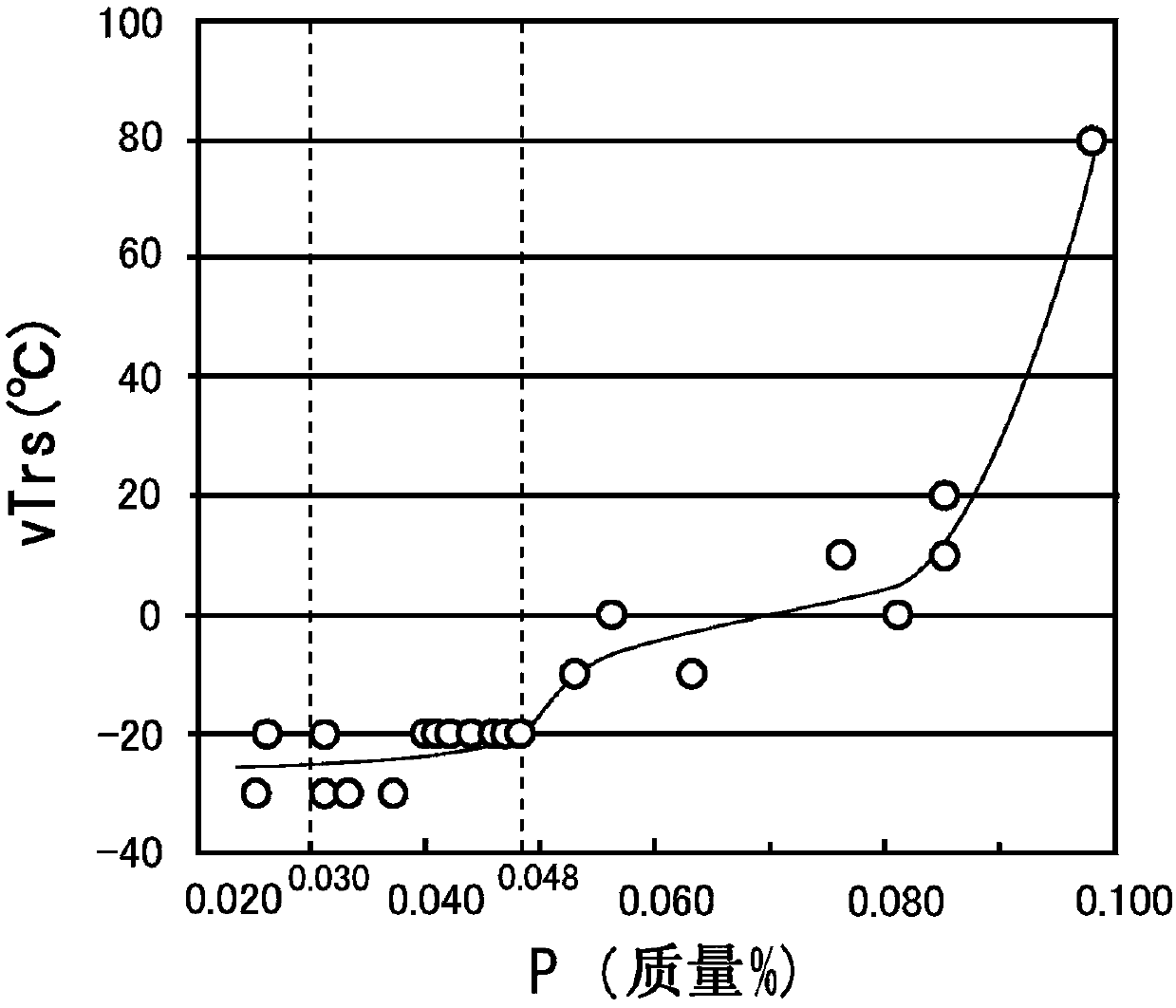

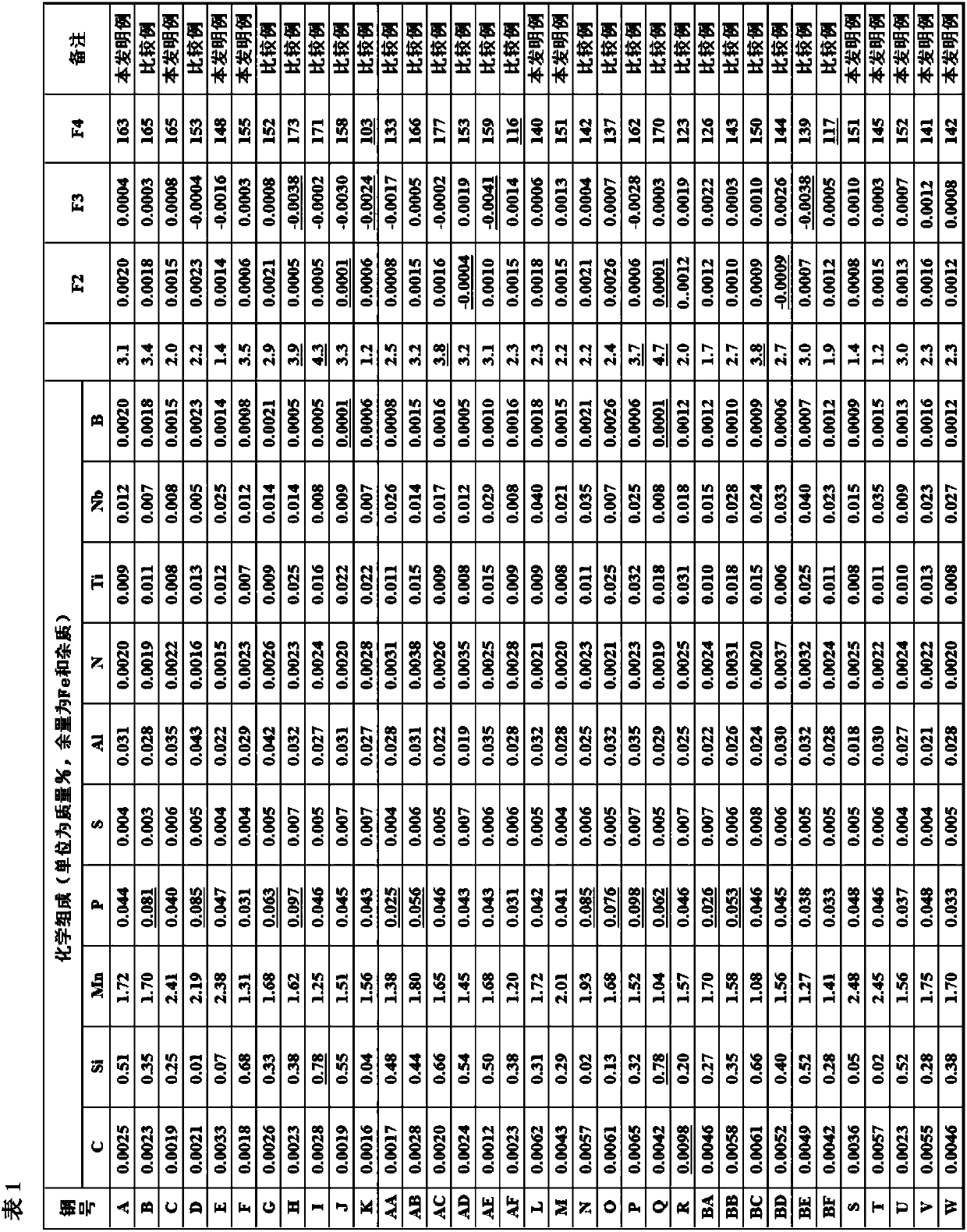

Alloying molten zinc-plated steel sheet and manufacturing method therefor

InactiveCN107923017AHigh strengthImprove deep drawing performanceHot-dipping/immersion processesFurnace typesChemical compositionCrack resistance

Provided is an alloying molten zinc-plated steel sheet with high strength and excellent deep drawability as well as excellent slab cracking resistance and secondary working embrittlement resistance. The base steel sheet for this alloying molten zinc-plated steel sheet contains, in mass%, C: 0.0080% or less, Si: 0.7% or less, Mn: 1.0-2.5%, P: greater than 0.030-0.048%, S: 0.025% or less, Al: 0.005-0.20%, N: 0.010% or less, Ti: 0.005-0.040%, Nb: 0.005-0.060%, and B: 0.0005-0.0030%, the balance being obtained from Fe and impurities, and has a chemical composition that satisfies expression (1) - expression (4). The alloying molten zinc-plating layer contains 7-15 mass% Fe. 25 * P + 4 * Si <= 3.6 (1) B X1 >= 0.0005 (2) C (12 / 93) * Nb X2 >= 0.0035 (3) 110 * Si + 48 * Mn + 550 * P >= 120 (4).

Owner:NIPPON STEEL CORP

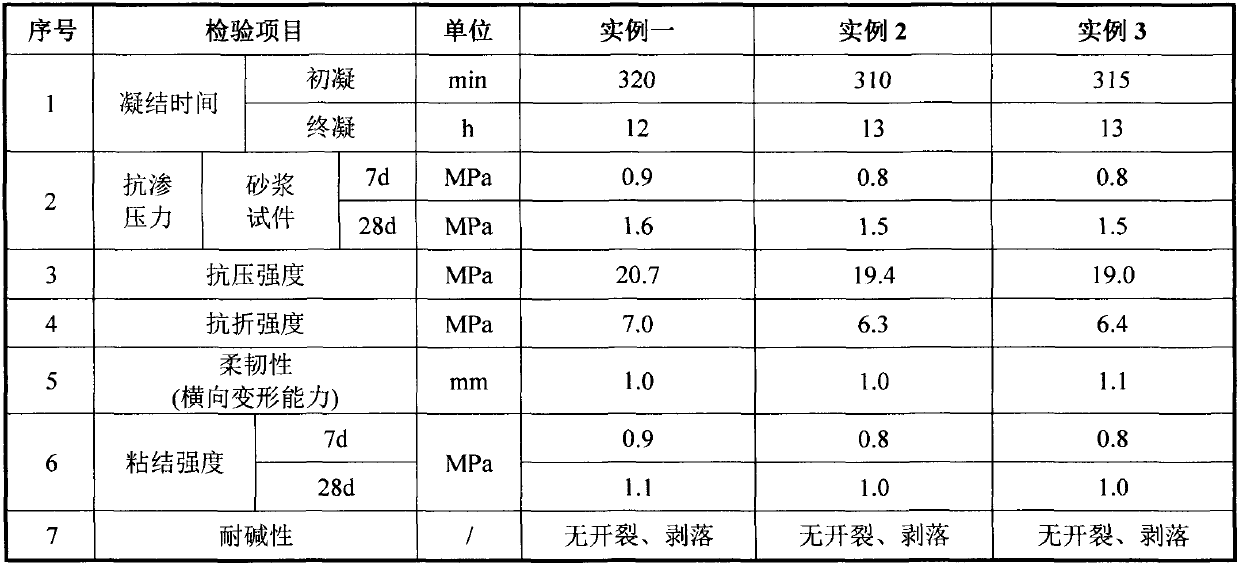

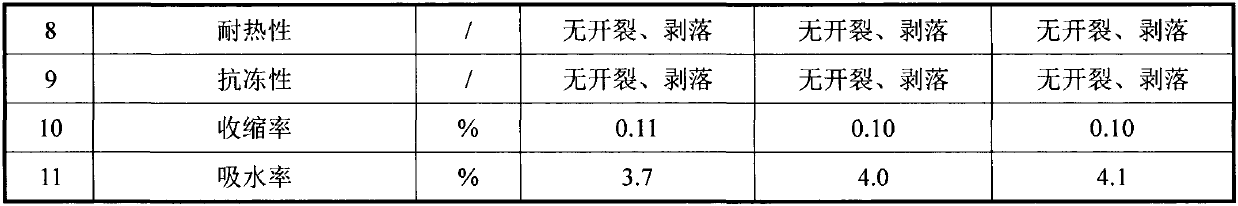

Green high-performance polymer cement waterproof mortar adopting aeolian sand and preparation method of waterproof mortar

The invention discloses green high-performance polymer cement waterproof mortar adopting aeolian sand and a preparation method of the waterproof mortar. The mortar is prepared from components as follows: 34-36 parts of cement, 29-32 parts of quartz sand, 23-26 parts of the aeolian sand, 8-10 parts of latex powder, 0.2-0.6 parts of fibers, 0.1-0.2 parts of a water reducer and 0.2-0.4 parts of a defoaming agent. The aeolian sand is utilized to equivalently replace part of the quartz sand, so that the green high-performance polymer cement waterproof mortar with properties including liquidity, caking property, impermeability and the like better than those of common polymer cement waterproof mortar is prepared. The problem of shortage of existing building raw materials is solved, the problem ofincreasingly serious desertization at present can be solved, the aeolian sand as a waste resource is sufficiently utilized, waste is changed into wealth, and sustainable development of the building waterproofing industry can be promoted.

Owner:NANJING FORESTRY UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com