Anti-fracturing solid wood composite board and processing method thereof

A processing method, solid wood composite technology, applied in the field of wood processing, can solve problems such as cracks, and achieve the effect of simple and easy processing method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

[0028] Combine below figure 1 Embodiments of the present invention will be described in detail.

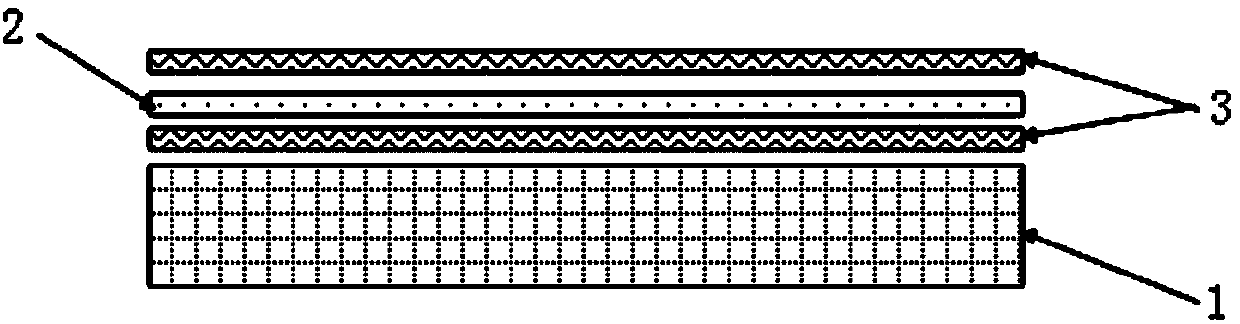

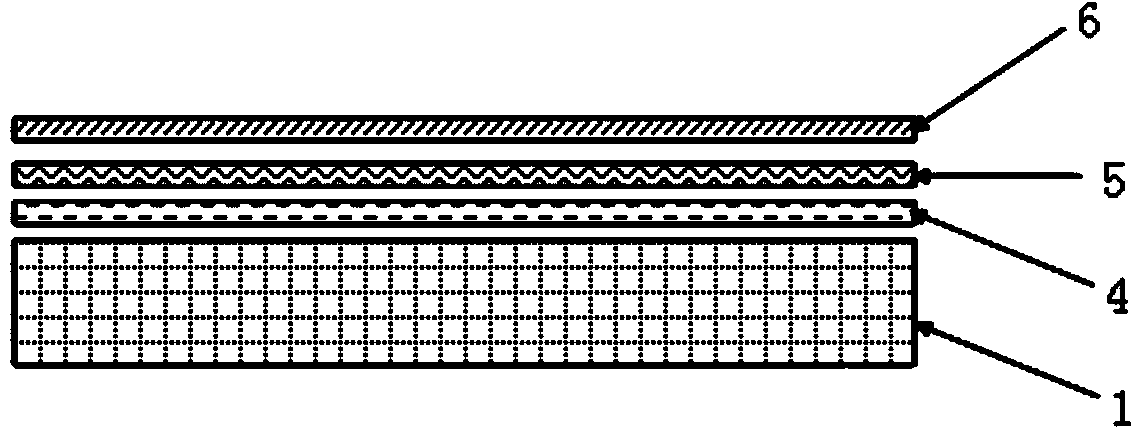

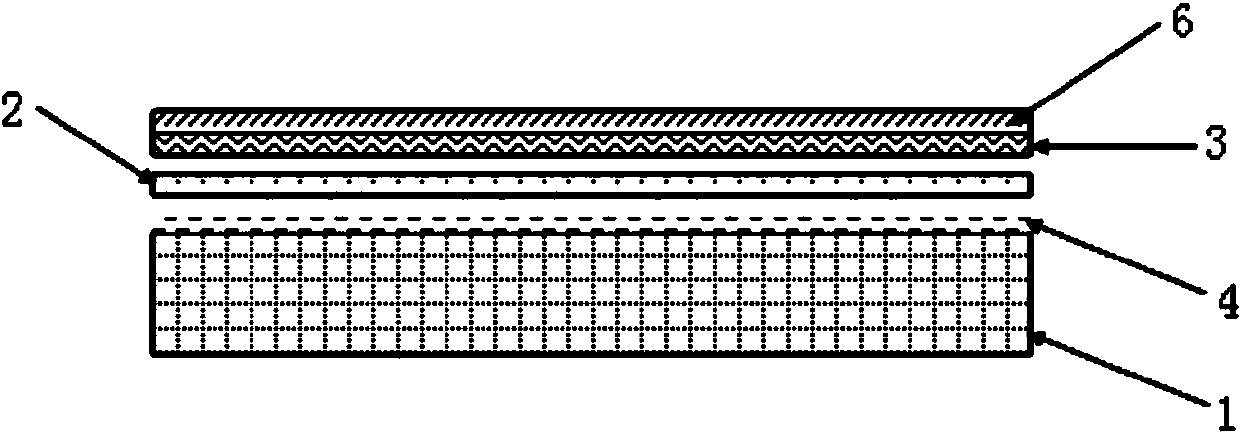

[0029] figure 1 A schematic structural diagram of Embodiment 1 of the present invention is shown. Such as figure 1 As shown, the present invention provides a kind of anti-cracking solid wood composite board, on the substrate, there are impregnated decorative pattern layer, non-impregnated dry paper layer and impregnated decorative pattern layer sequentially from top to bottom, unimpregnated The dry paper layer and the upper and lower impregnated layers form a crack-resistant fiber cushion. Place the substrate on the lower template of the press, and place the above-mentioned fiber buffer layer on the substrate. The temperature of the upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com