Patents

Literature

928results about How to "Won't crack" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gravel attapulgite flower ceramsite

ActiveCN102503372BHigh strengthLower sintering temperatureCeramic materials productionCeramicwarePhysical chemistryMaterials science

The invention discloses gravel attapulgite flower ceramsite. The key point of the technical scheme is that the gravel attapulgite flower ceramsite consists of high-viscosity attapulgite clay powder, attapulgite clay tailing powder, red bentonite powder, sludge, kieselguhr tailing powder and rice husk powder.t. The gravel attapulgite flower ceramsite is produced by the following steps of mixing the ingredients, pelleting, baking, cooling, smashing, sieving and packaging. The gravel attapulgite flower ceramsite is an irregularly-shaped granule, and has a rough and porous surface, light weight, high strength and high water absorption. The gravel attapulgite flower ceramsite can be soaked in water without being cracked and release nutrition required by flowers continuously and slowly. The gravel attapulgite flower ceramsite is produced by utilizing the sludge and tailings comprehensively, so that the utilization rate of resources is improved, waste materials are changed into wealth, and environment is protected. Besides, the gravel attapulgite flower ceramsite is suitable for planting the flowers and vegetables.

Owner:江苏世澳非金属应用科技有限公司

Spherical attapulgite flower ceramsite

ActiveCN102503539AReduce manufacturing costHigh strengthCeramic materials productionCeramicwareMetallurgyBentonite powder

The invention discloses spherical attapulgite flower ceramsite. The key points of the technical scheme are that the spherical attapulgite flower ceramsite consists of high-adhesion attapulgite clay powder, attapulgite clay tailing powder, red bentonite powder, sludge, diatomite tailing powder and rice husk powder. The spherical attapulgite flower ceramsite is produced by the following steps of mixing the ingredients, pelleting, roasting, cooling, screening and packaging. The spherical attapulgite flower ceramsite has a rough and porous surface, is light in weight, high in strength and water absorption rate, can be immersed in water throughout the year without cracking and can continuously and slowly release nutrition required by flowers. Moreover, the spherical attapulgite flower ceramsite is produced by comprehensively utilizing the sludge and tailings, so that the resource utilization rate is improved, waste is turned into wealth, and environment is protected. Besides, the cylindrical attapulgite flower ceramsite is applicable to cultivation of various flowers and vegetables.

Owner:江苏世澳非金属应用科技有限公司

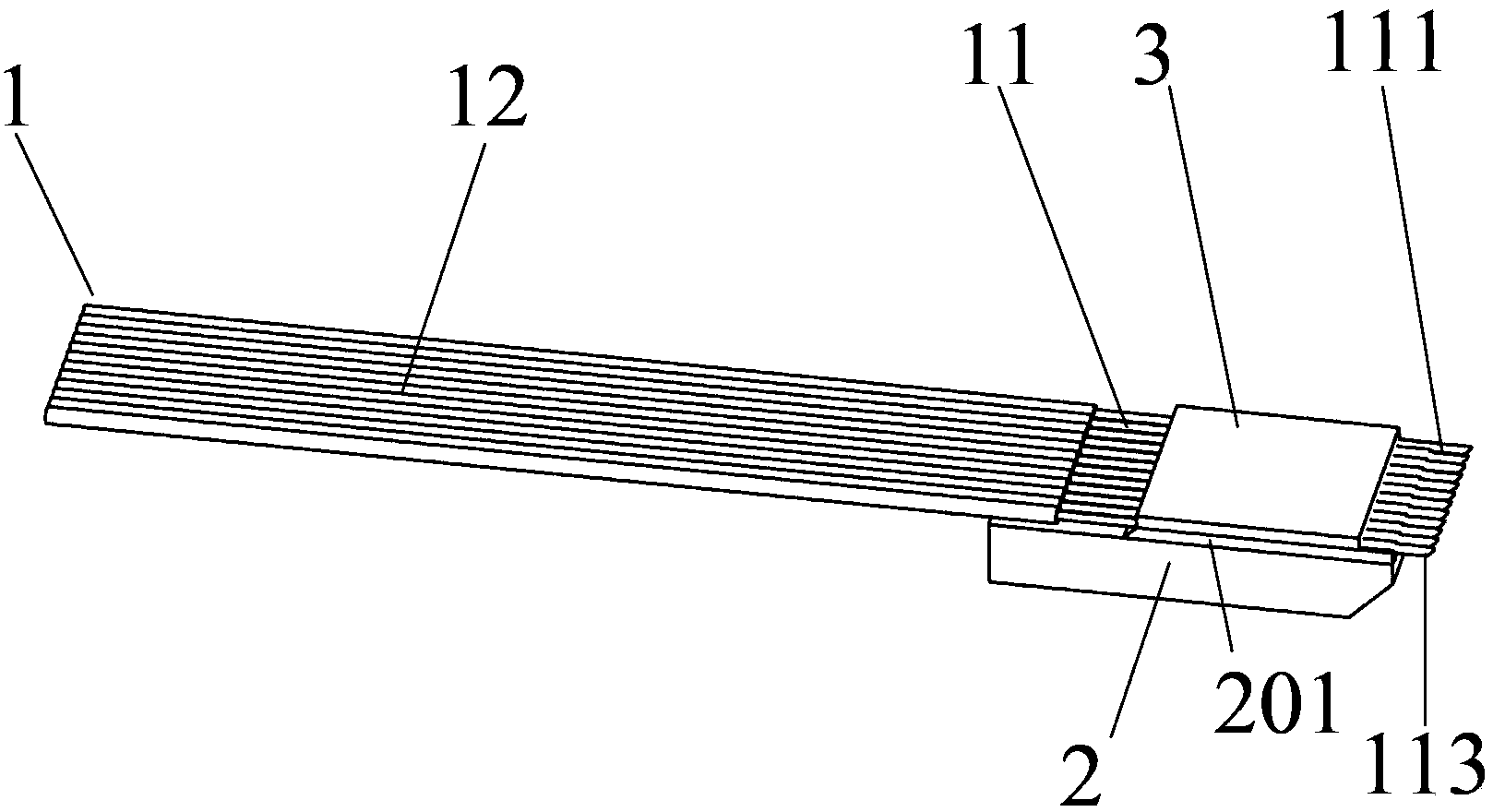

Foldable display device

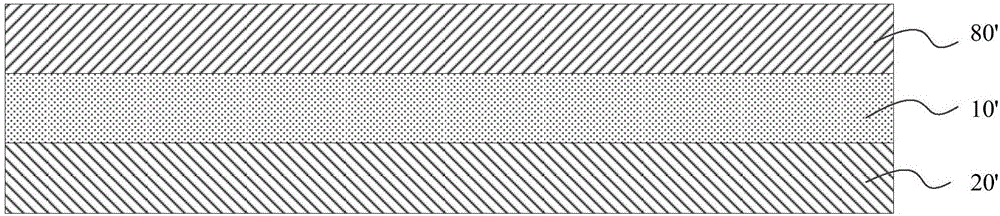

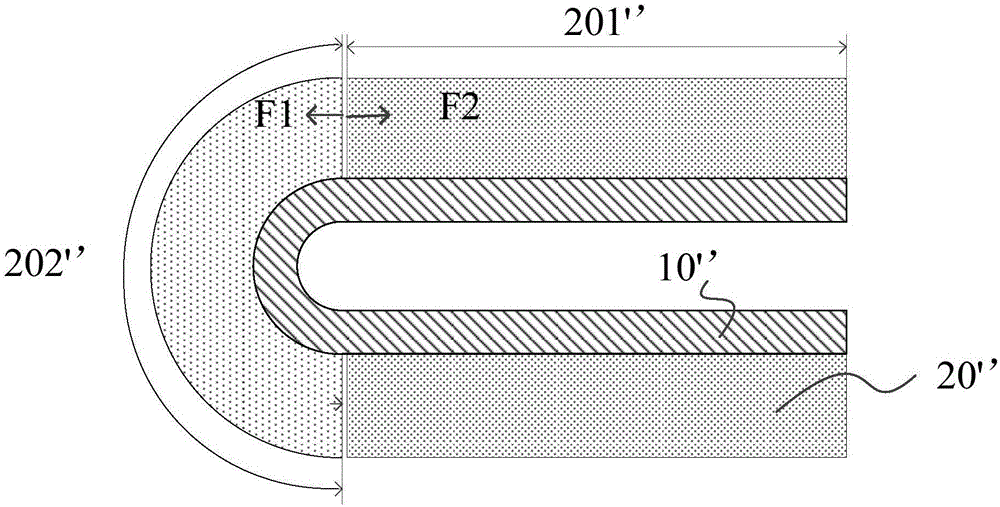

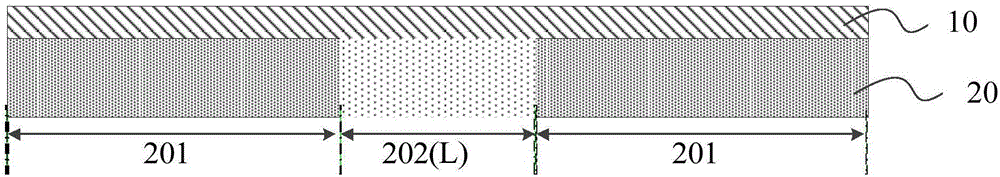

ActiveCN106652802AImprove rigidityWith bending resistanceIdentification meansDisplay deviceEngineering

The invention provides a foldable display device, comprising a display panel and a support plate arranged on a backlight side of the display panel, wherein the support plate includes a folded area and an unfolded area, the folded area and the unfolded area are integrated without an interface, the folded area comprises a flexible portion, and the unfolded area comprises a rigid portion, the elastic modulus of which is greater than the elastic modulus of the flexible portion, therefore, the folded area has resistance to bending, and the unfolded area has relatively strong rigidity to achieve foldable display in a fixed area. The folded area and the unfolded area are integrated without the interface, so that cracking at the interface while bending is avoided.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Cylindrical attapulgite flower ceramsite

ActiveCN102503537AHigh strengthLower sintering temperatureCeramic materials productionCeramicwareMetallurgyBentonite powder

The invention discloses cylindrical attapulgite flower ceramsite. The key points of the technical scheme are that the cylindrical attapulgite flower ceramsite consists of high-adhesion attapulgite clay powder, attapulgite clay tailing powder, red bentonite powder, sludge, diatomite tailing powder and rice husk powder. The cylindrical attapulgite flower ceramsite is produced by the following stepsof mixing the ingredients, pelleting, roasting, cooling, screening and packaging. The cylindrical attapulgite flower ceramsite has a rough and porous surface, is light in weight, high in strength andwater absorption rate, can be immersed in water throughout the year without cracking and can continuously and slowly release nutrition required by flowers. Moreover, the cylindrical attapulgite flower ceramsite is produced by comprehensively utilizing the sludge and tailings, so that the resource utilization rate is improved, waste is turned into wealth, and environment is protected. Besides, thecylindrical attapulgite flower ceramsite is applicable to cultivation of various flowers and vegetables.

Owner:江苏世澳非金属应用科技有限公司

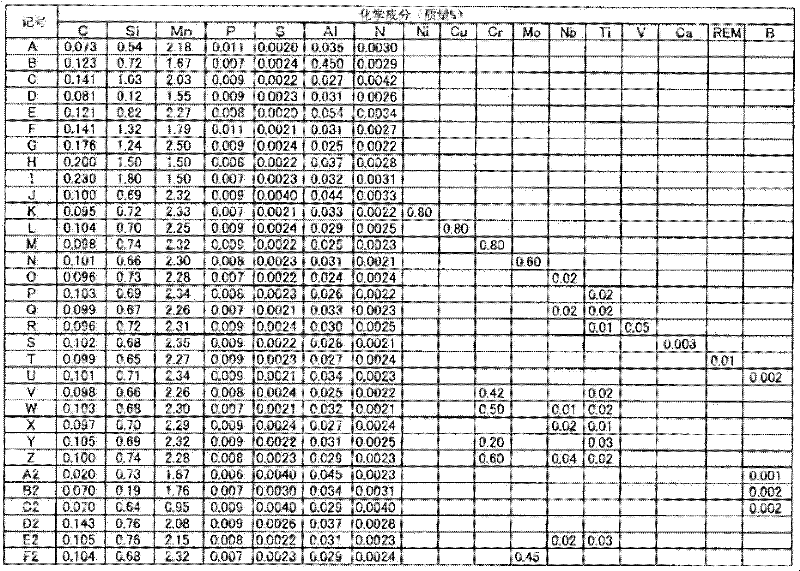

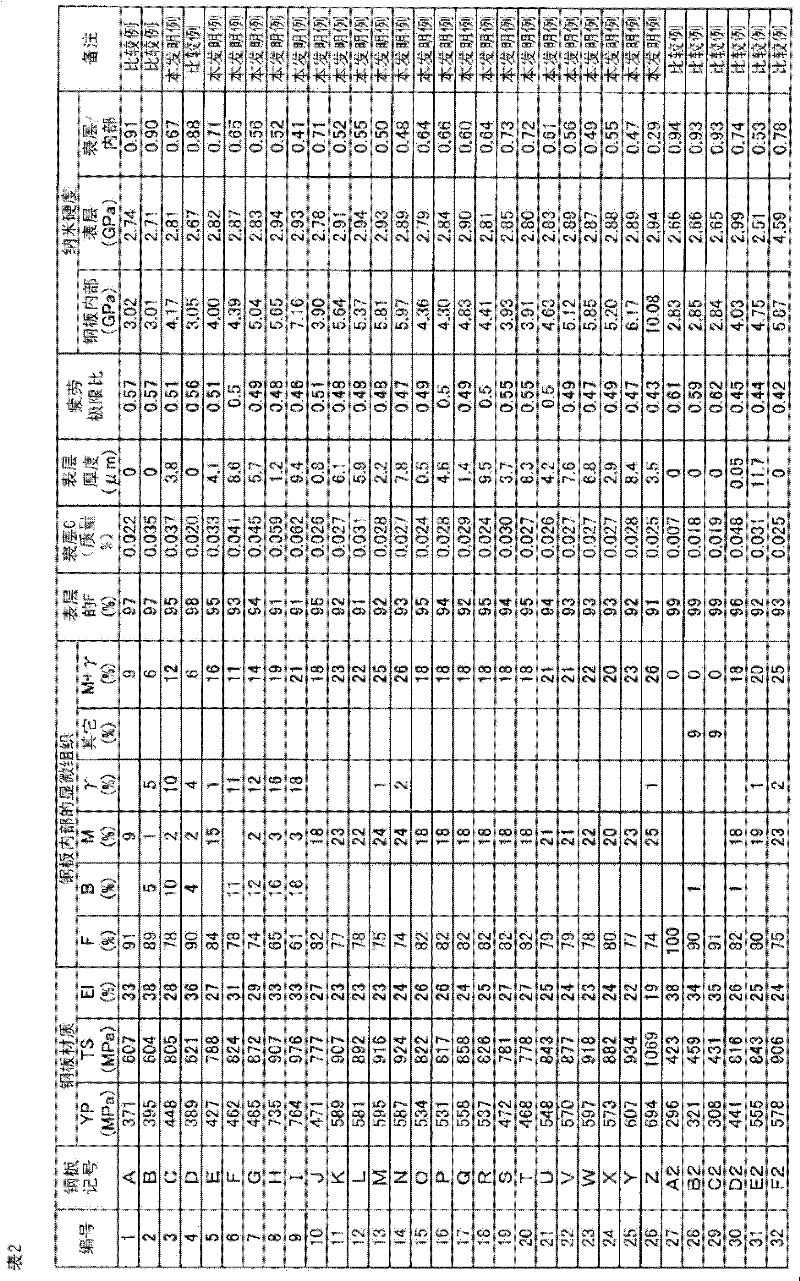

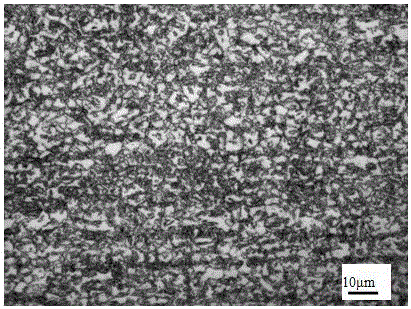

High-strength hot-dip galvanized steel sheet and process for producing same

ActiveCN102482753AImprove fatigue durabilityExcellent resistance to hydrogen embrittlementHot-dipping/immersion processesFurnace typesSoft layerHigh intensity

Disclosed is a hot-dip galvanized steel sheet which comprises a steel sheet part and a deposit formed on the surface of the steel sheet part and has a tensile strength of 770 MPa or higher, wherein the deposit is a zinc layer formed by hot-dip plating or an alloyed zinc layer formed by hot-dip plating, the steel sheet part comprises a soft layer, which is in direct contact with the deposit, and an inner layer, which is the part other than the soft layer, and the thickness (D) of the soft layer is 0.001 to 5% of the thickness (t) of the steel sheet part. In a cross-section along the thickness direction of the steel sheet part, when the hardness of the soft layer measured by a nanoindentation method is expressed by H1 and the representative hardness of the steel sheet part measured by the nanoindentation method is expressed by Ha, then H1 is 5-75% of Ha.

Owner:NIPPON STEEL CORP

Inorganic powder texture coating, and its applying method

ActiveCN1757688AEasy constructionUnique texturePowdery paintsCement coatingsInorganic pigmentsMaterials science

A inorganic dry powder paint with good mass sensation is prepared proportionally from cement, color sand, re-dispersed emulsoid powder, hydrophobic agent, inorganic pigment and filler. Its advantages are high adhesion to concrete, high weatherability, good air permeability, and no pollution. Its application method is also disclosed.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

Continuous hot galvanizing method for 1180 MPa-grade Q&P steel

InactiveCN105886750AImprove adhesionGood mechanical propertiesHot-dipping/immersion processesFurnace typesTime rangeHydrogen content

The invention discloses a continuous hot galvanizing method for 1180 MPa-grade Q&P steel. Continuous hot galvanizing is carried out on chilled rolls of the Q&P steel and comprises the heating stage, the soaking stage, the quenching stage, the reheating stage, the partitioning stage, the hot galvanizing stage and the cooling stage; in the heating stage, the chilled rolls are pre-oxidized, the pre-oxidization temperature ranges from 610 DEG C to 750 DEG C, the pre-oxidization time ranges from 10 seconds to 60 seconds, the pre-oxidization atmosphere is the mixed atmosphere of nitrogen gas and air, and the final oxygen content ranges from 300 ppm to 20000 ppm; in the soaking stage, the soaking temperature ranges from 800 DEG C to 950 DEG C, the soaking time ranges from 30 seconds to 150 seconds, the hydrogen content in the furnace atmosphere ranges from 4% to 5%, and the dew point ranges from minus 35 DEG C to 50 DEG C; in the quenching stage, high hydrogen or water is adopted for quenching, and the steel is cooled to 280-350 DEG C; in the reheating stage and the partitioning stage, the partitioning temperature is heated to 380-450 DEG C at the rate of 8-20 DEG C / s, and the partitioning time ranges from 60 seconds to 300 seconds; in the hot galvanizing stage, the hot galvanizing temperature is 460 DEG C, and the hot galvanizing time ranges from 3 seconds to 10 seconds; in the cooling stage, the air or the nitrogen gas is adopted for cooling, the cooling rate is 15 DEG C / s, and the steel is cooled to 150 DEG C. The hot galvanizing adhesion performance of the Q&P steel is improved through the method.

Owner:HEBEI IRON AND STEEL

Flexible stretchable conductive circuit and preparation method and use thereof

InactiveCN108668431AReduce dosageAchieve mass productionLithography/patterningConductive pattern formationWire widthImage resolution

The invention provides a flexible stretchable conductive circuit, a preparation method and use thereof. The invention also provides double-sided wiring, multilayer board, flexible display, flexible electronics, and / or sensor comprising the flexible stretchable circuit described above. The method for preparing flexible stretchable conductive circuit provided by the invention is simple and rapid, and is generally applicable to various substrate materials, the liquid metal is used in a small amount, does not require additional external force, and the pattern does not generate cracks, the wire width is controllable, has a high resolution and it's very suitable for mass production.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

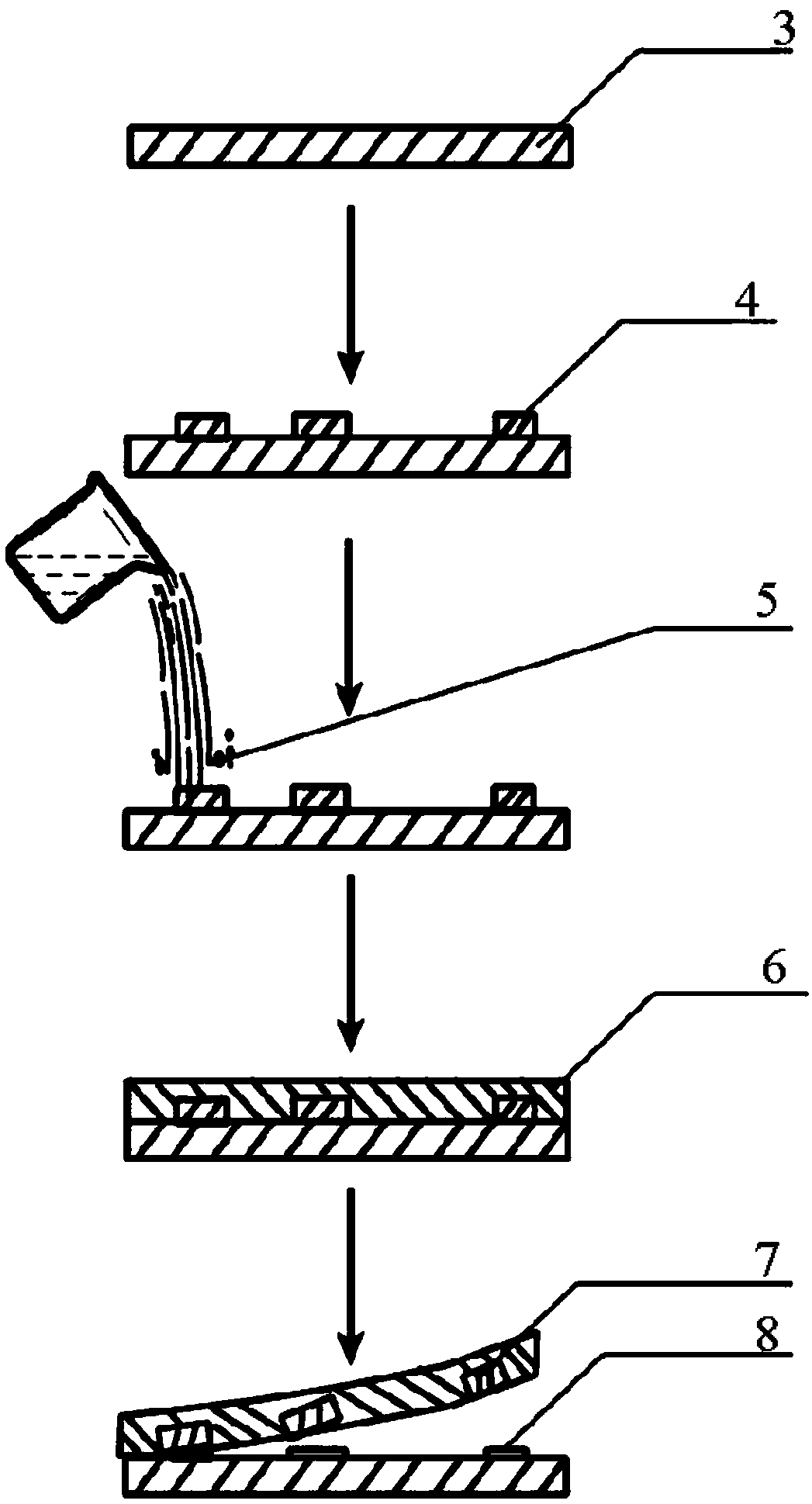

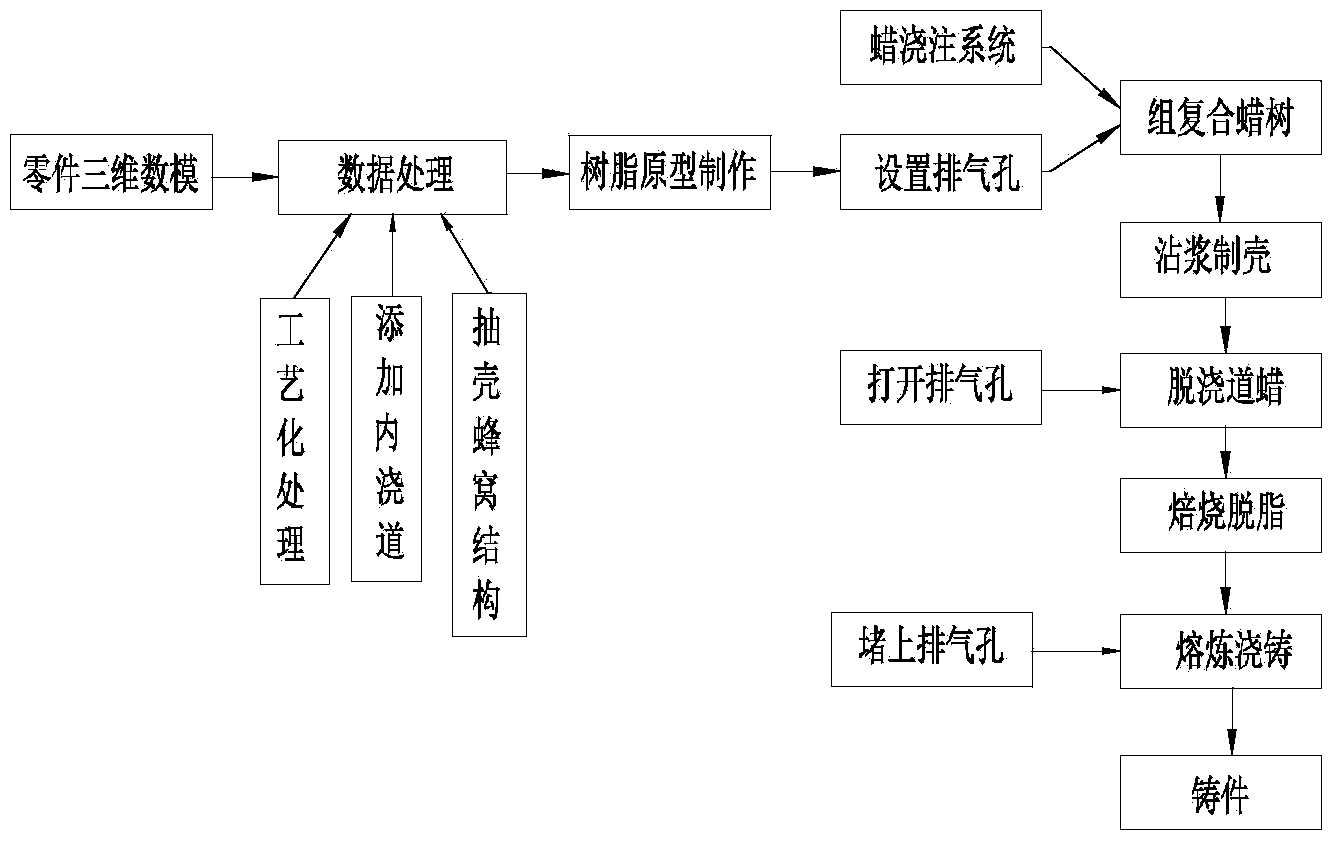

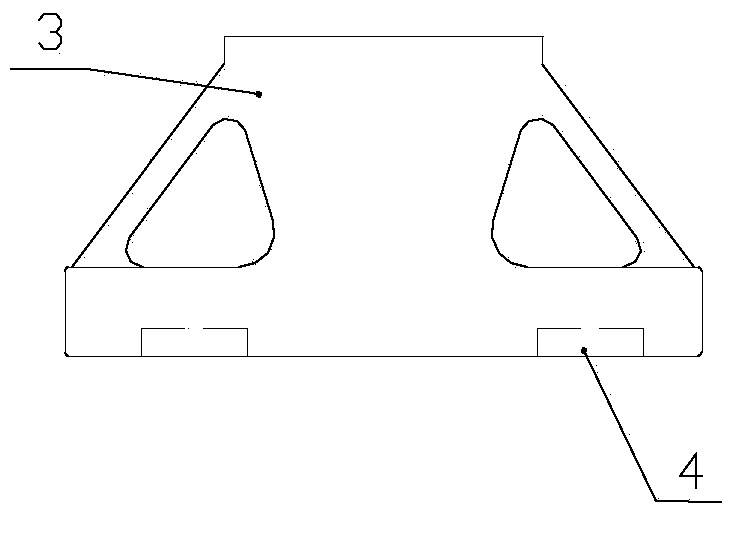

Rapid investment casting method based on stereolithography (SL)

Owner:无锡市交大增智增材制造技术研究院有限公司

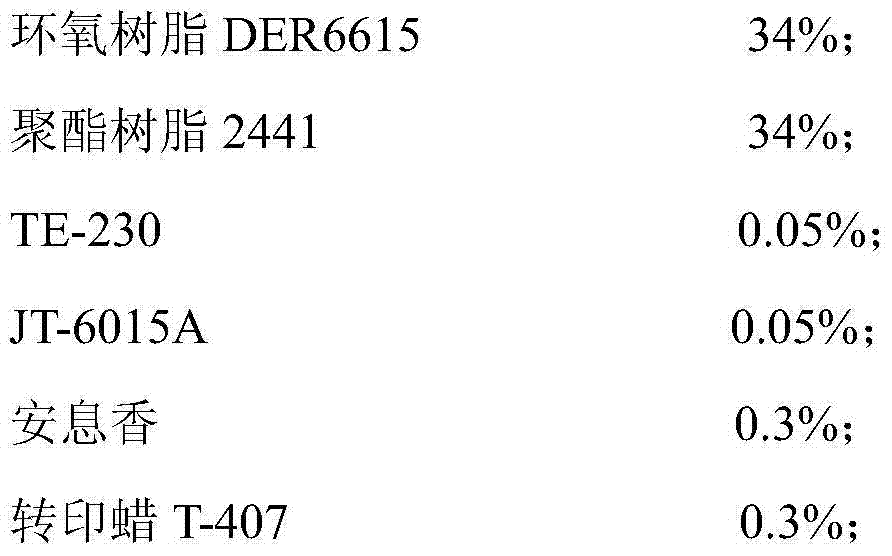

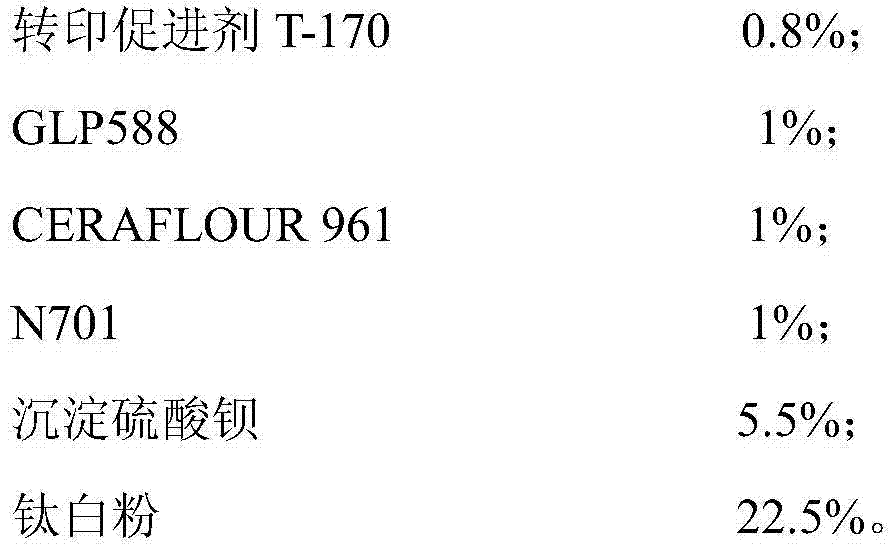

Powder coating for MDF transfer printing and application method of powder coating

PendingCN104497808AImprove texture clarityEasy to tear offDuplicating/marking methodsPowdery paintsWeather resistanceWear resistance

The invention relates to powder coating and particularly relates to powder coating for MDF transfer printing and an application method of the powder coating. The powder coating is prepared from the following raw materials in percentage by weight: 53-90% of resin, 0-6.7% of a curing agent, 0.1-0.5% of a curing accelerant, 3-25% of auxiliaries, 5-30% of filler and 0.8-25% of pigment. After the powder coating is used for transfer printing, the texture is clear, the penetration is deep, the third dimension is strong, the transfer printing paper can be easily uncovered, the thermal transfer printing product is durable in use, and the patterns are not dropped, cracked or faded; moreover, the thermal transfer printing only achieves a surface decoration effect without changing the characteristics of the original glossiness, the wear resistance, the weather resistance, the acid and alkali resistance, and the like of the product. The invention also provides an application method of the powder coating.

Owner:山东朗法博粉末涂装科技有限公司

Cigarette aluminum-foil paper with anti-counterfeiting label

InactiveCN105178107AImprove temperature resistanceImprove aging resistanceFlexible coversWrappersHazardous substanceLaser patterning

The invention provides cigarette aluminum-foil paper with an anti-counterfeiting label. The cigarette aluminum-foil paper comprises liner paper and an aluminum foil layer. An anti-counterfeiting laser film is arranged on the surface of the aluminum foil layer. The manufacturing process comprises the steps that the laser film is manufactured, an aluminum foil body coated with glue is heated and baked, the laser film and the aluminum foil are composited, a BOPP film is stripped from a cured semi-finished product, a BOPP base film on a cooled composited film is removed, a complexing agent for connecting the liner paper and the aluminum foil layer is prepared, and finally the liner paper and the aluminum foil layer are composited. The BOPP base film has the good temperature resistance and ageing resistance, materials are soft, no transparent de-bonding layer needs to coat the materials, and the technological process is simple; the anti-counterfeiting film is transferred onto aluminum foil, laser patterns will not disappear and are not likely to be damaged, and the while film is good in high temperature resistance and will not crack. The complexing agent between the liner paper and the aluminum foil layer is not likely to volatilize to generate hazardous substances, the temperature is high, and adhesive force can be provided for the liner paper and the aluminum foil layer for a long time.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

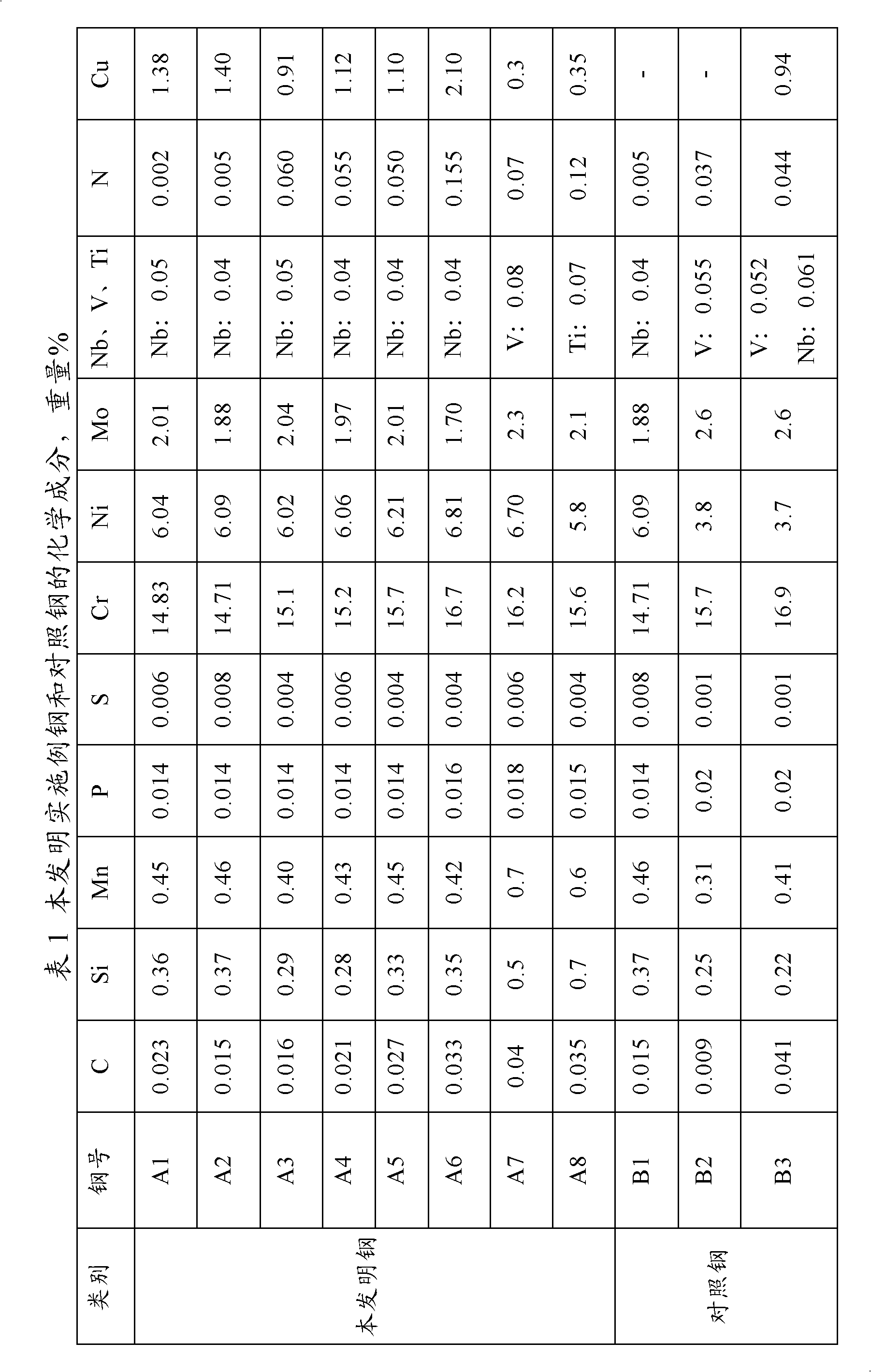

Martensitic stainless steel for oil casing and manufacturing method thereof

InactiveCN102534418AHigh strengthPrevent precipitationFurnace typesHeat treatment furnacesDouble phaseMartensitic stainless steel

The invention relates to a martensitic stainless steel for an oil casing and a production method thereof. The artensitic stainless steel comprises the following chemical components in percentage by weight: at most 0.04% of C, 0.20-1% of Si, 0.30-1% of Mn, at most 0.02% of P, at most 0.010% of S, 14-17% of Cr, less than 5% and at most 7% of Ni, 1.5-2.3% of Mo, 0-0.16% of N, 0.05-2.5% of Cu, one or more of 0.01-0.10% of Nb, 0.01-0.10% of V and 0.01-0.10% of Ti, and the balance of iron and inevitable trace impurity elements. The manufacturing method of the steel comprises the following steps: heating the oil casing to 950-1100 DEG C, cooling to below 200 DEG C by air cooling, oil cooling or water cooling, and heating to 550-650 DEG C to implement tempering. The steel has a microstructure which uses a tempered martensite phase as a base phase, and contains high-temperature ferrite (delta-ferrite), austenite and other second phases of which the volume contents are respectively below 10% or the total content is below 15%. The steel provided by the invention has the characteristics of high strength (the yield strength is up to Grade 110-150ksi), strong carbon dioxide / chloride ion corrosion resistance and the like, and can partially substitute double-phase stainless steel to be used in deep wells, superdeep wells and other severe well conditions.

Owner:BAOSHAN IRON & STEEL CO LTD

Grinding roller manufacturing/remanufacturing abrasion-resistant material and preparation method thereof

InactiveCN106238709AWide adjustment of hardnessWidth adjustment toughnessFurnace typesWelding/cutting media/materialsCouplingBoron containing

The invention discloses a grinding roller manufacturing / remanufacturing abrasion-resistant material and a preparation method thereof. A grinding roller is formed by a core roller body, a substrate abrasion-resistant layer, a transition layer and a roller face abrasion-resistant shape layer in a coupling mode. A core material is provided with the highly-abrasion-resistant modified boron-containing high-chromium cast iron substrate abrasion-resistant layer through casting and compounding. The substrate abrasion-resistant layer comprises, by mass, 1.75%-3.0% of C, 12.0%-18.0% of Cr, 0.2%-2.0% of B, 0.4%-0.8% of Mn, 0.4%-1.2% of Si, 0.30%-0.80% of Ni, 0.02%-0.04% of Mg, 0.03%-0.05% of Ce, 0.05%-0.10% of Ti, 0.006%-0.015% of N, 0-0.04% of S, 0-0.04% of P, and the balance Fe. Then surfacing of materials of the roller face abrasion-resistant shape layer is conducted on the surface of the transition layer. The roller face abrasion-resistant shape layer is formed by flux-cored wires through surfacing. The flux-cored wires comprises, by mass, 2.3%-3.5% of C, 14.0%-26.0% of Cr, 1.5%-2.0% of Ni, 0.8%-2.0% of Nb, 1.3%-2.0% of Mo, 1.2%-2.3% of Si, 1.0%-1.7% of Ti, 0.3%-1.0% of V, 0.2%-1.5% of B, 0-<0.007% of S, 0-0. 015% of P, and the balance Fe.

Owner:镇江富华轧辊有限公司

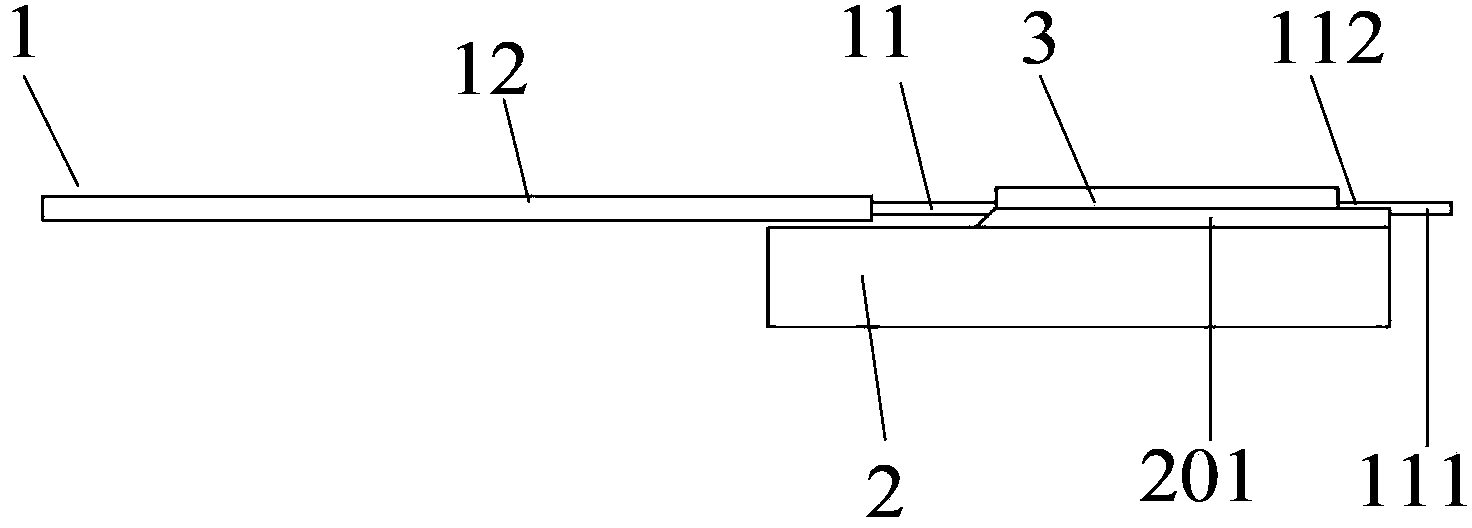

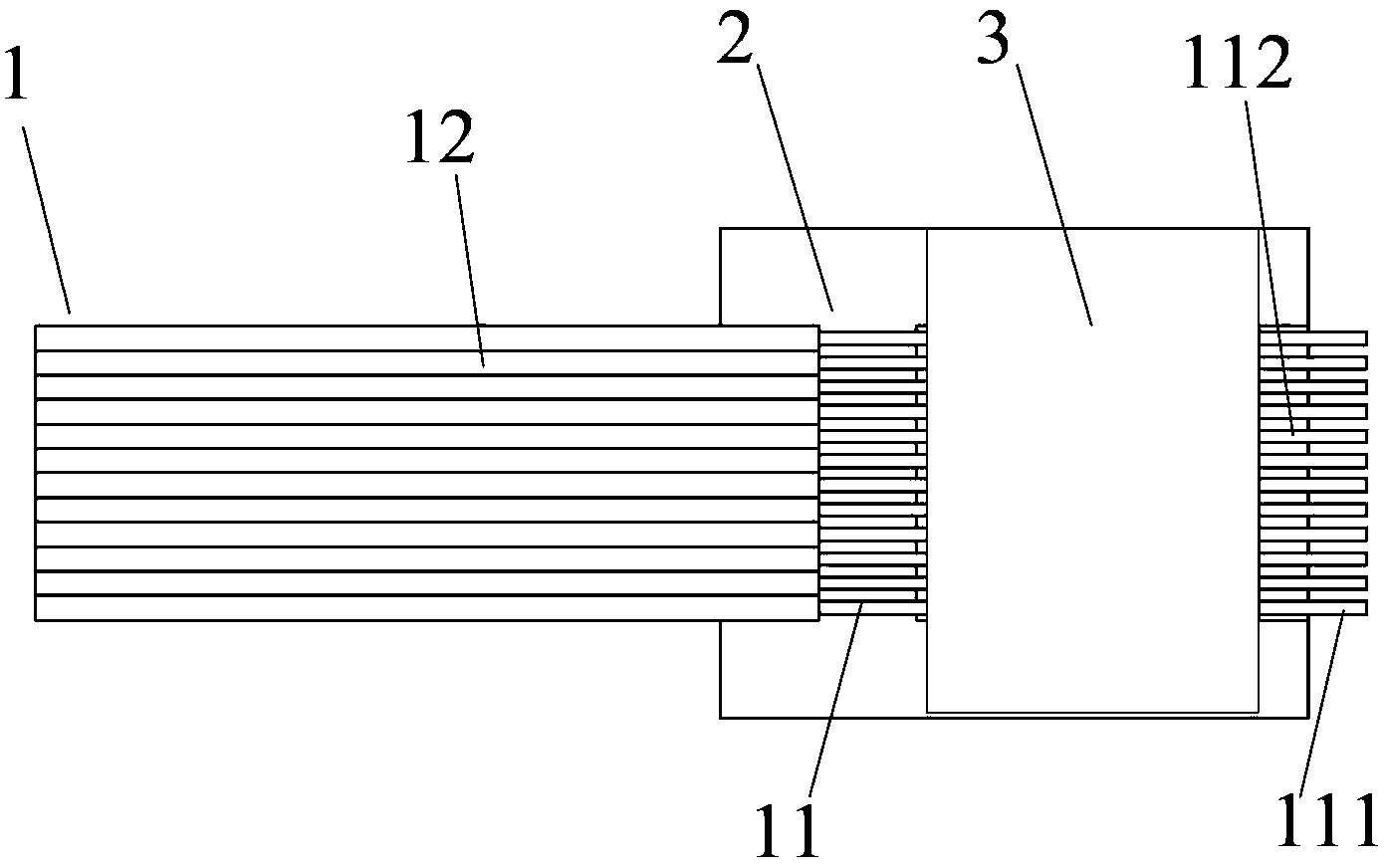

Fiber array coupled with VSCEL or PIN array and manufacturing method of fiber array

ActiveCN103383482AEfficient couplingAvoiding Adjustment Coupling Distance IssuesCoupling light guidesFiberCoupling

The invention relates to a fiber array coupled with a VSCEL or PIN array and a manufacturing method of the fiber array. The fiber array comprises a cover slip, a carving groove substrate and a fiber micro-strip, the fiber micro-strip comprises an exposed fiber micro-strip portion without a fiber coating, a V-shaped carving groove for holding the exposed fiber micro-strip portion is formed in the carving groove substrate, the cover slip presses the groove of the exposed fiber micro-strip portion, the carving groove substrate, the cover slip and the exposed fiber micro-strip portion are fixedly connected through binding agents, the cover slip is shorter than the V-shaped carving groove, the end face of the exposed fiber micro-strip portion is an optical plane with a 45-degree oblique angle, and the optical plane faces the carving groove substrate. The coupling distance between the 45-degree optical plane of the exposed fiber micro-strip portion and the VSCEL or PIN array is controlled by the aid of the cover slip of the fiber array, the thickness of the cover slip can be customized, and high-efficiency coupling is realized. The method for manufacturing the fiber array is simple, easy to implement and low in cost.

Owner:WUHAN POWERISE OPTOELECTRONICSAL TECH

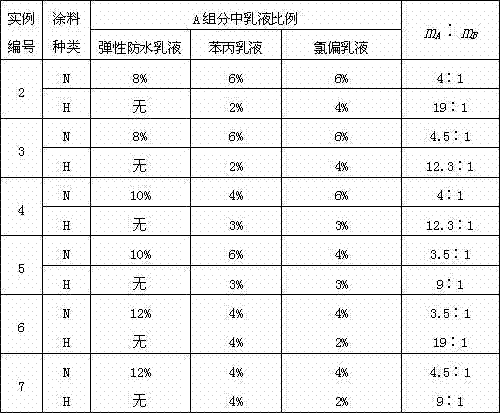

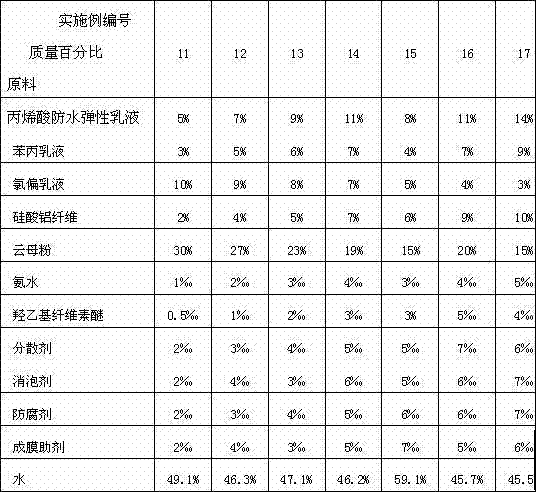

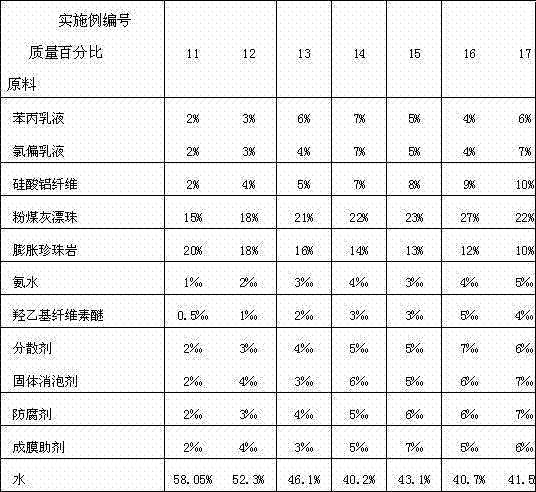

Preparation method for anti-corrosion and flameproof integrated coating for thick-type steel structure

The invention discloses a preparation method for an anti-corrosion and flameproof integrated coating for a thick-type steel structure. The coating is characterized by: preparing an anti-corrosion primer for a fire resistant-type steel structure, wherein the primer is prepared through mixing a component A and silicate cement, wherein the component A comprises emulsions such as acrylic acid waterproof elastic emulsion and the like, aluminium silicate fiber, mica powder, an assistant agent and water; preparing a flameproof coating for a thick-type steel structure, wherein the coating is preparedthrough mixing a component C and the silicate cement, wherein the component C comprises emulsions such as styrene-acrylate emulsion and the like, the aluminium silicate fiber, fly ash floater, expanded perlite, an assistant agent and the water; carrying out steps of cleaning process, the anti-corrosion primer coating, burnishing, the flameproof coating coating and the like for the surface of the steel structure to obtain the anti-corrosion and flameproof integrated coating for the thick-type steel structure, wherein the integrated coating is a system comprising the emulsion, the cement and the aluminium silicate fiber. The prepared coating provided by the present invention has characteristics of low comprehensive cost, anti-corrosion and flameproof integrated coating, and is applicable for the corrosion prevention and the flame protection for load-bearing steel structure components of various buildings in the industries of spaceflight, petroleum, chemical engineering, electric power, metallurgy, national defense, textile and the like.

Owner:四川金和时代建筑工程有限公司

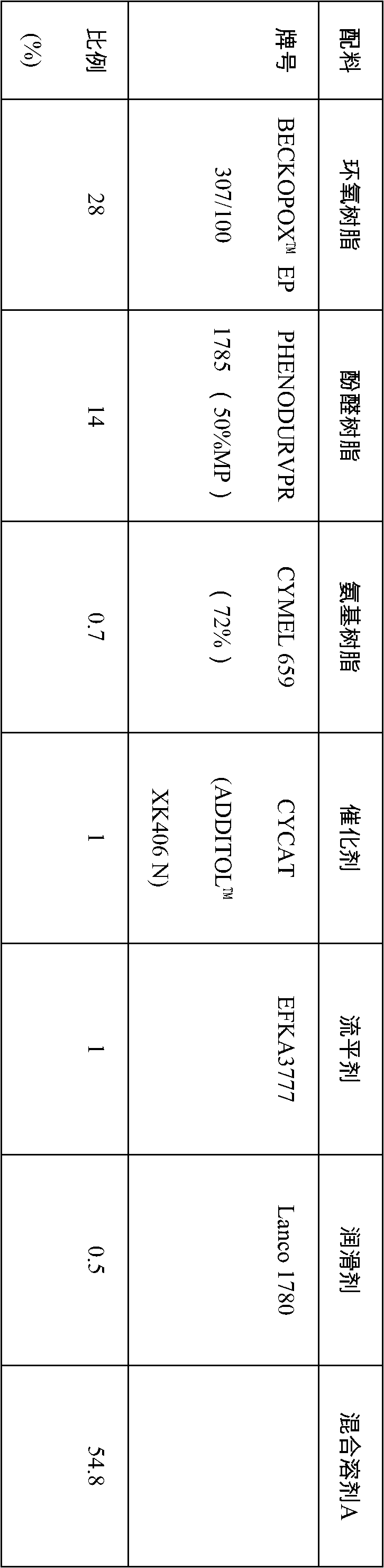

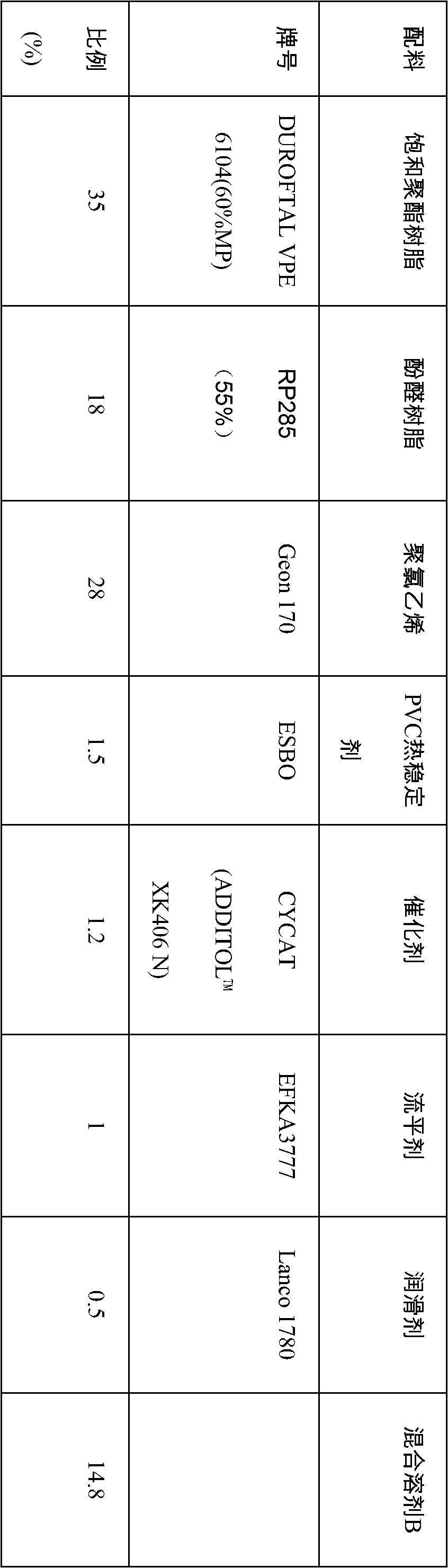

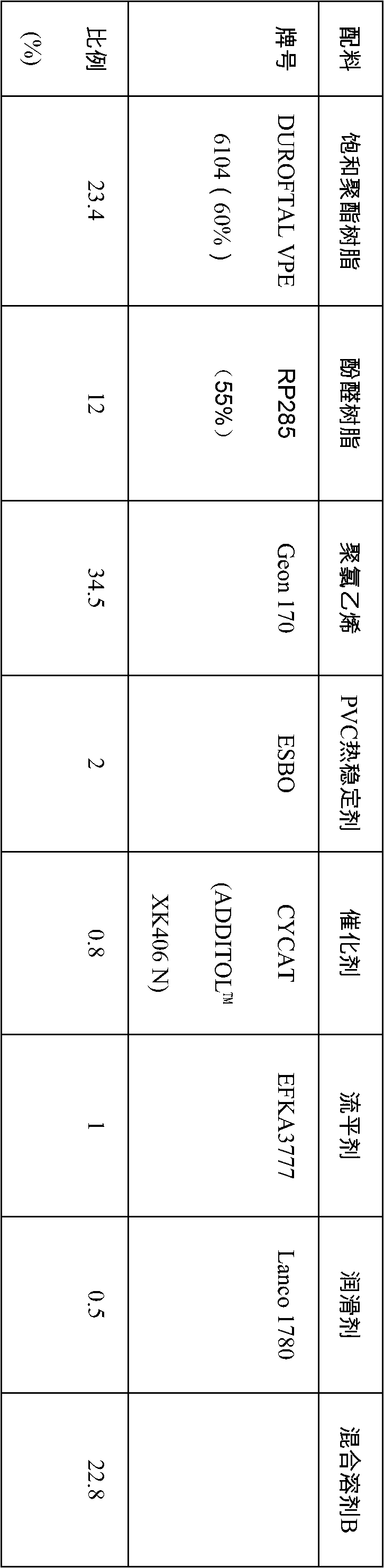

Coating composition and application of coating composition to metal base material

The invention discloses a coating composition and an application of the coating composition to a metal base material. The solid content of the coating composition is 40-70%. The coating composition comprises the following components of, by weight, 5-60% of saturation polyester resins, 0-25% of crylic acid resins, 2-30% of crossing-link agents, 20-80% of polyvinyl chloride homopolymer, 0-15% of additives, 0-40% of pigments and the balance dilution solvents, wherein average molecular weight Mn of the saturation polyester resins is 3000-8000, the vitrification temperature of the saturation polyester resins is 10-20 DEG C, the acid value of the saturation polyester resins is 0-5, the hydroxyl value of the saturation polyester resins is 30-90, and the saturation polyester resins are free of neopentyl glycol. The coating composition is free of bisphenol-A diglycidyl glycerol ether (BADGE) and bisphenol A (BPA). According to the coating composition, the polyester resins which meet requirements can be easily obtained, improved space of resin performances is large, 40%-70% of the solid content of final products can be achieved, and a large quantity of organic solvents are saved.

Owner:HANGZHOU CPMC +1

Preparation method of flexible epitaxial ferroelectric film

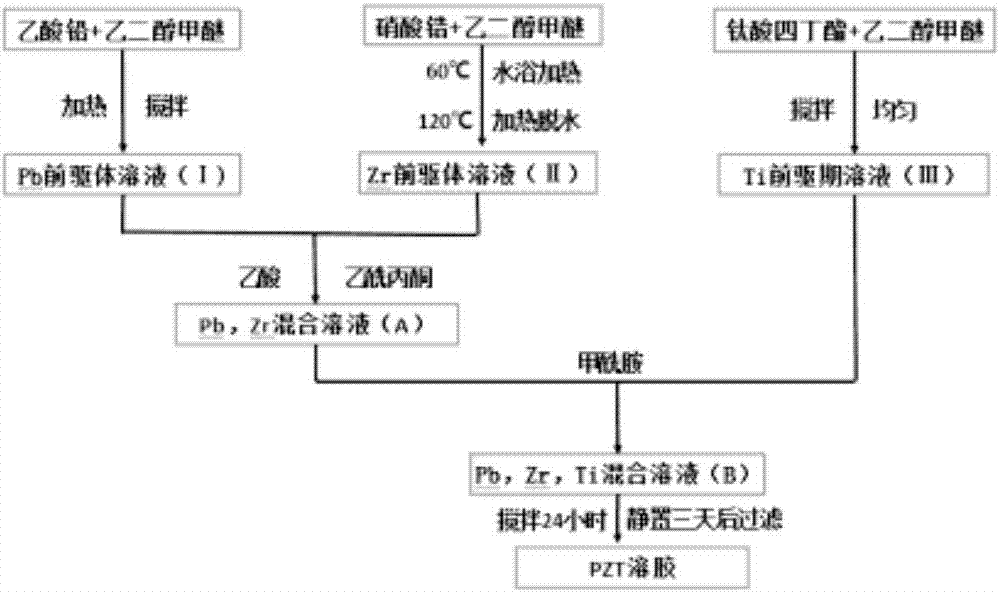

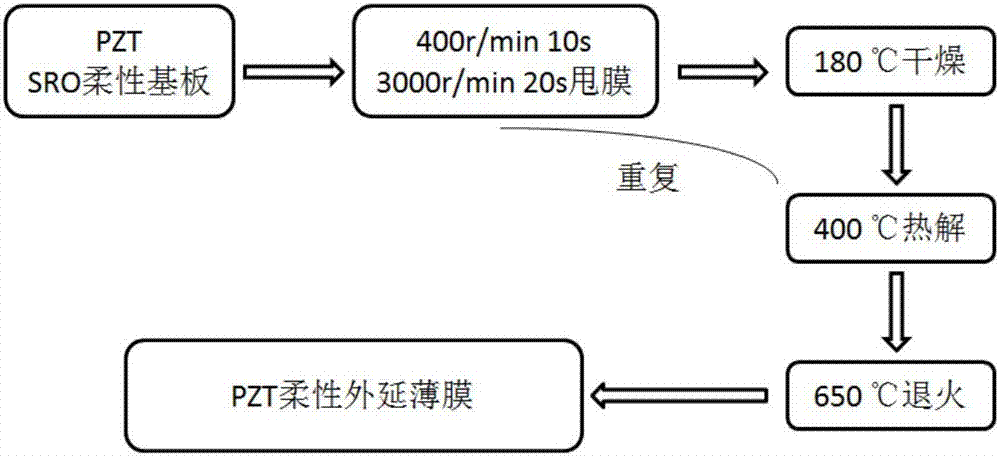

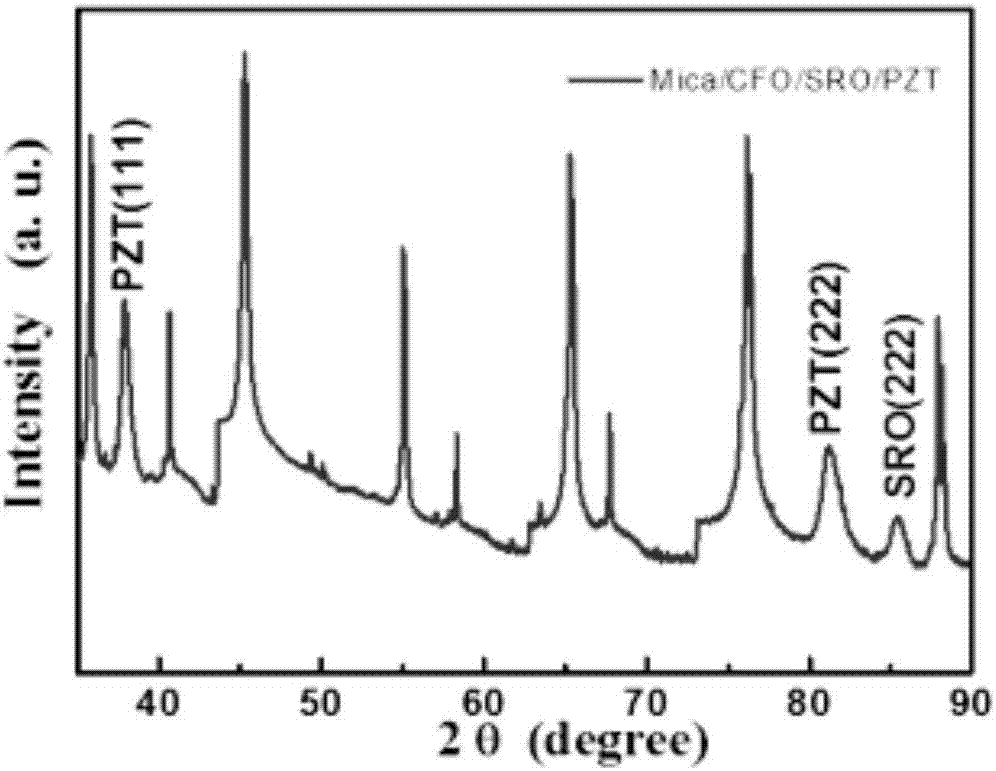

ActiveCN107256866AExcellent ferroelectric propertiesFormulation technology optimizationSolid-state devicesVacuum evaporation coatingStrontium ruthenateFilm material

The invention discloses a preparation method of a flexible epitaxial ferroelectric film. The preparation method is characterized by 1) preparing a perovskite structure oxide strontium ruthenate bottom electrode by a laser pulse deposition method; 2) preparing a precursor solution of the ferroelectric film by means of a sol-gel method, wherein the concentration of the precursor solution is 0.1-0.5mol / L, the ferroelectric film material is selected from any one of lead zirconate titanate, barium titanate or bismuth ferrite; 3) preparing the flexible epitaxial ferroelectric film, spin-coating the above-mentioned strontium ruthenate bottom electrode with the precursor solution by means of a spin coating method to obtain a uniform wet film; 4) drying, pyrolyzing and annealing the obtained uniform wet film; and (5) repeating steps 3) and 4) for 3-8 times to obtain the target flexible epitaxial ferroelectric film, and the thickness of the film is in the range of 100nm-300nm. The flexible epitaxial ferroelectric film is simple in technology and excellent in ferroelectric performance.

Owner:XIANGTAN UNIV

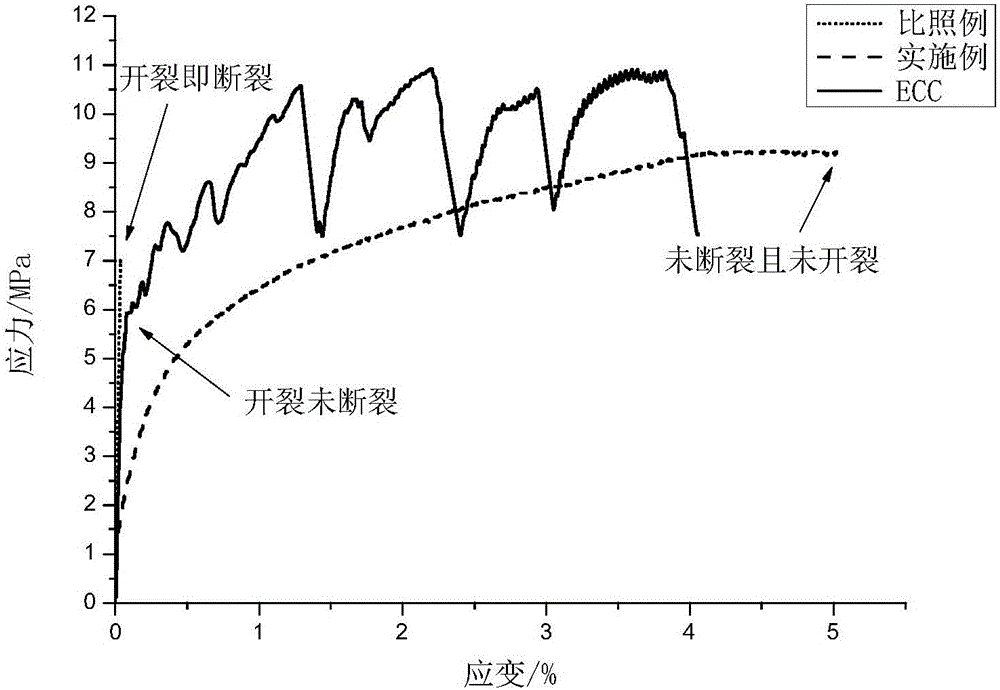

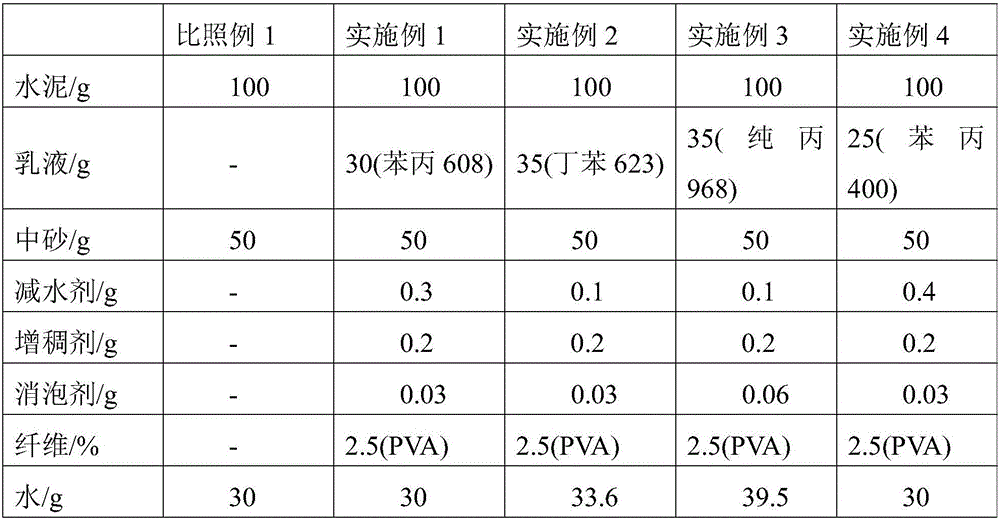

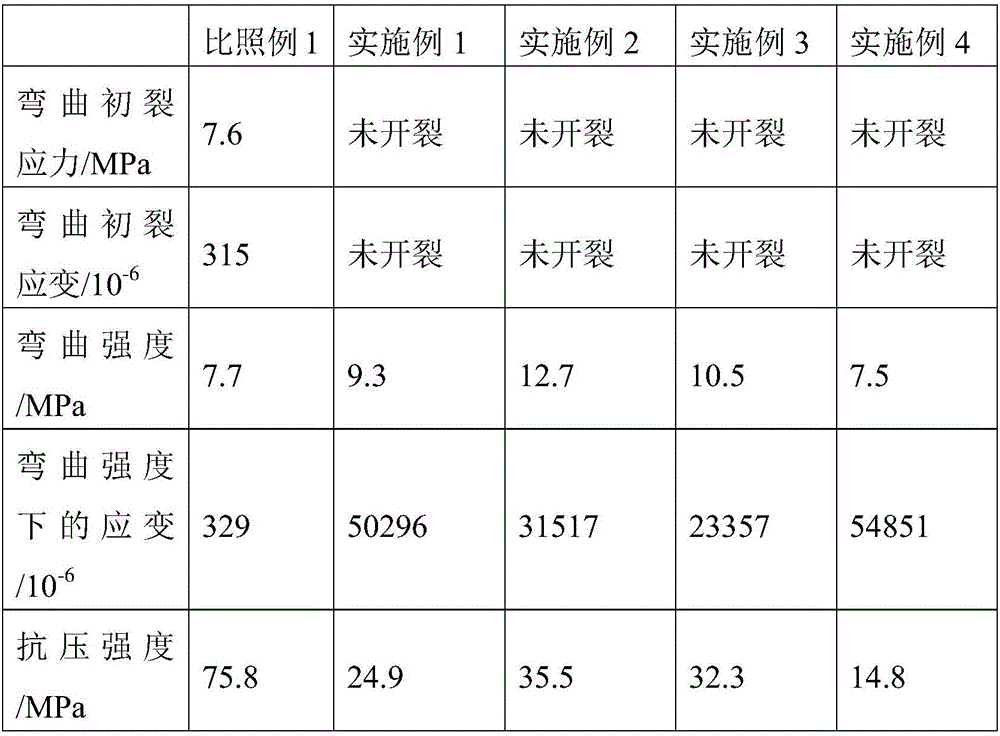

Ultrahigh-toughness fiber-reinforced polymer modified cementitious composite and preparation method

InactiveCN106478007AHigh bending strain at first crackHigh flexural crack stressPolymer modifiedPolymer science

The invention relates to an ultrahigh-toughness fiber-reinforced polymer modified cementitious composite and a preparation method. The ultrahigh-toughness fiber-reinforced polymer modified cementitious composite is prepared from raw materials in parts by weight as follows: 100 parts of comprising cement, 50 parts of medium sand, 25-35 parts of polymer emulsion (in terms of solid content), synthetic polymer fibers, 0.1-0.5 parts of a water reducing agent, an antifoaming agent, 0.1-0.5 parts of a thickener and 30-40 parts of water according to a formula, wherein the synthetic polymer fibers account for 2.5% of the total volume of the composite, and the antifoaming agent accounts for 0.05%-0.2% of the mass of the polymer emulsion. Compared with the prior art, the ultrahigh-toughness fiber-reinforced polymer modified cementitious composite has the advantages of ultrahigh initial cracking strain, higher bending stress, higher initial cracking stress and the like.

Owner:TONGJI UNIV

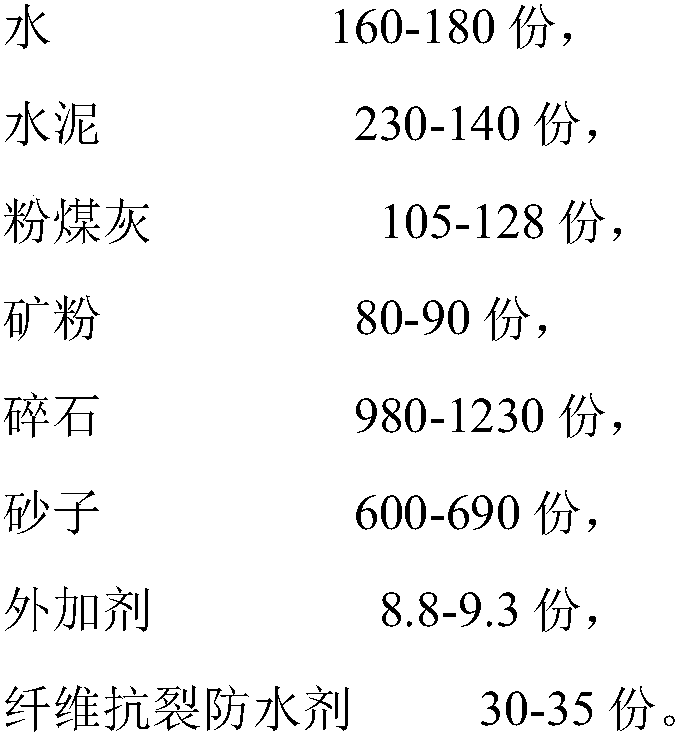

Anti-cracking mass concrete

InactiveCN107777956AMitigation of temperature cracksImprove crack resistanceCrack resistanceMaterials science

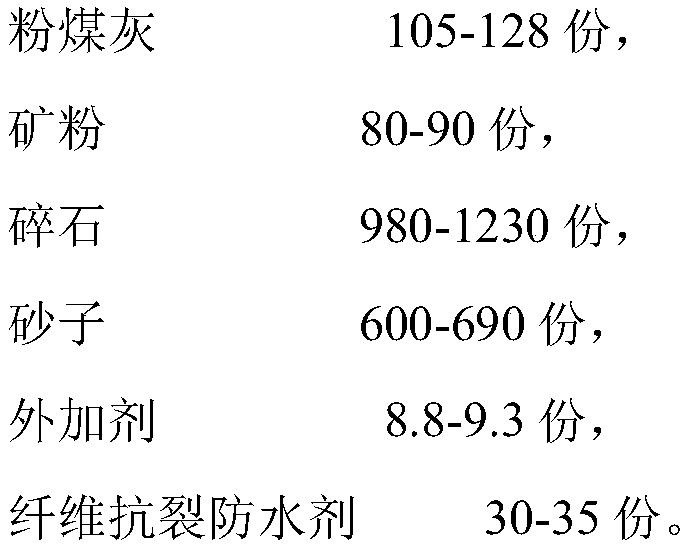

The invention discloses anti-cracking mass concrete which is characterized by comprising the following components in parts by weight: 160-180 parts of water, 140-230 parts of cement, 105-128 parts offly ash, 80-90 parts of mineral powder, 980-1230 parts of macadam, 600-690 parts of sand, 8.8-9.3 parts of an admixture and 30-34 parts of a fibrous anti-cracking water-proofing agent. The cracking resistance of the mass concrete is improved by improving the ratio of the components in the concrete.

Owner:天津顺德混凝土工程有限公司

Method for smearing wood wax oil on surface of wood product

InactiveCN103182725AIncrease exerciseIncrease oil intakeCoating impregnationCoatingsWaxEnvironmentally friendly

The invention relates to a method for smearing wood wax oil on the surface of a wood product, which comprises the following steps: 1, smoothening; 2, smearing the wood wax oil; 3, kneading a wax oil coating on the surface; 4, wiping floating oil; 5, drying; 6, repeating the steps 2-5 for one or two times; 7, polishing till the hand feeling is smooth; and 8, spraying polishing wax, polishing and entering a next assembly process. By using the method, the crack of the wood product can be effectively prevented, and the service life is prolonged; the operation is simple, and materials, labors and oil are saved; the wood wax oil is a green and environmentally-friendly coating and a low-carbon environmentally-friendly product; and by using the method, the wide application of the wood wax oil can be promoted, and an important significance on environment friendliness is realized.

Owner:张克广

Modified cement-based self-leveling mortar and preparation method and application thereof

The invention relates to improved cement-based self-leveling mortar and a preparation method and application thereof. The improved cement-based self-leveling mortar comprises the following components in percentage by weight: 50%-70% of aggregate, 31%-40% of cement, 13%-15% of anhydrite, 5%-15% of ground calcium carbonate, 0.05%-0.3% of water-retaining agent, 0.05%-0.2% of carbonate, 0.4%-0.9% of retarder, 0.3%-0.9% of lignocellulose, 0.2%-0.3% of antifoaming agent, 0.6%-0.9% of water reducer and 1.5%-4.5% of pure acrylic emulsion powder. The invention has the advantages of simple preparation and application methods, good construction peaceability, good waterproofness, greatly reduced microcracks, high mechanical physics property, good self-leveling performance and impact resistance, and excellent flexibility; no cracking and shrinkage occur to constructed ground; and in addition, the invention can effectively solve the problems of complex site operation process, unstable mortar performance, environmental pollution and the like of the existing dual-component cement-based self-leveling mortar, thus the self-leveling mortar is a green building material because no toxic and harmful matter is contained.

Owner:北京天维宝辰化学产品有限公司

Thermal sublimation transferring-printing coating pulp and method for carrying out thermal sublimation transferring-printing by using same

ActiveCN104073103AGood light fastnessExcellent outdoor aging resistanceDuplicating/marking methodsEpoxy resin coatingsCross-linkPolyester

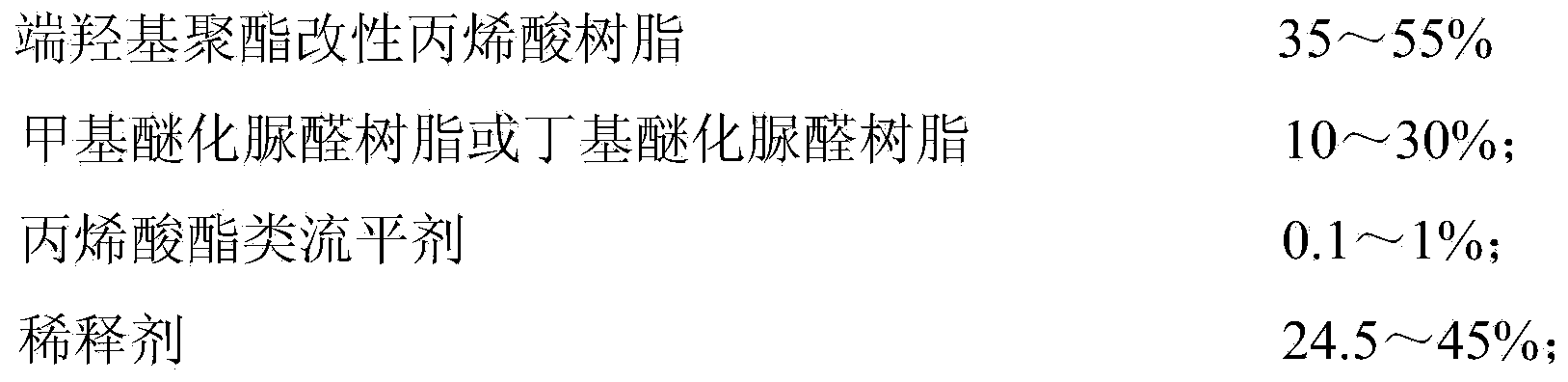

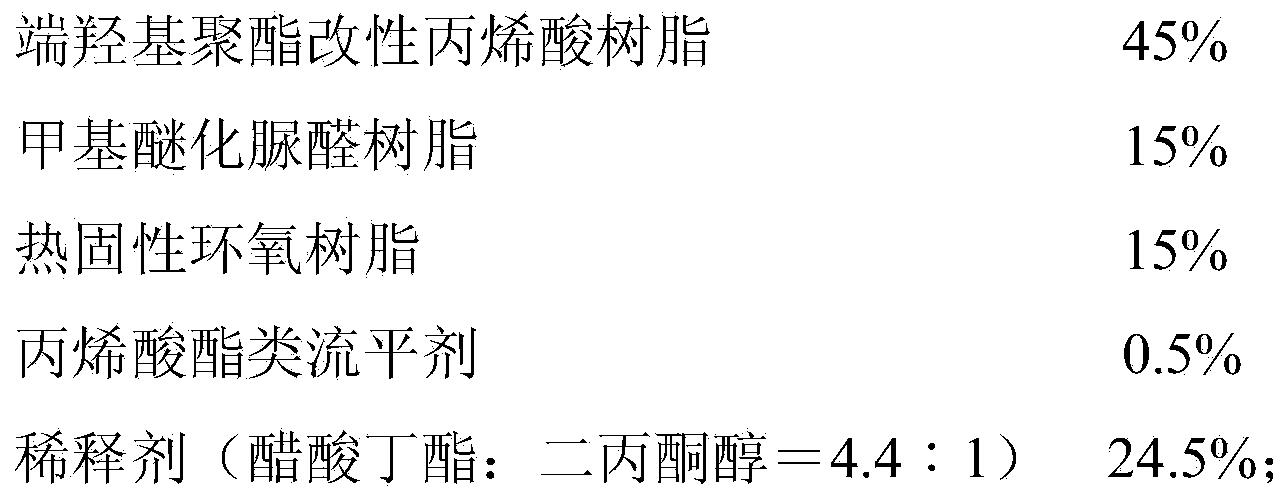

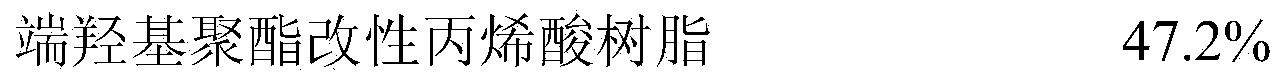

The invention discloses thermal sublimation transferring-printing coating pulp which comprises the following components in percentage by mass: 35-55% of hydroxyl-terminated polyester modified crylic acid resin, 10-30% of methyl etherified urea resin or butyl etherified urea resin, 0.1-1% of acrylic leveling agent and 24.5-45% of diluent, wherein the solid content of the hydroxyl-terminated polyester modified crylic acid resin is 60%+ / -2%, and the acid value is 3-5mgKOH / g; the solid content of methyl etherified urea resin or butyl etherified urea resin is 75%+ / -2%, the acid value is less than 1mgKOH / g; the diluent is a mixture of n-butyl acetate and diacetone alcohol. When the coating pulp is coated on the surface of a printed article and is heated, the hydroxyl-terminated polyester modified crylic acid resin has cross-linking reaction with methyl etherified urea resin or butyl etherified urea resin to form a net-shaped structure, and thus the pattern generated after transferring-printing is clear, full, high in color fastness, long-lasting without fading, and high in glossiness.

Owner:东莞隽思印刷有限公司

Artistic sculpture shaping mud

A solidifiable plastic material for shaping sculpture artwork is prepared through preparing component A by proportionally mixing epoxy resin with filler, preparing component B by proportionally mixing solidifying agent with filler, and mixing components A with B before it is used. Its advantages are no need of water, the solidifying time from 40 min to 16 hr, and not cracking.

Owner:SHENZHEN POLYTECHNIC

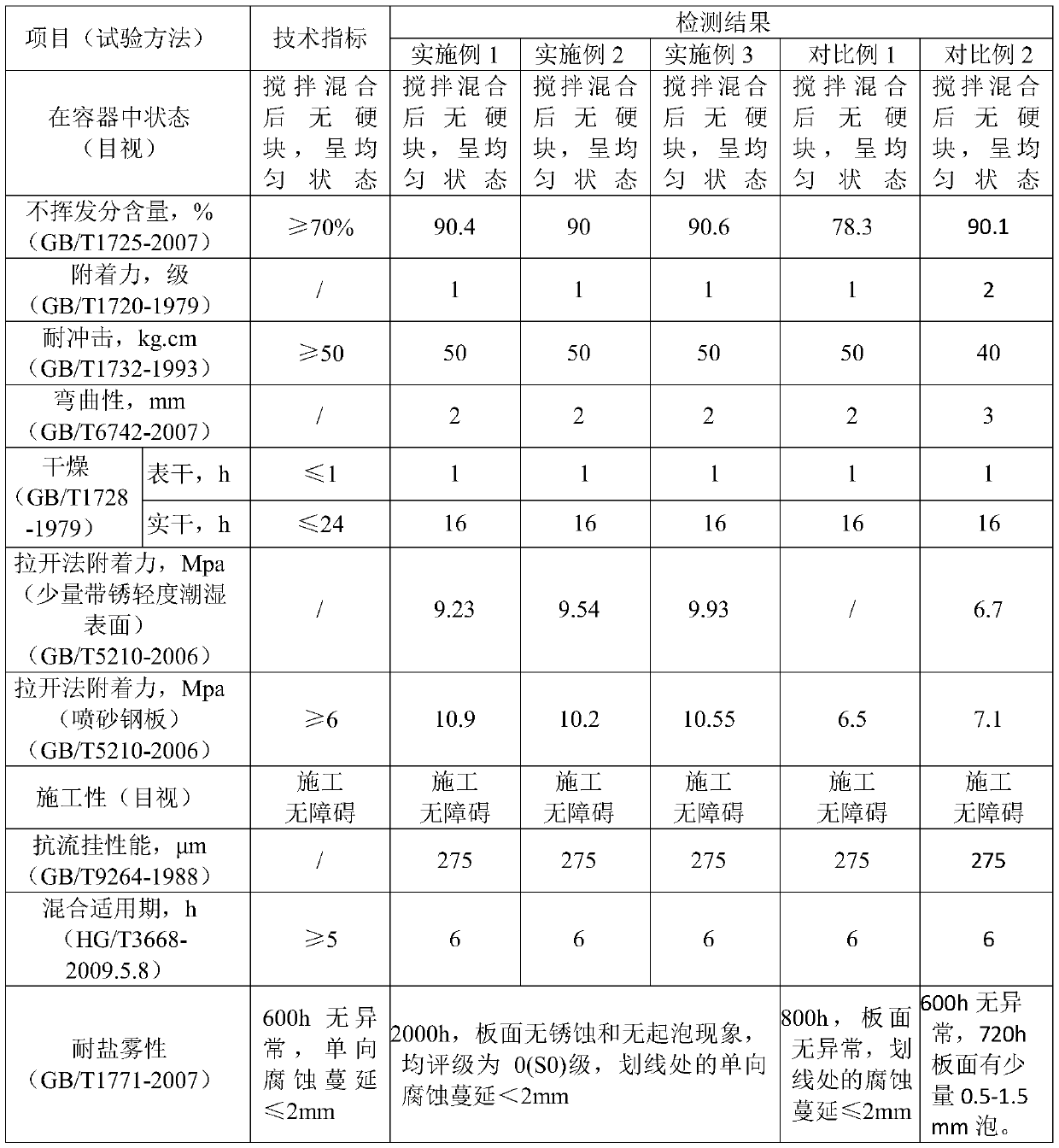

High-solid surface-tolerant epoxy zinc-rich primer and preparation method and application thereof

ActiveCN110144160AIncrease crosslink densityImprove penetration resistanceAnti-corrosive paintsEpoxy resin coatingsChemical industryEpoxy

The invention relates to a high-solid surface-tolerant epoxy zinc-rich primer. The primer is prepared from a component A and a component B according to a weight ratio of (16-20):1; the component A comprises the following components in parts by weight: 5-9 parts of liquid phenolic epoxy resin, 6-15 parts of E20 solid epoxy resin, 0.5-1.5 parts of an active diluent, 0.1-0.3 part of a dispersing agent, 70-80 parts of main rust-proof pigment, 2-6 parts of chemical anti-rust pigment, 1.5-2.5 parts of an anti-settling agent and 3-4 parts of an organic mixed solvent; and the component B comprises thefollowing components in parts by weight: 1.5-2.5 parts of a polyamide curing agent, 2-3 parts of a Mannich base curing agent, 0.3-0.6 part of a silane coupling agent and 0.2-0.6 part of an organic mixed solvent. The invention also relates to a preparation method of the primer and a coating film. The primer is high in solid content and low in VOC content, is resistant to corrosion, has a long effect, has good adhesive force and salt fog resistance, and is particularly suitable for repairing and maintaining equipment in industries such as chemical industry, thermoelectricity, machinery and thelike.

Owner:江阴市大阪涂料有限公司

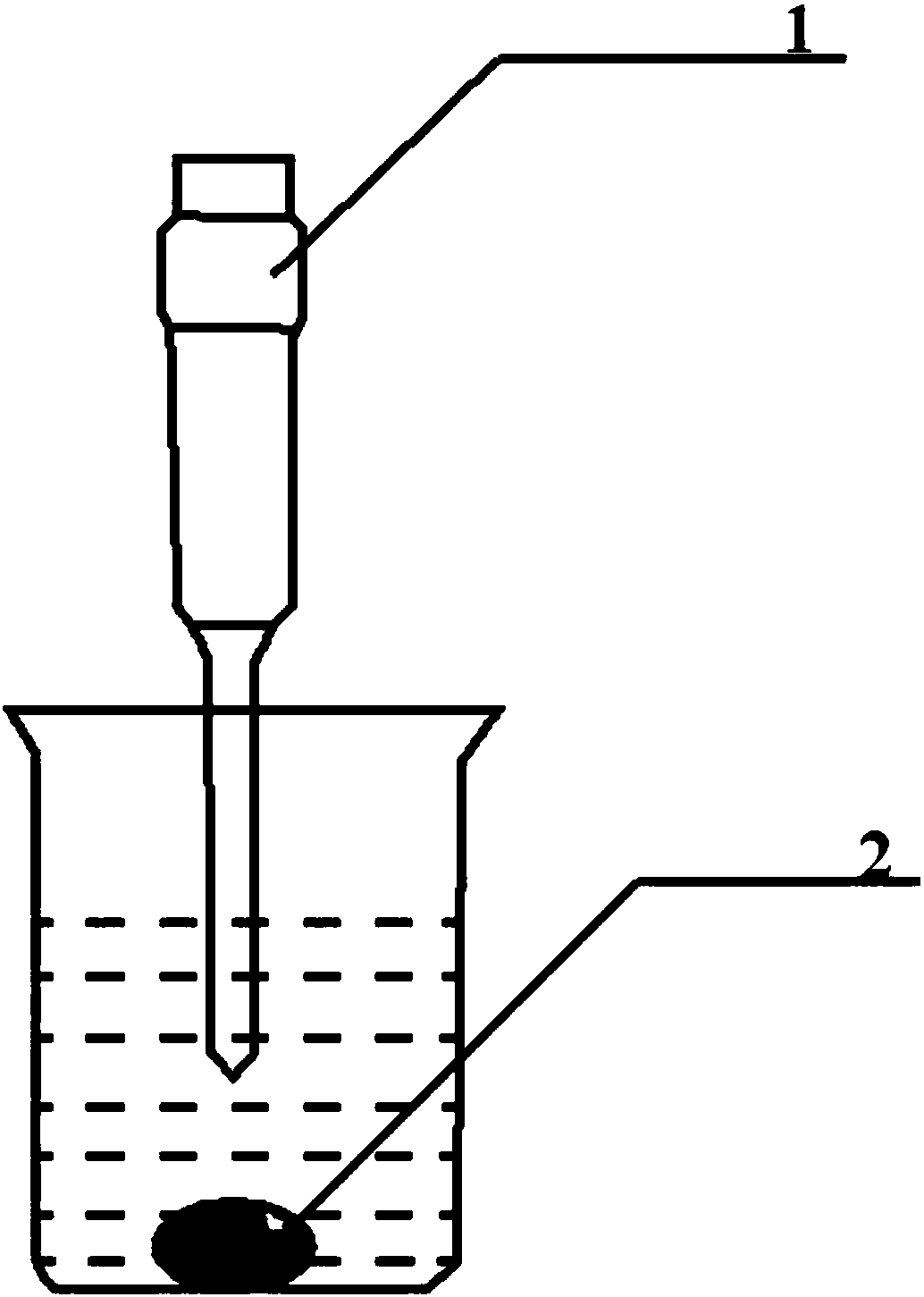

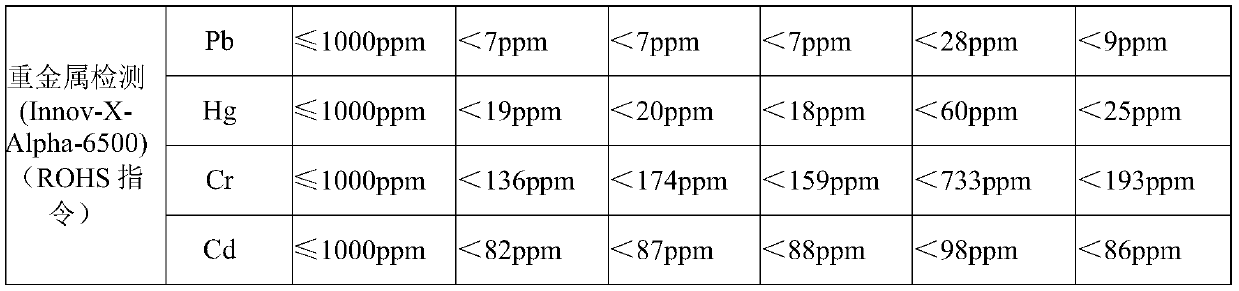

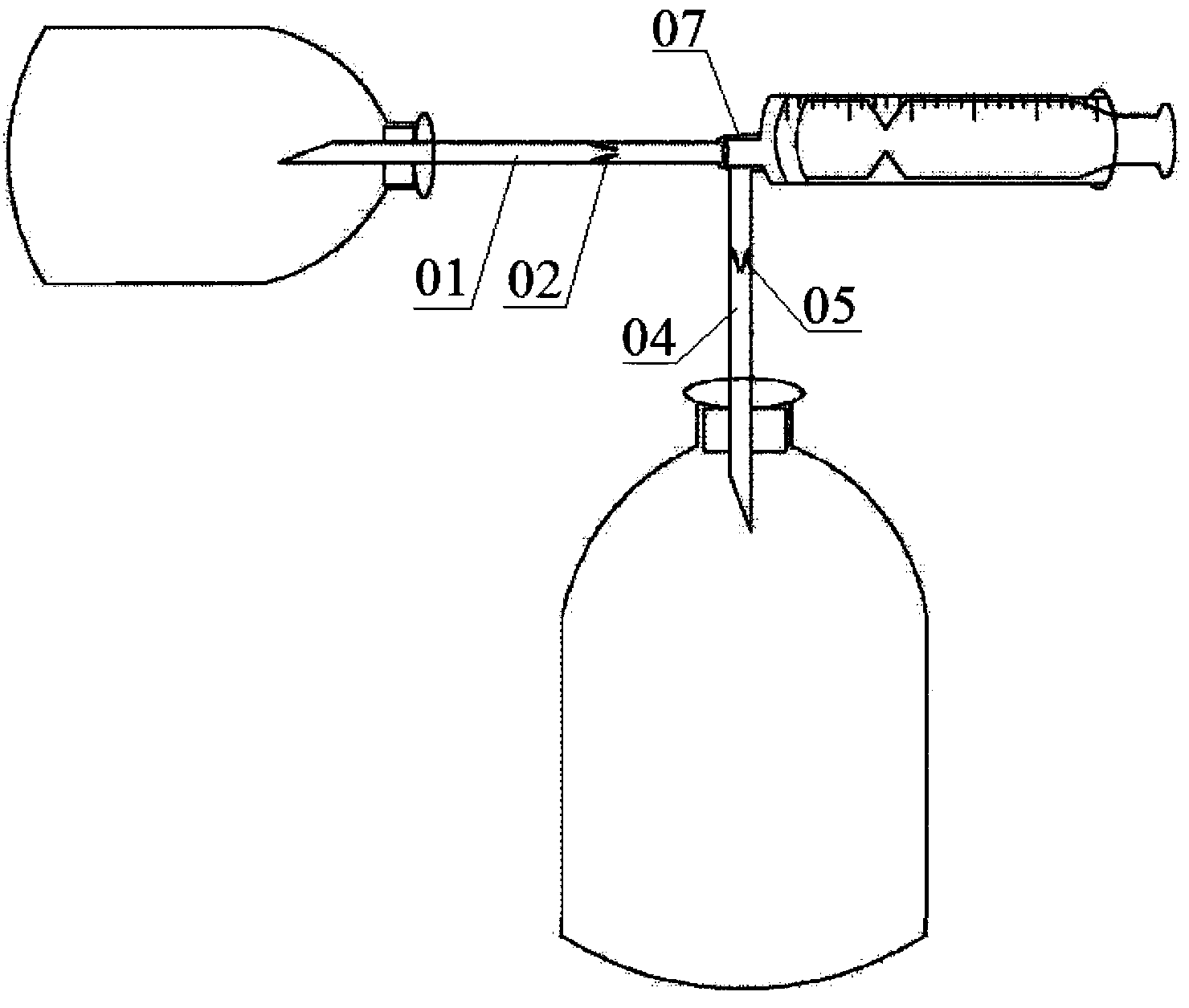

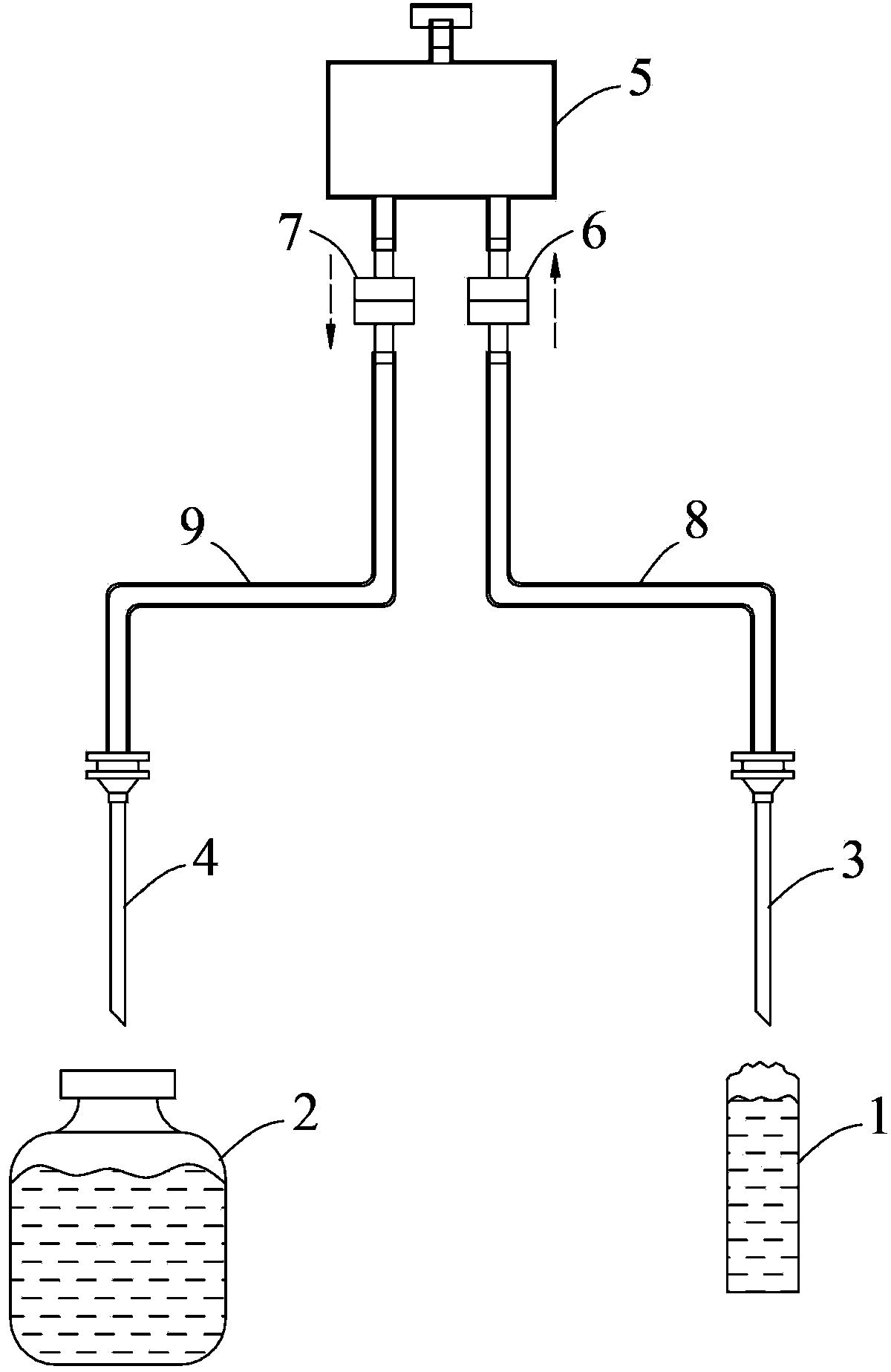

Medicine preparation method for ampoules and one-way valve type medicine preparation device

ActiveCN104248512AEasy to operateImprove dispensing efficiencyPharmaceutical containersMedical packagingEngineeringBiomedical engineering

The invention discloses a medicine preparation method for ampoules and a one-way valve type medicine preparation device. The medicine preparation method comprises the following steps: making a preparation, inserting needles into uncapped ampoules and an infusion bag, sucking liquid medicine in the ampoules into a transition container through a one-way valve I, injecting the liquid medicine in the transition container into the infusion bag through a one-way valve II, and pulling out the needles to complete medicine preparation. The one-way valve type medicine preparation device comprises a liquid catheter I and a liquid catheter II, wherein the liquid catheter I and the liquid catheter II are respectively connected with an interface I and an interface II on the transition container, the one-way valve I and the one-way valve II are respectively arranged on the liquid catheter I and the liquid catheter II, an interface III on the transition container is connected with an air pump, and a needle II further comprises a ventilating needle hole. The medicine preparation method disclosed by the invention can realize automatic preparation of liquid medicine in the ampoules and the operation is convenient to conduct; the ventilating needle hole in the needle II can balance internal and external pressure of the infusion bag, the medicine preparation becomes easier in combination with a liquid level controller, and the infusion bag is prevented from being expanded and cracked; since a chuck I and a chuck II respectively on a needle I and the needle II cooperate with a mechanical automatic control device, the automatic medicine preparation efficiency is further improved.

Owner:CHENGDU TECHCAL UNIV

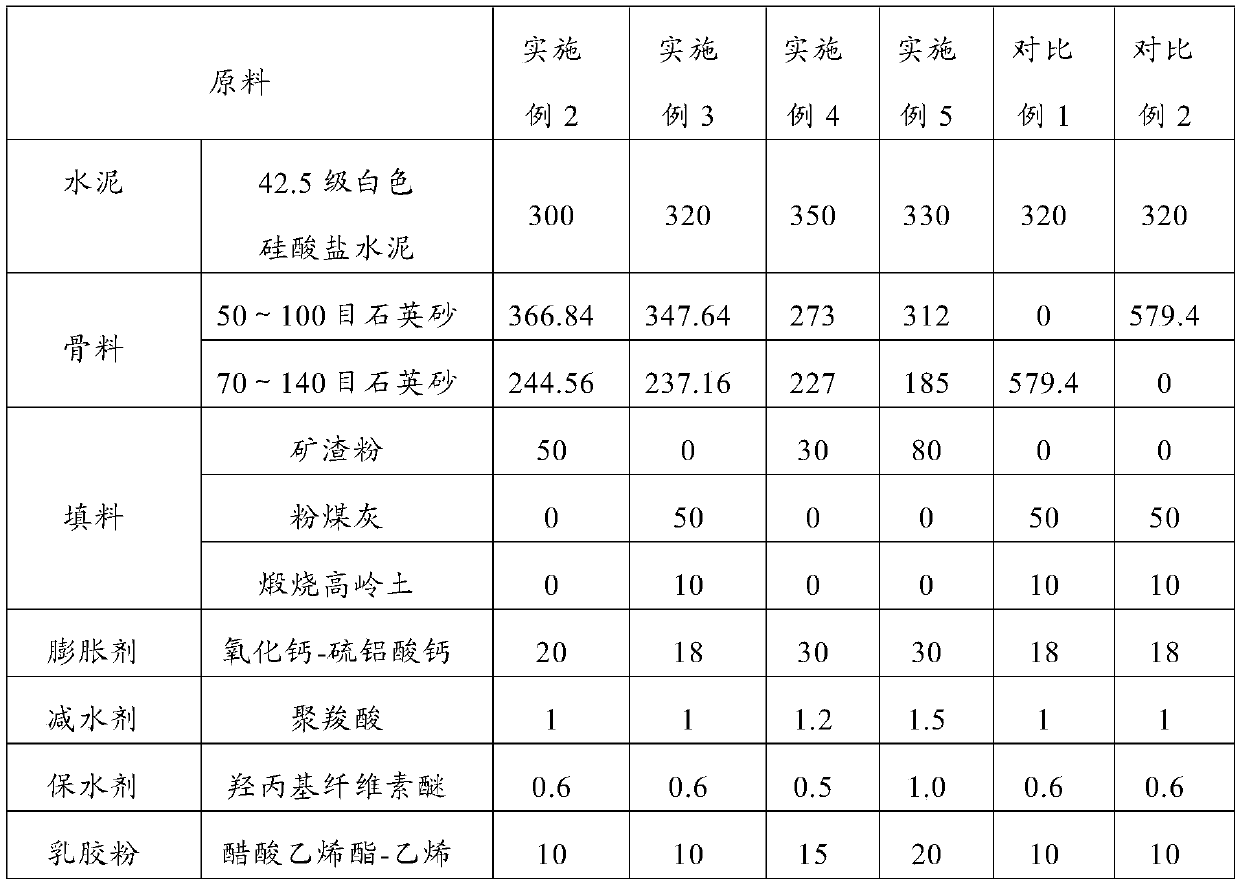

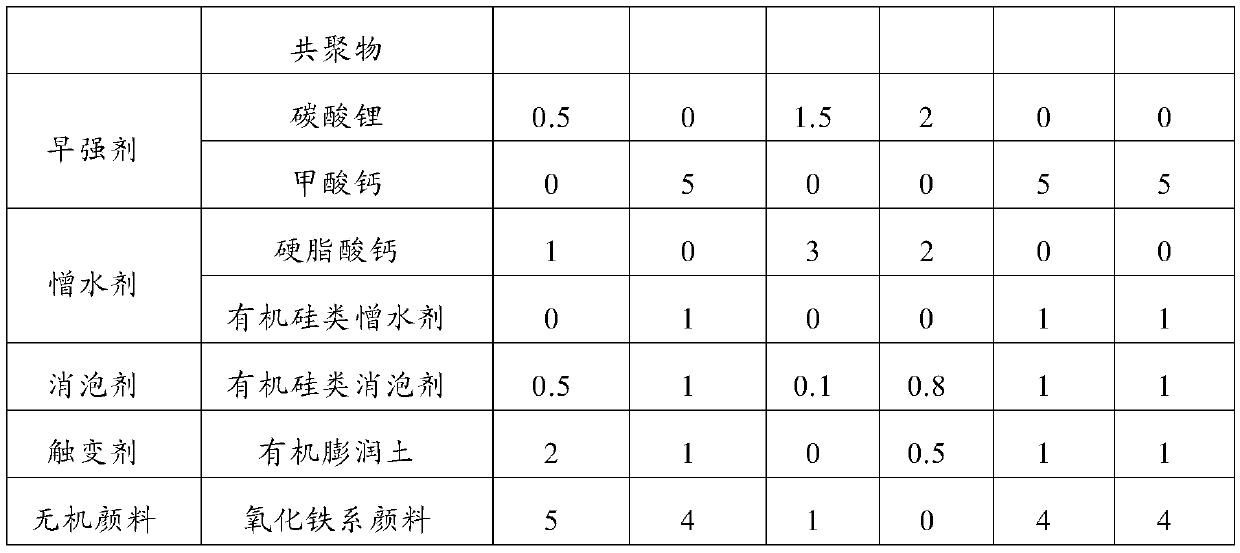

Tile grout composition and preparation method and application thereof

InactiveCN105503072AImprove the level ofImprove compactnessSolid waste managementWater leakageMoisture

The invention provides a tile grout composition and a preparation method and an application thereof, and belongs to the technical field of building materials. The tile grout composition can solve the problems of waste in time and labor, low construction efficiency, and difficulty in dense filling during the existing ground joint filling. The tile grout composition comprises cement, an aggregate, a filler, an expansion agent, a water reducing agent, a water retaining agent, emulsion powder, an early strength agent, a moisture repellent, a defoaming agent, a thixotropic agent and other raw materials; after the tile grout composition is mixed with water, the joint is filled, so that the leveling of the tile grout is good, a miniature gap can be fully filled, and the self-leveling is realized. The tile grout composition has the advantages that the density after hydration is good, the shrinkage rate is low, the strength is high, the joint filling construction of ground tiles is convenient, the early strength after construction is higher, the adhering strength after hardening is higher, and the cracking and water leakage after joint filling are avoided; the preparation method is simple, and the tile grout composition is suitable for industrial production, and is especially suitable for filling ground tile joints in building material industry.

Owner:VASA MORTAR CO LTD

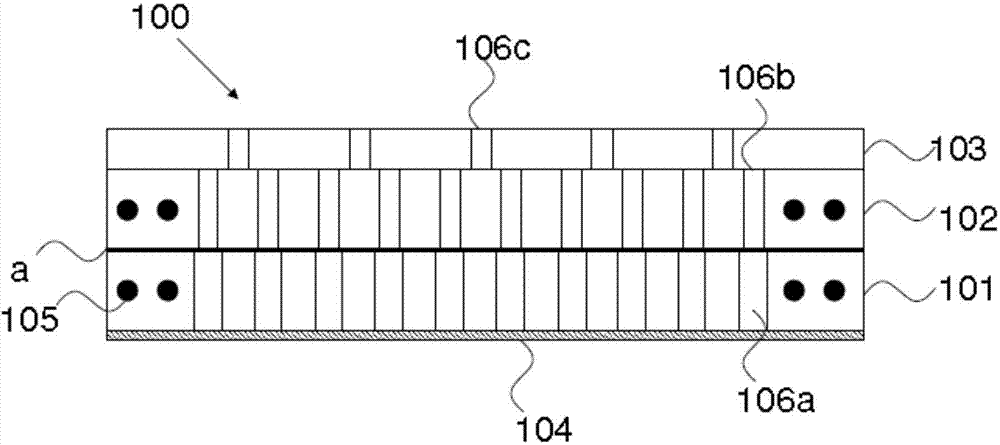

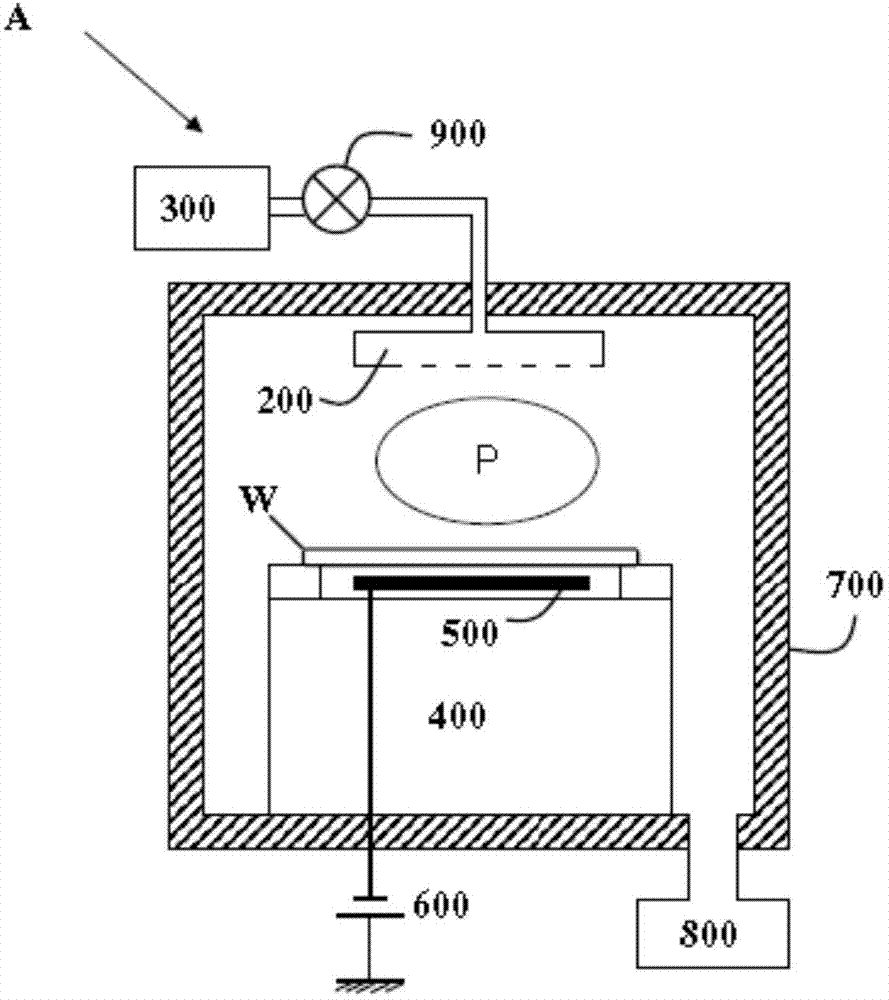

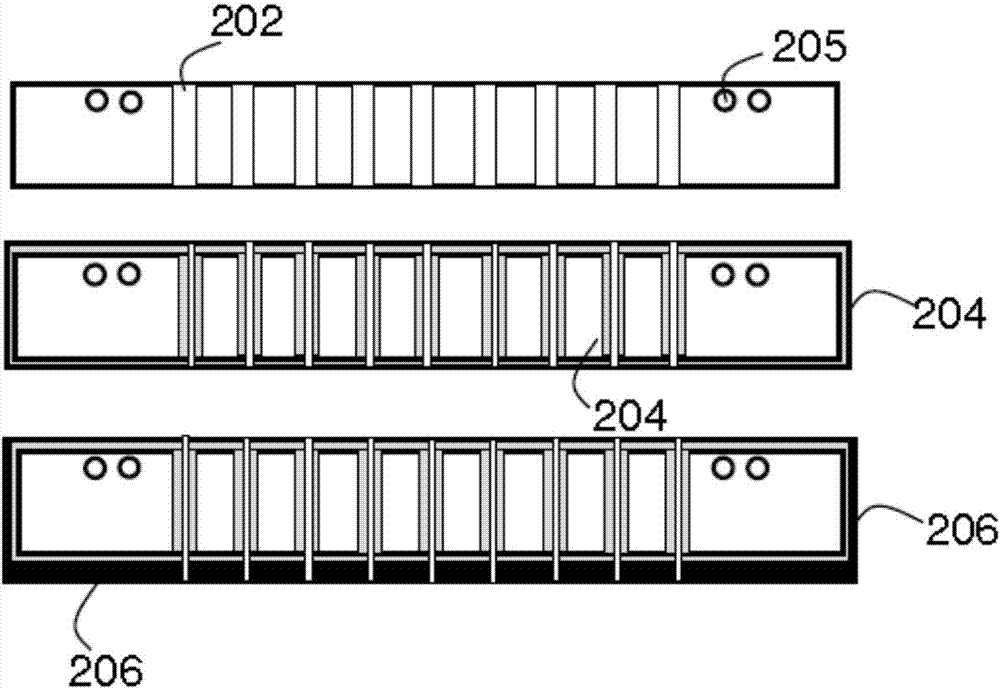

Plasma processing cavity, gas spraying head and manufacturing method thereof

ActiveCN104715993AStable structureSimple processElectric discharge tubesSemiconductor/solid-state device manufacturingEngineering

The invention provides a plasma processing cavity, a gas spraying head and a manufacturing method thereof. The gas spraying head is integrally molded and is provided with a plurality of gas through holes machined at a time, and the outer wall of the gas spraying head and inner walls of the gas through holes are each covered with a first anti-corrosion layer. The plasma processing cavity and the gas spraying head are simple in process, and low in manufacturing cost. The gas spraying head is more stable and more reliable in structure; in addition, the anti-corrosion layers are free of pores, are denser and will not crack. The manufacturing process of a base sheet of the plasma processing cavity is more stable.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

Method for producing automotive rear shelf

The invention relates to a method for producing an automotive rear shelf. The method is characterized by comprising the following steps of: (1) heating: hanging polypropylene sheets in a two-layer drying oven and heating, wherein the temperature of an upper-layer drying oven of the two-layer drying oven is between 240 and 260 DEG C; the temperature of a lower-layer drying oven of the two-layer drying oven is between 325 and 345 DEG C; and the heating time is 85 to 95 seconds; (2) pressing and forming: laying a fabric on two layers of PP sheets flatly, and pressing and forming the fabric in a die to obtain a half-finished product, wherein the pressure during pressing and forming is 70 to 90kg / cm<2>, and the forming time is 60 to 70 seconds; (3) cooling and shaping: cooling and shaping the half-finished product at the normal temperature, wherein the cooling time is 30 to 50 seconds; (4) installing accessories: installing the accessories on the half-finished product to obtain an automotive rear shelf finished product; and (5) examining and packing, wherein the fabric is a non-woven fabric, and the PP sheets are PP wood powder sheets with glue. The method ensures the performance indexes of light weight, high strength, difficult contraction distortion and the like of a rear shelf, greatly reduces the weight of the rear shelf, and meets the requirement for lightweight vehicle design; and as the material has a double-layer wood powder sheet structure, the product is fuller.

Owner:WUXI GISSING AUTO ACOUSTIC PARTS TECH CO LTD

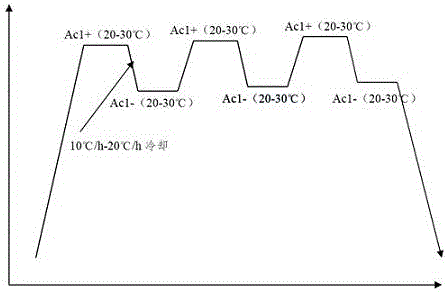

Spheroidizing annealing method for medium-and-low-carbon alloy cold forging steel

InactiveCN106011404AGood ball organizationGood effectFurnace typesHeat treatment furnacesSingle passCarbon alloy

The invention discloses a spheroidizing annealing method for medium-and-low-carbon alloy cold forging steel. The method technology includes the steps that firstly, cold drawing deforming is conducted, wherein cold drawing deforming with the deformation ranging from 25% to 40% is conducted on an alloy steel wire of the medium-and-low-carbon alloy cold forging steel; secondly, spheroidizing is conducted, wherein the temperature of the alloy steel wire obtained after cold drawing deforming is increased to Ac1+20 DEG C to Ac1+30 DEG C, heat insulation is conducted, then the temperature is reduced to Ac1-20 DEG C to Ac1-30 DEG C, and heat insulation is conducted; and thirdly, discharging is conducted, wherein the alloy steel wire obtained after spheroidizing is slowly cooled and discharged. By means of the method, an adjusting drawing and spheroidizing technology is combined with a spheroidizing annealing technology with the single-pass deformation larger than 25% so that the spheroidizing effect of medium-and-low-carbon alloy cold forging steel can reach the fifth level or higher, and the spheroidizing structure is good and cannot crack in the subsequent cold forging process; and the beneficial effects that the technology is simple and effects are good are achieved. When multiple times of repeated spheroidizing annealing periods are adopted in the method, although several times of cooling is added, the total annealing time is not prolonged, the cost is not affected, and the beneficial effects that effects are good and cost is low are achieved.

Owner:XINGTAI IRON & STEEL

Method for preparing film made from compound Nano carbon fiber

InactiveCN1660692AWon't crackEasy to controlDecorative surface effectsChemical vapor deposition coatingFiberCarbon fibers

A process for preparing the composite carbon nanofibre film includes providing a substrate, depositing a metallic catalyst layer, putting it in low-pressure chemical vapor deposition system, adding carbon nanotubes and carbon nanofibres, and growing film.

Owner:上海纳晶科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com