Patents

Literature

991results about How to "Improve penetration resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

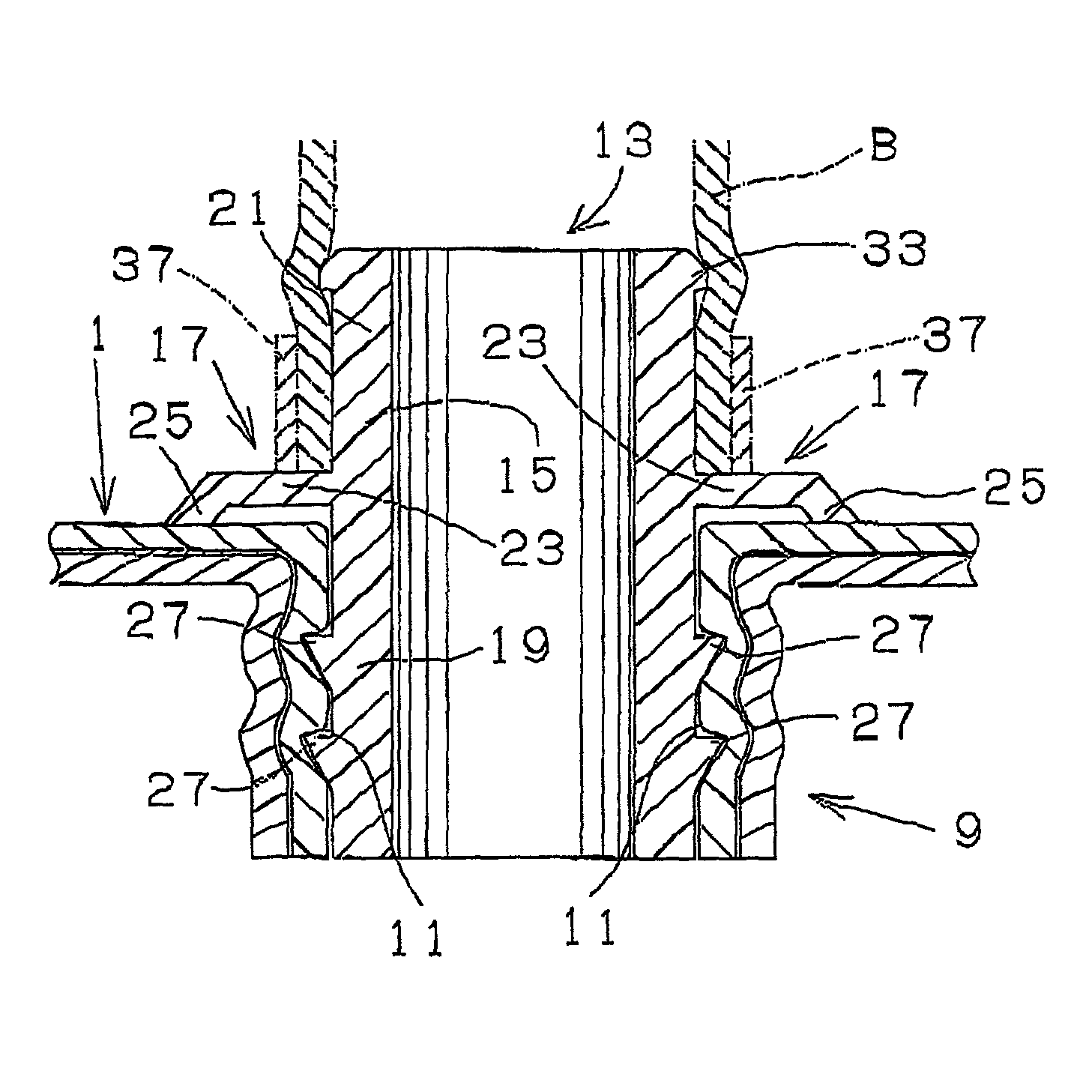

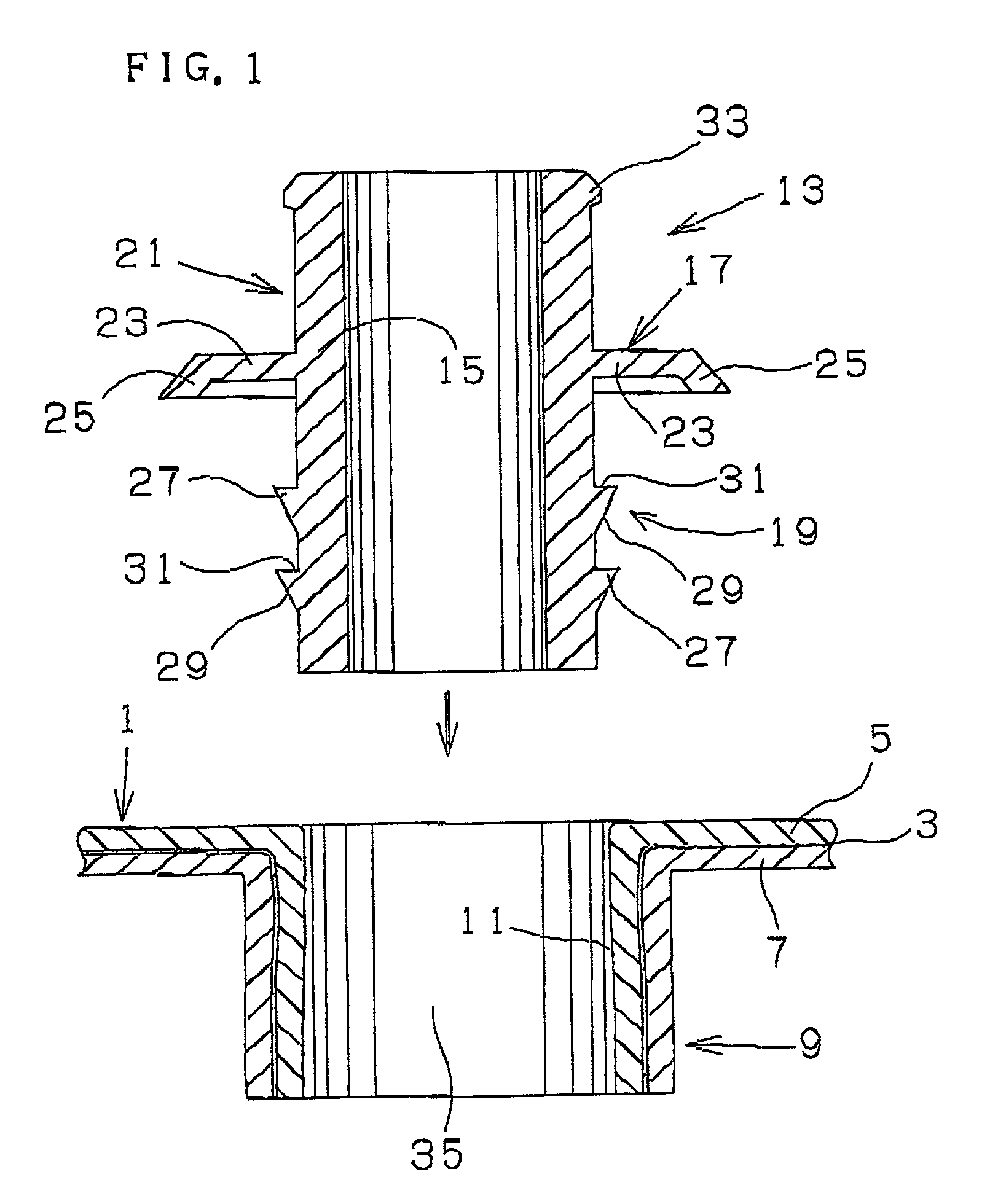

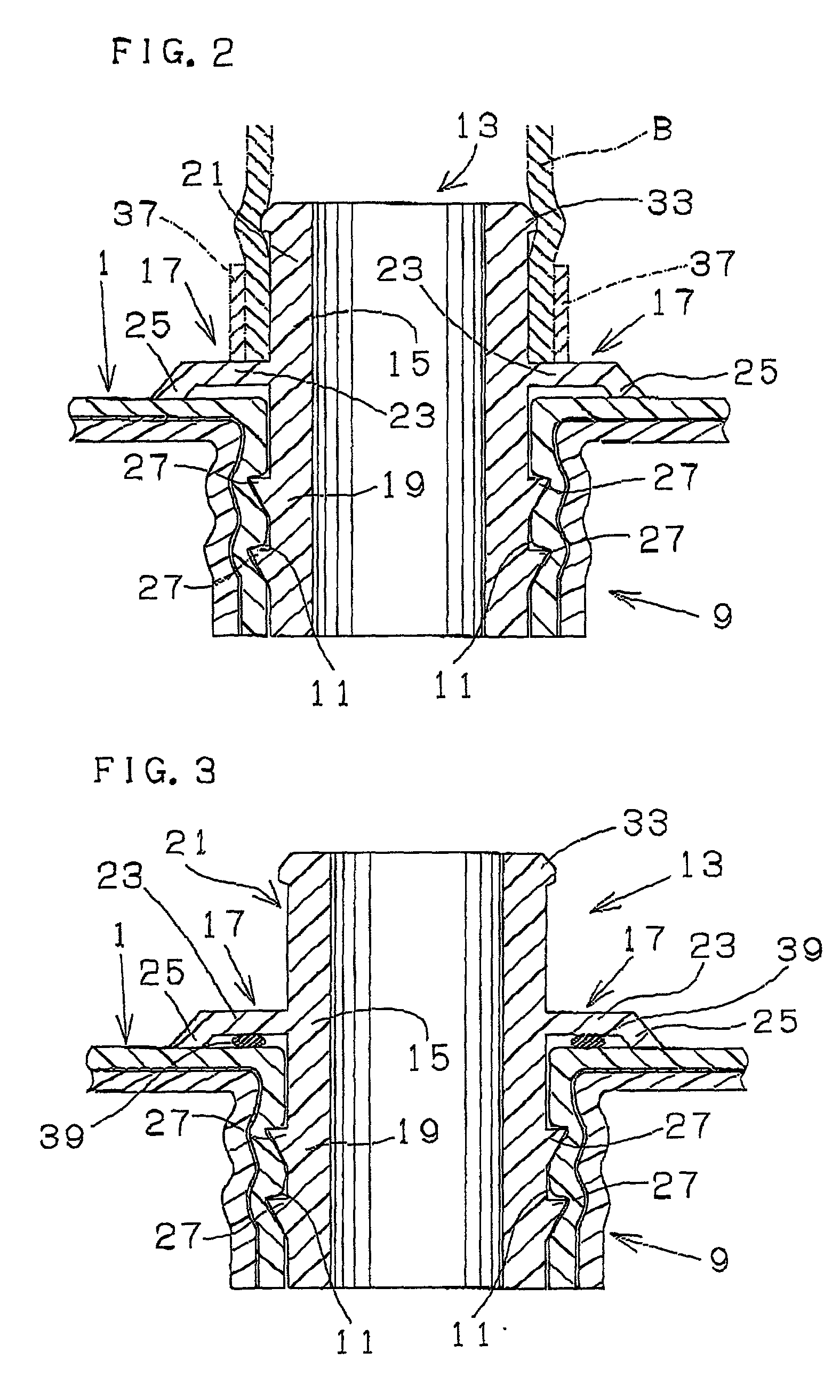

Structure for connecting tubular member to fuel tank

InactiveUS20020130515A1Improve penetration resistanceAvoid DimensionsLarge containersUnderstructuresFuel tank

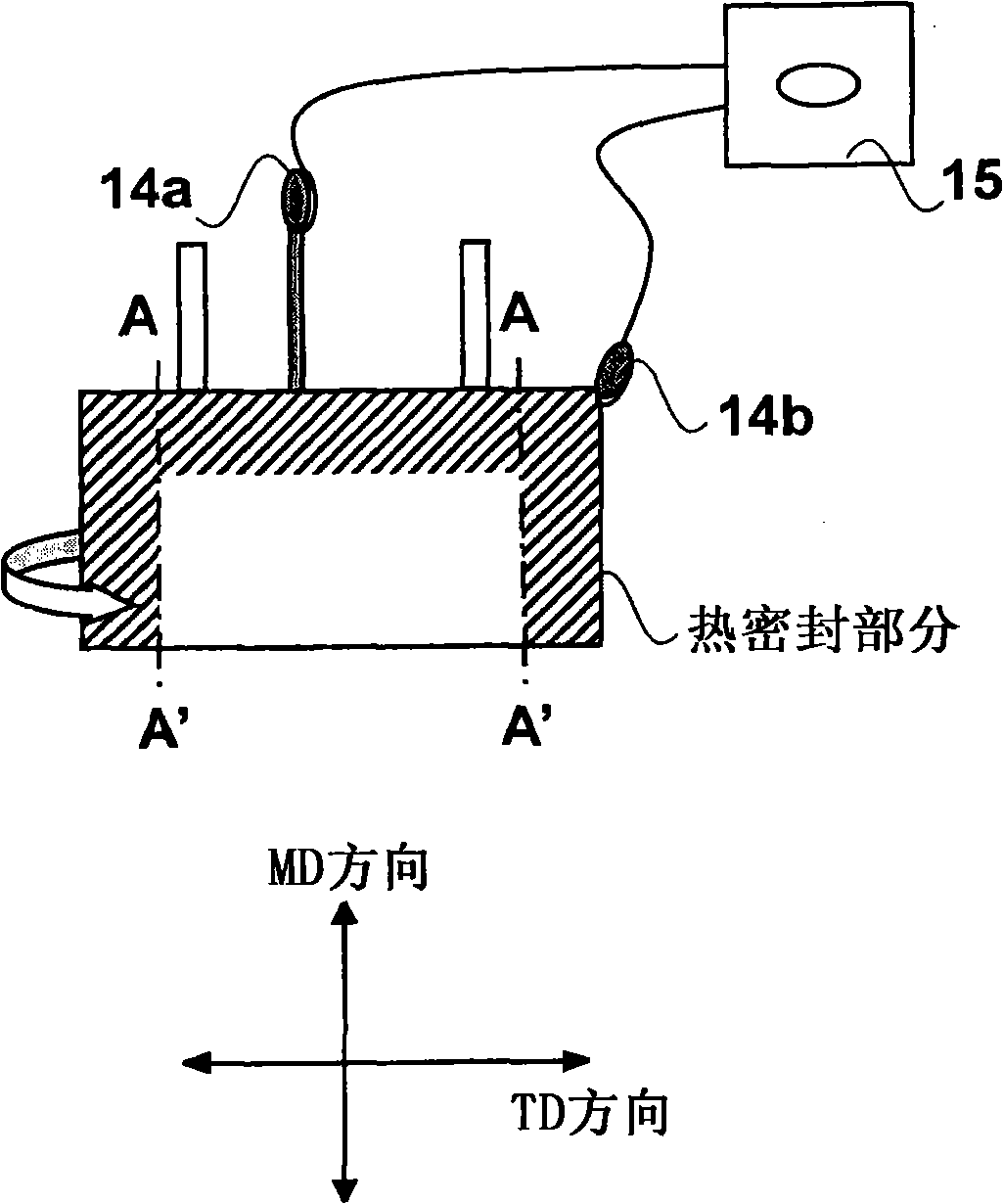

An cylindrical convex portion of which opposite ends are open is integrally formed onto a fuel tank made of RDPE therewith so as to inwardly extend in the fuel tank, to provide an opening thereon. A press-fit portion of a filler hose connecting pipe made of PA as a tubular member is press-fitted in the cylindrical convex portion to connecting the tubular member to the fuel tank. At least one annular projection is provided on the outer peripheral surface of the press-fit portion of the tubular member so as to bite in the inner peripheral surface of the cylindrical connvex portion. A face of the annular projection in direction axially of one end of tubular member is formed so as to extend outwardly and inclinedly with respect to the axial direction of the tubular member form one end toward the other end thereof.

Owner:SUMITOMO RIKO CO LTD

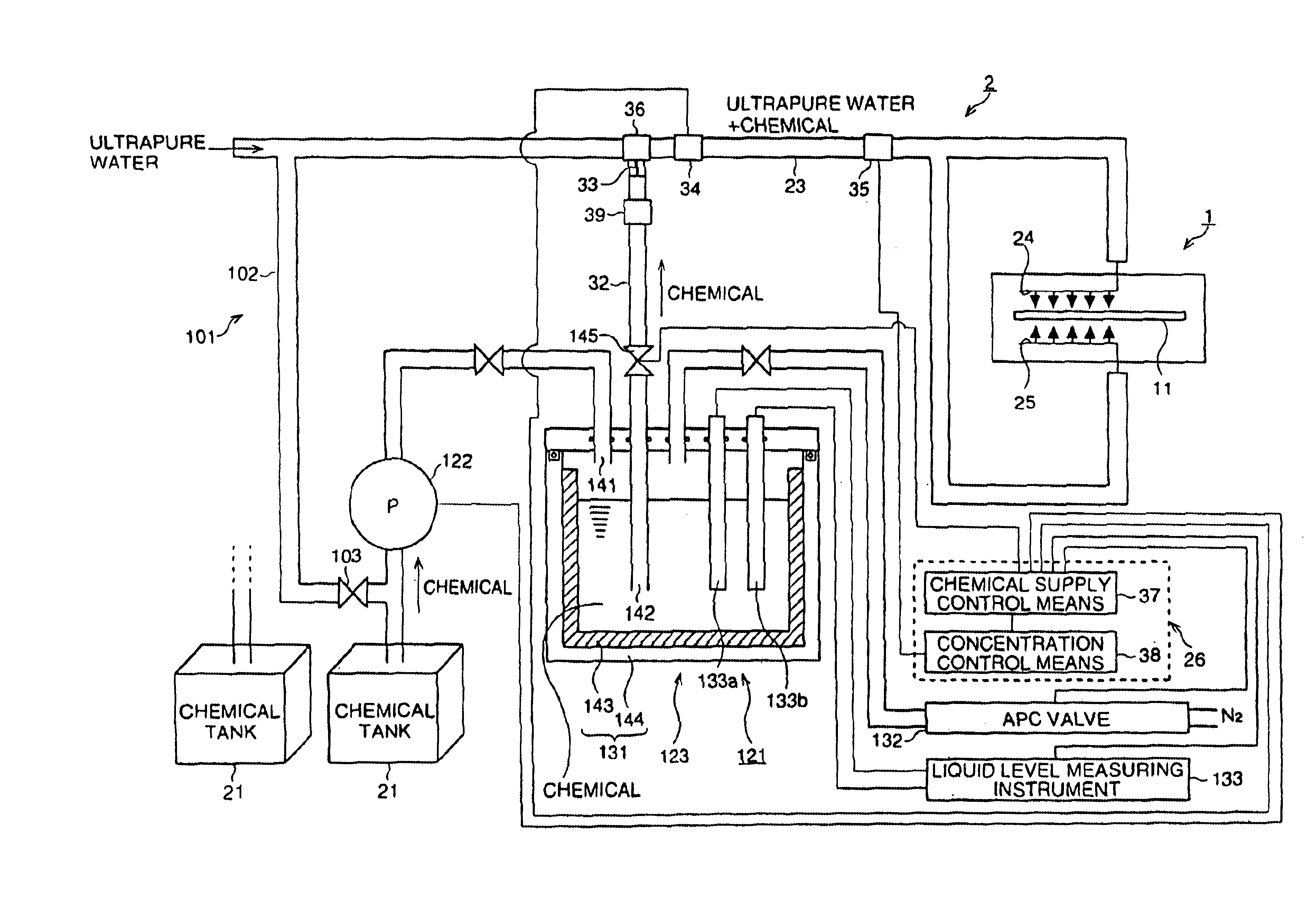

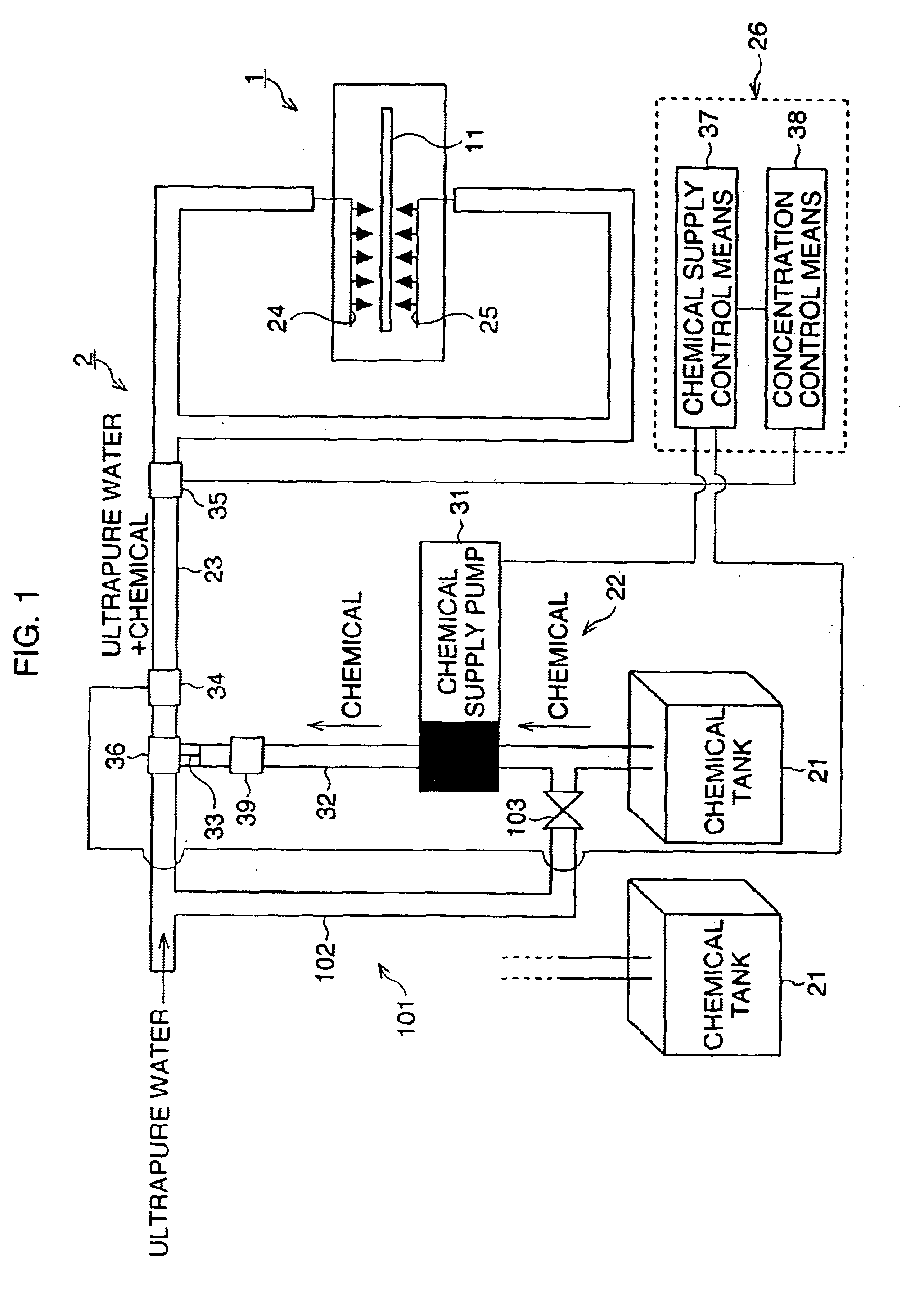

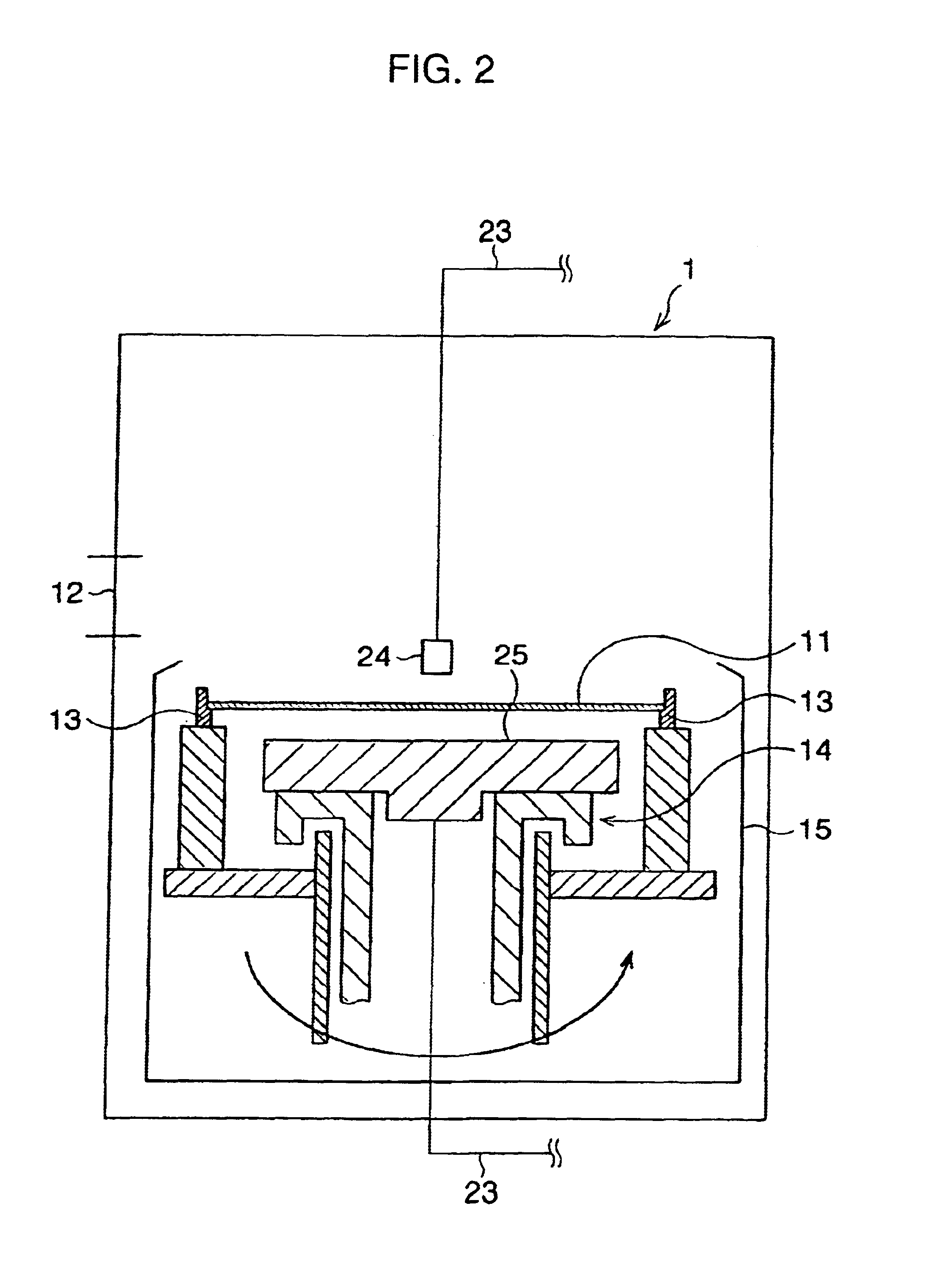

Chemical supply system

InactiveUS6764212B1Improve anti-corrosion performanceEasy to control its porosityDiaphragm valvesShaking/oscillating/vibrating mixersChemical storageMiniaturization

A chemical supply system comprises, as principal elements, a chemical storage tank in which a liquid chemical for cleaning is stored in the state of its formulated concentrate, a chemical supply apparatus connected to the chemical storage tank for positively performing chemical supply, a piping system connected to the chemical supply apparatus to form a supply flow passage that is a passage for ultrapure water which the liquid chemical is to be mixed with, a pair of discharge nozzles disposed at end portions of the piping system so as to oppose surfaces of a wafer set in a cleaning chamber to supply a cleaning liquid onto the surfaces. Thereby, remarkable miniaturization / simplification of a cleaning liquid supply system including chemical tanks is intended, it is made possible easily and rapidly to compound and supply a cleaning liquid at an accurate chemical concentration, and particles or the like being generated and mixing in a cleaning liquid, are suppressed to the extremity.

Owner:ULTRACLEAN TECH RES INST

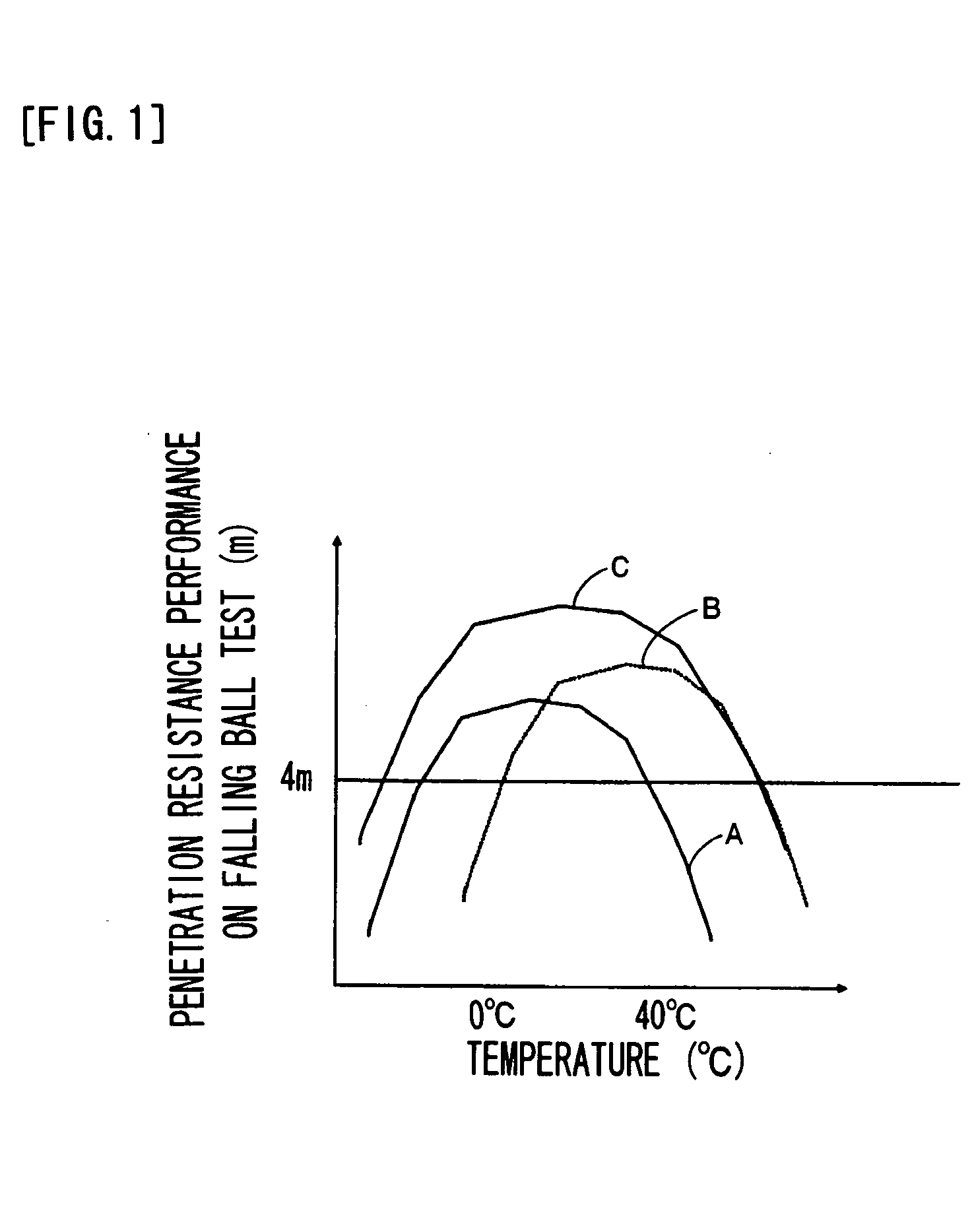

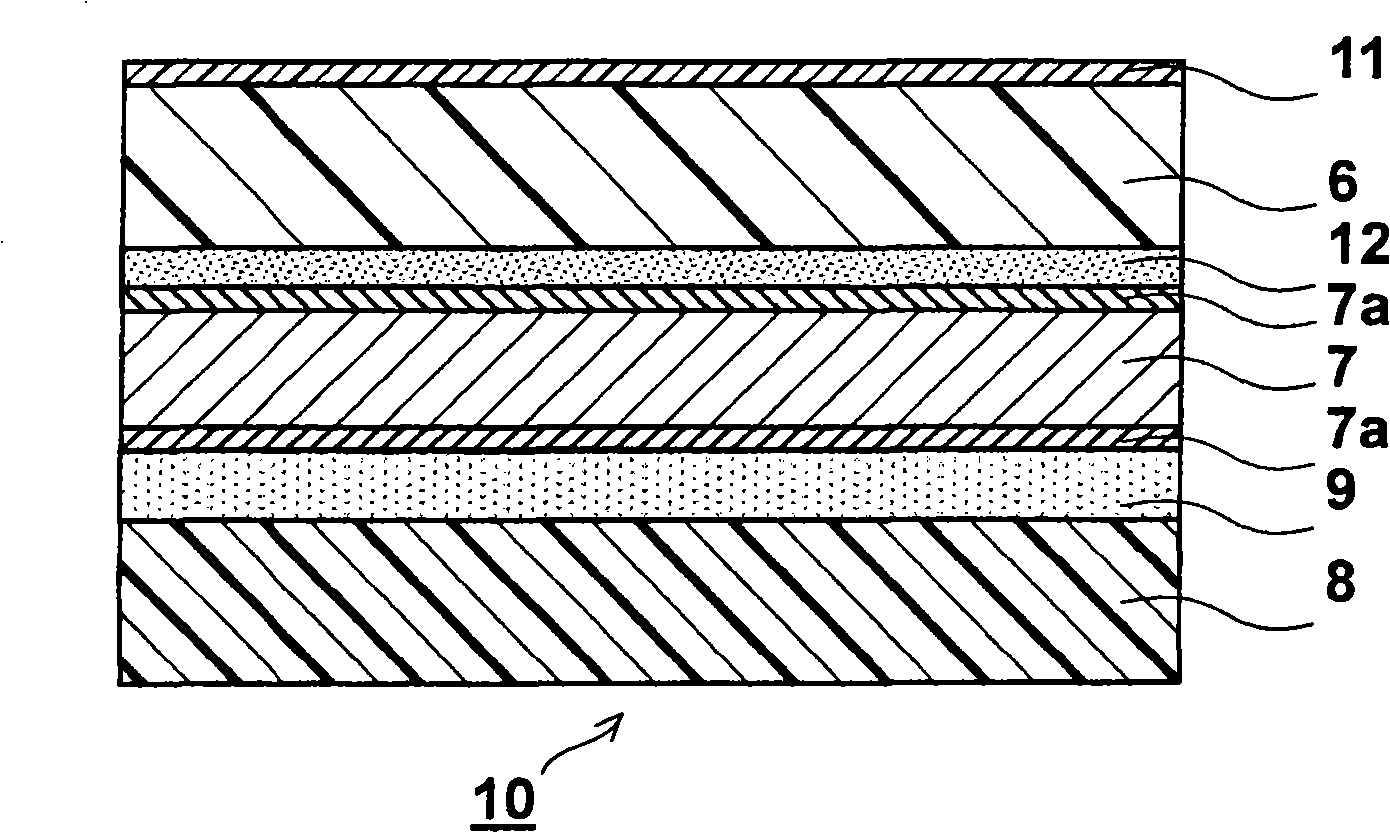

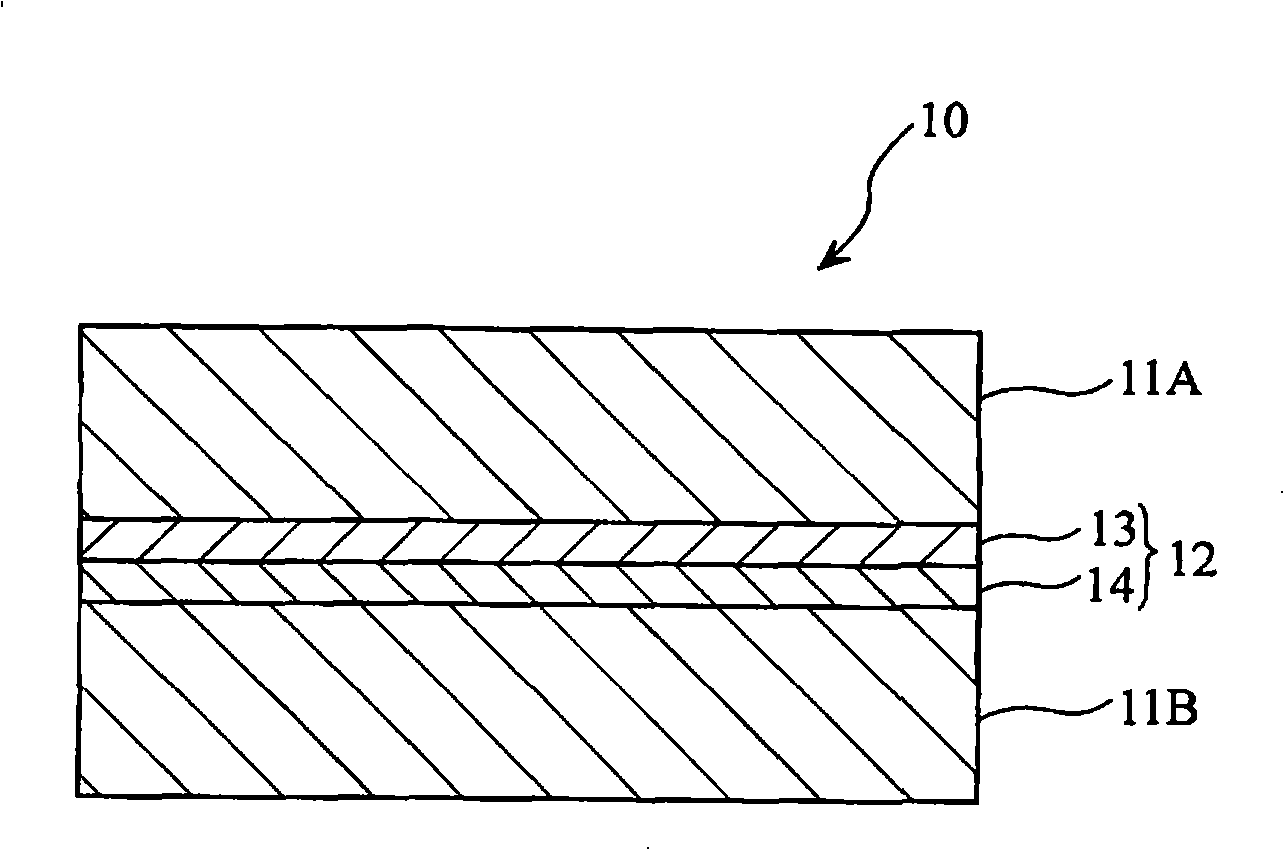

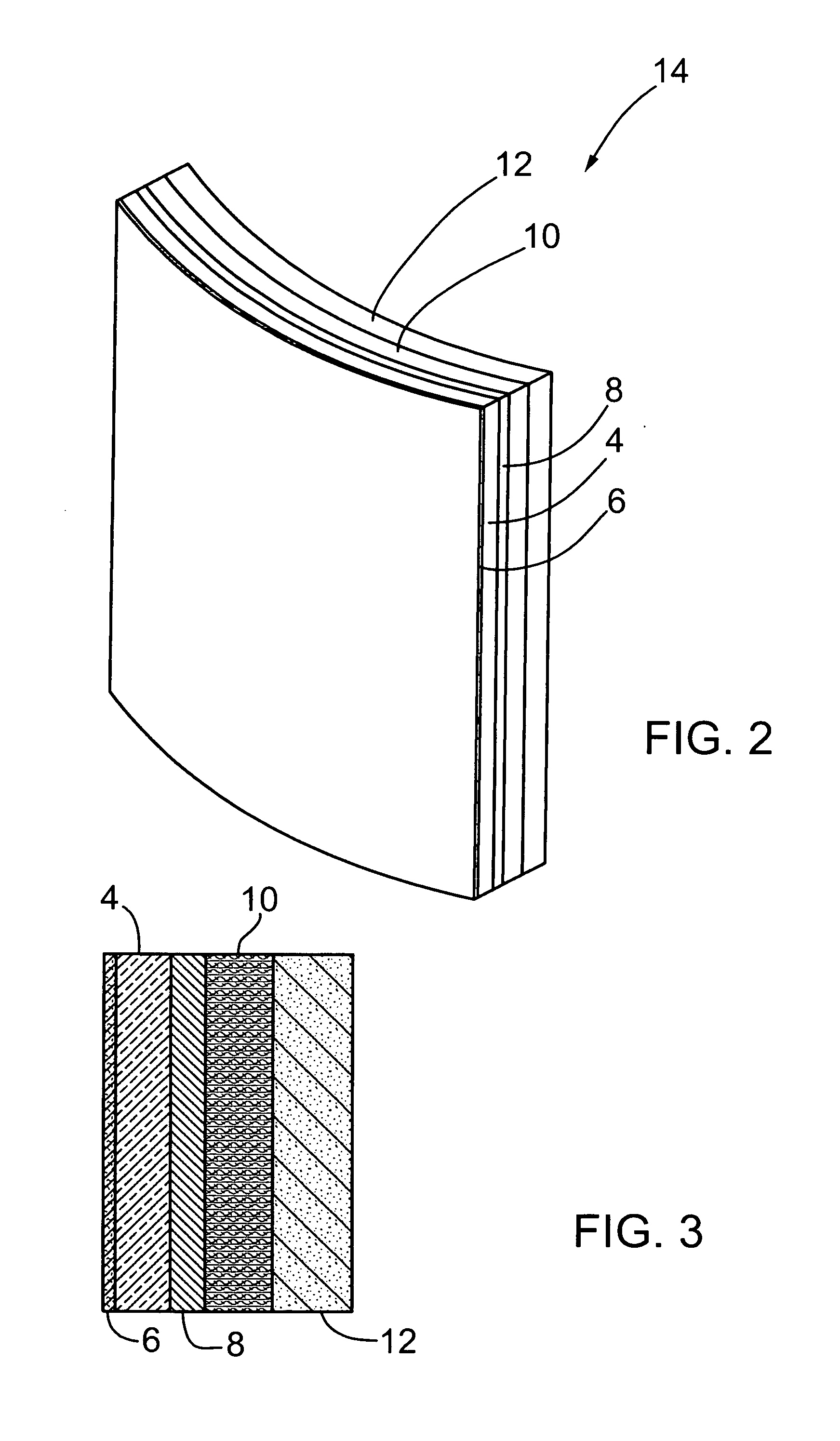

Thermoplastic resin sheet and laminate

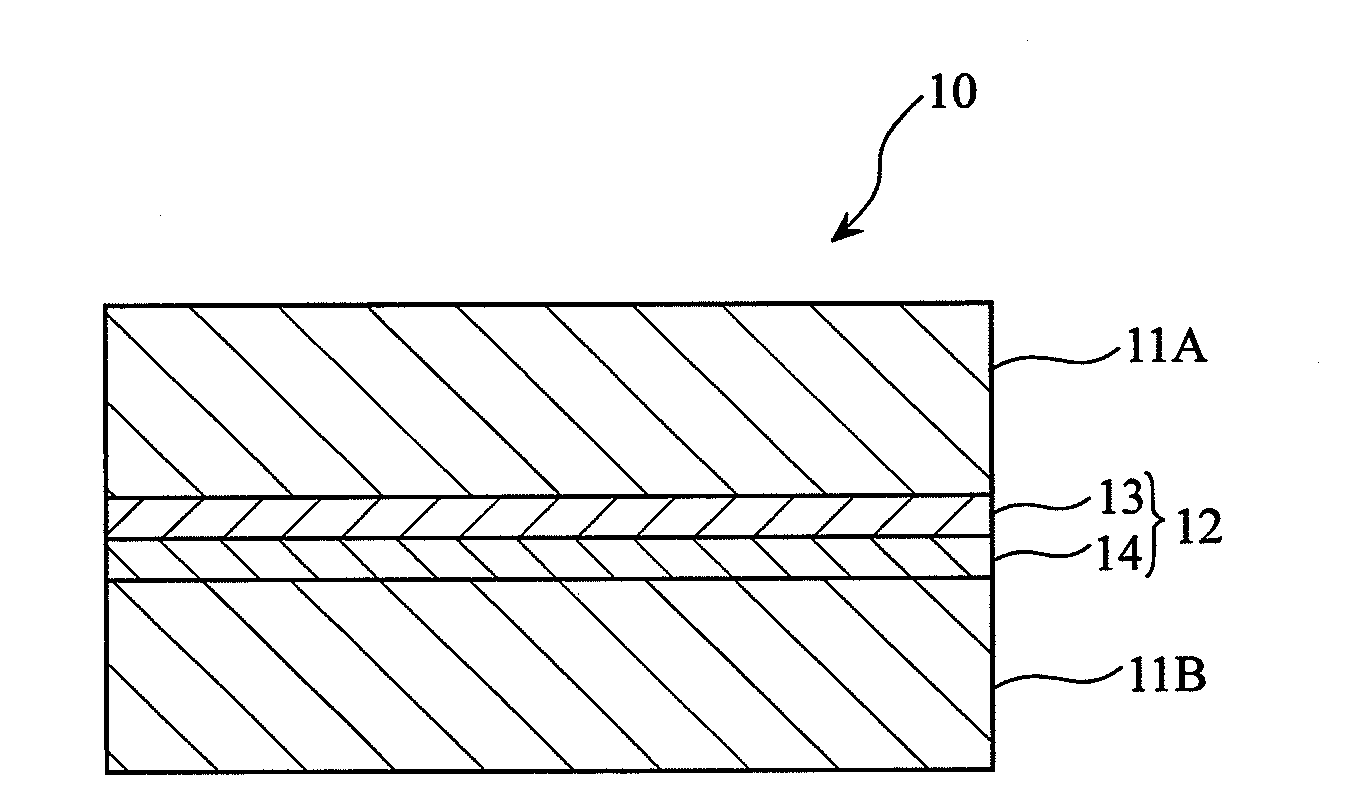

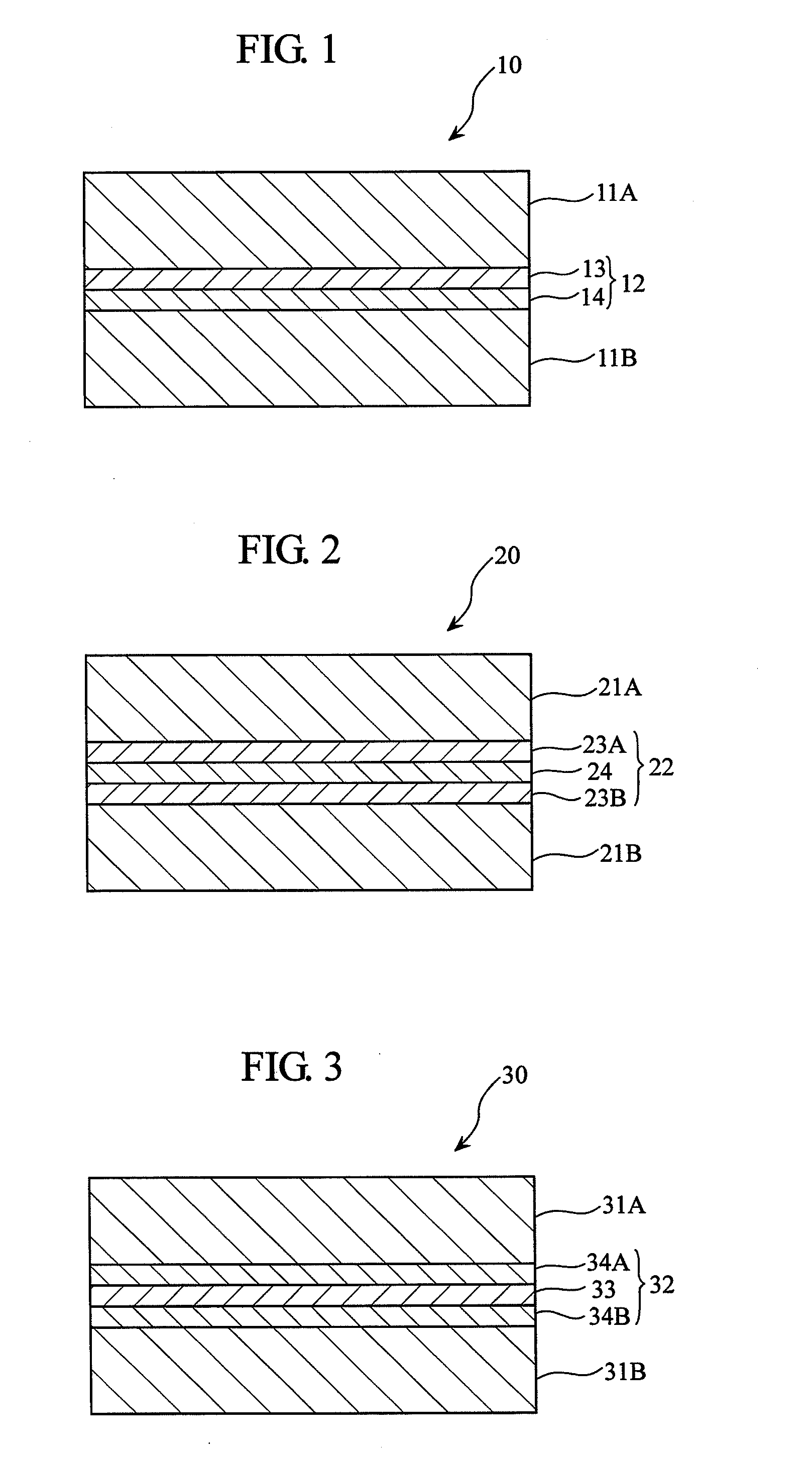

ActiveUS20070014976A1Improve impact resistanceReduced in surface densitySynthetic resin layered productsVehicle componentsAcetic acidPVA - Polyvinyl alcohol

A thermoplastic resin sheet is provided which has good penetration resistance over a range from low to high temperature region and can be used as an intermediate film of a laminated glass. The thermoplastic resin sheet has such a layered structure that a first polyvinyl acetal resin layer (A) is provided on each side of a second polyvinyl acetal resin layer (B). The first polyvinyl acetal resin layer (A) is comprised mainly of an acetalized product of polyvinyl alcohol with aldehyde (a) having 4-6 carbon atoms. The second polyvinyl acetal resin layer (B) is comprised mainly of a coacetalized product of polyvinyl alcohol with aldehyde (a) having 4-6 carbon atoms and aldehyde (b) having 1-3 carbon atoms. A polymer unit (X) derived from the aldehyde (a) and a polymer unit (Y) derived from the aldehyde (b), in total, account for at least 55% by mole while the first polymer unit (X) alone accounts for 0.5-80% by mole of the total of the coacetalized product.

Owner:SEKISUI CHEM CO LTD

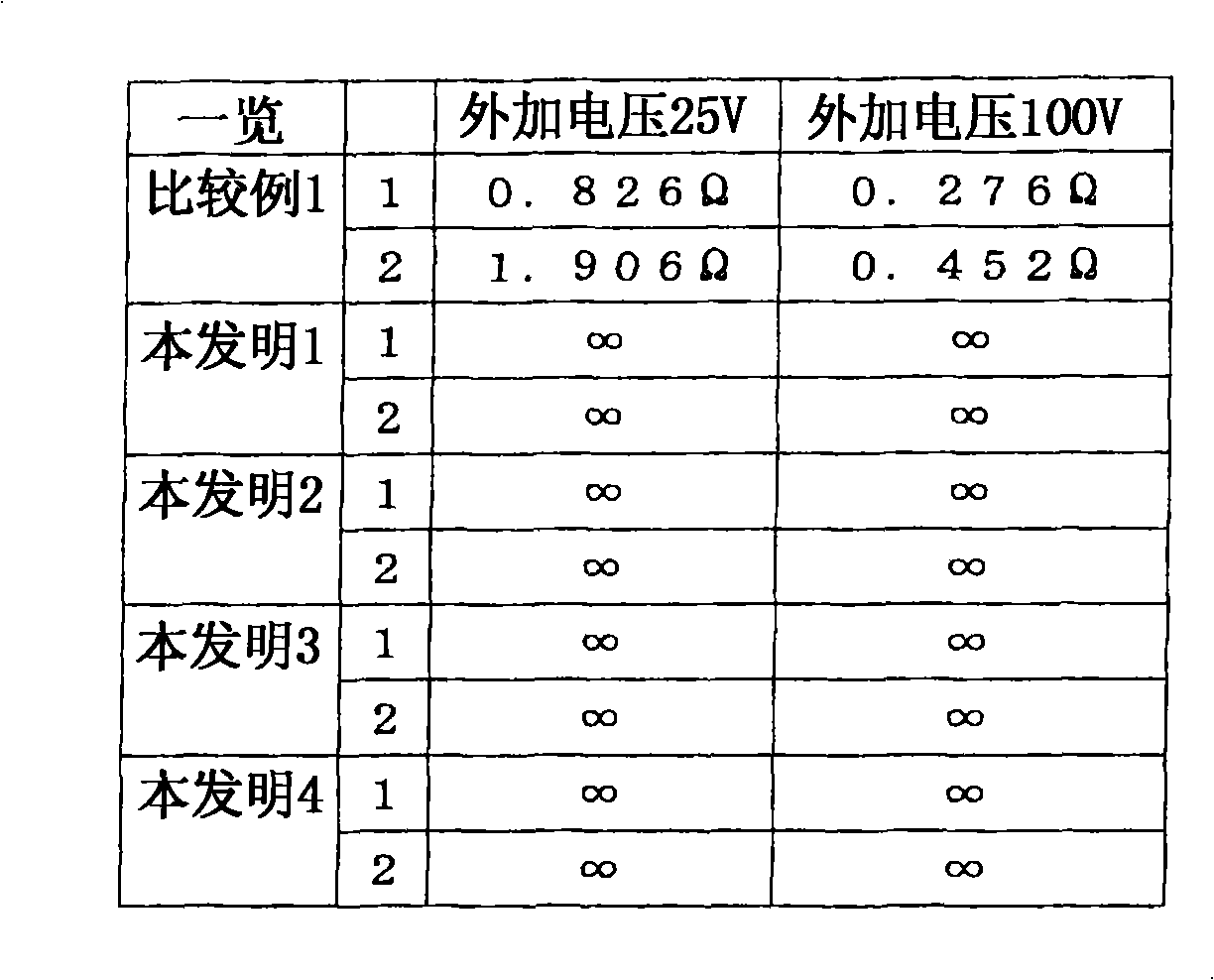

Packaging material for flat electrochemical cell

In a packaging material for electrochemical cell, a thermally adhesive resin layer is configured of a resin having a propylene based elastomer resin in a propylene based resin. This propylene based elastomer resin is a copolymer composed of a constitutional unit derived from propylene and a constitutional unit derived from an alpha-olefin having from 2 to 20 carbon atoms; when the total sum of the constitutional unit derived from propylene and the constitutional unit derived from an alpha-olefin is defined as 100% by mole, contains 50% by mole or more of the constitutional unit derived from propylene; and is satisfied with (a) a Shore A hardness (ASTM D2240) of from 65 to 90, (b) a melting point of from 130 DEG C to 170 DEG C, (c) a density (ASTM D1505) of from 860 to 875 kg / m3 and (d) a glass transition temperature as measured by DSC of from -25 DEG C to -35 DEG C.

Owner:DAI NIPPON PRINTING CO LTD +1

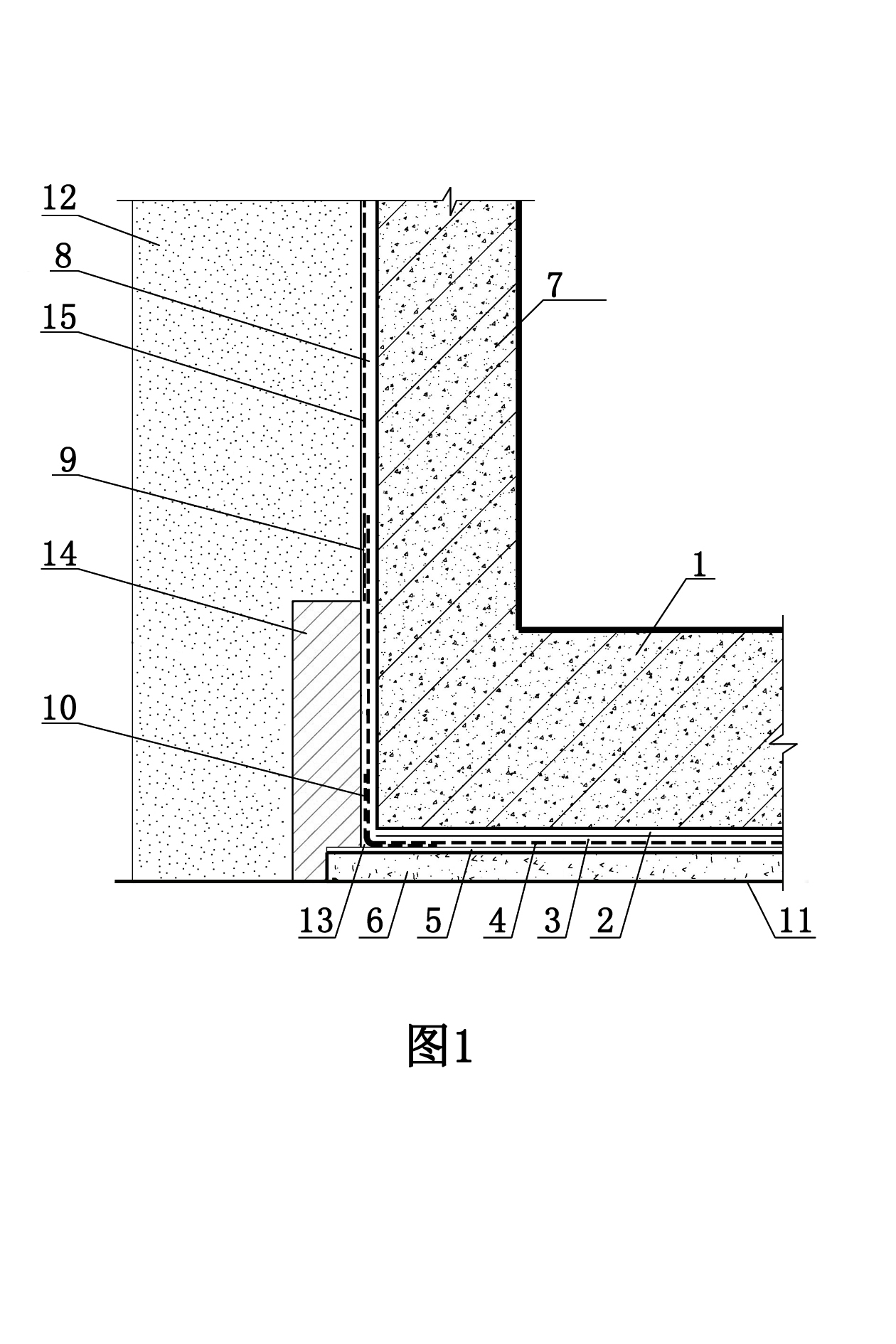

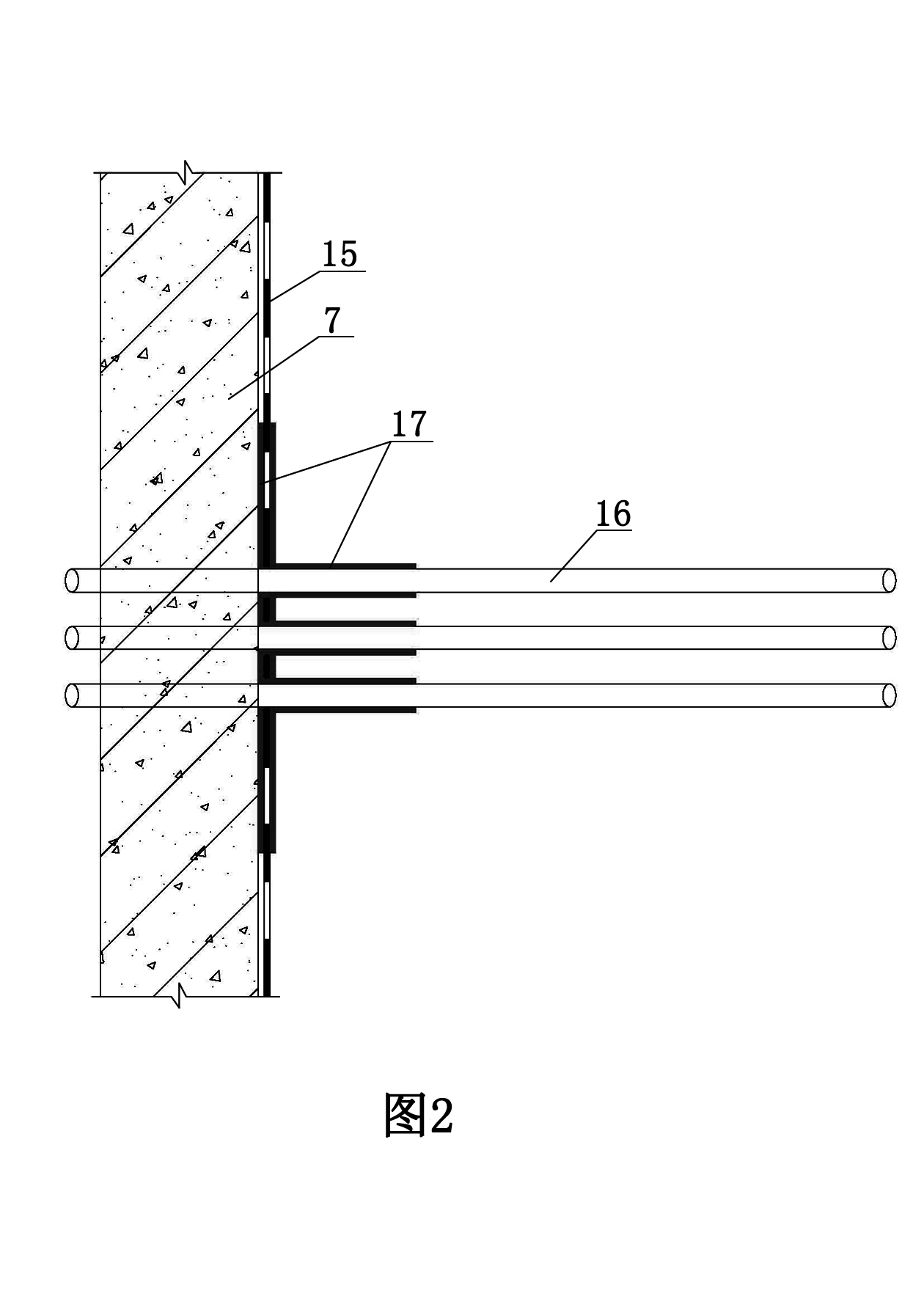

Waterproof system for basement bottom board and wall surface and construction method thereof

InactiveCN101914927AReduce weightHigh tensile strengthArtificial islandsBuild-up roofsBasementBituminous waterproofing

The invention relates to a waterproof system for a basement bottom board and a wall surface and a construction method thereof. The construction method comprises the steps of: horizontally spreading and pasting a self-adhesive rubber bituminous waterproof sheet material on a concrete base layer, and building up a brick permanent protection wall outside a preset position of a basement wall surface, wherein the bottom of the brick permanent protection wall is vertically connected with the concrete base layer, the self-adhesive rubber bituminous waterproof sheet material spreads over corners of the basement wall surface and then is upward folded to be spread and pasted on the water attaining surface of the brick permanent protection wall, then the self-adhesive rubber bituminous waterproof sheet material is lapped with another self-adhesive rubber bituminous waterproof sheet material pasted above the brick permanent protection wall, a self-adhesive rubber bituminous waterproof sheet material is pasted on an outer vertical surface of the basement wall surface. The construction method has the advantages of strong construction continuity, fast speed, good construction environment, low cost and the like, eliminates the hidden danger of fire since the heating is avoided in the construction process, is safe and reliable, completely changes and improves the traditional waterproof construction environments and the waterproof construction technology. The waterproof system can be widely applied in basements, underground structures and roofs.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

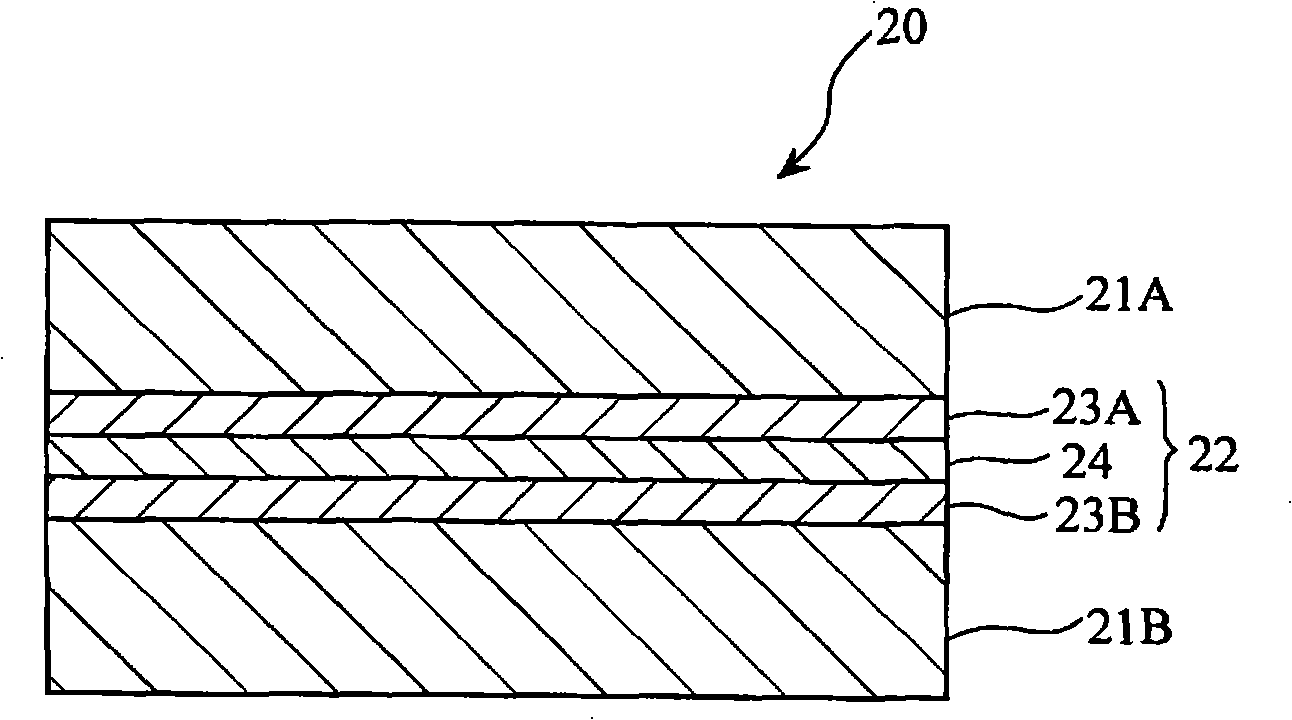

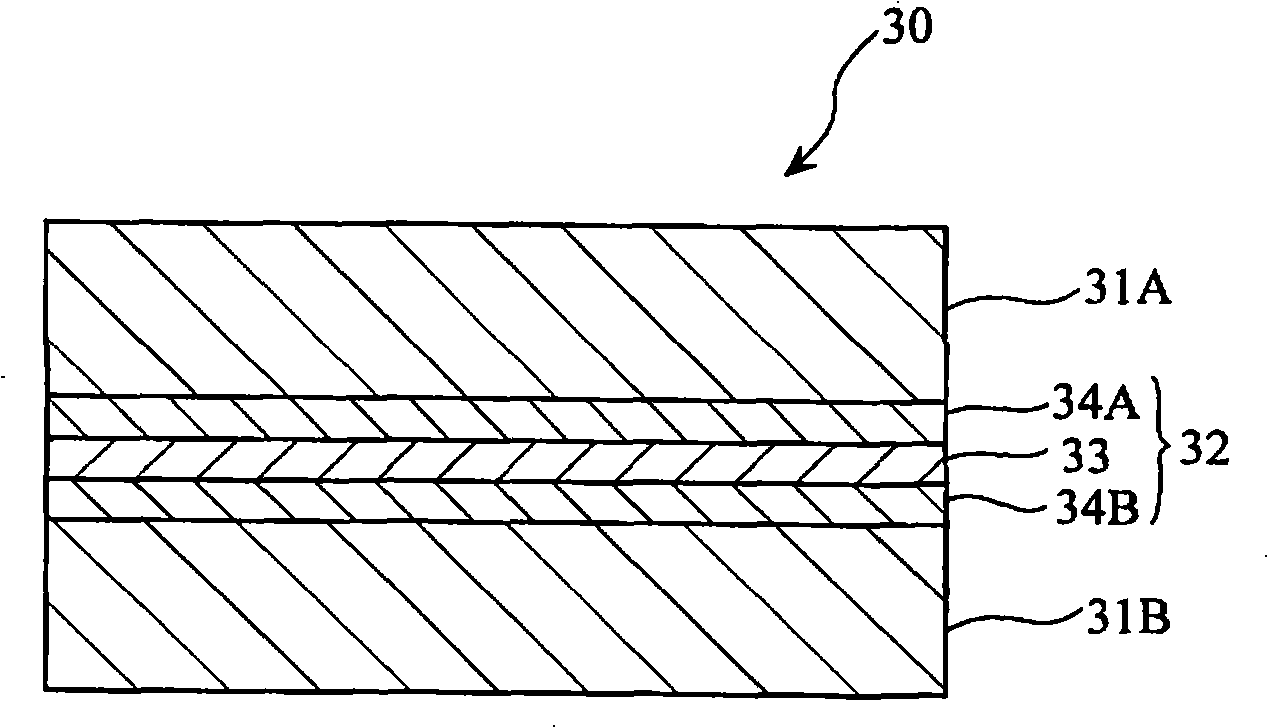

Intermediate film for laminated glass, laminated glass using the same, and method for production of the laminated glass

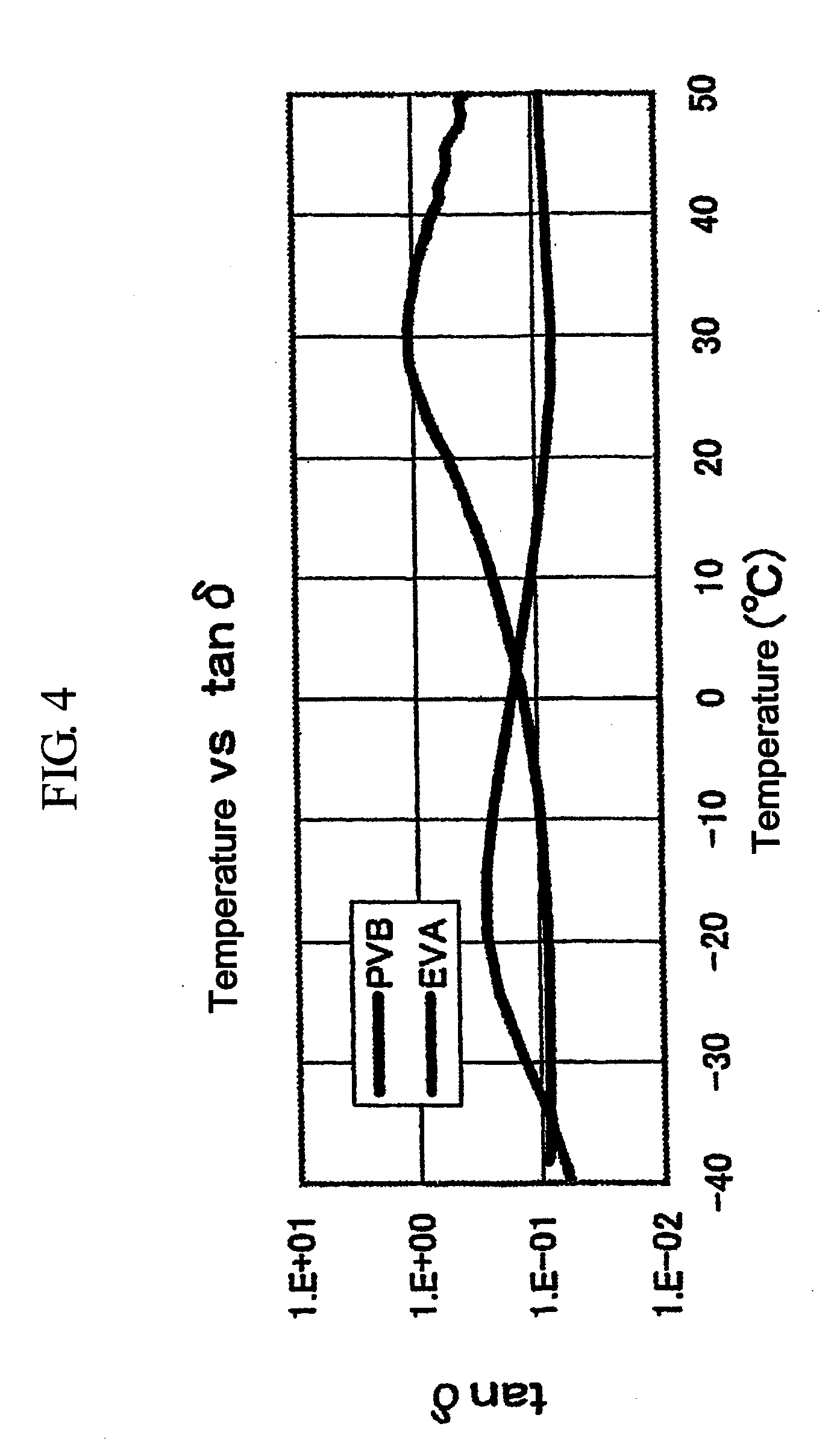

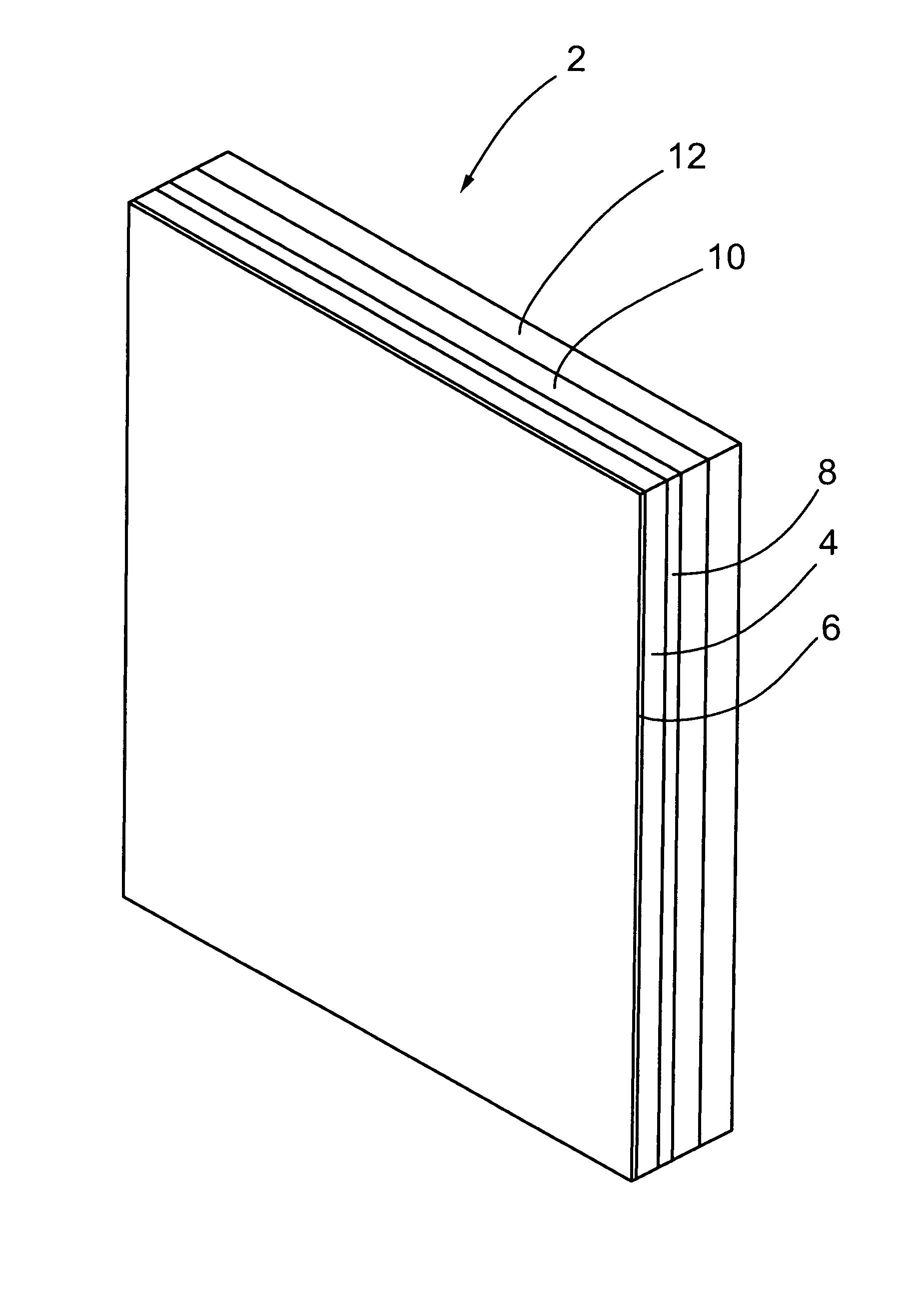

InactiveCN101410341AHigh transparencyGood penetration resistanceSynthetic resin layered productsGlass/slag layered productsWeather resistanceUv absorber

The object of the present invention is to provide an intermediate film for a laminated glass having excellent transparency, adhesion, impact resistance and penetration resistance as well as excellent light resistance and weather resistance, and scarcely turning yellow in a heating treatment during its preparation. An intermediate film for a laminated glass comprising a laminate consisting of a layer (PVB layer) of a composition comprising polyvinyl butyral and a layer (EVA layer) of a composition comprising ethylene / vinyl acetate copolymer containing an organic peroxide, wherein the composition comprising polyvinyl butyral contains a benzophenone compound as an ultraviolet absorber; a laminated glass; and a process for the preparation of the same.

Owner:BRIDGESTONE CORP

Air brick for magnesia carbon ladle and method for producing the same

The invention discloses an air brick used for a magnesium and carbon ladle, and a producing method thereof, aiming at producing high-quality air bricks used for the ladles. The mass percentage of the chemical compositions of the air brick is: 55 to 99 percent of MgO, 0 to 20 percent of C, 0 to 20 percent of AI2O3, 0 to 5 percent of ZrO2, 0 to 5 percent of AI, 0 to 5 percent of AI-Mg alloy, 0 to 5 percent of CaB6, and 0 to 2 percent of B4; the physical property indexes are: volume density (g / cm<3>): 3.00 to 3.15, apparent porosity (%): 1.5 to 5.0, cold compressive strength (MPa): 40 to 65, and distortion resistance at high temperature (MPa): 14.0 to 25.0. Raw materials adopted by the invention comprise fused magnesite, magnesite clinker, crystalline flake graphite, corundum, zirconia and oxidation inhibitor. The raw materials are added into a pug mill and externally added with a bonding agent for mulling. Mulled pug is added into a mould, and molded by utilizing isopressing equipment or a friction brick press or a hydraulic press. The invention obviously reduces the apparent porosity of the air brick, not only can improve the basic slag corrosion resistant capability of the air brick, but also can reduce the cost of the raw materials by more than two thirds.

Owner:UNIV OF SCI & TECH LIAONING

Preparation method of metalized film of induction cooker capacitor

ActiveCN103112169AImprove performanceGood removal effectVacuum evaporation coatingSputtering coatingMetallised filmRejection rate

The invention relates to the field of preparation of a capacitor, and in particular relates to a preparation method of a metalized film of an induction cooker capacitor. The preparation method comprises the following steps of: selection and preparation of raw materials, extruding a melt through an extruder, cooling the melt through a chilling roller and an air shower, drawing the melt in a vertical direction, drawing the melt in a transverse direction, testing the thickness of the drawn melt, performing procedures of trimming and corona treatment, rolling, time sequence treatment, slicing, and vacuum-evaporating the metalized film. Through the steps, the prepared metalized film is comparatively high in performance, comparatively low in rejection rate, low in cost and high in current carrying capability.

Owner:NINGBO GREAT SOUTHEAST WAN XIANG SCI & TECH

High temperature and wear resistant graphene coating and preparation method thereof

The invention relates to a high temperature and wear resistant graphene coating, and the graphene coating is characterized by comprising the following components by weight percent: 35.0-60.0wt% of silicate, 0.01-20.0wt% of graphene, 0.1-25.0wt% of additive, and the balance of water as a solvent. The invention further provides a method for preparing the coating. The high temperature and wear resistant graphene coating disclosed by the invention can be used for well protecting matrixes by coating on pipelines, chemical equipment, storage, kiln furnace, medicine, aerospace and sewage, the service life of the matrix is prolonged, and the performance of the coating is much greater than that of a common material.

Owner:ZHUHAI LETONG NEW MATERIAL TECH CO LTD

Preparation technique of waste residue composite light-weight thermal-insulation wallboard

ActiveCN102863189ALow costCost enoughSolid waste managementCeramic shaping apparatusAggregate (composite)Engineering

The invention discloses a preparation technique of a waste residue composite light-weight thermal-insulation wallboard, which comprises the following steps: preparing a waste residue base material; preparing a composite admixture A; preparing waste residue light-weight aggregate; preparing a composite admixture B; preparing a wallboard blank material; preparing a wallboard blank; putting the wallboard blank in a curing chamber, and curing in a 75-80 DEG C saturated steam environment for 4-5 hours; and when the difference between inside temperature and outside temperature of the curing chamber is 25-40 DEG C, putting the wallboard blank outside the chamber, and demolding to obtain the waste residue composite light-weight thermal-insulation wallboard. According to the preparation method disclosed by the invention, the wallboard blank can be cured and demolded within 8.5-12 hours, and the demolded wallboard can be immediately put into engineering use, thereby shortening the processing cycle, and preparing the high-strength favorable-water-resistance light-weight wallboard under the conditions of changing wastes into valuable substances and using low production cost. The wallboard can be widely used in various types of construction engineering.

Owner:杜世永

Dispersive air brick and preparation method thereof

The present invention relates to a dispersive air brick and a preparation method thereof. According to the technical scheme of the invention, 50 to 80 wt% of plate-shaped corundum is adopted as an aggregate. 12 to 32 wt% of aluminum oxide fine powders, 5 to 10 wt% of alumina micro powders and 3 to 8 wt% of a binding agent are adopted as matrix materials. According to the method, firstly, the matrix materials are uniformly mixed, and then the matrix materials and the aggregate are put into a mixer. 0.1 to 0.3 wt% of a water reducing agent and 4 to 6 wt% of water, counted relative to the sum of the aggregate and the matrix materials, are additionally added. The obtained mixture is stirred for 3 to 5 minutes, and then is cast and molded. After an obtained product is standing at the room temperature for 20 to 30 hours, the obtained product is dried for 22 to 26 hours at the temperature of 90 to 120 DEG C. then the obtained product is thermally insulated for 3 to 6 hours at the temperature of 1450 to 1650 DEG C. In this way, the dispersive air brick can be obtained. The plate-shaped corundum is in the form of equal-diameter particles, and the particle sizes of the equal-diameter particles are 2 to 5 mm. The method has the advantages of simple process, low labor intensity, high production efficiency, no pollution to the environment, and low cost. The prepared dispersive air brick is good in air permeability, strong in impurity-removing capability, excellent in thermal shock stability and good in penetration resistance performance.

Owner:江苏锦耐新材料科技有限公司

Nano composite latex paint and preparing method thereof

The composition of the invented nano composite latex paint comprises (wt%) 0.3-1% of moistening dipersant, 2-70% of nano pulp, 1-4% of film-forming adjuvant, 0.5-2% of anti-sedimentation agent, 0.8-15% of antifreeze agent, 0.5-3% of defoaming agent, 5-30% of pigment, 0-30% of filling material, 10-45% of emulsion, 0.2-2% of thickening agent, 0.2-2% of leveling agent, 0-2% of pH regulating agent, 0-2% of microbiocide and 2-35% of water. Its preparation method includes two steps: firstly, preparing dispersion stable nano material pulp, then adding said nano material pulp into the latex component according to a certain process so as to obtain the invented high-performance product.

Owner:中科纳米涂料技术(苏州)有限公司

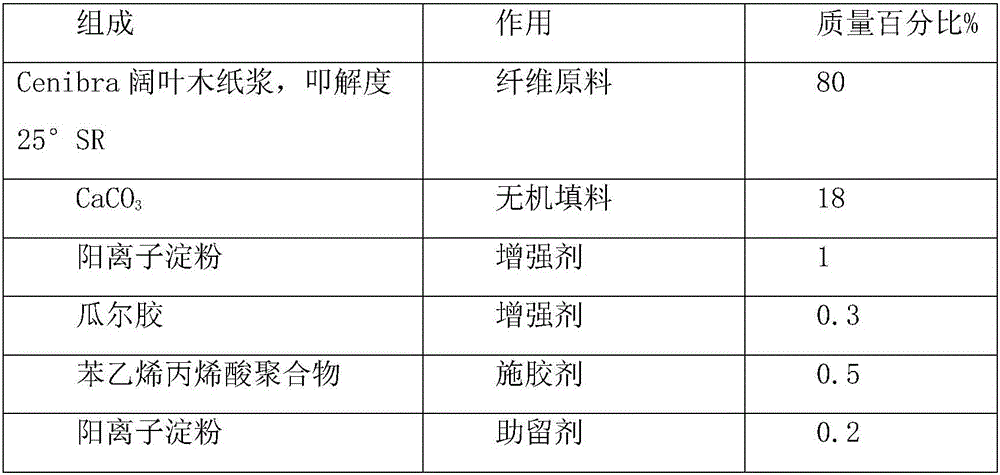

Heating non-combustible cigarette paper and preparation method thereof

ActiveCN106368069ANo tar spotsDoes not start carbonationInorganic fibres/flakesSpecial paperFiberBurn cigarette

The invention discloses heating non-combustible cigarette paper and a preparation method thereof. The preparation method of the heating non-burning cigarette paper comprises the following steps: 1) pulping the plant fiber with the length of 0.5 to 4mm, or adding the appropriate proportion of inorganic fiber; 2) adding the inorganic filler in the process of dilution of the pulp, wherein the addition ratio of the inorganic filler is 5 to 50% of the mass of the pulp; 3) sizing the paper to improve water and oil resistance, and cigarette paper is quantified at 50 to 120 g / m<2>. Compared with the existing heated non-combustible cigarette paper that is heated at 350 DEG C, the non-combustible cigarette paper of the present invention has very few yellow stitches, and no tar spots and carbonization, while the entire surface of the existing non-combustible cigarette paper turns yellow, with large tar penetrating and carbonized. In addition, the non-combustible cigarette paper of the present invention is rarely present broken in actual production, and there is almost no deformation and wrinkling after being sucked as the heated cigarette paper.

Owner:中烟摩迪(江门)纸业有限公司

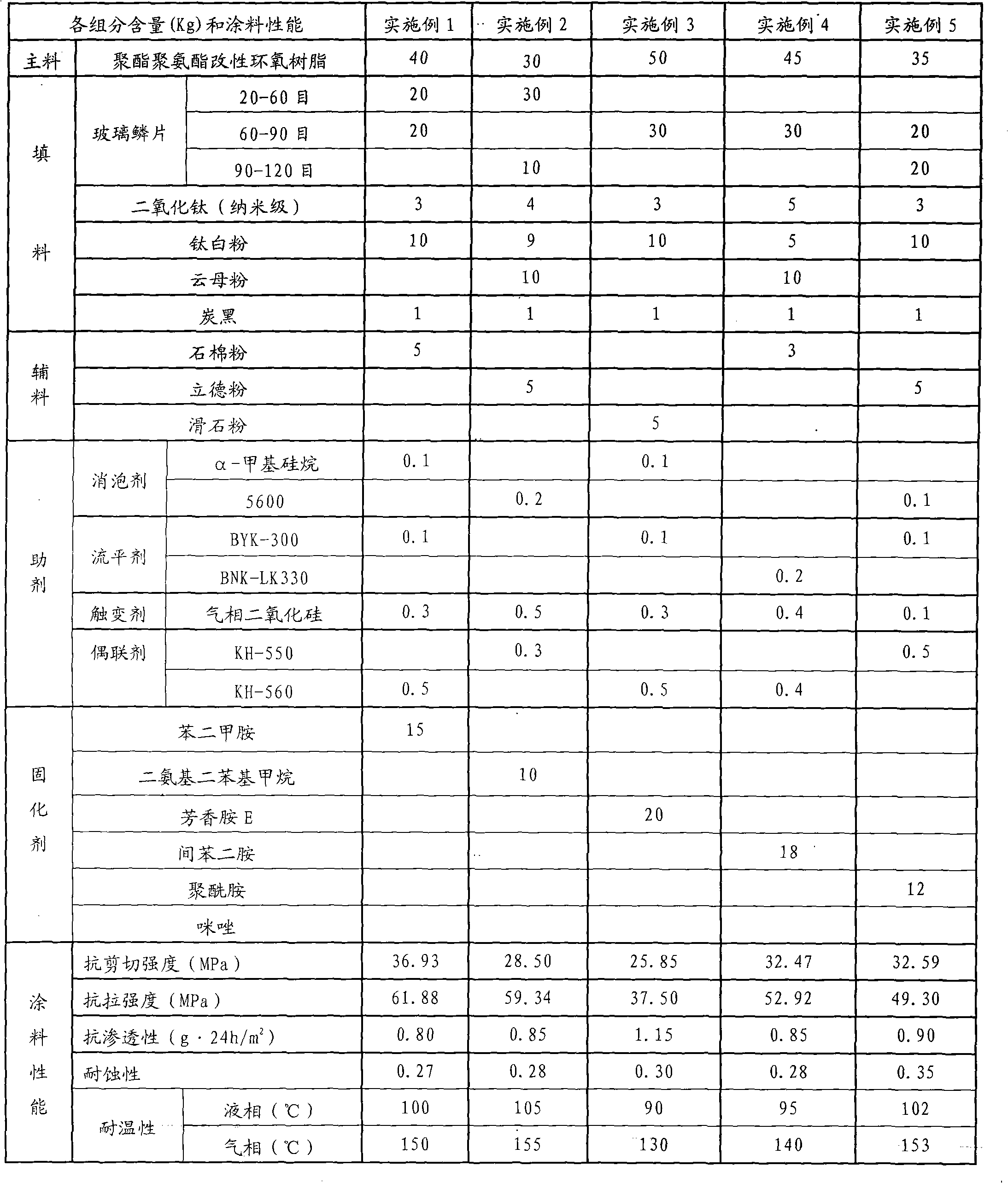

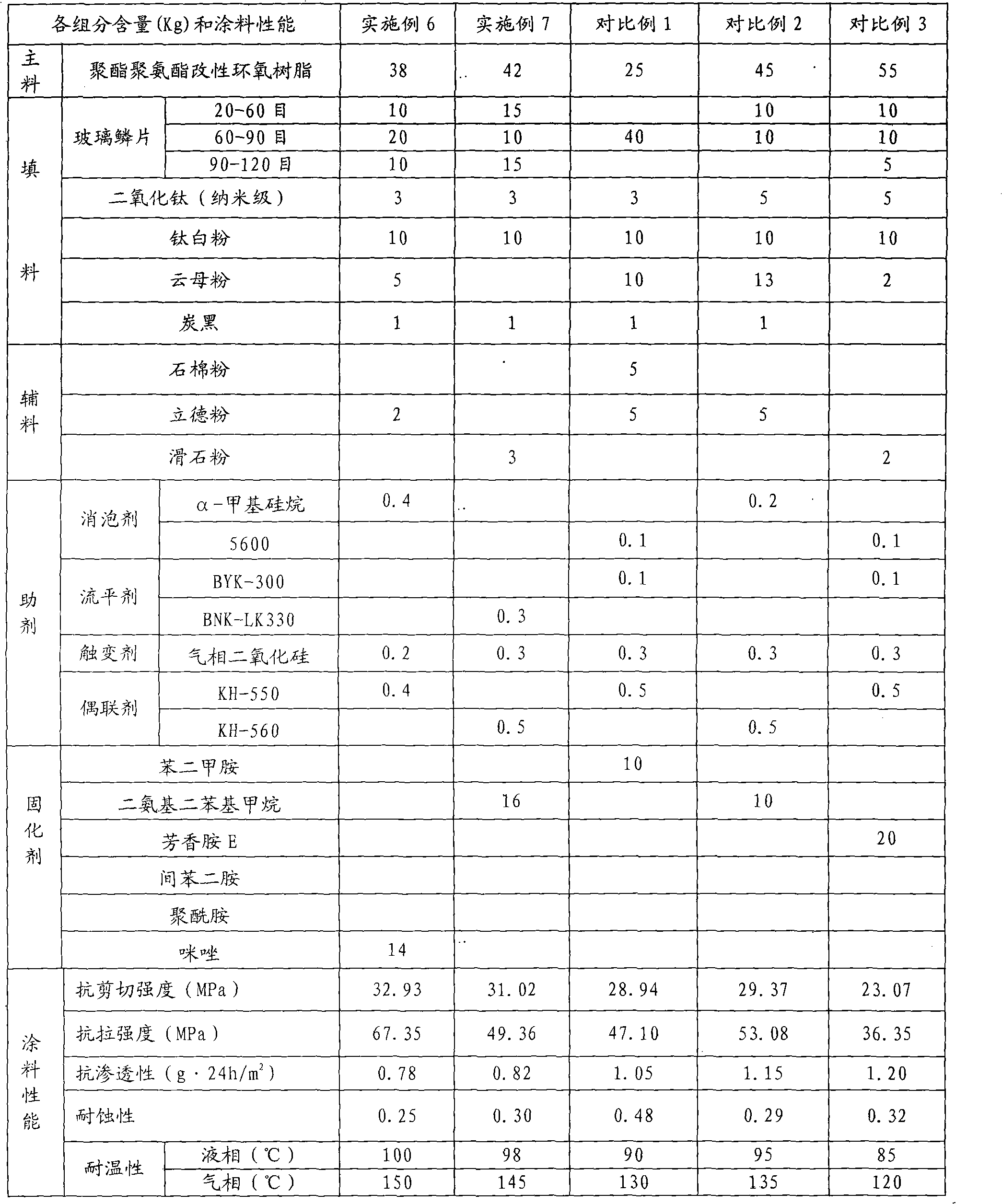

Novel polymer anticorrosion painting material

ActiveCN102181218AHigh bonding strengthImprove penetration resistanceAnti-corrosive paintsEpoxy resin coatingsChemistryEpoxide

The invention relates to a novel polymer anticorrosion painting material. The painting material is characterized by consisting of a component A and a component B, wherein the component B is a curing agent and accounts for 10-30 percent relative to the weight parts of the component A; and the component A comprises the following components in parts by weight: 30-50 parts of polyester polyurethane modified epoxide resin which serves as a main material and has the solid content of 100 percent, 30-50 parts of glass flakes with different flake diameters, 3-5 parts of nanoscale titanium dioxide and 10-20 parts of at least one of titanium pigment, mica powder and carbon black in any ratio, 1-5 parts of at least one of asbestos powder, lithopone and talc powder serving as auxiliary materials in any ratio, and 0.3-1 part of at least three of defoaming agent, flatting agent, thixotropic agent and coupling agent serving as aids in any ratio. The coating material has the advantages of convenience and rapidness of construction, high bonding strength, low using cost, high corrosion resistance, high wear resistance, favorable penetration resistance, higher temperature resistance and solid content of 100 percent.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Novel modified emulsifying olefin concrete curing agent

The invention relates to a novel modified emulsified paraffin concrete curing agent. Aiming at overcoming the defects that the existing concrete curing agent cannot reach the industrial standard on building material in terms of the water retention property and is unfavorable for environmental protection, the price is high and the decoration at later stage is also affected, the following technical proposal is provided: the curing agent is mixed with the following materials and water: 10-20% of vinyl acetate-ethene high molecular polymer emulsion, 0-5% of silicone resin modified acrylic polymer emulsion, 50-75% of paraffin emulsion, 0.1-0.5% of colloidal dispersing agent of the emulsified paraffin for stabilizing the emulsion state and 0.05-0.02% of special defoamer for emulsion. The invention has the beneficial effects that: the chemical curing method which is adopted for retaining water is an innovation for the traditional curing method; compared with the prior art, the method is labor-saving, time-saving and water-saving and is convenient to operate, can improve the film formation ability and the sealing ability of the emulsified paraffin emulsion, and can improve the bonding and absorbing capacity of the emulsified paraffin emulsion on the concrete surface, which leads the effective water retention rate of the coating film to reach more than 90%.

Owner:LIAONING BUILDING SCI RES INST

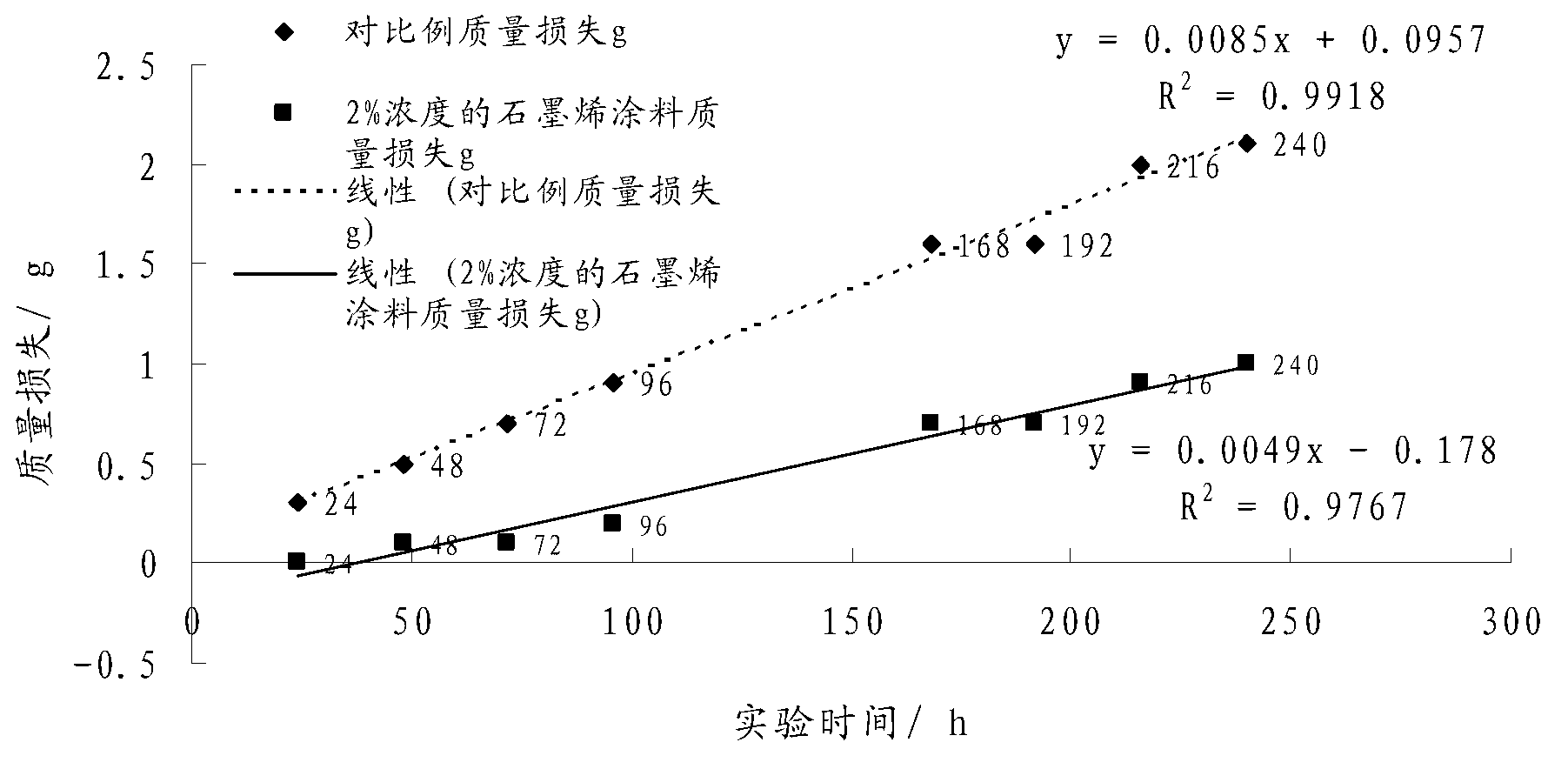

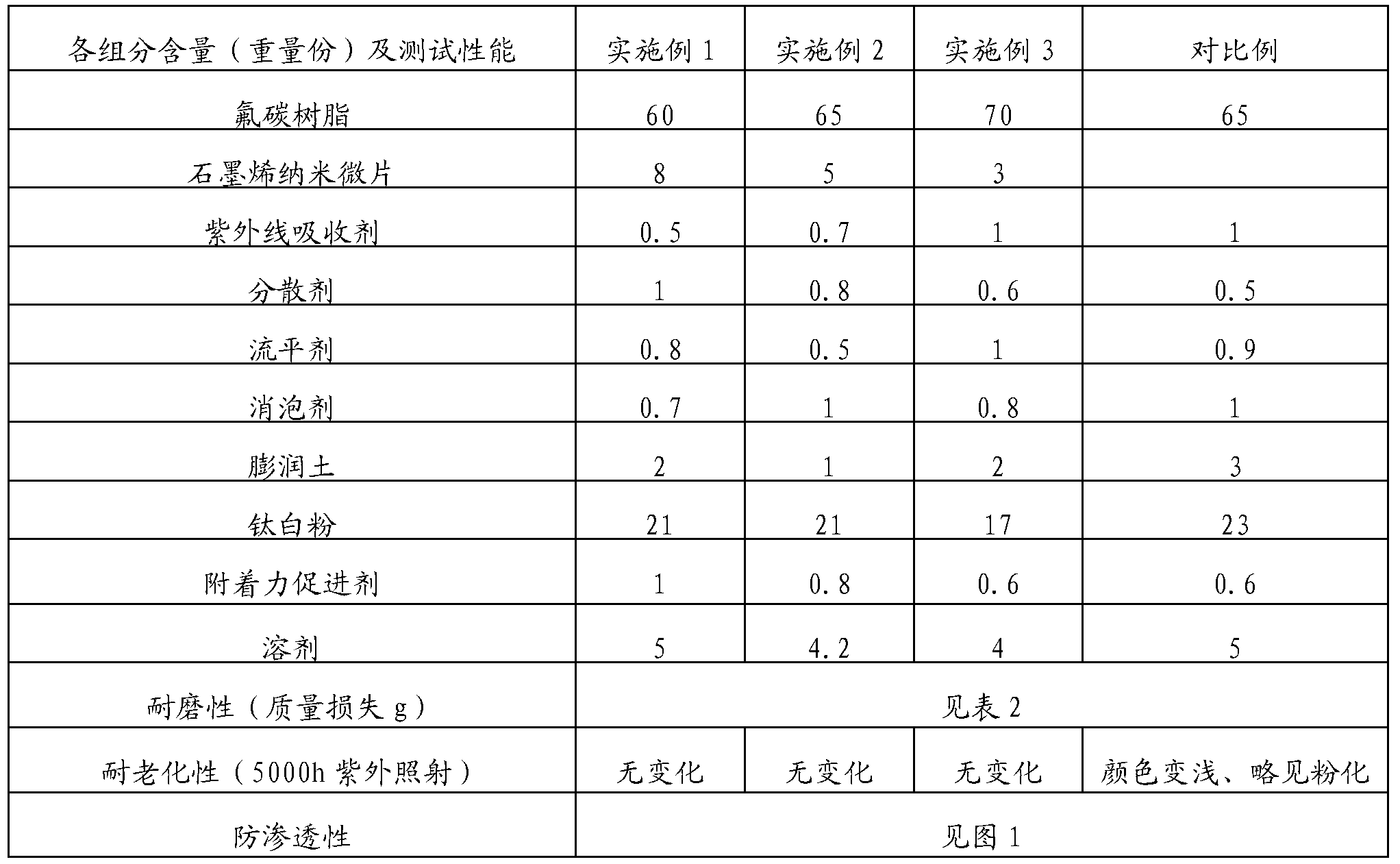

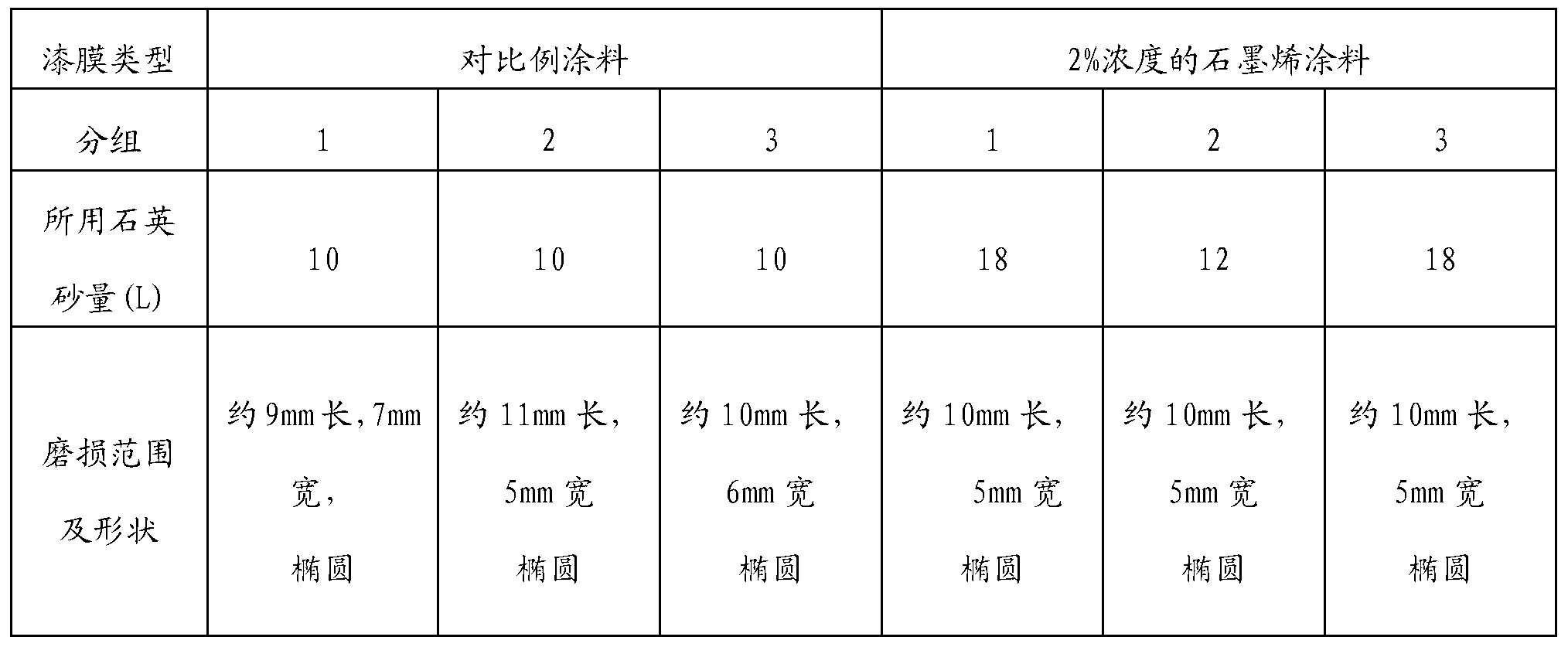

Novel anti-corrosion, anti-ultraviolet, anti-bacteria and wear-resistant paint and preparation method for same

The invention provides a novel anti-corrosion, anti-ultraviolet, anti-bacteria and wear-resistant paint and a preparation method for the same. The novel anti-corrosion, anti-ultraviolet, anti-bacteria and wear-resistant paint is composed of an agent A and an agent B, wherein the agent A is composed of the following components in percentage by weight: 60-70% of fluorocarbon resin, 1-8% of graphene nanometre micro-sheets, 0-2% of an ultraviolet absorber, 0.5-1% of a dispersing agent, 0.5-1% of a levelling agent, 0.5-1% of a defoaming agent, 1-3% of bentonite, 20-25% of titanium dioxide, 0.5-1% of an adhesion promoter and 2-5% of a solvent; and the agent B is a curing agent used with the agent A. The preparation method provided by the invention is simple in operation and preparation processes; the prepared graphene anti-corrosion paint is excellent in wear-resistant, ageing-resistant, anti-bacteria and anti-corrosion performances; and moreover, graphene has no toxic and side effects, as well as is efficient and environment-friendly.

Owner:青岛科孚纳米技术有限公司

Concrete releasing agent for aluminum alloy template of building

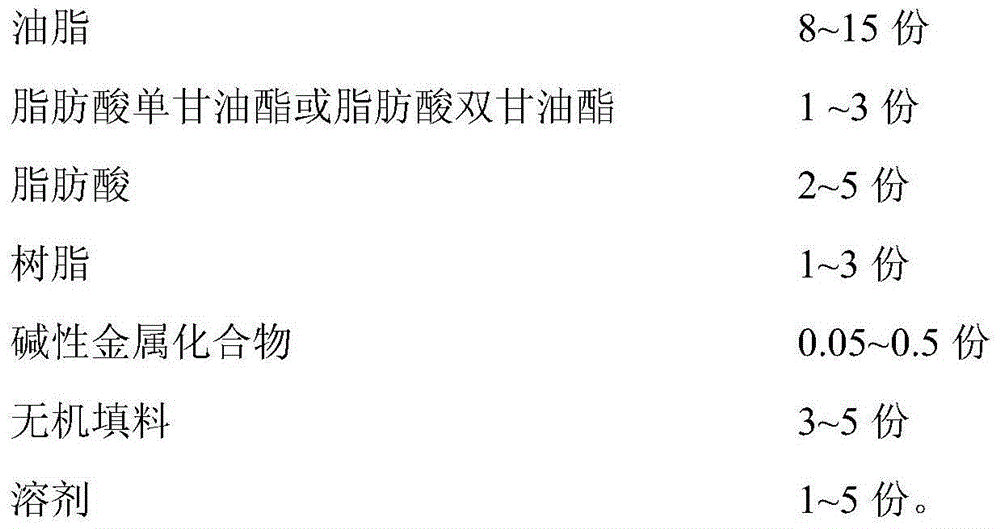

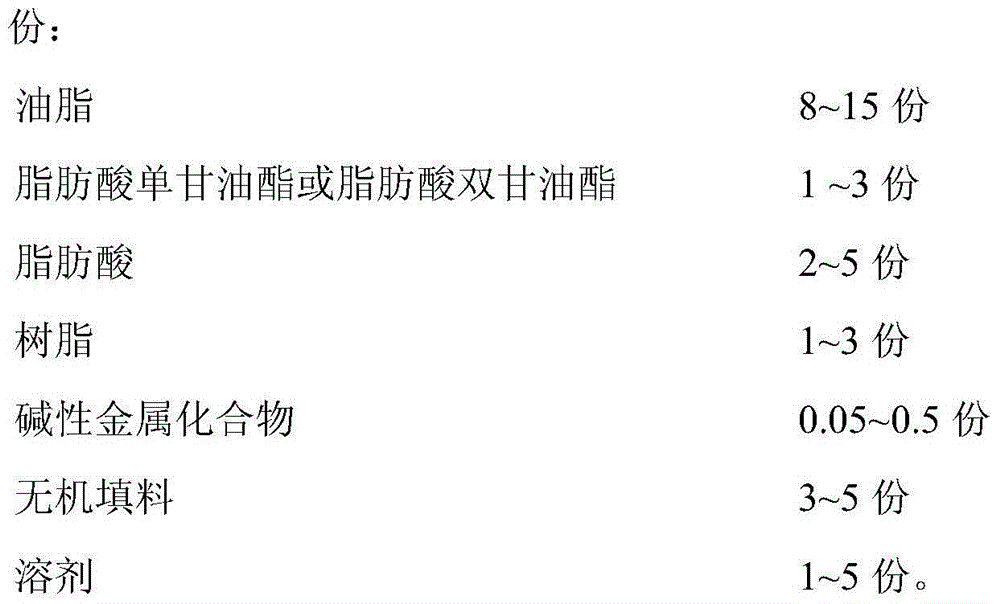

InactiveCN104629885ABlock penetration throughAvoid destructionCeramic shaping apparatusLubricant compositionMonoglycerideDiglyceride

The invention provides a concrete releasing agent for an aluminum alloy template of a building. The releasing agent comprises the following components in parts by weight: 8-15 parts of grease, 1-3 parts of fatty acid monoglyceride or fatty acid diglyceride, 2-5 parts of fatty acid, 1-3 parts of resin, 0.05-0.5 parts of basic metal compound, 3-5 parts of inorganic filler and 1-5 parts of solvent. The releasing agent coats the aluminum alloy template of the building and is used in the concrete pouring technology, the concrete releasing quality is good without obvious blister, and the releasing agent residue surface matter is easily removed and the releasing agent is suitable for use for single or multiple times, and the service life of the template is prolonged.

Owner:SHANGHAI JIAO TONG UNIV

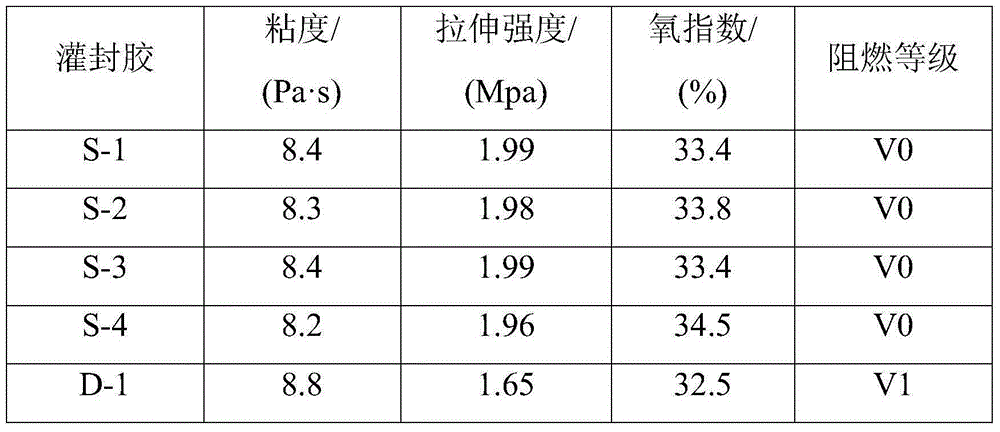

Flame-retardant microcapsule as well as preparation method and application thereof

InactiveCN105218714AColorless, odorless, low boiling pointLow boiling pointNon-macromolecular adhesive additivesMicroballoon preparationInternal pressureLiquid core

The invention discloses a flame-retardant microcapsule as well as a preparation method and application thereof. The flame-retardant microcapsule comprises a core material and a coating layer coating at the outer side of the core material, wherein the core material is liquid heptafluoropropane or liquid hexafluoropropane; and the coating layer is a polymethacrylate polymer and is prepared by polymerization by virtue of a suspension polymerization method. The flame-retardant microcapsule can be used as a flame-retardant filler singly, and also can be used as a flame-retardant filler together with magnesium hydroxide / aluminum hydroxide for preparing an electronic-pouring sealant in combination. The flame-retardant microcapsule disclosed by the invention is high in thermal stability and good in penetration resistance, and cannot generate leakage of the core material in a normal state; and only when subjected to high-temperature combustion, the coating layer is softened and the liquid core material is vaporized at the same time so that the internal pressure is increased and results in expansion breakage of the coating layer, and then the core material is released at last to quickly retard inflaming and put out a fire, so that the flame-retardant microcapsule has a broad use prospect in the field of preparation of the electronic-pouring sealant.

Owner:浙江中天东方氟硅材料股份有限公司

Stemming and purpose thereof

Owner:XINJIANG BAYI IRON & STEEL

Polyaniline modified metal-ceramic nano coating and preparation method thereof

ActiveCN101643607AOvercoming the easy formation of hard precipitatesOvercome the hardnessEpoxy resin coatingsEpoxyPhytic acid

The invention relates to coating technology, in particular to a polyaniline modified metal-ceramic nano coating and a preparation method thereof to solve the problems that compositions of a base stockof the coating existing in the prior art are easy to form hard precipitation, and the coating has low hardness. The polyaniline modified metal-ceramic nano coating mainly comprises nano-whisker, polyaniline and phytic acid modified zinc powder, epoxy resin and a curing agent. The preparation method takes the epoxy resin as a binder and organically combines the metal zinc and the nono ceramic whisker, so that the coating has ductility. The nano-whisker ceramic material reinforces the epoxy coating, strengthens the ductility and the permeability resistance of the epoxy coating; and the polyaniline modified zinc powder improves the corrosion resistance of the coating. The coating is widely used for heavy-duty anticorrosion of petrochemical equipment, maritime facilities and traffic facilities.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Intermediate film for laminated glass, laminated glass using the intermediate film, and process for the preparation of the laminated glass

InactiveUS20100233453A1High transparencyImprove penetration resistanceSynthetic resin layered productsLaminationPolyvinyl butyralWeather resistance

[Problem to be Solved]The object of the present invention is to provide an intermediate film for a laminated glass having excellent transparency, adhesion, impact resistance and penetration resistance as well as excellent light resistance and weather resistance, and scarcely turning yellow in a heating treatment during its preparation.[Means for Solving Problem]An intermediate film for a laminated glass comprising a laminate consisting of a layer (PVB layer) of a composition comprising polyvinyl butyral and a layer (EVA layer) of a composition comprising ethylene / vinyl acetate copolymer containing an organic peroxide, wherein the composition comprising polyvinyl butyral contains a benzophenone compound as an ultraviolet absorber; a laminated glass; and a process for the preparation of the same.

Owner:BRIDGESTONE CORP

Drilling fluid for shale hydrocarbon reservoir exploration

InactiveCN104610941AInhibition of hydrationPrevent collapseDrilling compositionWell drillingPotassium silicate

The invention provides a drilling fluid for shale hydrocarbon reservoir exploration. The drilling fluid is based on water, and comprises 4-6wt% of bentonite, 2-5wt% of potassium silicate, 0.2-0.5wt% of a coating inhibitor, 0.2-1.5wt% of a flow pattern regulator, 4-6wt% of a fluid loss additive, 2-3wt% of a shale caving inhibitor, 2-3wt% of a plugging agent, 0.5-1wt% of a filter cake surface modifier, 2-4wt% of a lubricant and 0.4-0.6wt% of a pH value regulator. The drilling fluid has the characteristics of good plugging property, strong inhibition, good lubricity and stable high temperature performances to shale hydrocarbon reservoir stratums, and is suitable for the exploration of shale hydrocarbon reservoirs.

Owner:CHINA PETROCHEMICAL CORP +1

Self-cleaning nona composite environment-friendly type emulsion paint and preparation method thereof

The invention discloses a self-cleaning nanometer composite environmental protection latex paint and preparing method, which comprises the following parts: 0.5-5% wetting disperser, 0.5-50% nanometer concentrated slurry, 0.5-10% hydrophobic agent, 0.5-10% anion powder, 0.5-8% filming adjuvant, 0.1-2% anti-settling agent, 0.8-10% antifreeze agent, 0.1-3% defoamer, 4-30% dye, 0-30% filler, 15-45% emulsion, 0.1-4% thickener, 0.1-3% levelling agent, 0-3% pH adjuster, 0-4% microbe eliminating agent and 0.5-45% water. The preparing method comprises the following steps: 1) placing water in the container with high-speed disperser; adding microbe eliminating agent, nanometer condensing slurry, hydrophobic agent, anion powder; blending evenly; adding dye and filler; dispersing until finesse reaches 20-60um; 2) adding emulsion, pH value adjuster, thickener and leveling agent continuously.

Owner:中科纳米涂料技术(苏州)有限公司

Taphole stemming used for oversize blast furnaces

Belonging to the technical field of refractory materials, the invention relates to taphole stemming used for oversize blast furnaces over 4500m<3>. The taphole stemming used for oversize blast furnaces comprises by weight: 25-50% of brown corundum, 5-20% of silicon carbide, 7-25% of ferro-silicon nitride, 15-30% of a composite carbon material, 5-15% of kaolin, 3-7% of composite refractory material micropowder, and 1-5% of composite metal powder. The stemming is prepared by the steps of: conducting weighing and burdening according to the above ratio of various raw materials, mixing them well and adding a coal tar binder accounting for 15-25% of the total weight of the additionally added dry materials, then conducting rolling and mulling so as to obtain a mud material. The stemming of the invention has good comprehensive performance, stable taphole depth, long tapping time, good erosion and scouring resistance, as well as good construction performance.

Owner:BAOSHAN IRON & STEEL CO LTD

Tundish magnesium dry-type stock adding aluminum hydroxide

The invention discloses a magnesia-based dry material for a tundish with aluminum hydroxide, which belongs to a refractory material. The magnesia-based dry material for the tundish with the aluminum hydroxide comprises the following compositions in percentage by weight: 1 to 15 percent of aluminum hydroxide fine powder, 82 to 89 percent of magnesia, and 1.5 to 6.5 percent of bonding agent. During the baking and use, the aluminum hydroxide fine powder is decomposed to produce activated alumina and vapor, the vapor moistens the surfaces of particles inside the dry material to ensure that the surfaces of the magnesia and silica fume in the dry material are hydrated, and the bonding agent is partially dissolved and diffused to bond with the surface of the magnesia. The generated activated alumina has a spinel reaction with magnesia fine powder at a temperature higher than 900 DEG C to form a large quantity of fine magnesium aluminate spinels, which remarkably improves the penetration-resistant action of the dry material on molten steel and steel slag and plays a role in ceramic bonding. The dry material does not depend on carbon-containing bonding agents such as phenolic resin, asphalt, which avoids the carburization to molten steel of low carbon steel and also reduces the poisonous fume emission. The construction of the magnesia-based dry material adopts a dry-press process, and then the dry material is subjected to heat conduction through the heating on a metal mold to make the bonding agent fused or solidified to form a fixed tundish working lining for receiving the molten steel.

Owner:江苏苏嘉集团新材料有限公司

Ceramic armour and method of construction

InactiveUS20120174754A1Reduce distortionImprove penetration resistanceProtective equipmentLayered productsHigh energyMetal

An armor for protection against armor piercing and / or high energy projectiles has a ceramic layer with a confinement layer on a front thereof. The ceramic layer is backed by a first metal layer and the first metal layer in turn is backed by a composite layer. A second optional confinement layer may be included between the ceramic and first metal layers. The composite layer is backed by an optional second metal layer, which in turn is backed by an optional anti-trauma layer. The armor is used to protect personnel and objects such as vehicles.

Owner:STRIKE FACE TECH

Lightweight dispersion-type ventilating brick and preparation method thereof

The invention provides a lightweight dispersion-type ventilating brick and a preparation method thereof. A technical scheme is as below: stirring an aggregate of 40-72wt% of lightweight corundum, matrix materials including 10-22wt% of sintered spinel, 15-31wt% of calcined alumina powder and 3-7wt% of rho-Al2O3 powder, and water-reducing agent accounting for 0.8-1.0wt% of the total weight of the aggregate and the matrix materials and water accounting for 20-30wt% of the total weight of the aggregate and the matrix materials for 4-6 min; casting, allowing to stand at room temperature for 18-26 h, drying at 100-120 DEG C for 24-32 h, then insulating at 1400-1680 DEG C for 3-6 h to obtain the lightweight dispersion-type ventilating brick. The lightweight corundum through pores accounted for 30-40% in volume of the lightweight corundum particles. The present invention has the advantages of easiness to control process, low cost and little environmental pollution; and the prepared lightweight dispersion-type ventilating brick has good, penetration, excellent anti-osmotic performance and high strength.

Owner:江苏锦耐新材料科技有限公司

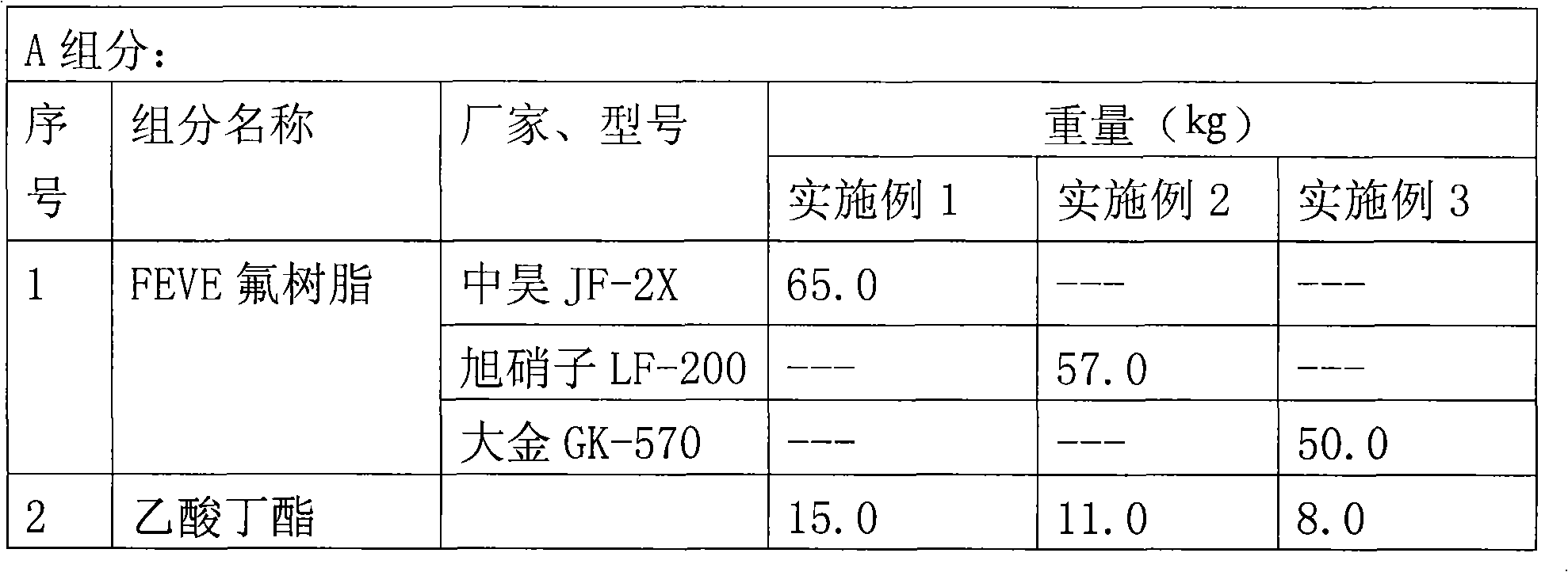

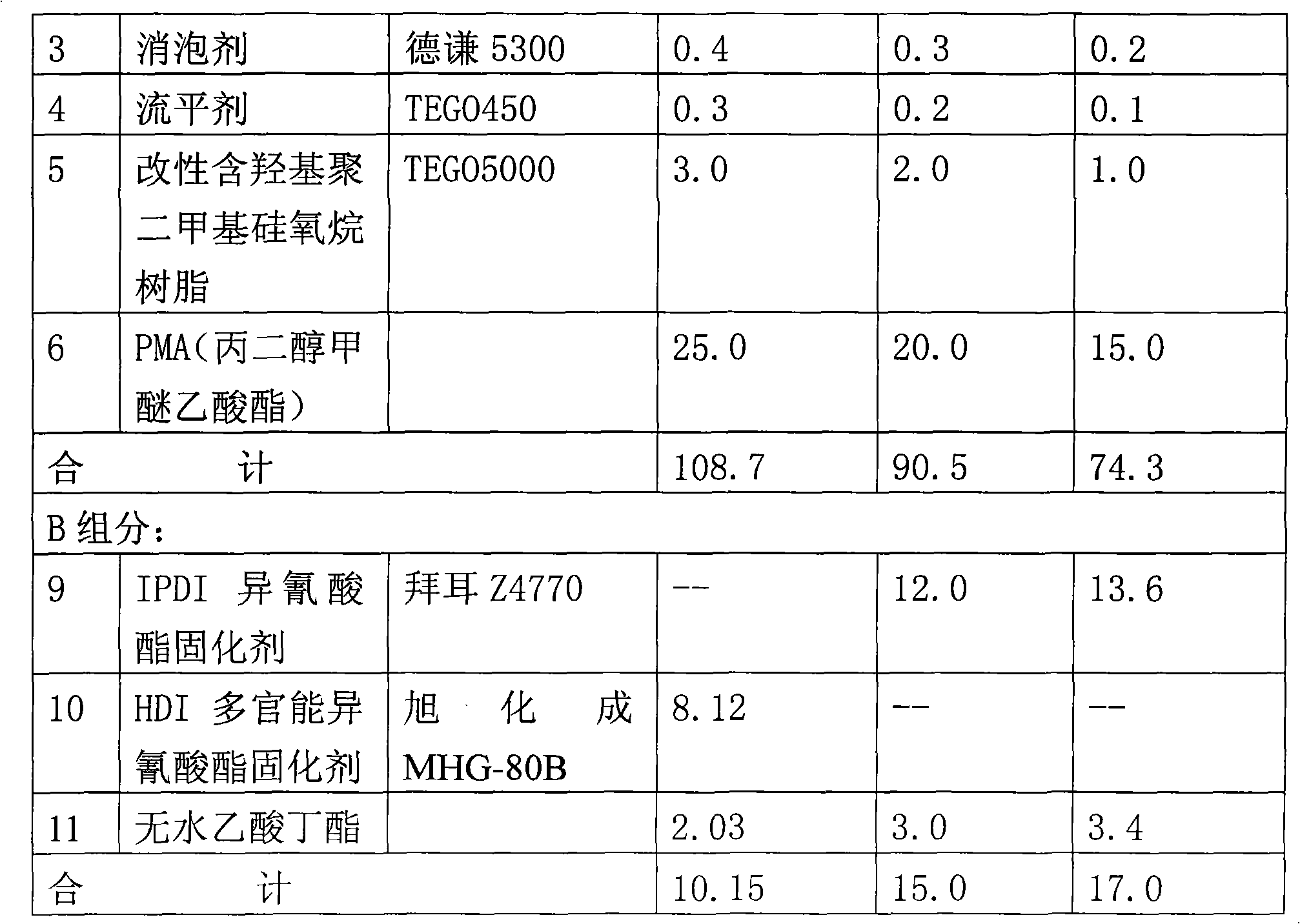

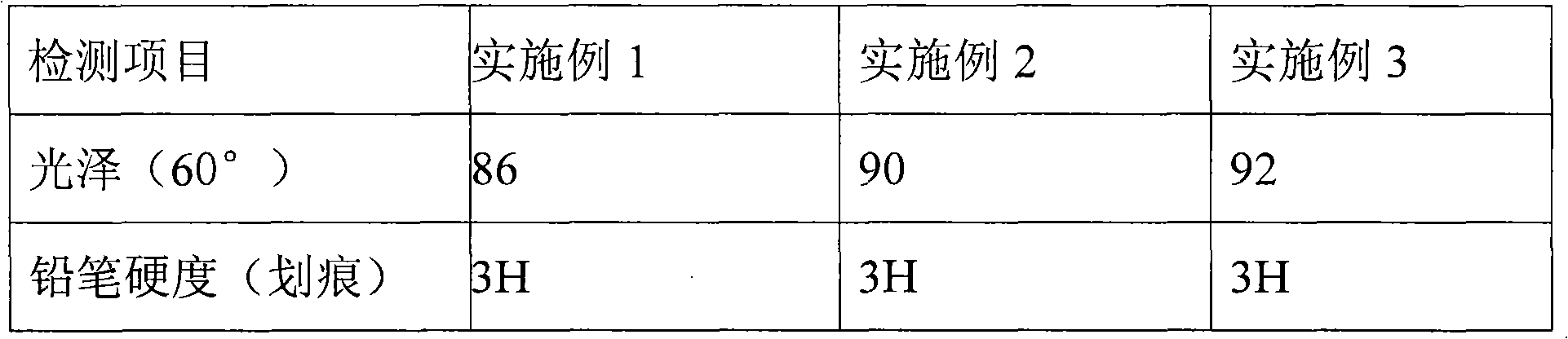

Anti-paste and anti-graffiti fluorocarbon coating and use method thereof

ActiveCN101629049AIncrease crosslink densityImprove the compactness of the paint filmPolyurea/polyurethane coatingsChemistryHardness

The invention relates to an anti-paste and anti-graffiti fluorocarbon coating which is prepared by mixing a component A and a component B in a proportion of OH / NCO=1:(1.0-1.1), wherein the component A comprises the following components in percentage by weight: 50-65 percent of FEVE fluororesin, 1-3 percent of modified polydimethylsiloxane resin containing hydroxide radicals, 8-15 percent of butyl acetate, 15-25 percent of propylene glycol methyl ether acetate, 0.2-0.4 percent of defoaming agent and 0.1-0.3 percent of flatting agent; and the component B is prepared by mixing 80 parts of IPDI isocyanate curing agent or GDI multifunctional isocyanate curing agent by weight and 20 parts of anhydrous butyl acetate by weight. The coating has high film crosslinking density and hardness, low surface tension, extremely strong permeability resistance and excellent anti-paste and anti-graffiti performance, and intractable oil pen graffiti can also be easily and completely wiped out. The coating also has excellent wear-resistant, scouring resistant and weather resistant properties and is suitable for long-term outdoor use. The coating can be painted and can also be sprayed after being diluted by adding 10-20 percent of PMA or polyurethane coating diluent.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Nano-composite electric conduction anticorrosive paint and preparation method thereof

InactiveCN103627297AImprove conductivityImprove corrosion resistanceAnti-corrosive paintsPigment treatment with macromolecular organic compoundsEpoxySolubility

The invention discloses nano-composite electric conduction anticorrosive paint and a preparation method thereof. The preparation method is characterized in that firstly organic acid dodecylbenzene sulfonic acid is used as a doping agent so as to overcome the low solubility of doped polyaniline, a carbon nanotube is used for improving the electric conductivity of composite powder, and then the carbon nanotube is compounded with a precursor of organic acid dodecylbenzene sulfonic acid doped polyaniline and epoxy resin so as to prepare the nano-composite electric conduction anticorrosive paint. According to the technical scheme, the polyaniline / carbon nanotube and the epoxy resin are compounded, so that the excellent characteristics of the polyaniline / carbon nanotube and the epoxy resin are organically combined together. The nano-composite electric conduction anticorrosive paint has relatively high electric conduction performance and very high anticorrosive performance and is relatively low in cost; required processing equipment is simple; the industrialization of the nano-composite electric conduction anticorrosive paint is easy to realize.

Owner:TIANJIN UNIV

Chromium-free nano composite polyurethane aircraft coating and preparation method thereof

ActiveCN102618156APromote environmental protectionImprove penetration resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsChromium freeSolvent

The invention relates to the nanometer technology and corrosion resistance technology, in particular to a chromium-free nano composite polyurethane aircraft coating and a preparation method thereof. The chromium-free nano composite polyurethane aircraft coating consists of two components. By weight, the first component include 0.2-30 parts of nano pulp, 10-85 parts of synthetic resin, 0-40 parts of tinting pigment, 0.01-5 parts of organic corrosion inhibitor, 5-40 parts of rust-resistant pigment and the like, and is made by dispersing the synthetic resin, the solvent, the nano pulp, auxiliary and the like at high speed, grinding and filtering the same. The second component is formed by dispersing curing agent and the solvent. The two components are mixed uniformly to obtain the coating. By adding the rust-resistant pigment and the organic corrosion inhibitor to prepare the chromium-free nano composite polyurethane aircraft coating, nano powder can be dispersed in the coating stably, corrosion resistance of the coating is improved. Further, the prepared coating is beneficial to environment protection due to the chromium-free rust-resistant pigment.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com