Anti-paste and anti-graffiti fluorocarbon coating and use method thereof

A fluorocarbon coating and anti-graffiti technology, applied in the field of coatings, can solve the problems of reduced anti-graffiti function, adhesion of dust, and difficulty in cleaning, etc., and achieve the effects of low surface tension, good scrub resistance, and strong permeability resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

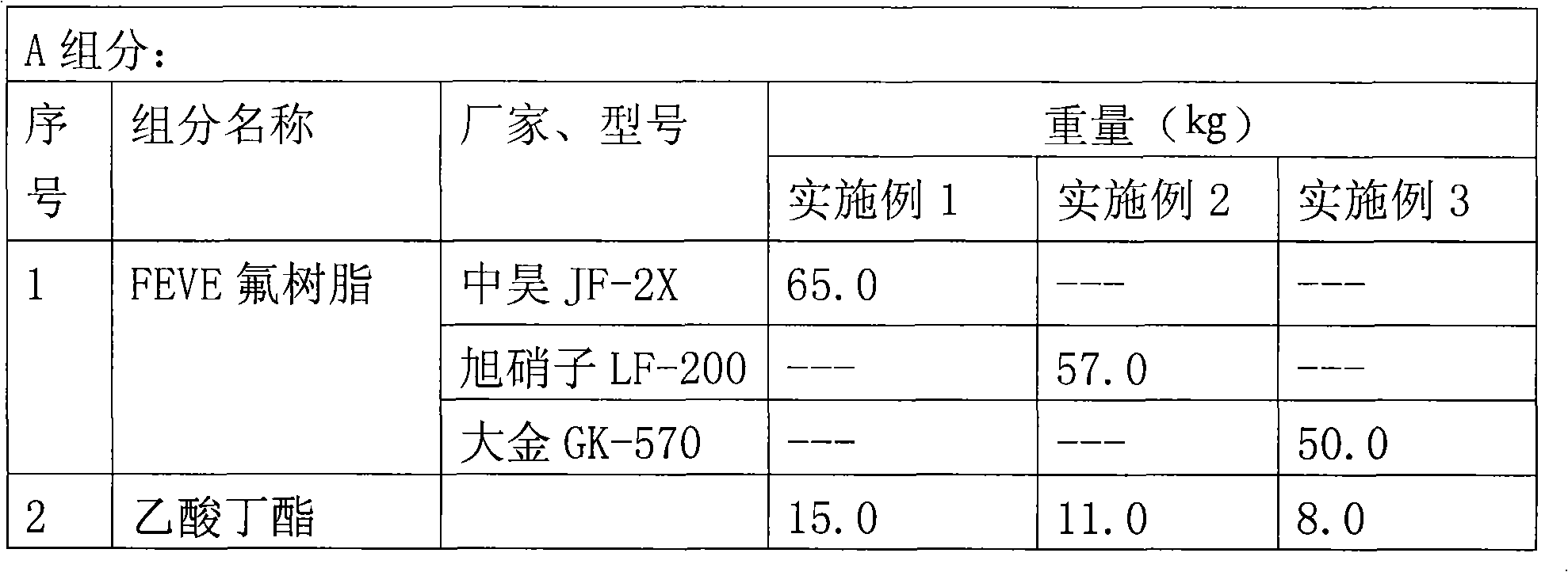

[0035] First prepare anti-sticking anti-graffiti paint component A of the present invention:

[0036] Get each component by the weight shown in embodiment 1 in table 1, and preparation method is according to the following steps:

[0037] Step 1: Add 65.0kg of JF-2X fluororesin and 15.0kg of butyl acetate solvent into the paint mixing container and stir at low to medium speed for 3 minutes, and add 0.4kg of Deqian 5300 defoamer and 0.3kg of TEGO450 leveling agent under stirring kg, after adding, continue to stir at medium speed for more than 3 minutes.

[0038]Step 2: Add 3.0 kg of TEGO5000 modified hydroxyl-containing polydimethylsiloxane resin from Tego Company into the mixture obtained in Step 1 under strong stirring, and continue stirring vigorously for more than 15 minutes after adding.

[0039] Step 3: Add 25.0 kg of PMA solvent under low to medium speed stirring, and continue stirring at low to medium speed for more than 3 minutes after adding. After passing the inspec...

Embodiment 2

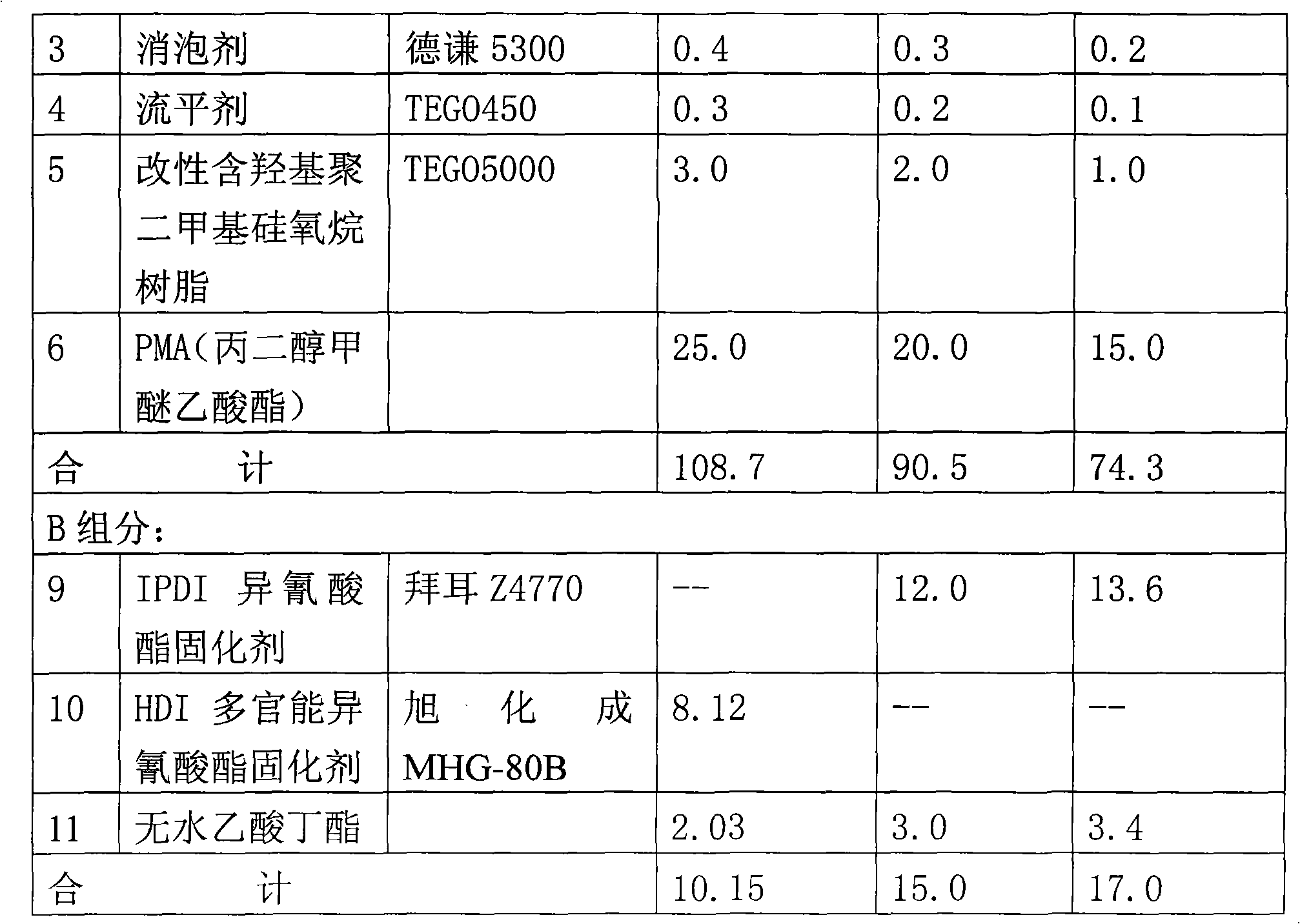

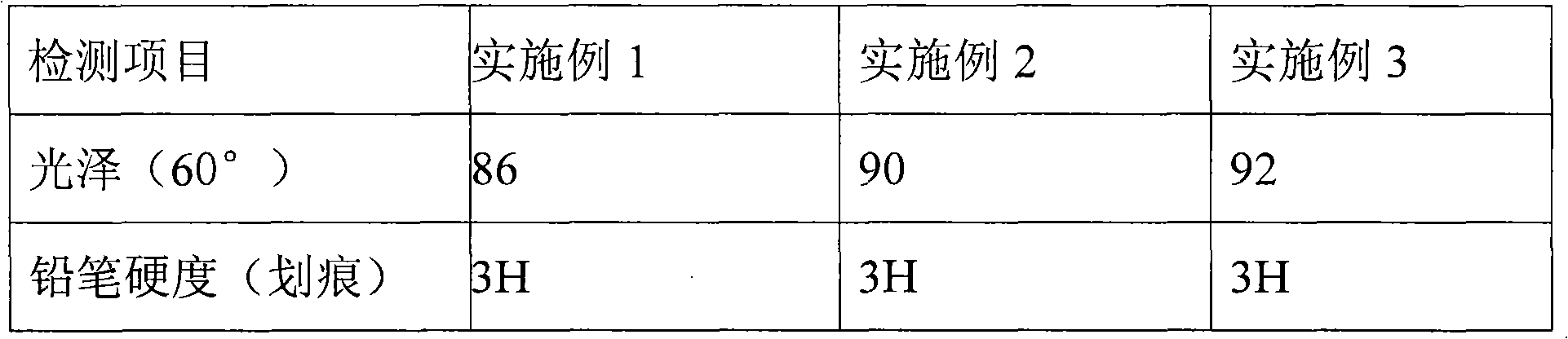

[0044] According to the weight of each component in Example 2, the method described in Example 1 was repeated to prepare component A and component B of the anti-sticking and anti-graffiti paint. According to the weight ratio of component A: component B = 90.5: 15.0 (OH: NCO = 1: 1.06), mix evenly and let it stand for more than 5 minutes to brush. The surface dry time does not exceed 1 hour, and the dry time is 24 hours. The performance testing results are shown in the corresponding data of Example 2 in Table 2. If the construction method is spraying, you need to add 15% PMA or polyurethane paint thinner, and the performance test results are the same.

Embodiment 3

[0046] According to the weight of each component in Example 3, the method described in Example 1 was repeated to prepare component A and component B of the anti-sticking and anti-graffiti paint. According to the weight ratio of component A: component B = 74.3: 17.0 (OH: NCO = 1: 1.1), mix evenly and let it stand for more than 5 minutes to brush. The surface dry time does not exceed 1 hour, and the dry time is 24 hours. The performance testing results are shown in the corresponding data of Example 3 in Table 2. If the construction method is spraying, you need to add 20% PMA or polyurethane paint thinner, and the performance test results are the same.

[0047] Table 2

[0048]

[0049]

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com