Patents

Literature

168 results about "Paint thinner" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A paint thinner is a solvent used to thin oil-based paints or clean up after their use. Commercially, solvents labeled "Paint Thinner" are usually mineral spirits having a flash point at about 40 °C (104 °F), the same as some popular brands of charcoal starter.

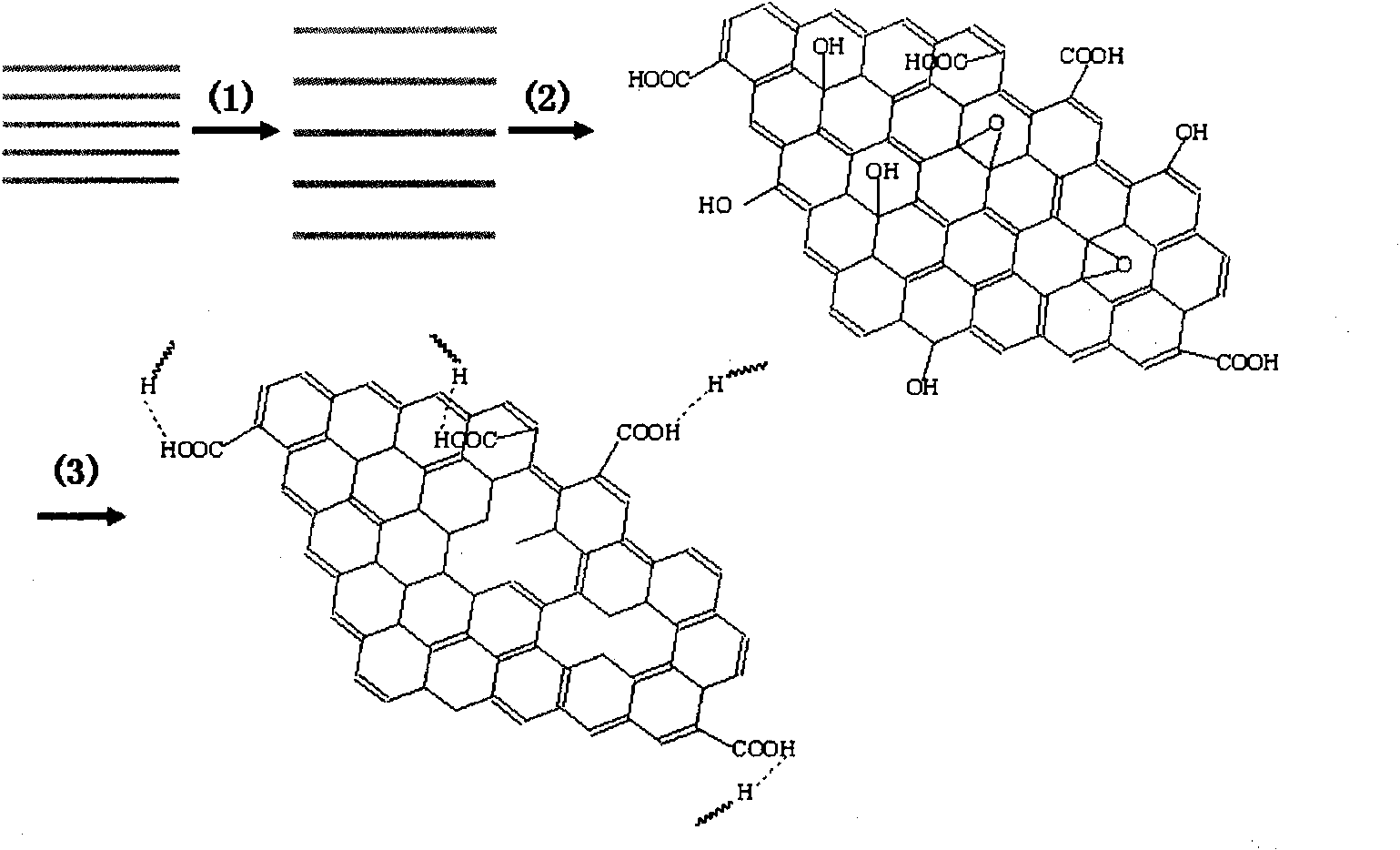

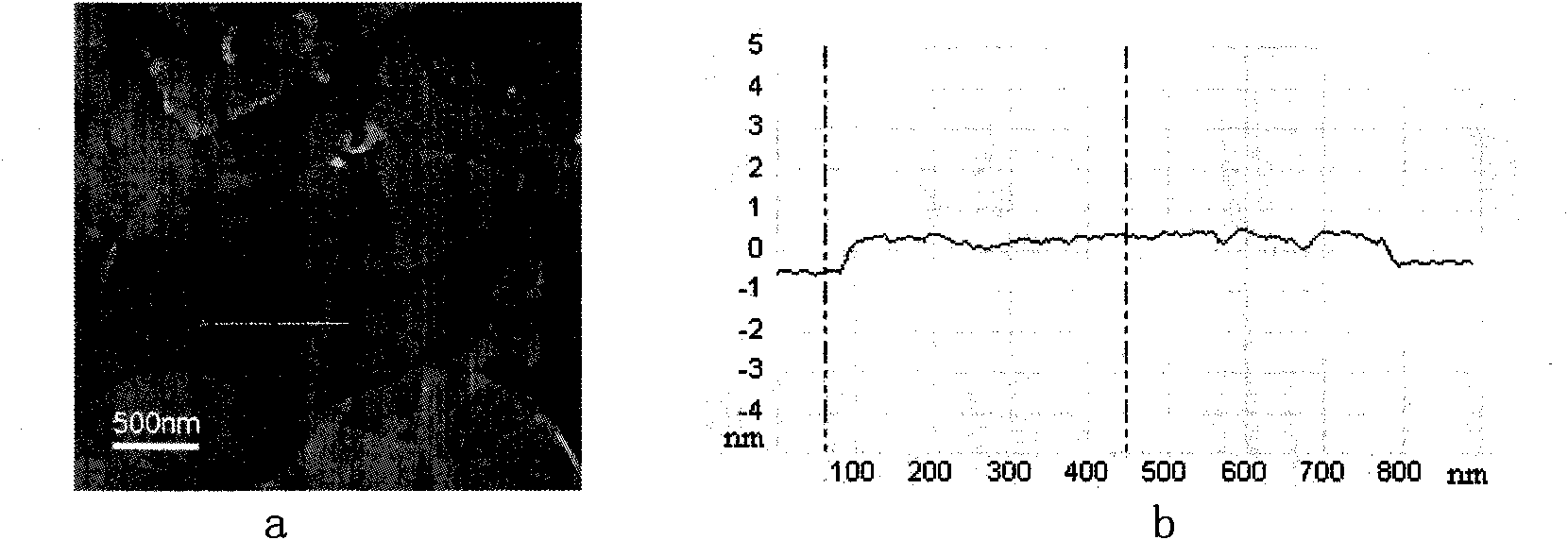

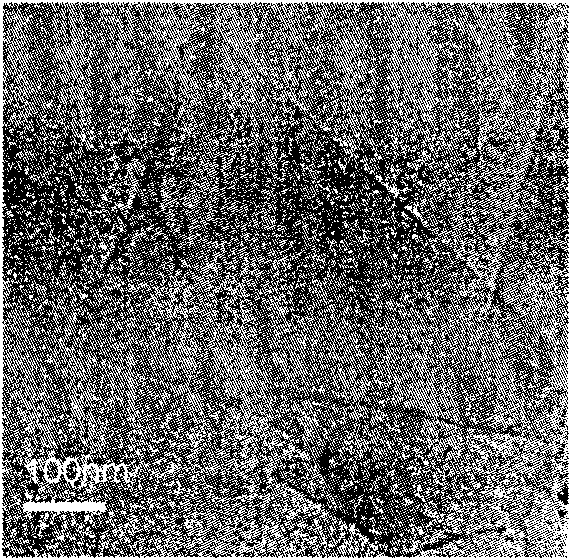

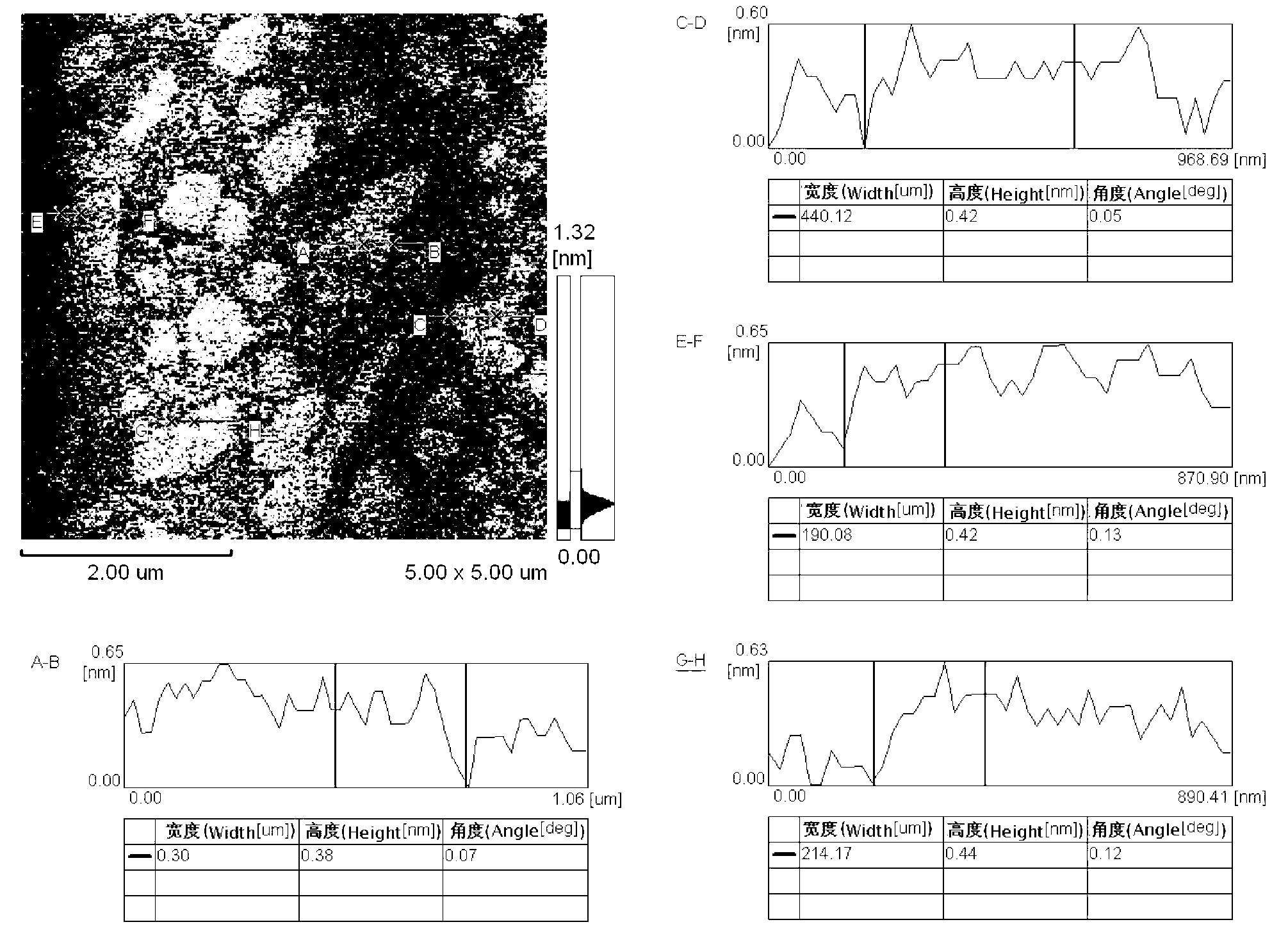

Preparation method of graphene based on ascorbic acid

ActiveCN101602504AEase of mass productionShort reaction timeNanostructure manufactureMaterials scienceReducing agent

The invention relates to a preparation method of graphene based on ascorbic acid, belonging to the technical field of nano materials. The preparation method comprises the following steps: preparing brown graphite suspending liquid; preparing luminous yellow graphite diluent; preparing graphite oxide solid; dispersing graphite oxide into deionized water, separating graphene oxide by ultrasonic separation treatment for 1 hour and preparing graphene oxide solution; and fully mixing the graphene oxide solution and ascorbic acid water solution, stewing and obtaining the graphene solution. The preparation adopts the ascorbic acid as a reducing agent, shortens reaction time under the condition that no stabilizing agent is added, obtains single-layer grapheme with the thickness of 0.8 to 1.2nm and is beneficial to batch production of the grapheme.

Owner:上海碳源汇谷新材料科技有限公司

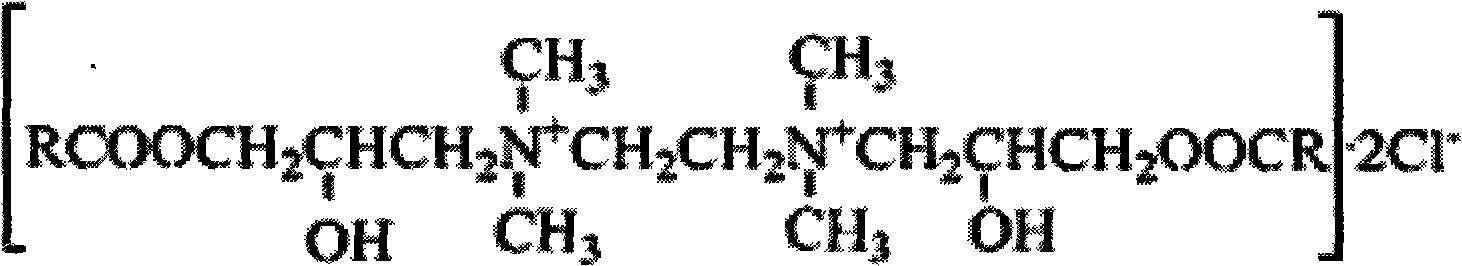

Warm-mixed asphalt additive and preparation method thereof

InactiveCN101602862AReduce stirringReduce the temperatureClimate change adaptationPaint thinnerChemistry

The invention discloses a warm-mixed asphalt additive and a preparation method thereof. The additive is prepared by the following steps: adding deionized water into prepared polyvinyl alcohol water solution, then adding rosin quaternary ammonium salt, aromatic quaternary ammonium salt emulsifier, aliphatic quaternary ammonium salt emulsifier and nonionic surfactant into the water solution in turn, stirring and dissolving the mixture, adding prepared polyacrylamide water solution and triethanolamine into the mixture, and mixing and stirring the mixture till the mixture is evenly dissolved so as to obtain a finished product. During application, when the temperature of the asphalt mixture reaches 110 to 130 DEG C, 5 percent of the diluent of the additive is added by the mass of asphalt in a spraying mode so as to realize the warm mixing technology of mixing and spreading the asphalt mixture; and test data show that various road indexes of the warm-mixed asphalt mixture are not lower than that of hot-mixed asphalt mixture under the condition that the mixing and molding temperature of the warm-mixed asphalt mixture is obviously reduced relative to the hot-mixed asphalt mixture.

Owner:TIANJIN UNIV

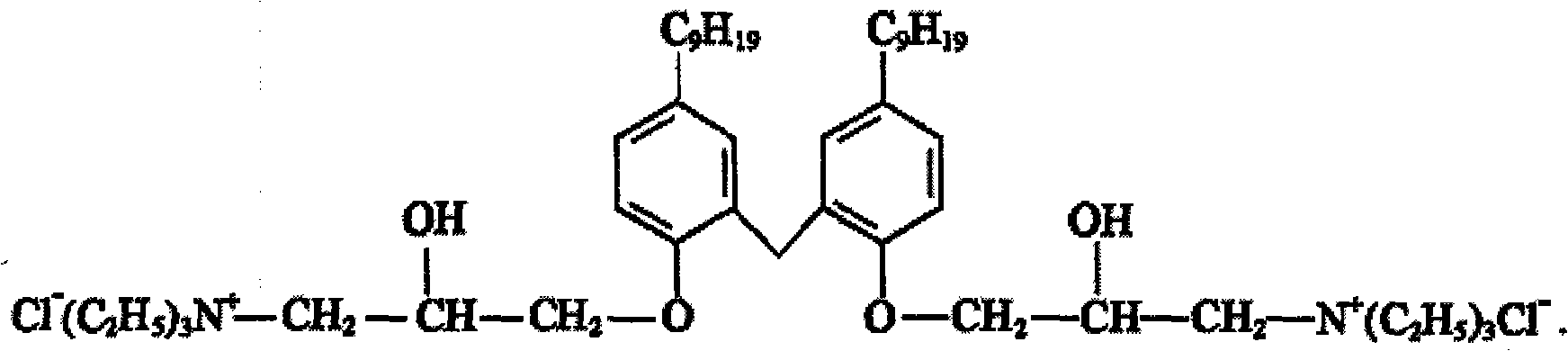

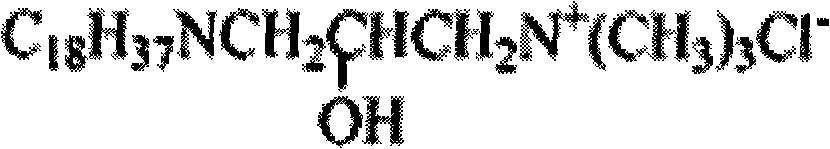

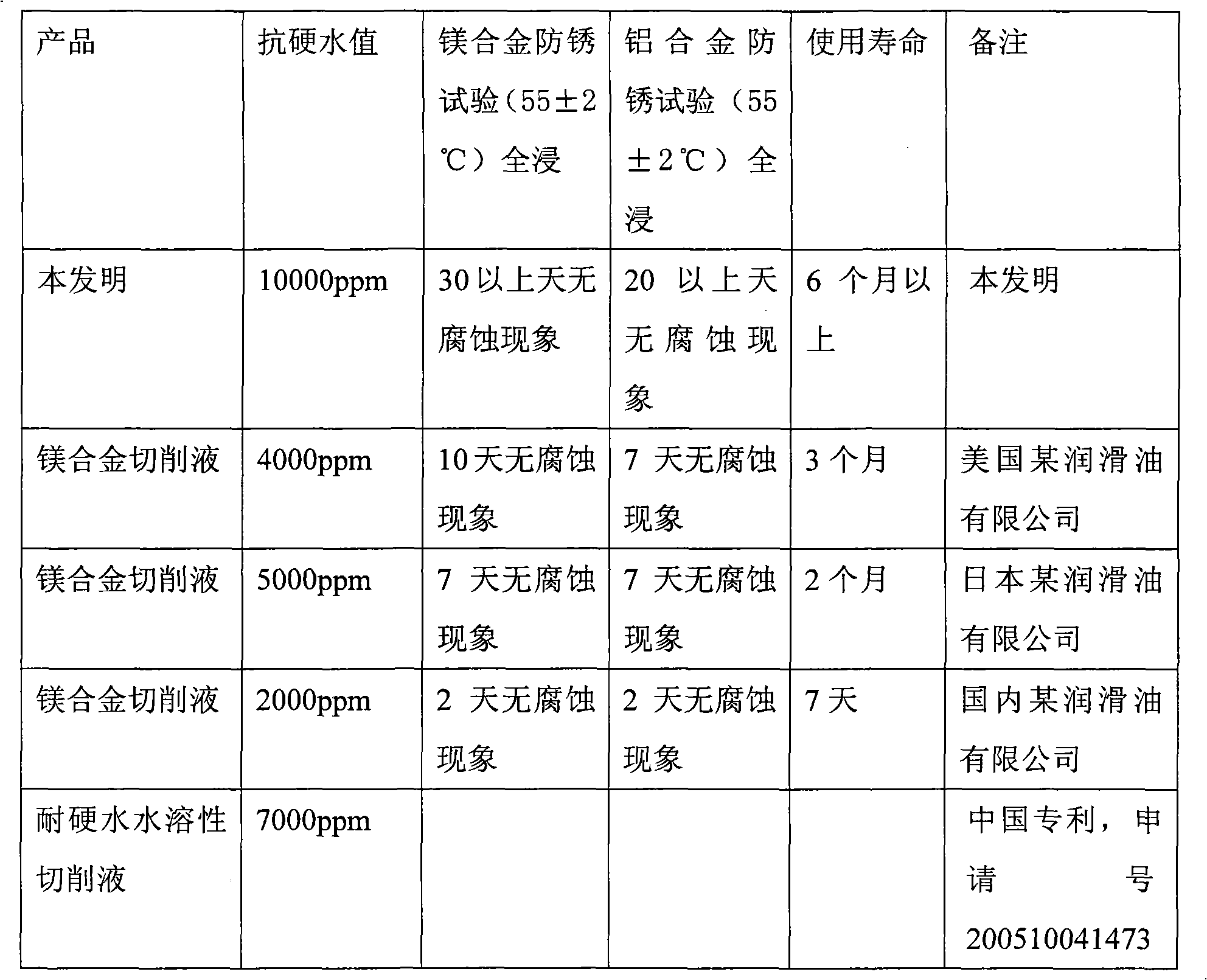

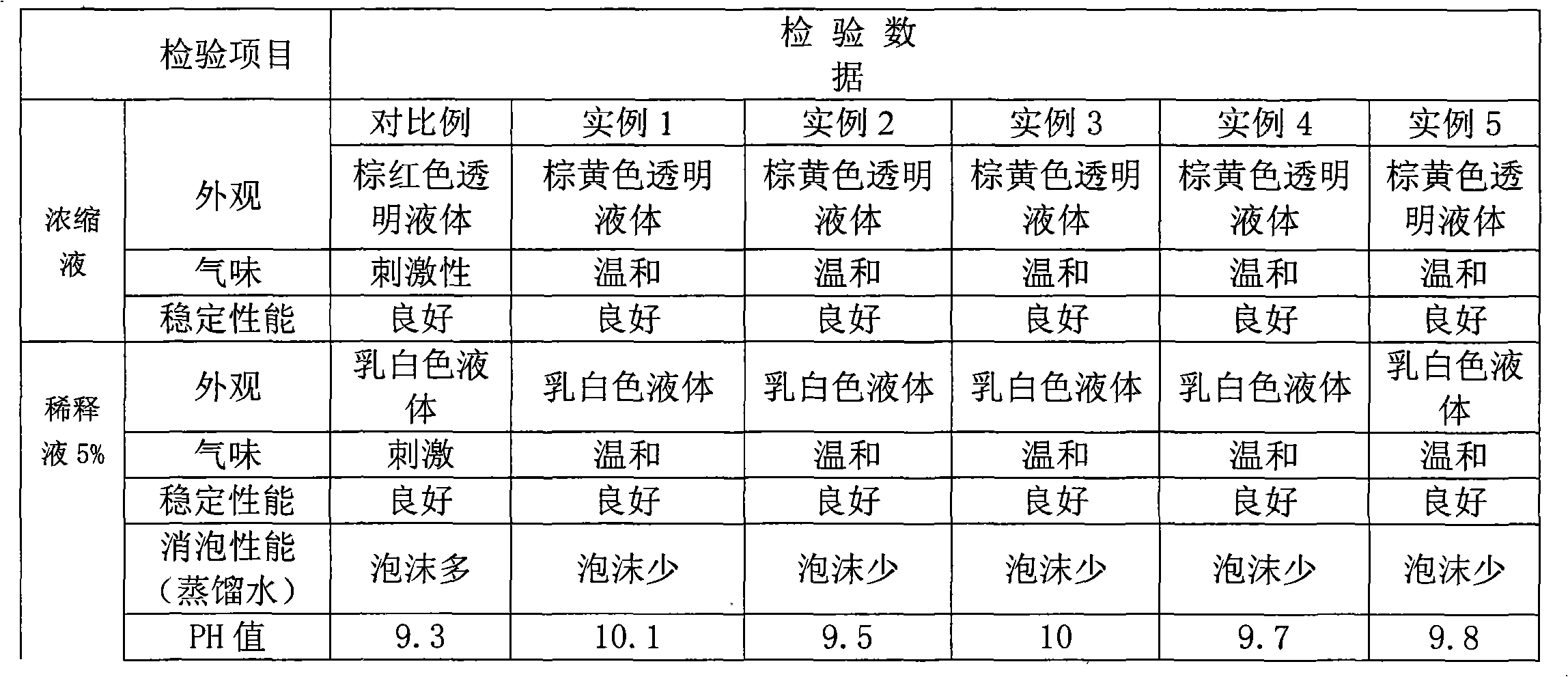

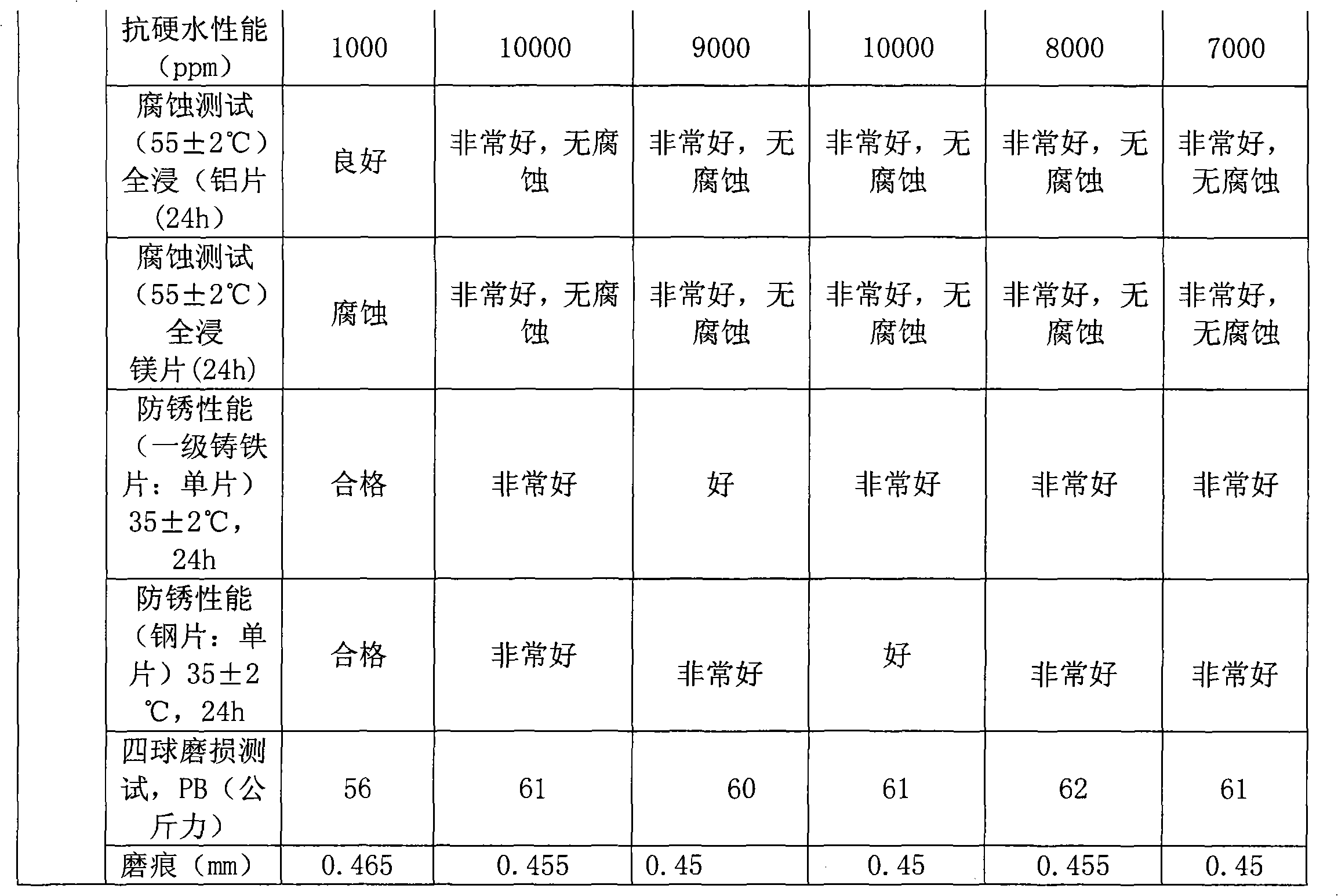

Magnesium alloy cutting liquid

ActiveCN101870909AImprove rust resistanceInhibition of hydrogen evolutionAdditivesColor changesCast iron

The invention relates to metal cutting liquid, in particular to magnesium alloy cutting liquid, which comprises basic oil, nonionic surfactants, anionic surfactants, antirust agents, lubricating agents, coupling agents, corrosion inhibitors and bactericide raw materials. The unique recipe in the invention has the advantages that magnesium alloy can no generate color change corrosion phenomena after being continuously soaked for more than 30 days at 55 DEG C in 5 percent diluent, the hydrogen release phenomenon of the magnesium alloy in water can be effectively inhabited, in addition, the hardwater resistance of the product is as high as 10000 ppm, and in addition, the work liquid can be used for more than half a year. At the same time, the invention has excellent performance such as rust prevention, lubrication, cooling and the like. In addition, the cutting liquid can be used for processing the magnesium alloy, and can also be used for processing metals such as aluminium alloy, cast iron, stainless steel and the like.

Owner:东莞太平洋博高润滑油有限公司

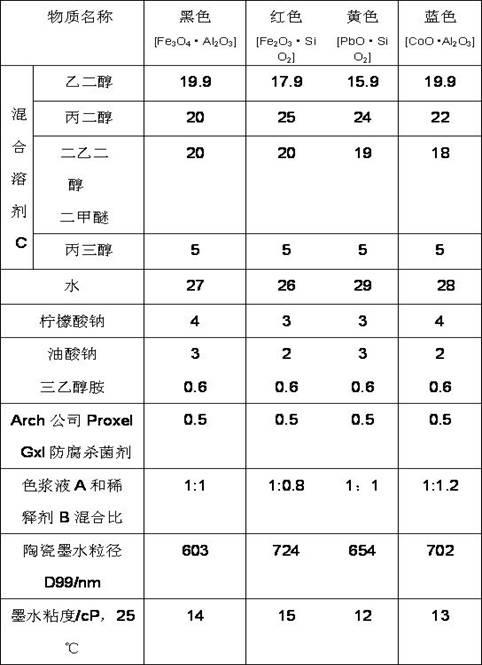

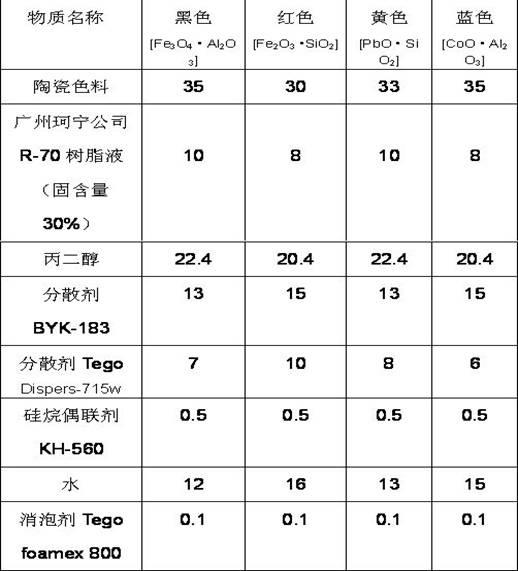

Water-based ceramic three-dimensional pattern printing ink and preparation method thereof

The invention discloses water-based ceramic three-dimensional pattern printing ink and a preparation method thereof. The water-based ceramic three-dimensional pattern printing ink consists of two parts, namely color serous fluid A and diluent B, wherein the color serous fluid A comprises the following components in percentage by weight: 30%-40% of ceramic pigment, 2%-15% of resin, 18%-25% of propylene glycol, 12%-25% of water, 10%-37% of dispersing agent, 0.3%-5% of silane coupling agent and 0.05%-0.5% of defoaming agent; the diluent B comprises the following components in percentage by weight: 60%-70% of mixed solvent C, 25%-30% of water, 0.5%-10% of auxiliary dispersing agent, 0.5%-5% of pH regulating agent and 0.1%-1% of anticorrosion bactericide; and the mixed weight ratio of the color serous fluid A to the diluent B is 1:0.8-1.2. The water-based ceramic three-dimensional pattern printing ink disclosed by the invention has relatively low viscosity and surface tension, can be suitable for ink-jet printing of three-dimensional patters, can be used for printing on an Xaar jet-head printer and has the characteristics of being environment-friendly, strong in color development capability, wide in application range and smooth in printing and preventing an injection head from being blocked as being water-based.

Owner:山东国瓷康立泰新材料科技有限公司

pH-buffered alkylene carbonate nail polish and paint remover

InactiveUS20050202982A1Good chemical stabilityGood curative effectCosmetic preparationsToilet preparationsGeneral purposePaint thinner

A composition with improved chemical stability and increased the efficacy as an alkylene carbonate-containing nail polish remover or general purpose solvent, such as a paint thinner or stripper is disclosed. The composition includes: (i) between 10% and 98% by weight of at least one alkylene carbonate solvent, (ii) between 1.5% and 25% by weight water, and (iii) an effective amount of a pH-buffering agent that maintains the pH of the composition between approximately pH 2 and pH 6.5 and that is chemically inert in the composition. The water in the composition functions to increase the rate at which the composition dissolves, e.g., nail lacquers, and the pH-buffering agent functions to stabilize the alkylene carbonate solvent against hydrolytic decomposition from pH-altering contaminants that may be introduced into the composition.

Owner:PERLMAN DANIEL

Combined test kit for bacterial vagina disease

InactiveCN1850985AComprehensive detectionSimple and fast operationMicrobiological testing/measurementSucrosePhosphate

The invention provides the reagent box checking the bacterial vaginal disease, it includes the dry chemic reacting setting, the diluent and the liquid showing the color; the reacting setting has three blind holes placed the reagent mat testing the chroma of excessive oxidation hydrogen, the chroma of the leucocyte ester enzyme and the active ability of the saliva acid enzyme; the regent mat testing the chroma of the excessive oxidation hydrogen is dipped in the enzyme solution containing the peroxide enzyme, the phosphate amoritizing liquid, the 4-amino antipyrine, the 3,5-double chlorine double hydroxide group dobesilate and the vitamin C and dried. The reagent mat testing the chroma of the leucocyte ester enzyme is dipped in the enzyme solution containing the 5 bromine-4 chlorin- 3 heteroauxing salt and the cane suger and is dried; the reagent mat testing the active ability of the saliva acid enzyme is dipped in the 5 bromine-4 chlorin-3 indloe nerve arginine salt, the acetic acid salt cushioning liquid and the fucose and is dried; the cushioning liquid is composed of the physiological brine and MES cushioning liquid; the liquid showing the color is the B solution fixing the purple. The entironment, the cleanliness of the procreating path of the checked and the condition of the bug inducing the bacterial vagina can be test at the same time; it has many merits such as the easy handling, the celerity and the cheap cost.

Owner:北京中生金域诊断技术股份有限公司

High performance biodegradation type metal machining protection liquid

InactiveCN102618372APromote degradationImprove the lubrication effectLubricant compositionCarboxylic acidLubrication

The invention discloses high performance biodegradation type metal machining protection liquid, which is composed of high polymer carboxylic acid, organic amine, higher alcohol, a surfactant, plant oil or synthetic lubrication grease, pure water, an antifoaming agent and preservative or bacteriacide. The high performance biodegradation type metal machining protection liquid is good in biodegradable performance. A formula of the high performance biodegradation type metal machining protection liquid can be designed by choosing the plant oil or synthetic ester and other additives. Biochemical oxygen demand (BOD) / chemical oxygen demand (COD) of 3.3% of diluent is larger than or equal to 1.0, so that the high performance biodegradation type metal machining protection liquid is excellent in lubrication performance. The frictional factor mu of the 3.3% of diluent is smaller than or equal to 0.03, and tapping torque of the 3.3% of diluent is smaller than or equal to 400N*cm, so that the high performance biodegradation type metal machining protection liquid is safe, hygienic and reliable in quality. The biological median lethal dose LD50 of the high performance biodegradation type metal machining protection liquid is larger than or equal to 5,000mg / kg, the medical lethal concentration LC50 is larger than or equal to 5,000mg / m<3>, respiratory tract mucous membrane irritation is smaller than or equal to 1 level, and the high performance biodegradation type metal machining protection liquid is friendly to human and environment.

Owner:SHANGHAI YUSHIRO CHEM IND +1

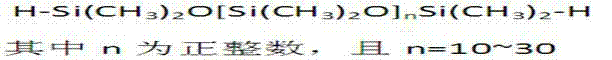

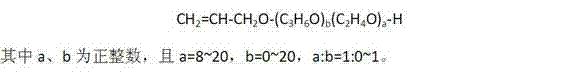

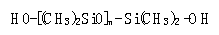

Hydroxyl polyether-terminated polydimethylsiloxane and blue light emulsion of hydroxyl polyether-terminated polydimethylsiloxane as well as preparation method of blue light emulsion

The invention discloses hydroxyl polyether-terminated polydimethylsiloxane and a blue light emulsion of hydroxyl polyether-terminated polydimethylsiloxane as well as a preparation method of the blue light emulsion. The blue light emulsion of hydroxyl polyether-terminated polydimethylsiloxane has a function of enabling a base material to be anti-sticky, dry and smooth, which is the same as the functions of conventional negative ion, positive ion and nonionic hydroxyl silicone oil emulsions. Different from the conventional negative ion, positive ion and nonionic hydroxyl silicone oil emulsions, the blue light emulsion of hydroxyl polyether-terminated polydimethylsiloxane has the characteristics that the water diluent (the solid content is 0.5-5%) of the blue light emulsion and the blending diluent (the solid content is 0.5-5%) formed by the blue light emulsion and an amino silicon oil emulsion at random ratio are highly stable; when the blue light emulsion is placed for a long time (above 90 days), the blue light emulsion does not layer and has no floating oil or oil spots; the blue light emulsion does not contain any thickening agent and can realize high solid content (the solid content convenient for use can reach 50%); as the blue light emulsion belongs to a non-ionic type, the wide compatibility can also be realized.

Owner:HUAIAN KAIYUE TECH DEV

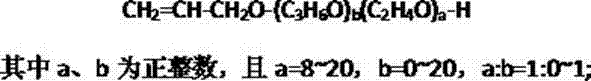

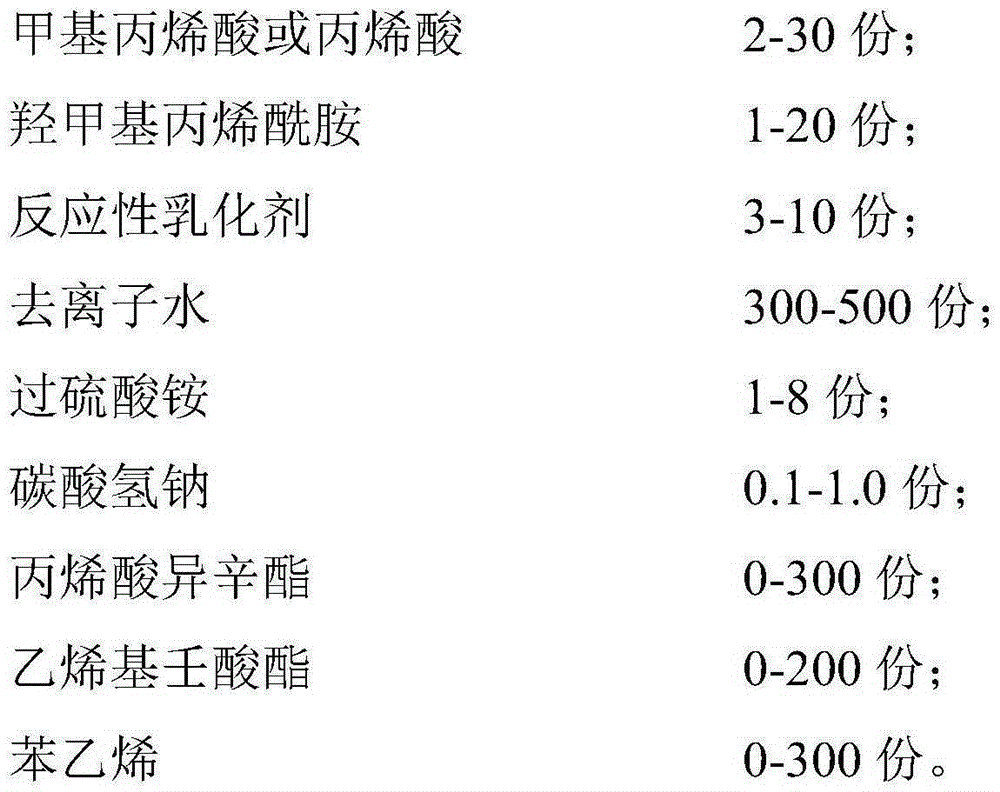

Water-based adhesive, preparation method, adhesive tape and preparation method thereof

InactiveCN105255403AStable electrical insulationEasy to useFilm/foil adhesivesEster polymer adhesivesWater basedSodium bicarbonate

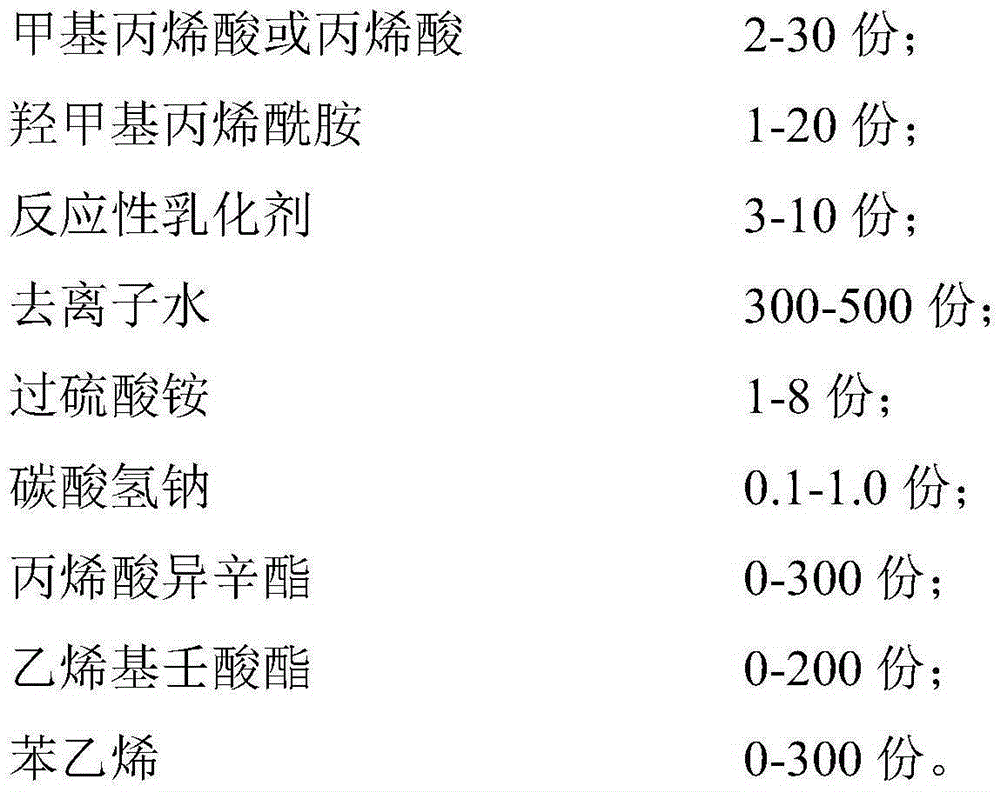

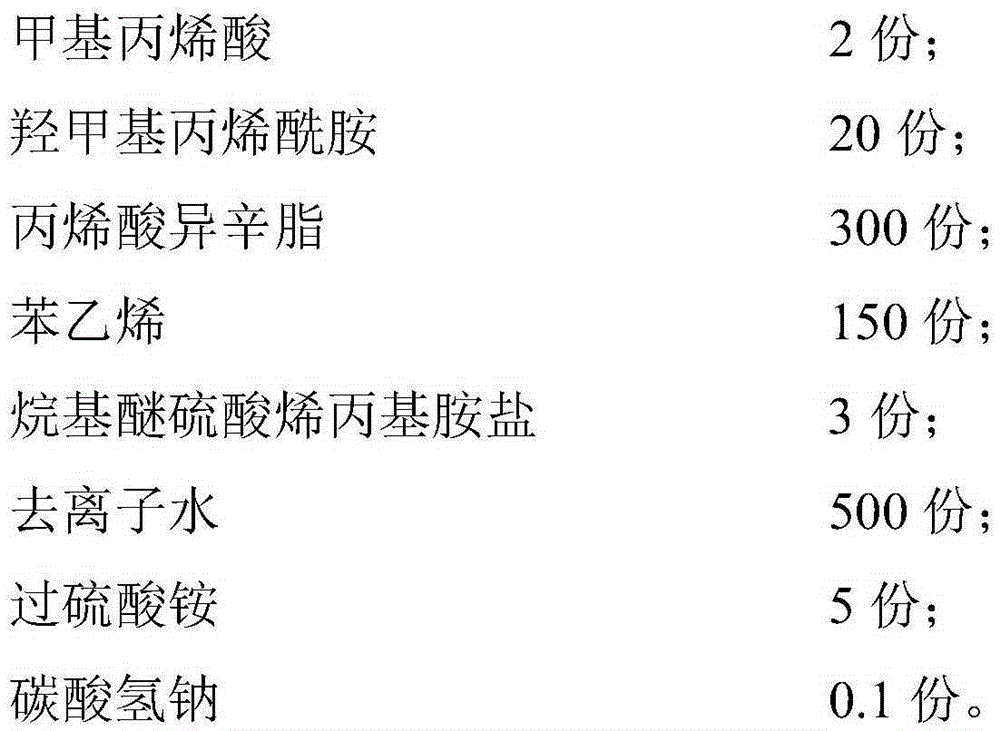

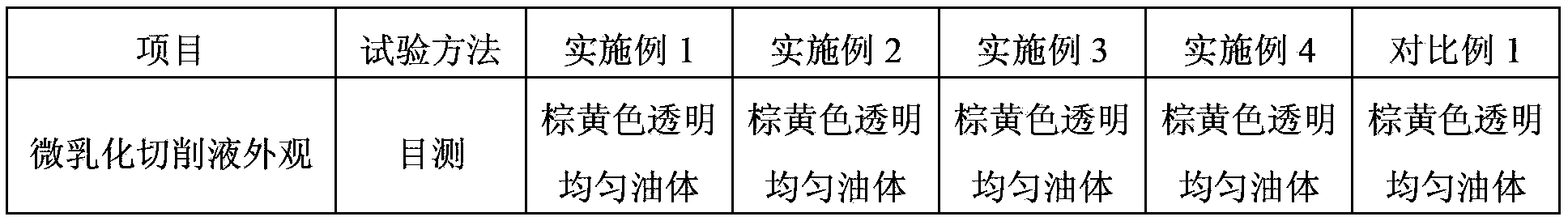

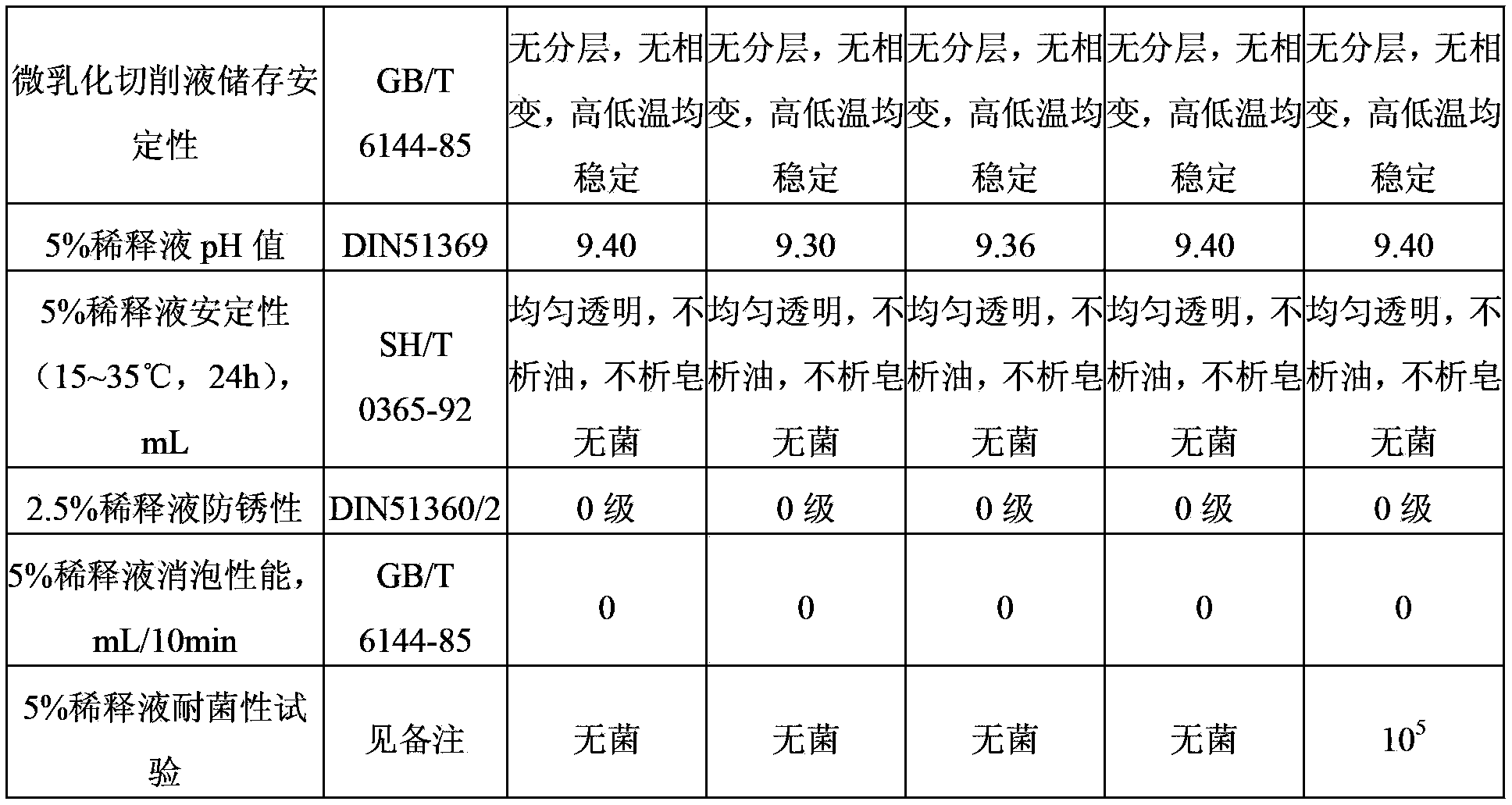

The invention relates to a water-based adhesive, a preparation method, an adhesive tape and a preparation method thereof. The preparation method of the water-based adhesive comprises the following steps of: preparing pre-emulsified liquid, adding 2.5-9.5 parts of reactive emulsifying agent and 0.08-0.9 part of sodium bicarbonate into a pre-emulsifying kettle, mixing with 100-250 parts of deionized water, stirring uniformly, adding 2-30 parts of methacrylic acid or acrylic acid, 1-20 parts of hydroxymethyl acrylamide and ethylhexyl acrylate and the like, stirring uniformly, and adding 150-350 parts of deionized water, the reactive emulsifying agent and the sodium bicarbonate into a reaction kettle; rising the temperature to be 75-85 DEG C, and adding 1-5% of pre-emulsified liquid prepared in the step S1 and diluted liquid prepared by adding 0.3-6 parts of ammonium persulfate and 20-30 parts of deionized water; preserving heat for 10 minutes, starting to drip the pre-emulsified liquid prepared by the step S1 and the diluted liquid prepared by the remaining ammonium persulfate and 20-50 parts of deionized water, and dripping within 2-5 hours completely; preserving heat for 10-60 minutes, then eliminating, reducing the temperature to be below 45 DEG C, neutralizing, discharging, adding a defoaming agent and a sterilizing agent, finally filtering by a net and discharging.

Owner:江苏晶华新材料科技有限公司

Scratch-resistant, abrasion-resistant, quick-drying, environment-friendly and water-borne wood varnish and method for manufacturing same

The invention discloses scratch-resistant, abrasion-resistant, quick-drying, environment-friendly and water-borne wood varnish. The scratch-resistant, abrasion-resistant, quick-drying, environment-friendly and water-borne wood varnish comprises, by weight, 60%-80% of nanometer water-borne acrylic resin emulsion, 3%-5% of slipping abrasion-resistant agents, 2%-5% of coalescing agents, 0.5%-1.8% of dispersing agents, 0.8%-1.2% of thickeners, 0.1%-0.5% of wetting agents, 2%-4% of bamboo charcoal powder, 0.1%-0.5% of defoaming agents, 5%-20% of water, 0.1%-0.3% of preservatives, 0.5%-0.8% of rheological agents, 0.05%-0.1% of leveling agents and 0.03%-0.1% of driers. The invention further discloses a method for manufacturing the vanish. The method includes steps of adding the nanometer water-borne acrylic resin emulsion into a dispersing cylinder and dispersing the nanometer water-borne acrylic resin emulsion at medium speeds; mixing the dispersing agents, the bamboo charcoal powder and diluent of the slipping abrasion-resistant agents into the nanometer water-borne acrylic resin emulsion; dispersing the dispensing agents, the bamboo charcoal powder, the diluent of the slipping abrasion-resistant agents and the nanometer water-borne acrylic resin emulsion at high speeds for 15-30 minutes; adding the coalescing agents, the water, the thickeners, the wetting agents, the defoaming agents and other components into the dispensing agents, the bamboo charcoal powder, the diluent of the slipping abrasion-resistant agents and the nanometer water-borne acrylic resin emulsion; dispersing the coalescing agents, the water, the thickeners, the wetting agents, the defoaming agents, the other components, the dispensing agents, the bamboo charcoal powder, the diluent of the slipping abrasion-resistant agents and the nanometer water-borne acrylic resin emulsion at medium speeds for 40 minutes; sampling finished products and detecting the fineness and the viscosity of the finished products; filtering the finished products, filling cans with the finished products and packaging the cans. The scratch-resistant, abrasion-resistant, quick-drying, environment-friendly and water-borne wood varnish and the method have the advantages that the contents of VOC (volatile organic compounds) of the products can be greatly reduced, the drying time can be shortened, and the varnish is excellent in abrasion-resistant and scratch-resistant performance.

Owner:CHONGQING PINSHENG PAINT

Steel rolling oil sludge clearing agent and clearing method

ActiveCN103466908ARealize resource utilizationSolve hard-to-exploit puzzlesSludge treatmentFerric oxidesPaint thinnerHydrogen

The invention provides a steel rolling oil sludge clearing agent and a clearing method. The clearing agent comprises the following components in percentage by mass: 1-2% of non-ionic surfactant 6501, 1-3% of anionic surfactant LAS, 2-4% of builder and the balance of water, wherein the builder comprises sodium tripolyphosphate, sodium silicate and sodium sulfate. The clearing method comprises the steps of preparing a clearing agent solution by utilizing the components in proportion, adding water with the amount 3-4 times that of the solution, adding hot rolling oil sludge into the diluted solution in the ratio of (1:4)-(1:5), uniformly stirring, adding cold rolling waste alkali mud in twice till the pH (Potential Of Hydrogen) value of the mixed liquid is adjusted to 6-8 and standing the suspension liquid for more than 5 minutes so as to separate the oil from iron scale in the oil sludge. The clearing agent and the clearing method provided by the invention have the advantages that the clearing cost is low; the clearing effect is good; the production process is friendly to environment; no secondary pollution is produced; the oil sludge, the cold rolling waste acid mud and the waste alkali mud in metallurgical works are fully utilized; the resource utilization of wastes is realized; the problem of oil sludge utilization is solved.

Owner:ANGANG STEEL CO LTD

Microemulsion cutting fluid, cutting diluent and preparation and application methods of microemulsion cutting fluid

InactiveCN104073328AGood antibacterial effectImprove rust resistanceLubricant compositionAlkylphenolFatty alcohol

The invention discloses microemulsion cutting fluid, a cutting diluent and preparation and application methods of the microemulsion cutting fluid. The microemulsion cutting fluid comprises the following raw materials: 22-32% of mineral oil, 2-10% of anionic surfactant, 1-5% of non-ionic surfactants, 1-3% of emulsion stabilizer, 5-10% of oiliness additives, 5-10% of extreme pressure additive, 5-15% of antirust additive, 0.5-3% of preservatives and bactericides, 0.1-0.3% of antifoam additive and the balance of water, wherein the total percent is 100%; the non-ionic surfactants are alkylphenol polyoxyethylene ether and / or fatty alcohol polyoxyethylene ether with EO (epoxyethane) number of 5-7; the preservatives and bactericides are Kathon and / or benzisothiazolin-one. The microemulsion cutting fluid and the diluent have excellent bacteria resistance, good lubricating properties and cooling properties and long service lives, dispense with replenishing bactericides and pH value improvers when in use, are environment-friendly and can provide good antirust properties for machined parts and improve the machining precision of the machined parts.

Owner:上海德润宝特种润滑剂有限公司

Fluorocarbon spraying method for aluminum alloy profile

InactiveCN107511312AImprove bindingNot easy to fall offHot-dipping/immersion processesLiquid surface applicatorsAcrylic resinToxic material

The invention discloses a fluorocarbon spraying method for an aluminum alloy profile. The fluorocarbon spraying method comprises the process steps of dust removal, degreasing treatment, pickling activation treatment, hot galvanizing, chromium passivation treatment, suspension polishing, primer layer spraying, first-time curing, finishing paint layer spraying and second-time curing. The sprayed primer layer comprises the following raw materials of, by weight, 10-20 parts of ethyl acetate, 30-60 parts of thermoplastic acrylic resin, 3-5 parts of diethylene glycol monoethyl ether, 10-20 parts of magnesium powder, 0.5-3 parts of propylene glycol methyl propyl ether, 0.5-2 parts of diethylene glycol monoethyl ether and 0.05-0.5 part of polydimethylsiloxane. The sprayed fluorocarbon finishing paint layer comprises the raw materials of, by weight, 5-20% of a mixture, subjected to surface modification through a silane coupling agent, of nanometer titanium dioxide and alumina, 20-30% of fluorocarbon primers and 40-60% of paint thinners. According to the aluminum alloy profile produced by the fluorocarbon spraying method, the overall appearance quality is good, the good anti-corrosion effect is achieved, the adhesive ability is high, toxic substances are not generated, and the environment is not polluted.

Owner:YUNNAN SANYUANDELONG ALUMINUM IND

Water Based Paint Thinner

InactiveUS20100279912A1Low VOCReduce materialDuplicating/marking methodsChemical paints/ink removersPaint thinnerWater based

A paint thinner and cleaner includes a methyl soy ester and dibasic ester and satisfies a less than 25 grams per liter Volatile Organic Compound (VOC) rating which permits the thinner and cleaner to be used for cleaning and thinning in government regulated areas. Requirements for reducing VOCs are well recognized. The paint thinner and cleaner of the present invention performs as well as products (for example, hydrocarbon based thinners) having greater than 25 grams per liter VOC products. Further, the paint thinner and cleaner according to the present invention has less than one tenth of the hazardous ingredients present in the other paint thinners. The paint thinner and cleaner is suitable for reducing water and oil based coatings and material.

Owner:BORTZ STEVEN H

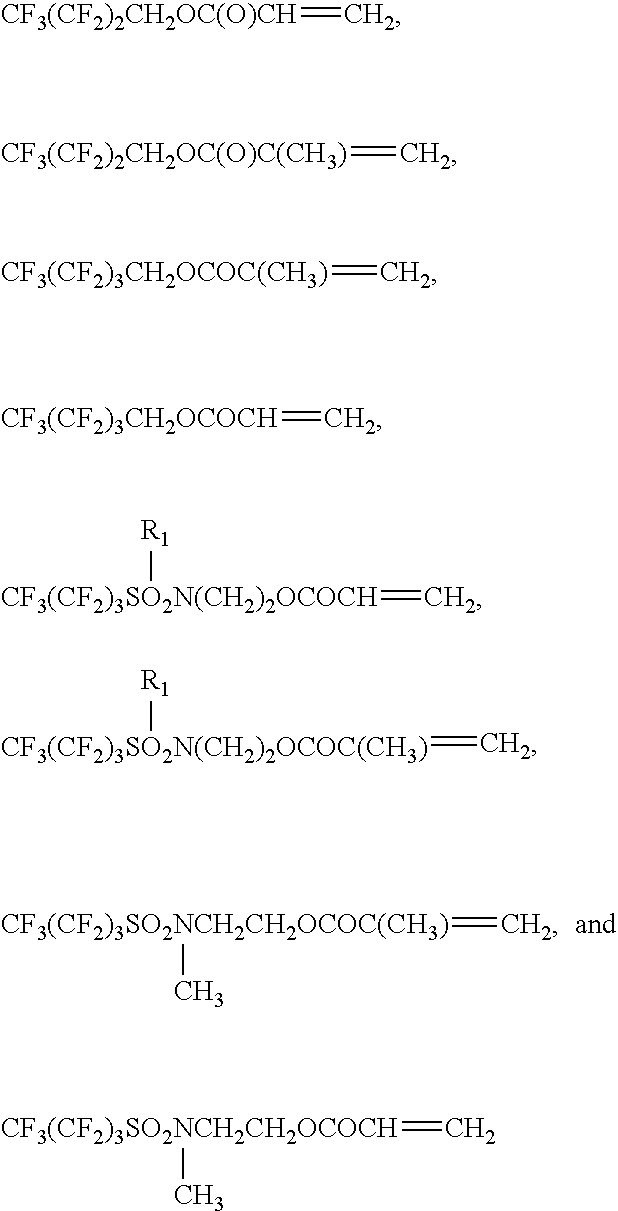

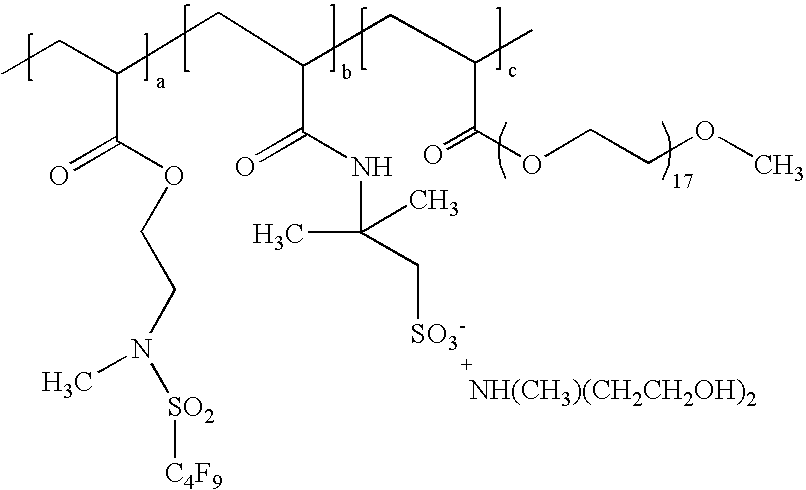

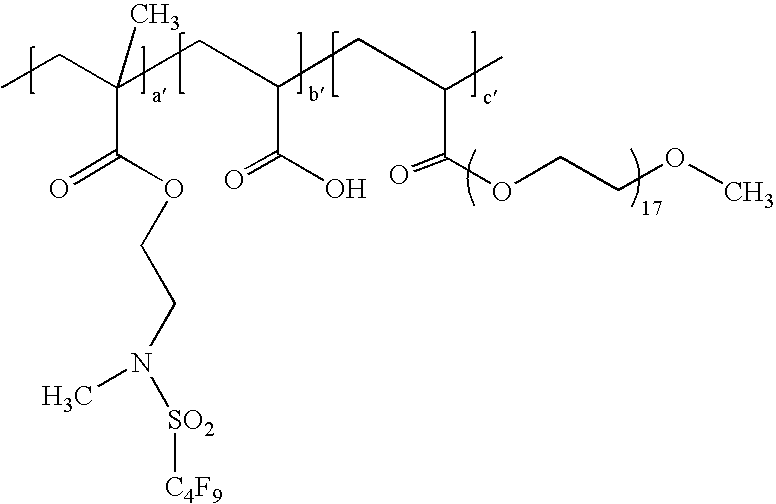

Compositions for aqueous delivery of fluorinated oligomeric silanes

The invention relates to a dilutable, non-aqueous concentrate and an aqueous dilution used for aqueous delivery of fluorinated oligomeric silanes to a substrate, a method of treating a substrate with the aqueous dilution composition to render it oil and water repellent, and articles having coatings made from the aqueous dilution.

Owner:3M INNOVATIVE PROPERTIES CO

Preparation method of water-borne inorganic paint and method for preparation of inorganic coating from water-borne inorganic paint

ActiveCN105907294AHigh strengthImprove toughnessNon-macromolecular adhesive additivesAntifouling/underwater paintsPaint thinnerPtru catalyst

The invention relates to a preparation method of a water-borne inorganic paint and a method for preparation of an inorganic coating from the water-borne inorganic paint. The method is characterized by including the preparation steps of: firstly dispersing metal silicate in silica sol to obtain a silicate silica sol solution; then adding a trimethoxy silane mixture into water, stirring the substances evenly, then adding an inorganic acidic catalyst, further stirring the substances evenly to obtain an organosilicon prepolymer solution; finally mixing the silicate silica sol solution with the organosilicon prepolymer solution, then adding a film-forming assistant, a leveling agent and a defoaming agent, and stirring the substances evenly to obtain the water-borne inorganic paint; and adding a proper amount of water into the inorganic paint to obtain an inorganic paint's diluent solution with a solid content of 10%-30%, brushing or spraying the diluent solution to a matrix surface, and performing natural drying, thus obtaining an inorganic transparent coating. The strength and toughness of the coating are improved, and the water-borne inorganic paint has the advantages of good hydrophobic, waterproof and anti-mildew effects, etc.

Owner:福建釉时代环保涂料有限公司

Method for preparing high-quality sodium alginate

The invention relates to a method for preparing high-quality sodium alginate, which comprises the steps of brown algae soaking, brown algae chopping, washing, draining, color fixation, digestion, dilution, floating, filtering, flocculation, squeezing dehydration, neutralization, drying and milling. The method is characterized in that: in the floating step is to add a biosurfactant chitosan auxiliary floating agent into diluent; the filtering step is tumbling precoating vacuum-pumping filtration; the flocculation step is low-acidification flocculation. In the preparation method, by adopting the tumbling precoating vacuum-pumping filtration and the low-acidification flocculation, water insoluble substances of the prepared sodium alginate is reduced from 0.6 percent to less than 0.3 percent, calcium content is lowered from 0.4 to less than 0.1 percent, the quality indexes of products can reach U.S. FMC standards; and the sodium alginate is obvious in energy-saving effect by combining the biosurfactant auxiliary floating agent, namely water consumption is reduced from 1,200 tons to 800 tons in the sodium alginate per ton, energy consumption and emission are reduced by 40 percent; and thus, the additional value of the sodium alginate in our country is improved greatly.

Owner:庞作斌

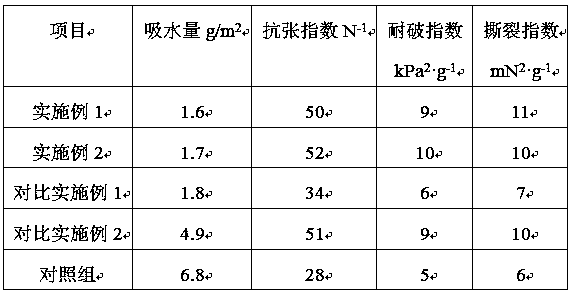

Method of using waste paper fiber to prepare flame-retardant waterproof corrugated paper packaging buffer material

The invention discloses a method of using waste paper fiber to prepare a flame-retardant waterproof corrugated paper packaging buffer material. The method includes: adding water into rosin, heating inwater bath while stirring, taking out for cooling after melting, adding a composite foamer into a rosin adhesive obtained, nucleating agent citric acid and plasticizer glycerin, continuously stirring, pouring in waste paper fiber paper pulp, enzyme-process modified chitosan and starch gelatinized coated modified calcium carbonate filler, continuing stirring for sufficient mixing, pouring into a mould to make a block, putting into a microwave oven for foaming, putting into a far infrared drying box for drying, and taking out to obtain a corrugated paper packaging buffer material; preparing a styrene-acrylic emulsion into a dilutent, adding a compound flame retardant and a silicon-containing water repellent agent, coating and applying glue onto the corrugated paper packaging buffer materialto control retention rate of the flame retardant and the styrene-acrylic emulsion, drying in a dryer, and allowing curing reaction in a drying box to obtain the flame-retardant waterproof corrugatedpaper packaging buffer material.

Owner:马鞍山市康辉纸箱纸品有限公司

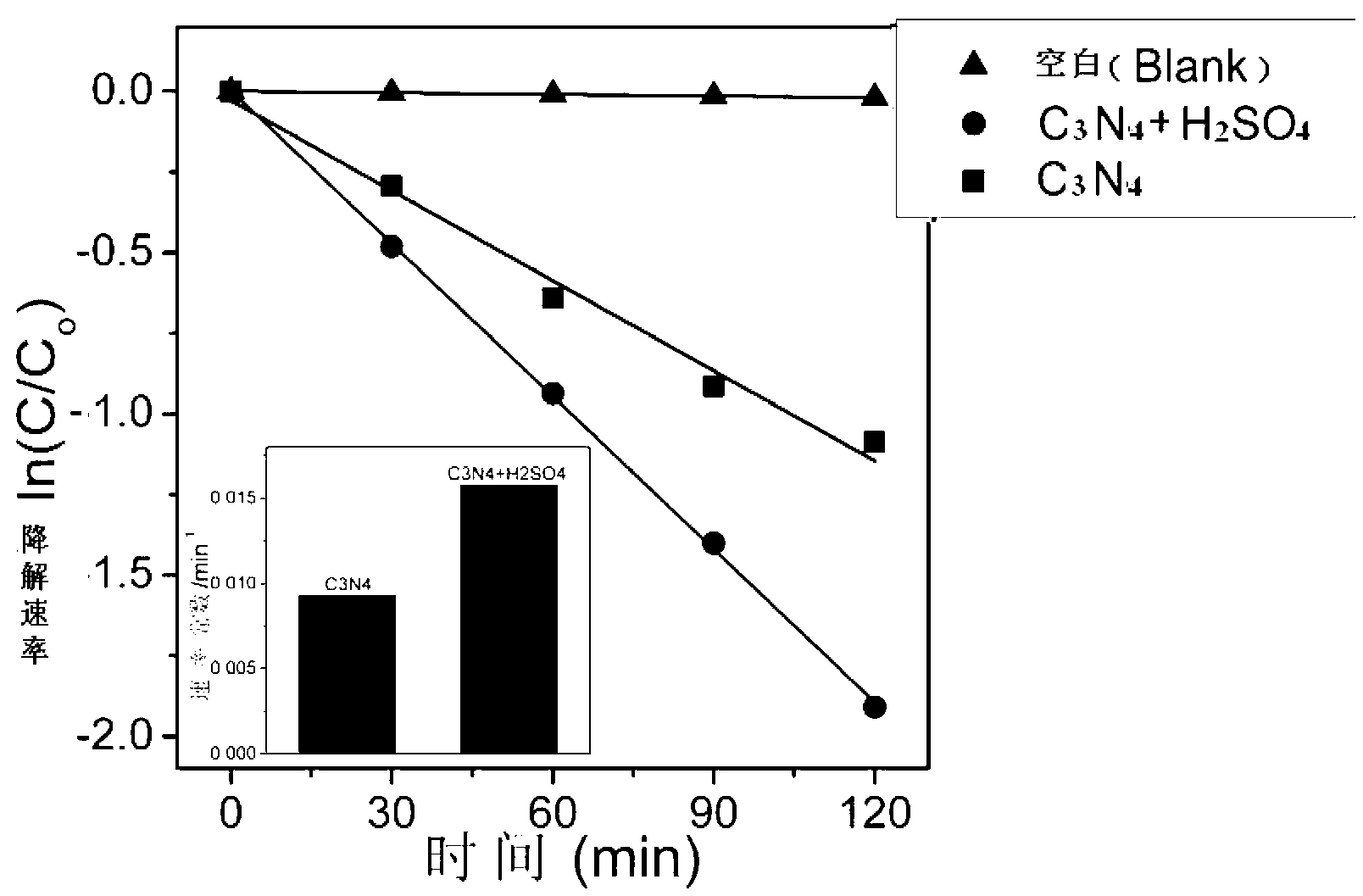

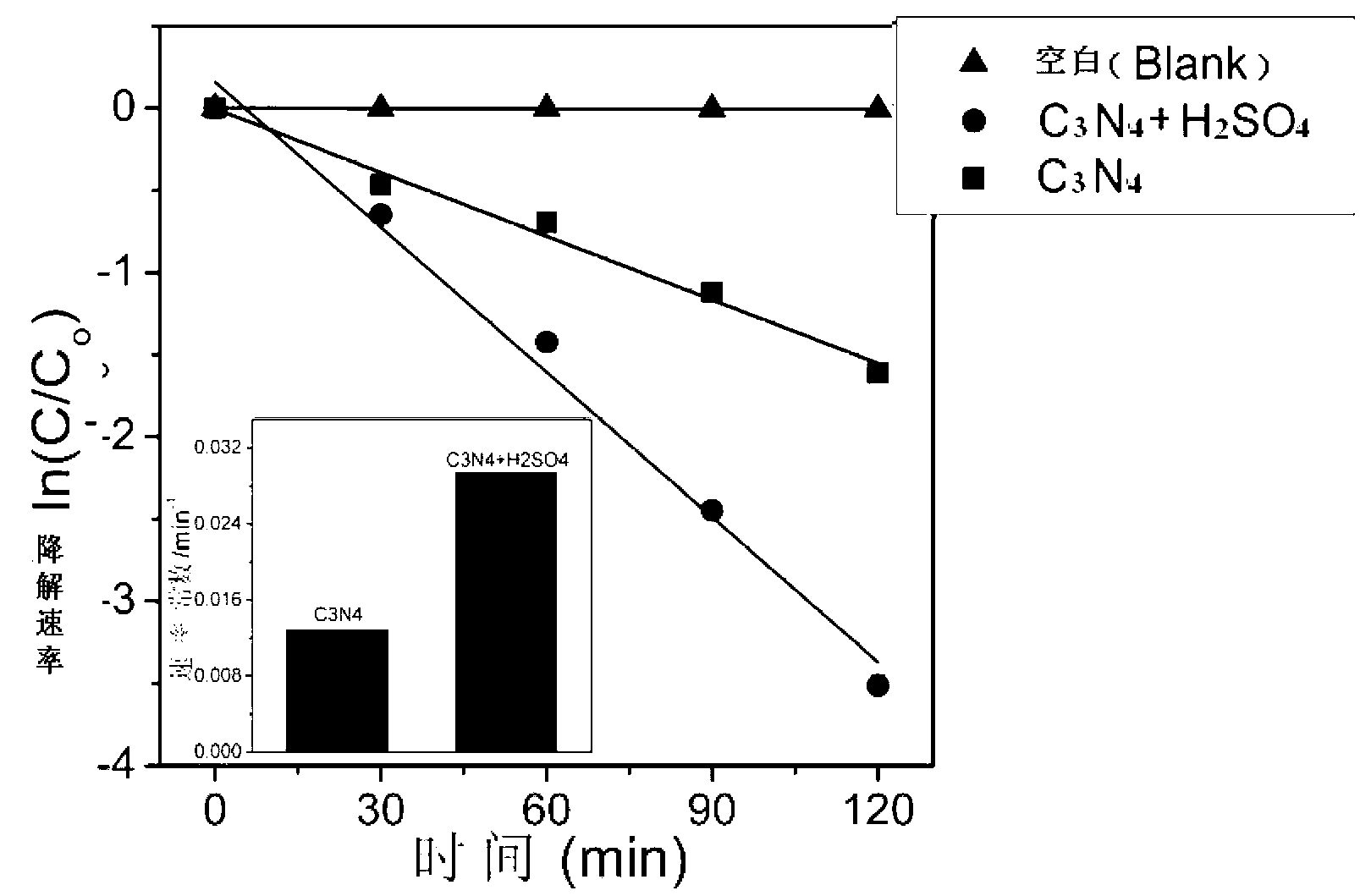

Carbon-nitrogen alkene photocatalyst and preparation method thereof

InactiveCN102974377ASave raw materialsSimple processPhysical/chemical process catalystsPhotocatalytic degradationPhotocurrent

The present invention discloses a carbon-nitrogen alkene photocatalyst and a preparation method thereof. The method comprises the following steps: (1) dispersing carbon nitride in concentrated sulfuric acid and stirring to obtain a mixed liquid; (2) adding deionized water to the obtained mixed liquid to obtain a diluted solution; and (3) carrying out centrifugation on the diluted solution, and adopting deionized water to wash the obtained precipitate after centrifugation to achieve a neutral state to obtain the carbon-nitrogen alkene photocatalyst. The single-layer sheet-like structure carbon-nitrogen alkene photocatalyst prepared by the preparation method has good performances of photocatalysis degradation of pollutants and photocurrent response. The preparation method has characteristics of inexpensive raw materials, simple process and effectively reduced product cost, is suitable for industrial mass production, and has high application prospects and practical values.

Owner:TSINGHUA UNIV

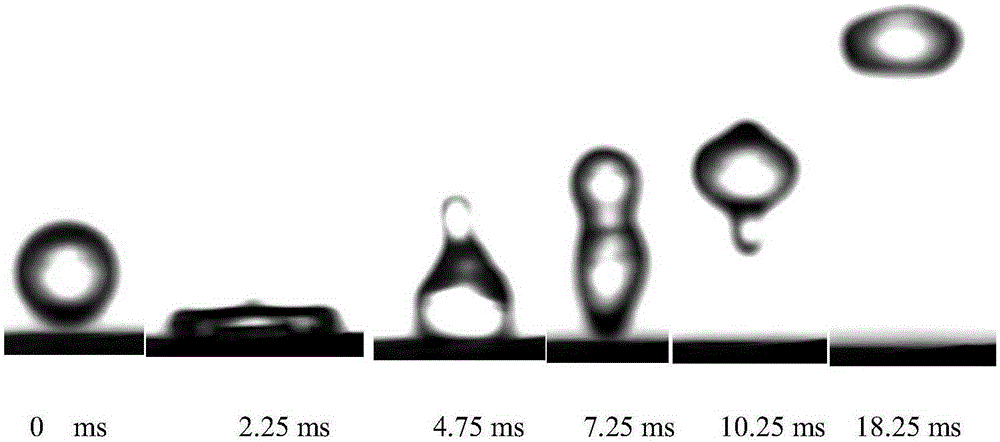

Composition for preventing water-drops from bouncing and sputtering on super-hydrophobic surface

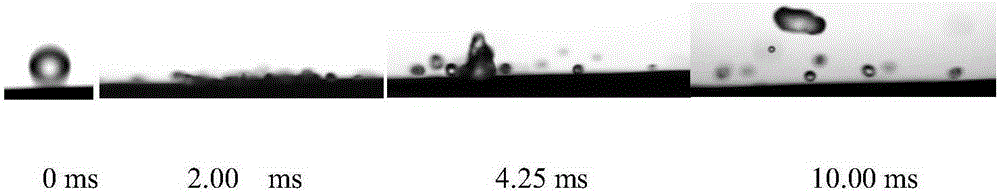

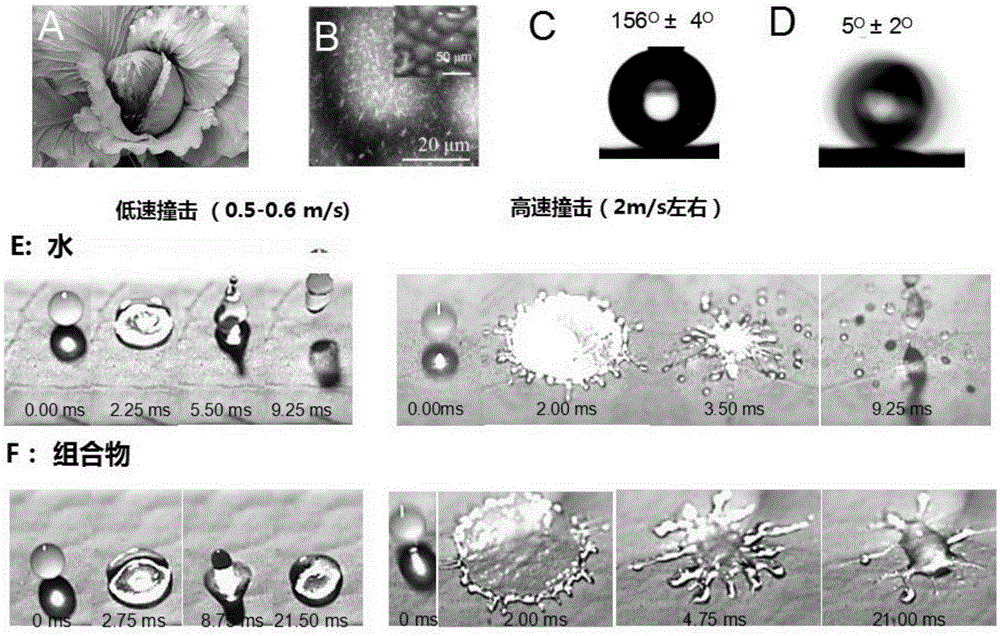

The present invention relates to a composition for preventing water-drops from bouncing and sputtering on a super-hydrophobic surface. The composition comprises two or three of the following substances: 1) a surfactant capable of reducing dynamic surface tension and equilibrium surface tension; 2) a synthesized or natural polymer; and 3) nanoparticles. The composition can be a combination of 1) and 2), and also can be a combination of 1), 2) and 3). Content of the composition is in an aqueous solution or a pesticide diluent and a paint diluent is that in the aqueous solution, the surfactant accounts for 0.1%-1%, the polymer accounts for 0.005%-1%, and the nano particles account for 1%-20%. The composition for preventing water-drops from bouncing and sputtering on the super-hydrophobic surface disclosed by the invention has the advantages of integrating low dynamic surface tension, low equilibrium surface tension, viscosity of the polymer and a thixotropic material, thereby jointly solving problems of the aqueous solution bouncing and sputtering on the super-hydrophobic surface.

Owner:BEIJING NATURE STONE SCI TECH DEVP

Method for extracting anthocyanin from red rice red

The invention discloses a method for extracting anthocyanin from red rice red. The method comprises the following steps of: diluting a red rice red pigment by using water, standing and removing impurities; filtering the diluent obtained after the impurities are removed to obtain filtrate of 0.22 to 0.45mum, adsorbing the filtrate by using macroporous adsorption resin, and resolving the filtrate by using alcohol to obtain a resolved solution; and treating the resolved solution by using ion exchange resin, concentrating and spraying, and thus obtaining the anthocyanin. According to the method, the impurities such as macromolecular saccharide, protein and the like can be effectively removed by using the macroporous resin; organic substances and inorganic salt substances can be effectively removed by using the ion exchange resin; therefore, the anthocyanin content is effectively improved. By the method, the purity and the quality of the anthocyanin are improved, the content of the obtained anthocyanin reaches over 30 weight percent, and the using range of the anthocyanin is effectively expanded.

Owner:CHENGUANG BIOTECH GRP CO LTD

High-stability silicon rubber latex or emulsion and preparation method thereof

The invention discloses high-stability silicon rubber latex or emulsion. The latex or emulsion comprises 40-75wt% of high-viscosity silicon rubber, 10-25wt% of emulsifier and 15-50wt% of water. The solid content of the high-stability silicon rubber latex or emulsion can be adjusted in the range of 50-85% at will, the high-stability silicon rubber latex or emulsion is further diluted with water in application until the solid content is 0.1-50%, the diluent is also stable, and no oil floating or layering can be caused after 180 days. The prepared latex or emulsion can be used for surface treatment and has lasting obviously-enhanced smooth and thick feeling style, and the style can be maintained for more than half a year and is not changed.

Owner:HUAIAN KAIYUE TECH DEV

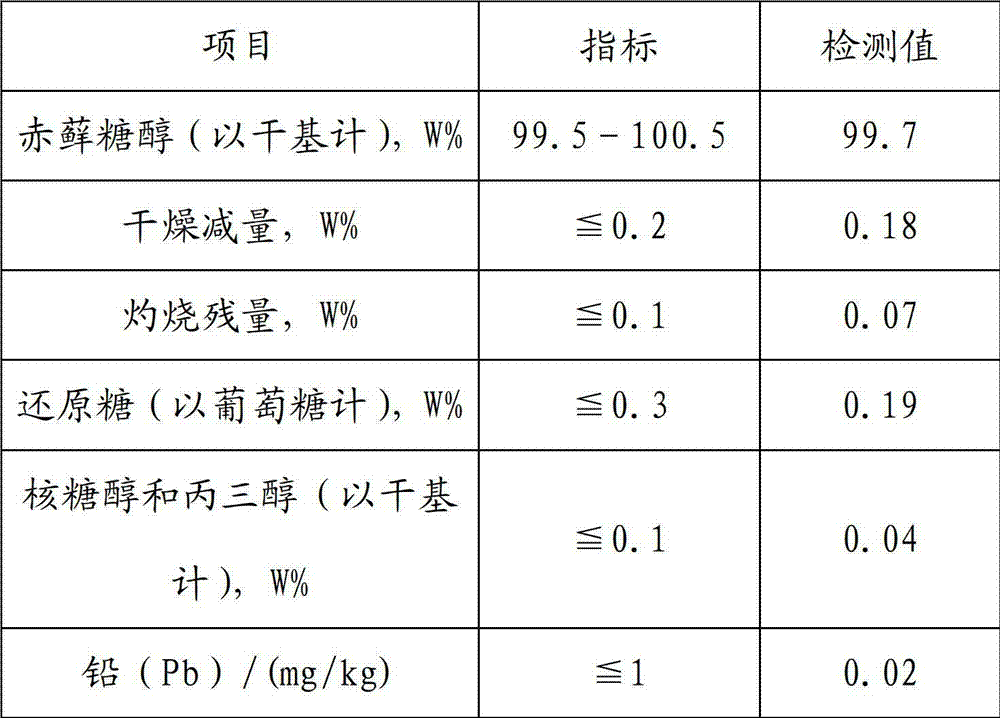

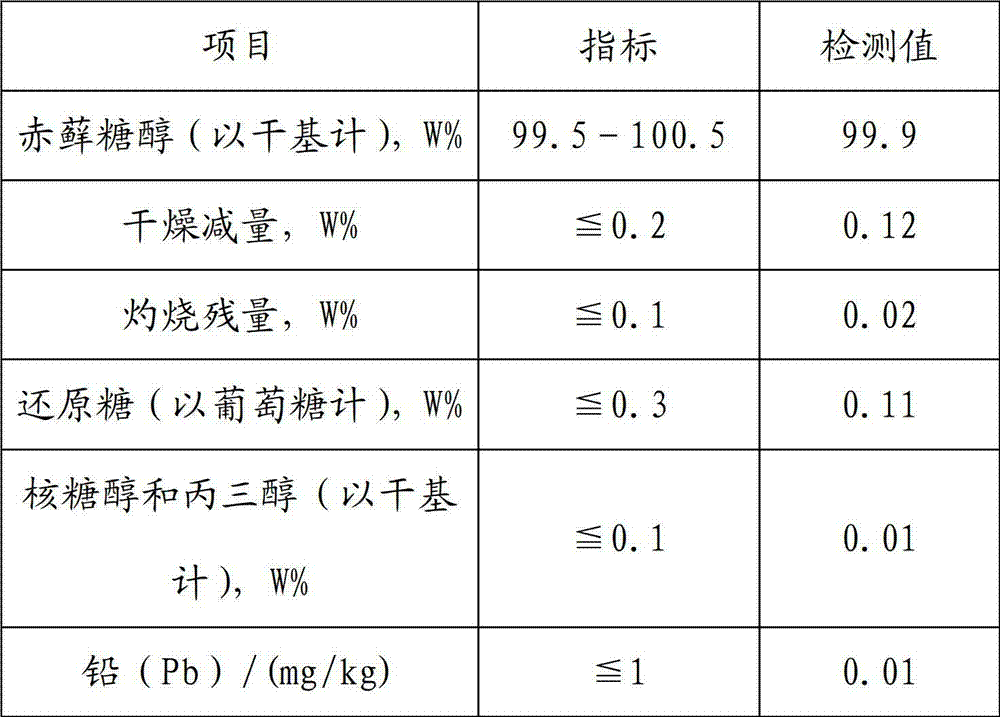

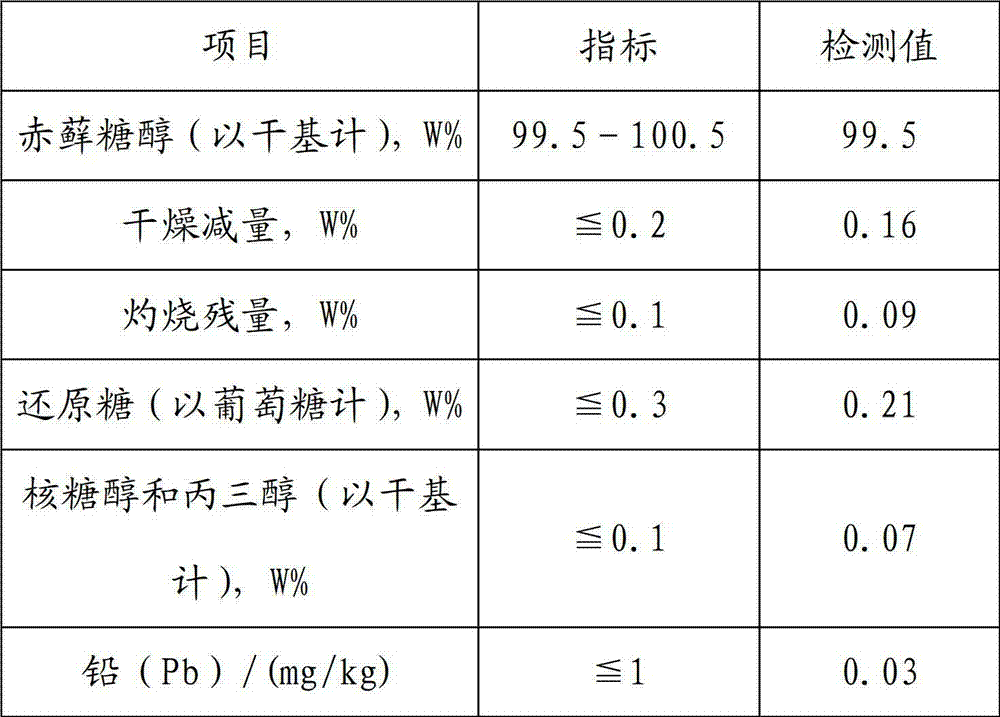

Method for recovering erythritol from erythritol crystallization mother liquor

ActiveCN102964213AGood effect of removing impuritiesHigh yieldHydroxy compound separation/purificationPaint thinnerBrix

The invention discloses a method for recovering erythritol from erythritol crystallization mother liquor. The method is characterized by comprising the following steps: 1, pre-treating: diluting the erythritol crystallization mother liquor by pure water, so as to obtain the diluted solution containing 30 to 50% of Brix; 2, filtering by a ceramic membrane: filtering the diluted solution by the ceramic membrane which has the separation aperture of 20 to 100 nanometers, so as to obtain the ceramic membrane filtering dialyzate; 3, nano-filtering: treating the ceramic membrane filtering dialyzate obtained in step 2 by non-filtering through a Dalton nanofiltration membrane with molecular weight cutoff of 150 to 350, so as to obtain the nano-filtering dialyzate; and 4, concentrating and crystallizing: concentrating the nano-filtering dialyzate in vacuum, and then crystallizing to obtain erythritol crystal containing more than 99.5% of erythritol. By adopting the technical scheme, the method has the beneficial effects that the Dalton nanofiltration membrane with molecular weight cutoff of 150 to 350 is adopted, and the processes such as purifying and decolorizing can be realized by one step, so that the production technology is simplified, the production cost is reduced, and the advantage of being high in product yield is brought.

Owner:SEPATEC ENVIRONMENTAL PROTECTION TECH XIAMEN

Montmorillonite modified wood-plastic composite material plate

The present invention discloses a montmorillonite modified wood-plastic composite material plate and a preparation method thereof. According to the present invention, a silane coupling agent, ethanol and water are prepared into a diluent, wood powder is placed into the diluent to prepare modified wood powder, the modified wood powder, nanometer montmorillonite, waste polyvinyl chloride, calcium carbonate powder, a silane coupling agent, talc powder, a light stabilizer and a thermal stabilizer are placed into a mixer, high speed mixing is performed, and then one time extrusion is performed to obtain the composite material plate; and with the technical scheme, the adhesion of the wood powder and the plastic is improved, the impact resistance, the strength and the hardness of the wood-plastic composite plate are improved, and the application field of the wood-plastic composite material plate is expanded.

Owner:SUZHOU CITY XIANGCHENG DISTRICT MINGDA COMPOSITE MATERIAL FACTORY

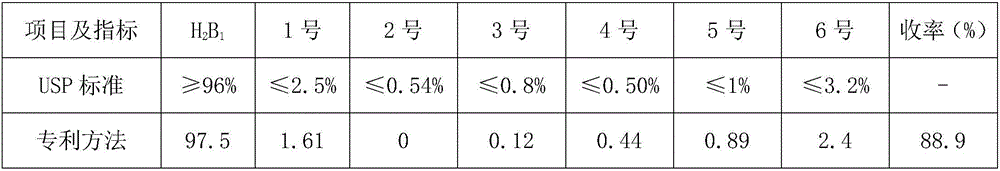

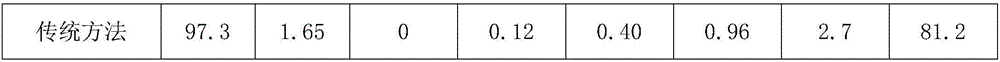

Preparation method of ivermectin

ActiveCN106188185ACrystallization EfficientPromote growthSugar derivativesSugar derivatives preparationPaint thinnerFiltration

The invention discloses a preparation method of ivermectin. The preparation method comprises the following steps: (1) preparing an ivermectin rough product; (2) dissolving the ivermectin rough product with a solvent, heating, stirring until the ivermectin rough product is completely dissolved, and maintaining the temperature; (3) adding purified water and formamide into a rough product solution, controlling the fed-batch flow velocity, and cooling, so as to obtain a diluent; (4) adding seed crystals into the diluent, and growing the crystals; (5) carrying out cooling crystallization on the diluent until reaching a certain temperature; and (6) carrying out suction filtration, washing and drying, so as to obtain high-purity ivermectin fine powder. The yield of the preparation method reaches above 85%, and a preparation process having the beneficial effects of simple process, stable yield and capability of producing high-purity ivermectin in a large scale is provided.

Owner:NORTH CHINA PHARMA GROUP AINO

Water-based complete-synthesis cutting liquid for steel grit die-casting aluminum material as well as preparation method and using method thereof

ActiveCN103343033ASolve stickingImprove protectionLubricant compositionWater basedHazardous substance

The invention discloses water-based complete-synthesis cutting liquid for a steel grit die-casting aluminum material as well as a preparation method and a using method thereof. The cutting liquid comprises the following raw materials: a benzotriazole derivative agent, a non-ionic emulsifier, a water-based extreme-pressure lubricant, boric acid, glycerol, triethanolamine, a dicarboxylate-based composite antirust agent, an n-caprylic acid coupling agent, a hard water resistant agent, a defoaming agent and the balance of pure water, wherein the total amount is 100 percent. The cutting liquid prepared by the method can be used after being diluted by adding water according to the ratio of the cutting liquid to the water of 1:(10-30); the diluent has excellent lubricating property, antirust property and settling property, and has a good protective effect special for steel grit. All the indexes of the 5% diluent reach or exceed the related indexes of GB6144-2010. The cutting liquid has long service life, does not contain harmful substances such as formaldehyde and nitrite, reduces emission, avoids environmental pollution and saves economic cost.

Owner:AMER TECH CO LTD

Preparation method for high-strength wood-plastic composite material

The invention discloses a preparation method for a high-strength wood-plastic composite material, belonging to the technical field of preparation of wood-plastic composite materials. The preparation method provided by the invention comprises the following steps: taking bamboo sheets and carrying out drying to a constant weight, carrying out crushing and sieving, then carrying out secondary carbonization so as to prepare carbonized bamboo powder for subsequent usage, then taking a silane coupling agent KH-550 and the like so as to prepare a macromolecular coupling agent, then mixing the macromolecular coupling agent with deionized water and glacial acetic acid, adding an ethylene-vinyl acetate copolymer emulsion diluent and the like so as to prepare an impregnating agent, soaking glass fiber in the impregnating agent, taking the soaked glass fiber out of the impregnating agent and carrying out drying, then mixing the dried glass fiber with the prepared carbonized bamboo powder and the like, and carrying out extrusion granulating so as to prepare the high-strength wood-plastic composite material. The invention has the following beneficial effects: the preparation method has simple preparation steps; the prepared material has high strength; the carbonized bamboo powder, the impregnating agent soaked glass fiber and resin are fully utilized to prepare the wood-plastic composite material; pertinence is strong; and the problems of weak impact resistance and easy generation of gaps and cracks are effectively solved.

Owner:周荣

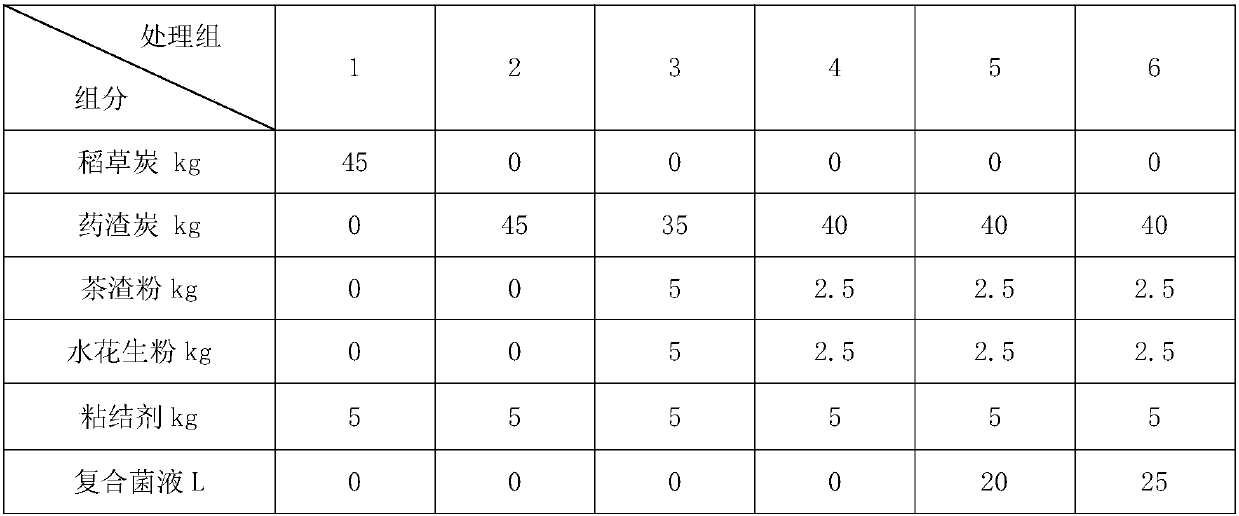

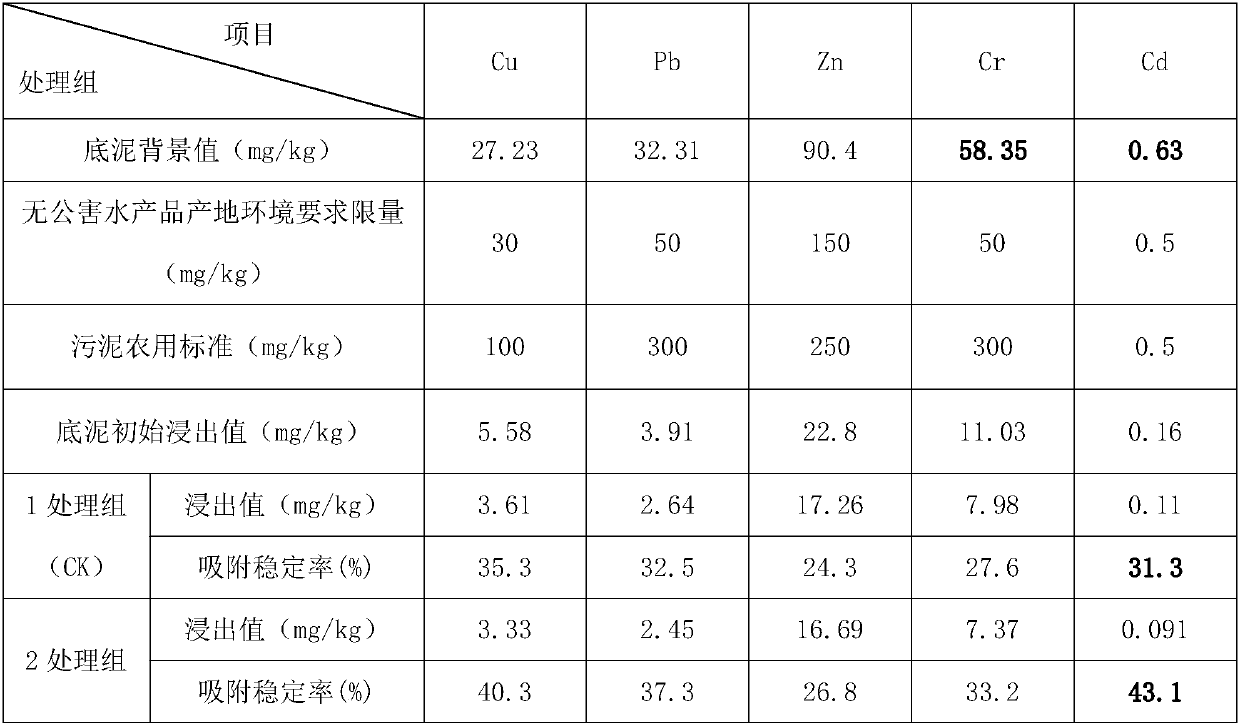

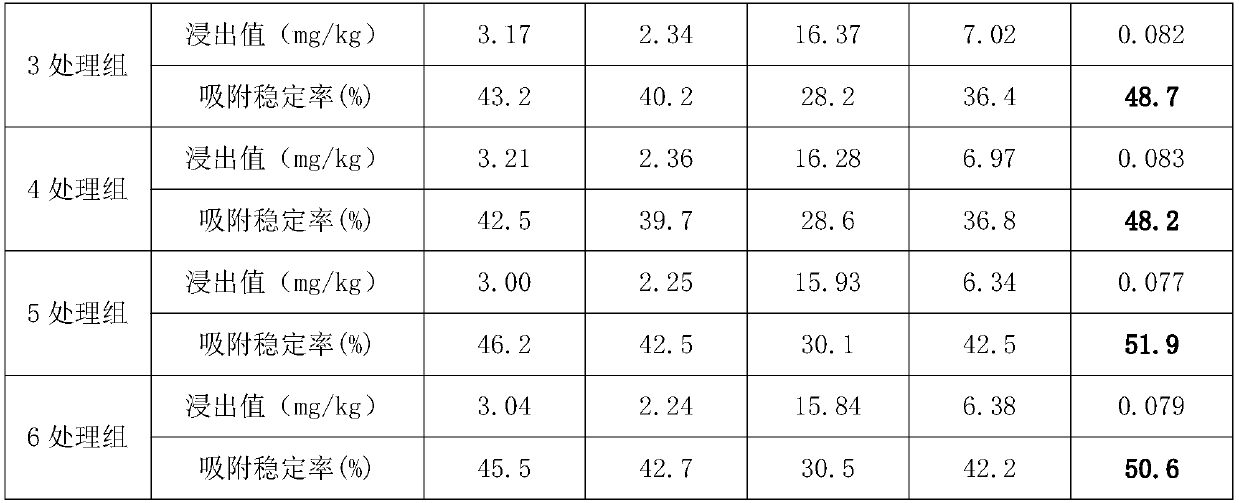

Heavy metal stabilizer for bottom mud in aquaculture pond, and manufacturing method and application thereof

ActiveCN107935339AImprove adsorption capacityFull of nutritionFungiBacteriaMicrobial agentSoil heavy metals

The invention relates to a heavy metal stabilizer for bottom mud in an aquaculture pond, and a manufacturing method and an application thereof. The heavy metal stabilizer comprises a microbial carrierand a composite microbial agent loaded on the microbial carrier, wherein the microbial carrier is a mixture of Mailuoning herb residue biomass carbon powder, tea residue powder, alternanthera philoxeroides powder and a binder; and a composite active bacterial liquid is obtained through the following steps: mixing a bottom mud sample and deionized water so as to obtain a supernatant diluent, carrying out culturing so as to obtain a seed solution of bacillus and yeast, adding an EM active bacterial liquid, and carrying out culturing under the condition of aerobic fermentation. The preparation method comprises the following preparation process: (1) allowing Mailuoning herb residues to be converted into biomass carbon at a high temperature, and mixing the biomass carbon with raw materials soas to obtain the microbial carrier; and (2) loading the composite microbial agent onto the microbial carrier. According to the invention, the bottom mud fermented by stacking with the heavy metal stabilizer can be used as a base fertilizer and applied to soil, so the fertility of the soil is improved; the effectiveness of heavy metals in the soil is reduced; the usage amount of an inorganic fertilizer is decreased; and the yield and quality of crops are improved.

Owner:HOHAI UNIV

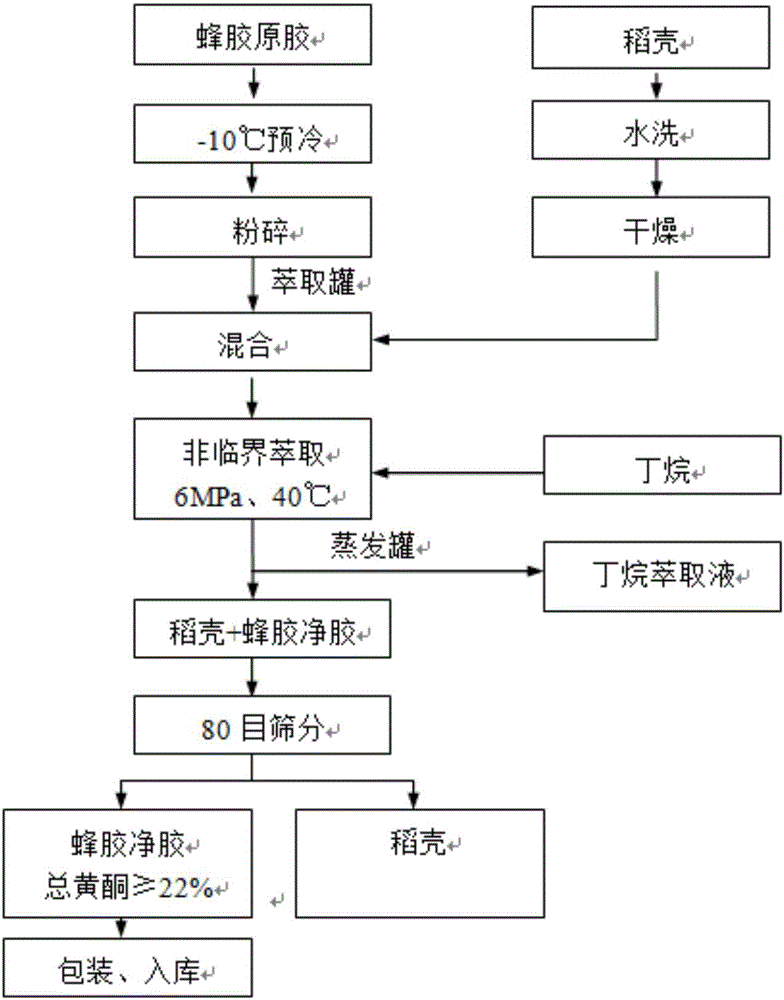

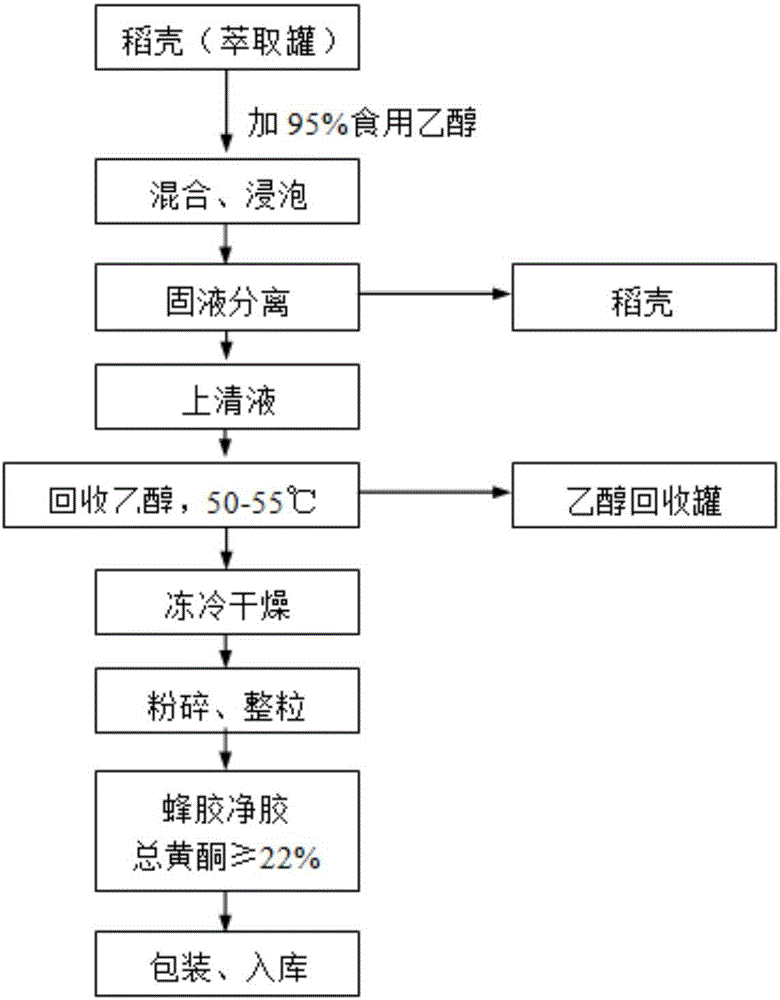

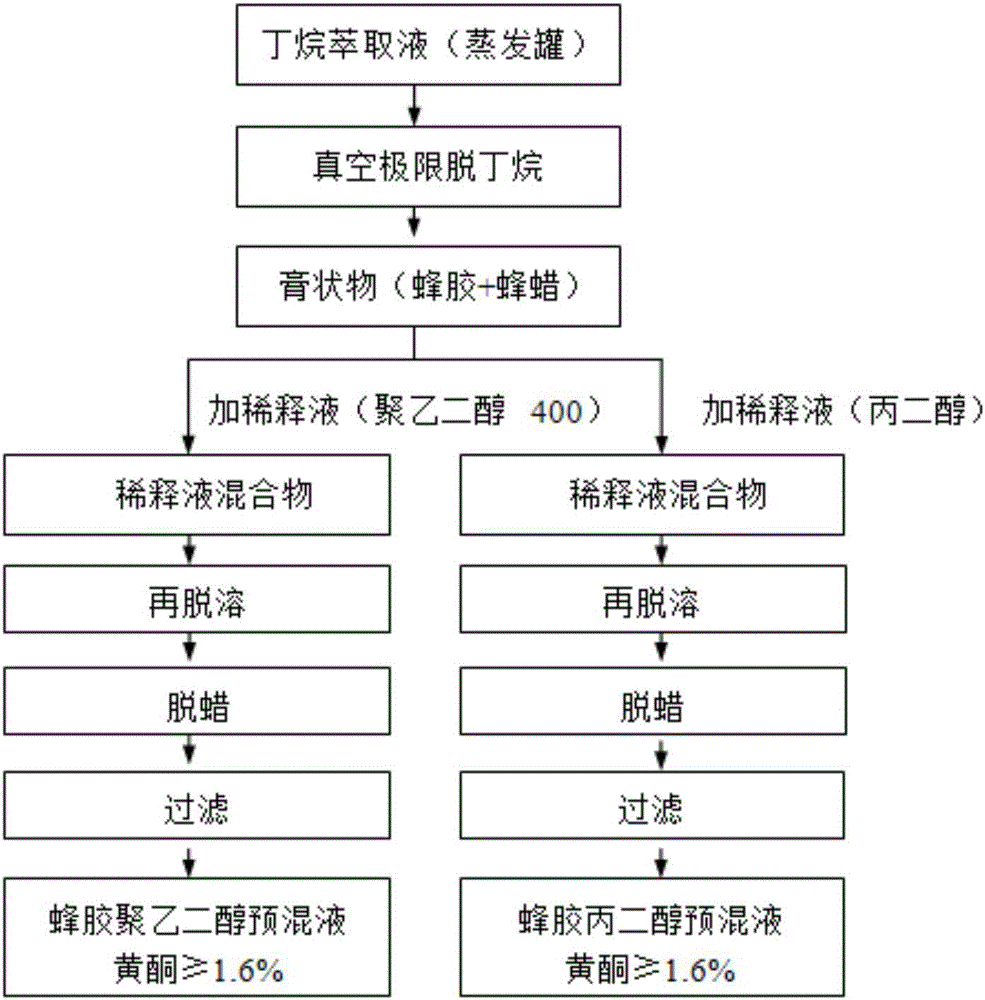

Comprehensive extraction and utilization production technology for propolis

ActiveCN106551330AHigh extraction rateHigh in flavonoidsCosmetic preparationsAntipyreticPropolisFreeze-drying

The invention discloses a comprehensive extraction and utilization production technology for propolis. The method comprises the following steps: 1) pretreatment; 2) mixing; 3) non critical fluid extraction; 4) removal of n-butane through ultimate vacuum; 5) addition of a weak solution for mixing; 6) removal of n-butane through ultimate vacuum; 7) de-waxing; and 8) solid-liquid separation. The invention employs an extraction technology by taking low-temperature non critical fluid n-butane as a solvent, Brazilian A-grade propolis is taken as a raw material, and the propolis particles can be prepared by steps of selection, refrigeration at the temperature of -10 DEG C, crushing, blending with rice husk, extraction by employing non-critical fluid, screening, freeze drying, crushing and package, and propolis premix liquid is prepared by the steps of desolvation through ultimate vacuum, addition of a diluents, de-waxing, filtering and package. propolis yield is 30-35%, the general flavone content is 22-25%, the general flavone content in propolis freeze-drying powder is 22-25%, and the lead content is 0.48-0.50 mg / kg.

Owner:NANJING XIYUAN BIOPHARML SCI & TECH

Carbon steel total synthetic waterborne stamping oil and preparation method thereof

InactiveCN107974338AReduce dependencePromote degradationLubricant compositionPetrochemicalCleansing Agents

The invention provides a carbon steel total synthetic waterborne stamping oil and a preparation method thereof. The carbon steel total synthetic waterborne stamping oil comprises, by weight ratio, 20-40 parts of synthetic ester, 5-20 parts of vegetable oleic acid, 2-10 parts of rust-proof additive, 5-20 parts of alkali, and 20-50 parts of water. According to the preparation method, the synthetic ester is used as a main lubricant component, the vegetable oleic acid, the rust-proof additives, the alkali and the water are mixed and formulated to form a transparent diluent through a specific process, most of the raw materials belong to renewable energy sources, have a high biodegradable rate, and are friendly to environment, a dependence on petrochemical raw materials is reduced, and the product is non-volatile, and has a low odor, so that working environment is not affected after the use of the product, thereby reducing an incidence rate of occupational diseases in workers; the product has no flash point, so that the product still can be safely used under a high temperature condition; workpieces can be washed with water after processing, and use of special cleaning agents is not needed, thereby effectively reducing subsequent cleaning cost, and reducing pollution on water bodies; and the proportion of water in the product can be adjusted according to processing difficulty requirements of the workpieces, so as to meet processing requirements of carbon steel with different degrees of difficulty, therefore, the product has a good market prospect.

Owner:东莞市伟思化学科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com