Method of using waste paper fiber to prepare flame-retardant waterproof corrugated paper packaging buffer material

A buffer material and waste paper fiber technology, applied in the field of corrugated paper, can solve the problems of reduced paper strength performance and limited technology, and achieve the effect of increasing mechanical properties, high strength performance, and strong shear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

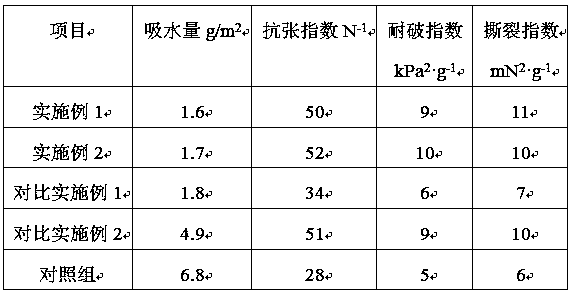

Examples

Embodiment 1

[0029] A method for preparing a flame-retardant and waterproof corrugated paper packaging cushioning material from waste paper fibers, characterized in that it comprises the following steps:

[0030] (1) Enzymatic modification of chitosan:

[0031] Add sodium acetate buffer solution to 3 parts of chitosan to prepare a chitosan solution with a concentration of 0.3%, add methanol at 1:10 to 3 parts of p-hexyloxyphenol, and mix with the chitosan solution at 40- Shake and stir in a water bath at 50°C for 5 minutes, add laccase to react for 5 hours, centrifuge for 5 minutes, add NaOH solution to precipitate, wash the precipitate with distilled water and methanol for 10 minutes, then extract with methanol for 10 hours, wash with water to remove methanol, and freeze-dry to obtain the enzyme method Modified chitosan;

[0032] (2) Starch gelatinization coated modified calcium carbonate filler:

[0033] Add deionized water to 10 parts of cornstarch to make a suspension with a concentr...

Embodiment 2

[0043] A method for preparing a flame-retardant and waterproof corrugated paper packaging cushioning material from waste paper fibers, characterized in that it comprises the following steps:

[0044] (1) Enzymatic modification of chitosan:

[0045]Add sodium acetate buffer solution to 5 parts of chitosan to prepare a chitosan solution with a concentration of 0.3%, add methanol at 1:10 to 5 parts of p-hexyloxyphenol, and mix with the chitosan solution at 40- Shake and stir in a water bath at 50°C for 10 minutes, add laccase to react for 6 hours, centrifuge for 10 minutes, add NaOH solution to precipitate, wash the precipitate with distilled water and methanol for 15 minutes, then extract with methanol for 12 hours, wash with water to remove methanol, and freeze-dry to obtain the enzyme method Modified chitosan;

[0046] (2) Starch gelatinization coated modified calcium carbonate filler:

[0047] Add deionized water to 20 parts of cornstarch to make a suspension with a concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com