Patents

Literature

35results about How to "Stable electrical insulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Epoxy resin composite insulating material and preparation method thereof

InactiveCN109294166AStable electrical insulationExtend your lifeMicroballoon preparationMicrocapsule preparationChemical compositionRuthenium

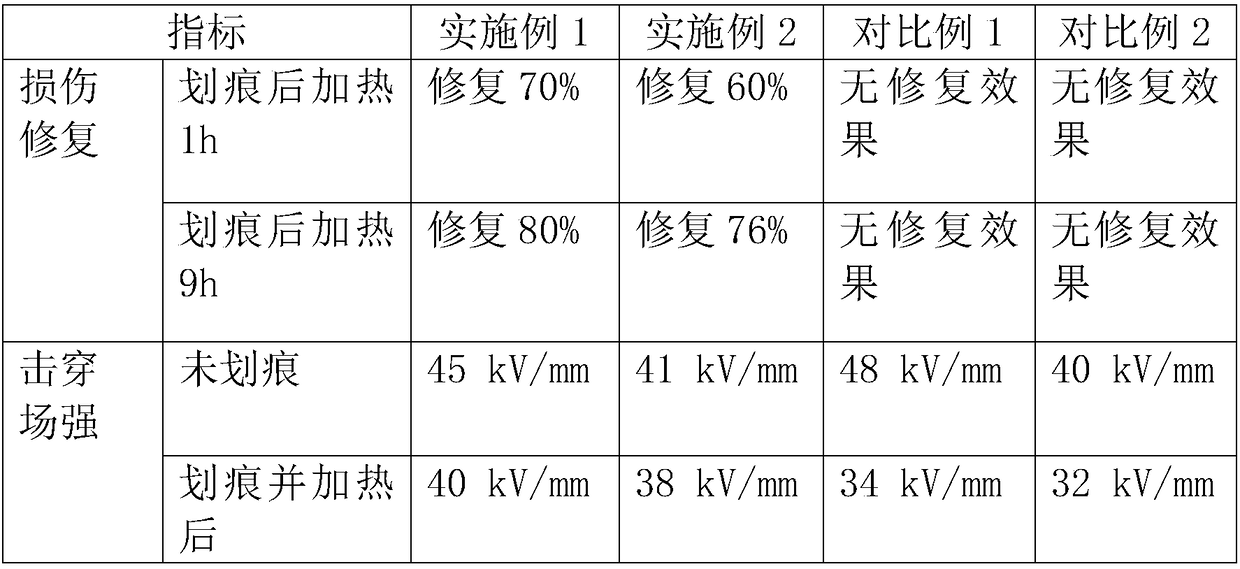

The invention provides an epoxy resin composite insulating material and a preparation method thereof. The epoxy resin composite insulating material is formed by preparing microcapsules, a ruthenium carbene complex catalyst, and a component including at least a bisphenol A type epoxy resin, a first curing agent, a curing accelerator, and a toughening agent. The microcapsules are formed by preparinga urea-formaldehyde resin performed polymer composition and a core material composition in the presence of a second curing agent and a modifier, the urea-formaldehyde resin performed polymer composition is formed by stirring and heating urea, formaldehyde and deionized water under alkaline conditions, and the core material composition is formed by stirring an emulsifier, dicyclopentadiene and deionized water under heating condition. The epoxy resin composite insulating material has the ability to self-repair when damaged.

Owner:CHONGQING UNIV

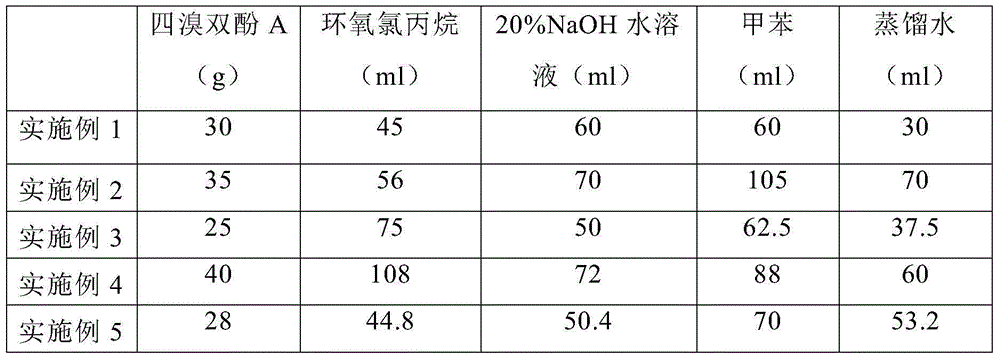

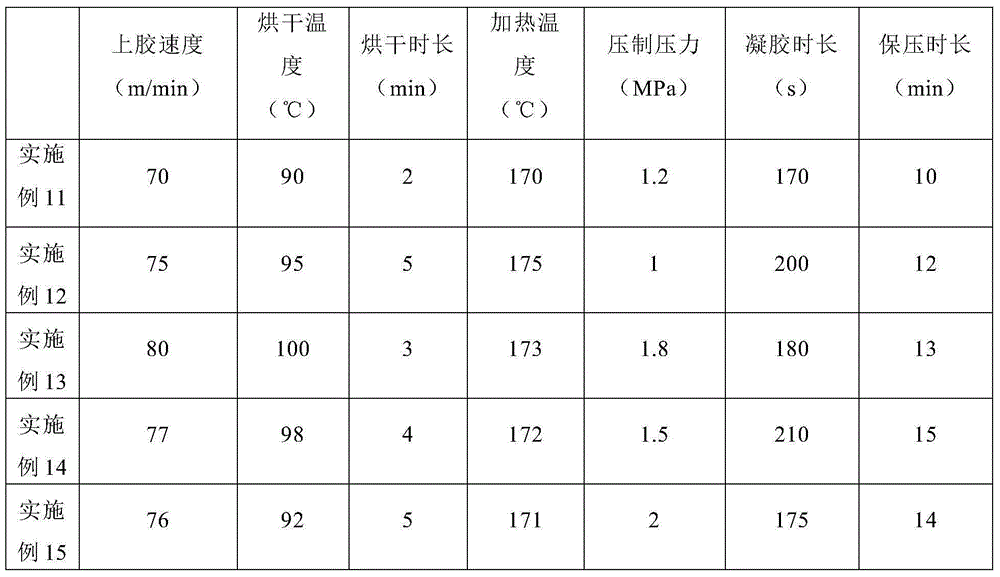

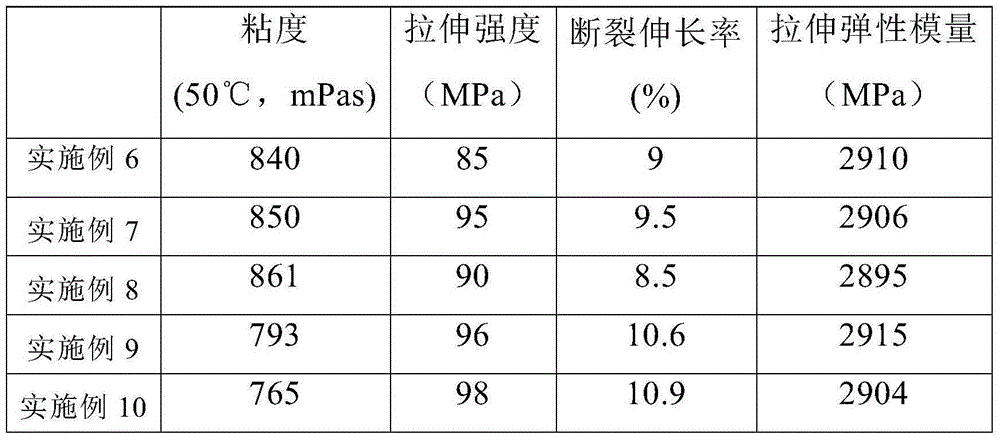

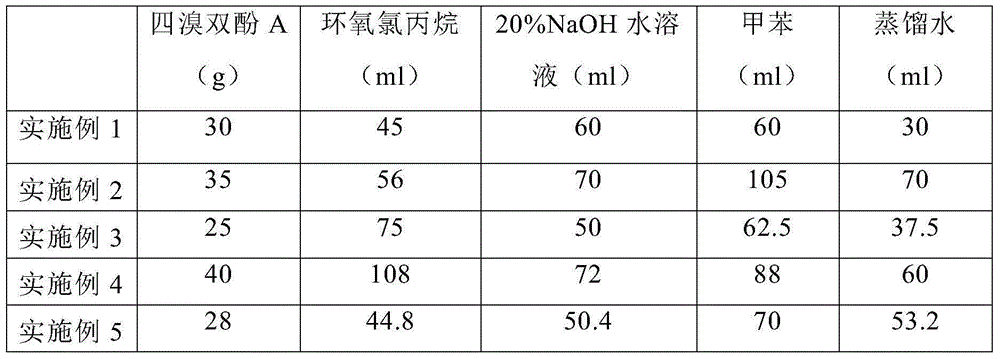

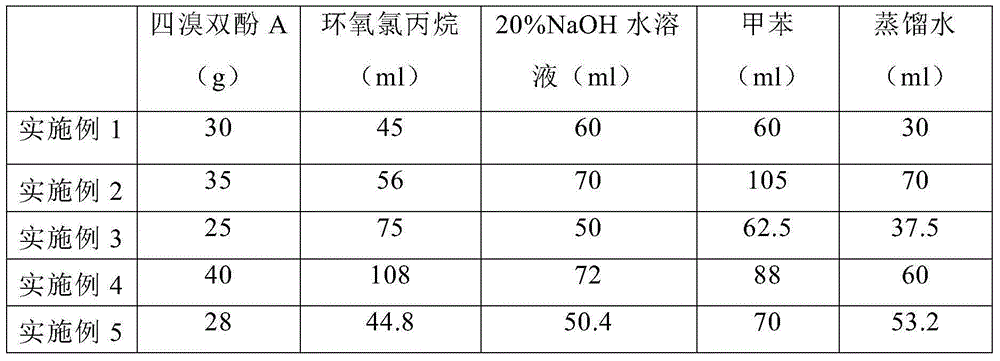

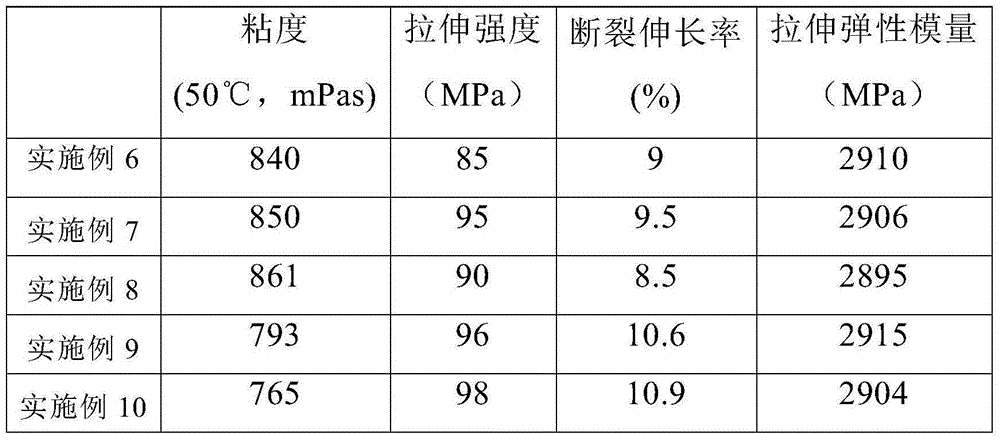

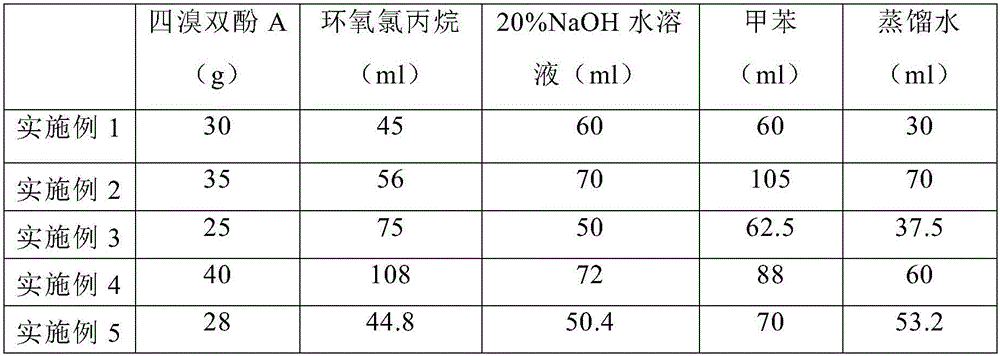

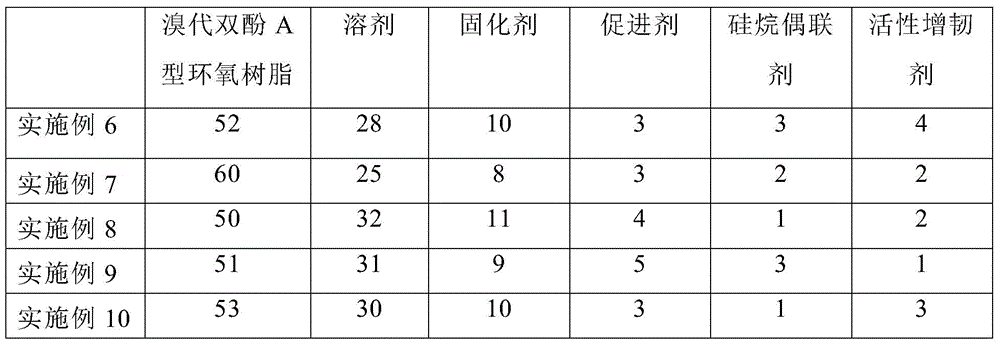

Manufacturing method of epoxy glass-cloth-matrix copper clad laminate

InactiveCN105150662AGood adhesivenessImprove flame retardant performanceLaminationLamination apparatusGlass fiberAlkali free

The invention provides a manufacturing method of an epoxy glass-cloth-matrix copper clad laminate. The manufacturing method comprises the following steps: 1) preparing a glue solution; 2) getting a roll of alkali-free glass fiber cloth, opening the roll, and immersing the roll into the glue solution by passing the roll through a glue container at a speed of 70-80 m / min; 3) sending the roll to a drying chamber for drying to obtain a prepreg; 4) cutting the dried base board into pieces, laminating 8 pieces of the base board into one group, covering two surfaces of the plurality of laminated base boards with copper foil, putting a layer of a release film on the bottom of the plurality of laminated base boards, and putting the obtained product between two stainless steel plates; and 5) putting the obtained product into a laminating machine for heating and pressurization, taking the obtained product out, and performing cutting and checking to obtain a finished product of the epoxy glass-cloth-matrix copper clad laminate. According to the method, a special-prepared brominated bisphenol A epoxy resin is mixed with a plurality of preparations to form the glue solution, and manufacturing processes and manufacturing conditions are optimized and combined to obtain the copper clad laminate with high-temperature resistance and good flame resistance.

Owner:忠信(太仓)绝缘材料有限公司

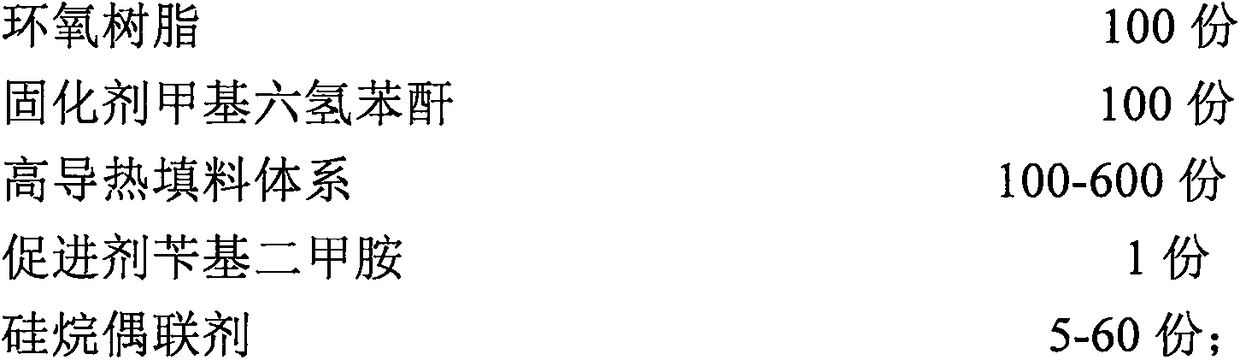

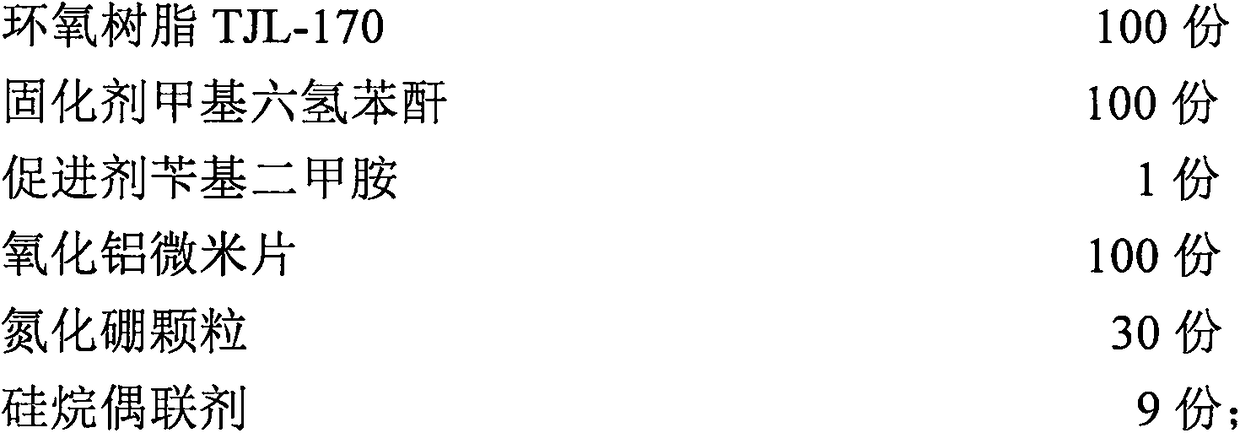

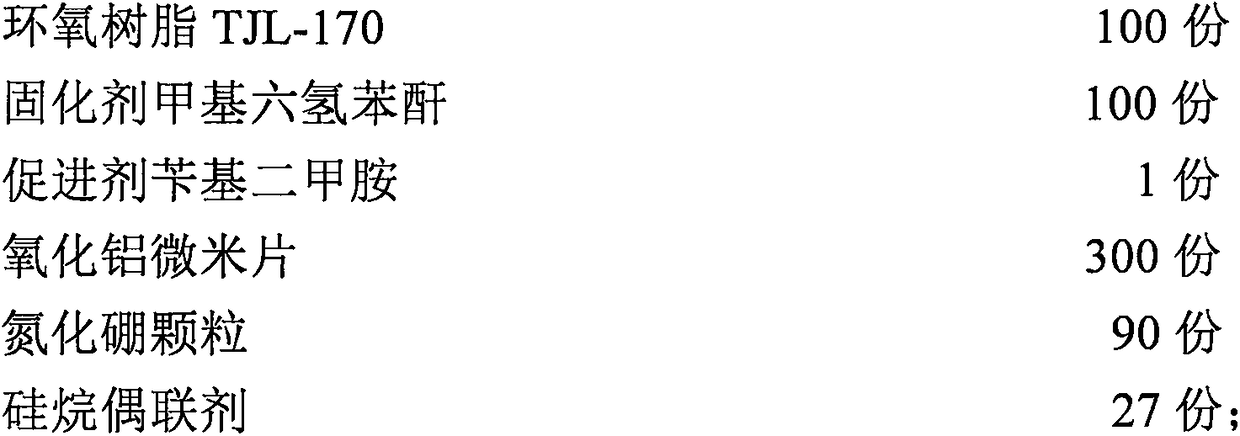

High-thermal conductivity epoxy resin-based alumina-boron nitride micro-nano composite insulation material

InactiveCN108690324AImprove thermal conductivityStable electrical insulationPlastic/resin/waxes insulatorsHeat-exchange elementsMicro nanoEpoxy

The invention discloses a high-thermal conductivity epoxy resin-based alumina-boron nitride micro-nano composite insulation material. A filler forms a high-thermal conductivity filler system, a fillerbearing ball structure is formed in an epoxy resin matrix, and the material has an excellent thermal conductivity, can meet the heat dissipation requirements of power components, has a stable electrical insulation performance, and can ensure the lasting and safe running of electrical and electronic equipment. A preparation method of the material has the advantages of simple processing process andgood universality, and allows the high-thermal conductivity epoxy resin-based composite insulation material to be easily prepared.

Owner:深圳市圳田科技有限公司

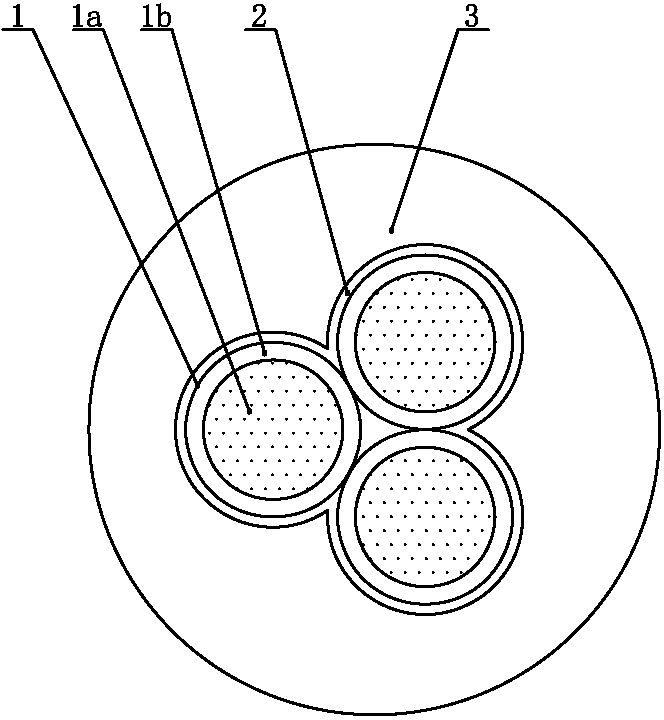

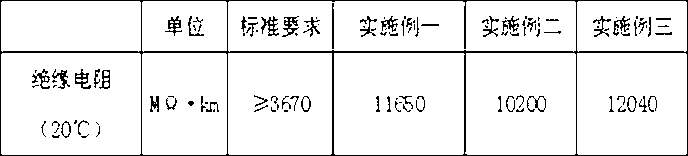

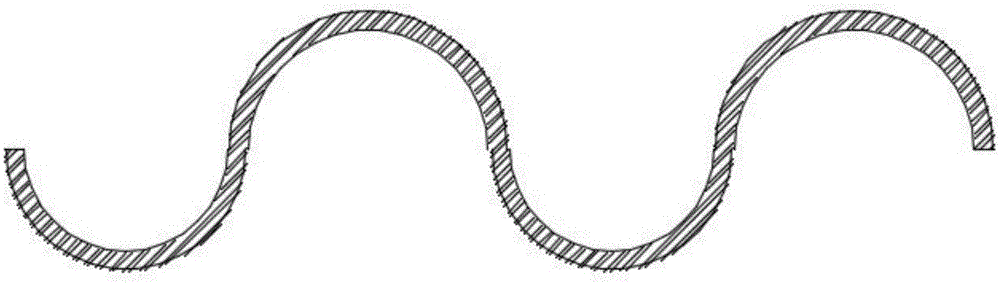

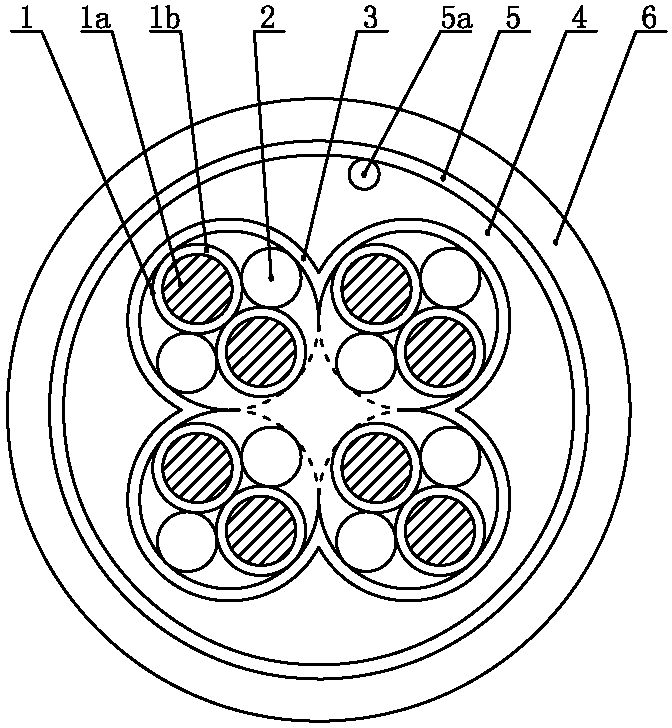

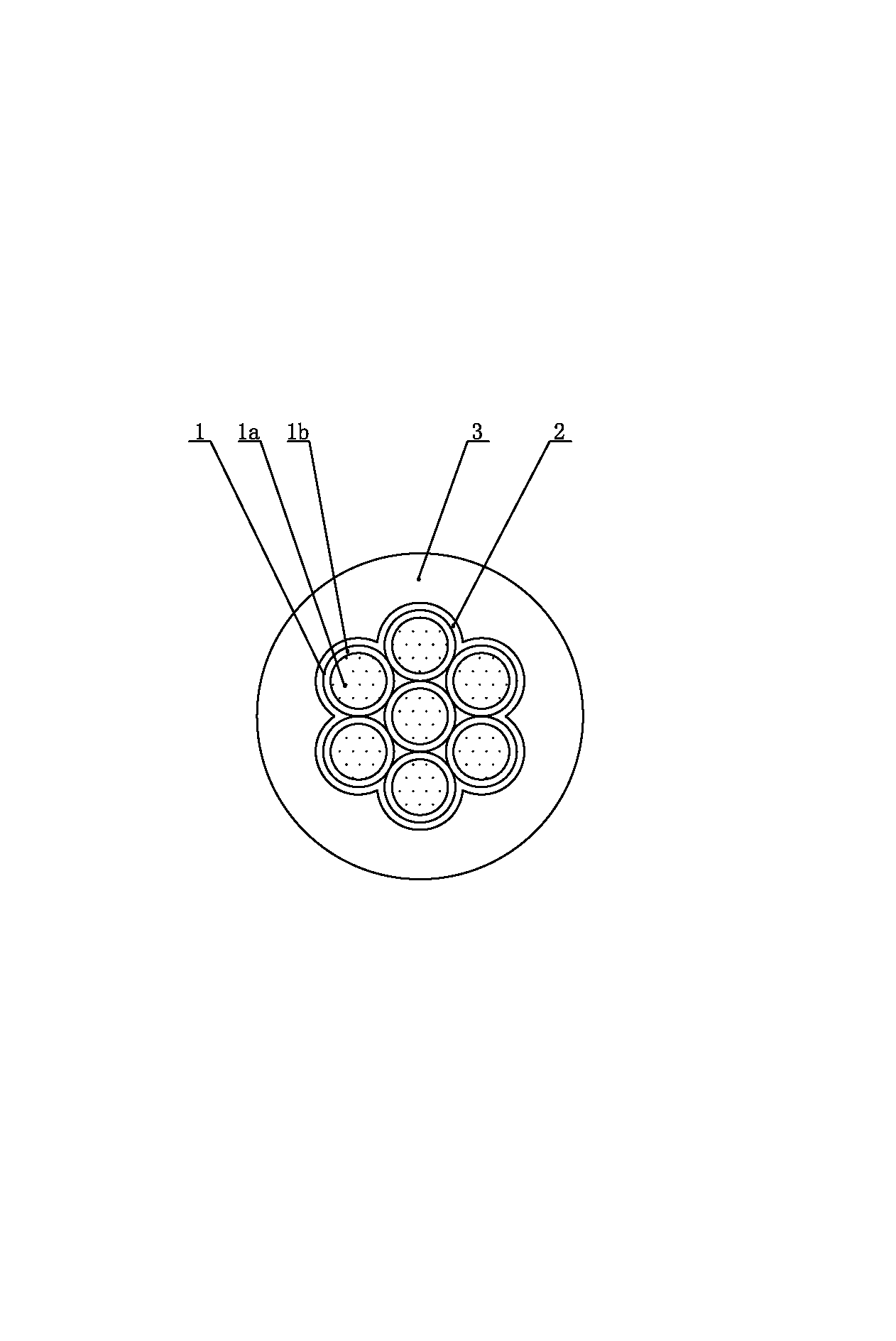

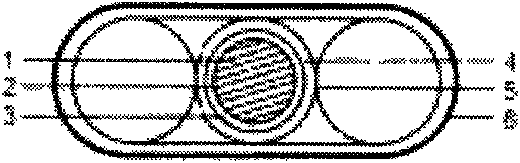

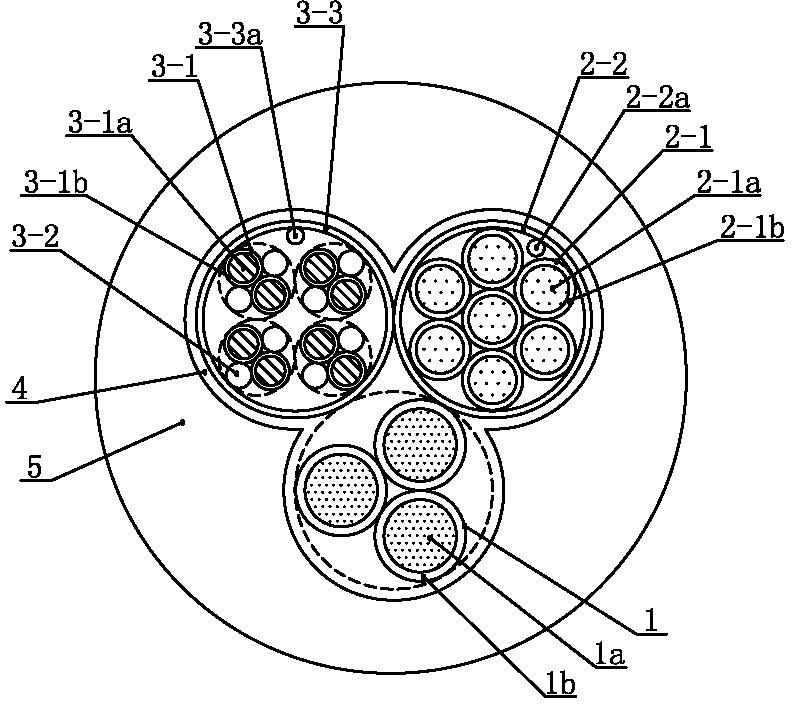

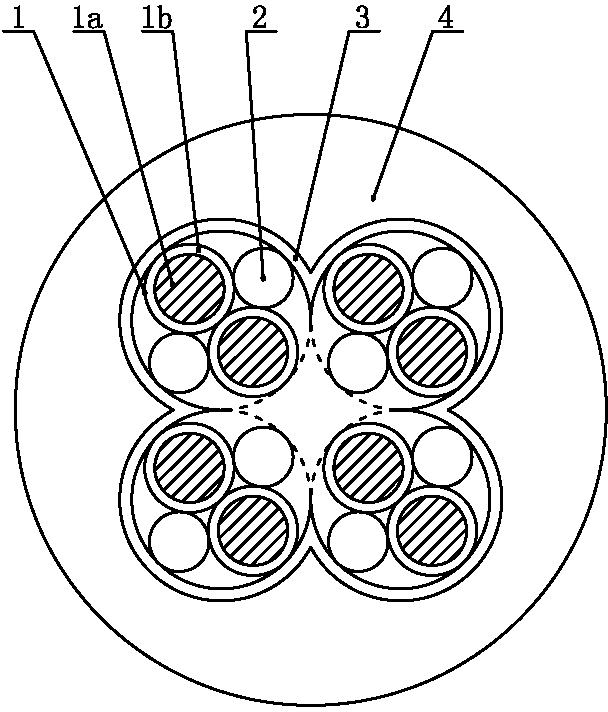

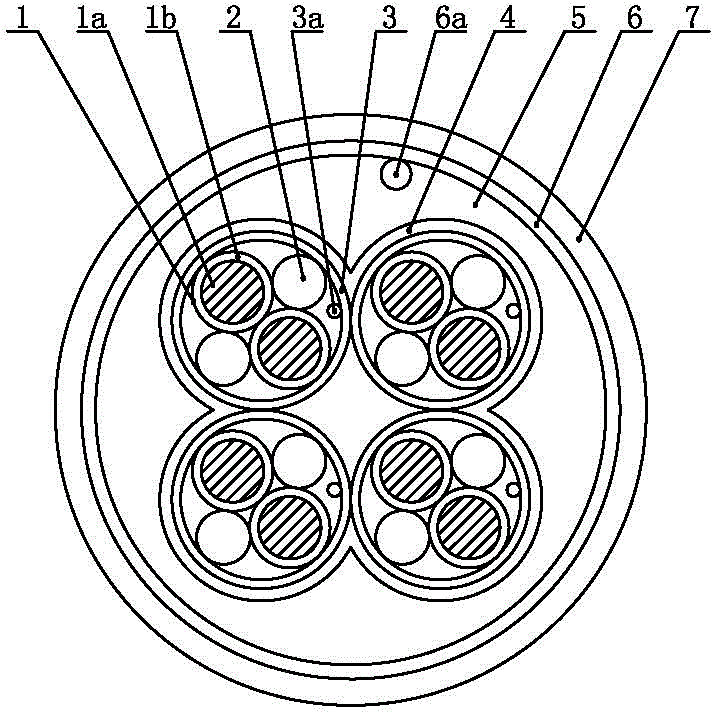

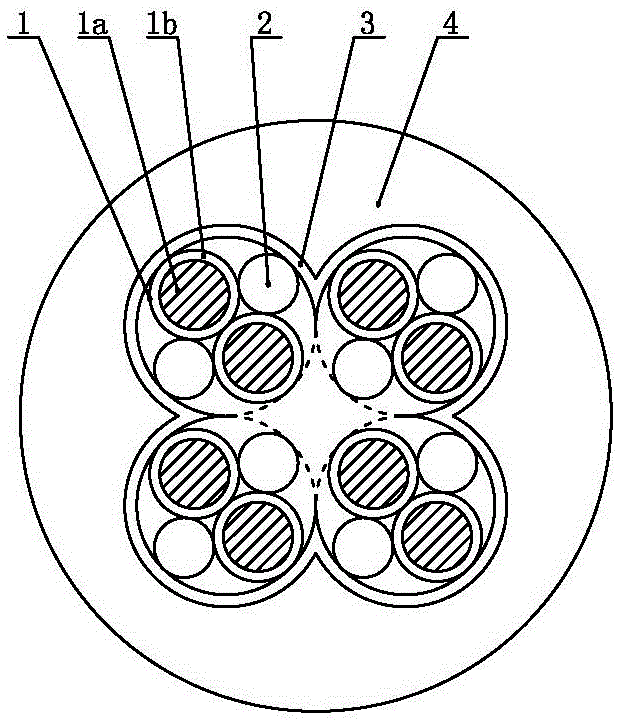

Salt corrosion resistant and twisting resistant power cable for ocean wind power and manufacturing method of power cable

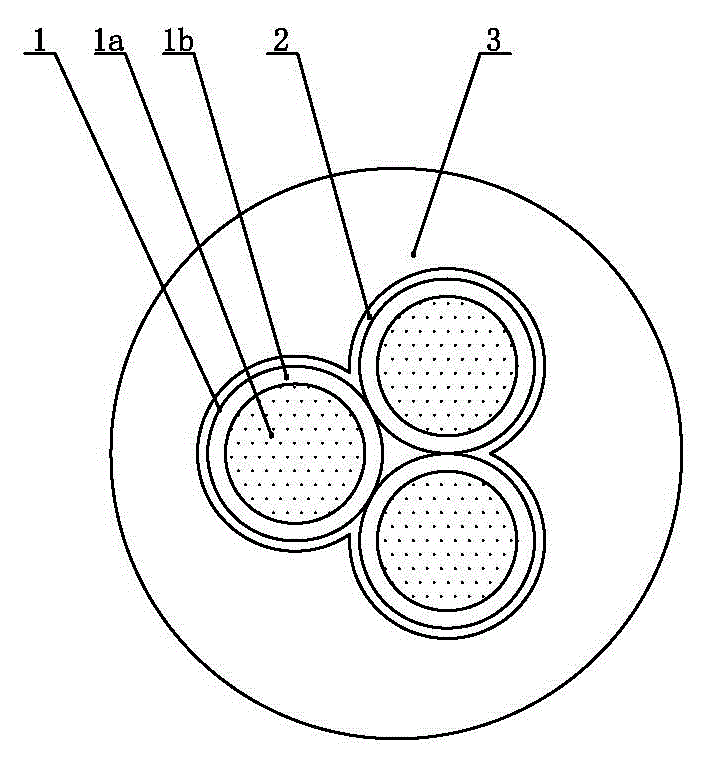

ActiveCN103227008AReduce tensionEliminate voidsPower cablesInsulating conductors/cablesCopper conductorElectricity

The invention relates to a salt corrosion resistant and twisting resistant power cable for ocean wind power and a manufacturing method of the power cable. A stranded copper conductor is uniformly wrapped in a salt corrosion resistant and twisting resistant extruded rubber insulation layer to form a power cable insulated core; a plurality of power cable insulated cores are mutually stranded to form a power cable core; the power cable core is wrapped in a low-strength non-woven fabric longitudinal wrap on the periphery; and the low-strength non-woven fabric longitudinal wrap is wrapped in an extruded sheath. The power cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits the power cable insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the power cable insulated cores are eliminated, convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheath is not stuck to the insulated cores, and provides convenience for stripping the sheath in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

Salt corrosion resistance twisted cable insulation rubber used for ocean wind power and preparation method thereof

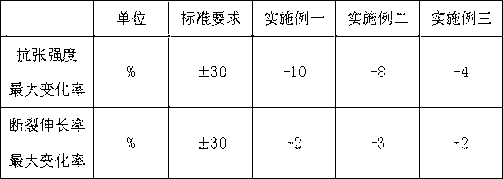

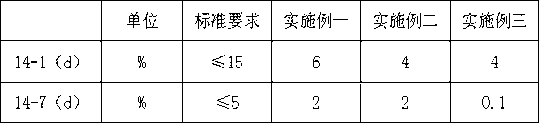

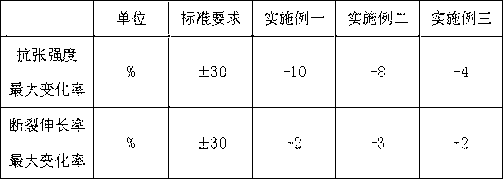

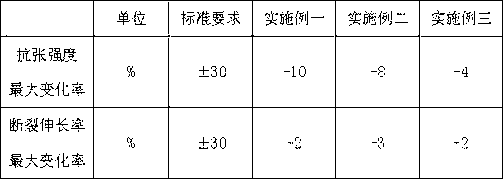

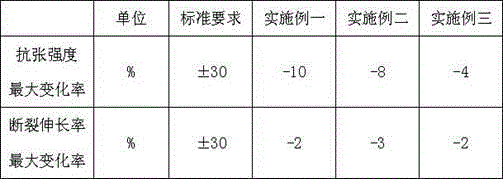

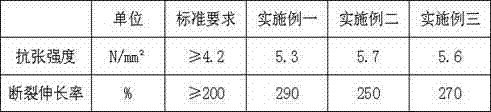

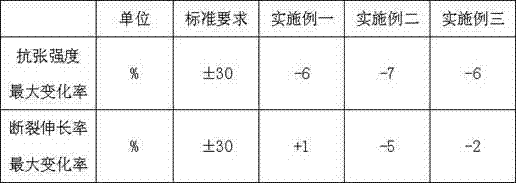

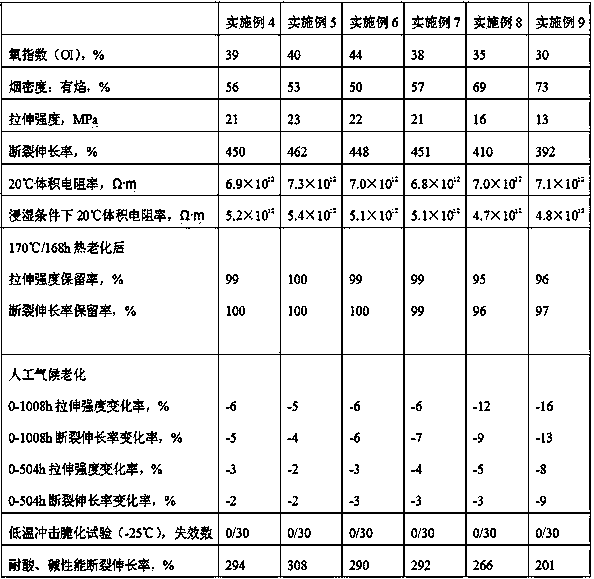

ActiveCN103224669AIncrease working temperatureAnti-aging propertiesPlastic/resin/waxes insulatorsInsulated cablesRubber materialVulcanization

The invention discloses salt corrosion resistance twisted cable insulation rubber used for ocean wind power and a preparation method of the salt corrosion resistance twisted cable insulation rubber. By weight, raw materials comprise 8 parts of Keltan5508, 12 parts of DutralTER4044, 5-7 parts of EP-20, 0.5-0.7 part of DCP, 0.3-0.5 part of TAC, 0.2-0.4 part of HVA-2, 0.2-0.4 part of RD, 0.2-0.4 part of MB, 0.2-0.4 part of KH-550, 2.1-2.5 part of hydration zinc borate, 1-1.5 parts of antimony trioxide, 25-40 parts of aluminum hydroxide, 0.8-1.2 part of red lead, 0.5-1 part of stearic acid, 1.5-2 parts of nan-zinc oxide, 2-5 parts of paraffin oil Sunpar2280, 0.5-1 part of chlorinated paraffin-52, and 1-3 parts of hydration silicon dioxide. According to the method, firstly, the EPDM rubber Keltan5508, the DutralTER4044 and the EP-20 are mixed for 1-1.5 minutes, and then other components except for a vulcanizing agent and a co-vulcanization agent are added. After mixing is carried out for 7-8 minutes, discharging and airing are carried out for more than 24 hours. Then the rubber materials are mixed for 2-3 minutes, the vulcanizing agent and the co-vulcanization agent are added at the last 20 seconds, and the mixed materials are loaded on an open mill for milling, triangular injection molding and square injection molding and then sheeted. The insulation rubber is good in mechanical performance, anti-corrosion performance and anti-aging performance and long in service life.

Owner:浙江华威设备制造有限公司

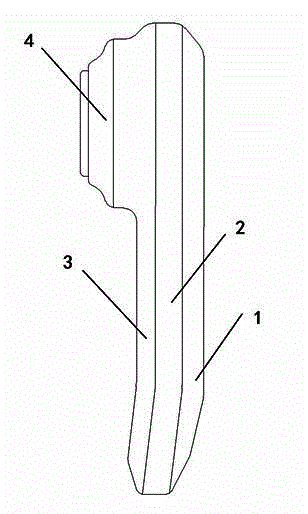

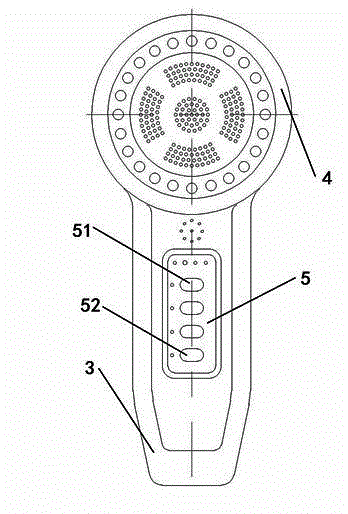

Cell regeneration apparatus

InactiveCN104689478AAvoid cross usagePromote regenerationLight therapyElectrical resistance and conductanceCoupling

The invention provides a cell regeneration apparatus comprising a handle and a housing composed of an expansion portion, a power supply model arranged in the housing, a main control circuit board and a beautifying head. The beautifying head is arranged on the expansion portion and is provided with a plurality of electrodes arrayed neatly; the power supply model, the main control circuit board and the electrodes are connected mutually; the handle is provided with a control panel provided with control keys, and the control panel is connected to the main control circuit board electrically; a soft cap made of soft materiel is arranged out of the beautifying head. The cell regeneration apparatus has the advantages that according to different skin resistance of different bodies, the multi-electrode contact type coupling is adopted, and the contact of the electrodes and bodies is evener and more reliable.

Owner:深圳市瑞吉思科技有限公司

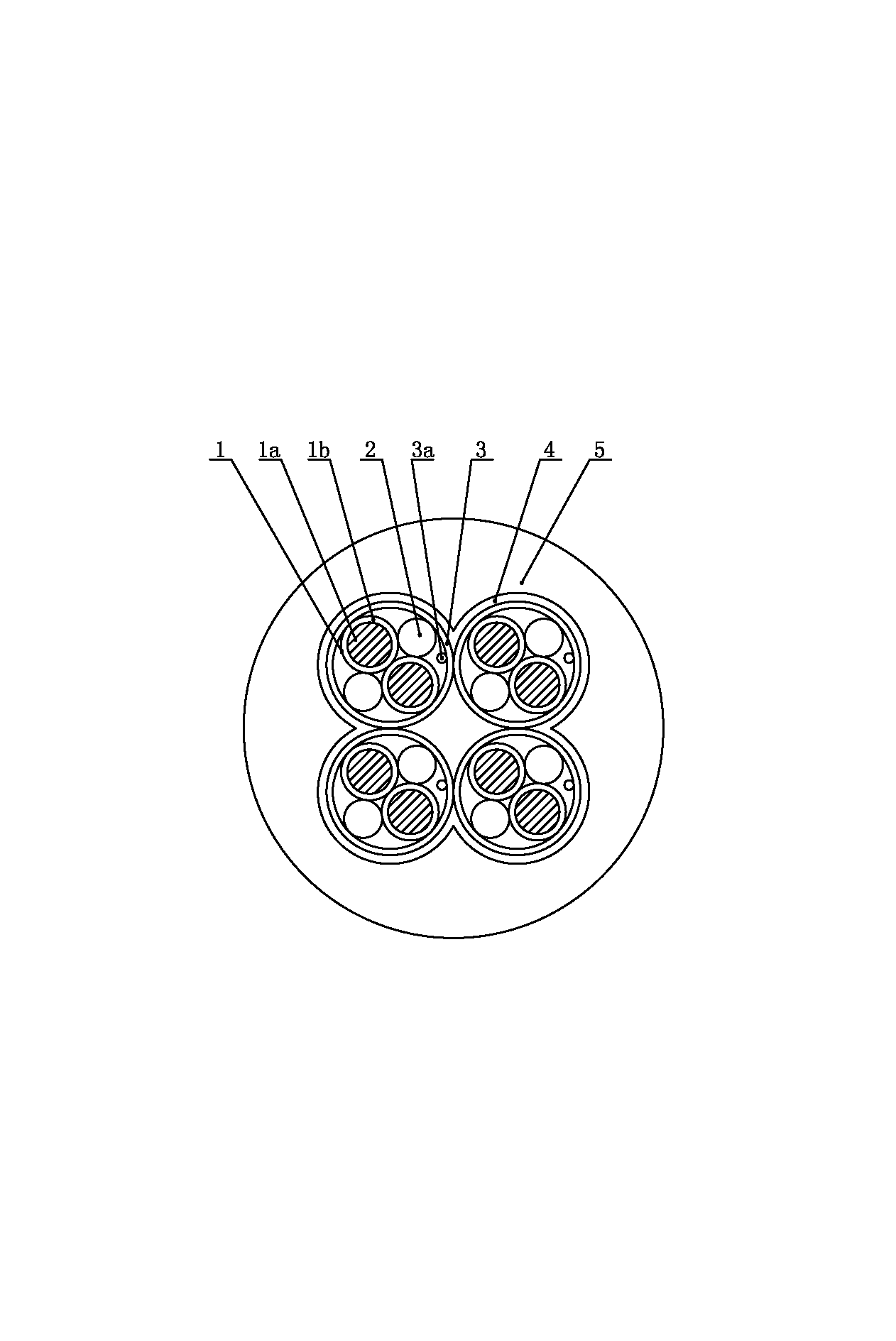

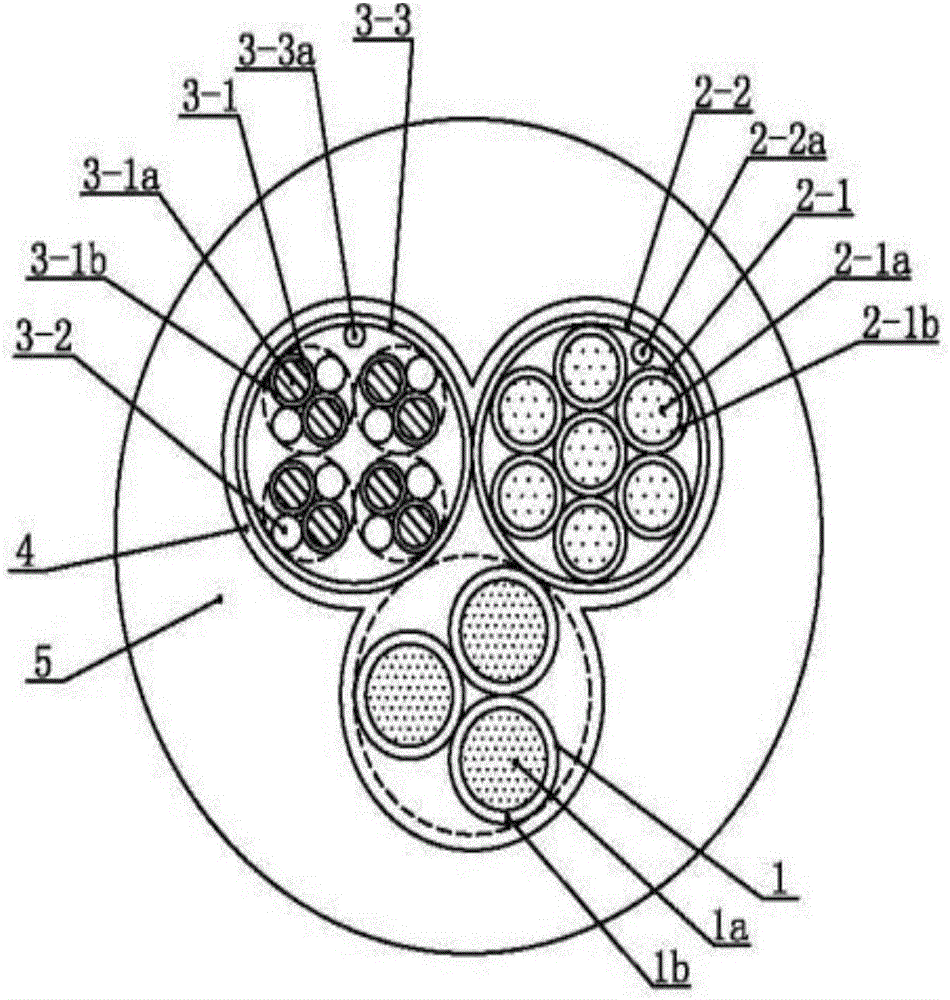

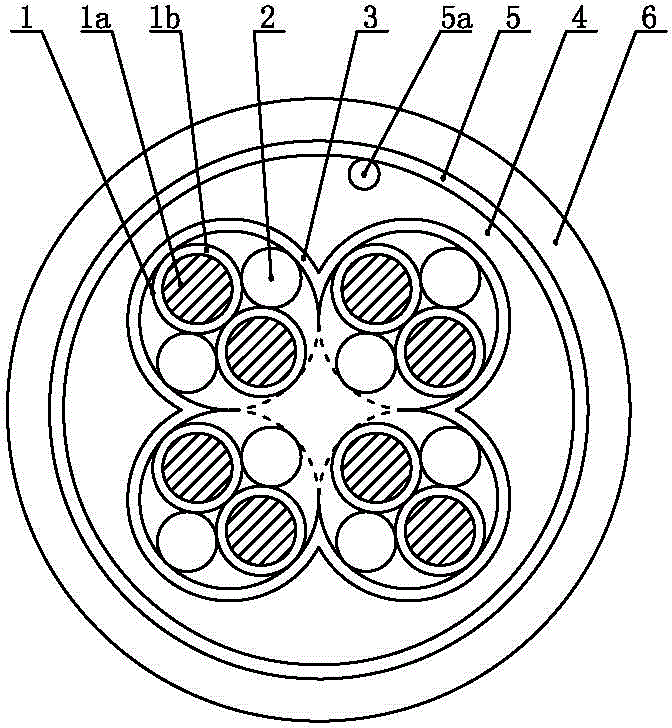

Salt corrosion and torsion resisting type shielding telecommunication cable used for ocean wind power and manufacturing method thereof

ActiveCN103187127AEliminate voidsExcellent impregnationRubber insulatorsInsulating conductors/cablesCopper conductorFiber

The invention relates to a salt corrosion and torsion resisting type shielding telecommunication cable used for ocean wind power and a manufacturing method thereof. A salt corrosion and torsion resisting type rubber insulating layer is uniformly extruded to wrap the peripheries of stranded copper conductors in order to form insulating wires, the insulating wires are stranded in pairs to form a stranded wire pair, the gap of the stranded wire pair is filled with a flame-retardant non-hygroscopic fiber filling core, the periphery of each group of stranded wire pair is wound with a copper foil polyester compounding belt shielding layer to form a stranded group, multiple stranded groups are mutually stranded to form a cable core, and the periphery of the cable core is wrapped with low strength non-woven fabrics, and is extruded with a protective sleeve. According to the salt corrosion and torsion resisting type shielding telecommunication cable, a longitudinal low strength non-woven fabric wrapping layer is adopted, and is completely matched with the insulating wire core in shape, so that the gap between the longitudinal low strength non-woven fabric wrapping layer and the insulating wire core is eliminated, a flame can be favorably prevented from being continuously transmitted to the inside under the combustion condition, and the humidity steeping resistance is improved. Meanwhile, the longitudinal low strength non-woven fabric wrapping layer can ensure that the protective sleeve does not adhere to the insulating wire core, and facilitates the stripping of the protective sleeve in the construction process without damages on the insulating wire core.

Owner:浙江华威设备制造有限公司

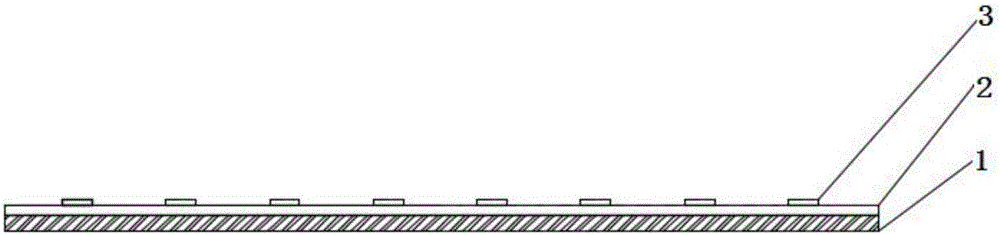

LED patch light source

InactiveCN106838642AStable electrical insulationExtended service lifeLighting heating/cooling arrangementsLight fasteningsInsulation layerOptoelectronics

The invention provides an LED patch light source. The LED patch light source comprises a flexible and bendable PCB (printed circuit board) which is 150-300 mm long and 3-8 mm wide, wherein the PCB board comprises an insulation layer and a heat dissipation layer; the insulation layer is formed by sintering ceramic slurry; the heat dissipation layer is a flexible aluminum foil which is 0.1-0.6 mm thick. The preparation method of the LED patch light source comprises steps as follows: (1) cleaning; (2) die bond; (3) wire welding; (4) dam surrounding; (5) uniformization of adhesive dispensing powder, and the LED patch light source is obtained. The problems that a hard-ceramic-matrix PCB aluminum substrate has poor plasticity and easily breaks during flexible bending are solved. The method for preparing the PCB substrate is simple and high in preparation efficiency. The prepared LED patch light source has stable performance and long service life.

Owner:GUANGDONG REAL FAITH LIGHTING TECH

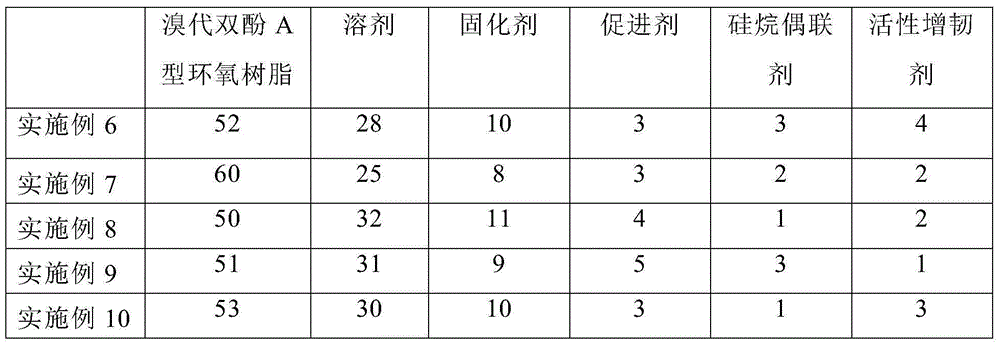

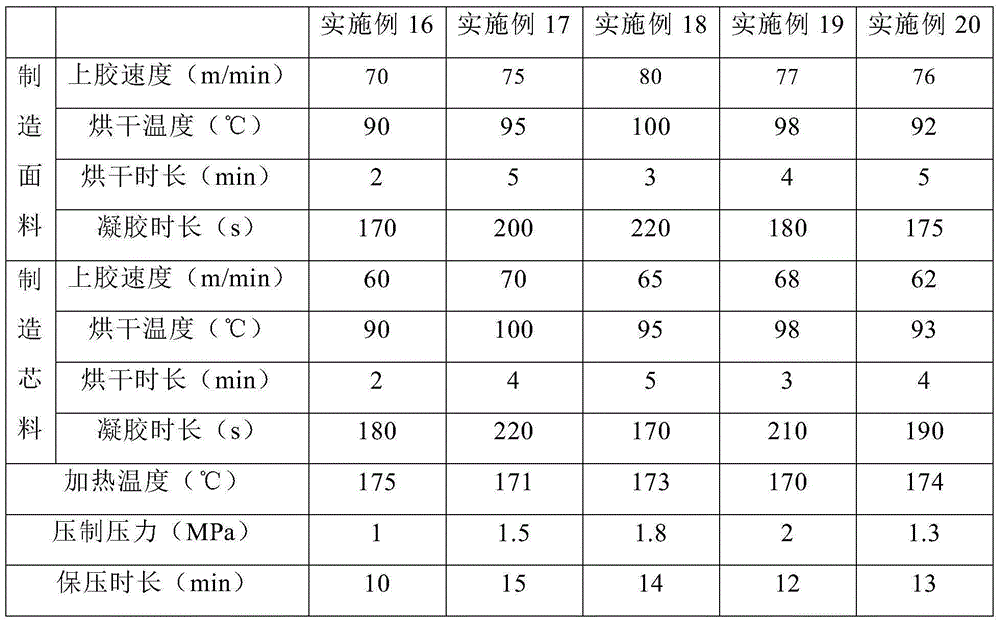

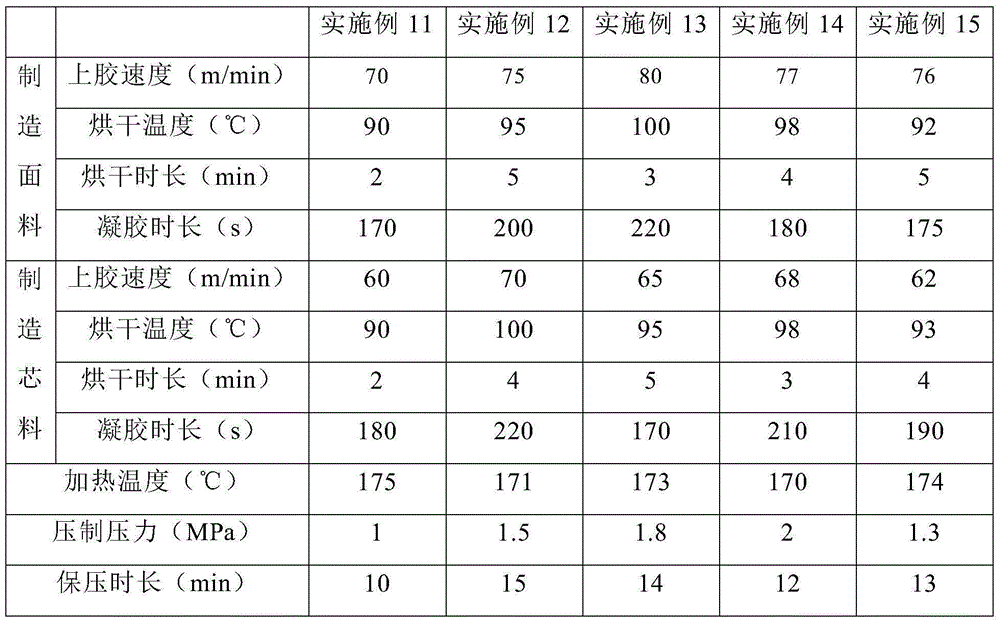

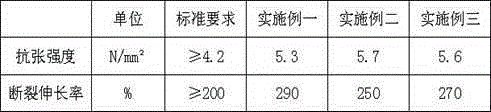

Manufacturing method for CEM-1 type copper clad laminate

ActiveCN105058946AGood adhesivenessImprove flame retardant performanceLaminationHeat resistant fibresCopper foilUltimate tensile strength

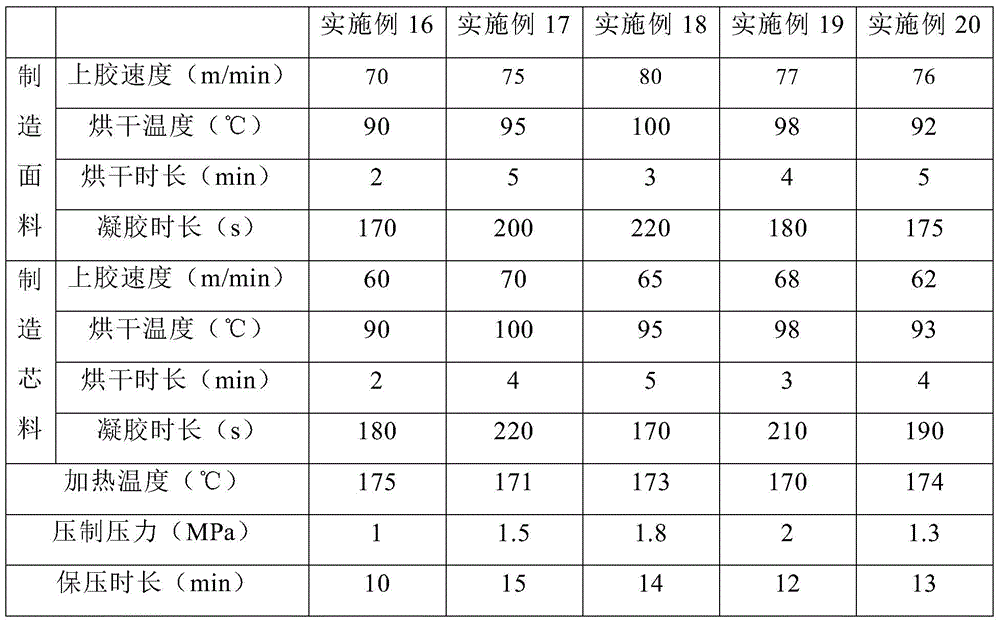

The invention provides a manufacturing method for a CEM-1 type copper clad laminate. The method comprises the steps of: 1) preparing a fabric impregnation glue solution; 2) preparing a core material impregnation glue solution; 3) making the fabric; 4) making the core material; 5) stacking the obtained fabric and core material, then covering the stacked several substrates' upper surface with a copper foil, putting a layer of release film under the undersurface, then putting the materials between two stainless steel plates; 6) putting the product into a laminating machine to conduct heating and pressurization treatment, with the temperature being 170-175DEG C and the pressure being 1-2MPa, maintaining the pressure for 10-15min, then taking the product out, and carrying out cutting and inspection, thus obtaining the CEM-1 type copper clad laminate finished product. The method employs specially-made brominated bisphenol A epoxy resin and a plurality of preparations to cooperate to form the flue solution, and through optimized combination of the manufacturing process and manufacturing conditions, twice glue impregnation, and impregnation of two glue solution, the strength of the core material is ensured, and the high temperature resistant and high flame retardant copper clad laminate can be obtained.

Owner:忠信(太仓)绝缘材料有限公司

CEM-3 type copper-clad laminated plate base paper manufacturing method

InactiveCN105128497AGood adhesivenessImprove flame retardant performanceLayered product treatmentLaminationPaper manufacturingCopper foil

The present invention provides a CEM-3 type copper-clad laminated plate base paper manufacturing method, which comprises: 1) preparing an impregnating glue liquid; 2) manufacturing a surface material; 3) manufacturing a core material; 4) stacking the obtained surface material and the obtained core material, covering copper foil on the upper surface of the plurality of the stacked base plates, covering a layer of a release film on the bottom surface, and then placing between two stainless steel plates; 5) placing into a laminator, carrying out a heating and pressurization treatment at a heating temperature of 170-175 DEG C under a pressure of 1-2 MPa, maintaining the pressure for 10-15 min, taking out, cutting, and testing to obtain the CEM-3 type copper-clad laminated plate base paper finished product. According to the present invention, the brominated bisphenol A type epoxy resin specially made through the method is matched with a variety of preparations to form the glue liquid, and the manufacturing process and the manufacturing conditions are subjected to the optimized combination so as to obtain the copper-clad laminated plate with characteristics of high temperature resistance and high fire-retardant property.

Owner:忠信(太仓)绝缘材料有限公司

Salt corrosion-resistant and torsion-resistant integral shielding telecommunication cable for offshore wind power and manufacturing method of integral shielding telecommunication cable

ActiveCN103227011AReduce tensionEliminate voidsInsulating conductors/cablesCables with twisted pairs/quadsCopper conductorTelecommunications cable

The invention relates to a salt corrosion-resistant and torsion-resistant integral shielding telecommunication cable for offshore wind power and a manufacturing method of the integral shielding telecommunication cable. Salt corrosion-resistant and torsion-resistant rubber insulating layers are uniformly extruded on the peripheries of stranded copper conductors in a wrapping way to form insulated wire cores; the insulated wire cores are stranded in pair to form pair-twist wire pairs; gaps of the pair-twist wire pairs are filled with flame-retardant non-absorbent fiber fillers; a plurality of groups of pair-twist wire pairs are stranded to form a cable core; and the periphery of the cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer, an inner jacket, a copper foil polyester composite belt shielding layer and an outer jacket sequentially from the inside out. The integral shielding telecommunication cable disclosed by the invention adopts the low-intensity non-woven fabric longitudinally-covered layer of which the shape is completely in fit with that of each insulated wire core, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the insulated wire cores are eliminated, flame can be conveniently prevented from being spread and transferred inwards under the burning condition, and resistance to impregnation of humidity can be enhanced; and meanwhile, the low-intensity non-woven fabric longitudinally-covered layer can ensure that the inner jacket and the insulated wire cores are not adhered, so that the insulated wire cores are not damaged when the inner jacket is stripped during construction.

Owner:浙江华威设备制造有限公司

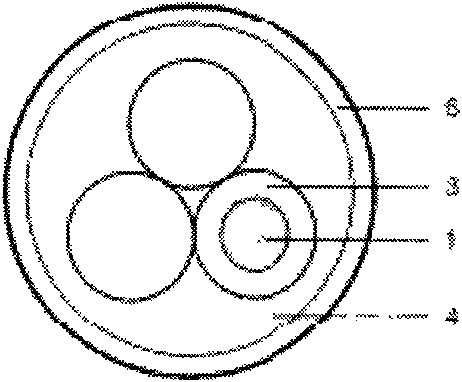

Salt corrosion resistant and twisting resistant control cable for ocean wind power and manufacturing method of control cable

ActiveCN103227000AReduce tensionEliminate voidsRubber insulatorsInsulated cablesCopper conductorInsulation layer

The invention relates to a salt corrosion resistant and twisting resistant control cable for ocean wind power and a manufacturing method of the control cable. A stranded copper conductor is uniformly wrapped in a salt corrosion resistant and twisting resistant extruded rubber insulation layer to form a control cable insulated core; a plurality of control cable insulated cores are mutually stranded to form a control cable core; the control cable core is wrapped in a low-strength non-woven fabric longitudinal wrap; and the low-strength non-woven fabric longitudinal wrap is wrapped in an extruded sheath. The control cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits the control cable insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the control cable insulated cores are eliminated, convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheath is not stuck to the insulated cores, and provides convenience for stripping the sheath in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

High-temperature submersible electric pump cable

ActiveCN101834030AStable electrical insulationImprove performancePower cablesEngineeringEPDM elastomer

Owner:天津小猫天缆集团有限公司

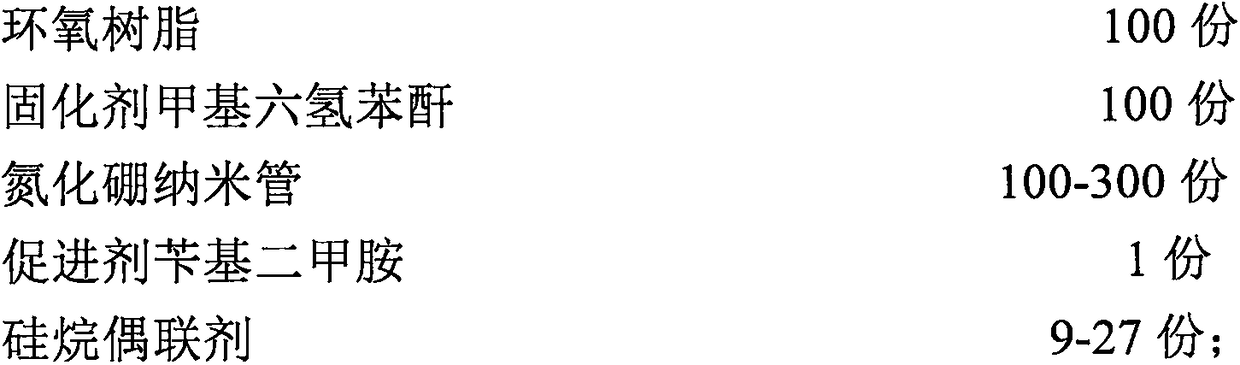

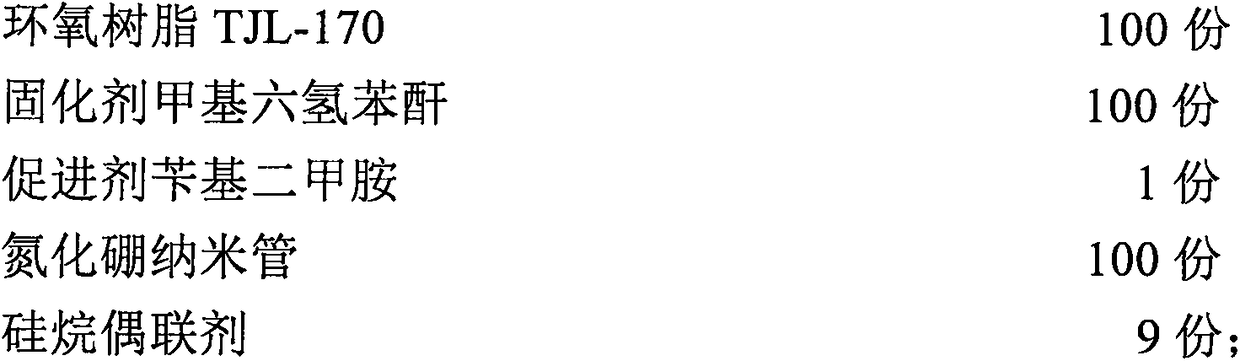

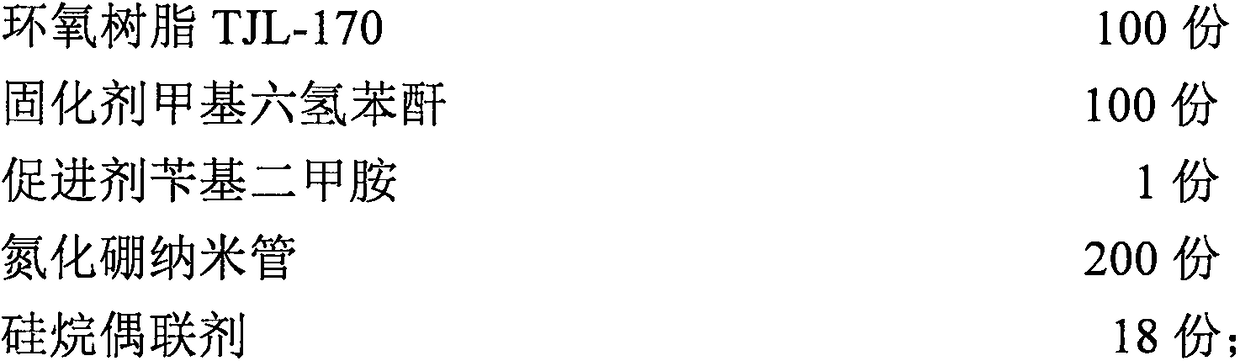

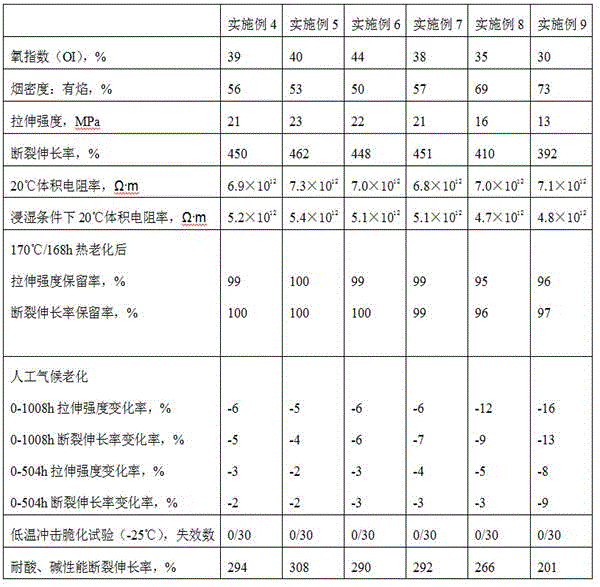

High-thermal conductivity epoxy resin-based boron nitride nano-tube composite insulating material prepared by electric field regulation

The invention discloses a high-thermal conductivity epoxy resin-based boron nitride nano-tube composite insulating material prepared by electric field regulation. An electric field is applied in the curing process of the material, and the oriented and orderly arrangement of a thermal conduction filler in the composite material is realized by electric field regulation. The material has an excellentthermal conductivity, can meet heat dissipation requirements of power components, has a stable electrical insulating performance, and can ensure the lasting and safe running of electrical and electronic equipment. A preparation method of the material has the advantages of simple processing process and good universality, and allows the high-thermal conductivity epoxy resin-based boron nitride nano-tube composite insulating material to be easily prepared.

Owner:深圳市圳田科技有限公司

Insulated and flame-retardant cable

ActiveCN105694193ASmall water absorptionImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesPolymer sciencePolyvinyl chloride

The invention relates to the technical field of materials for cables, in particular to an insulated and flame-retardant cable. Raw materials of an insulating layer comprise 100 parts of an ethylene-methacrylic acid copolymer, 20-30 parts of polyamide resin, 60-80 parts of hyperbranched polyether modified melamine and 1-10 parts of an auxiliary. According to the insulated and flame-retardant cable, halogen-containing polyvinyl chloride and other halogen-containing base materials are not required to be added, and a better flame retardant effect can be realized; under the synergistic effect of all components, the water absorbency of the insulating material is reduced, the high flame retardant effect is realized, meanwhile, the high electric insulation effect is realized, and the insulating material still has better electric insulation stability under the wet condition; the problems that mixing is difficult, the extrusion pressure is high and the like in the processing process are solved, the production process is simplified, the requirements for equipment are reduced, the production cost is reduced, and the purpose of industrial production is achieved.

Owner:JINAN CITY CHANGQING DISTRICT POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

High thermal conductivity epoxy composite material and its preparation method and application

ActiveCN112048270BDurable and safe operationHigh thermal conductivityNon-macromolecular adhesive additivesGrain treatmentsResin matrixFirming agent

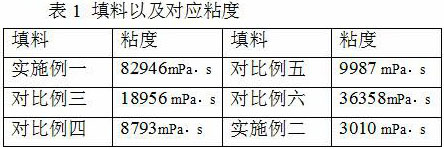

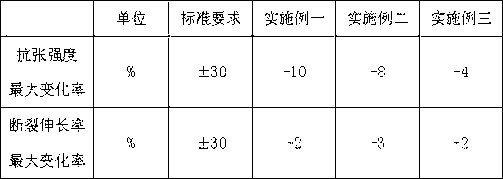

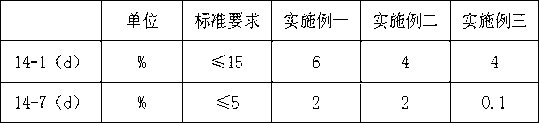

The invention discloses a high thermal conductivity epoxy composite material and its preparation method and application. The high thermal conductivity epoxy composite material is obtained by mixing epoxy resin, curing agent and high thermal conductivity micro-nano boron nitride particles and curing; hydrogen peroxide, The boron nitride powder treated by the coupling agent is put into the planetary ball mill, and the ball distribution and speed are adjusted to ball mill the boron nitride particles, thereby greatly increasing the filling amount of the boron nitride powder in the resin matrix and reducing Glue viscosity. In the present invention, the surface-treated boron nitride particles are ball-milled to obtain high-thermal-conductivity micro-nano boron nitride particles, without other steps, and the ball-milling parameters are limited, so that the obtained high-thermal-conductivity micro-nano boron nitride particles and epoxy resin are prepared as a composite insulating material, In the case of excellent thermal conductivity, the potting viscosity is reduced, especially the adhesive force is improved, which can meet the higher requirements of the rapid development of the market for packaging technology.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST +1

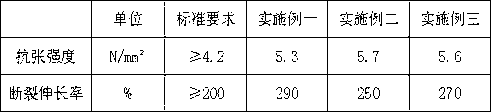

Salt corrosion resistant and twisting resistant composite cable for ocean wind power and manufacturing method of composite cable

ActiveCN103227007AReduce tensionEliminate voidsRubber insulatorsPower cables with screens/conductive layersElectricityCombustion

The invention relates to a salt corrosion resistant and twisting resistant composite cable for ocean wind power and a manufacturing method of the composite cable. Power cable insulation layers, control cable insulation layers and meter cable insulation layers are all salt corrosion resistant and twisting resistant rubber insulation layers and are mutually stranded to form a composite cable core; the composite cable core is wrapped in a low-strength non-woven fabric longitudinal wrap on the periphery; and the low-strength non-woven fabric longitudinal wrap is wrapped in an extruded sheath. The composite cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the insulated cores are eliminated convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheath is not stuck to the insulated cores, and provides convenience for stripping the sheath in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

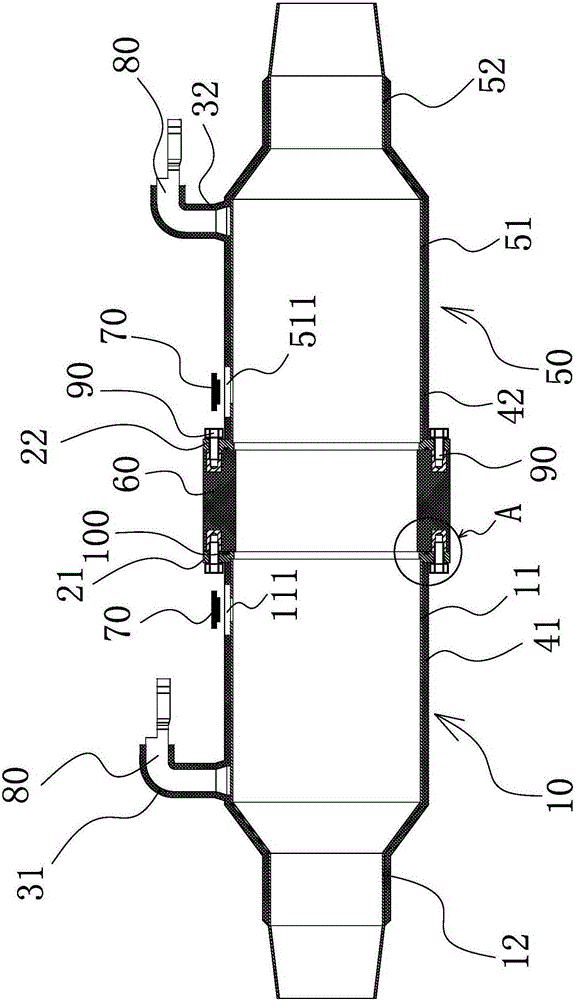

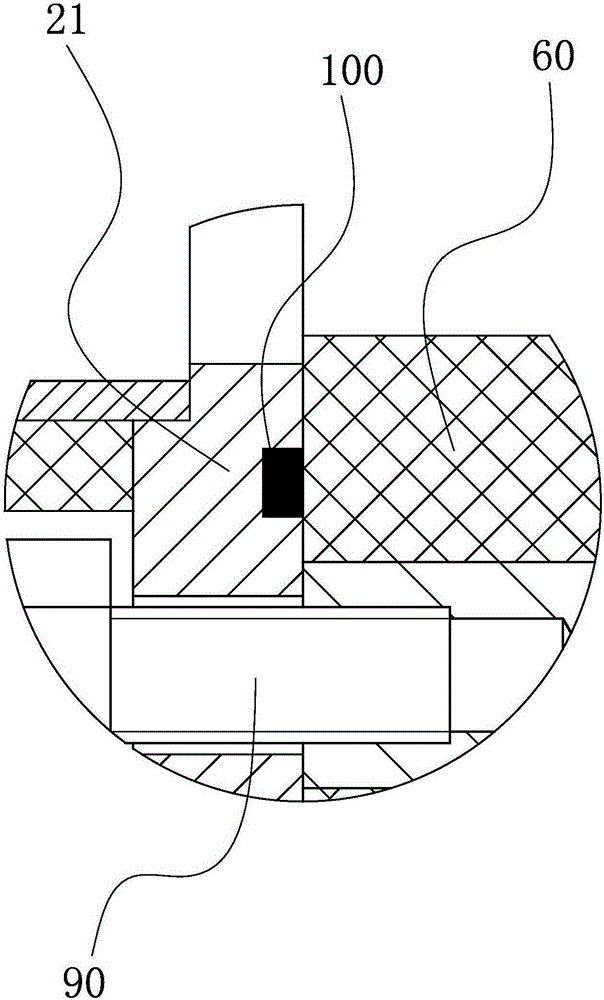

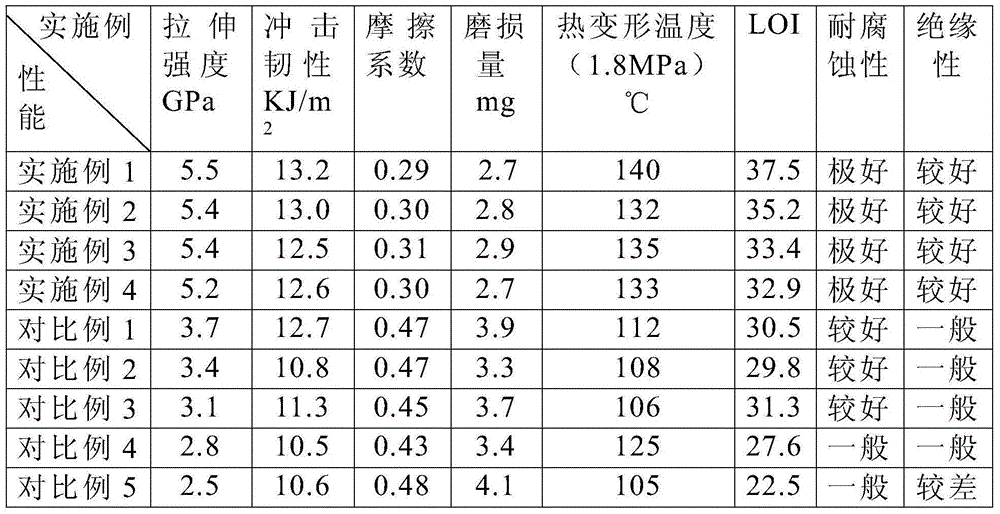

220kv epoxy type insulating copper casing

The invention provides a 220kV epoxy type insulating copper casing and belongs to the field of electrical techniques. The 220kV epoxy type insulating copper casing comprises a left copper tube, a right copper tube, an epoxy insulating part, a left insulating layer and a right insulating layer, wherein the left copper tube comprises a first large copper tube body and a first small copper tube body, a left copper sleeve flange is mounted on the first large copper tube body in a sealed manner, and a left wiring end close to the first small copper tube body is arrangd on one side of the first large copper tube body; the right copper tube comprises a second large copper tube body and a second small copper tube body, a right copper sleeve flange is mounted on the second large copper tube body in a sealed manner, a right wiring end close to the second small copper tube is arranged on one side of the second large copper tube body, and the right wiring end and the left wiring end are arranged on the same side; the epoxy insulating part is annularly arranged, molded by casting an epoxy resin material and arranged between the left copper sleeve flange and the right copper sleeve flange, and the epoxy insulating part, the left copper sleeve flange and the right copper sleeve flange are connected in a sealed manner; the left insulating layer and the right insulating layer are made from an epoxy resin composite composed of specific components. The 220kV epoxy type insulating copper casing is reasonable in design and has stable electrical insulation performance, high comprehensive performance and long service life.

Owner:宁波东昊电力科技股份有限公司

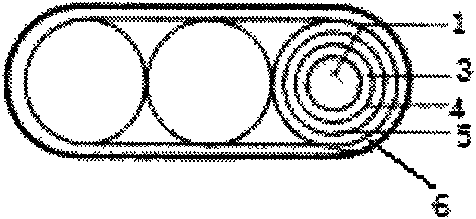

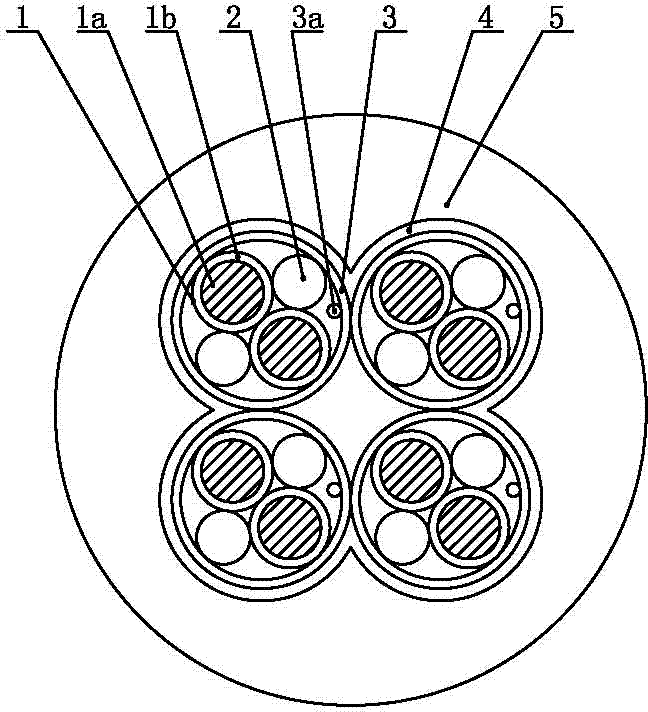

Salt corrosion-resistant and torsion-resistant telecommunication cable for offshore wind power and manufacturing method of telecommunication cable

ActiveCN103227009AEliminate voidsEase of transmissionRubber insulatorsInsulating conductors/cablesEngineeringElectrical conductor

The invention relates to a salt corrosion-resistant and torsion-resistant telecommunication cable for offshore wind power and a manufacturing method of the telecommunication cable. Salt corrosion-resistant and torsion-resistant rubber insulating layers are uniformly extruded on the peripheries of stranded copper conductors in a wrapping way to form insulated wire cores; the insulated wire cores are stranded in pair to form pair-twist wire pairs; gaps of the pair-twist wire pairs are filled with flame-retardant non-absorbent fiber fillers; pair-twist wire pairs adopt different stranding pitches, a plurality of groups of pair-twist wire pairs are stranded to form a cable core; the periphery of the cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer; and a jacket is extruded on the periphery of the low-intensity non-woven fabric longitudinally-covered layer in a wrapping way. The telecommunication cable disclosed by the invention adopts the low-intensity non-woven fabric longitudinally-covered layer of which the shape is completely in fit with that of each insulated wire core, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the insulated wire cores are eliminated, flame can be conveniently prevented from being spread and transferred inwards under the burning condition, and resistance to impregnation of humidity can be enhanced; and meanwhile, the low-intensity non-woven fabric longitudinally-covered layer can ensure that the jacket and the insulated wire cores are not adhered, so that the insulated wire cores are not damaged when the jacket is stripped during construction.

Owner:嘉兴君宏光学有限公司

Salt corrosion-resistant and torsion-resistant composite cable and manufacturing method thereof

InactiveCN106653152AReduce tensionEliminate voidsRubber insulatorsPower cables including communication wiresInsulation layerCombustion

The invention relates to a salt corrosion-resistant and torsion-resistant composite cable and a manufacturing method thereof. A power cable insulation layer, a control cable insulation layer and an instrument cable insulation layer are salt corrosion-resistant and torsion-resistant rubber insulation layers. A power cable core, a control cable core and an instrument cable core are twisted into a composite core. The periphery of the composite core is coated with a low-intensity non-woven longitudinal cladding. A sheath is arranged at the periphery of the low-intensity non-woven longitudinal cladding by means of extrusion. The low-intensity non-woven longitudinal cladding which has a shape completely consistent with the appearance of an insulated wire core is adopted, and the gap between the low-intensity non-woven longitudinal cladding and the insulated wire core is eliminated, so that flame can be prevented from spreading to the inside under the condition of combustion, and the resistance to moisture impregnation can be enhanced. Moreover, the low-intensity non-woven longitudinal cladding can ensure that the sheath and the insulated wire core are not adhered together, and the insulated wire core is not damaged when the sheath is tripped in the process of construction.

Owner:重庆三峡电线电缆科技股份有限公司

Salt corrosion resistant and twisting resistant double-shielded communication cable for ocean wind power and manufacturing method of communication cable

ActiveCN103227012AReduce tensionEliminate voidsInsulating conductors/cablesCables with twisted pairs/quadsCopper conductorInsulation layer

The invention relates to a salt corrosion resistant and twisting resistant double-shielded communication cable for ocean wind power and a manufacturing method of the communication cable. Each stranded copper conductor is wrapped in a salt corrosion resistant and twisting resistant extruded rubber insulation layer to form an insulated core; each two insulated cores are stranded to form a twisted pair of which the gaps are filled with fillers; each twisted pair is wrapped in a twisted pair copper foil shielding layer to form a twisted-pair group; the twisted-pair groups are mutually stranded to form a cable core; and the cable core is wrapped in a low-strength non-woven fabric longitudinal wrap, an inner sheath, a cable core copper foil shielding layer and an outer sheath in sequence from inside to outside. The communication cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits the insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the insulated cores are eliminated, convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheaths are not stuck to the insulated cores, and provides convenience for stripping the sheathes in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

Salt-corrosion-resistant torsion-resistant cable insulating rubber for marine wind power and manufacturing method thereof

ActiveCN103224669BIncrease resistanceImprove cleanlinessPlastic/resin/waxes insulatorsInsulated cablesRubber materialVulcanization

The invention discloses salt corrosion resistance twisted cable insulation rubber used for ocean wind power and a preparation method of the salt corrosion resistance twisted cable insulation rubber. By weight, raw materials comprise 8 parts of Keltan5508, 12 parts of DutralTER4044, 5-7 parts of EP-20, 0.5-0.7 part of DCP, 0.3-0.5 part of TAC, 0.2-0.4 part of HVA-2, 0.2-0.4 part of RD, 0.2-0.4 part of MB, 0.2-0.4 part of KH-550, 2.1-2.5 part of hydration zinc borate, 1-1.5 parts of antimony trioxide, 25-40 parts of aluminum hydroxide, 0.8-1.2 part of red lead, 0.5-1 part of stearic acid, 1.5-2 parts of nan-zinc oxide, 2-5 parts of paraffin oil Sunpar2280, 0.5-1 part of chlorinated paraffin-52, and 1-3 parts of hydration silicon dioxide. According to the method, firstly, the EPDM rubber Keltan5508, the DutralTER4044 and the EP-20 are mixed for 1-1.5 minutes, and then other components except for a vulcanizing agent and a co-vulcanization agent are added. After mixing is carried out for 7-8 minutes, discharging and airing are carried out for more than 24 hours. Then the rubber materials are mixed for 2-3 minutes, the vulcanizing agent and the co-vulcanization agent are added at the last 20 seconds, and the mixed materials are loaded on an open mill for milling, triangular injection molding and square injection molding and then sheeted. The insulation rubber is good in mechanical performance, anti-corrosion performance and anti-aging performance and long in service life.

Owner:浙江华威设备制造有限公司

Salt-corrosion-resistant torsion-resistant double-shielded communication cable for marine wind power and manufacturing method thereof

ActiveCN103227012BEasy not to hurtEliminate voidsInsulating conductors/cablesCables with twisted pairs/quadsCopper conductorElectricity

The invention relates to a salt corrosion resistant and twisting resistant double-shielded communication cable for ocean wind power and a manufacturing method of the communication cable. Each stranded copper conductor is wrapped in a salt corrosion resistant and twisting resistant extruded rubber insulation layer to form an insulated core; each two insulated cores are stranded to form a twisted pair of which the gaps are filled with fillers; each twisted pair is wrapped in a twisted pair copper foil shielding layer to form a twisted-pair group; the twisted-pair groups are mutually stranded to form a cable core; and the cable core is wrapped in a low-strength non-woven fabric longitudinal wrap, an inner sheath, a cable core copper foil shielding layer and an outer sheath in sequence from inside to outside. The communication cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits the insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the insulated cores are eliminated, convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheaths are not stuck to the insulated cores, and provides convenience for stripping the sheathes in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

Salt-corrosion-resistant torsion-resistant overall shielded communication cable for marine wind power and manufacturing method thereof

ActiveCN103227011BReduce tensionEliminate voidsInsulating conductors/cablesCables with twisted pairs/quadsCopper conductorTelecommunications cable

The invention relates to a salt corrosion-resistant and torsion-resistant integral shielding telecommunication cable for offshore wind power and a manufacturing method of the integral shielding telecommunication cable. Salt corrosion-resistant and torsion-resistant rubber insulating layers are uniformly extruded on the peripheries of stranded copper conductors in a wrapping way to form insulated wire cores; the insulated wire cores are stranded in pair to form pair-twist wire pairs; gaps of the pair-twist wire pairs are filled with flame-retardant non-absorbent fiber fillers; a plurality of groups of pair-twist wire pairs are stranded to form a cable core; and the periphery of the cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer, an inner jacket, a copper foil polyester composite belt shielding layer and an outer jacket sequentially from the inside out. The integral shielding telecommunication cable disclosed by the invention adopts the low-intensity non-woven fabric longitudinally-covered layer of which the shape is completely in fit with that of each insulated wire core, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the insulated wire cores are eliminated, flame can be conveniently prevented from being spread and transferred inwards under the burning condition, and resistance to impregnation of humidity can be enhanced; and meanwhile, the low-intensity non-woven fabric longitudinally-covered layer can ensure that the inner jacket and the insulated wire cores are not adhered, so that the insulated wire cores are not damaged when the inner jacket is stripped during construction.

Owner:浙江华威设备制造有限公司

Salt-corrosion-resistant torsion-resistant communication cable for offshore wind power and method for manufacturing the same

ActiveCN103227009BReduce tensionEliminate voidsRubber insulatorsInsulating conductors/cablesCopper conductorTelecommunications cable

The invention relates to a salt corrosion-resistant and torsion-resistant telecommunication cable for offshore wind power and a manufacturing method of the telecommunication cable. Salt corrosion-resistant and torsion-resistant rubber insulating layers are uniformly extruded on the peripheries of stranded copper conductors in a wrapping way to form insulated wire cores; the insulated wire cores are stranded in pair to form pair-twist wire pairs; gaps of the pair-twist wire pairs are filled with flame-retardant non-absorbent fiber fillers; pair-twist wire pairs adopt different stranding pitches, a plurality of groups of pair-twist wire pairs are stranded to form a cable core; the periphery of the cable core is coated with a low-intensity non-woven fabric longitudinally-covered layer; and a jacket is extruded on the periphery of the low-intensity non-woven fabric longitudinally-covered layer in a wrapping way. The telecommunication cable disclosed by the invention adopts the low-intensity non-woven fabric longitudinally-covered layer of which the shape is completely in fit with that of each insulated wire core, so that gaps between the low-intensity non-woven fabric longitudinally-covered layer and the insulated wire cores are eliminated, flame can be conveniently prevented from being spread and transferred inwards under the burning condition, and resistance to impregnation of humidity can be enhanced; and meanwhile, the low-intensity non-woven fabric longitudinally-covered layer can ensure that the jacket and the insulated wire cores are not adhered, so that the insulated wire cores are not damaged when the jacket is stripped during construction.

Owner:浙江华威设备制造有限公司

Salt corrosion and torsion resisting type shielding telecommunication cable used for ocean wind power and manufacturing method thereof

ActiveCN103187127BEliminate voidsExcellent impregnationRubber insulatorsInsulating conductors/cablesCopper conductorFiber

The invention relates to a salt corrosion and torsion resisting type shielding telecommunication cable used for ocean wind power and a manufacturing method thereof. A salt corrosion and torsion resisting type rubber insulating layer is uniformly extruded to wrap the peripheries of stranded copper conductors in order to form insulating wires, the insulating wires are stranded in pairs to form a stranded wire pair, the gap of the stranded wire pair is filled with a flame-retardant non-hygroscopic fiber filling core, the periphery of each group of stranded wire pair is wound with a copper foil polyester compounding belt shielding layer to form a stranded group, multiple stranded groups are mutually stranded to form a cable core, and the periphery of the cable core is wrapped with low strength non-woven fabrics, and is extruded with a protective sleeve. According to the salt corrosion and torsion resisting type shielding telecommunication cable, a longitudinal low strength non-woven fabric wrapping layer is adopted, and is completely matched with the insulating wire core in shape, so that the gap between the longitudinal low strength non-woven fabric wrapping layer and the insulating wire core is eliminated, a flame can be favorably prevented from being continuously transmitted to the inside under the combustion condition, and the humidity steeping resistance is improved. Meanwhile, the longitudinal low strength non-woven fabric wrapping layer can ensure that the protective sleeve does not adhere to the insulating wire core, and facilitates the stripping of the protective sleeve in the construction process without damages on the insulating wire core.

Owner:浙江华威设备制造有限公司

An insulated flame retardant cable

ActiveCN105694193BSmall water absorptionImprove flame retardant performancePlastic/resin/waxes insulatorsInsulated cablesElectricityHalogen

Owner:JINAN CITY CHANGQING DISTRICT POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

Salt-corrosion-resistant torsion-resistant power cable for offshore wind power and manufacturing method thereof

ActiveCN103227008BReduce tensionEliminate voidsPower cablesInsulating conductors/cablesCopper conductorElectricity

The invention relates to a salt corrosion resistant and twisting resistant power cable for ocean wind power and a manufacturing method of the power cable. A stranded copper conductor is uniformly wrapped in a salt corrosion resistant and twisting resistant extruded rubber insulation layer to form a power cable insulated core; a plurality of power cable insulated cores are mutually stranded to form a power cable core; the power cable core is wrapped in a low-strength non-woven fabric longitudinal wrap on the periphery; and the low-strength non-woven fabric longitudinal wrap is wrapped in an extruded sheath. The power cable provided by the invention adopts the low-strength non-woven fabric longitudinal wrap which completely fits the power cable insulated cores in shape, so that gaps between the low-strength non-woven fabric longitudinal wrap and the power cable insulated cores are eliminated, convenience is provided for stopping flame from spreading inwards under a combustion condition and the resistance to moisture impregnation is enhanced; and meanwhile, the low-strength non-woven fabric longitudinal wrap can ensure that the sheath is not stuck to the insulated cores, and provides convenience for stripping the sheath in a construction process without damaging the insulated cores.

Owner:浙江华威设备制造有限公司

A method for manufacturing cem‑1 type copper-clad laminate base paper

ActiveCN105058946BGood adhesivenessImprove flame retardant performanceLaminationHeat resistant fibresPolymer scienceCopper foil

The invention provides a manufacturing method for a CEM-1 type copper clad laminate. The method comprises the steps of: 1) preparing a fabric impregnation glue solution; 2) preparing a core material impregnation glue solution; 3) making the fabric; 4) making the core material; 5) stacking the obtained fabric and core material, then covering the stacked several substrates' upper surface with a copper foil, putting a layer of release film under the undersurface, then putting the materials between two stainless steel plates; 6) putting the product into a laminating machine to conduct heating and pressurization treatment, with the temperature being 170-175DEG C and the pressure being 1-2MPa, maintaining the pressure for 10-15min, then taking the product out, and carrying out cutting and inspection, thus obtaining the CEM-1 type copper clad laminate finished product. The method employs specially-made brominated bisphenol A epoxy resin and a plurality of preparations to cooperate to form the flue solution, and through optimized combination of the manufacturing process and manufacturing conditions, twice glue impregnation, and impregnation of two glue solution, the strength of the core material is ensured, and the high temperature resistant and high flame retardant copper clad laminate can be obtained.

Owner:忠信(太仓)绝缘材料有限公司

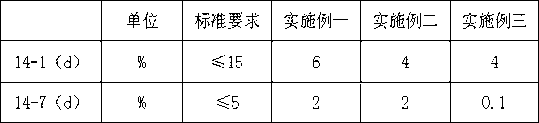

A kind of waxy crude oil pouring point and viscosity reducing composite agent

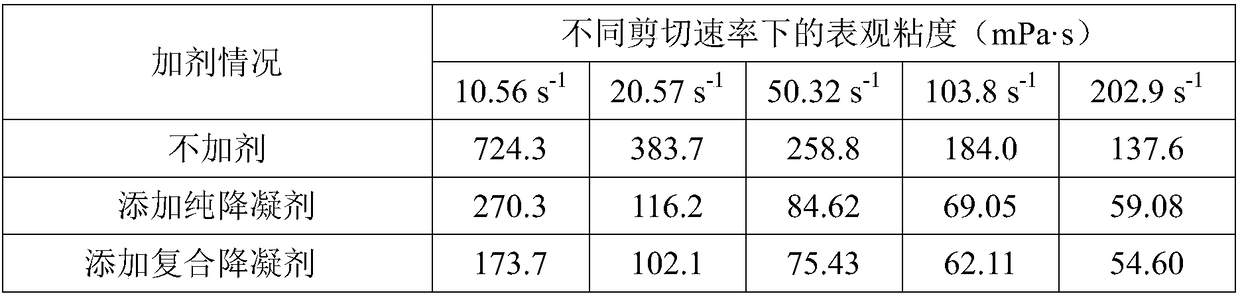

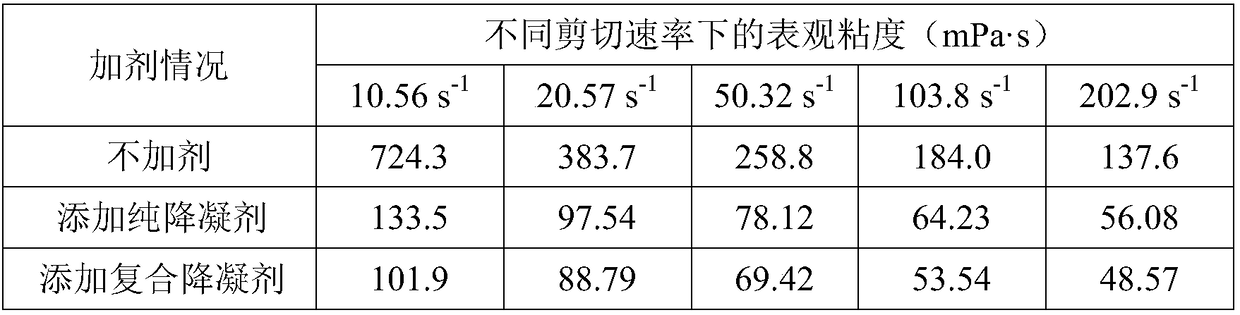

ActiveCN105889756BLow viscosityLean structureOther chemical processesPipeline systemsWaxOrganic solvent

The invention relates to a pour-point-depressing and viscosity-reducing complexing agent for wax-bearing crude. The pour-point-depressing and viscosity-reducing complexing agent for the wax-bearing crude is used for improving the low-temperature rheological properties of the wax-bearing crude. The pour-point-depressing and viscosity-reducing complexing agent is obtained through the blending, in a fused state or a liquid state, of the following components in percentages by mass: 1 to 50 percent of polysilsesquioxane particle, 1 to 99 percent of polymer type pour-point depressant and 0 to 98 percent of organic solvent. Compared with a conventional pour-point depressant, the pour-point-depressing and viscosity-reducing complexing agent for the wax-bearing crude has better effects of depressing a pour point and reducing low temperature viscosity and a structural yield value for the wax-bearing crude, and moreover, has longer action timeliness.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com