High-thermal conductivity epoxy resin-based boron nitride nano-tube composite insulating material prepared by electric field regulation

An insulating material and epoxy resin technology, which is applied in the field of preparation of high thermal conductivity epoxy resin-based boron nitride nanotube composite insulating materials, can solve problems such as low thermal conductivity of pure epoxy resin, and achieve long-lasting safe operation, Stable electrical insulation performance and good universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

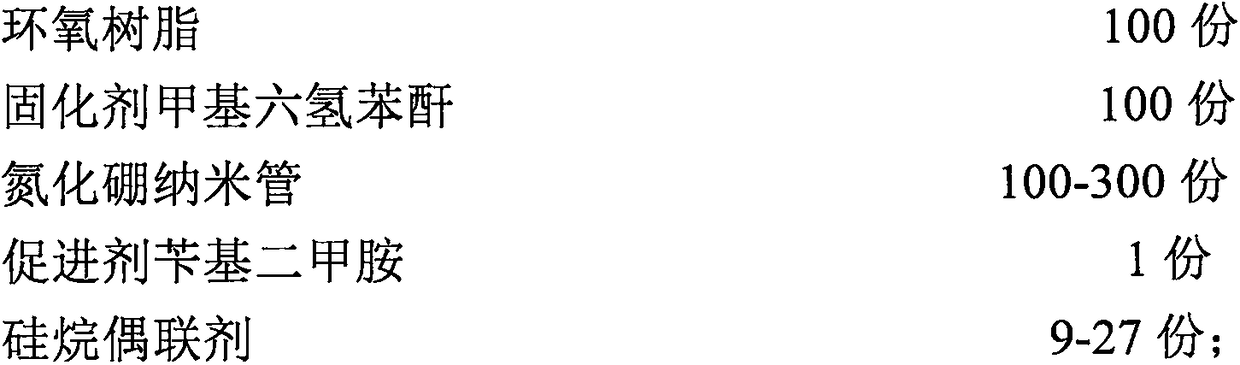

[0026] Example 1: Preparation of high thermal conductivity epoxy resin-based boron nitride nanotube composite insulating material under electric field regulation

[0027]

[0028] The specific preparation method is as follows:

[0029] 1) After drying and vacuuming bisphenol F epoxy resin, curing agent methyl hexahydrophthalic anhydride, accelerator benzyldimethylamine, filler and silane coupling agent, let it stand still, and put the mold into an oven to preheat at 80°C;

[0030] 2) Mix the epoxy resin and the curing agent methyl hexahydrophthalic anhydride, then add the silane coupling agent, stir thoroughly, vacuumize and defoam and let stand;

[0031] 3) The filler boron nitride nanotubes are added to the mixture in step 2), and after being fully stirred, vacuum pumping and degassing are carried out;

[0032] 4) ultrasonically vibrate the mixture of step 3);

[0033] 5) After adding accelerator benzyldimethylamine to the mixture in step 4), fully stir and vacuumize an...

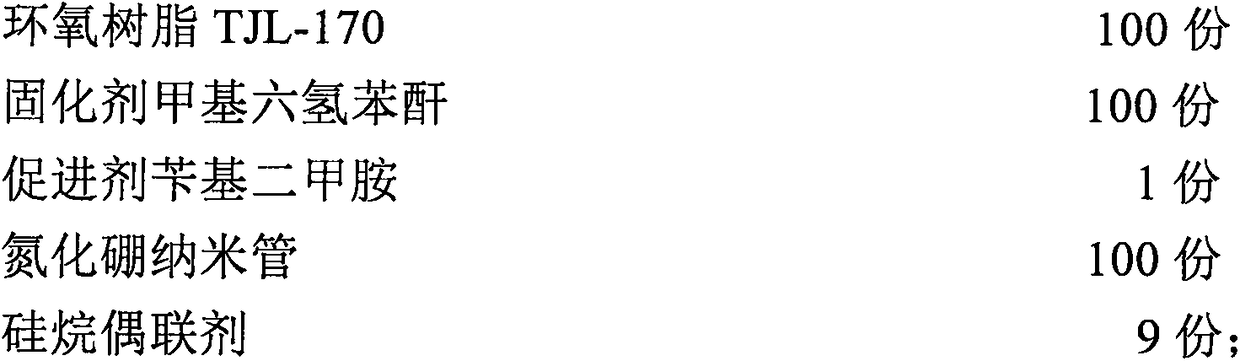

Embodiment 2

[0035] Example 2: Preparation of high thermal conductivity epoxy resin-based boron nitride nanotube composite insulating material under electric field regulation

[0036]

[0037] Embodiment 2 preparation method is the same as embodiment 1.

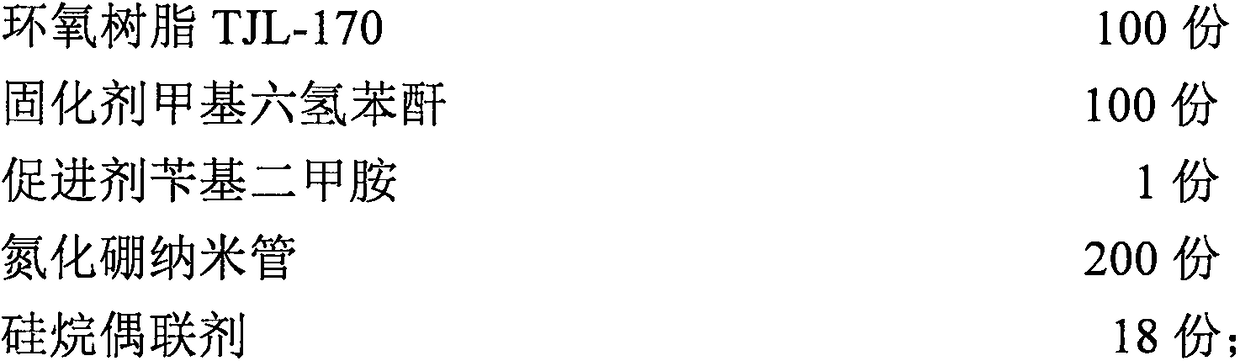

Embodiment 3

[0038] Example 3: Preparation of high thermal conductivity epoxy resin-based boron nitride nanotube composite insulating material under electric field regulation

[0039]

[0040] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com